Page 1

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK !ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO PARTS

WHOSE PART NUMBERS APPEAR AS SHOWN IN THIS

MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

SERVICE MANUAL

RC-819DV

BD-SP809M2

Ref. No. 4482

072014

They are 2 types to this model (Model No. BD-SP809(B)/(S)), in which a different type of Boards and the

color of BARCODE LABEL are used.

This service manual is for models that ends with

and

"Blue" BARCODE LABEL is adhered on the rear panel

Before servicing, make sure to confirm these differences from the other same number of models, due

to the 2 types of Boards are not compatible.

"M2" at the end of the Current Version of the Firmware

of the unit.

BLU-RAY DISC PLAYER

MODEL

BD-SP809(B)/(S)

Black/Silver model

B/S CUP2BP 110-240V AC, 50/60Hz

Page 2

TABLE OF CONTENTS

Precautions on 3D video images

This unit supports Blu-ray 3D. When servicing problems related to 3D image output, the following

equipments are needed.

- 3D capable TV

- 3D compatible HDMI cable

- 3D glasses

- Blu-ray 3D disc

Manufactured under license from Dolby Laboratories.

Dolby and the double-D symbol are trademarks of Dolby Laboratories.

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

Cabinet Disassembly Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5-1

How to Initialize the BLU-RAY Disc Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

Adjustment Instructions for BD Main CBA or BD Mechanism Assembly Replacement . . . . . . . . . . . . . . . . . . 1-8-1

Error Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Schematic Diagrams / CBA and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Packing View. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-2

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

Page 3

SPECIFICATIONS

General

Signal system NTSC / PAL Colour

Power requirements AC110-240 V, 50/60 Hz

Power consumption 21 W, standby: 0.3 W, standby(Power On Control): 3.5 W

Dimensions

(width x height x depth)

Weight 4.6 kg

Operating temperature 5 °C to 40 °C

Operating humidity Less than 80 % (no condensation)

BD Linear Audio 4 Hz–88 kHz (192 kHz)

DVD Linear Audio 4 Hz–44 kHz (96 kHz), 4 Hz–22 kHz (48 kHz)

Audio CD 4 Hz–20 kHz (44.1 kHz)

Signal to Noise Ratio 100 dB

Audio Dynamic Range 98 dB

THD (Total Harmonic Distortion)

USB input

TYPE A

Audio output (Analogue)

RCA jack x 2 L/R: 2 Vrms (output impedance:

Video output

RCA jack x 1 1Vp-p (75

Component video output

RCA jack x 3

Audio output (Digital)

RCA jack x 1

Optical jack x 1

HDMI output

HDMI jack x 2 Video: 480i/576i, 480p/576p, 720p, 1080i, 1080p, 1080p24 / Audio

ETHERNET terminal 10BASE-T/100BASE-TX

435 x 104 x 315 mm

Audio

0.005 % (1 kHz)

Terminals

USB 2.0

Bus power current: MAX. 500 mA

ƙ)

Y: 1 Vp-p (75 ƙ)

PB: 700 mVp-p (75 ƙ)

PR: 700 mVp-p (75 ƙ)

500 mVp-p (75 ƙ)

Digital connector

less than 1 kƙ

)

D Note

• The specifications and design of this product are subject to change without notice.

1-1-1 ECEB0SP

Page 4

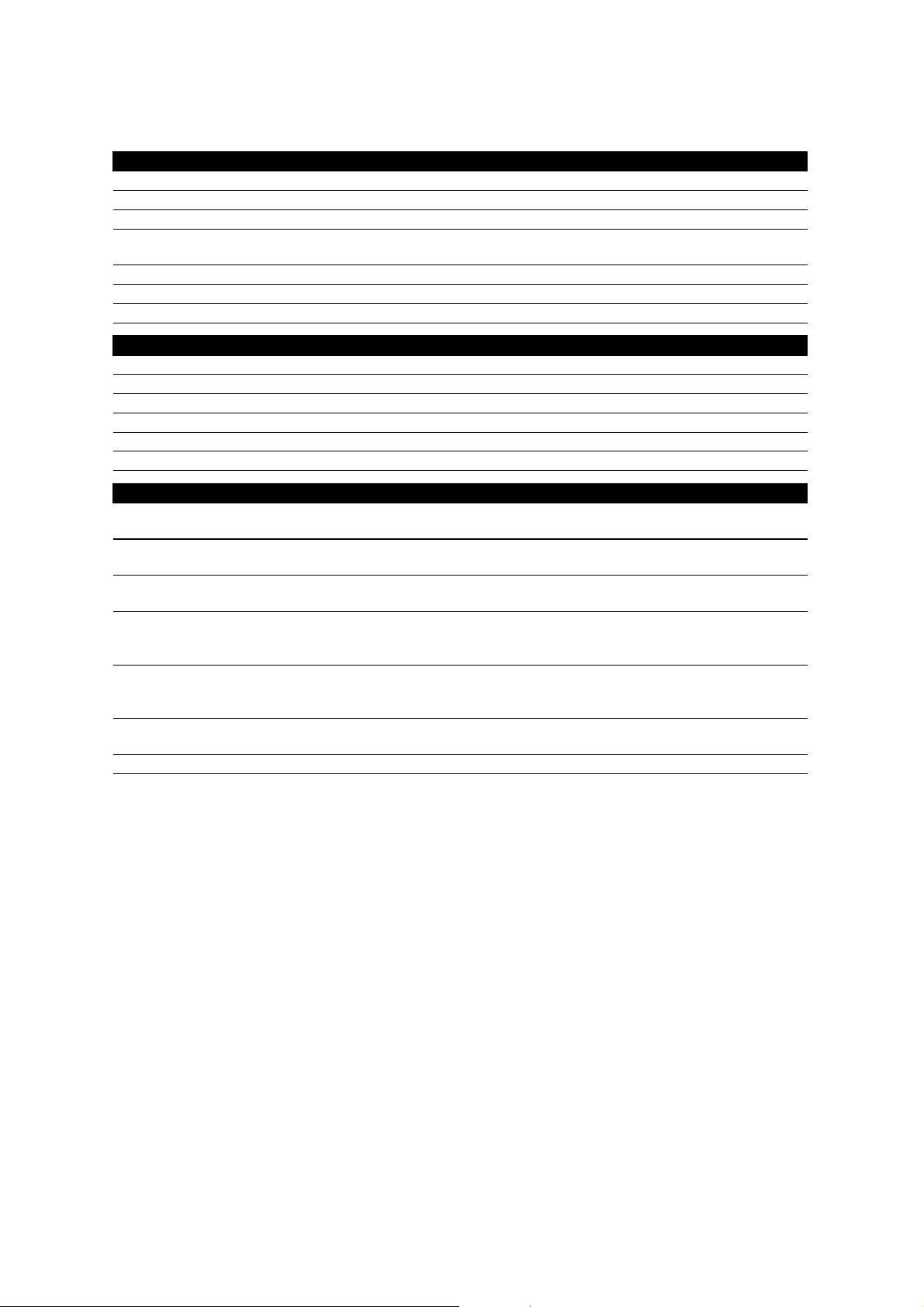

LASER BEAM SAFETY PRECAUTIONS

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

Drive Mechanism Assembly

Laser Beam Radiation

/Laser Pickup

Turntable

This BD player uses a pickup that emits a laser beam.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Location: Inside Top of BD mechanism.

1-2-1 B2PLBSP

Page 5

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a ! on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review

continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are carefully inspected to confirm

with the recognized product safety and electrical

codes of the countries in which they are to be sold.

However, in order to maintain such compliance, it is

equally important to implement the following

precautions when a set is being serviced.

Precautions during Servicing

A. Parts identified by the ! symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heatsinks, oxide metal film

resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5~6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

L. When reassembling, be sure to use the original

screws or specified screws listed in the parts list.

M. This unit is classified as a CLASS 1 LASER

PRODUCT.

1-3-1 BDP_ISP

Page 6

Safety Check after Servicing

Table 2: Leakage current ratings for selected areas

Note: This table is unofficial and for reference only. Be sure to confirm the precise values.

AC Line Voltage Load Z Leakage Current (i)

One side of power cord plug

prongs (B) to:

230 V

2kRES.

Connected in

parallel

i0.7mA AC Peak

i2mA DC

RF or

Antenna terminals

50k RES.

Connected in

parallel

i0.7mA AC Peak

i2mA DC

A/V Input, Output

Examine the area surrounding the repaired location for

damage or deterioration. Observe that screws, parts,

and wires have been returned to their original positions.

Afterwards, do the following tests and confirm the

specified values to verify compliance with safety

standards.

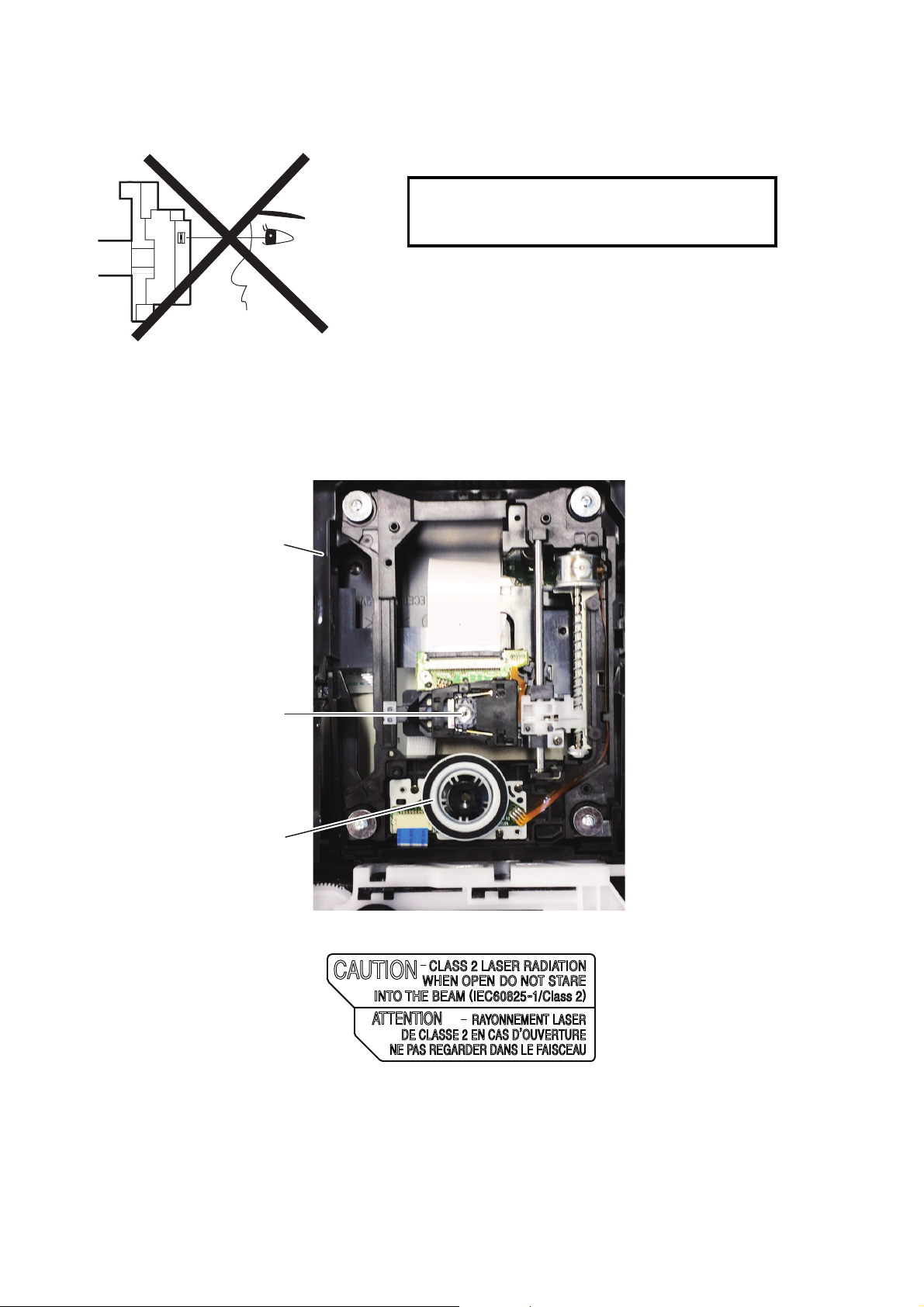

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1 : Ratings for selected area

AC Line Voltage Clearance Distance (d), (d’)

Chassis or Secondary Conductor

Primary Circuit

d' d

230 V

Note: This table is unofficial and for reference only.

Be sure to confirm the precise values.

3.2 mm(d)

6.0 mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON) :

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

Fig. 1

AC Voltmeter

(High Impedance)

1-3-2 BDP_ISP

Fig. 2

Page 7

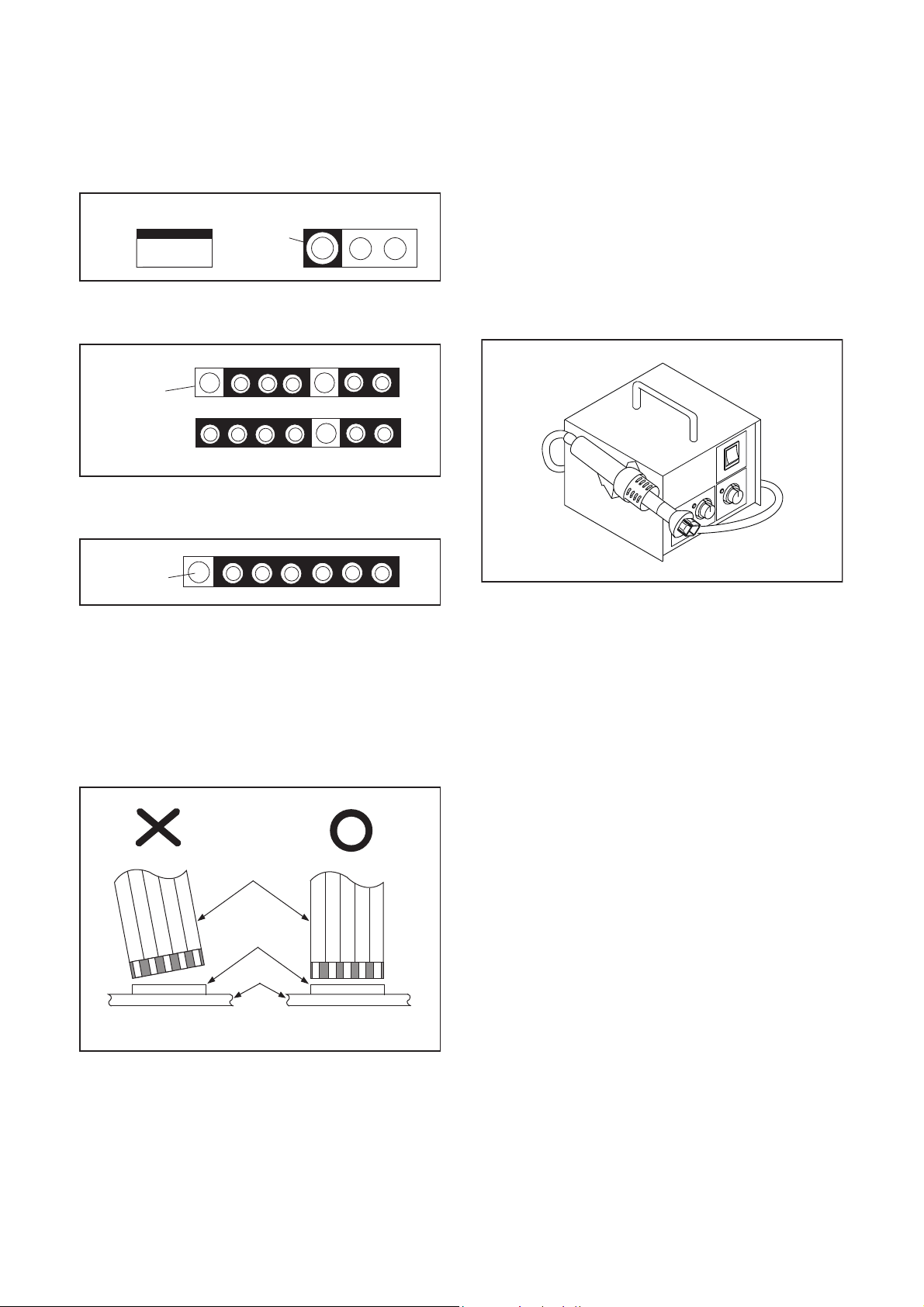

STANDARD NOTES FOR SERVICING

Top View

Out

In

Bottom View

Input

5

10

Pin 1

Pin 1

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

Fig. S-1-1

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

3. The 1st pin of every male connector is indicated as

shown.

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

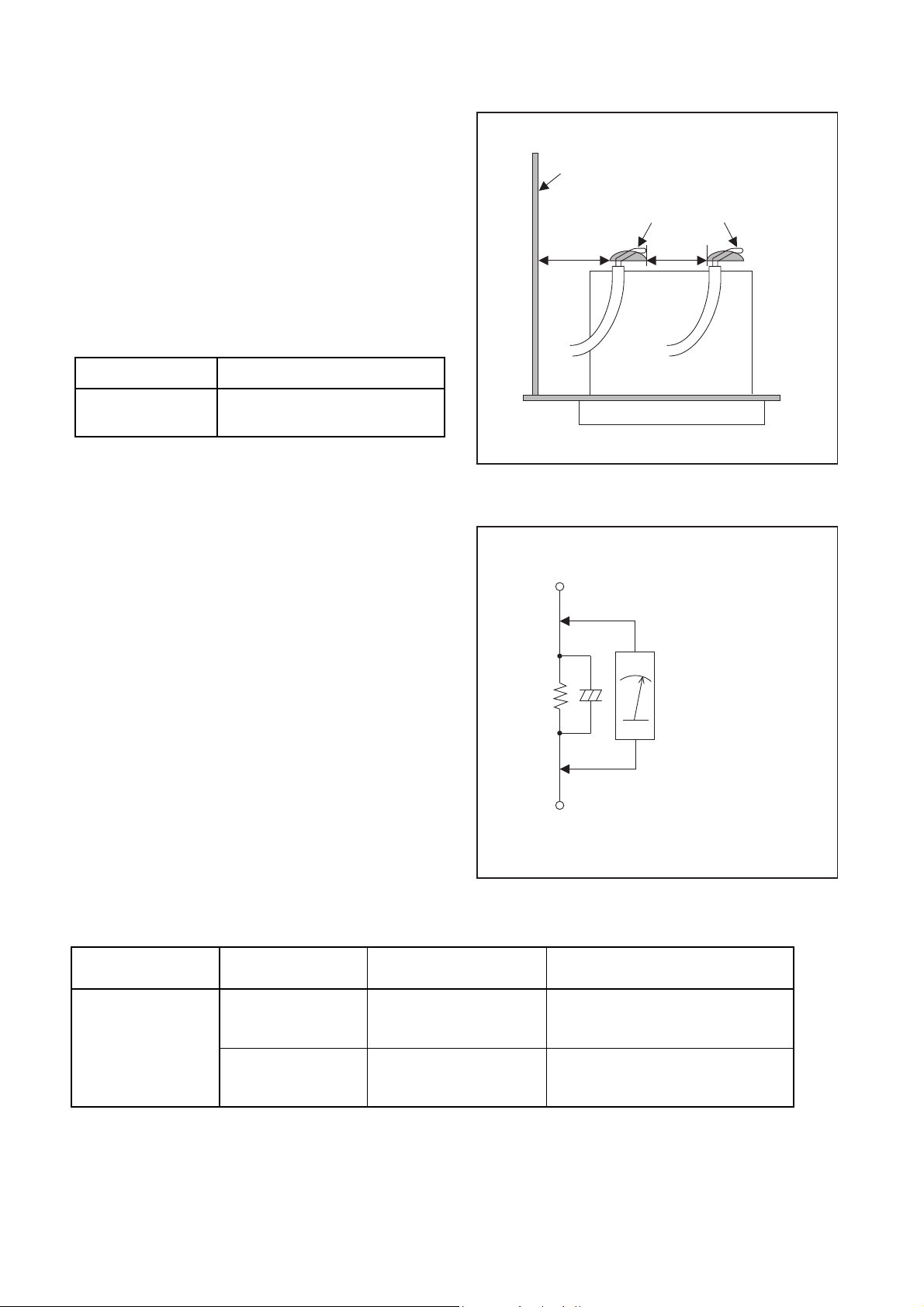

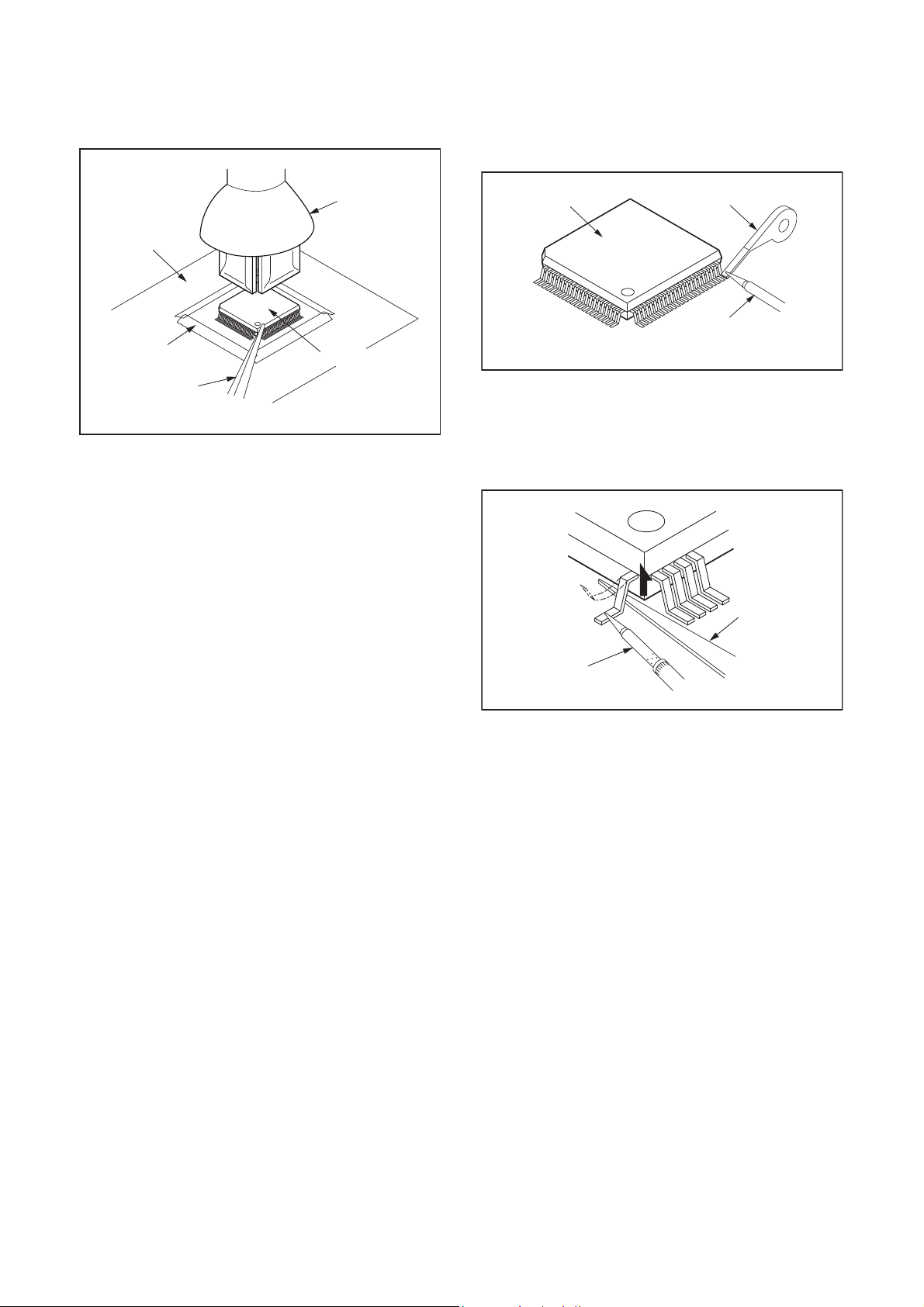

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-4-1 BDP_SN

Page 8

3. The flat pack-IC on the CBA is affixed with glue, so

Hot-air

Flat Pack-IC

Desoldering

Machine

CBA

Flat Pack-IC

Tweezers

Masking

Tape

Fig. S-1-2

Fine Tip

Soldering Iron

Sharp

Pin

Fig. S-1-4

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

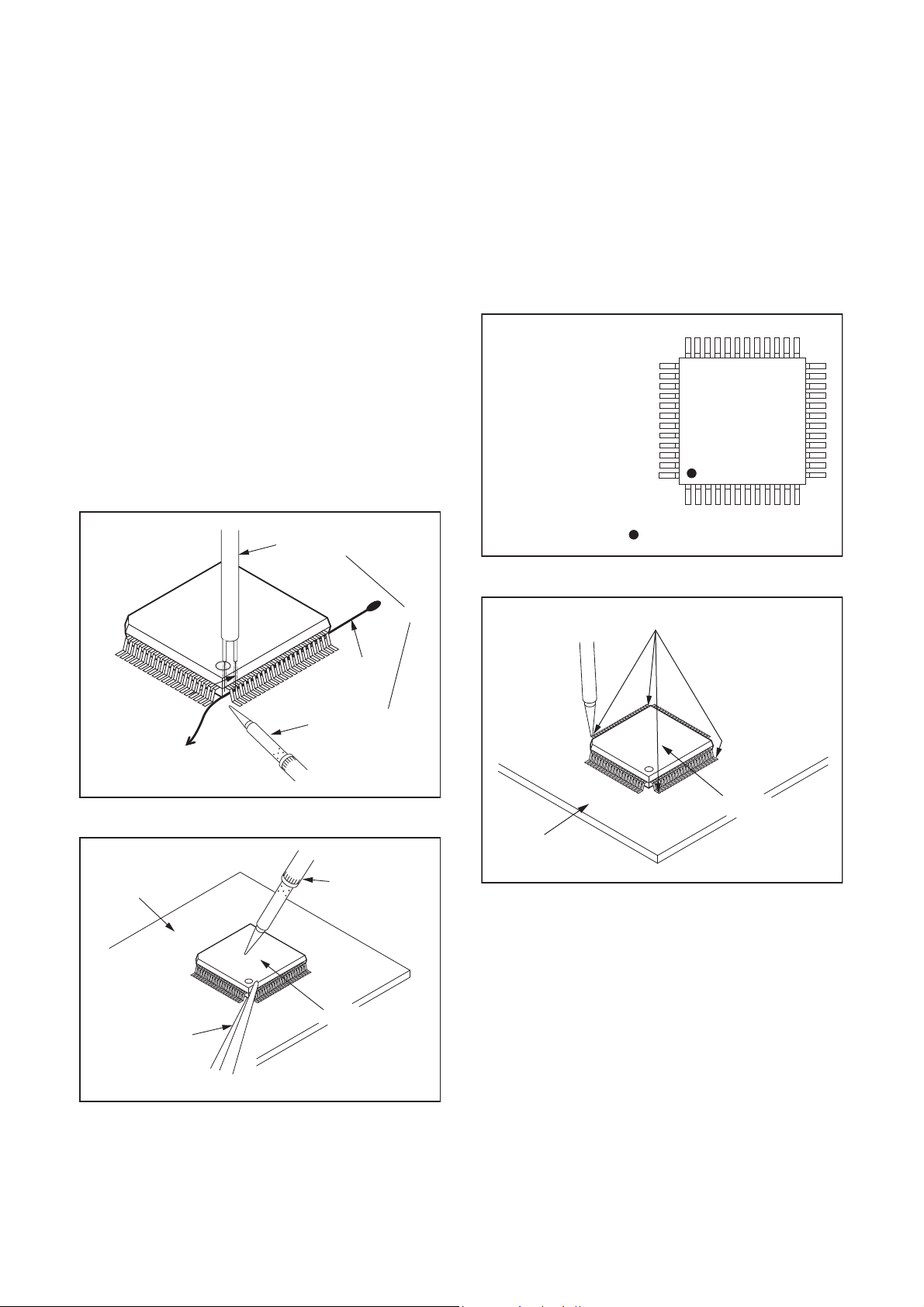

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

1-4-2 BDP_SN

Page 9

With Iron Wire:

To Solid

Mounting Point

Soldering Iron

Iron Wire

or

Hot Air Blower

Fig. S-1-5

Fine Tip

Soldering Iron

CBA

Flat Pack-IC

Tweezers

Fig. S-1-6

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “ I ” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

1-4-3 BDP_SN

Page 10

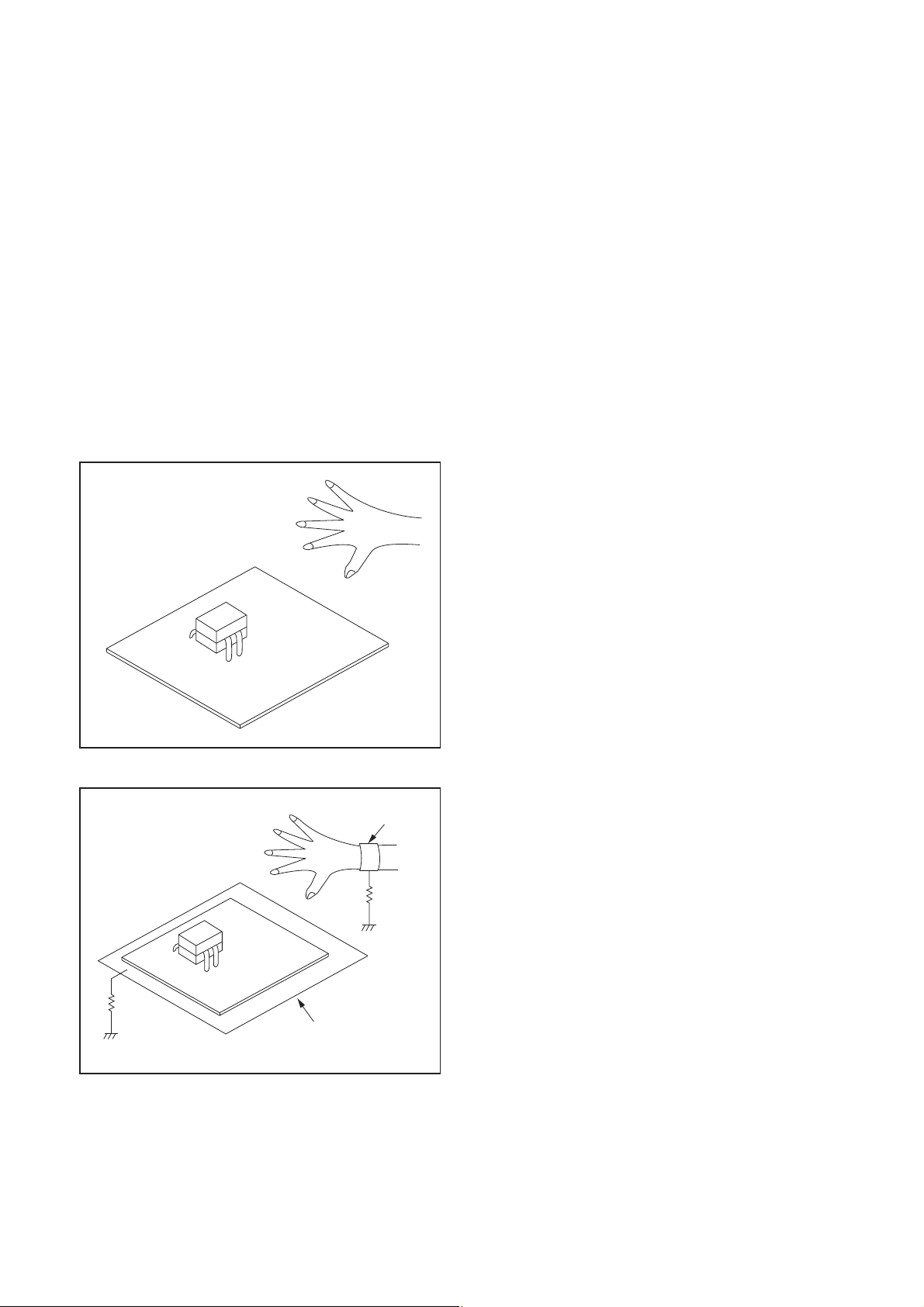

Instructions for Handling Semi-

<Incorrect>

CBA

Grounding Band

Conductive Sheet or

Copper Plate

1MΩ

1MΩ

<Correct>

CBA

conductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 M) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 M) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

1-4-4 BDP_SN

Page 11

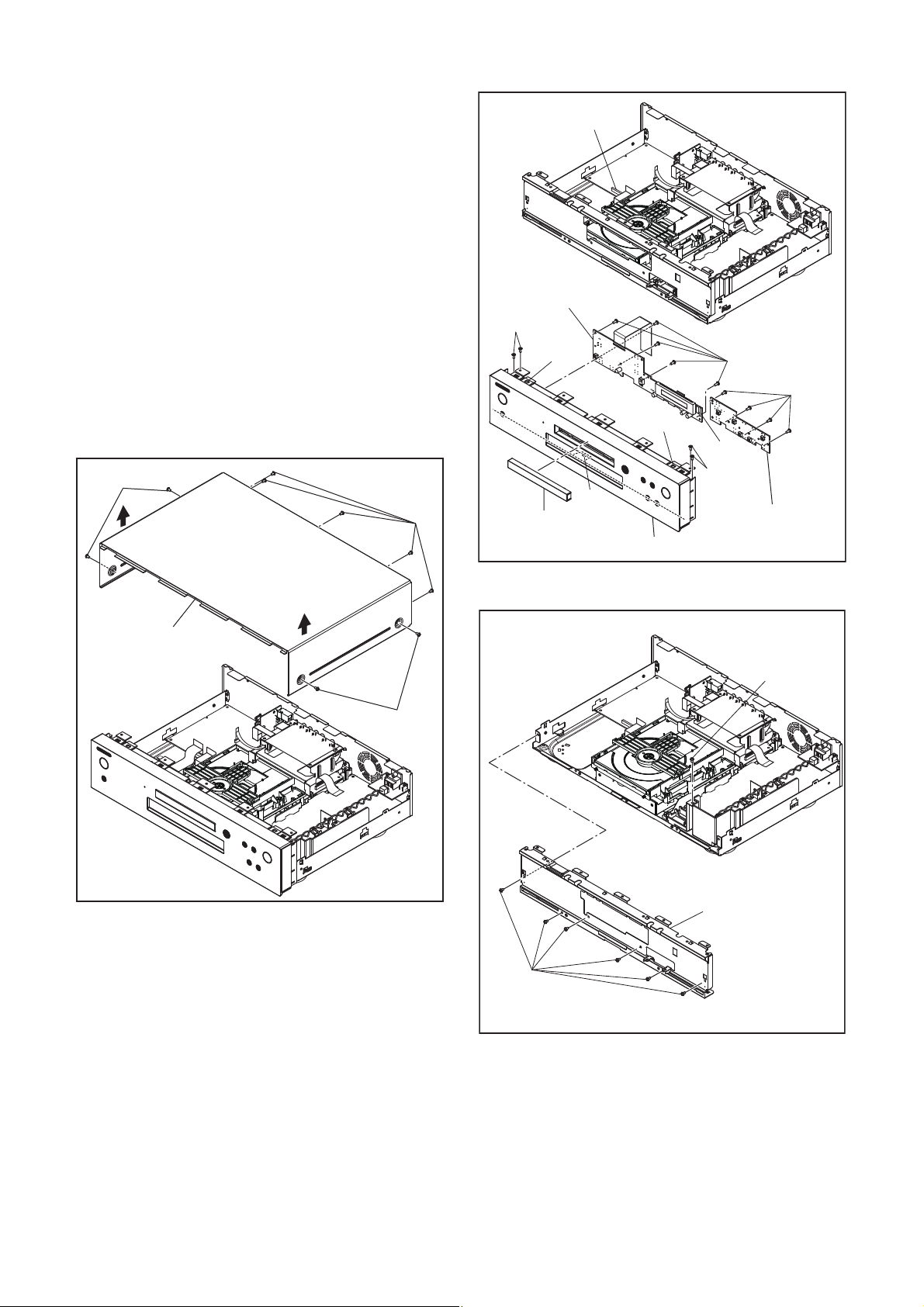

CABINET DISASSEMBLY INSTRUCTIONS

[3] Front

Assembly

[1] Top Cover

[2] Tray

Assembly

[9] Rear Panel

[11] Video CBA

[12] AV PCB

Bracket

[14] BD Main

CBA Unit

[18] Loader

Bracket

[8] RS232C

CBA

[7] Inlet CBA

[6] Front Bracket

[15] BD Mechanism

Assembly

[13] BD Main CBA

& BD Mechanism

Assembly

[17] Power

Holder

[16] Power

Supply CBA

[10] Audio CBA

[4] Front-A CBA

[5] Front-B CBA

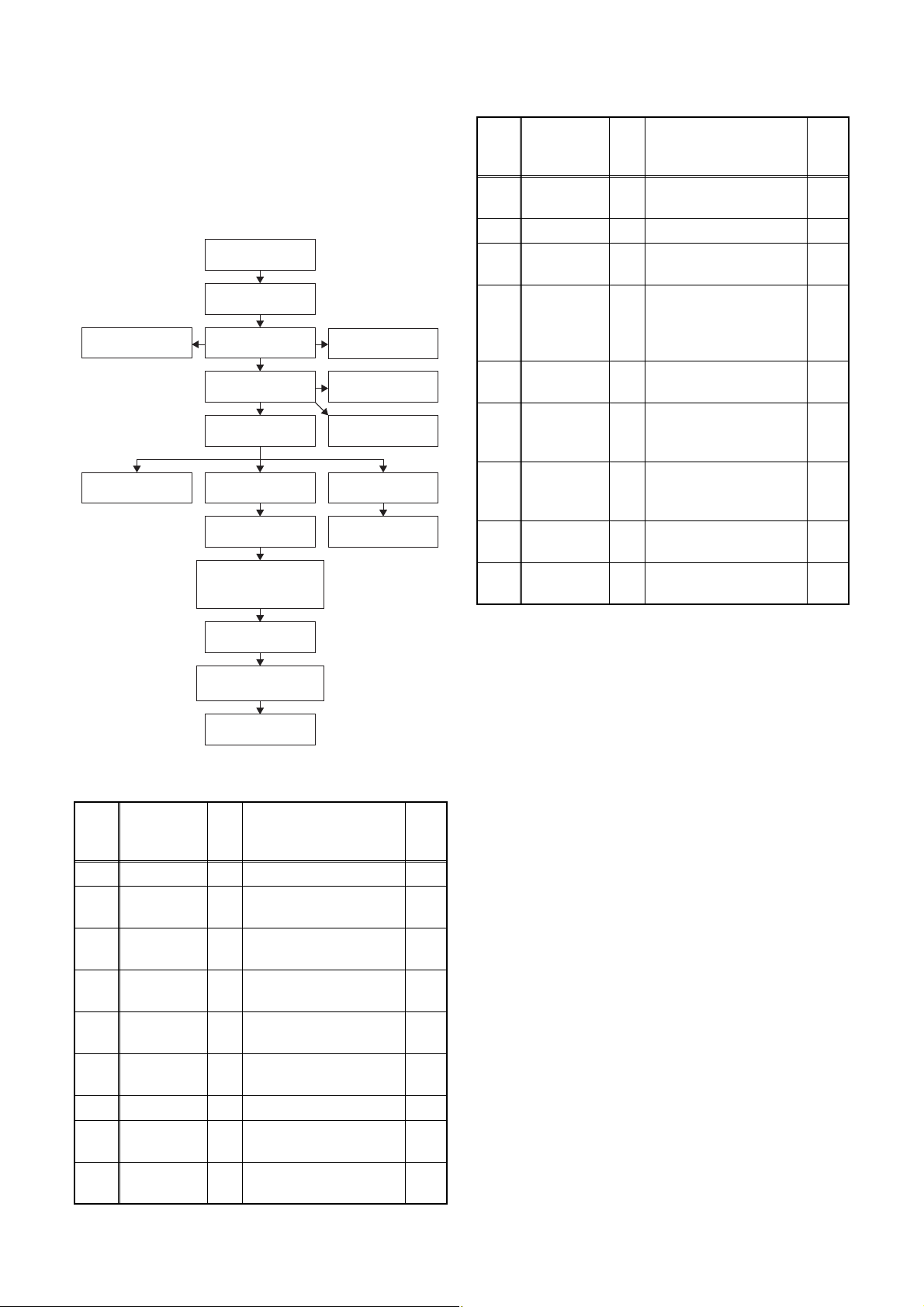

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to items to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

ID/

Loc.

Part

No.

[10] Audio CBA D5

Fig.

No.

4(S-12), CN2001,

CN2201

Removal

Note

[11] Video CBA D6 4(S-13), CN6901 ---

AV PCB

[12]

Bracket

D6 4(S-14) ---

BD Main

[13]

CBA & BD

Mechanism

2(S-15), 4(S-16),

D7

CN6101

Assembly

[14]

[15]

BD Main

CBA Unit

BD

Mechanism

Assembly

CN7001, CN7002,

D8

CN7003, Hook

4(S-17),

D8

Loader Holder

Power

[16]

Supply

D9 3(S-18), 2(S-19) ---

CBA

Power

[17]

[18]

(1)

Holder

Loader

Bracket

(2)

D9 3(S-20) ---

D9 6(S-21) ---

(3)

(4)

---

---

4

4

(5)

2. Disassembly Method

ID/

Loc.

No.

[1] Top Cover D1 9(S-1) ---

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9] Rear Panel D4

Part

Tr ay

Assembly

Front

Assembly

Front-A

CBA

Front-B

CBA

Front

Bracket

Inlet CBA

RS232C

CBA

Fig.

No.

D2 --------------- 1

D2

D2 CN3001 ---

D2 --------------- ---

D3 7(S-4) ---

D4 (S-5), 2(S-6), CN1002 5

D4 (S-7), 2(S-8), CN5501 ---

Removal

2(L-1), (L-2), 4(S-2),

9(S-3), CN2002

8(S-9), 2(S-10),

5(S-11)

Note

2

3

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

CN = Connector

e.g. 2(S-2) = two Screws of (S-2),

2(L-2) = two Locking Tabs of (L-2)

(5) Refer to “Reference Notes.”

1-5-1 ECEB0DC

Page 12

Reference Notes

1. How to remove Tray Assembly

1) Press the [A] button to open the tray.

2) Remove the Tray Assembly.

3) Press the [A] button to close the tray.

2. CAUTION 1: Locking Tabs (L-1) and (L-2) are

fragile. Be careful not to break them.

3. When reassembling, be sure to use the original

screws or specified screws listed in the parts

list.

4. When replacing the BD Mechanism Assembly

or BD Main CBA Unit, refer to “ADJUSTMENT

INSTRUCTIONS FOR BD MAIN CBA OR BD

MECHANISM ASSEMBLY REPLACEMENT.”

5. Make sure there is no gap left between the

Rear Panel and AC Inlet Terminal when

assembling Inlet CBA.

(S-1)

(S-1)

CN2002

[4] Front-A CBA

(S-2)

(L-1)

(L-2)

[2] Tray

Assembly

(S-3)

(L-1)

CN3001

(S-2)

[5] Front-B CBA

[3] Front Assembly

(S-3)

Fig. D2

[1] Top Cover

(S-4)

(S-1)

Fig. D1

[6] Front Bracket

(S-4)

Fig. D3

1-5-2 ECEB0DC

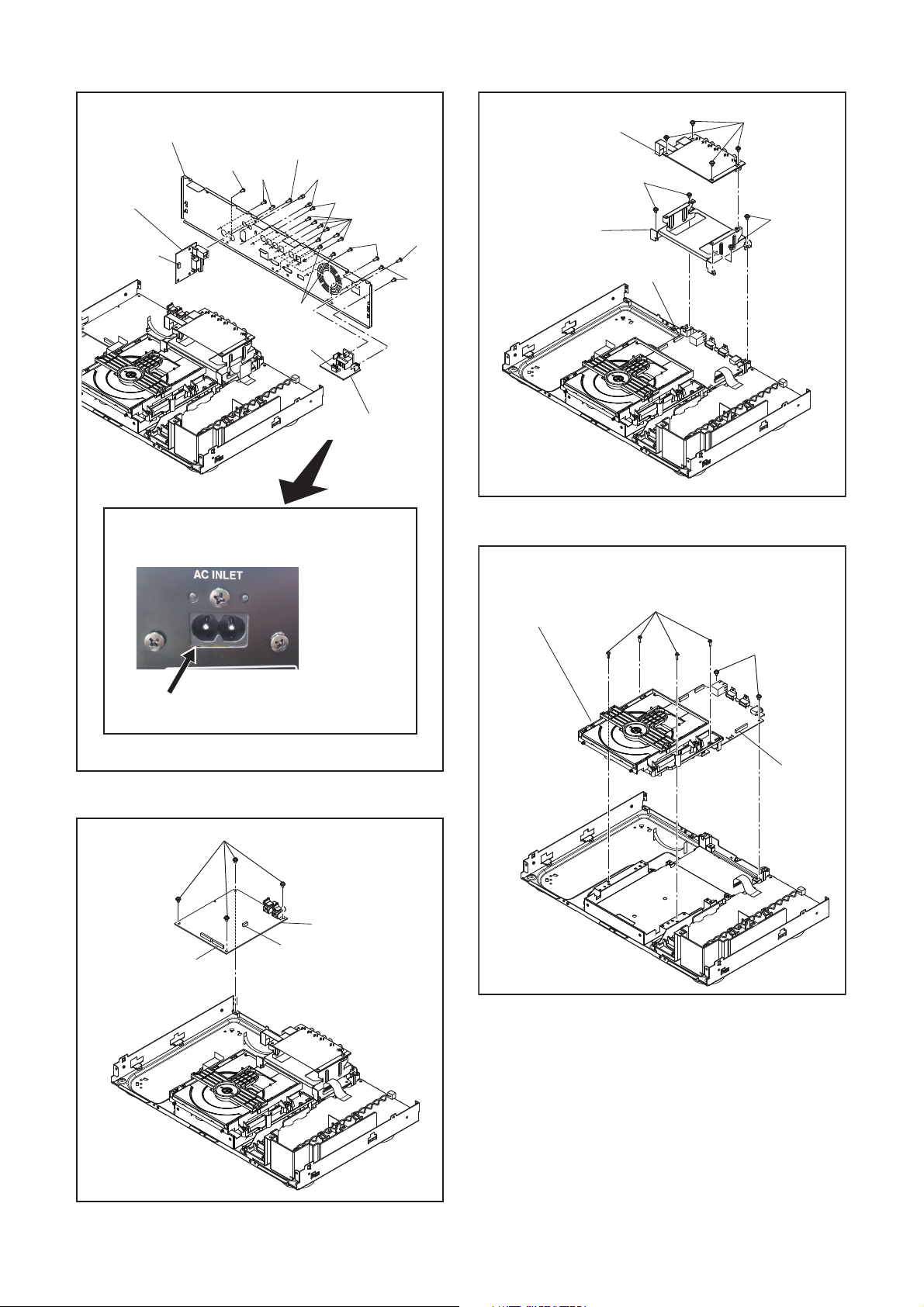

Page 13

*See Reference Note 3.

[9] *Rear Panel

(S-9)

(S-7)

(S-8)

(S-11)

(S-11)

[8] RS232C

CBA

CN5501

(S-10)

CN1002

[7] Inlet CBA

CAUTION: When assembling the Inlet CBA

(Rear View)

(S-9)

(S-11)

(S-5)

(S-6)

[11] Video CBA

(S-14)

[12] AV PCB

Bracket

CN6901

[13] BD Main CBA &

BD Mechanism

Assembly

(S-13)

(S-14)

Fig. D6

(S-16)

Make sure there is no gap left between

the Rear Panel and AC Inlet Terminal.

(S-12)

[10] Audio CBA

CN2201

CN2001

(S-15)

Fig. D4

CN6101

Fig. D7

Fig. D5

1-5-3 ECEB0DC

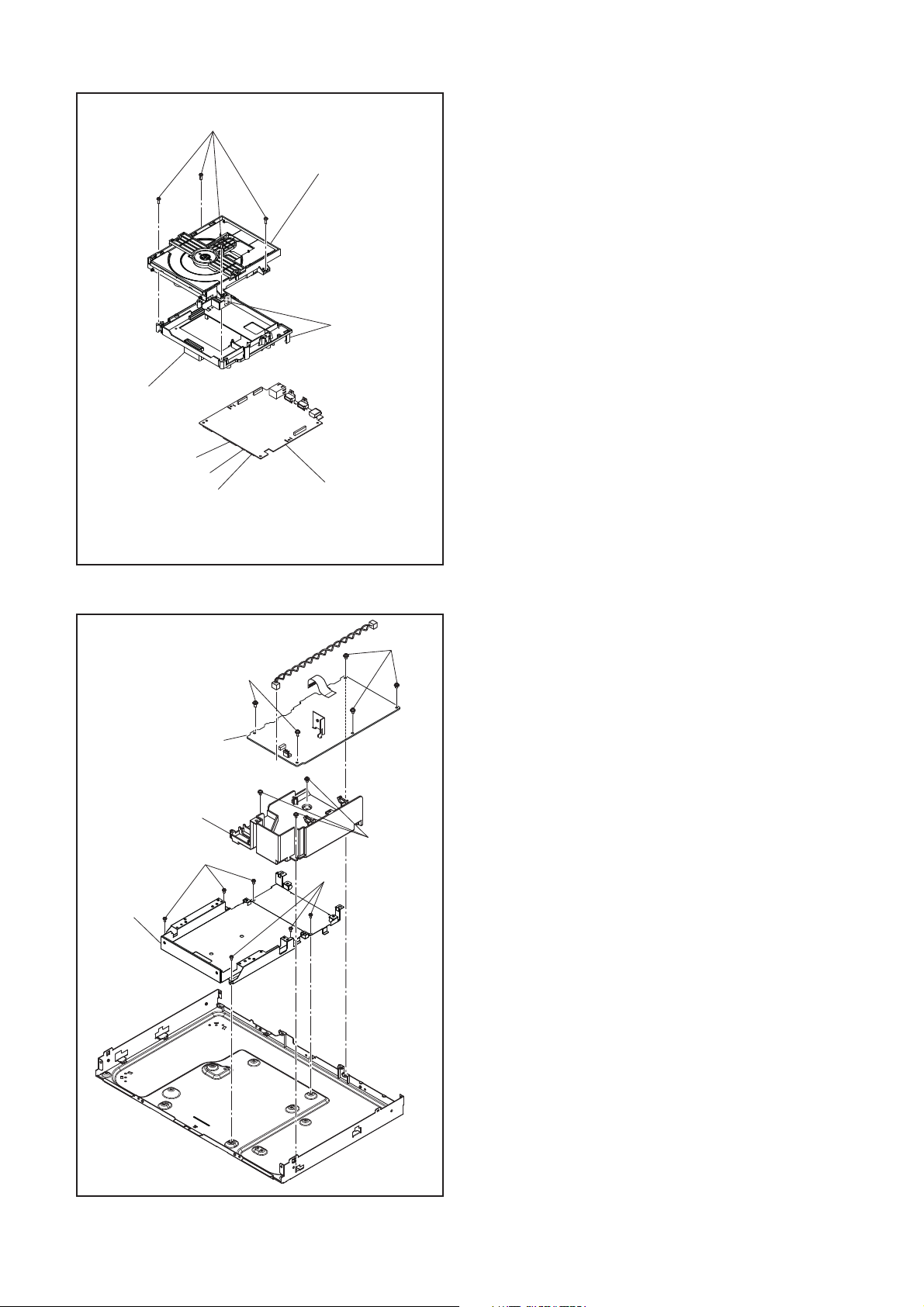

Page 14

Loader Holder

CN7003

CN7001

CN7002

(S-17)

[15] *BD Mechanism

Assembly

Hook

[14] *BD Main CBA Unit

* See Reference Note 4.

(S-19)

[16] Power Supply

CBA

[17] Power Holder

(S-21)

[18] Loader

Bracket

Fig. D8

(S-18)

(S-20)

(S-21)

Fig. D9

1-5-4 ECEB0DC

Page 15

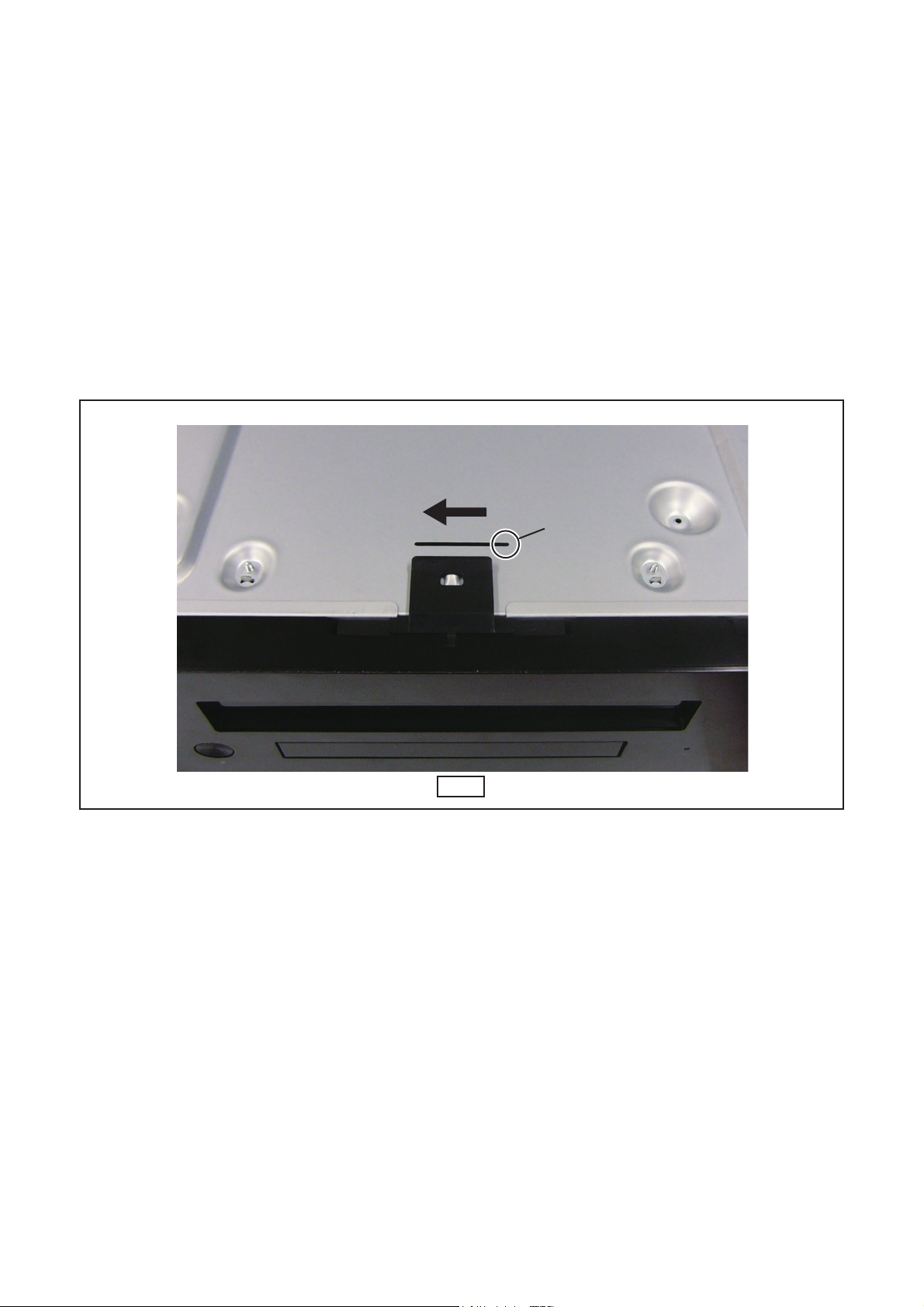

3. How to Eject a Disc

When a disc cannot be removed due to malfunction or when an unplayable disc is inserted, follow the

procedure below to remove the disc.

Procedure A

1. Unplug the AC power cord and then plug it in.

2. Turn the power on by pressing the [A] button and the disc tray will open automatically.

Procedure B

1. Unplug the AC power cord.

2. Turn the unit over.

3. Insert a straight shaft of 1.5mm in diameter or less into the location marked A below. (Refer to the

illustration below.)

4. Move the shaft slowly in the direction of the arrow. (Refer to the illustration below.)

5. Pull the tray slowly manually.

A

Front

1-5-5 ECEB0DC

Page 16

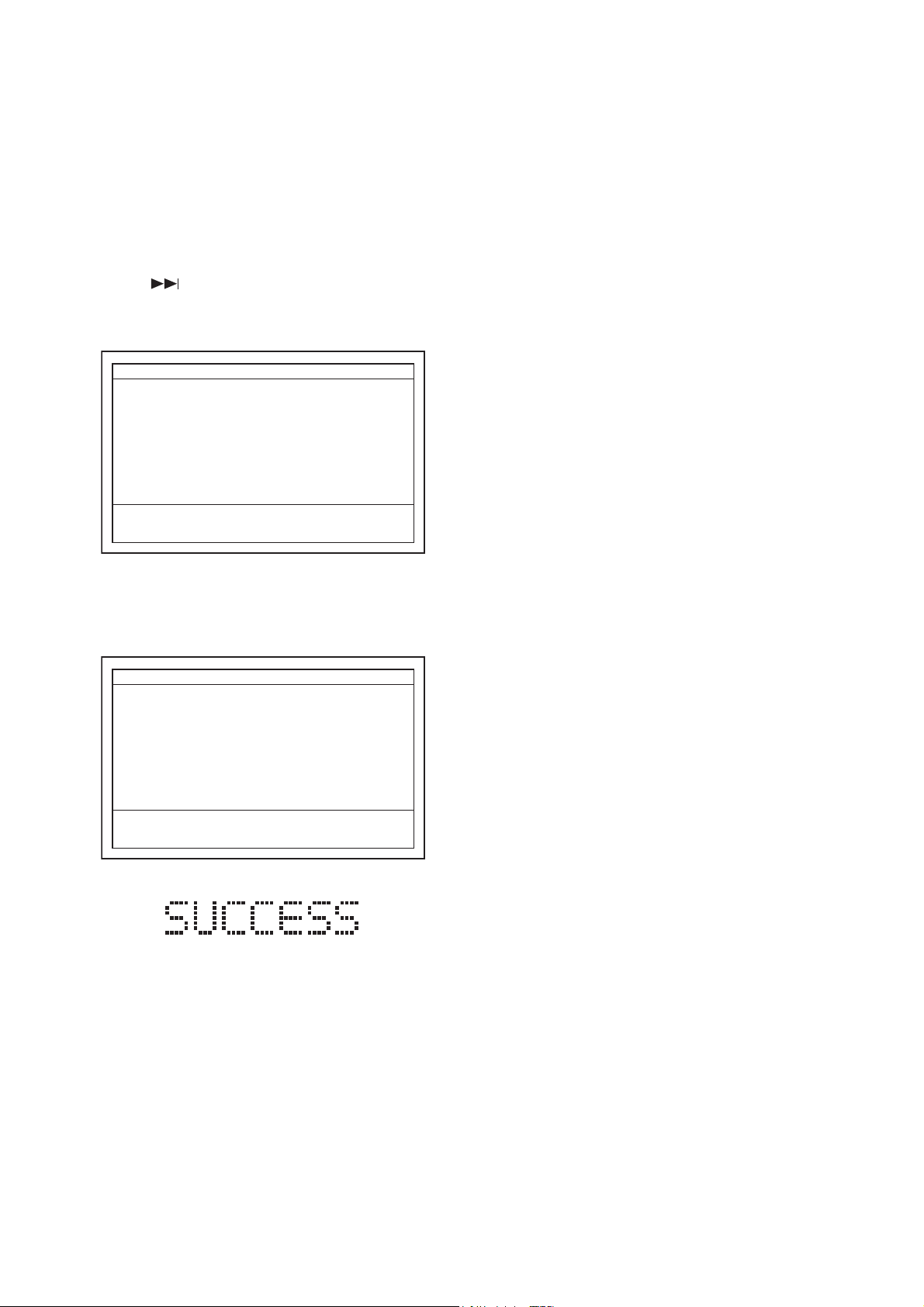

HOW TO INITIALIZE THE BLU-RAY DISC PLAYER

To put the program back at the factory-default,

initialize the BD player as the following procedure.

Note:

• By initializing, network is reset to disconnected state.

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [ ] (skip up), [1], [2], and [3] buttons on

the remote control unit in this order.

Fig. a appears on the screen. All VFD lights.

"*" differ depending on the models.

Version Display

F/W Name

Version

Region

Pickup

Default Setting : --

Default Setting : STOP End : STANDBY-ON

VFD/LED Check : OK

: *******

: *.**.**

: *-*

: **

Fig. a

4. Press [ C ] button on the remote control unit.

Fig. b appears on the screen and Fig. c appears

on the VFD.

"*" differ depending on the models.

Version Display

F/W Name

Version

Region

Pickup

Default Setting : SUCCESS

Default Setting : STOP End : STANDBY-ON

VFD/LED Check : OK

: *******

: *.**.**

: *-*

: **

Fig. b

Fig. c

5. After initializing, the power will turn off

automatically.

1-6-1 E5XF1INT

Page 17

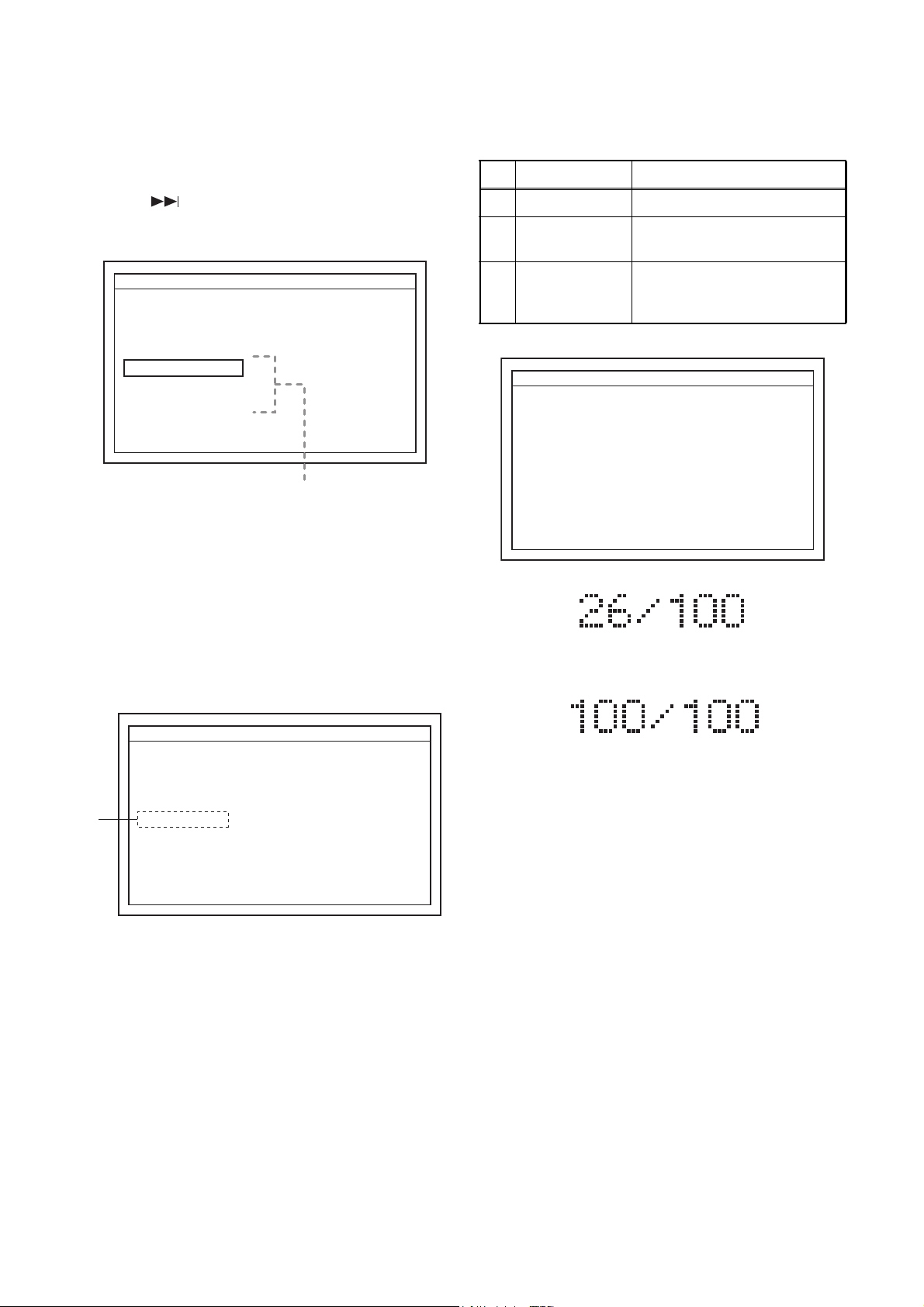

FIRMWARE RENEWAL MODE

"*" differ depending on the models.

F/W Version Mode

Please select software update mode.

Disc

USB

SD Card

F/W Name : ******* Ver *.**.**

The available software update mode will

differ depending on the model type.

"*" differ depending on the models.

F/W Version Mode

Loading Disc...

F/W Name : ******* Ver *.**.**

(*1)

Note: The file extension of the available firmware is

“b40”.

1. Turn the power on and remove the disc on the tray

and close the tray.

2. Press [ ] (skip up), [6], [5], and [4] buttons on

the remote control unit in that order.

Fig. a appears on the screen.

Fig. a Version Up Mode Screen (Example)

3. Select “Disc” or “USB” and press [ENTER] button

on the remote control unit. The tray will open

automatically, if “Disc” is selected.

4. Insert the disc or USB Flash Drive for version up.

5. The BD player enters the F/W version up mode

automatically. Fig. b will appear on the screen.

Make sure to insert the proper F/W for the state of

this model.

The appearance shown in (*1) of Fig. b is

described as follows:

No. Appearance State

1 Loading Disc Loading the disc

2 Reading...

Sending files into the

memory.

Writing new version data,

3See FLD.

the progress will be displayed

as shown in Fig. d.

"*" differ depending on the models.

F/W Version Mode

1. ALL

Version : *.**.**

CHECKSUM : ****

See FLD.

The unit will automatically turn off when update is completed,

and automatically turns back on.

F/W Name : ******* Ver *.**.**

***************.b40

Fig. c Version Up Mode

Fig. d VFD in Version Up Mode

6. After the update, Fig. e will appear on the VFD and

the power will turn off automatically.

Fig. b Programming Mode Screen (Example)

Fig. e

VFD upon Finishing the Programming Mode (Example)

7. The power turns on automatically. If disc mode

was selected, the tray will open automatically.

Remove the disc or USB Flash Drive from the unit.

Note: All the settings will be put back to factory-

default.

The following USB Flash Drive can be used for

software update. Make sure to use a device that has

enough space.

• USB Flash Drive (FAT16/FAT32 file system)

• Choose “USB” at Fig. a. when using a SD Card that

is connected to a Card Reader. Otherwise, the unit

will not be updated if “SD Card” is selected.

1-7-1 BD-SP809M2FW

Page 18

How to Verify the Firmware Version

Product Info

OK

Current Version : X.XX.XXM2

If you wish to check latest update or

other product information, please check

our Website.

"X" differ depending on the models.

www.onkyo.com

1. Turn the power on.

2. Press [Home] button on the remote control unit.

3. Select “Settings” on the home menu screen and

press [ENTER] button.

4. Select “Others” then press [ENTER] button.

5. Select “Product Info” then press [ENTER] button.

Refer to Fig. f below.

Fig. f

Note: There are two types to this model (Model

No.BD-SP809(B)/(S)), in which a different type

of Board is used.This service manual is for

models that ends with "M2" at the end of the

Current Version.

1-7-2 BD-SP809M2FW

Page 19

ADJUSTMENT INSTRUCTIONS FOR BD MAIN CBA OR

BD MECHANISM ASSEMBLY REPLACEMENT

When replacing either BD Main CBA or BD Mechanism Assembly, the unique OPU DATA of the BD Mechanism

needs to be written into the BD Main CBA. Follow the procedure below for OPU DATA write operation.

Equipments:

• PC (OS: Windows 7 strongly recommended)

• Barcode reader

• LAN cable (Cross Type)

• Short-circuit clip

• Specialized application (OpuDataWriter)

1. Preparation Of Work Environment

1-1.

For the OPU DATA write operation, refer to the connection diagram and connect each device as shown below.

Connection Diagram

Unit (Rear View)

PC

LAN cable

(Cross Type)

Barcode Reader

(To USB Port)

2. PC Setup

2-1. Change the PC's IP address to "192.168.0.1".

2-2. Install the VB6 Runtime.

If “mswinsck.ocx” exists under “C:\windows\system32\”, you do not need to install this.

2-3. Remove the Top Cover. Refer to the “CABINET DISASSEMBLY INSTRUCTIONS” section on page 1-5-1.

2-4. Connect the short-circuit clip as the illustration below.

1-8-1 B4.8P_AIR

Page 20

3. Application Setup

Status Display

Cursor position

Status Display

3-1. Save the application folder (OpuDataWriter) directly under the C: drive.

3-2. Create a shortcut for [OpuDataWriter.exe] which is located inside the folder on the desktop.

4. OPU DATA WRITE

4-1. Connect the unit’s AC power cord. Wait for about 30 seconds until the unit is in standby mode.

4-2. Double click on the [OpuDataWriter.exe] shortcut on the desktop to start the application.

4-3. Application start screen appears.

Check that [Please input OPU DATA] message is displayed in the Status Display.

Set the cursor position at the blank box next to the [OPU DATA].

4-4. Using the Barcode reader, scan the QR code attached to the BD Mechanism Assembly.

4-5. Check that [FE CONNECTION CHECK] message appears on the Status Display then turn the unit power on.

FE CONNECTION CHECK

If error occurs:

If an error occurs, the screen changes to a red display. In such case, close the window and then unplug the

unit AC power cord. Check if each device is properly connected then repeat from step 1.

1-8-2 B4.8P_AIR

Page 21

4-6. Data write begins. While writing data, the Status Display message will change.

Status Display

SEND LD PAR

[OK]

4-7. [OK] appears in the Status Display if data write has been completed successfully.

If error occurs:

• If an error occurs, the screen changes to a red display. In such case, close the window and then unplug the

unit AC power cord. Check if each device is properly connected then repeat from step 1.

• If an error other than connection error occurs for more than 3 times, the BD MAIN CBA or BD Mechanism

Assembly may be defected. Replace with a new one before performing the OPU DATA write.

[ERROR:1210] ComConnection TIME OUT.

4-8. After data write has been completed successfully, unplug the AC power cord.

4-9. Remove the LAN Cable.

1-8-3 B4.8P_AIR

Page 22

Error Code

Error Code Error Description

10 Start word error The first letter entered for [OPU DATA] does not match.

210 Start word error The first letter entered for [OPU DATA] does not match.

300 CheckSum NG

1010 Start word error The first letter entered for [OPU DATA] does not match.

2300 OPU Model Check NG The model type of OPU is not registered.

2310 Drive Parameter CheckSum NG Data checksum of acquired IOP data does not match.

3001

3002 LanConnectionChk Nop Error No response for NOP confirmation after LAN connection.

3003 LanConnectionChk Other Error Error occurred during LAN connection process.

3011 LanGenerationChk TIME OUT Generation check failed. (Timeout)

3012 LanGenerationChk Other Error Generation check failed. (Other error)

3021

3022

3141 LanB2LdParamSend TIME OUT LD Parameter data send process failed. (Timeout)

3142

3143

3161 LanB2IopSet ERROR0 IOP measure failed. (ERROR0)

3162 LanB2IopSet ERROR1 IOP measure failed. (ERROR1)

3163 LanB2IopSet TIME OUT IOP measure failed. (Timeout)

3164 LanB2IopSet ETC IOP measure failed. (ETC)

3165 LanB2IopSet ERROR0 Switching off LD process after IOP measure failed. (ERROR0)

3166 LanB2IopSet ERROR1 Switching off LD process after IOP measure failed. (ERROR1)

3167 LanB2IopSet TIME OUT Switching off LD process after IOP measure failed. (Timeout)

3168 LanB2IopSet ETC Switching off LD process after IOP measure failed. (ETC)

3169 LanB2IopSet TIME OUT

3170 LanB2IopSet Rcvdata Error

3171 LanB2IopSet Rcvdata Error

3172 CD Iop LIMIT NG Exceeds the CD lop limit value.

3174 DVD Iop LIMIT NG Exceeds the DVD lop limit value.

3176 BD Iop LIMIT NG Exceeds the BD lop limit value.

3178 LanB2IopSet Other Error

3181

3182

3183

3184

3185

LanConnectionChk Connection

Error

LanB2DDDDataSend TIME

OUT

LanB2DDDDataSend Other

Error

LanB2LdParamSend Rcvdata

Error

LanB2LdParamSend Other

Error

LanB2LdParamVerify TIME

OUT

LanB2LdParamVerify Rcvdata

Error

LanB2LdParamVerify Rcvdata

Error

LanB2LdParamVerify Rcvdata

Error

LanB2LdParamVerify Other

Error

The checksum of the entered OPU DATA(QR code) does not

match.

Cannot connect to LAN.

Error occurred while sending OPU data. (Timeout)

Error occurred while sending OPU data. (Other error)

LD Parameter data send process failed. (Return value is invalid)

LD Parameter data send process failed. (Other error)

IOP measure sequence failed in the middle of the process.

(Timeout)

IOP measure sequence failed in the middle of the process.

(Return value is invalid)

IOP measure sequence failed in the middle of the process.

(Return value is invalid)

IOP measure sequence failed in the middle of the process.

(Other error)

Verify process failed. (Timeout)

Verify process failed. (Return value is invalid)

Verify process failed. (Return value is invalid)

Verify process failed. (Return value is invalid)

Verify process failed. (Other error)

1-8-4 B4.8P_AIR

Page 23

Error Code Error Description

Pre-operation OPU DATA text file

Year(2014)Month(06)

1406

3231

3232

3233 LanFactoryInfoSave Other Error Failed to read FactoryInfo data. (Other error)

3241 CreateFactoryInfo Other Error Failed to create FactoryInfo file.

LanFactoryInfoSave OPU SN

Error

LanFactoryInfoSave Fac Data

Error

Failed to read FactoryInfo data. There is a problem in reading

OPU SN.

Failed to read FactoryInfo data. There is a problem in reading

FACTORY data.

5. Saving The Pre-Operation OPU DATA

OPU DATA before performing the OPU DATA write is saved in a folder automatically.

5-1. When the OPU DATA write operation has been completed successfully, a folder named [FactoryInfo] is

created in the application folder (OpuDataWriter).

5-2. In the [FactoryInfo] folder, a folder is created monthly in which text file data are saved.

This text file is created with a file name of the OPU serial number and contains the pre-operation OPU DATA.

5-3. The text file is necessary for analyzing the defective BD Mechanism. Submit this text file with the defective

BD Mechanism as necessary to the appropriate managing Department.

1-8-5 B4.8P_AIR

Page 24

ERROR MESSAGE

Note: Only error messages for the unit’s corresponding media will appear.

Disc Error

Playback feature may not be available on this Disc.

Error Message

Disc Error

Loader Error

- - Please eject the disc. - -

Disc Error

- - Please eject the disc. - Playback feature may not be available on this Disc.

Loader Error

The unit stopped automatically due to loader error.

Please open the disc tray once and then close it.

Parental Lock Error

Region Error

The device connected for HDMI

connection does not support HDCP

USB Error

BD-Live Network Connecting Error

LAN Cable Not Connected

Cannot Acquire DHCP Server

Cannot Acquire IP Address

Parental Lock On

The current selected parental level prohibits playback.

Region Error

Playback is not authorized in your region.

Region code of this disc :

(There is no message.)

The following error will appear on the VFD.

Memory Device Error

- - Please check the Memory Device. - There is no playback file on the Memory Device or Device has incorrect/

no format.

BD-Live Setting Error

Network connection is interrupted. Please confirm “BD-Live Setting”.

The cable is not connected.

Please confirm the connection of the cable.

DHCP cannot be acquired.

Please confirm connection or set it with the manual operation.

Internet Protocol address is not set.

Please confirm the set content.

Already Existing IP Address

No Response From Default

Gateway

Cannot Connect To DNS Server

Cannot Connect To Server

Cannot Confirm Firmware Version

The equipment with same Internet Protocol address already exists.

Please set another Internet Protocol address.

There is no response from Default gateway.

Please confirm the address of Default gateway.

It is not possible to connect to the DNS server.

Please confirm the Internet connection or the DNS address setting.

It is not possible to connect to the server.

Please contact our support center.

It is not possible to confirm the software version.

Please contact our support center.

1-9-1 E5XF1ER

Page 25

Error Message

Firmware Update Error

(Update File Error)

Cannot Connect To Download

Server

USB Error

Error detected.

File may be corrupted.

Please download software again.

Error detected.

Please confirm whether it is USB device that corresponds to software

update.

It is not possible to connect to the server.

Please contact our support center.

Error in the USB Connection. USB operation has been stopped

automatically. Please remove the USB device and restart the unit.

1-9-2 E5XF1ER

Page 26

BLOCK DIAGRAMS

System Control Block Diagram

VFD

TO POWER SUPPLY

BLOCK DIAGRAM

PWSW4

TO VIDEO/AUDIO

BLOCK DIAGRAM

VIDEO-MUTE

19 20 21 22

FL3002

REMOTE

RS3002

CN2002 CN3002CN002 CN2001

SENSOR

345

FL-SDA

FL-SCL

315

456

6

FL-STB

FL-RESET

P-ON+5V

16KEY-1

REMOTE

12 12

16

3D

D3004

Q3004

POWER

SW3008

SW3009

SOURCE DIRECT

KEY-1

17 17

15 15

2 2

CN3101 CN3001

FRONT-A CBA

(MAIN MICRO CONTROLLER)

IC100

A13

PWSW4

CEC-IN

B12

A8

VIDEO-MUTE

CK27XI

CK27XO

A10

B10

XRST

E16

XFERST

F20

151413

FL-SDA

FL-SCL

141312

C9E9D9

FL-SCL

FL-SDA

XTRST

D16

12

FL-STB

FL-RESET

FL-STB

6

2

REMOTE

KEY-1

621 1

D8

B11

KEY-1

REMOTE

KEY-2 KEY-2

3D-LED 3D-LED

3 3

E8

E13

KEY-2

3D-LED

XRST-STM

F15

F14

B13

C13

FL-RESET

RS232C-TXD

RS232C-RXD

AUDIO CBA

KEY

SWITCH

FRONT-B CBA

CN551CN4002 CN4000CN5501

12131515

RS232C-RXD

RS232C-TXD

12

13

REMOTE

VIDEO CBA

3

4

11

RS232C-RXD

RS232C-TXD

REMOTE

3

4

BD MAIN CBA UNIT

JK801

HDMI-

CONNECTOR

Q801

(MAIN)

BUFFER

13

CEC

X251

27MHz

X'TAL

IC251

RESET

EV+11V

1-10-1

IC254

RESET

EV+3.3V

RS232C CBA

RS232C

IC5500

12

INTERFACE

13

3RXD

CN5500

RS232C-

CONNECTOR

11

RS232C

I/F

14

2TXD

PHOTO

IC5550

JK5550

Q5551,Q5552

COUPLER

REMOTE

-OUT

BUFFER

3

4

1

2

REMOTE

-IN

ECEB0BLS

Page 27

Digital Signal Process 1 Block Diagram

VIDEO SIGNAL AUDIO SIGNAL

MPX

/LPP

WOB

TO DIGITAL SIGNAL

PROCESS 2 BLOCK

DIAGRAM

(IC100)

STREAM

CONTROL

FE

DIGITAL

SIGNAL

PROCESS

RF

EQUALIZER

TRACKING-CONTROL

C19

FOCUS1-CONTROL

B19

COPY

PROTECT

AACS

FOCUS2-CONTROL

A19

BD+

CSS

CPRM

EXPA-CONTROL

D19

EXPB-CONTROL

E19

SLED1-CONTROL

SLED2-CONTROL

B17

A1737

LOAD-CONTROL

F19

TRAY-IN

B18

SPINDLE-CONTROL

C1719

SPINDLE-FG

B2022

BD MAIN CBA UNIT

(MAIN MICRO CONTROLLER/DIGITAL SIGNAL PROCESS)

IC100

MATRIX

E26, F25

D26, E25,

B26, C25,

*1: 32, 33, 36, 37

*2: 31, 34, 35, 38

CN701

A-D *1

E-H *2

C26, D25

RF(-) 27

RF(+) 28

LDD-SDATA 20

OEIC

(BDCD/DVD)

RF

GENERATOR

LDD-SDATA

LDD-SCLK

L22

G26

L23

G25

LDD-SCLK 19

27

TRACKING

ACTUATOR

IC701 (MOTOR DRIVE)

262524

CN701

TD 3

TR 4

DRIVE

FR1 5

LASER

FOCUS 1

ACTUATOR

DRIVE

23

FD1 6

FR2 1

DIODE

DRIVE

FOCUS 2

22

FD2 2

EXPA(+) 44

29

ACTUATOR

DRIVE

21

EXPA(-) 45

162815

COLLIMATE

LENS

MOTOR DRIVE

201918

EXPB(-) 43

EXPB(+) 42

SLED

MOTOR DRIVE

17

40

41

CN702

SLD2(-) 7

SLD2(+) 6

SLED

MOTOR

7

38

SPINDLE

MOTOR

7

CN702

U4

DRIVE

11

10

V3

W2

SPINDLE

MOTOR

6

COM 1

BD MECHANISM

ASSEMBLY

LOADING

MOTOR DRIVE

4

5

2

1

CN703

SLD1(-) 9

LOAD(-) 2

SLD1(+) 8

LOAD(+) 1

LOADING

MOTOR

IC702 (MOTOR DRIVE)

TRAY-IN 4

TRAY-IN

1-10-2

ECEB0BLD1

Page 28

Digital Signal Process 2 Block Diagram

DDC DATA

DDC CLOCK

TMDS DATA2-

TMDS DATA2+

TMDS DATA1-

TMDS DATA1+

TMDS DATA0-

TMDS DATA0+

TMDS CLOCK+

TO VIDEO/AUDIO

BLOCK DIAGRAM

HOT PLUG DETECT

HDMI-CONNECTOR

(MAIN)

JK801

191516

31649

7

10

TMDS CLOCK-

12

HOT PLUG DETECT

HDMI-CONNECTOR

(SUB)

JK401

191516

DDC DATA

DDC CLOCK

TMDS DATA2-

TMDS DATA2+

31649

TMDS DATA1-

TMDS DATA1+

TMDS DATA0-

TMDS DATA0+

7

TMDS CLOCK+

TMDS CLOCK-

10

12

TO VIDEO/AUDIO

BLOCK DIAGRAM

VIDEO

VIDEO SIGNAL AUDIO SIGNAL

VIDEO-Y(I/P)

VIDEO-Pb/Cb

T1

R2

VIDEO-Pr/Cr

IC803

IC801 (SCALER)

T2

U1

DDR2 SDRAM

(DDR2 SDRAM)

DDR2-DQ (0-15)

DDR2-A (0-12)

A4-A6,B5,

C5,C6,D5,

E2-E4,F3,

F4

DATA-Y(0-11)

E4, E5,

F4-F6,

G4-G6,

H4, H5,

J4, J5

(512Mbit)

A2,A3,B1,

B3,B4,C2,

DATA-C(0-11)

E2, E3,

F2, F3,

K15

C15

C4,D3,E1,

G2-G4

G1-G3,

H1-H3,

J2, J3

P15

P16

C14

HDMI

SIGNAL

PROCESS

/SCALER

F1

G1

HSVSPCLK

E1

D1 D1

C1

N15

DATA

20MHz

X’TAL

X801

L16

L15

T14

N16

M15

M16

I/F

T15

XTAL1

XTAL2

DAC-SCK

DAC-BCK

DAC-LRCK

SPDIF

BD MAIN CBA UNIT

A8

C1

D2A9C8

B8

D8

A10

L2

E7E6B5A5B4A4B3A3A2

D7

B2

K3

DATA 0

L3

K2

K1

DATA 1

DATA 2

M2

M3

IEC

BCK

LRCK

DATA 3

E10

D10

C10

B9

K4

IC100 (MAIN MICRO CONTROLLER/DIGITAL SIGNAL PROCESS)

VIDEO

DAC

FROM DIGITAL

SIGNAL PROCESS 1

BLOCK DIAGRAM

(IC100)

JK451

DIGITAL

VIDEO

USBDP1

USBDN1

AF22

AE22

USB

JACK

OUT

MEDIA

PROCESSOR

I/P

CONVERTER

/SCALING

Java (BD-J)

MPEG-2

DiVX

VC-1

H.264

MII-RXD (0-3), MII-TXD (0-3)

ETHERNET

INTERFACE

IC501

JK501

TX(-) 2

TX(+) 1

RX(+) 3

DECODER

HD (TS)

RX(-) 6

SD (PS)

HDMI

I/F

(NAND FLASH MEMORY)

IC258

ED (0-7)

NAND FLASH

MEMORY (1Gbit)

DIGITAL

AUDIO

OUT

MEMORY

I/F

MMDQ (0-31)

MMA (0-13)

DDR3 SDRAM

(2Gbit x 2)

(DDR3 SDRAM)

IC101,IC102

(ETHERNET JACK)

1-10-3

ECEB0BLD2

Page 29

Video/Audio Block Diagram

VIDEO SIGNAL AUDIO SIGNAL

VIDEO CBA

75Ω

2dB

LPF 14

4dB

IC4000 (VIDEO DRIVER)

1

VIDEO OUT

JK4001

DRIVER

75Ω

AMP

2dB

6.75MHz

AMP

4dB

VIDEO-Y

OUT

JK4002

DRIVER

AMP

LPF

13.5/37MHz

AMP

3 12

REAR

VIDEO-Pb/Cb

OUT

JK4003

10

75Ω

DRIVER

2dB

AMP

LPF

13.5/37MHz

4dB

AMP

4

VIDEO-Pr/Cr

JK4004

9

75Ω

DRIVER

2dB

AMP

LPF

13.5/37MHz

4dB

AMP

5

OUT

MUTE

MUTE

7

6

DIGITAL

JK4000

BUFFER

Q4003

AUDIO OUT

(COAXIAL)

REAR

JK4005

DIGITAL

AUDIO OUT

(OPTICAL)

REAR

AUDIO(L)-

OUT

AUDIO(R)-

JK2200

JK2201

OUT

AUDIO CBA

BD MAIN CBA UNIT

VIDEO-MUTE

CN4000CN551

11VIDEO

VIDEO

VIDEO-Y(I/P)

33VIDEO-Y(I/P)

55VIDEO-Pb/Cb

77VIDEO-Pr/Cr

99VIDEO-MUTE

VIDEO-Pb/Cb

VIDEO-Pr/Cr

SPDIF

18 18

CN551 CN4000

SPDIF

IC601

(AUDIO D/A CONVERTER)

CN601 CN2201

(L-CH)

12

DAC-SCK

DAC-BCK

5

2

AUDIO(L)

AUDIO(R)

17

20

7

6

(R-CH)

AUDIO

DAC

13

15

DAC-LRCK

DATA

14

TO SYSTEM

CONTROL

BLOCK DIAGRAM

1-10-4

TO DIGITAL

SIGNAL

PROCESS 2

BLOCK DIAGRAM

ECEB0BLV

Page 30

Power Supply Block Diagram

TO SYSTEM

CONTROL

BLOCK

DIAGRAM

PWSW4

F1F2FL

EV+11V

BD MAIN CBA UNIT

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

T1001

EV+11V

EV+11V

13

12

17

7

45678

EV+11V

EV+11V

15

14

13

14

F1

F2

564 15

Q1204

FL

IC1003

Q1201

ERROR

VOLTAGE DET

Q1203

REG.

SHUNT

1

4

23

IC1011

COLD

9

18PWSW4

EV+11V

EV+11V

1

11

10

CN1004 CN001

Q1202

14

15

18

16

13

12

19

3

5

8

Q1002

BRIDGE

RECTIFIER

D1001-D1004

LINE

FILTER

L1001

8

VH

F1000

T2.5A H 250V

IC1001

SWITCHING

CONTROL

()

HOT CIRCUIT. BE CAREFUL.

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1000) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

X15

AC CORD

AC1001

Y

CN1000

Y

CN1002

W

W

INLET CBA

5

OUT

162

FB

SCD

1-10-5

HOT

VCC

POWER SUPPLY CBA

ECEB0BLP

Page 31

SCHEMATIC DIAGRAMS / CBA AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark “!” in

the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly

different or amended since these drawings were

prepared.

2. All resistance values are indicated in ohms

(K = 10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in F

(P = 10

5. All voltages are DC voltages unless otherwise

specified.

3

, M = 106).

-6

F).

1-11-1 BD4P_SC

Page 32

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

2

3

1

5.0

(2.5)

5.0

The same voltage for

both PLAY & STOP modes

Indicates that the voltage

is not consistent here.

PLAY mode

STOP mode

(Unit: Volt)

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to the line number

"1" of the area "D3".

2. "1-B1" means that line number "1" goes to the line number

"1" of the area "B1".

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

THE FOLLOWING PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE SAME TYPE

FUSE.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1000) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications for PLAY and STOP mode on the schematics are as shown below:

5. How to read converged lines

6. Test Point Information

The reference number of parts on Schematic Diagrams/CBA can be retrieved by

application search function.

3

AREA D3

2

1

ABCD

AREA B1

1-D3

1-B1

1-11-2 BD4P_SC

Page 33

Power Supply & Inlet Schematic Diagram

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

4

3

2

X15

AC

CORD

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1000) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

HOT CIRCUIT. BE CAREFUL.

AC1001

CN1002

INLET

CN1000

Y

Y

W

W

F1000

T2.5A H250V

SA1001

VARISTOR

L1001

LINE FILTER

C1002

0.068

/275V

C1013

0.022

/275V

D1002

1N5397-B

D1003

1N5397-B

CBA

C1040

1000P

/250V

C1041

1000P

/250V

R1014

82K

R1018

82K

IC1001

FA5640N-C6-TE3

SWITCHING

CONTROL

1.3

ZCD

1

0.7

FB

2

0

IS

3

0

GND

45

VH

NU

VCC

OUT

8

7

6

272.4

17.7

1.8

1.4

D

G

S

D1001

1N5397-B

D1004

1N5397-B

C1008

150

/400V

275.2

Q1002

TK3A65D

(SWITCHING)

0

C1001

33P

R1001

1.2/5W

C1015

56P

/1KV

R1003

100K

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

T1001

POWER TRANS

3

R1013

47K/2W

D1015

BA159

R1012

10

C1014

47/35V

C1010

0.01

/400V

D1007

BA159

4

5

8

7

14

15

18

16

13

12

19

17

D1013

SB3200BR

D1014

SB3200BR

R1034

CFS12V6T2R0

D1032

BA159

D1035

BA157

C1025

0.01

C1033

100/50V

C1018

4700/16V

C1029

220/25V

D1036

5V1BSB-T26

C1034

0.1

L1003

22uH

C1024

470/16V

R1205

47K

R1025

150

R1026

3.3K

POWER SUPPLY CBA

Q1202

MMBTSA1981Y

(SWITCHING)

10.0

10.2

9.4

R1206

3.9K

D1201

1SS400ST

R1209

R1208

6.8

6.8

Q1201

MMBTSA1504G

(SWITCHING)

33.3

R1204

47K

C1201

1

33.3

32.7

R1207

100K

D1202

1SS400ST

Q1204

MMBTSC3875G

(SWITCHING)

R1210

1K

R1212

10K

R1213

10K

R1214

10K

32.133.3

32.8

R1211

10

D1203

36BSA-T26

CN1004

3.3

1 PWSW4

0

2GND

0

3GND

32.1

4FL

8.4

5F1

5.2

6F2

0

7GND

0

8GND

0

9GND

11.1

10 EV+11V

11.1

11 EV+11V

11.1

12 EV+11V

11.1

13 EV+11V

11.1

14 EV+11V

11.1

15 EV+11V

0

16 GND

0

17 GND

0

18 GND

TO BD MAIN CBA

UNIT CN001

1

C1005

470P

C1004

0.01

R1007

470

D1006

SB140

R1009

10

R1010

4.7K

R1008

100

D1008

CRZ27

C1011

1000P

R1011

0.27

/2W

D1009

CRZ27

IC1003

EL817B

ERROR

VOLTAGE DET

0.7 9.3

4

0

32

1

8.3

HOT COLD

CDEFAB

1-11-3

R1016

2.2k

R1017

2.2K

IC1011

KIA431-AT/P

SHUNT

REG.

8.3

0

2.5

R1019

10K

C1012

0.1

R1020

1K

0

0.7

0

Q1203

MMBTSC3875G

(SWITCHING)

R1203

10K

ECEB0SCP

Page 34

Video Schematic Diagram

VIDEO CBA

3

2

TO BD MAIN CBA

UNIT CN551

CN4000

1VIDEO

2GND

3VIDEO-Y(I/P)

4GND

5VIDEO-Pb/Cb

6GND

7VIDEO-Pr/Cr

8GND

9VIDEO-MUTE

10P-ON+5V

11GND

12RS232C-RXD

13RS232C-TXD

14EV+3.3V

15REMOTE

16TEST-MODE

17GND

18SPDIF

0.6

0

0.6

0

0.9

0

0.9

0

3.3

5.0

0

3.4

3.4

3.4

3.4

3.4

0

1.6

TP4001

TEST

MODE

TP4002

GND

C4001 0.1

C4005 10/16V

C4002 0.1

C4003 1

C4004 1

L4306

WIRE

IC4000

BH76071FJ-E2

(VIDEO DRIVER)

2.1

1

2.2 5.0

2

VREF

2.1

3

3.0 0

4

3.0

5

3.3

6

MUTE

3.3

7

L4001

WIRE

L4000

WIRE

LPF

6.75MHz

LPF

6.75MHz

LPF

13.5/37MHz

LPF

13.5/37MHz

L4002

0

75Ω

DRIVER

75Ω

DRIVER

75Ω

DRIVER

75Ω

DRIVER

SD/HDMUTE

VCC

GND

14

13

12

11

10

1.8

1.6

2.0

2.0

9

4.6

8

C4011 1000/6.3V

C4012 1000/6.3V

C4013 1000/6.3V

C4014 1000/6.3V

R4057

10K

C4006

100/6.3V

C4007

0.1

R4044

75

R4045

75

R4046

75

R4047

75

R4052

0

R4053

0

R4054

0 JK4003

R4055

0

JK4001

JK4002

VIDEO-Y

OUT

VIDEO-Pb/Cb

OUT

JK4004

VIDEO-Pr/Cr

OUT

VIDEO OUT

(COMPOSITE)

REAR

1

TO RS232C

CBA CN5501

CN4002

1REMOTE

2EV+3.3V

3RS232C-TXD

4RS232C-RXD

5GND

R4043

2K

R4048

2.2K

R4049

2.2K

2.3

5.0

1.6

C

R4050

220

C4019

220/6.3V

Q4003

MMBTSC3875G

(BUFFER)

R4051

75

C4020

0.1

C4021

47/6.3V

JP4001

R4056

100K

L4003

0.47uH

C4025

0.1

JK4005

OC-0805T*002

FIBER OPTIC

TRANS,MODULE

VIN

3

VCC

2

GND

1

JK4000

DIGITAL

AUDIO OUT

(COAXIAL)

DIGITAL

AUDIO OUT

(OPTICAL)

REAR

EAB D

1-11-4

ECEB0SCV

Page 35

Audio Schematic Diagram

2

1

TO BD MAIN CBA

UNIT CN002

FL-SDA

FL-SCL 14

FL-STB

FL-RESET

EV+3.3V

REMOTE

P-ON+5V

3D-LED

TO BD MAIN CBA

UNIT CN601

F1

FL

GND 11

GND

F2

GND

GND

KEY-2

KEY-1

CN2001

17

16

15

13

12

10

9

8

7

6

5

4

3

2

1

CN2201

1GND

2AUDIO(R)

3GND

4GND

5AUDIO(L)

8.4

32.6

0.8

3.1

0.7

3.4

0

0

5.3

0

3.4

3.4

0

5.0

3.4

3.3

0

0

0

0

0

0

R2244

470

R2243

470

R2246

5.6K

R2247

5.6K

C2274

2200P

C2273

2200P

JK2201

AUDIO(R)

-OUT

JK2200

AUDIO(L)

-OUT

REAR

CN2002

1F1

2FL

3 FL-SDA

4 FL-SCL

5 FL-STB

6 FL-RESET

7 GND

8 GND

9F2

10 GND

11 EV+3.3V

12 REMOTE

13 GND

14 P-ON+5V

15 KEY-2

16 KEY-1

17 3D-LED

TO FRONT-A

CBA CN3002

A

AUDIO CBA

B

1-11-5

C

ECEB0SCA

Page 36

Front-A & Front-B Schematic Diagram

3

2

1

FRONT-A CBA

SW3125

PAUSE

R3122

0

R3119

560

R3128

330

R3127

220

SW3124

PLAY

R3124

1.2K

SW3126

SKIP

DOWN

SW3115

STOP

R3126

3.3K

SW3122

SKIP

UP

SW3107

OPEN/

CLOSE

CN3101

1NU

2 KEY-1

3 GND

FL3002 DM182-GINK

CN3001

1

2

3

(VFD)

R3028

0

C3003

1000P

RS3002

KSM-713TC5B-FU

(REMOTE SENSOR)

GND

Vcc

VOUT

23

1

L3001

100uH

R3027

6.8K

C3002

0.1

C3001

100/6.3V

R3025

180

R3026

0

SW3008

POWER

12KR3031

C3005

0.1

R3032

10

C3006

100/6.3V

R3030

1K

R3008

220

D3004

LTL1CHCBK2-F

3D

302927262524232221201918171615141312111098765214

C3008

0.1

R3033

10

C3009

0.1

SW3009

SOURCE

DIRECT

CN3002

1F1

2FL

3 FL-SDA

4 FL-SCL

5 FL-STB

6 FL-RESET

7 GND

8 GND

9F2

10 GND

11 EV+3.3V

12 REMOTE

13 GND

14 P-ON+5V

15 KEY-2

16 KEY-1

17 3D-LED

TO AUDIO CBA

CN2002

Q3004

MMBTRC102SS

3.4

(LED-DRIVE)

0.5

FRONT-B CBA

AD

1-11-6

CB

0

UNLESS OTHERWISE SPECIFIED:

SWITCHES ARE SKQSAB.

ECEB0SCF

Page 37

RS232C Schematic Diagram

RS232C CBA

2

C5503

0.1

C5504

0.1

R5553

3.3K

C5500

0.1

C5505

47/16V

C5506

47/16V

C5502

0.1

IC5500

SP3232ECN-L

(RS232C INTERFACE)

0

1

C1+

5.7

2

V+

-2.9

3

3.4

4

C2+

-2.9

5

C2-

-5.6

6

V-

7

NU T2IN

89

NU

R5552

10K

VCC

GND

T1OUTC1-

R1IN

R1OUT

T1IN

16

15

14

13

12

11

10

NU

R5551

10K

3.4

0

-5.6

0

3.4

3.4

0

C5501

0.1

C5553

100/10V

L5500

BEAD

L5501

BEAD

CN5500

CN5501

(RS232C-CONNECTOR)

1

NU

2 TXD

3 RXD

4NU

5 GND

6NU

NU7

8NU

9NU

TO VIDEO CBA

CN4002

5

GND

4 RS232C-RXD

3 RS232C-TXD

2 EV+3.3V

1 REMOTE

1

3.4

0

Q5551

MMBTRC106SS

(BUFFER)

0

Q5552

MMBTRC106SS

(BUFFER)

1.5

IC5550

EL817C

PHOTO

COUPLER

1.5

4

0

0

0

32

0

1

0

R5554

240

JK5550

REMOTE-OUT

REMOTE-IN

BCA

1-11-7

ECEB0SCRS

Page 38

BD Main 1 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC100.

IC100 is divided into eight and shown as IC100 (1/9) ~ IC100 (9/9) in this BD Main Schematic Diagram Section.

4

3

2

1

CONTINUE

BD MAIN 8

P-ON+3.3V

P-ON+5V(1)

A+8V

CONTINUE

BD MAIN 2

EXPB(-)

EXPB(+)

EXPA(-)

EXPA(+)

FD2

FR2

FD1

FR1

TR

TD

TO BD MECHANISM

ASSEMBLY

CN701

1FR2

2FD2

3TD

4TR

5FR1

6FD1

7GND

8GND

9AVCC

10AVCC

11GND

12A+8V

13A+8V

14GND

15GND

16TEST-V

17LDON

18DSEN

19LDD-SCLK

20LDD-SDATA

21GND

22GND

23NU

24MODEB

25MODEA

26GND

27RF(-)

28RF(+)

29GND

30AVCC

31G

32A

33C

34H

35F

36D

37B

38E

39VC-PD

40THERMO

41GND

42EXPB(+)

43EXPB(-)

44EXPA(+)

45EXPA(-)

C710

2.2

C702

0.1

C769

0.1

C703

0.1

C709

2.2

R702 1K

R705 1K

R703 1K

R704 1K

R713

10K

C706

0.1

R709 1K

R710 1K

C701

0.1

R715 4.7K

R716 10K

C707 1

C708 1

R711 1K

R712 1K

L701

BEAD

*1

IC100(1/9)

MN2WS0260A3

MAIN MICRO CONTROLLER

/DIGITAL SIGNAL PROCESS

VC-PDF24

THERMOD23

K22

MODEA

L26

MODEB

K24

J22

B22

G26

G25

NU

NU

TEST-V

LDD-SCLKL22

LDD-SDATAL23

LDONE20

DSENM23

RFA

RFB

GINC25

AINF25

CINE25

HINB26

FIND25

DIND26

BINE26

EINC26

NUH26

NUH25

COPY

PROTECT

AACS

BD+

CSS

CPRM

TO BD MAIN 7

IC100(7/9)

STREAM

CONTROL

FE

DIGITAL

SIGNAL

PROCESS

TO BD MAIN 2

IC100(2/9)

NU M22

SENSJ2 L24

SENSJ1 K23

SOT0 M24

SIN0 M25

NU N21

NU M21

NU N22

NU L25

NU N26

NU N25

NU J24

NU D22

LOAD(+) C22

NU J25

NU G24

NU A22

LOAD(-) C23

NU C21

NU D20

NU A20

NU A25

NU A24

NU B23

NU B25

NU B24

NU A23

VHALF

VHALFOUT

HDVREF

NU

NU

NU

NU

NU

NU

E23

F18

F23

D21

K25

K26

H21

G22

H24

L6

C731

0.1

C737

0.1

C763

0.082

R759 10K

R718

22K

R733

22K

R760 10K

R706

100K

R701

100K

C759 0.1

C760 1

C762 0.1

R764 10K

C764 8200P

C765 0.033

C766 0.1

C767 0.1

R765 10K

BD MAIN CBA UNIT

CN993

R763

1.5K

(NO CONNECTION)

1 SENSJ2

2 SENSJ1

3 GND

4 SOT0

5 SIN0

6 XFERST

CONTINUE

BD MAIN 5

XFERST

CONTINUE

BD MAIN 2

SINO

SOTO

VHALF

CONTINUE

BD MAIN 2

LOAD(+)

LOAD(-)

1-11-8

EABCD F

ECEB0SCBD1

Page 39

BD Main 2 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC100.

IC100 is divided into eight and shown as IC100 (1/9) ~ IC100 (9/9) in this BD Main Schematic Diagram Section.

4

3

2

1

BD MAIN CBA UNIT

*1

IC100(2/9)

MN2WS0260A3

MAIN MICRO CONTROLLER

/DIGITAL SIGNAL PROCESS

TRAY-IN

TO BD MAIN 1

IC100(1/9)

CONTINUE

BD MAIN 1

LOAD(+)

LOAD(-)

TO BD MECHANISM

ASSEMBLY

EXPA-CONTROL

EXPB-CONTROL

SLED1-CONTROL

SLED2-CONTROL

FOCUS1-CONTROL

TRACKING-CONTROL

FOCUS2-CONTROL

LOAD-CONTROL

SPINDLE-CONTROL

SPINDLE-FG

CN703

4TRAY-IN

3GND

2LOAD(-)

1LOAD(+)

BR-MTR

CTL-MTR

CONTINUE

BD MAIN 1

EXPB(-)

EXPB(+)

EXPA(-)

EXPA(+)

FD2

FR2

FD1

FR1

TR

TD

R748

R737

47K

R736

47K

C722

6800P

C721

6800P

10K

R738

4.7K

R739

4.7K

R732

R725

1.5

1.5

37

38

39

PSL2

40

41

42

GND

43

NU

44

NU

45

NU

46

NU

47

NU

SLED1

48

NU

MOTOR

DRIVE

IC701

AM9268Q

(MOTOR DRIVE)

123456789101112

R726

1.5

R747

1.5

VCC

FUNCTION

SELECT

SLED2

MOTOR

DRIVE

R734

4.7K

C755

0.1

GND

LOADING

MOTOR

DRIVE

RSL1

R720

47K

R721

47K

R724

4.7K

VCC

GND

FOCUS1

ACTUATOR

DRIVE

OSC

C728

180P

R735

3.9K

R723

4.7K

GND

C720

2700P

GND

C716

1000P

C717

1000P

TRACKING

ACTUATOR

DRIVE

FOCUS2

ACTUATOR

DRIVE

COLLIMATE

LENS MOTOR

DRIVE

COLLIMATE

LENS MOTOR

DRIVE

VCCNUNU

C724

0.1

252627282930313233343536

BIAS

C715

1000P

VMCOL

VCC

R722

4.7K

24

23

22

21

20

19

18

17

16

15

14

13

R719

47K

C726

0.1

C725

0.1

R730

22K

R731

22K

R728

47K

C719

1500P

C718

1500P

R729

47K

C756

0.1

C751

0.1

R753

11K

C749

10

C748

0.1

C747

C752

2.2

0.1

IC702

AM9293Q

(MOTOR DRIVE)

R754

33K

1

2

3

4

5

6

VDD1

DVCC

GND

VCCB

NU

R745

51K

FG(X3)

SPM V/V

REVERSE

CONVERTER

DETECT

BACK EMF

DETECTOR

STARTER

COMMUTATION

SPINDLE

MOTOR

DRVE

RNF

7891011

R755 1.2

R756 1.2

R757 1.2

RNF1

R744

10K

PWM

C723

8200P

1819202122

SELECT

FUNCTION

CSF

VDD2

GND

R742

47K

R743

12K

CONTINUE

BD MAIN 8

P-ON+10.5V

A+8V

P-ON+3.3V

P-ON+5V

17

16

C753

470P

15

14

13

12

C757

0.1

C750

0.1

C754

220/16V

R751

10K

R752

10K

R750

820

R749

3.3K

TO BD MECHANISM

ASSEMBLY

CN702

9 SLD1(-)

8 SLD1(+)

7 SLD2(-)

6 SLD2(+)

5NU

4U

3V

2W

1COM

CONTINUE

BD MAIN 1

SIN0

SOT0

VHALF

B18

NU

C20

D19

E19

A17

B17

B19

C19

A19

F19

C17

B20

PS

C18

D18

B21

NU

E18

G L

H

I

J

K

1-11-9

ECEB0SCBD2

Page 40

BD Main 3 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC100.

IC100 is divided into eight and shown as IC100 (1/9) ~ IC100 (9/9) in this BD Main Schematic Diagram Section.

4

3

BD MAIN CBA UNIT

R299

4.7K

IC258

TC58NVG0S3ETA00B3H

(NAND FLASH MEMORY)

NU

1

NU

2

3

NU

4

NU

5

NU

6

NU

7

R/B

8

/RE

9

/CE

10

NU

NU

11

VCC

12

13

VSS

14

NU

15

NU

CLE

16

17

ALE

18

/WE

19

/WP I/O1

NU

20

21

NU

22

NU

NU

23

NU

24

I/O7

I/O6

I/O5

I/O4

VCC

VSS

I/O3

I/O2

I/O0

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

ED7

ED6

ED5

ED4

ED3

ED2

ED1

ED0

ED0

ED1

ED2

ED3

ED4

ED5

ED6

ED7

R271 1K

R259 10KR274 1K

R260 10K

R275 1K

R261 10K

*1

IC100(3/9)

MN2WS0260A3

MAIN MICRO CONTROLLER

/DIGITAL SIGNAL PROCESS

ED0

AF25

ED1

AE26

ED2

AE25

ED3

AD26

ED4

AD25

ED5

AD24

AC26

AC25

AA23

AA24

AB26

AB25

AB24

AB23

AB22

AA25

Y25

Y24

Y23

Y22

R24

U25

U24

U23

U22

Y21

T25

ED6

ED7

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

NU

MEMORY

I/F

TO BD MAIN 7

IC100(7/9)

CONTINUE

BD MAIN 8

P-ON+3.3V

2

1

N

C261

0.1

C263

1

R287 10K

R285 10K

R280 10K

R279 10K

R278 10K

OP R

R284 10K

C258

10P

NANDRYBY

AC24

NFALE

AC23

NFCLE

AF23

XNFCE

AD23

XNFRE

AF24

XNFWE

AE24

XNFWP

AE23

NU

U21

NU

T22

NU

R25

NU

AA22

NU

AA21

NU

T24

NU

T23

NU

R22

NU

R21

NU

R23

NU

N3

NU

P24

NU

N23

NU

D17

NU

Y26

NU

P25

QM

NU

NU

NU

NU

XTRST

NU

A16

E17

B16

C16

D16

N24

R292 1K

C260 1

R294 10K

R295 10K

R296 10K

CONTINUE

BD MAIN 5

XTRST

1-11-10

ECEB0SCBD3

Page 41

BD Main 4 Schematic Diagram

*1

IC100(4/9)

MN2WS0260A3

MAIN MICRO CONTROLLER

4

3

2

1

/DIGITAL SIGNAL PROCESS

MEMORY

I/F

TO BD MAIN 7

IC100(7/9)

MMVCAL

MMROUT

DDR3PWCTL

MMDQ0

MMDQ1

MMDQ2

MMDQ3

MMDQ4

MMDQ5

MMDQ6

MMDQ7

MMDQ8

MMDQ9

MMDQ10

MMDQ11

MMDQ12

MMDQ13

MMDQ14

MMDQ15

MMDQ16

MMDQ17

MMDQ18

MMDQ19

MMDQ20

MMDQ21

MMDQ22

MMDQ23

MMDQ24

MMDQ25

MMDQ26

MMDQ27

MMDQ28

MMDQ29

MMDQ30

MMDQ31

MMDQS0

MMXDQS0

MMDQS1

MMXDQS1

MMDQS2

MMXDQS2

MMDQS3

MMXDQS3

MMDM0

MMDM1

MMDM2

MMDM3

MMA0

MMA1

MMA2

MMA3

MMA4

MMA5

MMA6

MMA7

MMA8

MMA9

MMA10

MMA11

MMA12

MMA13

MMBA0

MMBA1

MMBA2

MMCK

MMXCK

MMCKE0

MMCKE1

C0XCS0

MMXCS1

MMXWE

MMXCAS

MMXRAS

MMODT0

MMODT1

MMXRESET

MMVREF0

MMVREF1

NU

AF3

AE3

AF2

AC6

AB6

AD4