Omron ZFX BROCHURE

Cat. No. Z01E-EN-01

Smart Sensor

ZFX

Vision Sensor with built-in

touch screen

SHORT MANUAL

ZFX

Vision Sensor

with built-in touch screen

Short Manual

Ver. 1.0, January 2008

TABLE OF CONTENTS

SECTION 1

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-1 System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1-2 Connecting the Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-3 Installing the Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-4 Installing the Intelligent Cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-5 Installing the C-mount Cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-6 Installing the External Lightings (Only For ZFX-SC50/SC90) . . . . . . . . . . . . . . . . . . . . . . 14

1-7 Installing the External Lightings (Only For C-mount Camera (ZFX-S/SC)) . . . . . . . . . . . . 15

SECTION 2

Main Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-1 Operation Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-2 Adjusting the brightness of image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-3 Measurement Setting Example (Pattern Search) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-4 Position Correction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

2-5 Getting the clear image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2-6 Changing the Display Information (ADJ/RUN Mode) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-7 Re-measuring the saved image (ADJ Mode). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

SECTION 3

Run-Mode Measurement Process . . . . . . . . . . . . . . . . . . . . . 33

SECTION 4

Item Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-1 ITEM Overview (Pattern Search) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-2 ITEM Overview (Sensitive Search). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-3 ITEM Overview (Flexible Search) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4-4 ITEM Overview (Graphic Search) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-5 ITEM overview (Area) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4-6 ITEM Overview (Labeling). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4-7 ITEM Overview (Position) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4-8 ITEM Overview (Width) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-9 ITEM Overview (Count) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-10 ITEM Overview (Angle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4-11 ITEM Overview (Bright). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4-12 ITEM Overview (HUE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

4-13 ITEM Overview (Defect) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4-14 ITEM Overview (Grouping) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3

SECTION 5

Appendices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5-1 What is decided by AUTO setting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5-2 BANK and BANK-Group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4

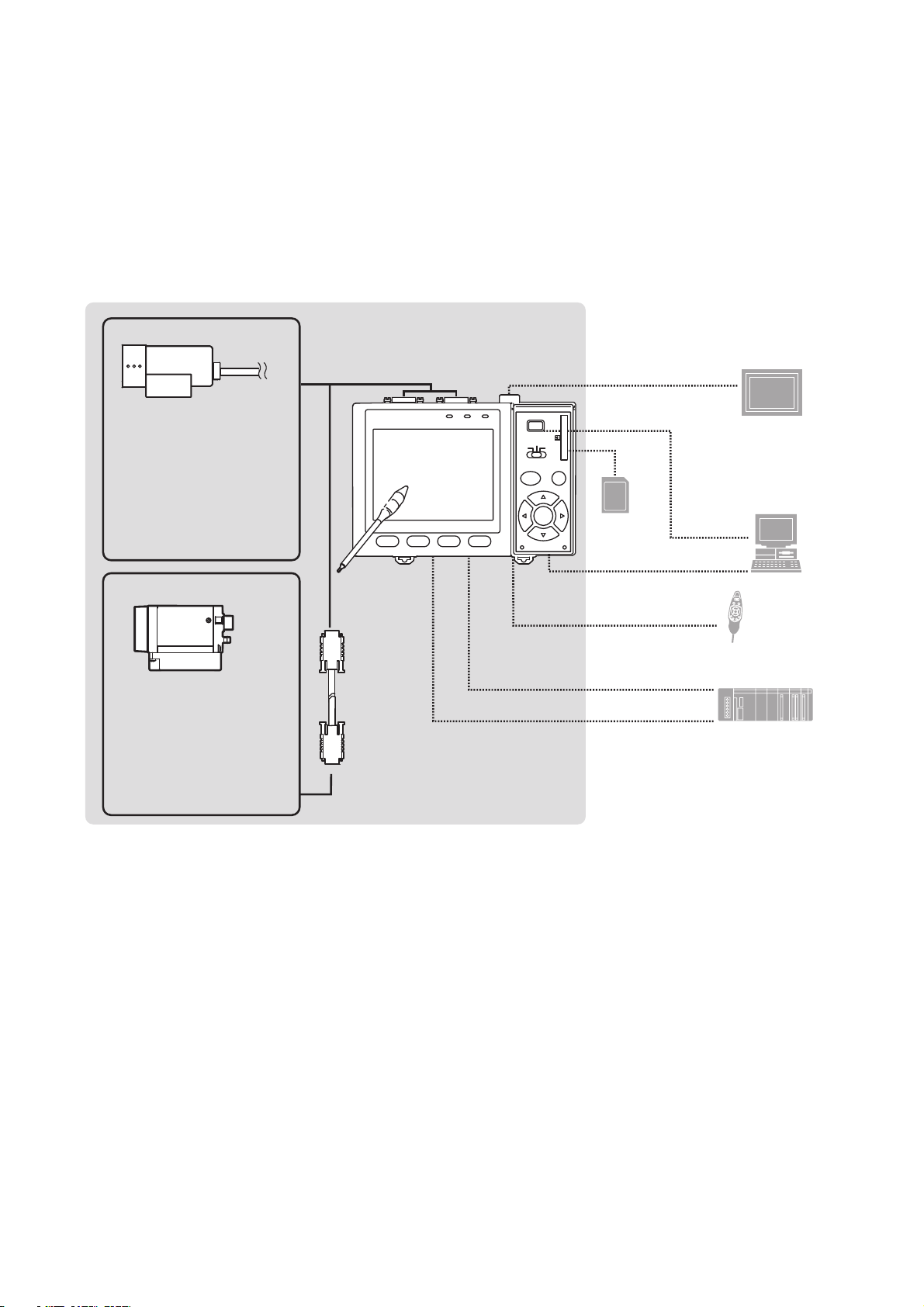

1-1 System Overview

3 42

1

Basically, the ZFX-C is configured by the Controller and the camera.

Other external devices can be selected to be used in combination with the

ZFX-C according to the user’s specific requirements.

Cameras with lighting

(cable built-in)

- Color camera

ZFX-SC10/SC50/SC50W

ZFX-SC90/SC90W

ZFX-SC150/SC150W

- Monochrome camera

ZFX-SR10/SR50

Camera only

- Color camera

ZFX-SC

- Monochrome camera

ZFX-S

A CCTV lens and light

source will be required.

ZFX-VS/VSR

Controller

(*5)

Touch pen

(*1)

Camera cable

ZFX-C10/15/20/25

Monitor cable

FZ-VM

SD Card (*4)

RS-232C cable

ZFX-XPT_A

RS-422 cable

ZFX-XPT_B

Parallel I/O cable

ZFX-VP

SECTION 1

Preparation

LCD monitor (option)

FZ-M08 (*2)

PC

USB

Ethemet

Console

ZFX-KP

(*3)

PLC

*1. The Touch Pen (ZFX-TP) is supplied with the Controller.

*2. The same image as in the Controller's LCD monitor can be displayed in the

LCD monitor (option).

*3. The console can be used instead of the Controller's keys and menu but-

tons.

*4. Conforms to the SD Card “Physical layer specifications 1.01.”

File format: FAT16

*5. ZFX-C20/25b can be connected with 2 cameras.

5

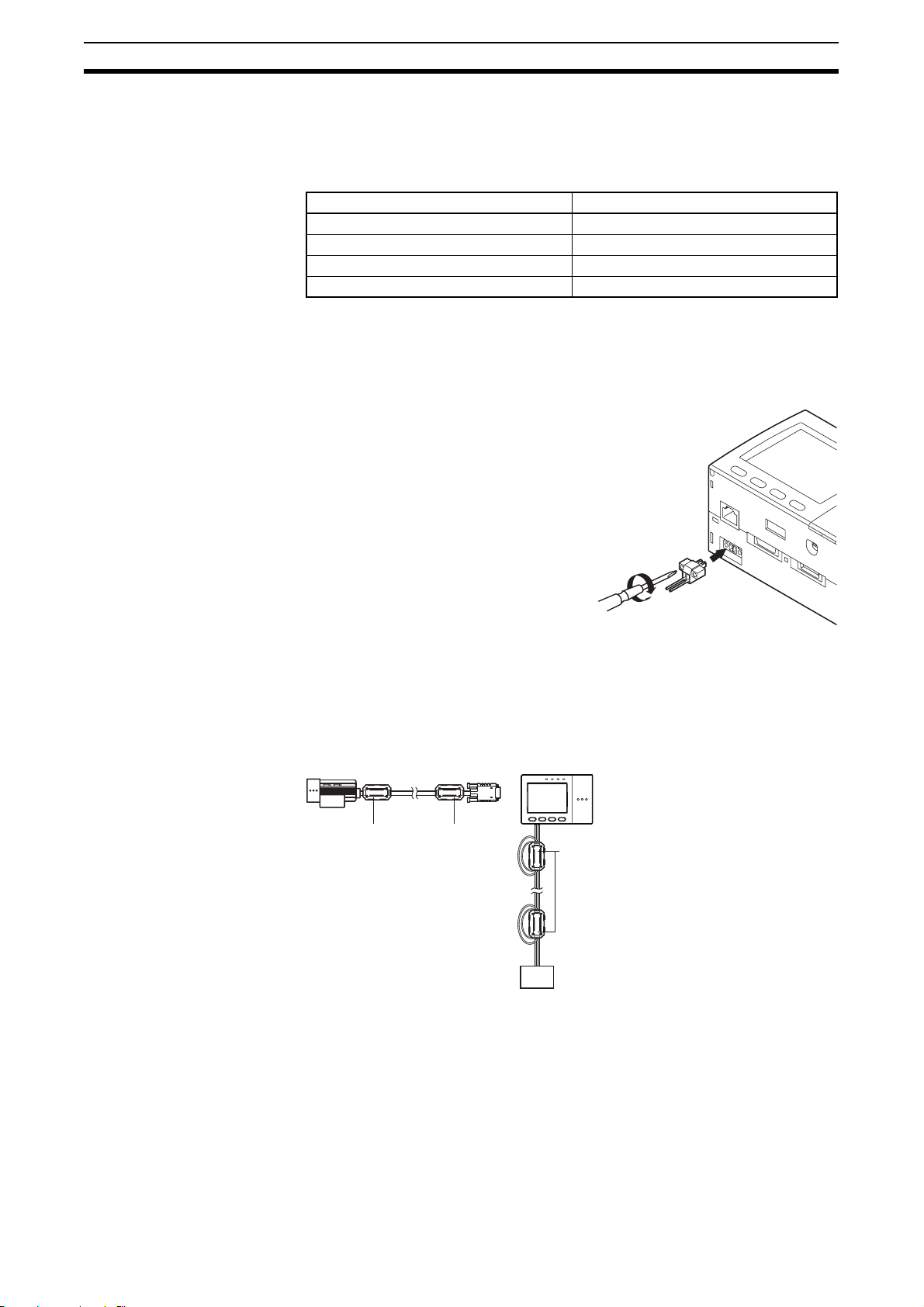

1-2 Connecting the Devices Preparation

1-2 Connecting the Devices

1-2-1 Connecting the Controller to the Power Supply

Use a power supply that meets the following specifications.

Item Specification

Power supply voltage Approx. 24 VDC (21.6 to 26.4 VDC)

Output current 1.5 A min.

Recommended power supply S8VS-06024 (24 VDC, 2.5 A)

Recommended electric wire size 0.14 to 1.5 mm² (max. 1 m)

Important Use a DC power supply with countermeasures against high voltages (safe

extra low-voltage circuits on the secondary side). If the system must meet UL

standards, use a UL class II power supply.

1. Loosen the two screws on the top of

the Power connector (male) using a

flat-blade screwdriver.

2. Insert the DC power terminal (wire)

into the Power connector (male) and

tighten the two screws on the top of

the Power connector to fasten the

power terminal with the screwdriver.

Tightening torque: 0.22 to 0.25 Nm.

3. Plug the Power connector (male) into

the Controller’s Power connector (female).

4. Tighten the two screws on the left and right of the Power connector (male)

with the screwdriver to fasten it. Tightening torque: 0.22 to 0.25 Nm.

+

-

24 VDC

1-2-2 Attaching Ferrite Cores

Attach ferrite cores (supplied) to both ends of the camera's cable and the

Controller's power cable, respectively.

Ferrite coreFerrite core

Ferrite core

When attaching ferrite cores to the

Controller's power cable, pass the

cable once through each ferrite core.

-

+

DC power

supply

6

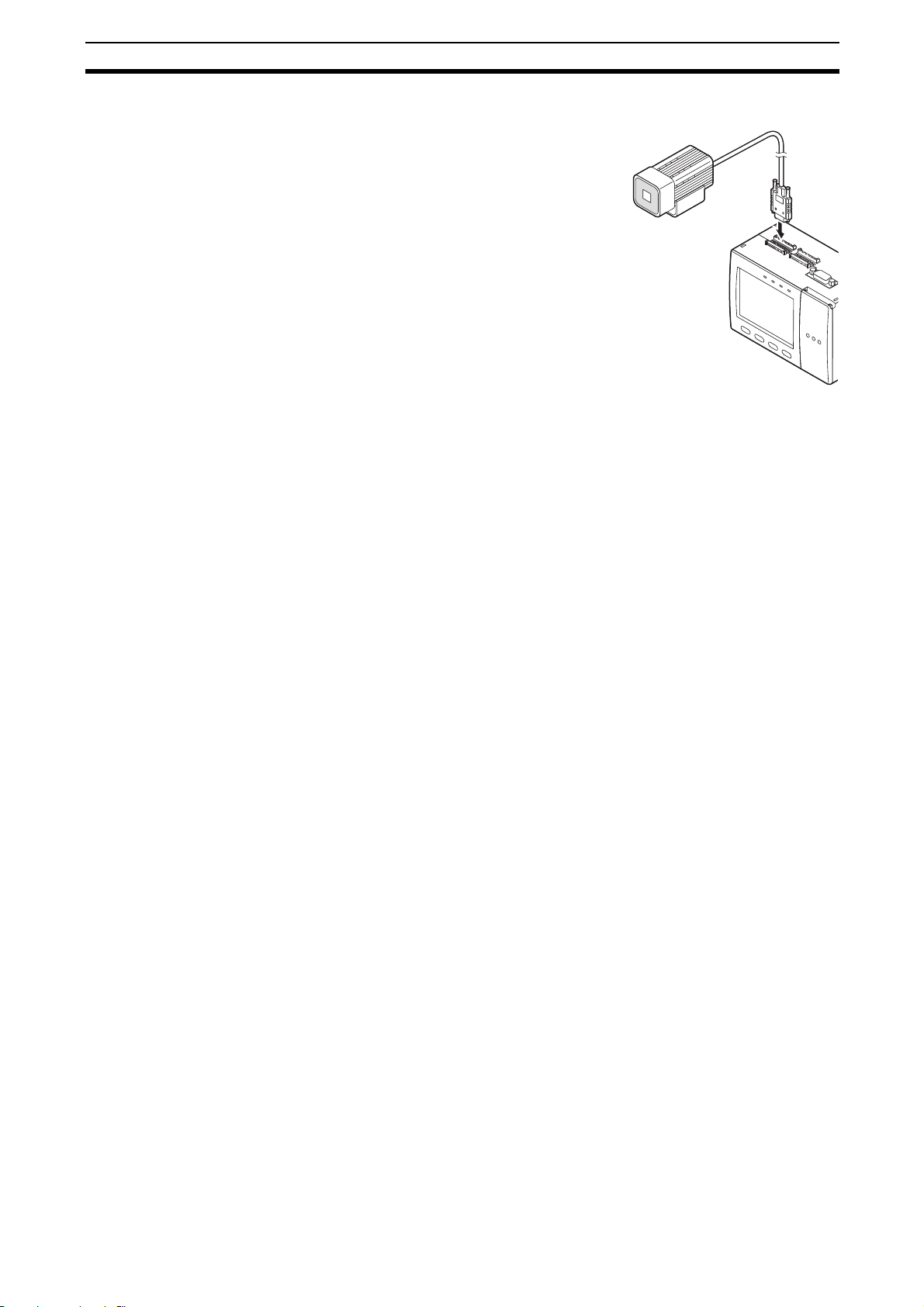

1-2 Connecting the Devices Preparation

1-2-3 Connecting the Camera to the Controller

1. Insert the camera’s connector into the

Controller’s Camera connector.

2. Tighten the two fastening screws of the

Controller’s Camera connector.

Tightening torque: 0.15 Nm.

Important Do not touch the terminals inside the connector.

Important Fasten the connector while making sure that it is not subjected to vibration or

shock.

Important Do not mount the Controller in such a way that a load is steadily applied on

the connector, for example, with tension applied to the cables.

Disconnection procedure

Loosen the fastening screws (two locations) to unlock the camera’s cable, and

then pull the camera’s cable connector straight out.

Important Be sure to hold the connector of the camera to disconnect it. Failure to do so

may damage the camera’s cable.

Important Do not touch the terminals inside the connector.

7

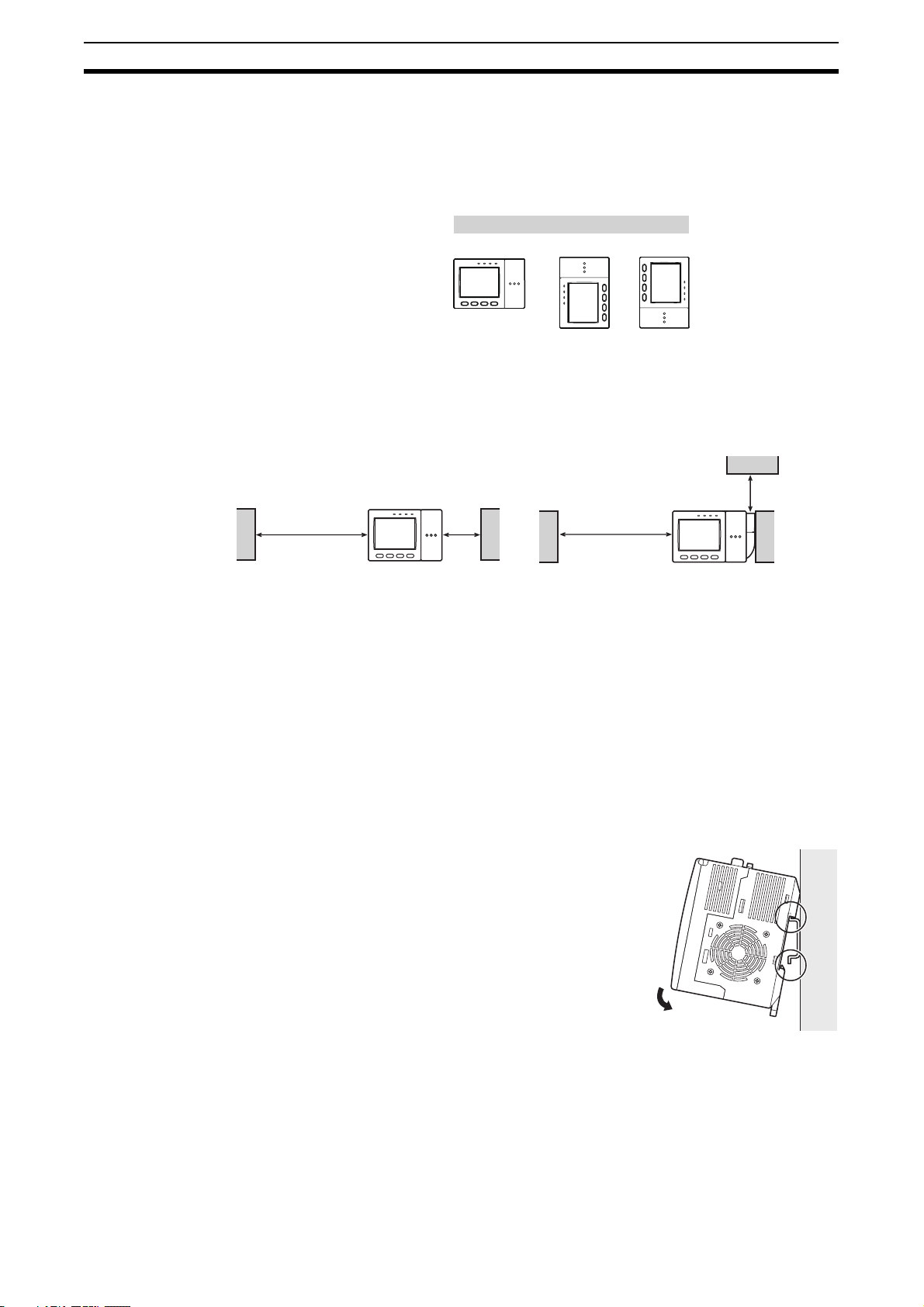

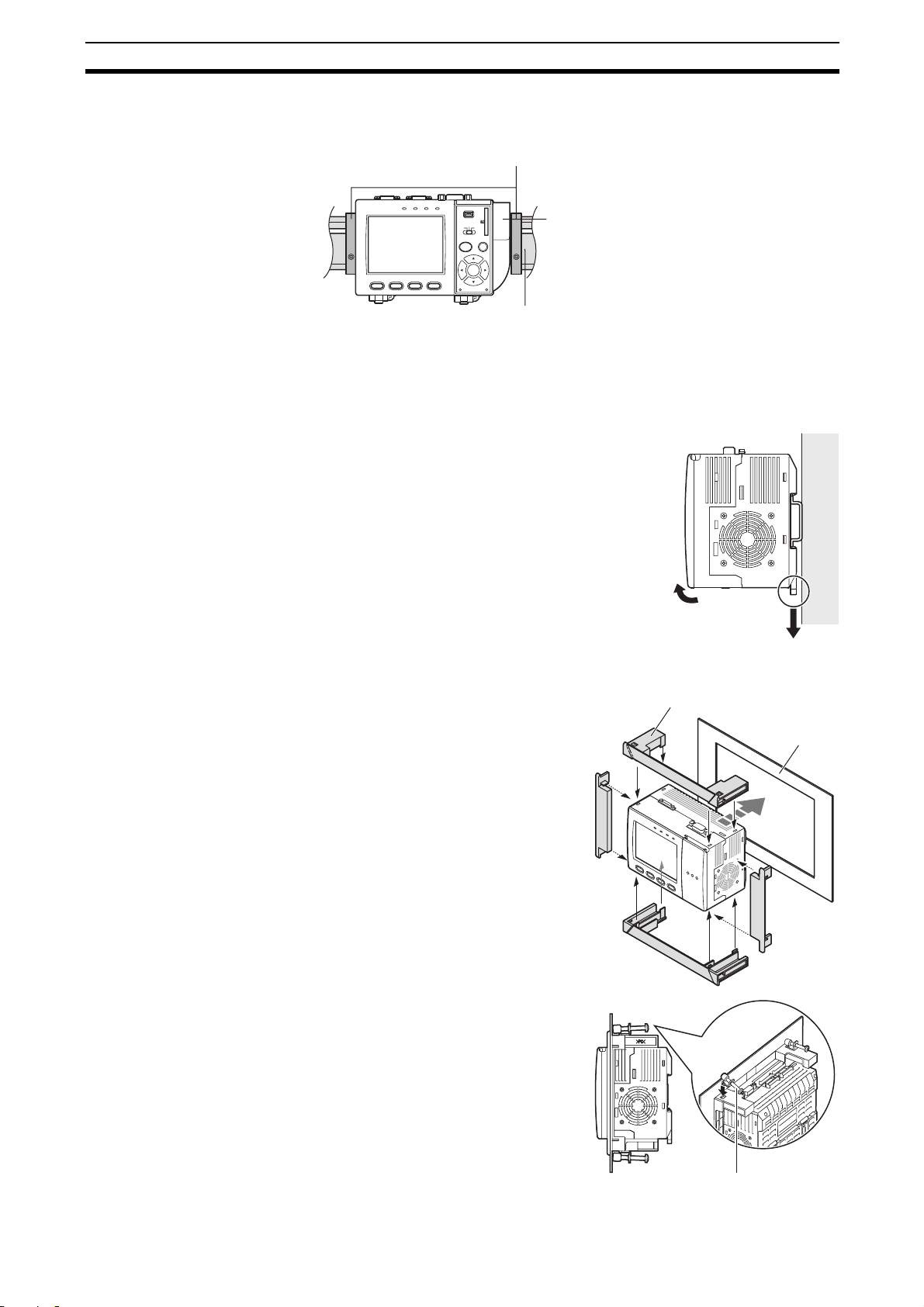

1-3 Installing the Controller Preparation

1-3 Installing the Controller

1-3-1 Installation Precautions

To improve heat radiation, install the Controller only in the orientation show

below.

Upward

Right

Important Install the Controller so that the distance between the Controller and other

devices is at least the dimensions shown in the figure below to improve the

ventilation.

When installing Controller only:

When installing the Controller With the Exhaust Unit

attached:

Wrong Wrong

Min. 15 mm

Min.

50 mm

Important Keep the ambient temperature less than 50 °C. If the ambient temperature is

higher than 50 °C, install a fan forced cooling system or an air conditioner to

keep the temperature lower than 50 °C.

Important Avoid mounting on a panel, in which high-voltage emitting devices are

installed to prevent ZFX-C operation from being affected by noise.

Important Allow at least 10 m between the Controller and power lines to keep noise at a

low level in the operating environment.

1-3-2 Installing on the DIN Track

1. Hook the Controller’s upper hook onto the

DIN track.

2. Push the Controller down onto the DIN track

until its lower hook is snapped into place.

Min.

15 mm

Min.

50 mm

1

2

Important Attach the End Plate (sold separately) to both sides of the Controller on the

DIN track.

8

1-3 Installing the Controller Preparation

Important Attach the Exhaust Unit (supplied) to the Controller when installing other

devices adjacently on the same DIN track as the Controller.

End Plate (sold separately)

PFP-M

Removing procedure

1. Pull the Controller’s lower hook downwards.

2. Lift up the Controller from its bottom to re-

OMRON

OUTPUT

RUN

ZFX-C10

1234

USB

ENABLE

ERROR

DIN track (sold separately)

SD

CARD

ADJ

MENU RUN

AUTO ESC

SET

PULL OPEN

PFP-100N (1 m)

PFP-50N (0.5 m)

PFP-100N2 (1 m)

move it from the DIN track.

Exhaust Unit

1

2

1-3-3 Mounting on the Panel

1. Install the long Panel Mount

Adapters on the four holes on the

Controller.

2. Install the short Panel Mount

Adapters on the two holes on the

long Panel Mount Adapter.

3. Install the Controller with Mount

Adapters attached onto the panel

from the front.

4. Hook the hooks of the mounting

bracket onto the two holes (two

each at top and bottom) of the

longer Mount Adapters and tighten the screws.

Tightening torque: 1.2 N•m.

5. Make sure that the Controller is

firmly fixed on the panel.

Panel mount adapters

Panel

1

3

2

2

1

4

Mounting bracket

9

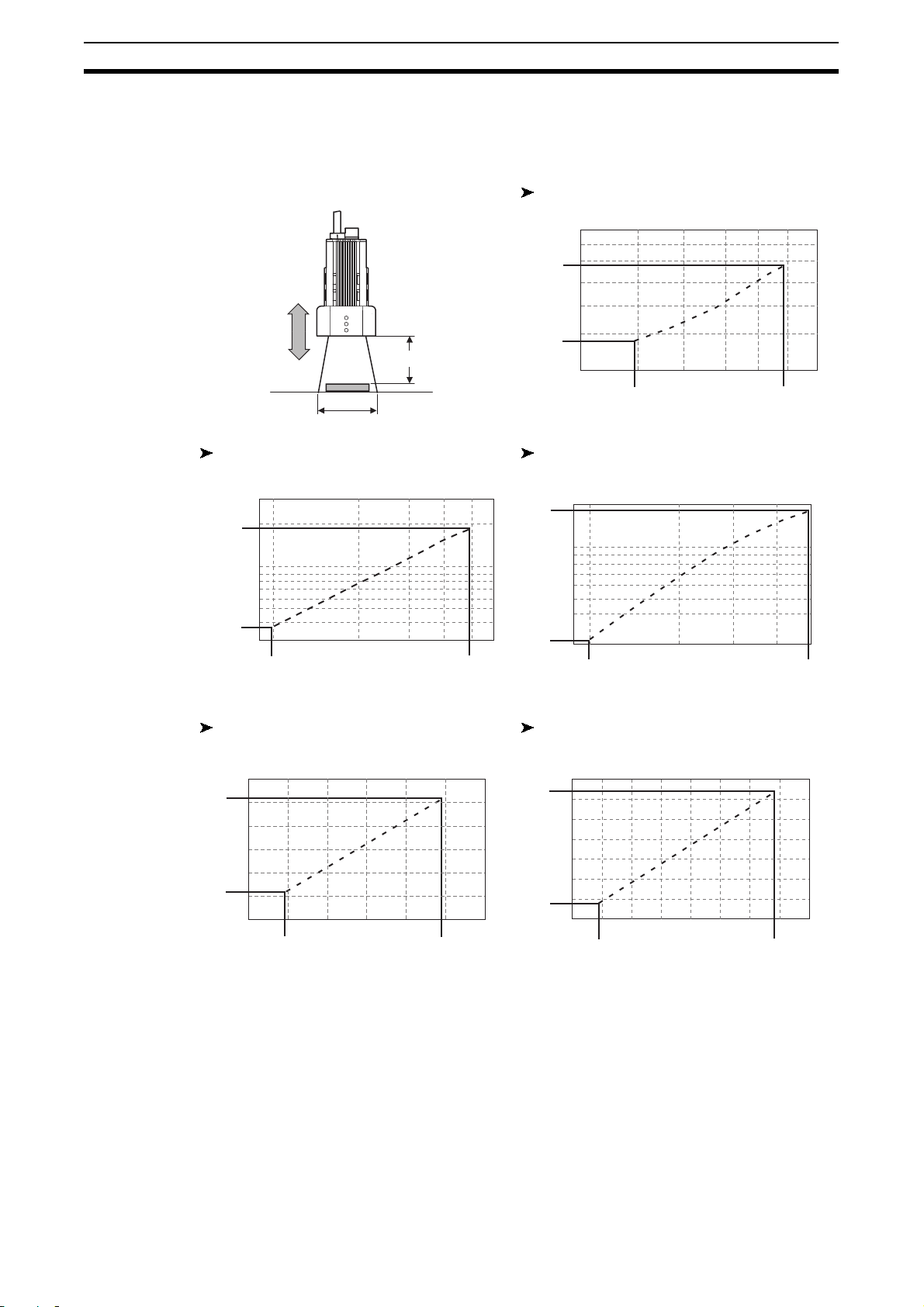

1-4 Installing the Intelligent Cameras Preparation

0

1-4 Installing the Intelligent Cameras

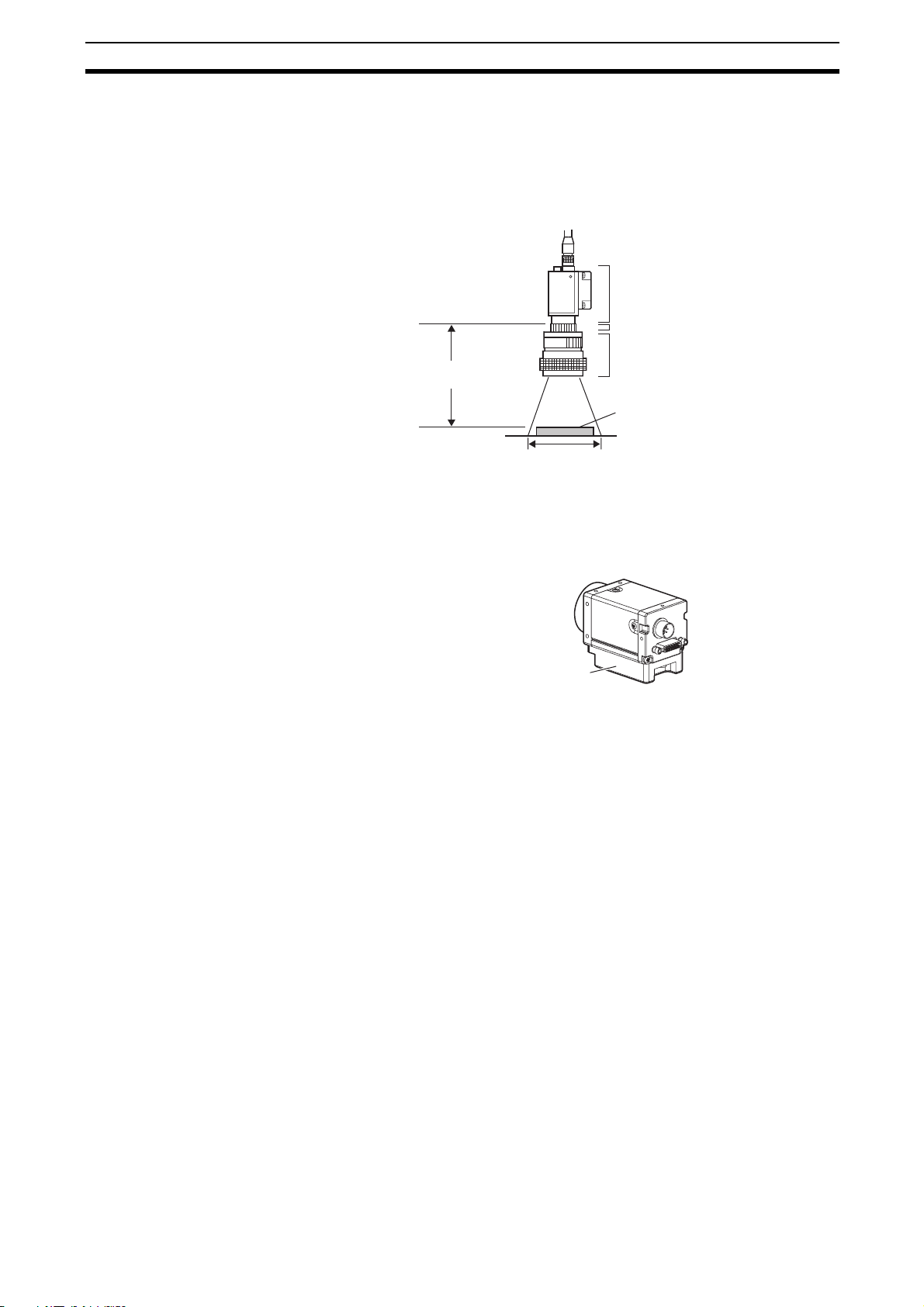

1-4-1 Optical chart

ZFX-SC10/SR10

Setting distance L (mm)

60

50

49

Setting distance (L)

Detection range (H)

ZFX-SR50 ZFX-SC50/SC50W

Setting distance L (mm)

300

194

100

38

30

9

9.8 49

Detection range H (mm)

ZFX-SC90/SC90W ZFX-SC150/SC150W

Setting distance L (mm)

160

142

6

34

0

Setting distance L (mm)

190

187

100

31

30

9.8

Setting distance L (mm)

240

227

4.9

Detection range H (mm)

Detection range H (mm)

104

8.9

49

10

67

115

180

100

89

12080

Detection range H (mm)

100

40

49

70

Detection range H (mm)

10040

89

Note • The lens has a fixed focal point. The actual detection range and focal point

vary from lens to lens, so adjust the distance to the measurement target

after replacing the lens or camera.

• The camera mounting distance listed in the following tables is an approximate value. Mount the Camera so that the distance to the measurement

target can be adjusted easily.

• If the object size and detection range are incompatible, use a combination

of a camera (without lighting), standard CCTV lens and light source.

160

148

1-4 Installing the Intelligent Cameras Preparation

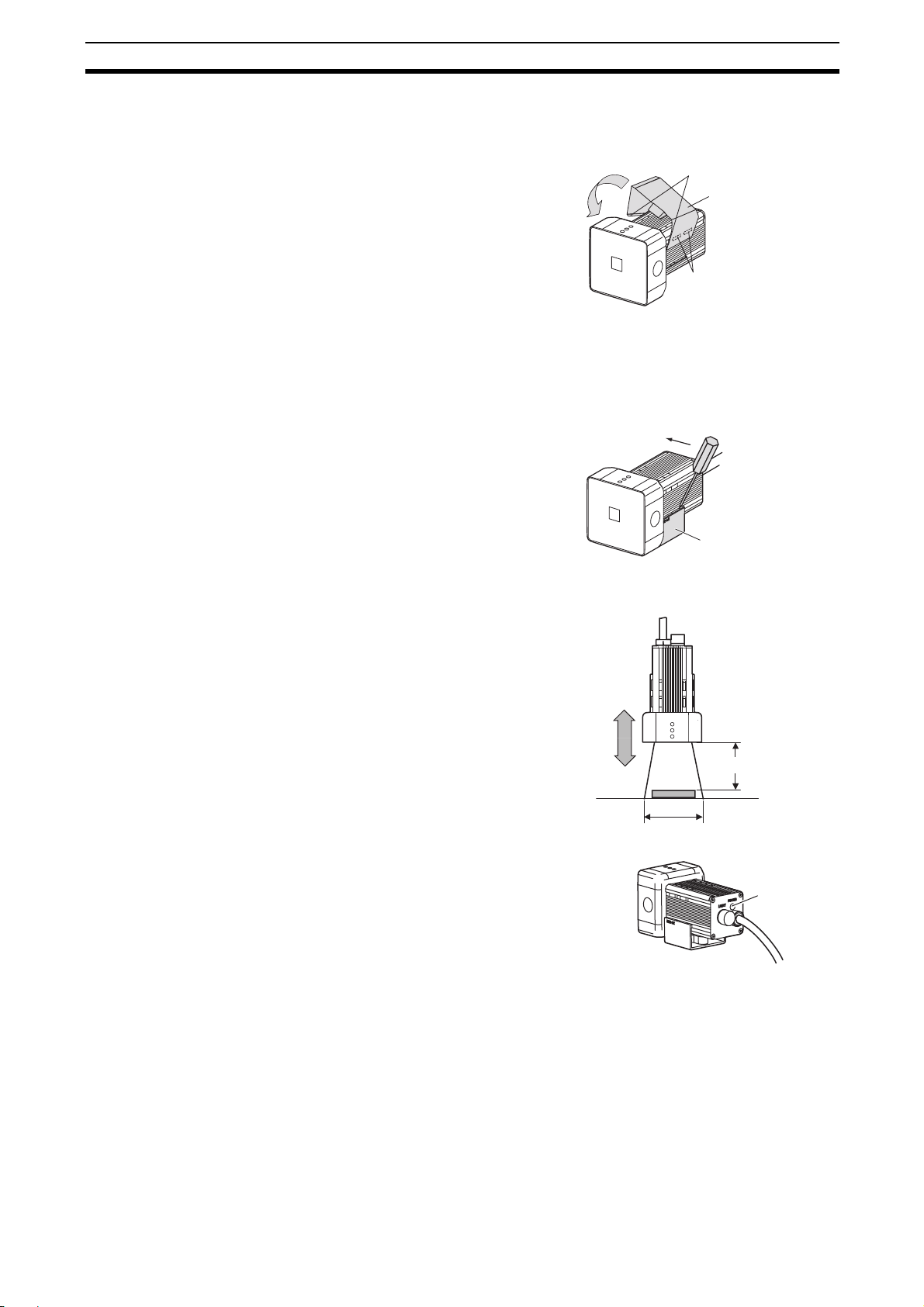

1-4-2 Installing the mounting fixture

The mounting fixture can be installed on all of the four mounting surfaces.

1. Align the two hooks on one side of

the mounting fixture with the two

grooves on the camera body.

2. Push the other hook down until it

is snapped into place.

Make sure that the mounting fixture is firmly fixed on the camera.

3. Fasten the mounting fixture at the

mounting location with screws.

Tightening torque

M4: 1.2 Nm

1/4”-20 UNC: 2.6 Nm

Removal procedure

1. Insert a screwdriver into the gap

(one of the two gaps) between the

mounting fixture and the camera

case, and remove the mounting

fixture.

Hooks

Mounting

fixture

Grooves on camera

1-4-3 Adjusting the camera focus

1. Adjust the distance between the

camera and the measurement target and fasten the camera.

Refer to the optical chart and set

the camera in a position so that

the area to be checked is within

the detection area (LCD monitor).

“Optical chart” p. 10.

2. Turn the focus adjustment control

to the left and right to adjust the

focus.

Mounting fixture

Setting distance (L)

Detection range (H)

Focus

adjustment

control

Note First turn the focus adjustment control slightly to the left and right, to make

sure that the Focus adjustment control is not at the upper or lower limit positions. Do not exert unnecessary force to turn the control at the upper or lower

limit positions as this might damage the control.

(For ZFX-SC90_/SC150_, the control stops turning at the nearest position. It

turns free at the farthest position.)

11

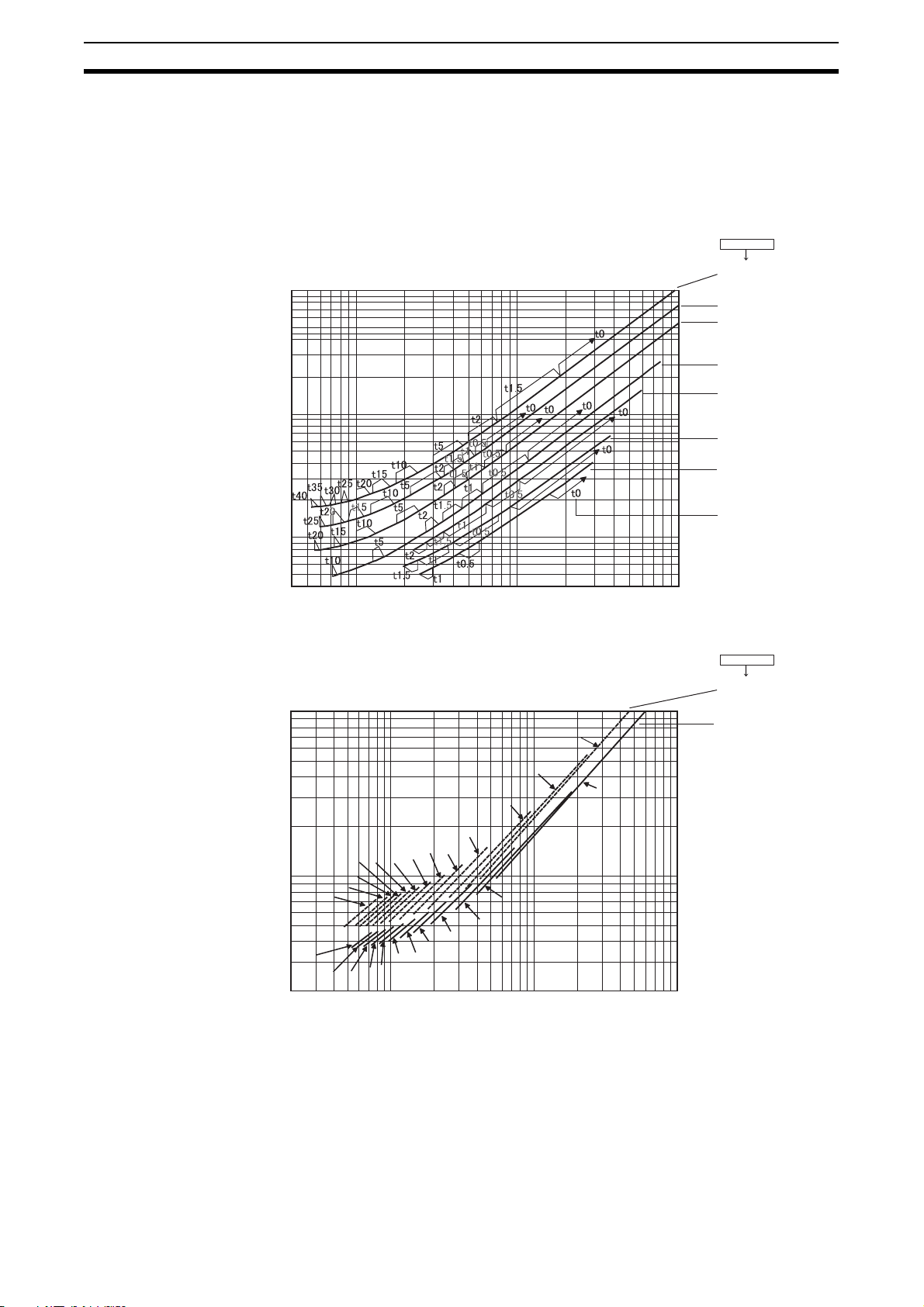

1-5 Installing the C-mount Cameras Preparation

1-5 Installing the C-mount Cameras

1-5-1 Optical chart

The values in the following chart are approximations, and the Camera must be

adjusted after it is mounted.

Lens model

3Z4S-LE

ML-5018

10000

ML-3519

ML-2514

ML-1614

Camera distance A(mm)Camera distance A(mm)

1000

10000

1000

100

40

4 10 100 1000

Detection range(mm)

t0

t2

t5

t10

t20

t15

t25

t35

t40

t30

t45

t50

t60

t10

t50

200

2 10 100 1000

t45

t40

t35

t30

t25

t20

t15

t2

t5

t0

Detection range(mm)

ML-1214

ML-0813

ML-0614

t: Extension tube

Example

t0: Extension tube

is not required.

t5: 5-mm extension

tube is required.

Lens model

3Z4S-LE

ML-10035

ML-7527

12

The X axis of the optical chart shows detection range L (mm), and the Y axis

shows the camera distance A (mm). The curves on the optical chart show the

relationship between the detection range and camera distance for each CCTV

lens. The values are significantly different for each lens, so double-check the

model of the lens before using the graph. The “t” values indicate the lengths of

the Extension Tubes. The value “t0” shows the case where an Extension Tube

1-5 Installing the C-mount Cameras Preparation

is not required and the value “t5.0” shows the case where a 5-mm Extension

Tube is used.

Example

When a 3Z4S-LE ML-5018 CCTV Lens is being used and a detection range of

40 mm is required at the measurement target, a camera distance of 500 mm

and 5-mm Extension Tube are required.

Camera

Extension Tube t_ (mm)

Lens

Camera distance A (mm)

Measurement object

Detection range L (mm)

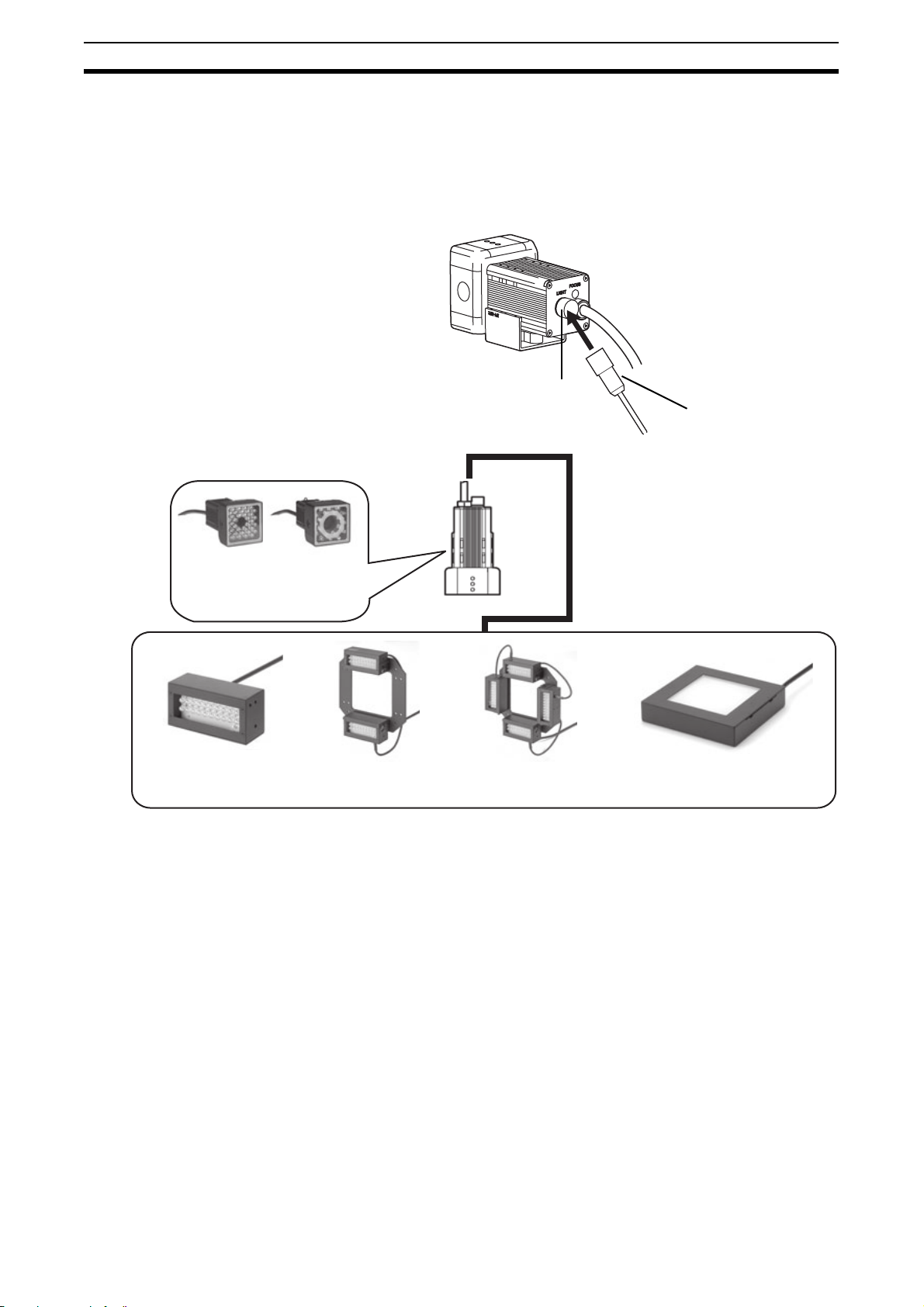

1-5-2 Installing the Camera Mounting Base

The camera mounting base mounted on the bottom of the camera can be

installed on all of the four mounting surfaces. To change the mounting surface,

remove the three mounting screws (M2 x 6) from the camera.

Camera Mounting Base

• Tightening torque when fastening the camera mounting base at the

mounting location

M4: 1.2 Nm

1/4”-20 UNC: 2.6 Nm

13

1-6 Installing the External Lightings (Only For ZFX-SC50/SC90) Preparation

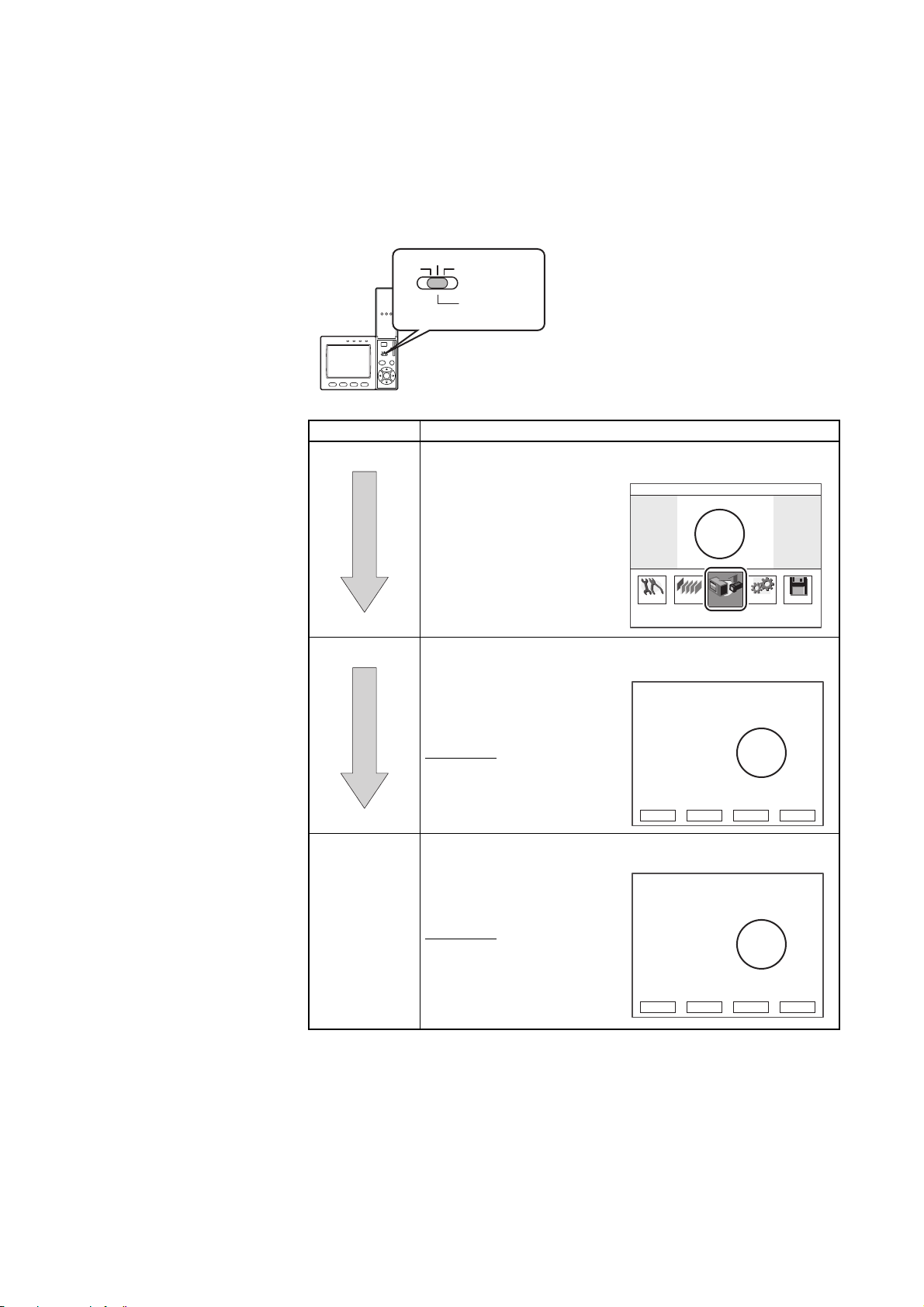

1-6 Installing the External Lightings (Only For ZFX-SC50/SC90)

1-6-1 Connecting the Optional Lighting to the Camera

The optional lighting can be mounted to the rear connector of the camera

(ZFX-SC50_/SC90_) with a single motion. Since the power is supplied from

the camera side, no power supply is required for the optional lighting.

ZFX-SC50 ZFX-SC90

Optional lighting can be used

with these two Cameras.

Bar Lighting

Double Bar Lighting

ZFV-LTL01

Remove the cap from the optional lighting connector on the rear of the camera.

ZFV-LTL02

Low-angle Bar Lighting

ZFV-LTL04

Connector of the

optional lighting

Through-beam Lighting

ZFV-LTF01

14

1-7 Installing the External Lightings (Only For C-mount Camera (ZFX-S/SC)) Preparation

1-7 Installing the External Lightings (Only For C-mount Camera (ZFX-S/SC))

1-7-1 Connecting the Optional Lighting to the camera

The optional lighting can be connected to the Strobe Controller. And the

Strobe Controller can be connected to the camera (ZFX-S/SC). No power

supply is required for the optional lighting.

Strobe Controller

Strobe Controller

3Z4S-LT MLEK-C100E1TSX

External Lighting

3Z4S-LT Series

The lighting that current consumption is 1.0A or less can be connected

15

1-7 Installing the External Lightings (Only For C-mount Camera (ZFX-S/SC)) Preparation

16

2-1 Operation Mode

ADJ

MENU

RUN

MENU mode This mode is for setting the

Main Operation

The ZFX-C has the following three

ADJ

MENU

RUN

Mode switch

Mode Description

measurement conditions.

The easy-to-follow iconbased display allows operations to be performed intuitively.

modes. Switch to the desired mode

before you start operation. To switch

the operation mode, use the mode

switch.

SECTION 2

Top Screen

Top menu

LIVE

TEA

ADJ mode This mode is for checking

the measurement status and

adjusting conditions. Measurement results are only

displayed on the monitor and

are not output.

Important

Trigger input isn’t acceptable

RUN mode This mode is used for per-

forming actual measurement. Measurement results

are displayed on the monitor and output.

Important

Measurement trigger by

menu operation is to push

[SET]-key & [UP]-key

Bank

Tool

Top Screen

353ms

OK

Camera 0

0.Bank00

0.Pattern Search

Judge OK

Correlation 92

Position X 462

Position Y 352

Angle 15

Previous Next

Top Screen

353ms

OK

Camera 0

0.Bank00

0.Pattern Search

Judge OK

Correlation 92

Position X 462

Position Y 352

Angle 15

Previous Next

System

Setup

Individual result

TEA

Dsplay SW

Individual result

TEA

Dsplay SW

Save

Adjust

Capture

17

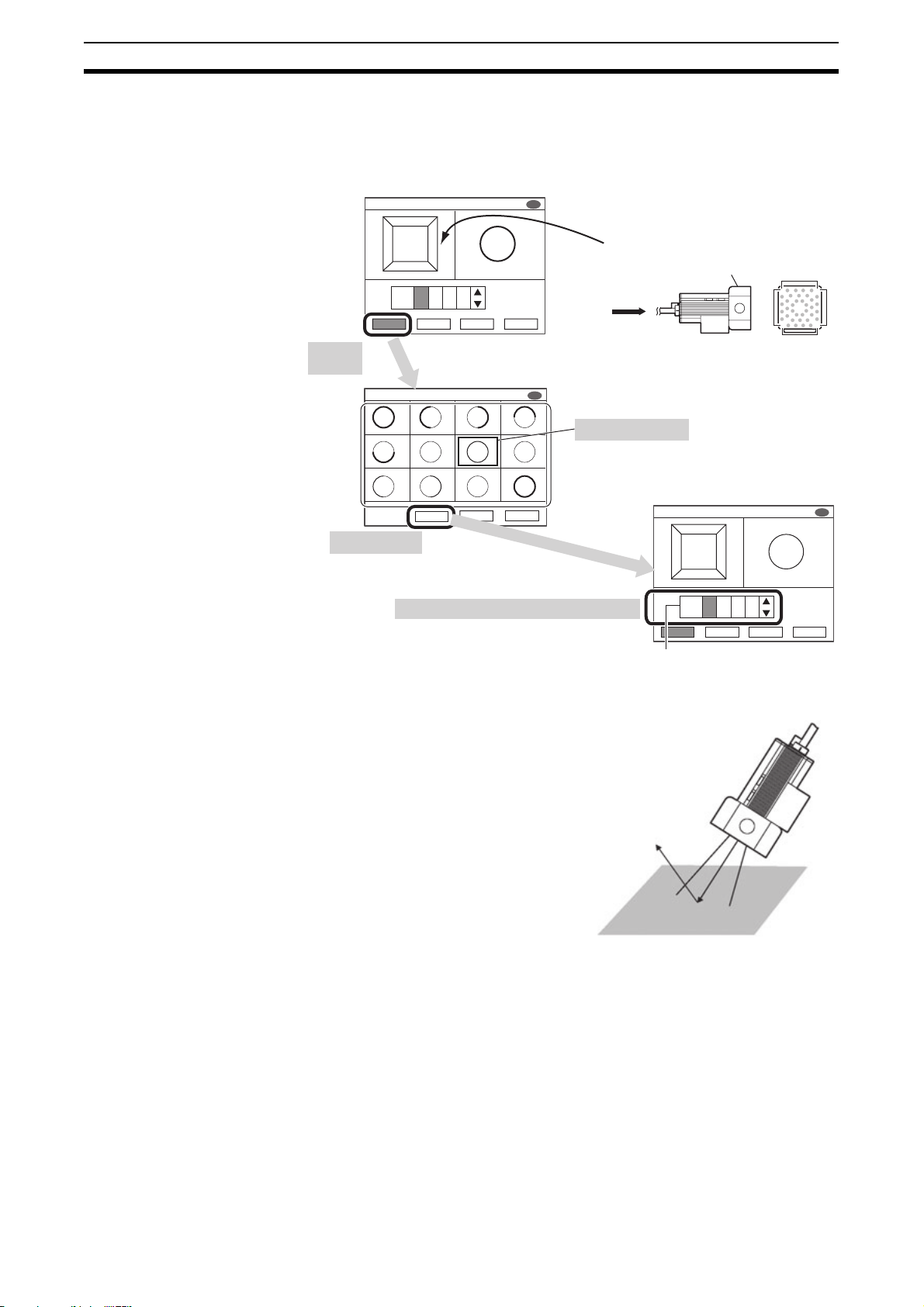

2-2 Adjusting the brightness of image Main Operation

2-2 Adjusting the brightness of image

2-2-1 Lighting Intensity (Only the intelligent Cameras)

MENU mode - [Setup] - [Cameras] - [Light Control]

1. Push

"Auto"

Light Control

A

DB

C

5

5

5B5

A

D

ALL

Auto

C

CancelApply Capture

The thumbnails of images automatically captured

under differen illumination patterns are displayed

TEA

SD

How blocks are displayed

Top surface (surface printed with model No.)

View from

this side

A

D

C

B

Light Control

TEA TEA TEA TEA

TEA TEA TEA TEA

TEA TEA TEA

Apply

Cancel

SD

Capture

3. Push "Apply"

The lighting condition of the

selected image is displayed

4. Fine-adjust these conditions as required.

Important If the workpiece is glossy, install the

camera at an angle to prevent mirror

reflection light from being picked up by

the camera.

2. Select the image

A

D

C

ALL

Auto

Auto

Amount of emitted light

Mirror reflection light

Light Control

B

2A3B2C3

Apply Cancel Capture

TEA

D

SD

18

Loading...

Loading...