Omron VARISPEED E7 DATASHEET

Manual No.

TOE-S616-56.1-03-OY

VARISPEED E7

Variable Torque Frequency Inverter

USER’S MANUAL

Table of Content

Warnings ............................................................................................... VII

Safety Precautions and Instructions for Use........................................ VIII

EMC Compatibility................................................................................. X

Line Filters ............................................................................................ XII

Registered Trademarks......................................................................... XV

1 Handling Inverters.................................................................. 1-1

Varispeed E7 Introduction ...........................................................................1-2

Varispeed E7 Applications .............................................................................................1-2

Varispeed E7 Models .....................................................................................................1-2

Confirmations upon Delivery .......................................................................1-4

Checks ...........................................................................................................................1-4

Nameplate Information ..................................................................................................1-4

Inverter Software Version ..............................................................................................1-5

Component Names ........................................................................................................1-6

Exterior and Mounting Dimensions ..............................................................1-9

IP00 Inverters ................................................................................................................1-9

NEMA 1 / IP20 Inverters ........................... ................................................ ...................1-10

IP54 Inverters ..............................................................................................................1-10

Checking and Controlling the Installation Site ...........................................1-13

Installation Site ....................................... .. ... ................................................................1-13

Controlling the Ambient Temperature .......................................................................... 1-13

Protecting the IP00 or NEMA 1 Inverter from Foreign Matter ......................................1-13

Additional Installation Precautions for the IP54 Inverters ............................................1-14

Keeping the IP54 protection ........................................................................................1-14

Installation Orientation and Space .............................................................1-15

Accessing the Inverter Terminals ..............................................................1-16

Removing the Terminal Cover (IP00 and NEMA 1 / IP20 Inverters) ...........................1-16

Attaching the Terminal Cover ......................................................................................1-16

Opening the Door (IP54 Inverters) ..............................................................................1-17

Closing the Door (IP54 Inverters) ...............................................................................1-17

Removing/Attaching the Digital Operator and Front Cover .......................1-18

Inverters of 18.5 kW or Less ........................................................................................1-18

Inverters of 22 kW or More ..........................................................................................1-20

2 Wiring....................................................................................... 2-1

Connection Diagrams ..................................................................................2-2

Circuit Descriptions ........................................................................................................2-4

Terminal Block Configuration ......................................................................2-5

Wiring Main Circuit Terminals ......................................................................2-7

Applicable Wire Sizes and Crimp Terminals ..................................................................2-7

Main Circuit Terminal Functions ..................................................................................2-15

Main Circuit Configurations ..........................................................................................2-16

Standard Connection Diagrams ...................................................................................2-18

Wiring the Main Circuits ...............................................................................................2-20

I

Wiring Control Circuit Terminals ...............................................................2-27

Wire Sizes ...................................................................................................................2-27

Control Circuit Terminal Functions ..............................................................................2-31

Control Circuit Terminal Connections ..........................................................................2-35

Control Circuit Wiring Precautions ..............................................................................2-36

Wiring Check .............................................................................................2-37

Checks ........................................................................................................................ 2-37

Installing and Wiring Option Cards ............................................................2-38

Option Card Models ........................................................ ............................................2-38

Installation in IP00 and NEMA 1 / IP20 Inverters ........................................................2-38

Installation in IP54 Inverters ......................... ...............................................................2-39

3 Digital Operator and Modes....................................................3-1

Digital Operator ...........................................................................................3-2

Digital Operator Display ................................................................................................3-2

Digital Operator Keys .............................................................................................. .. ....3-3

Modes .........................................................................................................3-5

Inverter Modes ..............................................................................................................3-5

Switching Modes ...........................................................................................................3-6

Drive Mode ....................................................................................................................3-8

Quick Programming Mode .............................................................................................3-9

Advanced Programming Mode .............................................. ... ...................................3-11

Verify Mode .................................................................................................................3-15

Autotuning Mode ............................................ ............................................. ................3-17

4 Trial Operation.........................................................................4-1

Trial Operation Procedure ...........................................................................4-2

Trial Operation ........................................................................................ ....4-3

Application Confirmation ...............................................................................................4-3

Setting the Power Supply Voltage Jumper

(400 V Class Inverters of 75 kW or Higher) ...................................................................4-3

Power ON ......................................................................................................................4-3

Checking the Display Status .........................................................................................4-4

Basic Settings ................................................................................................................4-5

Selecting the V/f pattern ................................................................................................4-7

Autotuning .....................................................................................................................4-7

Application Settings .......................................................................................................4-9

No-load Operation .........................................................................................................4-9

Loaded Operation .......................................................................................................... 4-9

Check and Recording User Parameters .................................................................... ..4-10

Adjustment Suggestions ...........................................................................4-11

5 User Parameters......................................................................5-1

User Parameter Descriptions ......................................................................5-2

Description of User Parameter Tables .......................................................................... 5-2

II

Digital Operation Display Functions and Levels ..........................................5-3

User Parameters Available in Quick Programmi ng Mode .............................................5-4

User Parameter Tables ...............................................................................5-6

Setup Settings: A ...........................................................................................................5-6

Application Parameters: b ..............................................................................................5-8

Tuning Parameters: C ............................................................................................. ... ..5-15

Reference Parameters: d .............................................................................................5-18

Motor Parameters: E .................................................................................................. ..5-20

Option Parameters: F ..................................................................................................5-22

Terminal Function Parameters: H ................................................................................5-23

Protection Function Parameters: L ..............................................................................5-29

Special Adjustments: n ................................................................................................5-35

Digital Operator Parameters: o ....................................................................................5-36

Motor Autotuning: T .....................................................................................................5-40

Monitor Parameters: U .................................................................................................5-41

Setting Values that Change with the V/f Pattern Selection (E1-03) .............................5-46

Factory Settings that Change with the Inverter Capacity (o2-04) ................................5-47

6 Parameter Settings by Function............................................ 6-1

Carrier Frequency Selection ........................................................................6-2

Setting the Carrier Frequency ........................................................................................6-2

Frequency Reference ..................................................................................6-5

Selecting the Frequency Reference Source ........................................................... ... ....6-5

Using Multi-Step Speed Operation ................................................................................6-7

Run Command ............................................................................................6-9

Selecting the Run Command Source ............................................................................6-9

Stopping Methods ......................................................................................6-11

Selecting the Stopping Method when a Stop Command is Input .................................6-11

Using the DC Injection Brake .......................................................................................6-13

Using an Emergency Stop .................................................................. .........................6-14

Acceleration and Deceleration Characteristics ..........................................6-15

Setting Acceleration and Deceleration Times ..............................................................6-15

Preventing the Motor from Stalling During Acceleration

(Stall Prevention During Acceleration Function) ..........................................................6-17

Stall Prevention During Deceleration Function ............................................................6-19

Adjusting Frequency References ..............................................................6-21

Adjusting Analog Frequency References ....................................................................6-21

Jump Frequency Function (Operation Avoiding Resonance) ...................................... 6-23

Speed Limit

(Frequency Reference Limit Function) ......................................................6-24

Limiting Maximum Output Frequency ..........................................................................6-24

Limiting Minimum Frequency .......................................................................................6-24

Frequency Detection .................................................................................6-25

Speed Agreement Function ................................................ .. .......................................6-25

Improved Operating Performance .............................................................6-27

Torque Compensation for Sufficient Torque at Start

and Low-speed Operation .................................................. .........................................6-27

Hunting Prevention Function .......................................................................................6-28

Machine Protection ....................................................................................6-29

Preventing Motor Stalling During Operation ................................................................6-29

Load Detection .............................................................................................................6-30

Motor Overload Protection ...........................................................................................6-33

III

Motor Overheat Protection Using PTC Thermistor Inputs ...........................................6-35

Limiting Motor Rotation Direction and Output Phase Rotation ....................................6-37

Automatic Restart ......................................................................................6-38

Restarting Automatically After Momentary Power Loss ..............................................6-38

Speed Search ............................................................. .. ............................................. ..6-39

Continuing Operation at Constant Speed When Frequency Reference Is Lost .......... 6-44

Restarting Operation After Transient Fault (Auto Restart Function) .............. ... ... .......6-45

Inverter Protection .....................................................................................6-47

Inverter Overheat Protection .......................................................................................6-47

Input Phase Loss Detection Level ...............................................................................6-48

Ground Fault Protection ..............................................................................................6-48

Cooling Fan Control ....................................................................................................6-49

Setting the Ambient Temperature .......... ... ..................................................................6-49

OL2 Characteristics at Low Speed ..............................................................................6-50

Soft CLA Selection ......................................................................................................6-51

Input Terminal Functions ...........................................................................6-52

Temporarily Switching Operation between Digital Operator

and Control Circuit Terminals ......................................................................................6-52

Blocking the Inverter Output (Baseblock Command) ..................................................6-53

Multifunction Analog Input A2 Disable/Enable ............................................................6-53

Drive Enable/Disable ...................................................................................................6-54

Bypass Drive Enable ........................ ............................................. ... ... ........................6-54

Stopping Acceleration and Deceleration

(Acceleration/Deceleration Ramp Hold) ...................................................................... 6-54

Raising and Lowering Frequency References Using

Digital Input Signals (UP/DOWN) ................................................................................6-55

Trim Control Function ..................................................................................................6-58

Analog Frequency Reference Sample/Hold ................................................................6-59

Switching Operation Source to Communication Option Card .....................................6-60

Switching Operation Source to MEMOBUS communication .......................................6-60

AUTO/HAND Mode Switching by Digital Input ............................................................6-61

Jog Frequency Operation without Forwar d and Reverse Commands (FJOG/RJOG) 6-62

Stopping the Inverter on External Faults (External Fault Function) .............................6-63

IV

Output Terminal Functions ........................................................................6-64

Monitor Parameters ...................................................................................6-67

Using the Analog Monitor Parameters ........................................................................6-67

Individual Functions ..................................................................................6-69

Using MEMOBUS Communications ............................................................................6-69

Using the Timer Function ............................................................................................ 6-86

Using PI Control ..........................................................................................................6-87

Energy-saving .............................................................................................................6-98

Setting Motor Parameters .......................................................... ... ... ...........................6-99

Setting the V/f Pattern ...............................................................................................6-100

Motor Preheat Function .............................................................................................6-106

Emergency Override Function ...................................................................................6-108

High Slip Braking .......................................................................................................6-109

Digital Operator Functions ......................................................................6-110

Setting Digital Operator Functions ............................................................................6-110

Copying Parameters ..................................................................................................6-113

Prohibiting Writing Parameters from the Digital Operator .........................................6-117

Setting a Password .......... .. .......................................................................................6-117

Displaying User-set Parameters Only ....................................................................... 6-118

7 Troubleshooting ..................................................................... 7-1

Protective and Diagnostic Functions ...........................................................7-2

Fault Detection ...............................................................................................................7-2

Alarm Detection .............................................................................................................7-8

Operator Programming Errors .....................................................................................7-11

Autotuning Faults ....................................................................... .................................7-13

Digital Operator Copy Function Faults .........................................................................7-13

Troubleshooting .........................................................................................7-15

If Parameters Cannot Be Set .......................................................................................7-15

If the Motor Does Not Operate .....................................................................................7-16

If the Direction of the Motor Rotation is Reversed .......................................................7-17

If the Motor Does Not Put Out Torque or If Acceleration is Slow .................................7-17

If the Motor Operates at Highe r Speed than the Frequency Reference ......................7-17

If Motor Deceleration is Slow .......................................................................................7-18

If the Motor Overheats .................................................................................................7-18

If peripheral devices like PLCs or other are influenced

by the starting or running inverter 7-.................................... ............................................19

If the Earth Leakage Breaker Oper ates when a RUN Command is Input ...................7-19

If There is Mechanical Oscillation ................................................................................7-19

If the Motor Rotates Even When Inverter Output is Stopped .......................................7-20

If OV (Overvoltage) or OC (Overcurrent) is Detected

When a Fan is Started, or a Fan Stalls ........................................................................7-20

If Output Frequency Does Not Rise to Frequency Reference .....................................7-20

8 Maintenance and Inspection.................................................. 8-1

Maintenance and Inspection ........................................................................8-2

Periodic Inspection ................................................. ... ............................................. ... ... .8-2

Periodic Maintenance of Parts ............................................ .. ... ......................................8-4

Cooling Fan Replacement Outline .................................................................................8-5

Removing and Mounting the Control Circuit Terminal Card ..........................................8-7

9 Specifications ......................................................................... 9-1

Standard Inverter Specifications ..................................................................9-2

Specifications by Model .......................................................................................... ... ....9-2

Common Specifications .................................................................................................9-5

10 Appendix ............................................................................... 10-1

Inverter Application Precautions ................................................................10-2

Selection ......................................................................................................................10-2

Installation ....................................................................................................................10-2

Settings ........................................................................................................................10-3

Handling .......................................................................................................................10-3

Motor Application Precautions ...................................................................10-4

Using the Inverter for an Existing Standard Motor .......................................................10-4

Using the Inverter for Special Motors ..........................................................................10-5

Power Transmission Mechanism (Speed Reducers, Belts and Chains) .....................10-5

User Parameters .......................................................................................10-6

V

VI

Warnings

Cables must not be connected or disconnected, nor signal tests carried out, while the power is

The Varispeed E7 DC bus capacitor remains charged even after the power has been switched off. To

avoid an electric shock hazard, disconnect the frequency inverter from the mains before carrying out

maintenance. Then wait for at least 5 minutes after all LEDs have gone out.

Do not perform a withstand voltage test on any part of the Varispeed. The frequency inverter contains semiconductors, which are not designed for such high voltages.

Do not remove the digital operator while the mains supply is switched on. The printed circuit board

must also not be touched while the inverter is connected to the power.

CAUTION

switched on.

Never connect general LC/RC interference suppression filters, capacitors or overvoltage protection devices to

the inverter input or output.

To avoid unnecessary overcurrent faults, etc. being displayed, the signaling contacts of any contactor or switch fitted between inverter and motor must be integrated into the inverter control logic

(e.g. baseblock).

This is absolutely imperative!

This manual must be read thoroughly before connecting and operating the inverter. All safety precautions and instructions for use must be followed.

The inverter may must be operated with the appropriate line filters, following the installation

instructions in this manual and with all covers closed and terminals covered.

Only then will adequate protection be provided. Please do not connect or operate any equipment

with visible damage or missing parts. The operating company is responsible for any injuries or

equipment damage resulting from failure to heed the warnings in this manual.

VII

Safety Precautions and Instructions for Use

General

Please read these safety precautions and instructions for use thoroughly before installing and operating this

inverter. Also read all of the warning signs on the inverter and ensure they are never damaged or removed.

Live and hot inverter components may be accessible during operation. Removal of housing components, the

digital operator or terminal covers runs the risk of serious injuries or damage in the event of incorrect installation or operation. The fact that frequency inverters control rotating mechanical machine components can give

rise to other dangers.

The instructions in this manual must be followed. Installation, operation and maintenance may only be carried

out by qualified personnel. For the purposes of the safety precautions, qualified personnel are defined as individuals who are familiar with the installation, starting, operation an d maintenance of frequency inv erters and

have the proper qualifications for this work. Safe operation of these units is only possible if they are used

properly for their intended purpose.

The DC bus capacitors can remain live for about 5 minutes after the inverter is disconnected from the power.

It is therefore necessary to wait for this time before opening its covers. All of the main circuit terminals m ay

still carry dangerous voltages.

Children and other unauthorized persons must not be allowed access to these inverters.

Keep these Safety Precautions and Instructions for Use readily accessible and supply them to all persons with

any form of access to the inverters.

Intended Use

Frequency inverters are intended for installation in electrical systems or machinery.

Their installation in machinery and systems must conform to the following product standards of the Low Volt-

age Directive:

EN 50178, 1997-10, Equipping of Power Systems with Electronic Devices

EN 60204-1, 1997-12Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)/

Please note: Includes Corrigendum of September 1998

EN 61010-1, A2, 1995Safety Requirements for Information Technology Equipment

(IEC 950, 1991 + A1, 1992 + A2, 1993 + A3, 1995 + A4, 1996, modified)

CE marking is carried out to EN 50178, using the line filters specified in this manual and following the appro-

priate installation instructions.

Transportation and storage

The instructions for transportation, storage and proper handling must be followed in accordance with the technical data.

Installation

VIII

Install and cool the inverters as specified in the documentation. The cooling air must flow in the specified

direction. The inverter may therefore only be operated in the specified position (e.g. upright). Maintain the

specified clearances. Protect the inverters against impermissible loads. Components must not be bent nor insulation clearances changed. To avoid damage being caused by static electricity, do not touch any electronic

components or contacts.

Electrical Connection

Carry out any work on live equipment in compliance with the national safety and accident prevention regulations. Carry out electrical installation in compliance with the relevant regulations. In particular, follow the

installation instructions ensuring electromagnetic compatibility (EMC), e.g. shielding, grounding, filter

arrangement and laying of cables. This also applies to equipment with the CE mark. It is the responsibility of

the manufacturer of the system or machine to ensure conformity with EMC limits.

Your sup plier or Omron Yaskawa Motion Control representative must be contacted when using leakage current circuit breaker in conjunction with frequency inverters.

In certain systems it may be necessary to use additional monitoring and safety devices in compliance with the

relevant safety and accident prevention regulations. The frequency inverter hardware must not be modified.

Notes

The Varispeed E7 frequency inverters are certified to CE, UL, and cUL except the IP54 version which is certified to CE only.

IX

EMC Compatibility

Introduction

This manual was compiled to help system manufacturers using OMRON YASKAWA Motion Control

(OYMC) frequency inverters design and install electrical switch gear. It also describes the measures necessary

to comply with the EMC Directive. The manual's installation and wiring instructions must therefore be followed.

Our products are tested by authorized bodies using the standards listed below.

Product standard: EN 61800-3:1996

EN 61800-3; A11:2000

Measures to Ensure Conformity of OYMC Frequency inverters to the EMC Directive

OYMC frequency inverters do not necessarily have to be installed in a switch cabinet.

It is not possible to give detailed instructions for all of the possible types of installation. This manual therefore

has to be limited to general guidelines.

All electrical equipment produces radio and line-borne interference at various frequencies. The cables pass

this on to the environment like an aerial.

Connecting an item of electrical equipment (e.g. drive) to a supply without a line filter can therefore allow HF

or LF interference to get into the mains.

The basic countermeasures are isolation of the wiring of control and power components, proper grounding and

shielding of cables.

A large contact area is necessary for low-impedance grounding of HF interference. The use of grounding

straps instead of cables is therefore definitely advisable.

Moreover, cable shields must be connected with purpose-made ground clips.

Laying Cables

Measures Against Line-Borne Interference:

Line filter and frequency inverter must be mounted on the same metal plate. Mount the two components as

close to each other as possible, with cables kept as short as possible.

Use a power cable with well-grounded shield. For motor cables up to 50 meters in length use shielded cables.

Arrange all grounds so as to maximize the area of the end of the lead in contact with the ground terminal (e.g .

metal plate).

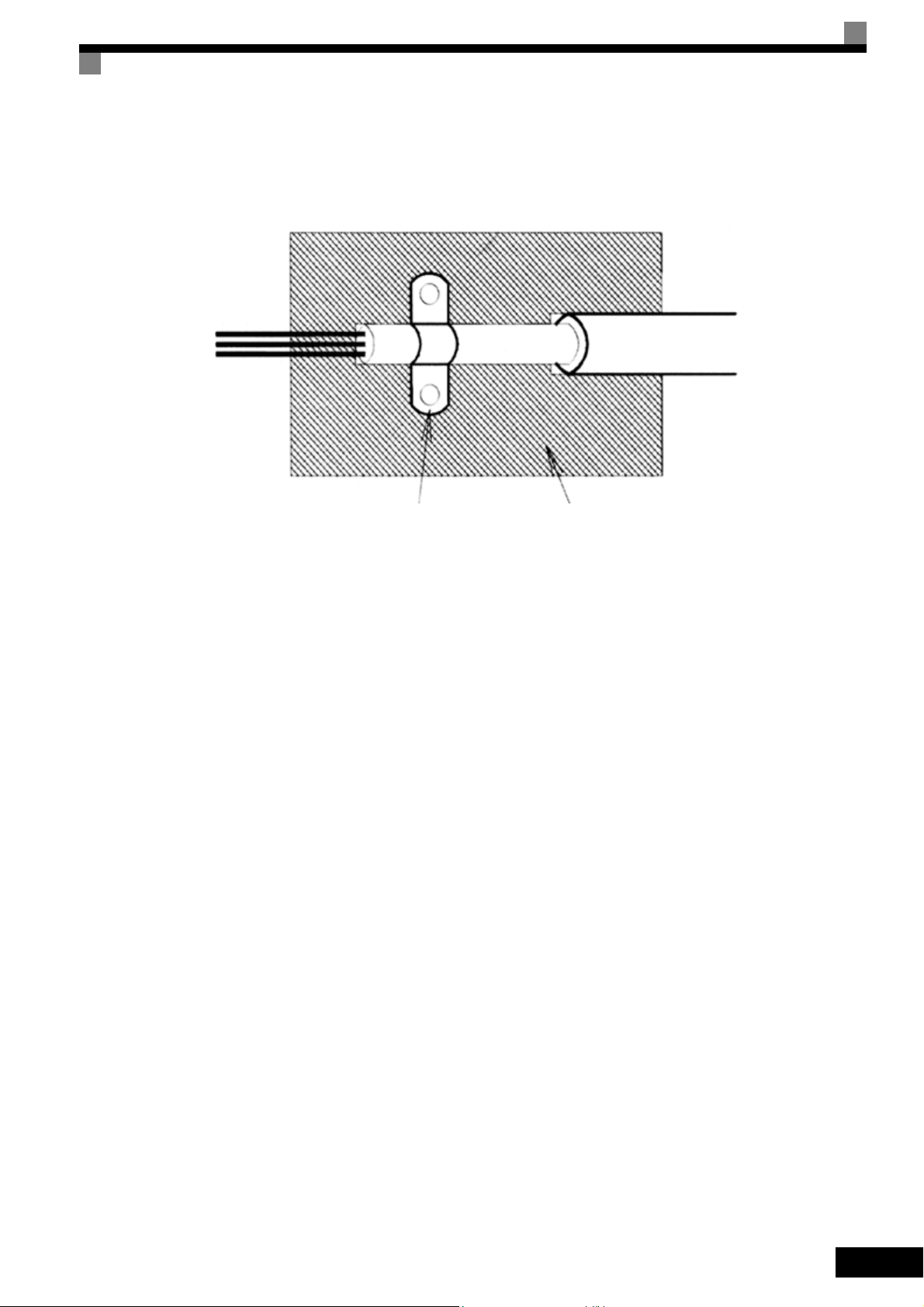

Shielded Cable:

– Use a cable with braided shield.

– Ground the maximum possible area of the shield. It is advisable to ground the shield by connecting the cable

to the ground plate with metal clips (see following figure).

X

Ground clip Ground plate

The grounding surfaces must be highly conductive bare metal. Remove any coats of varnish and paint.

– Ground the cable shields at both ends.

– Ground the motor of the machine.

Further informations can be found in the document EZZ006543 which can be ordered at O mron Yaskawa

Motion Control.

XI

Line Filters

The IP54 version is already equipped with a internal EMC filter. For the IP00 and NEMA 1 / IP20 versions of

the Varispeed E7 the recommended line filters are as follows:

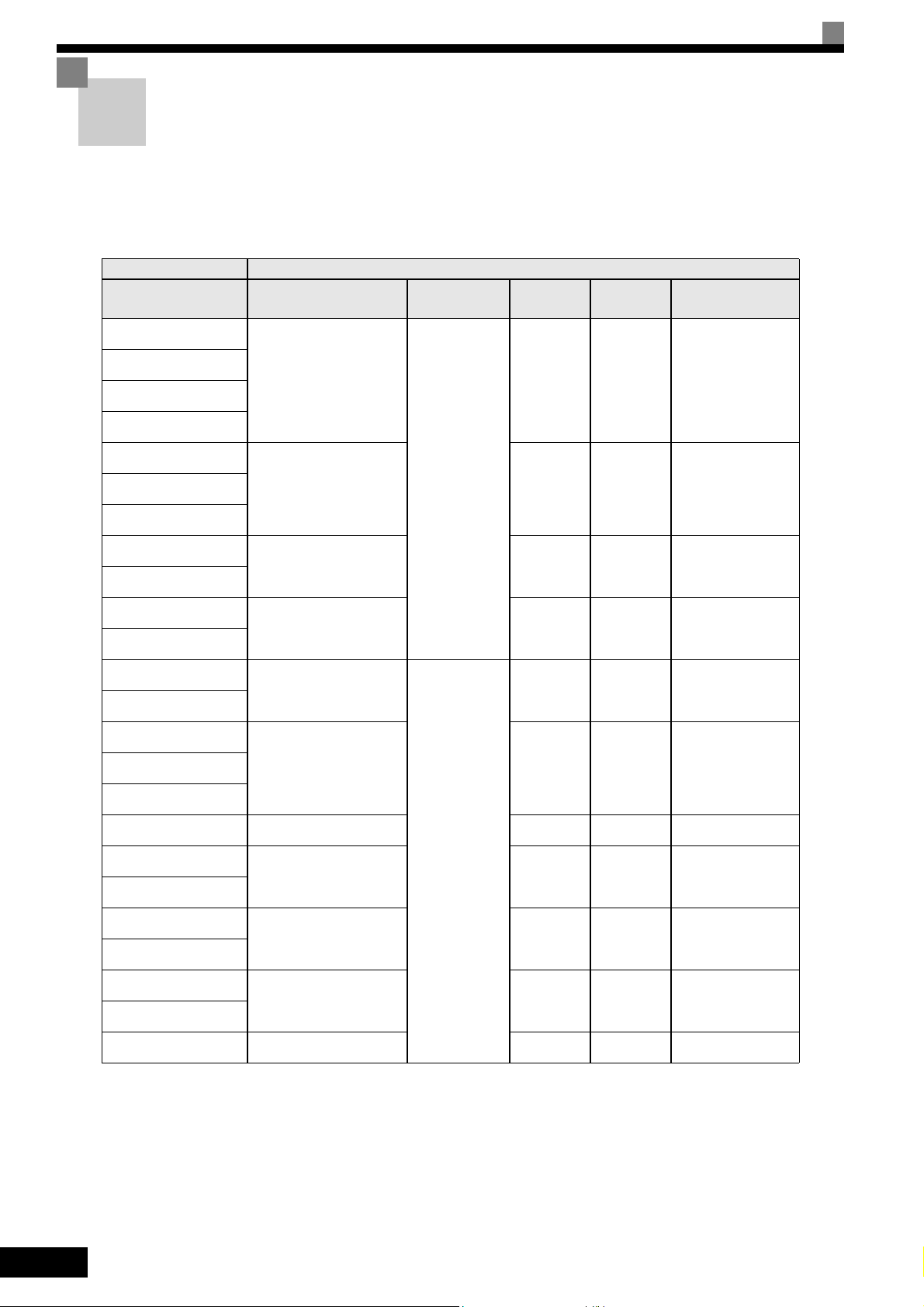

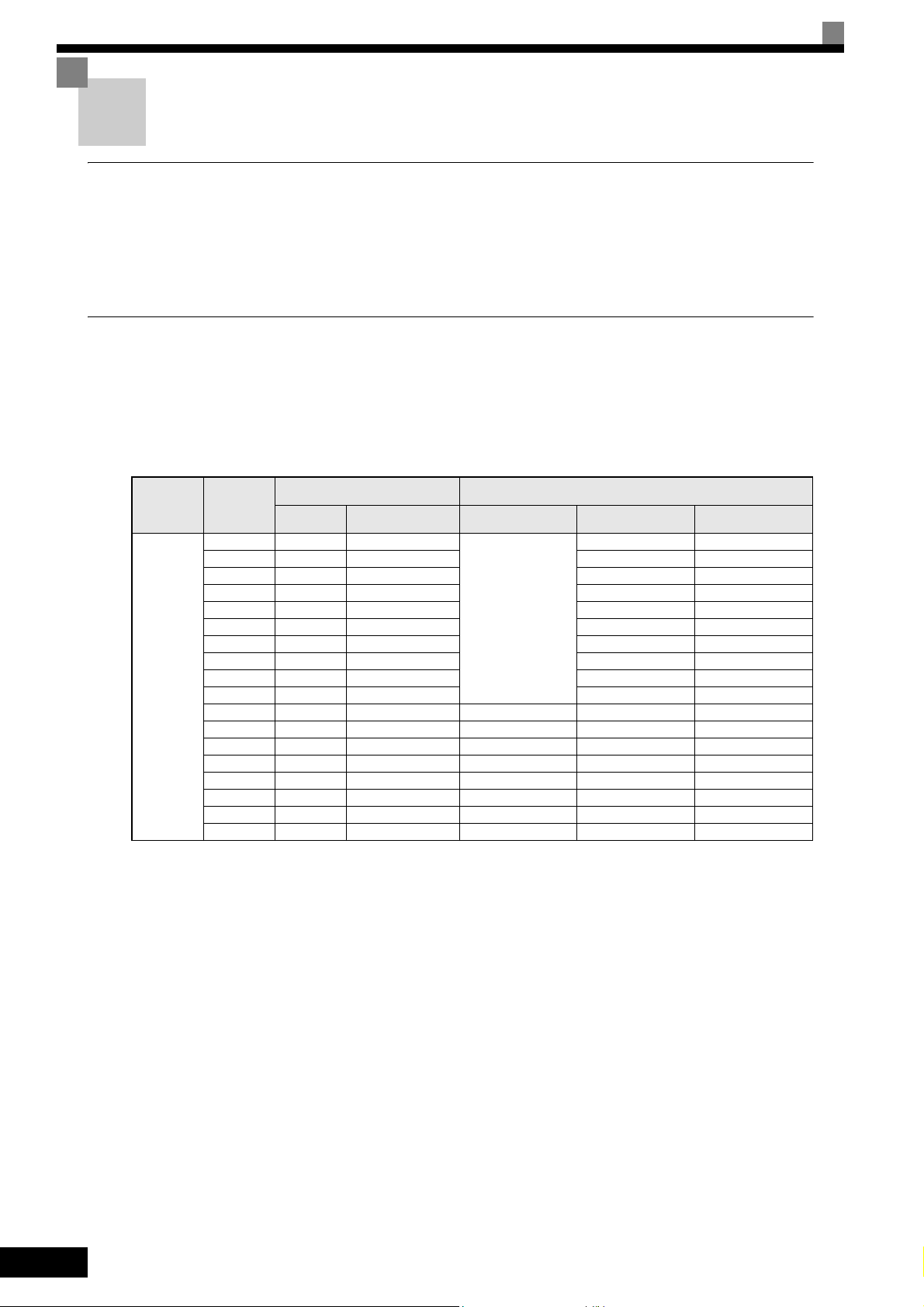

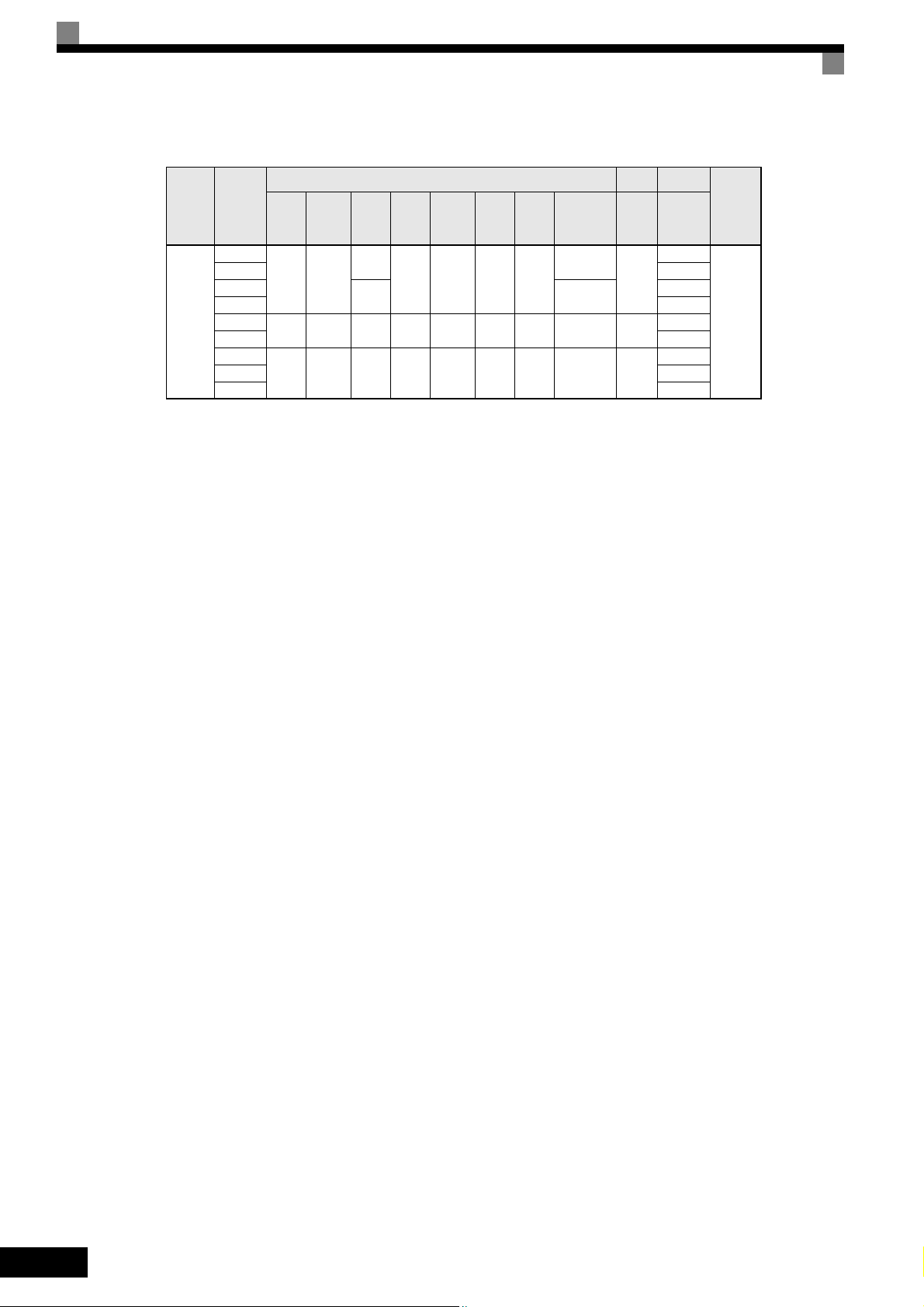

Recommended Line Filters for Varispeed E7 (IP00 and NEMA 1 / IP20)

Inverter Model Line Filter

Varispeed E7

(IP00/20)

CIMR-E7Z40P4

CIMR-E7Z40P7

CIMR-E7Z41P5

CIMR-E7Z42P2

CIMR-E7Z43P7

Model

3G3RV-PFI3010-SE

EN

55011 Class

Current

(A)

10 1.1 141 x 46 x 330

Weight

(kg)

Dimensions

W x D x H

3G3RV-PFI3018-SE 18 1.3 141 x 46 x 330CIMR-E7Z44P0

CIMR-E7Z45P5

CIMR-E7Z47P5

3G3RV-PFI3035-SE 35 2.1 206 x 50 x 355

CIMR-E7Z4011

CIMR-E7Z4015

3G3RV-PFI3060-SE 60 4.0 236 x 65 x 408

CIMR-E7Z4018

CIMR-E7Z4022

3G3RV-PFI3070-SE

CIMR-E7Z4030

CIMR-E7Z4037

3G3RV-PFI3130-SE 130 4.7 90 x 180 x 366CIMR-E7Z4045

CIMR-E7Z4055

CIMR-E7Z4075 3G3RV-PFI3170-SE 170 6.0 120 x 170 x 451

CIMR-E7Z4090

3G3RV-PFI3200-SE 250 11 130 x 240 x 610

CIMR-E7Z4110

CIMR-E7Z4132

3G3RV-PFI3400-SE 400 18.5 300 x 160 x 610

CIMR-E7Z4160

B, 25 m

A, 100 m

*1

70 3.4 80 x 185 x 329

XII

CIMR-E7Z4185

3G3RV-PFI3600-SE 600 11,0 260 x 135 x 386

CIMR-E7Z4220

CIMR-E7Z4300 3G3RV-PFI3800-SE 800 31.0 300 x 160 x 716

*1. Class A, 100 m

Permissible emission of power drive systems for commercial and light environm ent (EN61800-3, A11)

(general availability, 1st environment)

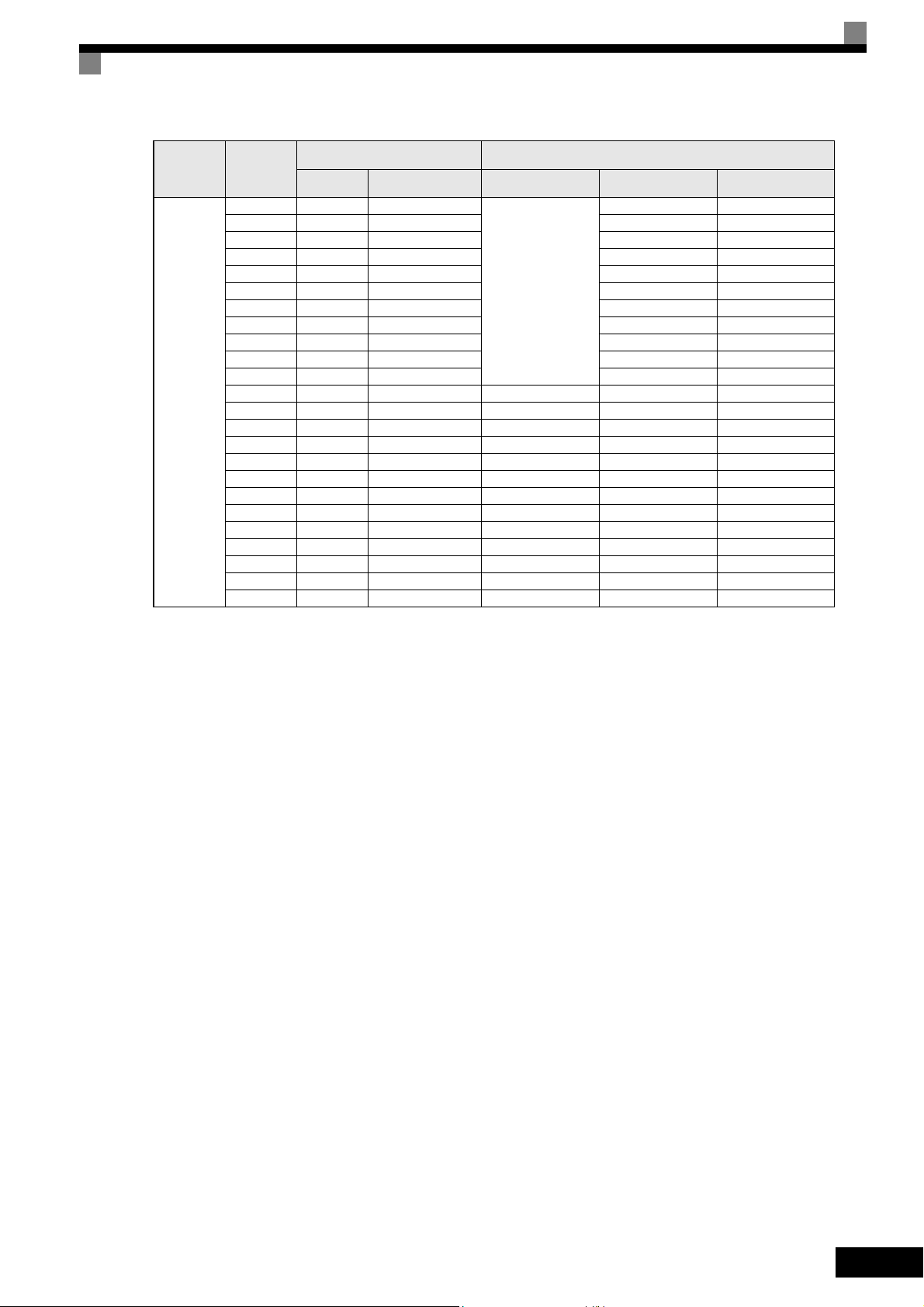

Inverter Model Line Filters

Varispeed E7

(IP00/20)

CIMR-E7Z20P4

Type

EN

55011

Class

Current

(A)

Weight

(kg)

Dimensions

W x D x H

3G3RV-PFI3010-SE

CIMR-E7Z21P5

CIMR-E7Z22P2 3G3RV-PFI3018-SE 18 1.3 141 x 46 x 330

CIMR-E7Z23P7

CIMR-E7Z25P5

3G3RV-PFI2035-SE 35 1.4 141 x 46 x 330

CIMR-E7Z27P5

3G3RV-PFI2060-SE 60 3 206 x 60 x 355

CIMR-E7Z2011

CIMR-E7Z2015

3G3RV-PFI2100-SE 100 4.9 236 x 80 x 408

CIMR-E7Z2018

CIMR-E7Z2022

3G3RV-PFI2130-SE

CIMR-E7Z2030

CIMR-E7Z2037 3G3RV-PFI2160-SE 160 6.0 120 x 170 x 451

CIMR-E7Z2045

3G3RV-PFI2200-SE 200 11.0 130 x 240 x 610

CIMR-E7Z2055

CIMR-E7Z2075

3G3RV-PFI3400-SE 400 18.5 300 x 160 x 564

CIMR-E7Z2090

B, 25 m

A, 100 m

*1

10 1.1 141 x 45 x 330CIMR-E7Z20P7

130 4.3 90 x 180 x 366

CIMR-E7Z2110 3G3RV-PFI3600-SE 600 11.0 260 x 135 x 386

*1. Class A, 100 ambient temperature: 45°C max

EMC Specifications of Varispeed E7 (IP54)

The Varispeed E7 IP54 is already equipped with an internal EMC filter. The Varispeed E7 IP54 complies with

EN55011 class A with a motor cable length up to 25m.

For the wiring methods to comply with the EMC regulations for the Varispeed E7 (IP54) refer to page Chap-

ter 2, Wiring.

XIII

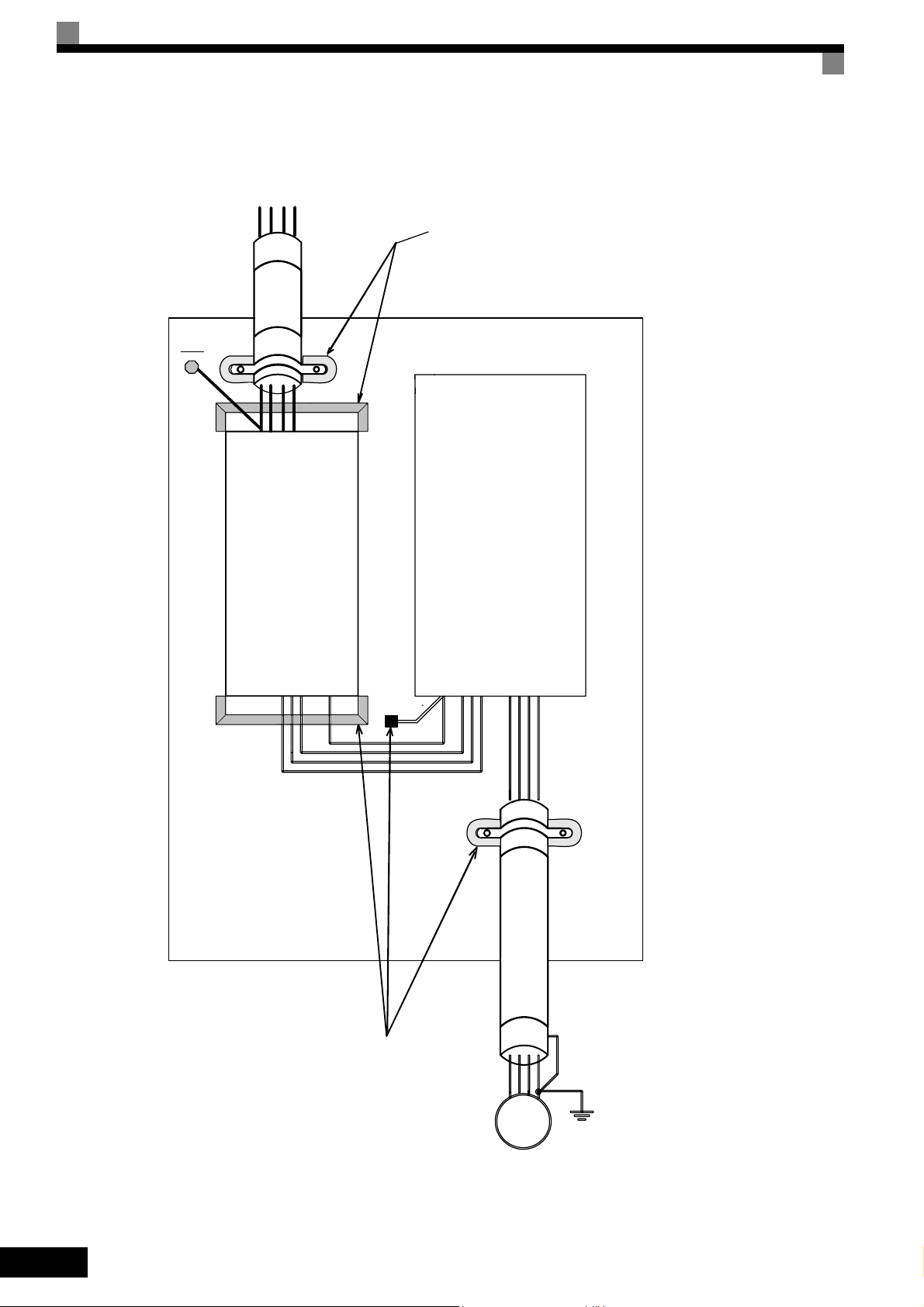

Installation inverters and EMC filters

L1 L3

L2

PE

PE

Line

Filter

Ground Bonds

( remove any paint )

Inverter

Load

Cable Length

as short as possible

Metal Plate

( remove any paint )

Ground Bonds

PE

L1L2L3

U

W

V

M

3~

PE

Motor cable

screened

XIV

Registered Trademarks

The following registered trademarks are used in this manual.

• DeviceNet is a registered trademark of the ODVA (Open DeviceNet Vendors Association, Inc.).

• InterBus is a registered trademark of Phoenix Contact Co.

• ControlNet is a registered trademark of ControlNet International, Ltd.

• LONworks is a registered trademark of the Echelon.

• Metasys is a registered trademark of Johnson Controls Inc.

• CANopen is a registered trademark of CAN in Automation e.V.

XV

XVI

Handling Inverters

This chapter describes the checks required upon receiving or installing an Inverter.

Varispeed E7 Introduction..................................................1-2

Confirmations upon Delivery..............................................1-4

Exterior and Mounting Dimensions....................................1-9

Checking and Controlling the Installation Site .................1-13

Installation Orientation and Space...................................1-15

Accessing the Inverter Terminals.....................................1-16

Removing/Attaching the Digital Operator and Front Cover1-18

1

Varispeed E7 Introduction

Varispeed E7 Applications

The Varispeed E7 is ideal for the following applications.

• Fan, blower and pump applications with variable torque characteristics.

Settings must be adjusted to the application for optimum operation. Refer to page 4-1, Trial Operation.

Varispeed E7 Models

The Varispeed E7 Series includes Inverters in two voltage classes: 200 V and 400 V. The maximum motor capacities

vary from 0.55 to 300 kW. The inverter is available in protection classes IP00, IP20 and IP54 according to the

following table:

Table 1.1 Varispeed E7 Models

Specifications

NEMA 1 (IEC IP20)

CIMR-E7Z

20P41 -

CIMR-E7Z

Voltage Class

200 V class

Maximum

Motor

Capacity

kW

0.55 1.2 CIMR-E7Z20P4

0.75 1.6 CIMR-E7Z20P7 20P71 -

18.5 27 CIMR-E7Z2018 20181 -

110 160 CIMR-E7Z2110 21100 --

Capacity kVA

1.5 2.7 CIMR-E7Z21P5 21P51 -

2.2 3.7 CIMR-E7Z22P2 22P21 -

3.7 5.7 CIMR-E7Z23P7 23P71 -

5.5 8.8 CIMR-E7Z25P5 25P51 -

7.5 12 CIMR-E7Z27P5 27P51 -

11 17 CIMR-E7Z2011 20111 -

15 22 CIMR-E7Z2015 20151 -

22 32 CIMR-E7Z2022 20220 20221 -

30 44 CIMR-E7Z2030 20300 20301 -

37 55 CIMR-E7Z2037 20370 20371 -

45 69 CIMR-E7Z2045 20450 20451 -

55 82 CIMR-E7Z2055 20550 20551 -

75 110 CIMR-E7Z2075 20750 20751 -

90 130 CIMR-E7Z2090 20900 --

Output

Varispeed E7

Basic Model Number

(Always specify through the protective structure when ordering.)

IEC IP00

CIMR-E7Z

Remove the top and bot-

tom covers from the IP20

model.

IEC IP54

1-2

Varispeed E7 Introduction

Voltage Class

400 V class

Maximum

Motor

Capacity

kW

0.55 1.4 CIMR-E7Z40P4

0.75 1.6 CIMR-E7Z40P7 40P71 -

18.5 30 CIMR-E7Z4018 40181 40182

110 160 CIMR-E7Z4110 41100 41101 -

132 200 CIMR-E7Z4132 41320 41321 -

160 230 CIMR-E7Z4160 41600 41601 -

185 280 CIMR-E7Z4185 41850 -220 390 CIMR-E7Z4220 42200

300 510 CIMR-E7Z4300 43000 --

Capacity kVA

1.5 2.8 CIMR-E7Z41P5 41P51 -

2.2 4.0 CIMR-E7Z42P2 42P21 -

3.7 5.8 CIMR-E7Z43P7 43P71 -

4.0 6.6 CIMR-E7Z44P0 44P01 -

5.5 9.5 CIMR-E7Z45P5 45P51 -

7.5 13 CIMR-E7Z47P5 47P51 47P52

11 18 CIMR-E7Z4011 40111 40112

15 24 CIMR-E7Z4015 40151 40152

22 34 CIMR-E7Z4022 40220 40221 40222

30 46 CIMR-E7Z4030 40300 40301 40302

37 57 CIMR-E7Z4037 40370 40371 40372

45 69 CIMR-E7Z4045 40450 40451 40452

55 85 CIMR-E7Z4055 40550 40551 40552

75 110 CIMR-E7Z4075 40750 40751 -

90 140 CIMR-E7Z4090 40900 40901 -

Output

Varispeed E7

Basic Model Number

(Always specify through the protective structure when ordering.)

IEC IP00

CIMR-E7Z

Remove the top and bot-

tom covers from the IP20

model.

--

Specifications

NEMA 1 (IEC IP20)

CIMR-E7Z

40P41 -

IEC IP54

CIMR-E7Z

1-3

Confirmations upon Delivery

Checks

Check the following items as soon as the Inverter is delivered.

Table 1.2 Checks upon delivery

Item Method

Has the correct Inverter model been delivered? Check the model number on the nameplate on the side of the Inverter.

Is the Inverter damaged in any way?

Are any screws or other components loose? Use a screwdriver or other tools to check for tightness.

Additionally check that following parts are delivered in the package with the IP54 inverter:

Table 1.3 Additional Deliveries with IP54 Inverters

Cable Gland (for Input) 1

Cable Gland (for Motor Output) 1

Cable Gland (for Control) 1

Inspect the entire exterior of the Inverter to see if there are any

scratches or other damage resulting from shipping.

Part Name Qty.

Cable Gland (for Fieldbus) 1

Door Key 1

Blind Plug (Control Cable Entry) 1

Blind Plug (Fieldbus Cable Entry) 1

If any irregularities in the above items are found, contact the agency from which the Inverter was purchased or

your Omron Yaskawa Motion Control representative immediately.

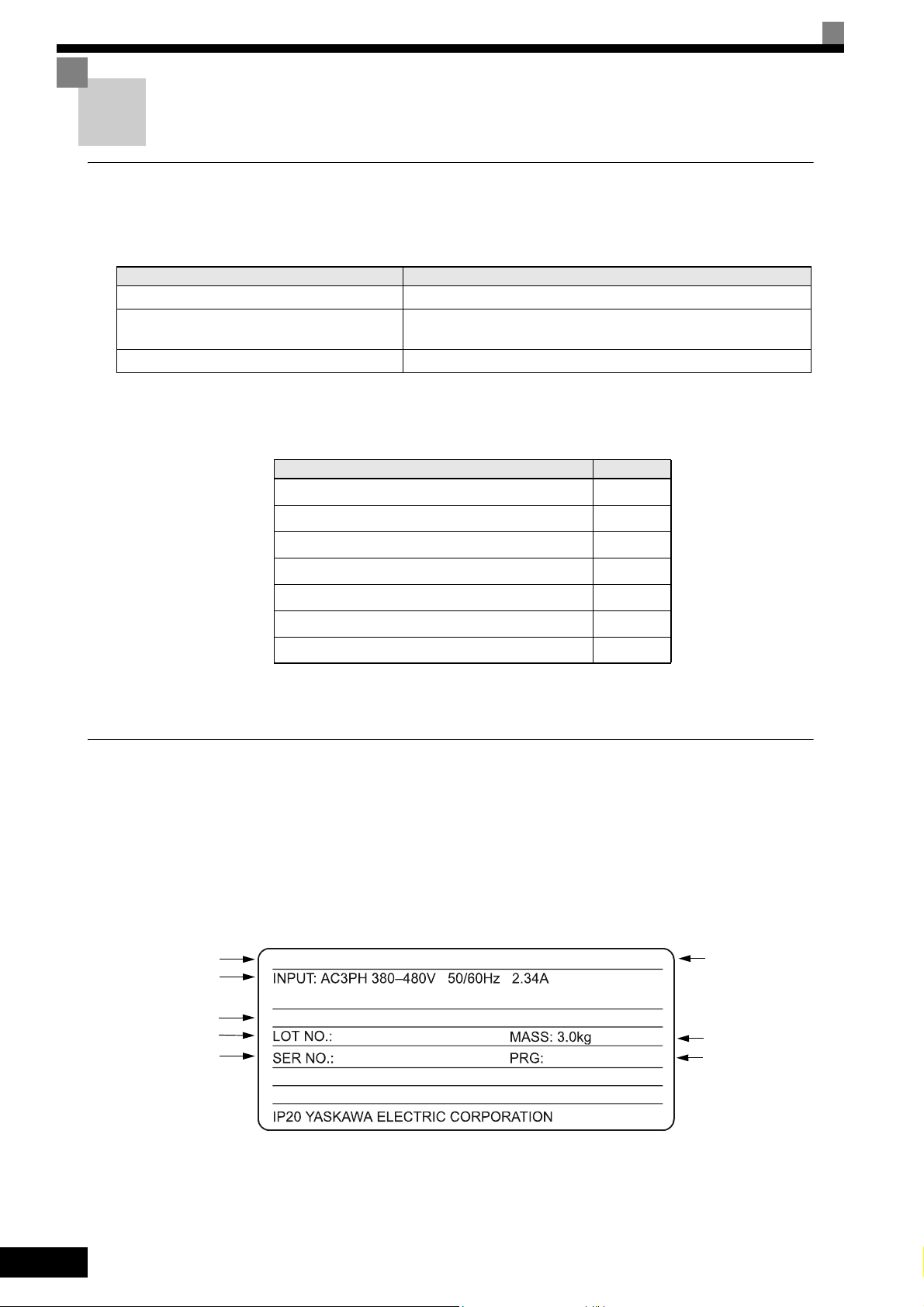

Nameplate Information

There is a nameplate attached to the side of each Inverter. The nameplate shows the model number, specifications, lot number, serial number, and other information on the Inverter.

Example Nameplate

The following nameplate is an example for a standard European Inverter: 3-phase, 400 VAC, 0.55 kW,

NEMA 1 / IP20 standards

Inverter model

Input specifications

Output specifications

Lot number

Serial number

MODEL: CIMR-E7Z40P4

OUTPUT: AC3PH 0-480V 0-200Hz 1.8A 1.4kVA

SPEC: 40P41A

Inverter

specifications

Mass

Software Number

1-4

Fig 1.1 Nameplate Example

Confirmations upon Delivery

T

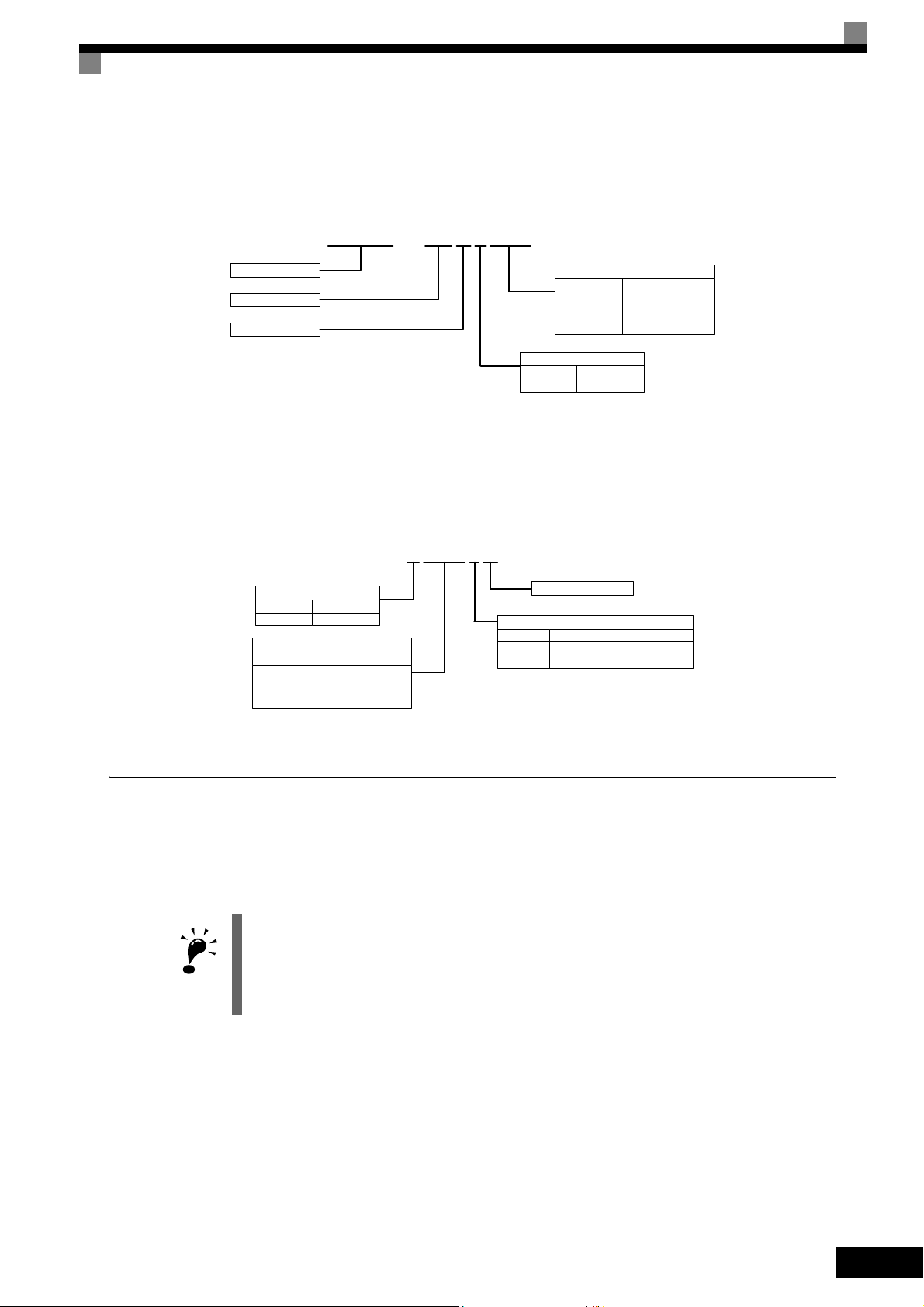

Inverter Model Numbers

The model number of the Inverter on the nameplate indicates the specification, voltage class, and maximum

motor capacity of the Inverter in alphanumeric codes.

CIMR – E7Z40P4

Inverter

Varispeed E7

European Spec.

Max. Motor Power

0P4 0.55 kW

0P7 0.75 kW

to to

300 300 kW

Voltage Class

2 200 V

4 400 V

Fig 1.2 Inverter Model Numbers

Inverter Specifications

The Inverter specifications (“SPEC”) on the nameplate indicate the voltage class, maximum motor capacity,

the protective structure, and the revision of the Inverter in alphanumeric codes.

40P41A

Voltage Class

2 200 V

4 400 V

Max. Motor Power

0P4 0.55 kW

0P7 0.75 kW

to to

300 300 kW

Revision

Protection

0 IP00

1 IP20

2 IP54

Fig 1.3 Inverter Specifications

Inverter Software Version

The Inverter software version can be read out from the monitor parameter U1-14. The parameter shows th e

last four digits of the software number (e.g. display is “3021” for the software version VSE103021).

This manual describes the functionality of the inverter software version VSE103021.

Older software versions do not support all described functions. Check the software versions before

IMPORTAN

starting to work with this manual.

1-5

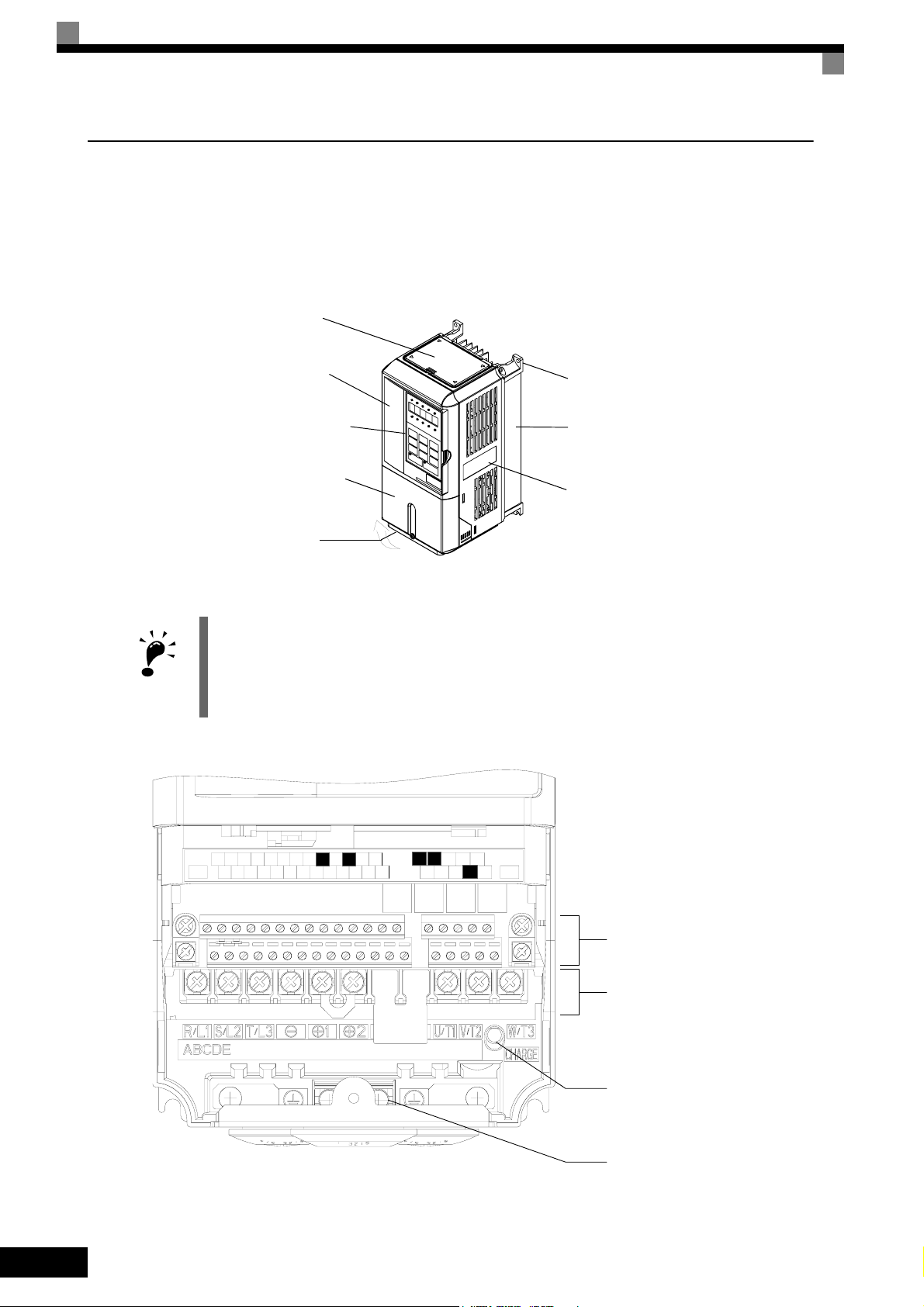

Component Names

Inverters of 18.5 kW or Less

The external appearance and component names of the Inverter are shown in Fig 1.4, the terminal arrangement

in Fig 1.5

Top cover

IMPORTANT

Front cover

Digital Operator

Mounting hole

Diecast case

Terminal cover

Nameplate

Bottom protective cover

Fig 1.4 NEMA 1 Inverter Appearance (18.5 kW or Less)

The top cover is a protection against foreign bodies (screws, metal scrap from drilling etc.), which could fall

into the inverter during the installation in the cabinet.

Remove the top cover when the installation is finished!

1-6

R+M5RPAC

MP

AC

-V

SCIGA2

SN M6

E(G)

S1 S4SPS7 M4

+V

A1

S3

FM

S6

S5 M1

R-

AC

AM

S+

S-

NOTUSED

Fig 1.5 Terminal Arrangement (18.5 kW or less)

MCMB

MA

M2

M3S2

E(G)

Control Circuit Terminals

Main Circuit Terminals

Charge Indicator

Ground Terminal

Confirmations upon Delivery

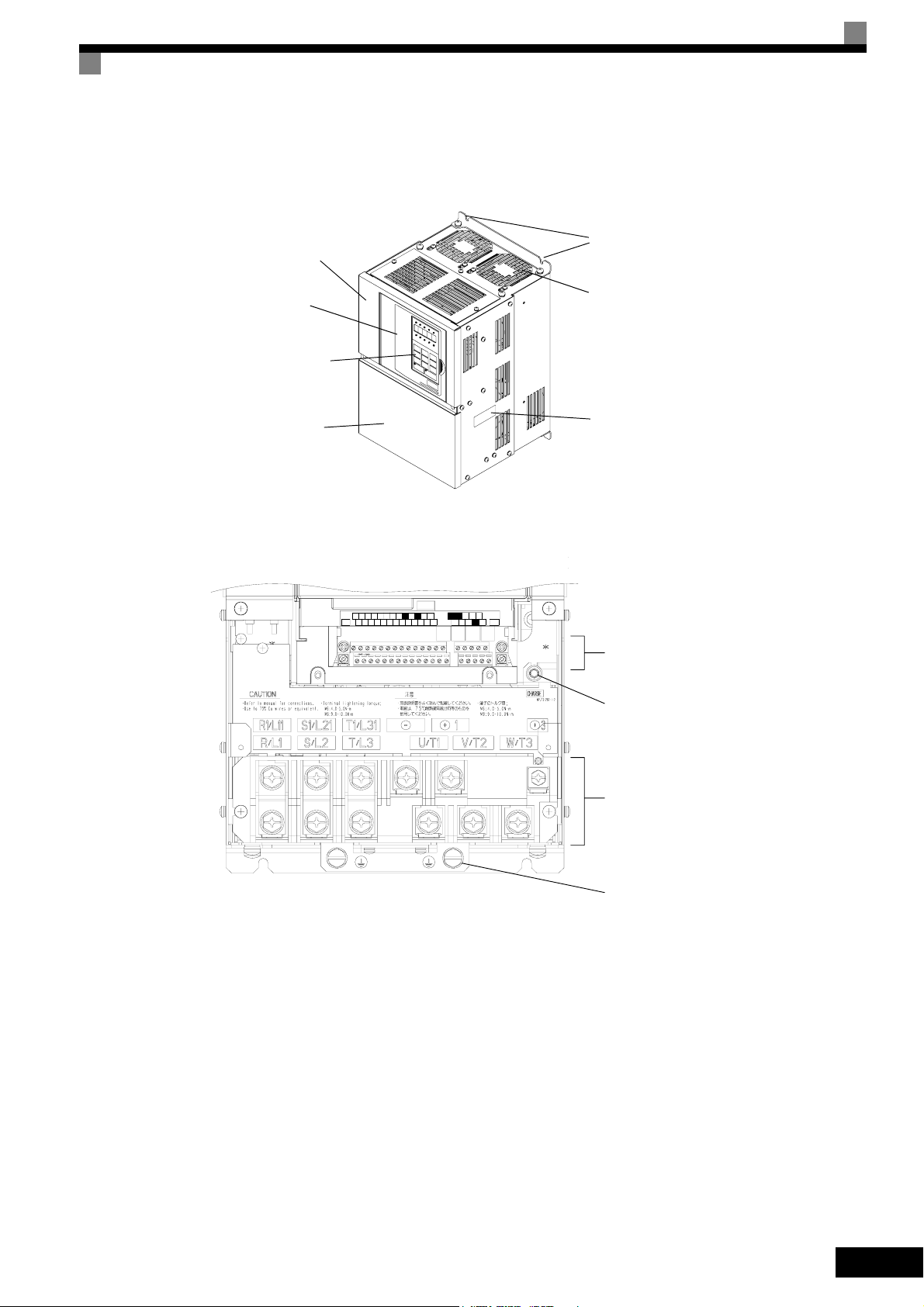

Inverters of 22 kW or More

The external appearance and component names of the Inverter are shown in Fig 1.6, the terminal arrangement

in Fig 1.7

Mounting holes

Inverter cover

Front cover

Digital Operator

Terminal cover

Cooling fan

Nameplate

Fig 1.6 Inverter Appearance (22 kW or More)

AC

R+M5RPAC

+VS3SCIGA2M2SN

A1

MP

R-

M6

MCMB

E(G)

S1 S4SPS7 M4

ACS6-VAM

FM

S5 M1

MA

S-

E(G)

M3S2 S+

Control Circuit Terminals

Carge Indicator

Fig 1.7 Terminal Arrangement (22kW or More)

Main Circuit Terminals

Ground Terminals

1-7

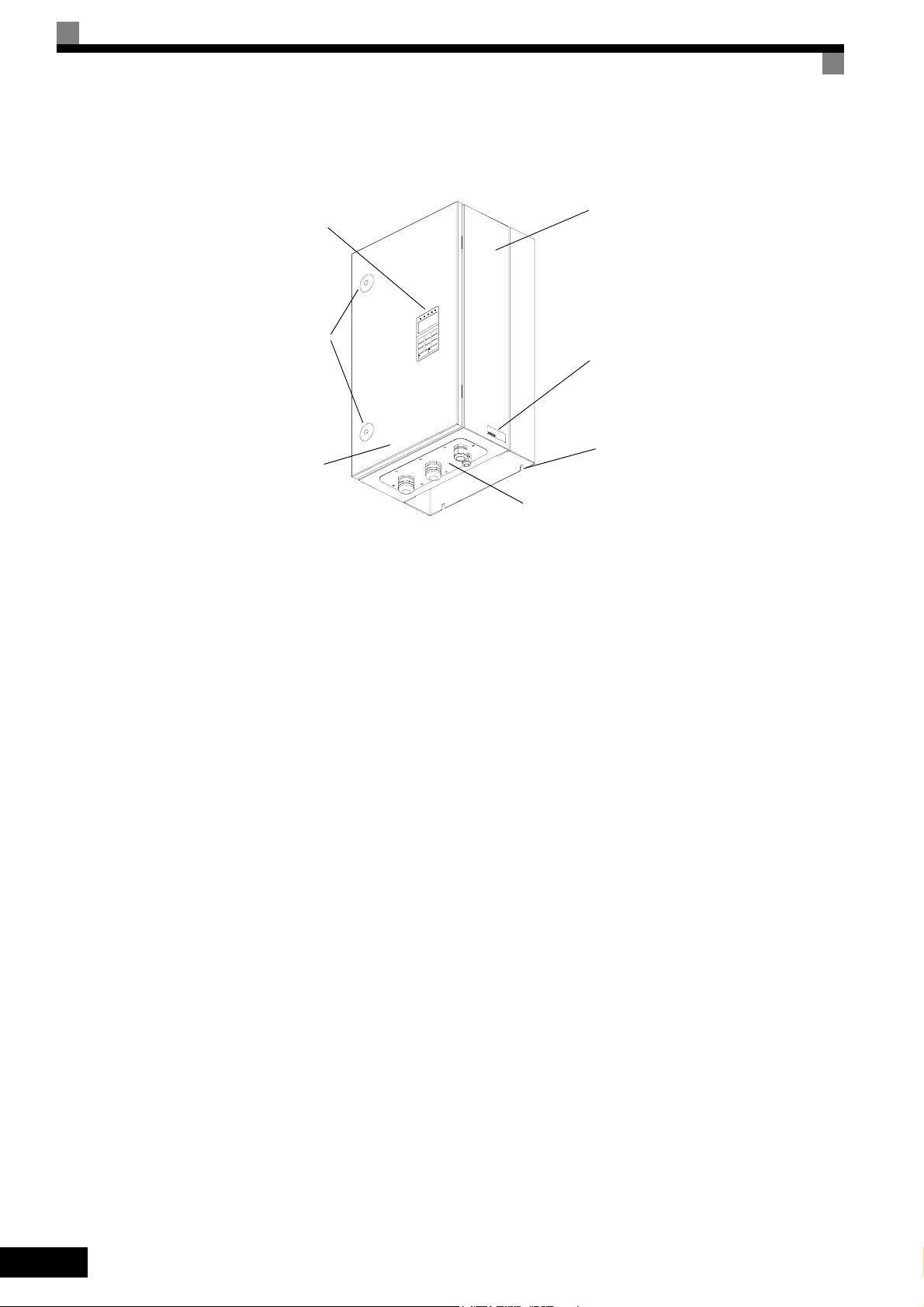

Protection Class IP54

The external appearance and component names of the Inverter are shown in Fig 1.8.

Inverter enclosure

Digital Operator

Door Locks

Nameplate

Mounting Holes

Door

Cable Entry Plate

Fig 1.8 IP54 Inverter Appearance

1-8

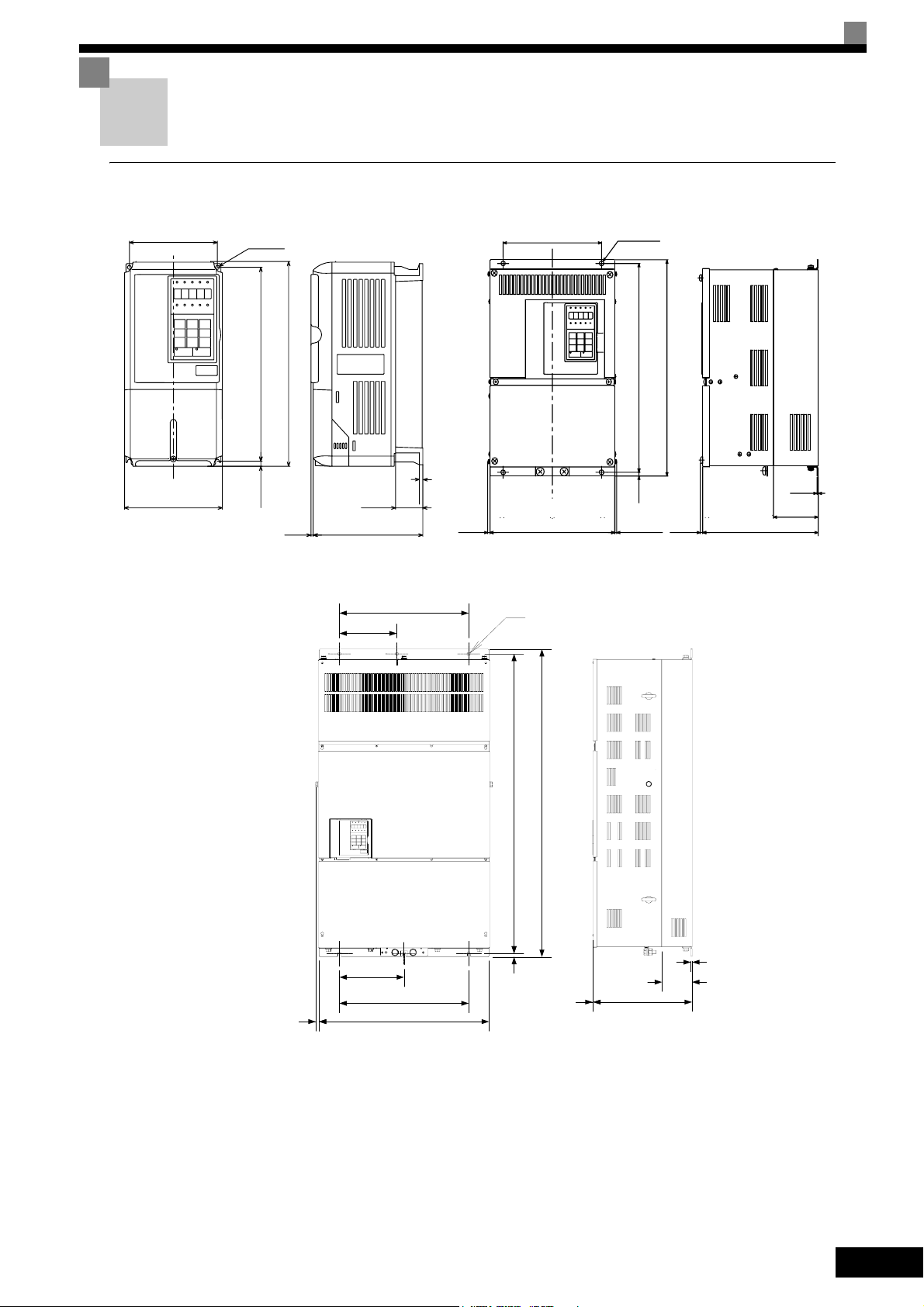

Exterior and Mounting Dimensions

IP00 Inverters

Exterior and Mounting Dimensions

W1

W

200 V/400 V Class Inverters of 0.55 to 18.5 kW

4-d

H1H2DH

D1

3

W2

W1

W1

t1

Max.10

200 V Class Inverters of 22 or 110 kW

400 V Class Inverters of 22 to 160 kW

W

Ø

4-d

H1

H2

Max.10

H

t1

D1

5

D

W3

W1

15

400 V Class Inverters of 185 to 300 kW

W

Fig 1.9 Exterior Diagrams of IP00 Inverters

H

H1

t1

H2

5

D1

D

1-9

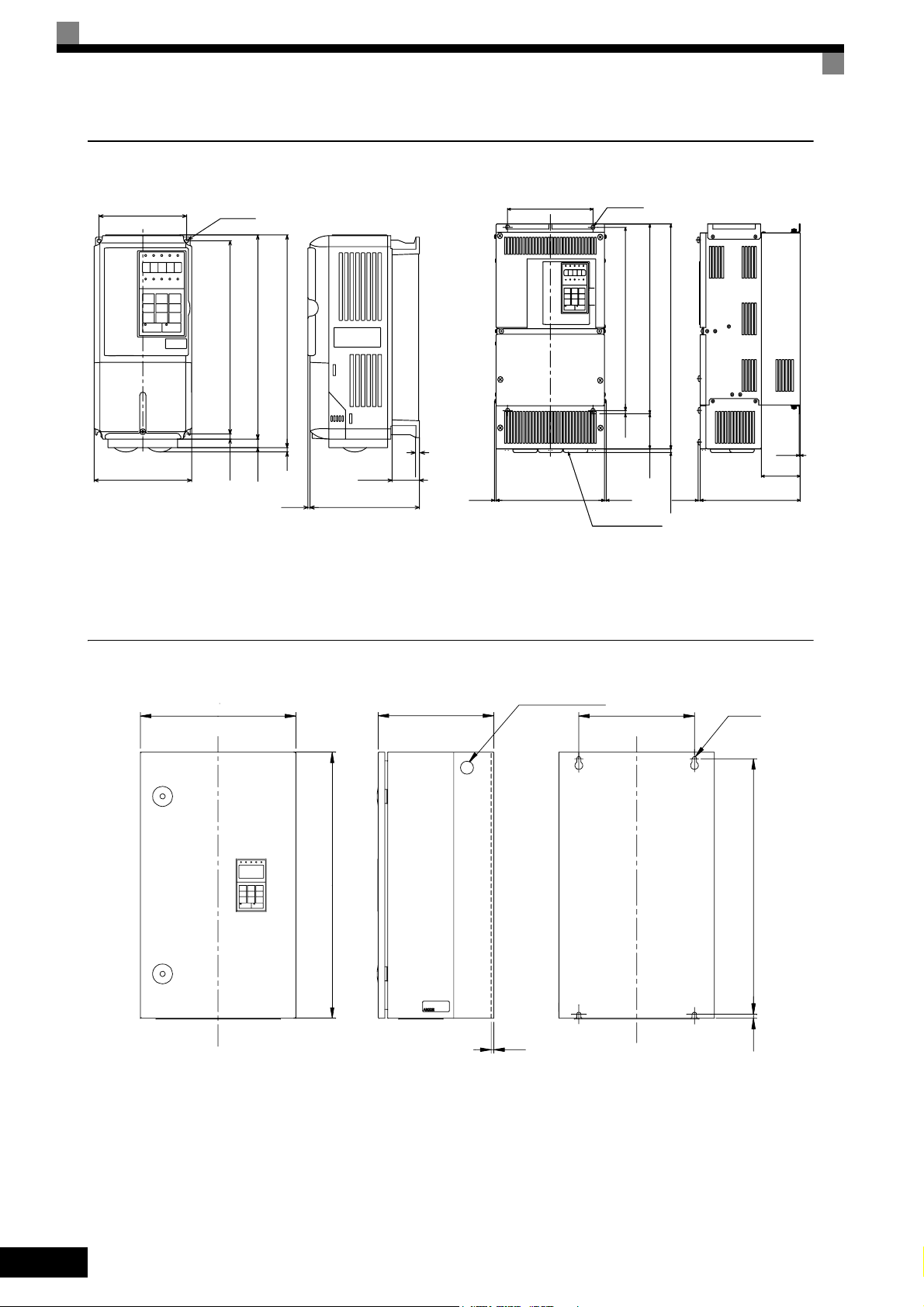

NEMA 1 / IP20 Inverters

W1

W

200 V/400 V Class Inverters of 0.55 to 18.5 kW

4-d

H1H2DH0

H3

4 H

3

Fig 1.10 Exterior Diagrams of NEMA 1 / IP20 Inverters

D1

W1

t1

Max.10

200 V Class Inverters of 22 to 75 kW

400 V Class Inverters of 22 to 160 kW

W

4-d

H1

H2

Max.10

Grommet

H0

H3

H

Max.10

t1

D1

D5

IP54 Inverters

WW1

D

H

2 - lifting holes

t1

Fig 1.11 Exterior Diagrams of IP54 Inverters

4-d

H1H2

1-10

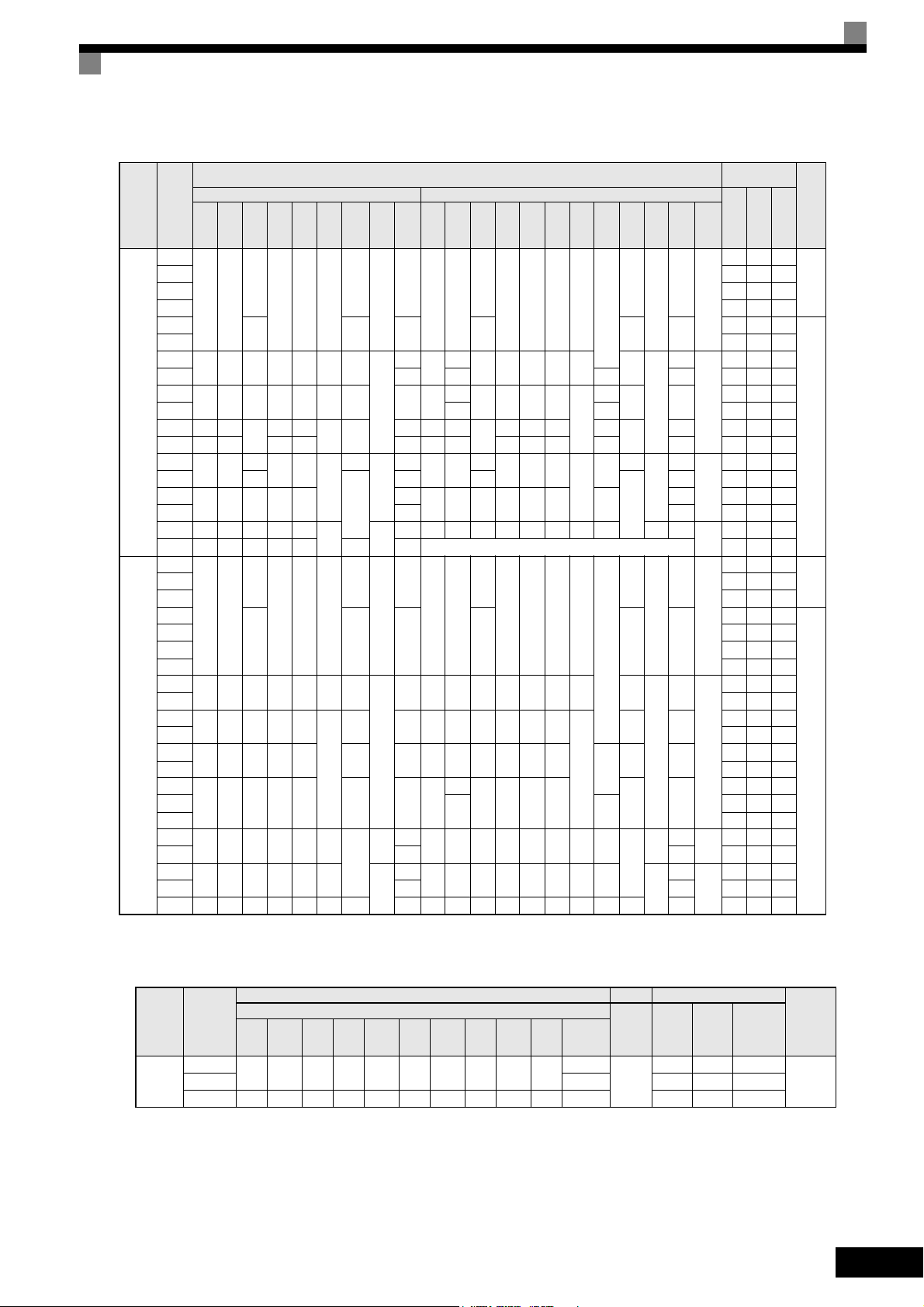

Exterior and Mounting Dimensions

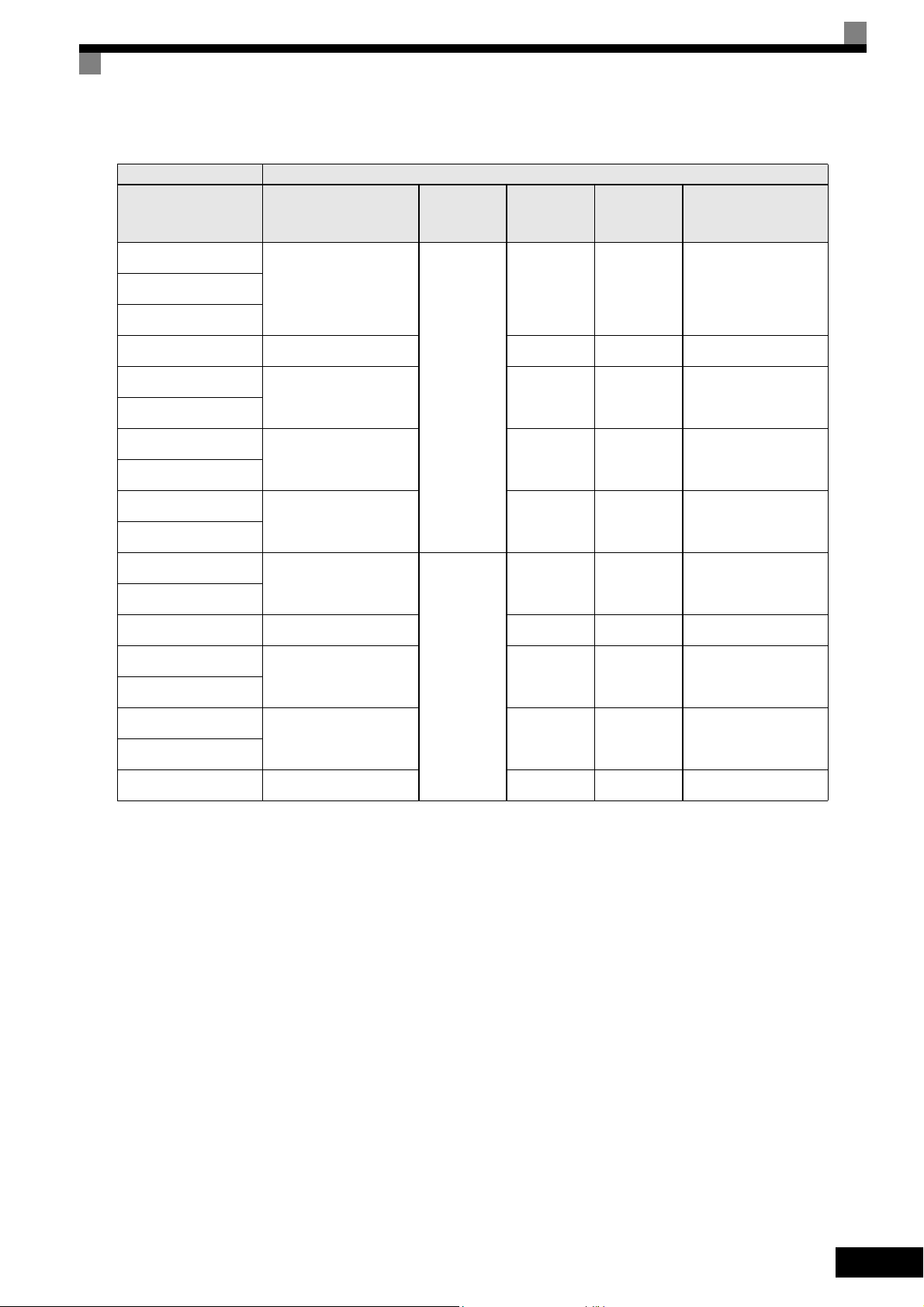

Table 1.4 Inverter Dimensions (mm) and Masses (kg) from 0.4 to 160 kW, IP00 and NEMA 1 / IP20

Max.

Voltage

Class

Appli-

cable

Motor

Output

W H D W1 H1 H2 D1 t1

[kW]

Protection Class IP00 Protection Class NEMA 1 / IP20

0.55

0.75 27 42 69

1.5 50 50 100

140 280

2.2 70 59 129

3.7

5.5 164 84 248

7.5

200 300 197 186 285 7.5 65.5

11 7 310 10 7 374 170 544

200 V

15

(3-

phase)

240 350 207 216 335 8 78 11 240

18.5 380 30 501 211 712

22 250 400

30 275 450 220 435 24 279 615 220 450 435 165 27 865 352 1217

37

375 600

45 328

55

450 725 348 325 700

75 87 95 2019 838 2857

90 500 850 358 370 820

110 575 885 378 445 855 140 150 --- 2733 1242 3975

157

39

126 266 7

177 59 4 177 59 4

2.3

195 385

258

298

250 575

7.5 100

12.5

100

3.2

130

15 4.5

0.55

0.75 17 41 58

157

39

1.5 36 48 84

140 280

2.2

3.7 80 68 148

4.0 91 70 161

126 266 7

177 59 4 177 59 4

5.5 127 82 209

7.5

200 300 197 186 285 8 65.5

11 252 158 410

15

400 V

(3-

phase)

240 350 207 216 335

18.5 426 208 634

22

279 450 258 220 435 100 21 279 535 258 220 450 435

30 678 317 995

78 10 240 350 207 216 350 335

2.3

7.5

37

325 550 283 260 535 105 36 329

45

55 1203 495 1698

75

450 725 348 325 700 12.5

90 89 97 1614 671 2285

110

500 850 358 370 820 15

132 120 130 2388 1002 3390

3.2

130

4.5

160 575 916 378 445 855 45.8 140 160 579 1324 378 445 916 855 46 408 140 170 2791 1147 3938

Dimensions (mm)

Appr

ox.

W H D W1 H0 H1 H2 H3 D1 t1

Mass

3

5

140 280

6

200

21 254 535

57

380 809

63 328

86

453 1027 348 325 725 700 302

157

126 280 266 7

300

197 186 300 285 8 65.5

350

207 216 350 335

195 400 385 135

258

298

250 600 575

7.5

12.5

0

0

209

39

78 11

100

100

130

108 504 1243 358 370 850 820 15 390 4.5 114

3

5

140 280

157

126 266 266 7

39

0

6 200 300 197 186 300 285 8 65.5

78 10

7.5

100 24

85

635

283 260 550 535 105 40

715 165

88

453 1027 348 325 725 700 12.5 302

102

504 1243 358 370 850 820 15 393

130

Appr

ox.

Mass

3

5

6

2.3

24 586 274 860

62

68 1266 505 1771

3.2

94 1588 619 2207

3

5

6

2.3

96

3.2

122

4.5

Moun

Exter

ting

nal

Holes

d*

20 39 59

M5

112 74 186

219 113 332

429 183 612

M6

1015 411 1426

M10

2437 997 3434

M12

14 39 53

M5

59 56 115

193 114 307

326 172 498

M6

466 259 725

784 360 1144

901 415 1316

1399 575 1974

M10

2097 853 2950

M12

Caloric Value

(W)

Total

Heat

Inter-

Gen-

nal

eration

Cool-

ing

Metho

d

Natu-

ral

Fan

Natu-

ral

Fan

Table 1.5 Inverter Dimensions (mm) and Masses (kg) of 400V Class Inverters of 185 kW to 300 kW, IP00

Dimensions (mm) Caloric Value (W)

Protection Class IP00

Approx.

Mass

260

Mount-

ing

Holes d

Exter-

Internal

nal

3237 1372 4609

M12

Total

Heat

Genera-

tion

Voltage

Class

400V

(3-phase)

Max.

Applica-

ble Motor

Output

[kW]

W H D W1 W2 W3 H1 H2 D1 t1

185

710 1305 413 540 240 270 1270 15 125.5 4.5

300 916 1475 413 730 365 365 1440 15 125.5 4.5 405 5838 2320 8158

Cooling

Method

Fan220 280 3740 1537 5277

1-11

Table 1.6 Inverter Dimensions (mm) and Masses (kg) of 400V class inverters 7.5 to 55 kW, IP54

Voltage

Class

400V

(3-phase)

Max.

Applica-

ble Motor

Output

[kW]

7.5

18.5 655

W H D W1 H1 H2 t1

11 423

350 600

15

22

410 650 300 270 620 12 2.5 43

30 989

37

580 750 330 410 714 11 2.5 71

45 1317

55 1701

Dimensions (mm)

Approx.

Mass

240

260 576 9 2.5

260 30

Mount-

ing

Holes d

25

∅ 10

M8

∅ 12

M10

∅ 14

M10

Total

Heat

Genera-

tion

302

531

754

1145

Cooling

Method

Fan

1-12

Checking and Controlling the Installation Site

Checking and Controlling the Installation Site

Install the Inverter in the installation site described below and maintain optimum conditions.

Installation Site

Install the Inverter under the following conditions in a pollution degree 2 environment.

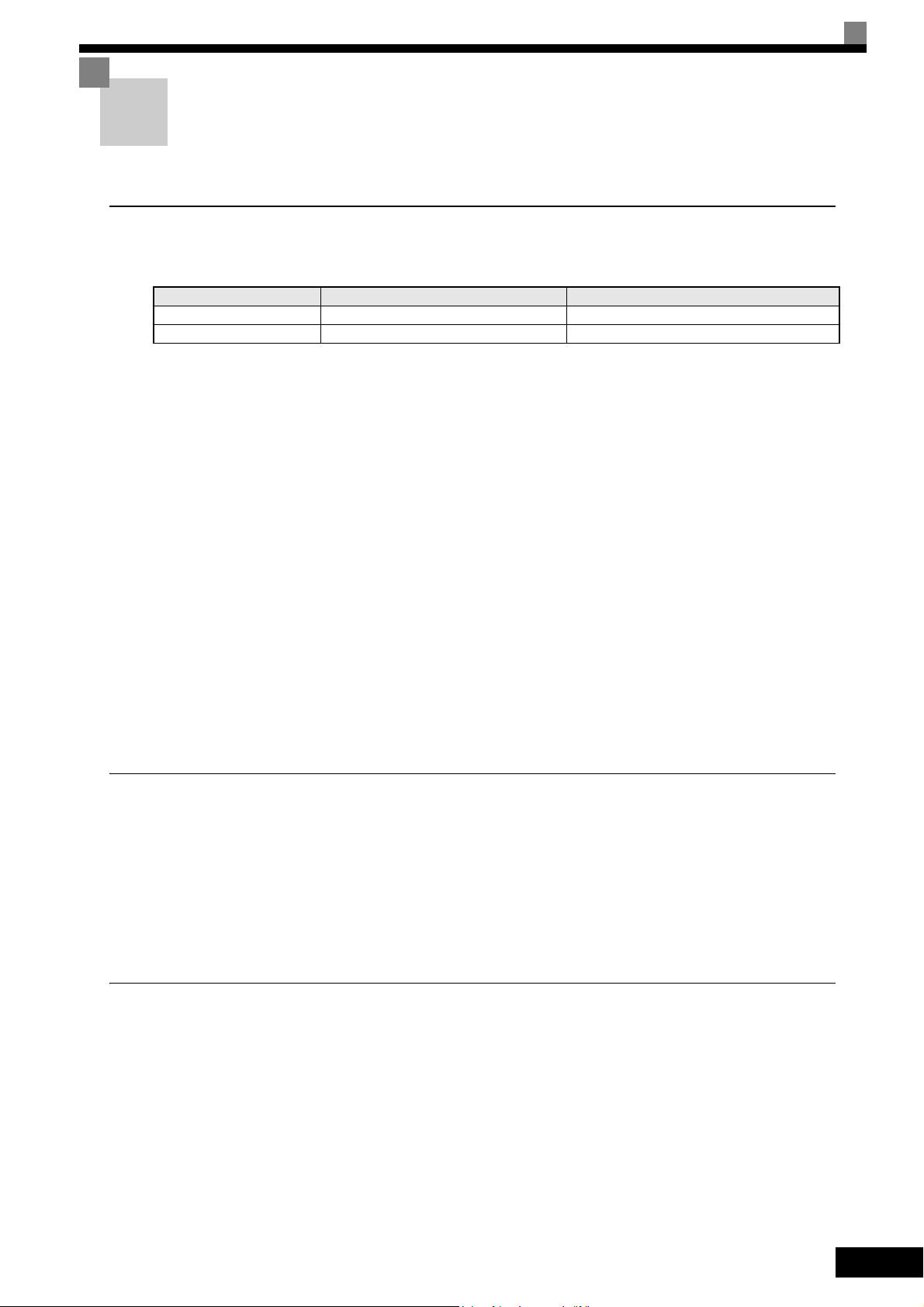

Type Ambient Operating Temperature Humidity

Protection Class IP20 and IP54 -10 to + 40 °C 95% RH or less (no condensation)

Protection Class IP00 -10 to + 45 °C 95% RH or less (no condensation)

Protection covers are attached to the top and bottom of the NEMA 1 and IP00 Inverters. Be sure to remove the

top cover before operating a 200 or 400 V Class Inverter with an output of 18.5 kW or less inside a panel.

• Observe the following precautions when mounting the Inverter.

• Install the Inverter in a clean location which is free from oil mist and d ust. It can be installed in a totally

enclosed panel that is completely shielded from floating dust.

• When installing or operating the Inverter, always take special care so that metal powder, oil, water, or

other foreign matter does enter the Inverter.

• Do not install the Inverter on combustible material, such as wood.

• Install the Inverter in a location free from radioactive materials and combustible materials.

• Install the Inverter in a location free from harmful gasses and liquids.

• Install the Inverter in a location without excessive oscillation.

• Install the Inverter in a location free from chlorides.

• Install the Inverter in a location without in direct sunlight.

• The IP54 Inverters provide protection from non-conductive dust and splashing water from all directions.

Install the Inverter indoors in a heated and controlled environment to avoid condensation inside the

Inverter.

• Keep any water or dust outside of the IP54 Inverter when wiring.

Controlling the Ambient Temperature

To enhance the reliability of operation, the Inverter should be installed in an environment free from extreme

temperature increases. If the IP00 or NEMA 1 Inverter is installed in an enclosed environment, such as a box,

use a cooling fan or air conditioner to maintain the internal air temperature below 45°C.

When the IP54 Inverter is installed in a environment with low temperatures or when the Invert er remains

switched off for a long time, condensation may occur inside the Inverter. In that case additional heaters may

effectively prevent condensation inside the inverter.

Protecting the IP00 or NEMA 1 Inverter from Foreign Matter

Place a cover over the Inverter during installation to shield it from metal power produced by drilling.

Always remove the cover from the Inverter after completing installation. Otherwise, ventilation will be

reduced, causing the Inverter to overheat.

1-13

Loading...

Loading...