Page 1

NCP1219PRINTGEVB

NCP1219 48 W Printer

Evaluation Board User's

Manual

Introduction

The NCP1219 is the newest part in the NCP12XX family

of current−mode flyback controllers. The controller features

dynamic self supply (DSS), eliminating the need for

external startup circuitry, contributing to a cost effective,

low parts count flyback controller design. The NCP1219

also includes a user programmable skip cycle threshold,

reducing power dissipation at light loads and in standby

mode. An externally provided latch signal delivered to the

Skip/latch pin allows the realization of protection

functionality.

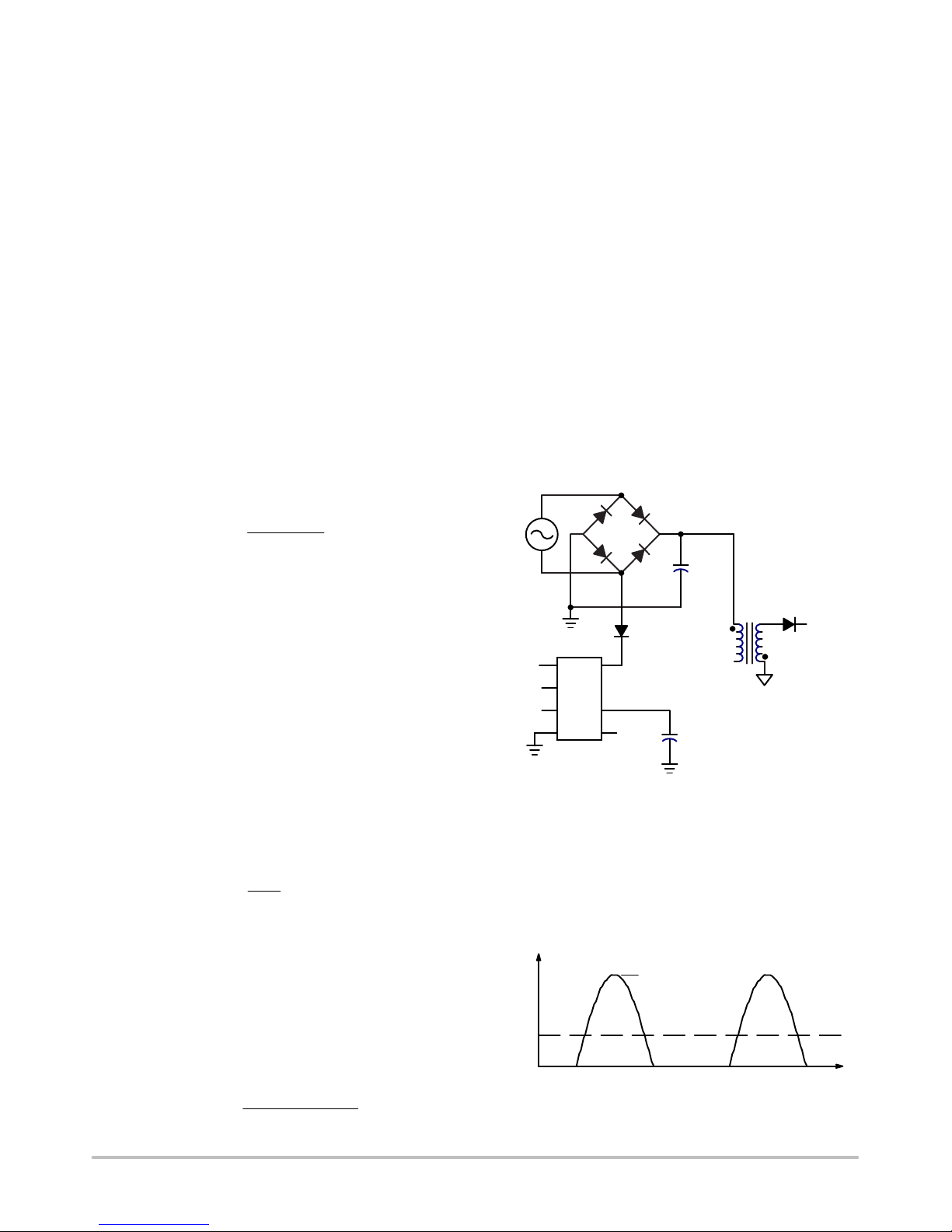

The 48 W ac adapter evaluation board targets a printer

adapter application with a 24 V output, reconfigurable to

7.25 V in standby mode selectable with an external signal.

The use of DSS mode is demonstrated for low input

voltages, while an auxiliary winding is used for higher input

voltages to maintain standby power below 1 W. The

NCP1219 evaluation board shows latched−mode protection

function through the optional primary and secondary

overvoltage protection circuits.

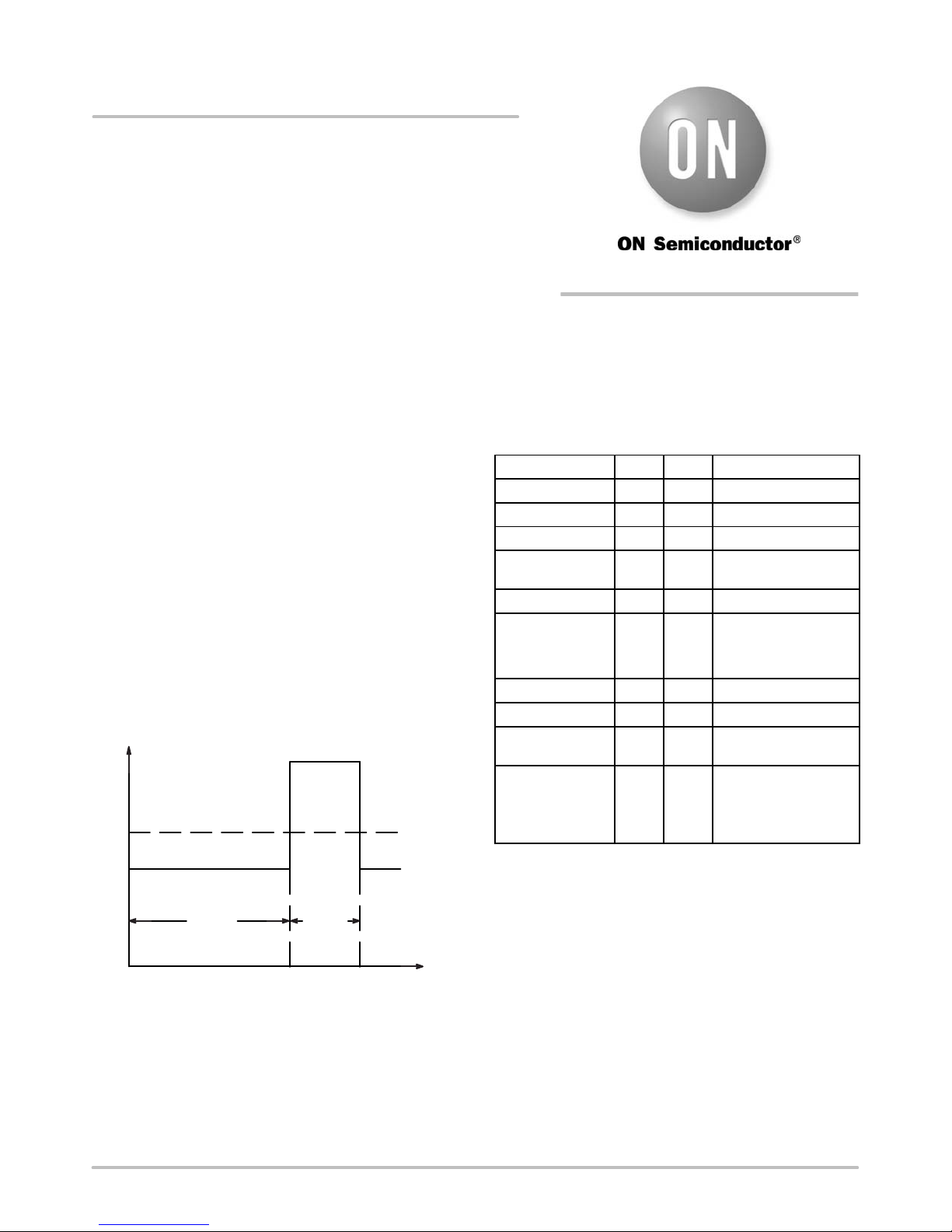

The evaluation board is designed as an off−line printer

adapter power supply. The adapter operates across universal

inputs, 85 Vac to 265 Vac (47 Hz – 63 Hz). The adapter

supplies a regulated 24 V output. It can deliver a steady state

30 W output with transient capability of 48 W, as defined in

Figure 1.

2.0 A

1.25 A

http://onsemi.com

EVAL BOARD USER’S MANUAL

bias is provided by either DSS for low input voltages, or an

auxiliary winding for higher input voltages. The

specifications are summarized in Table 1.

Table 1. SUMMARY OF EVALUATION BOARD

SPECIFICATIONS

Requirement Unit Min Max

Input Voltage Vac 85 265

Line Frequency Hz 47 63

Output Voltage Vdc 23.8 24.2

Output Current Adc − 1.25 (2.0 transient

Output Power W − 30 (48 transient peak)

Average

Efficiency (EPA

Energy Star 2.0

Compliance)

Standby Voltage Vdc 7 8

Standby Power W − 1

Output Ripple

Voltage

Output Voltage

Under/Overshoot

During Transient

Load Step from

0.92 A to 2.0 A

h

83.5 −

avg

mV − 200

mV − 200

peak)

Output Current (A)

Figure 1. Transient Output Current Specification

700 ms

time (ms)

300 ms

The system has a low voltage standby mode enabled by

pulling the MC node low. In standby mode the converter

supplies 70 mA of standby current at 7.25 V while

maintaining input power below 1 W. The system is

self−contained, with the NCP1219 bias being provided by

the bulk voltage through an internal startup circuit. The IC

© Semiconductor Components Industries, LLC, 2012

November, 2012 − Rev. 3

0.92 A

Design Procedure

The converter design procedure is divided into several

steps:

• Power Component Selection

• Loop Stability Analysis and Compensation

• IC Supply Circuits

• External Protection Circuits

• Standby Reconfiguration Circuit

Throughout this application note, the minimum and

maximum input voltages are referred as low and high line,

respectively.

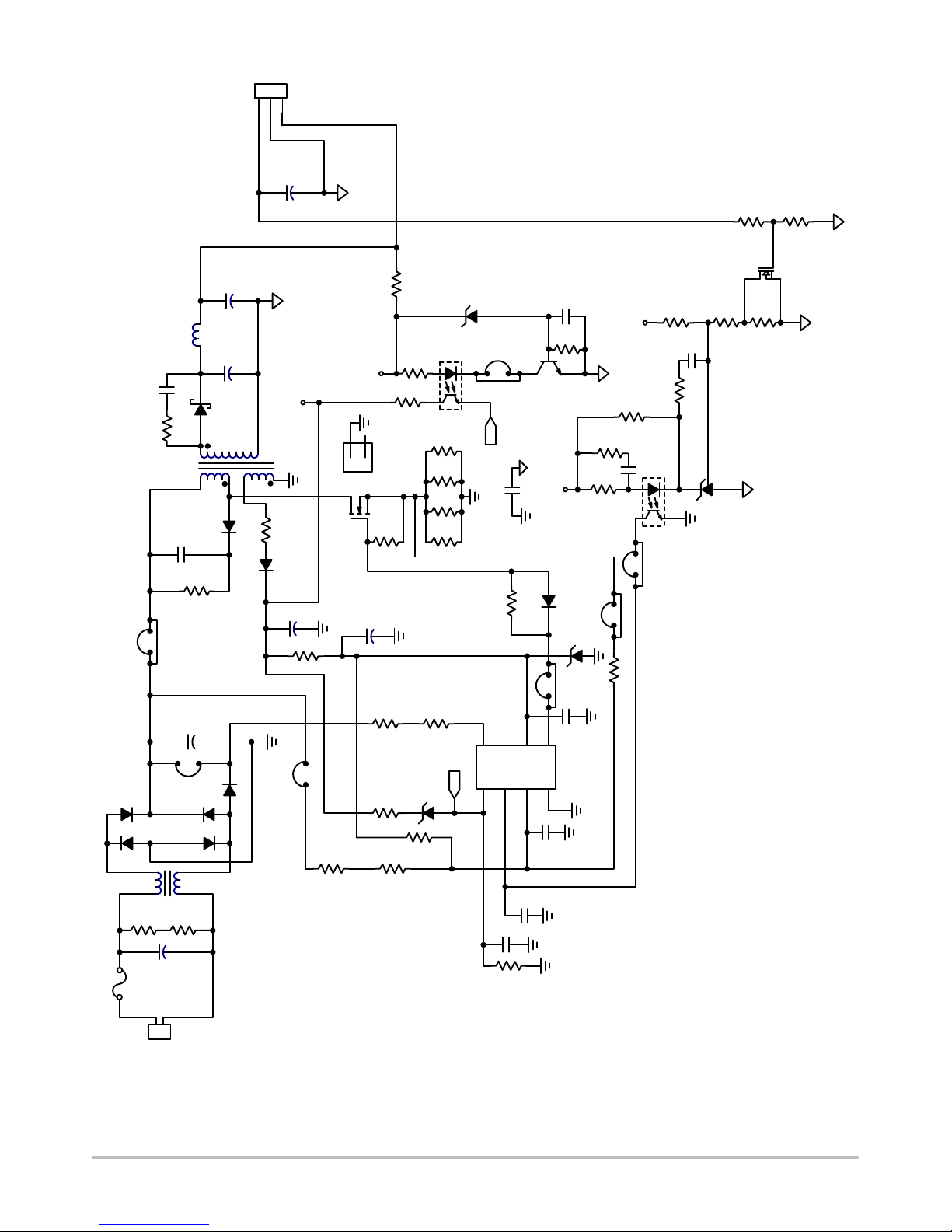

The evaluation board schematic is provided in Figure 2

for reference to component values throughout the design

procedure.

1 Publication Order Number:

EVBUM2161/D

Page 2

J5

123

C20

220uF/6.3V

SGND

NCP1219PRINTGEVB

R34

R35

10K

1k

R32

U4

TL431B

2.26K

Q6

2N7002L

R33

8.06k

330mF/35V

C16

L1

2.2u

1000uF/35V

C15

C14

470pF/250V

D12

100

R18

JP1

1N4007

D2

1N4007

D1

T1

4.75M

R1

F1

C1

2A/250V

C10

C6

JP3

10u, 1.4A

4.75M

R2

0.22mF/275V

MUR420RLG

5

T2

D10

4700pF/630V

R14

120K/0.5W

100u/400V

D13

D4

1N4007

D3

431

1N4007

6

1N4007RLG

1N4007

R15

D6

VCC

2

10

MMSD914T1G

C7

open

000

R13

JP2

1

HS1

Q5

R5

1.4M

VHOUT

2

C21

20

R9

R20

SPA07N65C3

R37

10K

22u/25V

1.82K

R41

open

R11

R8

1.4M

open

open

R10

R16

ZD1

open

12

4

U2

open

R51

1.69

R52

1.69

R53

1.69

R54

1.69

1.82K

R42

LATCH

open

ZD2

3

U1

open

LATCH

HV

Skip/

latch

C18

open

R30

Q3

1nF/440V

D5

J4

VCC

CS

C5

open

open

open

VHOUT

MMSD914T1G

ZD4

open

C3

0.1/25V

DRV

GND

NCP1219AD65R2G

100p

R12

open

C8

open

990

R23

J3

J2

R4

JP4

C9

R6

10

FB

C4

C2

1000p

R3

open

VHOUT

R24

2.49K

12

4

412

U3

SFH615A-3

R31

R25

3

19.6K

C19

0

0.033

J1

AC Connector C8

Figure 2. Evaluation Board Schematic

http://onsemi.com

2

Page 3

NCP1219PRINTGEVB

Transformer

The turns ratio, N, is chosen to minimize the voltage

stresses placed on main switch, Q5, and the secondary diode,

D12. N is calculated using Equation 1,

) V

Ǔ

f

bulk(max)

(eq. 1)

N +

@ǒV

BV

DSS

k

out

C

@ kD* VOS* V

N

S

+

N

P

where NS is the number of turns on the secondary winding,

N

is the number of turns on the primary winding, kc is the

P

clamp voltage ratio, V

is the regulated output voltage, V

out

is the forward voltage drop of the secondary rectifying

diode, BV

k

is the derating factor of the main switch, Vos is the clamp

D

voltage overshoot, and V

where f

I

out(crit)

is the breakdown voltage of the main switch,

DSS

bulk(max)

L

P(crit)

is the switching frequency of the controller, and

osc

is the maximum DC bulk

+

2 @ f

OSC

@ V

out

@ I

out(crit)

h @ V

@ǒV

is the load current at which the transition between

DCM and CCM occurs. By operating in the transition

between DCM and CCM, the secondary RMS current is

minimized, reducing the requirements on the transformer

and output capacitor. For the evaluation board design, with

a transition occurring at I

= 1.6 A, the primary inductance

out

is 350 mH.

Sense Resistor

To calculate the value of the current current sense resistor,

R

, the peak current of the primary winding of the

sense

transformer must first be calculated. The energy storage

relationship is used to determine the peak primary current,

calculated using Equation 3.

I

peak

+

Ǹ

L

P(crit)

@ f

out

OSC

@ h

(eq. 3)

2 @ P

Using the specified peak output power to calculate the

peak primary current:

Ǹ

2 @ 48 W

350 mH @ 65 kHz @ 85%

+ 2.23 A

The NCP1219 has a current limit comparator reference

voltage, V

, of 1 V, typical. R

ILIM

, is calculated using

sense

Equation 4.

V

+

PWM

I

peak

R

sense

This results in a value of 449 mW for R

(eq. 4)

sense

(R51||R52||R53||R54). A 430 mW resistor is chosen for

sufficient margin to deliver the peak output power.

voltage supplying the controller. Using a 650 V MOSFET

with a derating factor of 0.8 and a clamp voltage ratio, k

1.6 yields a turns ratio of 0.303. This maintains sufficient

margin for the voltage rating of the MOSFET.

The power components for the flyback topology can be

selected for operation in either discontinuous conduction

mode (DCM) or continuous conduction mode (CCM).

Measuring the tradeoffs of the two modes at the power level

required for this design, the transformer is designed to make

a transition between DCM and CCM at low line and a load

f

current of 1.6 A. This ensures that the converter operates in

DCM at nominal load. The critical primary inductance,

L

, to cause this transition is calculated using

P(crit)

Equation 2.

V

)V

out

bulk(min)

bulk(min)

2

ǒ

@

V

out

)

The primary rms current, I

f

Ǔ

N

)V

N

f

Ǔ@ǒ

V

)V

out

N

f

) h @ V

Ǔ

bulk(min)

is needed in order to

L(rms)

calculate the power dissipation in the R

maximum duty ratio, D

D

max

, is calculated using Equation 5.

max

V

+

V

out

out

) N @ V

bulk(min)

The maximum duty ratio determines the change in

primary current, ΔI

Finally, ΔIL is used to calculate I

I

+ D

L(RMS)

, as shown in Equation 6.

L

V

max

bulk(min)

L

pri

@ǒI

peak

@ f

DIL+

Ǹ

@ D

OSC

2

* I

max

as in Equation 7.

L(RMS)

@ DIL)

peak

The power dissipated in the sense resistor is then calculated

using Equation 8.

P

R

sense

+ I

L(RMS)

2

@ R

sense

The power rating of the resistor is chosen to handle the

maximum power dissipation. For this design, the worst case

peak power dissipation is calculated to be 400 mW. Four

1206 surface mount resistors in parallel are chosen to

dissipate the power. Note that this is the worst case power

dissipation calculated assuming a continuous output current

of 2 A. For normal operating conditions (I

out

power dissipation is 208 mW.

(eq. 2)

. First, the

sense

(eq. 5)

(eq. 6)

(eq. 7)

2

DI

L

Ǔ

2

(eq. 8)

= 1.25 A), the

c

, of

http://onsemi.com

3

Page 4

NCP1219PRINTGEVB

Primary Switch

The main MOSFET switch, Q5, is selected to operate at

a junction temperature of 120°C at an ambient temperature

of 85°C. The maximum power dissipation for Q5 is

calculated using Equation 9, where T

junction temperature, T

is the thermal resistance of the MOSFET.

R

JA

q

An isolated TO−220 with an R

is the ambient temperature, and

A

ǒ

T

* T

+

max

R

qJA

JA

q

P

max

maximum power dissipation of 438 mW. The R

is the maximum

MAX

Ǔ

A

(eq. 9)

of 80°C/W results in a

DS(on)

required to satisfy the maximum power dissipation at

nominal load is approximated by Equation 10. The value is

taken from the datasheet curves for the desired junction

temperature, provided by the MOSFET manufacturer.

P

R

DS(on)

+

I

L(RMS)

max

2

(eq. 10)

The MOSFET is sized so that the thermal requirements

are met under nominal load (30 W). Equation 3 is used to

determine the peak current, in this case using 30 W for P

out

yielding a peak current of 1.7 A.

The controller operates in DCM at low−line and nominal

load. The equation for the primary rms current in DCM is

shown in Equation 11. In this example, the primary rms

current is calculated to be 0.69 A.

D

max

I

L(RMS)

+ I

peak

Ǹ

@

3

(eq. 11)

Substituting the resulting primary rms current into

Equation 10, we find an R

of less than 1.1 W is

DS(on)

required. The Infineon SPA07N65C3 n−channel MOSFET,

with R

conservative approach to the selection of Q5. The R

= 600 mW is used in this design. This is a

DS(on)

used

JA

q

to calculate the maximum power dissipation assumes the

MOSFET operates in free air, without a heat sink. This

design includes an aluminum heat sink attached to the body

of the TO−220, reducing the thermal resistance and

increasing the maximum power capability of the MOSFET.

Secondary Rectifier

The peak inverse voltage, PIV, of D12 is calculated by

Equation 12.

PIV + V

375 V @ 0.303 ) 24 V + 138 V

bulk(max)

@ N ) V

out

(eq. 12)

Applying a silicon derating factor of 0.8 to PIV, the

minimum breakdown voltage of D12 must be greater than

173 V. An MUR420, 200 V ultrafast rectifier is selected.

The power dissipated in the secondary diode, P

approximated by Equation 13, where V

voltage of the selected diode, and I

out

is the forward

f

is the nominal output

current of the converter.

Pd+ Vf@ I

Output Capacitor

out

The output capacitor is selected to satisfy the output

voltage ripple requirements of the controller. The output

capacitor must supply the entire output current during the

controller on time. The capacitor value is calculated using

Equation 14,

I

@ t

out

C

+

out

where t

is the maximum on time of the controller,

on(max)

which can be calculated using D

on(max)

V

ripple

from Equation 5. For

max

this design, Equation 14 results in a capacitor value of 70 mF.

The effective series resistance, ESR, of the capacitor also

plays a significant role in the selection of the output

capacitor. The secondary peak current charges the output

,

capacitor during each cycle, and the ESR must not cause a

voltage drop greater than the ripple voltage. The acceptable

ESR is calculated using Equation 15,

V

ripple

I

sec(peak)

where I

sec(peak)

ESR v

is proportional to the primary peak current

by the turns ratio, as given by Equation 16.

I

I

sec(peak)

+

pri(peak)

N

An ESR of 31 mW is required to meet the 200 mV output

ripple requirement.

The output capacitor also has a specified rms current

capability that must be considered. The rms current seen by

the capacitor, I

where I

Cout(RMS)

I

Cout(RMS)

is the maximum dc load current supplied by

out(avg)

the converter and I

, is calculated using Equation 17,

Ǹ

+ I

sec(RMS)

sec(RMS)

is the secondary rms current. For

2

* I

out(avg)

the maximum load current, the controller operated in CCM

and I

sec(RMS)

For this design at maximum load, I

is calculated using Equation 18.

Cout(RMS)

output capacitor with an ESR of 18 mW and an rms ripple

current capability of 2.77 A is selected, and the resulting

capacitor value is 1000 mF.

is

d

(eq. 13)

(eq. 14)

(eq. 15)

(eq. 16)

2

(eq. 17)

is 2.44 A. An

I

sec(RMS)

+

Ǹ

(

1 * D

)

ǒ

I

@

max

sec(peak)

http://onsemi.com

DI

L

N2@ 3

2

(eq. 18)

Ǔ

DI

2

* I

sec(peak)

4

L

@

)

N

Page 5

NCP1219PRINTGEVB

Auxiliary Supply Regulator

The HV pin of the NCP1219 can be tied directly to the

bulk storage capacitor and used to supply the IC in the

absence of an auxiliary winding, for instance, during the

startup of the adapter. The startup current is controlled

internally and supplied to the V

V

pin. While VCC is less than the Inhibit threshold

CC

voltage, the V

capacitor is charged with a current source

CC

capacitor through the

CC

of 200 mA (typical). Once the inhibit threshold is exceeded,

the startup current (typically 13.5 mA) is supplied to the

VCC capacitor. When V

current source is disabled, and the V

discharged until V

decreases to less than V

CC

is exceeded, the internal

CC(on)

capacitor is

CC

CC(MIN)

, at

which time the startup current source is enabled, starting the

DSS cycle over again.

The evaluation board contains several options for the HV

pin connection and the biasing of V

is used to supply V

at high line conditions in order to

CC

. An auxiliary winding

CC

satisfy the low standby power requirement of 1 W.

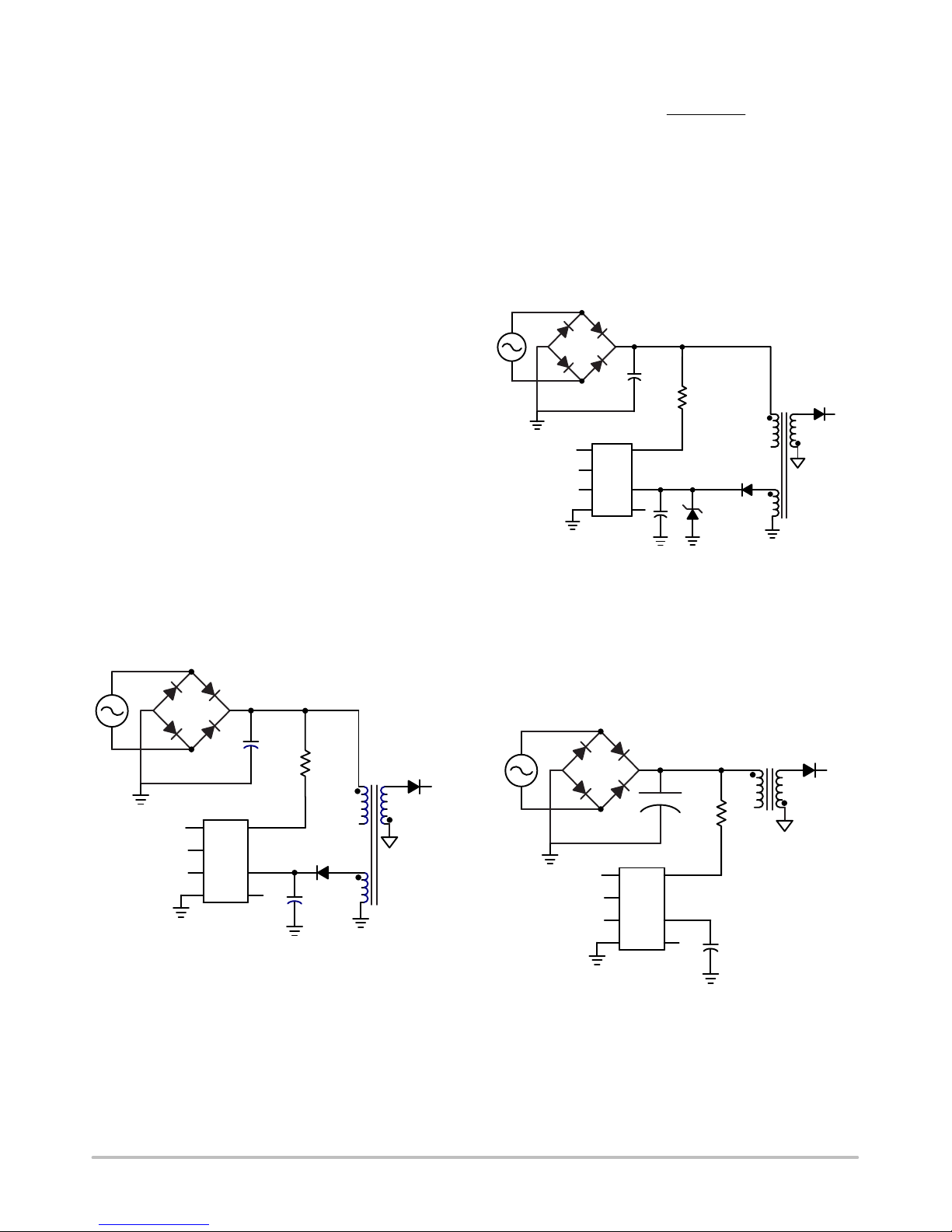

Option 1 – Bulk Connection with Forward Auxiliary

Winding

Connecting the HV pin to the bulk voltage and using a

forward auxiliary winding provides an IC bias dependant on

input voltage, but independent of the output voltage. This is

required in this design due to the dual output voltage design.

Otherwise the converter would require additional circuitry

to prevent the converter from entering DSS mode during the

standby conditions. Figure 3 shows this configuration. The

voltage is supplied by the auxiliary winding through a series

diode.

NAńNP+

ǒ

VCC) V

V

bulk

Ǔ

f

(eq. 19)

This implies that, as the input voltage drops, the auxiliary

winding can not supply the IC. When V

V

CC(MIN)

supplied to the V

, the startup circuit is enabled and the IC bias is

capacitor by the internal current source.

CC

reduces to

CC

Alternately, an auxiliary voltage greater than 20 V can be

used by clamping V

using a zener diode, minimizing the

CC

input voltage at which the controller enters DSS mode. This

is shown in Figure 4.

D12

V

out

Skip/

HV

latch

FB

CS

VCC

GND

DRV

NCP1219

Figure 4. VCC Connection using a Forward Auxilliary

Winding with Added Zener

Option 2 – Full−time DSS Mode (No Auxiliary Winding)

The auxiliary winding is not necessary with DSS mode, so

the connection to the auxiliary winding can be removed

altogether, as shown in Figure 5.

D12

V

out

Skip/

HV

latch

FB

CS

VCC

GND

DRV

NCP1219

Figure 3. VCC Connection Using a Forward Auxiliary

Winding with DSS at Low−Line

The voltage on the VCC pin can not exceed 20 V.

Therefore the ratio between the number of turns on the

auxiliary winding, NA, and the primary winding, N

chosen to maintain V

voltage. N

is calculated using Equation 19.

A/NP

below 20 V at the maximum input

CC

, is

A/NP

http://onsemi.com

D12

Skip/

HV

latch

FB

CS

VCC

GND

DRV

NCP1219

Figure 5. VCC Connection with Full−Time DSS Mode

(No Auxiliary Winding)

If standby power dissipation is not an issue, this option

eliminates the extra components used with the auxiliary

5

V

out

Page 6

NCP1219PRINTGEVB

winding. Care must be taken not to exceed the thermal

capability of the IC. The power dissipated during DSS mode

is approximated by Equation 20.

P

+ I

DSS

where VHV is the HV pin voltage, and I

CC3

@ V

HV

is the controller

CC3

supply current during normal switching operation. I

(eq. 20)

has

CC3

a component that is dependant on the gate charge of Q5, as

shown in Equation 21,

(eq. 21)

where Q

I

+ I

CC3

is the total gate charge of Q5.

g(tot)

CC2

) Q

g(tot)

@ f

SW

The amount of power the controller is capable of

dissipating depends on many factors, including the V

CC

capacitor value, airflow conditions, proximity of the

controller to other heat generating components on the board,

and the layout of the metal traces on the board and their heat

spreading characteristics. To determine the thermal

characteristics of the controller in the application, the

evaluation board is placed in a controlled ambient

temperature and the V

shutdown is measured. R

that results in temperature

HV

of the controller is given by

JA

q

Eequation 22,

T

* T

DSS

A

(eq. 22)

+

SHDN

P

R

qJA

where TA is the ambient temperature of the system and

T

is the junction temperature at which a thermal

SHDN

shutdown (TSD) fault occurs. For the evaluation board, with

the HV pin tied directly to V

a TSD event, and R

is calculated as 82.5°C/W.

JA

q

It is common to include a resistor, R

, a VHV of 257 V results in

bulk

, in series between

bulk

the bulk voltage and the HV pin to spread the power

dissipation between the controller and R

bulk

. R

bulk

often

consists of at least two resistors in series for protection

against shorted component testing. The same power

dissipation limit is imposed on the controller as in the case

where no series resistor is used. Therefore, adding R

bulk

allows the maximum bulk voltage to increase by dissipating

the difference in the power while the startup circuit is

charging C

. The increased bulk voltage is given by

CC

Equation 23,

P

+

I

DSS

CC3

) I

start

@ R

bulk

(eq. 23)

where P

the R

q

V

bulk

is found by rearranging Equation 22 and using

DSS

measured above.

JA

When adding the series resistors, it is recommended to

maintain a minimum V

headroom to allow the startup circuit to supply I

V

pin. Therefore, at low line, the resistance between the

CC

of 40 V to ensure there is enough

HV

start

to the

bulk voltage and the HV pin can not exceed that given by

Equation 24,

ǒ

V

R

bulk

bulk(min)

v

I

start(min)

* 40 V

Ǔ

(eq. 24)

where I

start(min)

provided to the V

V

bulk(min)

more than 10 kW. For the evaluation board, R

as 3.6 kW so that I

range. For this evaluation board, with R

is the specified minimum startup current

CC

pin. I

start(min)

= 5 mA and assuming

= 90 V, the added series resistance should be no

is chosen

bulk

is 14.7 mA across the input voltage

start

= 3.6 kW, I

bulk

start

= 14.7 mA and a maximum ambient temperature of 85°C,

the resulting maximum V

is 310 V, a 53 V increase in

bulk

comparison to the limit when connecting directly to the bulk

voltage.

The power dissipated by R

during the DSS cycle is

bulk

found using the rms current supplied through the startup

circuit during the DSS cycle, given by Equation 25,

P

Rbulk

+ R

bulk

@ǒI

start(RMS)

Ǔ

(eq. 25)

2

Option 3 – Half−Wave Rectified Connection

To reduce the power dissipation of DSS mode at high

input voltage, the HV pin is connected to the half−wave

rectified node of the bridge rectifier in place of the bulk

voltage. Figure 6 illustrates this configuration.

D12

V

out

Skip/

HV

latch

FB

CS

VCC

DRV

GND

NCP1219

Figure 6. VCC Connection with Full−time DSS Mode

Supplied By the Half−Rectified Sine Wave

The average voltage applied to the HV pin is reduced

because, during half of the input voltage cycle, the HV

voltage is a function of the input sinusoid and the other half

of the cycle the input voltage is zero. The half−wave

rectified waveform is illustrated in Figure 7.

V

peak

V

AVG, (half-wave)

Half-Wave

Rectified Voltage

Figure 7. Half−Wave Rectified Waveform

time

http://onsemi.com

6

Page 7

NCP1219PRINTGEVB

The average HV pin voltage, V

AVG(half−wave)

, is

calculated using Equation 26.

V

V

AVG(half*wave)

+

Peak

p

(eq. 26)

In comparison, using the example from option 2

(full−time DSS mode with the HV pin connected to V

power dissipation, P

, of 270 mW, and a junction

DSS

bullk

temperature of 107°C is achieved.

The techniques mentioned above can be explored in

different combinations to optimize standby power and

thermal performance of the NCP1219.

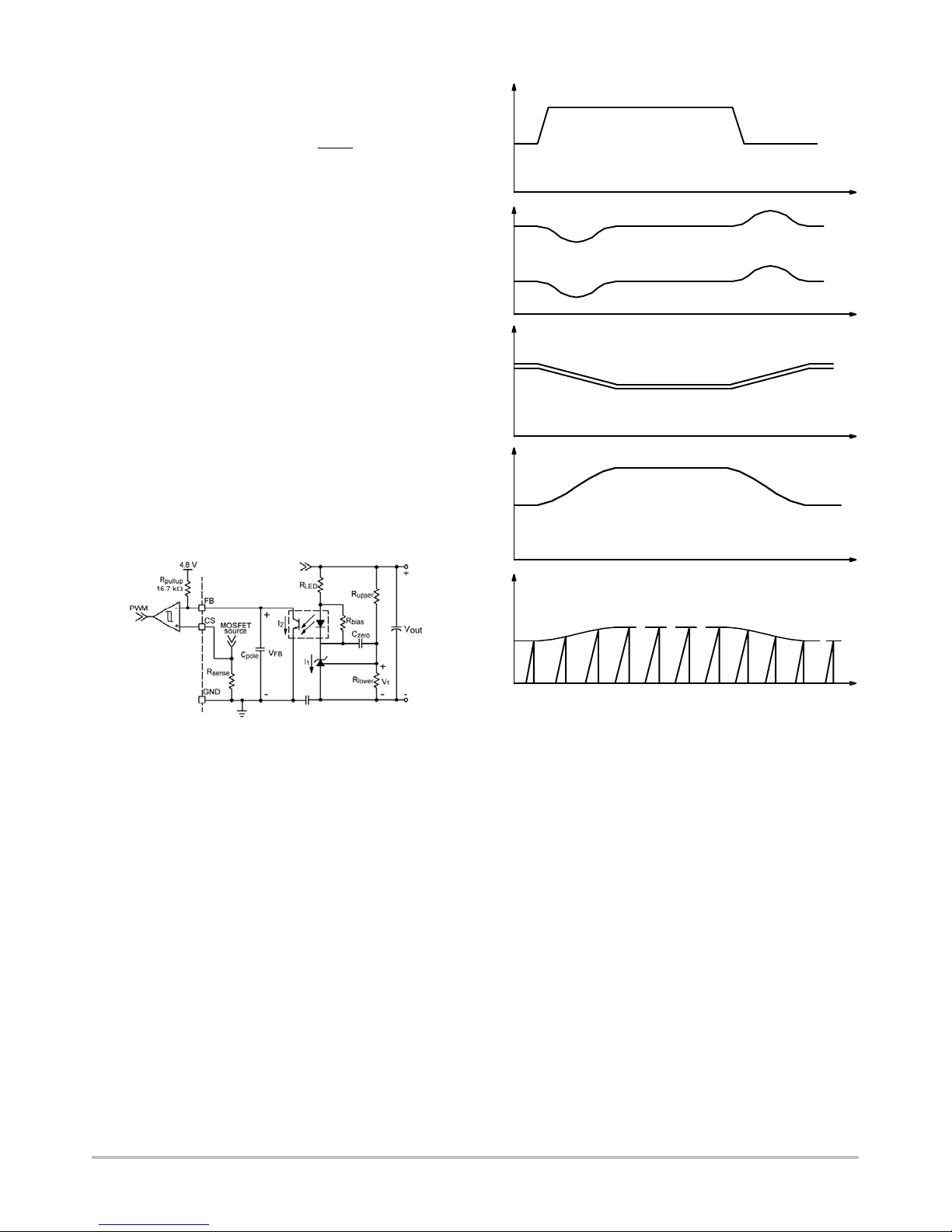

Feedback Network

The negative feedback loop that controls the output

voltage senses the output voltage using a voltage divider and

compares it to the internal reference voltage of a TL431

precision reference. The output current of the TL431 is then

a function of the bias that is required to force the internal

reference of the TL431 and the output voltage to be equal.

The TL431 output drives the cathode of an optocoupler,

providing isolation between the primary and secondary side

of the converter. The collector of the optocoupler is

connected to the FB pin of the NCP1219, closing the

feedback loop, as shown in Figure 8.

out

I

),

1

,V

out

V

2

,I

1

I

FB

V

Figure 8. Feedback Network

VFB is compared to VCS to determine the on time. If there

is an increase in load current, V

V

. This causes I1 to decrease. The optocoupler collector

out

current, I

, also decreases causing VFB to increase,

2

begins to decrease with

1

increasing on time for the next switching cycle. The timing

diagram describing the feedback loop is shown in Figure 9.

L,pri

I

time

Figure 9. Feedback Loop Timing Diagram

Standby Reconfiguration Control

The evaluation board has a dual output voltage mode. In

normal operation, the converter provides a 24 V regulated

output. During standby mode, the output supplies 7.25 V

with a standby current of 70 mA. The output voltage level

is selected by actively altering the voltage divider supplying

the feedback loop. An additional resistor is connected in

series with R32. A small signal MOSFET (Q6) is placed in

parallel with the added resistance, as shown in Figure 10.

http://onsemi.com

7

Page 8

NCP1219PRINTGEVB

Figure 10. Standby Mode Reconfiguration Circuit

When 5 V is applied to the MC pin, Q6 turns on and R33

is bypassed. In this mode, the voltage divider is set by R31

and R32 only, providing 24 V to the output. If the MC pin is

grounded or floating Q6 is off connecting R33 in series with

R32. This reduces the voltage divider value and sets the

output to 7.25 V.

Loop Stability

The output voltage regulation is provided by the negative

feedback loop described in the previous section. If the

feedback loop is not stable, the converter oscillates. To

ensure the stability of the converter, the closed loop

frequency response phase margin should be greater than 45°

at the crossover frequency. The first step in stabilizing the

closed control loop is to analyze the frequency response of

the power stage. Its contribution will determine the pole and

zero placement. The gain and pole and zero placement of the

feedback network are selected to achieve the desired

crossover frequency and phase margin.

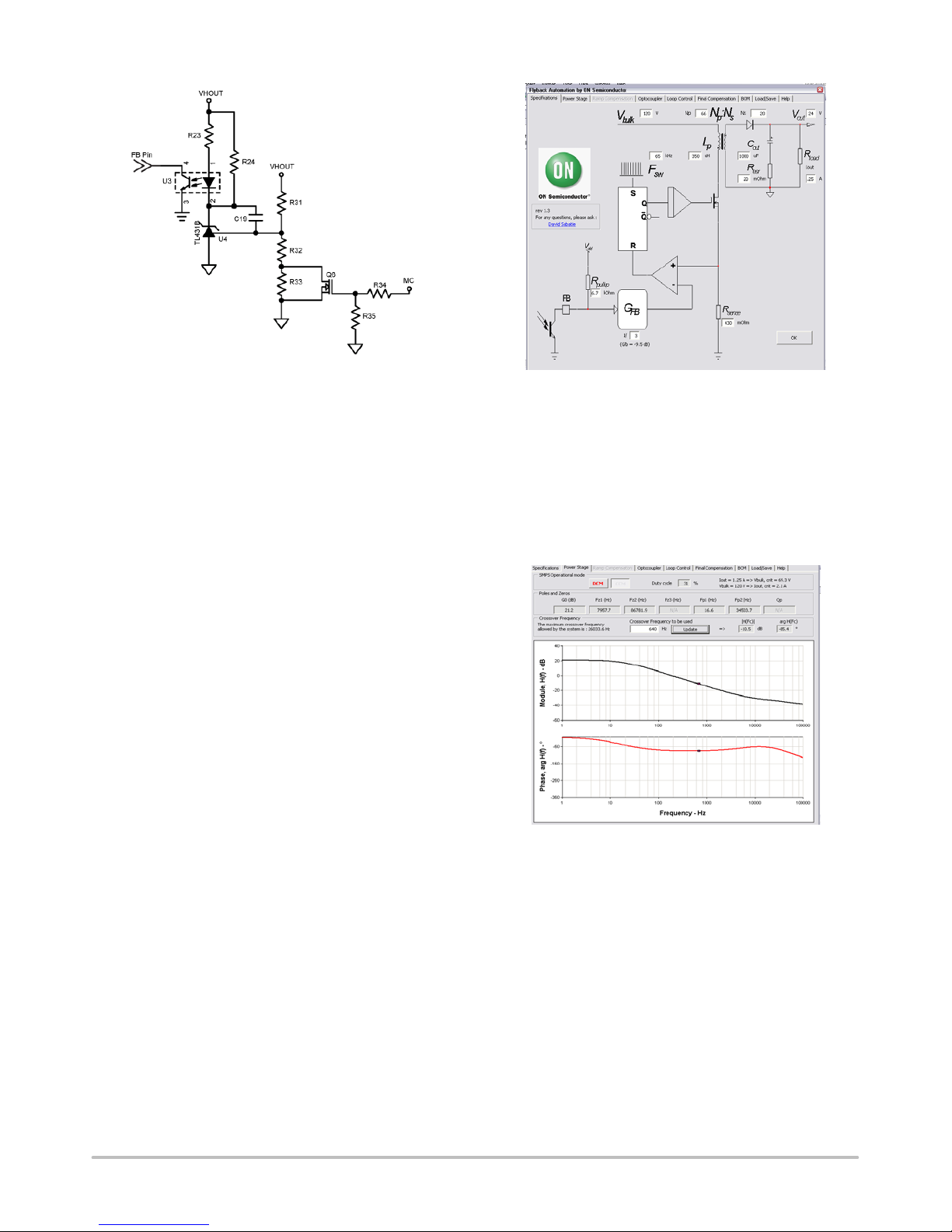

ON Semiconductor provides the excel based design tool

”FLYBACK AUTO”. It provides an automated method of

compensating the feedback loop of an isolated flyback

converter using the TL431 and an optocoupler. The tool

takes system level inputs from the user, such as bulk input

voltage, output voltage, output current, and controller

switching frequency. A screenshot of the parameter capture

screen is shown in Figure 11.

Figure 11. Screenshot of the Parameter Capture

Screen from the Design Tool FLYBACK AUTO

After the input and output parameters are entered, the

frequency response of the power stage is calculated. The

response is presented both numerically, showing the

frequency of each pole and zero, along with the dc gain of

the power stage and graphically through the use of a Bode

plot. This is shown in the screenshot presented in Figure 12.

Figure 12. Screenshot of the Power Stage Frequency

Response from the FLYBACK AUTO tool

Next, the contribution of the optocoupler to the frequency

response of the system is considered. The pole of the

compensation is selected to be less than that of the

optocoupler. The user enters information about the

optocoupler collected from the datasheet or through

frequency response characterization of the chosen

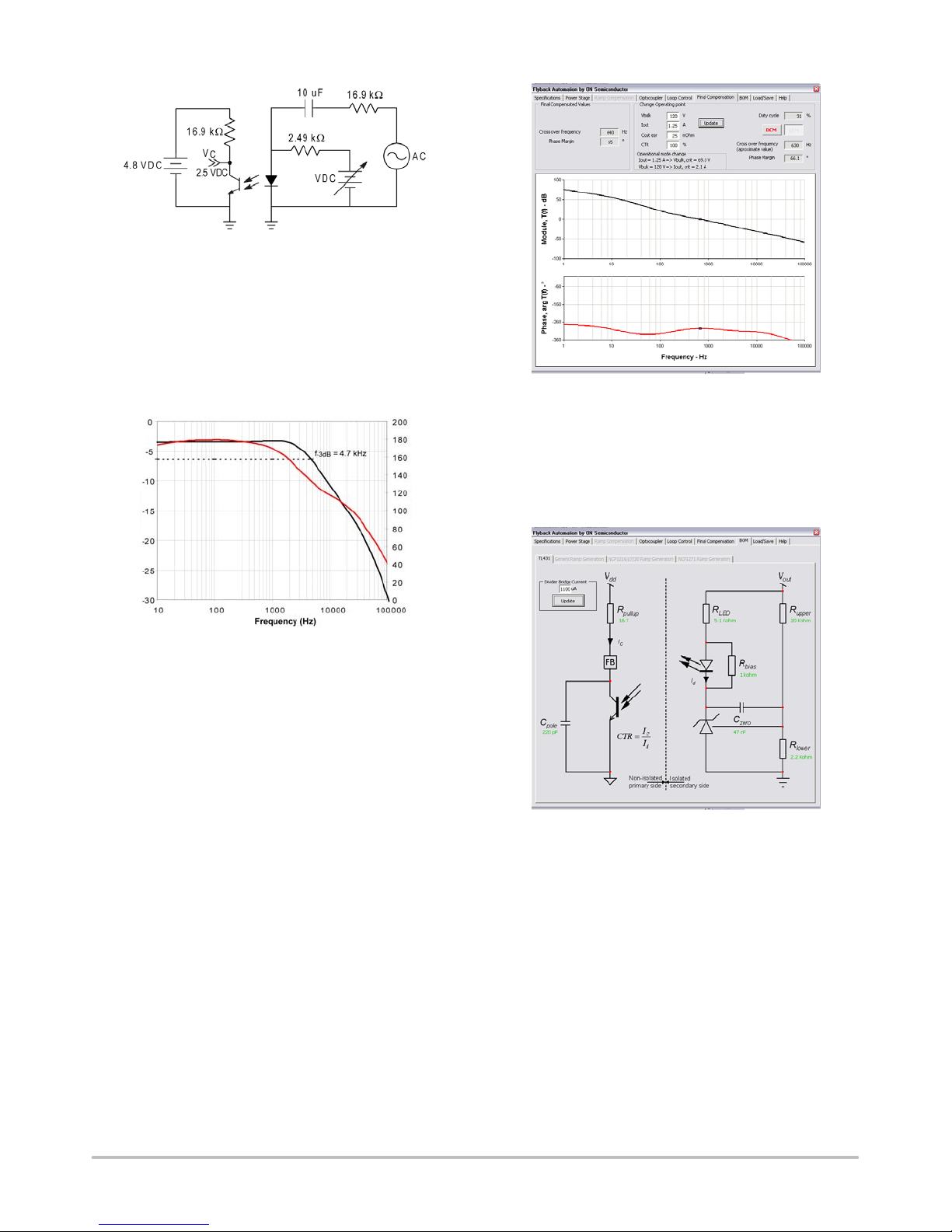

optocoupler. The optocoupler chosen for the evaluation

board design is a Vishay SFH615A−3. Using the test setup

shown in Figure 13, the optocoupler frequency response and

CTR are measured. For the frequency response

measurement, the dc bias of the 2.49 kW resistor is adjusted

until the collector of the optocoupler measured 2.5 V.

http://onsemi.com

8

Page 9

NCP1219PRINTGEVB

Figure 13. Optocoupler Frequency Analysis Test

Circuit

From Figure 14, the crossover frequency of the

SFH615A−3 is measured at 4.7 kHz. From the dc bias of the

optocoupler, the current transfer ratio, CTR is measured as

41%. These values are used in the optocoupler page of the

compensation tool.

MAG (dB)

PHASE (°)

Figure 15. Screenshot of the Total Frequency

Response Given By the Design Tool FLYBACK AUTO

A bill of materials for the compensation network is

provided by the tool based on the calculations of the

compensation network, as shown in Figure 16.

Figure 14. Frequency Response of Vishay’s

SFH615A3 Optocoupler

This data is entered into the tool and the capacitance

contribution of the optocoupler is calculated.

The pole and zero placement of the type 2 compensation

configuration is provided by the design tool based on the

desired crossover frequency and phase margin entered by

the user. If the desired crossover frequency causes the pole

frequency of the compensation network to exceed the pole

frequency of the optocoupler, then the crossover frequency

is automatically reduced.

The total loop response is provided by the design tool

based on the power stage response, optocoupler pole

location, and the type 2 compensation design. The user can

check the frequency response at various input voltages and

load conditions to verify system stability over all conditions,

as shown in Figure 15.

Figure 16. Screenshot of the Final Feedback Network

Bill of Materials

The design tool provides a good starting point; a solution

that allows the user to quickly set up a stable feedback

network. It does not, however, release the designer from

measuring the frequency response of the system and

optimizing the loop stability and transient response

tradeoffs. Using an AP Instruments AP200 frequency

response analyzer, the frequency response of the power

stage is confirmed, as shown in Figure 17. The measured

gain boost required for a crossover frequency of 1 kHz is

17 dB, slightly higher than estimated by the compensation

tool.

http://onsemi.com

9

Page 10

NCP1219PRINTGEVB

4 0

3 0

2 0

1 0

0

-1 0

Mag (dB)

-2 0

-3 0

-4 0

-5 0

-6 0

Mag (dB)

Phase (°)

1 1 0 1 0 0 1 0 0 0 1 0 0 0 0 1 0 0 0 0 0

Frequency (Hz)

Figure 17. Frequency Response of the Power Stage

The pole introduced by the optocoupler needs to be

considered. The pole location is dependant on the biasing

conditions of the optocoupler. The internal 16.7 kW pullup

resistor and the output capacitance of the optocoupler set the

pole at 4.7 kHz, as shown in Figure 14. The location of this

pole limits the available bandwidth of the system.

The evaluation board design uses the k−factor approach to

pole and zero placement, and a phase margin of 65° is

chosen. For the type 2 compensation network, the k−factor

is found using Equation 27,

k + tan

ǒ

2

) 45

Ǔ

(eq. 27)

PM * PS * 90

where PM is the desired phase margin, and PS is the phase

brought by the power stage. For a crossover frequency, f

c

, of

1 kHz, the phase caused by the power stage is −88°. The

resulting k value is 4.2. The pole frequency, f

, is calculated

p

using Equation 28.

fp+ fC@ k

(eq. 28)

The pole frequency for this design is equal to 4.2 kHz. The

zero frequency, f

, is calculated using Equation 29,

z

f

C

fz+

k

(eq. 29)

The zero frequency is set to 240 Hz.

The bandwidth of the optocoupler can be used to set the

pole location of the compensation network. In this case,

adding capacitance to satisfy the k−factor calculations limits

the bandwidth of the system and causes slowing of the

transient response and increased output ripple. The

capacitance needed to place the zero is calculated using

Equation 30.

C

+

zero

2 @ p @ fz@ R

For this design, a value of 33 nF is chosen for C

1

upper

zero

(eq. 30)

.

1 0 0

6 0

2 0

-2 0

-6 0

−17 dB

The required gain boost (G

-1 0 0

-1 4 0

-1 8 0

-2 2 0

-2 6 0

-3 0 0

PHASE (°)

) needed to compensate the

fc

system and provide a crossover frequency of 1 kHz is

measured as 17 dB. The gain provided by the compensation

network is calculated using Equation 31.

G

The R

fC

G + 10

value needed to produce this gain is calculated

LED

20

(eq. 31)

using Equation 32.

R

@ CTR

+

pullup

G

R

LED

From the measurements and the resulting gain, R

(eq. 32)

LED

is

990 W.

The open loop response is measured by injecting an ac

signal across R19 using a network analyzer and an isolation

transformer as shown in Figure 18. The open loop response

is the ratio of B to A.

Figure 18. Open Loop Frequency Response

Measurement Setup

The resulting loop response after compensation is shown

in Figure 19, where the crossover frequency is 1.3 kHz, with

a phase margin of 60°, measured at low−line and nominal

load current.

http://onsemi.com

10

Page 11

NCP1219PRINTGEVB

Figure 19 compares the measured results to the frequency

response produced by the “FLYBACK AUTO” tool. There

is good agreement for frequencies at or below the crossover

frequency. There is divergence at higher frequencies due to

the double pole of the output filter on the evaluation board.

The frequency of the double pole (f

) is given by

dp

Equation 33.

70

60

50

40

30

20

Mag (dB)

10

0

−10

−20

−30

10 100 1000 10000 100000

Figure 19. Total Loop Response Measured at Low Line and Nominal Load Current

Mag (dB)

SimMag (dB)

Phase (deg)

Sim Phase (deg)

FREQUENCY (Hz)

fdp+

2 @ p @ L1 @ C16

1

Ǹ

where L1 is the output inductor and C16 is the output filter

capacitor, which results in a pole frequency of 7.2 kHz. The

“FLYBACK AUTO” tool does not include an output filter

in the compensation design.

200

160

120

PM = 60°

fC = 1.3 kHz

80

40

0

−40

−80

−120

−160

−200

PHASE (°)

(eq. 33)

Skip Mode for Reduced Standby Power Dissipation

The NCP1219 employs an adjustable skip level that

reduces input power in light load and standby conditions.

V

is compared to V

FB

V

Skip/latch

causes V

, the drive pulses stop until the feedback loop

FB

Skip/latch

to increase to greater than V

. If VFB decreases to less than

Skip/latch

. V

Skip/latch

2 V

R

upper

42.0 k

R

lower

51.3 k

V

Skip/latch

+

-

Skip/latch

R

skip

C

skip

FB

Figure 20. Adjustable Skip Level Circuit Configuration

is adjustable by connecting an external resistor between the

Skip/latch and GND pins, as shown in Figure 20. If no

resistor is connected between the pins, the skip threshold is

the default value, V

. If the voltage on the Skip/latch pin

skip

exceeds 1.3 V, then the skip threshold is clamped to

V

skip(MAX)

V

latch

+

-

V

Skip

, typically 1.3 V.

when VCC< V

50 us

filter

V

Skip(MAX)

V

Skip/Latch

Skip

latch-off, reset

CC(reset)

S

R Q

+

-

Comparator

To DRV

latch

reset

http://onsemi.com

11

Page 12

NCP1219PRINTGEVB

Under light load conditions, the controller enters skip

mode. As seen in Figure 21, when V

than V

Skip/latch

causes V

Figure 21. Skip Mode Operation Waveforms; C1 =

(C1) the drive pulses stop (C4). This in turn

to increase as V

FB

V

Skip/latch

, C2 = VCC, C3 = VFB, C4 = V

out

Peak Primary Current

(C3) decreases to less

FB

decreases.

DRV

For the evaluation board design, the NCP1219 default

skip threshold is used to reduce component count. Selecting

a higher skip threshold has tradeoffs. If the skip voltage is set

too high, during normal operation at nominal loads the

system is in skip mode. This can cause audible noise. On the

other hand, when the board is operating in standby mode and

the load is very low, a higher skip threshold minimizes the

number of switching cycles per skip cycle. This reduces

standby power.

Overpower Compensation

For this evaluation board, without overpower

compensation, overcurrent protection occurs at a measured

output power of 67.2 W at high line and 57.4 W at low line

conditions. The variation in overcurrent output power with

input voltage is due to the propagation delay (t

PWM comparator. t

has an increased effect on the power

delay

delay

) of the

delivered at high line than at low line as shown in Figure 22.

Higher peak current

I

peak

230 Vac

120 Vac

0

t

delay

t

delay

Figure 22. Overpower Effect Due to Propagation Delay

Slope = V

bulk/Lp

time

http://onsemi.com

12

Page 13

NCP1219PRINTGEVB

This effect is called “Over power” because it increases the

power at which the overcurrent protection disables the

controller. Specifically, for a DCM flyback system, the total

power delivered to the output including the propagation

delay effect is:

delay

2

Ǔ

@ fSW@ h

V

1

P

+

out

@ LP@ǒI

2

peak

)

bulk

L

@ t

p

The NCP1219 is designed with a very short t

delay

(eq. 34)

(59 ns

typical). This minimizes the overpower. If a tighter

overpower limit is required, then overpower compensation

is implemented by using the circuits shown in Figures 23

and 24.

V

bulk

HV

Skip/

R

OPP

latch

FB

CS

GND

R

comp

VCC

DRV

R

sense

Figure 23. Overpower Compensation Circuit Using

the Bulk Capacitor Voltage

HV

Skip/

latch

R

FB

CS

comp

VCC

DRVGND

R

sense

Pri

Aux

R

OPP

Figure 24. Overpower Compensation Circuit Using a

Forward Auxiliary Winding

The circuit in Figure 23 modifies the I

peak

setpoint

proportional to the HV bulk level. The voltage divider

formed by R

OPP

and R

creates an offset that

comp

compensates for the propagation delay, but increases power

dissipation. Figure 24 provides another option that results in

reduced power dissipation. By altering the connection of the

auxiliary winding diode, a new setpoint is created whose

voltage is proportional to V

reduced by a factor of (N

. The power dissipation is

in

pri:Naux

)2.

To determine the required amount of compensation, first

the peak current for the overcurrent power at high line is

calculated using Equation 35.

I

peak

+

Ǹ

Lp@ f

OSC

out

@ h

(eq. 35)

2 @ P

Using the measured output power at high line, the

calculated peak current of 2.63 A causes a voltage on the

sense resistor, as in Equation 36.

V

sense(peak)

+ I

peak

@ R

sense

(eq. 36)

The resulting sense voltage is 1.13 V. Under high line

conditions, the desired overpower output current is 2.5 A

(60 W). Calculate the sense voltage associated with the

desired output power using the same method. In this case, an

output power of 60 W results in a sense voltage of 1.06 V.

The difference between the calculated sense voltages is

given by Equation 37.

V

CS(offset)

For this design V

+ V

sense(peak1)

CS(offset)

* V

sense(peak2)

(eq. 37)

is 70 mV. This represents the

offset voltage required on the CS pin to force the controller

to enter overcurrent protection at the desired output power.

If the circuit in Figure 23 is chosen, the R

resistor is

OPP

selected to ensure the power dissipation of the circuit does

not exceed the desired maximum, P

. For this design

OPP

50 mW is selected. The resistor value is calculated using

Equation 38.

2

P

OPP

, creating

comp

) on the CS pin to

(eq. 38)

R

+

OPP

R

creates a current that flows through R

OPP

the necessary offset (V

CS(offset)

V

bulk(max)

compensate for the propagation delay. The current is

calculated with Equation 39.

I

OPP

+

V

bulk(max)

V

CS(offset)

* 1V

(eq. 39)

The ramp compensation resistor also creates an offset

voltage due to the ramp compensation current supplied by

the controller. The internal current ramp has a slope of

8.12 mA/ms. The controller on time is measured near the

current limit in order to determine the peak voltage on the

ramp compensation resistor. The total effect of the added

compensation is shown in Equation 40.

V

R

+

ramp

8.12 Ańs @ ton)

R

is chosen to be 2.8 MW. R

OPP

CS(offset)

V

bulk(max)

R

OPP

is chosen to be 412 W

ramp

*1

(eq. 40)

to achieve an overcurrent limit at 60 W under high line

conditions. The low line overcurrent limit must also be

confirmed to ensure that the peak power is delivered with the

overpower compensation circuit. The low line current limit

for this design is measured to be 2.2 A (52.8 W).

http://onsemi.com

13

Page 14

NCP1219PRINTGEVB

Overvoltage Protection

Overvoltage protection (OVP) is implemented on this

evaluation board using one of two options; primary side

overvoltage protection or secondary side overvoltage

protection.

Primary side OVP is implemented as shown in Figure 25.

With the auxiliary winding in a flyback configuration, V

CC

is proportional to the output voltage. A zener diode and

series current limiting resistor are connected between the

Skip/latch pin of the controller and V

voltage starts to rise, V

rises and current starts to flow

CC

. If the output

CC

through ZD1. The zener current causes the voltage on the

Skip/latch pin to exceed the latch threshold and the

controller enters latched fault mode.

D6

R15

R11

ZD1

Skip/

latch

FB

CS

GND

HV

VCC

DRV

C7

options included on this evaluation board. For example, the

latch pin may be used to implement temperature shutdown

externally using an NTC element driving the base of a

bipolar transistor, Q1, as shown in Figure 27. The NTC

value is chosen so that the voltage divider made between it

and R

controller enters a latched fault, V

than V

turn on Q1 at the proper temperature. Once the

be

must decrease lower

CC

CC(reset)

to reset the controller. This is typically

achieved by removing power from the mains.

R

be

Q1

NTC

Skip/

HV

latch

FB

CS

VCC

GND

DRV

Figure 27. Temperature Shutdown Latch Circuit

Figure 25. Primary Overvoltage Protection Circuit

A secondary side OVP latch function is implemented

using the circuit shown in Figure 26. The primary and

secondary sides are isolated using an optocoupler. The zener

diode ZD2 starts to conduct if the output voltage exceeds the

regulated voltage. The current conducted by ZD2 biases Q3

and causes current to flow from the cathode of the

optocoupler. The optocoupler transistor turns on and the

voltage on the Skip/latch pin increases, latching the

controller. The value of R10 is chosen in order to limit the

voltage applied to the Skip/latch pin during a fault condition.

VHOUT

VCC

Skip/

latch

FB

CS

VCC

DRVGND

HV

R10

U2

R20

ZD2

Q3

R30 C18

Figure 26. Secondary Overvoltage Protection Circuit

Latch Protection

The latching fault protection offered by the NCP1219 can

also be used to implement other convenient board level

protection functions besides the overvoltage protection

Any other generic latched fault can be implemented using

a circuit similar to Figure 28. A fault signal is applied to the

base of an npn bipolar transistor, Q2, whose cathode drives

the base of a pnp bipolar transistor, Q1, bringing the

Skip/latch pin high.

Q1

Skip/

HV

Latch Off

Signal

Q2

latch

FB

CS

GND

VCC

DRV

Figure 28. Generic Latched Shutdown Example

SOFT−START

Soft−start reduces stress during power up by slowly

increasing the peak current until the soft−start timer expires.

The NCP1219 implements soft−start by comparing the CS

pin voltage to the lesser of the internal divided by three FB

voltage or the internal soft−start ramp. The soft−start

management block of the NCP1219 controller enables the

soft−start voltage ramp to rise in 4.8 ms. Figure 29 shows the

current sense waveform taken differentially across the sense

resistor, as the current ramps up during the first 4.8 ms of the

startup time.

http://onsemi.com

14

Page 15

NCP1219PRINTGEVB

Figure 29. Startup Waveforms Showing Soft−Start Behavior; C1 = V

Board Layout

The evaluation board is built using a double sided FR4

board. Through hole components are placed on the top layer

and surface mount components on the bottom layer. The

board is constructed using 2 oz copper.

During the layout process care was taken to:

1. Minimize trace length, especially for high current

loops.

2. Use wide traces for high current connections.

, C4 = VCS/20

out

3. Use a single ground connection.

4. Keep sensitive nodes away from noisy nodes such

as the drain of the power switch.

5. Place decoupling capacitors close to the pins of IC.

6. Sense output voltage at the output terminal to

improve load regulation.

Figure 30 shows the top layer of the PC board, including

the silkscreen, copper, and soldermask.

http://onsemi.com

15

Page 16

NCP1219PRINTGEVB

Figure 30. Layer 1 (Top)

Figure 31. Layer 2 (Bottom)

http://onsemi.com

16

Page 17

NCP1219PRINTGEVB

Figure 31 shows the bottom layer of the PC board,

including the silkscreen, copper, and soldermask.

The layout files may be available. Please contact your

sales representative for availability.

Design Validation

The top and bottom view of the board are shown in

Figures 32 and 33, respectively.

Figure 32. NCP1219 Evaluation Board Top View

Figure 33. NCP1219 Evaluation Board Bottom View

http://onsemi.com

17

Page 18

NCP1219PRINTGEVB

The bill of materials that accompanies the evaluation board circuit schematic of Figure 2 is listed in Table 2.

Table 2. BILL OF MATERIALS

Desig-

nator

C10 1 Capacitor,

C14 1 Capacitor,

C15 1 Capacitor,

C16 1 Capacitor,

C18 1 Capacitor,

C19 1 Capacitor,

C20 1 Capacitor,

C21 1 Capacitor,

D1, D2,

D3, D4,

D10,

D13

D5, D6 2 Switching Diode 100 V - SOD-123 ON

D12 1 Diode, Ultrafast

HS1 1 Heatsink - - Custom Ye s Ye s

Qty Description Value

C1 1 Capacitor,

C2 1 Capacitor,

C3 1 Capacitor,

C4 1 Capacitor,

C5 1 Capacitor,

C6 1 Capacitor,

C7 1 Capacitor,

C9 1 Capacitor,

F1 1 Fuse, Radial Lead 2 A, 250 V - Radial Littelfuse 3921200000 Ye s Ye s

J1 1 AC Connector IEC 320-C8 - Through

J2 1 Electrical

J3 1 Electrical

J4 1 Electrical

Metalized Poly

Film

Ceramic, SMD

Ceramic, SMD

Ceramic, SMD

Ceramic, SMD

Electrolytic

Electrolytic

Ceramic, Y-cap

Ceramic, Through

Hole

Ceramic, Through

Hole

Electrolytic

Electrolytic

Ceramic, SMD

Ceramic, SMD

Electrolytic

Electrolytic

6 Diode, Rectifier 1 A, 1000 V - Axial ON

Rectifier

Connection on Top

Layer of PCB

Connection on Top

Layer of PCB

Connection on Top

Layer of PCB

0.22 uF, 1000 V 20% Radial Kemet/

1000 pF 10% SM/0805 Vishay VJ0805Y102KXXA Ye s Yes

0.1 uF 10% SM/0805 Vishay VJ0805Y104KXXA Ye s Yes

open - SM/0805 - - Yes Ye s

100 pF 10% SM/0805 Vishay VJ0805Y101KXXA Ye s Ye s

100 uF, 400 V 20% Radial United

open - - - - Yes -

1 nF, 1000 V 20% Radial Kemet/

4700 pF, 630 V 5% Radial TDK FK20C0G2J472J Ye s Ye s

470 pF, 250 V 10% Radial TDK FK18C0G2E471J Ye s Ye s

1000 uF, 35 V 20% Radial United

330 uF, 35 V 20% Radial United

open - SM/0805 - - Yes Ye s

0.033 uF 10% SM/0805 Vishay VJ0805Y333KXJA Ye s Ye s

220 uF, 6.3 V 20% Radial United

22 uF, 25 V 20% Radial United

4 A, 200 V - Axial ON

- - - - - - -

- - - - - - -

- - - - - - -

Toler-

ance

Footprint Manufacturer

Evox-Rifa

Chemicon

Evox-Rifa

Chemicon

Chemicon

Chemicon

Chemicon

Semiconductor

Semiconductor

Semiconductor

Hole

Qualtek 770W-X2/10 Yes Ye s

Manufacturer Part

Number

PHE840MX6220MB06 Yes Ye s

EKXG401ELL820MM25S Ye s Ye s

ERO610RJ4100M Ye s Ye s

EKZE350ELL102MK25S Ye s Ye s

EKZE350ELL331MJ16S Ye s Ye s

ESMG6R3ELL221ME11D Ye s Ye s

ESMG250ELL220ME11D Yes Ye s

1N4007RLG No Yes

MMSD914T1G No Ye s

MUR420RLG No Ye s

Substi-

tution

Allowed

Lead

Free

http://onsemi.com

18

Page 19

NCP1219PRINTGEVB

Table 2. BILL OF MATERIALS

Desig-

nator

J5 1 Header, 1 Row of

JP1 1 Electrical

JP2

JP3

JP4 1 Electrical

L1 1 Inductor, Power 2.2 uH - Radial Coilcraft RFB0807-2R2L Ye s Ye s

MECHA

NICAL

MECHA

NICAL

Q3 1 Transistor, NPN

Q5 1 MOSFET, Power 7 A, 650 V - TO-220-3

Q6 1 MOSFET, Small

R1, R2 2 Resistor, SMD

R3 1 Resistor, SMD

R4 1 Resistor, SMD

R5, R8 2 Resistor, SMD

R6 1 Resistor, SMD

R9 1 Resistor, Through

R10

R11

R13 1 Resistor, Through

R14 1 Resistor, Through

R15 1 Resistor, SMD

R16 1 Resistor, Through

R18 1 Resistor, Through

R20 1 Resistor, Through

R23 1 Resistor, SMD

R24 1 Resistor, SMD

R25 1 Resistor, SMD

R30 1 Resistor, SMD open - SM/0805 - - Yes -

R31 1 Resistor, SMD

R32 1 Resistor, SMD

R33 1 Resistor, SMD

R34 1 Resistor, SMD

R35,

R37

2 jumper wire 22 AWG - - Belden 8021 Ye s Ye s

1 Screw M3 8 mm - - Building

2 Insulating tubing 22 AWG - - SPI

2 Resistor, SMD open - SM/1206 - - Yes -

2 Resistor, SMD

3

Connection on Top

Layer of PCB

Connection on Top

Layer of PCB

Bipolar

Signal

Hole

Hole

Hole

Hole

Hole

Hole

- - 0.156 Molex 26-64-4030 Ye s Ye s

- - - - - -

- - - - - - -

open - SOT-23 - - Ye s -

115 mA, 60 V - SOT-23 ON

4.75 MW

14 kW

412 W

1.4 MW

10 W

20 W

0 W

120 kW

10 W

open - Axial - - Yes -

100 W

open - Axial - - Yes -

976 W

2.49 kW

0 W

19.6 kW

2.26 kW

8.06 kW

1 kW

10 kW

Toler-

anceValueDescriptionQty

Fasteners

Technology

-31,

FullPAK

0.01 SM/1206 Vishay CRCW12064754FN Ye s Ye s

0.01 SM/0805 Vishay CRCW080520K0FN Ye s Ye s

0.01 SM/0805 Vishay CRCW08054120FN Yes Ye s

0.01 SM/1206 Vishay CRCW12061404FN Yes Ye s

0.01 SM/1206 Vishay CRCW120610R0FN Yes Ye s

0.01 Axial Yageo MFR-25FBF-20R0 Ye s Ye s

Jumper Axial Panasonic -

0.05 Axial Vishay HVR3700001203JR500 Yes Ye s

0.01 SM/1206 Vishay CRCW120610R0FN Yes Ye s

0.05 Axial Vishay 5093NW100R0JBC Yes Yes

0.01 SM/0805 Vishay CRCW08059760FN Yes Ye s

0.01 SM/1206 Vishay CRCW08052491FN Yes Ye s

0.01 SM/0805 Vishay CRCW08050000FN Yes Ye s

0.01 SM/1206 Vishay CRCW080519K6FN Ye s Ye s

0.01 SM/0805 Vishay CRCW08052K26FN Ye s Ye s

0.01 SM/0805 Vishay CRCW08058061FN Yes Ye s

0.01 SM/0805 Vishay CRCW08051K00FN Ye s Ye s

0.01 SM/0805 Vishay CRCW08051001FN Yes Ye s

Infineon SPA07N65C3 Yes Ye s

Semiconductor

ECG

Manufacturer Part

NumberManufacturerFootprint

MPMS 003 0008 PH Ye s Ye s

TTI-S22-1100-NAT Ye s Ye s

2N7002LT1G No Ye s

ERD-S2T0V Yes Ye s

Substi-

tution

Allowed

Lead

Free

http://onsemi.com

19

Page 20

NCP1219PRINTGEVB

Table 2. BILL OF MATERIALS

Desig-

nator

R41,

R42

R51,

R52,

R53,

R54

T1 1 Inductor, Common

T2 1 Transformer,

U1 1 Switchmode

U2 1 Optocoupler open - DIP-4 - - Yes -

U3 1 Optocoupler 150% CTR - DIP-4 Vishay SFH615A-3 Ye s Ye s

U4 1 Programmable

ZD1 1 Diode, Zener open - SOD-123 - - Ye s -

ZD2,

ZD4

2 Resistor, SMD

4 Resistor, SMD

Mode Choke

Flyback

Controller

Precision

Reference

2 Diode, Zener open - SOD-123 - - Yes -

1.8 kW

1.69 W

10 mH -30%,

400 uH - Custom,

NCP1219 - SOIC-7 ON

TL431B - TO-92 ON

Toler-

anceValueDescriptionQty

0.01 SM/1206 Vishay CRCW12061801FN Yes Ye s

0.01 SM/1206 Vishay CRCW12061R69FN Yes Ye s

+50%

Through

Hole

Through

Hole

Epcos B82732R2142B30 Ye s Ye s

ICE

Components

Semiconductor

Semiconductor

Manufacturer Part

NumberManufacturerFootprint

TO09002-1 Ye s Yes

NCP1219AD65R2G No Ye s

TL431BCLPRMG Ye s Ye s

1. Coilcraft components can be ordered at http://www.coilcraft.com

2. Epcos components can be ordered at http://www.epcos.com

3. ICE Components can be ordered at http://www.icecomponents.com

4. Infineon components can be ordered at http://www.infineon.com

5. Kemet components can be ordered at http://www.kemet.com

6. TDK components can be ordered at http://www.tdk.com

7. Vishay Components can be ordered at http://www.vishay.com

Substi-

tution

Allowed

Lead

Free

The converter performance is evaluated and compared to the original goals. From Table 1, the evaluation criteria includes:

1. Efficiency.

2. Standby input power.

3. Step load response.

4. Output voltage ripple.

The efficiency of the converter is measured across the

universal input voltage range. Figure 34 shows the

efficiency vs output current at 90 Vac, 100 Vac, 115 Vac,

230 Vac and 265 Vac.

100

90

80

70

60

50

40

Efficiency (%)

30

20

10

0

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Load Current (1.25 A = 100%)

90 Vac−47 Hz 100 Vac−47 Hz 115 Vac−60 Hz

230 Vac−50 Hz 265 Vac−50 Hz

Figure 34. Efficiency vs. output current

The average efficiency, h

, as defined by the Energy

avg

Star 2.0 External Power Supply (EPS) specification, was

calculated for various input voltages. The results are shown

in Figure 35. The converter is Energy Star 2.0 compliant,

maintaining h

greater than 83.5%.

avg

http://onsemi.com

20

Page 21

90

89

88

87

86

85

84

Average Efficiency (%)

83

82

81

80

50 300100 150 200 250

NCP1219PRINTGEVB

Input Voltage (Vac)

Figure 35. Average Efficiency vs. Line Voltage

The standby input power requirement is less than 1 W

over the range of input voltage. Figure 36 shows the standby

input power versus input voltage. Starting at low line, the

input power rises with increasing input voltage. At line

voltages less than 180 Vac, the controller operates in DSS

mode, because the forward auxiliary winding voltage is less

than that required to maintain V

1200

1100

1000

900

800

greater than V

CC

CC(MIN)

DSS mode

700

STANDBY POWER (mW)

600

A portion of the standby input power is due to the startup

circuit. As the input voltage increases, the auxiliary winding

begins to supply the controller and the startup circuit is no

longer active. A sudden drop in the standby input power is

observed when DSS is disabled. As the input voltage

continues to increase, so does the input power.

.

Aux winding

mode

500

80 100 120 140 160 180 280260240220200

Figure 36. Standby Power versus Input Voltage (Forward Auxiliary Winding Connection)

INPUT VOLTAGE (Vac)

http://onsemi.com

21

Page 22

NCP1219PRINTGEVB

The output voltage ripple is measured at 16 mV at high

line and full load. It is significantly less than the 50 mV

target. The output voltage ripple waveform at high line and

full load is shown in Figure 37. The ripple measured at the

switching frequency appears as expected. The output filter

eliminates the ripple associated with the switching

frequency, leaving only low amplitude spikes of noise that

are due to the switch transitions.

Figure 37. Output Voltage Ripple at High−line and Full Load

If the output ripple is observed on a longer time scale, a

component of the NCP1219 frequency jitter is observed.

The frequency jitter generated by the controller spreads the

energy generated during switching, reducing

electromagnetic interference, EMI. The bandwidth of the

system is not high enough to prevent this component. This

is shown in Figure 38. The output ripple due to the frequency

jitter is still within the target limits.

Figure 38. Frequency Jitter Component of Output Ripple at Nominal Load Current

http://onsemi.com

22

Page 23

NCP1219PRINTGEVB

The dynamic response of the converter at 24 V is

evaluated stepping the load current from 0.92 A to 2.0 A and

from 2.0 A to 0.92 A. The step load response is shown in

Figure 39. The output response to the load step is measured

as 150 mV, and recovery occurs in less than 5 ms. Response

to the transient load condition confirms the results of the

loop stability analysis.

Figure 39. Output Voltage Response to a Step Load from 0.92 A to 2.0 A

The frequency jitter component of the output waveform

previously described can be seen during the transient

response measurement.

http://onsemi.com

23

Page 24

NCP1219PRINTGEVB

Thermal Performance

This evaluation board is designed to operate with out

forced airflow as in an external printer power supply. The

thermal performance of the board is evaluated using an

infrared camera. Figures 40 through 43 show several images

of the board during a continuous load step as described in

Figure 1. Images include top and bottom layers at low and

high line. All images were taken in open air conditions

without forced airflow.

Figure 40. Thermal Image of the Top of the Board at Low Line During a Continuous Load Step Condition

Figure 41. Thermal Image of the Bottom of the Board at Low Line During a Continuous Load Step Condition

http://onsemi.com

24

Page 25

NCP1219PRINTGEVB

Figure 42. Thermal Image of the Top of the Board at High Line During a Continuous Load Step Condition

Figure 43. Thermal Image of the Bottom of the Board at High Line During a Continuous Load Step Condition

http://onsemi.com

25

Page 26

NCP1219PRINTGEVB

Most of the losses on the board are on the main switch,

transformer, secondary rectifier (D12) and secondary

snubber resistor (R18). The main switch losses are

dominated by on state conduction losses, but the aluminum

heat sink reduces the power dissipation in the device. High

peak currents during the load step create heating in the

transformer, as seen in Figures 40 and 42. The losses in D12

during load step conditions are shown in the lower

right−hand corner of the board in Figures 40 and 42. The

heat spreading from D12 can also be seen on the bottom side

of the board. The secondary snubber is designed to prevent

overvoltage stress on the secondary rectifier. The power

dissipation in R18 occurs at high line conditions when the

snubber acts to clamp the voltage on the diode, as seen in the

upper right hand corner of the board. At low line, DSS mode

is active and the power dissipation in the controller and the

series HV resistors (R41 and R42) can be seen in Figure 41.

Summary

A 30 W (48 W) converter is designed and built using the

flyback topology. The converter is implemented using the

NCP1219. The average load efficiency is measured above

83.5% over the complete operating range.

The standby input power is measured below 1 W under

universal mains operating ranges. The low standby power is

achieved using a forward auxiliary winding with DSS

operating at low line conditions only. The converter

complies with Energy Star 2.0 EPS requirements.

The converter provides excellent transient response by

minimizing overshoot, undershoot, and recovery time.

Output voltage ripple is measured at 16 mV. Phase margin

and crossover frequency are measured at 60° and 1.3 kHz,

respectively.

This evaluation board is designed to demonstrate the

features and flexibility of the NCP1219. This design is a

guideline only and does not guarantee performance for any

manufacturing or production purposes.

References

1. Basso, Christophe P. Switch−Mode Power

Supplies SPICE Simulations and Practical

Designs. 1st ed. New York, NY: MacGraw Hill.

2. Pressman, Abraham I. Switching Power Supply

Design. 1st ed. New York, NY: MacGraw Hill.

3. PWM Controller with Adjustable Skip Level and

External Latch Input Datasheet NCP1219,

www.onsemi.com.

http://onsemi.com

26

Page 27

NCP1219PRINTGEVB

TEST PROCEDURE FOR THE NCP1219PRINTGEVB EVALUATION BOARD

Required Equipment

(*Equivalent test equipment may be submitted.)

• *Chroma 61604 AC Power Source

• *Chroma 66202 Digital Power Meter

• *Agilent 34401A Multimeter

• *Chroma 6314 Electronic Load with *Chroma 63102

Module

• *Agilent E3649A DC Power Supply

Test Procedure

1. Set multimeter M1 to measure current.

2. Connect input terminal “I” of multimeter M1 to

pin 3 of connector J5.

3. Connect the input terminal “LO” of multimeter

M1 to the positive terminal of the electronic load.

4. Connect the negative terminal of the electronic

load to pin 2 of connector J5.

5. Set multimeter M2 to measure voltage.

6. Connect the input terminal “HI” of multimeter M2

to pin 3 of connector J5.

7. Connect the input terminal “LO” of multimeter

M2 to pin 2 of connector J5.

8. Connect the positive terminal of the dc power

supply to pin 1 of connector J5.

9. Connect the negative terminal of the dc power

supply to pin 2 of connector J5.

10. Connect the ac power source and power analyzer

to connector J1 as shown in Figure 44.

11. Set the current compliance limit on the ac source

to 4 A.

12. Set the ac source to 115 Vac / 60 Hz.

13. Set the electronic load to the lowest current range

setting.

14. Set the electronic load to 70 mA.

15. Set the dc power supply connected to pin1 of J5 to

0 V.

16. High voltages are present on the primary side

of the converter during testing. Use Caution.

17. Turn the dc source on.

18. Turn the ac source on.

19. Set the power analyzer to integrate power for 5

minutes and start the integration cycle.

20. Measure V

OUT(standby)

multimeter. Record the results in Table 5. Verify it

is within the limits of Table 4.

21. Measure and the integrated P

power analyzers it may be necessary to convert to

P

from W*h using the equation:

IN

using the corresponding

IN(standby)

. For some

PIN+

W h

5minutes

60minutes

1hour

+ (W h) 12

Record the results in Table 5. Verify it is within the

limits of Table 4.

22. Repeat steps 19 through 21 for a line voltage of

230 Vac / 50 Hz.

23. Set the ac power source to 115 Vac / 60 Hz.

24. Set the electronic load to 1.25 A.

25. Set the dc power supply to 5 V.

26. Perform a 5 minute burn in at the line and load

conditions given in steps 23 and 24.

27. Measure and the output voltage (V

) using the

OUT

corresponding multimeter. Record the results in

Table 6. Verify it is within the limits of Table 4.

28. Measure the output current (I

) using the

OUT

corresponding multimeter. Record the results in

Table 6.

29. Measure the input power (P

) using the power

IN

analyzer. Record the results in Table 6.

30. Calculate the efficiency (h) using the equation

I

V

h +

OUT

OUT

IN

100%

P

Record the results in Table 6.

31. Repeat steps 27 - 30 for all ac source and

electronic load settings (0.01 A, 0.3125 A,

0.625 A, 0.9375 A, 1.25 A, 2.00 A) specified in

Table 3.

32. Calculate the average efficiency (h

) using the

avg

equation:

h

avg

where h

+

25%

) h

h

25%

, h

50%

, h

50%

75%

) h

4

and h

75%

) h

100%

100%

are the

efficiencies calculated for the 25%, 50%, 75% and

100% load conditions given in Table 3.

Record the results in Table 6. Verify it is within

the limits of Table 4.

33. Turn off the ac source.

34. Turn off the dc source.

35. Disconnect the ac source.

36. Disconnect the dc source.

37. Disconnect the electronic load.

38. Disconnect both multimeters.

39. End of test.

http://onsemi.com

27

Page 28

NCP1219PRINTGEVB

Table 3. NORMAL OPERATING CONDITIONS

Input Voltage

(Vac)

115 60

230 50

Line Frequency

(Hz)

Load Current (A)

0.01

0.3125 (25%)

0.675 (50%)

0.9375 (75%)

1.25 (100%)

2.00

0.01

0.3125 (25%)

0.675 (50%)

0.9375 (75%)

1.25 (100%)

2.00

Figure 44. Test Setup

Table 4. DESIRED RESULTS

Input Voltage I

For 115 Vac /

60 Hz input

For 230 Vac /

50 Hz input

Table 5. STANDBY MODE MEASURED RESULTS

Input Voltage Parameter Result

115 Vac / 60 Hz

230 Vac / 50 Hz

Input

Input

OUT

70 mA 7 V < V

70 mA PIN < 1 W

I

specified

OUT

in Table 3

25%, 50%,

75%, 100%

V

OUT

h

avg

70 mA 7 V < V

70 mA PIN < 1 W

I

specified

OUT

in Table 3

25%, 50%,

75%, 100%

V

OUT(standby)

P

IN(standby)

V

OUT(standby)

P

IN(standby)

V

OUT

h

avg

OUT(standby)

8V

= 24 ±0.2 V

> 83.5%

OUT(standby)

8V

= 24 ±0.2 V

> 83.5%

<

<

http://onsemi.com

28

Page 29

NCP1219PRINTGEVB

Table 6. NORMAL MODE MEASURED AND

CALCULATED RESULTS

Input

Voltage

115 Vac /

60 Hz

Input

Load Cur-

rent (A)

0.01 V

0.3125

(25%)

0.675

(50%)

0.9375

(75%)

1.25

(100%)

2.00 V

Parameter Result

(V)

OUT

I

(A)

OUT

PIN (W)

V

(V)

OUT

I

(A)

OUT

PIN (W)

h

25%

V

(V)

OUT

I

(A)

OUT

PIN (W)

h

50%

V

(V)

OUT

I

(A)

OUT

PIN (W)

h

75%

V

(V)

OUT

I

(A)

OUT

PIN (W)

h

100%

(V)

OUT

I

(A)

OUT

PIN (W)

h

avg

230 Vac /

50 Hz

Input

0.01 V

0.3125

(25%)

0.675

(50%)

0.9375

(75%)

1.25

(100%)

2.00 V

OUT

I

OUT

PIN (W)

V

OUT

I

OUT

PIN (W)

h

25%

V

OUT

I

OUT

PIN (W)

h

50%

V

OUT

I

OUT

PIN (W)

h

75%

V

OUT

I

OUT

PIN (W)

h

100%

OUT

I

OUT

PIN (W)

h

avg

(V)

(A)

(V)

(A)

(V)

(A)

(V)

(A)

(V)

(A)

(V)

(A)

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC owns the rights to a number of patents, trademarks,

copyrights, trade secrets, and other intellectual property. A listing of SCILLC’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. SCILLC

reserves the right to make changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without

limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications

and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC

does not convey any license under its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for

surgical implant into the body, or other applications intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where

personal injury or death may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and

its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly,

any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture

of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

http://onsemi.com

29

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

EVBUM2161/D

Loading...

Loading...