Page 1

Enclosed Switch

ZC-@55

Small, High-precision Enclosed Switch

• Employs a modified version of Z Basic Switch as built-in switch.

• Same mounting pitch as Z Basic Switch.

• Pre-wired molded terminal models are available.

• Requires less operating force than conventional limit switches.

• Long life expectancy and economical.

• UL, CSA, and EN models are available.

Model Number Structure

■ Model Number Legend

ZC-@55

1

1. Actuator

D: Plunger

Q: Panel mount plunger

Q22: Panel mount roller plunger

Q21: Panel mount crossroller plunger

N22: Sealed roller plunger

N21: Sealed crossroller plunger

Ordering Information

■ List of Models

Actuator Model Actuator Model

Plunger

Panel mount

plunger

Panel mount

roller plunger

Panel mount

crossroller plunger

ZC-D55 ZC-W55

ZC-Q55 ZC-W155

ZC-Q2255 ZC-W255

ZC-Q2155 ZC-W2155

W: Short hinge lever

W1: Hinge lever

W2: Short hinge roller lever

W21: Hinge roller lever

W3: One-way action short hinge roller lever

W31: One-way action hinge roller lever

Short hinge

lever

Hinge lever

Short hinge

roller lever

Hinge roller

lever

Limit

Switches

Sealed roller

plunger

Sealed crossroller

plunger

Note: 1. Use molded terminal models (refer to page 117) when using the Switch under one of the following conditions:

a) dusty, b) high amount of dripping oil, or c) high humidity

2. Micro-load models are available.

e.g. Standard model

ZC-Q55 ZC-Q55-01

ZC-N2255 ZC-W355

ZC-N2155 ZC-W3155

Micro-load model

One-way action

short hinge roller

lever

One-way action

hinge roller lever

Enclosed Switch ZC-@55 F-109

Page 2

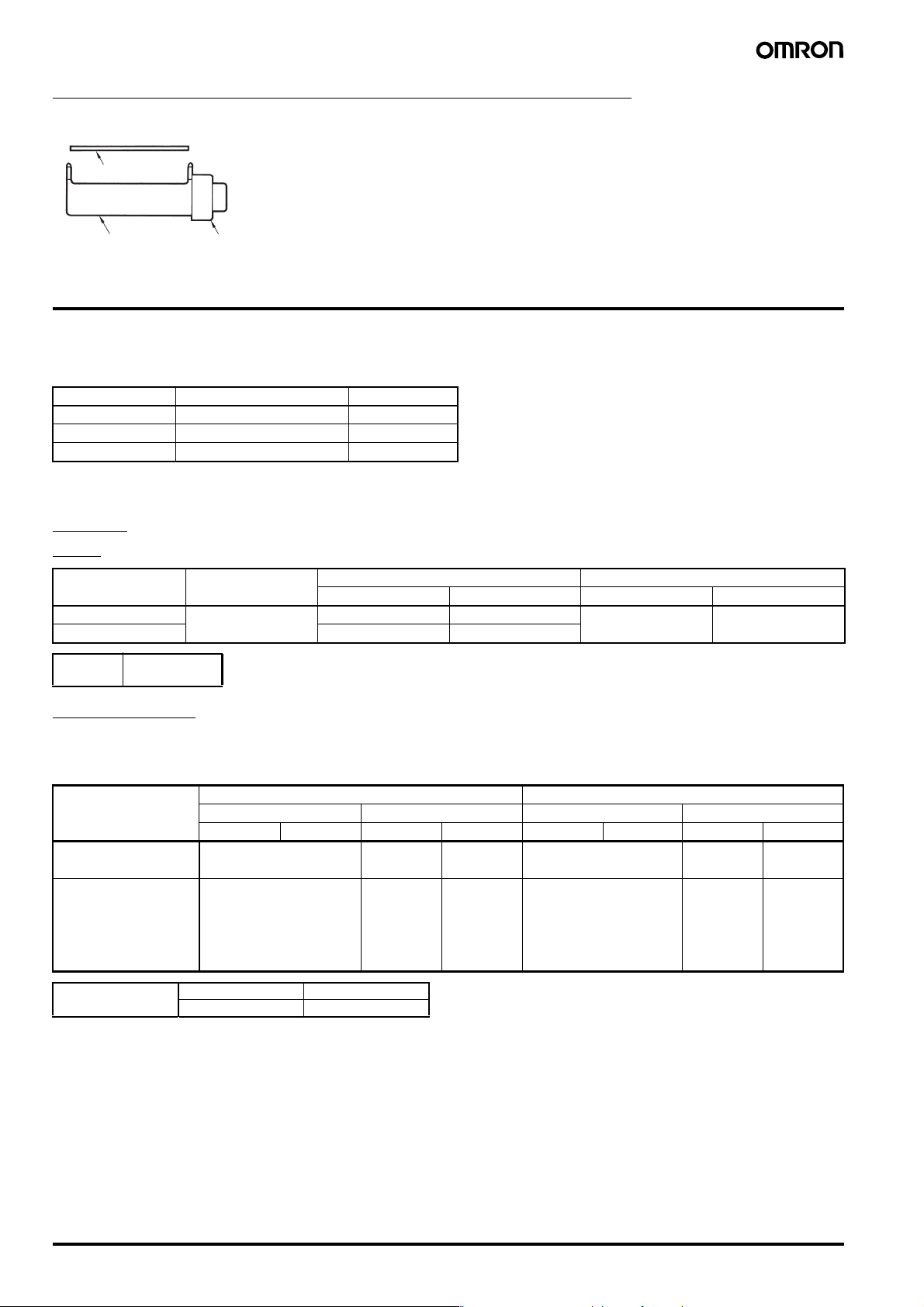

Terminal Protective Cover, Seal Rubber, and Rubber Packing

(The Switch is equipped with these 3 items as a standard.)

• ZC Terminal Cover

Rubber packing

Terminal cover

Seal rubber

(Product code: ZC55-0002H)

• ZC Seal Rubber

(Product code: SC-1404C)

• ZC Rubber Packing

(Product code: ZC55-9999G)

Specifications

■ Approved Standards

(Except Molded Terminal Models and Operation Indicator-equipped Model)

Agency Standard File No.

UL UL508 E76675

CSA C22.2, No. 14 LR45258

TÜV Rheinland EN60947-1, EN60947-5-1 J9650089

■ Approved Standard Ratings

UL/CSA

A300

Voltage Carry current Current Volt-amperes

Make Break Make Break

120 VAC 10 A 60 A 6 A 7,200 VA 720 VA

240 VAC 30 A 3 A

Micro load 0.1 A, 125 VAC

0.1 A, 30 VDC

TÜV Rheinland

250 V, 10 A (AC12)

■ Ratings

Rated voltage Non-inductive load Inductive load

Resistive load Lamp load Inductive load Motor load

NC NO NC NO NC NO NC NO

125 VAC 10 A 3 A 1.5 A 10 A 5 A 2.5 A

250 VAC 10 A 2.5 A 1.25 A 10 A 3 A 1.5 A

8 VDC 10 A 3 A 1.5 A 6 A 5 A 2.5 A

14 VDC 10 A 3 A 1.5 A 6 A 5 A 2.5 A

30 VDC 6 A 3 A 1.5 A 5 A 5 A 2.5 A

125 VDC 0.5 A 0.4 A 0.4 A 0.05 A 0.05 A 0.05 A

250 VDC 0.25 A 0.2 A 0.2 A 0.03 A 0.03 A 0.03 A

Inrush current NC 30 A max.

NO 15 A max.

Note: 1. The above figures are for steady-state currents.

2. Inductive loads have a power factor of 0.4 min. (AC) and a time constant of 7 ms max. (DC).

3. Lamp load has an inrush current of 10 times the steady-state current.

4. Motor load has an inrush current of 6 times the steady-state current.

5. The above ratings were tested under the following conditions according to JIS C4508.

Ambient temperature: 20±2°C

Ambient humidity: 65±5%

Operating frequency: 20 operations/min

F-110 Enclosed Switch ZC-@55

Page 3

■ Characteristics

Degree of protections IP67

Durability Mechanical: 10,000,000 operations min.

Operating speed 0.05 mm to 0.5 m/s (at pin plunger)

Operating frequency Mechanical: 120 operations/min

Insulation resistance 100 MΩ min. (at 500 VDC)

Contact resistance 15 mΩ max. (initial value)

Dielectric strength 1,000 VAC, 50/60 Hz for 1 min between non-continuous terminals

Rated insulation voltage (U

Pollution degree

(operating environment)

Short-circuit protective device 10 A-fuse type gG (IEC 269)

Protection against electric

shock

PT1 (tracking characteristics) 175

Switch category D (IEC335)

Rated operating current (Ie) 10 A

Rated operating voltage (Ue) 250 VAC

Vibration resistance Malfunction: 10 to 55 Hz, 1.5-mm double amplitude (see note)

Shock resistance

Ambient temperature Operating: –10°C to 80°C (with no icing)

Ambient humidity Operating: 35% to 95%

Weight Approx. 92 g (in case of ZC-Q22(21)55)

Note: Less than 1 ms under a free state at the operating limits.

Electrical: 500,000 operations min.

Electrical: 20 operations/min

2,000 VAC, 50/60 Hz for 1 min between current-carrying metal part and ground, and between each terminal

and non-current-carrying metal parts

) 1,000 VAC

i

3 (IEC947-5-1)

Class II

2

Destruction: 1,000 m/s

Malfunction: 300 m/s

max.

2

max. (at pin plunger) (see note)

Limit

Switches

■ Operating Characteristics

Model ZC-D55 ZC-Q55 ZC-Q2255 ZC-Q2155 ZC-N2255 ZC-N2155

OF max. 11.8 N 11.8 N 6.86 N

RF min. 4.90 N 4.90 N 1.67 N

PT max. 1.5 mm 1.5 mm 1.5 mm

OT min. 2.4 mm 3 mm 2.5 mm

MD max. 0.2 mm 0.2 mm 0.2 mm

OP 32.4±0.8 mm 38.2±0.8 mm 47.4±0.8 mm

Model ZC-W55 ZC-W155 ZC-W255 ZC-W2155 ZC-W355 ZC-W3155

OF max. 3.92 N 2.75 N 3.92 N 2.75 N 3.92 N 2.75 N

RF min. 0.78 N 0.59 N 0.78 N 0.59 N 0.78 N 0.59 N

OT min. 6 mm 8.4 mm 6 mm 8.4 mm 6 mm 8.4 mm

MD max. 1 mm 1.4 mm 1 mm 1.4 mm 1 mm 1.4 mm

OP 28.5±1.2 mm 28.5±1.2 mm 43±1.2 mm 43±1.2 mm 53±1.2 mm 53±1.2 mm

FP max. 34.7 mm 36.7 mm 49.2 mm 51.3 mm 59.2 mm 61.2 mm

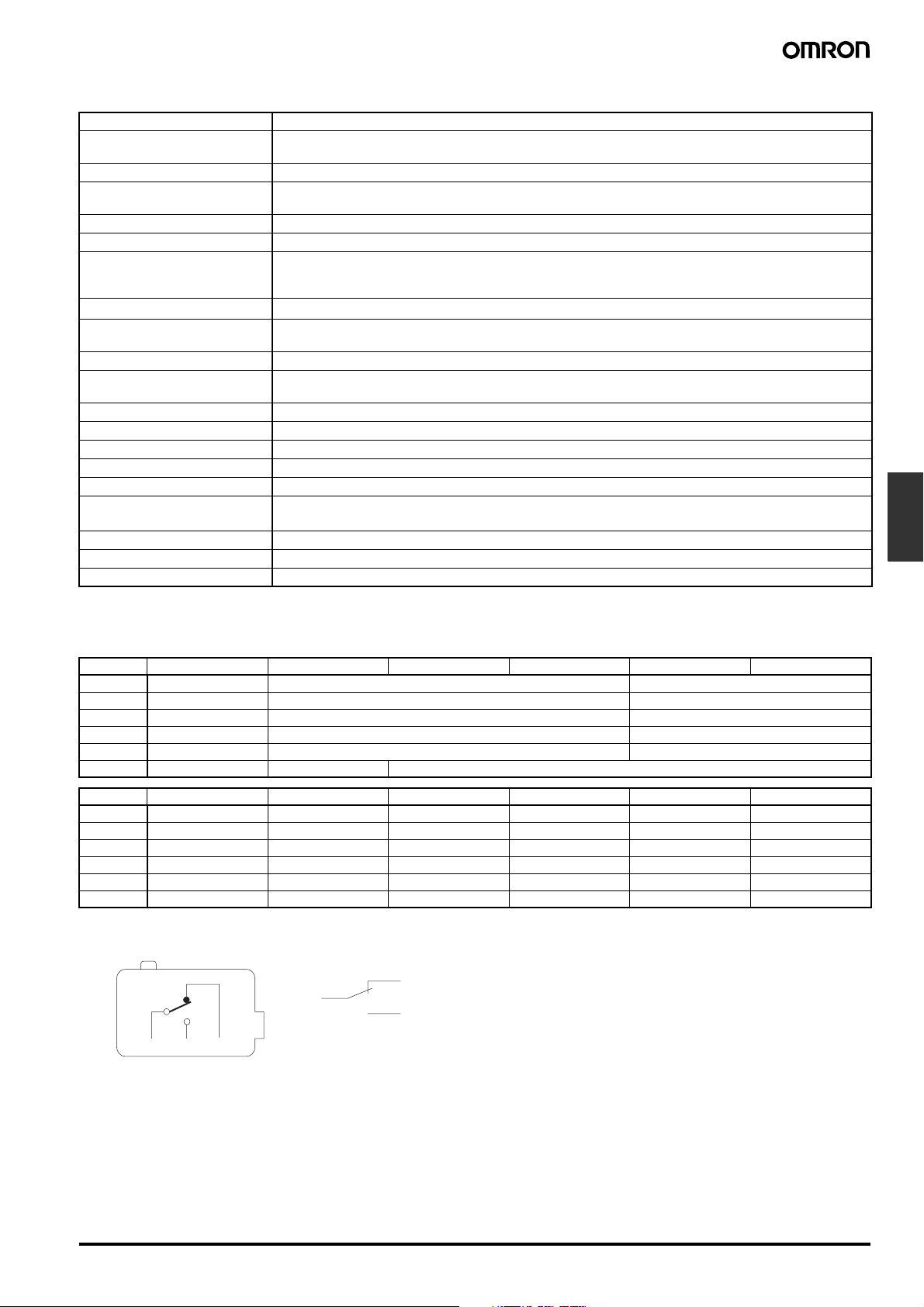

■ Contact Form

NC

COM NO NC

COM

EN60947-5-1

NO

Enclosed Switch ZC-@55 F-111

Page 4

Engineering Data

)

■ Mechanical Durability

■ Electrical Durability

(for ZC-Q55)

Operating temperature: 20±2°C

Operating humidity: 65±5%

No load

Operating frequency: 120 operations/min

operations)

operations)

4

Durability (x 10

OT (mm)

4

Durability (x 10

Operating temperature: 20±2°C

Operating humidity: 65±5%

Operating frequency: 20 operations/min

Switching current (A

Nomenclature

Changing the Terminal Protective Cover around allows the cable to be pulled out from either the right or the left.

Roller

Plunger

Case

NC fixed contact

Switch

Packing

Terminal

Protective

Cover

Common

terminal

(COM)

Normally

open

terminal

(NO)

Normally

closed

terminal

(NC)

Moving contact

NO fixed contact

Seal rubber

Note: M4 binding head screws (with toothed washers) are used as the terminal screws.

F-112 Enclosed Switch ZC-@55

Page 5

Dimensions

Note: 1. All units are in millimeters unless otherwise indicated.

2. Unless otherwise specified, a tolerance of ±0.4 mm applies to all dimensions.

Plunger

ZC-D55

7.8 dia.

(see note)

22 max.

15

Terminal

Protective

Cover

Two, 4.3±0.1 dia.

mounting holes

14 dia

(21 × 21)

Note: Stainless steel plunger

Seal rubber (NBR)

Panel Mount Plunger

ZC-Q55

22 max.

(See

note 2)

Terminal

Protective

Cover

7.8 dia.

(see note 1)

M14 × 1 mounting screw

Two hexagon nuts

(thickness: 3

width: 17)

(15)

Two, 4.3±0.1 dia.

mounting holes

(21 × 21)

Note: 1. Stainless steel plunger

Seal rubber (NBR)

2. The length of the imperfect threads

is 1.5 mm maximum.

3. Do not use the M14 mounting

screw and the case mounting hole

at the same time.

Limit

Switches

Enclosed Switch ZC-@55 F-113

Page 6

Panel Mount Roller Plunger

ZC-Q2255

(See

note 2)

11 dia. × 4.7

(see note 1)

Set position

indication line

Two hexagon nuts

(thickness: 3

width: 17)

M14 × 1 mounting

screw

22 max.

Terminal

Protective

Cover

Panel Mount Crossroller Plunger

22 max.

Set position

indication

line

Terminal

Protective

Cover

ZC-Q2155

Sealed Roller Plunger

ZC-N2255

22 max.

Terminal

Protective

Cover

Sealed Crossroller Plunger

ZC-N2155

15

Two, 4.3±0.1 dia.

mounting holes

M14 × 1 mounting

screw

Two hexagon nuts

(thickness: 3

width: 17)

15

Two, 4.3±0.1 dia.

mounting holes

9.5 dia. × 4.7

(see note)

Rubber boot

(chloroprene

rubber)

15

Two, 4.3±0.1 dia.

mounting holes

Rubber boot

(chloroprene

rubber)

(21

× 21)

11 dia. × 4.7

(see note 1)

× 21)

(21

× 21)

(21

Seal rubber (NBR)

Seal rubber (NBR)

Seal rubber (NBR)

9.5 dia. × 4.7

(see note)

Note: 1. Stainless sintered alloy roller

2. The length of the imperfect

threads is 1.5 mm maximum.

3. Do not use the M14 mounting

screw and the case mounting

hole at the same time.

Note: 1. Stainless sintered alloy roller

2. The length of the imperfect

threads is 1.5 mm maximum.

3. Do not use the M14 mounting

screw and the case mounting

hole at the same time.

Note: Stainless sintered alloy roller

22 max.

Terminal

Protective

22 max.

Cover

t = 1

(see note)

5

Terminal

Protective

Cover

Short Hinge Roller Lever

ZC-W55

F-114 Enclosed Switch ZC-@55

34.6

50R

15

Two, 4.3±0.1 dia.

mounting holes

15

Two, 4.3±0.1 dia.

mounting holes

(21

(21

× 21)

× 21)

Note: Stainless sintered alloy roller

Seal rubber (NBR)

Note: Stainless steel lever

Seal rubber (NBR)

Page 7

Hinge Lever

ZC-W155

Short Hinge Roller Lever

ZC-W255

22 max.

t = 1

(see note)

Terminal

Protective

Cover

t = 1

(see note1)

34.6

34.6

50R

70R

15

Two, 4.3±0.1 dia.

mounting holes

(21 × 21)

12.7 dia. × 7.5

(see note 2)

Note: Stainless steel lever

Seal rubber (NBR)

22 max.

Terminal

Protective

22 max.

Cover

t = 1

(see note1)

Terminal

Protective

Cover

Hinge Roller Lever

ZC-W2155

One-way Action Short Hinge Roller Lever

ZC-W355

t = 1

(see note1)

22 max.

Terminal

Protective

Cover

One-way Action Hinge Roller Lever

ZC-W3155

34.6

34.6

Angle of

roller

swing:

90

°

54R

34.6

70R

Operating

direction

15

Two, 4.3±0.1 dia.

mounting holes

15

Two, 4.3±0.1 dia.

mounting holes

15

Two, 4.3±0.1

dia. holes

Operating

direction

(21 × 21)

(21 × 21)

12.7 dia. × 7.5

(see note 2)

(21 × 21)

12.7 dia. × 7.5

(see note 2)

Seal rubber (NBR)

12.7 dia. × 7.5

(see note 2)

Seal rubber (NBR)

Seal rubber (NBR)

Note: 1. Stainless steel lever

2. Stainless steel roller

Note: 1. Stainless steel lever

2. Stainless steel roller

Note: 1. Stainless steel lever

2. Stainless steel roller

Limit

Switches

22 max.

t = 1

(see note1)

Terminal

Protective

Cover

73R

Angle of

roller

swing:

90°

15

Two, 4.3±0.1 dia.

mounting holes

(21 × 21)

Note: 1. Stainless steel lever

2. Stainless steel roller

Seal rubber (NBR)

Enclosed Switch ZC-@55 F-115

Page 8

■ Operation Indicator-equipped Models

All the models can be equipped upon request with a operation indicator to facilitate maintenance and inspection.

Because the indicator is incorporated in the Terminal Protective Cover, the dimensions of the Limit Switch are not affected. In this model, the lead

wire is to be connected to the screw terminal. (A connecting washer is provided on the tip of the lead wire).

The lead wire can be connected to either the NC or NO terminal.

Operating characteristics are the same as the standard model from which the operation indicator equipped model is fabricated.

AC Operation

The operating voltage range is from 90 to 250 VAC.

The dimensions are the same as the standard type. The top of the

Terminal Protective Cover is transparent to allow checking the operation easily.

When placing your order for the indicator equipped, AC-operated

model, add suffix “L” to the end of the model number.

Example:

Standard type: ZC-Q2255

Indicator equipped type: ZC-Q2255-L

Neon lamp position

DC Operation

The DC-operated is provided with an LED indicator.

Since a rectifier stack is incorporated into the unit to permit reversing

the polarity, this type can also operate on AC power source. An external 24VDC power supply can be used, eg. OMRON S8VS or S82K.

The LED projects from the housing for easy visibility.

When placing your order, add suffix “L2” to “L5” to the model number

of the standard type.

Example:

Standard type: ZC-Q2255

Indicator equipped type: ZC-Q2255-L2

Terminal Protective Cover (transparent)

Contact Circuit

NC terminal

NO terminal

Note: If the wiring is as shown above, the operation of the respective

parts will be as follows:

Contact Neon lamp Load Actuator

NC ON Does not operate Operates

OFF Operates Does not

NO ON Does not operate Does not

OFF Operates Operates

Power source

Neon lamp

Built-in switch

Power source

Built-in switch

Neon lamp

R = 240 k

Load

Load

R = 240 kΩ

Ω

operate

operate

LED

Type Voltage rating Leakage current Internal

resistance

L2 12 V Approx. 2.4 mA 4.3 kΩ

L4 24 V Approx. 1.2 mA 18 kΩ

Contact Circuit

NC terminal

NO terminal

Note: If the wiring is as shown above, the operation of the respective

parts will be as follows:

Contact LED Load Actuator

NC ON Does not operate Operates

OFF Operates Does not operate

NO ON Does not operate Does not operate

OFF Operates Operates

Power source

LED

Resistance

Load

Built-in switch

Power source

Built-in switch

Load

Resistance

LED

F-116 Enclosed Switch ZC-@55

Page 9

Molded Terminal Models

■ Molded Terminal Model

The molded-terminal model is available with right-hand, left-hand

and underside leads and is recommended for use where the Switch

is exposed to dust, oil or moisture.

The molded-terminal model is not approved by UL and CSA.

ML

MD

Suffix by Location of Lead Outlet

Location of lead output Model

COM, NC and NO

Right-hand ZC-@-MR

Left-hand ZC-@-ML

Underside ZC-@-MD

Lead Supplies

MR

Note: When placing your order for the Switch, specify the required

length of V.C.T. cable in addition to the model number of the

Switch.

Example:

Standard type: ZC-Q2155

Location of lead output: Underside

Length of lead: 1 m (V.C.T. lead)

When placing your order for the above Switch, specify the model

number as ZC-Q2155-MD VCT 1 m.

Limit

Switches

Leads Nominal

V.C.T. (vinyl cabtire cable)

cross-sectional area

1.25 mm

2

Finished outside

diameter

3 core: 10.5 dia. Black: COM

Terminal connections Standard length

White: NO

Red: NC

1, 3, 5 m

Enclosed Switch ZC-@55 F-117

Page 10

Precautions

■ Correct Use

Dog Angle

When operating the roller type, be sure to set the dog angle to less

than 30° (even when operating at a low speed). Operating the model

at a dog angle exceeding 30° will soon cause abrasion or damage.

Do not apply a twisting force to the plunger. Set the OT to 70% to

100% of the specified value so that the actuator will not exceed the

OT.

Handling

When detaching the Terminal Protective Cover, insert a screwdriver

and apply a force in the opening direction. Do not use excess force to

remove the cover. Doing so may cause deformation in the fitting section and reduce the holding force.

Screwdriver

Terminal Protective Cover

When mounting the Terminal Protective Cover to the case, align the

cover on the case and then press the cover down to mount it firmly. If

the cover is pressed down in an inclined position, rubber packing will

deform and thus affect the sealing capability.

Rubber packing

• A 8.5- to 10.5-dia. cable can be applied as seal rubber for the lead

wire outlet. (Use two- or three-core cable of VCT1.25 mm

• Use weather-proof rubber (chloroprene rubber) as seal rubber for

the ZC-N22(21)55.

Mounting

• When mounting the Switch with screws on a side surface, fasten

the Switch with M4 screws and use washers, spring washers, etc.,

to ensure secure mounting.

Mounting Holes

Two, 4.3-dia. or M4 screw holes

• When mounting the Panel Mount-type Enclosed Switch (ZC-Q55,

ZC-Q2255, or ZC-Q2155) with screws on a side surface, remove

the hexagonal nuts from the actuator.

Rubber packing

2

.)

Mounting Hole Dimensions

+0.2

14.5

dia.

0

Tightening Torque

A loose screw may result in a malfunction. Be sure to tighten each

screw to the proper tightening torque as shown below.

No. Type Torque

1 Terminal screw 0.78 to 1.18 N·m

2 Panel mounting screw 4.90 to 7.84 N·m

3 Side mounting screw 1.18 to 1.47 N·m

Operation

With the ZC-Q22(21)55, an appropriate OT line is marked on the

plunger. Set the OT so that it is between the two X-surface lines.

Appropriate OT line

X-surface

Micro-load Applicable Ranges

Using a standard load switch for opening and closing a micro-load

circuit may cause wear on the contacts. Use the switch within the

operating range. (Refer to the diagram below.) Even when using

micro-load models within the operating range shown below, if inrush

current occurs when the contact is opened or closed, it may cause

the contact surface to become rough, and so decrease life expectancy. Therefore, insert a contact protection circuit where necessary.

The minimum applicable load is the N-level reference value. This

value indicates the malfunction reference level for the reliability level

of 60% (λ

the estimated malfunction rate is less than 1/2,000,000 operations

with a reliability level of 60%.

Voltage (VDC)

Model ZC-@55-01 ZC-@55

Minimum

applicable load

). The equation λ60 = 0.5 × 10−6/operations indicates that

60

0.8 W

100 mA

30

24

12

Unusable

area

5

0

Operating area for

ZC-@55-01 microload models

1 mA

1 10 100 1,0000.1

26 mA

100 mA 160 mA

Current (mA)

Operating

area for

ZC-@55

standard

models

1 mA at 5 VDC 160 mA at 5 VDC

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. C025-E1-09

In the interest of product improvement, specifications are subject to change without notice.

F-118 Enclosed Switch ZC-@55

Loading...

Loading...