Cat. No. SCHA-719A

Z4LB V2

Parallel Beam

Linear Sensor

INSTRUCTION MANUAL

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the

products. Please consult your OMRON representative if you

have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free

from defects in materials and workmanship for a period of

one year (or other period if specified) from date of sale by

OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON–INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR

PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR

USER ALONE HAS DETERMINED THAT THE PRODUCTS

WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL,

INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF

PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH

CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is

asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR

WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING

THE PRODUCTS UNLESS OMRON’S ANALYSIS CON-

FIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND

NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE,

OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE

NOT SAFETY RATED. THEY ARE NOT DESIGNED OR

RATED FOR ENSURING SAFETY OF PERSONS, AND

SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer to separate catalogs for OMRON’s

safety rated products.

OMRON shall not be responsible for conformity with any

standards, codes, or regulations that apply to the combination of products in the customer’s application or use of the

product.

At the customer’s request, OMRON will provide applicable

third party certification documents identifying ratings and

limitations of use that apply to the products. This information

by itself is not sufficient for a complete determination of the

suitability of the products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which

particular attention must be given. This is not intended to be

an exhaustive list of all possible uses of the products, nor is

it intended to imply that the uses listed may be suitable for

the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amuse-

ment machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk

to life or property.

Please know and observe all prohibitions of use applicable

to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS

BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT

THE OMRON PRODUCT IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE

OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a

guide for the user in determining suitability and does not

constitute a warranty. It may represent the result of OMRON’s test conditions, and the users must correlate it to actual application requirements. Actual performance is subject

to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at

any time based on improvements and other reasons.

It is our practice to change model numbers when published

ratings or features are changed, or when significant

construction changes are made. However, some specifications of the product may be changed without any notice.

When in doubt, special model numbers may be assigned to

fix or establish key specifications for your application on

your request. Please consult with your OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used

for manufacturing purposes, even when tolerances are

shown.

ERRORS AND OMISSIONS

The information in this document has been carefully

checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence

thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions

without permission.

This document is protected by copyright and is intended

solely for use in conjunction with the product. Please notify

us before copying or reproducing this document in any manner, for any other purpose. If copying or transmitting this

document to another, please copy or transmit it in its entirety.

Z4LB V2

Parallel Beam Linear Sensor

Instruction Manual

Notice:

OMRON products are manufactured for use according to proper procedures

by a qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in

this manual. Always heed the information provided with them. Failure to

heed precautions can result in injury to people or damage to property.

DANGER Indicates an imminently hazardous situation which, if not

!

avoided, will result in death or serious injury.

WARNING Indicates a potentially hazardous situation which, if not

!

avoided, could result in death or serious injury.

Caution Indicates a potentially hazardous situation which, if not

!

avoided, may result in minor or moderate injury, or property

damage.

Visual Aids

The following headings will help you locate different types of information.

Note Indicates information of particular interest for efficient and con-

venient operation of the product.

→ Indicates pages where additional information can be found.

1 Indicates a procedure. The step numbers in the procedure

correspond to the numbers in any related illustrations.

OMRON, 1999

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted,

in any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this publication.

iv

PRECAUTIONS ix. . . . . . . . . . . . . . . . . . . . .

1 Laser Safety x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Application Precautions xxi. . . . . . . . . . . . . . . . . . . . . . . . . .

3 Environment xxii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Maintenance xxii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 General Precautions xxii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Checking the Package xxiii. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 1

Application Example 1. . . . . . . . . . . . . . . . .

1-1 Inspection for Loose Bottle Caps 2. . . . . . . . . . . . . . . .

SECTION 2

Preparations 9. . . . . . . . . . . . . . . . . . . . . . . .

2-1 Nomenclature 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2 Wiring 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-3 Connections 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Axis and Gain Adjustments 18. . . . . . . . . . . . . . . . . . . .

2-5 Sensor Installation 19. . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 3

Basic Settings 23. . . . . . . . . . . . . . . . . . . . . . . .

3-1 Selecting the Measurement Unit 24. . . . . . . . . . . . . . . .

3-2 Setting Thresholds 26. . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 4

Optional Settings 35. . . . . . . . . . . . . . . . . . . . .

4-1 Optional Functions 36. . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Key Settings 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3 Selector Settings 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 5

Timing Charts 49. . . . . . . . . . . . . . . . . . . . . . .

5-1 Normal 50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-2 Peak Hold 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-3 Bottom Hold 52. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-4 Sample Hold 53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-5 Peak-to-peak Hold 54. . . . . . . . . . . . . . . . . . . . . . . . . . .

5-6 Self-peak Hold 55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-7 Self-bottom Hold 56. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION 6

Troubleshooting 57. . . . . . . . . . . . . . . . . . . . .

SECTION 7

Specifications and Dimensions 59. . . . . . . . . .

7-1 Specifications 60. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7-2 Dimensions 64. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About this Manual:

This manual describes the installation and operation of the Z4LB V2 Parallel Beam Linear Sensor and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided

before attempting to install and operate the Z4LB V2 Parallel Beam Linear Sensor.

Section 1 provides practical information on the connections, wiring, and operation of the

Z4LB V2 with a typical application example. Read this section for a quick application reference.

Section 2 provides information on preparations that must be made before turning ON the

Sensor, such as wiring, connecting, and installing Sensors and Amplifiers.

Section 3 provides information on basic settings, such as the threshold settings for good/

improper product discriminations.

Section 4 provides information on the optional functions that can be set in addition to the

basic settings.

Section 5 provides timing charts to show the operation of the hold modes.

Section 6 provides information on error messages and remedies to be taken. Refer to

this section before requesting service from your OMRON representative.

Section 7 provides the Sensor specifications and dimensions.

WARNING Failure to read and understand the information provided in this

!

manual may result in personal injury or death, damage to the

product, or product failure. Please read each section in its

entirety and be sure you understand the information provided

in the section and related sections before attempting any of

the procedures or operations given.

vii

PRECAUTIONS

This section provides general precautions for using the Z4LB V2 Parallel Beam Linear

Sensor.

The information contained in this section is important for the safe and reliable

application of the Z4LB V2 Parallel Beam Linear Sensor. You must read this section

and understand the information contained before attempting to set up or operate a

Z4LB V2 Parallel Beam Linear Sensor.

1 Laser Safety x. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Application Precautions xxi. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3 Environment xxii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Maintenance xxii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 General Precautions xxii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Checking the Package xxiii. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ix

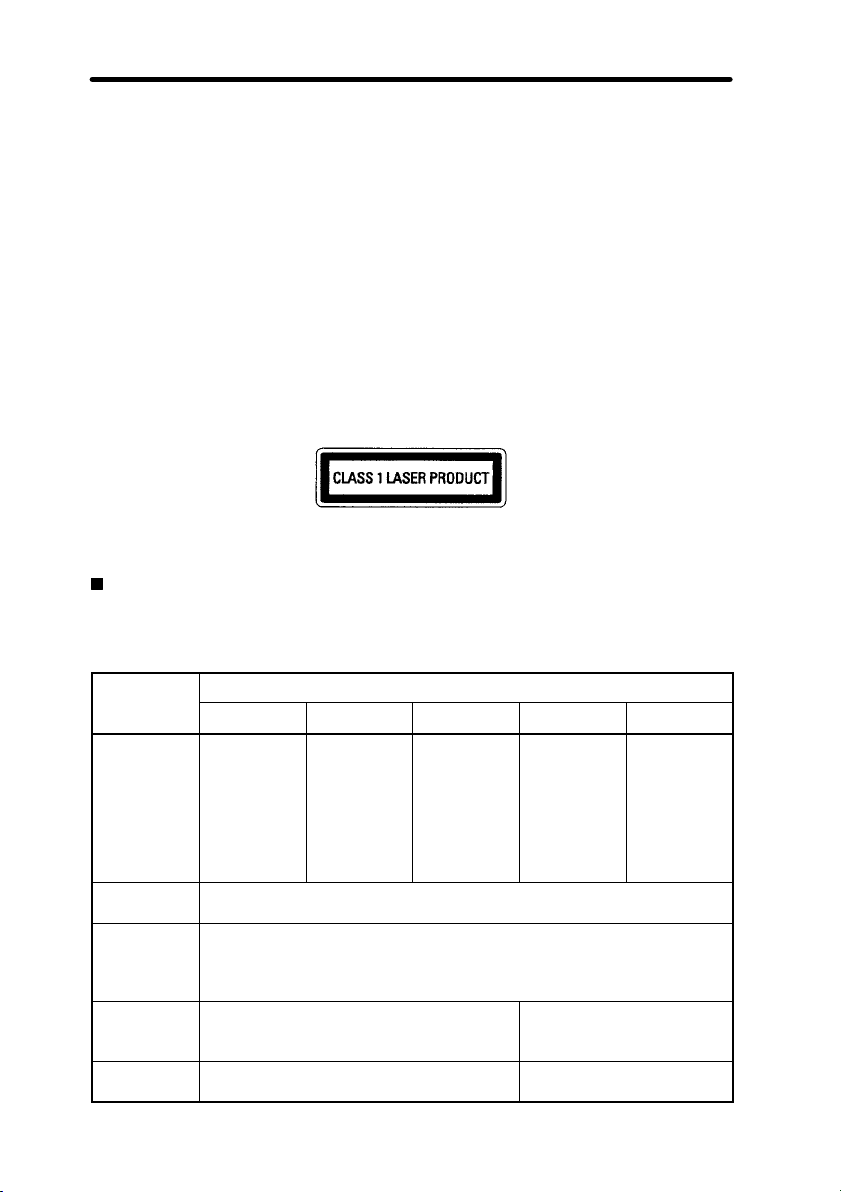

1 Laser Safety

The Z4LB V2 Parallel Beam Linear Sensor, is a Class 1 Laser Product according to

EN60825-1 (IEC825-1) and a Class II Laser Product according to FDA (21 CFR1040.10) (see

note). The Z4LB V2 is meant to be built into final system equipment. Pay special attention to

the following precautions for the safe use of the product:

Note: Europe: Class 1 of EN60825-1: 1994 = IEC825-1: 1993

U.S.A.: Class II of FDA (21 CFR1040.10)

1. Use this product as specified in this instruction manual. Otherwise, you may be exposed

to hazardous laser radiation.

2. Be careful not to expose your eyes directly to the laser radiation or indirectly to laser

radiation reflected from mirror or shiny surfaces.

3. To avoid exposure to hazardous laser radiation, do not displace nor remove the

protective housing during operation, maintenance, and any other servicing.

4. The user should return the product to OMRON for all repair and servicing.

5. As for other countries, observe the regulations and standards specified by each country.

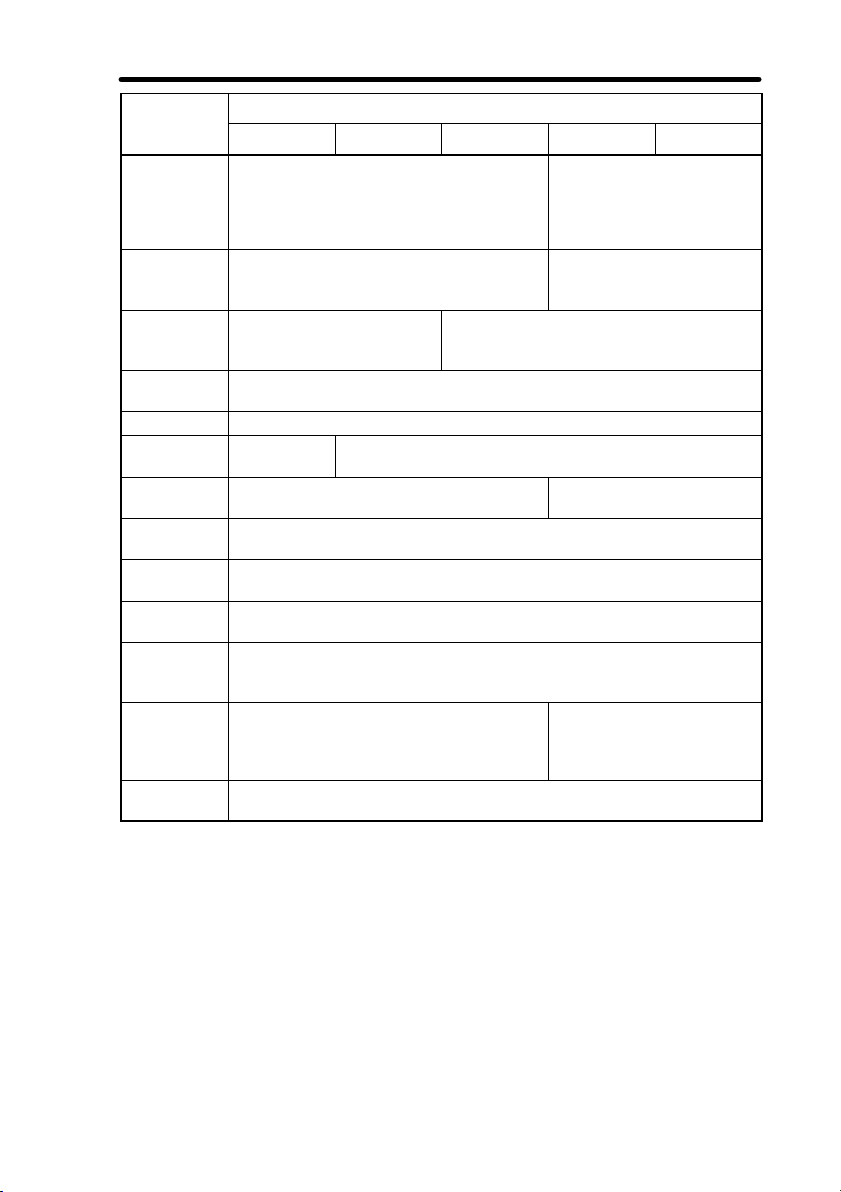

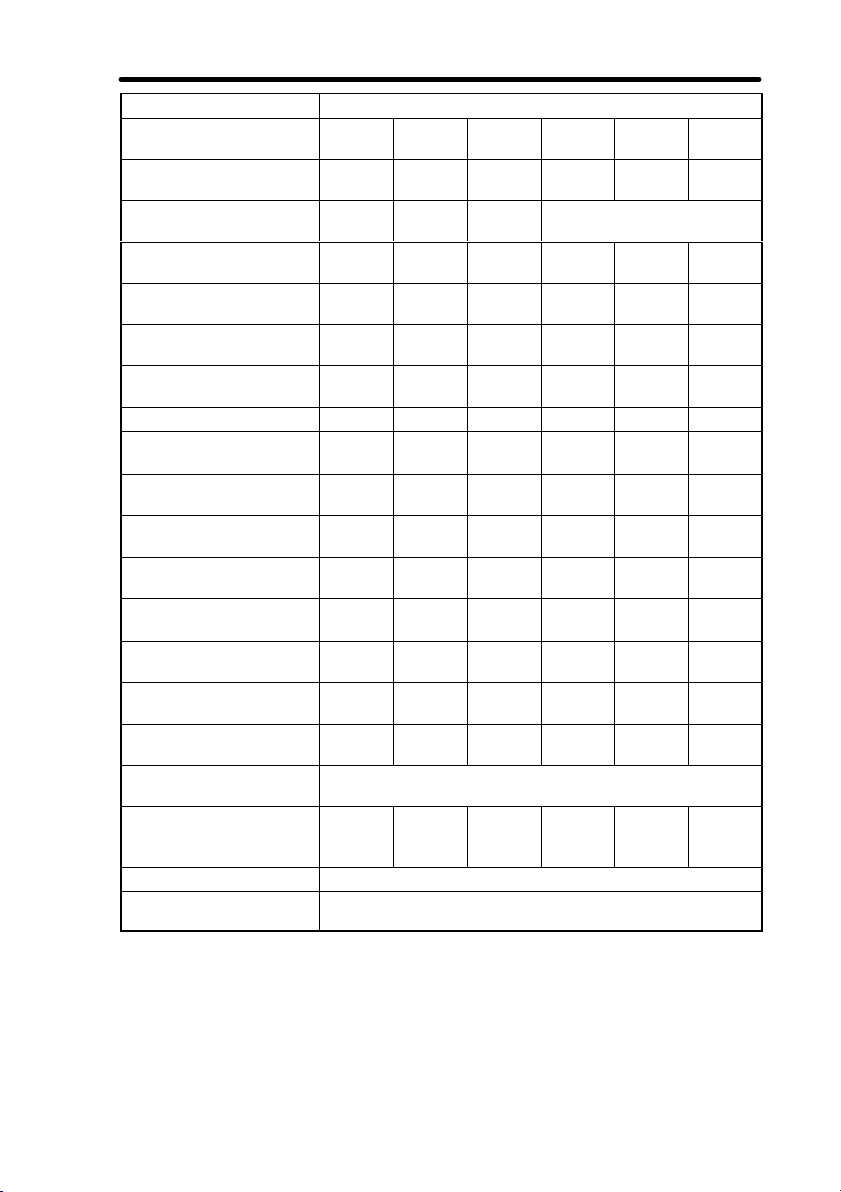

Requirements from Regulations and Standards

EN60825-1 “Safety of Laser Products, Equipment Classification, Requirements and

User’s Guide”

Summary of Manufacturer’s Requirements

Require-

ments;

Sub-clause

Description

of hazard

class

Protective

housing

Safety interlock in protective housing

Remote control

Key control Not required Laser inoperative when key

Class 1 Class 2 Class 3A Class 3B* Class 4

Safe under

reasonably

foreseeable

conditions

Required for each laser product; limits access necessary for performance of functions of the products

Designed to prevent removal of the panel until accessible emission values are below the AEL (see note 2) for the class assigned

Not required Permits easy addition of ex-

Low power;

eye protection normally afforded

by aversion

responses

Classification

Same as

Class 2. Direct intrabeam viewing with optical aids may

be hazardous

Direct intrabeam viewing may be

hazardous

ternal interlock in laser

installation

is removed

High power;

diffused reflection may

be hazardous

1Laser Safety

x

1Laser Safety

Require-

ments;

ments;

Sub-clause

Sub-clause

Emission

warning device

Attenuator Not required Gives means beside ON/

Location

controls

Viewing optics

Scanning Scan failure shall not cause product to exceed its classification

Class label Required

Aperture label

Service

entry label

Override interlock label

User information

Purchasing

and service

information

Medical

products

Fibre optic Cable service connections require tool to disconnect if disconnection

* With respect to the requirements of remote interlock connector, key control, emission warn-

ing and attenuator, Class 3B laser products not exceeding five times the AEL of Class 2 in

the wavelength range of 400 nm to 700 nm are to be treated as Class 3A laser products.

Note: 1. This table is intended to provide a convenient summary of requirements. See text

Not required Gives audible or visible

Not required Controls so located that there is no danger

Emission from all viewing systems must be below Class 1 AEL’s as applicable

Figures A and B and specified wording

wording

Not required Specified wording required

Required as appropriate to the class of accessible radiation

Required under certain conditions as appropriate to the class of laser

used

Operation manuals must contain instructions for safe use

Promotion brochures must reproduce classification labels; service manuals must contain safety information

Special calibration instructions required Special calibration instruc-

breaks protective housing and permits access above Class 1

of this standard for complete requirements.

2. AEL: Accessible Emission Limit

The maximum accessible emission level permitted within a particular class.

For your reference, see ANSI Z136.1-1993, Section 2.

ClassificationRequire-

Class 4Class 3B*Class 3AClass 2Class 1

warning when laser is

switched on or if capacitor

bank of pulsed laser is being charged

OFF switch to temporarily

block beam

of exposure to AEL above Classes 1 or 2

when adjustments are made.

tions, means for measurement and target-indicator

required

xi

Symbol and border: black

Background: yellow

Figure A Warning label – Hazard symbol

Legend and border: black

Background: yellow

1Laser Safety

xii

Figure B Explanatory label

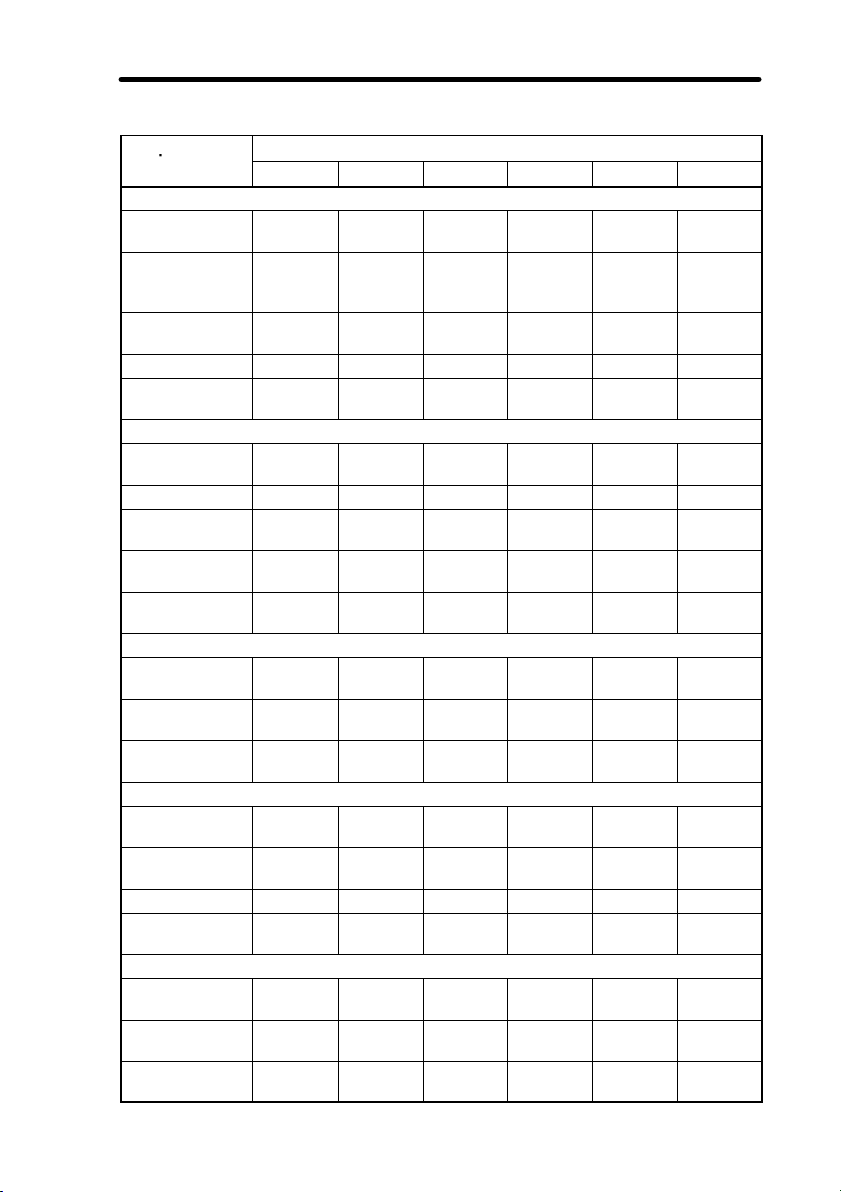

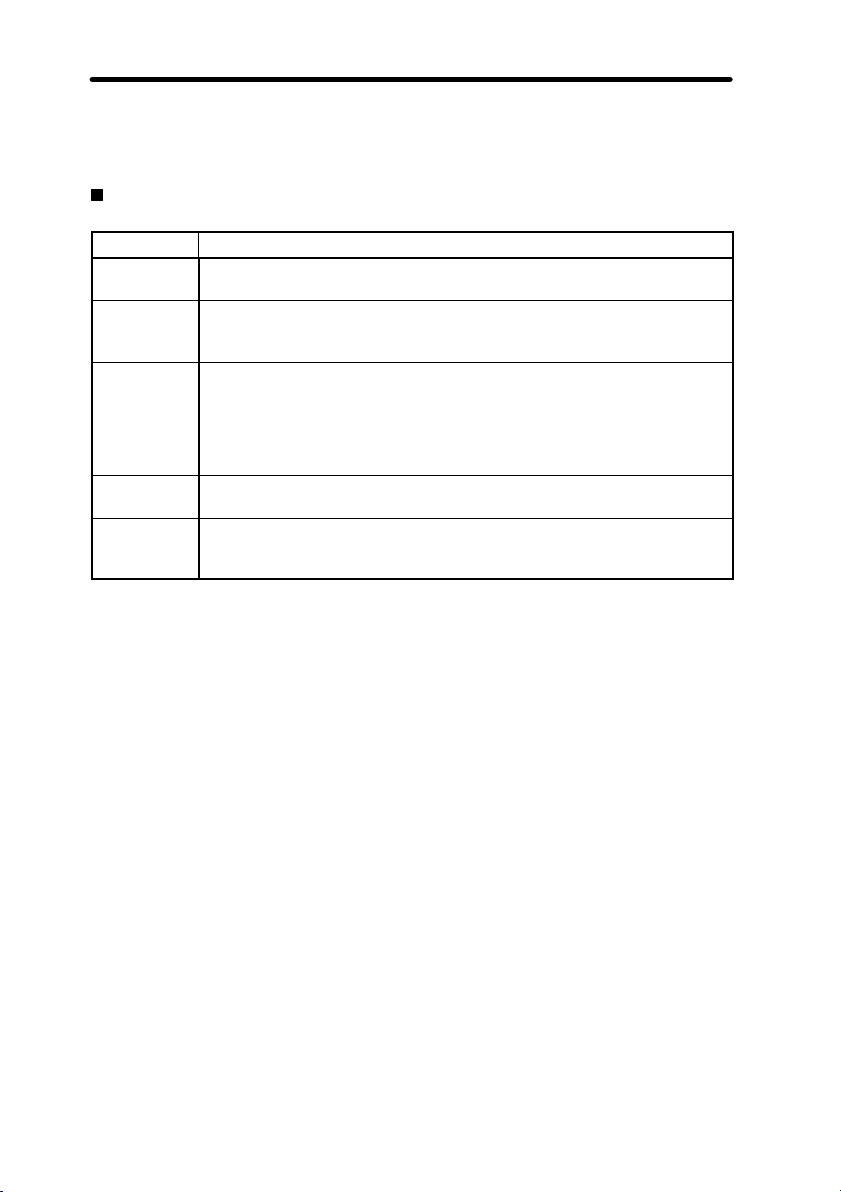

FDA (Compliance Guide for Laser Products, 1985, according to 21 CFR1040.10)

q

1Laser Safety

Requirements

I IIa II IIIa IIIb IV

Performance (all laser products)

Protective

housing

Safety interlock R (see

Location of controls

Viewing optics R R R R R R

Scanning safeguard

Performance (laser systems)

Remote control

connector

Key control N/A N/A N/A N/A R R

Emission indicator

Beam attenuator

Reset N/A N/A N/A N/A N/A R (see

Performance (specific purpose products)

Medical S S S S (see

Surveying, leveling, alignment

Demonstration S S S S S (see

Labeling (all laser products)

Certification &

identification

Protective

housing

Aperture N/A N/A R R R R

Class warning N/A R (see

Information (all laser products)

User information

Product literature

Service information

R (see

note 2)

notes 3,

4)

N/A R R R R

R R R R R R

N/A N/A N/A N/A R R

N/A N/A R R R (see

N/A N/A R R R R

S S S S NP NP

R R R R R R

D (see

note 5)

R R R R R R

N/A R R R R R

R R R R R R

R (see

note 2)

R (see

notes 3,

4)

D (see

note 5)

note 6)

Class (see note 1)

R (see

note 2)

R (see

notes 3,

4)

D (see

note 5)

R (see

note 7)

R (see

note 2)

R (see

notes 3,

4)

note 8)

D (see

note 5)

R (see

note 9)

R (see

note 2)

R (see

notes 3,

4)

note 10)

S (see

note 8)

note 11)

D (see

note 5)

R (see

note 12)

R (see

note 2)

R (see

notes 3,

4)

R (see

note 10)

note 13)

S (see

note 8)

(see

note 11)

D (see

note 5)

R (see

note 12)

xiii

Abbreviations:

R: Required.

N/A: Not applicable.

S: Requirements: Same as for other products of that Class.

Also see footnotes.

NP: Not permitted.

D: Depends on level of interior radiation.

Footnotes:

1. Based on highest level accessible during operation.

2. Required wherever & whenever human access to laser radiation above Class I limits is

not needed for product to perform its function.

3. Required for protective housings opened during operation or maintenance, if human

access thus gained is not always necessary when housing is open.

4. Interlock requirements vary according to Class of internal radiation.

5. Wording depends on level & wavelength of laser radiation within protective housing.

6. Warning statement label.

7. CAUTION logotype.

8. Requires means to measure level of laser radiation intended to irradiate the body.

9. CAUTION if 2.5 mW cm

10.Delay required between indication & emission.

11.Variance required for Class IIb or iV demonstration laser products and light shows.

12.DANGER logotype.

13.Required after August 20, 1986.

2

or less, DANGER if greater than 2.5 mW cm–2.

1Laser Safety

xiv

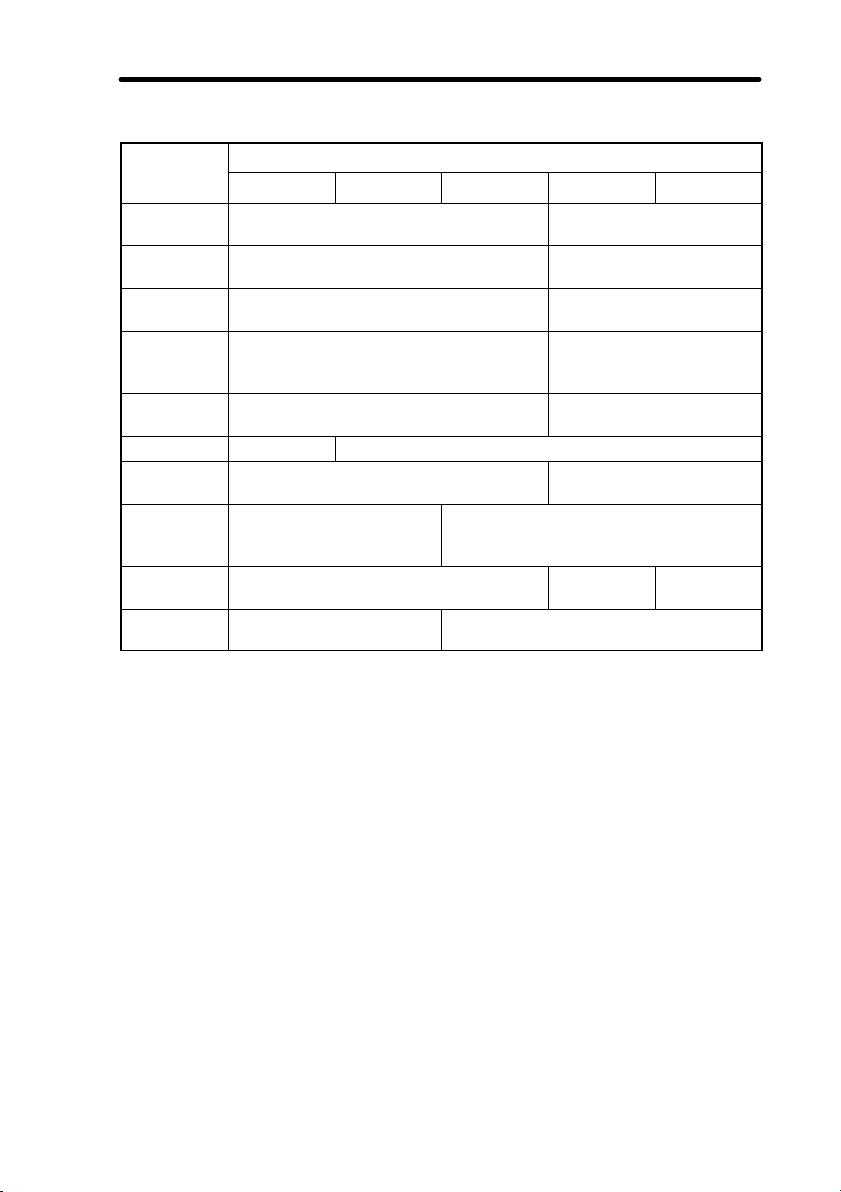

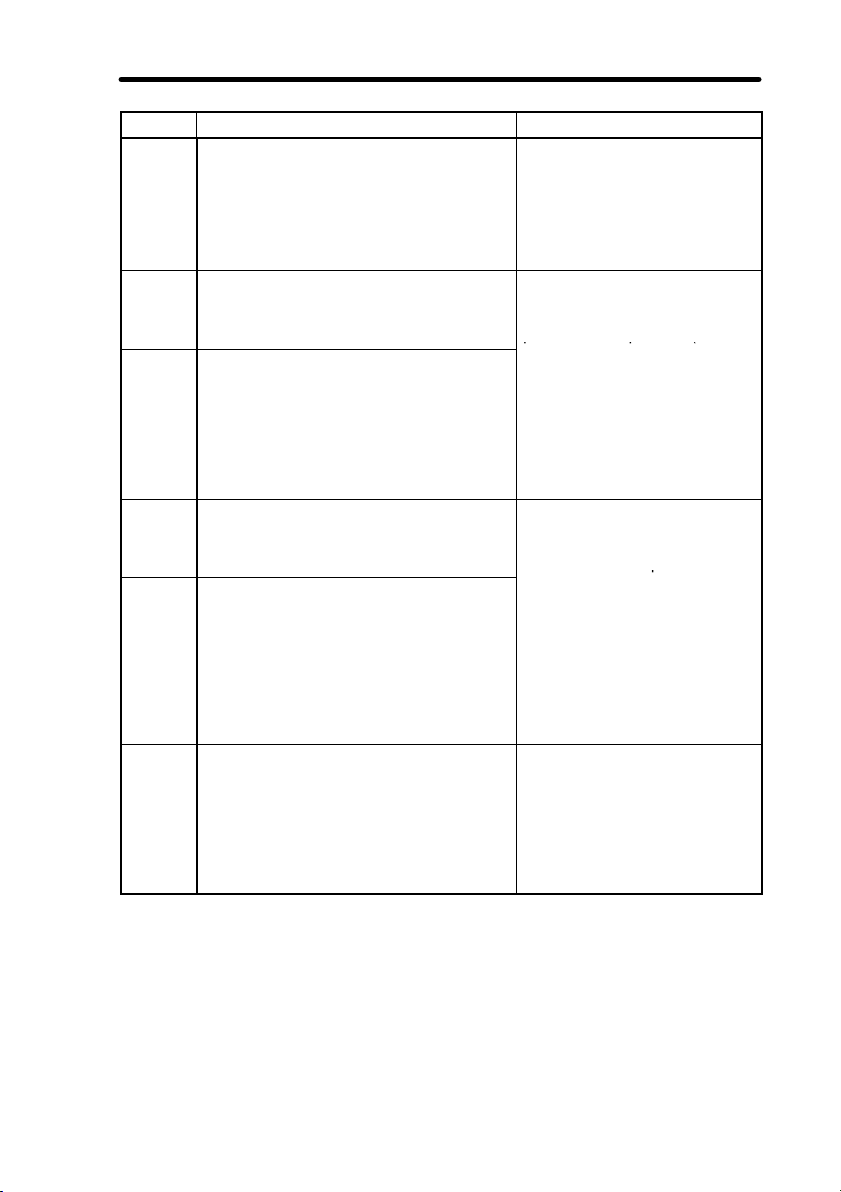

Use Precautions

EN60825-1

Require-

ments;

Sub-clause

Remote interlock

Key control Not required Remove key when not in

Beam attenuator

Emission indicator device

Warning

signs

Beam path Not required Terminate beam at end of useful length

Specular reflection

Eye protection

Protective

clothing

Training No requirements Required for all operator and maintenance

Class 1 Class 2 Class 3A Class 3B* Class 4

Not required Connect to room or door

Not required When in use prevents inad-

Not required Indicates laser is energized

Not required Follow precautions on

No requirements Prevent unintentional re-

No requirements Required if engineering and administrative

No requirements Sometimes

Classification

circuits

use

vertent exposure

warning signs

flections

procedures not practicable and MPE exceeded

required

personnel

Specific requirements

1Laser Safety

* With respect to the requirements of remote interlock connector, key control, beam attenua-

tor, and emission indicator, Class 3B laser products not exceeding five times the AEL of

Class 2 in the wavelength range of 400 nm to 700 nm are to be treated as Class 3A laser

products.

Note: This table is intended to provide a convenient summary of requirements. See text of

this standard for complete precautions.

xv

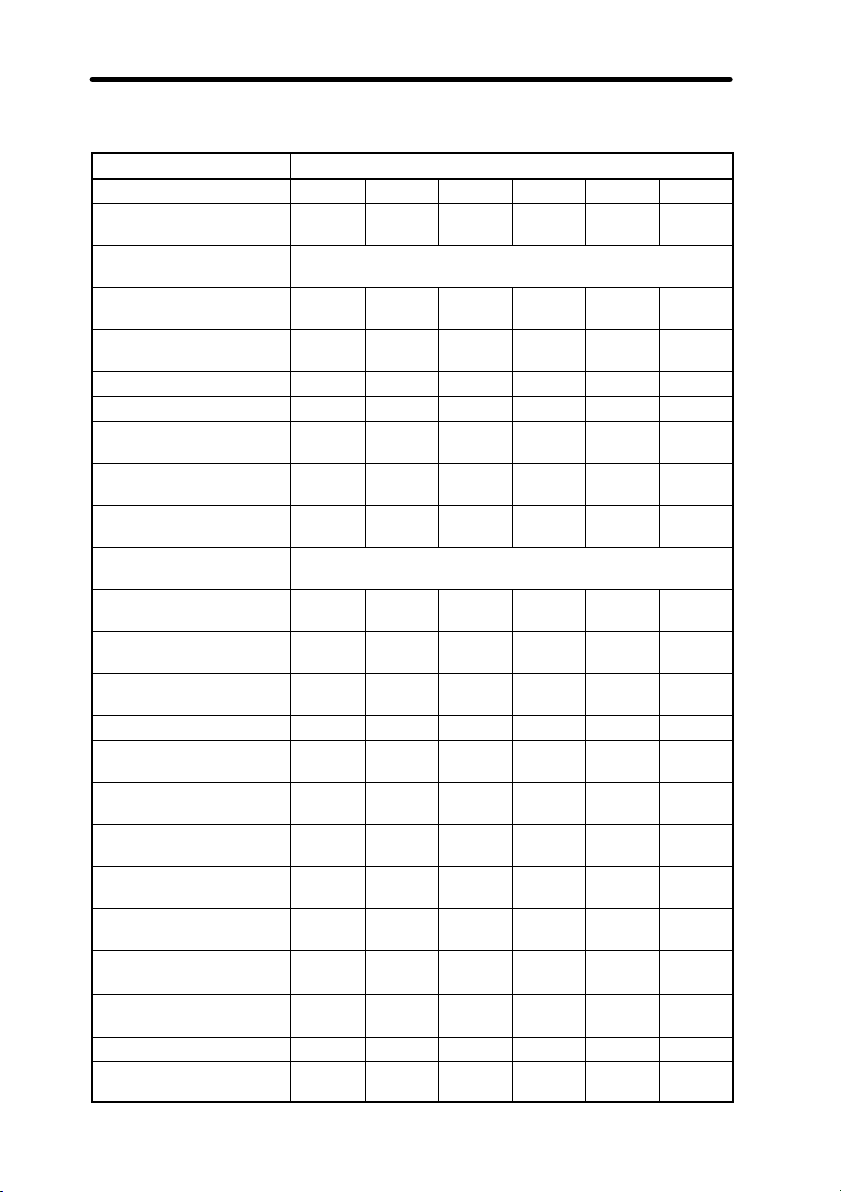

ANSI Z136.1:1993 “American National Standard for the Safe Use of Lasers”

Control Measures for the Four Laser Classes

1Laser Safety

Control measures

Engineering Controls 1 2a 2 3a 3b 4

Protective Housing

(4.3.1)

Without Protective Housing (4.3.1.1)

Interlocks on Protective

Housing (4.3.2)

Service Access Panel

(4.3.3)

Key Control (4.3.4) --- --- --- ---

Viewing Portals (4.3.5.1) --- --- MPE MPE MPE MPE

Collecting Optics

(4.3.5.2)

Totally Open Beam Path

(4.3.6.1)

Limited Open Beam Path

(4.3.6.2)

Enclosed Beam Path

(4.3.6.3)

Remote Interlock Connector (4.3.7)

Beam Stop or Attenuator

(4.3.8)

Activation Warning Systems (4.3.9)

Emission Delay (4.3.9.1) --- --- --- --- --- X

Indoor Laser Controlled

Area (4.3.10)

Class 3b Laser Controlled Area (4.3.10.1)

Class 4 Laser Controlled

Area (4.3.10.2)

Laser Outdoor Controls

(4.3.11)

Laser in Navigable Airspace (4.3.11.2)

Temporary Laser Controlled Area (4.3.12)

Remote Firing & Monitoring (4.3.13)

Labels (4.3.14 and 4.7) X X X X X X

Area Posting (4.3.15) --- --- ---

X X X X X X

LSO (see note 2) shall establish Alternate Controls

l l l l

l l l l

MPE MPE MPE MPE MPE MPE

--- --- --- --- X

--- --- --- --- X

None is required if 4.3.1 and 4.3.2 fulfilled

--- --- --- ---

--- --- --- ---

--- --- --- ---

--- --- --- --- X

--- --- --- --- X ---

--- --- --- --- --- X

--- --- --- --- X

--- --- ---

l

MPElMPElMPElMPE

--- --- --- --- ---

Classification

S S S

S

X X

X X

S

NHZ

NHZ

S

S

S

NHZ

NHZ

--- ---

X

NHZ

X

X

NHZ

X

NHZ

X

X

X

X

NHZ

X

NHZ

S

X

NHZ

xvi

Control measures Classification

Administrative & Procedural Controls

Standard Operating Procedures (4.4.1)

Output Emission Limitations (4.4.2)

Education and Training

(4.4.3)

Authorized Personnel

(4.4.4)

Alignment Procedures

(4.4.5)

Protective Equipment

(4.4.6)

Spectator (4.4.7) --- --- --- ---

Service Personnel (4.4.8)

Demonstration with General Public (4.5.1)

Laser Optical Fiber Systems (4.5.2)

Laser Robotic Installations (4.5.3)

Eye Protection (4.6.2) --- --- --- ---

Protective Windows

(4.6.3)

Protective Barriers and

Curtains (4.6.4)

Skin Protection (4.6.5) --- --- --- --- X

Other Protective Equipment (4.6.5)

Warning Signs and Labels (4.7) (Design Requirements)

Service and Repairs (4.8) LSO Determination

Modification of Laser

Systems (4.9)

1 2a 2 3a 3b 4

--- --- --- ---

--- --- --- LSO Determination

--- ---

--- --- --- --- X X

--- --- X X X X

--- --- --- ---

l

MPElMPElMPElMPE

MPE {

MPE MPE MPE MPE X X

--- --- --- --- X

--- --- --- --- X

--- --- --- ---

Use may be required

--- ---

LSO Determination

--- X X X X

S S

S S

S

X X

S

S

X X

NHZ

S

MPE

NHZ

S S

MPEX MPE

X

NHZ

X

X

X

X

NHZ

X

MPE

X

NHZ

X

NHZ

1Laser Safety

Note: 1. LEGEND

X: Shall

S: Should

---: No requirement

l: Shall if enclosed Class 3b or Class 4

MPE: Shall if MPE is exceeded

NHZ: Nominal Hazard Zone analysis required

{: Applicable only to UV and IR Lasers (4.5.1.2)

xvii

1Laser Safety

2. LSO: Laser Safety Officer

An individual shall be designated the Laser Safety Officer with the authority

and responsibility to monitor and enforce the control of laser hazards, and to

effect the knowledgeable evaluation and control of laser hazards.

For your reference, see ANSI Z136.1-1993, Section 1.3.

Laser Product Classifications

EN

Class

Class 1 Lasers which are safe under reasonably foreseeable conditions of opera-

tion.

Class 2 Lasers emitting visible radiation in the wavelength range from 400 nm to

700 nm. Eye protection is normally afforded by aversion responses including the blink reflex.

Class 3A Lasers which are safe for viewing with the unaided eye. For laser emitting

in the wavelength range from 400 nm to 700 nm, protection is afforded by

aversion responses including the blink reflex. For other wavelengths the

hazard to the unaided eye is no greater than for Class 1. Direct intrabeam viewing of Class 3A lasers with optical aides (e.g., binoculars, telescopes, microscopes) may be hazardous.

Class 3B Direct intrabeam viewing of these lasers is always hazardous. Viewing

diffuse reflections is normally safe (see note).

Class 4 Lasers which are also capable of producing hazardous diffuse reflections.

They may cause skin injuries and could also constitute a fire hazard.

Their use requires extreme caution.

Note: Conditions for safe viewing of diffuse reflections for Class 3B visible lasers are: mini-

mum viewing distance of 13 cm between screen and cornea and a maximum viewing

time of 10 s. Other viewing conditions require a comparison of the diffuse reflection

exposure with the MPE.

Description

xviii

Comparison of Classifications between FDA and ANSI

pp(

p

Class

Class

I/1

Class

IIa/2a

Class

II/2

Class

IIIa/3a

Class

IIIb/3b

Class

IV/4

Limits applicable to devices that have

emissions in the ultraviolet, visible, and

infrared spectra, and limits below which

biological hazards have not been established.

Limits applicable to products whose visible

emission does not exceed Class I limits for

emission durations of 1,000 seconds or

less and are not intended for viewing.

Limits applicable to products that have

emissions in the visible spectrum (400 to

710 nm) for emission durations in excess

of 0.25 second, providing that emissions

for other durations and/or wavelengths do

not exceed the Class I limits. Class II products are considered hazardous for direct

long-term ocular exposure.

Limits to products that have emissions in

the visible spectrum and that have beams

where the total collectable radiant power

does not exceed 5 milliwatts.

Limits applicable to devices that emit in the

ultraviolet, visible, and infrared spectra.

Class IIIb products include laser systems

ranging from 5 to 500 milliwatts in the visible spectrum. Class IIIb emission levels

are ocular hazards for direct exposure

throughout the range of the Class, and

skin hazards at the higher levels of the

Class.

Exceeding the limits of Class IIIb and are a

hazard for scattered reflection as well as

for direct exposure.

FDA definition ANSI description

1Laser Safety

A Class 1 laser is considered to

be incapable of producing damaging radiation levels during operation and maintenance and is,

therefore, exempt from any control measures or other forms of

surveillance.

Class 2 lasers are divided into

two subclasses, 2 and 2a. A

Class 2 laser emits in the visible

portion of the spectrum (0.4 to

0.7 µm) and eye protection is

normally afforded by the aversion response including the

blink reflex.

Class 3 lasers are divided into

two subclasses, 3a and 3b. A

Class 3 laser may be hazardous

under direct and specular reflection viewing conditions, but

the diffuse reflection is usually

not a hazard.

A Class 4 laser is a hazard to

the eye or skin from the direct

beam and sometimes from a diffuse reflection and also can be

fire hazard. Class 4 lasers may

also produce laser-generated

air contaminants and hazardous

plasma radiation.

xix

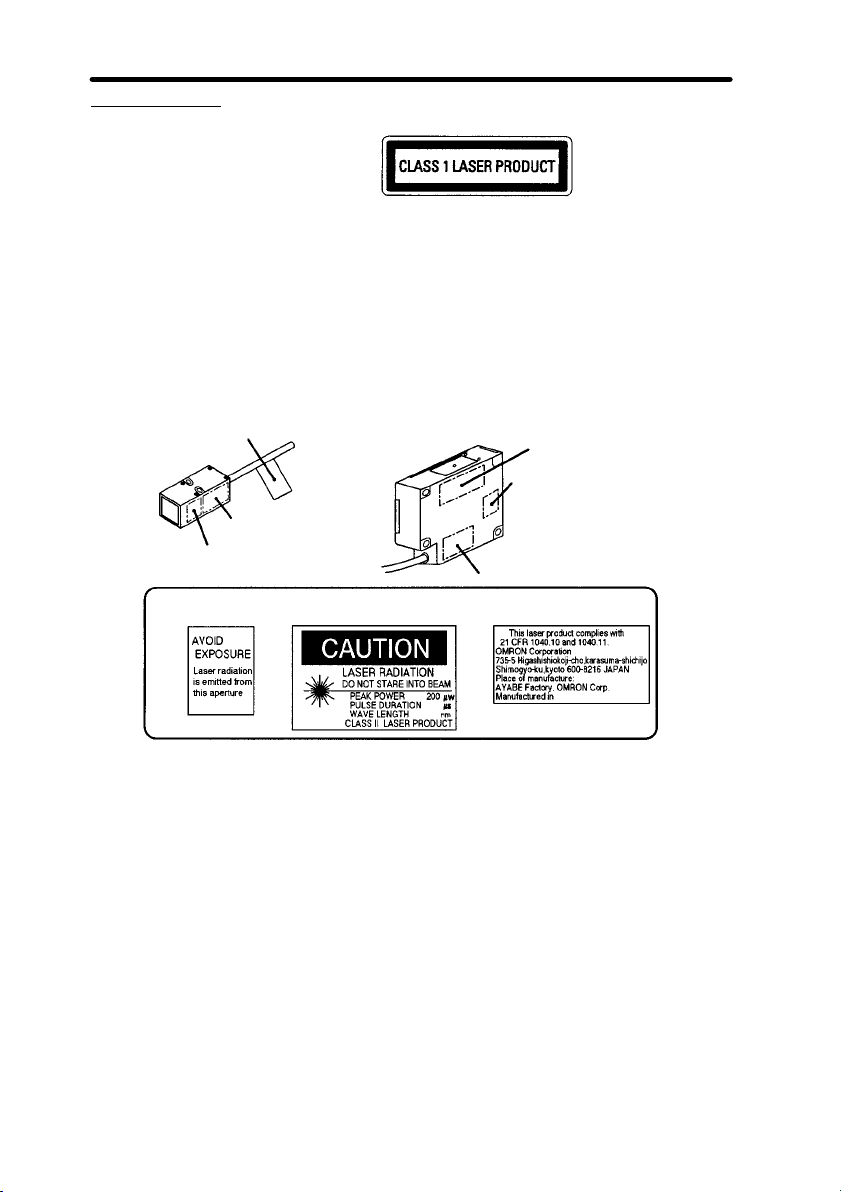

Label Indications

EN

FDA

Z4LB-S10V2

Z4LB-A1040jV2

1Laser Safety

Note Use of controls, adjustments, or procedures other

than those specified herein may result in hazardous

radiation exposure.

Z4LB-S30V2

Z4LB-A3040jV2

FDA Certification Label

FDA Caution Label

FDA Laser Aperture Label

FDA Laser

Aperture Label

Note Use of controls, adjustments, or procedures other

FDA Certification Label

FDA Laser Aperture Label

FDA Caution Label

FDA Caution Label FDA Certification Label

44

650

than those specified herein may result in hazardous

radiation exposure.

xx

2 Application Precautions

1. Users must operate the product according to the procedures and specifications

described in this manual. (Refer to 7-1 Specifications.)

2. Do not connect or disconnect a connector between the Sensor and Controller when the

power is turned ON, otherwise the Sensor may be damaged.

3. Warm up the Z4LB V2 for approximately 5 minutes after turning ON the power.

Power Supply and Wiring

1. Do not impose voltage exceeding the rated voltage, otherwise the Sensor may be

damaged.

2. When supplying power to the sensor, make sure that the polarity of the power is correct,

otherwise, the sensor may be damaged.

3. Do not short-circuit the load supplied with open collector output, otherwise the Sensor

may be damaged.

4. The Z49-C13 Extension Cable (3 or 8 m in length) can be connected to the sensor

cables or amplifier cables. The total length of the sensor cables or amplifier cables,

however, must be 10 m or less. Use a shielded cable to extend the amplifier cable, in

which case, a shielded cable that is the same as that of the amplifier cable must be used.

5. Do not lay a power supply cable for the Z4LB V2 together with high-voltage lines or

power lines to prevent interference, damage, and malfunction.

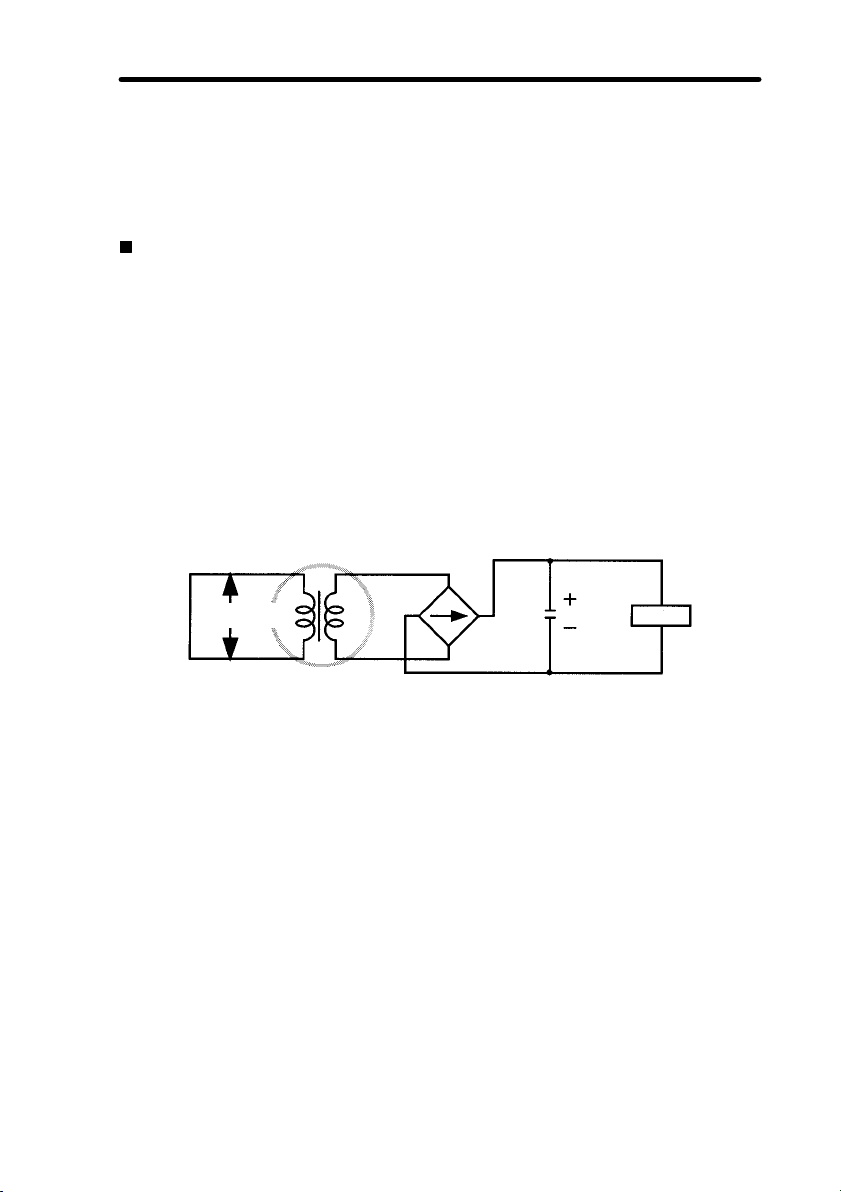

6. Use an isolation transformer for the power supply of the Z4LB V2 as shown in the

following.

2Application Precautions

Commercial

power supply

Isolation transformer

7. When using a switching regulator, use a FG (frame ground) terminal as a ground.

Z4LB V2

xxi

3 Environment

1. Do not use the Sensor in strong electromagnetic fields or in an environment where the

operation of the Sensor is subject to the reflection of intense light (such as other laser

beams or electric arc-welding machine.)

2. The Sensor cannot accurately detect the following types of objects:

• Mirror-like objects

• Transparent objects

• Objects with an extremely low reflection ratio

• Objects smaller than the Sensor’s sensing spot diameter

• Largely inclined objects

3. Do not install the Z4LB V2 in locations subject to the following conditions:

• Direct vibration or shock

• Direct sunlight or heaters

• High humidity

• Dust, salt, or iron particles

• Corrosive or flammable gasses

• Water, oil, or chemical fumes or spray

• Strong magnetic or high-voltage fields

• Condensation due to rapid temperature fluctuations

• Icing due to low temperature

4 Maintenance

1. Turn OFF the power when making adjustments or removing the Sensor.

2. Install the Sensor in a clean environment and keep the filter on the front panel of the

Sensor free from oil and dust. If affected by oil or dust, clean the filter as follows:

• Use a blower brush (used to clean camera lenses) to blow large dust particles from the

surface. Do not blow the dust away with your mouth.

• Use a soft cloth (for lenses) with a small amount of alcohol to remove the remaining

dust. Do not use a scrubbing action when cleaning as scratches on the filter could result in the Sensor malfunctioning.

• Do not use thinner or benzene. They will damage the optical characteristics of a filter.

5General Precautions

5 General Precautions

The user must operate the product according to the performance specifications described in

the instruction manual.

Consult your OMRON representative before using the product under conditions which are not

described in the manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines,

safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used improperly.

Make sure that the ratings and performance characteristics of the product are sufficient for the

systems, machines, and equipment, and be sure to provide the systems, machines, and

equipment with double safety mechanisms.

xxii

6 Checking the Package

When the product package is delivered, check if the package contains the following items. Although careful attention has been paid to packing the product, please contact your OMRON

representative if any item is found to be missing.

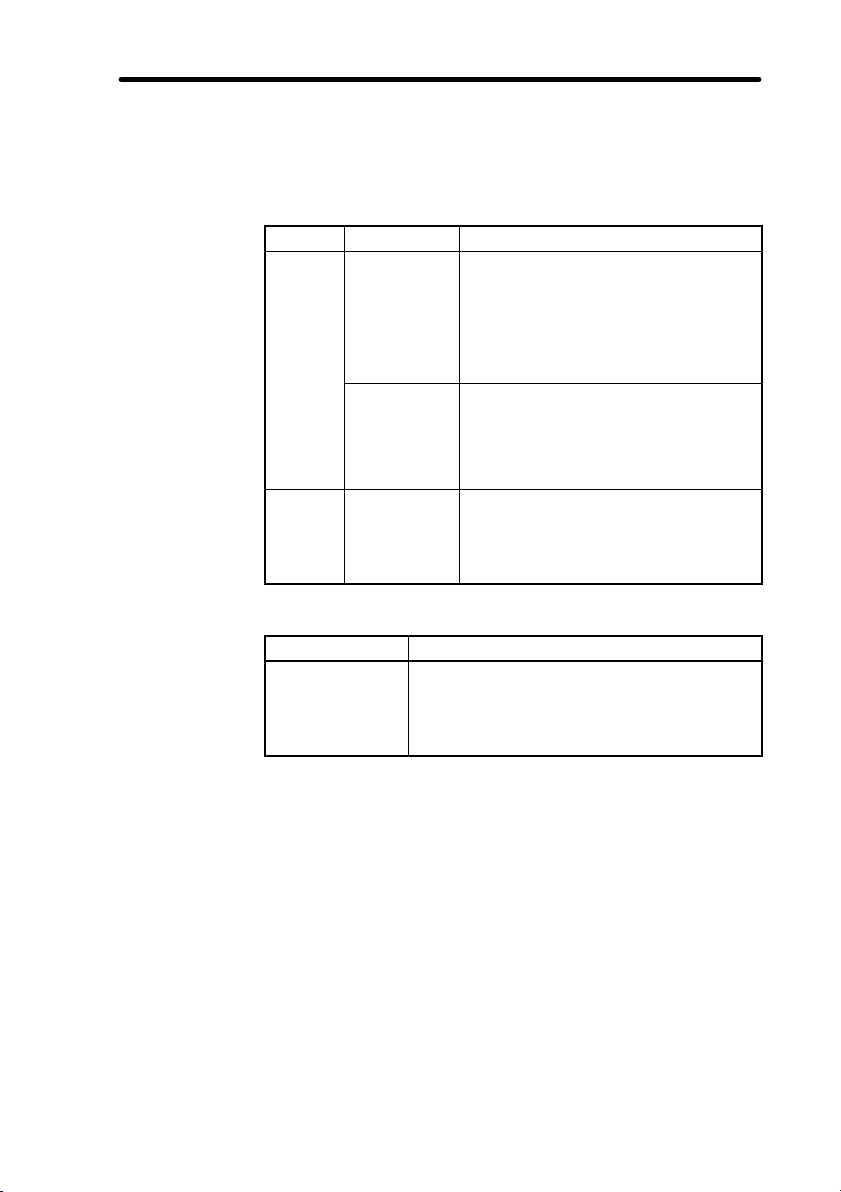

Standard Models (Separate Type)

Product Model Packing items

Sensor

Amplifier Z4LB-CV2

One-side Interruption High-precision Models (Integrated Type)

Z4LB-A1040V2

Z4LB-A1040PV2

Z4LB-A3040V2

Z4LB-A3040PV2

Z4LB-S10V2

Z4LB-S30V2

Z4LB-CPV2

Model Packing items

j One Z4LB-S10V2 Sensor

j Two mounting brackets

j Four M3 screws (25-mm long)

j Four M3 nuts

j Five labels

j One Z4LB-S30V2 Sensor

j Two mounting brackets

j Six M4 screws (25-mm long)

j Five labels

j One Z4LB-CV2 or Z4LB-CPV2

Amplifier

j One instruction manual (this manual)

j One screwdriver

j One Z4LB-A1040V2, Z4LB-A1040PV2,

Z4LB-A3040V2, or Z4LB-A3040PV2 Sensor

j One instruction manual (this manual)

j Five labels

6Checking the Package

xxiii

SECTION 1

Application Example

This section provides practical information on the connections, wiring, and operation of the

Z4LB V2 with a typical application example. Read this section for a quick application reference.

1-1 Inspection for Loose Bottle Caps 2. . . . . . . . . . . . . . . . .

1-1-1 Wiring and Connections 3. . . . . . . . . . . . . . . . . . . . .

1-1-2 Axis and Gain Adjustments 4. . . . . . . . . . . . . . . . . .

1-1-3 Setting Measurement Unit 5. . . . . . . . . . . . . . . . . . .

1-1-4 Setting Thresholds 6. . . . . . . . . . . . . . . . . . . . . . . . .

1-1-5 Detection 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

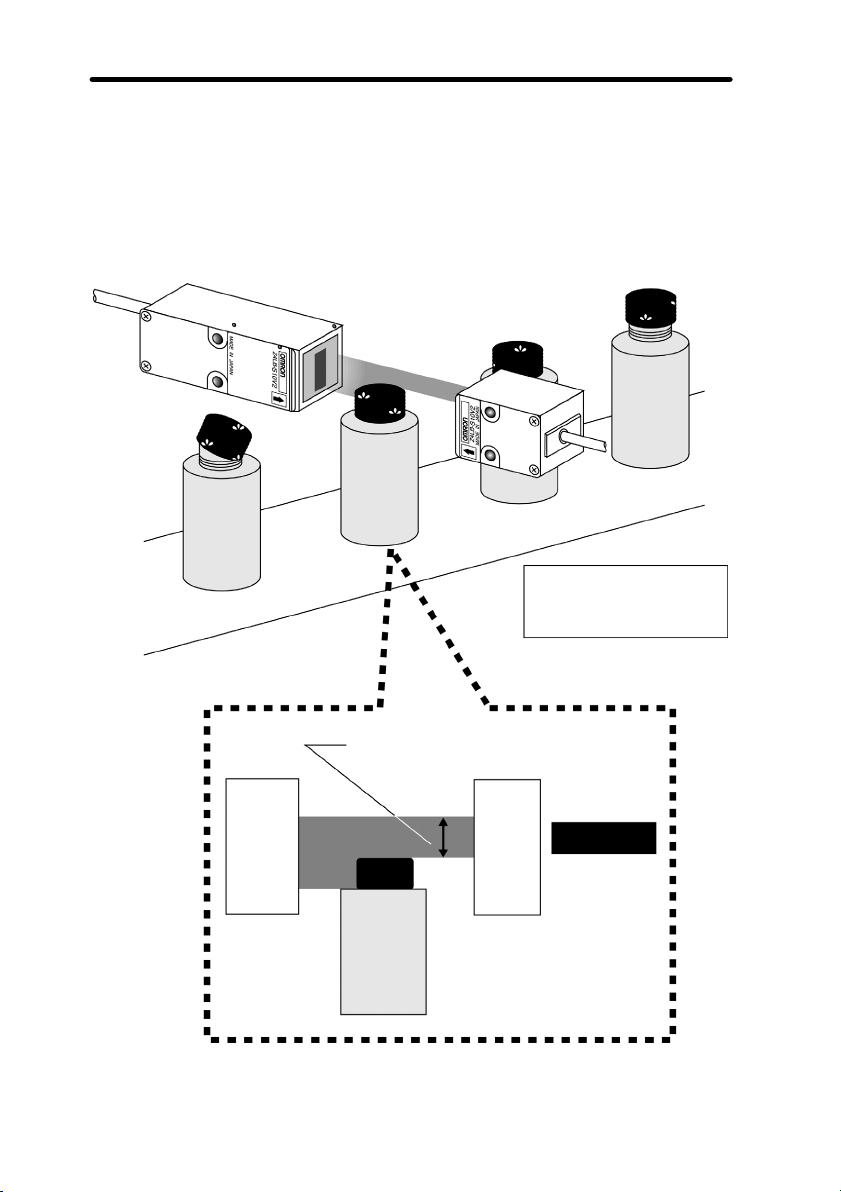

1-1 Inspection for Loose Bottle Caps

In this application, the height of the cap of each bottle is inspected to see if the caps are loose.

Example

Sensor: Z4LB-S10V2

Amplifier: Z4LB-CV2

1-1SectionInspection for Loose Bottle Caps

The amount of light incident on the receiver is detected.

Emitter

Good

product

Receiver

2

Operation Flow

Item Applicable Sensors

1-1-1 Wiring and Connections Standard and One-side

1-1-2 Axis and Gain Adjustments Standard

1-1-3 Setting Measurement Unit Standard

1-1-4 Setting Thresholds Standard and One-side

1-1-5 Detection Standard and One-side

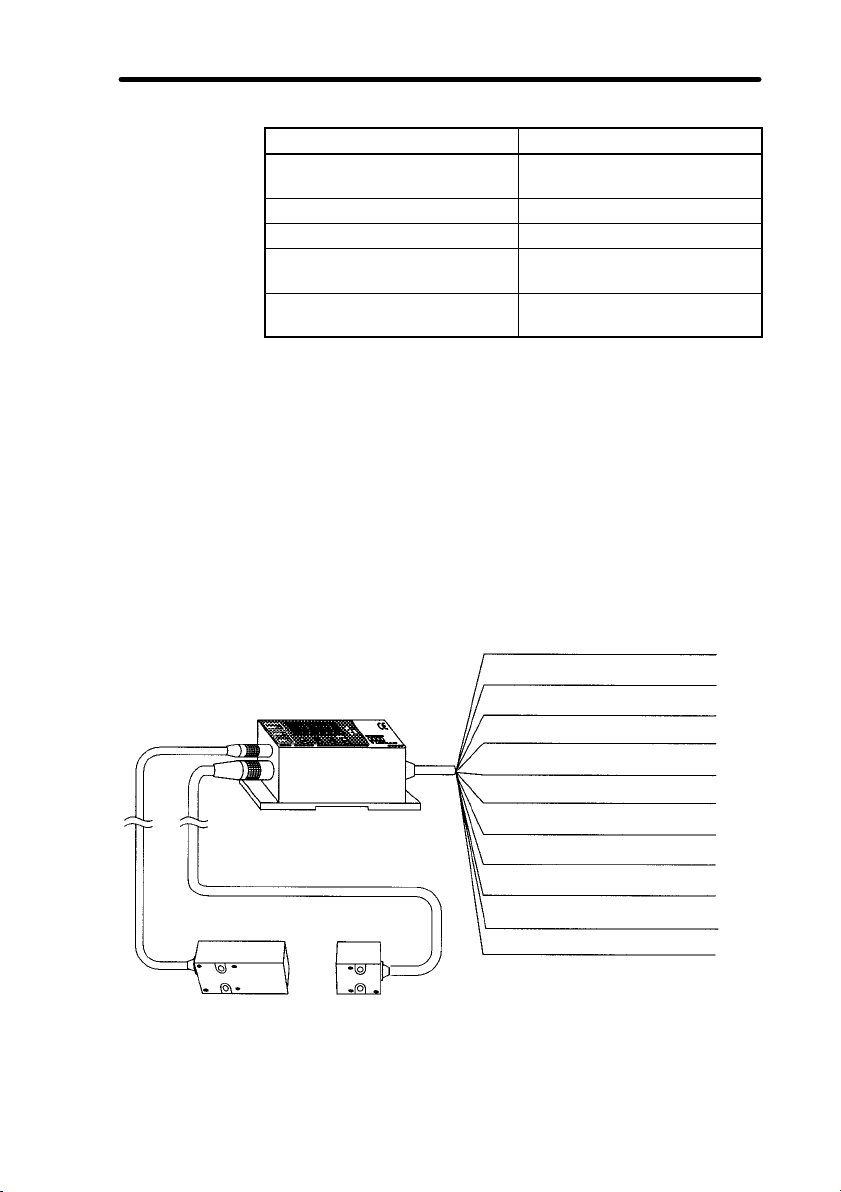

1-1-1 Wiring and Connections

The following information is the same for both Standard and

One-side Interruption High-precision Sensors.

1 Wire and connect the sensor components as shown below.

V/mm → Refer to 2-2 Wiring (p. 14) and 2-3 Connections (p. 18).

1-1SectionInspection for Loose Bottle Caps

Interruption High-precision

Interruption High-precision

Interruption High-precision

Amplifier

Emitter Receiver

2 Turn ON the power.

Brown (12 to 24 VDC)

Blue (0 V)

White (HIGH/PASS output)

Gray (LOW/NG output)

Black (1- to 5-V linear output)

Shield (Linear GND)

Green (Bank selection input)

Purple (Timing input)

Red (Hold reset input)

Orange/Purple (Forced-zero input)

Pink (LD OFF input)

3

1-1-2 Axis and Gain Adjustments

The following information is for Standard Sensors only.

Adjust the laser axis and gain according to the sensing distance.

1 Set the selectors on the Amplifier as shown below.

2 Closely attach the emitter and the receiver with the name-

plates of both the emitter and the receiver facing the same

direction.

1-1SectionInspection for Loose Bottle Caps

3 Use the provided screwdriver and turn the gain adjuster so

that the display on the Amplifier reads 5.000 ± 0.1 V.

Turn clockwise

or counterclockwise

4 Mount the emitter and the receiver in the desired positions.

Secure the receiver and tentatively secure the emitter.

5 Change the angle of the emitter upwards, downwards, left,

and right with no sensing object and secure the position of

the emitter at the angle where the maximum value is displayed.

6 Turn the gain adjuster so that the display reads

5.000 ± 0.005 V.

4

1-1-3 Setting Measurement Unit

The following information is for Standard Sensors only.

The measurement unit can be set to linear output voltage (V) or

length (mm). In the following example, the unit is set to mm.

Display

Set the measurement unit selector to mm. The Sensor is now

ready to display in millimeters.

Checking Measurement Width

Display

1-1SectionInspection for Loose Bottle Caps

1 Press the TEACH and SET Keys simultaneously for 3 s.

The present measurement width will be displayed.

2 Press the SET Key.

The Sensor will return to RUN mode.

Note If the displayed width is different from the measured width,

change the measurement width of the Amplifier. Otherwise the

linear output voltage will not be converted into length correctly.

→ Refer to Z4LB-S30V2 under 3-1 Selecting the Measure-

ment Unit (p. 24).

5

1-1-4 Setting Thresholds

The following information is the same for both Standard and

One-side Interruption High-precision Sensors.

Set the thresholds for good/improper product discrimination.

There are three methods to set the thresholds. The following description provides information on setting the thresholds by teaching based on a reference workpiece.

→ Refer to 3-2 Setting Thresholds (p. 26).

Example

No cap

Measured value

(Incident light)

1-1SectionInspection for Loose Bottle Caps

Discrimination

indicators

HIGH threshold

LOW threshold

Emitter

Emitter

Emitter

Improper

product

Normal

Good

product

Cap rise

Improper

product

Receiver

Receiver

Receiver

Lit

Not lit

6

1-1SectionInspection for Loose Bottle Caps

HIGH indicator

LOW indicator

HIGH Threshold Setting

1 Set the operating mode selector to H.

The HIGH indicator will start flashing and the present HIGH

threshold will be displayed.

2 Set the workpiece and press the TEACH Key.

Teaching will be performed. The teaching value plus an

approximate value of 0.7% F.S. (see note) will be displayed

as the HIGH threshold.

Note “F.S.” stands for full scale. In the case of the Z4LB-S10V2, for ex-

ample, the F.S. value is 10 mm.

Teaching value of reference workpiece

Display

HIGH threshold

Fine Adjustment of Values

The thresholds that are taught are reference values that can

be changed to desired values. Go to step 3 to change the

thresholds, otherwise go to step 5.

3 Press the Right Key to move the cursor to the digit to be

changed.

The selected

digit flashes.

4 Press the Up Key and change the value.

05.000 06.000 07.000

05.000 05.000

7

5 Press the SET Key.

The set value will be entered and the value will flash twice.

LOW Threshold Setting

6 Set the operating mode selector to L.

The LOW indicator will start flashing and the present LOW

threshold will be displayed.

7 Take steps similar to 2 and 5 to set the LOW threshold.

The LOW threshold obtained from the teaching value minus

an approximate value of 0.7% F.S. will be displayed.

Teaching value of reference workpiece

1-1-5 Detection

The following information is the same for both Standard and

One-side Interruption High-precision Sensors.

1-1SectionInspection for Loose Bottle Caps

LOW threshold

Set the operating mode selector to RUN.

The Sensor will start taking measurements and the indicator will

turn ON at the preset threshold value.

8

SECTION 2

Preparations

This section provides information on preparations that must be made before turning ON the

Sensor, such as wiring, connecting, and installing Sensors and Amplifiers.

2-1 Nomenclature 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-1-1 Standard Sensors (Separate Type) 10. . . . . . . . . . . . .

2-1-2 One-side Interruption High-precision Sensors

2-2 Wiring 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-1 I/O Signals 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-2-2 I/O Stage Circuit Diagrams 16. . . . . . . . . . . . . . . . . .

2-3 Connections 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-4 Axis and Gain Adjustments 18. . . . . . . . . . . . . . . . . . . . .

2-5 Sensor Installation 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-1 Sensors 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-5-2 Amplifiers 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(Integrated Type) 12. . . . . . . . . . . . . . . . . . . . . . . . . .

9

2-1 Nomenclature

2-1-1 Standard Sensors (Separate Type)

Z4LB-S10V2 (Sensor)

2-1SectionNomenclature

Emitter

Z4LB-S30V2 (Sensor)

Emitter

Receiver

Receiver

10

NPN: Z4LB-CV2 (Amplifier)

PNP: Z4LB-CPV2 (Amplifier)

2-1SectionNomenclature

Operating

mode selector

LD ON indicator

(Laser emission

warning)

Discrimination

indicators

Measurement unit selector (p. 24)

Light/dark mode selector (p. 47)

Response time selector (p. 48)

Display

Operation keys

OFF delay selector (p. 48)

Forced-zero

indicator

(p. 31)

Gain adjuster

(p. 18)

11

2-1-2 One-side Interruption High-precision Sensors

(Integrated Type)

NPN: Z4LB-A1040V2 (Sensor)

PNP: Z4LB-A1040PV2 (Sensor)

Emitter Receiver

2-1SectionNomenclature

12

NPN: Z4LB-A3040V2 (Sensor)

PNP: Z4LB-A3040PV2 (Sensor)

Emitter

Receiver

NPN: Z4LB-Ajj40V2 (Amplifier)

PNP: Z4LB-Ajj40PV2 (Amplifier)

2-1SectionNomenclature

LD ON indicator

(Laser emission

warning)

Discrimination

indicators

Measurement unit selector (p. 24)

Light/dark mode selector (p. 47)

Response time selector (p. 48)

Display

Operation keys

OFF delay selector (p. 48)

Forced-zero

indicator

(p. 31)

Operating

mode selector

13

2-2 Wiring

2-2-1 I/O Signals

2-2SectionWiring

Brown

Blue

White

Gray

Black

Shield

Green

Purple

Red

Orange/Purple

Pink

(1) 12 to 24 VDC

(2) 0 V

(3) HIGH/PASS output

(4) LOW/NG output

(5) Linear output (1 to 5 V)

(6) Linear GND

(7) Bank selection input

(8) Timing input

(9) Hold reset input

(10) Forced-zero input

(11) LD OFF input

(1)12 to 24 VDC

Power terminal. Connect to 12 to 24 VDC power supply.

(2)0 V

0 V power terminal. Also, common terminals for forced zero

input, timing input, and LD OFF input.

(3)HIGH Output

Turns ON when the measured value is less than or equal to

the HIGH threshold. (Depends on the discrimination output

methods.)

PASS Output

Turns ON when the measured value is above the LOW

threshold and below the HIGH threshold. (Depends on the

discrimination output methods.)

(4)LOW Output

Turns ON when the measured value is equal to or greater

than the LOW threshold. (Depends on the discrimination

output methods.)

NG Output

Turns ON when the measured value is equal to or less than

the LOW threshold or equal to or greater than the HIGH

threshold. (Depends on the discrimination output methods.)

(5)Linear Output (1 to 5 V)

Outputs 1 to 5 VDC in proportion to light received or interrupted. (Selectable with light/dark mode switch)

(6)Linear GND

Connect to input device as linear output GND.

14

(7)Bank Selection Input

Selects the thresholds to use for measurement.

Bank 1

NPN: Open or connect to 1.

PNP: Open or connect to 2.

Bank 2

NPN: Connect to 2.

PNP: Connect to 1.

(8)Timing Input

Forcibly turns HIGH/PASS output and LOW/NG output OFF

if timing input is turned ON during normal measurement operations. The sampling timing turns ON if the timing input is

turned ON during hold measurement operation. ON or OFF

input time is set to 0.25 ms or more.

(9)Hold Reset Input

Resets the value held in memory if turned ON during hold

measurement operation. ON or OFF input time is set to

0.25 ms or more.

(10)Forced-zero Input

Zero will be displayed for the measured value if forced-zero

input is turned ON when the length (mm) is displayed on the

display. The value will be set if forced-zero input is ON for

0.2 to 0.8 s and cleared if it is input for 1 s or more.

(11)LD OFF Input

Stops laser emission. “ldoff” will be displayed on the display. The linear output, HIGH/LOW indicator, and the discrimination outputs will maintain the current status.

Warm up for 5 min after releasing LD OFF. The response

time required to turn laser emission ON or OFF is 30 ms.

2-2SectionWiring

→ Refer to 4-2-2 Selecting the Discrimination Outputs (p. 39).

15

2-2-2 I/O Stage Circuit Diagrams

NPN Sensors

Standard Sensor: Z4LB-CV2

One-side Interruption High-precision Sensors: Z4LB-AjjV2

Brown

100 Ω

Black

1- to 5-V linear output

2-2SectionWiring

Internal circuits

Shield

White

Gray

Blue 0 V

Pink

Purple

Red

Orange/Purple

Green

Linear output GND

HIGH/PASS output

LOW/NG output

Load

Load

30 VDC

max.

LD OFF input

Timing input

Hold reset input

Forced-zero input

Bank selection input

12 to 24 VDC

16

PNP Sensors

2-2SectionWiring

Standard Sensor: Z4LB-CPV2

One-side Interruption High-precision Sensors: Z4LB-AjjPV2

Brown

100 Ω

Black

1- to 5-V linear output

Internal circuit

Shield

White

Gray

Blue 0 V

Pink

Purple

Red

Orange/Purple

Green

Linear output GND

HIGH/PASS output

LOW/NG output

Load

Load

LD OFF input

Timing input

Hold reset input

Forced-zero input

Bank selection input

12 to

24

VDC

17

2-3 Connections

Connect the connector cables from the emitter and the receiver

to the side of the Amplifier as below. The connection method is

the same for Standard and One-side Interruption High-precision

Sensors.

Amplifier

Emitter Receiver

2-4 Axis and Gain Adjustments

After installing the emitter and the receiver for a Standard Sensor, adjust the laser axis and gain according to the sensing distance. No axis or gain adjustment is required for One-side Interruption High-precision Sensors because proper axis and gain

adjustments are made before shipping.

Procedure

1 Set the selectors on the Amplifier as shown below.

2-3SectionConnections

18

2-5SectionSensor Installation

2 Closely attach the emitter and the receiver with the name-

plates of both the emitter and the receiver facing the same

direction.

3 Use the provided screwdriver and turn the gain adjuster so

that the display on the Amplifier reads 5.000 ± 0.1 V.

Turn clockwise

or counterclockwise

4 Mount the emitter and the receiver in the desired position.

Secure the receiver and tentatively secure the emitter.

5 Change the angle of the emitter upwards, downwards, left,

and right with no sensing object and secure the position of

the emitter at the angle where the maximum value is displayed.

6 Turn the gain adjuster so that the display reads

5.000 ± 0.005 V.

2-5 Sensor Installation

2-5-1 Sensors

Caution Do not touch the optical filter of a Sensor. If it is stained with finger

!

prints or other material, measurements may not be performed

correctly. If you touch the filter by mistake, clean it with a soft

cloth.

19

Z4LB-S10V2 Sensor

Screws (M3, Length: 25, provided)

2-5SectionSensor Installation

1 Screw the mounting brackets to the emitter and the receiver.

The same mounting bracket is used for both the emitter and

the receiver.

Nuts (M3, provided)

2 Secure the mounting brackets.

Screws (M3)

→ Refer to 7-2 Dimensions for mounting dimensions (p. 64).

Z4LB-S30V2 Sensor

Emitter Receiver

Screws

(M4, Length 25, provided)

20

1 Screw the mounting brackets to the emitter and the receiver.

The same mounting bracket is used for the emitter and the

receiver, but the screw holes are different.

Screws

(M4, Length 25, provided)

2 Secure the mounting brackets.

Screws (M4)

→ Refer to 7-2 Dimensions for mounting dimensions (p. 64).

Z4LB-Ajj40V2/Z4LB-Ajj40PV2 Sensors

There are two mounting holes, one on the right and one on the

left. Screw the holes to install and secure the emitter and the receiver. When installed, the head of screws should not enter the

beam.

2-5SectionSensor Installation

Screws (M4)

→ Refer to 7-2 Dimensions for mounting dimensions (p. 64).

Note Do not disconnect the coupling bracket that connects the receiv-

er and the emitter, otherwise proper measurement will not be

possible.

2-5-2 Amplifiers

There are two mounting holes. Insert the screws into the holes to

install the Amplifier. The Amplifier can also be mounted to DIN

Track.

Screws (M4)

→ Refer to 7-2 Dimensions for mounting dimensions (p. 64).

21

SECTION 3

Basic Settings

This section provides information on basic settings, such as the threshold settings for good/

improper product discriminations.

3-1 Selecting the Measurement Unit 24. . . . . . . . . . . . . . . . .

3-2 Setting Thresholds 26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-2-1 Direct Setting Thresholds 27. . . . . . . . . . . . . . . . . . . .

3-2-2 Teaching Thresholds 29. . . . . . . . . . . . . . . . . . . . . . .

3-2-3 Forced-zero Setting 31. . . . . . . . . . . . . . . . . . . . . . . .

23

3-1 Selecting the Measurement Unit

The measurement unit can be set to linear output voltage (V) or

length (mm). In the following example, the unit is set to mm.

Display

Set the measurement unit selector to mm.

The Sensor will display in millimeters.

Z4LB-S30V2 Sensor

The default setting for the measurement width of the Z4LB-CV2

Amplifier and Z4LB-CPV2 Amplifier is 10 mm. The measurement width of the Z4LB-S30V2 is 30 mm. Therefore, if the Z4LBCV2 or Z4LB-CPV2 Amplifier is connected to the Z4LB-S30V2,

the Amplifier cannot convert a linear output voltage range between 1 and 5 V into length correctly unless the measurement

width of the Amplifier is changed to 30 mm. There is no need to

change the measurement width for a One-side Interruption Highprecision Sensor.

Note Before using the Z4LB-S10V2 Sensor, check that the measure-

ment width is set to 10 mm. Refer to steps 1, 2, and 4.

3-1SectionSelecting the Measurement Unit

24

Checking and Changing the Measurement Width

Display

1 Set the operating mode selector to RUN.

2 Press the TEACH and SET Keys simultaneously for 3 s.

The present measurement width will be displayed.

(The default setting is 10.)

3 Press the Up Key twice and change the value from 1 to 3.

3-1SectionSelecting the Measurement Unit

The value 1 flashes.

10

Press the Up Key.

20

Press the Up Key.

30

4 Press the SET Key.

The set value will be entered and the indicator will flash

twice.

25

3-2 Setting Thresholds

Set the thresholds for good/improper product discrimination.

3-2SectionSetting Thresholds

Example

HIGH threshold

LOW threshold

No cap

Emitter

Normal

Emitter

Cap rise

Emitter

Measured value

(Incident)

Receiver

Receiver

Receiver

Measured value > HIGH threshold:

Improper product

LOW threshold < Measured value <

HIGH threshold: Good product

Measured value < HIGH threshold:

Improper product

Note The discrimination outputs can be changed. Refer to 4-2-2 Se-

lecting the Discrimination Outputs for details (p. 39).

26

Example

There are three methods to set thresholds. Select the most convenient method according to the application.

1 Direct Settings: The thresholds are set directly.

2 Teaching Settings: The thresholds are set based on a refer-

ence workpiece.

Measured value: 4 V

The LOW threshold is set.

The HIGH threshold is set.

3 Forced-zero settings: A measured value based on a refer-

ence workpiece is set as zero. Add or subtract a tolerance

directly to and from the reference value (zero) to set the results as thresholds.

The LOW threshold is set.

The HIGH threshold is set.

Note Discrimination outputs use HIGH and LOW threshold hysteresis

values. Refer to 4-2-3 Hysteresis Setting for the relationship between discrimination output ON/OFF points and thresholds.

→ Refer to Discrimination Outputs Timing Charts (p. 40).

3-2-1 Direct Setting Thresholds

The following method is convenient if the threshold value for discriminating good/improper products is known because values

are input directly in this method.

3-2SectionSetting Thresholds

HIGH indicator

LOW indicator

HIGH Threshold Setting

1 Set the operating mode selector to H.

The display will show the present HIGH threshold and the

HIGH indicator will flash. If the bank selection is enabled, the

bank number will be displayed.

→ Refer to 4-2-5 Enabling the Bank Selection (p. 44).

Display

27

3-2SectionSetting Thresholds

2 Press the Right Key to move the cursor to the value to be

changed.

The cursor will shift to the right by one digit whenever the

Key is pressed.

The selected value flashes.

3 Press the Up Key to change the value.

The value will increase by 1 whenever the Key is pressed.

4 Press the SET Key.

The value will be entered and the indicator will flash twice.

LOW Threshold Setting

5 Set the operating mode selector to L.

The LOW indicator will flash and the display will show the

present LOW threshold.

6 Take steps similar to 2 and 4 to set the LOW threshold.

00.000

Press the Right Key.

00.000

Press the Right Key.

00.000

00.000

Press the Up Key.

00.100

Press the Up Key.

00.200

28

3-2-2 Teaching Thresholds

3-2SectionSetting Thresholds

HIGH indicator

LOW indicator

HIGH Threshold Setting

1 Set the operating mode selector to H.

The display will show the present HIGH threshold and the

HIGH indicator will flash. If the bank selection is enabled, the

bank number will be displayed.

→ Refer to 4-2-5 Enabling the Bank Selection (p. 44).

2 Set the workpiece and press the TEACH Key.

Teaching will be performed. The HIGH threshold obtained

from the teaching value plus an approximate value of 0.7%

F.S. will be displayed.

Teaching value of reference workpiece

Display

HIGH threshold

Fine Adjustment of Values

The thresholds after teaching are reference values that can

be changed to desired values. Go to step 3 to change the

thresholds, otherwise go to step 5.

29

3-2SectionSetting Thresholds

3 Press the Right Key to move the cursor to the value to be

changed.

The cursor will shift to the right by one digit whenever the

Key is pressed.

The selected value flashes.

4 Press the Up Key and change the value.

The value will increase by 1 whenever the Key is pressed.

02.746

02.846

02.946

5 Press the SET Key.

The value will be entered and the indicator will flash twice.

02.746

Press the Right Key.

02.746

Press the Right Key.

02.746

Press the Up Key.

Press the Up Key.

LOW Threshold Setting

6 Set the operating mode selector to L.

The LOW indicator will flash and the display will show the

present LOW threshold.

7 Take steps similar to 2 and 5 to set the LOW threshold.

The teaching value minus an approximate value of 0.7% FS

will be displayed as the LOW threshold.

Teaching value of reference workpiece

30

LOW threshold

3-2-3 Forced-zero Setting

To set the thresholds, a measured value based on a reference

workpiece is first set as zero. A tolerance is then added to and

subtracted from the reference value (zero) to set the results as

HIGH and LOW thresholds. Forced-zero settings are possible

only if the unit is set to mm.

The HIGH and LOW thresholds are kept on hold when the reference workpiece is changed, which enables easy changeovers.

Thresholds are displayed between –9.999 and F.S. (see note),

but the linear output voltage will not change.

Note 1 “F.S.” stands for full scale. In the case of the Z4LB-S10V2,

for example, the F.S. value is 10 mm.

2 Forced-zero Indicator

When the forced-zero settings are enabled, the forced-zero

indicator will turn ON.

Forced zero is set.

SET

3 s

3-2SectionSetting Thresholds

05.697 00.000.

HIGH indicator

LOW indicator

Display Unit Selection

1 Set the measurement unit selector to mm.

Reference Value Setting

2 Set the operating mode selector to RUN.

3 Set the workpiece and press the SET Key for 3 s.

The forced-zero indicator will turn ON, when the measured

value will be set as the reference value (0).

The forced-zero indicator will turn ON.

Forced-zero indicator

Display

31

• Clearing Forced-zero Settings

• Forced-zero settings are possible through the forced-zero

Note When forced-zero settings are enabled, HIGH or

HIGH Threshold Setting

4 Set the operating mode selector to H.

The HIGH indicator will flash and the display will show the

present HIGH threshold.

5 Press the Right Key to move the cursor to the value to be

changed.

The cursor will shift to the right by one digit whenever the

Key is pressed.

3-2SectionSetting Thresholds

To clear the forced-zero settings, press the SET value for

3 s.

input terminal. The value is set if forced-zero input is ON

for 0.2 to 0.8 s and cleared if it is input for 1 s or more.

LOW threshold cannot be set by teaching. Add or

subtract a tolerance directly to and from the reference value (zero) to set the results as thresholds.

32

The selected value flashes.

00.000

Press the Right Key.

00.000

Press the Right Key.

00.000

6 Press the Up Key and set the tolerance to be added to the

reference value.

The value will increase by 1 whenever the Key is pressed.

00.000

Press the Up Key.

00.100

Press the Up Key.

00.200

7 Press the SET Key.

The value will be entered and the indicator will flash twice.

LOW Threshold Setting

8 Set the operating mode selector to L.

The LOW indicator will flash and the display will show the

present LOW threshold.

9 Take steps similar to steps 5 and 7 to set the LOW threshold.

Displaying Negative Values

80.500

Press the Up Key.

90.500

Press the Up Key.

Ć0.050

Bank Selection

If the bank selection is enabled, the screen to select the bank

number appears after the operating mode selector is set to H or

L. Set the thresholds after setting the bank number.

3-2SectionSetting Thresholds

Locate the cursor to the leftmost digit

and press the Up Key until the value

changes to 9.

Press the Up Key once again. The

negative symbol will appear.

Procedure

→ Refer to 4-2-5 Enabling the Bank Selection (p. 44).

1 Set the operating mode selector to H or L.

The bank number will be displayed and the HIGH or LOW

indicator will flash.

2 Press the Up Key and select the bank number where the

threshold will be set.

bank1 bank2

Bank 1 Bank 2

3 Press the SET Key.

The bank number will be entered and the display will show

the present threshold.

4 Set the HIGH or LOW thresholds.

33

SECTION 4

Optional Settings

This section provides information on the optional functions that can be set in addition to the

basic settings.

4-1 Optional Functions 36. . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2 Key Settings 38. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-2-1 Setting the Measurement Width (scale)38. . . . . . . .

4-2-2 Selecting the Discrimination Outputs (oUt)39. . . . . .

4-2-3 Hysteresis Setting (hys)40. . . . . . . . . . . . . . . . . . . . .

4-2-4 Display/Output Value Hold (hold)42. . . . . . . . . . . .

4-2-5 Enabling the Bank Selection (bank)44. . . . . . . . . . .

4-2-6 Enabling Backup (baUp)45. . . . . . . . . . . . . . . . . . . .

4-2-7 Initialization (reset)46. . . . . . . . . . . . . . . . . . . . . . .

4-3 Selector Settings 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-1 Light/Dark Mode 47. . . . . . . . . . . . . . . . . . . . . . . . . .

4-3-2 Response Time Selection 48. . . . . . . . . . . . . . . . . . . .

4-3-3 OFF Delay 48. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

35

4-1 Optional Functions

y

The optional settings are made with the selectors or operation

keys on the Amplifier.

Setting method Function Display Page

Key

Selectors

Measurement width

Discrimination outputs

Hysteresis setting

Hold

Bank selection

Backup

Initialization

Light/dark mode selection --- 47

Response time selection --- 48

OFF delay --- 48

Measurement unit selection --- 24

scale

oUt

hys

hold

bank

baUp

reset

38

39

40

42

44

45

46

4-1SectionOptional Functions

36

Function Settings with Keys

Press TEACH+SET Keys for 3 s.

Press TEACH Key for 3 s.

scale

Measurement width

4-1SectionOptional Functions

10

Run

mode

out

Discrimination outputs

hĆl1

pass

hĆl2

hys

Hysteresis setting Display unit: V Display unit: mm

hold

Hold

0.020 00.050

norml

pĆh

bĆh

sĆh

ppĆh

bank

Bank selection

spĆh

sbĆh

off

on

1.000

Display unit: V Display unit: mm

1.000

Display unit: V Display unit: mm

00.000

00.000

banp

Backup

reset

Initialization

on

off

All set value initialized

* Shaded settings are the default settings.

37

4-2 Key Settings

4-2-1 Setting the Measurement Width (scale)

The following settings are required only if the Z4LB-S30V2 Sensor is to be used with the measurement unit set to mm.

The following steps make it possible to change the measurement width. For details, refer to 3-1 Selecting the Measurement

Unit.

→ Refer to Z4LB-S30V2 Sensor under 3-1 Selecting the Mea-

surement Unit (p. 24).

Procedure

There are two procedures that can be used to set thresholds. Select the easier method according to the application. The following

example shows how to set the measurement width in function

selection mode.

1 Set the operating mode selector to RUN.

2 Press the TEACH Key for 3 s.

The Sensor will enter function selection mode.

3 Press the Up Key to go to measurement width setting.

scale

Measurement width

4-2SectionKey Settings

The figure 1 flashes.

38

4 Press the SET Key.

5 Press the UP Key twice to change 1 to 3.

10 20 30

6 Press the SET Key.

The set value will be entered and the display will flash twice.

7 Press the TEACH Key to return to RUN mode.

4-2-2 Selecting the Discrimination Outputs (oUt)

There are three methods to discriminate and output measurement data. Select the best method for the application.

1 HIGH/LOW Output Mode (hĆl1)

Measured value x HIGH threshold: HIGH output ON

Measured value y LOW threshold: LOW output ON

2 PASS/NG Output Mode (pass)

LOW threshold < Measured value < HIGH threshold:

PASS output ON

Measured value x LOW threshold or

Measured value y HIGH threshold:

NG output ON

3 HIGH/LOW Inverted Output Mode (hĆl2)

Measured value y HIGH threshold: HIGH output ON

Measured value x LOW threshold: LOW output ON

HIGH threshold

4-2SectionKey Settings

HIGH/LOW

output mode

PASS/NG

output mode

HIGH/LOW

inverted output mode

Procedure

LOW threshold

Discrimination output

Indicator

Discrimination output

Indicator

Discrimination output

Indicator

1 Set the operating mode selector to RUN.

2 Press the TEACH Key for 3 s.

The Sensor will enter function selection mode.

Measured value

ON

OFF

39

3 Press the Up Key to go to the discrimination outputs.

scale oUt

Measurement width Discrimination outputs

4 Press the SET Key.

The discrimination outputs can now be selected.

5 Press the Up Key and select the discrimination outputs.

hĆl1 pass hĆl2

HIGH/LOW output PASS/NG output HIGH/LOW

inverted output

6 Press the SET Key

The discrimination outputs will be entered and the Sensor

will return to function selection mode.

7 Press the TEACH Key to return to RUN mode.

4-2SectionKey Settings

4-2-3 Hysteresis Setting (hys)

The hysteresis can be set to provide a margin in making discrimination outputs.

Discrimination Outputs Timing Charts

HIGH/LOW Output Mode

HIGH threshold

Measured value

LOW threshold

HIGH output

LOW output

40

ON

OFF

ON

OFF

Hysteresis

PASS/NG Output Mode

HIGH threshold

Measured value

LOW threshold

4-2SectionKey Settings

Hysteresis

Procedure

PASS output

NG output

ON

OFF

ON

OFF

HIGH/LOW Inverted OUTPUT Mode

Hysteresis

HIGH threshold

Measured value

LOW threshold

HIGH output

LOW output

ON

OFF

ON

OFF

1 Set the operating mode selector to RUN.

2 Press the TEACH Key for 3 s.

The Sensor will enter function selection mode.

3 Press the Up Key to go to the hysteresis setting.

scale oUt hys

Measurement

width

4 Press the SET Key.

The hysteresis can now be set.

5 Press the Right Key to move the cursor the digit to be

changed and press the Up Key to set the hysteresis.

Discrimination

outputs

Hysteresis

setting

41

4-2SectionKey Settings

Default setting: The hysteresis is set to 0.020 when the

measurement unit is V, to 00.050 when the measurement

unit is mm and the measurement width is 10 mm, and to

00.150 when the measurement unit is mm and the measurement width is 30 mm.

Setting Range

Measurement width of the Sensor

10 mm 30 mm

V 0.002 to 0.800

mm 0.005 to 2.000 0.015 to 6.000

The selected digit flashes.

Measured value

display unit

00.050 00.050 00.060

Select the digit. Set the value.

6 Press the SET Key.

The set value will be entered and the Sensor will return to

function selection mode.

7 Press the TEACH Key to return to RUN mode.

4-2-4 Display/Output Value Hold (hold)

There are six methods to hold the display and output values. Select the best method for the application.

Display Name Description Page

Normal The result of measurement is always

norml

Peak hold The maximum value while the timing input is

pĆh

Bottom hold The minimum value while the timing input is

bĆh

Sample hold The current value when the timing input turns

sĆh

Peak-to-peak

ppĆh

hold

Self-peak hold The maximum value while the measured

spĆh

Self-bottom hold The minimum value while the measured

sbĆh

displayed and output. The hold does not

work.

ON is displayed, output, and held.

ON is displayed, output, and held.

ON is displayed, output, and held.

The difference between the maximum and

minimum values while timing input is ON is

displayed, output, and held.

value is equal to or greater than the trigger

level is displayed, output, and held.

value is equal to or less than the trigger level

is displayed, output, and held.

50

51

52

53

54

55

56

42

Procedure

1 Set the operating mode selector to RUN.

2 Press the TEACH Key for 3 s.

The Sensor will enter function selection mode.

3 Set the Up Key to go to the hold.

scale oUt hys hold

Measurement

width

Discrimination

outputs

Hysteresis

setting

4 Press the SET Key

The hold can now be selected.

5 Press the Up Key and select the hold.

norml pĆh bĆh sĆh

Normal Peak hold Bottom hold Sample hold

sbĆh spĆh ppĆh

Self-bottom hold Self-peak hold Peak-to-peak hold

4-2SectionKey Settings

Hold

If the self-peak hold or self-bottom hold was selected, go to

step 6 and set the trigger level, otherwise go to step 8.

6 Press the SET Key.

The selected hold will be set.

7 Press the Right Key to move the cursor the digit to be

changed and press the Up Key to set the trigger level.

Default setting: The trigger level is set to 01.000 when the

measurement unit is V and 00.000 when the measurement

unit is mm.

The selected digit flashes.

8 Press the SET Key.

The trigger level will be entered and the Sensor will return to

function selection mode.

9 Press the TEACH Key to return to RUN mode.

00.000 00.000 03.000

Select the digit. Set the value.

43

4-2-5 Enabling the Bank Selection (bank)

The Z4LB V2 has two banks in which thresholds can be set independently. Having different sets of threshold values enables easier changeovers.

If the bank selection is enabled, select the bank when setting the

thresholds. Refer to 3-2 Setting Thresholds for details.

→ Refer to Bank Selection (p. 33).

Procedure

1 Set the operating mode selector to RUN.

2 Set the TEACH Key for 3 s.

The Sensor will enter function selection mode.

3 Press the Up Key to go to bank selection.

scale oUt hys hold

Measurement

width

Discrimination

outputs

Hysteresis

setting

Bank selection

4-2SectionKey Settings

Hold

bank

Bank Selection

44

4 Press the SET Key.

The bank selection can now be set.

5 Press the Up Key to enable or disable the bank selection.

off on

Disabled Enabled

6 Press the SET Key

The bank selection setting will be entered and the Sensor

will return to function selection mode.

7 Press the TEACH Key to return to RUN mode.

The bank can be selected externally using the bank selection

(green).

Bank NPN Sensors PNP Sensors

Bank 1 Open or connect to 12 to 24 VDC. Open or connect to 0 V.

Bank 2 Connect to 0 V. Connect to 12 to 24 VDC.

4-2-6 Enabling Backup (baUp)

Determine whether the forced-zero value is to be backed up or

not, i.e., to hold the value after the Sensor is turned OFF. If the

backup is not enabled, the value will be lost when the Sensor is

turned OFF.

Note If the backup is enabled, the forced-zero value will be written to

the internal EEPROM, which is a nonvolatile. The EEPROM has