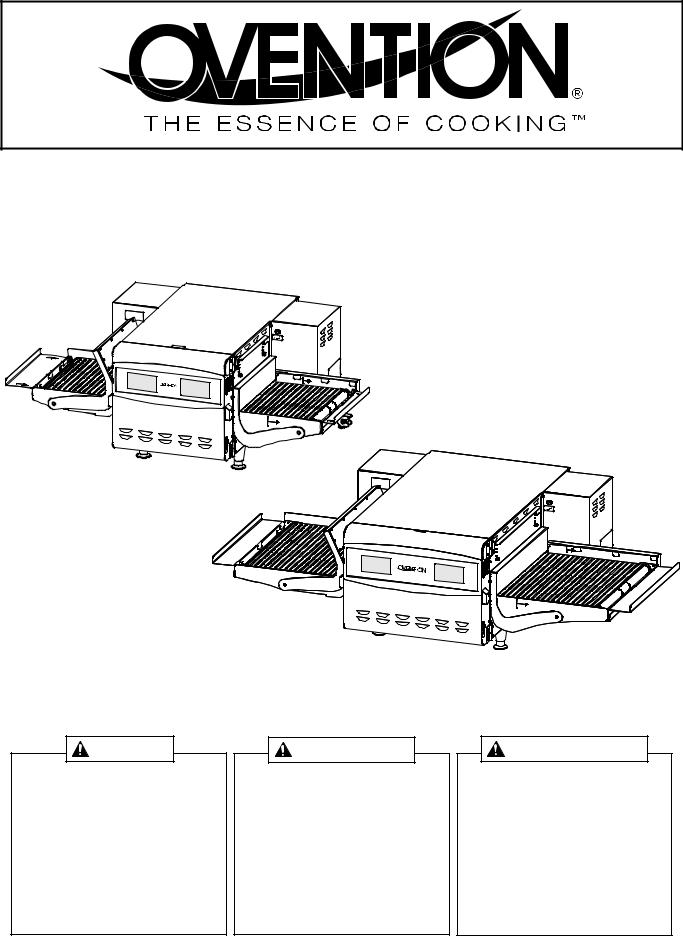

Ovention S2000, S1200 User Manual

Shuttle® Oven

Models: S1200, S2000

Installation and Operating Manual

WARNING

Do not operate this equipment unless you have read and understood the contents of this manual! Failure to follow the instructions contained in this manual may result in serious injury or death. This manual contains important safety information concerning the maintenance, use, and operation of this product. If you’re unable to understand the contents of this manual, please bring it to the attention of your supervisor. Keep this manual in a safe location for future reference.

P/N 07.04.653.00

ADVERTENCIA

No opere este equipo al menos que haya leído y comprendido el contenido de este manual! Cualquier falla en el seguimiento de las instrucciones contenidas en este manual puede resultar en un serio lesión o muerte. Este manual contiene importante información sobre seguridad concerniente al mantenimiento, uso y operación de este producto. Si usted no puede entender el contenido de este manual por favor pregunte a su supervisor. Almacenar este manual en una localización segura para la referencia futura.

AVERTISSEMENT

Ne pas utiliser cet équipement sans avoir lu et compris le contenu de ce manuel ! Le non-respect des instructions contenues dans ce manuel peut entraîner de graves blessures ou la mort. Ce manuel contient des informations importantes concernant l'entretien, l'utilisation et le fonctionnement de ce produit. Si vous ne comprenez pas le contenu de ce manuel, veuillez le signaler à votre supérieur. Conservez ce manuel dans un endroit sûr pour pouvoir vous y référer plus tard.

© 2016 Ovention, Inc.

CONTENTS

Important Owner Information .............................................. |

2 |

Introduction........................................................................... |

2 |

Important Safety Information............................................... |

3 |

Model Description................................................................. |

4 |

Model Designation................................................................ |

5 |

Specifications........................................................................ |

5 |

Plug Configurations ............................................................. |

5 |

Electrical Rating Chart ......................................................... |

5 |

Temperature Range ............................................................. |

5 |

Dimensions .......................................................................... |

6 |

Installation ............................................................................. |

7 |

General ................................................................................ |

7 |

Operation............................................................................... |

8 |

General ................................................................................ |

8 |

menu Item Information......................................................... |

8 |

Startup.................................................................................. |

8 |

Cooking — Shuttle Mode..................................................... |

9 |

Cooking — Conveyor Mode .............................................. |

10 |

Shutdown ........................................................................... |

10 |

Programming menu Items ................................................. |

10 |

Editing Setpoint Temperatures........................................... |

13 |

Changing Temperature Unit of measure............................ |

13 |

Uploading from a USB Drive ............................................. |

14 |

Maintenance ........................................................................ |

15 |

General .............................................................................. |

15 |

Daily Cleaning.................................................................... |

15 |

monthly Cleaning ............................................................... |

15 |

Troubleshooting Guide ...................................................... |

17 |

Options and Accessories................................................... |

18 |

Limited Warranty................................................................. |

19 |

Authorized Parts Distributors............................ |

Back Cover |

IMPORTANT OWNER INFORMATION

|

|

|

Record the model number, serial number, voltage, and |

Business |

|

purchase date of the unit in the spaces below (specification |

Hours: |

7:00 am to 5:00 Pm |

label located on the left side of the unit). Please have this |

|

Central Standard Time (CST) |

information available when calling Ovention® for service |

|

(Summer Hours: June to September – |

assistance. |

|

|

model No. ________________________________________ |

|

7:00 am to 5:00 Pm CST monday through Thursday |

|

7:00 am to 4:00 Pm CST Friday) |

|

Serial No. ________________________________________ |

Telephone: |

855-298-6836 (Ovention Hotline) |

Voltage __________________________________________ |

E-mail: |

partsandservice@oventionovens.com |

Date of Purchase __________________________________ |

additional information can be found |

|

by visiting our web site at www.oventionovens.com.

Need help?

Call our 24 hour, toll-free

Ovention Hotline

INTRODUCTION

Ovention Shuttle® Ovens set a new standard in cooking quality, speed, flexibility, and efficiency. a new discovery in air handling not only speeds the cooking process, but “scrubs” and recirculates the air through the oven—eliminating the need for a hood system in most installations (non-catalyst [NC] models require a hood system). Using icon-driven touchscreens, operators can use, edit, and develop over 1000 custom menu items. menu items can be developed to include up to three cooking stages, each with varying heat profiles, upper and lower air velocity settings, and timing.

Ovention Shuttle Ovens are designed with multi-function touchscreen controllers and conveyor belt that enable individual cooking sequences as well as non-stop operation of the oven. Shuttle doors on each side of the oven chamber maintain control and efficiency when cooking items with specific settings. Ovention Shuttle Ovens are products of extensive research and field testing. The materials used were selected for maximum durability, attractive appearance, and optimum performance. Every unit is inspected and tested thoroughly prior to shipment.

This manual provides the installation, safety, and operating instructions for Ovention Shuttle Ovens. Ovention recommends all installation, operating, and safety instructions appearing in this manual be read prior to installation or operation of the oven. Safety information that appears in this manual is identified by the following signal word panels:

WARNING WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION CAUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

NOTICE NOTICE is used to address practices not related to personal injury.

2 |

Form No. OVSm-0116 |

|

IMPORTANT SAFETy INFORMATION

Read the following important safety information before using this .equipment to avoid serious injury or death and to avoid damage to equipment or property

WARNING

ELECTRIC ShOCK hAzARD:

• Plug unit into a properly grounded electrical receptacle of the correct voltage, size, and plug configuration. If plug and receptacle do not match, contact a qualified electrician to determine and install proper voltage and size electrical receptacle.

• Unit must be grounded properly. Failure to ground unit properly could result in serious personal injury or death.

• Turn off Standby switch, allow unit to cool, and unplug unit/turn OFF Main Disconnect switch before performing any cleaning, adjustments, or maintenance.

• DO NOT submerge or saturate with water. Unit is not waterproof. Do not operate if unit has been submerged or saturated with water.

• Unit is not weatherproof. Locate unit indoors where ambient air temperature is a minimum of 70°F (21°C).

• Do not steam clean or use excessive water on unit.

• This unit is not “jet-proof” construction. Do not use jetclean spray to clean this unit.

• Do not clean unit when it is energized or hot.

• Do not clean unit with metal scouring pads. Metal pieces can break off pad and touch electrical components, creating risk of electric shock.

• Do not pull unit by power cord.

• Keep power cord away from heated surfaces.

• Do not allow power cord to hang over edge of counter.

• Discontinue use if power cord is frayed or worn.

• Do not attempt to repair or replace a damaged power cord. Cord must be replaced by an Authorized Ovention Service Agent or a person with similar qualifications.

• This unit must be serviced by qualified personnel only. Service by unqualified personnel may lead to electric shock or burn.

• Use only Genuine Ovention Replacement Parts when service is required. Failure to use Genuine Ovention Replacement Parts will void all warranties and may subject operators of the equipment to hazardous electrical voltage, resulting in electrical shock or burn. Genuine Ovention Replacement Parts are specified to operate safely in the environments in which they are used. Some aftermarket or generic replacement parts do not have the characteristics that will allow them to operate safely in Ovention equipment.

FIRE hAzARD:

• Do not install unit on or around combustible surfaces. Discoloration or combustion could occur. Unit must be installed in non-combustible surroundings only.

• Do not use an extension cord. If power cord is too |

|

short, contact a qualified electrician to determine and |

|

install proper voltage and size electrical receptacle near |

|

unit. |

|

Form No. OVSm-0116 |

3 |

|

WARNING

ExPLOSION hAzARD: Do not store or use gasoline or other flammable vapors or liquids in the vicinity of this or any other appliance.

Install unit in accordance with installation instructions in this manual.

This oven is designed specifically to heat or cook—NOT for industrial or laboratory use.

In the event of emergency, turn OFF Main Disconnect switch.

Make sure all operators have been instructed on the safe and proper use of the unit.

This unit is not intended for use by children or persons with reduced physical, sensory, or mental capabilities. Ensure proper supervision of children and keep them away from the unit.

Unit may be located adjacent to a slippery floor.

This unit has no “user-serviceable” parts. If service is required on this unit, contact an Authorized Ovention Service Agent or contact the Ovention hotline at 855-298-6836.

BURN hAzARD:

CAUTION

• Some exterior surfaces on unit will get hot. Avoid unnecessary contact with unit.

• Pan/tray will be very hot upon removal—use oven mitt, pan gripper, or other utensil to remove.

Do not turn off Main Disconnect switch or unplug unit immediately after use. Internal fans must cool oven to avoid damage to electrical components.

Locate unit at proper counter height in an area that is convenient for use. Location should be level to prevent unit or its contents from falling accidentally and strong enough to support the weight of the unit and contents.

DO NOT lift unit by conveyor frame on each side of oven chamber. Conveyor is not designed to support weight of unit. Lift from underneath oven chamber only.

Do not move or relocate unit for cleaning. Unit is bulky and heavy.

Do not place anything on top of unit; doing so may subject personnel to injury or could damage unit.

Do not heat sealed containers or products such as whole eggs in oven. These items may explode.

Do not store any materials or items inside oven chamber when not in use.

Improper cleaning of oven could damage catalyst and will void unit warranty.

IMPORTANT SAFETy INFORMATION

|

|

NOTICE |

|

|

NOTICE |

|

|

Allow a minimum clearance of 1″ (25 mm) along the sides |

Use non-abrasive cleaners and cloths only. Abrasive |

||||||

and rear of unit for proper ventilation. Do not block or |

cleaners and cloths could scratch finish of unit, marring its |

||||||

cover any cabinet venting. |

appearance and making it susceptible to soil accumulation. |

||||||

|

|

|

|

|

|

|

|

Do not cover racks or any other part of oven with metal foil. |

Clean unit daily to avoid malfunctions and maintain |

||||||

Airflow restriction will cause oven to overheat. |

sanitary operation. |

||||||

|

|

|

|

|

|

|

|

Do not lay unit on front or back side. Damage to unit could |

|

|

|

||||

occur. |

|

|

|

||||

MODEL DESCRIPTION |

|

|

|

|

|

All Models |

Operator controls consist of two touchscreens, a Standby switch, |

||||

Ovention® Shuttle® Ovens are designed to provide unequaled |

and a main Disconnect switch. adjustable door panels on each |

||||

flexibility in both kitchen and front-of-the-house installations. The |

side of the oven chamber can be used to customize the chamber |

||||

opening height. Two removable crumb trays, one below each side |

|||||

variety of menu options, small footprint, low heat escape, and the |

|||||

of the conveyor, allow for easy cleanup. a USB port allows the |

|||||

option for hood-less installation make the Shuttle Oven a single |

|||||

uploading of pre-programmed menu items, installation of software |

|||||

solution alternative to multiple pieces of cooking equipment. |

|||||

updates, and opportunity for service diagnostics. a 6′ (1829 mm) |

|||||

|

|||||

Each Shuttle Oven is equipped with dedicated upper and lower |

cord and plug set is standard. |

|

|

||

heating elements and air blowers. The air blowers direct heated |

NOTE: To prevent delay |

in obtaining warranty |

coverage, |

||

air through upper and lower jet plates inside the oven chamber, |

|||||

complete online |

warranty registration. |

See |

the |

||

above and below the food. a conveyor belt moves product from |

|||||

ImPORTaNT OWNER INFORmaTION section |

for |

||||

one side of the conveyor, through the oven chamber, to the |

|||||

opposite side of the conveyor. Two cooking modes, Shuttle |

details. |

|

|

Mode and Conveyor Mode, allow the oven to cook single items |

|

with specific heat/time settings as well as multiple items |

|

continuously like a standard conveyor oven. |

|

Left Side

of Conveyor Oven Chamber

Shuttle Door (open position)

Conveyor Belt

Conveyor

End Stop

Optical Sensor |

|

Oven Door |

Touchscreens |

|

USB Port |

Optical |

|

Sensor |

Standy Switch |

|

model Description (model S2000 shown)

4

Right Side

of Conveyor

Adjustable

Door Panel

Conveyor

End Stop

Crumb Shuttle Door Tray

Crumb Shuttle Door Tray

(closed position)

Form No. OVSm-0116

|

|

MODEL DESIGNATION |

|

|

|

|

|

|

|

S X X X X |

|

|

Oven Type: |

Model Number: |

|

|

S = Shuttle |

1200 = 12" x 12" Cavity With Catalyst |

|

|

|

2000 = 20" x 20" Cavity With Catalyst |

|

|

|

2000NC = 20" x 20" Cavity, No Catalyst |

|

|

|

|

|

SPECIFICATIONS

Plug Configuration

Units are equipped with an electrical cord and plug appropriate for the electrical rating of the unit. Unit must be connected to a dedicated circuit.

WARNING |

|

|

ELECTRIC ShOCK hAzARD: Plug unit into a properly |

NEMA 6-30P |

NEMA 6-50P |

grounded electrical receptacle of the correct voltage, size, |

|

|

and plug configuration. If plug and receptacle do not |

|

|

match, contact a qualified electrician to determine and |

Plug Configuration |

|

install proper voltage and size electrical receptacle. |

NOTE: Receptacle not supplied by Ovention. |

|

|

||

Electrical Rating Chart

Model |

Voltage |

Watts |

Amps |

S1200 |

208/240 |

5408 |

26 |

S1200CSa |

208 |

4992 |

24 |

S1200 (HW) |

208/240 |

6656 |

32 |

S2000 |

208/240 |

9152/11760 |

44/49 |

S2000CSa |

208 |

8320 |

40 |

NOTE: Ovention Shuttle Ovens with the voltage shown as “208/240” are designed to accept either 208 VAC or 240 VAC. The oven will adjust automatically to the input voltage.

Phase |

hertz |

Plug Configuration |

Unit Weight |

1 |

60 |

NEma 6-30P |

167 lbs. (76 kg) |

1 |

60 |

NEma 6-30P |

167 lbs. (76 kg) |

1 |

60 |

NEma 6-50P |

167 lbs. (76 kg) |

1 |

60 |

NEma 6-50P |

230 lbs. (104 kg) |

1 |

60 |

NEma 6-50P |

230 lbs. (104 kg) |

NOTE: The specification label is located on the left side of the unit. See the label for the serial number and verification of unit electrical information.

Temperature Range

The operating temperature range of the Shuttle Ovens is 300°–525°F (149°–274°C).

Form No. OVSm-0116 |

5 |

|

|

|

SPECIFICATIONS |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions |

|

|

|

|

|

|

|

|

|

|

|

Model |

Overall |

Depth |

height |

Footprint |

Footprint |

Rear |

Platform |

Body |

|

|

|

Width (A) |

(B) |

(C) |

Width (D) |

Depth (E) |

Width (F) |

Width (G) |

Width (h) |

||

|

|

S1200 |

50-1/16″ |

31″ |

20-1/4″ |

16-7/16″ |

22″ |

31-3/16″ |

13-1/2″ |

17-1/8″ |

|

|

|

|

(1271 mm) |

(787 mm) |

(514 mm) |

(417 mm) |

(558 mm) |

(891 mm) |

(343 mm) |

(434 mm) |

|

|

|

S2000 |

63-5/16″ |

36-7/8″ |

20-1/4″ |

20-5/16″ |

26″ |

35-1/8″ |

17-7/8″ |

21″ |

|

|

|

|

(1608 mm) |

(936 mm) |

(514 mm) |

(516 mm) |

(659 mm) |

(891 mm) |

(454 mm) |

(533 mm) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

|

|

|

B |

|

|

|

C

D

D

Front View

Power Cord

F

Specification Label on left side of unit.

E

E

Side View

Oven Cavity Dimensions

Model S1200

16" W x 16″ D x 3-1/4″ H (406 x 406 x 82 mm)

Model S2000

20" W x 20″ D x 3-1/4″ H (508 x 508 x 82 mm)

G

G

H

H

G

G

Top View

6 |

Form No. OVSm-0116 |

|

Loading...

Loading...