Page 1

Mounting Instructions for

PIM Modules (Q0, Q1, Q2,

F1, F2)

AND9867/D

Introduction

This application note covers the mounting instructions for

ON Semiconductor Power Integrated Modules (PIMs) using the

following packages:

• Q0

• Q1

• Q2

• F1

• F2

This application note covers the following topics

• PCB hole sizes and plating

• PCB design

• Heatsink and Thermal Interface Material (TIM)

• Press−in process

• Soldering process

• Mounting module to the heatsink

• Mounting heatsink and module to PCB

www.onsemi.com

APPLICATION NOTE

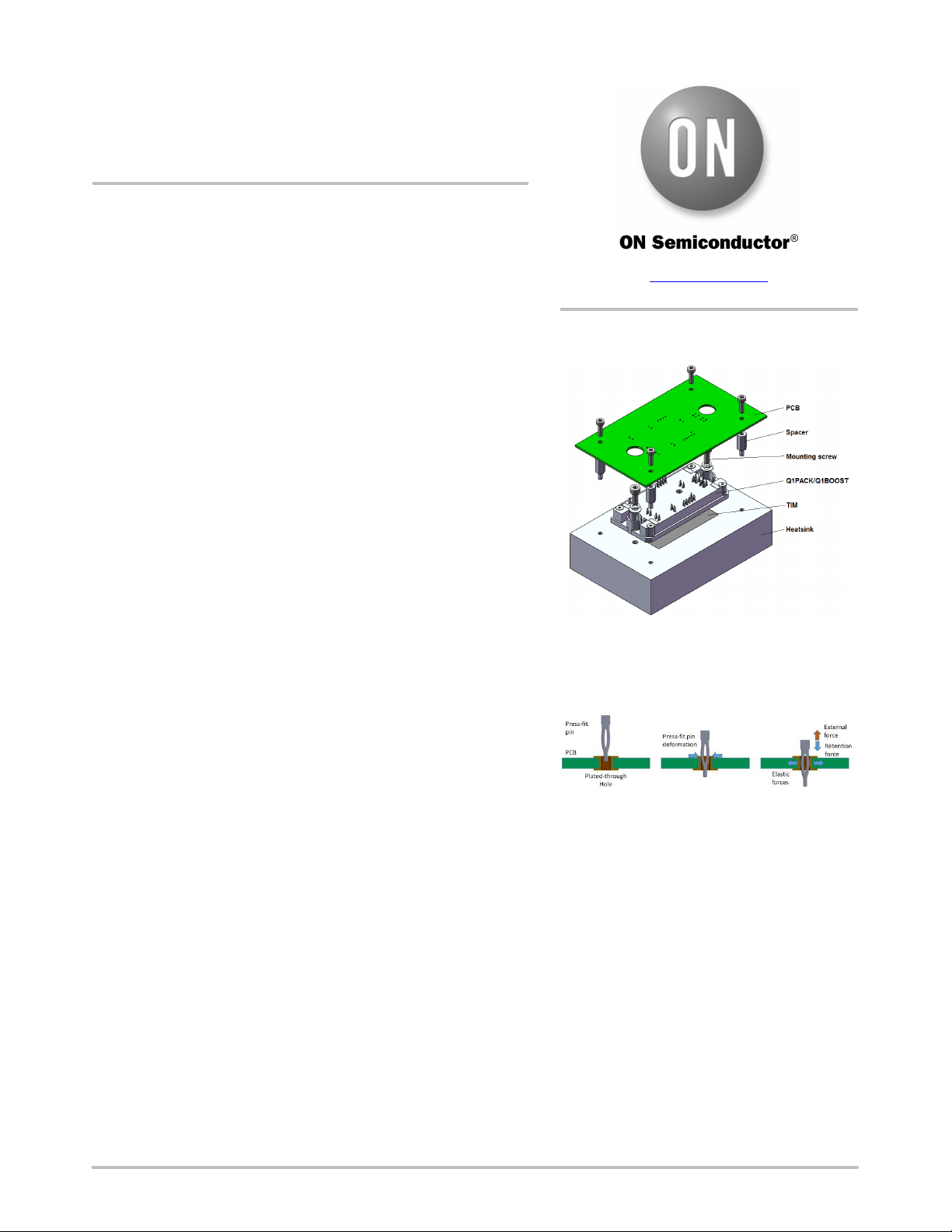

ON Semiconductor family of Power Integrated Modules has

package options using solder pins or press−fit pins for the connection

of the module to a Printed Circuit Board (PCB). Figure 1 shows a Q1

module with press−fit pins as an example.

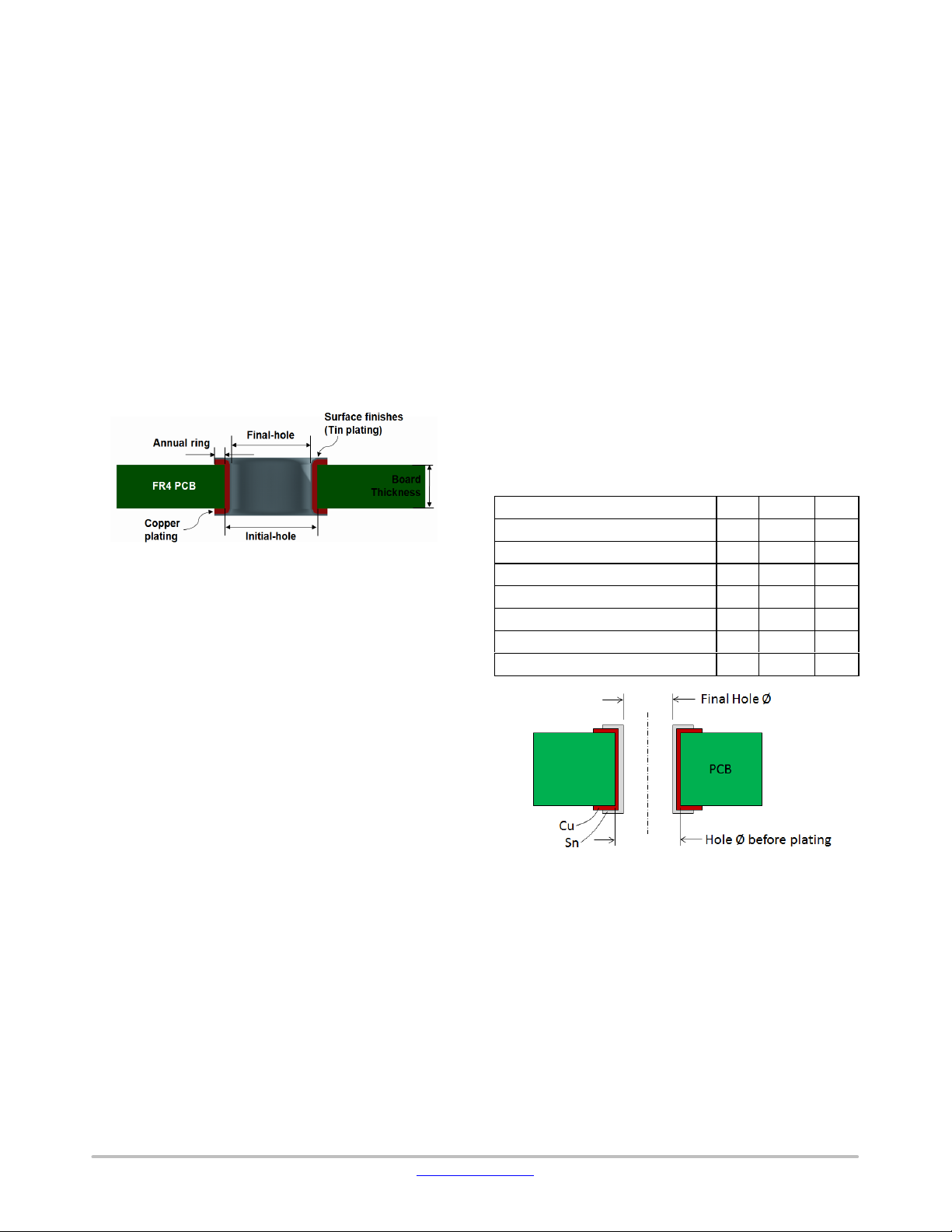

After mounting, press−fit pins provide a cold−welding connection

between pins and plated through holes (PTH) of the PCB. This easy

assembly method avoids extra heating, avoids contamination and

provides good mechanical and electrical performance. Press−fit

assembly is a well−established connection method for power

semiconductor modules. The press−fit pins provide a gas−tight metal

to metal contact between the press−fit pin and the plated through hole

(Figure 2).

Modules having solder pins are soldered into the PCB. Modules

having press−fit pins can also be soldered into the PCB, but with larger

holes than used for the standard press−fit process.

The purpose of this application note is to provide recommendations

for the PCB and to recommend mounting and dismounting methods

with proper tools to achieve the required reliability and performance

with either press−fit or solder connections.

Figure 1. Q1 Module with PCB and

Heatsink

Figure 2. Press−fit Process

© Semiconductor Components Industries, LLC, 2019

January, 2021 − Rev. 2

1 Publication Order Number:

AND9867/D

Page 2

AND9867/D

PCB SPECIFICATION

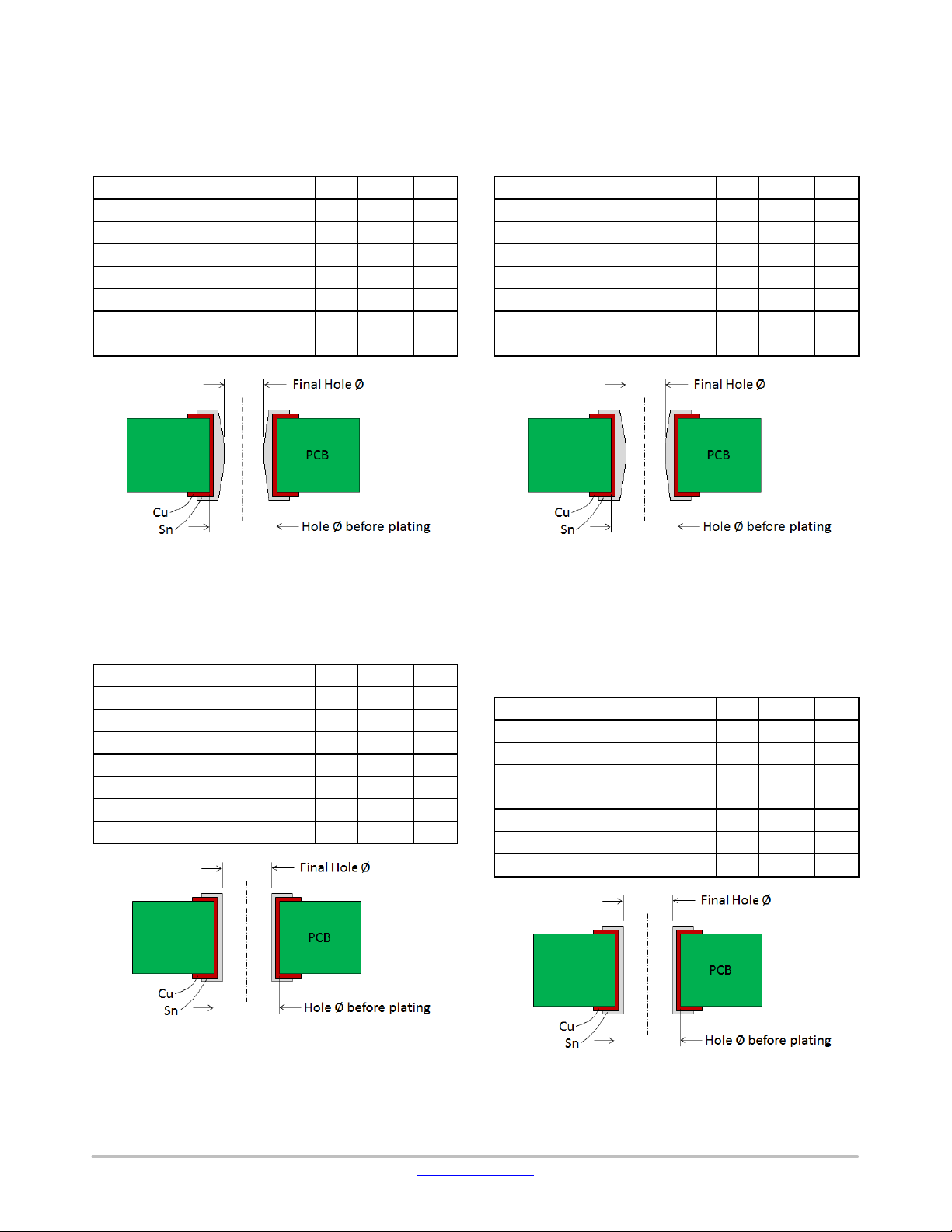

Correct design of the plated through holes (PTH) in the

PCB is essential to obtain good quality press−fit or solder

connections.

PCB Specification

The schematic structure of a plated through hole is shown

in Figure 3. If the initial drilled hole diameter is too small,

the press−in force into the PTH will be too high and

mechanical damage on both press−fit pin and PTH will

occur. If the final hole diameter is too small, damage to the

pin and the hole may also occur. If the final hole diameter is

too large, it may not provide a reliable connection between

plated through hole and press−fit pin.

The effect of the pad size in reducing the creepage and

clearance between pins should always be considered in

minimum permissible spacing calculations.

Figure 3. Cross−section of PCB

Tables 1−4 list the recommended PCB specification based

on the evaluation of the press−fit technology according to

the IEC 60352−5 standard.

Specification for Modules with Press−fit Pins,

Soldered to the PCB

It is not recommended that press−fins are just soldered

without being pressed into the PCB in mass production. If

modules with press−fit pins are reused after being removed

from the PCB, it can be soldered on the PCB to reinforce the

contact.

The pcb pad diameter is determined by the minimum

annular ring size, the production alignment tolerance (level

A, B or C) and the drilling tolerance as detailed in IPC−2222.

The effect of the pad size in reducing the creepage and

clearance between pins should always be considered in

minimum permissible spacing calculations.

Specification for Modules with Solder Pins,

Soldered to the PCB

The recommended final PCB hole diameter for solder pins

is 1.2 mm when using 1 mm pins used in F1, F2, Q0, Q1 and

Q2 modules.

The pcb pad diameter is determined by the minimum

annular ring size, the production alignment tolerance (level

A, B or C) and the drilling tolerance as detailed in IPC−2222.

The effect of the pad size in reducing the creepage and

clearance between pins should always be considered in

minimum permissible spacing calculations.

For 1 mm diameter pin, the final pad diameter for level B

manufacturing is calculated as 1.8 mm: allowing for 50 mm

absolute minimum annular ring, 0.5 mm alignment

tolerance and 1.2 mm actual PCB hole size.

Table 1. PCB SPECIFICATIONS FOR F1 AND F2

MODULES WITH 1.2 MM PRESS−FIT PINS −

IMMERSION OR GALVANIC TIN. Pins are IEC qualified for

immersion tin plating.

Min. Typ. Max.

Initial Drilled Hole Diameter Ø [mm] 1.12 1.15

Cu Thickness in the Hole [mm]

Sn Thickness [mm] (Chemical Tin)

Final Hole Ø [mm] 0.98 1.09

Annular ring [mm]

Thickness of Conductive Layer [mm]

Board Thickness [mm] 1.6

Figure 4.

25 50

15

200

35 70−105 400

www.onsemi.com

2

Page 3

AND9867/D

Table 2. PCB SPECIFICATIONS FOR F1 AND F2

MODULES WITH 1.2 MM PRESS−FIT PINS − HAL

PLATING.

immersion/galvanic tin is recommended for more consistent

mounting.

Initial (Drill) Hole Ø [mm] 1.12 1.15

Cu Thickness in the Hole [mm]

Sn Thickness [mm]

Final Hole Ø [mm] 0.94 1.09

Annular ring [mm]

Thickness of Conductive Layer [mm]

Board Thickness [mm] 1.6

Pins are IEC qualified for HAL plating but

Min. Typ. Max.

25 50

40

200

35 70−105 400

Table 4. PCB SPECIFICATIONS FOR Q0, Q1 AND Q2

MODULES WITH 1.6 MM PRESS−FIT PINS − HAL

PLATING.

immersion/galvanic tin is recommended for more consistent

mounting.

Initial (Drill) Hole Ø [mm] 1.57 1.60

Cu Thickness in the Hole [mm]

Sn Thickness [mm]

Final Hole Ø [mm] 1.41 1.56

Annular ring [mm]

Thickness of Conductive Layer [mm]

Board Thickness [mm] 1.6

Pins are IEC qualified for HAL plating but

Min. Typ. Max.

25 50

40

200

35 70−105 400

Figure 5.

Table 3. PCB SPECIFICATIONS FOR Q0, Q1 AND Q2

MODULES WITH 1.6 MM PRESS−FIT PINS −

IMMERSION OR GALVANIC TIN.

immersion tin plating.

Initial Drilled Hole Diameter Ø [mm] 1.57 1.60

Cu Thickness in the Hole [mm]

Sn Thickness [mm] (Chemical Tin)

Final Hole Ø [mm] 1.41 1.56

Annular ring [mm]

Thickness of Conductive Layer [mm]

Board Thickness [mm] 1.6

Pins are IEC qualified for

Min. Typ. Max.

25 50

15

200

35 70−105 400

Figure 7.

Table 5. PCB SPECIFICATIONS FOR F2 MODULES

WITH EON PRESS−FIT PINS − IMMERSION OR

GALVANIC TIN.

plating. For HAL tin coating, a thicker tin thickness of up to

40 um is permitted reducing the hole size to 0.94 mm but this

requires additional approval from ON Semiconductor.

Initial Drilled Hole Diameter Ø [mm] 1.12 1.15

Cu Thickness in the Hole [mm]

Sn Thickness [mm] (Chemical Tin)

Final Hole Ø [mm] 1.02 1.09

Annular ring [mm]

Thickness of Conductive Layer [mm]

Board Thickness [mm] 1.6

Pins are IEC qualified for immersion tin

Min. Typ. Max.

25 50

15

200

35 70−105 400

Figure 6.

Figure 8.

www.onsemi.com

3

Page 4

AND9867/D

PCB DESIGN

PCB Layout Restrictions

PCB bending during the press−in process causes

mechanical stress to other PCB components, such as

capacitors and resistors. Experiments to verify a safe

minimum distance between passive components and the

plated through hole were conducted with FR4 PCB. Various

sizes (0603, 0805, 1206, 1210, 1812, and 2220) of

mechanically sensitive components were evaluated. Based

on experimental results, the recommended minimum space

between center of the plated through hole and the edge of the

component is 4 mm, as shown in Figure 9.

Mounting with Distance of 12 mm

Option 1: without spacers

Figure 10. Mounting Height with Module as Spacer

Option 2: with spacers

Figure 11. Mounting Height with Spacer in case of

using Recommended Press−fit Tool

Example: Q1 Module with Press−fit Pins

Figure 12 shows an example of mounting a Q1 module.

The Q1 package has its power connectors/terminals

distributed across the surface of the plastic case. Electrical

connections are made by connecting these terminals to

a print circuit board (PCB) by soldering or press−fit

technology.

Figure 9. PCB Design Restriction: Distance

from Center of PTH to Edge of Components

The minimum distance between the edge of the PCB and

the centre of the pin hole must be more than 4 mm.

The minimum distance between the center of the pin hole

and a neighbored component on the PCB must be more than

4 mm.

Recommended PCB−thicknesses and Mounting

Heights by Module Type

The distance between the top surface of the heatsink and

the bottom plane of the PCB is defined by the module height

of 12 mm for Q0, Q1, F1 and F2 packages or 17 mm for Q2

packages. PCB spacers can be used for fixing. The number

and the position of the fixing points depend on the design of

the circuit, location of different masses like capacitors or

inductor and the environment of the system. General

recommendations cannot be given. The recommended

heights of these spacers are given in the following sections

Figure 12. Q1 Package Mounting Example

The PCB has four mounting holes for the spacers, two

cut−out holes for accessing the heatsink mounting screws

through the PCB and the holes for the pin connections.

The dimensions and positions of the cut−out holes, the

PTH holes and mounting holes are specified in the datasheet

drawing for the specific module.

The Q0 solder pin modules have plastic mounting clips

which require different shaped cut−outs in the PCB as

specified in the datasheet.

www.onsemi.com

4

Page 5

AND9867/D

HEATSINK AND THERMAL INTERFACE

MATERIAL

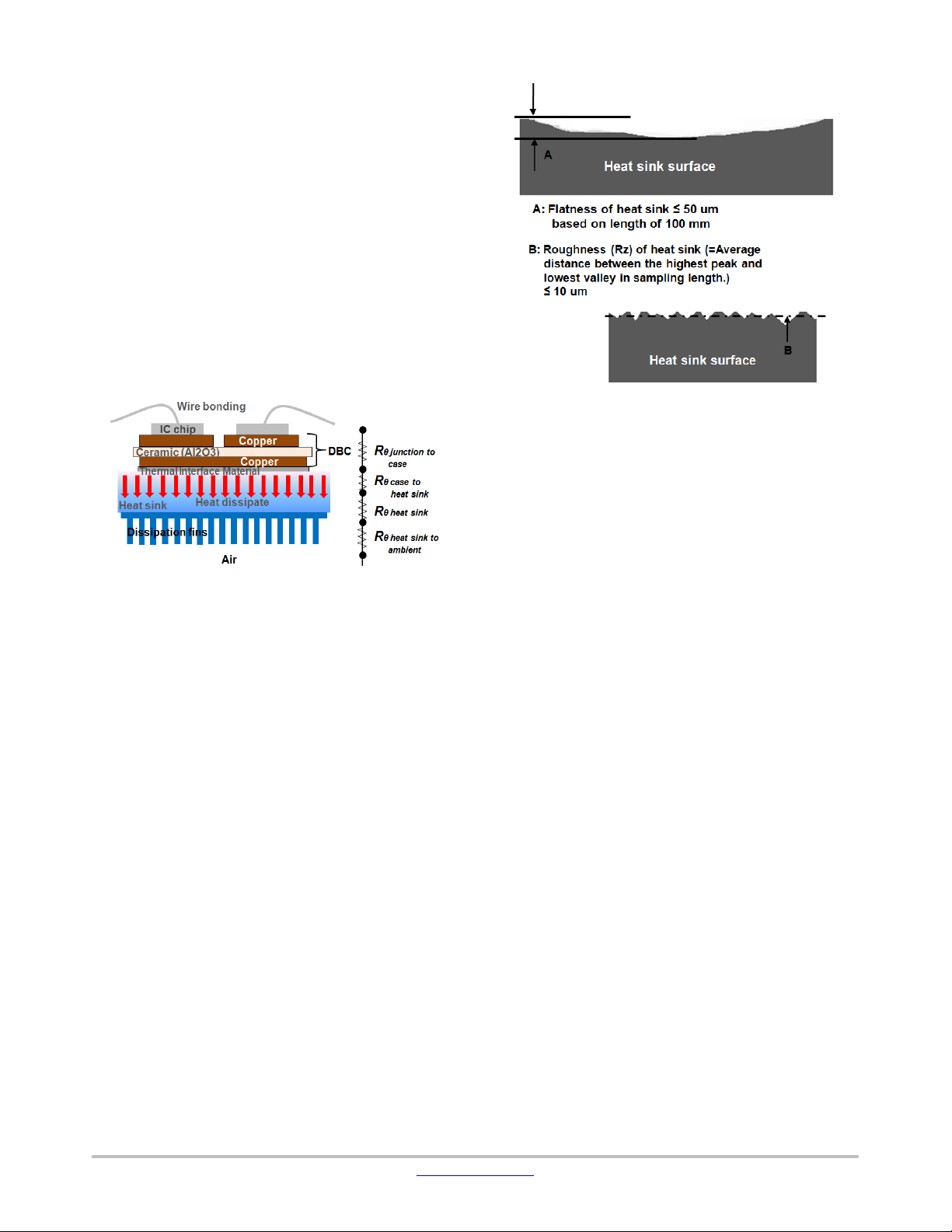

Power semiconductor modules generate heat that needs to

be dissipated to protect against overheating. In general,

module operation temperature should not exceed the

maximum allowable junction temperature (T

in the datasheet. Thermally conductive metal heatsinks that

absorb and disperse heat are commonly used for cooling

high power electronics. The thermal performance of

a module, in combination with a heatsink, can be

characterized by the thermal resistance R

sum of all thermal resistances in the thermal path:

junction−to−case (R

), and heatsink−to−ambient (R

(R

sink

q

), case−to−heatsink (R

jc

q

sa

q

Figure 13.

) specified

Jmax

, which is the

ja

q

), heatsink

cs

q

), as shown in

Figure 14. Microscopic View of Surfaces.

A is Flatness and B is Roughness (Rz)

The interface surface of the heatsink must be free of

particles and contamination. Avoid handling the heatsink

surface with bare hands or contacting any foreign materials.

If it is necessary to remove contamination from heatsink,

cleaning can be accomplished using dry cloth soaked with

solvent, such as isopropyl or ethylene alcohol.

Figure 13. Thermal Model of Power Module &

Heatsink

Generally, air convection is the dominant heat transfer

mechanism in electronics. The heat transfer by air

convection strongly depends on the air velocity and the area

of the heat−transferring surface. Proper contact between

module substrate and the surface of the heatsink is crucial for

managing the overall thermal efficiency of the system.

Thermal Interface Materials (TIMs) are thermally

conductive materials used to achieve good mating of the two

surfaces and improve heat transfer.

Heatsink Surface

The contact surface of a heatsink must be flat and clean to

maximize heat transfer. Rough surfaces result in large voids

between the substrate of the module and the surface of the

heatsink. The following surface qualities are required for the

heatsink to achieve a good thermal conductivity, according

to DIN 4768−1. Roughness (Rz) should be 10 mm or less and

flatness, based on a length of 100 mm, should be 50 mm or

less. The heatsink should have no contamination,

unevenness, and burrs on the surface contacting the module.

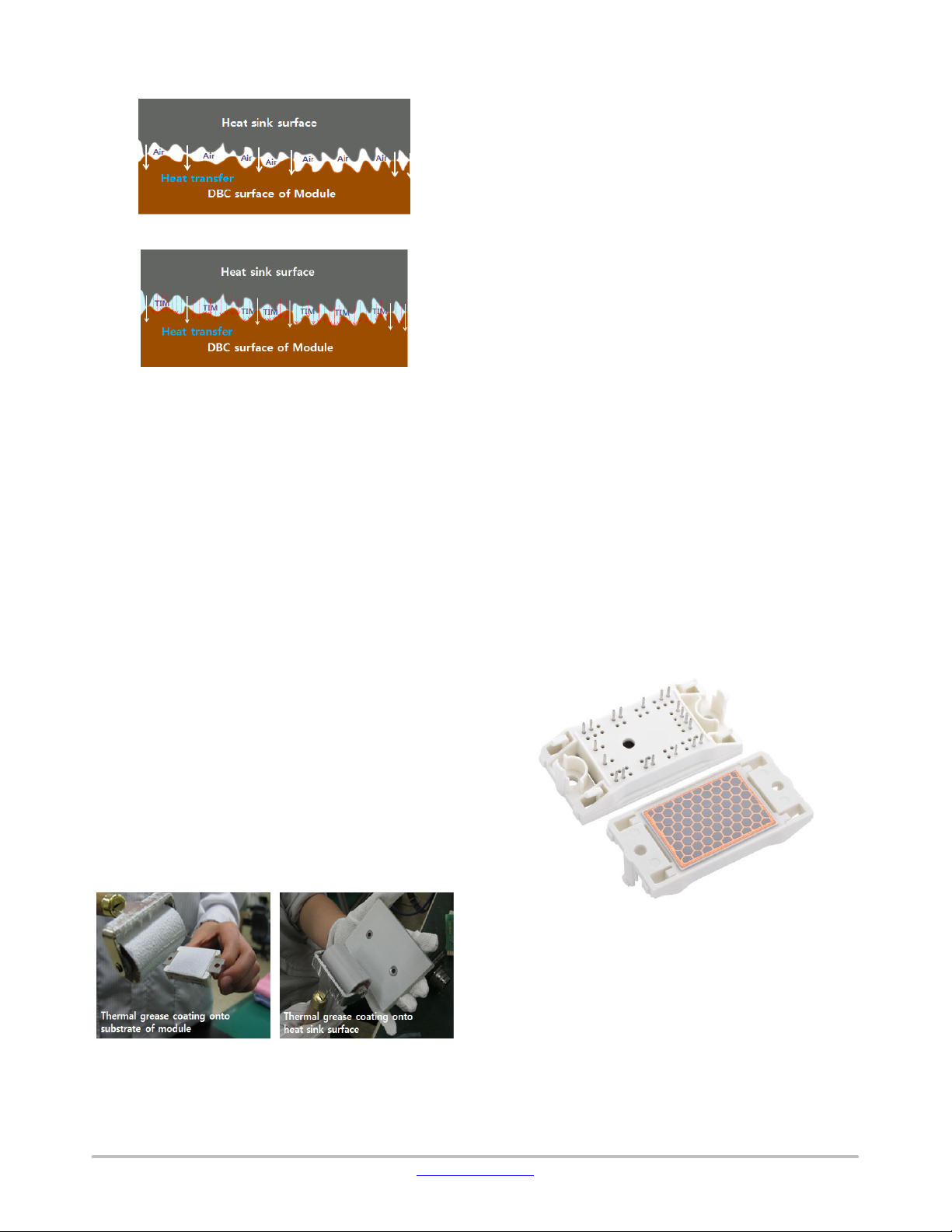

Thermal Interface Material (TIM)

The backside of the module and the surface of the heatsink

are not ideally smooth. TIM is used to prevent air cavities

and help the thermal dissipation. Such TIM material may be

a thermal pad, foil, grease, or any other similar material. The

material selection should consider the thermal conductivity,

drying out behavior during aging, and shape maintaining

properties during power ON/OFF cycling.

The surfaces of the heatsink and the substrate of the

module are not perfectly flat. After the module is mounted

to a heatsink, air gaps can form between these two surfaces

and the effective contact is limited to the area shown in

Figure 15. Air is a poor heat conductor with 0.03 W/m⋅K

thermal conductivity. It acts as a thermal barrier that limits

the efficiency of heat transfer from the device.

www.onsemi.com

5

Page 6

AND9867/D

(a)

(b)

Figure 15. (a) Heat Transfer, Module to Heatsink,

(b) Heat Transfer with Thermal Interface Material

Thermal interface materials are widely used in the

industry to fill air gaps between contact surfaces. Thermal

interface material provides better thermal performance than

air and compensates for imperfect mating surfaces, such as

roughness and flatness shown in Figure 14. There are

various thermal interface materials available in the market.

The right choice of material is an essential factor for the

application. It should be selected considering the following

features:

• High Thermal Conductivity

• Ease of Distribution with Low Contact Pressure

• Minimal Thickness

• Degradation of Characteristics Over Time

• Stability of Characteristics Over Time

• Toxicity (Non−Toxic Optimal)

• Ease in Handling during Application or Removal

1. Choose one side of the surface, module substrate,

or heatsink to apply thermal grease.

2. Coat a rubber roller with thermal grease.

3. Paint the surface repeatedly using the rubber roller

to create a uniform layer of thermal grease around

80–100 mm thick.

Since the thermal grease has the lowest thermal

conductivity in the thermal path, a layer as thin as possible

is necessary to keep the overall thermal resistance low.

Recommended thickness of printing layer is 60–100 mm to

fill the gap between two contact surfaces completely. Check

the thermal grease thickness with thickness gauges, such as

wet film combs or wet film wheels. Because manual control

of the printing pressure and speed can be learned by

experience, training is needed to achieve a technique for

good quality printing layer in real application.

Alternatively, apply thermal paste by screen printing, for

example using a honeycomb pattern. The recommended

thermal paste thickness is 80−100 mm A thickness of the

TIM layer in excess of this recommendation will

unnecessarily increase thermal resistance.

When applying thermal grease, the material must be

applied uniformly on the whole surface which is in contact

to the module substrate surface. If the module is

re−mounted, surfaces should be cleaned and TIM needs be

applied again.

Pre−applied Thermal Interface Material

As an option the module may be prepared or provided with

a pre−applied PCM layer. The recommended pattern for

such PCM layer is shown in Figure 17.

Thermal Grease

The most common thermal interface materials are thermal

greases. Thermal grease can be applied to the heatsink or the

module substrate using a rubber roller or spatula or by screen

printing. A rubber roller, as shown in Figure 16, is an easy

and fast method for applying thermal grease.

Figure 16. Applying Thermal Grease

www.onsemi.com

Figure 17. Printing Pattern Example for TIM Material

Modules Shipped with Pre−applied Phase−change

Material

Please refer to the application note referring to handling

modules with pre−applied TIM material.

6

Page 7

AND9867/D

PRESS IN PROCESS OF MODULES WITH

PRESS−FIT PINS

The press−fit process is a cost−effective way to assemble

power modules without introducing additional thermal

stress. The press−fit connection generates a good electrical,

and also strong mechanical connection between the module

and the PCB. This section deals with the mounting process

to achieve suitable press−fit connections.

There are several types of presses available; from simple

toggle presses to the automated pneumatic presses shown in

Figure 18. If possible, monitor the press−in/press−out

distance, speed, and force to achieve mechanical stability

and high reliability of the press−fit connection. The travel

distance during the press−in process should be controlled to

ensure that the press−fit zone of the pins sits properly in the

plated through hole. The speed also influences the quality of

the press−fit connection; therefore, speed recommended by

IEC standard should be applied.

Figure 19. Recommended Tooling Construction for

the Press−in Process

Figure 18. Press−in Presses

Generally, a module can be pressed in until the stand−offs

on the four corners of the module touch the PCB. If, for

example, more than one module is mounted on a PCB at

short distances or assemblies are subjected to mechanical

shocks in the application, the press−in method as described

in Figure 23 is recommended.

Press−in Tool Construction

The preferred method is to press the module into the PCB

from the top. Pressing multiple modules into one PCB can

be done one by one; or all at once.

Pressing multiple modules at the same time requires

a press−in tool according to the above detailed single tool.

The tool has to ensure the correct leveling of the modules

and the PCB to avoid any mechanical stress.

Figure 20. Press−in Tools Closed,

Module is Pressed in

Press−in Process Parameters

The total press−in force is the result of the number of pins

in a module, multiplied with the force required for a single

pin. Press−in forces lower than 60 N/pin mean that press−fit

pin may have a less secure connection in the plated through

hole. The primary reason for the low press−fit force is that

the diameter of plated through hole is too large for the

press−fit pins. Press−in forces higher than 150 N/pin can

cause mechanical damage to the press−fit terminal, the PTH,

or to the tracks on the PCB. The recommended press−in

speed ranges from 25 mm/min to 50 mm/min in accordance

with the recommendations in IEC 60352−5.

www.onsemi.com

7

Page 8

AND9867/D

The press−fit pins have to be pressed into the holes of the

PCB to the correct depth. The center of the press−fit zone has

to be at least 0.5 mm below the top surface and at least

0.5 mm above the bottom surface of the PCB (Figure 21).

Figure 21. Press−in Depth in PCB

General Press−in Process

Figure 22 shows the general sequence of the press−in

procedure. The press−in tool is comprised of two parts: the

upper press−in tool is flat to contact with the module

backside evenly and the lower press−in tool has engraved

spaces to accommodate the press−fit pins.

The two parts of the tool need to be aligned to each other

(a). In the first step of the assembly, the printed circuit board

is placed on the alignment pins of the lower part of the

press−in tool (b).

Then, the module is placed on top of the printed circuit

board using the alignment pins. It is necessary to check if the

module and the printed circuit board are in alignment (c). In

the next step, the press−in force is applied via the upper part

of the press−in tool to the backside of the module evenly. The

module should be pressed−in with a speed of

25~50 mm/min until the stand−offs on the four corners of

the module touch the surface of the printed circuit board

while press−in distance and force are monitored at the same

time (d).

It is required to adjust the traveling distance of the press

to avoid damages to the module case due to pressure being

applied. A simple manual press does not use a distance

sensing system, so a distance keeper should be designed on

the press−in tool to terminate press−in process

appropriately. The next section describes the function of the

distance keeper more in detail.

Figure 22. Press−in Process

www.onsemi.com

8

Page 9

AND9867/D

Press−in Process for Multiple Modules

In case multiple modules are assembled to the same PCB

and heatsink, height tolerances can result in unintended

bending of the PCB or inappropriate heatsink contact.

Therefore, if more than one module is mounted on the

same PCB, it is required to minimize the height tolerances

between those modules. This section presents a modified

press−in process related to that.

Figure 23 shows a press−in tool including distance

keepers. The distance keeper terminates the press−in

process and limits the press−in depth.

By contacting the printed circuit board ahead of the

module case, it prevents direct contact between the case and

the PCB. If the distance keeper contacts the surface, press−in

force rises sharply and the press−in process can be

terminated by reaching the limit of the press−in force. The

distance keeper should be designed to avoid the collision

with other PCB components.

The press−in process using the distance keeper is

described in Figure 23. First, the PCB should be placed on

the lower press−in tool (a). Then, a module is placed on the

lower press−in tool and aligned with the PCB (b). The

press−in stroke is applied to the backside of the module until

the distance keeper touches the surface of the PCB (c).

Figure 23. Press−in Process with Distance Keepers

Figure 24. Schematic Description of the Press−in Process using Distance Keeper

www.onsemi.com

9

Page 10

AND9867/D

As illustrated in Figure 25, depending on the length of the

distance keeper, the contact length between press−fit pins

and the plated through hole is determined. The total height

of the module is 12.00 ±0.30 mm for Q0, Q1, F1 and F2

modules. It is recommended that the length of the distance

keeper should be 12.40 (+0.05/−0) mm to achieve a stable

contact length.

A: Package height (DBC bottom to case top) is 12.00 +0.30/−0.30 (mm)

B: Distance keeper height is 12.40+0.05/−0

C: Air gap between case top and surface of the PCB

Figure 25. Press−in Depth in Accordance with Length of Distance Keeper

Press−in Tool Design Comments

Some design options should be considered to avoid

press−in failure. First, the contact plate of the upper press−in

tool must be larger than the module DBC substrate size. If

the contact area of the upper press−in tool is smaller than the

module substrate and pressure is applied to the center area

of the module only, the module can be mechanically

damaged during the press−in process. The press−in tool

design should consider the size of the module.

If other components (capacitors, resistors) are assembled

on the PCB next to the module mounting area, the press−in

tool design should avoid collision during the press−in

process. As shown in Figure 20, the lower press−in tool is

designed with engraved spaces for the press−fit pin and other

PCB Based on experimental results, components did not

exhibit mechanical or electrical damages due to board

bending during the press−in process when the distance

between the center of the plated through hole and the edge

Consequently, an air gap between the top of the case and

the surface of the PCB remains. Screwing the PCB down to

the stand−offs of the module case, as shown in Section 5, is

not allowable. Instead, the assembly should use space posts

to support the PCB.

(mm)

of the component is 4 mm or more. It is also important to

keep a certain area to provide support for the PCB.

Press−out Process

In some situations, it is necessary to remove power

modules from the PCB. It is possible to disconnect the

contact between module pins and PTH. The press−out

process can be performed with the same equipment used in

the press−in process.

Careful handling in the press−out process is essential to

avoid mechanical damage to both the module and the PCB.

PCB can be re−used once with a new module.

Please note: in case a module which was pressed out of a

PCB should be used again, it is necessary to solder the

module to the PCB; this is because the press−fit zone will

remain deformed after the press−out process. An additional

press−in cycle will result in low holding forces between the

press−fit pin and PCB hole.

www.onsemi.com

10

Page 11

AND9867/D

Figure 26. Press−out Tools

Figure 27. Press−out Process

The press−out tool consists of an upper and a lower

press−out tool, as shown in Figure 26. The upper press−out

tool should be parallel and aligned to the lower press−out

tool (a). The assembled board should be placed on the lower

press−in tool (b). The upper press−out tool moves down and

contacts the projecting part of the pins. Press−out force

should be applied to all pins evenly within 3−12 mm/min of

press−out speed according to IEC 60352−5 (c). The module

falls down to the lower tool as it is disassembled from the

PCB. The press−out distance should be monitored to ensure

the upper press−out tool does not apply unnecessary

pressure on the PCB after the module is fully pressed−out

(d).

Press−out Tool Design

The upper and lower press−out tools should be parallel to

each other to prevent stress on the module during press−out

process. Some pins may have contact with the upper

press−out tool while other pins have no contact with tool.

Pulling force can be exerted on the press−fit pins where

upper the press−out tool does not contact.

The press−out tool design should consider other

components assembled on the PCB next to the module

mounting area to avoid collision during the press−out

process. The specific tool to disassemble the modules from

the PCBs has two parts similar to the press−in tool. The

lower part serves as a support for the PCB. It has a cavity and

supporting pins. It is important that the size of the cavity is

close to the dimensions of the module. The supporting pins

are in line with the fixing pins of the upper part. There may

be components mounted to the PCB in the area of the tool,

in such case it is possible to cut out the nest.

The upper part consists of two pressing plates that are

connected by springs. The pins on the lower plate serve to

fix the PCB. With the aid of these parts, the bending of the

PCB can be prevented during pressing.

The ram fastened to the upper plate is designed according

to the positions of the parts on the PCB and the layout of the

pins.

It is not possible to press the module out with a flat plate

if the PCB is thicker than 2.5 mm due to the overhang of the

pins. In this case, pressing sticks positioned according to the

pin layout are necessary.

Recommended spring force: 25 N/mm

Recommended number of springs: 4 pcs

www.onsemi.com

11

Page 12

AND9867/D

Figure 28. Press−out Failure Mode: Upper and Lower

Press−out Tools Not Parallel

Due to the stress relaxation between contact partners, the

initial contact force tends to reduce over time. In addition,

the press−out force varies in relation to the contact ratio

between press−fit pin and plated through hole. As shown in

Table 6, the press−out force should be higher than 40 N per

pin.

Table 6. PRESS−OUT FORCE AND SPEED

SPECIFICATION

Min. Typ. Max.

Press−Out Force (per Pin) 40 N

Press−Out Speed 3–12 mm/min

This condition is automatically fulfilled with the use of the

recommended press−in tool.

SOLDERING TO PCB

PCB holes with fully plated through−holes will enable

100% wetting and fillets between pin and both sides of PCB.

Figure 29. Solder Wetting of PCB Through Hole

Figure 30. Wave Solder Profile

MODULE MOUNTING TO HEATSINK

This section describes how the modules are mounted to

the heatsink. The different module family members have

different sized mounting holes and recommendations.

It is extremely important that the contact surface of

heatsink must be flat and free of particles. Avoid handling

the heatsink surface with bare hands or contacting with any

foreign materials. If it is necessary to remove

contaminations from heatsink, please clean it using a dry

cloth soaked with solvent such as isopropyl or ethylene

alcohol.

Methods of Screw Clamping

There are two recommended screw clamping methods

which apply to all modules. The F1 module is used as an

example. Figure 31 describes one method for fastening the

module to the heatsink. Fasten two screws simultaneously to

prevent tilting or rising of one side of module during

fastening. Electric screwdrivers can tighten the screws with

the specified torque. Additional flat or spring washers are

permissible, considering clearance and creepage distances

specified later in this section.

Screw holes on heatsink need to be countersunk.

If method 1 cannot be applied, the method as described in

Figure 32 is also acceptable. Fasten the first screw loosely

to prevent tilting or rising of the module (step 1). Then insert

the second screw with final torque so as to be fully tightened

with the heatsink (step 2). Finally, apply full torque to the

first screw for solid tightening with the heatsink.

For F1/F2 packages in full plastic cases, the

recommended torque is between 1.6−2.0 Nm using M4

screws.

Wave soldering profile

www.onsemi.com

12

Page 13

AND9867/D

Mtorque

1.6−2.0 Nm

Mtorque

1.6−2.0 Nm

Figure 31. Illustration of Screw Clamping with Heatsink (Method 1)

Torque Values Apply to F1/F2 Packages. See Later Diagrams for Other Packages

Mtorque

1.6−2.0 Nm

Mtorque

1.6−2.0 Nm

Figure 32. Screw Clamping Steps (Method 2)

Torque Values Apply to F1/F2 Packages. See Later Diagrams for Other Packages

Q0/Q1 Modules

When using screws with flat washers:

Metric screw: M4 (recommended screw type DIN7984)

Flat washer: D = 8 mm ISO 7092 (DIN 433)

Spring washer: D = 8 mm DIN 127 or DIN 128

Mounting torque: 1.6−2.0 Nm

Screw holes on heatsink need to be countersunk.

A torque wrench shall be used to tighten the mounting

screws at the specified torque. Excessive torque may result

in damage or degradation of the device. The inaccuracy of

torque wrench tightening method can range up to ±12%.

This has to be taken into account to prevent over−tightening

the fastener.

Due to excessive temperature fluctuations washers should

be used to prevent the loosening of the screws. After

accurate tightening of the screws the spring washer exerts

a constant force on the joint. The flat washer distributes this

force on the plastic surface.

When using screws with pre−assembled washers:

Screws with pre−assembled washers (SEMS or kombi

screws) combine the screw and the washers into a single

component. These screws eliminate the need to slip the

www.onsemi.com

13

Page 14

AND9867/D

washers into place by hand, boosting the speed and

efficiency of the assembly process. The specifications of

these screws are provided below:

Screw size: M4 according to DIN 6900 (ISO 10644;

JIS B1188)

Flat washer: According to DIN 6902 Type C (ISO 10673

Type S; JIS B1256)

Washer outer diameter:

8 mm diameter can be fitted onto the module

Split lock spring washer:

According to DIN 6905(JIS B1251)

Mounting torque range: 1.6−2.0 Nm

See Figure 33.

Step 2: pre−mount

with 0.4−0.6N.M

Step 1: pre−mount

with 0.4−0.6N.M

Step 4: mount with

1.6−2N.M

Figure 33. Q0/Q1 Modules − Mounting to Heatsink

Step 3: mount with

1.6−2N.M

MOUNTING HEATSINK AND MODULE TO PCB

Mounting screws for attaching module to PCB

Screwing the PCB to the stand−offs on the module is one

of the assembly methods. By adding this screw connection

to the stand−offs, securing the assembly of module and PCB

can be expected. Figure 35 shows the key dimensions of the

stand−off. Self−tapping screws are recommended so that the

screws form the thread in the hole.

For F1 and F2 modules, metric screws, self−tapping, with

dimensions of 2.5xL or 2.6xL have been verified. The length

of the screws (L) may differ depending on the thickness of

the PCB. Typically, an 8 mm long screw (M2.5X8) can be

used with 1.6 mm−thick PCB. Recommended mounting

torque is 0.4~0.5 Nm for each screw. See Figure 30. This

shows the recommended sequence for mounting the PCB to

the module. Straight inserting avoids mechanical damage to

the module case. An electric screwdriver helps achieve

uniform force and speed for inserting the screws.

For Q2 modules, metric screws, self−tapping, with

dimensions of 2.5xL have been verified. The length of the

screws (L) may differ depending on the thickness of the

PCB. Typically, an 8 mm long screw (M2.5X8) can be used

with 1.6 mm−thick PCB. Recommended mounting torque is

0.3~0.5 Nm for each screw. See Figure 36. This shows the

recommended sequence for mounting the PCB to the

module. Straight inserting avoids mechanical damage to the

module case. An electric screwdriver helps achieve uniform

force and speed for inserting the screws.

Q0 and Q1 modules do not have screw holes for mounting

onto the PCB.

Q2 Modules

Use M5 screws with torque of 3.0–5.0 Nm.

See Figure 34.

Figure 34. Q2 Modules − Mounting to Heatsink

www.onsemi.com

14

Page 15

AND9867/D

Figure 35. Q2 Screw Clamping on Stand−offs and Key Dimensions of Screw Hole

NOTE: Do not screw the PCB down to the stand−offs of

the module if an air gap remains between case

top and PCB after press−in. This can lead to

deformation of the PCB or other mechanical

damage.

Assembly of the PCB and Heatsink

The overall structure of the mounted module should be

considered.

If the PCB is large and heavy with other components

assembled to it, there is some risk the PCB can bend, creating

mechanical stress to the module and the PCB. When

www.onsemi.com

multiple modules are applied to the same PCB, height

tolerance between modules can result in the mechanical

stresses on the board and modules. To reduce stress, space

posts should be added on the heatsink, as illustrated in to

prevent movement of the PCB.

The recommended height of the space posts is 12.4

(+0/−0.1) mm. The effective distance between center of

stand−off and the space post (= X) is 50 mm minimum. If

distance keepers are used during the press−in process,

resulting in tighter height tolerances; distances between the

15

Page 16

AND9867/D

stand−off of the case and the space post (= X) smaller than

50 mm can be used.

Figure 36 shows the assembly procedure when space

posts are used and the overall assembly structure:

Modules are first pressed into the PCB following the

recommendations introduced in Section “Heatsink Surface”

before heatsink mounting. Maintaining tight height

Figure 36. Space Posts for Assembly of PCB to Heat Sink

tolerances between module and PCB is important. Next, the

thermal interface material is applied. Then the modules and

the PCB are placed on the heatsink (a).

Then the module is mounted onto the heatsink via the

module’s metal or plastic clamp. Refer to Section “Q2

Modules” for instructions of screw clamping (b). Finally, the

PCB needs to be fixed on the space posts, as described in (c).

Figure 37. Example of Whole Assembly Process for PCB and Heatsink with Space Posts

www.onsemi.com

16

Page 17

AND9867/D

During the assembly process, a single pin is not allowed

to be drawn or pushed inwards or outwards from substrate

more than ±0.2 mm or loaded with a force greater than 35 N

(except during pressing−in of press−fit pins). The special

design of press−fit pins prevents a deformation of pins

greater than 0.1 mm during the press−in process. The tension

of the pin must not exceed ±5 N at a maximum substrate

temperature of 100 °C.

Creepage and Clearance Considerations

The spacing of the assembly between the module and PCB

must meet the clearance and creepage distance required by

the relevant standards. After F1 or F2 modules are mounted

to the PCB and heatsink, the minimum clearance is the

distance between the screw head and the bottom surface of

the PCB. The size (height) of the screw head and potential

use of an additional washer, as well as the air gap between

PCB and top side of the module, influence the creepage

distance between the screw and the PCB and the module

pins. F1 and F2 modules are mounted on the heatsink using

M4 hexagon socket head screws, according to ISO 4762.

Additional washers, according to ISO 7089, can be used.

A distance of 6.8 mm between the screw and the PCB, as

shown in Figure 38, can be maintained.

Figure 38. Distance between PCB and Screw

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf. ON Semiconductor reserves the right to make changes without further notice to any products herein.

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Email Requests to: orderlit@onsemi.com

ON Semiconductor Website: www.onsemi.com

◊

TECHNICAL SUPPORT

North American Technical Support:

Voice Mail: 1 800−282−9855 Toll Free USA/Canada

Phone: 011 421 33 790 2910

www.onsemi.com

17

Europe, Middle East and Africa Technical Support:

Phone: 00421 33 790 2910

For additional information, please contact your local Sales Representative

Loading...

Loading...