Page 1

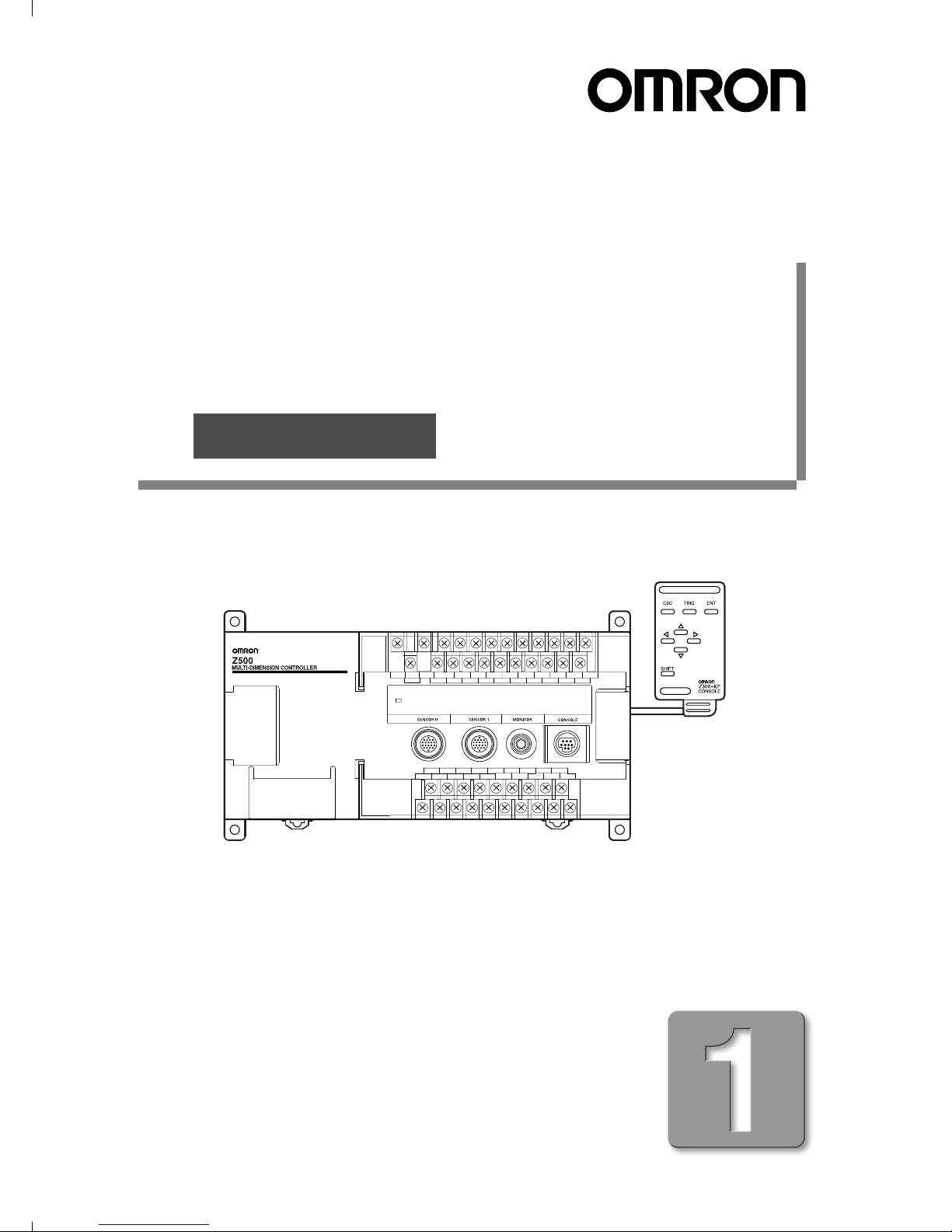

Multi-Dimensional Controller

Multi-Dimensional Controller

Z500

Setup Manual

Cat. No. Z158-E1-1

Manual

Page 2

About this Manual

Please read the following manuals carefully and be sure you understand the information provided

before attempting to install or operate the Z500.

Manual 1: Setup Manual

Multi-Dimensional Controller

Multi-Dimensional Controller

Z500

Setup Manual

Manual

Cat. No. Z000-E1-1

Cat. No. Z158-E1-1

Manual 2: Operation Manual

Installation

This manual describes the hardware for the Z500

(Multi-Dimensional Controller) and how to install the

components.

Be sure to read this manual first.

Wiring

Multi-Dimensional Controller

Z500

Operation Manual

Manual

Cat. No. Z000-E1-1

Cat. No. Z159-E1-1

Starting the Z500

and Positioning

the Workpiece

Adjusting Images

Setting

Measurement

Conditions

and Executing

SECTION 2 Basic Operations

This section describes how to start the Z500

and how to display images on the monitor.

SECTION 3

Menus for Conversational Menu

• Basic settings required for measurement

• Measurement of consistent workpieces

Menus for Conversational Menu

Settings can be made easily by entering

information as requested - just as

though you are having a conversation

with the Z500.

SECTION 4 Menus for Expert Menu

• Customized settings

• Detailed settings

• Measurement of workpieces placed at different

positions

Menus for Expert Menu

More detailed setting, such as position

compensation for workpieces placed at

different positions, can be made.

Outputting to

External Devices

SECTION 7 I/O Format

This section provides details on the inputs and outputs

used for communications with external devices via

terminal blocks or RS-232C.

• Communications settings

• I/O format

• Timing for communications

Page 3

Multi-Dimensional Controller

Z500

Z500-MC10

Setup Manual

INTRODUCTION 3

SECTION 1

Wiring and Connection

SECTION 2

Installation

SECTION 3

Connecting External Devices

SECTION 4

Troubleshooting and Maintenan ce

INTRODUCTION

SECTION 1 SECTION 2 SECTION 3 SECTION 4

17

25

39

51

Manual

1

Page 4

Special or Crit ica l Applica tio n s

When the Z500 will be us ed in one o f the conditions or application s listed below, allow extra safety

margins in ratings and functions, add extra safety feature such as fail-safe systems, and consult your

OMRON representative.

• Operating conditions or environments which are not described in the manual

• Nuclear power control systems, railroad systems, aviation systems, vehicles, combustion systems,

medical equipment, amusem ent equipment, or safety equipment

• Other sys tems, machines, and equipment that may have a serious influence on lives and property and

require extra safety features

Product Availability

Some of the products listed may not be available in some countries. Please contact your nearest

OMRON sales office by referring to the addresses provided at the back of this manual.

© OMRON, 2002

All right s reserved. No part of this public ation may be reproduc ed, stored in a retriev al syst em, or transmi tted, in any

form, or by any means , mechanical, ele ctronic, photoc opying, reco rding, or other wise, without the prior wr itten

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRO N is co nstantly striving to improve its h igh-quality products, the information contained in this manual is subject

to change without notice. Every precaut ion ha s been taken in the pre paration of this manual. Nevertheless, OMRON

assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use

of the information contained in this publication.

Z500

2

Setup Manual

Page 5

INTRODUCTION

Table of Contents

INTRODUCTION.................................................................................... 3

INTRODUCTION

Table of Contents..........................................................................................................3

Precautions on Safety..................................................................................................4

Laser Safety............................. ..... .. ....... ..... .. .......... .. ..... ....... ..... ....... .. ..... ....... ..... .. ....... .5

Export of the Products .................................................................................................9

Caution.........................................................................................................................10

Notice...........................................................................................................................11

Confirming Package Contents................................................... ..... .. ....... ..... ..... .. ......15

Editor's Note................................................................................................................16

SECTION 1

Wiring and Connection...................................................................... 17

1-1 Basic System Configuration..............................................................................18

1-2 Component Names and Functions ...................................................................20

1-3 Power Supply and Ground.................................................................................22

SECTION 2

Table of Contents

Installation .......................................................................................... 25

2-1 Mounting the Controller.....................................................................................26

2-2 Mounting the Sensor..........................................................................................28

SECTION 3

Connecting External Devices............................................................ 39

3-1 Terminal Block Connections.............................................................................40

3-2 RS-232C Connections........................................................................................44

3-3 Linear Sensor Controller Connections.............................................................46

SECTION 4

Troubleshooting and Maintenance................................................... 51

4-1 Troubleshooting .................................................................................................52

4-2 Maintenance........................................................................................................54

4-3 Specifications and Dimensions .........................................................................55

Z500

Setup Manual

3

Page 6

INTRODUCTION

INTRODUCTION

Precaution on Safety

OMRON products are manufactured for use according to proper procedures by a qualified operator and

only for the purposes described in this manual.

Precaution on Safe ty

The following conventions are used to indicate and classify precaut ions in this manual. Always heed the

information provided with them. Failure to heed precautions can result in injury to people or damage to

property.

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if not avoided, will result in death or

seriou s in jury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

seriou s in jury.

Indica tes a potential ly hazar dous s ituation which, if not a voided, may re sult in m inor or

moderate in jury, or pr operty d amage .

WARNING Fa ilure to read and understand the information pro vided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read

each section in its entirety and be sure you understand the information provided in

the section and related sections before attempting any of the procedures or operations given.

Z500

4

Setup Manual

Page 7

INTRODUCTION

Laser Safety

This manual uses the followin g signs and s y mb o ls to ensure safe operation of the Z500.

These signs and symbols are important for avoiding injury to people or damage to the product. Be sure

to pay attent ion t o t hem.

Their meanings are given below.

Warning

INTRODUCTION

Laser Safety

WARNING

Indic at e s an im m in ently ha zardous si tuation whic h , if no t

avoided, will result in death or serious injury.

Signs and Symbols

Laser Beam Hazard

Caution s to In di ca te Potenti al La se r B ea m H az ard

Safety precautions for using laser equipment

WARNING

Do not to expose your eyes to the laser radiation either directly or

indirectly (i.e., after reflection from a mirror or shiny surface).

The laser radiation has a high power density and exposure may

result in loss of sight.

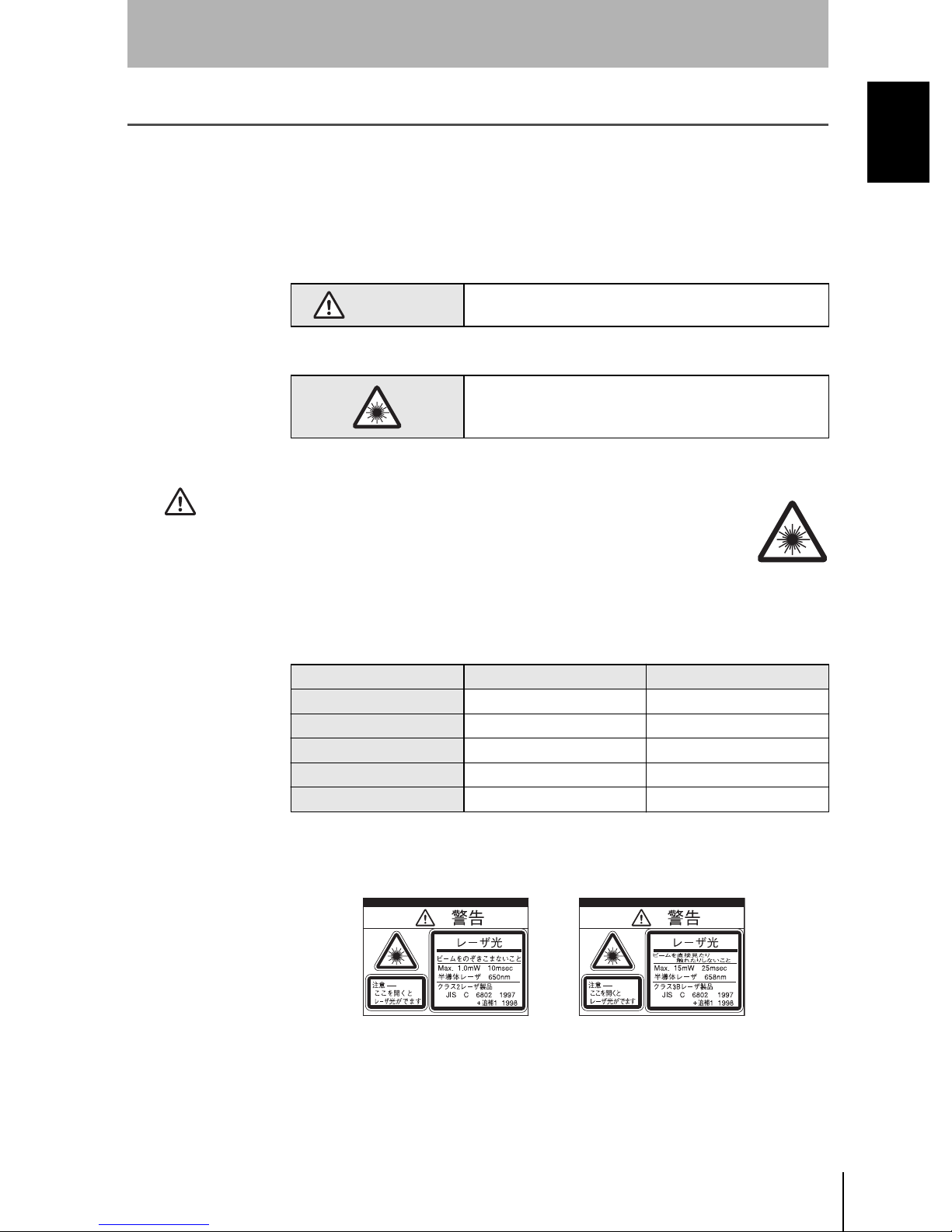

The Z500 series uses laser as the light source and is classified as shown below

according to the IEC standard (IEC60825-1).

Wavelength 650 nm 658 nm

Maxi mum pulse dura tion 10 ms 17.5 ms

Cycle 0.5 to 10 ms 0.5 to 25 ms

Peak power 1 mW max. 15 mW max.

Class 23B

Z500-SW2 Z500-SW17

Labeling on Laser Use

The Z500 has, on the side of its sensor, a warning label as shown below.

Z500-SW2 Z500-SW17

Z500

Setup Manual

5

Page 8

INTRODUCTION

INTRODUCTION

Safety Device

The Z500 is equipped with laser radiation warning lamp and laser off input

circuit. Interlocking unit can be configured in the external circuit.

Laser Safety

Unle ss th e produ ct is in Run Mode, however, laser off input from the external

circuit is disabled. This ensures stable measurement. Be sure to use lasershielding safety goggles when installing or adjusting Z500-SW17.

Safety Instructions

• Use laser enclosure device to prevent specular object from reflecting laser

beam.

When used without an enclosure, be sure to avoid a laser path from eye level.

• Safe distance (Nominal Optical Hazard Distance: NOHD) is approximately 1

m; it is advisable, however, to terminate the laser on its path if possible. Nonreflective, flatting material is recommendable for termination.

• Be sure to use laser-shielding safety goggles when installing or adjusting

Z500-SW17.

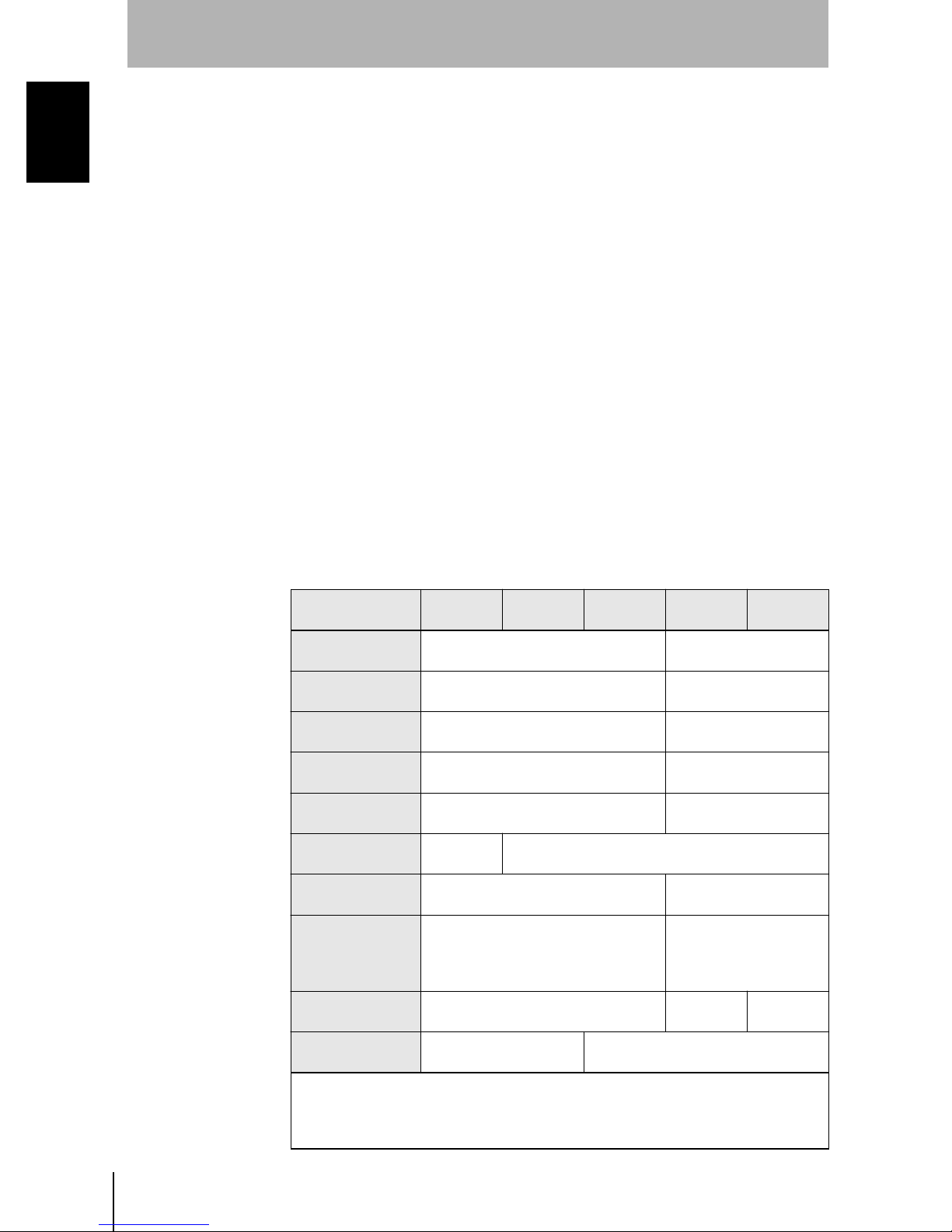

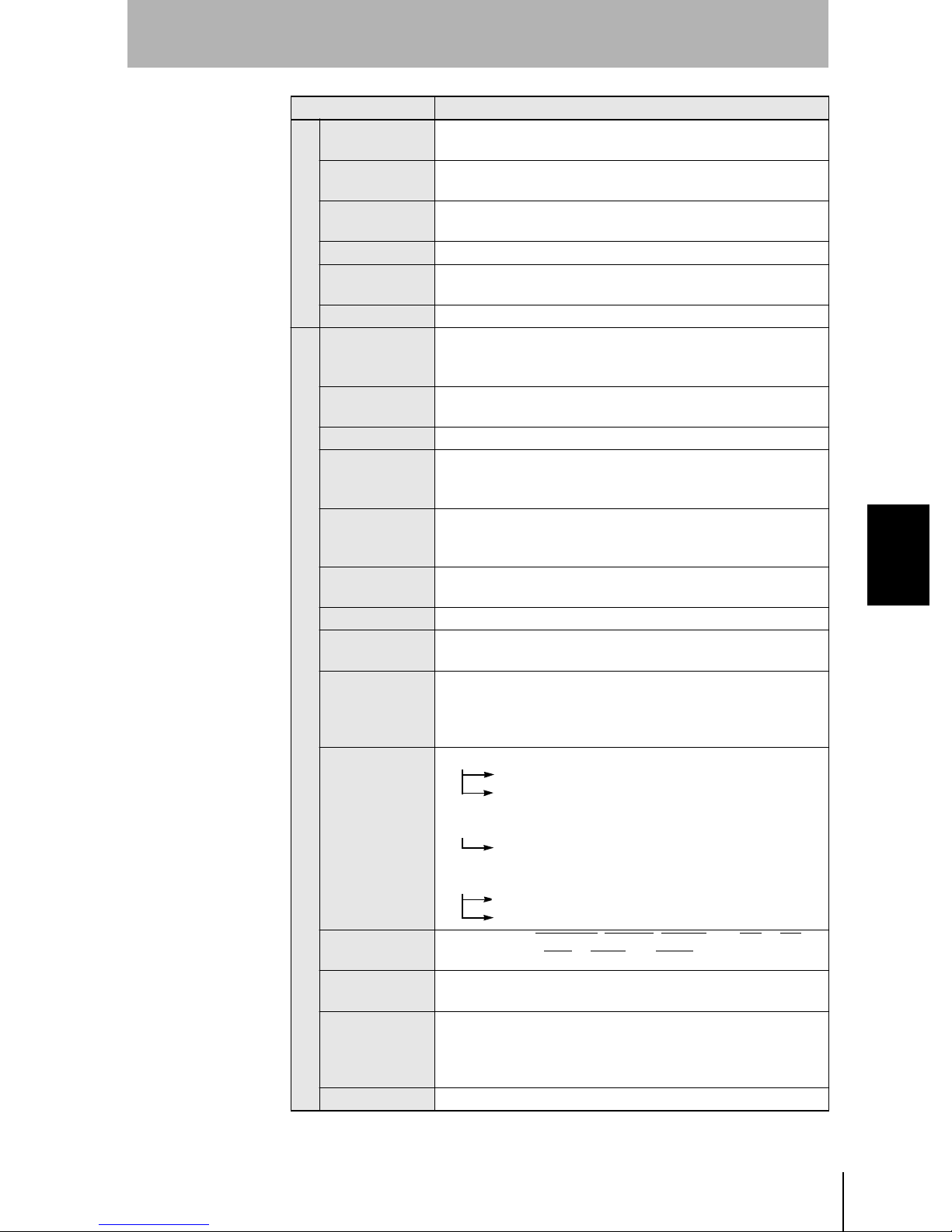

Outline of IEC60825 Standard

The following are the safety measures to be taken by the user for each type of

laser equipment.

Classification

Requirements

Remote interlock Not required

Key control Not required

Beam attenuator Not required

Emission

indicator device

Warning signs Not required

Beam pa th

Specular

reflection

Eye protection Not required

Protective

clothing

Training Not required

* With respect to the requirements of remote interlock connector, key control, beam

attenuator, and emission indicator, Class 3B laser products no t exceedin g f iv e t i mes

the AEL of Cla ss 2 in t he wave length r an ge of 400 nm to 700 nm are to be treated as

Class 3A laser products.

Class 1 Class 2 Clas s 3A Class 3B* Class 4

Connect to room or door

circuits

Remove key when not in

use

When in use preve n t s

inadve r te nt exp os ure

Not required

Not

required

Not required

Not required

Terminate bea m at e nd of us e ful leng th

Required for all operator and

mainte nance pe r s onnel

Indicates laser is

energized

Follow precautions on

warnin g si gns

Prevent unintentional

reflections

Required if engineering

and admi ni strati v e proc edures n ot prac ti ca bl e an d

MPE exceeded

Sometimes

required

Specific

requireme nts

Z500

6

Setup Manual

Page 9

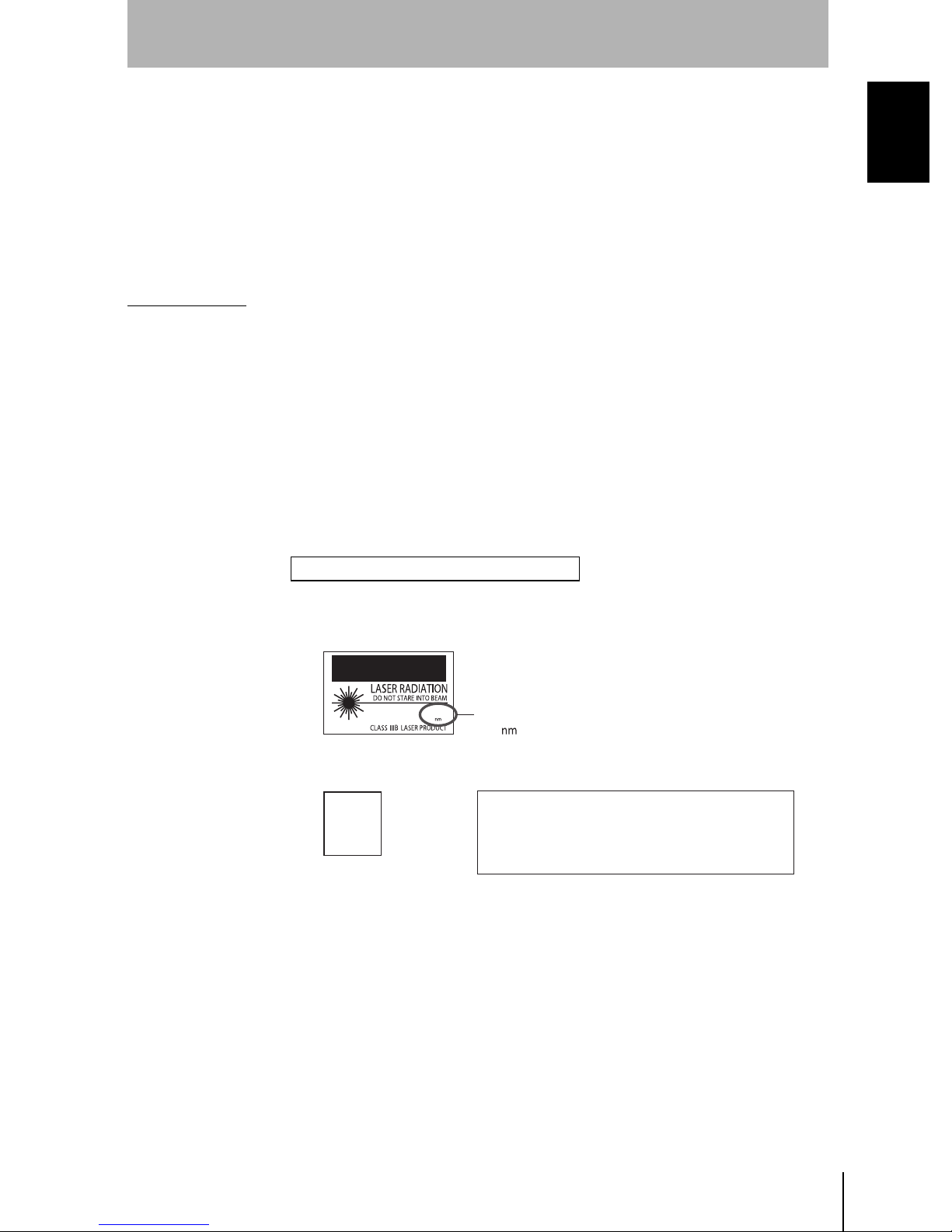

Re-labeling

CAUTION

Use in the U.S.

INTRODUCTION

Two di fferent labels are provided, to be used selectively according to countries.

• for use in the U.S.: FDA label

• for use in countries other than the U.S.: Warning label

Be sure to turn off the sensor before replacing the label, or your hand or other

body p arts ma y be expose d to th e haza rdous l aser b eam ra diatin g from the

sensor.

When a laser product mounted on a certain device is to be used in the U.S., it has

to meet the requirements set forth by the FDA (regulations for laser products set

forth by the Food and Drug Administration). Three different FDA labels are

enclosed in the package. Attach them to the sensor body.

Applic ati o ns h ave been app roved by CD RH (C enter fo r De vi ce s and Rad iol o gical

Health) for Z500-SW17. Z500-SW2 should not be used in the U.S. at this

moment since the application for this model has not been approved yet.

FDA Labels for Laser Products

The Z500 is designed to be bu ilt into the finished sys tem unit. Refer to the

following technical standard for installation.

INTRODUCTION

Laser Safety

21CFR1040.10 and 1040.11

FDA Labels

lass III B Caution logo type

CAUTION

µw

15000

PEAK POWER

PULSE DURATION

WAVE LENGTH

Z500-SW17

Aperture Label Certification and Identification Label

AVOID

EXPOSURE

Laser radiation

is emitted from

this aperture

Be sure to attach FDA la be ls; do n ot att ac h En gl ish WARNING labels by mistake .

15000

25000

658

µw

µs

25000

µs

658

This laser product complies with

21 CFR 1040.10 and 1040.11.

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

Place of manufacture:

AYABE Factory, OMRON Corp.

Manufactured in

Z500

Setup Manual

7

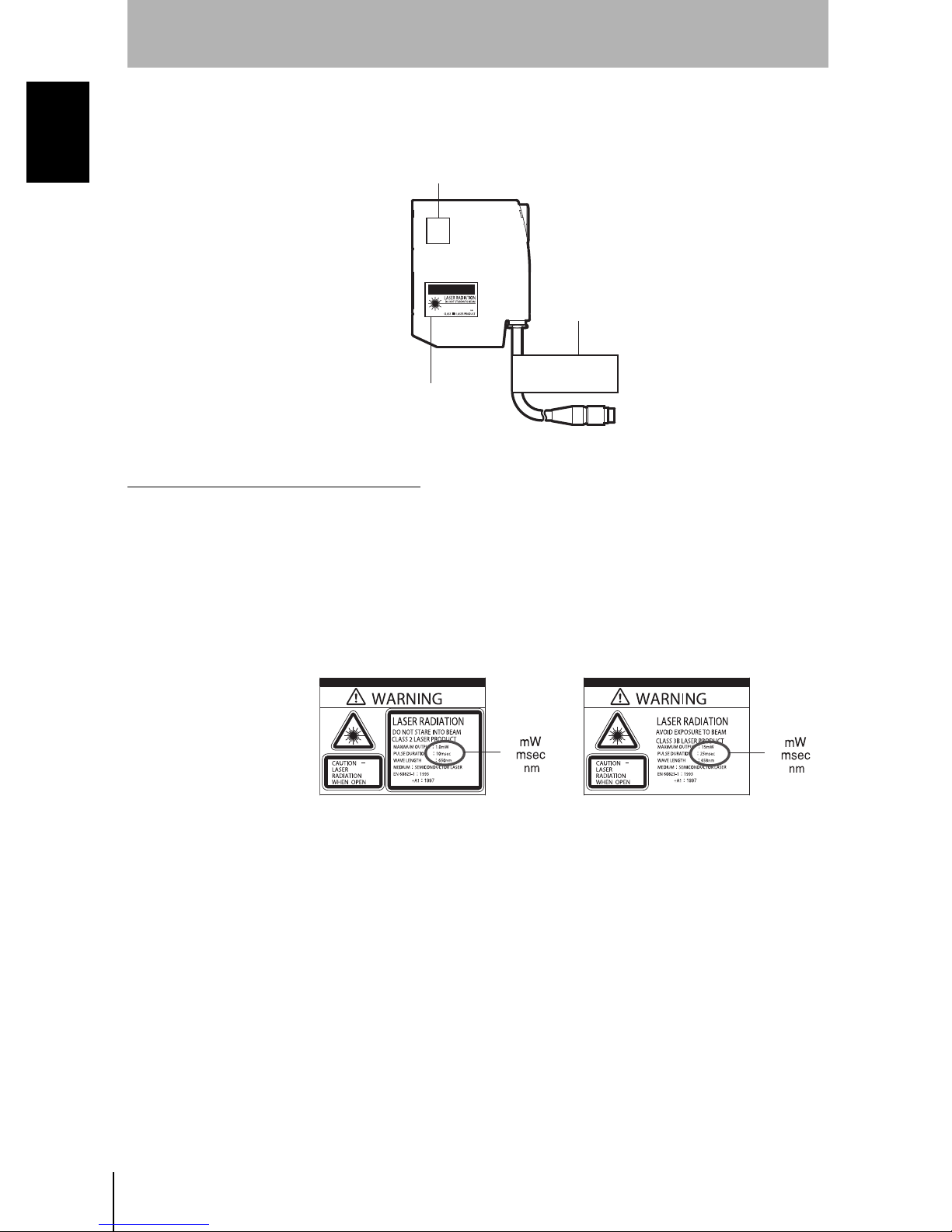

Page 10

INTRODUCTION

CAUTION

INTRODUCTION

Areas to Attach Labels

Z500-SW17

Laser Safety

AVOID

EXPOSURE

Laser radiation

is emitted from

this aperture

CAUTION

Class III B

PEAK POWER

PULSE DURATION

WAVE LENGTH

µw

15000

µs

25000

658

Certification and

Identification Label

This laser product complies with

21 CFR 1040.10 and 1040.11.

OMRON Corporation

Shiokoji Horikawa, Shimogyo-ku,

Kyoto 600-8530 JAPAN

Place of manufacture:

AYABE Factory, OMRON Corp.

Manufactured in

Caution logo type

Use in Countries Other than the U.S.

Replace the warning label in Japanese on the sensor main body with the

attached English one upon use in countries other than the U.S. Attach the label

in the area where the original Japanese warning label was provided.

European EN60825-1 standard is applied to products exported to European

countries. The Z500 conforms to the standard.

Aperture Label

Warni ng Labels

1.0

10

650

15

25

658

Z500-SW17Z500-SW2

Z500

8

Setup Manual

Page 11

INTRODUCTION

Export of the Products

Z500-SW2 is considered as special freight under the Foreign Exchange and Foreign Trade Laws and

theref ore requ ires a lice nse for ex port. As for other coun tries, o bserve the laws spec ified by each

country.

INTRODUCTION

Export of the Products

Z500

Setup Manual

9

Page 12

INTRODUCTION

INTRODUCTION

Caution

Installation Environment Precautions

CAUTION

Caution

CAUTION

Do not use the Z500 in environments with flammable or explosive gases.

Install the Z500 away from high-voltage devices and moving machinery to a llow

safe access during operation and maintenance.

Power Supply and Wiring Precautions

CAUTION

CAUTION

CAUTION

CAUTION Confirm that wiring has been performed correctly before turning ON the power

CAUTION

CAUTION

Use the Z500 with the power supply voltages specified in this manual.

Use crimp terminals for wiring. Do not connect the power supply wires by just

twisting stranded wire and connecting directly to the terminals.

Use the wire and crimp terminals of the p roper sizes as specified in this manual.

supply.

Cover the terminal blocks with the Terminal Block Protection Covers.

Uncovered terminal blocks can result in electric shock.

Use a DC power supply with countermeasures against high-voltage spikes (safe

extra low-voltage circuits on the secondary side).

CAUTION

Other Precautions

CAUTION

CAUTION

Be sure to securely tighten the screws when mounting the Z500.

Do not attempt to dismantle, repair, or modify the Z500.

Dispose of the Z500 as industrial waste.

Z500

10

Setup Manual

Page 13

INTRODUCTION

Notice

The Z500 is highly reliabl e and resis tant to most environmen t factor s. The followi ng guidel ines, however,

must be followed to ensure reliability and opti m u m use of th e Z500.

Installation of the Controller

INTRODUCTION

Notice

Installation Site

Do not install the Z500 in locations subjected to the following conditions:

• Ambient temperature outside of 0 to +50 ºC

• Condensation due to rapid temperature fluctuations

• Relativ e humidities outside 35 to 85%

• Corrosive or flammable gases

• Dust, salt, or iron particles

• Direct vib ration or shock

• Reflection of intense light

(such as other laser beams or electric arc-welding machine)

• Strong magnetic fields

• Direct sunlight

• Water, oil, or chemical fumes or spray

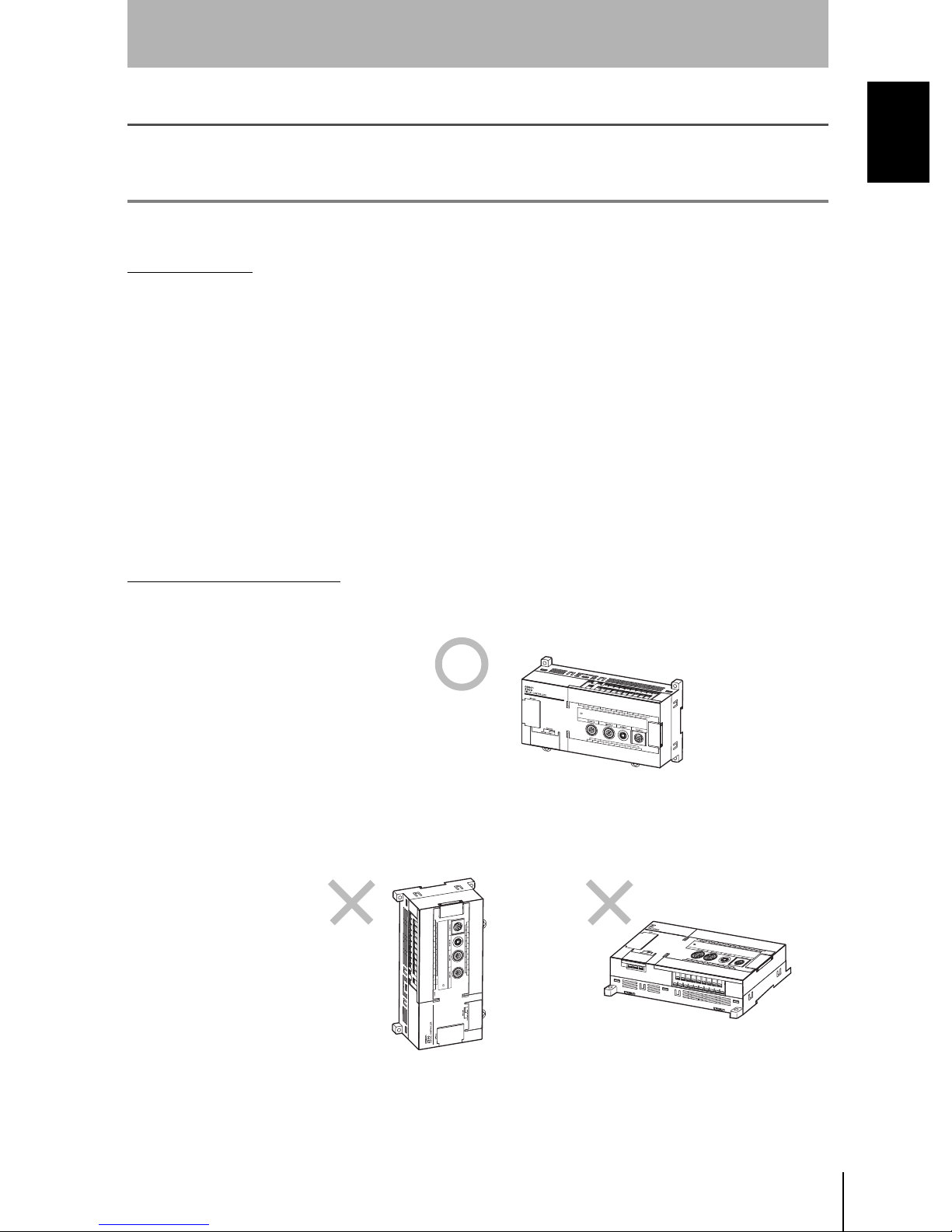

Mounti ng of the Controller

To im pr ove heat d issipat io n, install the C ontro ller in th e follo wing di re ction only:

CORRECT

Do not install the Controller in the orientations shown in the following diagram.

INCORRECT

Z500

Setup Manual

11

Page 14

INTRODUCTION

2

INTRODUCTION

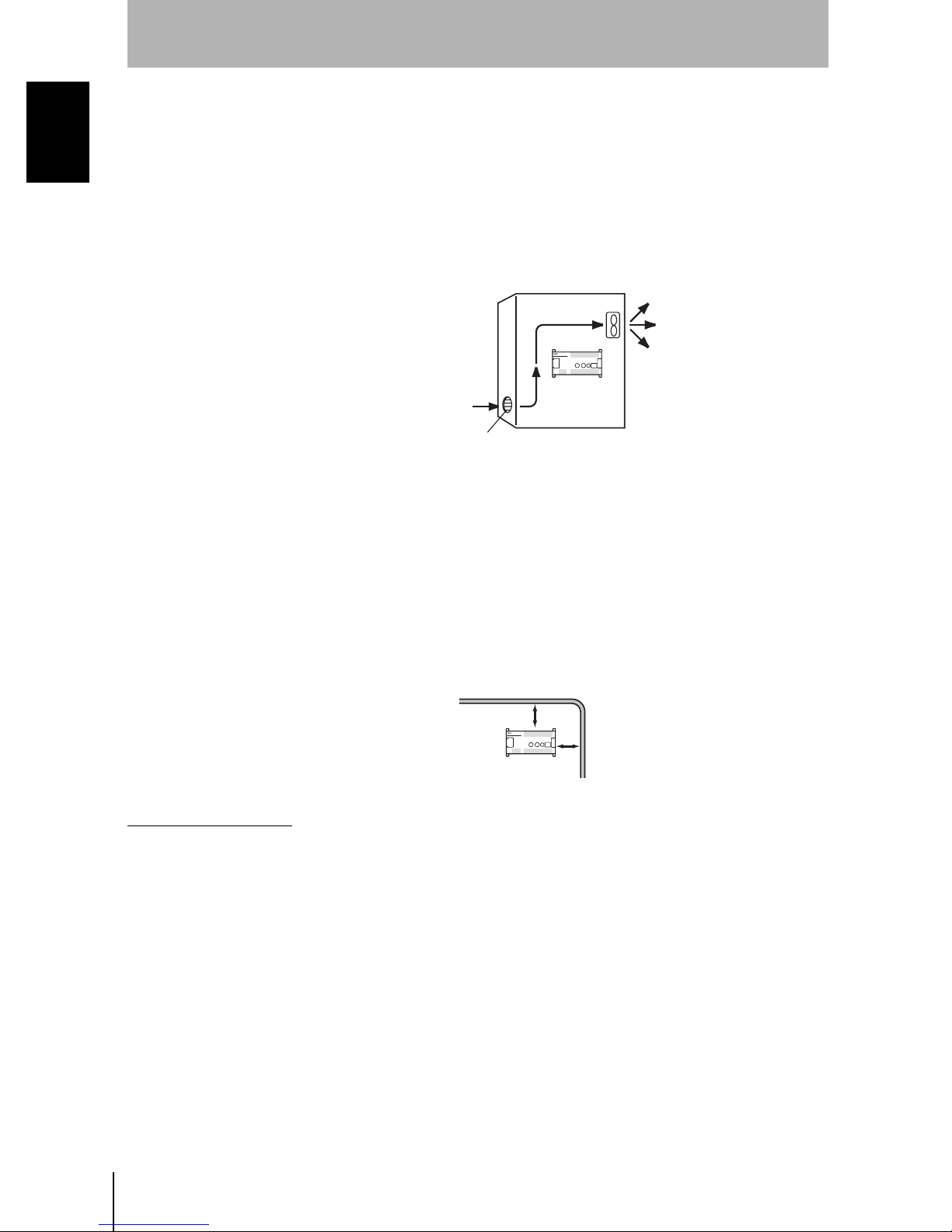

Ambient temperature

• Maintain a minimum clearance of 50 mm above and below the Z500 to

improve air circulation.

Notice

• Do not install the Z500 immediately above significant heat sources, such as

heaters, transformers, or large-capacity resistors.

• Do not let the ambient temperature exceed 50 ºC.

• Provide a fo rc ed-air fan co o ling or air conditioning if the ambient temperature

is near 50 ºC so that the ambient temperature never exceeds 50 ºC.

Control panel

Z500

Z500

ouver

Sensor Maintenance

Ambient Illumination

• Do not let the ambient illumination exceed 3000lx.

• When using the Z500 near lighting equipment that turns ON and OFF

continuously, reduce the influence of the light by, for example, using a light

baffle.

Noise resistance

• Do not install the Z500 in a cabinet containing high-voltage equipment.

• Do not install the Z500 within 200 mm of power cables.

Power cable

00 mm min.

Z500

200 mm min.

Z500

Install the Sensor in a clean environment and keep the filter on the front panel of

the Sensor free from oil and dust. If affected by oil or dust, clean the filter as

follows:

• Use a blower brush (used to clean camera lenses) to blow large dust particles

from th e surfac e. Do not blo w the dust a way wit h your mouth.

• Use a soft cloth (for lenses) with a small amount of alcohol to remove the

remaining dust. Do not use a scrubbing action when cleanin g as scratches on

the f ilter c ou ld result in the S e nsor m a l func tioning.

Environment

The Sensor cannot accurately detect the following types of objects:

* Objects with an extremely low reflection ratio

* Objects with a small curvature

* Largely inclined objects

Z500

12

Setup Manual

Page 15

Component Installation and Handling

INTRODUCTION

INTRODUCTION

Components

The Sensor and Console must be products designed specifically for the Z500.

• Sensor (Z500-SW2 and Z500-SW17)

• Console (Z300-KP)

Connecting Cables

Always turn OFF the Z500's power before connecting or disconnecting cable.

Touching Signal Lines in Connectors or Terminals

To prevent damage from static electricity, use a wrist strap or another de vice for

preventing electrostatic discharges when touching terminals or signal lines in

connectors.

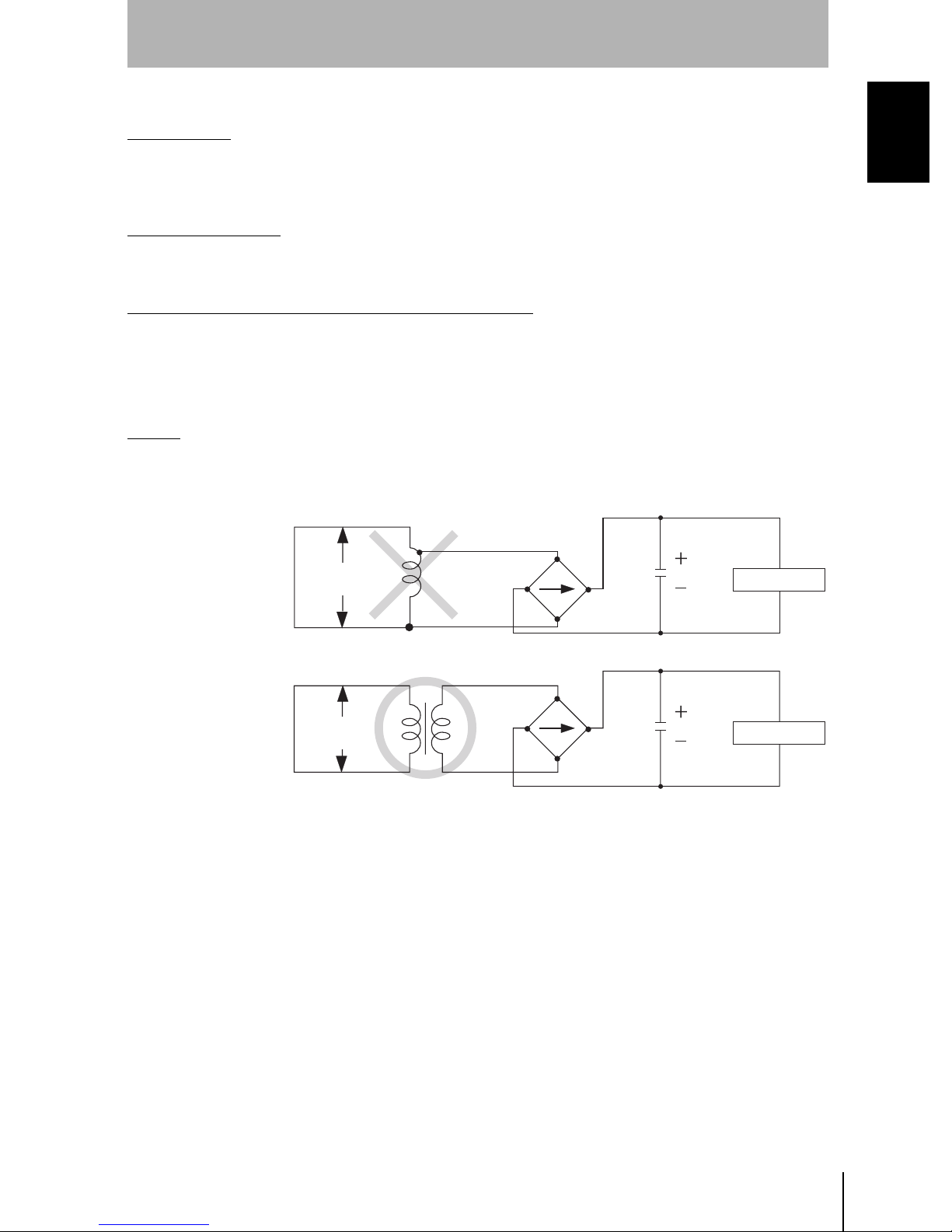

Wiring

When using a transformer for the Z500's driving power supply, use an isolation

transformer in the way shown below. Do not use an auto-transformer. Doing so

may result in equipment failure.

Auto-transformer

Commercial

power supply

Notice

Z500-MC10

Isolation transformer

Commercial

power supply

Z500-MC10

Z500

Setup Manual

13

Page 16

INTRODUCTION

INTRODUCTION

Turning OFF the Power

Do not turn OFF the power while a message is being displayed indicating that

processing is being performed. Data in memory will be destroyed, and the Z500

Notice

may not operate correctly the next time it is started.

Scn 0

Saving

Save

Using the RESET Signal

Do not input the RESET input immediately after power is turned ON. When

using the RESET input to synchronize startup timing, wait at least 1 second after

the Z500's power supply is turned ON before turning ON the RESET terminal.

Securing the Video Monitor (When Using the Recommended F150-M09)

If the video monitor case is metallic, observe the following precautions to

prevent noise interference, because the video monitor case is connected to the

0V line in the internal circuits.

• Do not ground the video monitor.

• Do not ground the metallic part of the connector.

• Secure the video monitor with plastic screws if it is being mounted to a

meta llic su rface.

Warming Up

After tu rn in g

before use. The circuits are unstable immediately after the power supply is

turne d ON and attem pting me as ure me nt may res ult in inconsist ent measuremen t

values.

Z500

14

Setup Manual

ON the power

supply, allow the Z500 to stand for at least 30 minutes

Page 17

INTRODUCTION

Confirmi ng Package C ontents

Check the contents of the package as soon as you receive the Z500.

It is e xtremely rare for co m ponents to be missi ng, but contact the nearest OMRON representative if any

of the following items are missing.

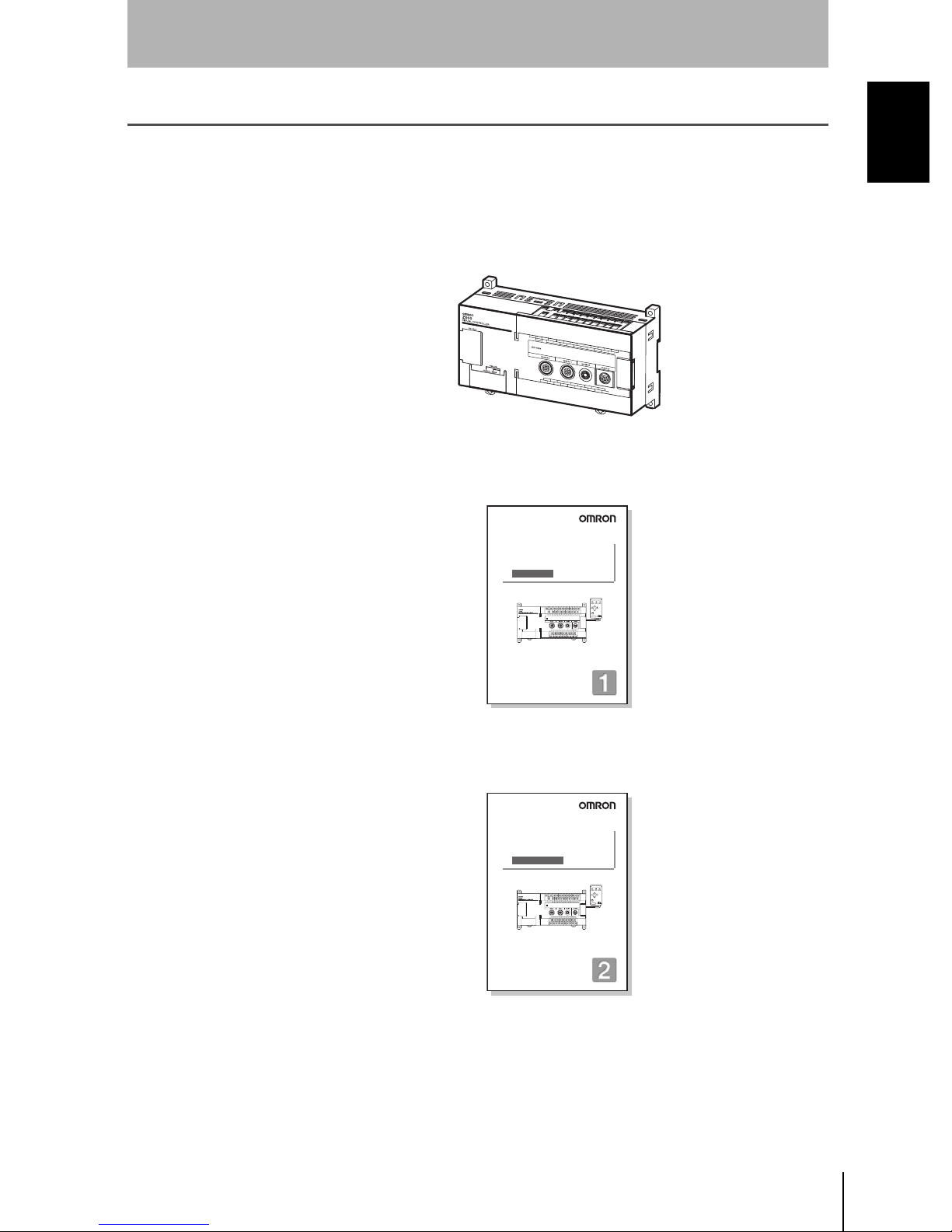

Z500 Controller. . . . . . . . . . . . . . . . . . . . . . . . . . Qty: 1

Manual 1: Setup Manual (This Manual) . . . . . . Qty: 1

INTRODUCTION

Confirming Package Contents

Multi-Dimensional Controller

Multi-Dimensional Controller

Z500

Setup Manual

Manual

Cat. No. Z000-E1-1

Manual 2: Operation Manual . . . . . . . . . . . . . . . Qty: 1

Multi-Dimensional Controller

Z500

Operation Manual

Manual

Cat. No. Z000-E1-1

Z500

Setup Manual

15

Page 18

INTRODUCTION

INTRODUCTION

Editor's Note

Visual Aids

Editor's Note

NOTICE Indicates information required to take full advantage of the functions and perfor-

CHECK

REFERENCE

HELP

The following headings appear in the left column of the manual to help you

locate different types of information.

mance of the product. Incorrect application methods may result in the loss or

damage to the product. Read and follow all precautionary information.

Indicates points that are important in using product functions or in application

procedures.

Indicates where to find related information.

Indicates information helpful in operation.

OMRON Product References

All OMRON products are capitalized in this manual. The word "Unit" is also capitalized when it refers to an OMRON product, regardless of whether or not it

appears in the proper name of the product.

Z500

16

Setup Manual

Page 19

Z500

Setup Manual

SECTION 1

Wiring and Connection

1-1 Basic System Configuration 18

1-2 Component Names and Functions 20

1-3 Power Supply and Ground 22

SECTION 1 Wiring an d C on nec ti on

17

Page 20

SECTION 1

Wiring and Connection

1-1 Bas i c Syst em Co n fig ur at io n

SECTION 1

1-1 Basic System Configuration

NOTICE

• The following dia gram shows the basic Z500 system configuration. Some of the

components shown in the configuration diagram are special OMRON products that cannot

be substituted with comparable de v ices. Thes e items a re in dicated with an asterisk.

• Always turn OFF the power supply before connecting or disconnecting cables. The

peripheral devic e m ay be da maged if connected or disco nnected with the power supp ly

turned ON.

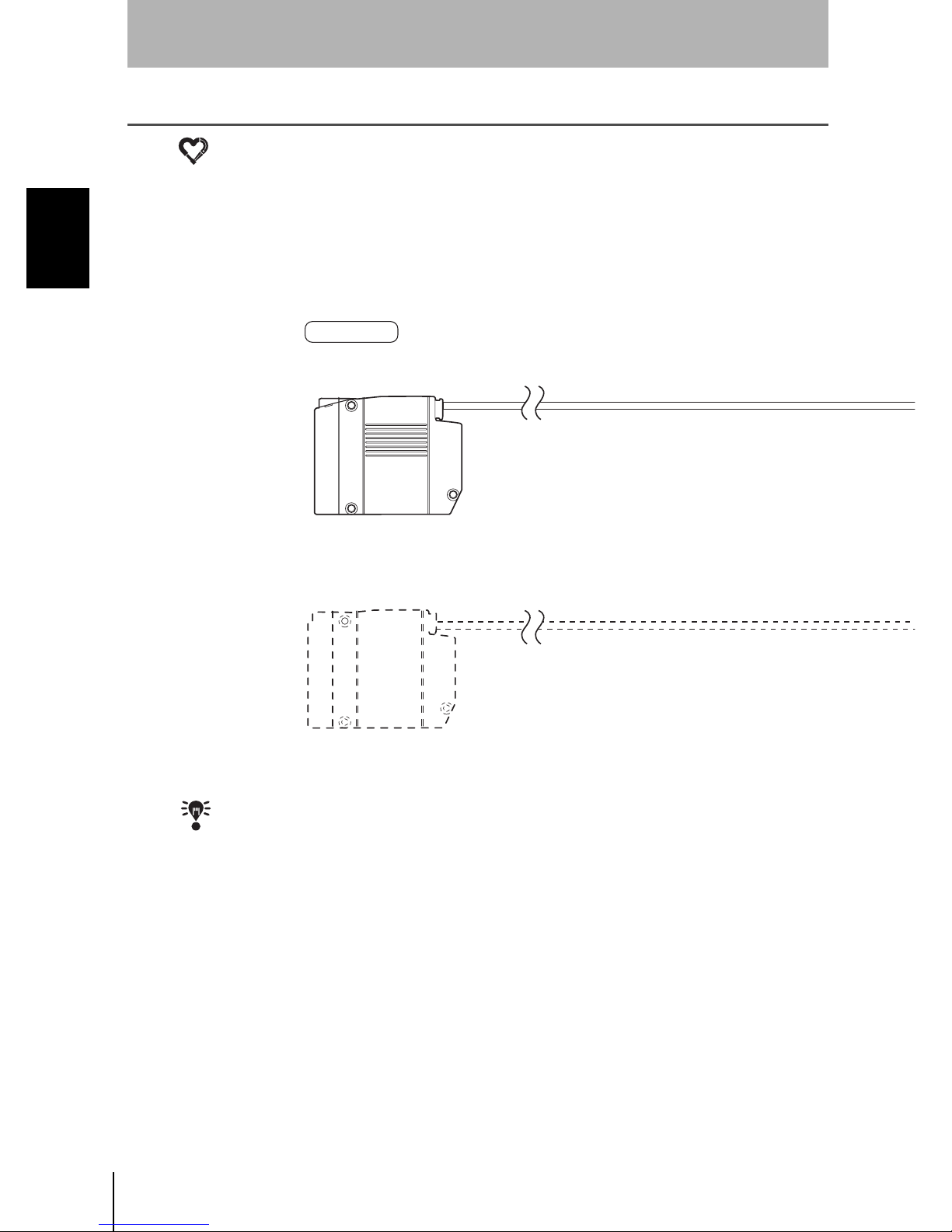

Sensor

Z500-SW2 (2-m cable)

Z500-SW17 (2-m cable)

* Sensor Extension Cable

Z309-SC1 (3 m, 8 m, or 13 m)

Specify the required cable length when ordering.

CHECK

Up to 2 S en sors can be connec t ed .

Z500

18

Setup Manual

Page 21

SECTION 1

Wiring and Connection

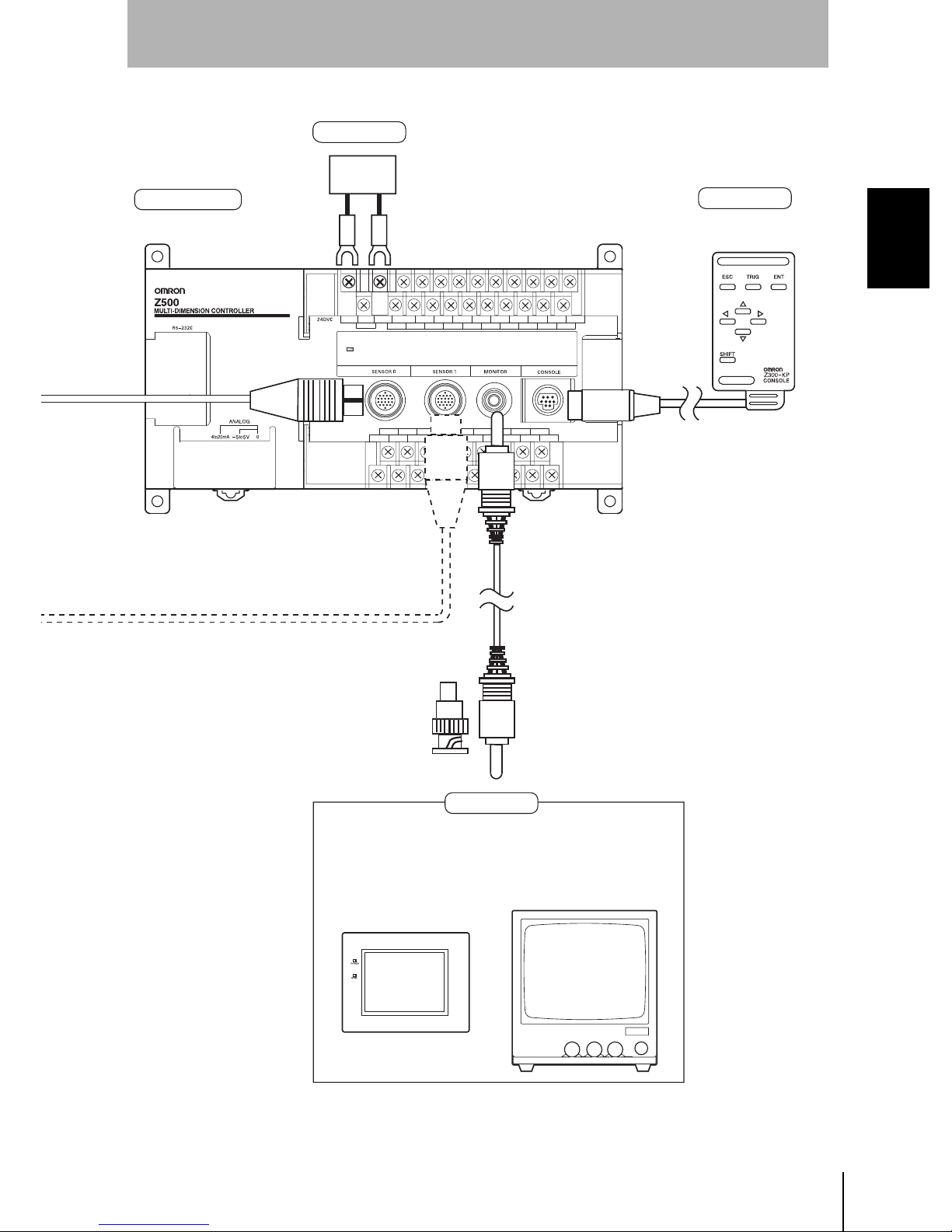

Controller

Z500-MC10

Power Supply

Recommended model:

OMRON S82K-05024

F150-VM Monitor Cable (2 m)

Console

*

Z300-KP

(2-m cable)

SECTION 1

1-1 Basic System Configuration

BNC Jack

(included with

the F150-VM)

Monitors

F150-M05L

Color Liquid

Crystal Monitor (pin input)

The Monitor is used to check the image and display menu where making settings.

F150-M09

Monochrome

CRT Video Monitor

(BNC input)

Z500

Setup Manual

19

Page 22

SECTION 1

Wiring and Connection

1-2 Component Names and Functions

1-2-1 Sensor

SECTION 1

1-2 Component Names and Functions

Z500-SW2

Z500-SW17

1. LASER indicators

6. Beam cover

5. Monitor

2. Emitter

4. Light

3. Receiver

2. Emitter

1. LASER indicators

3. Receiver

1. Provides laser beam warning indicators.

• For 15 to 25 seconds after the pow er supply i s tur ned O N, both indicators

will be OFF indicating that the laser beam is OFF.

• When the laser beam turns ON, both indicators will light.

• When the laser beam turns OFF, both indicators will turn OFF.

2. Emits laser beam.

3. Receives laser beam.

4. Light used when displaying surrounding images.

5. Captures surrounding images.

6. Used for switching between display of surrounding images and measurement.

To display surrounding images, move the beam cover lever to the left. To

perform measurement, move the lever to the right.

CHECK

CHECK

Tighten the le ver screw s with a flat- b laded scr e wd river to a torque in the range 0.15 to 0.3

N·m (1.5 to 3 kgf·cm).

When Using the Z500-SW2

• When performing measurement with the beam cover removed, attach the monitor cap

provid ed wit h the Se nso r ove r the Li gh t and Mon it or i n t he wa y sho wn o n th e n ext page .

• When displaying surrounding images, be sure to attach the beam cover. Surrounding

images cannot be displayed correctly without the beam cover attached.

Z500

20

Setup Manual

Display of

surrounding images

Move the beam cover

lever to the left.

Measurement

Move the beam cover

lever to the right.

Page 23

SECTION 1

Wiring and Connection

1-2-2 Controller

Z500-MC10

Z500

MULTI-DIMENSION CONTROLLER

POWER

17.

indicator

RS-232C

16.

connector

Beam cover attached

Lever screws:

M2 × 5

wo, M2 × 4

7. Ground terminal 9. Output terminals

8. Power Supply

terminals

10. Input terminals

Beam cover removed

Monitor cap

(provided as an accessory)

SECTION 1

1-2 Component Names and Functions

11. Monitor connector

Do not remove the

sticker on the side.

14. Analog output

terminals

Shading indicates parts that are lifted to see the terminals underneath.

9. Output terminals

Do not open.

12. Console connector13. Sensor connectors15. DIP switch

7. Connected to the ground wire.

8. Connected to the power supply.

9. Connected to external devices such as a PLC.

10. Connected to external devices such as a PLC.

11 Connected to the monitor.

12. Connected to a console.

13. Connected to the sensor.

14. Connected when using analog output.

15. Do not use. (Turn OFF the DIP switch.)

16. Connected to external devices such as a personal computer or PLC.

17. Lit while power is ON.

Z500

Setup Manual

21

Page 24

SECTION 1

SECTION 1

Wiring and Connection

1-3 Power Supply and Ground

Wire the power supply and the ground to their respective terminals. Tighten the screws to a torque of

between 0.5 and 0.6 N

m. After wiring, confirm that the wiring is correct.

·

1-3 Power Supply and Ground

NOTICE

Re-cover the terminal blocks with the Terminal Block Protection Covers.

Unco ve red terminal b loc k s can resul t in el ec t ric s ho ck.

1-3-1 Cr i mp Te rminals a nd Cables

The terminal block uses M3 terminal screws.

Use appr opriate cri mp terminals for M 3 screws as show n b elow.

Recommended Crimp Terminals

Type Manufacturer Model

Forked

6.2 mm max.

Round

6.2 mm max.

1-3-2 Ground Wiring

J.S.T. Mfg Co., Ltd. V1.25-N3A

J.S.T. Mfg Co., Ltd. V1.25-MS3

Recommended

wire size

1.31 to 1.65 mm

2

To avoid grounding problems, do not share the ground wire with any other

devices or wire the ground to the building's steel framing. Always connect a

ground wire to the Z500's ground terminal.

Use a grounding point that is as close as possible and keep the ground wiring as

short as possible.

×× × × × × × × × × × ×

×

Ground to 100 Ω

or less.

× × × × × × ×

POWER

× × ×

DI1 DI2 DI4 DI6

DI1 DI3 DI5 DI7

Z500

22

Setup Manual

Page 25

1-3-3 Wiring the Power Supply

Wire the Power Supply Unit independently of other devices. In particular, keep

the power supply wired separately from inductive l oads.

Use a power supply that meets the following specifications.

Recommended Power Supply

Output current Power supply voltage

1.6 A min. 24 VDC (21.6 to 26.4VDC)

Recommended Model

Manufacturer Model

OMRON Corp. S82K-05024

SECTION 1

Wiring and Connection

SECTION 1

1-3 Power Supply and Ground

CHECK

• Use a DC power supply with countermeasures against high-voltage spikes (safe extra

low-voltage circuits on the secondary side). Excessively high voltages can result in

electric shock.

• If UL recognition is required, use a UL class II power supply.

• Keep the power supply wiring as short as possible.

+

24 VDC

POWER

-

DI1 DI 2 DI 4 DI 6

DI1 DI3 DI 5 DI7

Z500

Setup Manual

23

Page 26

SECTION 1

1-3 Power Supply and Ground

SECTION 1

Wiring and Connection

MEMO

Z500

24

Setup Manual

Page 27

Z500

Setup Manual

SECTION 2

Installation

2-1 Mounting the Controller 26

2-2 Mounting the Sensor 28

SECTION 2 Installation

25

Page 28

SECTION 2

2-1 Mount ing the Controller

SECTION 2

Installation

2-1 Mounting the Controller

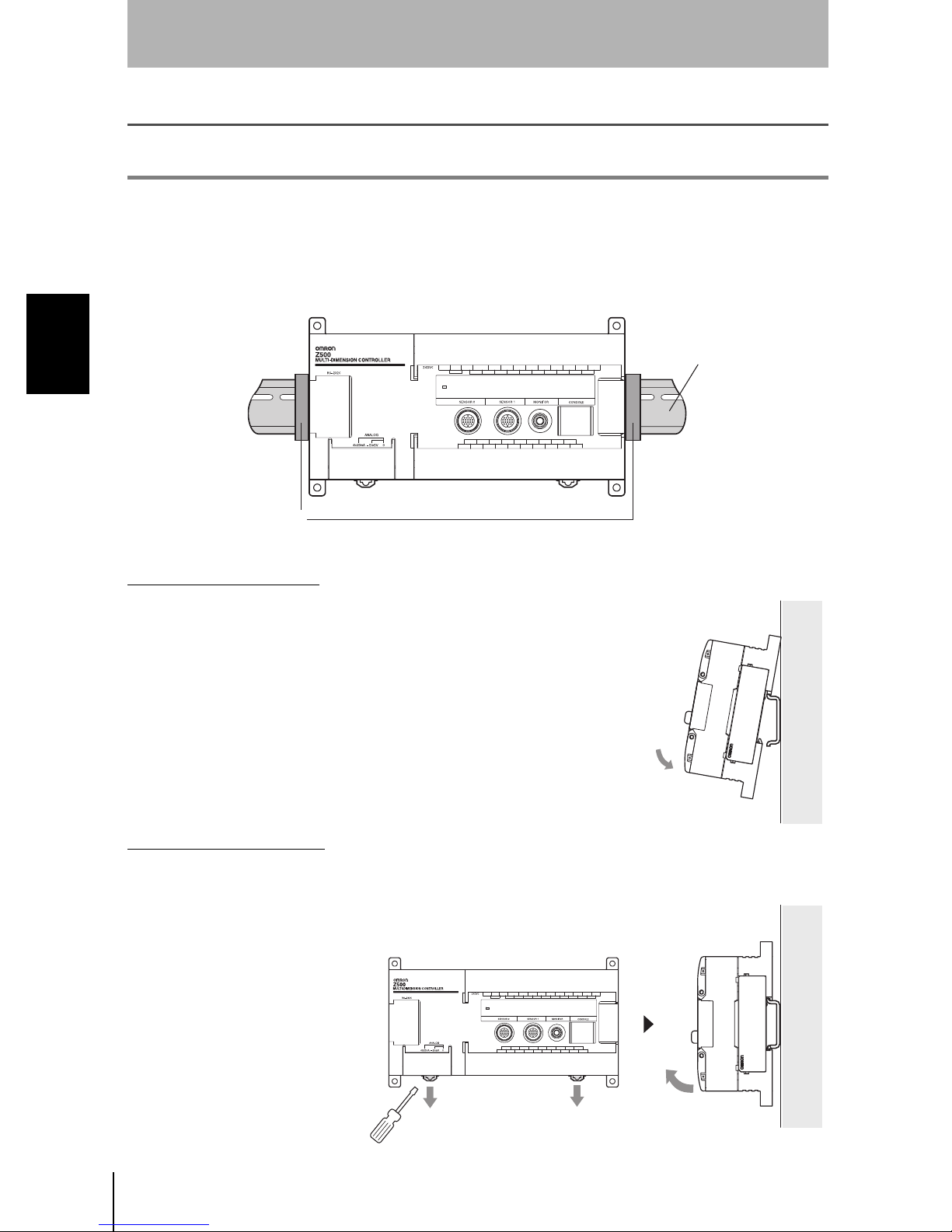

There are two ways to mount the Controller: DIN Track mounting or surface-mounting.

2-1-1 DIN Track Mounting

The Controller can be easily mounted to or removed from 35-mm DIN Track.

DIN Track

The following DIN Tracks are

available from OMRON.

PFP-100N (1 m)

PFP-50N (50 cm)

PFP-100N2 (1 m)

PFP-M

End Plate (OMRON)

Mounting the Controller

Hook the Controller into the DIN Track as shown in

the diagram and then press in at the bottom until

the Controller locks into place.

Removing the Controller

Use a flat-bladed screwdriver to pull the hook down and then pull out the

Controller from the bottom.

Z500

26

Setup Manual

Page 29

2-1-2 Surface Mounting

SECTION 2

Installation

Four, M4

100±0.2

185±0.2

(Unit: mm)

SECTION 2

2-1 Mount ing the Controller

8

Z500

Setup Manual

27

Page 30

SECTION 2

Installation

2-2 Mounting the Sensor

Up to 2 Sensors can be connected per Controller.

SECTION 2

2-2 Mount ing the Sensor

NOTICE

2-2-1 Sensor Types

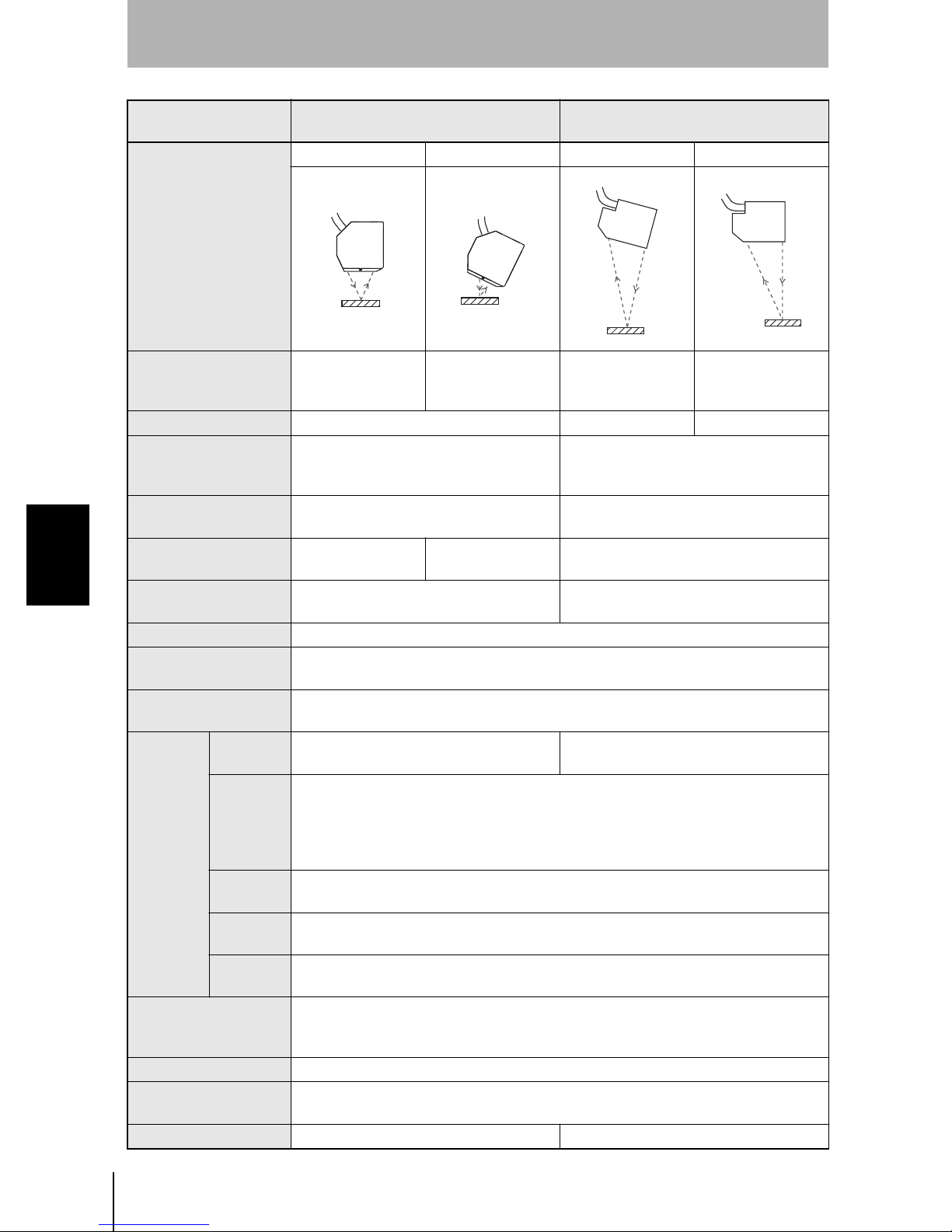

Type

Super High-precision

Model

Z500-SW2

Long-range Model

Z500-SW17

measurement

Only co ntrollers de si gned s pecifi cally f or the Z500 can be used.

Using another type of controller may result in damage to the sensor or controller.

Distance to

Height

center (A)

20 mm ±0.8 mm

100 mm ±20 mm

(B)

Measurement range

Width

(D)

B= +0.8 mm : 4.0 mm

(The width of t he measurement

region is 2.2 mm.)

B= 0 mm : 4.0 mm

(The width of t he measurement

region is 2.3 mm.)

B= -0.8 mm : 4.0 mm

(The width of t he measurement

region is 2.4 mm.)

B= +20 mm : 40 mm

(The width of t he measurement

region is 14.5 mm.)

B= 0 mm : 45 mm

(The width of t he measurement

region is 17.3 mm.)

B= -20 mm : 50 mm

(The width of t he measurement

region is 20.1 mm.)

Spot diameter

(C)

B= +0.8 mm : 40 µm

B= 0 mm : 20 µm

B= -0.8 mm : 40 µm

B= +20 mm : 280 µm

B= 0 mm : 60 µm

B= -20 mm : 280 µm

CHECK

A

Dista nc e to m ea sureme nt center (A), Heig ht (B ) , Width (D) , and Spot diameter (C)

Front View

Z500-SW2

Line beam

+0.8mm

0mm

-0.8mm

D

B

C

+20mm

Z500-SW17

0mm

-20mm

Line beam

D

Z500

28

Setup Manual

Page 31

2-2-2 Measurement Range

Super High-precision Model: Z500-SW2

SECTION 2

Installation

CHECK

20mm

+0.8mm

0mm

-0.8mm

Relation betw een Measurement Mode and Measurement Range

Wide Mode

+0.8mm

0mm

0.8mm

2.2mm

(±1.1mm)

2.3mm

(±1.15mm)

2.4mm

(±1.2mm)

Measurement

range

+0.8mm

0mm

-0.8mm

SECTION 2

2-2 Mount ing the Sensor

Zoom Mode

0.73mm

0.76mm

0.80mm

Z500

Setup Manual

29

Page 32

SECTION 2

-

SECTION 2

Installation

Long-range Model: Z500-SW17

100mm

20mm

0mm

Measurement

range

2-2 Mount ing the Sensor

CHECK

-20mm

Relation betw een Measurement Mode and Measurement Range

Wide Mode

+20mm

0mm

20mm

14.5mm

(±7.25mm)

17.3mm

(±8.65mm)

20.1mm

(±10.05mm)

+20mm

0mm

20mm

Zoom Mode

4.8mm

5.7mm

6.7mm

Z500

30

Setup Manual

Page 33

2-2-3 Mounting Dimensions

Super High-precision Model: Z500-SW2

• Dimensions for Diffuse Reflection

SECTION 2

Installation

Reception axis

51.7±0.1

Mounting Holes

Two, M4

24.1±0.1

• Dimensions for Mirror Reflection

Reception axis

Measurement center

5.2 77.2

51.74.7

24.149.3

Measurement

78.4

center

13.8

Emission axis

Reference plane

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

20

16

(4)

4

50

65

57

(Unit: mm)

SECTION 2

2-2 Mount ing the Sensor

Connector

(Unit: mm)

Two, 4.5-dia. holes

4

57±0.1

Mounting Holes

Two, M4

32

56.5

Emission axis

Reference plane

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

18.1

25

25

20

20

65

Connector

Z500

Setup Manual

31

Page 34

SECTION 2

2-2 Mount ing the Sensor

SECTION 2

Installation

Long-range Model: Z500-SW17

• Dimensions for Diffuse Reflection

Measurement center

70±0.1

9.5±0.1

Three, M4

100

Emission axis

25

25

Reception axis

Reference plane

4

16.4

9.5

80

72

70

(Unit: mm)

Three, 4.5-dia. holes

25

100

69

69±0.1

Mounting Holes

• Dimensions for Mirror Reflection

Measurement center

Emission axis

37.7 15.6

68.3±0.1

24.2±0.1

Three,

M4

16.9

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

94

9.3

24.2

12.5

25

Reception axis

Reference plane

95.9

68.3

45.1

Connector

(Unit: mm)

Three, 4.5-dia. holes

23.5

15.2

109.6

65.3

Mounting Holes

Z500

32

Setup Manual

65.3±0.1 15.2±0.1

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

Connector

Page 35

2-2-4 Mounting Orientation

Mounting Near Walls

Errors will occur if light reflected off a wall surface is received by the Sensor.

If it is not possible to mount the Sensor away from the wall, mount in the way

shown below, i.e., so that the plane containing the emission axis and the

reception axis is parallel to the wall surface.

Also, applying matt black coating to the wall surface will help to reduce the

amount of light reflected.

SECTION 2

Installation

SECTION 2

2-2 Mount ing the Sensor

Narrow Grooves or Indentations

If measurement is performed in an indentation between two walls, or in a

groove, mount the Sensor in the way shown below, i.e., so that the path along

the emission and reception axes is not interrupted by a wall.

Z500

Setup Manual

33

Page 36

SECTION 2

2-2 Mount ing the Sensor

SECTION 2

Installation

Level Differences

When measuring w orkpieces with level differences, the i nfluence of the level

difference can be minimized by mounting the Sensor so that the plane containing

the emission axi s and th e reception axis is parallel to the boundary between the

different levels.

Rotating Workpieces

When measuring rotating workpieces, the influence of position displacement

and blurring of the rotating workpiece can be minimized by mounting the Sensor

so that the plane containing the emission axis and the reception axis is parallel

to the axis of rotation.

Z500

34

Setup Manual

Page 37

SECTION 2

Installation

Projections When measuring the tops of projections on the workpieces, mount the Sensor

so tha t the entire projection pas ses through the line beam.

Front View

Line beam

SECTION 2

2-2 Mount ing the Sensor

Z500

Setup Manual

35

Page 38

SECTION 2

2-2 Mount ing the Sensor

SECTION 2

Installation

2-2-5 Mounting Distance

After selecting the Sensor mounting status in the menu item Environment,

mount the Sensor in a location where the status can be measured correctly.

REFERENCE

Refer to page 146 in the Operation Manual.

Super High-precision Model: Z500-SW2

• Dimensions for Diffuse Reflection

50

• Dimensions for Mirror Reflection

mission axis

mission axis

Workpiece

Workpiece

25 25

Reception

axis

Reception axis

16±

0.8mm

5.2±0.8mm

*

±

0.8mm

20

Z500

36

Setup Manual

* Beam cover attached

Page 39

Long-range Model: Z500-SW17

• Dimensions for Diffuse Reflection

SECTION 2

Installation

SECTION 2

• Dimensions for Mirror Reflection

Reception

axis

2.5

Emission

axis

25

Workpiece

12.5 12.5

100±20mm

2-2 Mounting the Sensor

Reception

axis

Workpiece

Emission

axis

94±16mm

Z500

Setup Manual

37

Page 40

SECTION 2

2-2 Mounting the Sensor

SECTION 2

Installation

2-2-6 Mutual Interference

When using 2 or more Sensors mounted adjacently, make sure that the spots

(shown below) for other Sensors are outside the shaded areas.

Super High-precision Model: Z500-SW2

(Unit: mm)

Long-range Model: Z500-SW17

2.2

2.2

1.3

1.2

2.3

18.9

21.1

2

(Unit: mm)

Z500

38

Setup Manual

79 80

121

3

20

42

428

100

40

45

50

Page 41

Z500

Setup Manual

SECTION 3

Connecting External Devices

3-1 Terminal Block Connections 40

3-2 RS-232C Connections 44

3-3 Linear Sensor Controller Connections 46

SECTION 3 Connecting External Devices

39

Page 42

SECTION 3

Connecting External Devices

3-1 Terminal Block Connections

This section explains how to connect I/O to the Z500 through its terminal block to input signals such as

measurement commands or output signals suc h as measurement results.

Refer to the Operation manual for details on I/O formats.

SECTION 3

3-1 Terminal Block Connections

NOTICE

Re-cov er the t ermi na l bl oc ks wi th the Te rm inal Blo ck Pro t ecti on Cove r s. Uncove red te rminal bloc ks can result i n electr ic sho ck .

3-1-1 Cr i mp Te rminals a nd Cables

The terminal block uses M3 terminal screws.

Use appropriate crimp terminals for M3 screws as shown below. Tighten the

screws to a torque of between 0.5 and 0.6 N·m.

Recommended Crimp Terminals

Type Manufacturer Model

Forked

6.2 mm max.

Round

6.2 mm max.

J.S.T. Mfg Co., Ltd. V1.25-N3A

J.S.T. Mfg Co., Ltd. V1.25-MS3

Recommended

wire size

1.31 to 1.65 mm

2

Z500

40

Setup Manual

Page 43

3-1-2 Internal Specifications

+

SECTION 3

Connecting External Devices

CHECK

Use a DC power supply with countermeasur es again st hig h -v oltage s pi k e s (safe extra lowvoltage circui ts on the secondary side). Exce ssively high voltages can result in electric

shock.

Input Specifications

Input voltage 12 to 24 V DC ±1 0 %

ON current 5 to 15 mA

ON vol tage 8.8 V max.

OFF current 0.1 mA max.

OFF voltage 4.5 V min.

ON delay

OFF delay

Intern al circuit

RESET input: 10 ms max.

Other inputs: 0.5 ms max.

RESET input: 15 ms max.

Other inputs: 0.7 ms max.

COM IN

Input

terminal

SECTION 3

3-1 Terminal Block Connections

Output Specifications

Output voltage 12 to 24 V DC ±1 0 %

Load current 45 mA max.

ON res i d ual volt age 2 V max.

OFF leakage current 0.1 mA max.

Intern al circuit

Output terminal

Load

COM OUT

+

Z500

Setup Manual

41

Page 44

SECTION 3

Connecting External Devices

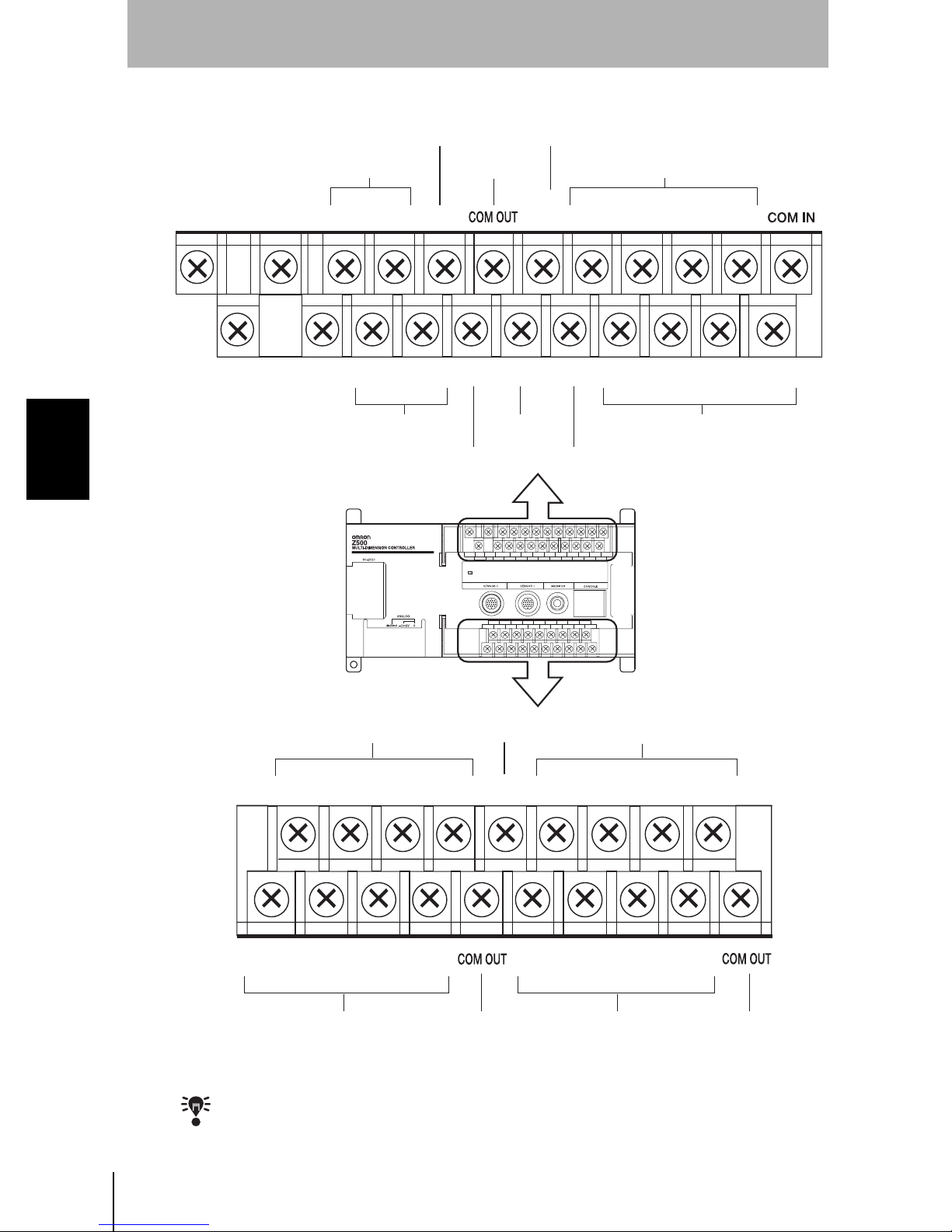

3-1-3 Terminal Names

SECTION 3

3-1 Terminal Block Connections

Control terminal

Measurement result outputs Command inputs

DO 16 DO 18

DO 17

Common

for DO 16 to 19

DO 19

Control terminal

NC

RESET

Reset the Z500

LDOFF

TRIGGER

Control terminalNot connected

DI 1

DI 3

Command inputsMeasurement result outputs

DI 5

DI 6GATE DI 4DI 2DI 0

DI 7

Measurement result outputs

DO 1

DO 0

Measurement result outputs

CHECK

DO 2

Refer to page 152 in the Operation Manual for details on control termin al function.

Z500

42

Setup Manual

DO 3

DO 5

DO 4 DO 6

Not connected

DO 7

for DO 0 to 7

NC

Measurement result outputs

DO 9

DO 8

Measurement result outputsCommon

DO 11

DO 10

DO 12

DO 13

DO 15

DO 14

Common

for DO 8 to 15

Page 45

SECTION 3

Connecting External Devices

NOTICE

CHECK

• Do not rev erse t he connect ions of the signal terminals and COM terminals.

• Using the RESET Signal

Do not input the RESET input immediately after turning ON the power. When using

RESET inp ut to syn chron ize sta rtup tim ing , wait at l east 1 seco nd af ter turn ing ON the

Z500's power supply b efo re tu rni ng O N the R ESET term in al .

The initial s ta t u s of the outp ut terminal s is OFF. The t er m in al s, however, may t ur n O N fo r

approximat ely 0.5 s econd s wh e n t he power is t u r ned ON .

Be sure to allow for this when connecting to an extern al dev ice .

SECTION 3

3-1 Terminal Block Connections

Z500

Setup Manual

43

Page 46

SECTION 3

Connecting External Devices

3-2 RS-232C Connections

The Z500's RS-232C port can be used to connect input signals such as measurement triggers or output

signals such as measurement results. Additionally, data that has been s et in the Z500 can be backed up

in a personal computer.

Refer to the Operation manual for details on communications settings and I/O formats.

SECTION 3

3-2 RS-232C Connections

NOTICE

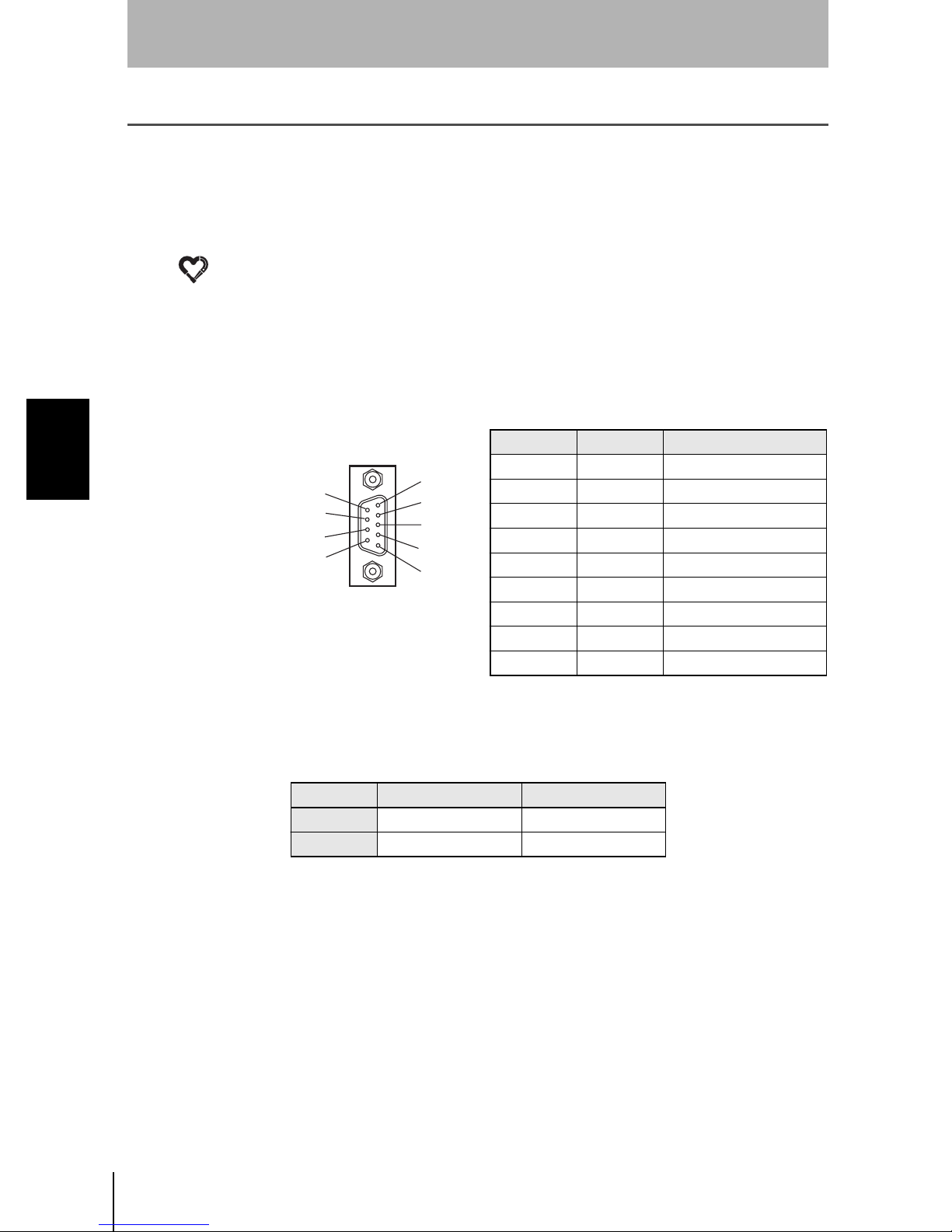

3-2-1 Connector

In some situations, the RS-232C terminal transmits signals whether the power supply is

ON, OFF, or RESET.

Be sure to allow for this when connecting to an extern al dev ice .

The Z500's RS-232C connector uses 9-pin D-SUB female connectors.

Pin arrangement

Pin No. Signal Function

1 FG (GND) Protective frame ground

5

4

3

2

1

2 SD (TXD) Send D ata

3 RD (RXD) Receive Data

4 RS (RTS) Request to Send

5 CS (CTS) Clear to Send

6 NC Not connected

7 NC Not connected

8 NC Not connected

9 SG (GND) Signal ground

Use a compatible connector.

Recommended Plug and Hood

Type Manufacturer Model

Plug OMRON Corp. XM2A-0901

Hood OMRON Corp. XM2S-0911

Z500

44

Setup Manual

Page 47

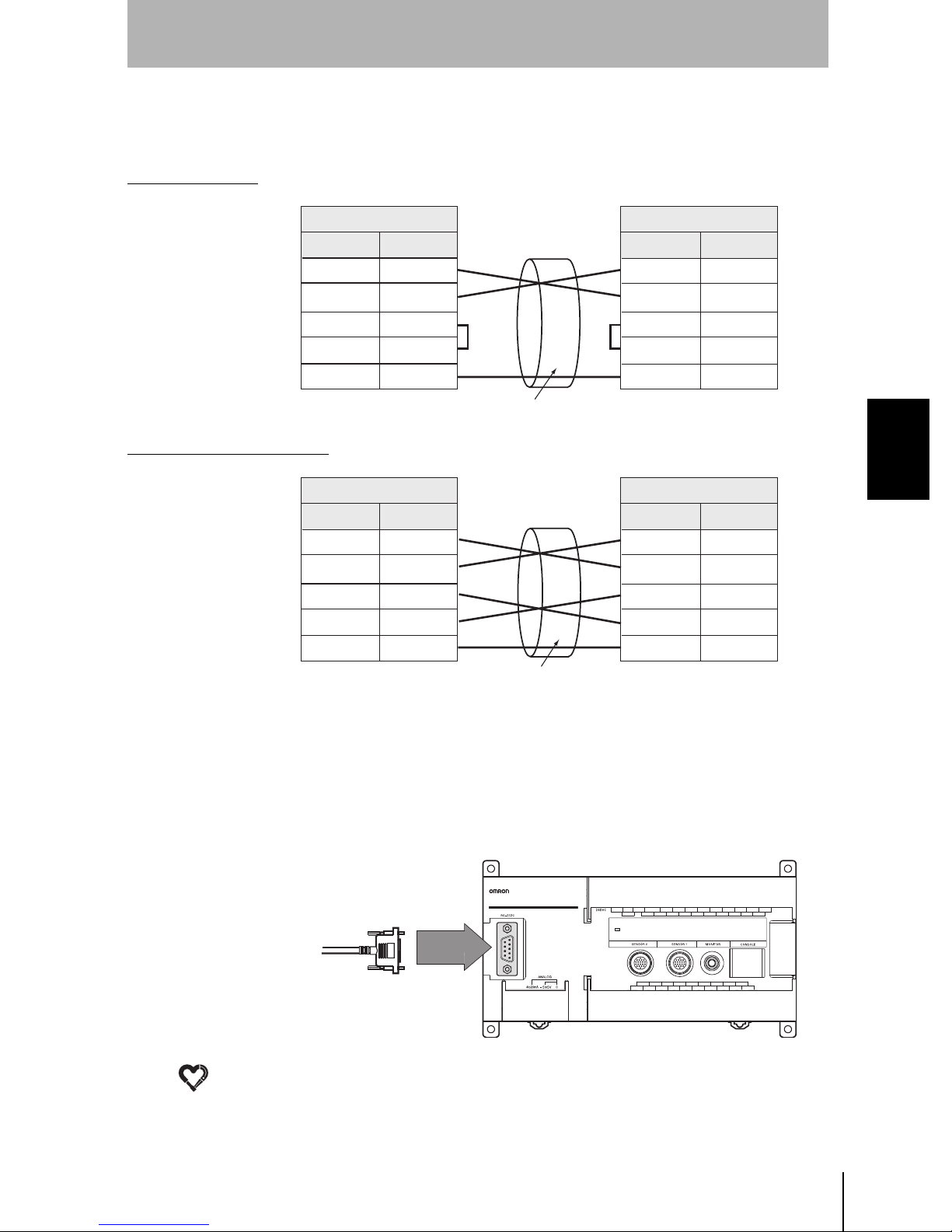

3-2-2 Wiring

Standard Wiring

SECTION 3

Connecting External Devices

The maximum cable length is 15 m.

SD (TXD)

RD (RXD)

RS (RTS)

CS (CTS)

SG (GND)

Wiring for RS/CS Control

SD (TXD)

RD (RXD)

RS (RTS)

CS (CTS)

SG (GND)

Signal

Signal

Z500

Z500

Pin No.

2

3

4

5

9

Pin No.

2

3

4

5

9

Use a shielded cable.

External device

Pin No.

*

*

*

*

*

External device

Pin No.

*

*

*

*

*

Signal

SD (TXD)

RD (RXD)

RS (RTS)

CS (CTS)

SG (GND)

Signal

SD (TXD)

RD (RXD)

RS (RTS)

CS (CTS)

SG (GND)

SECTION 3

3-2 RS-232C Connections

3-2-3 Connection

NOTICE

Use a shielded cable.

* Pin numbers on the external device will depend on the device being connected.

Refer to the manual for the personal computer or PLC being connected.

Align the connector with the socket and press the connect or straight into place.

Tighten the two screws on the edges of the connector.

Z500

MULTI-DIMENSION CONTROLLER

• Always turn OFF the power supply before connecting or disconnecting cables. The

peripheral devic e m ay be da maged if connected or disconnected w ith the pow er supply

turned ON.

• Always tighten the connector screws.

Z500

Setup Manual

45

Page 48

SECTION 3

4

Connecting External Devices

3-3 Linear Sensor Contro l ler Con nections

3-3-1 Cr i mp Te rminals a nd Cables

The terminal block uses M3 terminal screws.

Use appropriate crimp terminals for M3 screws as sho wn b e low.

Tighten the screws to a torque of between 0.5 and 0.6 N·m.

Recommended Crimp Terminals

SECTION 3

3-3 Linear Sensor Controller Connections

Forked

6.0 mm max.

Round

6.0 mm max.

3-3-2 Terminal Names

NOTICE

Re-cover the termin al blocks with the Terminal Block P rotection Covers. Uncovere d

terminal bloc ks can result in electric shock.

Type Manufacturer Model

J.S.T. Mfg Co., Ltd. V1.25-B3A

J.S.T. Mfg Co., Ltd. V1.25-MS3

Recommended

wire size

1.31 to 1.65 mm

2

to20mA -5to5V

Z500

46

Setup Manual

0

Analog output ground connected to input devices.

Analog output terminal for voltage output in the range -5 to 5 V.

Analog output terminal for current output in the range 4 to 20 mA.

Page 49

3-3-3 Internal Specifications

SECTION 3

Connecting External Devices

12V

Internal circuit

12V-12V

Analog output:

4 to 20 mA

Analog output:

-5 to 5V

Analog ground

3-3-4 Connection Examples for the Linear Sensor Controller

Connecting to the Linear Sensor Digital Panel Meter (K3TS)

K3TS-SD12B

10 11

1 2 4 5 6 7 8 93

12 13

14

15 16

17

Load

300 max.

SECTION 3

3-3 Linear Sensor Controller Connections

Shield line

24 VDC

4to20mA-5to5V

0

Z500

Setup Manual

47

Page 50

SECTION 3

Connecting External Devices

Connecting to the Linear Sensor Controller (K3AS)

SECTION 3

3-3 Linear Sensor Controller Connections

24 VDC

10

9

8

7

6

5

4

3

2

1

30

29

28

27

25

24

23

22

21

31

K3AS

2032

19

18

17

1626

15

14

13

12

1133

Shield line

Z500

MULTI-DIMENSION CONTROLLER

4to20mA-5to5V

0

Connecting to the Scaling Meter (K3TJ)

1 2 4 5 6 7 8 93

Analog output

Shield line

K3TJ-A116R

24 VDC

Z500

MULTI-DIMENSION CONTROLLER

4to20mA-5to5V

0

Z500

48

Setup Manual

Page 51

Connecting to the Digital Panel Meter (K3NX)

10 11 12 13 14 15 16 17

1 5 6 7 8 93 42

Shield line

24 VDC

Z500

MULTI-DIMENSION CONTROLLER

SECTION 3

Connecting External Devices

K3NX-AD2A

SECTION 3

4to20mA-5to5V

0

Connecting to the Linear Sensor Interface Unit (CQM1-LSE)

Z500

MULTI-DIMENSION CONTROLLER

ZERO

RES

4to20mA-5to5V

0

COM

+24V

DC

1

3

5

7

9

11

13

15

17

CQM1-LSE01

0

2

4

6

8

10

12

14

16

4 to 20 mA

T/O

ZRES

+24V

DC

24 VDC

3-3 Linear Sensor Controller Connections

Z500

Setup Manual

49

Page 52

SECTION 3

SECTION 3

Connecting External Devices

MEMO

3-3 Linear Sensor Controller Connections

Z500

50

Setup Manual

Page 53

Z500

Setup Manual

SECTION 4

Trouble s hooting and Mai ntenance

4-1 Troubleshooting 52

4-2 Maintenance 54

4-3 Specifications and Dimensions 55

SECTION 4 Troublesh ooting and Maintenance

51

Page 54

SECTION 4

Troubleshooting and Maintenance

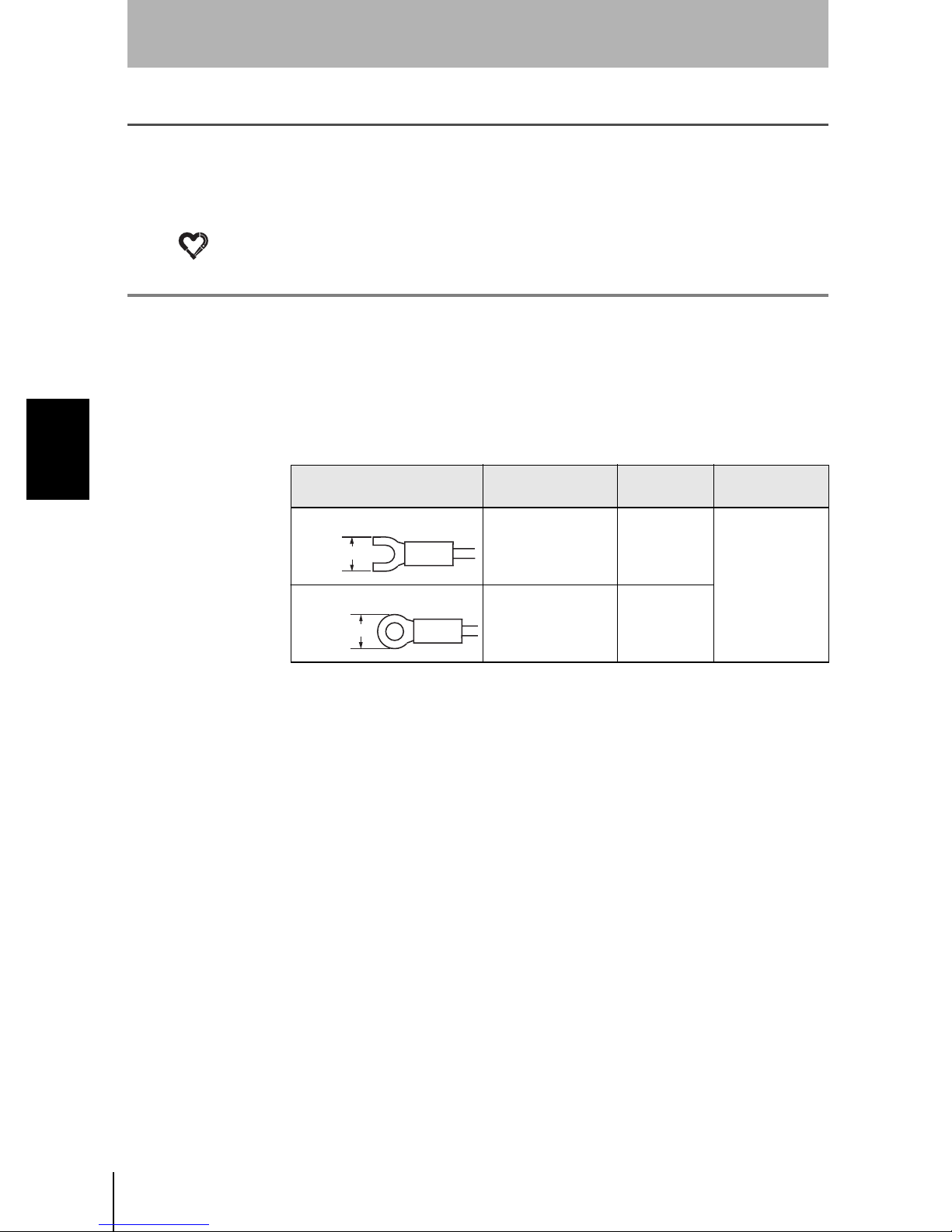

4-1 Troubleshooting

This section provides information on hardware errors and r emedies to be taken. Refer to this section

before requesting service from your OMRON represent ative.

SECTION 4

4-1 Troubleshooting

HELP

Connection Errors

Problem Probable cause References

The Power indicator is

not lit.

The V i deo Moni t o r is

blank.

The V i deo Moni t o r

image is not clear.

Cannot make key

inputs from the

console.

No images are

displayed.

• The Power Supply is not connected properly.

• The 24-VDC (21. 6 to 26.4-V DC) suppl y volt age

has dropped.

• The po w e r to th e Vid eo M on ito r i s not ON.

• The Mon itor Cabl e is not connecte d properly .

• The Video Moni tor is malfun c t io ning.

• When using a Liquid Crystal Monitor, the power

supply ca pacity i s ins ufficien t.

• There is el ec tric nois e en teri ng from th e po w er

supply or cables.

• The Mon itor Cabl e is not connecte d properly .

• The Cons ole Cable is no t cor rec t l y co nn ec t e d. p.19

• The Sens or cabl e is no t co nn ec t e d to the

Controller correctly.

• There is no workpiece inside the measurement

range.

• The Sensor is not mo unted in the cor r ec t

position.

p.22

p.19

——

p.19

p.28

Z500

52

Setup Manual

Page 55

SECTION 4

Troubleshooting and Maintenance

HELP

HELP

Terminal Block Errors

Problem Probable cause References

Trigger signals

(input signals) are not

received.

Signals cannot be

output externally.

• The cables are not correctly wired.

• The sign al line i s discon ne cted.

• The Z500 is not in Run mode.

• The tri gg er si gn al has not been input.

• The cables are not correctly wired.

• The sign al line i s discon ne cted.

• The Z500 is not in Run mode.

RS-232C Communication Errors

Problem Probable cause References

• The cables are not correctly wired.

No communication s

are possible.

The Unit o perates w ell

initially, but after a

while there is no

response from the

Z500.

• The Z500's communications specifications do

not m atc h thos e of the external d ev ice .

• The Z500 is not in Run mode.

• The reception bu ffer on t he external device

(e.g., personal computer) is full.

Check that settings allow the data to be properly

received.

p.40

p.40

p.44

——

SECTION 4

4-1 Troubleshooting

Z500

Setup Manual

53

Page 56

SECTION 4

Troubleshooting and Maintenance

4-2 Maintenance

In order t o ensu re performanc e, carry out the maintenance procedures given below.

SECTION 4

4-2 Maintenance

NOTICE

• Turn OFF the power and take safety precautions before conducting inspections.

Electric shock can result from attempting safety inspections with the power turned ON.

• Do not use thinners or benzene to clean the Z500.

4-2-1 Cleaning

Optical Filter on Front Panel of Sensor

• Use a blower brush (used to clean camera lenses) to blow large dus t particles

from th e surfac e. Do not blo w the dust a way wit h your mouth.

• Use a soft cloth (for lenses) with a small amount of alcohol to remove the

rema in ing dust.

NOTICE

Do not use a scrubbing action when cleaning as scratches on the filter could result in the

Sensor malfunctioning.

Cleaning of Equipment

Remove dirt on equipment by gent ly wiping with a soft cloth.

4-2-2 Regular Inspections

Inspection point Details

Power su pply

Ambient

temperature

Ambient

humidity

Installation

The vo ltage measured at the power supply termin als

must be 24 VDC + 10 %/ - 10 %.

The operating ambient temperature inside the

cabinet must be between 0 and 50 ºC

The oper a tin g am bient humi dity in si de th e cabine t

must be be tw e en 35% an d 85 %.

Each component must be firmly secured.

Each cabl e co nn ecto r mu st be co rr ectl y in se rte d an d

locked.

Tools

required

Circuit tester

Thermometer

Hygrometer

Phillips

screwdriver

Z500

54

Setup Manual

Page 57

4-3 Specifications and Dimensions

4-3-1 Sensor

Z500-SW2 Sensor

SECTION 4

Troubleshooting and Maintenance

(Unit: mm)

26.4

12

eceiver

Light

Z500-SW17 Sensor

Optical axis

Reference plane

Reception axis

Measurement center

3.5

3

56.5

Monitor

Emitter

Emission axis

Reference plane

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

32

16

(4)

20

4

12

18.1

25

25

65

57

Two, 4.5-dia. holes

4

20

20

Reference plane

65

Operation indicators

4

17 dia.

Connector

(Unit: mm)

20

6.5

SECTION 4

4-3 Specifications and Dimensions

92.1

46

22.7

13 dia.

Emitter

Receiver

18

Optical axis

100

25

4

16.4

16.9

Measurement center

Emission axis

5

2

Reception axis

Reference plane

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

9.5

80

72

70

45.1

36

Three, 4.5-dia. holes

Operation indicators

25

82

100

69

(5)

Connector

8

21 dia.

(15)

9.5

Z500

Setup Manual

55

Page 58

SECTION 4

Troubleshooting and Maintenance

SECTION 4

4-3 Specifications and Dimensions

Model

Run Mode

Distance to

measurement center

Measurement range ±0.8 mm ±16 mm ±20 mm

Light source

Beam dim e nsi ons

(See note 1.)

Linearity

Resolution

Sampling period 9.96 ms

LED indicators

(LASER indicators)

Temper ature character-

istic (See note 9.)

Degree of

protection

Ambient

operating

illumination

Environment

resistance

Materials

Cable le ngth 2 m

Minimum bending

radius

Weight Approx. 350g Approx. 600g

(receiver

side)

Ambient

temperature

Ambient

humidity

Vibration

resistance

(Super High-precision Model)

Mirror reflection Diffuse reflection Mirror reflection Diffuse reflection

20 mm

(with beam cover

attached: 16 mm)

Visible-light semiconductor laser

Refere nc e dis tance : 20 µm × 4 mm TYP.

(Measurement re gion : 2 mm)

±0.1 %F.S.

(See no te 2. )

10 to 150 Hz (double amplitude: 0.35 mm) for 8 min each in X, Y, and Z directions

Z500-SW2

5.2 mm 94 mm 100 mm

Visible-light semiconductor laser

(Waveleng th 65 0 nm ,

1 mW max., Class 2 )

Refere nce dist ance: 60 µm × 45 mm TYP.

(Measurement region: 17 mm)

±0.1 %F.S.

(See note 3.)

0.1 µm

(See no te 5 an d 6.)

Lit while laser is ON.

±0.01 %F.S./ºC

IP64 IP66 (See note 10.)

Illuminatio n at light-receiving surface: 3,000 lx max., incandescent light

Operating: 0 to 50 ºC (with no icing or condensation)

Storage: -15 to 60 ºC (with no icing or condensation)

Operat ing and st orage: 35 % to 85 % (with no condensation)

Controller: Die-cast aluminum

Cable sheathing: Heat-resistant chlorinated vinyl

Connector: zinc alloy and brass

68 mm

Z500-SW17

(Long-range Model)

(Wavelength 658 nm,

15 mW max. , Class 3B )

±0.1 %F.S.

(See note 4.)

1 µm

(See note 7 and 8.)

Z500

56

Setup Manual

Page 59

SECTION 4

Troubleshooting and Maintenance

2

Note 1: Defined at 1/e

present outsid e this range and if the reflection f actor of the light around the

workpiece is high compared to the workpiece, measurement may be affected.

Note 2: Error with respect to the theoretical line representing the displacement output for

measu rement of OMRON standa rd quart z glass. The li nearity v aries wit h the

type of workpiece.

Note 3: Error with respect to the theoretical line representing the displacement output for

measu rement of O MRON stan dard SUS bl ocks. The li nearity va ries with t he

type of workpiece.

Note 4: Error with respect to the theoretical line representing the displacement output for

measu r em e nt of O MRON standard white al u mina cera mics. The linea r i t y varie s

with the type of workpiece.

(13.5%) of the density at the light center. Light may, however, be

Z500-SW17

Note 5: Displacement conve rs io n value fo r pe ak -to-peak of d is placem e nt outp ut. These

figures are for measurement of OMRON standard quartz glass (mirror reflection)

or OMRON standard SUS blocks (diffuse reflection) at the measurement center.

In magnetic fields, it may not be possible to maintain resolution performance

characteristics.

Note 6: These figur es are for w hen the Sensor is connected to the Z500-MC 10, the

average number of measurements is 16.

Note 7: Displacement conversion value for peak-to-peak of displacement output (for

measu rement of OMRON sta ndard white al umina c eramic at the mea surem ent

center). In strong magnetic fields, it may not be possible to maintain resolution

performance characteristics.

Note 8: With t he Z 50 0- M C 1 0, at an ave r ag e nu mb er of m ea su r em e nts o f 64.

Note 9: Value for measurement with the space between the Sensor and the workpiece

(white alum in a ce r a mic) sec ured with an al um inum jig.

Note 10: Enqui re se parat el y ab ou t pr od u cts c onformi ng to IP67.

120mm

Digital output

80mm

80mm

±0.1 % max.

120mm

Distance

SECTION 4

4-3 Specifications and Dimensions

Z500

Setup Manual

57

Page 60

SECTION 4

Troubleshooting and Maintenance

4-3-2 Controller

Z500-MC10 Controller

SECTION 4

4-3 Specifications and Dimensions

87.9

75.5

9 × 7.7=69.3

9 × 7.7=69.3

81.71 23.6

195

83.7

Connector

12.5 dia.

4.1

8

(32.5)

(66.5)

2 × 7.62=15.24

10

98.1 24.5 20

185

3.85

Indicator

148.38

8 × 7.7=61.6

3.85

10

(Unit: mm)

25.1

35.3

8

4

90

100

53.1

36.2

Four, 4.5-dia.

holes

110

50

9 × 7.7=69.3

Item Specification

Supply vo ltag e 21.6 to 26 .4 VD C

Current

consumption

Insulation

resistance

Dielectric

strength

Leakage current 10 mA max.

Noise

resistance

Gener al specifications

Vibration

resistance

Shock

resistance

1A max. (with 2 Sensors connected)

20 MΩ min. between all DC external terminals and GR terminal

(100 VDC Megger, with internal surge absorber removed)

1,000 VAC, 50/60 Hz between all DC external terminals and GR

termi na l (w ith internal surge absorber removed)

1,500 Vp-p; Pulse width: 0.1 µs/1 µs; Risi ng ed ge: 1-n s pu ls e

10 to 1 50 Hz ( double a mplitude: 0.1 mm) for 8 min each in

X, Y, and Z dir ections

2

200m/s

, 3 times each in 6 direc ti ons

44.8

23.3

99.5

Z500

58

Setup Manual

Page 61

SECTION 4

Troubleshooting and Maintenance

Item Specification

Ambient

temperature

Ambient

humidity

Ambient

environment

Ground Ground th e Z 5 00 's gr ound te rm inal to less th a n 100 Ω

Degree of

General specifications

protection

Case material Controller: ABS

Number of

Sensors that

can be mounted

Number of

scenes

Average Average number of times (9 stages, 1 to 256 times)

Light intensity

tracking

function

Measurement

item

Region

specification

Hold functions Sampling, peak, bottom, peak-to-peak, and average

Measurement

data

Equations

Performance specifications

Results output

Terminal block

Monitor

interface

Analog output

resolution

Weight Approx. 70 0g (Co nt roller only )

Note: For measurement at an average number of times of 64 with an OMRON K3AS

Linear Sensor Controller connected.

Operating: 0 to 50 ºC (with no icing or condensation)

Storage: -15 to 60 ºC (with no icing or condensation)

Operating and s torage: 35 % to 85 % (w i t h no conden sation)

No corr o sive ga s e s

IEC60529 IP20 (in-panel)

2

16

Automatic (The li ght intensity tracking range can be specified.)

Fixed ( Sel ect from 3 1 stages .)

Multip le (The light in tensity range c an be s pe c ified.)

Select from the following 8 types:

Height, Step: 2 pts, Step: 3 pts, Edge position, Width,

Edge center, Peak/Bo tto m , Define

Region specification of line beam and displacement direction is

possible.

8 outputs m ax . per sce ne

Equat io ns a re perfor me d w ith r e sp e ct to t he m easu r e me nt

results.

Four-rule equation: +, -, ×, ÷, plus ( )

Functional equation: ABS ( ), MAX ( ), MIN ( ), AVE ( )

• Judgement output A (HIGH, PASS, LOW, ERROR)

RS-232C output

Terminal block output

(Number of simultaneous outputs: 4)

• Judgement output B (OK, NG)

Terminal block output

(Number of simultaneous outputs: 8)

• Measurement value output (measurement value)

RS-232C output

Analog output

11 input points: TRIGGER

21 output poi nts: DO0 to DO19 and GATE

1 channe l ( for pi n jack or ove rsc an mo nit or)

The full scale for output can be divided into a maximum of

40,000 gradations.

Resolution (See note.) 0.25 mV (± 5V)

0.4 µA (4 to 20 µA)

, LD-OFF, RESET, and DI0 to DI7

SECTION 4

4-3 Specifications and Dimensions

Z500

Setup Manual

59

Page 62

SECTION 4

Troubleshooting and Maintenance

4-3-3 Console

Z300-KP Console

(Unit: mm)

SECTION 4

4-3 Specifications and Dimensions

12 dia.

40

34

General specifications

Weight Appro x. 13 5g

4.8 dia.

2000

Item Specification

Vibration

resistance

Shock

resistance

Ambient

temperature

Ambient

humidity

Ambient

environment

Degree of

protection

Minimum

bending radius

Materials

10 to 150 Hz; single-amplitude: 0.15 mm, 4 times for 8 minutes

each in 3 directions

196 m/s

Operating: 0 to +50 ºC (with no icing or condensation)

Storage: -25 to +65 ºC (with no icing or condensation)

Operating and s torage: 35 % to 85 % (w i t h no conden sation)

No corr o sive ga s e s

IEC60529 IP20 (in-panel)

75 mm

Console: ABS

Cable sheathing: Heat-resistant chlorinated vinyl

Connector: PC and PBT

50

23

2

; 3 times each in 6 dire ct ions

510

131.5

87

12.5

Z500

60

Setup Manual

Page 63

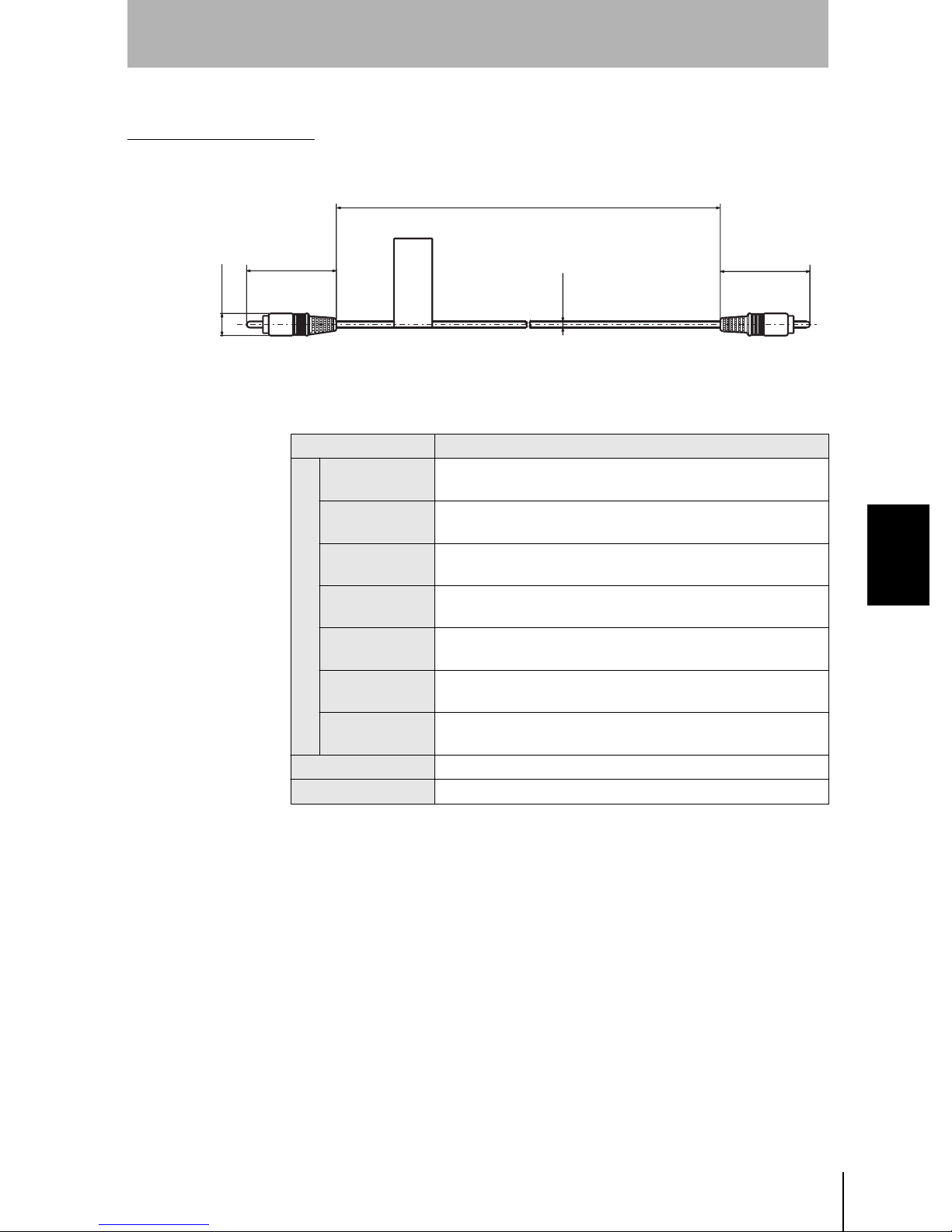

4-3-4 Monitor Cable

F150-VM Monitor Cable

SECTION 4

Troubleshooting and Maintenance

11.5 dia.

46.7

Item Specification

Vibration

resistance

Shock

resistance

Ambient

temperature

Ambient

humidity

Ambient

environment

General specifications

Materials

Minimum

bending radius

Weight Appro x. 40 g

Accessories BNC Jack Adapter

10 to 150 Hz; single-amplitude: 0.15 mm, 4 times for 8 minutes

each in 3 directions

196 m/s

Operating: 0 to +50 ºC (with no icing or condensation)

Storage: -25 to +65 ºC (with no icing or condensation)

Operating and s torage: 35 % to 85 % (w i t h no conden sation)

No corr o sive ga s e s

Cable sheathing: Super he at-resistant chlorinated vinyl

Connector: PVC

50 mm

2

; 3 times each in 6 dire ct ions

2000

(Unit: mm)

46.7

3.3 dia.

SECTION 4

4-3 Specifications and Dimensions

Z500

Setup Manual

61

Page 64

SECTION 4

Troubleshooting and Maintenance

4-3-5 Color Liquid Crystal Monit or

F150-M05L Color Liquid Crystal Monitor

Mounting plate thickness: 1.6 to 4.8

(46 max.)

Mounting brackets

(Unit: mm)

SECTION 4

4-3 Specifications and Dimensions

Panel cutout

dimensions

(100)

143

132

(5.5)

(155)

(145)

50 min.

185

F150-VM Monitor cable

42.2

• Tolerance: ±1mm

174

+0.5mm

133.5

0

+0.5mm

175.5

0

Item Specification

Supply vo ltag e 20 .4 to 26.4 VDC

Curr ent consum ption

Vibration

resistance

Shock resistance 150 m/s

Ambient

temperature

700 mA max.

10 to 150 Hz; single-amplitude: 0.1 mm; maximum accelera-

tion: 15 m/s

2

, 10 times for 8 minutes each in 3 dir e ctions

2

, 3 times each in 6 directions

Operating: 0 to +50 ºC (with no icing or co nd ensati on)

Storage: -25 to +65 ºC (with no icing or co nd ensati on)

Ambient humidity Operating and storage: 35 % to 85 % (with no condensation)

Ambient en vir o nme nt

General specifications

Degree of protection

No corrosive gases

IEC60529 IP20

Materials Case: ABS/PC Display surface: PMMA (Acrylic)

Panel si ze 5.5 inches (111.36 × 83.52 mm (H × V))

Panel type TFT color liquid crystal

Resolution 320 × 240 dots

Image pitch 0.348 (H) × 0.348 (V) mm

Contrast 85:1 (typical)

Viewable angle 25º up/down and 50º left/right (with a contrast ratio > 10)

Luminance 250 cd/m

2

(typical)

Backlight Cold cathode fluorescent light

Resp onse sp eed 60 ms max.

Performance specifications

Input signal NTSC composite video (1.0 V/75 Ω termination)

Weight Approx. 1 kg

Accessories 4 mounting brackets

Z500

62

Setup Manual

Page 65

4-3-6 Video Monitor

F150-M09 Video Monitor

SECTION 4

Troubleshooting and Maintenance

(Unit: mm)

222

2335

143

190

Item Specification

Supply vo ltag e 85 to 264 VAC, 50/60 Hz

Power

consumption

Vibration

resistance

Ambient

temperature

Ambient

humidity

General sp ec ific ati ons

Ambient

environment

Materials

CRT size 9 inch ( 1 64 × 123 mm (H × V))

CRT type Monochrome CRT

Resolution 800 TV lines min. (at center)

System

I/O impedance 75 Ω, high impedance (selectable)

I/O level and

polarity

Performance specifications

Input signal NT SC composit e video (1.0 V/75 Ω termination)

Weight Appro x. 4. 5 kg

20 W max .

5 to 100 Hz; 0.16 -mm dou bl e-ampl itu de or ac celer a t ion of

7.35 m /s

6 times for 10 minutes each in 3 directions

Operating: -10 to +50 ºC (with no icing or condensation)

Storage: -20 to +65 ºC (with no icing or condensation)

Operating and s torage: 10 % to 90 % (w i t h no conden sation)

No corr o sive ga s e s

Front: ABS plastic

Metal pa r t: SE C C (g al vaniz ed s tee l sh ee t )

Number of scanning lines: 600

Horizontal frequency: 15.75 kHz

Field freque ncy: 60 Hz

Composite image signal: 1 V (peak to peak)

Image: 0.7 V (pea k to pe ak ) , pos i ti v e

Synchronization: 0.3 V (peak to peak), negative

2

(whichever is smaller),

50

250

22

160

SECTION 4

4-3 Specifications and Dimensions

Z500

Setup Manual

63

Page 66

Revision History

A manual revision code appears as a suffix to the catalog number on the front cover of the manual.

at. No. Z158-E1-1

Revision code

The f ollowin g tab l e outlin es the changes made to the manual during each revision. Page numbers refer

to the previous version.

Revision code Date Revi sed content

1 Febr uary 20 02 Origin al productio n

Z500

64

Setup Manual

Page 67

OMRON Corporation

Industrial Automation Company

Application Sensors Division

Sensing Devices and Components Division H.Q.

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 Japan

Tel:(81)75-344-7068 / Fax:(81)75-344-7107

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz Str. 4, D-71154 Nufringen,

Germany

Tel:(49)7032-811-0 / Fax:(49)7032-811-199

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel:(1)847-843-7900 / Fax:(1)847-843-8568

OMRON ASIA PACIFIC PTE.LTD.

83 Clemenceau Avenue, #11-01, UE Square,

239920 Singapore

Tel:(65)835-3011 / Fax:(65)835-2711

OMRON CHINA CO.,LTD.

BEIJING OFFICE

Room 1028, Office Building,

Beijing Capital Times Square,

No.88 West Chang'an Road,

Beijing, 100031 China

Tel:(86)10-8391-3005 / Fax:(86)10-8391-3688

Page 68

Authorized Distributor:

Cat. No. Z158-E1-1 Note: Specifications subject to change without notice. Printed in Japan

0202-

Loading...

Loading...