Page 1

© Semiconductor Components Industries, LLC, 2005

July, 2005 − Rev. 3

1 Publication Order Number:

NCP1215/D

NCP1215

Low Cost Variable OFF Time

Switched Mode Power

Supply Controller

The NCP1215 is a controller for low power off−line flyback

Switchemode Power Supplies (SMPS) featuring low size, weight and

cost constraints together with a good low standby power performance.

The operating principle uses switching frequency reduction at light

load by increasing the OFF Time. Also, when OFF T ime expands, the

peak current is gradually reduced down to approximately 1/4 of the

maximum peak current to prevent from exciting the transformer

mechanical resonances. The risk of acoustic noise is thus greatly

diminished while keeping good standby power performance.

A low power internal supply block also ensures very low current

consumption at startup without hampering the standby power

performance.

A special primary current sensing technique minimizes the impact

of SMPS switching on control IC operation. The choice of peak

voltage across the current sense resistor allows dissipation to be

further reduced. The negative current sensing technique offers

advantages over a traditional approach by avoiding the voltage drop

incurred by traditional MOSFET source sensing. Thus, the IC drive

capability is greatly improved.

Finally, the bulk input ripple ensures a natural frequency dithering

which smooths the EMI signature.

Features

• Pb−Free Package is Available

• Variable OFF Time Control Method

• Very Low Current Consumption at Startup

• Natural Frequency Dithering for Improved EMI Signature

• Current Mode Control Operation

• Peak Current Compression Reduces Transformer Noise

• Programmable Current Sense Resistor Peak Voltage

• Undervoltage Lockout

Typical Applications

• Auxiliary Power Supply

• Standby Power Supply

• AC−DC Adapter

• Off−line Battery Charger

1

8

SOIC−8

D SUFFIX

CASE 751

18

5

3

4

(Top View)

FB

CS

NC

PIN CONNECTIONS

7

6

2

NC

CT

GND

Gate

V

CC

MARKING

DIAGRAMS

FAA = Specific Device Code

A = Assembly Location

L = Wafer Lot

Y = Year

W = Work Week

1

6

TSOP−6

(SOT23−6, SC59−6)

SN SUFFIX

CASE 318G

FAAYW

1

6

SOIC−8

1

3

FB

CS

2GND

CT

4

Gate

6

(Top View)

5

V

CC

TSOP−6

ORDERING INFORMATION

P1215

ALYW

Device Package Shipping

†

NCP1215DR2 SOIC−8 2500 Tape & Reel

NCP1215SNT1 TSOP−6

3000 Tape & Reel

†For information on tape and reel specifications,

including part orientation and tape sizes, please

refer to our Tape and Reel Packaging Specification

s

Brochure, BRD801 1/D.

1

8

http://onsemi.com

NCP1215DR2G SOIC−8

(Pb−Free)

2500 Tape & Reel

Page 2

NCP1215

http://onsemi.com

2

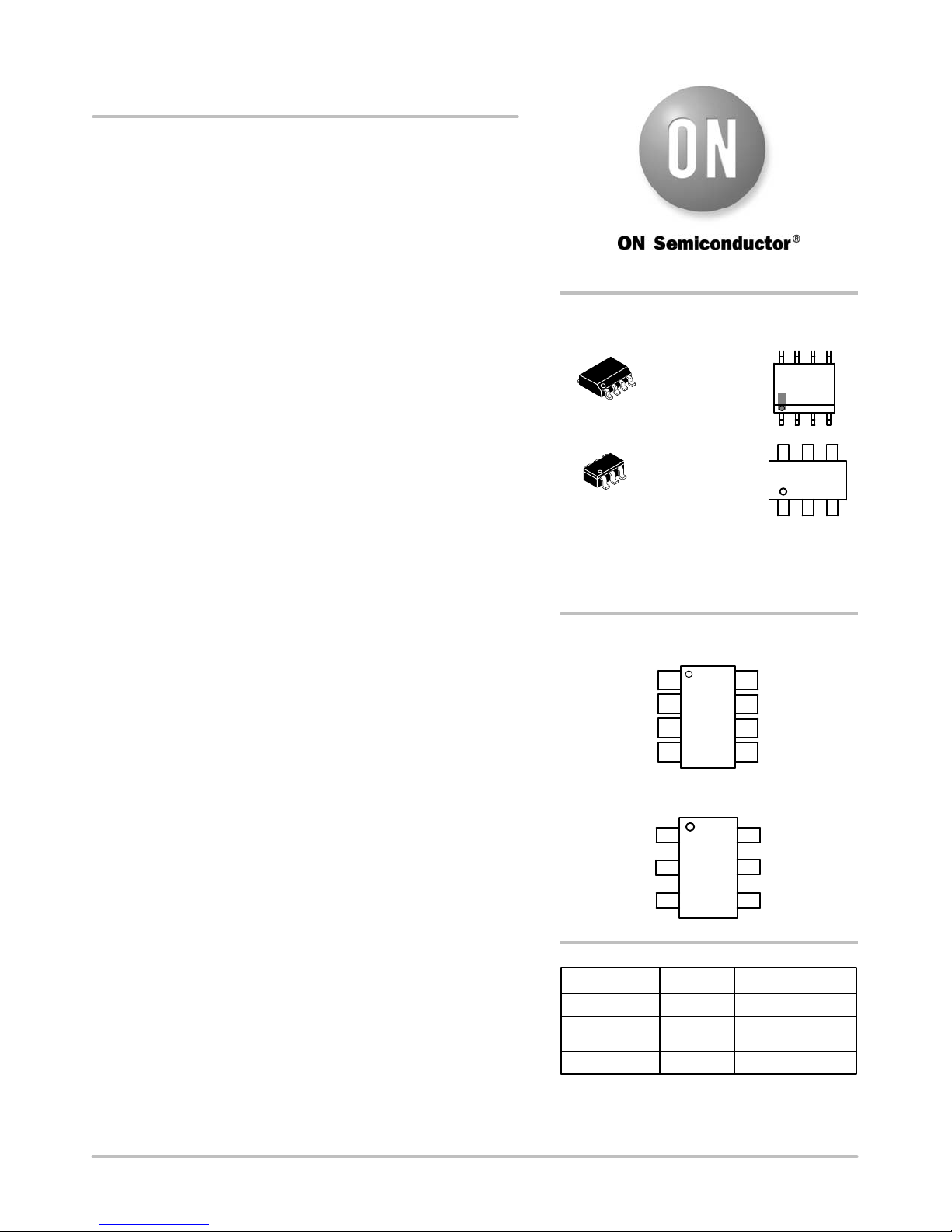

Figure 1. Typical Application

LineLine

N

+

FB

GND

CT

CS

Gate

Vcc

NC

NC

+

+

+

−

*

*If your application requires a gate−source resistor, please refer to design guidelines in this document.

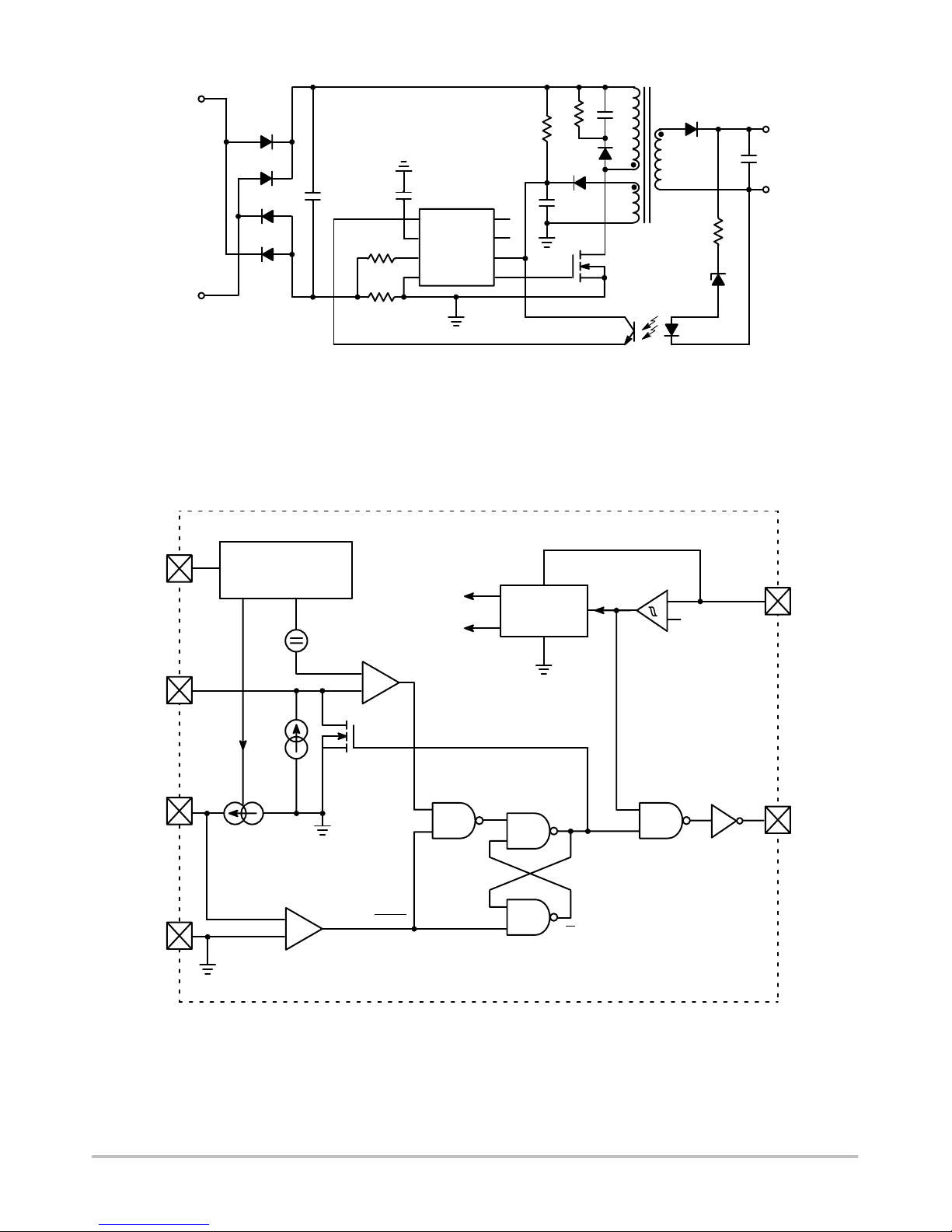

Figure 2. Representative Block Diagram

Feedback Loop

Control

−

+

FB

+

−

Off−Time

Comparator

CT

Voffset

0−7 V

10 mA

12.5−50 mA

CS

+

−

GND

Current Sense Comparator

Reset

Set

Q

Q

Reference

Regulator

V

DD

I

ref

−

+

Undervoltage

Lockout

12/8.5 V

Gate

V

CC

Gate Driver

Page 3

NCP1215

http://onsemi.com

3

БББББББББББББББББББББББББББББББ

Á

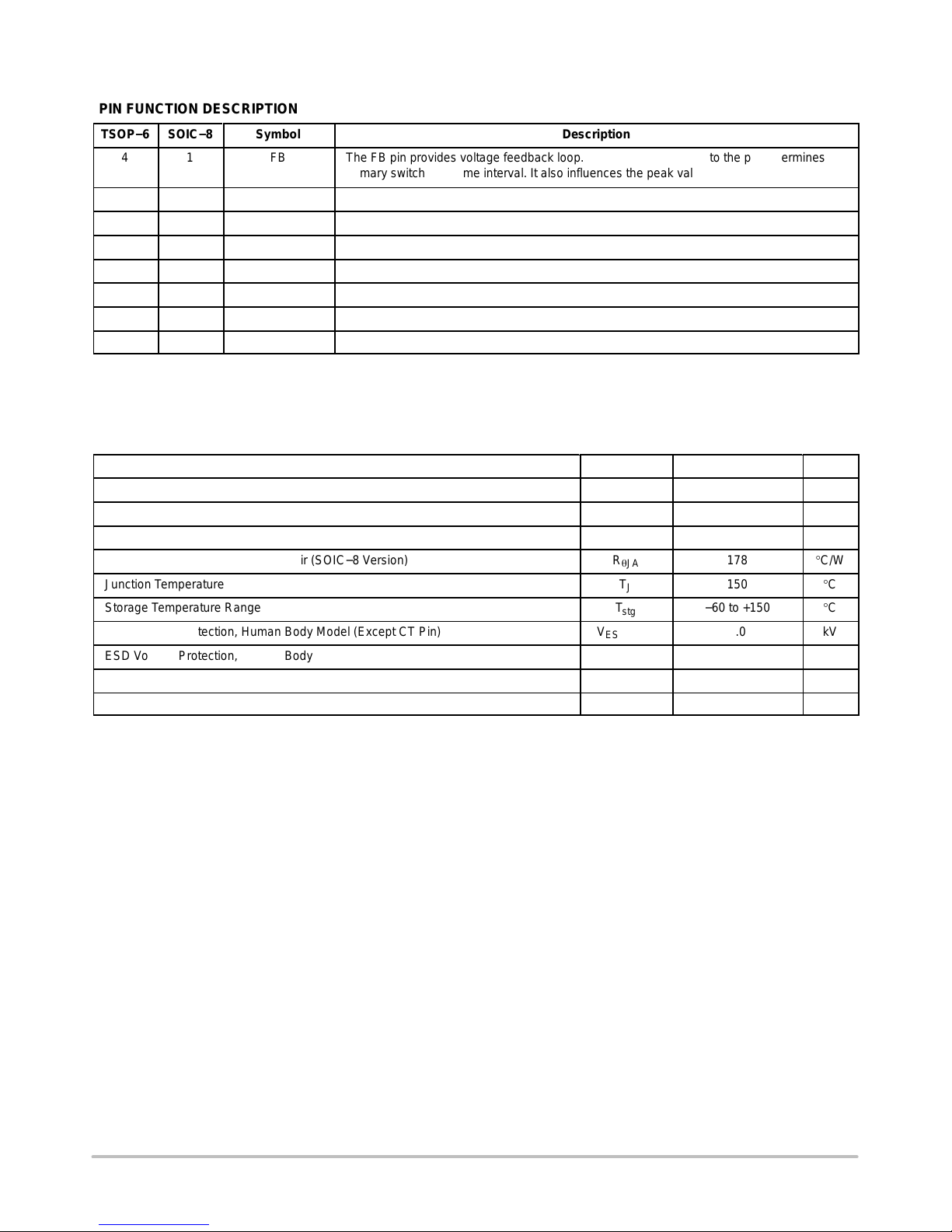

PIN FUNCTION DESCRIPTION

TSOP−6

SOIC−8

Symbol

ББББББББББББББББББББББ

Description

4 1 FB The FB pin provides voltage feedback loop. The current injected into the pin determines the

primary switch OFF time interval. It also influences the peak value of the primary current.

3 2 CT Connection for an external timing programming capacitor.

1 3 CS The CS pin senses the power switch current.

2 4 GND Primary and internal ground.

6 5 Gate Output drive for an external power MOSFET.

5 6 Vcc Power supply voltage and Undervoltage Lockout.

7 7 NC Unconnected pin.

8 8 NC Unconnected pin.

БББББББББББББББББББББББББББББББ

Á

MAXIMUM RATINGS

Rating

Symbol

Value

Unit

Power Supply Voltage V

cc

18 V

FB Pins Voltage Range V

FB

−0.3 to 18 V

CS and CT Pin Voltage Range V

in

−0.3 to 10 V

Thermal Resistance, Junction−to−Air (SOIC−8 Version)

R

q

JA

178 °C/W

Junction Temperature T

J

150 °C

Storage Temperature Range T

stg

−60 to +150 °C

ESD Voltage Protection, Human Body Model (Except CT Pin) V

ESD−HBM

2.0 kV

ESD Voltage Protection, Human Body Model for CT Pin V

ESD−HBM−CT

1.5 kV

ESD Voltage Protection, Machine Model (Except CT Pin) V

ESD−MM

200 V

ESD Voltage Protection, Machine Model for CT Pin V

ESD−MM−CT

150 V

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously . If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

Page 4

NCP1215

http://onsemi.com

4

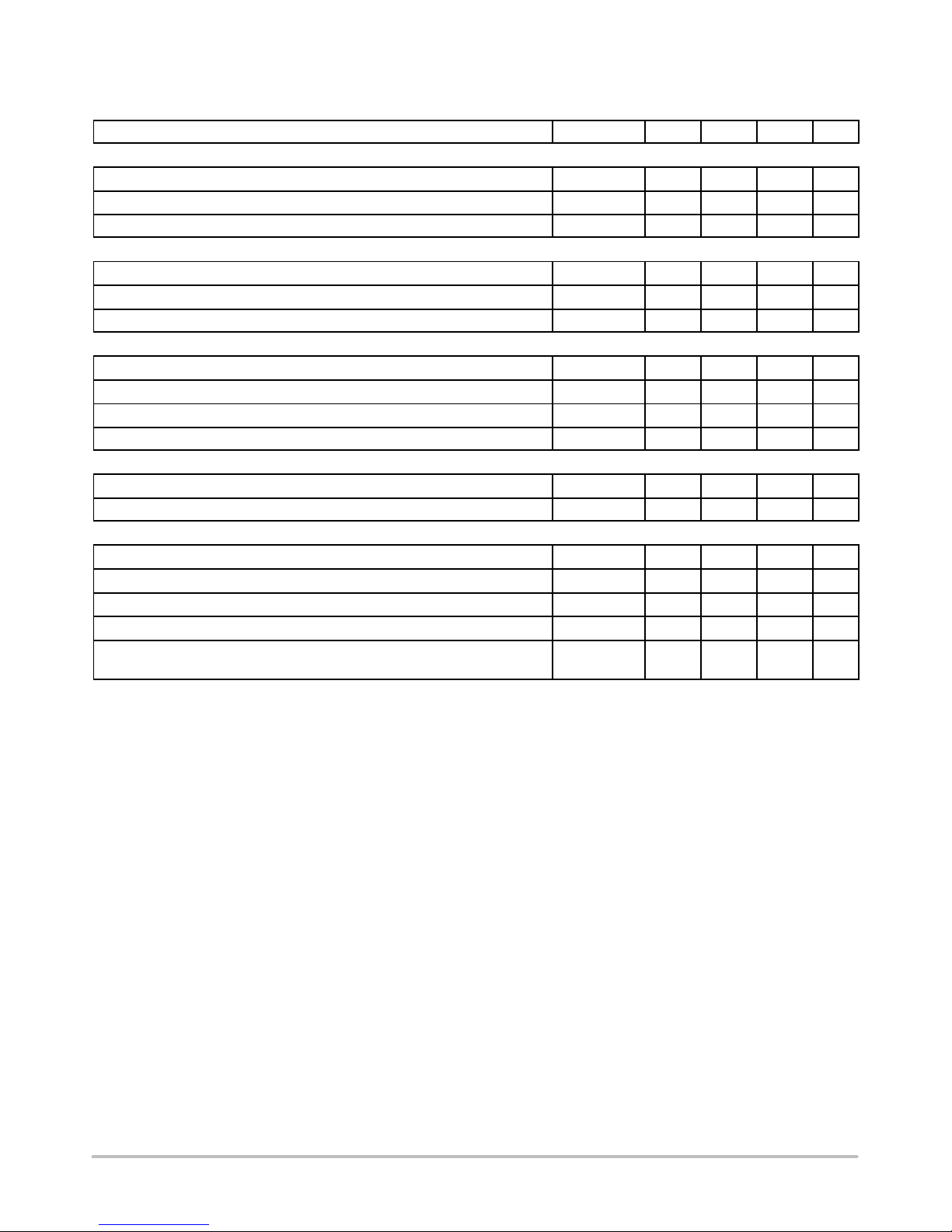

ELECTRICAL CHARACTERISTICS (V

CC

= 12 V, for typical values Tj = 25°C, for min/max values Tj = 0°C to +105°C, unless

otherwise noted.)

Characteristic Symbol Min Typ Max Unit

VOLTAGE FEEDBACK

Offset Voltage

V

offset

1.05 1.19 1.34 V

Maximum CT Pin Voltage at FB Current = 25 mA (Including V

offset

) V

CT−25mA

2.4 3.1 4.3 V

Maximum CT Pin Voltage at FB Current = 50 mA (Including V

offset

) V

CT−50mA

3.6 4.6 6.2 V

CT PIN − OFF TIME CONTROL

Source Current (CT Pin Grounded)

I

CT

8.0 9.8 11.5

mA

Source Current Maximum Voltage Capability V

CT−max

− 6.5 − V

Minimum CT Pin Voltage (Pin Unloaded, Discharge Switch Turned On) V

CT−min

− − 20 mV

CURRENT SENSE

Minimum Source Current (I

FB

= 180 mA, CT Pin Grounded)

I

CS−min

8.0 12.5 16

mA

Maximum Source Current (IFB = 0 mA, CT Pin Grounded)

I

CS−max

40 49 58

mA

Comparator Threshold Voltage V

th

15 42 80 mV

Propagation Delay (CS Falling Edge to Gate Output) t

delay

− 215 310 ns

GATE DRIVE

Sink Resistance (I

sink

= 30 mA) R

OL

25 40 90

W

Source Resistance (I

source

= 30 mA) R

OH

60 80 130

W

POWER SUPPLY

V

CC

Startup Voltage V

startup

− 12.5 14.2 V

Undervoltage Lockout Threshold Voltage V

UVLO

7.2 9.0 − V

Hysteresis (V

startup

− V

UVLO

) V

hys

2.2 3.5 − V

VCC Startup Current Consumption (V

CC

= 8.0 V) I

CC−start

− 2.8 6.5

mA

VCC Steady State Current Consumption

(C

GATE

= 1.0 nF, f

SW

= 100 kHz, FB open)

I

CC−SW

0.55 0.9 1.75 mA

Page 5

NCP1215

http://onsemi.com

5

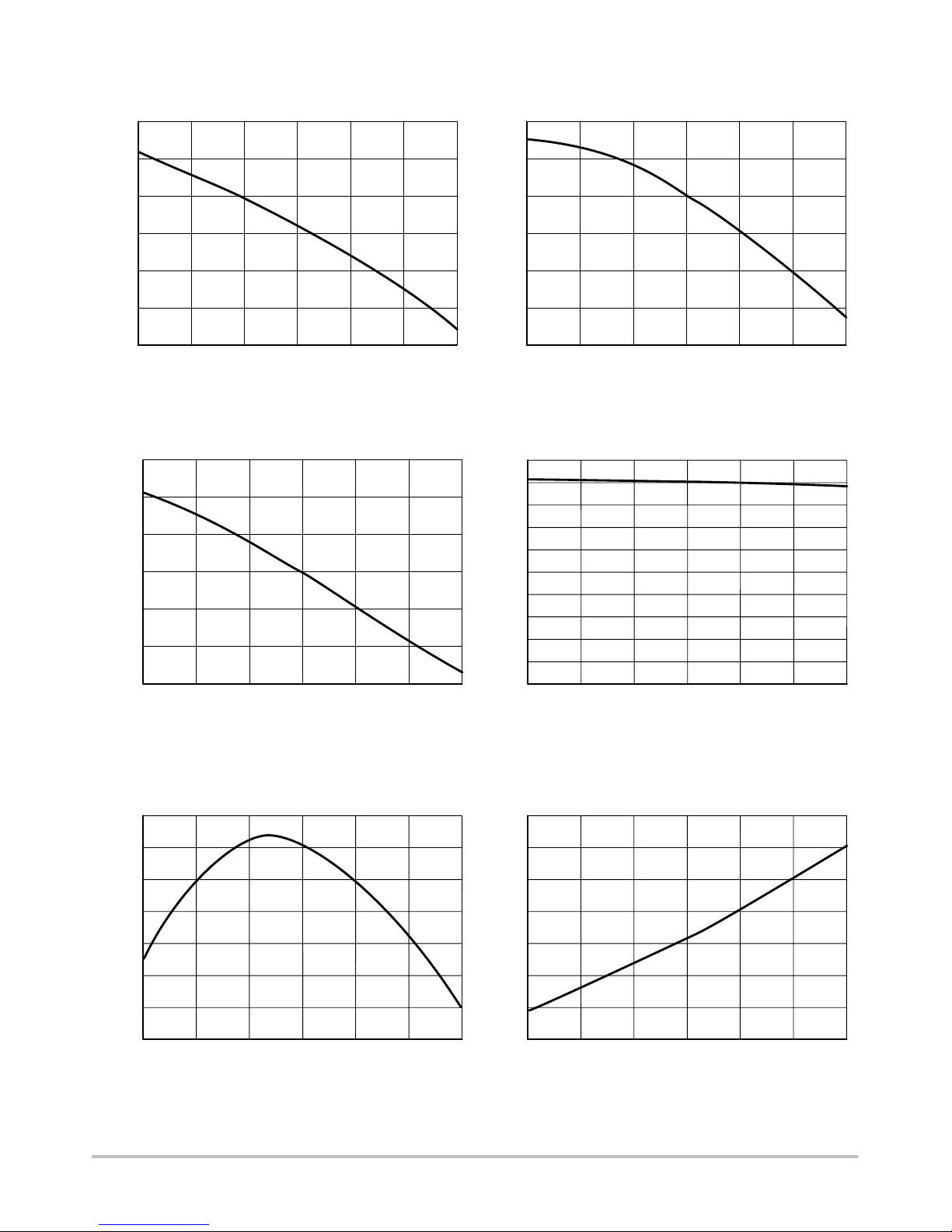

TYPICAL CHARACTERISTICS

−25

11.5

50

11.2

250

V

startup

, (V)

11.0

TJ, JUNCTION TEMPERATURE (°C)

11.6

TJ, JUNCTION TEMPERATURE (°C)

11.1

11.3

11.4

125

V

offset

, (V)

1.08

Figure 3. V

startup

Threshold vs. Junction

Temperature

Figure 4. V

UVLO

Threshold vs. Junction

Temperature

Figure 5. Operating Current Consumption vs.

Junction Temperature

Figure 6. Offset Voltage vs. Junction

Temperature

TJ, JUNCTION TEMPERATURE (°C)

Figure 7. Current Sense Source Current vs.

Junction Temperature

TJ, JUNCTION TEMPERATURE (°C)

Figure 8. Current Sense Threshold vs.

Junction Temperature

TJ, JUNCTION TEMPERATURE (°C)

1.12

1.00

1.16

1.20

75 100 −25

8.7

50

8.4

250

V

UVLO

, (V)

8.2

8.8

8.3

8.5

8.6

12

5

75 100

−25

0.985

50

0.970

250

I

CC−SW

, (mA)

0.960

0.990

T

J

, JUNCTION TEMPERATURE (°C)

0.965

0.975

0.980

125

75 100 −25 5025012

5

75 100

1.04

1.06

1.10

1.14

1.18

1.02

−25

48.0

50

46.5

250

I

CS−max

, (

m

A)

45.5

49.0

46.0

47.0

47.5

12575 100

48.5

−25

55

50

40

250

V

CS−th

, (mV)

30

65

35

45

50

12

5

75 100

60

Page 6

NCP1215

http://onsemi.com

6

−25

9.9

50

9.6

250

I

CT

, (

m

A)

9.4

T

J

, JUNCTION TEMPERATURE (°C)

10.0

TJ, JUNCTION TEMPERATURE (°C)

9.5

9.7

9.8

125

I

CS

, (mA)

40.0

Figure 9. CT pin Source Current vs. Junction

Temperature

Figure 10. CT pin Threshold vs. Junction

Temperature

Figure 11. Drive Sink and Source Resistance

vs. Junction Temperature

Figure 12. Current Sense Source Current vs.

Feedback Current

Ifb, FEEDBACK CURRENT (mA)

60.0

0.0

75 100 −25 50

10

250

V

CT−min

, (mV)

6

16

8

12

14

12

5

75 100

−25

100

50

40

250

R

source

−R

sink,

(

W

)

0

120

T

J

, JUNCTION TEMPERATURE (°C)

20

60

80

125

75 100 5025012

5

75 100

20.0

30.0

50.0

10.0

R

source

R

sink

TJ = 25°C

Page 7

NCP1215

http://onsemi.com

7

APPLICATION INFORMATION

The NCP1215 implements a current mode SMPS with a

variable OFF−time dependant upon output power demand.

It can be seen from the typical application that NCP1215 is

designed to operate with a minimum number of external

component. The NCP1215 incorporates the following

features:

• Frequency Foldback: Since the switch−off time

increases when power demand decreases, the switching

frequency naturally diminishes in light load conditions.

This helps to minimize switching losses and offers

excellent standby power performance.

• Very Low Startup Current: The patented internal

supply block is specially designed to offer a very low

current consumption during startup. It allows the use of

a very high value external startup resistor, greatly

reducing dissipation, improving efficiency and

minimizing standby power consumption.

• Natural Frequency Dithering: The quasi−fixed T

on

mode of operation improves the EMI signature since

the switching frequency varies with the natural bulk

ripple voltage.

• Peak Current Compression: As the load becomes

lighter, the frequency decreases and can enter the

audible range. To avoid exciting transformer

mechanical resonances, hence generating acoustic

noise, the NCP1215 includes a patented technique,

which reduces the peak current as power goes down.

As such, inexpensive transformer can be used without

having noise problems.

• Negative Primary Current Sensing: By sensing

the total current, this technique does not modify the

MOSFET driving voltage (Vgs) while switching.

Furthermore, the programming resistor together with the

pin capacitance, forms a residual noise filter which

blanks spurious spikes. Also fixing primary current level

to a maximum value sets the maximum power limit.

• Programmable Primary Current Sense: It offers a

second peak current adjustment variable which improves

the design flexibility.

• Secondary or Primary Regulation: The feedback

loop arrangement allows simple secondary or primary

side regulation without significant additional external

components.

A detailed description of each internal block within the IC

is given in the following.

Feedback Loop Control

The main task of the Feedback Loop Block is to control

the SMPS output voltage through the change of primary

switch OFF time interval. It sets the peak voltage of the

timing capacitor, which varies upon the output power

demand. Figure 13 shows the simplified internal schematic:

Figure 13. Feedback Loop − OFF Time Control

FB

17 k

Current

Mirror

1:1

Current

Mirror

1:1

−

+

To OFF

Time

Comparator

45 k

V

offset

V

CC

The voltage feedback signal is sensed as a current injected

through the FB pin.

Figure 14. FB Loop Transfer Characteristic

OFF−Time Comparator Input Voltage

V

DD

V

offset

0 mA

FB Pin Sink Current

The transfer characteristic (output voltage to input

current) of the feedback loop control block can be seen in

Figure 14. V

DD

refers to the internal stabilized supply

whereas the offset value sets the maximum switching

frequency in lack of optocoupler current (e.g. an output

short−circuit).

To keep the switching frequency above the audio range in

light load condition the FB pin also regulates in certain range

the peak primary current. The corresponding block diagram

can be seen from Figure 15.

Page 8

NCP1215

http://onsemi.com

8

Figure 15. Feedback Loop − Current Sense Control

FB

17 k

Current

Mirror

4:3

37.5 mA 12.5 mA

CS

To Current Sense Comparator

The resulting current sense regulation characteristic can

be seen from Figure 16.

Figure 16. Current Sense Regulation Characteristic

CS Pin Source Current

2.5 mA

50 mA

140 m

A

100 mA50 mA0 mA

FB Pin Sink Current

When the load goes light, the compression circuitry

decreases the peak current. This has the effect of slightly

increasing the switching frequency but the compression

ratio is selected to not hamper the standby power.

OFF Time Control

The loop signal together with the internal current source,

via an external capacitor, controls the switch−off time. This

is portrayed in Figure 17.

Figure 17. OFF Time Control

−

+

+

−

CT

Voffset

10 mA

From Feedback Loop Block

V

offset

to V

DD

To Latch’s Set Input

To Latch’s Output

GND

CT

During the switch−ON time, the CT capacitor is kept

discharged by a MOSFET switch. As soon as the latch

output changes to a l o w s t a te, t he v olta ge a cros s CT created

by the internal current source, starts to ramp−up until its

value reaches the threshold given by the feedback loop

demand.

Figure 18. CT Pin Voltage (P

out

1 u P

out

2 u P

out

3)

V

offset

V

DD

V

CT Pin

Voltage

P

OUT

Goes Down

P

OUT

Goes Up

t

off−min

t

P3

P2

P1

The voltage that can be observed on CT pin is shown in

Figure 18. The bold waveform shows the maximum output

power when the OFF time is at its minimum. The IC allows

an OFF time of several seconds.

Page 9

NCP1215

http://onsemi.com

9

Primary Current Sensing

The primary current sensing circuit is shown in Figure 19.

CS

R

shift

V

shift

R

CS

V

CS

GND

+

−

To Latch

I

primary

Figure 19. Primary Current Sensing

12.5 mA

B

50 mA

Feedback Loop

Control

FB

When the primary switch is ON, the transformer current

flows through the sense resistor R

cs

. The current creates a

voltage, V

cs

which is negative with respect to GND. Since

the comparator connected to CS pin requires a positive

voltage, the voltage V

shift

is developed across the resistor

R

shift

by a current source which level−shifts the negative

voltage V

cs

. The level−shift current is in range from 12.5 to

50 mA depending on the Feedback Loop Control block

signal (see more details in the Feedback Loop Control

section).

The peak primary current is thus equal to:

I

pk

+

R

shift

R

CS

·I

CS

(eq. 1)

A typical CS pin voltage waveform is shown in Figure 20.

Figure 20. CS Pin Voltage

0

tSwitch

Turn−on

I

shift

= 12.5 mA

I

shift

= 50 mA

V

Figure 20 also shows the effect of the inductor current of

differing output power demand.

The primary current sensing method we described, brings

the following benefits compared to the traditional approach:

• Maximum peak voltage across the current sense resistor

is determined and can be optimized by the value of the

shift resistor.

• CS pin is not exposed to negative voltage, which could

induce a parasitic substrate current within the IC and

distort the surrounding internal circuitry.

• The gate drive capability is improved because the

current sense resistor is located out of the gate driver

loop and does not deteriorate the turn−on and also

turn−off gate drive amplitude.

Gate Driver

The Gate Driver consists of a CMOS buffer designed to

directly drive a power MOSFET.

It features an unbalanced source and sink capabilities to

optimize turn ON and OFF performance without additional

external components. Since the power MOSFET turns−off

at high drain current, to minimize its turn−off losses the sink

capability of the gate driver is increased for a faster turn−off.

To the opposite, the source capability is lower to slow−down

power MOSFET at turn−on in order to reduce the EMI noise.

Whenever the IC supply voltage is lower than the

undervoltage threshold, the Gate Driver is low, pulling down

the gate to ground. It eliminates the need for an external

resistor.

Startup Circuit

An external startup resistor is connected between high

voltage potential of the input bulk capacitor and Vcc supply

capacitor. The value of the resistor can be calculated as

follows:

R

startup

+

V

bulk

* V

startup

I

startup

(eq. 2)

Where:

V

startup

Vcc voltage at which IC starts operation

(see spec.)

I

startup

Startup current

V

bulk

Input bulk capacitor’s voltage

Since the V

bulk

voltage has obviously much higher value

than V

startup

the equation can be simplified in the following

way:

R

startup

+

V

bulk

I

startup

(eq. 3)

The startup current can be calculated as follows:

I

startup

+ C

Vcc

V

startup

t

startup

) I

CC−start

(eq. 4)

Where:

C

Vcc

Vcc capacitor value

t

startup

Startup time

I

CC−start

IC current consumption (see spec.)

Page 10

NCP1215

http://onsemi.com

10

If the IC current consumption is assumed constant during

the startup phase, one can obtain resulting equation for

startup resistor calculation:

R

startup

+

V

bulk

C

Vcc

V

startup

t

startup

) I

CC−start

(eq. 5)

Switching Frequency

The switching frequency varies with the output load and

input voltage. The highest frequency appears at highest

input voltage and maximum output power.

Since the peak primary current is fixed, the on time

portion of the switching period can be calculated:

ton+ L

p

I

pk

V

bulk

(eq. 6)

Where:

L

p

Transformer primary inductance

I

pk

Peak primary current

Using equation for peak primary current estimation the

switch−on time is:

ton+ L

p

R

shift

Rcs·V

bulk

50 · 10

−6

(eq. 7)

Minimum switch−on time occurs at maximum input

voltage:

t

on−min

+ L

p

R

shift

Rcs·V

bulk−max

50 · 10

−6

(eq. 8)

As it can be seen from the above equation, the switch−on

time linearly depends on the input bulk capacitor voltage.

Since this voltage has ripple due to AC input voltage and

input rectifier, it allows natural frequency dithering to

improve EMI signature of the SMPS.

The switch−off time is determined by the charge of an

external capacitor connected to the CT pin. The minimum

Toff value can be computed by:

t

off−min

+ C

T

V

offset

I

Ct

+ C

T

1.2

10

−5

(eq. 9)

+ 0.12 · 106C

T

Where:

V

offset

Offset voltage (see spec.)

I

Ct

CT pin source current (see spec.)

The maximum switching frequency then can be evaluated

by:

(eq. 10)

f

sw−max

+

1

t

on−min

) t

off−min

+

1

Lp·R

shift

V

bulk·Rcs

·50·10−6) 0.12 · 106·C

T

As output power diminishes, the switching frequency

decreases because the switch−off time prolongs upon

feedback loop. The range of the frequency change is

sufficient to keep output voltage regulation in any light load

condition.

Application Design Example

An example of the typical wall adapter application is

described hereafter.

As a wall adapter it should be able to operate properly with

wide range of the input voltage from 90 VAC up to 265 VAC.

The bulk capacitor voltage then can be calculated:

(eq. 11)

V

bulk−min

+ V

AC−min

2Ǹ+ 90 · 2Ǹ+ 127 VDC

(eq. 12)

V

bulk−max

+ V

AC−max

2Ǹ+ 265 · 2Ǹ+ 375 VDC

The requested output power is 5.2 Watts.

Assuming 80% efficiency the input power is equal to:

(eq. 13)

P

in

+

P

out

h

+

5.2

0.8

+ 6.5 W

The average value of input current at minimum input

voltage is:

(eq. 14)

I

in−avg

+

P

in

V

bulk−min

+

6.5

127

+ 51.2 mA

The suitable reflected primary winding voltage for 600 V

rated MOSFET switch is:

(eq. 15)

V

flbk

+ 600 V * V

bulk−max

* V

spike

+ 600 * 375 * 100 + 125 V

Using calculated flyback voltage the maximum duty cycle

can be calculated:

(eq. 16)

d

max

+

V

flbk

V

flbk

) V

bulk−min

+

125

125 ) 127

+ 0.496 + 0.5

Following equation determines peak primary current:

(eq. 17)

I

ppk

+

2·I

in−avg

d

max

+

2·51.2·10

−3

0.5

+ 204.7 mA

The desired maximum switching frequency at minimum

input voltage is 75 kHz.

The highest switching frequency occurs at the highest

input voltage and its value can be estimated as follows:

(eq. 18)

f

max−high

+ f

max−low

V

bulk−max

V

bulk−min

d

max

+ 75 · 10

3

375

127

0.5 + 110.7 kHz

This frequency is much below 150 kHz, so that the desired

operating frequency can be exploited for further calculation

of the primary inductance:

(eq. 19)

L

p

+

V

bulk−min

· d

max

I

ppk·fsw−max

+

127 · 0.5

0.2047 · 75 · 10

3

+ 4.14 mH

Page 11

NCP1215

http://onsemi.com

11

The EF16 core for transformer was selected. It has

cross−section area A

e

= 20.1 mm2. The N67 magnetic

allows to use maximum operating flux density

B

max

= 0.28 Tesla.

The number of turns of the primary winding is:

(eq. 20)

n

p

+

Lp·I

ppk

B

max·Ae

+

4.14 · 10−3· 0.2047

0.28 · 20.1 · 10

−6

+ 150 turns

The AL factor of the transformer’s core can be calculated:

(eq. 21)

A

L

+

L

p

(np)

2

+

4.14 · 10−3·

(150)

2

+ 184 nH

For an adapter output voltage of 6.5 V, the number of turns

of the secondary winding can be calculated accounting

Schottky diode for output rectifier as follows:

(eq. 22)

n

s

+

(Vs) V

fwd

)(1 * d

max)np

d

max·Vbulk−min

+

(6.5 ) 0.7)(1 * 0.5)150

0.5 · 127

+ 8.5 + 9 turns

The number of turns for auxiliary winding can be

calculated similarly:

(eq. 23)

n

s

+

(Vs) V

fwd

)(1 * d

max)np

d

max·Vbulk−min

+

(12 ) 1)(1 * 0.5)150

0.5 · 127

+ 15.35 + 15 turns

The peak primary current is known from initial

calculations. The current sense method allows choosing the

voltage drop across the current sense resistor. Let’s use a

value of 0.5 V. The value of the current sense resistor can

then be evaluated as follows:

(eq. 24)

R

CS

+

V

CS

I

ppk

+

0.5

0.2047

+ 2.442 W + 2.7 W

The voltage drop across the sense resistor needs to be

recalculated:

(eq. 25)

VCS+ RCS·I

ppk

+ 2.7 · 0.2047 + 0.553 V

Using the above results the value of the shift resistor is:

(eq. 26)

R

shift

+

V

CS

I

CS

+

0.553

50 · 10

−6

+ 11.06 kW + 11 kW

The value of timing capacitor for the off time control has

to be calculated for minimum bulk capacitor voltage since

at these conditions the converter should be able to deliver

specified maximum output power. The value of the timing

capacitor is then given by the following equation:

(eq. 27)

C

T

+

1

f

sw

*

Lp ·I

ppk

V

bulk−min

1.2 · 10

6

+

1

75 ·10

3

*

4.14 ·10*3· 0.2047

127

0.12 · 10

6

+ 55.5 pF + 56 pF

The value of the startup resistor for startup time of 200 ms

and Vcc capacitor of 200 nF is following:

(eq. 28)

R

startup

+

V

bulk−min

C

Vcc

V

startup

t

startup

) I

CC−start

MAX

+

127

200 · 10

−9

12

0.2

) 10 · 10

−6

+ 5.77 MW + 5.6 MW

The result of all the calculations is the application

schematic depicted in Figure 21.

Page 12

NCP1215

http://onsemi.com

12

Figure 21. Adaptor Application Schematic

Line

J1

1

S250

3

D1

N

eutralJ21

4

2

2.2 mF/

400 V

C1 +

+

1

L1

2.2 mH

2.2 mF/

400 V

C2 + R3

2M7

R4

2M7

C5

100 nF

D5

LL4448

IC1

GND

CS

CT

FB

10 nF

4

3

2

1

C3

C4

56 pF

11 k R2

R1

2.7

NCP1215

Gate

V

CC

NC2

NC1

X

X

5

6

7

8

R5

220

C6

100 nF

R7

47 k

R6

47 k

1 nF/

500 V

C7

D8

MURA160T3

MTD1N60

Q1

1

2

345

8

D9

MBRS360T3

J3

1

+6.5 V

@

800 mA

L2

4.7 mH

+

C9

470 mF/

16 V

R8

220

10 mF/

16 V

+

C10

BZX84C5V6

R9

1 k

D7

J4

1

GND

ISO1

PC817

−

T1

C8

1 nF/Y

The following oscilloscope snapshots illustrate the

operation of the working adapter. The Channel 3 in

Figure 22 shows CT pin voltage at full output load. The

Channel 1 is a gate driver output.

The CT voltage at no load condition is depicted in

Figure 23.

Figure 22. CT Voltage at Full Load Condition Figure 23. CT Voltage at No Load Condition

Page 13

NCP1215

http://onsemi.com

13

Figure 24 shows CT voltage and also by Channel 2 the

switch’s drain voltage at light load conditions.

Figure 24. CT and Drain at Light Load

The waveform on the current sense pin at full load

conditions can be observed from Channel 3 in Figure 25.

Figure 25. CS Pin at Full Load Condition

Figure 26 demonstrates the reduction of the peak primary

current at light load conditions.

Figure 26. CS Pin at Light Load Condition

Gate−Source Resistor Design Guidelines

In some applications, there is a need to wire a resistor

between the MOSFET gate and source connections. This

can preclude an eventual MOSFET destruction if, in the

production stage, the converter is powered whilst the gate is

left unconnected. However, dealing with an extremely low

startup current implies a careful selection of the gate−source

resistance. W ith the NCP1215, the gate−source resistor must

be calculated to allow the growth of the V

CC

capacitor to

4.0 V in order to not interfere with the power−on sequence.

The following equation helps deriving Rgate−source,

accounting for the minimum rectified input voltage and the

startup resistor: Vin

min

x Rgate−source/(Rgate−source +

Rstartup) u 4.0 V. If we take a V in

min

of 100 VDC, a startup

resistor of 4.0 MW, then Rgate−source equals 180 kW as a

minimum normalized value.

Page 14

NCP1215

http://onsemi.com

14

PACKAGE DIMENSIONS

SOIC−8

D SUFFIX

CASE 751−07

ISSUE AG

SEATING

PLANE

1

4

58

N

J

X 45

_

K

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

A

B

S

D

H

C

0.10 (0.004)

DIMAMIN MAX MIN MAX

INCHES

4.80 5.00 0.189 0.197

MILLIMETERS

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

−X−

−Y−

G

M

Y

M

0.25 (0.010)

−Z−

Y

M

0.25 (0.010) Z

SXS

M

____

1.52

0.060

7.0

0.275

0.6

0.024

1.270

0.050

4.0

0.155

ǒ

mm

inches

Ǔ

SCALE 6:1

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

SOLDERING FOOTPRINT*

Page 15

NCP1215

http://onsemi.com

15

PACKAGE DIMENSIONS

TSOP−6

CASE 318G−02

ISSUE M

0.95

0.037

1.9

0.075

0.95

0.037

ǒ

mm

inches

Ǔ

SCALE 10:1

1.0

0.039

2.4

0.094

0.7

0.028

23

456

A

L

1

S

G

D

B

H

C

0.05 (0.002)

DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A 0.1142 0.12202.90 3.10

B 0.0512 0.06691.30 1.70

C 0.0354 0.04330.90 1.10

D 0.0098 0.01970.25 0.50

G 0.0335 0.04130.85 1.05

H 0.0005 0.00400.013 0.100

J 0.0040 0.01020.10 0.26

K 0.0079 0.02360.20 0.60

L 0.0493 0.06101.25 1.55

M 0 10 0 10

S 0.0985 0.11812.50 3.00

____

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. MAXIMUM LEAD THICKNESS INCLUDES

LEAD FINISH THICKNESS. MINIMUM LEAD

THICKNESS IS THE MINIMUM THICKNESS

OF BASE MATERIAL.

4. DIMENSIONS A AND B DO NOT INCLUDE

MOLD FLASH, PROTRUSIONS, OR GATE

BURRS.

M

J

K

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

SOLDERING FOOTPRINT*

Page 16

NCP1215

http://onsemi.com

16

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

NCP1215/D

The product described herein (NCP1215), may be covered by the following U.S. patents: 6,385,060, 6,605,978. There may be other patents pending.

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

Loading...

Loading...