Orban FM 2200-D, FM 2200 Service manual

Operating Manual

OPTIMOD-FM 2200

Digital Audio Processor

Models 2200 and 2200-D

®

IMPORTANT NOTE: Refer to the unit’s rear panel for your Model #.

Model Number: |

Description: |

2200-D/U |

OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, Digital I/O, |

|

Protection Structure, Two-Band Structure, |

|

set to 115V (for 98-130V operation), switchable to 50 s or 75 s. |

2200-D/E |

OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, Digital I/O, |

|

Protection Structure, Two-Band Structure, |

|

set to 230V (for 196-264V operation), switchable to 50 s or 75 s. |

2200-D/J |

OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, Digital I/O, |

|

Protection Structure, Two-Band Structure, |

|

set to 100V (for 89-120V operation), switchable to 50 s or 75 s. |

2200/U |

OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, |

|

Protection Structure, Two-Band Structure, |

|

set to 115V (for 98-130V operation), switchable to 50 s or 75 s. |

2200/E |

OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, |

|

Protection Structure, Two-Band Structure, |

|

set to 230V (for 196-264V operation), switchable to 50 s or 75 s. |

2200/J |

OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, |

|

Protection Structure, Two-Band Structure, |

|

set to 100V (for 89-120V operation), switchable to 50 s or 75 s. |

MANUAL: |

|

|

Part Number: |

Description: |

|

96079-000-04 |

2200/2200-D Manual |

|

|

|

|

|

|

|

CAUTION: TO REDUCE THE RISK OF ELECTRICAL SHOCK, DO NOT REMOVE COVER (OR BACK). NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

WARNING: TO REDUCE THE RISK OF FIRE OR ELECTRICAL SHOCK, DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

This symbol, wherever it appears,

alerts you to the presence of uninsulated dangerous voltage inside the enclosure — voltage that may be sufficient to constitute a risk of shock.

This symbol, wherever it appears, alerts you to important operating and

maintenance instructions in the accompanying literature. Read the manual.

IMPORTANT SAFETY INSTRUCTIONS

All the safety and operating instructions should be read before the appliance is operated.

Retain Instructions: The safety and operation instructions should be retained for future reference.

Heed Warnings: All warnings on the appliance and in the operating instructions should be adhered to.

Follow Instructions: All operation and user instructions should be followed.

Water and Moisture: The appliance should not be used near water (e.g., near a bathtub, washbowl, kitchen sink, laundry tub, in a wet basement, or near a swimming pool, etc.).

Ventilation: The appliance should be situated so that its location or position does not interfere with its proper ventilation. For example, the appliance should not be situated on a bed, sofa, rug, or similar surface that may block the ventilation openings; or, placed in a built-in installation, such as a bookcase or cabinet that may impede the flow of air through the ventilation openings.

Heat: The appliance should be situated away from heat sources such as radiators, heat registers, stoves, or other appliances (including amplifiers) that produce heat.

Power Sources: The appliance should be connected to a power supply only of the type described in the operating instructions or as marked on the appliance.

Grounding or Polarization: Precautions should be taken so that the grounding or polarization means of an appliance is not defeated.

Power-Cord Protection: Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed upon or against them, paying particular attention to cords at plugs, convenience receptacles, and the point where they exit from the appliance.

Cleaning: The appliance should be cleaned only as recommended by the manufacturer.

Non-Use Periods: The power cord of the appliance should be unplugged from the outlet when left unused for a long period of time.

Object and Liquid Entry: openings.

Damage Requiring Service: The appliance should be serviced by qualified service personnel when: The power supply cord or the plug has been damaged; or

Objects have fallen, or liquid has been spilled into the appliance; or The appliance has been exposed to rain; or

The appliance does not appear to operate normally or exhibits a marked change in performance; or The appliance has been dropped, or the enclosure damaged.

Servicing: The user should not attempt to service the appliance beyond that described in the operating instructions. All other servicing should be referred to qualified service personnel.

The Appliance should be used only with a cart or stand that is recommended by the manufacturer.

Safety Instructions (European)

Notice For U.K. Customers If Your Unit Is Equipped With A Power Cord.

WARNING: THIS APPLIANCE MUST BE EARTHED.

The cores in the mains lead are coloured in accordance with the following code:

GREEN and YELLOW - Earth BLUE - Neutral BROWN - Live

As colours of the cores in the mains lead of this appliance may not correspond with the coloured markings identifying the terminals in your plug, proceed as follows:

The core which is coloured green and yellow must be connected to the terminal in the plug marked with the letter E, or with the earth symbol, (

), or coloured green, or green and yellow.

), or coloured green, or green and yellow.

The core which is coloured blue must be connected to the terminal marked N or coloured black. The core which is coloured brown must be connected to the terminal marked L or coloured red.

The power cord is terminated in a CEE7/7 plug (Continental Europe). The green/yellow wire is connected directly to the unit’s chassis. If you need to change the plug and if you are qualified to do so, refer to the table below.

WARNING: If the ground is defeated, certain fault conditions in the unit or in the system to which it is connected can result in full line voltage between chassis and earth ground. Severe injury or death can then result if the chassis and earth ground are touched simultaneously.

CONDUCTOR |

WIRE COLOR |

||

|

|

Normal |

Alt |

L |

LIVE |

BROWN |

BLACK |

N |

NEUTRAL |

BLUE |

WHITE |

|

|

|

|

E |

EARTH GND |

GREEN-YELLOW |

GREEN |

AC Power Cord Color Coding

Safety Instructions (German)

Gerät nur an der am Leistungsschild vermerkten Spannung und Stromart betreiben.

Sicherungen nur durch solche, gleicher Stromstärke und gleichen Abschaltverhaltens ersetzen. Sicherungen nie überbrücken.

Jedwede Beschädigung des Netzkabels vermeiden. Netzkabel nicht knicken oder quetschen. Beim Abziehen des Netzkabels den Stecker und nicht das Kabel enfassen. Beschädigte Netzkabel sofort auswechseln.

Gerät und Netzkabel keinen übertriebenen mechanischen Beaspruchungen aussetzen.

Um Berührung gefährlicher elektrischer Spannungen zu vermeiden, darf das Gerät nicht geöffnet werden. Im Fall von Betriebsstörungen darf das Gerät nur Von befugten Servicestellen instandgesetzt werden. Im Gerät befinden sich keine, durch den Benutzer reparierbare Teile.

Zur Vermeidung von elektrischen Schlägen und Feuer ist das Gerät vor Nässe zu schützen. Eindringen von Feuchtigkeit und Flüssigkeiten in das Gerät vermeiden.

Bei Betriebsstörungen bzw. nach Eindringen von Flüssigkeiten oder anderen Gegenständen, das Gerät sofort vom Netz trennen und eine qualifizierte Servicestelle kontaktieren.

Safety Instructions (French)

On s’assurera toujours que la tension et la nature du courant utilisé correspondent bien à ceux indiqués sur la plaque de l’appareil.

N’utiliser que des fusibles de même intensité et du même principe de mise hors circuit que les fusibles d’origine. Ne jamais shunter les fusibles.

Eviter tout ce qui risque d’endommager le câble seceur. On ne devra ni le plier, ni l’aplatir. Lorsqu’on débranche l’appareil, tirer la fiche et non le cäble. Si un cäble est endommagé, le remplacer immédiatement.

Ne jamais exposer l’appareil ou le cäble ä une contrainte mécanique excessive.

Pour éviter tout contact averc une tension électrique dangereuse, on n’oouvrira jamais l’appareil. En cas de dysfonctionnement, l’appareil ne peut être réparé que dans un atelier autorisé. Aucun élément de cet appareil ne peut être réparé par l’utilisateur.

Pour éviter les risques de décharge électrique et d’incendie, protéger l’appareil de l’humidité. Eviter toute pénétration d’humidité ou fr liquide dans l’appareil.

En cas de dysfonctionnement ou si un liquide ou tout autre objet a pénétré dans l’appareil couper aussitôt l’appareil de son alimentation et s’adresser à un point de service aprésvente autorisé.

Safety Instructions (Spanish)

Hacer funcionar el aparato sólo con la tensión y clase de corriente señaladas en la placa indicadora de características.

Reemplazar los fusibles sólo por otros de la misma intensidad de corriente y sistema de desconexión. No poner nunca los fusibles en puente.

Proteger el cable de alimentación contra toda clase de daños. No doblar o apretar el cable. Al desenchufar, asir el enchufe y no el cable. Sustituir inmediatamente cables dañados.

No someter el aparato y el cable de alimentación a esfuerzo mecánico excesivo.

Para evitar el contacto con tensiones eléctricas peligrosas, el aparato no debe abrirse. En caso de producirse fallos de funcionamiento, debe ser reparado sólo por talleres de servicio autorizados. En el aparato no se encuentra ninguna pieza que pudiera ser reparada por el usuario.

Para evitar descargas eléctricas e incendios, el aparato debe protegerse contra la humedad, impidiendo que penetren ésta o líquidos en el mismo.

En caso de producirse fallas de funcionamiento como consecuencia de la penetración de líquidos u otros objetos en el aparato, hay que desconectarlo inmediatamente de la red y ponerse en contacto con un taller de servicio autorizado.

Safety Instructions (Italian)

Far funzionare l’apparecchio solo con la tensione e il tipo di corrente indicati sulla targa riportante i dati sulle prestazioni.

Sostituire i dispositivi di protezione (valvole, fusibili ecc.) solo con dispositivi aventi lo stesso amperaggio e lo stesso comportamento di interruzione. Non cavallottare mai i dispositivi di protezione.

Evitare qualsiasi danno al cavo di collegamento alla rete. Non piegare o schiacciare il cavo. Per staccare il cavo, tirare la presa e mai il cavo. Sostituire subito i cavi danneggiati.

Non esporre l’apparecchio e il cavo ad esagerate sollecitazioni meccaniche.

Per evitare il contatto con le tensioni elettriche pericolose, l’apparecchio non deve venir aperto. In caso di anomalie di funzionamento l’apparecchio deve venir riparato solo da centri di servizio autorizzati. Nell’apparecchio non si trovano parti che possano essere riparate dall’utente.

Per evitare scosse elettriche o incendi, l’apparecchio va protetto dall’umidità. Evitare che umidità o liquidi entrino nell’apparecchio.

In caso di anomalie di funzionamento rispettivamente dopo la penetrazione di liquidi o oggetti nell’apparecchio, staccare immediatamente l’apparecchio dalla rete e contattare un centro di servizio qualificato.

®

PLEASE READ THIS FIRST!

Manual

The Operating Manual contains instructions to verify the proper operation of this unit and initialization of certain options. You will find these operations are most conveniently performed on the bench before you install the unit in the rack.

Please review the Manual, especially the installation section, before unpacking the unit.

Trial Period Precautions

If your unit has been provided on a trial basis:

You should observe the following precautions to avoid reconditioning charges in case you later wish to return the unit to your dealer.

Note the packing technique and save all packing materials. It is not wise to ship in other than the factory carton. (Replacements cost $35.00).

(1)Avoid scratching the paint or plating. Set the unit on soft, clean surfaces.

(2)Do not cut the grounding pin from the line cord.

(3)Use care and proper tools in removing and tightening screws to avoid burring the heads.

(4)Use the nylon-washered rack screws supplied, if possible, to avoid damaging the panel. Support the unit when tightening the screws so that the threads do not scrape the paint inside the slotted holes.

Packing

When you pack the unit for shipping:

Tighten all screws on any barrier strip(s) so the screws do not fall out from vibration.

Wrap the unit in its original plastic bag to avoid abrading the paint.

Seal the inner and outer cartons with tape.

If you are returning the unit permanently (for credit), be sure to enclose:

•The Manual(s)

•The Registration Card

•The Line Cord

•All Miscellaneous Hardware (including the Rack Screws)

•The Extender Card

•The COAX Connecting Cable

Your dealer may charge you for any missing items.

If you are returning a unit for repair, do not enclose any of the above items.

Further advice on proper packing and shipping is included in Section 5: Troubleshooting.

Trouble

If you have problems with installation or operation:

(1)Check everything you have done so far against the instructions in the Manual. The information contained therein is based on our years of experience with OPTIMOD and broadcast stations.

(2)Check the other sections of the Manual (consult the Table of Contents and Index) to see if there might be some suggestions regarding your problem.

(3)After reading the section on Factory Assistance, you may call Orban Customer Service for advice during normal California business hours. The number is (1) 510/351-3500.

OPTIMOD-FM 2200 |

CONDENSED SETUP CS-1 |

Condensed Setup of OPTIMOD-FM Models 2200 and 2200-D

This setup guide is for qualified personnel only. Use this guide to help you get your 2200 installed and operating as quickly as possible. If, at any time, you require more details to complete installation, refer to the relevant steps in Section 2 of the 2200 Operating Manual.

1. Unpack and inspect. (Refer to page 2-2.)

A |

If you note obvious physical damage, contact the carrier immediately to make a |

|

damage claim. A complete list of items included in the 2200 package is on page 2-2. |

B |

Save all packing materials, in case you should ever have to ship the 2200. |

C |

Complete the Registration Card and return it to Orban. |

2.Change standard factory configuration, if required. (Refer to page 2-3.)

[Skip this step if your installation does not have any special requirements.]

The 2200 is supplied from the factory with its jumpers set to the configuration correct for most installations.

Stereo Encoder Composite Output Impedance |

0Ω |

|

Input Impedance |

|

10kΩ |

Input Sensitivity |

− 10dBu or greater (+5dBu to +27dBu peak) |

|

A

B

If you are changing any jumper settings, remove the top cover of the 2200 to access the main circuit board. (Make sure power is not connected.)

Refer to Figure 2-1 in the manual to find the jumpers on the main circuit board and to position them according to your application.

C Replace the 2200 top cover.

3. Check the line voltage, fuse and power cord. (Refer to page 2-7.)

A

B

DO NOT connect power to the unit yet!

Check the voltage selector on the rear panel, and change the setting if it is incorrect.

Refer to the unit’s rear panel for your Model Number and the inside of the front cover of the 2200 manual for your Model Number’s line voltage setting.

C  Check the value of the fuse and change the fuse if the value is incorrect.

Check the value of the fuse and change the fuse if the value is incorrect.

For safety, the fuse must be Slow-Blow 1⁄2-amp for 115V, or 250mA (1⁄4-amp) “T” type for 230V.

CS-2 QUICK SETUP |

OPTIMOD-FM 2200 |

D Check power cord.

If you need to change the plug to meet your country’s standard and you are qualified to do so, refer to the manual. Otherwise, purchase a new mains cord with the correct line plug attached.

4.Set Ground Lift switch. (Refer to page 2-8.)

The GND LIFT switch, located on the rear panel, is shipped from the factory set to GND (to connect the 2200’s circuit ground to its chassis ground). If you are using the 2200’s stereo encoder, and are driving its composite output into an unbalanced exciter input, set the GND LIFT switch to LIFT. If you are not using the 2200’s stereo encoder, or are using it to drive a balanced exciter input, set the GND LIFT switch to GND.

5.Mount the 2200 in a rack. (Refer to page 2-8.)

The 2200 requires one standard rack unit (13⁄4 inches/4.4 cm). There should be a good

ground connection between the rack and the 2200 chassis — check this with an ohmmeter to verify that the resistance is less than 0.5Ω .

6.Connect remote control (optional). (Refer to page 2-2.)

7.Connect inputs and outputs. (Refer to page 2-9.)

See the hook-up and grounding information in the manual.

8.Power up the 2200. (refer to page 2-14.)

A Plug in the 2200’s power cord.

With no input program material, the red Gated LED and one of the green Function LEDs should be on. The AGC meter should indicate 10.0. The main screen appears in the front window display.

9. Recall Classical Protect preset. (Refer to page 2-17.)

A |

Press Recall Preset button, turn control knob until next: is CLASSICAL PROTECT, then |

|

press the RECALL NEXT soft key button. |

10.Set pre-emphasis to the standard used in your country. (Refer to page 2-18.)

A

Press System Setup button, press STEREO ENCODER soft key button, then set processing (PROC PRE-E) to your country’s standards:

Press System Setup button, press STEREO ENCODER soft key button, then set processing (PROC PRE-E) to your country’s standards:

75 s NORTH, CENTRAL, SOUTH AMERICA

50 s EUROPE, ASIA, AFRICA, PACIFICA EXCEPT

75 s TAIWAN, KOREA, THAILAND

OPTIMOD-FM 2200 |

CONDENSED SETUP CS-3 |

11. Set Analog Output pre-emphasis. (Refer to page 2-18.)

[Skip this step if you are not using the 2200’s analog outputs.]

A

Access ANLG OUTP CALIB control screen: Press System Setup button, press I/O CALIB soft key button, then press ANLG OUTP CALIB soft key button.

Access ANLG OUTP CALIB control screen: Press System Setup button, press I/O CALIB soft key button, then press ANLG OUTP CALIB soft key button.

B  Set Analog Output pre-emphasis to [flat] or [pre-emph].

Set Analog Output pre-emphasis to [flat] or [pre-emph].

This controls whether the analog left/right outputs produce a flat signal, or a pre-emphasized signal, following the pre-emphasis set with Stereo Encoder PROC PRE-E control in the previous step.

12.Model 2200-D only: Set Digital Output pre-emphasis status. (Refer to page 2-19.)

[Skip this step if you are not using the 2200-D’s digital output.]

A  Access I/O CALIB control screen: Press System Setup button, press the I/O CALIB soft key button, then press DIG OUTP CALIB soft key button..

Access I/O CALIB control screen: Press System Setup button, press the I/O CALIB soft key button, then press DIG OUTP CALIB soft key button..

B  Set DO PRE-E (Digital Output pre-emphasis status).

Set DO PRE-E (Digital Output pre-emphasis status).

See page 2-19 for an explanation of the the following options: [flat], [pre-emph], [J.17], or [J.17+pre-e].

13.Model 2200-D only: Enable Analog Inputs. (Refer to page 2-20.)

[Skip this step if you are not using the 2200-D’s analog inputs.]

A |

Access ANLG INP CALIB control |

|

CALIB soft key button, then press |

screen: Press System Setup button, press the I/O soft key button.

B Enable Analog Inputs.

14. Adjust analog left/right input peak clipping level. (Refer to page 2-20.)

[Skip this step if you are not using the 2200’s analog inputs.]

A  Press the meter button so that the L/R Channel Input meters are active.

Press the meter button so that the L/R Channel Input meters are active.

B  Access ANLG INP CALIB control screen: Press System Setup button, press I/O CALIB soft key button, then press ANLG INP CALIB.

Access ANLG INP CALIB control screen: Press System Setup button, press I/O CALIB soft key button, then press ANLG INP CALIB.

C  Set Analog Input Clip level.

Set Analog Input Clip level.

This step calibrates the level at which the 2200’s A-D (Analog-to-Digital) converter clips to the absolute maximum peak level that your installation supplies to the 2200’s analog input.

This setup maximizes the 2200’s signal-to-noise ratio. If the clip level is set too low, the 2200’s analog-to-digital converters will overload and

CS-4 QUICK SETUP |

OPTIMOD-FM 2200 |

distort on program peaks. If the clip level is set too high, the signal-to-noise ratio will suffer. Use care and attention in setting this adjustment.

a)Play program material from your studio at a much higher level than normal — turn the faders up all the way! This will produce the highest peak level output that your system can produce.

b)Adjust the 2200’s AI CLIP so that the program peaks just reach to − 3dB on the L/R Channel Input meters.

Hold down the button directly below the words “AI CLIP,” turn the control knob to scroll from +5.0dBu to +27.0dBu (or − 17.0dBu to + 5dBu, if input sensitivity jumpers were reset), then release the button.

Observe the L/R Channel Input meters on the 2200 for a long period of time; be sure to observe live announcer voice. If this setting is mis-adjusted, distortion will result.

0dB indicates input clipping on the 2200. These meters should never peak as high as 0dB with program material.

c)If you are using an Orban 4000A Transmission Limiter or Orban 8200ST OPTIMOD ahead of the 2200, activate the tone oscillator on

either unit. Then adjust the 2200’s AI PEAK so that the 2200’s L/R Channel Input meters reads − 3dB.

15.Calibrate analog inputs to your standard studio level. (Refer to page 2-22.)

[Skip this step if you are not using the 2200’s analog inputs.]

A |

Press the meter button so that the L/R Channel Input meters are active. |

B |

Access ANLG INP CALIB control screen: Press System Setup button, press I/O CALIB |

|

soft key button, then press ANLG INP CALIB. |

C |

Set Analog Input Reference level. |

This step calibrates the 2200 to the level to which your studio operators peak their program material on the studio meters. This assures that the 2200’s processing presets will operate in their preferred range.

If you are able to interrupt or distort programming, use a standard refer- ence/line-up level tone from your studio or play program material; this will achieve the most precise calibration. Adjust the appropriate 2200 reference level control (either AI REF VU or AI REF PPM) for an average of − 10dB on the Master Gain Reduction meter when audio is peaking at normal levels (e.g., 0VU).

If you cannot interrupt or distort programming, calibrate by numbers, adjusting the appropriate 2200 reference level control (either AI REF VU or AI REF PPM) to your studio’s reference level.

16. Model 2200-D only: Enable Digital Input. (Refer to page 2-23.)

[Skip this step if you are not using the digital input.]

OPTIMOD-FM 2200 |

CONDENSED SETUP CS-5 |

|

A |

Access DIG INP CALIB control screen: Press System Setup button, press the I/O CALIB |

|

|

soft key button, then press DIG INP CALIB. |

|

Note: If DIG STAT is no lock, then the AES/EBU digital input is not valid.

Check connections, cabling, and digital source.

B Enable Digital Input.

17. Calibrate Digital Input to your standard studio level. (Refer to page 2-22.)

[Skip this step if you do not have Model 2200-D or if you are not using the 2200-D’s digital input.]

A |

Press System Setup button, press the I/O CALIB soft key button, then press DIG INP |

|

CALIB. |

B |

Set Digital Input Reference level. |

This step calibrates the 2200 to the level to which your studio operators peak their program material on the studio meters. This assures that the 2200’s processing presets will operate in their preferred range.

If you are able to interrupt or distort programming, play program material; this will achieve the most precise calibration. Then adjust the appropriate 2200 reference level control (either DI REF VU or DI REF PPM) for an average of − 10dB on the AGC Gain Reduction meter when audio is peaking at normal levels (e.g., 0VU).

If you cannot interrupt or distort programming, calibrate by numbers, adjusting the appropriate 2200 reference level control (either DI REF VU or DI REF PPM) to your studio’s reference level. Note that the numbers you see represent dB below digital full-scale.

18. Adjust Composite Output level controls. (Refer to page 2-25.)

[Skip this step if you are not using the 2200’s composite outputs. These are the outputs of the 2200’s stereo encoder.]

A Feed the 2200 with program material or activate the built-in 400Hz TEST tone.

To turn on the TEST tone: Press System Setup button, press TEST soft key button, set TONE to 400Hz (hold down the TONE soft key button, turn the control knob to 400 Hz, then release the button), and activate 400Hz test tone (hold down the MODE soft key button, turn the control knob to scroll to tone, then release the button).

To turn off TEST tone, hold down the MODE tone soft key button, turn the control knob to scroll to operate, then release the button.

B  Adjust the 2200’s Comp 1 and Comp 2 level controls — screwdriver slots on the left side of the front panel — for 100% Total Peak Modulation of your FM exciter, as indicated on a modulation monitor, or modulation indicator on your exciter.

Adjust the 2200’s Comp 1 and Comp 2 level controls — screwdriver slots on the left side of the front panel — for 100% Total Peak Modulation of your FM exciter, as indicated on a modulation monitor, or modulation indicator on your exciter.

In the U.S., you can modulate higher than 100% when using SCAs. Refer to the appropriate FCC rules.

CS-6 QUICK SETUP |

OPTIMOD-FM 2200 |

19.Adjust Analog Left/Right or Digital Output level controls. (Refer to page 2-25.)

A

B

20.Select a preset that complements the program format of your station. (Refer to page 2-26.)

A Press Recall Preset button to access the Recall Preset screen, then select a preset.

21. Quick Setup Completed!

If you want to set up additional input/output parameters, or reset any setup adjustments, continue to “System Setup Controls,” starting on page 2-27. If you are ready to use the 2200, proceed to Section 3 for important 2200 operation information.

Operating Manual

OPTIMOD-FM 2200

Digital Audio Processor

Models 2200 and 2200-D

®

WARNING

This equipment generates, uses, and can radiate radio-frequency energy. If it is not installed and used as directed by this manual, it may cause interference to radio communication. This equipment complies with the limits for a Class A computing device, as specified by FCC Rules, Part 15, Subpart J, which are designed to provide reasonable protection against such interference when this type of equipment is operated in a commercial environment. Operation of this equipment in a residential area is likely to cause interference. If it does, the user will be required to eliminate the interference at the user’s expense.

WARNING

“This digital apparatus does not exceed the Class A limits for radio noise emissions from digital apparatus set out in the Radio Interference Regulations of the Canadian Department of Communications.” “Le present appareil numerique n’emet pas de bruits radioelectriques depassant les limites applicables aux appareils numeriques (de las class A) prescrites dans le Reglement sur le brouillage radioelectrique edicte par le ministere des Communications du Canada.”

IMPORTANT

Perform the installation under static control conditions. Simply walking across a rug can generate a static charge of 20,000 volts. This is the spark or shock you may have felt when touching a doorknob or some other conductive item. A much smaller static discharge is likely to completely destroy one or more of the CMOS semiconductors employed in OPTIMOD-FM. Static damage will not be covered under warranty.

There are many common sources of static. Most involve some type of friction between two dissimilar materials. Some examples are combing your hair, sliding across a seat cover or rolling a cart across the floor. Since the threshold of human perception for a static discharge is 3000 volts, many damaging discharges will not even be noticed.

Basic damage prevention consists of minimizing generation, discharging any accumulated static charge on your body or work station and preventing that discharge from being sent to or through an electronic component. A static grounding strap (grounded through a protective resistor) and a static safe workbench with a conductive surface should be used. This will prevent any buildup of damaging static.

The OPTIMOD-FM 2200 Digital Audio Processor is protected by U.S. patents 4,208,548; 4,249,042; 4,412,100; 4,460,871; 5,050,217; and U.K. patent 2,001,495. Other patents pending.

Orban is a registered trademark.

All trademarks are property of their respective companies.

This manual is part number 96079-000-04

Copyright 2000

1525 Alvarado Street, San Leandro, CA 94577 USA

Phone: (1) 510/351-3500; Fax: (1) 510/351-0500; E-mail: custserv@orban.com; Web: www.orban.com

Orban

OPTIMOD-FM 2200

Operating Manual

page contents

1-1 Section 1: Introduction

OPTIMOD-FM 2200 DIGITAL Audio Processor

Presets in the 2200

The Two-Band Structure

Protection Limiting: Orban’s Approach

Input/Output Configurations

Location of OPTIMOD-FM

About Transmission Levels and Metering

Line-Up Facilities

Warranty, Feedback

2-1 Section 2: Installation

Installation of 2200

Basic System Setup

System Setup Controls

3-1 Section 3: Operation

2200 Controls and Meters Introduction to Processing About the Processing Structures Factory Programming Presets

Customizing the 2200’s Two-Band Sound Two-Band Structures Processing Controls Details Customizing the Protection Limiter Structure Sound 2200 Screen Displays

Continued on next page

Orban

OPTIMOD-FM 2200

Operating Manual

page contents

4-1 Section 4: Maintenance

Routine Maintenance

Getting Inside the Chassis

In-System Testing (“Proof of Performance”)

Field Audit of Performance

Field Alignment

5-1 Section 5: Troubleshooting

Problems and Possible Causes

Troubleshooting IC Opamps

Technical Support

Factory Service

Shipping Instructions

6-1 Section 6: Technical Data

Specifications

Circuit Description

Parts List

Schematics, Assembly Drawings

Abbreviations

INDEX on next page

Index

!

4000 2-21 8200ST 2-21

A

abbreviations 6-51

AC line cord wire standard 2-7 AGC

defeating 3-13 AGC meter 2-16

analog input clip level 2-21, 2-29 analog input reference level 2-22, 2-28 analog input sensitivity 2-4

analog input termination 2-3 analog inputs 2-20, 2-22 assembly drawings 6-34 audible distortion 3-5, 5-2 audible noise 5-3

audio

connections 2-10 input 2-10, 6-2 output 2-11, 6-2

B balanced

inputs 2-10

output transformer 2-11 bass equalization 3-11 Bass meter 2-16

block diagram 6-35 buttons

Function 2-16 buzzes 5-2 bypass gain 2-36 bypass mode 2-35 bypass preset 1-10

C

cable 2-8, 2-10

cable shielding 2-10 - 2-11 chassis

getting inside 4-3 ground 2-12

circuit boards access to 4-3 front panel 4-3

circuit description 6-5 circuit ground 2-12 CIT25 0-2, 2-8 cleaning 4-2

clicks 5-2 clipping 3-5

common-mode rejection 2-10, 2-12 Comp 1 level control 3-4

Comp 2 level control 3-4 composite

isolation transformer 0-2, 2-8 metering 1-9

composite level control 2-16 composite level output 2-16 Composite meter 2-16, 3-4 composite output impedance 2-3 compression 3-5

computer interface 0-2

connectors audio 2-10

Constrast button 3-3 Contrast

control 2-15, 3-3 control knob 2-15, 3-3 controls 2-15, 3-3

Comp 1 3-4

Comp 2 3-4 Composite 1 2-16 Composite 2 2-16 Contrast 2-15, 3-3 Escape 2-15 Escape button 3-3

Modify Processing 2-16 System Setup 2-16

crosstalk test 2-33 customer service 5-7

D

D-connector 6-9 dBm (defined) 6-51 dBu (defined) 6-51 density 3-14

digital i/o 1-6

digital input 2-23, 2-30

digital input/output connectors 2-11 digital output 2-30

distortion 5-2 dull sound 5-4

E

EBS tones failure 5-5

enabling analog inputs 2-20 enabling digital input 2-23 Escape button 2-15, 3-3 exciter interface 2-13

F

factory service 5-8 field audit 4-16

final clipper drive 3-17

frequency response verification 4-16 front panel 2-15, 3-3

Function button 2-16, 3-4 Function meter 2-16, 3-4 fuse 2-7

G

gain reduction 3-14, 3-19 meters 3-4

Gain Reduction meters 2-16 gate compressor 3-13 Gated LED 2-16, 3-4

gating 3-13 - 3-14 grounding 2-12 - 2-13, 5-2

difficult situations 0-2, 2-8 ground loop 0-2, 2-8

H

harshness 5-4

HF Limiting 2-16, 3-4, 3-15 LEDs 2-16

high-frequency limiting 3-15

high-pass filter 3-11 protection structure 3-19

hum 5-2

I

impedance 2-10 - 2-11 input

balanced 2-10 impedance 2-10 level 2-10 overload point 2-10 sensitivity 2-4 termination 2-3 unbalanced 2-10

input level line-up 1-8

input level meters 1-9

input select A or D 2-28, 2-30 inspection of contents 0-1, 2-2 installation 2-1

internal clock 2-30 introduction 1-1

J jumpers

access to 4-3 analog I/O card 2-3 input sensitivity 2-4 options 2-3

L

L-R null 4-11 LEDs

Gated 2-16, 3-4

HF Limiting 2-16, 3-4 limiting 3-5

high-frequency 3-15 line voltage 2-7

line-up tones failure 5-4

location 2-8 location of 2200 1-7 digital input 2-30 loudness 3-5, 3-14

M

mainsub 2-33 maintenance, routine 4-2 Master meters 2-16 meters

AGC 2-16

Bass 2-16 Composite 2-16, 3-4 Function 2-16, 3-4 Gain Reduction 2-16 Master 2-16

PPM 2-22 - 2-23 studio 1-7

VU 2-22 - 2-23 Modify Processing

control 2-16 modulation

cannot control 5-2 modulation mode 2-33 mono

performance verification 4-8 mono left 2-33

mono right 2-33 mono sum 2-33

mono/stereo select 2-33

N

noise and distortion verification 4-16

O

operate mode 2-35 operation 3-1 ordering parts 6-23 output

impedance 2-11 level 2-11 unbalanced 2-11

output level meters 1-9 overshoot 5-2

P

packing for shipment 5-8 packing list 2-2

parts

list 6-22 ordering 6-23

peak control 3-16 peak modulation

cannot control 5-2 physical dimensions 6-4 pilot level 2-33

pilotoff 2-33 power 0-2, 2-7

cord 0-2, 2-6 - 2-7 requirements 6-4 PPM meter 2-22 - 2-23 pre-emphasis 2-30, 3-5

selection 2-18, 2-32, 2-35 - 2-36 problems 5-2

processing structures 3-7 remote control 2-34 programming presets 3-7 proof of performance 4-7 protection limiter structure

high-pass filter 3-19

R

rack-mounting unit 2-8 rear panel

connections 2-6 digital input 2-30 registration card 1-10 remote control 0-2, 2-9 return authorization 5-8 RF suppression 5-2 RFI 2-7, 2-13

filter 2-7 rotary encoder

control knob 2-15 controls 3-3

S

digital output 2-31 schematics 6-34 screen

contrast 3-3 display 3-3 saver 3-3

screen displays 2-15 screen saver 2-15 screens

Constrast button 2-15 presets 2-26

selecting a preset 2-26 service 5-8

setup

expanded 2-27 system 2-17

shipping

damage 0-1, 2-2 instructions 5-8

shrillness 5-4

soft keys 2-15, 3-3 specifications 6-2

spectral gain intermodulation 1-5 stereo

interference 5-5 performance verification 4-10

stereo modulation 2-33 stereo/mono select 2-33 structures

two-band 1-4 submain 2-33 subcarrier input 2-12 digital output 2-31

System Setup 2-16 - 2-17, 3-4

T

technical support 5-7 temperature 2-8

test mode 2-35 test tone 2-36 tone 2-36

tone generator internal 1-10

tone mode 2-35 troubleshooting 5-1

IC opamps 5-7 two-band structure

bass eq 3-11 setup 3-13

two-band structures 1-4

gating 3-13

high-frequency limiting 3-15 high-pass filter 3-11 loudness, density 3-14 peak control 3-16

setup 1-4

spectral balance 3-15

U unbalanced

input 2-10 load 2-11

user tone preset 1-10

V

VU meter 2-22 - 2-23

W

warranty 6-4 whistle, on air 5-4

X

XLR connectors 1-6, 2-10

OPTIMOD-FM 2200 |

INTRODUCTION 1-1 |

Section 1

Introduction

page contents

1-3 OPTIMOD-FM 2200 DIGITAL Audio Processor

1-4 Presets in the 2200

1-4 The Two-Band Structure

1-5 Protection Limiting: Orban’s Approach

1-6 Input/Output Configurations

1-7 Location of OPTIMOD-FM

1-7 About Transmission Levels and Metering

1-8 Figure 1-1: Absolute Peak Level, VU and PPM Reading

1-9 Line-Up Facilities

1-10 Warranty, Feedback

1-2 INTRODUCTION |

OPTIMOD-FM 2200 |

OPTIMOD-FM 2200 |

INTRODUCTION 1-3 |

OPTIMOD-FM 2200 DIGITAL Audio Processor

Orban’s OPTIMOD-FM 2200 DIGITAL Audio Processor is a complete audio processing system for FM broadcast. Model 2200 is configured for analog inputs and outputs. Model 2200-D also includes digital inputs and outputs. Features for all versions include:

•Universal transmitter protection and audio processing for FM broadcast. The 2200 can be configured to interface ideally with any commonly-found transmission system in the world.

•User-friendly Interface: A simple liquid-crystal display (LCD) makes setup, adjustment and programming easy. Front panel bargraphs show metering functions of the processing preset in use. Push one of the clearly labeled soft keys to RECALL a preset, to MODIFY PROCESSING, or to access SYSTEM SETUP controls.

•8 factory-programmed presets, based on Orban’s Two-Band and Protection/Limiting Processing Structures. These presets can be modified and saved.

•8 user presets to store customized settings.

•Pre-emphasis limiting for the internationally-used pre-emphasis curves of 50 s and 75 s. The pre-emphasis control is almost never audibly apparent, producing a clean, open sound with subjective brightness matching the original program.

•Extremely tight peak control; overshoot is limited to ± 0.3dB!

•DSP-based stereo encoder (stereo generator) produces a circuit with excellent specs, high stability, and uncompromising baseband spectrum control.

•Remote-control, via optically-isolated terminals that can be operated with contact closures (to facilitate interfacing to older-technology remote controls).

•Built-in line-up tone generator facilitating quick and accurate level setting in any system and a Bessel Null tone for calibrating modulation.

1-4 INTRODUCTION |

OPTIMOD-FM 2200 |

Presets in the 2200

There are two distinct kinds of presets in the 2200: Factory Processing Presets and User Presets.

The 8 Factory Processing Presets include a protection/limiting preset, a two-band general purpose preset, and 6 other presets derived from the two-band structure. All of the factory processing presets are stored in the 2200’s non-volatile memory, and cannot be erased. You can change the settings of a Factory Processing Preset, but you must then store those settings as a User Preset. The factory preset remains unchanged. You may store your new settings in one of the 8 numbered User Presets.

User Presets cannot be created from “scratch.” You must always start by recalling a Factory Preset, make changes, then store the changes in a User Preset.

The Two-Band Structure

The Two-Band Structure consists of a slow single-band gated AGC (Automatic Gain Control) for gain riding, followed by a gated two-band compressor and a high-frequency limiter. A two-band equalizer is available before the input of the Two-Band structure.

The Two-Band Structure is an improved version of Orban’s classic 8100A OPTIMODFM, but with increased high frequency clarity. (This is the same structure used in our OPTIMOD-FM 8200.) It is operated after a phase rotator (time-dispersion filter) to improve its loudness capability by making positive and negative peaks more symmetrical, particularly with voice.

The Two-Band Structure has an open, easy-to-listen-to sound that is similar to the source material if the source material is of good quality. However, if the spectral balance between the bass and high-frequency energy of the program material is incorrect, the Two-Band Structure (when its bass coupling control — BASS COUPL — is operated toward 0%) can gently correct it without introducing obvious coloration.

Two-Band Presets

The Two-Band Factory Programming Presets are designed to help you get on the air quickly. In most cases, they will suit your needs without the need for further adjustment. Or, if you desire, you can always experiment with the LESS-MORE control to fine-tune the processing to your taste.

The basic Two-Band preset, 2B General Purpose, provides an average amount of processing. The other Two-Band presets provide a sound tailored for a specific program format. For example, Music-Light produces a very open, unprocessed sound while Music+Bass Medium provides a very punchy, clean, open sound. Presets include: 2B GENERAL PURPOSE,

TALK, MUSIC-LIGHT, MUSIC-MEDIUM, MUSIC HEAVY, MUSIC+ BASS MEDIUM and MUSIC+ BASS HEAVY.

OPTIMOD-FM 2200 |

INTRODUCTION 1-5 |

Using the Two-Band Structure for Classical Music

Classical music is traditionally broadcast with a wide dynamic range. However, with many recordings and live performances, the dynamic range is so great that the quiet passages disappear into the noise on most car, portable, and table radios. As a result, the listener either hears nothing, or must turn up the volume control to hear all the music. Then, when the music gets loud, the radio blasts and distorts, making the listening rather unpleasant.

The Two-Band Structure is well-suited for classical formats during daytime hours when most people in the audience are likely to be listening in autos or to be using the station for background music. This audience is best served when the dynamic range of the program material is compressed 10-15dB so that quiet passages in the music never fade into inaudibility under these less-favorable listening conditions. OPTIMOD-FM controls the level of the music in ways that are, for all practical purposes, inaudible to the listener. Low-level passages are increased in level by up to 10dB, while the dynamics of crescendos are maintained.

The same station may wish to switch to the Protection Structure during the evening hours when the audience is more likely to listen critically.

Protection Limiting: Orban’s Approach

The Protection Limiter Structure is designed for stations wanting the highest possible fidelity to the source, such as a station broadcasting concert music at night when it’s audience is likely to listen in a more critical manner. While the Protection Limiter Structure can readily reduce the dynamic range, it is designed to do so without increasing program density, loudness, or the consistency of sound from different sources. It’s primary function is to protect the transmitter from over-deviation while preserving the spectral and textured quality of the source material.

The 2200 has one Protection Limiter factory preset , named CLASSICAL PROTECT.

Traditionally, protection limiters have used peak-sensing automatic gain control (AGC) processors to control peak levels. This approach ignores one crucial requirement for protection limiter performance: the limiter must provide natural-sounding control that is undetectable to the ear except by an A/B comparison to the original source material. To achieve natural sound quality, the gain control section of the limiter must respond like the ear. This means that the gain control must respond approximately to the power (not the peak level) in the signal. Further, because the sensitivity of the ear decreases dramatically below 150Hz, the control must be frequency-weighted to compensate. Otherwise, heavy bass would audibly modulate the loudness of midrange program material, a problem called spectral gain intermodulation.

1-6 INTRODUCTION |

OPTIMOD-FM 2200 |

Input/Output Configurations

The OPTIMOD-FM 2200 DIGITAL is designed to simultaneously accommodate:

•

•

•

analog left/right inputs and outputs

Digital AES/EBU left/right inputs and outputs (Model 2200-D only)

stereo analog baseband composite output

Analog Left/Right Input/Output

The left and right analog inputs are on XLR-type female connectors on the rear panel. Input impedance is greater than 10kΩ ; balanced and floating. Inputs can accommodate up to +27dBu (0dBu = 0.775Vrms). The left and right analog outputs are on XLR-type male connectors on the rear panel. Output impedance is 30Ω ; balanced and floating. Outputs can drive up to +20dBm into 600Ω .

Level control of the analog inputs and outputs is via software control through SYSTEM SETUP. (See page 2-20 and 2-6.)

Digital AES/EBU Left/Right Input/Output (Model 2200-D only)

The digital input and output follow the professional AES/EBU standard. The left/right digital input is on one XLR-type female connector on the rear panel; the left/right digital output is on one XLR-type male connector on the rear panel.

The 2200-D is designed to simultaneously accommodate digital and analog inputs and outputs. You select whether the 2200-D uses the digital or the analog input via software control through System Setup (DIG INP CALIB or ANLG INP CALIB screen), or by remote interface. Both analog and digital outputs are active continuously. Level control of the AES/EBU input is via software control through System Setup.

The 2200-D’s digital I/O operates at a 32kHz, 44.1kHz, or 48kHz sample rate. Its output can be flat, pre-emphasized (to the 50µ s or 75µ s curve selected for the processing), J.17 pre-emphasized, or J.17 plus 50µ s or 75µ s pre-emphasized.

Please note that the AES/EBU standard is not the same as the S/P-DIF (Sony/Philips Digital Interface) standard used in consumer digital applications, such as the “digital outputs” of CD players. The AES/EBU interface will not work with S/P-DIF signals.

A 2200 cannot be upgraded to a 2200-D.

Stereo Analog Baseband Composite Output

The stereo encoder has two unbalanced analog baseband outputs on two BNC connectors on the rear panel. Each output can be strapped for 0Ω or 75Ω source impedance, and can drive up to 8V peak-to-peak into 75Ω in parallel with up to 0.047 F (100ft/30m of RG-59/U cable) before any noticeable performance degradation occurs.

OPTIMOD-FM 2200 |

INTRODUCTION 1-7 |

Level control of each output is via a separate screwdriver control accessible from the front panel.

A ground lift switch is available on the rear panel. This is useful to prevent ground loops between the 2200 and the transmitter.

Location of OPTIMOD-FM

Best Location for OPTIMOD-FM

The best location for OPTIMOD-FM is as close as possible to the transmitter, so that its stereo encoder output can be connected to the transmitter through a circuit path that introduces the least possible change in the shape of OPTIMOD-FM’s carefully peak-limited waveform — a short length of coaxial cable.

We very strongly recommend that you use the 2200’s internal stereo encoder and feed its output directly to the baseband input of the exciter through less than 100 feet (30 meters) of coaxial cable. You will achieve a louder sound on the air, with better control of peak modulation, than if you use an external stereo encoder.

About Transmission Levels and Metering

Meters

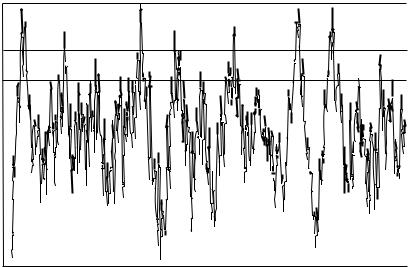

Studio engineers and transmission engineers consider audio levels and their measurements differently, so they typically use different methods of metering to monitor these levels.

The VU meter is an average-responding meter (measuring the approximate RMS level) with a 300ms rise time and decay time; the VU indication usually under-indicates the true peak level by 8 to 14dB.

The Peak Program Meter (PPM) indicates a level between RMS and the actual peak. The PPM has an attack time of 10ms, slow enough to cause the meter to ignore narrow peaks and under-indicate the true peak level by 5dB or more.

The absolute peak-sensing meter or LED indicator shows the true peak level. It has an instantaneous attack time, and a release time slow enough to allow the engineer to easily read the peak level.

Figure 1-1 shows the relative difference between the absolute peak level, and the indications of a VU meter and a PPM.

1-8 INTRODUCTION |

OPTIMOD-FM 2200 |

ABSOLUTE PEAK

PPM

VU

Figure 1-1: Absolute Peak Level, VU and PPM Reading

For a Few Seconds of Music Program

Studio Line-up Levels and Headroom

The studio engineer is primarily concerned with calibrating the equipment to provide the required input level for proper operation of each device, and so that all devices operate with the same input and output levels. This facilitates patching devices in and out without recalibration. For line-up, the studio engineer uses a calibration tone at a studio standard level, commonly called line-up level, reference level, or operating level.

Metering at the studio is by a VU meter or PPM (Peak Program Meter). As discussed above, the VU or PPM indication lags the true peak level. Most modern studio audio devices have a clipping level of no less than +21dBu, and often +24dBu or more. So the studio standardizes on a maximum program indication on the meter that is lower than the clipping level, so that peaks that the meter doesn’t indicate will not be clipped. Line-up level is usually at this same maximum meter indication.

In facilities that use VU meters, this level is usually at 0VU, which corresponds to the studio standard level, typically +4 or +8dBu. For facilities using +4dBu standard level, instantaneous peaks can reach +18dBu or higher (particularly if the operator overdrives the console or desk). Older facilities with +8dBu standard level and equipment that clips at +18 or +21dBu will experience noticeable clipping on some program material.

In facilities that use the BBC-standard PPM, maximum program level is usually PPM4 for music, PPM6 for speech. Line-up level is usually PPM4, which corresponds to +4dBu. Instantaneous peaks will reach +17dBu or more on voice.

In facilities that use PPMs that indicate level directly in dBu, maximum program and line-up level is often +6dBu. Instantaneous peaks will reach +11dBu or more.

OPTIMOD-FM 2200 |

INTRODUCTION 1-9 |

Transmission Levels

The transmission engineer is primarily concerned with the peak level of a program to prevent overloading or over-modulation of the transmission system. This peak overload level is defined differently, system to system. In FM modulation (FM/VHF radio and television broadcast, microwave or analog satellite links), it is the maximum-permitted RF carrier frequency deviation. In AM modulation, it is negative carrier pinch-off. In analog telephone/post/PTT transmission, it is the level above which serious crosstalk into other channels occurs, or the level at which the amplifiers in the channel overload. In digital, it is the largest possible digital word.

For metering, the transmission engineer uses an oscilloscope, absolute peak-sensing meter, calibrated peak-sensing LED indicator, or a modulation meter. A modulation meter usually has two components — a semi-peak reading meter (like a PPM), and a peak-indicating light which is calibrated to turn on whenever the instantaneous peak modulation exceeds the over-modulation threshold.

Line-Up Facilities

Metering of Levels

The 2200’s front panel metering includes bargraphs displaying the following I/O levels: L/R Input, L/R Output and Composite Output.

L/R Input Level

Left and right input level is shown on a VU-type scale (0dB to − 27dB), while the metering indicates absolute instantaneous peak (much faster than a standard PPM or VU meter). 0dB indicates A/D converter clipping (analog input) or digital full-scale (digital input, 2200-D only).

Left/Right Output Level

Left and right output level is shown on a VU-type scale (0dB to − 27dB), where the metering indicates absolute instantaneous peak (much faster than a standard PPM or VU meter).

The meter is scaled so that 0dB is calibrated to the highest left and right peak modulation level, before de-emphasis, that the processing will produce, under any program, processing, or setup condition (except when the processing is switched to bypass). The meter indication is not affected by the setting of the analog or digital output level control.

Composite Output Level

The Orban 2200 Audio Processor controls instantaneous, absolute peak levels to a tolerance of approximately ± 0.3dB. Composite modulation is indicated in % modulation, absolute instantaneous peak indicating. 100% is calibrated to the highest composite peak modulation level that the processing will produce, including the pilot tone, under any program, processing, or setup condition (except when the processing is switched to bypass). 100% ordinarily corresponds to ± 75kHz carrier deviation.

1-10 INTRODUCTION |

OPTIMOD-FM 2200 |

Built-in Calibrated Line-up Tones

To facilitate matching the output level of the 2200 to the transmission system that it is driving, the 2200 contains an adjustable tone that produces sine waves at 2200’s analog, digital and composite outputs. The frequency of the line-up tones can be adjusted from the front panel. The modulation is always 100%.

When the 2200’s left/right analog output is switched to flat, a de-emphasis filter is inserted between the output of the 2200’s audio processing and its line output. Thus, as the frequency of the tone preset is changed, the level at the 2200’s line output will follow the selected de-emphasis curve.

In most cases the pre-emphasis filter in the driven equipment will undo the effect of the 2200’s internal de-emphasis, and the 2200’s output level should be adjusted so that the tone produces 100% modulation of the transmission link as measured after the link’s pre-empha- sis filter. At 100Hz, switching the de-emphasis out or in will have negligible effect on the level appearing at the 2200’s left and right audio outputs.

Built-in Calibrated Bypass

Bypass is available to transparently pass line-up tones generated earlier in the system. It will also pass program material, with no gain reduction or protection against overmodulation. It can transparently pass any line-up tone applied to its input up to about 130% output modulation, at which point clipping may occur. Access bypass in the System Setup TEST MODE screen.

Note that BYPASS applies 50 s or 75 s pre-emphasis, as determined by the setting of PROC PRE-E, in the System Setup STEREO ENCODER screen.

Warranty, Feedback

Warranty

The warranty, which can be enjoyed only by the first end-user of record, is located on the inside back cover of this manual. Save it for future reference. Details on obtaining factory service are provided on page 5-9.

User Feedback Form

We are very interested in your comments about this product. Your suggestions for improvements to either the product or the manual will be carefully reviewed. A postpaid User Feedback Form is provided in the back of this manual for your convenience. If it is missing, please write us at the address printed in the front of the manual, or call or fax our offices at the number listed. We will be happy to hear from you.

OPTIMOD-FM 2200 |

INSTALLATION 2-1 |

Section 2

Installation

page contents

2-2 |

Installation of 2200 |

2-7 |

Figure 2-1: AC Line Cord Wire Standard |

2-9 |

Figure 2-2: Wiring the 25-pin Remote Control Connector |

2-17 |

Basic System Setup |

2-27 |

System Setup Controls |

2-27 |

I/O CALIB (I/O Calibration) |

2-32 |

Stereo Encoder (and processing Pre-Emphasis) |

2-34 |

Remote Interface |

2-35 |

TEST Mode |

CAUTION

The installation and servicing instructions in this manual are for use by qualified personnel only. To avoid electric shock, do not perform any servicing other than that contained in the Operating Instructions unless you are qualified to do so. Refer all servicing to qualified service personnel.

2-2 INSTALLATION |

OPTIMOD-FM 2200 |

Installation of 2200

Allow about 2 hours for installation.

Installation consists of: (1) unpacking and inspecting the 2200, (2) optional resetting of jumpers for 2200 options (composite output impedance, input termination, input sensitivity), (3) checking the line voltage setting, fuses and power cord, (4) mounting the 2200 in a rack, (5) connecting inputs, outputs and power, (6) setting the switch, (7) and optional connecting of remote control leads.

When you have finished installing the 2200, proceed to “System Setup,” on page 2-16.

1. Unpack and inspect.

A  If you note obvious physical damage, contact the carrier immediately to make a damage claim. Packed with the 2200 are:

If you note obvious physical damage, contact the carrier immediately to make a damage claim. Packed with the 2200 are:

1Operating Manual

1Quick Setup Guide

1Line Cord

21⁄2A Replacement Fuses for “U” and “J” Versions

2250mA Replacement Fuses for “E” Version

1Orban green screwdriver (Xcelite R3323)

1Booklet: Audio Quality in the FM Plant

B

C

Save all packing materials! If you should ever have to ship the 2200 (e.g., for servicing), it is best to ship it in the original carton with its packing materials because both the carton and packing material have been carefully designed to protect the unit.

Complete the Registration Card and return it to Orban. |

(please) |

The Registration Card enables us to inform you of new applications, performance improvements, and service aids that may be developed, and it helps us respond promptly to claims under warranty without our having to request a copy of your bill of sale or other proof of purchase. Please fill in the Registration Card and send it to us today. (The Registration Card is located after the cover page).

We do not sell or give away our customer’s names to anyone.

OPTIMOD-FM 2200 |

INSTALLATION 2-3 |

2.Change standard factory configuration, if required.

[Skip this step if your installation does not have any special requirements.]

The 2200 is supplied from the factory with its jumpers set to the configuration correct for most installations.

|

Stereo Encoder Composite Output Impedance |

0Ω |

|

|

Input Impedance |

|

10kΩ |

|

Input Sensitivity |

− 10dBu or greater (+5dBu to +27dBu peak) |

|

A |

To change any jumpers you must remove the top cover of the 2200 to access the main |

||

|

circuit board. (Make sure power is not connected.) Remove all screws holding the |

||

|

cover in place, then lift it off. (Be careful not to strip threads when opening the |

||

|

cover.) |

|

|

B |

Refer to Figure 2-1 to find the jumpers on the main circuit board and to position them |

||

|

according to your application. |

|

|

The following information is provided to explain each jumper and its settings in detail.

• Stereo encoder composite output impedance.

[Do not change the default 0Ω jumper setting unless your installation needs 75Ω source impedance.]

The stereo encoder is shipped from the factory with 0Ω source impedance. This is correct for virtually all installations. However, the 2200 stereo encoder can be changed to 75Ω source impedance if desired.

The frequencies in the stereo baseband are low by comparison to RF or video, and the characteristic impedance of coaxial cable is not 75Ω at lower frequencies, so the transmission system will have more accurate amplitude and phase response (and thus, better stereo separation) if the cable is driven by a very low source impedance (0Ω ) and is terminated with greater than 1kΩ at the exciter.

However, a few broadcast organizations require that FM composite be transmitted in impedance-matched coaxial cable with 75Ω source and load impedances.

To change the source impedance of one or both of the composite outputs:

To change the source impedance of composite output #1, move jumper JA to the “75Ω ” position (Fig 2-1). To change the source impedance of composite output #2, move jumper JB to the “75Ω ” position (Fig 2-1).

• Analog left/right input termination.

[Do not change the default setting unless your installation requires 600Ω termination on the analog left/right inputs.]

The analog left/right inputs are shipped from the factory with balanced bridging (10kΩ ) input impedance. However, the 2200 analog inputs can be changed to 600Ω input impedance.

Loading...

Loading...