SECTION 6

Troubleshooting

Troubleshooting 70

SECTION 6

Troubleshooting

CIDRW System

User’s Manual

69

SECTION 6

Troubleshooting

Troubleshooting

Errors are indicated by the presence or absence of a response to an Amplifier Unit command, and by the

indicators.

List of Error Messages

SECTION 6

Troubleshooting

Type

Host communications error

Communications

error between

the CIDRW Head

and ID Tag

CPU hardware

error

Response

code

14 Format error There is a mistake in the command format. (For example, the com-

70 Communications

71 Verification error Correct data cannot be written to an ID Tag.

72 No Tag error Either there is no ID Tag in front of the CIDRW Head, or the CIDRW

7B Outside write area

7E ID system error (1) The ID Tag is in a status where it cannot execute the command pro-

7F ID system error (2) An inapplicable ID Tag has been used.

9A Hardware error in

Name Description

mand portion is undefined, or the page or address specification is

inappropriate.)

Noise or another hindrance has occurred during communications with

error

error

CPU

an ID Tag, and communications cannot be completed normally.

Head is unable to detect the ID Tag due to environmental factors (e.g.,

noise).

The ID Tag is at a position where reading is possible but writing is not,

so writing does not complete normally.

cessing.

An error occurred when writing to EEPROM.

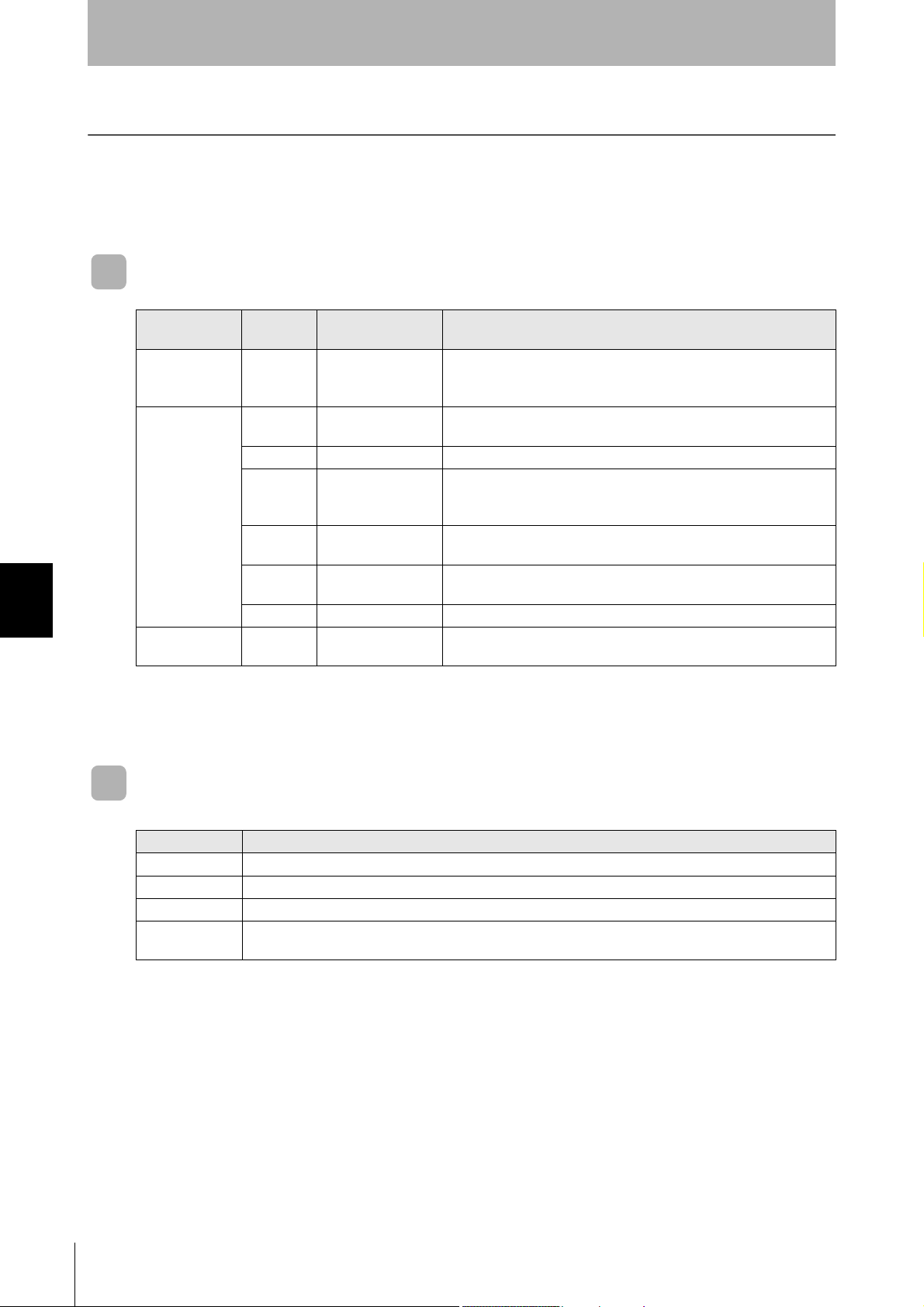

Amplifier Unit Indicators

Name Indications

RUN (green) Turns ON when the Amplifier Unit is in normal operation.

COMM (orange) Turns ON during communications with the host device or during communications with an ID Tag.

NORM (green) Turns ON when the communications finish with no error.

ERROR (red) Turns ON when an error occurs during communications with the host device, or during communications

with an ID Tag.

70

CIDRW System

User’s Manual

SECTION 6

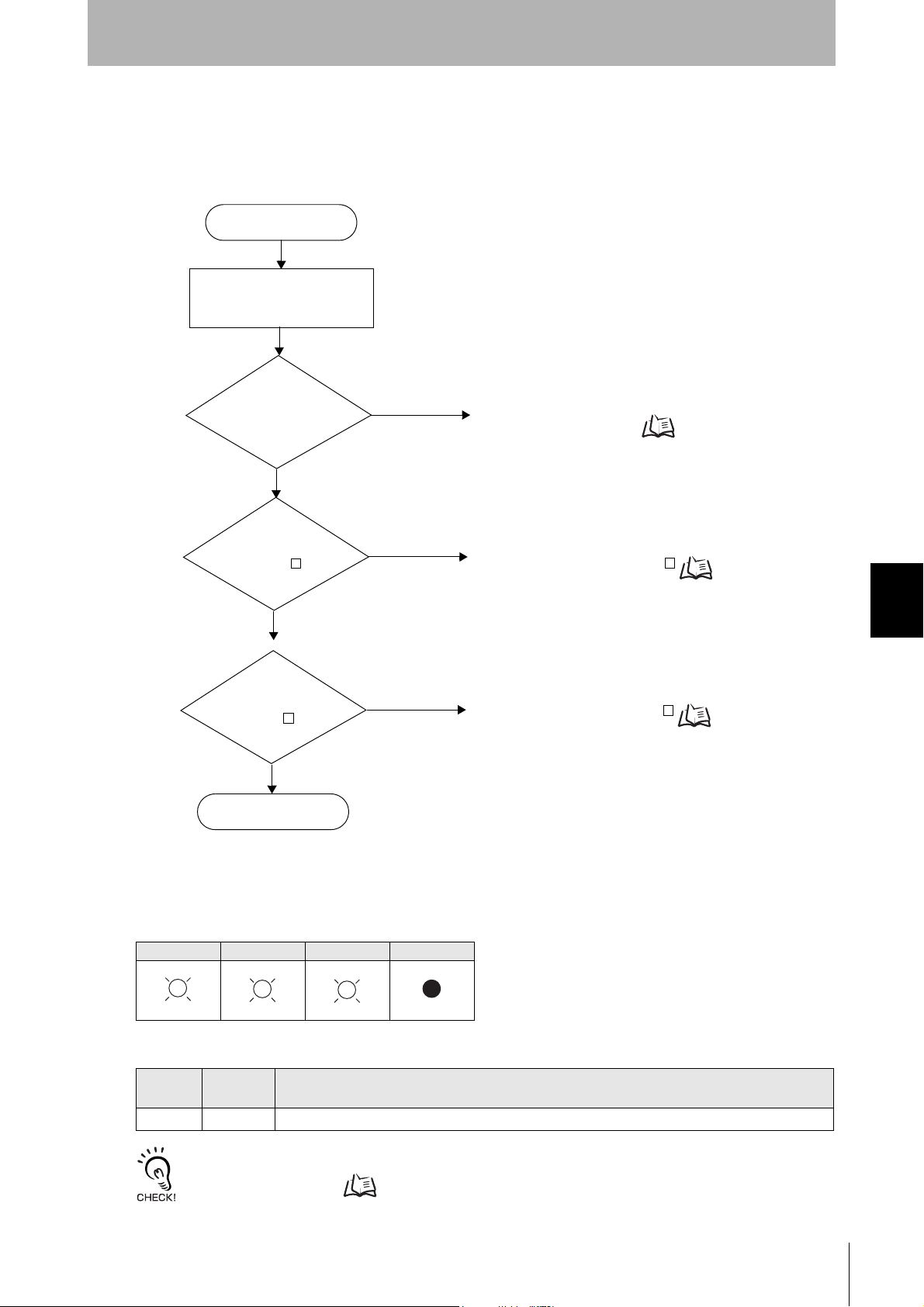

Error occurrence

Test command transmission

RUN indicator

OFF?

No

Yes

An error has occurred at the Amplifier Unit.

Amplifier Unit error Refer to page 72.

Check if the Amplifier Unit settings are correct.

If There Is No Response to the Command: Refer to page 72.

Response received?

Yes

Check the nature of the response.

If there is a response to the command

Refer to page 72.

No

(Lights once)

Troubleshooting

Operation Check Flowchart

■ From Installation to Trial Operation

Errors are indicated by whether or not a response to the test command is received and by the status of

the Amplifier Unit indicators.

• If the Test Command Was Received Normally:

Indicators

RUN COMM NORM ERROR

SECTION 6

Troubleshooting

Response Code for the Response

Type

Normal 00 The command was received normally.

Response

code

Function

CIDRW System

User’s Manual

71

SECTION 6

(Lights once)

(Lights once)

SECTION 6

Troubleshooting

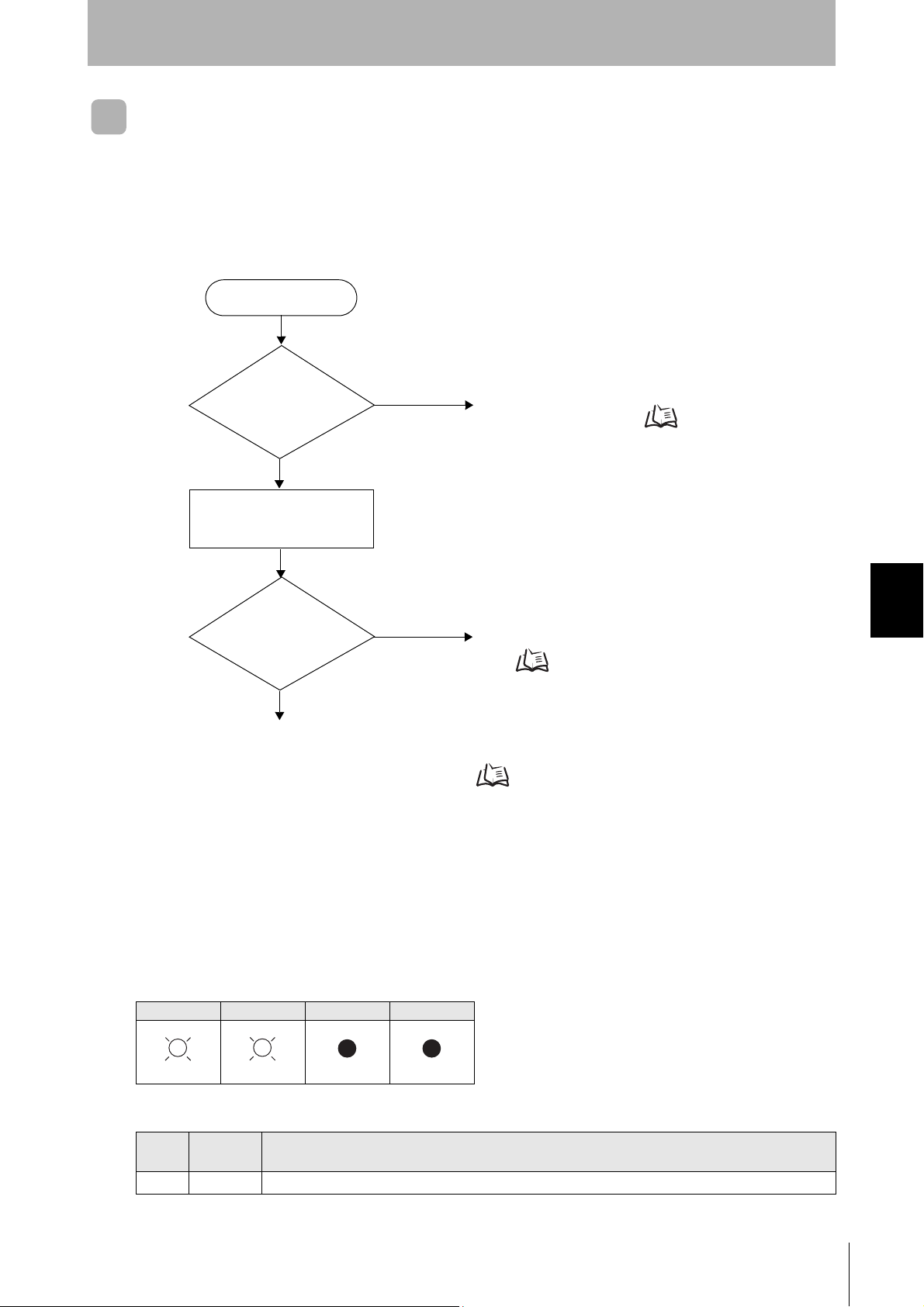

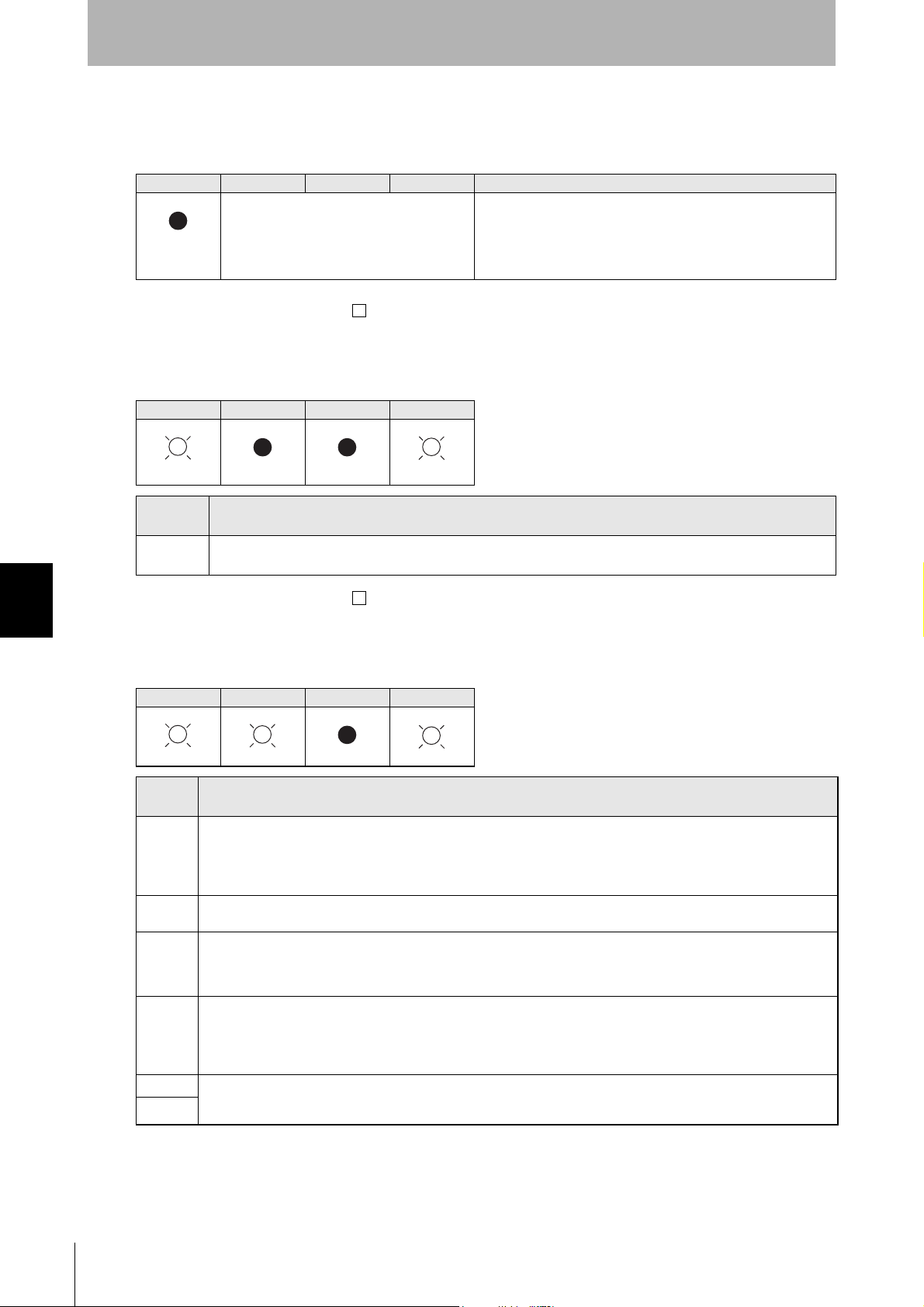

• Amplifier Unit Error

Check the status of the indicators after transmission of the test command.

After taking appropriate corrective action, restart the Amplifier Unit, send the test command again and

check again.

RUN COMM NORM ERROR Main check points

—

(If RUN is OFF, the status of the other indicators can be ignored.)

• Influence of background noise (change installation position)

• Amplifier Unit power supply

If the error cannot be resolved after checking, the Amplifier Unit

may be damaged.

• If There Is No Response to the Command:

Check the status of the indicators after transmission of the test command.

After taking appropriate corrective action, restart the Amplifier Unit, send the test command again and

check again.

RUN COMM NORM ERROR Main check points

• Amplifier Unit baud rate settings

• Node numbers of the Amplifier Units (do not match the node

number in the test command)

• Connection and wiring of the cable between the host device

and Amplifier Unit

• Routing of each cable (influence of background noise)

If the error cannot be resolved after checking, the Amplifier Unit

may be damaged.

• Amplifier Unit baud rate settings

• Connection and wiring of the cable between the host device

and Amplifier Unit

• Routing of the cables (influence of background noise)

Troubleshooting

• If There Is a Response to the Command:

Check the status of the indicators after transmission of the test command.

After taking appropriate corrective action, restart the Amplifier Unit, send the test command again and

check again.

RUN COMM NORM ERROR Main check points

• Node numbers of the Amplifier Units (The same number is set

for more than one Unit)

If the error cannot be resolved after checking, the Amplifier

Unit may be damaged.

There is a mistake in the command format (number of characters, character code, etc.).

72

CIDRW System

User’s Manual

SECTION 6

Error occurrence

Is the response

code 1 ?

No

Yes

Check the command format.

If the response code is 1 Refer to page 74.

Ye s

Communications with the ID Tag has failed.

If the response code is 7 Refer to page 74.

Write command sent

RUN indicator

OFF?

No

Yes

An error has occurred at the Amplifier Unit.

Amplifier Unit error Refer to page 74.

Is the response

code 7 ?

Communications OK

No

(Lights once)

(Lights once)

Troubleshooting

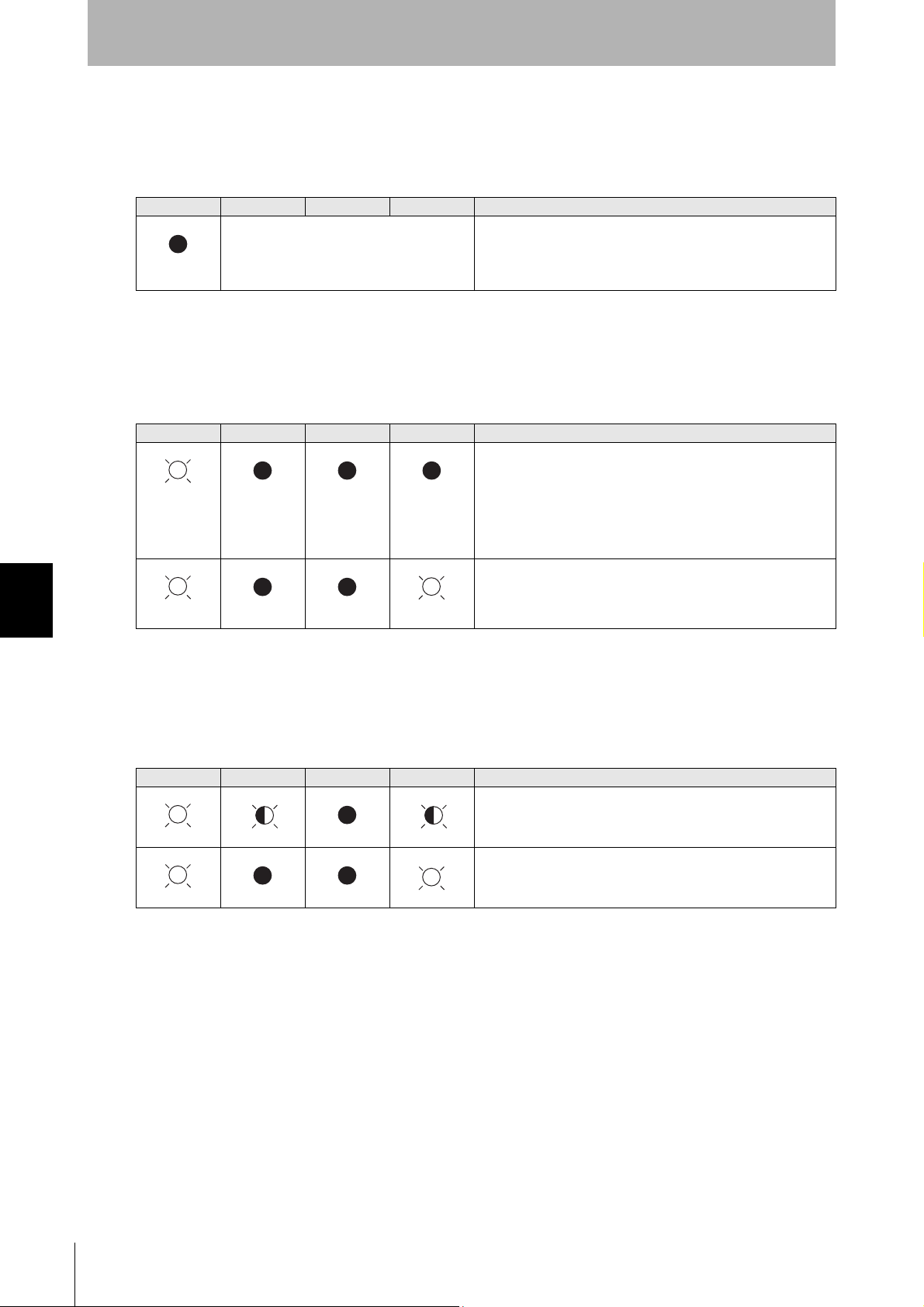

■ From Trial Operation to Communications

Errors are indicated by the status of the indicators after transmission of the write command, and by the

response code of the response.

• If the ID Tag Was Processed Normally:

Indicators

RUN COMM NORM ERROR

SECTION 6

Troubleshooting

Response Code for the Response

Normal 00 The ID Tag was processed normally.

Type

Response

code

If there is no response to the write command, refer to the From Installation to Trial Operation,

Operation Check Flowchart. Refer to page 71.

Function

CIDRW System

User’s Manual

73

SECTION 6

(Lights once)

(Lights once)

(Lights once)

Troubleshooting

• Amplifier Unit Error

Check the status of the indicators after transmission of the command. After taking appropriate corrective action, send the write command again and check again.

RUN COMM NORM ERROR Main check points

—

(If RUN is OFF, the status of the other indicators can be ignored.)

• Influence of background noise (Change installation position)

• Amplifier Unit power supply

If the error cannot be resolved by checking the two points above,

the Amplifier Unit may be damaged.

• If the Response Code is 1 :

There is a host device communications error.

Check the status of the indicators and the response code of the response after transmission of the

command. After taking appropriate corrective action, send the write command again and check again.

RUN COMM NORM ERROR

SECTION 6

Troubleshooting

Response

code

14 Command format

(Command code, page designation, address designation, processed data volume, etc.)

Main check points

• If the Response Code is 7 :

There is a communications error in communications between the CIDRW Head and ID Tag.

Check the status of the indicators and the response code of the response after transmission of the

command. After taking appropriate corrective action, send the write command again and check again.

RUN COMM NORM ERROR

Response

code

70

71 • ID Tag overwrite life (Replace the ID Tag)

72 • Connection to the CIDRW Head

7B • Distance between the ID Tag and CIDRW Head

7E • Type/specifications of the ID Tags used

7F

• Background noise levels of the CIDRW Head (Check the surroundings with the environmental noise level measurement

function)

• Distance to another CIDRW Head

• Influence of background noise (Change installation position)

If the error cannot be resolved after checking, the Amplifier Unit may be damaged.

• Environment of use of the ID Tags (ID Tag breakage due to use in unanticipated ways)

• Distance between the ID Tag and CIDRW Head

• CIDRW Head background noise levels (Check the surroundings with the environmental noise level measurement function)

• Distance to another CIDRW Head

• Background noise levels of the CIDRW Head (Check the surroundings with the environmental noise level measurement

function)

• Distance to another CIDRW Head

• Influence of background noise (Change installation position)

• Settings of the ID Tags used (The ID Tag lock function is used.*)

• Environment of use of the ID Tags (ID Tag breakage due to use in unanticipated ways)

Main check points

74

* The ID Tag has a lock function, but the Amplifier Unit has no function for locking an ID Tag.

CIDRW System

User’s Manual

SECTION 7

Appendix

Specifications and Dimensions 76

Connection Examples 80

Characteristic Data According to Conditions of Use 81

ID Tag Memory Maps 111

Regular Inspection 112

ASCII Code Table 113

Protective Construction 114

SECTION 7

Appendix

CIDRW System

User’s Manual

75

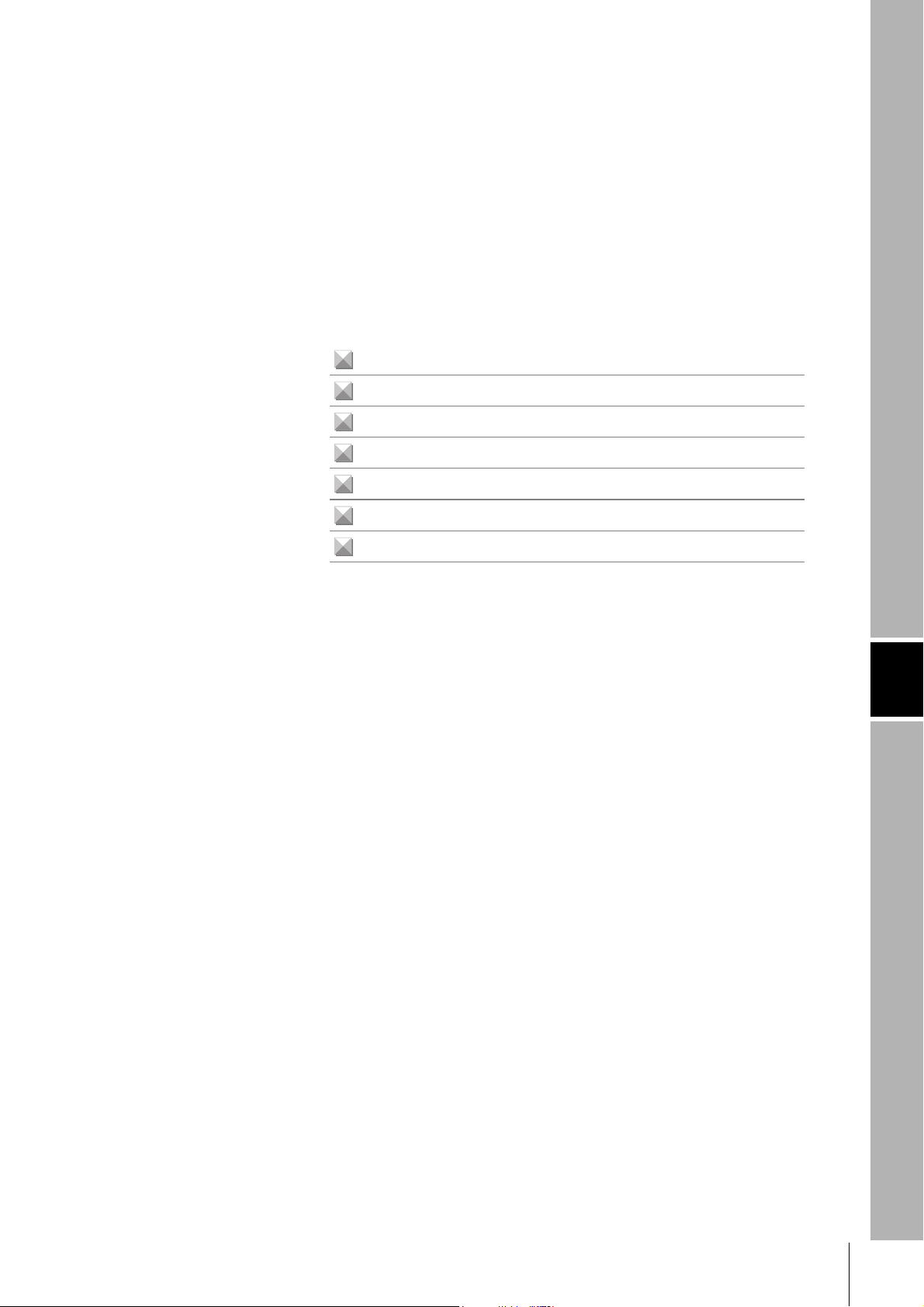

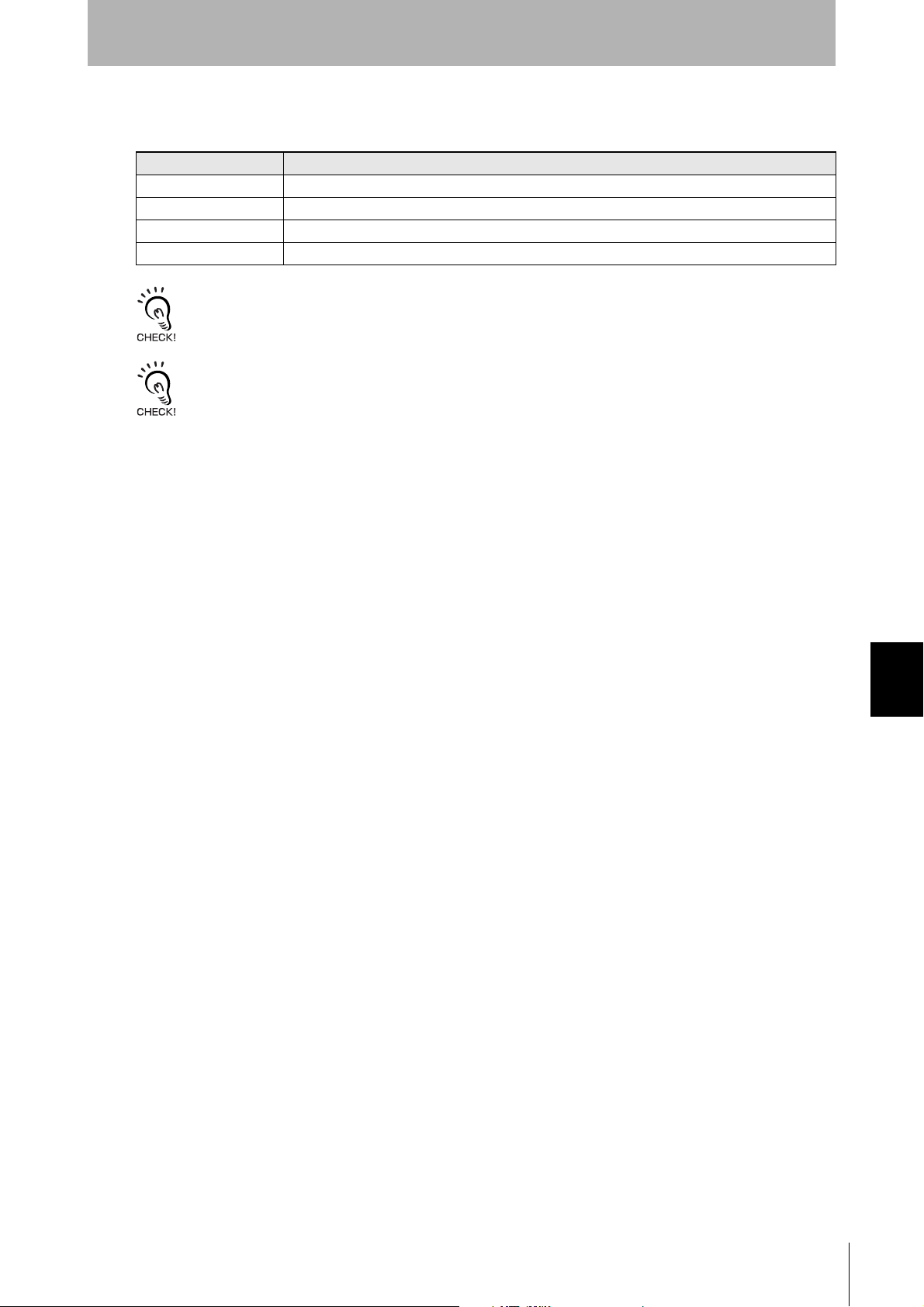

SECTION 7

DIP switch

(Unit: mm)

Mounting dimensions

Four, 4.5-dia. holes

DC power supply connector

MAC address label

Ethernet connector

Four operation indicators

Appendix

Specifications and Dimensions

Amplifier Units

V640-HAM11-ETN and V640-HAM11-L-ETN

SECTION 7

(15.8)

(31.95)

(13)

(18)

6.86.86.80.6

55.5

160

175

185

175±0.5

(11.5)

465680

(5.7)

5

(18.2)

(12)

(22.5)

43

(32.5)

Specifications and Dimensions

■ General Specifications

Item

Power supply voltage 24 VDC +10% -15%

Current consumption 150 mA max. 400 mA max.

Ambient temperature Operating: 0 to +40°C Storage: -15 to +65°C (with no icing)

Ambient humidity Operating/Storage: 35% to 85% (with no condensation)

Degree of protection IP20 (IEC60529 standard)

Insulation resistance 20 MΩ min. between power supply terminals and the frame ground terminal (100 VDC M)

Dielectric strength Leak current not to exceed 5 mA on application of 1000 VAC (50/60 Hz for 1 minute) between both

Vibration resistance Frequency: 10 to 150 Hz; double amplitude: 0.20 mm; acceleration: 15 m/s

Shock resistance Shock of 150 m/s

Ground Ground to 100 Ω or less.

Case material PC/ABS resin

Shape 80×185×43 mm (W×D×H)

Weight Approx. 250 g

CIDRW Head V640-HS61 V640-HS62

4-M4

Specifications

V640-HAM11-ETN V640-HAM11-L-ETN

power supply terminals and the frame ground terminal

8 minutes, 10 times each in X, Y, and Z directions

2

in X, Y, and Z directions, 3 times each for 18 repetitions

0.5

±

46

2

for

76

CIDRW System

User’s Manual

■ Host Communications Specifications

Item Description

Compliant standards 10Base-T and 100Base-TX

Protocol TCP/IP

Applicable port TCP/IP: port 7090

MTU 1,500 bytes

Access to an Amplifier Unit is possible from only one host device at a time. If a host device (A) is connected to an Amplifier Unit and another host device (B) connects to the Amplifier Unit, the connection between host device A and the

Amplifier Unit will be automatically broken and host device B will have the control right.

Communications with the ID Tag will be aborted if the Ethernet cable is disconnected or the connection is broken while

the Amplifier Unit is communicating with an ID Tag.

SECTION 7

Appendix

SECTION 7

Specifications and Dimensions

CIDRW System

User’s Manual

77

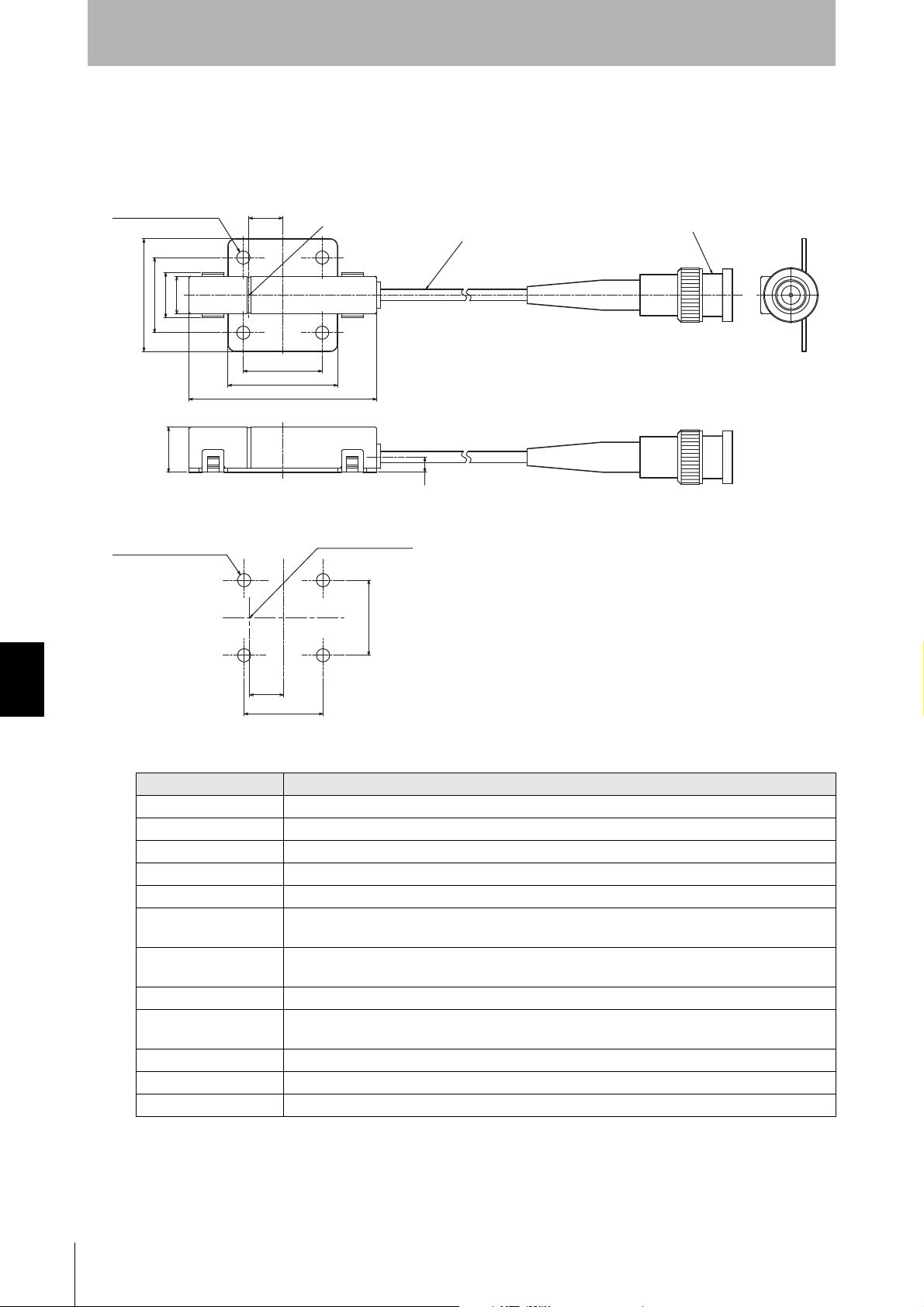

SECTION 7

Coaxial cable 3.0 dia., standard length 2 m

(Unit: mm)

Connector

Antenna center

Antenna center

Mounting dimensions

Four M3 or 3.5-dia. holes

Appendix

CIDRW Heads

V640-HS61

Four, 3.5-dia. holes

SECTION 7

Specifications and Dimensions

Transmission frequency 134 kHz

Ambient temperature Operating: 0 to +40°C Storage: -15 to +65°C (with no icing)

Ambient humidity Operating/Storage: 35% to 85% (with no condensation)

Degree of protection IP60 (IEC60529)

Insulation resistance 20 MΩ min. between all terminals and the case (100 VDC M)

Dielectric strength Leak current not to exceed 5 mA on application of 1000 VAC (50/60 Hz for 1 minute) between all

Vibration resistance Frequency: 10 to 150 Hz; double amplitude: 0.20 mm; acceleration: 15 m/s

Shock resistance Shock of 150 m/s

Casing material ABS/epoxy resin

Weight Approx. 70 g

Cable length 2 m

Cable specification 3-mm-dia. coaxial cable

Item Specifications

terminals and the case

8 minutes, 10 times each in X, Y, and Z directions

2

in X, Y, and Z directions, 3 times each for 18 repetitions

Stainless steel mount

2

for

78

CIDRW System

User’s Manual

V640-HS62

302012

10

9

65

39.2

21

Max.28

12

4

49

14.5

Max.20.5

9

21

±0.2

20±0.2

Ferrite core

(Unit: mm)

Connector

Coaxial cable, Dia.: 3.0, Length: 1.9 m

Center of coil

Mounting Hole Dimensions

Four M3 or 3.5-dia. holes

Four 3.5-dia. (mounting holes)

Center of coil

SECTION 7

Appendix

Item Specifications

Transmission frequency 134 kHz

Ambient temperature Operating: 0 to +40°C Storage: -15 to +65°C (with no icing)

Ambient humidity Operating/Storage: 35% to 85% (with no condensation)

Degree of protection IP60 (IEC60529)

Insulation resistance 20 MΩ min. between all terminals and the case (100 VDC M)

Dielectric strength Leak current not to exceed 5 mA on application of 1000 VAC (50/60 Hz for 1 minute) between all

Vibration resistance Frequency: 10 to 150 Hz; double amplitude: 0.20 mm; acceleration: 15 m/s

Shock resistance Shock of 150 m/s

Casing material ABS/epoxy resin

Weight Approx. 100 g

Cable length 1.9 m

Cable specification 3-mm-dia. coaxial cable

terminals and the case

8 minutes, 10 times each in X, Y, and Z directions

Stainless steel mount

2

in X, Y, and Z directions, 3 times each for 18 repetitions

2

SECTION 7

Specifications and Dimensions

for

CIDRW System

User’s Manual

79

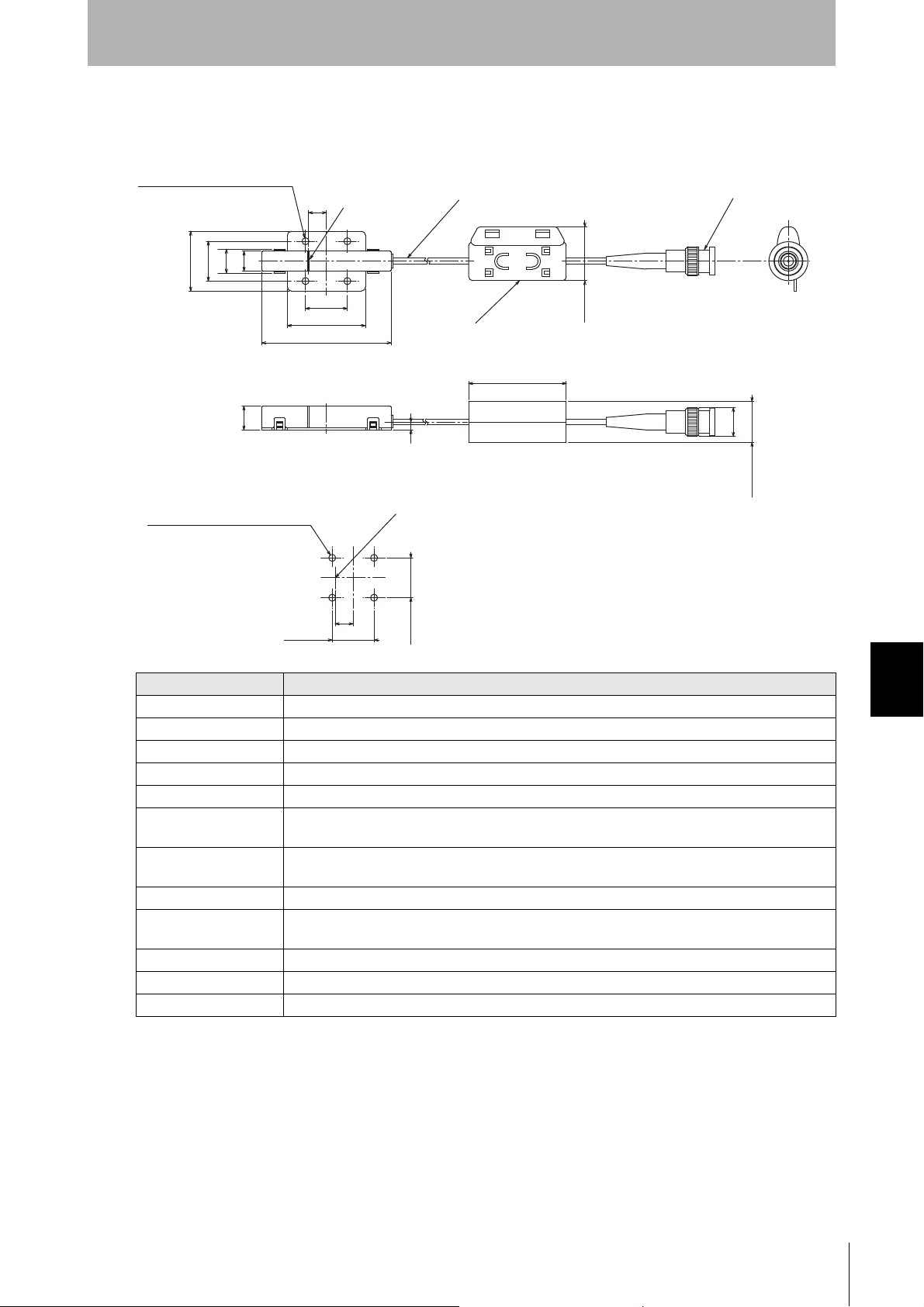

SECTION 7

Host device

Host computer,

device controller, etc.

CIDRW Head

V640-HS61

Amplifier Unit

V640-HAM11-ETN

Ethernet hub

LAN cable

LAN cable

CIDRW Head

V640-HS61

Amplifier Unit

V640-HAM11-ETN

LAN cable

CIDRW Head

V640-HS61

Amplifier Unit

V640-HAM11-ETN

LAN cable

The Amplifier Unit controls the

CIDRW Head. Up to 256 Amplifier Units can be connected.

The CIDRW Head is the

antenna. It reads and writes

carrier IDs and performs

other processing for ID Tags.

Host device

Host computer,

device controller, etc.

CIDRW Head

V640-HS62

Amplifier Unit

V640-HAM11-L-ETN

Ethernet hub

LAN cable

LAN cable

CIDRW Head

V640-HS62

Amplifier Unit

V640-HAM11-L-ETN

LAN cable

CIDRW Head

V640-HS62

Amplifier Unit

V640-HAM11-L-ETN

LAN cable

The Amplifier Unit controls the

CIDRW Head. Up to 256 Amplifier Units can be connected.

The CIDRW Head is the

antenna. It reads and writes

carrier IDs and performs

other processing for ID Tags.

Appendix

Connection Examples

V640-HAM11-ETN

Connect the host device and Amplifier Unit using a LAN cable.

SECTION 7

Connection Examples

V640-HAM11-L-ETN

Connect the host device and Amplifier Unit using a LAN cable.

80

CIDRW System

User’s Manual

SECTION 7

0

10

20

30

40

50

60

70

80

90

100

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

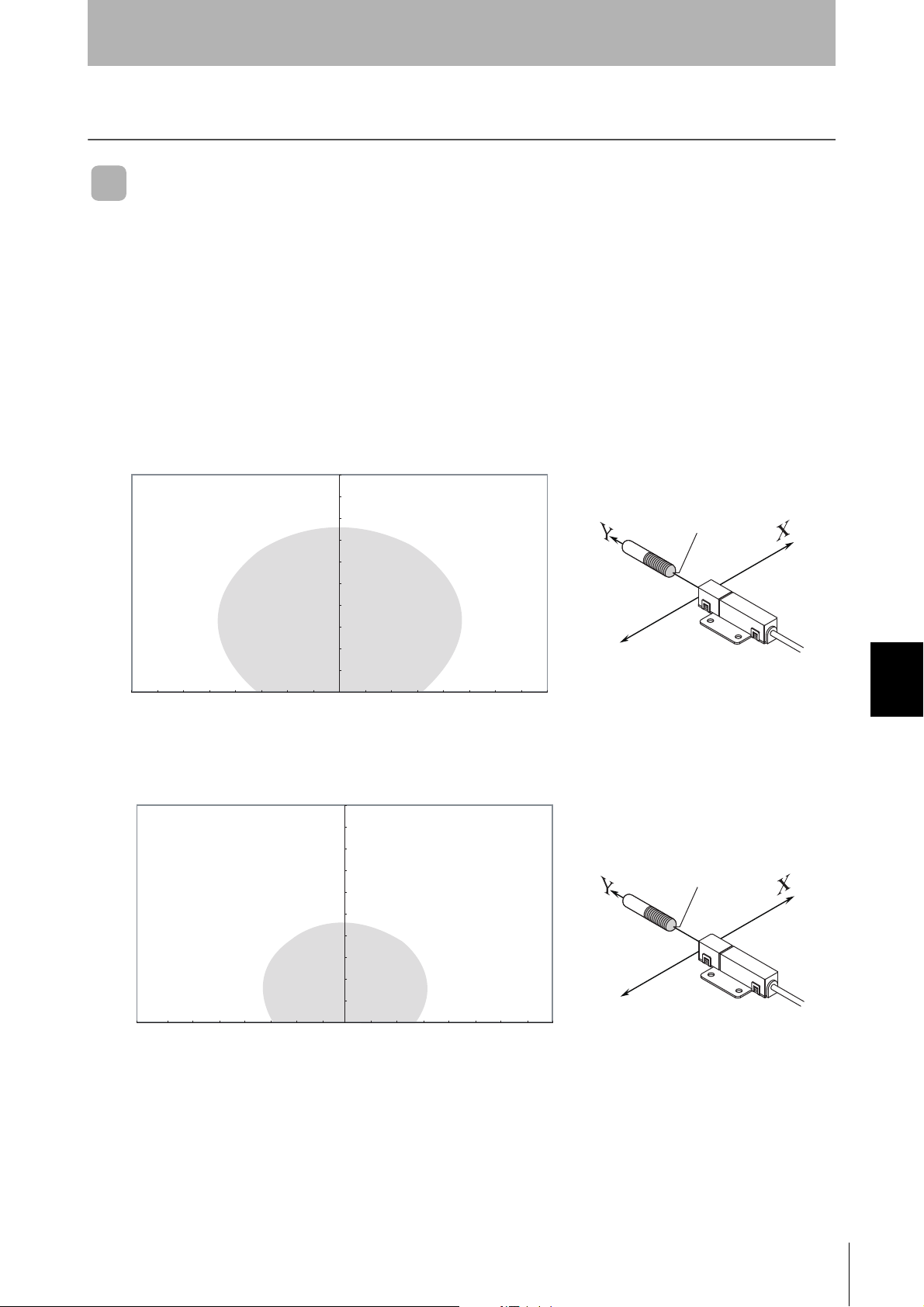

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement point

0

10

20

30

40

50

60

70

80

90

100

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Communications Area (WRITE)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement point

Appendix

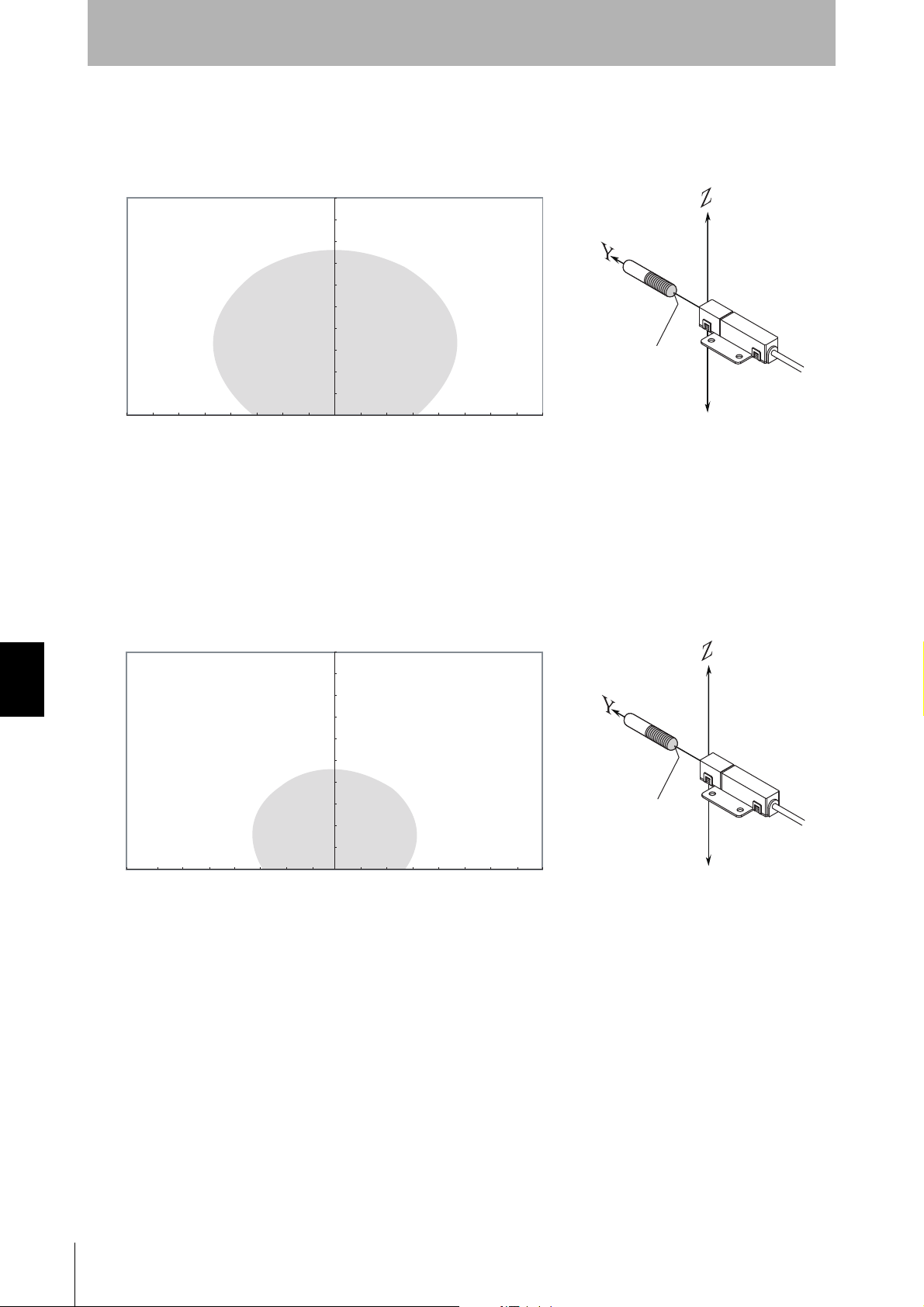

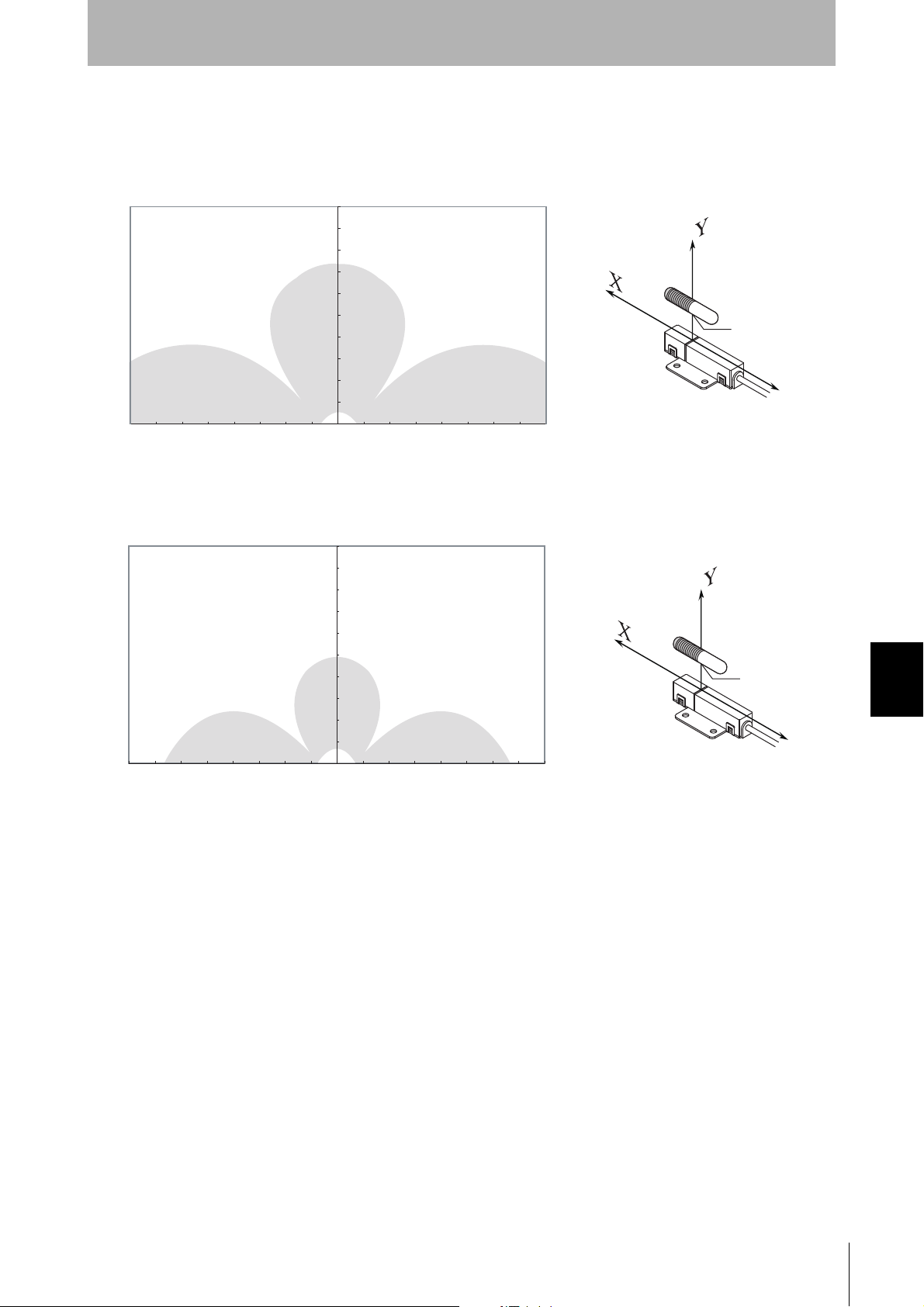

Characteristic Data According to Conditions of Use

Maps of Communications Areas (Reference Only)

The figures given below for communications areas (communications distances) are reference values

only. The maps of communications areas will vary according to the ID Tags that you use, the background metals, the ambient noise, the effects of temperature and so on, and should be thoroughly confirmed on installation. The direction of the ID Tags will affect communications performance. Check the

direction of the coils in the ID Tags before using the ID Tags.

■ V640-HAM11-ETN

• Coaxial Mounting (RI-TRP-DR2B)

• READ

• WRITE

CIDRW System

User’s Manual

SECTION 7

Characteristic Data According to Conditions of Use

81

SECTION 7

0

10

20

30

40

50

60

70

80

90

100

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Communications Area (READ)

Distance in Z direction (mm)

Measurement point

Distance in Y direction (mm)

Communications Area (WRITE)

Distance in Z direction (mm)

Measurement point

Distance in Y direction (mm)

Appendix

• Coaxial Mounting (RI-TRP-DR2B)

• READ

SECTION 7

Characteristic Data According to Conditions of Use

• WRITE

100

90

80

70

60

50

40

30

20

10

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

0

82

CIDRW System

User’s Manual

• Parallel Mounting (RI-TRP-DR2B)

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

10

20

30

40

50

60

70

80

90

100

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

0

Communications Area (WRITE)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

• READ

100

90

80

70

60

50

40

30

20

10

0

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

• WRITE

SECTION 7

Appendix

CIDRW System

User’s Manual

SECTION 7

Characteristic Data According to Conditions of Use

83

SECTION 7

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

0

10

20

30

40

50

60

70

80

90

100

010-10 20-20-30 30 40-40-50 50-60-70-80 60 70 80

Communications Area (WRITE)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Appendix

• Parallel Mounting (RI-TRP-DR2B)

• READ

100

90

80

70

60

50

40

30

20

10

0

010-10 20-20-30 30 40-40-50 50-60-70-80 60 70 80

• WRITE

SECTION 7

Characteristic Data According to Conditions of Use

84

CIDRW System

User’s Manual

• Vertical Mounting (RI-TRP-DR2B)

0

10

20

30

40

50

60

70

80

90

100

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

0

10

20

30

40

50

60

70

80

90

100

-80 -70 -60 -50 -40 -30 -20 -10 0 10 20 30 40 50 60 70 80

Communications Area (WRITE)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

• READ

• WRITE

SECTION 7

Appendix

CIDRW System

User’s Manual

SECTION 7

Characteristic Data According to Conditions of Use

85

SECTION 7

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (WRITE)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Appendix

• Vertical Mounting (RI-TRP-DR2B)

• READ

100

90

80

70

60

50

40

30

20

10

0

010-10 20-20-30 30 40-40-50 50-60-70-80 60 70 80

SECTION 7

Characteristic Data According to Conditions of Use

• WRITE

100

90

80

70

60

50

40

30

20

10

0

010-10 20-20-30 30 40-40-50 50-60-70-80 60 70 80

86

CIDRW System

User’s Manual

• Coaxial Mounting (RI-TRP-WR2B)

0

30

60

90

120

150

180

-200 0 50 100 150 200-200 -150 -100 -50

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

0

30

60

90

120

150

180

-200 0 50 100 150 200-150 -100 -50

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (WRITE)

• READ

SECTION 7

Appendix

• WRITE

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

87

SECTION 7

0

30

60

90

120

150

180

-200 0 50 100 150 200-150 -100 -50

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

0

30

60

90

120

150

180

-200 0 50 100 150 200-150 -100 -50

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (WRITE)

Appendix

• Coaxial Mounting (RI-TRP-WR2B)

• READ

• WRITE

SECTION 7

Characteristic Data According to Conditions of Use

88

CIDRW System

User’s Manual

• Parallel Mounting (RI-TRP-WR2B)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

0

30

60

90

120

150

180

-200 0 20050 100 150-150 -100 -50

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (WRITE)

• READ

180

150

120

90

60

30

SECTION 7

Appendix

-200 0 50 100 150 200-150 -100 -50

• WRITE

0

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

89

SECTION 7

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (WRITE)

Appendix

• Parallel Mounting (RI-TRP-WR2B)

• READ

180

150

120

90

60

30

SECTION 7

Characteristic Data According to Conditions of Use

-200 -150 -100 -50 0 50 100 150 200

0

• WRITE

180

150

120

90

60

30

0

0 50 100 150 200-200 -150 -100 -50

90

CIDRW System

User’s Manual

• Vertical Mounting (RI-TRP-WR2B)

0

30

60

90

120

150

180

-200 0 20050 100 150-150 -100 -50

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (WRITE)

• READ

• WRITE

SECTION 7

Appendix

-200 0 20050 100 150-150 -100 -50

180

150

120

90

60

30

0

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

91

SECTION 7

0

30

60

90

120

150

180

-200 0 20050 100 150-150 -100 -50

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Appendix

• Vertical Mounting (RI-TRP-WR2B)

• READ

• WRITE

SECTION 7

Characteristic Data According to Conditions of Use

180

150

120

90

60

30

-200 -150 -100 -50 50 100 150 2000

0

CIDRW System

92

User’s Manual

■ V640-HAM11-L-ETN

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement point

0-20

0

20

40

60

80

100

120

140

-40-60-80-100-120-140-160-180 18016014012010080604020

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement point

0-20

0

20

40

60

80

100

120

140

-40-60-80-100-120-140-160-180 18016014012010080604020

• Coaxial Mounting (RI-TRP-DR2B)

• READ

SECTION 7

Appendix

• WRITE

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

93

SECTION 7

Communications Area (READ)

Distance in Z direction (mm)

Measurement point

Distance in Y direction (mm)

Communications Area (READ)

Distance in Z direction (mm)

Measurement point

Distance in Y direction (mm)

Appendix

• Coaxial Mounting (RI-TRP-DR2B)

• READ

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

• WRITE

0-20

SECTION 7

Characteristic Data According to Conditions of Use

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

0-20

94

CIDRW System

User’s Manual

• Parallel Mounting (RI-TRP-DR2B)

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

• READ

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

• WRITE

0-20

SECTION 7

Appendix

-40-60-80-100-120-140-160-180 18016014012010080604020

140

120

100

80

60

40

SECTION 7

Characteristic Data According to Conditions of Use

20

0

0-20

CIDRW System

User’s Manual

95

SECTION 7

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Appendix

• Parallel Mounting (RI-TRP-DR2B)

• READ

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

• WRITE

0-20

SECTION 7

Characteristic Data According to Conditions of Use

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

0-20

96

CIDRW System

User’s Manual

• Vertical Mounting (RI-TRP-DR2B)

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

• READ

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

• WRITE

0-20

SECTION 7

Appendix

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

0-20

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

97

SECTION 7

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Appendix

• Vertical Mounting (RI-TRP-DR2B)

• READ

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

0-20

SECTION 7

Characteristic Data According to Conditions of Use

• WRITE

140

120

100

80

60

40

20

0

-40-60-80-100-120-140-160-180 18016014012010080604020

0-20

98

CIDRW System

User’s Manual

• Coaxial Mounting (RI-TRP-WR2B)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

㪇

㪇

㪄㪌㪇

㪊㪇

㪌㪇

㪍㪇

㪐㪇

㪈㪉㪇

㪈㪌㪇

㪈㪏㪇

㪄㪈㪇㪇 㪈㪇㪇㪄㪈㪌㪇 㪈㪌㪇㪄㪉㪇㪇 㪉㪇㪇

• READ

180

150

120

90

60

30

0

-100 100-150 150-200 200

-50

0

50

SECTION 7

Appendix

• WRITE

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

99

SECTION 7

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Appendix

• Coaxial Mounting (RI-TRP-WR2B)

• READ

180

150

120

90

60

30

0

0

• WRITE

-100 100-150 150-200 200

-50

50

SECTION 7

Characteristic Data According to Conditions of Use

180

150

120

90

60

30

0

-100 100-150 150-200 200

-50

0

50

100

CIDRW System

User’s Manual

• Parallel Mounting (RI-TRP-WR2B)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

• READ

180

150

120

90

60

30

0

-100 100-150 150-200 200

-50

0

50

SECTION 7

Appendix

• WRITE

180

150

120

90

60

30

0

-100 100-150 150-200 200

-50

0

50

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

101

SECTION 7

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Appendix

• Parallel Mounting (RI-TRP-WR2B)

• READ

180

150

120

90

60

30

0

0

• WRITE

-100 100-150 150-200 200

-50

50

SECTION 7

Characteristic Data According to Conditions of Use

180

150

120

90

60

30

0

-100 100-150 150-200 200

-50

0

50

102

CIDRW System

User’s Manual

• Vertical Mounting (RI-TRP-WR2B)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in X direction (mm)

Measurement

point

Communications Area (READ)

• READ

180

150

120

90

60

30

SECTION 7

Appendix

• WRITE

180

150

120

0

0

90

60

30

0

0

50

50

-100 100-150 150-200 200

-100 100-150 150-200 200

-50

-50

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

103

SECTION 7

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Distance in Y direction (mm)

Distance in Z direction (mm)

Measurement

point

Communications Area (READ)

Appendix

• Vertical Mounting (RI-TRP-WR2B)

• READ

180

150

120

90

60

30

SECTION 7

Characteristic Data According to Conditions of Use

• WRITE

180

150

120

0

0

90

60

30

0

0

50

50

-100 100-150 150-200 200

-100 100-150 150-200 200

-50

-50

CIDRW System

104

User’s Manual

SECTION 7

1 m min.

• V640-HS61

• V640-HS62

2 m min.

1 m min.

• V640-HS61

• V640-HS62

2 m min.

1 m min.

• V640-HS61

• V640-HS62

2 m min.

Appendix

Mutual Interference Distances (Reference Only)

If Amplifier Units are connected using multidrop connections and multiple CIDRW Heads are used, the

CIDRW Heads will not process commands simultaneously. In this case, install the CIDRW Heads at

least 0.1 m apart from each other.

Distance between Antennas and Changes in Communications Distances (Reference Only)

• V640-HS61 • V640-HS62

Distance between Antennas Change in communications distance Distance between Antennas Change in communications distance

1,000 mm 100% 2,000 mm 99%

900 mm 100% 1,600 mm 99%

800 mm 100% 1,400 mm 95%

700 mm 99% 1,200 mm 84%

600 mm 90% 1,000 mm 68%

500 mm 74% 800 mm 53%

400 mm 55% 600 mm 34%

300 mm 40% 400 mm 15%

200 mm 15% 200 mm 0%

If CIDRW Heads in separate CIDRW systems process commands simultaneously when the CIDRW

Systems are installed close to each other, mutual interference between the Heads can result in malfunctions. If this is a problem, install the CIDRW Heads separated at least by the distances shown in

the following illustrations.

■ For Coaxial Installation

■ For Parallel Installation

SECTION 7

Characteristic Data According to Conditions of Use

■ For Face-to-Face Installation

CIDRW System

User’s Manual

105

SECTION 7

Metal body (material: AL, SUS)

(Thickness: 1 mm)

10 mm min.

10 mm min.

20 mm min.

20 mm min.

Metal body (material: AL, SUS)

• V640-HS61

• V640-HS62

20 mm min.

20 mm min.

30 mm min.

30 mm min.

Metal body (material: AL, SUS)

Appendix

Influence of Background Metals (Reference Only)

The CIDRW Head can also communicate from an opening in a ceiling panel (metal body).

However, ensure the distances indicated below between the CIDRW Head and the metal body. If you

do not ensure these distances the communications distance will be substantially shortened.

SECTION 7

Characteristic Data According to Conditions of Use

V640-HS62

CIDRW HEAD

MADE IN JAPAN

CIDRW System

106

User’s Manual

SECTION 7

Host

Amplifier Unit

Command

Response

Communications time

TAT

Rounding up

Transmission time (ms) =

Number of bits per character (bits)

Baud rate (bps)

× total number of characters of command and response

TAT ( ms) =

10

9600

× (A + B) + Communications time (ms)

Appendix

Communications Time

Regardless of whether SECS is used or not, take the time required for processing between the host

device and Amplifier Units into account when designing the system.

Time Description

Communications time This is the time required for communications between an ID Tag and the CIDRW Head.

TAT This is the time required for processing at the Amplifier Unit, seen from the host device.

Communications time calculation formula (unit: ms)

READ: 150.5 × (number of pages) + 6.1

SAME WRITE: 468.6 × (number of pages) + 80.3

BYTE WRITE: 468.6 × (number of pages/8) + 229.9

TAT calculation formula (units: ms)

TAT = command and response transmission time + communications time

The command and response transmission time differs depending on the number of characters

sent and the communications conditions.

This calculation applies to continuous transmission in which the Controller uses no spaces

between command characters.

SECTION 7

Characteristic Data According to Conditions of Use

Example of TAT calculation:

Number of command characters: A; number of response characters: B

Baud rate: 9600 bps, data length: 8 bits, non parity, 1 stop bit

CIDRW System

User’s Manual

107

SECTION 7

0

500

1000

1500

2000

2500

3000

3500

Read

Number of pages processed

Communications time

Communications time (ms)

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

1246810121416

Communications time (ms)

Write (SAME WRITE)

Number of pages processed

Communications time

Appendix

The graph for communications time for communications between the ID Tag and CIDRW Head, and

TAT (when the baud rate is 9600 bps), is shown below.

The communications time and TAT, however, may increase substantially according to the conditions of

use.

SECTION 7

Characteristic Data According to Conditions of Use

108

CIDRW System

User’s Manual

SECTION 7

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

5500

6000

6500

7000

7500

8000

8500

1 16 32 48 64 80 96 112 128

Communications time (ms)

BYTE WRITE

Number of bytes processed

Communications time

Appendix

SECTION 7

Characteristic Data According to Conditions of Use

CIDRW System

User’s Manual

109

SECTION 7

Noise level

Communications distance (mm)

Relationship between noise level and communications distance (reference values)

(Max.)

Noise level

Communications distance (mm)

Relationship between noise level and communications distance (reference values)

(Max.)

Appendix

Communications Distance Characteristics vs. Ambient Noise

The graph below compares the results of measurement using the noise measurement function with

communications distances.

At installation implement measures in regard to metal in the vicinity of the CIDRW Head, power supply

noise, and atmospheric noise, to ensure that the noise level does not exceed 10.

NOISE MEASUREMENT command (applies only when SECS is not used) Refer to page 49.

■ V640-HAM11-ETN

90

80

70

60

SECTION 7

Characteristic Data According to Conditions of Use

50

40

30

20

10

0

02040608099

■ V640-HAM11-L-ETN

140

120

100

(MAX)

110

CIDRW System

User’s Manual

80

60

40

20

0

0 20 40 60 80 100

(MAX)

ID Tag Memory Maps

Page 8 bytes/1 page

1 00h 01h 02h 03h 04h 05h 06h 07h

2 08h 09h 0Ah 0Bh 0Ch 0Dh 0Eh 0Fh

3 10h 11h 12h 13h 14h 15h 16h 17h

4 18h 19h 1Ah 1Bh 1Ch 1Dh 1Eh 1Fh

5 20h 21h ••• ••• 27h

6 28h 29h ••• ••• 2Fh

7 30h 31h ••• ••• 37h

8

9 :

10 : :

11 :

12

13

14 68h 69h ••• ••• 6Fh

15 70h 71h ••• ••• 77h

16 78h 79h ••• ••• 7Fh

17 80h 81h ••• ••• 87h

DATASEG LENGTH

Carrier

ID

16

"S01" 8

"S02" 8

"S03" 8

"S04" 8

"S05" 8

"S06" 8

"S07" 8

"S08" 8

"S09" 8

"S10" 8

"S11" 8

"S12" 8

"S13" 8

"S14" 8

"S15" 8

Carrier ID

(16 byte)

Data area

(Total of 120

bytes)

■ RI-TRP-DR2B

ID Tag Memory Map

Example of data

segment settings

Page 8 bytes/1 page

1 00h 01h 02h 03h 04h 05h 06h 07h

DATASEG LENGTH

Carrier ID 8

Carrier ID

(8 byte)

■ RI-TRP-WR2B

ID Tag Memory Map

Example of data

segment settings

The memory maps of the RI-TRP-DR2B and RI-TRP-WR2B ID Tags are given below.

SECTION 7

Appendix

• The carrier ID memory area starts from page 1 (fixed).

• 00h to 87h in the table are addresses.

• The RI-TRP-WR2B has a memory capacity of 136 bytes.

• The RI-TRP-WR2B has a memory capacity of 8 bytes.

SECTION 7

ID Tag Memory Maps

CIDRW System

User’s Manual

111

Regular Inspection

In order to maintain optimum performance of the functions of the CIDRW system, daily and periodic

inspections are necessary.

Supply voltage fluctuation Check that the supply voltage fluctuation

Environment Ambient tem-

I/O power

supply

SECTION 7

Regular Inspection

Mounting condition Check that each device is securely

SECTION 7

Appendix

Inspection item Detail Criteria Tools required

To be within supply voltage rating. Multimeter

at the power supply terminal block is

within the permissible range.

Check that there are no frequent instantaneous power failures or radical voltage

drops.

Check that the ambient temperature and

perature

Ambient

humidity

Vibration and

shock

Dust Check that the system is free of dust

Corrosive gas Check that no metal part of the system is

Voltage fluctuation

Ripple

humidity are within specified range.

Check that no vibration or shock is transmitted from any machines.

accumulation.

discolored or corroded.

Check on the I/O terminal block that the

voltage fluctuation and ripple are within

the permissible ranges.

mounted.

Check that each connector is securely

connected.

Check that no wire is broken or nearly

broken.

Check if grounding to 100 Ω or less has

been done.

To be within permissible voltage fluctua-

tion range.

To be within the specified range. Maximum and

To be none.

To be within the specified range. Multimeter

There must be no loose screws. —

Each connector must be locked or

securely tightened with screws.

There must be no wire that is broken or

nearly broken.

To be grounded to 100 Ω or less.

Power supply

analyzer

minimum thermometer

Hygrometer

Oscilloscope

112

CIDRW System

User’s Manual

ASCII Code Table

Leftmost

bits

Rightmost bits

b8 to b5

0000 1001 0010 0011 0100 0101 0110 0111 1000 110 1 1010 1011 11 00 1101 1110 1111

b4 to b1

Row

Line

0 1

2 3 4 5 6 7 8 9 10 11 12 13 14 15

0000 0

NUL TC7(DLE)

(SP) 0 @ P ` p

Undefined Undefined Undefined

0001 1

TC1(SOH) DC

1

!1AQaq

0010 2

TC2(STX) DC

2

"2BRbr

0011 3

TC3(ETX) DC

3

#3CScs

0100 4

TC4(EOT) DC

4

$4DTd t

0101 5

TC5(NEQ) TC8(NAK)

%5EUe u

0110 6

TC6(ACK) TC9(SYN)

&6FV f v

0111 7

BEL TC10(ETB)

'7GWgw

1000 5

FE0(BS) CAN

(8HXhx

1001 9

FE1(HT) EM

)9IYiy

1010 10

FE2(LF) SUB

*:JZjz

1011 11

FE3(VT) ESC

+;K[k{

110 0 12

FE4(FF) IS4(FS)

,<L\ l |

110 1 13

FE5(CR) IS3(GS)

-=M]m}

1110 14

S0 IS2(RS)

.>N^nÅP

1111 15

S1 IS1(US)

/?O_oDEL

SECTION 7

Appendix

CIDRW System

User’s Manual

SECTION 7

ASCII Code Table

113

SECTION 7

Appendix

Protective Construction

IP- is governed by the test methods described below. Check in advance the seal characteristics under

the actual environment and conditions of use.

IP is the abbreviation of International Protection.

■ IEC (International Electrotechnical Commission)

Standard (IEC60529: 1989-11)

(A) First numeral in code: Class of protection against entry of solid foreign material

Class Degree of protection

0 No protection

SECTION 7

Protective Construction

1 Protected against access by solid objects with a diameter of 50 mm or greater (e.g., human hands).

2 Protected against access by solid objects with a diameter of 12.5 mm or greater (e.g., fingers).

3 Protected against access by wires and solid bodies with a diameter of 2.5 mm or greater.

4 Protected against access by wires and solid bodies with a diameter of 1 mm or greater.

5 Entry of volumes of dust that would cause difficulties in normal operation of devices or compromise

safety is prevented.

6 Entry of dust is prevented.

(B) Second numeral of code: Class of protection against the entry of water

Class Degree of protection Outline of test methods (tests using water)

0 No special protection No protection against the

1 Protection against droplets

of water

entry of water.

The product suffers no ill

effects from droplets of water

falling vertically onto it.

No test

Water droplets are

sprayed onto the product

from directly above for 10

minutes by water droplet

exposure test apparatus.

114

2 Protection against droplets

CIDRW System

User’s Manual

of water

The product suffers no ill

effects from droplets of water

directed at it at an angle of up

to 15° to vertical.

The water droplet exposure test apparatus is set

to 15° from vertical and

water droplets sprayed

onto the product for 10

minutes (total of 25 minutes in each direction).

SECTION 7

0.07 L/min.

per hole in the

spray nozzle

0.07 L/min.

per hole in the

spray nozzle

Diameter of spray

nozzle head: 6.3

Diameter of spray

nozzle head: 12.5

Appendix

Class Degree of protection Outline of test methods (tests using water)

3 Protection against spraying

water

4 Protection against splashing

water

The product suffers no ill

effects from a water spray

directed at it at up to 60° from

vertical.

The product suffers no ill

effects from water splashed

on it from all directions.

Using the test apparatus

shown in the figure to the

right, water is sprayed

from both directions, onto

both sides of the product,

at angles up to 60° from

vertical for 10 minutes.

Using the test apparatus

shown in the figure to the

right, water is splashed

onto the product from all

directions for 10 minutes.

5 Protection against water

jets

6 Protection against powerful

jets of water

7 Protection against immer-

sion in water

8 Protection against

immersion in water

The product suffers no ill

effects from a water jet aimed

directly at it from all directions.

Water does not enter the

product when a powerful jet of

water is directed at it from all

directions.

No entry of water on

immersion in water at the

stipulated pressure for the

stipulated time.

The product can be used

while continually immersed in

water.

Using the test apparatus

shown in the figure to the

right, a water jet is directed

at the product from all

directions for 1 minute per

square meter of outer casing, with a minimum total

exposure of 3 minutes.

Using the test apparatus

shown in the figure to the

right, a water jet is directed

at the product from all

directions for 1 minute per

square meter of outer casing, with a minimum total

exposure of 3 minutes.

Immerse in water for 30

minutes at a depth of 1

meter (when the height of

the apparatus is less than

850 mm).

Depends on arrangements made between the

manufacturer and the user

of the product.

SECTION 7

Protective Construction

CIDRW System

User’s Manual

115

SECTION 7

Appendix

SECTION 7

Protective Construction

116

CIDRW System

User’s Manual

Revision History

Cat. No. Z308-E1-01

Revision code

A manual revision code appears as a suffix to the catalog number on the front cover of the manual.

The following table outlines the changes made to the manual during each revision. Page numbers refer to the previous

version.

Revision code Date Revised content

01 September 2010 Original production

OMRON Corporation Industrial Automation Company

Tokyo, JAPAN

Contact: www.ia.omron.com

Regional Headquarters

OMRON EUROPE B.V.

Sensor Business Unit

Carl-Benz-Str. 4, D-71154 Nufringen, Germany

Tel: (49) 7032-811-0/Fax: (49) 7032-811-199

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON ELECTRONICS LLC

One Commerce Drive Schaumburg,

IL 60173-5302 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

Authorized Distributor:

© OMRON Corporation 2010 All Rights Reserved.

In the interest of product improvement,

specifications are subject to change without notice.

Cat. No. Z308-E1-01

Printed in Japan

0910

Loading...

Loading...