Omron VARISPEED G7 DATASHEET

VARISPEED G7

General purpose inverter (Advanced Vector Control)

INSTRUCTION MANUAL

Manual No.

TOE-S616-60.2

YASKAWA

Varispeed G7

INSTRUCTION MANUAL

GENERAL PURPOSE INVERTER (ADVANCED VECTOR CONTROL)

MODEL: CIMR-G7C

200V CLASS 0.4 to 110kW (1.2 to 160kVA)

400V CLASS 0.4 to 300kW (1.2 to 460kVA)

Upon receipt of the product and prior to initial operation, read these instructions

thoroughly, and retain for future reference.

YASKAWA MANUAL NO. TOE-S616-60.2

Preface

This manual is designed to ensure correct and suitable

application of Varispeed G7-Series Inverters. Read

this manual before attempting to install, operate, maintain, or inspect an Inverter and keep it in a safe, convenient location for future reference. Before you

understand all precautions and safety information

before attempting application.

General Precautions

• The diagrams in this manual may be indicated without covers or safety shields to show details.

Be sure to restore covers or shields before operating the Units and run the Units according to the

instructions described in this manual.

• Any illustrations, photographs, or examples used in this manual are provided as examples only

and may not apply to all products to which this manual is applicable.

• The products and specifications described in this manual or the content and presentation of the

manual may be changed without notice to improve the product and/or the manual.

• When ordering a new copy of the manual due to damage or loss, contact your Yaskawa representatives or the nearest Yaskawa sales office and provide the manual number shown on the front

cover.

• If nameplates become warn or damaged, order new ones from your Yaskawa representatives or

the nearest Yaskawa sales office.

i

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed precautions provided in this manual can result in serious or possibly even fatal injury or damage to

the products or to related equipment and systems.

WARNING

CAUTION

IMPORTANT

Indicates precautions that, if not heeded, could possibly result in loss of life or serious injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor injury, damage

to the product, or faulty operation.

Failure to heed a precaution classified as a caution can result in serious consequences depending

on the situation.

Indicates important information that should be memorized.

ii

Safety Precautions

Confirmations upon Delivery

• Never install an Inverter that is damaged or missing components.

Doing so can result in injury.

Installation

• Always hold the case when carrying the Inverter.

If the Inverter is held by the front cover, the main body of the Inverter may fall, possibly resulting in injury.

• Attach the Inverter to a metal or other noncombustible material.

Fire can result if the Inverter is attached to a combustible material.

• Install a cooling fan or other cooling device when installing more than one Inverter in the same

enclosure so that the temperature of the air entering the Inverters is below 45°C.

Overheating can result in fires or other accidents.

CAUTION

CAUTION

Wiring

• Always turn OFF the input power supply before wiring terminals.

• Wiring must be performed by an authorized person qualified in electrical work.

• Be sure to ground the ground terminal. (200 V class: Ground to 100 Ω or less, 400 V class: Ground

• Always check the operation of any emergency stop circuits after they are wired.

• Never touch the output terminals directly with your hands or allow the output lines to come into con-

• Check to be sure that the voltage of the main AC power supply satisfies the rated voltage of the

• Do not perform voltage withstand tests on the Inverter.

• Connect braking resistors, Braking Resistor Units, and Braking Units as shown in the I/O wiring

• Tighten all terminal screws to the specified tightening torque.

• Do not connect AC power to output terminals U, V, and W.

• Do not connect phase-advancing capacitors or LC/RC noise filters to the output circuits.

WARNING

Otherwise, an electric shock or fire can occur.

Otherwise, an electric shock or fire can occur.

to 10 Ω or less)

Otherwise, an electric shock or fire can occur.

Otherwise, there is the possibility of injury. (Wiring is the responsibility of the user.)

tact with the Inverter case. Never short the output circuits.

Otherwise, an electric shock or ground short can occur.

CAUTION

Inverter.

Injury or fire can occur if the voltage is not correct.

Otherwise, semiconductor elements and other devices can be damaged.

examples.

Otherwise, a fire can occur.

Otherwise, a fire may occur.

The interior parts of the Inverter will be damaged if voltage is applied to the output terminals.

The Inverter can be damaged or internal parts burnt if these devices are connected.

iii

• Do not connect electromagnetic switches or contactors to the output circuits.

If a load is connected while the Inverter is operating, surge current will cause the overcurrent protection circuit inside the

Inverter to operate.

Setting User Constants

• Disconnect the load (machine, device) from the motor before performing rotational autotuning.

The motor may turn, possibly resulting in injury or damage to equipment. Also, motor constants cannot be correctly set

with the motor attached to a load.

• Stay clear of the motor during rotational autotuning.

The motor may start operating suddenly when stopped, possibly resulting in injury.

Trial Operation

• Check to be sure that the front cover is attached before turning ON the power supply.

An electric shock may occur.

• Do not come close to the machine when the fault reset function is used. If the alarmed is cleared,

the machine may start moving suddenly.

Also, design the machine so that human safety is ensured even when it is restarted.

Injury may occur.

• Provide a separate emergency stop switch; the Digital Operator STOP Key is valid only when its

function is set.

Injury may occur.

• Reset alarms only after confirming that the RUN signal is OFF.

Injury may occur.

CAUTION

CAUTION

WARNING

CAUTION

• Don't touch the radiation fins (heatsink), braking resistor, or Braking Resistor Unit. These can

become very hot.

Otherwise, a burn injury may occur.

• Be sure that the motor and machine is within the applicable ranges before starting operation.

Otherwise, an injury may occur.

• Provide a separate holding brake if necessary.

Always construct the external sequence to confirm that the holding brake is activated in the event

of an emergency, a power failure, or an abnormality in the Inverter.

Failure to observe this caution can result in injury.

• If using an Inverter with an elevator, take safety measures on the elevator to prevent the elevator

from dropping.

Failure to observe this caution can result in injury.

• Don't check signals while the Inverter is running.

Otherwise, the equipment may be damaged.

• Be careful when changing Inverter settings. The Inverter is factory set to suitable settings.

Otherwise, the equipment may be damaged.

iv

Maintenance and Inspection

• Do not touch the Inverter terminals. Some of the terminals carry high voltages and are extremely

dangerous.

Doing so can result in electric shock.

• Always have the protective cover in place when power is being supplied to the Inverter. When

attaching the cover, always turn OFF power to the Inverter through the MCCB.

Doing so can result in electric shock.

• After turning OFF the main circuit power supply, wait until the CHARGE indicator light goes out

before performance maintenance or inspections.

The capacitor will remain charged and is dangerous.

• Maintenance, inspection, and replacement of parts must be performed only by authorized personnel.

Remove all metal objects, such as watches and rings, before starting work. Always use grounded tools.

Failure to heed these warning can result in electric shock.

• A CMOS IC is used in the control board. Handle the control board and CMOS IC carefully. The

CMOS IC can be destroyed by static electricity if touched directly.

The CMOS IC can be destroyed by static electricity if touched directly.

• Do not change the wiring, or remove connectors or the Digital Operator, during operation.

Doing so can result in personal injury.

WARNING

CAUTION

Other

WARNING

• Do not attempt to modify or alter the Inverter.

Doing so can result in electrical shock or injury.

v

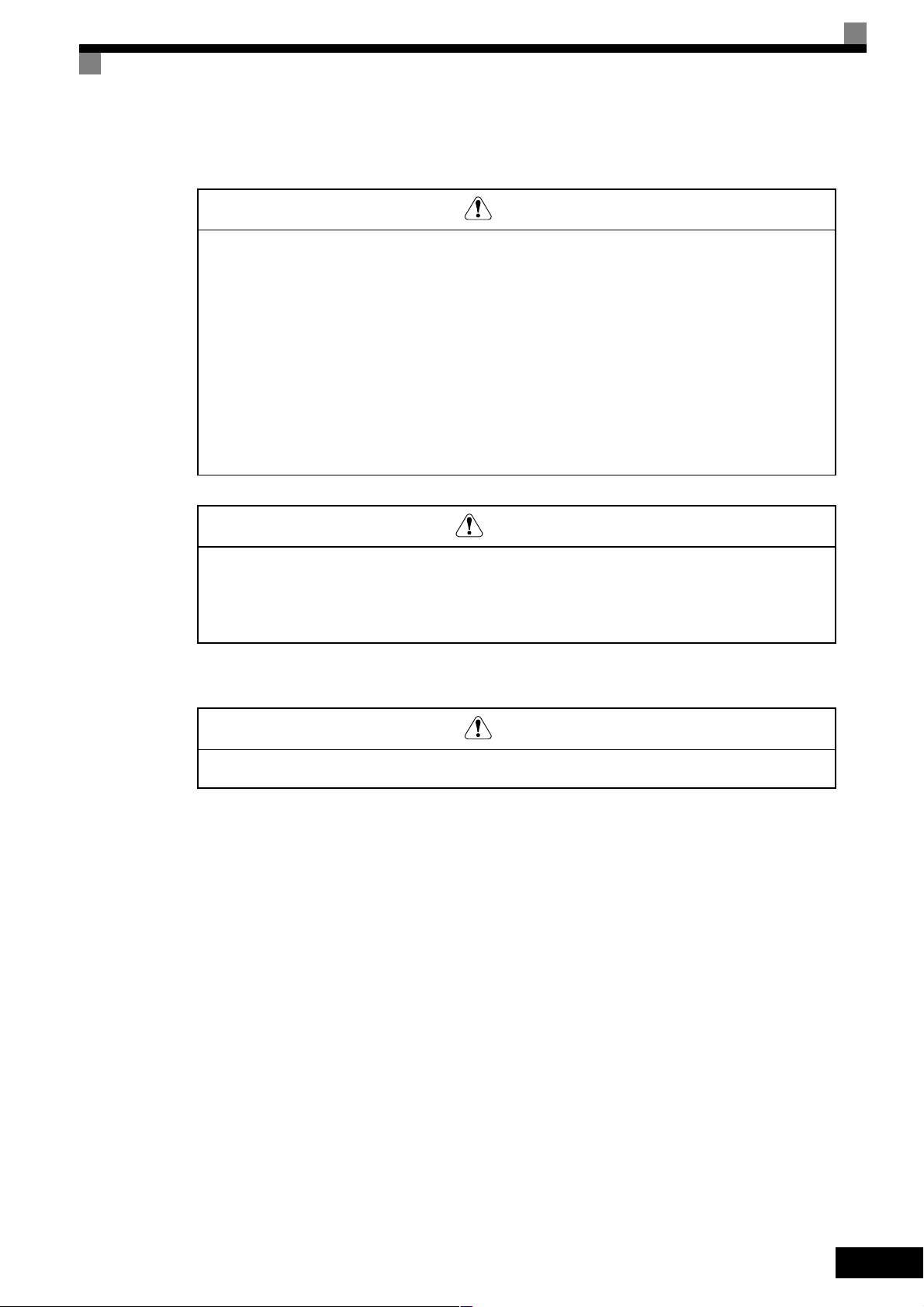

Warning Information and Position

There is warning information on the Inverter in the position shown in the following illustration.

Always heed the warnings.

Warning

information

position

Warning

information

position

Illustration shows the CIMR-G7C20P4

Warning Information

!

WARNING

Risk of electric shock.

Read manual before installing.

Wait 5 minutes for capacitor discharge

after disconnecting power supply.

!

AVERTISSEMENT

Risque de decharge electrique.

Lire le manuel avant l' installation.

Attendre 5 minutes apres la coupure de

l' allmentation. Pour permettre la

'

decharge des condensateurs.

!

Illustration shows the CIMR-G7C2018

'

'

'

vi

Registered Trademarks

The following registered trademarks are used in this manual.

• DeviceNet is a registered trademark of the ODVA (Open DeviceNet Vendors Association,

Inc.).

• InterBus is a registered trademark of Phoenix Contact Co.

• ControlNet is a registered trademark of ControlNet International, Ltd.

• LONworks is a registered trademark of the Echolon.

vii

viii

Contents

1 Handling Inverters .................................................................. 1-1

Varispeed G7 Introduction ............................................................................1-2

Varispeed G7 Models .....................................................................................................1-2

Confirmations upon Delivery ........................................................................1-3

Checks............................................................................................................................1-3

Nameplate Information ...................................................................................................1-3

Component Names.........................................................................................................1-5

Exterior and Mounting Dimensions...............................................................1-7

Open Chassis Inverters (IP00) .......................................................................................1-7

Enclosed Wall-mounted Inverters (NEMA1 Type 1) .......................................................1-7

Checking and Controlling the Installation Site ..............................................1-9

Installation Site ...............................................................................................................1-9

Controlling the Ambient Temperature .............................................................................1-9

Protecting the Inverter from Foreign Matter....................................................................1-9

Installation Orientation and Space..............................................................1-10

Removing and Attaching the Terminal Cover .............................................1-11

Removing the Terminal Cover ...................................................................................... 1-11

Attaching the Terminal Cover........................................................................................1-11

Removing/Attaching the Digital Operator and Front Cover ........................1-12

Inverters of 15 kW or Less............................................................................................1-12

Inverters of 18.5 kW or More ........................................................................................1-15

2 Wiring....................................................................................... 2-1

Connections to Peripheral Devices ..............................................................2-2

Connection Diagram.....................................................................................2-3

Terminal Block Configuration........................................................................2-5

Wiring Main Circuit Terminals.......................................................................2-6

Applicable Wire Sizes and Closed-loop Connectors ......................................................2-6

Main Circuit Terminal Functions ...................................................................................2-11

Main Circuit Configurations...........................................................................................2-12

Standard Connection Diagrams....................................................................................2-13

Wiring the Main Circuits................................................................................................2-14

Wiring Control Circuit Terminals .................................................................2-20

Wire Sizes and Closed-loop Connectors......................................................................2-20

Control Circuit Terminal Functions ...............................................................................2-22

Control Circuit Terminal Connections ...........................................................................2-26

Control Circuit Wiring Precautions................................................................................2-27

ix

Wiring Check.............................................................................................. 2-28

Checks ......................................................................................................................... 2-28

Installing and Wiring Option Cards............................................................. 2-29

Option Card Models and Specifications ....................................................................... 2-29

Installation ....................................................................................................................2-29

PG Speed Control Card Terminals and Specifications................................................. 2-30

Wiring ........................................................................................................................... 2-32

Wiring Terminal Blocks................................................................................................. 2-36

Selecting the Number of PG (Encoder) Pulses............................................................ 2-37

3 Digital Operator and Modes....................................................3-1

Digital Operator ............................................................................................ 3-2

Digital Operator Display ................................................................................................. 3-2

Digital Operator Keys .....................................................................................................3-2

Modes ..........................................................................................................3-4

Inverter Modes ............................................................................................................... 3-4

Switching Modes ............................................................................................................ 3-5

Drive Mode .....................................................................................................................3-6

Quick Programming Mode.............................................................................................. 3-7

Advanced Programming Mode....................................................................................... 3-9

Verify Mode .................................................................................................................. 3-12

Autotuning Mode .......................................................................................................... 3-13

4 Trial Operation .........................................................................4-1

Trial Operation Procedure ............................................................................4-2

Trial Operation Procedures .......................................................................... 4-3

Setting the Power Supply Voltage Jumper (400 V Class Inverters of 55 kW or Higher) 4-3

Power ON ....................................................................................................................... 4-3

Checking the Display Status .......................................................................................... 4-4

Basic Settings................................................................................................................. 4-5

Settings for the Control Methods.................................................................................... 4-7

Autotuning ......................................................................................................................4-9

Application Settings...................................................................................................... 4-14

No-load Operation ........................................................................................................ 4-14

Loaded Operation......................................................................................................... 4-14

Check and Recording User Constants ......................................................................... 4-15

Adjustment Suggestions ............................................................................ 4-16

5 User Constants ........................................................................5-1

User Constant Descriptions.......................................................................... 5-2

Description of User Constant Tables .............................................................................. 5-2

x

Digital Operation Display Functions and Levels...........................................5-3

User Constants Settable in Quick Programming Mode.................................................. 5-4

User Constant Tables ...................................................................................5-8

A: Setup Settings............................................................................................................5-8

Application Constants: b ...............................................................................................5-10

Autotuning Constants: C...............................................................................................5-20

Reference Constants: d ................................................................................................5-26

Motor Constant Constants: E........................................................................................5-32

Option Constants: F......................................................................................................5-38

Terminal Function Constants: H ...................................................................................5-45

Protection Function Constants: L..................................................................................5-57

N: Special Adjustments.................................................................................................5-67

Digital Operator Constants: o........................................................................................5-70

T: Motor Autotuning ......................................................................................................5-74

U: Monitor Constants ....................................................................................................5-75

Factory Settings that Change with the Control Method (A1-02) ...................................5-83

Factory Settings that Change with the Inverter Capacity (o2-04).................................5-86

6 Constant Settings by Function.............................................. 6-1

Frequency Reference ...................................................................................6-2

Selecting the Frequency Reference Source...................................................................6-2

Using Multi-Step Speed Operation .................................................................................6-5

Run Command .............................................................................................6-7

Selecting the Run Command Source .............................................................................6-7

Stopping Methods.........................................................................................6-9

Selecting the Stopping Method when a Stop Command is Sent.....................................6-9

Using the DC Injection Brake........................................................................................6-13

Using an Emergency Stop ............................................................................................6-14

Acceleration and Deceleration Characteristics...........................................6-15

Setting Acceleration and Deceleration Times...............................................................6-15

Accelerating and Decelerating Heavy Loads (Dwell Function).....................................6-19

Preventing the Motor from Stalling During Acceleration (Stall Prevention During

Acceleration Function)..................................................................................................6-20

Preventing Overvoltage During Deceleration (Stall Prevention During Deceleration

Function).......................................................................................................................6-22

Adjusting Frequency References ...............................................................6-24

Adjusting Analog Frequency References .....................................................................6-24

Operation Avoiding Resonance (Jump Frequency Function) .......................................6-27

Adjusting Frequency Reference Using Pulse Train Inputs ...........................................6-29

Speed Limit (Frequency Reference Limit Function) ...................................6-30

Limiting Maximum Output Frequency...........................................................................6-30

Limiting Minimum Frequency........................................................................................6-30

Improved Operating Efficiency ...................................................................6-32

Reducing Motor Speed Fluctuation (Slip Compensation Function)..............................6-32

Compensating for Insufficient Torque at Startup and Low-speed Operation

(Torque Compensation) ................................................................................................6-34

Hunting-prevention Function.........................................................................................6-36

xi

Stabilizing Speed (Speed Feedback Detection Function)............................................ 6-37

Machine Protection .................................................................................... 6-38

Reducing Noise and Leakage Current ......................................................................... 6-38

Limiting Motor Torque (Torque Limit Function) ............................................................ 6-41

Preventing Motor Stalling During Operation................................................................. 6-43

Changing Stall Prevention Level during Operation Using an Analog Input .................. 6-44

Detecting Motor Torque ................................................................................................ 6-44

Changing Overtorque and Undertorque Detection Levels Using an Analog Input ....... 6-48

Motor Overload Protection ........................................................................................... 6-49

Setting Motor Protection Operation Time ..................................................................... 6-51

Motor Overheating Protection Using PTC Thermistor Inputs ....................................... 6-52

Limiting Motor Rotation Direction .................................................................................6-54

Continuing Operation ................................................................................. 6-55

Restarting Automatically After Power Is Restored........................................................ 6-55

Speed Search............................................................................................................... 6-56

Continuing Operation at Constant Speed When Frequency Reference Is Lost ........... 6-62

Restarting Operation After Transient Error (Auto Restart Function) ............................ 6-63

Inverter Protection...................................................................................... 6-64

Performing Overheating Protection on Mounted Braking Resistors............................. 6-64

Reducing Inverter Overheating Pre-Alarm Warning Levels .........................................6-65

Input Terminal Functions ............................................................................ 6-66

Temporarily Switching Operation between Digital Operator and Control Circuit

Terminals ......................................................................................................................6-66

Blocking Inverter Outputs (Baseblock Commands)...................................................... 6-67

Stopping Acceleration and Deceleration (Acceleration/Deceleration Ramp Hold)....... 6-68

Raising and Lowering Frequency References Using Contact Signals (UP/DOWN) .... 6-69

Accelerating and Decelerating Constant Frequencies in the Analog References

(+/- Speed) ................................................................................................................... 6-72

Hold Analog Frequency Using User-set Timing ........................................................... 6-73

Switching Operations between a Communications Option Card and Control Circuit

Terminals ......................................................................................................................6-73

Jog Frequency Operation without Forward and Reverse Commands (FJOG/RJOG) . 6-74

Stopping the Inverter by Notifying Programming Device Errors to the Inverter

(External Fault Function) .............................................................................................. 6-75

Monitor Constants ......................................................................................6-76

Using the Analog Monitor Constants............................................................................ 6-76

Using Pulse Train Monitor Contents............................................................................. 6-79

Individual Functions ...................................................................................6-81

Using MEMOBUS Communications............................................................................. 6-81

Using the Timer Function .............................................................................................6-93

Using PID Control......................................................................................................... 6-94

Energy-saving ............................................................................................................ 6-103

Setting Motor Constants............................................................................................. 6-105

Setting the V/f Pattern ................................................................................................6-107

Torque Control ........................................................................................................... 6-114

Speed Control (ASR) Structure .................................................................................. 6-122

xii

Droop Control Function...............................................................................................6-127

Zero-servo Function....................................................................................................6-128

Digital Operator Functions ........................................................................6-132

Setting Digital Operator Functions..............................................................................6-132

Copying Constants .....................................................................................................6-135

Prohibiting Writing Constants from the Digital Operator .............................................6-139

Setting a Password.....................................................................................................6-140

Displaying User-set Constants Only...........................................................................6-141

Options .....................................................................................................6-142

Performing Speed Control with PG.............................................................................6-142

Using Digital Output Cards .........................................................................................6-146

Using an Analog Reference Card...............................................................................6-148

Using a Digital Reference Card ..................................................................................6-149

7 Troubleshooting ..................................................................... 7-1

Protective and Diagnostic Functions ............................................................7-2

Fault Detection................................................................................................................7-2

Alarm Detection ..............................................................................................................7-9

Operation Errors ...........................................................................................................7-13

Errors During Autotuning .............................................................................................7-15

Errors when Using the Digital Operator Copy Function................................................7-16

Troubleshooting..........................................................................................7-17

If Constant Constants Cannot Be Set...........................................................................7-17

If the Motor Does Not Operate......................................................................................7-18

If the Direction of the Motor Rotation is Reversed ........................................................7-19

If the Motor Does Not Put Out Torque or If Acceleration is Slow..................................7-20

If the Motor Operates Higher Than the Reference .......................................................7-20

If the Slip Compensation Function Has Low Speed Precision......................................7-20

If There is Low Speed Control Accuracy at High-speed Rotation in Open-loop Vector

Control Mode ................................................................................................................7-21

If Motor Deceleration is Slow........................................................................................7-21

If the Motor Overheats ..................................................................................................7-22

If There is Noise When the Inverter is Started or From an AM Radio...........................7-22

If the Ground Fault Interrupter Operates When the Inverter is Run..............................7-23

If There is Mechanical Oscillation.................................................................................7-23

If the Motor Rotates Even When Inverter Output is Stopped........................................7-24

If 0 V is Detected When the Fan is Started, or Fan Stalls.............................................7-24

If Output Frequency Does Not Rise to Frequency Reference ......................................7-24

8 Maintenance and Inspection.................................................. 8-1

Maintenance and Inspection.........................................................................8-2

Outline of Maintenance...................................................................................................8-2

Daily Inspection ..............................................................................................................8-2

Periodic Inspection .........................................................................................................8-2

xiii

Periodic Maintenance of Parts ....................................................................................... 8-3

Cooling Fan Replacement Outline ................................................................................. 8-4

Removing and Mounting the Control Circuit Terminal Card........................................... 8-6

9 Specifications ..........................................................................9-1

Standard Inverter Specifications .................................................................. 9-2

Specifications by Model.................................................................................................. 9-2

Common Specifications.................................................................................................. 9-4

Specifications of Options and Peripheral Devices ....................................... 9-5

10 Appendix ................................................................................10-1

Varispeed G7 Control Modes .....................................................................10-2

Control Modes and Features........................................................................................ 10-2

Control Modes and Applications................................................................................... 10-5

Inverter Application Precautions ................................................................ 10-7

Selection.......................................................................................................................10-7

Installation ....................................................................................................................10-8

Settings ........................................................................................................................10-8

Handling ....................................................................................................................... 10-9

Motor Application Precautions ................................................................. 10-10

Using the Inverter for an Existing Standard Motor...................................................... 10-10

Using the Inverter for Special Motors......................................................................... 10-11

Power Transmission Mechanism (Speed Reducers, Belts, and Chains) ................... 10-11

Conformance to CE Markings .................................................................. 10-12

CE Markings............................................................................................................... 10-12

Requirements for Conformance to CE Markings........................................................10-12

User Constants......................................................................................... 10-19

xiv

Handling Inverters

This chapter describes the checks required upon receiving or installing an Inverter.

Varispeed G7 Introduction ...........................................1-2

Confirmations upon Delivery........................................1-3

Exterior and Mounting Dimensions..............................1-7

Checking and Controlling the Installation Site .............1-9

Installation Orientation and Space .............................1-10

Removing and Attaching the Terminal Cover ............ 1-11

Removing/Attaching the Digital Operator

and Front Cover..........................................................1-12

Varispeed G7 Introduction

Varispeed G7 Models

The Varispeed-G7 Series of Inverters included two Inverters in two voltage classes: 200 V and 400 V. Maximum

motor capacities vary from 0.4 to 300 kW (41 models).

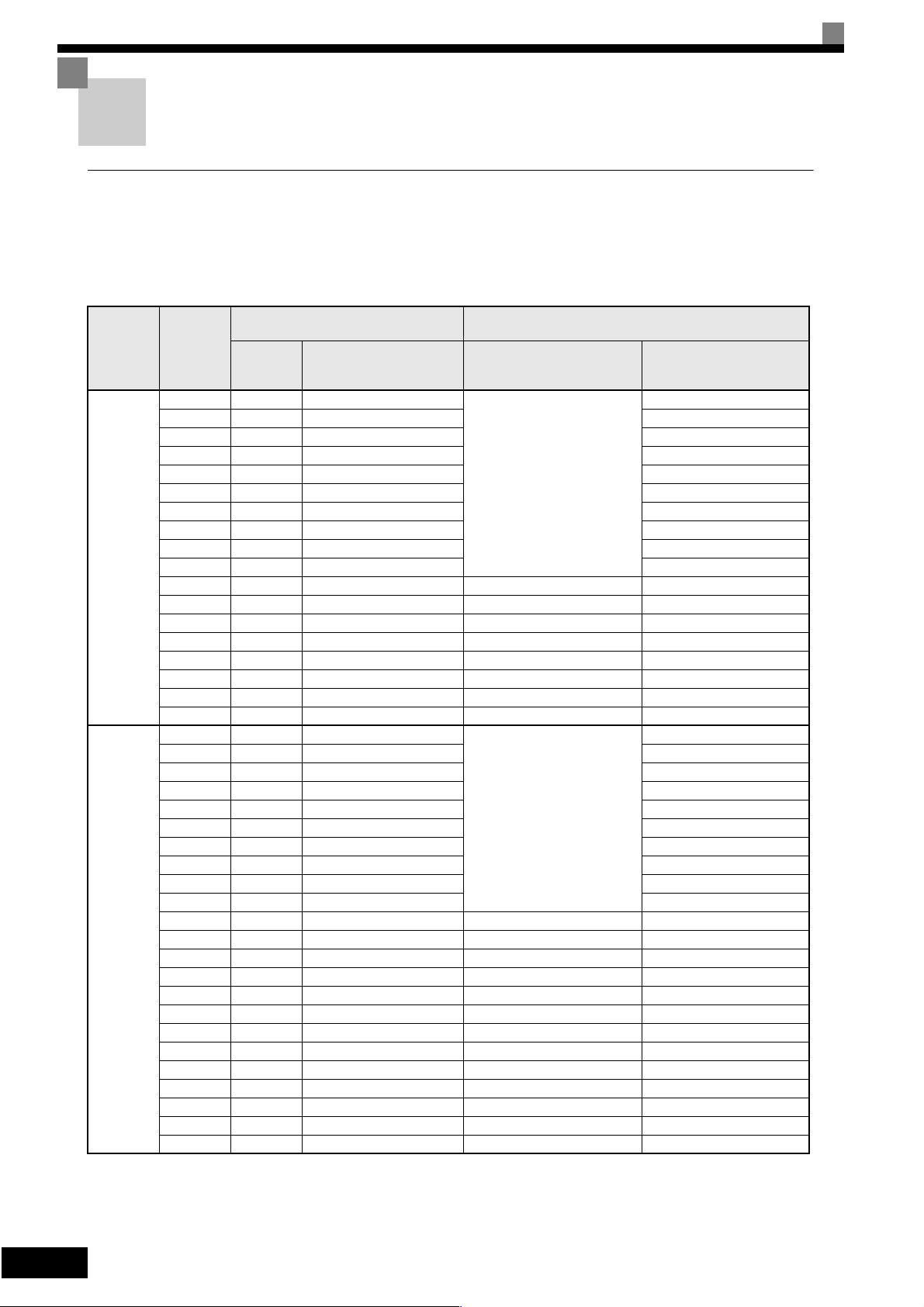

Table 1.1 Varispeed G7 Models

Voltage

Class

200 V class

400 V class

Maximum

Motor

Capacity

kW

0.4 1.2 CIMR-G7C20P4

0.75 2.3 CIMR-G7C20P7 20P71

1.5 3.0 CIMR-G7C21P5 21P51

2.2 4.6 CIMR-G7C22P2 22P21

3.7 6.9 CIMR-G7C23P7 23P71

5.5 10 CIMR-G7C25P5 25P51

7.5 13 CIMR-G7C27P5 27P51

11 19 CIMR-G7C2011 2011

15 25 CIMR-G7C2015 20151

18.5 30 CIMR-G7C2018 20181

22 37 CIMR-G7C2022 20220 20221

30 50 CIMR-G7C2030 20300 20301

37 61 CIMR-G7C2037 20370 20371

45 70 CIMR-G7C2045 20450 20451

55 85 CIMR-G7C2055 20550 20551

75 110 CIMR-G7C2075 20750 20751

90 140 CIMR-G7C2090 20900 -

110 160 CIMR-G7C2110 21100 -

0.4 1.4 CIMR-G7C40P4

0.75 2.6 CIMR-G7C40P7 40P71

1.5 3.7 CIMR-G7C41P5 41P51

2.2 4.7 CIMR-G7C42P2 42P21

3.7 6.9 CIMR-G7C43P7 43P71

5.5 11 CIMR-G7C45P5 45P51

7.5 16 CIMR-G7C47P5 47P51

11 21 CIMR-G7C4011 40111

15 26 CIMR-G7C4015 40151

18.5 32 CIMR-G7C4018 40181

22 40 CIMR-G7C4022 40220 40221

30 50 CIMR-G7C4030 40300 40301

37 61 CIMR-G7C4037 40370 40371

45 74 CIMR-G7C4045 40450 40451

55 98 CIMR-G7C4055 40550 40551

75 130 CIMR-G7C4075 40750 40751

90 150 CIMR-G7C4090 40900 40901

110 180 CIMR-G7C4110 41100 41101

132 210 CIMR-G7C4132 41320 41321

160 230 CIMR-G7C4160 41600 41601

185 280 CIMR-G7C4185 41850 -

220 340 CIMR-G7C4220 42200 -

300 460 CIMR-G7C4300 43000 -

Output

Capacity

kVA

Va risp ee d G 7

Basic Model Number

(Always specify through the protective structure when ordering.)

Open Chassis

(IEC IP00)

CIMR-G7

Remove the top and bottom cov-

ers from the Enclosed Wall-

mounted model.

Remove the top and bottom cov-

ers from the Enclosed Wall-

mount model.

Specifications

Enclosed Wall-mounted

(IEC IP20, NEMA 1)

CIMR-G7C

20P41

40P41

1-2

Confirmations upon Delivery

Checks

Check the following items as soon as the Inverter is delivered.

Table 1.2 Checks

Item Method

Has the correct model of Inverter been

delivered?

Check the model number on the nameplate on the side of the Inverter.

Confirmations upon Delivery

Is the Inverter damaged in any way?

Are any screws or other components

loose?

Inspect the entire exterior of the Inverter to see if there are any scratches or

other damage resulting from shipping.

Use a screwdriver or other tools to check for tightness.

If you find any irregularities in the above items, contact the agency from which you purchased the Inverter or

your Yaskawa representative immediately.

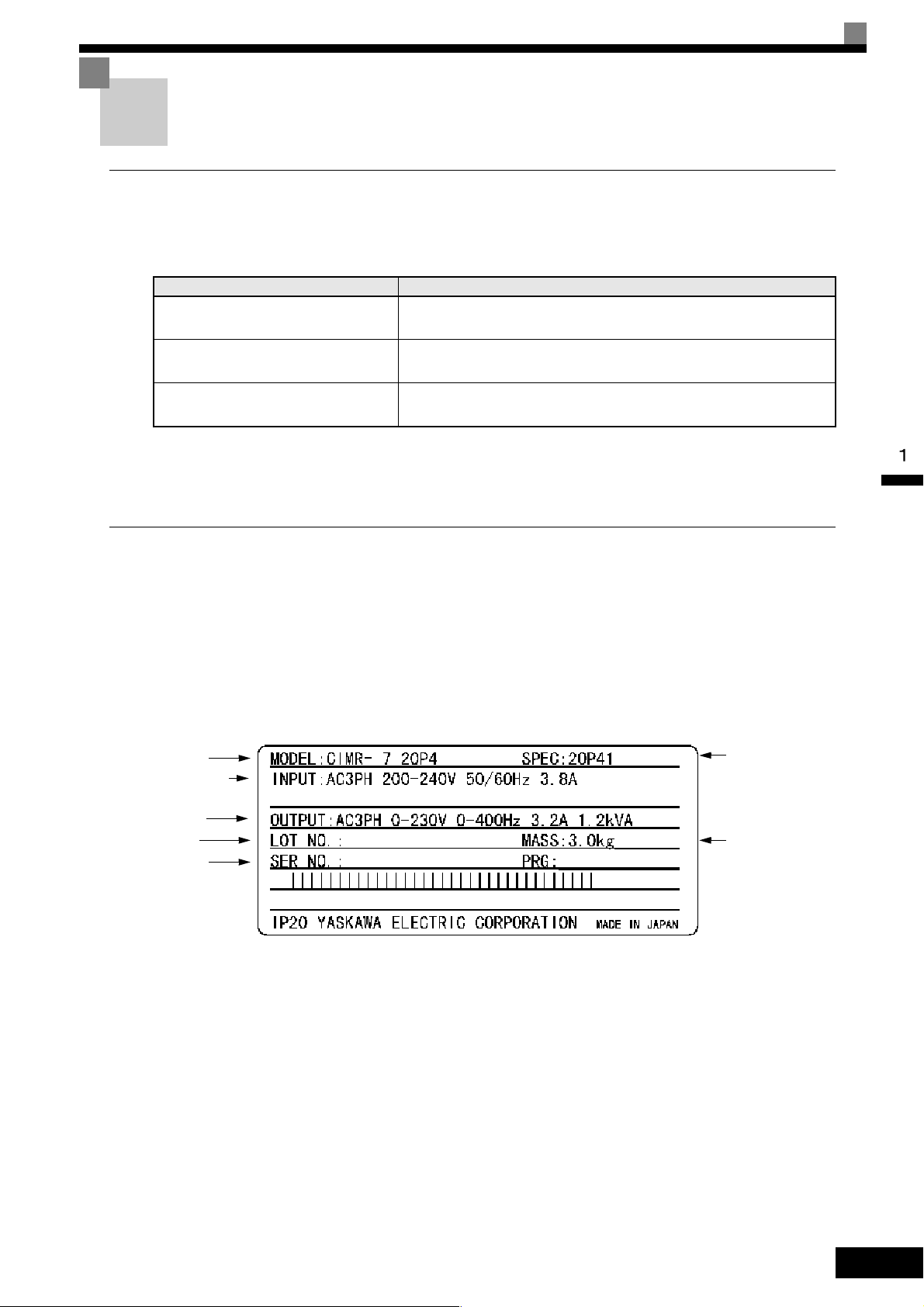

Nameplate Information

There is a nameplate attached to the side of each Inverter. The nameplate shows the model number, specifications, lot number, serial number, and other information on the Inverter.

Example Nameplate

The following nameplate is an example for a European standard Inverter: 3-phase, 200 VAC, 0.4 kW, IEC

IP20 and NEMA 1 standards

Inverter model

Input specifications

Input specifications

Output

specifications

Lot number

Serial number

GC

Inverter

specifications

Mass

Fig 1.1 Nameplate

1-3

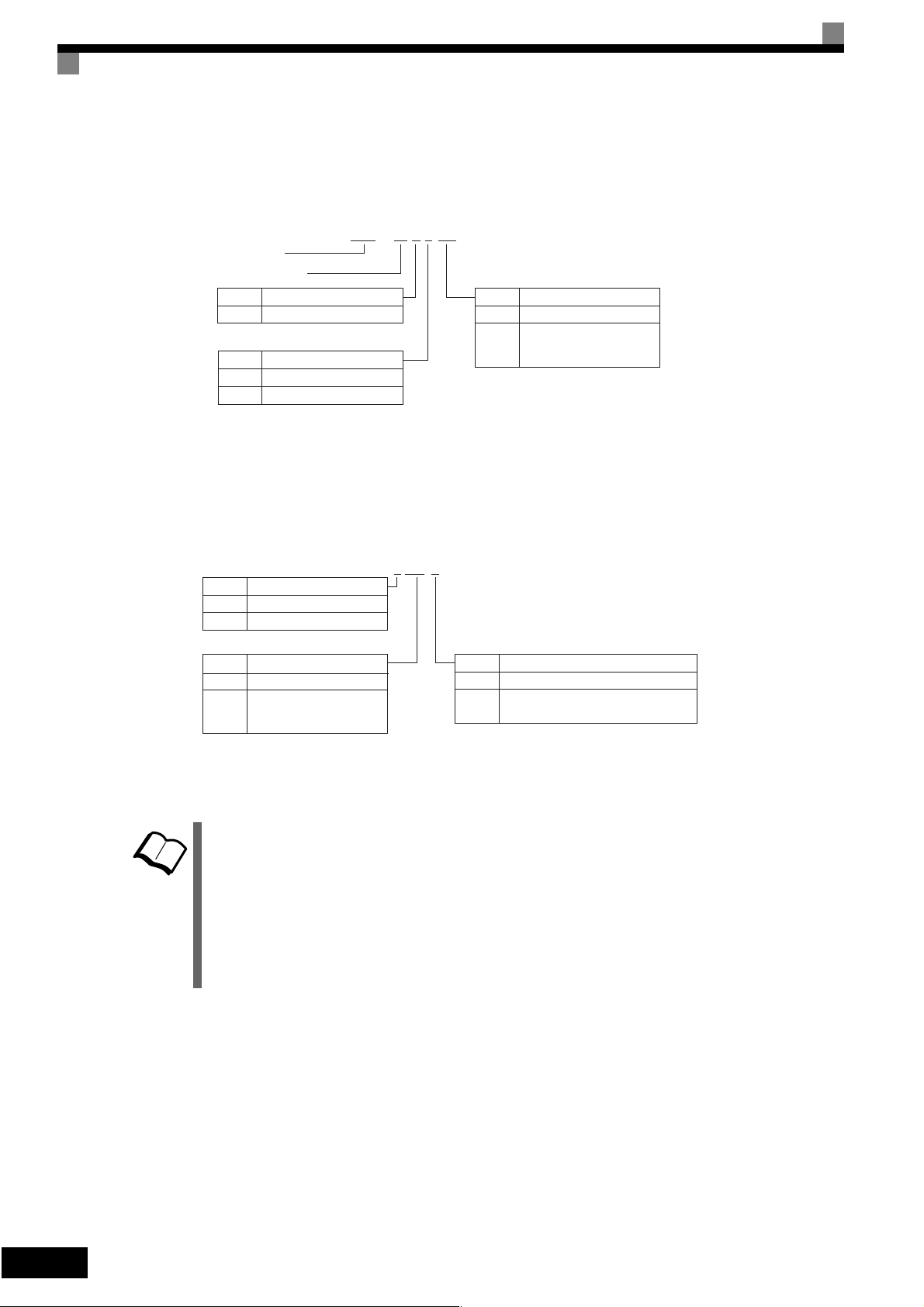

Inverter Model Numbers

The model number of the Inverter on the nameplate indicates the specification, voltage class, and maximum

motor capacity of the Inverter in alphanumeric codes.

CIMR - G7 C 2 0P4

Inverter

Varispeed G7

No.

C

No.

2

4

Specification

European standard

Voltage Class

AC input, 3-phase, 200 V

AC input, 3-phase, 400 V

0P4

0P7

300

"P" indicates the decimal point.

Fig 1.2 Inverter Model Numbers

Max. Motor Capacity

No.

0.4 kW

to to

0.75 kW

300 kW

*

Inverter Specifications

The Inverter specifications (“SPEC”) on the nameplate indicate the voltage class, maximum motor capacity,

the protective structure, and the revision of the Inverter in alphanumeric codes.

2 0P4 1

No.

2

4

Voltage Class

AC input, 3-phase, 200 V

AC input, 3-phase, 400 V

TERMS

Max. Motor Capacity

No.

0P4

0P7

to

300

"P" indicates the decimal point.

0.4 kW

0.75 kW

to

300 kW

*

No.

0

1

Protective Structure

Open chassis (IEC IP00)

Enclosed wall-mounted (IEC IP20,

NEMA 1 Type 1)

Fig 1.3 Inverter Specifications

Open Chassis Type (IEC IP00)

Protected so that parts of the human body cannot reach electrically charged parts from the front when the

Inverter is mounted in a control panel.

Enclosed Wall-mounted Type (IEC IP20, NEMA 1 Type 1)

The Inverter is structured so that the Inverter is shielded from the exterior, and can thus be mounted to the

interior wall of a standard building (not necessarily enclosed in a control panel). The protective structure conforms to the standards of NEMA 1 in the USA.

Top protective cover must be installed to conform with IEC IP20 and NEMA 1 Type 1 requirements. Refer to

Fig. 1.4 for details.

1-4

Confirmations upon Delivery

NPJT31278-1-0

CAUTION

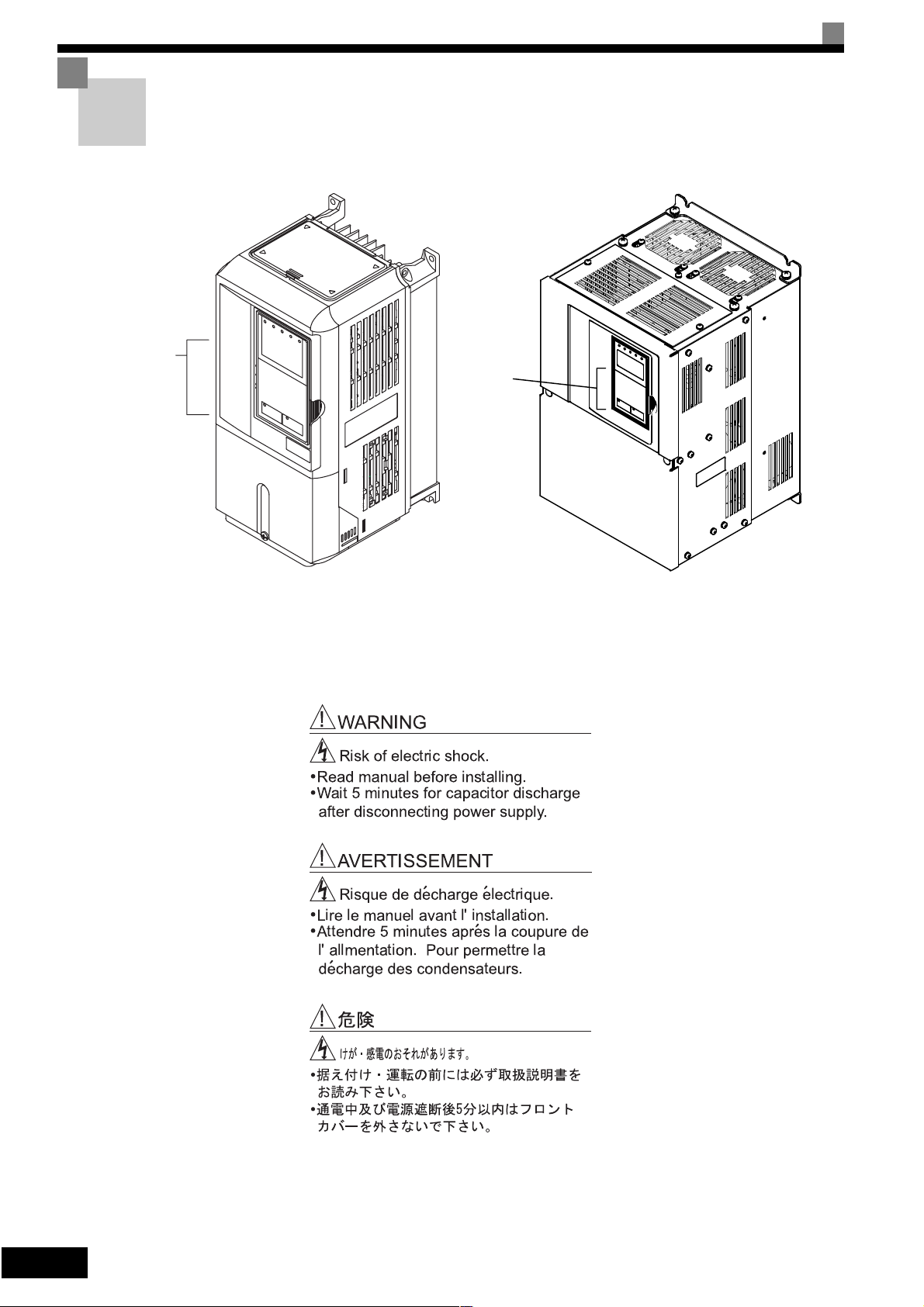

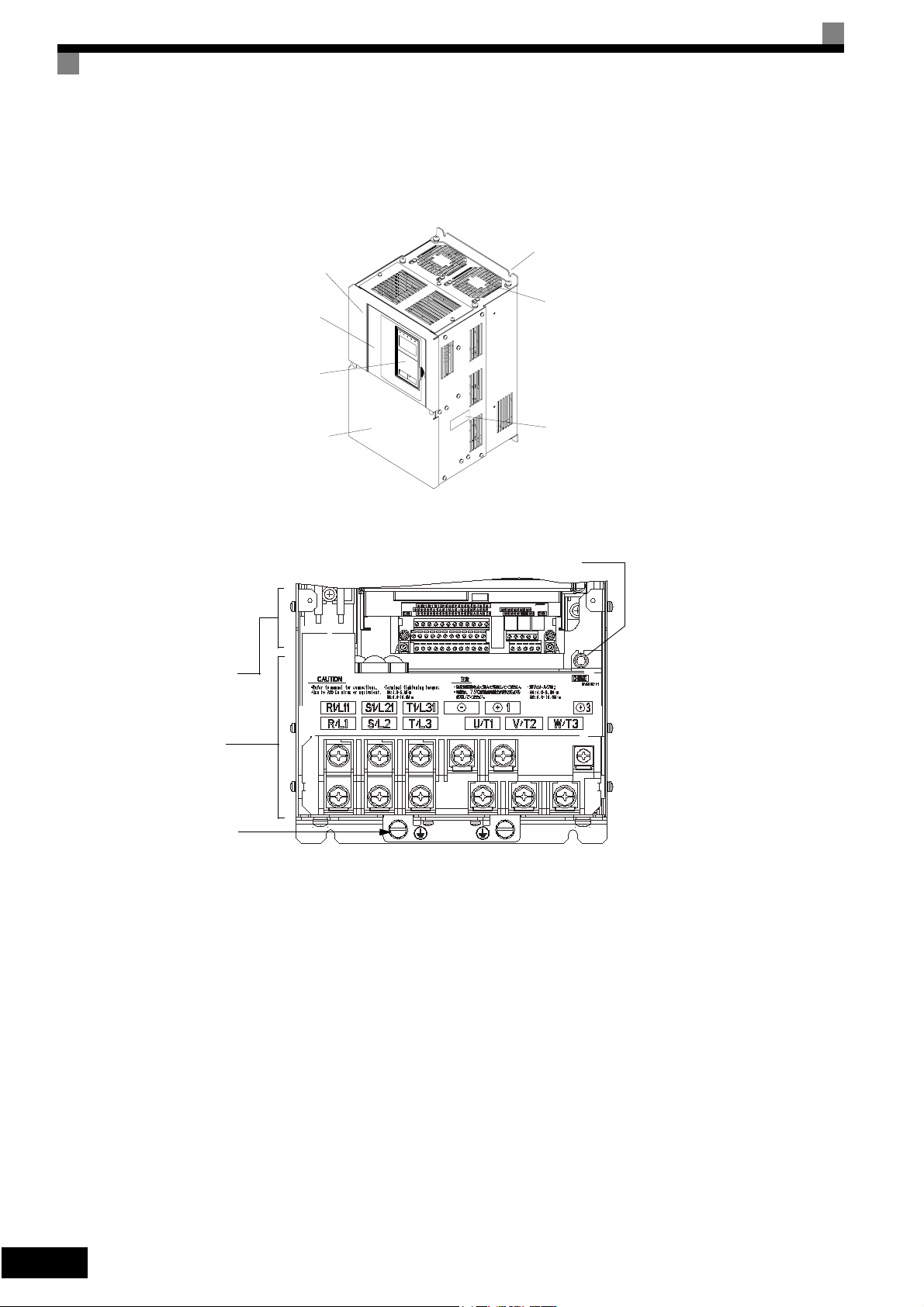

Component Names

Inverters of 15 kW or Less

The external appearance and component names of the Inverter are shown in Fig 1.4. The Inverter with the terminal cover removed is shown in Fig 1.5.

Top protective cover

Front cover

Digital Operator

Terminal cover

Fig 1.4 Inverter Appearance (15 kW or Less)

Mounting hole

Diecast case

Nameplate

Bottom protective cover

Control circuit terminals

CAUTION

NPJT31278-1-0

Fig 1.5 Terminal Arrangement (15 kW or Less)

Main circuit terminals

Charge indicator

Ground terminal

1-5

Inverters of 18.5 kW or More

The external appearance and component names of the Inverter are shown in Fig 1.6. The Inverter with the terminal cover removed is shown in Fig 1.7.

Mounting holes

Inverter cover

Control circuit

terminals

Main circuit

terminals

Front cover

Digital Operator

Terminal cover

Cooling fan

Nameplate

Fig 1.6 Inverter Appearance (18.5 kW or More)

Charge indicator

1-6

Ground terminal

Fig 1.7 Terminal Arrangement (18.5 kW or More)

Exterior and Mounting Dimensions

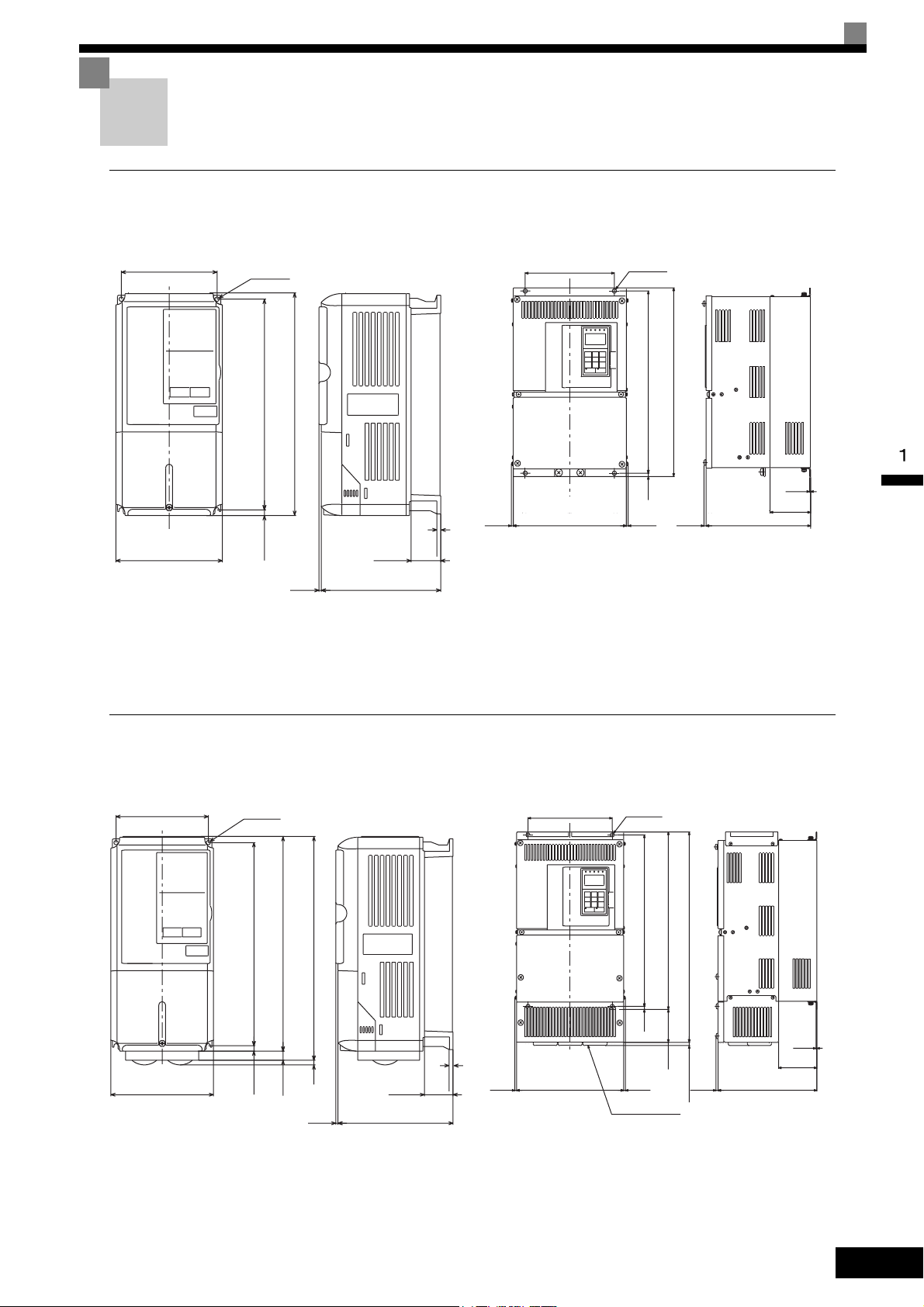

Open Chassis Inverters (IP00)

Exterior diagrams of the Open Chassis Inverters are shown below.

Exterior and Mounting Dimensions

W1

W

200 V/400 V Class Inverters of 0.4 to 15 kW

4-d

H1H2DH

3

Fig 1.8 Exterior Diagrams of Open Chassis Inverters

D1

(5)

4-d

H1

H2

H

t1

(5)

D1

D

W1

t1

(5)

200 V Class Inverters of 18.5 or 22 kW

400 V Class Inverters of 30 to 45 kW

W

Enclosed Wall-mounted Inverters (NEMA1 Type 1)

Exterior diagrams of the Enclosed Wall-mounted Inverters (NEMA1 Type 1) are shown below.

W1

W

200 V/400 V Class Inverters of 0.4 to 15 kW

4-d

H1H2DH0

H3

4 H

3

D1

W1

t1

W

200 V Class Inverters of 18.5 or 22 kW

400 V Class Inverters of 30 to 45 kW

4-d

H1

H2

(5)(5)

Grommet

H0

H3

H

Max.10

t1

D1

D(5)

Fig 1.9 Exterior Diagrams of Enclosed Wall-mounted Inverters

1-7

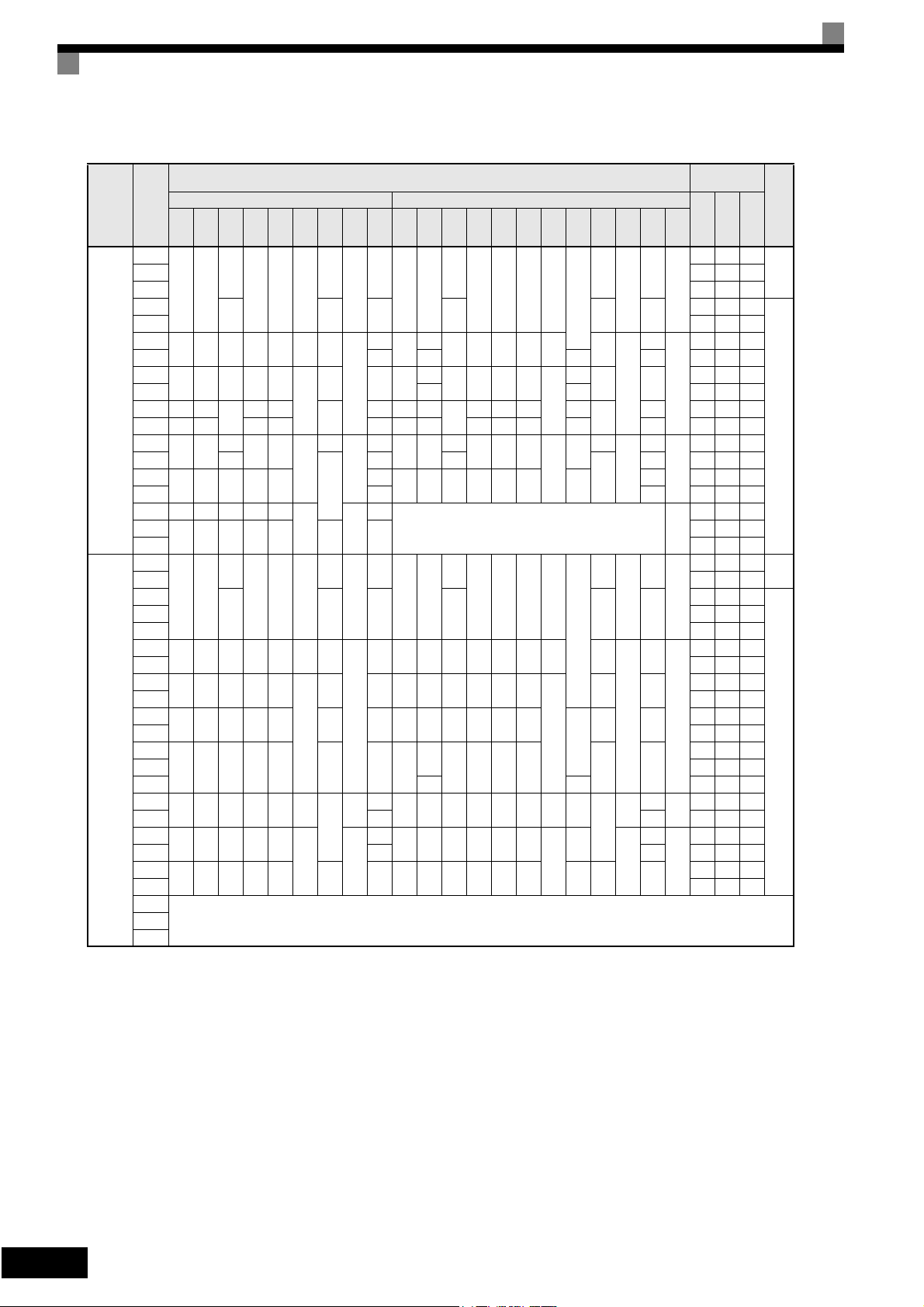

Table 1.3 Inverter Dimensions (mm) and Masses (kg)

Max.

Appli-

Voltage

cable

Class

Motor

Output

W H D W1 H1 H2 D1 t1

[kW]

0.4

0.75 27 42 69

140 280

1.5 50 50 100

2.2

3.7 11274186

5.5

200 300 197 186 285 8 65.5

7.5 7 310 10 7 219 113 332

11

240 350 207 216 335

200 V

(3-phase)

15 380 30 429 183 612

18.5 250 400

22 275 450 220 435 24 279 615 220 450 435 165 27 586 274 860

30

375 600

37 330

45

450 725 350 325 700

55 87 95 1588 619 2207

75 500 850 360 370 820

90

575 885 380 445 855 140 150

110 2733 1242 3975

0.4

0.75 17 41 58

1.5

140 280

2.2 59 56 115

3.7 80 68 148

5.5

200 300 197 186 285 8 65.5

7.5 193 114 307

11

240 350 207 216 335

15 326 172 498

18.5

275 450 258 220 435 100 21 279 535 258 220 450 435

400 V

(3-phase)

22 466 259 725

30

325 550 283 260 535 105 36 329

37 784 360 1144

45 715 165 901 415 1316

55

450 725 350 325 700 13

75 89 97 1399 575 1974

90

500 850 360 370 820

110 120 130 2097 853 2950

132

575 925 380 445 895 140 160 580 1325 380 445 925 895 400 140 170

160 2791 1147 3938

185

300

* Same for Open Chassis and Enclosed Wall-mounted Inverters.

Open Chassis (IP00) Enclosed Wall-mounted (NEMA1)

157

126 266 7

39

5

177 59 4 177 59 4

2.3

78 11 240

7.5

100

100

13

3.2

258

300

195 385

250 575

130

15 4.5

157

126 266 7

39

5

177 59 4 177 59 4

78 10 240 350 207 216 350 335

2.3

7.5

3.2

130

15 4.5

Dimensions (mm)

Ap-

prox.

W H D W1 H0 H1 H2 H3 D1 t1

Mass

3

140 280

6

200

21 254 535

57

380 890

63 330

86

455 1100 350 325 725 700 305

157

126 280 266 7

300

197 186 300 285 8 65.5

350

207 216 350 335

195 400 385 135

258

300

250 600 575

7.5

13

0

0

210

108

--- M12

3

140 280

157

126 280 266 7

0

6 200 300 197 186 300 285 8 65.5

7.5

85

635

283 260 550 535 105 40

88

455 1100 350 325 725 700 13 305

102

505 1245 360 370 850 820

395

15

Under development220

prox.

Mass

39

5

2.3

78 11

100

100

3.2

130

39

5

78 10

2.3

100 24

3.2

130

122

4.5

Heat Genera-

tion (W)

Tot a l

Exter

Mount-

Ap-

ing

Holes

d*

Heat

Inter-

Gen-

nal

nal

eration

20 39 59

3

M5

70 59 129

6

164 84 248

374 170 544

M6

24 501 211 712

62

68 1015 411 1426

94 1266 505 1771

865 352 1217

M10

2019 838 2857

2437 997 3434

14 39 53

3

36 48 84

M5

127 82 209

6

252 158 410

M6

426 208 634

678 317 995

96

1203 495 1698

M10

1614 671 2285

M12

2388 1002 3390

Cool-

ing

Method

Natu-

ral

Fan

Natu-

ral

Fan

1-8

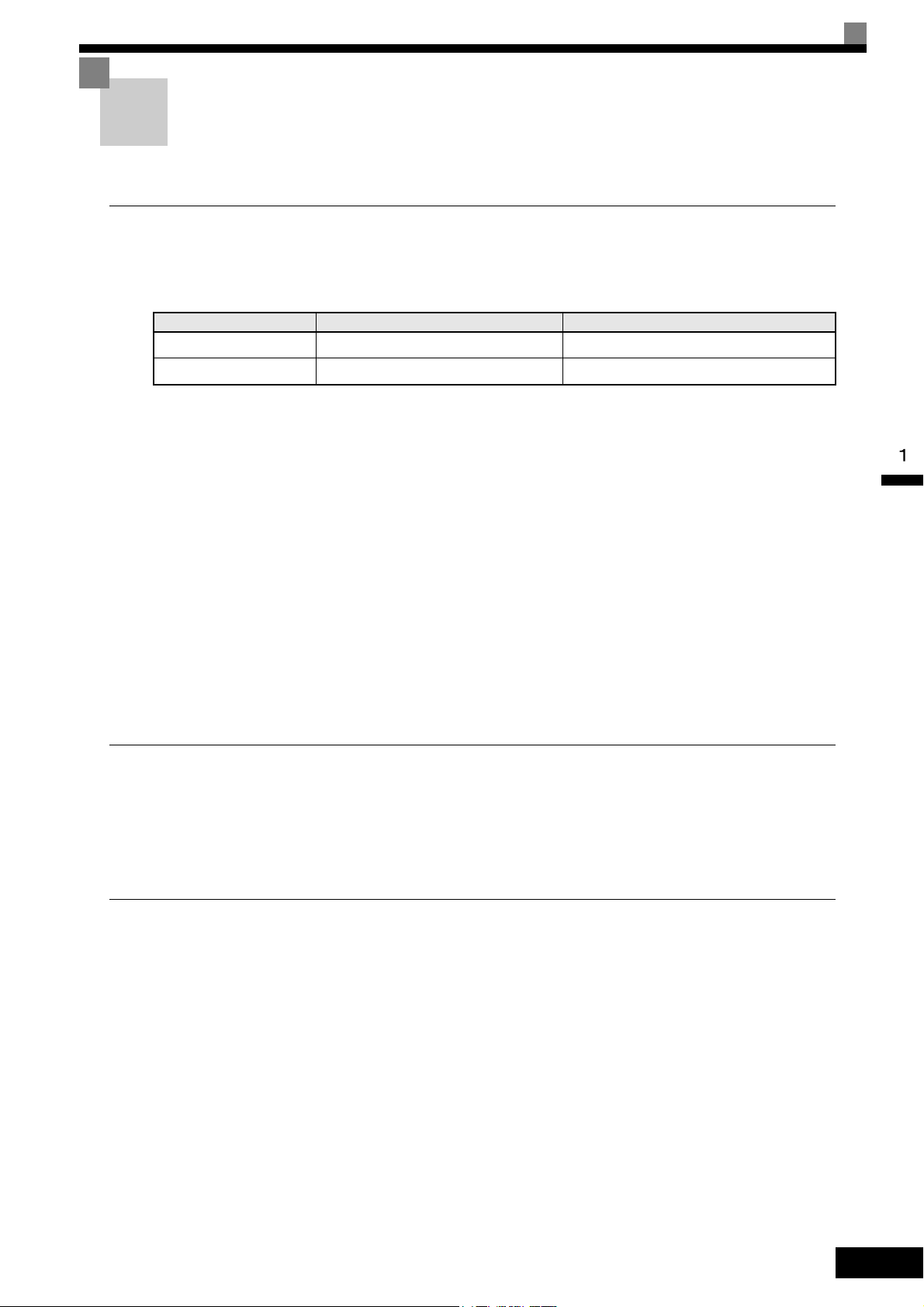

Checking and Controlling the Installation Site

Checking and Controlling the Installation Site

Install the Inverter in the installation site described below and maintain optimum conditions.

Installation Site

Install the Inverter under the following conditions.

Table 1.4 Installation Site

Type Ambient Operating Temperature Humidity

Enclosed wall-mounted -10 to + 40 °C 95% RH or less (no condensation)

Open chassis -10 to + 45 °C 95% RH or less (no condensation)

Protection covers are attached to the top and bottom of the Inverter. Be sure to remove the protection covers

before installing a 200 or 400 V Class Inverter with an output of 15 kW or less in a panel.

Observe the following precautions when mounting the Inverter.

• Install the Inverter in a clean location free from oil mist and dust. It can be installed in a totally enclosed

panel that is completely shielded from floating dust.

• When installing or operating the Inverter, always take special care so that metal powder, oil, water, or other

foreign matter does not get into the Inverter.

• Do not install the Inverter on combustible material, such as wood.

• Install the Inverter in a location free from radioactive materials and combustible materials.

• Install the Inverter in a location free from harmful gasses and liquids.

• Install the Inverter in a location without excessive oscillation.

• Install the Inverter in a location free from chlorides.

• Install the Inverter in a location not in direct sunlight.

Controlling the Ambient Temperature

To enhance the reliability of operation, the Inverter should be installed in an environment free from extreme

temperature increases. If the Inverter is installed in an enclosed environment, such as a box, use a cooling fan

or air conditioner to maintain the internal air temperature below 45°C.

Protecting the Inverter from Foreign Matter

Place a cover over the Inverter during installation to shield it from metal power produced by drilling.

Always remove the cover from the Inverter after completing installation. Otherwise, ventilation will be

reduced, causing the Inverter to overheat.

1-9

Installation Orientation and Space

Install the Inverter vertically so as not to reduce the cooling effect. When installing the Inverter, always

provide the following installation space to allow normal heat dissipation.

120 mm min.

Air

30 mm min.

IMPORTANT

30 mm min.

120 mm min.

Air

Vertical SpaceHorizontal Space

Fig 1.10 Inverter Installation Orientation and Space

1. The same space is required horizontally and vertically for both Open Chassis (IP00) and Enclosed Wallmounted (IP20, NEMA 1 Type 1) Inverters.

2. Always remove the protection covers before installing a 200 or 400 V Class Inverter with an output of

15 kW or less in a panel.

Always provide enough space for suspension eye bolts and the main circuit lines when installing a 200 or

400 V Class Inverter with an output of 18.5 kW or more in a panel.

1-10

Removing and Attaching the Terminal Cover

Removing and Attaching the Terminal Cover

Remove the terminal cover to wire cables to the control circuit and main circuit terminals.

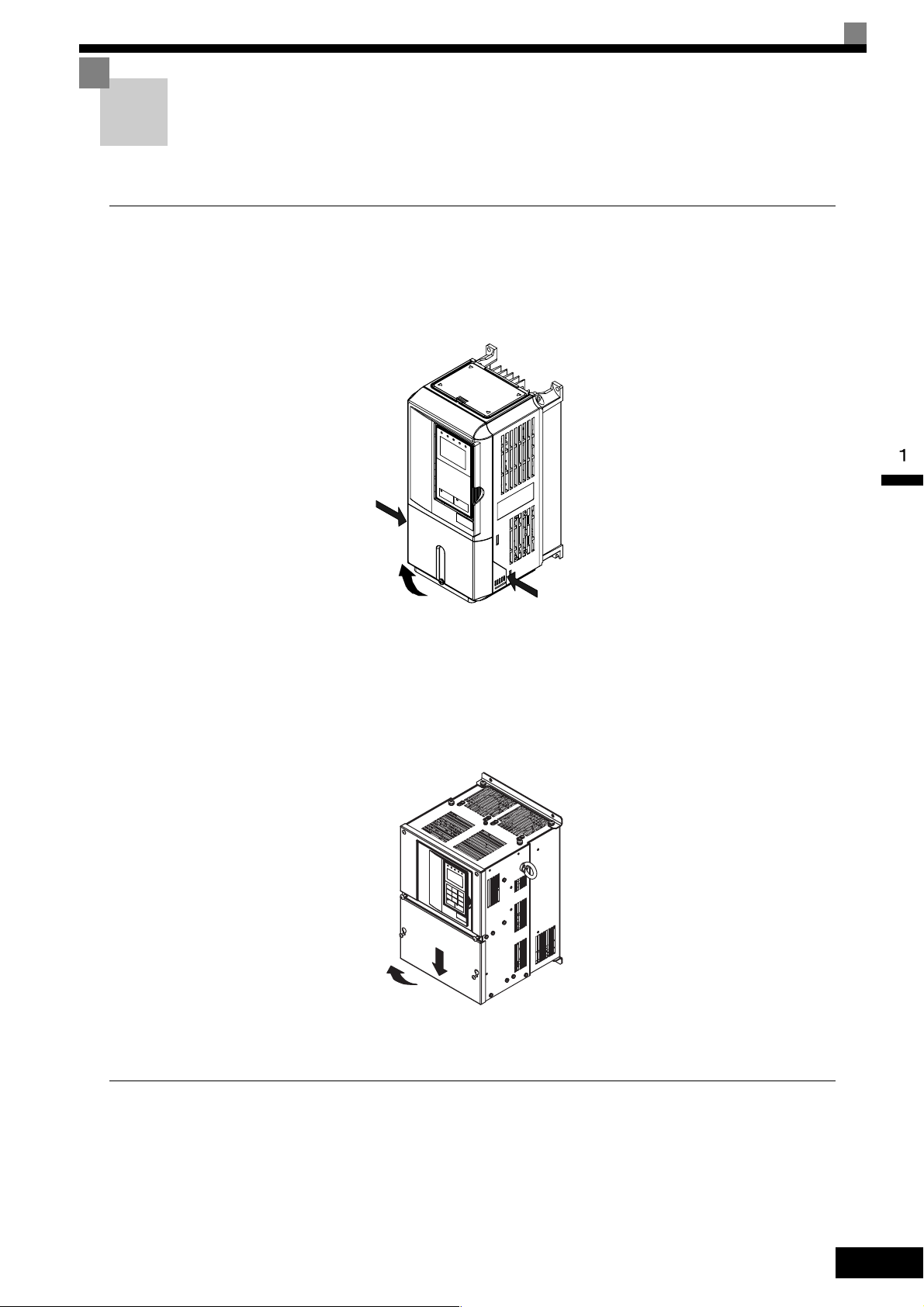

Removing the Terminal Cover

Inverters of 15 kW or Less

Loosen the screws at the bottom of the terminal cover, press in on the sides of the terminal cover in the direc-

tions of arrows 1, and then lift up on the terminal in the direction of arrow 2.

1

2

1

Fig 1.11 Removing the Terminal Cover (Model CIMR-G7C23P7 Shown Above)

Inverters of 18.5 kW or More

Loosen the screws on the left and right at the top of the terminal cover, pull out the terminal cover in the direction of arrow 1 and then lift up on the terminal in the direction of arrow 2.

1

2

Fig 1.12 Removing the Terminal Cover (Model CIMR-G7C2018 Shown Above)

Attaching the Terminal Cover

When wiring the terminal block has been completed, attach the terminal cover by reversing the removal procedure.

For Inverters with an output of 15 kW or less, insert the tab on the top of the terminal cover into the grove on

the Inverter and press in on the bottom of the terminal cover until it clicks into place.

1-11

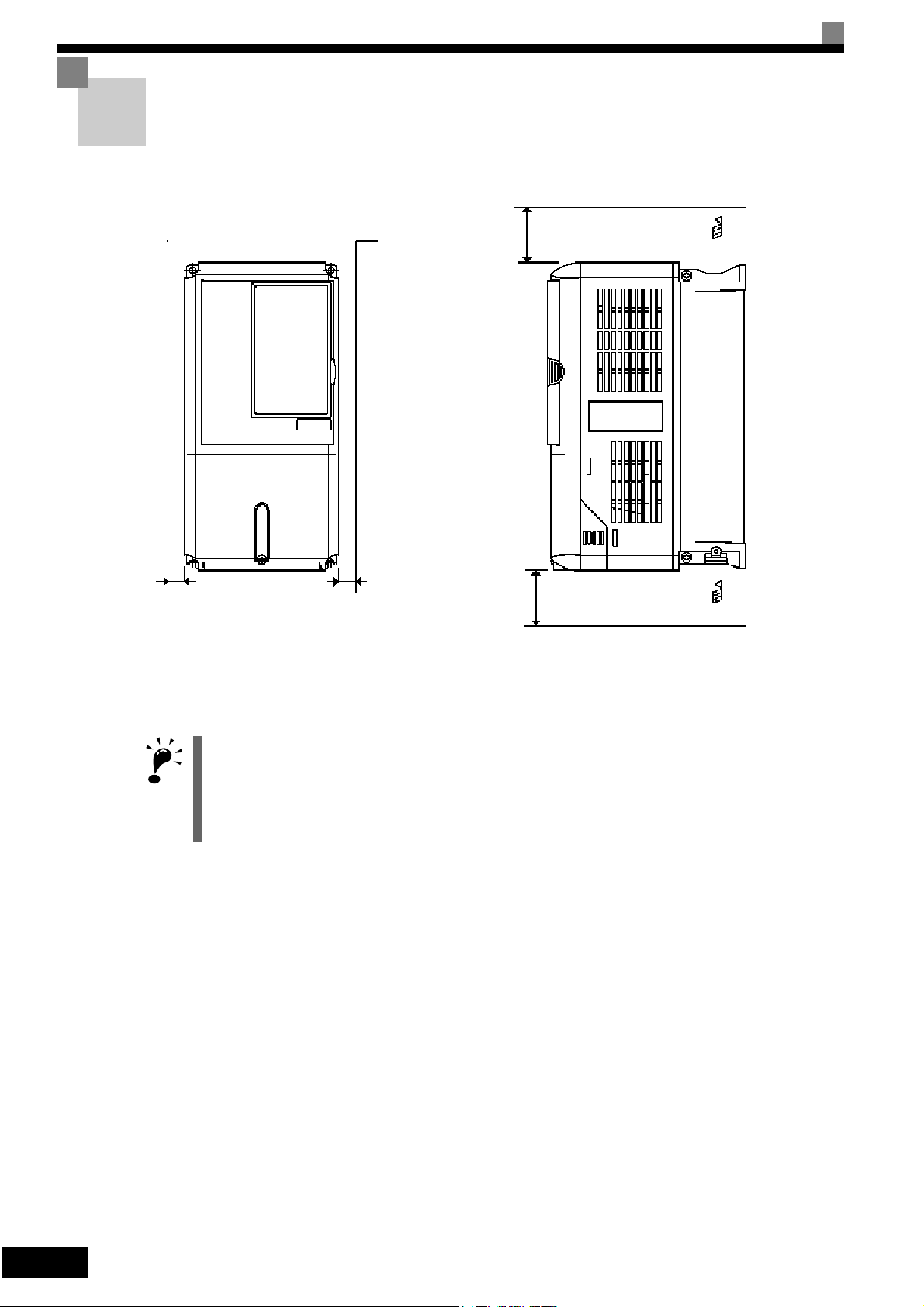

Removing/Attaching the Digital Operator and Front Cover

The methods of removing and attaching the Digital Operator and Front Cover are described in this section.

Inverters of 15 kW or Less

To attach optional cards or change the terminal card connector, remove the Digital Operator and front cover in

addition to the terminal cover. Always remove the Digital Operator from the front cover before removing the

terminal cover.

The removal and attachment procedures are given below.

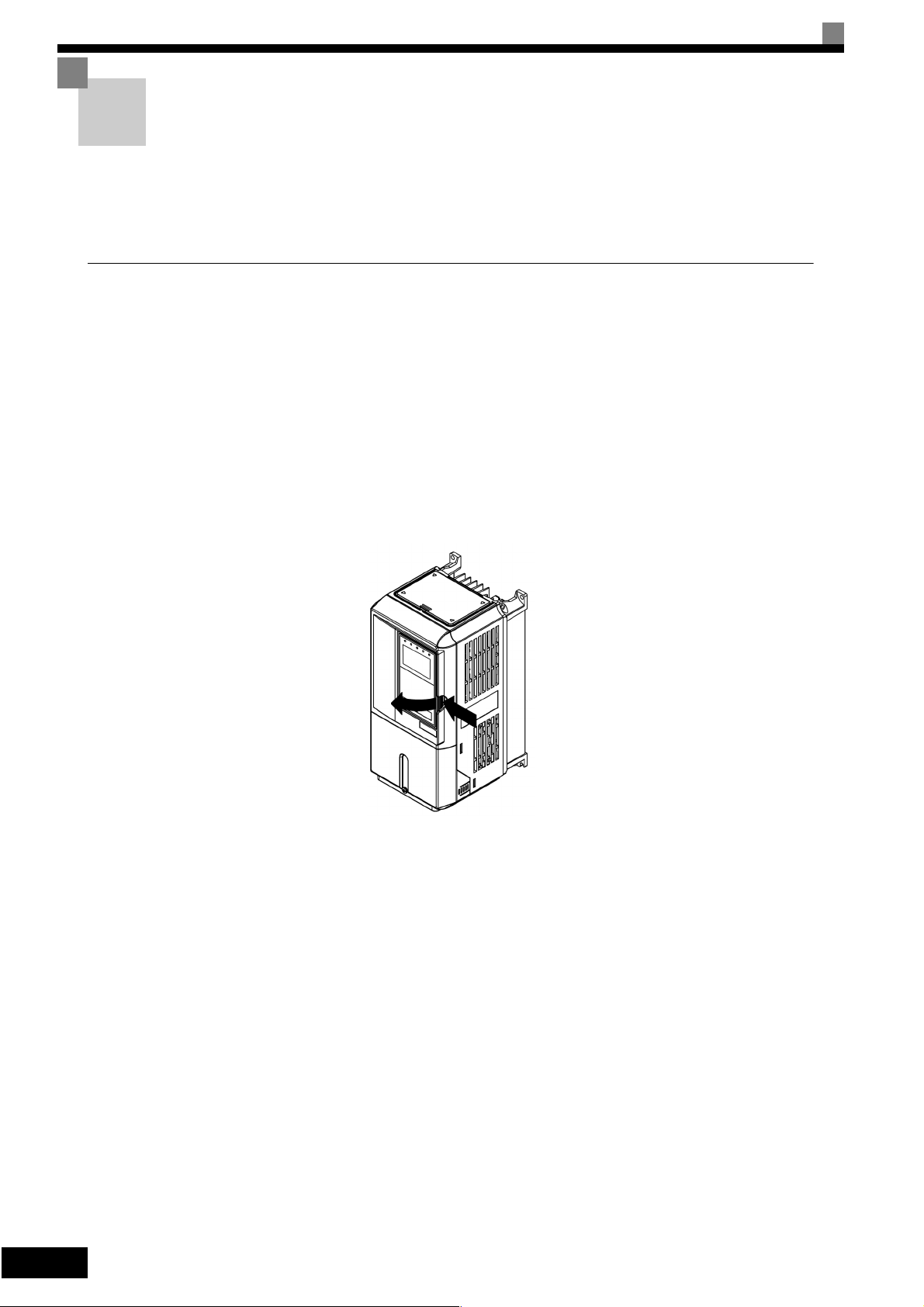

Removing the Digital Operator

Press the lever on the side of the Digital Operator in the direction of arrow 1 to unlock the Digital Operator

and lift the Digital Operator in the direction of arrow 2 to remove the Digital Operator as shown in the following illustration.

2

Fig 1.13 Removing the Digital Operator (Model CIMR-G7C43P7 Shown Above)

1

1-12

Removing/Attaching the Digital Operator and Front Cover

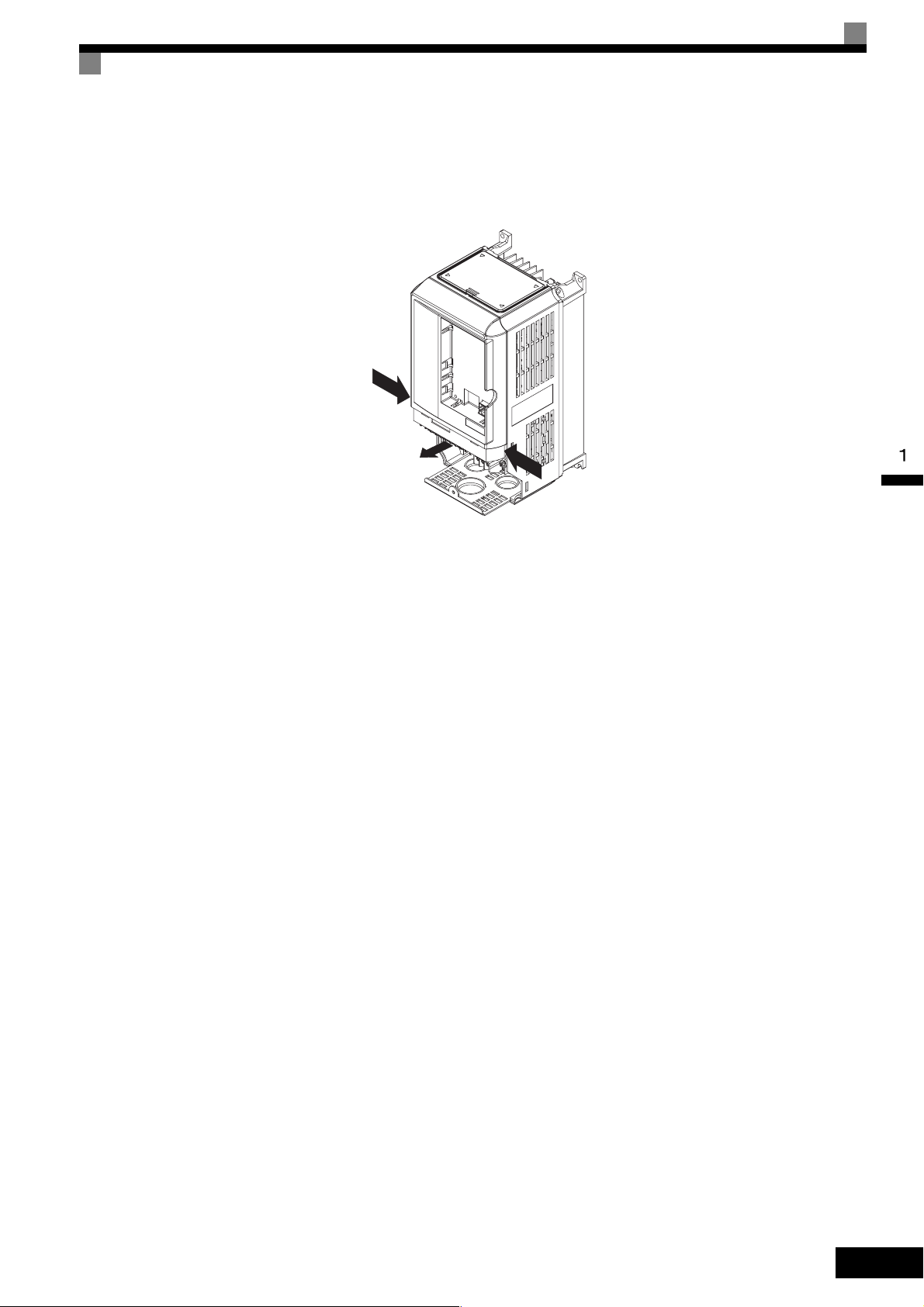

Removing the Front Cover

Press the left and right sides of the front cover in the directions of arrows 1 and lift the bottom of the cover in

the direction of arrow 2 to remove the front cover as shown in the following illustration.

1

1

2

Fig 1.14 Removing the Front Cover (Model CIMR-G7C43P7 Shown Above)

Mounting the Front Cover

After wiring the terminals, mount the front cover to the Inverter by performing in reverse order to the steps to

remove the front cover.

1. Do not mount the front cover with the Digital Operator attached to the front cover; otherwise, Digital

Operator may malfunction due to imperfect contact.

2. Insert the tab of the upper part of the front cover into the groove of the Inverter and press the lower part of

the front cover onto the Inverter until the front cover snaps shut.

Mounting the Digital Operator

After attaching the terminal cover, mount the Digital Operator onto the Inverting using the following procedure.

1. Hook the Digital Operator at A (two locations) on the front cover in the direction of arrow 1 as shown in

the following illustration.

2. Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

1-13

Loading...

Loading...