Page 1

查询400WA10M12.5X16供应商

AND8098/D

Low−Cost 100 mA

High−Voltage Buck and

Buck−Boost Using NCP1052

Prepared by: Kahou Wong

ON Semiconductor

INTRODUCTION

This application note presents low-cost high-voltage

100 mA non-isolated power supply using NCP1052 by

buck and buck-boost topology. The NCP1052 is one of the

latest low-cost switching controllers with integrated 700 V/

300 mA power switch from ON Semiconductor. It is

primarily designed for isolated 10 W-range flyback

converter. If isolation is not needed, the IC can also be used

as stepping-down buck and buck-boost converter for

further cost saving by removing optocoupler and replacing

the transformer by an inductor. The output current capability

is 100 mA. The possible operating range is from input range

between 20 Vdc and 700 Vdc to output range of 5.0 V or

above with 100 mA. Typical efficiency around 65% is

obtained in the 12 V buck demo board.

Advantages of the proposed circuits include:

• Comparing to flyback, buck and buck-boost eliminates

optocoupler and replaces transformer by an inductor for

cost saving.

• Buck and buck-boost offers smaller voltage stress in

switches comparing to flyback. It minimizes the

switching loss and increases efficiency.

• NCP105x can power up itself from the high input

voltage with wide range between 20 Vdc and 700 Vdc.

It needs no extra supply circuit.

• NCP105x operates at 44, 100, or 136 kHz and

accommodates low-cost components such as aluminum

electrolytic capacitors and powered-iron core magnetic.

• NCP105x offers frequency jittering for reduced

electromagnetic inference (EMI).

• NCP105x offers thermal and short circuit fault

protection.

• Simple design as no control-loop compensation is

concerned.

The proposed buck and buck-boost converters are very

similar to each other. Their major difference is that buck

provides a positive output voltage but buck-boost provides

a negative output voltage referring to the input ground.

http://onsemi.com

APPLICATION NOTE

PRINCIPLE OF OPERATION

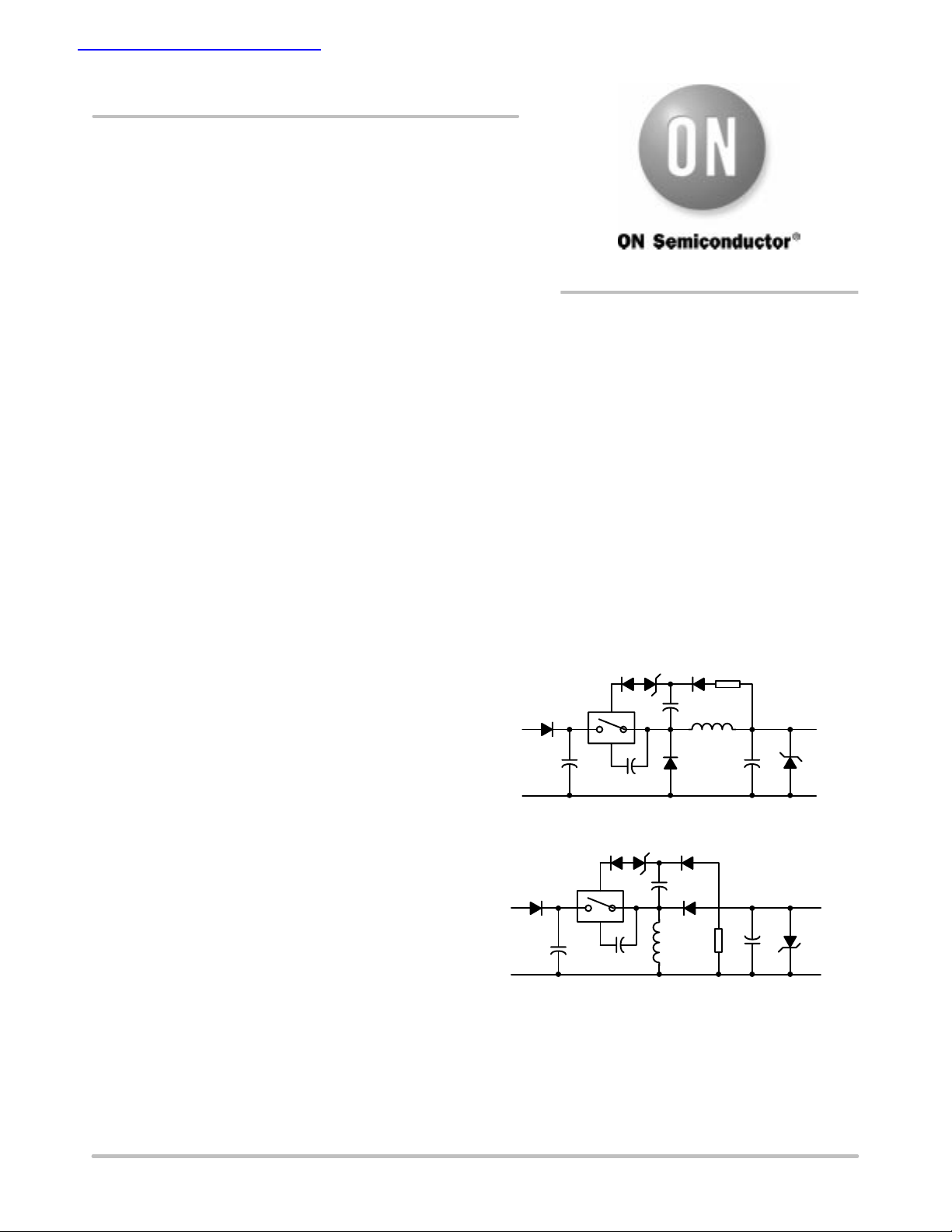

Figure 1 shows the proposed buck and buck-boost

converters. The rectifier circuit, which consists of capacitor

C3 and diode D3, is in the front end for AC or DC input

voltage. Then, the NCP1052 is self-powered up from the

rectified input voltage directly with a VCC capacitor C2.

When the switch inside the IC is opened, there is a voltage

across Drain (D) and Source (S) pins of the IC. If this voltage

is greater than 20 V, an internal current source I

(typ.) inside the IC charges up C2 and a voltage in C2 is built

up for the operation of the IC. Comparing to the switching

frequency, the V

voltage level is in a lower-frequency

CC

7.5-8.5 V hysteresis loop. This VCC hysteresis loop is for

frequency jittering features to minimize EMI and

short-circuit fault timing function.

C

D

(a) Buck

D

C

1

D

L

D

1

R

1

1

L

C

1

C

R

1

D

2Z2

D

Input Output

C

D

3

Input Output

Figure 1. Proposed Circuit Using NCP1052

FB

3

DS

V

CC

3

DS

V

C

FB

CC

3

C

2

D

2Z2

C

2

(b) Buck-boost

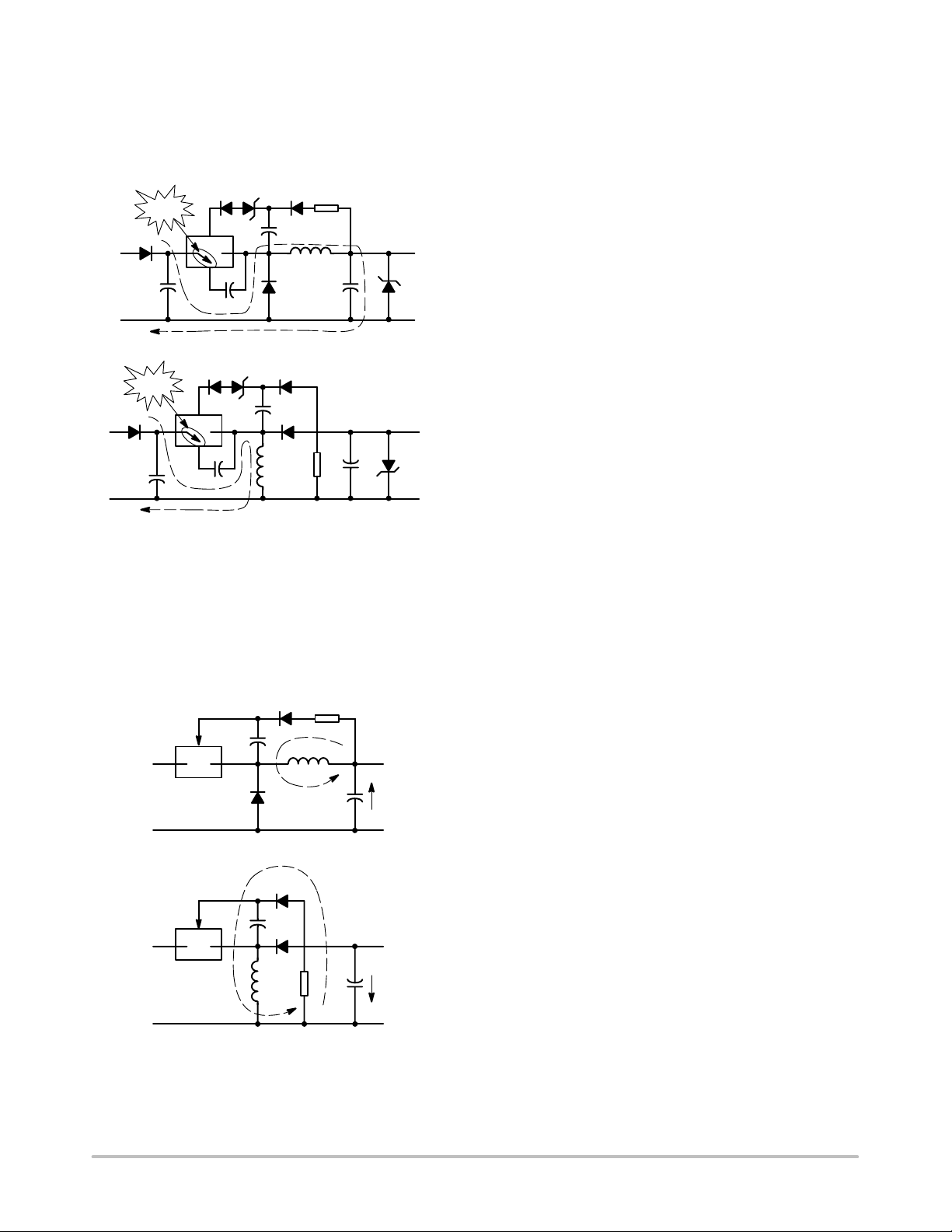

In Figure 2a it is noted that in the buck topology the input

voltage powers up the IC through the path across the

inductor L and capacitor C. This charging path passes

Z

Z

start

1

1

= 6.3 mA

Semiconductor Components Industries, LLC, 2003

June, 2003 - Rev. 1

1 Publication Order Number:

AND8098/D

Page 2

AND8098/D

through the output and a low-frequency ripple will be found

in the output voltage. Hence, the value of C2 is needed to be

small enough to increase this charging frequency f

VCC

in

order to reduce output voltage ripple because some

efficiency is lost due to this low-frequency ripple.

C

D

(a) Buck

D

C

1

D

L

D

1

R

1

1

L

Z

1

C

1

Z

1

C

R

1

2

D

FB

V

CC

D

C

2

2Z2

C

2

2Z2

(b) Buck-boost

I

start

D

3

DS

Input Output

C

3

I

start

D

3

Input Output

C

FB

DS

V

CC

3

Figure 2. Charging Current of C

In Figure 2b it is noted that in the buck-boost topology the

charging current path is blocked by diode D and hence the

charging of C

does not affect the output voltage directly.

2

However, it still affects the output voltage indirectly and

slightly by adding some low-frequency noise on the

inductor. Hence, small value of C

C

1

(a) Buck

(b) Buck-boost

Figure 3. Output Voltage Couples to C1 with a

Charging Current

is also wanted.

2

D

1

D

1

C

1

R

1

R

1

V

out

V

out

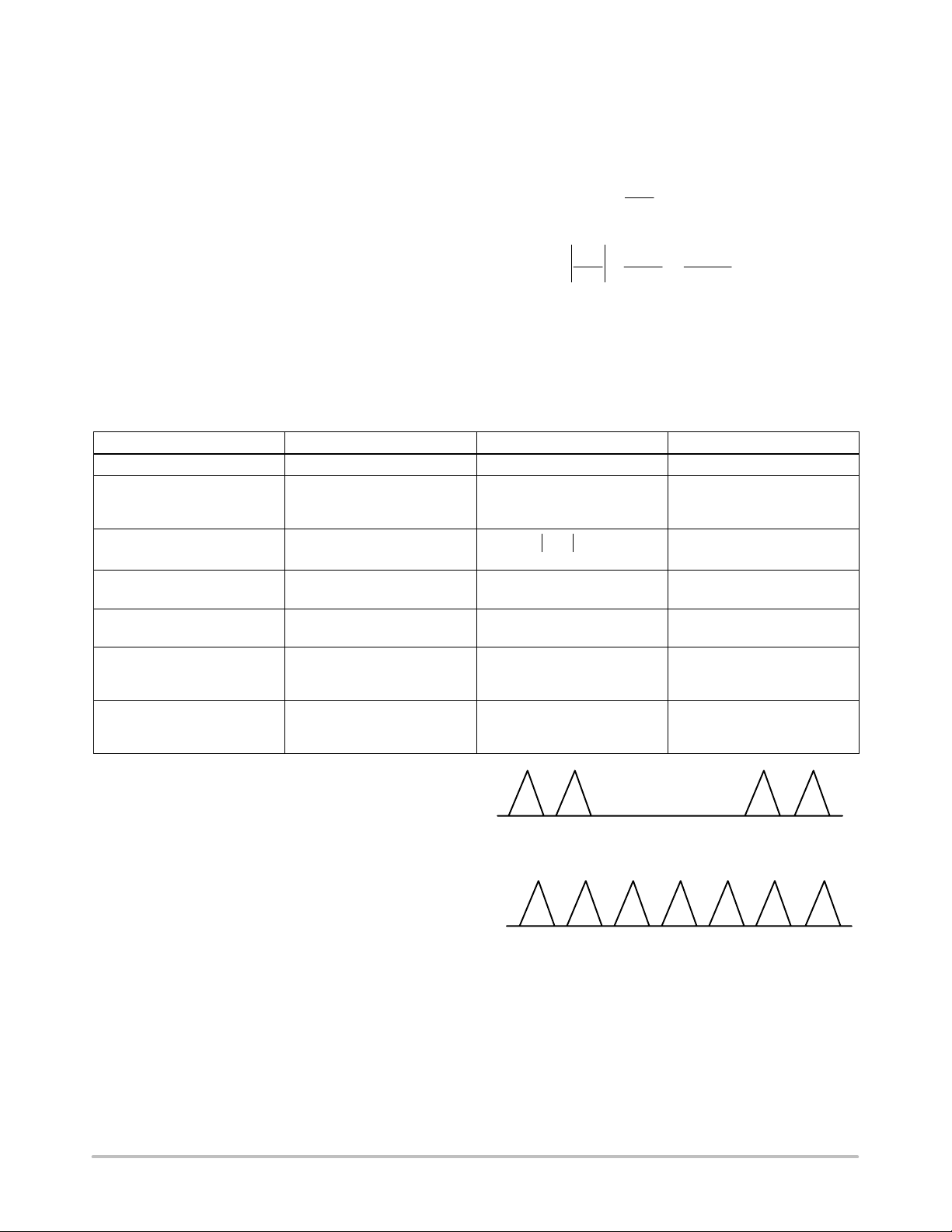

The function of diode D1, capacitor C1 and resistor R1 are

to transfer the magnitude of output voltage to a voltage

across C1 so that the IC can regulate the output voltage. In

Figure 3, when the main switch inside the IC is opened and

the diode D is closed. In buck, the potential of the IC

reference ground (pin S) becomes almost 0 V in this

moment. In buck-boost, the potential of the IC reference

ground (pin S) becomes -V

in this moment. The voltage

out

in C1 will be charged to the output voltage. On the other

hand, when main switch is closed and the diode D is opened,

diode D

and Vin+V

is reverse biased by a voltage with magnitude V

1

respectively. Hence, D1 does not affect the

out

normal operation of the buck and buck-boost converter.

It is noted that the instantaneous voltage in C1 can be

possibly greater than the output voltage especially when

output current or output ripple is too large. It directly affects

the load regulation of the circuit since the IC regulates the

output voltage based on the voltage in C

. In order to solve

1

it, larger values of L and R1 can help to slow down the

charging speed o f C1. It reduces the maximum instantaneous

voltage in C

so that output voltage at high output current

1

can be pulled up and a good regulation is made.

Larger value of L can help the load regulation but it

usually unwanted because it is bulky. Hence, resistor R1 is

recommended. Larger value of R

makes higher output

1

voltage. Hence, it is called as a “pull-up resistor” and it can

help to pull up the output voltage slightly.

The voltage in C1 representing the output voltage is

feedback to the feedback (FB) pin of the NCP1052 through

a diode D

and zener diode Z2. When output voltage is too

2

high, there will be a greater-than-50 A current inserting

into the feedback pin of the NCP1052. The NCP1052 will

stop switching when it happens. When output voltage is not

high enough, the current inserting into the feedback is

smaller than 50 A. The NCP1052 enables switching and

power is delivered to the output until the output voltage is

too high again.

The purpose of the diode D

is to ensure the current is

2

inserting into the feedback pin because the switching of

NCP1052 can also be stopped when there is a

greater-than-50 A current sinking from the FB pin. The

purpose of the zener diode Z

is to set the output voltage

2

threshold. The FB pin of NCP1052 with a condition of

50 A sourcing current is about 4.3 V. The volt-drop of the

diode D

is loosely about 0.7 V at 50 A. Hence, the output

2

voltage can be loosely set as follows:

V

zener 4.3 V 0.7 V

out

zener 5V

(eq. 1)

According to (1), the possible minimum output voltage of

the circuit is 5.0 V when there is no zener diode Z2.

If there is no load, the IC will automatically minimize its

duty cycle to the minimum value but the output voltage is

still possible to be very high because there is no passive

component in the circuit try to absorb the energy. As a result,

in

http://onsemi.com

2

Page 3

AND8098/D

output voltage will rise up dramatically and burn the output

capacitor eventually. Hence, a zener diode Z1 or minimum

“dummy” load resistor is needed to consume the minimum

amount of energy as shown in Figure 1. It is also noted that

when R1 pulls up the output voltage at a given output current

condition, the output voltages at lower output current

conditions are also pulled up. Hence, the clamping zener

diode Z

is needed to be with the breakdown voltage as same

1

as the output voltage but it will reduce some of the ef ficiency

at lower output current conditions.

DESIGN CONSIDERATION

Topology

Buck circuit is to step down a voltage. Buck-boost circuit

is to step up or down a voltage. The output voltage is

inverted. The maximum duty of NCP1052 is typically 77%.

Because of burst-mode control, the effective maximum

duty is lower and said to be 70% roughly. When a buck

converter is in continuous conduction mode (CCM), the

input voltage V

and output voltage V

in

are related by the

out

duty ratio D.

V

out

D 0.7

V

in

The relationship in buck-boost is

V

V

out

in

D

1 D

0.7

1 0.7

2.33

Another aspect on topology is the output current. The

maximum output current is always smaller than the

maximum switch current in non-isolated topologies.

However, in isolated topologies such as flyback the

maximum output current can be increased by a transformer.

Table 1. Summary of Topology Difference Using NCP1052

Buck Buck-boost Flyback

Output voltage < 0.7 V

Output current < 300 mA << 300 mA, output current is

Input voltage < 700 V

Operating mode in nominal

condition

Standby ability on VCC charging

current

Transformer / Auxiliary winding It is only for standby

Isolation No No Yes. Opto coupler can be

in

Continuous Continuous Discontinuous

Bad. The current flows through

output even if there is no load

improvement or additional

output

Negative & < 2.33 Vin Depending on transformer ratio

only a portion of the inductor

current

700 V

700 V

Good. The current passes

through inductor only

It is only for standby

improvement or additional

output

out

V

< 10 W. It depends on operating

condition and audible noise level

<< 700 V. It depends on

transformer ratio

Good. The current passes

through primary winding only

It is a must for the main output.

Additional auxiliary winding can

improve standby performance

eliminated if isolation is not

needed

(eq. 2)

(eq. 3)

Burst-mode Operation

The NCP1052 is with a burst-mode control method. It

means the MOSFET can be completely off for one or more

switching cycles. The output voltage is regulated by the

overall duration of dead time or non-dead time over a

number of switching cycles. This feature offers advantages

on saving energy in standby condition since it can reduce the

effective duty cycle dramatically. In flyback topology, the

circuit is mainly designed for discontinuous conduction

mode (DCM) in which the inductor current reaches zero in

every switching cycle. The DCM burst-mode waveform can

be represented in Figure 4. It is similar to the pulse-width

modulation (PWM) one.

http://onsemi.com

Burst mode

PWM

Figure 4. DCM Inductor Currents in Burst Mode

and PWM Control

3

Page 4

AND8098/D

In non-isolated topologies such as buck or buck-boost,

the circuits are mainly designed for CCM. The CCM

burst-mode waveform is different to the PWM waveform in

Figure 5. Because of this characteristic, burst mode requires

a higher peak value of the inductor current in order to have

the same level of averaged inductor current (or output

current).

Burst mode

FB current

Output waveforms with big enough VCC capacitor

V

out

V

CC

time

PWM

Figure 5. CCM Inductor Currents in Burst Mode

and traditional PWM Control

As shown in Figure 4 and 5 burst-mode control produces

low-frequency waveform comparing to the switching

frequency. Part of the power loss in this low frequency

becomes audible noise. Therefore, burst-mode control is

not suitable for high power applications such as more than

20 W.

VCC Capacitor

The VCC capacitor C2 is the key component to make the

circuit operate in normal mode or fault mode. The device

recognizes a fault condition when there is no feedback

current in the FB pin during the time from VCC = 8.5 V to

7.5 V. The VCC capacitor directly affects this time duration.

In normal mode, the V

hysteresis loop. When the circuit is in fault mode, the V

follows a 8.5 V-7.5 V-8.5 V

CC

CC

follows a 8.5 V-7.5 V-4.5 V-8.5 V hysteresis loop. The

device keeps its MOSFET opened except for the time from

V

= 8.5 V to 7.5 V and delivers a little amount of power

CC

to the output in fault mode.

A common and extreme case to enter fault condition is the

startup. The MOSFET begins switching at the VCC is firstly

charged to 8.5 V and hence output voltage rises. The output

voltage needs some time to build up the output voltage from

0 V to a desired value. When the desired level is reached, a

feedback current flows into the device to stop its switching.

If the feedback current is determined before V

reaches

CC

7.5V, the circuit will remain in normal mode. Otherwise, the

circuit will enter the fault mode and cannot provide the

output voltage at its desired level. Therefore, the V

CC

capacitor is needed to be big enough to ensure sufficient time

for VCC going from 8.5 V to 7.5 V to sample feedback

current in startup.

Desired level of V

Output waveforms with too small VCC capacitor

Figure 6. Startup Scenarios of the Circuits with

Big Enough or Too Small VCC Capacitor

out

V

V

CC

out

time

Practically, the NCP1052 consumes approximately 0.5

mA in normal operation. The concerned fault sampling time

for feedback signal is from 8.5 V to 7.5V. Hence,

dt

dV

0.5 10

C I

0.5 10-3· sampling time

-3

1

· sampling time

(eq. 4)

For example, if sampling time or startup transient is

designed to be 20 ms, 10 µF VCC capacitor is needed.

Inductor

The 300 mA current limit in the NCP1052 is measured

with a condition that the di/dt reaches 300 mA in 4 µs. When

the buck or buck-boost circuit is designed for universal ac

input voltage (85 to 265 Vac), the rectified input voltage will

be possibly as high as 375 Vdc. In order to keep the 4 µs

condition, the inductance value will be 5 mH by (5) and (6).

For buck,

di

dt

Vin V

L

out

V

in

L

(eq. 5)

For buck-boost,

V

di

in

dt

L

(eq. 6)

The 5 mH is practically too high and hence not very

practical. Therefore, the inductor is basically selected by

market available inductor models which is with a normally

smaller inductance (but not too small). It must have enough

saturation current level (>300 mA). If inductance is too

http://onsemi.com

4

Page 5

AND8098/D

small, the di/dt becomes too high and the NCP1052 will

have a very high current limit effectively because there is a

propagation delay (typically 135 ns) to turn off the switch.

The current flowing through the inductor L includes three

parts. First, there is a VCC charging current I

It happens when V

needs charging. Its magnitude is 6.3

CC

in Figure 2.

start

mA. It is noted that the VCC discharging current does not

flow through the inductor. Second, it is the main inductor

current to deliver the output current. It is noted that the peak

of burst-mode inductor current is higher than PWM one as

in Figure 5 for the same level of averaged inductor current

(or output current). Finally, there is a current flowing

through diode D

to charge up C1. It also flows through the

1

inductor as shown in Figure 3. Its magnitude is a

greater-than-50 µA current and practically it is about 1 mA.

Hence, the saturation current of the inductor L is needed to

be bigger than their sum.

Another consideration on the inductor is the low-pass

filtering capability for the V

hysteresis low frequency

CC

(and the 50/ 60 Hz rectified AC line voltage ripple). As

shown in Figure 2, there is a low-frequency charging current

with magnitude 6.3 mA flowing through the inductor and

causes low-frequency ripple in the output voltage. A higher

value of the inductance can help to reduce the output ripple.

It is noted that when the output power is higher, the startup

time becomes longer. It needs bigger V

capacitor and

CC

makes lower VCC charging frequency. As a result, a bigger

inductance is needed.

The last consideration is the effect of load regulation.

Large inductor can limit the inrush current flowing into

capacitor C

as shown in Figure 3. High inrush current is not

1

desirable because it can make the C1 voltage higher than the

output voltage. It makes load regulation poor. If there is no

pull-up resistor R1, inductor value L is chosen to be as large

as possible, say 2 mH.

Output Capacitor

Because of the burst-mode characteristic and the

low-frequency VCC charging current, the output ripple is

larger than those in PWM. Hence, a relatively bigger output

capacitor is needed to keep output ripple small. However,

big output capacitor needs a long time to build up the output

voltage initially and hence the circuit may enter into fault

mode in the startup in Figure 6.

Buffering Capacitor

Buffering capacitor C2 is to provide a greater-than-50 µA

to the feedback pin of NCP1052. It is relatively much

smaller than the output capacitor because the current

consumption in this capacitor is much smaller and the output

voltage cannot copy to this buffering capacitor if the

buffering capacitor voltage is higher than the output voltage.

Diodes

D and D1 are recommended to be the same part for

compatibility in speed and voltage drop. It helps the voltage

in the capacitor C

to be similar to the output voltage. The

1

reverse blocking voltage of D and D1 is needed to be large

enough to withstand the input voltage in buck and input

voltage plus output voltage in buck-boost respectively.

D

is not a critical component. Its function is to make sure

2

that feedback current is only in one direction. The accuracy

of its voltage drop used in (1) is not important since the 4.3V

reference voltage in the NCP1052 is loosely set.

Zener Diodes

Z1 is to clamp the output voltage when there is light load

or no load. Hence, the accuracy of Z

helps the regulation

1

accuracy in the light load or no load condition. It is also the

main component to consume energy when the circuit is in no

load condition. The output voltage is clamped and hence the

output capacitor is protected.

Z

and R1 are to set the output voltage at the nominal load

2

current. Hence, their accuracy affects the regulation

accuracy at the nominal load condition. The relationship

between zener voltage and output voltage is shown in (1).

Higher value of R1 helps to pull up the output voltage higher

by reducing the charging rate of the buffering capacitor C

Standby Condition

The standby ability of the proposed buck converter is not

good. It i s because there is a VCC charging current I

start

flows

through the output capacitor in Figure 2(a). This charging

current is a low-frequency pulsating signal. As a result, the

voltage in the output capacitor continuously rises up by the

charging current pulses. In order to prevent over voltage in

the output capacitor, the zener Z

absorbs the charging

1

current. It consumes main portion of energy in standby.

.

1

http://onsemi.com

5

Page 6

AND8098/D

The proposed buck-boost is better in term of the standby

ability . I t i s because the VCC charging current in Figure 2(b)

only passes through the inductor. The charging current

pulses become an averaged energy stored in the inductor and

consume smaller amount of power comparing to the buck

case.

(a) Buck

fault mode with the 4.5 V-8.5 V-7.5 V-4.5 V hysteresis

loop.

Another method to supply the VCC voltage is coupling

capacitor technique in Figure 8. The output voltage is

coupled to the inserted capacitor when the diodes are closed.

The voltage drop of the diodes compensate each other.

Hence, the diode voltage drop effect can be neglected. The

NCP1052 needs a nominal V

resistor consumes some voltage from the output voltage V

voltage of 8V. The inserted

CC

out

to make a 8V to the VCC pin. Based on the 0.5mA typical

current consumption of V

value is (V

- 8) / 0.5 k.

out

pin. The inserted resistance

CC

(a) Buck

(b) Buck-boost

Figure 7. Auxiliary Winding to improve standby

Abillity

The auxiliary winding to supply the VCC voltage in Figure

7 is a method to improve the standby ability. The auxiliary

winding keeps the VCC voltage above 7.5 V and disable the

V

charging current and hence its standby loss. The

CC

auxiliary winding is coupled from the inductor L with

polarity same as the regulated output voltage. The V

CC

voltage in the auxiliary winding is designed to be between

the normal VCC limits of 7.5 and 8.5 V typically. The

frequency jittering feature loses when the V

voltage is

CC

fixed. When output is shorted, there will be no voltage

coming from the auxiliary winding and the circuit will enter

http://onsemi.com

(b) Buck-boost

Figure 8. Coupling Capacitor Technique to

Improve Standby Abillity

T emperature Rise

The NCP1052 is a very compact package with the control

circuit and high-voltage power switch. Its typical on

resistance is 22 Ω. Temperature rise exists. It is

recommended to design the PCB board with a large copper

area next to the device as a heatsink. This heatsink decreases

6

Page 7

AND8098/D

the temperature rise and reduces the on resistance. Finally,

the efficiency of the circuit is benefited.

As shown in Figure 9, a 2 inch by 1.5 inch small

surface-mount demo board of 12 V / 100 mA buck is

presented. The design is made on a single-sided board. The

EXAMPLES

bill of material is shown in Table 2. The component symbols

are those in Figure 1. In order to have sufficient startup

12 V / 100 mA NCP1052 Buck Demo Board

ability, the V

capacitor is 6.8 µF which gives a 3.4 ms fault

CC

sampling time. Because of this feature, the circuit enters

fault mode when output current exceeds 200mA after startup

as shown in Figure 10(b). The efficiency of the circuit is

typically 65% at 100 mA.

Figure 9. Layout of the Demo Board

Table 2. Bill of Material of Buck Demo Board

Part No Description Manufacturer

IC NCP1052ST136 Switching Regulator ON Semiconductor

D, D

1

D

2

D

3

Z

1

Z

2

R

1

C 594D227X9016R2T 220 µF, 16 V, tantalum Vishay

C

1

C

2

C

3

L UP2B-681 680µH Cooper

MURS160T3 1A 600V ultrafast ON Semiconductor

MMSD914T1 General diode ON Semiconductor

MRA4005T1 1A 600V standard recovery ON Semiconductor

MMSZ12T1 12V 5% zener ON Semiconductor

MMSZ6V8T1 6.8V 5% zener ON Semiconductor

CRCW08052001FRT1 2 kΩ Vishay

VJ1206Y224KXXAT 0.22 µF, 25 V, ceramic Vishay

595D685X9016A2T 6.8µF, 16V, tantalum Vishay

400WA10M12.5X16 400V 10µF Rubycon

http://onsemi.com

7

Page 8

AND8098/D

14

12

10

8

6

4

OUTPUT VOLTAGE (V)

2

0

80

70

60

50

40

30

EFFICIENCY (%)

20

VIN = 100 Vdc

50

VIN = 300 Vdc

VIN = 200 Vdc

150

OUTPUT CURRENT (mA)

(a) Load Regulation

VIN = 100 Vdc

VIN = 200 Vdc

VIN = 300 Vdc

Dual Output Buck-boost with Increased Output

Current Capability

Replacing NCP1052 by NCP1055, which is with a current

limit of 680 mA, the output current capability is increased.

Larger value of inductor L is selected for high current. On

the other hand, the current consumption of NCP1055 is

higher than NCP1052 and the startup transient time is longer

in a higher power application. Hence, the V

capacitor is

CC

increased. When the VCC capacitor increased, its charging

frequency is decreased. Output capacitor is also needed to b e

increased to reduce this lower-frequency charging current/

ripple.

In addition, by adding one more auxiliary winding to the

250200100

300

3500

inductor a secondary output is made. A typical example is

shown in Figure 11. In higher output current application, the

load regulation is the major problem. The 5.1kΩ resistor

plays an important role for the load regulation. The primary

output voltage is higher than the secondary because it can

increase the output current ability by stepping up the current

in the transformer. The line regulation is shown in Figure 12

when the output currents are constant.

10

0

50

OUTPUT CURRENT (mA)

150

(b) Efficiency

Figure 10. 12V / 100mA Buck Performance

NCP1055P100

1N4005

Universal

AC Input

10µF

250200100

1N4005 1N4746 MUR160

22µF

3000

1µF

1.2mH / 92.3µH

5.1k

MUR160

MUR160

-24V / 200mA

150µF

GND

220µF

-5V / 150mA

Figure 11. Dual Output Buck-boost

http://onsemi.com

8

Page 9

AND8098/D

0

-5

-10

-15

OUTPUT VOLTAGE (V)

-20

-25

50 300

Figure 12. Line Regulation of the Dual Output

Output 2 with 150 mA

Output 1 with 200 mA

150

INPUT VOLTAGE (Vac)

Buck-boost

250200100

CONCLUSION

100 mA high-voltage low-cost buck and buck-boost

circuits using NCP1052 are presented. These circuits are

designed for cost-saving non-isolated application so that

optocoupler and transformer are saved. The possible input

voltage range is from 20 Vdc to 700 Vdc so that it is suitable

for general AC/DC and DC/DC applications with positive or

negative output voltages. It is noted that the standby ability

of the circuits is not good because of the V

capacitor

CC

charging current. However, it can be improved by adding an

auxiliary winding to the V

. The design consideration of

CC

each component in the circuits is explained. By replacing the

NCP1052 with NCP1055, the output current can be

increased. By adding an auxiliary winding, multi-output can

be obtained. A 12 V / 100 mA demo board is presented with

typical 65% efficiency.

http://onsemi.com

9

Page 10

AND8098/D

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make

changes without further notice to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any

particular purpose, nor does SCILLC assume any liability arising out of the application or use of any product or circuit, and specifically disclaims any and all

liability, including without limitation special, consequential or incidental damages. “Typical” parameters which may be provided in SCILLC data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be

validated for each customer application by customer’s technical experts. SCILLC does not convey any license under its patent rights nor the rights of others.

SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body, or other applications

intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC

and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees

arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that

SCILLC was negligent regarding the design or manufacture of the part. SCILLC is an Equal Opportunity/Affirmative Action Employer.

PUBLICATION ORDERING INFORMATION

Literature Fulfillment:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303-675-2175 or 800-344-3860 Toll Free USA/Canada

Fax: 303-675-2176 or 800-344-3867 Toll Free USA/Canada

Email: ONlit@hibbertco.com

N. American Technical Support: 800-282-9855 Toll Free USA/Canada

http://onsemi.com

JAPAN: ON Semiconductor, Japan Customer Focus Center

2-9-1 Kamimeguro, Meguro-ku, Tokyo, Japan 153-0051

Phone: 81-3-5773-3850

ON Semiconductor Website: http://onsemi.com

For additional information, please contact your local

Sales Representative.

AND8098/D

10

Loading...

Loading...