OMRON Z500 Operation Manual

Profile Measuring System Z500 Manual 2: Operation Manual

Profile Measuring System

Z500

Operation Manual

Authorized Distributor:

Cat. No. Z159-E1-2 Note: Specifications subject to change without notice. Printed in Japan

0103-0.5C

Manual

Cat. No. Z159-E1-2

Cat. No. Z159-E1-2

About this Manual

Please read the following manuals carefully and be sure you understand the information provided

before attempting to install or operate the Z500.

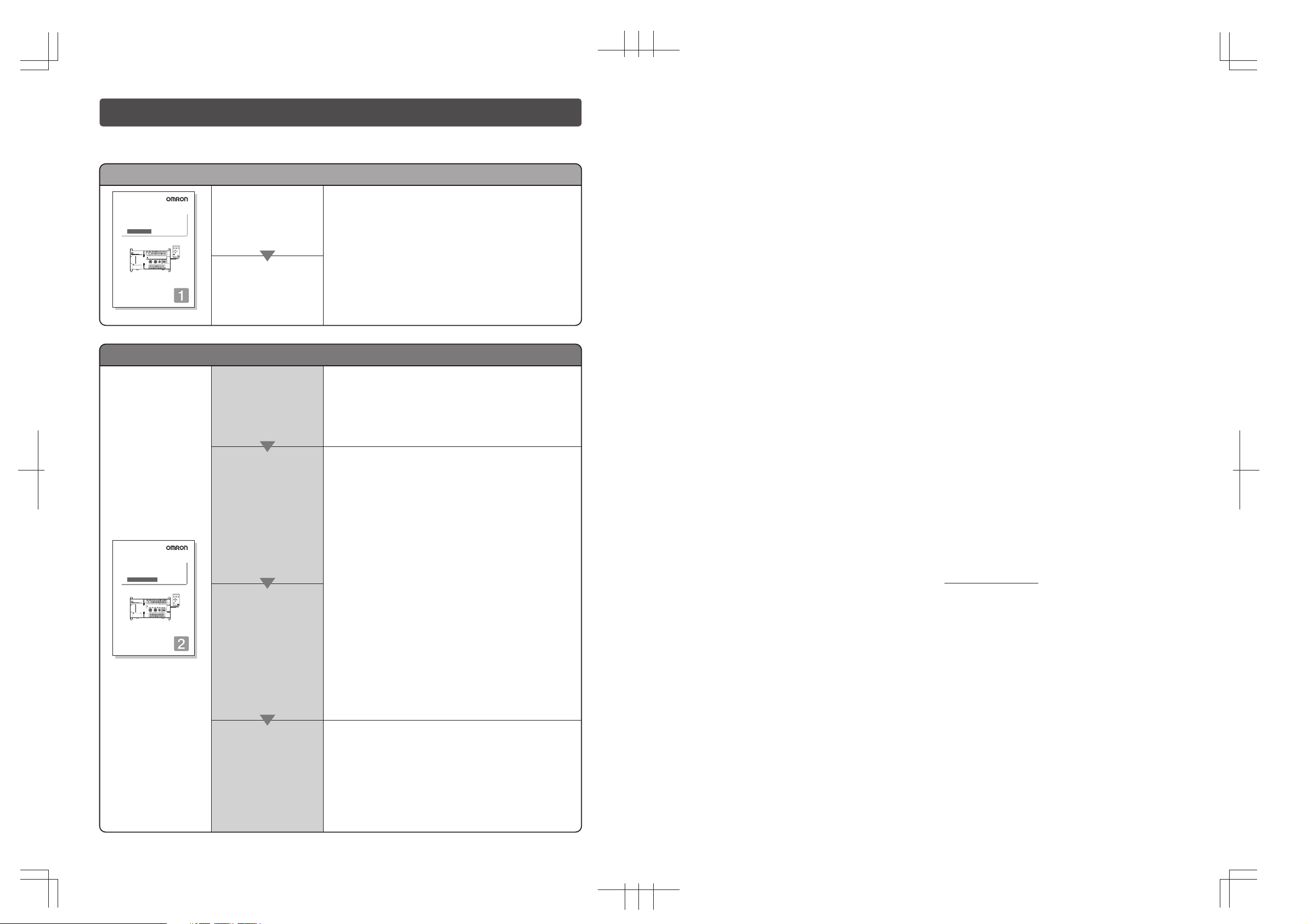

Manual 1: Setup Manual

Multi-Dimensional Controller

Multi-Dimensional Controller

Z500

Setup Manual

Manual

Cat. No. Z000-E1-1

Cat. No. Z158-E1-2

Manual 2: Operation Manual

Installation

This manual describes the hardware for the Z500

(Multi-Dimensional Controller) and how to install the

components.

Be sure to read this manual first.

Wiring

Multi-Dimensional Controller

Z500

Operation Manual

Manual

Cat. No. Z000-E1-1

Cat. No. Z159-E1-2

Starting the Z500

and Positioning

the Workpiece

Adjusting Images

Setting

Measurement

Conditions

and Executing

Outputting to

External Devices

SECTION 2 Basic Operations

This section describes how to start the Z500

and how to display images on the monitor.

SECTION 3

Menus for Conversational Menu

• Basic settings required for measurement

• Measurement of consistent workpieces

Menus for Conversational Menu

Settings can be made easily by entering

information as requested - just as

though you are having a conversation

with the Z500.

SECTION 4 Menus for Expert Menu

• Customized settings

• Detailed settings

• Measurement of workpieces placed at different

positions

Menus for Expert Menu

More detailed setting, such as position

compensation for workpieces placed at

different positions, can be made.

SECTION 7 I/O Format

This section provides details on the inputs and outputs

used for communications with external devices via

terminal blocks or RS-232C.

• Communications settings

• I/O format

• Timing for communications

OMRON Corporation

Industrial Automation Company

Application Sensors Division

Sensing Devices and Components Division H.Q.

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 Japan

Tel:(81)75-344-7068 / Fax:(81)75-344-7107

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz Str. 4, D-71154 Nufringen,

Germany

Tel:(49)7032-811-0 / Fax:(49)7032-811-199

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel:(1)847-843-7900 / Fax:(1)847-843-8568

OMRON ASIA PACIFIC PTE.LTD.

83 Clemenceau Avenue, #11-01, UE Square,

239920 Singapore

Tel:(65)835-3011 / Fax:(65)835-2711

OMRON CHINA CO.,LTD.

BEIJING OFFICE

Room 1028, Office Building,

Beijing Capital Times Square,

No.88 West Chang'an Road,

Beijing, 100031 China

Tel:(86)10-8391-3005 / Fax:(86)10-8391-3688

Multi-Dimensional Controller

Z500

Z500-MC10E/MC15E

Operation Manual

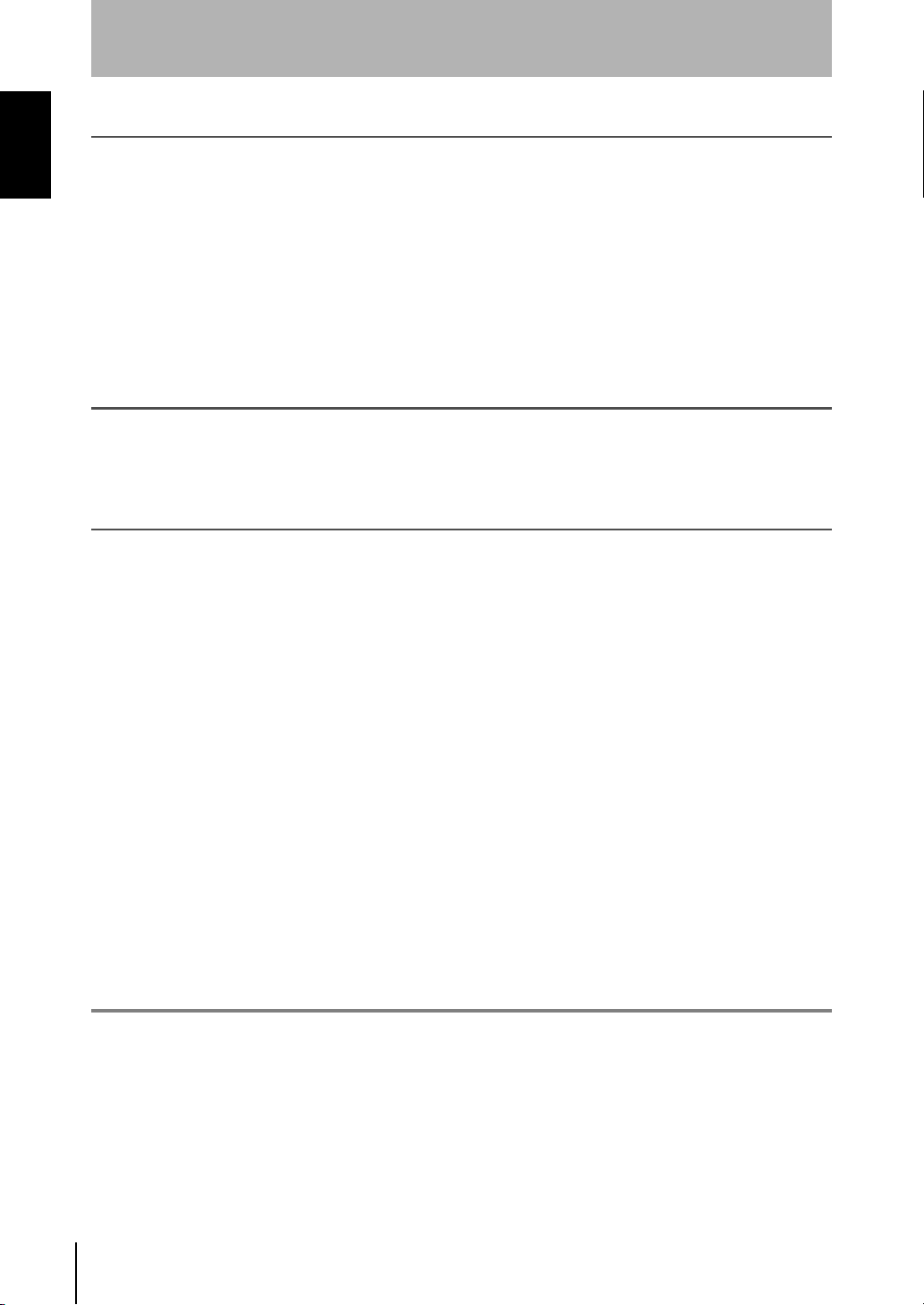

INTRODUCTION 2

SECTION 1

Features

SECTION 2

Basic Operations

SECTION 3

Menus for Conversational Menu

SECTION 4

Menus for Expert Menu

INTRODUCTION

SECTION 1 SECTION 2 SECTION 3 SECTION 4 SECTION 5 SECTION 6 SECTION 7 SECTION 8

9

19

39

53

SECTION 5

Other Functions

SECTION 6

System Settings

SECTION 7

I/O Format

SECTION 8

Troubleshooting

109

143

153

183

Manual

1

INTRODUCTION

Special or Critical Applications

INTRODUCTION

Special or Critical Applications

When the Z500 will be used in one of the conditions or applications listed below, allow extra safety mar-

gins in ratings and functions, add extra safety feature such as fail-safe systems, and consult your

OMRON representative.

• Operating conditions or environments which are not described in the manual

• Nuclear power control systems, railroad systems, aviation systems, vehicles, combustion systems,

medical equipment, amusement equipment, or safety equipment

• Other systems, machines, and equipment that may have a serious influence on lives and property and

require extra safety features

Product Availability

Some of the products listed may not be available in some countries. Please contact your nearest

OMRON sales office by referring to the addresses provided at the back of this manual.

Regulations and Standards

The Z500 complies with the international regulations and standards below:

• EC Regulations

EMC Directive: No.89/336/EEC

• EN Standards (European Standards)

EN61326:1997 + A1:1998 + A2:2001 (EMI:Class A)

© OMRON, 2003

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written

permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject

to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON

assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use

of the information contained in this publication.

Z500

Operation Manual

2

INTRODUCTION

Table of Contents

INTRODUCTION.................................................................................... 3

INTRODUCTION

Table of Contents......................................................................................................... 3

Precaution on Safety ................................................................................................... 5

Menus............................................................................................................................ 6

Editor's Note................................................................................................................. 8

SECTION 1

Features ............................................................................................... 9

1-1 Features of the Z500............................................................................................10

1-2 Operational Flow.................................................................................................. 14

SECTION 2

Basic Operations................................................................................ 19

2-1 Starting the Z500 and Displaying Images.......................................................... 20

2-2 Menu Operations ................................................................................................ 23

2-2-1 Input Device ...............................................................................................23

2-2-2 Screen Displays......................................................................................... 24

2-2-3 Menu Tree ..................................................................................................25

2-2-4 Inputting Values ........................................................................................ 27

2-2-5 Adjustment Menu ...................................................................................... 28

2-3 Screen Types and Display Methods ..................................................................29

2-3-1 Image Monitor............................................................................................30

2-3-2 Profile Monitor ...........................................................................................33

2-3-3 Digital Monitor ...........................................................................................35

2-3-4 Trend Monitor ............................................................................................ 36

2-4 Saving Settings and Exiting the Z500................................................................ 37

Table of Contents

SECTION 3

Menus for Conversational Menu....................................................... 39

3-1 Setting Measurement Conditions Using the Conversational Menus............... 40

Step

1 Starting Conversational Menus ................................................................40

Step

2 Setting Basic Measurement Conditions ..................................................41

Step

3 Setting Measurement Contents ................................................................48

Step

4 Setting Measurement Conditions .............................................................49

Step

5 Setting Output Contents............................................................................50

Step

6 Starting Measurements .............................................................................51

3-2 Saving Settings and Exiting the Z500................................................................ 52

Operation Manual

Z500

3

INTRODUCTION

Table of Contents

INTRODUCTION

SECTION 4

Menus for Expert Menu...................................................................... 53

4-1 Setting Measurement Conditions Using the Expert Menus.............................54

Step

1 Starting Up Expert Menu and Entering Set Mode ..................................54

Step

2 Adjusting Images ....................................................................................... 56

Step

3 Position Compensation .............................................................................64

Step

4 Measurement Settings............................................................................... 70

Step

5 Measurement Conditions ..........................................................................88

Step

6 Output Settings ........................................................................................ 100

Step

7 Performing Measurement........................................................................107

4-2 Saving Settings and Exiting the Z500.............................................................. 108

SECTION 5

Other Functions ............................................................................... 109

5-1 Executing Force-zero ........................................................................................ 110

5-2 Entering Display Mode ......................................................................................112

5-3 Changing the Screen Display ...........................................................................113

5-4 Changing Scenes .............................................................................................. 125

5-5 Entering Tools Mode ......................................................................................... 128

5-6 Testing Measurement Performance (Test) ......................................................129

5-7 Checking the Line Beam Position (Surrounding image) ...............................135

5-8 Backing Up Data to a Computer.......................................................................136

SECTION 6

System Settings ............................................................................... 143

6-1 Entering System Mode ......................................................................................144

6-2 Setting RS-232C Communications Specifications (Comm) .......................... 145

6-3 Environment Settings........................................................................................ 146

6-4 Downloading the Sensor Information to the Controller................................ 148

6-5 Compensating Installation Error (Slant correct).............................................149

6-6 Initializing the Z500 (Initialize) ..........................................................................151

6-7 Checking the System Version (Version) ........................................................ 152

SECTION 7

I/O Format ......................................................................................... 153

7-1 Terminal Blocks ................................................................................................. 154

7-2 RS-232C..............................................................................................................159

7-3 Analog Output....................................................................................................180

SECTION 8

Troubleshooting ............................................................................... 183

8-1 Troubleshooting ................................................................................................184

Index .................................................................................................. 187

4

Z500

Operation Manual

INTRODUCTION

Precaution on Safety

OMRON products are manufactured for use according to proper procedures by a qualified operator and

only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed the

information provided with them. Failure to heed precautions can result in injury to people or damage to

property.

INTRODUCTION

Precaution on Safety

DANGER

WARNING

CAUTION

WARNING Failure to read and understand the information provided in this manual may result in

Indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury, or property damage.

personal injury or death, damage to the product, or product failure. Please read

each section in its entirety and be sure you understand the information provided in

the section and related sections before attempting any of the procedures or opera-

tions given.

Operation Manual

Z500

5

INTRODUCTION

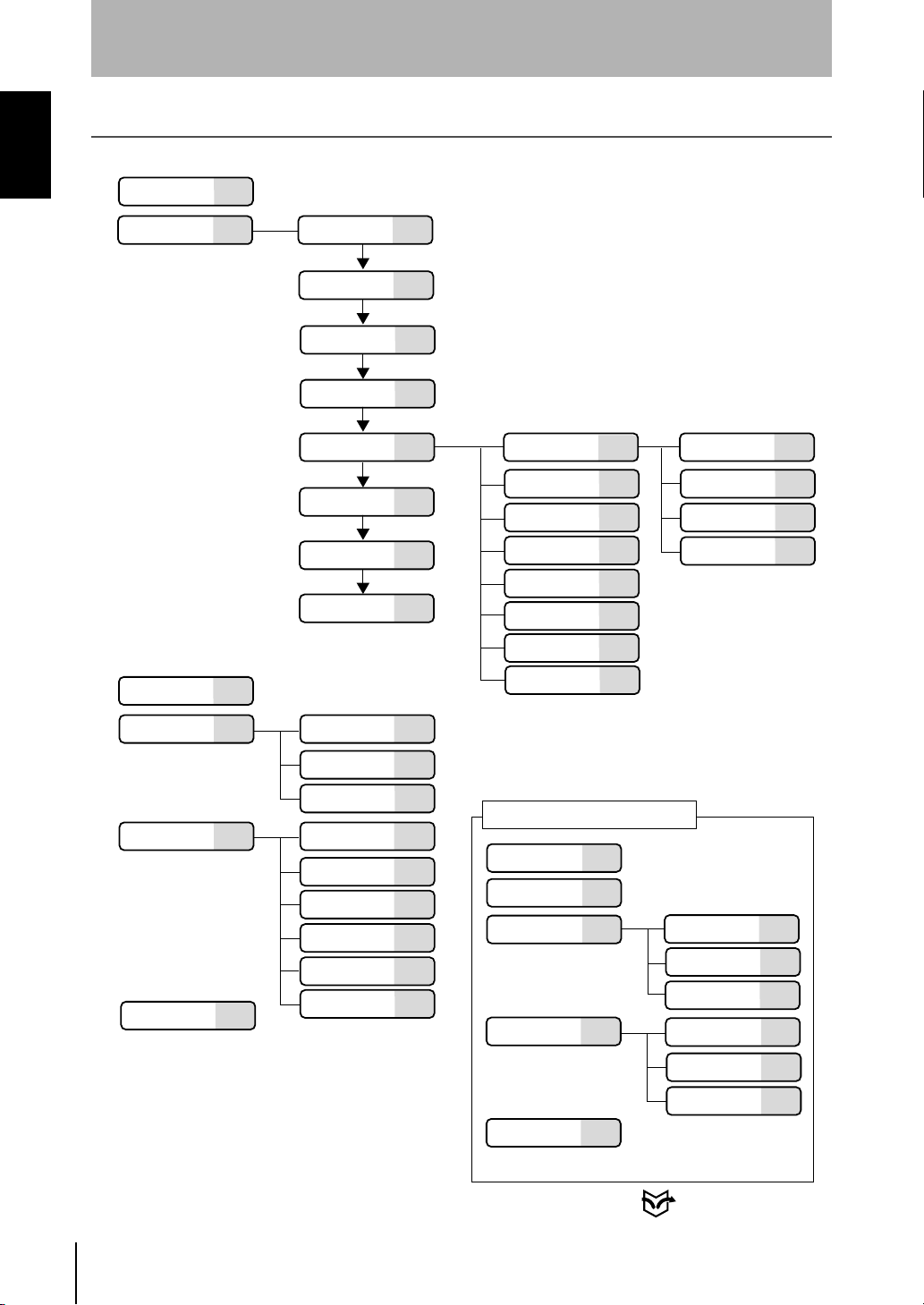

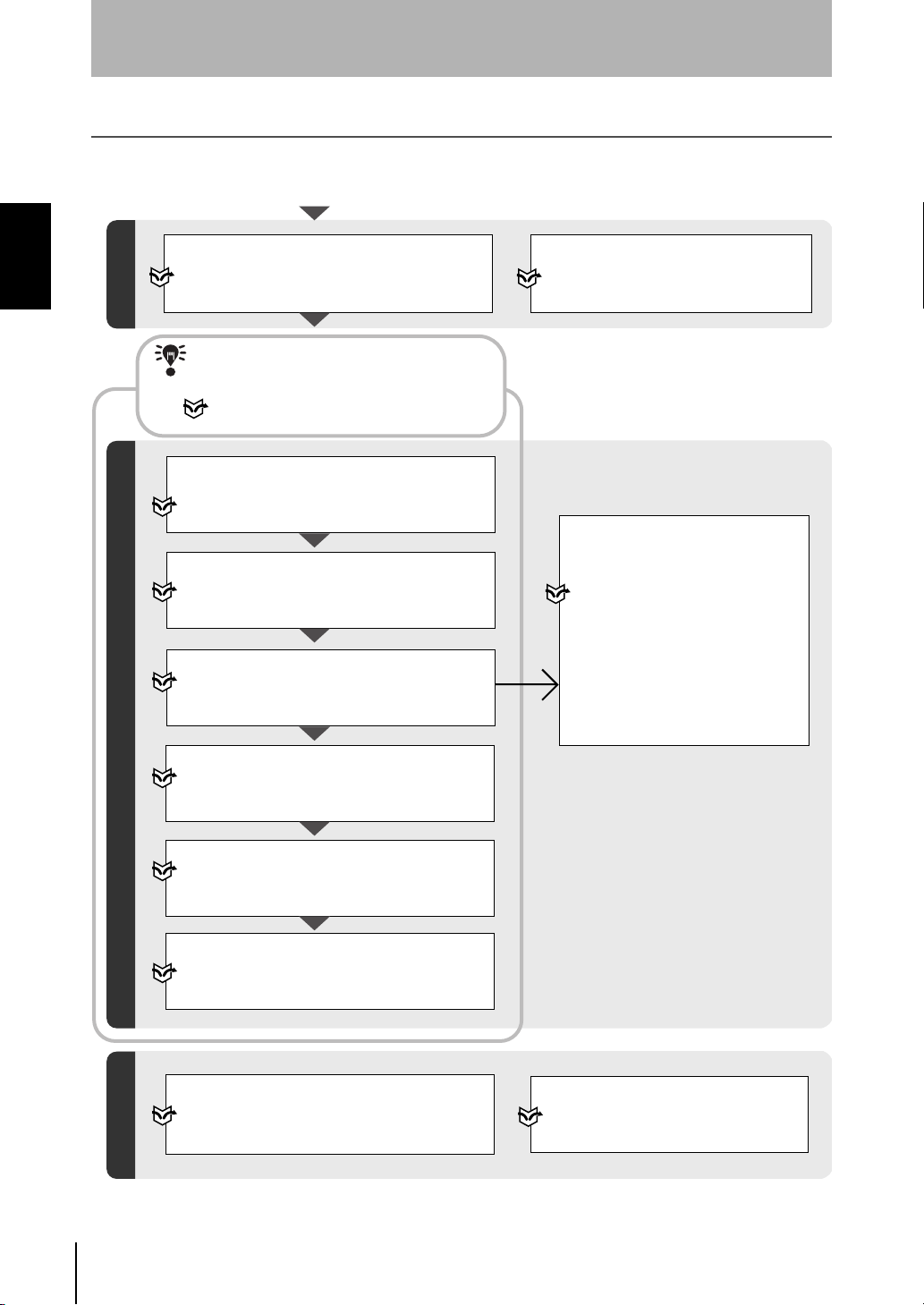

Menus

INTRODUCTION

Menus

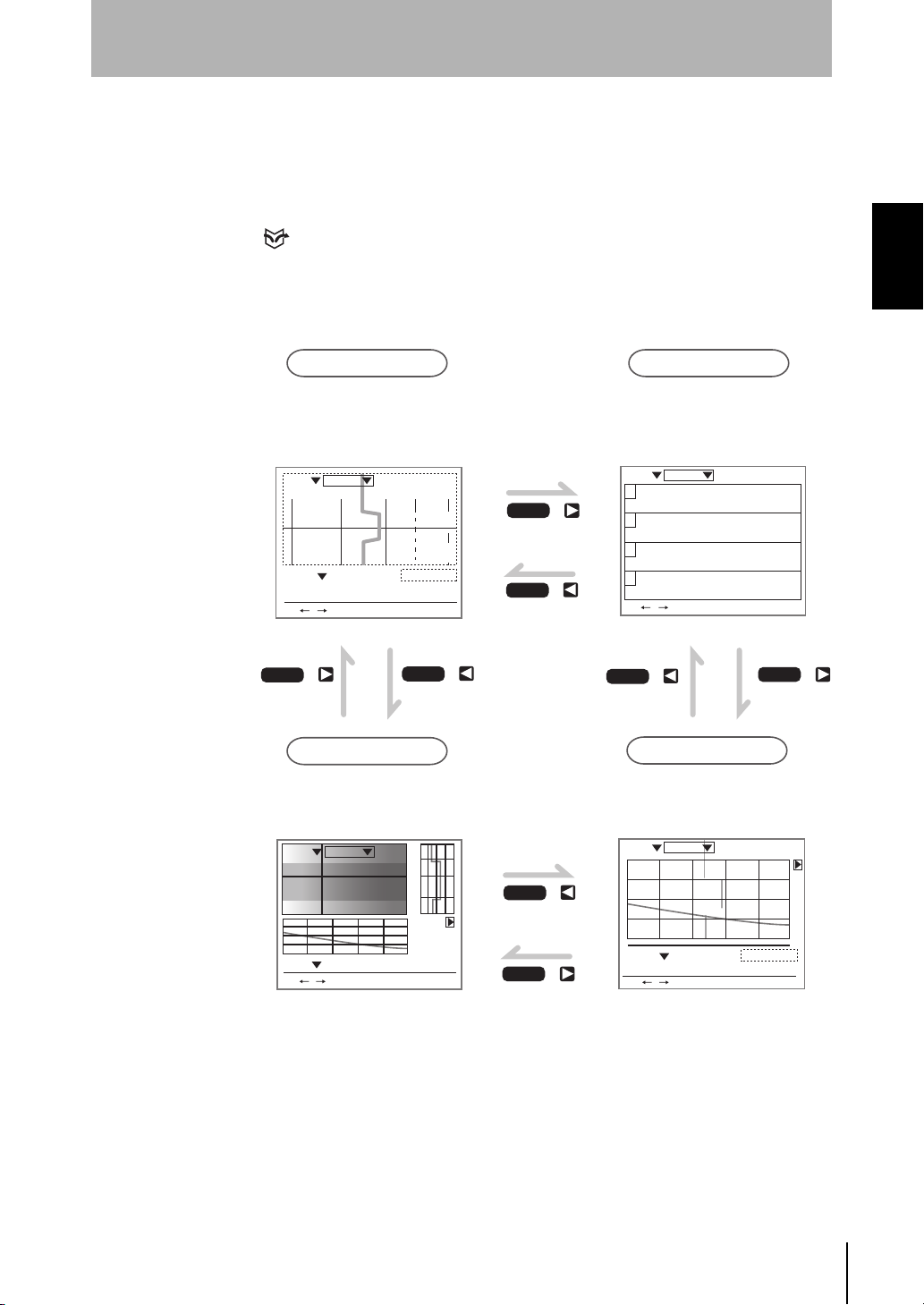

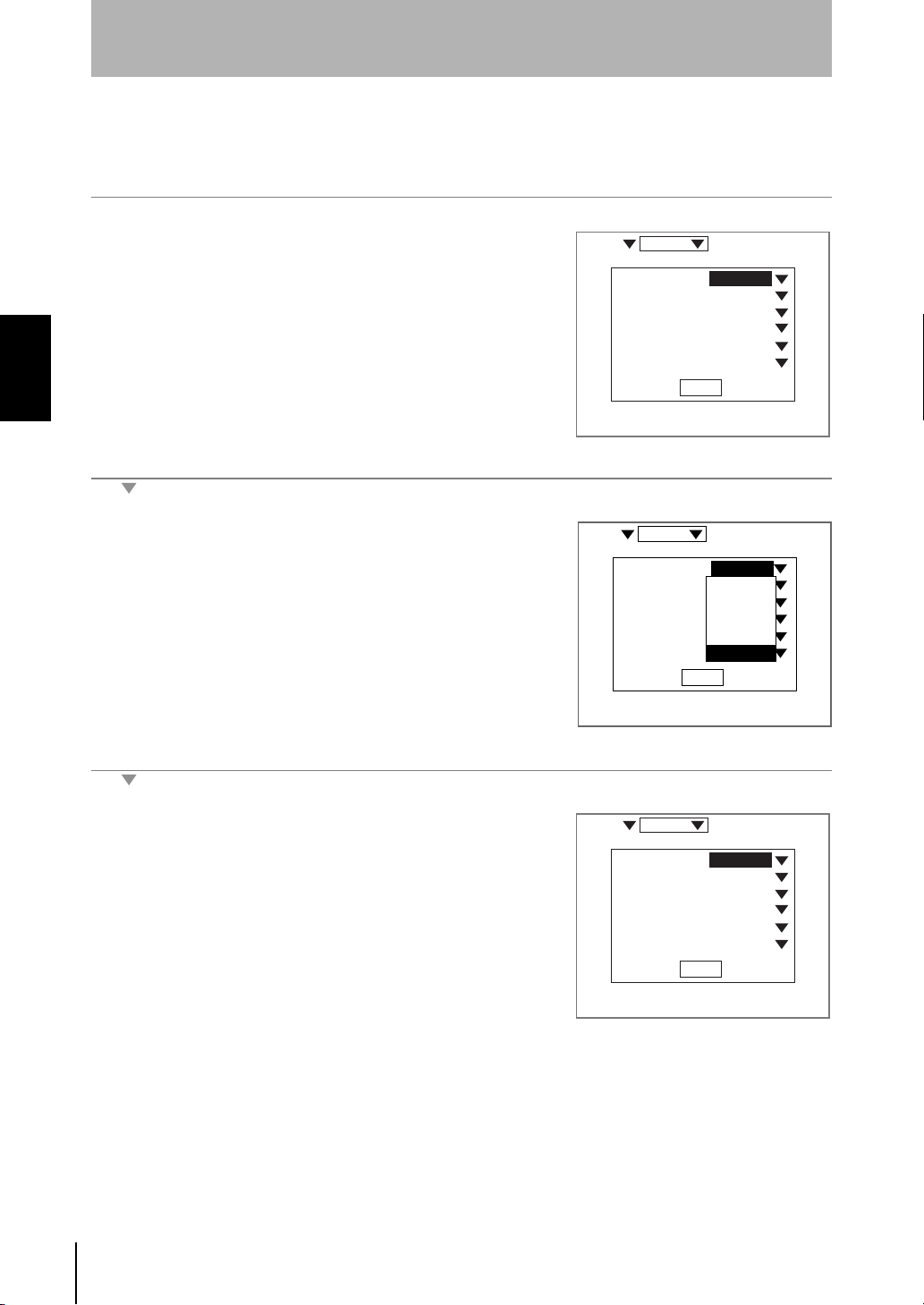

Menus for Conversational Menu

Scn

Set Start setting

P.125

P.40

(0 to 15)

P.40

Run

Tools

System

Save

P.51

P.128

P.144

P.37

Meas method

Measurement

region

Sensitivity

Meas set

(OUT0 to OUT7)

Conditions

Output contents

End setting

Test

Surrounding

image

Backup

Comm

Slant correct

Initialize

Version

P.41

P.43

P.44

P.48

P.49

P.50

P.52

P.129

P.135

P.136

P.145

P.146Environment

P.148Download

P.149

P.151

P.152

Height

Step: 2 pts

Step: 3 pts

Edge position

Width

Edge center

Peak/bottom

Define

Item and hierarchy that can be set

through only the adjustment menu

Sensitivity

Details

Conditions

Output

P.70

P.72

*1

P.70

*1

P.74

*1

P.70

*1

P.70

*1

P.70

*1

P.76

*1

*

1:The same construction

as that for

P.59

P.63

P.88

P.100

When

Define

setting of

Height

has been selected, however,

Calibrate

Change

Calibrate

Output

Delete

is disabled.

# to avg

Trigger

Details

Analog

P.86

P.78

P.84

P.87

P.88

P.90

P.96

P.100

6

Z500

Operation Manual

Display

P.112

Terminals

RS-232C P.105

*2:The hierarchy under

*2

Display Mode varies

depending on the type

of screen being displayed.

Adjustment Menu p.28

P.103

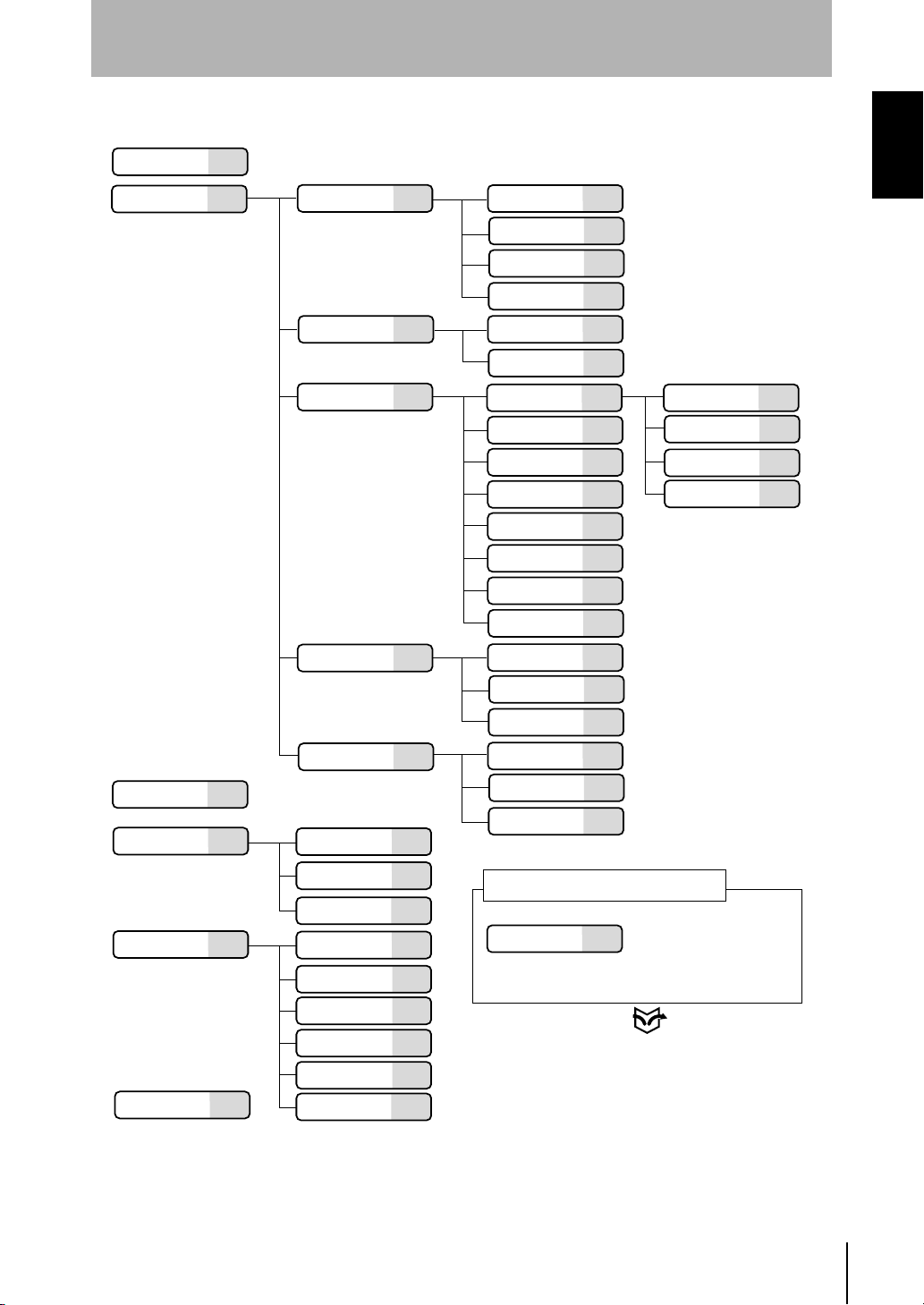

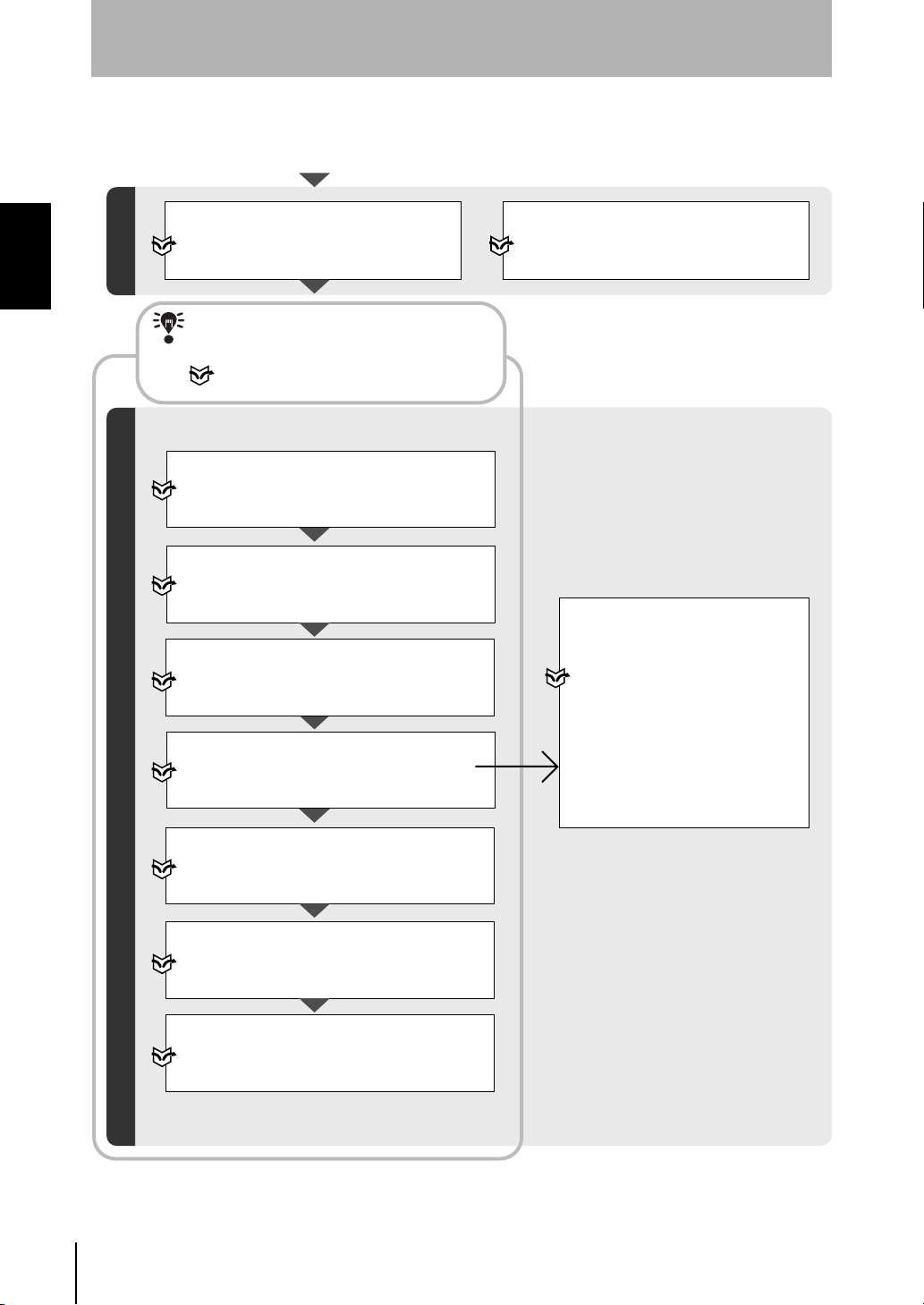

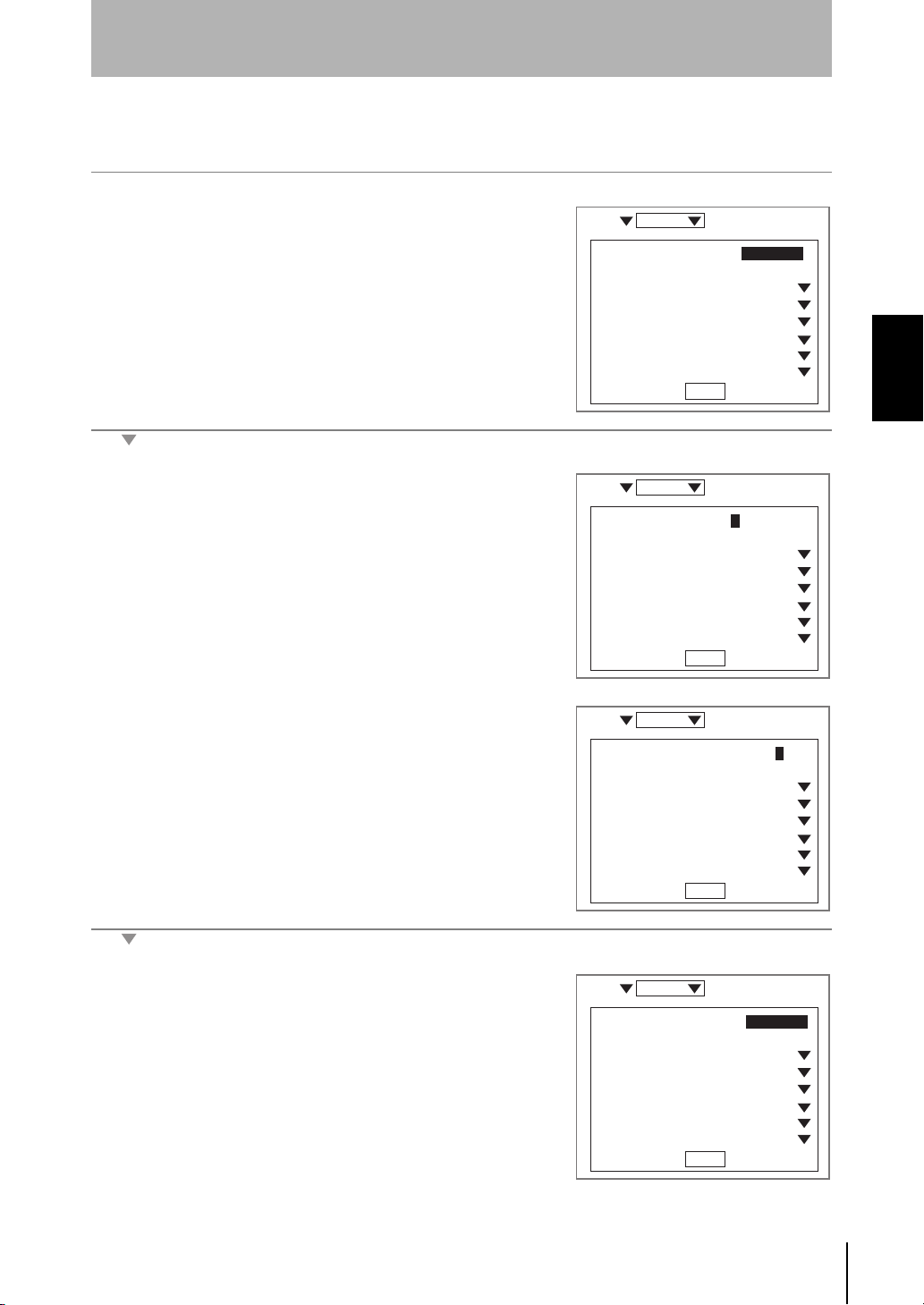

Menus for Expert Menu

INTRODUCTION

INTRODUCTION

Scn

Set

P.125

P.54

(0 to15)

Image

Compensatn

Meas set

(OUT0 to OUT7)

Conditions

P.56

P.64

P.70

P.88

Meas method

Region

Sensitivity

Details

Reference

Compensation

method

Height

Step: 2 pts

Step: 3 pts

Edge position

Width

Edge center

Peak/bottom

Define

# to avg

P.56

P.58

P.59

P.63

P.65

P.69

P.70

P.72

P.70

P.74

P.70

P.70

P.70

P.76

P.88

Change

*1

*1

*1

*1

*1

*1

*1

Calibrate

Output

Delete

*1:The same construction

as that for

Define

When

selected, however,

setting of

disabled.

P.86

P.78

P.84

P.87

Height

has been

Calibrate

Menus

is

Run

Tools

System

Save

P.51

P.128

P.144

P.37

Output

Test

Surrounding

image

Backup

Comm

Slant correct

Initialize

Version

P.100

P.129

P.135

P.136

P.145

P.146Environment

P.148Download

P.149

P.151

P.152

Trigger

Details

Analog

Terminals

RS-232C

Item and hierarchy that can be set

through only the adjustment menu

Display

P.90

P.96

P.100

P.103

P.105

P.112

*2

*2:The hierarchy under Display Mode

varies depending on the type of screen

being displayed.

Adjustment Menu p.28

Operation Manual

Z500

7

INTRODUCTION

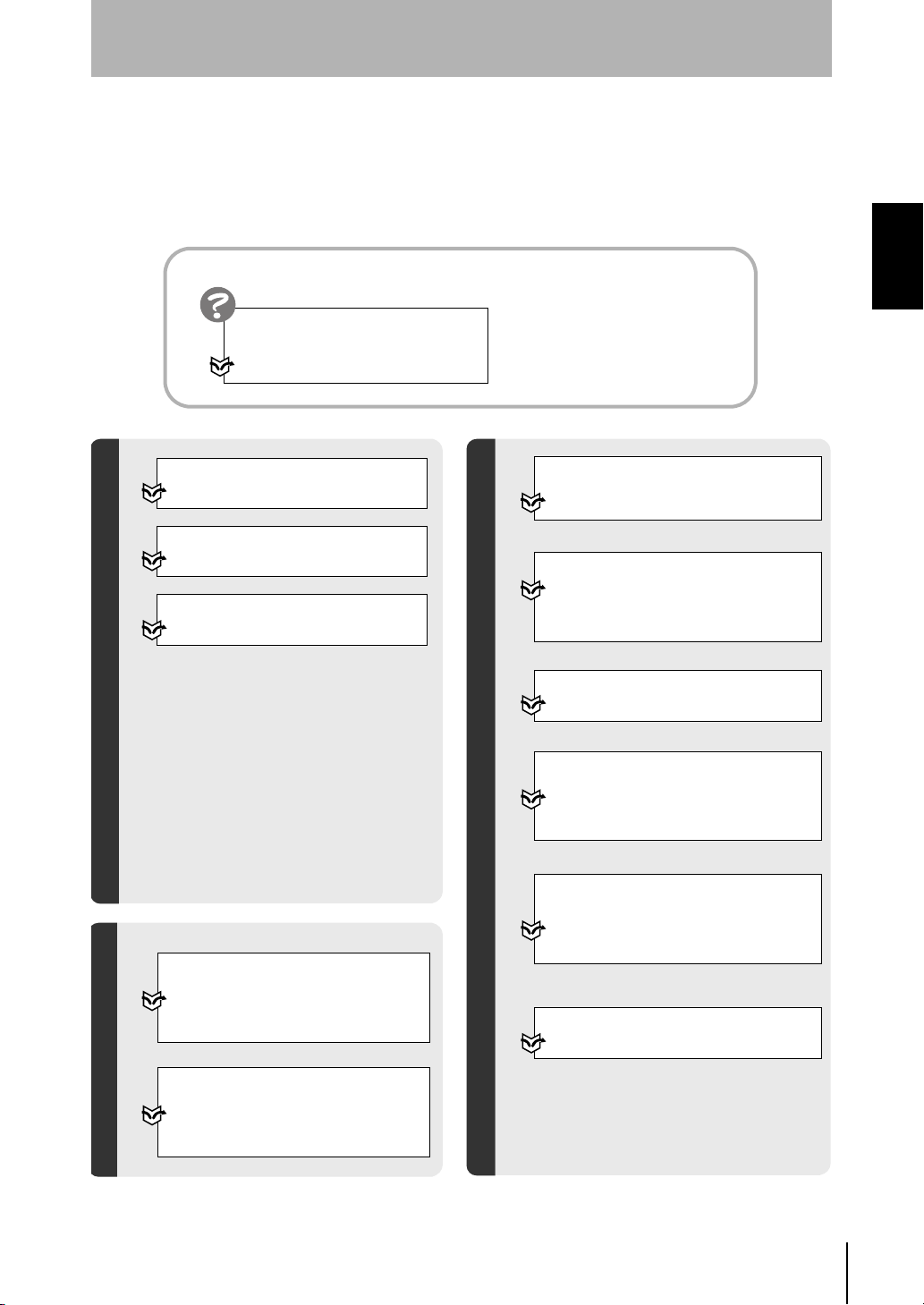

Editor’s Note

INTRODUCTION

Editor’s Note

Visual Aids

The following headings appear in the left column of the manual to help you

locate different types of information.

NOTICE

CHECK

REFERENCE

TwoSensor

HELP Indicates information helpful in operation.

Indicates information required to take full advantage of the functions and

performance of the product. Incorrect application methods may result in the loss

of damage or damage to the product. Read and follow all precautionary

information.

Indicates points that are important in using product functions or in application

procedures.

Indicates where to find related information.

Indicates information required when using 2 sensors.

Notation

Screen Messages

In this manual, screen message are given in bold/italic.

E.g.: System

System/Backup means the Menu is hierarchical.

OMRON Product References

All OMRON products are capitalized in this manual. The world "Unit" is also

capitalized when it refers to an OMRON product, regardless of whether or not it

appears in the proper name of the product.

8

Z500

Operation Manual

Z500

Operation Manual

SECTION 1

Features

SECTION 1 explains the features of the Z500 and the flow of operation using the

Conversational and Expert Menus.

1-1 Features of the Z500 10

1-2 Operational Flow 14

SECTION 1 Features

9

SECTION 1

Features

1-1 Features of the Z500

1-1-1 Eight Measurement Items for Various Detection Needs

SECTION 1

Select the measurement item according to application.

Complicated detection is also possible, by combining multiple measurement

items and with detailed settings.

Simultaneous measurement can be performed at 8 points.

1-1 Features of the Z500

REFERENCE

Refer to page 70.

•

Height

•

Edge position

•

Peak/bottom

1-1-2 Simple Setup Using Menus

The Z500 has 2 types of menu. Set the measurement contents according to the

menus displayed on the monitor screen.

Menus for Conversational Menu

Settings can be made easily by entering information as requested - just as

though you are having a conversation with the Z500.

REFERENCE

Refer to page 39.

Menus for Expert Menu

More detailed setting, such as position compensation for workpieces placed at

different positions, can be made.

•

Step : 2 pts

•

Width

•

Define

•

Step : 3 pts

•

Edge center

REFERENCE

Refer to page 53.

1-1-3 A Variety of Output Formats

Not only is analog output available, but data output to external devices can also

be performed via terminal blocks or RS-232C.

REFERENCE

Refer to page 100.

Z500

Operation Manual

10

1-1-4 Monitoring While Viewing the Measurement Status

The Z500 has 4 types of monitor. Monitoring suited to the application is possible

at every stage from installation and measurement settings to operation and

maintenance.

REFERENCE

Refer to page 29.

SECTION 1

Features

SECTION 1

1-1 Features of the Z500

Image Monitor

This is the main monitor of the Z500.

Three pieces of information;

measurement status, sensitivity, and

measurement result, can be checked

together with their target images.

Scn 0 Run

NEAR

OUT 0

BRIGHT

+0005.18800

S+ / :Display S+ENT:Adjust

SHIFT

DARK

9.96ms

Sen0

[ 15]

LV

[ 170]

PEAK

Sen1

LV

PEAK

Zero's OFF

PASSmm

SHIFT

FAR

[ .]

[ ]

+

Profile Monitor

Chronological change of height

distribution of 126 points (profile)

can be checked on a shaded 3-D

image.

Scn 0 Run

1div x: 1.000 [s]

y:+10.0000[mm]

Thru

+0005.18800

Sen 0

S+ / :Display S+ENT:Adjust

mm

9.96ms

PASS

SHIFT

SHIFT

SHIFT

SHIFT

Digital Monitor

Two or more measurement results

can be checked at the same time.

Scn 0 Run

+0002.65432mm

0

+

+

PASS

+0004.65432mm

1

PASS

+0000.00000mm

2

ERROR

-----------mm

3

S+ / :Display S+ENT:Adjust

+

SHIFT

9.96ms

HI=+0010.00000

LO=-0010.00000

HI=+0010.00000

LO=-0010.00000

HI=+0010.00000

LO=-0010.00000

HI=+0010.00000

LO=-0010.00000

SHIFT

++

Trend Monitor

Chronological change of measured

values can be checked.

Scn 0 Run

+

Thru

+

OUT 0

S+ / :Display S+ENT:Adjust

9.96ms

1div x: 1.000 [s]

y:+10.0000[mm]

Zero's OFF

mm+0005.18800

PA S S

Operation Manual

Z500

11

SECTION 1

Features

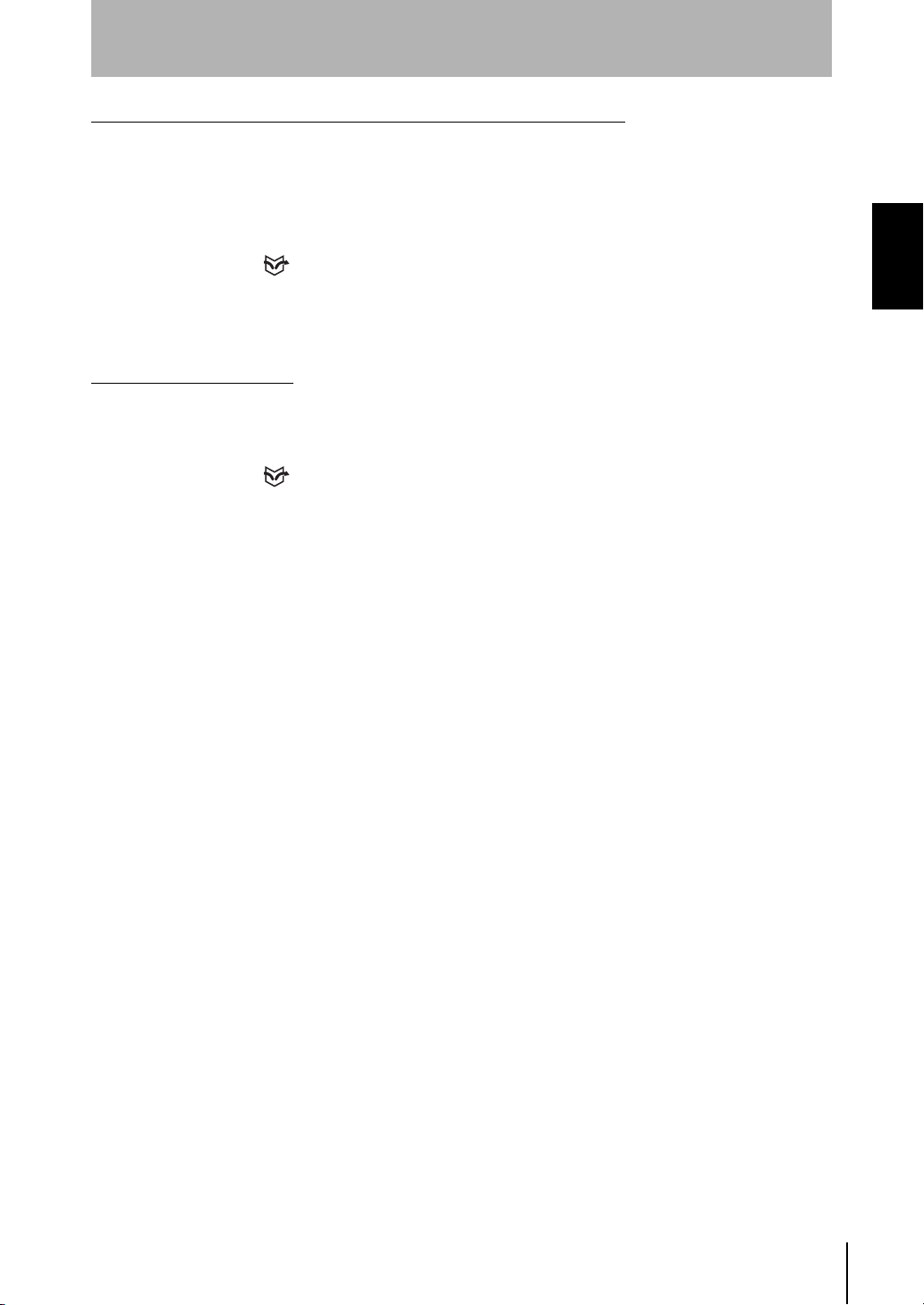

1-1-5 Flexible Settings for Data Output to External Devices

In addition to simply outputting measurement results, equations can be set to

output to external devices using measurement and judgment results.

SECTION 1

1-1 Features of the Z500

1-1-6 A Wide Variety of Useful Functions

Any Type of Workpiece can be Measured by Using the Image Adjustment Function

REFERENCE

Refer to page 70.

Z500

Higher measurement accuracy can be assured by using the sensitivity

adjustment function, even if the workpieces to be measured have different

brightness.

REFERENCE

Refer to pages 44 and 59.

Adjustment Menu

Six types of adjustments are available on shortcut keys by displaying the

adjustment menu.

REFERENCE

Refer to page 28.

Checking Surrounding Images of the Area that the Line Beam Strikes

Displays images of the area surrounding the part that the line beam strikes.

This function is useful when the Sensor is mounted inside an installation and the

measurement area cannot be checked directly.

REFERENCE

Refer to page 135.

Z500

Operation Manual

12

Specifying Measurement Timing by Using the Trigger Function

Measurement timing can be specified arbitrarily by using the self-trigger and

external trigger functions. Characteristic quantity can be held while the

measurement is carried out.

(Measurement status at a set timing can be checked on the monitor screen.)

REFERENCE

SECTION 1

Features

SECTION 1

Refer to page 90.

Smooth Setup Changes

Scenes can be used to change between up to 16 types of measurement setups.

Simply change the scene to change to a different measurement setup.

Refer to page 125.

1-1 Features of the Z500

REFERENCE

Operation Manual

Z500

13

SECTION 1

Features

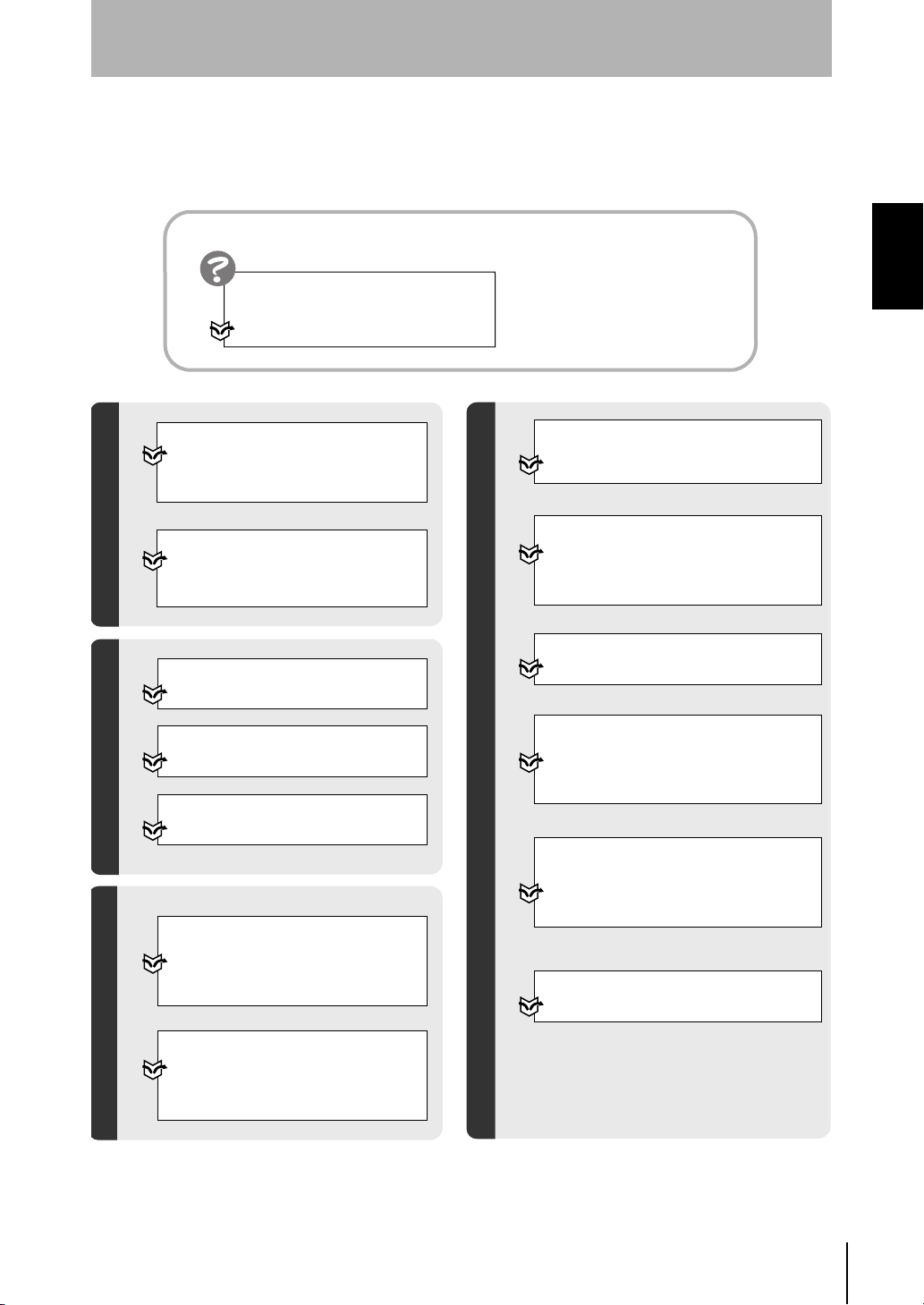

1-2 Operational Flow

1-2-1 Menus for Conversational Menu

SECTION 1

1-2 Operational Flow

Turn ON the power.

Displaying Images on the Monitor

Refer to page 20,

Starting the Z500 and Displaying Images.

2-1

Preparations for Detection

Refer to this section to learn about the basic

operational flow from setting measurement

conditions to executing measurements.

CHECK

Refer to page 39 for information on

settings using Conversational Menu.

Starting Up Conversational Menu and

Entering Set Mode

Refer to page 40, See

Step 1 : Starting Conversational Menus.

Setting Basic Measurement Conditions

Refer to page 41, See

Step 2 :

Setting Basic Measurement Conditions.

Selecting and Setting Measurement Items

Refer to page 48, See

Step 3 : Setting Measurement Contents.

Refer to page 70 for details.

Screen Types and Display Methods

Refer to page 29.

Selecting Measurement Item

Appropriate to the

Measurement Goal

Refer to page 70.

Height

Step: 2 pts

Step: 3 pts

Edge position

Width

Edge center

Define

14

Setting Measurement Conditions (if necessary)

Refer to page 49, See

Step 4 :

Setting Measurement Conditions.

Refer to page 88 for details.

Setting Output Contents

Refer to page 50, See

Setting Detection Conditions and Executing

Step 5 : Setting Output Contents.

Refer to page 100 for details.

Starting Measurements

Refer to page 51, See

Step 6 : Starting Measurements.

Performing Test

Refer to page 129,

Testing Measurement Performance (Test).

5-6

Confirming Settings

Z500

Operation Manual

Checking the Line Beam Position

Refer to page 135,

Beam Position (Surrounding image).

5-7Checking the Line

Troubleshooting

When an error message has

been displayed on the screen,

Refer to page 184,

8-1Troubleshooting.

SECTION 1

Features

SECTION 1

1-2 Operational Flow

Changing Measurement Contents

Refer to page 86.

Clearing Measurement Items

Refer to page 87.

Changing the Screen Display

Refer to page 113.

Changing and Deleting Settings

Saving Detection Conditions

Refer to page 52,

Saving Settings and Exiting the Z500.

3-2

Executing Force-zero

Refer to page 110.

Communications with External Devices

Refer to page 145,

Setting RS-232C

Communications Specifications (Comm).

6-2

I/O Format

Refer to page 153.

Setting Conditions by Model Type

Refer to page 125,

Changing Scenes.

5-4

Setting System Environment

Application Setting Operations

Conditions

Refer to page 146,

Environment Settings.

6-3

Initializing the Z500

Refer to page 151.

Saving Settings

Backing up Data

Refer to page 136,

to a Computer (Backup).

5-8 Backing Up Data

Operation Manual

Z500

15

SECTION 1

Features

1-2-2 Menus for Expert Menu

SECTION 1

1-2 Operational Flow

Turn ON the power.

Displaying Images on the Monitor

Refer to page 20,

Starting the Z500 and Displaying Images.

2-1

Preparations for Detection

Refer to this section to learn about the basic

operational flow from setting measurement

conditions to executing measurements.

CHECK

Refer to page 54 for information on

settings using Expert Menu.

Starting Up Expert Menu and Entering Set Mode

Refer to page 54,

Expert Menu and Entering Set Mode.

Step 1 : Starting Up

Screen Types and Display Methods

Refer to page 29.

Adjusting Images

Refer to page 56,

Step 2 : Adjusting Images.

Setting Position Compensation

Refer to page 64,

Step 3 : Position Compensation.

(if necessary)

Selecting and Setting Measurement Items

Refer to page 70,

Step 4: Measurement Settings.

Setting Measurement Conditions

Refer to page 88,

Step 5 : Measurement Conditions.

Setting Detection Conditions and Executing

Setting Output Contents

Refer to page 100,

Step 6 : Output Settings.

(if necessary)

Starting Measurements

Refer to page 107,

Step 7 : Performing Measurement.

Selecting Measurement Item

Appropriate to the

Measurement Goal

Refer to page 70.

Height

Step: 2 pts

Step: 3 pts

Edge position

Width

Edge center

Define

16

Z500

Operation Manual

Troubleshooting

When an error message has been

displayed on the screen,

Refer to page 184,

8-1Troubleshooting.

SECTION 1

Features

SECTION 1

1-2 Operational Flow

Performing Test

Refer to page 129,

Testing Measurement Performance

(Test).

5-6

Checking the Line Beam Position

Refer to page 135,

Confirming Settings

Checking the Line Beam Position

(Surrounding image).

5-7

Changing Measurement Contents

Refer to page 86.

Clearing Measurement Items

Refer to page 87.

Changing the Screen Display

Refer to page 113.

Changing and Deleting Settings

Saving Detection Conditions

Refer to page 108,

Saving Settings and Exiting the Z500.

4-2

Executing Force-zero

Refer to page 110.

Communications with External Devices

Refer to page 145,

Setting RS-232C

Communications Specifications (Comm).

6-2

I/O Format

Refer to page 153.

Setting Conditions by Model Type

Refer to page 125,

Changing Scenes.

5-4

Setting System Environment

Application Setting Operations

Conditions

Refer to page 146,

Environment Settings.

6-3

Initializing the Z500

Refer to page 151.

Backing up Data

Saving Settings

Refer to page 136,

Backing Up Data to a Computer

(Backup).

5-8

Operation Manual

Z500

17

SECTION 1

Features

MEMO

SECTION 1

1-2 Operational Flow

18

Z500

Operation Manual

Z500

Operation Manual

SECTION 2

Basic Operations

SECTION 2 shows basic menu operations of the Z500.

2-1 Starting the Z500 and Displaying Images 20

2-2 Menu Operations 23

2-2-1 Input Device 23

2-2-2 Screen Displays 24

2-2-3 Menu Tree 25

2-2-4 Inputting Values 27

2-2-5 Adjustment Menu 28

2-3 Screen Types and Display Methods 29

SECTION 2 Basic Operations

2-3-1 Image Monitor 30

2-3-2 Profile Monitor 33

2-3-3 Digital Monitor 35

2-3-4 Trend Monitor 36

2-4 Saving Settings and Exiting the Z500 37

19

SECTION 2

Basic Operations

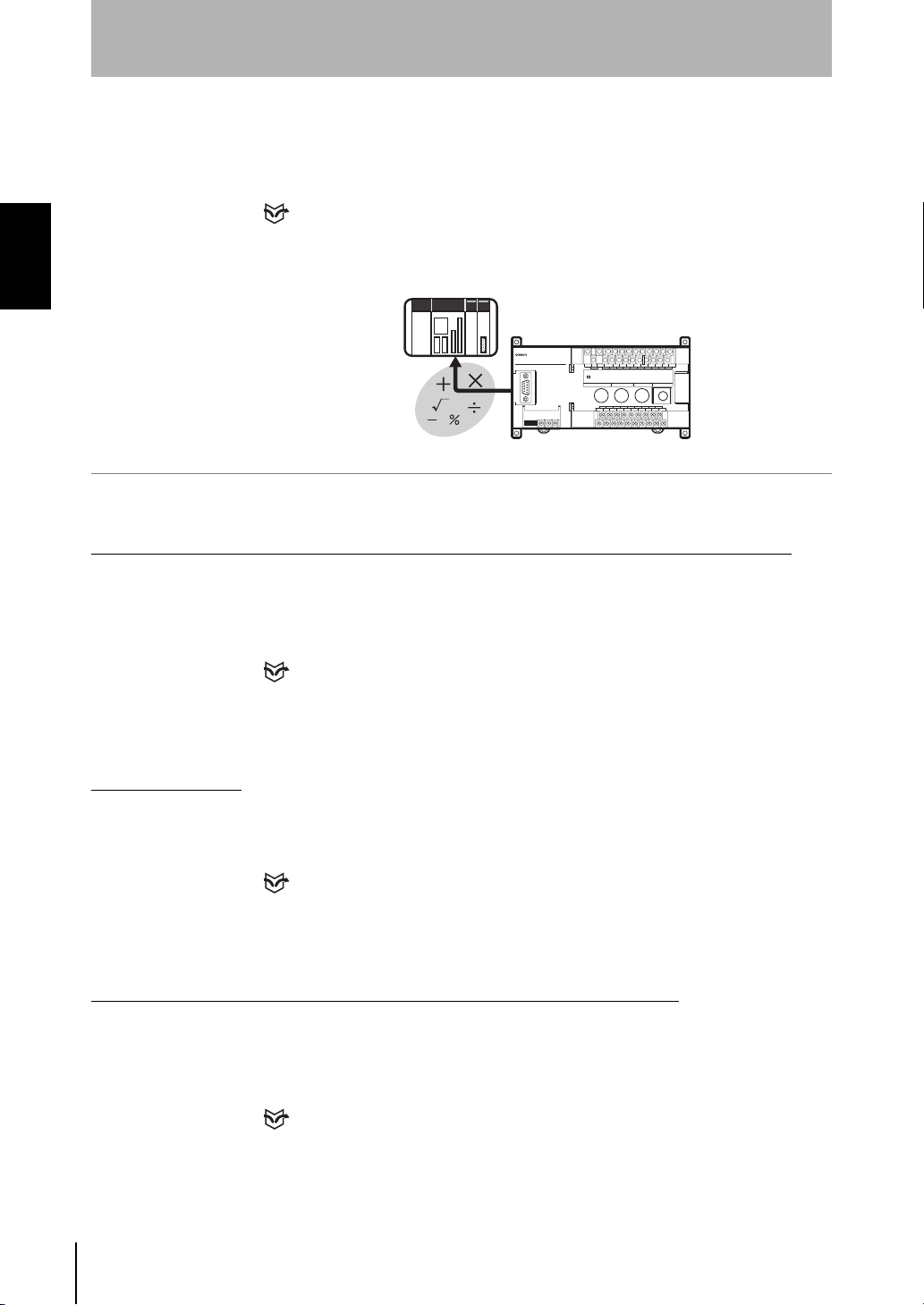

2-1 Starting the Z500 and Displaying Images

This section describes how to start the Z500 and how to display images on the monitor.

Place the workpiece and adjust the Sensor position while monitoring the displayed image.

Starting the Z500

#1

SECTION 2

2-1 Starting the Z500 and Displaying Images

1.

CHECK

2.

3.

Be sure that the basic Z500 components have been connected correctly.

Power Supply

Console

ENT

ESC TRIG

SHIFT

CONSOLE

Sensor

Z500

×× × × × × × × × × × ×

×× × × × × ××

× × × × × × ×

× × × × × × × × × ×

× × ×

× ×

Monitor

Before connecting components or wiring power supply lines and grounding wires, be sure

to refer to the relevant section in the

REFERENCE

Setup Manual

.

Refer to page 16 in the Setup Manual.

Turn ON the power supply to the monitor.

Turn ON the power supply to the Z500.

The Image Monitor will be displayed.

CHECK

Z500

Operation Manual

20

Scn 0 Run

NEAR

OUT 0

+0005.18800

S+ / :Display S+ENT:Adjust

If the Image Monitor is not displayed, use the

SHIFT

on the console to change the Monitors.

REFERENCE

Refer to page 29, Screen Types and Display Methods.

+

Right

Keys or

BRIGHT

DARK

SHIFT

9.96ms

Sen0

[ 15]

LV

[ 170]

PEAK

Sen1

[ .]

LV

[ ]

PEAK

Zero's OFF

PA S Smm

Left

+

Keys

FAR

Position the Workpiece and Adjust the Image

#2

Position the workpiece to be measured and adjust the displayed image in the

measurement range.

The measurement range varies depending on the Sensor models connected.

REFERENCE

Refer to page 26 in the Setup Manual.

Example: Z500-SW17

Sensor

100mm

SECTION 2

Basic Operations

SECTION 2

+20mm

2-1 Starting the Z500 and Displaying Images

0mm

Height

1.

Measurement range

+20mm

0mm

-20mm

Position

-20mm

Position the workpiece.

In this example, the workpiece shown in

the right figure will be described.

14.5mm

(±7.25mm)

17.3mm

(±8.65mm)

20.1mm

(±10.05mm)

Operation Manual

Z500

21

SECTION 2

Basic Operations

A profile graph showing the level differences in the workpiece will be displayed.

SECTION 2

2-1 Starting the Z500 and Displaying Images

2.

CHECK

Adjust the position of the workpiece if

necessary.

Adjust the workpiece position if the

Profile graph is not appeared in the

center of the monitor.

Scn 0 Run

NEAR

BRIGHT

DARK

OUT 0

+0005.18800

Profile

9.96ms

Sen0

[ 15]

LV

[ 170]

PEAK

Sen1

[ .]

LV

[ ]

PEAK

Zero's OFF

PA S Smm

FAR

S+ / :Display S+ENT:Adjust

If the lines representing level differences have swollen elliptically, the light density is

excessive. If the lines are too thin to see, the light density is insufficient. In either case,

adjust the sensitivity.

REFERENCE

Refer to page 59 for information on how to adjust sensitivity.

22

Z500

Operation Manual

2-2 Menu Operations

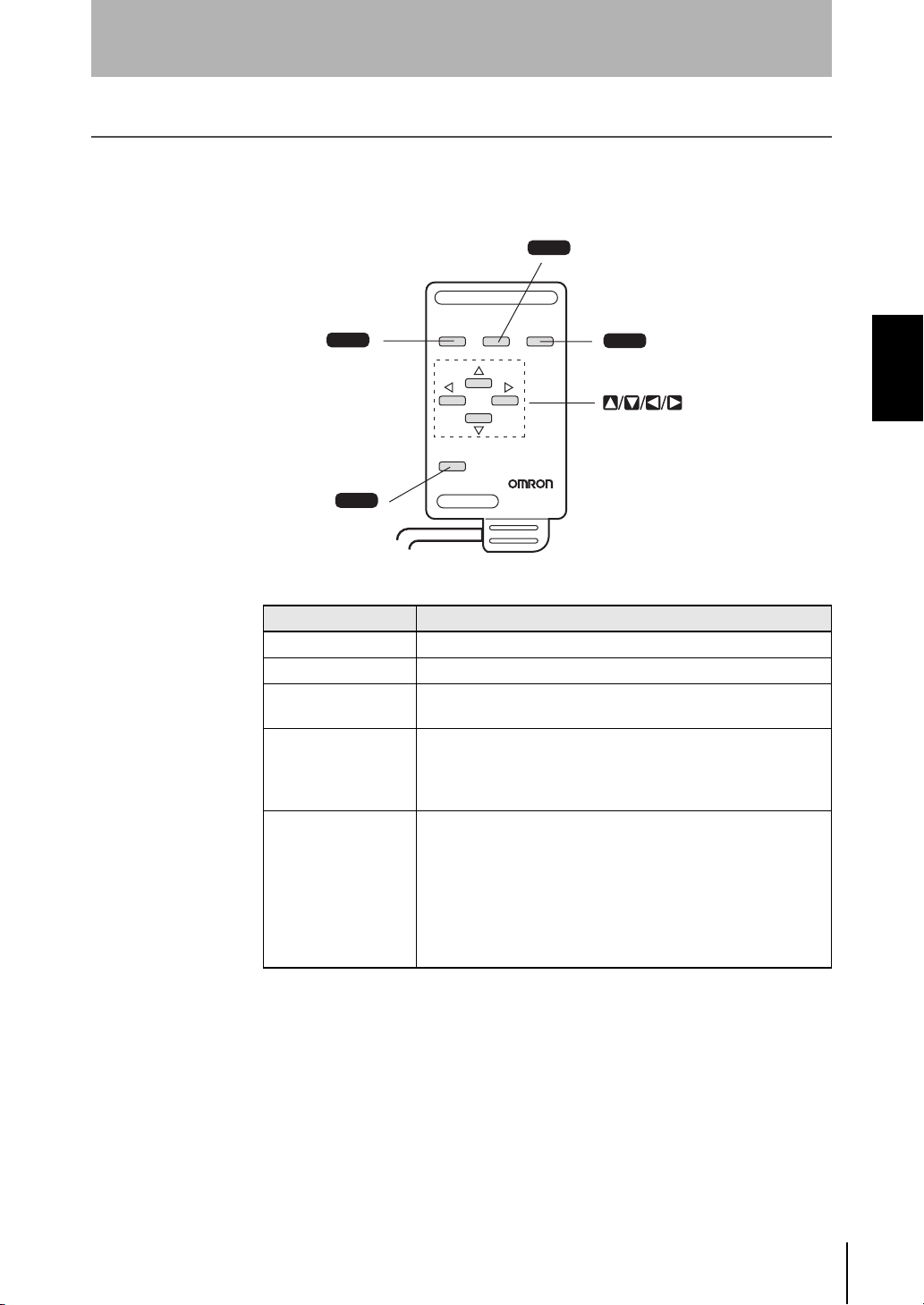

2-2-1 Input Device

Menu operations are performed on the Console.

SECTION 2

Basic Operations

Trigger Key

TRIG

Escape Key

ESC

SHIFT Key

SHIFT

Key Function

Escape Key Returns the cursor to the previous menu display or operation.

Trigger Key The effect of the Trigger Key varies with the function.

Enter Key

SHIFT Key

Up, Down, Left, and

Right Keys

ESC TRIG

SHIFT

Executes a function or sets a value.

Note: On the F160-KP, also functions as a Cursor Key.

Must be pressed in combination with another key to have any

effect.

Specific functions are assigned to combinations of the

Key and other keys for specific screens.

The Up and

down and also to set values.

Use the Up Key to increase a value by 1.

Left

Down

and

Use the

Hold down the Up or

a value.

The

right.

ENT

Z300-KP

CONSOLE

Down

Keys are used to move the cursor up and

Key to decrease a value by 1.

Right

Enter Key

ENT

Up, Down, Left, and Right Keys

Down

Key to quickly increase or decrease

Keys are used to move the cursor left or

SHIFT

SECTION 2

2-2 Menu Operations

Operation Manual

Z500

23

SECTION 2

2-2 Menu Operations

SECTION 2

Basic Operations

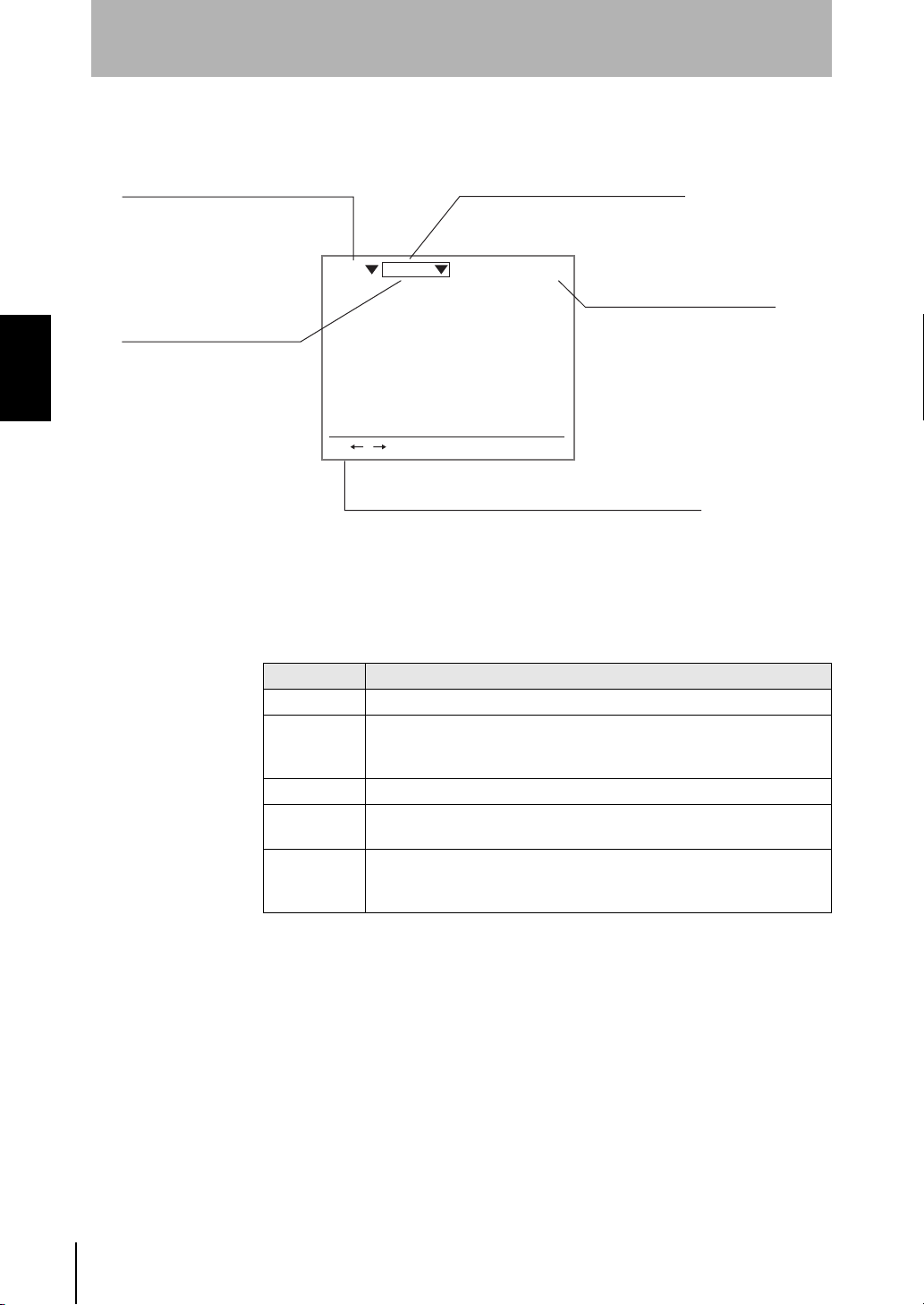

2-2-2 Screen Displays

The Z500 is operated by selecting functions displayed on the screen. Familiarize yourself with each

function before operating the Z500.

Scene Number

There are 16 scenes.

Setting different measurement

conditions for each one allows

easy switching between different

setups.

Cursor Keys

The cursor is moved to the

desired function by pressing

the Up, Down, Left,

and Right Keys.

Scn 0 Run

S+ / :Display S+ENT:Adjust

Key Operations

Displays special key combinations at the bottom of the screen

where available. S refers to the SHIFT Key. "S + ENT" indicates

that the ENT Key should be pressed while the SHIFT Key is pressed.

Mode (See the table below)

The current operating mode is displayed.

9.96ms

Measurement period (Sampling time)

It varies depending on the item

to be measured.

Mode

Display Description

Set Mode to set the inspection conditions.

Performs measurement.

Run

Tools Used to save settings and images to a computer as backup.

System

Save

The measurement results are output to an external device via terminal

block or RS-233C.

Used to set system conditions for the Z500. Select this mode to switch

menus and settings for communications with external devices.

Used to save data to flash memory in the Z500.

If new settings have been made, be sure to save the data before quitting.

24

Z500

Operation Manual

SECTION 2

Basic Operations

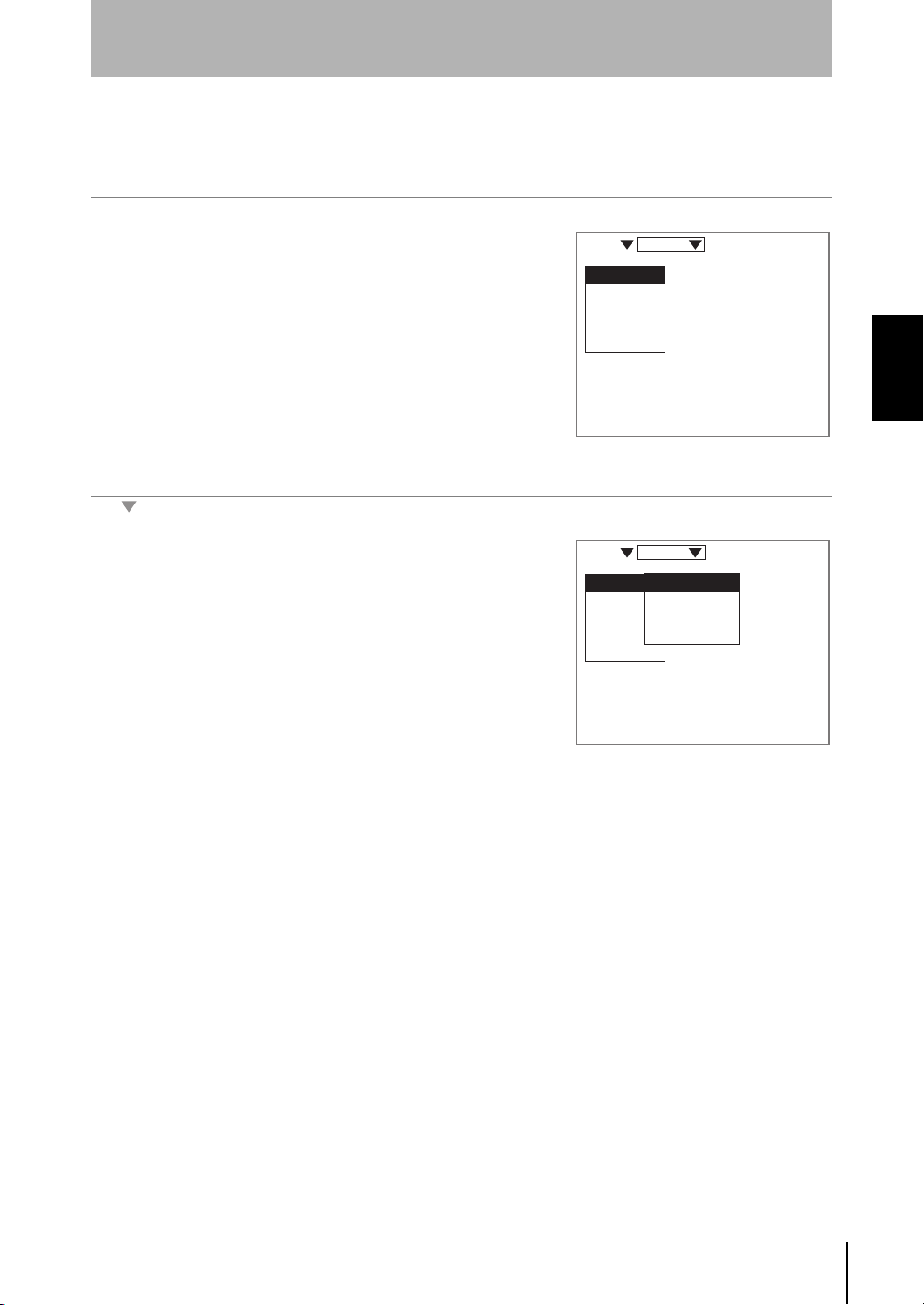

2-2-3 Menu Tree

Z500 menus are hierarchical. The cursor is moved to the required functions to set measurement

conditions. Use the following procedures to move around the menu tree.

1.

2.

In this example, the cursor will move to the Image Menu.

3.

Move the cursor to the item to be moved.

(Move the cursor to the desired function

in Set Mode using the Up and Down

Keys.)

Press the ENT Key.

Repeat (1.) and (2.) to move the cursor

to lower levels.

Press the ESC Key once to move to the

upper level.

Scn 0 Set

Image

Compensatn

Meas set

Conditions

Output

Scn 0 Set

Image

Compensatn

Meas set

Conditions

Output

SECTION 2

2-2 Menu Operations

Meas method

Region

Sensitivity

Details

Operation Manual

Z500

25

SECTION 2

2-2 Menu Operations

SECTION 2

Basic Operations

Triangle Mark

Items with an inverted triangle after them have a list of alternatives.The method for selecting the

alternatives is given here.

Scn 0 System

:

1.

2.

Move the cursor to the item to be set.

In this example, move the cursor to

Baud rate.

Press the ENT Key.

Baud rate

Data Length

Parity

Stop bits

Delimiter

Flow

38400bps

:

:

:

:

:

End

8bit

None

1bit

CR

None

The selections will be displayed.

3.

Move the cursor to the desired baud rate

using the Up and Down Keys.

4.

Press the ENT Key.

The selections will be registered.

Scn 0 System

Baud rate

Data Length

Parity

Stop bits

Delimiter

Flow

Scn 0 System

Baud rate

Data Length

Parity

Stop bits

Delimiter

Flow

:

38400bps

:

2400bps

:

4800bps

:

9600bps

:

19200bps

:

38400bps

End

:

38400bps

:

:

:

:

:

End

8bit

None

1bit

CR

None

8bit

None

1bit

CR

None

26

Z500

Operation Manual

SECTION 2

Basic Operations

2-2-4 Inputting Values

The section explains how to input values when setting judgment or measurement conditions.

1.

Move the cursor to the item for which a

value is to be changed.

2.

Press the ENT Key.

The cursor will change to a cursor the size of a single digit.

3.

Move the cursor to the digit to be

changed using the Left and Right Keys.

4.

Change the value.

Use the Up Key to increase the value.

Use the Down Key to decrease the

value.

5.

6.

Repeat (4.) to change other values.

Press the ENT Key.

Scn 0 Set

judgement width

Edge width

Smoothing

Noise

Level

Error data

Profile

Peak/btm width

Scn 0 Set

judgement width

Edge width

Smoothing

Noise

Level

Error data

Profile

Peak/btm width

Scn 0 Set

judgement width

Edge width

Smoothing

Noise

Level

Error data

Profile

Peak/btm width

:

[ 0.01000]

:

[ 0.00000]

:

:

50.0%

:

Clamp

:

:

:

End

:

[0000.01000]

:

[ 0.00000]

:

:

50.0%

:

Clamp

:

:

:

End

:

[0000.02000]

:

[ 0.00000]

:

:

50.0%

:

Clamp

:

:

:

End

None

2pixel

None

5pixel

None

2pixel

None

5pixel

None

2pixel

None

5pixel

SECTION 2

2-2 Menu Operations

The values will be set.

Scn 0 Set

judgement width

Edge width

Smoothing

Noise

Level

Error data

Profile

Peak/btm width

:

[ 0.02000]

:

[ 0.00000]

:

:

:

:

:

:

End

Operation Manual

None

2pixel

50.0%

Clamp

None

5pixel

Z500

27

SECTION 2

Basic Operations

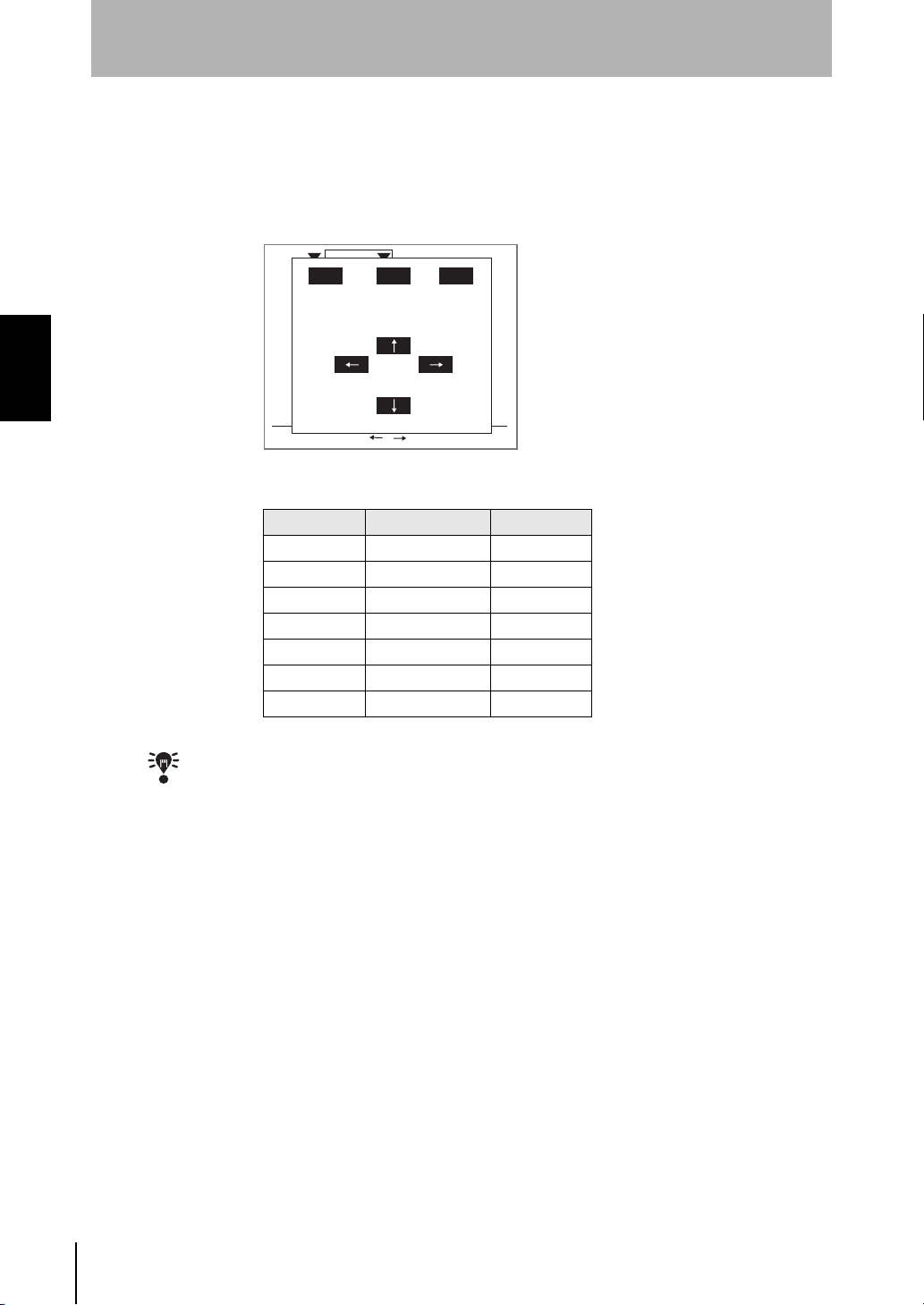

2-2-5 Adjustment Menu

Press the SHIFT + ENT Keys in Run Mode. The adjustment menu will be displayed.

The adjustment menu is useful to display the set screens of the following six items without passing

through the menu hierarchies.

SECTION 2

2-2 Menu Operations

CHECK

Scn 0 Run

ESC TRG ENT

Display

Sensitvy

Output

Conditns

ESC:Back S+ / :Switch display

Key Allocation Reference

Trigger Key Display P.112

Enter Key Test P.129

Up Key Sensitivity P.59

Down Key Conditions P.88

Left Key Output P.100

Right Key Meas set P.70

Escape Key None -

The adjustment menu can be performed from the Image Monitor, the Digital Monitor, the

Profile Monitor, or the Trend Monitor.

9.96ms

Test

Meas set

28

Z500

Operation Manual

Loading...

Loading...