Page 1

Operating Manual

OPTIMOD-FM

2200

Digital Audio Processor

Models 2200 and 2200-D

®

Page 2

IMPORTANT NOTE: Refer to the unit’s rear panel for your Model #.

Model Number: Description:

2200-D/U OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, Digital I/O,

Protection Structure, Two-Band Structure,

set to 115V (for 98-130V operation), switchable to 50µs or 75µs.

2200-D/E OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, Digital I/O,

Protection Structure, Two-Band Structure,

set to 230V (for 196-264V operation), switchable to 50µs or 75µs.

2200-D/J OPTIMOD-FM 2200 DIGITAL, Stereo Encoder, Digital I/O,

Protection Structure, Two-Band Structure,

set to 100V (for 89-120V operation), switchable to 50µs or 75µs.

2200/U OPTIMOD-FM 2200 DIGITAL, Stereo Encoder,

Protection Structure, Two-Band Structure,

set to 115V (for 98-130V operation), switchable to 50µs or 75µs.

2200/E OPTIMOD-FM 2200 DIGITAL, Stereo Encoder,

Protection Structure, Two-Band Structure,

set to 230V (for 196-264V operation), switchable to 50µs or 75µs.

2200/J OPTIMOD-FM 2200 DIGITAL, Stereo Encoder,

Protection Structure, Two-Band Structure,

set to 100V (for 89-120V operation), switchable to 50µs or 75µs.

MANUAL:

Part Number: Description:

96079-000-04 2200/2200-D Manual

CAUTION: TO REDUCE THE RI S K OF ELECTRICAL SHOCK, DO NOT REMOVE COVER (OR BACK ).

NO USER SERV ICEABLE PA RTS INSIDE. REFER SE RVICING TO QUALIFI E D S E RVICE PERSONNEL.

WARNING: TO REDUCE THE RISK OF FIRE O R E LE CTRI CAL SHOCK,

DO NOT EXPOSE THIS APPLIANCE TO RAIN OR MOISTURE.

This symbol, wherever it appears, This symbol, wherever it appears,

alerts you to the presence of uninsul at e d alerts you to important operating and

dangerous voltage inside the enc los ure — volt age maintenance instruc tions i n the ac company i n g

that may be suff icient to constitute a risk of s hock. literature. Read the manual.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

All the safety and operating inst ruc tions shoul d be read bef ore t he applianc e is operated.

Retain Instructions: The saf ety and operati on ins truc t i ons should be ret ai ned for f uture ref erenc e.

Heed Warnings: All warnings on the appliance and in the operat i ng inst ruc ti ons should be adhered to.

Follow Instructions: All operation and user instructions should be foll owed.

Water and Moisture: The appliance should not be used near water (e.g., near a batht ub, was hbowl, kitc hen si nk , laundry tub, in a wet

basement, or near a swimming pool, etc .).

Ventilation: The appliance s hould be situated s o that its locat ion or posit ion does not int erfere wit h its proper ventilat ion. For example, the

appliance should not be situated on a bed, sofa, rug, or similar surface that may block the ventilation openings; or, placed in a built-in

installation, suc h as a book cas e or cabinet that m ay im pede the f low of air t hrough the v ent il at ion openi ngs.

Heat: The appliance should be situated away from heat sources such as radiators, heat registers, stoves, or other appliances (including

amplifiers) that produce heat .

Power Sources: The appliance should be connected to a power supply only of the type described in the operating instructions or as

marked on the appliance.

Grounding or Polarization: Precautions should be taken so that t he grounding or polarizati on means of an appliance is not defeat ed.

Power-Cord Protection: Power-supply cords should be routed so that they are not likely to be walked on or pinched by items placed

upon or against them, paying particular attent ion to cords at plugs, convenienc e receptacles, and the point where they exit from the appli ance.

Cleaning: The appliance should be cleaned onl y as recomm ended by the manuf ac t urer.

Non-Use Periods: The power cord of the appliance shoul d be unplugged from the out let when l eft unused f or a long peri od of time.

Object and Liquid Entry: Care should be taken so that objects do not fall and liquids are not spilled into the enclosure through

openings.

Damage Requiring Service: The appliance should be serv ic ed by quali f ied serv i ce pers onnel when:

The power supply cord or the plug has been damaged; or

Objects have fall en, or li quid has been s pi ll ed into the appliance; or

The appliance has been expos ed t o rai n; or

The appliance does not appear to operate normally or exhibi t s a mark ed change i n perf ormance; o r

The appliance has been dropped, or t he enclosure damaged.

Servicing: The user should not attempt to service the appliance beyond that described in the operating instructions. All other servicing

should be referred to qualified service pers onnel.

The Appliance should be used only with a cart or stand that is recommended by the manufacturer.

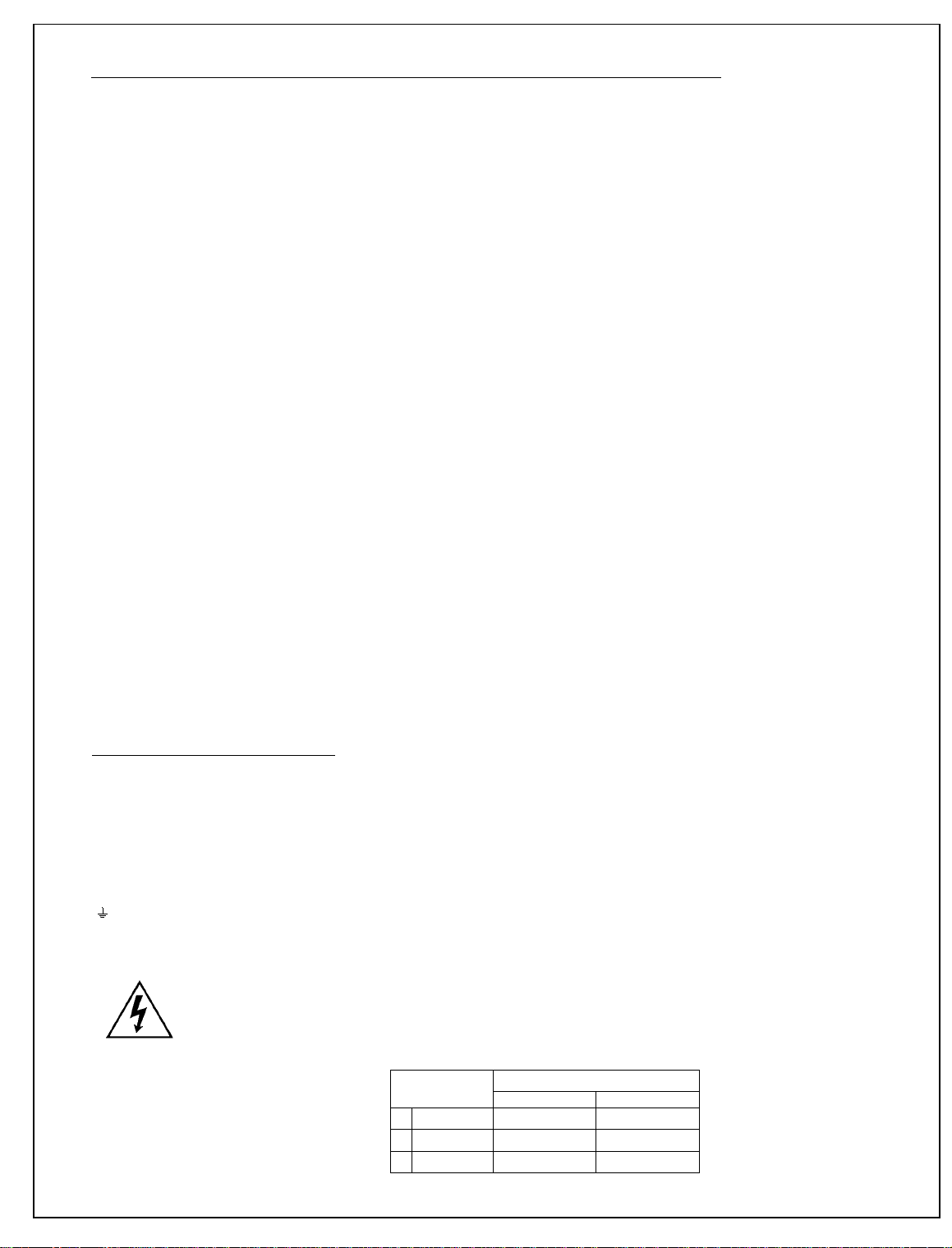

Safety Instructions ( European)

Notice For U.K. Customers If Your Unit Is Equipped With A Power Cord.

WARNING: THIS APPL IANCE MUST BE EARTHED.

The cores in the mains lead are coloured in accordanc e wi t h the f oll owing code:

As colours of the cores in the mai ns lead of thi s applianc e may not corres pond wi th the c oloured m ark ings i dent ify ing t he t ermi nals in your

plug, proceed as follows :

The core which is coloured green and yellow must be connec t ed to t he term inal in the pl ug mark ed wi t h the let ter E , or wit h the eart h sy mbol ,

( ), or coloured green, or green and yellow.

The core which is coloured blue must be connect ed to t he termi nal m ark ed N or coloured bl ack .

The core which is coloured brown must be connected t o the t erm inal mark ed L or coloured red.

GREEN and YELLOW - Eart h BLUE - Neutral BROWN - Live

The power cord is terminated in a CEE7/7 plug (Continental Europe). The green/yellow wi re i s connected direc tl y to the unit’s c h assis. If

you need to change the plug and if you are qualified to do so, refer to the ta ble below.

WARNING: If the ground is defeated, ce rtain f ault conditions in the unit or in the system to which it is conne cted ca n result in full line

voltage between chassis and eart h ground. Severe i njury or death can then resul t if the chassis and earth ground are touched simultaneously.

CONDUCTOR

L LIVE BROWN BLACK

NEUTRAL BLUE WHITE

N

EARTH GND GREEN-YELLOW GREEN

E

WIRE COLOR

Normal Alt

AC Power Cord Color Coding

Page 4

Safety Instruct ions ( German)

Gerät nur an der am Leistungsschild verm erk t en Spannung und S tromart bet rei ben.

Sicherungen nur durch solche, gleicher S troms t ärk e und gl eic hen Abs chal t verhalt ens ers et zen. Si cherungen nie überbrücken.

Jedwede Beschädigung des Netzkabels vermeiden. Netzkabel nicht knicken oder quetschen. Beim Abziehen des Netzkabels den

Stecker und nicht das Kabel enf as sen. Beschädigte Netzkabel sofort auswechseln.

Gerät und Netzkabel keinen übert riebenen mec hanis chen B eas pruchungen aus s etz en.

Um Berührung gefährlicher elektris cher Spannungen zu vermei den, darf das G erät nicht geöffnet werden. Im Fall von Betriebsstörun-

gen darf das Gerät nur Von befugten Servicestellen instandgesetzt werden. Im Gerät befinden sich keine, durch den Benutzer

reparierbare Teile.

Zur Vermeidung von elektrischen Schlägen und Feuer ist das Gerät vor Nässe zu schützen. Eindringen von Feuchtigkeit und

Flüssigkeiten in das G erät vermeiden.

Bei Betriebsstörungen bzw. nach Eindringen von Flüssigkeiten oder anderen G egenständen, das Gerät sofort vom Netz trennen und

eine qualifizierte Servi ces t elle k ont ak tieren.

Safety Instruct ions (Fr ench)

On s’assurera toujours que la tension et l a nature du c ourant util isé corres pondent bien à ceux indiqués sur la pl aque de l’appareil.

N’utiliser que des fus ibles de même int ensit é et du même princ ipe de mise hors circui t que les fusibles d’origine. Ne jamais shunter les

fusibles.

Eviter tout ce qui risque d’endommager le câble sec eur. On ne devra ni le plier, ni l’aplatir. Lorsqu’on débranche l’appareil, tirer la fiche

et non le cäble. Si un cäble est endommagé, le rem plac er i mmédiatement.

Ne jamais exposer l’apparei l ou le cäble ä une contrainte mécanique excessive.

Pour éviter tout contact averc une tension électrique dangereuse, on n’oouvrira jamais l’appareil. En cas de dysfonctionnement,

l’appareil ne peut être réparé que dans un at eli er aut oris é. Aucun élément de cet appareil ne peut être réparé par l’utilisateur.

Pour éviter les risques de décharge électrique et d’incendie, protéger l’appareil de l’humidité. Eviter toute pénétration d’humidité ou fr

liquide dans l’appareil.

En cas de dysfonctionnement ou si un liquide ou tout autre objet a pénétré dans l’appareil couper aus sitôt l’appareil de son aliment ation

et s’adresser à un point de serv ice aprés v ent e aut ori sé.

Safety Instructions ( Spanish)

Hacer funcionar el aparato sólo con l a tens ión y clas e de c orriente s eñaladas en la placa indicadora de características.

Reemplazar los fusibles sólo por otros de la misma intens idad de corrient e y sist ema de des conexi ón. No poner nunc a l os f usi bles en

puente.

Proteger el cable de alimentación contra toda clase de daños. No doblar o apretar el cable. Al desenchufar, asir el enchufe y no el

cable. Sustituir inmedi at ament e cabl es dañados.

No someter el aparato y el cable de aliment ac i ón a esfuerzo mecánico excesivo.

Para evitar el contacto con tens iones eléctric as peligrosas, el aparato no debe abrirse. En caso de produc irse fallos de funcionami ento,

debe ser reparado sólo por talleres de servicio autori zados. En el aparato no se enc uentra ninguna pieza que pudiera ser reparada por

el usuario.

Para evitar descargas eléc t ri cas e inc endi os, el aparat o debe prot egers e cont ra l a humedad, impidi endo que penet ren ésta o líquidos

en el mismo.

En caso de producirse fallas de funcionamiento como consecuencia de la penetración de líquidos u otros objetos en el aparato, hay

que desconectarlo inmediat ament e de la red y ponerse en c ont ac to con un t all er de serv ic io a utoriz ado.

Safety Instructions (Italian)

Far funzionare l’apparecchio sol o con la tens i one e il tipo di corrent e indi cat i sul la targa ri port ant e i dat i sull e pres t az ioni.

Sostituire i dispositi vi di protezione (v alvole, fusibil i ecc.) sol o con disposi tivi av enti lo stes so amperaggio e lo stesso co mportamento di

interruzione. Non cavallot t are mai i dis pos iti vi di protez ione.

Evitare qualsiasi danno al cavo di collegamento all a rete. Non piegare o schiac ci are il cavo. Per stac c are il cavo, tirare l a pres a e mai

il cavo. Sostituire s ubito i cavi danneggiati.

Non esporre l’apparecchio e il cavo ad esagerate s ol lec it az ioni mecc ani che.

Per evitare il contatto con le tensioni elettriche pericolose, l’apparecchio non deve venir aperto. In caso di anomal ie di funz ionam ent o

l’apparecchio deve venir ri parato solo da c entri di serv izio autorizz ati. Nell’apparec chio non si trovano parti che possano essere riparate

dall’utente.

Per evitare scosse elet tric he o i nc endi, l’apparecchio va protetto dall’umidità. E v itare c he umidità o liquidi entrino nell’apparecchio.

In caso di anomalie di funzionamento rispettivamente dopo la penetrazione di liquidi o oggetti nell’apparecchio, staccare immedi-

atamente l’apparecchi o dalla ret e e c ont at tare un c ent ro di serv i z io qual ifi cat o.

Page 5

®

PLEASE READ THIS FIRST!

Manual

The Operating Manual contains inst ruc ti ons to verif y the proper operat i on of this unit and init ial izat i on of cert ain opt ions .

You will find these operations are most conv enient ly performed on t he benc h bef ore you i ns tall the unit i n the rac k.

Please review the Manual, es pec ial ly the i ns tall at ion s ect i on, before unpac k ing the uni t .

Trial Period Precautions

If your unit has been provided on a trial bas is:

You should observe the following precaut ions to av oi d rec ondit i oning charges i n case y ou later wi s h to ret urn the unit to

your dealer.

Note the packing technique and sav e all pack ing mat erial s. It is not wi se to s hip in ot her t han t he fac tory cart on. (Replac e-

ments cost $35.00).

(1) Avoid scratching t he paint or plat i ng. Set the uni t on sof t, cl ean surf ac es .

(2) Do not cut the grounding pin from the line cord.

(3) Use care and proper tools in removing and tight eni ng sc rews to avoid burri ng t he heads.

(4) Use the nylon-washered rack screws supplied, i f pos sibl e, to av oid damaging t he panel . S upport the unit when

tightening the screws s o t hat the threads do not scrape the paint ins ide the s l otted holes.

Packing

When you pack the unit for shipping:

Tighten all s crews on any barrier st ri p(s ) so t he sc rews do not fall out from vi brat ion.

Wrap the unit in its original plast i c bag to av oid abradi ng the paint .

Seal the inner and outer cartons wit h tape.

If you are returning the unit permanently (for credit ), be sure t o enc los e:

• The Manual(s)

•

The Registration Card

• The Line Cord

•

All Miscellaneous Hardware (including the Rack Screws)

•

The Extender Card

•

The COAX Connecting Cable

Your dealer may charge you for any missing items.

If you are returning a unit for repair, do not enclose any of the above items.

Further advice on proper packing and shi pping i s inc luded in S ec ti on 5: Troubleshooting.

Trouble

If you have problems with ins tall at ion or operat i on:

(1) Check everything you have done so far agai ns t t he ins truc t ions in t he Manual. The inf orm at ion cont ai ned therein i s

based on our years of experience with OPTIMOD and broadcast stations.

(2) Check the other sections of the M anual (cons ul t the Table of Contents and Index) to s ee i f there mi ght be some

suggestions regarding your problem.

(3) After reading the section on Factory Assist ance, you may call Orban Customer S ervi ce for advice during normal

California business hours. The num ber is (1) 510/351-3500.

Page 6

OPTIMOD-FM 2200 CONDENSED SETUP

Condensed Setup of OPTIMOD-FM Models

2200 and 2200-D

This setup gu ide is f or qualif ied pe rsonne l only. Use this gu ide to h elp you get y our 220 0

installed and ope rating as quick ly as possible. If, at any time, you require more deta ils to

complete installation, refer to the relevant steps in Section 2 of the 2200 Operating Manual.

1. Unpack and inspect. ( Refer to page 2-2.)

A If you note obviou s physical damage, contact the carrier immed iately to make a

damage claim. A complete list of items included in the 2200 package is on page 2-2.

B Save all packing materials, in case you should ever have to ship the 2200.

C Complete the Registration Card and return it to Orban.

2. Change standard factor y configuration, if req ui r ed. (Refer to page 2-3.)

CS-1

[Skip this step if your installation does not have any special requirements.]

The 2200 is s upplied from the f ac tory with its jumpe rs set to th e con figur ation c orre ct

for most installations.

Stereo Encoder Composite Output Impedance 0Ω

Input Impedance 10kΩ

Input Sensitivity −10dBu or greater (+5dBu to +27dBu peak)

A If you are changing any jumper settings, remove the top cover of the 2200 to access

the main circuit board. (Make sure power is not connected.)

B Refer to Figure 2-1 in the manual to find the jump ers on the main c ircuit board and

to position them according to your application .

C Replace the 220 0 top cover.

3. Check the line voltage, f use an d p ow er cord. (Refer to page 2-7.)

A DO NOT connect power to the unit yet!

B Check the voltage selector on the rear panel, and change the setting if it is incorrect.

Refer to the unit’s re ar panel fo r your Model Numb er and the in side o f th e

front cover of the 2200 manual for your Model Number’s line voltage

setting.

C Check the value of the fuse and change the fuse if the value is incorrect.

For safety, the fuse must be Slow-Blow 1⁄2-amp for 115V, or 250mA

1

(

⁄4-amp) “T” type fo r 23 0V.

Page 7

CS-2

QUICK SETUP OPTIMOD-FM 2200

D Check power cord.

If you need to change the plug to meet your country’s standard and you are

qualified to do so, refer to the manual. Otherwise, purchase a new mains

cord with the correct line plu g attach ed .

4. Set Ground Lift swi t ch. ( Refer to page 2-8.)

The

GND LIFT switch, located o n the rear panel, is ship pe d f ro m the fa cto ry se t to GND

(to connect the 2200’s circuit ground to its chassis ground). If you are using the 2200’s

stereo encoder, and are dr iving its composite output into an unbalanced exciter input,

set the

using it to drive a balanced exciter input, set the

GND LIFT switch to LIFT. If you are not using the 2200’s stereo encoder, or are

GND LIFT switch to GND.

5. Mount the 2200 in a r ack. (Refer to page 2-8.)

3

The 2200 requir es on e s tanda rd ra ck un it (1

⁄4 inches/4.4 cm). Th er e shou ld be a goo d

ground connection between the rack and the 2200 chassis — check this with an

ohmmeter to verify that the resistance is less than 0.5Ω.

6. Connect remote contr ol ( optional). (Refer to page 2- 2. )

7. Connect inputs and ou tp ut s. (Refer to page 2-9.)

See the hook-up and grounding information in the manual.

8. Power up the 2200. (r efer to page 2-14.)

A Plug in the 2200’s power cord.

With no i np ut pr og ra m mat eri al, the re d Gat ed LE D and o ne of t he green

Function LEDs should be on. The AGC meter should indicate 10.0. The

main screen app ears in the front window display.

9. Recall Classical Pro tect preset. (Refer to page 2-17.)

A Press Recall Preset button, turn control knob until next: is CLASSICAL PROTECT, then

press the

RECALL NEXT soft key button.

10. Set pre-emphasis to the standard used in your country. (Refer to page

2-18.)

A Press System Setup button, press STEREO ENCODER soft key button, then set

processing (

PROC PRE-E) to your country’s standards:

75µs NORTH, CENTRAL, SOUTH AMERICA

50µs EUROPE, ASIA, AFRICA, P ACIFICA

75

EXCEPT

µs TAIWAN, KOREA, THAILAND

Page 8

OPTIMOD-FM 2200

CONDENSED SETUP

1 1. Set Analo g Outp ut pre-em phasi s. (Refer to page 2-18. )

[Skip this step if you are not using the 2200’s analog outputs.]

A Access ANLG OUTP CALIB control screen: Press System Setup button, press I/O CALIB

soft key button, then press ANLG OUTP CALIB soft key button .

B Set Analog Output pre-emphasis to [flat] or [pre-emph].

This controls whether the analog left/right outputs produce a flat signal, or a

pre-emphasiz ed signal, following the pre- emphasis set with Ster eo Encode r

PRE-E

control in the previous step.

PROC

12. Model 2200-D only: Set Digital O utput pr e-emphasis stat us. (Refer to pag e

2-19.)

[Skip this step if you are not using the 2200-D’s digital output.]

A Access I/O CALIB control screen: Press System Setup button, press the I/O CALIB soft

key button, then press

DIG OUTP CALIB soft ke y bu tt on ..

CS-3

B Set DO PRE-E (Digital Output pre-emphasis status).

See page 2-19 for an explana tion of the the fo llowin g options:

[

flat], [pre-emph], [J.17], or [J.17+pre -e ].

13. Model 2200-D only: Enable Analog Inputs. (Refer to page 2-20.)

[Skip this step if you are not using the 2200-D’s analog inputs.]

A Access ANLG INP CALIB contro l screen: Press System Setu p button, press the I/O

CALIB soft key button, then press ANLG INP CALIB soft key button.

B Enable Analog Inputs.

14. Adjust analog l eft/right input peak cli pping level. (Refer to pag e 2-20.)

[Skip this step if you are not using the 2200’s analog inputs.]

A Press the meter button so that the L/R Channel Input meters are active.

B Access ANLG INP CALIB control screen: Press Sy ste m S etu p butto n, pr es s I/O CALIB

soft key button, then press ANLG INP CALIB.

C Set Analog Input Clip level.

This step calibrates th e level at which the 2200’s A-D (Analog-to-Digital)

converter clips to the absolute maximum peak level that your installation

supplies to the 2200’s analog input.

This setup maximizes the 2200’s signal-to-noise ratio. If the clip level is

set too low, the 2200’s analog-to-digital converters will overload and

Page 9

CS-4

QUICK SETUP OPTIMOD-FM 2200

distort on program peaks. If the clip level is set too high, the signal-to -noise

ratio will suffer. Use care and atten tion in setting this adju stm ent.

a) Play program material from your studio at a much higher level than

normal — turn the fad ers up all th e way! This will produ ce the highest

peak level output that your system can produce .

b) Adjust th e 2200’ s

on the L/R Chan nel Input meters.

AI CLIP so that the program peaks just reach to −3dB

Hold down the button directly below the words “

control knob to scroll from +5.0dBu to +27.0dBu (or −17.0dBu to

+5dBu, if input sensitivity jumpe rs were reset), then release the button.

Observe the L/R Channel Input meters on the 2200 for a long

period of time; be sure to observe live announcer voice. If this

setting is mis-adjusted, distortion will result.

0dB indicates input clipping on the 2200. These meters should

never peak as high as 0dB with pro gram material.

c) If you are using an Orban 4000A Transmission Limiter or Orban

8200ST OPTIMOD ahead of the 2200, activate the tone oscillator on

either unit. Then adjust the 2200’s

Channel Input meters reads −3dB.

AI PEAK so that the 2200’s L/R

AI CLIP,” turn the

15. Calibrate analog in puts to your standar d studio level . (Refer to page 2-22. )

[Skip this step if you are not using the 2200’s analog inputs.]

A Press the meter button so that the L/R Channel Input meters are active.

B Access ANLG INP CALIB control screen: Press Sy ste m S etu p butto n, pr es s I/O CALIB

soft key button, then press ANLG INP CALIB.

C Set Analog Input Reference level.

This step calibrates the 2200 to the level to which your studio operators

peak their program material on the studio meters. This assures that the

2200’s processing prese ts will ope ra te in their preferred range.

If you are able to interrupt or distort programming, use a standard reference/line-up level tone from your studio or pla y program material; this will

achieve the most prec ise calibration . Adjust the appro priate 2200 refe rence

level control (either

on the Master Gain Reduction meter when audio is peaking at normal

levels (e.g., 0VU).

If you cannot interrupt or distort programming, calibrate by numbers,

adjusting the appropria te 2200 ref erence le vel contro l (either

AI REF PPM) to your s tudio’s reference level.

AI REF VU or AI REF PPM) for an average of −10dB

AI REF VU or

16. Model 2200-D only: Enab le Di gital Input. (Refer to page 2-23. )

[Skip this step if you are not using the digital input.]

Page 10

OPTIMOD-FM 2200

A Access DIG INP CALIB control screen: Press System Setup button, press the I/O CALIB

CONDENSED SETUP

soft key button, then press DIG INP CALIB.

Note: If DIG STAT is no lo ck , then the AES/EBU digital input i s not valid .

Check connections, cab ling , an d dig ital sour ce .

B Enable Digital Input.

17. Calibrate Digi tal I n p u t to yo ur stan dard studio level. (Refer to pag e 2-22.)

[Skip this step if you do not hav e Model 2200-D or if you are not using the 2200-D’s

digital input.]

A Pre ss Sy stem Se tup button, press the I/O CALIB soft ke y button, then pr ess DIG INP

CALIB.

B Set Digital Input Reference level.

This step calibrates the 2200 to the level to which your studio operators

peak their program material on the studio meters. This assures that the

2200’s processing prese ts will ope ra te in their preferred range.

If you are able to interrupt or distort programming, pla y program mater ial;

this will achieve the most precise calibration. Then adjust the appropriate

2200 reference level control (either

average of −10dB on the AGC Gain Reduction meter when audio is

peaking at normal levels (e.g., 0VU).

If you cannot interrupt or distort programming, calibrate by numbers,

adjusting the appropriate 2200 reference level control (either

or DI REF PPM) to your studio ’s referenc e level. Note th at the numbers yo u

see represent dB below digital full-scale.

DI REF VU or DI REF PPM) for an

DI REF VU

CS-5

18. Adjust Composi t e Out p u t level co ntrols. (Refer to page 2-25.)

[Skip this ste p if you are not us ing the 22 00 ’s co m po site ou tpu ts. T he se are the outputs

of the 2200’s stereo encoder .]

A Feed the 2200 with program material or activate the built-in 400Hz TEST tone.

To turn on the TEST tone : Press System Setup b utton, p ress TEST sof t key

button, set

control knob to 400 Hz, then release the button), and activate 400Hz test

tone (hold d own the

to

tone, then release the button).

To turn off

control knob to scroll to

B Adjust the 2200’s Comp 1 and Comp 2 level controls — screwdriver slots on the left

TONE to 400Hz (hold down the TONE sof t key b utton, tur n the

MODE soft key button, turn the control kn ob to scroll

TEST tone, hold d own the MODE tone soft key bu tton, turn th e

operate, the n re lea se the button.

side of the fr ont p anel — fo r 100% Total Peak Mod ulation of your F M exc iter, as

indicated on a modulation monitor, or modulation indicator on your exciter.

In the U.S., you can modulate higher than 100% when using SCAs. Refer

to the appropriate FCC rules.

Page 11

CS-6

QUICK SETUP OPTIMOD-FM 2200

19. Adjust Analog Left/Right or Digital Output level controls. (Refer to page

2-25.)

[Skip this step if you are not using the analog Left/Right or Digital Outputs.]

A Access analog or digital output level control: Press System Setup button, then press

ANLG OUTP CALIB or DIG OUTP CALIB as required.

B Set Output level.

Hold down AO 100% or DO 100%, as applicable, and adjust the knob.

Adjust the output level controls for 100% Total Modulation of your FM

exciter, or discr ete left/r ight ST L, a s indica ted on a modulatio n monito r, or

modulation indicator o n your exciter or STL . In the U.S., you can m odulate

higher than 100% when using SCAs. Refer to the ap pr opria te F CC rule s.

20. Select a preset that complements the program format of your station.

(Refer to page 2-26.)

A Press Recall Preset button to access the Recall Preset screen, then select a preset.

21. Quick Setup Compl et ed!

If you want to set up additional input/outp ut parame ters, or re set any setup

adjustments, continue to “System Setup Controls,” starting on page 2-27.

If you are ready to use the 2200, proceed to Section 3 for important 2200

operation informa tion.

Page 12

Operating Manual

OPTIMOD-FM

2200

Digital Audio Processor

Models 2200 and 2200-D

®

Page 13

WARNING

This equipment generates, uses, and can radiate radio-frequency energy. If it is not

installed and used as directed by this manual, it may cause interference to radio

communication. This equipment complies with the limits for a Class A computing

device, as specified by FCC Rules, Part 15, Subpart J, which are designed to provide

reasonable protection against such interference when this type of equipment is operated in a commercial envi ronment . Operat ion of thi s equipm ent i n a res ident i al area is

likely to cause interference. If it does, the user will be required to eliminate the

interference at the user’s expense.

WARNING

“This digital apparatus does not exceed the Class A limits for radio noise emissions

from digital apparatus set out in the Radio Interference Regulations of the Canadian

Department of Communicat ions.” “Le present appareil numerique n’emet pas de bruits

radioelectriques depassant les limites applicables aux appareils numeriques (de las

class A) prescrites dans le Reglement sur le brouillage radioelectrique edicte par le

ministere des Communications du Canada.”

IMPORTANT

Perform the installation under static control conditions. Simply walking across a rug can

generate a static charge of 20,000 volts. This is the spark or shock you may have felt when

touching a doorknob or some other conductive item. A much smal ler static disc harge is likely to

completely destroy one or more of the CMOS semiconductors employed in OPTIMOD-FM.

Static damage will not be covered under warranty.

There are many common sources of static. Most involve some type of friction between two

dissimilar materials. Some examples are combing your hair, sliding across a seat cover or

rolling a cart across the floor. S ince t he thres hol d of human percept ion f or a stat ic dis charge is

3000 volts, many damaging dis c harges will not even be noticed.

Basic damage prevention consists of minimizing generation, discharging any accumulated

static charge on your body or work station and preventing t hat dis charge f rom bei ng sent to or

through an electronic component. A static grounding strap (grounded through a protective

resistor) and a static safe workbenc h with a conductive surfac e should be used. This will prevent

any buildup of damaging static.

The OPTIMOD-FM 2200 Digi t al A udi o P roc es s or is protected by U.S. pat ent s 4,208,548; 4,249,042; 4,412,100; 4, 460,871; 5,050,217;

and U.K. patent 2,001, 495. Other patents pending.

Orban is a registered trademark.

All trademarks are property of their res pec ti ve compani es .

This manual is part number 96079-000-04

Copyright 2000

1525 Alvarado Street, San Leandro, CA 94577 USA

Phone: (1) 510/351-3500; Fax: (1) 510/351-0500; E-mail: custserv@orban.com; Web: www.orban.com

Page 14

OPTIMOD-FM

Operating Manual

page contents

1-1 Section 1: Introduction

OPTIMOD-FM 2200 DIGI TAL Audio Processor

Presets in the 2200

The T wo-Band Str uctur e

Protection Limiting: Orban’s Approach

Input/Output Configurations

Location of OPTIMO D-F M

About Trans m iss ion Lev els and M eter ing

Line-Up Facilities

Warrant y, Feedback

Orban

2200

2-1 Section 2: Installat ion

Installation of 2200

Basic System Setup

System Setup Controls

3-1 Section 3: Operation

2200 Controls and Meters

Introduction to Processing

About the Processing Struct ures

Factory Programming Pres et s

Customizing the 2200’s Two-Band Sound

T wo-Band St ruct ur es Pr oces sing Cont rols Det ails

Customizing the Protect ion Lim it er St r uct ur e Sound

2200 Screen Displays

Continued on next page

Page 15

OPTIMOD-FM

Operating Manual

page contents

4-1 Section 4: Maintenance

Routine Maintenance

Getting Inside the Chassis

In-System Testing (“Proof of Performance”)

Field Audit of Performance

Field Alignment

Orban

2200

5-1 Section 5: Troubleshooting

Problems and Possible Causes

Troubleshoot ing IC O pam ps

Technical Support

Factory Service

Shipping Instructions

6-1 Section 6: Technical Data

Specifications

Circuit Description

Parts List

Schematics, Assembly Dr awings

Abbreviations

INDEX on next page

Page 16

Index

!

4000 2-21

8200ST 2-21

A

abbreviations 6-51

AC line cord wire standard 2-7

AGC

defeating 3-13

AGC meter 2-16

analog input clip level 2-21, 2-29

analog input reference level 2-22, 2-28

analog input sensitivity 2- 4

analog input termination 2-3

analog inputs 2-20, 2-22

assembly drawings 6-34

audible di stortion 3-5, 5-2

audible no ise 5-3

audio

connections 2-10

input 2-10, 6-2

output 2-11, 6-2

B

balanced

inputs 2-10

output transformer 2-11

bass equalizati on 3-11

Bass meter 2-16

block diagram 6-35

buttons

Function 2-16

buzzes 5-2

bypass gain 2-36

bypass mode 2-35

bypass preset 1-10

C

cable 2-8, 2-10

cable shie lding 2-10 - 2-11

chassis

getting inside 4-3

ground 2-12

circuit boards

access to 4-3

front pane l 4-3

circuit description 6-5

circuit ground 2-12

CIT25 0-2, 2-8

cleaning 4-2

clicks 5-2

clipping 3-5

common-mode rejection 2-10, 2-1 2

Comp 1 level control 3-4

Comp 2 level control 3-4

composite

isolation transformer 0-2, 2-8

metering 1-9

composit e level control 2-1 6

composit e level output 2-16

Composite meter 2-16, 3-4

composite output impedance 2-3

compression 3-5

computer inte rfa ce 0-2

connectors

audio 2-10

Constrast bu tt on 3-3

Contrast

control 2-15, 3-3

control knob 2-15, 3-3

controls 2-15, 3-3

Comp 1 3-4

Comp 2 3-4

Composite 1 2-16

Composite 2 2-16

Contrast 2-15, 3-3

Escape 2-15

Escape bu tton 3-3

Modify Processing 2-16

System Setup 2-16

crosstalk test 2-33

customer service 5-7

D

D-connector 6-9

dBm (defined) 6-51

dBu (defined) 6-51

density 3-14

digital i/ o 1-6

digital in pu t 2-23, 2-30

digital input/output connectors 2-11

digital ou tp ut 2-30

distortion 5-2

dull sound 5-4

E

EBS tones

failure 5-5

enabling analog inputs 2-20

enabling digital input 2-23

Escape butt on 2-15, 3-3

exciter interface 2-13

F

factory service 5-8

field audi t 4-16

final clip pe r d riv e 3-17

frequency response verification 4-16

front panel 2-15, 3-3

Function button 2-16, 3-4

Function meter 2-16 , 3-4

fuse 2-7

G

gain reduct ion 3-14, 3-19

meters 3-4

Gain Reduction meters 2-16

gate compressor 3-13

Gated LED 2-16, 3-4

gating 3-13 - 3-14

grounding 2-1 2 - 2-13 , 5-2

diffic ul t si tu ations 0-2, 2-8

ground loop 0-2, 2-8

H

harshness 5-4

HF Limiting 2-16, 3-4, 3-15

LEDs 2-16

high-frequency

limiting 3-15

high-pass filter 3-11

protection structure 3-19

hum 5-2

I

impedance 2-10 - 2-11

input

balanced 2-10

impedance 2-10

level 2-10

overloa d point 2-10

sensitivity 2-4

termination 2-3

unbalanced 2-10

input leve l

line-up 1-8

input leve l me ters 1-9

input select A or D 2-28, 2-30

inspecti on of contents 0-1 , 2- 2

installation 2-1

internal cloc k 2-30

introduction 1-1

J

jumpers

access to 4-3

analog I/O card 2-3

input sensitivity 2-4

options 2-3

L

L-R null 4-11

LEDs

Gated 2-16, 3-4

HF Limiting 2-16, 3-4

limiting 3-5

high-freque nc y 3-15

line voltage 2-7

line-up tones

failure 5-4

location 2-8

location of 2200 1-7

digital in pu t 2 -30

loudness 3-5, 3-14

Page 17

M

mainsub 2-33

maintenance, routine 4-2

Master meters 2-16

meters

AGC 2-16

Bass 2-16

Composite 2-16 , 3-4

Function 2-16, 3-4

Gain Reduction 2-16

Master 2-16

PPM 2-22 - 2-23

studio 1-7

VU 2-22 - 2-23

Modify Processing

control 2-16

modulation

cannot control 5-2

modulation mode 2-33

mono

performance verification 4-8

mono left 2-33

mono right 2-33

mono sum 2-33

mono/stereo select 2-33

N

noise and distortion verific at io n 4 -16

O

operate mode 2-35

operation 3-1

ordering parts 6-23

output

impedance 2-11

level 2-11

unbalanced 2-11

output level meters 1-9

overshoot 5-2

P

packing for shipmen t 5-8

packing li st 2-2

parts

list 6-22

ordering 6-23

peak cont rol 3-16

peak modulation

cannot control 5-2

physical dimensions 6-4

pilot leve l 2-33

pilotoff 2-33

power 0-2, 2-7

cord 0-2, 2-6 - 2-7

requirements 6-4

PPM meter 2-22 - 2-23

pre-emphasis 2-30, 3-5

selection 2-18, 2-32, 2-35 - 2-36

problems 5-2

processing st ructures 3-7

remote control 2-34

programming prese ts 3-7

proof of performance 4-7

protectio n li mi ter structure

high-pass fi lt er 3-19

R

rack-mounting un it 2-8

rear panel

connections 2-6

digital in pu t 2 -30

registration card 1-10

remote control 0-2, 2-9

return authoriza tion 5-8

RF suppression 5-2

RFI 2-7, 2-13

filter 2-7

rotary encoder

control knob 2-15

controls 3-3

S

digital ou tp ut 2-31

schematics 6-34

screen

contrast 3-3

display 3-3

saver 3-3

screen displa ys 2-15

screen saver 2-15

screens

Constrast button 2-15

presets 2-26

selectin g a preset 2-26

service 5-8

setup

expanded 2-27

system 2-17

shipping

damage 0-1, 2-2

instructions 5-8

shrilln ess 5-4

soft keys 2-15, 3-3

specifications 6-2

spectral gain intermod ul at io n 1-5

stereo

interference 5-5

performance verification 4-10

stereo modu la tion 2-33

stereo/mono select 2-33

structures

two-band 1-4

submain 2-33

subcarrier input 2-12

digital ou tp ut 2-31

System Setup 2-1 6 - 2-17 , 3-4

T

technical support 5-7

temperature 2-8

test mode 2-35

test tone 2-36

tone 2-36

tone generator

internal 1-10

tone mode 2-35

troubleshooting 5-1

IC opamps 5-7

two-band structure

bass eq 3-11

setup 3-13

two-band structures 1-4

gating 3-13

high-frequency limiting 3-15

high-pass filter 3-11

loudness, densit y 3-14

peak control 3-16

setup 1-4

spectral balanc e 3-15

U

unbalanced

input 2-10

load 2-11

user tone pres et 1-10

V

VU meter 2-22 - 2-23

W

warranty 6-4

whistle, on air 5-4

X

XLR connectors 1-6, 2-10

Page 18

OPTIMOD-FM 2200 INTRODUCTION

pagecontents

Section 1

Introduction

page contents

1-3 OPTIMOD-FM 2200 DIGITAL Audio Processor

1-4 Presets in the 2200

1-4 The Two-Band Structure

1-1

1-5 Protection Limiting: Orban’s Approach

1-6 Input/Output Configurati ons

1-7 Location of OPTIMOD-FM

1-7 About Transmission Levels and Metering

1-8 Figure 1-1: Absolute Peak Level, VU and PPM Reading

1-9

1-10 Warranty, Feedback

Line-Up Facilities

Page 19

1-2

INTRODUCTION OPTIMOD-FM 2200

Page 20

OPTIMOD-FM 2200 INTRODUCTION

OPTIMOD-FM 2200 DIGITAL Audio Processor

Orban’s OPTIMOD-FM 2200 DIGITAL Audio Processor is a complete audio processing

system for FM br oadcas t. Mode l 2200 is conf igured fo r analog inp uts and outputs . Model

2200-D also includes digital inputs and outputs. Features for all versions include:

Universal transmitter protection and audio processing for FM broadcast. The

•

2200 can be configured to interface ideally with any commonly-found transmission system in the world .

User-friendly Interface: A simple liquid-crystal display (LCD) makes setup,

•

adjustment and pro gramming easy. Front panel bar graphs show me tering fu nctions of the proce ss ing pre set in use. Push one of th e cle ar ly lab ele d soft keys to

RECALL a preset, to MODIFY PROCESSING, or to access SYSTEM SETUP

controls.

8 factory-programmed presets, based on Orban’s Two-Band and Protection/Lim-

•

iting Processing Structures. These presets can be modified and saved.

1-3

8 user presets to store customized settings.

•

Pre-emphas is limiting for the in ternationally -used pre-e mphasis cur ves of 50µs

•

and 75

µs. The pre-emphasis control is almost never audibly apparent, producing

a clean, open sound with subjective brightness matching the original program.

Extremely tight peak control; overshoot is limited to ±0.3dB!

•

DSP-based stereo encoder (stereo generator) produces a circuit with excellent

•

specs, high stability, and uncompromis ing baseband spec trum control.

Remote-control, via optically-isolated terminals that can be operated with contact

•

closures (to facilitate interfacing to older-technology remote controls).

Built-in line-up tone generator facilitating quick and accurate level setting in any

•

system and a Bessel Null tone for calibrating modulation.

Page 21

1-4

INTRODUCTION OPTIMOD-FM 2200

Presets in the 2200

There are two distinct kinds of pr esets in the 2200: Facto ry Processing P resets and User

Presets.

The 8 Factory P rocessin g Prese ts include a protec tion/limiting pres et, a two-ban d general

purpose pres et, an d 6 oth er pr es ets de rived from th e two- band s tructu re. A ll of the fac tory

processing presets are stored in the 2200’s non-volatile memory, and cannot be erased. You

can change the settings of a Factory Processing Preset, but you must then store those settings

as a User Prese t. The fa ctory pre set rema ins uncha nged. You may sto re your new settings

in one of the 8 numbered User Presets.

User Presets cannot be created from “scratch.” You must always start by recalling a Factory

Preset, make changes, then store the changes in a User Preset.

The Two-Band Structure

The Two-Band Structure consists of a slow single-band gated AGC (Automatic Gain

Control) for g ain riding, followed by a gated two-band compr essor and a high- frequency

limiter. A two-band equalizer is available before the input of the Two-Band structure.

The Two-Band Structure is an improved version of Orban’s classic 8100A OPTIMODFM, but with increased high frequency clarity. (This is the same structure used in our

OPTIMOD-FM 8200.) It is ope rated after a phase ro tator (time-di spersion filte r) to improve

its loudness capability b y making positive an d negative pea ks more symmetric al, particularly with voice.

The Two-Band Structu re has an o pen, easy-to -listen-to so und that is simila r to the source

material if the source material is of good quality. However, if the spectral balance between

the bass and high- frequency energy of the pro gram material is incorrect, the Two- Band

Structure ( when its ba ss coupling control —

gently correct it without introducing obvious coloration.

Two-Band Presets

The Two-Band Factory Programming Presets are designed to help you get on the air quickly.

In most cases, th ey will su it yo ur needs without the need for further adju stme nt. Or , if yo u

desire, you can always experiment with the

to your taste.

The basic Two-B and prese t, 2B G ener al Pur pose , pr ovide s an ave ra ge amou nt of p roce ssing. The other Two-Band presets provide a sound tailored for a specific program format. For

example, Mus ic-Light produces a very open, unprocessed sound while Music+Bass Me dium provide s a very punchy, clean, open so un d. P re se ts in clu de:

TALK, MUSIC-LIGHT, MUSIC-MEDIUM, MUSIC HEAVY, MUSIC+BASS MEDIUM and MUSIC+BASS HEAVY.

BASS COUPL — is operated toward 0%) ca n

LESS-MORE control to fine-tune the processing

2B GENERAL PURPOSE,

Page 22

OPTIMOD-FM 2200 INTRODUCTION

Using the Two-Band Structure for Classical M u si c

Classical music is traditionally broadcast with a wide dynamic range. However, with many

recordings a nd live performances, th e dynamic range is so grea t that the quiet passages

disappear into the noise on most car, portable, and table radios. As a result, the listener either

hears nothin g, or must turn up the volume control to hear all the mus ic. Then, when the

music gets loud, the radio blasts and distorts, making the listening rather unpleasant.

The Two-Band S tructure is well-suited for classical for mats during daytime hours when

most people in the a ud ien ce a re lik ely to b e liste nin g in a uto s o r to be us ing the sta tion fo r

background mus ic. This audience is best served when the dynamic rang e of the program

material is compressed 10-15dB so that quiet passages in the music never fade into

inaudibility under these less-favorable listening conditions. OPTIMOD-FM controls the

level of the music in ways that are, for all practical purposes, inaudible to the listen er.

Low-level passages are increased in level by up to 10dB, while the dynamics of crescendos

are maintained.

The same station ma y wish to sw itch to the P rotec tion Structu re durin g the eve ning hour s

when the audience is more likely to listen critically.

1-5

Protection Limiting: Orban’s Approach

The Protection Limiter Structure is designed for stations wanting the highest possible

fidelity to the source, such as a station broadcasting concert music at night when it’s

audience is likely to listen in a more critical manner. While the Protection Limiter Structure

can readily red uce the dynamic ra nge, it is design ed to do so withou t increasing program

density, loudness, or the consistency of sound from different sources. It’s primary function

is to protect th e tra ns mitter f ro m o ve r- de via tion wh ile pr es erving the spectr al an d te xtu re d

quality of the source material.

The 2200 has one Protection Limiter factory preset , named

Traditionally, protection limiters have used peak-sensing automatic gain control (AGC)

processors to control peak levels. This approach ignores one crucial requirement for

protection limiter performance: the limiter must provide natural-sounding con trol that is

undetectable to the ear except by an A/B compar ison to the original source material. To

achieve natur al sound quality , the gain con trol s ection of the limiter mus t re spond lik e the

ear. This means that the gain control must respond approximately to the power (not the peak

level) in the signal. Further, because the sensitivity of the ear decreases dramatically below

150Hz, the control must be frequency-weighted to compensate. Otherwise, heavy bass

would audibly modulate the loudness of midrange program material, a problem called

spectral gain interm odulation.

CLASSICAL PROTECT.

Page 23

1-6

INTRODUCTION OPTIMOD-FM 2200

Input/Output Configurations

The OPTIMOD-FM 2200 DIGIT AL is de sig ne d t o simu l tan eo us ly ac co m mod ate :

analog left/right inputs and outputs

•

Digital AES/EBU left/righ t in put s an d ou tput s (Mod el 22 00 -D on ly)

•

stereo analog baseband composite output

•

Analog Left/Right In put/Ou tp ut

The left and right analog inputs are on XLR-type female connectors on the rear panel. Input

impedance is greater than 10kΩ; balanced and floating. Inputs can accommodate up to

+27dBu (0dBu = 0.775Vrms). The left and right analog outputs are on XLR-type male

connectors on the rear panel. Output impedance is 30Ω; balanced and floating. Outputs can

drive up to +20dBm into 600Ω.

Level control of the analog inputs and outputs is via software control through SYSTEM

SETUP. (See page 2-20 an d 2-6. )

Digital AES/EBU Lef t/Ri ght Input/Output (Model 2200-D only)

The digital input and output follow the professional AES/EBU standard. The left/right

digital input is on one XLR- type female connector on the rear pan el; the left/righ t digital

output is on one XLR-type male con necto r on the rear pan el.

The 2200-D is designed to simultaneously accommodate digital and analog inputs and

outputs. You sele ct whether the 2 200-D uses the digital o r the analog input via s oftware

control through System Setup (

interface. Both analog and digital outputs are active continuously. Level control of the

AES/EBU input is via so ftwa re con trol th roug h Sys tem Set u p.

The 2200-D’s digital I/O operates at a 32kHz, 44.1kHz, or 48kHz sample rate. Its output can

be flat, pre-emphasized (to the 50µs or 75µs curve selected for the processing), J.17

pre-emphasized, or J.17 plus 50µs or 75µs pre-emphasized.

Please note that the AES/EBU standard is not the same as the S/P-DIF

(Sony/Philips Digital Inte rface) standard use d in consum er digita l applica tions, such as the “digital outputs” of CD player s. The AES/EBU inte rface

will not work with S/P-DIF signals.

A 2200 cannot be upgraded to a 2200-D.

DIG INP CALIB or ANLG INP CALIB screen), or by remote

Stereo Analog Baseband Compo site Ou tp ut

The stereo encoder has two unbalanced analog baseband outputs on two BNC connectors

on the rear pan el. Each ou tput can b e strapp ed for 0Ω or 75Ω so urce impedan ce, and can

drive up to 8V peak-to-peak into 75Ω in parallel with up to 0.047

cable) before any noticeable performance degradation occurs.

µF (100ft/3 0m of RG- 59/U

Page 24

OPTIMOD-FM 2200 INTRODUCTION

Level control of eac h ou tput is via a separate screwdriver co ntrol accessible from th e fro nt

panel.

A ground lift s witch is ava ilable on th e rear p anel. This is u seful to preve nt ground loops

between the 2200 and the transmitter.

Location of OPTIMOD-FM

Best Location for OP T IM O D-F M

The best location for OPTIMOD-FM is as close as possible to the transmitter, so that its

stereo encoder output can be connected to the transmitter through a circuit path that

introduces the least possible change in the shape of OPTIMOD-FM’s carefully peak-limited

waveform — a short length of coaxial cable.

We very stro ngly re comm end that yo u use the 22 00’s internal st ereo e ncoder a nd feed

its output directly to the baseband input of the exciter through less than 100 feet (30

meters) of coaxial cable. You wi ll achieve a louder sound on the air, with bet ter control

of peak modulation, than if you use an external stereo encoder.

1-7

About Transmission Levels and Metering

Meters

Studio engineers and transmission engine ers consider audio levels and their measuremen ts

differently, so they typically use different methods of metering to monitor these levels.

The VU meter is an average- responding mete r (measuring the appr oximate RMS leve l) with

a 300ms rise time an d de ca y time; th e VU in dic ation u su ally un de r- indicates the true pea k

level by 8 to 14dB.

The Peak Program Meter (PPM) indicates a level between RMS and the actual peak. The

PPM has an attack time of 10ms, slow enough to cause the meter to ignore narrow peaks

and under-indicate the true peak level by 5dB or more.

The absolute peak-sensing meter or LED indicator shows the true p eak level. It has an

instantaneous attack time, and a release time slow enough to allow the e ngineer to eas ily

read the peak level.

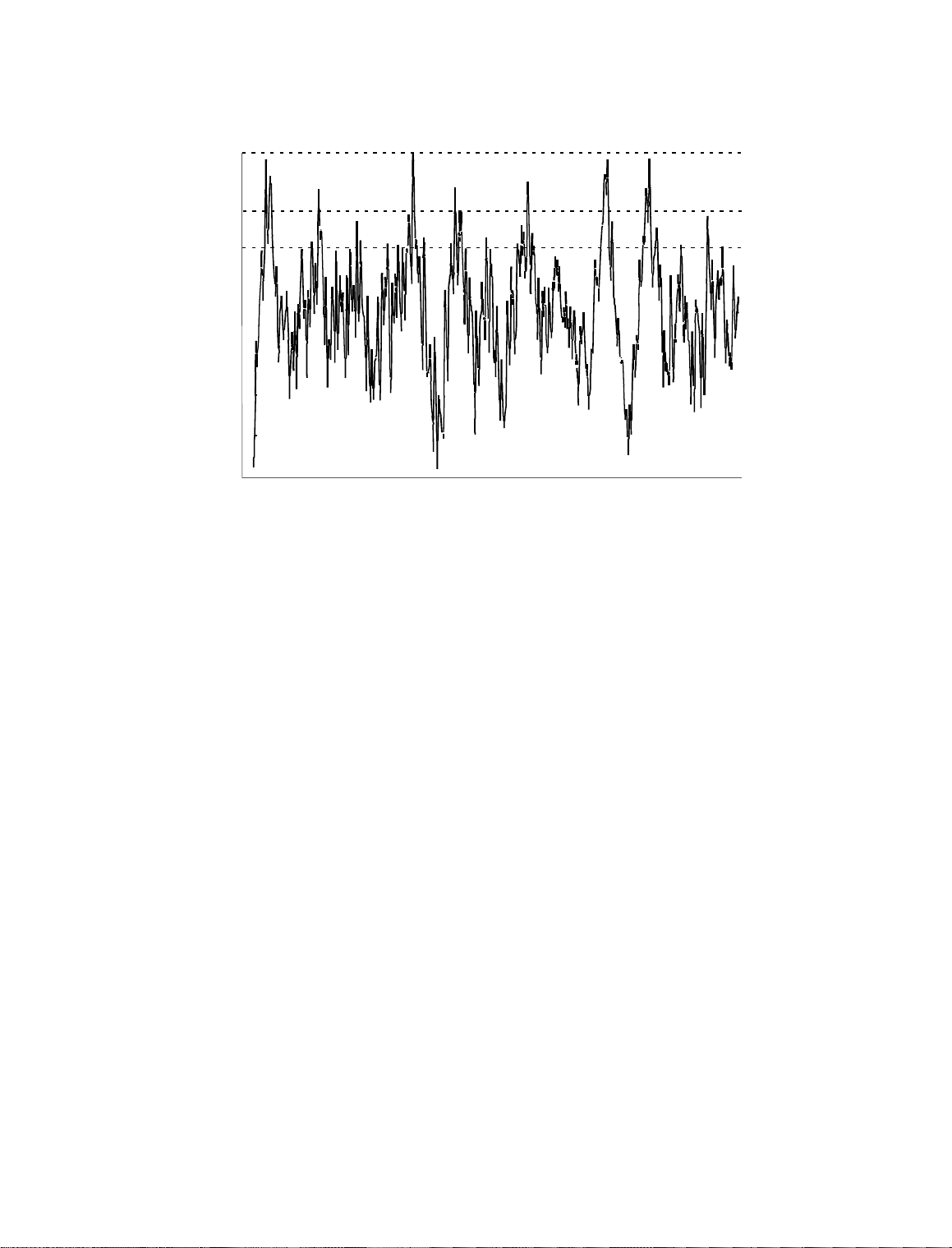

Figure 1-1 shows the relative difference between the absolute peak level, and the indications

of a VU meter and a PPM.

Page 25

1-8

INTRODUCTION OPTIMOD-FM 2200

ABSOLUTE PEAK

PPM

VU

Figure 1-1: Absolute Peak Lev el, VU and PPM Reading

For a Few Seconds of Music Pr ogram

Studio Line-u p Levels and Headroom

The studio enginee r is primarily con cerned with calibr ating the equipment to prov ide the

required input level for proper operation of each device, and so that all devices operate with

the same input and output levels. This facilitates patching devices in and out without

recalibration . For line-up, the s tudio engineer uses a calibration tone at a stud io standard

level, commonly called line-up level, reference level, or operating level.

Metering at the studio is by a VU meter or PPM (Peak Program Meter). As discussed above,

the VU or PPM indi c ati o n l a gs the t ru e p ea k l evel. Most modern st ud io a udio devices have

a clipping level of no less than +21dBu, and often +24dBu or more. So the studio

standardizes on a maximum program indication on the meter that is lower than the clipping

level, so that pea ks that the meter doesn’t indicate will no t be clipped. Line-up level is

usually at this same maximum meter indication.

In facilities that use VU meters, this level is usually at 0VU, which corresponds to the studio

standard level, typically +4 or +8dBu. For facilities using +4dBu standard level, instantaneous peaks can reach +18dBu or higher (particularly if the operator overdrives the console or

desk). Older facilities with +8dBu standard level and equipment that clips at +18 or +21dBu

will experience noticeable clipping on some program material.

In facilities that use the BBC-standard PPM, maximum program level is usually PPM4 for

music, PPM6 f or speech. Line-up leve l is usually PPM4, which corres ponds to +4dBu.

Instantaneous peaks will reach +17dBu or more on voice.

In facilities that use PPMs that indicate level directly in dBu, maximum program and line-up

level is often +6dBu. Instantaneous peaks will reach +11dBu or more.

Page 26

OPTIMOD-FM 2200 INTRODUCTION

T ran smi ssi on Levels

The transmission engineer is primarily concerned with the peak level of a program to

prevent ove rloading or over-modulatio n of the transmission s ystem. This peak overloa d

level is defined differently, system to system. In FM modulation (FM/VHF radio and

television broadc as t, micr owave or an alo g sa tellite links ), it is the maximu m-p er mitted RF

carrier fr equency de viation. In AM modulation, it is negative c arrier p inch-off. In analog

telephone/post/P TT transmission, it is the le vel above which serious cr osstalk into other

channels occurs, or the level at which the amplifiers in the channel overload. In digital, it is

the largest possible digital word.

For metering, the transmission engineer uses an oscilloscope, absolute peak-sensing meter,

calibrated peak-sensing LED indicator, or a modulation meter. A modulation meter usually

has two compone nts — a semi -peak readi ng meter (like a PPM) , and a p eak-indi cating l ight

which is calibrated to turn on whenever the instantaneous peak modula tion exceeds the

over-modulation threshold.

Line-Up Facilities

1-9

Metering of Levels

The 2200’s front panel metering includes bargraphs displaying the following I/O levels: L/R

Input, L/R Output and Composite Output.

L/R Input Level

Left and right input level is shown on a VU-type scale (0dB to −27dB), while the metering

indicates absolute instantaneous peak (much faster than a standard PPM or VU meter ). 0dB

indicates A/D conve rter clipp ing (analog input) or digital full-s cale (digita l input, 2200-D

only).

Left/Right Output Level

Left and right output level is shown on a VU-type scale (0dB to −27dB), where the metering

indicates absolute instantaneous peak (much faster than a standard PPM or VU meter).

The meter is sca led so tha t 0dB is calibrate d to the highest left a nd right pea k modulation

level, before de-emphasis, that the processing will produce, under any program, processing,

or setup condition (except when the processing is switched to bypass). The meter indication

is not affected by the setting of the analog or digital output level control.

Composite Output Level

The Orban 2200 Audio Processor controls instantaneous, absolute peak levels to a tolerance

of approximately ±0.3dB. Composite modulation is indicate d in % modulation, absolute

instantaneous peak indicating. 100% is calibrated to the highest composite peak modulation

level that the processing will produce, including the pilot tone, under any program, processing, or setup condition (except when the processing is switched to bypass). 100% ordinarily

corresponds t o ±75kHz carrier deviation.

Page 27

1-10

INTRODUCTION OPTIMOD-FM 2200

Built-in Calibrated Line-up Tones

To facilitate matchin g the output level of the 2200 to the tra nsmission system that it is

driving, the 2200 c ontains an adjustable ton e that produces sine w aves at 2200’s analog ,

digital and compos ite ou tputs. The frequen cy of the lin e- up tone s can be ad jus ted fr om the

front panel. The modulation is always 100%.

When the 2200’s left/right analog output is switched to flat, a de-emphasis filter is inserted

between the output of the 2200’s audio processing and its line output. Thus, as the frequency

of the tone pres et is changed, the level at the 2200 ’s line output will follow the selecte d

de-emphas i s cu rv e.

In most cases the pre-empha sis filter in the dr iven equipment w ill undo the effect of th e

2200’s internal de-emphasis, and the 2200’s output level should be adjusted so that the tone

produces 100% modulation of the transmission link as measured after the link’s pre-emphasis filter. At 100Hz, switchin g the de- emphasis out or in will ha ve ne gligible ef fect o n the

level appearing at the 2200’s left and right audio outputs.

Built-in Calibrated Bypass

Bypass is available to transparently pass line-up tones generated earlier in the system. It will

also pass program material, with no gain reduction or protection against overmodulation. It

can transparently pass any line-up tone applied to its input up to about 130% output

modulation, at w hich point c lipp ing ma y oc cur. Acc ess b ypas s in the S ystem S etup TEST

MODE screen.

Note that BYPASS applies 50µs or 75µs pre-e mphasis, as determined by the setting of

PROC PRE-E, in the System Setup STEREO ENCODER screen.

Warranty, Feedback

Warranty

The warranty, whic h can be enjo yed only by the first end- user of reco rd, is located on the

inside back cover of this manua l. Sa ve it fo r futu re re fe renc e. De tails on ob taining factor y

service are provided on page 5-9.

User Feedback Form

We are very interested in your comments about this product. Your suggestions for improvements to either the product or the manual will be carefully reviewed. A postpaid User

Feedback Form is provided in the back of this manual for your convenience. If it is missing,

please write us at the address printed in the front of the manual, or call or fax our offices at

the number listed. We will be happy to hear from you.

Page 28

OPTIMOD-FM 2200 INSTALLATION

Section 2

Installation

page contents

2-2 Installation of 2200

2-7 Figure 2-1: AC Line Cord Wire Standard

2-9 Figure 2-2: Wiring the 25-pin Remote Control Connector

2-1

2-17

2-27 System Setup Controls

2-27 I/O CALIB (I/O Calib rat ion )

2-32 Stereo Encoder (and processing Pre-Emphasis)

2-34 Remote Inte rface

2-35 TEST Mod e

Basic System Setup

CAUTION

The installation and servicing instructions in this manual are for

use by qualified personnel only. To avoid electric shock, do not

perform any servicing other than that contained in the Operating

Instructions unless you are qualified to do so. Refer all servicing

to qualified service personnel.

pagecontents

Page 29

2-2

INSTALLATION OPTIMOD-FM 2200

Installation of 2200

Allow about 2 hours for installation.

Installation co nsists of: (1) unpacking and insp ecting the 2200, (2) optional rese tting of

jumpers for 2200 op tions (compos ite output impedance , input termination, inp ut sensitivity), (3) checking the line voltage setting, fuses and power cord, (4) mounting the 2200 in a

rack, (5) connecting inputs, outputs and power, (6) setting the

optional connecting of remote control leads.

When you have finished installing the 2200, proceed to “System Setup,” on page 2-16.

1. Unpack and inspect.

A If you note obviou s physical damage, contact the carrier immed iately to make a

damage claim. Packed with the 2200 are:

1 Operating Manual

1 Quick Setup Guide

1Line Cord

2

1

⁄2A Replacement Fuses for “U” and “J” V ersions

2 250mA Replacement Fuses for “E” Version

1 Orban green screwdriver (Xcelite R3323)

1 Booklet: Audio Quality in the FM Plant

GROUND LIFT switch, (7 ) and

B Save all packing materials! If you should ever have to ship the 2200 (e.g., for

servicing), it is best to ship it in the original carton with its packing materials because

both the carton and packing material have been carefully designed to protect the unit.

C Complete the Registration Card and return i t to Orban. (please)

The Registration Card enables us to inform you of new applications,

performance improve ments, and service aids tha t may be develo ped, and it

helps us respond promptly to cla ims unde r warr anty with out our hav ing to

request a copy of your bill of sale or other proof of purchase . Please f ill in

the Registration Card and send it to us today. (The Registration Card is

located aft er the cover page).

We do not sell or give away our customer’s names to anyone.

Page 30

OPTIMOD-FM 2200 INSTALLATION

2. Change standard factor y con fi g uration, if required.

[Skip this step if your installation does not have any special requirements.]

The 2200 is s upplied from the f ac tory with its jumpe rs set to th e con figur ation c orre ct

for most installations.

Stereo Encoder Composite Output Impedance 0Ω

Input Impedance 10kΩ

Input Sensitivity −10dBu or greater (+5dBu to +27dBu peak)

A To change any jumpers you must remove the top cover of the 2200 to access the main

circuit board. (Make sure p ower is not con nected. ) Remove all scr ews ho lding the

cover in place, then lift it off. (B e caref ul not to strip threads when opening the

cover.)

B Refer to Figure 2-1 to find the jumpers on the main circuit board and to position them

according to your application.

The following inf ormation is provided to explain each jumper and its settings in detail.

2-3

Stereo encoder composite output impedance.

•

[Do not change the default 0Ω jumper setting unless your installation

needs 75Ω source impedance.]

The stereo encoder is shipp ed from the facto ry with 0Ω source impedan ce.

This is correct for virtually all installations. However, the 2200 stereo

encoder can be changed to 75Ω source impedance if desired.

The frequencies in the stereo baseband are low by comparison to RF or

video, and the ch aracteristic imped ance of coaxial cab le is not 75Ω at lower

frequencies, so the transmission system will ha ve more accu rate amplitud e

and phase response (and thus, better stereo separ ation) if the cab le is driven

by a very low source impedance (0Ω) and is terminated with greater than

1kΩ at the exciter.

However, a few broadcast organizations require that FM composite be

transmitted in impedan ce-matche d coaxial ca ble with 75Ω sourc e and load

impedances.

To change the source impedance of one or both of the composite

outputs:

To change the sou rc e imp ed ance of comp osite ou tpu t #1, move jum per JA

to the “75Ω” position (Fig 2-1). To change the source impedance of

composite output #2, move jumpe r JB to the “7 5Ω” po sition (Fig 2-1).

Analog left/right input termination.

•

[Do not change the default setting unless your installation requires 600Ω

termination on the analog left/right inputs.]

The analog left/right inputs are shipped from the factory with balanced

bridging (1 0kΩ) input impe dance. Howev er, the 2200 a nalog inputs ca n be

changed to 600Ω input impedance.

Page 31

2-4

INSTALLATION OPTIMOD-FM 2200

To change the input impedance of the analog left /rig ht inputs:

Move jumpers J301 and J305 according to Figure 2-1. Jumper J301 sets

the left channel and jumpe r J305 sets the right channel.

Set analog left/right input sensitivity.

•

[Skip this step if your installation will supply the 22 00 with nominal input

level of −10dBu or greater (+5dBu to +27dBu peak).]

The analog left/right inputs are shipped from the factory with input sensitivity to accommodate inputs whose absolute maximum peak level is

between +5dBu and +27dBu.

If VU meters are used, +5dBu to +27dBu absolute peak corresponds to a

0VU level of approximate ly −9dBu to +13dBu.

If PPMs are used, +5dBu to +27dBu absolute peak corresponds to a PPM

level of approximate ly −2dBu to +20dBu.

However, in unusual circumstances where the input level is very low, the

2200 analog inputs can be changed for greater sensitivity. This usually

occurs only when the stu dio-to-transmitter link is a lon g te lephone or post

line with a passive equalize r at the re ceive end a nd no amplifier to make u p

the loss of the line and the equalizer .

To increase the input sensitivity of the analog input to accommodate

absolute peak levels of −17dBu to +5dBu (nominal levels down to

−30dBu):

Move jumpers J302, J303, J306, J307 and J308 according to Figure 2-1.

Jumpers J30 2 and J303 set the left channel and jumpers J306 and J307 se t

the right channel. Jumper J308 sets the co ntrol cir cuit to r ecogniz e the n ew

input sensitivity.

C Replace the 220 0 top cover.

Replace all screws snugly. (Be ca re ful not to strip thr ea ds by fa stenin g the

screws too tightly.)

Page 32

OPTIMOD-FM 2200 INSTALLATION

2-5

Page 33

2-6

INSTALLATION OPTIMOD-FM 2200

2200 Rear Panel

Voltage Selector (for Model Numbers 2200/U, 2200-D/U, 2200/E and 2200-D/E) can

be set to 115V (for 100-132V operation) or 230V (for 200-264V operation); (for

Model 2200/J and 2200-D/J) set to 115V (for 89-120V operation).

Fuse values can be changed to support 115V or 230V operation. Fuse must be 3AG

Slow-Blow,

Power Cord is detachabl e and is termina ted in a “U- ground ” plug (USA st andard), or

CEE7/7 plug (Continental Europe), as appropriate to your 2200’s Model Number.

GND LIFT (Ground Lift) Switch can be set to

ground to its chassis) , or to

driving its composite output into an unbalanced exciter input).

Remote Cont rol In terf ace is pr ov ided to conn ect the 2200 to a re mote contr ol. Th e

2200 remote control accepts a DB-25 connector and supports user-programmable

selection of up to eight inputs fo r any one of the fo llowing para meters: u ser presets ,

factory presets, bypass, tone, exit test, stereo, mono left, mono right, mono sum, analog

input, digital inp ut (Model 2200-D only), digital input + J.17 pre-emphas is (Model

2200-D only).

COMPOSITE 1 OUTPUT and COMPO SITE 2 OUTPUT are provided, each with

independent output level control (via front panel Comp 1 and Comp 2 controls). Each

output uses a BNC connector.

1

⁄2-amp for 115V, or 1⁄4-amp (250mA) “T ” type for 230V.

GND ( to connect the 2 200’s circuit

LIFT (if you a re using the 2200 ’s ster eo enc oder, an d are

A valid signal is a momentary tr ansition from no-c urrent to cu rrent flowing

through the particular remote signal pins. Current must flow for at least

50ms for the signal to be interpreted as valid. It is acceptable to apply

current continuously to an input, DC or AC. Do not exceed 9 volts unless

you use an external current-limiting resistor that limits curr ent to 10mA.

ANALOG INPUT and ANALOG OUTPUT provided to support left and right audio

signals through XLR-type connectors.

Digital AES/EBU INPUT and AES/EBU OUTPUT (Model 2200-D only) are

provided to support two-channel AES/EBU-standard digital audio signals through

XLR-type connectors.

Page 34

OPTIMOD-FM 2200 INSTALLATION

3. Check the line voltage, fuse an d power cord.

A DO NOT connect power to the unit yet!

B Check the voltage selector. This is on the rear panel.

Refer to the unit’s re ar panel fo r your Model Numb er and the in side o f th e

front cover of this manual for your Model Number’s line volta ge settin g.

Model Numbers 2200/U, 2200-D/U, 2200/E and 2200-D/E are shipped

configured for either 100-132V or 200-264V, 50Hz or 60Hz operation, as

indicated on the rear pane l. To change the opera ting voltage, set the voltag e

selector to 115V (for 100-132V) or 230V (f or 200 -264 V) as appro pr iate .

Model Number 2200/J and 2200-D/J are shipped for 89-120V, 50/60Hz

operation. The voltage selecto r shou ld be set to 115V (f or 89-12 0V) .

C Check the value of the fuse and change the fuse if the value is incorrect.

For safety, the fuse must be Slow-Blow 1⁄2-amp for 115V, or 250mA

1

(

⁄4-amp) “T” type fo r 23 0V.

TYPE 18/3 SVT COR, TYP

(3 x .82 mm2)

WIRE COLOR

NORMAL ALT

BROWN

BLUE

GREEN-YELLOW

BLACK

WHITE

GREEN

PLUG FOR

115 VAC

(USA)

CONDUCTOR

L

LINE

NEUTRAL

N

E

EARTH GND

2-7

TYPE H05VV - F - 0.75

PLUG FOR

(EUROPEAN)

Figure 2-1: AC Line Cord Wire Standar d

D Check power cord.

AC power passes through an IEC-standard mains connector and an RF

filter designed to meet the standa rd s of all inter na tion al sa fe ty au tho ritie s.

The power cord is terminated in a “U-ground” plug (USA standard), or

CEE7/7 plug (Continental Europe), as appropriate to your 2200’s Model

Number. The green/yellow wire is connected directly to the 2200 chassis.

If you need to change the plug to meet your country’s standard and you are

qualified to do so, see Figure 2-2. Otherwise, purchase a new mains cord

with the correct line plug attache d.

230 VAC

CONDUCTOR WIRE COLOR

L

NEUTRAL

N

E

EARTH GND

LINE

BROWN

BLUE

GREEN-YELLOW

Page 35

2-8

INSTALLATION OPTIMOD-FM 2200

4. Set Ground Lift switch.

GND LIFT switch is located on the rear panel.

The

GND LIFT switch is shipped fr om the fac tory set to ground (to co nnect the 2200’s

The

circuit ground to its chassis ground). If you are using the 2200’s stereo encoder, and are

driving its composite outp ut into an unbalanced exciter input, s et the

to

LIFT.

GND LIFT switch

This will break a ground loop that could otherwise occur.

Unbalanced exciter inputs can cause hum and noise because it is difficult to control the

system ground ing. If hum or n oise appears that cannot be c ured by rese tting the

LIFT

switch, we suggest that y ou ins tall the optional Orban CIT25 Composite Iso latio n

Transformer at the exciter’s input to balance it. If you use the CIT25, set the 2200’s

LIFT

switch to GND.

GND

GND

If you are not using the 2200’s stereo encoder, set the GND LIFT switch to ground.

5. Mount the 2200 in a r ack.

The 2200 requires one standard rack unit (1

3

⁄4 inches/4.4 cm).

There shou ld be a good gr ound connec tion betwee n the rack a nd the 2200 ch assis —

check this with an ohmmeter to verify that the resistance is less than 0.5Ω.

Mounting the unit o ver large heat-producing devic es (such as a vacuum- tube power

amplifier) may sh or ten c omp on en t lif e an d is no t recommended. A mbie nt te mpe rature

should not exceed 113°F/45°C when equipment is powered.

Equipment life will be exten de d if the unit is mou nte d away from sou rc es of vibration,

such as large blowers.

The shorter the baseband cable run from the 2200 to exciter, the less likely that ground

loops or other nois e problems will oc cu r in the in sta llatio n. I f yo u re qu ire a lo ng c ab le

run, it is usually best to mount the RF exciter close to the 2200 , and to make the long

cable carry the RF output from the exciter to the transmitter’s RF power amplifiers.

Page 36

OPTIMOD-FM 2200 INSTALLATION

6. Connect remote control. (optional)

The 2200 has extensive remote control provisions, which are described on page 2-34.

Optically-isolated remote control connections are terminated in a type DB-25 male

connector located on the rear panel. It is wired according to Fig. 2-2. To select the desired

function, apply a 5-12V A C or DC pulse be tween the a ppropriate

The (−) terminals can be conne cted togethe r and then c onnected to gr ound at pin 1 to

create a

composition resistor in series with the

current limiting. A current-limited +9VDC source is available on pin 25.

REMOTE COMMON. If you use 48V, connect a 3.6K 10%, 1-watt carbon

REMOTE COMMON or the (+) terminal to provide

In a high-RF environment, these wires should be short and should be run

through foil-shielded cable, with the shield connected to the connector

shell at both ends.

PIN ASSIGNMENT

REMOTE terminals.

2-9

REMOTE INTERFACE

Figure 2-2: Wiring the 25-pin Remote Control Connector

7. Connect inputs and outputs.

See the hook-up and grounding information on the following pages.

Audio Input and Audio Output Connections Page 2-10

Composite Output Page 2-12

AES/EBU Digital Input and Output (2200-D only) Page 2-11

Grounding Page 2-12

Page 37

2-10

INSTALLATION OPTIMOD-FM 2200

Audio Input and Output Connections

Cable

We recommend usin g two-conductor foil-shielded cable (such as Belden 8451 or

equivalent), because signal current flows through the two conductors only. The shield

does not carry signal, and is used only for shielding.

Connectors

Input and output connectors are XLR-type connectors.

•

In the XLR-type c onne ctors, pin 1 is CHASSIS GROUND, while pin 2 and

pin 3 are a balanced, floating pair. This wiring scheme is compatible with

any studio wiring standard: If one pin is considered

automatically

HIGH.

Analog Audio Input

LOW, the other pin is

Nominal input level between −30dBu and +8dBu will result in normal operati on

•

of the 2200. (See step 2 on page 2-3 for a full discussion).

(0dBu = 0.775Vrms. For this application, the dBm @600Ω scale on

voltmeters can be read as if it were ca libr ate d in dBu. )

The peak input level that causes overload is dependent on the se tting of the AI

•

CLIP control. It is adjustable from −17dBu to +27dBu in two ranges.

The electronically -bal anced i nput uses an ultra low noise and distortion differ-

•

ential amplifier for best common mode rejection, and is co mpatible with most

professional and semi-pro fessional audio equipment, balanced or unbalanced,

having a source impedance of 600Ω or less. The input is EMI suppressed.

Input connec tion s a re th e sa me w he the r the d riv ing sou rc e is balanced or unbal-

•

anced.

Connect the red (or white) wire to the pin on the XLR-type connec tor (#2 or #3)

•

that is considered

wire to the pin on the XLR - typ e c on ne cto r (# 3 or #2) th at is considered

the standards of your organization. (Note: International Standard is pin 2

*In low RF fields (like a studio site), do not connect the cable shield at the 2200

•

input — it should be con ne cte d at the sou rc e en d on ly. In h igh RF fields (like a

transmitter site), also connect the shield to pin 1 of the male XLR-type connector