Page 1

NO Repair Parts Availavility.

BLU-RAY DISC PLAYER

MODEL BD-SP309(B)/(S)

BD-SP309

Ref. No. 4289

042011

B CUP2BP

B CUA4BP

B CUR6CP

B CUT3AP

B CDC1AN

S CUP2BP

S CUR6CP

100~240V AC, 50/60Hz

120V AC, 60Hz

100~240V AC, 50/60Hz

RC-825DV

Black and Silver models

EU

AUSTRALIA/NEW ZEALAND

RUSSIA

HONG KONG/SINGAPORE/MALAYSIA/THAILAND/KOREA

US/CANADA

EU

RUSSIA

(CDC only)

RC-826DV

(except CEC)

Page 2

SERVICE PROCEDURE - 1

BD-SP309

This Player is classified as a CLASS 1 LASER product.

The CLASS 1 LASER PRODUCT label is located on

the rear cover.

This product contains a low power laser device. To

ensure continued safety do not remove any cover or

attempt to gain access to the inside of the product.

Refer all servicing to qualified personnel.

Precautions for using lead-free solder

Employing lead-free solder

• “All PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals.

The alphabetical character following LF shows the type of lead-free solder.

Example:

L F a

Indicates lead-free solder of tin, silver and copper.

Using lead-free wire solder

• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause damage or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 C, we recommend you to use a dedicated soldering

bit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering

• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 C which is higher than the conventional lead solder by 40 C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may be

peeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm the

steady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit as

required.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

Indicates lead-free solder of tin, silver and copper.

L F a/a

• Be careful when replacing parts with polarity indication on the PWB silk.

Page 3

SERVICE PROCEDURE - 2

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the

servicing guidelines which follow:

BD-SP309

WARNING

1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

CA U T I O N : F O R C O N T I N U E D PROTECTION

AGAINST A RISK OF FIRE REPLACE ONLY WITH

SAME TYPE FUSE.

F101, F102 (250V 2A)

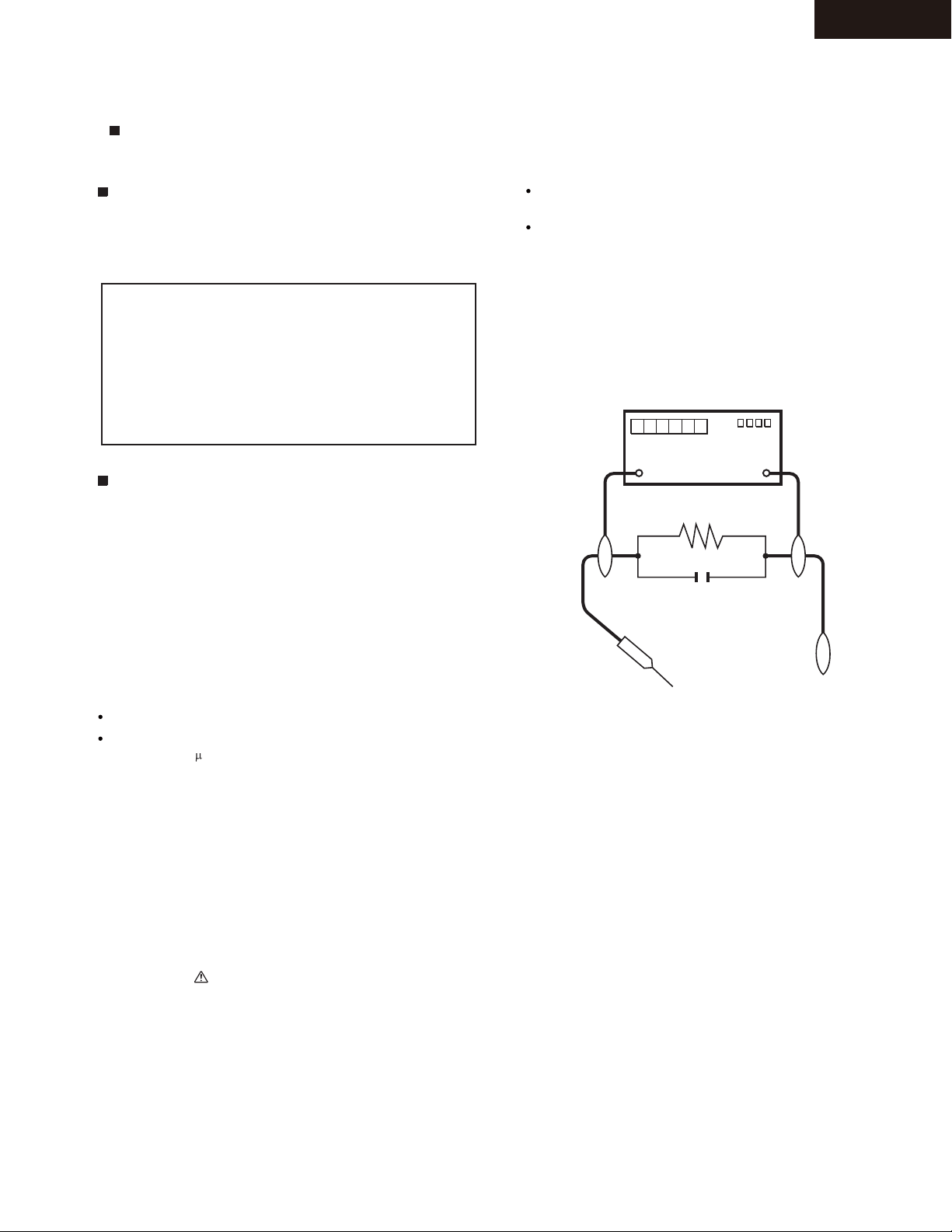

Use an AC voltmeter having with 5000 ohm per volt, or higher, sensitivity or measure the AC voltage drop across the resistor.

Connect the resistor connection to all exposed metal parts having a

return to the chassis (antenna, metal cabinet, screw heads, knobs

and control shafts, escutcheon, etc.) and measure the AC voltage

drop across the resistor.

All checks must be repeated with the AC cord plug connection

reversed. (If necessary, a nonpolarized adaptor plug must be used

only for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) or

more is excessive and indicates a potential shock hazard which

must be corrected before returning the monitor to the owner.

DVM

BEFORE RETURNING THE BD PLAYER (Fire &

Shock Hazard)

Before returning the BD player to the user, perform the following

safety checks:

3. Inspect all lead dress to make certain that leads are not pinched,

and check that hardware is not lodged between the chassis and

other metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,

insulation materials, cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor networks, mechanical

insulators, etc.

5. To be sure that no shock hazard exists, check for leakage current in

the following manner.

Plug the AC cord directly into a 230 volt AC outlet.

Using two clip leads, connect a 1.5k ohm, 10 watt resistor paralleled by a 0.15 F capacitor in series with all exposed metal cabinet

parts and a known earth ground, such as electrical conduit or electrical ground connected to an earth ground.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

TO EXPOSED

METAL PARTS

AC SCALE

1.5k ohm

10W

0.15µF

TEST PROBE

CONNECT TO

KNOWN EARTH

GROUND

SAFETY NOTICE

Many electrical and mechanical parts in BD player have special safety

-related characteristics.

These characteristics are often not evident from visual inspection, nor

can protection afforded by them be necessarily increased by using

replacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics are

identified in this manual; electrical components having such features

are identified by " " and shaded areas in the Replacement Parts List

and Schematic Diagrams.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

For continued protection, replacement parts must be identical to those

used in the original circuit.

The use of a substitute replacement parts which do not have the same

safety characteristics as the factory recommended replacement parts

shown in this service manual, may create shock, fire or other hazards.

IMPORTANT SERVICE NOTICE

1. When replacing the main PWB, update its software using a CD or USB memory.

2. The IC2501, IC7201, IC8501 and IC8502 have the software already written and cannot be replaced by new ones.

3. The IC7801-4 (DDR) are of BGA (Ball Grid Array) type and can only be replaced using a specific device.

Page 4

BD-SP309

UPGRADE FIRMWARE

Consult with your Services Company as we cannot provide the upgrading software.

1. Procedure with a CD

1. Write the updated software on a CD to prepare the version-upgrading CD.

2. Connect the set to the monitor with an HDMI cable. (Keep the HDMI cable connected until the version-upgrading has been comple ted.)

3. Using the “POWER” key (on the set itself or on the remote controller), turn on the power.

* Do not turn on the power with the “EJECT” key.

4. Press the “EJECT” key to open the tray. Place the upgrading CD on the tray and press the “EJECT” key again to close the tray.

5. The CD is opened and the power turns off itself.

6. The power turns on itself and the upgrading gets started.

LCD display: V-UP blinking V-UP kept on

Mode display: Blue LED blinking Blue LED kept on

Monitor screen: Upgrading progress displayed

7. When the software has been 100% overwritten, the tray opens itself and the power turns off itself.

8. Take the CD out of the tray and press the “POWER” key to turn on the power again.

9. When the wallpaper shows up, hold down the “POWER” key to do the resetting. (Keep the “POWER” key depressed until the RESET message

appears on the LCD. (About 10 seconds))

10.Press the “POWER” key again to turn on the power.

11.When the wallpaper shows up again, move from [Settings] to [Version] to make sure the software is upgraded.

12.When the upgrading has been successfully made, close the [Version] confirm screen and turn off the power. If it has failed, take the procedure

over again from Step 3 above.

2. Procedure with a USB memory

1. Write the updated software on a USB memory to prepare the version-upgrading USB memory.

2. Connect the set to the monitor with an HDMI cable. (Keep the HDMI cable connected until the version-upgrading has been comple ted.)

3. Using the “POWER” key (on the set itself or on the remote controller), turn on the power.

* Do not turn on the power with the “EJECT” key.

4. Insert the upgrading USB memory into the USB port.

5. When the USB memory has been recognized (the “x” mark on the USB icon disappears and the USB recognition on-screen display appears),

move from [Settings], [Software Update Settings], [Manual Update] to [USB Memory], and then press the “ENTER” or “ ” key.

6. Press “OK” on the USB recognition confirm screen.

7. The power turns on itself and the upgrading gets started.

LCD display: V-UP blinking V-UP kept on

Mode display: Blue LED blinking Blue LED kept on

Monitor screen: Upgrading progress displayed

8. When the software has been 100% overwritten, the power turns off itself.

9. Draw the USB memory out of the USB port and press the “POWER” key to turn on the power again.

10.When the wallpaper shows up, hold down the “POWER” key to do the resetting. (Keep the “POWER” key depressed until the RESET message

appears on the LCD. (About 10 seconds))

11.Press the “POWER” key again to turn on the power.

12.When the wallpaper shows up again, move from [Settings] to [Version] to make sure the software is upgraded.

13.When the upgrading has been successfully made, close the [Version] confirm screen and turn off the power. If it has failed, take the procedure

over again from Step 3 above.

Page 5

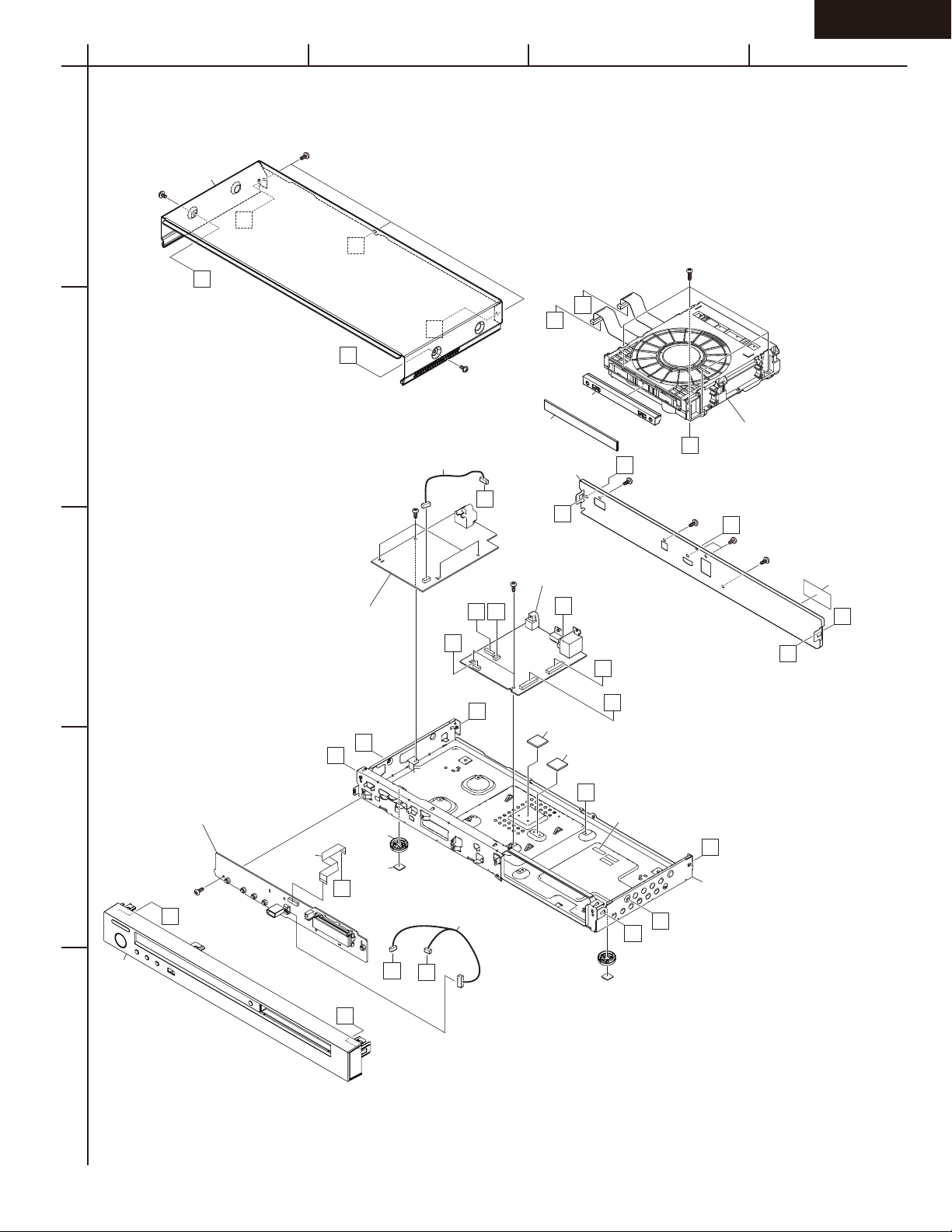

EXPLODED VIEW

A

1

2

3

4

5

B C D

BD-SP309

A010

A

C

B

K

J

A008

A013

D

U001

MAIN Unit

H

A007

M

A

C

U002

POWER Unit

A

A001

L

F

G

Z001

BD DRIVE Unit

B

A014

Except

US, EU.

A

L

K

D

J

A005

M

A012

x 3 pcs.

D

A012

U003

DISPLAYUnit

A003

D

C

E

A016

A015

F

A004

A006

E

H

E

A002

G

C

E

Page 6

BD-SP309

A

SCHEMATIC DIAGRAMS - 1

BLOCK DIAGRAM (MAIN)

1

2

B C D E F G H

3

4

5

Page 7

BD-SP309

A

SCHEMATIC DIAGRAMS - 2

MAIN1

3AMME

3FP

1

TO POWER

AT_5V

MAIN_P-CON

D_3.3V

D_GND

A_GND

D_1.8V

D_1.1V

DRIVE_3.3V

CN7203

N0058CE

LED_1

LED_0

TESTMODE0

XFRWR_ENABLE

GND

3.3V

U_TXD1

2

3

FE_UART

FE_Serial DAC

FE_JTAG

NRSTB/EJTRSTB

BKTGIOB/EJDINT

SDA1SO

SDA2SO

SDAENZ

SDACLK

SVMON

VREF

NDO/EJTDO

NDI/EJTDI

NCLK/EJTCK

NMOD/EJTMS

FE_OEIC_SW1

FE_OEIC_SW2

FE_OPIC_TSC

FE_SEN_LD

FE_LDG_SW

FE_LD_PDOUT

FE_I2C_SCL

FE_I2C_SDA

FE_EEP_WP

N0058CE

GND

3.3V

FE_EJ_SW

FE_F1DRV

FE_F2DRV

FE_SDRV1

FE_SDRV2

U_RXD1

CN7204

VCC

GND

RESET

BKTGIOB

FE_VREF

FE_LDEN

FE_SCLK

FE_SDIO

FE_E1

FE_G1

FE_F1

FE_H1

FE_RFN

FE_RFP

FE_A1

FE_B1

FE_C1

FE_D1

FE_CL1

FE_CL2

FE_FG

FE_MDRV

FE_CTL1

FE_CTL2

FE_TDRV

FE_LDIN

4

N0060CE

N-Wire/JTAG0

NDO/EJTDO

NDI/EJTDI

NCLK/EJTCK

NMOD/EJTMS

NRSTB/EJTRSTB

VCC

GND

RESET

BKTGIOB/EJDINT

BKTGIOB

5

CN7202

DRIVE_3.3V

8

7

6

5

4

3

2

1

1

2

3

4

5

6

7

8

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

6

7

8

9

10

1JI

TL7485

TL7486

TL7488

TL7489

TL7490

TL7491

TL7492

TL7493

CN7205

N0060CE

R7357

TL7494

TL7495

TL7496

FE_LDEN

FE_OEIC_SW1

FE_OEIC_SW2

FE_OPIC_TSC

FE_SCLK

FE_SDIO

FE_SEN_LD

FE_EJ_SW

FE_LDG_SW

FE_LD_PDOUT

FE_E1

FE_G1

FE_F1

FE_H1

FE_RFN

FE_RFP

FE_A1

FE_B1

FE_C1

FE_D1

FE_I2C_SCL

FE_I2C_SDA

FE_EEP_WP

FE_CL1

FE_CL2

FE_F1DRV

FE_F2DRV

FE_FG

FE_MDRV

FE_CTL1

FE_CTL2

FE_TDRV

FE_SDRV1

FE_SDRV2

FE_LDIN

BKTGIOB

R7202

47K

EJTDO

EJTDI

EJTCK

EJTMS

EJTRST

R72031KR7201

1JI

R7204

BKTGIOB

D_3.3V

R7341

10K

R7342

10K

R7345

R7343

100

10K

R7346

100

R7344

10K

R7347

100

R7348

100

R7349

100

R7350

100

FE_DDO

R7353 47K

R7354

FE_DDI

47K

R7355

FE_DCK

47K

R7356

FE_DMS

47K

47K

FE_DRST

FE_VREF

FB7201

A021WJ

MainCPU(EJTAG)

SubCPU(EJTAG)

SubCPU

(EJTAGmulti mode)

AudioDSP0

AudioDSP0

AudioDSP1

MainCPU SubCPU

(EJTAGmulti mode)

Normal(JTAG)

PWB

R7206

47K

R7207

10K

R7208

10K

R7209

10K

R7210

10K

PWB

10K

R7213

47K

0

B C D E F G H

2SA1530AR

L7201

Q7203

Q7202

R7247

RT1N241C

10K

R7246

1K

AT_5V

MAIN_P-CON

D_GND

D_1.1V

FE_LED1

FE_LED0

FE_TESTMODE0

FE_TESTMODE1

FE_TXDA

FE_RXDA

F7201

0056TA

C7348

C7347

1000P

FE_SDA1SO

FE_SDA2SO

FE_SDAEN

FE_SDACLK

FE_SVMON

R7358

3.3K

CY

R7228

0

3 4

TMODE 2

H

L

L

LH

L

AudioCPU

AudioDSP1

H H

L L

H H

L

H H H

L L L

L

H

L

H H

R7221

47K

R7222

47K

R7223

47K

R7224

47K

R7225

47K

R7226

47K

R7227

47K

VCXO_PWM

X7202

UAA089WJQZ

C7350

1000P

4

3

C7351

33P

220u

6.3V

RT1N441C

TL7202

TL7210

1 2

C7349

1u

Q7204

SDCLK

SDCMD

SDDAT0

SDDAT1

SDDAT2

SDDAT3

SDCD

SDWP

SDMPOWER

Pmodel

4.7K

4.7K

R7351

R7352

FE_TESTMODE1

FE_SDAEN

FE_OEIC_SW1

FE_CL2

FE_CTL2

FE_SEN_LD

FE_LDEN

FE_OEIC_SW2

FE_CTL1

FE_SCLK

FE_SDIO

FE_EEP_WP

FE_SDACLK

FE_SDA2SO

FE_SDA1SO

FE_LED0

FE_LED1

FE_TESTMODE0

FE_DDO

FE_DDI

FE_SVMON

FE_DMS

FE_DCK

FE_DRST

FE_TXDA

FE_RXDA

TL7211

R7235

0

TL7502

TL7503

FB7206

A018WJ

FB7205

FB7203

FB7202

A018WJ

A018WJ

A018WJ

10u

C7201

FE_OPIC_TSC

FE_RFP

FE_RFN

C7346

0.1u

TL7212

TL7213

TL7228

TL7229

S0CKOUT

S0DOUT

S0DIN

FE_LD_PDOUT

FE_LDIN

TL7231

AOHLRCK

AOHMCK

AOHBCK

AVDD33

AVDD33

DAOUT0

C7210

C7207

8P

8P

X7201

SCA169WJ

48MHz

0

R7236

22

PWB

XO/CLK48IN

B1

C1

D1

AOHBD1

E1

AOHBD3

P53

F1

P55

G1

PSIO

H1

P51

TL7501

J1

P52

K1

PB6

L1

PA6

TL7222

M1

SDCS1Z

N1

PA2

C7204

0.01u

P1

REQ

R1

R7237

6.2K

F

TL7224

D1

T1

FE_D1

B1

U1

FE_B1

V1

C7345

0.1u

RFN

W1

RFN2

R7241

Y1

0

CAD

AA1

C7205

0.1u

FPDVINN

CBC

C7202

AB1

0.1u

TL7230

TL7250

DAOUT2

CBHLPP

AC1

TL7498

C7203

0.01u

AD1

FE_F2DRV

SDRV1

AE1

FE_SDRV1

R7242

100

C7208

33P

PWB

R7243

330

R7252

R7258

3.3K

A4

A3XIA2

USBPVSS

R7253

10K

B2

VODY5

C2

AOHBD2

D2

E2

F2

P54

G2

P56

H2

PSI2

J2

PB5

K2

PB7

L2

PC1

M2

PA1

N2

SDIO

C7206

1u

SDA2

P2

AGND

R2

A1

T2

FE_A1

C1

U2

FE_C1

H1

V2

FE_H1

RFP

W2

RFP2

Y2

CWAGC

AA2

TL7249

AB2

AC2

FDRV

AD2

FE_F1DRV

SDRV2

AE2

FE_SDRV2

RSTSWB

AF2

B4

B3

CLK27IN

CLKSEL

ET_RXD1

C3

C4

VODY9

VODC6

D3

D4

VODE

VODY6

E3

E4

VODC5

VODC9

F3

F4

VOCLK

VOVSB

G3

G4

AOHBD0

P57

H3

H4

P50

PSI1

J3

J4

PB4

PA0

TL7258

K3

K4

PC2

PA5

L3

L4

PB2

SDCS0Z

M3

M4

PB3

PA7

N3

N4

PA3

SDCK

PA4

SCL2

P3

P4

FE_I2C_SDA

FE_CL1

FE_I2C_SCL

ADIN0

RFTST4

R3

R4

TL7263

TL7497

C7212

0.022u

CAGC2

AVDD33

T3

T4

TL7279

REF16

RFTST3

U3

U4

TL7280

TL7264

C7216

AGND

E1

V3

V4

FE_E1

F1

W3

W4

FE_G1

FE_F1

R7248

AGND

AGND

Y3

Y4

0

C7209

1u

TL7248

FPDVINP

RFTST1

AA3

AA4

TL7267

FPDVINP2

RLD3

AB3

AB4

R7249

TL7268

0

R7255

0

CBHWBL

TDRV

AC3

AC4

TL7284

FE_TDRV

AVDD33

MDRV

C7211

AD4

AD3

0.01u

C7213

FE_MDRV

1u

AGND

EJTMS

AE3

AE4

EJTMS

EJTRST

EJTCK

AF3

AF4

EJTRST

D_1.8V

C7219

220u

6.3V

AAP

CY

1

FB7215

C7254

0.1u

C7261

0.1u

C7257

0.1u

C7258

10u

C7263

0.1u

C7253

0.01u

C7264

NCLE NRBB0

NCSB1

NCSB0 NDATA0

C7271

0.1u

D1ADD[0-15]

D1DQ[0-31]

0

R7214

D_3.3V

C7269

HAVSS

HAVDD11

HAVDD11

HDVSS

HDVDD33

HDVDD33

C7256

0.1u

PLSVGND

PLSVVDD

PLSCVDD

VDD11

VDD11

VDD11

VDD11

100u

6.3V

APF

VDD33

NDATA6

NDATA6

NDATA5

NDATA5

NRBB1

NRBB1

NRBB0

NDATA4

NDATA4

NDATA0

FB7219

A018WJ

C7290

C7278

0.1u

C7280

FB7218

GND

GND

C7279

0.1u

CYB

GND

GND

C7277

1u

F

D0CKE

D0CLK

PWB

C7281

4.7u

0.01u

A018WJ

PGND1

0.1u

C7276

D0BA1

D0BA2

D0BA2

D0CKE

A13

HTXCN

B13

HTXCP

C13

HAVDD33

R7271

10K

F

D13

HAVDD33

E13

HDSDA

F13

HDSCL

G13

HDVDD11

C7282

0.1u

H13

HDVDD11

IC7201

IXD094WJQZ

K13

GND

L13

GND

C7285

0.01u

M13

VDD11

N13

GND

GND

P13

C7286

0.01u

VDD11

R13

PLSYVDD

T13

C7287

0.01u

CYB

PLSYGND

U13

MVDD18

W13

D1DQ6

Y13

D1DQ[6]

D1DQ1

AA13

D1DQ[1] D1DQ[3]

D1DQ4

AB13

D1DM1

D1DQ[4]

D1DQ14

AC13

D1DQ[14]

D1DQ12

AD13

D1DQ[12] D1DQ[11]

D1DQS1

AE13

D1DQS1

D1DQS1B

AF13

D1DQS1B

D0BA0

D0DQS3B

D0DQS2B

D0DQS1B

D0BA0

D0BA1

D0DQS2B

D0DQS3B

D0DQS1B

4.7u

A14

VDD33

B14

GND

C14

HHPD

D14

AIBCK

DIR_BCLK

E14

AILRCK

DIR_LRCLK

R7272

F14

VID11

G14

VDD33

H14

GND

K14

VDD11

L14

VDD11

M14

VDD11

N14

GND

GND

P14

VDD11

R14

MGND11

T14

MVDD11

U14

GND

W14

D1DM0

Y14

D1DQ3

AA14

D1DM1

AB14

D1DQ9

AC14

D1DQ[9]

D1DQ11

AD14

GND

AE14

GND

AF14

D0DQS3

D0DQS0B

D0DQS3

D0DQS0B

A15

VID15

GPIO12

B15

GPIO12

C15

AMCKOUT

DIR_MCLK

R7273

47K

D15

AIBD

DIR_DATA

E15

VID14

47K

F15

VID7

G15

GND

H15

GND

K15

PLAUGND

L15

PLAUVDD

M15

VDD11

C7295

N15

GND

GND

P15

VDD11

R15

MGND11

T15

C7294

0.1u

MVDD11

U15

MVDD18

W15

GND

Y15

D1DM0

D1DQ0

AA15

D1DQ[0]

D1DQ2

AB15

D1DQ[2] D1DQ[5]

D1DQ8

AC15

D1DQ[8]

D1DQ10

AD15

D1DQ[10] D1DQ[13]

D1DQS0

AE15

D1DQS0

D1DQS0B

AF15

D0DM3

D0DQS0

D0DQS2

D0DQS1

D0DQS0

D0DQS1

D0DQS2

D0DM3

A17

A16

VID13

VIFLD

B17

B16

VID12

VID6

C17

C16

VIHSB

VID5

D_1.1V

D17

D16

VICLK

VID10

47K

R7274

DIR_LRCLK

E17

E16

VIVSB

VID3

EMMA_DATA2

F17

F16

VID9

VID1

G17

G16

VDD33

GND

C7299

0.1u

H17

H16

GND

GND

C7306

100u

6.3V

FB7222

FB7223

A018WJ

C7300

0.01u

K17

K16

MIPSGND

VDD11

C7309

C7301

1u

0.01u

D_GND

L17

L16

VDD11

MIPSVDD

C7310

1u

M17

M16

GND

GND

C7303

0.1u

10u

CKZ

N16

N17

MGND11

MVDD11

MVDD11

MGND11

P16

P17

C7307

0.1u

GND

GND

C7308

0.01u

R17

R16

C7311

0.1u

VDD11

VDD11

T16

T17

C7305

C7297

0.01u

0.01u

VDD11

VDD11

U16

U17

MVDD18

GND

W16

W17

C7298

0.1u

D1CKERSTB

GND

D1RQ1

Y16

Y17

33K

51

F

R7275

R7280

D1DQ7

D1ADD14

AA16

AA17

D1DQ[7] D1DQ[20] D1DQ[17]

D1ADD[14] D1ADD[10]

D1DQ5

D1ADD1

AB16

AB17

D1ADD[1]

D1ADD[4]

D1DQ15

D1ADD7

AC16

AC17

D1ADD[7]

D1DQ13

AD16

D1ADD[12] D1ADD[5] D1ADD[13]

GND

AE16

D1CLK

GND

AF16

D0DM0

D0WEB

D0CSB

D0RASB

D0CASB

D0CSB

D0DM1

D0DM0

D0WEB

D0CASB

D0RASB

D1ADD12

AD17

D1CLK

AE17

D1CLKB

AF17

D1ADD[8] D1ADD[11]

D1CLKB

D1DQ[15]

D1DQS0B

D0DM1

D0DM2

D0DM2

AO1BCK

A18

A19

A20

AGNDRGB

VID4

AO1BCK

AO1LRCK

B18

VID8

C18

VID2

D18

VID0

E18

AO0BD2

F18

AO1MCK

G18

VDD33

H18

GND

A018WJ

GND

W18

Y18

D1ADD10

AA18

D1ADD4

AB18

D1ADD8

AC18

D1ADD5

AD18

GND

AE18

GND

AF18

B20

B19

AVDDRGB

AO1LRCK

SPDIF

C20

C19

AVDDRGB

ATX

D20

D19

AO0LRCK

AO0BD3

EMMA_LRCLK

EMMA_DATA3

E20

E19

AO0BCK

AO1BD

EMMA_BCLK

F20

F19

AO0BD0

AO0BD1

EMMA_DATA0

EMMA_DATA1

G20

G19

AO0MCK

GND

EMMA_MCLK

C7319

0.01u

10u

C7315

H20

H19

MVDD18

GND

D0DQ[16]

J20

J19

D0DQ16

GND

C7314

0.1u

K20

K19

GND

GND

D0VREF1

L20

L19

GND

D0VREF1

M20

M19

GND

MVDD18

27K

R7212

N20

N19

GND

D0CKERSTB

R7281

33K

MVDD18

GND

P19

P20

C7316

0.01u

GND

TMODE0

R20

R19

TMODE2

D0VREF0

T20

T19

D0VREF0

TMODE2

TMODE1

GND

U20

U19

GND

D1DQ1

V20

V19

D0DQ[1]

D1VREF1

GND

W19

W20

C7317

0.01u

D1DQ22

D1DM2

Y19

Y20

27K

D1DM2

R7211

D1CASB

D1DQ20

AA19

AA20

D1CASB

D1WEB

D1ODT

AB19

AB20

D1WEB

D1ODT

D1ADD11

D1BA2

AC20

AC19

D1BA2 D1CSB

D1ADD0

D1ADD13

AD19

AD20

D1ADD[0]

D1ADD3

D1ADD15

AE19

AE20

D1ADD[3]

D1ADD[15]

D1ADD9

D1ADD6

AF19

AF20

D1ADD[6] D1ADD[2]

D1ADD[9]

D1BA2

D1ODT

D1CLK

D1BA0

D1CKE

D1BA1

D1CLKB

D1DQS1B

D1DQS2B

D1DQS3B

D1DQS3B

D1BA2

D1BA1

D1CKE

D1DQS2B

D1CLKB

D1CLK

D1BA0

D1ODT

4.7u

A12

A11

HTXN0

HTXN1

B12

B11

HTXP0

HTXP1

C7265

22u

C12

C11

HEXTN

R7270

F

10K

D12

D11

HEXTP

C7266

0.01u

E12

E11

HDVSS

F12

F11

HDVSS

G12

G11

HDVSS

C7268

0.1u

H12

H11

HDVSS

FB7204

A018WJ

PGND1H

K11

K12

PLMVGND

L12

L11

PLMVVDD

M11

M12

GND

N12

N11

GND

P12

P11

GND

VDD11

R11

R12

T12

T11

GND

U11

U12

GND

D1VREF0

W11

W12

C7267

0.1u

D1VREF0

GND

Y12

Y11

GND

AA11

AA12

AB11

AB12

GND

AC11

AC12

AD11

AD12

MVDD18

AE11

AE12

MVDD18

AF11

AF12

R7269

R7266

1K

1K

F

D0CLK

D0ODT

D0VREF1

0

D0CLKB

D0VREF0

0

R7268

R7267

MEM0VREF

D0CLKB

D0ODT

C7243

FB7211

USB_DM2

USBDM2

USB_DP2

USBDP2

USBDGND

USBVDD33

USBDGND

ETMDIO

ET_TXEN

ETTXEN

VDD33

C7236

1u

UA0TXDB

UA0TXDB

UA0RXDB

S0CKOUT

S0CKOUT

SDDAT0

SDDAT0

SDMPOWER

SDMPOWER

SDCLK

SDCLK

A018WJ

A8

B8

C8

D8

E8

F8

GND

G8

H8

J8

GND

K8

GND

C7237

0.1u

L8

GND

M8

GND

N8

GND

P8

R8

GND

T8

GND

U8

GND

V8

W8

AA8

SDA0

AB8

SDA0 SCL0

SDWP

AC8

SDWP

AD8

AE8

AF8

VDD33

USBOCI2

USB_PPON2

USBPPON2

USB_PPON1

USBPPON1

VDD33

AGND11_WBAD1

S0DOUT

NDATA7

TO DDR2

FB7213

A018WJ

10u

C7239

1u

C7240

0.01u

A10

A9

HTXN2

B10

B9

GND

HTXP2

C9

C10

GND

HAVSS

USB_OCI1USB_OCI2

D10

D9

USBOCI1

SCL1

E10

E9

SCL1

SDA1

F10

F9

SDA1

G10

G9

VDD33

H10

H9

GND

GND

C7215

220u

6.3V

FB7212

AAP

1

CY

22u

K10

C7244

VDD11

L10

VDD11

M10

PLSCGND

N10

VDD11

C7251

0.01u

VDD11

P10

GND

R10

VDD11

T10

VDD11

C7247

U10

10u

AVDD11_WBAD

C7248

W9

W10

0.1u

GND

AGND11_WBAD2

Y9

Y10

NDATA1

AA9

AA10

NDATA1

S0DOUT

NDATA2

SCL0

AB10

AB9

NDATA2

NDATA3

AC10

AC9

NDATA3

NDATA7

NCLE

NREB

AD10

AD9

NREB

NCSB1

NWEB

AE9

AE10

NWEB

NALE

NCSB0

AF9

AF10

NALE

D0DQ[0-31]

D0ADD[0-15]

A018WJ

USBAVSS

ETREFCLK

C7221

FPDVINN2

USBRREF

ETRXD1

RFTSTIN2

FB7210

A018WJ

C7230

R7263

1.6K

0.01u

A5

C7222

0.1u

B5

C5

ET_CLK

D5

E5

VODY7

F5

VODC8

G5

VODC7

H5

VODY1

J5

VODC0

K5

VODC1

L5

VODC3

M5

VOHSB

N5

PB1

PC0

P5

FE_LDG_SW

ADIN1

R5

CEQ

T5

VREFIO

U5

TL7290

V5

RFTST2

W5

AVDD33

Y5

AA5

TL7293

DAOUT1

AB5

GPIO3

AC5

GPIO3

GPIO6

AD5

GPIO6

EJTDO

AE5

EJTDO

EJTDI

AF5

EJTDIEJTCK

47u

C7231

F

0.1u

C7232

0.01u

C7223

USB_DM1

A7

A6

USBAVDD

USBDM1

USB_DP1

B6

B7

USBDP1

USBDGND

C7

C6

GND

USBVDD33

ET_TXD0

D6

D7

ETTXD0

USBDGND

ET_TXD1

ET_RXER

E7

E6

ETTXD1

ETRXER

ET_RXD0

F7

F6

ETRXD0

VODY8

ET_MDC ET_MDIO

G7

G6

ETMDC

VODY0

ET_CRS

H7

H6

VODY2

ETCRSDV

J7

J6

GND

VODY3

K7

K6

VDD33

VODY4

L7

L6

VODC2

GND

M7

M6

VODC4

AGND11_RVAD2

TL7295

C7235

0.1u

N7

N6

FE_FG

FG

AGND11_RVAD1

AVDD11_RVAD

VDD33

PB0

P7

P6

FE_EJ_SW

AGND

GND

C7224

R7

R6

0.01u

C7226

C7238

1u

0.01u

C7228

4.7u

AVDD33

CAGC1

T7

T6

TL7297

AVDD33

AGND

U7

U6

C7225

C7233

1u

0.01u

AVDD33

RFTSTIN1

V7

V6

C7229

TL7298

1u

AGND

CREG

W7

W6

TL7299

RLD1Y8UA0RXDB

RLD2

Y7

Y6

1

0

37LT0037LT

GPIO0

S0DIN

AA6

AA7

GPIO0

S0DIN

SDDAT1

GPIO5

AB6

AB7

GPIO5

SDDAT1

GPIO1

SDCMD

AC6

AC7

GPIO1

SDCMD

GPIO7

SDDAT3

AD6

AD7

GPIO7

SDDAT3

GPIO2

SDCD

AE6

AE7

GPIO2

SDCD

GPIO4

SDDAT2

AF6

AF7

SDDAT2

GPIO4

FB7208

TL7499TL7500

C7220

0.1u

TL7289

1u

TL7291

G1

TL7292

C7217

0.01u

1u

R7260

0

TL7283

C7218

0.01u

FB7225

A22

A21

VAR

AGNDRGB

B22

B21

VAB

AVDDRGB

C7330

R7283

0.1u

F

1.6K

PWB

C22

C21

VARSETRGB

AVDDRGB

C7328

0.1u

D22

D21

VACOMPRGB

AGNDRGB

PWB

C7329

0.1u

E22

E21

AGNDRGB

VACOMPYC

F21

F22

GND

DVDDRGB

D0DQ[21] D0DQ[24]

G21

G22

D0DQ21

VDD33

D0DM2

D0DQ[23]

H21

H22

D0DQ23

D0DM2

D0DQ[18]

D0DQ[19] D0DQ[25] D0DQ[28]

J22

J21

D0DQ19

D0DQ18

D0DQ[20]

D0DQ[17] D0DQ[30]

K21

K22

D0DQ17

D0DQ20

D0DQ[22]

D0ODT

L21

L22

D0DQ22

D0ODT

D0CASB

M22

M21

D0ADD10

DOCASB

D0ADD[10]

D0ADD[14] D0ADD[1] D0ADD[4]

N22

N21

D0ADD14

D0ADD1

D0ADD8

D0ADD7

P22

P21

D0ADD[8] D0ADD[5] D0ADD[3]

D0ADD[7]

D0ADD12

D0RQ1

R22

R21

51F

D0ADD[12]

R7282

D0DQ7

D0DQ5

T22

T21

D0DQ[5] D0DQ[15]

D0DQ[7]

D0DQ2

D0DQ0

U22

U21

D0DQ[0]

D0DQ[2] D0DQ[8] D0DQ[10]

D0DQ3

D0DM0

V22

V21

D0DM0

D0DQ6

MVDD18

W22

W21

C7325

0.1u

D0DQ[6]

MVDD18

VDD33

Y22

Y21

D1DQ[23]

D1DQ23

D1DQ17

AA22

AA21

D1DQ16

D1DQ19

AB21

AB22

D1DQ[19] D1DQ[16] D1DQ[21]

D1CSB

D1DQ18

AC21

AC22

D1DQ[18] D1DQ[30]

D1DQ28

D1RASB

AD21

AD22

D1RASB

D1DQ[28]

D1CKE

D1BA1

AE21

AE22

D1BA1 D1CKE

D1ADD2

D1BA0

AF21

AF22

D1BA0

D1DM3

D1DM0

D1DM2

D1DM1

D1DQS3

D1DQS0

D1DQS1

D1DQS2

D1DQS0B

D1DQS2

D1DQS1

D1DQS3

D1DM1

D1DM2

D1DQS1B

D1DQS0B

D1DM3

D1DQS0

A018WJ

A23

VAG

B23

AGNDYC

C23

VAREFRGB

C7331

0.1u

PWB

D23

VAREFYC

E23

AVDDYC

C7333

0.01u

D0DQ[31] D0DQ[29]

F23

D0DQ31

G23

D0DQ24

D0DQ[27]

H23

D0DQ27

J23

D0DQ25

K23

D0DQ30

D0RASB

L23

D0RASB

D0BA2 D0WEB D0CLKB

M23

D0BA2

N23

D0ADD4

D0ADD5

P23

D0ADD13

R23

D0ADD[13]

D0DQ15

T23

D0DQ8

U23

D0DQ9

V23

D]3[QD0D

D0DQ14

W23

D0DQ[14]

D0DQ4

Y23

D0DQ[4]

C7334

MVDD18

AA23

D1DQ21

AB23

D1DQ30

AC23

D1DQ25

AD23

D1DQ[25]

GND

AE23

GND

AF23

R7287

F

C7338

0.1u

D1CSB

D1WEB

D1RASB

D1CASB

D1VREF0

R7285

D1DM0

D1CSB

D1CASB

D1RASB

D1WEB

PWB

R7205

9[QD0

]

D1DQS3

1K

D1VREF1

0

150

R7288

1.6K

D0DQ[11]

0.01u

D1DM3

VARSETYC

1u

D1DQS3B

R7286

0

MEM1VREF

AGNDYC

AVDDYC

F

C7336

AGNDYC

D0DQ29

D0DQ26

D0DM3

D0DQ28

D0CKE

D0CSB

D0WEB

D0ADD0

D0ADD3

D0ADD11

D0DQ13

D0DQ10

D0DM1

D0DQ11

D0DQ12

MVDD18

AA24

D1DM3

AB24

D1DQ27

AC24

AD24

D1DQS3

AE24

AF24

10u

C7339

A24

TL7201

B24

VAY

C24

PWB

D24

E24

D0DQS2B

F24

D0DQ[26]

G24

D0DM3

H24

J24

D0CKE D0BA0

K24

D0CSB

L24

M24

D0ADD[0]

N24

P24

R24

T24

D0DQ[13]

U24

V24

D0DM1

W24

D0DQS1

Y24

D0DQ[12]

D1DQ[24] D1DQ[31]

D1DQ[26] D1DQ[29]

D1DQ[27]

GND

D1DQS2B D1DQS2

D1DQS3B

R7284

1K

F

A25

VAC

GPIO11

B26

B25

GPIO11

AVDDYC

GPIO9

DVDDYC

MVDD18

D0DQS2B

D0DQS3B

D0BA0

D0CLKB

D0ADD2

D0ADD9

D0DQS0

D0DQS1

TMODE4

D1DQ24

D1DQ26

D1DQS2B

C7332

D_GND

0.1u

GPIO9

GPIO10

C26

C25

GPIO10

GPIO8

D26

D25

GPIO8

0.01u

C7340

E26

E25

F25

G25

GND

H25

J25

GND

K25

L25

GND

M25

N25

GND

P25

R25

GND

T25

U25

GND

V25

W25

Y25

AA25

AB25

GND

AC25

AD25

GND

AE25

TEST

AF25

C7214

10u

MVDD18

D0DQS2

F26

D0DQS2

G26

GND

D0DQS3

D0DQS3B

H26

D0DQS3

J26

GND

D0BA1

K26

D0BA1

L26

GND

D0CLK

M26

D0CLK

N26

GND

D0ADD15

P26

D0ADD[2]

D0ADD[15]

D0ADD6

R26

D0ADD[9]D0ADD[11]

D0ADD[6]

GND

T26

D0DQS0B

U26

D0DQS0

D0DQS0B

GND

V26

D0DQS1B

W26

D0DQS1B

TMODE3

Y26

TMODE3

TMODE4

D1DQ31

AA26

D1DQ29

AB26

GND

AC26

D1DQS2

AD26

GND

AE26

0

R7216

PWB

F

0.1u

R7292

1.5K

C7343

R7291

1.5K

R7294

F

1K

F

R7293 0

R7295

0

R7296

F

1K

PWB

3.3K

R7217

3.3K

3.3K

R7215

R7219

PWB

TMODE2

TMODE3

TMODE4

1

2

3

N0060CE

GND

CN7206

D_3.3V

TMODE[2]4TMODE[3]5TMODE[4]

SW-Jigu

PWB

10uH

R7250

C7352

100u

6.3V

TP7202

GPIO3

TP7203

GPIO4

TP7204

GPIO5

GPIO9

TP7205

GPIO6

TP7206

GPIO7

GPIO12

GPIO0

GPIO1

GPIO2

GPIO8

TL7440

TL7441

TL7442

TL7443

R7302

2.2K

SDA1

SCL1

SDA0

SCL0

6

9

10

CEB

RSTSWB

BOOT_MODE[0]7BOOT_MODE[1]8BOOT_MODE[2]

100

C7353

0.1u

TL7435

TL7334

GPIO10

USB_DP1

USB_DM1

USB_DP2

USB_DM2

USB_OCI1

USB_OCI2

USB_PPON1

USB_PPON2

Secure_Boot

AO1MCK

AO1LRCK

AO1BCK

AO1BD

R7322

2.2K

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

GPIO8

GPIO9

GPIO10

GPIO11

GPIO12

ET_CLK

ET_MDIO

ET_MDC

ET_RXD1

ET_RXD0

ET_RXER

ET_TXEN

ET_TXD0

ET_TXD1

ET_CRS

R7304

10K

R7305

10K

R7327

22

R7328

22

R7329

22

TP7201

EMMA_DATA3

EMMA_DATA2

EMMA_DATA1

EMMA_DATA0

EMMA_LRCLK

EMMA_BCLK

EMMA_MCLK

SPDIF

DIR_DATA

DIR_LRCLK

DIR_BCLK

DIR_MCLK

NDATA0

NDATA1

NDATA2

NDATA3

NDATA4

NDATA5

NDATA6

NDATA7

NCSB0

NCSB1

NREB

NWEB

NRBB0

NRBB1

NALE

NCLE

TL7204

TL7209

TL7214

UA1RXDB

UA1TXDB

FL_BUSY

notuse

notuse

notuse

notuse

notuse

notuse

notuse

ET_RESET

E2P_WP

notuse

R7331

22

R7332

22

UA0TXDB

R7333

22

UA0RXDB

PWB

PWB

2.2K

2.2K

R7244

R7218

R7239

FRONT_RXD

FRONT_TXD

FL_BUSY

TL7206

DRIVE_SW_AB TO F_uCON

F_MUTE

R7323

R7303

2.2K

2.2K

R7338

22

R7339

22

R7340

0

R7306

NAN_DATA0

0

R7307

NAN_DATA1

0

R7308

NAN_DATA2

0

R7309

NAN_DATA3

0

R7310

NAN_DATA4

0

R7311

NAN_DATA5

0

R7312

NAN_DATA6

0

R7313

NAN_DATA7

0

R7314

0

R7315

CY

0

R7316

0

R7317

0

R7318

0

R7319

0

R7320

0

R7321

0

NAN_CSB0

NAN_CSB1

NAN_REB

NAN_WEB

NAN_RBB0

NAN_ALE

NAN_CLE

47K

ET_RESET

TL7340

TL7341

TL7342

TL7343

R7245

COLD_RST#

F_MUTE

123

TL7471

TL7472

TL7473

TL7474

TL7475

TL7476

TL7477

TL7479

TL7480

TL7481

TL7482

TL7483

TL7484

J7201

TOTX177L

TO HDMI

HDMI_SDA

HDMI_SCL

HDMI_HPD

HDMI_TXCP

HDMI_TXCN

HDMI_TX0P

HDMI_TX0N

HDMI_TX1P

HDMI_TX1N

HDMI_TX2P

HDMI_TX2N

D_GND

TO ETHER

ET_CLK

ET_MDIO

ET_MDC

ET_RXD1

ET_RXD0

ET_RXER

ET_TXEN

ET_TXD0

ET_TXD1

ET_CRS

ET_RESET

TO USB

USB_DP1

USB_DM1

USB_DP2

USB_DM2

USB_OCI1

USB_OCI2

USB_PPON1

USB_PPON2

P7203

N0054CE

UATXD0

1

UARXD0

2

GND

3

D_3.3V

4

2.2K

TO F_uCON

FRONT_RXD

FRONT_TXD

FL_BUSY

COLD_RST#

VCXO_PWM

Secure_Boot

F_MUTE

TO NAND_EEPROM

I2CSDA0

I2CSDA0

I2CSCL0

I2CSCL0

E2P_WP0GPIO11

E2P_WP0

TO NAND_EEPROM

NAN_DATA0

NAN_DATA1

NAN_DATA2

NAN_DATA3

NAN_DATA4

NAN_DATA5

NAN_DATA6

NAN_DATA7

NAN_CSB0

NAN_CSB1

NAN_REB

NAN_WEB

NAN_RBB0

NAN_ALE

NAN_CLE

NOT US E

Page 8

BD-SP309

A

SCHEMATIC DIAGRAMS - 3

MAIN2

1

2

3

B C D E F G H

TO POWER

TO EMMA3PF3

D0ADD[0-15]

D0DQ[0-31]

MEM0VREF

D_1.8V

D_GND

FL7804

NA119WJ

R7810

0

D0CLKB

D0ODT

D0CKE

D0BA2

D0BA1

D0BA0

D0CASB

D0RASB

D0WEB

D0CSB

D0ADD[14]

D0ADD[2]

D0ADD[0]

D0ADD[4]

D0ADD[15]

D0ADD[12]

D0ADD[3]

D0ADD[5]

D0ADD[8]

D0ADD[6]

D0ADD[13]

D0ADD[11]

D0ADD[7]

D0ADD[9]

D0ADD[10]

D0ADD[1]

0

R7801

D0ODT

D0CLKB

D0CLK

D0CKE

D0BA1

D0BA0

D0DQS3B

D0DQS2B

D0DQS1B

D0DQS0B

D0DQS3

D0DQS2

D0DQS1

D0DQS0

D0DM3

D0DM2

D0DM1

D0DM0

D0WEB

D0CASB

D0RASB

D0BA2

D0CSB

MEM0_DCKB

R7811

0

R7812

R7813

R7814

R7815

R7816

R7817

R7818

R7819

R7820

R7802

R7803

R7804

R7805

R7806

R7807

R7808

R7809

R7842

R7843

R7844

R7845

R7846

R7847

R7848

R7849

MEM0_DCKD0CLK

0

MEM0_DODT

0

MEM0_DCKE

0

MEM0_DBA2

0

MEM0_DBA1

0

MEM0_DBA0

0

MEM0_DCASB

0

MEM0_DRASB

0

MEM0_DWEB

0

MEM0_DCSB

0

MEM0_DA[14]

0

MEM0_DA[2]

0

MEM0_DA[0]

0

MEM0_DA[4]

0

MEM0_DA[15]

0

MEM0_DA[12]

0

MEM0_DA[3]

0

MEM0_DA[5]

0

MEM0_DA[8]

0

MEM0_DA[6]

0

MEM0_DA[13]

0

MEM0_DA[11]

0

MEM0_DA[7]

0

MEM0_DA[9]

0

MEM0_DA[10]

0

MEM0_DA[1]

D0DM3

D0DM2

R7832

MEM0_DCKE

MEM0_DA[13]

300

PWB

TL7801

D0DM1

D0DM0

D0DQS3B

D0DQS3

D0DQS2B

D0DQS2

D0DQS1B

D0DQS1

D0DQS0B

D0DQS0

D0DQ[30]

D0DQ[25]

D0DQ[27]

D0DQ[28]

D0DQ[29]

D0DQ[26]

D0DQ[24]

D0DQ[31]

D0DQ[22]

D0DQ[17]

D0DQ[19]

D0DQ[20]

D0DQ[21]

D0DQ[18]

D0DQ[16]

D0DQ[23]

D0DQ[14]

D0DQ[9]

D0DQ[11]

D0DQ[12]

D0DQ[13]

D0DQ[10]

D0DQ[8]

D0DQ[15]

D0DQ[6]

D0DQ[1]

D0DQ[3]

D0DQ[4]

D0DQ[5]

D0DQ[2]

D0DQ[0]

D0DQ[7]

FL7805

NA119WJ

C7802

10u

FL7806

NA119WJ

PWB

C7813

0.1u

A1

B1

D0DQ[9]

C7818

0.01u

C1

D1

D0DQ[11]

C7819

0.01u

E1

F1

D0DQ[3]

G1

D0DQ[1]

H1

J1

C7820

0.1u

MEM0_DBA2

L1

N1

C7822

0.1u

PWB

R1 R2 R3

PWB

PWB

D0DQ[10]

D0DQ[0]

MEM0_DBA0

MEM0_DA[10]

MEM0_DA[3]

MEM0_DA[7]

MEM0_DA[12]

NC

A2

B2

C2

D2

NC

E2

F2

G2

H2

J2

C7804

0.1u

MEM0_DCKE

K2

L2

M2

N2

P2 P3

A3

B3

D0DM1

C3

D3

D0DQ[8]

E3

F3

D0DM0

PWB

C7824

0.01u

G3

D0DQ[4]

H3

J3

MEM0_DWEB

K3

MEM0_DBA1

L3

MEM0_DA[1]

M3

MEM0_DA[5]

N3

MEM0_DA[9]

NC

DDR2MEMORY

IC7802

IXD233WJQZ

C7806

0.1u

C7826

0.01u

MEM0_DRASB

MEM0_DCASB

MEM0_DA[2]

MEM0_DA[6]

MEM0_DA[11]

A7

D0DQS1

PWB

C7

D7

D0DQ[13]

E7

F7

D0DQS0

G7

D0DQ[7]

H7

J7

K7

L7

M7

N7

P7 P8

R7NCR8

D0DQS1B

D0DQ[15]

D0DQS0B

PWB

D0DQ[2]

MEM0_DCK

R7837

300

MEM0_DCKB

MEM0_DCSB

MEM0_DA[0]

MEM0_DA[4]

MEM0_DA[8]

PWB

C7832

0.1u

A9A8

B9

B8B7

D0DQ[12]

C9

C8

D9

D8

D0DQ[14]

C7830

PWB

0.01u

E9

E8

F9

F8

D0DQ[6]

G8

G9

D0DQ[5]

H9

H8

J9

J8

PWB

C7831

0.01u

CZ

MEM0_DODT

K9

K8

L8

M8

M9

C7834

N8

0.1u

P9

NC

FL7810

NA119WJ

FL7811

NA119WJ

FL7812

C7808

NA119WJ

10u

PWB

PWB

C7840

0.1u

A1

B1

D0DQ[28]

C7841

0.01u

PWB

C1

D1

D0DQ[30]

C7842

0.01u

PWB

E1

F1

D0DQ[22]

G1

D0DQ[19]

H1

J1

C7843

0.1u

MEM0_DBA2

L1

N1

C7844

0.1u

PWB

R1 R2 R3

NC

A3

A2

B3

B2

D0DM3

D0DQ[24]

C3

C2

D3

D2

D0DQ[26] D0DQ[29]

NC

E3

E2

F3

F2

D0DM2

PWB

C7845

0.01u

G3

G2

D0DQ[17]

H2

J2

MEM0_DCKE

K2

MEM0_DBA0

L2

MEM0_DA[10]

M2

MEM0_DA[3]

N2

MEM0_DA[7]

P2 P3

MEM0_DA[12]

C7810

0.1u

D0DQ[20]

MEM0_DWEB

MEM0_DBA1

MEM0_DA[15]

MEM0_DA[9]

DDR2MEMORY

IC7804

H3

IXD233WJQZ

J3

K3

L3

M3

N3

NC

A7

B7

D0DQS3

C7812

0.1u

C7

D7

D0DQ[31]

E7

F7

D0DQS2

C7847

0.01u

PWB

G7

D0DQ[18]

H7

J7

MEM0_DRASB

K7

MEM0_DCASB

L7

MEM0_DA[2]

M7

MEM0_DA[6]

N7

MEM0_DA[11]

P7 P8

R7

NCR8NC

DDR2

NOT USE

PWB

C7852

0.1u

D0DQS3B

A9

A8

B9

B8

D0DQ[27]

D0DQ[25]

PWB

C9

C8

D9

D8

PWB

C7853

D0DQS2B

0.01u

E9

E8

F9

F8

D0DQ[23]

D0DQ[16]

G9

G8

D0DQ[21]

H9

H8

MEM0_DCK

J9

J8

C7854

0.01u

R7841

PWB

300

CZ

MEM0_DCKB

MEM0_DODT

K9

K8

MEM0_DCSB

L8

MEM0_DA[0]MEM0_DA[1]

M8

M9

MEM0_DA[14]

N8

C7856

0.1u

PWB

MEM0_DA[8]

P9

FL7801

NA119WJ

FL7802

C7801

R7821

0

D1CLKB

D1CLK

D1ODT

D1CKE

D1BA2

D1BA1

D1BA0

D1CASB

D1RASB

D1WEB

D1CSB

D1ADD[4]

D1ADD[2]

D1ADD[0]

D1ADD[14]

D1ADD[5]

D1ADD[12]

D1ADD[3]

D1ADD[15]

4

TO EMMA3PF3

MEM1VREF

D1ODT

D1CLKB

D1CLK

D1CKE

D1BA1

D1BA0

D1DQS3B

D1DQS2B

D1DQS1B

D1ADD[0-15]

D1DQ[0-31]

D1DQS0B

D1DQS3

D1DQS2

D1DQS1

D1DQS0

D1DM3

D1DM2

D1DM1

D1DM0

D1WEB

D1CASB

D1RASB

D1BA2

D1CSB

5

D1ADD[8]

D1ADD[6]

D1ADD[13]

D1ADD[11]

D1ADD[7]

D1ADD[9]

D1ADD[10]

D1ADD[1]

MEM1_DCKB

R7822

0

R7823

R7824

R7825

R7826

R7827

R7828

R7829

R7830

R7831

R7850

R7851

R7852

R7853

R7854

R7855

R7856

R7857

R7858

R7859

R7860

R7861

R7862

R7863

R7864

R7865

MEM1_DCK

0

MEM1_DODT

0

MEM1_DCKE

0

MEM1_DBA2

0

MEM1_DBA1

0

MEM1_DBA0

0

MEM1_DCASB

0

MEM1_DRASB

0

MEM1_DWEB

0

MEM1_DCSB

0

MEM1_DA[4]

0

MEM1_DA[2]

0

MEM1_DA[0]

0

MEM1_DA[14]

0

MEM1_DA[5]

0

MEM1_DA[12]

0

MEM1_DA[3]

0

MEM1_DA[15]

0

MEM1_DA[8]

0

MEM1_DA[6]

0

MEM1_DA[13]

0

MEM1_DA[11]

0

MEM1_DA[7]

0

MEM1_DA[9]

0

MEM1_DA[10]

0

MEM1_DA[1]

D1DM3

D1DM2

R7833

D1DM1

MEM1_DCKE

D1DM0

D1DQS3B

D1DQS3

D1DQS2B

D1DQS2

D1DQS1B

D1DQS1

D1DQS0B

D1DQS0

D1DQ[30]

D1DQ[25]

MEM1_DA[13]

D1DQ[27]

D1DQ[28]

D1DQ[29]

D1DQ[26]

D1DQ[24]

D1DQ[31]

D1DQ[22]

D1DQ[17]

D1DQ[19]

D1DQ[20]

D1DQ[21]

D1DQ[18]

D1DQ[16]

D1DQ[23]

D1DQ[14]

D1DQ[9]

D1DQ[11]

D1DQ[12]

D1DQ[13]

D1DQ[10]

D1DQ[8]

D1DQ[15]

D1DQ[6]

D1DQ[1]

D1DQ[3]

D1DQ[4]

D1DQ[5]

D1DQ[2]

D1DQ[0]

D1DQ[7]

10u

300

PWB

TL7802

NA119WJ

FL7803

NA119WJ

PWB

C7814

0.1u

A1

B1

D1DQ[14]

C7815

0.01u

PWB

C1

D1

D1DQ[8]

C7816

0.01u

PWB

E1

F1

D1DQ[4]

G1

H1

D1DQ[1]

J1

C7817

0.1u

MEM1_DBA2

L1

N1

C7821

0.1u

PWB

R1 R2 R3

NC

A2

B2

D1DQ[10]

C2

D2

NC

E2

F2

G2

D1DQ[3]

H2

J2

MEM1_DCKE

K2

MEM1_DBA0

L2

MEM1_DA[10]

M2

MEM1_DA[3]

N2

MEM1_DA[7]

P2 P3

MEM1_DA[12]

A3

B3

D1DM1

PWB

C7823

0.01u

C3

D3

D1DQ[11]

E3

F3

D1DM0

G3

DDR2MEMORY

D1DQ[6]

IC7801

H3

IXD233WJQZ

J3

C7803

0.1u

MEM1_DWEB

K3

MEM1_DBA1

L3

M3

MEM1_DA[5]

N3

MEM1_DA[9]

NC

C7805

0.1u

C7825

0.01u

MEM1_DRASB

MEM1_DCASB

MEM1_DA[2]MEM1_DA[1]

MEM1_DA[6]

MEM1_DA[11]

A7

D1DQS1

PWB

C7

D7

D1DQ[12]

E7

F7

D1DQS0

PWB

G7

D1DQ[5]

H7

J7

K7

L7

M7

N7

P7 P8

R7NCR8

D1DQS1B

D1DQ[9]

D1DQS0B

D1DQ[7]

MEM1_DCK

R7836

300

MEM1_DCKB

MEM1_DCSB

MEM1_DA[0]

MEM1_DA[4]

MEM1_DA[8]

PWB

C7827

0.1u

A8

A9

B9

B8B7

D1DQ[15]

C9

C8

D9

D8

D1DQ[13]

PWB

C7828

0.01u

E9

E8

F9

F8

D1DQ[0]

G8

G9

D1DQ[2]

H9

H8

J9

J8

C7829

0.01u

PWB

CZ

MEM1_DODT

K8

K9

L8

M8

M9

N8

C7833

0.1u

PWB

P9

NC

FL7807

NA119WJ

FL7808

NA119WJ

C7807

FL7809

PWB

10u

C7835

NA119WJ

0.1u

NC

A1

A2

A3

B3

B1

B2

D1DQ[29]

C1

C2

D1

D2

NC

E1

E2

F1

F2

G1

G2

D1DQ[19]

H1

H2

J2

J1

C7838

C7809

0.1u

0.1u

MEM1_DCKE

K2

MEM1_DBA0

L2

L1

MEM1_DA[10]

M2

MEM1_DA[3]

N2

N1

MEM1_DA[7]

P2 P3

0.1u

PWB

MEM1_DA[12]

R1 R2 R3

D1DQ[26]

D1DQ[17]

MEM1_DWEB

MEM1_DBA1

MEM1_DA[1]

MEM1_DA[15]

MEM1_DA[9]

D1DM3

C3

D3

E3

F3

D1DM2

G3

DDR2MEMORY

IC7803

H3

IXD233WJQZ

J3

K3

L3

M3

N3

NC

D1DQ[25]

C7836

0.01u

PWB

D1DQ[28]

C7837

0.01u

PWB

D1DQ[16]

D1DQ[18]

MEM1_DBA2

C7839

B7

D1DQS3

C7811

0.1u

C7

D7

D1DQ[27]

E7

F7

D1DQS2

C7846

0.01u

PWB

G7

D1DQ[21]

H7

J7

MEM1_DRASB

K7

MEM1_DCASB

L7

MEM1_DA[2]

M7

MEM1_DA[6]

N7

MEM1_DA[11]

P7 P8

R7NCR8

PWB

C7848

0.1u

D1DQS3B

A9A8A7

B9

B8

D1DQ[30]

D1DQ[31]

PWB

C8

C9

D8

D9

D1DQ[24]

C7849

PWB

D1DQS2B

0.01u

E8

E9

F9

F8

D1DQ[20]

PWB

C7850

0.01u

G9

G8

D1DQ[22]

D1DQ[23]

H8

H9

MEM1_DCK

J9

J8

C7851

0.01u

R7840

PWB

300

CZ

MEM1_DCKB

MEM1_DODT

K9

K8

MEM1_DCSB

L8

MEM1_DA[0]

M8

M9

MEM1_DA[14]

N8

C7855

0.1u

PWB

MEM1_DA[8]

P9

NC

Page 9

BD-SP309

A

SCHEMATIC DIAGRAMS - 4

MAIN3

TO POWER

1

TO EMMA3PF3

2

D_3.3V

D_GND

I2CSCL0

I2CSDA0

E2P_WP0

B C D E F G H

A0

1

A1

2

A2

3

GND5SDA

4

IC8501

M24C64WN

NAND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

IC8502

IXC598WJQZ

NC

NC

NC

NC

NC

NC

RY/BY-

RE-

CE-

NC

NC

VCC

VSS

NC

NC

CLE

ALE

WE-

WP-

NC

NC

NC

NC

NC

NC

NC

NC

NC

I/O8

I/O7

I/O6

I/O5

NC

NC

NC

VCC

VSS

NC

NC

NC

I/O4

I/O3

I/O2

I/O1

NC

NC

NAND FLASH 128MB(1Gb)

NC

NC

R8507

NAN_DATA7

R8508

R8509

R8510

R8511

R8512

R8513

R8515

R8516

R8517

R8518

3.3K

PWB

3.3K

3.3K

PWB

3.3K

3.3K

PWB

3.3K

3.3K

3.3K

PWB

3.3K

3.3K

3.3K

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

NAN_DATA7

NAN_DATA6

NAN_DATA5

NAN_DATA4

NAN_DATA3

NAN_DATA2

NAN_DATA1

NAN_DATA0

Q8502

RT1N441C

R8506

3.3K

NAN_DATA0

NAN_DATA1

NAN_DATA2

NAN_DATA3

NAN_DATA4

NAN_DATA5

NAN_DATA6

NAN_CSB0

NAN_REB

NAN_ALE

NAN_CLE

C8501

0.1u

VCC

8

WP

7

SCL

6

R8501

10K

NAN_RBB0

NAN_REB

NAN_CSB0

NAN_CLE

NAN_ALE

NAN_WEB

R8502

4.7K

0.1u

C8502

R8504

10K

BOOT STRAP

NDATA0

NDATA1

NDATA2

NDATA3

NDATA4

NDATA5

NDATA6

NDATA7

NCSB0

NCSB1

NREB

NALE

NCLE

NAND_INFO[0]

NAND_INFO[1]

NAND_INFO[2]

NAND_INFO[3]

NAND_INFO[4]

NAND_INFO[5]

BOOT_MODE[0]

BOOT_MODE[1]

BOOT_MODE[2]

ETHER_CLK_MODE

SCLK_SEL

CPU_CLK_SEL[0]

CPU_CLK_SEL[1]

NOT USE

3

TO EMMA3PF3

NAN_DATA0

NAN_DATA1

NAN_DATA2

NAN_DATA3

NAN_DATA4

NAN_DATA5

NAN_DATA6

NAN_DATA7

TO F_uCON

Secure_Boot

NAN_CSB0

NAN_CSB1

NAN_REB

NAN_WEB

NAN_RBB0

NAN_ALE

NAN_CLE

4

TL8502

NAN_DATA0

NAN_DATA1

NAN_DATA2

NAN_DATA3

NAN_DATA4

NAN_DATA5

NAN_DATA6

NAN_DATA7

NAN_CSB0

NAN_CSB1

NAN_REB

NAN_WEB

NAN_RBB0

NAN_ALE

NAN_CLE

5

Page 10

BD-SP309

A

SCHEMATIC DIAGRAMS - 5

MAIN4

1

2

ToPOWER

AT_12V

AT_5V

DRIVE_P-CON

MAIN_P-CON

SUB_SHORT_DET

DRIVE_12V

D_GND

HP75

N0566FJ

AT_3.3V

RS232C_RXD

RS232C_TXD

N0565FJ

KEY_OPC2

KEY_OPC1

AT_3.3V

AT_5V

DRIVE_12V

P2501

TL2529

1

TL2524

2

TL2525

3

TL2530

GND

4

P2502

TL2533

1

TL2527

2

TL2528

3

232C_RXD

232C_TXD

R2540

10K

R2541

10K

KEY_OPE2

KEY_OPC1

AT_12V

B C D E F G H

OCu_F

3.3K

6.8K

R2503

R2504

CZ

CZ

FRONT_RXD

IC2504

PST8246N

5

4

1 2 3

C2520

0.1u

R2511

10K

VHD

D2504

DA1010

IC2502

4

NC

PST8420N

GND

VCC

2

3

R2508

4.7K

CZ

C2519

R2512

1u

18K

R2509

2.7K

PWB

CZ

R2510

180

CZ

SUB_SHORT_DET

5

CT

VOUT

C2512

0.047u

1

D2505

TL2514

FL_BUSY

PWB

DA1010

R/C_PULSE

1 2

OUT

5

IC2505

PWB

GND

MM3293DN

C2522

2.2u

47P

C2515

C2521

1u

3

CTLVCC

C

4

TP2501

BL_LCD

LED_PON

LED_STBY

F_AT_3.3V

F_MUTE

LED_PLAY

KEY_OPE2

KEY_OPC1

FRONT_RXD

FRONT_TXD

COLD_RST#

FRONT_TXD

FL_BUSY

COLD_RST#

F_MUTE

N

VCXO_PWM

TO HDMI

FR_HDMI_SDA

FR_HDMI_SCL

F_HDMI_HPD

FR_CECIN_1

FR_CECOUT_1

FR_CECINOUT

F_AT_3.3V

TO EMMA3PF3

FRONT_RXD

FRONT_TXD

FL_BUSY

COLD_RST#

VCXO_PWM

F_MUTE

Secure_Boot

TO NAND_EEPROM

Secure_Boot

NOT USE

C2513

R2553

10K

Q2501

2SC3928AR

R2554

150K

Q2502

RT1N241C

0.33u

PWB

VHD

TL2526

D2503

R2552

10K

DA1010

PWB

IC2503

RESET

4

PST8214N

5

1

23

C2518

R2556

47K

PWB

R2557

470

CZ

C2514

100u

6.3V

APF

R2555

1K

1u

OEM

32.768KHz

F

R2518

R2517

15K

0

R2520

15K

F

R2547

15K

F

37

F_BUSY

38

R2539

1K

C2504

0.1u

R2543

10K

PWB

R2506

10M

PWB

X2501

SC0032TA

220K

R2507

1

C2510

12P

4

2

C2511

3

15P

R2544

10K

R2538

10K

FL2501

CA031WJ

3

2

1

CRM

C2508

22u

6.3V

CKZ

C2506

0.1u

CEC_IN

CEC_OUT

39

40

RESET

41

XCOUT

42

XCIN

43

R2534

C2505

DEBUG_FLMD0

0

44

XOUT

CZ

1M

45

R2537

XIN

PWB

46

REGC

1u

47

VSS

48

VDD

1 2 3 4 5 6 7 8 9

R2536

2.2K

R2505

2.2K

R2502

2.2K

R2501

2.2K

TL2501

GND

14

TL2502

GND

13

RESET

FLMD0

TL2503

12

TL2504

11

TL2505

10

TL2506

9

TL2507

8

TL2508

7

TL2509

6

TL2510

5

TL2511

4

TL2512

3

TL2513

2

TL2515

1

TL2518

1

GND

TL2519

2

TL2520

3

TL2521

4

TL2522

5

TL2523

6

KEY_EJECT

KEY_STBY

UNTILPP

F_uCON

VersionUp

LED_STBY

LED_PON

LCD_DATA

LCD_CLK

LCD_CS

LCD_RST

BL_LCD

LED_PLAY

R/C_PULSE

N0534FJQ1

N0056CE

AT_5V

CN2501

CN2504

3

4

TOOL_0

TOOL_1

AT_3.3V

KEY_EJECT

R2526

KEY_STBY

0

R2513

0

LED_STBY

R2527

LED_PON

0

R2514

232C_TXD

0

R2528

LCD_DATA

0

R2529

R2531

0

C2501

0.1u

232C_RXD

R2521

0

LCD_CLK

HP25

LCD_CS

LCD_RST

R2524

0

BL_LCD

0

R2525

0

LED_PLAY

OEM

R/C_PULSE

TOOL_0

FLMD0

TOOL_1

R2551

100

R2519

HDMI_SCL

PWB

10K

3536

SECURE_BOOT

R/C_PULSE

HDMI_SDA

100K

R2515

34

PQLS_PWM_OUT

LCD_CLK

LCD_CLK

PWB

10K

R2516

33

LED_BACK_LIGHT

LCD_DATA

R2542

LCD_DATA

32

10K

LED_PON

R/C_PULSE

OEM

R2535

31

100

LCD_RST

30

LED_STANDBY

IC2501

IXD269WJQZ

LCD_RST

LCD_CS

LED_PLAY

LCD_CS

R2522

29

F_MUTE

DEBUGSEREAL0

F_RESET_OUT

10K

28

HPD

CEC_INOUT

R2550

100K

R2523

2627

CBOOT

KEY_OPE2

F_TO_H_TXD

H_TO_F_RXD

COLD_RST

232C_TXD

232C_RXD

SHORT_DET

MAIN_POW

KEY_EJECT

KEY_STBY

10 11 12

10K

100P

C2516

C2517

KEY_EJECT

KEY_STBY

DR_POW

PWB

25

VREF

PFAIL

DEBUGSEREAL1

100P

VSS

KEY_OPC1

24

23

22

21

20

19

18

17

16

15

14

13

10K

10K

R2530

R2532

232C_TXD

232C_RXD

SUB_SHORT_DET

C2502

0.1u

C2503

100u

16V

APF

C2507

1u

DA1010

R2533

0

FB2501

D2501

0051TA

PWB

5

TOOL_1

TOOL_0

Page 11

BD-SP309

A

SCHEMATIC DIAGRAMS - 6

MAIN5

POWER

1

2

LUG9002

LUG9001

3

SC9001

NA340WJ

ToPOWER

AT_12V

AT_12V

AT_12V

D_GND

D_GND

D_GND

4

PWB

C9040

1000P

CYB

C9037

0.1u

CYB

TL9001

1

TL9002

2

TL9003

3

R9038

TL9005

4

10K

TL9006

5

TL9007

6

BA041WJFM

1

1

E9001

E9002

BA041WJFM

E9003

BA041WJFM

B C D E F G H

DRIVE_12V

VHD

VHD

D

V2.5

CD-C

456

R9007

10K

RT1N241C

1

1

E9004

BA041WJFM

1 2 3

R9060

CZ

1M

2.2K

R9031

CZ

RT1N241C

Q9003

Q9002

VS

C9034

VS

DRIVE_12V

Q9014

RTQ035P02

R9061

680K

CZ

10u

CKZ

R9033

10K

RT1N241C

Q9005

2SC3928AR

R9032

10K

R9020

10K

Q9004

RT1N441C

VS

Q9015

R9016

Q9001

2SC3928AR

VS

5

7

6

8

LX

COMP

LX

PGND

1

IC9004

AOZ1016

VIN

2

AGND

EN

3

C9025

10u

16V

KZA510WJPZ

FB

4

L9004

10uH

PB299WJQZ

C9028

22u

6.3V

KZA214WJ

C9027

1000P

FB9007

A018WJ

PWB

KZA510WJPZ

CZB

C9026

10u

16V

C9055

100u

16V

APF

VS

R9048

Q9011

10K

RT1N241C

10K

1.1V DC-DC

5

8

6

FB

COMP7EN

SS

C9003

IC9001

0.1u

BD9329EF

SW4GND

VIN

BST

C9001

FB9001

10u

16V

A018WJ

KZA510WJPZ

KZA510WJPZ

KZA510WJPZ

C9002

10u

16V

PWB

C9011

1000P

CZB

C9033

0.1u

CZB

FB9003

A018WJ

PWB

C9010

10u

16V

R9012

1K

R9014

47K

1

IC9002

BST2VIN

1

C9009

10u

16V

KZA510WJPZ

2

C9007

0.1u

CZB

7

EN8SS

COMP

BD9328EF

C9008

0.1u

CZB

3

6

3SW4

L9001

4.7uH

PB297WJQZ

C9004

22u

6.3V

CKZ

D-CDV3.3

CONVERTOR:

5

FB

GND

L9002

10uH

PB299WJQZ

C9012

22u

6.3V

CKZ

CONVERTOR:

8

5

7

FB6COMP

EN

SS

C9019

IC9003

0.1u

CZB

BD9328EF

BS

SW4GND

IN

1

3

C9017

10u

16V

KZA510WJPZ

2

C9038

0.1u

CZB

L9003

4.7uH

PB297WJQZ

C9020

22u

6.3V

CKZ

FB9005

A018WJ

PWB

KZA510WJPZ

C9018

10u

16V

CONVERTOR:

C9031

470P

CCZ

R9029

270K

CZ

C9029

22u

6.3V

KZA214WJ

R9011

C9035

820P

CZB

C9005

22u

6.3V

CKZ

R9019

8.2K

CZ

C9015

3300P

CZB

C9013

22u

6.3V

CKZ

6

V

.5

12

C9032

100P

CCZ

C9030

PWB

390P

CCZ

R9028

R9027

47K

8.2K

CZ

CZ

F

F

R9026

10K

CZ

F

1.107V

CONVERTOR:

C9036

33K

470P

CCZ

CCZ

C9006

15P

PWB

R9008

R9006

2.2K

1K

F

F

R9009

10K

F

PWB

V3

3C

03.

C9016

100P

CCZ

PWB

CCZ

C9014

100P

PWB

R9015

R9013

4.7K

22K

F

F

CZ

CZ

R9017

10K

F

CZ

V908.1CD-CDV8.1

R9024

4.7K

CZ

C9023

5600P

CZB

C9021

22u

6.3V

CKZ

PWB

PWB

C9024

680P

CZB

CZB

C9022

560P

PWB

R9021

R9022

100

10K

F

F

R9023

10K

F

FB9002

A018WJ

FB9008

A018WJ

FB9004

A018WJ

TL9016

FB9006

A018WJ

TL9019

TL9017

D_1.1V

TL9018

D_1.8V

D_3.3V

AT_5V

R9062

560

CY

456

D_3.3V

DRIVE_5V

Q9012

RTQ035P02

1 2 3

R9053

CZ

1M

VS

Q9013

RT1N241C

R9054

680K

CZ

D9015

RB551V30

C9039

100u

6.3V

APF

D9014

RB551V30

R9010

10K

CZ

DRIVE_3.3V

2.2uH

L9005

TO F-uCOM

AT_12V

D_GND

DRIVE_P-CON

MAIN_P-CON

SUB_SHORT_DET

AT_5V

DRIVE_12V

TO FRONT_END

DRIVE_12V

DRIVE_5V

DRIVE_3.3V

D_GND

TO EMMA3P

DRIVE_3.3V

D_3.3V

D_1.8V

D_1.1V

D_GND

A_GND

AT_5V

MAIN_P-CON

TO DDR2

D_1.8V

D_GND

TO FLASH

D_3.3V

D_GND

TO HDMI

AT_5V

D_GND

D_3.3V

TO ETHER

D_3.3V

D_GND

TO USB

DRIVE_5V

D_3.3V

D_GND

5

R9002

0

R9003

0

R9004

0

R9005

0

R9001

0

NOT USE

Page 12

BD-SP309

A

SCHEMATIC DIAGRAMS - 7

MAIN6

HDMI

1

TO EMMA3PF3

HDMI_SDA

HDMI_SCL

HDMI_HPD

HDMI_TXCP

HDMI_TXCN

HDMI_TX0P

HDMI_TX0N

HDMI_TX1P

HDMI_TX1N

HDMI_TX2P

HDMI_TX2N

2

TL4203

202122

1

2

3

4

5

SC4201

ZA224WJPZ

6

7

8

9

10

11

TL4204

12

13

14

TL4201

15

TL4206

16

17

18

19

TL4205

23

3

4

5

TO FuCON

FR_CECINOUT

FR_CECOUT_1

FR_CECIN_1

FR_HDMI_SDA

FR_HDMI_SCL

F_HDMI_HPD

D_GND

HDMI_SDA

HDMI_SCL

HDMI_HPD

HDMI_TXCP

HDMI_TXCN

HDMI_TX0P

HDMI_TX0N

HDMI_TX1P

HDMI_TX1N

HDMI_TX2P

HDMI_TX2N

D_GND

SG4201

VXA187WJQZ

SG4202

VXA187WJQZ

C4201

1u

14

VCC

IC4201

1 2 3 4 5 6 7

C4202

0.01u

PWB

VXA187WJQZ

SG4203

VXA187WJQZ

VXA187WJQZ

SG4206

SG4204

13

VXA187WJQZ

VXA187WJQZ

SG4207

SG4205

SG4209

VXA187WJQZ

101112

R4202

220

B C D E F G H

VXA187WJQZ

SG4208

R4204

9

VXA187WJQZ

PWB

SG4210

SG4211

VXA187WJQZ

0

NC

8

LCX125FT

GND

R4205

0

R4212

R4213

R4214

R4215

R4216

R4217

R4218

R4219

SG4212

VXA187WJQZ

PWB

R4209

HDMICN_SCL

HDMICN_SDA

PWB

F

27K

R4211

10K

0

0

0

0

0

0

0

0

D4201

VHD

DA1010

HDMI_TX2P

HDMI_TX2N

HDMI_TX1P

HDMI_TX1N

HDMI_TX0P

HDMI_TX0N

HDMI_TXCP

HDMI_TXCN

10u

C4206

DA1010

D4202

PWB

C4203

2.2u

R4223

10K

KZA176WJ

CYB

C4204

1u

1 2 3

VCC GND

OUT

PWB

FuCON:5V

PWB

FR_HDMI_SDA

R4224

1.8K

IC4202

MM3293EN

R4203

R4241

10K

R4242

10K

PWB

FR_HDMI_SCL

R4225

PWB

R4239

4.7K

C4211

0.1u

PWB

R4244

0

SDAB

SCLB

VCCB

5

EN

PWB

6

7

8

R4247

0

4

GND

3

SDAA

2

SCLA

1

VCCA

IC4203

PCA9517

R4245

0

R4246

0

47K

1.8K

R4227

CTL

NC

45

0

R4248

PWB

R4240