Page 1

查询NCP1200P60供应商

NCP1200

PWM Current−Mode

Controller for Low−Power

Universal Off−Line Supplies

Housed in SOIC−8 or PDIP−8 package, the NCP1200 represents a

major leap toward ultra−compact Switchmode Power Supplies. Due to

a novel concept, the circuit allows the implementation of a complete

offline battery charger or a standby SMPS with few external

components. Furthermore, an integrated output short−circuit

protection lets the designer build an extremely low−cost AC−DC wall

adapter associated with a simplified feedback scheme.

With an internal structure operating at a fixed 40 kHz, 60 kHz or

100 kHz, the controller drives low gate−charge switching devices like

an IGBT or a MOSFET thus requiring a very small operating power.

Due to current−mode control, the NCP1200 drastically simplifies the

design of reliable and cheap offline converters with extremely low

acoustic generation and inherent pulse−by−pulse control.

When the current setpoint falls below a given value, e.g. the output

power demand diminishes, the IC automatically enters the skip cycle

mode and provides excellent efficiency at light loads. Because this

occurs at low peak current, no acoustic noise takes place.

Finally, the IC is self−supplied from the DC rail, eliminating the

need of an auxiliary winding. This feature ensures operation in

presence of low output voltage or shorts.

Features

• No Auxiliary Winding Operation

• Internal Output Short−Circuit Protection

• Extremely Low No−Load Standby Power

• Current−Mode with Skip−Cycle Capability

• Internal Leading Edge Blanking

• 250 mA Peak Current Source/Sink Capability

• Internally Fixed Frequency at 40 kHz, 60 kHz and 100 kHz

• Direct Optocoupler Connection

• Built−in Frequency Jittering for Lower EMI

• SPICE Models Available for TRANsient and AC Analysis

• Internal Temperature Shutdown

• Pb−Free Packages are Available

http://onsemi.com

SOIC−8

8

8

1

xxx = Device Code: 40, 60 or 100

y = Device Code:

A = Assembly Location

L = Wafer Lot

Y, YY = Year

W, WW = Work Week

D SUFFIX

CASE 751

1

PDIP−8

P SUFFIX

CASE 626

4 for 40

6 for 60

1 for 100

PIN CONNECTIONS

Adj

18

FB

2

3

CS

GND

4

(Top View)

MARKING

DIAGRAMS

8

200Dy

ALYW

1

8

1200Pxxx

YYWW

1

HV

7

NC

V

6

CC

Drv

5

AWL

T ypical Applications

• AC−DC Adapters

• Offline Battery Chargers

• Auxiliary/Ancillary Power Supplies (USB, Appliances, TVs, etc.)

Semiconductor Components Industries, LLC, 2004

December, 2004 − Rev. 13

1 Publication Order Number:

ORDERING INFORMATION

See detailed ordering and shipping information in the package

dimensions section on page 14 of this data sheet.

NCP1200/D

Page 2

NCP1200

Á

Á

Á

Á

Á

Á

Á

Á

C3

+

10 F

400 V

EMI

Filter

Universal Input

*Please refer to the application information section

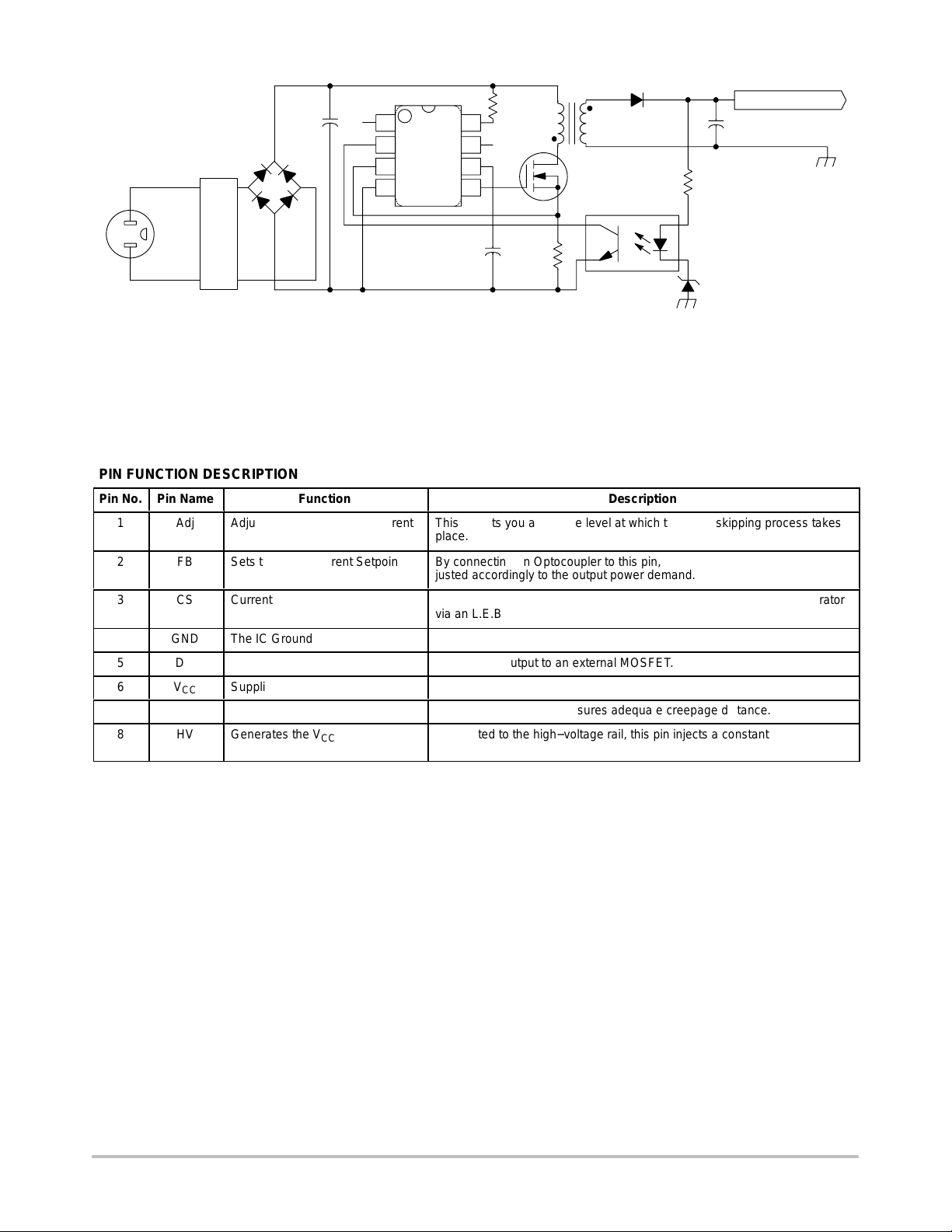

PIN FUNCTION DESCRIPTION

Pin No.

ÁÁ

ÁÁ

1

2

3

4

5

6

7

8

Pin Name

Adj

ÁÁ

FB

CS

ÁÁ

GND

Drv

V

CC

NC

HV

Function

Adjust the Skipping Peak Current

БББББББ

Sets the Peak Current Setpoint

Current Sense Input

БББББББ

The IC Ground

Driving Pulses

Supplies the IC

No Connection

Generates the VCC from the Line

*

HV

V

NC

CC

Drv

8

7

6

5

1

Adj

2

FB

3

CS

GND

4

+

C5

10 F

R

sense

Figure 1. T ypical Application

This pin lets you adjust the level at which the cycle skipping process takes

place.

БББББББББББББББББ

By connecting an Optocoupler to this pin, the peak current setpoint is adjusted accordingly to the output power demand.

This pin senses the primary current and routes it to the internal comparator

via an L.E.B.

БББББББББББББББББ

The driver’s output to an external MOSFET.

This pin is connected to an external bulk capacitor of typically 10 F.

This un−connected pin ensures adequate creepage distance.

Connected to the high−voltage rail, this pin injects a constant current into

the V

bulk capacitor.

CC

1N5819

M1

MTD1N60E

Description

D2

+

Rf

470

D8

5 V1

C2

470 F/10 V

6.5 V @ 600 mA

http://onsemi.com

2

Page 3

NCP1200

Á

Á

Á

Á

Adj

FB

Current

Sense

Ground

1

HV Current

8

HV

Source

75.5 k

1.4 V

2

Skip Cycle

Comparator

+

−

Internal

V

CC

UVLO

High and Low

Internal Regulator

7

NC

29 k

Q Flip−Flop

Set

3

250 ns

L.E.B.

40, 60 or

100 kHz

Clock

4

+

V

ref

−

5.2 V

60 k8 k

20 k

+

−

1 V

DCmax = 80%

Reset

Q

6

V

CC

5

Drv

±110 mA

Overload?

Fault Duration

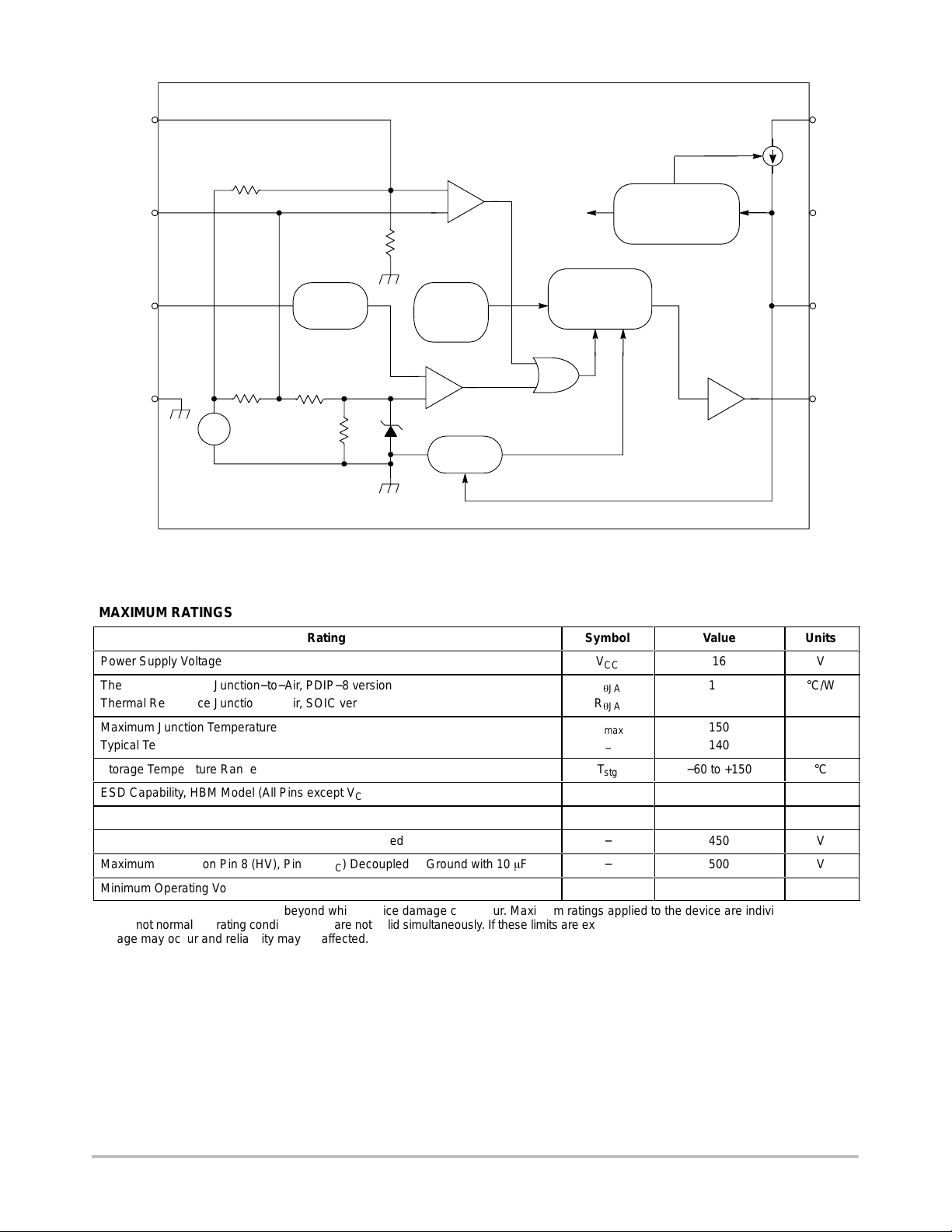

Figure 2. Internal Circuit Architecture

MAXIMUM RATINGS

Rating

Power Supply Voltage

Thermal Resistance Junction−to−Air, PDIP−8 version

Thermal Resistance Junction−to−Air, SOIC version

БББББББББББББББББББ

Maximum Junction Temperature

Typical Temperature Shutdown

Storage Temperature Range

ESD Capability, HBM Model (All Pins except VCC and HV)

ESD Capability, Machine Model

Maximum Voltage on Pin 8 (HV), pin 6 (VCC) Grounded

Maximum Voltage on Pin 8 (HV), Pin 6 (VCC) Decoupled to Ground with 10 F

Minimum Operating Voltage on Pin 8 (HV)

Maximum ratings are those values beyond which device damage can occur. Maximum ratings applied to the device are individual stress limit

values (not normal operating conditions) and are not valid simultaneously . If these limits are exceeded, device functional operation is not implied,

damage may occur and reliability may be affected.

Symbol

V

CC

R

JA

R

JA

ÁÁÁ

T

Jmax

−

T

stg

−

−

−

−

−

Value

16

100

178

ÁÁÁÁ

150

140

−60 to +150

2.0

200

450

500

30

Units

V

°C/W

ÁÁ

°C

°C

kV

V

V

V

V

http://onsemi.com

3

Page 4

NCP1200

ELECTRICAL CHARACTERISTICS (For typical values T

V

= 11 V unless otherwise noted)

CC

Rating

= +25°C, for min/max values TJ = −25°C to +125°C, Max TJ = 150°C,

J

Pin Symbol Min Typ Max Unit

DYNAMIC SELF−SUPPLY (All Frequency Versions, Otherwise Noted)

VCC Increasing Level at Which the Current Source Turns−off 6 V

VCC Decreasing Level at Which the Current Source Turns−on 6 V

VCC Decreasing Level at Which the Latchoff Phase Ends 6 V

Internal IC Consumption, No Output Load on Pin 5 6 I

CCOFF

CCON

CClatch

CC1

10.3 11.4 12.5 V

8.8 9.8 11 V

− 6.3 − V

− 710 880

Note 1

Internal IC Consumption, 1 nF Output Load on Pin 5, FSW = 40 kHz 6 I

CC2

− 1.2 1.4

Note 2

Internal IC Consumption, 1 nF Output Load on Pin 5, FSW = 60 kHz 6 I

CC2

− 1.4 1.6

Note 2

Internal IC Consumption, 1 nF Output Load on Pin 5, FSW = 100 kHz 6 I

CC2

− 1.9 2.2

Note 2

Internal IC Consumption, Latchoff Phase 6 I

CC3

− 350 − A

INTERNAL CURRENT SOURCE

High−voltage Current Source, VCC = 10 V 8 I

High−voltage Current Source, VCC = 0 V 8 I

C1

C2

2.8 4.0 − mA

− 4.9 − mA

DRIVE OUTPUT

Output Voltage Rise−time @ CL = 1 nF, 10−90% of Output Signal

Output Voltage Fall−time @ CL = 1 nF, 10−90% of Output Signal 5 T

Source Resistance (drive = 0, Vgate = V

− 1 V) 5 R

CCHMAX

Sink Resistance (drive = 11 V, Vgate = 1 V) 5 R

5 T

OH

OL

r

f

− 67 − ns

− 28 − ns

27 40 61

5 12 25

CURRENT COMPARATOR (Pin 5 Un−loaded)

Input Bias Current @ 1 V Input Level on Pin 3 3 I

Maximum internal Current Setpoint 3 I

Default Internal Current Setpoint for Skip Cycle Operation 3 I

Propagation Delay from Current Detection to Gate OFF State 3 T

Leading Edge Blanking Duration 3 T

IB

Limit

Lskip

DEL

LEB

− 0.02 − A

0.8 0.9 1.0 V

− 350 − mV

− 100 160 ns

− 230 − ns

INTERNAL OSCILLATOR (VCC = 11 V, Pin 5 Loaded by 1 k)

Oscillation Frequency, 40 kHz Version − f

Oscillation Frequency, 60 kHz Version − f

Oscillation Frequency, 100 kHz Version − f

Built−in Frequency Jittering, FSW = 40 kHz − f

Built−in Frequency Jittering, FSW = 60 kHz − f

Built−in Frequency Jittering, FSW = 100 kHz − f

OSC

OSC

OSC

jitter

jitter

jitter

36 42 48 kHz

52 61 70 kHz

86 103 116 kHz

− 300 − Hz/V

− 450 − Hz/V

− 620 − Hz/V

Maximum Duty Cycle − Dmax 74 80 87 %

FEEDBACK SECTION (VCC = 11 V, Pin 5 Loaded by 1 k)

Internal Pullup Resistor 2 Rup − 8.0 − k

Pin 3 to Current Setpoint Division Ratio − Iratio − 4.0 − −

SKIP CYCLE GENERATION

Default skip mode level 1 Vskip 1.1 1.4 1.6 V

Pin 1 internal output impedance 1 Zout − 25 − k

1. Max value @ TJ = −25°C.

2. Max value @ T

= 25°C, please see characterization curves.

J

A

mA

mA

mA

http://onsemi.com

4

Page 5

NCP1200

60

50

40

30

20

LEAKAGE (A)

10

0

−25

9.85

9.80

9.75

9.70

(V)

9.65

CCON

V

9.60

9.55

9.50

9.45

−25 755025 100 1250

11.70

11.60

11.50

(V)

11.40

CCOFF

V

11.30

11.20

0 −25 755025 100 1250

TEMPERATURE (°C)

5025

75

100 125

11.10

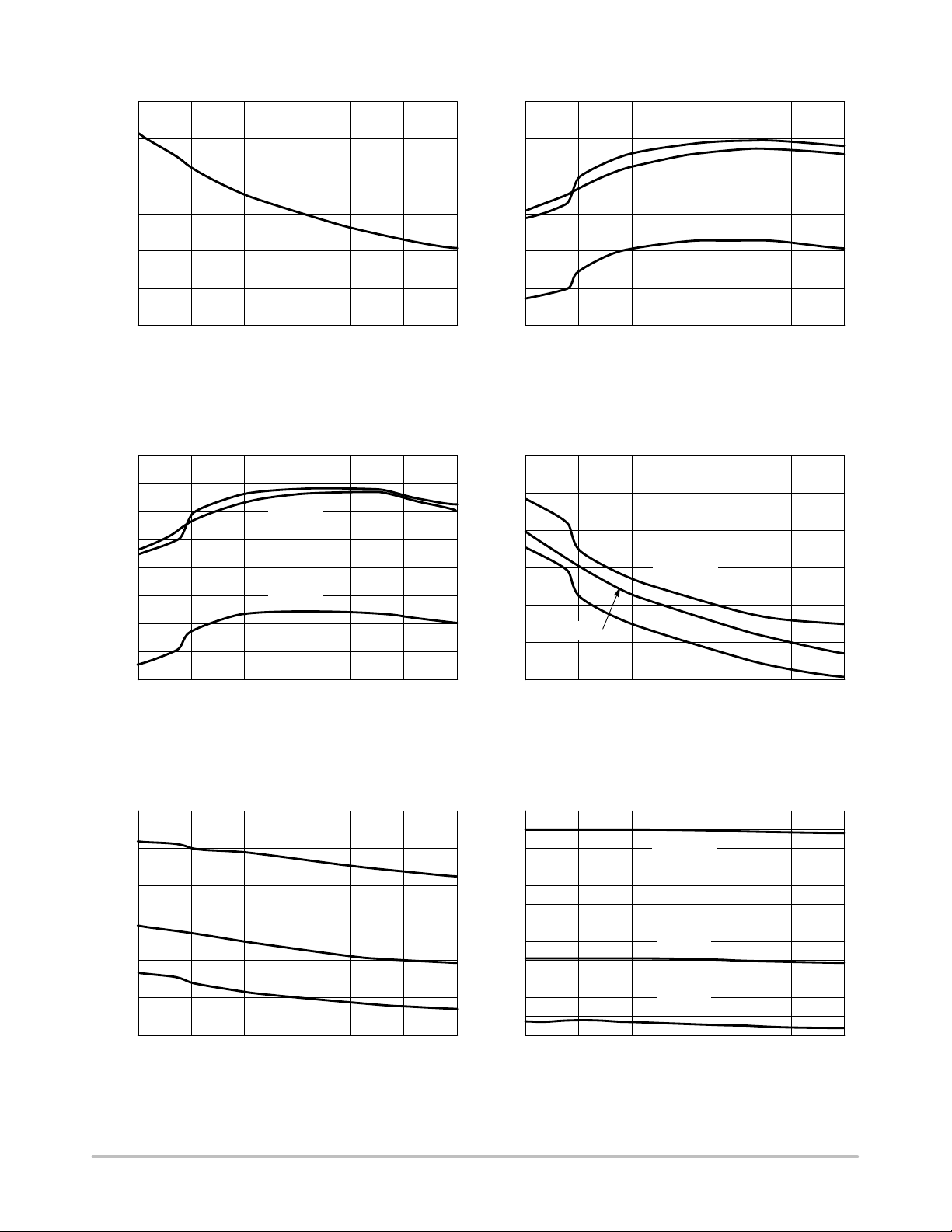

Figure 3. HV Pin Leakage Current vs.

Temperature

100 kHz

60 kHz

40 kHz

TEMPERATURE (°C)

900

850

800

(A)

750

CC1

I

700

650

600

−25 755025 100 1250

100 kHz

60 kHz

40 kHz

TEMPERATURE (°C)

Figure 4. VCC OFF vs. Temperature

100 kHz

60 kHz

40 kHz

TEMPERATURE (°C)

2.10

1.90

1.70

(mA)

1.50

CC2

I

1.30

1.10

0.90

−25 755025 100 1250

Figure 5. VCC ON vs. Temperature

100 kHz

60 kHz

40 kHz

TEMPERATURE (°C)

Figure 7. I

vs. Temperature

CC2

110

104

98

92

86

80

(kHz)

74

SW

68

F

62

56

50

44

38

−25 755025 100 1250

http://onsemi.com

5

Figure 6. I

TEMPERATURE (°C)

vs. Temperature

CC1

100 kHz

60 kHz

40 kHz

Figure 8. Switching Frequency vs. T

J

Page 6

NCP1200

6.50

6.45

6.40

(V)

6.35

CCLATCHOFF

6.30

V

6.25

6.20

−25

60

50

40

30

20

10

460

430

400

370

340

(A)

310

CC3

I

280

250

220

250

TEMPERATURE (°C)

50 75 100

125

190

TEMPERATURE (°C)

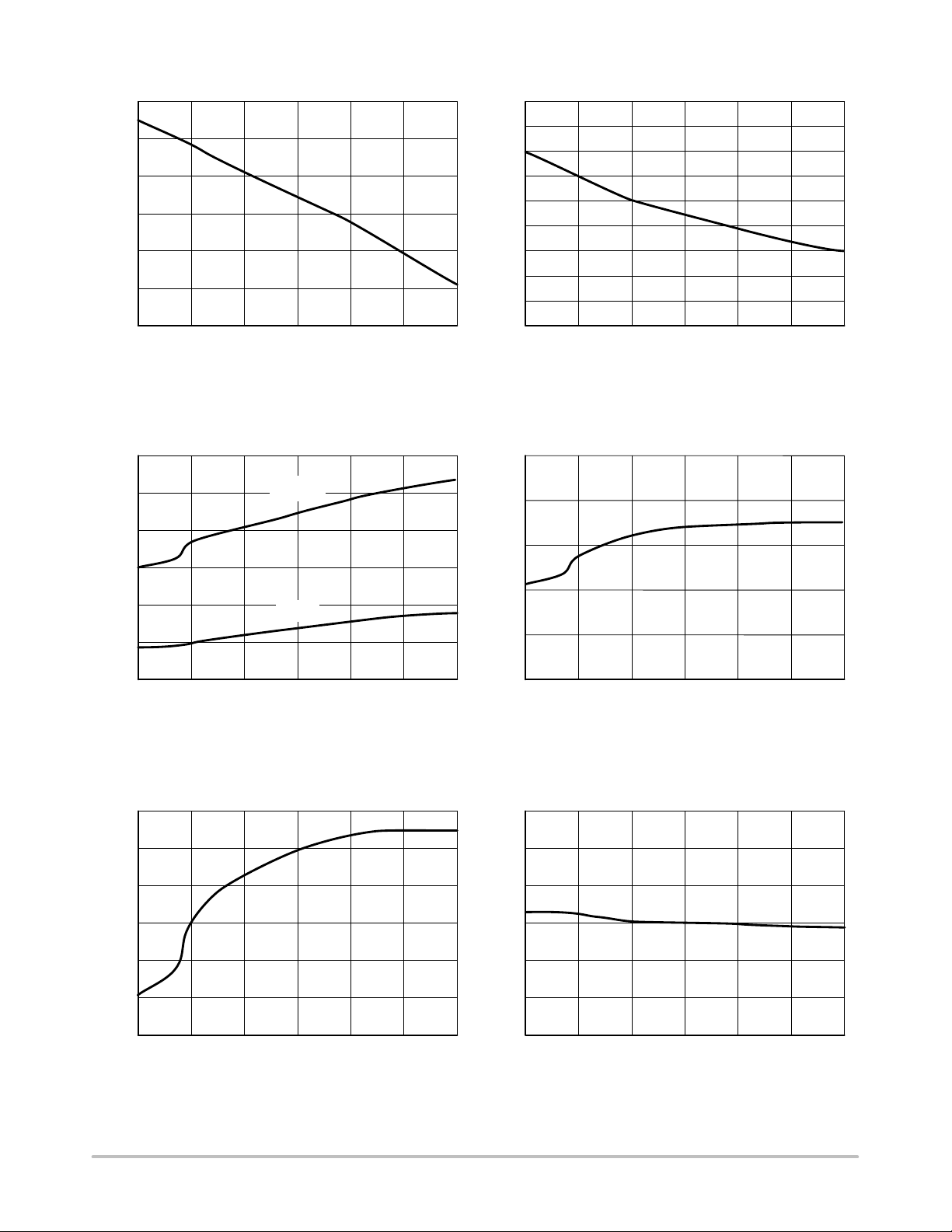

Figure 9. VCC Latchoff vs. Temperature Figure 10. I

1.00

Source

Sink

0.96

0.92

0.88

0.84

CURRENT SETPOINT (V)

50 75250 100−25 125

vs. Temperature

CC3

1.34

1.33

1.32

(V)

1.31

skip

V

1.30

1.29

1.28

0

TEMPERATURE (°C)

Figure 11. DRV Source/Sink Resistances

50 75250 100−25 125

TEMPERATURE (°C)

Figure 13. V

vs. Temperature

skip

0.80

TEMPERATURE (°C)

50 75250 100−25 12550 75250 100−25 125

Figure 12. Current Sense Limit vs. Temperature

86.0

84.0

82.0

80.0

78.0

DUTY−MAX (%)

76.0

74.0

TEMPERATURE (°C)

50 75250 100−25 125

Figure 14. Max Duty Cycle vs. T emperature

http://onsemi.com

6

Page 7

NCP1200

APPLICATIONS INFORMATION

INTRODUCTION

The NCP1200 implements a standard current mode

architecture where the switch−off time is dictated by the

peak current setpoint. This component represents the ideal

candidate where low part−count is the key parameter,

particularly in low−cost AC−DC adapters, auxiliary

supplies etc. Due to its high−performance High−Voltage

technology, the NCP1200 incorporates all the necessary

components normally needed in UC384X based supplies:

timing components, feedback devices, low−pass filter and

self−supply. This later point emphasizes the fact that ON

Semiconductor’s NCP1200 does NOT need an auxiliary

winding to operate: the product is naturally supplied from

the high−voltage rail and delivers a V

to the IC. This

CC

system is called the Dynamic Self−Supply (DSS).

V

= 11.4 V

CCOFF

10.6 V Avg.

ON

Dynamic Self−Supply

The DSS principle is based on the charge/discharge of t h e

VCC bulk capacitor from a low level up to a higher level. W e

can easily describe the current source operation with a bunch

of simple logical equations:

POWER−ON: IF V

CC

< V

THEN Current Source

CCOFF

is ON, no output pulses

IF VCC decreasing > V

THEN Current Source is

CCON

OFF, output is pulsing

IF V

increasing < V

CC

THEN Current Source is

CCOFF

ON, output is pulsing

Typical values are: V

CCOFF

= 11.4 V, V

CCON

= 9.8 V

To better understand the operational principle, Figure 15’s

sketch offers the necessary light:

V

CC

V

= 9.8 V

CCON

10.00M 30.00M 50.00M 70.00M 90.00M

Figure 15. The Charge/Discharge Cycle

Over a 10 F VCC Capacitor

The DSS behavior actually depends on the internal IC

consumption and the MOSFET’s gate charge, Qg. If we

select a MOSFET like the MTD1N60E, Qg equals 11 nC

(max). W ith a maximum switching frequency of 48 kHz (for

the P40 version), the average power necessary to drive the

MOSFET (excluding the driver efficiency and neglecting

various voltage drops) is:

Fsw Qg V

cc

with

Fsw = maximum switching frequency

Qg = MOSFET’s gate charge

VCC = VGS level applied to the gate

To obtain the final driver contribution to the IC

consumption, simply divide this result by VCC: Idriver =

Fsw Qg = 530 A. The total standby power consumption

at no−load will therefore heavily rely on the internal IC

consumption plus the above driving current (altered by the

driver’s efficiency). Suppose that the IC is supplied from a

400 V DC line. To fully supply the integrated circuit, let’s

imagine the 4 mA source is ON during 8 ms and OFF during

50 ms. The IC power contribution is therefore: 400 V . 4 mA

OFF

Output Pulses

Current

Source

. 0.16 = 256 mW. If for design reasons this contribution is

still too high, several solutions exist to diminish it:

1. Use a MOSFET with lower gate charge Qg

2. Connect pin through a diode (1N4007 typically) to

one of the mains input. The average value on pin 8

2*V

becomes

mains PEAK

. Our power contribution

example drops to: 160 mW.

Dstart

1N4007

C3

4.7 F

+

400 V

EMI

Filter

Figure 16. A simple diode naturally reduces the

average voltage on pin 8

NCP1200

1

Adj

2

FB

3

CS

GND Drv

4

V

HV

NC

CC

8

7

6

5

http://onsemi.com

7

Page 8

NCP1200

3. Permanently force the VCC level above V

CCH

with

an auxiliary winding. It will automatically

disconnect the internal startup source and the IC

will be fully self−supplied from this winding.

Again, the total power drawn from the mains will

significantly decrease. Make sure the auxiliary

voltage never exceeds the 16 V limit.

Skipping Cycle Mode

The NCP1200 automatically skips switching cycles when

the output power demand drops below a given level. This is

accomplished by monitoring the FB pin. In normal

operation, pin 2 imposes a peak current accordingly to the

load value. If the load demand decreases, the internal loop

asks for less peak current. When this setpoint reaches a

determined level, the IC prevents the current from

decreasing further down and starts to blank the output

pulses: the IC enters the so−called skip cycle mode, also

named controlled burst operation. The power transfer now

depends upon the width of the pulse bunches (Figure 18 ).

Suppose we have the following component values:

Lp, primary inductance = 1 mH

F

, switching frequency = 48 kHz

SW

Ip skip = 300 mA (or 350 mV / Rsense)

The theoretical power transfer is therefore:

1

Lp Ip2 Fsw 2.2 W

2

If this IC enters skip cycle mode with a bunch length of

10 ms over a recurrent period of 100 ms, then the total power

transfer is: 2.2 . 0.1 = 220 mW.

To better understand how this skip cycle mode takes place,

a look at the operation mode versus the FB level

immediately gives the necessary insight:

When FB is above the skip cycle threshold (1.4 V by

default), the peak current cannot exceed 1 V/Rsense. When

the IC enters the skip cycle mode, the peak current cannot go

below Vpin 1 / 4 ( F i g u r e 19) . The user still has the flexibility

to alter this 1.4 V by either shunting pin 1 to ground through

a resistor or raising it through a resistor up to the desired

level.

P1

P2

P3

Figure 18. Output pulses at various power levels

(X = 5 s/div) P1<P2<P3

Max Peak

Current

Skip Cycle

Current Limit

FB

Normal Current Mode Operation

Skip Cycle Operation

Ip

= 350 mV / R

min

Figure 17. Feedback Voltage Variations

sense

4.8 V

3.8 V

Figure 19. The skip cycle takes place at low peak

currents which guarantees noise free operation

1.4 V

http://onsemi.com

8

Page 9

NCP1200

Power Dissipation

The NCP1200 is directly supplied from the DC rail

through the internal DSS circuitry. The current flowing

through the DSS is therefore the direct image of the

NCP1200 current consumption. The total power dissipation

can be evaluated using:

(V

11 V) ICC2. If we

HVDC

operate the device on a 250 VAC rail, the maximum rectified

voltage can go up to 350 VDC. As a result, the worse case

dissipation occurs on the 100 kHz version which will

dissipate 340 . 1.8 mA@Tj = −25°C = 612 mW (however

this 1.8 mA number will drop at higher operating

temperatures). Please note that in the above example, I

CC2

is based on a 1 nF capacitor loading pin 5. As seen before,

I

will depend on your MOSFET’s Qg: I

CC2

CC2

= I

CC1

+ F

sw

x Qg. Final calculations shall thus account for the total

gate−charge Q

your MOSFET will exhibit. A DIP8

g

package offers a junction−to−ambient thermal resistance

of R

100°C/W. The maximum power dissipation can

J−A

thus be computed knowing the maximum operating

ambient temperature (e.g. 70°C) together with the

maximum allowable junction temperature (125°C):

Pmax

Jmax

R

RJA

Amax

= 550 mW. As we can see, we do not

T

T

reach the worse consumption budget imposed by the 100

kHz version. Two solutions exist to cure this trouble. The

first one consists in adding some copper area around the

NCP1200 DIP8 footprint. By adding a min−pad area of 80

2

mm

of 35 copper (1 oz.) R

drops to about 75°C/W

J−A

which allows the use of the 100 kHz version. The other

solutions are:

1. Add a series diode with pin 8 (as suggested in the

above lines) to drop the maximum input voltage

down to 222 V ((2 350)/pi) and thus dissipate

less than 400 mW

2. Implement a self−supply through an auxiliary

winding to permanently disconnect the self−supply.

SOIC−8 package offers a worse R

compared to that of

J−A

the DIP8 package: 178°C/W. Again, adding some copper

area around the PCB footprint will help decrease this

number: 12 mm x 12 mm to drop R

down to 100°C/W

J−A

with 35 copper thickness (1 oz.) or 6.5 mm x 6.5 mm with

70 copper thickness (2 oz.). One can see, we do not

recommend using the SOIC package for the 100 kHz version

with DSS active as the IC may not be able to sustain the

power (except if you have the adequate place on your PCB).

However, using the solution of the series diode or the

self−supply through the auxiliary winding does not cause

any problem with this frequency version. These options are

thoroughly described in the AND8023/D.

Overload Operation

In applications where the output current is purposely not

controlled (e.g. wall adapters delivering raw DC level), it is

interesting to implement a true short−circuit protection. A

short−circuit actually forces the output voltage to be at a low

level, preventing a bias current to circulate in the

optocoupler LED. As a result, the FB pin level is pulled up

to 4.1 V, as internally imposed by the IC. The peak current

setpoint goes to the maximum and the supply delivers a

rather high power with all the associated effects. Please note

that this can also happen in case of feedback loss, e.g. a

broken optocoupler. To account for this situation, the

NCP1200 hosts a dedicated overload detection circuitry.

Once activated, this circuitry imposes to deliver pulses in a

burst manner with a low duty cycle. The system recovers

when the fault condition disappears.

During the startup phase, the peak current is pushed to the

maximum until the output voltage reaches its target and the

feedback loop takes over. This period of time depends on

normal output load conditions and the maximum peak

current allowed by the system. The time−out used by this IC

works with the V

VCC decreases from the V

decoupling capacitor: as soon as the

CC

level (typically 11.4 V) the

CCOFF

device internally watches for an overload current situation.

If this condition is still present when V

is reached, the

CCON

controller stops the driving pulses, prevents the self−supply

current source to restart and puts all the circuitry in standby ,

consuming as little as 350 A typical (I

parameter). As

CC3

a result, the VCC level slowly discharges toward 0. When

this level crosses 6.3 V typical, the controller enters a new

startup phase by turning the current source on: V

CC

rises

toward 11.4 V and again delivers output pulses at the

UVLOH crossing point. If the fault condition has been

removed before UVLOL approaches, then the IC continues

its normal operation. Otherwise, a new fault cycle takes

place. Figure 20 shows the evolution of the signals in

presence of a fault.

http://onsemi.com

9

Page 10

11.4 V

9.8 V

6.3 V

V

Drv

CC

NCP1200

Regulation

Occurs Here

Latchoff

Phase

Time

Driver

Pulses

Internal

Fault

Flag

Startup Phase

Figure 20. If the fault is relaxed during the VCC natural fall down sequence, the IC automatically resumes.

If the fault persists when VCC reached UVLOL, then the controller cuts everything off until recovery.

Calculating the VCC Capacitor

As the above section describes, the fall down sequence

depends upon the V

level: how long does it take for the

CC

VCC line to go from 11.4 V to 9.8 V? The required time

depends on the startup sequence of your system, i.e. when

you first apply the power to the IC. The corresponding

transient fault duration due to the output capacitor charging

must be less than the time needed to discharge from 11.4 V

to 9.8 V, otherwise the supply will not properly start. The test

consists in either simulating or measuring in the lab how

much time the system takes to reach the regulation at full

load. Let’s suppose that this time corresponds to 6ms.

Therefore a V

fall time of 10 ms could be well

CC

appropriated in order to not trigger the overload detection

circuitry. If the corresponding IC consumption, including

the MOSFET drive, establishes at 1.5 mA, we can calculate

the required capacitor using the following formula:

V C

t

, with V = 2V. Then for a wanted t of 10 ms,

i

C equals 8 F or 10 F for a standard value. When an

overload condition occurs, the IC blocks its internal

circuitry and its consumption drops to 350 A typical. This

appends at V

= 9.8 V and it remains stuck until V

CC

reaches 6.5 V: we are in latchoff phase. Again, using the

calculated 10 F and 350 A current consumption, this

latchoff phase lasts: 109 ms.

Fault Occurs Here

Protecting the Controller Against Negative Spikes

is the designer’s duty to avoid the presence of negative

spikes on sensitive pins. Negative signals have the bad habit

to forward bias the controller substrate and induce erratic

behaviors. Sometimes, the injection can be so strong that

internal parasitic SCRs are triggered, engendering

irremediable damages to the IC if they are a low impedance

path is offered between V

pin is often the seat of such spurious signals, the

high−voltage pin can also be the source of problems in

certain circumstances. During the turn−off sequence, e.g.

when the user unplugs the power supply, the controller is still

fed by its V

ON and OFF with a peak current limited by Rsense.

Unfortunately , if the quality coefficient Q of the resonating

network formed by Lp and Cbulk is low (e.g. the MOSFET

Rdson + Rsense are small), conditions are met to make the

circuit resonate and thus negatively bias the controller . Since

we are talking about ms pulses, the amount of injected

charge (Q = I x t) immediately latches the controller which

brutally discharges its V

CC

is of sufficient value, its stored energy damages the

controller. Figure 21 depicts a typical negative shot

occurring on the HV pin where the brutal VCC discharge

testifies for latchup.

As with any controller built upon a CMOS technology, it

Driver

Pulses

Time

Fault is

Relaxed

capacitor and keeps activating the MOSFET

CC

Time

and GND. If the current sense

CC

capacitor. If this VCC capacitor

CC

http://onsemi.com

10

Page 11

NCP1200

Figure 21. A negative spike takes place on the Bulk capacitor at the switch−off sequence

Simple and inexpensive cures exist to prevent from

internal parasitic SCR activation. One of them consists in

inserting a resistor in series with the high−voltage pin to

keep the negative current to the lowest when the bulk

becomes negative (Figure 22). Please note that the negative

spike is clamped to –2 x Vf due to the diode bridge. Please

refer to AND8069/D for power dissipation calculations.

3

Rbulk

> 4.7 k

2

+

Cbulk

1

2

3

4

8

7

6

1

5

+

CV

CC

Figure 22. A simple resistor in series avoids any

latchup in the controller

A Typical Application

Figure 24 depicts a low−cost 3.5 W AC−DC 6.5 V wall

adapter. This is a typical application where the wall−pack

must deliver a raw DC level to a given internally regulated

apparatus: toys, calculators, CD players etc. Due to the

Another option (Figure 23) consists in wiring a diode from

V

to the bulk capacitor to force VCC to reach UVLOlow

CC

sooner and thus stops the switching activity before the bulk

capacitor gets deeply discharged. For security reasons, two

diodes can be connected in series.

3

+

Cbulk

1

2

3

4

8

7

6

5

1

D3

1N4007

+

CV

CC

Figure 23. or a diode forces VCC to reach

UVLOlow sooner

inherent short−circuit protection of the NCP1200, you only

need a bunch of components around the IC, keeping the final

cost at an extremely low level. The transformer is available

from different suppliers as detailed on the following page.

http://onsemi.com

11

Page 12

NCP1200

Universal

Input

R9

10

C3

4.7 F

400 V

330 H

+

330 H

R7

L5

C2

4.7 F

400 V

L6

+

NCP1200

HV1

Adj

FB

CS

GND

V

Drv

NC

CC

C9

10 F

2

3

4

8

7

6

5

Clamping

Network

R

clamp

Clamp

D

clamp

M1

MTD1N60E

+

Figure 24. A typical AC−DC wall adapter showing the reduced part count due to the NCP1200

T1: Lp = 2.9 mH, Np:Ns = 1:0.08, leakage = 80 H, E16 core, NCP1200P40

T1

R6

2.8

D3

1N5819

Snubber

R

Snubber

C

SFH615A−2

Snubber

IC1

2.2 H

+

C5

470 F/

10 V

L4

6.5 V @ 600 mA

+

C10

4.7 F/

10 V

Optional

Networks

R2

220

D6

5 V1

To help designers during the design stage, several manufacturers propose ready−to−use transformers for the above

application, but can also develop devices based on your particular specification:

Eldor Corporation Headquarter

Via Plinio 10,

22030 Orsenigo

(Como) Italia

Tel.: +39−031−636 111

Fax : +39−031−636 280

Email: eldor@eldor.it

www.eldor.it

ref. 1: 2262.0058C: 3.5 W version

(Lp = 2.9 mH, Lleak = 80 H, E16)

ref. 2: 2262.0059A: 5 W version

(Lp = 1.6 mH, Lleak = 45 H, E16)

EGSTON GesmbH

Grafenbergerstrae 37

3730 Eggenburg

Austria

Tel.: +43 (2984) 2226−0

Fax : +43 (2984) 2226−61

Email: info@egston.com

Atelier Special de Bobinage

125 cours Jean Jaures

38130 ECHIROLLES FRANCE

Tel.: 33 (0)4 76 23 02 24

Fax: 33 (0)4 76 22 64 89

Email: asb@wanadoo.fr

ref. 1: NCP1200−10 W−UM: 10 W for USB

(Lp = 1.8 mH, 60 kHz, 1:0.1, RM8 pot core)

Coilcraft

1102 Silver Lake Road

Cary, Illinois 60013 USA

Tel: (847) 639−6400

Fax: (847) 639−1469

Email: info@coilcraft.com

http://www.coilcraft.com

ref. 1: Y8844−A: 3.5 W version

(Lp = 2.9 mH, Lleak = 65 H, E16)

ref. 2: Y8848−A: 10 W version

(Lp = 1.8 mH, Lleak = 45 H, 1:01, E core)

http://www.egston.com/english/index.htm

ref. 1: F0095001: 3.5 W version

(Lp = 2.7 mH, Lleak = 30 H, sandwich configuration, E16)

http://onsemi.com

12

Page 13

NCP1200

Improving the Output Drive Capability

The NCP1200 features an asymmetrical output stage used

to soften the EMI signature. Figure 25 depicts the way the

driver is internally made:

V

CC

Q

2

7

40

1

12

5

Q\

3

Figure 25. The higher ON resistor slows down

the MOSFET while the lower OFF resistor

ensures fast turn−off.

In some cases, it is possible to expand the output drive

capability by adding either one or two bipolar transistors.

Figures 26, 27, and 28 give solutions whether you need to

improve the turn−on time only, the turn−off time or both. Rd

is there to damp any overshoot resulting from long copper

traces. It can be omitted with short connections. Results

showed a rise fall time improvement by 5X with standard

2N2222/2N2907:

1

2

NCP1200

3

4

8

7

6

5

Rd

2N2222

2N2907

Figure 26. Improving Both Turn−On and

Turn−Off Times

1

2

NCP1200

3

4

8

7

6

5

1N4148

2N2907

Figure 27. Improving T urn−Off Time Only

1

2

NCP1200

3

4

8

7

6

5

1N4148

2N2222

To Gate

To Gate

To Gate

http://onsemi.com

13

Figure 28. Improving T urn−On Time Only

Page 14

NCP1200

If the leakage inductance is kept low, the MTD1N60E can

withstand accidental avalanche energy, e.g. during a

high−voltage spike superimposed over the mains, without

the help of a clamping network. If this leakage path

permanently forces a drain−source voltage above the

MOSFET BVdss (600 V), a clamping network is mandatory

and must be built around Rclamp and Clamp. Dclamp shall

react extremely fast and can be a MUR160 type. T o calculate

the component values, the following formulas will help you:

R

clamp =

2 V

C

clamp

clamp

(V

L

V

ripple

clamp

leak

V

Fsw R

(V

out

Ip2 Fsw

clamp

clamp

Vf sec) N)

with:

V

: the desired clamping level, must be selected to be

clamp

between 40 V to 80 V above the reflected output voltage

when the supply is heavily loaded.

V

+ Vf: the regulated output voltage level + the secondary

out

diode voltage drop

L

: the primary leakage inductance

leak

N: the Ns:Np conversion ratio

FSW: the switching frequency

V

: the clamping ripple, could be around 20 V

ripple

Another option lies in implementing a snubber network

which will damp the leakage oscillations but also provide

more capacitance at the MOSFET’s turn−off. The peak

voltage at which the leakage forces the drain is calculated

by:

L

V

max

where C

Ip

represents the total parasitic capacitance seen

lump

C

lump

leak

at the MOSFET opening. Typical values for Rsnubber and

Csnubber in this 4W application could respectively be 1.5

k and 47 pF . Further tweaking is nevertheless necessary to

tune the dissipated power versus standby power.

Available Documents

“Implementing the NCP1200 in Low−cost AC−DC

Converters”, AND8023/D.

“Conducted EMI Filter Design for the NCP1200’’,

AND8032/D.

“Ramp Compensation for the NCP1200’’, AND8029/D.

TRANSient and AC models available to download at:

http://onsemi.com/pub/NCP1200

NCP1200 design spreadsheet available to download at:

http://onsemi.com/pub/NCP1200

ORDERING INFORMATION

Device Type Marking Package Shipping

NCP1200P40 1200P40 PDIP−8 50 Units / Rail

NCP1200P40G

NCP1200D40R2

NCP1200D40R2G 200D4 SOIC−8

NCP1200P60 1200P60 PDIP−8 50 Units / Rail

NCP1200P60G

NCP1200D60R2

NCP1200D60R2G 200D6 SOIC−8

NCP1200P100 1200P100 PDIP−8 50 Units / Rail

NCP1200P100G

NCP1200D100R2

NCP1200D100R2G 200D1 SOIC−8

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging

Specifications Brochure, BRD8011/D.

FSW = 40 kHz

FSW = 60 kHz

FSW = 100 kHz

1200P40 PDIP−8

(Pb−Free)

200D4 SOIC−8 2500 Units /Reel

(Pb−Free)

1200P60 PDIP−8

(Pb−Free)

200D6 SOIC−8 2500 Units /Reel

(Pb−Free)

1200P100 PDIP−8

(Pb−Free)

200D1 SOIC−8 2500 Units / Reel

(Pb−Free)

50 Units / Rail

2500 Units /Reel

50 Units / Rail

2500 Units /Reel

50 Units / Rail

2500 Units / Reel

†

http://onsemi.com

14

Page 15

NCP1200

PACKAGE DIMENSIONS

SOIC−8

D SUFFIX

CASE 751−07

ISSUE AC

−Y−

−Z−

−X−

A

58

B

1

S

0.25 (0.010)

4

M

M

Y

K

G

C

SEATING

PLANE

0.10 (0.004)

H

D

0.25 (0.010) Z

M

Y

SXS

N

X 45

M

J

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

MILLIMETERS

DIMAMIN MAX MIN MAX

4.80 5.00 0.189 0.197

B 3.80 4.00 0.150 0.157

C 1.35 1.75 0.053 0.069

D 0.33 0.51 0.013 0.020

G 1.27 BSC 0.050 BSC

H 0.10 0.25 0.004 0.010

J 0.19 0.25 0.007 0.010

K 0.40 1.27 0.016 0.050

M 0 8 0 8

N 0.25 0.50 0.010 0.020

S 5.80 6.20 0.228 0.244

INCHES

SOLDERING FOOTPRINT*

1.52

0.060

7.0

0.275

0.6

0.024

4.0

0.155

1.270

0.050

SCALE 6:1

inches

mm

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

http://onsemi.com

15

Page 16

NOTE 2

−T−

SEATING

PLANE

H

58

−B−

14

F

−A−

C

N

D

G

0.13 (0.005) B

NCP1200

PACKAGE DIMENSIONS

PDIP−8

P SUFFIX

CASE 626−05

ISSUE L

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

DIM MIN MAX MIN MAX

A 9.40 10.16 0.370 0.400

B 6.10 6.60 0.240 0.260

C 3.94 4.45 0.155 0.175

L

J

K

M

M

A

T

M

M

D 0.38 0.51 0.015 0.020

F 1.02 1.78 0.040 0.070

G 2.54 BSC 0.100 BSC

H 0.76 1.27 0.030 0.050

J 0.20 0.30 0.008 0.012

K 2.92 3.43 0.115 0.135

L 7.62 BSC 0.300 BSC

M −−− 10 −−− 10

N 0.76 1.01 0.030 0.040

INCHESMILLIMETERS

The product described herein (NCP1200), may be covered by the following U.S. patents: 6,271,735, 6,362,067, 6,385,060, 6,429,709, 6,587,357. There may

be other patents pending.

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

“Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over time. All

operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights

nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death may occur. Should

Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees, subsidiaries, affiliates,

and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death

associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal

Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 61312, Phoenix, Arizona 85082−1312 USA

Phone: 480−829−7710 or 800−344−3860 Toll Free USA/Canada

Fax: 480−829−7709 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Japan: ON Semiconductor, Japan Customer Focus Center

2−9−1 Kamimeguro, Meguro−ku, Tokyo, Japan 153−0051

Phone: 81−3−5773−3850

http://onsemi.com

ON Semiconductor Website: http://onsemi.com

Order Literature: http://www.onsemi.com/litorder

For additional information, please contact your

local Sales Representative.

NCP1200/D

16

Page 17

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...