Page 1

Four-Output PTIC Control IC

TCC-404

Introduction

TCC−404 is a four−output high−voltage digital to analog control IC

specifically designed to control and bias ON Semiconductor’s Passive

Tunable Integrated Circuits (PTICs).

These tunable capacitor control circuits are intended for use in

mobile phones and dedicated RF tuning applications. The

implementation of ON Semiconductor’s tunable circuits in mobile

phones enables significant improvement in terms of antenna radiated

performance.

The tunable capacitors are controlled through a bias voltage ranging

from 1 V to 28 V. The TCC−404 high−voltage PTIC control IC has

been specifically designed to cover this need, providing four

independent high−voltage outputs that control up to four different

tunable PTICs in parallel. The device is fully controlled through a

MIPI RFFE digital interface.

Key Features

• Controls ON Semiconductor’s PTIC Tunable Capacitors

• Compliant with Timing Needs of Cellular and Other Wireless System

Requirements

• 30 V Integrated Boost Converter with Four up to 28 V Programmable

DAC Outputs

• Low Power Consumption

• MIPI RFFE Interfaces (1.8 V) with 26 MHz Read and 52 MHz Write

• Automatic On−chip Turbo Calculation − Simplified Turbo Messaging

• ASDIV Switch Support over GPIO Toggle or RFFE Command to

facilitate Dual Settings for two Antennae (Dual Radio)

• Integrated Diode and Reduced External Components

• Reduced Value 2.2 mH − 4.7 mH Inductor

• Small Form Factor 1575 x 1025 mm, WLCSP 4x3 Array

• This is a Pb−Free Device

www.onsemi.com

WLCSP12

CASE 567WF

MARKING DIAGRAM

T44x

ALYWG

G

T44x= Specific Device Code

x = a or b

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

G = Pb−Free Package

(Note: Microdot may be in either location)

ORDERING INFORMATION

See detailed ordering and shipping information on page 39 of

this data sheet.

Typical Applications

• Multi−band, Multi−standard, Advanced and Simple Mobile Phones

• Tunable Antenna Matching Networks

• Compatible with Closed−loop and Open−loop Antenna Tuner

Applications

© Semiconductor Components Industries, LLC, 2019

March, 2021 − Rev. 2

1 Publication Order Number:

TCC−404/D

Page 2

VDDA

GND

L_BOOST VHV

VIO

VDDA

VREG

VHV

Booster

TCC−404

vio_on

ibias_start / vref_start

Regulators

Bandgap

VREG

POR

RC

OSC

VIO

AD

VIO

POR

Start

Reference

Interface

Level

Shifter

CLK DATA

A3

4 bit

DAC

por_vreg

Registers

7 bit

7

DAC

7 bit

7

DAC

7 bit

7

Level

Shifter

OTP

Figure 1. Control IC Functional Block Diagram

A2

A1

A1

OUTD

DAC

7 bit

7

DAC

A2

VHV

OUTA

OUTB

OUTC

OUTD

A3

L_BOOST

B3

C3

B2

C2

B1

C1

D1D2D3

B1

OUTC

C1

OUTB

D1

OUTA

B2

GNDA

C2

AD

D2

DATA

B3

VDDA

C3

VIO

D3

CLK

Figure 2. RDL Padout, Bump Side View (left), PCB footprint (right), with RDL Bump Assignment

www.onsemi.com

2

Page 3

TCC−404

RDL Pin Out

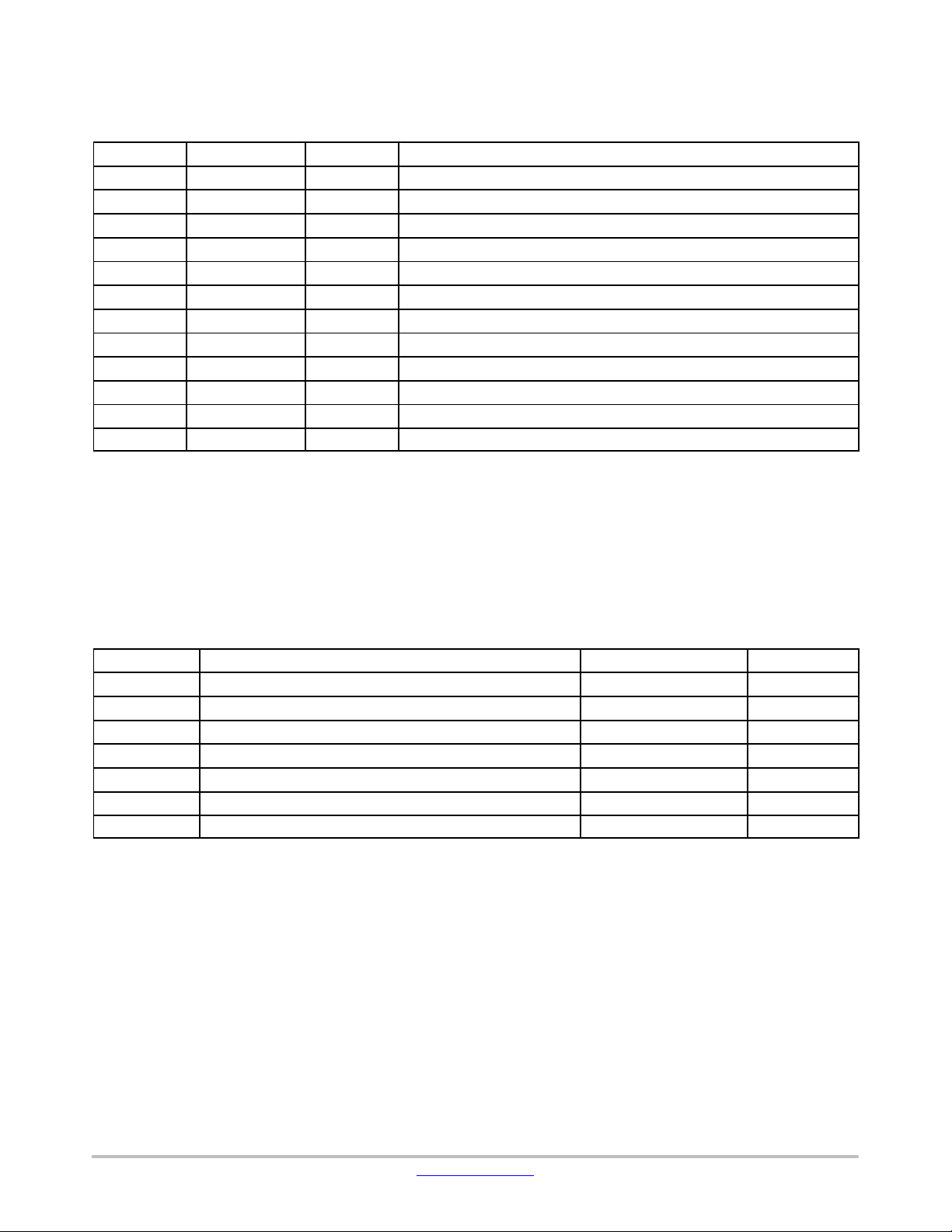

Table 1. PAD DESCRIPTIONS

RDL Name Type Description

A1 OUTD AOH High Voltage Output D

A2 VHV AOH / AIH Boost High Voltage (can be forced externally)

A3 L_BOOST AOH Boost Inductor

B1 OUTC AOH High Voltage Output C

B2 GNDA P Analog Ground

B3 VDDA P Analog Supply

C1 OUTB AOH / AI High Voltage Output B

C2 AD DIO Antenna Diversity (Note 1)

C3 VIO P Digital IO Supply

D1 OUTA AOH / AI High Voltage Output A

D2 DATA DIO MIPI RFFE Digital IO

D3 CLK DI MIPI RFFE Clock

Legend: Pad Types

AIH= High Voltage Analog Input

AOH= High Voltage Analog Output

DI= Digital Input

DIO= Digital Input/Output (IO)

P= Power

1. To be grounded if not utilized.

ELECTRICAL PERFORMANCE SPECIFICATIONS

Table 2. ABSOLUTE MAXIMUM RATINGS

Symbol Parameter Rating Unit

VDDA Analog Supply Voltage −0.3 to +5.5 V

VIO IO Reference Supply Voltage −0.3 to +2.5 V

V

I/O

V

HVH

V

ESD (HBM)

T

STG

T

AMB_OP_MAX

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

Input Voltage Logic Lines (DATA, CLK) −0.3 to VIO + 0.3 V

VHV Maximum Voltage −0.3 to 33 V

Human Body Model, JESD22−A114, All I/O 2,000 V

Storage Temperature −55 to +150 °C

Max Operating Ambient Temperature without Damage +110 °C

www.onsemi.com

3

Page 4

TCC−404

Table 3. RECOMMENDED OPERATING CONDITIONS

Rating

Symbol Parameter

T

AMB_OP

T

J_OP

Operating Ambient Temperature −30 − +85 °C

Operating Junction Temperature −30 − +125 °C

VDDA Analog Supply Voltage 2.3 − 5.5 V

VIO IO Reference Supply Voltage 1.62 − 1.98 V

Functional operation above the stresses listed in the Recommended Operating Ranges is not implied. Extended exposure to stresses beyond

the Recommended Operating Ranges limits may affect device reliability.

Min Typ Max

Unit

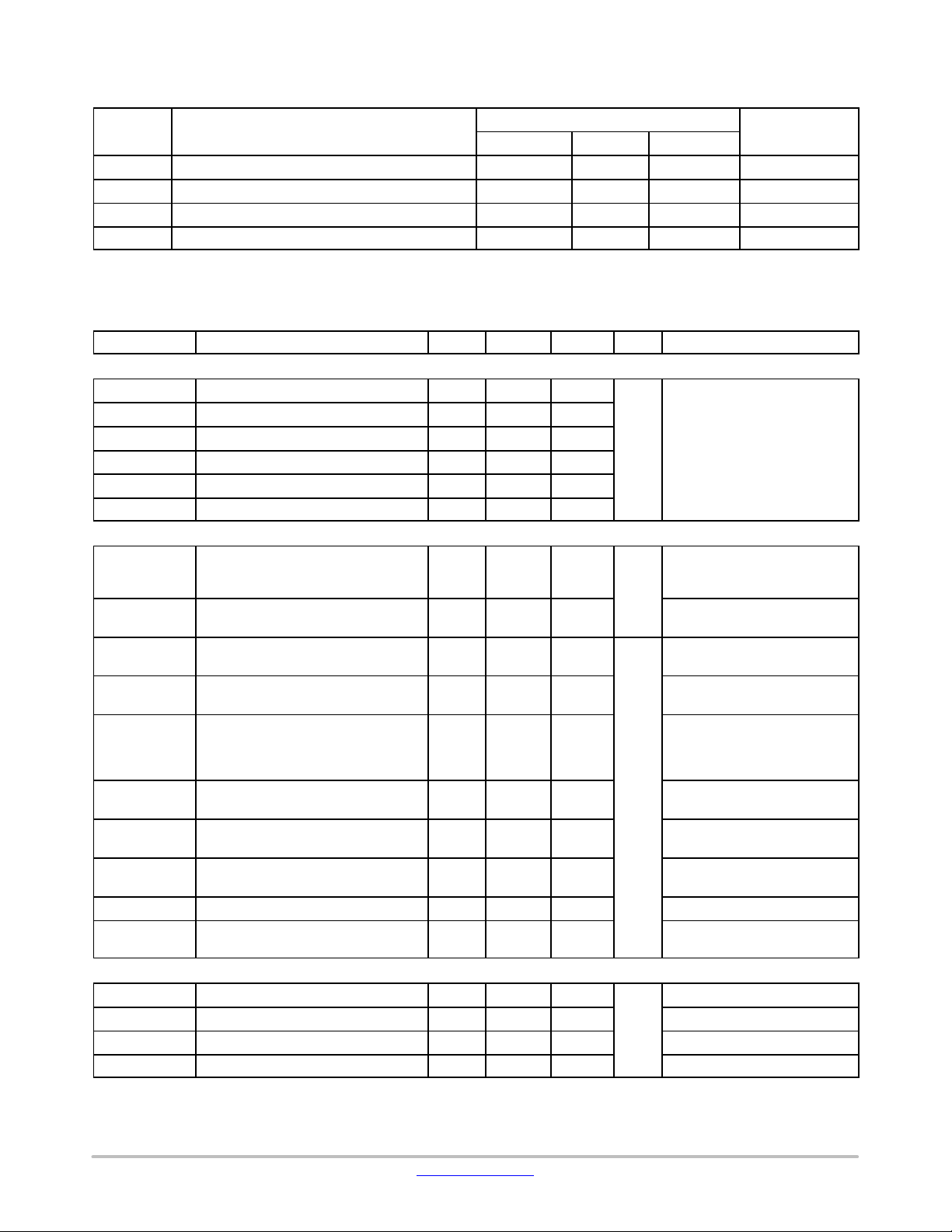

Table 4. DC CHARACTERISTICS (T

equivalent series load of 5.6 kW and 2.7 nF; C

Symbol

Parameter Min Typ Max Unit Comment

= −30 to +85°C; V

A

= 22 nF; L

HV

= 15 V for each output; 2.3 V<VDDA< 5.5 V; VIO = 1.8 V; R

OUTX

= 2.2 mH; unless otherwise specified)

BOOST

LOAD

=

SHUTDOWN MODE

I

VDDA

I

L_BOOST

I

BATT

I

VIO

I

CLK

I

DATA

VDDA Supply Current − − 1.5 mA

L_BOOST Leakage − − 1.5

Battery Current − − 2.5

VIO Supply Current −1 − 1

CLK Leakage −1 − 1

DATA Leakage −1 − 1

VIO Supply is Low

ACTIVE MODE

I

BATT

Average battery current, 2 outputs actively switching 16 V for 1205 ms to 2 V

− 1200 1600 mA At VHV = 20 V

VDDA = 3.3 V

for 1705 ms to 8 V for 1705 ms

I

BATT_SS0

I

BAT_SS2

I

BATT_SS16

I

L_BOOST

Average battery current, 4 outputs @

0 V steady state

Average battery current, 4 outputs @

2 V steady state

Average battery current, 4 outputs @

16 V steady state

Average inductor current, 2 outputs actively switching 16 V for 1205 ms to 2 V

− 750 950 At VHV = 20 V

VDDA = 3.3 V

− 850 1200 mA At VHV = 20 V

VDDA = 3.3 V

− 1000 1300 At VHV = 20 V

VDDA = 3.3 V

− 1000 1400 At VHV = 20 V

VDDA = 3.3 V

for 1705 ms to 8 V for 1705 ms and 3

outputs are @ 16 V steady state

I

L_BOOST_SS0

I

L_BOOST_SS2

I

L_BOOST_SS16

I

VIO_INACT

I

VIO_ACTIVE

Average inductor current, 4 outputs @

0 V steady state

Average inductor current, 4 outputs @

2 V steady state

Average inductor current, 4 outputs @

16 V steady state

− 550 750 At VHV = 20 V

VDDA = 3.3 V

− 700 1000 At VHV = 20 V

VDDA = 3.3 V

− 850 1100 At VHV = 20 V

VDDA = 3.3 V

VIO average inactive current − − 3 VIO is high, no bus activity

VIO average active current − − 250 VIO = 1.8 V, master sending

data at 26 MHz

LOW POWER MODE

I

VDDA

I

L_BOOST

I

BATT

I

VIO

VDDA Supply Current − − 25 mA

L_BOOST Leakage − − 6

Battery Current − − 31 I

VDDA

+ I

L_BOOST

VIO Supply Current − − 3 No bus activity

Product parametric performance is indicated in the Electrical Characteristics for the listed test conditions, unless otherwise noted. Product

performance may not be indicated by the Electrical Characteristics if operated under different conditions.

www.onsemi.com

4

Page 5

TCC−404

Table 5. BOOST CONVERTER CHARACTERISTICS

(VDDA from 2.3 V to 5.5 V; VIO = 1.8 V; TA = –30 to +85°C; CHV = 22 nF; L

Symbol

VHV_min Minimum programmable output volt-

Parameter Conditions Min Typ Max Unit

Active mode − 15 −

age (average), DAC Boost = 0h

VHV_max Maximum programmable output volt-

Active mode − 30 −

age (average), DAC Boost = Fh

Resolution Boost voltage resolution 4−bit DAC − 1 −

I

L_BOOST_LIMIT

Inductor current limit − 300 − mA

Table 6. ANALOG OUTPUTS (OUT A, OUT B, OUT C, OUT D)

(VDDA from 2.3 V to 5.5 V; VIO = 1.8 V; VHV = 26 V; TA = –30 to +85°C; R

Parameter

SHUTDOWN MODE

Z

OUT

OUT A, OUT B, OUT C, OUT D

output impedance

ACTIVE MODE

V

OH

V

OL

Maximum output voltage − 24 or

Minimum output voltage − − 1 V DAC A, B, C, D = 01h, DAC Boost =

Slew Rate − 3 10

R

PD

OUT A, OUT B, OUT C, OUT D set

in pull−down mode

Resolution Voltage resolution (1−bit) − 189 /

V

OFFSET

Zero scale, least squared best fit −1 − +1 LSB

Gain Error −3.0 − +3.0 %V

DNL Differential non−linearity least

squared best fit

INL Integral non−linearity least squared

best fit

I

SC

V

RIPPLE

Over current protection − 5 65 mA Any DAC output shorted to ground

Output ripple with all outputs at

steady state

Description Min Typ Max Unit Comment

7 − −

28

− − 1000

220

−0.9 − +0.9 LSB 1 V to 24 V with 26 V VHV

−1 − +1 LSB 1 V to 24 V with 26 V VHV

− − 40 mV RMS 1 V to 24 V with 26 V VHV

= 2.2 mH; unless otherwise specified)

BOOST

= ∞ unless otherwise specified)

load

MW

DAC disabled

− V DAC A, B, C, D = 7Fh,

DAC Boost = Fh, I

0h to Fh, I

ms

W

2 V to 20 V step, measured at

V

OUT

R

LOAD

5.6 kW and 2.7 nF, Turbo enabled

DAC A, B, C, D = 00h, DAC Boost =

0h to Fh, selected output(s) is

disabled

− mV (1 LSB = 1−bit) based on VOH

selection

OUT

1 V to 24 V with 26 V VHV

V

< 10 mA

OH

< 10 mA

OH

= 15.2 V,

= equivalent series load of

www.onsemi.com

5

Page 6

TCC−404

THEORY OF OPERATION

Overview

The control IC outputs are directly controlled by

programming the four DACs (DAC A, DAC B, DAC C,

DAC D) through the digital interface.

The DAC stages are driven from a reference voltage,

generating an analog output voltage driving a high−voltage

amplifier supplied from the boost converter (see Figure 1 −

Control IC Functional Block Diagram).

The control IC output voltages can be programmed to

scale from 0 V to 24 V, with 127 steps of 189 mV. The

nominal control IC output can be approximated to 189 mV

x (DAC value).

The control IC output voltages can also be programmed to

scale from 0 V to 28 V, with 127 steps of 220 mV. The

nominal control IC output can be approximated to 220 mV

x (DAC value).

For performance optimization the boost output voltage

(VHV) can be programmed to levels between 15 V and 30 V

via the DAC_boost register (4 bits with 1 V steps). The

startup default level for the boosted voltage is VHV = 28 V.

For proper operation and to avoid saturation of the output

devices and noise issues, it is recommended to operate the

boosted VHV voltage at least 2 V (>4 V [6 V recommended]

if using Turbo−Charge Mode) above the highest

programmed V

Operating Modes

voltage of any of the three outputs.

OUT

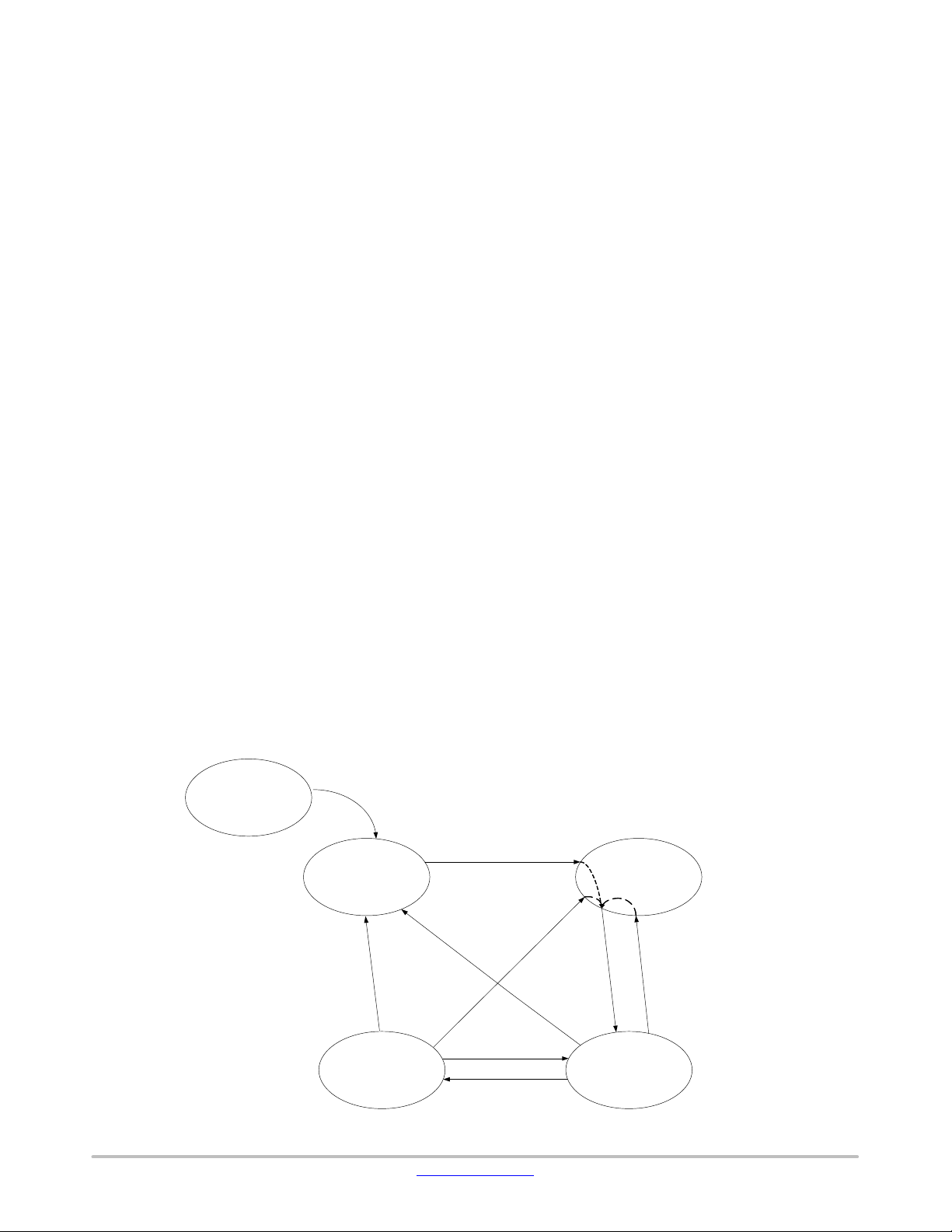

The following operating modes are available:

1. Shutdown Mode: All circuit blocks are off, the

DAC outputs are disabled and placed in high Z

state and current consumption is limited to

minimal leakage current. The shutdown mode is

entered upon initial application of VDDA or upon

VIO being placed in the low state. The contents of

the registers are not maintained in shutdown mode.

2. Startup Mode: Startup is only a transitory mode.

Startup mode is entered upon a VIO high state. In

startup mode all registers are reset to their default

states, the digital interface is functional, the boost

converter is activated, outputs OUT A, OUT B,

OUT C and OUT D are disabled and the DAC

outputs are placed in a high Z state. Control

software can request a full hardware and register

reset of the TCC−404 by sending an appropriate

PWR_MODE command to direct the chip from

either the active mode or the low power mode to

the startup mode. From the startup mode the device

automatically proceeds to the active mode.

3. Active Mode: All blocks of the TCC−404 are

activated and the DAC outputs are fully controlled

through the digital interface, DACs remain off

until enabled. The DAC settings can be

dynamically modified and the HV outputs will be

adjusted according to the specified timing

diagrams. Each DAC can be individually

controlled and/or switched off according to

application requirements. Active mode is

automatically entered from the startup mode.

Active mode can also be entered from the low

power mode under control software command.

4. Low Power Mode: In low power mode the serial

interface stays enabled, the DAC outputs are

disabled and are placed in a high Z state and the

boost voltage circuit is disabled. Control software

can request to enter the low power mode from the

active mode by sending an appropriate

PWR_MODE command. The contents of all

registers are maintained in the low power mode.

VDDA = 0

Shutdown

VIO = LOW

automatic

Low Power

(User Defined)

Battery insertion

VIO = HIGH

PWR_MODE =

0bx1

VIO = LOW

PWR_MODE = 0b00

PWR_MODE = 0b10

Figure 3. Modes of Operation

www.onsemi.com

6

Startup

(Registers reset)

PWR_MODE =

0bx1

Active

(User Defined)

Page 7

TCC−404

VDDA Power−On Reset (POR)

Upon application of VDDA, TCC−404 will be in

shutdown mode. All circuit blocks are off and the chip draws

only minimal leakage current.

VIO Power−On Reset and Startup Conditions

A high level on VIO places the chip in startup mode which

provides a POR to TCC−404. POR resets all registers to their

default settings. VIO POR also resets the serial interface

circuitry. POR is not a brown−out detector and VIO needs to

be brought back to a low level to enable the POR to trigger

again.

Table 7. VIO POWER−ON RESET AND STARTUP

Default State for

Register

DAC Boost [1101] VHV = 28 V

Power Mode [01]>[00] Transitions from shutdown to startup and then automatically to active mode

DAC Enable [0000] V

DAC A Output in High−Z Mode

DAC B Output in High−Z Mode

DAC C Output in High−Z Mode

DAC D Output in High−Z Mode

VIO POR

A, B, C, D Disabled

OUT

Comment

VIO Shutdown

A low level at any time on VIO places the chip in shutdown mode in which all circuit blocks are off. The contents of the

registers are not maintained in shutdown mode.

Table 8. VIO THRESHOLDS (VDDA from 2.3 V to 5.5 V; T

Parameter

VIORST VIO Low Threshold − − 0.2 V When VIO is lowered below this threshold level the

Description Min Typ Max Unit Comments

= –30 to +85°C unless otherwise specified)

A

chip is reset and placed into the shutdown mode

Power Supply Sequencing

The VDDA input is typically directly supplied from the battery and thus is the first on. After VDDA is applied and before VIO

is applied to the chip, all circuits are in the shutdown mode and draw minimum leakage currents. Upon application of VIO,

the chip automatically starts up using default settings and is placed in the active state waiting for a command via the serial

interface.

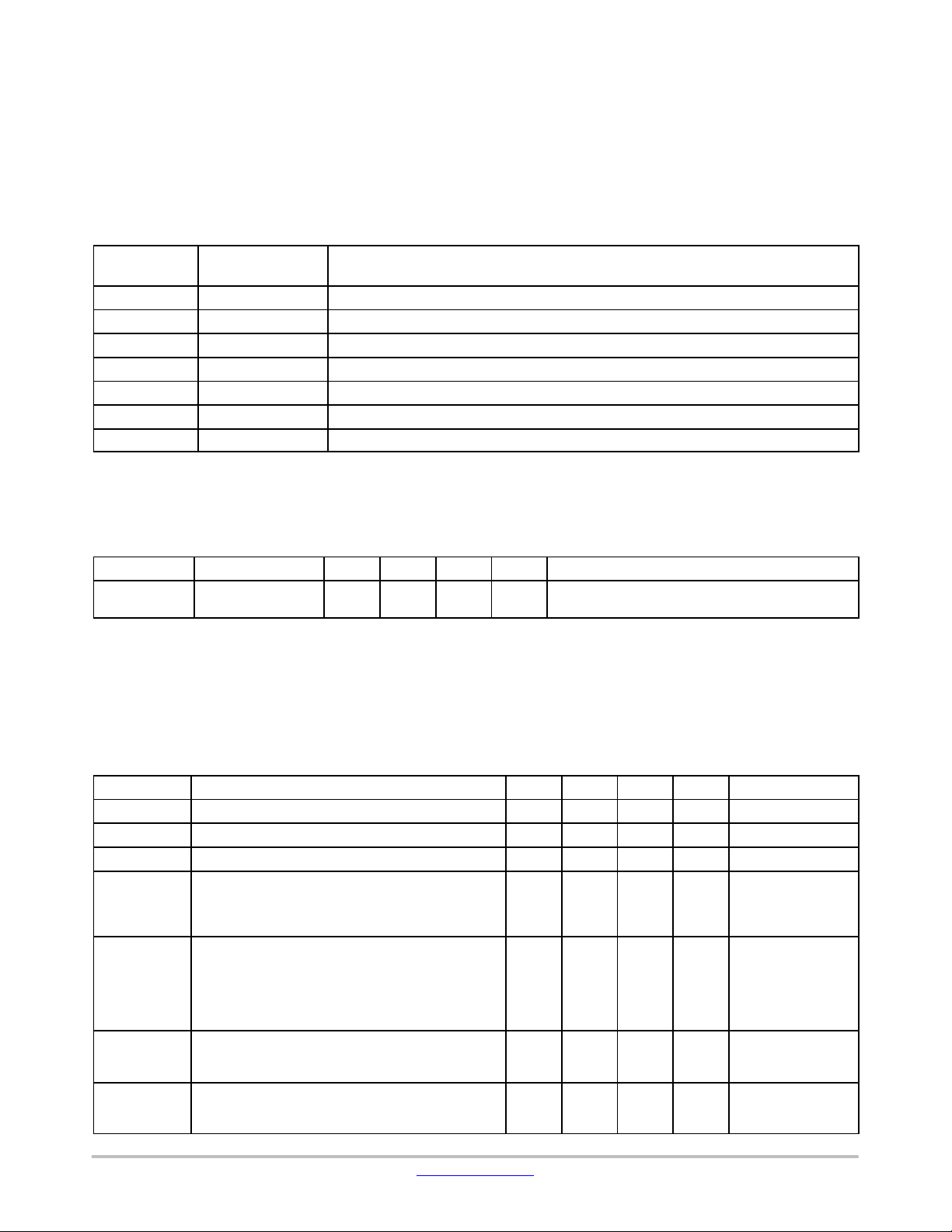

Table 9. TIMING (VDDA from 2.3 V to 5.5 V; V

= 2.2 mH; VHV = 20 V; Turbo−Charge mode off unless otherwise specified)

L

BOOST

Parameter

T

POR_VREG

T

BOOST_START

T

SD_TO_ACT

T

SET+

T

SET−

T

SET+

T

SET−

Internal bias settling time from shutdown to active mode − 50 120

Time to charge CHV @ 95% of set VHV − 130 −

Startup time from shutdown to active mode − 180 250

Timing for a 2 V to 16 V transition, measured when

voltage reaches within 5% of target voltage, measured between the R (5.6 kW) and C (2.7 nF) of an

equivalent PTIC series load.

Timing for a 16 V to 2 V transition, measured when

voltage reaches within 5% of target voltage, measured between the R (5. 6 kW) and C (2.7 nF) of an

equivalent PTIC series load.

Output A, B, C, D positive settling time with Turbo − 35 −

Output A, B, C, D negative settling time with Turbo − 35 −

Description Min Typ Max Unit Comments

= 1.8 V; TA = –30 to +85°C; OUT A, OUT B, OUT C, OUT D; CHV = 47 nF;

IO

For info only

For info only

Voltage settling time

connected on V

Effective PTIC

tuning voltage

settling time,

measured between

an equivalent R and

C PTIC load

Voltage settling time

connected on V

Voltage settling time

connected on V

− 50 60

− 50 60

ms

ms

ms

ms

ms

ms

ms

A, B, C, D

A, B, C, D

A, B, C, D

OUT

OUT

OUT

www.onsemi.com

7

Page 8

TCC−404

g

Figure 4. Output Settling Diagram

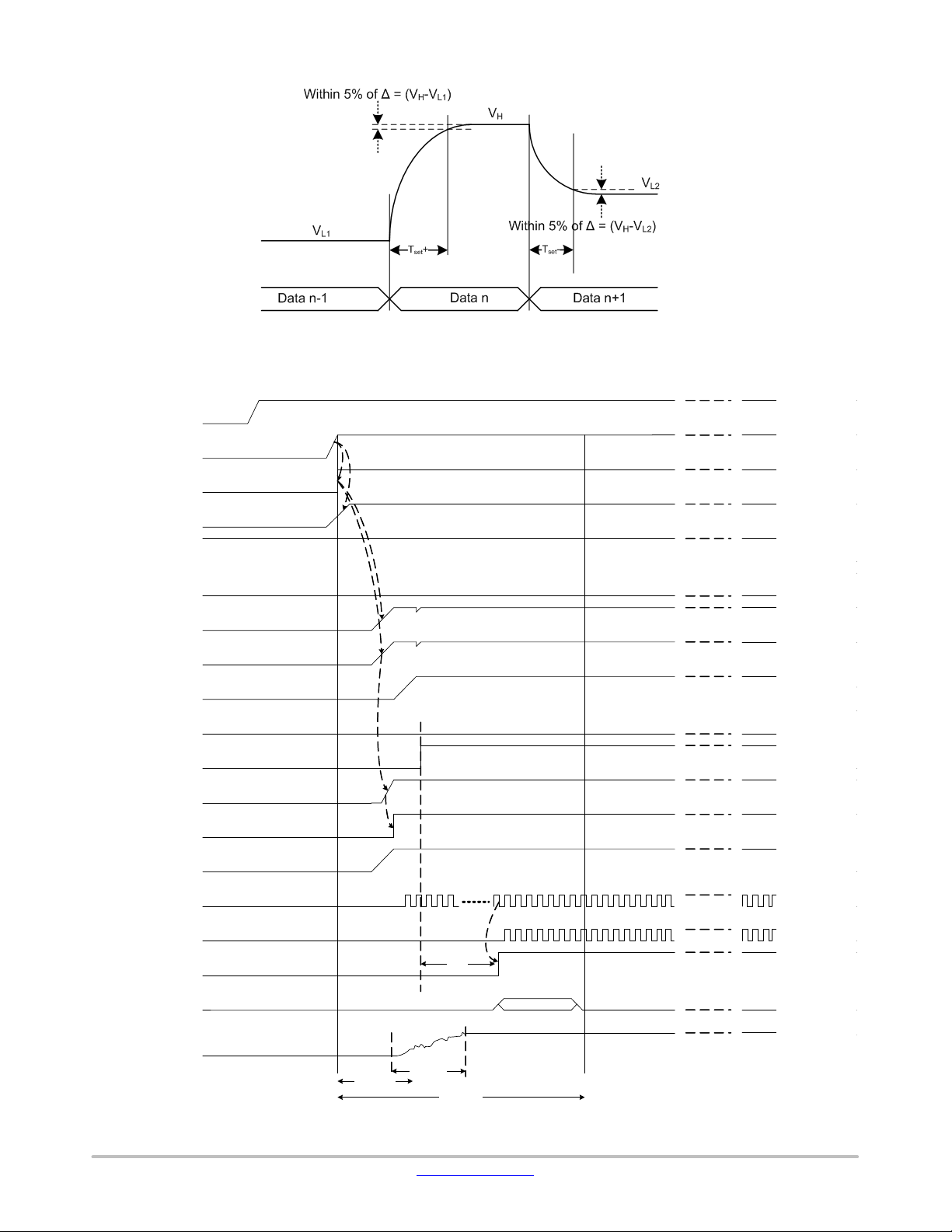

Shutdown Startup

VDDA

VIO

vio_on

startup

references

dvreg_en

vreg_short

avreg

dvreg

vref

nvbg_en

vbg_ok

dvreg_on (digital supply monitoring)

nforce_reset = VIO_ON& DVREG_ON)

Active

rc_enable

rc osc

clk_dig = rc_osc 64us after

nforce_reset & vbg_ok & rc_enable

nreset_dig = latched 64us after

(nforce_reset & vbg_ok_osc_on)

OTP read

VHV

32us

T

T

POR_VREG

Fi

boost_start

T

SD_TO_ACT

ure 5. Startup Timing Diagram

www.onsemi.com

8

Page 9

TCC−404

Boost Control

TCC−404 integrates an asynchronous current control

boost converter. It operates in a discontinuous mode and

features spread−spectrum circuitry for Electro−Magnetic

Interference (EMI) reduction.

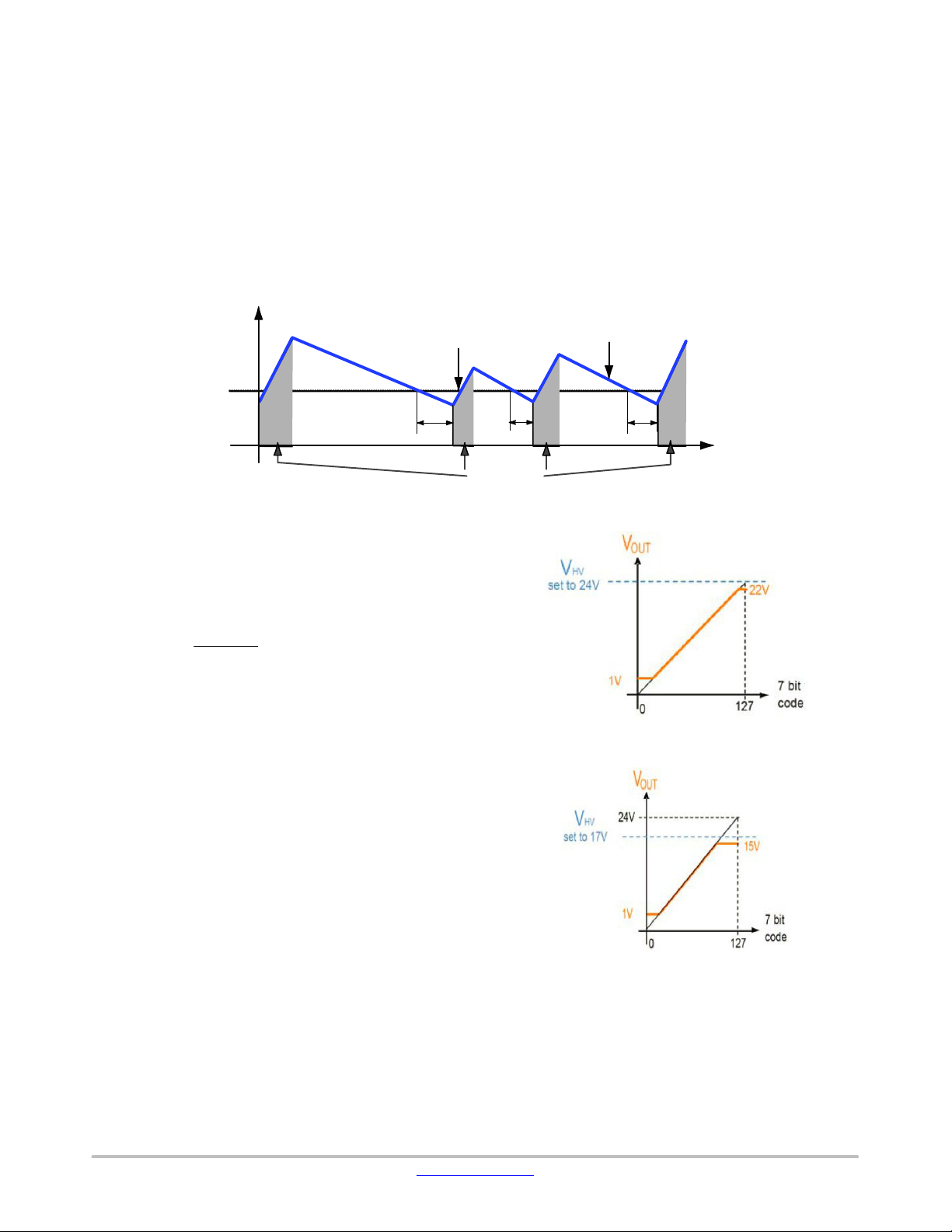

Boost Output Voltage (VHV) Control Principle

The asynchronous control starts the boost converter as

soon as the VHV voltage drops below the reference set by

the 4−bit DAC and stops the boost converter when the VHV

voltage rises above the reference again.

Recharge

Set

VHV

Figure 6. VHV Voltage Waveform

High Impedance (High Z) Feature

In shutdown mode the OUT pins are set to a high

impedance mode (high Z). Following is the principle of

operation for the control IC:

1. The DAC output voltage V

OUT

DAC code

+

127

24 or 28 V

V

is defined by:

OUT

(eq. 1)

2. The RFFE_REG_0x05 controls the range of the

DAC (24 or 28 V).

3. The voltage VHV defines the maximum supply

voltage of the DAC supply output regulator and is

set by a 4−bit control.

4. The maximum DAC DC output voltage V

OUT

is

limited to (VHV – 2 V). DAC can achieve higher

output voltages, but timing is not maintained for

swings above VHV − 2 V.

5. The minimum output DAC voltage V

OUT

is 1.0 V

max.

CHV

Delay

Due to the slow response time of the control loop, the

VHV voltage may drop below the set voltage before the

control loop compensates for it. In the same manner, VHV

can rise higher than the set value. This effect may reduce the

maximum output voltage available. Please refer to Figure 6

below.

The asynchronous control reduces switching losses and

improves the output (VHV) regulation of the DC/DC

converter under light load, particularly in the situation

where TCC−404 only maintains the output voltages to fixed

values.

CHV

Boost

Running

Discharge

Delay

Figure 7. DAC Output Range Example A

VHV

Delay

Time

www.onsemi.com

9

Figure 8. DAC Output Range Example B

Page 10

TCC−404

Digital Interface

The control IC is fully controlled through a digital

interface (DATA, CLK). The digital interface is described in

the following sections of this document.

Turbo−Charge Mode

The TCC−404 control IC has an autonomous

Turbo−Charge Mode that significantly shortens the system

settling time when changing programming voltages.

In Turbo−Charge Mode the DAC output target voltage is

temporarily set to either a delta voltage above or a delta

voltage below the actual desired target. The delta voltage is

4 volts.

After the DAC value message is received, the delta

voltage is calculated by hardware, and is applied in digital

format to the input of the DAC, right after trigger is received.

The period for which the delta voltage is maintained to the

input of the DAC, the Turbo time, is autonomously

calculated and based on the following considerations:

• DACA CONTROL[1:0] / DACB CONTROL[1:0] /

DACC CONTROL[1:0] / DACD CONTROL[1:0] :

These are the DAC operational mode control bits. The

bit[0] in the control defines the step size of the DAC as

189 mV (0) or 220 mV (1). The bit[1] in the control

enables the autonomous turbo mode. In order the Turbo

operation to be enabled each DAC has to have this bit

set. Otherwise the DAC values are applied without

Turbo.

• TurboUpMultiplier[2:0]: If the Turbo direction is UP,

the base autonomous Turbo time calculated is

multiplied with this configuration factor. The default

state of this configuration provides the optimum time

for the Turbo UP operation. The factor decoding is as

below:

‘000’: multiplication by 1.0

‘001’: multiplication by 1.125

‘010’: multiplication by 1.25

‘011’: multiplication by 1.375 (default)

‘100’: multiplication by 1.5

‘101’: multiplication by 1.625

‘110’: multiplication by 1.75

‘111’: multiplication by 1.875

• TurboDownMultiplier[2:0]: If the Turbo direction is

DOWN, the base autonomous Turbo time calculated is

multiplied with this configuration factor. The default

state of this configuration provides the optimum time

for the Turbo DOWN operation. The factor decoding is

as below:

‘000’: multiplication by 1.0

‘001’: multiplication by 1.125

‘010’: multiplication by 1.25

‘011’: multiplication by 1.375 (default)

‘100’: multiplication by 1.5

‘101’: multiplication by 1.625

‘110’: multiplication by 1.75

‘111’: multiplication by 1.875

• TurboDownFactor[1:0]: If the Turbo direction is

DOWN and the target voltage is below 4V the Turbo

time calculation further adjusted with this factor. The

default setting provides the optimum Turbo DOWN

operation.

• GL_A / GL_B / GL_C / GL_D: These are the DAC

update mode configuration fields, which need to be set

to turbo mode at the new DAC value update and prior

to the SW trigger (optional). These bits are part of the

DAC value register. If they are set to 0, the DAC is in

Turbo Mode, as long as the corresponding DAC

CONTROL register is configured so. If the Turbo is not

enabled the DAC value is applied as is.

• The Turbo UP or DOWN voltage is decided based on

the comparison of the new DAC value and the old DAC

value. If the new value is greater, the turbo direction

will be UP. Otherwise it will be DOWN. In case of both

DAC values being equal, there is no DAC update

applied. After a turbo request is received, any trigger

will start the turbo output transition. The trigger could

be:

♦ A MIPI−RFFE software trigger controlled by

RFFE_PM_TRIG register

♦ An AD pad toggle if the GPIO is enabled as trigger

source or MIPI−RFFE command is sent to trigger

the AD.

♦ An internal generated trigger after the corresponding

DAC value is updated, as described in section DAC

Update Triggering.

The DAC values send by digital turbo−charge logic to

DACs are:

• During turbo−charge delay duration the value applied is

“DAC_new ±4 V” (the polarity of the 4 V turbo will

depend on if turbo charge is up or down)

• If DAC_new > DAC old, and DAC_new+4 V is

exceeding the word length of the DAC, it is saturated to

max value possible.

• If DAC_new < DAC_old, and DAC_new−4 V is a

negative number, a DAC value of 0 is applied.

♦ After turbo−charge delay duration the value applied

is the actual DAC_new.

www.onsemi.com

10

Page 11

TCC−404

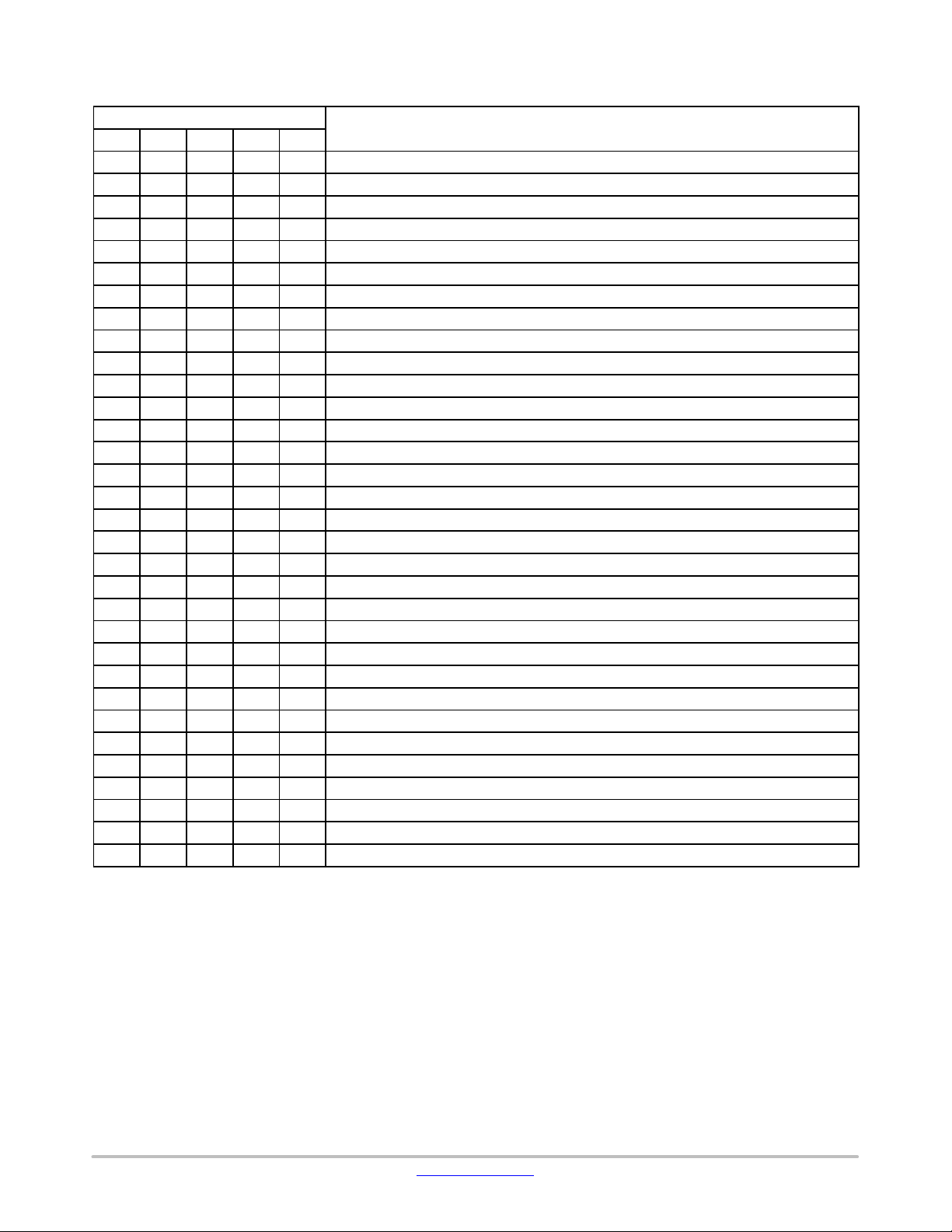

Table 10. GLIDE TIMER STEP DURATION

DAC GLIDE TIMER [4:0]

Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 0 0 0 0 2

0 0 0 0 1 4

0 0 0 1 0 6

0 0 0 1 1 8

0 0 1 0 0 10

0 0 1 0 1 12

0 0 1 1 0 14

0 0 1 1 1 16

0 1 0 0 0 18

0 1 0 0 1 20

0 1 0 1 0 22

0 1 0 1 1 24

0 1 1 0 0 26

0 1 1 0 1 28

0 1 1 1 0 30

0 1 1 1 1 32

1 0 0 0 0 34

1 0 0 0 1 36

1 0 0 1 0 38

1 0 0 1 1 40

1 0 1 0 0 42

1 0 1 0 1 44

1 0 1 1 0 46

1 0 1 1 1 48

1 1 0 0 0 50

1 1 0 0 1 52

1 1 0 1 0 54

1 1 0 1 1 56

1 1 1 0 0 58

1 1 1 0 1 60

1 1 1 1 0 62

1 1 1 1 1 64

Glide Step Duration in Glide Mode [ms]

Transition from Turbo to Turbo or Immediate Update

In the event a new trigger is received during a turbo

transition, the ongoing turbo operation is halted and the new

DAC value is applied immediately. There won’t be any

Turbo and the hi_slew is kept low.

Transition from Turbo to Glide

In the event that a new glide transition is triggered during

a turbo event, then the turbo process is stopped and the

current target value is set at the DAC output immediately

without hi_slew. The new glide is started from this value.

www.onsemi.com

DAC Disable during Turbo (including active to low

power mode transition)

If the DAC, which is in Turbo is disabled, the target DAC

value is immediately applied without hi_slew. The DAC

does not continue with the Turbo when it is re−enabled.

Turbo coming out of Low Power Mode

If the DAC, which is in low power mode is triggered with

a new Turbo DAC update, the DAC_old value is taken as 0V

in autonomous Turbo calculation.

11

Page 12

TCC−404

Glide Mode

The TCC−404 control IC has a Glide Mode that

significantly extends the system transition time when

changing programming voltages.

Glide Mode is controlled by the following registers:

• GLIDE TIMER STEP SIZE [4:0]: This register is used

only in glide mode and shared between all DACs. It

defines the step duration of each glide step. If each

DAC is updated over and over with the same glide step,

these fields do NOT need to be updated at each DAC

update. The various configuration values are listed in

Table 10.

• GL_A / GL_B / GL_C / GL_D: These are the DAC

updatemode configuration fields, which need to be set

to glide mode at the new DAC value update and prior to

the SW trigger (optional). These bits are part of the

DAC value register. If they are set to 1, the DAC is in

glide mode.

After a Glide request is received, any trigger will start the

Glide output transition.

The trigger could be:

• a MIPI−RFFE software trigger controlled by

RFFE_PM_TRIG register

• An AD pad toggle if the GPIO is enabled as trigger

source or MIPI−RFFE command is sent to trigger the

AD

• an internal generated trigger after the corresponding

DAC value is updated, as described in a later section.

Immediately after the trigger, the DAC_old value is loaded

in the MSB’s of the upper byte of a 15 bit accumulator, while

the lower byte of accumulator is being reset to 0x00.

At the same time a count step is calculated:

GLIDE_STEP[6:0] = DAC_new – DAC_old; if

DAC_new > DAC_old

GLIDE_STEP[6:0] = DAC_old – DAC_new; if

DAC_new < DAC_old

ACCUMULATOR[14:0] = DAC_old, 0x00;

NOTE: Glide is disabled if DAC_new = DAC_old.

From the moment the trigger is received, a tick is

generated internally, with a frequency controlled by the

GLIDE TIMER STEP SIZE register. Each DAC has its own

tick generator running independently of the other DAC.

Each time a trigger is received for a DAC, the setting of the

GLIDE TIMER STEP SIZE register is sampled in a counter

dedicated to that DAC. Any update of the GLIDE TIMER

STEP SIZE register after trigger is received will be ignored

until the next trigger is received

Each time a tick is generated, the content of the

accumulator is either incremented or decremented,

depending whether DAC_new is either bigger or smaller

than DAC_old.

ACCUMULATOR[14:0] = ACCUMULATOR[14:0] +

GLIDE_STEP; if DAC_new > DAC_old

ACCUMULATOR[14:0] = ACCUMULATOR[14:0] −

GLIDE_STEP; if DAC_new < DAC_old

Each time a tick is generated, the output of the DAC[6:0]

is updated with the value of ACCUMULATOR[14:8];

The Gliding process continues until, upper 7 bits of the

accumulator matches the value of the DAC_new.

ACCUMULATOR[14:8] ≥ DAC_new, when DAC_new

> DAC_old

ACCUMULATOR[14:8] ≤ DAC_new, when DAC_new

< DAC_old

The Glide timer will reference the 2 MHz clock divided to

provide between 2 ms and 64 ms per glide step.

Each DAC is independent in terms of its switching

operation, thus each DAC may be independently

programmed for Normal, Turbo or Glide regardless of the

switching operation of the other DACs.

Transition from Glide to Glide

In the event a new glide request is received during a glide

transition, the ongoing glide operation is halted and the new

glide operation is started from the DAC value, where the

previous glide has left off. The DAC timers can be updated

to a new value at the trigger.

Transition from Glide to Turbo or Normal Switching

In the event that a new Normal switching or Turbo DAC

value is received during a Glide transition, then the Glide

process is stopped and the DAC immediately switches to the

newly received target value without Turbo or Glide. The

hi_slew is not applied.

DAC Disable during Glide (including active to low

power mode transition)

If the DAC, which is gliding is disabled, the DAC value

holds on to the value where the glide stops. The DAC does

not continue with the glide when it is re−enabled. It drives

the last calculated DAC value without a hi_slew.

www.onsemi.com

12

Page 13

TCC−404

ASDIV − Dual Radio Control

The TCC−404 carries two sets of registers (Radio0 and

Radio1) for only DAC_A/B/C/D Value Registers. The

Radio0 set consists of RFFE_REG_0x06,

RFFE_REG_0x07, RFFE_REG_0x08, RFFE_REG_0x09.

The Radio1 set consists of RFFE_REG_0x0A,

RFFE_REG_0x0B, RFFE_REG_0x0C,

RFFE_REG_0x0D. These registers set the actual DAC

values when their set is active and control the glide turn on

and off.

The Dual Radio Control field at RFFE_REG_0x0E

register governs the operation of the Dual Radio

functionality. The AD pad can be enabled to switch between

the Radio0 and Radio1 values according to the state of this

pad. The reset state of this register is to disable the Dual

Radio operation.

The control register has the following states:

0: The AD (Antenna Diversity) pad is disabled. There is

no toggling between the Radio0 and Radio1 Registers. The

Radio0 DAC registers are used as the active shadow

registers for trigger.

1: The AD (Antenna Diversity) pad is enabled. The

Radio0 register set is triggered when the pad input

transitions into “0” from “1”. The Radio1 register set is

triggered when the pad input transitions into “1” from “0”.

The RC clock domain retimed AD pad value defines which

set of shadow registers are active for all triggering purposes.

2: The AD (Antenna Diversity) pad is disabled. The

Radio0 DAC registers are triggered in any transition into

this control value. Rewriting of the same value does not issue

a re−trigger. The RC clock domain retimed register activates

the Radio0 set of registers. A SW trigger or immediate

update captures these Radio0 shadow content into active

registers in any consecutive triggering.

3: The AD (Antenna Diversity) pad is disabled. The

Radio1 DAC registers are triggered in any transition into

this control value. . Rewriting of the same value does not

issue a re−trigger. The RC clock domain retimed register

activates the Radio1 set of registers. A SW trigger or

immediate update captures these Radio1 shadow content

into active registers in any consecutive triggering.

The AD pad does not have any pull on it. It has to be

physically connected to ground or VIO supply

externally. The RC domain retimed state of the dual radio

control can be observed through the upper nibble of the Dual

radio control register (0x0E). A write into this field is

ignored. The sampling of the AD pad is blocked during any

RFFE communication to prevent trigger collision between

the AD pad and the RFFE Interface. Since the conventional

triggering occurs at the end of an RFFE frame, this aligns all

sources of triggering.

If a DAC is disabled, the dual radio triggering does not

apply to this DAC. It holds the last triggered active register

value prior to getting disabled.

ASDIV − Dual Radio Operation Disabled (State0)

This is the single Radio operation, where the Radi0 set of

registers in address range 0x06 to 0x09 are the shadow

registers mapped to active registers. They are triggered by

either immediate update (depending on SW trigger

masking) or SW trigger.

The AD pad state is still captured at RC oscillator clock

domain continuously. This register output can still be read

over the RFFE interface at the dual radio control address

(0x0E). This reading does not reflect the active DAC

register. The active DAC register is enforced to be the

Radio0 set.

This allows the AD pad to be utilized for any system signal

state detection when the dual radio is not active.

In this mode of operation the data read back from the

Radio0 or Radio1 set of registers always returns the

triggered active data sourced from Radio0 set of registers

ASDIV – AD PAD Enabled (State1)

The AD pad defines the active set of registers for

triggering. At each transition of the AD pad the

corresponding set of DAC value registers are triggered.

Only the set of registers the AD pad is pointing to can be

used to trigger an immediate update. In case of the SW

trigger enable, only the registers AD pad is activating will be

triggered. Therefore there is no possibility to trigger Radio0

and Radio1 set of registers at the same time.

The read back from Radio0 or Radio1 set of registers

return only the triggered active register values. The source

of the trigger could be either set, only the current active

register is read back.

If any exit from this mode is requested, the active registers

hold their state (unless the request is to transition into State2

or State3). The exit itself is not a source of trigger.

If the AD Pad value switches under low power mode, the

state of the pad can’t be detected until the part is active and

the DACs are re−enabled. At this point, if its state is different

than the state entering into low power mode, the trigger is

applied.

ASDIV – Dual Radio over RFFE – Radio0 Trigger

(State2)

The AD pad value is ignored in this mode of operation.

The status register at address 0x0E reflects the current active

set of Radio registers. In case of the low power mode, there

could be a difference between this reading and the dual radio

control register value, since the register would not be

sampled until the part goes back to active mode.

The transition into this state triggers the Radio0 set of

registers. If the register is updated as part of an extended

register write, the trigger waits until the end of the frame.

This way under the same frame the corresponding Radio0

registers can be updated and a trigger is requested.

The immediate update or SW triggering can still be

utilized using the Radio0 set of registers.

www.onsemi.com

13

Page 14

TCC−404

The read back from the Radio0 or Radio1 addresses return

the active register values triggered from the Radio0 source.

While in this mode the Radio1 registers can still be

updated. This will not trigger anything.

The exit from this state itself is not a source of trigger.

If the transition into this state occurs during the low power

mode, the trigger is applied as soon as the part is out of the

low power mode and the DACs are re−enabled.

This Dual Radio triggering over the RFFE Interface has

to respect the same timing as the SW triggering

ASDIV – Dual Radio over RFFE – Radio1 Trigger

(State3)

The AD pad value is ignored in this mode of operation.

The status register at address 0x0E reflects the current active

set of Radio registers. In case of the low power mode, there

could be a difference between this reading and the dual radio

control register value, since the register would not be

sampled until the part goes back to active mode.

The transition into this state triggers the Radio1 set of

registers. If the register is updated as part of an extended

register write, the trigger waits until the end of the frame.

This way under the same frame the corresponding Radio1

registers can be updated and a trigger is requested.

The immediate update or SW triggering can still be

utilized using the Radio1 set of registers.

The read back from the Radio0 or Radio1 addresses return

the active register values triggered from the Radio1 source.

While in this mode the Radio0 registers can still be

updated. This will not trigger anything.

The exit from this state itself is not a source of trigger.

If the transition into this state occurs during the low power

mode, the trigger is applied as soon as the part is out of the

low power mode and the internal oscillator has started.

The Dual Radio triggering over the RFFE Interface has to

respect the same timing as the SW triggering.

ASDIV – Glide Handling

The glide operation under the dual radio triggering can be

governed globally for all DACs using the Glide Control field

of the RFFE_REG_0x0E. The intension is to help reducing

the RFFE transactions necessary. In its default state of

State0, the glide is purely controlled by the GL_X fields of

the DAC value registers.

When the glide control is set to State1, after each dual

radio triggering, the corresponding GL bit of the DAC target

rffe register is cleared. This allows a “single shot” operation,

where the GL_X bits in DAC target registers are considered

as a single execution order.

If the dual radio triggering should not be resulting in any

glide at all, the glide control can be set to State2. This is

effectively a global mask to GL bits in dual radio triggering.

The DAC rffe registers hold on to their GL values, the dual

radio triggering ignores them.

If the dual radio triggering should always execute a glide

in transitions, the glide control can be set to State3. In this

case again the GL bits in the source rffe registers hold on to

their values. The dual radio triggering enforces the glide bits

to be set during the triggering.

www.onsemi.com

14

Page 15

TCC−404

DAC Update Triggering

The entire digital logic responsible for DAC updates is

using the clock provided by the internal RC oscillator. In

order to minimize the power consumption, the RC clock is

set at a low frequency around 2 MHz.

DAC Writes

Figure 9 shows the diagram of the DAC data path, from

the moment data is written into DACx_value register, until

it is sent out to DAC.

After the DACx_value register is written using

MIPI−RFFE clock, the data is copied on RC clock domain,

into the first data stage represented in Figure 9 as

‘Completed’. The data is moved into ‘New’ and ‘DAC−Out’

stages by the DAC driver state machine, once the trigger is

detected. The Turbo path also highlights the glide

calculation.

If SW trigger is not enabled, then data will flow through

the stages right after the corresponding DAC is updated,

without waiting for a trigger (MIPI write is considered as the

trigger).

Figure 9. DACx Data Path

To bypass the SW trigger and enable an immediate trigger

the Mask bits under the RFFE_PM_TRIG register should be

set according to the USID control of the DAC. Trigger Mask

2 is controller with USID_2, Trigger Mask 1 is controlled

with USID_1 and Trigger Mask 0 is controlled with USID_0.

In MIPI−RFFE configuration, if RFFE_PM_TRIG /

Trigger_Mask_2 = ‘1’, and RFFE_PM_TRIG /

Trigger_Mask_1 = ‘1’ and RFFE_PM_TRIG /

Trigger_Mask_0 = ‘1’ (all software triggers are masked), then

each DAC value is copied into ‘Completed’ stages of each

DAC, after the messages RFFE_REG_0x06,

RFFE_REG_0x07, RFFE_REG_0x08 or

RFFE_REG_0x09 respectively are received, as shown in

following sequence.

MIPI_RFFE_WRITE #1: send DAC_A_value and

glide/turbo mode to RFFE_REG_0x06

MIPI_RFFE_WRITE #2: send DAC_B_value and

glide/turbo mode to RFFE_REG_0x07

MIPI_RFFE_WRITE #3: send DAC_C_value and

glide/turbo mode to RFFE_REG_0x08

MIPI_RFFE_WRITE #4: send DAC_D_value and

glide/turbo mode to RFFE_REG_0x09

The individual writes above could be combined into a

single extended write with all DACs controlled with the

same USID or the DURs of the DACs are sitting at “11”

configuration. Right after MIPI_RFEE_WRITE #1 to

RFFE_REG_0x06, above, is received the DAC_A value

register is copied in ‘Completed’ stage of DAC_A. The glide

step, dac control or turbo control DO NOT need to be

updated for each DAC update. But if they need to be, they

can be updated as part of a full extended write or single write

prior to the DAC value updates without any timing

limitation. Since the SW trigger is masked, next RC clock

cycle after DAC values are copied in ‘Completed’ stage, the

data will move in next stages ‘New’ and ‘DAC−Out’

without waiting for any trigger.

The similar events occur for DAC_B, DAC_C and

DAC_D after the MIPI_RFEE_WRITE #2 and

MIPI_RFEE_WRITE #3.

Due to the fact that the MIPI−RFFE master can send

DAC updates messages at a higher frequency, than RC

clock, the data buffer ‘Completed’, can be overwritten if

new DAC updates occur in

the same time when the buffer is

loaded.

www.onsemi.com

15

Page 16

TCC−404

While data and configuration are copied from

DACx_value register into ‘Completed’ stage, the

MIPI−RFFE master must not send any new DAC updates to

DACx_value registers or configurations. The time required

for the data to be copied from DACx_value register into

‘Completed’ stage is Max 1500 ns, which is defined by the

three RC clock cycles required to synchronize data from

MIPI−RFFE clock domain to RC clock domain.

In Figure 10, DAC_UPDATE_LAT represents the period

when MIPI−RFFE master is not allowed to send any new

DAC updates to DACx_value registers and DAC

configuration registers.

DAC_UPDATE_LAT = Min 1500ns

A) RADIO0 DAC updates without SW_TRIG

AD PAD enabled at State0

RFFE_REG_0x03to RFFE_REG_0x05 RFFE_REG_0x06/7/8/9 RFFE_REG_0x03 to RFFE_REG_0x09

B) RADIO0 DAC updates with SW_TRIG

AD PAD enabled at State0

RFFE_REG_0x03to RFFE_REG_0x09

The DAC enables (RFFE_REG_0x00) and Booster

configurations (RFFE_REG_0x02) are applied

immediately without waiting any trigger. These registers

should be configured prior, so that the DAC updates are

effective as fast as possible.

If there is already an ongoing DAC update and the Dual

Radio control is changed, this is considered as a transition.

Even if the dual radio triggering occurs in lesser than

DAC_UPDATE_LAT duration from the RFFE triggering,

this is handled as a proper transition.

It takes approximately the same duration as an RFFE

trigger to propagate the dual radio trigger

TRIG Edge

RFFE_REG_0x03to RFFE_REG_0x09

DAC_UPDATE_LAT = Min 1500ns

A) RADIO1 DAC updates without SW_TRIG

AD PAD enabled at State1

RFFE_REG_0x03to RFFE_REG_0x5 RFFE_REG_0x0A/B/C/D

B) RADIO1 DAC updates with SW_TRIG

AD PAD enabled at State1

RFFE_REG_0x03 to RFFE_REG_0x05 and

RFFE_REG_0x0A to RFFE_REG_0x0D

Figure 10. DAC_UPDATE_LAT Requirement

The SW trigger as well as immediate trigger can be

configured in many combinations using the DUR settings of

the DACs and the USID values. The SW trigger masks can

only be changed with the write access using the slave

address of their corresponding USID. But the corresponding

triggers can be set by accesses over broadcast, with

broadcast ID (0x0) or GSID.

The triggering and DAC register access is governed by

these rules:

• The DUR configuration assigns a DAC to a USID. The

corresponding DAC registers can only be accessed with

USID defined by its DUR.

DAC_UPDATE_LAT = Min 1500ns

RFFE_REG_0x03 to RFFE_REG_0x05 and

RFFE_REG_0x0A to RFFE_REG_0x0D

TRIG Edge

RFFE_REG_0x03to RFFE_REG_0x05 and

RFFE_REG_0x0A to RFFE_REG_0x0D

DAC_UPDATE_LAT = Min 1500ns

• The immediate update of this DAC is enabled if the SW

trigger mask of the corresponding USID is set (disabled).

• The PM_TRIG register bit0 (SW trigger0) is masked by

bit4 and assigned to DACs triggering, which are mapped

to USID0 or all USIDs (the DAC DUR=0 or 3).

• The PM_TRIG register bit1 (SW trigger1) is masked by

bit5 and assigned to DACs triggering, which are mapped

to USID1 or all USIDs (the DAC DUR=1 or 3).

• The PM_TRIG register bit2 (SW trigger2) is masked by

bit6 and assigned to DACs triggering, which are mapped

to USID2 or all USIDs (the DAC DUR=2 or 3).

www.onsemi.com

16

Page 17

TCC−404

• For a DAC with DUR=3, all SW masks need to be set

for that DAC to be triggered with direct access to its

target register.

If all DACs are kept at DUR values of 3 and the USIDs are

kept the same (reset condition), the part behaves according

to the MIPI spec with single USID. If some of the USIDs are

different while DUR=3, the part responds to the accesses

with these different USIDs the same fashion.

If all USIDs are kept equal, the part functions with a single

USID. But the DUR settings still control the SW trigger

mapping for the DACs independent of the USID values. The

DACs which are not holding a DUR value of 3 will be under

the control of the SW trigger−mask duo mapped by their

DUR setting.

In Table 11 some example register settings for listed

functionality are provided. For the given functionality the

response of the part to DAC updates and SW triggers are

tabulated. In this table the “DAC trigger” corresponds to a

trigger happening at the time of the DAC value update. The

“SW trigger” corresponds to a trigger happening with the

PM_TRIG register write. At this point, it is assumed that the

DACs are enabled and the new DAC value is not matching

to the existing pre−triggered DAC value in the active

register. Some of the abbreviations utilized in the table are:

TRG = successful trigger of the new targets

HLD = no trigger, hold on to existing DAC drives

WR = The new DAC values are captured into RFFE shadow

registers

NW = The RFFE write to shadow registers are blocked, no

register update.

www.onsemi.com

17

Page 18

TCC−404

Table 11. IMMEDIATE vs SOFTWARE TRIGGERING USING USIDs and DURs

DACA

DACA

DACA

DACA

Trigger

Trigger

Trigger

Trigger

FUNCTIONALITY & EXAM-

PLE REGISTER VALUES

(DEFAULT) DAC TRIGGER

– SINGLE USID – DUR=3

DUR_A = 3 (USIDx, TRGx)

SW−TRG Mask = 3’b111

USID0,1,2 = 4b0111

SW TRIGGER −SINGLE

USID – DUR =3

DUR_A = 3 (USIDx, TRGx)

SW−TRG Mask = 3’b101

USID0,1,2 = 4b0111

DAC TRIGGER −SINGLE

USID – DUR=0

DUR_A = 0 (USID0, TRG0)

SW−TRG Mask = 3’b101

USID0,1,2 = 4b0111

SW TRIGGER −SINGLE

USID – DUR =1

DUR_A = 1 (USID1, TRG1)

SW−TRG Mask = 3’b101

USID0,1,2 = 4b0111

DAC TRIGGER – (1,2)

USIDs – DUR=2

DUR_A = 2 (USID2, TRG2)

SW−TRG Mask = 3’b100

USID0,1 = 4b0111, USID2 =

4b1000

SW TRIGGER – (1,2)

USIDs – DUR =2

DUR_A = 2 (USID2, TRG2)

SW−TRG Mask = 3’b000

USID0,1 = 4b0111, USID2 =

4b1000

DAC TRIGGER – (2,1)

USIDs – DUR = 1

DUR_A = 1 (USID1, TRG1)

SW−TRG Mask = 3’b110

USID0,1 = 4b0111, USID2 =

4b1000

SW TRIGGER – (2,1)

USIDs –DUR = 1

DUR_A = 1 (USID1, TRG1)

SW−TRG Mask = 3’b100

USID0,1 = 4b0111, USID2 =

4b1000

DAC TRIGGER – (1,1,1)

USIDs – DUR = 0

DUR_A = 0 (USID0, TRG0)

SW−TRG Mask = 3’b001

USID0 = 4b0111, USID1 =

4b1000, USID2 = 4b1001

SW TRIGGER – (1,1,1)

USIDs – DUR = 0

DUR_A = 0 (USID0, TRG0)

SW−TRG Mask = 3’b000

USID0 = 4b0111, USID1 =

4b1000, USID2 = 4b1001

WR

ID0

TRG

(WR)

HLD

(WR)

TRG

(WR)

HLD

(WR)

HLD

(NW)

HLD

(NW)

TRG

(WR)

HLD

(WR)

TRG

(WR)

HLD

(WR)

WR

ID1

TRG

(WR)

HLD

(WR)

TRG

(WR)

HLD

(WR)

HLD

(NW)

HLD

(NW)

TRG

(WR)

HLD

(WR)

HLD

(NW)

HLD

(NW)

WR

ID2

TRG

(WR)

HLD

(WR)

TRG

(WR)

HLD

(WR)

TRG

(WR)

HLD

(WR)

HLD

(NW)

HLD

(NW)

HLD

(NW)

HLD

(NW)

WR

3b111

3b111

Broad

ID0

HLD

HLD HLD HLD HLD HLD HLD HLD All USIDs are the same. All

ID1

3b111

ID2

(NW)

HLD

TRG TRG TRG TRG HLD TRG HLD All USIDs are the same.

(NW)

HLD

HLD HLD HLD HLD HLD HLD HLD All USIDs are the same.

(NW)

HLD

TRG TRG TRG TRG HLD TRG HLD All USID’s are the same.

(NW)

HLD

HLD HLD HLD HLD HLD HLD HLD USID2 is different, only

(NW)

HLD

HLD HLD TRG TRG HLD HLD TRG USID2 is different, only

(NW)

HLD

HLD HLD HLD HLD HLD HLD HLD Since USID0 = USID1 both

(NW)

HLD

TRG TRG HLD TRG HLD TRG HLD Same as above but SW

(NW)

HLD

HLD HLD HLD HLD HLD HLD HLD The DAC is mapped to

(NW)

HLD

TRG HLD HLD TRG TRG HLD HLD The DAC is mapped to

(NW)

3b111

Broad

Trigger

3b001

Broad

Trigger

3b010

Broad

Trigger

3b100

Broad

Comments

SW triggers are masked.

The USID DAC writes trigger immediately.

Only trigger 1 is enabled.

This enables the SW trigger since DUR=3, mapping

the DAC to all triggers

Only trigger 1 is enabled.

The DUR of the DAC is

mapping it to trigger 0

(masked). Therefore SW

trigger is disabled.

Only trigger 1 is enabled.

The DUR of the DAC is

mapping it to trigger 1 (enabled). Therefore SW trigger is enabled.

USID2 dac access is allowed and the DAC triggers immediately, since the

SW trigger mask is set.

USID2 dac access is allowed. Trigger 2 is unmasked, SW trigger is enabled. Only trigger 2 is active for USID2.

USID0, USID1 DAC target

writes are allowed. SW

trigger1 masked; SW triggering disabled

trigger 1 is enabled; SW

triggering enabled. USID0,

USID1 are the same but

the DAC is mapped to Trg1

only. Trg0 alone does not

trigger.

USID0 and the corresponding trigger is

masked. It triggers immediately at DAC update with

USID0

USID0 and the TRG0 is

enabled. It triggers only at

TRG0 with USID0 or

Broadcast access

www.onsemi.com

18

Page 19

TCC−404

MIPI RFFE Interface

TCC−404 is a slave device and is compliant to the MIPI

Alliance Specification for RF Front−End Control Interface

(RFFE) Version 2.0 excluding the interrupt support,

extended long R/W, double byte product ID and dual GSID.

Following MIPI RFFE commands are supported:

1. Register 0 WRITE

2. Register WRITE

3. Register READ

4. Extended Register WRITE

5. Extended Register READ

Registers 0x00 to 0x3F are available to be read/written.

The writes in extended speed frequency and reads in

standard speed frequency are supported. The slew rate on the

read access can be configured by the SDATA Pad Slew bit.

The extended register write long and read long commands

are not supported. If an extended register write long

command is received, no register is written and the

RFFE_STATUS.WURE flag is set. If an extended register

read long command is received, the part responds with bus

idle and the RFFE_STATUS.RURE flag is set.

The read access to registers RFFE_REG_0x03 to

RFFE_REG_0x0D returns the active register content,

which is the register updated after a trigger. The pre−trigger

shadow register does not have read access.

Some registers are exact remapping to meet the RFFE 2.0

register mapping. The GSID is mapped to both address 0x1B

and 0x22. The UDR_RST is mapped to both address 0x1A

and 0x23. The ERR_SUM is mapped to both address 0x24

and 0x1A.

This can reduce EMI in expense of longer read delay.

Table 12. MIPI RFFE INTERFACE SPECIFICATION

= −30 to +85°C; 2.3 V < VDDA < 5.5 V; 1.1 V < VIO < 1.8 V; unless otherwise specified)

(T

A

Parameter

F

SCLK_EXT

T

SCLK_EXT

T

SCLKIH_EXT

T

SCLKIL_EXT

F

SCLK_STD

T

SCLK_STD

T

SCLKIH_STD

T

SCLKIL_STD

V

TP

V

TN

V

H

I

IH

I

IL

C

CLK

C

DATA

TD

SETUP

TD

HOLD

T

READ_ACCESS

T

READ_ACCESS

Clock Extended Speed

Frequency

Clock Extended Speed Period 0.0192 − 32

CLK Input Extended High Time 6.0 − − ns Extended Speed

CLK Input Extended Low Time 6.0 − − ns Extended Speed

Clock Standard Speed Frequency

Clock Standard Speed Period 0.038 − 32

CLK Input Standard High Time 11.25 − − ns Standard Speed

CLK Input Standard Low Time 11.25 − − ns Standard Speed

Positive Going Threshold

Voltage

Negative Going Threshold

Voltage

Hysteresis Voltage

(V

Input Current High

Input Current Low

Input Capacitance − − 2.2 pF CLK Pin

Input Capacitance − − 2.5 pF DATA Pin

Write DATA Setup Time − − 1 ns Extended Speed

Write DATA Hold Time − − 5 ns Extended Speed

Read DATA valid from CLK

rising edge

Read DATA valid from CLK

rising edge

Description Min Typ Max Unit Comments

0.032 − 52 MHz Extended Speed Operation:

0.032 − 26 MHz Standard Speed Operation:

0.4 x VIO − 0.7 x VIO V CLK, DATA, 1.8 V Bus

0.3 x VIO − 0.6 x VIO V CLK, DATA, 1.8 V Bus

– VTN)

TP

0.1 x VIO − 0.4 x VIO V CLK, DATA, 1.8 V Bus

−2 − +10

−1 − +10

−2 − +1

−1 − +1

− − 4.0 ns VIO = 1.80 V, +25°C, and max

− − 1.93 ns VIO = 1.80 V, +25°C, and max

1.65 V < VIO < 1.95 V

Extended Speed Operation:

ms

1.65 V < V

1.65 V < V

Standard Speed Operation:

ms

1.65 V < V

SDATA = 0.8 x VIO

mA

SCLK = 0.8 x VIO

mA

SDATA = 0.2 x VIO

mA

SCLK = 0.2 x VIO

mA

15 pF load on DATA pin. SDATA

Pad Slew = 1.

15 pF load on DATA pin. SDATA

Pad Slew = 0.

< 1.95 V

IO

< 1.95 V

IO

< 1.95 V

IO

www.onsemi.com

19

Page 20

TCC−404

Table 12. MIPI RFFE INTERFACE SPECIFICATION (continued)

= −30 to +85°C; 2.3 V < VDDA < 5.5 V; 1.1 V < VIO < 1.8 V; unless otherwise specified)

(T

A

Parameter CommentsUnitMaxTypMinDescription

T

READ_ACCESS

T

READ_ACCESS

CLK

Read DATA valid from CLK

rising edge

Read DATA valid from CLK

rising edge

− − 8.0 ns VIO = 1.80 V, +25°C, and max

− − 3.81 ns VIO = 1.80 V, +25°C, and max

60 pF load on DATA pin. SDATA

Pad Slew = 1.

60 pF load on DATA pin. SDATA

Pad Slew = 0.

CLK

DATA

DATA

T

READ_ACCESS

T

SDATAOTR

TD

SETUP

TD

HOLD

TD

SETUP

TD

HOLD

Figure 11. MIPI−RFFE Signal Timing during Master Writes to PTIC Control IC

T

READ_ACCESS

T

SDATAOTR

CLK

DATA

Bus Park Cycle

T

SDATAZ

Figure 12. MIPI−RFFE Signal Timing during Master

Reads from PTIC Control IC

www.onsemi.com

Figure 13. Bus Park Cycle Timing

when MIPI−RFFE Master Reads

from PTIC Control IC

20

Page 21

TCC−404

The control IC contains eighteen 8−bit registers. Register content is described in Table 13. Some additional registers

implemented as provision, are not described in this document.

Table 13. MIPI RFFE ADDRESS MAP

Address

Description USID Purpose Access Size [bits]

0x00 RFFE_REG_0x00 All DAC enables, Extended Write/Read

0x01 RFFE_REG_0x01 All DUR for DAC_A/_B/_C/_D R/W 8

0x02 RFFE_REG_0x02 All Booster settings R/W 8

0x03 RFFE_REG_0x03 All Glide settings R/W 8

0x04 RFFE_REG_0x04 All Autonomous Turbo Settings R/W 8

0x05 RFFE_REG_0x05 All DACs Control R/W 8

0x06 RFFE_REG_0x06 DUR_A DAC_A Value Radio0 R/W 8

0x07 RFFE_REG_0x07 DUR_B DAC_B Value Radio0 R/W 8

0x08 RFFE_REG_0x08 DUR_C DAC_C Value Radio0 R/W 8

0x09 RFFE_REG_0x09 DUR_D DAC_D Value Radio0 R/W 8

0x0A RFFE_REG_0x0A DUR_A DAC_A Value Radio1 R/W 8

0x0B RFFE_REG_0x0B DUR_B DAC_B Value Radio1 R/W 8

0x0C RFFE_REG_0x0C DUR_C DAC_C Value Radio1 R/W 8

0x0D RFFE_REG_0x0D DUR_D DAC_D Value Radio1 R/W 8

0x0E RFFE_REG_0x0E All Dual Radio Control R/W 8

0x0F to 0x17 SPARE N/A Spare for future product development

0x18 USID_1 USID_1

& Broadcast

0x19 USID_2 USID_2

& Broadcast

0x1A RFFE_STATUS All RFFE status register R/W 8

0x1B RFFE_GROUP_SID All The Group Broadcast ID R/W 8

Control, DATA pad slew

Spare [7:6]

[5,4] = Manufacturer ID [9:8]

USID_1 [3:0]

Spare [7:6]

[5,4] = Manufacturer ID [9:8]

USID_2 [3:0]

R/W

RegWrite0

R/W 8

R/W 8

7

0x1C RFFE_PM_TRIG All

& Broadcast

0x1D PID_0, default All MIPI Product ID (Note 2) R 8

0x1E Manufacturer ID Register All

0x1F USID_0, default USID_0

& Broadcast

0x20 to 0x21 RFFE 2.0 RESERVED N/A Unsupported fields in TCC404 defined by

0x22 RFFE_GROUP_SID_EXT All The Group Broadcast ID R/W 8

0x23 UDR_RST All User defined registers software reset R/W 8

0x24 ERR_SUM All User−defined Error Logging R 8

0x25 to 0x2B RFFE 2.0 RESERVED N/A Unsupported fields in TCC404 defined by

Power Mode & Trigger Control

PWR_MODE [7:6]

TRIG_REG [5:0]

MN (10bits long) Manufacturer ID[7:0]

(Note 2)

Spare [7:6]

[5,4] = Manufacturer ID [9:8] (Note 3)

USID [3:0]

RFFE 2.0

RFFE 2.0

R/W 8

R 8

R/W 8

www.onsemi.com

21

Page 22

TCC−404

Table 13. MIPI RFFE ADDRESS MAP (continued)

Address Size [bits]AccessPurposeUSIDDescription

0x2C TEST_PATT All Slave Fixed Test Pattern R 8

0x2D to 0x3F RFFE 2.0 RESERVED N/A Unsupported fields in TCC404 defined by

2. The least significant bits from the Product ID register are refined by OTP. The other seven bits of product ID are hardcoded in ASIC.

3. The manufacturer ID is hardcoded in ASIC, mapped in a READ−only register.

RFFE 2.0

Register Content Details

Register RFFE: RFFE_REG_0x00 Address RFFE A[4:0]: [0x00]

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘01’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits N/A spare SDATA Pad

Slew

Reset U−0 U−0 W−0 W−0 W−0 W−0 W−0 W−0

Extended

DAC Jump

DAC D en DAC C en DAC B en DAC A en

Bit [3:0] Each DAC is enabled when the corresponding bit is set. The enable or disable occurs immediately without waiting

for a trigger. 0: Off (default) 1: enabled

Bit [4]: In extended write or read jump the address increment over the DACs, which are not intended to be accessed based on

the USID of the frame and the DUR configuration of the corresponding DAC. If the access starts intentionally from one of these

registers, the address for the first access can’t jump. The consecutive increments take into account the state of the DUR and

access USID. The addresses with the “All” notation are never skipped

Bit [5]: The Sdata slew can be controlled with this bit. When there isn’t a high load on the RFFE interface, to reduce the EMI,

this bit can be set to increase the slew on the DATA toggling. It will only impact the EMI during the read from tcc404.If the

load on the line is very high and the read timing could be jeopardized, the slew bit should be kept low.

Bit [7]: Register 0 write command excludes this bit. The extended writes to this address ignores bit 7. The bit is not utilized

www.onsemi.com

22

Page 23

TCC−404

Register RFFE:

RFFE_REG_0x01 Address RFFE A[4:0]: 0x01

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits DUR_D [1:0] DUR_C [1:0] DUR_B [1:0] DUR_A [1:0]

Reset W−1 W−1 W−1 W−1 W−1 W−1 W−1 W−1

DUR_x [1:0] (DAC x USID response)

‘00’: Responds only to USID_0 in DAC register write. SW trigger0 mask defines the triggering source.

‘01’: Responds only to USID_1 in DAC register write. SW trigger1 mask defines the triggering source.

‘10’: Responds only to USID_2 in DAC register write. SW trigger2 mask defines the triggering source.

‘11’: Responds to any 3 USID in DAC register write. Any trigger mask cleared enables the SW triggering.

Register RFFE: RFFE_REG_0x02 Address RFFE A[4:0]: 0x02

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits Reserved boost_pwm_en Reserved boost_en Boost voltage value

Reset U−0 W−1 U−0 W−1 W−1 W−1 W−0 W−1

Bit [6]: Enables the boost oscillator pwm function. This

signal should be turned off in case the booster generates low

voltages to reduce the ripple.

Bit [4]: Enable/disable of the booster. Booster must be

turned off when the high voltage is provided externally.

Bit [3:0]: Boost voltage value. Refer to Table 14 for

values

Table 14. BOOST VOLTAGE SETTING

Boost Voltage Value[3:0] VHV [V] Note Boost Voltage Value[3:0] VHV [V] Note

0000 15

0001 16 1001 24

0010 17 1010 25

0011 18 1011 26

0100 19 1100 27

0101 20 1101 28 (default)

0110 21 1110 29

0111 22 1111 30

Target values

1000 23

Target values

Register RFFE: RFFE_REG_0x03 Address RFFE A[4:0]: 0x03

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits Reserved GLIDE TIMER STEP SIZE

Reset U−0 U−0 U−0 W−0 W−1 W−1 W−1 W−1

Bit [4:0] For the definition of the glide timer step size field, see Table 10.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register.

www.onsemi.com

23

Page 24

TCC−404

Register RFFE:

RFFE_REG_0x04 Address RFFE A[4:0]: 0x04

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits TurboUpMultiplier TurboDownMultiplier TurboDownFactor

Reset W−0 W−0 W−0 W−0 W−1 W−1 W−1 W−1

Bit [7:5]: The Turbo−Up Multiplier. The autonomous Turbo Up time calculated is multiplied with this factor and reloaded into

Turbo Timer at the last stage of the Turbo. Effectively the Turbo time calculation is multiplied by a factor if 1.x. The decoding

is as below:

‘000’: The autonomous turbo up time is applied with a factor of 1.0

‘001’: The autonomous turbo up time is applied with a factor of 1.125

‘010’: The autonomous turbo up time is applied with a factor of 1.25

‘011’: The autonomous turbo up time is applied with a factor of 1.375

‘100’: The autonomous turbo up time is applied with a factor of 1.5

‘101’: The autonomous turbo up time is applied with a factor of 1.625

‘110’: The autonomous turbo up time is applied with a factor of 1.75

‘111’: The autonomous turbo up time is applied with a factor of 1.875

Bit [4:2]: The Turbo−Down Multiplier. The autonomous Turbo Down time calculated is multiplied with this factor and

reloaded into Turbo Timer at the last stage of the Turbo. Effectively the Turbo time calculation is multiplied by a factor if 1.x.

The decoding is as below:

‘000’: The autonomous turbo down time is applied with a factor of 1.0

‘001’: The autonomous turbo down time is applied with a factor of 1.125

‘010’: The autonomous turbo down time is applied with a factor of 1.25

‘011’: The autonomous turbo down time is applied with a factor of 1.375

‘100’: The autonomous turbo down time is applied with a factor of 1.5

‘101’: The autonomous turbo down time is applied with a factor of 1.625

‘110’: The autonomous turbo down time is applied with a factor of 1.75

‘111’: The autonomous turbo down time is applied with a factor of 1.875

Bit [1:0]: The Turbo−Down Factor. The autonomous Turbo Down time calculation is adjusted further with these two bits if

the Turbo Down is active with a target voltage below 4V. The adjustment is done prior to the Turbo−Down Multiplier being

applied

NOTE: The read access to this register will return the active content post−trigger, not the shadow register.

Register RFFE: RFFE_REG_0x05 Address RFFE A[4:0]: 0x05

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits DACD Control DACC Control DACB Control DACA Control

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

DACx Control :

‘00’: Auto Turbo Mode enabled with 189mV DAC steps, reaching to 28V with +/− 4V delta control

‘01’: Auto Turbo Mode enabled with 220mV DAC steps, reaching to Booster level with +4V delta

‘10’: Turbo Mode disabled, normal update activated with 189mV DAC steps reaching to 24V

‘11’: Turbo Mode disabled, normal update activated with 220 mV DAC steps reaching to 28V

NOTE: The read access to this register will return the active content post−trigger, not the shadow register.

Register RFFE: RFFE_REG_0x06 Address RFFE A[4:0]: 0x06

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_A Radio0 DAC A value [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_A=1, the update is done with glide. If GL_A =0 and the DACA Turbo/Norm is zero, Turbo is started with

the new DAC A value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

www.onsemi.com

24

Page 25

TCC−404

Register RFFE:

RFFE_REG_0x07 Address RFFE A[4:0]: 0x07

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘01’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_B Radio0 DAC B value [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_B=1, the update is done with glide. If GL_B =0 and the DACB Turbo/Norm is zero, Turbo is started with

the new DAC B value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

www.onsemi.com

25

Page 26

TCC−404

Register RFFE:

RFFE_REG_0x08 Address RFFE A[4:0]: 0x08

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_C Radio0 DAC C value [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_C=1, the update is done with glide. If GL_C =0 and the DACC Turbo/Norm is zero, Turbo is started with

the new DAC C value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

Register RFFE:

RFFE_REG_0x09 Address RFFE A[4:0]: 0x09

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_D Radio0 DAC D value Radio0 [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_D=1, the update is done with glide. If GL_D =0 and the DACD Turbo/Norm is zero, Turbo is started with

the new DAC D value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

Register RFFE:

RFFE_REG_0x0A Address RFFE A[4:0]: 0x0A

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_A Radio1 DAC A value Radio1 [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_A=1, the update is done with glide. If GL_A =0 and the DACA Turbo/Norm is zero, Turbo is started with

the new DAC A value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

Register RFFE:

RFFE_REG_0x0B Address RFFE A[4:0]: 0x0B

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_B Radio1 DAC B value Radio1 [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_B=1, the update is done with glide. If GL_B =0 and the DACB Turbo/Norm is zero, Turbo is started with

the new DAC B value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

Register RFFE:

RFFE_REG_0x0C Address RFFE A[4:0]: 0x0C

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_C Radio1 DAC C value Radio1 [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_C=1, the update is done with glide. If GL_C =0 and the DACC Turbo/Norm is zero, Turbo is started with

the new DAC C value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

www.onsemi.com

26

Page 27

TCC−404

Register RFFE:

RFFE_REG_0x0D Address RFFE A[4:0]: 0x0D

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits GL_D Radio1 DAC D value Radio1 [6:0]

Reset W−0 W−0 W−0 W−0 W−0 W−0 W−0 W−0

Bit [7] If the GL_D=1, the update is done with glide. If GL_D =0 and the DACD Turbo/Norm is zero, Turbo is started with

the new DAC D value.

NOTE: The read access to this register will return the active content post−trigger, not the shadow register. The DAC value read−back is

not the actual analog drive, it is the target level.

Register RFFE:

RFFE_REG_0x0E Address RFFE A[4:0]: 0x0E

Reset Source: nreset_dig or SWR = ‘1’ or PWR_MODE = ‘X1’ (transition through STARTUP mode)

7 6 5 4 3 2 1 0

Bits Reserved AD State Glide Control Dual Radio Control

Reset U−0 U−0 U−0 R−0 W−0 W−0 W−0 W−0

Bit [4]: This bit field is used to read back the state of the active dual radio mode control. It shows whether the Radio0 or Radio1

set of registers are active. If the dual radio operation is disabled, the AD pad value is captured and it is not used internally for

any control.

Bit [3:2]: These bits provide global glide control under the dual radio triggering. They don’t change the glide operation under

the conventional triggering (SW or immediate). The glide control is active in both AD pad and Dual Radio rffe control

triggering.

‘00’: Standard (Default): The glide is active, only if the corresponding target Radio DAC register GL bit is set. The GL bit

holds its value after the trigger. Therefore glide is used consecutively as long as GL is set.

‘01’: Single Shot: After any trigger the corresponding GL bit in the DAC rffe register is cleared. Therefore the glide is

executed only once. This avoids the need to clear the GL bit in each DAC register.

‘10’: Glide Masked: Independent of the GL configurations in DAC registers, the dual radio triggering results in Turbo or

Normal update. The GL bits in DAC registers are ignored, “0” values enforced at triggering. The DAC rffe registers hold

their values. This is effectively a global mask to the GL bits.

‘11’: Glide Enforced: Independent of the GL configurations in DAC rffe registers, the dual radio triggering results in glide

transition. The GL bits in DAC registers are ignored, “1” values enforced at triggering. The DAC shadow registers hold their

values. This is effectively a global overdrive on GL bits.

Bit [1:0]: These fields control the dual radio operation; enabling the operation as well as selecting the active set of DAC registers

if the AD pad is not utilized.

‘00’: The AD pad is disabled. There is no toggling between the Radio0 and Radio1 Registers. The Radio0 DAC registers

are used as the active shadow registers.

‘01’: The AD pad is enabled. The Radio0 register set is triggered when the pad input transitions into “0” from “1”. The Radio1