Cat. No. Z161-E1-03B Z300 V3 High

Cat. No. Z161-E1-03B

-precision Visual Displacement Measurement System

Z300 V3

High-precision Visual Displacement

Measurement System

Manual 1: SETUP MANUAL

Manual 1:

SETUP MANUAL

Cat. No. Z161-E1-03B

Authorized Distributor:

Note: Specifications subject to change without notice. Printed in Japan

1104-0.5M (M)

Z300 V3

High-precision Visual Displacement Measurement System

Manual 1: Setup Manual

Revised November 2004

1

2

TABLE OF CONTENTS

PRECAUTIONS ................................................................................... 7

READ AND UNDERSTAND THIS DOCUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

LIMITATIONS OF LIABILITY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SUITABILITY FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CHANGE IN SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

DIMENSIONS AND WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ERRORS AND OMISSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

PROGRAMMABLE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

COPYRIGHT AND COPY PERMISSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Meanings of Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Meanings of Alert Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Regulations and standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Precautions for Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Confirming Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Product Availability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Visual Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

SECTION 1

Features ............................................................................................... 21

1-1 Monitoring While Viewing the Measurement Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

1-2 Simple Setup Using Menus! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-3 A Wide Variety of Useful Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

SECTION 2

Wiring and Connection ...................................................................... 25

2-1 Component Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

2-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

2-3 Connecting Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

2-4 Power Supply and Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

2-5 Terminal Block Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-6 RS-232C Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

2-7 Linear Sensor Controller Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

SECTION 3

Installation .......................................................................................... 47

3-1 Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

3-2 Mounting the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

SECTION 4

Non-visual Mode................................................................................. 63

4-1 Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

4-2 DIP Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

SECTION 5

Maintenance........................................................................................ 71

3

SECTION 6

Troubleshooting ..................................................................................73

SECTION 7

Appendix..............................................................................................77

7-1 Specifications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

7-2 Laser Product Classifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

Index.....................................................................................................95

Revision History ..................................................................................96

4

About this Manual:

This manual describes the hardware for the Z300 (High-precision Visual Displacement Measurement System) and how to install the components, and it includes the sections described below.

This is one of two manuals used to operate the Z300. Refer to the following table for the contents of

each manual.

Manual Contents Cat. No.

1: Setup Manual Provides information on system hardware and instal-

lation. Be sure to read this manual first.

2: Operation Manual Describes operation of the Z300.

Please read the above manuals carefully and be sure you understand the information provided

before attempting to install or operate the Z300.

Section 1 Features introduces the features of the Z300.

Section 2 Wiring and Connection describes procedures for wiring power supplies and ground

wires and for connecting to external devices.

Section 3 Installation provides installation methods for the Controller and Sensor.

Section 4 Non-visual Mode explains how to make settings for Z300 operation using the DIP

switch instead of the menus.

Section 5 Maintenance explains maintenance procedures for ensuring the Z300's performance.

Section 6 Troubleshooting provides information on hardware errors that may occur with the

Z300. Refer to this section before requesting service from your OMRON representative.

Section 7 Specifications and Dimensions provides the specifications and dimensions of the

Z300 and its peripheral devices.

Z161

Z162

WARNING Failure to read and understand the information provided in this manual may

result in personal injury or death, damage to the product, or product failure.

Please read each section in its entirety and be sure you understand the information provided in the section and related sections before attempting any of the procedures or operations given.

5

6

PRECAUTIONS

This section provides general precautions for using the Z300 V3 Sensor.

The information contained in this section is important for the safe and reliable application of the Z300 V3

Sensor. You must read this section and understand the information contained before attempting to set up

or operate a Z300 V3 Sensor.

READ AND UNDERSTAND THIS DOCUMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

LIMITATIONS OF LIABILITY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

SUITABILITY FOR USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

PERFORMANCE DATA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

CHANGE IN SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

DIMENSIONS AND WEIGHTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

ERRORS AND OMISSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

PROGRAMMABLE PRODUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

COPYRIGHT AND COPY PERMISSION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Meanings of Signal Words. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Meanings of Alert Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Laser Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Regulations and standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Precautions for Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Confirming Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Product Availability. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Visual Aids. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Notation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

7

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship

for a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE

HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF

THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR

IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE,

OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on

which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER

CLAIMS REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE

PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT

SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR

REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please

refer to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents

identifying ratings and limitations of use that apply to the products. This information by itself is not

sufficient for a complete determination of the suitability of the products in combination with the end

product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is

not intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that

the uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions

or uses not described in this document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND

INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability

and does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the

users must correlate it to actual application requirements. Actual performance is subject to the

OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and

other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or

establish key specifications for your application on your request. Please consult with your OMRON

representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however,

no responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

PRECAUTIONS

Meanings of Signal Words

The following signal words are used in this manual.

WARNING

Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally there may be

significant property damage.

Meanings of Alert Symbols

The following alert symbols are used in this document.

Cautions to indicate potential laser beam hazard

10

PRECAUTIONS

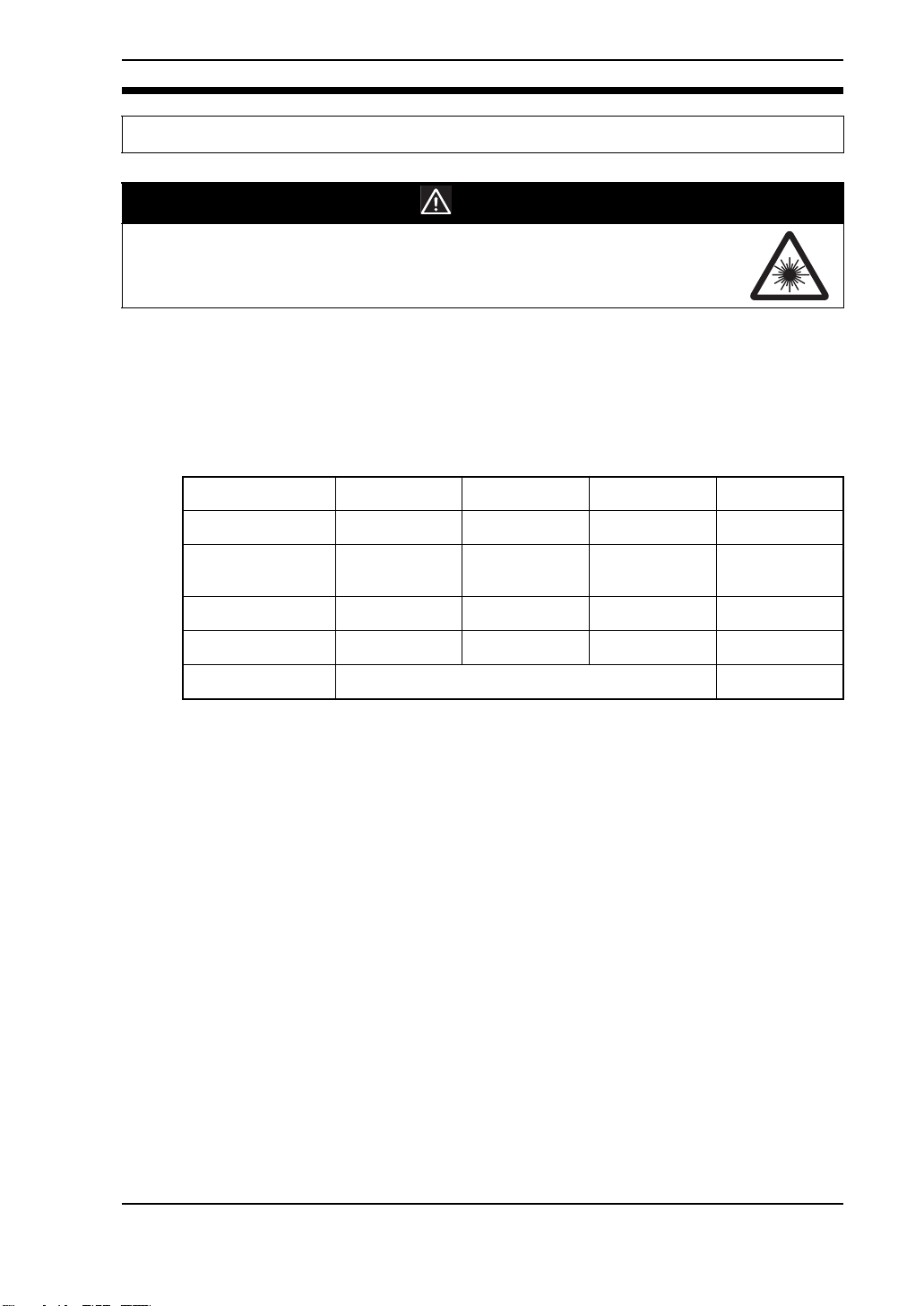

Laser Safety

b WARNING

The laser radiation has a high power density and exposure may result in loss of sight.

Do not to expose your eyes to the laser radiation either directly or indirectly (i.e., after

reflection from a mirror or shiny surface).

Sensor Head is a Class 3B Laser Product according to EN60825-1 (IEC60825-1) and Class II Laser

Product according to FDA (21 CFR1040.10) (see note). The Z510 Series is meant to be built into final

system equipment. Pay special attention to the following precautions for the safe use of the product:

Note:Europe: Class 2 and Class 3B of EN60825-1: 1994 = IEC60825-1: 1993

U.S.A.: Class II and Class IIIB of FDA (21 CFR1040.10).

Z300-S2T Z300-S5T Z300-S10 Z300-S60

Wave length 650 nm 670 nm 670 nm 658 nm

Maximum pulse

duration

Cycle 0.5 to 10 ms 0.5 to 10 ms 0.5 to 10 ms 0.5 to 25 ms

Peak power 1 mW max. 1 mW max. 1 mW max. 15 mW max.

Class 23B

(1)Use this product as specified in the operation manual. Otherwise, you may be exposed to

hazardous laser radiation.

(2)The Z300 series radiates laser beams in the visible light range. Do not expose your eyes directly to

the laser radiation. Ensure that the laser beam path is terminated during use. If a mirror or shiny

surface is positioned in the laser beam path, ensure that the reflected beam path is also terminated.

If the Unit must be used without terminating the laser beam path, position the laser beam path so

that it is not at eye level.

(3)To avoid exposure to hazardous laser radiation, do not displace nor remove the protective housing

during operation, maintenance, and any other servicing.

(4)The user should return the product to OMRON for all repair and servicing.

(5)As for countries other than those of Europe and the U.S.A., observe the regulations and standards

specified by each country.

7 ms 7 ms 7 ms 17.5 ms

As for the Laser Product Classifications, refer to the Appendix.

Refer to page 77.

11

PRECAUTIONS

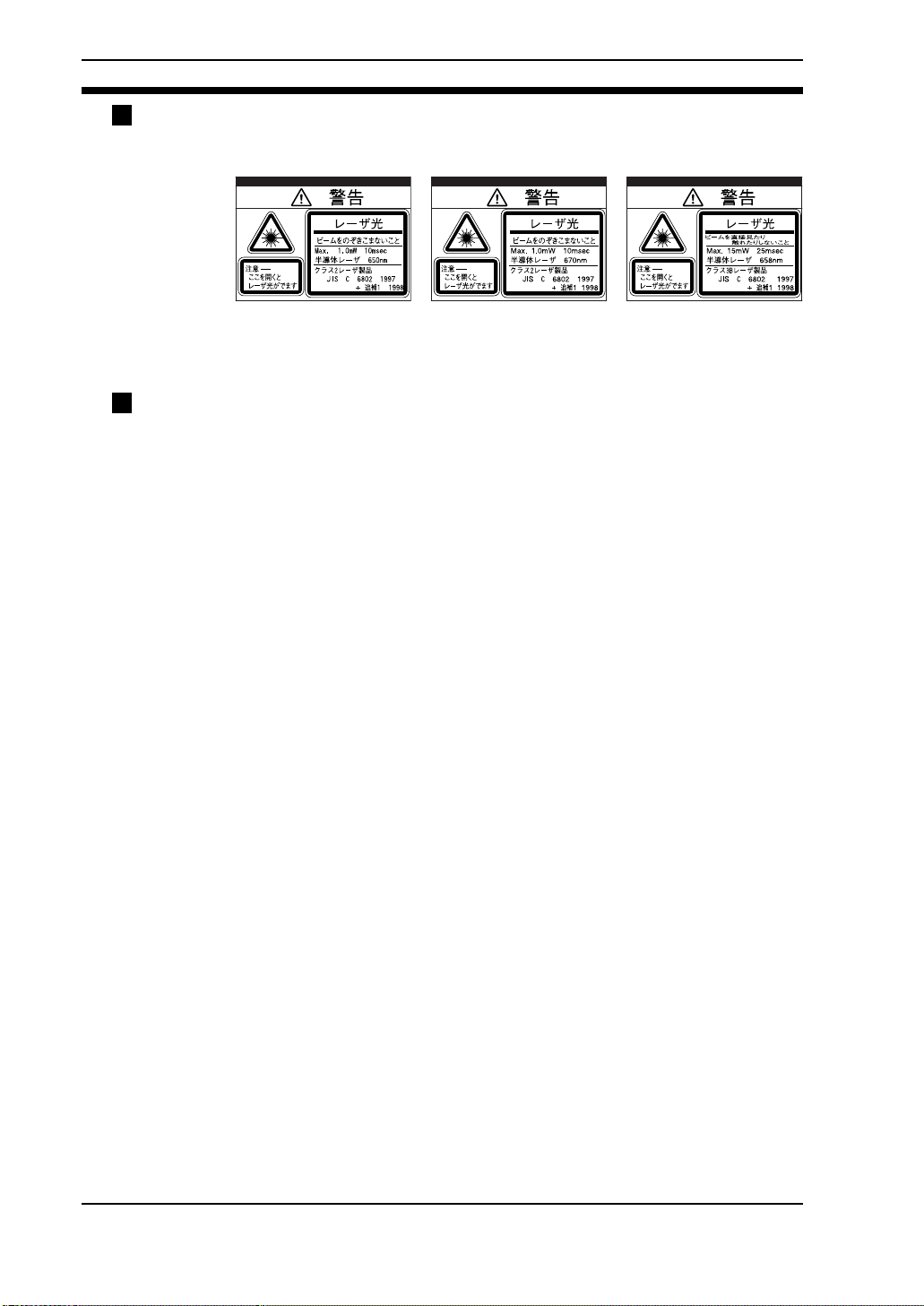

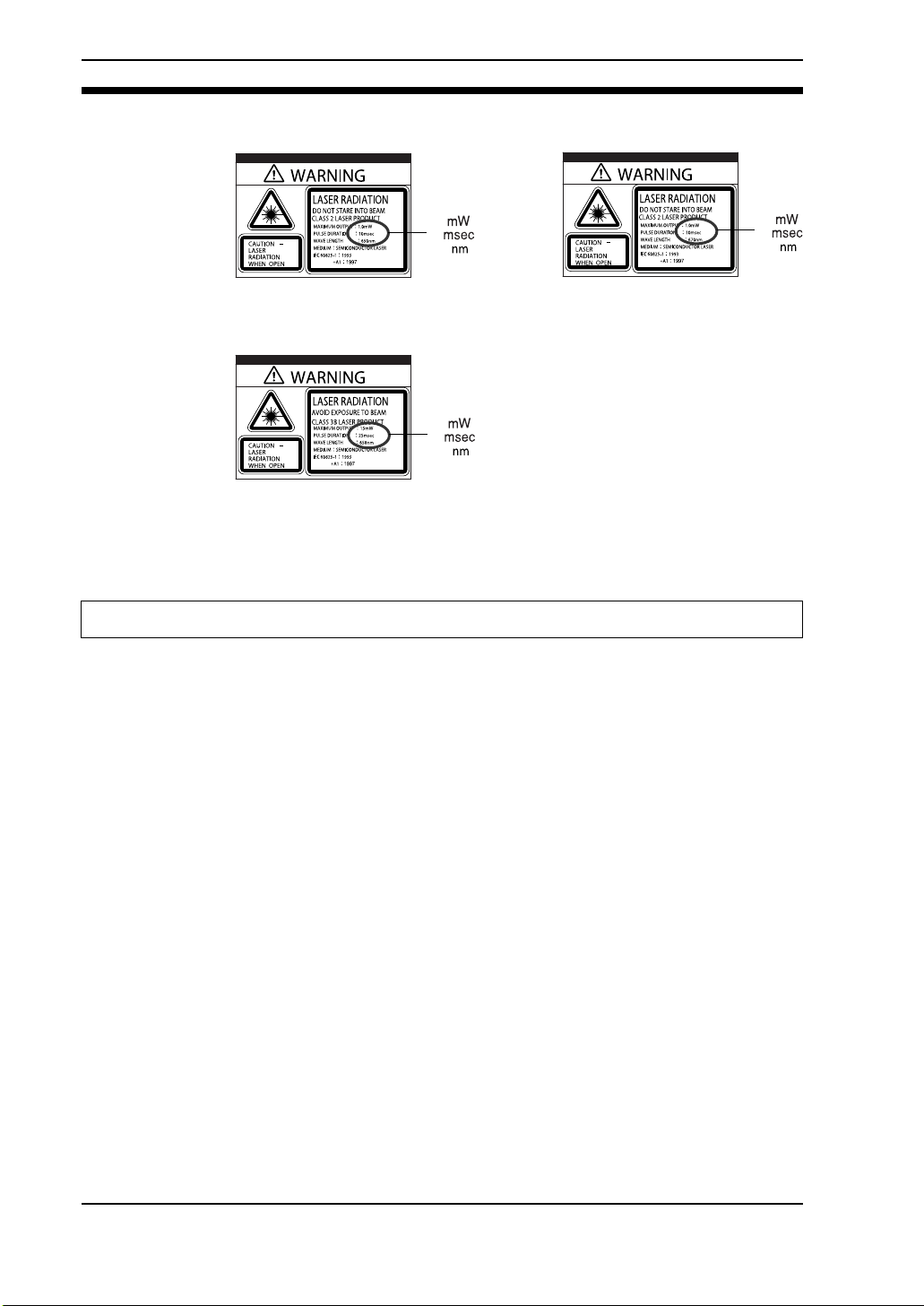

Labeling on Laser Use

The Sensor has the following WARNING label on the side.

Z300-S2T

Z300-S5T

Z300-S60

Z300-S10

Re-labeling

The following labels are provided, to be used selectively according to countries.

for use in the U.S.: FDA label (Aperture label, Caution logo label, Certification and

Identification label)

for use in countries other than the U.S.: Warning label according to EN/IEC standards.

Be sure to turn off the sensor before replacing the label, or your hand or other body parts may

be exposed to the hazardous laser beam radiating from the sensor.

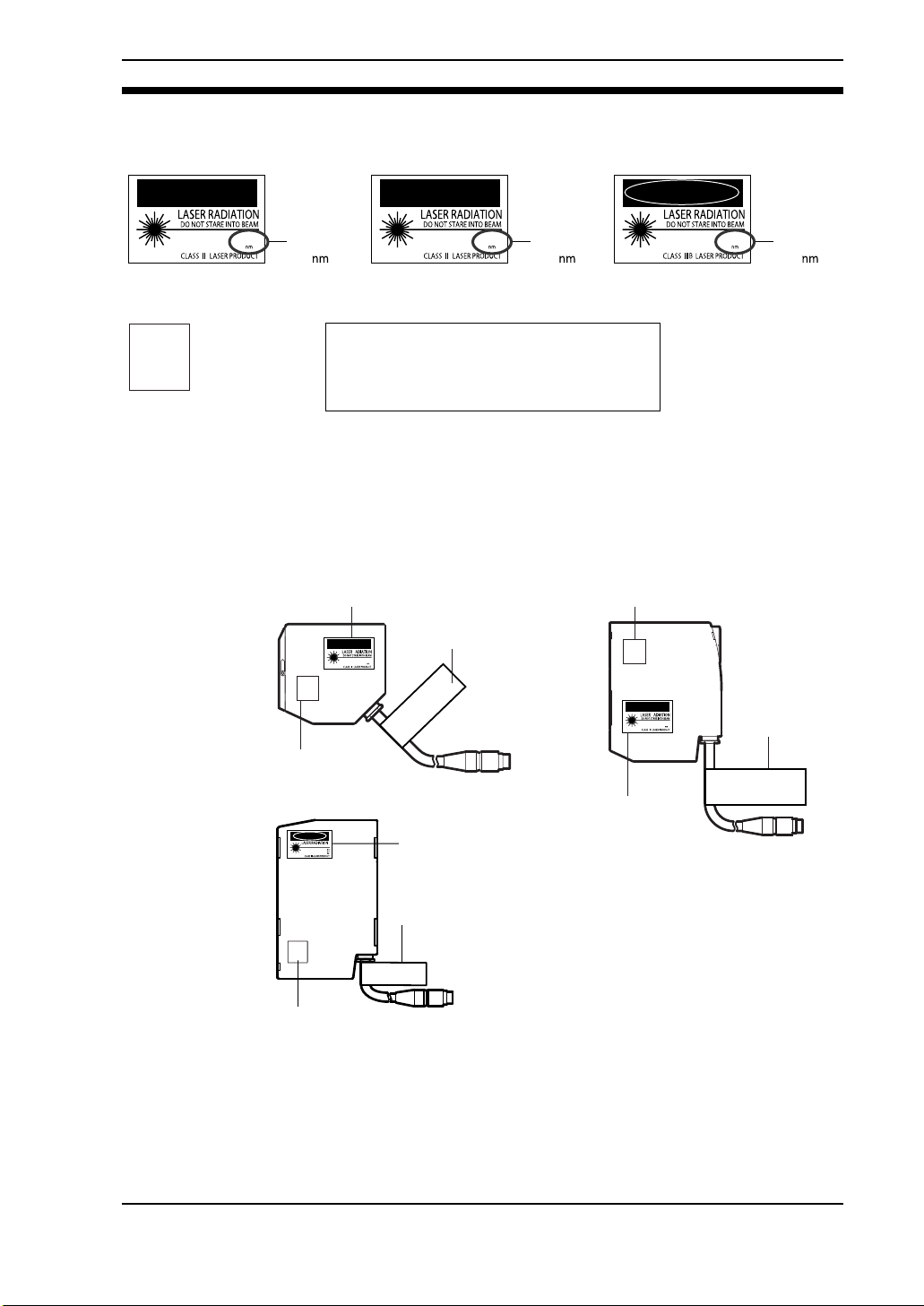

§ Use in the U.S.

When a laser product mounted on a certain device is to be used in the U.S., it has to meet the

requirements set forth by the FDA (regulations for laser products set forth by the Food and

Drug Administration).

Applications have been approved by CDRH (Center for Devices and Radiological Health) for

Z300-S2T, Z300-S5T, Z300-S10, Z300-S60. Three different FDA labels are enclosed in the

sensor package. Attach them to the sensor body.

The Z300 is designed to be built into the finished system unit. Refer to the following technical

standard for installation.

21CFR1040.10 and 1040.11

12

DANGER

DANGER

PRECAUTIONS

FDA Labels for Laser Products

ClassIICautionlogotype ClassIICautionlogotype

CAUTION

PEAKPOWER

PULSEDURATION

WAVELENGTH

Z300-S2T

1000

10000

650

µs

10000

650

µs

µw

1000

µw

CAUTION

PEAKPOWER

1000

PULSEDURATION

10000

WAVELENGTH

670

Z300-S5T/S10

µs

10000

670

µs

µw

1000

µw

ApertureLabel CertificationandIdentificationLabel

AVOID

EXPOSURE

Laserradiation

isemittedfrom

thisaperture

Be sure to attach FDA labels; do not attach English WARNING labels by mistake.

Thislaserproductcomplieswith

21CFR1040.10and1040.11.

OMRONCorporation

ShiokojiHorikawa,Shimogyo-ku,

Kyoto600-8530JAPAN

Placeofmanufacture:

AYABEFactory,OMRONCorp.

Manufacturedin

Areas to Attach Labels

Z300-S2T

ClassII

Cautionlogotype

Certificationand

CAUTION

PEAKPOWER

PULSEDURATION

WAVELENGTH

AVOID

EXPOSURE

Laserradiation

isemittedfrom

thisaperture

ApertureLabel

Z300-S60

DANGER

AVOID DIRECT EXPOSURE TO BEAM

PEAK POWER

15000

PULSE DURATION

25000

WAVE LENGTH

658

µw

1000

µs

10000

650

IdentificationLabel

Thislaserproductcomplieswith

21CFR1040.10and1040.11.

OMRONCorporation

ShiokojiHorikawa,Shimogyo-ku,

Kyoto600-8530JAPAN

Placeofmanufacture:

AYABEFactory,OMRONCorp.

Manufacturedin

ClassIIIB

Dangerlogotype

ClassIIIBDangerlogotype

DANGER

PEAK POWER

PULSE DURATION

WAVE LENGTH

Z300-S60

Z300-S5T/S10

ApertureLabel

AVOID

EXPOSURE

Laserradiation

isemittedfrom

thisaperture

CAUTION

µw

PEAKPOWER

1000

µs

PULSEDURATION

10000

WAVELENGTH

670

ClassII

Cautionlogotype

µw

15000

µs

25000

658

Certificationand

IdentificationLabel

Thislaserproductcomplieswith

21CFR1040.10and1040.11.

OMRONCorporation

ShiokojiHorikawa,Shimogyo-ku,

Kyoto600-8530JAPAN

Placeofmanufacture:

AYABEFactory,OMRONCorp.

Manufacturedin

15000

25000

658

µw

µs

Certificationand

IdentificationLabel

AVOID

EXPOSURE

L

a

se

r ra

d

ia

tio

n

is e

m

itte

d

fro

m

th

is a

p

e

rture

T

h

i

s

l

a

s

e

r

p

r

o

d

u

c

t

c

o

m

p

l

i

e

s

w

i

t

h

2

1

C

F

R

1

0

4

0

.

1

0

a

n

d

1

0

4

0

.

1

1

.

O

M

R

O

N

C

o

r

p

o

r

a

t

i

o

n

S

h

io

k

o

ji H

o

rik

a

w

a

, S

h

im

o

g

y

o

-k

u

,

K

y

o

to

6

0

0

-8

5

3

0

J

A

P

A

N

P

l

a

c

e

o

f

m

a

n

u

f

a

c

t

u

r

e

:

A

Y

A

B

E

F

a

c

to

ry

, O

M

R

O

N

C

o

rp

.

M

a

n

u

f

a

c

t

u

r

e

d

i

n

ApertureLabel

§ Use in Countries Other than the U.S.

Replace the warning label in Japanese on the sensor main body with the attached EN/IEC

warning label upon use in countries other than the U.S. Attach the label in the area where the

original Japanese warning label was provided.

EN60825-1(IEC60825-1) standard is applied to products exported to European countries.

The Z300 conforms to the standard.

13

PRECAUTIONS

Warning Labels

1.0

10

650

Z300-S2T

15

25

658

Z300-S60

Be sure to attach correct warning labels; do not attach FDA labels by mistake.

Regulations and standards

The Z300 conforms to the following EC directives and EN standards.

1. EC Directives

EMC Directive: No.89//336/EEC

2. EN Standards

EN61326: 1997+A1:1998+A2:2001(EMI:Class A)

Z300-S5T

Z300-S10

1.0

10

670

14

PRECAUTIONS

Precautions for Safe Use

Please observe the following precautions for safe use of the product.

(1) Do not use the Z300 in environment with flammable or explosive gases.

(2) Install the Z300 away from high-voltage devices and moving machinery to

allow safe access during operation and maintenance.

(3) Use the Z300 with the power supply voltages specified in this manual.

(4) Use crimp terminals for wiring. Do not connect the power supply wires by just

twisting stranded wire and connecting directly to the terminals.

(5) Use the wire and crimp terminals of the proper sizes as specified in this man-

ual.

(6) Confirm that wiring has been performed correctly before turning ON the

power supply.

(7) Cover the terminal blocks with the Terminal Block Protection Covers.

Uncovered terminal blocks can result in electric shock.

(8) Use a DC power supply with countermeasures against high-voltage spikes

(safe extra low-voltage circuits on the secondary side).

(9) Be sure to securely tighten the screws when mounting the Z300.

(10)Do not attempt to dismantle, repair, or modify the Z300.

(11)Dispose of the Z300 as industrial waste.

15

PRECAUTIONS

Precautions for Correct Use

Please observe the following precautions to prevent failure to operate, malfunctions, or undesirable

effects on product performance.

Components

The Sensor and Console connected to the Z300-VC10V4 Controller must be

products designed specifically for the Z300.

- Sensor (Z300-S2T, Z300-S5T, Z300-S10, Z300-S60)

- Console (Z300-KP)

Installation Site

Do not install the Z300 in locations subjected to the following conditions:

- Ambient temperature outside of 0 to +40°C for the F300-M09 Video Monitor

(recommended monitor) or outside of 0 to +50°C for other Z300 components.

- Condensation due to rapid temperature fluctuations

- Relative humidities outside 35 to 85%

- Corrosive or flammable gases

- Dust, salt, or iron particles

- Direct vibration or shock

- Reflection of intense light (such as other laser beams or electric arc-welding machine)

- Strong magnetic fields

- Direct sunlight

- Water, oil, or chemical fumes or spray

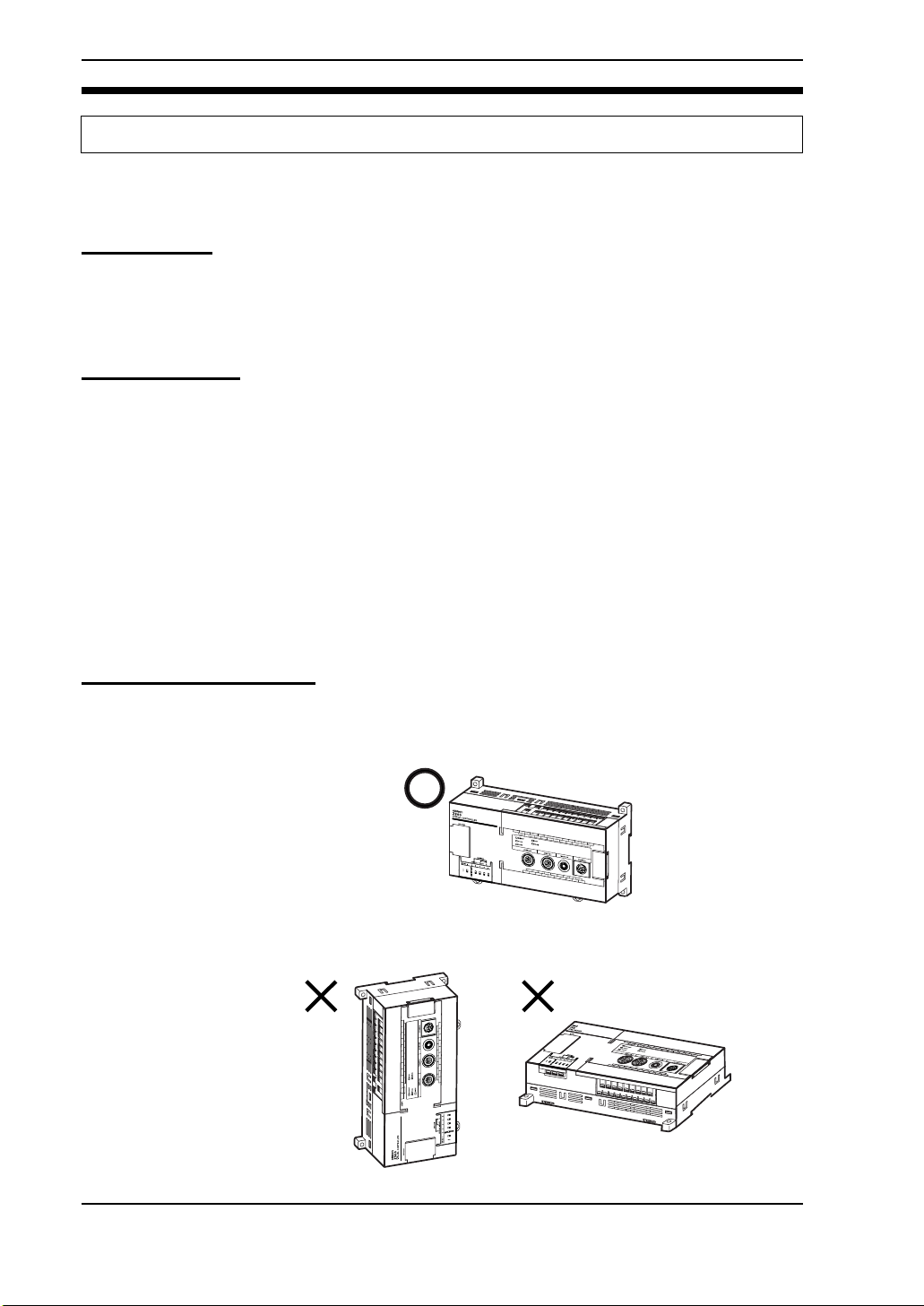

Installation Orientation

Orientation of Controller

To improve heat dissipation, install the Controller in the following direction only:

CORRECT

Do not install the Controller in the orientations shown in the following diagram.

INCORRECT

16

PRECAUTIONS

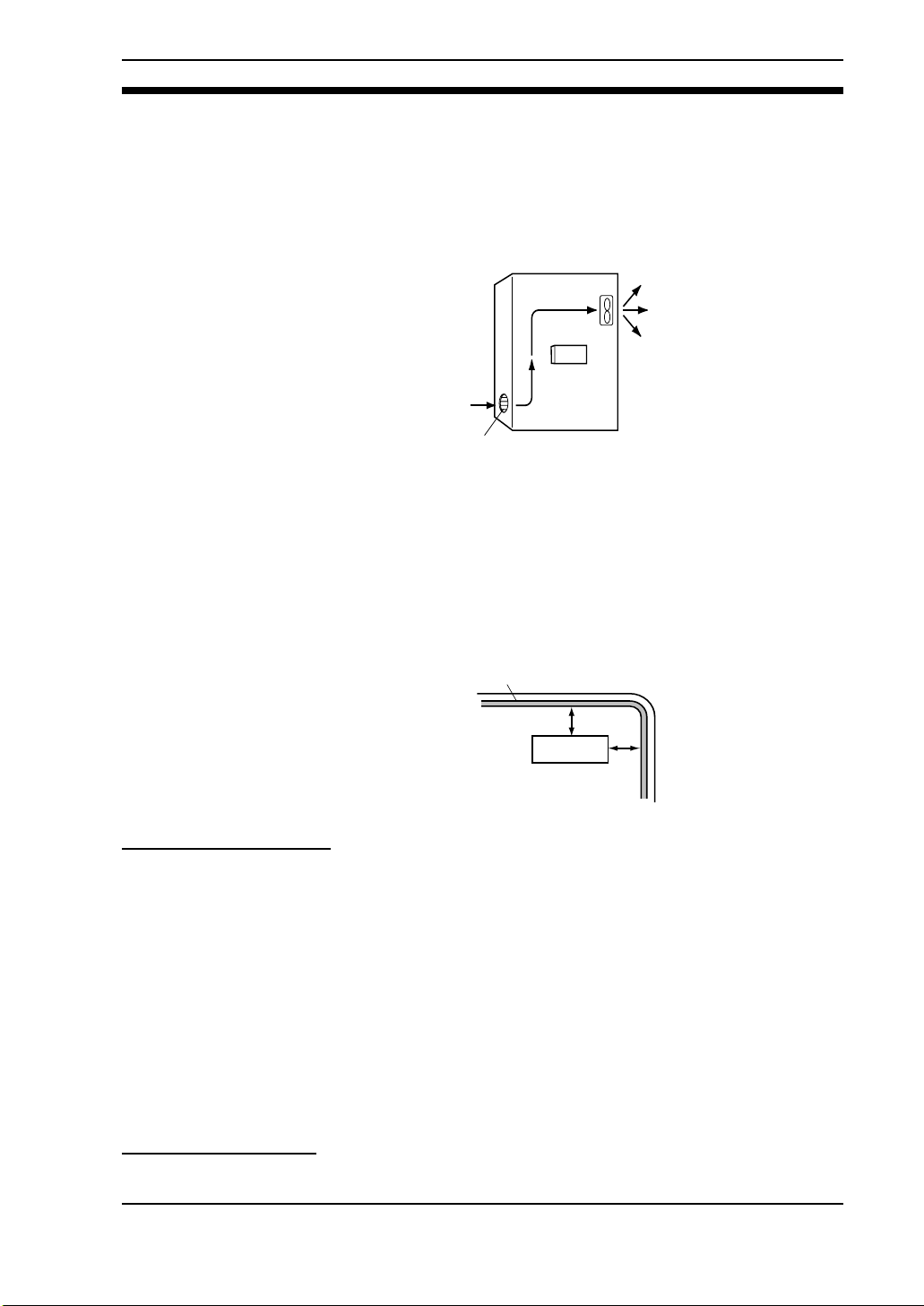

Ambient Temperature

- Maintain a minimum clearance of 50 mm above and below the Z300 to

improve air circulation.

- Do not install the Z300 immediately above significant heat sources, such as

heaters, transformers, or large-capacity resistors.

- Do not let the ambient temperature exceed 50°C.

- Provide a forced-air fan cooling or air conditioning if the ambient temperature is near 50°C so that the ambient temperature never exceed 50°C.

Control panel

Z300

Louver

Ambient Illumination

Although the Z300 is rated for use in environments where the ambient illumination does not exceed 3000lx, if possible, do not use the Z300 near lighting equipment that turns ON and OFF continuously. If this is unavoidable, reduce the

influence of the light by, for example, using a light baffle.

Noise Resistance

- Do not install the Z300 in a cabinet containing high-voltage equipment.

- Do not install the Z300 within 200 mm of power cables.

Sensor Maintenance

- Install the Sensor in a clean environment and keep the filter on the front panel

of the Sensor free from oil and dust. If affected by oil or dust, clean the filter as

follows:

1. Use a blower brush (used to clean camera lenses) to blow large dust particles from the surface. Do not blow the dust away with your mouth.

2. Use a soft cloth (for lenses) with a small amount of alcohol to remove the

remaining dust. Do not use a scrubbing action when cleaning as scratches

on the filter could result in the Sensor malfunctioning.

Environment

The Sensor cannot accurately detect the following types of objects:

- Objects with an extremely low reflection ratio

- Objects with a small curvature

- Largely inclined objects

Connecting Cables

Always turn OFF the Z300's power before connecting or disconnecting cable.

Power cable

200 mm min.

Z300

200 mm min.

17

PRECAUTIONS

Touching Signal Lines in Connectors or Terminals

To prevent damage from static electricity, use a wrist strap or another device for

preventing electrostatic discharges when touching terminals or signal lines in

connectors.

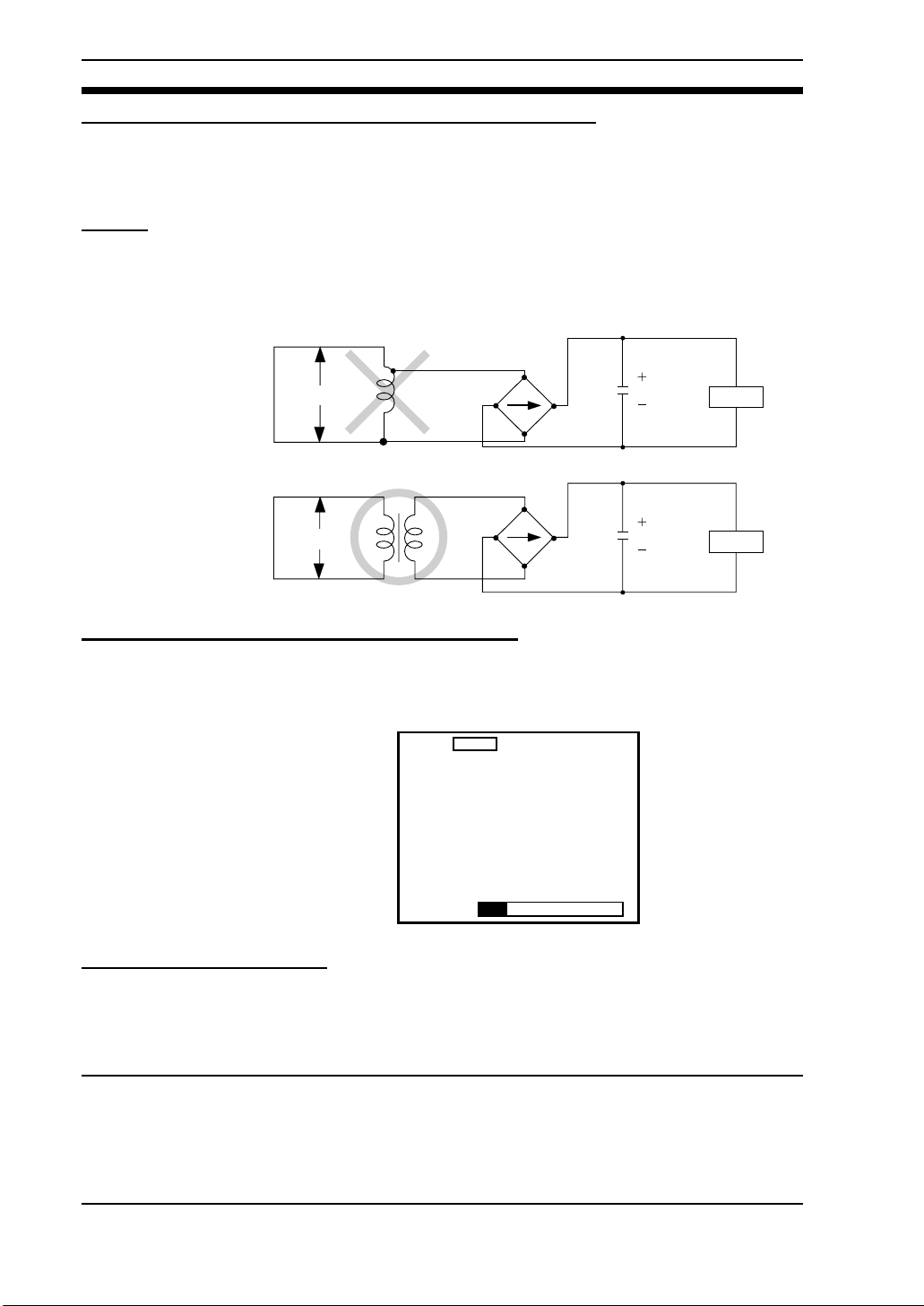

Wiring

When using a transformer for the Z300's driving power supply, use an isolation

transformer in the way shown below. Do not use an auto-transformer. Doing so

may result in equipment failure.

Auto-transformer

Commercial

power supply

Isolation transformer

Commercial

power supply

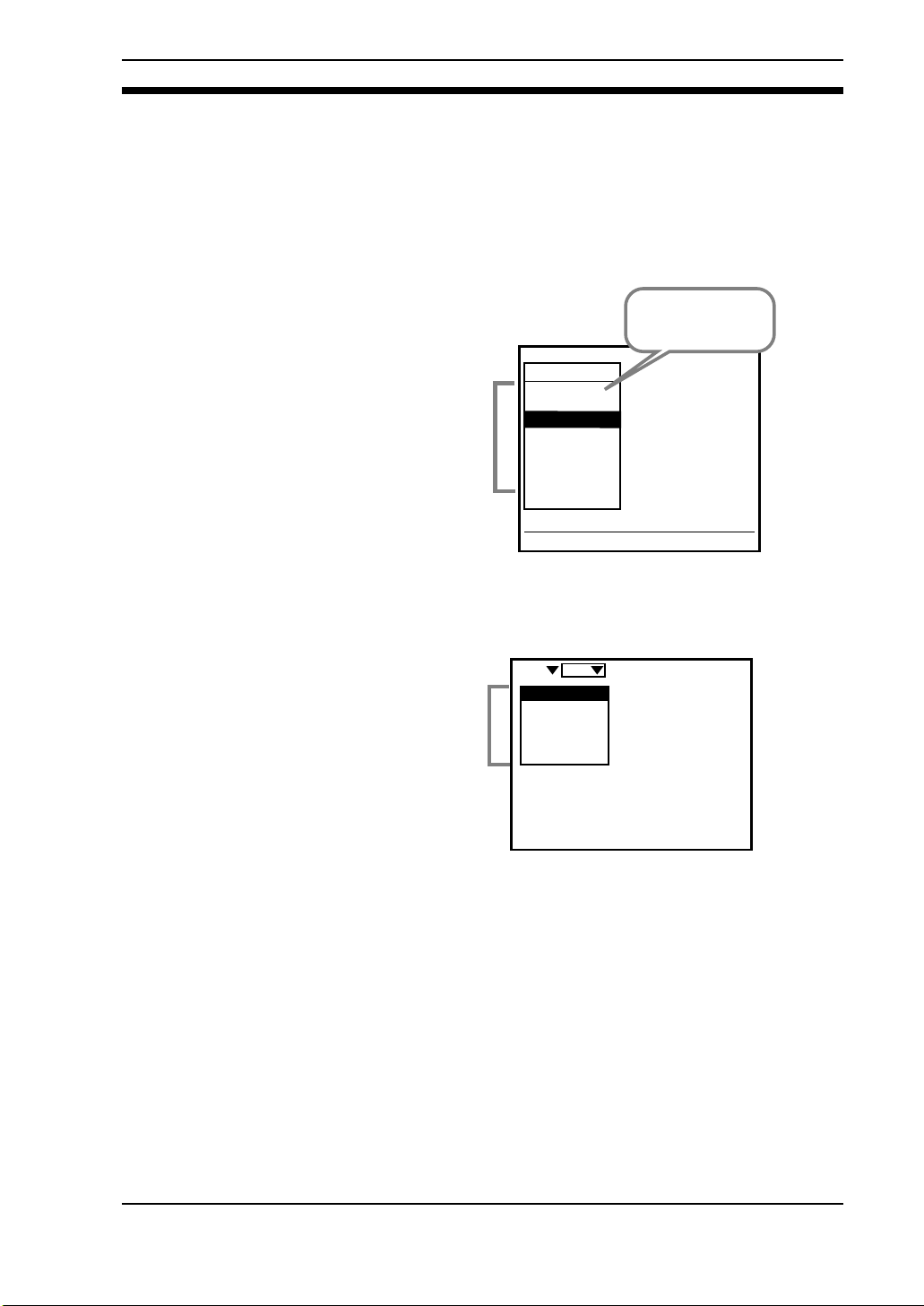

Turning OFF the Power (Visual Mode Only)

Do not turn OFF the power while a message is being displayed indicating that

processing is being performed. Data in memory will be destroyed, and the Z300

may not operate correctly the next time it is started.

Scn 0▼

SAVE▼

Z300

Z300

Saving data.

Using the RESET Signal

Do not use the RESET input immediately after power is turned ON. When using

the RESET input to synchronize startup timing, wait at least 1 second after the

Z300's power supply is turned ON before turning ON the RESET terminal.

Securing the Video Monitor (When Using the Recommended F150-M09)

Observe the following precautions to prevent noise interference, because the

video monitor case is connected to the 0 V line in the internal circuits.

1. Do not ground the video monitor.

2. Do not ground the metallic part of the connector.

3. Secure the video monitor with plastic screws if it is being mounted to a metallic surface.

18

PRECAUTIONS

Warming Up

After turning ON the power supply, allow the Z300 to stand for at least 30 minutes before use. The circuits are unstable immediately after the power supply is

turned ON and attempting measurement may result in inconsistent measurement values.

Confirming Package Contents

Check the contents of the package as soon as you receive the Z300. It is extremely rare for components to be missing, but contact the nearest OMRON representative if any of the following items are

missing.

1. Z300-VC10EV3 Controller Qty: 1

2. SETUP MANUAL (This Manual) Qty: 1

3. OPERATION MANUAL Qty: 1

Product Availability

Some of the products listed may not be available in some countries. Please contact your nearest

OMRON sales office by referring to the addresses provided at the back of this manual.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient operation

Notice Indicates information required to take full advantage of the functions and perfor-

CHECK Indicates points that are important in using product functions or in application

1,2,3... Indicates lists of one sort or another, such as procedures, checklists, etc.

SeeAlso Indicates where to find related information.

of the product.

mance of the product. Incorrect application methods may result in the loss of

damage or damage to the product. Read and follow all precautionary information.

procedures.

Notation

Screen Messages In this manual, screen message are given in bold/italic.

E.g.: Application

19

20

SECTION 1

This section introduces the features of the Z300.

1-1 Monitoring While Viewing the Measurement Status . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1-2 Simple Setup Using Menus! . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-3 A Wide Variety of Useful Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Features

21

Monitoring While Viewing the Measurement Status Section 1-1

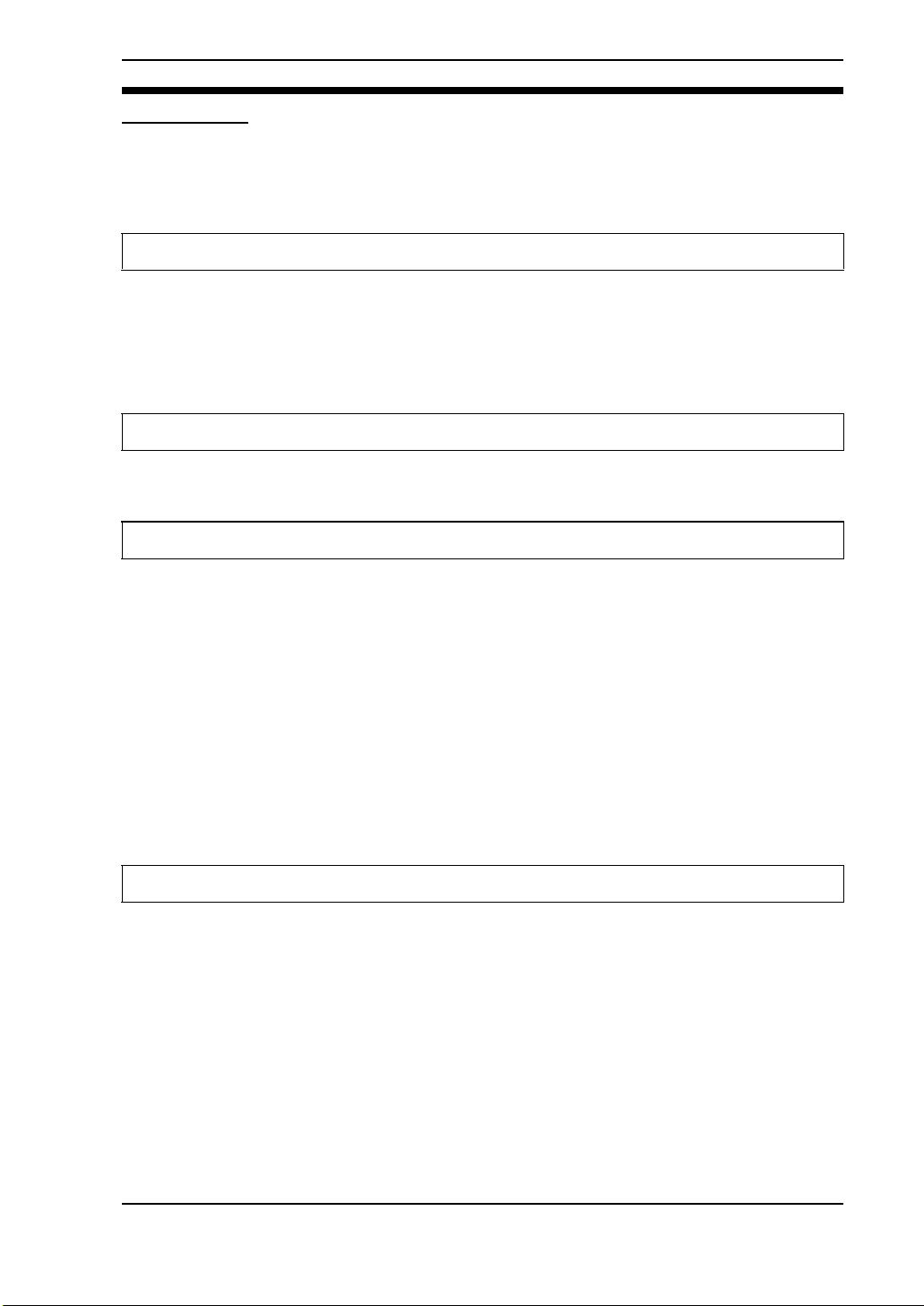

1-1 Monitoring While Viewing the Measurement Status

Monitoring suited to the application is possible at every stage from installation

and adjustment to operation and maintenance.

For details on the display, refer to page 12 in the Operation Manual.

Z300

Monitor

Sensor

The status of laser beam images can be

displayed on the monitor screen.

It is possible to make fine adjustments to

the measurement position and to confirm

that the light density is not excessive or

insufficient.

Linear sensor controller-style digital display

is also possible.

SCN0 0.48ms

OUT 0

SCN0 0.48ms

POWER

SYNC

RUN

NEAR

HI LO ZERO OFF

+001.6070 mm

RUN

+001.6070

PASS

BRIGHT

Sensor

+

+

DARK

LV [ 12]

PEAK[199]

Sensor

LV [---]

PEAK[---]

PASS

mm

0

1

22

Waveforms with measurement values ar-

ranged in chronological order can be dis-

played and so the shapes of the workpieces

moving along the line can be checked.

OUT 0

HI=+005.0000 mm

LO=-005.0000 mm

RUN

SCN0 0.48ms

H

L

thru

OUT 0

+001.6070 mm PASS

RO OFF

+

ZERO OFF

Simple Setup Using Menus! Section 1-2

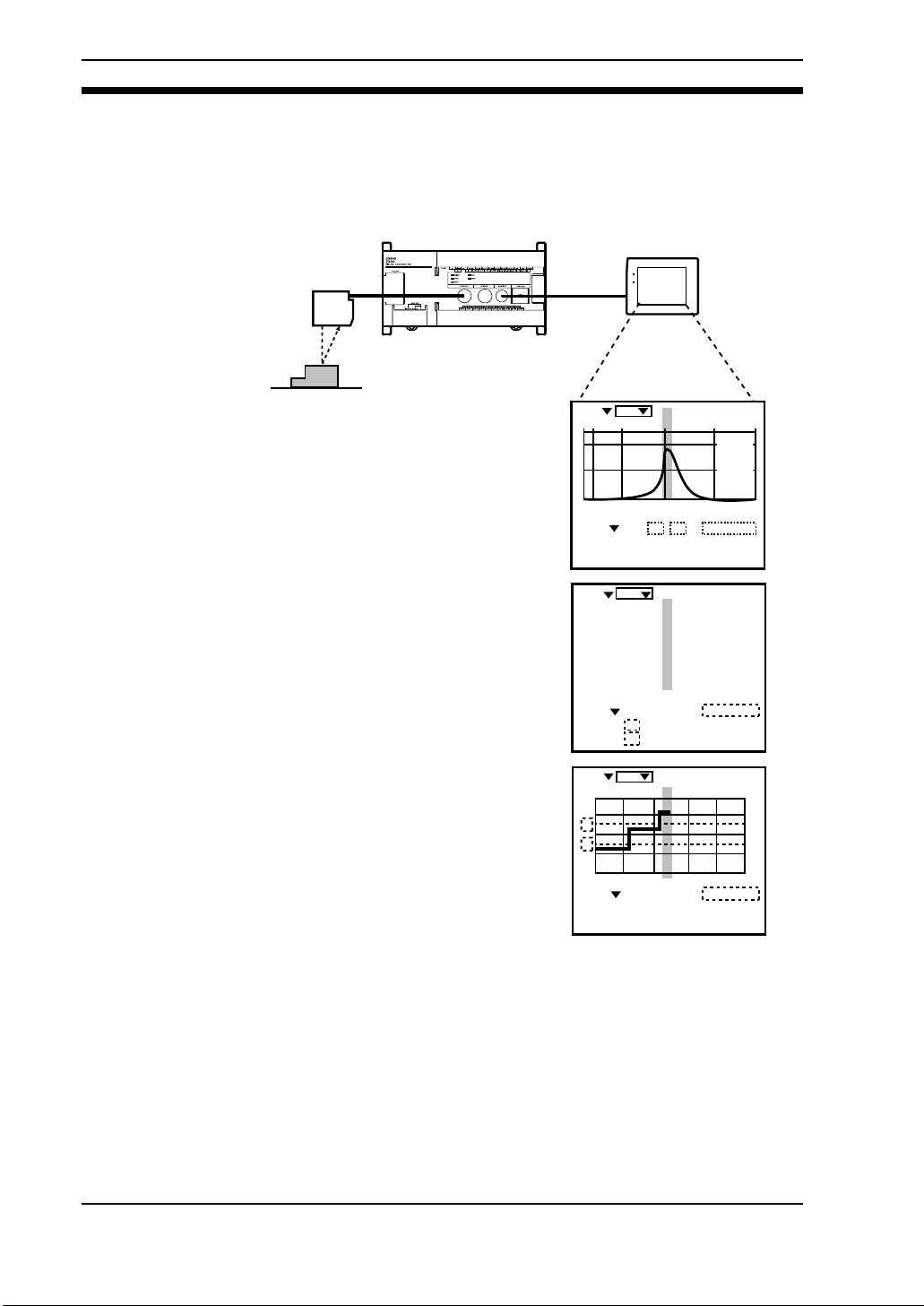

1-2 Simple Setup Using Menus!

Set the measurement conditions on the Console according to the menus displayed on the monitor screen. The Z300 has 2 types of menu.

First, try out the Application Menu.

Measurement conditions for a representative application are already set and so

setting can be performed simply by selecting the measurement items.

Refer to page 28 in the Operation Manual.

The Z300 is factory-set to

perform surface displacement measurement when

the power supply is turned

ON.

Application

Sf displace

Spot displace

Select from these items.

Use the Expert Menu to set different measurement conditions from the preset

ones, or to add more detailed settings to the Application Menu settings.

Refer to page 43 in the Operation Manual.

Max. height

Groove/dent

Step

Transp thick

Step(2sensor)

Thik(2sensor)

Select the application

ENT:Next ESC:Back

Select the item

to be set.

SET

Scn0

Point/Equation

Conditions

Hold

Avg/Filter

Details

23

A Wide Variety of Useful Functions Section 1-3

1-3 A Wide Variety of Useful Functions

Useful Feature for Sensor Installation!

The Sensor's installation conditions and orientation can be adjusted while monitoring the CCD's received light density.

Refer to page 118 in the Operation Manual.

Useful for Analyzing the Causes of NG Images!

Laser beam images and waveforms for NG images can be recorded. Recorded

images can be reproduced to help analyze the cause of NG images.

Refer to page 122 in the Operation Manual.

Easy Settings for Measuring Workpiece Thickness and Level Differences!

Two Sensors can be connected to the Controller, allowing measurement conditions to be set easily.

(Connect the same models of Sensor.)

Refer to page 29 in the Operation Manual.

A Variety of Output Formats!

Not only is analog output available, but communications with external devices

can also be performed via terminal blocks or RS-232C.

For details on terminal block output, refer to page 150 in the Operation

Manual.

For details on RS-232C output, refer to page 157 in the Operation Manual.

For details on analog output, refer to page 173 in the Operation Manual.

Comprehensive Hold Functions!

Hold Mode can be set freely at up to 4 points (times).

Refer to page 65 in the Operation Manual.

24

SECTION 2

Wiring and Connection

Procedures for wiring power supplies and ground wires and for connecting to external devices are described in

this section.

2-1 Component Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-3 Connecting Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-4 Power Supply and Ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

2-5 Terminal Block Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2-6 RS-232C Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

2-7 Linear Sensor Controller Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

25

Component Names and Functions Section 2-1

2-1 Component Names and Functions

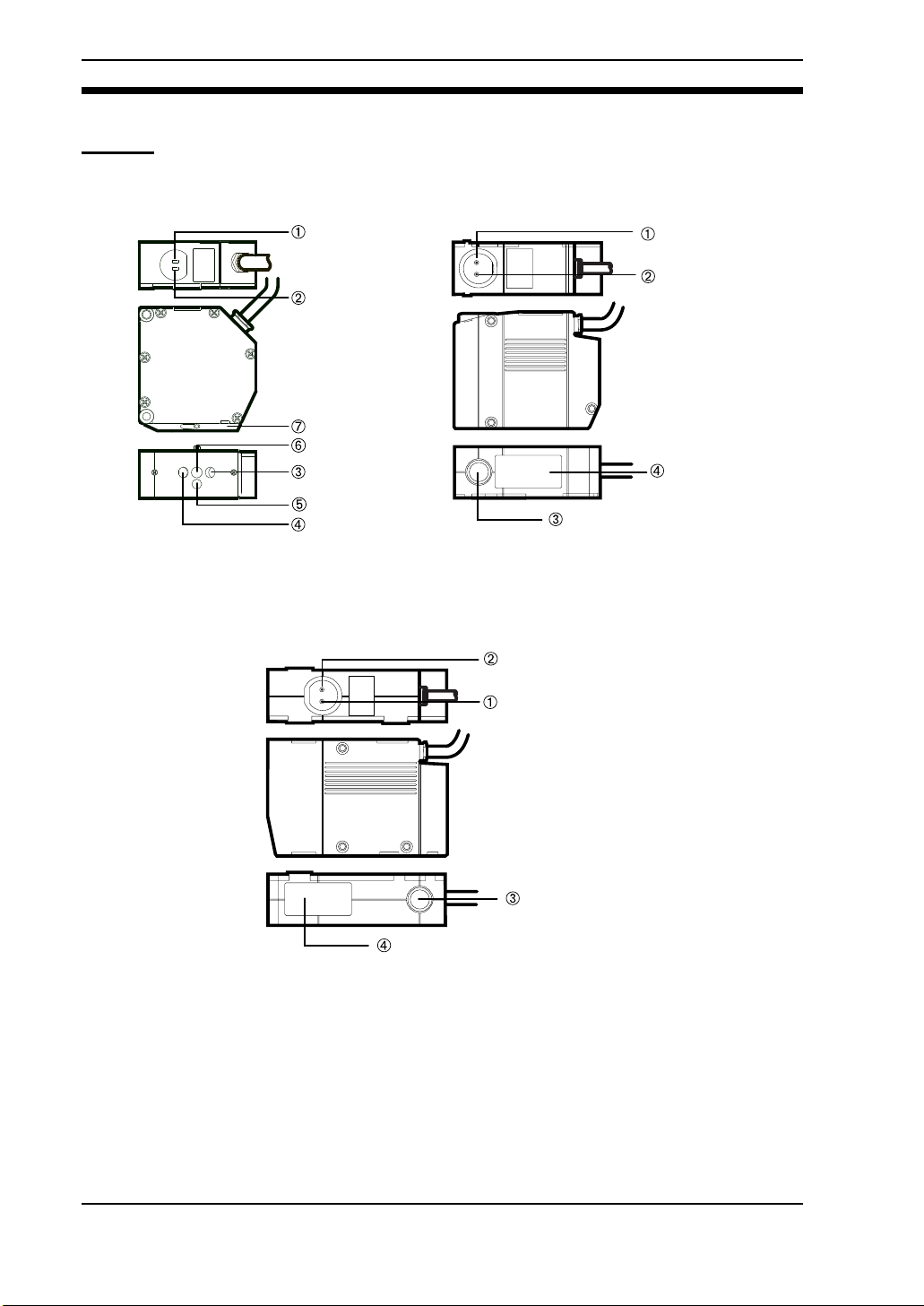

Sensor

Z300-S2T Sensor

NEAR indicator

FAR indicator

Beam cover

Monitor

Emitter

Light

Receiver

Z300-S60 Sensor

Z300-S5T Sensor

Z300-S10 Sensor

NEAR indicator

FAR indicator

Receiver

Emitter

FAR indicator

NEAR indicator

26

Emitter

Receiver

Component Names and Functions Section 2-1

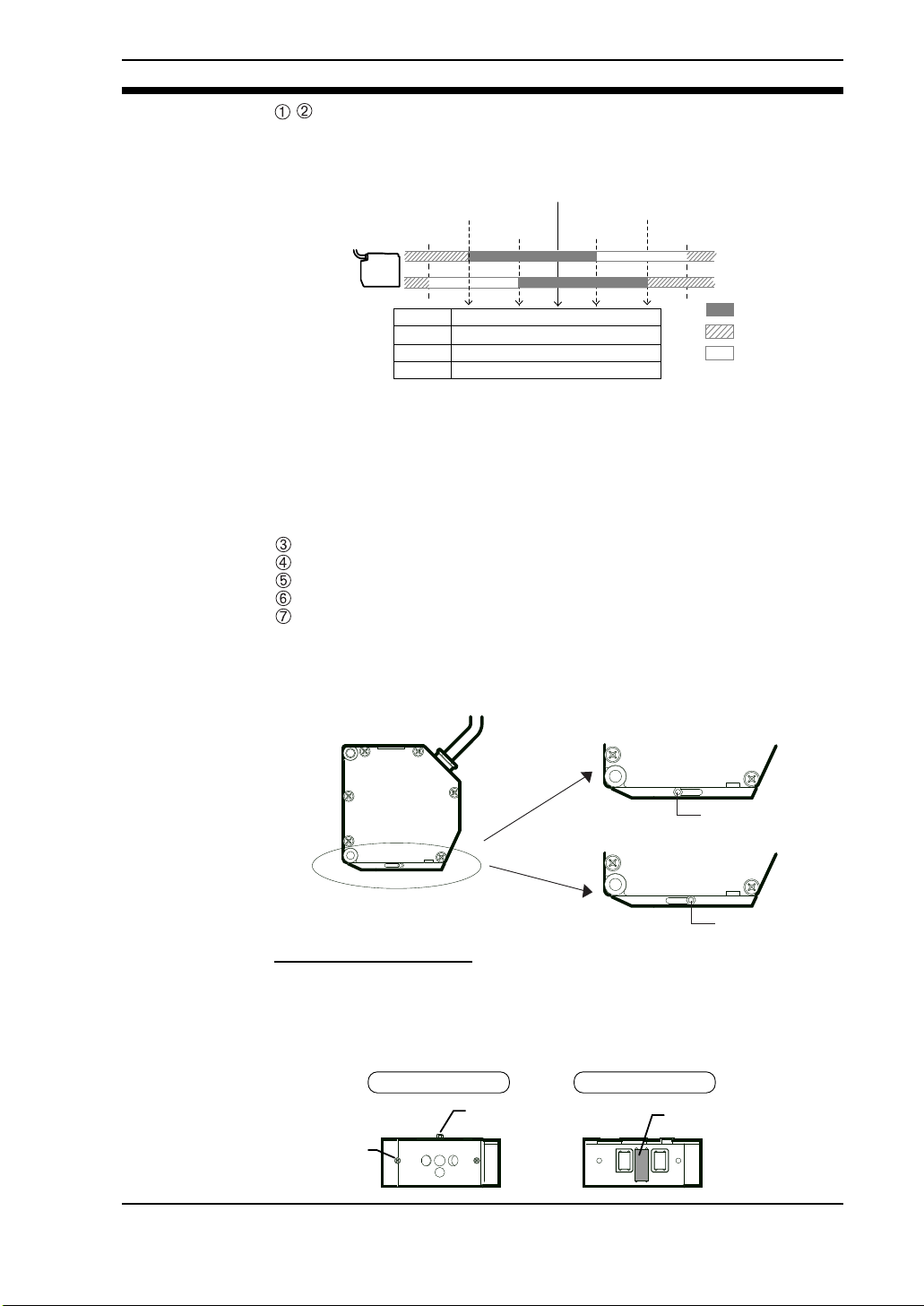

, If the distance between the front of the Sensor and the workpiece is the

measurement range, these indicators turn ON or OFF according to the distance.

If the workpiece is outside the measurement range or if the light density is insufficient, both indicators will flash.

Distance to measurement center

Measurement range lower limit

Outside measurement range

Z300-S2T

Z300-S10

Z300-S5T

Z300-S60

19

80

45

250

19.9

98

49.5

565

20

100

50

600

These indicators also act as laser beam warning indicators.

- Immediately after the power supply is turned ON, one or both of these indicators will light or flash.

- For 15 to 25 seconds after the power supply is turned ON, both indicators will

be OFF indicating that the laser beam is OFF.

- When the laser beam turns ON, one of these indicators will light or flash.

- When the laser beam turns OFF, both indicators will turn OFF.

Emits laser beam.

Receives laser beam.

Light used when displaying surrounding images.

Captures surrounding images.

Used for switching between display of surrounding images and measurement. To display surrounding images, loosen the screws of the beam cover

lever and move the lever to the left. To perform measurement, move the lever to

the right. Tighten the lever screws with a flat-bladed screwdriver to a torque in

the range 0.15 to 0.3 N•m (1.5 to 3 kgf•cm).

Measurement range upper limit

Outside measurement range

20.1

50.5

102

635

21

120

55

950

(Unit: mm)

NEAR indicator

FAR indicator

Lit

Flashing

Not lit

CHECK When Using the Z300-S2T

- When performing measurement with the beam cover removed, attach the

monitor cap provided with the Sensor in the way shown below.

- When displaying surrounding images, be sure to attach the beam cover. Surrounding images cannot be displayed correctly without the beam cover

attached.

Beam Cover Attached

Two, M2 × 4

Lever screws: M2 × 5

Display of surrounding images

Lever

Measurement

Lever

Beam Cover Removed

Monitor cap

(provided as an accessory)

27

Component Names and Functions Section 2-1

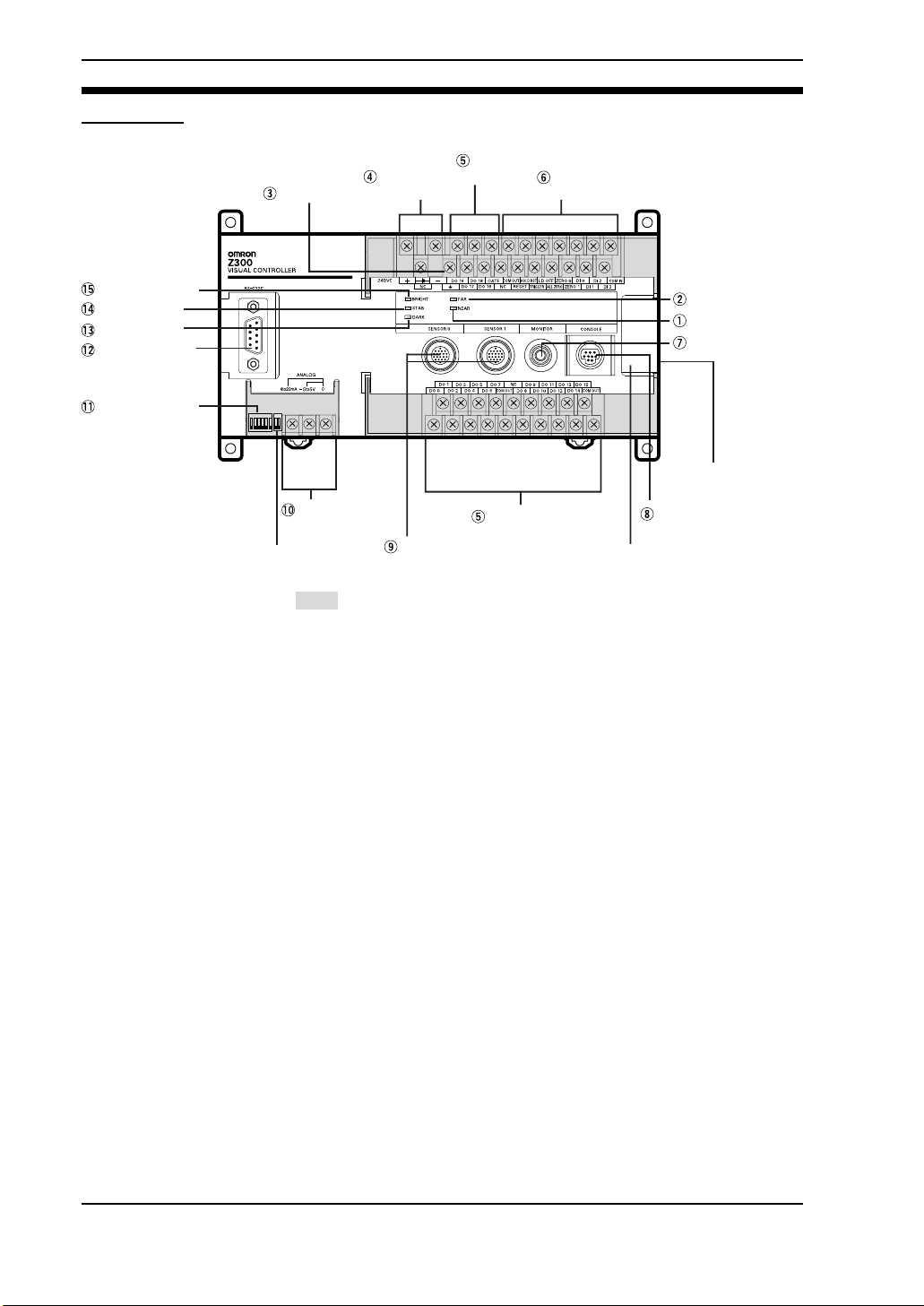

Controller

Output

Ground terminal

Power Supply

terminals

terminals

Input

terminals

BRIGHT indicator

STAB indicator

DARK indicator

RS-232C

connector

DIP Switch

Analog

Output terminals

* Do not use.

FAR indicator

NEAR indicator

Monitor connector

*Do not remove

the sticker on the side.

Output terminals

Sensor Connector

* Do not open.

Console connector

Shading indicates parts that are lifted to see the terminals underneath.

28

Component Names and Functions Section 2-1

, If the distance between the front of the Sensor and the workpiece is the

measurement range, these indicators turn ON or OFF according to the distance.

If the workpiece is outside the measurement range or if the light density is insufficient, both indicators will flash.

Distance to measurement center

Measurement range lower limit

Outside measurement range

Z300-S2T

Z300-S10

Z300-S5T

Z300-S60

19

80

45

250

19.9

98

49.5

565

20

100

50

600

These indicators also act as laser beam warning indicators.

- Immediately after the power supply is turned ON, one or both of these indicators will light or flash.

- For 15 to 25 seconds after the power supply is turned ON, both indicators will

be OFF indicating that the laser beam is OFF.

- When the laser beam turns ON, one of these indicators will light or flash.

- When the laser beam turns OFF, both indicators will turn OFF.

Connects to the ground wire.

Connects to the power supply.

, Connects to external devices such as a PLC.

Connects to the monitor.

Connects to a console.

Connects to the sensor.

Connected when using analog output.

Set when using the Z300 in Non-visual Mode.

Refer to page 55.

Connects to external devices such as a personal computer or PLC.

,,

Turn ON according to the light density at the Sensor.

If LDOFF is input via the terminal block or RS-232C, or if the Sensor is not connected, all of the indicators flash.

- BRIGHT indicator···Turns ON when the light density is too high.

- DARK indicator ···Turns ON when the light density is insufficient.

- STAB indicator ···Turns ON when the light density is suitable.

Measurement range upper limit

Outside measurement range

20.1

50.5

102

635

21

120

55

950

(Unit: mm)

NEAR indicator

FAR indicator

Lit

Flashing

Not lit

29

System Configuration Section 2-2

2-2 System Configuration

2-2-1 System Configuration for Visual Mode

The Z300 is provided with menus that allow easy setting of measurement conditions to suit the application. Perform settings on the Console using the menu

items displayed on the monitor. Waveform measurement results can also be displayed on the monitor.

The mode used for this type of operation is called "Visual Mode." If the DIP

switch on the Controller is set to VISUAL, the Z300 goes into Visual Mode when

the power supply is turned ON. The DIP switch is factory-set to VISUAL.

∗Components marked with

an asterisk are specially

designed for the Z300.

Other products cannot be used.

Z300-VC10EV3/Z300-VC15EV3 Controller

∗

Sensor (See page 50)

Z300-S2T (2-m cable)

Z300-S5T (2-m cable)

Z300-S10 (2-m cable)

Z300-S60 (0.5-m cable)

Power Supply

Recommended model: OMRON

S82K-05024(See page 36)

ESC TRIG

ENT

∗

Sensor Extension Cable

Z309-SC1R (1.5m, 3 m, 8 m, 13 m, or 18 m)

Specify the required cable length

when ordering.

CHECK - Up to 2 Sensors can be connected.

When performing measurement with 2 Sensors at the same time, use Sensors of the same model. It is possible to connect different Sensors but it will

not be possible to perform measurement using both at the same time.

For details on using different models, refer to page 146 in the Operation

Manual.

30

SHIFT

CONSOLE

∗

Console

Z300-KP(2-m cable)

System Configuration Section 2-2

CHECK When Using the Z300-S60

- When using the Extension Cable, set the length of the Extension Cable in

SYS/ Environment. This reduces errors due to the extended cable length.

For details, refer to page 140 in the Operation Manual

F150-VM Monitor Cable(2 m)

BNC Jack (provided with the F150-VM)

Expand the System to Suit the Application

Programmable Controller

F150-M05L Liquid

Crystal Monitor

(pin input)

POWER

SYNC

F300-M09 CRT

Video Monitor(BNC input)

POWER

Personal Computer

Linear Sensor Controller

K3TS

K3AS

K3TJ

K3NX

0

8

9.012

12.345 67.891

CQM1-LSE

See page 44

Notice Always turn OFF the power supply before connecting or disconnecting cables.

The peripheral device may be damaged if connected or disconnected with the

power supply turned ON.

31

System Configuration Section 2-2

2-2-2 System Configuration for Non-visual Mode

The Z300 can be used without a monitor but with a Linear Sensor Controller

connected. In this case, the Z300's menus cannot be used. The way in which the

Z300's analog outputs are used is set at the Linear Sensor Controller.

The mode for this type of operation (without being able to see menus and waveforms) is called "Non-visual Mode." To perform operation in Non-visual Mode,

the DIP switch on the Controller must be set to NON VISUAL.

Refer to page 55.

Notice Turn OFF the power supply before changing the DIP switch settings.

∗Components marked with

an asterisk are specially

designed for the Z300.

Other products cannot be used.

89.0

0

1

12.345

2

67.891

Linear Sensor Controller (See page 44)

K3TS (Linear Sensor Digital Panel Meter)

K3AS (Linear Sensor Controller)

K3TJ (Scaling Mater)

K3NX (Digital Panel Meter)

CQM1-LSE (Linear Sensor Interface Unit)

Power Supply

Recommended model:

OMRON S82K-05024

(See page 36)

∗

∗

Sensor Extension Cable

Z309-SC1R

(1.5 m, 3 m, 8 m, 13 m, or 18 m)

Specify the required cable

length when ordering.

Sensor (See page 48)

Z300-S2T (2-m cable)

Z300-S5T (2-m cable)

Z300-S10 (2-m cable)

Z300-S60 (0.5-m cable)

CHECK When Using the Z300-S60

Use with a cable extension length of less than 3 m in Non-visual Mode.

CHECK Only 1 Sensor can be connected. Connect it to SENSOR 0.

Notice Always turn OFF the power supply before connecting or disconnecting cables.

The peripheral device may be damaged if connected or disconnected with the

power supply turned ON.

32

Connecting Peripheral Devices Section 2-3

2-3 Connecting Peripheral Devices

This section shows how to connect peripheral devices to the Controller.

Notice Always turn OFF the power supply before connecting or disconnecting a periph-

eral device's cable. The peripheral device may be damaged if it is connected

while the power is ON.

Notice The various connectors on the Controller are capped when the Controller is

shipped.

When a connector is not being used, leave the cap in place or replace the cap to

protect against dust, dirt, and static electricity.

Connecting a Console

Connect the console Z300-KP to the Controller's console connector.

ESC TRIG

SHIFT

CONSOLE

ENT

CONSOLE

Connecting a Monitor

Connect the monitor cable F150-VM to the Controller's monitor connector.

MONITOR

POWER

SYNC

33

Connecting Peripheral Devices Section 2-3

Connecting a Sensor

Connect the sensor to the Controller's sensor connector. Three ferrite cores

(supplied with the sensor) must be attached to the sensor cable. Two ferrite

cores can be connected within 100 mm from the sensor and within 100 mm from

the controller's connector, respectively.

Within 100 mm

Ferrite core (standard accessory)

Ferrite core

(Ferrite cores have already been

installed on the sensor. However,

their positions can be changed if

necessary.)

Within 100 mm

Ferrite core (standard accessory)

When using an extension cable, make sure that two ferrite cores are connected

within 100 mm from the sensor and within 100 mm from the controller's connector, respectively.

Within 100 mm

Ferrite core (standard accessory)

Ferrite core

(Ferrite cores have already been

installed on the sensor. However,

their positions can be changed if

necessary.)

Within 100 mm

Ferrite core (standard accessory)

SENSOR

SENSOR

34

Power Supply and Ground Section 2-4

2-4 Power Supply and Ground

Wire the power supply and the ground to their respective terminals.

2-4-1 Crimp Terminals and Cables

The terminal block uses M3 terminal screws. Use appropriate crimp terminals

for M3 screws as shown below. Tighten the screws to a torque of between 0.5

and 0.6 N•m. After wiring, confirm that the wiring is correct.

Notice Cover the terminal blocks with the Terminal Block Protection Covers. Uncov-

ered terminal blocks can result in electric shock.

Forked Round

6.2 mm max.

Forked J.S.T. Mfg Co.,Ltd V1.25-N3A

Round J.S.T. Mfg Co.,Ltd V1.25-MS3

2-4-2 Ground Wiring

100Ω or less.

Notice -Be sure to ground to 100Ω or less.

-Always connect a ground wire to the Z300's ground terminal. To avoid

grounding problems, do not share the ground wire with any other devices or

wire the ground to the building's steel framing.

-Use a grounding point that is as close as possible and keep the ground wiring

as short as possible.

Ground to

6.2 mm max.

Recommended Crimp Terminals

Manufacturer Model Recommended wire size

1.31 to 1.65mm

2

35

Power Supply and Ground Section 2-4

2-4-3 Wiring the Power Supply

Use a power supply that meets the following specifications.

CHECK Use a DC power supply with countermeasures against high-voltage spikes (safe

extra low-voltage circuits on the secondary side).Excessively high voltages can

result in electric shock.

Recommended Power Supply: OMRON S82K-05024

Output current 1.6 A min.

Power supply voltage 24 VDC (21.6 to 26.4VDC)

+

24VDC

-

Notice - Wire the Power Supply Unit independently of other devices. In particular,

keep the power supply wired separately from inductive loads.

- Keep the power supply wiring as short as possible. (10 m max.)

- If UL recognition is required, use a UL class II power supply.

36

Terminal Block Connections Section 2-5

2-5 Terminal Block Connections

2-5-1 Crimp Terminals and Cables

The terminal block uses M3 terminal screws. Use appropriate crimp terminals

for M3 screws as shown below. Tighten the screws to a torque of between 0.5

and 0.6 N•m.

Notice Cover the terminal blocks with the Terminal Block Protection Covers. Uncov-

ered terminal blocks can result in electric shock.

Forked Round

6.2 mm max.

Recommended Crimp Terminals

Manufacturer Model Recommended wire size

Forked J.S.T. Mfg Co.,Ltd V1.25-N3A

Round J.S.T. Mfg Co.,Ltd V1.25-MS3

6.2 mm max.

1.31 to 1.65mm

2-5-2 Internal Specifications

CHECK Use a DC power supply with countermeasures against high-voltage spikes (safe

extra low-voltage circuits on the secondary side). Excessively high voltages can

result in electric shock.

Input Specifications

Item Specification

Model Z300-VC10EV3 (NPN mode) Z300-VC15EV3 (PNP mode)

Input voltage 12 to 24 VDC ±10%

ON current *1 5 to 15 mA

ON voltage *1 8.8 V max.

OFF current *2 0.1 mA max.

OFF voltage *2 4.5 V min.

ON delay

OFF delay

RESET input:10 ms max.

Other inputs: 0.5 ms max

RESET input:15 ms max.

Other inputs: 0.7 ms max.

2

Internal circuits

COM IN

+

Input

terminal

Input

terminal

+

COM IN

37

Terminal Block Connections Section 2-5

Output Specifications

Item Specification

Model Z300-VC10EV3 (NPN mode) Z300-VC15EV3 (PNP mode)

Output voltage 12 to 24 VDC ±10%

Load current 45 mA max.

ON residual volt-

age

OFF leakage cur-

rent

2 V max.

0.1 mA max.

Internal circuits

Notice Do not exceed the maximum load current specified for the Controller.

*1 ON Current/ON Voltage

*2 OFF Current/OFF Voltage

Output terminal

Load

COM OUT

+

COM OUT

+

Load

Output terminal

This refers to the current or voltage values needed to shift from the OFF→ON

state.

The ON voltage value is the potential difference between each of the input terminals and COM IN.

This refers to the current or voltage values needed to shift from the ON→OFF

state.

The OFF voltage value is the potential difference between each of the input terminals and COM IN.

38

Terminal Block Connections Section 2-5

2-5-3 Terminal Names

24VDC

Output terminals

Input terminals

+

-

DO 1

DO 16

DO 3

DO 18

DO 17

DO 5

GATE

DO 19

DO 7

(∗1)

NCNC

RESET

NC

HOLD-

RST

TRIGGER

DO9

LDOFF

ZERO 0

ALL-

ZERO

DO 11

DI 0

ZERO 1

DO 13

DI 2

DI 1

DO 15

DI 3

DO 0

DO 2

DO 4 DO 6

DO 14

DO 12

DO 10

DO 8

(∗2) (∗3)

Output terminals

CHECK There are 3 types of COM OUT (*1 to *3) for each output terminal. Connect with

reference to the table at right.

39

Terminal Block Connections Section 2-5

2-5-4 Terminal Applications Output Terminals

Name Application Name Application

DO 0

DO 1 DO 15

DO 2 DO 16

DO 3 DO 17

DO 4 DO 18

DO 5 DO 19

DO 6

DO 7

DO 8

DO 9

DO 10

DO 11

DO 12

DO 13

Measurement results output

DO 14

GATE

COM OUT

(*1)

COM OUT

(*2)

COM

OUT(*3)

Measurement results output

Control terminals

For details, refer to page

150 in the Operation Manual.

Common for DO 16 to 19

and GATE

Common for DO 0 to 7

Common for DO 8 to 15

Input Terminals

Name Application

HOLD RST

LD OFF

TRIGGER

ALL ZERO

ZERO 0

ZERO 1

DI 0

DI 1

DI 2

DI 3

RESET For resetting the Z300

COMIN Common for all input terminals

Notice - Do not reverse the connections of the signal terminals and COM terminals.

- Do not input the RESET input immediately after turning ON the power.

When using RESET input to synchronize startup timing, wait at least 1 s after

turning ON the Z300's power supply before turning ON the RESET terminal.

CHECK - The initial status of the output terminals is OFF. The terminals, however,

may turn ON for approximately 0.5 s when the power is turned ON. Be sure

to allow for this when connecting to an external device.

Control terminals

For details, refer to page 150 in the Operation

Manual.

Command input

40

RS-232C Wiring Section 2-6

2-6 RS-232C Connections

2-6-1 Connector

The Z300 uses 9-pin D-SUB female connectors. Use a compatible connector.

Recommended Plug and Hood

'

#

Plug: XM2A-0901

Hood: XM2S-0911

Model Manufacturer

OMRON Corp.

$

Pin No. Signal Name

1 FG(GND)

2 SD(TXD) Send Data

3 RD(RXD) Receive Data

4 RS(RTS) Request to Send

5 CS(CTS) Clear to Send

6 NC Not connected

7 NC Not connected

8 NC Not connected

9 SG(GND) Signal ground

Protective frame

ground

41

RS-232C Wiring Section 2-6

2-6-2 Wiring

Only use a shielded RS-232C cable. The maximum cable length is 15 m.

Standard Wiring

Wiring for RS/CS Control

Note Pin numbers on the external device will depend on the device being connected.

Refer to the manual for the personal computer or PLC being connected.

Z300

Signal

SD(TXD)

RD(RXD)

RS(RTS)

CS(CTS)

SG(GND)

SD(TXD)

RD(RXD)

RS(RTS)

CS(CTS)

SG(GND)

Z300

Pin No.

2

3

4

5

9

Pin No.Signal

2

3

4

5

9

Shield

Shield

External device

Pin No.

∗

∗

∗

∗

∗

Signal

SD(TXD)

RD(RXD)

RS(RTS)

CS(CTS)

SG(GND)

External device

Pin No.

∗

∗

∗

∗

∗

Signal

SD(TXD)

RD(RXD)

RS(RTS)

CS(CTS)

SG(GND)

2-6-3 Connection

Align the connector with the socket and press the connector straight into place.

Tighten the two screws on the edges of the connector.

Notice - Always turn OFF the power supply before connecting or disconnecting

- Always tighten the connector screws.

42

cables. The peripheral device may be damaged if connected or disconnected with the power supply turned ON.

Linear Sensor Controller Connections Section 2-7

2-7 Linear Sensor Controller Connections

2-7-1 Crimp Terminals and Cables

The terminal block uses M3 terminal screws. Use appropriate crimp terminals

for M3 screws as shown below. Tighten the screws to a torque of between 0.5

and 0.6 N•m.

Caution Cover the terminal blocks with the Terminal Block Protection Covers. Uncov-

ered terminal blocks can result in electric shock.

Forked Round

6.0 mm max.6.0 mm max.

Recommended Crimp Terminals

Manufacturer Model Recommended wire size

Forked J.S.T. Mfg Co.,Ltd V1.25-B3A

Round J.S.T. Mfg Co.,Ltd V1.25-MS3

1.31 to 1.65mm

2-7-2 Terminal Names

2

Name Application

4 to 20mA Analog output terminal for current output in the range 4 to 20 mA.

-5 to 5V Analog output terminal for voltage output in the range -5 to 5 V.

0 Connected to input devices as a ground for analog output.

CHECK Terminal 0 and the 4 to 20-mA terminal can be used for 1 to 5-V voltage output

by connecting the 250-Ω resistor provided.

43

Linear Sensor Controller Connections Section 2-7

2-7-3 Internal Specifications

.

2-7-4 Connection Examples for the Linear Sensor Controller Connecting to the Linear Sensor Digital Panel Meter (K3TS)

44

Linear Sensor Controller Connections Section 2-7

Connecting to the Linear Sensor Controller (K3AS)

Connecting to the Scaling Meter (K3TJ)

K3TJ-A116R

45

Linear Sensor Controller Connections Section 2-7

Connecting to the Digital Panel Meter (K3NX)

Connecting to the Linear Sensor Interface Unit (CQM1-LSE)

0

1

2

3

4

5

6

7

4to20mA

-5to5V

COM

11

+24V

DC

13

15

17

CQM1-LSE01

ZERO

RES

0V

8

10

12

14

16

4 to 20mA

+24V

DC

T/O

ZRES

24 VDC

9

46

SECTION 3

Installation

This section provides installation methods for the Controller and Sensor.

3-1 Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3-2 Mounting the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

47

Mounting the Controller Section 3-1

3-1 Mounting the Controller

There are two ways to mount the Controller: DIN Track mounting or surfacemounting.

3-1-1 DIN Track Mounting

The Controller can be easily mounted to or removed from 35-mm DIN Track.

DIN Track

The following DIN Tracks are available

from OMRON.

PFP-100N (1 m)

PFP-50N (50 cm)

PFP-100N2 (1 m)

OMRON's PFP-M

End Plate

Mounting the Controller

Hook the Controller into the DIN Track as shown in the diagram and then press

in at the bottom until the Controller locks into place.

48

Removing the Controller

Use a flat-bladed screwdriver to pull the hook down and then pull out the Controller from the bottom.

Hook

Mounting the Controller Section 3-1

3-1-2 Surface Mounting

Use the holes and dimensions shown in the following diagram.

Four, M4

100±0.2

185±0.2

(Unit: mm)

8

49

Mounting the Sensor Section 3-2

3-2 Mounting the Sensor

Up to 2 Sensors can be connected per Controller. When using the Z300 in Nonvisual Mode, however, only 1 Sensor can be connected.

WARNING Do not to expose your eyes to the laser radiation either directly or indi-

rectly (i.e., after reflection from a mirror or shiny surface). The laser radiation has a high power density and exposure may result in loss of sight.

Notice Only sensors specifically for the Z300 can be used.

Using another type of sensor may result in damage to the sensor or controller.

3-2-1 Sensor Types

View in the direction of the arrows

Front View

A

Super-precision

Model: Z300-S2T

High-precision

Model: Z300-S5T

Long-range Model:

Z300-S10

Super Long-range

Model: Z300-S60

B

Reference

distance

(A)

20mm ±1mm

50mm ±5mm

100mm ±20mm

600mm ±350mm

Z300-S2T/S5T/S10

Measure-

ment

range

(B)

Line beam

DC

Spot diameter

(C)

B=-1mm : 50µm

B=0mm : 20µm

B=+1mm : 50µm

B=-5mm : 140µm

B=0mm : 30µm

B=+5mm : 140µm

B=-20mm : 280µm

B=0mm : 60µm

B=+20mm : 280µm

B=-350mm : 0.8mm

B=0mm : 0.4mm

B=+350mm : 1.3mm

Z300-S60

Line beam

D

Line beam width

(D)

0.3mm

(The width of the measurement

region is 0.2 mm)

0.4mm

1.0mm

B=-350mm : 10mm

(The width of the measurement

region is 5.0mm)

B=0mm : 18mm

(The width of the measurement

region is 12.4mm)

B=+350mm : 26mm

(The width of the measurement

region is 20mm)

50

Mounting the Sensor Section 3-2

3-2-2 Mounting Dimensions Dimensions for Diffuse Reflection

Super-precision Model: Z300-S2T

5.2 77.2

51.7

0.1

Two, M4

0.1

24.1

Mounting Hole

Cutout Dimensions

Reception

axis

24.149.3

78.4

Emission axis

Measurement

center

13.8

Reference plane

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

High-precision Model: Z300-S5T

50

4

Emission axis

Measurement center

Three, M4

0.1

69

9.5

70

0.1

0.1

Mounting Hole

Cutout Dimensions

Reception axis

Reference plane

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

30

25

16.4

16.9

(Unit: mm)

51.74.7

50

Connector

(Unit: mm)

80

72

70

9.5

45.1

Three, 4.5-dia. holes

25

100

69

Connector

51

Mounting the Sensor Section 3-2

Long-range Model: Z300-S10

(

Unit: mm

)

9.5

70

0.1

0.1

Measurement center

Three, M4

Reception axis

100

Emission axis

25

25

4

16.4

9.5

80

72

70

Three, 4.5-dia. holes

25

100

69

0.1

69

Mounting Hole

Reference plane

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

Cutout Dimensions

Super Long-range Model: Z300-S60

Reception axis

Measurement

center

Reference plane

7

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

0.1

45

Mounting Hole

Cutout Dimensions

65

0.1

Three,

M4

16.9

600

Emission axis

5

16.4

45.1

57

75

65

Connector

(Unit: mm)

4728

Three, 4.5-dia. holes

4525

2

120

Connector

52

Mounting the Sensor Section 3-2

Dimensions for Mirror Reflection

Super-precision Model: Z300-S2T

(

Unit: mm

)

Reception axis

Measurement center

(4)

16

20

4

65

57

Two, 4.5-dia. holes

4

32

56.5

Two,

0.1

57

Mounting Hole

Cutout Dimensions

M4

Emission axis

Reference plane

18.1

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

High-precision Model: Z300-S5T

44

10.3

Emission axis

18.6

15

30

67.6

Measurement center

0.1

0.1

27

Three,

M4

28.8

Reception axis

0.1

Reference plane

18.1

25

25

27

67.6

20

98.5

65

20

Three, 4.5-dia. holes

18.1

Connector

(Unit: mm)

23.1

110.9

64.2

Mounting Hole

Cutout Dimensions

0.1

64.2

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

Connector

53

Mounting the Sensor Section 3-2

Long-range Model: Z300-S10

0.1

68.3

0.1

24.2

Mounting Hole

Cutout Dimensions

37.7 15.6

Three,

M4

94

Measurement

center

Reference plane

0.1 0.1

65.3 15.2

9.3

Emission

axis

12.5

25

Reception axis

Vinyl-insulated round cable 6.8 dia.

Standard length 2m

24.2

95.9

68.3

3-2-3 Mounting Orientation Boundaries between Different Colors and Textures

If there are parts of the workpiece where the color or texture are significantly different, measurement errors can be reduced by mounting the Sensor in the way

shown below, i.e., so that the plane containing the emission axis and the reception axis is parallel to the boundary between the contrasting sections of the

workpiece.

(Unit: mm)

Three, 4.5-dia. holes

23.5

15.2

109.6

65.3

Connector

54

Emission axis

Boundary

Reception axis

Mounting the Sensor Section 3-2

Mounting Near Walls

Errors will occur if light reflected off a wall surface is received by the Sensor. If it

is not possible to mount the Sensor away from the wall, mount in the way shown

below, i.e., so that the plane containing the emission axis and the reception axis

is parallel to the wall surface. Also, applying matt black coating to the wall surface will help to reduce the amount of light reflected.

Narrow Grooves or Indentations

If measurement is performed in an indentation between two walls, or in a

groove, mount the Sensor in the way shown below, i.e., so that the path along

the emission and reception axes is not interrupted by a wall.

Level Differences

When measuring workpieces with level differences, the influence of the level difference can be minimized by mounting the Sensor so that the plane containing

the emission axis and the reception axis is parallel to the boundary between the

different levels.

55

Mounting the Sensor Section 3-2

Rotating Workpieces

When measuring rotating workpieces, the influence of position displacement

and blurring of the rotating workpiece can be minimized by mounting the Sensor

so that the plane containing the emission axis and the reception axis is parallel

to the axis of rotation.

Thickness Measurement

When measuring the thickness of boards, select the Sensor mounting method

according to the board material.

Opaque

Workpiece

Sensor mounting

status

Controller settings

Diffuse reflection

Example: Ceramic

Diffuse reflection

mounting status

Specular reflection Example:

Stainless steel

Mirror reflection mounting status

Transparent

Example: Glass

56

Workpiece

Workpiece

Mounting the Sensor Section 3-2

Projections

When measuring the tops of projections on the workpieces, mount the Sensor

so that the entire projection passes through the line beam.

3-2-4 Mounting Distance

After selecting the Sensor mounting status in the menu item Environment,

mount the Sensor in a location where the status can be measured correctly.

For more details, refer to page 140 in the Operation Manual.

When using Non-visual Mode, refer to page 55.

Diffuse Reflection

Super-precision Model: Z300-S2T

High-precision Model: Z300-S5T

57

Mounting the Sensor Section 3-2

Long-range Model: Z300-S10

Super Long-range Model: Z300-S60

58

Mounting the Sensor Section 3-2

Mirror Reflection

Super-precision Model: Z300-S2T

High-precision Model: Z300-S5T

Long-range Model: Z300-S10

CHECK It is recommended that Sensor mounting is performed while monitoring the

amount of received light in the menu item Check position.

For details, refer to page 118 in the Operation Manual.

59

Mounting the Sensor Section 3-2

3-2-5 Mutual Interference

When using 2 or more Sensors mounted adjacently, mutual interference will not

occur as long as the spots (shown below) for other Sensors are outside the

shaded areas.

Z300-S2T

Z300-S5T

60

Mounting the Sensor Section 3-2

Z300-S10

Z300-S60

61

62

SECTION 4

Non-visual Mode

In Non-visual Mode, Z300 operation is performed according to the DIP switch settings without using the menus.

Because the menus are not used, the monitor and console are not required. Make settings for the Sensor mounting status, sensitivity, and response time using the DIP switch on the Controller.

The way that the Z300's analog outputs are used is set at the Linear Sensor Controller. For details, refer to the

operation manual for the Linear Sensor Controller connected.

4-1 Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4-2 DIP Switch Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-2-1 Switching to Non-visual Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-2-2 Selecting the Sensor Setting Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4-2-3 Setting the Sensor’s Sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4-2-4 Selecting the Analog Output Response Time. . . . . . . . . . . . . . . . . . . . . . . . 69

4-2-5 Selecting the Output Method for Measurement Failure. . . . . . . . . . . . . . . . 70

63

Restrictions Section 4-1

4-1 Restrictions

If the DIP switch setting is changed to NON VISUAL, the Controller's settings

can be changed using the DIP switch without having to connect a monitor or a

console.

Notice Turn OFF the power supply before changing the DIP switch settings.

The restrictions that apply when using the Z300 in Non-visual Mode are provided below.

- Measurement conditions set using the monitor and console are disabled.

- Even if a monitor and console are connected, console operations will have

no effect.

- Only 1 Sensor can be connected. It must be connected to SENSOR 0.

- Measurement is based on the following conditions.

- Sampling time: 0.96 ms

- Smoothing: None

- Noise removal: None

- Output: Analog output only

- Input: LD-OFF input only

- The settings that can be changed are as follows.

- The Sensor mounting status can be selected.

- The Sensor's sensitivity can be set.

- The response time for analog outputs can be selected.

- The output method for measurement failure can be selected.

Refer to page 55 for details of setting methods.

64

DIP Switch Settings Section 4-2

4-2 DIP Switch Settings

Mode

Sensor mounting

status

Notice Turn OFF the power supply before changing the DIP switch settings.

4-2-1 Switching to Non-visual Mode

Set when a Linear Sensor Controller is connected instead of a

monitor and console. Making this setting enables the other DIP

switch settings.

1234567

123 4 567 8

Sensitivity

8

Analog output

response time

Not used

Output method for

measurement failure

Set when using a monitor and console. Making this setting allows measurement conditions to be set on the console using

the menu items displayed on the monitor screen. Waveform

measurement results can also be displayed on the monitor.

Other DIP switch settings are disabled.

65

DIP Switch Settings Section 4-2

4-2-2 Selecting the Sensor Setting Status

The analog output appropriate for the mounting status is set. Measurement at

close to the actual dimensions is possible immediately after mounting.

Adjust the mounting position while monitoring the values of the Linear Sensor

Controller connected.

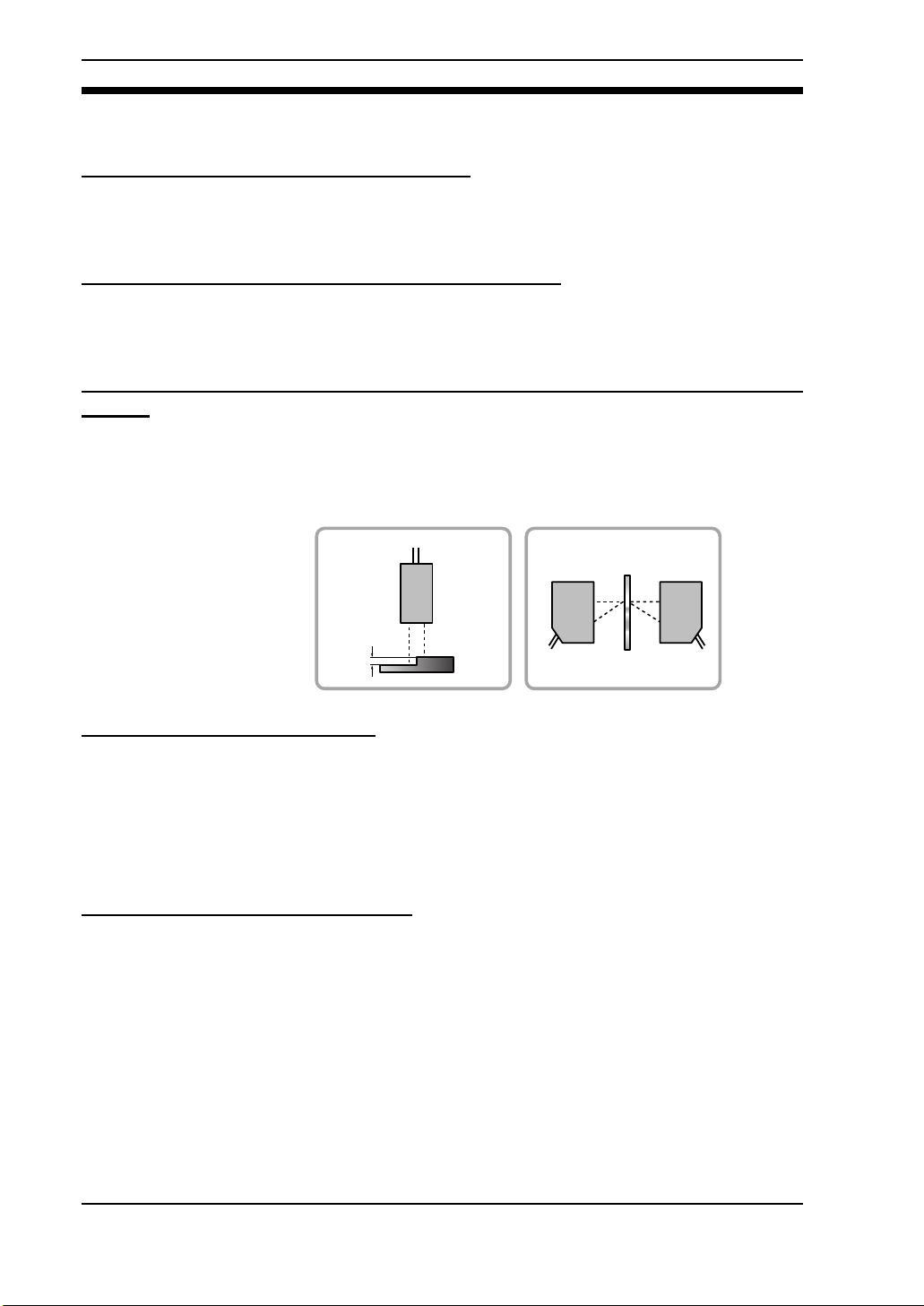

Mirror reflection

Light that is regularly reflected at the workpiece is

received directly. With this method, measurement

is possible even for shiny workpieces, such as

metallic workpieces.

Diffuse reflection