Page 1

SERVICE MANUAL

SERVICE MANUAL

BLU-RAY DISC PLAYER

MODEL BD-SP808(B)CDC1N

BD-SP808(US)

Ref. No. 4246

092010 (CDC1N)

Black model

120 V AC, 60HzB CDC1N

SAFETY-RELATED COMPONENT

WARNING!!

COMPONENTS IDENTIFIED BY MARK ON THE

SCHEMATIC DIAGRAM AND IN THE PARTS LIST ARE

CRITICAL FOR RISK OF FIRE AND ELECTRIC SHOCK.

REPLACE THESE COMPONENTS WITH ONKYO

PARTS WHOSE PART NUMBERS APPEAR AS SHOWN

IN THIS MANUAL.

MAKE LEAKAGE-CURRENT OR RESISTANCE

MEASUREMENTS TO DETERMINE THAT EXPOSED

PARTS ARE ACCEPTABLY INSULATED FROM THE

SUPPLY CIRCUIT BEFORE RETURNING THE

APPLIANCE TO THE CUSTOMER.

RC-792DV

Page 2

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4-1

Cabinet Disassembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5-1

How to Initialize the BLU-RAY Disc Player . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

Home Network (DLNA) Error Code. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8-1

Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9-1

Schematic Diagrams / CBA and Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10-1

Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11-1

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13-1

Manufactured under license from Dolby Laboratories.

Dolby and the double-D symbol are trademarks of Dolby Laboratories.

Page 3

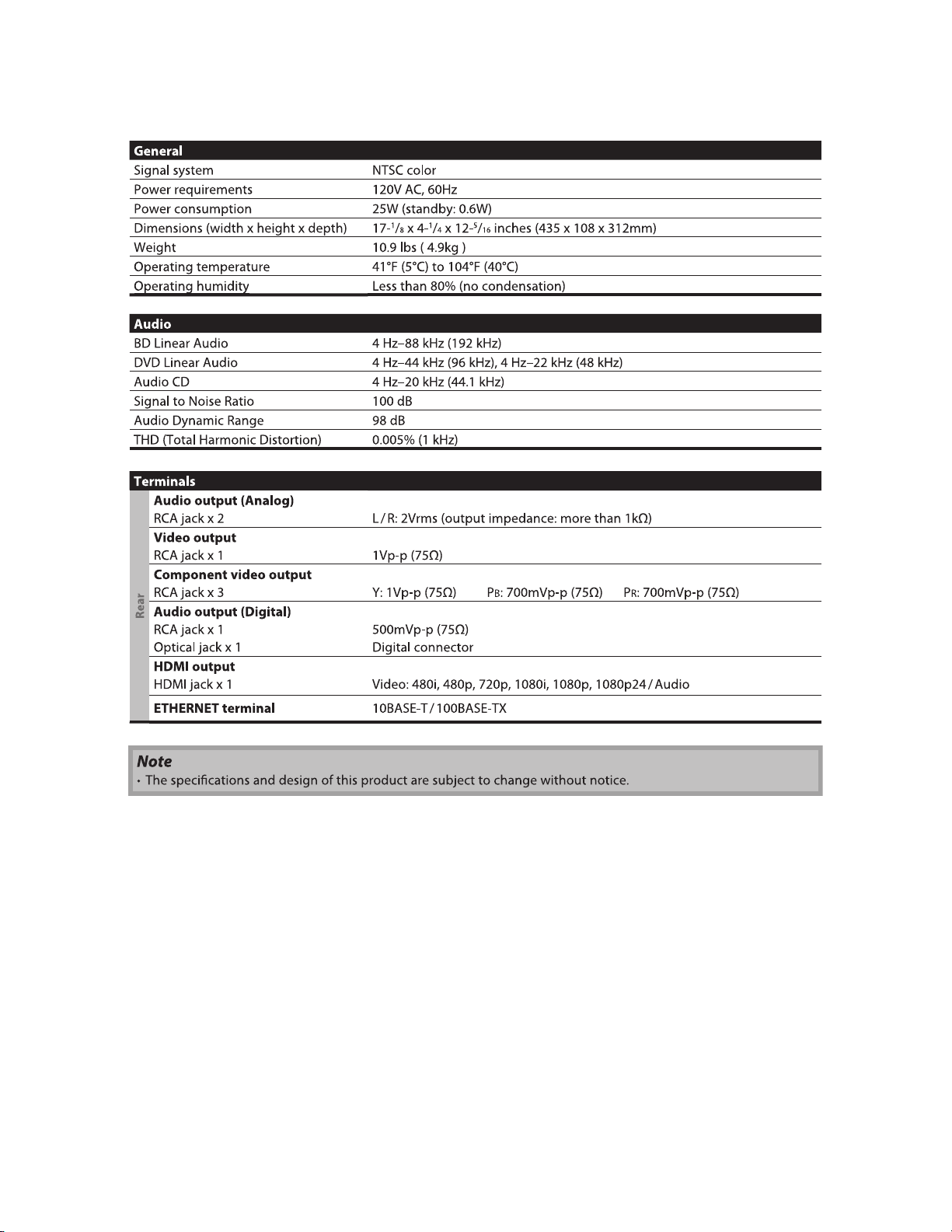

SPECIFICATIONS

1-1-1 E5SE0SP

Page 4

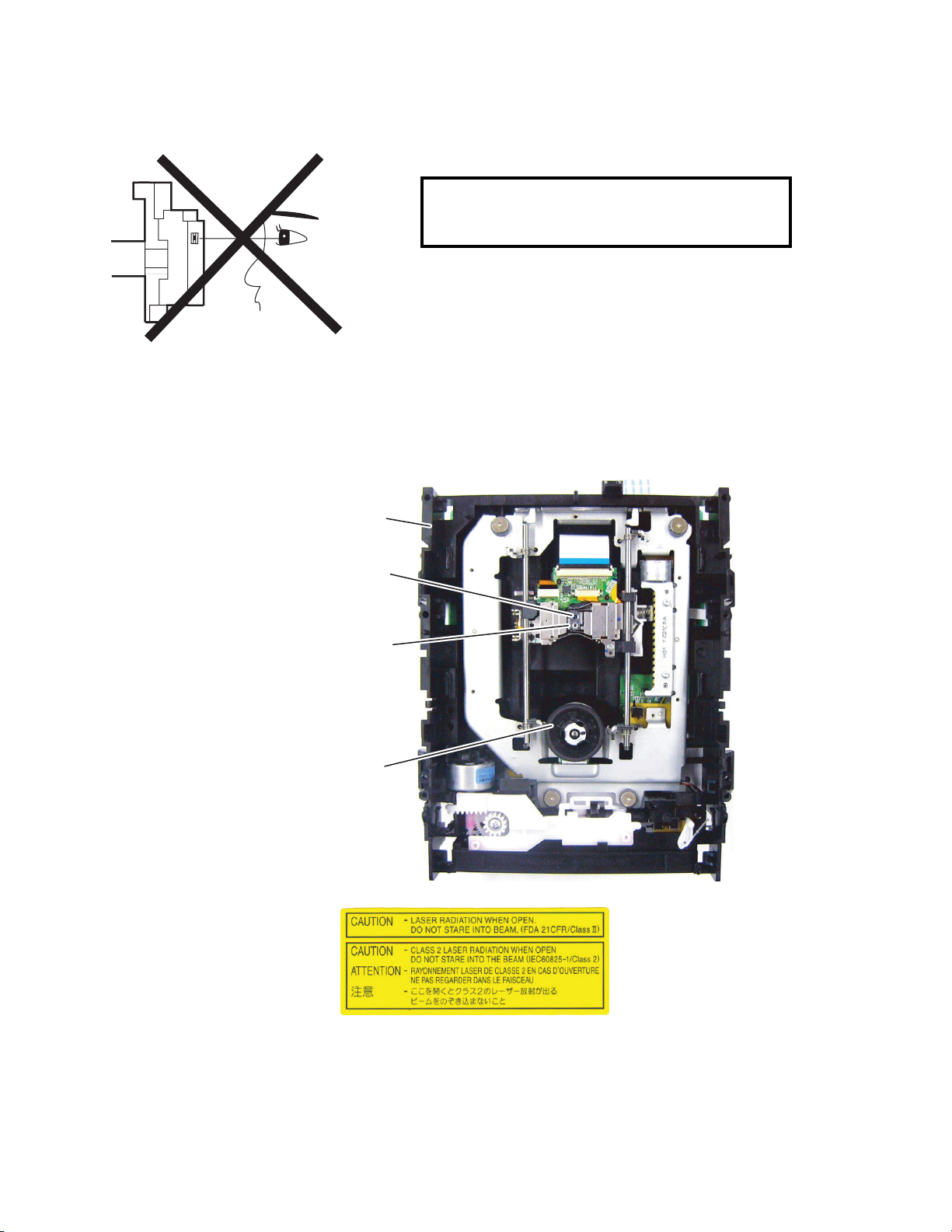

LASER BEAM SAFETY PRECAUTIONS

This BD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 30 cm away from the pickup lens when the diode is turned on. Do not look directly at the laser

beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of BD mechanism.

1-2-1 B2NLBSP

Page 5

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a # on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review

continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are carefully inspected to confirm

with the recognized product safety and electrical

codes of the countries in which they are to be sold.

However, in order to maintain such compliance, it is

equally important to implement the following

precautions when a set is being serviced.

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

5 - 6 kg of force in any direction will not loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

L. When reassembling, be sure to use the original

screws or specified screws listed in the parts list.

1-3-1 BDN_ISP

Page 6

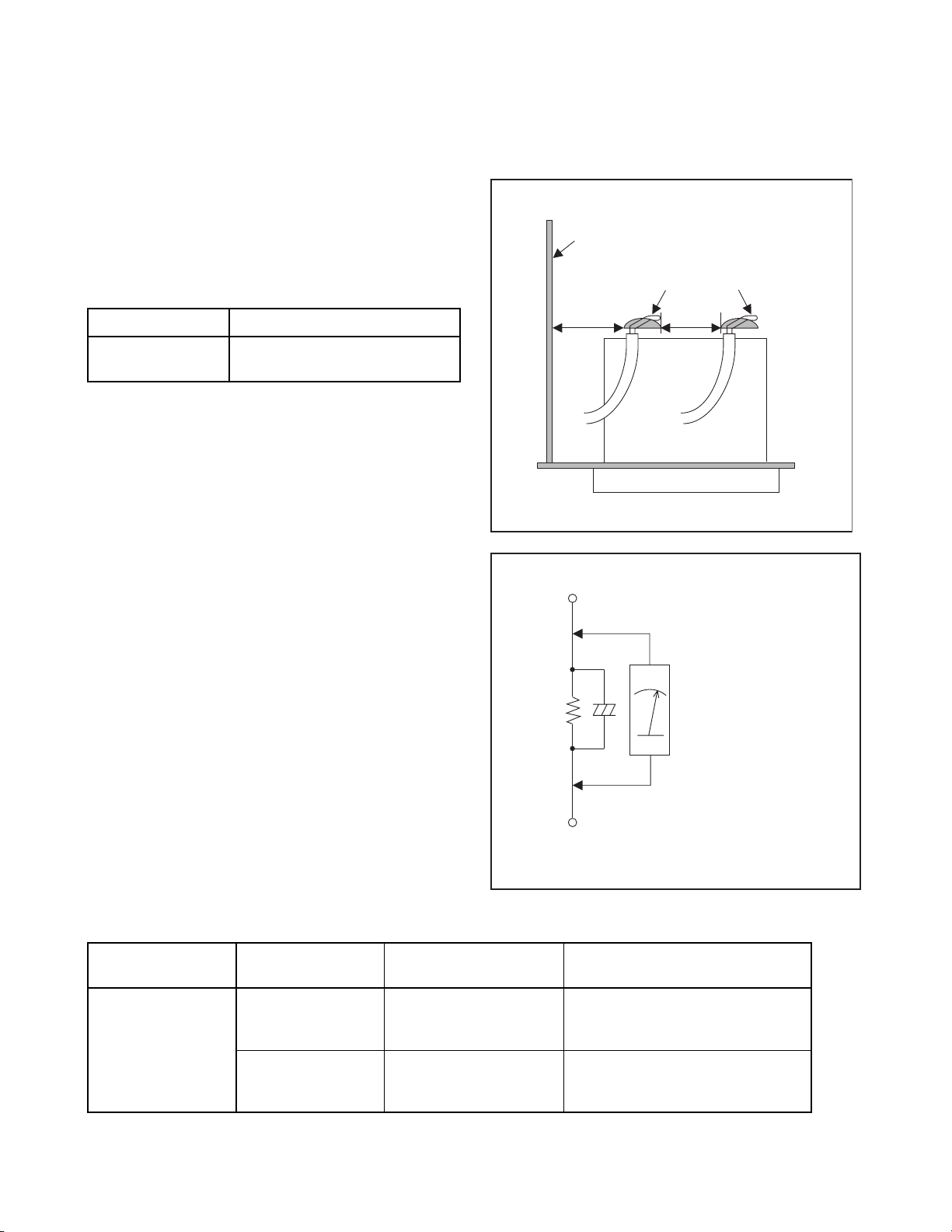

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d’)

120 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

≥ 3mm(d)

≥ 4mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

d' d

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

Fig. 1

AC Voltmeter

(High Impedance)

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

Connected in

parallel

120 V

50kΩ RES.

Connected in

parallel

Note:This table is unofficial and for reference only. Be sure to confirm the precise values.

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

1-3-2 BDN_ISP

One side of power cord plug

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 2

Page 7

STANDARD NOTES FOR SERVICING

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

To p Vi e w

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

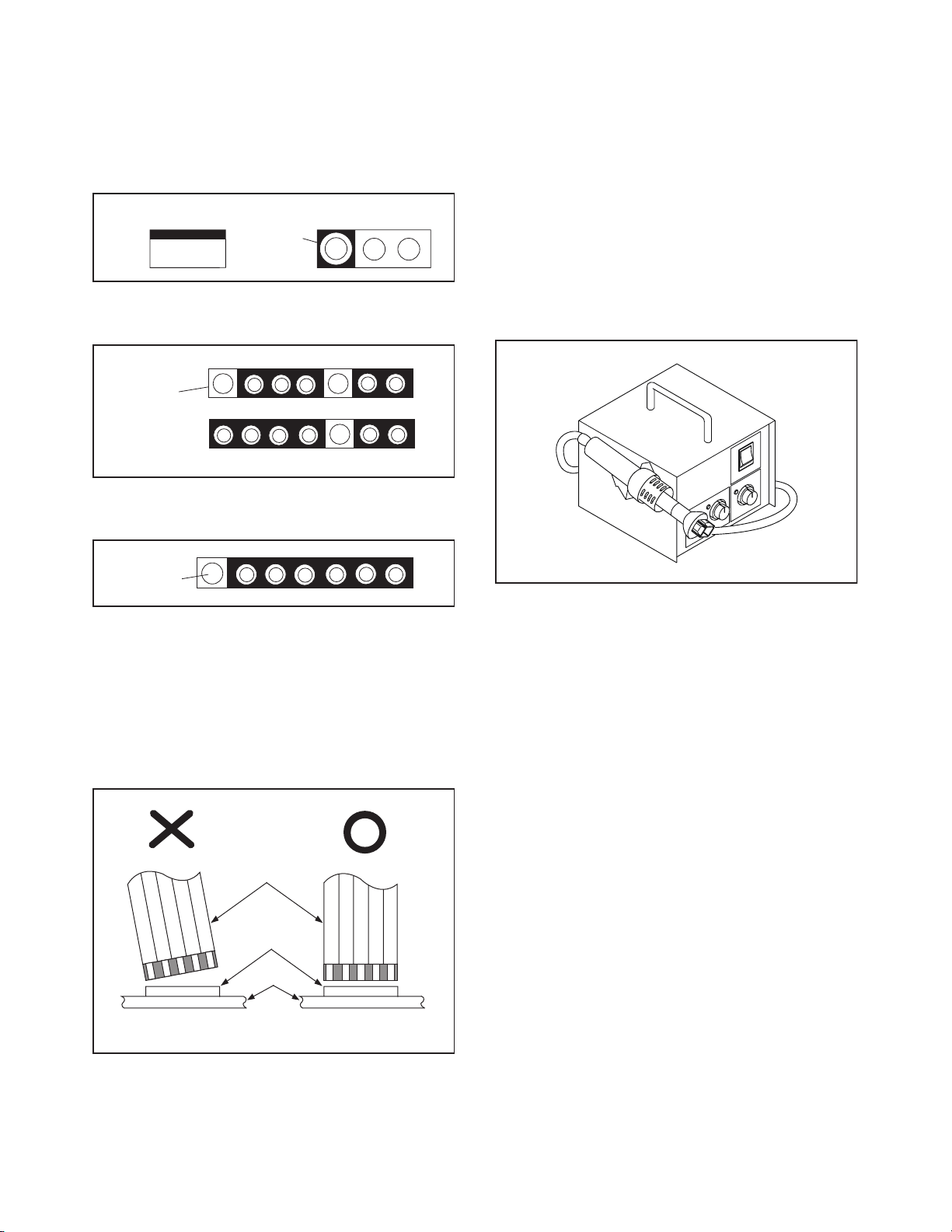

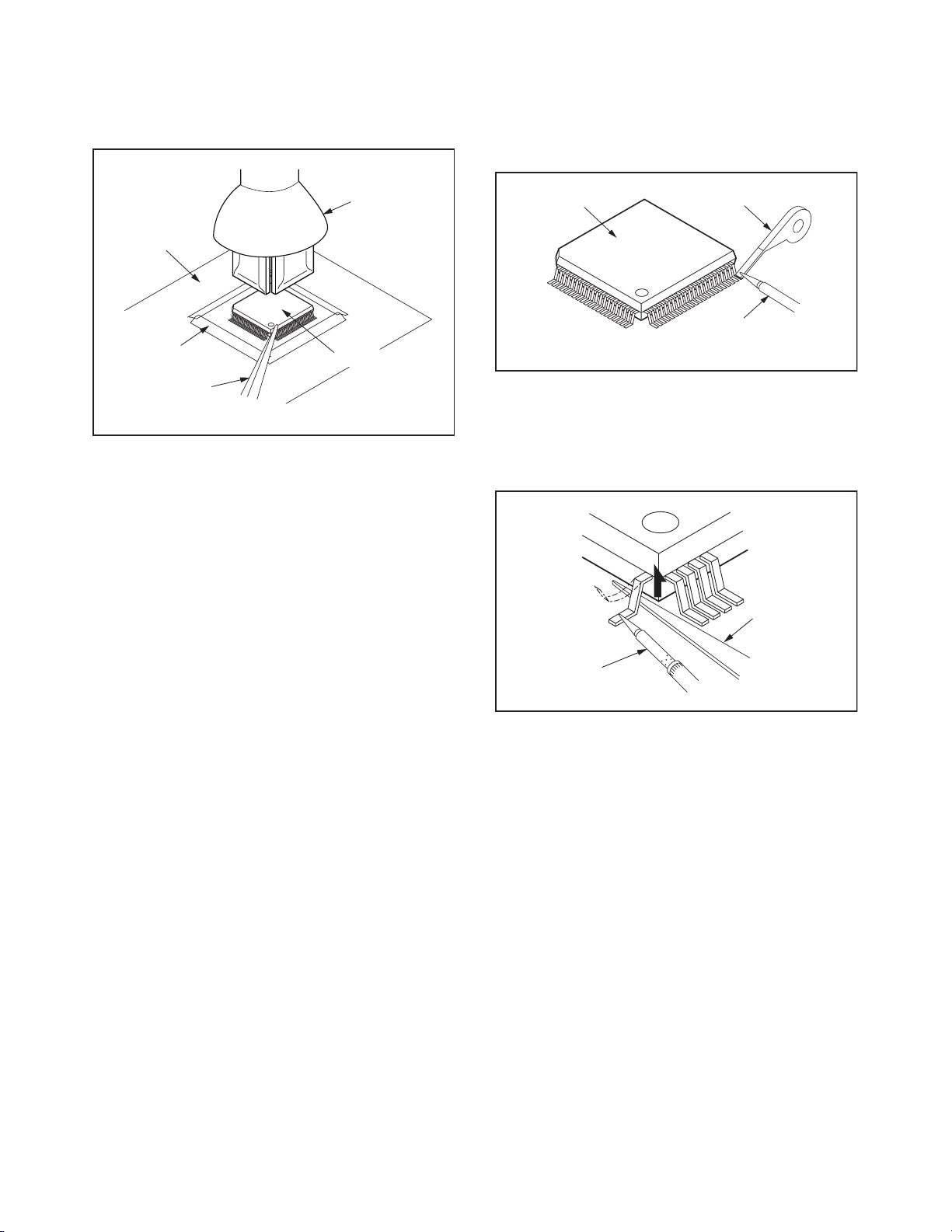

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-4-1 BDN_SN

Page 8

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

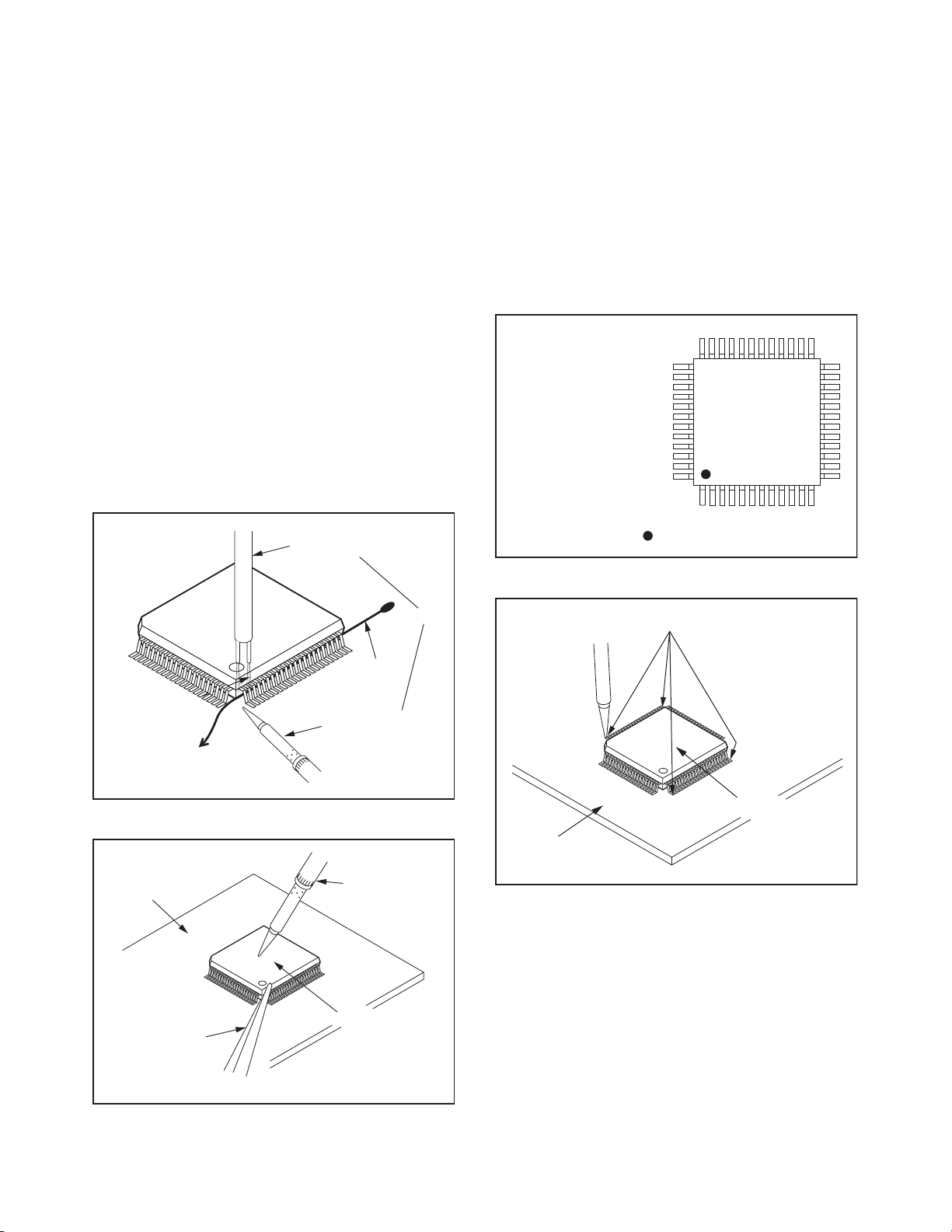

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Ta pe

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

1-4-2 BDN_SN

Page 9

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “ I ” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

1-4-3 BDN_SN

Page 10

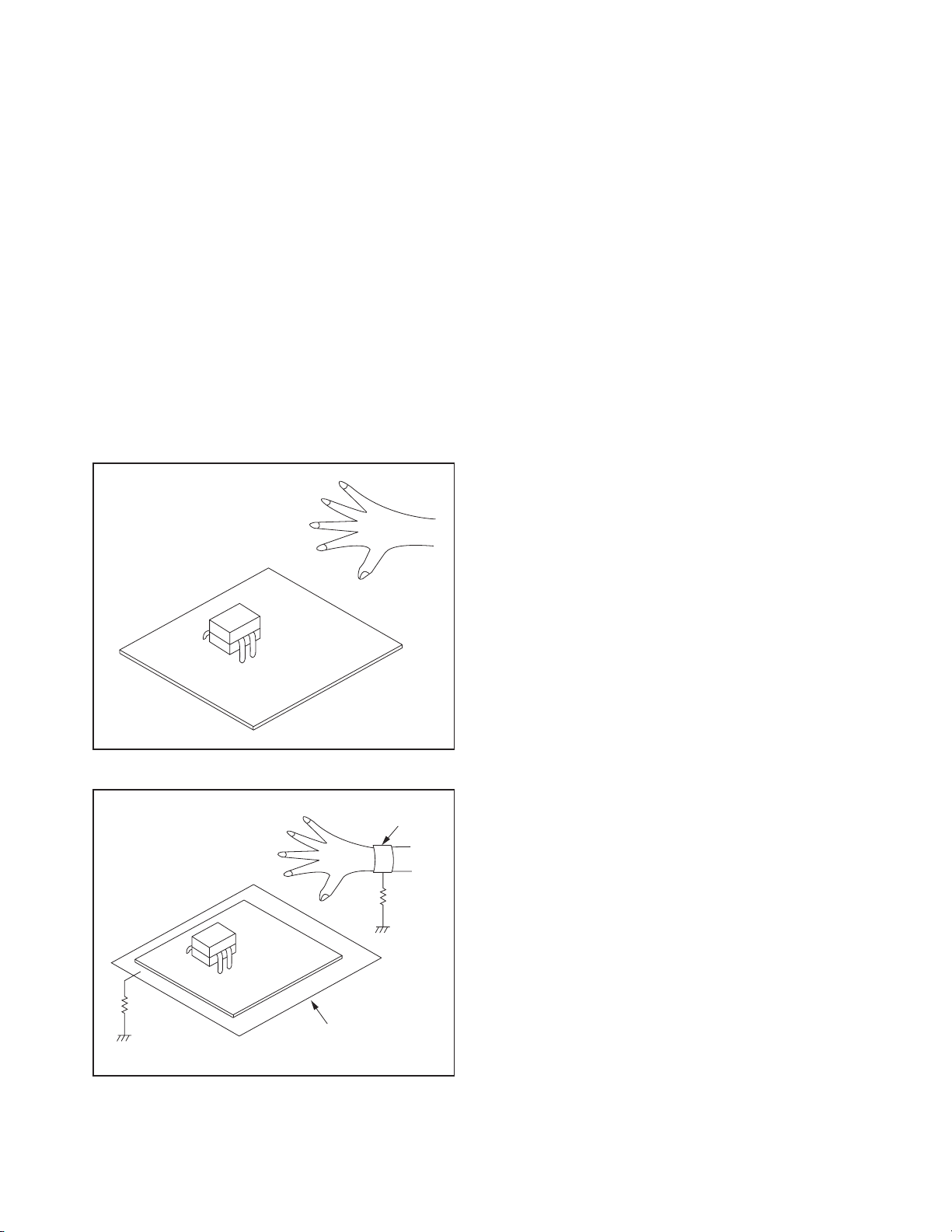

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 BDN_SN

Page 11

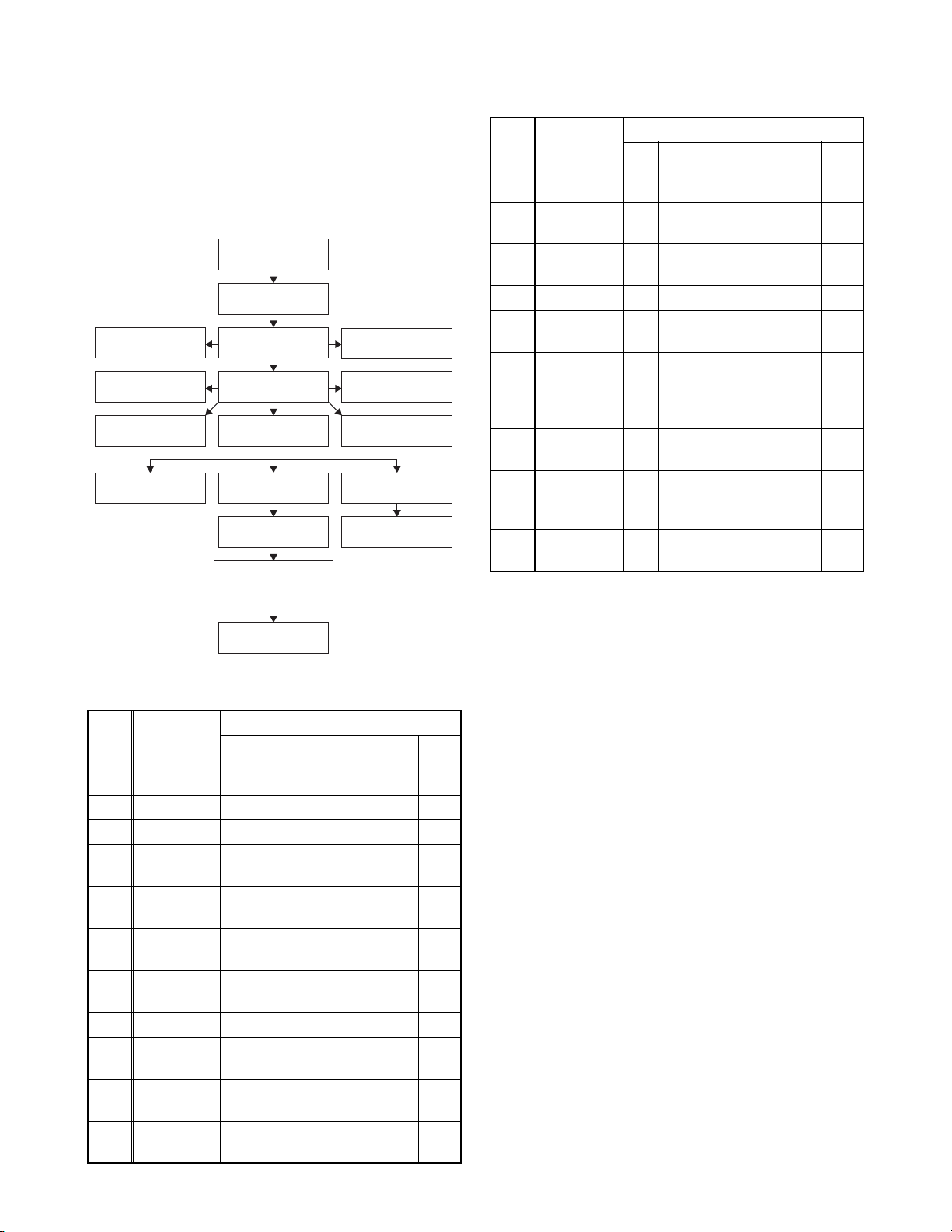

CABINET DISASSEMBLY INSTRUCTIONS

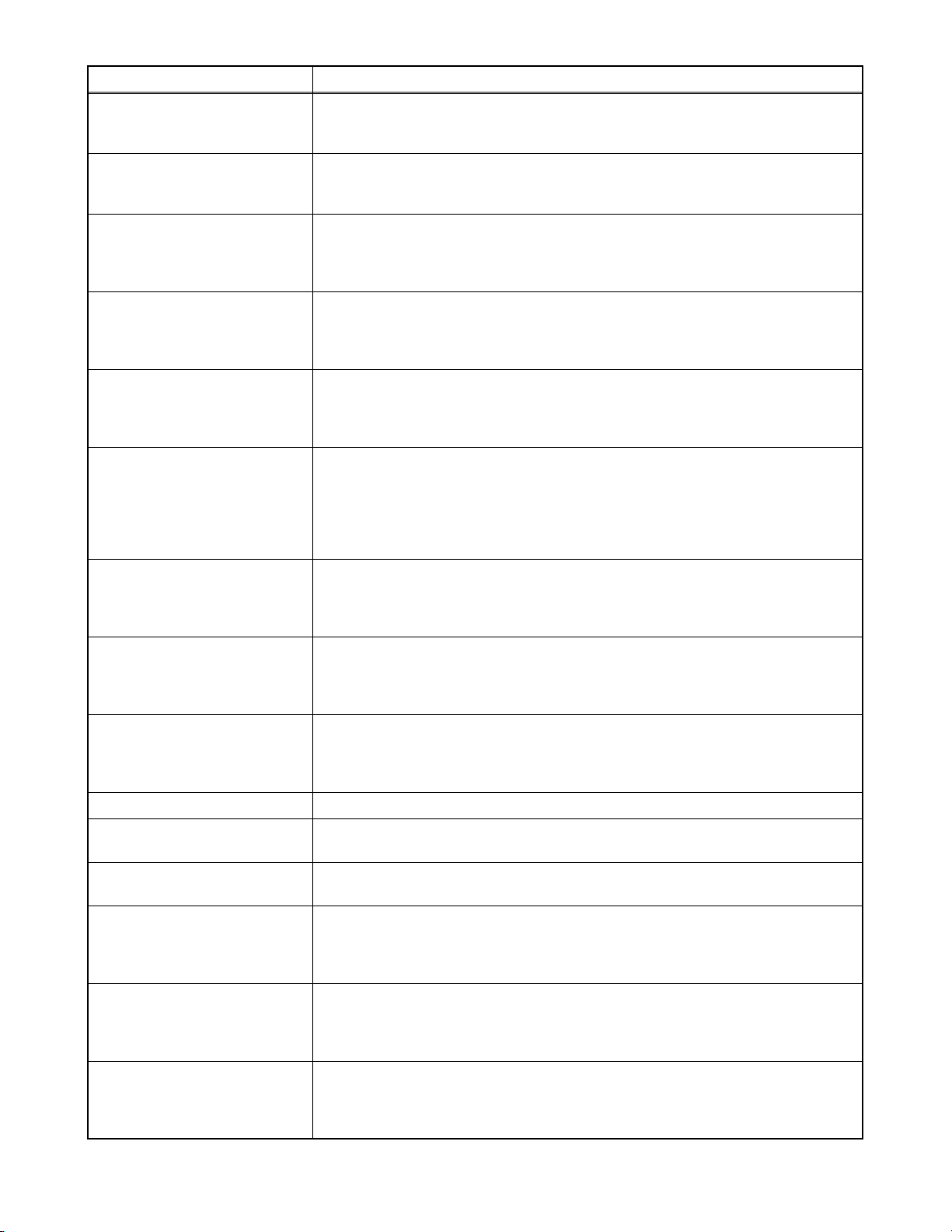

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to item(s) to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

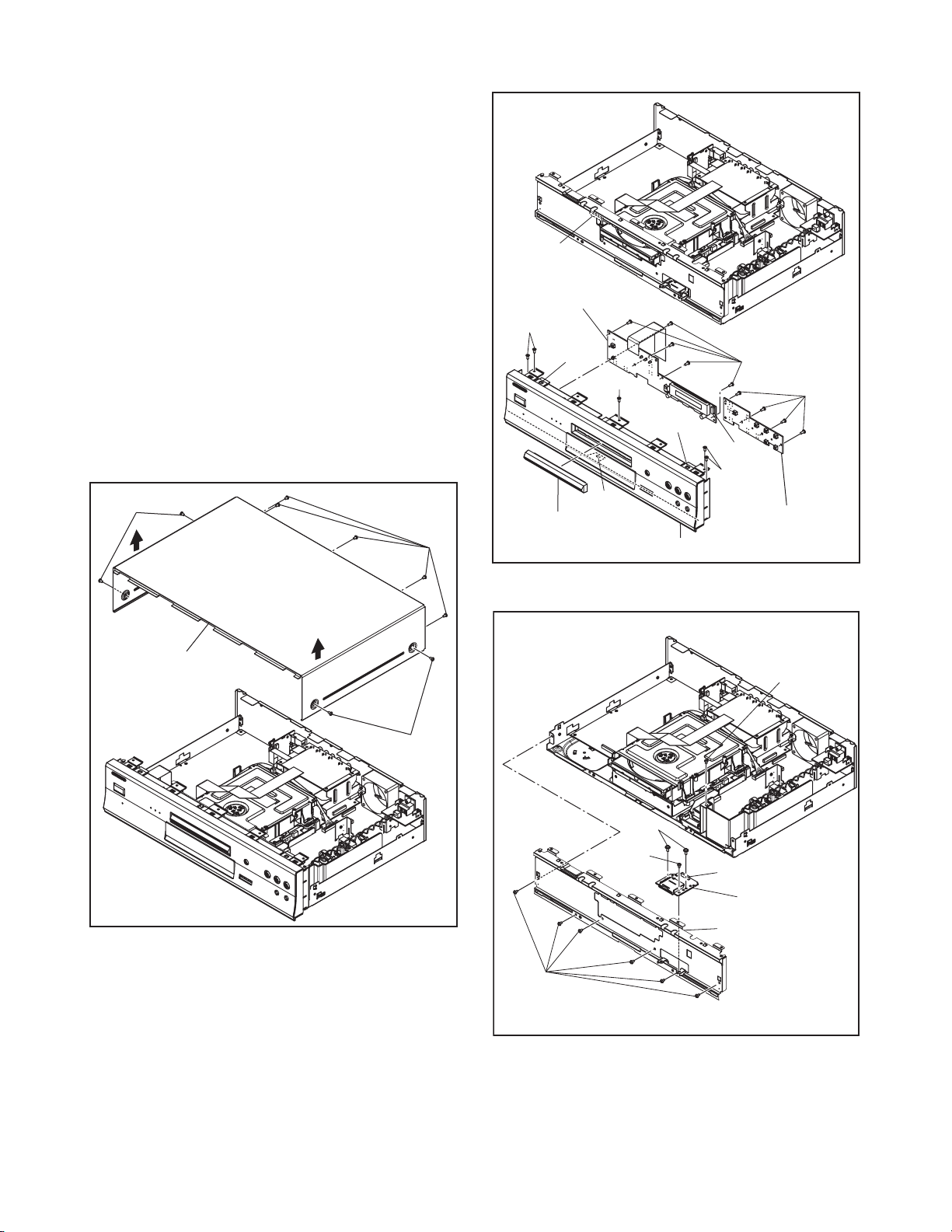

[1] Top Cover

[2] Tray Panel

[5] Front-B CBA

[7] SD CBA

[9] Motor

DC Fan

[12] Audio CBA

[3] Front

Assembly

[6] Front Bracket

[11] Rear Panel

[13] Video CBA

[14] AV PCB

Bracket

[15] BD Main CBA

& BD Mechanism

Assembly

[4] Front-A CBA

[8] Inlet CBA

[10] RS232C

CBA

[17] Power

Supply CBA

[18] Power

Holder

ID/

Loc.

Part

No.

[11] Rear Panel D4

[12] Audio CBA D5

Remove/*Unhook/

Fig.

No.

Unlock/Release/

Unplug/Desolder

8(S-12), (S-13),

5(S-14)

6(S-15), *CN2005,

*CN2007, *CN2008

Note

[13] Video CBA D6 4(S-16), *CN7101 ---

Removal

AV PCB

[14]

Bracket

D6 4(S-17) ---

BD Main

[15]

CBA & BD

Mechanism

2(S-18), 4(S-19),

D6

*CN1003, *CN1100

Assembly

Loader

[16]

Bracket

D6 6(S-20) ---

Power

[17]

Supply

D7 2(S-21), 2(S-22) ---

CBA

Power

[18]

↓

(1)

Holder

↓

(2)

D7 3(S-23) ---

↓

(3)

↓

(4)

4

---

3

↓

(5)

[16] Loader

Bracket

2. Disassembly Method

ID/

Loc.

No.

Part

Fig.

No.

[1] Top Cover D1 9(S-1) ---

[2] Tray Panel D2 --------------- 1

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

Front

Assembly

Front-A

CBA

Front-B

CBA

Front

Bracket

SD CBA

Inlet CBA

Motor DC

Fan

RS232C

CBA

*2(L-1), *(L-2), 5(S-2),

D2

9(S-3), *CN2002

D2 *CN3001 ---

D2 --------------- ---

D3 7(S-4), (S-5) ---

D3 2(S-6), *CN5001 ---

2(S-7), (S-8),

D4

*CN1001

D4 2(S-9), *CN1005 ---

(S-10), 2(S-11),

D4

*CN5501

Removal

Remove/*Unhook/

Unlock/Release/

Unplug/Desolder

Note

2

---

---

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

CN = Connector

* = Unhook, Unlock, Release, Unplug, or Desolder

e.g. 2(S-2) = two Screws (S-2),

2(L-2) = two Locking Tabs (L-2)

(5) Refer to “Reference Notes.”

1-5-1 E5SE0DC

Page 12

Reference Notes

1. How to remove tray panel

1) Connect the wall plug to an AC outlet and press

the [ A] button to open the tray.

2) Lift up and remove the tray panel.

3) Press the [ A] button again to close the tray.

4) Press the [ON/STANDBY] button to turn the

power off.

5) Unplug the AC cord.

2. CAUTION 1: Locking Tabs (L-1) and (L-2) are

fragile. Be careful not to break them.

3. The BD Main CBA & BD Mechanism Assembly

is adjusted as a unit at factory. Therefore, do

not disassemble it. Replace the BD Main CBA

& BD Mechanism Assembly as a unit.

4. When reassembling, be sure to use the original

screws or specified screws listed in the parts

list.

CN2002

[4] Front-A CBA

(S-2)

(L-1)

(S-2)

(S-3)

(S-3)

(L-1)

CN3001

(S-2)

(S-1)

[1] Top Cover

(S-1)

(S-1)

Fig. D1

(L-2)

[2] Tray Panel

[3] Front Assembly

(S-6)

(S-5)

CN5001

[6] Front Bracket

[5] Front-B CBA

Fig. D2

(S-4)

[7] SD CBA

(S-4)

Fig. D3

1-5-2 E5SE0DC

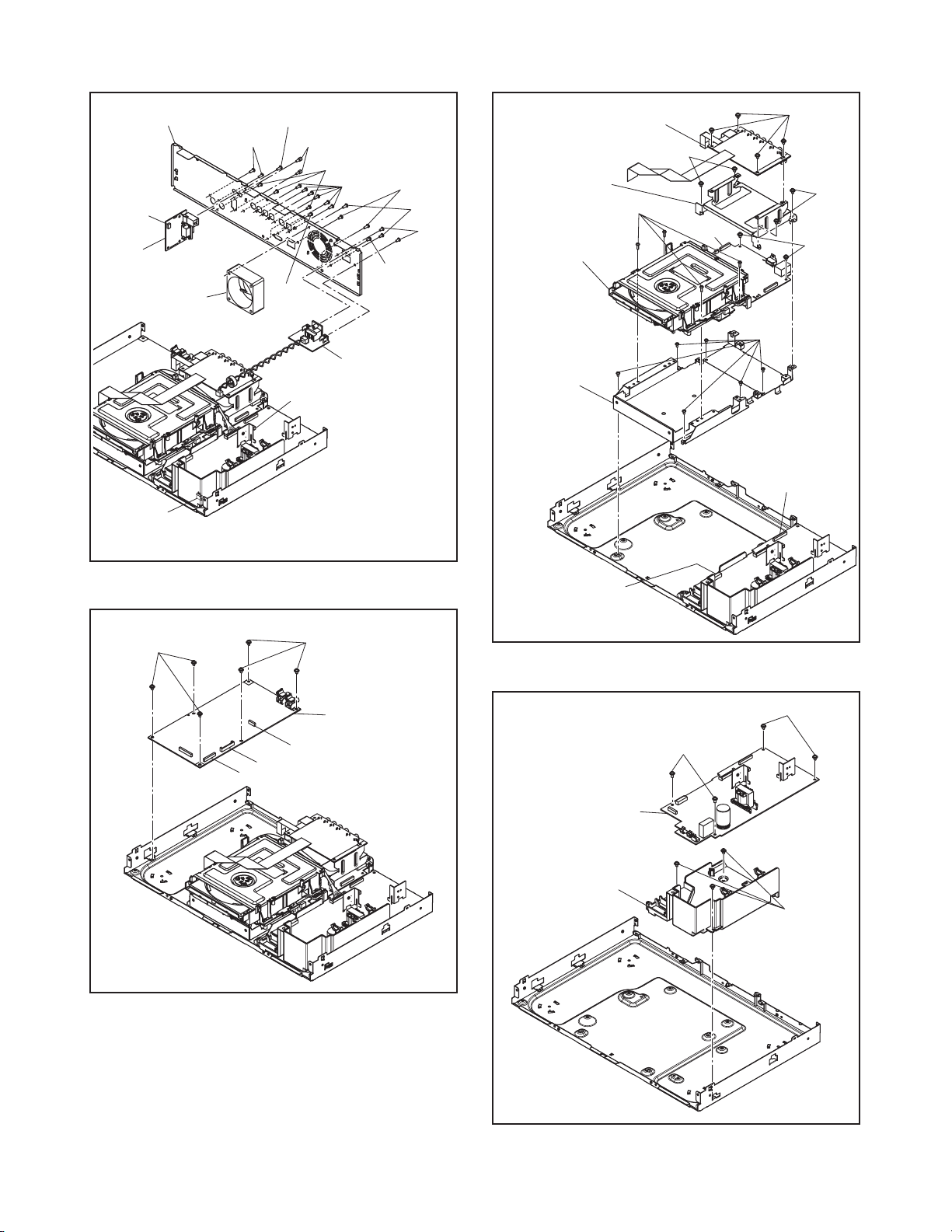

Page 13

[11] *Rear Panel

CN5501

[10] RS232C

CBA

[9] Motor

DC Fan

(S-12)

(S-10)

(S-11)

(S-13)

(S-14)

(S-12)

(S-8)

(S-14)

(S-9)

(S-7)

[13] Video CBA

[14] AV PCB

Bracket

(S-19)

[15] *BD Main CBA

& BD Mechanism

Assembly

(S-16)

(S-17)

(S-17)

CN7101

(S-18)

(S-20)

CN1001

*See Reference Note 4.

(S-15)

CN2005

CN1005

CN2007

CN2008

[8] Inlet CBA

(S-15)

[12] Audio CBA

Fig. D4

[16] Loader

Bracket

CN1100

* See Reference Note 3.

[17] Power Supply

CBA

CN1003

Fig. D6

(S-22)

(S-21)

Fig. D5

[18] Power Holder

(S-23)

Fig. D7

1-5-3 E5SE0DC

Page 14

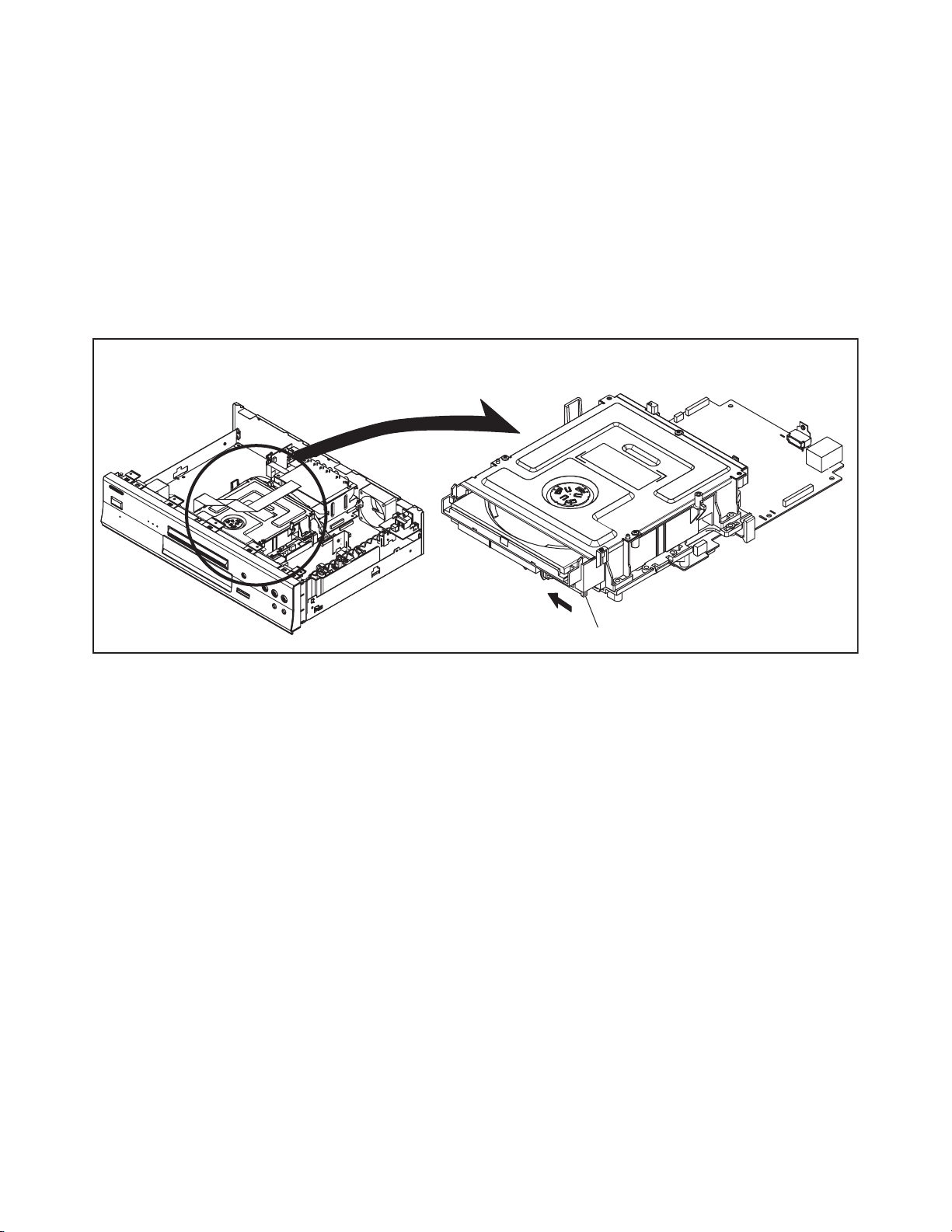

3. How to Eject a Disc

When a disc cannot be removed due to malfunction or when an unplayable disc is inserted, follow the

procedure below to remove the disc.

Procedure A

1. Unplug the AC power cord and then plug it in.

2. Turn the power on by pressing the [ A] button and the disc tray will open automatically.

Procedure B

1. Remove the Top Cover.

2. Slide the portion A in the direction of the arrow.

3. Pull the tray out manually and remove the disc.

Portion A

1-5-4 E5SE0DC

Page 15

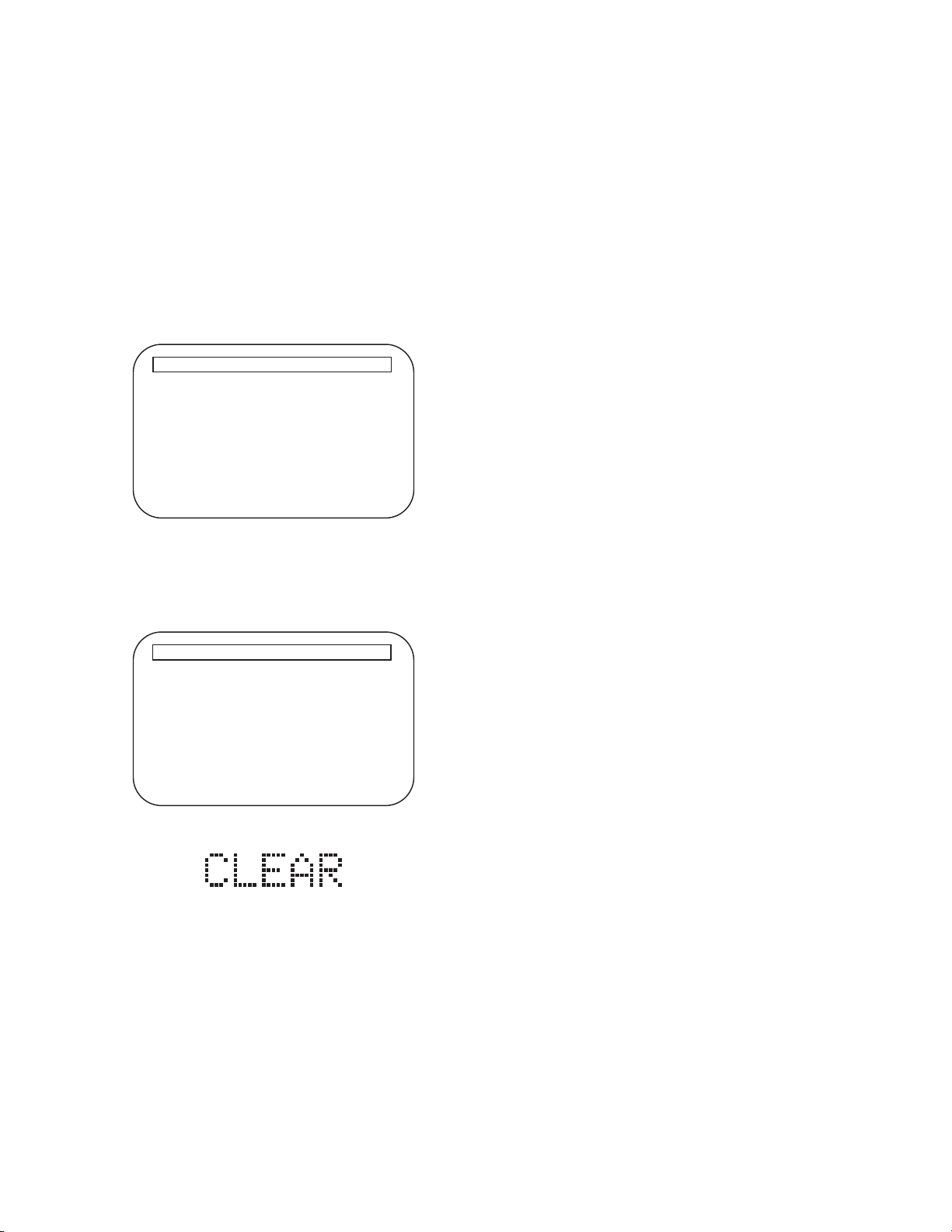

HOW TO INITIALIZE THE BLU-RAY DISC PLAYER

To put the program back at the factory-default,

initialize the BD player as the following procedure.

Note: By initializing, network is reset to disconnected

state and “Network Service Disclaimer”

appears on the screen.

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. a appears on the screen.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

Pickup

ESN

DRM

: *******

: *.***

: *-*

: **

: ***********************************

: OK

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. a

4. Press [ C ] button on the remote control unit.

Fig. b appears on the screen and Fig. c appears

on the VFD.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

Pickup

ESN

DRM

EEPROM CLEAR : OK

: *******

: *.***

: *-*

: **

: ***********************************

: OK

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. b

Fig. c

5. To exit this mode, press [ON/STANDBY] button.

1-6-1 E5SE0INT

Page 16

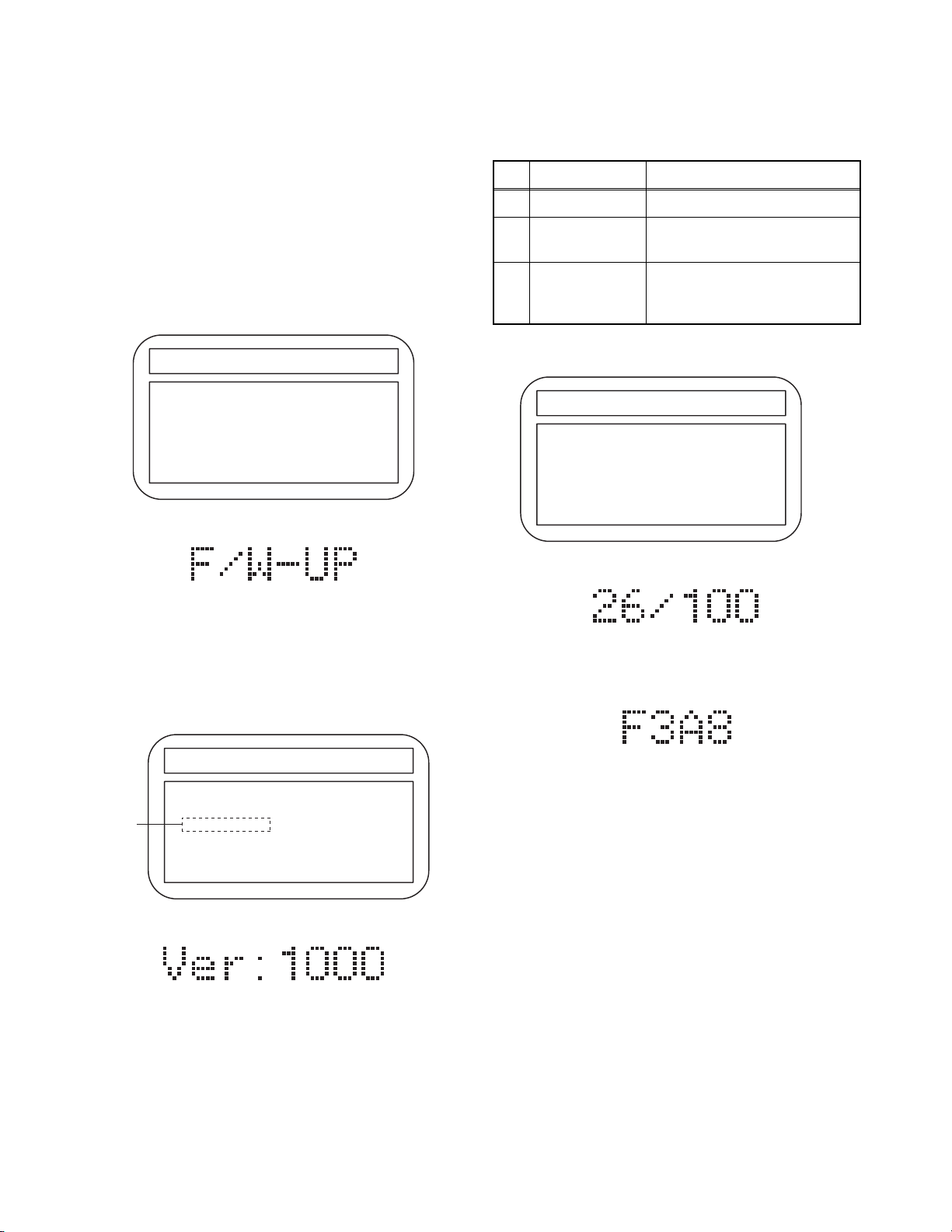

FIRMWARE RENEWAL MODE

Note: The file extension of the available firmware is

“b35”.

1. Turn the power on and remove the disc on the tray

and close the tray.

2. To put the BD player into version up mode, press

[9], [8], [7], [6], and [POP UP MENU/MENU]

buttons on the remote control unit in that order.

The tray will open automatically.

Fig. a appears on the screen and Fig. b appears

on the VFD.

"

" differs depending on the models.

*******

F/W VERSION UP MODE F/W Name: ******* Ver. *.***

Please Insert a Disc

for F/W Version Up

Fig. a Version Up Mode Screen

The appearance shown in (*1) of Fig. c is

described as follows:

No. Appearance State

1 Now Loading... Loading the disc

2 Reading...

Sending files into the

memory.

Writing new version data,

3 See FL Display.

the progress will be displayed

as shown in Fig. f.

"

" differ depending on the models.

*******

F/W VERSION UP MODE F/W Name: ******* Ver. *.***

1. ALL

Version : *.*** **************.b35

CHECKSUM : ****

See FL Display.

EXIT : POWER

Fig. e Version Up Mode

Fig. b VFD in Version Up Mode

3. Load the disc for version up.

4. The BD player enters the F/W version up mode

automatically. Fig. c appears on the screen and

Fig. d appears on the VFD. Make sure to insert the

proper F/W for the state of this model.

"

" differ depending on the models.

*******

F/W VERSION UP MODE F/W Name: ******* Ver. *.***

(*1)

Now Loading...

Fig. c Programming Mode Screen (Example)

Fig. d VFD in Programming Mode (Example)

Fig. f VFD in Version Up Mode

5. After programming is finished, the checksum on

the VFD (Fig. g).

Fig. g

VFD upon Finishing the Programming Mode (Example)

Checksum appears on the VFD then the tray will

open automatically. Remove the disc on the tray.

At this time, no button is available.

6. Unplug the AC cord from the AC outlet. Then plug

it again.

7. Turn the power on.

Note: All the settings will be put back to factory-

default.

1-7-1 E5SE0FW

Page 17

How to Verify the Firmware Version

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [1], [2], [3], [4], and [DISPLAY] buttons on

the remote control unit in that order.

Fig. h appears on the screen.

"

" differ depending on the models.

*******

Version Info

F/W Name

Version

Region

Pickup

ESN

DRM

: *******

: *.***

: *-*

: **

: ***********************************

: OK

EXIT <POWER>EEPROM CLEAR <STOP>

Fig. h

4. To exit this mode, press [ON/STANDBY] button.

1-7-2 E5SE0FW

Page 18

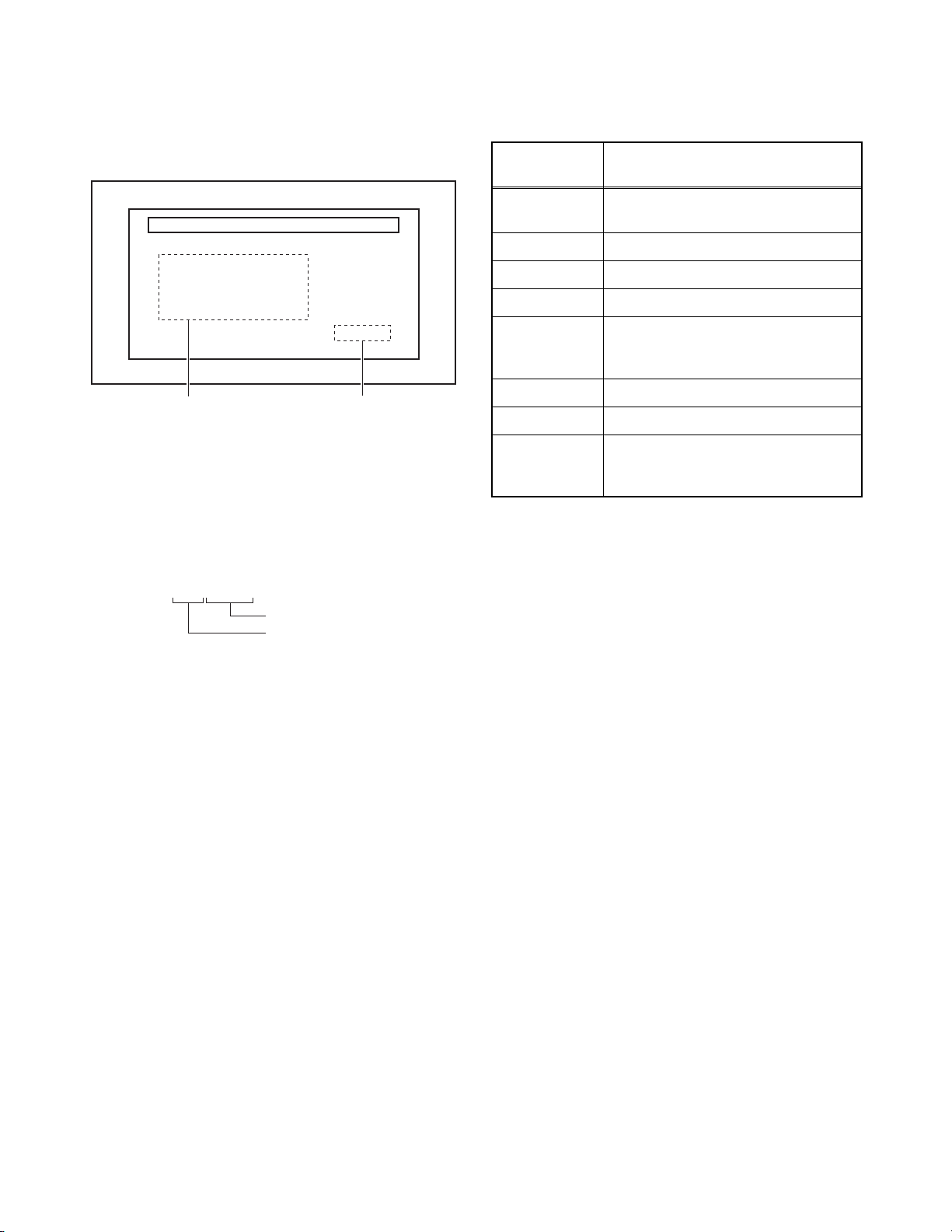

HOME NETWORK (DLNA) ERROR CODE

Error Code appears in the error screen when the unit

detects an error, as shown below. The code is used to

specifically determine the cause of error.

Network Error

Cannot connect to server.

Please check your settings.

Press ‘ENTER’.

00202010

Error message

Error Code

Fig. 1: Error Code (Example)

Error Code are displayed with “ ******** ” (“*” is error

code) as shown above.

Error Code Form

In the Home Network (DLNA), Error Code are used as

follows.

002XXXXX

“Summary Error Code” are shown in the list below.

Summary

Error Code

02

Cannot connect to server. Please

check your settings.

Error message

03 Playback Error

05 No playable files found.

20 System Error

Unable to display files from the

21

server. Please check server

settings.

22 List Updated.

23 Connection with server lost.

Unable to connect to more than 10

24

servers. Please turn off or stop

broadcasting 1 or more servers.

Detailed Error Code

Summary Error Code

Fig. 2

1-8-1 E5SF1ER

Page 19

Detailed Error Code table (DLNA – HTTP Status Code)

Status Code Description

201 Created A new resource was created by this unit’s request.

202 Accepted This unit’s request was accepted but its processing is not completed.

204 No Content Though the server processed the request, there was no content.

205 Reset Content No content.

• There are multiple choices.

• The server could not determine its response.

300 Multiple Choices

301 Moved Permanently

302 Found

• Requested information contains multiple representations.

This status is handled as Redirection by default and complies with the content

of Location HEAD related to this response.

• Moved Permanently.

• Requested resource has been assigned to a new permanent URI (Uniform

Resource Identifier). Any future references to this source must use one of the

returned URIs.

• Indicates that requested information is moved to the URI specified by the

Location HEAD. When this status is received, the default action is tracking

the Location HEAD related to the response. When the original request

method is POST, the redirected request will use GET.

• Found.

• Requested resource resides temporarily under a different URI.(Uniform

Resource Identifier)

• Indicates that requested information exists in the URI specified by the Location HEAD. When this status is received, Location HEAD related to the

response will be tracked by default. When the request method is POST the

redirected request will use GET.

• See other.

• The response to the request can be found under a different URI (Uniform

Resource Identifier) and to get this response, GET HTTP method will be

303 See Other

304 Not Modified

305 Use Proxy

400 Bad Request The server could not understand this unit’s request.

401 Unauthorized Indicates that the resource requested by this unit requires authentication.

403 Forbidden The server received this unit’s request, but refused to fulfill it.

404 Not Found The requested URI was not found.

405 Method Not Allowed

406 Not Acceptable

used.

• As a result of POST, client will be automatically redirected to the URI specified by the Location HEAD. GET will be used for requesting to a resource

specified by the Location HEAD.

This unit caches the latest resource and the requested resource is not

modified. (exception protocol error)

• Proxy will be used.

• The requested resource must be accessed through the proxy specified by the

Location field.

• Indicates that request must use the URI given by the Location HEAD to use

the proxy server.

• The method is not allowed.

• The HTTP behavior used is not allowed.

• Indicates that request method (POST or GET) is not allowed by the

requested resource.

• The client could not find an acceptable response.

• Indicates that the client specifies not to accept arbitrary representation for

Accept header which could be used by the resource.

1-8-2 E5SF1ER

Page 20

Status Code Description

407 Proxy Authentication

Required

408 Request Timeout

409 Conflict

410 Gone

411 Length Required

412 Precondition Failed

• Proxy authentication is required.

• Indicates that the requested proxy will request authentication. Proxy-authenticate header contains the detailed method for authentication.

• While waiting for request, the server timed out.

• Indicates that the client did not send a request within the expected time by

the server.

• There is a conflict.

• The server timed out while waiting for a request.

• Indicates that the client did not send a request within the expected time by

the server.

• No longer available.

• The requested resource could not be found at the server and forwarding

address is unknown.

• Indicates that requested resource is no longer available.

• Length required.

• The server refused to accept the request where Content-Length was undefined.

• Indicates Content-length header is not defined.

• Fails to fulfill precondition.

• The precondition in one or more of the requested header field has been

tested false by the server.

• The precondition given in the request could not be fulfilled and the request

failed. Precondition can be set using If-Match, If-None-Match, If-UnmodifiedSince request header.

• The requested entity is too large.

413 Request Entity Too

Large

414 Request-URI Too Long

415 Unsupported Media

Ty pe

500 Internal Server Error Internal server error occurred.

501 Not Implemented

502 Bad Gateway

503 Service Unavailable

504 Gateway Timeout

• The server refused to process the request since the requested entity is larger

than the server is willing or able to process.

• Indicates that the request is too large for the server to process.

• The Request-URI is too long.

• The server refused to process the request because the request URI (Uniform

Resource Identifier) is too long for the server to interpret.

• Indicates that the URI is too long.

• The media type is not supported.

• The server refused to process the request because the format of request

entity is not supported by the requested resource for the requested method.

• Indicates the requested format is not supported.

The server does not support functionalities required to process the request

from this unit.

The proxy server between this unit and the server received an invalid reply from

another proxy or the original server.

• Service is unavailable.

• The service is temporarily overloaded.

• Because of overloading or maintenance, the server is temporarily unavailable.

• Gateway timed out.

• While waiting for gateway, the request timed out.

• Indicates that the intermediate proxy server has timed out while waiting for a

response from another proxy or original server.

505 Version Not Supported

• The version is not supported.

• The server refuses or does not support the version of protocol given in the

request message.

• Indicates that requested version is not supported by the server.

1-8-3 E5SF1ER

Page 21

Detailed Error Code table (DLNA – Application Status Code)

Status Code Description

001 Nothing List

010 LAN Disconnect This unit’s LAN is disconnected.

020 Application Status Error Error was detected in the DLNA application’s internal state.

021 Application Status Error Error was detected in the DLNA application’s internal state.

022 Application System Error Error was detected in the DLNA application system.

023 Unsupported Audio

Format

As a result of list creation process, there is no item to be displayed from the

received data.

An unsupported audio format was discovered.

024 Server Number Over

Limit

025 Changed List The contents list currently displayed has been updated.

026 Disconnected Server The original server of the displaying contents list has been disconnected.

027 Application System Error Error was detected upon start of DLNA application.

600 Disconnected Server The original server of the contents has been disconnected.

601 Not Exist Content Content does not exist.

602 Critical Error System error.

603 Changed List The contents list has been updated at the server.

620 Not Exist Content Image content does not exist.

621 Get failure Image data get error. (an error other than HTTP status and under 500s)

622 File Open Error Image data working file open error.

623 File Read Error Image data working file read error.

624 File Close Error Image data working file close error.

625 Decode mode Error Image data decode mode error.

626 Header Error Image data header error.

627 Struct Error Image data header structural error.

628 Decode Error Image data decode error.

Discovered server numbers over limit.

629 Unsupported Format Unsupported format.

630 Unsupported Size Unsupported data size.

631 Attach Error Shared memory attach error.

632 Detach Error Shared memory detach error.

633 Server Time Out Error Server timed out.

640 File Read Error File read error.

641 Unsupported Format Unsupported Format.

642 No Change Decode

Frame

643 Stream Get Error Stream get error.

660 File Read Error File read error.

661 Unsupported Format Unsupported format.

662 Video Analyze Error Video analyze error.

663 Audio Analyze Error Audio analyze error.

No updates of decode frame.

1-8-4 E5SF1ER

Page 22

Status Code Description

664 1sec Offset Get Error 1sec offset get error.

665 Address Search Error Address search error.

680 RFS_EVENT_SOCKET_

ERROR

681 RFS_EVENT_HTTP_

RES_SERVER_

REFUSED

682 RFS_EVENT_HTTP_

RES_NOT_FOUND

683 RFS_EVENT_HTTP_

RES_SERVER_ERROR

684 RFS_EVENT_HTTP_

RES_UNEXPECTED_

CODE

685 RFS_EVENT_HTTP_

RES_RANGE_NOT_

SATISFIABLE

686 RFS_EVENT_RECV_

TIMEOUT

687 RFS_EVENT_DTCP_

ERROR

688 RFS_EVENT_DTCP_

CONNECT_ERROR

689 RFS_EVENT_DTCP_

KEY_MNG_ERROR

Socket error.

Server refusal notification.

The specified contents could not be found.

Server error.

Unexpected status code.

The specified range is not satisfiable.

Timed out while waiting for response.

RCVC internal error. (DTCP originated)

DTCP connection error.

Kx key error.

690 RFS_EVENT_

RESPONSE_DATA_

ERROR

691 RFS_EVENT_SYSTEM_

ERROR

692 RFS_EVENT_TCP_

DISCONNECTED

693 RFS_EVENT_

CONNECT_TIMEOUT

694 RFS_EVENT_RECV_

ERROR

700 Refresh Error Failed to update server list.

701 Disconnected Server The server has been disconnected while displaying contents list.

702 Server Not Found The server has been disconnected while getting contents list.

703 Server Info Error Failed to get server information while getting contents list.

704 Contents List Error Failed to get contents list.

705 Server Config Error Failed to configure server.

706 List Not Found Failed to get contents list.

707 Changed List Displayed contents list has been updated.

708 Object Not Found Neither folders or playable contents was found.

Received message is invalid.

RCVC internal error.

The TCP connection has been disconnected by the server during streaming.

Time out occurred while establishing TCP connection.

Could not receive contents.

709 Object Not Found By

Filter

Playable contents was not found by filter.

1-8-5 E5SF1ER

Page 23

Status Code Description

710 Object Count Zero Nothing was found in the folder.

711 ILLEGAL Server Info The contents information from the server is invalid.

712 ILLEGAL Total Count The total counts of contents from the server is invalid.

713 Folder not Exist

714 Critical Error An error occurred on the system.

The specified folder does not exist. (The current contents list displayed has

been updated)

1-8-6 E5SF1ER

Page 24

BLOCK DIAGRAMS

System Control Block Diagram

RS3001

VFD

19 20 21 22

(SUB MICRO CONTROLLER)

IC2000

TO POWER SUPPLY

PWSW3

PWSW1

PWSW2

FAN-LOCK

17

PWSW116PWSW215PWSW3

23 VIDEO-MUTE

BLOCK DIAGRAM

FAN-CONT1

6FAN-CONT1

40

FAN-LOCK

CEC-CONT

22

CEC-CONT

XIN

XOUT

9

11

TO AUDIO

BLOCK DIAGRAM

AUDIO-MUTE

7AUDIO-MUTE

CEC-IN32CEC-OUT

31

FRONT-A CBA

FL3001

SENSOR

REMOTE

SUB-RXD

SUB-TXD

48

47

345

FL-SDA

345

CN2002 CN3002

28

FL-SDA

SYS-RESET

20

FL-SCL

FL-STB

27

29

FL-SCL

FL-STB

EV+5VD3004

BD

Q3004

6

12

FL-RESET

REMOTE

6

12

21 21BD-LED

30

26

43

BD-LED

REMOTE

FL-RESET

EV+3.3V

DVD

D3003

LED DRIVE

17

-LED

STANDBY

17

19 19DVD-LED

20 20CD-LED

44

50

49

CD-LED

DVD-LED

STANDBY-LED

LED DRIVE

Q3003

16KEY-1

16

42

KEY-1

D3005

CD

LED DRIVE

Q3005

Q3001

STANDBY

D3002

POWER

SW3003

CN3001 CN3101

2 2

KEY-1

RS232C-RXD

34 RS232C-TXD

33

21 232C-PW-CONT

KEY

SWITCH

FRONT-B CBA

AUDIO CBAVIDEO CBA

CN2005

1818

VIDEO-MUTE

CN4001

VIDEO-MUTE

TO VIDEO

BLOCK DIAGRAM

X2000

BD MAIN CBA

10MHz

X'TAL

Q7504, Q7505

Q7502

CN2005

13

14

CEC-IN

13

14 CEC-OUT

CN4001

CN4000

13CEC-IN

14

13

14 CEC-OUT

CN7101

SWITCHING

BUFFER

BUFFER

Q7503

IC6001

(MAIN MICRO CONTROLLER)

CN2005

10

SUB-TXD

101010

CN4001

SUB-TXD

CN7101 CN4000

U34

RXD1

9

11

SUB-RXD

SYS-RESET

11

99

1111 9

SUB-RXD

SYS-RESET

V32

TXD1

T34

XRST

A27

AE32

XTRST

XFERST

Q6702

IC6701

Q6701

RESET

2 1

RS232C CBA

EV+5V

Q5500,Q5501

RS232C

INTERFACE

IC5500

123

CN2005CN4002 CN4001CN5501

RS232C-RXD

RS232C-TXD

RS232C-PW-CONT

12333

4

5

RS232C-RXD

RS232C-TXD

RS232C-PW-CONT

4

5

SWITCHING

11

12

16

VCC

RS232C

I/F

13

14

66

REMOTE

11

REMOTE

IC5550

PHOTO

JK5550

BUFFER

Q5551,Q5552

4

COUPLER

1

3

2

JK7501

HDMI-

CONNECTOR

13

CEC

1-9-1

P-ON+1.8V

3RXD

CN5500

RS232C-

CONNECTOR

2TXD

REMOTE

-OUT

REMOTE

-IN

E5SE0BLS

Page 25

Digital Signal Process 1 Block Diagram

VIDEO SIGNAL AUDIO SIGNAL

(MAIN MICRO CONTROLLER/DIGITAL SIGNAL PROCESS)

IC6001

MPX

MATRIX

B31,C31

A32,B32,

/LPP

WOB

B30,C30

A30,A31,

TO DIGITAL SIGNAL

PROCESS 2 BLOCK

DIAGRAM

(IC6001)

STREAM

CONTROL

FE

DIGITAL

SIGNAL

PROCESS

RF

EQUALIZER

RF

GENERATOR

B34

C33

G30

G31

SD ATA 2

M31

SCLK2

M32

TRACKING-CONTROL

E23

27

TRACKING

ACTUATOR

IC302 (MOTOR DRIVE)

262524

DRIVE

COPY

FOCUS1-CONTROL

A24

FOCUS 1

ACTUATOR

DRIVE

23

PROTECT

FOCUS 2

22

AACS

FOCUS2-CONTROL

D23

29

ACTUATOR

BD+

DRIVE

21

CSS

CPRM

EXPA-CONTROL

B22

162815

COLLIMATE

LENS

201918

EXPB-CONTROL

D22

MOTOR DRIVE

17

40

SLED1-CONTROL

SLED2-CONTROL

D24

C24

37

38

SLED

MOTOR DRIVE

2

41

TRAY-OUT

TRAY-IN

LOAD-CONTROL

C22

D21

LOADING

MOTOR DRIVE

1

4

5

SPINDLE-CONTROL

E217E24

10

IC301 (MOTOR DRIVE)

242119131415161718

SPINDLE

MOTOR

DRIVE

SPINDLE-FG

B25

4

12

Q101

*1: 14, 16, 18, 26

*2: 13, 15, 27, 29

CN101

A-D *1

E-H *2

Q102

BUFFER

BUFFER

RF(-) 21

RF(+) 20

BDRF(+) 23

OEIC

(CD/DVD)

CN101

TD 3

TR 4

FR1 5

FD1 6

FD2 2

LASER

DIODE

FR2 1

DRIVE

EXPA(-) 10

EXPB(-) 8

EXPA(+) 9

EXPB(+) 7

SCLK2 39

SD ATA 2 3 8

BDRF(-) 24

OEIC

(BD)

CN301

SLD2(+) 4

SLD2(-) 3

SLED

CN302

SLD1(-) 1

SLD1(+) 2

MOTOR

LOAD(-) 17

LOAD(+) 16

LOADING

MOTOR

1-9-2

TRAY-OUT 14

TRAY-IN 13

TRAY-OUT

CN302

V3

U4

W2

TRAY-IN

HU(-) 7

HU(+) 6

SPINDLE

HV(-) 9

VH(-) 12

HV(+) 8

HW(-) 11

HW(+) 10

MOTOR

BD MECHANISM BD MAIN CBA

E5SE0BLD1

Page 26

Digital Signal Process 2 Block Diagram

TO

VIDEO

BLOCK

DIAGRAM

PRMCLK

VFC-P-CLK

VFC-VSYNC

N16

VFC-HSYNC

L16

D11

C11

REC656-D(6,7)

REC656-D(2,3)

VIDEO SIGNAL AUDIO SIGNAL

REC656-D(8,9)

REC656-D(4,5)

VFC-Y(0-11)

VFC-C(0-11)

A12,A14,A15,

D15,D16,E15,

E16,F16,G15,

G16,H14,H16,

J15,J16,K15

B12,B13,B14,

B16,C15,E13,

F13,F14,G14

+3.3V

IC8901

RESET

A9

SCL3

SDA3

TO

VIDEO

HDMI-DATA0

HDMI-DATA1

HDMI-DATA2

REC656-CLK

BLOCK

DIAGRAM

HDMI-DATA3

HDMI-BCK

HDMI-MCK

HDMI-LRCK

MC

MD

HDMI-SPDIF

DAC-SCK

DAC-BCK

TO AUDIO

BLOCK

DIAGRAM

MS1

DAC-LRCK

DATA

SPDIF

IC8001 (SCALER)

A5,A6,B5,

C4~C7,

D5~D7,

BP1-C(2-11)

REC656-D(4,5)

A4,A8,A9,B4,

B9,C5,C9,

C11,D8,D10,

DIGITAL

VIDEO

OUT

MEDIA

PROCESSOR

SIGNAL

PROCESS

/SCALER

A2~A4,B1,

B3,B4,

C1,C2,

D1~D3,E4

E3,F4

BP1-Y(2-11)

REC656-D(8,9)

E10,E11

A3,A6,A7,B7,

C4,C6,C7,C8,

D6,D9,E8,

E12

E2,G4

REC656-D(2,3)

REC656-D(6,7)

A5,E7

B8,E9 E1,F3

VFC-DQ (0-15)

IC8801 (SDRAM)

MEMORY

CONTROLLER

VFC-A (0-12)

SDRAM

I/P CONVERTER

/SCALING

Java (BD-J)

MPEG-2

CLK-OUT2

BP1-P-CLK

BP1-VSYNC

B7

A2 F1

B6

CLK

VSYNC

DiVX

VC-1

H.264

CLK-OUT1

VFC-VSYNC

VFC-HSYNC

BP1-HSYNC

A7

X6701

1

IC6702 (CLOCK GENE.)

789

B5

AL5

AL34

HSYNC

33M CLOCK

33M CLOCK

DECODER

HD (TS)

SCL

27MHz

OSC

2

16

SCL

CLOCK

GENE.

E20

A19

74M CLOCK

27M CLOCK

SD (PS)

RESET

CLK IN2

SDA

A8C9B9

3

SDA

10

D20

768K CLOCK

R33

SCL3

U31

SDA3

D7

E13

B10

REC656-CLK

B11

A10

A11

D11

C12

C10

B14

A12

B13

A13

D12

B12

AC31

C14

DIGITAL

AUDI O

OUT

IC6001 (MAIN MICRO CONTROLLER/DIGITAL SIGNAL PROCESS)

BD MAIN CBA

CN5000 CN7602CN1101CN5001 CN1100

5

SDDAT0

5

11

SDDAT0

5

SD DATA(0-3)

SD I/F

AF32,AG34,

AH33,AJ34

3

15

SDDAT1

SDDAT2

3

15

139

13

SDDAT1

SDDAT2

3

15

SD

13

SDDAT3

13

SDDAT3

13

CARD

SLOT

SDCLK

AH34

7

SDCLK

7

SDCLK

7

POWER

SUPPLY CBA

SD CBA

FROM DIGITAL

SIGNAL PROCESS 1

BLOCK DIAGRAM

(IC6001)

MII-RXD (0-3), MII-TXD (0-3)

ETHERNET

INTERFACE

IC6401

JK6401

TX(-) 2

RX(-) 6

TX(+) 1

RX(+) 3

(ETHERNET JACK)

1-9-3

(NAND FLASH MEMORY)

IC6901

ED (0-7)

NAND FLASH

MEMORY (2Gbit)

MEMORY

I/F

C0BA (0-12)

C0DQ (0-31)

DDR2 SDRAM

(DDR2 SDRAM)

IC6501,IC6502

(1Gbit )

C1BA (0-12)

C1DQ (0-31)

DDR2 SDRAM

(DDR2 SDRAM)

IC6601,IC6602

(512Mbit)

E5SE0BLD2

Page 27

Video Block Diagram

VIDEO-Y

OUT

JK4001

JK4002

VIDEO OUT

VIDEO SIGNAL AUDIO SIGNAL

75Ω

DRIVER

75Ω

DRIVER

75Ω

2dB

AMP

2dB

AMP

2dB

LPF 14

4dB

AMP

1

LPF

6.75MHz

4dB

AMP

3 12

13.5/37MHz

4dB

VIDEO CBABD MAIN CBA

IC4000 (VIDEO DRIVER)

REAR

VIDEO-Pb/Cb

OUT

JK4003

10

DRIVER

AMP

LPF

13.5/37MHz

AMP

4

VIDEO-Pr/Cr

JK4004

9

75Ω

DRIVER

2dB

AMP

LPF

13.5/37MHz

4dB

AMP

5

OUT

MUTE

6

MUTE

7

HDMI-CONNECTOR

JK7501

96

AUTHENT

/CATION

KEY

EXCHANGE

HOT PLUG

DETECT

191516

DDC

I/F

DDC DATA

DDC CLOCK

T.M.D.S DATA2-

31649

22241820141612

98

97

T.M.D.S DATA2+

T.M.D.S DATA1-

T.M.D.S DATA1+

T.M.D.S DATA0-

TMDS

SERIALIZER

TMDS

ENCODER

HDCP

CIPHER/

ENCRYPTOR

AV

CONTROLLER

T.M.D.S DATA0+

T.M.D.S CLOCK+

T.M.D.S CLOCK-

7

10

12

10

VIDEO-MUTE

TO SYSTEM

CONTROL

CN4000CN7101

33VIDEO-Y(I/P)

55VIDEO-Pb/Cb

77VIDEO-Pr/Cr

11VIDEO

39

434244

CLKIN-A

CLKIN-B

IC8501(VIDEO DAC)

63

30

55586162535459

REC656-D(2,3)

REC656-D(8,9)

REC656-D(4,5)

BLOCK DIAGRAM

VIDEO

DAC

60

14-18,

VFC-C(2-11)

REC656-D(6,7)

2-9,

12,13

25-29

VFC-Y(2-11)

SCL

P-VSYNC

SDA

232221

20

S-VSYNC

P-HSYNC

49

REGISTER

IIC

I/F

IC7501 (HDMI INTERFACE)

27

29

S-HSYNC

50

CLK

1

VIDEO

I/F

VS

HS

31

32

51-56,58,59,

71,72,74,75

35-37,39-41,

43,44,66-68,70

AUDIO

I/F

86848583918889

81

VFC-P-CLK

REC656-CLK

TO DIGITAL

SIGNAL

PROCESS 2

BLOCK

DIAGRAM

1-9-4

SCL3

SDA3

VFC-VSYNC

PRMCLK

VFC-HSYNC

VFC-C(0-11)

VFC-Y(0-11)

TO DIGITAL

SIGNAL

PROCESS 2

BLOCK

DIAGRAM

HDMI-DATA0

HDMI-DATA1

HDMI-DATA2

HDMI-DATA3

HDMI-MCK

HDMI-BCK

HDMI-LRCK

HDMI-SPDIF

E5SE0BLV

Page 28

Audio Block Diagram

REAR

AUDIO SIGNAL

IC2200

(OP AMP)

AUDIO(L)-

OUT

JK2200

MUTE-ON

Q2203

DRIVE

Q2200

7

6

222419

20

AUDIO(R)-

JK2201

Q2202

Q2201

1

2

OUT

MUTE-ON

DRIVE

AUDIO-MUTE

TO SYSTEM CONTROL

BLOCK DIAGRAM

REAR

DIGITAL

AUDIO OUT

(OPTICAL)

AUDIO OUT

(COAXIAL)

JK4005

VIDEO CBABD MAIN CBA

DIGITAL

JK4000

BUFFER

Q4003

AUDIO CBA

IC7001

(AUDIO D/A CONVERTER)

CN7001 CN2007

AUDIO(L)

AUDIO(R)

AUDIO(L)-MUTE

AUDIO(R)-MUTE

222419

20

1

14

15

L-CH

(R-CH)

AUDIO

DAC

DAC-BCK

DAC-LRCK

MUTE

MS1

(L-CH)

3458276

MCMDDAC-SCK

R-CH

DATA

SPDIF

18 18

CN7101 CN4000

16

MUTE

SPDIF

TO DIGITAL

SIGNAL

PROCESS 2

BLOCK DIAGRAM

1-9-5

E5SE0BLA

Page 29

Power Supply Block Diagram

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

FAN-LOCK

FAN-CONT1

TO SYSTEM

CONTROL

BLOCK

PWSW2

PWSW3

DIAGRAM

PWSW1

CEC-CONT

F1F2FL

P-ON+12.5V

Q2601

Q2602

Q2604

CEC+3.9V

EV+3.3V

EV+5V

P-ON+5V

Q2603

SW+3.9V

Q2637, Q2638

Q2614

SWITCHING

+3.3V REG.

IC2002

AUDIO CBA

FAN

FAN

FAN-LOCK

1

2

CN1005

FAN

CONTROL

Q1121,Q1122

"Ce symbole reprèsente un fusible à fusion rapide."

"This symbol means fast operating fuse."

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

F

A V

T1001

SW+12.5V

Q1120

SW+14.5V

Q1106

11

2

CURRENT

SW+10.5V

Q1108

LIMIT

Q1109, Q1110

Q1103

12

CN2008

FAN-LOCK

16 16

CN1004

)

12

15

PWSW3

FAN-CONT1

12

15

Q1104

15

4

10

PWSW2

PWSW1

11 11

10

Q1002

5

TO BD MAIN

CBA

24 P-ON+5V(2)

CN1003

IC1451

1

4

(CN6101)

P-ON+1.2V

2 P-ON+5V(1)

3,4 P-ON+10.5V

18-21

+1.8V REG.

2

3

P-ON+1.8V

5,6 P-ON+3.3V

9-12

+3.3V REG.

IC1301

Q1301

165

4

2

F1F2FL

EV+5V

45613 3

10

P-ON+5V

9

LIMIT

CURRENT

Q1204, Q1205

Q1201

SW+5V

SW+5V

Q1203

Q1202

16

14

7

6

IC1401

IC1004

ERROR

VOLTAGE DET

+1.2V REG.

P-ON+12.5V

2

CN1004 CN2008

13

COLD

BRIDGE

RECTIFIER

D1010 - D1013

SWITCHING

CONTROL

SWITCHING CONTROL

IC1002

INLET CBA

INLET CBA

(

261

LINE

FILTER

L1001

F

F1001

2A 250V

A V

HOT CIRCUIT. BE CAREFUL.

CN1001

AC120V

AC120V

AC120V

AC120V

11

22

11

22

AC CORD

AC CORD

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

AC1001

AC1001

CN1002

VDD

3

1-9-6

HOT

Q1001

POWER SUPPLY CBA

E5SE0BLP

Page 30

SCHEMATIC DIAGRAMS / CBA AND TEST POINTS

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark “#” in

the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly

different or amended since these drawings were

prepared.

2. All resistance values are indicated in ohms

(K = 10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in µF

(P = 10

5. All voltages are DC voltages unless otherwise

specified.

6. Electrical parts such as capacitors, connectors,

diodes, IC’s, transistors, resistors, switches, and

fuses are identified by four digits. The first two

digits are not shown for each component. In each

block of the diagram, there is a note such as

shown below to indicate these abbreviated two

digits.

3

, M = 106).

-6

µF).

1-10-1 BDN_SC

Page 31

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

r

THE FOLLOWING PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE

F

A V

SAME TYPE FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQES D'INCELE N'UTILISER

QUE DES FUSIBLE DE MÊME TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

This symbol means fast operating fuse.

Ce symbole represente un fusible a fusion rapide.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications for PLAY and STOP mode on the schematics are as shown below:

2

1

(Unit: Volt)

The same voltage for

both PLAY & STOP modes

5.0

3

5.0

(2.5)

Indicates that the voltage

is not consistent here.

PLAY mode

STOP mode

5. How to read converged lines

1-D3

Distinction Area

Line Number

(1 to 3 digits)

Examples:

1. "1-D3" means that line number "1" goes to the line numbe

"1" of the area "D3".

2. "1-B1" means that line number "1" goes to the line number

"1" of the area "B1".

3

AREA D3

2

1

ABCD

AREA B1

1-D3

1-B1

6. Test Point Information

: Indicates a test point with a jumper wire across a hole in the PCB.

: Used to indicate a test point with a component lead on foil side.

: Used to indicate a test point with no test pin.

: Used to indicate a test point with a test pin.

1-10-2 BDN_SC

Page 32

Audio 1 Schematic Diagram

1-10-3

E5SE0SCA1

Page 33

Audio 2 Schematic Diagram

1-10-4

E5SE0SCA2

Page 34

Video Schematic Diagram

1-10-5

E5SE0SCV

Page 35

Power Supply & Inlet Schematic Diagram

"Ce symbole reprèsente un fusible à fusion rapide."

CAUTION !

For continued protection against fire hazard,

replace only with the same type fuse.

ATTENTION : Pour une protection continue les risqes

d'Incele n'utiliser que des fusible de même type.

Risk of fire-replace fuse as marked.

"This symbol means fast operating fuse."

A V

F

CAUTION !

Fixed voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F1001) is blown , check to see that all components in the power supply

circuit are not defective before you connect the AC plug to the AC power supply.

Otherwise it may cause some components in the power supply circuit to fail.

NOTE:

The voltage for parts in hot circuit is measured using

hot GND as a common terminal.

1-10-6

E5SE0SCP

Page 36

Front-A & Front-B Schematic Diagram

1-10-7

E5SE0SCF

Page 37

SD Schematic Diagram

1-10-8

E5SE0SCSD

Page 38

RS232C Schematic Diagram

1-10-9

E5SE0SCRS

Page 39

BD Main 1 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-10

E5SE0SCBD1

Page 40

BD Main 2 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-11

E5SE0SCBD2

Page 41

BD Main 3 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-12

E5SE0SCBD3

Page 42

BD Main 4 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-13

E5SE0SCBD4

Page 43

BD Main 5 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-14

E5SE0SCBD5

Page 44

BD Main 6 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-15

E5SE0SCBD6

Page 45

BD Main 7 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-16

E5SE0SCBD7

Page 46

BD Main 8 Schematic Diagram

1-10-17

E5SE0SCBD8

Page 47

BD Main 9 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-18

E5SE0SCBD9

Page 48

BD Main 10 Schematic Diagram

1-10-19

E5SE0SCBD10

Page 49

BD Main 11 Schematic Diagram

1 NOTE:

The order of pins shown in this diagram is different from that of actual IC6001.

IC6001 is divided into nine and shown as IC6001 (1/9) ~ IC6001 (9/9) in this BD Main Schematic Diagram Section.

1-10-20

E5SE0SCBD11

Page 50

BD Main 12 Schematic Diagram

2 NOTE:

The order of pins shown in this diagram is different from that of actual IC8001.

IC8001 is divided into nine and shown as IC8001 (1/2) ~ IC8001 (2/2) in this BD Main Schematic Diagram Section.

1-10-21

E5SE0SCBD12

Page 51

BD Main 13 Schematic Diagram

2 NOTE:

The order of pins shown in this diagram is different from that of actual IC8001.

IC8001 is divided into nine and shown as IC8001 (1/2) ~ IC8001 (2/2) in this BD Main Schematic Diagram Section.

1-10-22

E5SE0SCBD13

Page 52

Audio CBA, Video CBA, Front-A CBA & Front-B CBA Top View

Front-A CBA

SW3003

SW3008

BE5SE0F0101

D3001

D3002

RED

J2141

JK2201

JK2200

LFCLS

FR

JK2202BSL

SubSR

BSR

JK2203

C2212

C2211

C2816

C2815

C2828

C2827

C2840

C2839

C2853

C2852

G

3 C

D3006

V-7

J3009

EV+3V3

C3007

2

003WS1003WS

C2204

IC2200

C2807

IC2601

3082C2082CC2804

IC2602

IC2603

IC2604

J2140

J2139

8312J7312J6312J

J3008

FL+

D3005

C2205

C2806

C2855

7582C6582C

J3007

REMOCON

C2822

C2821

C2834

C2847

C2846

J3003

LED5

J3011

EV+5V

C2208

C2207

C2810

C2809

C2833

D3004

J3010

EV+3V3

EV+5V

J3002

C2283

AUDIO+5V

J2135

AUDIO+5V

ZSW

ZFL3

J2132

J2133

AUDIO+5V

AUDIO+12V5

J2128

J2129

AUDIO+12V5

AUDIO+5V

J2126

J2127

SW3004

SW3006

SW3007

J3001

J2118

J2116

J2115

26

J2134

AUDIO+12V5

19

AUDIO+5V

AUDIO+12V5

J2130

J2131

J2106

J2105

J2104

J2103

J2102

J2101

BE5SE0F01013

J3012

DGND

AG

D2281

PON+12V5

JP2120

AG

D2282

R2326

R2622

D2625

RS3001

J2123

J2075

JP2074

Q2636

JP2125

SAFTY2

L2306

J2068

J2067

R2278

D2648

J2043

16

VID+5V

GNDA

J2073

J2072

J2071

R2279

R2327

J2061

J2059

L2607

L3001

J2121

L2202

ZFL3

ZSW

ZLFE

ZLFE

AUDIO+12V5

J2114

J2113

J2112

J2111

J2110

J2142

J2109

CN2007

J2108

J2107

1

JP2085

J2082

JP2081

J2080

JP2079

J3005

J3004

REMOCON-VCC

ZFL1

ZFR1

ZFR3

ZFL3

ZSW

GND

ZC

ZSSR

ZBS

GND

C2281

AG

AG

SW3005

AD-KEY2-B

J2124

C2285

JP2122

J2119

J2117

Q2280

D2280

C2282

EV+3V3

DGND

J3014

GNDA

Q2302

D2301

C2301

C2220

C3001

MAIN-PON

FAN-LOCK

EV+3V3

PWSW2

FAN-CONT1

GNDA

GNDA

IC2002

C2651

GNDA

SAFTY2

PWSW3

JP2011

J2078

J2065

J2064

J2063

232C-PW-CONT

J2062

JP2060

GNDA

JP2048

JP2046

J2044

GNDA

J2042

Front-B CBA

CN2008

GNDD

JP2070

GNDA

PWSW1

J2077

J2076

J2069

/MUTE2

/MUTE1

REMOTE

J2056

J2055

J2066

CEC+3V9

SYS-RESET

RDY

GNDA

J2047

GNDD

J2045

EV+3V3

GNDA

GNDA

/AMUTE

CN2003

J2041

1

+FL

F2-IN

J2052

J2053

GNDA

SD/HD

J2054

JP2030

D2624

C2016

GNDD

J2021

F1-IN

J2051

EV+5V

J2049

C2637

MODE

6

J2023

SW3113

SW3118

SW3117SW3116

SW3108

FL3001

1

1

J2083

J2040

EV+5V

J2039

EV+5V

CEC-OUT

232C-RXD

J2036

J2035

EV+3V3

J2022

D2640

GNDD

JP2033

232C-TXD

J2034

J2027

JP2028

JP2029

FL-RST

FL-CLK

FL-DAT

J2032

J2050

CEC-IN

J2037

X2000

C3006

J2038

GNDD

J2026

FL-STB

J2007

GNDD

IC2000

JP2004

SW3119

R2602

D2601

EV+5V

EV+3V3

REMOTE

VID+5V

GNDD

Q2602

J2008

J2003

SW3112

SW3106

CN2005

J2084

FL+

R2601

JP2020

Q2604

D2602

J2018

GNDA

JP2017

J2016

J2015

J2014

J2011

J2010

J2009

GNDD

SW2001

SAFTY2

SUB-TXD

SUB-RXD

J2002

JP2006

JP2012

SAFTY2

21

R2608

Q2601

J2013

J2012

SAFTY2

R2615

R2616

GNDD

J2081

27

D2603

R2617

R2618

F2-IN

J2019

CN2002

21

LINE3

LINE2

LINE1

DET

SAFTY1

JP2005

J2001

SW3111

SW3115SW3114

SW3104

CN3001

3

1

SW3110

SW3102

DIP

1

234

D2604

R2619

1

17

3 A

EV+3V3

BE5SE0F0101

V-7

AB

CVBS

J4006

JK4001

J4007

Y

JK4002

J4032

Cb

JK4003

Cr

JK4004

C4014

L4003

JK4000

COAXIAL

JP4001

SPDIF

JK4005

OPTICAL

1

J4008

Pr-D

J4029

C4021

J4015

C4013

Pb-D

PY-D

Pr-D

VG

JP4022

J4028

DIGITAL+5V

C4023

V-7

C4011

C4005

C4012

C4016

C4010

C4019

G

GND

J4030

J4021

C4301

D4301

SW3101

3 D

BE5SE0F0101

5

V-7

BE5SE0F0101

18

J4002

J4003

J4004

J4005

IC4000

J4018

C4006

D4282

L4001

L4306

C4008

L4000

1

SW3109

CN3101

3

SW3107

7

SW3103

SW3105

CN4002CN4000

16

Pb-D

PY-D

Pr-D

VG

J4011

J4013

J4014

J4010

J4012

GNDD

EV+5V

REMOTE

232C-TXD

232C-PW-CONT

GND

J4016

EV+3V3

J4017

J4031

J4020

JP4019

GNDD

J4023

EV+3V3

J4025

J4026

VIDEO+5V

J4027

EV+3V3

Q4000

R4326

R4327

Q4302

P

b

F

3 B

J4009

232C-RXD

GNDD

VIDEO+5VVIDEO+5V

CN4001

J4024

Q4002Q4001

G

1

CN4003

10

1

27

Audio CBA

1-10-23

Video CBA

BE5SE0F01013

Page 53

Audio CBA, Video CBA, Front-A CBA & Front-B CBA Bottom View

Q4002

Front-B CBA

R4406

C4000

1

R4405

CN4003

10

C4404

C4402

1

232C-RXD

R4037

VIDEO+5V

R4034

R4042

R4326

R4327

232C-TXD

GNDD

CN4001

27

EV+3V3

VIDEO+5V

R4031

Q4001

R4032

R4033

R4035

R4036

5

21

R4039

1

3

7

CN3101

CN4002

PY-D

Pr-D

Pb-D

VG

232C-PW-CONT

EV+5V

R4027

EV+3V3

R4057

GNDD

VIDEO+5V

R4028

R4029

R4040

R4030

16

REMOTE

R4011

R4012

R4026

R4041

SW3103

R4007

R4021

GNDD

D4282

R4023

R4025

Q4000

R4024

SW3109

R3120

SW3107

SW3105

5

R4401

C4401

C4403

R4002

R4004

R4006

R4020

C4004

GND

R4058

C4006

L4001

L4306

L4000

C4301

Q4302

C4003

C4015

18

R4003

R4005

R4017

R4019

C4007

R4402

R4001

C4008

D4301

R4403

R4000

C4002

SW3101

C4005

IC4000

C4016

L4002

C4010

C4009

C4017

R4043

R4328

SW3114

CN4000

R4016

R4015

R4049

R4329

R3121

R3113

DIP

PY-D

Pr-D

Pb-D

C4011

R4022

R4018

C4001

C4012

GND

R4056

C4019

C4024

C4020

R4038

R4045

R4010

R4047

C4014

VG

C4022

R3125

R4046

C4013

L4003

Q4003

R4048

SPDIF

1

C4023

G

R3115

R3114

1234

R4404

R4052

R4053

Pr-D

C4021

R4051

OPTICAL

SW3110

R4044

C4027

R4054

R4055

C4026

C4018

R4050

JK4005

C4025

SW3102

JK4001

CVBS

Y

JK4002

Q4004

JK4003

Cb

JK4004

Cr

COAXIAL

JK4000

CN3001

3

1

R3117

SW3111

C3009

R2036

R2051

R2052

R2049

JC2002

R2071

C2014

C2015

R2072

SW3115

SW3104

R3032

C3006

R3034

D2604

R2619

CN2002

R2039

R2045

27

D2603

R2618

1

LINE3

LINE2

LINE1

DET

SAFTY1

R2061

R2059

EV+3V3

R2004

SAFTY2

C3008

R2608

R2617

R2616

Q2604

F2-IN

21

SW2001

R2047

R3123

C3005

SAFTY1

R2615

R2037

R3118

R3119

R3031

R2607

Q2601

GNDA

GNDD

EV+5V

EV+3V3

GNDD

SAFTY2

SW3112

R2999

R2017

R2018

R2012

R2006

R3030

R2601

R2604

D2602

REMOTE

R2015

C2065

R2011

39

SUB-TXD

SUB-RXD

R2007

R2009

R2010

R3124

SW3106

CN2005

GNDD

R2605

R2020

27

IC2000

R2035

R2050

SW3119

R2602

Q2602

Q2603

Q2002

R2031

R2032

52

R2055

R2058

D2601

JC2001

R2033

26

1

R2057

VID+5V

GNDD

R2603

FL-STB

GNDD

R2034

R2001

R2063

R2073

C2007

R2056

R3116

GNDD

FL-RST

R2076

13

R2023

R2024

R3122

1

EV+5V

FL-DAT

Q2637

R2013

Q2638

R2016

R2014

R2025

SW3118

FL3001

232C-TXD

232C-RXD

FL-CLK

EV+3V3

R2026

CEC-OUT

Q2614

C2637

C2005

X2000

SW3113

SW3117 SW3116

SW3108

CEC-IN

R2075

C2008

MODE

D2640

1

EV+5V

EV+5V

R2000

R2002

R2074

F1-IN

R2665

R2003

R2666

C2006

GNDD

CN2003

F2-IN

GNDA

EV+3V3

C2016

+FL

SD/HD

D2624

C2009

R2029

CN2008

/MUTE1

R2053

1

/MUTE2

CEC+3V9

GNDD

GNDA

/AMUTE

R2027

GNDD

REMOTE

GNDA

GNDA

NRST

GNDA

PWSW1

PWSW2

FAN-CONT1

SYS-RESET

RDY

232C-PW-CONT

Q2302

D2301

C2301

R2661

C2626

C2651

PWSW3

R3035

R3036

SAFTY2

R2328

C2650

GNDA

C3002

MAIN-PON

FAN-LOCK

EV+3V3

C2220

C2649

GNDA

DGND

C3001

16

R2278

R2279

GNDA

GNDA

R2329

J3014

GNDA

SAFTY1

L2306

VID+5V

GNDA

IC2002

RS3001

R3027

L2607

R2623

R2625

D2282

R2326

Q2280

D2280

C2282

R2660

R2624

R2284

GNDA

D2648

Q2636

C3003

PON+12V5

R2327

D2281

GND

R2280

SW3005

C3004

R3028

ZFL1

ZFR1

ZFR3

ZFL3

ZSW

R2939

R2940

ZC

ZSSR

ZBS

R2973

R2957

R2971

R2974

R2958

R2972

R2977

R2980

R2979

R2621

C2627

D2625

Front-A CBA

R3025

R3023

R3024

AD-KEY2-B

R3029

AG

C2286

AG

R2224

R2221

R2230

R2206

R2229

R2220

R2223

R2918

R2911

R2919

R2916

R2917

R2943

R2944

R2945

R2281

R2622

C2281

EV+3V3

C2280

Q2629

R2912

Q2630

R2914

Q2633

R2915

R2913

AG

AG

Q3003

DGND

REMOCON-VCC

L3001

L3002

C2285

AUDIO+12V5

L2202

Q2201

Q2200

R2207

Q2623

1

Q2622

R2910

Q2626

ZFL3

ZSW

ZLFE

ZLFE

SW3004

SW3006

SW3007

C2284

AUDIO+5V

26

D3004

EV+5V

C2283

AUDIO+12V5

CN2007

AUDIO+12V5

LED5

AUDIO+5V

AUDIO+5V

ZFL3

AUDIO+12V5

AUDIO+5V

AUDIO+12V5

AUDIO+5V

Q3004

Q3005

R3009

EV+3V3

ZSW

R3008

R3007

EV+5V

C2208

R2217

C2207

C2810

R2941

C2809

C2822

R2992

C2821

C2834

R2994

C2833

C2847

R2993

C2846

D3005

REMOCON

1

R3033

C2209

R2208

C2823

R2904

R2907

C2836

C2835

R2906

R2909

C2849

C2848

R2908

FL+

R2209

C2210

C2205

R2903

C2812

C2806

C2811

R2920

R2905

C2824

C2855

C2857

C2856

C3007

R2211

C2206

R2922

C2805

R2947

C2820

R2960

C2832

R2982

C2845