Page 1

Factory Packaged Controls

PREHEAT-X Controller

Technical Guide

Page 2

PART NUMBER CROSS REFERENCE TABLE

PART DESCRIPTION

PREHEAT-X Controller OE377-26-00061 V48510 V48510

VCC-X Controller OE338-23B-VCCX V43420 N/A

VCB-X Controller OE332-26B-VCBX V28940 J00142

VCM-X E-BUS Controller OE332-23E-VCMX V07150 31422

Leaving Air Temperature Sensor OE231 P87140 28503

Entering Air Temperature Sensor OE250 P87150 N/A

EBC E-BUS Cables - varying lengths EBC-XXXF V167XX N/A

HSSC Cables - varying lengths HSSC-XXXF Varies N/A

WattMaster Controls Inc.

8500 NW River Park Drive · Parkville, MO 64152

Toll Free Phone: 866-918-1100

PH: (816) 505-1100 · FAX: (816) 505-1101 ·

E-mail: mail@wattmaster.com

Visit our web site at www.orioncontrols.com

WattMaster Form: AA-PREHEATX-TGD-01C

ORION

www.aaon.com

AAON® Manual Part No.: V48520

Copyright April 2015 WattMaster Controls, Inc.

®

AAON

is a registered trademark of AAON, Inc., Tulsa, OK.

Neither WattMaster Controls, Inc. nor AAON® assumes any

responsibility for errors or omissions in this document.

This document is subject to change without notice.

AAON

TULSA

AAON

COIL

Page 3

TABLE OF CONTENTS

GENERAL INFORMATION ................................................................................................................4

Overview ..................................................................................................................................................................4

Features ...................................................................................................................................................................4

INSTALLATION & WIRING ............................................................................................................... 5

Important Wiring Considerations ..............................................................................................................................5

Input Wiring ..............................................................................................................................................................6

Output Wiring ...........................................................................................................................................................7

INPUTS/OUTPUTS ........................................................................................................................... 8

OPERATION MODES ........................................................................................................................ 9

Stand-Alone Mode ...................................................................................................................................................9

Communicating Mode ..............................................................................................................................................9

LCD DISPLAY SCREENS ................................................................................................................12

TROUBLESHOOTING ..................................................................................................................... 21

LED Diagnostics ....................................................................................................................................................21

Troubleshooting Conditions & Alarms ..........................................................................................................................21

Temperature Sensors ...................................................................................................................................................22

APPENDIX A - Temperature Sensors ............................................................................................ 23

Leaving Air Temperature Sensor Installation .........................................................................................................23

Leaving Air Temperature Sensor Wiring Chart .......................................................................................................24

APPENDIX B - PREHEAT-X BACnet ............................................................................................... 25

PREHEAT-X BACnet MS/TP Connection ..............................................................................................................25

PREHEAT-X BACnet Points...................................................................................................................................26

PREHEAT-X Technical Guide

3

Page 4

OVERVIEW

General Information

Overview

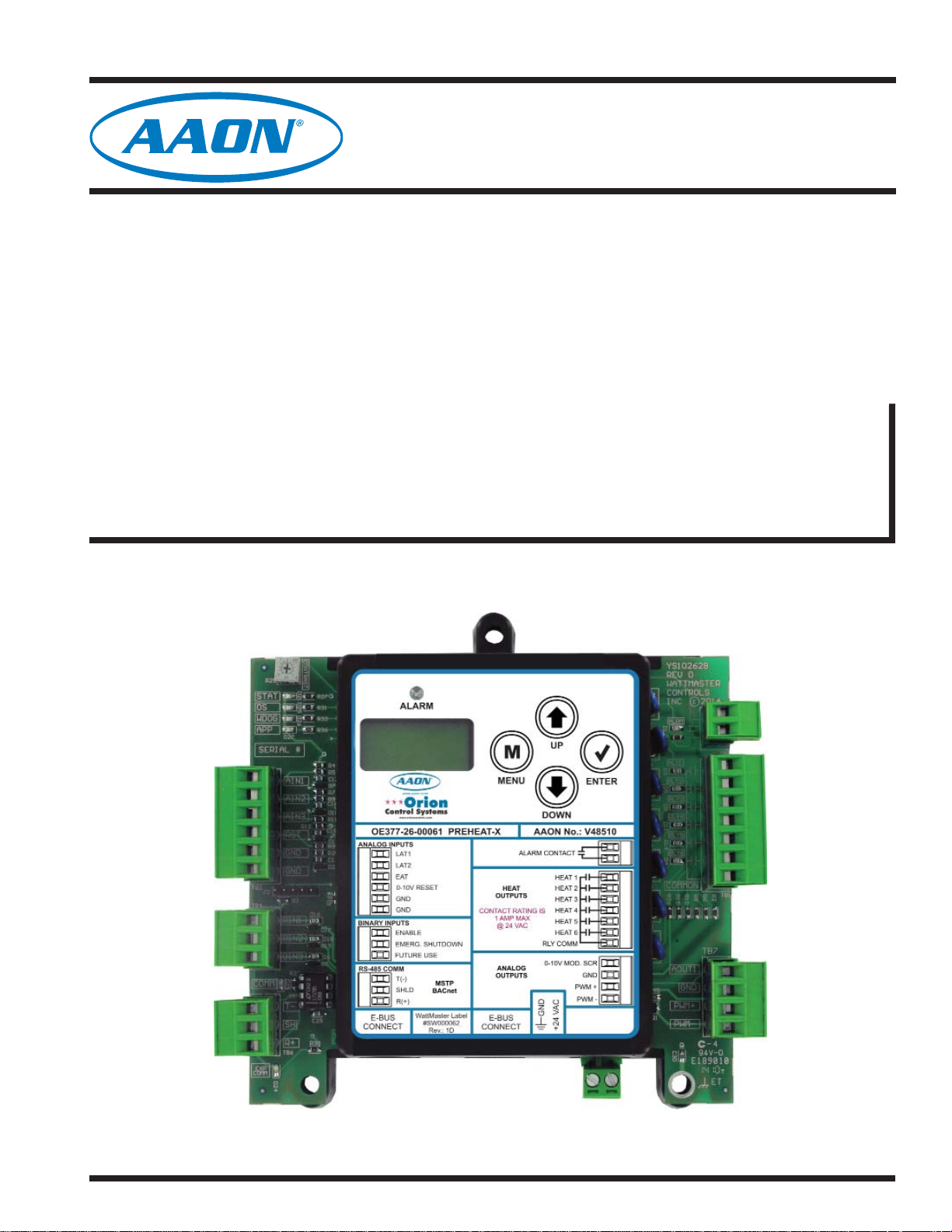

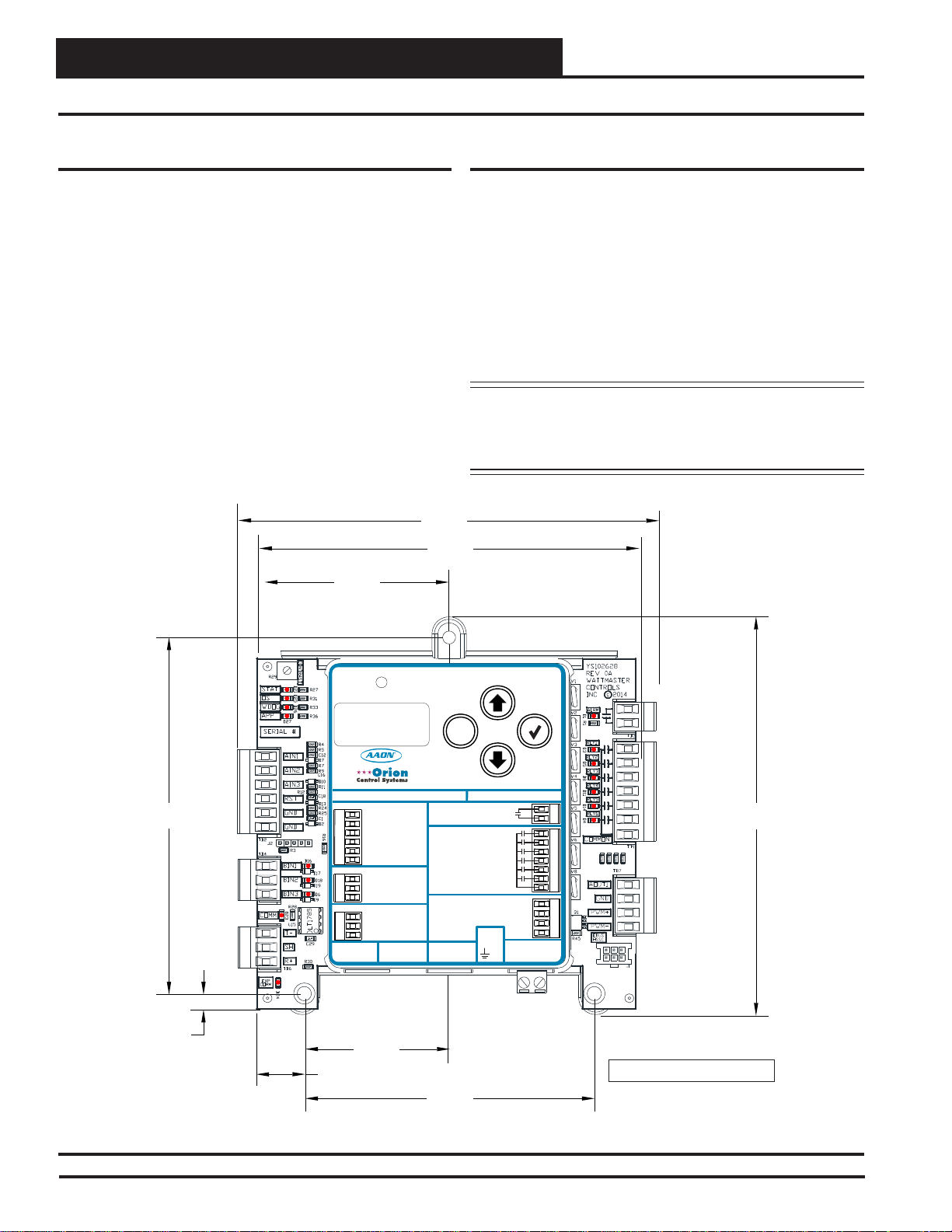

The OE377-26-00061 PREHEAT-X Controller (AAON Part No.

V48510) is designed to control fi xed stages of Preheat and optional

modulating Preheat to maintain a desired Preheat Leaving Air T emperature Setpoint. See Figure 1 for dimensions.

The controller can be used as a stand-alone controller or communicating with an AAON Unit Controller. The PREHEAT-X controller

connects to an AAON unit controller via a modular cable. See Figur e

2, page 5 for wiring details.

5.73

5.24

2.62

Features

The PREHEAT-X Controller:

• Can be operated as a stand-alone controller or

communicating with the VCC-X, VCB-X, and

VCM-X E-BUS Controllers

• Monitors the Preheater Leaving Air Temperature and

Leaving Air Reset Signal and controls to maintain

Setpoint

• Contains a 2 x 8 LCD character display and 4 buttons

that allow for status display and setpoint changes

NOTE: The PREHEAT-X Controller contains no user-

serviceable parts. Contact qualifi ed technical

personnel if your

operating correctly.

PREHEAT-X Controller is not

5.04

0.21

ALARM

ALARM

M

M

MENU

www.aaon.com

www.aaon.com

www.orioncontrols.com

www.orioncontrols.com

OE377-26-00061 PREHEAT-X AAON No.: V48510

OE377-26-00061 PREHEAT-X AAON No.: V48510

ANALOG INPUTS

ANALOG INPUTS

LAT1

LAT1

LAT2

LAT2

EAT

OAT

0-10V RESET

0-10V RESET

GND

GND

GND

GND

BINARY INPUTS

BINARY INPUTS

ENABLE

ENABLE

EMERG. SHUTDOWN

EMERG. SHUTDOWN

FUTURE USE

FUTURE USE

RS-485 COMM

RS-485 COMM

T(-)

T(-)

MSTP

SHLD

SHLD

BACnet

R(+)

R(+)

WattMaster Label

E-BUS

#LB102XXX-A

Rev.: 1A

CONNECT

E-BUS

WattMaster Label

CONNECT

#S 000062W

Rev.: 1D

MENU

ALARM CONTACT

ALARM CONTACT

HEAT

OUTPUTS

HEAT

OUTPUTS

CONTACTRATING IS

1 AMP MAX

CONTACTRATING IS

@ 24 VAC

1 AMP MAX

@ 24 VAC

ANALOG

ANALOG

OUTPUTS

OUTPUTS

E-BUS

E-BUS

CONNECT

CONNECT

DOWN

DOWN

RLYCOMM

RLYCOMM

0-10V MOD. SCR

0-10V MOD. SCR

GND

GND

2.04

0.57

4.09

UP

UP

HEAT1

HEAT1

HEAT2

HEAT2

HEAT3

HEAT3

HEAT4

HEAT4

HEAT5

HEAT5

HEAT6

HEAT6

ENTER

ENTER

5.63

GND

GND

PWM +

PWM +

PWM -

PWM -

+24 VAC

+24 VAC

Note: iDepth s 1.49 inches.

Figure 1: OE377-26-00061 PREHEAT-X Controller Dimensions (In Inches)

4

PREHEAT-X Technical Guide

Page 5

WIRING

Important Wiring Considerations

Important Wiring Considerations

Please read carefully and apply the following information when

wiring the

requires the following electrical connections:

1.

2.

3. Leaving Air Temperature Sensors, Entering Air

4. All 24 VAC wiring must be connected so that all ground

PREHEAT-X Controller. The PREHEAT-X Controller

18 gauge minimum wire unless otherwise noted.

24 VAC power connection with an appropriate VA rating.

Temperature Sensor, and Heat Enable must have 24 gauge

minimum wire.

wires remain common. Failure to follow this procedure can

result in damage to the module and connected devices.

5. All wiring is to be in accordance with local and

national electrical codes and specifi cations.

6. Check all wiring leads at the terminal block for tightness.

Be sure that wire strands do not stick out and touch

adjacent terminals. Confi rm that all transducers required for

your system are mounted in the appropriate location and

wired into the correct terminals.

WARNING: Observe polarity! All boards must be wired

GND-to-GND and 24 VAC-to-VAC. Failure

to observe polarity could result in damage to

the board.

PREHEAT-X Technical Guide

5

Page 6

WIRING

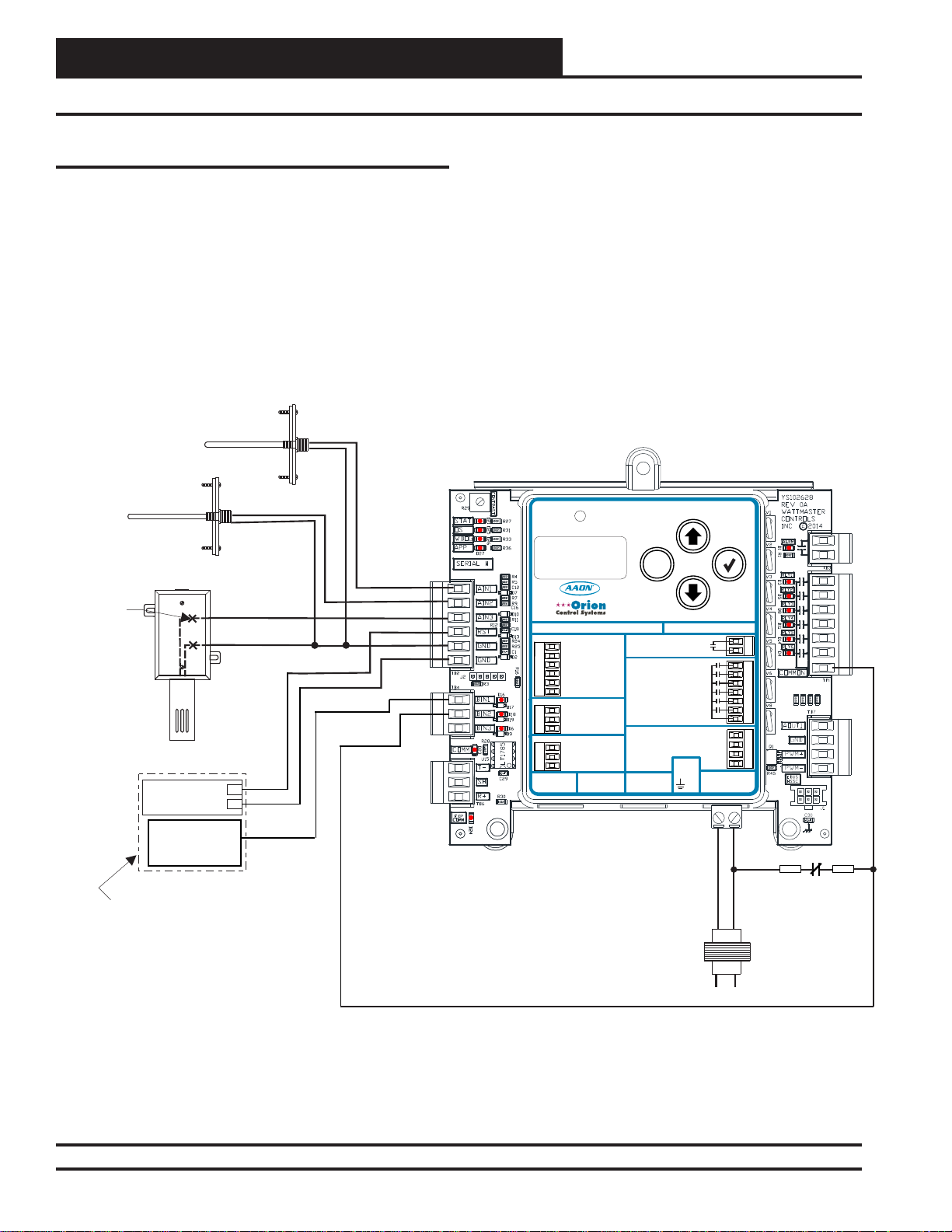

Inputs Wiring

Inputs Wiring

The PREHEA T-X Controller works as Stand-Alone or communicating with the VCM-X E-BUS, VCB-X, or VCC-X Controller. For

connection to a VCM-X E-BUS, VCB-X, or VCC-X Controller,

use an E-BUS Cable connecting to the appropriate E-BUS ports on

those controllers. The Reset Input and Heat Enable are only used in

Stand-Alone Mode. See Figure 2 below for Inputs Wiring.

Mount Inside PREHEAT-X

Leaving Air 2

Temperature Sensor

Mount Inside PREHEAT-X

Box Wall

Entering Air

Temperature Sensor

Make Splice

Connections

Inside Sensor

Enclosure

As Shown. Seal All

Conduit Fittings

With Silicone

Mount Sensor Outdoors

In Shaded Protected

Area & In Upright

Position As Shown

Reset In

Signal (24 VAC)

NOTE: Reset In And Heat

Enable Inputs Are Used In

Stand-Alone Mode Only

Leaving Air 1

Temperature Sensor

Box Wall

0-10 VDC

GND

+

-

Heat Enable

W1

Emergency

Shutdown

AIN1

AIN2

AIN3

RST

GND

GND

BIN1

BIN2

PREHEAT-X CONTROLLER

(OE377-26-00061)

ALARM

ALARM

UP

UP

M

M

MENU

www.aaon.com

www.aaon.com

www.orioncontrols.com

www.orioncontrols.com

OE377-26-00061 PREHEAT-X AAON No.: V48510

OE377-26-00061 PREHEAT-X AAON No.: V48510

ANALOG INPUTS

ANALOG INPUTS

LAT1

LAT1

LAT2

LAT2

EAT

OAT

0-10V RESET

0-10V RESET

GND

GND

GND

GND

BINARY INPUTS

BINARY INPUTS

ENABLE

ENABLE

EMERG. SHUTDOWN

EMERG. SHUTDOWN

FUTURE USE

FUTURE USE

RS-485 COMM

RS-485 COMM

T(-)

T(-)

MSTP

SHLD

BACnet

SHLD

R(+)

R(+)

WattMaster Label

WattMaster Label

E-BUS

#LB102XXX-A

CONNECT

Rev.: 1A

E-BUS

#S 000062W

CONNECT

Rev.: 1D

MENU

ALARM CONTACT

ALARM CONTACT

HEAT

OUTPUTS

HEAT

OUTPUTS

CONTACTRATING IS

1 AMP MAX

CONTACTRATING IS

@ 24 VAC

1 AMP MAX

@ 24 VAC

ANALOG

ANALOG

OUTPUTS

OUTPUTS

E-BUS

E-BUS

CONNECT

CONNECT

DOWN

DOWN

HEAT1

HEAT1

HEAT2

HEAT2

HEAT3

HEAT3

HEAT4

HEAT4

HEAT5

HEAT5

HEAT6

HEAT6

RLYCOMM

RLYCOMM

0-10V MOD. SCR

0-10V MOD. SCR

PWM +

GND

GND

+24 VAC

+24 VAC

GND

PWM +

PWM -

PWM -

GND

ENTER

ENTER

GND

24VAC

40 VA

Transformer

Minimum

N.C.

SAFETIES

(BY OTHERS)

COM

Figure 2: PREHEAT-X Inputs Wiring Diagram

6

Line

PREHEAT-X Technical Guide

Page 7

WIRING

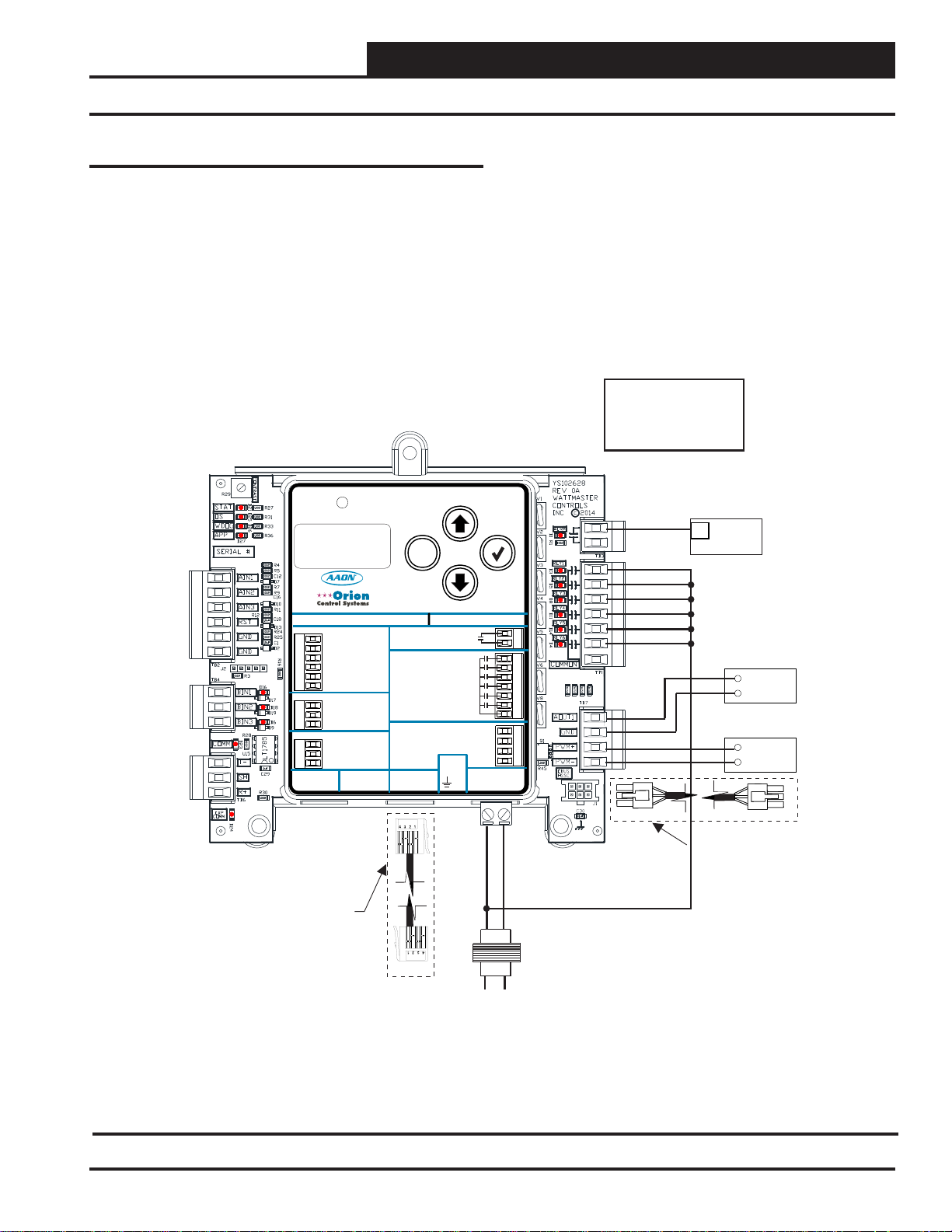

Outputs Wiring

The PREHEA T-X Controller works as Stand-Alone or communicating with the VCM-X E-BUS, VCB-X, or VCC-X Controller. For

connection to a VCM-X E-BUS, VCB-X, or VCC-X Controller , use

an E-BUS Cable connecting to the appropriate E-BUS ports on those

controllers. See Figure 3 below for Outputs Wiring.

Outputs Wiring

PREHEAT-X CONTROLLER

(OE377-26-00061)

ALARM

ALARM

UP

UP

M

M

MENU

www.aaon.com

www.aaon.com

www.orioncontrols.com

www.orioncontrols.com

OE377-26-00061 PREHEAT-X AAON No.: V48510

OE377-26-00061 PREHEAT-X AAON No.: V48510

ANALOG INPUTS

ANALOG INPUTS

LAT1

LAT1

LAT2

LAT2

EAT

OAT

0-10V RESET

0-10V RESET

GND

GND

GND

GND

BINARY INPUTS

BINARY INPUTS

ENABLE

ENABLE

EMERG. SHUTDOWN

EMERG. SHUTDOWN

FUTURE USE

FUTURE USE

RS-485 COMM

RS-485 COMM

T(-)

T(-)

MSTP

SHLD

SHLD

BACnet

R(+)

R(+)

WattMaster Label

WattMaster Label

E-BUS

#LB102XXX-A

CONNECT

Rev.: 1A

E-BUS

#S 000062W

CONNECT

Rev.: 1D

MENU

ALARM CONTACT

ALARM CONTACT

HEAT

OUTPUTS

HEAT

OUTPUTS

CONTACTRATING IS

1 AMP MAX

CONTACTRATING IS

@ 24 VAC

1 AMP MAX

@ 24 VAC

ANALOG

ANALOG

OUTPUTS

OUTPUTS

E-BUS

E-BUS

CONNECT

CONNECT

DOWN

DOWN

HEAT1

HEAT1

HEAT2

HEAT2

HEAT3

HEAT3

HEAT4

HEAT4

HEAT5

HEAT5

HEAT6

HEAT6

RLYCOMM

RLYCOMM

0-10V MOD. SCR

0-10V MOD. SCR

PWM +

PWM +

GND

GND

+24 VAC

+24 VAC

GND

PWM -

PWM -

ENTER

ENTER

GND

Note:

All Relay Outputs Are

Normally Open And Rated

For 24 VAC Power Only.

1 Amp Maximum Load.

Alarm

Relay

Contact

Heat 1 Relay

Heat 2 Relay

Heat 3 Relay

Heat 4 Relay

Heat 5 Relay

Heat 6 Relay

Modulating SCR

(0-10 VDC)

+

–

PWM SSR

+

–

EBC E-BUS Cable

Connects To

VCC-X Or VCB-X Controller’s

Expansion Port

Figure 3: PREHEAT-X Outputs Wiring Diagram

PREHEAT-X Technical Guide

GND

24VAC

40 VA

Transformer

Minimum

Line

HSSC E-BUS Cable

Connects To

VCM-X Controller’s

Expansion Port

7

Page 8

INPUTS & OUTPUTS

Inputs and Outputs

I/O Map

See Table 1 below to reference the inputs and outputs that are avail-

able on the PREHEAT-X Controller.

Analog Inputs

1 Leaving Air Temperature 1 (LAT1)

2 Leaving Air Temperature 2 (LAT2)

3 Entering Air Temperature Sensor

4 Reset In (0-10 VDC)

Binary Inputs

1 Heat Enable

2 Emergency Shutdown

3 Future Use

Analog Outputs

1 0-10 VDC Mod SCR

2 PWM SSR

Relays

1 Alarm

2 Heat 1

3 Heat 2

4 Heat 3

5 Heat 4

6 Heat 5

7 Heat 6

NOTE: For AIN1 through AIN3, all T emperature Sensors must

be Thermistor Type III which provide 77.0°F @ 10K

Ohms Resistance.

Reset Input (0-10 VDC)

Used only in stand-alone operation. The Leaving Air Temperature

Setpoint can be reset by supplying a 0-10 VDC signal to the RST

IN low voltage terminal block. This reset signal is optional and need

only be used if you require resetting of the discharge air temperature.

Binary Inputs

Heat Enable Contact (HEAT EN)

This input is only required when the controller is used in stand-alone

operation; it is not required when communicating with an AAON

Unit Controller. The Heat Enable input is activated by a 24VAC

signal supplied from a building automation system to enable the

PREHEAT-X Controller. The controller will not operate without

24VAC being applied to this input terminal when used in a standalone confi guration. When the Heat Enable signal is lost or turned

off, all stages de-activate immediately.

Emergency Shutdown Input

This wet contact (24 VAC) input is used to initiate shutdown of the

HV AC unit when a N.C. Smoke Detector (by others), Firestat (by others), or other shutdown condition (by others) occurs and the contact

is opened. The controller remains active and can initiate alarm relays.

Analog Outputs

Table 1: PREHEAT-X Controller Inputs & Outputs

Analog Inputs

Leaving Air Temperature 1 (LAT1)

When enabled, the PREHEAT-X Controller will control to a Leaving Air Temperature Setpoint. The Controller can be confi gured to

use only LAT 1 for this purpose. Typically, the average of LAT1

and LAT2 is used.

Leaving Air Temperature 2 (LAT2)

When enabled, the PREHEAT-X Controller will control to a Leaving Air Temperature Setpoint. The Controller can be confi gured to

use only LAT 2 for this purpose. Typically, the average of LAT1

and LAT2 is used.

Entering Air Temperature

When the Entering Air Temperature falls below the Entering Air

Temperature Setpoint, preheat will be enabled.

8

0-10 VDC Modulating SCR

Depending on the type of Heat used, this output will supply a 0-10

VDC output signal for control of the modulating SCR Heat.

Pulse Width Modulating SSR

Depending on the type of Heat used, this output will supply a 12 V

PWM Output Signal for control of the modulating SSR Heat.

Relay Outputs

Relay #1 - Alarm

This relay sends a signal when an alarm is enabled.

Relays #2 - 6—Fixed Stage Heat Outputs

PREHEAT-X Technical Guide

Page 9

OPERATION MODES

Outputs and Operation Modes

Operation Modes

The PREHEA T -X Controller can be used stand-alone or communicating with an AAON Unit Controller using a modular cable.

Stand-Alone Mode

When used in a stand-alone application, the PREHEA T -X Controller

will modulate SCR or SSR Heat and stage any additional fi xed stages

to maintain the Leaving Air T emperature setpoint con fi gured on the

PREHEA T-X Controller LCD display . The PREHEA T-X Controller

is activated by a 24VAC signal to the HEAT EN input.

Communicating Mode

When the PREHEA T-X Controller is connected and communicating

with an AAON Unit Controller via a modular cable, the necessary

information will be passed between the PREHEAT-X and the Main

Unit Controller to properly operate in the Heating Mode.

If the communication is interrupted between the PREHEAT-X

Controller and the Main Controller, both boards will show an alarm

and the PREHEA T-X outputs will turn off. When communication is

restored, the alarms will go away.

In this confi guration, the Leaving Air T emperature Setpoints and the

Preheat Enable Sepoints are set using the Main Controller.

PREHEAT-X Technical Guide

9

Page 10

SEQUENCE OF OPERATIONS

Operation Modes

Zone

Zone

Preheat Enable

Stand Alone Mode

Enabled when the Binary Input is closed and the Entering Air Temperature is below setpoint.

E-BUS Communications Mode

Enabled by an E-BUS command when the Entering Air T emperature

falls below the Preheat Setpoint.

BACnet Communications Mode

Enabled by BACnet command or Binary Input, whichever occurs

fi rst.

Leaving Air Sensor

The controller can be confi gured to use one of three sensor confi gu-

rations for control.

• Leaving Air Sensor 1 only (LAT1)

• Leaving Air Sensor 2 only (LAT2)

• Average Leaving Air Temperature which averages

LAT1 and LAT2

Modulating Heat

• If confi gured, the Modulating Heat output will be used

as the fi rst stage of heat.

• Analog Voltage Output can be adjusted between

0-10 VDC as needed to maintain the Leaving Air

Setpoint.

• Controlled by an Internal PID Loop.

Heat Staging Up

The following conditions must be met before the fi rst (next) stage

of heat can be energized:

• Preheat Enable Signal/Command must be active.

• The LAT must be below the LAT Setpoint by any

amount.

• If Mod Heat is confi gured, it must be at 100% for the

Stage Up Delay.

• The Minimum Off Time must be met.

• The Stage Up Delay must be met (for second stage

and above).

Leaving Air Setpoint

Stand Alone

• Leaving Air Temperature Setpoint can be reset

between the LAT Setpoint and LAT Setpoint Reset

Limit.

• The Reset Source is based on a 0-10 VDC input and

range can be adjusted using the LAT Setpoint Reset

Source Low and LAT Setpoint Reset Source High

Setpoints.

E-BUS and BACnet Communications Mode

• A Leaving Air Temperature Setpoint will be sent to

the controller.

• This value is stored in volatile memory and will be

lost at reset.

• There are separate Leaving Air T emperature Setpoints,

depending on if the unit is in Heating, Vent, or Cool

Mode.

Heat Staging Down

The following conditions must be met before a stage of heat can be

de-energized:

• Preheat Enable Signal/Command is deactivated

-OR- the LAT must be above the LAT Setpoint by the

LAT Deadband.

• If Modulating Heat is confi gured, it must be at 0% for

the stage down delay.

• The Minimum Run time must be met.

• The Stage Down Time must be met.

10

PREHEAT-X Technical Guide

Page 11

Emergency Shutdown

The Emergency Shutdown input must always be used and wired

as a 24 VAC normally closed contact. If an Emergency Shutdown

occurs, and that contact opens:

• All outputs will be immediately de-energized.

• An alarm will be generated.

High Leaving Air Temperature Alarm

• If the Leaving Air T emperature is above the LA T High

Temperature Alarm Limit for more than the Alarm

Delay all heating outputs will be de-energized

immediately.

• An alarm will be generated.

• A manual reset will be required.

SEQUENCE OF OPERATIONS

Operation Modes

Low Leaving Air Temperature Alarm

If the Leaving Air Temperature is below the LAT Low Temperature

Alarm Limit for more than 2 minutes, the heat will remain on but

an alarm will be generated.

PREHEAT-X Technical Guide

11

Page 12

LCD DISPLAY SCREENS

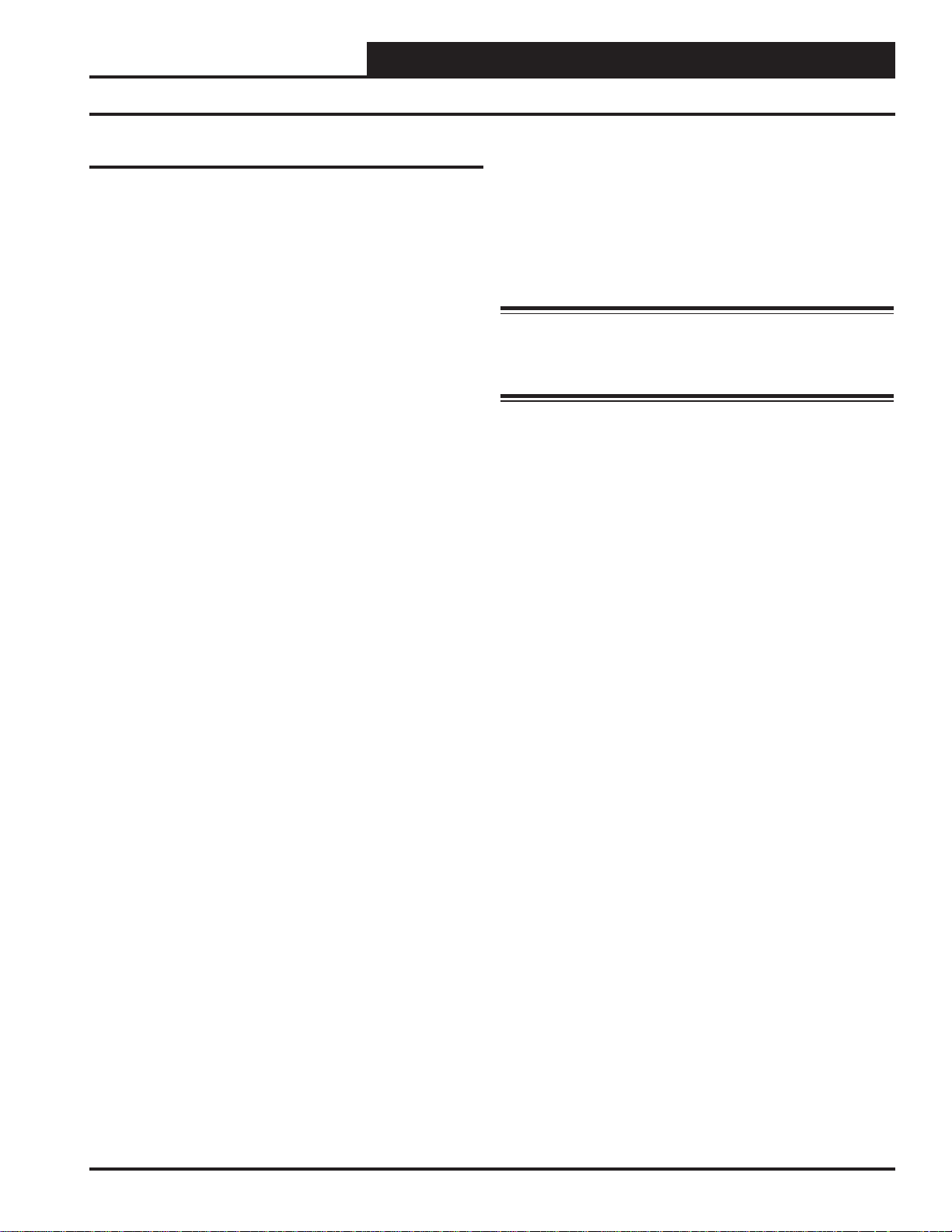

Navigation Keys

LCD Display Screen & Navigation

Keys

The PREHEAT-X Controller allows you to make confi guration

changes, view status, change setpoints, create force modes, and

perform diagnostics using the keypad next to the LCD display. See

Figure 4 and refer to Table 2 for descriptions.

Figure 4: LCD Display and Navigation Keys

NAVIGATION

KEY

MENU

UP

DOWN

ENTER

Use the MENU key to navigate through the

PREHEAT-X Main Menu Screens.

Use this key to adjust setpoints and change

confi gurations.

Use this key to adjust setpoints and change

confi gurations.

Use the Enter key to move through screens

within Main Menu categories. Also, use this

key to save setpoints and confi guration

changes.

KEY FUNCTION

Table 2: Navigation Key Functions

12

PREHEAT-X Technical Guide

Page 13

LCD DISPLAY SCREENS

Main Screens Map

PREHEAT

CONTROL

STATUS

SOFTWARE

VER X.XX

PREHEAT

ENABLED

CONT TMP

50.3

LA SPT

70.0

STGS ON

2

MOD HEAT

32%

SET

POINTS

LA SPT

70.0

RST LMT

70.0

EA EN SP

55.0

LA1 CAL

0.0

LA2 CAL

0.0

EA CAL

0.0

ALARMS

NO

ALARMS

E-SHDN

OK

LA1 SENS

OK

LA2 SENS

OK

LOW LAT

OK

HI LAT

OK

CONFIG

HEAT STG

3

MOD HEAT

YES

LAT CFG

AVERAGE

AOUT VLO

0.0

AOUT VHI

10.0

MOD Kp

15.0

COMM

CONFIG

COM MODE

S-ALONE

EBUS CFG

VCB-X

MAC ADDR

0

BAC ID

15000

BAC BAUD

38.400

LA1 TEMP

50.6

LA2 TEMP

50.0

AVG TEMP

50.3

ENT AIR

26.6

EA SENS

OK

COM STAT

OK

MOD Ki

6.0

MOD TIME

10.0

MOD Kd

4.0

STG UP

20

STG DWN

20

MIN RUN

20

MIN OFF

20

Figure 5: PREHEAT-X Main Screens Map

PREHEAT-X Technical Guide

SCALING

DEG.F

13

Page 14

LCD DISPLAY SCREENS

PREHEAT-X Main Screens

PREHEAT-X Main Screens

Refer to the following map when navigating through the LCD Main

Screens. The fi rst screen is an initialization screen. To scroll through

the rest of the screens, press the

Press to scroll through PREHEAT Screens.

Press to go to STATUS Screens.

Press to scroll through STATUS Screens.

Press to go to SETPOINTS Screens.

<MENU> button.

PREHEAT

CONTROL

STATUS

CONFIG

Press to scroll through CONFIGURATION Screens.

Press to go to COMM Confi guration Screens.

COMM

CONFIG

Press to scroll through COMM Screens.

SET

POINTS

Press to scroll through SETPOINTS Screens.

Press to go to ALARMS Screens.

ALARMS

Alarms will display automatically.

Press to go to CONFIGURATION Screens.

14

PREHEAT-X Technical Guide

Page 15

LCD DISPLAY SCREENS

Status Screens

Status Screens

Refer to the following map when navigating through the Status

Screens. From the STATUS Screen, press

through the screens.

STATUS

Status Screens shown below will scroll automatically if LCD display is

left on this screen for 20 seconds.

SOFTWARE

V.XXX

CURRENT SOFTWARE VERSION

Displays the current software version installed in the controller.

PREHEAT

ENABLED/DISABLED

PREHEAT

Gives the Enabled status for the Preheat Mode. The controller can

be enabled from one of the following: (1) Binary Input in Stand-Alone

Mode, (2) E-BUS command from VCB-X or VCM-X, (3) BACnet Point.

<ENTER> to scroll

STGS ON

#

CURRENT NUMBER OF ACTIVE STAGES

Displays the number of heat stages currently energized.

This includes the First Modulating Stage of Heat.

MOD HEAT

XX.X%

MODULATING HEATING OUTPUT

Displays the current Modulation output Percentage of both

the Analog and PWM outputs (they control together).

LA1 TEMP

XX.X

LEAVING AIR TEMPERATURE 1

Displays the Leaving Air Temperature 1 Sensor’s current reading.

CONT TMP

XX.X

CONTROL TEMPERATURE

Displays the current controlling temperature. This could be one of the

following based on confi guration: (1) Leaving Air Sensor 1,

(2) Leaving Air Sensor 2, or (3) the average of both.

LA SPT

LEAVING AIR TEMPERATURE SETPOINT

Displays the current Leaving Air Setpoint that the controller is trying to

maintain. This value can come from the following based on

confi guration: (1) Internal Setpoints +/- Setpoint Reset Input, (2) E-BUS

input from VCM-X, VCB-X, VCC-X, or (3) BACnet Point.

LA2 TEMP

XX.X

LEAVING AIR TEMPERATURE 2

Displays the Leaving Air Temperature 2 Sensor’s current reading.

AVG TEMP

XX.X

AVERAGE TEMPERATURE

Displays the current average temperature of both

Leaving Air Temperature Sensors.

ENT AIR

XX.X

ENTERING AIR TEMPERATURE

Displays the current Entering Air Temperature Sensor reading.

PREHEAT-X Technical Guide

15

Page 16

LCD DISPLAY SCREENS

Setpoint Screens

Setpoint Screens

Refer to the following map when navigating through the Setpoint Screens. From the SETPOINTS Screen, press <ENTER>

to scroll through the screens and change setpoints. Use the <UP>

and <DOWN> arrow keys to change your selections. Then press

<ENTER> to save the new setpoint.

NOTE: When the PREHEAT-X is operating in

Communications Mode, these setpoint screens

will not appear on the LCD display because

they are controlled by the Main Controller.

SET

POINTS

LA SP

XX.X°F

XX.X°C

LEAVING AIR TEMPERATURE SETPOINT

Will display only in stand-alone mode. This is the target temperature

while the heating is enabled. If you are using the reset signal, this is the

setpoint it will calculate to at zero volts.

The LA Setpoint is set by the LCD Display in stand-alone mode and is

set by the Main Controller in communicating mode.

EA EN SP

XX.X°F

XX.X°C

ENTERING AIR ENABLE SETPOINT

This is the temperature at which Preheat is enabled. The Entering Air

Enable Setpoint is set by the LCD Display in stand-alone mode and is

set by the Main Controller in communicating mode.

Minimum Default Maximum

-40°F

-40°C

55°F

12.7°C

90°F

32°C

LA1 CAL

XX.X°F

XX.X°C

LEAVING AIR SENSOR 1 CALIBRATION OFFSET

If the sensor is reading incorrectly, you can use this screen to enter an

offset temperature to adjust the sensor’s temperature. Enter a positive

value to raise the sensor’s temperature or a negative value to lower the

sensor’s temperature.

Minimum Default Maximum

-100.0°F

-55.5°C

0.0°F

0.0°C

100.0°F

55.5°C

Minimum Default Maximum

35°F

1.6°C

70°F

21°C

90°F

32°C

RST LMT

XX.X°F

XX.X°C

RESET LIMIT SETPOINT

Will display and be used only in stand-alone mode. If Remote Reset is

being utilized, this will be the Leaving Air Setpoint when the Reset Voltage Input is at 10VDC.

Minimum Default Maximum

0°F

°C

70°F

°C

120°F

°C

LA2 CAL

XX.X°F

XX.X°C

LEAVING AIR SENSOR 2 CALIBRATION OFFSET

If the sensor is reading incorrectly, you can use this screen to enter an

offset temperature to adjust the sensor’s temperature. Enter a positive

value to raise the sensor’s temperature or a negative value to lower the

sensor’s temperature.

Minimum Default Maximum

-100.0°F

-55.5°C

0.0°F

0.0°C

100.0°F

55.5°C

16

PREHEAT-X Technical Guide

Page 17

LCD DISPLAY SCREENS

Setpoint & Alarm Screens

EA CAL

XX.X°F

XX.X°C

ENTERING AIR SENSOR CALIBRATION OFFSET

If the sensor is reading incorrectly, you can use this screen to enter an

offset temperature to adjust the sensor’s temperature. Enter a positive

value to raise the sensor’s temperature or a negative value to lower the

sensor’s temperature.

Minimum Default Maximum

-100.0°F

-55.5°C

0.0°F

0.0°C

100.0°F

55.5°C

Alarm Screens

Refer to the following map when viewing Alarm Screens. These

screens will display automatically when alarms are present. For

alarm troubleshooting, see pages 21-22.

ALARMS

ALARMS

The alarms are as follows:

NO ALARMS: This will be shown if there are no current alarms.

E-SHDN: If 24VAC is removed from the Emergency Shutdown Input,

this alarm will activate and the controller will turn off all outputs. The

alarm will be disabled when voltage has returned.

LA1 SENS: The fi rst Leaving Air T emperature Sensor has been discon-

nected, shorted, open, or missing for more than 60 seconds. This alarm

will be disabled when the sensor is working again.

LA2 SENS: The second Leaving Air Temperature Sensor has been

disconnected, shorted, open, or missing for more than 60 seconds. This

alarm will be disabled when the sensor is working again.

LO LAT: This indicates a Leaving Air Temperature Cutoff Alarm condi-

tion which is activated if the Controlling Leaving Air Temperature has

dropped below 35ºF for more than 2 minutes. The alarm will be disabled

if after a fi xed delay period the Leaving Air Temperature has risen above

35ºF.

HI LA T: This indicates a Leaving Air Temperature Cutof f Alarm condition

which is activated if the Controlling Leaving Air Temperature has risen

above 120ºF. All outputs will stage off.

EA SENS: The Entering Air Temperature Sensor has been disconnect-

ed, open, shorted, or missing for more than 60 seconds. This alarm will

be disabled when the sensor is working again.

COM STAT: Communications have been lost with the main controller

for more than 30 seconds. This alarm will disable when communications

resume.

PREHEAT-X Technical Guide

17

Page 18

LCD DISPLAY SCREENS

Confi guration Screens

Confi guration Screens

Refer to the following map when navigating through the Con guration Screens. From the CONFIG Screen, press

<ENTER> to

scroll through the screens and change setpoints. Use the <UP> and

<DOWN> arrow keys to change your selections. Press <ENTER> to

save any changes.

CONFIG

HEAT STG

0-6

# OF HEAT STAGES

Select the total number of Heat Stages including the Modulating

Stage. Range is 0-6. Default is 0.

MOD HEAT

YES/NO

AOUT VHI

0.0-10.0 VOLTS

MAXIMUM SCR VOLTAGE

This is the High Voltage setting for the Analog Output. It sets the volt-

age level needed for 100%. Range is 0 -10. Default is 10.

MOD Kp

15.0

INTEGRAL CONSTANT

This is the Internal PID Kp Constant. Do not make changes to this

value unless told to do so by WattMaster Technical Support.

.

MOD Ki

6.0

MODULATING HEAT

If either the Analog or PWM Modulating Heat output is being used, this

must be set to YES. Default is NO.

LAT CFG

LAT1,LAT2,

AVERAGE

LEAVING AIR TEMPERATURE SENSOR CONFIGURATION

LAT1: Use Leaving Air Temperature Sensor 1 as the Controlling Temp.

LAT2: Use Leaving Air Temperature Sensor 2 as the Controlling Temp.

AVERAGE: Use the Average of LAT1 & LAT2 as the Controlling Temp.

Default is AVERAGE.

AOUT VLO

0.0-10.0 VOLTS

MINIMUM SCR VOLTAGE

This is the Low Voltage setting for the Analog Output. It sets the

voltage level needed for 0%. Range is 0 -10. Default is 0.

.

AIRFLOW INTEGRAL

This is the Internal PID Ki Constant. Do not make changes to this value

unless told to do so by WattMaster Technical Support.

MOD TIME

1-120 SEC

MODULATION RATE

This is the time period setting that determines how often a change is

made to the modulating output. Range is 1 - 120 seconds.

Default is 20.

MOD Kd

6.0

DERIVATIVE CONSTANT

This is the Internal PID Kd Constant. Do not make changes to this

value unless told to do so by WattMaster Technical Support.

18

PREHEAT-X Technical Guide

Page 19

LCD DISPLAY SCREENS

Confi guration Screens

STG UP

0-1200 SECONDS

STAGE UP DELAY

If confi gured for SCR modulation, this is the amount of time (in sec-

onds) the controller must wait to activate an additional stage of heat if

the Min Off Time is met. Range is 0 - 1200. Default is 180.

STG DWN

0-1200 SECONDS

STAGE DOWN DELAY

If confi gured for SCR modulation, This is the amount of time (in sec-

onds)the controller must wait to deactivate a stage of heat if the Min

Run time is met. Range is 0 - 1200. Default is 180.

MIN RUN

0-1200 SECONDS

MIN OFF

0-1200 SECONDS

MINIMUM OFF TIME

This is the amount of time (in seconds) a stage of heat must remain off

before it can be activated. Range is 0 - 1200. Default is 60.

SCALING

DEG. F

DEG. C

TEMPERATURE SCALE

Fahrenheit (default) or Celsius.

This setting is used only in stand-alone mode.

MINIMUM RUN TIME

This is the amount of time (in seconds) a stage of heat must remain on

before it can be deactivated. Range is 0 - 1200. Default is 120.

PREHEAT-X Technical Guide

19

Page 20

LCD DISPLAY SCREENS

Communicating Confi guration Screens

Communication Confi guration Screens

Refer to the following map when navigating through the Communicating Con guration Screens. From the COM CONFIG Screen,

press

<ENTER> to scroll through the screens and change setpoints.

Use the <UP> and <DOWN> arrow keys to change your selections.

Press <ENTER> to save any changes.

COMM

CONFIG

COMM MODE

BACNET, EBUS,

S-ALONE

This setting confi gures the communications mode. The choices are (1)

BACNET, (2) EBUS, or (3) S-ALONE (default).

COMMUNICATION MODE

MAC ADDR

0-128

BACnet® - CURRENT MAC ADDRESS

Valid range is 0 to 128. Default is 0.

BAC ID

0-30,000

®

BACnet

Range is 0-30,000. Default is 15,000..

BACnet® - CURRENT BAUD RATE

9600, 19200, 38400, 57600, 76800. Default is 38400.

- CURRENT ID Start

BAC BAUD

38400

E-BUS CFG

VCM-X, VCB-X,

VCC-X or NONE

E-BUS CONFIGURATION

Select the type of controller that the PREHEAT-X is connected to. The

choices are VCM-X, VCB-X, VCC-X, or NONE (default). NOTE: You

must cycle power after changing this setting.

20

PREHEAT-X Technical Guide

Page 21

TROUBLESHOOTING

LED Diagnostics & Alarms

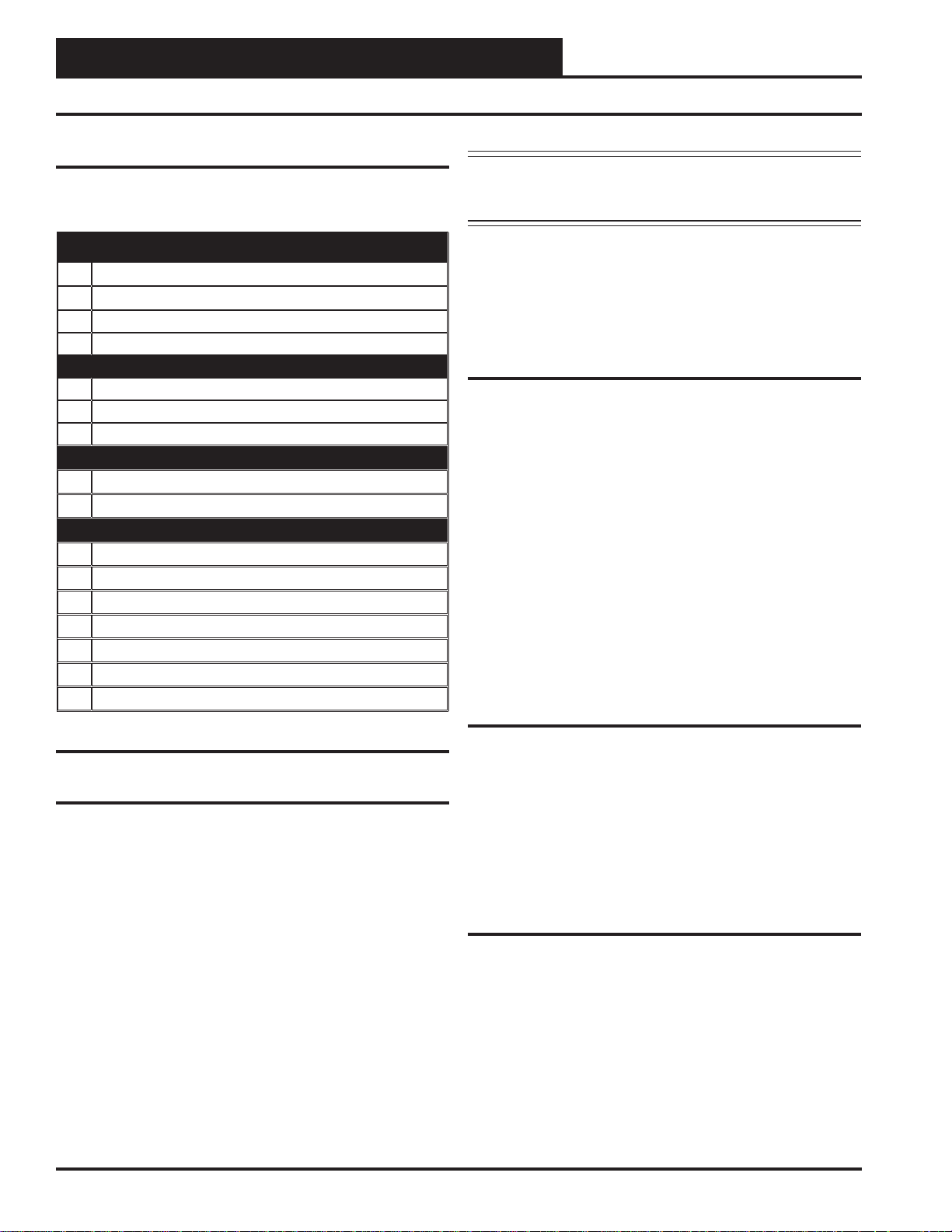

LED Diagnostics

The PREHEAT-X Controller is equipped with LEDs that can be

used to verify operation and perform troubleshooting. See Figure

6, below for the LED locations. The LEDs associated with these

inputs and outputs allow you to see what is active without using a

voltmeter. The LEDs and their uses are as follows:

STATUS LEDs

POWER - This green LED will light up to indicate that 24 VAC

power has been applied to the controller.

Diagnostic LEDs

ALARM - This red LED located on the PREHEAT-X Controller’s

cover above the LCD display will light up to indicate an alarm. The

type of alarm(s) will be shown on the LCD display.

ALARM LED

Communication LED

COMM - This yellow LED will light up and blink when communica-

tions are detected.

Relay LEDs

RL Y 1-6 - These green LEDs will light up and stay lit as long as the

Heat Relay(s) is active.

Binary Input LEDs

HEAT EN - This green LED will light up when Heat is enabled.

EMERGENCY SHUTDOWN - This green LED will light up when

Emergency Shutdown is enabled.

STAT LED

OS LED

WDOG LED

APP LED

HEAT ENABLE LED

EMERGENCY

SHUTDOWN LED

COMM LED

ALARM

UP

M

www.aaon.com

www.orioncontrols.com

OE377-26-00061 PREHEAT-X AAON No.: V48510

ANALOG INPUTS

LAT1

LAT2

EAT

0-10V RESET

GND

GND

BINARY INPUTS

ENABLE

EMERG. SHUTDOWN

FUTURE USE

RS-485 COMM

T(-)

MSTP

SHLD

BACnet

R(+)

WattMaster Label

E-BUS

CONNECT

#S 000062W

Rev.: 1D

MENU

ALARM CONTACT

HEAT

OUTPUTS

CONTACT RATING IS

1 AMP MAX

@ 24 VAC

ANALOG

OUTPUTS

E-BUS

CONNECT

DOWN

HEAT 1

HEAT 2

HEAT 3

HEAT 4

HEAT 5

HEAT 6

RLY COMM

0-10V MOD. SCR

GND

+24 VAC

Figure 6: PREHEAT-X Controller LED Locations and Descriptions

GND

PWM +

PWM -

ALARM LED

ENTER

PREHEAT-X Technical Guide

21

Page 22

TROUBLESHOOTING

Alarms & LED Locations

Troubleshooting Alarms

Mechanical Failure:

• Check relay outputs on the PREHEAT-X for 24 VAC

output.

• Verify output voltage (VOUT and GND) to SCR or

PWM

• Verify that the Leaving Air Temperature Sensor(s) is

connected to AIN1 and/or AIN2 and GND on the

PREHEAT-X

• Verify Leaving Air Temperature Sensor probe(s) is

mounted correctly

• Remove AIN1 and AIN2 and GND wiring from the

PREHEAT-X and ohm the sensor out (this may

indicate open or failed wiring). Refer to chart in back

of this guide for readings.

Leaving Air Temperature Failure:

• Verify that the Leaving Air Temperature Sensor(s) is

connected to the AIN1 and/or AIN2 and GND on the

PREHEAT-X.

• Remove AIN1 and AIN2 and GND wiring from the

PREHEAT-X and ohm the sensor out (this may

indicate open or failed wiring). Refer to chart in back

of this guide for readings.

Communications Loss:

• Check COMM LED on PREHEAT-X.

• Verify 24 VAC power to all interconnected

WattMaster controllers.

• Verify connection between the PREHEAT-X

and associated WattMaster controllers.

• In communication mode (connected to a an AAON

Unit with modular cable), verify PREHEAT-X

confi guration on AAON unit.

22

PREHEAT-X Technical Guide

Page 23

APPENDIX A

Leaving Air Temperature Sensor Installation

Mounting the Leaving Air Temperature

Sensor

• The Leaving Air T emperature (LA T) Sensor should be

located in PREHEAT-X box’s output location.

• Locate the sensor in the center of the widest part of the

PREHEA T -X box wall. Use the supplied template and a

5/16” drill to make a hole for the sensor.

• Install the gasket over the probe and mount securely to

the box wall using the supplied sheet metal screws. Be sure

the gasket is compressed to provide an air tight seal.

• For best accuracy, apply insulation on the outside of the

box wall, over the sensor. This will help prevent thermal

gradients from affecting the sensor.

Leads Are Non-Polarized. Butt Splice Leads

To 24 Gauge Wire Minimum.

Connect Leads to ”AIN1 And/Or “AIN2” And “GND” On

PREHEAT-X Controller. See Figure 2 on page 5 for

details.

WARNING: Make sure your Leaving Air Temperature

Sensor(s) are mounted and wired according

to these instructions prior to testing the unit

or else the modulating valve will not control

properly and may damage your equipment.

Inside Wall of PREHEAT-X Box

Figure 7: Leaving Air Temperature Sensor Installation

PREHEAT-X Technical Guide

23

Page 24

TROUBLESHOOTING

LAT Sensor Testing

Leaving Air Temperature Sensor

If you suspect the Leaving Air Temperature Sensor is not reading

correctly, make sure the wiring terminal connections are tight and

that any wiring splices are properly connected. You can check the

operation of the Leaving Air Temperature Sensor by measuring

the resistance or voltage using a digital multimeter. Set the meter

to DC Volts. Place the positive probe on the AIN terminal and the

negative probe on the GND terminal. Read the DC Volts and fi nd

that voltage in Table 3.

Read the temperature corresponding with that voltage and determine

if this is close to the actual temperature the sensor is exposed to. If the

temperature from the chart is different by more than a few degrees,

you probably have a defective or damaged sensor. You can also

check the sensor resistance to determine correct operation. To read

the resistance, set the meter to Ohms. Unplug the sensor connector

from the board and measure the resistance across the disconnected

wires. This resistance should match the corresponding temperature

from Table 3.

Temperature to Resistance/Voltage Chart

Temp

(°F)

-10 -23.3 93333 2.98

-5 -20.6 80531 2.94

0 -17.8 69822 2.89

5 -15.0 60552 2.83

10 -12.2 52500 2.77

15 -9.4 45902 2.71

20 -6.7 40147 2.64

25 -3.9 35165 2.57

30 -1.1 30805 2.49

35 1.6 27140 2.41

40 4.4 23874 2.33

45 7.2 21094 2.24

50 10.0 18655 2.15

52 11.1 17799 2.11

54 12.2 16956 2.08

56 13.3 16164 2.04

58 14.4 15385 2.00

60 15.6 14681 1.96

62 16.7 14014 1.93

64 17.8 13382 1.89

66 18.9 12758 1.85

Table 3: 0-3.3 V Temperature Sensor - Voltage &

Resistance for Type III Sensors

Temp

(°C)

Resistance

(Ohms)

Voltage @

Input (VDC)

Temperature to Resistance/Voltage Chart

Temp

(°F)

68 20.0 12191 1.81

69 20.6 11906 1.79

70 21.1 11652 1.78

71 21.7 11379 1.76

72 22.2 11136 1.74

73 22.7 10878 1.72

74 23.3 10625 1.70

75 23.9 10398 1.68

76 24.4 10158 1.66

78 25.6 9711 1.63

80 27.8 9302 1.59

82 27.8 8893 1.55

84 28.9 8514 1.52

86 30.0 8153 1.48

88 31.1 7805 1.45

90 32.2 7472 1.41

95 35.0 6716 1.33

100 37.8 6047 1.24

105 40.6 5453 1.16

110 43.3 4923 1.09

115 46.1 4449 1.02

120 48.9 4030 .95

125 51.7 3656 .88

130 54.4 3317 .82

135 57.2 3015 .76

140 60.0 2743 .71

145 62.8 2502 .66

Temp

(°C)

Resistance

(Ohms)

Voltage @

Input (VDC)

Table 3, continued: 0-3.3 V Temperature Sensor Voltage & Resistance for Type III Sensors

Thermistor Sensor Testing Instructions

1.) Use the resistance column to check the thermistor sensor while

disconnected from the controllers (not powered).

2.) Use the voltage column to check sensors while connected to

powered controllers. Read voltage with meter set on DC volts. Place

the “-” (minus) lead on GND terminal and the “+” (plus) lead on the

sensor input terminal being investigated.

If the voltage is above 3.3 VDC, the sensor or wiring is “open.” If

the voltage is less than 0.05 VDC, the sensor or wiring is shorted.

24

PREHEAT-X Technical Guide

Page 25

PREHEAT-X BACnet® Connection To MS/TP Network

Programming Note:

Use Communication

Configuration Screens In

LCD Display To Program

The BACnet Settings.

See Page 20

MS/TP Connection

To BACnet

For Details.

®

APPENDIX B

PREHEAT-X

CONTROLLER

ALARM

ALARM

ALARM

UP

UP

UP

M

M

M

MENU

MENU

www.aaon.com

www.aaon.com

www.aaon.com

www.orioncontrols.com

www.orioncontrols.com

www.orioncontrols.com

OE377-26-00061 PREHEAT-X AAON No.: V48510

OE377-26-00061 PREHEAT-X AAON No.: V48510

OE377-26-00061 PREHEAT-X AAON No.: V48510

ANALOG INPUTS

ANALOG INPUTS

ANALOG INPUTS

LAT1

LAT1

LAT1

LAT2

LAT2

LAT2

OAT

EAT

OAT

0-10V RESET

0-10V RESET

0-10V RESET

GND

GND

GND

GND

GND

GND

BINARY INPUTS

BINARY INPUTS

BINARY INPUTS

ENABLE

ENABLE

ENABLE

EMERG. SHUTDOWN

EMERG. SHUTDOWN

EMERG. SHUTDOWN

FUTURE USE

FUTURE USE

FUTURE USE

RS-485 COMM

RS-485 COMM

RS-485 COMM

T(-)

T(-)

T(-)

MSTP

MSTP

SHLD

SHLD

SHLD

BACnet

BACnet

R(+)

R(+)

R(+)

WattMaster Label

E-BUS

E-BUS

#LB102XXX-A

Rev.: 1A

CONNECT

CONNECT

E-BUS

WattMaster Label

WattMaster Label

#S 000062W

#S 000062W

CONNECT

Rev.: 1D

Rev.: 1B

MENU

ALARM CONTACT

ALARM CONTACT

ALARM CONTACT

HEAT

HEAT

OUTPUTS

OUTPUTS

HEAT

OUTPUTS

CONTACT RATING IS

CONTACT RATING IS

1 AMP MAX

1 AMP MAX

CONTACT RATING IS

@ 24 VAC

@ 24 VAC

1 AMP MAX

@ 24 VAC

ANALOG

ANALOG

ANALOG

OUTPUTS

OUTPUTS

OUTPUTS

E-BUS

E-BUS

E-BUS

CONNECT

CONNECT

CONNECT

DOWN

DOWN

DOWN

HEAT 1

HEAT 1

HEAT 1

HEAT 2

HEAT 2

HEAT 2

HEAT 3

HEAT 3

HEAT 3

HEAT 4

HEAT 4

HEAT 4

HEAT 5

HEAT 5

HEAT 5

HEAT 6

HEAT 6

HEAT 6

RLY COMM

RLY COMM

RLY COMM

0-10V MOD. SCR

0-10V MOD. SCR

0-10V MOD. SCR

PWM +

PWM +

PWM +

PWM -

PWM -

GND

GND

GND

+24 VAC

+24 VAC

+24 VAC

ENTER

ENTER

ENTER

GND

GND

GND

PWM -

T SHLD

R +

Typical Terminal Blocks. All

Line Voltage

Wiring To Be T To T, SHLD

(G) To SHLD (G) & R To R

Wiring Notes:

1.) All wiring to be in accordance with local and national electrical

codes and specifications.

2.) All communication wiring to be 18 gauge minimum, 2 conductor

twisted pair with shield. Use Belden #82760 or equivalent.

Figure 8: PREHEAT-X BACnet Connection to MS/TP Network

GND

24VAC

Size Transformer For

Correct Total Load.

PREHEAT-X Controller =

40 VA

PREHEAT-X Technical Guide

25

Page 26

APPENDIX B

PREHEAT-X BACnet® Points

BACnet® Properties for the PREHEAT-X

PARAMETER OBJECT DESCRIPTION LIMITS

Active

Controlling

Setpoint

Number of

Heat Stages

On

Modulating

Output

Position

All Alarms

Bitfi eld

Entering Air

Temperature

Leaving Air

Temp Sensor 1

Leaving Air

Temp Sensor 2

Leaving Air

Average Temp

Reset Input

Percentage

Enable Input

Value

Shutdown

Input Value

Preheat Enable

Status

Alarm Relay

Status

Heat 1 Relay

Status

Heat 2 Relay

Status

Heat 3 Relay

Status

Heat 4 Relay

Status

Heat 5 Relay

Status

Heat 6 Relay

Status

AI: 1 The current Active

Controlling Setpoint

AI:2 The current number of heat

stages on

AI: 3 The current Modulating

Output Position

AI: 4 The current Alarm Status

in a Bitfi eld

AI: 5 The current Entering Air

Temperature

AI:6 The current Leaving Air

Sensor 1 Temperature

AI:7 The current Leaving Air

Sensor 2 Temperature

AI: 8 The current Average

Leaving Air Temperature

AI:9 The current Setpoint Reset

Input Percentage

BI: 1 The current value of the

Enable Binary Input

BI: 2 The current value of the

Emergency Shutdown

Binary Input

BI: 3 The current Enable status

of the controller

BI: 4 The current status of the

Alarm Relay

BI: 5 The current status of the

Heat 1 Relay

BI: 6 The current status of the

Heat 2 Relay

BI: 7 The current status of the

Heat 3 Relay

BI: 8 The current status of the

Heat 4 Relay

BI: 9 The current status of the

Heat 5 Relay

BI: 10 The current status of the

Heat 6 Relay

Read Only

Read Only

Read Only

Read Only

See Alarm

Bits, this page.

Read Only

Read Only

Read Only

Read Only

Read Only

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

BACnet® Properties for the PREHEAT-X

PARAMETER OBJECT DESCRIPTION LIMITS

Emergency

Shutdown

Alarm

Leaving Air

Sensor 1

Alarm

Leaving Air

Sensor 2

Alarm

Low Leaving

Air Temp

Alarm

High Leaving

Air Temp

Alarm

Entering Air

Sensor Alarm

Remote Enable AV: 1 Enables the Preheat from

Remote

Leaving Air

Setpoint

Remote

Entering

Air Enable

Setpoint

BI: 11 The current Emergency

Shutdown Alarm status

BI: 12 The current Leaving Air

Sensor 1 Alarm status

BI: 13 The current Leaving Air

Sensor 2 Alarm status

BI: 14 The current Low Leaving

Air Temp Alarm status

BI: 15 The current High Leaving

Air Temp Alarm status

BI: 16 The current Entering Air

Sensor Alarm status

the BACnet front end

AV: 2 Controlling Leaving Air

Setpoint from the BACnet

front end

AV: 3 Entering Air Enable

Setpoint from the BACnet

Front end

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read Only

0 = Off

1 = On

Read / Write

0 = Disabled

1 = Enabled

Read/ Write

35.0 ºF

Read / Write

-40.0 ºF90.0

PREHEAT-X BACnet® Property

Identifi er

BACNETPropertyIdentifi er :

AllAlarmGroup1Bits ::= BIT STRING {

Reserved (0),

BadLeavingAir1 (1),

BadLeavingAir2 (2),

LowLeavingAir (3),

HighLeavingAir (4),

Reserved (5),

BadEnteringAir (6),

CommAlarm (7),

ShutDownAlarm (8)

Volatile

Volatile

90.0

ºF

Volatile

ºF

26

PREHEAT-X Technical Guide

Page 27

NOTES

PREHEAT-X Technical Guide

27

Page 28

www.aaon.com

2425 So. Yukon Ave • Tulsa, OK 74107-2728

Ph: (918) 583-2266 • Fax: (918) 583-6094

AAON® Manual Part No. V48520

WattMaster Manual Form No: AA-PREHEATX-TGD-01C

Loading...

Loading...