Omron ZG2-WDC11, ZG2-WDC11A, ZG2-WDC41, ZG2-WDC41A Instruction Sheet

Model

ZG2-WDC□□

Smart Sensor

Sensor Controller

for ZG2-WDS□□□

INSTRUCTION SHEET

Thank you for selecting OMRON product. This sheet primarily describes

precautions required in installing and operating the product.

Before operating the product, read the sheet thoroughly to acquire

sufficient knowledge of the product. For your convenience, keep the

sheet at your disposal.

TRACEABILITY INFORMATION:

Importer in EU:

OMRON Europe B.V.

Wegalaan 67-69,

NL-2132 JD Hoofddorp

The Netherlands

The following notice applies only to products that carry the CE mark:

Notice:

This is a class A product. In residential areas it may cause radio

interference, in which case the user may be required to take adequate

measures to reduce interference.

OMRON Corporation

©

PRECAUTIONS FOR SAFE USE

Please observe the following precautions for safe use of the product:

1. Do not use the product in environments where it can be exposed to

inammable/explosive gas.

2. Do not disassemble, repair or modify this product.

3. Be sure to make sure that locking mechanisms are locked before use.

4. The supply voltage must be within the rated range.

5. Use the power supply within the rated load.

6. Dispose of this product as industrial waste.

PRECAUTIONS FOR CORRECT USE

1. Do not install the product in locations subjected to the following conditions:

・ Direct sunlight or near heaters

・ Condensation caused by high humidity

・ Sudden changes in humidity

・ Cold conditions that may cause freezing

・ Presence of corrosive or ammable gases

・ Direct vibration or shock

・ Build-up of dust or metal chips

・ Spraying by organic solvents, water, oil or other liquids

・ Strong magnetic or electric eld

・

Reection of intense light (such as other laser beams or electric arc-welding machines)

2. Power Supply and Wiring

・ Reverse connection of power supply is not allowed. Connection to AC power supply

is also not allowed.

・ Open-collector outputs should not be short-circuited.

・ Use the Extension Cable ZG2-XC□□CR: length 25m/15m/8m/3m for extending

the cable between the Sensor Head and Sensor Controller. The total length differs

according to the Extension cable.

・ High-voltage lines and power lines must be wired separately from this product.

Wiring them together or placing them in the same duct may cause induction,

resulting in malfunction or damage.

・ When using a commercially available switching regulator, make sure that the FG

(Frame Ground) terminal is grounded.

・ If surge currents are present in the power lines, connect surge absorbers that suit the

operating environment.

・ Before connecting/disconnecting the Sensor Head, make sure that the Sensor

Controller is turned OFF. The Sensor Controller may break down if it is connected

or disconnected while the power is ON.

・ Use only the specied combinations of Sensor Head and Sensor Controller.

Manufacturer:

OMRON Corporation,

Shiokoji Horikawa, Shimogyo-ku,

Kyoto. 600-8530 JAPAN

2016 All Rights Reserved.

9309251-6B

3. Orientation when Installing the Sensor Controller

To improve heat radiation, install the Sensor Controller only in the orientation show

below.

Correct

Do not install the Sensor Controller in the following orientations.

IncorrectIncorrect

4. Cleaning

・ Do not use paint thinner, benzene, acetone or kerosene to clean the Sensor

Controller. Doing so will melt the surface of the Sensor Controller.

・ Use commercially available alcohol.

■Communication with a Host Device

Before communicating with a host device, make sure that the product has started up.

Also, clear the receive buffers on the device in use or perform other measures since

undetermined signals might be output from the host interface when this product is

started up.

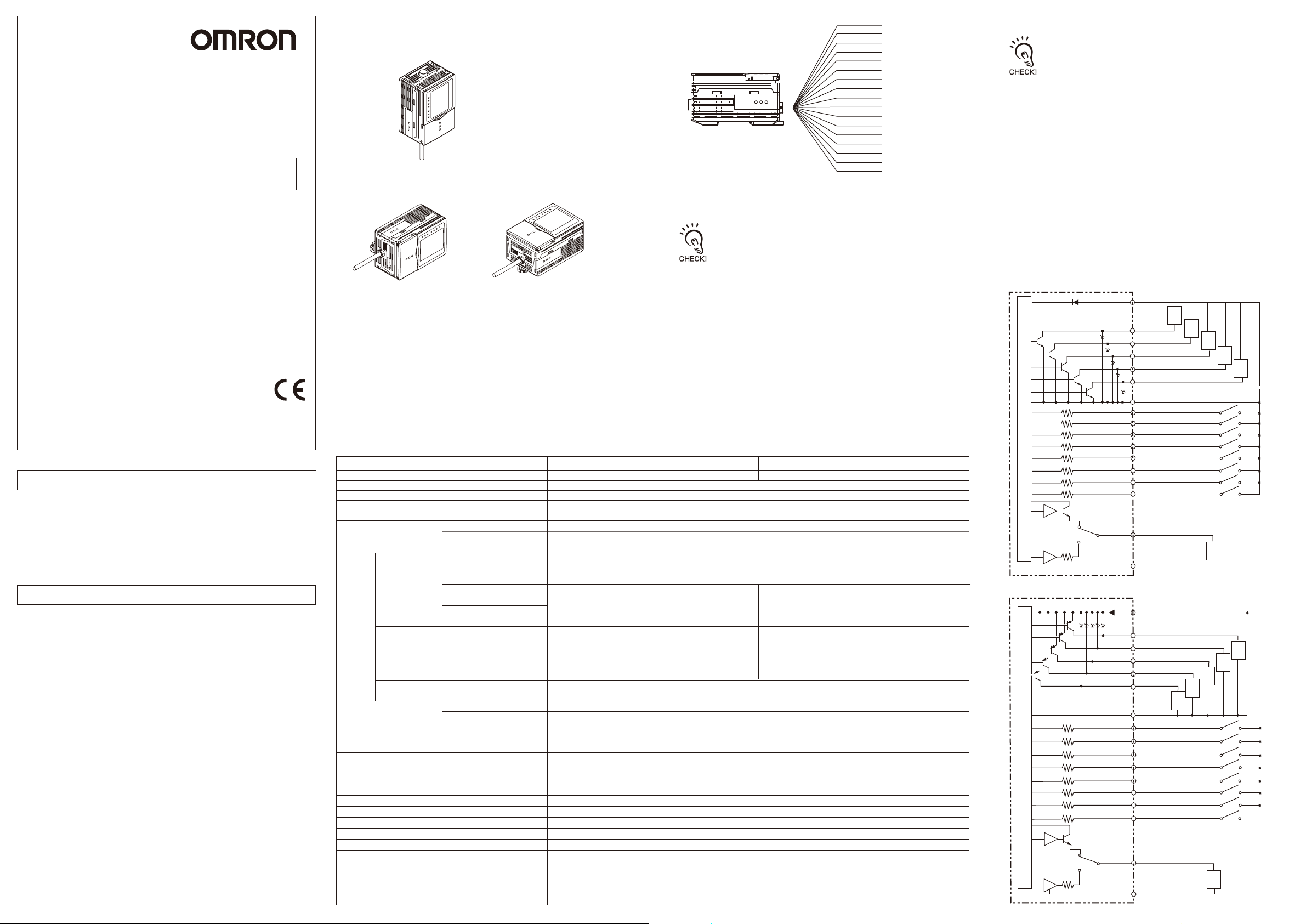

■Specifications

Item Model

Output method

No. of mounted Sensors

Measurement time

Unit of minimum display

Range of display

Display LCD monitor

LED monitor

Analog output

Output

Judgement output

(ALL-PASS/NG/ERROR)

External

I/F

Input

Trigger assistance output

(ENABLE/GATE)

Laser off input(LD-OFF)

Zero reset input(ZERO-RESET)

Trigger input (TRIG)

Bank setting input

(BANK A/BANK B/BANK C/BANK D)

Serial I/O

Functions

USB2.0

RS-232C

Bank selection

Sensitivity adjustment

Measurement items

Trigger mode

Power supply voltage

Current consumption

Dialectic strength

Ambient temperature

Ambient humidity

Degree of protection

Vibration resistance (destructive)

Shock resistance (destructive)

Materials

Cord length

Weight

Accessories

ZG2-WDC11/WDC11A

NPN

1 per Sensor Controller

5ms/8ms/16ms

10nm

-999.99999~999.99999

TFT2.2-inch Color LCD (display dots:557×234pix)

・

Judgement result indicator (color:orange):T1/T2/T3/T4 ・Laser on indicator (color:green):LD ON

・

Zero reset indicator (color:green):ZERO-RESET ・Trigger indicator (color:green):TRIG

Selectable from 2types voltage/current output (selected by side switch on base)

・

At voltage output:-10 to +10V,output impedance:40Ω

・

At current output:4 to 20mA,max.load resistance:300Ω

NPN open-collector,30VDC,50mA max.,

Residual voltage:1.2V max.

ON:Short-circuited with 0V terminal or 1.5V max.

OFF:Open (leakage current:0.1mA max.)

1 port,FULL-SPEED[max.12Mbps],MINI-B

1 port,max. 115200bps

16banks per Sensor Controller

MULTI/HIGH SPEED MULTI/AUTO/FIXED

Height/2-point step/3-point step/Edge position/Edge width/Angle/Intersection angle/Intersection coordinates/

Cross-sectional area/Calculations between tasks (max. 8 items simultaneously selectable)

External trigger/Continuous

21.6V DC to 26.4V DC(including ripple)

0.8A max.

Across all lead wires and controller case,1000VAC,50/60Hz,1min

Operating:0 to 50℃,Storage:-15 to 60℃ (with no icing or condensation)

Operating and storage:35% to 85% RH (with no condensation)

IEC60529,IP20

Destruction:10 to 150Hz,0.35-mm single amplitude,10 times each X,Y,and Z directions for 8min

Destruction:150m/s ,3 times each 6 directions(up/down,left/right,forward/backward)

2

Case: Polycarbonate (PC), Cable sheath: heat-resistant PVC

2m

Approx.300g(including cord)

ZG2-WDC□1 : ferrite core (large) (1 p’ ce), Insure Lock (1 p’ ce), Instruction Sheet (This sheet)

ZG2-WDC□1A : ferrite core (large) (1 p’ ce), ferrite core (small) (2 p’ ces),

Insure Lock (1 p’ ce), Instruction Sheet (This sheet), Smart Monitor ZG2 (exclusive PC software, CD-ROM), USB cable

■External I/O

Brown

Blue

Red

Green

Black

Pink

Gray

Co-axial (black)

Shield

Yellow

Light blue

Yellow green

Yellow/Black

Purple

White

Orange

White/Black

(1) Power supply(24V)

(2) GND(0V)

(3) OUT0

(4) OUT1

(5) OUT2

(6) OUT3

(7) OUT4

(8) Analog output

(9) Analog GND

(10) IN0

(11) IN1

(12) IN2

(13) IN3

(14) IN4

(15) IN5

(16) IN6

(17) IN7

(1) Power supply

This connects the 24 V DC (±10%) power supply. When using a Sensor

Controller with a PNP output, the power supply terminal is also the common I/O

terminal for all I/O except for the Analog output.

・

Supply power from a DC power supply unit that has a countermeasure (safety

ultra-low voltage circuit) built-in for preventing high voltages from occurring.

・ Wire the power supply separately from other devices. Wiring them together

or placing them in the same duct may cause induction, resulting in

malfunction or damage.

(2) GND

The GND terminal is the 0V power supply terminal. When using a Sensor

Controller with an NPN output, the GND terminal is also the common I/O

terminal for all I/O except for the Analog output.

(3) OUT0 (ALL PASS output)

This outputs judgment results (ALL PASS).

(4) OUT1 (NG output)

This outputs judgment results (NG).

(5) OUT2 (ERROR output)

This turns on when an error is generated.

(6) OUT3 (ENABLE output)

This turns ON when the sensor is ready for TRIG input.

(7) OUT4 (GATE output)

This turns ON when the measurement data can be aquired.

(8) Analog output

The Analog output outputs a current or voltage in accordance with the measured value.

ZG2-WDC41/WDC41A

PNP

PNP open-collector,50mA max.,

Residual voltage:1.2V max.

ON:

Supply voltage short-circuited or within supply voltage -1.5V max.

OFF:Open (leakage current:0.1mA max.)

(9) Analog GND

The Analog GND terminal is the 0V terminal for the Analog output.

・This ground wire must be wired separately from the other ground

wires.

(10) IN0 (BANK A)

Bank switching input A.

(11) IN1 (BANK B)

Bank switching input B.

(12) IN2 (BANK C)

Bank switching input C.

(13) IN3 (BANK D)

Bank switching input D.

(14) IN4 (LD-OFF)

Laser ON/OFF switch input. If this signal is set on,the laser will stop emission.

(15) IN5 (ZERO-RESET)

Zero reset input.

(16) IN6 (TRIG)

External Trigger input.

(17) IN7 (HOLD-RESET)

Hold reset input.

■I/O circuit diagrams

・NPN type (ZG2-WDC11/WDC11A)

Brown

24 V DC

Load

Red

OUT0

OUT1

OUT2

OUT3

OUT4

GND (0V)

IN0

IN1

IN2

IN3

IN4

IN5

IN6

IN7

24 V DC

OUT0

OUT1

OUT2

OUT3

OUT4

Load

GND(0V)

IN0

IN1

IN2

IN3

IN4

IN5

IN6

IN7

Load

Analog output

Analog GND

Load

Analog output

Analog GND

Load

Load

Load

Current output: 300 Ω or lower

Load

Voltage output: 10 k

Load

Load

Load

Current output: 300 Ω or lower

Load

Voltage output: 10 kΩ or higher

24 V

DC

24 V DC

Ω

or higher

Internal circuit

Current output

40Ω

4 to 20mA

Voltage output

±10V

Current/voltage

output switch

・PNP type (ZG2-WDC41/WDC41A)

Internal circuit

Current output

40Ω

4 to 20mA

Voltage output

±10V

Current/voltage

output switch

Green

Black

Pink

Gray

Blue

Yellow

Light blue

Yellow green

Yellow/Black

Purple

White

Orange

White/Black

Co-axial (black)

Shield

Brown

Red

Green

Black

Pink

Gray

Blue

Yellow

Light blue

Yellow green

Yellow/Black

Purple

White

Orange

White/Black

Co-axial (black)

Shield

■Attaching the ferrite core

Attach the ferrite core (provided with the Sensor Controller) to the I/O cable of the

Sensor Controller.

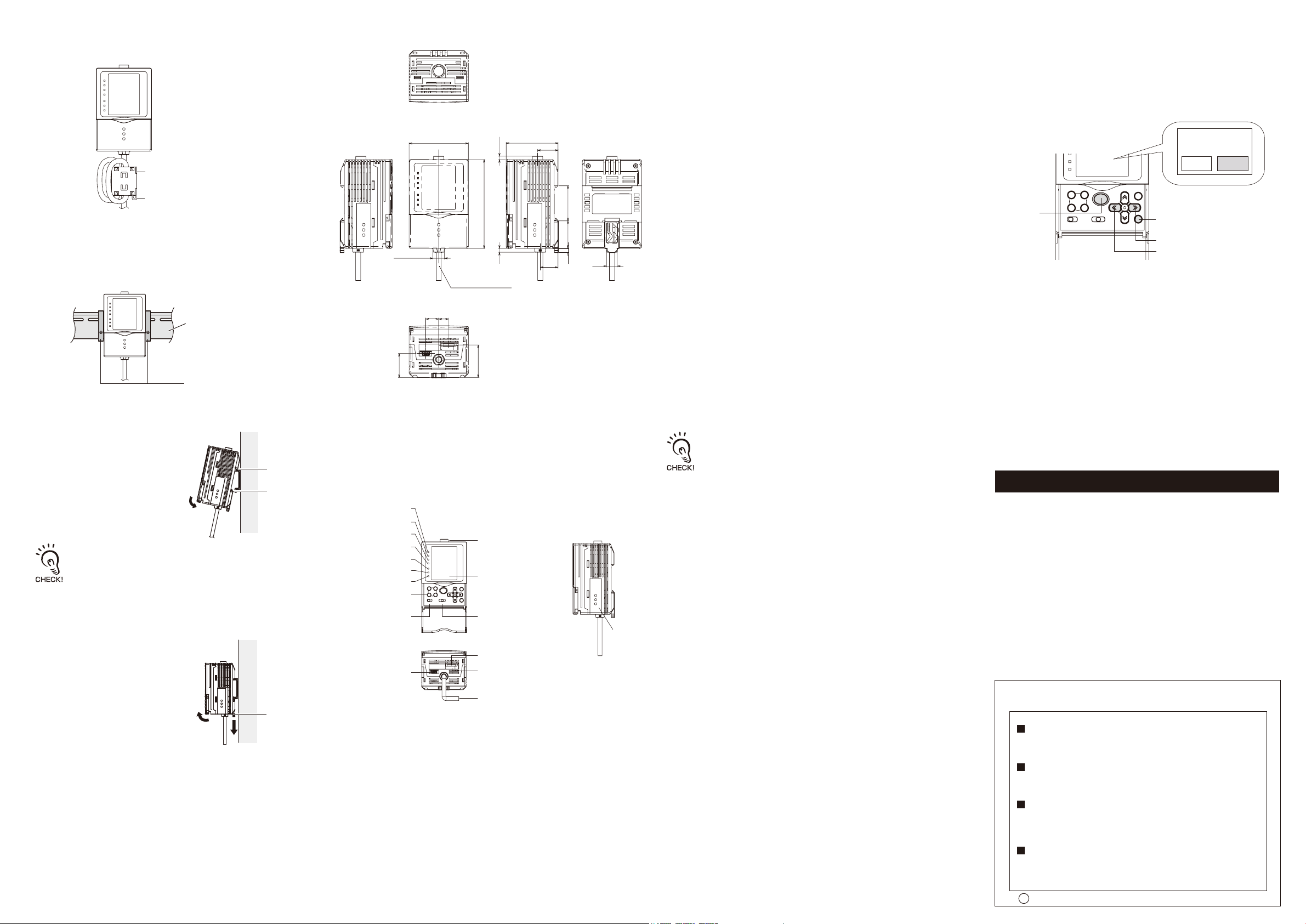

■Dimensions

(unit: mm)

(6)ZERO-RESET indicator

The ZERO-RESET indicator lights when the zero reset function is enabled.

(7) TRIG indicator

The TRIG indicator lights while inputting the trigger signal.

(8) Control keys

The Control keys are for setting measurement conditions and information.

■How to Switch the Display Language to English

Only when power supply rst time is turned on,The language switch menu is

automatically displayed.Please select[ENG(English)] or [JPN(Japanese)] with a right

and left key,and decide it with the SET key.

The content of the selection is reected when starting.

*If you want to start language selection menu since the second times,Please turn on

power while pushing the menu key.

Ferrite core

Insulation lock

*Please two turns and install the cable.

■Mounting

DIN track (sold separately)

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

End plate (sold separately)

PFP-M

■Installing the DIN track

The following describes how to attach the 35 mm wide DIN track by quick, easy operation.

① Hook the hook on the connector end

onto the DIN track.

Hook on connector

end

②

Push the Sensor Controller down onto

the DIN track until the hook on the I/O

Hook on I/O cable

end

cable side is locked.

Push down until you hear it snap into

place.

When Sensor Controllers are used gang-mounted, attach the End

Plate (sold separately PFP-M) on the DIN track beforehand.

Always hook the hook on the connector end on the DIN track rst.

Hooking the I/O cable end on the DIN track rst may impair the

mounting strength of the DIN track attachment.

■Removing the DIN track

The following describes how to remove the Sensor Controller from the DIN track.

① Pull the hook on the I/O cable end of

the Sensor Controller downwards.

60

11.7mmdia.

HEAT-RESISTANTPVCCORD

5.7DIA.,16CORES,

STANDARDLENGTH2M

10

13

24.2

■Part Names and Functions

(1)T1 indicator

(2)T2 indicator

(3)T3 indicator

(4)T4 indicator

(5)LD ON indicator

(6)ZERO-RESET indicator

(7)TRIG indicator

(8)Control keys

(17)USB port

52.5

3.34

90

3.9

32.9

(12)Sensor Head connector

(11)LCD monitor

(10)Mode selector switch(9)Menu selector switch

(14)RS-232C connector

(15)Voltage/current switch

20.8

18.4

(9) Menu selector switch

This switch selects the setup menu.

STD : Standard menu.Select this mode when setting the minimum require

items for measurement.

EXP : Expert menu.Select this mode when making a more detailed setup.

PLEASESELECT

LANGUAGE

ENG

JPN

(10) Mode selector switch

35.527.94.3

10.8

This switch selects the operating mode.

FUN : Select this mode when setting measurement conditions.

ADJ : Select this mode when adjusting the judgement threshold value.

RUN : Select this mode when performing measurement.

Output is performed only when the RUN mode is currently selected.

(11) LCD monitor

MENUkey

SETkey

RIGHTkey

LEFTkey

The LCD monitor displays setup menus and images captured from the sensor

head.

(12) Sensor Head connector

This connector connects the Sensor Head.

(13) Coupler

This coupler connects the Controller Unit when gang-mounting Sensor

Controllers.

(14) RS-232C connector

Connect the RS-232C cable when you are connecting the Sensor Controller to a

PLC or a personal computer.

(15) Voltage/current switch

The Voltage/Current switch selects between voltage output and current output.

Before operating this switch, make sure that the Sensor Controller is turned OFF.

Also, make sure that the load connected to "Analog output wire (co-axial)

- Analog GND wire" satises the rating (see I/O circuit diagram) of the set

• Notice for Korea Radio Law

A급 기기(업무용 방송통신기자재)

이 기기는 업무용(A급) 전자파적합기기로서 판매자

또는 사용자는 이 점을 주의하시기 바라며,가정외의

지역에서 사용하는 것을 목적으로 합니다.

state (voltage or current output) before turning the Sensor Controller ON.

Otherwise, the Sensor Controller may be damaged.

(16) I/O cable

The I/O cable connects the Sensor Controller to the power supply and external

devices, such as sync sensors or programmable controllers.

(17) USB port

Connect the USB cable to the USB port to connect to a personal computer.

Omron Companies shall not be responsible for conformity with any standards,

codes or regulations which apply to the combination of the Product in the

Buyer’s application or use of the Product. At Buyer’s request, Omron will

provide applicable third party certification documents identifying ratings and

limitations of use which apply to the Product. This information by itself is not

sufficient for a complete determination of the suitability of the Product in

Suitability for Use

combination with the end product, machine, system, or other application or

use. Buyer shall be solely responsible for determining appropriateness of the

particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING

SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE

(13)Coupler

SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS,

AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

See also Product catalog for Warranty and Limitation of Liability.

② Lift up the Sensor Controller from the

I/O cable, and remove it from the DIN

track.

Hook on I/O cable

end

(16)I/O cable

(1) T1 indicator

The T1 indicator lights When the judgement result of TASK1/TASK5 is [OK].

(2) T2 indicator

The T2 indicator lights When the judgement result of TASK2/TASK6 is [OK].

(3) T3 indicator

The T3 indicator lights When the judgement result of TASK3/TASK7 is [OK].

(4) T4 indicator

The T4 indicator lights When the judgement result of TASK4/TASK8 is [OK].

(5) LD ON indicator

The LD ON indicator lights while the Sensor Head is emitting a laser beam.

OMRON Corporation

Tokyo, JAPAN

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen, Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

s

Oct, 2014

D

Industrial Automation Company

Contact: www.ia.omron.com

Loading...

Loading...