Omron VARISPEED F7 DATASHEET

Cat. No.

I66E-EN-01

English

The Industrial Workhorse

Model: CIMR-F7Z

200V Class 3-phase 0.4 to 110 kW

400V Class 3-phase 0.4 to 300 kW

Deutsch

Español

FrançaisItaliano

Português

Pyccкий

F7Z Quick Start Guide

Table of Contents

Warnings ...................................................................... EN-2

Safety Precautions and Instructions ........................................................................... EN-3

EMC Compatibility ......................................................................................................EN-4

Installation .................................................................... EN-6

Mechanical Installation ............................................................................................... EN-6

Electrical Connection .................................................................................................. EN-8

Wiring Main Circuit Inputs ........................................................................................ EN-12

Keypad Operation ...................................................... EN-14

Digital Operator Display (optional) ............................................................................ EN-14

Power Up and Basic Parameter Setup ..................... EN-15

Start Up Procedure .................................................................................................. EN-15

Before Power Up ...................................................................................................... EN-16

Display after Power Up ............................................................................................. EN-16

Autotuning ................................................................................................................ EN-16

User Parameter .......................................................... EN-18

Troubleshooting ......................................................... EN-21

General Faults and Alarms ....................................................................................... EN-21

Operator Programming Errors .................................................................................. EN-23

Autotuning Faults ..................................................................................................... EN-24

1

Warnings

The Varispeed F7 DC bus capacitor remains charged even after the power has been

switched off. To avoid an electric shock hazard, disconnect the frequency inverter from the

mains before carrying out maintenance. Then wait for at least 5 minutes after all LEDs

have gone out.

Do not perform a withstand voltage test on any part of the Varispeed. The frequency

inverter contains semiconductors, which are not designed for such high voltages.

Do not remove the digital operator while the mains supply is switched on. The printed circuit board must also not be touched while the inverter is connected to the power.

CAUTION

CAUTION

Cables must not be connected or disconnected, nor signal tests carried out,

while the power is switched on.

Never connect general LC/RC interference suppression filters, capacitors or overvoltage

protection devices to the inverter input or output.

To avoid unnecessary overcurrent faults, etc. being displayed, the signaling contacts of any

contactor or switch fitted between inverter and motor must be integrated into the inverter

control logic (e.g. baseblock).

This is absolutely imperative!

This manual must be read thoroughly before connecting and operating the inverter. All

safety precautions and instructions for use must be followed.

The inverter may must be operated with the appropriate line filters, following the installation

instructions in this manual and with all covers closed and terminals covered.

Only then will adequate protection be provided. Please do not connect or operate any

equipment with visible damage or missing parts. The operating company is responsible

for any injuries or equipment damage resulting from failure to heed the warnings in this

manual.

EN-2

Safety Precautions and Instructions

General

Please read these safety precautions and instructions for use thoroughly before installing and operating this inverter. Also read all of the warning signs on the inverter and ensure they are never damaged or removed.

Live and hot inverter components may be accessible during operation. Removal of housing components, the digital operator or terminal covers runs the risk of serious injuries or damage in the event

of incorrect installation or operation. The fact that frequency inverters control rotating mechanical

machine components can give rise to other dangers.

The instructions in this manual must be followed. Installation, operation and maintenance may only

be carried out by qualified personnel. For the purposes of the safety precautions, qualified personnel

are defined as individuals who are familiar with the installation, starting, operation and maintenance

of frequency inverters and have the proper qualifications for this work. Safe operation of these units

is only possible if they are used properly for their intended purpose.

The DC bus capacitors can remain live for about 5 minutes after the inverter is disconnected from

the power. It is therefore necessary to wait for this time before opening its covers. All of the main circuit terminals may still carry dangerous voltages.

Children and other unauthorized persons must not be allowed access to these inverters.

Keep these Safety Precautions and Instructions for Use readily accessible and supply them to all

persons with any form of access to the inverters.

Intended Use

Frequency inverters are intended for installation in electrical systems or machinery.

Their installation in machinery and systems must conform to the following product standards of the

Low Voltage Directive:

EN 50178, 1997-10, Equipping of Power Systems with Electronic Devices

EN 60204-1, 1997-12 Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)/

Please note: Includes Corrigendum of September 1998

EN 61010-1, A2, 1995 Safety Requirements for Information Technology Equipment

(IEC 950, 1991 + A1, 1992 + A2, 1993 + A3, 1995 + A4, 1996, modified)

CE marking is carried out to EN 50178, using the line filters specified in this manual and following

the appropriate installation instructions.

Transportation and storage

The instructions for transportation, storage and proper handling must be followed in accordance with

the technical data.

Installation

Install and cool the inverters as specified in the documentation. The cooling air must flow in the

specified direction. The inverter may therefore only be operated in the specified position (e.g.

upright). Maintain the specified clearances. Protect the inverters against impermissible loads. Components must not be bent nor insulation clearances changed. To avoid damage being caused by

static electricity, do not touch any electronic components or contacts.

EN-3

Electrical Connection

Carry out any work on live equipment in compliance with the national safety and accident prevention

regulations. Carry out electrical installation in compliance with the relevant regulations. In particular,

follow the installation instructions ensuring electromagnetic compatibility (EMC), e.g. shielding,

grounding, filter arrangement and laying of cables. This also applies to equipment with the CE mark.

It is the responsibility of the manufacturer of the system or machine to ensure conformity with EMC

limits.

Your supplier or Omron Yaskawa Motion Control representative must be contacted when using leakage current circuit breaker in conjunction with frequency inverters.

In certain systems it may be necessary to use additional monitoring and safety devices in compliance with the relevant safety and accident prevention regulations. The frequency inverter hardware

must not be modified.

Notes

The Varispeed F7 frequency inverters are certified to CE, UL, and cUL

EMC Compatibility

Introduction

This manual was compiled to help system manufacturers using OMRON YASKAWA Motion Control

(OYMC) frequency inverters design and install electrical switch gear. It also describes the measures

necessary to comply with the EMC Directive. The manual's installation and wiring instructions must

therefore be followed.

Our products are tested by authorized bodies using the standards listed below.

Product standard: EN 61800-3:1996

EN 61800-3; A11:2000

Measures to Ensure Conformity of OYMC Frequency inverters to the EMC Directive

OYMC frequency inverters do not necessarily have to be installed in a switch cabinet.

It is not possible to give detailed instructions for all of the possible types of installation. This manual

therefore has to be limited to general guidelines.

All electrical equipment produces radio and line-borne interference at various frequencies. The

cables pass this on to the environment like an aerial.

Connecting an item of electrical equipment (e.g. drive) to a supply without a line filter can therefore

allow HF or LF interference to get into the mains.

The basic countermeasures are isolation of the wiring of control and power components, proper

grounding and shielding of cables.

A large contact area is necessary for low-impedance grounding of HF interference. The use of

grounding straps instead of cables is therefore definitely advisable.

Moreover, cable shields must be connected with purpose-made ground clips.

EN-4

Laying Cables

Measures Against Line-Borne Interference:

Line filter and frequency inverter must be mounted on the same metal plate. Mount the two compo-

nents as close to each other as possible, with cables kept as short as possible.

Use a power cable with well-grounded shield. For motor cables up to 50 meters in length use

shielded cables. Arrange all grounds so as to maximize the area of the end of the lead in contact

with the ground terminal (e.g. metal plate).

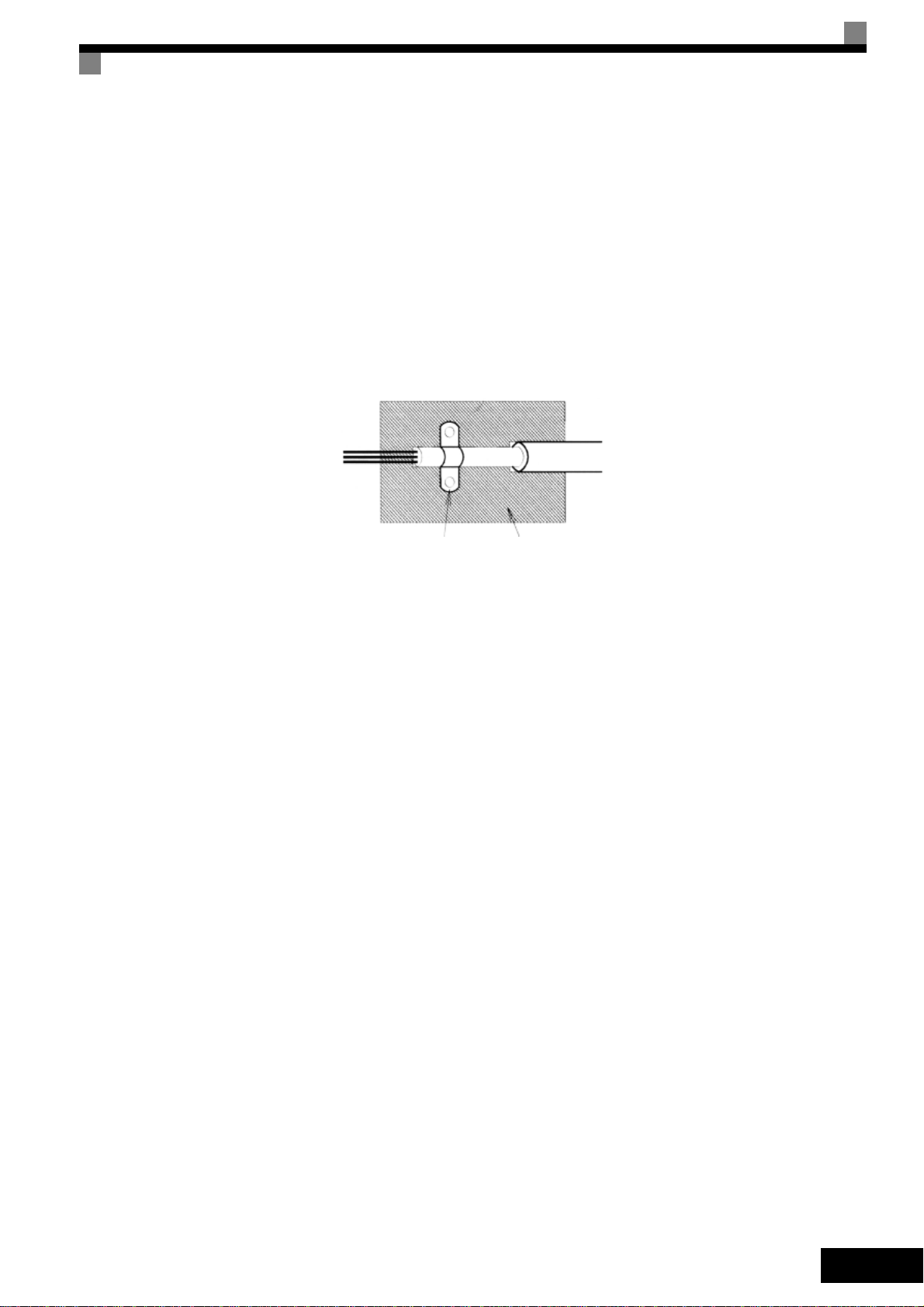

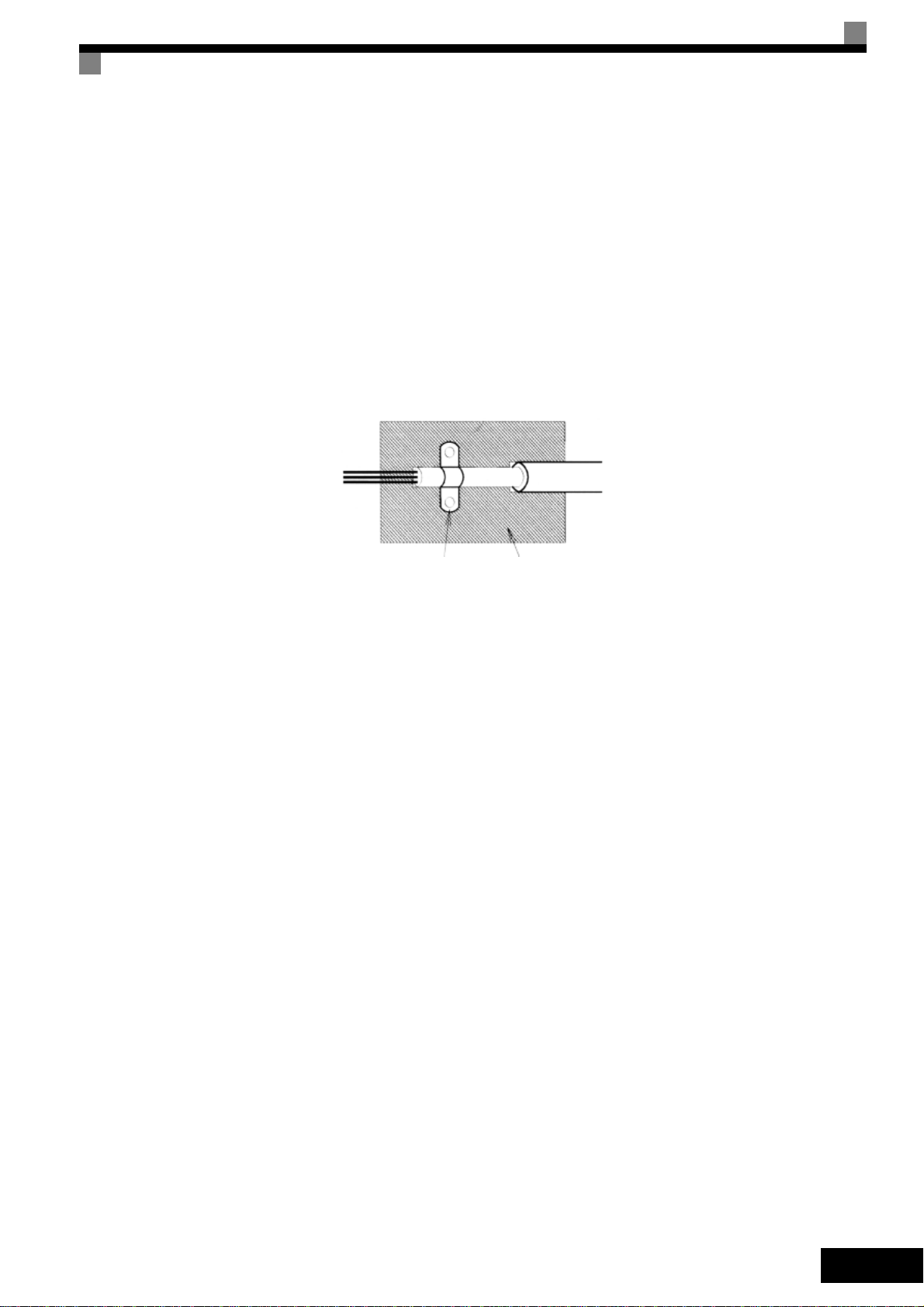

Shielded Cable:

• Use a cable with braided shield.

• Ground the maximum possible area of the shield. It is advisable to ground the shield by connect-

ing the cable to the ground plate with metal clips (see following figure).

Ground Clip

Fig 1 Earthing the cable shield with metal clips

The grounding surfaces must be highly conductive bare metal. Remove any coats of varnish and

paint.

– Ground the cable shields at both ends.

– Ground the motor of the machine.

Ground Plate

EN-5

Installation

Mechanical Installation

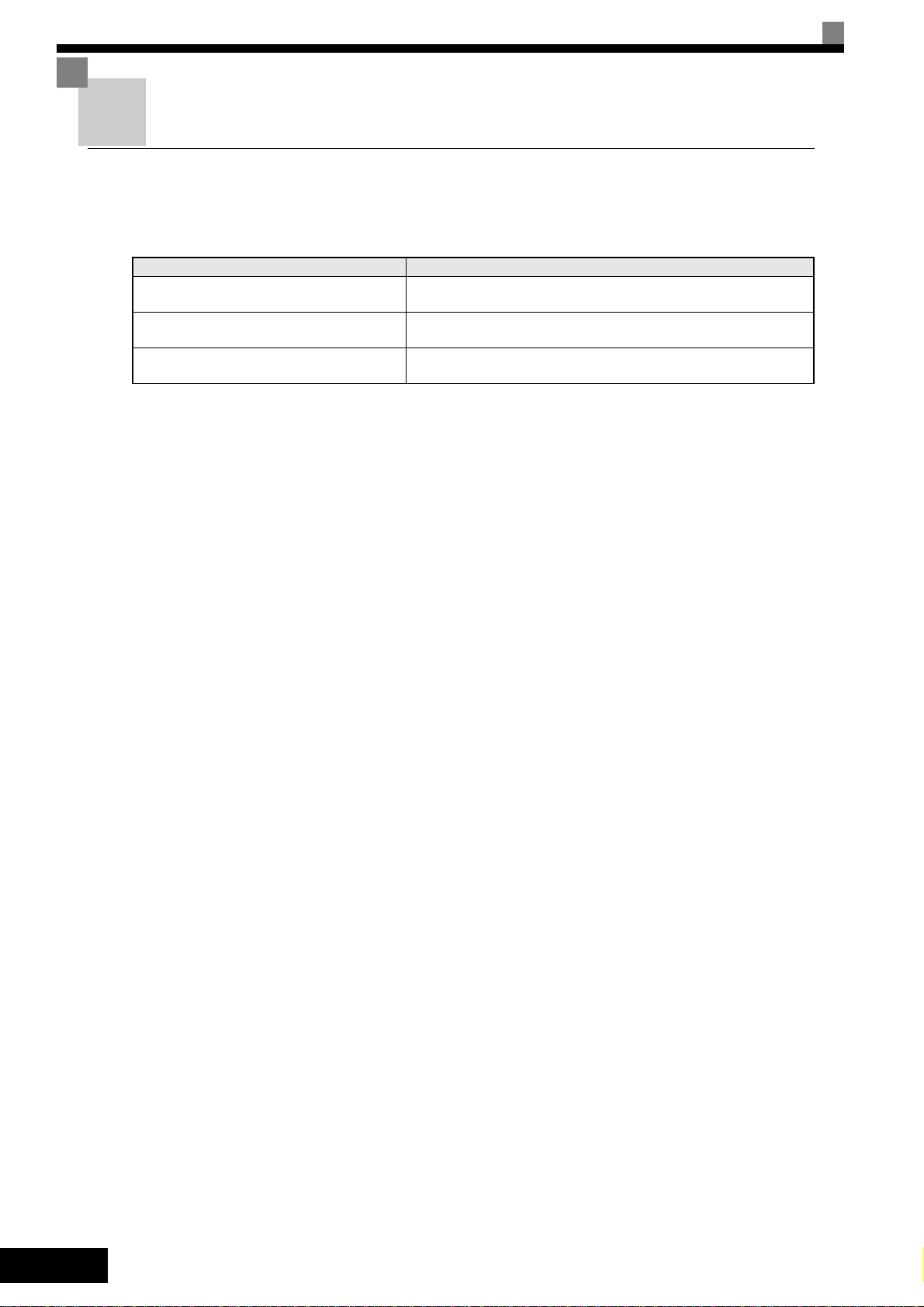

Unpacking the Inverter

Check the following items after unpacking the inverter.

Item Method

Has the correct Inverter model been

delivered?

Is the Inverter damaged in any way?

Are any screws or other components

loose?

If any irregularities in the above items are found, contact the agency from which the Inverter was purchased or your Omron Yaskawa Motion Control representative immediately.

Checking the Installation Site

Protection covers are attached to the top and bottom of the NEMA 1 / IP20 Inverters. Be sure to

remove the top cover before operating a 200 or 400 V Class Inverter with a capacity of 18.5 kW or

less inside a panel.

Observe the following precautions when mounting the Inverter:

• Install the Inverter in a clean location which is free from oil mist and dust. It can be installed in a

totally enclosed panel that is completely shielded from floating dust.

• When installing or operating the Inverter, always take special care so that metal powder, oil,

water, or other foreign matter does enter the Inverter.

• Do not install the Inverter on combustible material, such as wood.

• Install the Inverter in a location free from radioactive materials and combustible materials.

• Install the Inverter in a location free from harmful gasses and liquids.

• Install the Inverter in a location without excessive oscillation.

• Install the Inverter in a location free from chlorides.

• Install the Inverter in a location without direct sunlight.

Check the model number on the nameplate on the side of the

Inverter.

Inspect the entire exterior of the Inverter to see if there are any

scratches or other damage resulting from shipping.

Use a screwdriver or other tools to check for tightness.

EN-6

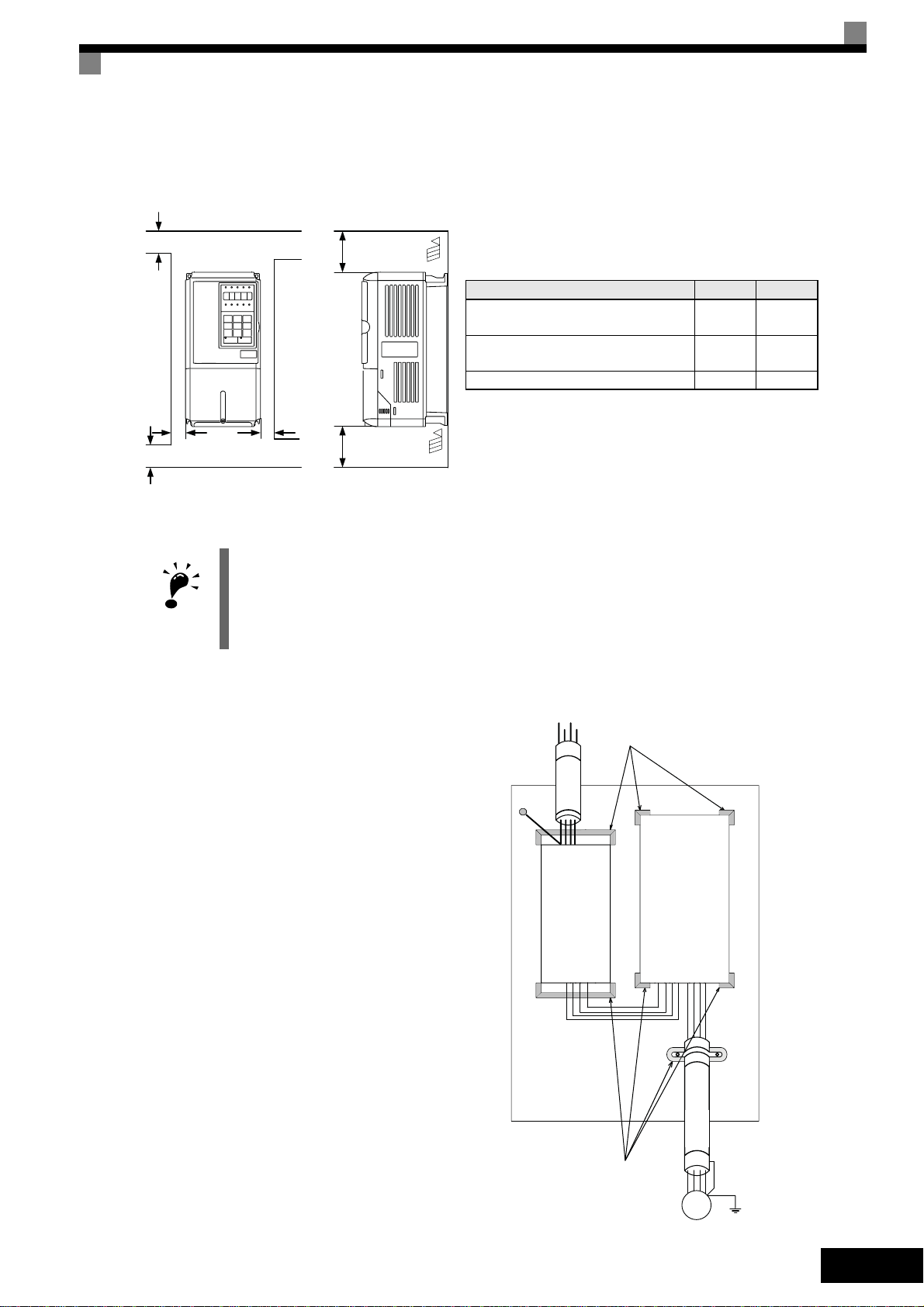

Installation Orientation

Install the Inverter vertically so as not to reduce the cooling effect. When installing the Inverter,

always provide the following installation space to allow normal heat dissipation.

A

30mm min.

50mm

min.

Horizontal Space

30mm min.

B

Air

120mm min.

Air

Vertical Space

Fig 2 Installation space

1. The same space is required horizontally and vertically for IP00, IP20 and NEMA 1 Inverters.

2. Always remove the top protection cover after installing an Inverter with an output of 18.5 kW or less in a

panel.

IMPORTANT

IMPORTANT

Always provide enough space for suspension eye bolts and the main circuit lines when installing an

Inverter with an output of 22 kW or more in a panel.

Installation of Inverters and EMC filters

For an EMC rules compliant installation

consider the following points:

• Use a line filter.

• Use shielded motor cables.

• Mount the inverter and filter on a

grounded cunductive plate.

• Remove any paint or dirt before mount-

ing the parts in order to reach the lowest possible grounding impedance.

A B

200V class inverter, 0.55 to 90 kW

400V class inverter, 0.55 to 132 kW

200V class inverter, 110 kW

400V class inverter, 160 to 220 kW

50 mm 120 mm

120 mm 120 mm

400V class inverter, 300 kW 300 mm 300 mm

PEL1L2

L3

Ground Bonds

Remove any paint!

PE

Line

Inverter

Filter

Fig 3 EMC filter installation

Cable Lenght

as short as possible

Grounded

Metal Plate

Load

GND

Ground Bonds

Remove any paint!

L2

V

GND

W

U

L1

L3

Screened

Motor cable

M

~3

EN-7

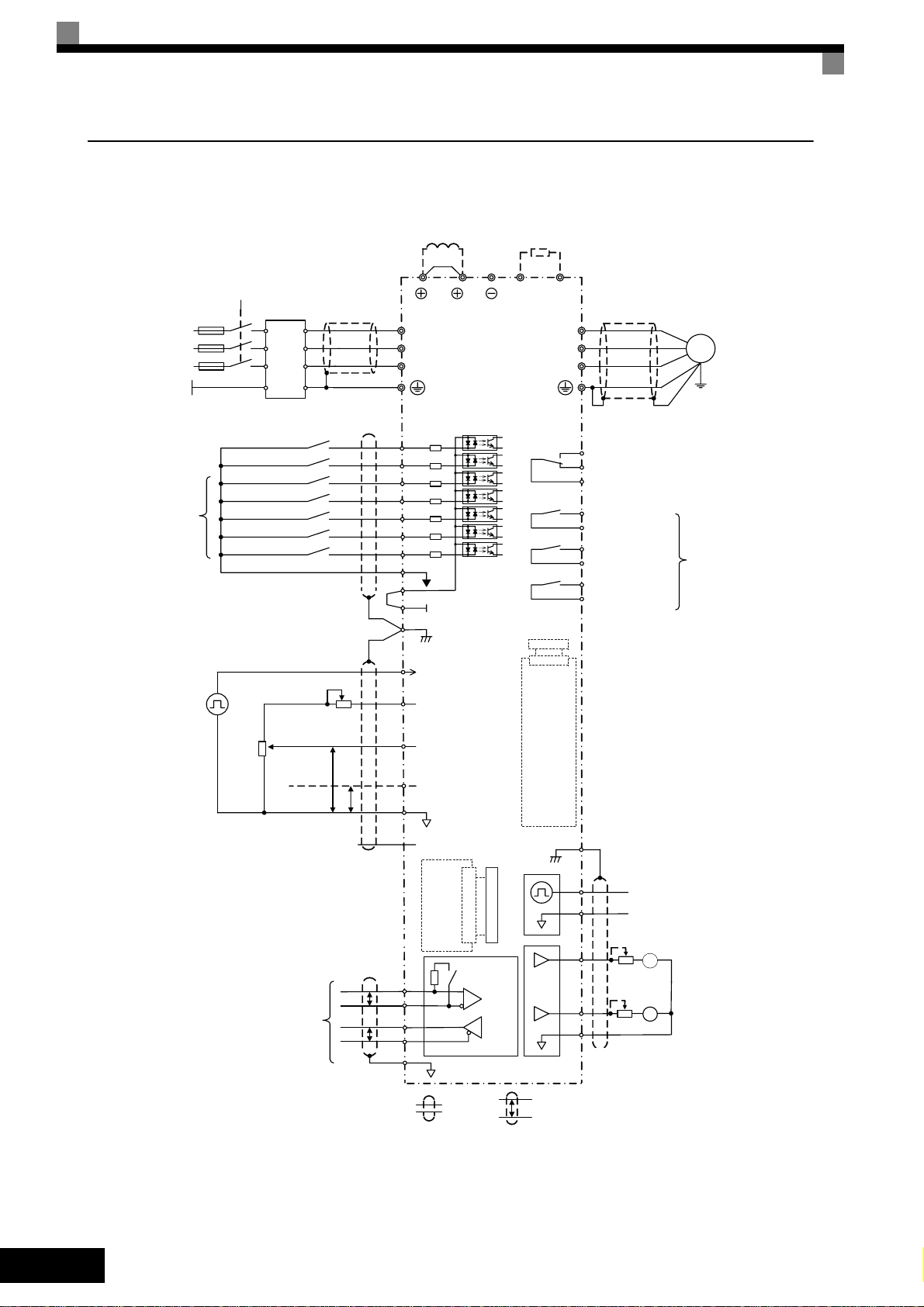

Electrical Connection

Wiring the Inverter

Main Contactor

T

Fuses

PE

L1

L2

L3

Line

Filter

3-phase power

380 to 480 V

50/60 Hz

DC reactor to improve input

power factor (optional)

Short-circuit bar

R/L1

S/L2

T/L3

2

Varispeed F7

Braking resistor unit (optional)

1

B1

B2

U/T1

V/T2

W/T3

M

Multi-function

digital inputs

[Factory setting]

Forward Run / Stop

Reverse Run / Stop

External Fault

Fault reset

Multi-step speed setting 1

Multi-step speed setting 2

Jog frequency selection

Analog input setting

adjustment

0 to 10 V

2 k

Ω

4 to 20 mA

MEMOBUS

communication

RS-485/422

S1

S2

S3

S4

S5

S6

S7

SN

SC

SP

24 V

E(G)

Shield

terminal

Pulse train input [Default:

RP

Frequency reference input]

0 to 32 kHz

+V

Analog input power supply

Ω

2 k

PP

15 V, 20 mA

Analog input 1: Master

A1

frequency reference

0 to 10 V (20 k

Multi-function analog input 2

A2

[Default: Frequency bias

4 to 20 mA (20 k

AC

-V

Analog input power supply

-15 V, 20 mA

Ω)

Ω)]

0 V

Input

Option

Card

R+

P

R-

S+

P

S-

IG

2CN

Terminating

resistance

Option

Shield

terminal

2CN

PG

Card

MA

Fault relay output

MB

250 VAC, 1 A max.

30 VDC, 1 A max.

MC

M1

M2

M3

M4

M5

Relay output 3

[Default:

M6

Frequency agree 1]

E(G)

MP

AC

FM

AM

AC

Relay output 1

[Default: Running]

Relay output 2

[Default: Zero speed]

Pulse train output

0 to 32 kHz (2.20 k

[Default: Output frequency]

Adjustment,

20 k

Ω

+

FM

Adjustment,

20 k

Ω

+

AM

Multi-function digital output

250 VAC, 1 A max.

30 VDC, 1 A max.

Ω)

-

Multi-function analog output 1

(-10 to +10 V, 2 mA / 4 to 20 mA)

[Default: Output frequency, 0 to 10 V)

4 to 20 mA (20 k

-

Multi-function analog output 2

(-10 to +10 V, 2 mA / 4 to 20 mA)

[Default: Output current, 0 to 10 V)

4 to 20 mA (20 k

Ω)]

Ω)]

EN-8

Shielded

wires

Fig 4 Wiring Diagram

Twisted-pair

P

shielded wires

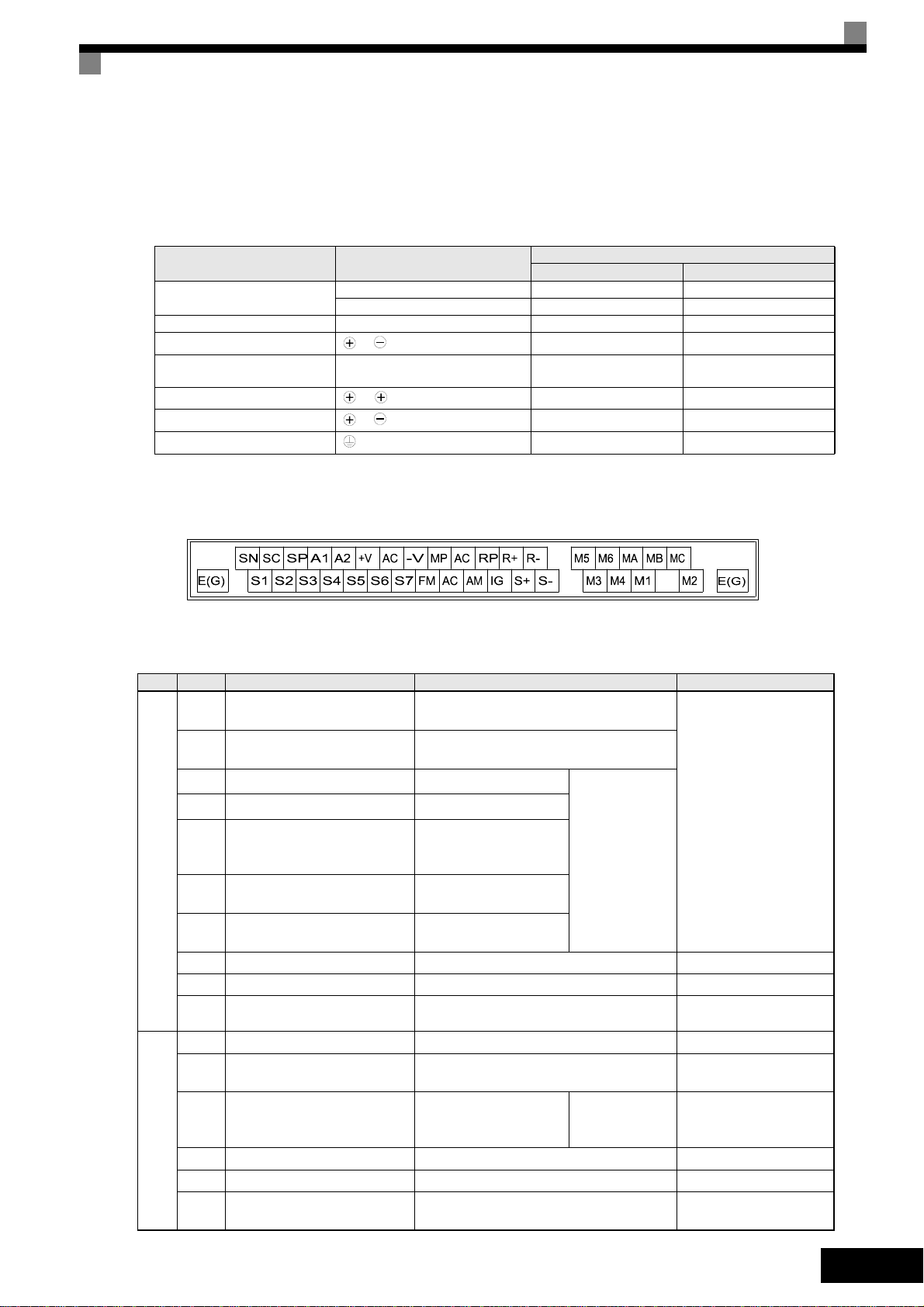

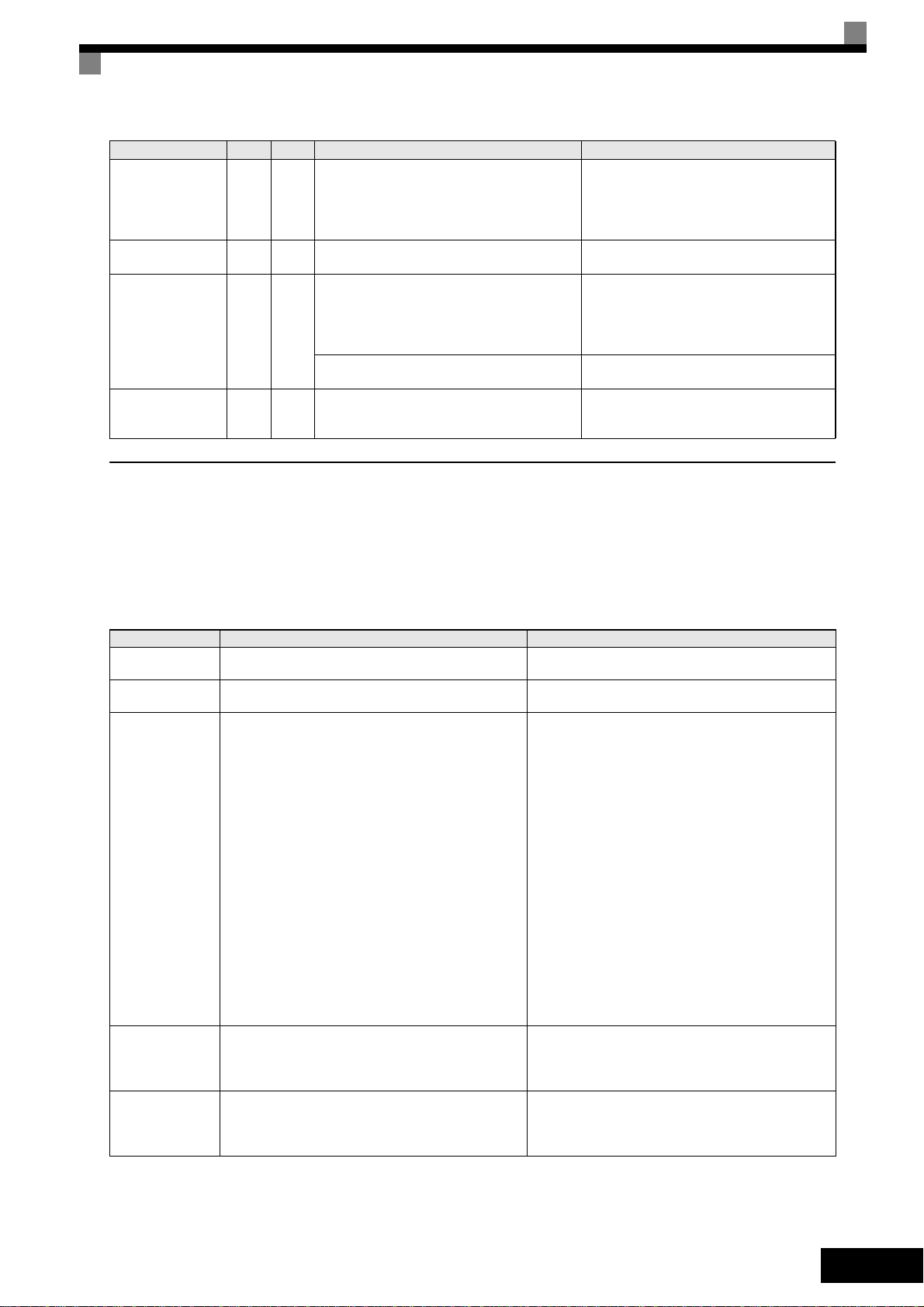

Main Circuit Terminals

Main circuit terminal functions are summarized according to terminal symbols in Ta b l e 1 . Wire the

terminals correctly for the desired purposes.

Table 1 Main Circuit Terminal Functions (200 V Class and 400 V Class)

Purpose Terminal Symbol

Main circuit power input

Inverter outputs U/T1, V/T2, W/T3 20P4 to 2110 40P4 to 4300

DC bus terminals

Braking Resistor Unit Connec-

tion

DC reactor connection

Braking Unit connection

Ground 20P4 to 2110 40P4 to 4300

R/L1, S/L2, T/L3 20P4 to 2110 40P4 to 4300

R1/L11, S1/L21, T1/L31 2022 to 2110 4022 to 4300

1,

B1, B2 20P4 to 2018 40P4 to 4018

1, 2

3,

Model: CIMR-F7Z

200 V Class 400 V Class

20P4 to 2110 40P4 to 4300

20P4 to 2018 40P4 to 4018

2022 to 2110 4022 to 4300

Control Circuit Terminals

Fig 5 shows the control terminal arrangement. The functions of the control circuit terminals are

shown in Tabl e 2 . Use the appropriate terminals for the correct purposes.

Fig 5 Control terminal arrangement

Table 2 Control Circuit Terminals with default settings

Ty p e No. Signal Name Function Signal Level

S1 Forward run/stop command

S2 Reverse run/stop command

S3

External fault input

S4

Fault reset

*1

Multi-step speed reference 1

*1

S5

(Master/auxiliary switch)

Multi-step speed reference 2

S6

Digital input signals

*1

S7

Jog frequency reference

*1

Forward run when ON; stopped when

OFF.

Reverse run when ON; stopped when

OFF.

Fault when ON.

Reset when ON

Auxiliary frequency reference when ON.

Multi-step speed 2

when ON.

Jog frequency when

*1

ON.

Functions are

selected by setting H1-01 to

H1-05.

24 VDC, 8 mA

Photocoupler isolation

SC Digital input common – –

SN Digital Input Neutral – –

SP Digital Input Power Supply +24VDC power supply for digital inputs

24 VDC, 250 mA max.

*2

+V 15 V power output 15 V power supply for analog references 15 V (Max. curr.: 20mA)

A1 Frequency reference 0 to +10 V/100%

Auxiliary Frequency Refer-

A2

ence

Auxiliary analog frequency reference;

4 to 20 mA (250Ω)

Function is

selected by setting H3-09.

–10 to +10 V (20 kΩ)

0 to +10 V (20 kΩ)

4 to 20 mA (250 Ω)

0 V to +10 V (20 kΩ)

0 to 20 mA (250 Ω)

-V –15 V power output –15 V power supply for analog references

AC Analog reference common – –

Analog input signals

Shield wire, optional ground

E(G)

line connection point

––

EN-9

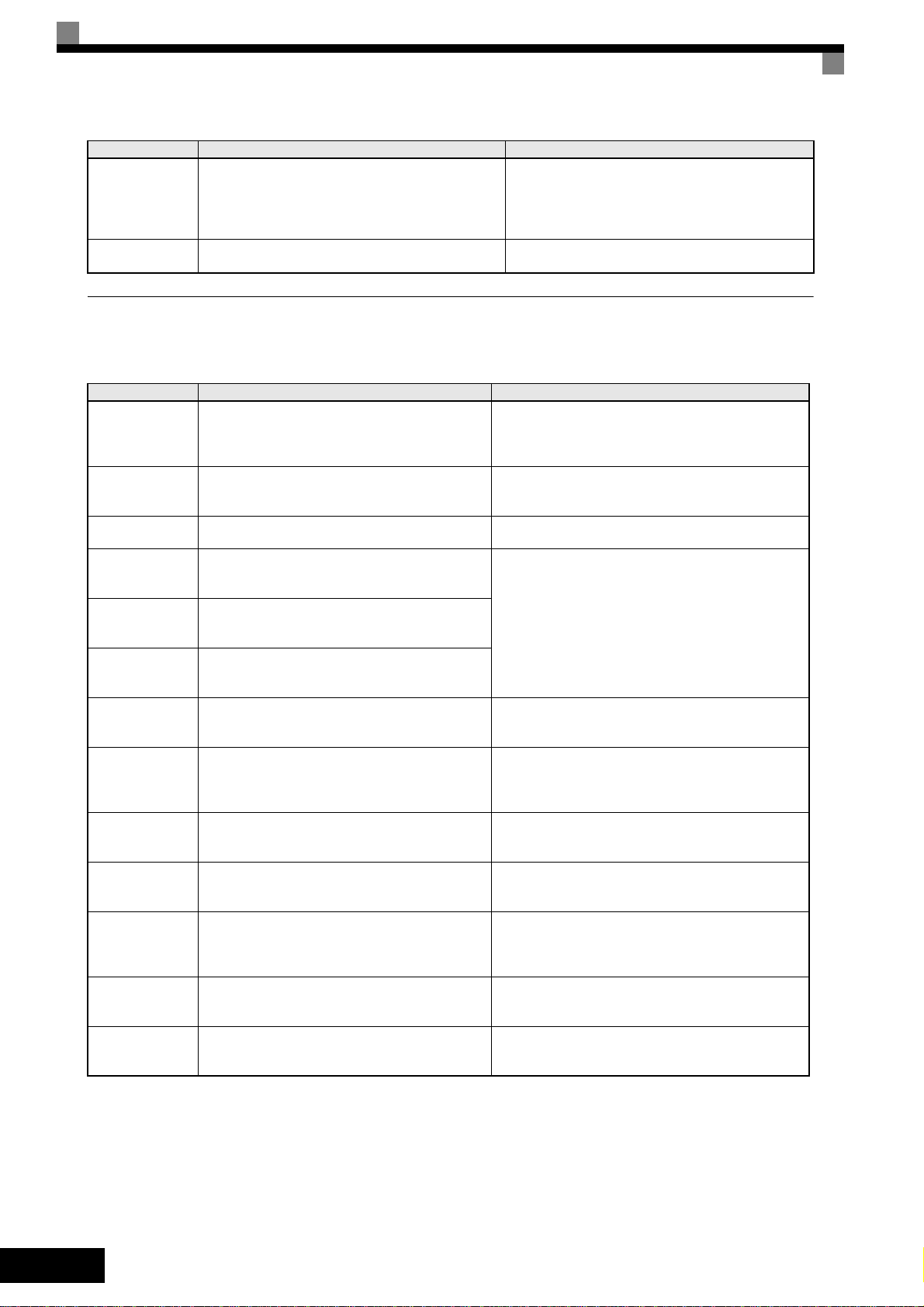

Ty p e No. Signal Name Function Signal Level

M1

During run (NO) Closed during Run

M2

M3

M4

M5

M6

MA

Digital output signals

MB

Zero speed (NO)

Speed agreement detection

(NO)

Fault output signal

Closed when output

frequency at zero level

(b2-01) or below

Within ± 2 Hz of set frequency when ON

Closed across MA and MC during faults

Open across MB and MC during faults

Function

selected by

H2-01 to H2-03

Relay contacts

Contact capacity:

1 A max. at 250 VAC

1 A max. at 30 VDC

MC

FM Output frequency

AC Analog common –

AM Inverter output power

Analog output signals

Analog output frequency signal;

0 to 10 V; 10V=FMAX

Analog output power

signal;

0 to 10V; 10V=max.

appl. motor capacity

Function

selected by

H4-01

Function

selected by

H4-04

0 to +10 V max. ±5%

2 mA max.

–10 to +10 V max. ±5%

2 mA max

4 to 20 mA

0 to 32 kHz (3kΩ)

*4

RP Pulse Input

H6-01 (Frequency reference input)

High level voltage 3.5 to

13.2 V

Pulse I/O

MP Pulse Output H6-06 (Output frequency)

R+

MEMOBUS communications

input

R-

S+

MEMOBUS communications

output

S-

RS-485/422

For 2-wire RS-485, short R+ and S+

as well as R- and S-.

0 to 32 kHz

+15 V output (2.2kΩ)

Differential input,

PHC isolation

Differential input,

PHC isolation

IG Signal common – –

*1. The default settings are given for terminals S3 to S7. For a 3-wire sequence, the default settings are a 3-wire sequence for S5, multi-

step speed setting

1 for S6 and multi-step speed setting 2 for S7.

*2. Do not use this power supply for supplying any external equipment.

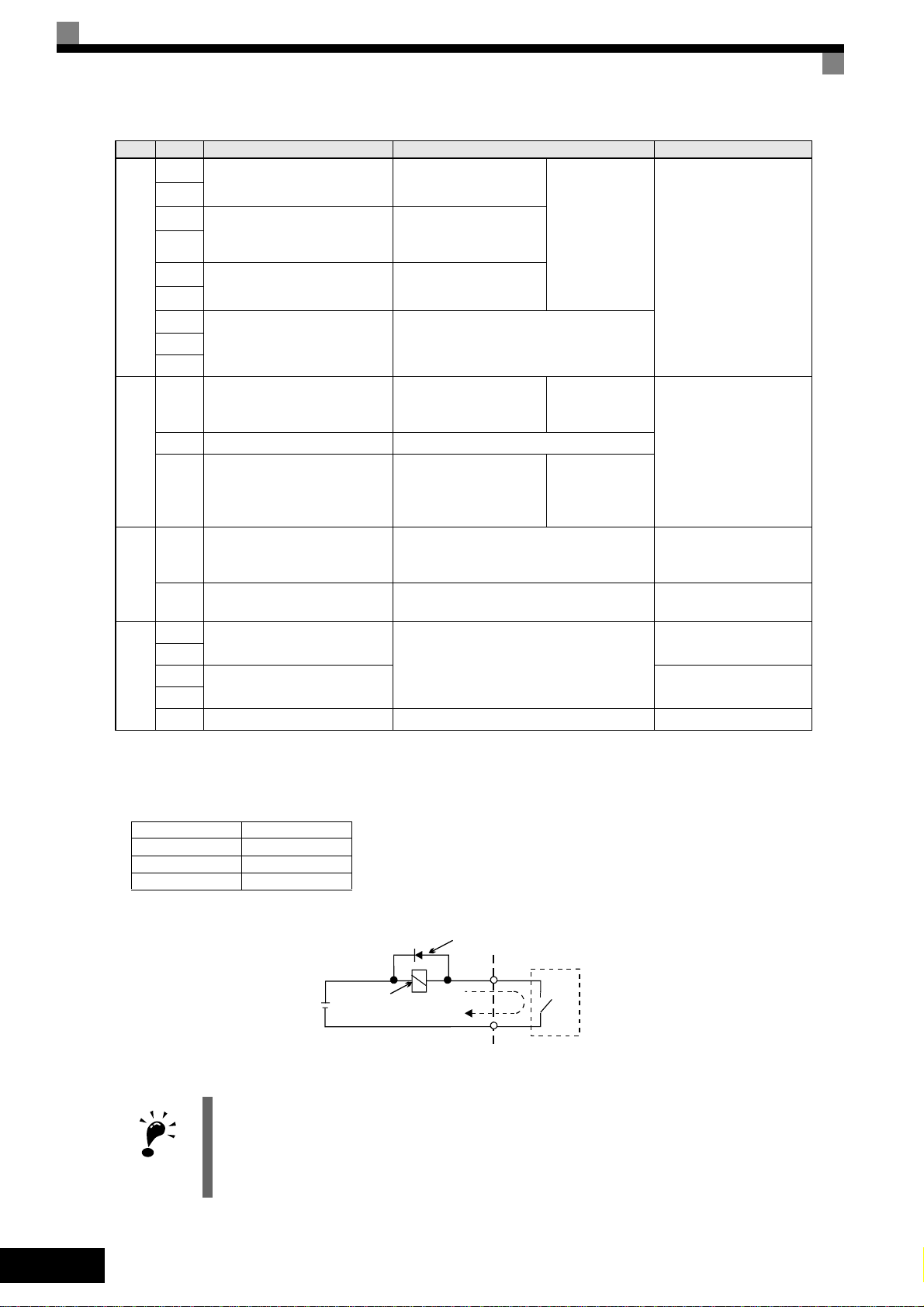

*3. When driving a reactive load, such as a relay coil with DC power supply, always insert a flywheel diode as shown in Fig 6

*4. Pulse input specifications are given in the following table:

Low level voltage 0.0 to 0.8 V

High level voltage 3.5 to 13.2 V

H duty 30% to 70%

Pulse frequency 0 to 32 kHz

*3

EN-10

IMPORTANT

Flywheel diode

The rating of the flywheel diode must

External power:

30 VDC max.

Coil

1 A max.

be at least as high as the circuit voltage.

Fig 6 Flywheel Diode Connection

1. In Fig 4 the wiring of the digital inputs S1 to S7 is shown for the connection of contacts or NPN transistors (0V common and sinking mode). This is the default setting.

For the connection of PNP transistors or for using a 24V external power supply, refer to Ta b l e 3 .

2. A DC reactor is an option only for Inverters of 18.5 kW or less. Remove the short circuit bar when connecting a DC reactor.

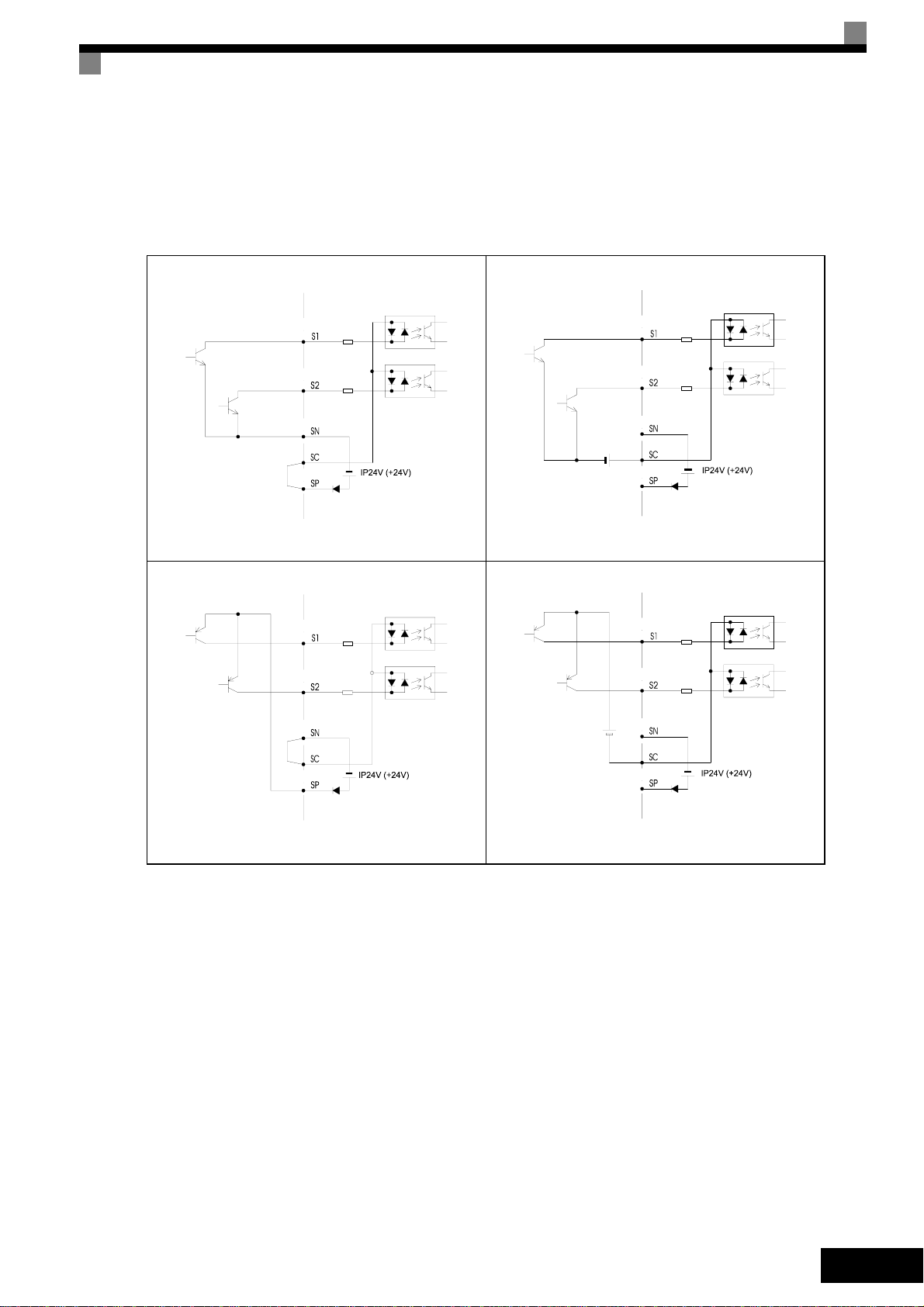

Sinking/Sourcing Mode (NPN/PNP Selection)

Int

(PNP)

Ext

(PNP)

The input terminal logic can be switched over between sinking mode (0-V common, NPN) and

sourcing mode (+24V common, PNP) by using the jumper CN5. An external power supply is also

supported, providing more freedom in signal input methods.

Table 3 Sinking / Sourcing Mode and Input Signals

Internal Power Source - Sinking Mode (NPN)

ernal Power Source - Sourcing Mode

External Power Source - Sinking Mode (NPN)

External +24 V

ernal Power Source - Sourcing Mode

External +24 V

EN-11

Wiring Main Circuit Inputs

Installing Fuses

To protect the inverter, it is recommended to use semiconductor fuses like they are shown in the

table below.

Table 4 Input Fuse Selection

Rated Inverter

Inverter Type

20P4 3.2 240 10 12~25 A60Q12-2 600V / 12A 17

20P7 4.1 240 10 12~25 A60Q12-2 600V / 12A 17

21P5 7.0 240 15 23~55 A60Q15-2 600V / 15A 26

22P2 9.6 240 20 34~98 A60Q20-2 600V / 20A 41

23P7 15 240 30 82~220 A60Q30-2 600V / 30A 132

25P5 23 240 40 220~610 A50P50-4 500V / 50A 250

27P5 31 240 60 290~1300 A50P80-4 500V / 80A 640

2011 45 240 80 450~5000 A50P80-4 500V / 80A 640

2015 58 240 100 1200~7200 A50P125-4 500V / 125A 1600

2018 71 240 130 1800~7200 A50P150-4 500V / 150A 2200

2022 85 240 150 870~16200 A50P150-4 500V / 150A 2200

2030 115 240 180 1500~23000 A50P200-4 500V / 200A 4000

2037 145 240 240 2100~19000 A50P250-4 500V/ 250A 6200

2045 180 240 300 2700~55000 A50P300-4 500V / 300A 9000

2055 215 240 350 4000~55000 A50P350-4 500V / 350A 12000

2075 283 240 450 7100~64000 A50P450-4 500V / 450A 20000

2090 346 240 550 11000~64000 A50P600-4 500V / 600A 36000

2110 415 240 600 13000~83000 A50P600-4 500V / 600A 36000

Output

Current (A)

Voltage (V) Current (A)

Fuse Selection Selection Example (Ferraz)

I2t (A2s)

Model Rating

I2t (A2s)

40P4 1.8 480 5 6~55 A60Q10-2 600V / 10A 10

40P7 2.1 480 5 6~55 A60Q10-2 600V / 10A 10

41P5 3.7 480 10 10~55 A60Q12-2 600V / 12A 17

42P2 5.3 480 10 18~55 A60Q15-2 600V / 15A 26

43P7 7.6 480 15 34~72 A60Q20-2 600V / 20A 41

44P0 8.7 480 20 50~570 A60Q30-2 600V / 30A 132

45P5 12.5 480 25 100~570 A60Q30-2 600V / 30A 132

47P5 17 480 30 100~640 A60Q30-2 600V / 30A 132

4011 24 480 50 150~1300 A70P50-4 700V / 50A 300

4015 31 480 60 400~1800 A70P70-4 700V / 70A 590

4018 39 480 70 700~4100 A70P80-4 700V / 80A 770

4022 45 480 80 240~5800 A70P80-4 700V / 80A 770

4030 60 480 100 500~5800 A70P100-4 700V / 100A 1200

4037 75 480 125 750~5800 A70P125-4 700V / 125A 1900

4045 91 480 150 920~13000 A70P150-4 700V / 150A 2700

4055 112 480 150 1500~13000 A70P200-4 700V / 200A 4800

4075 150 480 250 3000~55000 A70P250-4 700V / 250A 7500

4090 180 480 300 3800~55000 A70P300-4 700V / 300A 11000

4110 216 480 350 5400~23000 A70P350-4 700V / 350A 15000

4132 260 480 400 7900~64000 A70P400-4 700V / 400A 19000

4160 304 480 450

4185 370 480 600

4220 506 480 700

4300 675 480 900

14000~250000

20000~250000

34000~400000

52000~920000

A70P450-4 700V / 450A 24000

A70P600-4 700V / 600A 43000

A70P700-4 700V / 700A 59000

A70P900-4 700V / 900A 97000

Consider the following precautions for the main circuit power supply input.

• If a moulded case circuit breaker is used for the power supply connection (R/L1, S/L2, and T/L3),

ensure that the circuit breaker is suitable for the Inverter.

• If an earth leakage breaker is used, it should be able to detect all kinds of current in order to

ensure a safe earth leakage current detection

EN-12

• A magnetic contactor or other switching device can be used at the inverter input. The inverter

should not be powered up more than once per hour.

• The input phases (R/S/T) can be connected in any sequence.

• If the Inverter is connected to a large-capacity power transformer (600 kW or more) or a phase

advancing capacitor is switched nearby, an excessive peak current could flow through the input

power circuit, causing an inverter damage. As a countermeasure install an optional AC Reactor

at the inverter input or a DC reactor at the DC reactor connection terminals.

• Use a surge absorber or diode for inductive loads near the Inverter. Inductive loads include mag-

netic contactors, electromagnetic relays, solenoid valves, solenoids, and magnetic brakes.

Wiring the Output Side of the Main Circuit

The following precautions should be considered for the output circuit wiring.

• Never connect any power source to the inverter output terminals. Otherwise the inverter can be

damaged.

• Never short or ground the output terminals. Otherwise the inverter can be damaged.

• Do not use phase correction capacitors. Otherwise the inverter and capacitors can be damaged.

• Check the control sequence to make sure, that the magnetic contactor (MC) between the Inverter

and motor is not turned ON or OFF during inverter operation. If the MC is turned ON during the

Inverter is operation, a large inrush current will be created and the inverter’s overcurrent protection may operate.

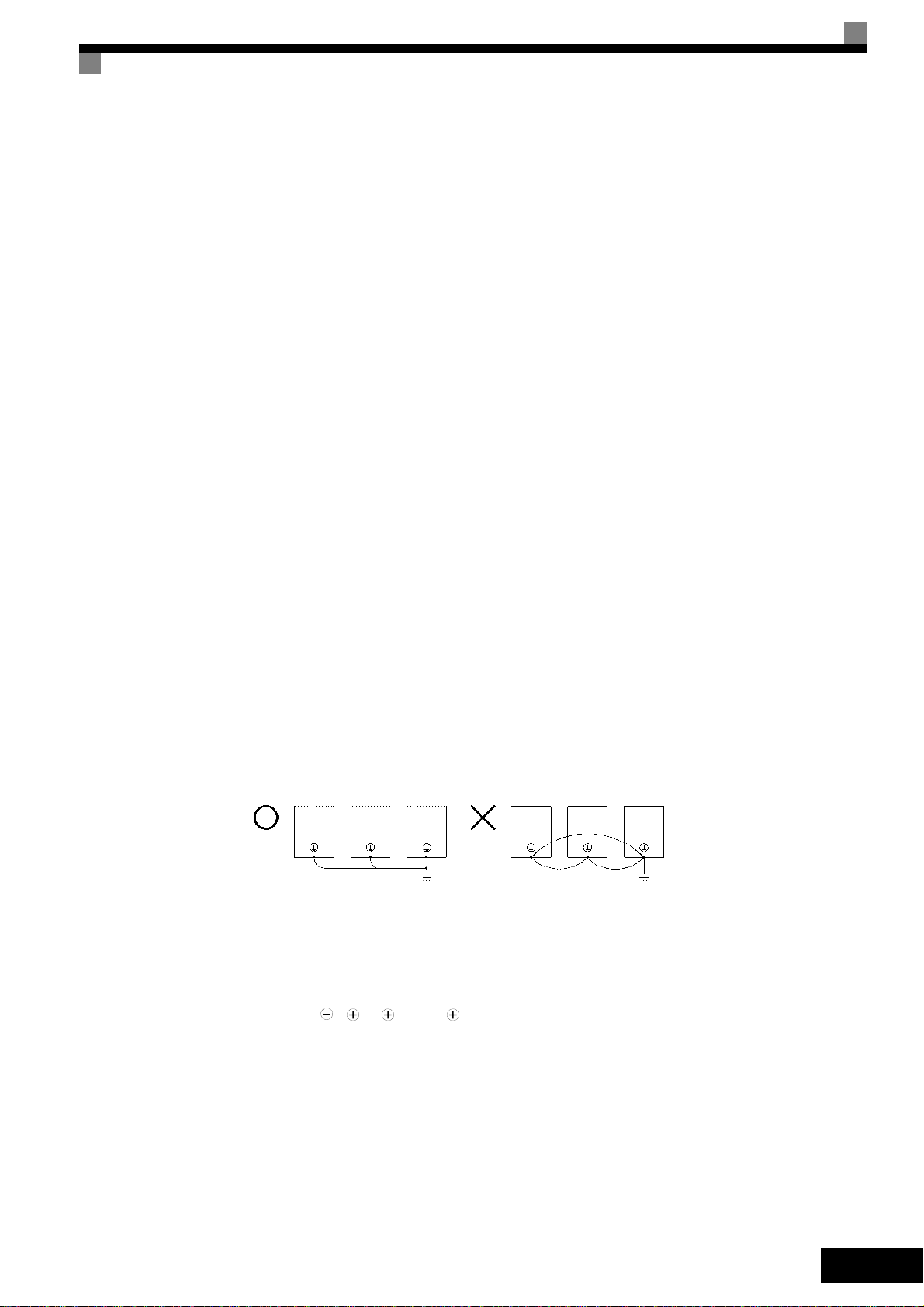

Ground Connection

The following precautions should be considered for the ground connection.

• Do not share the ground wire with other devices, such as welding machines or power tools.

• Always use a ground wire, that complies with technical standards on electrical equipment and

minimize the length of the ground wire.

Leakage current is caused by the Inverter. Therefore, if the distance between the ground electrode and the ground terminal is too long, potential on the ground terminal of the Inverter will

become unstable.

• When more than one Inverter is used, do not to loop the ground wire.

OK

Fig 7 Ground Wiring

NO

Control Circuit Wiring Precautions

Consider the following precautions for wiring the control circuits.

• Separate control circuit wiring from main circuit wiring (terminals R/L1, S/L2, T/L3, B1, B2, U/T1,

V/T2, W/T3, B1, B2, , 1, 2, and 3, PO, NO) and other high-power lines.

• Separate wiring for control circuit terminals MA, MB, MC, M1 to M6 (relay outputs) from wiring to

other control circuit terminals.

• If an optional external power supply is used, it should be a UL Listed Class 2 power supply.

• Use twisted-pair or shielded twisted-pair cables for control circuits to prevent operating faults.

• Ground the cable shields with the maximum contact area of the shield and ground.

• Cable shields have to be grounded on both cable ends.

EN-13

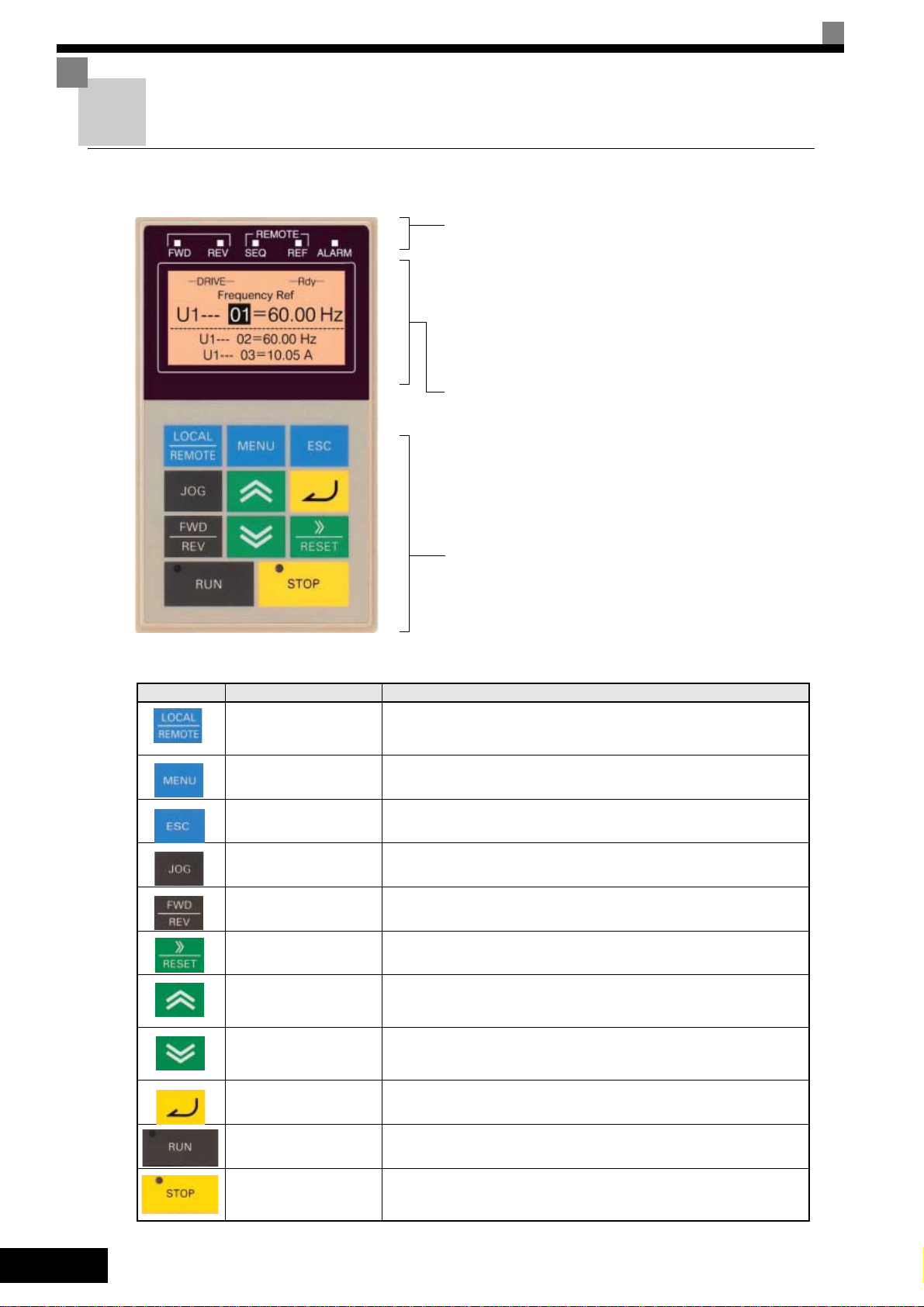

Keypad Operation

Digital Operator Display (optional)

The key names and functions of the Digital Operator are described below

Drive Mode Indicators

FWD: Lights up when a forward run command is

REV: Lights up when a reverse run command is

SEQ: Lights up when any other run command

REF: Lights up when any other frequency reference

ALARM: Lights up when an error or alarm has

Data Display

Displays monitor data, parameter numbers, and settings.

Mode Display (displayed at the upper left of the data display

DRIVE: Lights up in Drive Mode.

QUICK: Lights up in Quick Programming Mode.

ADV: Lights up in Advanced Programming Mode.

VERIFY: Lights up in Verify Mode.

A. TUNE: Lights up in Autotuning Mode.

input.

input.

source than the Digital Operator is selected.

source than the Digital Operator is selected.

occurred.

Digital Operator Keys

Key Name Function

LOCAL/REMOTE Key

MENU Key Selects the modes.

ESC Key Returns to the status before the DATA/ENTER Key was pressed.

JOG Key

FWD/REV Key

Shift/RESET Key

Increment Key

Decrement Key

Keys

Execute operations such as setting user parameters,

monitoring, jogging, and autotuning.

Switches between operation via the Digital Operator (LOCAL) and

the settings in b1-01 and b1-02 (REMOTE).

This key can be enabled or disabled by setting parameter o2-01.

Enables jog operation when the Inverter is being operated from the

Digital Operator.

Selects the rotation direction of the motor when the Inverter is being

operated from the Digital Operator.

Sets the active digit when programming user parameters.

Also acts as the Reset key when a fault has occurred.

Selects user parameter numbers and increments parameter settings.

Used to move to the next item or data.

Selects user parameter numbers and decrements parameter settings.

Used to move to the previous item or data.

EN-14

DATA/ENTER Key Enters menus and parameters and validates parameter settings.

RUN Key

STOP Key

Starts operation when the Inverter is being controlled by the Digital

Operator (LOCAL Mode).

Stops Inverter operation (LOCAL and REMOTE Mode).

This key can be enabled or disabled when operating from a source

different tan the operator by setting parameter o2-02.

Power Up and Basic Parameter Setup

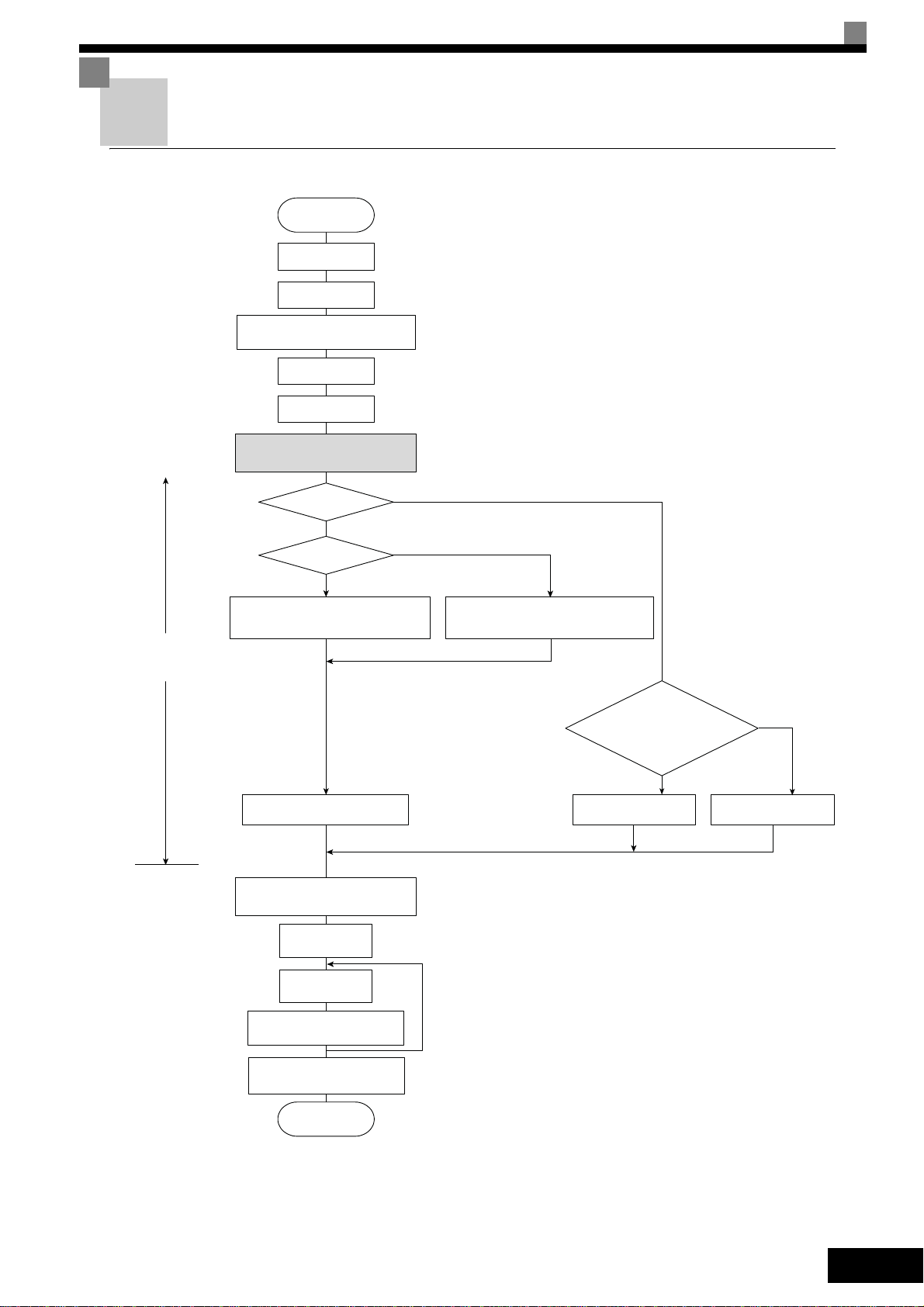

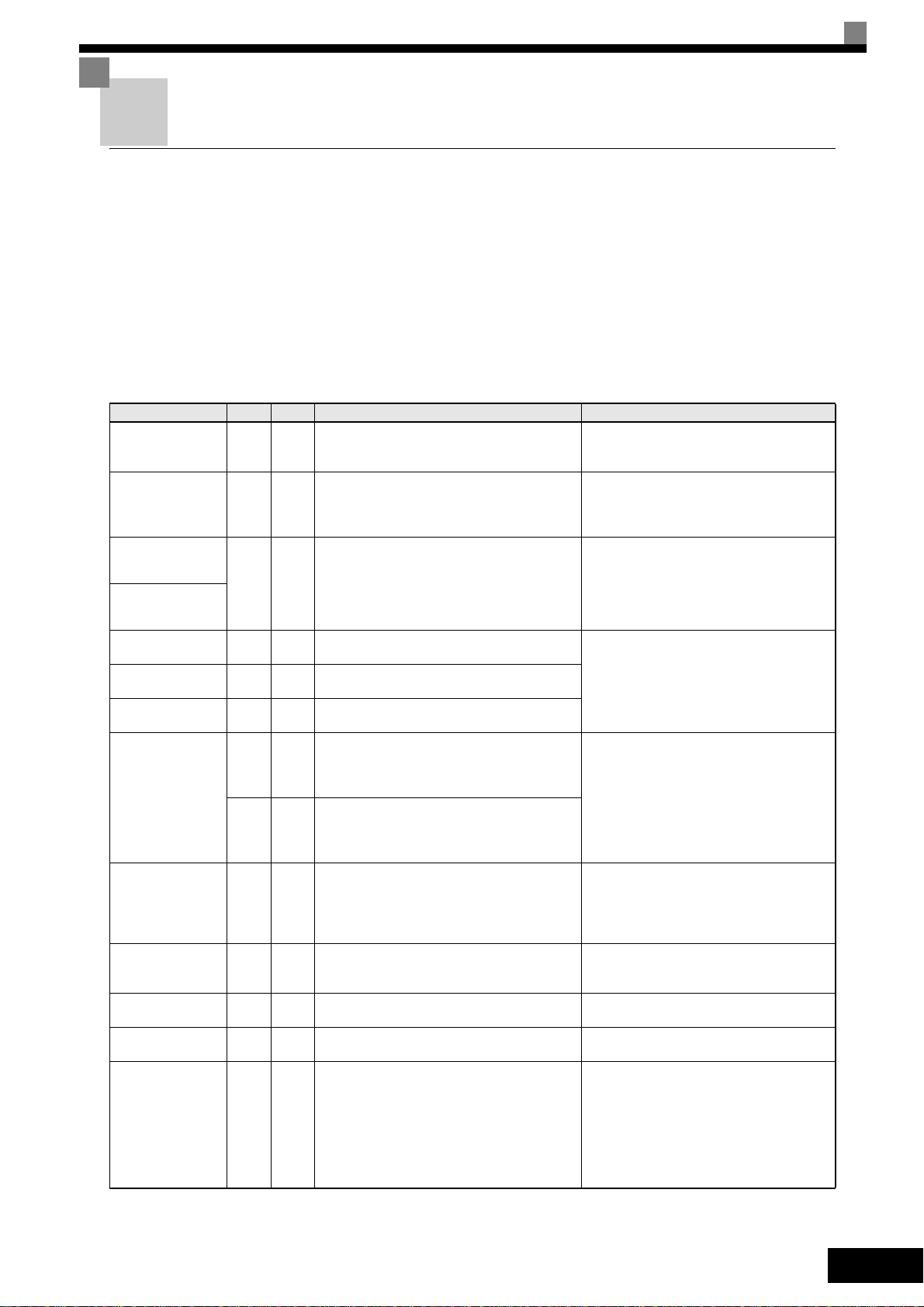

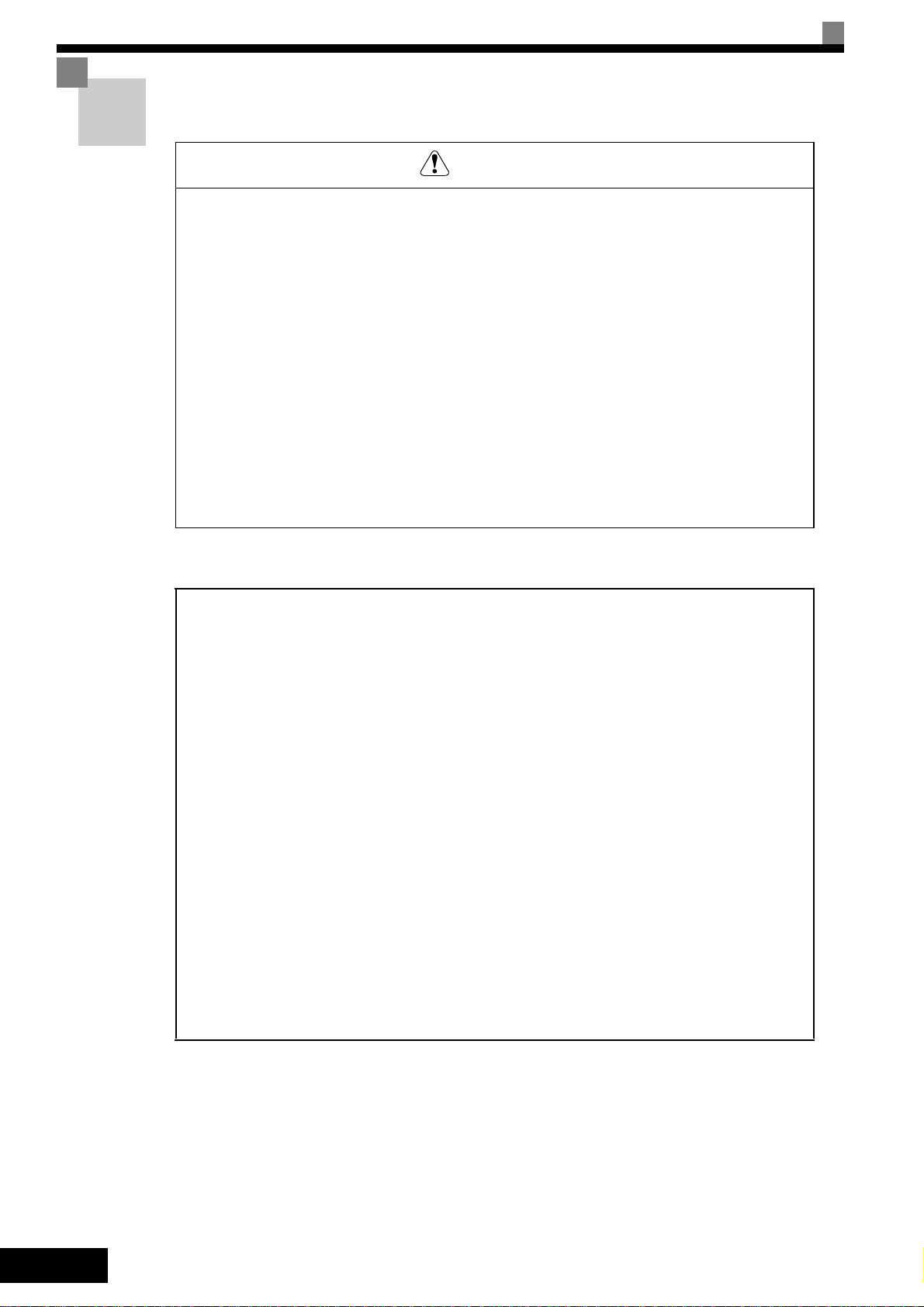

Start Up Procedure

START

Installation

Wiring

Set power supply

voltage jumper *1

Turn ON power

Confirm status

Select control

method.

Settings according

to control mode

Basic settings

(Quick programming mode)

V/f control

YES

PG?

NO

V/f control

Set E1-03.

V/f default: 200V/50Hz (400V/50Hz)

Non-rotating autotuning

for line-to-line resistance

Application settings

(Advanced programming mode)

No-load

operation

Loaded

operation

Optimum adjustments

and parameter settings

Check/record

parameter settings

END

NO

YES

Vector Control (A1-02 = 2 or 3) *5

V/f Control with PG (A1-02 = 1

Set E1-03, E2-04 and F1-01. *2

V/f default: 200V/50Hz (400V/50Hz)

Motor

operation possible

during autotuning?

*3

YES

*4

Rotating

autotuning

*6

NO

Non-rotating

autotuning

*6

1.Set for 400 V Class Inverter for 75 kW or more.

2.If there is a reduction gear between the motor and PG, set the

reduction ratio in F1-12 and F1-13 in advanced programming

mode.

3.Use rotational autotuning to increase autotuning accuracy

whenever it is okay for the motor to be operated.

4.If the motor cable changes to 50 m or longer for the actual

installation, perform non-rotating autotuning for the line-to-line

resistance only on site.

5.The default control mode is Open Loop Vector control

(A1-02=2).

6.If the maximum output frequency and the base frequency are

different, set the maximum output frequency (E1-04) after

autotuning.

Fig 8 Trial Operation Flowchart

EN-15

Before Power Up

The following points should be checked carefully before the power is switched on.

• Check if the power supply meets the inverter specification.

• Check if the power supply cables are tightly connected to the right terminals (L1, L2, L3).

• Check if the motor cables are tightly connected to the right terminals on the inverter side (U, V,

W) as well as on the motor side.

• Check if the braking unit / braking resistor is connected correctly.

• Check if the Inverter control circuit terminal and the control device are wired correctly.

• Set all Inverter control circuit terminals to OFF.

• When a PG card is used, check if it is wired correctly.

Display after Power Up

After normal power up without any problems the operator display shows the following messages

Display for normal

operation

-DRIVE-

Frequency Ref

U1- 01=50.00Hz

U1-02=50.00Hz

U1-03=10.05A

Rdy

The frequency reference monitor is displayed in the data display section.

When a fault has occurred or an alarm is active a fault or alarm message will appear. In this case,

refer to page 21, Troubleshooting.

Display for fault operation

-DRIVE-

UV

DC Bus Undervolt

A fault or alarm message is shown on the

display.

The example shows a low voltage alarm.

Autotuning

Autotuning sets motor parameters automatically when using Open Loop or Closed Loop Vector control, when the cable length is long or the installation has changed.

Setting the Autotuning Mode

One of the following three autotuning modes can be set.

• Rotating autotuning

• Non-rotating autotuning

• Non-rotating autotuning for line-to-line resistance only

EN-16

Rotating Autotuning (T1-01 = 0)

Rotating autotuning is used for Open Loop and Closed Loop Vector control only. Set T1-01 to 0,

input the data from the motor nameplate, and then press the RUN key on the Digital Operator. The

Inverter will operate the motor for approximately 1 minute and set the required motor parameters

automatically.

Non-rotating Autotuning (T1-01 = 1)

Non-rotating autotuning is used for Open Loop and Closed Loop Vector control only. Set T1-01 to 1,

input the data from the motor nameplate, and then press the RUN key on the Digital Operator. The

inverter will supply power to the non-rotating motor for approximately 1 minute and some of the

motor parameters will be set automatically. The remaining motor parameters will be set automatically during the first time operation.

Non-rotating Autotuning for Line-to-Line Resistance (T1-01 = 2)

Non-rotating autotuning for line-to-line resistance can be used in any control mode. This is the only

possible autotuning for V/f control and V/f control with PG.

It can be used to improve the performance when the motor cable is long, the cable length has

changed or when the motor and inverter have different capacities.

To perform autotuning in V/f control or V/f control with PG, set T1-02 (Motor rated power) and T1-04

(Motor rated current) and then press the RUN key on the Digital Operator. The Inverter will supply

power to the non-rotating motor for approximately 20 seconds and the Motor line-to-line resistance

and cable resistance will be automatically measured.

1. Power will be supplied to the motor during autotuning but the motor will not turn. Do not touch the motor

until autotuning has been completed.

IMPORTANT

2. Ensure that all motor contactors are closed before the autotuning is started.

3. To cancel autotuning press the STOP key on the Digital Operator.

Other Alarms and Faults During Autotuning

For an overview of possible autotuning alarms or faults and corrective actions refer to page 24, Auto-

tuning Faults.

EN-17

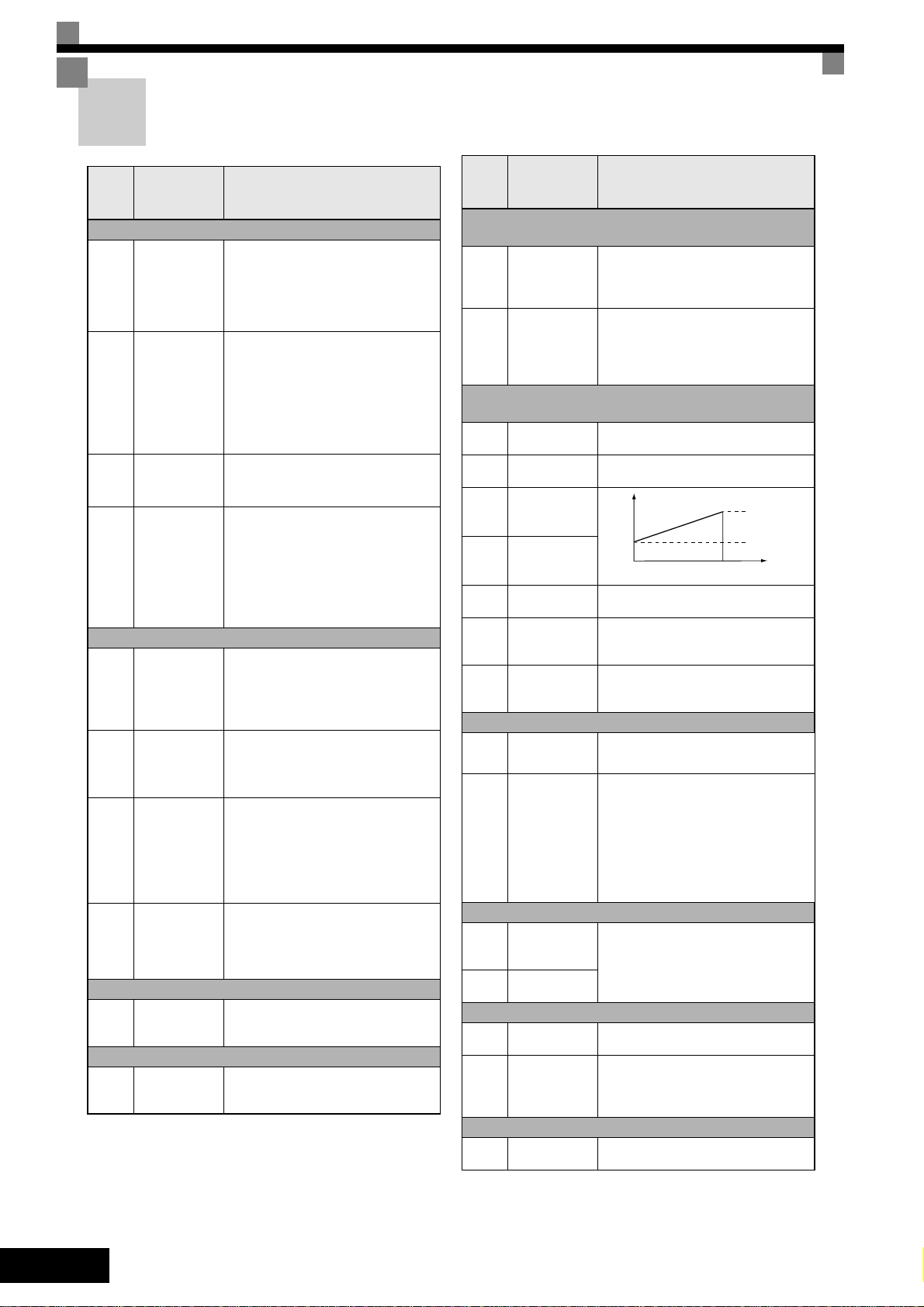

User Parameter

Param-

eter

Num-

ber

Name Description

Initialize Data

Language

selection for

Digital Opera-

A1-00

tor display(JVOP160-OY only)

Parameter

A1-01

access level

Control method

A1-02

selection

A1-03 Initialize

0:English

2:German

3:French

4:Italian

5:Spanish

6:Portuguese

0:Monitoring only (Monitoring drive

mode and setting A1-01 and A1-04.)

1:Used to select user parameters (Only

parameters set in A2-01 to A2-32 can

be read and set.)

2:Advanced

(Parameters can be read and set in

both, quick programming mode (Q)

and advanced programming mode

(A).

0:V/f control

1:V/f control with PG

2:Open loop vector control

3:Closed loop vector control

0: No initializing

1110: Initializes using the user

parameters

2220: Initializes using a two-wire

sequence. (Initializes to the

factory setting.)

3330: Initializes using a three-wire

sequence.

Sequence / Reference Source

Sets the frequency reference input

method.

0:Digital Operator

1:Control circuit terminal (analog input)

2:Serial communication (RS422 / 485)

3:Option Card

Sets the run command input method.

0:Digital Operator

1:Control circuit terminal (digital inputs)

2:Serial communication (RS422 / 485)

3:Option Card

Selects the stopping method when the

Run signal is removed

0:Deceleration to stop

1:Coast to stop

2:DC injection to stop

3:Coast to stop with timer (New Run

commands are disregarded while

coasting.)

0:Reverse enabled

1:Reverse disabled

2:Output Phase Rotation (both rota-

tional directions are enabled)

3:Output Phase Rotation with Reverse

disabled.

b1-01

b1-02

b1-03

b1-04

Reference

source selection

RUN command source

selection

Stopping

method selection

Prohibition of

reverse operation

Acceleration / Deceleration Settings

C1-

Acceleration/

Deceleration

times

Sets the time to accelerate/decelerate

from 0 Hz to the maximum output frequency.

S-Curve Settings

C2-

S-curve characteristic time

at acceleration

Sets the S-curve characteristic at acceleration start and end.

Param-

eter

Num-

ber

Name Description

Motor Slip Compensation (not available in V/f with

PG)

Used to improve speed accuracy

• Increase if output frequency is too low

• Decrease if output frequency is too

high.

Sets the slip compensation delay time

• Increase if output frequency is not

stable

• Decrease setting when slip compensation responsiveness is low.

C3-01

C3-02

Slip compensation gain

Slip compensation delay time

(only available

in V/f and OLV)

Speed Control (ASR) (only available in V/f with PG

and CLV)

C5-01

C5-02

C5-03

C5-04

C5-06

C5-07

C5-08

ASR proportional gain 1

ASR integral

time 1

ASR proportional gain 2

ASR integral

time 2

ASR delay time

(only CLV)

ASR switching

frequency

(only CLV)

ASR integral

limit

(only CLV)

Sets the proportional gain of the speed

loop (ASR)

Sets the integral time of the speed loop

(ASR)

P,I

0 E1-04

Sets the ASR filter time constant.

Sets the frequency for switching

between ASR gain 1, 2 and ASR integral

time 1, 2

Sets the limit for the integral part of the

ASR controller.

P=C5-01

I=C5-02

P=C5-03

I=C5-04

Motor

speed (Hz)

Carrier Frequency

C6-01

C6-02

Heavy/Normal

duty selection

Carrier frequency selection

0:Heavy Duty

1:Normal Duty 1

2:Normal Duty 2

Selects the carrier frequency (factory

setting depends on Inverter capacity)

0: Low noise, low carrier

1: 2.0 kHz

2: 5.0 kHz

3: 8.0 kHz

4: 10.0 kHz

5: 12.5 kHz

6: 15.0 kHz

F: Programmable pattern

Speed Settings

Multi speed

d1-01

to

references 1 to

d1-16

d1-17

16

Jog frequency

reference

Sets the multi-step speed references.

Torque Control (only available in CLV)

d5-01

d5-06

Torque control

selection

Speed/torque

control switch

over timer

0:Speed control

1:Torque control

Sets the delay from inputting a “speed/

torque control change” signal (by digital

input) until the control is acutally

changed

V/f Pattern Settings

E1-01

Input voltage

setting

This setting is used as a reference value

for protection functions.

EN-18

Param-

eter

Num-

ber

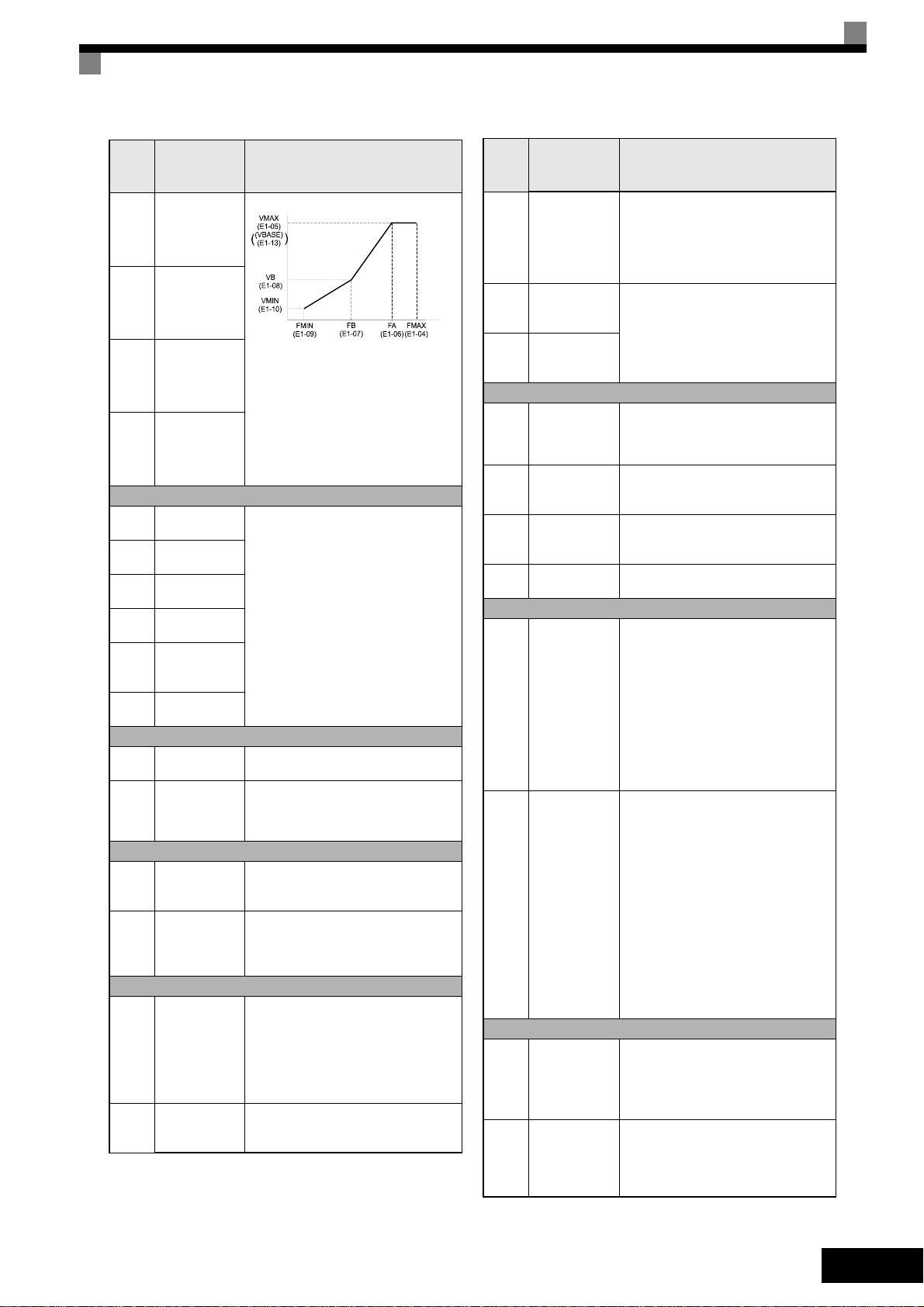

E1-04

E1-05

E1-06

E1-13

Name Description

Max. output

frequency

(FMAX)

Max. output

voltage

(VMAX)

Base frequency (FA)

Base Voltage

(VBASE)

Motor Data Settings

Motor rated

E2-01

current

Motor rated

E2-02

slip

Motor no-load

E2-03

current

Number of

E2-04

motor poles

Motor

E2-09

mechanical

losses

Motor rated

E2-11

output power

PG Option Setup

F1-01 PG constant

F1-05 PG rotation

Digital I/O Settings

Terminal S3 to

H1-01

S7 function

to

H1-05

selection

Terminal M1-

H2-01

M2 and M3-

and

M4 function

H2-02

selection

Analog I/O Settings

Analog input

H3-08

A2 signal level

selection

Analog input

H3-09

A2 function

selection.

Output Voltage (V)

Frequency (Hz)

To set V/f characteristics in a straight

line, set the same values for E1-07

and E1-09. In this case, the setting for

E1-08 will be disregarded.

Always ensure that the four frequencies are set in the following order:

E1-04 (FMAX) ≥ E1-06 (FA) > E1-07

(FB) ≥ E1-09 (FMIN)

Sets the motor data.

Sets the number of PG pulses per

revolution

0:Phase A leads with forward run

command

1:Phase B leads with forward run

command

Refer to page 20, Digital Input Func-

tion Selections (H1-01 to H1-05) for a

list of selections

Refer to page 20, Digital Output Func-

tion Selections for a list of selections

Selects the signal level input at multifunction analog input A2.

0:0 to +10 V (11 bit).

1:-10 to +10 V

2:4 to 20 mA (9-bit input).

Ensure to switch S1-2 to “V” before

using a voltage input.

Selects the multi-function analog

input function for terminal A2.

Param-

eter

Num-

ber

H3-13

H4-01

H4-04

Name Description

Terminal A1/

A2 switching

Terminal FM

monitor selection

Terminal AM

monitor selection

Pulse Train I/O

Pulse train

H6-01

input function

selection

Pulse train

H6-02

input scaling

Pulse train

H6-06

monitor selection

Pulse monitor

H6-07

scaling

Stall Prevention

Stall prevention selection

during accel

L3-01

(not available

in CLV)

Stall preven-

L3-04

tion selection

during decel

Fault Restart

Number of

L5-01

auto restart

attempts

Auto restart

L5-02

operation

selection

Selects on which terminal the main

frequency reference can be input.

0:Use analog input 1 on terminal

A1 for main frequency reference.

1:Use analog input 2 on terminal A2

for main frequency reference.

Sets the number of the monitor

item to be output (U1-) at terminal

FM/AM.

Selects the pulse train input function

0:Frequency reference

1:PID feedback value

2:PID target value

Sets the number of pulses in Hz that

is equivalent to 100% of the input item

selected in H6-01.

Selects the pulse train monitor output

item (U1-)

Sets the number of pulses output in

Hz when the monitor item is 100%.

0:Disabled (Acceleration as set.

With a heavy load, the motor may

stall.)

1:Enabled (Acceleration stopped

when L3-02 level is exceeded.

Acceleration starts again when the

current has fallen below the stall

prevention level).

2:Intelligent acceleration mode (Using

the L3-02 level as a basis, acceleration is automatically adjusted. Set

acceleration time is disregarded.)

0:Disabled (Deceleration as set. If

deceleration time is too short, a

DC bus overvoltage may result.)

1:Enabled (Deceleration is stopped

when the DC bus voltage exceeds

the stall prevention level. Deceleration restarts when the voltage falls

below the stall prevention level

again.)

2:Intelligent deceleration mode

(Deceleration rate is automatically

adjusted so that the Inverter can

decelerate in the shortest possible

time. The set deceleration time is

disregarded.)

3:Enabled with braking resistor

Sets the number of auto restart

attempts.

Automatically restarts after a fault and

conducts a speed search from the run

frequency.

Sets whether a fault relay is activated

during fault restart.

0:No output (Fault relay is not acti-

vated.)

1:Output (Fault relay is activated.)

EN-19

Param-

o

eter

Num-

ber

Name Description

Torque Limit (only OLV and CLV)

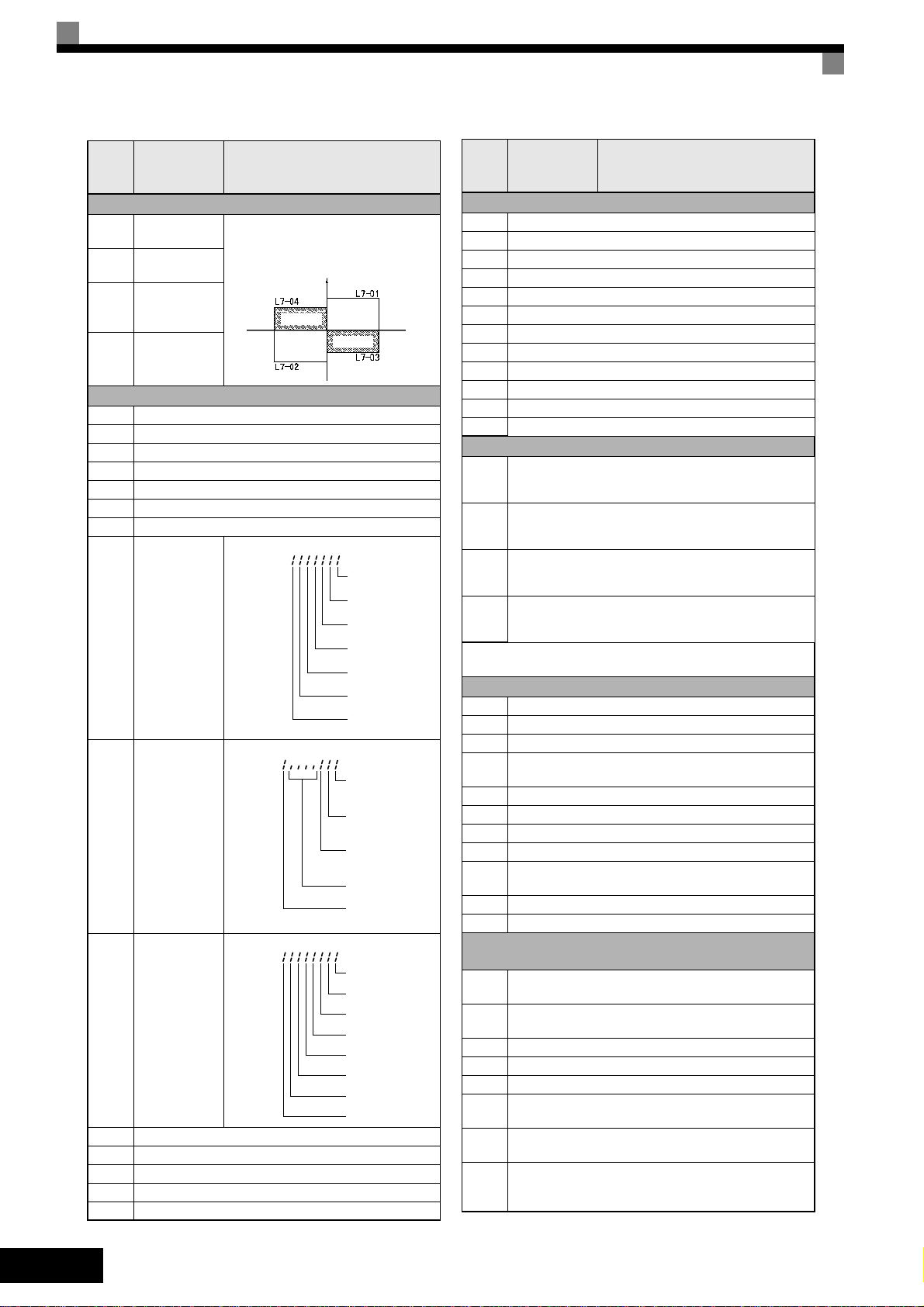

L7-01

L7-02

L7-03

L7-04

Forward drive

torque limit

Reverse drive

torque limit

Forward

regenerative

torque limit

Reverse

regenerativ

torque limit

Sets the torque limit vlaue as a percentage of the motor rated torque.

Four individual regions can be set.

Reverse

Output torque

Regen.

Monitor Data

U1-01 Frequency reference in Hz / rpm

U1-02 Output frequency in Hz / rpm

U1-03 Output current in A

U1-06 Output voltage in VAC

U1-07 DC bus voltage in VDC

U1-08 Output power in kW

U1-09 Torque reference

Shows input ON/OFF status.

U1-10 =

Input terminal

U1-10

status

Shows output ON/OFF status.

U1-11 =

Output termi-

U1-11

nal status

Inverter operating status.

U1-12 =

Operation

U1-12

status

U1-13 Cumulative operation time in hrs.

U1-21 ASR input

U1-22 ASR output

U1-34 OPE fault parameter

U1-40 Cooling fan operating time in hrs.

Positive torque

No.

motor

rotations

Regen.

Negative torque

Forward

1: FWD command

(S1) is ON

1: REV command

(S2) is ON

1: Multi input 1

(S3) is ON

1: Multi input 2

(S4) is ON

1: Multi input 3

(S5) is ON

1: Multi input 4

(S6) is ON

1: Multi input 5

(S7) is O N

1: Multi-function

contact output 1

(M1-M2) is ON

1: Multi-function

contact output 2

(M3-M4) is ON

1: Multi-function

contact output 3

(M5-M6) is ON

Not used

(Always 0).

1: Error output

(MA/MB-MC) is ON

Run

1: Zero speed

1: Reverse

1: Reset signal input

1: Speed agree

1: Inverter ready

1: Minor fault

1: Major fault

Param-

eter

Num-

ber

Name Description

Fault Trace Data

U2-01 Current fault

U2-02 Last fault

U2-03 Reference frequency at fault

U2-04 Output frequency at fault

U2-05 Output current at fault

U2-07 Output voltage reference at fault

U2-08 DC bus voltage at fault

U2-09 Output power at fault

U2-11 Input terminal status at fault

U2-12 Output terminal status at fault

U2-13 Operation status at fault

U2-14 Cumulative operation time at fault

Fault History Data

U3-01

to

Last fault to fourth last fault

U3-04

U3-05

to

Cumulative operation time at fault 1 to 4

U3-08

U3-09

to

Fifth last to tenth last fault

U3-14

U3-15

to

Accumulated time of fifth to tenth fault

U3-20

* The following faults are not recorded in the error log:

CPF00, 01, 02, 03, UV1, and UV2.

Digital Input Function Selections (H1-01 to H1-05)

3 Multi-step speed reference 1

4 Multi-step speed reference 2

5 Mulit-step speed reference 3

Jog frequency command (higher priority than multi-

6

step speed reference)

7 Accel/decel time selection 1

F Not used (Set when a terminal is not used)

14 Fault reset (Reset when turned ON)

19 PI control disable

External fault; Input mode: NO contact/NC contact,

20 to

2F

Detection mode: Normal/during operation

71 Speed/torque control change (ON: Torque control)

77 Speed control (ASR) gain switching (ON: C5-03)

Digital Output Function Selections

(H2-01 and H2-02

During run 1 (ON: run command is ON or voltage is

0

being output)

Inverter operation ready; READY: After initialization or

6

no faults

F Not used. (Set when the terminal is not used.)

10 Minor fault (Alarm) (ON: Alarm displayed)

1A During reverse run (ON: During reverse run)

Motor overload (OL1, including OH3) pre-alarm (ON:

1F

90% or more of the detection level)

During torque limit (current limit) (ON: During torque

30

limit)

Activated if the ASR is operating for torque limit. The

32

ASR output becomes the torque reference, the motor

is rotating at the speed limit.

EN-20

Troubleshooting

General Faults and Alarms

Faults and Alarms indicate unsusal inverter / application conditions.

An alarm does not necessarily switch off the inverter but a message is displayed on the keypad (i.e.

a flashing alarm code) and an alarm output can be generated at the multi-function outputs (H2-01

and H2-02) if programmed. An alarm automatically disappears if the alarm condition is not present

anymore.

A fault switches the inverter output off immediately, a message is displayed on the keypad and the

fault output is switched. The fault must be reset manually after the cause and the RUN signal have

been removed.

The following table shows a list of faults and alarms with their corrective actions.

Display

BUS

Option Com Err

CF

Out of Control

CPF00

COM-

ERR(OP&INV)

CPF01

COM-

ERR(OP&INV)

CPF02

BB Circuit Err

CPF03

EEPROM Error

CPF04

INternal A/D Err

DEV

Speed Deviation

EF

External Fault

EF0

Opt External Flt

EFx

Ext Fault Sx

Ext Run Active

Cannot Reset

GF

Ground Fault

Alarm Fault

Meaning Corrective Actions

Option Card Communication Alarm

After initial communication was established, the

connection was lost.

Control Fault

A torque limit was reached continuously for 3

seconds or longer during a deceleration stop in

Open Loop Vector control

Digital Operator Communication Fault 1/2

• Communication fault between Operator and

Inverter

• CPU External RAM Fault

CPF02 Fault

Baseblock circuit error

CPF03

EEPROM error

CPF04

CPU Internal A/D Converter Fault

F1-04 = 0, 1 or 2 and A1-02 = 1 or 3

The speed deviation has been greater than the

setting in F1-10 for a time longer than the setting

F1-11.

F1-04 = 3 and A1-02 = 1 or 3

The speed deviation has been greater than the

setting in F1-10 for a time longer than the setting

F1-11.

Forward/Reverse Run Commands Input

Together

Both the forward and the reverse run commands

are input simultaneously for 500ms or more.

This alarm stops the motor.

External fault input from Communications

Option Card

External fault at terminal Sx (x stands for terminals S3 to S7)

Detected after a fault when a RESET command

is input while the RUN command is still active

Ground Fault

The ground current at the Inverter output

exceeded 50% of the Inverter rated output current and L8-09=1 (Enabled).

Check the connections and all user-side software configurations.

Check the motor parameters

• Disconnect the Digital Operator and then

connect it again.

• Cycle the Inverter power supply.

• Replace the Inverter.

• Perform an initialization to factory defaults.

• Cycle the Inverter power supply.

• Replace the Inverter.

• Reduce the load.

• Lengthen the acceleration and deceleration

time

• Check the mechanical system

• Check the settings of F1-10 and F1-11

• Check the sequence and if the brake is

opened when the inverter starts to increase

the speed.

Check external sequence logic, so that only

one input is activated at a time.

• Check for an external fault condition.

• Verify the parameters.

• Verify communication signals

Eliminate the cause of the external fault condition.

Remove the RUN signal first and reset the

error.

• Remove the motor and run the Inverter

without the motor.

• Check the motor for a phase to ground

short.

• Check the output current with a clampmeter

to verify the DCCT reading.

• Check the control sequence for wrong

motor contactor signals.

EN-21

Display

OC

Over Current

OH

Heatsnk Overtemp

OH1

Heatsink Max Temp

OL1

Motor Overload

OL2

Inv Overload

OS

Overspeed Det.

OV

DC Bus Overvolt

PF

Input Phase Loss

PGO

PG Open

Alarm Fault

(only in

stop

condi-

tio)

Meaning Corrective Actions

Over Current

The Inverter’s output current exceeded the overcurrent detection level.

Heatsink Overheat

L8-03 = 0,1 or 2 and the temperature of the

Inverter's cooling fin exceeded the L8-02 value.

Inverter's Cooling Fan Stopped

L8-03 = 3 or 4 and the temperature of the

Inverter's cooling fin exceeded the L8-02 value.

Heatsink Overheat

The temperature of the Inverter’s heatsink

exceeded 105 °C.

Inverter’s Cooling Fan Stopped

Motor Overload

Detected when L1-01 is set to 1,2 or 3 and the

Inverter’s I²t value exceeded the motor overload

curve.

The overload curve is adjustable using parameter

E2-01 (Motor Rated Current), L1-01 (Motor Protection Selection) and L2-02 (Motor Protection

Time Constant)

Inverter Overload

The Inverter output current exceeded the Inverters’s overload capability

F1-03 = 0, 1 or 2 and A1-02 = 1 or 3

The motor speed feedback (U1-05) exceeded

the setting in F1-08 for a time longer than the

setting of

F1-09

F1-03 = 3 and A1-02 = 1 or 3

The motor speed feedback (U1-05) exceeded

the setting in F1-08 for a time longer than the

setting of

F1-09

The DC bus voltage has exceeded the overvoltage detection level.

Default detection levels are:

200 V class: 410 VDC

400 V class: 820 VDC

Input Phase Loss

Too big DC bus voltage ripple.

Only detected when L8-05=1 (enabled)

PG Disconnection

Detected when F1-02 = 0, 1 or 2 and A1-02 = 1

or 3.

Detected when no PG (encoder) pulses have

been received for a time longer than the setting

in F1-14.

PG Disconnection

Detected when F1-02 = 3 and A1-02 = 1 or 3.

PG (encoder) pulses have not been received for

a time longer than the setting in F1-14.

• Remove the motor and run the Inverter

without the motor.

• Check the motor for a phase-to-phase

short.

• Verify the accel/decel times (C1-).

• Check the Inverter for a phase-to-phase

short at the output.

• Check for dirt build-up on the fans or heatsink.

• Reduce the ambient temperature around

the drive.

• Replace the cooling fan(s).

• Check for dirt build-up on the fans or heatsink.

• Reduce the ambient temperature around

the drive.

• Replace the cooling fan(s).

• Recheck the cycle time and the size of the

load as well as the accel/decel times

(C1-).

• Check the V/f characteristics (E1-).

• Check the setting of Motor Rated Current

Setting (E2-01).

• Recheck the cycle time and the size of the

load as well as the accel/decel times

(C1-).

• Check the V/f Characteristics (E1-).

• Check if the inverter rated current matches

the motor rated current.

• Adjust the ASR settings in the C5 parameter groupt

• Check the reference circuit and reference

gain.

• Check the settings in F1-08 and F1-09

• Increase the deceleration time (C1-02/04)

or connect a braking option.

• Check the power supply and decrease the

voltage to meet the inverter’s specifications.

• Check the braking chopper / resistor.

• Tighten the input terminal screws

• Check the power supply voltage

• Fix the broken/disconnected wiring.

• Supply power to the PG properly.

• Check the sequence and if the brake is

opened when the inverter starts to increase

the speed.

EN-22

Display

PUF

DC Bus Fuse Open

RR

DynBrk Transistr

UV1

DC Bus Undervolt

UV2

CTL PS Undervolt

Alarm Fault

(only in

stop

condi-

tio)

Meaning Corrective Actions

DC Bus Fuse Open

The fuse in the main circuit is blown.

Warning:

PG (encoder) pulses have not been received for

a time longer than the setting in F1-14.

Dynamic Braking Transistor

The built-in dynamic braking transistor failed

The DC bus voltage is below the Undervoltage

Detection Level

(L2-05). The default settings are:

200V class: 190 VDC

400 V class: 380 VDC

Main Circuit MC Operation Failure

No MC response during Inverter operation.

Control Power Supply Undervoltage

Undervoltage of the control circuit while the

Inverter was running.

• Check the motor and the motor cables for

short circuits or insulation failures (phaseto-phase).

• Replace the inverter after correcting the

fault.

• Cycle power to the inverter.

• Replace the inverter.

• Check the input voltage.

• Check the wiring of the input terminals.

• Check the input voltage and the wiring of

the input terminals.

• Extend the settings in C1-01/03

Replace the Inverter.

• Remove all connection to the control terminals and cycle the power to the Inverter.

• Replace the Inverter.

Operator Programming Errors

An Operator Programming Error (OPE) occurs when two or more parameter related to each other

are set inappropriately or an individual parameter setting is incorrect. The Inverter does not operate

until the parameter setting is corrected; however, no other alarm or fault output will occur. If an OPE

occurs, change the related parameter by checking the cause shown in the table below. When an

OPE error is displayed, press the ENTER key to see U1-34 (OPE Detected). This monitor displays

the parameter that is causing the OPE error.

Display Meaning Corrective Actions

OPE01

kVA Selection

OPE02

Limit

OPE03

Terminal

OPE05

Sequence Select

OPE06

PG Opt Missing

Inverter kVA Setting Error Enter the correct kVA setting in o2-04.

Parameter setting is out of its range Verify the parameter settings.

One of the following errors has been made in the multifunction input (H1-01 to H1-05) settings:

• Duplicate functions were selected.

• UP/DOWN Command(10 and 11) were not selected

simultaneously.

• The up/down commands (10 and 11) and Accel/

Decel Ramp Hold (A) were selected at the same

time.

• More than one of the Speed Search inputs (61, 62,

64) were set simultaneously.

• External Baseblock NO (8) and External Baseblock

NC (9) were selected at the same time.

• The up/down commands (10 and 11) were selected

while PID Control was enabled.

• The Emergency Stop Command NO (15) and NC(17)

are set simultaneously.

• PID is enabled and UP and/or DOWN (10 / 11) command are set.

• HSB (68) and KEB (65/66) command are set simultaneously.

RUN/Reference Command Selection Error

The Reference Source Selection b1-01 and/or the RUN

Source Selection parameter b1-02 are set to 3 (option

board) but no option board is installed.

Control Method Selection Error

One of the control methods needing a PG feedback

was selected (A1-02 = 1 or 3), but a PG option board is

not installed.

Verify the parameter settings in H1-

• Verify that the board is installed. Remove the power

supply and re-install the option board again

• Recheck the setting of b1-01 and b1-02

Verify the control method selection in parameter A1-02

and/or the installation of the PG option board.

EN-23

Display Meaning Corrective Actions

Function Selection Error

OPE08

Constant Selection

OPE010

V/f Ptrn Setting

A setting has been made that is applicable with the current control method.

Example: A function used only with open loop vector

control was selected for V/f control.

V/f Parameter Setting Error

Verify the control method and the function.

Check parameters (E1-). A frequency/voltage value

may be set higher than the maximum frequency/voltage.

Autotuning Faults

Autotuning faults are shown below. When the following faults are detected, the fault is displayed on

the digital operator and the motor coasts to stop. No fault or alarm outputs will be operated.

Display Meaning Corrective Actions

• Check the input data.

Er-01

Fault

Er-02

Minor Fault

Er-03

STOP key

Er-04

Resistance

Er-05

No-Load Current

Er-08

Rated slip

Er-09

Accelerate

Er-11

Motor Speed

Er-12

I-det. Circuit

Er-13

Leakage Induc-

tance Fault

End-1

V/f Over Setting

End-2

Saturation

End-3

Rated FLA Alm

Motor data fault

Alarm

STOP key input -

Line-to-Line Resistance Fault

Autotuning result is outside the parameter setting

range.

No-Load Current Fault

Autotuning result is outside the parameter setting

range.

Rated Slip Fault

Autotuning result is outside the parameter setting

range.

Acceleration Fault (Rotating autotuning only)

The motor did not accelerate in the specified time

(C1-10+10sec.)

Motor Speed Fault (Rotating autotuning only)

The torque reference exceeded 100% during acceleration. Deteceted only when A1-02 = 2 or 3 (Vector

control modes).

Current Detection Fault

• The current exceeded the motor rated current.

• Any of U/T1, V/T2 and W/T3 has open-phase.

Leakage Inductance Fault

Autotuning result is outside the parameter setting

range.

Rated Current Setting Alarm

Displayed after auto-tuning is complete

During auto-tuning, the measured value of motor

rated current (E2-01) was higher than the set value.

Motor Core Saturation Alarm

(only for rotating autotuning)

Rated Current Setting Alarm

During autotuning the measured value of motor rated

current (E2-01) was greater than the set value.

• Check the Inverter and motor capacity.

• Check the motor rated current and no-load current setting.

• Check the input data.

• Check wiring and the machine.

• Check the load.

• Check the input data.

• Check the motor wiring.

• If the motor is connected to the machine, disconnect it.

• If the setting of T1-03 is higher than the Inverter input

power supply voltage (E1-01), change the input data.

• Increase C1-01(Acceleration time)

• Increase L7-01 and L7-02 (Torque limits)

• If the motor is connected to the machine, disconnect it.

• If the motor is connected to the machine, disconnect it.

• Increase C1-01

• Check the input data (particularly the number of PG

pulses and the number of motor poles)

Check wiring of the Inverter and the mounting.

Check motor wiring.

Check the motor rated current value.

• Check the input data

• Check the motor wiring.

• If the motor is connected to the machine, disconnect it.

Check the motor rated current value

EN-24

F7Z Kurzanleitung

Inhaltsverzeichnis

Warnhinweise ............................................................... DE-2

Sicherheitshinweise und Anleitungen ......................................................................... DE-3

Elektromagnetische Verträglichkeit ............................................................................ DE-4

Installation .................................................................... DE-6

Mechanische Installation ............................................................................................ DE-6

Elektrischer Anschluss ............................................................................................... DE-8

Verdrahtung der Spannungsversorgung .................................................................. DE-12

Bedienung über die Tastatur .................................... DE-14

Digitale Bedienkonsole (optional) ............................................................................. DE-14

Einschalten und Grundparameter-Einstellungen ... DE-15

Inbetriebnahme ........................................................................................................ DE-15

Vor dem Einschalten ................................................................................................. DE-16

Anzeige nach dem Einschalten ................................................................................ DE-16

Autotuning ................................................................................................................ DE-16

Anwenderparameter .................................................. DE-18

Fehlerbehebung .........................................................DE-21

Allgemeine Fehler und Alarme .................................................................................DE-21

Fehler bei der Programmierung durch den Anwender ............................................. DE-23

Autotuning-Fehler ..................................................................................................... DE-24

1

Warnhinweise

Solange die Versorgungsspannung eingeschaltet ist, dürfen weder Kabel an- oder

abgeklemmt werden, noch dürfen Signalprüfungen durchgeführt werden.

Der Zwischenkreis des Varispeed F7 bleibt auch dann geladen, wenn die

Spannungsversorgung unterbrochen wurde. Trennen Sie den Frequenzumrichter vor

Ausführung von Wartungsarbeiten von der Spannungsversorgung, um einen elektrischen

Schlag zu vermeiden. Warten Sie anschließend mindestens 5 Minuten, bis alle LEDs

erloschen sind.

Führen Sie an keinem Teil des Varispeed Spannungsfestigkeitstests durch. Der

Frequenzumrichter enthält Halbleiter, die für derart hohe Spannungen nicht ausgelegt sind.

Die digitale Bedienkonsole darf nicht bei eingeschalteter Spannungsversorgung abgebaut

werden. Berühren Sie keine Platinen, wenn der Frequenzumrichter an die

Spannungsversorgung angeschlossen ist.

ACHTUNG

ACHTUNG

Schließen Sie niemals LC/RC-Entstörfilter, Kondensatoren oder

Überspannungsschutzgeräte an den Ein- oder Ausgang des Frequenzumrichters an,

die nicht speziell für den Frequenzumrichter vorgesehen sind.

Um unnötige Überstromfehler usw. zu vermeiden, müssen die Signalkontakte aller Schütze

oder Schalter, die zwischen Frequenzumrichter und Motor geschaltet sind, in die

Steuerungslogik (z. B. Endstufensperre) eingebunden sein.

Das ist zwingend erforderlich!

Dieses Handbuch muss vor Anschluss und Inbetriebnahme des Frequenzumrichters

sorgfältig durchgelesen werden. Alle Sicherheitshinweise und Anleitungen müssen

beachtet werden.

Der Frequenzumrichter muss gemäß Installationsanleitungen in diesem Handbuch mit

geeigneten Netzfiltern betrieben werden. Zudem müssen alle Abdeckungen geschlossen

und alle Klemmen abgedeckt sein.

Nur dann ist ein angemessener Schutz gesichert. Geräte mit sichtbaren Beschädigungen

oder fehlenden Teilen dürfen nicht angeschlossen oder in Betrieb genommen werden.

Der Betreiber der Geräte ist für alle Verletzungen oder Geräteschäden verantwortlich,

die aus Nichtbeachtung der Warnhinweise in diesem Handbuch entstehen.

DE-2

Sicherheitshinweise und Anleitungen

Allgemein

Lesen Sie diese Sicherheitshinweise und Anleitungen vor Installation und Inbetriebnahme dieses

Frequenzumrichters. Lesen Sie auch alle Warnhinweise, die auf dem Frequenzumrichter

angebracht sind, und achten Sie darauf, dass diese nicht beschädigt oder entfernt werden.

Während des Betriebs können unter Spannung stehende oder heiße Bauteile zugänglich sein.

Durch Entfernen von Verkleidungsteilen, der digitalen Bedienkonsole oder Klemmenabdeckungen

besteht im Falle einer fehlerhaften Installation oder Bedienung das Risiko von ernsthaften

Verletzungen. Durch die Tatsache, dass Frequenzumrichter drehende mechanische Teile von

Maschinen steuern, können weitere Gefahren entstehen.

Den Anleitungen in diesem Handbuch muss Folge geleistet werden. Installation, Bedienung oder

Wartung darf nur durch qualifiziertes Personal erfolgen. Aus Sicherheitsgründen sind als

qualifizierte Mitarbeiter nur solche anzusehen, die mit der Installation, dem Starten, der Bedienung

und der Wartung von Frequenzumrichtern vertraut sind und für diese Arbeiten entsprechende

Qualifikationen besitzen. Ein sicherer Betrieb dieser Geräte ist nur möglich, wenn diese auch für

den vorgesehenen Zweck eingesetzt werden.

Der Zwischenkreis kann nach Abschalten der Versorgungsspannung des Frequenzumrichters noch

ca. 5 Minuten lang unter Spannung stehen. Aus diesem Grund muss diese Zeitspanne vor dem

Öffnen von Geräteabdeckungen abgewartet werden. Alle Klemmen des Hauptstromkreises können

noch gefährliche Spannungen führen.

Kinder und andere nicht autorisierte Personen dürfen keinen Zugang zu Frequenzumrichtern haben.

Bewahren Sie diese Sicherheitshinweise und Anleitungen griffbereit auf, und lassen Sie sie allen

Personen zukommen, die Zugang zu den Frequenzumrichtern haben.

Vorgesehener Verwendungszweck

Frequenzumrichter sind für den Einbau in elektrische Systeme oder Maschinen gedacht.

Ihr Einbau in Maschinen oder Systeme muss folgenden Produktstandards der Niederspannungs-

richtlinie entsprechen:

EN 50178, 1997-10, Ausrüstung von Starkstromanlagen mit elektronischen Betriebsmitteln

EN 60204-1, 1997-12 Sicherheit von Maschinen - Elektrische Ausrüstung von Maschinen

Teil 1: Allgemeine Anforderungen (IEC 60204-1: 1997)/

Bitte beachten Sie Folgendes: Enthält Ergänzungen von September 1998

EN 61010-1, A2, 1995 Sicherheitsbestimmungen für elektrische Mess-, Steuer-, Regel- und

Laborgeräte

(IEC 950, 1991 + A1, 1992 + A2, 1993 + A3, 1995 + A4, 1996, modifiziert)

Die CE-Kennzeichnung erfolgt gemäß EN 50178 bei Verwendung der in diesem Handbuch

spezifizierten Netzfilter und dem Befolgen der entsprechenden Installationsanleitungen.

Transport und Lagerung

Die Anleitungen für Transport, Lagerung und richtige Handhabung müssen unter Beachtung der

technischen Daten befolgt werden.

Installation

Installieren und kühlen Sie Frequenzumrichter wie in der Dokumentation spezifiziert. Die Kühlluft

muss in der angegebenen Richtung strömen. Der Frequenzumrichter darf dementsprechend nur in

der spezifizierten Position (z. B. aufrecht) betrieben werden. Halten Sie die angegebenen Freiräume

ein. Schützen Sie die Frequenzumrichter vor unzulässigen Lasten. Bauteile dürfen nicht verbogen

werden. Isolationsabstände dürfen nicht geändert werden. Berühren Sie keine elektronischen

Bauteile oder Kontakte, um Beschädigungen durch statische Elektrizität zu vermeiden.

DE-3

Elektrischer Anschluss

Führen Sie jegliche Arbeiten an unter Spannung stehenden Geräten gemäß der gültigen

Sicherheits- und Unfallverhütungsvorschriften durch. Führen Sie die elektrische Installation in

Übereinstimmung mit den geltenden Vorschriften durch. Insbesondere müssen Sie die

Anweisungen zur Sicherstellung der elektromagnetischen Verträglichkeit (EMV), z. B. Abschirmung,

Erdung, Filteranordnung und Verlegung von Kabeln, beachten. Das gilt auch für Geräte, die das CEZeichen tragen. Es liegt in der Verantwortung des Herstellers von System oder Maschine, die

Konformität mit den EMV-Richtlinien zu gewährleisten.

Wenden Sie sich an Ihren Lieferanten oder die Omron Yaskawa Motion Control-Vertretung, wenn

Fehlerstrom-Schutzschalter in Verbindung mit Frequenzumrichtern Verwendung finden.

Für bestimmte Systeme kann es erforderlich sein, gemäß den gültigen Sicherheits- und

Unfallverhütungsvorschriften zusätzliche Überwachungs- und Sicherheitseinrichtungen zu verwenden.

An der Hardware des Frequenzumrichters dürfen keine Änderungen vorgenommen werden.

Hinweise

Die Frequenzumrichter Varispeed F7 sind gemäß CE, UL und cUL zertifiziert.

Elektromagnetische Verträglichkeit

Einführung

Dieses Handbuch wurde erstellt, um Systemhersteller, die OMRON YASKAWA Motion Control

(OYMC)-Frequenzumrichter verwenden, bei der Konstruktion und Installation von elektrischen

Schaltgeräten zu unterstützen. Zudem werden die zur Einhaltung der EMV-Richtlinie erforderlichen