Page 1

www.orioncontrols.com

®

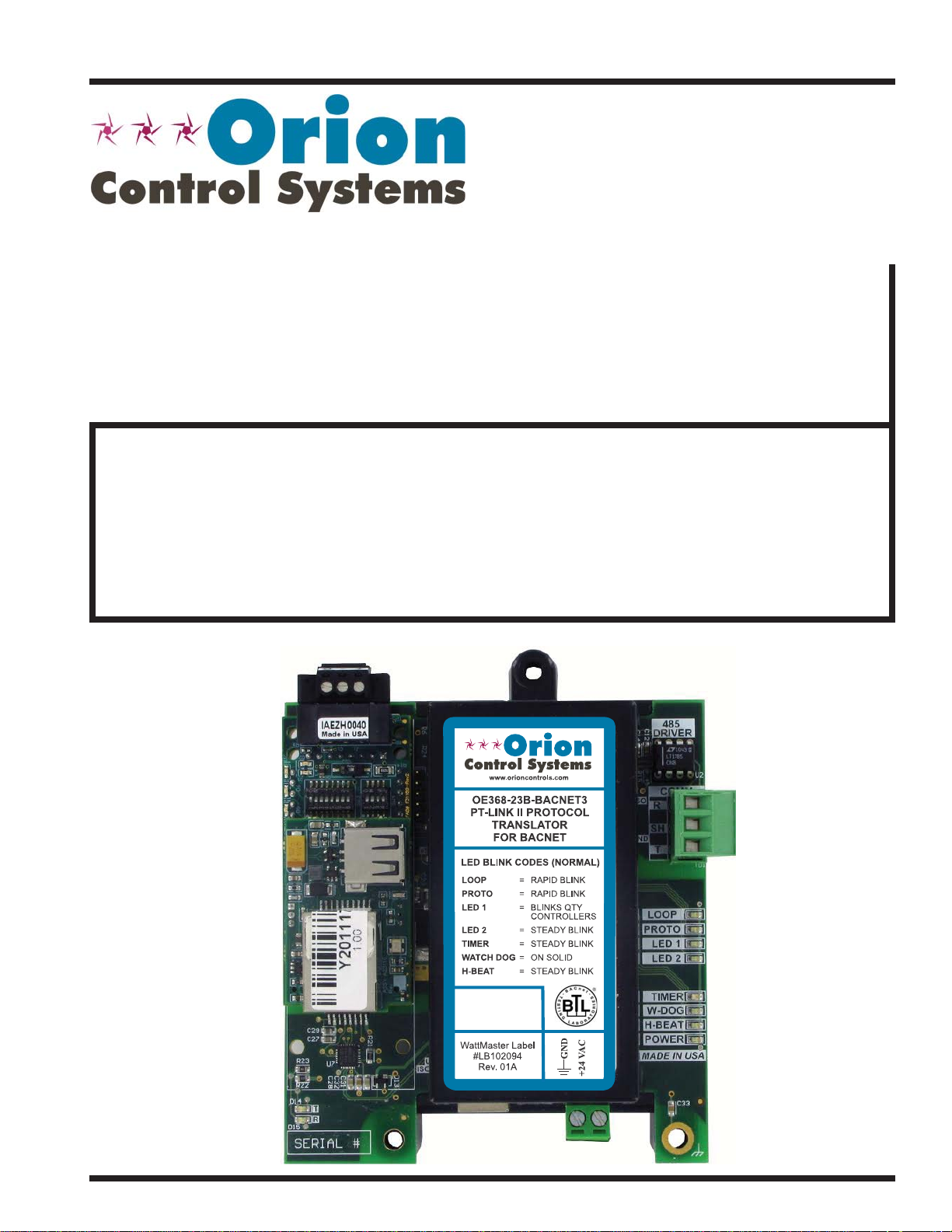

PT-Link II BACnet3

Technical Guide

RNE Controller Code: SS1045

VCB-X Controller Code: SS1051 Version 2.0

VCM-X Controller Code: SS1026 & Y200920 Version 2.0 and up;

VCM-X Modular Controller Code: SS1030 & SS1034

VCM-X WSHP Controller Code: SS1032 & SS1033

SA Controller Code: Y200921

VCM Controller Code: SS1016, Y200409, Y200616, Y200822

Page 2

Zone

TABLE OF CONTENTS

Zone

1. GENERAL INFORMATION ................................................................................. 4

1.1 Overview and System Requirements ................................................................................................................4

1.1.1 Data Sharing ............................................................................................................................................4

1.1.2 Scheduling ...............................................................................................................................................4

1.1.3 Hardware Specifi cations ..........................................................................................................................4

1.1.4 System Requirements .............................................................................................................................4

2. SETTING UP YOUR PT-LINK II ......................................................................... 5

2.1 Quick Start Guide ..............................................................................................................................................5

2.2 Connection and Wiring Information ...................................................................................................................6

2.3 Confi guring the PT-Link DIP Switches ..............................................................................................................7

2.3.1. Set the BACnet MS/TP Baud Rate ..........................................................................................................7

2.3.2. Set the BACnet MS/TP MAC Address .....................................................................................................7

3. PT-LINK CONFIGURATION ............................................................................... 8

3.1 FS-GUI ..............................................................................................................................................................8

3.2 PT-Link II Ethernet Connection .........................................................................................................................9

3.3 IP Address Confi guration ................................................................................................................................10

3.3.1 Computer IP Address Set-up for Windows XP, Vista, 7 & 8 ..................................................................10

3.3.1.1 Computer IP Address Set-up for Windows NT & XP .................................................................10

3.3.1.2 Computer IP Address Set-up for Windows Vista, 7 & 8 ............................................................. 11

3.3.2 BACnet MS/TP: Setting Node_Offset to Assign Specifi c Device Instances ......................................... 12

3.4 Changing the Confi g.sys File ................................................................................................................... .......13

3.4.1 Verifying Communications .....................................................................................................................15

4. UPDATING THE SOFTWARE ........................................................................... 16

4.1 Updating the PT-Link II Controller ...................................................................................................................16

4.1.1 Programming the PT-Link II with BootLoader ........................................................................................16

4.1.2 Finding What COM Port Number the PT-Link II is Using .......................................................................18

4.1.3 Changing the USB COM Port Number ..................................................................................................19

4.2 Updating the Field Server Software ................................................................................................................20

WattMaster Controls, Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 · E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

Form: OR-PTLNK3BTL-TGD-01D

Copyright June 2015 WattMaster Controls, Inc.

BACnet® is a registered trademark of ASHRAE Inc., Atlanta, GA.

FieldServer is a Registered Trademark of FieldServer T echnologies, Milpetas, CA

WattMaster Controls, Inc. assumes no responsibility for errors or omissions.

This document is subject to change without notice.

2

PT-Link II BACnet3 Interface

Page 3

TABLE OF CONTENTS

5. TROUBLESHOOTING ...................................................................................... 21

5.1 Troubleshooting Communications ...................................................................................................................21

5.1.1 Check Wiring and Settings ....................................................................................................................21

5.1.2 Verifying Communications .....................................................................................................................21

5.2 Troubleshooting LEDs .....................................................................................................................................22

5.2.1 PT-Link Board LEDs ..............................................................................................................................22

5.2.2 PT-Link Module LEDs ............................................................................................................................23

5.3 Troubleshooting the PT-Link Controller ...........................................................................................................24

5.3.1 Addressing WattMaster Devices in a BACnet® Network. ......................................................................24

5.3.2 CAS BACnet Explorer for Validating PT-Link in the Field ......................................................................24

5.3.2.1 Downloading the CAS Explorer and Requesting an Activation Key .......................................... 24

5.3.2.2 CAS BACnet MS/TP Setup ........................................................................................................25

5.3.3 Viewing Diagnostic Information .............................................................................................................25

5.4 FieldServer Diagnostic Utilities .......................................................................................................................26

5.4.1 Diagnostic Capture Procedures ............................................................................................................. 26

6. DATA ARRAYS ................................................................................................. 28

6.1 VCB-X & VCM-X Modular Data Arrays ...........................................................................................................28

6.2 VCM-X WSHP Coil & VCM-X WSHP Tulsa / RNE Data Arrays ......................................................................29

6.3 VCM-X & SA Data Arrays ................................................................................................................................30

6.4 VCM Data Array ..............................................................................................................................................31

7. PARAMETER TABLES ..................................................................................... 32

7.1 VCB-X BACnet Parameters ............................................................................................................................33

7.1.1 VCB-X PT-Link II BACnet® Property Identifi er ......................................................................................43

7.2 VCM-X Modular BACnet Parameters .............................................................................................................44

7.3 VCM-X WSHP (Tulsa) & RNE BACnet Parameters ........................................................................................45

7.4 VCM-X WSHP (Coil) BACnet Parameters ......................................................................................................47

7.5 VCM-X PT-Link II BACnet® Property Identifi er ...............................................................................................48

7.5.1 VCB-X PT-Link II BACnet® Property Identifi er ......................................................................................53

7.6 SA Controller BACnet Parameters ..................................................................................................................54

7.6.1 SA Controller PT-Link-BACnet®Property Identifi er:...............................................................................57

7.7 VCM BACnet Parameters ...............................................................................................................................58

7.7.1 VCM PT-Link II BACnet® Property Identifi er: ........................................................................................63

8. FIELDSERVER GRAPHICAL USER INTERFACE .............................................. 64

8.1 The FieldServer Graphical User Interface (FS-GUI) with Confi guration Parameter page Navigation Tree ....64

8.2 Network Settings .............................................................................................................................................65

8.3 Setting a Password for the FS-GUI .................................................................................................................65

9. NODE ID (DEVICE INSTANCE) & MAC ADDRESS ........................................... 67

10. BACNET PIC STATEMENT ............................................................................ 70

10.1 Protocessor Driver - (PICS) BACnet Protocol Implementation Conformance Statement .............................70

PT-Link II BACnet3 Interface

3

Page 4

Zone

1. GENERAL INFORMATION

1.1 Overview and System Requirements

Zone

The OE368-23B-BACNET3, PT -Link II BACnet® provides bi-directional communication between your BACnet® MS/TP protocol network and

up to four* of any of the following types of Orion controllers—VCM-X,

VCB-X, RNE, SA, VCM, MUA II, or VAV/CAV:

VCM-X Controller (SS1026, SS1030, SS1032, SS1033,

SS1034, Y200920)

VCB-X Controller (SS1051)

RNE Controller (SS1045)

SA Controller (Y200921)

VCM Controller (SS1016, Y200409, Y200616, Y200822)

**VAV/CAV Controller (SS1003, Y200301) and

MUA II Controller (SS1004, Y200405)

To determine what controller you have, you must look at the label located

on the controller. NOTE: The label is located on the EPROM on older

devices. If the controller label does not match any of the SS or Y numbers

listed above, your controller will not work with the PT -Link II BACnet®.

*NOTE: The PT-Link II BACnet® device can be used to con-

nect to four Orion controllers. If more than four Orion

controllers are present in a system, you will need additional PT-Link II BACnet® devices.

1.1.2 Scheduling

• Allows BACnet

to the Orion controller side of the gateway by using

standard BACnet® services.

®

devices to send Schedule events

1.1.3 Hardware Specifi cations

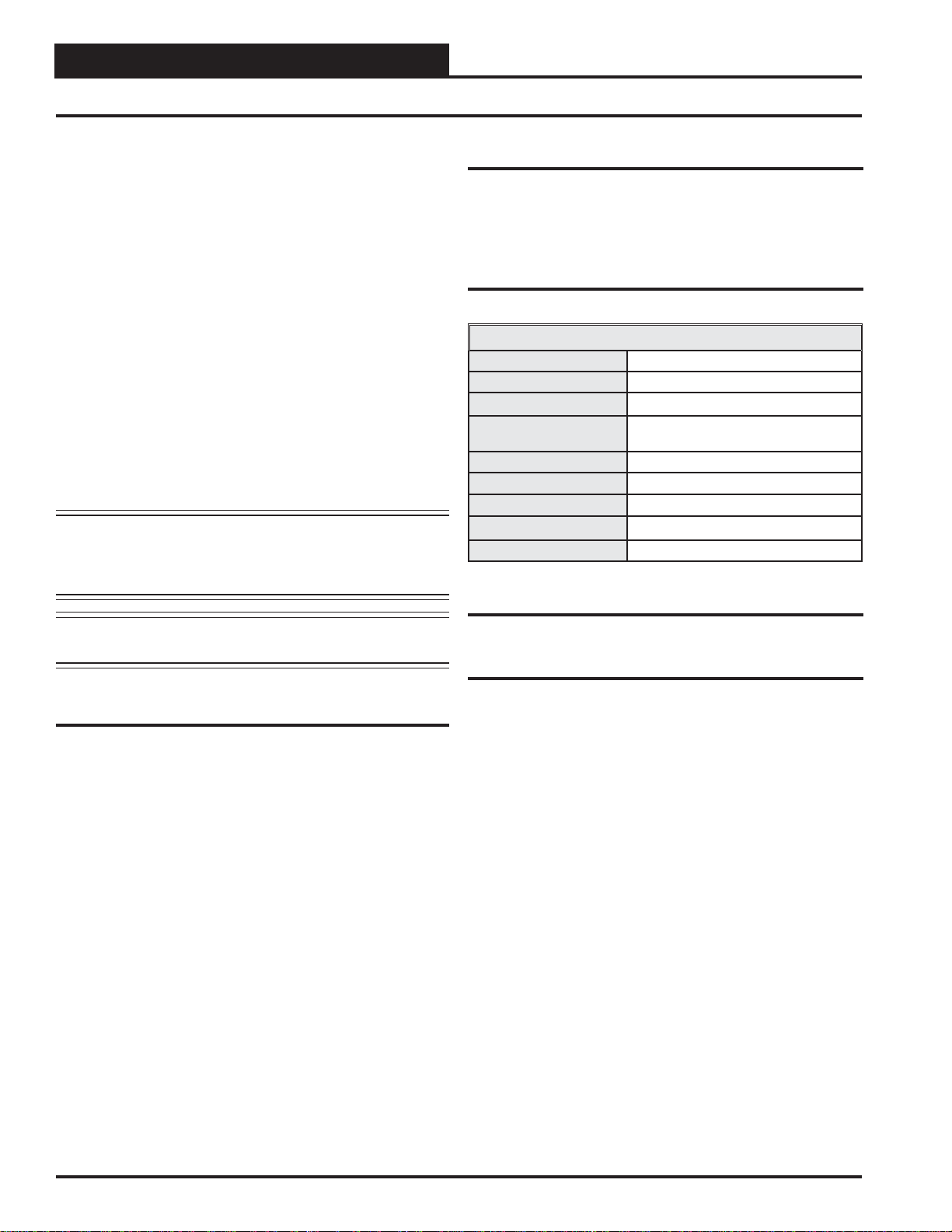

Technical Data

BACnet®-MS/TP Loop

Controller Loop

Network Protocol

Protocol

(WattMaster Loop)

Power Input Voltage

Power Consumption

Operating T emp

Operating Humidity

Weight

Table 1: PT-Link II BACnet® Interface

Technical Data

9600, 19200, 38400, 76800 Mbps

RS-485, 9600 Baud Rate

BACnet®

HSI Open Protocol Token Passing

24 VAC

10 VA Maximum

-30°F to 150°F

90% RH Non-Condensing

4.5 oz.

**NOTE: Documentation is available for MUA II/VAV/CA V on

our Orion Controls website: www.orioncontrols.com.

1.1.1 Data Sharing

• Provides values from points on the Orion side of the

gateway to BACnet® devices as if the values were

originating from BACnet® objects.

• Allows BACnet

Orion controller side of the PT-Link II BACnet® by using

standard BACnet

®

devices to modify point values on the

®

write services.

1.1.4 System Requirements

• The PT-Link II BACnet

assembled for panel mounting. Panel mounting components

are included for your convenience.

• Computer running Microsoft Windows

system.

®

interface is packaged and

TM

operating

• Ethernet Crossover Cable (supplied).

• PT-Link II BACnet software—located on included CD-

ROM and downloadable from www.orioncontrols.com.

4

PT-Link II BACnet3 Interface

Page 5

2. QUICK PT-LINK SET-UP

2.1 Quick Start Guide

The following steps will get you up and running in no time:

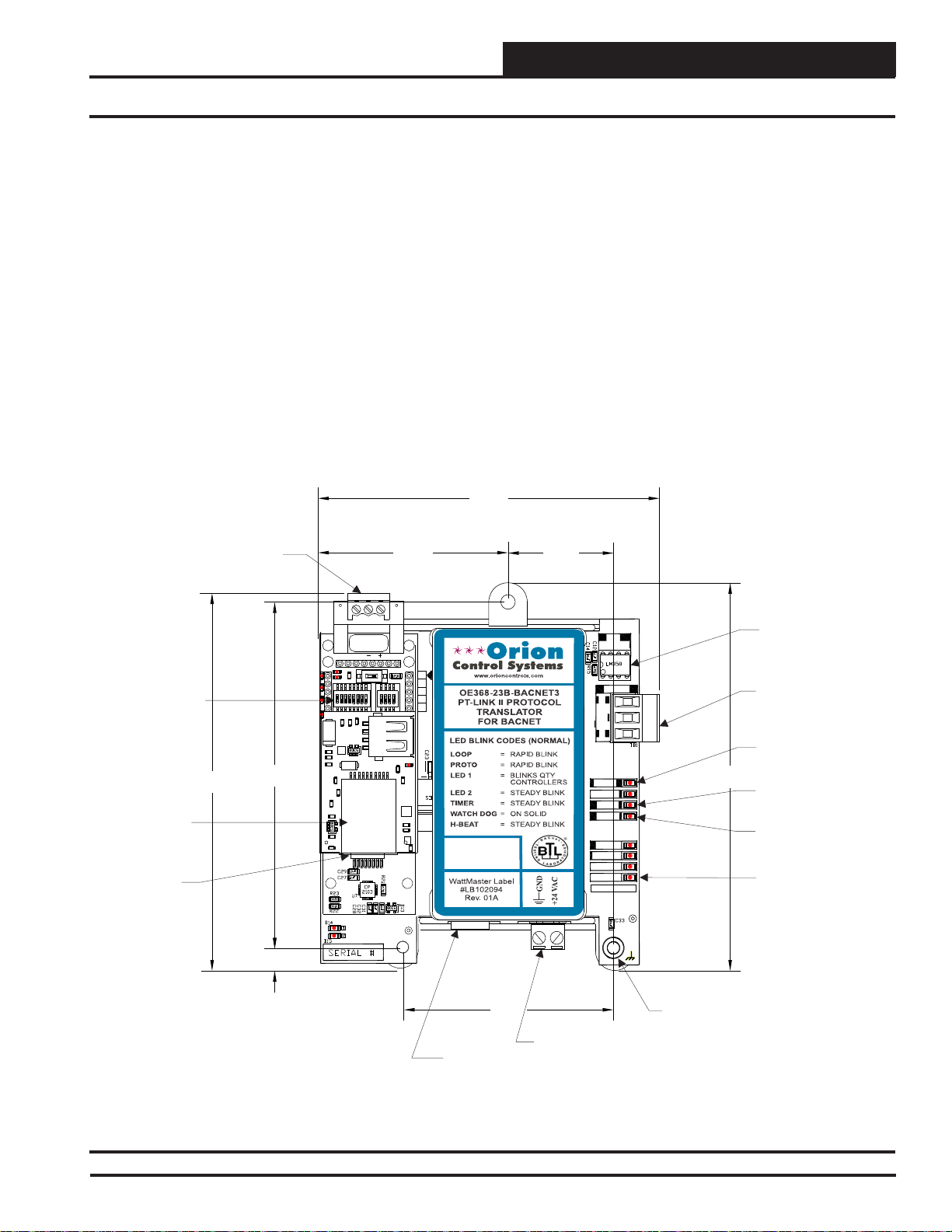

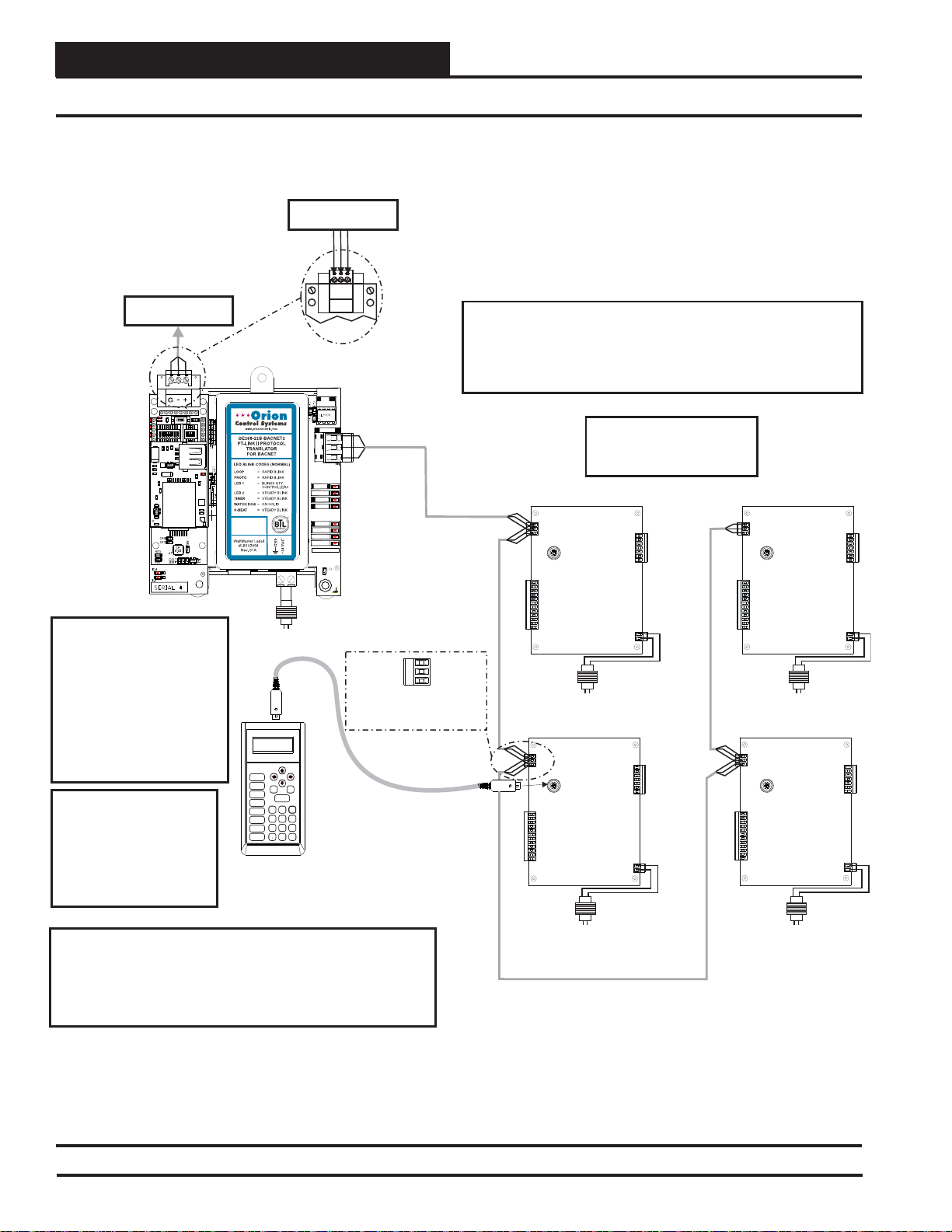

1. Familiarize yourself with the PT-Link II components (Figure 1).

2. Connect your PT-Link II to the Controller(s) on your system (up

to four) and connect your PT-Link II to the BACnet Network

(Figure 2). NOTE: Controllers must be addressed as

1, 2, 3 & 4.

3. Obtain the following from your Building Automation System

Integrator: the BACnet MAC address (System Node ID) and the

MS/TP network baud rate. Also, relay to your System Integrator

that the BACnet Device Instance Number for the PT-Link will be

the MAC address + 50,000. If this Device Instance will not work,

then continue to the full setup.

®

BACnet

Communications

Wiring Terminal

2.37

4. Confi gure your PT Link DIP Switches. See Section 2.3, page 7.

• Set the BACnet MS/TP baud rate via the B Bank set of DIP

switches.

• Set the BACnet MS/TP MAC Address using the PT-Link A

Bank DIP switches. The BACnet MS/TP MAC Address

MUST be set between 1 and 127.

4.25

1.31

Configuration

DIP Switches

®

BACnet

Protocessor

Module

Ethernet

Port

4.70

4.31

0.27

O

N

2

1

IAEZH004

Made in USA

RSGND

345

678

485

DRIVER

Local Loop

Communications

Driver Chip

ON

O

N

4

2

3

1

COMM

R

SH

T

Local Loop

Communications

Wiring Terminal

Communications

LED

4.82

Diagnostic

LED #1

Diagnostic

LED #2

Power

LED

2.61

LOOP

PROTO

LED1

LED2

TIMER

W_DOG

H-BEAT

POWER

MADE IN USA

0.20 Dia.

Mounting Hole

Typ. 3 PL.

USB

24 VAC Power

Terminal

Port

Figure 1: PT-Link II BACnet® Dimensions and Components

PT-Link II BACnet3 Interface

5

Page 6

2. QUICK PT-LINK SET-UP

2.2 Connection and Wiring Information

Zone

Zone

MS/TP Connection

To Network

BACnet

®

MS/TP Connection

To Network

BACnet

®

PT-Link Interface

485

RSGND

ON

O

O

N

N

4

2

345

678

2

3

1

1

Caution: The BACnet

®

Communication Terminal Block

Line Voltage

DRIVER

COMM

R

SH

T

LOOP

PROTO

LED1

LED2

TIMER

W_DOG

H-BEAT

POWER

MADE IN USA

24 VAC

(10 VA)

Must Be Disconnected Before

Connecting The Modular

Service Tool. After

Programming The

Controller(s), Disconnect The

Service Tool and Then

Typical Terminal Blocks. All

Wiring To Be T To T, SHLD

(G) To SHLD (G) & R To R

Reconnect The

Communication Terminal

Block.

Note: All Programming Of

Controllers Must Be Done

Using The Modular Service

Tool. The Modular System

Manager Should Not Be

Used On A System That

Modular Service Tool

Mode

Selection

STATUS

SETPOINTS

SCHEDULES

OVERRIDES

ALARMS

CONFIGURATION

BALANCE - TEST

ON

UP

PREV

DOWN

ESC

ENTER

13

2

708

DEC

NEXT

CLEAR

654

9

MINUS

-

Has A PT-Link Installed.

Wiring Notes:

1.) All wiring to be in accordance with local and national electrical

codes and specifications.

IMPORTANT WIRING NOTE:

Use the Daisy-Chain Topology As Shown in This Diagram.

DO NOT Use a Star Topology with Multiple Units Tied

Directly to the PT-Link II.

Up To 4 Controllers

Can Be Interconnected.

Address Controllers

As Shown.

Controller

Address 1

T

SHLD

R

24 VAC

(8 VA)

Line Voltage

Controller

Address 3 Address 4

24 VAC

(8 VA)

Line Voltage

Controller

Address 2

24 VAC

(8 VA)

Line Voltage

Controller

24 VAC

(8 VA)

Line Voltage

2.) All communication wiring to be 18 gauge minimum, 2 conductor

twisted pair with shield. Use Belden #82760 or equivalent.

Figure 2: PT-Link II BACnet® Interface Wiring

6

PT-Link II BACnet3 Interface

Page 7

2. QUICK PT-LINK SET-UP

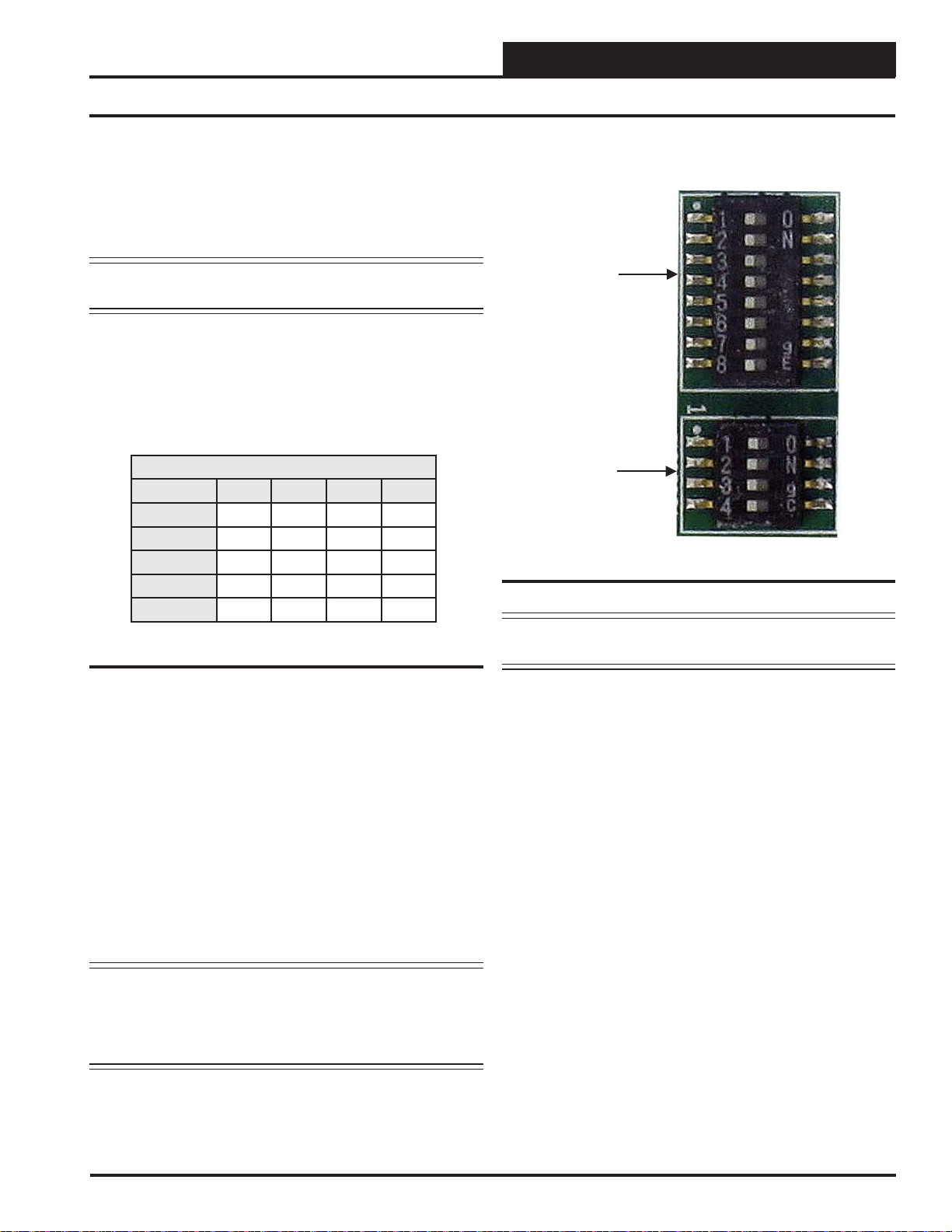

2.3 Confi guring the PT-Link DIP Switches

The DIP Switches allow you to set the protocol between BACnet MS/TP

and BACnet IP, set the BACnet MS/TP Baud Rate, and set the BACnet

MS/TP MAC address, and set the BACnet MS/TP device instance. You

can obtain the MAC address, Device Instance, and baud rate from your

Building Automation System (BAS) Integrator. The DIP Switches are

shown in Figure 3.

NOTE: Y ou must cycle power after making changes to the DIP

Switch Settings for the settings to take effect.

2.3.1 Set the BACnet MS/TP Baud Rate

“B” bank DIP switches B1 – B4 is used to set the BACnet MS/TP baud

rate of the PT -Link. This matches the baud rate required by the Building

Management System for BACnet MS/TP.

Using B1 – B4 to Set Baud Rate

Baud B1 B2 B3 B4

9600 ON ON ON ON

19200 OFF OFF OFF ON

38400 ON ON OFF ON

57600 OFF OFF ON ON

76800 ON OFF ON ON

Table 2: Baud Rate Settings

FFP-485

DIP

Switch

Bank A

DIP

Switch

Bank B

Figure 3: DIP Switches

CAUTION: DIP Switch 8 in Bank A must always remain off

for proper operation.

2.3.2 Set the BACnet MS/TP MAC Address

1. Only (1) MAC address is set for the PT-Link regardless of how

many devices are connected to it.

2. Set the BACnet MS/TP MAC addresses of the PT-Link to a value

between 1 and 127 (MAC Master Addresses). This is so that the BMS

Front End can fi nd the PT-Link via the BACnet auto discovery func-

tion. MAC addresses from 128 to 255 cannot be auto discovered by

the BMS Front End.

3. Set “A” bank DIP switches A1 – A7 to assign a MAC Address to

the PT-Link for BACnet MS/TP. Please refer to Section 9, page 67

for the complete range of MAC Addresses and DIP switch settings.

NOTE: The BACnet Device’s Instance is generated by adding

the MAC address to the Node Offset, which defaults to

50,000. If the Device Instance must be set to something

other than in the range of 50,001 to 50,127, see Section

3.3.2, page 12 to change the Node Offset value.

PT-Link II BACnet3 Interface

7

Page 8

3. PT-LINK CONFIGURATION

3.1 Graphical User Interface

Zone

Zone

The PT-Link is confi gured using a Graphic User Interface (GUI)

which is a password protected web browser-based interface that uses

a combination of technologies and devices to provide a platform from

which you can gather and process information. The GUI allows you

to do the following:

• Change the BACnet Device Instance to something other

than 50,001 to 50,127

• Check the status and diagnostics of the PT-Link,

such as network settings, connection information, node

information, map descriptors, and error messages

• Monitor the PT-Link’s internal data and parameters

• Change or update the PT-Link’s internal data and

parameters

• Restart the PT-Link

The following items are needed to be able to run the GUI:

• PC Requirements—a computer with a web browser that

connects over the Ethernet on port 80*

*NOTE: Computer and network fi rewalls must be

opened for Port 80 to allow the GUI to function.

• Software Requirements—Mozilla Firefox 13.0 and up,

Microsoft Internet Explorer 8 & 9**, Google Chrome 19.0

and up, Opera 11 and up, or Safari 4.1 and up

**NOTE: Internet Explorer 8 does have some limitations

in terms of graphical features. Some effects such as rounded

corners and semi-opaque backgrounds are not supported.

So, although technical functionality is operational, the looks

might be slightly different

8

PT-Link II BACnet3 Interface

Page 9

3. PT-LINK CONFIGURATION

Ethernet Cable

Ethernet Hub

Or Switch

Connect Ethernet

Cable To

Ethernet

Connect

Ethernet

Cables To

Ethernet Hub

Ports

1

2

3

4

Ethernet Cable

Connect Ethernet

Crossover Cable

To PT-Link Ethernet

Port

PT-Link BACnet

485

DRIVER

COMM

R

SH

T

LOOP

PROTO

LED1

LED2

TIMER

W_DOG

H-BEAT

POWER

MADE IN USA

Computer

1

2

34567

8

O

N

O

N

1

2

3

4

ON

RSGND

5308

1210

5308

IAEZH004

Made in USA

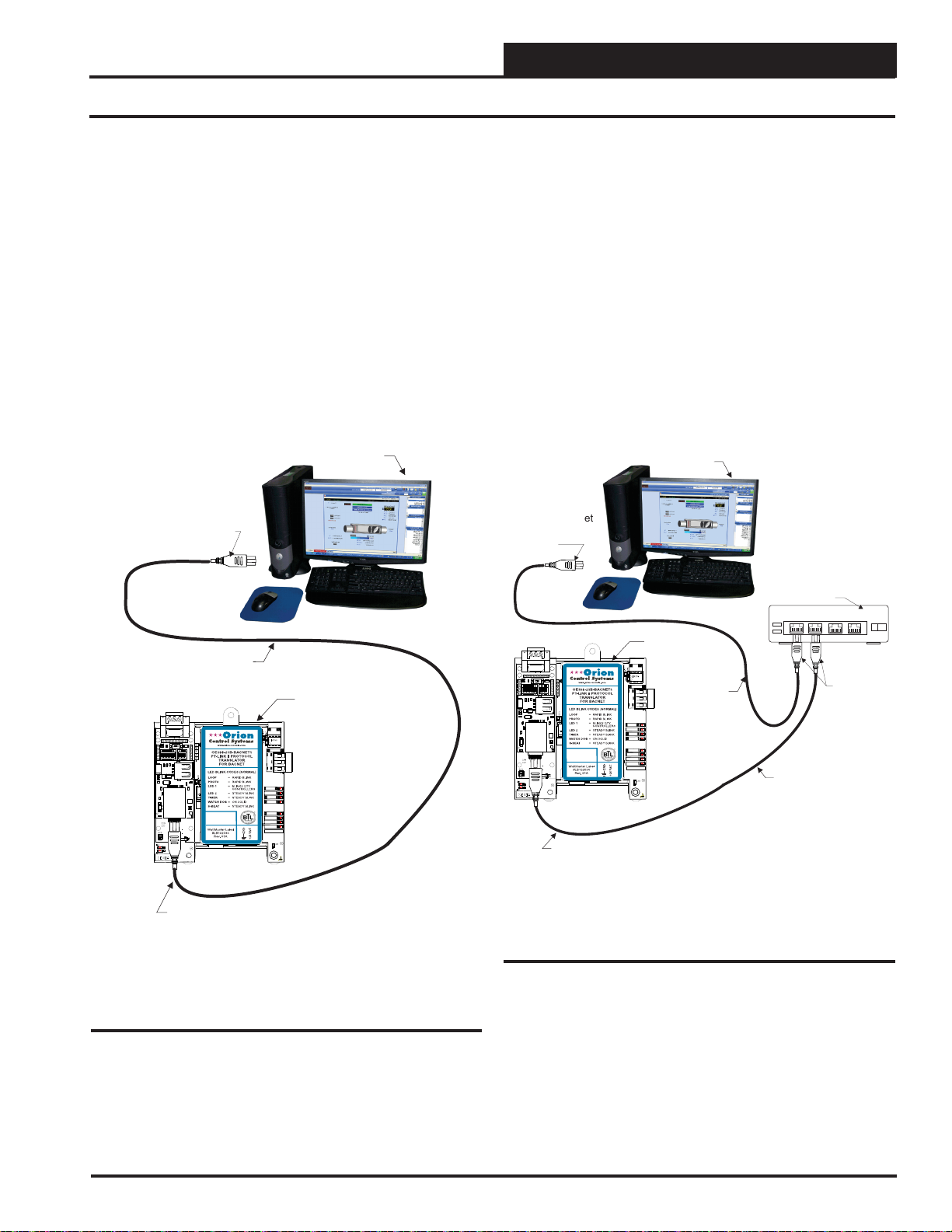

3.2 PT-Link II Ethernet Connection

You have two options for connecting the PT-Link II to your PC via

Ethernet:

1.) You may connect the PT-Link II directly to your PC by

using a standard CAT5 or crossover cable (by others) as

shown. See Figure 4 for details.

2.) You can also connect both your PC and the PT-Link II to

an Ethernet Hub or Ethernet Switch with standard CAT5

cables. See Figure 5 for details.

Computer

Connect Ethernet

Crossover Cable Directly

To PC Ethernet Card Port

Locate a CA T5 cable and plug one end into your computer’s Ethernet port.

If connecting directly, plug the other end of the Cable into the Ethernet

port on the PT -Link II. If connecting through an Ethernet Hub or Switch,

plug the other end of the PC cable into the hub, and use a second CAT5

cable to connect the PT-Link II to the hub as well.

Power up the PT-Link II by plugging in the power cable. The PT-Link

II may take up to three minutes to power up completely. Once the PTLink II is powered up, you should notice that the RUN LED is blinking

continuously on the ProtoCessor Board. See Figure 28, page 23 for a

diagram showing the location of the ProtoCessor RUN LED.

Ethernet Crossover Cable

PT-Link BACnet

IAEZH004

Made in USA

RSGND

1210

ON

O

O

N

N

4

2

2

3

34567

8

1

1

5308

5308

Connect Ethernet

Crossover Cable

To PT-Link Ethernet

Port

Figure 4: Connecting With Crossover Cable

485

DRIVER

COMM

R

SH

T

LOOP

PROTO

LED1

LED2

TIMER

W_DOG

H-BEAT

POWER

MADE IN USA

Figure 5: Connecting With Ethernet Cable & Hub

PT-Link II BACnet3 Interface

9

Page 10

3. PT-LINK CONFIGURATION

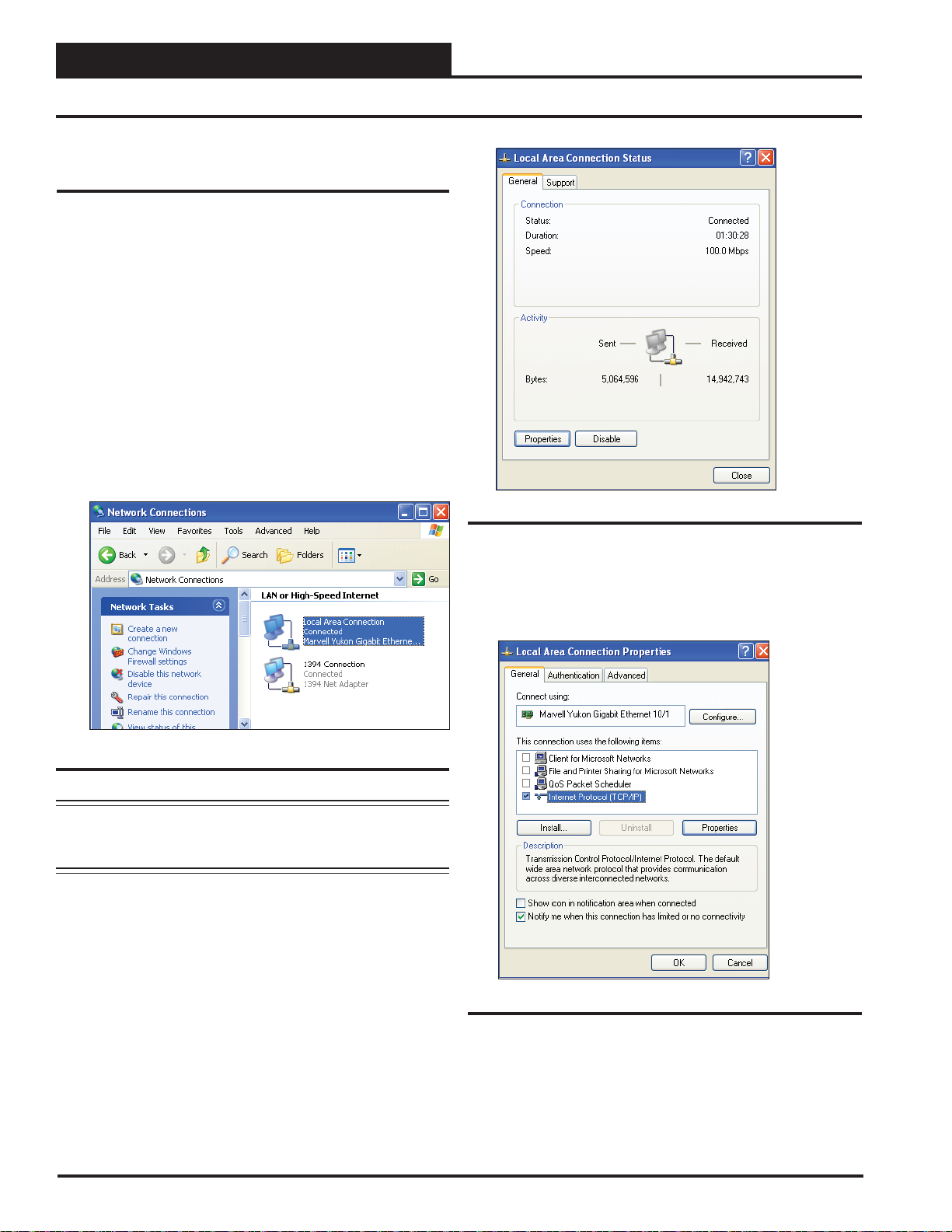

3.3 IP Address Confi guration

3.3.1 Computer IP Address Set-up for

Windows XP, Vista, 7 & 8

In order for the PT -Link II to communicate properly, it is imperative to

set the IP address of both the PT-Link II as well as the computer to be

within the same netmask. You need to change the IP address on your

computer. The following instructions will explain how to con fi gure the IP

address for Microsoft® Windows XP, V ista, 7, and 8 operating systems.

3.3.1.1 Computer IP Address Set-up for

Windows NT & XP

1.) Click <start>; then click <Control Panel>.

2.) Double-click on the Network Connections icon.

The Network Connections Window will appear (Figure 6).

Zone

Zone

Figure 6: Network Connections Window

NOTE: If any wireless connections are listed, disable them

by right-clicking the connection and selecting

<Disable>.

3.) In the Network Connections Window, double-click the

Local Area Connections entry. The Local Area Connection

Status Window will appear (Figure 7).

Figure 7: Local Area Connection Status Window

4.) As shown in Figure 7, click <Properties> in the lower

left of the window. The Local Area Connection Properties

Window will appear.

10

Figure 8: Local Area Connection Properties Window

5). As shown in Figure 8, in the Connection Items list box,

be sure the Internet Protocol (TCP/IP) is checked. Select the

Internet Protocol (TCP/IP) item to highlight it and then click

<Properties>. The Internet Protocol Properties Window will

appear.

PT-Link II BACnet3 Interface

Page 11

3. PT-LINK CONFIGURATION

3.3 IP Address Confi guration

3.3.1.2 Computer IP Address Set-up for

Windows Vista, 7 & 8

1.) Click <start>; then click <Control Panel> (Vista &

Windows 7). Click <start>; then right-click for <All apps>.

Click <All apps> and then click <Control Panel>

(Windows 8).

2.) Click on the Network and Internet icon.

3.) Click Network and Sharing Center.

4.) From the shaded box in the left side of the window, select

Manage Network Connections (Vista) or Change adapter

settings (Windows 7).

5.) Right-click on the Local Area Connection icon and select

<Properties> for the drop down window.

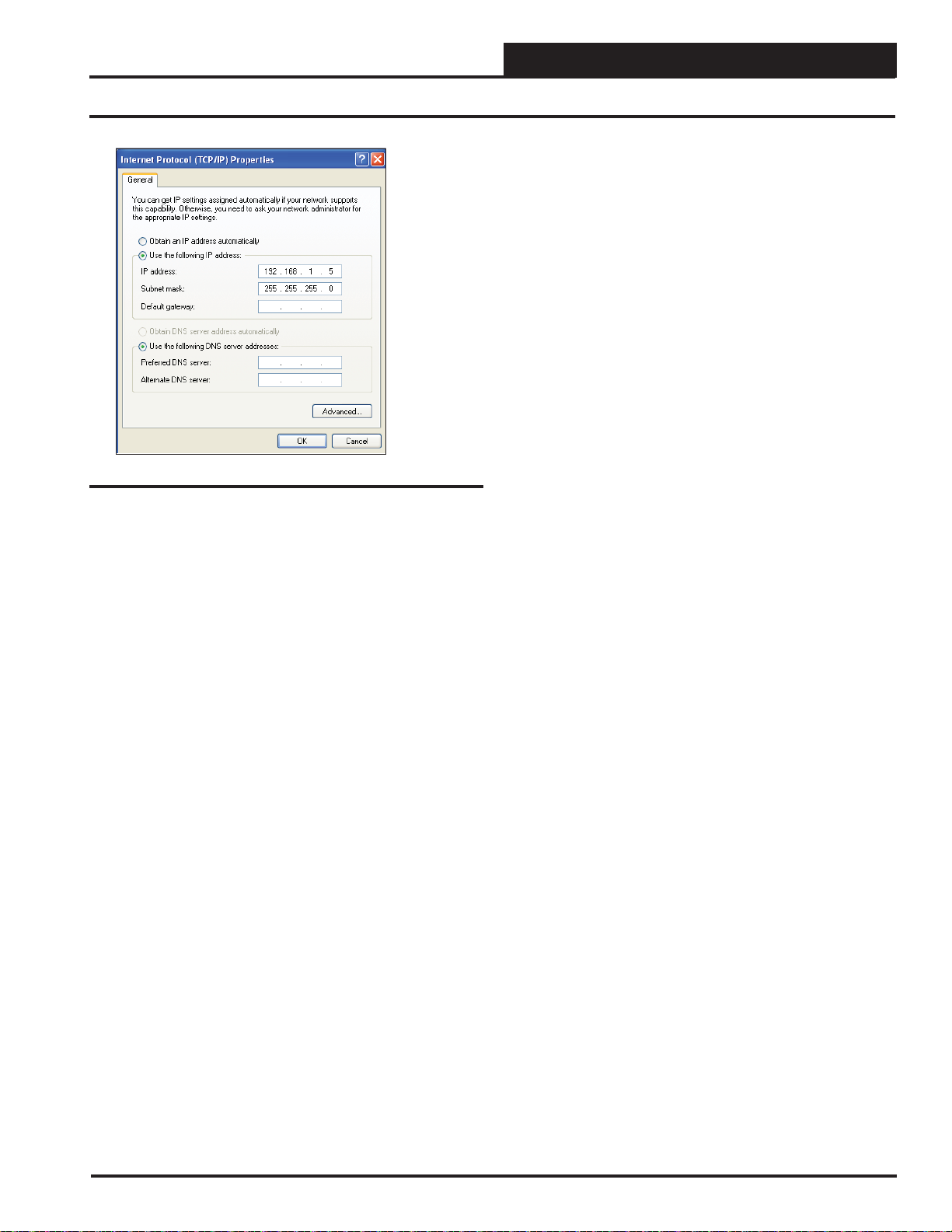

Figure 9: Internet Protocol Properties Window

6). Select the radio button in front of Use the following

IP address (Figure 9) and write down the current defaults

so that you can re-enter them when you fi nish confi guring

the PT-Link and then type in the following

information:

a.) IP address 192.168.1.5

b.) Subnet mask 255.255.255.0

c.) Default Gateway is blank

7.) Click <OK> until all of the above network confi guration

windows are closed. You may have to reboot the computer

before the new values are valid.

6.) Choose Internet Protocol Version 4 (TCP/IPv4) by

highlighting it and then click <Properties>. The Internet

Protocol Properties Window will appear (Figure 9).

7.) Select the radio button in front of Use the following

IP address (Figure 9) and write down the current defaults

so that you can re-enter them when you fi nish confi guring

the PT-Link and then type in the following

information:

a.) IP address 192.168.1.5

b.) Subnet mask 255.255.255.0

c.) Default Gateway is blank

8.) Click <OK> until all of the above network confi guration

windows are closed. You may have to reboot the computer

before the new values are valid.

PT-Link II BACnet3 Interface

11

Page 12

3. PT-LINK CONFIGURATION

3.3 IP Address Confi guration

3.3.2 BACnet MS/TP - Setting Node_

Offset to Assign Specifi c Device

Instances

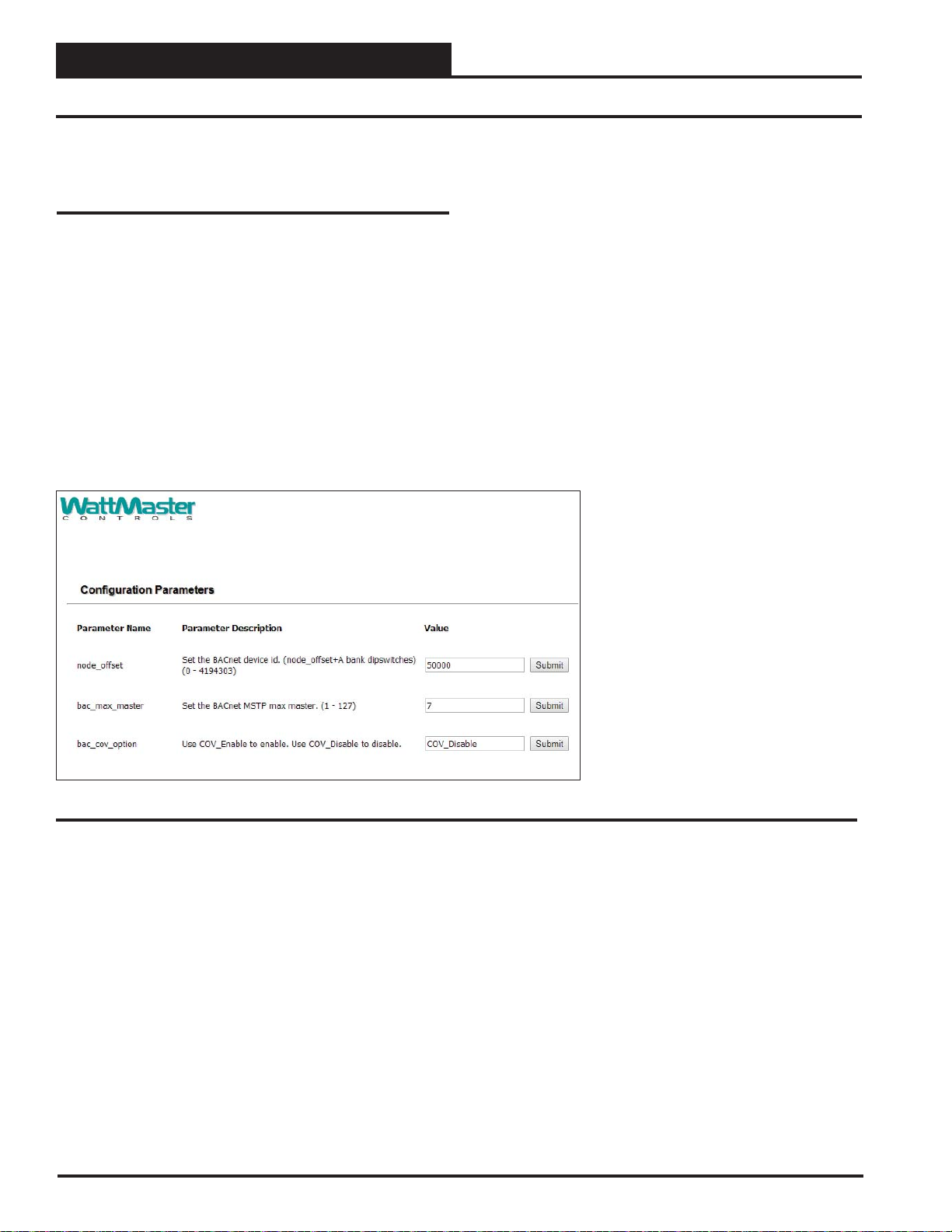

After setting your PC to be on the same subnet as the PT-Link,

open a web browser on your PC and enter the IP address of

the PT-Link; the default address is 192.168.1.24. (Figure 10).

1. If the IP address of the PT-Link has been changed by previous

confi guration, you will need to get the assigned IP address from the

network administrator or use the FieldServer ToolBox to fi nd the

IP Address.

2. The confi guration page will be displayed as your landing page.

(Figure 10)

3. The node offset can be changed on the confi guration page.

Zone

Zone

Figure 10: BACnet MS/TP Settings for Node_Offset

4. The Node_Offset fi eld will be presented displaying the current

value (default = 50,000).

5. Change the value of Node_Offset to establish the desired Device

Instance value, and click <Submit>.

Device Instance = Node_Offset +

A bank DIP switch setting

(A1-A7)

12

PT-Link II BACnet3 Interface

Page 13

3. PT-LINK CONFIGURATION

3.4 Changing the Confi g.csv File

NOTE: You may need Administration rights to perform this

function. See the Password Section, page 65.

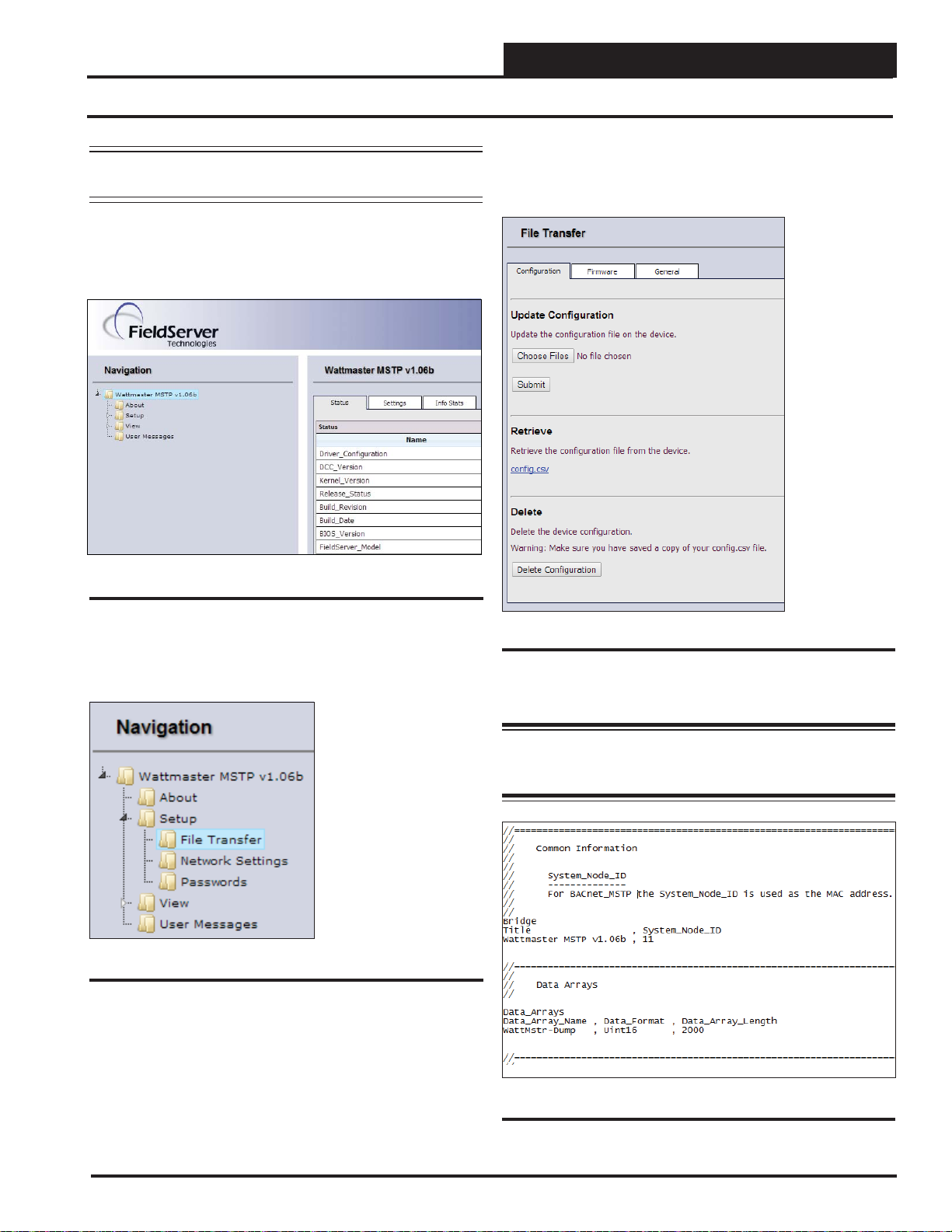

1.) Open your web browser, and type the IP Address of the PT-Link,

which defaults to <192.168.1.24>, and press <ENTER>. The GUI

will launch. See Figure 11.

Figure 11: The FS-GUI Main Screen

3.) Refer to the File Transfer Window below (Figure 13). In the Con-

fi guration Tab, under Retrieve, click the confi g.csv fi le in order to save

it to a destination and then open it.

2.) In the Navigation Window on the left of the FS-GUI Screen, click

<Setup> and then click <File Transfer>. See Figure 12.

Figure 12: Navigation Window - File Transfer

Figure 13: File Transfer - Confi guration Tab

4.) Open the confi g.csv fi le in Notepad. See Figure 14.

WARNING: Only edit the confi g.csv fi le using Notepad. DO

NOT use Excel. Using Excel to edit the confi g.csv fi le will

corrupt its contents!

PT-Link II BACnet3 Interface

Figure 14: Confi g.csv File

13

Page 14

3. PT-LINK CONFIGURATION

3.4 Changing the Confi g.csv File

Zone

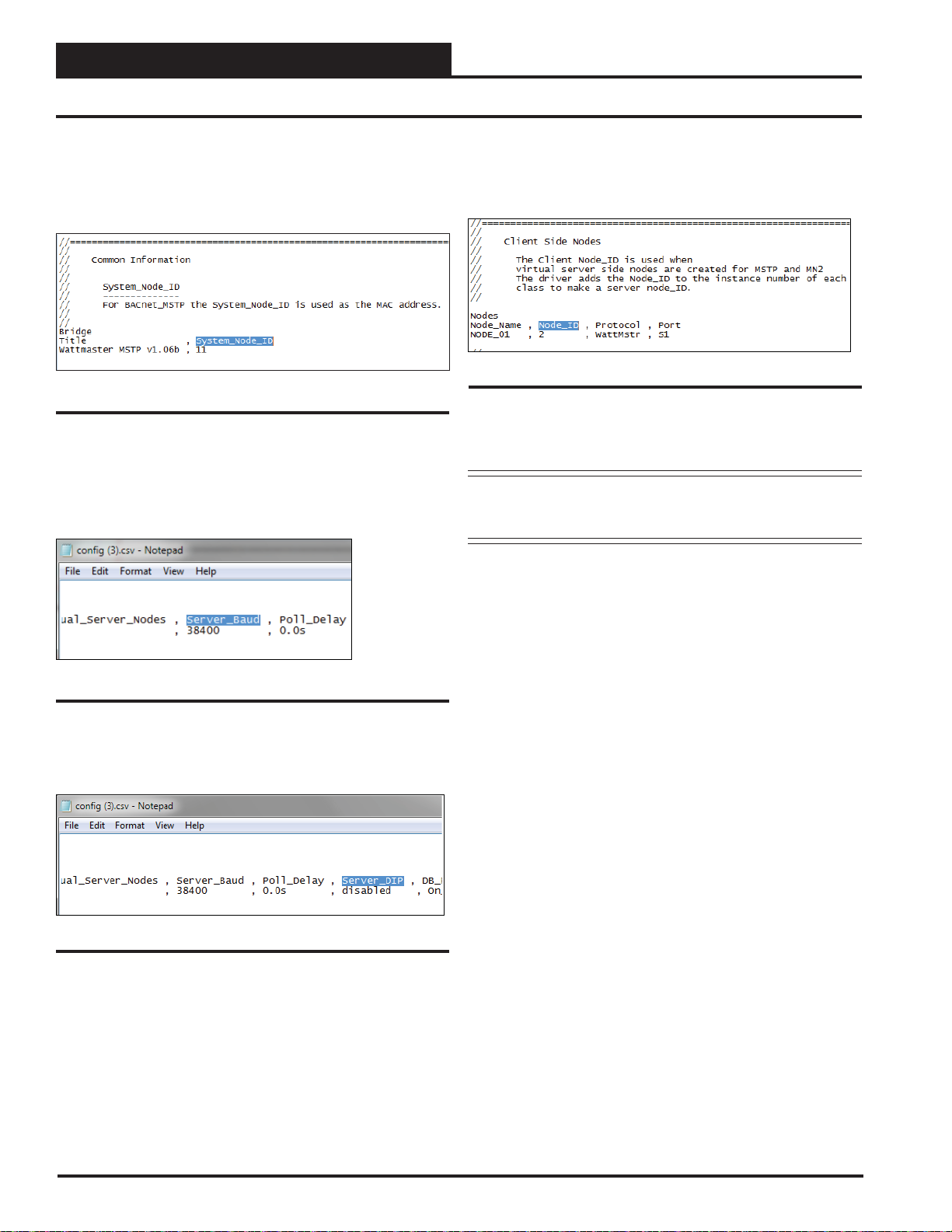

Zone

5.) Near the top of the text fi le under ‘System_Node_ID’, change the

BACnet MAC address from the default of 11 (Figure 15). You can

obtain this address to enter from your Building Automation System

(BAS) Integrator.

Figure 15: System Node ID

6.) If you need to change the server baud rate, under ‘Connections’,

change the Server_Baud (Figure 16). Possible Baud Rate values are

(9600, 19200, 38400, and 76800). The default Baud Rate is 38400. You

can obtain the correct baud rate from your BAS Integrator.

8.) The last change you may need to make is the Node_ID under ‘Client

Side Nodes’ which is the BACnet Device Instance Number (Figure 18).

The default is 1.Y ou can obtain the Node ID from your BAS Integrator.

Figure 18: Client Node ID

9.) Once all changes have been made to the text fi le, while still in

Notepad, click <File> in the upper left and then click <Save>. Now

close the fi le and return to the FS-GUI Screen open in your browser.

NOTE: Do not rename the fi le. The fi le must always be named

“confi g.csv”; otherwise, it will be ignored by the PT-

Link.

Figure 16: Server Baud Rate

7.) Inside the text fi le under ‘Connections’, change the ‘Server_DIP’

parameter from ‘Enabled’ to ‘Disabled’. (See Figure 17).

Figure 17: Server Dip Switch

14

PT-Link II BACnet3 Interface

Page 15

3. PT-LINK CONFIGURATION

3.4 Changing the Confi g.csv File

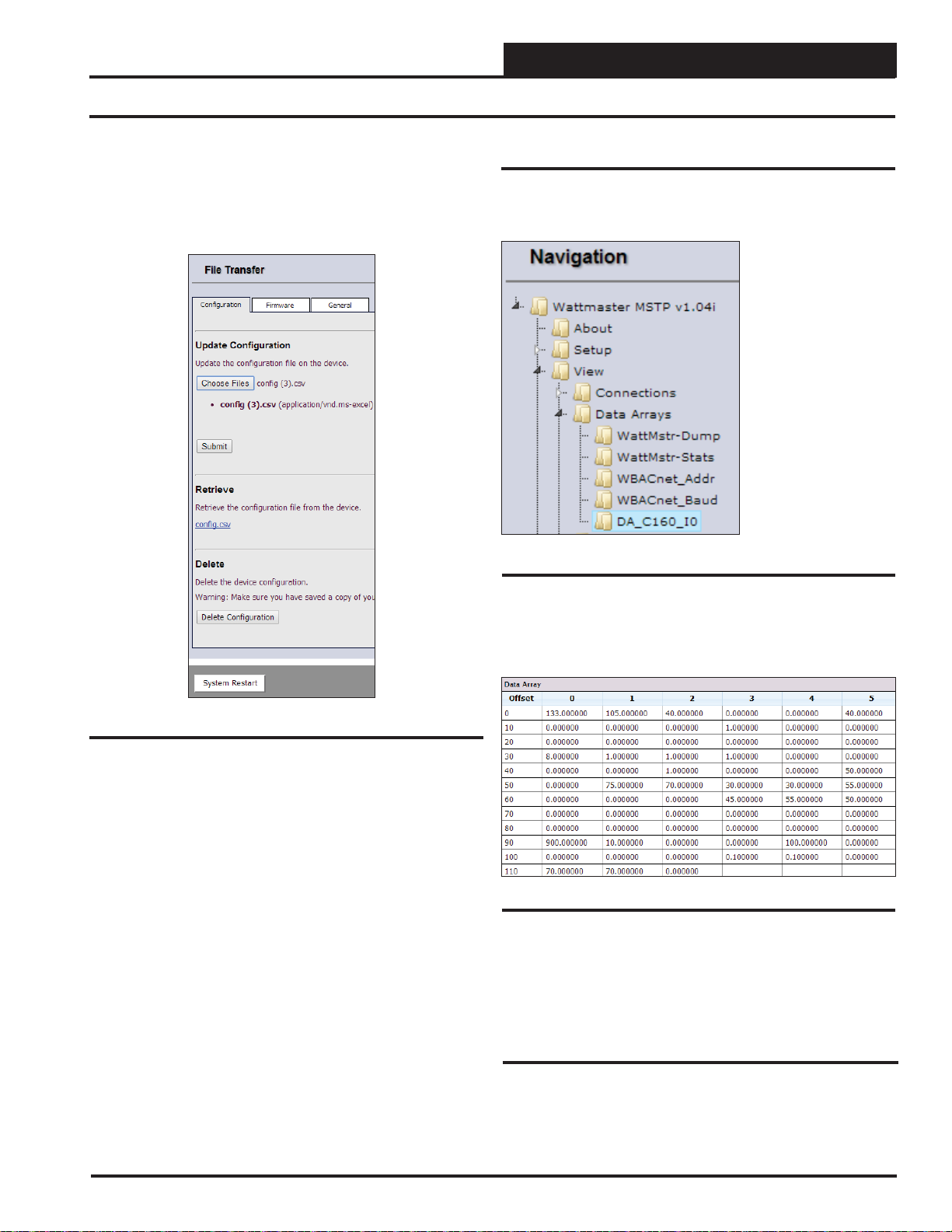

10.) In the File Transfer Window under Update Confi guration, click

<Choose Files> or <Browse>and locate the confi g.csv fi le you just

saved. Then click <Submit>. See Figure 19. Wait until the message,

“Confi guration update complete” appears and then click the <System

Restart> button at the bottom of the File Transfer W indow to activate

the new confi guration fi le.

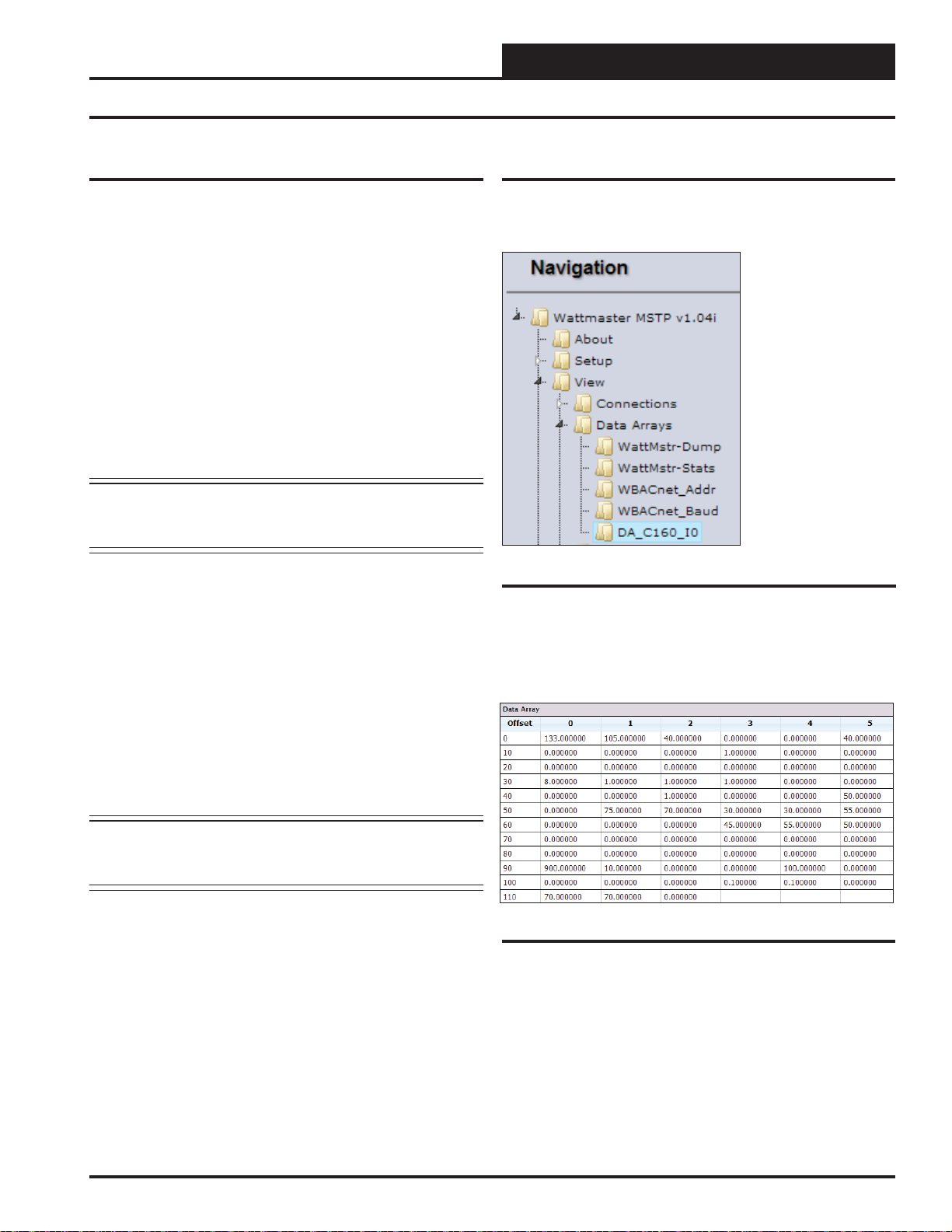

3.4.1 Verifying Communications

1. ) In the Navigation Window on the left of the FS-GUI Main Screen,

click

<View> and then click <Data Arrays>. See Figure 20.

Figure 20: Navigation Window - View Data Arrays

Figure 19: Update Confi guration

NOTE: The following fi les can also be udpated in File Transfer W indow:

Firmware Files: The FieldServer Firmware contains the application

program commonly referred to as the DCC or the PCC. This program

contains the protocol drivers applicable to the application and the FieldServer Operating System Kernel. A Firmware update is only required

when updated fi les are received from FieldServer support. Firmware

fi les have a *.bin extension. The procedure for updating these is the

same as for the confi guration fi les, but the update needs to be made in

the Firmware Tab.

General (Other) Files: Other fi les that can be updated include the FS-

GUI image and other fi les described in driver manuals. The procedure for

updating these is the same as for the confi guration fi les, but the update

needs to be made in the General Tab.

2. ) Click on the Controller name. In this case, it is DA_C160_I0, a

VCM-X Controller. The Controller’s Data Array Table will display.

See Figure 21.

Figure 21: VCM-X Data Array Table

3 ) You can now cross reference the values shown in Figure 21 with

the listed parameter names in the appropriate Data Array Table for your

controller type. These tables can be found on pages 28-31.

3.4.2 FS-GUI Reference Guide

PT-Link II BACnet3 Interface

An FS-GUI Reference Guide can be found in Section 8, page 64.

15

Page 16

4. UPDATING THE SOFTWARE

4.1 Updating the PT-Link II Controller

Zone

Zone

4.1.1 Programming the PT-Link II with

BootLoader

The PT-Link II is equipped with the ability to update its software with

the use of a computer. You will need the following before you begin:

• PT-Link II in need of an update (powered up,

no other connections necessary)

• Computer running Microsoft Windows

system

TM

operating

• Prism 2 software from www.orioncontrols.com

• Latest version of PT-Link II software (e-mailed from our

tech support staff or downloaded from any of our websites)

and software sheet

• USB Driver Setup.exe fi le from PT-Link II CD or

downloaded from any of our websites.

• USB cable

Follow these simple steps to update the PT-Link II:

1.) Turn on your computer and download the latest Prism 2 software

from www.orioncontrols.com.

2.) Either download the PT -Link II update fi le from http://techsupport.

wattmaster.com or save the fi le to your computer from the e-mail you

received from Tech Support. Record the path and name of the fi le for

later use. Also, print the software sheet provided for future reference.

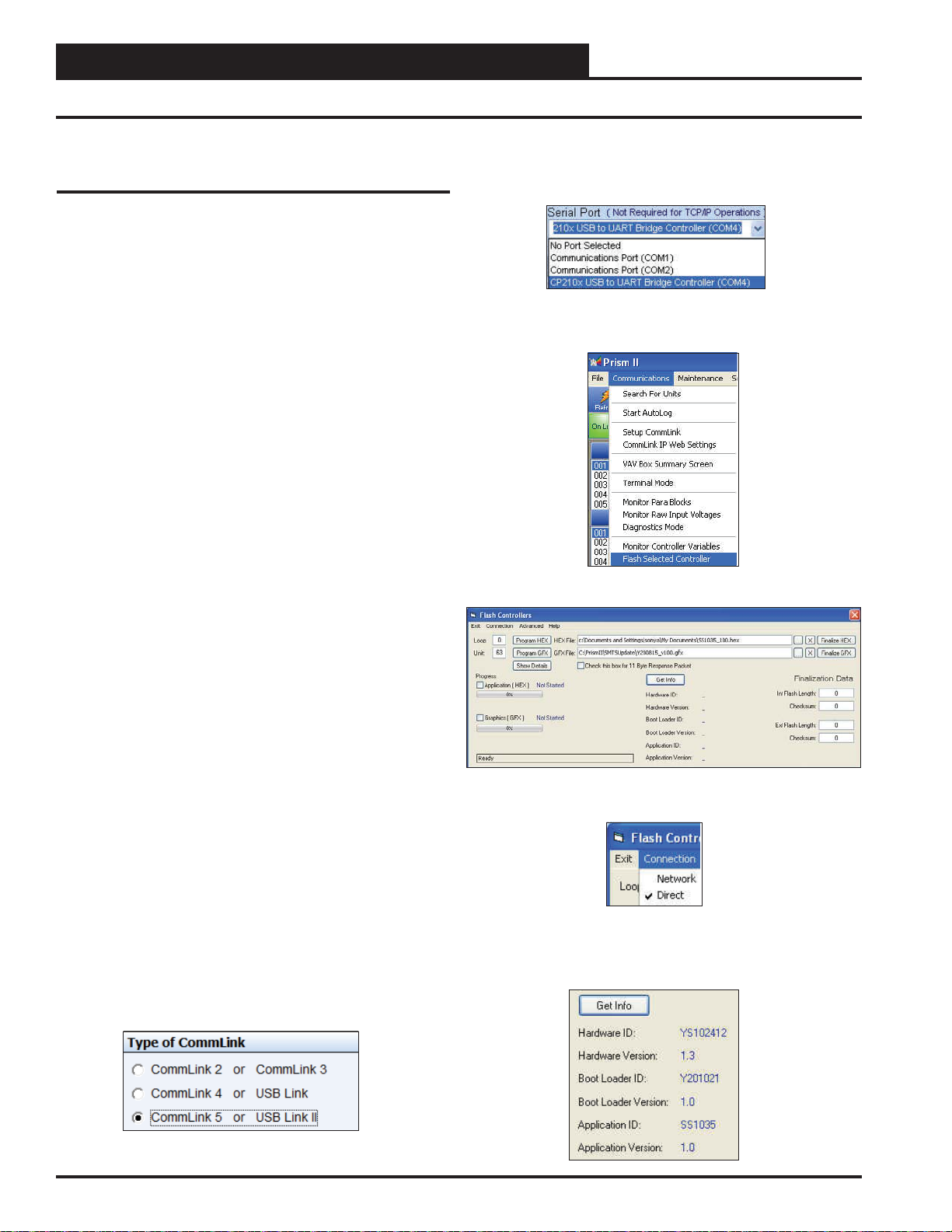

8.) In the Job-Sites Window, from the Serial Port drop down list, select

the correct COM port. If you don’t know the COM port number or if

the number is 10 or higher, follow the directions on pages 18 and 19.

9.) From Prism 2’s Communications tab, select “Flash Selected

Controller.”

10.) The Flash Controller Window will appear.

3.) Run the USB Driver Setup.exe fi le (found on the PT-Link II CD or

downloaded from any of our websites) so that Prism can communicate

to the PT Link II. Unzip the fi le to the directory where you saved your

PT-Link II software.

4.) Plug the USB cable into the computer’s and PT-Link II’s USB

ports.

5.) A message will pop-up from the lower menu bar of Windows that

reads, “Found New Hardware.” Click on this message and follow the

instructions that appear to install the USB drivers.

6.) Open Prism 2 and Login with the User Name, admin and the Password, admin. If successful, “Administrator Access” will appear at the

lower right of the Prism program. NOTE: If using a Prism 2 version

prior to 4.0, the Login is fl ash. If successful, “Level 4 Access” will ap-

pear at the lower right of the Prism program.

7.) Click on the <Job-Site> icon. The Job-Sites Window will appear. In the Type of CommLink Dialog Box, select “CommLink 5.”

11.) From the Flash Controller Window’s Connection tab, select

“Direct”. Keep the Flash Controller Window open.

12.) Cycle power to the PT-Link II and within 5 seconds, click the

<Get Info> button in the Flash Controller W indow. The PT-Link II in-

formation will now appear in the window under the <Get Info> button.

16

PT-Link II BACnet3 Interface

Page 17

4. UPDATING THE SOFTWARE

4.1 Updating the PT-Link II Controller

13.) The Application ID should be SS1035 and the Application V ersion

should match the software version you will be updating to.

14.) In the HEX File fi eld, enter the path and name of the HEX fi le you

downloaded and/or copied to your hard drive. Use the Browse button

(...) to the right of the fi eld if you need help in locating the fi le.

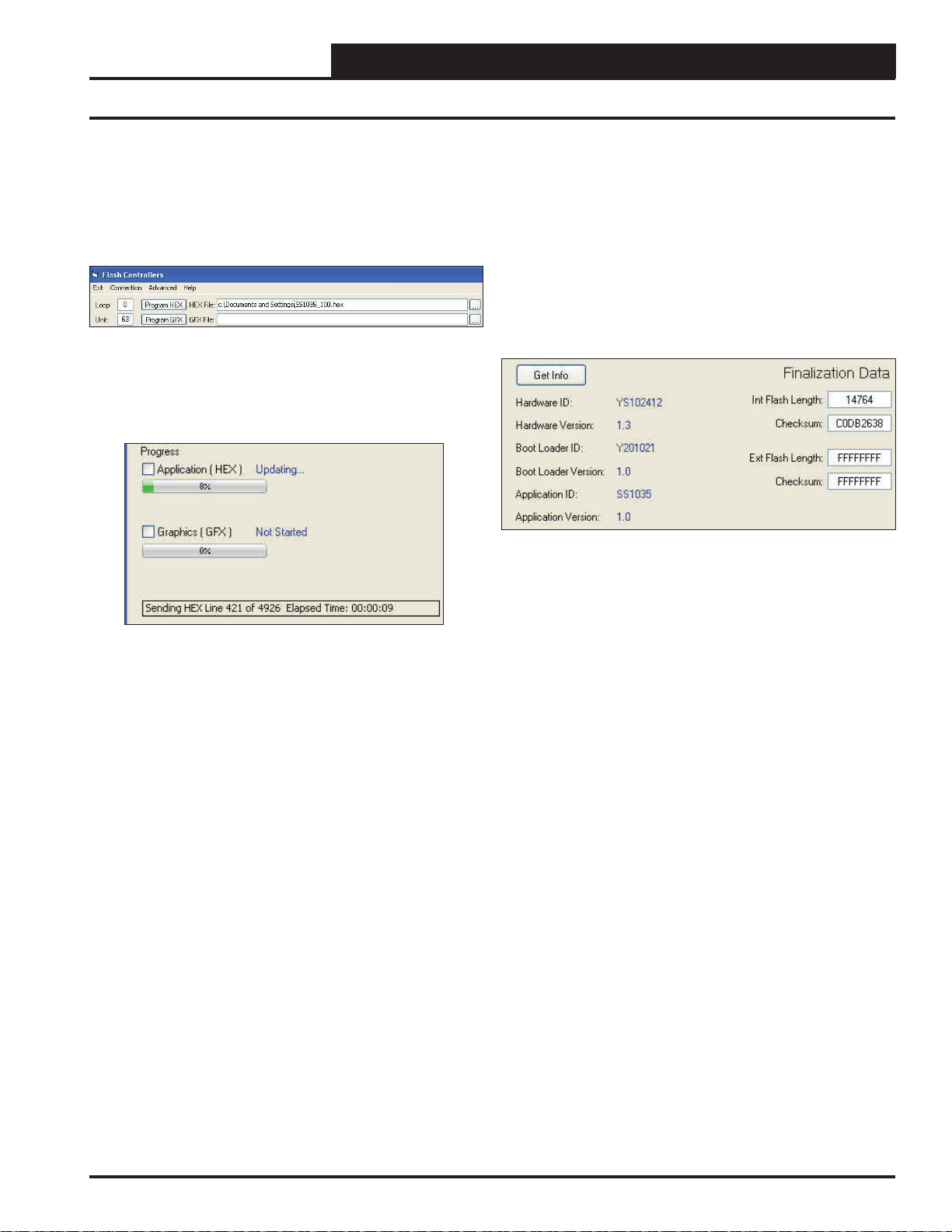

15.) Now, cycle power to the PT-Link II once again and within 5

seconds click on the <Program HEX> button (shown above). If successful, you should see the Progress Application HEX bar showing the

progress percentage.

16.) When the bar shows 100% completed, verify the PT-Link II’s

software is running by observing the Timer LED blinking.

17.) Verify the PT -Link II’ s Application Version by once again cycling

power to the PT-Link II and within 5 seconds clicking the <Get Info>

button.

18.) Verify all fi elds are correct in the information below the <Get

Info> button and under “Finalization Data.” The “Int Flash Length”

and “Checksum” values should match the values provided with the

software sheet.

PT-Link II BACnet3 Interface

17

Page 18

4. UPDATING THE SOFTWARE

4.1 Updating the PT-Link II Controller

Zone

Zone

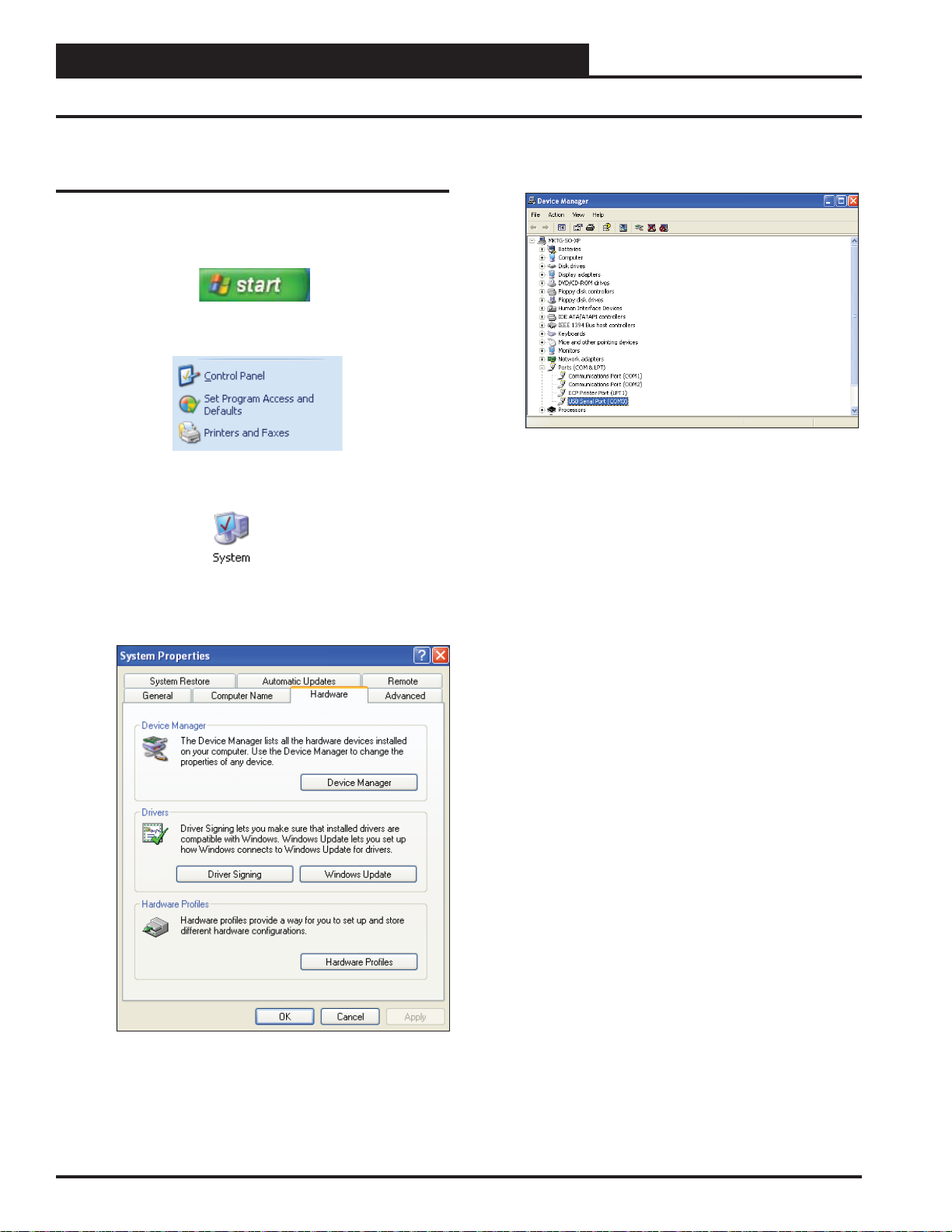

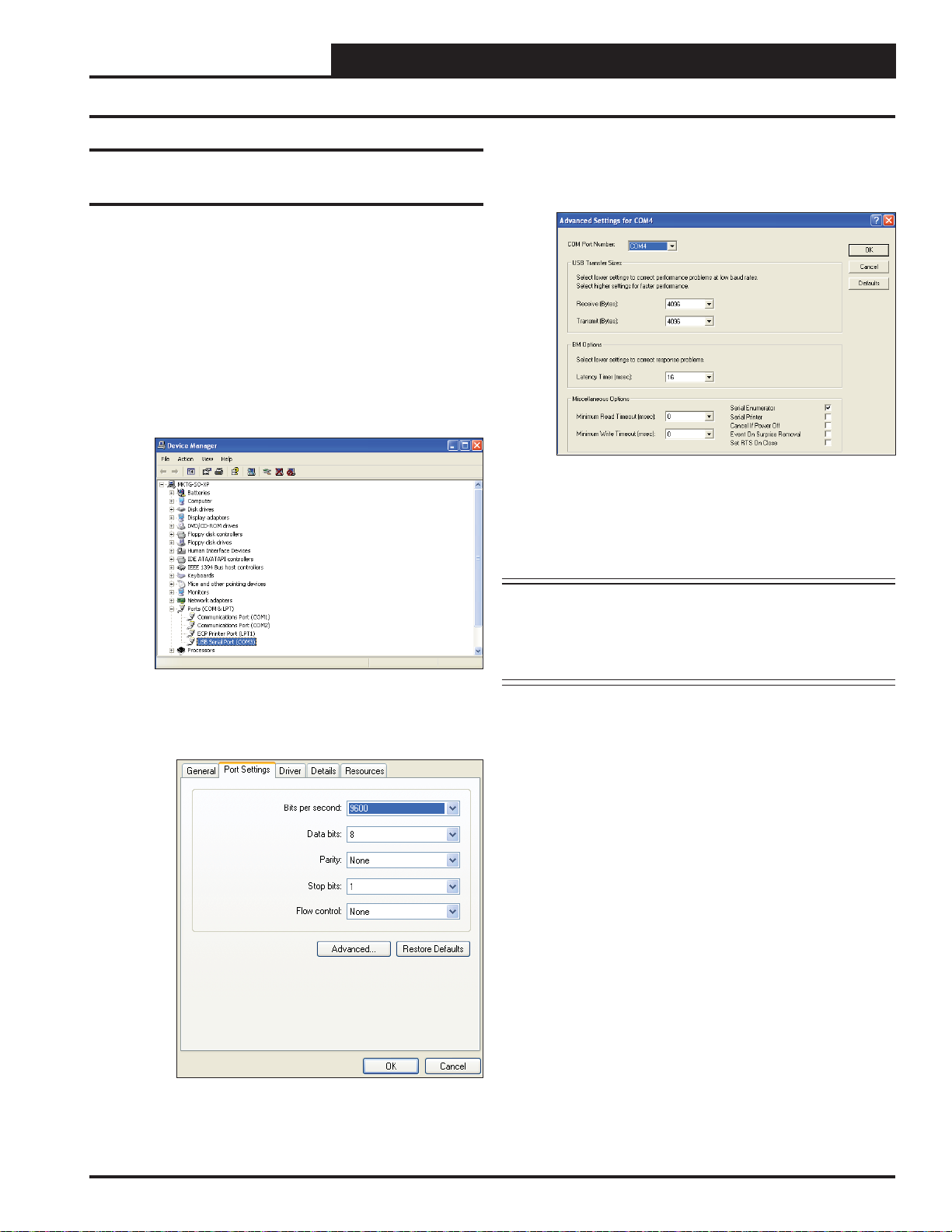

4.1.2 Finding What COM Port Number

the PT-Link II is Using

1. Left-click on <Start>, located on the bottom

left of the Windows Tool Bar.

2. Select <Control Panel>.

3. Double-click the System Icon.

6. Click on the plus sign next to Ports to see all of the

common ports.

7. Locate the USB Serial Port (COM#). The COM# in

parentheses is the port it is located on. Write this COM

port number down. You will need to know this when

setting up the Prism software.

8. If the COM port number is 10 or greater, go to

“Changing the USB COM Port Number” on page 19.

4. Click the <Hardware> tab.

18

5. Click the <Device Manager> button.

PT-Link II BACnet3 Interface

Page 19

4. UPDATING THE SOFTWARE

4.1 Updating the PT-Link II Controller

4.1.3 Changing the USB COM Port

Number

When the PT-Link II is fi rst plugged in, it will be assigned a COM port

number to be used for communicating with the Prism software. If the

port number is 10 or greater, it needs to be changed to a value less than

10 to be recognized by Prism.

1. Click <Start>, click <Control Panel>, click

<System>, click the <Hardware> tab, and then

click <Device Manager> to get to the Device

Manager Window.

2. Click on the plus sign next to Ports to see all of the

COM ports.

4. To assign a port number less than 10, click on

<Advanced>. The Advanced Settings Window

will appear.

5. In the COM Port Number drop box, select which

COM port you wish to use. Make sure you select a

COM port number that is not currently in use (you can

see the ports in use in the Device Manager Window).

Select a port that is less than 10.

NOTE: Windows

that has ever been installed on your computer. So if

there are no available ports below 10, choose a port

number less than 10 for a device listed that you know

you are not currently using.

®

will assign a port number to every device

3. Right-click on “USB Serial Port (COM#)” and select

<Properties>. In the Properties Window, select the

<Port Settings> tab.

6. Once you select the correct COM port number, click

<OK> and close any windows opened in the process

of changing the port number. Make note of this number

because you will need it for your Prism setup.

PT-Link II BACnet3 Interface

19

Page 20

Zone

Zone

4. UPDATING THE SOFTWARE

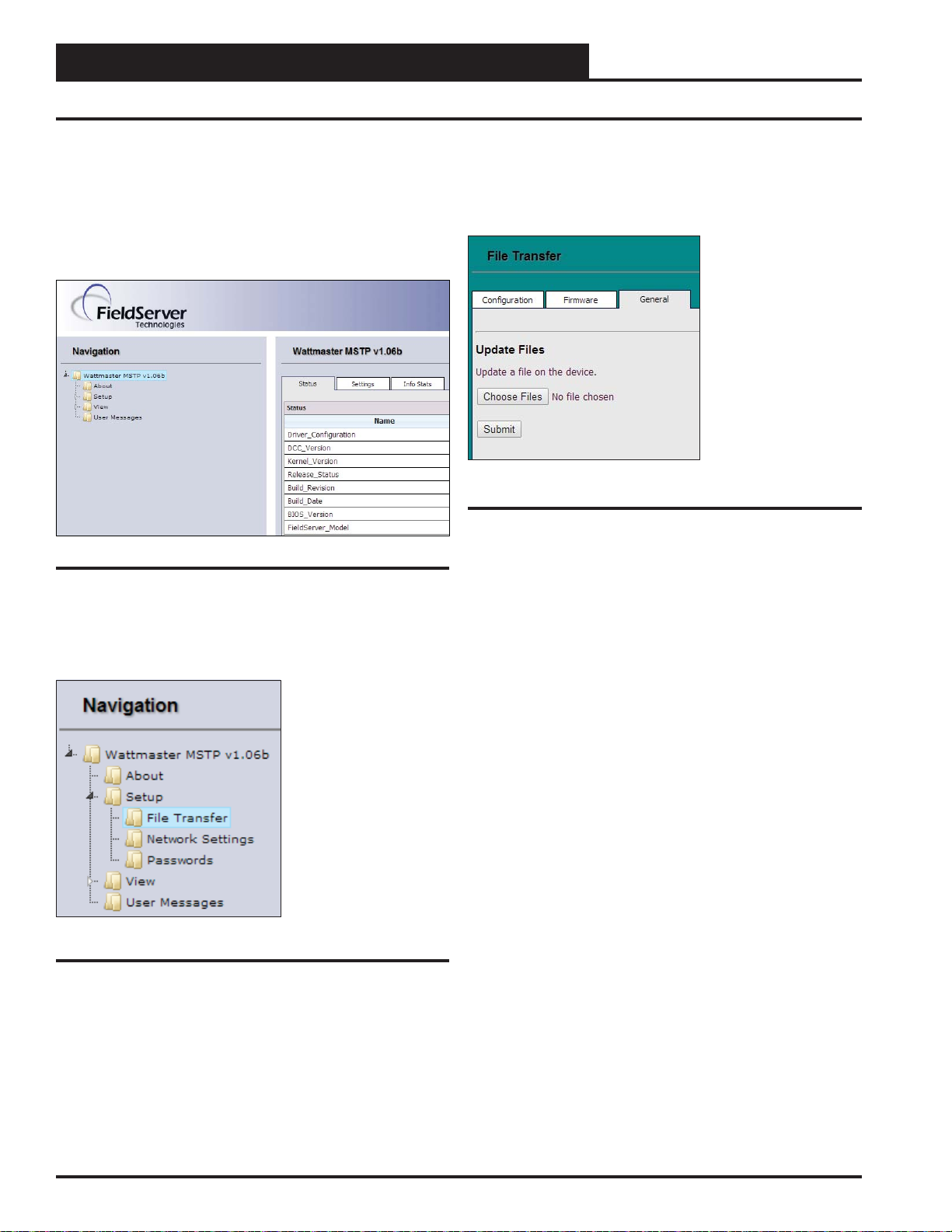

4.2 Updating the Field Server Software

Zone

Zone

1.) Extract and save the update fi le you receive from Field Server onto

your PC.

2.) Open your web browser, and type the IP Address of the PT-Link,

which defaults to <192.168.1.24>, and press <ENTER>. The GUI

will launch. Click <Diagnostic and Debugging>. The Main Screen

will appear. See Figure 22.

Figure 22: The FS-GUI Main Screen

4.) Refer to the File Transfer W indow below (Figure 24). In the General

Tab, click <Browse> and locate the fi le you saved in Step 1. Then click

on <Submit>. When the download is complete, click on the <System

Restart> button.

Figure 24: File Transfer - General Tab

3.) In the Navigation Window on the left of the FS-GUI Screen, click

<Setup> and then click <File Transfer>. See Figure 23.

Figure 23: Navigation Window - File Transfer

20

PT-Link II BACnet3 Interface

Page 21

5. TROUBLESHOOTING

5.1 Troubleshooting Communications

5.1.1 Check Wiring and Settings

No COMS on WattMaster side

If TX/RX are not fl ashing rapidly, then there is a COM issue on the

WattMaster side and you need to check the following things:

• Visual observations of LEDs on ProtoNode.

(Figure 28, page 23)

• Check baud rate, parity, data bits, stop bits

• Check WattMaster device address

• Verify wiring

• Verify all the WattMaster devices that were discovered

in FST Web Confi gurator. (page 12)

NOTE: If the problem still exists, a Diagnostic Capture

needs to be taken and sent to W attMaster Technical

Support. See page 26.

Field COM problems

• Visual observations of LEDs on PT-Link. (Figure 27,

page 22)

5.1.2 Verifying Communications

1. ) In the Navigation Window on the left of the FS-GUI Main Screen,

click <View> and then click <Data Arrays>. See Figure 25.

Figure 25: Navigation Window - View Data Arrays

2. ) Click on the Controller name. In this case, it is DA_C160_I0, a

VCM-X Controller. The Controller’s Data Array Table will display.

See Figure 26.

• Visual dipswitch settings (using correct baud rate and

device instance)

• Verify IP address setting

• Verify wiring

NOTE: If the problem still exists, a Diagnostic Capture

needs to be taken and sent to W attMaster Technical

Support. See page 26.

Figure 26: VCM-X Data Array Table

3 ) You can now cross reference the values shown in Figure 26 with

the listed parameter names in the appropriate Data Array Table for your

controller type. These tables can be found on pages 28-31.

PT-Link II BACnet3 Interface

21

Page 22

5. TROUBLESHOOTING

5.2 Troubleshooting LEDs

5.2.1 PT-Link II Board LEDs

The PT-Link II BACnet® is equipped with LEDs that can be used for

troubleshooting. There are eight LEDs on the PT -Link board. See Figure

27 for the locations of the LEDs on the PT -Link board. The LED descriptions and functions are listed in the following paragraphs.

POWER LED

When the PT-Link II BACnet® is powered up, the “POWER” LED

should light up and stay on continuously. If it does not light up, check

to be sure that you have 24 VAC connected to the board, that the wiring

connections are tight, and that they are wired for correct polarity. The 24

V AC power must be connected so that all ground wires remain common.

If after making all these checks the “POWER” LED still does not light

up, please contact WattMaster Controls Technical Support at our Toll

Free number—866-918-1100—for assistance.

LOOP LED

When power is applied to the PT-Link II BACnet®, the “LOOP” LED

will also light up. The LED should fl icker rapidly, indicating that the

PT-Link is trying to communicate with the controllers on the loop. A

“fl icker” is defi ned as a brief moment when the LED turns off and

back on. If the “LOOP” LED does not operate as indicated above, fi rst

power down the unit and then reapply power. If this does not work,

please contact WattMaster Controls Technical Support at our Toll Free

number—866-918-1100—for assistance.

Zone

Zone

LED 1

When power is fi rst applied, “LED 1” will be off temporarily and then

will blink one time for each controller it is communicating with. For

example, if you have 4 controllers on the loop connected to the PT -Link,

“LED 1” will blink 4 times. If the amount of blinks does not match the

number of controllers connected to the loop, it indicates there is a communications problem. The best way to fi nd out which board is not com-

municating is to go to each controller and look at its “COMM” LED. The

“COMM” LED should be solid and will fl icker occasionally indicating

communication with the PT-Link II BACnet®. If the “COMM” LED

does not fl icker, there is no communication with that controller.

LED 2

When power is fi rst applied, “LED 2” will be off temporarily and then

will blink slowly indicating that the PT -Link baseboard is communicating

with the ProtoCessor Module. If “LED 2” does not blink, check that the

ProtoCessor Module is installed correctly on the PT -Link baseboard and

that the “PWR” LED is lit up on the ProtoCessor Module.

PROTO LED

When the PT-Link II is fi rst powered up, the “PROTO” LED should

blink rapidly and may appear to be on solid. This LED verifi es com-

munication with the board and the ProtoCessor. If the LED doesn’t

light up, check that the ProtoCessor is installed correctly and fi rmly

connected to the Base Board. The “PWR” LED should also be lit on

the ProtoCessor Module.

Figure 27: PT-Link II BACNET® LED Locations

WATCH DOG LED

The “W-DOG” LED is used for troubleshooting by W attMaster Controls

Technical Support. The “W-DOG” LED should always be on solid.

HEARTBEAT LED

The “H-BEAT” LED blinks to show the PT-Link II board software is

running. If the LED doesn’t light up, and all other checks have been

made, please contact W attMaster Controls T echnical Support at our T oll

Free number—866-918-1100—for assistance.

TIMER LED

The “TIMER” LED is used for troubleshooting by W attMaster Controls

Technical Support. The “TIMER” LED should always be blinking

steadily.

22

PT-Link II BACnet3 Interface

Page 23

5. TROUBLESHOOTING

5.2 Troubleshooting LEDS

5.2.2 PT-Link Module LEDs

Refer to Figure 28 for LED locations.

PWR LED

When the PT -Link II is fi rst powered up, the “PWR” green LED should

light up and stay on continuously. If the LED doesn’t light up, check

that the ProtoCessor is installed correctly and fi rmly connected to the

Base Board.

RX & TX LEDs

During normal operation, the “RX” LED will fl ash when a message is

received on the fi eld port of the ProtoCessor and the “TX” LED will

fl ash when a message is sent on the fi eld port of the ProtoCessor The

“TX” and “RX” LEDs work together to indicate that communication

is being established with the desired protocol network. If both LEDs

are blinking, then communication is working properly. If not, check

the protocol network wiring and the baud rate in the confi guration fi le.

RUN LED

Upon powerup, the “RUN” LED should light up and stay solid for 15

seconds. It should then blink steadily, signifying normal operation. The

Protocessor will be able to access RUINET once this LED starts fl ashing.

RUN2 LED

The “RUN2” LED should blink steadily after power up, signifying

normal operation. The Protocessor will be able to access RUINET once

this LED starts fl ashing.

SYS ERR LED

The “SYS ERR” LED will go on solid 15 seconds after power up and

then shut off. A steady red light will indicate there is a system error on

the ProtoCessor. If this occurs, immediately report the related “system

error” shown in the error screen of the Remote User Interface to FieldServer Technologies for evaluation.

NODE OFFLINE LED

The “NODE OFFLINE” amber LED will go on solid 15 seconds after

power up and then shut off. A steady amber light indicates the ProtoCessor is not communicating with a device that it is polling.

Figure 28: PT-Link II BACnet3® LED Locations

NOTE: If all of these tests are made and the controller still doesn’t

operate, please contact W attMaster Controls T echnical

Support at our T oll Free number—866-918-1100—for

assistance.

Figure 29: PT-Link II BACnet3® Components

PT-Link II BACnet3 Interface

23

Page 24

Zone

5. TROUBLESHOOTING

5.3 Troubleshooting the PT-Link Controller

Zone

5.3.1 Addressing WattMaster Devices

in a BACnet® Network

Each PT-Link II BACnet® generates only one BACnet® device regardless of the number of W attMaster controls connected to it. This

device will have all the properties of all the WattMaster controls

connected. The instance of the device is equal to the unit address. The

properties of each control can be differentiated by an offset of 500.

Examples:

1.) Properties of the controller address as 1 will range

from 0 to 499.

2.) Properties of the controller address as 2 will range

from 500 to 999.

3.) Properties of the controller address as 3 will range

from 1000 to 1499.

To search for the instance of a specifi c property, follow the next

formula:

Property Instance = ((Controller Address – 1) * 500) + Instance

Number from table.

Example:

5.3.2 CAS BACnet Explorer for Validating PT-Link in the Field

Sierra Monitor Corporation has arranged a complimentary 2-week

fully functional copy of CAS BACnet Explorer (through Chipkin

Automation) that can be used to validate BACnet MS/TP communications of PT-Link in the fi eld without having to have the BMS

Integrator on site. A Serial or USB to RS-485 converter is needed

to test BACnet MS/TP.

5.3.2.1 Downloading the CAS Explorer

and Requesting an Activation Key

To request the complementary BACnet CAS key, go to http://app.

chipkin.com/activation/twoweek/ and fi ll in all of the information.

See Figure 30. Enter Vendor Code “WattMaster2BACnet”. Once

completed, the email address that was submitted will be registered.

1.) The PT-Link II BACnet® has a Node ID equal to fi ve.

2.) Two VCM controllers connected and addressed to one

and four.

3.) Searching for the Outdoor Temperature of each

controller.

4.) Instance of the Outdoor Temperature in the VCM table

equal to AI: 54.

5.) Client will only see Device 5.

6.) Under Device 5 it will see AI: 54 for the Outdoor

Temperature of the unit addressed as 1 and AI: 1554

for the Outdoor Temperature of the unit addressed as 4.

NOTE: To simplify the calculation, we recommend that the

WattMaster controllers be addressed in sequential

order from one to the last controller without any

unused address(es) in between.

Figure 30: Requesting a Two-Week Trial

24

PT-Link II BACnet3 Interface

Page 25

5. TROUBLESHOOTING

5.3 Troubleshooting the PT-Link Controller

Go to the website http://www.chipkin.com/technical-resources/

cas-bacnet-explorer/, and download and install the CAS BACnet

Explorer to your PC.

Open CAS BACnet Explorer. In the CAS Activation form, enter

the email address that was registered, and click on “Request a key”.

The CAS key will then be emailed to the registered address. Cut/

paste the key from the email into the Product key fi eld and click

<Activate>. See Figure 31.

5.3.2.2 CAS BACnet MS/TP Setup

1. Using the Serial or USB to RS-485 converter, connect it to your

PC and the 3 Pin BACnet MS/TP connector on PT-Link FPC-N34.

2. Open CAS Explorer.

3. Click on

4. Check the BACnet MS/TP box and uncheck the BACnet/IP and

BACnet Ethernet boxes

5. Set the BACnet MS/TP MAC address to 0.

6. Set the BACnet MS/TP Baud Rate to 38400.

7. Click

8. On the bottom right-hand corner, make sure that the BACnet

MS/TP box is green

9. Click on discover.

10. Check all 4 boxes.

11. Click <Send>.

<Settings>.

<Ok>.

5.3.3.1 Viewing Diagnostic Information

Figure 31: Requesting an Activation Key

1. T ype the IP address of the PT-Link into your web browser or use

the FieldServer Toolbox to connect to the PT-Link

2. Click on

and then click on <Connections>. See Figure 32.

3. If there are any errors showing in the Connections Window, please

refer to Section 5.1.1, page 21 for the relevant wiring and settings.

<Diagnostics and Debugging> then click on <View>,

Figure 32: Connections Window

PT-Link II BACnet3 Interface

25

Page 26

5. TROUBLESHOOTING

5.4 FieldServer Diagnostic Utilities

Zone

Zone

5.4.1 Diagnostic Capture Procedures

1. Once the Diagnostic Capture is complete, email it to

support@protocessor.com. The Diagnostic Capture will

allow us to rapidly diagnose the problem.

2. Ensure that FieldServer Toolbox is Loaded on the PC

that is currently being used, or download FieldServer Toolbox.zip at http://www.protocessor.com/tech-support/

utilities-and-design-documents.php

3. Extract the executable fi le and complete the installation.

4. Disable any wireless Ethernet adapters on the

PC/Laptop. See Figure 33.

5. Disable fi rewall and virus protection software if

possible.

6. Connect a standard Cat 5 Ethernet cable between the PC

and ProtoNode.

7. Double-click on the FS Toolbox Utility.

8. Click on the diagnose icon of the desired device.

See Figure 34.

Figure 33: Ethernet Port Location

Figure 34: FieldServer Toolbox - Diagnostic Icon

26

PT-Link II BACnet3 Interface

Page 27

5. TROUBLESHOOTING

5.4 FieldServer Diagnostic Utilities

9. Select Full Diagnostic. See Figure 35.

Figure 35: Full Diagnostic

10. If desired, the default capture period can be changed.

See Figure 36.

11. Click on

<Start Diagnostic>. Figure 36.

11. Wait for the Capture period to fi nish. The Diagnostic

Test Complete Window will appear. Figure 37.

Figure 37: Diagnostic Test Complete Window

12. Once the Diagnostic test is complete, a .zip fi le will be

saved on the PC.

13. Click

to launch explorer and have it point directly at the

correct folder.

14. Send the Diagnostic zip fi le to support@fi eldserver.com.

<Open> in the Diagnostic Test Complete Window

Figure 36: Set Capture Period and Start Diagnostic

PT-Link II BACnet3 Interface

27

Page 28

Zone

6. DATA ARRAYS

Zone

6.1 VCB-X & VCM-X Modular Data Arrays

VCB-X Modular Data Array For Field Server

Offset 0 1 2 3 4 5 6 7 8 9

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

150

160

170

AppVer ClSt HtSt SpcTp SaTp OaTp UnitMode CtrlSts ClEnbl HtEnbl

EcoEnbl FanDly OnRlys EcoPos VfdBwPos AlmSts AlmGrp1 AlmGrp2 AlmGrp3 SaTpAlm

OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFlAlm SmokeAlm LoSaAlm HiSaAlm CtrlTpCF

CtrlTpHF CtrlTp InRh InRhStM MdClPos MdHtPos OcpClSt OcpHtSt UnClOst UnHtOst

SaClSt SaHtSt SpcTpOst SaTpOst OaTpOst SchdFrc OnRly1 OnRly2 OnRly3 OnRly4

OnRly5 OnRly6 MnExRly1 MnExRly2 MnExRly3 MnExRly4 MnExRly5 RlExRly1 RlExRly2 RlExRly3

RlExRly4 RlExRly5 RlExRly6 RlExRly7 RlExRly8 RlExRly9 RlExRly10 RlExRly11 RlExRly12 MinEcoSt

OaCFM EtCFM SaCFM FrcHvacM FrcFanSp FrcEcono SaTpStM RaTp OaRh StaticPr

CO2 BuildPr EtFnSpd CoilTp RaCFM HeadPr RtVlvPos LvWtrTp MdGsVPos HeadPrSt

CdCtrSg1 OaClSt OaHtSt WmupTg RhDewpSt EcoEnbSt RaTpOst ColTpOft LWAmbnt PreHtAmb

C02MinLv C02MaxLv InRhSt StatPrSt RfPrSt OACfmMin HiInRh ClHdPrSt HtHdPrSt LoClTpSt

HiClTpSt SaClRt SaHtRt ClLoRt ClHiRt HtLoRt HtHiRt CtrlMod DschgTp OaWtbl

OaDewPt SucPr CoilTpSt RetBydmp RaDmp RaRH SldAdOfs MdSelDb ClStgWdw HtStgWdw

MchClLkt MchHtLkt LoSaCf HiSaCf DfrSt LvH2OOst CO2Ost CTpHiAlm CTpLoAlm HpLkt

VFDClMin VFDHtMin VFDVtMin MaxEcoHt MaxEcoCO HpDfrInt AptDfr DuctPfDb RlfPrDb OaCfmDb

SZVAVFnI SaWmupSt SaCldnSt RehtEnbl EmHtEnbl RaTpAlm MisEM1 ColPfAlm CO2Alm DschgAlm

OaCfmAlm ExtCmSr SaCfmSr RaCfmSr MisMHGRV MisMDGAS Mis12Rly HiCtrlMd LoCtrlMd DigCmpCf

DigCmpLk HiHedPr H2OProf LoSucPr HiSucPr – – – – –

Table 3: VCB-X Modular Data Array For Field Server

VCM-X Modular Data Array For Field Server

Offset 0 1 2 3 4 5 6 7 8 9

0

10

20

30

40

50

60

70

80

90

100

110

120

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp OaTp DuctPr

OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl FanDly PofCfg CO2Cfg MdHt2Ins

Rt2Ins OnRlys ExRlys12 ExRlys34 EcoPos VfdBwPos VfdExPos AlmSts AlmGrp1 AlmGrp2

AlmGrp3 SaTpAlm OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos MdHtPos MdHt2Pos

Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt SaClSt SaHtSt WmupSt SpcTpOst

SaTpOst RaTpOst OaTpOst CoilTpSt DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1

OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14 ExRly15 ExRly16

CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr OaDwpt CoilTp SaTpStM PreHtSp

OaCFM EtCFM SaCFM OACfmSt OACfmRs OACfmStM MdCmp2 HdPr1 HdPr2 CdFan1

CdFan2 RmVFDPos SaClRt SaHtRt ClLoRt ClHiRt HtLoRt HtHiRt T24EcFb T24TpAlm

T24NEWS T24EWISN T24DpAlm T24ExsOA RaTpAlm AlmGrp5 HdPr22 HdPr22 CdFan21 CdFan22

Table 4: VCM-X Modular Data Array For Field Server

28

PT-Link II BACnet3 Interface

Page 29

6. DATA ARRAYS

6.2 VCM-X WSHP Coil & VCM-X WSHP Tulsa / RNE Data Arrays

VCM-X WSHP (Tulsa) & RNE Data Array For Field Server

Offset 0 1 2 3 4 5 6 7 8 9

0

10

20

30

40

50

60

70

80

90

100

110

120

130

140

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp OaTp DuctPr

OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl FanDly PofCfg CO2Cfg MdHt2Ins

Rt2Ins OnRlys ExRlys12 ExRlys34 EcoPos VfdBwPos VfdExPos AlmSts AlmGrp1 AlmGrp2

AlmGrp3 SaTpAlm OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos MdHtPos MdHt2Pos

Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt SaClSt SaHtSt WmupSt SpcTpOst

SaTpOst RaTpOst OaTpOst CoilTpSt DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1

OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14 ExRly15 ExRly16

CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr OaDwpt CoilTp SaTpStM PreHtSp

OaCFM EtCFM SaCFM OACfmSt OACfmRs OACfmStM MdCmp2 HdPr1 HdPr2 CdFan1

CdFan2 WaterTpA WaterTpB A1LSPAlm A1LktAlm A2LSPAlm A2LktAlm B1LSPAlm B1LktAlm B2LSPAlm

B2LktAlm LWT1Alm LWT2Alm POWF1Alm POWF2Alm ComMAlm RmVFDPos SaClRt SaHtRt ClLoRt

ClHiRt HtLoRt HtHiRt T24EcFb T24TpAlm T24NEWS T24EWISN T24DpAlm T24ExsOA RaTpAlm

AlmGrp5 HdPr22 HdPr22 CdFan21 CdFan22 – – – – –

Table 5: VCM-X WSHP (Tulsa) / RNE Data Array For Field Server

VCM-X WSHP (Coil) Data Array For Field Server

Offset 0 1 2 3 4 5 6 7 8 9

0

10

20

30

40

50

60

70

80

90

100

110

120

130

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp OaTp DuctPr

OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl FanDly PofCfg CO2Cfg MdHt2Ins

Rt2Ins OnRlys ExRlys12 ExRlys34 EcoPos VfdBwPos VfdExPos AlmSts AlmGrp1 AlmGrp2

AlmGrp3 SaTpAlm OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos MdHtPos MdHt2Pos

Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt SaClSt SaHtSt WmupSt SpcTpOst

SaTpOst RaTpOst OaTpOst CoilTpSt DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1

OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14 ExRly15 ExRly16

CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr OaDwpt CoilTp SaTpStM PreHtSp

OaCFM EtCFM SaCFM OACfmSt OACfmRs OACfmStM MdCmp2 HdPr1 HdPr2 CdFan1

CdFan2 WaterTpA A1LSPAlm A1LktAlm B1LSPAlm B1LktAlm LWT1Alm POWF1Alm ComMAlm RmVFDPos

SaClRt SaHtRt ClLoRt ClHiRt HtLoRt HtHiRt T24EcFb T24TpAlm T24NEWS T24EWISN

T24DpAlm T24ExsOA RaTpAlm – – – – – – –

Table 6: VCM-X WSHP (Coil) Data Array For Field Server

PT-Link II BACnet3 Interface

29

Page 30

Zone

6. DATA ARRAYS

Zone

6.3 VCM-X & SA Data Arrays

VCM-X Data Array For Field Server

Offset 0 1 2 3 4 5 6 7 8 9

0

10

20

30

40

50

60

70

80

90

100

110

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp OaTp DuctPr

OaRh UnitMode CtrlSts ClEnbl HtEnbl EcoEnbl FanDly PofCfg CO2Cfg MdHt2Ins

Rt2Ins OnRlys ExRlys12 ExRlys34 EcoPos VfdBwPos VfdExPos AlmSts AlmGrp1 AlmGrp2

AlmGrp3 SaTpAlm OaTpAlm SpcTpAlm MchClAlm MchHtAlm PofAlm DrtFAlm SmokeAlm LoSaAlm

HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM DptStM MdClPos MdHtPos MdHt2Pos

Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt SaClSt SaHtSt WmupSt SpcTpOst

SaTpOst RaTpOst OaTpOst CoilTpSt DptSt InRhSt DuctPrSt RfPrSt SchdFrc OnRly1

OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14 ExRly15 ExRly16

CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr OaDwpt CoilTp SaTpStM PreHtSp

OaCFM EtCFM SaCFM OACfmSt OACfmRs OACfmStM SaClRt SaHtRt ClLoRt ClHiRt

HtLoRt HtHiRt – – – – – – – –

Table 7: VCM-X Data Array For Field Server

SA Controller Data Array For Field Server

Offset 0 1 2 3 4 5 6 7 8 9

0

10

20

30

40

50

60

70

80

90

AppVer ClSt HtSt TpDmnd SpcTp SaTp DuctPr UnitMode CtrlSts ClEnbl

HtEnbl EcoEnbl FanDly MdHt2Ins Rt2Ins EcoPos VfdBwPos SaTpAlm SpcTpAlm MchClAlm

MchHtAlm PofAlm DrtFAlm LoSaAlm HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM

DptStM MdClPos MdHtPos MdHt2Pos Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst SaClSt

SaHtSt WmupSt SpcTpOst SaTpOst CoilTpSt DptSt InRhSt DuctPrSt SchdFrc OnRly1

OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2 ExRly3 ExRly4 ExRly5 ExRly6

ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12 ExRly13 ExRly14 ExRly15 ExRly16

CoilTp SaTpStM PreHtSp EaTp EwTp EaRH HdPr1 HdPr2 CoilTp2 EaDpt

WSEByp WSEByp2 MdCmp2 CoilTpSt CdPos1 CdPos2 EaTpAlm EmerAlm PoWFAlm DrnAlm

EaTpOst EwTpOst SaClRt SaHtRt ClLoRt ClHiRt HtLoRt HtHiRt – –

Table 8: SA Controller Data Array For Field Server

30

PT-Link II BACnet3 Interface

Page 31

6. DATA ARRAYS

6.4 VCM Data Array

VCM Data Array For Field Server

Offset 0 1 2 3 4 5 6 7 8 9

0

10

20

30

40

50

60

70

80

90

100

Table 9: VCM Data Array For Field Server

AppVer ClSt HtSt OaWtbl TpDmnd SpcTp SaTp RaTp OaTp DuctPr

OaRh UnitMode CtrlSts ClDmnd HtDmnd DehmDmnd ClEnbl HtEnbl EcoEnbl FanDly

WmupDmnd PofCfg CO2Cfg MdHt2Ins Rt2Ins OnRlys ExRlys12 ExRlys34 EcoPos VfdBwPos

VfdExPos AlmSts AlmGrp1 AlmGrp2 AlmGrp3 SaTpAlm OaTpAlm SpcTpAlm MchClAlm MchHtAlm

PofAlm DrtFlAlm SmokeAlm LoSaAlm HiSaAlm CtrlTpCF CtrlTpHF CtrlTp InRh InRhStM

DptStM MdClPos MdHtPos MdHt2Pos Rt2Pos OcpClSt OcpHtSt UnClOst UnHtOst WtblSt

SaClSt SaHtSt WmupSt SpcTpOst SaTpOst RaTpOst OaTpOst CoilTpSt DptSt InRhSt

DuctPrSt RfPrSt SchdFrc OnRly1 OnRly2 OnRly3 OnRly4 OnRly5 ExRly1 ExRly2

ExRly3 ExRly4 ExRly5 ExRly6 ExRly7 ExRly8 ExRly9 ExRly10 ExRly11 ExRly12

ExRly13 ExRly14 ExRly15 ExRly16 CO2St MinEcoSt CO2Level ByPasDmp RaDmp RfPr

OaDwpt CoilTp SaTpStM PreHtSp – – – – – –

PT-Link II BACnet3 Interface

31

Page 32

7. PARAMETER TABLES

7.1 VCB-X BACnet Parameters

Zone

Zone

NOTE: When using Celsius scaling, all temperature values will

need to be divided by 10 by the BMS to properly read

the status and setpoint values, e.g., a value of 200º C

needs to be divided by 10 for an actual value of 20º C.

BACnet Properties for the VCB-X Controller

Param-

eter

Bad or

Missing 12

Relay

Expansion

Board.

Alarm

Group 1

Alarm

Group 2

Alarm

Group 3

Alarm

Status

Application

Software

Version

Unit Mode UnitMode AI:123 See Unit Mode

Building

Pressure

Building

Pressure

Setpoint

Building

Pressure

Control

Deadband

CO

2

CO

2

Sensor

Calibration

Deadband

Offset

Name Object Description

Mis12Rly BI: 376 The 12 Relay

Expansion Board

is confi gured but

not detected.

AlmGrp1 AI: 104 See Alarm

AlmGrp2 AI: 105 See Alarm

AlmGrp3 AI: 106 See Alarm

AlmSts AI: 1 Indicates that

there is an alarm.

AppVer AI: 99 Current version

of the software

in the unit.

BuildPr AI:272 Current value of

the Building

Pressure Sensor.

RfPrSt AV:118 Current Building

Pressure

Setpoint.

RfPrDb AV:358 Value above

and below the

Building Pres-

sure Setpoint

where no control

change occurs.

CO2 AI:271 Current CO2

Level.

CO2Ost AV: 348 If the CO2

Sensor is reading

incorrectly, you

can use this

option to enter

an offset value

to adjust the

Sensor’s CO2

reading.

Limits

Group Bits on

page 43.

Group Bits on

page 43.

Group Bits on

page 43.

0 = Off

1 = On

See Alarm

Group Bits on

page 43.

Bits on page

43.

-.20 .20

.01 0.1

-500

ppm

500

ppm

BACnet Properties for the VCB-X Controller

Param-

eter

CO

2

Minimum

Setpoint

CO

2

Maximum

Setpoint

Bad CO

Sensor

Coil

Tempera-

ture

Coil

Tempera-

ture Offset

Bad Coil

Pressure

Sensor

Coil Tem-

perature

Setpoint

Name Object Description

CO2MinLv AV:287 This is the

CO2

MaxLv

CO2Alm BI: 368 Failure of the

2

CoilTp AI: 181 Current coil

ColTpOft AV:284 If the Coil

ColPrAlm BI: 367 Failure of the

CoilTpSt AI: 334 This is the

AV:288 This is the CO2

threshold CO

level at which

the Economizer

begin to be reset

level at which

the Economizer

be reset to the

Economizer Max

Position in High

CO2 . In between

Max CO2 levels

the Economizer

Position will be

proportionally

reset between the

confi gured Min

Damper Position

Position in High

Sensor is reading

incorrectly, use

this offset to adjust the Sensor’s

Coil Pressure

Sensor. W ill shut

calculated Coil

Dehumidifi cation

Min Damper

Position

Setpoint will

higher.

Min Damper

Position will

the Min and

Min Damper

and the Max

CO2 .

CO2 Sensor.

temperature

reading.

Temperature

Temperature.

unit down.

current

Suction

Temperature

target during

Mode.

Limits

0 2000

2

0 2000

-100 100

32

PT-Link II BACnet3 Interface

Page 33

7. PARAMETER TABLES

7.1 VCB-X BACnet Parameters

BACnet Properties for the VCB-X Controller

Param-

eter

Low Coil

Temperature

Setpoint

Limit

High Coil

Temperature

Setpoint

Limit

Com-

pressor

Discharge

Tempera-

ture

Bad Com-

pressor

Discharge

Sensor

Control

Mode

Name Object Description

LoClTpSt AV:295 This is the low-

est that the Coil

Temperature will

be reset to during

Space Humid-

ity Reset of the

Coil Suction

Temperature

Setpoint. If no

coil temperature

reset is required,

this value should

be set the same

as the High Coil

Temperature

Setpoint.

HiClTpSt AV:296 This is the high-

est that the Coil

Temperature will

be reset to during

Space Humid-

ity Reset of the

Coil Suction

Temperature

Setpoint. If no

coil temperature

reset is required,

this value should

be set the same

as the Low Coil

Temperature

Setpoint.

DschgTp AI: 331 Current value of

the Compressor

Discharge T em-

perature Sensor.

DschgAlm BI: 369 Failure of the

Digital Compres-

sor Discharge

Temperature

Sensor.

CtrlMod AI: 97 1=Constant

Limits

35 70

35 70

Volume

2=Supply Air

Cooling Only

3=Outdoor

Temp Control

4=Single Zone

VAV

5=Supply Air

Tempering

6=Space Temp

Control w/

High OA

Content

Unoccupied

BACnet Properties for the VCB-X Controller

Param-

eter

Control

Tem-

perature

Cooling

Failure

Control

Tem-

perature

Heating

Failure

High

Control

Mode

Tempera-

ture

Low Control Mode

Tempera-

ture

Cooling

Low Reset

Source

Name Object Description

CtrlTpCF BI: 108 Activated if the

control tempera-

ture does not get

within 5°F to the

occupied cooling

setpoint in an

hour in the cool-

ing mode. This

alarm is not used

in 100% outside

air units or sup-

ply air control.

CtrlTpHF BI: 109 Activated if the

control tempera-

ture does not get

within 5°F to the

occupied heating

setpoint in an

hour in the heat-

ing mode. This

alarm is not used

in 100% outside

air units or sup-

ply air control.

HiCtrlMd BI: 377 Occurs when the

Controlling Sen-

sor Temperature

rises above the

Cooling Mode

Enable Setpoint

plus the Control

Mode High

Alarm Offset.

Applies only to

Space or Return

Air Temperature

controlled units.

LoCtrlMd BI: 378 Occurs when the

Controlling Sensor Temperature

falls below the

Heating Mode

Enable Setpoint

minus the Con-

trol Mode Low

Alarm Offset.

Applies only to

Space or Return

Air Temperature

controlled units.

ClLoRt AV: 326 If doing Supply

Air Setpoint

Reset, this is

the Low Reset

Source value in

Cooling that will

correspond to

the Supply Air

Cool High Reset

Setpoint.

Limits

1 150

PT-Link II BACnet3 Interface

33

Page 34

7. PARAMETER TABLES

7.1 VCB-X BACnet Parameters

Zone

Zone

BACnet Properties for the VCB-X Controller

Param-

eter

Cooling

High Reset

Source

Condenser

Control

Signal

Controlling

Sensor

High

Alarm

Offset

Controlling

Sensor

Low Alarm

Offset

Control

Status

Control

Tempera-

ture

Cooling

Enabled

Name Object Description

ClHiRt AV: 327 If doing Supply

Air Setpoint

Reset, this is

the High Reset

Source value in

Cooling that will

correspond to

the Supply Air

Cooling Setpoint

(Low Reset).

CdCtrSg1 AI:280 Condenser Fan

Signal 1 Status.

CTpHiAlm AV: 349 If the tem-

perature of the

controlling sen-

sor rises above

the Occupied

Cooling Setpoint

by this value,

a High Control

Temp Alarm

will occur. Only

applies if confi g-

ured for Space

or Return Air

Temp Control, or

as Single Zone

VAV.

CTpLoAlm AV: 350 If the tempera-

ture of the con-

trolling sensor

falls below the

Occupied Heat-

ing Setpoint by

this value, a Low

Control Temp

Alarm will oc-

cur. Only applies

if confi gured for

Space or Return

Air Temp Con-

trol, or as Single

Zone VAV.

CtrlSts AI: 4 Current

operational

status.

CtrlTp AI: 9 Current value of

the control

temperature

sensor.

ClEnbl AI: 6 Status that

indicates

mechanical

cooling is

enabled to

operate.

Limits

1 150

050

050

See Control

Status Bits on

page 43.

BACnet Properties for the VCB-X Controller

Param-

eter

Mechani-

cal Cooling

Lockout

Mechani-

cal Cooling

Alarm

Cooling

Setpoint

Mirror

Cool

Staging

Window

Adaptive

Defrost

Interval

Adjust-

ment

Dewpoint

Setpoint

Name Object Description

MchClLkt AV: 342 The VCB-X

will Lockout

Mechanical

Cooling when

the Outdoor Air

Temperature

is below this

Setpoint.

MchClAlm BI: 94 Compressor Re-

lays are enabled

but the Supply

Air Temperature

has not fallen

5°F within a

user-adjustable

time period. This

does not apply

for Modulating

Cooling.

ClSt AI: 7 Occupied

Cooling Mode

Enable

Setpoint.

ClStgWdw AV: 340 In Cooling

Mode, if the

Supply Air

Temperature

drops below the

Active Supply

Air Cooling

Setpoint minus

this Staging Win-

dow, a Cooling

Stage will be

deactivated after

its Minimum

Run Time.

AptDfr AV: 356 Adjustment to

the Heat Pump

Defrost Interval

depending on

whether the

Defrost Mode

lasts 10 minutes

or less than 10

minutes.

RhDewpSt AV:282 On a MUA unit,

if the outdoor

dewpoint rises

above this

setpoint, the unit

will

activate Dehu-

midifi cation.

Limits

-30 100

130

0 Min 30

Min

35 80

34

PT-Link II BACnet3 Interface

Page 35

7. PARAMETER TABLES

7.1 VCB-X BACnet Parameters

BACnet Properties for the VCB-X Controller

0% 100%

0% 100%

2

Limits

-30 80

Param-

eter

Digital

Compres-

sor Cutoff

Digital

Com-

pressor

Lockout

Dirty Filter

Alarm

Economiz-

er Enabled

Economiz-

er Enable

Setpoint

Economiz-

er Position

Max

Economiz-

er in Heat

Mode

Max

Econo-

mizer in

High CO2

Mode

Minimum

Econo-

mizer

Position

Name Object Description

DigCmpCf BI: 379 Occurs if the