Page 1

CD/MD TUNER AMPLIFIER

MODEL FR-155

FR-155

Ref. No. 3662

092000

Silver model

UDT

UGT

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THA T EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

120V AC, 60Hz

220 -230V AC, 50/60Hz

TABLE OF CONTENTS

Specifications ----------------------------------------------------------Caution on replacement of optical pickup ---------------------------

Protection of eyes from laser beam during servicing ---------------

Laser W arning Label----------------------------------------------------

Service procedures -----------------------------------------------------

Front panel view --------------------------------------------------------

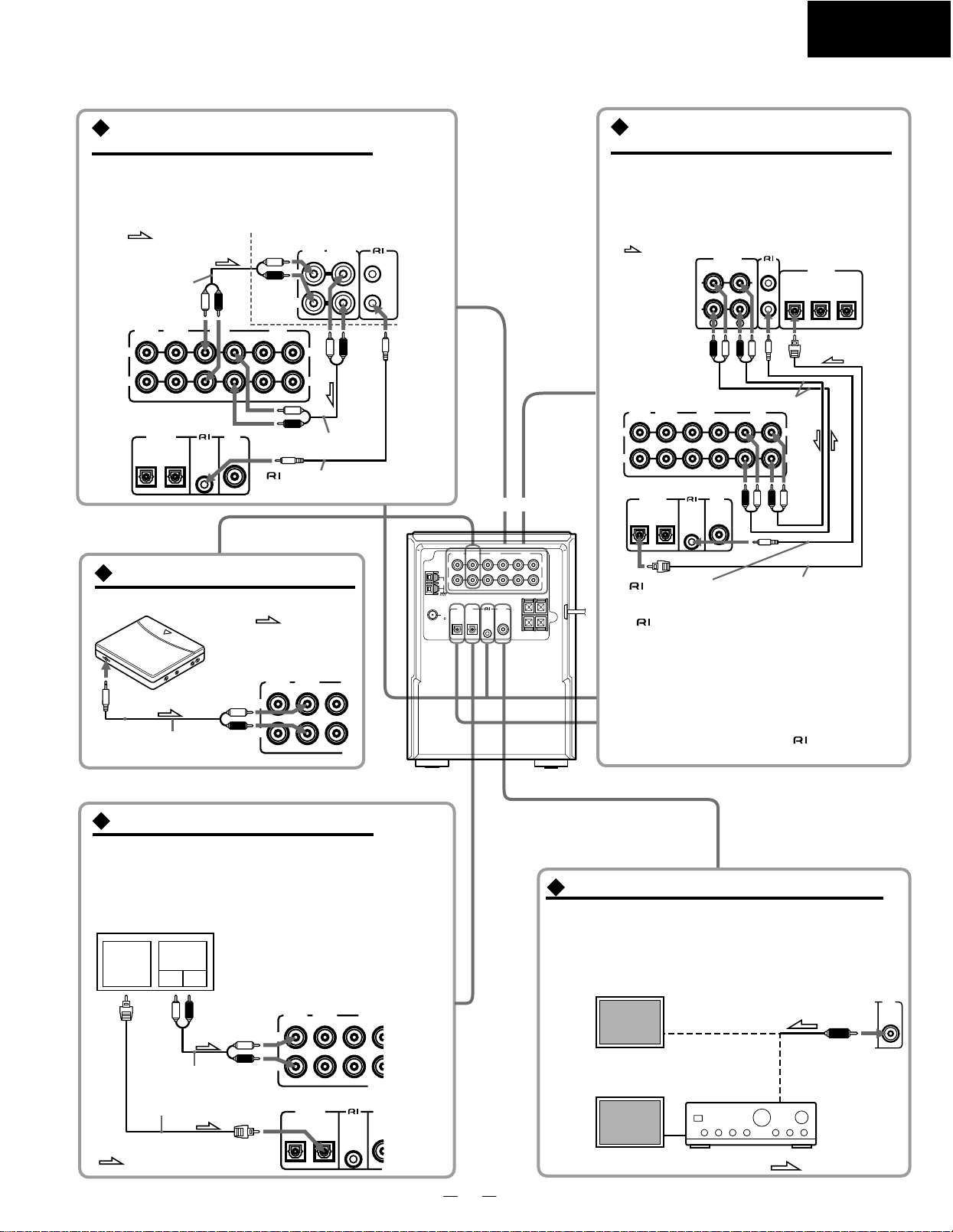

Connecting to Other Components------------------------------------

Remote controller -------------------------------------------------------

Setting the day of the Week and the Time----------------------------

IC Block diagram and descriptions -----------------------------------

Microprocessor Connection Diagram---------------------------------

Microprocessor Terminal Description--------------------------------

Operation of the Microprocessor--------------------------------------

MD Mechanism Exploded view-------------------------------------

MD Mechanism Disassembly ----------------------------------------

MD Mechanism Reassembly ----------------------------------------

MD Adjustment Procedures ------------------------------------------

MD Mount View / Messages--------------------------------------------

CD Mechanism Exploded View ---------------------------------------

CD Adjustment Procdedure-------------------------------------------

Clock Adjustment Procdedure-----------------------------------------

Handling of Pickup-----------------------------------------------------

Chassis Exploded View Parts List------------------------------------

Chassis Exploded View ------------------------------------------------

Block Diagram----------------------------------------------------------

Block Diagram (Power Supply Section)------------------------------

Schematic Diagram (Amplifire Section)-----------------------------

Printed Circuit Board View 1------------------------------------------

Schematic Diagram (CD&Microprocessor Section)----------------

Printed Circuit Board View 2------------------------------------------

Schematic Diagram (Power Supply Section)-----------------------

Printed Circuit Board View 3------------------------------------------

Printed Circuit Board View Parts List--------------------------------

Wiring V ie w-------------------------------------------------------------

Packing View Parts List------------------------------------------------

2

2

3

3

3

4

5

6

6

7

15

16

17

18~19

20,21

22

23~25

26

27,28

29

30

31

32

33

35

37

39

41

43

45

47

49

51~54

55

57

Page 2

FR-155

SPECIFICATIONS

General

Power supply AC 220-230 V, 50/60 Hz

AC 120 V, 60 Hz

Power consumption 63 W (220-230 V, 50/60 Hz)

82 W (120 V, 60 Hz)

(Standby) 7 W

(Energy Save) 1.5 W

Clock precision

Dimensions (W × H × D) 205 × 154 × 356 mm

Weight 5.5 kg, 12.1 lbs

Amplifier

Power output

Dynamic power 2 × 23 W at 4 W

Total harmonic distortion 0.4 % at rated power

IM distortion 0.2 % at rated power

Damping factor 25 at 8 Ω

Sensitivity and impedance LINE, TAPE:

Frequency response 10 to 50,000 Hz : +0dB / -3 dB

Tone Control S.BASS1: +4 dB at 40 Hz

Signal to noise ratio

Muting

CD player

Signal readout system Optical non-contact

Frequency response 10 Hz to 20 kHz ( 3 dB)

Wow and flutter Below threshold of

monthly error: 30 seconds

(at 25 degrees Celsius)

8-1/16" × 6-1/16"× 14"

2 × 26 W at 4 W EIAJ

2 × 21 W at 6 W EIAJ

Rated Power

2 × 19 W min, RMS at 4 W

1 kHz no more than

0.2 % THD

150 mV, 50 kW

CDR: 150 mV, 50 kW

S.BASS2: +8 dB at 50 Hz

S.BASS3: +4 dB at 10 kHz/

+8 dB at 50 Hz

LINE, CDR, TAPE: 100dB

(IHF-A)

50 dB

measurability

MD recorder

Signal readout system Optical non-contact

Recording time 320 minutes maximum

(at LP4 mode)

Frequency response 10 Hz to 20 kHz ( 3 dB)

Wow and flutter Below threshold of

measurability

Tuner

Tuning range FM: 87.50 to 108.00 MHz

(50 kHz steps)

AM: 522 to 1611 kHz

(9 kHz steps)

Usable sensitivity FM Mono:11.2 dBf,

1.0 µV (75 W IHF)

Stereo:17.2 dBf,

2.0 µV (75 W IHF)

AM: 30 µV

50 dB quieting sensitivity

Capture ratio 2.0 dB

Image rejection ratio FM: 85 dB

IF rejection ratio FM: 90 dB

Signal to noise ratio FM Mono : 73 dB IHF

Selectivity FM: 50 dB

Harmonic distortion FM: Mono: 0.7 %

Frequency response FM:

Stereo separation FM: 40 dB at 1,000 Hz

Specifications and features are subject to change without noitce.

FM Mono:17.2 dBf,

2.0 µV (75 W)

Stereo:37.2 dBf,

20.0 µV (75 W)

AM: 40 dB

AM: 40 dB

Stereo : 67 dB IHF

AM: 40 dB

( 300 kHz at 40 kHz devi.)

Stereo: 0.3 %

AM: 0.7 %

30 to 15,000 Hz ( 1.5 dB)

FM:

30 dB at 100 to 10,000 Hz

CAUTION ON REPLACEMENT OF OPTICAL PICKUP

The laser diode in the optical pickup block is so sensitive to

static electricity, surge current and etc., that the components

are liable to be broken down or its reliability remarkably

deteriorated.

PRECAUTIONS

1.Ground for the work-desk.

Place a conductive sheet such as a sheet of copper

(with impedance lower than 10 Mohm) on the workdesk and place the set on the conductive sheet so that

the chassis can be grounded.

2.Grounding for the test equipments and tools.

Test equipments and toolings should be grounded in

order that their ground level is the same the ground of

the power source.

During repair,carefully take the following precautions.

(The following precautions are included in the service

parts.)

3. Grounding for the human body.

Be sure to put on a wrist-strap for grounding whose

other end is grounded.

Be particularly careful when the workers wear

synthetic fiber clothes, or air is dry.

4. Select a soldering iron that permits no leakage and

have the tip of the iron well-grounded.

5. Do not check the laser diode terminals with the

probe of a circuit tester or oscilloscope.

2

.

Page 3

PROTECTION OF EYES FROM LASER BEAM DURING SERVICING

FR-155

This set employs a laser. Therefore, be sure to follow carefully

the instructions below when servicing.

WARNING!!

SERVICE WARNING : DO NOT APPROACH THE

LASER EXIT WITH THE EYE TOO CLOSELY.

IN CASE IT IS NECESSARY TO CONFIRM LASER

BEAM EMISSION, BE SURE TO OBSERVE FROM

A DISTANCE OF MORE THAN 30cm FROM THE

SURFACE OF THE OBJECTIVE LENS ON THE

OPTICAL PICK-UP BLOCK.

LASER WARNING LABEL

The label shown below are affixed.

1. Warning label

Laser Diode Properties

Material: GaAS/GaALAs

Wavelength: 780nm

Laser output: max. 0.5mW*

Emission Duration: continuous

*This output is the value measured at a distance about 1.8mm

from the objective lens surface on the Optical Pick-up Block.

2. Class 1 label

LUOKAN 1

LASERLAITE

"CLASS 1 LASER

PRODUCT"

KLASS 1

LASER APPARAT

SERVICE PROCEDURE

1. Replacing the fuses

This symbol located near the fuse indicates that the

fuse used is show operating type, For continued protection against

fire hazard, replace with same type fuse , For fuse rating, refer to

the marking adjest to the symbol.

Ce symbole indique que le fusible utilise est e lent.

Pour une protection permanente, n'utiliser que des fusibles de meme

type. Ce demier est indique la qu le present symbol est apposre.

REF.NO.

F901

PART NO.

252157

252083

NOTE : <DT> : 120 V model only

<GT> : 220 V~230 V model only

2. To initialize the unit

1. Press and the hold down the CD STOP button , then press the

STANDBY/ON button.

2. After " All lighting " is displayed, the preset memory and each

mode stored in the memory, are initialized and will return to the

factory settings.

3. Press the STANDBY/ON button.

4. Unplug the AC plug from the wall outlet.

DESCRIPTION

1.25A-UL/T-237, Fuse <DT>

0.4A-SE-EAW, Fuse <GT>

3. Safety-check out

(Only U.S.A. model)

After correcting the original service problem perform the

follwing safety check before releasing the set to the customer

Connect the insulating-resistance tester between the plug of

power supply cord and terminal GND on the back panel.

Specifications: More than 10Mohm at 500V

4. Memory Preservation

This unit does not require memory preservation batteries. A built-in

memory power back-up system preserves the contents of the

memory during power failures and even when the unit is un-plugged.

The unit must be plugged in order to charge the back-up

system.

The memory preservation period after the unit has been unplugged

varies depending on climate and placement of the unit. On the

average, memory contents are protected over a period of a few

weeks after the last time the unit has been unplugged. This period

is shorter when the unit is exposed to a highly humid climate.

5. Changing the AM band step

With the exception of the worldwide models, a tuning step selector

switch is not provided. When you change the band step, change

the parts as shown below.

To 10kHz To 9kHz

R748 open 1 kohms

R749 1 koms open

R748 and R749 on the microprocessor PC board (NADG-6933)

3

Page 4

FR-155

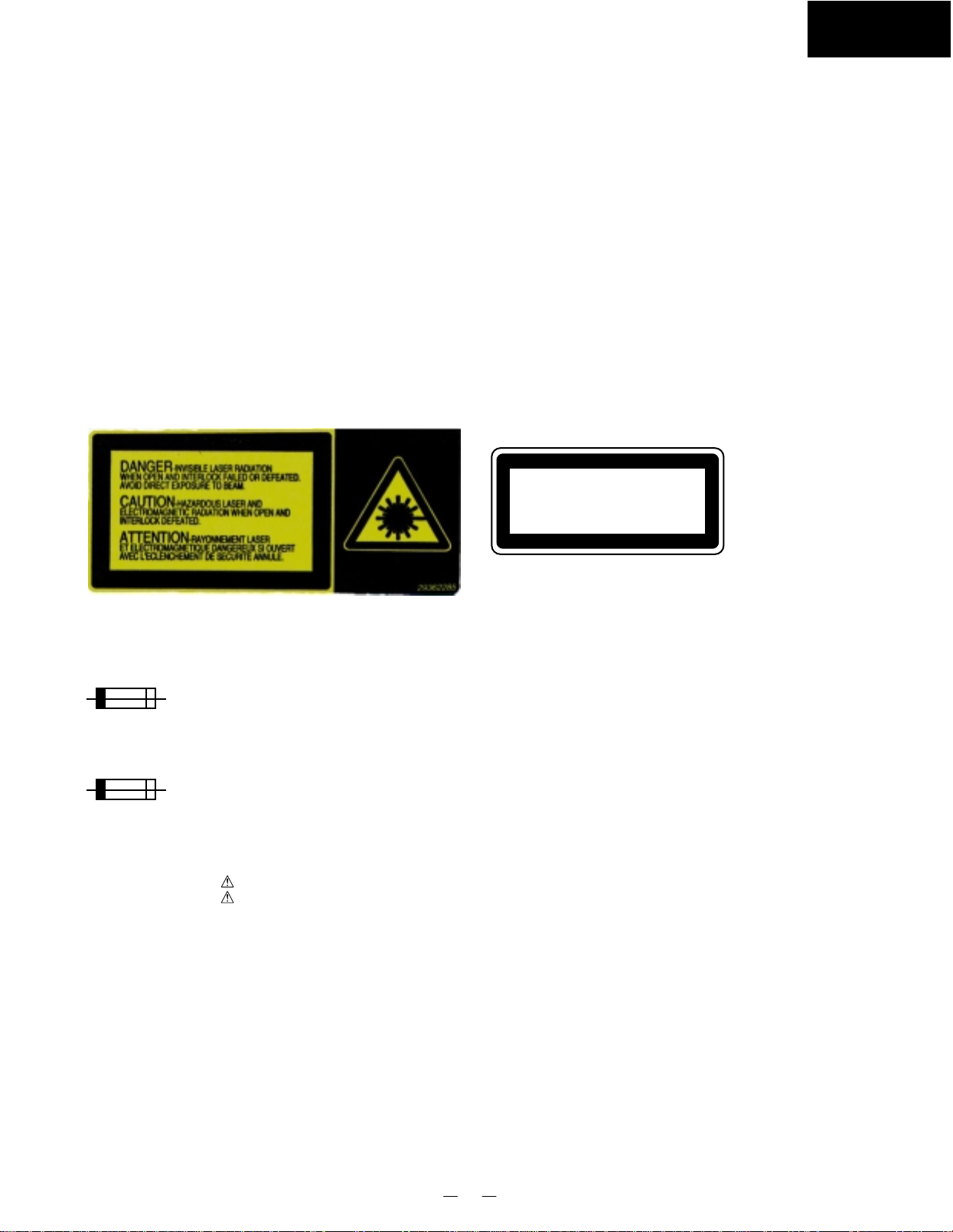

FRONT PANEL VIEW

MD disc slot

VOLUME control

ACOUSTIC

STANDBY/ON button

ENERGY SAVE button

REC MODE switc

Remote control sensor

PRESENCE

/indicator

CD disc tray

DISPLAY button

MD

CD/ MD TUNER AMPLIFIER

DISC LOADING MECHANISM

CD/ MD

FM/AM

button

MD

MD

button

button

CD/MD button

FM/AM button

OTHER

STANDBY/ON

ENERGY SAVE

WIDE RANGE AMPLIFIER

TECHNOLOGY

DISCRETE OUTPUT STAGE

ACOUSTIC

PRESENCE

VOLUME

MIN MAX

INPUTS

REC

CD DUBBING

MODE

AUTO/ MONO

OTHER INPUTS button

MD

REC button

CD DUBBING button

MODE button

AUTO/MONO button

button

CD

MULTI JOG dial

EDIT/CLEAR/NO button

REPEAT/YES button

CD

button

CD button

MULTI JOG

PUSH TO ENTER

EDIT/ CLEAR

REPEAT

NO

YESTUNING

PHONES

REC MODE

SP

LP2

MONO

h

LP4

DISPLAY

TIMER

PHONES jack

/ buttons

TUNING / buttons

DISPLAY

TIMER indicator

CD indicator

SOURCE indicator

Timer indicators

Recording level indicator

MUTING indicator

LEVEL-SYNC indicator

DIGITAL indicator

Playback mode indicators

SLEEP

SOURCE CD TIMER MD MDCHCD

ONCE

W.DAY

W.END

REC

MUTING

L

- 40 - 20 -10 0 OVER- 6 - 2-

R

LEVEL-SYNC DIGIT AL

CHAIN

REPEAT

1 TR MEMOR Y

RANDOM

DISC TRA CK ELAPSED REMAIN TITLE

CD MD

DUB

TUNEDSTEREOAUTOMONO

TIMER button

TOC

MD indicator

MD/CD setting indicator

Multi-purpose displa

s

y

CH (channel) indicator

When lit, the indicators show

what the mulit-purpose display

( Multi-purpose display) above

them is currently displaying.

TOC indicator

MD operation indicators

DUB indicator

CD operation indicators

Indicators for radio frequency

information

4

Page 5

CONNECTING TO OTHER COMPONETS

FR-155

Connecting an Onkyo stereo

cassette tape deck

The illustration below describes the connections to an Onkyo stereo

cassette tape deck.

TAPE OUT (REC) and IN (PLAY) jacks of the unit to the INPUT (REC) and

OUTPUT (PLAY) jacks of the cassette tape deck, respectively.

Audio

connection

cable

LINE-1 LINE-2 TAPE

L

R

FR-155's rear panel

DIGITAL

OUT IN

OPTICAL

To connect to another cassette tape deck, connect the

Onkyo stereo cassette

: Signal flow

tape deck rear panel

INPUT OUTPUT

white

(REC) (PLAY)

L

red

R

OUT IN OUT IN

(

REC)(PLAY

WOOFER

REMOTE

CONTROL PRE OUT

CDR

)(

)

REC

SUB

cable supplied with

the Onkyo stereo

cassette tape deck

L

R

)(

PLAY

Audio connection

cable

REMOTE

CONTROL

Connecting a portable MD player

Refer to the portable MD playerÕs Instruction Manual.

: Signal flow

Audio

connection

cable

white

red

LINE-1 LINE-2 T

L

R

OUT

(

REC

ANTENNA

Rear Panel View

LINE-1 LINE-2 TAPE

OUT IN OUT IN

L

R

AM

(

REC)(PLAY

CAUTION: SPEAKER IMPEDANCE

4 OHMS MIN./ SPEAKER

DIGITAL

SUB

WOOFER

OUT IN

REMOTE

FM

CONTROL PRE OUT

75

OPTICAL

CDR

)(

)

PLAY)(REC

SPEAKERS

L

R

Connecting an Onkyo compact

disc recorder

The following diagram shows how to connect an

optional Onkyo compact disc recorder to the FR-155.

Connect its CDR OUT (REC) jacks and IN (PLA Y)

jacks to the disc recorderÕs INPUT (REC) jacks and

OUTPUT (PLAY) jacks respectively.

: Signal flow

LINE-1 LINE-2 TAPE

L

R

FR-155's rear panel

DIGITAL

OUT IN

OPTICAL

L

R

+–

+–

cable that comes

An

with the compact disc recorder

jack connection enables you to use the

The

following functions:

ANALOG

INPUT

OUTPUT

(REC)

L

R

K

red

white

Audio connection cable

OUT IN OUT IN

(

)(

REC)(PLAY

SUB

WOOFER

REMOTE

CONTROL PRE OUT

¥ You can control a connected Onky o compact disc

recorder from the FR-155' s remote controller.

¥ When the connected Onkyo compact disc recorder

plays bac k, the Input Selector on the FR-155 is

automatically switched to CD-R.

¥ To connect both CD recorder and a cassette tape

deck to the FR-155, connect the

both devices.

Jacks on the compact disc

recorder's rear panel

REMOTE

CONTROL

(PLAY)

L

REC

INPUT1 INPUT2

L

R

CDR

L

R

)(

)

PLAY

Optical fiber audio cable

DIGITAL

OPTICAL

OUTPUT

connectors of

Connecting a DVD player

In addition to the optical digital audio connections,you must also

make analog connections.To connect to the Onkyo DVD player, be

sure to connect to the LINE-1 jacks with the audio connection cable,

not the LINE-2 jacks.

DVD player

Digital

audio

output

Analog

audio output

L R

Audio connection

cable

Optical fiber

audio cable

: Signal flow

FR-155's rear panel

white

L

R

red

LINE-1 LINE-2 TAPE

DIGITAL

OUT IN

OPTICAL

OUT

(

REC)(PL

REMOTE

CONTROL PR

S

WO

Connecting a subwoofer

The FR-155 has a SUBWOOFER PRE OUT jack. Connect

an active subwoofer (a subwoofer that contains an amplifier),

or connect an amplifier to the FR-155, then connect a nonactive subwoofer to the amplifier.

Active subwoofer

(with a built-in amplifier)

SUB

WOOFER

PRE OUT

Subwoofer

(without a built-in amplifier)

Amplifier

: Signal flow

5

Page 6

FR-155

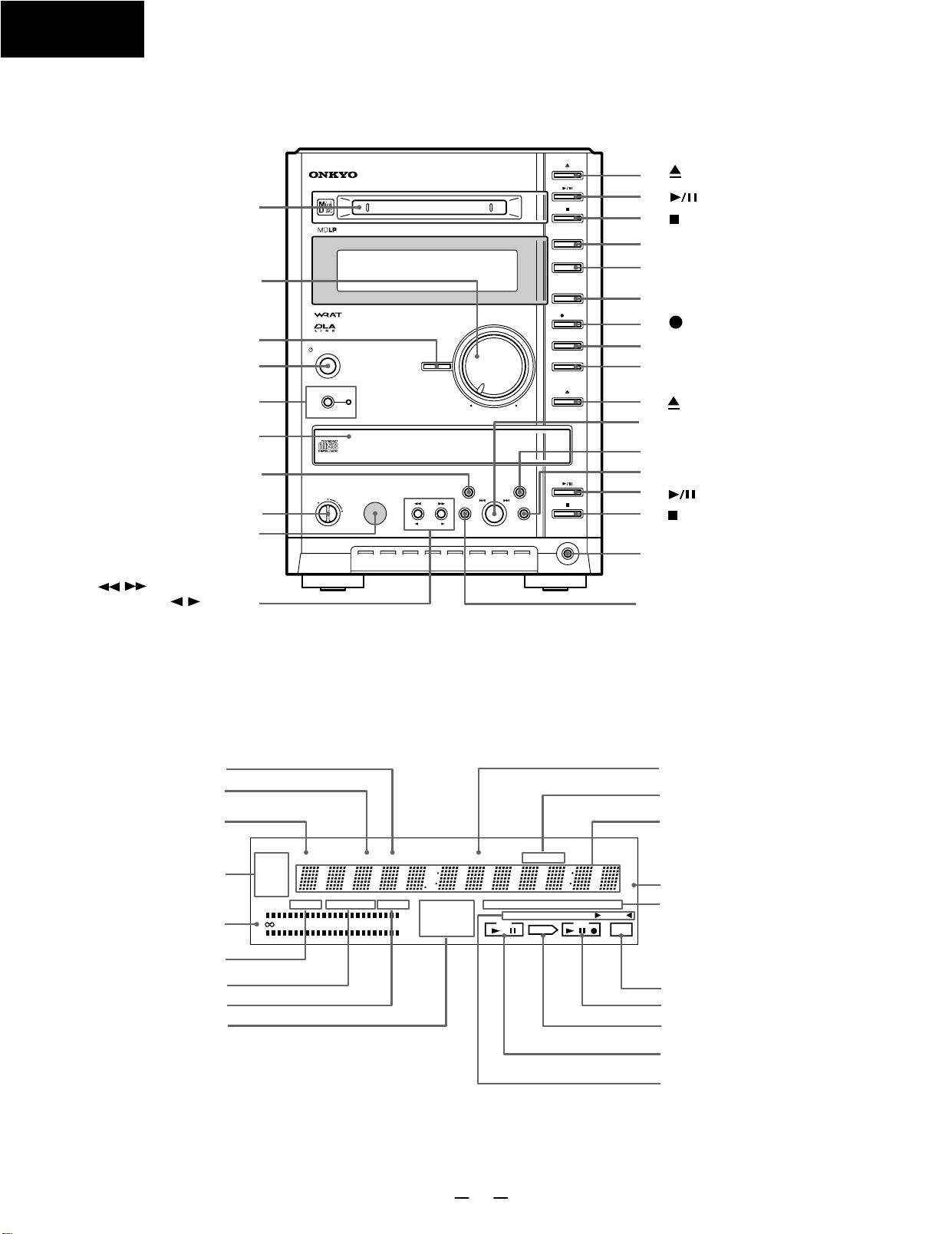

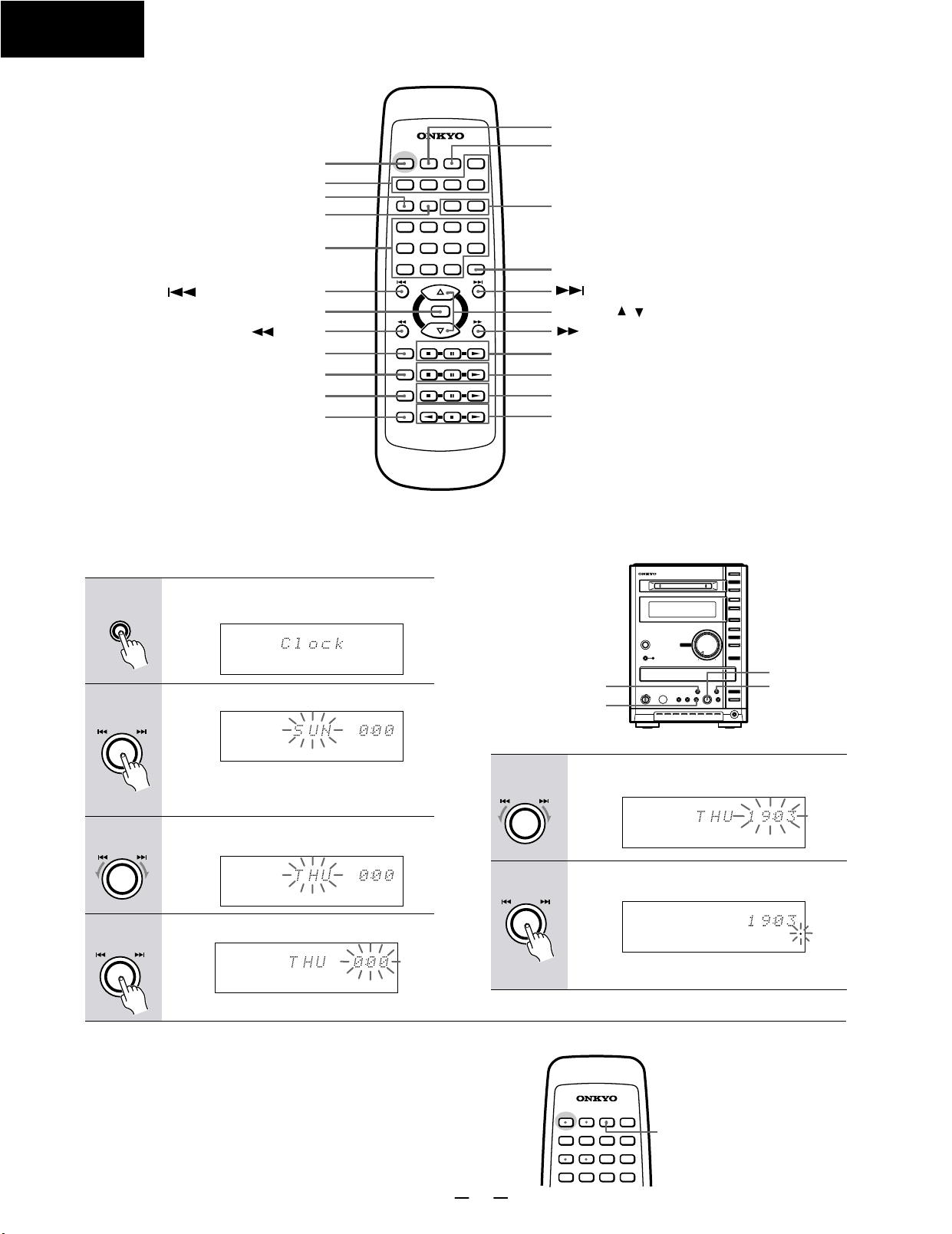

REMOTE CONTROLLER

STANDBY/ON button

CDR/TAPE/LINE/DIGITAL buttons

CD button

MD button

Number buttons

/TAPE REW button

MUTING button

button

MODE button

REPEAT button

CLEAR button

SCROLL button

STANDBY/ON SLEEP

TAPE REW

CD/MD/CDR

REPEAT

CLEAR

SCROLL

CLOCK

CALL

CDR TAPE LINE1 LINE2

CD MD FM AM

1 2 3 4

9 10/0 --/---

M

E

U

L

U

O

P

V

MUTING

V

N

O

L

W

U

O

M

E

D

MODE

REMOTE CONTROLLER

RC-434S

DIGITAL

INPUT

8765

A.PRESENCE

TAPE FF

CD

MD

CDR

TAPE

SLEEP button

CLOCK CALL button

FM/AM buttons

A.PRESENCE button

/TAPE FF button

VOLUME

/ buttons

button

CD operation buttons

MD operation buttons

Operation buttons for an Onkyo CDR

Operation buttons for an

Onkyo stereo cassette tape

dec

k

SETTING THE DAY OF THE WEEK AND THE TIME

You can select either the 12-hour display or

to set the time based on the 24-hour display.)

1

TIMER

2

MULTI JOG

PUSH TO ENTER

3

MULTI JOG

PUSH TO ENTER

4

MULTI JOG

PUSH TO ENTER

Press TIMER repeatedly

"Clock"

appears in the display.

SLEEP SOURCE C D TIMER M D M DCHC D

ONCE

W.DAY

W.END

REC

S.BASS

MUTING DIGITAL CHAIN

LEVEL - SYNC

L

-40-20-

-

10 0 OVER-6-2

R

Press MULTI JOG.

SLEEP SOURCE C D TIMER M D M DCHC D

ONCE

W.DAY

W.END

REC

S.BASS

MUTING DIGITAL CHAIN

LEVEL - SYNC

L

-40-20-

-

10 0 OVER-6-2

R

You can now set the day of the week.

If you prefer the 12-hour display, press

DISPLAY.

Turn MULTI JOG to select the

current day of the week.

SLEEP SOURCE C D TIMER M D M DCHC D

ONCE

W.DAY

W.END

REC

S.BASS

MUTING DIGITAL CHAIN

LEVEL - SYNC

L

-40-20-

-

10 0 OVER-6-2

R

Press MULTI JOG to confirm the

SLEEP SOURCE C D TIMER M D M DCHC D

ONCE

W.DAY

W.END

REC

S.BASS

MUTING DIGITAL CHAIN

LEVEL - SYNC

L

-40-20-

-

10 0 OVER-6-2

R

You can now set the time .

REPEAT

1 TR MEMORY

RANDOM

REPEAT

1 TR MEMORY

RANDOM

REPEAT

1 TR MEMORY

RANDOM

REPEAT

1 TR MEMORY

RANDOM

until

DISC TRACK ELAPSED REMAIN TITLE

RDS MONO AUTO STEREO TUNED

M D

C D

DUB TOC

DISC TRACK ELAPSED REMAIN TITLE

RDS MONO AUTO STEREO TUNED

M D

C D

DUB TOC

DISC TRACK ELAPSED REMAIN TITLE

RDS MONO AUTO STEREO TUNED

M D

C D

DUB TOC

DISC TRACK ELAPSED REMAIN TITLE

RDS MONO AUTO STEREO TUNED

C D

M D

DUB TOC

setting.

24-hour displa

DISPLAY

5

MULTI JOG

PUSH TO ENTER

6

MULTI JOG

PUSH TO ENTER

To cancel the clock setting

Press EDIT/CLEAR /NO.

y. (This section

explains how

1

Turn MULTI JOG to set the current

(This example

shows the 24-hour display.)

SLEEP SOURCE C D TIMER M D M DCHC D

ONCE

W.DAY

W.END

REC

LEVEL - SYNC

S.BASS

MUTING DIGITAL CHAIN

L

-40-20-

-

10 0 OVER-6-2

R

REPEAT

1 TR MEMORY

RANDOM

DISC TRACK ELAPSED REMAIN TITLE

RDS MONO AUTO STEREO TUNED

C D

Press MULTI JOG in sync with

signal.

SLEEP SOURCE C D TIMER M D M DCHC D

ONCE

W.DAY

W.END

REC

LEVEL - SYNC

S.BASS

MUTING DIGITAL CHAIN

L

-40-20-

-

10 0 OVER-6-2

R

The clock starts operating and a dot

indicating seconds starts to flash.

REPEAT

1 TR MEMORY

RANDOM

DISC TRACK ELAPSED REMAIN TITLE

RDS MONO AUTO STEREO TUNED

C D

2-6

EDIT/

CLEAR/NO

M D

DUB TOC

the time

M D

DUB TOC

time

.

Checking the time and the day of the week

To check the time and the day of the week, press

TIMER to display "Clock, then press DISPLAY.The

display now indicates the day of the week and the

current time.Alternatively,press CLOCK CALL on the

remote controller. To switch between the 12-hour and

24-hour displays,press DISPLAY while the current time

is indicated on the display.

STANDBY/ON SLEEP

CLOCK

CALL

DIGITAL

CDR TAPE LINE1 LINE2

CD MD FM AM

1 2 3 4

INPUT

CLOCK CALL

6

Page 7

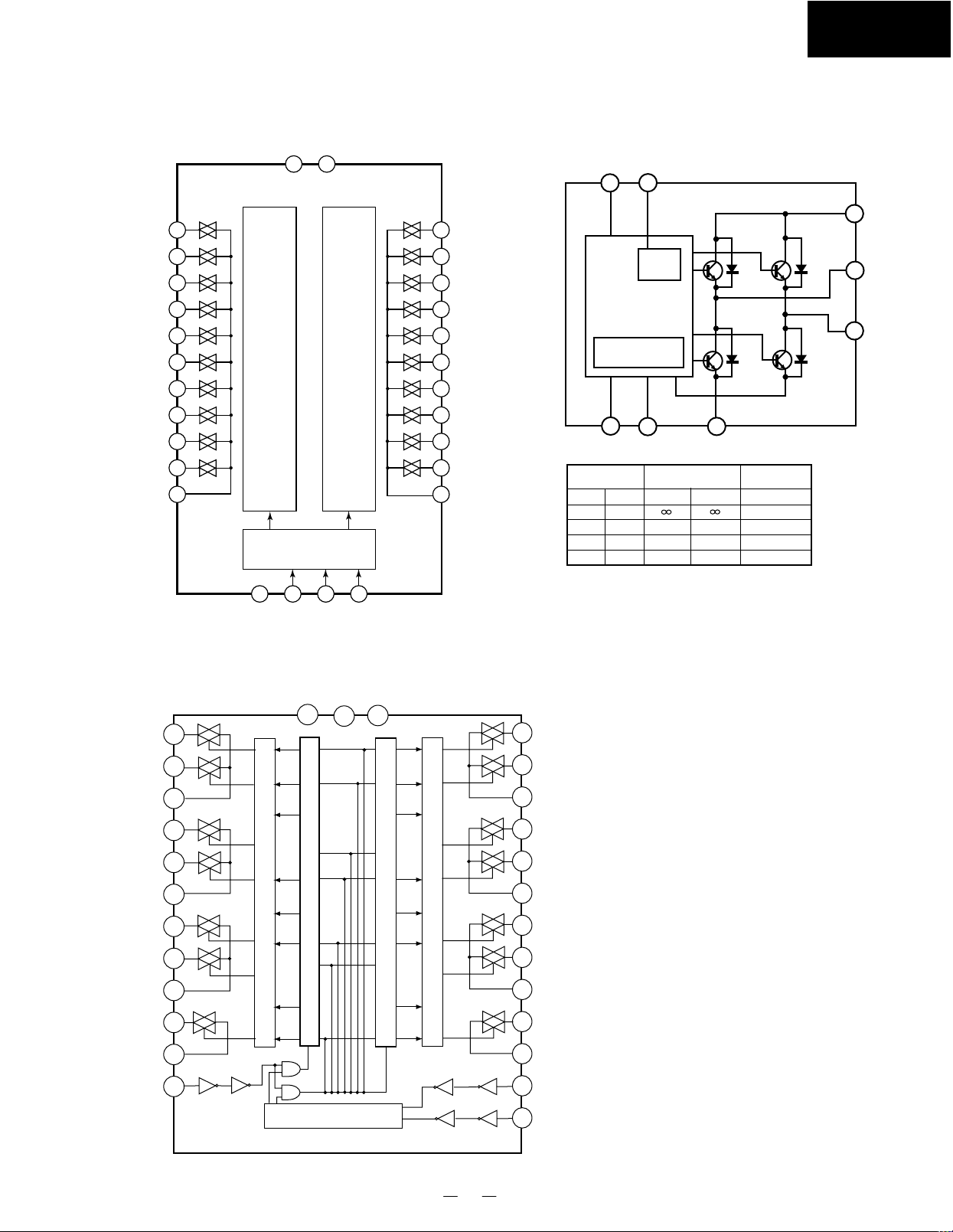

I C BLOCK DIAGRAM AND DESCRIPTIONS

FR-155

Q401:TC9273N-004 (Analog function switch)

VSS

VDD

128

2

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

OUT

10

11

12

3

4

5

6

7

8

9

10BITS LATCH CIRCUIT

LEVEL SHIFT AND

SHIFT REGISTER

13 14 15 16

GND CK DATA STB

10BITS LATCH CIRCUIT

27

26

25

24

23

22

21

20

19

18

17

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

OUT

Q103,Q181:TA7291S (Motor driver)

Vref

Vcc

2

8

REG

PROTECTOR

159

IN1 IN2 GND

INPUT

IN1

IN2

0

1

0

1

CCW : Counter clockwise direction

CW : Clockwise direction

OUTPUT

OUT1

0

0

1

1

OUT2

MODE

STOP

H

H

L

L

H

L

CW/CCW

CCW/SW

BRAKE

6

7

3

Vss

OUT1

OUT2

Q447:TC9162AN (Analog function switch)

S1

S2

S3

COM1

S4

S5

S6

COM2

S7

S8

COM3

ST

12

13

10

11

VSS

1

2

3

4

5

6

7

8

9

LATCH CIRCUIT

LEVEL SHIFTER

SHIFT REGISTER

GND

14

VDD

28

LATCH CIRCUIT

LEVEL SHIFTER

27

26

25

24

23

22

21

20

19

18

17

16

15

S1

S2

S3

COM1

S4

S5

S6

COM2

S7

S8

COM3

DATA

CK

7

Page 8

FR-155

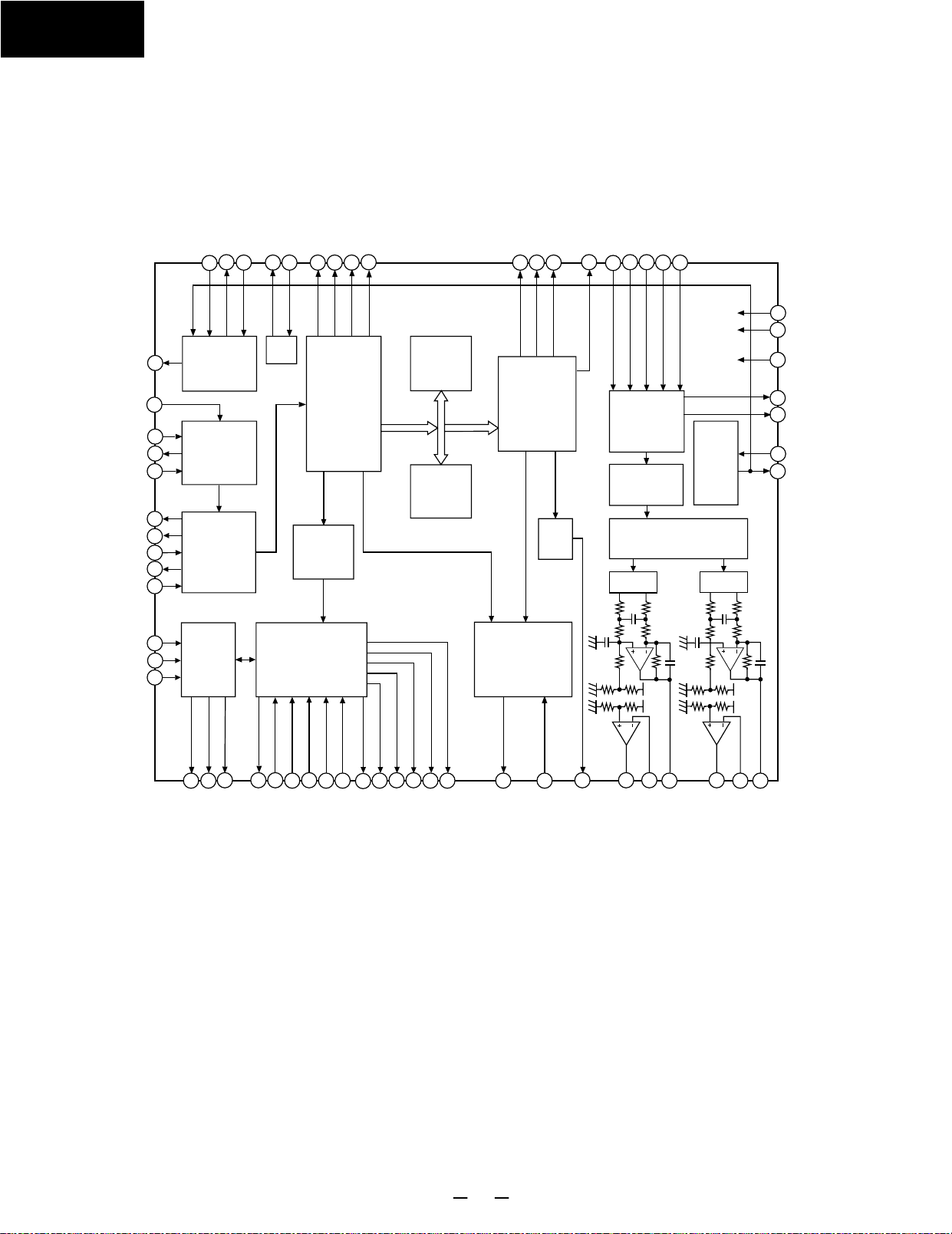

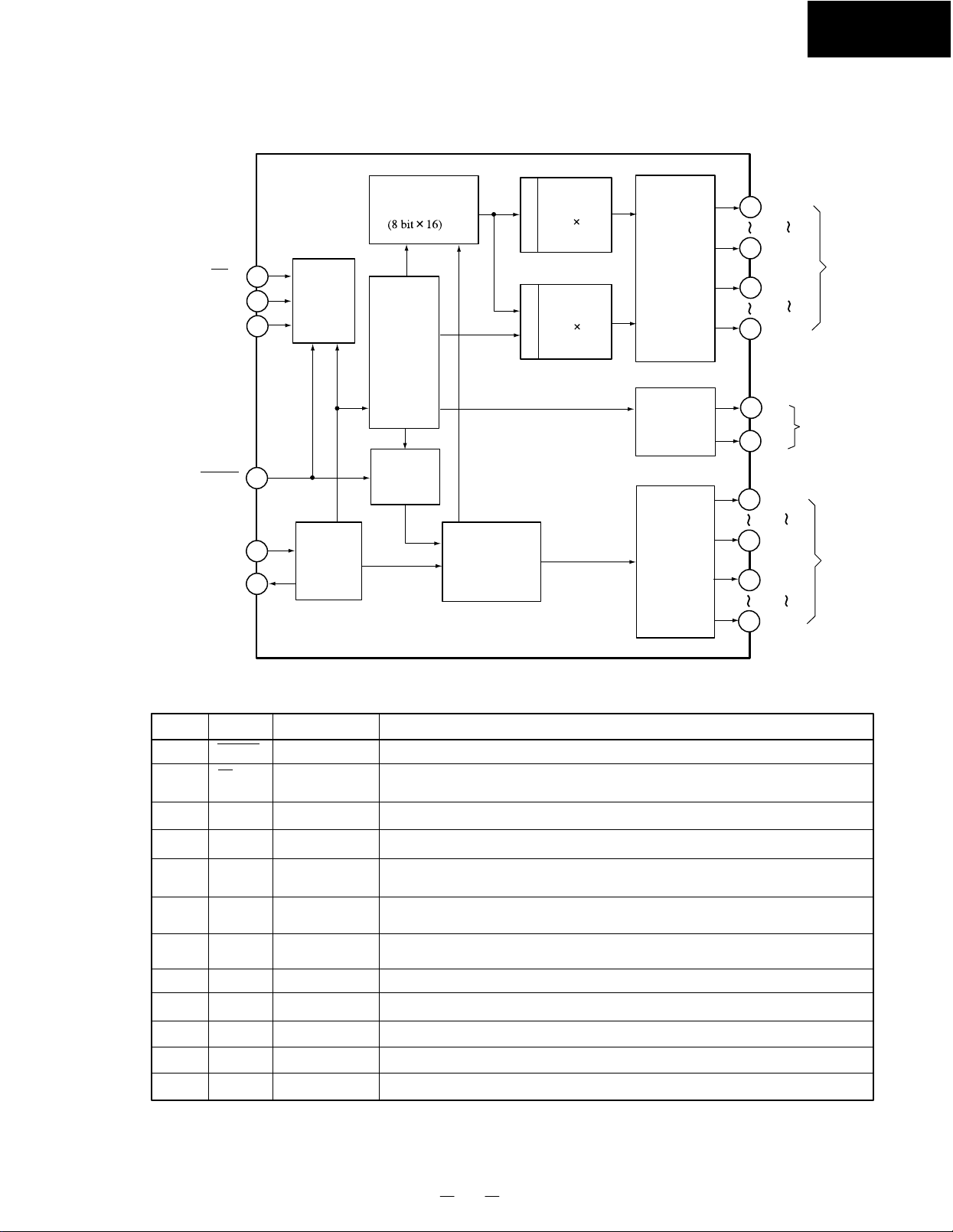

Q351:CXD2589Q (CD Digital Signal Processor)

Block Diagram

XTSL

VPCO

VCKI

V16M

VCTL

XUGF

GFS

EMPH

49

EFM

WFCK

56

54

C4M

RF

ASYI

ASYO

BIAS

XPCK

FILO

FILI

PCO

CLTV

52

52

35

35

37

37

38

36

36

48

48

30

30

31

31

29

29

33

38

33

51

51 25 26 27 28 47 49 54 56 50 39 41 43 55 40 42 44 62

25

Clock

28

26

47

27

OSC

Generator

demodurator

Asymmetry

Corrector

Digital

PLL

Sub Code

Processor

Error

Corrector

16K

RAM

C2PO

LRCK

39

50

D/A

Interface

Digital

OUT

PCMD

41

BCK

EMPHI

LRCKI

40

424344

55

Serial-In

Interface

Over Sampling

Digital Filter

Noise Shaper

PWM

PCMDI

BCKI

SYSM

62

3rd-Order

Timing

Logic

PWM

24

24

23

23

79

79

70

70

71

71

3

3

2

2

TES1

TEST

XRST

RMUT

LMUT

XTAI

XTAO

FOK

SEIN

CNIN

18

18

10

10

11

11

Servo

Auto

Sequencer

12 13 14 6 7 8 9 15 16 17 57 58 59 5 4 21 22 53 74 75 76 67 66 65

14

13

12

DATO

CLKO

XLTO

CPU

Interface

65

7

SENS

DATA

XLAT

15 16 17

CLOK

SPOA

XLON

SPOB

57

58

SCOR

9

8

59

EXCK

SBSO

4

SQCK

SQSO

Digital

CLV

21

MDP

22

53

PWMI

DOUT

74

LOUT2

75

76

AIN2

AOUT2

67

LOUT1

66

65

AIN1

AOUT1

8

Page 9

PIN Description

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

Symbol

VSS

LMUT

RMUT

SQCK

SQSO

SENS

DATA

XLAT

CLOK

SEIN

CNIN

DATO

XLTO

CLKO

SPOA

SPOB

XLON

FOK

VDD

VSS

MDP

PWMI

TEST

TES1

VPCO

VCKI

V16M

VCTL

PCO

FILO

FILI

AVSS

CLTV

AVDD

RF

BIAS

ASYI

ASYO

LRCK

LRCKI

PCMD

PCMDI

I/O

GND

—

Left-channel zero detection flag.

O

Right-channel zero detection flag.

O

SQSO readout clock input.

I

Sub Q 80-bit serial output.

O

SENS output to CPU.

O

Serial data input from CPU.

I

Latch input from CPU. Serial data is latched at the

I

falling edge.

Serial data transfer clock input from CPU.

I

SENS input from SSP.

I

Track jump count signal input.

I

Serial data output to SSP.

O

Serial data latch output to SSP. Latched at the falling

O

edge.

Serial data transfer clock output to SSP.

O

Microcomputer extended interface (input A).

I

Microcomputer extended interface (input B).

I

Microcomputer extended interface (output).

O

Focus OK input.

I

Used for SENS output and the servo auto sequencer.

Power supply (+5V).

—

GND

—

Spindle motor servo control.

O

Spindle motor external control input.

I

TEST pin; normally GND.

I

TEST pin; normally GND.

I

Charge pump output for the wide-band EFM PLL.

O

VCO2 oscillation input for the wide-band EFM PLL.

I

VCO2 oscillation output for the wide-band EFM

O

PLL.

VCO2 control voltage input for the wide-band EFM

I

PLL.

Master PLL charge pump output.

O

Master PLL (slave = digital PLL) filter output.

O

Master PLL filter input.

I

Analog GND.

—

Master VCO control voltage input.

I

Analog power supply (+5V).

—

EFM signal input.

I

Constant current input of the asymmetry circuit.

I

Asymmetry comparator voltage input.

I

EFM full-swing output (low = VSS, high = VDD).

O

D/A interface. LR clock output f = Fs.

O

LR clock input.

I

D/A interface. Serial data output (two's complement,

O

MSB first).

D/A interface. Serial data input (two's complement,

I

MSB first).

Description

Pin

No.

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

Symbol

BCK

BCKI

VSS

VDD

XUGF

XPCK

GFS

C2PO

XTSL

C4M

DOUT

EMPH

EMPHI

WFCK

SCOR

SBSO

EXCK

VSS

VDD

SYSM

AVSS

AVDD

AOUT1

AIN1

LOUT1

AVSS

XVDD

XTAI

XTAO

XVSS

AVSS

LOUT2

AIN2

AOUT2

AVDD

AVSS

XRST

VDD

I/O

D/A interface. Bit clock output.

O

D/A interface. Bit clock input.

I

GND

—

Power supply (+5V).

—

XUGF output. Switched to MNT1 or RFCK output

O

by a command.

XPLCK output. Switched to MNT0 output by a com-

O

mand.

GFS output. Switched to MNT3 or XRAOF output

O

by a command.

C2PO output. Switched to GTOP output by a com-

O

mand.

Crystal selector input. Low: 16.9344MHz;

I

high: 33.8688MHz.

4.2336MHz output. 1/4 frequency-divided VCKI out-

O

put in CAV-W mode.

Digital Out output.

O

Outputs a high signal when the playback disc has

O

emphasis, and a low signal when there is no emphasis.

Inputs a high signal when de-emphasis is on, and a

I

low signal when de-emphasis is off.

WFCK output.

O

Outputs a high signal when either subcode sync S0

O

or S1 is detected.

Sub P to W serial output.

O

SBSO readout clock input.

I

GND

—

Power supply (+5V).

—

Mute input. Active when high.

I

Analog GND.

—

Analog power supply (+5V).

—

Left-channel analog output.

O

Left-channel operational amplifier input.

I

Left-channel LINE output.

O

Analog GND.

—

Power supply for master clock.

Crystal oscillation circuit input. Input the external

I

master clock via this pin.

Crystal oscillation circuit output.

O

GND for master clock.

Analog GND.

—

Right-channel LINE output.

O

Right-channel operational amplifier input.

I

Right-channel analog output.

O

Analog power supply (+5V).

—

Analog GND.

—

System reset. Reset when low.

I

Power supply (+5V).

—

Description

FR-155

9

Page 10

FR-155

Q101:CXA1992BR (RF Signal Processing Servo Amplifier)

Block Diagram

FE-BIAS

V

TEO

LPFI

TEI

ATSC

TZC

TDFCT

VC

FZC

O

RF

M

FE

-

LDON

I

RF

323334353637

VEE

LEVEL S

VEE

MIRR

VCC

LPCL

LPC

TGFL

IIL DATA REGISTER

INPUT SHIFT REGISTER

ADDRESS DECODER

SENS SELECTOR

OUTPUT DECODER

DFCTO IFB1-6

VCC

FS1

FS2

Charge

VEE

8

SRCH

BAL1-4

TOG1-4

up

CP

31

VCC

9

TGU

30

VEE

FS1-4 TG1-2

TG2

10

CB

MIRR

TG2

VCC

DFCT

IIL

TTL

TN1-7 PS1-4

TM3

FSET

11

CC1

DFCT1

FSET

CC2

2829

CC1

12

FOK

27

26

SENS2

IIL

TTL

TTL

IIL

ISET

VCC

VCC

TM4

TM6

TM3

TM5

VEE

VEE

13

O

M

-

TA

TA

25

SENS1

24

C.OUT

23

XRST

22

DATA

XLT

21

CLK

20

LOCK

19

VCC

V

CC

18

ISET

17

16

SL-O

15

SL-M

14

SL-P

TM2

M

-

RFTC

RF SUMMING AMP

FO.BIAS

WINDOW COMP.

RF

FOK

FOH

FOL

TGH

TGL

BALH

BALL

ATSC

TZC

FZC

PD

VEE

APC

LASER POWER CONTROL

IFB5

IFB3

IFB4

TRK.GAIN

WINDOW COMP

LD

VEE

FE AMP

IFB6

PD1

PD2

3839

PD1 IV

PD2 IV

AMP

AMP

40

41

F

42

E

EI

43

EE

44

F IV AMP

E IV AMP

BAL1

BAL2

BAL3

TOG2

TOG3

BAL4

TOG4

VEE

TOG1

TGFL

VCC

VCC

IFB2

IFB1

VEE

45

E-F BALANCE

46

WINDOW COMP.

47

48

ATSC

WINDOW

COMP.

TZC COMP.

49

50

VCC

DFCT

TM1

TG1

TRACKING

PHASE COMPENSATION

51

VCC

VEE

52

FZC COMP.

12

FEI

FEO

FOCUS

PHASE COMPENSATION

DFCT

FS4

45

3

FDFCT

FGD

FLB

6

7

O

-

FE

10

Page 11

Pin Description

Pin

Symbol

No.

1 FEO O

2 FEI Focus error input. I

34FDFCT

FGD I

5 FLB

6 FE_O

7 FE_M

8 SRCH

9

TGU

10 TG2

11

FSET

12 TA_M I Tracking amplifier inverted input.

TA_O

13

14

SL_P

15 SL_M

16 SL_O O Sled drive output.

17 ISET I Connect an external capacitance to set the current

18

VCC

19 LOCK I

20 CLK

XLT

21

22 DATA

XRST I Reset input; resets at Low. (no pull-up resistance)

23

24 C. OUT

SENS1

25

I/O

Focus error amplifier output.

Connected internally to the window comparator input

for bias adjustment.

I

Capacitor connection pin for defect time constant.

Ground this pin through a capacitor for cutting the

focus servo high-frequency gain.

External time constant setting pin for boosting the

I

focus servo low-frequency.

O

Focus drive output.

I Focus amplifier inverted input.

I

External time constant setting pin for generating

focus search waveform.

I External time constant setting pin for switching track-

ing high-frequency gain.

External time constant setting pin for switching track-

I

ing high-frequency gain.

Peak frequency setting pin for focus and tracking

I

phase compensation amplifier.

O Tracking drive output.

I Sled amplifier non-inverted input.

I Sled amplifier inverted input.

which determines the Focus search, Track jump, and

Sled kick heights.

I Positive power supply.

The sled overrun prevention circuit operates when

this pin is Low. (no pull-up resistance)

I

Serial data transfer clock input from CPU.

(no pull-up resistance)

I

Latch input from CPU. (no pull-up resistance)

Serial data input from CPU. (no pull-up resistance)

I

O

Track number count signal output.

O

Outputs FZC, DFCT1, TZC, BALH, TGH, FOH,

ATSC, and others according to the command from

CPU.

Description

FR-155

Pin

Symbol

No.

26 SENS2 O

27

FOK

28

CC2 I

CC1

29

30 CB I Connection pin for defect bottom hold capacitor.

31 CP

32

RF_I I

33 RF_O O

34 RF_M

35 RFTC I

LD O APC amplifier output.

36

37 PD I APC amplifier input.

PD1

38

39

PD2

40

FE_BIAS

41

F

42IE

43 EI

44

VEE

45 TEO O

46 LPFI I Comparator input for balance adjustment.

47

TEI

ATSC

48

49

TZC

50

TDFCT

51

VC

52 FZC

I/O

Outputs DFCT2, MIRR, BALL, TGL, FOL, and

others according to the command from the CPU.

O Focus OK comparator output.

Input for the defect bottom hold output with capacitance coupled.

O Defect bottom hold output. Connected internally to

the interruption comparator input.

Connection pin for MIRR hold capacitor.

I

MIRR comparator non-inverted input.

Input for the RF summing amplifier output with capa-

citance coupled.

RF sunning amplifier output. Eyepattern check point.

RF summing amplifier inverted input.

I

The RF amplifier gain is determined by the resistance

connected

between this pin and RFO pin.

External time constant setting pin during RF level

control.

I

RF I-V amplifier inverted input. Connect these pins

to the photo diode A + C and B + D pins.

I

I

Bias adjustment of focus error amplifier.

Leave this pin open for automatic adjustment.

I

F I-V and E I-V amplifier inverted input.

Connect these pins to photo diodes F and E.

—

I-V amplifier E gain adjustment.

(When not using automatic balance adjustment)

—

Negative power supply.

Tracking error amplifier output. E-F signal is output.

(Input from TEO through LPF)

Tracking error input.

I

Window comparator input for ATSC detection.

I

I

Tracking zero-cross comparator input.

I

Capacitor connection pin for defect time constant.

O (VCC + VEE)/2 direct voltage output.

I

Focus zero-cross comparator input.

Description

11

Page 12

FR-155

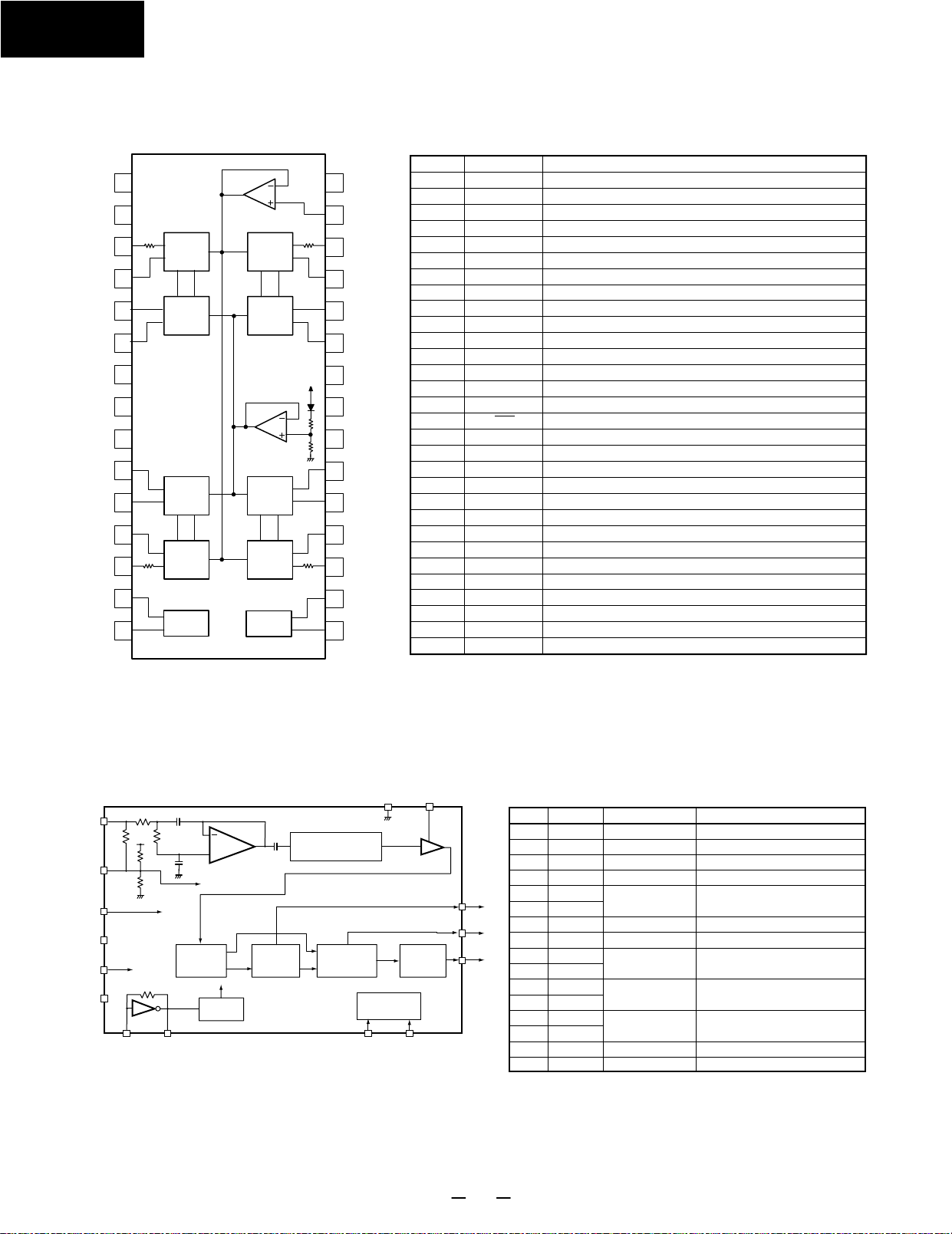

Q102:LA6541D (CD 4-channel BTL Driver )

Vcc

Mute

VIN1

VG1

Vo1

Vo2

GND

GND

GND

Vo3

Vo4

VG2

VI2

Reg OUT

Reg IN

10

11

12

13

14

15

Pin No. Pin Name Description

Vcc

1

2

3

Level shift

1

Level shift

4

4

5

BTL AMP

1

BTL AMP

4

6

30

29

28

27

26

25

Vref

VIN4

VG4

Vo8

Vo7

1

2

3

4

5

6

7

8

9

10

11

12

GND

7

8

Vcc

24

23

GND

13

14

15

16

GND

9

22

17

18

BTL AMP

2

BTL AMP

3

21

20

Vo6

Vo5

19

20

21

22

Level shift

2

Level shift

3

19

18

VG3

VIN3

23

24

25

26

Regulator

RESET

17

16

CD

RES

27

28

29

30

VCC

Mute ON/OFF control for all BTLAMP outputs

VIN1

VG1 BTL AMP 1 input (for gain control)

Vo1

Vo2

GND GND (minimum electric potential)

GND GND (minimum electric potential)

GND GND (minimum electric potential)

V

O

V

O

VG2 BTL AMP 2 input (for gain control)

V

IN

REG OUT Connection for collector of external transistor (PNP); 5 V supply output

REG IN Connection for base of external transistor (PNP)

RES

C

V

IN

VG3 BTL AMP 3 input (for gain control)

V

O

V

O

GND GND (minimum electric potential)

GND GND (minimum electric potential)

GND GND (minimum electric potential)

V

O

V

O

VG4 BTL AMP 4 input (for gain control)

V

IN4

V

REF

V

CC

Power supply (shorted with pin 30)

BTL AMP 1 input

BTL AMP 1 output (non-inverting side)

BTL AMP 1 output (inverting side)

3 BTL AMP 2 output (inverting side)

4 BTL AMP 2 output (non-inverting side)

2 BTL AMP 2 input

Reset output

Reset output delay time setting (with capacitor)

D

3 BTL AMP 3 input

5 BTL AMP 3 output (non-inverting side)

6

BTL AMP 3 output (inverting side)

7 BTL AMP 4 output (inverting side)

8 BTL AMP 4 output (non-inverting side)

BTL AMP 4 input

Reference voltage input for level shift circuit

Power supply (shorted with pin 1)

(Function)

Q171:BU1923(RDS Decoder)

100k

(4)

MUX

VREF

VDD1

VSS1

VDD2

VSS2

120k

(3)

(5)

(6)

(12)

(11)

Analog

Power supply

Digital

power supply

(13) (14)

X1

XO

100k

PLL

57kHz

RDS/ARI

Reference

+

anti-aliasing

filter

clock

PLL

1187.5Hz

capacitor filter

8ch Switched

Bi-phase

decoder

Measurement

(10)

VSS3

circuit

CMP

(7)

Comparator

Differential

decoder

(9)

T2T1

(8)

(16)

(1)

(2)

Pin No.

RCLK

QUAL

RDATA

Symbol

QUAL

1

RDATA

2

3

4

VDD1

5

6

7

8

9

10

VDD2

11

12

13

14

15

RCLK

16

Vref

MUX

Vss1

Vss3

CMP

T2

T1

Vss2

XI

XO

(NC)

Pin name

Demodulator quality

Demodulator data

Reference voltage

Input

Analog power supply

GND

Comparator input

Test input

Digital power supply

Crystal oscillor

-

Demodulator clock

Function

Good data : High , bad data : Low

Refer to output data trimming

1/2 VDD1 (refer to input/output circuits)

Composite signal input

4.5V to 5.5V

C-junction

Open or connected to ground

4.5V to 5.5V

Connects to 4.332MHz oscillator

(refer to input/output circuit)

-

1187.5Hz clock

12

Page 13

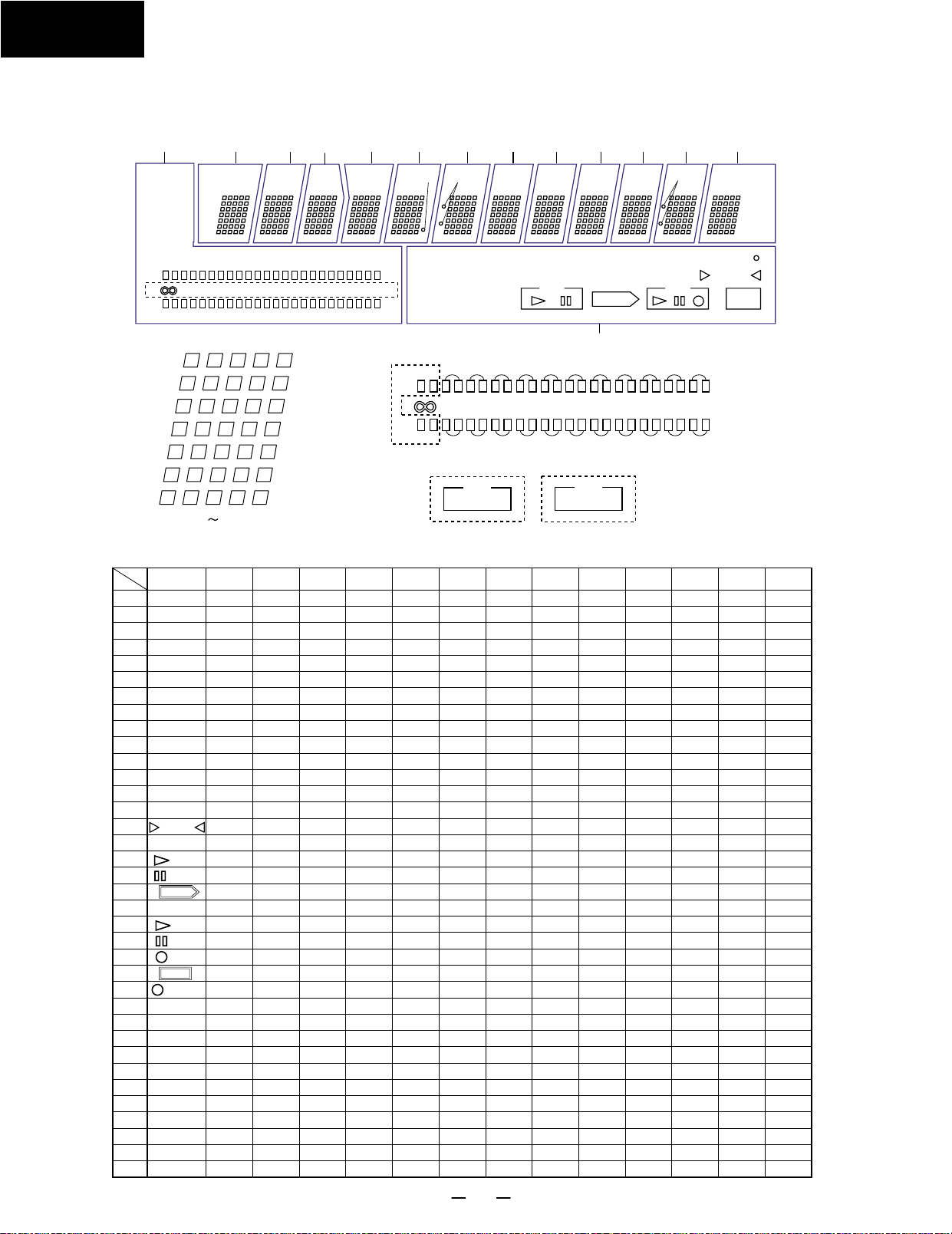

Q752:M66004F (FL Tube Driver)

FR-155

Chip select

input

Shift clock

input

Serial data

input

Reset

input

Clock

input

Clock

output

CS

SCK

SDATA

RESET

XIN

XOUT

15

16

13

21

22

14

Serial

receive

circuit

Clock

generator

Display code

register

code

write

Code /

command

control

circuit

Display

control

register

RAM

write

code

select

Display controller

CG ROM

(35bit 160)

Decoder

CG RAM

(35bit 16)

Decoder

Segment

output circuit

Output port

(2bits)

Digit

output circuit

12

59

33

31

23

18

17

1

64

61

SEG00

SEG26

SEG27

SEG35

P0

P1

DIG00

DIG11

DIG12

DIG15

Segment

output

Output

ports

Digit

outputs

Pin No.

13

14

15

16

21,

22

1-12

61-64

23-31

33-59

17,18

19

60

22

32

Symbol Pin name Function

RESET Reset input This pin is used to initialize the internal state on the M66004

CS Chip select input

"L" : communication with the MCU is possible.

"H" : any instruction from teh MCU is neglected.

SCK Shift select input At the rising edge from "L"to"H" , input data is shifted.

SDATA Serial data input Character code or command data to display is input from MSB.

XIN,

XOUT

DIG00 -

Clock input

Clock output

Digit output

Set oscillation frequency

These pins are used to connect to digit pins of VFD.

DIG15

SEG00 -

Segment output

These pins are used to connect to segment pins of VFD.

SEG35

P0,PI Output port (static operation)

VCC1

VCC2

VSS

Positive power supply for internal logic.

Positive power supply for high-pressure-resistant output port.

GND

VP Negative power supply for VFD drive.

13

Page 14

FR-155

Q751:BJ780GNK(FL T ube)

13G 12G 11G 10G 9G 8G 7G 6G 5G 4G 3G 2G 1G

Dp

SLEEP SOURCE C D TIMER M D M DCHC D

ONCE

W.DAY

W.END

REC

S.BASS

MUTING DIGITAL

LEVEL - SYNC

L

-

-

40-20-10 0 OVER

-

S2

-

6

2

R

1-1 2-1 3-1 4-1 5-1

1-2 2-2 3-2 4-2 5-2

1-3 2-3 3-3 4-3 5-3

1-4 2-4 3-4 4-4 5-4

1-5 2-5 3-5 4-5 5-5

1-6 2-6 3-6 4-6 5-6

1-7 2-7 3-7 4-7 5-7

(12G 1G)

(13G)

L

-

R

(14G)

Col-2

CHAIN

REPEAT

1 TR MEMORY

RANDOM

S1

B12 B13 B14 B15 B16 B17 B18 B19 B20 B21 B22

-

40

B1 B2 B3 B4 B5 B6 B7 B8 B9 B10 B11

C D

S3

DISC TRACK ELAPSED REMAIN TITLE

RDS MONO AUTO STEREO TUNED

C D

-

20

-

10 0 OVER

DUB TOC

14G

-

6

M D

S4

Col-1

M D

-

2

14G 13G 12G 11G 10G 9G 8G 7G 6G 5G 4G 3G 2G 1G

P1

P2

P3

P4

P5

P6

P7

P8

P9

P10

P11

P12

P13

P14

P15

P16

P17

P18

P19

P20

P21

P22

P23

P24

P25

P26

P27

P28

P29

P30

P31

P32

P33

P34

P35

P36

CHAIN

REPEAT

1 TR

MEMORY

RANDOM

DISC

TRACK

ELAPSED

REMAIN

TITLE

RDS

MONO

AUTO

STEREO

TUNED

S3

(CD)

(CD)

DUB

S4

(MD)

(MD)

(MD)

TOC

(TITLE)

-

-

-

-

-

-

-

-

-

-

-

B1

B8

B12

B19

S1

B2

B9

B13

B20

S2

B3

B10

B14

B21

OVER

B4

B11

B15

B22

SLEEP

B5

ONCE

B16

W.DAY

W.END

B6

REC

S.BASS

MUTING

B18

LEVEL-SYNC

B7

DIGITAL

-

B17

-

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

SOURCE

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

-

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

CD

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

TIMER

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

Dp

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

col 2

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

MD

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

-

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

MD

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

CD

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

col 1

1-1

2-1

3-1

4-1

5-1

1-2

2-2

3-2

4-2

5-2

1-3

2-3

3-3

4-3

5-3

1-4

2-4

3-4

4-4

5-4

1-5

2-5

3-5

4-5

5-5

1-6

2-6

5-7

4-7

3-7

2-7

1-7

5-6

4-6

3-6

CH

14

Page 15

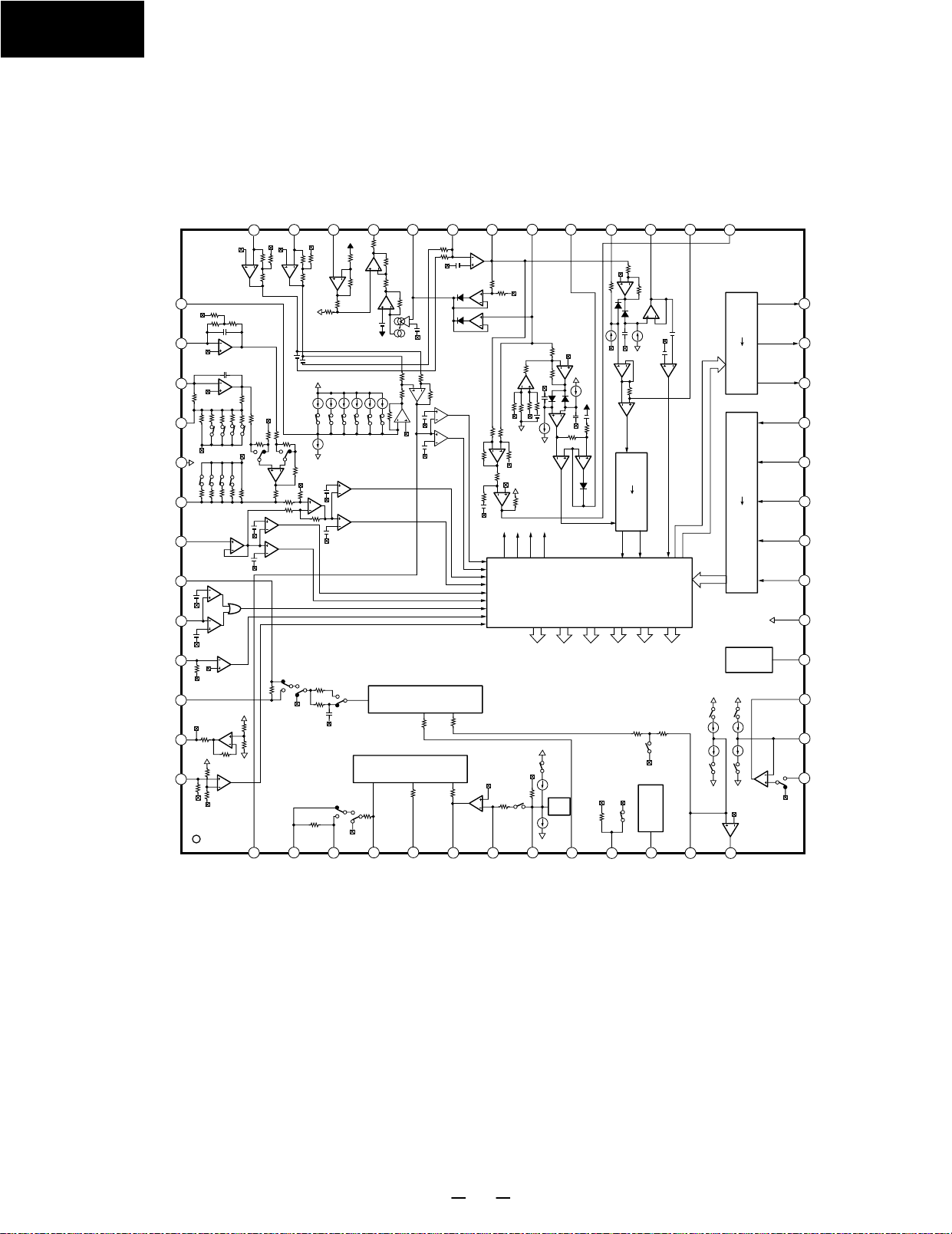

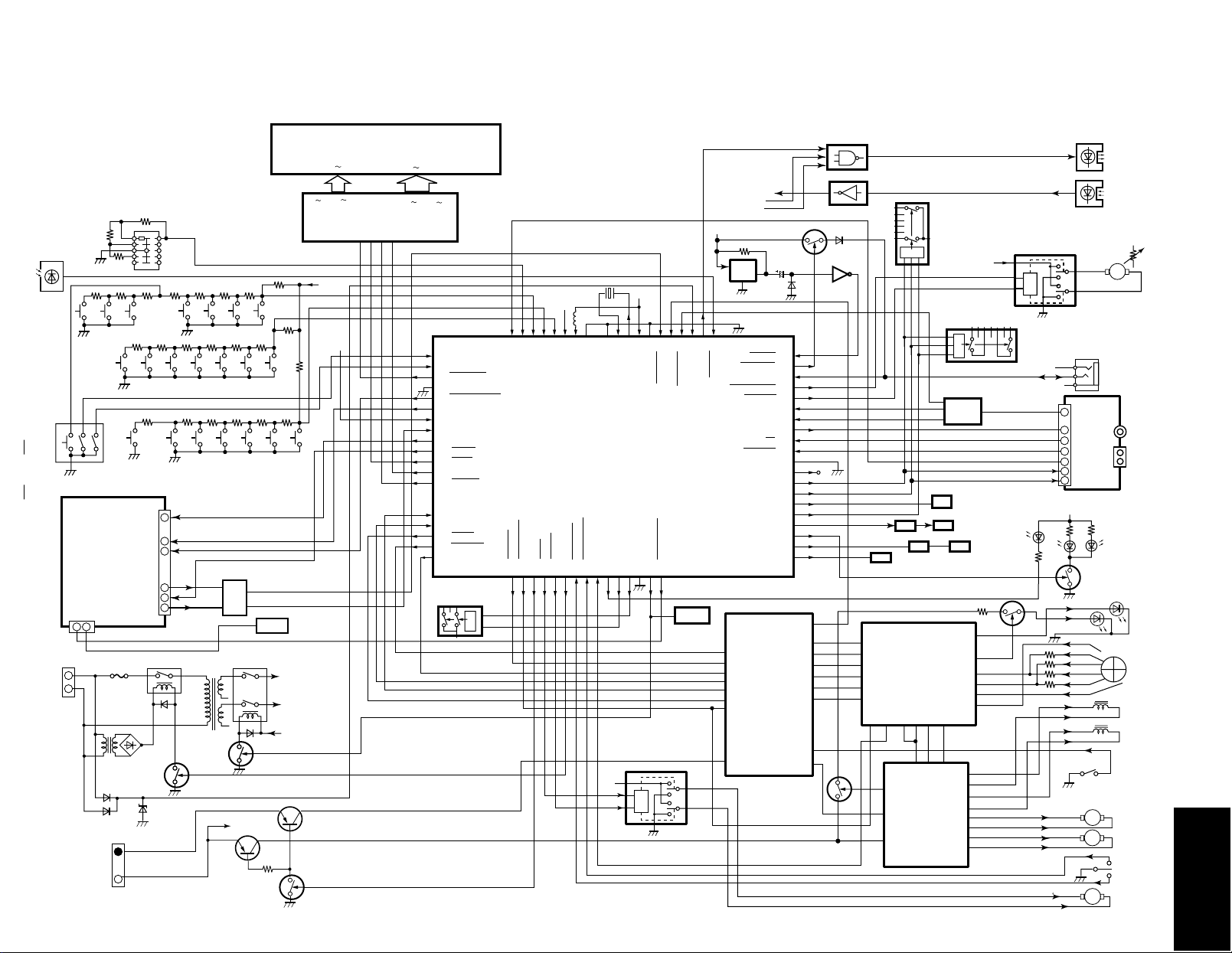

MICROPROCESSOR CONNECTION DIAGRAM

Q751

FL TUBE

REMOTE

SENSOR

15

AC IN

Q753

P907

to POWER

SUPPLY

NAPS-6928

REC MODE SW

ST

LP2

LP4

YES

CD

STOP

CD

PLAY

REC

OTHER

INPUT

CD

EDIT

EJECT

/NO

MULTI JOG

MD MECHANISM

CN105

RC DATA

RC REQ

SHUT DOWN

MD REQ-2

15

MD CLK

F901

P913B

D901

Q901

POWER

16

17

MD RST

MD DATA-2

14 AMOT

15

CN102

RELAY DRIVE

2

5

6

RL901

F.F

MONO

MD

FM

/CDMDSTOPMDPLAY

/AM

ENERGY

SAVE

Q902

POWER

SWITCH

REW

STANDBY

T901

AMP

Q112

M66004F

DISPLAY

A.PRES

RL902

+5.6 V

Q752

FL TUBE

DRIVER

TIMER

MD

EJECT

MODE

Q391

BUFFER

TO POWER AMP

PC BOARD

(NAAF-6930)

+B

1G 14G

1 12,60 64

GRID

+5 V

+5.6 V

CD.DUB

Q203,Q204

MD MUT

Q112

Q112

CD POWER

CONTROL

RESCSSCK

131415

P1 P36

23 31,33 59

SEGMENT

DATA

16

1 ROTEN 2

2 ROTEN 1

3 FLRESET

4 GND

5 SHUT DOWN

6 RCREQ

7 +5 V

8 MD DATA

9 RC DATA

10 S CLK

11 FLCE

12 FL DATA

13 FL CLK

14 TXD

15 RXD

16 SQSO

17 SESN

18 SQCK

19 CD CLK

20 CD DATA

Q222 TC4052BP

REC LEVEL

CONTROL

SIGNAL 80

21 CD XLT

K 2 78

K 1 77

MD REC MODE 79

22 CD RESET

23 CD POWER

24 OPEN

X701 5MHz

+5.6 V

72

K 0 76

+5 V 75

+5 V 74

GND 71

GND 73

Q701

MPD780058GC

MICROPRCESSOR

25 CLOSE

26 AC POWER

27 OPEN SW

28 CLOSE SW

29 SENS 2

30 ECO LED

+5.6 V

IN2

IN1

TRAY MOTOR DRIVER

+5.6 V

+5 V 68

GND 67

CLOCK 70

CLOCK 69

MD REQ 66

31 REC VOL 1

32 REC VOL 2

33 GND

34 RC POWER

35 MD RESET

Q449 POWER

2

1

9

5

Q103 TA7291S

POFF 63

SCOR 65

RDS CLK 64

36 BAND 0

37 BAND 1

38 AM 10K

AMPLIFIRE

CONTROL

3

OUT2

7

OUT1

MD MECHA

AUX-MD IN

A MUTE

MD OUT

+5.6 V

D OUT 62

REMIN 61

39 RD SEN

40

Q705

RESET

IN

OUT

RESET 60

SYS OUT 59

SYS IN 58

VOL DOWN 57

VLO UP 56

RDS DATA 55

RDS SIG 54

PLLCE 53

SD 52

STEREO 51

MODEL 1 50

FREQCAL 49

C DATA 48

C CLK 47

TU MUT 46

FCE/VCE 45

REC MUT 44

AP LED 43

SEL MUT 42

CD MUT 41

9

8

7

Q351

6

CXD2589Q

5

CD DIGITAL

4

SIGNAL

79

PROCESSOR

19

Q704

Q371

TC74HCT00AF

BUFFER

Q372

TC7WU04FU

BUFFER

Q401

TC9273N-004

INPUT

Q703

RESET

SELECTOR

+5.6 V

Q447

TC9162AN

ACOUSTIC

PRESENCE SELECTOR

Q171 BU1923

Q253

TUNER MUTING

Q223,Q224

Q707

MUT

Q448

SEL MUT

Q702

CD MUT

57

Q112

20

21

22

24

25

27

23

26

15

19

30

Q101

CXA1992BR

RF SIGNAL

PROCESSING

SERV O AMP

28 3 13

Q102

LA6541D

FOCUS

/TRACKING

& SLED

/SPINDLE

MOTOR

DRIVER

14

13

12

11

10

18

15

21

MD REC

MUTING

Q443

,Q444

Q114 LD DRIVE

37

36

39

38

41

42

1361615

5

6

10

11

25

26

21

20

Q171

BU1923

VOLUME MOTOR

DRIVER

2

1

IN2

IN1

9

5

RDS

DECODER

ENERGY

SAVE

LED

TUNER UNIT

3

7

+5 V

OUT2

OUT1

PLLCE

SD

STEREO

SIGNAL

DAT A

CLK

LD

S.STOP

Q372

OUT

DIGITAL

OPTICAL

Q372

IN

VOLUME

MOTOR

M

RI

REMOTE

CONTROL

ACOUSTIC

PRESECE

LED

Q706

LED DRIVE

PD

E

A

B

C

F

FOCUSING

COIL

TRACKING

COIL

SLED

M

MOTOR

M

SPINDLE

MOTOR

OPEN

/CLOSE SW

M

TRAY

MOTOR

ANTENNA

FM

AM

FR-155

Page 16

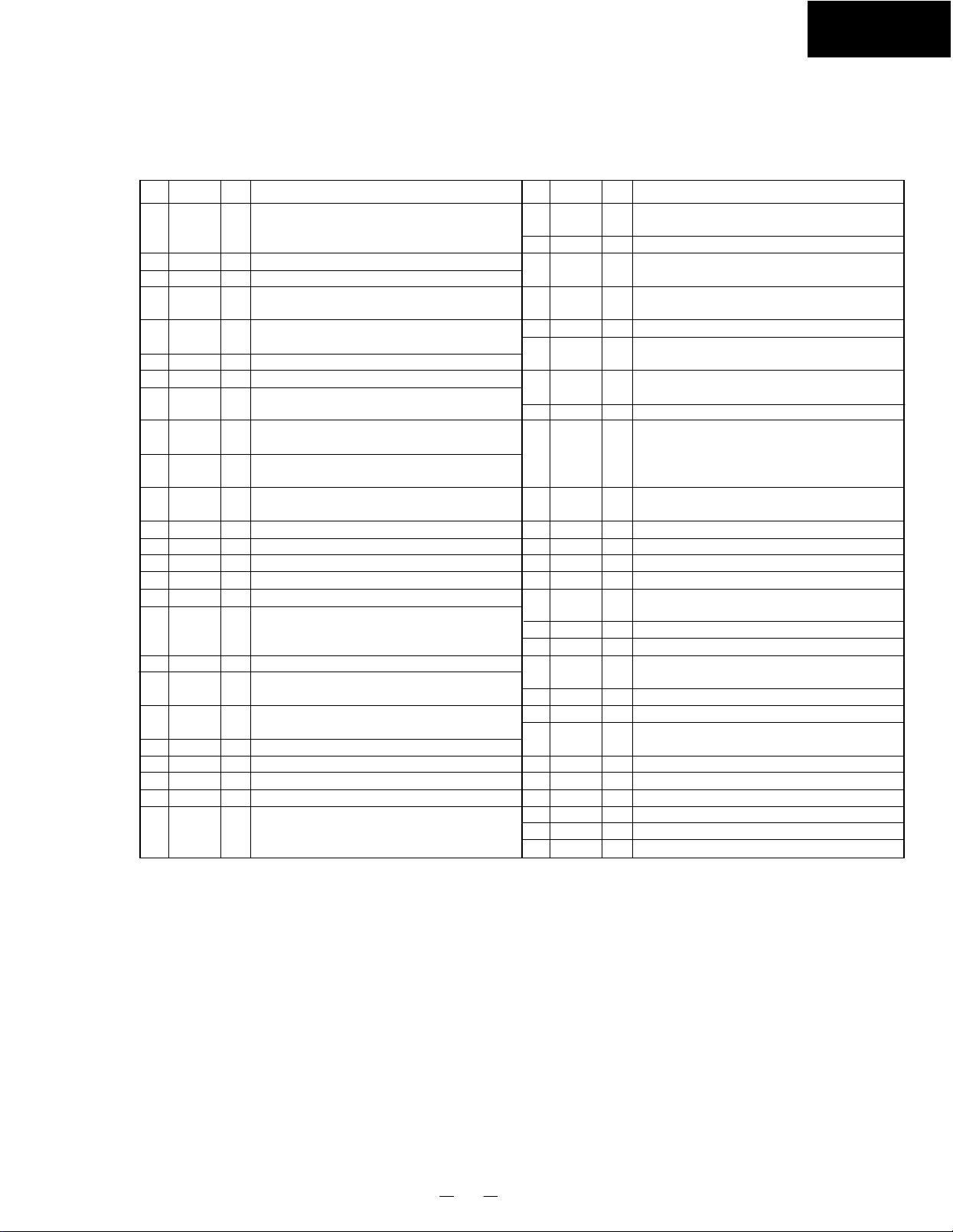

MICROPROCESSOR TERMINAL DESCRIPTION

Q701:MPD780058GC-8BT

16

PIN

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

Function

ROTEN2

ROTEN1

FLRESET

GND

SHUTDOWN

RCREQ

AVDD

MDDATA

RCDATA

SCLK

FLCE

FLDATA

FLCLK

TXD

RXD

SQSO

SENS

SQCK

CDCLK

CDDATA

CDXLT

CDRESET

CDPOWER

OPEN

CLOSE

ACPOWER

OPENSW

CLOSESW

SENS2

ECOLED

RECVOL1

RECVOL2

GND

RCPOWER

MDRESET

BAND0

BAND1

AM10K

RDSEN

I/O

I

Pulse input pin 1 from rotary encoder.

I

Pulse input pin 2 from rotary encoder.

O

Reset signal output pin for FL driver IC(M66004)

I

Ground pin.

O

Output pin of power failure signal for MD mechanism microcomputer.

O

Serial data output pin for communication of MD microcomputer.

I

Power supply pin for A/D converter.

I

Serial transfer data input pin from MD mechanism microcomputer.

O

Serial transfer data output pin to MD mechanism microcomputer.

O

Serial transfer clock output pin to MD mechanism microcomputer.

O

Chip enable signal output pin for FL drover IC(M66004).

O

Serial data output pin for FL drover IC(M66004).

O

Clock data output pin for FL drover IC(M66004).

O

Output pin for flash writer.

I

Input pin for flash writer.

I

Input pin of subcode data from CD signal processor IC(CXD2589).

I

Input pin of sens data from CD signal processor IC(CXD2589).

O

Clock signal output pin for read out to signal processor IC(CXD2589).

O

Command output pin for transfer the clock signal to CD signal processor IC(CDX2589).

O

Command output pin for transfer the data signal to CD signal processor IC(CXD2589).

O

Command output pin for transfer the latch signal to CD signal processor IC(CXD2589).

O

Reset signal output pin for CD circuit ICs(CXD2589,CXA1992)

O

Control signal output pin for CD circuit.

O

Control signal output pin for motor driver IC of CD tray.

O

Control signal output pin for motor driver IC of CD tray.

O

Control signal output pin for relay of main power supply.

I

Detection signal input pin for the opening completion of CD tray.

I

Detection signal input pin for the closing completion of CD tray.

I

Sens2 signal input pin from CD servo IC(CXA1992)

O

Control output pin of energy save indicator.

O

Output pin 1 for MD recording level adjust IC.

O

Output pin 2 for MD recording level adjust IC.

I

Ground pin.

O

Output pin for control relay of power supply in receiver section.

O

Output pin of reset signal for MD mechanism.

I

Initializing input pin 1 for FM band.

I

Initializing input pin 2 for FM band.

I

Initializing input pin 2 for AM band step.

I

Initializing input pin of RDS function. (H=Function, L=Not function)

I

Not used.(ground)

Description

PIN

Function

No.

CDMUT

41

SELMUT

42

APLED

43

RECMUT

44

FCE/VCE

45

TUMUT

46

CCLK

47

CDATA

48

FREQCAL

49

MODEL1

50

STEREO

51

SD

52

PLLCE

53

RDSSIG

54

RDSDATA

55

VOLUP

56

VOLDOWN

57

SYSIN

58

SYSOUT

59

RESET

60

REMIN

61

DOUT

62

POFF

63

RDSCLK

64

SCOR

65

MDREQ

66

GND

67

VDD

68

CLOCK

69

CLOCK

70

GND

71

72

GND

73

VDD

74

AVDD

75

K0

76

K1

77

K2

78

MDRECMODE

79

SIGNAL

80

I/O

Muting signal output pin for CD analog signal.

O

Muting signal output pin for audio section.

O

Control output pin of acoustic presence indicator.

O

Muting signal output pin for muting of MD recording signal.

O

Chip enable signal output pin for function ICs(T9273,TC9162).

O

Muting signal output pin for tuner signal.

O

Clock data output pin for Ics of receiver section.

O

Serial data output pin for Ics of receiver section.

O

Output pin for adjustment of main clock frequency

O

Initialization input pin for model set.

I

FM stereo broadcast detection input pin.

I

Broadcast detection input pin.

I

Chip enable signal output pin for tuner PLL IC.

O

Not used.

I

Not used.

I

Control output pin for motor driver IC of volume.

O

Control output pin for motor driver IC of volume.

O

System code input pin.

I

System code output pin.

O

System reset input pin.

I

Signal input pin from remote sensor.

I

Control output pin for CD/MD digital output selector. (H=CD, L=MD)

O

Power failure detect input pin.

I

Not used.

I

Detection signal input pin CD signal processor IC(CXD2589).

I

Signal input pin for communication from MD mechanism microprocessor.

I

Ground pin.

I

Power supply pin. (+5V)

I

Master clock connection pin.

O

Master clock connection pin. (connect the trimming capacitor)

I

Not used. (connect ground)

I

Not used.

O

Not used. (connect ground)

I

Power supply pin. (+5V)

I

Power supply for A/D converter.

I

Operation key-1 connection input pin.

I

Operation key-2 connection input pin.

I

Operation key-3 connection input pin.

I

Connect the MD recording mode serector.

I

Signal level input pin for automatic memory.

I

Description

FR-155

Page 17

OPERATION OF THE MICROPROCESSOR

OPERATION OF THE MICROPROCESSOR TERMINAL LINKED WITH THE ENERGY SAVE FUNCTION

In the energy save mode (including the preparation period). only the STANDBY/ON button and the ENERGY SAVE button can be operated.

60 seconds after the energy save is operated. the microprocessor is turned to the energy save mode.

Even if the AC cord is removed. the energy save mode is stored. (the stored period is about 2 or 3 weeks that are the same as the stored

period of the preset values for the tuner.) When the initial values are set. the energy save mode is released.

(*1) : The back-up voltage for the microprocessor is supposed to be 0 volt after the initial values are set.

(*2) : The energy save mode is set when the power supply is on.

When the ENERGY SAVE button is pressed in the stand-by state. you can also enter the energy save mode.

SETTING

OPERATION

SET. STATE

ENERGY SAVE LED

FL TUBE

Q701 (Microprocessor)

Terminal

NO.

60

Function

Name

RESET

Connect the

AC cord.(*1)

Power

supply

is off.

Light goes out.

Time is

indicated.

Press the

STANDBY/ON

button.

Stand-by

state

Light goes out.

Press the

ENERGY SAVE

button.(*2)

Power supply is turned ON.

Light comes on.

Press the

STAND/BY

button.

Energy save

(under preparation)

Energy save mode

Light blinks. Light comes on.

After the " Energy save " is

scrolled. the light goes out.

Press the

ENERGY SAVE

button.

Stand-by

Light goes out.

Time is

indicated.

Disconnect

the AC cord.

Power

supply

is off.

FR-155

AC POWER

26

MD

ON

ON

ON

60 sec.

60 sec.

CD

CONTROL

ON

OFF

FM/AM

ON

CONTROL

OFF

RC POWER

34

SEL MAT

42

35

3

MDRESET

FLRESET

1sec.

OPERATION of RECVOL1 and RECVOL 2

Analog switch (TC-4052) is controlled here.

Terminal

No.

31

32

Function

Name

REC VOL1

REC VOL2

1

L

L

Rec. Level

2

3

H

L

L

H

OTHER OPERATIONS

1sec.

4

H

H

5 sec.

OPERATION of CDMUT. TUMUT and REC MUT

ON means that the mute function is always on and OFF means that the mute function is always off.

The mute functions shown by CONTROL become ON or OFF according to the set states.

41

46

44

Function

Name

CD MUT

TU MUT

REC MUT

Terminal

No.

H means the high level and L means the low level. The state shown by CONTROL varies with the set state.

Terminal

No.

3

5

6

9

10

11

12

13

14

15

18

19

20

21

22

23

24

25

26

30

Function

Name

~FLRESET

~SHUTDOWN

~RICKRACK

RCDATA

~SILK

~FACE

FLAT

~FLCLK

TAD

RED

~SACK

~CDCLK

CDDATA

~CDXLT

~CDRESET

CDPOWER

~OPEN

~CLOSE

ACPOWER

EQUALLED

Input Selector

CD

CONTROL

H

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

L

L

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

H

CONTROL

CD Except

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

L

L

L

L

L

L

L

L

H

H

H

CONTROL

In stand-by

state

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

H

L

L

L

L

L

L

L

L

H

H

H

In energy

save state

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

L

CONTROL

Terminal

No.

31

32

33

34

35

41

42

43

44

45

46

47

48

49

53

56

57

59

62

Function

Name

RECVOL1

RECVOL2

GOD

RCPOWER

~MDRESET

CDMUT

SELMUT

AILED

RECUT

FCE/VCE

TUMULT

CLACK

DATA

FRECKLE

PLACE

~VOLUP

~VOLDOWN

~SYSOUT

DOLT

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

Input Selector

TAPE

CD R

ON

ON

ON

ON

OFF

OFF

Input Selector

-

H

L

CD Except

CONTROL

CONTROL

H

CONTROL

L

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

L

CONTROL

CONTROL

CONTROL

CONTROL

CONTROL

CD

1sec.

-

LINE-1

ON

ON

OFF

In stand-by

state

CONTROL

LINE-2

ON

ON

OFF

L

L

L

H

L

H

L

H

L

H

L

L

L

L

H

H

L

DIGITAL

ON

ON

ON

In energy

save state

L

L

L

L

L

H

L

H

L

H

L

L

L

L

L

L

CONTROL

L

17

Page 18

FR-155

MD MECHANISM EXPLODED VIEW(1)

(KMK-260BCN)

35

34

35

35

13

11

9

SW1-SW4

19

15

14

16

17

10

18

8

32

3

4

7

6

5

13

11

26

31

20

33

21

23

24

27

Ref. No. Part No. Description

Motor Plate ass'y

Screw(+PTT2.6 4 Type S)

L-SW pc board

Flexible flat cable(5 core)

Gear(Relay B)

Gear(Relay A)

Slot Frame ass'y

Spring(Slot arm), Tension coil

Slot Arm

Load Frame ass'y

Insulator

Screw, Step

Slide Frame

Head Arm,

Spring, SP Tension

10

11

13

14

15

16

1

2

3

4

5

6

7

8

9

-

7685-790-09

-

2646-555-02

2646-554-11

X2646-249-1

2646-563-01

2646-556-01

2646-548-01

2647-337-01

2646-559-02

2646-561-01

2

1

2

30

Parts which have been described to the

NOTE column of the undermentioned

part list as NSP are not supplied.

NOTE

NSP

NSP

NSP

NSP

NSP

Ref. No. Part No. Description

17

18

19

20

21

23

24

26

27

30

31

32

33

34

35

2646-562-01

2646-560-02

1669-181-11

2627-529-01

1500-518-11

7685-791-09

2646-545-01

X2626-328-1

7627-852-38

7685-780-09

-

7621-259-25

Spring

Gear

Head flexible pc board

Screw (+P1.7 2.5)

MD Over write head

MD mount

Screw (+PTT2.6 5 Type S)

Spring(Door arm), Tension coil

Case(Lower)

Loading motor ass'y

Special screw(+P1.7 1.8 Type 3)

Screw (+TT2 3 Type S)

Loading ass'y

Case(Upper)

Screw (+P2.6 4)

NOTE

NSP

NSP

NSP

NSP

18

Page 19

MD MECHANISM EXPLODED VIEW(2)

FR-155

(KMK-260BCN)

51

55

54

52

54

53

57

69

65

65

56

66

64

67

70

58

51

62

61

63

74

71

72

51

Ref. No. Part No. Description

51

52

53

54

55

56

57

58

61

62

63

64

65

66

67

68

69

70

71

72

74

2627-404-01

2646-453-01

1783-387-11

7627-850-79

1677-526-11

-

1669-180-11

2646-452-01

2627-529-01

2647-338-01

2646-567-01

2627-431-01

X2626-329-2

2646-571-11

7627-852-18

X2626-327-1

X2626-330-1

2646-574-03

2646-573-01

A4672-541-A

Screw (+P1.4 3.5 Type3)

Sub Guide

Flexible flat cable(7 core)

Special screw(+P1.4 1.8 Type 3)

D-SW pc board

Mechanical Chassis

Bracket, Spindle motor

Flexible pc board, Optical pick-up

Guide Shaft

Screw (+P1.7 2.5)

Rack Spring

Pre load Plate

Special screw(1.2 3.3)

Slid motor ass'y

Gear (MD)

Special screw(+P1.7 4 Type 3)

Spindle motor Ass'y

Lead screw Ass'y

Lead holder(A)

Lead holder(B)

KMS-260A/JIN

68

NOTE

NSP

NSP

19

Parts which have been described to the NOTE column

of the undermentioned part list as NSP are not supplied.

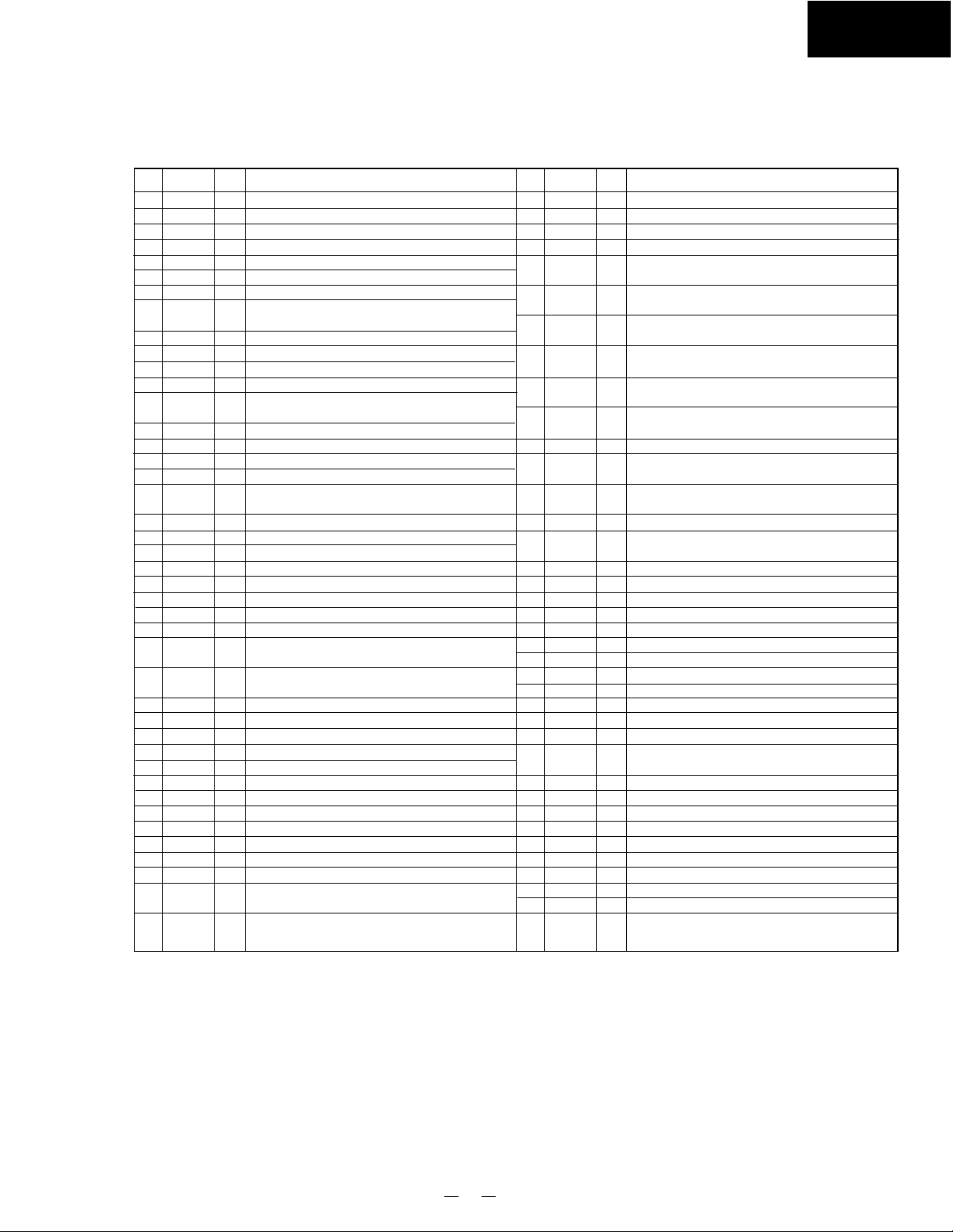

Ref. No. Part No. Description

-

-

IC101

IC102

IC103

IC104

IC121

IC122

IC125

IC152

IC171

IC181

IC201

IC301

Q101,Q163

Q102

Q162

Q181

Q182

Q303

D101

D181,D183

X201

SW1~4

SW5

CN101

CN102

CN103

CN104

CN105

CN107

CN110

-

-

8752-080-95

1781-569-21

8729-903-10

8759-689-63

8752-404-64

8759-234-20

8759-498-44

8759-574-24

8759-640-39

8759-523-35

8759-919-21

8759-689-64

8729-028-91

8729-026-52

8729-101-07

8729-018-75

8729-017-65

8729-028-73

223233R1

8719-046-87

1767-179-31

1771-092-21

1771-327-11

1691-385-21

1774-794-11

1779-341-11

1778-283-11

1779-345-11

-

1779-353-21

L-SW PWB

D-SWPWB

MD PWB

CXA2523AR

90 MHz

FMW1-T-148

RH5RZ35CA-TI

CXD2662R

TC7S08F

MSM51V4400D-70TSK

BA5984FP-E2

BR24C02F-WE2

TC74ACT02FT(EL)

CXP740010-048R

AK4522VF-E2

DTA144EUA-T106

2SA1576A-T106-QR

2SB798-T1DK

2SJ278MY

2SK1764KY

DTA114EUA-T106

1SS355TE-17

F1J6, Diode

12 MHz, Crystal

Push switch(1key)

2pin push switch (2key)

FFC/FPC connector 21P

FFC/FPC connector 26P

FFC/FPC connector 23P

FFC/FPC connector 4P

FFC/FPC connector 7P

FFC/FPC connector 5P

FFC/FPC connector 5P

NOTE

NSP

NSP

NSP

NSP

Page 20

FR-155

MD MECHANISM DISASSEMBLY

1

MD Mechanism KMK-260BCN

Remove the spring(Z3) from the door MD(Z3).

2

Remove the case (lower)(27) by unscrewing the four

5

screws (step)(13).

Screw(step)

Screw(step)

Remove the two special screws(31)used to

6

fix the loading motor.

Screw(step)

Screw(step)

Special Screw(31)

Door MD(Z2)

Remove the spring(26) from the case (lower)(27).

3

Spring(26)

Remove the case (upper)(34) by unscrewing the

4

five screws.

Screw

Screw

Spring(Z3)

Case (lower)(27)

screw

Remove the screw(24) used to fix the

7

MD mount(23)

Keep the MD mount(23) upright.

8

MD mount(23)

Screw(24)

Screw

Pickup unit(74)

Screw

Case (upper)(34)

20

Page 21

MD MECHANISM DISASSEMBLY

Short circuit with solder the short land on the

pick-up unit(74).

9

[NOTE]