Page 1

AR0330CS

AR0330CS and AR0330SR

1/3-Inch CMOS Digital

Image Sensor

General Description

The AR0330CS can be operated in its default mode or programmed

for frame size, exposure, gain, and other parameters. The default mode

output is a 2304 x 1296 image at 30 frames per second (fps). The

sensor outputs 10− or 12−bit raw data, using either the parallel or serial

(MIPI) output ports.

The ON Semiconductor AR0330CS is a 1/3−inch CMOS digital

image sensor with an active−pixel array of 2304 (H) x1536 (V). It can

support 3.15 megapixel (2048H x 1536 V) digital still image capture

and a 1080p30 +20%EIS (2304H x 1296 V) digital video mode. It

incorporates sophisticated on−chip camera functions such as

windowing, mirroring, column and row subsampling modes, and

snapshot modes.

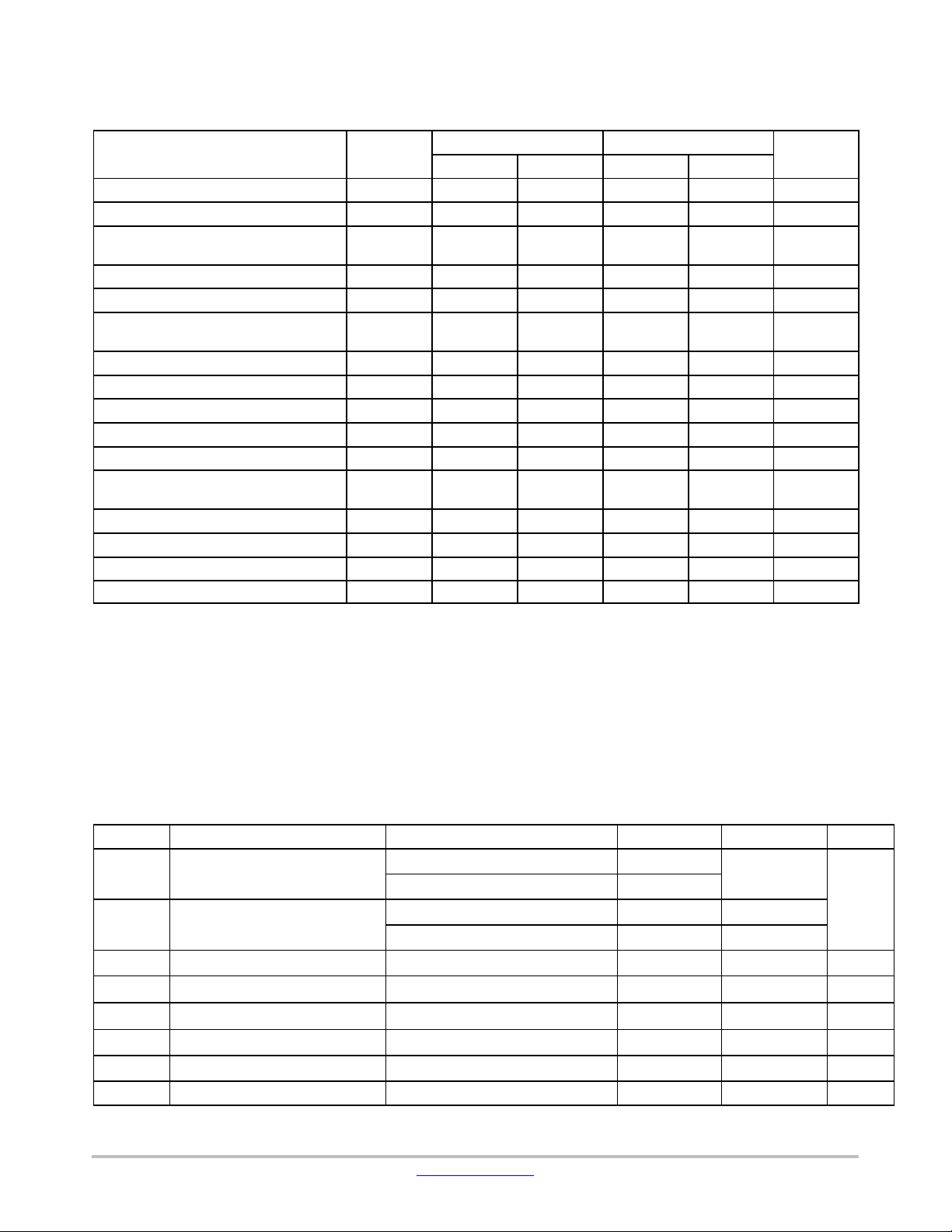

Table 1. KEY PARAMETERS

Parameter Typical Value

Optical Format 1/3−inch (6.0 mm)

Entire Array: 6.09 mm

Still Image: 5.63 mm (4:3)

HD Image: 5.82 mm (16:9)

Active Pixels 2304(H) x 1536(V): (Entire Array):

5.07 mm (H) x 3.38 mm (V)

2048(H) x 1536(V) (4:3, Still Mode)

2304(H) x 1296(V) (16:9, sHD Mode)

Pixel Size

Color Filter Array RGB Bayer

Shutter Type ERS and GRR

Input Clock Range 6 – 27 MHz

Output Clock Maximum

(CLK_OP)

Responsivity 2.0 V/lux−sec

Power Consumption

SNR

MAX

Dynamic Range 69.5 dB

Supply

Voltage

Operating Temperature

(junction) −T

Package Options 6.28 mm x 6.65 mm CSP

I/O/Digital 1.7–1.9 V (1.8 V Nominal) or

Digital 1.7–1.9 V (1.8 V Nominal)

Analog 2.76–2.9 V

J

2.2 mm x 2.2 mm

98 Mp/s (Parallel, MIPI)

1080P30 MIPI Mode: 282 mW

1080P30 Parallel Mode: 252 mW

39 dB

2.4–3.1 V (2.8 V Nominal)

–30°C to + 70° C

11.43 mm x 11.43 mm PLCC

www.onsemi.com

PLCC48

11.43x11.43

CASE 776AM

ORDERING INFORMATION

See detailed ordering and shipping information on page 2 of

this data sheet.

Features (continued)

ODCSP64

6.278x6.648

CASE 570BH

• 2.2 mm Pixel with ON Semiconductor

A−Pix

™ technology

• Superior Low−light Performance

• 3.5 Mp Active Array, 2.9 Mp (16:9) Video

3.4 Mp (3:2) and 3.15 Mp (4:3) Still Images

• Support for External Mechanical Shutter

• Support for External LED or Xenon Flash

• Data Interfaces: Two−lane Serial MIPI or

Parallel Interface

• On−chip phase−locked Loop (PLL)

Oscillator

• Integrated Position−based Color and Lens

Shading Correction

• Simple Two−wire Serial Interface

• Auto Black Level Calibration

• 12−to−10 bit Output A−Law Compression

• Slave Mode for Precise Frame−rate Control

and for Synchronizing Two Sensors

Applications

• 1080P30 High−definition Digital Video

Camcorder

• Web Cameras and Video Conferencing

Cameras

• Security

© Semiconductor Components Industries, LLC, 2012

January, 2019 − Rev. 8

1 Publication Order Number:

AR0330CS/D

Page 2

AR0330CS

ORDERING INFORMATION

Table 2. AVAILABLE PART NUMBERS

Part Number

AR0330CS1C12SPKA0−CP 3.5 MP, 1/3−inch, 12 Deg CRA, Parallel, MIPI, CSP Tray, Protective Film

AR0330CS1C12SPKA0−CR 3.5 MP, 1/3−inch, 12 Deg CRA, Parallel, MIPI, CSP Tray, No Protective Film

AR0330CSSC12SPBA0−DR 3.5 MP, 1/3−inch, 12 Deg CRA, Parallel, PLCC Tray, No Protective Film

AR0330SR1C00SUKA0−CP 3.5 MP, 1/3−inch, 0 Deg CRA, Parallel, CSP Tray, Protective Film

AR0330SR1C00SUKA0−CR 3.5 MP, 1/3−inch, 0 Deg CRA, Parallel, CSP Tray, No Protective Film

AR0330CS1C12SPKAH3−GEVB 3.5 MP, 1/3− inch, 12 Deg CRA, Parallel, MIPI, CSP Evaluation board

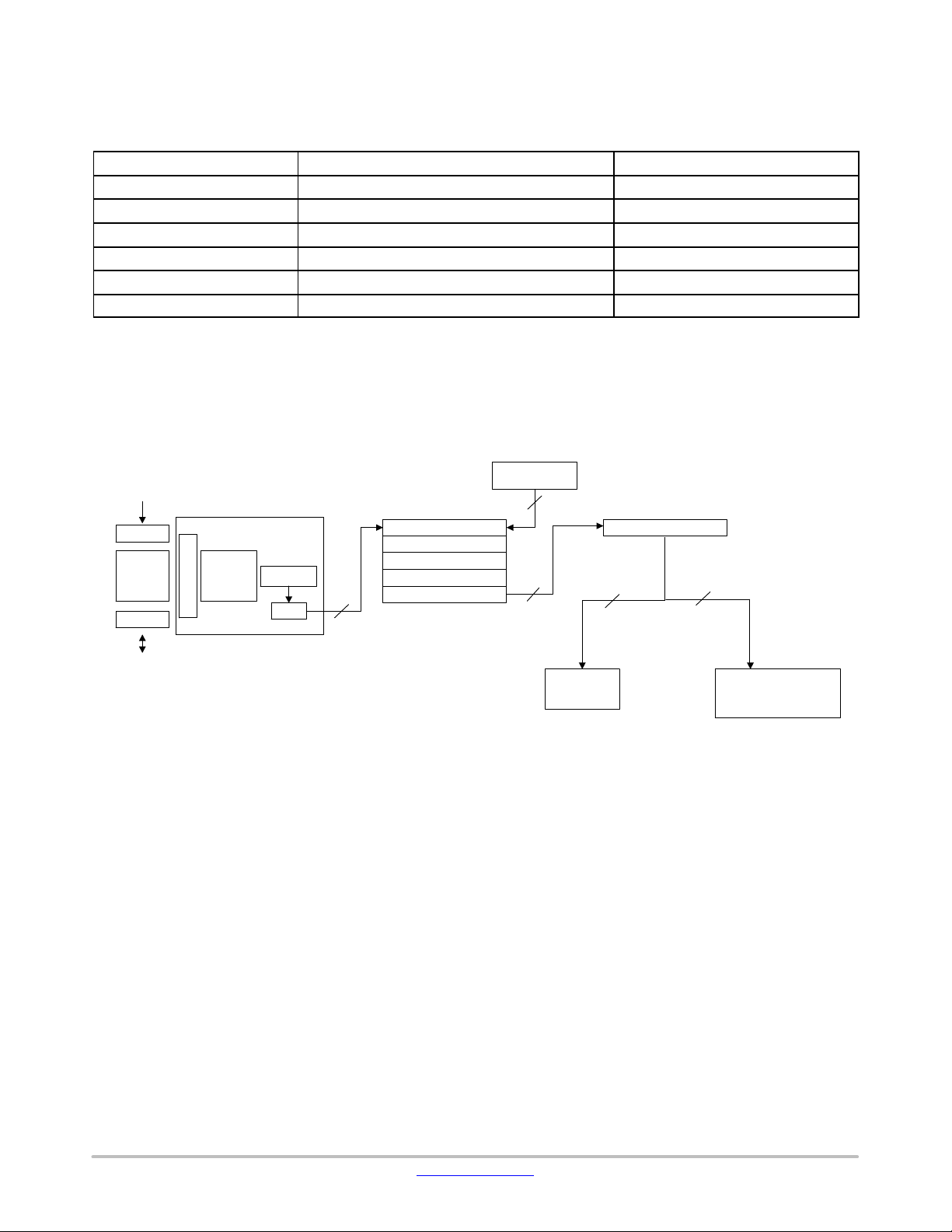

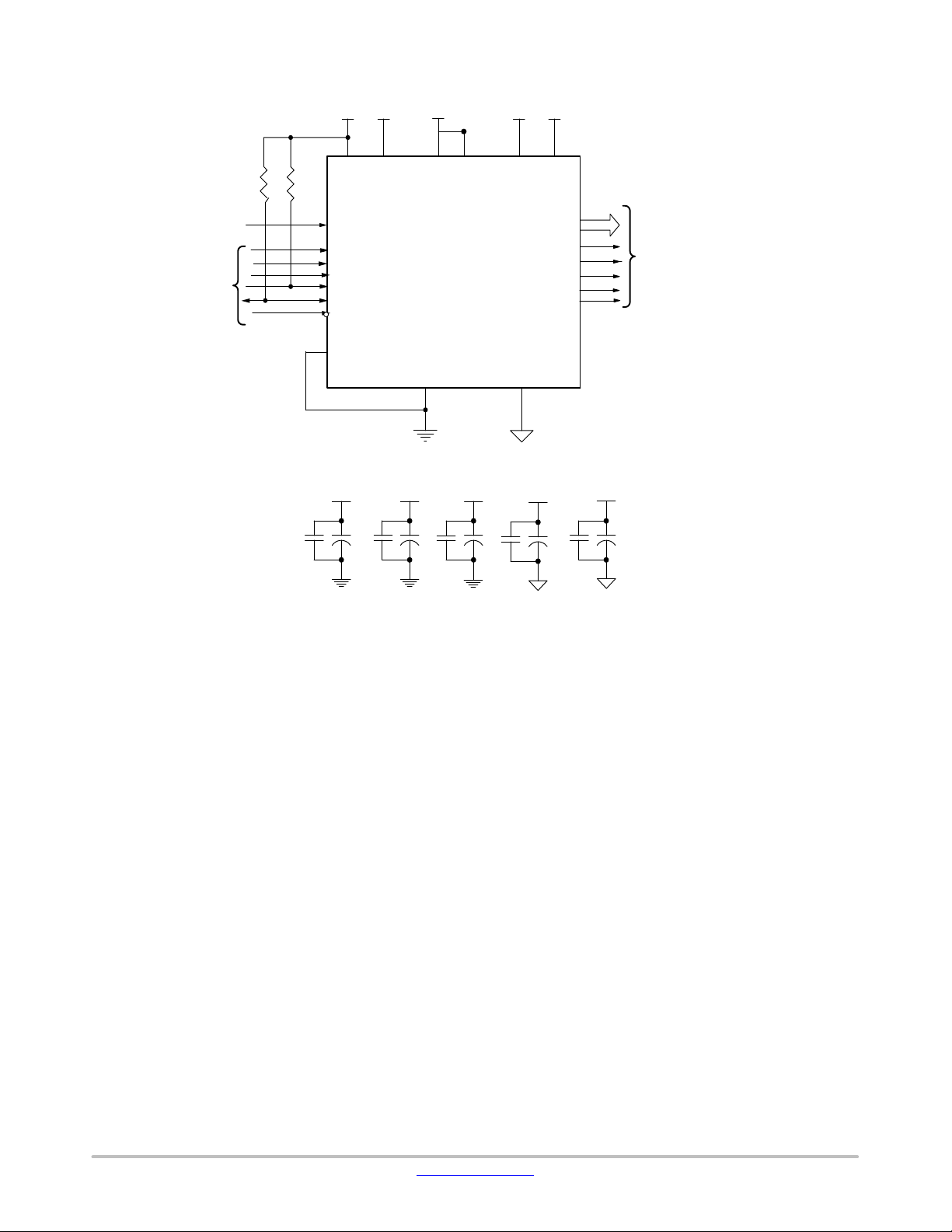

FUNCTIONAL OVERVIEW

The AR0330CS is a progressive−scan sensor that

generates a stream of pixel data at a constant frame rate. It

uses an on−chip, phase−locked loop (PLL) that can generate

all internal clocks from a single master input clock running

Ext

Clock

Analog Core

PLL

Timing

and

Control

Registers

Pixel Array

Row Drivers

Column

Amplifiers

ADC

12−bit

Product Description Orderable Product Attribute Description

between 6 and 27 MHz. The maximum CLK_OP is 98 Mp/s

using MIPI serial interface and 98 Mp/s using the parallel

interface.

Test Pattern

Generator

Digital Core

Row Noise Correction

Black Level Correction

Lens Shading Correction

Digital Gain

Data Pedestal

12−bit

12−bit

Output Data−Path

Compression (optional)

12−bit

8, 10, or

12−bit

Two−wire serial I/F

Figure 1. Block Diagram

User interaction with the sensor is through the two−wire

serial bus, which communicates with the array control,

analog signal chain, and digital signal chain. The core of the

sensor is a 3.5 Mp active− pixel sensor array. The timing and

control circuitry sequences through the rows of the array,

resetting and then reading each row in turn. In the time

interval between resetting a row and reading that row, the

pixels in the row integrate incident light. The exposure is

Parallel I/O:

PIXCLK, FV,

LV, D

OUT [11:0]

Ma x 98 Mp/s

MIPI I/O:

CLK P/N,

1. Two lane data paths

only 2. 98 Mp/sec

Max CLK_OP 98 Mp/s

controlled by varying the time interval between reset and

readout. Once a row has been read, the signal from the

column is amplified in a column amplifier and then digitized

in an analog−to−digital converter (ADC). The output from

the ADC is a 12−bit value for each pixel in the array. The

ADC output passes through a digital processing signal chain

(which provides further data path corrections and applies

digital gain).

www.onsemi.com

2

Page 3

AR0330CS

WORKING MODES

The AR0330CS sensor working modes are specified from

the following aspect ratios:

Table 3. AVAILABLE ASPECT RATIOS IN THE AR0330CS SENSOR

Aspect Ratio Sensor Array Usage

3:2 Still Format #1 2256(H) x 1504(V)

4:3 Still Format #2 2048 (H) x 1536 (V)

16:10 Still Format #3 2256 (H) x 1440 (V)

16:9 FHD Format 2304 (H) x 1296 (V)

The AR0330CS supports the following working modes.

To operate the sensor at full speed 98Mp/s the sensor must

operate at full−speed (98 Mp/s) when using the parallel

interface.

use 2−Lane MIPI or parallel interface. The sensor will

Table 4. AVAILABLE WORKING MODES IN THE AR0330CS SENSOR

Active

Readout

Mode Aspect Ratio

1080p + EIS 16:9 2304 x 1296 2304 x 1296 30 30 – 100%

3M Still

WVGA + EIS 16:9 2304 x 1296 1152 x 648 60 60 2 x 2 100%

4:3 2048 x 1536 2048 x 1536 30 25 – 100%

3:2 2256 x 1504 2256 x 1504 30 25 – 100%

Window

Sensor Output

Resolution

FPS

(2 lane MIPI,

12 bit)

FPS (Parallel

Interface)

Subsampling FOV

www.onsemi.com

3

Page 4

Digital

I/O

power

1

AR0330CS

Digital

Core

1

power

PLL

power

1

Analog

power

1

Analog

1

power

Master clock

(6–27MHz)

From

controller

3, 4

1.5kΩ

3, 4

VDD_IO

1.5kΩ

EXTCLK

TRIGGER

SADDR

SCLK

SDATA

RESET_BAR

TEST

VDD_IO VDD_PLLVDD

0.1 μF10 μF

VDD

VAA VAA_PIX

DATA1_P

V DD_MIPI

VDD_PLL

DATA1_N

DATA2_P

DATA2_N

CLK_P

CLK_N

To

controller

(MIPI − serial interface)

SHUTTER

FLASH

GND AGND

D

Digital

ground

0.1 μF10 μF

10 μF

0.1 μF

Analog

ground

VAA

0.1 μF10 μF

10 μF

VAA_PIX

0.1 μF

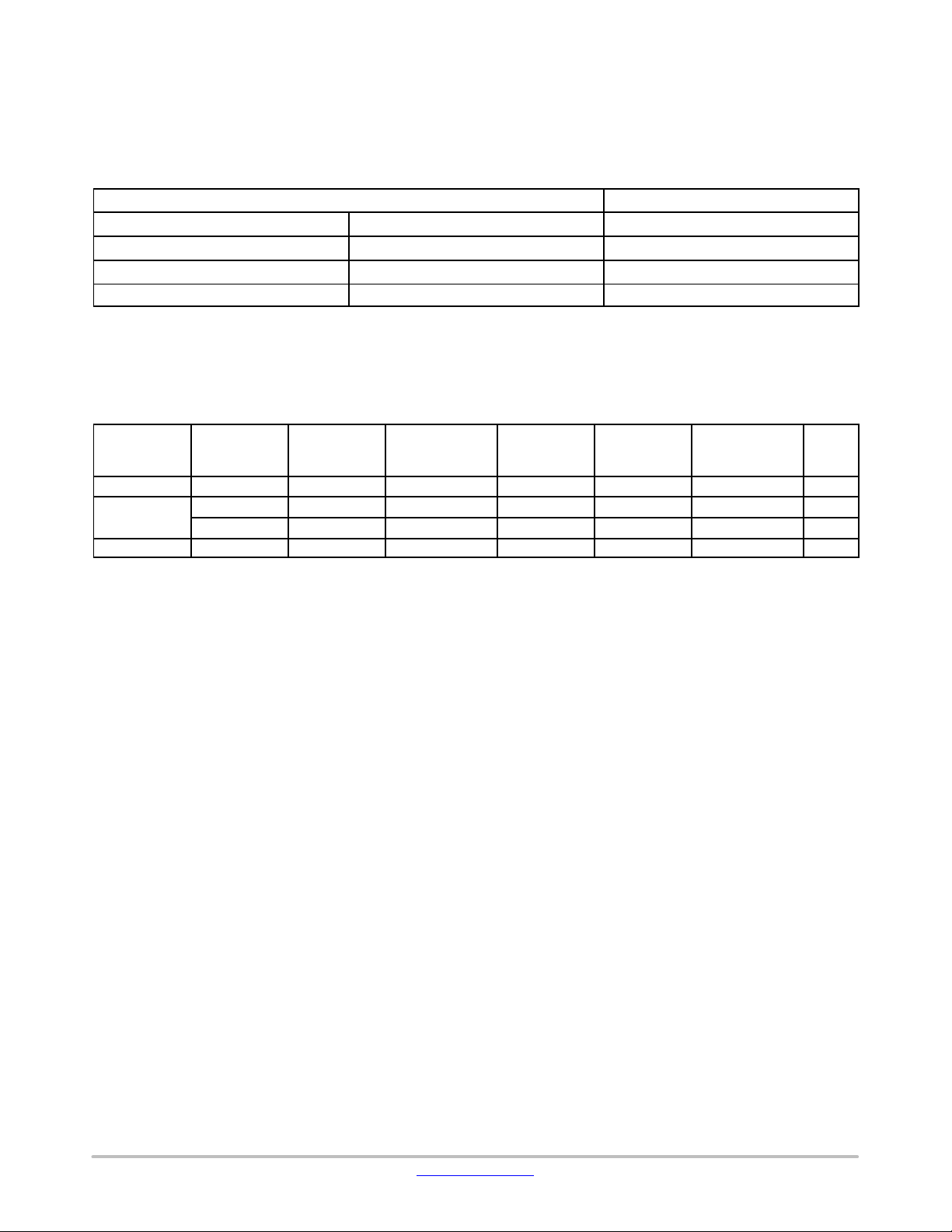

1. All power supplies must be adequately decoupled. ON Semiconductor recommends having 10 mF and 0.1 mF decoupling capacitors for

every power supply. If space is a concern, then priority must be given in the following order: V

DD. Actual values and results may vary depending on layout and design considerations.

and V

AA, VAA_PIX, VDD_PLL, VDD_MIPI, VDD_IO,

2. To allow for space constraints, ON Semiconductor recommends having 0.1 mF decoupling capacitor inside the module as close to the

pads as possible. In addition, place a 10 mF capacitor for each supply off−module but close to each supply.

3. ON Semiconductor recommends a resistor value of 1.5 kW, but a greater value may be used for slower two−wire speed.

4. The pull−up resistor is not required if the controller drives a valid logic level on S

CLK at all times.

5. ON Semiconductor recommends that analog power planes are placed in a manner such that coupling with the digital power planes is

minimized.

6. TEST pin must be tied to D

7. ON Semiconductor recommends that GND_MIPI be tied to D

DD_MIPI is tied to VDD_PLL in the CSP package. ON Semiconductor strongly recommends that VDD_MIPI must be connected to a

8. V

DD_PLL in a module design since VDD_PLL and VDD_MIPI are tied together in the die.

V

GND for the MIPI configuration.

GND.

9. The package pins or die pads used for the parallel interface must be left floating.

10.If the SHUTTER or FLASH pins or pads are not used, then they must be left floating.

11.If the TRIGGER or OE_BAR pin or pad is not used, then it should be tied to D

GND.

Figure 2. Typical Configuration: Serial MIPI

www.onsemi.com

4

Page 5

Master clock

(6–27 MHz)

From

Controller

3, 4

AR0330CS

Digital

Digital

core

I/O

1

power

power

VDD_IO

3, 4

1.5k

1.5k

VDD

EXTCLK

OE_BAR

TRIGGER

SADDR

SCLK

SDATA

RESET_BAR

TEST

PLL

GND

D

power

1

V DD_PLL

1

VDD_MIPI

Analog

Analog

1

power

power

VAA_PIX

VAA

DOUT [11:0]

PIXCLK

LINE_VALID

FRAME_VALID

FLASH

SHUTTER

AGND

1

To

controller

10 μF

DD_IO VDD_PLLVDD

V

0.1 μF

10 μF

Digital

ground

10 μF

0.1 μF

10 μF

Analog

ground

0.1 μF

VAA

VAA_PIX

10 μF0.1 μF

0.1 μF

12.All power supplies must be adequately decoupled. ON Semiconductor recommends having 10 mF and 0.1 mF decoupling capacitors for

every power supply. If space is a concern, then priority must be given in the following order: V

AA, VAA_PIX, VDD_PLL, VDD_IO, and VDD.

Actual values and results may vary depending on layout and design considerations.

13.To allow for space constraints, ON Semiconductor recommends having 0.1 mF decoupling capacitor inside the module as close to the

pads as possible. In addition, place a 10 mF capacitor for each supply off−module but close to each supply.

14.ON Semiconductor recommends a resistor value of 1.5 kW, but a greater value may be used for slower two−wire speed.

15.The pull−up resistor is not required if the controller drives a valid logic level on S

CLK at all times.

16.ON Semiconductor recommends that analog power planes are placed in a manner such that coupling with the digital power planes is

minimized.

17.TEST pin should be tied to the ground.

18.The data and clock package pins or die pads used for the MIPI interface must be left floating.

19.The V

DD_MIPI package pin and sensor die pad should be connected to a 2.8 V supply as it is tied to the VDD_PLL supply both in the

package routing and also within the sensor die itself.

20.If the SHUTTER or FLASH pins or pads are not used, then they must be left floating.

21.If the TRIGGER or OE_BAR pin or pad is not used, then it should be tied to D

GND.

Figure 3. Typical Configuration: Parallel Pixel Data Interface

www.onsemi.com

5

Page 6

AR0330CS

PIN DESCRIPTIONS

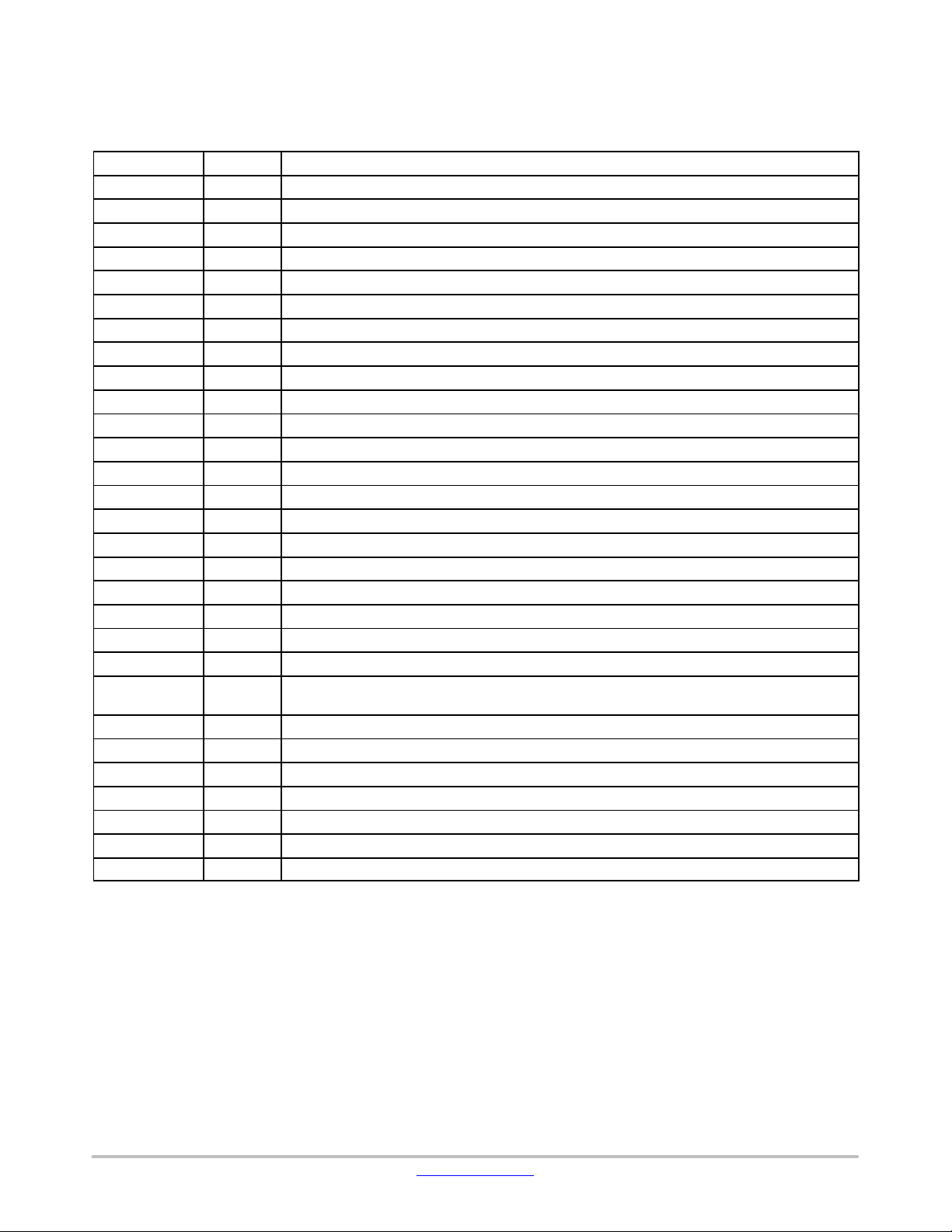

Table 5. PIN DESCRIPTIONS

Name Type Description

RESET_BAR Input Asynchronous reset (active LOW). All settings are restored to factory default

EXTCLK Input Master input clock, range 6 − 27 MHz

TRIGGER Input Receives slave mode VD signal for frame rate synchronization and trigger to start a GRR frame

SADDR Input Two−wire serial address select

SCLK Input Two−wire serial clock input

TEST Input Enable manufacturing test modes. Tie to DGND for normal sensor operation

OE_BAR Input Parallel port output enable, active low

SDATA I/O Two−wire serial data I/O

PIXCLK Output Pixel clock out. DOUT is valid on rising edge of this clock

DOUT[11:0] Output Parallel pixel data output

FLASH Output Flash output. Synchronization pulse for external light source. Can be left floating if not used

FRAME_VALID Output Asserted when DOUT data is valid

LINE_VALID Output LINE_VALID output asserted when DOUT data is valid

SHUTTER Output Control for external mechanical shutter. Can be left floating if not used

DATA1_P Output MIPI serial data, lane 1, differential P

DATA1_N Output MIPI serial data, lane 1, differential N

DATA2_P Output MIPI serial data, lane 2, differential P

DATA2_N Output MIPI serial data, lane 2, differential N

CLK_P Output Output MIPI serial clock, differential P

CLK_N Output Output MIPI serial clock, differential N

VDD_MIPI Power MIPI power supply

VAAHV_NPIX Power Power supply pin used to program the sensor OTPM (one−time programmable memory). This pin

VDD Power Digital power

VDD_IO Power IO supply power

VDD_PLL Power PLL power supply

DGND Power Digital GND

VAA Power Analog power

VAA_PIX Power Pixel power

AGND Power Analog GND

should be open if OTPM is not used

www.onsemi.com

6

Page 7

AR0330CS

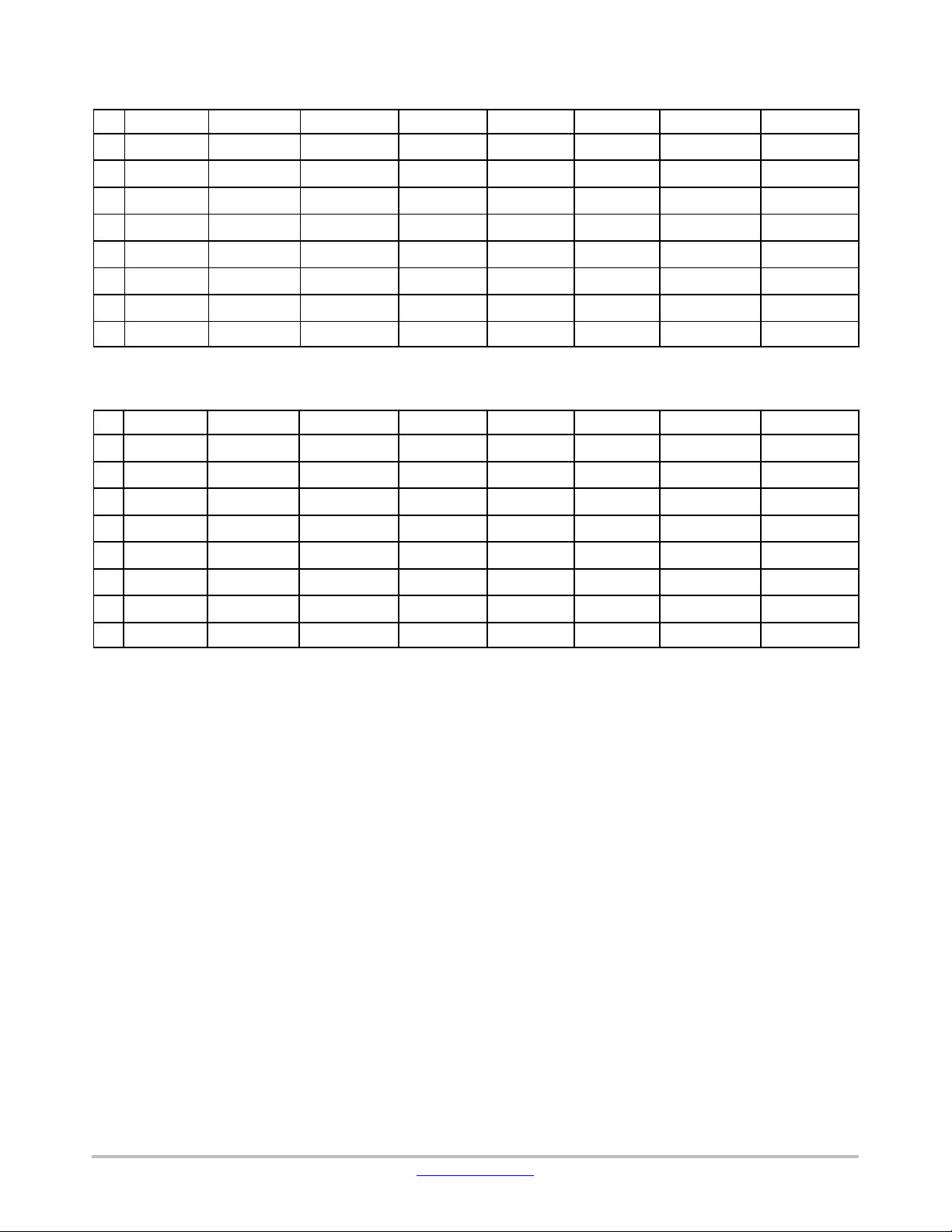

Table 6. AR0330CS CSP (PARALLEL/MIPI) PACKAGE PINOUT

1 2 3 4 5 6 7 8

A

B

C

D

E

F

G

H

22.NC = Do not connect. For manufacturing test purpose only.

VAA VAAHV_NPIX AGND NC VAA_PIX VAA VDD_IO VDD

VDD SDATA FRAME_VALID DGND AGND DGND TEST SHUTTER

SADDR FLASH LINE_VALID DGND DGND DGND TRIGGER RESET_BAR

SCLK VDD_IO DOUT10 DGND VDD_IO VDD_IO EXTCLK DATA_N

PIXCLK DOUT11 DOUT9 DOUT7 VDD_IO DGND CLK_N DATA_P

– – DOUT8 DOUT6 DOUT4 VDD_IO CLK_P VDD_PLL

DGND VDD DOUT5 DOUT3 DOUT1 DOUT0 DATA2_N VDD

– DGND DGND DOUT2 VDD_IO VDD_MIPI DATA2_P VDD_MIPI

Table 7. AR0330SR CSP (PARALLEL) PACKAGE PINOUT

1 2 3 4 5 6 7 8

A

B

C

D

E

F

VAA VAAHV_NPIX AGND NC VAA_PIX VAA VDD_IO VDD

VDD SDATA FRAME_VALID DGND AGND DGND TEST SHUTTER

SADDR FLASH LINE_VALID DGND DGND DGND TRIGGER RESET_BAR

SCLK VDD_IO DOUT10 DGND VDD_IO VDD_IO EXTCLK –

PIXCLK DOUT11 DOUT9 DOUT7 VDD_IO DGND – –

– – DOUT8 DOUT6 DOUT4 VDD_IO – VDD_PLL

G

DGND VDD DOUT5 DOUT3 DOUT1 DOUT0 – VDD

H

23.NC = Do not connect. For manufacturing test purpose only.

– DGND DGND DOUT2 VDD_IO VDD_PLL – VDD_PLL

www.onsemi.com

7

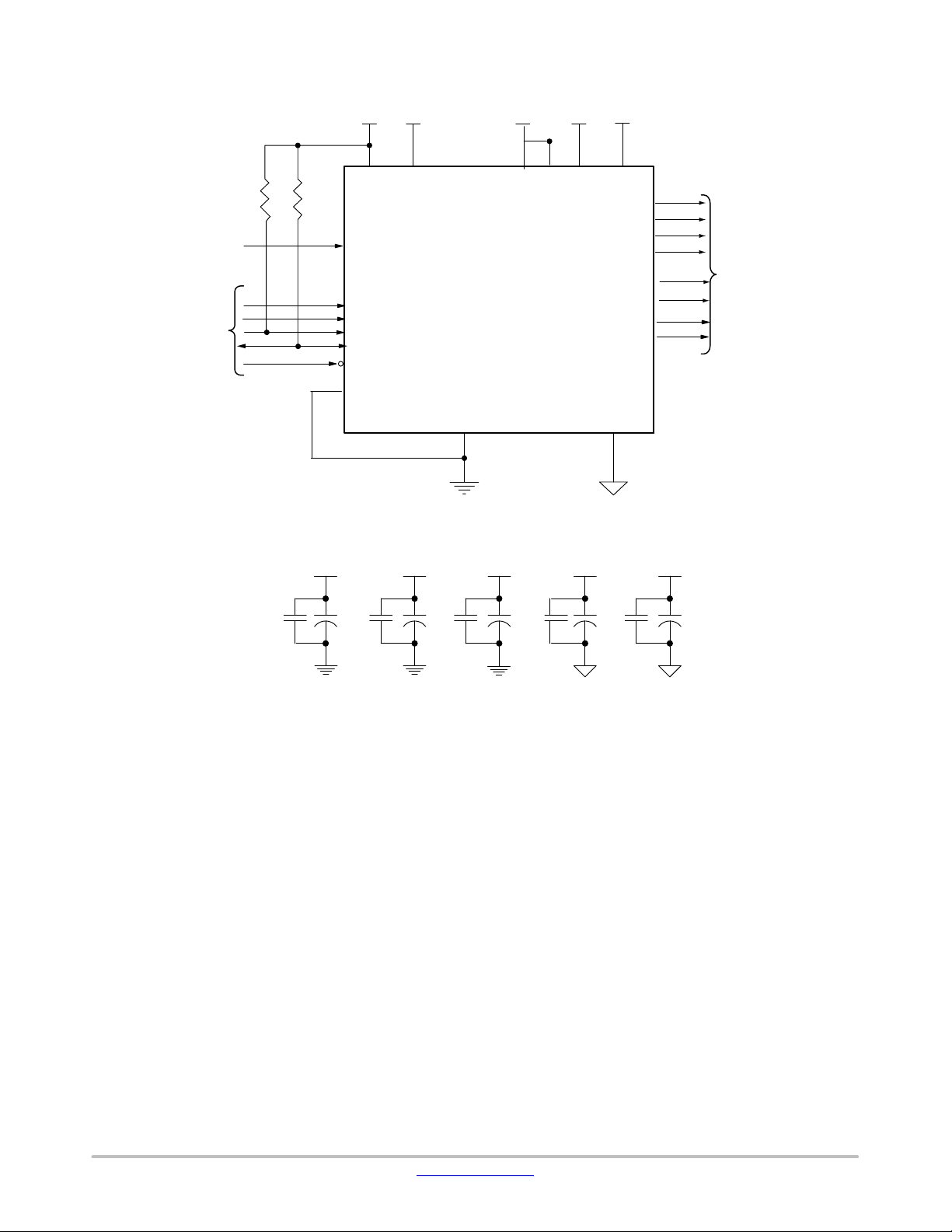

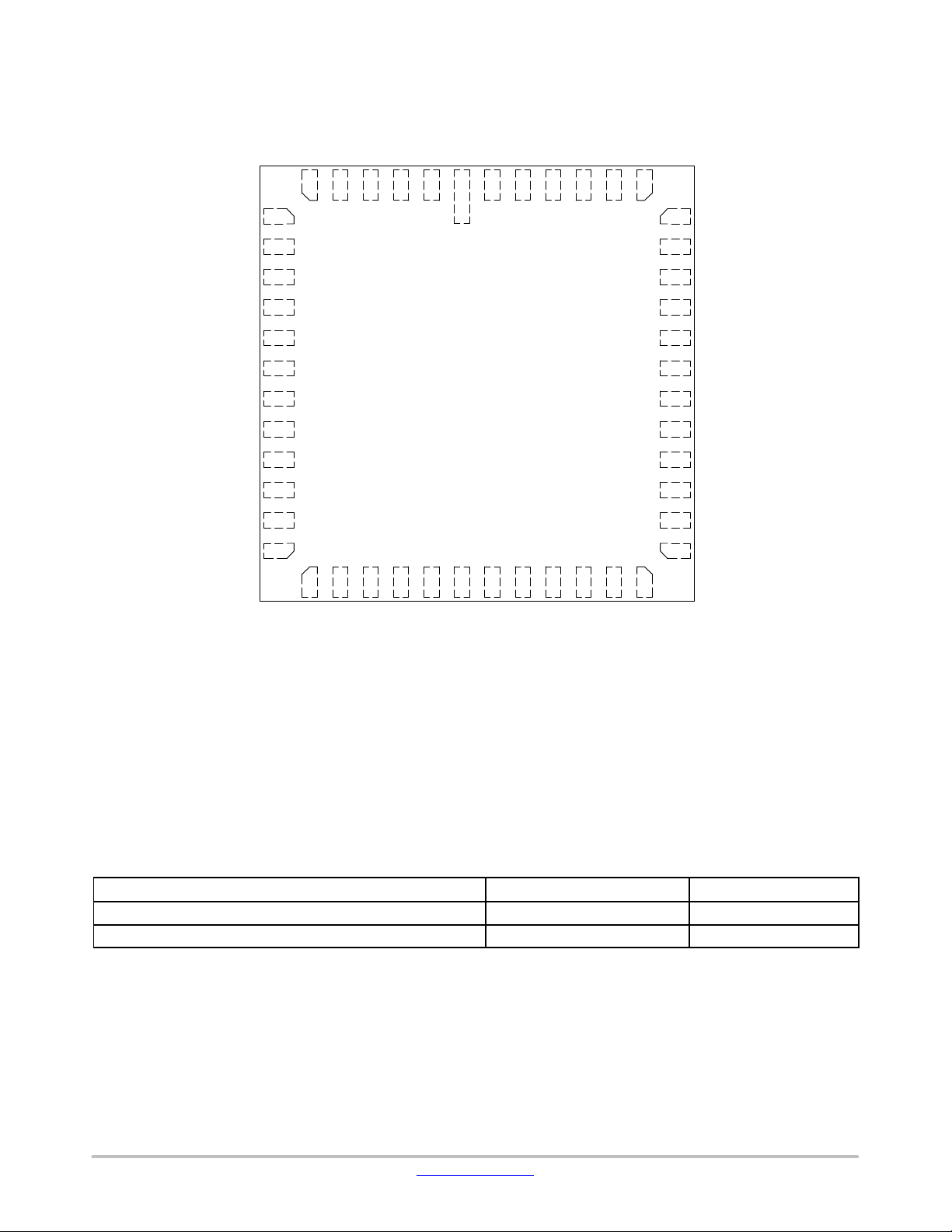

Page 8

AR0330CS

GND

V

DD_IO 7

V

DD_IO 8

CLK 9

S

S

ADDR 10

EXTCLK 11

PIXCLK 12

FLASH 13

S

DATA 14

FRAME_VALID 15

LINE_VALID 16

OUT 11 17

D

DOUT10 18

6 DGND

5 DGND

4 VDD

3 VDD

2 D

1 V DD _PLL

48 AGND

47 AGND

46 VAA

45 VAA

44 VAA

43 AGND

42 AGND

41 VAA_PIX

AA_PIX

40 V

39 AGND

38 AGND

37 NC

AA HV_NPIX

36 V

35 NC

34 V

DD

33 TRIGGER

32 OE_BAR

31 TEST

OUT 9 19

D

D

D

D

OUT 4 24

D

D

OUT 5 23

OUT 6 22

OUT 7 21

OUT 8 20

TOP VIEW

Figure 4. PLCC Pinout

Table 8. AR0330CS PLCC PACKAGE THERMAL RESISTANCE

Junction to ambient air thermal resistance (qJA) (°C/W)

Junction to board thermal resistance (qJB) (°C/W)

OUT 3 25

D

D

D

D

NC 29

OUT 0 28

OUT 1 27

OUT 2 26

RESET_BAR 30

Using JEDEC 1S0P Board Using JEDEC 2S2P Board

51.47 36.92

22.16 21.73

www.onsemi.com

8

Page 9

AR0330CS

SENSOR INITIALIZATION

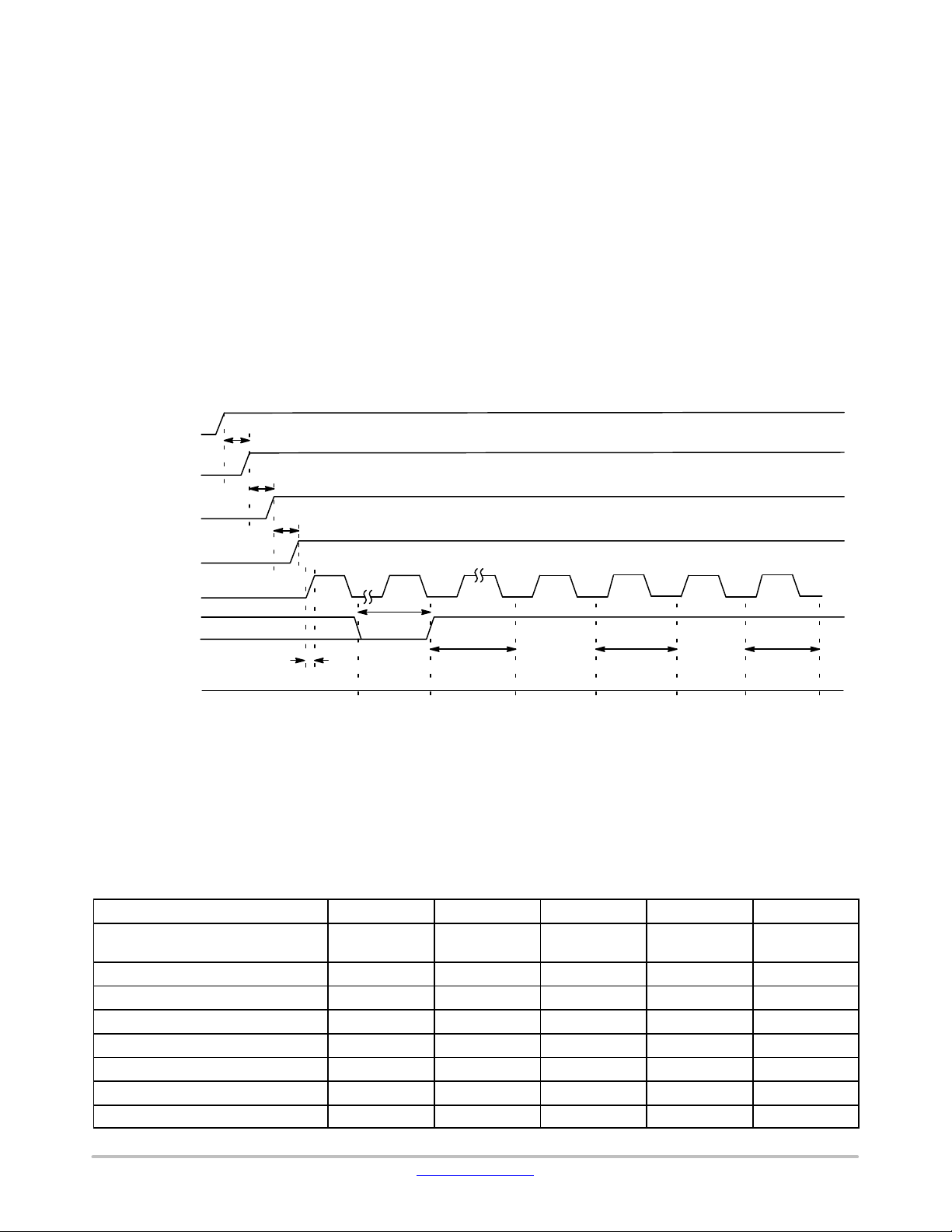

Power−Up Sequence

The recommended power−up sequence for the

AR0330CS is shown in Figure 5. The available power

supplies (V

must have the separation specified below.

DD

DD_IO, VDD_PLL, VDD_MIPI, VAA, VAA_PIX)

1. Turn on V

2. After 100 μs, turn on V

DD_PLL and VDD_MIPI power supplies

AA and VAA_PIX power

supply

3. After 100 μs, turn on V

4. After 100 μs, turn on V

DD power supply

DD_IO power supply

5. After the last power supply is stable, enable

EXTCLK

6. Assert RESET_BAR for at least 1ms

V

DD

_MIPI (2.8)

V

AA

(2.8)

AA

t

0

t

1

7. Wait 150,000 EXTCLKs (for internal initialization

into software standby

8. Write R0x3052 = 0xA114 to configure the internal

register initialization process

9. Write R0x304A = 0x0070 to start the internal

register initialization process

10. Wait 150,000 EXTCLK periods

11. Configure PLL, output, and image settings to

desired values

12. Wait 1 ms for the PLL to lock

13. Set streaming mode (R0x301A[2] = 1)

V

(1.8)

DD

V

_IO (1.8/2.8)

DD

EXTCLK

RESET_BAR

24.A software reset (R0x301A[0] = 1) is not necessary after the procedure described above since a Hard Reset will automatically triggers

a software reset. Independently executing a software reset, should be followed by steps seven through thirteen above

25.The sensor must be receiving the external input clock (EXTCLK) before the reset pin is toggled. The sensor will begin an internal

initialization sequence when the reset pin toggle from LOW to HIGH. This initialization sequence will run using the external input clock.

Power on default state is software standby state, need to apply two−wire serial commands to start streaming. Above power up sequence

is a general power up sequence. For different interface configurations, MIPI, and Parallel, some power rails are not needed. Those not

needed power rails should be ignored in the general power up sequence..

t

2

t

3

t

X

t

4

t

5

Software

Standby PLL Clock

t

6

Figure 5. Power Up

Table 9. POWER−UP SEQUENCE

Definition Symbol Min Ty p Max Unit

VDD_PLL, VDD_MIPI to VAA/VAA_PIX

(Note 28)

VAA/VAA_PIX to VDD t1 0 100 –

VDD to VDD_IO t2 0 100 –

External clock settling time tx – 30 (Note 26) – ms

Hard Reset t3 1 (Note 27) – – ms

Internal Initialization t4 150000 – – EXTCLKs

Internal Initialization t5 150000 – – EXTCLKs

PLL Lock Time t6 1 – – ms

t0 0 100 –

ms

ms

ms

Streaming

www.onsemi.com

9

Page 10

AR0330CS

26.External clock settling time is component−dependent, usually taking about 10 – 100 ms.

27.Hard reset time is the minimum time required after power rails are settled. In a circuit where Hard reset is held down by RC circuit, then the

RC time must include the all power rail settle time and Xtal settle time.

28.It is critical that V

others. If the case happens that V

current draw on this supply.

DD_MIPI is tied to VDD_PLL in the CSP package and must be powered to 2.8 V.

29.V

Power−Down Sequence

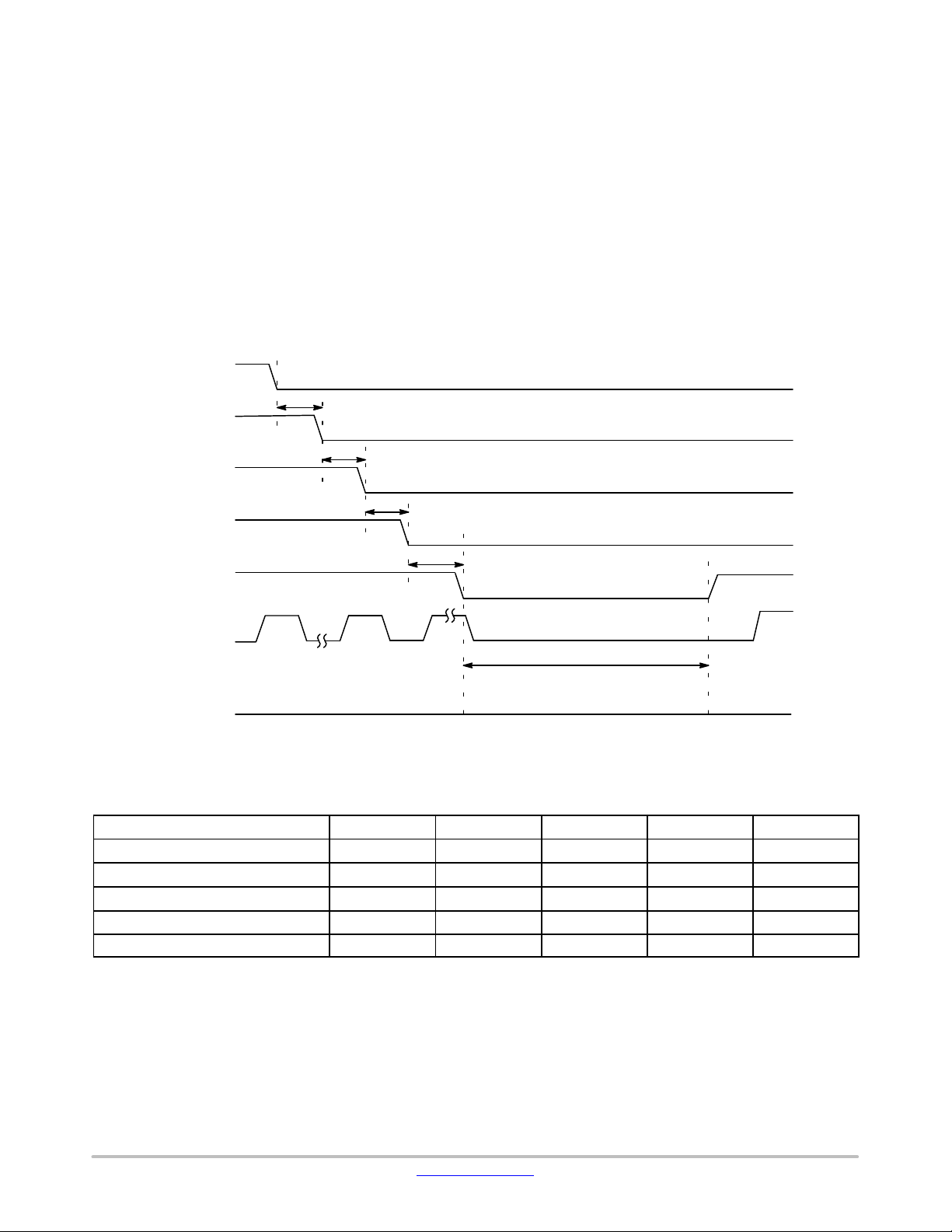

The recommended power−down sequence for the

AR0330CS is shown in Figure 6. The available power

supplies (V

must have the separation specified below.

1. Disable streaming if output is active by setting

standby R0x301a[2] = 0

VDD_HiSPi_TX (0.4)

V

_IO (1.8/2.8)

DD

DD

DD_PLL is not powered up after the other power supplies. It must be powered before or at least at the same time as the

DD_PLL is powered after other supplies then sensor may have functionality issues and will experience high

2. The soft standby state is reached after the current

row or frame, depending on configuration, has

DD_IO, VDD_PLL, VDD_MIPI., VAA, VAA_PIX)

ended

3. Turn off V

4. Turn off V

DD_IO

DD

5. Turn off VAA/VAA_PIX

V

_HiSPi (1.8)

DD

6. Turn off V

t

0

t

1

t

2

DD_PLL, VDD_MIPI

VAA_PIX, VAA (2.8)

t

3

V

DD

_MIPI (2.8)

DD

EXTCLK

t

4

Power Down until Next

Power Up Cycle

Figure 6. Power Down

Table 10. POWER−DOWN SEQUENCE

Definition Symbol Minimum Typical Maximum Unit

VDD_IO t0 0 – –

VDD_IO to VDD t1 0 – –

VDD to VAA/VAA_PIX t2 0 – –

VAA/VAA_PIX to VDD_PLL t3 0 – –

PwrDn until Next PwrUp Time t4 100 – – ms

30.t4 is required between power down and next power up time; all decoupling caps from regulators must be completely discharged.

ms

ms

ms

ms

www.onsemi.com

10

Page 11

STANDBY MODE

AR0330CS

Soft Standby

1. Disable streaming by setting standby R0x301a[2]

= 0

2. Delay 10 ms

3. Stop EXTCLK; pull EXTCLK pin LOW

Hard Standby

1. Disable streaming by setting standby R0x301a[2]

= 0

2. Delay 10 ms

3. Pull RESET_BAR to LOW

ELECTRICAL CHARACTERISTICS

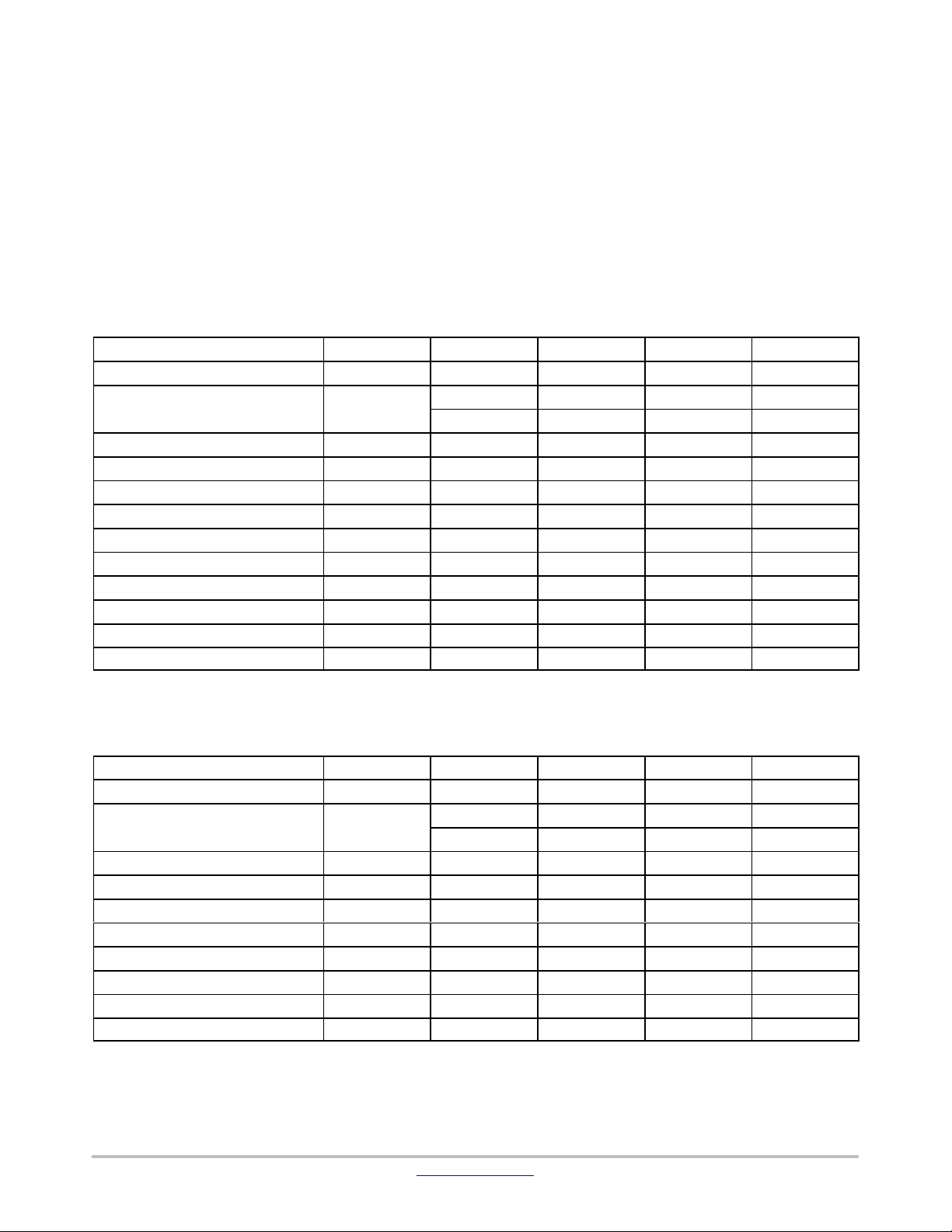

Table 11. DC Electrical Definitions and Characteristics (MIPI Mode)

f

EXTCLK = 24 MHz; VDD = 1.8 V; VDD_IO = 1.8 V; VAA = 2.8 V; VAA_PIX = 2.8 V;

DD_PLL = 2.8 V; Output load = 68.5 pF; T

V

Definition

Core digital voltage VDD 1.7 1.8 1.9 V

I/O digital voltage VDD_IO

Analog voltage VAA 2.76 2.8 2.9 V

Pixel supply voltage VAA_PIX 2.76 2.8 2.9 V

PLL supply voltage VDD_PLL 2.7 2.8 2.9 V

MIPI supply voltage VDD_MIPI 2.7 2.8 2.9 V

Digital operating current − 114 − mA

I/O digital operating current − 0 − mA

Analog operating current − 41 − mA

Pixel supply current − 9.9 − mA

PLL supply current − 15 − mA

MIPI digital operating current − 35 − mA

= 60°C; Data Rate = 588 Mbps; DLL set to 0; 2304 x 1296 at 30 fps

J

Symbol Min Typ Max Unit

1.7 1.8 1.9 V

2.4 2.8 3.1 V

Table 12. DC Electrical Definitions and Characteristics (Parallel Mode)

f

= 24 MHz; VDD = 1.8 V; VDD_IO = 1.8 V; VAA = 2.8 V; VAA_PIX = 2.8 V;

EXTCLK

DD_PLL = 2.8 V; Output load = 68.5 pF; TJ = 60°C; 2304 x 1296 at 30 fps

V

Definition

Core digital voltage VDD 1.7 1.8 1.9 V

I/O digital voltage VDD_IO

Analog voltage VAA 2.76 2.8 2.9 V

Pixel supply voltage VAA_PIX 2.76 2.8 2.9 V

PLL supply voltage VDD_PLL 2.7 2.8 2.9 V

Digital operating current I(VDD) 66.5 75 mA

I/O digital operating current I(VDD_IO) 24 35 mA

Analog operating current I(VAA) 36 44 mA

Pixel supply current I(VAA_PIX) 10.5 18 mA

PLL supply current I(VDD_PLL) 6 11 mA

Symbol Min Typ Max Unit

1.7 1.8 1.9 V

2.4 2.8 3.1 V

www.onsemi.com

11

Page 12

AR0330CS

Table 13. STANDBY POWER

f

= 24 MHz; VDD = 1.8 V; VDD_IO = 1.8 V; VAA = 2.8 V; VAA_PIX = 2.8 V;

EXTCLK

DD_PLL = 2.8 V; Output load = 68.5 pF; TJ = 60°C

V

Power Typical Max Unit

Hard Standby (CLK OFF)

Soft Standby (CLK OFF)

Soft Standby (CLK ON)

Table 14. ABSOLUTE MAXIMUM RATINGS

Symbol Definition Min Max Unit

VDD_MAX Core digital voltage –0.3 2.4 V

VDD_IO_MAX I/O digital voltage –0.3 4 V

VAA_MAX Analog voltage –0.3 4 V

VAA_PIX Pixel supply voltage –0.3 4 V

VDD_PLL PLL supply voltage –0.3 4 V

VDD_MIPI MIPI supply voltage –0.3 4 V

t

ST

Stresses exceeding those listed in the Maximum Ratings table may damage the device. If any of these limits are exceeded, device functionality

should not be assumed, damage may occur and reliability may be affected.

31.Exposure to absolute maximum rating conditions for extended periods may affect reliability.

Digital 19.8 35.8

Analog 5.8 7.0

Digital 23.5 39.7

Analog 5.4 5.9

Digital 15700 16900

Analog 5.5 5.7

mA

mA

mA

mA

mA

mA

Storage temperature –40 85 °C

SCLK

DATA

SCLK

SDATA

t

t

SRTH

t

SCLK

Write Address

Bit 7

SDH

t

SDS

Write Address

Bit 0

Write Start ACK

t

SHAR

Read Address

Bit 7

Read Address

Bit 0

Read Start

Figure 7. Two−Wire Serial Bus Timing Parameter

t

SHAW

ACK

tr_clk tf_clk

90%

10%

t

AHSW t

Register Address

Bit 7

t

AHSR

Register Value

Bit 7

t

SDHR

t

SDSR

Register Value

Register Value

Bit 0

Bit 0

90%

10%

STPS

tf_sdattr_sdat

t

STPH

www.onsemi.com

12

Page 13

AR0330CS

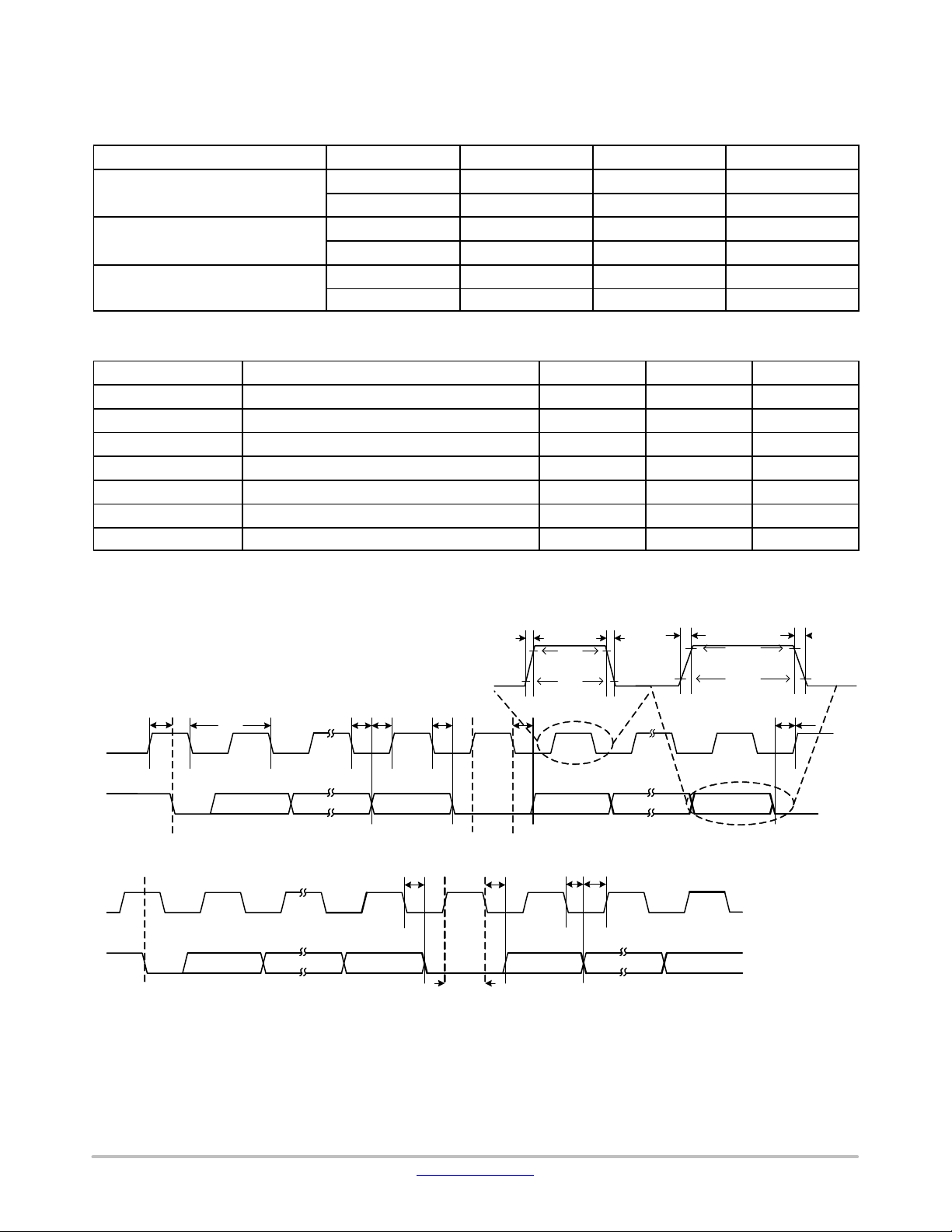

Table 15. TWO−WIRE SERIAL BUS CHARACTERISTICS

f

= 27 MHz; VDD = 1.8 V; VDD_IO = 2.8 V; VAA = 2.8 V; VAA_PIX = 2.8 V; VDD_PLL = 2.8 V; TA = 25°C

EXTCLK

Standard Mode Fast Mode

Parameter

SCLK Clock Frequency f

Symbol

SCL

Hold time (repeated) START condition

After this period, the first clock pulse is

generated

LOW period of the SCLK clock t

t

HD;STA

LOW

HIGH period of the SCLK clock tHIGH 4.0 − 0.6 −

Set−up time for a repeated START condi-

tSU;STA 4.7 − 0.6 −

tion

Data hold time tHD;DAT 0

Data set−up time tSU;DAT 250 − 100

Rise time of both SDATA and SCLK signals tr − 1000 20 + 0.1Cb

Fall time of both SDATA and SCLK signals tf − 300 20 + 0.1Cb

Set−up time for STOP condition tSU;STO 4.0 − 0.6 − ?s

Bus free time between a STOP and START

tBUF 4.7 − 1.3 − ?s

condition

Capacitive load for each bus line Cb − 400 − 400 pF

Serial interface input pin capacitance C

SDATA max load capacitance C

IN_SI

LOAD_SD

SDATA pull−up resistor RSD 1.5 4.7 1.5 4.7 K?

32.This table is based on I2C standard (v2.1 January 2000). Philips Semiconductor.

33.Two−wire control is I

34.All values referred to V

35. A device must internally provide a hold time of at least 300 ns for the S

36.The maximum

37.A Fast−mode I

2

C−compatible.

= 0.9 VDD and V

IHmin

t

HD;DAT has only to be met if the device does not stretch the LOW period (tLOW) of the SCLK signal.

2

C−bus device can be used in a Standard−mode I2C−bus system, but the requirement tSU; DAT 250 ns must then be met.

= 0.1VDD levels. Sensor EXCLK = 27 MHz.

ILmax

This will automatically be the case if the device does not stretch the LOW period of the S

period of the S

Standard−mode I

CLK signal, it must output the next data bit to the SDATA line

2

C−bus specification) before the SCLK line is released.

38.Cb = total capacitance of one bus line in pF.

Min Max Min Max

0 100 0 400 KHz

4.0 − 0.6 −

4.7 − 1.3 −

4

3.45

5

6

0

6

7

7

5

0.9

− ns

300 ns

300 ns

− 3.3 − 3.3 pF

− 30 − 30 pF

DATA signal to bridge the undefined region of the falling edge of SCLK.

t

r max + tSU;DAT = 1000 + 250 = 1250 ns (according to the

CLK signal. If such a device does stretch the LOW

Unit

ms

ms

ms

ms

ms

Table 16. I/O PARAMETERS

f

EXTCLK = 24 MHz; VDD = 1.8V; VAA = 2.8 V; VAA_PIX = 2.8 V; VDD_PLL = 2.8 V; Output load = 68.5 pF; TJ = 60°C; CLK_OP = 98 MPixel/s

Symbol Definition Conditions Min Max Units

VIH Input HIGH voltage

VDD_IO = 1.8 V 1.4

VDD_IO + 0.3

VDD_IO = 2.8 V 2.4

VIL Input LOW voltage

VDD_IO = 1.8 V GND – 0.3 0.4

VDD_IO = 2.8 V GND – 0.3 0.8

IIN Input leakage current No pull−up resistor; VIN = VDD OR DGND –20 20

VOH Output HIGH voltage At specified IOH VDD_IO − 0.4V – V

VOL Output LOW voltage At specified IOL – 0.4 V

IOH Output HIGH current At specified VOH – –12 mA

IOL Output LOW current At specified VOL – 9 mA

IOZ Tri−state output leakage current – 10

www.onsemi.com

13

V

mA

mA

Page 14

AR0330CS

t

EXTCLK

t

R

90 %

10 %

t

F

t

RP

90 %

10 %

t

FP

EXTCLK

t

CP

PIXCLK

t

PD

FRAME_VALID trails

LINE_VALID by 16 PIXCLKs.

Data[11:0]

AME_VALID/

LINE_VALID

*PLL disabled for

t

t

CP

PD

Pxl _ 0 Pxl _ 1 Pxl _ 2 Pxl _ n

t

PFH

t

PLH

FRAME_VALID leads LINE_VALID by 609 PIXCLKs.

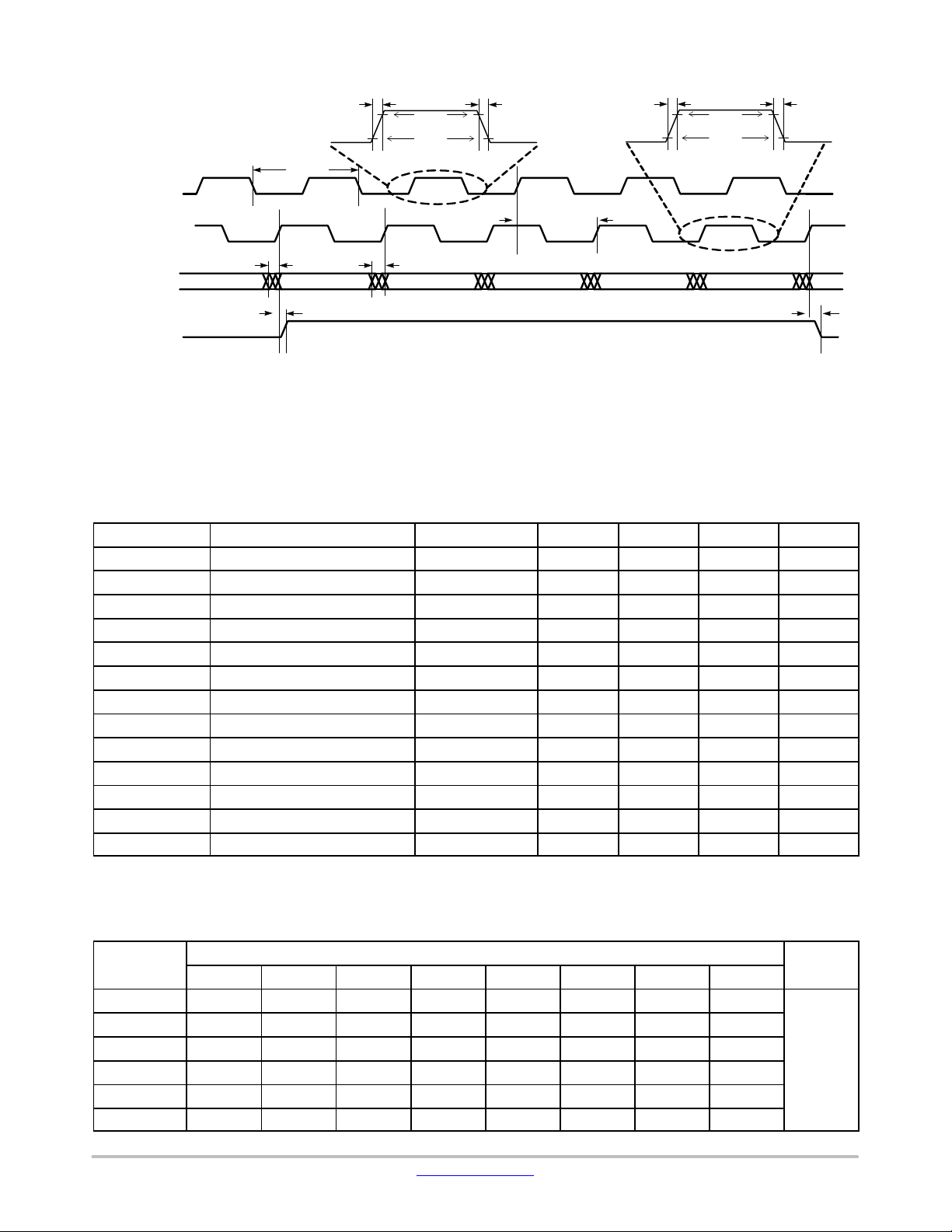

Figure 8. I/O Timing Diagram (Parallel Mode)

Table 17. I/O TIMING

f

EXTCLK = 24 MHz; VDD = 1.8 V; VDD_IO = 1.8 V; VAA = 2.8 V; VAA_PIX = 2.8 V; VDD_PLL = 2.8 V;

Output load = 68.5 pF; T

Symbol

fEXTCLK Input clock frequency PLL enabled 6 24 27 MHz

tEXTCLK Input clock period PLL enabled 166 41 20 ns

tR Input clock rise time 0.1 – 1 V/ns

tF Input clock fall time 0.1 – 1 V/ns

Clock duty cycle 45 50 55 %

tJITTER Input clock jitter – – 0.3 ns

Output pin slew Fastest CLOAD = 15 pF – 0.7 – V/ns

fPIXCLK PIXCLK frequency Default – 80 – MHz

tPD PIXCLK to data valid Default – – 3 ns

tPFH PIXCLK to FRAME_VALID HIGH Default – – 3 ns

tPLH PIXCLK to LINE_VALID HIGH Default – – 3 ns

tPFL PIXCLK to FRAME_VALID LOW Default – – 3 ns

tPLL PIXCLK to LINE_VALID LOW Default – – 3 ns

= 60°C; CLK_OP = 98 MPixel/s

J

Definition Conditions Min Typ Max Units

t

PFL

t

PLL

Table 18. PARALLEL I/O RISE SLEW RATE

f

EXTCLK = 24 MHz; VDD = 1.8 V; VAA = 2.8 V; VAA_PIX = 2.8 V; VDD_PLL = 2.8 V; Output load = 68.5 pF;

= 60°C; CLK_OP = 98 MPixel/s

T

J

Parallel Slew Rate (R0x306E[15:13])

V

DD_IO

0 1 2 3 4 5 6 7

1.70V 0.069 0.115 0.172 0.239 0.325 0.43 0.558 0.836

1.80V 0.078 0.131 0.195 0.276 0.375 0.507 0.667 1.018

1.95V 0.093 0.156 0.233 0.331 0.456 0.62 0.839 1.283

2.50V 0.15 0.252 0.377 0.539 0.759 1.07 1.531 2.666

2.80V 0.181 0.305 0.458 0.659 0.936 1.347 1.917 3.497

3.10V 0.212 0.361 0.543 0.78 1.114 1.618 2.349 4.14

www.onsemi.com

14

Units

V/ns

Page 15

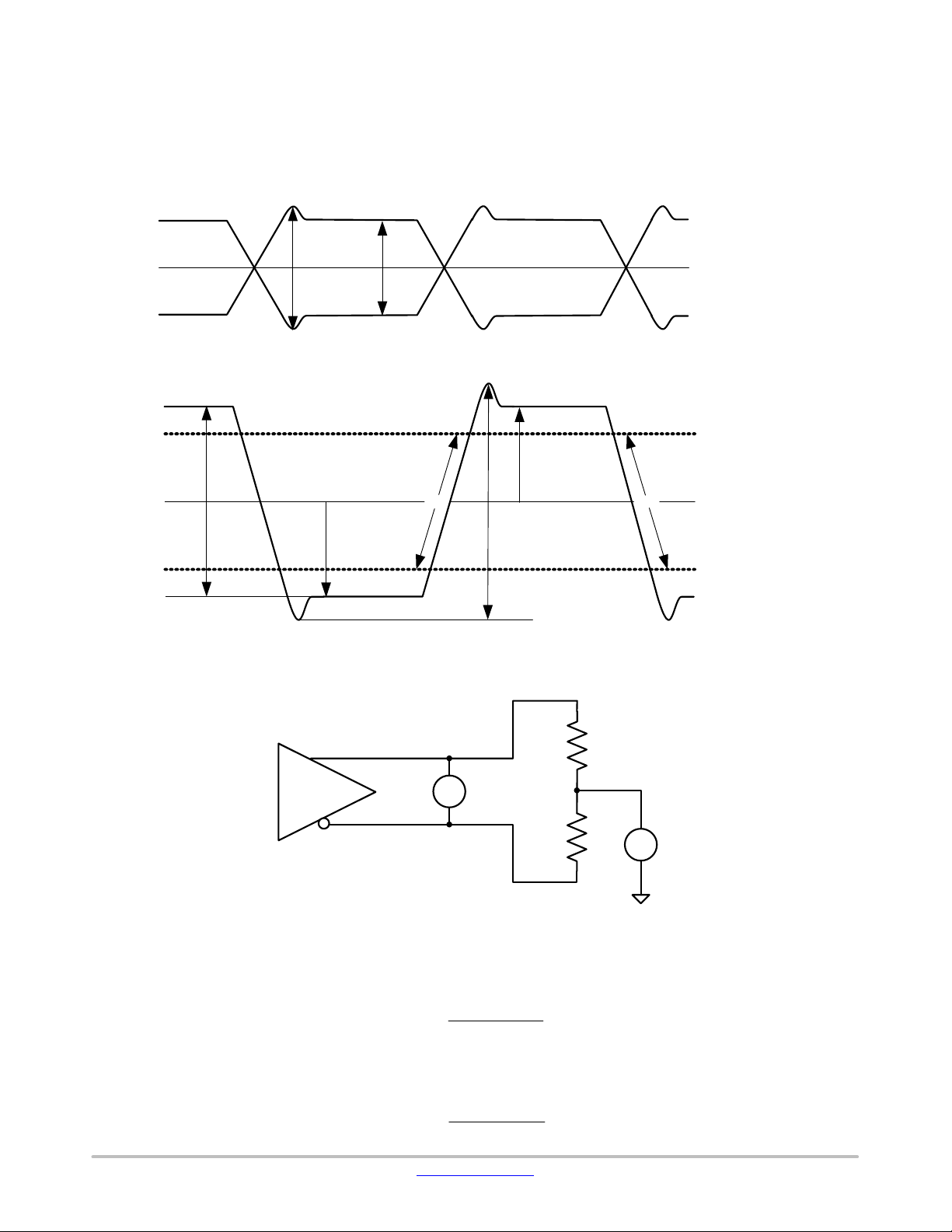

ELECTRICAL DEFINITIONS

Figure 9 is the diagram defining differential amplitude

V

, V

OD

V

CM

Single−ended signal

and rise and fall times. To measure VOD and

CM,

use the DC test circuit shown in Figure 10 and set the

V

o a

V

V

o b

Differential signal

0 V

O D_ A C

V

diff

V

OD

|V

o b

V

O D

=

– V

|

o a

AR0330CS

MIPI PHY to constant Logic 1 and Logic 0. Measure V

V

and VCM with voltmeters for both Logic 1 and Logic 0.

ob

R

t

V

diff

V

O D

|V

o a

_ pkpk

– V

,

oa

V

= (V

C M

8 0%

=

|

o b

t

F

2 0%

o a

+ V

o b

) / 2

Figure 9. Single−Ended and Differential Signals

V

o a

V

V

o b

5 0 Ω

5 0 Ω

V

C M

V

Figure 10. DC Test Circuit

VOD(m) +ŤVoa(m) * Vob(m)Ťwhere ȀmȀ is either ″ 1″ for logic 1 or ″ 0″ for logic 0

V

(1) ) VOD(0)

OD

+

V

OD

V

+ VOD(1) ) VOD(0)

diff

DVOD+ŤVOD(1) * VOD(0)

2

Ť

(eq. 1)

(eq. 2)

(eq. 3)

(eq. 4)

V

(1) ) VCM(0)

CM

+

V

CM

2

www.onsemi.com

15

(eq. 5)

Page 16

AR0330CS

DV

CM

Both VOD and VCM are measured for all output channels.

The worst case

V

between all channels regardless of logic level. And the

OD

worst case

difference in V

DV

is defined as the largest difference in

OD

DV

is similarly defined as the largest

CM

between all channels regardless of logic

CM

level.

Timing Definitions

1. Timing measurements are to be taken using the

Square Wave test mode

2. Rise and fall times are measured between 20% to

80% positions on the differential waveform, as

t

pw

Clock

Data

1 UI

0.5 UI

t

+ŤVCM(1) * VCM(0)

3. Mean Clock−to−Data skew should be measured

t

CHSKEW

Ť

(eq. 6)

shown in Figure 9: “Single−Ended and Differential

Signals”

from the 0V crossing point on Clock to the 0V

crossing point on any Data channel regardless of

edge, as shown in Figure 11. This time is

compared with the ideal Data transition point of

0.5UI with the difference being the Clock−to−Data

Skew (see Equation 7)

Figure 11. Clock−to−Data Skew Timing Diagram

t

t

4. The differential skew is measured on the two

single−ended signals for any channel. The time is

taken from a transition on V

Common−mode AC Signal

signal to

oa

V

CHSKEW

CHSKEW

CM_AC

(ps) + Dt *

Dt

(UI) +

t

pw

t

pw

2

* 0.5

corresponding transition on V

crossing point

t

DIFFSKEW

V

CM_AC

(eq. 7)

(eq. 8)

signal at V

ob

V

CM

V

CM

CM

Figure 12. Differential Skew

www.onsemi.com

16

Page 17

AR0330CS

Figure 12 also shows the corresponding AC V

CM

common−mode signal. Differential skew between the V

and Vob signals can cause spikes in the common−mode,

which the receiver needs to be able to reject. V

1.3 * V

OD

V

OD

0.7 * V

OD

0

Differential Amplitude

*0.7 * V

OD

*V

OD

*1.3 * V

OD

t

CM_AC

PRE

is

oa

Eye Width

measured as the absolute peak deviation from the mean DC

V

common−mode.

CM

Transmitter Eye Mask

Eye Height

t

POST

0 0.2 0.37 0.5 0.63 10.8

Normalized Time

Figure 13. Transmitter Eye Mask

Figure 13 defines the eye mask for the transmitter. 0.5 UI

point is the instantaneous crossing point of the Clock. The

area in white shows the area Data is prohibited from crossing

into. The eye mask also defines the minimum eye height, the

data t

skew (t

and t

pre

TJSKEW

times, and the total jitter pk−pk +mean

post

) for Data.

Clock

Figure 14. Clock Duty Cycle

t

HCLK

D

CYC

D

CYC

t

+

pw

Bitrate +

Clock Signal

t

is defined as the high clock period, and t

HCLK

defined as the low clock period as shown in Figure 14. The

clock duty cycle D

clock is either high (t

is defined as the percentage time the

CYC

HCLK

) or low (t

) compared with

LCLK

the clock period T.

t

LCLK

t

HCLK

(1) +

T

t

LCLK

(0) +

T

T

(i.e, 1 UI)

2

1

t

pw

LCLK

(eq. 9)

(eq. 10)

(eq. 11)

(eq. 12)

is

www.onsemi.com

17

Page 18

Figure 15 shows the definition of clock jitter for both the

period and the cycle−to−cycle jitter.

AR0330CS

t

HCLK

t

pw

Figure 15. Clock Jitter

Period Jitter (t

instantaneous clock t

measured for both the clock high period variation

and the clock low period variation Dt

) is defined as the deviation of the

CKJIT

from an ideal 1UI. This should be

PW

taking the RMS

LCLK

Dt

HCLK,

SEQUENCER

The sequencer digital block determines the order and

timing of operations required to sample pixel data from the

array during each row period. It is controlled by an

instruction set that is programmed into RAM from the

sensor OTPM (One Time Programmable Memory). The

OTPM is configured during production.

The instruction set determines the length of the sequencer

operation that determines the “ADC Readout Limitation”

(Equation 5) listed in the Sensor Frame−Rate section. The

instruction set can be shortened through register writes in

order to achieve faster frame rates. Instructions for

shortening the sequencer can be found in the AR0330CS

Developer Guide.

The sequencer digital block can be reprogrammed using

the following instructions:

t

LCLK

(RMS)

t

CKJIT

or 1−sigma standard deviation and quoting the worse case

jitter between

Dt

HCLK

and Dt

LCLK

.

If pk−pk jitter is also measured, this should be limited to

±3−sigma.

Program a new sequencer.

1. Place the sensor in standby

2. Write 0x8000 to R0x3088 (“seq_ctrl_port”)

3. Write each instruction incrementally to R0x3086

Each write must be 16−bit consisting of two bytes

{Byte[N], Byte[N+1]}

4. If the sequencer consists of an odd number of

bytes, set the last byte to “0”

Read the instructions stored in the sequencer.

1. Place the sensor in standby

2. Write 0xC000 to R0x3088 (“seq_ctrl_port”)

3. Sequentially read 2−bytes at a time from R0x3086

www.onsemi.com

18

Page 19

SENSOR PLL

VCO

AR0330CS

EXTCLK

(6−27 MHz)

pre_pll_clk_div

2 (1−64)

Figure 16. Relationship Between Readout Clock and Peak Pixel Rate

The sensor contains a phase−locked loop (PLL) that is

used for timing generation and control. The required VCO

clock frequency is attained through the use of a pre−PLL

clock divider followed by a multiplier. The multiplier is

followed by set of dividers used to generate the output clocks

CLK_PIX

All Digital

Blocks

Pixel Array

pll_multiplier

58 (32−384)

required for the sensor array, the pixel analog and digital

readout paths, and the output parallel and serial interfaces.

Dual Readout Paths

There are two readout paths within the sensor digital

block.

S erial Output

(MIPI or Parallel)

Pixel Rate = 2 x CLK_PIX

= # data lanes x CLK_OP

(Parallel or MIPI)

= CLK_OP (Parallel)

F

VCO

All Digital

Blocks

CLK_PIX

Figure 17. Sensor Dual Readout Paths

The sensor row time calculations refers to each data−path

individually. For example, the sensor default configuration

uses 1248 clocks per row (line_length_pck) to output 2304

F

V C O

E X T C L K

( 6−27 MHz)

pre_pll_clk_div

2 (1−64)

pll_multiplier

58 (32 − 384)

Figure 18. PLL for the Parallel Interface

active pixels per row. The aggregate clocks per row seen by

the receiver will be 2496 clocks (1248 x 2 readout paths).

Parallel PLL Configuration

vt_sys_clk_div

1 ( 1, 2, 4, 6, 8,

10, 12, 14, 16)

vt_pix_clk_div

6 (4−16)

1/2

CLK_OP

(Max 98 MPixel/s)

CLK_PIX

(Max 49 MPixels/s)

www.onsemi.com

19

Page 20

AR0330CS

The maximum output of the parallel interface is 98

Mpixel/s (CLK_OP). This will limit the readout clock

(CLK_PIX) to 49 MHz. The sensor will not use the F

F

SERIAL_CLK

when configured to use the parallel interface.

Table 19. PLL PARAMETERS FOR THE PARALLEL INTERFACE

Parameter Symbol Min Max Unit

External Clock EXTCLK 6 27 MHz

VCO Clock F

VCO

384 768 MHz

Readout Clock CLK_PIX 49 MHz

Output Clock CLK_OP 98 Mpixel/s

Table 20. EXAMPLE PLL CONFIGURATION FOR THE PARALLEL INTERFACE

Parameter Value Output

F

VCO

588 MHz (Max)

vt_sys_clk_div 1

vt_pix_clk_div 6

CLK_PIX 49 MHz (CLK_OP/2)

CLK_OP 98 Mpixel/s (= 588 MHz / 6)

Output pixel rate 98 MPixel/s

Serial PLL Configuration

SERIAL

,

E X T C L K

( 6−27 MHz)

pre_pll_clk_div

2 (1−64)

pll_multiplier

58 (32 − 384)

Figure 19. PLL for the Serial Interface

The sensor will use op_sys_clk_div and op_pix_clk_div

to configure the output clock per lane (CLK_OP). The

configuration will depend on the number of active lanes (1

F

F

V C O

V C O

vt_sys_clk_div

1 ( 1, 2, 4, 6, 8,

10, 12, 14, 16)

op_sys_clk_div

(constant = 1)

vt_pix_clk_div

6 (4−16)

op_pix_clk_div

12 (8, 10, 12)

1/2

F

or 2) configured. To configure the sensor protocol and

number of lanes, refer to “Serial Configuration”.

C L K_P IX

C L K _O P

F

S E R IA L

S E R IA L _C L K

www.onsemi.com

20

Page 21

AR0330CS

Table 21. PLL PARAMETERS FOR THE SERIAL INTERFACE

Parameter Symbol Min Max Unit

External Clock EXTCLK 6 27 MHz

VCO Clock F

Readout Clock CLK_PIX 98 MHz

Output Clock CLK_OP 98 Mpixel/s

Output Serial Data Rate Per Lane

Output Serial Clock Speed Per Lane

VCO

F

SERIAL

F

SERIAL_CLK

384 768 MHz

384 (MIPI) 768 (MIPI) Mbps

192 (MIPI) 384 (MIPI) MHz

The serial output should be configured so that it adheres

to the following rules:

• The maximum data−rate per lane (F

SERIAL

) is

768 Mbps/lane (MIPI)

• The output pixel rate per lane (CLK_OP) should be

configured so that the sensor output pixel rate matches

the peak pixel rate (2 x CLK_PIX)

♦ 2−lane: 2 x CLK_OP = 2 x CLK_PIX = Pixel Rate

♦ 1−lane: 1 x CLK_OP = 2 x CLK_PIX = Pixel Rate

Table 22. EXAMPLE PLL CONFIGURATIONS FOR THE SERIAL INTERFACE

2−lane 1−lane

Parameter

F

VCO

vt_sys_clk_div 2 2 4 4 4

vt_pix_clk_div 6 5 6 5 4

op_sys_clk_div 1 1 1 1 1

op_pix_clk_div 12 10 12 10 8

F

SERIAL

F

SERIAL_CLK

CLK_PIX 64 76 32 38.4 48 MHz

CLK_OP 64 76 64 76.8 96 Mpixel/s

Pixel Rate 128 144 64 76.8 96 Mpixel/s

12−bit 10−bit 12−bit 10−bit 8−bit

768 760 768 768 768 MHz

768 760 768 768 768 MHz

384 380 384 384 384 MHz

Notes

PIXEL OUTPUT INTERFACES

Parallel Interface

The parallel pixel data interface uses these output−only

signals:

• FV

• LV

• PIXCLK

• DOUT[11:0]

The parallel pixel data interface is disabled by default at

power up and after reset. It can be enabled by programming

R0x301A. Table 24 shows the recommended settings.

www.onsemi.com

When the parallel pixel data interface is in use, the serial

data output signals can be left unconnected. Set

reset_register[12] to disable the serializer while in parallel

output mode.

Output Enable Control

When the parallel pixel data interface is enabled, its

signals can be switched asynchronously between the driven

and High−Z under pin or register control, as shown in

Table 23.

21

Page 22

AR0330CS

Table 23. OUTPUT ENABLE CONTROL

OE_BAR Pin Drive Signals R0x301A–B[6] Description

Disabled 0 Interface High−Z

Disabled 1 Interface driven

1 0 Interface High−Z

X 1 Interface driven

0 X Interface driven

Configuration of the Pixel Data Interface

Fields in R0x301A are used to configure the operation of

the pixel data interface. The supported combinations are

shown in Table 23.

Table 24. CONFIGURATION OF THE PIXEL DATA INTERFACE

Serializer

Disable

R0x301

A–B[12]

0 0 1 Power up default.

1 1 0 Parallel pixel data interface, sensor core data output. Serial pixel data interface

1 1 1 Parallel pixel data interface, sensor core data output. Serial pixel data interface

Parallel

Enable

R0x301A–B[7]

Standby

End−of−Frame

R0x301A–B[4]

Description

Serial pixel data interface and its clocks are enabled. Transitions to soft

standby are synchronized to the end of frames on the serial pixel data

interface

and its clocks disabled to save power. Transitions to soft standby are

synchronized to the end of the current row readout on the parallel pixel data

interface

and its clocks disabled to save power. Transitions to soft standby are

synchronized to the end of frames in the parallel pixel data interface

MIPI Interface

The serial pixel data interface uses the following

output−only signal pairs:

• DATA1_P

• DATA1_N

• DATA2_P

• DATA2_N

• CLK_P

• CLK_N

The signal pairs use both single−ended and differential

signaling, in accordance with the the MIPI Alliance

Specification for D−PHY v1.00.00. The serial pixel data

interface is enabled by default at power up and after reset.

The DATA0_P, DATA0_N, DATA1_P, DATA1_N,

CLK_P and CLK_N pads are set to the Ultra Low Power

State (ULPS) if the serial disable bit is asserted

(R0x301A−B[12] = 1) or when the sensor is in the hardware

standby or soft standby system states.

When the serial pixel data interface is used, the

LINE_VALID, FRAME_VALID, PIXCLK and

D

OUT[11:0] signals (if present) can be left unconnected.

Serial Configuration

The serial format should be configured using R0x31AC.

This register should be programmed to 0x0C0C when using

the parallel interface.

The R0x0112−3 register can be programmed to any of the

following data format settings that are supported:

• 0x0C0C – Sensor supports RAW12 uncompressed data

format

• 0x0C0A – The sensor supports RAW12 compressed

format (10−bit words) using 12−10 bit A−LAW

Compression. See “Compression”

• 0x0A0A – Sensor supports RAW10 uncompressed data

format. This mode is supported by discarding all but the

upper 10 bits of a pixel value

• 0x0808 – Sensor supports RAW8 uncompressed data

format. This mode is supported by discarding all but the

upper 8 bits of a pixel value (MIPI only)

The serial_format register (R0x31AE) register controls

which serial interface is in use when the serial interface is

www.onsemi.com

22

Page 23

AR0330CS

enabled (reset_register[12] = 0). The following serial

formats are supported:

• 0x0201 – Sensor supports single−lane MIPI operation

• 0x0202 – Sensor supports dual−lane MIPI operation

The MIPI timing registers must be configured differently

for 10−bit or 12−bit modes. These modes should be

configured when the sensor streaming is disabled. See

Table 25.

• 0x0A0A – Sensor supports RAW10 uncompressed data

format. This mode is supported by discarding all but the

upper 10 bits of a pixel value

• 0x0808 – Sensor supports RAW8 uncompressed data

format. This mode is supported by discarding all but the

upper 8 bits of a pixel value (MIPI only)

Table 25. RECOMMENDED MIPI TIMING CONFIGURATION

Configuration

10−bit, 490 Mbps/lane 12−bit, 588 Mbps/lane

Register

0x31B0 40 36 Frame Preamble

0x31B2 14 12 Line Preamble

0x31B4 0x2743 0x2643 MIPI Timing 0

0x31B6 0x114E 0x114E MIPI Timing 1

0x31B8 0x2049 0x2048 MIPI Timing 2

0x31BA 0x0186 0x0186 MIPI Timing 3

0x31BC 0x8005 0x8005 MIPI Timing 4

0x31BE 0x2003 0x2003 MIPI Config Status

Clocking: Continuous

The serial_format register (R0x31AE) register controls

which serial interface is in use when the serial interface is

enabled (reset_register[12] = 0). The following serial

formats are supported:

• 0x0201 – Sensor supports single−lane MIPI operation

• 0x0202 – Sensor supports dual−lane MIPI operation

The MIPI timing registers must be configured differently

for 10−bit or 12−bit modes. These modes should be

configured when the sensor streaming is disabled. See

Table 25.

Description

PIXEL SENSITIVITY

Row Integration

Row Reset

(Start of integration)

Figure 20. Integration Control in ERS Readout

A pixel’s integration time is defined by the number of

clock periods between a row’s reset and read operation. Both

the read followed by the reset operations occur within a row

period (T

) where the read and reset may be applied to

ROW

different rows. The read and reset operations will be applied

to the rows of the pixel array in a consecutive order.

The integration time in an ERS frame is defined as:

(T

INTEGRATION

)

Row Readout

T

INTEGRATION

+ T

COARSE

* T

FINE

The coarse integration time is defined by the number of

row periods (T

) between a row’s reset and the row read.

ROW

The row period is the defined as the time between row read

operations (see Sensor Frame Rate).

T

COARSE

+ T

coarse_inegration_time

ROW

(eq. 13)

(eq. 14)

www.onsemi.com

23

Page 24

AR0330CS

Vertical Blanking

T

COARSE

8.33 ms = 654 rows x 12.7 ms/row

= coarse_integration_time x T

ROW

Read

Reset

Horizontal Blanking

Figure 21. Example of 8.33 ms Integration in 16.6 ms Frame

The fine integration is then defined by the number of pixel

clock periods between the row reset and row read operation

Start of Read Row N

and Reset Row K

Read Row N Reset Row K

T

= fine_integration _time x (1/CLK_PIX)

FINE

T

= line_length _pck x (1/CLK_PIX)

ROW

Vertical Blanking

within T

. This period is defined by the

ROW

fine_integration_time register.

T

= frame_length_lines x T

FRAME

16.6 ms = 1308 rows x 12.7 ms/row

Time

Start of Read Row N + 1

and Reset Row K + 1

ROW

Figure 22. Row Read and Row Reset Showing Fine Integration

T

+ fine_inegration_timeńclk_pix

FINE

The maximum allowed value for fine_integration_time is

line_length_pck − 1204.

T

= coarse_integration_time x T

COARSE ROW

20.7 ms = 1634 rows x 12.7 ms/row

Time

Read

Pointer

Shutter

Pointer

ON Semiconductor recommends that the

fine_integration_time in the AR0330CS be left at zero.

Vertical Blanking

Image

Horizontal Blanking

Vertical Blanking

Extended Vertical Blanking

Image

(eq. 15)

= frame_length_lines x T

T

FRAME

16.6 ms = 1308 rows x 12.7 ms/row

4.1 ms

ROW

Horizontal Blanking

Figure 23. The Row Integration Time is Greater Than the Frame Readout Time

www.onsemi.com

24

Page 25

AR0330CS

The minimum frame−time is defined by the number of

row periods per frame and the row period. The sensor

frame−time will increase if the coarse_integration_time is

set to a value equal to or greater than the frame_length_lines.

The maximum integration time can be limited to the frame

time by setting R0x30CE[5] to 1.

www.onsemi.com

25

Page 26

AR0330CS

GAIN STAGES

The analog gain stages of the AR0330CS sensor are

shown in Figure 24. The sensor analog gain stage consists of

column amplifiers and a variable ADC reference. The sensor

will apply the same analog gain to each color channel.

Digital gain can be configured to separate levels for each

color channel.

ADC

Reference

Coarse Gain:

1x, 2x, 4x, 8x

Fine Gain:

1−2x: 16 steps

2−4x: 8 steps

4−8x: 4 steps

Digital Gain

with Dithering

1x to 15.992x

(128 steps per 6dB)

“xxxx.Yyyy”

xxxx(15−0)

yyyyyyy( 127/128 to 0)

Figure 24. Gain Stages in AR0330CS Sensor

The level of analog gain applied is controlled by the

coarse_gain and fine_gain registers. The analog readout can

be configured differently for each gain level. The

recommended gain tables are listed in Table 26. It is

recommended that these registers are configured before

streaming images.

Table 26. RECOMMENDED SENSOR ANALOG GAIN TABLES

COARSE_GAIN FINE_GAIN Total Gain COARSE_GAIN FINE_GAIN Total Gain

R0x3060

[5:4]

0 1 0 1.00 1.00 0.00 0 1x 15 1.88 1.88 5.49

0 1 1 1.03 1.03 0.26 1 2x 0 1.00 2.00 6.00

0 1 2 1.07 1.07 0.56 1 2x 2 1.07 2.13 6.58

0 1 3 1.10 1.10 0.86 1 2x 4 1.14 2.29 7.18

0 1 4 1.14 1.14 1.16 1 2x 6 1.23 2.46 7.82

0 1 5 1.19 1.19 1.46 1 2x 8 1.33 2.67 8.52

0 1 6 1.23 1.23 1.80 1 2x 10 1.45 2.91 9.28

0 1 7 1.28 1.28 2.14 1 2x 12 1.60 3.20 10.10

0 1 8 1.33 1.33 2.50 1 2x 14 1.78 3.56 11.02

0 1 9 1.39 1.39 2.87 2 4x 0 1.00 4.00 12.00

0 1 10 1.45 1.45 3.25 2 4x 4 1.14 4.57 13.20

0 1 11 1.52 1.52 3.66 2 4x 8 1.33 5.33 14.54

0 1 12 1.60 1.60 4.08 2 4x 12 1.60 6.40 16.12

0 1 13 1.68 1.68 4.53 3 8x 0 1.00 8.00 18.00

0 1 14 1.78 1.78 5.00

Gain

(x)

R0x3060[3:0]

Gain

(x)

(x) (dB) R0x3060 [5:4]

Gain

(x)

R0x3060

[3:0]

Gain

(x)

(x) (dB)

Each digital gain can be configured from a gain of 0 to

15.992. The digital gain supports 128 gain steps per 6dB of

gain. The format of each digital gain register is

“xxxx.yyyyyyy” where “xxxx” refers an integer gain of 1 to

15 and “yyyyyyy” is a fractional gain ranging from 0/128 to

127/128.

www.onsemi.com

The sensor includes a digital dithering feature to reduce

quantization resulting from using digital gain can be

implemented by setting R0x30BA[5] to 1. The default value

is 0. Refer to “Real−Time Context Switching” for the analog

and digital gain registers in both context A and context B

modes.

26

Page 27

AR0330CS

Refer to “Real−Time Context Switching” for the analog

and digital gain registers in both context A and context B

modes.

www.onsemi.com

27

Page 28

AR0330CS

DATA PEDESTAL

The data pedestal is a constant offset that is added to pixel

values at the end of datapath. The default offset is 168 and

is a 12−bit offset. This offset matches the maximum range

used by the corrections in the digital readout path.

SENSOR READOUT

Image Acquisition Modes

The AR0330CS supports two image acquisition modes:

1. Electronic rolling shutter (ERS) mode

This is the normal mode of operation. When the

AR0330CS is streaming; it generates frames at a

fixed rate, and each frame is integrated (exposed)

using the ERS. When the ERS is in use, timing

and control logic within the sensor sequences

through the rows of the array, resetting and then

reading each row in turn. In the time interval

between resetting a row and subsequently reading

that row, the pixels in the row integrate incident

light. The integration (exposure) time is controlled

by varying the time between row reset and row

readout. For each row in a frame, the time between

row reset and row readout is the same, leading to a

uniform integration time across the frame. When

the integration time is changed (by using the

two−wire serial interface to change register

settings), the timing and control logic controls the

transition from old to new integration time in such

a way that the stream of output frames from the

AR0330CS switches cleanly from the old

integration time to the new while only generating

frames with uniform integration. See “Changes to

The data pedestal value can be changed if the lock register

bit (R0x301A[3]) is set to “0”. This bit is set to “1” by

default.

Integration Time” in the AR0330CS Register

Reference

2. Global reset mode

This mode can be used to acquire a single image at

the current resolution. In this mode, the end point

of the pixel integration time is controlled by an

external electromechanical shutter, and the

AR0330CS provides control signals to interface to

that shutter.

The benefit of using an external electromechanical

shutter is that it eliminates the visual artifacts

associated with ERS operation. Visual artifacts

arise in ERS operation, particularly at low frame

rates, because an ERS image effectively integrates

each row of the pixel array at a different point in

time

Window Control

The sequencing of the pixel array is controlled by the

x_addr_start, y_addr_start, x_addr_end, and y_addr_end

registers. The x_addr_start equal to 6 is the minimum setting

value. The y_addr_start equal to 6 is the minimum setting

value. Please refer to Table 27 and Table 28 for details.

Table 27. PIXEL COLUMN CONFIGURATION

Column Address Number Type Notes

0–5 6 Active Border columns

6–2309 2304 Active Active columns

2310–2315 6 Active Border columns

Table 28. PIXEL ROW CONFIGURATION

Row Address Number Type Notes

2–5 4 Active Not used in case of “edge effects”

6–1549 1544 Active Active rows

1550–1555 6 Active Not used in case of “edge effects”

www.onsemi.com

28

Page 29

AR0330CS

Readout Modes

Horizontal Mirror

When the horizontal_mirror bit (R0x3040[14]) is set in

the image_orientation register, the order of pixel readout

within a row is reversed, so that readout starts from

x_addr_end + 1and ends at x_addr_start. Figure 25 shows a

LINE_VALID

sequence of 6 pixels being read out with R0x3040[14] = 0

and R0x3040[14] = 1. Changing R0x3040[14] causes the

Bayer order of the output image to change; the new Bayer

order is reflected in the value of the pixel_order register.

horizontal_mirror = 0

[11:0]

D

OUT

horizontal_mirror = 1

[11:0]

D

OUT

Figure 25. Effect of Horizontal Mirror on Readout Order

G0[11:0] R0[11:0] G1[11:0] R1[11:0] G2[11:0] R2[11:0]

G3[11:0] R2[11:0] G2[11:0] R1[11:0] G1[11:0] R0[11:0]

Vertical Flip

When the vertical_flip bit (R0x3040[15]) is set in the

image_orientation register, the order in which pixel rows are

read out is reversed, so that row readout starts from

y_addr_end and ends at y_addr_start. Figure 30 shows a

FRAME_VALID

vertical_flip = 0

DOUT[11:0]

vertical_flip = 1

DOUT[11:0]

Row0[11:0] Row1[11:0] Row2[11:0] Row3[11:0] Row4[11:0] Row5[11:0]

Row6[11:0] Row5[11:0] Row4[11:0] Row3[11:0] Row2[11:0] Row1[11:0]

Figure 26. Effect of Vertical Flip on Readout Order

sequence of 6 rows being read out with R0x3040[15] = 0 and

R0x3040[15] = 1. Changing this bit causes the Bayer order

of the output image to change; the new Bayer order is

reflected in the value of the pixel_order register.

SUBSAMPLING

The AR0330CS supports subsampling. Subsampling

allows the sensor to read out a smaller set of active pixels by

either skipping or binning pixels within the readout window.

Isb

Isb

Figure 27. Horizontal Binning in the AR0330CS Sensor

Horizontal binning is achieved either in the pixel readout

or the digital readout. The sensor will sample the combined

2x or 3x adjacent pixels within the same color plane.

www.onsemi.com

The working modes described in the data sheet that use

subsampling are configured to use either 2x2 or 3x3

subsampling.

29

Page 30

AR0330CS

*

e

*

e

Figure 28. Vertical Row Binning in the AR0330CS Sensor

Vertical row binning is applied in the pixel readout. Row

binning can be configured of 2x rows within the same color

plane.

Pixel skipping can be configured up to 2x and 3x in both

the x−direction and y−direction. Skipping pixels in the

x−direction will not reduce the row time. Skipping pixels in

the y−direction will reduce the number of rows from the

sensor effectively reducing the frame time. Skipping will

introduce image artifacts from aliasing.

The sensor increments its x and y address based on the

x_odd_inc and y_odd_inc value. The value indicates the

addresses that are skipped after each pair of pixels or rows

has been read.

The sensor will increment x and y addresses in multiples

of 2. This indicates that a GreenR and Red pixel pair will be

Table 29. CONFIGURATION FOR HORIZONTAL SUBSAMPLING

x_odd_inc Restrictions:

No subsampling x_odd_inc = 1

skip = (1 + 1) × 0.5 = 1x

Skip 2x x_odd_inc = 3

skip = (1 + 3) × 0.5 = 2x

Skip 3x x_odd_inc = 5

skip = (1 + 5) × 0.5 = 3x

Analog Bin 2x x_odd_inc = 3

skip = (1 + 3) × 0.5 = 2x

col_sf_bin_en = 1

The horizontal FOV must be programmed to meet the following rule:

read together. As well, that the sensor will read a Gr−R row

first followed by a B−Gb row.

x subsampling factor +

y subsampling factor +

1 ) x_odd_inc

2

1 ) y_odd_inc

2

(eq. 16)

(eq. 17)

A value of 1 is used for x_odd_inc and y_odd_inc when

no pixel subsampling is indicated. In this case, the sensor is

incrementing x and y addresses by 1 + 1 so that it reads

consecutive pixel and row pairs. To implement a 2x skip in

the x direction, the x_odd_inc is set to 3 so that the x address

increment is 1 + 3, meaning that sensor will skip every other

Gr−R pair.

x_addr_end * x_addr_start ) 1

(x_odd_inc ) 1)ń2

+ even number

Digital Bin 2x x_odd_inc = 3

skip = (1+3) × 0.5 = 2x

col_bin = 1

Digital Bin 3x x_odd_inc = 5

skip = (1 + 5) × 0.5 = 3x

col_bin = 1

www.onsemi.com

30

Page 31

AR0330CS

Table 30. CONFIGURATION FOR VERTICAL SUBSAMPLING

y_odd_inc Restrictions:

No subsampling y_odd_inc = 1

skip = (1 + 1) × 0.5 = 1x

row_bin = 0

Skip 2x y_odd_inc = 3

skip = (1 + 3) × 0.5 = 2x

row_bin = 0

Skip 3x y_odd_inc = 5

skip = (1 + 5) × 0.5 = 3x

row_bin = 0

Analog Bin 2x y_odd_inc = 3

skip = (1 + 3) × 0.5 = 2x

row_bin = 1

The horizontal FOV must be programmed to meet the following rule:

y_addr_end * y_addr_start ) 1

(y_odd_inc ) 1)ń2

+ even number

www.onsemi.com

31

Page 32

AR0330CS

SENSOR FRAME RATE

The time required to read out an image frame (T

FRAME

can be derived from the number of clocks required to output

each image and the pixel clock.

The frame−rate is the inverse of the frame period.

fps + 1ńT

FRAME

(eq. 1)

The number of clocks can be simplified further into the

following parameters:

• The number of clocks required for each sensor row

(line_length_pck)

T

+ 1ń(CLK_PIX) [frame_length_lines line_lenght_pck ) extra_delay)

FRAME

)

This parameter also determines the sensor row period

when referenced to the sensor readout clock.

= line_length_pck x 1/CLK_PIX)

(T

ROW

• The number of row periods per frame

(frame_length_lines)

• An extra delay between frames used to achieve a

specific output frame period (extra_delay)

Vertical Blanking (VB)

Active Rows

(eq. 2)

Horizontal

Blanking

(HB)

Figure 29. Frame Period Measured in Clocks

Row Period (T

ROW

)

The line_length_pck will determine the number of clock

periods per row and the row period (T

) when combined

ROW

with the sensor readout clock. The line_length_pck includes

both the active pixels and the horizontal blanking time per

row. The sensor utilizes two readout paths, as seen in

Figure 17, allowing the sensor to output two pixels during

each pixel clock.

The minimum line_length_pck is defined as the

maximum of the following three equations:

ADC Readout Limitation:

1204(ADC_HIGH_SPEED) + 0

or

1116(ADC_HIGH_SPEED) + 1(0)

(eq. 3)

Options to modify this limit, as mentioned in the

“Sequencer” section, can be found in the AR0330CS

Developer Guide.

Minimumframe_length_lines +

y_addr_end * y_addr_start

(y_odd_inc ) 1)ń2

The sensor is configured to output frame information in

two embedded data rows by setting R0x3064[8] to 1

(default). If R0x3064[8] is set to 0, the sensor will instead

Active Columns

frame_length_lines = Active Rows + VB

Digital Readout Limitation:

x_addr_end * x_addr_start

1

ƪ

3

(x_odd_inc ) 1) 0.5

ƫ

(eq. 4)

Output Interface Limitations:

x_addr_end * x_addr_start

1

ƪ

2

Row Periods Per Frame

(x_odd_inc ) 1) 0.5

ƫ

(eq. 5)

The frame_length_lines determines the number of row

periods (T

) per frame. This includes both the active and

ROW

blanking rows. The minimum_vertical_blanking value is

defined by the number of OB rows read per frame, two

embedded data rows, and two blank rows.

) minimum_vertical_blanking

(eq. 6)

output two blank rows. The data configured in the two

embedded rows is defined in MIPI CSI−2 Specification

V1.00.

www.onsemi.com

32

Page 33

AR0330CS

Table 31. Minimum Vertical Blanking Configuration

R0x3180[0x00F0] OB Rows minimum_vertical_blanking

0x8 (Default) 8 OB Rows 8 OB + 4 = 12

0x4 4 OB Rows 4 OB + 4 = 8

0x2 2 OB Rows 2 OB + 4 = 6

The locations of the OB rows, embedded rows, and blank

rows within the frame readout are identified in Figure 30:

“Slave Mode Active State and Vertical Blanking” .

www.onsemi.com

33

Page 34

AR0330CS

OBRows (2, 4, or8rows)

Embedded Data Row(2 rows)

Active Data Rows

SLAVE MODE

The slave mode feature of the AR0330CS supports

triggering the start of a frame readout from a VD signal that

is supplied from an external ASIC. The slave mode signal

allows for precise control of frame rate and register change

updates. The VD signal is input to the trigger pin. Both the

GPI_EN (R0x301A[8]) and the SLAVE_MODE

(R0x30CE[4]) bits must be set to “1” to enable the slave

mode.

Frame Valid

Time

VD Signal

Start of frame N

Blank Rows (2 rows)

Extra Vertical Blanking

(frame_length_lines − min_frame_length_lines)

Extra Delay (clocks)

The period between the

rising edge of the VD signal

and the slave mode ready

state is T

FRAME

− 16 clocks.

Slave Mode Active State

Figure 30. Slave Mode Active State and Vertical Blanking

If the slave mode is disabled, the new frame will begin

after the extra delay period is finished.

The slave mode will react to the rising edge of the input

VD signal if it is in an active state. When the VD signal is

received, the sensor will begin the frame readout and the

End of frame N

Start of frame N + 1

slave mode will remain inactive for the period of one frame

time minus 16 clock periods (T

− (16 / CLK_PIX)).

FRAME

After this period, the slave mode will re−enter the active

state and will respond to the VD signal.

www.onsemi.com

34

Page 35

Frame

Valid

VD Signal

Rising

Edge

Rising

Edge

AR0330CS

Rising

Edge

Slave Mode

Trigger

Inactive

Rising edge of VD

signal triggers the start

of the frame readout.

Row 0

Row N

The Slave Mode will become

“Active” after the last row period.

Both the row reset and row read

operations will wait until the rising

edge of the VD signal. .

Active

Row reset and read

operations begin

after the rising edge

of the VD signal.

Figure 31. Slave Mode Example with Equal Integration and Frame Readout Periods

The integration of the last row is therefore started before

the end of the programmed integration for the first row.

The row shutter and read operations will stop when the

slave mode becomes active and is waiting for the VD signal.

The following should be considered when configuring the

sensor to use the slave mode:

1. The frame period (T

) should be configured

FRAME

to be less than the period of the input VD signal.

The sensor will disregard the input VD signal if it

appears before the frame readout is finished

ActiveInactive

Row Reset

(start of integration)

Row Readout

Programmed Integration

Integration due to

Slave Mode Delay

2. If the sensor integration time is configured to be

less than the frame period, then the sensor will not

have reset all of the sensor rows before it begins

waiting for the input VD signal. This error can be

minimized by configuring the frame period to be

as close as possible to the desired frame rate

(period between VD signals)

www.onsemi.com

35

Page 36

Frame

Valid

VD Signal

Rising

Edge

AR0330CS

Rising

Edge

Rising

Edge

Slave Mode

Trigger

Row 0

Inactive Active

8.33 ms

8.33 ms

Row N

Row reset and read

operations begin after

the rising edge of the

Vd signal.

Reset operation is

held during slave

mode “Active” state.

Figure 32. Slave Mode Example Where the Integration Period is Half of the Frame Readout Period

The sensor read pointer will have paused at row 0 while

the shutter pointer pauses at row N/2. The extra integration

caused by the slave mode delay will only be seen by rows 0

to N/2. The example below is for a frame readout period of

16.6 ms while the integration time is configured to 8.33 ms.

When the slave mode becomes active, the sensor will

pause both row read and row reset operations.

NOTE: The row integration period is defined as the

period from row reset to row read.

When the AR0330CS is working in slave mode, the

external trigger signal VD must have accurately controlled

timing to avoid uneven exposure in the output image. The

Inactive Active

Row Reset

(start of integration)

Row Readout

Programmed Integration

Integration due to

Slave Mode Delay

VD timing control should make the slave mode “wait

period” less than 32 pixel clocks.

To avoid uneven exposure, programmed integration time

cannot be larger than VD period. To increase integration

time more than current VD period, the AR0330CS must be

configured to work at a lower frame rate and read out image

with new VD to match the new timing.

The period between slave mode pulses must also be

greater than the frame period. If the rising edge of the VD

pulse arrives while the slave mode is inactive, the VD pulse

will be ignored and will wait until the next VD pulse has

arrived.

www.onsemi.com

36

Page 37

AR0330CS

FRAME READOUT

The sensor readout begins with vertical blanking rows

followed by the active rows. The frame readout period can

be defined by the number of row periods within a frame

Table 32. SERIAL SYNC CODES INCLUDED WITH EACH PROTOCOL INCLUDED WITH THE AR0330CS SENSOR

Start of Vertical

Interface/Protocol

Parallel Parallel interface uses FRAME VALID(FV) and LINE VALID (LV) outputs to denote start and end of line and frame.

MIPI No SYNC Code Ye s Ye s Yes Ye s

Blanking Row

(SOV)

Start of Frame

(SOF)

Figure illustrates how the sensor active readout time can

be minimized while reducing the frame rate.

CHANGING SENSOR MODES

(frame_length_lines) and the row period (line_length_pck).

The sensor will read the first vertical blanking row at the

beginning of the frame period and the last active row.

Start of Active

Line (SOA)

End of Line

(EOL)

End of Frame

(EOF)

Register Changes

All register writes are delayed by 1x frame. A register that

is written to during the readout of frame n will not be updated

to the new value until the readout of frame n + 2. This

includes writes to the sensor gain and integration registers.

Real−Time Context Switching

In the AR0330CS, the user may switch between two full

register sets A and B by writing to a context switch change

bit in R0x30B0[13]. When the context switch is configured

to context A the sensor will reference the “Context A

Registers”. If the context switch is changed from A to B

during the readout of frame n, the sensor will then reference

the context B coarse_integration_time registers in frame

n+ 1 and all other context B registers at the beginning of

reading frame n + 2. The sensor will show the same behavior

when changing from context B to context A.

www.onsemi.com

37

Page 38

AR0330CS

Table 33. LIST OF CONFIGURABLE REGISTERS FOR CONTEXT A AND CONTEXT B

Context A Context B

Register Description Address Register Description Address

Coarse_integration_time 0x3012 Coarse_integration_time_CB 0x3016

Fine_integration_time 0x3014 Fine_integration_time_CB 0x3018

Line_length_pck 0x300C Line_length_pck_CB 0x303E

Frame_length_lines 0x300A Frame_length_lines_CB 0x30AA

COL_SF_BIN_EN 0x3040[9] COL_SF_BIN_EN_CB 0x3040[8]

ROW_BIN 0x3040[12] ROW_BIN_CB 0x3040[10]

COL_BIN 0x3040[13] COL_BIN_CB 0x3040[11]

FINE_GAIN 0x3060[3:0] FINE_GAIN_CB 0x3060[11:8]

COARSE_GAIN 0x3060[5:4] COARSE_GAIN_CB 0x3060[13:12]

x_addr_start 0x3004 x_addr_start_CB 0x308A

y_addr_start 0x3002 y_addr_start_CB 0x308C

x_addr_end 0x3008 x_addr_end_CB 0x308E

y_addr_end 0x3006 y_addr_end_CB 0x3090

Y_odd_inc 0x30A6 Y_odd_inc_CB 0x30A8

X_odd_inc 0x30A2 X_odd_inc_CB 0x30AE

ADC_HIGH_SPEED 0x30BA[6] ADC_HIGH_SPEED_CB 0x30BA[7]

GREEN1_GAIN 0x3056 GREEN1_GAIN_CB 0x30BC

BLUE_GAIN 0x3058 BLUE_GAIN_CB 0x30BE

RED_GAIN 0x305A RED_GAIN_CB 0x30C0

GREEN2_GAIN 0x305C GREEN2_GAIN_CB 0x30C2

GLOBAL_GAIN 0x305E GLOBAL_GAIN_CB 0x30C4

39.ON Semiconductor recommends leaving fine_integration_time at 0.

Time

Serial SYNC Codes

Start of Vertical Blanking

Start of Frame

Start of Active Row

End of Line

End of Frame

1/60s

Row Reset Row ReadRow Reset Row Read

VB

(12 Rows)

1/60s

HB (192 Pixels/Column)

2304 x 1296

Vertical Blanking

Row Reset Row ReadRow Reset Row Read

End of Frame

Readout

HB (192 Pixels/Column)

VB

(12 Rows)

Figure 33. Example of Changing the Sensor from Context A to Context B

Active Rows

End of Frame

Readout

2304 x 1296

www.onsemi.com

38

Page 39

AR0330CS

COMPRESSION