Page 1

USER’S MANUAL

Electromagnetic Inductive RFID

System

V670 Series

Cat. No. Z148-E1-05

Page 2

Introduction

We sincerely appreciate your purchase of the V670 series of the Electromagnetic Induction Type RFID System. The V670 series is fully

supported by our cutting-edge technology and vast expertise. This user's manual provides vital information on its operational functions

and product performances, and includes full instructions for use.

Page 3

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON representative if you have any

questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for a period of one year (or

other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NON-INFRINGEMENT,

MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE PRODUCTS. ANY BUYER OR USER

ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET

THE REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS

OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON

CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT LIABILITY.

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which liability is asser ted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS REGARDING THE

PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS WERE PROPERLY HANDLED, STORED,

INSTALLED, AND MAINTAINED AND NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT DESIGNED OR RATED FOR

ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED UPON AS A SAFETY COMPONENT OR PROTECTIVE

DEVICE FOR SUCH PURPOSES. Please refer to separate catalogs for OMRON's safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the combination of products

in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying ratings and limitations of

use that apply to the products. This information by itself is not sufficient for a complete determination of the suitability of the

products in combination with the end product, machine, system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not intended to be an

exhaustive list of all possible uses of the products, nor is it intended to imply that the uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or uses not described in this

document.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical equipment, amusement

machines, vehicles, safety equipment, and installations subject to separate industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR PROPERTY WITHOUT

ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON

PRODUCT IS PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR

SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and does not constitute a

warranty. It may represent the result of OMRON’s test conditions, and the users must correlate it to actual application requirements.

Actual performance is subject to the OMRON Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other reasons.

It is our practice to change model numbers when published ratings or features are changed, or when significant construction

changes are made. However, some specifications of the product may be changed without any notice. When in doubt, special model

numbers may be assigned to fix or establish key specifications for your application on your request. Please consult with your

OMRON representative at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no responsibility is assumed

for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission. This document is protected by copyright and is

intended solely for use in conjunction with the product. Please notify us before copying or reproducing this document in any

manner, for any other purpose. If copying or transmitting this document to another, please copy or transmit it in its entirety.

Page 4

Meaning of Signal Words

The following signal words are used in this instruction manual.

CAUTION

The following alert symbols are used in this instruction manual.

The following alert statements apply to the products in this instruction manual. Each alert statement also appears at the locations needed

in the manual to attract your attention.

When you plug or unplug the connector into the programming console when the power supply turns on, take care not to

touch the controller wire. Otherwise, you may get an electric shock.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury or in property damage.

Meaning of Alert Symbols

Indicates the possibility of electric shock under specific conditions.

Alert Statement in this user’s Manual

CAUTION

Page 5

Precautions for safe use.

For the safety, be sure to follow the instructions below:

1. Do not operate this device in any flammable, explosive or corrosive gas environment.

2. Do not disassemble, repair nor remodel this device.

3. Tighten the base lock screws and terminal block screws completely.

4. Be sure to use wiring crimp terminal of a specified size.

5. If any cable has a locking mechanism, be sure to check that it has been locked before using it.

6. The DC power supply must meet the following items:

(1) Such DC power supply must be used for the V670 Series only and must not be connected to any other devices nor apparatuses.

(2) Voltage of such DC power supply must be within the specified rating (24 VDC+10%-10%).

7. Be sure to follow any other warnings, cautions and notices mentioned in this manual.

8. In the event that the system gives out a foul smell, is heated abnormally in the main body portion, emits smoke, or exhibits any other

abnormal condition, immediately stop using the system and turn off the power.

9. Dispose of this product as industrial waste.

Precautions for correct use.

Please observe the following precautions to prevent failure to operate, malfunctions, or undesirable effects on product performance.

♦ System Construction

• In consequence of diversification of small-size antennas/tags, the ID controller has been upgraded to Model V670-CD1D-V1. Be

sure to combine Model V670-H51 or Model V670-H51Q antenna with Model V670-CD1D-V1 controller. Combination of this

antenna with Model V670-CD1D controller might result in unstable communication.

♦ Installation Site

Install the product at a location where:

• It is not exposed to corrosive gases, dust, metal chips, or salt.

• The working temperature is within the range stipulated in the specifications.

• There are no sudden variations in temperature (no condensation).

• The relative humidity is within the range stipulated in the specifications.

• No vibration or shock exceeding the values stipulated in the specifications is transmitted directly to the body of the product.

• It is not subject to splashing water, oil, or chemical substances.

♦ Installation

• This device uses the frequency band 13.56 MHz to communicate with a tag. This frequency band 13.56 MHz is used also as the

ISM band (one of frequencies assigned to medical or industrial heater; ). So, such heater may affect the communication with a tag

or may damage the tag, if the heater is located near this device. If you must use this device near such heater, we would like you to

check the influence in advance.

• To minimize general influence of noise, follow the instructions below:

(1) Ground any metallic material located around this device according to Class D (Class III).

(2) Wire this device keeping away from high voltage and heavy current.

• Connectors are not waterproof. Avoid using the product in a humid environment.

• Do not use any chemical that may affect the materials of the product.

♦ Cleaning

• Do not use any thinner. Resin material and case paint are dissolved by thinner.

Page 6

Standard Conformity

1. FCC Rules (Federal Communications Commission)

This Product complies with Part 15 Subpart C of the FCC Rules.

FCC ID: E4E6CYCIDV6700206

FCC NOTICE

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference.

(2) This device must accept any interference received, including interference that may cause undesired operation.

FCC WARNING

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate

the equipment.

Properly shielded ground cables and connectors must be used for connection to host computer and/or peripherals in order to meet

FCC emission limits.

Ferrite cores (TDK Type ZCAT2032-0930 or its equivalent) must be attached to the cables connecting the power supply and ground

to suppress RF interference.

2. EC Declaration of Conformity

Hereby, OMRON Corporation declares that this RFID System, Antenna V670-H11, V670-H51, V670-H51Q and Controller V670CD1D-V1. Controller are in compliance with essential requirements and other relevant provisions of Directive 1995/5/EC, and satisfy tests for the appropriate requirements of the following relevant standards.

Radio: EN 300 330-2 V1.1.1 (06-2001) EN 300 300-1 V1.3.1 (06-2001)

EMC: EN 301 489-3 V1.4.1 (08-2002) EN 301 489-1 V1.4.1 (08-2002)

Safety: EN 61010-1: 2001 (2nd Edition)

Countries of intended use:

Austria, Belgium, Denmark, Estonia, Finland, France, Germany, Greece, Iceland, Ireland, Italy, Liechtenstein, Luxembourg, Netherlands, Norway, Portugal, Romania, Spain, Sweden, Switzerland, United Kingdom

3. Wireless Standards for China

V670-CD1D-V1/V670-H11

ID: 2006DJ0992

V670-CD1D-V1/V670-H51

ID: 2006DJ0990

Page 7

English Hereby, Omron, declares that the RFID System, Antenna V670-H11 Series, V670-H51 Series, V670-H51Q Series, and Controller V670-CD1D Series are

Finnish Omron vakuuttaa täten että RFID Säännös, Antenni V670-H11 Series, V670-H51 Series, V670-H51Q Series, jar Kontrollida V670-CD1D Series tyyp-

Dutch Hierbij verklaart Omron dat het toestel de RFID Systeem, Antenne V670-H11 ´Serie, V670-H51 ´Serie, V670-H51Q ´Serie, en Controleur V670-CD1D

French Par la présente Omron déclare que la RFID Système, Antenne V670-H11 Série, V670-H51 Série, V670-H51Q Série, et Contrôler V670-CD1D Série sont

Swedish Härmed intygar Omron att den RFID System, Antenn V670-H11 Serie, V670-H51 Serie, V670-H51Q Serie, och Kontrollant V670-CD1D Serie stär l öve-

Danish Undertegnede Omron erklærer herved, at følgende den RFID System, Antenne V670-H11 Serie, V670-H51 Serie, V670-H51Q Serie, og Kontrollør V670-

German Hiermit erklärt Omron, die RFID System, Antenne V670-H11 Serie, V670-H51 Serie, V670-H51Q Serie, und Kontrolleur V670-CD1D Serie in Überein-

Greek

Italian Con la presente Omron dichiara che la RFID Sistema, Antena V670-H11Serie, V670-H51 Serie, V670-H51Q Serie, e Controlleur V670-CD1D Serie sono

Spanish Por medio de la presente Omron declara que el RFID Sistema, Antena V670-H11 Serie, V670-H51 Serie, V670-H51Q Serie, y Controlador V670-CD1D

Portuguese Omron declara que a RFID Sistema, Antena V670-H11 Série, V670-H51 Série, V670-H51Q Série, e Controlador V670-CD1D Série ser conforme com os

Romanian

in compliance with the essential requirements and other relevant provisions of Directive 1999/5/EC.

pinen laite on direktiivin 1999/5/EY oleellisten vaatimusten ja sitä koskevien direktiivin muiden ehtojen mukainen.

´Serie in overeenstemming is met de essentiële eisen en de andere relevante bepalingen van richtlijh 1999/5/EG.

conforme aux exigences essentielles et aux autres dispositions pertinentes de la directive 1999/5/CE.

rensstämmelse med de väsentliga egenskapskrav och övriga relevanta bestämmelser som framgår av direktiv 1999/5/EG.

CD1D Serie overholder de væsentlige krav og øvrige relevante krav i direktiv 1999/5/EF.

stimmung mit den grundlegenden Anforderungen und den anderen relevanten Vorschriften der Richtlinie 1999/5/EG befindet. (BMWi)

ME THN PAPOYSA Omron DHLONEI RFID O

SYMMOPF ONETAI PPOS TIS OYSIODEIS APAITHSEIS KAI TIS LOIPES SXETIKES DIATAXEIS THS ODHGIAS 1999/5/EK.

conforme ai requisiti essenziali ed alle altre disposizioni pertinenti stabilite dalla direttiva 1999/5/CE.

Serie esta conforme a los requisitos esenciales y cualesquiera otras disposiciones aplicables o exigibles de la Directiva 1999/5/CE.

tequisitos essenciais e outras disposições da Directiva 1999/5/CE.

Prin prezenta, Omron declar c acest V670-H11, V670-H51, V670-H51Q, V670-CD1D este conform cu cerin ele principale çi cu celelalte prevederi

relevanate ale Directivei 1999/5/EC.

’YO’

GHMA, KEPAIA V670-H11 O’EIPA, V670-H51Q O’EIPA, KAI KOYPOLHPY V670-CD1D O’EIPA

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate

the equipment.

Properly shielded ground cables and connectors must be used for connection to host computer and/or peripherals in order to meet the

FCC emission limits.

Ferrite cores (TDK Type ZCAT2032-0930 or its equivalent) must be attached to the cables connecting the power supply and ground

to suppress RF interference.

Page 8

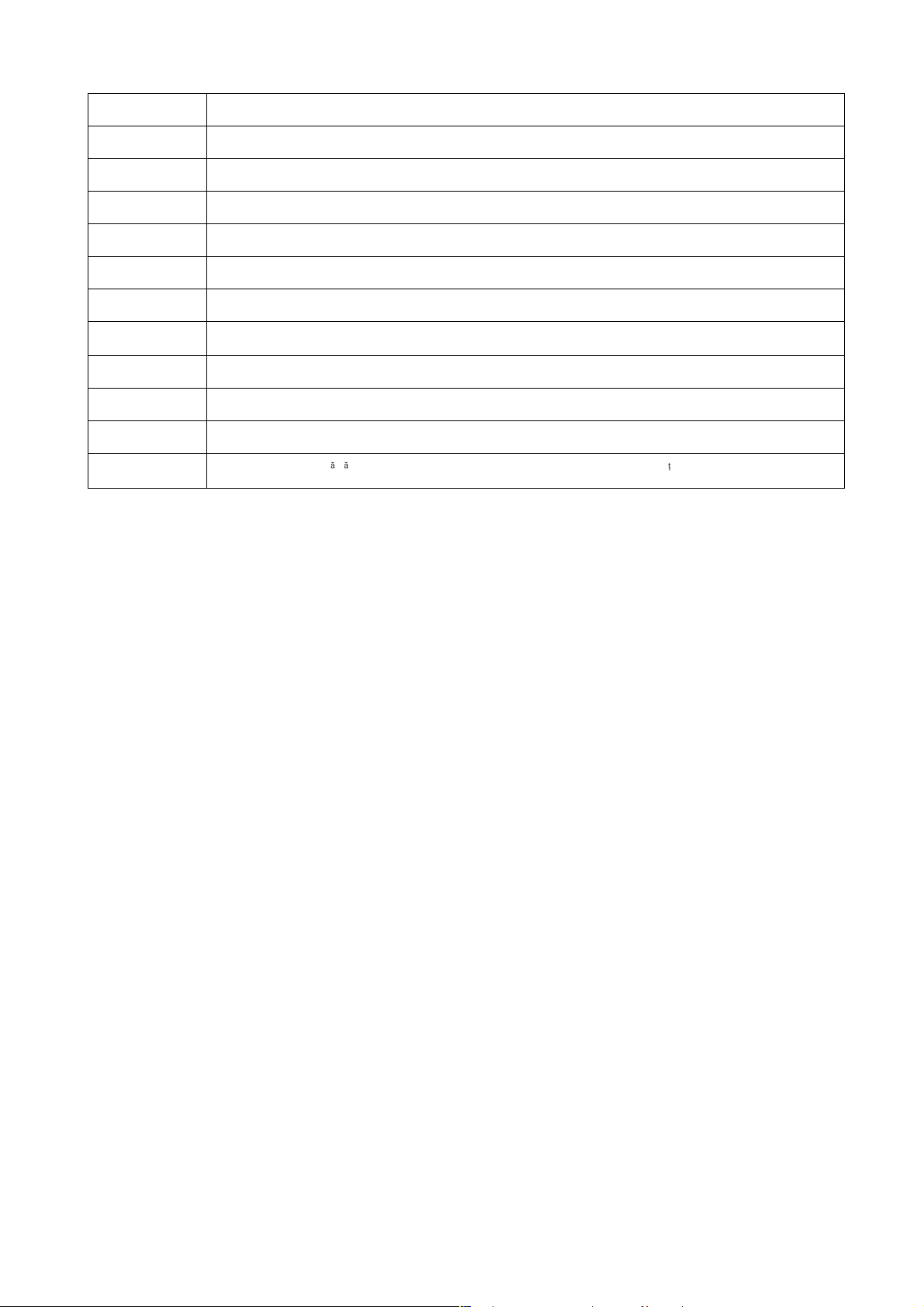

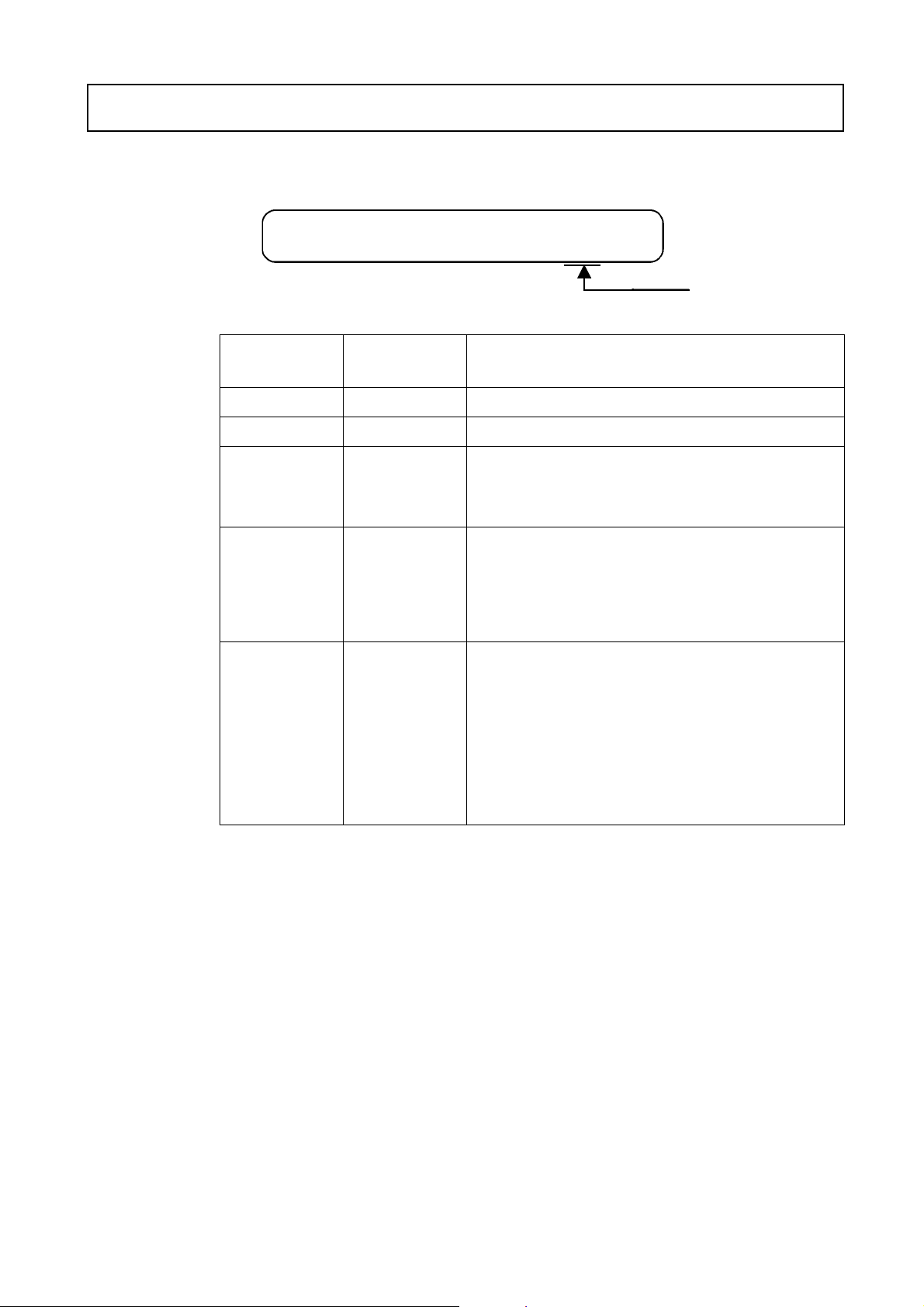

Manual Revision History

A manual revision history code is added to the end of catalog number shown at the left lower part of front cover

and back cover

Catalog No. Z148-E1-05

Revision code

Revision

Code

-- October 2000 First Edition

-02 May 2003 New models have been added.

-03 March 2005 Prefix (Standard Conformity): Last line in FCC WARNING

-04 January 2006 Pages 1-1, 2-1, 2-5, 2-6, 3-7, 3-10, 3-11, and appendix-2:

05 September 2006 Prefix (Standard Conformity): List of Chinese wireless

Date of

Revision

Reason of Revision / Revised Page

description changed and sentence added after table.

Warranty and Limitations of Liability page updated.

Romania added to list of countries of intended use.

Mark removed from V670-CD1D-V1 graphic.

Page 2-3: Insulation resistance changed to "20 MΩ or

more (at 100 VDC mega)."

Page 2-3: Withstand voltage changed to "Leakage current

20 mA or less at 1,000 VAC (for 1 minute)."

standards added.

Page 2-3: Impact changed to "15 m/s

Page 2-7: Leakage current under withstand voltage

changed to "20 mA or less."

Page 2-7: "Teflon" changed to "fluororesin" in table, total

cable length added, and note 2 changed from Teflon

explanation to cable extension description.

Page 2-8: Graphics for V670-H11 changed.

Page 2-13: Graphics for V670-A4@ changed.

2

."

Page 9

Contents

Chapter 1 Features and System Configuration

1-1 Features .........................................................................................................................1-1

1-2 System Configuration.....................................................................................................1-3

Chapter 2 Specifications and Performance

2-1 Controller........................................................................................................................2-1

2-1-1 Component Names and Functions .....................................................................................................2-1

2-1-2 General Specifications .......................................................................................................................2-3

2-1-3 Performance Specifications................................................................................................................2-3

2-1-4 Communication Specifications ..........................................................................................................2-4

2-1-5 I/O Specifications...............................................................................................................................2-4

2-1-6 Example of Wiring .............................................................................................................................2-5

2-1-7 Outside Dimension.............................................................................................................................2-6

2-2 Antenna ..........................................................................................................................2-7

2-2-1 Specifications.....................................................................................................................................2-7

2-2-2 Outside Dimension.............................................................................................................................2-8

2-3 Tag ..................................................................................................................................2-9

2-3-1 Specifications.....................................................................................................................................2-9

2-3-2 Outside Dimension...........................................................................................................................2-10

2-3-3 Memory Map.................................................................................................................................... 2-11

2-3-4 Attachment (Model V670-A81) for Model V670-D13F01H Tag....................................................2-12

2-4 Cable.............................................................................................................................2-13

2-4-1 Specifications...................................................................................................................................2-13

2-4-2 Outside Dimension...........................................................................................................................2-13

2-5 Communication Range Specifications .........................................................................2-14

2-5-1 Communication Area (Reference)...................................................................................................2-15

2-5-2 Operation Time (Reference) ............................................................................................................2-17

2-5-3 Traffic and Passing Speed (Reference)............................................................................................2-19

Page 10

Contents

Chapter 3 Setting and Installation

3-1 Controller........................................................................................................................3-1

3-1-1 Switch Setting ....................................................................................................................................3-1

3-1-1-1 How to Open Cover .................................................................................................................3-1

3-1-1-2 How to Set................................................................................................................................3-2

3-1-1-3 Setting List ...............................................................................................................................3-2

3-1-1-4 Setting Node Number Setup Switch ........................................................................................3-3

3-1-1-5 Setting a Dip Switch.................................................................................................................3-4

3-1-2 Installation Site ..................................................................................................................................3-6

3-1-3 How to Install.....................................................................................................................................3-7

3-1-4 How to Connect Antenna...................................................................................................................3-8

3-1-5 How to Connect Extension Cable and How to Extend Antenna........................................................3-9

3-1-6 How to Wire.......................................................................................................................................3-9

3-1-6-1 Wiring Power Supply and Grounding Cable..........................................................................3-10

3-1-6-2 Wiring Reset Signal ...............................................................................................................3-10

3-1-6-3 Wiring Output Signal.............................................................................................................3-11

3-1-7 Connecting RS-232C Interface ........................................................................................................3-12

3-2 Antenna ........................................................................................................................3-16

3-2-1 Installation Site ................................................................................................................................3-16

3-2-2 How to Install...................................................................................................................................3-16

3-3 Tag ................................................................................................................................3-18

3-3-1 Installation Site ................................................................................................................................3-18

3-3-2 How to Install...................................................................................................................................3-18

Chapter 4 Functions

4-1 Communication Designation Function........................................................................... 4-1

4-1-1 Designation of Command Trigger System Communication (ST)......................................................4-1

4-1-2 Designation of Automatic System Communication (SA/RA/PA) .....................................................4-2

4-1-3 Designation of External Trigger System Communication (SI/RI/PI)................................................4-3

4-2 Tag Designation Function...............................................................................................4-5

4-3 Operation Mode..............................................................................................................4-6

4-4 Operation Parameter Setting...........................................................................................4-8

4-4-1 Communication Restriction Time......................................................................................................4-8

4-4-2 Character Interval Monitoring Time..................................................................................................4-8

4-4-3 Response Ready Time........................................................................................................................4-9

4-5 Memory Check Function..............................................................................................4-10

4-6 Write Protect Function..................................................................................................4-11

Page 11

Chapter 5 Control From Host Device

5-1 Controller Operation Status ...........................................................................................5-1

5-2 Command Response Format...........................................................................................5-2

5-3 Command Response Flow..............................................................................................5-6

5-4 Command List ................................................................................................................5-7

5-5 Communication Designation List...................................................................................5-8

5-6 Communication Command.............................................................................................5-9

5-6-1 Read (RD)........................................................................................................................................ 5-10

5-6-2 Write (WT)....................................................................................................................................... 5-11

5-6-3 Computation Write (CW) ................................................................................................................5-12

5-6-4 Data Fill (DF)................................................................................................................................... 5-13

5-6-5 Memory Check (MD) ......................................................................................................................5-14

5-6-6 Tag Function Designation (TF)........................................................................................................ 5-15

5-6-7 ID Read (ID) .................................................................................................................................... 5-16

Contents

5-7 Communication Subcommand .....................................................................................5-17

5-7-1 Command Processing Abort (AA)................................................................................................... 5-17

5-7-2 Polling Query (PC) .......................................................................................................................... 5-17

5-8 Controller Control Command.......................................................................................5-18

5-8-1 Operation Mode Change (MO)........................................................................................................ 5-18

5-8-2 Data Retransmission (RR) ...............................................................................................................5-18

5-8-3 Reset (XZ)........................................................................................................................................ 5-19

5-8-4 Controller Control (CC)................................................................................................................... 5-19

5-8-5 Operation Condition Setting (SE).................................................................................................... 5-20

5-8-6 Parameter Setting (SP)..................................................................................................................... 5-22

5-9 Host Command.............................................................................................................5-23

5-9-1 Test (TS) .......................................................................................................................................... 5-23

5-9-2 Version Information (VS) ................................................................................................................ 5-23

5-10 Termination Code List ..................................................................................................5-24

5-11 Example of Communication Program..........................................................................5-25

Page 12

Contents

Chapter 6 How to Use Self-Execution Mode

6-1 Available Conditions ......................................................................................................6-1

6-2 Setting Procedure ..........................................................................................................6-2

6-3 Example of Setting .........................................................................................................6-3

Chapter 7 How to Use Programming Console

7-1 Component Name...........................................................................................................7-1

7-2 Outside Dimension .........................................................................................................7-2

7-3 Connection of Programming Console ............................................................................7-3

7-3-1 Inserting Key Sheet............................................................................................................................7-3

7-3-2 Connecting Cable...............................................................................................................................7-4

7-4 How to Use.....................................................................................................................7-5

7-5 Functions ........................................................................................................................7-6

7-5-1 Programming Console Function List.................................................................................................7-6

7-5-2 How to Operate..................................................................................................................................7-7

7-5-2-1 Password Input Screen.............................................................................................................7-7

7-5-2-2 Changing Operation Mode.......................................................................................................7-7

7-5-2-3 Accepting Key in Initial Screen of Monitor Mode ..................................................................7-8

7-5-2-4 Accepting Key in Initial Screen of Run Mode.........................................................................7-9

7-5-3 Displaying Details of Setting ...........................................................................................................7-10

7-5-4 Address Setting ................................................................................................................................7-12

7-5-4-1 For Reading............................................................................................................................ 7-12

7-5-4-2 For Writing.............................................................................................................................7-12

7-5-5 Data Setting......................................................................................................................................7-13

7-5-6 Reading/Writing Data ......................................................................................................................7-13

7-5-6-1 Reading ..................................................................................................................................7-13

7-5-6-2 Reading Again........................................................................................................................7-14

7-5-6-3 Writing ...................................................................................................................................7-15

7-5-6-4 Writing Again.........................................................................................................................7-15

7-5-7 Test ...................................................................................................................................................7-16

7-5-7-1 Setting Communication Mode ...............................................................................................7-16

7-5-7-2 Test Reading...........................................................................................................................7-16

7-5-7-3 Test Writing............................................................................................................................7-16

7-5-8 Reading Latest Error Information....................................................................................................7-17

7-5-9 Statistic Error Information ...............................................................................................................7-18

7-5-10 Execution Monitor ...........................................................................................................................7-19

Page 13

Chapter 8 From Startup to Run

8-1 Trial Operation................................................................................................................8-1

8-2 Diagnosis Function.........................................................................................................8-2

8-3 Errors and Countermeasures...........................................................................................8-3

8-4 Maintenance and Inspection ...........................................................................................8-4

8-5 Troubleshooting..............................................................................................................8-5

Chapter 9 Characteristic Data Depending on Operating Condition

(Reference)

Contents

9-1 Influence of Metal of Antenna (Reference)....................................................................9-1

9-2 Mutual Interference between Antennas (Reference) ......................................................9-3

9-3 Mutual Interference between Tags (Reference)..............................................................9-4

9-4 Influence of Back Metal of Tag (Reference) ..................................................................9-5

9-5 Influence of Tag Angle (Reference) ...............................................................................9-7

9-6 Chemical Resistance of Tag (Reference)........................................................................9-8

Appendix

Appendix 1 ASCII Code List................................................................................Appendix-1

Appendix 2 Order Format List.............................................................................. Appendix-2

Appendix 3 Protective Structure........................................................................... Appendix-3

Page 14

Page 15

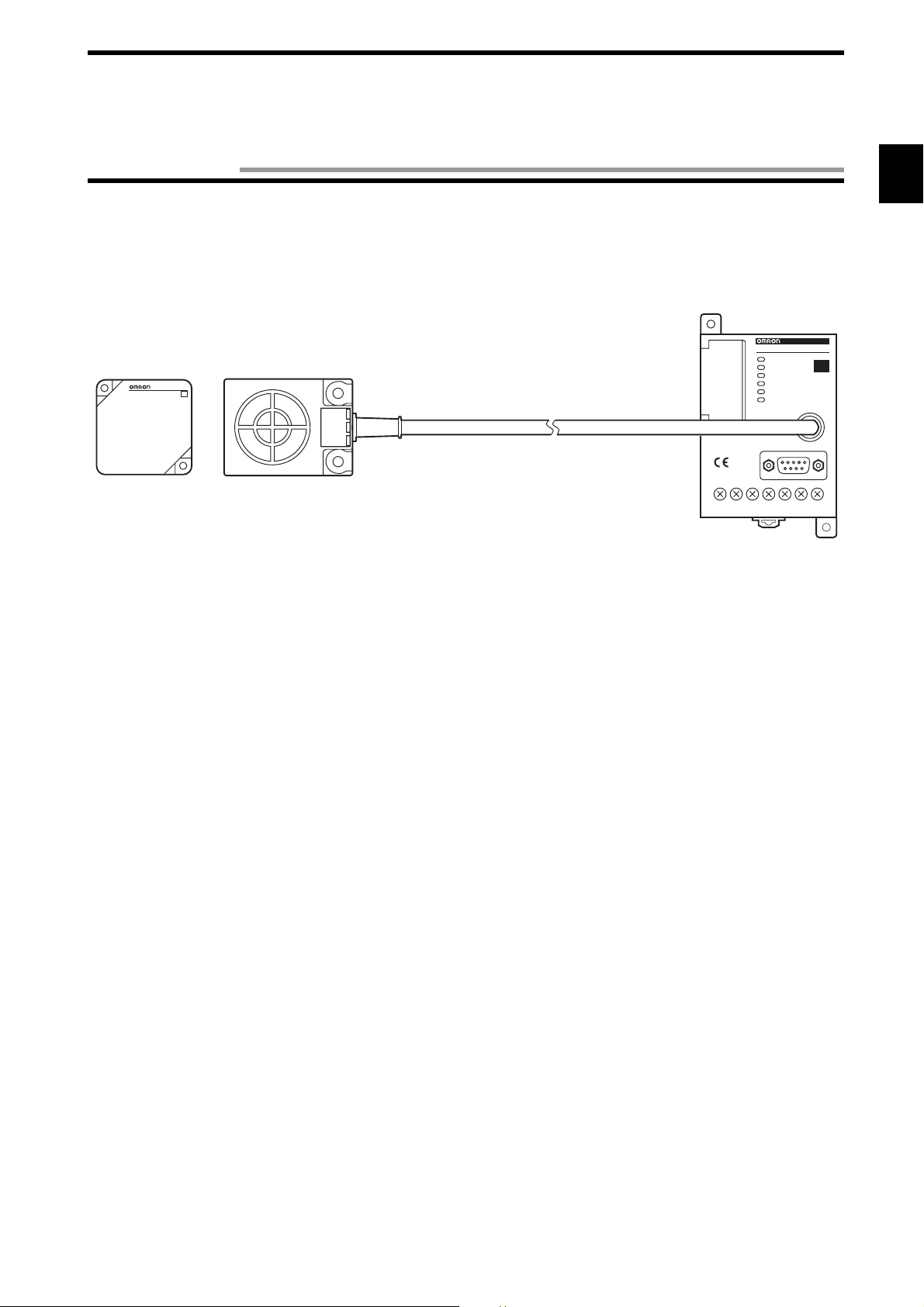

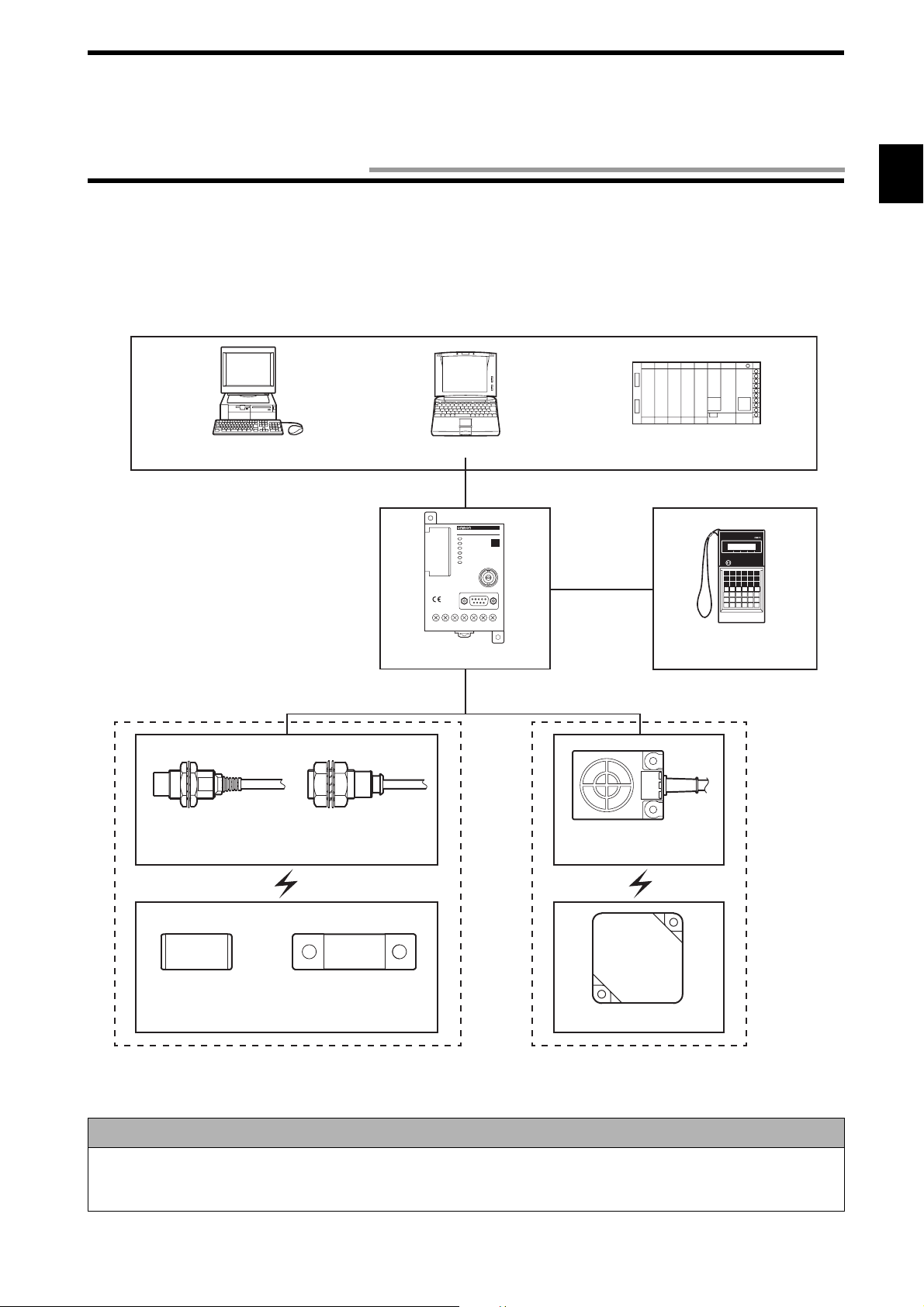

Chapter 1 Features and System Configuration

1-1 Features

The V670 Series is the electromagnetic inductive. RFID system which has achieved fast, long-life and high-performance communication. This ID system is the most suitable for process control of high-speed line and traffic control of moving object in a plant and an

application that information must be updated frequently in a process.

Model V670-CD1D-V1

Model V670-D13F03

V670-D13F03

ID

Model V670-H11

V6 7 0 - CD1 D

V670-CD1D-V1

♦ ID Controller (referred to as “Controller”)

• Model V670-CD1D-V1

Model V670-CD1D-V1 connects to a personal computer (referred to as "PC") and/or programmable controller (PLC) and controls

the RFID system.

Model V670-CD1D-V1 has a general-purpose I/O terminal and a function to judge and process independently (Self-Execution

mode) and, therefore, a very fast system can be configured for simple process only without any host device.

♦ Antenna (referred to as “Antenna”)

• Model V670-H11

Model V670-H11 is a waterproof antenna (standard antenna) with dimensions of 4 × 5.3 cm. Model V670-H11 can achieve the communication range of 20 mm in combination with model V670-D13F03. Model V670-H11 has a very fast communication performance and can transfer 12 bytes of data in approximately 5 ms.

ID

• Model V670-H51

Model V670-H51 is a cylindrically-shaped waterproof antenna. Model V670-H51 can achieve a communication range of 5.0 mm

when combined with Model V670-D13F01 or V670-D13F01H tag. Model V670-H51 has a communication performance as high as

that of Model V670-H11.

• Model V670-H51Q

Model V670-H51Q is a cylindrically-shaped antenna. Housed in a Teflon (tetrafluoroethylene) casing, Model V670-H51Q is highly

resistant to chemicals. Model V670-H51Q can achieve a communication range of 4.5 mm when combined with Model V670D13F01 or V670-D13F01H tag. Model V670-H51Q has a communication performance as high as that of Model V670-H11.

1-1

Page 16

1-1 Features

♦ ID tag (referred to as “Tag”)

• Model V670-D13F03

Model V670-D13F03 is a waterproof tag which has 128 bytes of memory capacity with dimensions of 40 × 40 mm. Model V670D13F03 uses high-performance nonvolatile memory called Ferroelectric RAM (FeRAM) as internal memory. So, memory life is

semi-permanent. (The memory can be accessed one billion times.)

• Model V670-D13F01

Model V670-D13F01 is a rectangular tag with dimensions of 8 mm × 16 mm. Model V670-D13F01 is highly resistant to chemicals

since it is housed in a PPS casing filled with chemical-resistant epoxy resin. Model V670-D13F01 has the same memory capacity

and characteristics as those of Model V670-D13F03.

• Model V670-D13F01H

Model V670-D13F01H is a tag provided with screw holes to assure the same performance and construction as those of Model V670D13F01, and is easy to install.

• Model V670-A81

Model V670-A81 is an attachment specially designed for Model V670-D13F01H. When combined with Model V670-A81, Model

V670-D13F01H retains its original communication range even when fitted to a steel structure. Made of PPS, Model V670-A81 is

highly resistant to chemicals.

♦ Easy to use

By connecting the programming console model C200H-PRO27 (unbundled, referred to as "ProCon") to the Controller via the special

cable model V700-P10 (unbundled), the system operation status and error log information can be read. This is useful for system startup and maintenance at a working site.

Ferroelectric RAM (FeRAM)

Ferroelectric RAM is one of nonvolatile RAMs and data can be written into and read from it faster than conventional memory (such

as EEPROM and flash ROM). Data can be written into the ferroelectric RAM semi-permanently.

While any conventional RAM cannot hold data if nothing is written into it for a specified period (approximately 10 years), the ferroelectric RAM can hold data if anything is written into or read from it. So, the characteristic of ferroelectric RAM is very excellent in

data-holding performance.

Precaution for Correct use

In consequence of diversification of small-size antennas/tags, the ID controller has been upgraded to Model V670-CD1D-V1. Be

sure to combine Model V670-H51 or Model V670-H51Q antenna with Model V670-CD1D-V1 controller. Combination of this

antenna with Model V670-CD1D controller might result in unstable communication.

1-2

Page 17

1-2 System Configuration

• Example of Model V670-CD1D-V1 system configuration

Model V670-CD1D-V1 contains a serial interface based on RS-232C and can connect easily to a general-purpose PC and programmable controller (PLC). Model V670-CD1D-V1 has a command execution mode and self-execution mode as an operation mode and

controls the communication to a tag according to the instructions from a host device (in the command execution mode) or the registered conditions (in the self-execution mode).

<Host Devices>

Desktop PC

Model V670-H51

Model V670-H51Q

Notebook PC

V6 70-CD1 D

V670-CD1D-V1

ID

Model V670-CD1D-V1

Model V670-A4

(Only when extension cable is used)

Programmable Controller

(PLC)

PRO27

Model V700-P10

Model C200H-PRO27

@

Model V670-H11

Model V670-D13F01 Model V670-D13F01H

Model V670-D13F03

Precaution for Correct use

In consequence of diversification of small-size antennas/tags, the ID controller has been upgraded to Model V670-CD1D-V1. Be

sure to combine Model V670-H51 or Model V670-H51Q antenna with Model V670-CD1D-V1 controller. Combination of this

antenna with Model V670-CD1D controller might result in unstable communication.

1-3

Page 18

1-4

Page 19

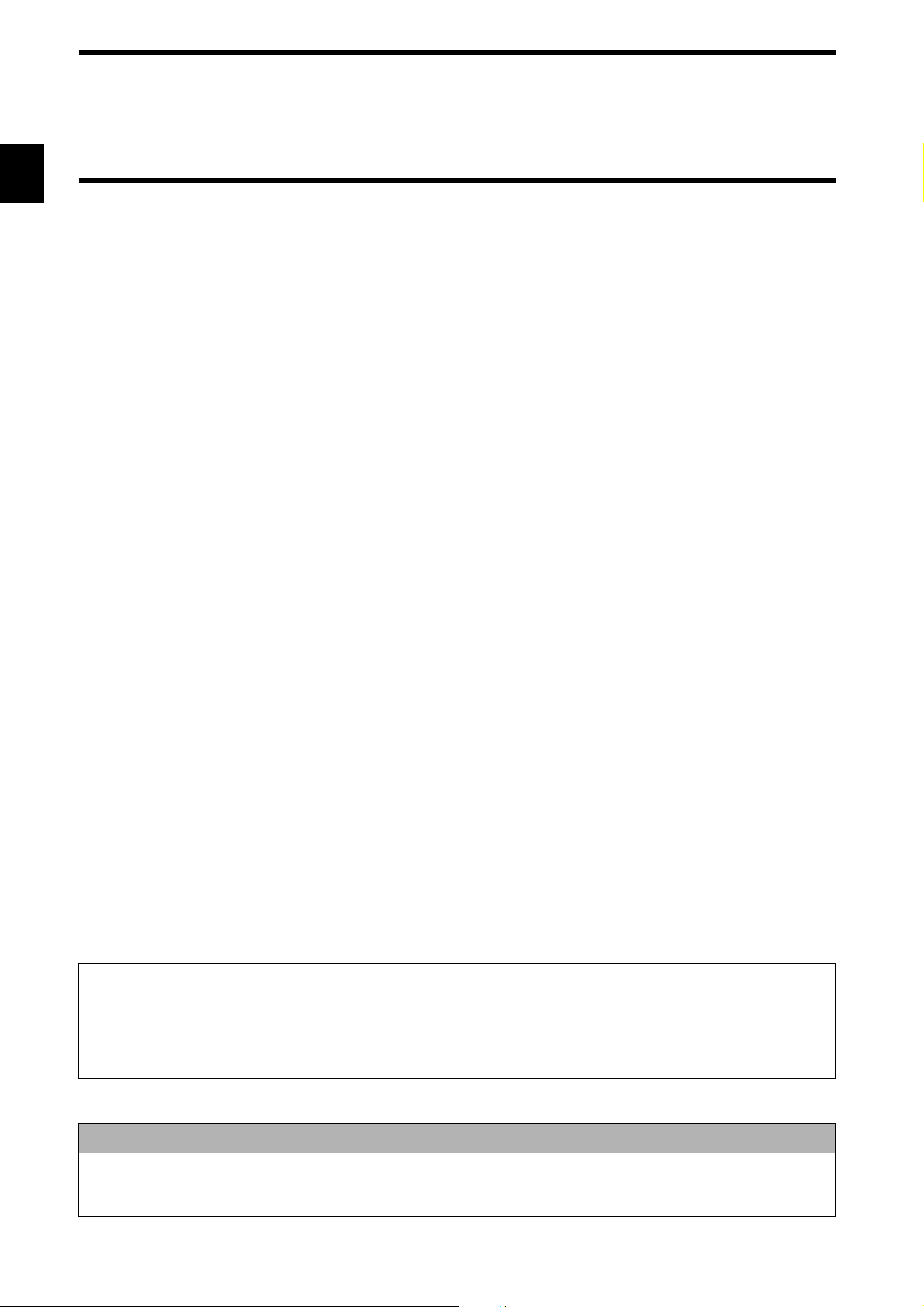

Chapter 2 Specifications and Performance

2-1 Controller

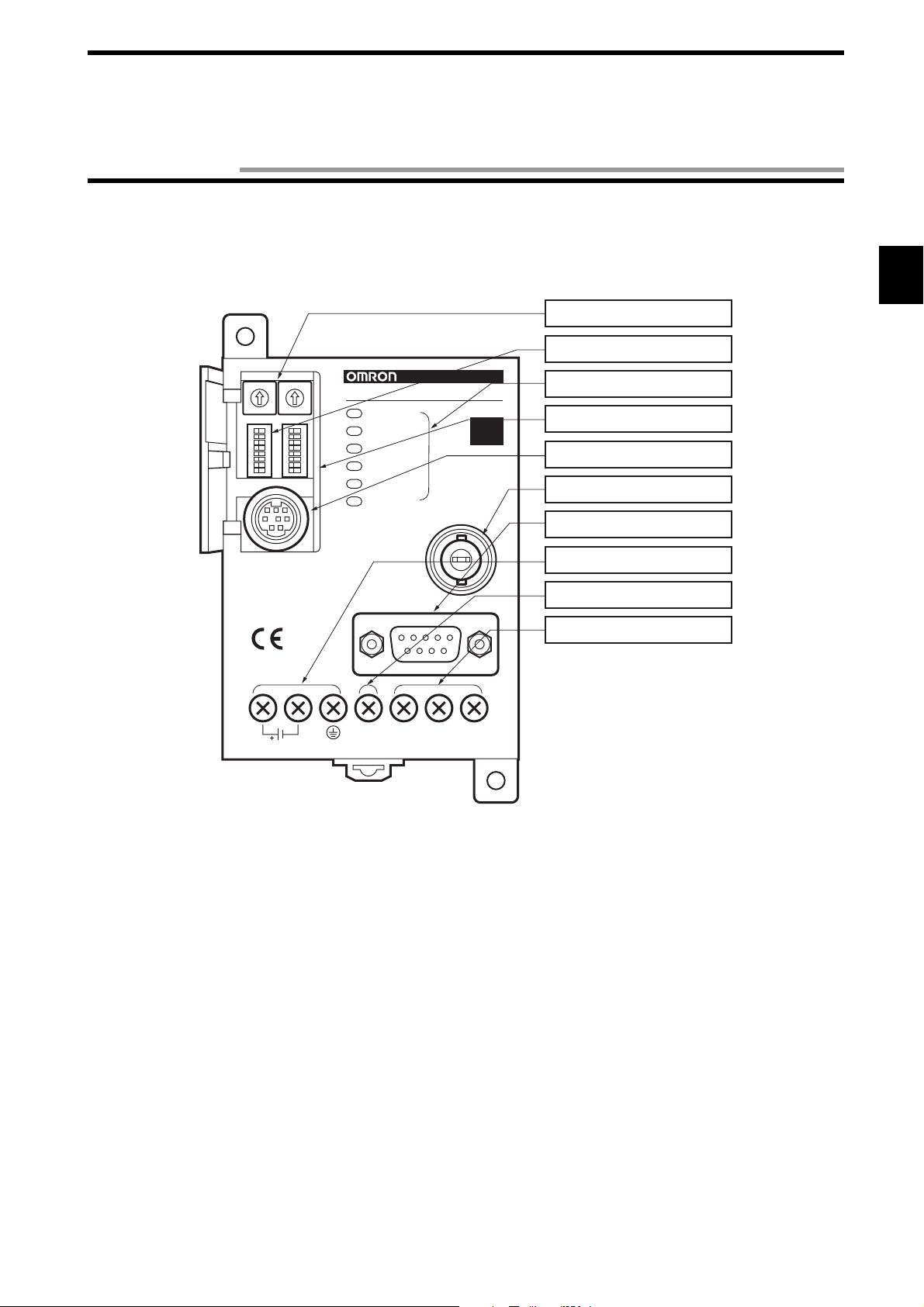

2-1-1 Component Names and Functions

• Model V670-CD1D-V1

(1)Node number setup switch

(2)Dip switch

SW1 SW2

0

0

1

9

9

2

8

8

3

7

7

4

6

6

5

SW3 SW4

24VDC 7W

24VDC

1

2

V670-CD1D-V1

3

4

5

RUN

COMM

NORM/ERR

RST/IN

OUT1

OUT2

V6 7 0 - CD1 D

ID

ANTENNA

(3)LED display

(4)Cover

(5)Connecting port for

programming console

(6)Connecting port for antenna

(7)RS-232C port

(8)Power supply terminals

RS-232C

(9)Reset terminal/Input terminal

(10)Output terminals

RST

GR

OUT1

/IN

O.COMOUT2

MADE IN JAPAN

2-1

Page 20

2-1 Controller

No.

(1) Note number setup switch Sets a controller node

Name Function Description

Used to identify the controllers when a maximum of 31

number.

controllers are connected to one host computer.

(2) Dip switch Sets every mode. Sets an input function, operation mode, protocol, com-

munication conditions, etc.

(3) LED display An operation status is shown on this LED displayed.

RUN Green Shows the RUN sta-

Turns on when an operation is normal.

tus.

COMM Green Shows an operation

Turns on during the communication to a tag.

status.

NORM/ERR Green Shows the end of

communication.

Turns on once and turns off when the communication has

ended correctly.

Red Shows an error. Turns on once and turns off when the communication has

ended due to an error. Turns on when a system error

occurs.

RST/IN Green

OUT1 Green

OUT2 Green

(4) Cover

(5) Connecting port for pro-

gramming console

Shows an input status.

Shows an output status.

Shows an output status.

Cover common to (1), (2) and (5).

Used to connect a

programming console.

Turns on when the RST/IN input signal turns ON.

Turns on when the OUT1 output signal turns ON.

Turns on when the OUT2 output signal turns ON.

Open as necessary.

Our programming console type C200H-PRO27 (unbundled) can connect to this port through the connecting

cable model V700-P10 (unbundled). When you operate

the programming console, use the key sheet that comes

with the V700-P10.

(6) Connecting port for antenna Used to connect an

antenna.

(7) RS-232C port Used to connect a

host device.

One antenna can connect to this port. To extend the

cable, use model V670-A4

(unbundled).

Based on the RS-232C, a general-purpose programmable controller (PLC) and PC can connect to this port.

(8) Power supply terminal Terminal for power supply.

24 VDC+ Supplies the power. Connects the "+" side of 24 VDC power supply.

24 VDC- Connects 0 V.

GR Ground Class D (Class III).

(9) Input terminal Terminal for input.

RST/IN Supplies a reset sig-

nal or trigger signal.

When external reset input and external trigger input are

used, they connects to this terminal together with 24

VDC- in pairs. Function can be selected with a dip

switch.

(10)

Output terminal Terminal for output.

OUT1 Output signal 1 When external output is used, it connects to this terminal

OUT2 Output signal 2

together with O.COM in pairs.

O.COM Output common

2-2

Page 21

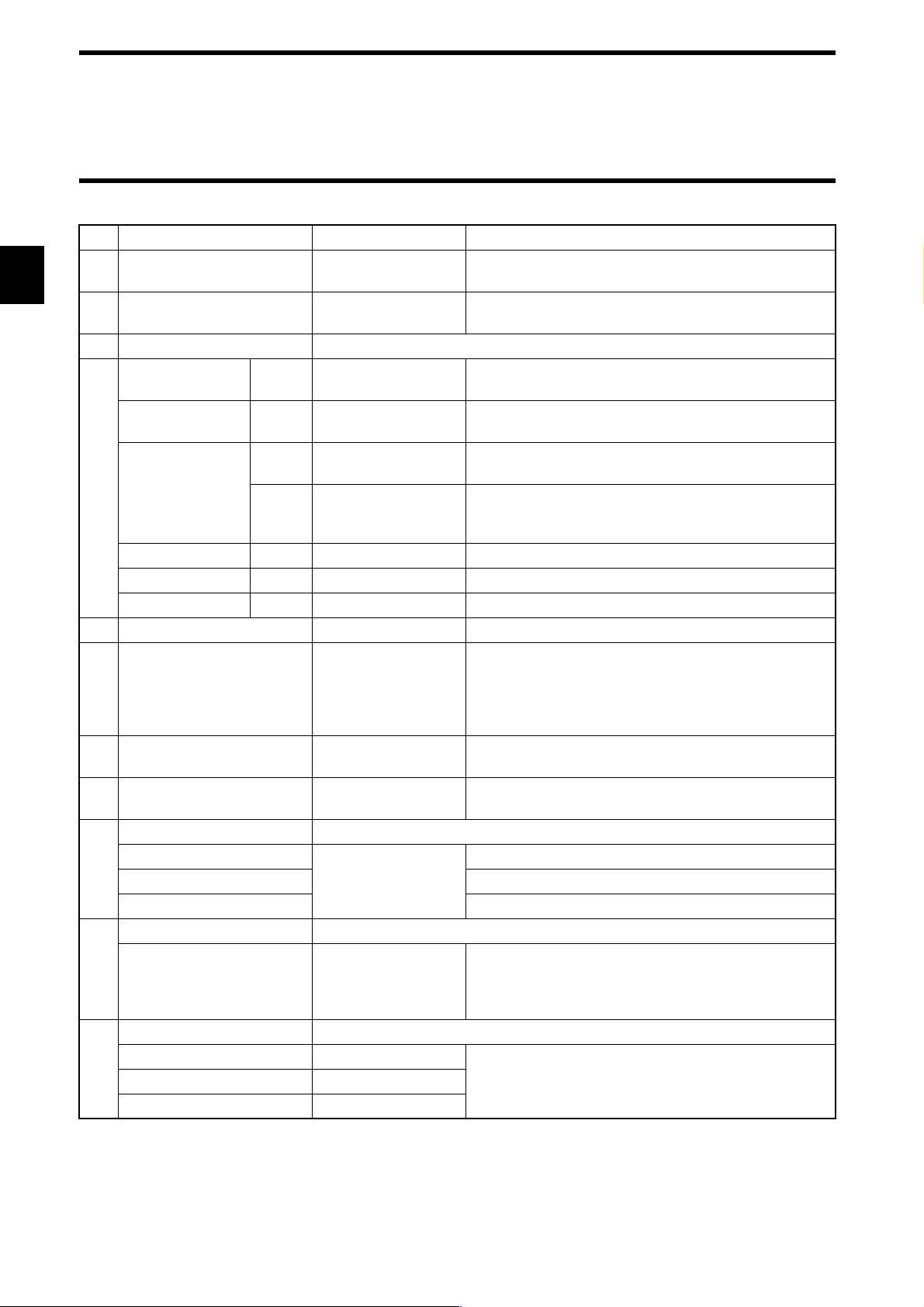

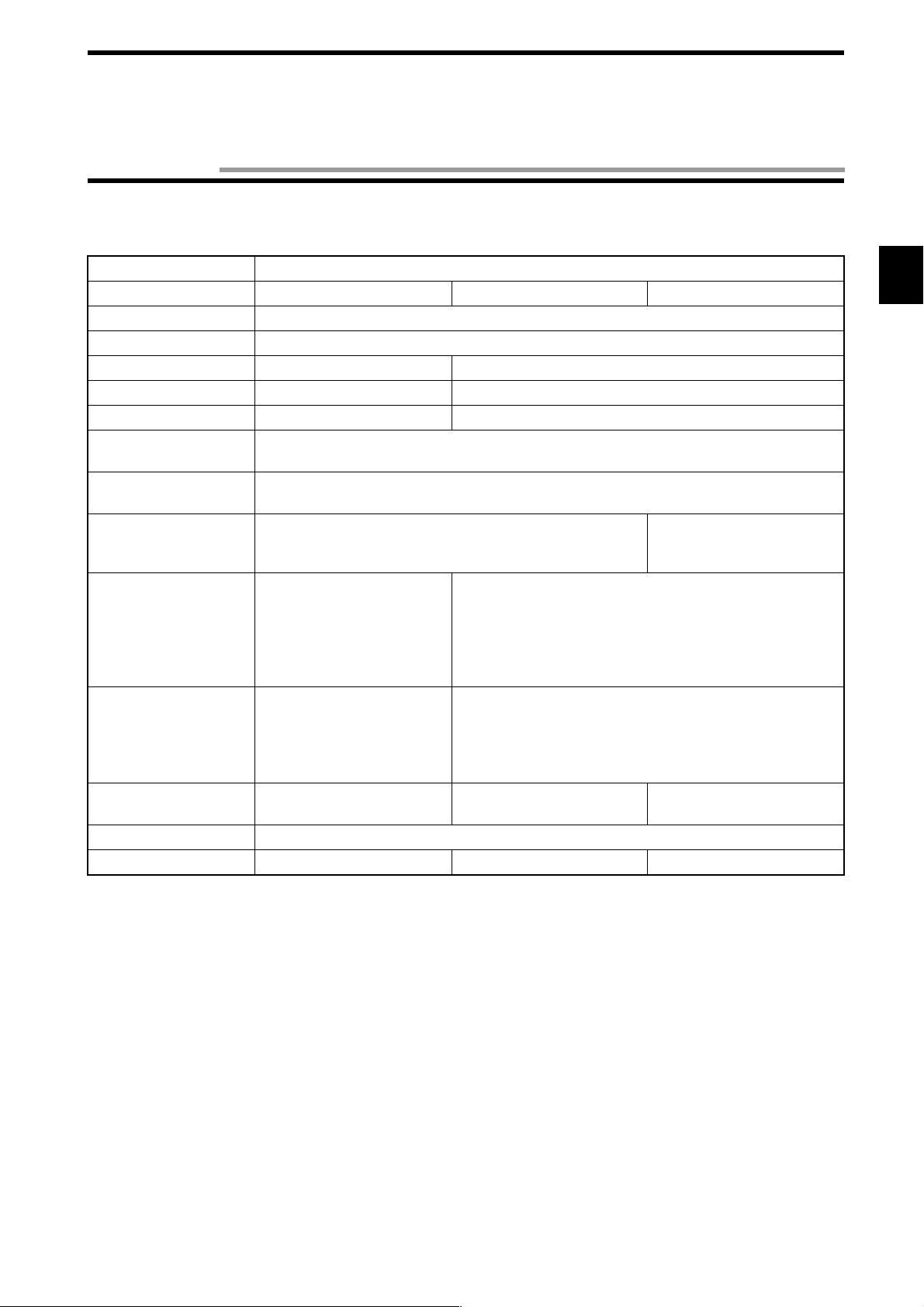

2-1-2 General Specifications

Item Specifications

Model V670-CD1D-V1

Power supply voltage

(Power consumption)

Ambient operating temperature

Ambient operating humidity

Ambient storage temperature

Ambient storage humidity 35 to 85%RH (no condensation)

Insulation resistance 20 MΩ or more (at 100 VDC mega) (1) to (6).

(1) Between a group of the power supply terminals and the grounding terminal.

(2) Between a group of the power supply terminals and a group of the output terminals.

(3) Between a group of the power supply terminals and the case.

(4) Between a group of the output terminals and the grounding terminal.

(5) Between a group of the output terminals and the case.

(6) Between the grounding terminal and the case.

Withstand voltage Leakage current 20 mA or less at 1,000 VAC (for 1 minute).

Protective structure Contains a panel.

Vibration resistance

Performing sweep 10 times for 8 minutes in an upward, downward, leftward, rightward, forward and backward directions.

Impact

Ground According to Class D (conventional Class III)

Material PC/ASA resin

Weight Approximately 270 g

Installation DIN or M4 screws

Giving impact of 15 m/s

10 to 150 Hz, double amplitude 0.2 mm, acceleration 15 m/s

35 to 85%RH (no condensation)

Impressed to (1) to (6) above.

2

3 times each in upward, downward, leftward, rightward, forward

and backward directions, i.e., 18 times in total.

24 VDC±10%

(7 W or less)

0 to +55°C (no icing)

-20 to +75°C (no icing)

2-1 Controller

2

.

2-1-3 Performance Specifications

Item Specifications

Communication

function

Maintenance

function

Diagnosis function

I/O function Input contact: 1 (RST/IN)

CPU error, host communication error, satellite communication error.

Single/Repeat/Input mode access function.

Write protect function/Memory check function

Self-Execution Function

Error reading function

Output contact: 2 (OUT1 and OUT2)

2-3

Page 22

2-1 Controller

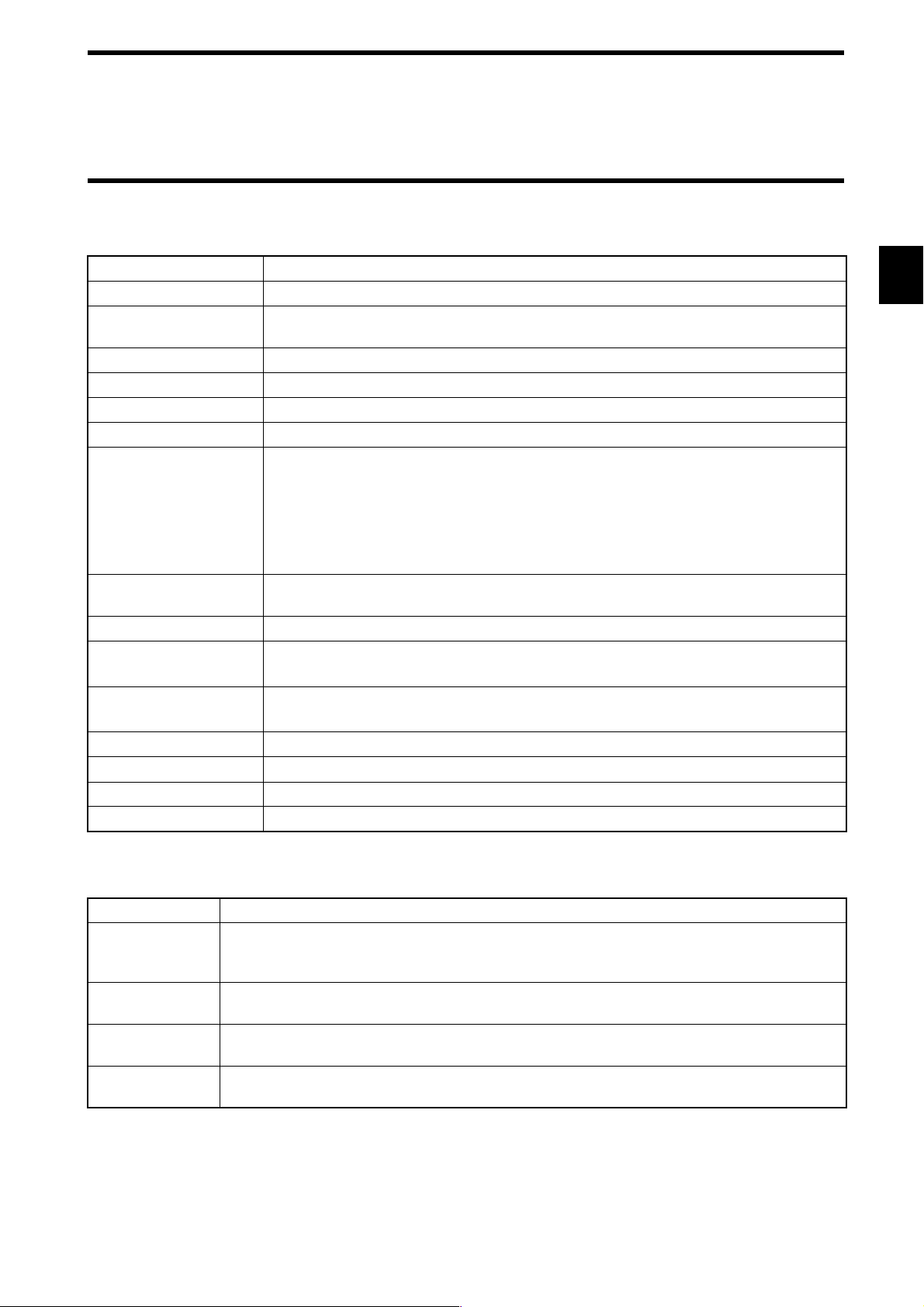

2-1-4 Communication Specifications

Item Specifications

Base specification RS-232C

Communication method

Transmission rate 9600 bps, 19200 bps, 38400 bps, 115200 bps *

Synchronization method

Start-stop synchronization (Stop bit 1 or 2) *

Transmission code

Error control Vertical parity (even, odd, nil)*. Horizontal parity is used as FCS.

Line length A maximum of 15 m.

Suitable connector

Model XM2A-0901 (plug) and model XM2S-0911 (hood), which come with our controller.

Recommendable cable

CO-MA-VV-SB 5Px28AWG (Hitachi Cable)

EIA/TIA-232-E

ASCII7 unit or JIS8 unit *

D-SUB 9-pin, male

* This can be set by a dip switch of the controller. For how to set, refer to Chapter 3.

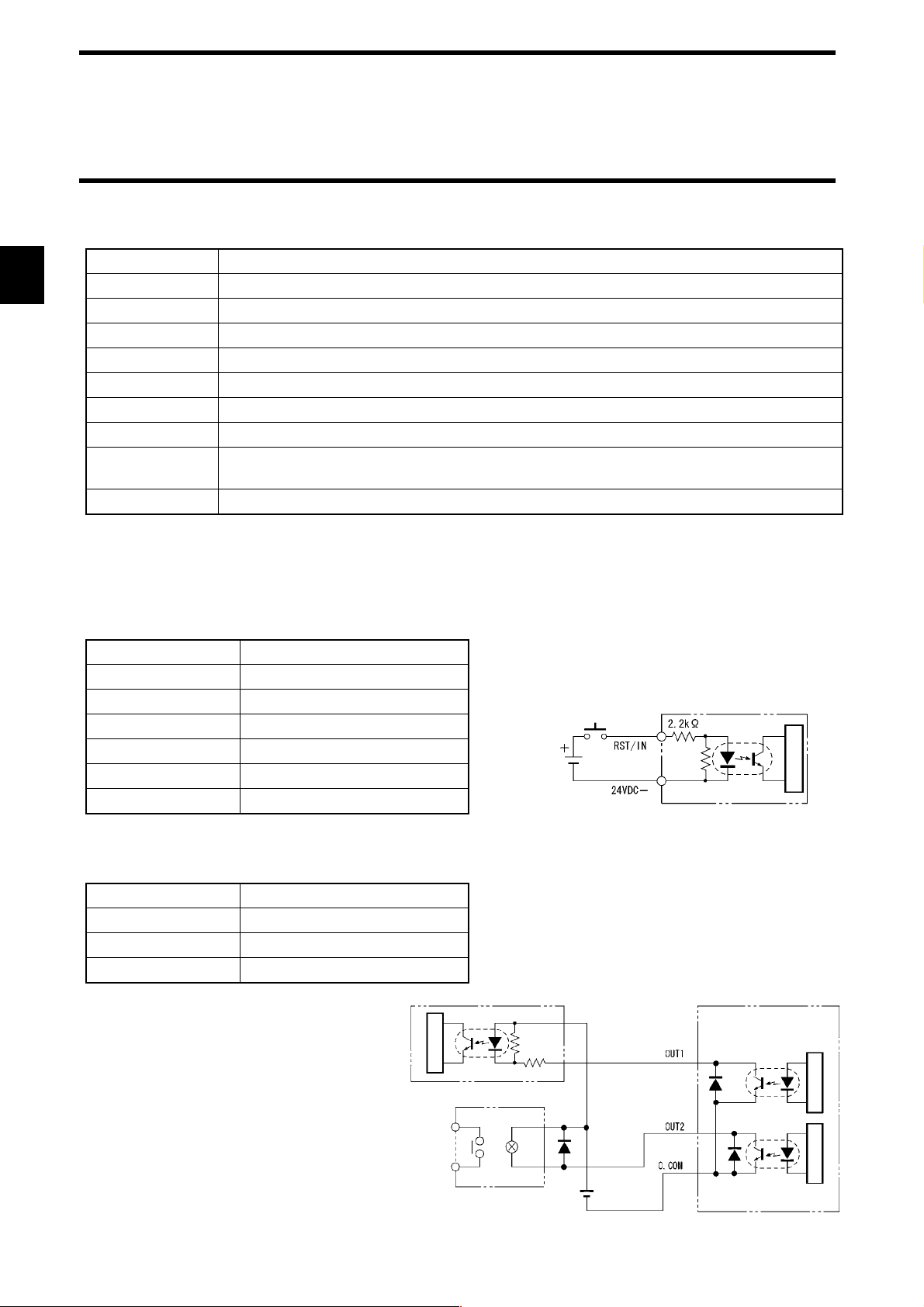

2-1-5 I/O Specifications

• Input Specifications (RST/IN)

Item Specifications

Input voltage 24 VDC ±10% (including ripple)

Input impedance 2.2 kΩ

Input current 10 mA TYP (24 VDC)

ON voltage 19 to 24 V

OFF voltage 5 V or less

Input response time 40 µs or less

• Output Specifications (OUT1/OUT2)

The output is the open collector specification.

Item Specifications

Maximum open/close ability

24 V ±10% 100 mA

Leakage current 1 µA or less

Residual voltage 1.0 V or less

Circuit Structure

24VDC

Circuit Structure

Controller input section

Internal

2-4

Input circuit Controller output section

Internal

Relay

24VDC

InternalInternal

Page 23

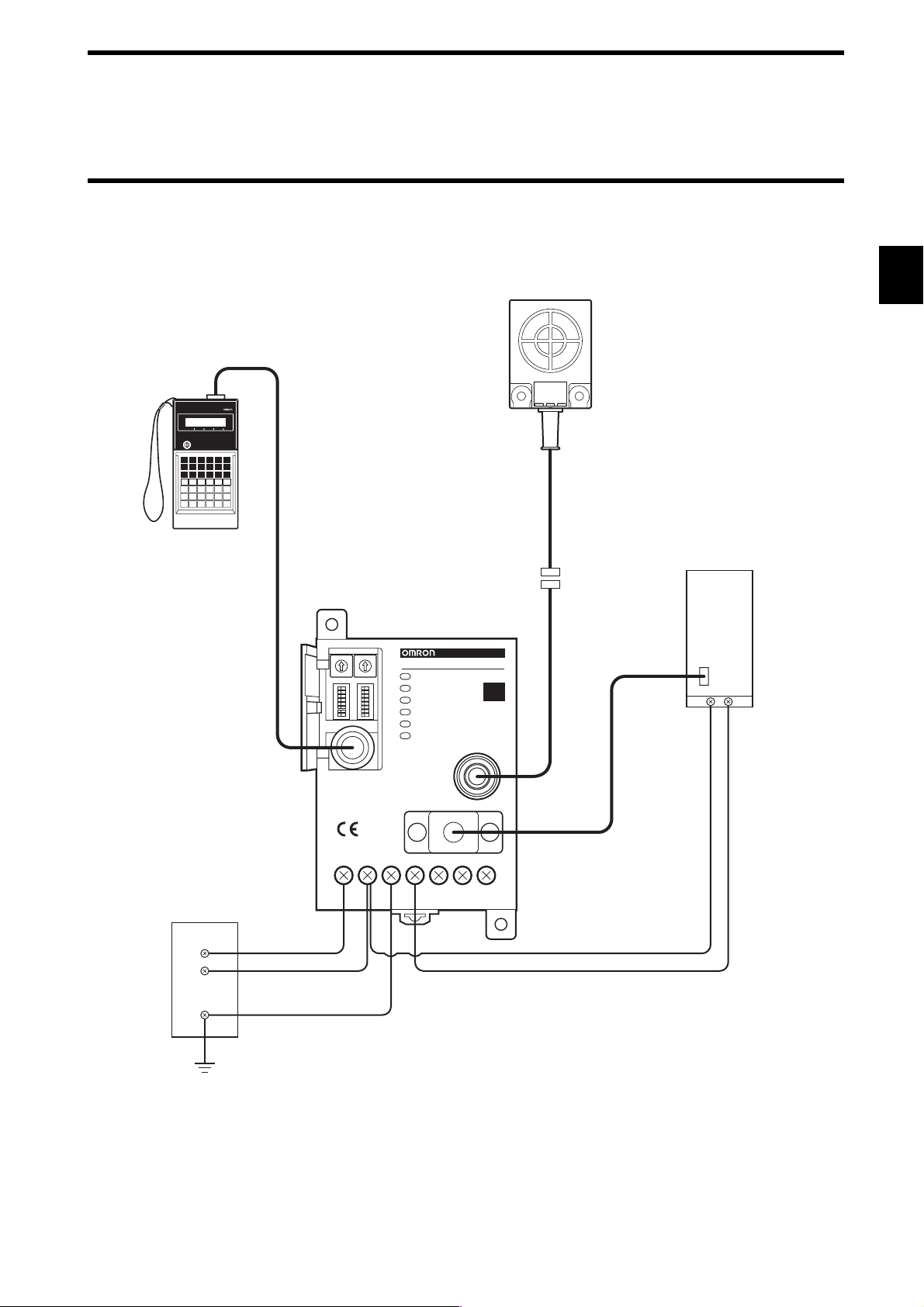

2-1-6 Example of Wiring

PRO27

2-1 Controller

Antenna Type

Model V670-H11

Connecting Cable

Model V700-P10

Programming Console

Model C200H-PRO27

24 VDC Power Supply

24VDC-

Controller

Model V670-CD1D-V1

SW1 SW2

0

0

1

1

9

9

2

2

8

8

3

3

7

4

6

5

SW3 SW4

24VDC

7

4

6

5

V670-CD1D-V1

RUN

COMM

NORM/ERR

RST/IN

OUT1

OUT2

RS-232C

+

SYNC

GR

–

ID

ANTENNA

COMRST

MADE IN JAPAN

Host Programmable

Controller (PLC)

Antenna Cable

Model V670-A4

(Only when extension

cable is used)

RS-232C

COM24VDC+

RESET

GR

2-5

Page 24

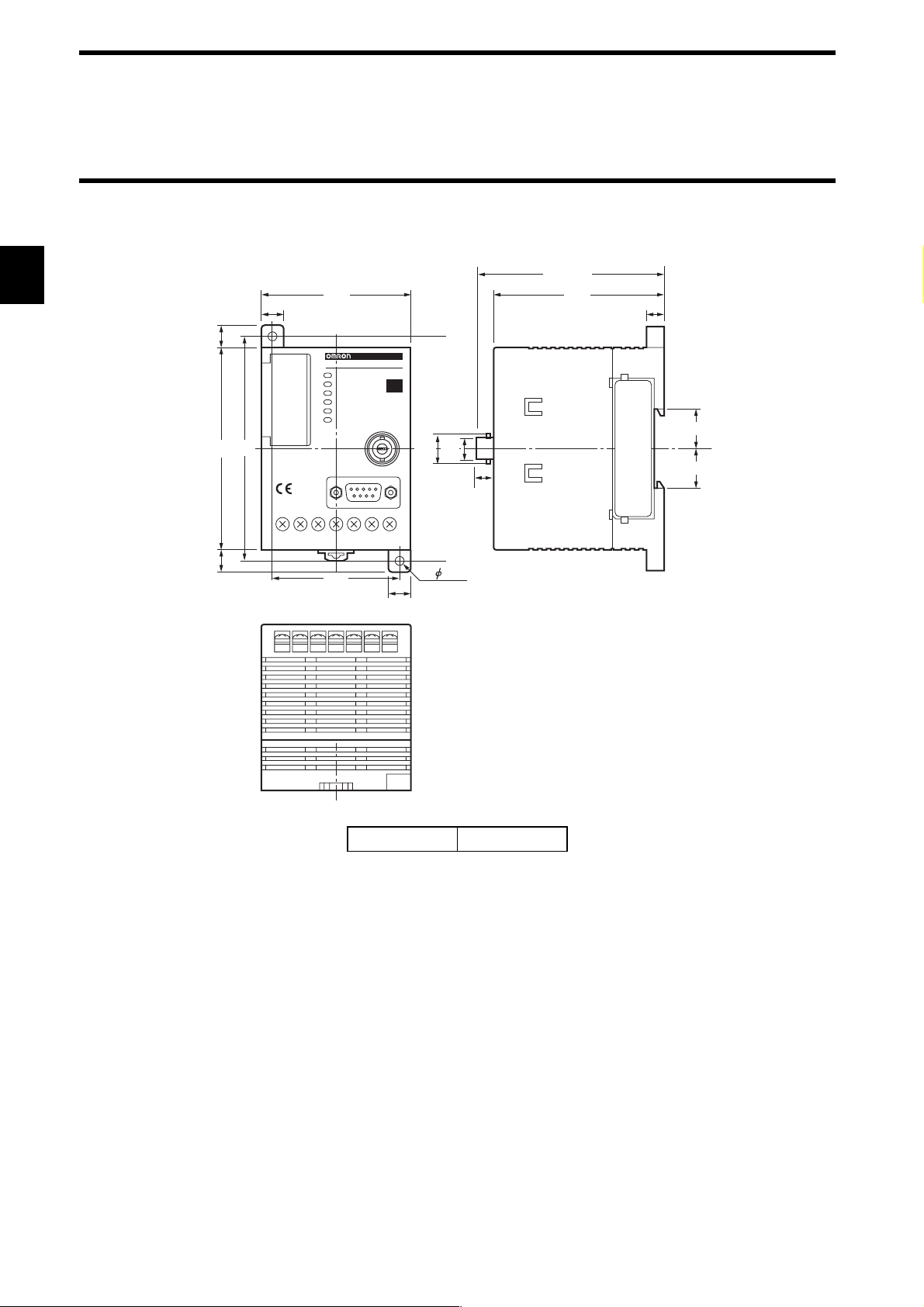

2-1 Controller

2-1-7 Outside Dimension

10 8

10

100

90

66

V6 7 0 - CD1 D

V670-CD1D-V1

Max. 85

75

ID

18

11.5 9.5

17.5

5.5

10

56

2- 4.5

10

Case material PC/ASA resin

(Unit: mm)

2-6

Page 25

2-2 Antenna

2-2-1 Specifications

Item Specifications

Model V670-H11 V670-H51 V670-H51Q

Oscillating frequency 13.56 MHz

Ambient operating temperature

Ambient operating humidity

Ambient storage temperature

Ambient storage humidity

Insulation resistance 20 MΩ or more (at 1,000 VDC mega).

Withstand voltage 1,000 VAC (for 1 minute).

Protective structure IP67 (IEC60529 Standard) *1

Vibration resistance

Impact

times each in upward, down-

forward and backward direc-

Material ABS/epoxy filler

(Cable section material is PVC.)

Cable length 2 m (total length: 30 m*2)

Weight Approximately 160 g Approximately 140 g Approximately 130 g

35 to 85%RH 35 to 95%RH

-25 to +85°C -25 to +75°C

35 to 85%RH 35 to 95%RH

Impressed between a group of terminals and a case.

Impressed between a group of terminals and a case. Leakage current 20 mA or less.

10 to 150 Hz, double amplitude

0.7 mm, acceleration 50 m/s

Performing sweep 10 times for

8 minutes in an upward, down-

ward, leftward, rightward, for-

ward and backward directions.

Giving impact of 150 m/s

ward, leftward, rightward,

tions, i.e., 18 times in total.

2

.

2

3

-10 to +70°C

IP67 (IEC60529 Standard) *1

IP67g (for communication

side only, JEM Standard)

10 to 500 Hz, double amplitude 1.5 mm, acceleration 100 m/s2.

Performing sweep 10 times for 11 minutes in an upward, down-

ward, leftward, rightward, forward and backward directions.

2

Giving impact of 300 m/s

ward, leftward, rightward, forward and backward directions,

i.e., 18 times in total.

PBT/brass/filled with epoxy

resin

3 times each in upward, down-

Fluororesin/filled with epoxy

resin

*1: Connectors are not waterproof.

*2: Extending the cable length reduces the communication distance. The communication distance also varies depending

on the type of extension cable. For details, refer to the section with communication distance specifications.

2-7

Page 26

2-2 Antenna

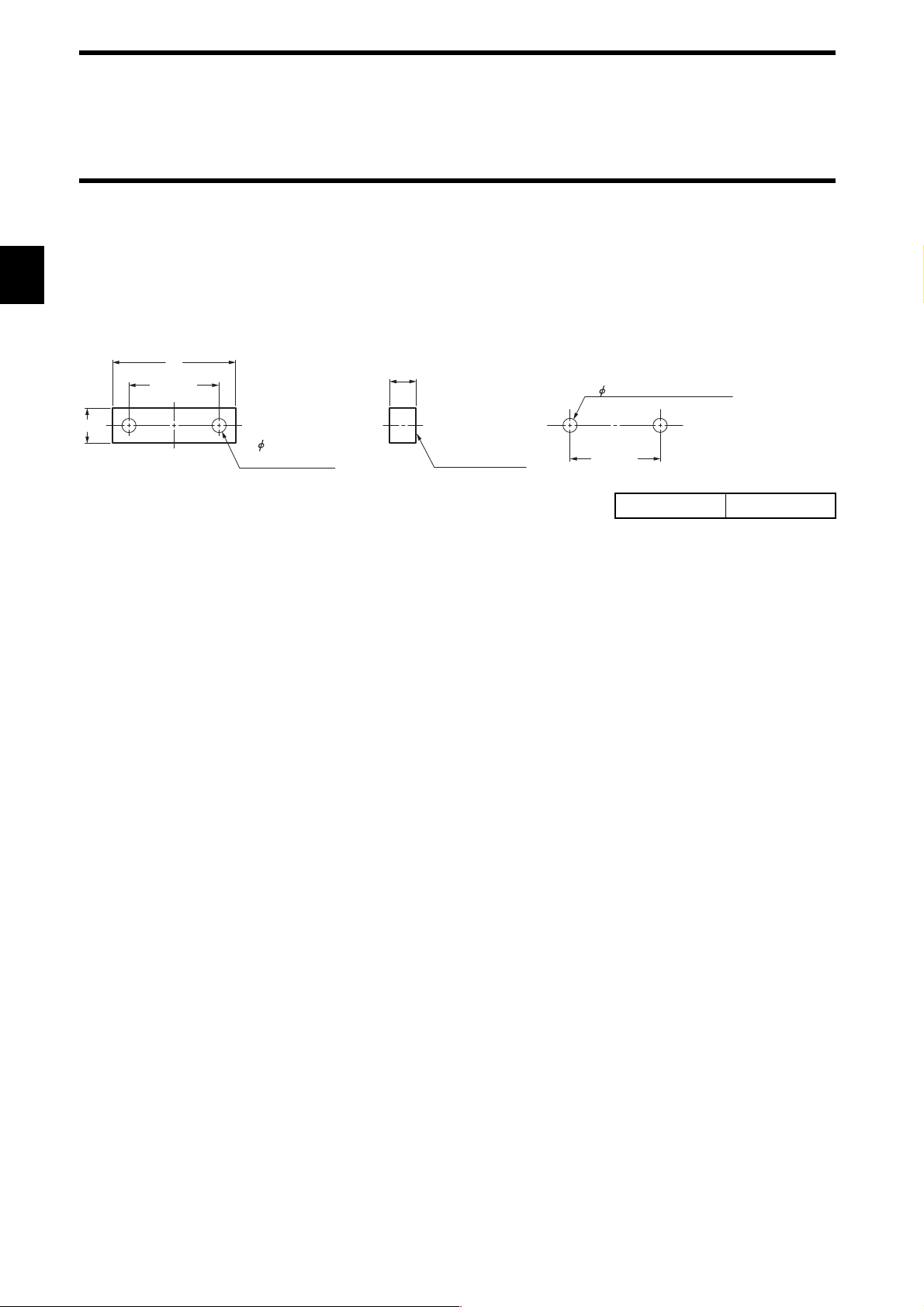

2-2-2 Outside Dimension

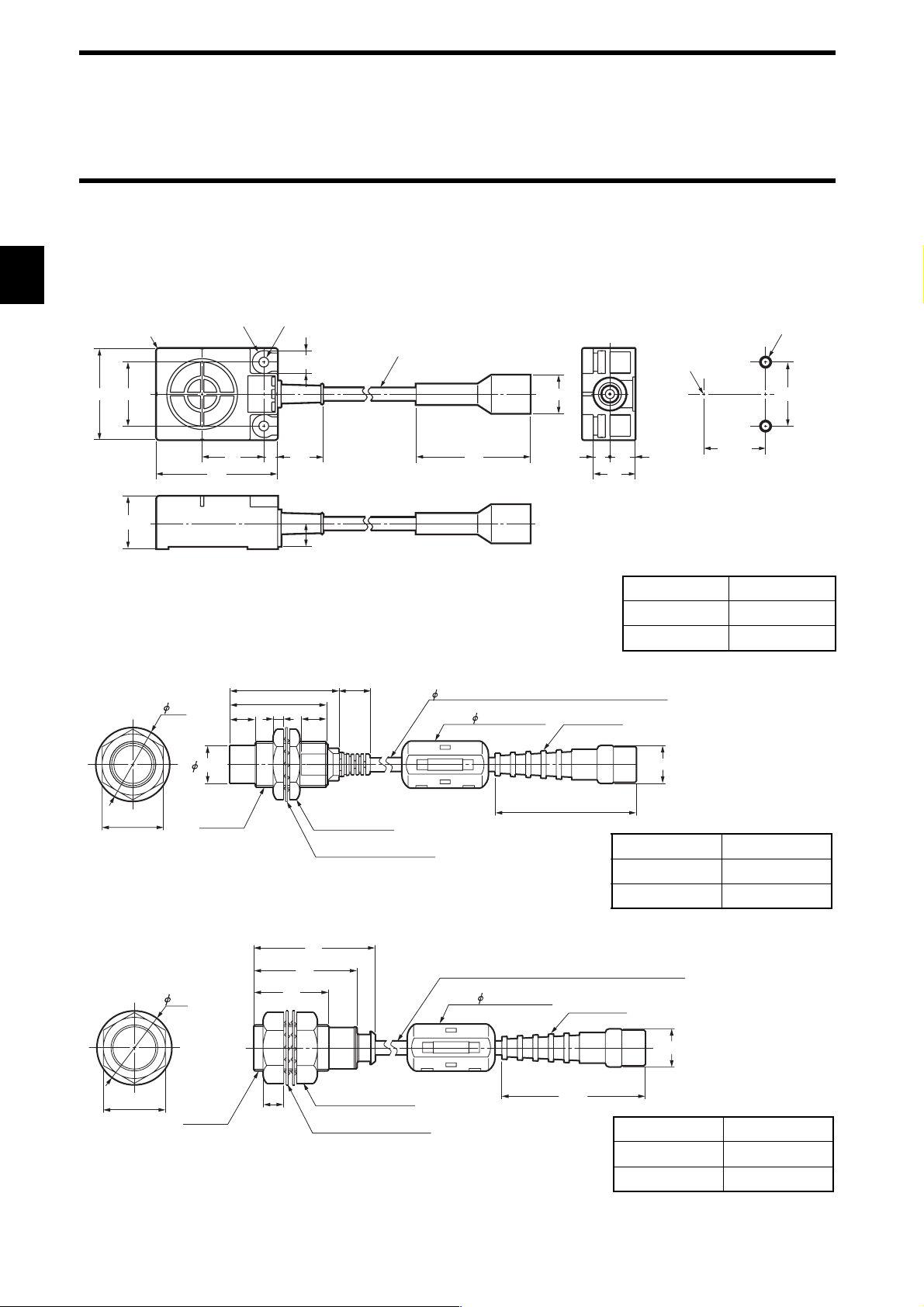

• Model V670-H11

28

±0.1

4-R1

Two, 10-dia.

Two, 4.5-dia. mounting holes

10

5.0 dia. coaxial cable

Standard length: 2 m

Mounting Hole Dimensions

2-M4

Center of Antenna

28

40

23

• Model V670-H51

29

14.8

24

M18 × 1

• Model V670-H51Q

53

10

627

20

11

43 12

38

410

2-stuffing nut

Toothed lock washer

16.8 dia.

50

135

18

Case material ABS resin

Filler resin Epoxy resin

Cable PVC

5.0 coaxial cable with a standard length of 2 m

Core 18 × 34 mm

Connector

15

60.3

Case material Brass/PBT

Filler resin Epoxy resin

Cable PVC

0.2

27±

(Unit: mm)

(Unit: mm)

28

±0.2

2-8

24

29

M18 × 1

47

40

29

8

2-stuffing nut

Toothed lock washer

5.0 coaxial cable with a standard length of 2 m

Core 18 × 34 mm

Connector

5

1

60.3

Case material Teflon

Filler resin Epoxy resin

Cable PVC

(Unit: mm)

Page 27

2-3 Tag

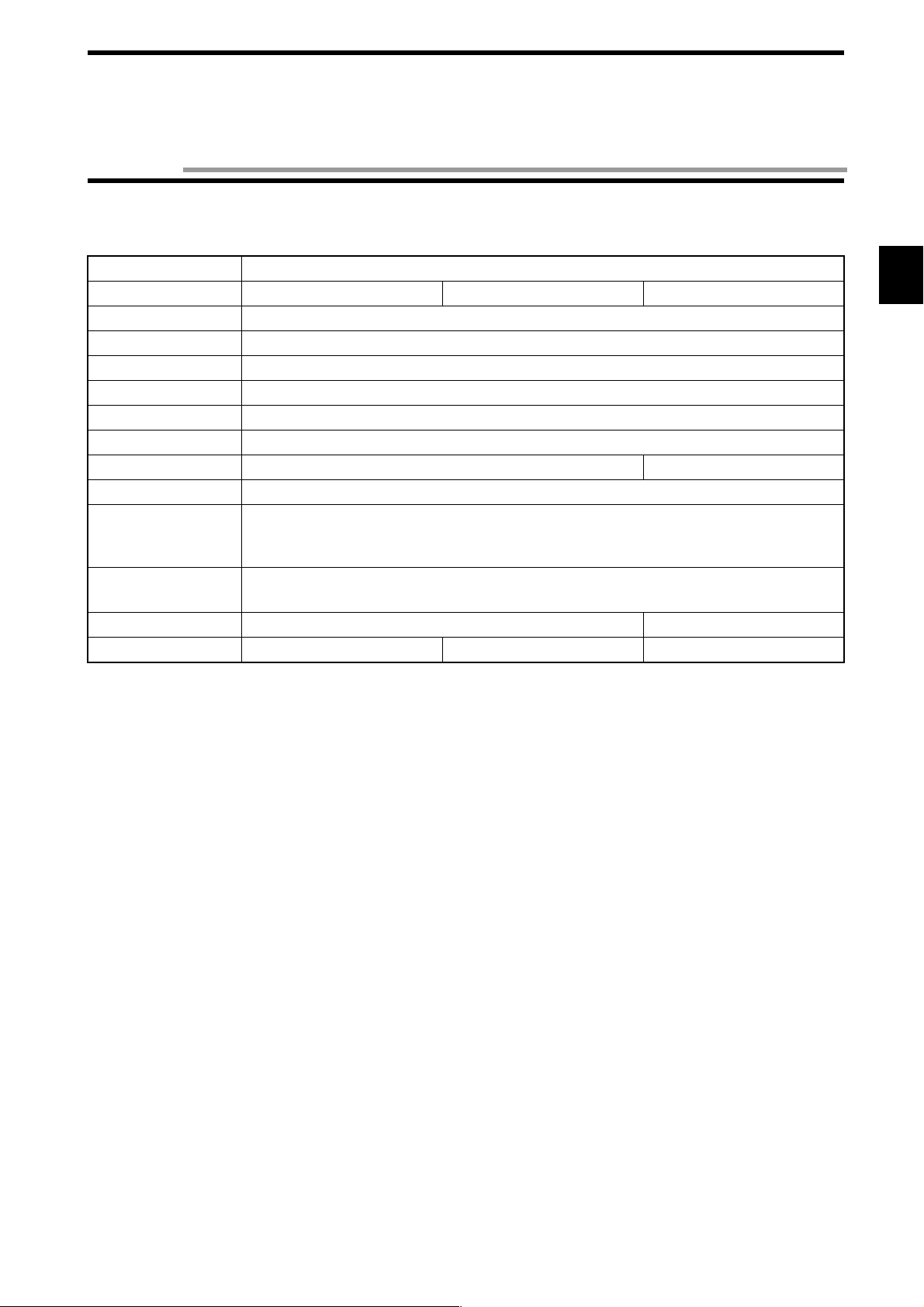

2-3-1 Specifications

Item Specifications

Model V670-D13F01 V670-D13F01H V670-D13F03

Memory capacity 128 bytes

Type of memory FeRAM (Ferroelectric RAM)

Memory life Number of accesses*: One billion

Data-holding period 10 years after accessing (read or write).

Ambient operating temperature

Ambient storage temperature

Ambient operating humidity

Protective structure IP67 (IEC60529 Standard)

Vibration

Performing sweep 10 times for 15 minutes in an upward, downward, leftward, rightward, for-

Impact

Material PPS/epoxy filler resin ABS/epoxy filler resin

Weight Approximately 1 g Approximately 1 g Approximately 6 g

Giving impact of 500m/s2 3 times each in upward, downward, leftward, rightward, forward and

10 to 2000 Hz, double amplitude 1.5 mm, acceleration 150 m/s

35 to 95%RH 35 to 85%RH

ward and backward directions.

backward directions, i.e., 18 times in total.

-10 to +70°C

-10 to +70°C

2

.

* Number of accesses is the total number of read/write communication times.

2-9

Page 28

2-3 Tag

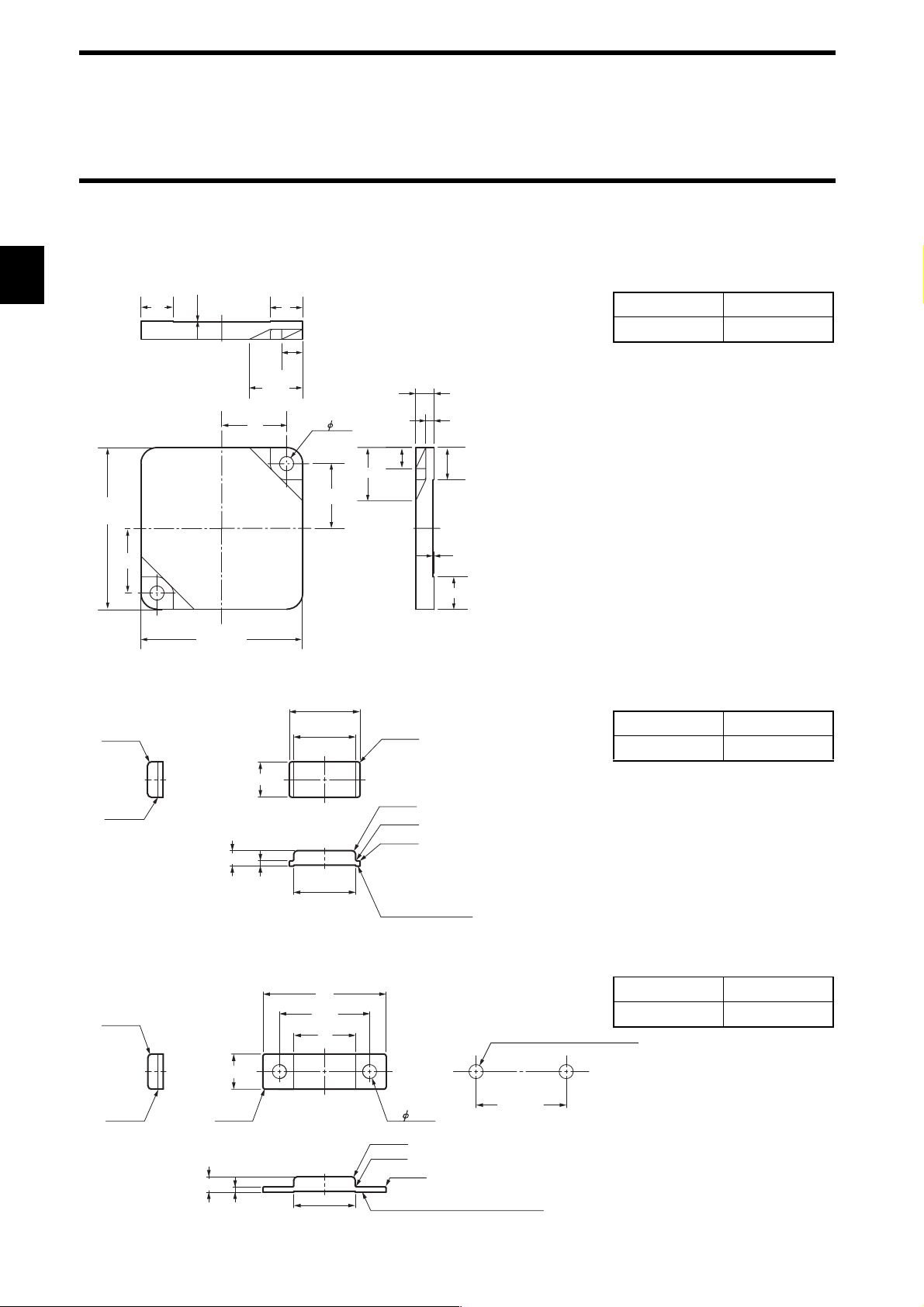

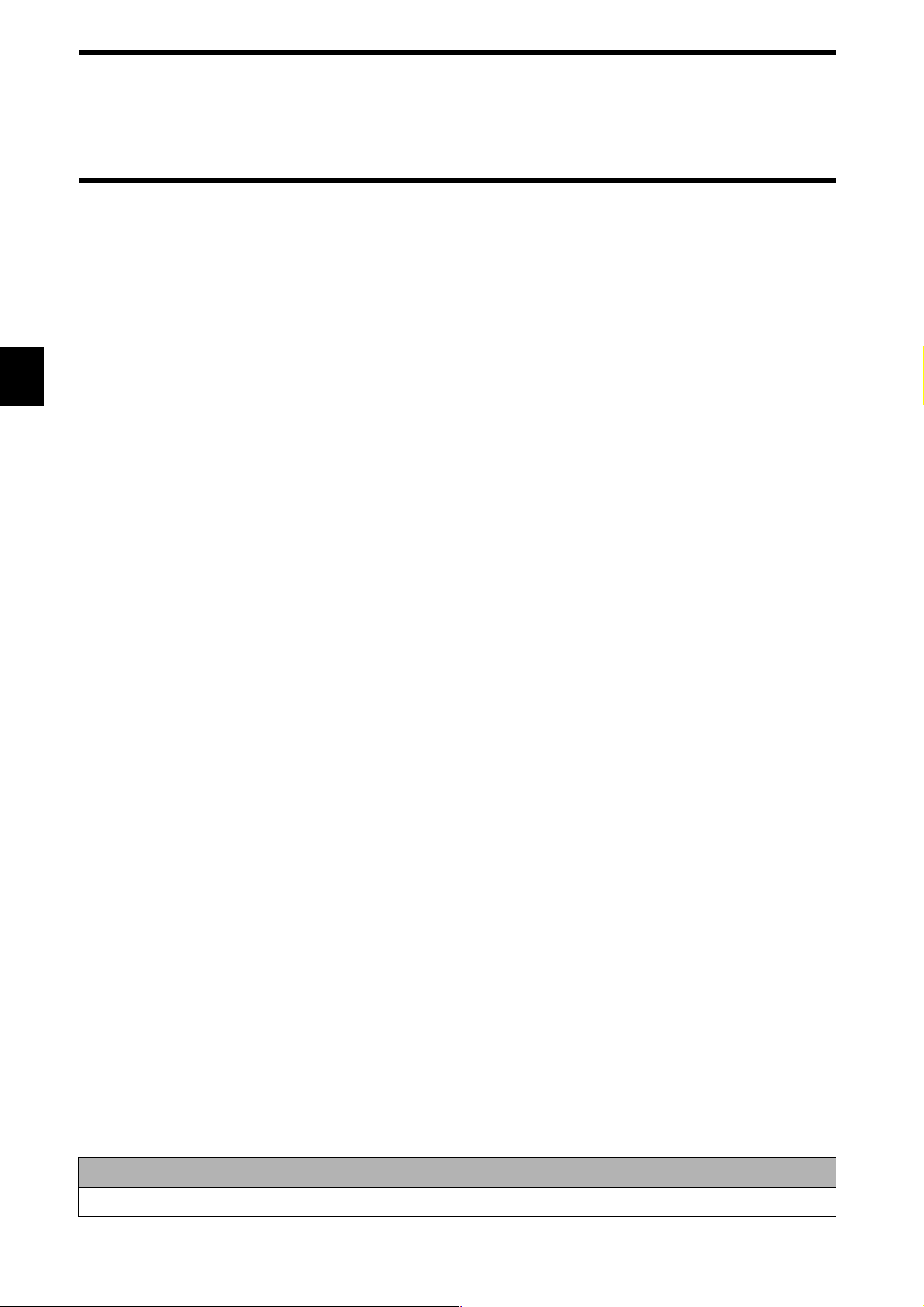

2-3-2 Outside Dimension

• Model V670-D13F03

0.2

8

8

5.2

13.2

Case material ABS resin

Filler resin Epoxy resin

4.5

40+ 0.1

- 0.5

16

40+ 0.1

- 0.5

• Model V670-D13F01

2-R0.8

2-R0.2

3.5

16

1.2

2- 3.5

5.2

13.2

16

2

8

0.2

8

(Unit: mm)

16

14

4-R0.5

Case material PPS resin

Filler resin Epoxy resin

8

2-R0.8

2-R0.2

2-R0.2

(Unit: mm)

14

Reference plane

for installation

• Model V670-D13F01H

2-R0.8

2-R0.2

4-R0.5

3.5

2-10

8

1.2

28

20.5

14

14

Fitting hole dimension

2-φ3.2 hole for M3 screw

2- 3.2

Reference hole for installation

2-R0.8

2-R0.2

2-R0.2

Reference plane for installation

20.5 ±

Case material PPS resin

Filler resin Epoxy resin

.1

(Unit: mm)

Page 29

2-3 Tag

2-3-3 Memory Map

There are a user area and ID code in memory in a tag. Memory capacity of user area is 128 bytes. You can write 1 byte of data into one

address. Memory area is divided into 4 bytes of pages and every page has its own address like 0000h to 0003h, 0004h to 0007, etc.

♦ Memory Map

Page User Address

$0000

1

.

.

.

.

* When a protect function is used, the addresses 0000h to 0003h are used as protect address information and cannot be used as a user

area. For details, refer to "4-6 Write Protection Function".

$0001

$0002

$0003

$0004

.

.

.

.

$007F

When a protect function is not used When a protect function is used

User Area

User Area

Specified address in a protect area

User Area

♦ ID Code

This is a 4-byte area where tag identification number (inherent tag number) is written. The ID code is written at shipment from a factory and it cannot be modified. The ID code can be read by an ID read command.

2-11

Page 30

2-3 Tag

2-3-4 Attachment (Model V670-A81) for Model V670-D13F01H Tag

When a tag is attached to a metal structure, the metal will reduce the communication range of the tag. Model V670-A81 is an attachment

specially designed for Model V670-D13F01H Tag. When combined with this attachment, Model V670-D13F01H tag retains its original

communication range even when installed on a metal structure.

Tag to be combined: Model V670-D13F01H

♦ Outside Dimension

28

± 0.1

20.5

8

2- 3.2 hole for

M3 screw

6

Reference plane

for installation

Fitting hole dimension

2- 3.2 hole for M3 screw

± 0.1

20.5

Reference hole for installation

Material PPS resin

♦ How to install

Place the attachment on the reference plane of the tag and adjust its position until the fitting holes align with each other. Then secure

both parts with M3 screws.

Screw tightening torque: 5 N • m

♦ For general applications

Conform to the tag specifications.

♦ Influence of back metal

Use of this attachment increases the distance between the tag and metal surface to 6 mm. Before use, refer to Chapter 9-4, "Influence

of Back Metal of Tag."

2-12

Page 31

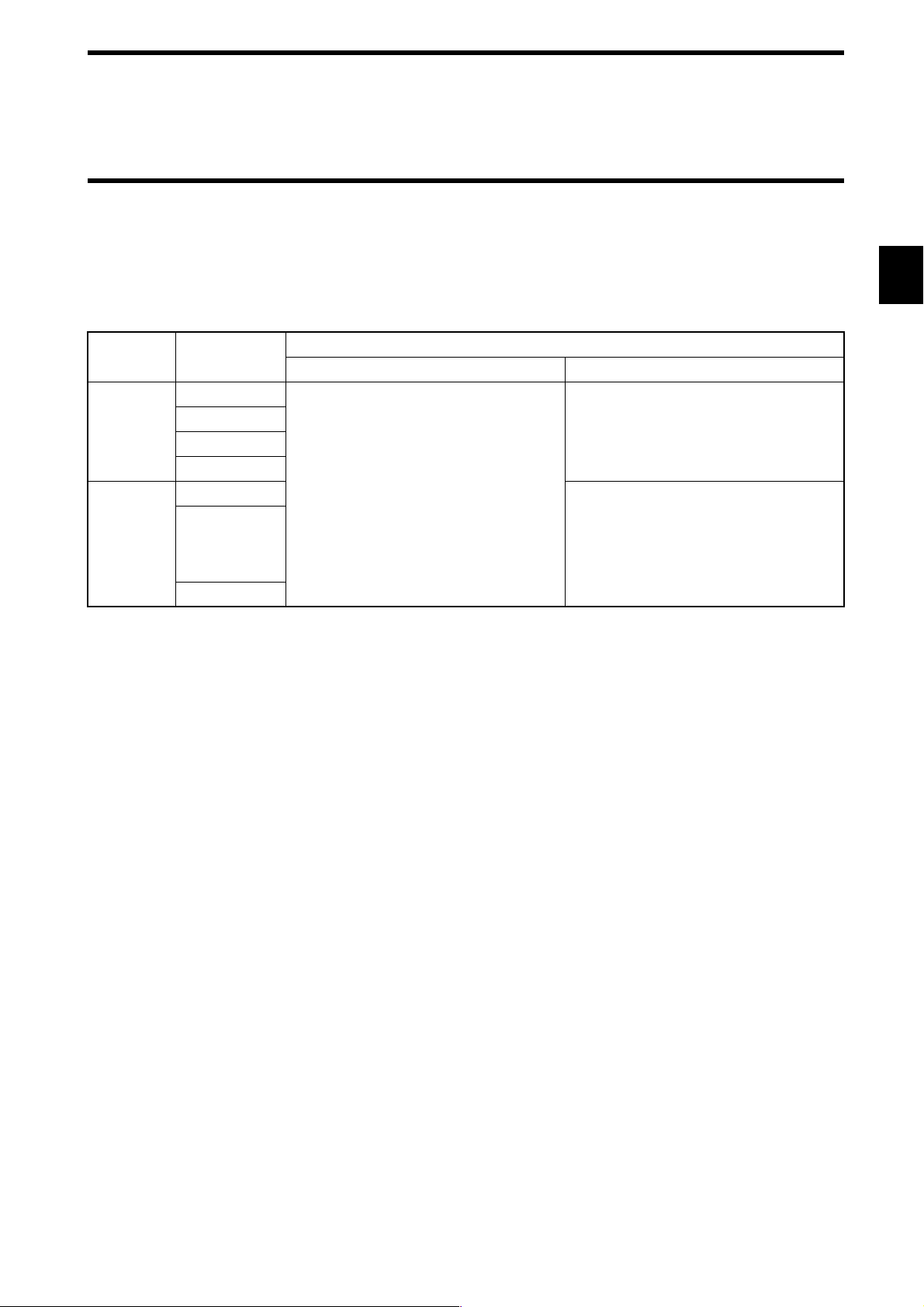

2-4 Cable

2-4-1 Specifications

Item

Insulation resistance

Model

50 MΩ or more between a terminal and

Model V700-P10 Model V670-A4

20 MΩ or more between a terminal and

sheathing (at 250 VDC mega).

sheathing (at 1000 VDC mega).

Withstand voltage 250 VAC, 1 minute. 1000 VAC, 1 minute.

Maximum operating

70°C70°C

temperature

Remarks Connector without waterproof specification. Connector without waterproof specification.

2-4-2 Outside Dimension

• Model V700-P10 (Programming console connecting cable)

Item Model V700-P10

Length Approximately 2 m

Weight Approximately 110 g

2000±

100

28.95

4.8

12

Connector (at a programming console side)

12

Connector (at a controller)

(Unit: mm)

• Model V670-A4 (Antenna extension cable)

Item

Model

Model V670-A40 Model V670-A41 Model V670-A42 Model V670-A43

Length Approximately 3 m Approximately 10 m Approximately 18 m Approximately 28 m

Weight Approximately 140 g Approximately 410 g Approximately 710 g Approximately 1100 g

L1 3000 mm 10000 mm 18000 mm 28000 mm

±100

L1

17

16.8 dia. 16.8 dia.

23

50

(See note.)

17

23

50

Note: 5.0 dia. coaxial cable

Standard length: 10 m

(Unit: mm)

2-13

Page 32

2-5 Communication Range Specifications

Communication range varies depending on the installation conditions and environment conditions. Check the conditions mentioned in

this manual carefully.

♦ Maximum communication range

Antenna / Controller ID Tag Communication Range

Model V670-H11

+ Model V670-CD1D-V1

Model V670-H51

+ Model V670-CD1D-V1

Model V670-H51Q

+ Model V670-CD1D-V1

Measurement conditions:

• Combination of Model V670-H11 with Model V670-D13F03

Model V670-D13F03 5 to 23 mm

(Area width 20 mm or more if the range between a tag

and antenna is 5 to 20 mm.)

Model V670-D13F01 /

Model V670-D13F01H

Model V670-D13F01 /

Model V670-D13F01H

Antenna

0.5 to 5.0 mm

0.5 to 4.5 mm

Ta g

Communication

range

Nonmetal Nonmetal

*Antenna extension cable (Model V670-A4: not used)

• Combination of Model V670-H51/H51Q with Model V670-D13F01/D13F01H

Ta g

Antenna

Communication

range

Nonmetal

*Antenna extension cable (Model V670-A4: not used)

♦ Use of extension cable (Model V670-A4)

Use of an extension cable will reduce the communication range.

Extension cable

Model V670-H11 Model V670-H51 Model V670-H51Q

Model V670-A40 (3 m) 5.0 to 21.5 mm 0.5 to 5.0 mm 0.5 to 4.5 mm

Model V670-A41 (10 m) 5.0 to 21.0 mm 0.5 to 5.0 mm 0.5 to 4.5 mm

Model V670-A42 (18 m) 5.0 to 20.5 mm 0.5 to 4.0 mm 0.5 to 3.5 mm

Model V670-A43 (28 m) 5.0 to 20.0 mm 0.5 to 4.0 mm 0.5 to 3.5 mm

Communication range

* For extension cable connection procedure, refer to the descriptions on pages 3-9 and the instruction manual packaged together with

the extension cable.

2-14

Page 33

2-5 Communication Range Specifications

m

X

X

)

2-5-1 Communication Area (Reference)

♦ Combination of Model V670-H11 with Model V670-D13F03

The communication area varies depending on the installation conditions and grounding environment.

The operation area formed on a plane, which is on an antenna center line and vertical to the antenna, is shown below.

Communication area characteristic

-40 -30 -20 -10 0 10 20 30 40

Y

30

25

20

15

10

5

X

Unit: m

Model V670-H11

Y (mm)

X (mm)

Model V670-D13F03

*Antenna extension cable (Model V670-A4: not used)

Nonmetal

Nonmetal

♦ Combination of Model V670-H51 with Model V670-D13F01/ D13F01H

The communication area varies depending on the installation conditions and grounding environment.

The operation area formed on a plane, which is on an antenna center line and vertical to the antenna, is shown below.

• When tag is attached perpendicular to the passing direction (X-direction) (typical example)

Communication area characteristic

• When tag is attached horizontally in relation to the passing direction (X-direction) (typical example)

Communication area characteristic

Y

9

8

7

6

5

4

3

2

1

0-15 -10 -5 5 10 15

Y

9

8

7

6

5

4

3

2

1

0-15 -10 -5 5 10 15

Unit: mm

Unit: mm

Model V670-D13F01 (H)

X (mm)

Y (mm)

Model V670-H51

*Antenna extension cable (Model V670-A4: not used)

Model V670-D13F01 (H

X (mm)

Y (mm)

Model V670-H51

Nonmetal

Nonmetal

*Antenna extension cable (Model V670-A4: not used)

2-15

Page 34

2-5 Communication Range Specifications

X

X

♦ Combination of Model V670-H51Q with Model V670-D13F01/ D13F01H

The communication area varies depending on the installation conditions and grounding environment.

The operation area formed on a plane, which is on an antenna center line and vertical to the antenna, is shown below.

• When tag is attached perpendicular to the passing direction (X-direction) (typical example)

Communication area characteristic

Y

9

8

7

6

5

4

3

2

1

0-15 -10 -5 5 10 15

Unit: mm

Model V670-D13F01 (H)

X (mm)

Y (mm)

Model V670-H51Q

*Antenna extension cable (Model V670-A4: not used)

• When tag is attached horizontally in relation to the passing direction (X-direction) (typical example)

Communication area characteristic

Y

9

8

7

6

5

4

3

2

1

0-15 -10 -5 5 10 15

Unit: mm

Model V670-D13F01 (H)

X (mm)

Y (mm)

Model V670-H51Q

Nonmetal

Nonmetal

2-16

*Antenna extension cable (Model V670-A4: not used)

Page 35

2-5-2 Operation Time (Reference)

There are TAT (Turn Around Time) and communication time in the operation time.

2-5 Communication Range Specifications

Command

Communication time

Response

TAT means the total processing time required to operate V670 from the viewpoint of a host device. The communication time means a

time required for the communication between an antenna and tag, excluding host communication.

♦ Communication time

Time required for the communication between an antenna and ID tag. The time varies depending on data amount to be read and written.

The communication time can be calculated from the charts and formulas below.

• Read • Write

Communication time (ms)

Communication time (ms)

Number of processed bytes (Byte)

• Write (with verification)

Communication time (ms)

Number of processed bytes (Byte)

Number of processed bytes (Byte)

Command Bytes Communication

time (ms)

Read 1 to 64 bytes

65 to 128 bytes

0.07 x N + 4.22

0.07 x N + 5.64

ID Read 4 bytes 1.59

Write 1 to 128 bytes 0.07 x N + 4.72

Write

(with verification)

1 to 64 bytes

65 to 128 bytes

0.14 x N + 6.45

0.14 x N + 7.79

N: Number of bytes to be processed

2-17

Page 36

2-5 Communication Range Specifications

In the communication with a tag, any data is read and written at every 4 bytes. Therefore, to minimize the communication time, specify

the address and the number of bytes suitably so that the address for writing can be a multiple of 4.

Example: If 4 bytes of data is written from the address 0001h, change the address to 0000h.

If you cannot change as stated above due to the structure of change system, add the following time to the communication time.

When a protect function is used +2.9 ms

When a start address is not a multiple of 4 +2.9 ms

When an end address (start address + the number of addresses) is not a multiple of 4 +2.9 ms

♦ TAT

Time from the start of command transmission by a host device to the end of receiving of response to the host device. It can be calculated

from the communication time and the number of characters of command/response. The formula is as follows:

TAT = command transfer time + communication time + response transmission time

Transmission time = × number of characters (second)

* The number of bits per character and baud rate vary depending on the communication conditions (baud rate, data length, parity and

stop bit).

Assuming that the number of characters of command is A, the number of characters of response is B, the baud rate is 9600 bps, data

length is 7 bits, parity is even and stop bit is 2 bits, the following formula can be obtained:

11 × (A + B)

TAT =

9600

Bits per character (bit)

Baud rate (bps)

+ communication time (second)

Correct Usage

The formula above calculates the time when processing (transmission of command) starts if the ID tag is within an area

of communication with an antenna. The time varies depending on a communication mode and ID tag status.

2-18

Page 37

2-5-3 Traffic and Passing Speed (Reference)

A

8

♦ Combination of Model V670-H11 with Model V670-D13F03

• Read

450

400

350

300

250

200

150

100

Maximum passing speed (m/min)

50

0

1 163248648096112128

Number of processed bytes (Byte)

Distance

10mm

15mm

20mm

Measurement Conditions:

Ta g

Distance (mm)

ntenna

2-5 Communication Range Specifications

Nonmetal

Passing speed (m/min)

• Write (without verification)

400

350

300

250

200

150

100

500

Maximum passing speed (m/min)

0

1 163248648096112128

Number of processed bytes (Byte)

Distance

• Write (with verification)

350

300

250

200

150

100

50

Maximum passing speed (m/min)

0

1 16324864809611212

Number of processed bytes (Byte)

Distance

10mm

15mm

20mm

10mm

15mm

20mm

Nonmetal

*Antenna extension cable (Model V670-A4: not used)

* Passing speed varies depending on the distance Y

(between tag and antenna), axial displacement, etc.

Refer to the data on communication area to use the

product over its widest communication range.

* Graphs are for reference only. Prior to practical applica-

tion, carry out the evaluation test of the product.

* Graphs do not include communication error correction.

• ID Read

Distance Passing speed

10 mm 750 m/min

15 mm 710 m/min

20 mm 600 m/min

2-19

Page 38

2-5 Communication Range Specifications

A

♦ Combination of Model V670-H51/H51Q with Model V670-D13F01/D13F01H

• Verti cal

• Read

200

180

160

140

120

100

80

60

40

Maximum passing speed (m/min)

20

0

1 163248648096112128

Number of processed bytes (Byte)

• Write (without verification)

200

180

160

140

120

100

80

60

40

Maximum passing speed (m/min)

20

0

1 163248648096112128

Number of processed bytes (Byte)

Distance

3mm

Distance

3mm

Measurement Conditions:

Nonmetal

Ta g

Distance (mm)

Passing speed (m/min)

ntenna

*Antenna extension cable (Model V670-A4: not used)

• Write (with verification)

100

90

80

70

60

50

40

30

20

Maximum passing speed (m/min)

10

0

1 163248648096112128

Number of processed bytes (Byte)

• ID Read

Distance Passing speed

3 mm 225 m/min

Distance

3mm

* Passing speed varies depending on the distance Y

(between tag and antenna), axial displacement, etc.

Refer to the data on communication area to use the

product over its widest communication range.

* Graphs are for reference only. Prior to practical applica-

tion, carry out the evaluation test of the product.

* Graphs do not include communication error correction.

2-20

Page 39

♦ Horizontal

A

• Read

200

180

160

140

120

100

80

60

40

Maximum passing speed (m/min)

20

0

1 163248648096112128

Number of processed bytes (Byte)

• Write (without verification)

200

180

160

140

120

100

80

60

40

Maximum passing speed (m/min)

20

0

1 163248648096112128

Number of processed bytes (Byte)

Distance

3mm

Distance

3mm

2-5 Communication Range Specifications

Measurement Conditions:

Nonmetal

Ta g

Passing speed (m/min)

Distance (mm)

ntenna

*Antenna extension cable (Model V670-A4: not used)

• Write (with verification)

120

100

80

60

40

20

Maximum passing speed (m/min)

0

1 163248648096112128

Number of processed bytes (Byte)

• ID Read

Distance Passing speed

3 mm 275 m/min

Distance

3mm

* Passing speed varies depending on the distance Y

(between tag and antenna), axial displacement, etc.

Refer to the data on communication area to use the

product over its widest communication range.

* Graphs are for reference only. Prior to practical applica-

tion, carry out the evaluation test of the product.

* Graphs do not include communication error correction.

2-21

Page 40

2-22

Page 41

Chapter 3 Setting and Installation

3-1 Controller

3-1-1 Switch Setting

To set the switches, open a cover at the upper left part of the unit.

3-1-1-1 How to Open Cover

To open the cover, insert a screwdriver, which comes with the controller, into a notch at the left end of the cover.

When the cover opens, you can see the two node number setup switches (SW1 and SW2), two dip switches (SW3 and SW4) and connecting port for programming console.

Node number setup switch

Dip switch

Connecting port for programming

console

3-1

Page 42

3-1 Controller

3-1-1-2 How to Set

Set the switch using the screwdriver which comes with the controller as shown below.

• Setting a node number

Turn clockwise or counterclockwise.

• Setting a dip switch

Set to the right or left.

3-1-1-3 Setting List

Set the switches according to the list below. (The switches are set to a default value at shipment from a factory.)

Name Function Default Value

SW1 Node number setup switch used in 1:N protocol. 00

SW2

(Left)

SW3-1

SW3-2 Switch to set an operation mode at startup.

SW3-3 Switch to enable or disable verification at writing. Disabling verification

SW3-4 Switch to set a protocol (1:1 / 1:N). 1:1 protocol

SW3-5 Set to OFF. OFF

SW3-6

SW3-7

SW3-8

SW4-1 Switch to set a communication speed of RS-232C. 9600 bps

SW4-2

SW4-3 Switch to set data length of RS-232C. 7 bits

SW4-4 Switch to set parity of RS-232C. Even parity

SW4-5

SW4-6 Switch to set stop bit of RS-232C. 2 bits

SW4-7 Set to OFF. OFF

SW4-8

Switch to change a function of input terminal (RST/IN).

Reset input

Command execution mode

3-2

(Right)

Page 43

3-1 Controller

3-1-1-4 Setting Node Number Setup Switch

♦ Node number

To connect several controllers to one host device using a link adapter etc., the host device needs to identify each of those controllers.

The number to identify them is referred to as node number. A unique node number must be assigned to every controller.

The command and response of 1:N protocol have the node number. So, unless the node number is assigned appropriately, any communication cannot be made.

♦ Setting node number

Set the node number with the two node number setup switch. SW1 (left) is for an upper order and SW2 (right) for a lower order. Av a i l able number range is from 00 to 31 as shown below.

SW1 SW2

Upper

order

000

011

022

033

044

055

066

077

088

099

1010

1111

:::

2929

3030

3131

3 2 Disabled

3 3 Disabled

:::

9 9 Disabled

Lower

order

Node Number

Example of setting:

Node No. 0

Node No. 17

The factory default setting of the node number is 00.

Correct Usage

Never assign the numbers 32 to 99 to the node number setup switch.

3-3

Page 44

3-1 Controller

3-1-1-5 Setting a Dip Switch

♦ SW3

SW3-1: Input function change

SW3-1 Description

ON Functions as trigger input.

OFF Functions as reset input.

SW3-2: Operation mode

SW3-2 Description

ON Starts in the Self-Execution mode when the power supply turns ON.

OFF Starts in the Command Execution mode when the power supply turns ON.

SW3-3: Verification at writing

SW3-3 Description

ON Enables verification.

OFF Disables verification.

SW3-4: Protocol designation

SW3-4 Description

ON Uses the 1:N protocol.

OFF Uses the 1:1 protocol.

Correct Usage

Set SW3-5, SW3-6, SW3-7 and SW3-8 to OFF always. Otherwise, any operation cannot be guaranteed.

3-4

Page 45

♦ SW4

SW4-1/4-2: Communication speed setting

SW4-2 SW4-1 Description

ON ON 115200 bps

OFF 38400 bps

OFF ON 19200 bps

OFF 9600 bps

SW4-3: Data length setting

SW4-3 Description

ON 8 bits

OFF 7 bits

3-1 Controller

SW4-4/4-5: Parity bit setting

SW4-5 SW4-4 Description

ON ON Even parity

OFF No parity

OFF ON Odd parity

OFF Even parity

SW4-6: Stop bit setting

SW4-6 Description