Page 1

Operating Manual

OPTIMOD-FM

8200

Digital Audio Processor

®

Page 2

IMPORTANT NOTE: Refer to the unit ’s rear panel for your Model #.

Model Number: Description:

8200/U3S OPTIMOD-FM 8200 DIGITAL with three DSP cards, Stereo Encoder,

Protection Structure, Two-band Purist Structure, Two-band Normal

Structure, Multi-band Processing Structure, set to 115V (for 90-130V

operation), switchable to 50µs or 75µs.

8200/E3S OPTIMOD-FM 8200 DIGITAL with three DSP cards, Stereo Encoder,

Protection Structure, Two-band Purist Structure, Two-band Normal

Structure, Multi-band Processing Structure, set to 230V, (for 180-260V

operation), switchable to 50µs or 75µs.

OPTIONS A VAILABLE:

Model Number: Description:

CIT25 Composite Isolation Transformer.

8200D/32 Digital I/O Card, 32kHz

8200 PC Remote Control Software for IBM PC compatible computers

MANUAL:

Part Number: Description:

95100-301-01 8200 Manual (includes 8200 PC Manual)

CAUTION: TO REDUCE THE RISK OF ELECTRICAL S HO CK , DO NO T REMOVE COVER (OR BACK).

NO USER SERV I CE A B LE PARTS I NS I DE . REFER SERVICING TO QUA LIFIED SERVICE P E RS ONNEL.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHO CK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

This symbol, wherever i t appears , This symbol, wherever i t appears ,

alerts you to the presence of unins ul ate d alerts you to important operat ing and

dangerous voltage inside the enc los ure — volt age maintenance instruc tions i n the ac c ompany in g

that may be suff ic i ent t o constitute a risk of shock. literature. Read the manual.

Page 3

All the safety and operating instructions should be read before the appliance is operated.

Retain Instructions:

The safety and operation instructions should be retained for future reference.

Heed Warnings:

All warnings on the appliance and in the operating instructions should be adhered to.

Follow Instructions:

All operation and user instructions should be followed.

Water and Moisture:

The appliance should not be used near water (e.g., near a bathtub, washbowl, kitchen sink, laundry tub, in a wet

basement, or near a swimming pool, etc.).

Ventilation:

The appliance should be situated so that its location or position does not interfere with its proper ventilation. For example, the

appliance should not be situated on a bed, sofa, rug, or similar surface that may block the ventilation openings; or, placed in a built-in

installation, such as a bookcase or cabinet that may impede the flow of air through the ventilation openings.

Heat:

The appliance should be situated away from heat sources such as radiators, heat registers, stoves, or other appliances (including

amplifiers) that produce heat.

Power Sources:

The appliance should be connected to a power supply only of the type described in the operating instructions or as

marked on the appliance.

Grounding or Polarization:

Precautions should be taken so that the grounding or polarization means of an applianceis not defeated.

Power-Cord Protection:

Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed

upon or against them,paying particular attention to cords at plugs,convenience receptacles, and the point where they exit from the appliance.

Cleaning:

The appliance should be cleaned only as recommended by the manufacturer.

Non-Use Periods:

The power cord of the appliance should be unplugged from the outlet when left unused for a long period of time.

Object and Liquid Entry:

Care should be taken so that objects do not fall and liquids are not spilled into the enclosure through

openings.

Damage Requiring Service:

The appliance should be serviced by qualified service personnel when:

The power supply cord or the plug has been damaged; or

Objects have fallen, or liquid has been spilled into the appliance; or

The appliance has been exposed to rain; or

The appliance does not appear to operate normally or exhibits a marked change in performance; or

The appliance has been dropped, or the enclosure damaged.

Servicing:

The user should not attempt to service the appliance beyond that described in the operating instructions. All other servicing

should be referred to qualified service personnel.

The Appliance should be used only with a cart or stand that is recommended by the manufacturer.

Safety Instruct ions (European)

Notice For U.K. Customers If Your Unit Is Equipped With A Power Cord.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The cores in the mains lead are coloured in accordance with the following code:

GREEN and YELLOW - Earth BLUE - Neutral BROWN - Live

As colours of the cores in the mains lead of this appliance may not correspond with the coloured markings identifying the terminals in your

plug, proceed as follows:

The core which is coloured green and yellow must be connected to the terminal in the plug marked with the letter E, or with the earth symbol,

( ), or coloured green, or green and yellow.

The core which is coloured blue must be connected to the terminal marked N or coloured black.

The core which is coloured brown must be connected to the terminal marked L or coloured red.

The power cord is terminated in a CEE7/7 plug (Continental Europe). The green/yellow wi re i s connected direc tl y to the unit ’s chassis. If

you need to change the plug and if you are qualified to do so, refer to the table below.

WARNING: If the ground is defeated, certain f ault conditions in the unit or in the sys tem to which it is conne cted ca n result in full line

voltage between chassis and eart h ground. Severe injury or de ath can then re sult if the chassis and earth ground are touched simultaneously.

AC Power Cord Color Coding

IMPORTANT SAFETY INSTRUCTIONS

CONDUCTOR

WIRE COLOR

Normal Alt

L LIVE BROWN BLACK

NEUTRAL BLUE WHITE

EARTH GND GREEN-YELLOW GREEN

N

E

Page 4

Safety Instruc tions ( G erm an)

Gerät nur an der am Leistungsschild vermerkten Spannung und Stromart betreiben.

Sicherungen nur durch solche, gleicher Stromstärke und gleichen Abschaltverhaltens ersetzen. Sicherungen nie überbrücken.

Jedwede Beschädigung des Netzkabels vermeiden. Netzkabel nicht knicken oder quetschen. Beim Abziehen des Netzkabels den

Stecker und nicht das Kabel enfassen. Beschädigte Netzkabel sofort auswechseln.

Gerät und Netzkabel keinen übertriebenen mechanischen Beaspruchungen aussetzen.

Um Berührung gefährlicher elektrischer Spannungen zu vermeiden, darf das Gerät nicht geöffnet werden. Im Fall von Betriebsstörun-

gen darf das Gerät nur Von befugten Servicestellen instandgesetzt werden. Im Gerät befinden sich keine, durch den Benutzer

reparierbare Teile.

Zur Vermeidung von elektrischen Schlägen und Feuer ist das Gerät vor Nässe zu schützen. Eindringen von Feuchtigkeit und

Flüssigkeiten in das Gerät vermeiden.

Bei Betriebsstörungen bzw. nach Eindringen von Flüssigkeiten oder anderen Gegenständen, das Gerät sofort vom Netz trennen und

eine qualifizierte Servicestelle kontaktieren.

Safety Instruct ions (Fr ench)

On sassurera toujours que la tension et la nature du courant utilisé correspondent bien à ceux indiqués sur la plaque de lappareil.

Nutiliser que des fusibles de même intensité et du même principe de mise hors circuit que les fusibles dorigine. Ne jamais shunter les

fusibles.

Eviter tout ce qui risque dendommager le câble seceur. On ne devra ni le plier, ni laplatir. Lorsquon débranche lappareil, tirer la fiche

et non le cäble. Si un cäble est endommagé, le remplacer immédiatement.

Ne jamais exposer lappareil ou le cäble ä une contrainte mécanique excessive.

Pour éviter tout contact averc une tension électrique dangereuse, on noouvrira jamais lappareil. En cas de dysfonctionnement,

lappareil ne peut être réparé que dans un atelier autorisé. Aucun élément de cet appareil ne peut être réparé par lutilisateur.

Pour éviter les risques de décharge électrique et dincendie, protéger lappareil de lhumidité. Eviter toute pénétration dhumidité ou fr

liquide dans lappareil.

En cas de dysfonctionnement ou si un liquide ou toutautre objet apénétré dans lappareil couper aussitôt lappareil de son alimentation

et sadresser à un point de service aprésvente autorisé.

Safety Instructions ( Spanish)

Hacer funcionar el aparato sólo con la tensión y clase de corriente señaladas en la placa indicadora de características.

Reemplazar los fusibles sólo por otros de la misma intensidad de corriente y sistema de desconexión. No poner nunca los fusibles en

puente.

Proteger el cable de alimentación contra toda clase de daños. No doblar o apretar el cable. Al desenchufar, asir el enchufe y no el

cable. Sustituir inmediatamente cables dañados.

No someter el aparato y el cable de alimentación a esfuerzo mecánico excesivo.

Para evitar el contacto con tensiones eléctricaspeligrosas, el aparato no debe abrirse. En caso de producirse fallosde funcionamiento,

debe ser reparado sólo por talleres de servicio autorizados. Enel aparato no se encuentra ninguna pieza que pudiera ser reparada por

el usuario.

Para evitar descargas eléctricas e incendios, el aparato debe protegerse contra la humedad, impidiendo que penetren ésta o líquidos

en el mismo.

En caso de producirse fallas de funcionamiento como consecuencia de la penetración de líquidos u otros objetos en el aparato, hay

que desconectarlo inmediatamente de la red y ponerse en contacto con un taller de servicio autorizado.

Safety Instructions (Italian)

Far funzionare lapparecchio solo con la tensione e il tipo di corrente indicati sulla targa riportante i dati sulle prestazioni.

Sostituire i dispositivi di protezione (valvole,fusibili ecc.) solo con dispositivi aventi lo stesso amperaggio e lo stesso comportamento di

interruzione. Non cavallottare mai i dispositivi di protezione.

Evitare qualsiasi danno al cavo di collegamento alla rete. Non piegare o schiacciare il cavo. Per staccare il cavo, tirare la presa e mai

il cavo. Sostituire subito i cavi danneggiati.

Non esporre lapparecchio e il cavo ad esagerate sollecitazioni meccaniche.

Per evitare il contatto con le tensioni elettriche pericolose, lapparecchio non deve venir aperto. In caso di anomalie di funzionamento

lapparecchio deve venir riparato soloda centri di servizio autorizzati. Nellapparecchionon si trovano partiche possano essereriparate

dallutente.

Per evitare scosse elettriche o incendi, lapparecchio va protetto dallumidità. Evitare che umidità o liquidi entrino nellapparecchio.

In caso di anomalie di funzionamento rispettivamente dopo la penetrazione di liquidi o oggetti nellapparecchio, staccare immedi-

atamente lapparecchio dalla rete e contattare un centro di servizio qualificato.

Page 5

PLEASE READ THIS FIRST!

Manual

The Operating Manual contains instructions to verify the proper operation of this unit and initialization of certain options.

You will find these operations are most conveniently performed on the bench before you install the unit in the rack.

Please review the Manual, especially the installation section, before unpacking the unit.

Trial Period Precautions

If your unit has been provided on a trial basis:

You should observe the following precautions to avoid reconditioning charges in case you later wish to return the unit to

your dealer.

Note the packing technique and save all packing materials. It is not wise to ship in other than the factory carton. (Replace-

ments cost $35.00).

(1) Avoid scratching the paint or plating. Set the unit on soft, clean surfaces.

(2) Do not cut the grounding pin from the line cord.

(3) Use care and proper tools in removing and tightening screws to avoid burring the heads.

(4) Use the nylon-washered rack screws supplied, if possible, to avoid damaging the panel. Support the unit when

tightening the screws so that the threads do not scrape the paint inside the slotted holes.

Packing

When you pack the unit for shipping:

Tighten all screws on any barrier strip(s) so the screws do not fall out from vibration.

Wrap the unit in its original plastic bag to avoid abrading the paint.

Seal the inner and outer cartons with tape.

If you are returning the unit permanently (for credit), be sure to enclose:

•

The Manual(s)

•

The Registration Card

•

The Line Cord

•

All Miscellaneous Hardware (including the Rack Screws)

•

The Extender Card

•

The COAX Connecting Cable

Your dealer may charge you for any missing items.

If you are returning a unit for repair, do not enclose any of the above items.

Further advice on proper packing and shipping is included in Section 5: Troubleshooting.

Trouble

If you have problems with installation or operation:

(1) Check everything you have done so far against the instructions in the Manual. The information contained therein is

based on our years of experience with OPTIMOD and broadcast stations.

(2) Check the other sections of the Manual (consult the Table of Contents and Index) to see if there might be some

suggestions regarding your problem.

(3) After reading the section on Factory Assistance, you may call Orban Customer Service for advice during normal

California business hours. The number is (1) 510/351-3500.

®

Page 6

MAINTAINING 8200 SECURITY

Important: Ensure 8200 se curity by making it standard polic y for each 8200 user to manually

re-enable loc kout when finished with normal operation.

If your 8200 uses security pascodes and TIMEOUT TO AUTO LOCK is OFF (as set in the

SET

PASCODE

screen), the last s ucce ssfu l pas code e ntry de fines th e cur re nt secur ity le vel. U ntil locko ut

is re-enabled , subs equent us er s with a low er se curity level will ha ve acc ess to mor e func tion s than

they should.

Therefore, we recommend that each user re-enable lockout mode when finished with normal

operation. R e-en abling lo ckou t ens ur es that ea ch us er is a llowed to enter a p ascode to hav e acc ess

to the correct amount of functions for which their pascode was previously assigned.

If a previous user does for ge t to re- ena bl e l oc kout , sim pl y com pl e te the fo ll owi ng ste ps:

If the

IDLE G/R screen does not appear, press ESC repeatedly until you see it.

Hold down the ESC button, while pressing HELP button.

With 8200 lockout now re-enabled, enter a valid pascode and continue with normal operation.

®

Page 7

Manual Addendum

8200 Version 3.0 Upgrade

For OPTIMOD-FM 8200 Digital

8200 Version 3.0 Manual Addendum

New Format Presets

Insert the following page, titled “New Format Presets In Version 3.00,” into

your 8200 Operation Manual, in Section 3, directly after the blue-tabbed

“About Processing Structures” page, at page 3-9.

There are 21 new format-specific presets, each named for a programming

format. There are two Urban/Rap presets, for instance, that add bottom-end

slam to the sound. Three new Rock presets add punch and sizzle while Adult

Contemporary and Country presets balance warmth and clarity, with up-front

vocals that stand out. There are also presets for Pop, Classical, Instrumental,

Jazz, Folk/Traditional, News, and Sports. There are even two Oldies presets

that ensure consistent sound balance with material from different eras.

Programmed by Bob Orban and Greg Ogonowski, each preset has full

LESS-MORE capability.

Multi-Band Controls

Insert the following “New Multi-Band Features For Version 3.00” pages into

your 8200 Operation Manual, in Section 3, at the end of the discussion on

“The Multi-Band Structure,” directly preceding the red-tabbed “Screen

Displays” page.

New controls include: High Frequency Coupling, Multi-Band Output Mix

controls, Bass Clip Threshold, and Phase Rotator In/Out. The range for the

existing Final Clip Drive has also been extended.

D-O Status Enable?

[Yes] or [No]

For 8200s equipped with the 8200 D/SRC, the 8200's controls now include a

switch that allows you to defeat Orban's special implementation of AES/EBU

status bits which are used to control Orban 8208 and 8218 Stereo Encoders.

This special implementation may be defeated to accommodate certain digital

STLs that misinterpret these status bits.

Beginning with V 1.20 software and revision 3.0 of the 8200D/SRC Digital

I/O board, the 8200 set the emphasis bits in the AES/EBU status bits (byte 0,

bits 2 through 4) accord ing to an Or ban p rop rietary standar d that extends the

AES/EBU official definition. The Orban standard allows the 8200 to

automatically set the 8218 (and 8208) Stereo Encoder's emphasis/deemphasis to complement the 8200's emphasis/de-emphasis.

Page 8

I-2

MANUAL ADDENDUM Orban

Byte 0 Bits 2-4 AES/EBU Definition 8200 Implementation 8218 Response

000 not indicated not indicated applies FM pre-emphasis

001 undefined undefined doesn't alter emphasis

010 undefined undefined doesn't alter emphasis

011 undefined undefined doesn't alter emphasis

100 no emphasis no emphasis applies FM pre-emphasis

101 undefined J.17+FM pre-e* applies J.17 de-emphasis

110 50/15µs FM pre-e* doesn't alter emphasis

111 J.17 J.17 applies J.17 de-emphasis

and FM pre-emphasis

* FM pre-emphasis is 50 or 75µs

Since the implementation of the Orban standard, some digital STLs were

released that misinterpret these status bits. Some respond to the AES/EBU

emphasis bits (110) by applying an EIAJ (50/15uS) shelving de-emphasis.

This will cause an audible (10.5 dB) loss of high frequencies. Version 3.00

software allows the user to enable- or disable the Orban implementation of

status bits. When disabled, the 8200 sends status bits identifying that

emphasis is “not indicated,” which ensures that the affected digital STLs will

not inappropriately apply EIAJ de-emphasis.

When these digital STLs are used in combination with an 8200 and 8218 (or

8208), DO STATUS ENABLE must be set to No, and the 8218 (or 8208),

cannot utilize the “AES determines emphasis” feature.

PC Security Enable

[On] or [Off]

The OPTIMOD 8200 with software Version 3.00 or higher, can be

controlled with a computer utilizing RS-232 and the Orban supplied 8200PC

software for Microsoft Windows, or through binary commands.

The Orban 8200PC software offers full access to all 8200 features, while the

binary communications method can only recall presets.

When set to On (default), this control allows remote control of the 8200

through RS-232 communications, only with the Orban supplied 8200PC

software for Microsoft Windows. Access to the 8200 is the same as under

Version 1.2x.

When set to Off, this mode disables all password protection entirely. PC

access using binary commands is allowed for recalling presets only.

Complete control by 8200PC is still allowed, however password protection is

Page 9

OPTIMOD-FM 8200 V3.00 UPGRADE MANUAL ADDENDUM

disabled. Please note that in this mode, unauthorized access is possible, so

take measures to insure that a secure link is used to the 8200. Concurrent

8200PC and binary communications method is not possible.

The binary communications method is intended to be used primarily by

programmers for third-party software development. Orban Customer Service

will supply a developer's white paper upon request. We cannot, however,

provide any technical support for third-party software.

New Format Presets In Version 3.00

The 21 named format presets in Version 3.00 are entirely new. They exploit new Version

3.00 features, including the OUTPUT MIX controls for the 5-Band Limiter and the

HIGH FREQUENCY COUPLING control. They apply appropriate amounts of BASS,

PRESENCE, and BRILLIANCE equalization.

Of these 21 presets, five are duplicates because we felt that they were appropriate for

more than one format. So there are actually 16 distinct and different presets. Each preset

has full

presets from which they were taken and the nominal

LESS-MORE

Capability. The table below shows the presets, including the source

LESS-MORE

setting of each preset.

I-3

Many of the presets come in several “flavors,” like “dense,” “medium,” and “open.”

These refer to the density produced by the processing. “Open” uses SLOW multi-band

release time, “Medium” uses MEDIUM-SLOW release, and “Dense” uses MEDIUMFAST. FAST release is only used in the NEWS/TALK and SPORTS presets.

Important!

control to trade off loudness against processing artifacts and side effects.

Once you have used LESS-MORE, save your edited preset as a USER

PRESET.

Do not be afraid to experiment with presets other than the ones named for your format if

you think these other presets have a more appropriate sound. Also, if you want to finetune the frequency balance of the programming, feel free to enter FULL CONTROL and

make small changes to the BASS, PRESENCE, and BRILLIANCE controls. Remember

to do this after you have decided on a

have edited a preset using FULL CONTROL,

that edited preset. (Of course,

want to go back to it. There is no way you can erase or otherwise damage the factory

presets. So feel free to experiment.)

These presets are only suggestions. Try using the LESS-MORE

LESS-MORE

LESS-MORE

is still available for the unedited preset if you

setting that's right for you. Once you

LESS-MORE

is no longer available for

Page 10

I-4

MANUAL ADDENDUM Orban

## PRESET NAME SOURCE PRESET NORMAL

LESS-MORE

____ __

FB GENERAL-MEDIUM ADLT CONTEMP-MED 5.0

FC GENERAL-OPEN ADLT CONTMP-OPEN 5.0

FD URBAN/RAP-DENSE URBAN/RAP-DENSE 7.0

FE URBAN/RAP-MEDIUM URBAN/RAP-MEDIUM 7.0

FF ROCK-DENSE ROCK-DENSE 7.0

FG ROCK-MEDIUM ROCK-MEDIUM 7.0

FH ROCK-OPEN ROCK-OPEN 7.0

FI ADLT CONTEMP-MED ADLT CONTEMP-MED 5.0

FJ ADLT CONTMP-OPEN ADLT CONTMP-OPEN 5.0

FK COUNTRY-MEDIUM ADLT CONTEMP-MED 5.0

FL COUNTRY-OPEN ADLT CONTMP-OPEN 5.0

FM POP-DENSE POP-DENSE 5.0

FN POP-MEDIUM POP-MEDIUM 5.0

FO POP-OPEN POP-OPEN 5.0

FP JAZZ JAZZ 5.0

FQ INSTRUMENTAL JAZZ 5.0

FR OLDIES-DENSE OLDIES-DENSE 7.0

FS OLDIES-OPEN OLDIES-OPEN 7.0

FT FOLK/TRADITIONAL POP-MEDIUM 5.0

FU NEWS/TALK N EWS/TALK 5.0

FV SPORTS SPORTS 5.0

Page 11

OPTIMOD-FM 8200 V3.00 UPGRADE MANUAL ADDENDUM

I-5

ROCK:

(although not as exaggerated as the URBAN/RAP presets). There is enough presence

energy to ensure that vocals stand out. A modest amount of HIGH FREQUENCY

COUPLING allows reasonable amounts of automatic HF equalization (to correct dull

program material), while still preventing exaggerated frequency balances and excessive

HF density. These presets are appropriate for general rock and contemporary

programming. For Contemporary Hit Radio (CHR) we recommend the DENSE or

MEDIUM versions. For Album-Oriented Rock (AOR) use ROCK-MEDIUM or OPEN,

although you might prefer the more conservative Adult Contemporary presets here.

URBAN/RAP:

more bass. They use the 3-pole (18dB/octave) shape on the bass equalizer. They are

appropriate for Urban, Rap, Black, R&B, Dance and other similar formats.

ADLT CONTEMP:

and POP. They have a gentle bass and treble lift, along with enough presence energy to

help vocals to stand out. This preset is also used for COUNTRY, and is a useful

candidate for AOR formats.

POP:

substantial HIGH FREQUENCY COUPLING to ensure that the high frequencie s do not

become dense. This is an ideal preset for formats designed primarily for women listeners

(who, by and large, dislike hyped treble) or for any preset designed for long time-spentlistening formats because of its open, clean sound, which leads to very low listener

fatigue. Because of its conservative nature, this preset is also used for the

FOLK/TRADITIONAL preset.

The ROCK presets are designed for a bright high end and punchy low end

The URBAN/RAP presets are similar to the ROCK presets, but with

The Adult Contemporary presets are a compromise between ROCK

POP is a more conservative preset designed for a mellow, open high end. There is

OLDIES:

less. This allows the preset to do substantially more automatic equalization than ROCK,

making recordings of different eras more uniform. OLDIES-OPEN might be a useful

alternative to FOLK/TRADITIONAL if the recordings being played are very

inconsistent in frequency balance.

JAZZ:

play mostly instrumental music. It has a relatively mellow high end and produces very

low listening fatigue.

NEWS/TALK:

FAST 5 Band Release Time setting, so it can quickly perform automatic equalization of

substandard program material, including telephone. It is very useful for creating a

uniform, intelligible sound from widely varying source material, particularly source

material that is “hot from the field” with uncontrolled quality.

SPORTS:

GATE THRESHOLD is higher. This recognizes that most sports programming has very

low signal-to-noise ratio due to crowd noise and other on-field sounds, so the preset does

not pump this up as the NEWS/TALK preset would tend to do.

OLDIES is similar to ROCK except HIGH FREQUENCY COUPLING is

JAZZ is quite similar to POP, and is specifically tailored toward stations that

This preset is quite different from the others above. It is based on the

Similar to NEWS/TALK except the AGC RELEASE TIME is slower and the

Page 12

I-6

MANUAL ADDENDUM Orban

New Multi-Band Features For Version 3.00

High Frequency Coupling Control (Band 3&4 Coupling)

High Frequency Coupling couples a certain percentage of the Band 3 gain control signal

into Bands 4 and 5. This forces Bands 4 and 5 to follow the gain reduction in Band 3 to a

user-adjustable extent. Because Band 3 has a slower release time than Bands 4 and 5,

this results in a more open high end. It also limits the amount of dynamic HF boost that

the processing can produce.

Even with the control at 100%, Bands 4 and 5 are still active and will produce further

gain reduction if this is necessary to prevent distortion. So in this mode they are acting as

a high frequency limiter.

Multi-Band Mix Controls (Band 1-5 Out Mix dB)

All of the equalization described so far occurs

advantage of this is that the multi-band limiter protects you against overloads or program

material with unusual spectral balance, which might otherwise combine with your

equalization curve to cause unpleasant distortion or coloration. In particular, it protects

the final clipper from being overdriven.

However, the

limiter tends to fight equalization settings that you made with the various equalizer

controls, reducing their effect. We have therefore provided a mix control with a ±3dB

range at the

These act as fixed equalizer controls because no gain reduction occurs after them. They

determine the overall target spectral balance of the processing when the multi-band

limiter exhibits substantial amounts of gain reduction. In popular music formats this is

almost always the case.

Please note that these controls are

limiter and multi-band clippers were tuned at great length to ensure that under virtually

no circumstances would program material come along to cause unpleasant clipping

distortion in the following clippers. By adjusting the multi-band mix controls, you upset

this carefully tuned relationship. Therefore, program material can come along that causes

unexpected (and sometimes very nasty-sounding) distortion because the final clippers are

being overdriven. This will occur if the program material in question has a significant

part of its energy concentrated in a frequency band that is being boosted.

downside

output

is that the “automatic equalization” effect of the multi-band

of each limiter in the five-band limiter.

very risky

. The thresholds of OPTIMOD-FM's 5-band

before

the multi-band limiter. The

In general, it is safe to turn a given output mix control

without danger of introducing distortion. However, you will lose loudness. If you turn an

output mix control up (+0.5 to +3dB range), you should listen at great length to a wide

variety of program material to make sure that nothing falls apart due to excessive

down

(in the 0 to –3dB range)

Page 13

OPTIMOD-FM 8200 V3.00 UPGRADE MANUAL ADDENDUM

clipping distortion. If it does, you will need to back off the control in question and/or

back off the

If you turn up the control for Band 1 (below 100 Hz), you may wish to turn down the

Bass Clip Thrsh dB

between the bass multi-band clipper and the final clipper.

Final Clip

control.

control by an equal amount. This will preserve the relationship

Bass Clip Threshold Control (Bass Clip Thrsh dB)

The 8200 uses Orban's patented multi-band distortion-cancelling clipper system to

achieve a low peak-to-average ratio without creating audible distortion due to clipping.

The bass clipper is part of this system. It is embedded in the multi-band crossover so that

harmonics created by clipping are rolled off by part of the crossover filters. The

threshold of this clipper is ordinarily set between 4dB and 6dB below the threshold of

the final clipper in the processing chain, depending on the setting of the

control in the parent preset upon which you are basing your full control adjustments.

This provides headroom for contributions from the other four bands, so that bass

transients don't smash against the final clipper and “shut it down,” momentarily blocking

any other program material and causing a sound similar to very hard pumping. The bass

clipper also protects against overt intermodulation distortion between the bass and higher

frequency program material.

LESS-MORE

I-7

Some 8200 users feel that the bass clipper unnecessarily reduces bass punch at its factory

settings. To accommodate these users, Version 3.00 software makes the threshold of the

bass clipper a user-adjustable control. The range (with reference to the final clip

threshold) is 0 to –6dB. As you raise the threshold of the clipper you will get more bass

but also more distortion and pumping. Be careful when setting this control; do not adjust

it casually. Listen to program material with heavy bass combined with spectrally sparse

midrange material (like a singer) and listen for IM distortion induced by the bass'

pushing the midrange into the final clippers. In general, unless you have a very good

reason to set the control elsewhere, we recommend leaving it at the factory settings,

which were determined as a result of exhaustive listening tests with many types of

critical program material.

Phase Rotator In/Out

The multi-band limiter receives the output of a three-pole phase rotation circuit. This has

a flat frequency response but a phase response that is nonlinear with frequency. Its

purpose is to make voice waveforms symmetrical, which minimizes clipping distortion

and makes voice (particularly live voice from microphone feeds) sound cleaner.

The downside of the phase rotator is that it subtly reduces the clarity and definition of

music. While this is unlikely to be heard on the vast majority of consumer radios, many

people listening with audiophile-quality gear will be able to perceive it. We therefore

have provided the ability to bypass this circuit, leaving only the phase rotation intrinsic

to the crossover topology in the multi-band limiter. This residual phase rotation is

Page 14

I-8

MANUAL ADDENDUM Orban

approximately 25% of the total phase rotation that occurs when the three-pole phase

rotator is active.

When you bypass the phase rotator, many voices sound audibly harsher because more

clipping occurs. This can be particularly problematical if you are processing heavily for

loudness. If you notice increased harshness on voice, we recommend that you use

external phase rotation (three cascaded poles, each tuned to 200Hz) in your live

microphone chain and in your production studio mic chain. If this is impractical, we

recommend leaving the 8200's built-in phase rotator active because we find the increased

voice distortion caused by leaving it off substantially more objectionable than the slight

loss of clarity that results when it is active.

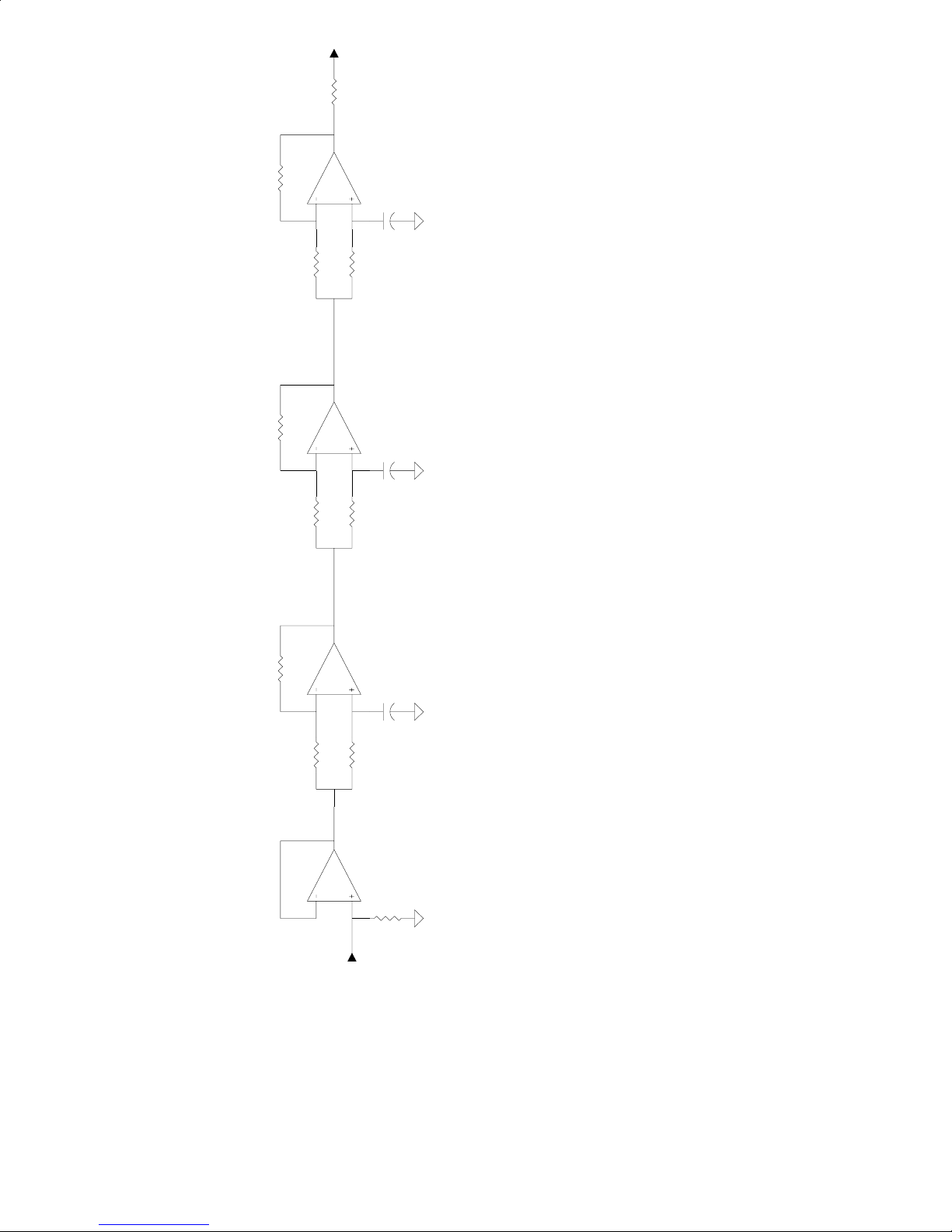

Refer to the “Phase Rotator For Microphone Channel” diagram, on the following page.

Page 15

OUTPUT

OPTIMOD-FM 8200 V3.00 UPGRADE MANUAL ADDENDUM

10K 1%

10K 1%

1K 5%

10K 1%

10K 1%

1/4 TL074

0.01uF 10%

82K 5%

1/4 TL074

0.01uF 10%

82K 5%

50V

50V

I-9

10K 1%

10K 1%

1/4 TL074

1/4 TL074

INPUT

0.01uF 10%

82K 5%

82K 5%

50V

Figure 1: Phase Rotator for Microphone Channel

If you substitute a high-speed amplifier, layout and power supply bypassing become more critical.

Many audio opamps could be substituted for the TL074, like a pair of NE5532s.

Bypass (+) and (−) Power Leads of TL074 to Ground with 0.1µF 50V monolithic ceramic capacitors.

Operate from +15V and −15V DC power.

Notes: Unity Gain, Line Level.

Page 16

I-10

MANUAL ADDENDUM Orban

Final Clip Drive Control

Version 3.00 extends the range of the

end of its range. This means that you can turn down the clipping by 3dB by comparison

to earlier versions of 8200 software. The purpose of this extension is to allow users in

ITU countries to comply with the requirements of ITU-R Recommendation BS.412-7 if

they are required to do so by the regulatory authority in their country.

Based on measurements with a wide variety of program material using the RundfunkBetriebstechnik, GMBH Hubmess System MPX-EBENE (a modulation analyzer), we

have developed the following formula for ensuring compliance. First, you must start with

one of the basic 2-Band or 5-Band factory presets with

then edit the preset (using

following settings:

Preset LESS-MORE Final Clip Drive

DA 5B SLOW 1.0 –1.5

DB 5B-MEDIUM SLOW 1.0 –1.5

DC 5B-MEDIUM FAST 1.0 –3.0

DD 5B-FAST 1.0 –2.5

FULL CONTROL

FINAL CLIP DRIVE

LESS-MORE

) to set the

control by 3dB at the lower

at 1.0. You must

FINAL CLIP DRIVE

to the

CA 2B-NOR PROCESSED 1.0 –1.5

To ensure that you meet the requirements, do not increase the settings of these controls

beyond the settings provided in

MULTI-BAND DRIVE

Note:

The BB (Purist Classical) and BA (Purist Processed) presets will comply with a

CLIPPING setting of –2 or lower. There is no need to reset the

control when using these presets.

The Protection Limiter Structure will not comply and cannot be adjusted to do so.

However, you can use the BB (Purist Classical) preset instead and set its

control to –2.

If you want to use any of the new presets in Version 3.00, you should follow a similar

formula. Set them for

1.5, except for “dense” presets (

CLIP DRIVE

presets using this formula and therefore cannot guarantee compliance, we believe that

compliance is nevertheless very likely.

= –2.5). While we have not specifically measured all of the Version 3.00

.

LESS-MORE

LESS-MORE

= 1.0. Then edit the

FINAL CLIP DRIVE

= 1.0:

RELEASE TIME, CLIPPING

FINAL CLIP DRIVE

CLIPPING

FINAL CLIP DRIVE

= –3.0) and News or Sports (

control for –

, and

FINAL

Page 17

OPTIMOD-FM 8200 V3.00 UPGRADE MANUAL ADDENDUM

8200 Software History

Version 3.00

•

Replaces the original factory “format” presets FB - FO with new format presets

FB- FV.

•

Adds new Multi-Band Control: High Frequency Coupling.

•

Removes EBS Test Mode.

Version 2.00

Multi-Band Controls

•

New controls include: Multi-Band Output Mix controls, Bass Clip

Threshold, and Phase Rotator In/Out. The range for the existing Final Clip

Drive has also been extended.

I-11

D-O Status Enable?

•

[Yes] or [No]

For 8200s equipped with the 8200 D/SRC, the 8200's controls now include a

switch that allows you to defeat Orban's special implementation of AES/EBU

status bits which are used to control Orban 8208 and 8218 Stereo Encoders.

This special implementation may be defeated to accommodate certain digital

STLs that misinterpret these status bits.

PC Security Enable

•

[On] or [Off]

When set to Off, password security is disabled, allowing access to 8200 via

remote PC, utilizing custom-developed software, and limited to recalling

presets only. When set to On, 8200 functions the same as under Version

1.2x, with full password security.

Version 1.20

•

8200PC Remote Control Software for Windows™

•

TIME TO SCREEN SAVER default setting is now 1:00 HRS. Removed Off

setting.

•

AGC IDLE GR (for Two-Band Normal, Two-Band Purist and Five-Band

processing) is now a value proportional to the AGC DRIVE, instead of a fixed

value of–10dB.

•

With Two-Band Normal, LF noise is no longer detectable at low drive levels.

•

For Five-Band processing, bass boost at low signal levels has been eliminated.

Page 18

I-12

MANUAL ADDENDUM Orban

•

A-O 100% LVL dB resolution has been increased for more accurate level

adjustment.

•

Cleaner Audio When Switching Between Analog and Digital Source Material.

•

Pressing DISABLE EBS now eliminates the EBS TEST button from the

RECALL PRESET

•

AGC DRIVE Control adjustable range changed to –10 to 25; previously 0 to

25.

screen.

Version 1.10

•

Software to control 8200D/SRC Digital Sampling Rate Converter.

•

D-O 100% LVL dB maximum level increased from –2.75dBFS to 0dBFS;

resolution has been increased for more accurate level adjustment.

Version 1.00

Calibration Controls

•

Adds Transmitter Overshoot and SCA Modulation Compensation.

•

Adds control for Stereo Encoder Modulation Type: [STEREO], [MONO

FROM L], [MONO FROM R].

•

Input Analog or Digital.

•

Clock Sync To, for synchronizing the 8200's real-time clock to the AC line

frequency (LINE) or to the internal crystal oscillator (XTAL).

•

Adds Pilot On/Off control.

Time and Date Controls

•

Daylight Savings Time.

•

Screen Saver.

Other Changes

•

Additional Remote Control Interface functions. Complete list includes: ##

PRESET NUMBER AND NAME, ST STEREO, ML MONO FROMLEFT,

MR MONO FROM RIGHT, ET EXIT TEST, TX1 MOD COMP %, TX2

MOD COMP %, SC1 MOD COMP %, SC2 MOD COMP %, IA INPUT

ANALOG, ID INPUT DIGITAL, RH RESET CLOCK TO HOUR, RM

RESET CLOCK TO MIDNIGHT.

•

EBS tone preset for use with the USA Emergency Broadcast System.

Page 19

OPTIMOD-FM 8200 V3.00 UPGRADE MANUAL ADDENDUM

•

Security PASCODE authorized for SYSTEM SETUP.

•

Protection Structure pre-emphasis filters are now phase-linear.

•

Adds Protection Limiter control: 30 Hz HPF switch to set the 30Hz high-pass

filter prior to the limiter in or out of the signal path.

•

Adds Two-Band Purist Structures: 2B-PUR PROCESSED, 2B-PUR

CLASSICAL.

•

Adds Two-Band control: AGC SWITCH.

•

Additional Multi-Band Controls, including: AGC SWITCH, HIGH

FREQUENCY CLIPPING, PRESENCE, LOW BASS BOOST, MID BASS

BOOST, BASS COUPLING, DJ BASS BOOST, NOISE REDUCTION

THRESHOLD, 30Hz HPF (Highpass Filter) switch.

•

EXIT TEST Test preset now stored as the BACKUP preset.

I-13

Page 20

I-14

MANUAL ADDENDUM Orban

This Page Intentionally Left Blank!

Page 21

Operating Manual

OPTIMOD-FM

8200

Digital Audio Processor

®

Page 22

The OPTIMOD-FM 8200 Digital Audio Processor is prot ec t ed by U.S. patents 4,249,042; 4, 208,548; 4,460,871; and U.K. patent 2, 001 ,495.

Other patents pending.

Orban and Hadamard Transform Baseband E ncoder are regi st ered tradem ark s.

All trademarks are property of their res pec ti v e compani es.

This manual is part number 95100-301-01

Copyright 1999/2000

1525 Alvarado Street, San Leandro, CA 94577 USA

Phone: (1) 510/351-3500; Fax: (1) 510/351-0500; E-mail: custserv@orban.com; Web: www.orban.com

WARNING

“This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communicat ions.” “Le present appareil numerique n’em et pas de bruits

radioelectriques depassant les limites applicables aux appareils numeriques (de las

class A) prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communic at ions du Canada.”

WARNING

This equipment generates, uses, and can radiate radio-frequency energy. If it is not

installed and used as directed by this manual, it may cause interference to radio

communication. This equipment complies with the limits for a Class A computing

device, as specified by FCC Rules, Part 15, Subpart J, which are designed to provide

reasonable protection against such interference when this type of equipment is operated in a commercial envi ronment . Operat ion of t hi s equipm ent in a res ident i al area i s

likely to cause interference. If it does, the user will be required to eliminate the

interference at the user’s expense.

IMPORTANT

Perform the installation under static control conditions. Simply walking across a rug can

generate a static charge of 20,000 volts. This is the spark or shock you may have felt when

touching a doorknob or some other conductive item. A much s maller static dis charge is likely to

completely destroy one or more of the CMOS semiconductors employed in OPTIMOD-FM or

the software module. Static dam age will not be covered under warrant y.

There are many common sources of static. Most involve some type of friction between two

dissimilar materials. Some examples are combing your hair, sliding across a seat cover or

rolling a cart across the floor. S ince t he thres hol d of human perc ept ion for a st at ic dis charge i s

3000 volts, many damaging disc harges will not even be noticed.

Basic damage prevention consists of minimizing generation, discharging any accumulated

static charge on your body or work station and prevent ing that di scharge f rom bei ng sent to o r

through an electronic component. A static grounding strap (grounded through a protective

resistor) and a static safe workbenc h with a conductive surfac e should be used. This will prevent

any buildup of damaging st at ic .

Page 23

Orban

OPTIMOD-FM

8200

Operating Manual

page contents

1-1 Section 1: Introduction

OPTIMOD-FM 8200 DIGI TAL Audio Proces sor

ESCape and HELP

Presets in the 8200

Input/Output Configurations

Location of OPTIMO D-F M

About Trans m iss ion Lev els and M eter ing

Line-Up Facilities

Internal Clock

Future Updates

Warrant y, Feedback

2-1 Section 2: Installat ion

Installation of 8200

Installation of Studio Level Cont roller

System Setup Using QUICK SETUP

System Setup Using Individual Calibration Contr ols

Time and Dat e

Security and Pascode Programm ing

Remote Control Interf ace Pr ogram ming

3-1 Section 3: Operation

8200 Controls and Meters

Introduction to Processing

Customizing the 8200’s Sound

About the Processing Struc tures

Factory Programming Presets

The Protection Limiter Structure

The T wo-Band Str uctur es

The Multi-Band Structure

8200 Screen Displays

Page 24

Orban

OPTIMOD-FM

8200

Operating Manual

page contents

4-1 Section 4: Maintenance

Routine Maintenance

Getting Inside the Chassis

In-System Testing (“Proof of Perform ance ”)

Field Audit of Performance

Field Alignment

5-1 Section 5: Troubleshooting

Problems and Possible Causes

Troubleshoot ing I C Opam ps

Technical Support

Factory Service

Shipping Instructions

6-1 Section 6: Technical Data

Specifications

Circuit Description

Parts List

Schematics, Assembly Dr awings

Abbreviations

8200 PC Operating Manual

1-1 Section 1: Introlduction

2-1 Section 2: Installation

3-1 Section 3: Operation

4-1 Section 4: Troubles hooting

A1-1 Appendix 1: Cables (Diagr am s)

A2-1 Appendix 2: M odem s

INDEX on next page

Page 25

Index

!

4000 2-37

464A 2-27, 2-31

8100A1 1-16

8100AST 1-16

8100AXT2 1-16

A

abbreviations 6-81

AC line cord wire standard 2-13

AGC

(exter nal) setu p 2-27

defeating 3-28, 3-40

external 1-16

analog I/O 6-10

analog input clip level 2-57

analog input ref level 2-58

analog input sens itivity 2- 7

analog input termination 2-6

arrow keys 2-25, 3-3

assembly drawings 6-45

audible di stortion 3-5, 3-7 , 5- 2

audible noise 5-3

audio

connections 2-16

input 2-16, 6-2

output 2-17, 6-3

AUTOMATION

buttons 3-60

Daily Events 3-60

Date Events 3-60

flow char t 3-61

screens 3-59 - 3-60

B

balance ad just 2-58

balanced

inputs 2-16

output transformer 2-17

Bass Coupling 3-39

bass equalization 3-37

block diagram 6-46

brightness 3-39

brillianc e 3-38

buttons

AUTOMATION 3-60

ESC 2-25, 3-3

HELP 2-25, 3-3

IDLE G/R LOCKOUT 3-42, 3-76

IDLE I/O LOCKOUT 3-42, 3-76

MODIFY FULL CONTROL 3-51

MODIFY FULL G/R 3-51

MODIFY LESS-MORE 3-51

RECALL PRESET 3-46

SAVE CHANGES 3-57

SET PASCODE 3-68, 3-71

SYSTEM SETUP 3-64

buzzes 5-2

bypass preset 1-20

C

cable 2-14, 2-16

cable shie lding 2-16 - 2-17

calibration 3-64

chassis

getting inside 4-3

ground 2-19

circuit boards

access to 4-3

front pane l 4-3

circuit description 6-9

circuit ground 2-19

CIT25 2-12, 6-7

cleaning 4-2

clicks 5-2

clipping 3-5, 3-19, 3-36, 3-39

transient 3-18

clock

internal 1-21, 2-61

common-mo de re je ction 2-16, 2-19

composite

isolation transf ormer 2-12 , 6-7

metering 6-19

COMPOSITE LEVEL contro l 2-25, 3-3

composit e level output 1/2 2-25, 3-3

composit e me te ring 1-19

composite output impedance 2-5

compression 3-5, 3-3 5

computer in te rface 1-10, 2-14

connectors

audio 2-16

CONTRAST

control 2-25, 3-3

Control board 6-2 1

contro l knob

settings 2-25, 3-3

controls 2-24, 3-3

COMPOSITE LEVEL 1 2-25, 3-3

COMPOSITE LEVEL 2 2-25, 3-3

CONTRAST 2-25, 3-3

PILOT LEVEL 2-25, 2-60, 3-3

SEPARAT ION 2-25, 3-3

customer service 5-8

D

D-connector board 4-6, 6-26

date set 2- 65

daylight savings time 2-65

dBm (defined) 6-81

dBu (defined) 6-81

density 3-25, 3-35 - 3-36

digital i/ o 1- 8

digital input ref level 2-61

digital input/output connectors 2-19

disassembly 4-3

distortio n 3-19 , 3-3 6, 3-39, 5-2

DJ Bass Boost 3-39

Downward Expander 3-39

dsp boards 6-19

dull sound 5-4

E

EBS

modify screen 2-62

EBS MODIFY screen 3-67

EBS tones

failure 5-5

escape button 2-25, 3-3

exciter interface 2-21

EXIT TEST

button 3-46

F

factory service 5-9

factory test presets 1-7

field audi t 4-15

final clipper drive 3-28, 3-38

flow charts

AUTOMATION 3-61

I/O CALIB CONTROL 3-67

I/O CALIB I/O 3-67

IDLE G/R LOCKOUT 3-77

IDLE I/O LOCKOUT 3-77

MODIFY FULL CONTROL 3-54 - 3-55

MODIFY FULL G/R 3-54 - 3-55

MODIFY LESS-MORE 3-52 - 3-53

RECALL PRESET 3-47

SET PASCODE 3-74

SYSTEM SETUP 3-65

FM Smart Clipper 3-18

frequency response verification 4-15

front pa nel 2-24, 3-3

fuse 2-12

G

gain reduct io n 3-8, 3-15, 3-25, 3-35, 3-40

metering 3-40

gate compressor 3-28

gating 3-18, 3-25 , 3-28, 3-38

grounding 2-19 - 2-20 , 5-2

diff icult situations 2-12

ground loop 2-12

H

harshness 5-4

HELP button 2-25, 3-3

HF limiting 3-20, 3-27

high-frequency

clipping 3-39

equalization 3-38

limiting 3-20, 3-2 7

high-pass fil te r 3-17, 3-29, 3-40

hum 5-2

Page 26

I

I/O CALIB CONTROL

flow char t 3-67

I/O CALIB I/O

flow char t 3-67

IDLE G/R LOCKOUT

buttons 3- 42, 3-76

flow char t 3-77

screens 3-41, 3-7 5 - 3 -76

IDLE I/O LOCKOUT

buttons 3- 42, 3-76

flow char t 3-77

screens 3-41, 3-7 5 - 3 -76

impedance 2-16 - 2-17

input

balanced 2-16

buffer 6-10

filter board 4-5, 6-25

impedance 2-16

level 2-16

overload point 2-16

sensit ivity 2-7

termination 2-6

unbalanced 2-16

input level

line-up 1-18

input leve l me ters 1-19

input select A or D 2-61

inspection of contents 2-3

installation 2-1

internal cloc k 1-21, 2-61

J

jumpers

access to 4-3

analog I/O card 2-6

input sensitivit y 2-7

options 2-6

L

L-R null 4-10

level calibra tion 2-28

limiting 3-5

high-freque nc y 3-20, 3-27

line voltage 2-12

line-up tones

failure 5-5

location 2-13

location of 82 00 1-12

loudness 3-5, 3-25, 3-35 - 3-36, 3-38

]

M

MAIN TO SUB switch 2 -25 , 3-3

maintenance, routine 4-2

metering

composite 6-19

meters

PPM 2-50

studio 1-17

VU 2-50

MODIFY

screens 3-49

MODIFY FULL CONTROL

buttons 3-51

flow chart 3-54 - 3-55

screens 3-50

MODIFY FULL G/R

buttons 3-51

flow chart 3-54 - 3-55

screens 3-50

MODIFY LESS-MORE

buttons 3-51

flow chart 3-52 - 3-53

screens 3-49

modulation

cannot control 5-2

mono

performance verification 4-8

mono/stereo select 2-60

multi-ban d st ruc ture 3-31

bass 3-37

brightness 3-39

clipping 3-36, 3-39

compression 3-35

customizing sett ings 3-34

density 3-35

distortion 3-36, 3-39

equalization 3-37 - 3-38

high-freque nc y 3-38

loudness 3-35 - 3-36

on-air 3-33

setup 3-35

multi-ban d st ructures

bass coup li ng 3-39

gating 3-38

loudness, densit y 3-35

N

nastinesses, various 3-24

noise 6-2

noise and di st ortion verification 4-15

O

OPERATE switch 2-25, 3-3

ordering parts 6-28

output

impedance 2-17

level 2-17

unbalanced 2-17

output level meters 1-19

overshoot 5-2

overshoot compensator 2-59

overshoot reduction 1-16

P

packing for shipmen t 5-9

packing li st 2-3

parts

list 6-27

ordering 6-28

pascode

forgotte n 5-7

peak cont rol 3-26

peak control criteria 1-11

peak modulation

cannot control 5-2

phase-linear processing 3-21

physical dimensions 6-4

PILOT LEVEL control 2-25, 2-60, 3-3

pilot, ultrastable 1-9

power 2-12

cord 2-12

LED 2-25, 3-3

requireme nt s 6-4

supply 4-6, 6-25

PPM meter 2-50

pre-emphasis 3-5

select ion 2-57

problems 5-2

processing st ructures 3-9

processing trade-offs 3-6

programming prese ts 3-9 - 3-10

proof of performance 4-7

protectio n li mi te r s tru ct ure 3-15

distort ion 3-19

high-freque nc y 3-20

setup 3-15

protectio n structures

high-pass fi lt er 3-15

Q

quick setup 2-42 , 3-65

R

rack-mounting un it 2-13

rear pa nel 4-4

rear pa nel connections 2-11

RECALL PRESET

buttons 3-46

flow char t 3-47

screen 3-45 - 3-46

registration card 1-22

remote control 1-10, 2-14

remote control programming 2-75

return authorization 5-9

RF suppres si on 5-2

RFI 2-12, 2-19, 4-3

filter 2-12

Page 27

S

SA VE CHANGES

button 3-57

screen 3-57

schematics 6-45

screen displa ys 3-41

screen saver 2-67

screens

AUTOMATION 3-59 - 3-60

IDLE G/R LOCKOUT 3-41, 3-75 - 3-76

IDLE I/O LOCKOUT 3-41, 3-75 - 3-76

MODIFY 3-49

MODIFY FULL CONTROL 3-50

MODIFY FULL G/R 3-50

MODIFY LESS-MORE 3-49

RECALL PRESET 3-45 - 3-46

SAVE CHANGES 3-57

SET PASCODE 3-68, 3-71

SYSTEM SETUP 3-63 - 3-64

SEP A RATION con tro l 2-25 , 3-3

service 5-9

SET PASCODE

buttons 3- 68, 3-71

flow char t 3-74

screen 3-68, 3-71

setup

expanded 2-55

quick 2-42

system 2-41

shipping

damage 2-3

instructions 5-9

shrilln ess 5-4

sinewaves , modulation of 3-19

soft keys 2-25, 3-3

software updates 1-21

source mate ria l 3-8

specifications 6-2

spectral gain intermodulation 3-17

speech

bass boost 3-39

stereo

encoder board 6-15

interferenc e 5-5

performance verification 4-9

stereo /mono sele ct 2-60

STL systems 1-13

structures

multi-band 3-31

protection limiter 3-15

two-band 3-21

studio chassis 2- 46

SUB TO MAIN switch 2 -25 , 3-3

subcarrier input 1-8, 2-18

switches

MAIN TO SUB 2-25, 3-3

OPERATE 2-25, 3-3

SUB TO MAIN 2-25, 3-3

TEST 2-25, 3-3

SYSTEM SETUP 2-41

buttons 3-64

flow char t 3-65

screens 3-63 - 3-64

T

technical support 5-8

telephone/post lines 6-2

temperature 2-13

TEST switch 2-25 , 3-3

time set 2-65

tone generator

internal 1-20

troubleshooting 5-1

IC opamps 5-8

two-band structure

setup 3-24

two-band structures 3-21

g/r metering 3-24

gating 3-28

high-frequency limiting 3-27

high-pass fi lt er 3-29

loudness, densit y 3-25

peak control 3-26

setup 3-23

spectral balanc e 3-26

U

unbalanced

input 2-16

load 2-17

user tone pres et 1-20

V

voice

bass boost 3-39

VU meter 2-50

W

warranty 6-8

whistle, on air 5-4

X

XLR connectors 1-7, 2-16

Page 28

This Page Intenti ona l ly Lef t Bl ank.

Page 29

pagecontents

Section 1

Introduction

page contents

1-3 OPTIMOD-FM 8200 DIGITAL Audio Processor

1-6 ESCape and HELP

1-6 Presets in the 8200

1-7 Input/Output Configurati ons

1-11 Location of OPTIMOD-FM

1-17 About Transmission Levels and Metering

1-17 Figure 1-1: Absolute Peak Level, VU and PPM Reading

1-19

Line-Up Facilities

1-21 Internal Clock

1-21 Future Updates

1-22 Warranty, Feedback

OPTIMOD-FM 8200 INTRODUCTION

1-1

Page 30

CONTROL KNOB

ARROW

KEYS

SCREEN

CONTRAST

CONTROL

SOFT KEY

BUTTONS

ESC

BUTTON

HELP

BUTTON

TEST

SWITCH

POWER

LED

STEREO

ENCODER

CONTROLS

1-2

INTRODUCTION OPTIMOD-FM 8200

Page 31

OPTIMOD-FM 8200 DIGITAL Audio Processor

Orban’s OPTIMOD-FM 8200 DIGITAL Audio Processor is a complete audio processing

system for FM broadcast.

User-Friendly Interf ace

•

A large liquid-crystal displa y (LCD) make s se tup, ad jus tmen t and program min g

of the 8200 easy. The screen clearly shows all metering functions of the processing structure in use.

•

Push one of the clearly labeled soft keys to RECALL a preset, to MODIFY

processing, to program Automation Preset Switching, or to access SYSTEM

SETUP.

•

HELP is always available a t the push of a b utton. If you g et lost, ESC will a lways

bring you back home. If you desire, you don’t even need this manual to adjust and

program the 8200. Step-by-step instructions are on the screen.

Absolute Control of Peak Modulation

•

The 8200 provides universal transmitter protection and audio processing for FM

broadcast. I t can be configured to in terface ideally with any common ly-found

transmission system in the world.

•

The 8200 Audio Processor provides pre-emphasis limiting for the internationallyused pre- emphasis curves of 50

µs and 75µs. Its pr e-emphasis control is almost

never audibly apparent, producing a clean, open sound with subjective brightness

matching the original program.

•

The 8200 achieves extremely tight peak control; overshoot is limited to <0.3dB!

•

The 8200’s st ereo encoder (ster eo generator) us es Orban’s ROM-base d, digitally controlled Hadamard-Transform circuit topology to produce a circuit with

excellent specs , h igh sta bility , a nd un compromising ba se ba nd sp ec tru m con tro l.

The encoder has two outputs with independent level controls, each capable of

driving 75Ω in parallel with 47,000pF, (100ft/30m of coaxial cable).

•

By integrating the stereo encoder with the audio processing, the 8200 eliminates

the overshoot problems that waste valuable modulation in traditional external

encoders.

•

The 8200 prevents aliasing distortion in subsequent stereo encoders or transmission links by providing band width-limiting and over shoot compens ated 15kHz

low-pass filters ahead of the 8200’s audio outputs and stereo encoder.

Flexible Config urati on to Inter face Wit h Analo g and Dig ital Systems

•

The 8200 Audio Processor is designed to meet all applicable international safety

standards.

OPTIMOD-FM 8200 INTRODUCTION

1-3

Page 32

•

The 8200 Audio Processor can be configured for analog and/or digital inputs and

outputs.

•

The analog inputs are transformerless, balanced 10kΩ instrumentation-amplifier

circuits, and the outputs are transformerless , balanced, and floating with 30Ω

impedance to ensure highest transparency and accurate pulse response.

•

The optional Digital I/O follows the AES/ E BU stan da rd, op eratin g at 32 kHz .

•

All input, output, and power connections are rigorously RFI-suppressed to Orban’s traditional exacting standards, ensuring trouble-free installation.

•

The 8200 Audio Proc essor is designed to work perfectly with Orban’s studio

level contro l units (which are common ly used to protect tran smission links in

installations where the audio is passed from studio to transmitter in left/right

form, using telephone/post lines, dual-microwave STLs, or similar).

Adaptability Through Switchable Aud io Processin g Structu res

•

A processing structure is a program that operates as a complete audio processing

system. Only one p rocessing str ucture can be active at a time. Ju st as there are

many possible ways of configuring a processing system using analog components

(such as equalizers, compressors, limiters, and clippers), there are many possible

processing s tructures achie vable by the 8200. The 8 200 realizes its pr ocessing

structures as a s eries of high-sp ee d mathematical computations mad e b y Dig ital

Signal Process in g (DSP) chi ps .

•

The 8200 is sh ipped in var ious versio ns containing d ifferent se ts of proce ssing

structures. R efer to the unit’s re ar pane l for your Mod el # and the insid e of the

front cover of this manual for the structures included in your model.

•

The optional Multi-Band Structure is the ultimate processing for the competitive

major market sound. I t gives your statio n more pun ch, more co nsistency, more

presence, a nd more brightn ess, without pump ing or other un natural artif acts. It

lets you set the speed limit — FAST, MEDIUM FAST, MEDIUM SLOW,

SLOW. FAST creates a synthetic sound, an illusion, a dramatic, “theatrical”

sound that is ideal for competitive, high-energy hit music formats. SLOW creates

a very open s ound, a sound that is v ery life -like with a d istinct impro vemen t in

clarity.

•

The Two-Band Normal Structure is an improved version of Orban’s classic

8100A OPTIMOD-FM sound that has helped make thousands of stations successful. It produces an open and natural sound, whether used for light control over

levels, or for the heavier processing often desired for some popular music

formats. It can be set up to maintain high fidelity to the source mater ial, or to

create a sound that is loud and dense.

•

The Two-Band Purist Structure is designed for the purist who wants to trade-off

3dB of loudness for constant group delay at all frequencies (linear phase)

throughout the 30Hz to 15kHz range.

1-4

INTRODUCTION OPTIMOD-FM 8200

Page 33

•

The Protection Structure is desig ned for sta tions wanting the highest possible

fidelity to the source, such as a station broadcasting concert music at night.

•

The 8200 applies to d igital proc essing a dis tillation of Orba n’s sixteen ye ars of

market-leading analog processing experience; the unit builds and improves on the

uniquely successful sound of the Orban analog processors.

•

All structures except th e Protec tion Str uctur e ride gain ov er a ran ge of as much

as 25dB, reducing dynamic range and compensating for gain riding errors on the

part of operators. The amount of dynamic range reduction ordinarily produced is

adjustable.

•

The 8200 can be changed from one processing structure to another almost

instantly.

Programmable

•

The 8200 is supplied from the factory with factory-programmed presets for

virtually all progr am f or mats . P r esets spe cif y bo th a processing struc tur e an d its

control settings.

•

Factory P re se ts ca n be user-modifie d a nd sto re d in 32 us er presets. They c an be

recalled either locally or by remote control.

Controllable

•

The 8200 Audio Processo r contains a versatile real-time clock, which pe rmits

presets to be recalled at pre-programmed times.

•

All compression, limiting, and clipping can be defeated by remote control to

permit broadcast system test and alignment or “proof of performance” tests.

The 8200 Audio Processor is fully remote-controllable from an RS-232/RS-422

serial port (for computer or modem interface) using the optional 8200 PC Remote

Control Softw are, and b y optically- isolated te rminals that ca n be operated with

contact closure s (to facilitate interfacing to older-te chnology remote controls) .

Orban’s optional 8200 PC Remote Control Program for IBM PC compatibles lets

you do everyth ing from the remote comp uter that you can do from the 8200’s

front panel.

•

The 8200 Audio Processor contains a built-in line-up tone generator, facilitating

quick and accu rate leve l setting in any syste m, as we ll as a Bes sel-null ton e for

calibrating modulation.

•

The 8200 Audio Processor can produce the standard EBS (U.S. standard Emergency Broadcast System ) to nes. It is FCC type ac cept ed.

Expandable

•

The 8200 is expandable, so you can add more DSP processing power as needed

to accommodate future software upgrades and processing structures.

OPTIMOD-FM 8200 INTRODUCTION

1-5

Page 34

ESCape and HELP

The front-panel ESCape and HELP buttons are always there to aid you in your travels

around the 8200’s functions.

Use ESCape to get back to the previous screen. Pressing ESC repeatedly will get you back

to the main gain reduction meter screen (

IDLE G/R), no matter where you are.

The 8200 offe rs exten sive on-sc reen help. Whe rever yo u are, you can press the dedic ated

HELP button to give you a b rie f e xp lan atio n o f wh at th at s cr ee n is show in g yo u, and wh at

it does. The names of the buttons of the screen being explained remain at the bottom. Press

a button, and you will get a detailed explanation of what that button will do. Press ESCape

to go back to the screen information. Press ESCape again to return to the screen from where

you first requested HELP.

Presets in the 8200

There are th ree distinc t kinds of pres ets in the 8200: Fa ctory Process ing Presets, Factory

Test Presets, and User Presets.

Factory Processing Presets (including Factory Programming Presets)

Factory Processing Presets are various “factory recommended settings” for each processing

structure. They are indicated on the RECALL PRESET list on the 8200 by a two-letter

designation followed by a description, such as “AA PROTECTION 0dB” or “DB 5BMEDIUM SLOW.” The description indicates the processing structure and the type of

processing.

Each Factory Processing Preset on the RECALL PRESET list is really a library of 20

separate presets, selected using the MODIFY LESS-MORE control to adjust the 8200 for

more or less processing.

Factory Pro cessing Presets are sto red in the 8200’s non-volatile memor y, and cannot be

erased. You can change the settings of a Factory Processing Preset, but you must then store

those settings as a User Preset, which you are free to name as you wish. The factory preset

remains unch an ged.

Factory Programming Presets are our “factory recommended settings” for various program

formats or types. They are indicated on the RECALL PRESET list on the 8200 by a

two-letter des ignatio n (b eginn ing w ith the letter F ) fo llowed b y a fo rmat de sc ription , such

as “FA CLASSICAL” or “FO TALK.” Each Factory Programming Preset is a Factory

Processing Preset set to the LESS-MORE setting that is likely to be appropriate for that

program format.

1-6

INTRODUCTION OPTIMOD-FM 8200

Page 35

Factory Test Presets

Factory Test Presets include TO USER TONE and BY BYPASS. But unlike Factory

Processing P re se ts, th e se tting s of F a cto ry T es t P r es ets ca n b e c hang ed , a nd these changes

are remembered in the Factory Test Preset. For example, you use the TO USER TONE

preset in the same way that you use any normal oscillator. Set the frequency and level, and

they remain that way until you change them.

User Presets

User Prese ts permit yo u to change a F actory P rocess ing Pres et or a Facto ry Test Pres et to

suit your requirements, and store those changes. You may store up to 32 User Presets. They

are indicated on the RECALL PRESET list by a number designation from 01 to 32, follo wed

by a description. You may enter in any description you wish, up to 16 characters.

User Presets cannot be created from “scratch.” You must always start by recalling a Factory

Preset. You ca n then immediately stor e this in a User Prese t, give it whatever name you

wish, then make changes to the settings. Or you can recall a Factory Preset, make the

changes, then store this in a User Pre set.

Either way, the Fa ctory Preset remains for you to retur n to if you wish.

Input/Output Configurations

The OPTIMOD-FM 8200 DIGIT AL is de sig ne d t o sim ul t aneo us ly ac co m mod at e:

•

analog left/right inputs and outputs

•

stereo analog baseband composite output

•

Digital AES/EBU left/righ t in put s an d ou tput s.

Each of these is accomplished with a plug-in ca rd. The standard configuration includes

analog in/out and stereo composite out. AES/EBU in/out is accommodated by a separate

optional, user-installed card, available from your dealer.

Analog Left/Righ t Inpu t/Ou tput

The left and right analog inputs are on XLR-type female connectors on the rear panel. Input

impedance is greater than 10kΩ; balanced and floating. Inputs can accommodate up to

+27dBu (0dBu = 0.775Vrms). The left and right analog outputs are on XLR-type male

connectors on the rear panel. Output impedance is 30Ω; balanced and floating. Outputs can

drive up to +24dBm into 600Ω.

Level control of the analog inputs and outputs is via software control through SYSTEM

SETUP. (See page 2-41 an d 2- 55 .)

Provided that th e A nalo g I/O Card is installe d, the left and right analog outputs are a lway s

available regardless of whether the Stereo Encoder Card and/or Digital I/O Card is installed.

OPTIMOD-FM 8200 INTRODUCTION

1-7

Page 36

Digital AES/EBU Left/Right In put/Ou tput

The digital input and output follow the professional AES/EBU standard. The left/right

digital input is on one XLR -type female connector on the rear p anel; the left/righ t digital

output is on one XLR-type male con nect o r on the rear pan el.

If digital AES/EBU left/right input or output is required and presently not installed, install

the Digital I/O Card according to the instructions provided with it.

The 8200 is designed to simultaneously accommodate digital and analog inputs and outputs.

You select whether the 8200 uses the digital or the analog input on the SYSTEM SETUP

I/O CALIB screen or by REMOTE INTERFACE. Both analog and digital outputs are

active continuously. Level control of the AES/EBU input is via software control through

SYSTEM SETUP.

At the time o f pu blic atio n of th is man ua l ( Ja nu ary, 1 995) , the re a re two a va ilab le ve rs ion s

of the optional Digital I/O Card. The less expensive version (8200D/32) operates at a 32kHz

sample rate, th e sta ndar d sample rate use d for transmission o f 15 kH z ba nd w idth au dio. Its

output is pre-emp hasized to the 50µs o r 75µs curve se lected for th e process ing. It cannot

provide a “flat” output. The more advan ced versio n (8200 D/SRC) in corporate s sampl e rate

conversion of 32, 44.1, or 48kHz.

Please note that the AES/EBU standard is not the same as the S/P-DIF

(Sony/Philips Digital Inte rface) standard u sed in consum er digita l applica tions, such as the “digital outputs” of CD player s. The AES/EBU inte rface

will not work with S/P-DIF signals.

Stereo Analog Baseband Com posi te Outp ut

The stereo encoder has two unbalanced analog baseband outputs on two BNC connectors

on the rear p anel. Each output can b e strapp ed for 0Ω or 75Ω so urce impedan ce, and can

drive up to 8V peak-to-peak into 75Ω in parallel with up to 0.047

µF (100ft/ 30m of RG- 59/U

cable) before any noticeable performance degradation occurs.

Level control of eac h ou tput is via a separa te sc re wdriver control ac ce ssible from the front

panel.

A ground lift s witch is ava ilable on th e rear p anel. This is u seful to preve nt ground loop s

between the 8200 and the transmitter.

Subcarriers

The stereo encoder has an unbalanced 600Ω subcarrier (SCA) input with rear-panel BNC

connector to accept any subcarrier at or above 23kHz. The subcarrier will be mixed into each

composite output, and its level will be affected by the composite level control for that output.

The gain is scaled so that 1.5V peak at the subcarrier input produces 10% subcarrier

injection with reference to 100% deviation of the FM carrier.

If the stereo en co de r is installed, a 19kH z TTL -le vel square wav e is a va ilab le on pin 18 of

the REMOTE INTERFACE, located on the rear panel of th e unit. This prov ides a means for

synchronizing an external subcarrier generator, like an RDS (Radio Data Systems) subcarrier, to the 19kHz pilot tone.

1-8

INTRODUCTION OPTIMOD-FM 8200

Page 37

The correct peak level of the stereo program applied to the stereo encoder sometimes

depends on the nu mbe r o f s ub ca rriers in use. S ome re gu lato ry auth orities require tha t total

baseband modulation be maintained within specified limits. Thus the level of the stereo main

and subchann el m us t b e redu ce d whe n a su bcarrier is turned on.

The 8200’s remo te control feature allo ws you to reduce the s tereo main and sub -channel

level by co nnecting an on /off signal f rom y our su bcar rier genera tor ( See p age 2-1 4). Yo u

define the amount of reduction in % on the SYSTEM SETUP

I/O CALIB screen (Se e

page 2-60). See page 2-74 for information on programming the remote control.

Ultrastable Pilot for the 8200 Stereo Enco der

This section explains how the OPTIMOD 8200 Stereo Encoder Board can be modified to

generate a pilot with ultrastable frequency.

This modification will allow a station’s carrier frequency to be maintained within 100Hz of

the assigned channel fr equency when using the 8200 ’s stereo p ilot as a refer ence. With a

100MHz carrier, this requires a stability of 1 part per million (ppm). This stability can only

be realized with a Temperature Compensated Crystal Oscillator (TCXO).

The 8200 Ster eo E ncod er B oar d ha s fo ur u nused pads that ar e spa ced f or a c er tain TCXO

package to be soldered into place. Four components also have to be removed from the Stereo

Encoder Board to make room for the TCXO. They are R102, Y1, C40 and C41.

We have found three different TCXOs th at c an be us ed on the 8 20 0 St ereo E ncod er Bo ard.

They are:

Manufacturer Model Frequency Stability

Monitor Produ ct s 7402 Series, Mo de l B 4.864MHz ±1.5ppm (−25°C to +60°C)

Raltron TF69100-4.864 4.864MHz ±1ppm (0°C to +50°C)

RXD 621B 4.864MHz ±1ppm (−10°C to +50°C)

As we do not have a Retrofit Kit available at the time this manual was printed, you will need

to contact the manu facturer’s repre sentative directly to pla ce an order. Add resses for the

manufacturers and their reps are listed below.

Monitor Products Raltron RXD

502 Vi a Del M onte 2315 NW 107th Ave. P.O. Box 1494

Oceanside, CA 92054 M iami , FL 33172 Norfolk, NE 68701

(619) 433-4510/434-0255 (fax) (305) 593-6033/594-3973 (fax) (402) 379-0112/3 79-30 74 (fax)

DLDI Kelex Electronics California Capacitor

13455 Ventura Blvd #220 16631 Milliken Ave. 1579 Centre Pointe Dr .

Sherman Oaks, CA 91423 Irvine, CA 92714 Milpitas, CA 95035

(408) 496-6996/(818) 995-6451 (fax) (714) 863-1230/474-1231 (fax) (408) 262-6000/262-0272 (fax)

OPTIMOD-FM 8200 INTRODUCTION

1-9

Page 38

Remote Control Interface

The Remote Control Interface is a set of eight optically-isolated inputs on a DB-25

connector that c an be activated by 6-24V DC or 6-24V AC 50 /60Hz signals. They can

control various functions of the 8200:

1) Recall any Factory Processing Preset, Factory Test Preset, User Preset, or exit from a test

preset to the previous processing preset.

2) Switch the stereo encoder to stereo, mono from left audio input, or mono from right audio

input.

3) Switch the 8200 to use either the analog input or the digital input.

4) Reduce the stereo main and subchannel modulation to compensate for transmitter

overshoot an d su bc arri e r inp ut s (SCAs).

The remote contro l o f ov er sh oo t comp en sation and SCA modulation (See page 2-59) is