Page 1

Vision Sensor

FH/FHV Series

Vision System

User's manual for Communication Settings

FH-1£££/FH-1£££-££

FH-2£££/FH-2£££-££

FH-3£££/FH-3£££-££

FH-5£££/FH-5£££-££

FH-L£££/FH-L£££-££

FHV7£-£££££-C

FHV7£-£££££-S££/FHV7£-£££££-S££-££

FHV7£-£££££-H££/FHV7£-£££££-H££-££

Z342I-E3-14

Page 2

NOTE

• All rights reserved.

• No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any

form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the

prior written permission of OMRON.

• No patent liability is assumed with respect to the use of the information contained herein. Moreover

because OMRON is constantly striving to improve its high-quality products, the information con-

tained in this manual is subject to change without notice. Every precaution has been taken in the

preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omis-

sions.

Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan

and other countries for OMRON factory automation products.

• This software is based in part on the work of the Independent JPEG Group.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or

trademarks of Microsoft Corporation in the United States and other countries.

• Intel, Core and Pentium are trademarks of Intel Corporation in the U.S. and/or other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation

GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD, SDHC, microSD, and microSDHC logos are trademarks of SD-3C, LLC.

,

• QR Code is a registered trademark of DENSO WA

VE INCORPORATED.

• MELSEC is a registered trademarks of Mitsubishi Electric Corporation.

Other company names and product names in this document are the trademarks or registered trade-

marks of their respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing the FH/FHV Series.

This manual contains information that is necessary to use the FH/FHV Series.

Please read this manual and make sure you understand the functionality and performance of the

FH/FHV Series before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual covers the following products.

• FH-1£££

• FH-1£££-££

• FH-2£££

• FH-2£££-££

• FH-3£££

• FH-3£££-££

• FH-5£££

• FH-5£££-££

• FH-L£££

• FH-L£££-££

• FHV7£-££££

Part of the specifications and restrictions are given in other manuals. Refer to Relevant Manuals on

Relevant Manuals on page 2 and Related Manuals on page 17.

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1

Page 4

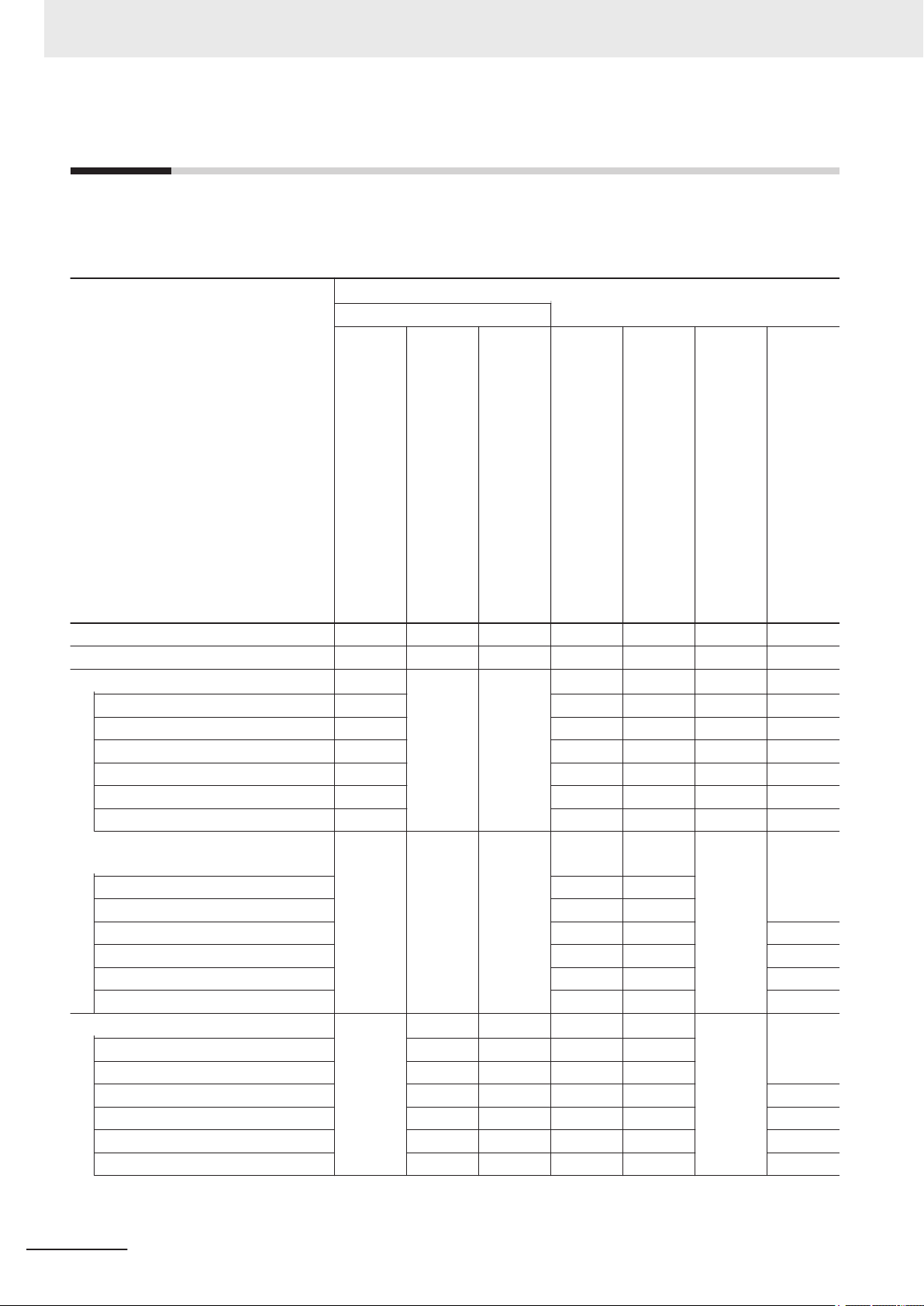

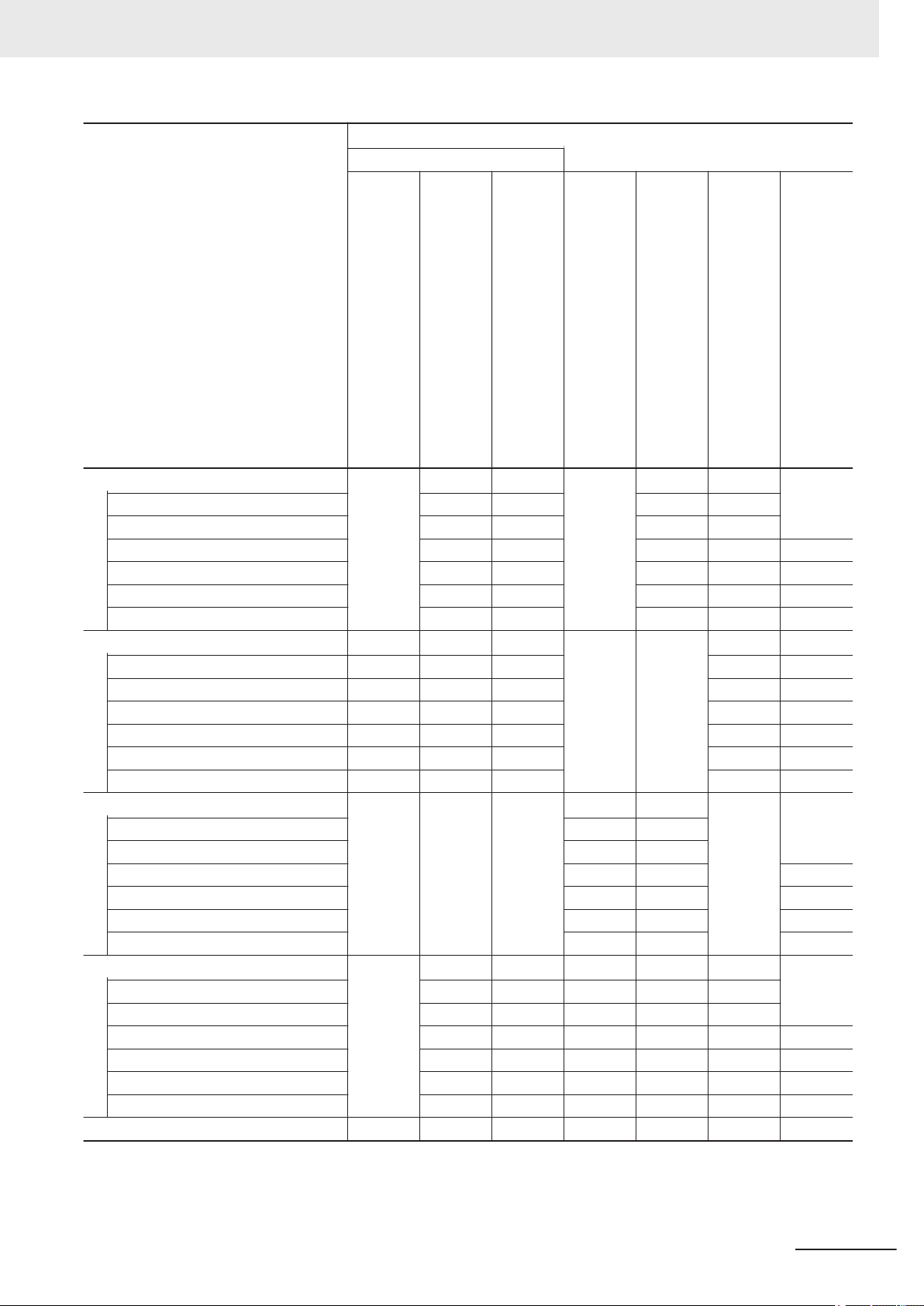

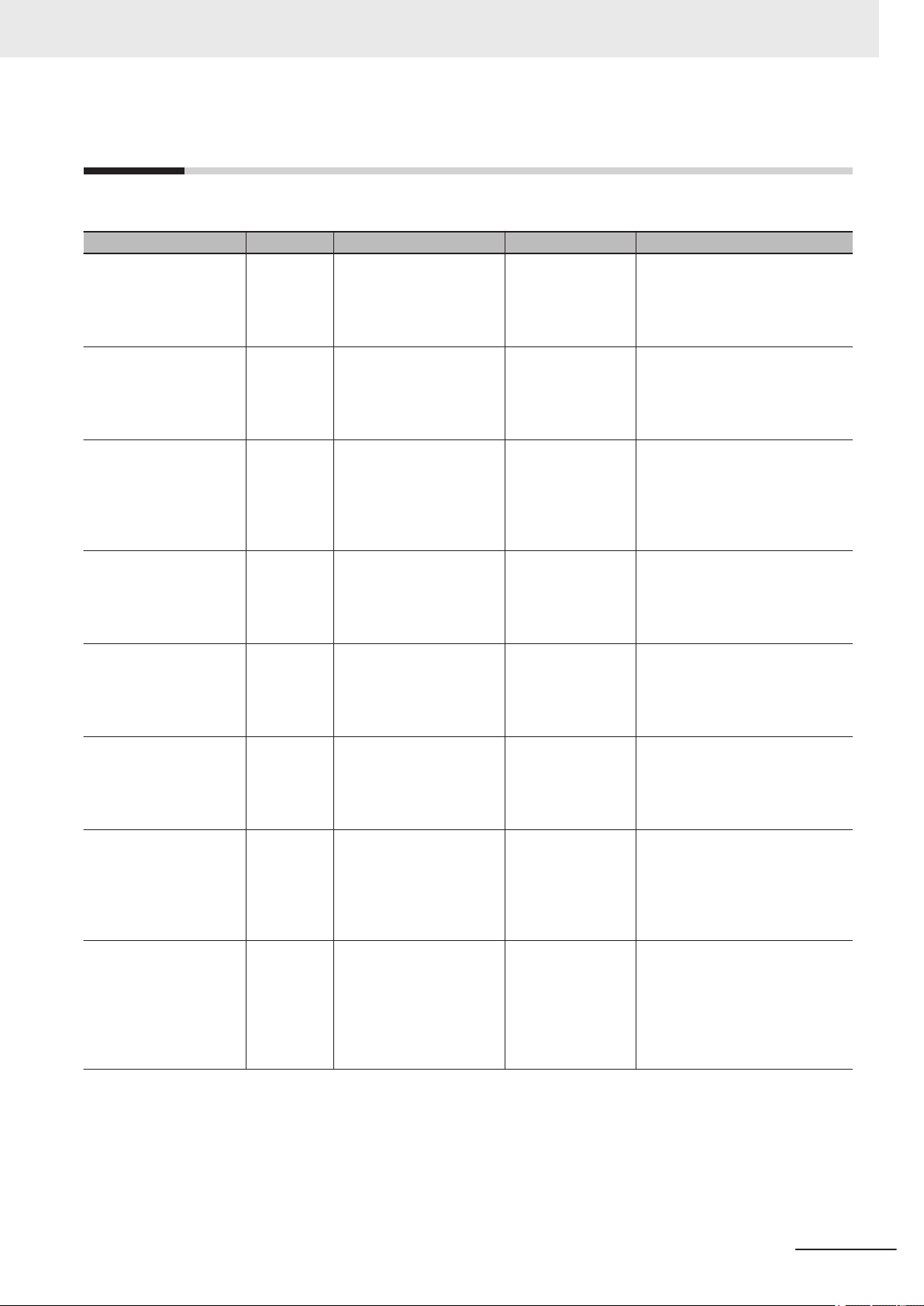

Relevant Manuals

Relevant Manuals

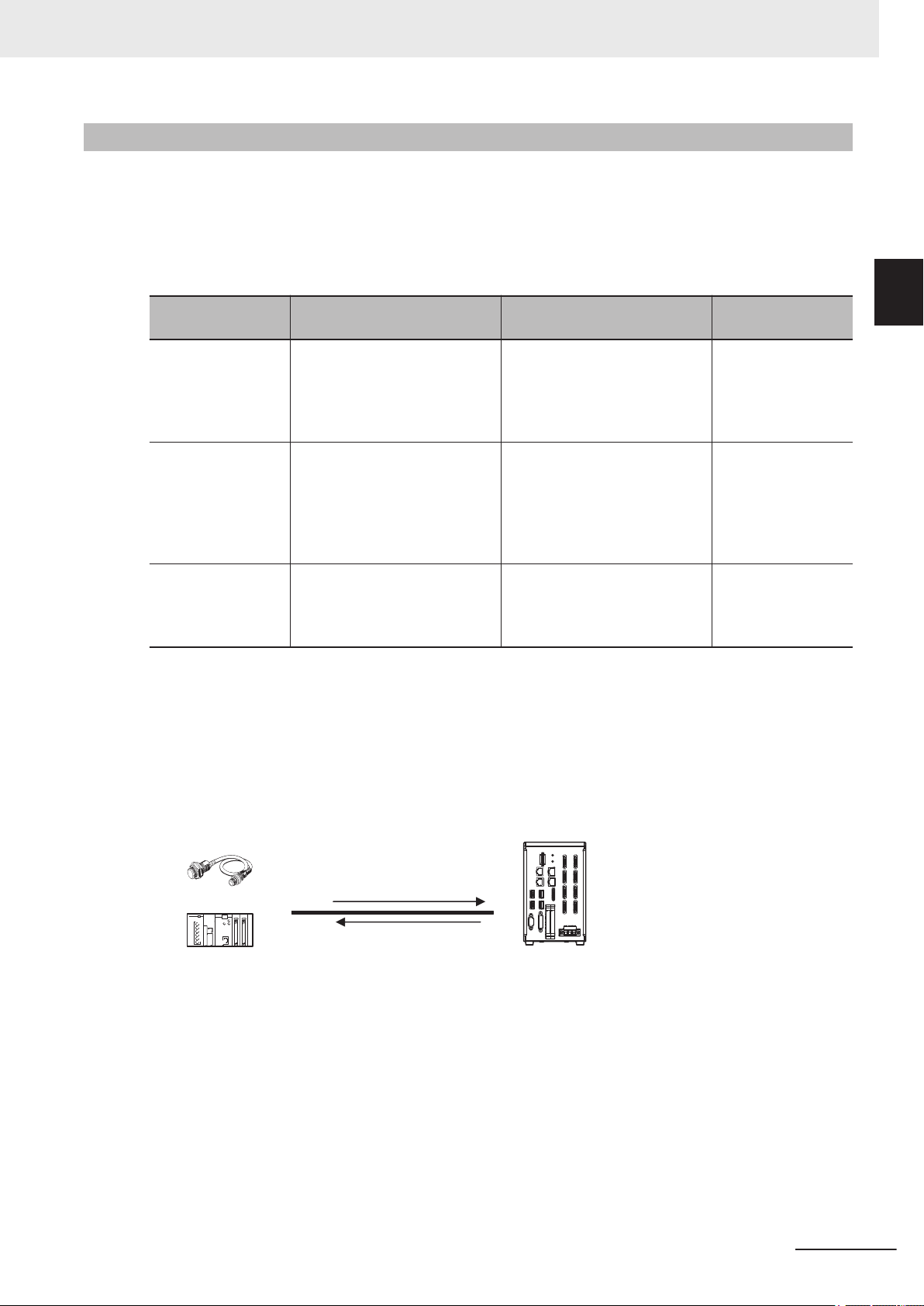

The following table provides the relevant manuals for the FH/FHV Series.

Read all of the manuals that are relevant to your system configuration and application before you use

the FH/FHV Series.

Purpose of use

Basic information

FH/FHV Series Vision System

User's Manual

Hardware Setup Manual

FH Series Vision System

FHV Series Smart Camera

Setup Manual

Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

FH Series Vision System

Macro Customize Functions

Programming Manual

FH/FHV Series Vision System

User’

s Manual for Communications Settings

FH/FHV Series Vision System

Operation Manual for Sysmac Studio

Overview of FH series

Overview of FHV7 series

Setup and Wiring

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the communication setting of Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Setup the Sensor Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

l l

l l

l l

l

l l l l

l

l l

2

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

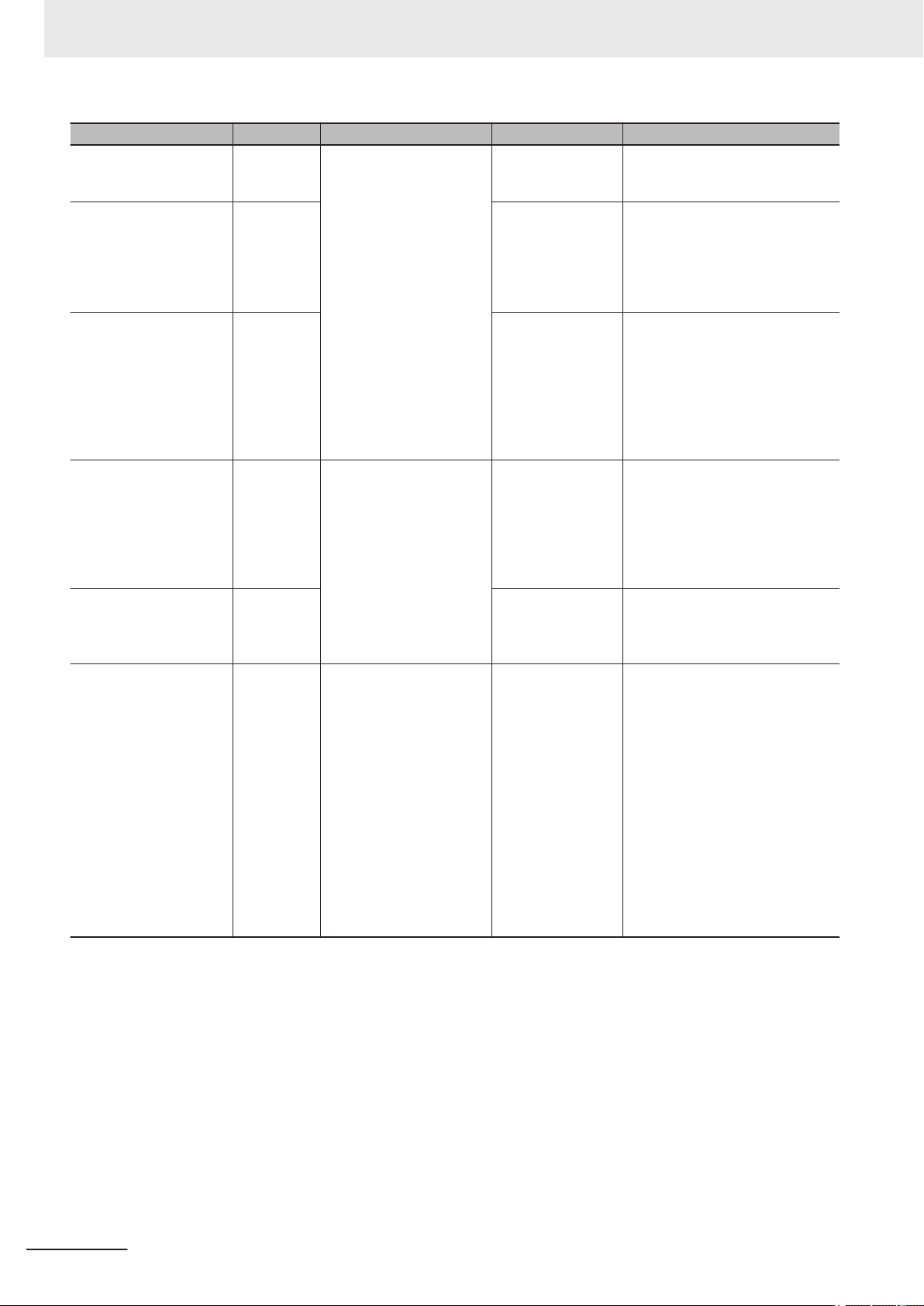

Page 5

Purpose of use

Basic information

FH/FHV Series Vision System

User's Manual

Hardware Setup Manual

FH Series Vision System

FHV Series Smart Camera

Setup Manual

Relevant Manuals

Manual

FH/FHV Series Vision System

Processing Item Function

Reference Manual

FH Series Vision System

Macro Customize Functions

Programming Manual

FH/FHV Series Vision System

User’

s Manual for Communications Settings

FH/FHV Series Vision System

Operation Manual for Sysmac Studio

Create and Set the Scene

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Optimizing the Scene Flow

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Connecting the Controller

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Using Helpful Functions

EtherCAT

EtherNet/IP

PROFINET

Ethernet

RS-232C

Parallel interface

Troubleshooting and Problem Solving

l

l l

l l

l

l l l l

l

l

l

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

3

Page 6

4-9

4 Installation and Wiring

NJ-series CPU Unit Hardware User’s Manual (W500)

stinU gnitnuoM 3-4

4

stnenopmoC rellortnoC gnitcennoC 1-3-4

4-3 Mounting Units

The Units that make up an NJ-series Controller can be connected simply by pressing the Units together

and locking the sliders by moving them toward the back of the Units. The End Cover is connected in the

same way to the Unit on the far right side of the Controller.

1 Join the Units so that the connectors fit exactly.

2 The yellow sliders at the top and bottom of each Unit lock the Units together. Move the sliders

toward the back of the Units as shown below until they click into place.

Precautions for Correct UsePrecautions for Correct Use

4-3-1 Connecting Controller Components

Connector

Hook

Hook holes

Slider

Lock

Release

Move the sliders toward the back

until they lock into place.

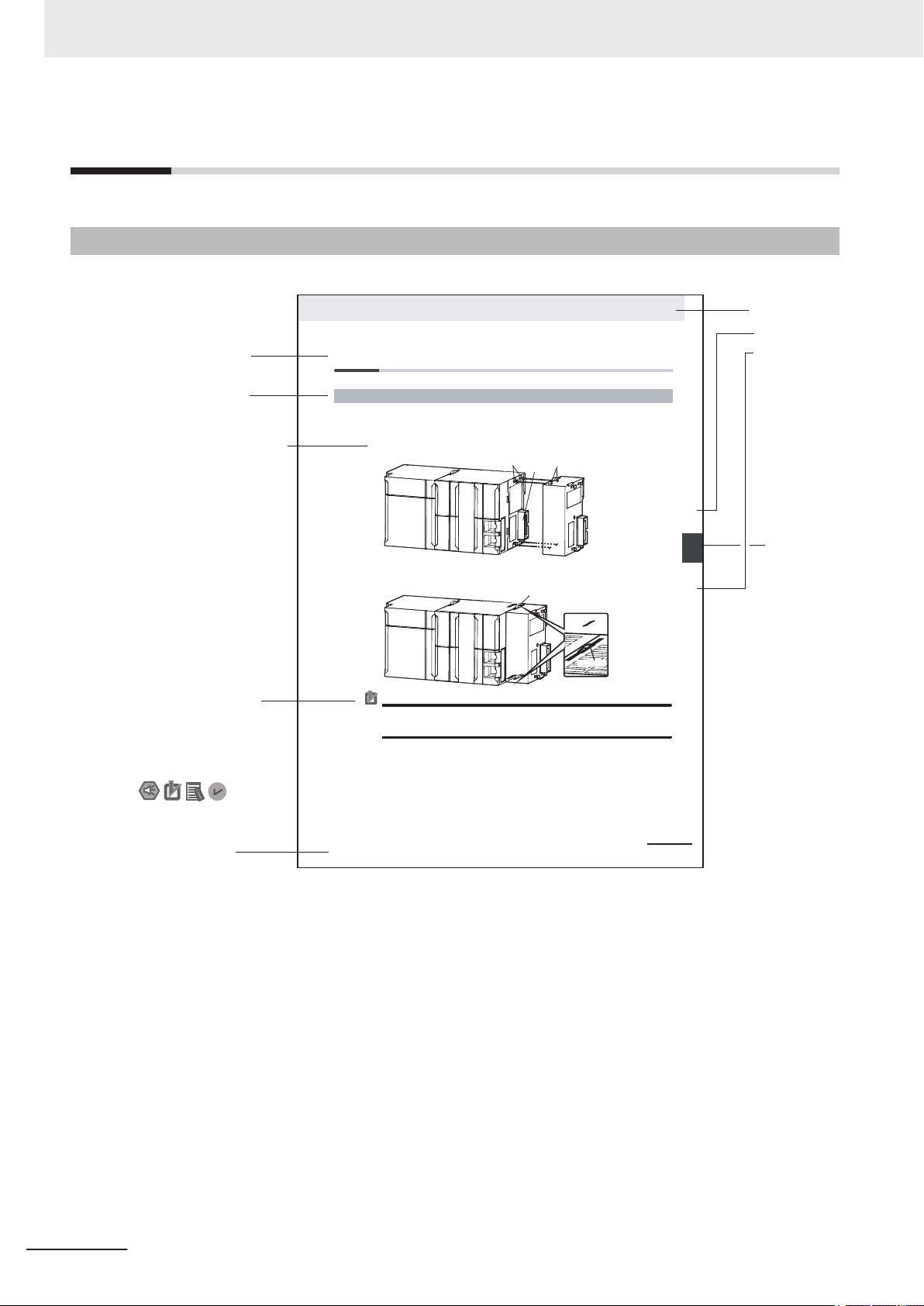

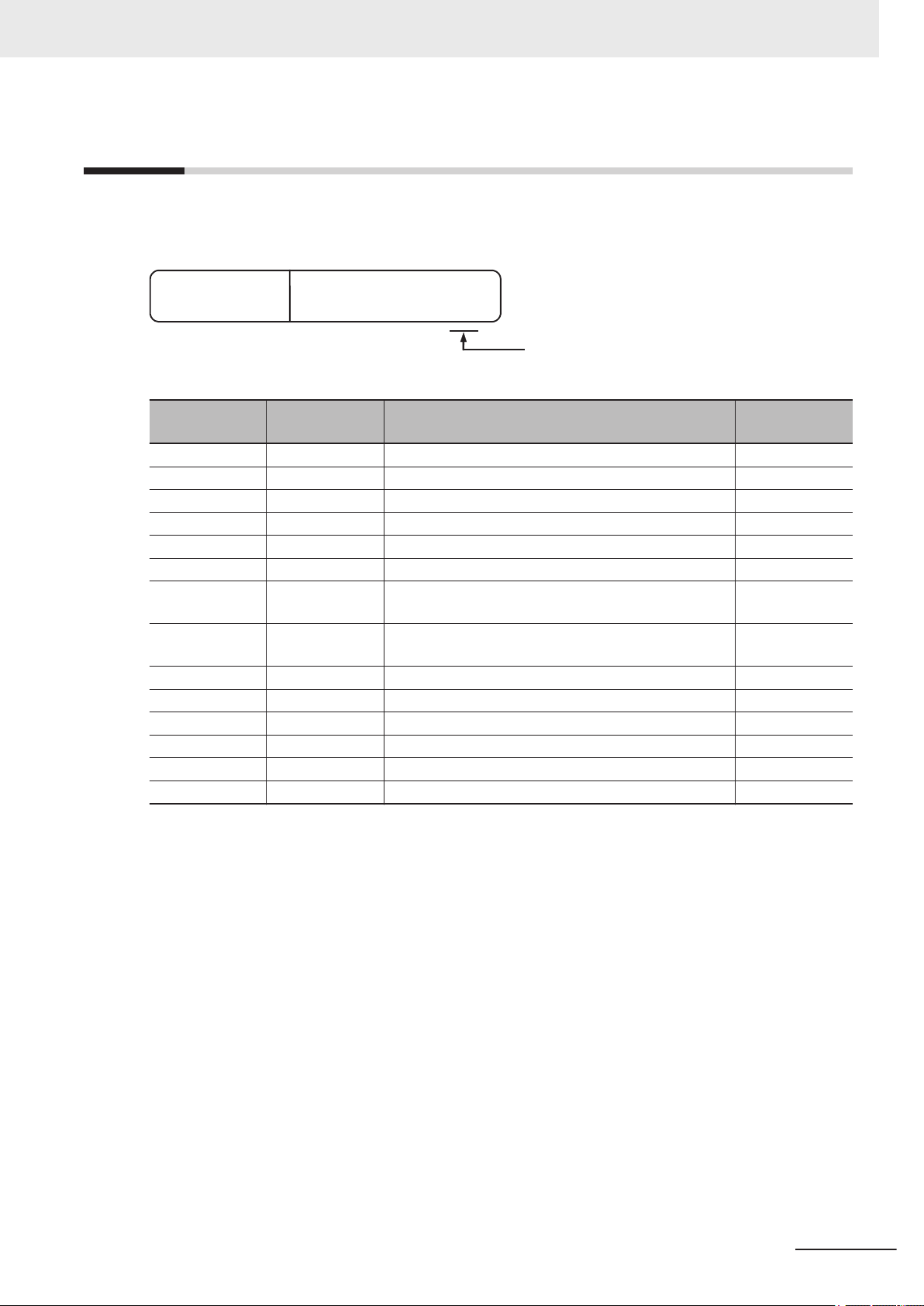

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Gives the current

headings.

Indicates a procedure.

Icons indicate

precautions, additional

information, or reference

information.

Gives the number

of the main section.

The sliders on the tops and bottoms of the Power Supply Unit, CPU Unit, I/O Units, Special I/O

Units, and CPU Bus Units must be completely locked (until they click into place) after connecting

the adjacent Unit connectors.

Manual Structure

Manual Structure

Page Structure

The following page structure is used in this manual.

Note This illustration is provided only as a sample. It may not literally appear in this manual.

4

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 7

Special Information

Special information in this manual is classified as follows:

Precautions for Safe Use

Precautions on what to do and what not to do to ensure safe usage of the product.

Precautions for Correct Use

Precautions on what to do and what not to do to ensure proper operation and performance.

Additional Information

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Manual Structure

Conventions Used in This Manual

Use of Quotation Marks and Brackets

In this manual, menus and other items are indicated as follows.

Bold Menu Indicates the menu names or processing items shown in the menu bar.

Italic Item name Indicates the item names displayed on the screen.

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

5

Page 8

Manual Structure

6

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 9

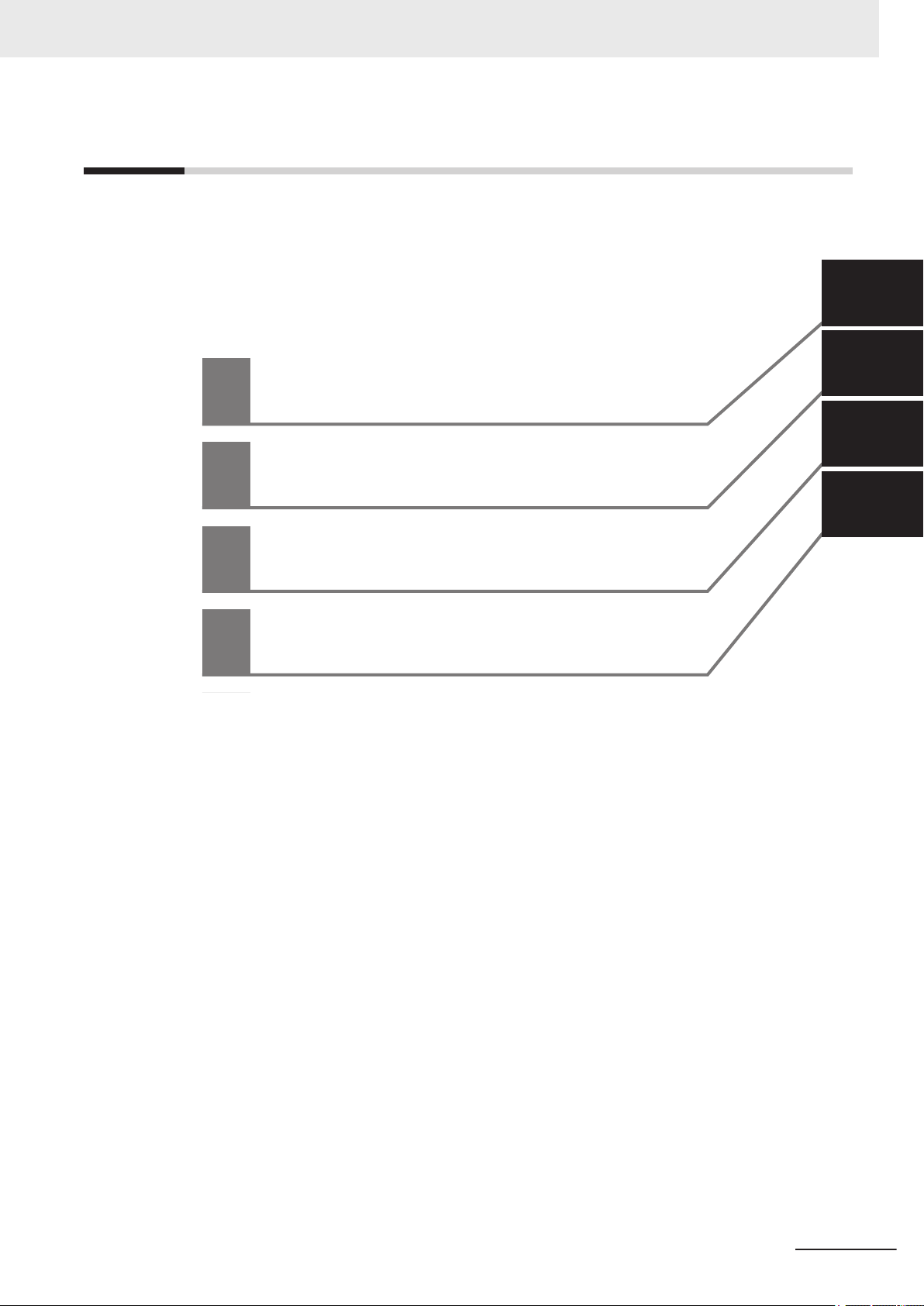

Sections in This Manual

1

2

A

I

1

2

A

I

Overview

Methods for Connecting and

Communicating with External Devices

Appendices

Index

Sections in This Manual

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

7

Page 10

CONTENTS

CONTENTS

Introduction .............................................................................................................. 1

Intended Audience...........................................................................................................................................1

Applicable Products

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 4

Page Structure.................................................................................................................................................4

Special Information .......................................................................................................................................... 5

Conventions Used in This Manual ................................................................................................................... 5

Terms and Conditions Agreement........................................................................ 11

Safety Precautions................................................................................................. 13

.........................................................................................................................................1

Precautions for Safe Use ...................................................................................... 14

Precautions for Correct Use ................................................................................. 15

Regulations and Standards .................................................................................. 16

Related Manuals..................................................................................................... 17

Revision History..................................................................................................... 19

Sections in This Manual .......................................................................................... 7

Section 1 Overview

1-1 Introduction ............................................................................................................................1-2

1-2 Confirming the System Configuration

1-2-1 System Configuration..................................................................................................................1-3

1-3 Communicating with an External Device.............................................................................1-4

1-3-1 Basic Control Operations of the Sensor Controller .....................................................................1-4

1-3-2 Communications between the Sensor Controller and an External Device..................................1-5

1-3-3 Control Methods for the Sensor Controller..................................................................................1-7

1-3-4 Communication Protocols for Communicating with the Sensor Controller..................................1-9

1-3-5 Saving Sensor Controller Data to an External Device ..............................................................1-11

1-4 Control Methods Using an External Device ......................................................................1-13

1-4-1 Control with Control Signals and Status Signals.......................................................................1-13

1-4-2 Command/Response Method ...................................................................................................1-16

1-4-3 Data Output after Measurements..............................................................................................1-17

1-5 Setting Procedures for Communications .......................................................................... 1-28

1-5-1 Communications Setup Procedures..........................................................................................1-28

1-5-2 Communications Protocols and Communications Modules ......................................................1-29

1-6 Differences in Specifications Based on the Communications Protocol ........................1-31

1-6-1 List of Supported Signals by Communications Protocol ...........................................................1-31

1-6-2 Restrictions when Using Different Communication Protocols Simultaneously..........................1-33

1-6-3 Restrictions in Communication Protocols by Operation Mode ..................................................1-33

1-6-4 Models being Compatible with Communication Protocol ..........................................................1-34

.................................................................................1-3

8

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 11

CONTENTS

Section 2 Methods for Connecting and Communicating with Ex-

ternal Devices

2-1 EtherCAT Connections .......................................................................................................... 2-4

2-1-1 Introduction to EtherCA

2-1-2 Structure of CAN Application Protocol over EtherCAT (CoE) .....................................................2-7

2-1-3 EtherCAT Slave Information Files (ESI Files) .............................................................................2-8

2-1-4 Transitions of Communications States........................................................................................2-9

2-1-5 Process Data Objects (PDOs) ..................................................................................................2-10

2-1-6 Service Data Objects (SDOs) ...................................................................................................2-13

2-1-7 Communications between Master and Slaves for EtherCAT ...................................................2-14

2-1-8 Communication Method of FH Sensor Controller Connected by EtherCAT ..............................2-15

2-1-9 Communications Settings .........................................................................................................2-20

2-1-10 Communications Module Settings (Startup Settings)................................................................2-22

2-1-11 Communication Specifications Settings ....................................................................................2-23

2-1-12 Output Data Settings (Processing Item Registration) ...............................................................2-28

2-1-13 Setting Output Data (Numerical Values/Character Strings) ......................................................2-31

2-1-14 EtherCAT Network Configuration Settings ................................................................................2-37

2-1-15 Communication Test..................................................................................................................2-38

2-1-16 I/O Ports by Area (PDO Mapping) and Memory Allocation .......................................................2-39

2-1-17 I/O Signals.................................................................................................................................2-45

2-1-18 Measurement Results for which Output is Possible (Fieldbus Data Output) ............................2-49

2-1-19 Command List ...........................................................................................................................2-51

2-1-20 Measurement Trigger Input.......................................................................................................2-54

2-1-21 Command Response Processing..............................................................................................2-55

2-1-22 Data Output...............................................................................................................................2-57

2-1-23 Timing Chart..............................................................................................................................2-60

2-1-24 EtherCAT Troubleshooting ........................................................................................................2-64

2-1-25 Sysmac Error Status .................................................................................................................2-66

2-1-26 Sysmac Device Features ..........................................................................................................2-84

2-1-27 Object Dictionary.......................................................................................................................2-87

2-2 Communicating by PLC Link ............................................................................................ 2-126

2-2-1 Communications Processing Flow ..........................................................................................2-126

2-2-2 Communications Settings .......................................................................................................2-128

2-2-3 Communications Module Settings (Startup Settings)..............................................................2-129

2-2-4 Communication Specifications Settings ..................................................................................2-131

2-2-5 Output Data Settings (Processing Item Registration) .............................................................2-152

2-2-6 Setting Output Data (Numerical Values and Character Strings) .............................................2-157

2-2-7 Testing Communications .........................................................................................................2-163

2-2-8 Memory Allocation...................................................................................................................2-167

2-2-9 I/O Signals...............................................................................................................................2-171

2-2-10 Output Items............................................................................................................................2-174

2-2-11 Command List .........................................................................................................................2-175

2-2-12 Command Response Processing............................................................................................2-179

2-2-13 Data Output.............................................................................................................................2-182

2-2-14 Timing Chart............................................................................................................................2-184

2-2-15 PLC Link Troubleshooting.......................................................................................................2-187

2-3 Communicating by EtherNet/IP ........................................................................................2-190

2-3-1 Introduction to EtherNet/IP......................................................................................................2-190

2-3-2 Data Exchange with EtherNet/IP.............................................................................................2-191

2-3-3 EtherNet/IP Communications..................................................................................................2-194

2-3-4 Communications Processing Flow ..........................................................................................2-195

2-3-5 Communications Settings .......................................................................................................2-197

2-3-6 Communications Module Settings (Startup Settings)..............................................................2-198

2-3-7 Communication Specifications Settings ..................................................................................2-199

2-3-8 Setting Tag Data Link ..............................................................................................................2-206

2-3-9 Output Data Settings (Processing Item Registration) .............................................................2-211

2-3-10 Setting Output Data (Numerical Values and Character Strings) .............................................2-216

2-3-11 Testing Communications .........................................................................................................2-222

2-3-12 Memory Allocation...................................................................................................................2-224

2-3-13 I/O Signals...............................................................................................................................2-234

2-3-14 Output Items............................................................................................................................2-238

T.............................................................................................................2-4

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

9

Page 12

CONTENTS

2-4 Communicating by PROFINET .........................................................................................2-259

2-5 Non-procedure Communications ..................................................................................... 2-313

2-6 Parallel Communications ..................................................................................................2-351

2-3-15 Command List .........................................................................................................................2-239

2-3-16 Command Response Processing

2-3-17 Data Output.............................................................................................................................2-247

2-3-18 Timing Chart............................................................................................................................2-249

2-3-19 Communicating with the Sensor Controller using EtherNet/IP Message Communications ....2-252

2-3-20 Example for Command Settings .............................................................................................2-255

2-3-21 EtherNet/IP Troubleshooting...................................................................................................2-256

2-4-1 Overview of PROFINET ..........................................................................................................2-259

2-4-2 PROFINET Communications ..................................................................................................2-262

2-4-3 Communications Processing Flow ..........................................................................................2-263

2-4-4 Communications Settings .......................................................................................................2-265

2-4-5 Communications Module Settings (Startup Settings)..............................................................2-266

2-4-6 Communication Specifications Settings ..................................................................................2-267

2-4-7 IO Data Communication Settings............................................................................................2-273

2-4-8 Output Data Settings (Processing Item Registration) .............................................................2-275

2-4-9 Setting Output Data (Numerical Values and Character Strings) .............................................2-279

2-4-10 Testing Communications .........................................................................................................2-285

2-4-11 Memory Allocation...................................................................................................................2-288

2-4-12 I/O Signals...............................................................................................................................2-294

2-4-13 Output Items............................................................................................................................2-298

2-4-14 Command List .........................................................................................................................2-299

2-4-15 Command Response Processing............................................................................................2-302

2-4-16 Data Output.............................................................................................................................2-305

2-4-17 Timing Chart............................................................................................................................2-307

2-4-18 PROFINET Troubleshooting ...................................................................................................2-310

2-5-1 Communications Processing Flow ..........................................................................................2-313

2-5-2 Communications Setup Procedures .......................................................................................2-314

2-5-3 Communications Module Settings (Startup Settings)..............................................................2-314

2-5-4 Communications Specifications Settings ................................................................................2-316

2-5-5 Output Data Settings (Processing Item Registration) ............................................................2-321

2-5-6 Output Data Settings (Numerical Values/Character Strings) ..................................................2-327

2-5-7 Testing Communications .........................................................................................................2-335

2-5-8 Output Items............................................................................................................................2-338

2-5-9 Command Formats .................................................................................................................2-340

2-5-10 Command List .........................................................................................................................2-342

2-5-11 Output Format .........................................................................................................................2-346

2-5-12 Non-procedure Communications Troubleshooting..................................................................2-348

2-6-1 Communications Processing Flow .........................................................................................2-351

2-6-2 Communications Setup Procedures .......................................................................................2-353

2-6-3 Communications Module Settings (Startup Settings)..............................................................2-354

2-6-4 Communications Specifications Settings ...............................................................................2-355

2-6-5 Output Data Settings (Processing Item Registration) .............................................................2-364

2-6-6 Output Data Settings (Numerical value/Judgment) ................................................................2-370

2-6-7 Testing Communications .........................................................................................................2-376

2-6-8 I/O Signals...............................................................................................................................2-378

2-6-9 Output Items............................................................................................................................2-389

2-6-10 Command Formats .................................................................................................................2-391

2-6-11 Time Charts.............................................................................................................................2-395

2-6-12 Parallel Troubleshooting..........................................................................................................2-409

............................................................................................2-243

Appendices

A-1 Command Control................................................................................................................. A-2

A-1-1 Parameter Notation Examples for Command Control

A-1-2 Details of Commands Used in EtherCAT Communications ....................................................... A-6

A-1-3 Command List ............................................................................................................................ A-7

A-1-4 Command Details for PLC Link, EtherNet/IP, EtherCAT, and PROFINET ............................... A-15

A-1-5 Non-procedure Command Details............................................................................................ A-85

10

................................................................ A-2

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 13

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

• Warranties

Exclusive Warranty:

Omron's exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed

in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations:

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NONINFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy:

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products unless Omron’s analysis confirms that the Products were properly handled, stored, installed and maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of any

Products by Buyer must be approved in writing by Omron before shipment. Omron Companies shall

not be liable for the suitability or unsuitability or the results from the use of Products in combination

with any electrical or electronic components, circuits, system assemblies or any other materials or

substances or environments. Any advice, recommendations or information given orally or in writing,

are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

• Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS

IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

Application Considerations Warranties

• Suitablity of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

11

Page 14

Terms and Conditions Agreement

and limitations of use which apply to the Product. This information by itself is not sufficient for a

complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use.

Buyer shall be solely responsible for determining appropriateness of the particular Product with respect to Buyer’

es.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A

WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

• Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product,

or any consequence thereof.

Disclaimers

• Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide

for the user in determining suitability and does not constitute a warranty. It may represent the result

of Omron’s test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron’s Warranty and Limitations of Liability.

• Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and

other reasons. It is our practice to change part numbers when published ratings or features are

changed, or when significant construction changes are made. However, some specifications of the

Product may be changed without any notice. When in doubt, special part numbers may be assigned

to fix or establish key specifications for your application. Please consult with your Omron’s representative at any time to confirm actual specifications of purchased Product.

• Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

s application, product or system. Buyer shall take application responsibility in all cas-

12

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 15

Safety Precautions

For details of Safety Precautions, refer to Safety Precautions in the Vision System FH/FHV Series

User's Manual (Cat. No. Z365).

Safety Precautions

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

13

Page 16

Precautions for Safe Use

Precautions for Safe Use

For details of Precautions for Safe Use, refer to Precautions for Safe Use in the Vision System

FH/FHV Series User's Manual (Cat. No. Z365).

14

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 17

Precautions for Correct Use

For details of Precautions for Correct Use, refer to Precautions for Correct Use in the Vision System

FH/FHV Series User's Manual (Cat. No. Z365).

Precautions for Correct Use

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

15

Page 18

Regulations and Standards

Regulations and Standards

For details of Regulations and Standards, refer to Regulations and Standards in the Vision System

FH/FHV Series User's Manual (Cat. No. Z365).

16

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 19

Related Manuals

The followings are the manuals related to this manual. Use these manuals for reference.

Name of Manual Cat. No.. Model Purpose Contents

Vision System

FH Instruction Sheet

Vision System

FH Instruction Sheet

Vision System

FH-L Instruction Sheet

Smart Camera

FHV Instruction Sheet

Smart Camera

Lighting Module

TM Instruction Sheet

FHV-L

Smart Camera Lens Module

FHV-LEM-S Instruction

Sheet

Smart Camera High-Speed

Lens Module

FHV-LEM-H Instruction

Sheet

FHV Series

Smart Camera

Setup Manual

9608337-2

3102269-4

9606631-1

3129404-0

3129276-4

3128622-5

3129408-2

Z408

FH-1£££

FH-1£££-££

FH-3£££

FH-3£££-££

FH-2£££

FH-2£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FHV7£-£££££-C

FHV-LTM££

-LEM-S££

FHV

-LEM-H££

FHV

FHV7£-£££££-C

FHV7£-£££££-S££

FHV7£-£££££-S££-£

£

FHV7£-£££££-H££

FHV7£-£££££-H££-£

£

To confirm the safety

and usage precautions of the V

System FH series

Sensor Controller

To confirm the safety

and usage precautions of the V

System FH series

Sensor Controller

To confirm the safety

and usage precautions of the Vision

System FH-Lite series Sensor Control-

.

ler

To confirm the safety

and usage precautions of the Smart

Camera FHV7 series.

To confirm the safety

and usage precautions of the Smart

camera lighting module FHV-LTM.

To confirm the safety

and usage precautions of the Smart

camera lens module

FHV-LEM-S.

To confirm the safety

and usage precautions of the Smart

camera high-speed

lens module FHVLEM-H.

When User want to

know about the hardware specifications

or to setup the Smart

camera FHV series.

ision

.

ision

.

Describes the definitions of basic

terms, meaning of signal words, and

precautions for correct use of FH

series in the manual.

To confirm the safety and usage precautions of the Vision System FH

series Sensor Controller.

Describes the definitions of basic

terms, meaning of signal words, and

precautions for correct use of FH-L

series in the manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

FHV7 series in the manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the lighting module FHV-LTM in the

manual.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the lens module FHV-LEM-S.

Describes the definitions of basic

terms, the meaning of signal words,

and precautions for correct use of

the high-speed lens module FHVLEM-H.

Describes FHV series specifications,

dimensions, part names, I/O information, installation information, and

wiring information.

Related Manuals

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

17

Page 20

Related Manuals

Name of Manual Cat. No.. Model Purpose Contents

Vision System

FH/FHV Series

User's Manual

Vision System

FH/FHV series

Processing Item Function

Reference Manual

Vision System

FH/FHV Series

User's manual for Communications Settings

Vision System

FH series

Hardware Setup Manual

ision System

V

FH series

Macro Customize Functions Programming Manual

Vision System

FH/FHV Series

Operation Manual

for Sysmac Studio

Z365

Z341 When User confirm

Z342 When User confirm

Z366

Z367 When User operate

Z343

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FHV7£-£££££-C

FHV7£-£££££-S££

FHV7£-£££££-S££-£

£

FHV7£-£££££-H££

FHV7£-£££££-H££-£

£

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FH-L£££

FH-L£££-££

FH-1£££

FH-1£££-££

FH-2£££

FH-2£££-££

FH-3£££

FH-3£££-££

FH-5£££

FH-5£££-££

FHV7£-£££££-C

FHV7£-£££££-S££

FHV7£-£££££-S££-£

£

FHV7£-£££££-H££

FHV7£-£££££-H££-£

£

When User want to

know about the

FH/FHV series.

the details of each

processing items at

the create the measurement flow or operate it.

the setting of communication functions.

When User want to

know about the

Hard-ware specifications or to setup the

Sensor Controller of

ision System

the V

FH series.

or programming using Macro Customize

functions.

When User connect

to NJ/NX series via

T communi-

EtherCA

cation.

Describes the soft functions, setup,

and operations to use FH/FHV series/

Describes the software functions,

settings, and operations for using

FH/FHV series.

Describes the functions, settings,

and communications methods for

communication between FH/FHV

series and PLCs.

The following communications protocol are described.

Parallel, PLC Link, EtherNet/IP

EtherCA

Describes FH series specifications,

dimensions, part names, I/O information, installation information, and

wiring information.

Describes the functions, settings,

and operations for using Macro Customize function of the FH series.

Describes the operating procedures

for setting up and operating FH/FHV

series Vision Sensors from the Sysmac Studio FH/FHV T

,

T, and Non-procedure.

ools.

18

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 21

Revision History

Revision code

Cat. No. Z342-E1-14

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision History

Rev. Code Rev. Date Revision Contents

01 Jul. 2013 First edition Ver. 5.00

02 Aug. 2013 Additions for software version upgrade Ver. 5.10

03 Sep. 2013 Additions for software version upgrade Ver. 5.12

04 Jan. 2014 Additions for software version upgrade Ver. 5.20

05 Jun. 2014 Additions for software version upgrade Ver. 5.30

06 Oc. 2015 Additions for software version upgrade Ver. 5.50

07 Apr. 2016 Additions for software revision upgrade and descrip-

tion of FH-L series

08 Mar. 2017 Corrected mistakes.

Additions for software revision upgrade

09 Jun. 2017 Additions for software version upgrade Ver. 5.72

10 Jul. 2018 Additions for software version upgrade Ver. 6.10

11 Nov. 2018 Additions for software version upgrade Ver. 6.20

12 Jul. 2019 Additions for software version upgrade Ver. 6.30

13 Nov. 2019 Corrected mistakes. Ver. 6.30

14 Jun. 2020 Corrected mistakes. Ver. 6.40

Software Ver-

sion

Ver. 5.60

Ver. 5.71

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

19

Page 22

Revision History

20

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 23

Overview

This section describes communication specifications to be used for communications

between FH/FHV and an external device, and the Sensor Controller control methods.

1

1

1-1 Introduction

1-2 Confirming the System Configuration .........................................................1-3

1-2-1 System Configuration ..................................................................................... 1-3

1-3 Communicating with an External Device..................................................... 1-4

1-3-1 Basic Control Operations of the Sensor Controller......................................... 1-4

1-3-2 Communications between the Sensor Controller and an External Device ..... 1-5

1-3-3 Control Methods for the Sensor Controller ..................................................... 1-7

1-3-4 Communication Protocols for Communicating with the Sensor Controller ..... 1-9

1-3-5 Saving Sensor Controller Data to an External Device ...................................1-11

1-4 Control Methods Using an External Device............................................... 1-13

1-4-1 Control with Control Signals and Status Signals .......................................... 1-13

1-4-2 Command/Response Method ....................................................................... 1-16

1-4-3 Data Output after Measurements ................................................................. 1-17

1-5 Setting Procedures for Communications ..................................................1-28

1-5-1 Communications Setup Procedures ............................................................. 1-28

1-5-2 Communications Protocols and Communications Modules.......................... 1-29

1-6 Differences in Specifications Based on the Communications Pro-

tocol................................................................................................................ 1-31

1-6-1 List of Supported Signals by Communications Protocol ............................... 1-31

1-6-2 Restrictions when Using Different Communication Protocols Simulta-

1-6-3 Restrictions in Communication Protocols by Operation Mode...................... 1-33

1-6-4 Models being Compatible with Communication Protocol.............................. 1-34

.................................................................................................... 1-2

neously .......................................................................................................... 1-33

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1-1

Page 24

1 Overview

1-1

Introduction

This section describes a basic overview of the Sensor Controller control methods and the communication specifications, which is required when the FH/FHV series communicate with an external device.

Confirming the System Configuration

This section describes the external device configuration that is required to perform measurement processing

with the FH/FHV.

For details, refer to

Communicating with an External Device

This section describes the basic operations of the Sensor Controller, and the communication specifications between the Sensor Controller and an external device.

For Basic Flow of Communications and Signals, refer to 1-3-1 Basic Control Operations of the Sensor Control-

on page

ler

1-4

• Process from Starting Measurements at the Sensor Controller to Data Output:

For details, refer to 1-3-2 Communications between the Sensor Controller and an External Device on page

1-5.

• Sensor Controller Control Methods (Control Signals, Commands, etc.)

For details, refer to 1-3-3 Control Methods for the Sensor Controller on page 1-7.

• Types of Communication Protocols for Communicating with the Sensor Controller

For details, refer to 1-3-4 Communication Protocols for Communicating with the Sensor Controller on page

1-9.

• Moving Data between the Sensor Controller and an External Device

For details, refer to 1-3-5 Saving Sensor Controller Data to an External Device on page 1-11.

Control Methods Using an External Device

This section describes the methods that you can use to control the Sensor Controller from an external device.

• Control with Control Signals and Status Signals

For details, refer to 1-4-1 Control with Control Signals and Status Signals on page 1-13.

• Command/Response Method

For details, refer to

• Data Output after Measurements

For details, refer to 1-4-3 Data Output after Measurements on page 1-17.

Setting Procedures for Communications

This section describes the procedures that are required to set up communications before starting communications between the Sensor Controller and an external device.

For details, refer to 1-5-1 Communications Setup Procedures on page 1-28.

ferences in Specifications Based on the Communications Protocol

Dif

This section describes the types and differences of communication protocols that are used for communications

with the Sensor Controller

For details, refer to

1-2 Confirming the System Configuration on page 1-3.

↓

↓

1-4-2 Command/Response Method on page 1-16.

↓

↓

.

1-5-2 Communications Protocols and Communications Modules on page 1-29.

1-2

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 25

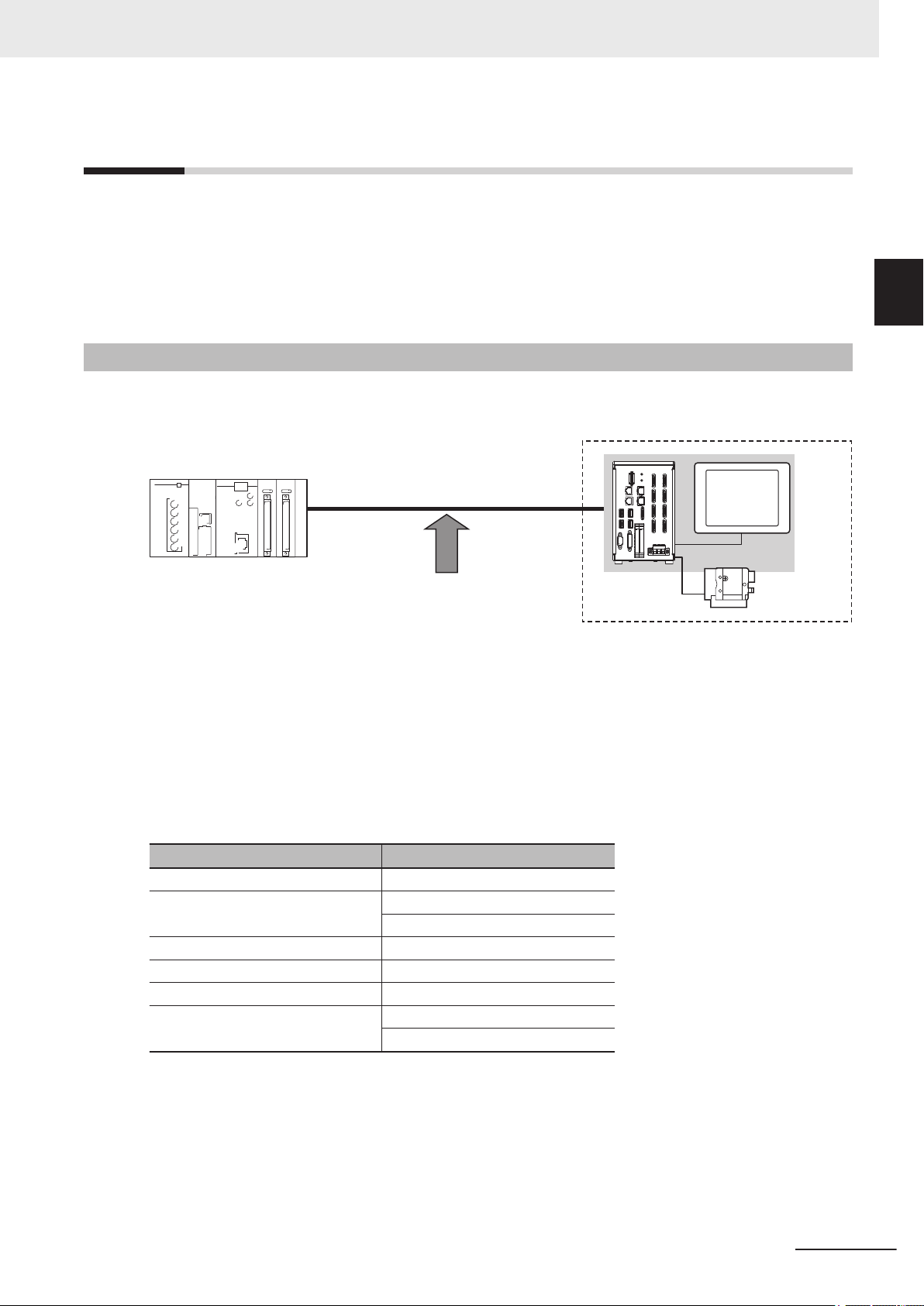

Sensor Controller

External device (e.g, PLC)

Camera

1 Overview

1-2 Confirming the System Con-

1-2

1-2-1

Confirming the System Configuration

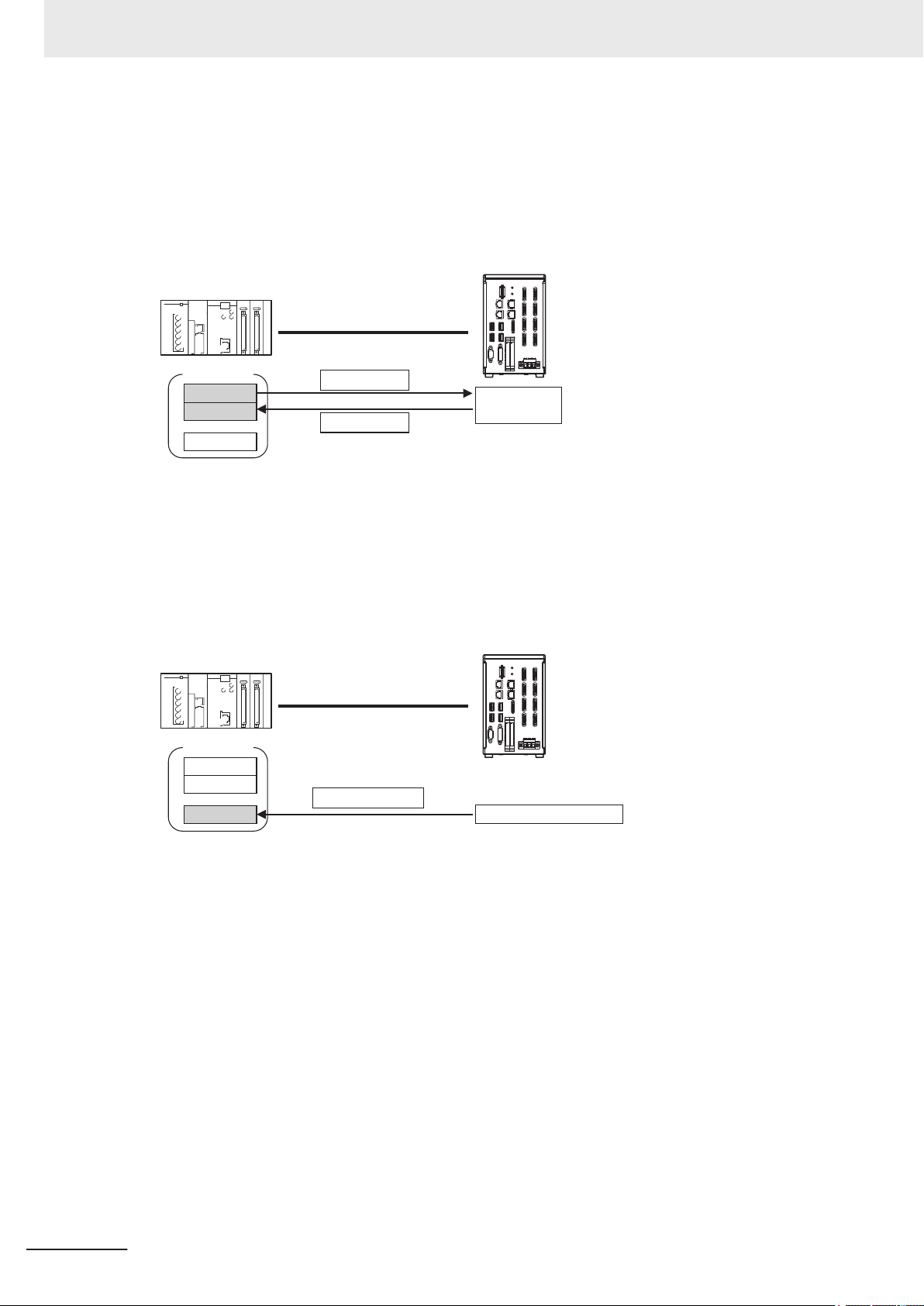

The FH/FHV are Vision Systems that perform measurement processing through the Sensor Controller

on measurement objects imaged by a Camera.

In a system configuration connected to an external device such as a PLC or a PC (personal computer), measurement commands can be received from and measurement results can be output to the external device.

System Configuration

An overview of the FH/FHV series system configuration is shown below.

figuration

1

1-2-1 System Configuration

The Sensor Controller and an external device (PLC, etc.) are connected with a communication cable

and communicate with each other using various communication protocols. For details of various com-

e

munication protocols, refer to S

Devices on page 2-1.

An LCD monitor (BOX type only) for operation and monitoring and a camera are connected to the

Sensor Controller unit.

For details, refer to Vision System FH Series User's Manual (Cat. No. Z365), Smart Camera FHV

Series Setup Manual (Cat. No. Z408), and the Instruction Manual provided with each individual device.

Communications Protocol Communication Cable

Parallel Parallel I/O cable

PLC Link

EtherNet/IP Ethernet cable

EtherCAT Ethernet cable

PROFINET Ethernet cable

Non-procedure

ction 2 Methods for Connecting and Communicating with External

Ethernet cable

RS-232C cable

Ethernet cable

RS-232C cable

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1-3

Page 26

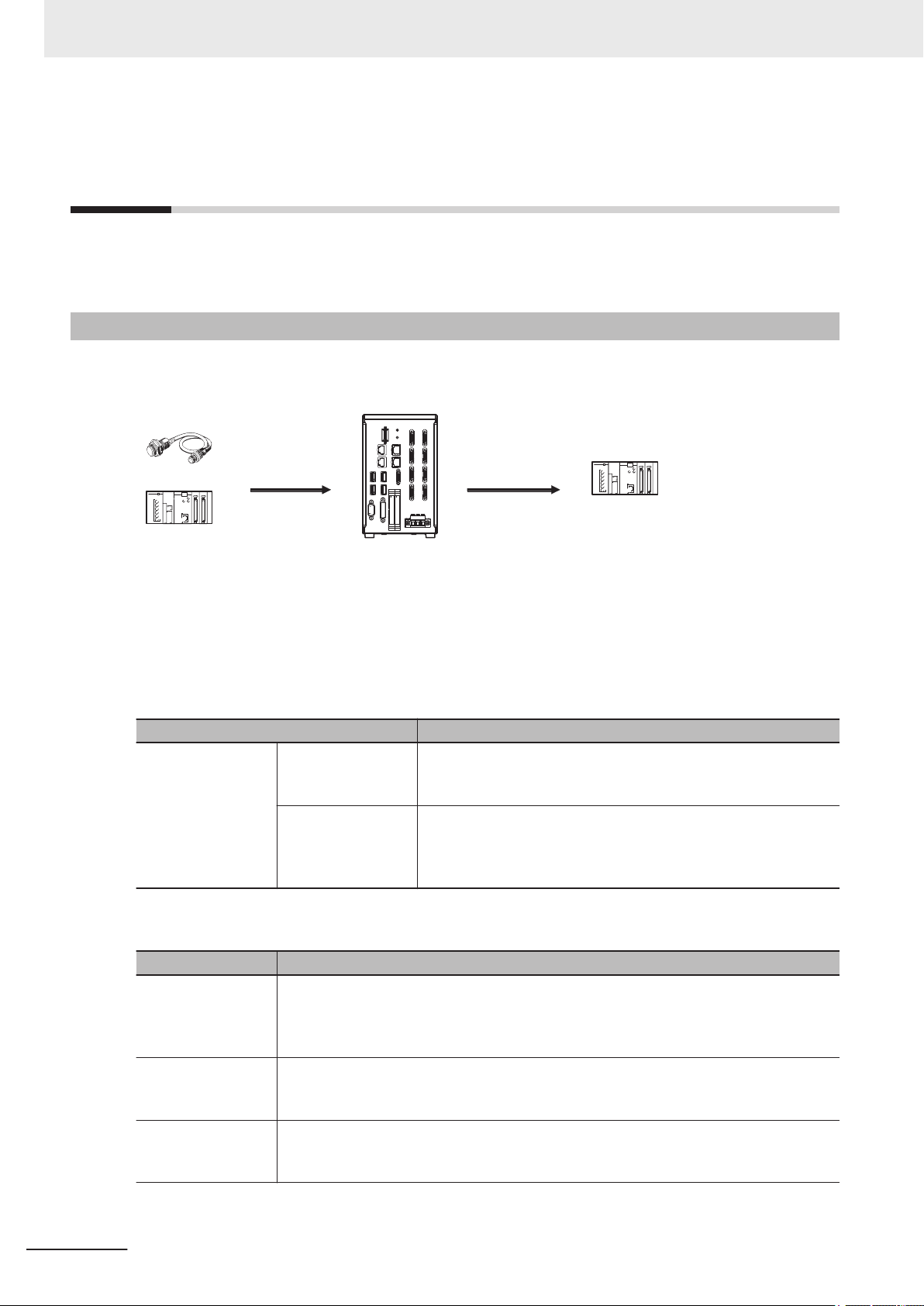

Trigger sensor

PLC

External device

External device

PLC

The measurement

results are output.

• Status signals

• Overall judgement

• Measured values

• Character output

Sensor Controller

Measurement triggers

and other control

commands are input.

1 Overview

1-3

1-3-1

Communicating with an External Device

This section describes the communication specifications, control methods in communications, and settings required before starting communications with an external device.

Basic Control Operations of the Sensor Controller

The following figure shows basic communications, and the flow of signals and data, between an external device and the Sensor Controller.

1-4

The following methods are used to exchange commands and data, between an external device and

the Sensor Controller.

From an external device to the Sensor Controller

Type Description

Control signals

(Input signal)

Control commands

Communications

command input

From the Sensor Controller to an external device

Type Description

When the Sensor Controller recognizes a control signal or communication command in-

Status signals

Overall judgment

Measured values

put and starts measurement processing, it reports its status to the external device using

status signals such as a BUSY signal. For details, refer to Control Signals and Status

Signals on page 1-13.

NG is output whenever there is one or more NGs in the judgment results for multiple

processing items. It can be output using the OR signal or the TJG output parameter. For

details, refer to

The measured values for processing items are output. The items to be output need to be

previously registered to the output data (data 0 to 7) using processing items for output.

For details, refer to Settings Required for Data Output on page 1-21.

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

A measurement is performed when a measurement trigger (i.e.,

STEP signal: ON) is input. For information of control signals, refer

to Control Signals and Status Signals on page 1-13.

Y

ou can send commands to perform measurements, switch scene

groups, or perform other tasks. The communication commands

depend on the communication protocol used. For details, refer to

the section for each communication protocol.

Control Signals and Status Signals on page 1-13.

Page 27

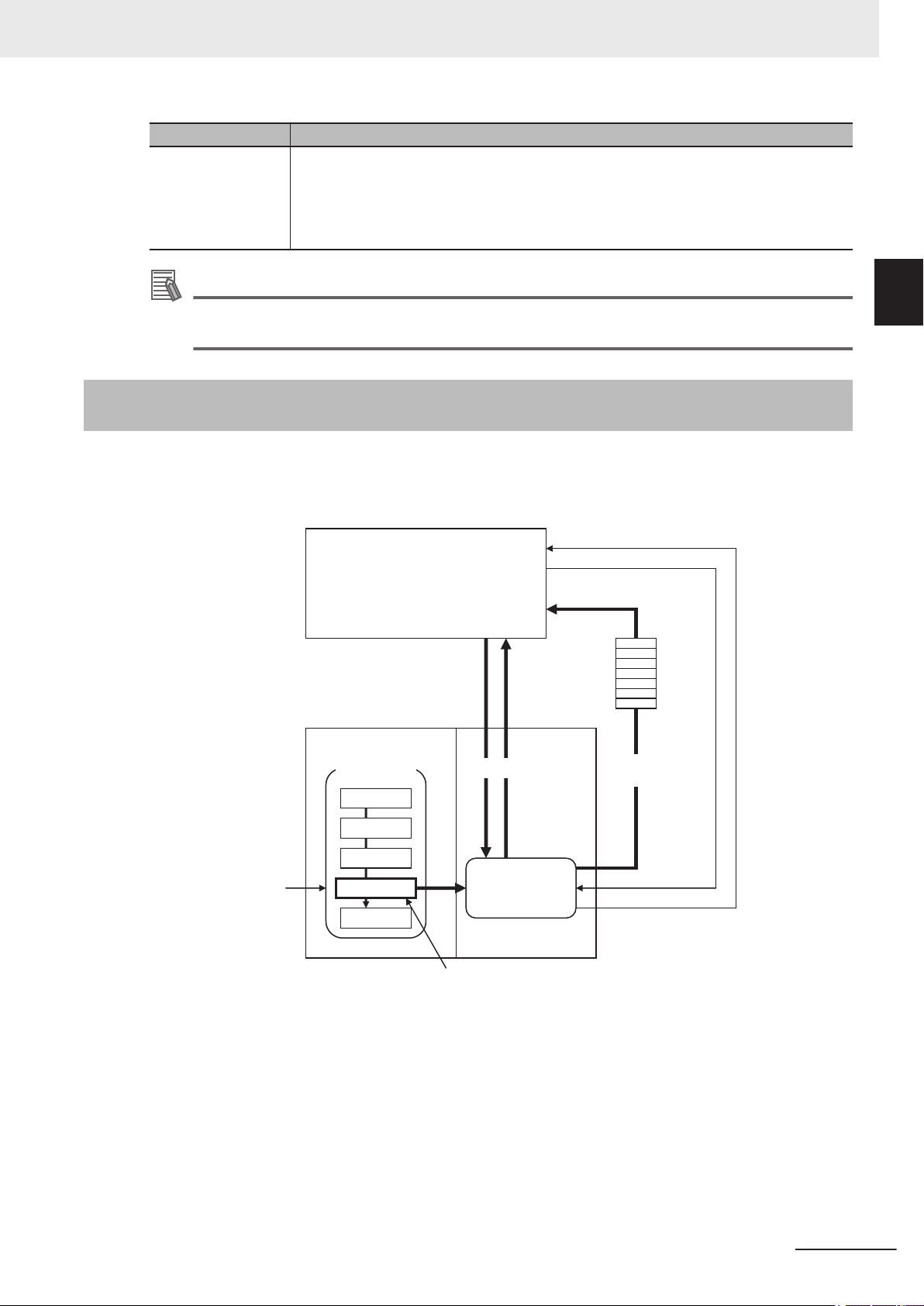

Type Description

PLC or other external device

Camera Input

Search

Output Unit

Measurement

flow

Sensor Controller

Communications

Module

Communications processing

Example: Starting a

measurement, etc.

Response

Data output request

(DSA signal)*1

Result Completion signal (GATE signal)*1

(1) Command

Communications

processing

(2) The data at this

point is output to the

Communications

Module.

An Output Unit processing item is required to

perform data output. (Multiple Output Unit items

can be used.)

(3) Data

output

Character output

1 Overview

This is valid in PLC Link and Non-procedure communications protocols.

You can output character strings and numbers read by processing items such as Character Inspection, Barcode, or 2D Code. Y

a measurement is performed. For details, refer to Items that can be Output as Output

Data on page 1-19.

ou can also use commands to acquire them after

1-3 Communicating with an Ex-

ternal Device

1-3-2

Additional Information

You can also use the FTP server to obtain logged image files and logged data files saved in the

FH/FHV (including external storage) from a FTP client such as web browser.

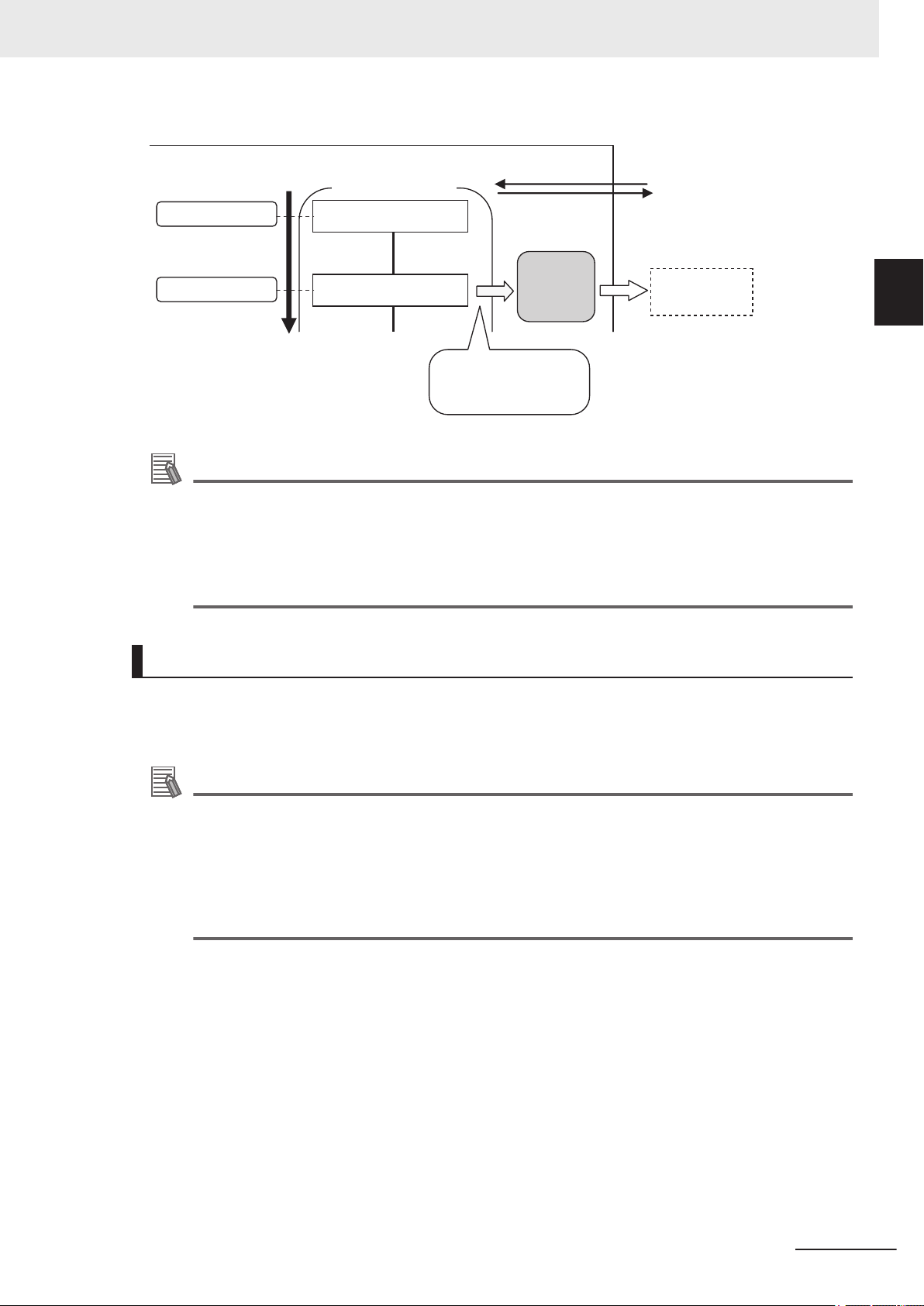

Communications between the Sensor Controller and an External

Device

Communications between the Sensor Controller and an external device are performed as shown below.

Here, describe how to start measurement with a communication command and to output data.

1

1-3-2 Communications between the Sensor Controller and an External Device

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

(1) When the Sensor Controller receives a command from an external device such as a PLC, it performs the

(2) The measured data is output via the Communication module by the Output Unit (an abbreviation for

(3)

command and returns a response.

Results Output Unit) placed in the measurement flow.

The measurement data is output when the Output Unit is performed and not when the measurement is

completed.

*2

1-5

Page 28

1 Overview

*1 When output control is set to handshaking (data output is controlled by the DSA and GATE signals).

*2

For details, refer to Control Signals and Status Signals on page 1-13.

When handshaking is performed in the output control, the measurement data is held in the Communication module until a data output request (DSA signal) is received from the external device.

For details, refer to Data Output Control with Handshaking on page 1-25.

Precautions for Correct Use

To output data, you must place an Output Unit processing item in the measurement flow.

You can place multiple Output Unit processing items in the measurement flow.

For details, refer to

Settings Required for Data Output on page 1-21.

1-6

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 29

Trigger sensor

External device

Status signal

Control signal

Sensor Controller

1 Overview

1-3 Communicating with an Ex-

1-3-3

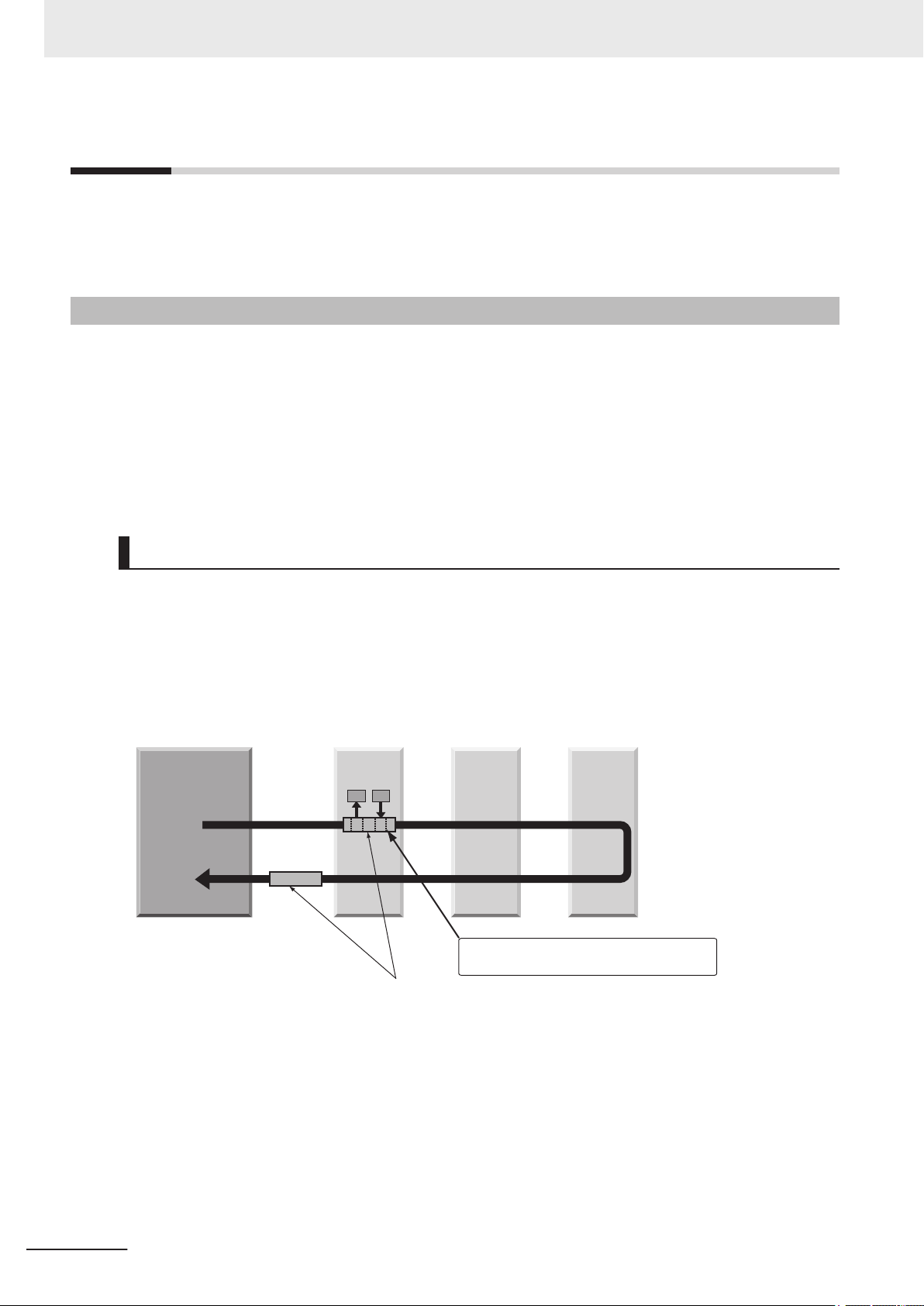

Control Methods for the Sensor Controller

There are three methods below to control the Sensor Controller with an external device such as a

PLC.

For details of each control method, refer to their corresponding section.

Control Methods

Method Overview Trigger type and area

Operation is controlled by the

Control signals and

status signals

Control with commands and responses

Data output after

measurement

ON/OFF status of the Measurement Trigger Signal (STEP)

and Command Request Bit

(EXE).

Operation is controlled by sending control commands. The results performed by the commands can be checked with responses from the Sensor Controller.

After measurement was performed, the previously specified

measurement data is automatically output.

ON/OFF status of the control

signals and status signals

The control command code is

stored in the I/O memory of the

PLC and then the Request bit is

turned ON.

Not required (Automatically output after measurement)

Signal and area to

be used

Control signals and

status signals

PLC I/O memory

(Command and Response Areas)

PLC I/O memory

(Data Output Area)

ternal Device

1

1-3-3 Control Methods for the Sensor Controller

1. Control with Control Signals and Status Signals (Refer to 1-4-1 Control with Control Signals

and Status Signals on page 1-13.)

Control and status check for the Sensor Controller is performed with the ON/OFF status of the control and status signals.

This method is best suited for basic operations such as measurement triggers or for checking the

operating status of the Sensor Controller.

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1-7

Page 30

External device

I/O memory

Sensor Controller

Command Area

Response Area

(1) Command

(3) Response

Output Area

(2) Command

execution

External device

I/O memory

Sensor Controller

Command Area

Response Area

(2) Measurement data

Output Area

(1) Measurement processing

1 Overview

2. Control with Commands and Responses (Refer to 1-4-2 Command/Response Method on

3. Data Output after Measurement (Refer to 1-4-3 Data Output after Measurements on page

page 1-16.)

Control is performed by storing a control command and the response to it to the PLC’s I/O memory

This method is best suited to send multiple commands to the Sensor Controller without using exclusive communication instructions for a PLC.

1-17.)

After measurement was performed, the previously specified measurement data is automatically

output to the PLC’

s specified I/O memory.

This allows you to output measurement results from the Sensor Controller to the PLC automatically

without sending data requests from the PLC.

.

1-8

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 31

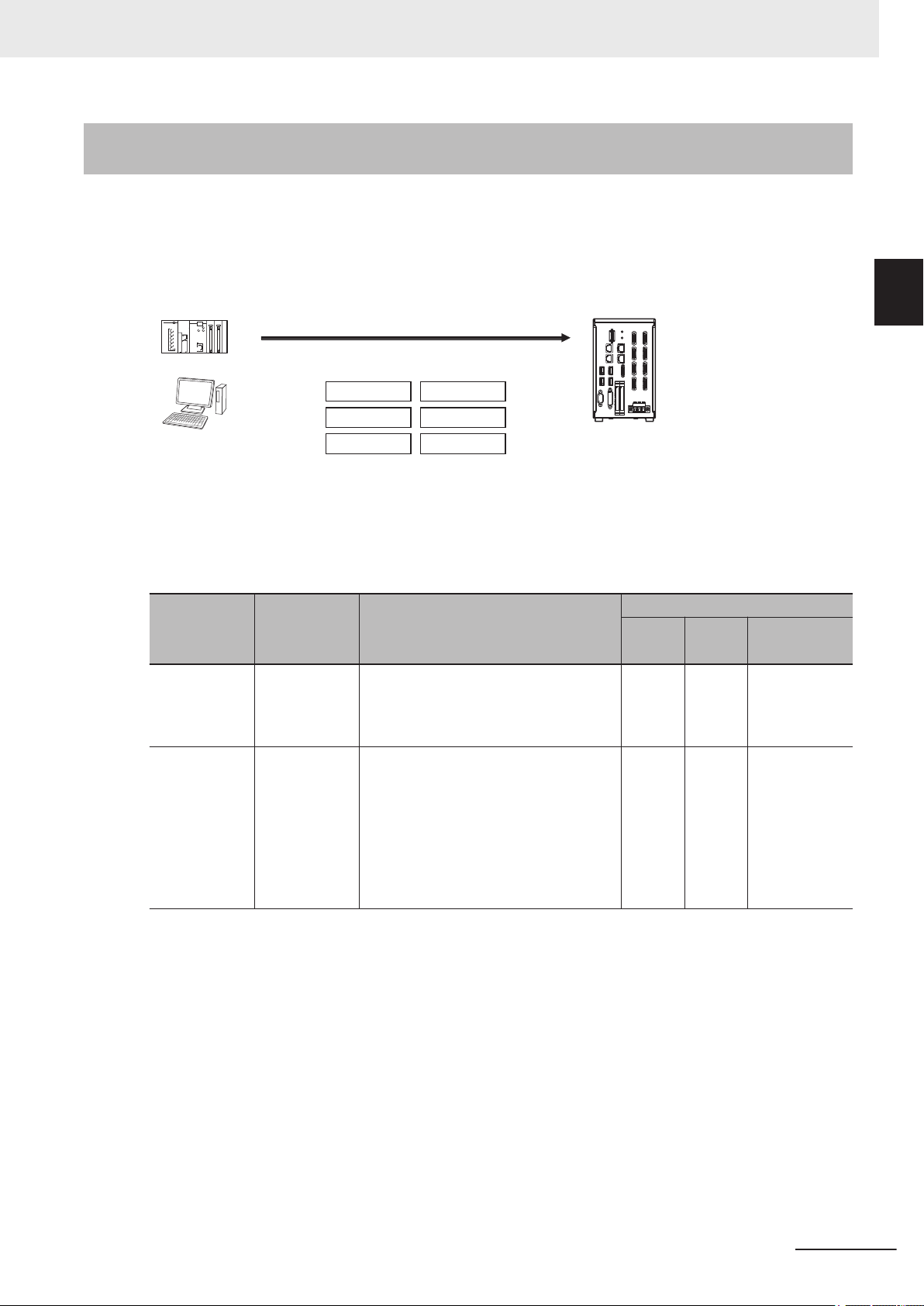

PLC

Computer

EtherNet/IP

EtherCAT

Non-procedure

Parallel

PLC Link

Sensor Controller

Control can be performed through different communications protocols.

PROFINET

1 Overview

1-3 Communicating with an Ex-

1-3-4

Communication Protocols for Communicating with the Sensor

Controller

The Sensor Controller can be controlled using various communication protocols by an external device

such as a PLC or a PC.

The communication protocols to control the Sensor Controller by an external device are described be-

.

low

● Applicable Communications Protocols

The communication protocols and summary for each communication method available in the Sensor

Controller are below.

OK: Supported, - : Not supported

ternal Device

1

1-3-4 Communication Protocols for Communicating with the Sensor Controller

Communica-

tion method

Contract

input

Frame

transmission

Communica-

tion

protocol

Parallel

Non-procedure

Overview

Using a combination of ON and OFF

signals of multiple physical contacts exchanges data between an external device and the Sensor Controller.

Without using any specific communication protocol, command frames are sent

to the Sensor Controller and response

frames are received from it.

By sending and receiving data in ASCII

or binary formats, data is communicated

between an external device such as a

PLC or a PC and the Sensor Controller.

Communication Cable Type

Parallel

I/O

OK

-

Ether-

net

- -

OK OK

RS-232C/

422

*2

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1-9

Page 32

1 Overview

Communica-

tion method

Communica-

tion

protocol

Overview

Parallel

This is a communication protocol for the

OMRON Vision System.

Areas for control signals, Command,

PLC Link

Response, and measurement data are

assigned in the PLC’

s I/O memory, and

data is communicated between the PLC

and the Vision System by sharing them

cyclically.

This is an open communication protocol.

Tag data links are used to communicate

with the Sensor Controller

.

Structure variables corresponding to the

EtherNet/IP

control signals, command data and response data, and measurement data

are created on the PLC. Those variables are used as tags to input and output data via the tag data links to exchange data between the PLC and the

Data

sharing

Sensor Controller.

This is an open communication proto-

*1

col.

Areas for control signals, Command,

PROFINET

Response, and measurement data are

assigned in the PLC’s I/O memory

, and

data is exchanged between the PLC

and the Vision System by sharing the

data via IO data CR.

This is an open communication protocol.

PDO (process data object) communications are used to communicate with the

Sensor Controller.

I/O ports corresponding to the control

EtherCAT

signals, command data, response data,

and measurement data are prepared in

advance, and the variables assigned to

the I/O ports are used to input and output data via PDO communications to

exchange data between the PLC and

the Sensor Controller

.

*1. When a CJ series PLC is connected, specify each area in the I/O memory.

*2. FH-1000/2000/3000/5000, and FHV series equip RS-232C only.

Communication Cable Type

RS-232C/

*2

422

I/O

Ether-

net

- OK OK

- OK -

- OK -

- OK -

1-10

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 33

Computer Sensor Controller

Ethernet

Saved directly.

• Logged images

• Logged data

Shared computer folder (the

shared folder settings must

be set on the computer)

The Sensor Controller is set

up to save to the shared

folder on the computer.

Computer

Browser

(FTP client)

Sensor Controller (FTP server)

Ethernet

Access via FTP

RAM disk

Images files moved to the computer.

Image files

This enables you to move logged images off of the Sensor Controller’s RAM disk before it becomes full.

1 Overview

1-3 Communicating with an Ex-

1-3-5

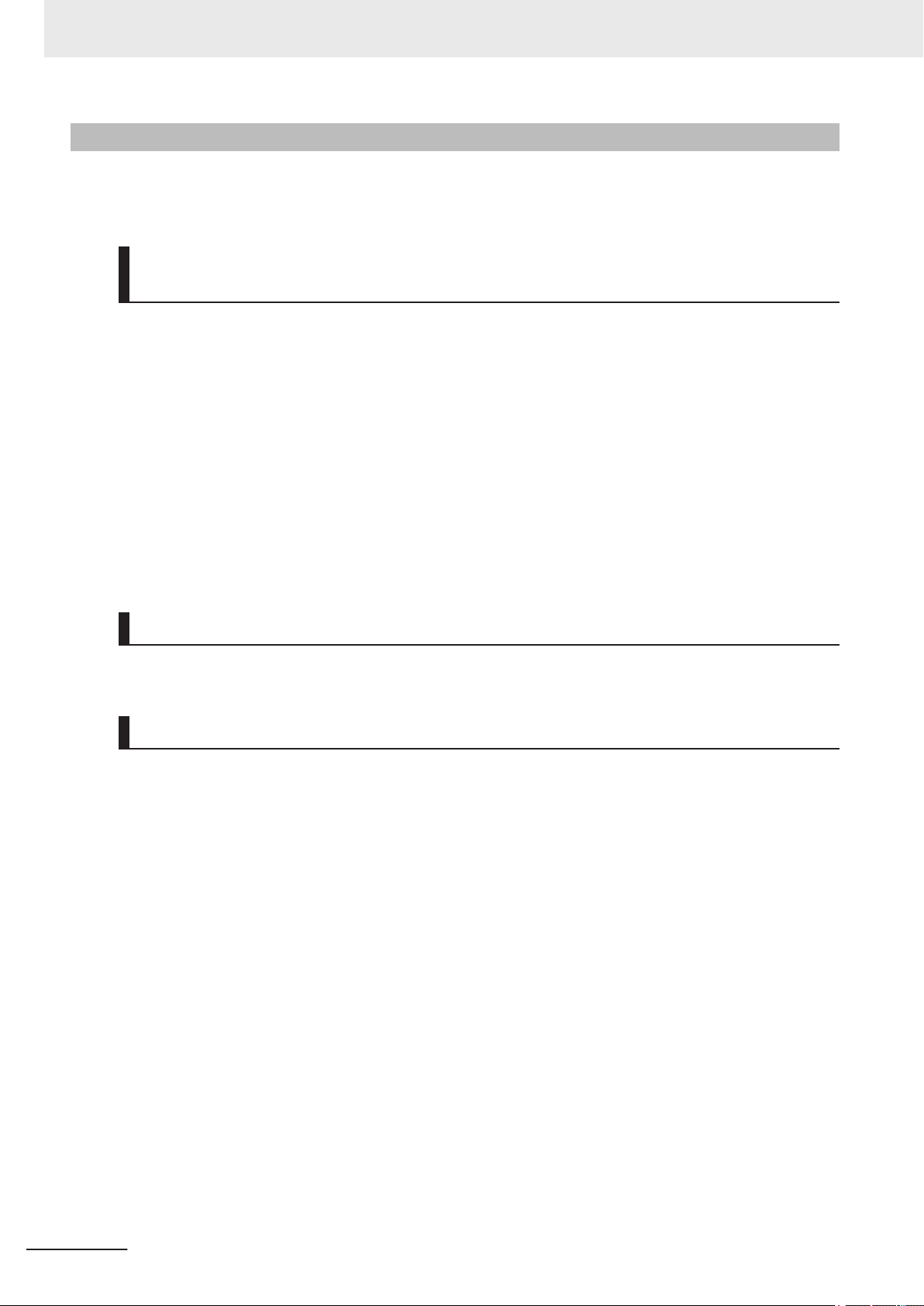

Saving Sensor Controller Data to an External Device

In addition to sending and receiving data via a communication protocol, you can also save data in the

Sensor Controller to an external device using the methods described below

For details, refer to the V

ision System FH/FHV Series User's Manual (Cat. No. Z365)..

Connecting the FH/FHV as an External Drive

In addition to the Sensor Controller's built-in RAM disk, you can directly save various types of data

such as scene data, scene group data, logged data, and logged images to the external media below.

• For external storage, refer to Using External Storage Devices in the Vision System FH/FHV Series

User’s Manual (Cat. No. Z365).

Data can be saved directly to a USB memory stick or SD Memory Card inserted into the slot on the

Sensor Controller.

• For network drive, refer to the Shared folder on a computer connected to the network in the Vision

System FH/FHV Series User’s Manual (Cat. No. Z365).

You can save data directly to a shared folder on a computer connected via Ethernet.

.

ternal Device

1

1-3-5 Saving Sensor Controller Data to an External Device

• For data transfer (FTP server), refer to the Saving Data to an External Device in the Vision System

FH/FHV Series User

’s Manual (Cat. No. Z365).

You can move logged image files and other data saved in the Sensor Controller’s RAM disk or a

USB memory stick to a computer via Ethernet.

The computer needs to have an FTP client function to access the Sensor Controller of the FH/FHV

series. The computer cannot be accessed directly from the Sensor Controller.

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1-11

Page 34

Sensor

Controller

Ethernet

Computer (FH/FZ5 Tool)

Hub

Sensor

Controller

Sensor

Controller

Operate/monitor

1 Overview

• For remote operation over a network, refer to the Remotely Operating the Controller (Remote

Operation) in the Vision System FH/FHV Series User

’s Manual (Cat. No. Z365).

If more than one Sensor Controller is connected via Ethernet, a computer (FZ tool) connected to the

same Ethernet network can operate and monitor all the Sensor Controllers at once.

1-12

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 35

Trigger sensor Sensor Controller

(1) Measurement trigger input

(STEP signal: ON).

Control signal

(2) Command received.

(BUSY signal turned ON.)

(3) Judgement results are output.

(OR signal turned ON.)

Status signals

External device

1 Overview

1-4 Control Methods Using an

1-4

1-4-1

Control Methods Using an External

Device

This section describes how to control the Sensor Controller from an external device such as a PLC.

Control with Control Signals and Status Signals

Control and status check for the Sensor Controller is performed with the ON and OFF status of the

control and status signals.

A PLC inputs measurement triggers or other commands as control signals.

The operating status of the Sensor Controller, judgment results, and other status information can be

checked with status signals output from the Sensor Controller.

External Device

1

1-4-1 Control with Control Signals and Status Signals

(1) The external device turns the STEP signal ON to input a measurement trigger to the Sensor Controller.

(2) When the Sensor Controller identifies that the STEP signal is turned ON, it outputs the BUSY signal to

notify the external device and starts measurement.

(3) When the Sensor Controller completes the measurement, it outputs the judgment results on the OR signal

to notify the external device.

Control Signals and Status Signals

The signal types that are input and output to the Sensor Controller as control and status signals are

described below.

Input Signals (PLC to Sensor Controller)

l

Signal Name Function

EXE

Command Request

rigger Measure Bit

T

STEP Measure Bit

DSA

(Used only for handshaking output control)

Result Set Request

ERCLR

Error Clear

Control Command Execution Signal

Data Output Request

Signal

Error Clear Bit

This is turned ON when the PLC will issue a command to the FH/FHV

This is turned ON when measurement will be performed.

This is turned ON when measurement will be performed.

During handshaking, the user (PLC) uses this signal

to request to output data output results performed in

the measurement flow to external from the Sensor

Controller of the FH/FHV series.

This is turned ON when the ERR signal from the

Sensor Controller will be cleared.

.

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1-13

Page 36

1 Overview

l

Signal Name Function

XEXE

Flow Command Request

DI (DI0 to DI7) Command Input Signals

ENCTRIG

Flow Command

Request Bit

Encoder Trigger Input

(Phase A, B, Z)

This is turned ON when a command will be performed while PLC Link, Fieldbus, or parallel flow

control is performed.

These are used to input commands from a parallel

interface.

This is the encoder input signal.

This signal is only available when the encoder trigger

will be used.

Output Signals (Sensor Controller to PLC)

Signal Name Function

This signal indicates that new requests cannot be

accepted because an external input such as a command is currently handled.

BUSY Busy Signal

FLG

Command Completion

TE

GA

Result Notification

READY

Trigger Ready

OR

Total Judgment

DI (DO0 to DO15) Data Output Signals

XFLG

Flow Command Completion

XBUSY

Flow Command Busy

XWAIT

Flow Command W

Trigger ACK

Command Ready

ait

Control Command Completion Signal

Data Output Completion

Signal

Camera Image

Input Enabled Signal

Overall Judgment Output

Signal

Flow Command

Completion Bit

Measurement Command

Busy Bit

Measurement Command

W

ait Bit

Trigger Signal Acknowledged Bit

Command Execution

Ready Bit

“ON” of this signal does not mean that a command is

currently performed. To check whether a command

is being executed, check the Command Completion

(FLG) signal.

The Sensor Controller of the FH/FHV series uses

this signal to inform the user (PLC) that a command

has been completed.

This signal informs the user (PLC) of the timing to

load output data.

“ON” of this signal indicates that the Sensor Control-

ler is outputting the data.

This signal indicates that the STEP (Measurement

T

rigger) signal or the T

When the multi-input function is used, following

STEP signal or Trigger signal is accepted only when

this signal is “ON”.

This signal notifies the overall judgment results.

These signals are used to output parallel data and

parallel judgment through a parallel interface.

This signal indicates that a command performed

while PLC Link or Fieldbus flow control is being performed has been completed.

This signal indicates that a command input while

PLC Link or Fieldbus flow control is being performed

is in execution.

This signal indicates that a command input can be

accepted while PLC Link or Fieldbus flow control is

being performed.

This signal indicates that the Sensor Controller of the

FH/FHV series has accepted a T

This signal indicates that a control command is executable.

*1

rigger signal can be input.

rigger signal.

*2

*3

1-14

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

Page 37

1 Overview

Signal Name Function

ERR

Error Status

RUN

Run Mode

ACK

SHTOUT

STGOUT Strobe Trigger Output This is the trigger signal for the strobe.

*1. This signal is linked to the Output Unit processing items in the measurement flow.

This has no linkage relation with the BUSY signal. Also, this has no linkage relation with the OR signal in

the parallel communication protocol. Note that the operation is different when PLC Link is used. For details, refer to

*2. This signal is always OFF during display of a through image.

When you use a camera with lighting controller, based on its type and connecting conditions, the time

required for the READY or T

it.

For details, refer to Camera Image Input FH, Camera Image Input HDR, or Camera Image Input FHV in

the Vision System FH/FHV Series User's Manual (Cat. No. Z365).

*3. The OR signal is output only when the Output option is selected in the Adjustment window.

2-2 Communicating by PLC Link on page 2-126.

Error Signal

Measurement Mode Signal

Command Completion

Flag

Exposure Completion

Signal

rigger Ready signal to turn OFF may increase in comparison with not using

This signal indicates that the FH/FHV detects the following errors.

• Camera connection error

• Battery error

• Fan error

• System error

• Communications timeout

• STEP input during measurement

The ERR signal does not turn OFF even after the error is eliminated. The signal turns OFF only when the

error status is cleared by a control command.

For details, refer to Error Messages and

T

roubleshooting in the

User's Manual (Cat. No. Z365)..

This is a notification signal indicating the Sensor

Controller of the FH/FHV series is in Run mode (In a

measurement capable state with RUN signal output

checked in the Layout settings for the currently displayed line).

This signal indicates that the DI command execution

has been completed.

This signal indicates that Camera exposure has

been completed.

Vision System FH/FHV Series

1-4 Control Methods Using an

External Device

1

1-4-1 Control with Control Signals and Status Signals

FH/FHV Series Vision System User's manual for Communication Settings (Z342-E1)

1-15

Page 38

DI7 DI6 DI4 DI3 DI2 DI1 DI0

Execution

Command

Command information

DI5

(1) Command Area

(5) Response Area

(2) Command

(4) Response

PLC

CPU Unit

I/O memory

(communications areas)

• Switch Scene Number

• Single Measurement, etc.