Page 1

OPTIMOD-FM 8200 MAINTENANCE

Section 4

Maintenance

page contents

4-2 Routine Maintenance

4-3 Getting Inside the Chassis

4-3 Front panel — open and close

4-4 Rear panel — remove and replace

4-5 Input Filter Board — remove, repla ce

4-6 D-Connector Board — remove, repla ce

4-6 Power Supply — remove, replace

4-1

4-7 In-System Testing (“Proof of Performance”)

4-8 Monophonic Performance Verification

4-9 Stereo Performance Verification

4-15 Field Audit of Performance

4-19 Field Alignment

4-20 Prepare the Unit

4-20 Test Power Supplies (optional )

4-22 Calibrate and Test Card #1 (Analo g Input /O utpu t Circuitry)

4-24 Calibrate and Test Card #2 (Ana log Stereo Baseband En cod er)

4-28 Figure 4-1: Separation Scope Trace

4-29

Return OPTIMOD-FM to Service

CAUTION

The installation and servicing instructions in this manual are for

use by qualified personnel only. To avoid electric shock do not

perform any servicing other than that contained in the Operating

Instructions unless you are qualified to do so. Refer all servicing

to qualified service personnel.

Page 2

4-2

MAINTENANCE OPTIMOD-FM 8200

page

Routine Maintenance

The 8200 OPTIMOD-FM Audio Processor uses highly stable analog and digital circuitry

throughout. Recommended routine maintenance is minimal.

1. Periodically check aud i o level an d gain reduction meter read i ng s.

Become familiar with normal audio level meter readings, and with the normal performance of the G/R metering. If any meter reading is ab normal, see Section 5 for troubleshooting information.

2. Listen to the 8200’s output.

A good ear will pick up many faults. Familiarize yourself with the “sound” of the 8200

as you have set it up, and be sensitive to changes or deteriorations. But if problems arise,

please don’t jump to the conclusion that the 8200 is at fault. The troubleshooting

information in Se ctio n 5 wi ll he lp you det ermine if the pro blem i s wi th OPT IMOD-FM

or is somewhere else in the station’s equipment.

3. Periodically ch eck fo r corr osi o n.

Particularly in humid or salt-spr ay envir onments, ch eck for co rrosion at the input an d

output connectors and at those places where the 8200 chassis contacts the rack.

4. Periodically check fo r lo ss of gr ou nding.

Check for loss of grounding due to corrosion or loosening of rack mounting screws.

5. Clean the front panel w hen i t gets so i l ed.

Wash the front panel with a mild household detergent and a damp cloth. Stronger

solvents should not be used because they may damage plastic parts, paint, or the

silk-screene d lettering (99% isopropyl alcohol can be safely used).

Page 3

OPTIMOD-FM 8200 MAINTENANCE

Getting Inside the Chassis

Access the AC POWER switch by opening the 8200’s front panel (see below). The

•

AC POWER switch is located on the power supply module to the right of the chassis.

The VOLTAGE SELECTOR switch and the two fuses are on the 8200’s rear panel.

•

Access the circuit cards by opening the 8200’s front panel.

•

Most set-up and adjustment of the 8200 can be done from the front panel without

•

accessing the interior of the chassis. Alignment of the 8200 requires access only

to the front and rear panels and to those interior parts of the unit behind the front

panel. Almost all servicing can be done without removing either the top or bottom

covers.

Further disassembly of the 8200 may be required for some service procedures.

For access to: See page:

4-3

Behind front panel 4-3

Behind rear panel 4-4

Input Filter Board 4-5

D-Connector Board 4-6

Power Supply 4-6

For best RFI protection, replace all screws and tighten them firmly. If screws are lost,

replace them with screws of the same length (longer screws may cause mechanical interference or inter nal short circu its). Most screw s used in the 8200 are equipped w ith integral

lockwashers fo r secure fastening. I f a pan head screw is subs tituted, use an internal-star

lockwasher. All sc rews are steel, plated with zinc.

Front panel — open and close

To open:

1) Disconnect power to the unit.

WARNING: Hazardous voltage is exposed with the fr ont pa ne l open an d

the power ON.

2) Remove the six Philips head screws at the top and bottom of the front panel with a Philips

screwdriver.

3) Grasp the edges of the panel, pull slightly forward, and, while holding the panel vertical,

guide it forward a nd downw a rd on its s up ports . The n r ota te th e top of the panel toward

you and down until it rests on its supports.

Page 4

4-4

MAINTENANCE OPTIMOD-FM 8200

To close:

1) Check that the internal

AC POWER switch is set to ON (depressed).

2) Rotate the panel until it is vertical. Raise the panel while guiding it in on its supports.

3) Fasten the six screws that secure it in place with a Philips screwdriver.

Rear panel — remove and replace

To remove:

1) Disconnect the 8200 and remove it from the rack.

It is not practical to remove the rear panel when the 8200 is mounted in a

rack.

2) Set the unit upright on a padded surface with the rear panel facing you.

3) Remove the four screws holding the power supply.

4) Remove the sixteen screws that hold the rear panel to the chassis.

Leave about six inches (15c m) between the re ar panel and the edge of your

work surfac e.

5) Very carefully pull the rear panel about 3⁄4-inch (2cm) toward you until the internal

connectors become unplugged.

The internal connec tors are de licate and easily damaged. Be sure to pull th e

panel directly and straight away from the chassis.

Take care to n ot damage th e conne ctor pins on the Motherbo ard while the y

are expose d.

6) Tilt the top of the panel slightly downward and disconnect the cables that plug into the

Motherboard.

To replace:

1) Tilt the rear panel up until it is nearly vertical and plug the two or three cables (depending

on your unit’s Model #) into the Motherboard.

2) Very carefully line up the three connectors on the input Filter Board and the two or three

connectors on the D-Connector Board with their mating connectors on the Motherboard.

Be sure that all six connectors are properly engaged and push the rear panel in to seat the

connectors.

The connectors are de licate and easily damaged. Do no t force them.

Take care that no wires are pinched between the pane l and the ch assis.

If you encounter difficulty, you may remove the top cover to gain visual

access to the connectors. When replacing the top, be sure that the circuit

cards and the card guide s ar e aligned.

3) Replac e all twenty screws previously removed.

Do not tighten any screws until they are all loosely in place.

Page 5

OPTIMOD-FM 8200

4) Return the 8200 to its rack, connect and ground unit.

MAINTENANCE

Input Filter Board — remove, replace

To remove Input Filter Boa rd:

1) Remove the rear panel.

See page 4-4.

2) Remove the hex nuts f rom the SCA input, composite 1 outpu t, and compo site 2 output

BNC connectors.

3) Remove the 4-40 machine screw between the left input and output XLR connectors.

4) Using a small screwdriver, unlock each XLR connector insert.

The lock is accessible through a small hole in the face of the connector.

Turn the lock

5) Remove the Input Filter Board by gently pulling the board away from the panel.

To replace Input Fil ter Boa rd:

1

⁄4 turn counter-cloc kwise to re lease.

4-5

1) Place the board in position over the panel and insert the XLR and BNC connectors into

the panel.

Be sure that the washers on the BNC connectors are in place.

2) Lock the XLR connectors

Turn the lock 1⁄4 turn clockwi se .

3) Replace th e screw between the left inpu t and output XLR connectors and re place the

BNC connector hex nuts.

4) Replace the rear panel.

See page 4-4.

Page 6

4-6

MAINTENANCE OPTIMOD-FM 8200

D-Connector Board — remove, replace

To remove:

1) Remove the rear panel.

See page 4-4.

2) Remove the six hex nut jackscrews holding the D-connectors to the rear panel.

3) Remove the one 4-40 screw holding the D-Conn ec tor Board to the rear pane l.

To replace:

1) Position the boa rd with th e D-c onnecto rs thro ugh the rear pane l. Replac e the o ne 4-4 0

screw and the six jackscrews.

Do not tighten any screws until all screws are loosely in plac e.

2) Replace the rear panel.

See page 4-4.

Power Supply — remove, replace

To remove:

1) Disconnect the line cord.

2) Remove the four screws holding the power supply to the rear panel.

3) Open the f ront panel.

See page 4-3.

4) Grasp the power supply module (located at the far right of the chassis) by its handle and

pull it forward u ntil it un-mates from its connector. Then slide the module out of the

chassis to free it.

To replace:

1) Align the power supply module with its guide rails and push it back until it mates firmly

with its connector on the Motherboard.

2) Replac e and tighten the four screws that mount the power supply to the rear panel.

3) Close the 8200’s front panel.

See page 4-3.

Be sure that the internal

4) Re-connect the line cord.

AC POWER switch is set to ON (depressed).

Page 7

OPTIMOD-FM 8200 MAINTENANCE

In-System Testing (“Proof of Performance”)

The FCC (Federal Communications Commission — U.S.A.) no longer requires periodic

Proof of Performance measurements for FM stations. However, many stations will still wish

to make periodic e quipment performan ce measurements to ensure tha t their transmission

system is working correctly and that they comply with all government regulations. The text

below provide s the gene ral info rmation that is ne eded to per form measu remen ts verifyin g

the performanc e of a transmission sy stem including the 8200. I nstructions for bench -top

verification of 820 0 performance outside of the tra nsmission system are found be low in

Field Audit of Performance starting on page 4-15.

These instruction s are written w ith the assumption that the analog inputs and outputs are

used. If the optional digital I/O is used instead, follow the procedures below by analogy —

you will have to supply digitized test tones.

The NAB Broadcast and Audio System Test CD provides a good source of digitally-

generated te st ton es o n co mpa ct dis c. N o te, h ow e ve r, that thes e ton es are at a 44.1kH z

sampling rate. They cannot be directly applied to the 8200’s optional 8200D/32

AES/EBU digital input, which only accepts audio d igitized at a 32kHz sample rate. They

can be applied to the 8200’ s AES/EBU inp ut if you are u sing the 820 0D/SRC in terface

card. This test CD is available from:

4-7

NAB Services

1771 N Street N.W.

Washington, D.C. 2003 6, U.S.A.

order: (1) (8 00) 368-5644

Required Equipment:

Ultra-low distortion sine-wave oscillator/THD analyzer/audio voltmeter

•

(With verified residual distortion below 0.01%. Sound Tec hnology 1710B;

Audio Precision System One, or similar hig h-pe rf or manc e syste m. )

(The NAB Broadcast and Audio System Test CD is an excellent source

of test signals when used with a high-q ua lity CD pla ye r. )

Precision FM modulation monitor or demodulator

•

(Belar FMM-2; TFT 844, or similar.)

Precision stereo monitor or demodulator

•

(Belar FMS-2; TFT 844, or similar.)

optionally, baseband spectrum analyzer, 0-100kHz

•

(Tektronix 5L4 N plug-in with 5 111 bistable stora ge mainfram e or similar.)

Page 8

4-8

MAINTENANCE OPTIMOD-FM 8200

Monophonic Performance V erifi cation

Monophonic performance verification is straightforward. Put the 8200 in MONOL Mode,

recall the test preset BY BYPASS, and drive the left OPTIMOD-FM input with the test

signal. Suff icient head room is av ailable to modula te well beyo nd 100% at all f requencies

from 50 to 15,000Hz.

1. Prepare the unit.

A From the IDLE screen, press SYSTEM SETUP button, then press I/O CALIB to

access the

B Scroll to the MODULATION TYPE parameter and set to MONOL.

C Press ESC to return to the IDLE sc re en.

D From the IDLE screen, press RECALL PRESET button to access the RECALL

PRESET screen.

E Scroll to BY BYPASS.

I/O CALIB screen.

F Press RECALL& MODIFY button to put BY BYPASS on the air and access its

screen controls.

This test tone defeats all compression, limiting, and c lipping, but le aves the

15kHz low-pass filter in the signal path.

G Set the controls, as follows:

BYPASS GAIN dB +6

30Hz HPF OFF

This scales the gain through the 8200 so that a 50Hz tone applied to the

analog input at 6dB below the A-I CLIP LVL dBu that you preset (in the

I/O CALIB screen) produces the following output levels:

a) at the left and right analog outputs: the level in dBu that you preset a s

the A-O MAX LVL dBu (in the

screen);

b) at the optional AES/EBU digital output: 2.76dB below the maximum

digital word on both left and right channels (8200D/32 Card) or the

level that you preset as the D-O 100% LVL dB (in th e

I/O CALIB CONTROL

I/O CALIB

CONTROL screen), if you’re using the 8200D/SRC I/O Card; and

c) at the output of the optional stereo encoder (analog or digital): 100%

monophonic modulation.

Please note that OPTIMOD-FM’s fr equency re sponse drops o ff extre mely

rapidly above 15kHz. If the test oscillator is mis-calibrated, OPTIMODFM may appear not to mee t its fre quency respo nse sp ecific ation at 15kHz .

Before blaming OPTIMOD-FM, measure the output frequency of the test

oscillator with an accurate counter to make sure th at it is actually producing

15kHz, and not some slightly high er fre qu en cy .

H Press ESC to return to the IDLE screen.

Page 9

OPTIMOD-FM 8200

MAINTENANCE

Stereo Performance Verification

Many stations may wish to verify that they meet the requirements of the old part 73.322 of

the FCC Rules (which was deleted in 1983 , and which referred to st ereo performan ce). Part

73.322 referred to the performance of the transmitter only (starting with stereo encoder input

terminals), and measurements may be made by connecting the test oscillator directly to the

OPTIMOD-FM main aud io inputs. Fol lowing is a n outline o f the appropr iate measurem ents

and how to perform them.

1. Prepare the unit.

A From the IDLE screen, press SYSTEM SETUP button, then press I/O CALIB to

access the

B Scroll to the MODULATION TYPE parameter and set to STEREO.

C Press ESC to return to the IDLE screen.

D From the IDLE screen, press RECALL PRESET button to access the RECALL

PRESET screen.

I/O CALIB screen.

4-9

E Scroll to BY BYPASS.

F Press RECALL& MODIFY button to put BY BYPASS on the air and access its

screen controls.

This test tone defeats all compression, limiting, and c lipping, but le aves the

15kHz low-pass filter in the signal path.

G Set the controls, as follows:

BYPASS GAIN dB +6

30Hz HPF OFF

This scales the gain through the 8200 so that a 50Hz tone applied to the

analog input at 6dB below the A-I CLIP LVL dBu that you preset (in the

I/O CALIB screen) produces the following output levels:

a) at the left and right analog outputs: the level in dBu that you preset a s

the A-O MAX LVL dBu (in the

screen);

b) at the optional AES/EBU digital output: 3dB below the maximum

digital word on both left and right channels; and

c) at the output of the optional stereo encoder (analog or digital): 100%

monophonic modulation

d) at the output of the optional stereo encoder (analog or digital): 100%

modulation including pilot tone.

[NOTE: Because of the “interleaving” effect in the pilot tone stereo

system, the peak modulation of the com posite baseban d sign al is appr oximately equal to the higher of the peak modulations that would have been

caused by a given channel’s (left or right) driving the system alone. This

is an analog OR f un ctio n; there is no summa tion . The relatio nship i s exact

when the pilot tone is not present; however, when the pilot tone is present

the peak composite modulation increases about 2.8% when first one, and

I/O CALIB CONTROL

Page 10

4-10

MAINTENANCE OPTIMOD-FM 8200

then both channels are driven at maximum level. This occurs because the

pilot tone has a fixed phase relationship to the suppressed 38kHz stereo

subcarrier and is thus correlated to it and does not add randomly to the

composite waveform.]

H Press ESC to return to the IDLE screen.

2. Test the main channel.

A Connect the oscillator to the left and right OPTIMOD-FM analog inputs in-polarity

(“in-phase”).

B Set the oscillator to 50Hz an d its lev el to 6dB be low th e r ef er en ce clip pin g level in

your system.

C Observe the L−R meter on your stereo monitor.

If L−R fails to null below −40dB, suspect a differential phase error

between the left and right chan nels within the 820 0. Such an err or will also

cause L+R and L−R to have p oor freq ue ncy respo nse, even i f t h e l ef t a nd

right channels have accurate frequency response. Such an error could be

caused by certa in failures in the phase cor rectors for th e analog reconstr uction filters located on Card #1.

If you are doing the measurement from a remote location and driving the

oscillator into a transmission link prior to the 8200’s input terminals,

suspect a differential phase error be tween the left an d right channe ls of the

transmission link. If L−R fails to null below −20dB, this indicates that the

phase error is large enough to potentially cause audible errors in the

frequency response of the L+R signal.

D Using the L+R me ter and output of your stereo mo nitor, measure the frequency

response, total harmonic distortion, and noise characteristics of the main channel.

As a minimum, measure harmonic distortion at 50, 100, 400, 1000, 5000,

10000, and 15000Hz, at 25%, 5 0%, an d 1 00% mo dulation. If you have an

automatic sweeping distortion test set, this can provide sub sta ntia lly m or e

detailed information about system performance than does the spot-frequency tests because the distortion is mea sured at many m ore fr equenc ies.

However, bear in mind that the oscillator output level of any such instrument must be conditioned to follow the inverse of the FM pre-emphasis

curve to hold percentage modulation constant and to prevent over-modulation at high frequencies. (The NAB Broadca st and Audio Systems Test

CD has a series of tones whose levels precisely follow the 75

de-emphasis curves, and which can be applied to a pre- emphasized system

without need to readjust levels to hold modulation approximately constant.)

The old FCC Rules were ambiguous regarding the bandwidth of the

stereophonic distortion measurement s. Strict interpretatio n requires measurement of all distortion products up to 30kHz. The only way this can be

done is by using a spectrum analyzer to examine the demodulated baseband, and by calculating a R.S.S. (root-sum-square) sum of all harmonics

to 30kHz with appropria te correctio n for de-e mphasis. Ho wever, a ll stereo

monitors introduce a sharp-cutoff lowpass filter at 15kHz, and practical

considerations thus limit statio ns without a spectr um analyzer to measuring

only distortion products extending to 15kHz.

µs and 50µs

Page 11

OPTIMOD-FM 8200

If the monitor’s 15kHz lo wpass filter is inadequa te, leakage of the pilot into

the monitor output may influence both THD and noise measurements. If

this is the case, an external 19kHz notch filter may have to be used bef ore

the noise and distortion meter.

MAINTENANCE

3. Test the stereophonic subchannel.

A Reverse the polarity of the right channel input to the 8200.

B Observe th e L+R meter on your ste reo monitor.

You should see the same amount of crosstalk as seen in the subchannel in

step 2-C.

C Measure frequency response, total harmonic distortion, and noise for the stereo

subchannel using the same techniques that you used for the main channel, but using

the L−R meter and output of your stereo monitor.

Once again, only a spectrum analyzer can measure harmonic distortion to

30kHz (in this case, 38kHz±30kHz), and practical considerations usually

limit the bandwidth of the measur em en t to 15k Hz.

Measuring L−R noise is particularly problematical because most stereo

monitors have no provision for applying de-emphasis to the L−R meter.

Provided that the noise is uncorrelated (i.e., is dominated by hiss, rather

than hum or discrete tones), then you can calculate the L−R noise by the

formula:

where

s = 10 log (10

c/10

− 10

m/10

)

4-11

s is the L−R noise in dB below 100% modulation;

c is the left or right channel noise in dB below 100% modulation

(assuming left and r ight noise measurements are almost equal); and,

m is the L+R noise in dB below 100% modulation.

4. Measure separation.

Careful reading of the old FCC Rule 73.322 reveals that there are no explicit requirements for frequency response, harmonic distortion, or noise performance of left or right

channels. The only requirement specifically applicable to left and right channels is that

separation must exceed 29.7dB, 50 to 15,000Hz, left-into-right and right-into-left.

A Connect the oscillator to the left OPTIMOD-FM analog input.

B Short out the right OPTIMOD-FM analog input by connecting pin #2 of the input

XLR connector to pin #3.

If you fail to do this, the right input can pick up stray crosstalk from the

oscillator that will falsify the separation measurement.

Page 12

4-12

MAINTENANCE OPTIMOD-FM 8200

C As a minimum, measure left-into-right separation at 50, 100, 400, 1000, 5000,

10000, and 15000Hz at 100% modulation.

Remember to reduce the oscillator lev el at hig h frequen cies to co mpensate

for the FM pre-emphasis curve.

Because of the instability of many stereo monitors, the monitor should

always be aligned according to the manufacturer’s instructions before

separation measure ments are performed. It is partic ularly important no t to

misalign the OPTIMOD-FM stereo encoder to compensate for a misaligned stereo monitor. In general, the only stable and reliable way of

aligning the OPTIMOD-FM stereo encoder for correct separation is the

oscilloscope baseline method described in step 8-C on page 4-27. If you

use this technique, turn off the pilot tone by scrolling the cursor to

PILOT

on the 8200’s display, and tur nin g the soft kno b so that the pilot is OFF.

D Disconnect the oscillator from the left OPTIMOD-FM analog input, and connect it

to the right OPTIMOD-FM an al o g inp ut .

E Short out the left OPTIMOD-FM analog input by connecting pin #2 of the input

XLR connector to pin #3.

F As a minimum, measure right-into-left separation at 50, 100, 400, 1000, 5000,

10000, and 15000Hz at 100% modulation.

5. Measure main-channel-to-subchannel and subchannel-to-main-channel

crosstalk.

This step measure s the crosstalk in the transmitter by using the 8200’s internal

STALK TEST

between the left and right channels. The

3

a

⁄32 size screwdriver through the access hole on the front panel.

OPTIMOD-FM’s internal

channel-to-subchannel and subchannel-to-main-channel crosstalk. The

switch to eliminate tr ivial linear crosstalk d ue to slight phase differen ces

CROSSTALK TEST switch is operated by inserting

CROSSTALK TEST switch facilitates measurement of main-

CROSSTALK TEST

CROS-

switch applies the output of the left channel audio processing directly to either the main

channel or su bchannel stereo encoder input, and s cales in ternal ga ins approp riately in

the stereo encoder to keep total composite modulation constant.

A Connect the oscillator to the 8200’s left analog inpu t.

B Set the 8200’s CROSSTALK TEST switch to MAIN-TO-SUB.

C Set the oscillator to the desired frequency, and adjust its output level to obtain 100%

composite modulation.

As a minimum, do the test at 50, 100, 400, 1000, 5000, 10000, and

15000Hz.

D Measur e the sign al level appear ing in the ster eophonic s ubchannel (L−R) on your

stereo monitor. This is the main-channel to subchannel crosstalk.

E Set the 8200’s CROSSTALK TEST switch to SUB-TO-MAIN.

Page 13

OPTIMOD-FM 8200

F Measure the signal level appearing in the stereophonic main channel (L+R) on your

MAINTENANCE

stereo monitor. This is the subchannel to main-channel crosstalk.

Because crosstalk measurements on stereo monitors are usually derived

from stable passive filters, these measure ments ar e usually far m ore stable

and reliable than separa tion measurements.

You can also measure the crosstalk levels on a spectrum analyzer connected to the demodulated composite output of the modulation monitor.

This can be rev ea ling, be ca use the spe ctr um a nalyz er sho ws the diffe re nc e

between linear c rosstalk and n on-lin ear cr osstalk. Lin ear c rosstalk appe ars

in the main channel at the same frequency as the oscillator, and in the

subchannel at 38kHz ± [the oscillator frequency]. Non-linear crosstalk is

crosstalk appearing at other frequencies than the linear crosstalk. Linear

crosstalk is innocuous unless its level is very high (less than 20dB below

100% modulation), while non-linear crosstalk is distortion and will be

demodulated as such by the receiver.

G Repeat steps 5-B through 5-F for each frequency at which crosstalk is to be

measured.

6. Measure 38kHz Subcarrier Sup pr essi on .

4-13

A Set the CROSSTALK TEST switch to SUB-TO-MAIN.

B Be sure that the oscillator is still connected to the 8200’s left analog input.

C Set the oscillator frequency to 7.5kHz.

D Set the oscillator output level to produce 100% composite modulation.

E Measure the 38kHz subcarrier level on your stereo mon itor.

You can also measure the 38kHz subcarrier level on a spectrum analyzer

connected to the composite output of the modulation monitor.

7. Measure pilot tone frequency.

A Suppress the oscillator.

B Connect a frequency counter to the 8200’s composite output.

C Make sure that the pilot tone is turned on, and, measu re the pilot tone frequency on

the counter.

It should be 19,000Hz ±1Hz.

Page 14

4-14

MAINTENANCE OPTIMOD-FM 8200

8. Measure pilot ton e i nj ect i on .

This is most easily measured on your s tereo monitor. All monitors have the ability to

directly indicate the pilot tone injection, which should be between 8% and 10%

modulation.

If you do not have a stereo monitor, you can measure the pilot to ne injection with a

spectrum ana lyzer con necte d to the 82 00’s composite output. The p ilot tone shou ld be

19kHz at −21dB below 100% modulation (for 9% injection).

The 8200 itself has p ilot injection metering. Reach it from the

following menu sequence:

IDLE→SYSTEM SETUP→I/O CALIB→PIL OT LE VEL.

Note that if the 8200’s PILOT INJECTION control has been seriously

misadjusted, the 8200’s pilot injection meter can read incorrectly. If turning the 8200’s PILOT INJECTION control down (counterclockwise)

causes the meter to rise, then the pilot injection is below 7.5%. Turn the

PILOT INJECTION control clockwise until the meter dips to 7.5% and

then starts to rise. It is now reading correctly. (Ordinarily, you adjust the

PILOT INJECTION to make the meter read 9% injection.)

IDLE screen by the

Page 15

OPTIMOD-FM 8200 MAINTENANCE

Field Audit of Performanc e

Required Equipment:

Ultra-low distortion sine-wave oscillator/THD analyzer/audio voltmeter

•

(With verified residual distortion below 0.01%. Sound Tec hnology 1710B;

Audio Precision System One, or similar hig h-pe rf or manc e syste m. )

(The NAB Broadcast and Audio System Test CD is an excellent source

of test signals when used with a high-q ua lity CD pla ye r. )

Spectrum analyze r with tracking generator

•

(Tektronix 5L4 N plug-in with 5111 bistab le storage mainfr ame, or similar.

Alternatively, a sweep generator with 50 – 15,000Hz logarithmic sweep

can be used with an oscilloscope in X/Y mode, o r you can use a computer controlled test set like the Audio Precision System One . )

Two 620Ω ±5% resistors.

•

4-15

This procedu re is useful f or detecting and diagnosin g problems with the 8200’s pe rformance. It includes checks of frequency response, noise and distortion performance, and output

level capability. It requires the Analog I/O Card.

The 8200 performs a self-test of important digital circuitry upon power-up. Many problems

that could occur in the digital cir cuitry c an be au tomatically diagnos ed by this se lf-tes t. If

the 8200 fails the self-test, this will be indicated on the front panel, along with a fault

diagnosis (if possible).

The self test does not test the Analog I/O Card, the analog stereo encoder, part of the optional

AES/EBU digital I/O circuitry, and some of the microprocessor-based control circuitry.

(The microprocessor supervises the self-test, and will obviously be unable to complete it if

the microprocessor or its vital supporting circuitry is faulty.)

This performance audit assesses the performance of the analog-to-digital and digital-to-analog converters a nd v eri fie s tha t t h e dig i tal sig na l p roce ss ing s ec t ion ( DSP) is pa ss ing si g na l

correctly. Ordinarily, if the DSP section passes sign al n ormally in th is s tatic te st mode, and

if it passes th e power -up self- test, then the re is a h igh pro bability that it is per forming the

dynamic signal proc es sing corr ec tly. The re is th eref or e no nee d to me asur e suc h thing s a s

attack and release times — these are defined by software, and will automatically be correct

if the DSP is otherwise operating normally.

It is often more co nv en ien t to ma ke mea su rements on the bench aw a y fr om hig h RF field s

which could affe ct results. In a high RF field it is, for example , ve ry difficult to accurately

measure the v ery low THD produced by a prop erly-operating 8200 a t most frequencies.

However, in an emergency situation (and is there any other kind?), it is usually possible to

detect many of the more severe faults which co uld develop in the 8200 circuitry even in

high-RF environments.

Page 16

4-16

MAINTENANCE OPTIMOD-FM 8200

See the assembly drawings in Section 6 for component locations. Be sure to turn the power

off before removing or installing circuit cards.

Follow these instr uct i ons in or der without skipping steps.

There are s ome countries where regulator y authorities require peak ou tput levels to not

exceed a spec ified level whe n driving pos t office lines . Germany, for example, limits the

level to 4.5Vpeak ( +12.3 dBu). The

I/O CALIB CONTROL screen allows you to preset

the peak output level (A-O MAX LVL dBu) produced by the processing in its normal

operating mode. Th e absolute maximu m output lev el in any test mode is 3dB higher than

this. So, fo r examp le, Ger man user s sho uld neve r prese t the pe ak outpu t level high er tha n

+9.3dBu if they are driving post lines.

There are no tests in this procedure that require output levels above +10dBu. Users in

countries wit h a +12.3dBu limit should therefore have no difficulty completing the tests.

(The maximum possible output lev el f ro m the analo g outputs is +24dBu, as determined by

the clipping point of the 8200’s line driver amplifiers.)

1. Prepare the unit.

A Set the GROUND LIFT switch to CONNECT.

B From the IDLE screen, press RECALL PRESET button to access the RECALL

PRESET screen. (Press the soft key directly below the words “RECALL PRE-

SET.”)

C Scroll to BY BYPASS.

D Press RECALL& MODIFY button to put BY BYPASS on the air and access its

screen controls.

This test tone defeats all compression, limiting, and clipping , but retains all

audio bandwidth-limitin g filte rs (both an alo g an d DSP) in-line.

E Set the controls, as follows:

BYPASS GAIN dB 0

30Hz HPF OFF

F Press ESC to return to the IDLE screen.

G Press SYSTEM SETUP button to access the SYSTEM SETUP screen. (Press the

soft key directly below the words “SYSTEM SETUP.”)

H Press I/O CALIB button to access a detailed listing of all system calibrations.

I Set the controls listed below, as follows:

A-I CLIP LVL dBu +10.0

A-I BAL R CH dB 0

A/O FLAT

A/O 100% LVL dBu +10.0

Page 17

OPTIMOD-FM 8200 MAINTENANCE

J Connect one 620Ω ±5% resistor between pin #2 and pin #3 of the L ANALOG OUTPUT

XLR connector, an d one 620Ω ±5% resistor between pin #2 and pin #3 of the R

ANALOG OUTPUT

K Connect the audio voltmeter between pin #2 and pin #3 of the L ANALOG OUTPUT XLR

XLR connector.

connector.

L Connect the sine-wave oscillator to pins #2 and #3 of the 8200’s L ANALOG INPUT XLR

connector. Set the oscillator to 50Hz, and adjust its output level to produce a level of

2.45Vrms (+10dBu) at the

This level corresponds to 100% mo dulation.

M Disconnect the oscillator from the L ANALOG INPUT XLR connector, and connect it to

the

R ANALOG INPUT XLR connector.

N Disconnect the audio voltmeter from the L ANALOG OUTPUT XLR connector, and

connect it between pin #2 and pin #3 of the

O Verify that the level at the R ANALOG OUTPUT XLR connector is 2.45Vrms (+10dBu).

P Disconnect the oscillator and audio voltmeter from the 8200.

L ANALOG OUTPUT XLR connector.

R ANALOG OUTPUT XLR connector.

4-17

2. Check frequency response.

If a tracking or sweep generator and spectrum analyzer are not available, the frequency

response can be measured with an audio oscillator and N/D test set. If you will be doing

this, ignore the re st of step 2, and instead: Conne ct the oscillator as in step 1-L, but

reduce its output le vel by 20dB (to avoid o verloading the 8200 at h igh frequencies).

Connect the N/D test set to pins #2 and #3 of the 8200’s

L ANALOG OUTPUT XLR

connector. Measure the f requen cy re spon se w ith the o scillato r se t to 1kHz, the n verif y

that response at 50Hz, 100Hz , 400Hz, 5kHz, 10k Hz, and 15kHz is within ±0.5dB of that

measured at 1kHz. Repeat for the right channel.

A Connect the output of a tracking or sweep generator to pins #2 and #3 of the L ANALOG

INPUT

XLR connector. Set the generator for a 20 – 20,000Hz logarithmic sweep.

B Connect the input of a spectrum ana lyzer or os cilloscope to pin s #2 and #3 of the

8200’s

C Adjust the output level of the tracking or sweep generator to obtain 0.33Vrms

L ANALOG OUTPUT XLR connector.

(−7.4dBu) or less at the 8200’s output (to avoid clipping the 8200 at high frequencies

because of pre-emphasis).

D Verify that the swept output is flat ±0.5dB from 50 – 15,000Hz.

E Disconnect trac king or sweep gen erator from the L ANALOG INPUT XLR connector,

and connect it to the

R ANALOG INPUT XLR connector.

F Discon nect the spectr um analy zer or oscillos cope f rom the L ANAL OG OUT PUT XLR

connector and connect it to the

R ANALOG OUTPUT XLR connector.

Page 18

4-18

MAINTENANCE OPTIMOD-FM 8200

G Verify that the swept output is flat ±0.5dB from 50 – 15,000Hz.

H Discon nect the tracking or s weep generator and the spectrum analyzer or oscillo-

scope from the 8200.

3. Check noise and disto rti on per fo rm ance.

A Connect a THD analyzer to the L ANALOG OUTPUT XLR connector. Set the THD

analyzer’s bandwidth to 80kHz.

B Connect the oscillator to the L ANALOG INPUT XLR connector.

C Set the oscillator’s frequency to 1kHz and adjust its output level to produce

2.45Vrms at the 8200’s

This level is equivalent to 10 0% modu latio n.

D Verify that THD does not exceed 0.01%.

In many cases, measur ed results will be c onstr ained entir ely by the qua lity

of the oscillator and distortion analyzer, and/or by the presence of RF

fields.

L ANALOG OUTPUT XLR connector.

E Disconnect the THD analyzer from the L ANALOG OUTPUT XLR connector, and

connect to the

F Disconnect the oscillator from the L ANALOG INPUT XLR connector and connect to the

R ANALOG INPUT XLR connector.

G Repeat steps 3-C through 3-D for the right channel.

H Disconnect the oscillator an d THD analyzer from the 8200.

I Short the 8200’s left and righ t inputs by connecting pins #2 and #3 of the L ANALOG

INPUT

XLR connector together, and by connecting pins #2 and #3 of the R ANALOG

XLR connector together.

INPUT

J Verify that the noise at the L ANALOG OUTPUT XLR connector and the R ANALOG

OUTPUT

XLR connector is below −70dBu (80dB below 100% modulation).

R ANALOG OUTPUT XLR connector.

Note that hum or buzz due to test equipment grounding problems and/or

high-RF fields may result in falsely high readings. Such problems should

become immediately apparent if the output of the THD analyzer is monitored with an oscilloscope.

K Remove the shorting jumpers from the 8200’s inputs.

4. Return OPTIMOD-FM t o ser vi ce.

A Remove the 620Ω resistors connected across the output in step 1-J.

B Recall your normal operating preset.

Page 19

OPTIMOD-FM 8200 MAINTENANCE

Field Alignment

The only cards re quiring calibra tion are the Analog Inpu t/Output Card (Card #1) and the

optional Analog Stereo Encoder (Card #2). Because the calibration procedure compensates

only for the accumulated tolerances of stable metal film resistors used in the circuitry,

calibration is usually done once at time of manufacture, and is very unlikely to be required

again over the life of the equipment. These field alignment instructions are therefore

included primarily for reference — routine alignment is neither necessary nor desirable due

to the high stability of the circuitry.

Required Equipment

Ultra-low distortion sine-wave oscillator/THD analyzer/audio voltmeter

•

(With verified residual distortion below 0.01%. Sound Tec hnology 1710B;

Audio Precision System 1, or similar high -p er form an ce system.)

(The NAB Broadcast and Audio System Test CD is an excellent source

of test signals when used with a high-q ua lity CD pla ye r. )

4-19

Spectrum analyzer with tracking generator, ≥120kHz range

•

Tektronix 5L4N plug- in with 5111 bi stable storage m ainfr ame, or sim ilar.

Audio Precision System One, or similar.

Digital voltmeter

•

Accurate to ±0.1%

Oscilloscope

•

DC-coupled, trigge re d- sweep , with 5MHz or greater vertical bandwid th.

It is assumed that the technician is thoroughly familiar with the operation

of this equipment.

CAUTION

If calibration is nec es sary, we st rongly rec ommend t hat t he circ uit

card in question be returned to the factory for calibration by our

experienced technicians . They have acces s to special test fixtures

and a supply of exact-replacement spare parts. Only in an emergency should you attempt to align and calibrate the 8200 in the

field.

Follow these instructions in order, without skipping steps.

Refer to the drawings in Section 6 for locations of components and test points.

Page 20

4-20

MAINTENANCE OPTIMOD-FM 8200

Prepare the Unit

1) Set the GROUND LIFT switch to CONNECT.

2) Remove the 8200 from its rack and place it on a test bench away from RF fields.

3) Open up the 8200’s front panel.

See page 4-3 for instructions.

4) Set the AC POWER switch to ON.

Allow the 8200 to finish its diagnostic routine bef ore pr oceeding.

Test Power Supplies (optional)

1. Test ±12 volt supply (Display Board).

A Measure the +12 volt supply with the DVM. Verify the presence of 12 volts

(±0.75V).

The +12 volt supply appe ars between the positive le ad of C301 a nd ground

on the Display Board.

B Using the oscilloscope, measure the total ripple and noise on the +12 volt supply.

The ripple and noise should not exc eed 75mVp-p.

C Measure the −12 volt supply with the DVM. Verify the presence of −12 volts

(±0.75V).

The −12 volt supply appears between the negative lead of C302 an d ground

on the Display Board.

D Using the oscilloscope, measure the total ripple and noise on the −12 volt supply.

The ripple and noise should not exc eed 50mVp-p.

2. Test Digital +5 volt supply (Display Board).

A Measure the +5 volt supply with the DVM. Verify the presence of 5 volts (±0.25V).

The +5 volt digital supply appears between the positive lead of C300 and

ground on the Display Board.

B Using the oscillos cope, measure the total ripp le and noise on the +5 volt digital

supply.

The ripple and noise should not exc eed 50mVp-p.

C Set the 8200’s AC POWER switch to OFF.

Page 21

OPTIMOD-FM 8200

MAINTENANCE

3. Test Local ±5 volt supply (Stereo Encoder Card).

A Make sure that the 8200’s AC POWER switch is OFF.

B Remove Card #2 from its slot, insert an extender card (included with your 8200) into

slot #2, then insert Card #2 into the extender card.

C Set the AC POWER sw itch to ON.

Allow the 8200 to finish its diagnostic routine bef ore pr oceeding.

D Measure the +5 volt supply with the DVM. Verify the presence of 5 volts (±0.25V).

The +5 volt supply appears between TP9 and ground test point TP13 on

Card #2 (Stereo Encoder Card).

E Using the oscilloscope, measure the total ripple and noise on the +5 volt supply.

The ripple and noise should not exc ee d 25mV.

F Measure the −5 volt supply with the DVM. Verify the presence of 5 volts (±0.25V).

The −5 volt supply appears between TP11 and ground test point TP13 on

Card #2 (Stereo Encoder Card).

4-21

G Using the oscilloscope, measure the total ripple and noise on the −5 volt supply.

The ripple and noise should not exc ee d 25mV.

H Set the 8200’s AC POWER switch to OFF.

I Remove Card #2 from the extender card, remove the extender card from slot #2, then

re-insert Card #2 into its slot.

4. Test ±15 volt supply (Analog I/O Card).

A Make sure that the 8200’s AC POWER switch is OFF.

B Remove Card #1 from its slot, insert an extender card (included with your 8200) into

slot #1, then insert Card #1 into the extender card.

C Set the AC POWER sw itch to ON.

Allow the 8200 to finish its diagnostic routine bef ore pr oceeding.

D Measure the +15 volt supply with the DVM. Verify the presence of 15 volts

(±0.75V).

The +15 volt supply appears between TP11 and ground test point TP7 on

Card #1 (Analog I/O Card).

E Using the oscilloscope, measure the total ripple and noise on the +15 volt supply.

The ripple and noise should not exc ee d 100m Vp- p.

Page 22

4-22

MAINTENANCE OPTIMOD-FM 8200

F Measure the −15 volt supply with the DVM. Verify the presence of 15 volts

(±0.75V).

The −15 volt supply appears between TP10 and ground test point TP7 on

Card #1 (Analog I/O Card).

G Using the oscilloscope, measure the total ripple and noise on the −15 volt supply.

The ripple and noise should not exc ee d 10 0mVp- p.

5. Test Local ±5 volt supply (Analog I/O Card).

A Measure the +5 volt supply with the DVM. Verify the presence of 5 volts (±0.25V).

The +5 volt supply appears between TP6 and ground test point TP7 on

Card #1 (Analog I/O Card).

B Using the oscilloscope, measure the total ripple and noise on the +5 volt supply.

The ripple and noise should not exc ee d 100m V.

C Measure the −5 volt supply with the DVM. Verify the presence of 5 volts (±0.25V).

The −5 volt supply appears between TP8 and ground test point TP7 on

Card #1 (Analog I/O Card).

D Using the oscilloscope, measure the total ripple and noise on the −5 volt supply.

The ripple and noise should not exc ee d 100m V.

Calibrate and Test Card #1 (Analog Input/Output Circuitry)

1. Prepare for test.

A If Card #1 is not re ady for testing (in serted in an exten der car d in slot #1 ), turn AC

POWER

#1, then insert Card #1 into the extender card.

B Turn the 8200’s AC POWER switch is ON.

C From the IDLE screen, press RECALL PRESET button to access the RECALL

PRESET screen. (Press the soft key directly below the words “RECALL PRE-

SET.”)

D Scroll to TO USER TONE.

E Press RECALL& MODIFY button to put TO USER TONE on the air and acces s its

screen controls.

switch to OFF, remove Card #1 from its slot, insert the extender card into slot

Allow the 8200 to complete its diagnostic routine.

Page 23

OPTIMOD-FM 8200 MAINTENANCE

F Set the controls, as follows:

FREQUENCY Hz 400Hz

MODULATION LEVEL % 100%

MODULA T ION TYPE L+R

PILOT OFF

This test tone applies a digitally-generated 400Hz sinewave at exactly

100% modulation to the 8200’s D/A converte rs.

G Press ESC to return to the IDLE screen .

2. Calibrate reconstr uct i on filter gains.

A Connect the audio voltmeter/THD analyzer between circuit ground and TP3 on Card

#1.

B Adjust trimpot R175 (LEFT GAIN TRIM) so that the audio voltmeter indicates +12.6dBu

±0.1dBu.

C Connect the audio voltmeter between TP3 and TP9.

The voltmeter must have an accurately balanced, differential input. A

portable battery-powered DVM (digital voltmeter) is ideal for this test

because its common-mode rejec tion is essentially infinite.

4-23

D Adjust trimpot R 177 to null the meter reading.

Increase the sensitivity of the meter as necessary. The null should be very

deep (typically 60dB or better ).

3. Test frequency response of reconstructio n f i lter s (o ptional).

A From the IDLE screen, press RECALL PRESET button to access the RECALL

PRESET screen. (Press the soft key directly below the words “RECALL PRE-

SET.”)

B Scroll to TO USER TONE.

C Press RECALL& MODIFY button to put TO USER TONE on the air and access its

screen controls.

D Set the controls, as follows:

FREQUENCY Hz 400Hz

MODULATION LEVEL % 0%

MODULA T ION TYPE L+R

PILOT OFF

This test tone applies a digitally-generated 400Hz sinewave at 0% modulation to the 8200’s D/A converters. The result is no signal being applied

to the reconstruction filters.

E Press ESC to return to the IDLE screen .

F Conne ct the sweep tone ge nerator outpu t of a spectrum a nalyzer to TP1 3. Set the

sweep range from 20 Hz to 15 0k Hz.

Page 24

4-24

MAINTENANCE OPTIMOD-FM 8200

This applies a swept sine wave input signal to the left channel reconstruction filter.

G Adjust the sweep tone lev el to 2.12 volts peak or less.

H Connect the spectrum analyze r input to TP3.

I Verify that the frequency response is a low pass type. It should have a peaked

response of +0.35dB at 24kHz and +0.25dB at 15kHz.

J Connect the sw eep tone genera tor ou tput to TP 14 and th e spectr um analyz er input

at TP9.

This applies a swept sine wave input signal to the rig ht channel r econstruc tion filter.

K Repeat steps 3-C through 3-E for the right channel, then continue to step 3-H.

L Set the 8200’s AC POWER switch to OFF.

M Remove Card #1 from the extender card, remove the extender card from slot #1, then

re-insert Card #1 into its slot.

Calibrate and Test Card #2 (Analog Stereo Baseband Encoder)

1. Prepare for test.

A Make sure that the 8200’s AC POWER switch is OFF.

B Remove Card #2 from its slot, insert the extender card into slot #2, then insert Card

#2 into the extender card.

C Set the AC POWER sw itch to ON.

Allow the 8200 to complete its diagnostic routine.

D From the IDLE screen, press RECALL PRESET button to access the RECALL

PRESET screen. (Press the soft key directly below the words “RECALL PRE-

SET.”)

E Scroll to TO USER TONE.

Press RECALL& MODIFY button to put TO USER TONE on the a ir and

access its screen controls.

Page 25

OPTIMOD-FM 8200

F Set the controls, as follows:

MAINTENANCE

FREQUENCY Hz 5000Hz

MODULATION LEVEL % 91%

MODULA T ION TYPE L+R

PILOT ON

2. Measure 38kHz null.

A If it is not there already, place the TEST switch in the OPERATE position.

The TEST switch is a screwdrive r-oper ated switch mounted on the fro nt of

Card #2. From counter-clockwise to clockwise, its three positions are

MAIN-TO-SUB CROSSTALK TEST, SUB-TO-MAIN CROSSTALK TEST, and OP-

ERATE

. So OPERATE is the clockwise position.

B Connect the spectrum analyzer to the 8200’s COMPOSITE OUTPUT 1. Adjust its span to

10kHz/div and its start frequency to 0kHz. Adjust its vertical scale to 10dB/division.

Adjust its sensitivity so that the 5kHz spur is 6dB below the top of the screen.

The top of the screen now corresponds to 100% stereo modulation

(±75kHz deviation).

C Using the spectrum analyzer, verify that the 38kHz component is <−65dB.

38kHz null is maintained by DC servos IC3-A and IC4-A. These prevent

DC from appearing across analog switch IC10. If excessive 38kHz appears, check these serv os for pro per op er atio n.

4-25

3. Null 114kHz sidebands.

A Place the TEST switch in the SUB-TO-MAIN posit i o n.

B Adjust the spectrum a nalyzer display so that the 109kH z and 119kHz sidebands

around 114kHz are visible. (You will have to set the start frequency to at least

20kHz.)

C Adjust trimmer R12 (114KHZ NULL) for minimum 114kHz sidebands.

The sidebands will typically be >75dB below the top of the scree n.

4. Null Subchannel -t o- M ai n Channel crosstalk.

A Set the spectrum analyzer start frequency to 0kHz. 5kHz should be visible.

B The 5kHz compone nt you see on the spectr um analyzer is sub- to-main crosstalk.

Adjust trimmer R35 (

SUB TO MAIN XTALK) to null the 5kHz as much as possible

(typically −75dB)

Setting the spectrum ana lyzer to 5kHz per division will make the cr osstalk

easier to see.

Page 26

4-26

MAINTENANCE OPTIMOD-FM 8200

C Set the controls, as follows:

FREQUENCY Hz 15000Hz

MODULATION LEVEL % 91%

MODULA T ION TYPE L+R

PILOT ON

D Adjust tr immer capacito r C3 (HF SUB-TO-M AIN XTALK) to null the 1 5kHz compo nent

as much as possible.

E Set the controls, as follows:

FREQUENCY Hz 5000Hz

MODULATION LEVEL % 91%

MODULA T ION TYPE L+R

PILOT ON

Re-check the null at 5kHz. If necessary, slightly trim R35 to improve the

null.

5. Null Main-Chann el-to Subchannel cro sstal k.

A Place the TEST switch in the MAIN-TO-SUB XTALK position.

This is the counter-clockwise position of the TEST switch.

B Adjust the spectr um a na lyz er frequency s pa n so that the 5kH z side ba nd s surround-

ing 38kHz (33kHz an d 43kHz) are visible.

C The 5kHz sidebands that you see on the spectrum analyzer are the main-to-sub

crosstalk. A d jus t trimmer R4 (

MAIN SUB XTALK) to null the 5k Hz sideb ands as muc h

as possible (typically −80dB)

Setting the spectrum ana lyzer to 5kHz per division will make the cr osstalk

easier to see.

D Set the controls, as follows:

FREQUENCY Hz 15000Hz

MODULATION LEVEL % 91%

MODULA T ION TYPE L+R

PILOT ON

E Adjust trimmer capacito r C2 (HF MAIN-TO-SUB XTALK) to null the 15kHz component

as much as possible.

F Set the controls, as follows:

FREQUENCY Hz 5000Hz

MODULATION LEVEL % 91%

MODULA T ION TYPE L+R

PILOT ON

Re-check the null at 5kHz. If necessary, slightly trim R35 to improve the

null.

Page 27

OPTIMOD-FM 8200 MAINTENANCE

6. Test pilot tone.

A Place the TEST switch in the OPERATE position.

OPERATE is the clockwise position.

B Set the controls, as follows:

FREQUENCY Hz 5kHz

MODULATION LEVEL % 0%

MODULA T ION TYPE L+R

PILOT ON

C Verify that the 19kHz pilot is 21dB below the top of the screen (for 9% injection).

D Monitor th e composite output with the frequenc y meter and verify that the pilot

frequency is 19 ,000Hz (±1Hz).

E Monitor the composite output with the THD analyzer and verify that the THD of the

pilot is below 0.25%.

7. V er ify DC offset null.

4-27

A Set the controls, as follows:

FREQUENCY Hz 5kHz

MODULATION LEVEL % 0%

MODULA T ION TYPE L+R

PILOT OFF

B Connect COMPOSITE OUTPUT #1 to a DC voltmeter.

C Verify that the observed DC output voltage is 0.00V (±5mV).

DC offset null is maintained with servo IC4-B.

D Repeat for COMPOSITE OUTPUT #2.

8. Calibrate high frequ ency sep arat i on.

A Set the controls, as follows:

FREQUENCY Hz 15000Hz

MODULATION LEVEL % 100%

MODULA T ION TYPE LEFT

PILOT OFF

B Make sure that the TEST switch is in the OPERATE position.

This is the clockwise position of the TEST switch.

C Observe the COMPOSITE OUTPUT #1 with the scope. Trigger the scope externally from

the

L ANALOG OUTPUT. Set the scope sensitivity to 0.5 V/div, and input coupling to

“DC.” Set the horizontal timebase to 0.2ms/div.

D Adjust R66 (8200 OUTPUT ATTEN 1 CONTROL) until the COM POSITE OU TPUT LEVEL is

4Vp-p.

Page 28

4-28

MAINTENANCE OPTIMOD-FM 8200

E Adjust trimmer R26 on Card #2 (HIGH FREQUENCY SEPARATION/TILT) and front-panel

control R37 (

SEPARATION) to obtain the flattest baseline possible . To ma ke the final

adjustment accurately, expan d th e v er tical scale by a factor of ten and r e-adjust the

controls if necessary.

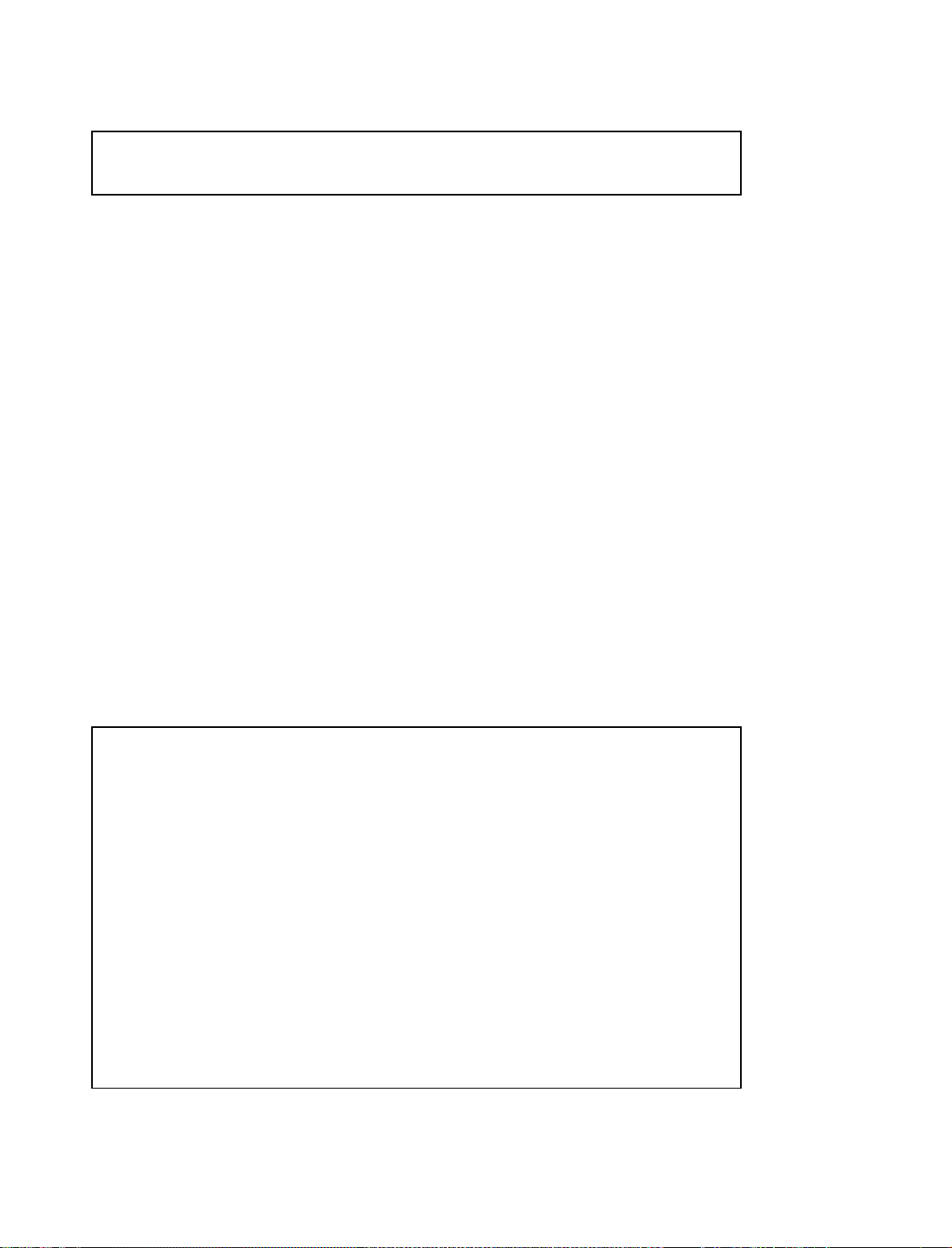

Variation from horizontal will ty pically be unde tectab le by e ye. It mu st be

less than

DO NOT USE AN ATTENUATOR PROBE. Such probes typically have

enough phase error to com pletely invalid ate any sep aration mea surements.

Note also that some scopes have enough phase error in their vertical

amplifiers to make separation measurements inaccurate. If separation appears inadequate in this test, check it with another scope before assuming

that the 8200 is faulty.

1

⁄2 of a minor division on the scope gratic ule.

Figure 4-1: Separation Sc ope Trace

9. Check low-frequency separatio n.

A Set the controls, as follows:

FREQUENCY Hz 400Hz

MODULATION LEVEL % 100%

MODULA T ION TYPE LEFT

PILOT OFF

B Verify that the baseline is still flat.

You will have to slow the oscilloscope timebase to see the wave form .

Page 29

OPTIMOD-FM 8200

Return OPTIMOD-FM to Service

1) Disconnect all test instruments from the 8200.

MAINTENANCE

4-29

2) Set the

3) Remove Ca rd #2 fr om the car d ex ten de r, remove the car d ex ten de r fr om the 820 0, then

insert Card #2 into slot #2.

4) Set the

5) Close front panel.

6) Return the 8200 to its rack and reconnect it.

7) After the 820 0 has been powered fr om the AC line, re call the de sired ope rating pre set,

either locally or by remote control.

AC POWER switch to OFF.

AC POWER switch to ON.

See page 4-3 for instructions.

If you recall presets by the 8200’s internal automation, be assured tha t this

function will start working as soon as you apply AC power. The next

programmed preset will be recalle d at the pr ogrammed time for that pre set.

Page 30

4-30

MAINTENANCE OPTIMOD-FM 8200

This Page Intentionally Left Blank.

Loading...

Loading...