Page 1

Welding Bead Sensor

Flatness OK ( 0/ 201) Last

Step

Depth:Bead :

Gap

Flatness

PEAK-BTM

Length

Z510

• Inspect for welding flaws by measuring the bead shape.

• Accumulate and output the profile data. Greatly simplify the management

of welding bead quality.

• The high-speed 10-ms measurement

period allows 100% in-line inspection.

• Automatic light intensity (brightness)

adjustment provides stable measurement of fluctuating metal surfaces.

• The compact sensor head contains

both the transmitter and receiver, so

mounting space is not an issue.

In-line Inspection of Welding Beads

Z510

Improve quality by performing 100% inspection of weld strength uniformity.

Display the Inspection Results or 3D Shape Data

Detect Various Bead Flaws

Flatness OK ( 0/ 201) Last

Step

:

Depth:Bead :

Gap

Flatness

PEAK-BTM

Length

ESC: Back SFT + ENT/ESC : Save/Load

−0000. 51846 mm PASS

−0000. 33351 mm PASS

:

+0000. 24302 mm PASS

:

−0000. 23053 mm PASS

:

+0000. 50820 mm PASS

:

+0000. 25458 mm PASS

Bead shape

Cracks or pinholes

Gaps in the weld

Features

Wide laser beam for

fast, highly accurate

inspections

B-53Z510

Page 2

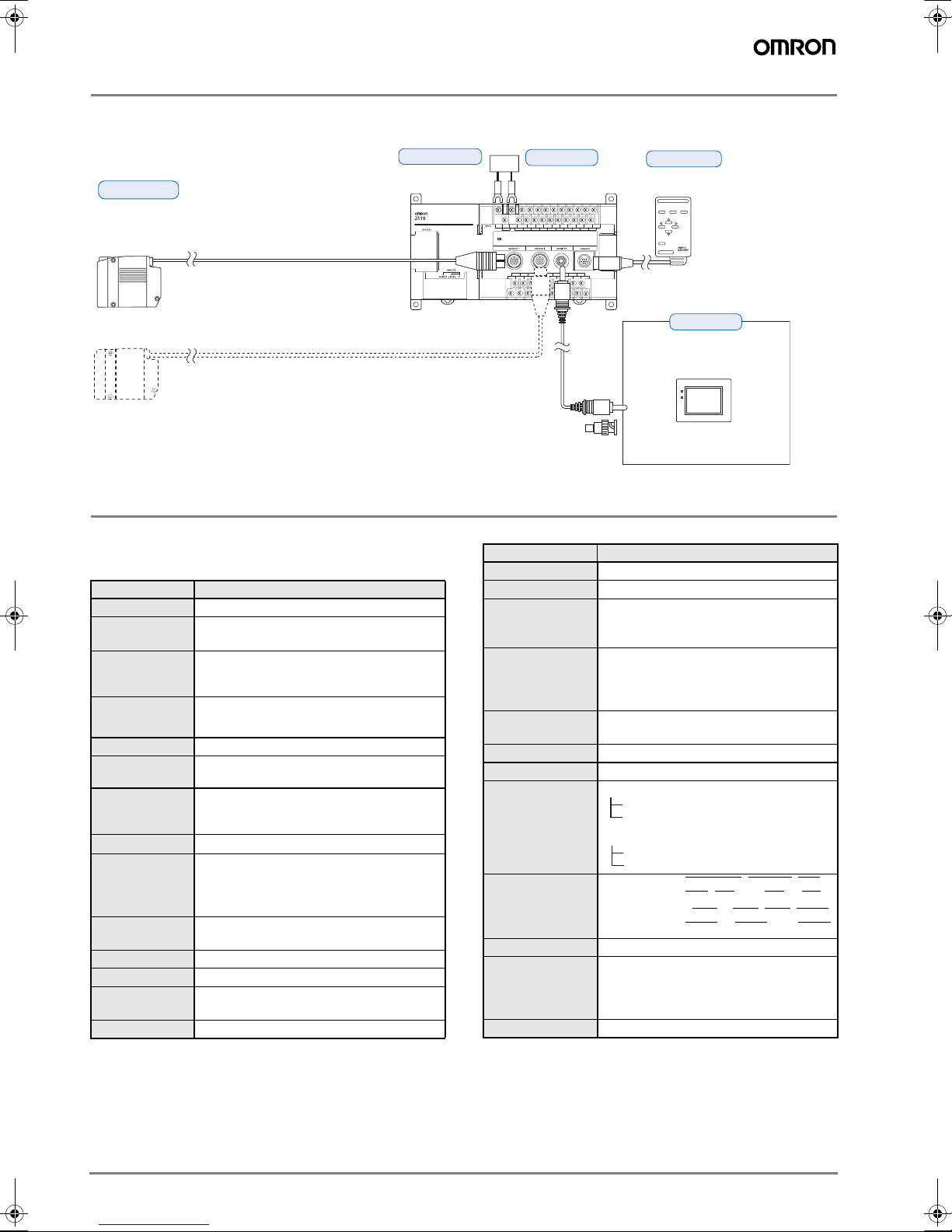

Basic System Configuration

g

Sensors

Z510-SW2T (0.5-m cable)

Z510-SW6 (0.5-m cable)

Z510-SW17 (0.5-m cable)

Sensor Extension Cables

Z519-SCIR (1.5 m, 3 m, 6 m, 8 m, 13 m, or 18 m)

Specify the required cable length when ordering.

Up to 2 Sensors can be connected.

Specifications

Controllers:

Z510-WC10E and Z510-WC15E

General Specifications

Item Specification

Supply voltage 21.6 to 26.4 VDC

Current

consumption

Insulation

resistance

Dielectric

strength

Leakage current 10 mA max.

Noise resistance

Vibration

resistance

Shock resistance

Ambient

temperature

Ambient

humidity

Atmosphere No corrosive gases

Grounding

Degree of

protection

Material Case: ABS

1 A max. (with 2 Sensors connected)

20 MΩ min. (at 100 V DC) between DC exter-

nal terminals and GR terminal

(with internal surge absorber removed)

1,000 VAC, 50/60 Hz between DC external terminals and GR terminal (with internal surge

absorber removed)

1,500 V

P-P; pulse width: 0.1 µs/1 µs; rising

edge: 1-ns pulse

10 to 150 Hz (double amplitude of 0.1 mm)

for 8 minutes each in the X, Y, and Z directions

2

200 m/s

3 times each in 6 directions

Operating: 0 to 50°C (with no icing or condensation)

Storage: -15 to 60°C (with no icing or condensation)

Operating and storage: 35% to 85% (with no

condensation)

Less than 100 Ω

IEC60529 IP20 (In-panel)

Controllers

Z510-WC10E

Z510-WC15E

F150-VM

Monitor Cable (2 m)

Power supply

BNC Jack

(Included with the F150-VM)

Console

Z300-KP

(2-m cable)

ESC TRIG

ENT

SHIFT

CONSOLE

Monitors

F150-M05L

Color Liquid Crystal Monitor

(pin input)

POWER

SYNC

Use the Monitor to check

the image and display

menus when making

Characteristics

Item Specification

Number of Sensors Up to 2 Sensors can be connected.

Number of scenes 16

Light intensity

tracking function

Automatic (The light intensity tracking

range can be specified.)

Fixed (Select one of 31 stages.)

Select one of the following 6 items:

Measurement

items

Deviation from reference surface, Bead

height, Width, Bead change, Peak/Bottom,

Inspection length

Region

specification

A region can be specified in the direction of

the line beam.

Data storage 2,048 points max.

Trigger function Free-run, External 1, External 2, or Auto

• Judgement output

RS-232C output

Terminal block output

Results output

Terminal block

• Measurement value output

(measurement value)

RS-232C output

output

Analo

8 input points: TRIGGER

, LD-OFF, RE-

SET, DI0, and DI4 to DI7

12 output points:DO0 to DO5, DO8, DO15,

to DO19, and GATE

DO17

Monitor interface 1 channel (for pin jack or overscan monitor)

The full-scale output can be divided into

Analog output

resolution

40,000 gradations max.

Resolution (See note.): 0.25 mV (± 5 V)

0.4 µA (4 to 20 mA)

Weight Approx. 700 g (Controller only)

Note: This resolution is for measurements with an OMRON K3AS Linear Sen-

sor Controller connected and values averaged over 64 measurements.

B-54 Displacement sensors / Width-measuring Sensors

Page 3

Sensors: Z510-SW2T, Z510-SW6, and Z510-SW17

Sensor model Z510-SW2T Z510-SW6 Z510-SW17

Mirror reflection Diffuse

reflection

Measurement mode

Diffuse

reflection

Mirror reflection Diffuse

reflection

Mirror reflection

Measurement distance at center

20 mm (16 mm with

beam cover mounted)

5.2 mm 50 mm 44 mm 100 mm 94 mm

Measurement range ±0.8 mm ±5 mm ±4 mm ±20 mm ±16 mm

Light source

Visible semiconductor laser

(Wavelength: 670 nm, 15 mW

Visible semiconductor laser

(Wavelength: 658 nm, 15 mW max., class 3B)

max., class 3B)

Beam dimensions (See note 1.)

Linearity

20 µm × 4 mm typical at the reference distance

(2-mm measurement region)

±0.1% F.S.

(See note 2.)

±0.1% F.S.

(See note 3.)

30 µm × 24 mm typical at the ref-

erence distance

(6-mm measurement region)

±0.1% F.S. (See note 4.)

60 µm × 45 mm typical at the ref-

erence distance

(17-mm measurement region)

Resolution 0.25 µm (See notes 5 and 6.) 0.3 µm (See notes 7 and 8.) 1 µm (See notes 7 and 8.)

Sampling period 9.94 ms

LED indicator (Laser indicator) Lit when the laser is ON.

Temperature characteristic

0.01% F.S./° C

(See note 9.)

Degree of protec-

IP64 IP66

tion

Environmental resistance

Ambient operating illumination

Ambient temperature

Illumination at light-receiver surface: 3,000 lx max. (incandescent light)

Operating: 0 to 50°C (with no icing or condensation)

Storage: -15 to 60°C (with no icing or condensation)

Ambient humidity Operating and storage: 35% to 85% (with no condensation)

Vibration (de-

10 to 150 Hz (double amplitude of 0.35 mm) for 8 minutes each in the X, Y, and Z directions

struction)

Controller: Die-cast aluminum

Materials

Cable sheathing: Heat-resistant PVC

Connector: Zinc alloy and brass

Cable length 0.5 m

Minimum bending radius 68 mm

Weight Approx. 350 g Approx. 600 g

Z510

Note: 1. The minimum light intensity at the edges of the beam is defined as 1/e2 (13.5%) of the intensity at the center of the beam. Some light will

scatter beyond this beam region and the measurement may be affected if the immediate vicinity around the workpiece is highly reflective.

2. This is the error with respect to the theoretical line of the displacement output when measuring the standard OMRON quartz glass. The

linearity may vary depending on the workpiece being used.

3. This is the error with respect to the theoretical line of the displacement output when measuring a standard OMRON stainless-steel block.

The linearity may vary depending on the workpiece being used.

4. This is the error with respect to the theoretical line of the displacement output when mea-

suring the standard OMRON white alumina ceramic. The linearity may vary depending on

the workpiece being used.

5. This is the displacement output’s peak-to-peak displacement conversion value. These fig-

ures are for measurement of the standard OMRON quartz glass (mirror reflection) or standard OMRON stainless-steel block (diffuse reflection) at the center of the measurement

region. The resolution performance characteristics may not be met when operating in a

magnetic field.

6. These figures are for Sensors connected to a Z510-WC10E or Z510-WC15E and averaged over 16 measurements. The averaged data

was transmitted to a PC through an RS-232C connection for storage and processing.

7. This is the displacement output’s peak-to-peak displacement conversion value. (These figures are for measurement of the standard OM-

RON white alumina ceramic at the center of the measurement region.)

The resolution performance characteristics may not be met when operating in a strong magnetic field.

8. These figures are for Sensors connected to a Z510-WC10E or Z510-WC15E and averaged over 64 measurements. The averaged data

was transmitted to a PC through an RS-232C connection for storage and calculations.

9. This is the value measured when the gap between the Sensor and workpiece (white alumina ceramic) is fixed with an aluminum jig.

Z510-SW17

120 mm

Digital output

80 mm

80 mm

±0.1% max.

120 mm

Distance

B-55Z510

Page 4

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. Q03E-EN-02

In the interest of product improvement, specifications are subject to change without notice.

B-56 Displacement sensors / Width-measuring Sensors

Loading...

Loading...