Page 1

©

S

A

u

A

M

G

e49

Pre

p

I

n

C

o

mod

e

p

res

e

U

T

h

•••

H

W

T

h

give

n

•••

•

S

W

B

e

JRE

‘jav

a

b

e i

nTh

b

e d

o

http:

/

4958

M

a

emiconductor Com

p

gust 31, 2011

IS4

9

tting s

t

587 Ev

a

ared by: Ind

troductio

ngratulations,

h

m demonstrat

i

nt document

w

npack yo

u

e evaluation ki

•

2 AMIS-

4

p

lugged on

D

•

2 USB se

r

•

This man

u

W

requir

e

e material nec

hereunder:

•

1 PC run

n

free.

•

2 AMIS-

4

•

2 USB ca

b

•

2 mains

c

connector.

connect to

L

require

fore starting t

h

6.13 or highe

r

.com/getjava’.

stalled automa

t

e User Interfa

c

wnloaded fro

m

/www.onsemi.

7

ins connection

onents Industries, L

L

– Rev. 008

587

arted

w

luatio

n

ustrial ASSP

n

ere is the AM

I

on kit from O

N

ill help you to

r materi

a

t contains the

fo

9587 evaluatio

aughter Boar

d

ial cables

al

ments

essary to run

a

ing Windows

9587 evaluatio

les

ables. To con

n

(not included)

ine and Neutr

a

ments

e PLC UI, ma

k

is installed

o

On MS Wind

o

ically.

e Software an

d

:.

com/PowerSol

u

D

a

C, 2011

ith th

e

kit

- ON Semic

o

S-49587 pow

e

Semiconduct

o

get the kit wor

k

l

llowing elem

e

n boards (Mot

h

)

communicati

o

XP or higher

w

n boards

ect to the M

o

. Please take

l.

e sure the Jav

a

r download a

n

ws based plat

f

most recent d

o

tions/product.

ughter Board

Mothter Boar

AMIS

-

nductor

r line carrier

r, Inc.. The

ing quickly.

nts:

er Board and

n with the ki

t

ith 2 USB p

o

ther Board m

care to corre

c

Runtime Eng

d install it fr

o

orms the JRE

w

cumentation c

a

do?id=AMIS-

USB con

n

d

1

is

rts

ain

tly

ine

m

ill

n

c

odo

I

MdeDi

o

f

m

ection

AMIS-49587

RESET

The USB p

o

nverter. A de

d

wnload it fro

m

http://www.ft

d

Setting u

Once you get

t

Step 1:

Connect the b

o

Step 2:

Connect the P

L

Step 3

:

Power the PL

C

PORTANT

monstration

sconnect the

b

it. Be sure

anipulate it.

USB con

n

Mains conne

c

http://onse

m

rt communic

a

icated USB

d

the FTDI we

b

ichip.com/FT

D

p the har

d

he above liste

d

th PLC MOD

E

C MODEM

m

MODEM.

REMARK:

2

board. Kee

p

oard from t

h

that only tr

a

ection

tion

Publication

i.com

tes with a

F

river is need

e

site:

rivers.htm.

ware

elements, you

M’s to the US

ains plug to th

e

30V mains

a

the board

e mains befo

r

ained people

Order Number

:

AMIS-49587

TDI serial

U

d for this. Y

o

need to:

B ports of the

P

mains.

re present o

n

in a safe

e any manipu

l

are authoriz

e

ART

u can

C.

the

area.

ation

d to

Page 2

AMIS-49587

http://onsemi.com

2

Setting up the software

The kit is delivered with a CDROM. Insert the CDROM in the

CD drive. For MS Windows based platforms, an installer

application is available: ONSemiPLCInstall.exe. The installer

application checks if the required Java Runtime Engine is installed.

If it is not, the installer will start downloading it from the Sun

website and install it.

For non MS Windows based platforms see SW requirements.

When the required Java Runtime Engine is installed, installation

of the ON Semiconductor PLC Modem application will proceed.

1.4.7

| AMIS49587 GUI application note.pdf

| plcui.chm

| PlcUi.jar

| rxtxSerial.dll

| Slave 7.1.plc.xml

| Master 7.1.plc.xml

| Spy 7.1.plc.xml

|

\---lib

AbsoluteLayout.jar

appframework-1.0.3.jar

RXTXcomm.jar

swing-worker-1.1.jar

PlcUi.jar is the main application, ‘AMIS49587 GUI application

note.pdf’ is this manual and ‘Master 7.1.plc.xml’ and ‘Slave

7.1.plc.xml’ are MODEM configuration files. Plcui.chm is the

source code documentation.

All other files are supporting libraries.

Running the Graphical user interface

The graphical user interface consists of 3 types of windows. The

main window allows the user to open a configuration file for a PLC

MODEM and implements a log of messages that traces user

activities and MODEM events. This event log can be cleared or

saved into a text file from the file menu. When a correct MODEM

configuration file is opened, a new window will appear,

implementing a user interface tailored to the type of configuration

that is opened (master, slave, monitor or spy). Master and slave

windows look very similar. Only the area where the MODEM’s

status is displayed is different. The application limits the number

of master or slave windows to 6.

The logging level can be set from 0 to 3 to choose the level of

detail of the log messages. Level 3 gives most details. The status

fields of the master and slave windows will update when the button

‘Update Status’, Reset’ or ‘Write Config’ are clicked or,

automatically, when the status pane is activated.

Figure 1 Main Window

Figure 2 Master Window

The MODEM’s can be forced to disconnect (lose

synchronization) by clicking the ‘De-sync’ button. The ‘Reset’

button shall be clicked when the modem is in an unknown state or

the user would like to start from a not configured MODEM.

When parameters, listed in the configuration file and exposed in

the GUI are changed, these changes can be saved into a new

configuration file by picking ‘Save Configuration’ from the master

or slave window file menu, or by pressing ‘CTRL-S’ (for now,

only the communication port and the MAC layer filter setting can

be changed from the GUI).

Note that all MODEM’s settings can be modified by editing the

configuration file in a text editor. The configuration file is an

XML file. Each MODEM parameter is encapsulated in parameter

name and value keywords. All parameters are to be coded in

hexadecimal numbers. Below is an example that shows how the

local MAC address is set to 0x555:

<LocalMac>

<Bits>16</Bits>

<Value>555</Value>

<Note>Number within FIMA to LIMA range</Note>

</LocalMac>

Only the value between <Value> and </Value> should be changed.

New settings can be activated by loading the new configuration file

from the main window.

The current PLC GUI implements a simple chat, data loop or file

transfer application between a master and a client. Before being

able to exchange data, one master configuration and at least one

slave configuration needs to be opened from the main window on

one or more PC’s.

To start communication, the following steps need to be executed

for both the master and the slave(s) windows:

Common to all 3 communication examples are:

1) Pick the serial port that is connecting the PLC master

MODEM. Only the serial communication ports available in

the PC are listed. Success or failure to open the chosen

communication port can be monitored in the log that is

displayed in the main window.

2) Click the ‘Reset’ button to bring the MODEM into a

known, not configured state.

3) Click the ‘Write Config.’ button to send the configuration

parameters to the MODEM. Check the main window log to

find out if this step completed without errors.

Page 3

AMIS-49587

http://onsemi.com

3

Chat Application

When the Chat application is chosen:

1) Type the address of the MODEM to whom you would like

to send a message in the ‘Destination Address’ field. The

MODEM address is coded in the configuration file and

displayed in the status area.

2) Type a message in the bottom single line text field and hit

‘Enter’.

When the first message is sent from the master window, the

slave will synchronize with the master and display the message it

received in its text frame above its text input field. Follow the log

in the main window to check if all goes well. The first message

always needs to be initiated from the master window. When the

slave is properly synchronized, messages can be transmitted from

slave to master.

Depending on the previous state of the master, the first message

may fail to deliver. Initiate the send request again.

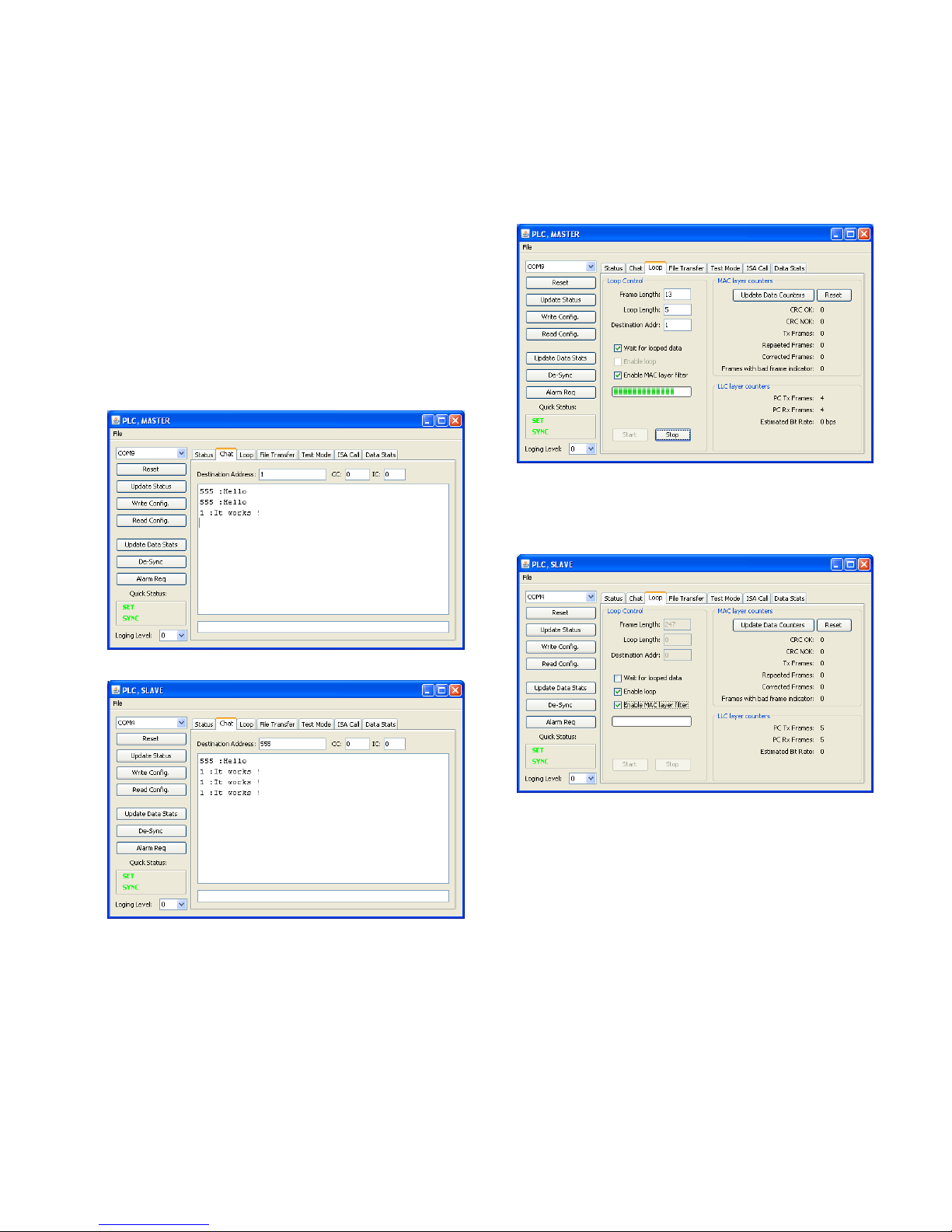

Figure 3 Master Window, configured with chat trace

Figure 4 Slave Window with chat trace

Data Loop Application

In the data loop application a constant data frame is sent from

one node (master or slave) and is received by the addressed node.

The receiver node can be configured to send the data back to the

sending node, implementing a data loop.

To setup a data loop, make sure the configuration file is written

to the MODEMs and in one node:

1) Check the ‘Enable loop’ checkbox to make this node into a

receiver and loop node.

In the window of the transmitter node:

2) Enter the frame length. The maximum is 247 bytes, the

minimum is 13 bytes.

3) Enter the number of times the data needs to be transmitted

4) Enter the destination address

5) Check the ‘Wait for looped data’ checkbox to make sure the

transmitter doesn’t send a new frame before receiving the

looped data.

6) Click the start button

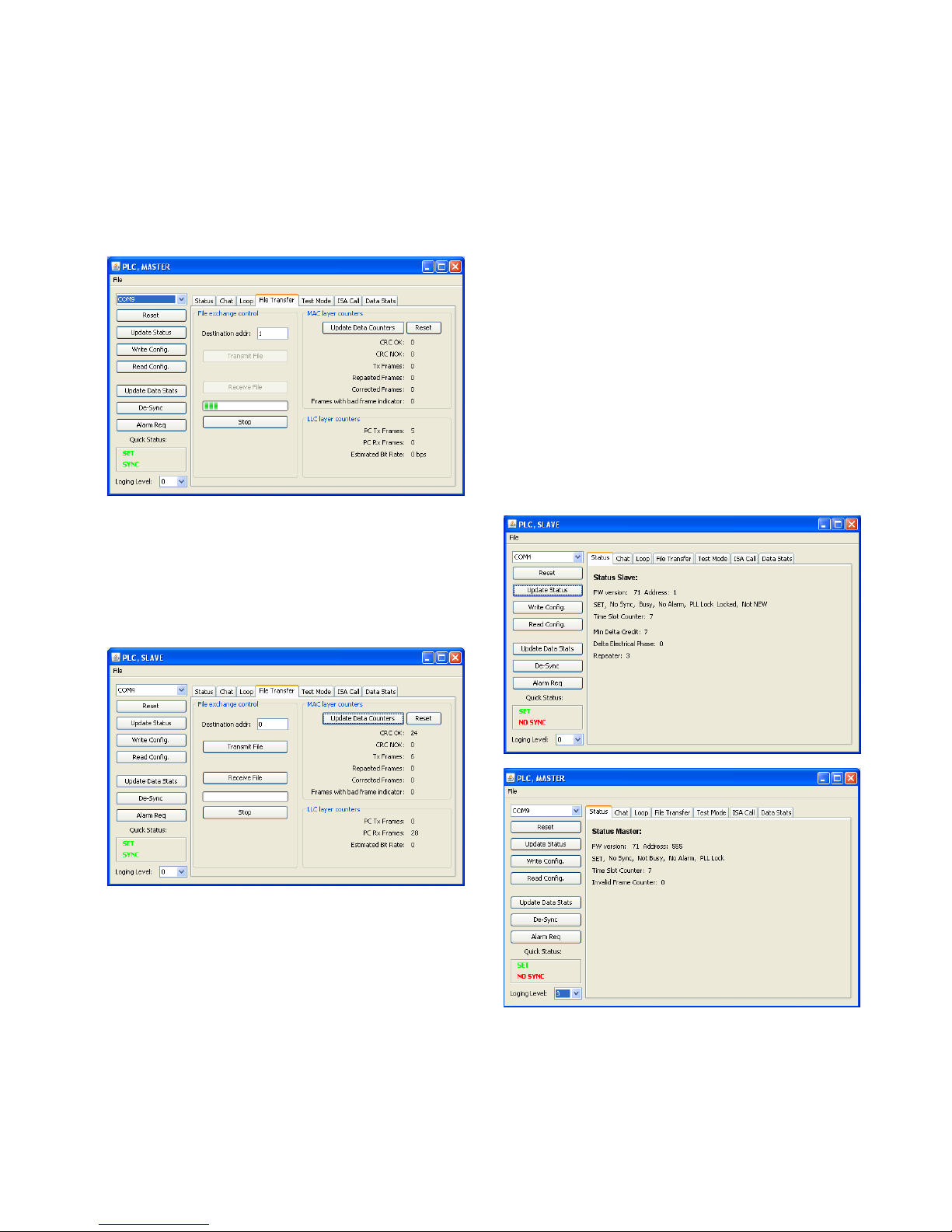

Figure 5 Initiator node of the data loop

The LLC layer counters indicate the number of transmitted and

received frames. The approximate bit rate is calculated at the end

of transmit and receive sequence.

Figure 6 Receiving and looping node

By clicking the ‘Update Data Counters’ button, the MAC layer

counters that are kept in the MODEM are retrieved. The number

of received frames is the total of ‘CRC OK’ and ‘CRC NOK’

frames. All counter values can be reset by clicking the ‘Reset’

button.

The current implementation of the data loop does not check for

errors in the looped data.

Page 4

AMIS-49587

http://onsemi.com

4

File Transfer Application

The file transfer application sends a file from the transmitter to

the receiver. Before initiating transmit, the addressed node should

be ready to receive the file. Click on ‘Receive File’ to open a file

save dialog box. Enter the file name. The receiver node is now

waiting for the complete file to arrive. On the transmitter node,

click the ‘Transmit File’ button. A file open dialog box will

appear. Choose the file to be sent. Transmit will start

immediately.

Figure 7 Node transmitting a file

Transmit or receive can be aborted at any time by clicking the

‘Stop’ button.

The file transfer application can be used to implement a BER

test. Bit error rate can be calculated by comparing the received file

with the original (not implemented by this application).

Figure 8 Node receiving a file

Special Scenarios

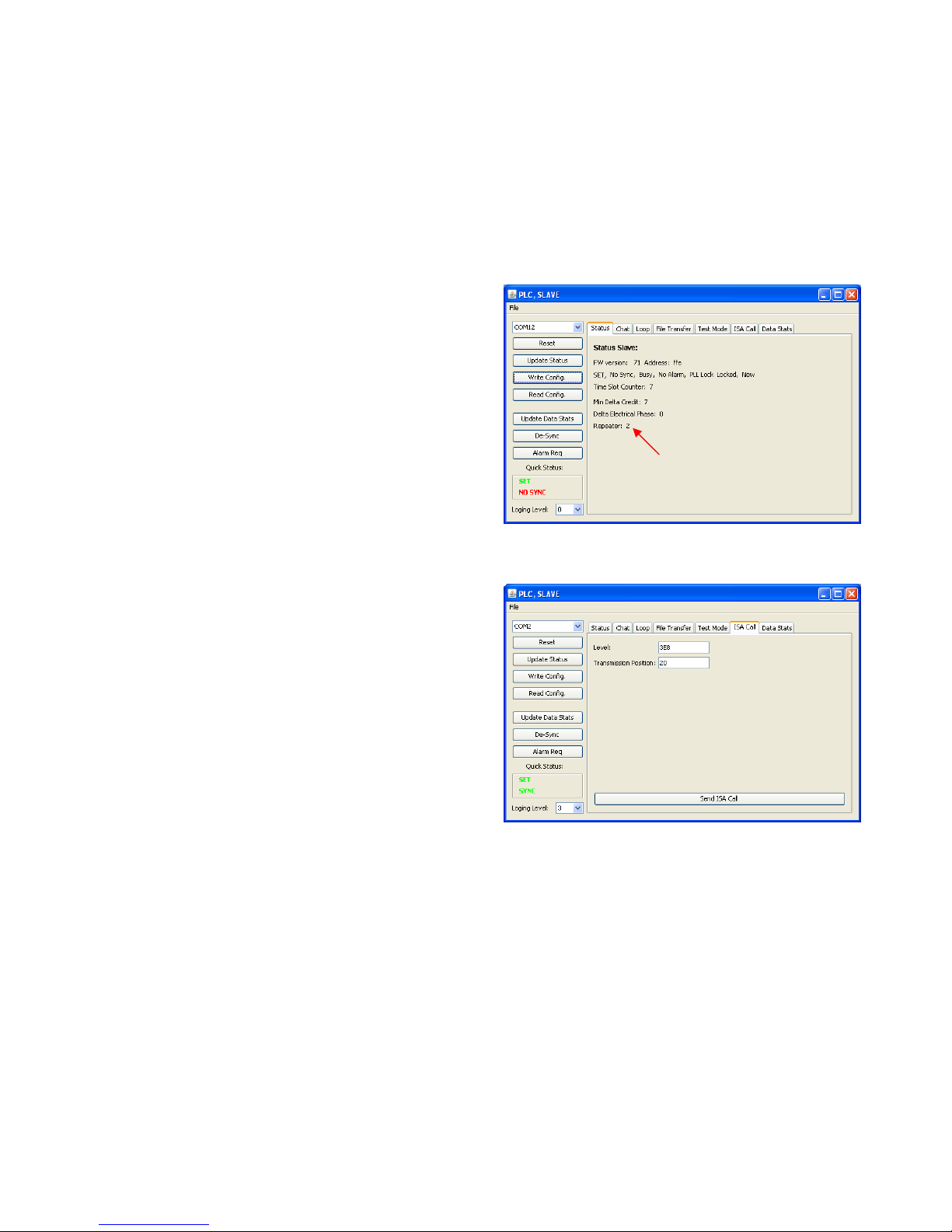

Repetition with Credit and Time Slot Counter change.

When the configuration for a server is setting the MODEM as a

repeater: set 1,2 or 3 in the Repeater section of the xml

configuration file, the MODEM will repeat messages addressed to

a different MODEM only when the current credit field in the data

frame is higher than 0

…

<Repeater>

<Bits>2</Bits>

<Value>3</Value>

<Note>

0 Never Repeater or Mode=Master,

1 Always Repeater,

2 Not Repeater (accept frame ISACall),

3 Repeater (accept frame ISACall)

</Note>

</Repeater>

The time slot counter is communicated to an external processor

or to the GUI by means of the time slot field in the status message.

The time slot counter should be used by the external processor to

block data transmission when repetition is ongoing.

The default value of the time slot counter is 7 (maximum

number of repetitions is 8: from 0 to 7) and indicates that the

communication channel is free for transmission. When the

MODEM is repeating a message, it is decrements it’s time slot

counter every time the MODEM autonomously sends the message

on the power line. At the same time the MODEM decrements the

current credit field in the frame.

This process can be partially visualized using the GUI. 3

MODEMS are needed:

One with master configuration

One with slave configuration

One with Spy configuration

Steps to follow, after all MODEMS have been configured:

1) Make sure the Spy window is set to logging level 1 and

master to level 3.

2) Make sure the master/slave are not synchronized

3) Check the status of both MODEMS and witness that the

time slot counter is in both 7.

4) Open the chat window in master

5) Set CC (Current Credit) and IC (Initial Credit) to 2

6) Set the Address field to an address that is different (!!)

from the slave address

Page 5

Y

o

time

0 or

1

Resp

W

agai

n

repe

a C

will

repe

a

the f

r

MO

N

MO

NMON

0

6

7MONMONMONMON

0

6

7MONMONMON

MO

N

0

6

7MONMONMONcorMON

7) Send a m

e

u will notice

t

slot counter in

, depending o

n

onse.

hen you upda

t

set at 7 beca

u

ted 2 times alr

e

heck the log t

h

be visible 3 t

i

ted by the sla

v

ame is lowere

d

ITOR:15:43

:

ITOR:15:43

:

ITOR:15:43

:

0 6c 6c 48

8 9 a b c

ITOR:15:43

:

ITOR:15:43

:

ITOR:15:43

:

ITOR:15:43

:

0 6c 6c 44

8 9 a b c

ITOR:15:43

:

ITOR:15:43

:

ITOR:15:43

:

ITOR:15:43

:

0 6c 6c 40

8 9 a b c

ITOR:15:43

:

ITOR:15:43

:

ITOR:15:43

:

rectly

ITOR:15:43

:

ssage from th

e

hat both MO

D

the slave wind

o

how fast and

w

e the slave sta

se by now th

e

ady.

e spy has gen

e

mes: one tim

e

e. Also check

each transmis

47:745:Spy

47:854:Spy

S

47:854: Re

c

55 50 6 15

d e f 10 1

1

47:854: Sp

y

47:854: Al

a

47:964:Spy

S

47:964: Re

c

55 50 6 15

d e f 10 1

1

48:073: Sp

y

48:073: Al

a

48:183:Spy

S

48:183: Re

c

55 50 6 15

d e f 10 1

1

48:183: Sp

y

48:183: Al

a

48:292: Sp

y

48:292: Re

c

master.

EMS synchr

o

w is different

w

hen the slave

tus, the time sl

received fra

m

rated. The tr

a

from the m

a

that the curre

n

sion.

Synchroniz

a

ubFrame

eived SDU:

41 41 41 41

12 13 14 1

No Alarm

F

rm pattern:

ubFrame

eived SDU:

41 41 41 41

12 13 14 1

No Alarm

F

rm pattern:

ubFrame

eived SDU:

41 41 41 41

12 13 14 1

No Alarm

F

rm pattern:

No Sub F

eived SDU:

A

nize and that

from 7. It will

sent out the s

y

ot counter will

e will have b

e

nsmitted mess

a

ster and 2 ti

m

t credit counte

r

tion Found,

41 1 2 3

4

5 39 f6 b7

ound

2 db

41 1 2 3

4

5 a3 8a 31

ound

2 fb

41 1 2 3

4

5 d2 f9 e6

ound

1 26

rame recei

v

MIS-49

5

http://onsemi.c

o

5

the

be

nc.

be

en

ge

es

in

5

5

5

ed

a

pdePLquthGU

to

ei

t

re

s

eBu

87

m

Sending an

a

When a slave

plication laye

r

cide to send

o

C master ap

p

erying more i

is behavior in

u

1) Make s

u

configur

a

<

NbAla

r

<Bi

t

<Va

l

<No

t

<

/NbAl

a

2) Open ma

s

3) Make su

r

couple o

f

chat appl

i

4) Hit the al

a

5) Hit the st

a

6) Witness t

h

Update exp

e

Not all MOD

E

I. To chang

e

be edited wit

h

her close the

m

load the new c

o

Note that aft

e

nd to the M

O

tton.

larm

encounters a

n

on the exter

n

ut an alarm n

o

lication layer

nformation on

sing the GUI:

re the Nb

A

tion file is set

t

m>

s>4</Bits>

ue>8</Value

e>Number of

Alarm, 0

functiona

rm>

ter and slave c

e master and s

characters fro

m

cation.

rm request bu

t

tus update but

t

at the status c

h

rt settings

M configurati

all parameter

a regular text

e

aster/slave/sp

y

nfiguration fr

o

r reloading th

e

DEM by cli

c

alarm condit

i

al controller,

tification on

t

will start sen

d

the alarm co

n

larm param

e

o 8.

>

repetition

for Disable

lity</Note>

onfiguration.

lave are synch

r

the master t

o

ton on the sla

v

on on the mas

t

anges from n

o

on settings ca

n

s, the configur

a

ditor. To acti

v

node frame a

n

m the node wi

n

configuratio

n

king ‘reset’

a

on, managed

b

the applicatio

n

he power line

.

ing out data

f

dition. To

m

ter in the

s of a Phy

Phy Alarm

onized by sen

d

the slave, usi

n

e window.

er window.

alarm to alar

m

be altered fr

o

tion .xml file

ate the new s

e

d open a new

o

dow file men

u

it still needs

nd ‘Write C

o

y the

may

The

rames

onitor

slave

ing a

g the

.

m the

needs

ttings

ne or

.

to be

nfig.’

Page 6

AMIS-49587

http://onsemi.com

6

All MODEM parameters are listed in the xml configuration file

as follows:

<parameter string representation>

<Bits> the number of bits</Bits>

<Value> the parameter value </Value>

<Note> Some notes on the parameter </Note>

</parameter string representation>

The parameter string representation and the number of bits

should not be modified!

All number fields in the xml configuration file are to be written

in hexadecimal numbers without prefix like ‘0x’.

Send and receive ISA call pattern

ISA or Repeater Call is part of the CIASE protocol. The purpose

of the RepeaterCall service is to adapt the repeater status of server

systems depending on the topology of the electrical network. It

allows the automatic configuration of the repeater status on the

whole network. In the RepeaterCall mode, the client and the

servers transmit short frames – two bytes long each – and measure

the level of the signal to determine if a server system should be a

repeater or not.

The ISA call request has 2 parameters:

1) Time slot: This pattern is transmitted on a pre definded

timeslot:

a. The local MAC address when the slave is not

having address yet or has address NEW.

b. A random time slot between Max_Adr_MAC and

Max_Adr_MAC + (Nb_Tslot_For_New * 21).

Max_Adr_MAC and Nb_Tslot_For_New are

transmitted to the servers in a regular

MA_DataRequest and are kept by the application

layer. Note that if Nb_Tslot_For_New is 0, the

servers in NEW state should not participate in the

ISA call.

2) Reception_Threshold or level represents the signal level

in dBµV threshold. The default value is 104.

The participation of the servers in the repeater call process and

the effect of the process on their repeater status depend on the

repeater management variable and the signal level heard:

1) Servers configured as never repeater do not participate:

they do not transmit during their sub-timeslot and their

repeater_status is not affected;

2) Servers configured as always repeater participate: they

transmit during their timeslot but their repeater_status is

not affected;

3) Servers configured as dynamic repeater participate: they

transmit during their sub-timeslot, if they have not heard

a signal before from the client or from any servers, which

is above the reception threshold. If during the whole

repeater call process, a server does not hear a signal from

the client or from other servers, which is above the

reception threshold, then its repeater status will be

TRUE: the server will repeat all frames. If a server hears

a signal from the client or from other servers, which is

above the reception threshold, then its repeater status will

be FALSE: the server won't repeat any frames. NOTE If

each server configured as dynamic repeater hears a

signal, which is above the reception threshold this means

that they are all close to a client, and no repetition is

needed. So, none of them will become a repeater.

The embedded SW in our PLC silicon only issues the error

message LM_SE, or syntax error at MAC level when:

1) The MODEM is master(client) and the transmission

position is different from 1.

2) The MODEM is slave(server) and the transmission

position is 0 or 1.

The embedded SW in our PLC silicon issues the error message

LM_TU1, or NEG at the MAC level when:

1) Slave MODEM is set to 'never repeater'

2) The MODEM is busy handling other events. In this case

the ISA call should be repeated until success.

Build a setup with one master (client) and one slave (server).

Make sure the server or slave configuration sets the Repeater

mode to 2: No repeater, but support for ISA call, or dynamic

repeater. Open a slave or server node window.

Synchronize master and slave by typing few lines on the master

Chat application, use slave MAC address or any other.

Open the ISA call tab. Enter any timeslot different from 1 and

any level. Set the logging level to 3.

Hit the ‘Send ISA Call’ button many times quickly after each

other until the logging shows an ISA confirm message with data ff.

SLAVE :09:50:50:625: Sending ISAREQUEST

SLAVE :09:50:50:703: Message was sent to MODEM

SLAVE :09:50:50:703: Received message from

MODEM: 62 0

SLAVE :09:50:50:703:IsaConfirm

SLAVE :09:50:50:781: Sending ISAREQUEST

SLAVE :09:50:50:843: Message was sent to MODEM

SLAVE :09:50:50:843: Received message from

MODEM: 62 0

SLAVE :09:50:50:843:IsaConfirm

SLAVE :09:50:50:906: Sending ISAREQUEST

SLAVE :09:50:50:984: Message was sent to MODEM

SLAVE :09:50:51:203: Received message from

MODEM: 62 ff

SLAVE :09:50:51:203:IsaConfirm

Page 7

AMIS-49587

http://onsemi.com

7

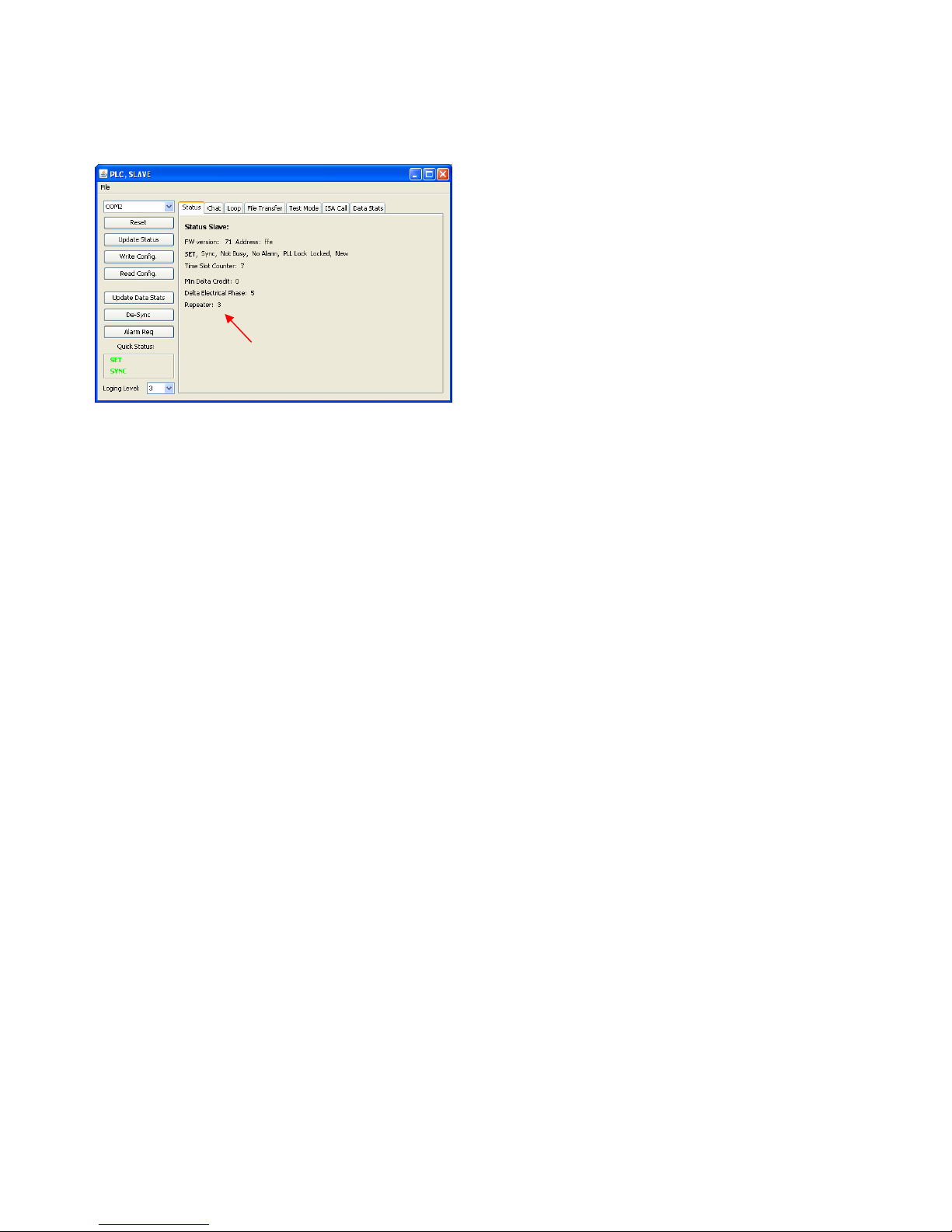

Go back to the status pane on the slave node and witness that the

repeater status has changed from no repeater to repeater because

the server did not receive any ISA call pattern from any other

MODEM.

Note that the MODEM may respond negative (62 00) many

times because its physical layer is busy. The management

application should send ISA call request in polling for success

(62 ff) loop.

Other scenarios can be tested where level and transmission

position is set depending on system topology in a multi-server

network with proper line attenuators.

Page 8

©

S

A

u

No

t

O

N

any

p

arisi

n

“Typ

i

oper

a

nor t

h

inten

Buy

e

and

d

asso

c

Opp

o

P

LI

T

Liter

a

P.O.

Pho

n

Fax:

Emai

emiconductor Com

p

gust 31, 2011

es

Semiconductor

a

roducts herein. S

g out of the appli

c

cal” parameters

w

ting parameters, i

n

e rights of others

.

ded to support or

r purchase or use

S

istributors harml

e

iated with such

u

rtunity/Affirmative

UBLICATION

O

ERATURE FULFI

L

ture Distribution Ce

n

Box 5163, Denver,

C

e: 303-675-2175 or

303-675-2176 or 80

0

l: orderlit@onsemi.

c

onents Industries, L

L

– Rev. 008

nd are registe

r

CILLC makes no

w

ation or use of an

hich may be prov

i

cluding “Typicals

”

SCILLC products

sustain life, or for

CILLC products f

o

ss against all clai

m

nintended or una

u

Action Employer.

RDERING IN

F

LMENT:

ter for ON Semicon

d

olorado 80217 US

A

800-344-3860 Toll

F

-344-3867 Toll Fre

e

om

C, 2011

ed trademarks of

S

arranty, represent

a

y product or circu

i

ded in SCILLC da

t

must be validate

d

are not designed,

any other applicat

i

r any such uninte

n

s, costs, damag

e

thorized use, eve

n

This literature is s

u

ORMATION

uctor

ree USA/Canada

USA/Canada

emiconductor Co

m

tion or guarantee

t, and specifically

a sheets and/or s

for each custome

r

intended, or autho

r

on in which the f

a

ded or unauthoriz

e

s, and expenses,

a

if such claim all

e

bject to all applica

N. Ameri

c

Toll Free

Europe,

Support:

Phone: 4

2

Japan C

u

Phone: 8

1

8

ponents Industri

e

regarding the suit

a

disclaims any and

pecifications can

a

application by cu

s

ized for use as co

m

ilure of the SCILL

C

d application, Bu

y

nd reasonable att

o

ges that SCILLC

w

ble copyright laws

an Technical Sup

p

USA/Canada

Middle East a

n

1 33 790 2910

stomer Focus Cen

t

-3-5773-3850

s, LLC (SCILLC).

S

bility of its produc

t

all liability, includ

i

nd do vary in diff

e

tomer's technical

e

ponents in syste

m

product could cr

e

er shall indemnify

a

rney fees arising

w

as negligent reg

a

and is not for resal

e

ort: 800-282-9855

d Africa Techni

ter

CILLC reserves th

e

t

s for any particul

a

ng without limitati

o

rent applications

xperts. SCILLC d

o

s intended for su

r

ate a situation w

h

nd hold SCILLC a

out of, directly or

rding the design

in any manner.

cal

ON Se

m

Order L

i

For add

Sales

R

Publication

right to make ch

a

r purpose, nor do

e

n special, conseq

and actual perfor

m

es not convey an

y

gical implant into

t

ere personal injur

y

nd its officers, em

p

indirectly, any cla

i

or manufacture of

iconductor Website

terature: http://www

.

itional information, p

epresentative

Order Number

:

AMIS-49587

nges without furt

h

s SCILLC assume

uential or incident

a

ance may vary o

v

license under its

p

he body, or other

a

or death may oc

c

loyees, subsidiari

e

m of personal inj

u

the part. SCILLC

: www.onsemi.com

onsemi.com/orderlit

lease contact your l

o

er notice to

any liability

l damages.

er time. All

atent rights

pplications

ur. Should

s, affiliates,

ry or death

is an Equal

cal

Loading...

Loading...