Page 1

Cat. No. Z276-E1-01

V400-R1CF/R1CS

Ultra small

Multi-code Reader

USER’S MANUAL

Page 2

Introduction

Contents

Contents 1

Safety Precautions 5

Regulations and Standards 6

Precautions for Safe Use 7

Precautions for Correct Use 9

How to Use This Manual 11

Visual Aids 13

Section 1 Product Overview 15

Introduction Contents

Features 16

Basic Configuration 18

Part Names and Functions 19

Section 2 Introduction Procedure 21

Introduction Flow Chart 22

Preliminary Examination 24

Wiring and Connection 29

Preparation 35

Installation and Reading 40

Section 3 Basic Knowledge of Operation 43

Operation Flow Chart 44

Communication Data Format 50

Section 4 Setting Method 53

How to Use a Menu Sheet/Command 54

V400-R1CF/R1CS

User’s Manual

1

Page 3

Introduction Contents

Section 5 Appendix 97

Introduction

Menu Sheet/Command List 56

Maintenance 98

Troubleshooting 99

Specifications and External Dimension 100

ASCII Code Table 107

Quick-Reference Tables of Data Capacities 108

V400-R1CF/R1CS

2

User’s Manual

Page 4

Introduction

READ AND UNDERSTAND THIS DOCUMENT

Please read and understand this document before using the products. Please consult your OMRON

representative if you have any questions or comments.

WARRANTY

OMRON’s exclusive warranty is that the products are free from defects in materials and workmanship for

a period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING

NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE

PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR

STRICT LIABILITY.

Introduction

In no event shall responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON’S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

SUITABILITY FOR USE

THE PRODUCTS CONTAINED IN THIS DOCUMENT ARE NOT SAFETY RATED. THEY ARE NOT

DESIGNED OR RATED FOR ENSURING SAFETY OF PERSONS, AND SHOULD NOT BE RELIED

UPON AS A SAFETY COMPONENT OR PROTECTIVE DEVICE FOR SUCH PURPOSES. Please refer

to separate catalogs for OMRON’s safety rated products.

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to

the combination of products in the customer’s application or use of the product.

At the customer’s request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the

uses listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this document.

V400-R1CF/R1CS

User’s Manual

3

Page 5

Introduction

Introduction

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT IS PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PERFORMANCE DATA

Performance data given in this document is provided as a guide for the user in determining suitability and

does not constitute a warranty. It may represent the result of OMRON’s test conditions, and the users

must correlate it to actual application requirements. Actual performance is subject to the OMRON

Warranty and Limitations of Liability.

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the product may be

changed without any notice. When in doubt, special model numbers may be assigned to fix or establish

key specifications for your application on your request. Please consult with your OMRON representative

at any time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

ERRORS AND OMISSIONS

The information in this document has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user’s programming of a programmable product, or any

consequence thereof.

COPYRIGHT AND COPY PERMISSION

This document shall not be copied for sales or promotions without permission.

This document is protected by copyright and is intended solely for use in conjunction with the product.

Please notify us before copying or reproducing this document in any manner, for any other purpose. If

copying or transmitting this document to another, please copy or transmit it in its entirety.

V400-R1CF/R1CS

4

User’s Manual

Page 6

Introduction

Safety Precautions

Meanings of safety symbols

z

In this operation manual, precautions are indicated using the following symbols and signal words to

ensure safe use of the V400-R1CF/R1CS. The precautions indicated by these symbols and signal words

are important to ensure safety and must be observed.

The symbols and signal words are as follows:

Indicates a potentially hazardous situation which, if not avoided, will result in

WARNING

Meanings of alert symbols

z

minor or moderate injury, or may result in serious injury or death. Additionally

there may be significant property damage.

Introduction

Indicates general prohibitions for which there is no specific symbol.

Warning display

z

WARNING

This product is not designed or rated for ensuring safety of persons.

Do not use it for such purposes.

V400-R1CF/R1CS

User’s Manual

5

Page 7

Introduction

Introduction

Regulations and Standards

This product complies with the following standards.

LED safety standard IEC 60825-1+A2: 2001 Class 1

JIS C 6802: 2005 Class 1

EC directive No. 2004/108/EC

EN standard EN61326

V400-R1CF/R1CS

6

User’s Manual

Page 8

Precautions for Safe Use

Observe the following precautions to ensure safe use of the product.

1. Installation Environment

• Do not use the product in environments containing flammable or explosive gases.

• Do not use the product in environments containing corrosive or combustible gases.

• Do not use the product in environments containing dust, salt, or metallic powders.

• Do not use the product in environments containing droplets, water or mist, oil or

chemical agents.

• Do not use the product in environments that may be affected by a CRT's flashing or

other ambient light.

• Do not install or use the product outdoors.

Introduction

Introduction

• For the purpose of ensuring safe operation and maintenance, do not install the

product close to high-voltage devices or electrically powered devices.

2. Power Supply and Wiring

• To assure noise and insulation resistance, be sure to use S8VS-01505 (made by

OMRON) as a driving power supply.

• Do not connect a voltage or AC power supply that has a voltage exceeding the rating

voltage (5 V+/-10%).

• Avoid reverse connection of power supply. Do not short circuit a load on OK/NG

output signal (open collector).

• Avoid applying a load that exceeds the rating.

• Be sure to turn the power OFF before connecting or disconnecting a cable.

Connecting or disconnecting a cable while the power is ON may cause failure.

• Connect different cables from high-voltage or power cables to the product. If the

same cable or duct is used, electromagnetic induction may result, which may result in

malfunction or damage.

• Tighten the fixing screws at the torque specified in this manual.

3. Communication with Upper Equipment

• Check that the product has started up, and then start communication with upper

equipment.

• Indefinite signals may be generated from the upper interface while the product starts

up. Clear the receive buffer of the devices before starting initial operation.

V400-R1CF/R1CS

User’s Manual

7

Page 9

Introduction

Introduction

4. Other

• Do not use the product in a safety circuit for nuclear or life-support systems.

• Never attempt to disassemble, repair, modify, deform by applying pressure, or burn

the product.

• Dispose of the product as industrial waste.

• If the product becomes extremely hot, or abnormal odors or smoke are emitted, stop

using the product immediately, turn the power OFF, and consult with your OMRON

representative.

V400-R1CF/R1CS

8

User’s Manual

Page 10

Introduction

Precautions for Correct Use

Always observe the following precautions to prevent operation failures, malfunctions, and adverse effects

on performance and equipment.

1. Installation location

The product must not be installed in a place:

• where ambient temperature is outside the range defined in the specifications,

• where a rapid temperature change (dew condensation) occurs,

• where ambient humidity is outside the range defined in the specifications,

• where direct vibration or shock may affect the product,

• where exposed to intense ambient light (laser, arc welding, or UV light),

• where exposed to direct sunlight or heat from heating appliances, and

Introduction

• where a strong magnetic or electric field exists.

Because of the protection rating described in the manual, avoid using

locations containing:

• corrosive or combustible gases,

• dust, salt, or metallic powders,

• droplets, water mist, oil or chemical agents.

2. Power supply, connection, and wiring

• Be sure to use S8VS-01505 (made by OMRON) as a driving power supply.

• Do not install the product in a location where a high-voltage device is installed.

• Be sure to user the supplied insulation board to assure the noise resistance.

• After connecting the cables, check that the correct power supply is used, that there is

no load short-circuiting or other inappropriate connections, and that the load current is

correct before turning the power ON. Faulty wiring may be the cause of failure.

• Use a wrist strap or other similar device to avoid electrostatic charge when you touch

terminals and signal lines within a connector, and to avoid damage due to static

electricity.

• Try to keep the length of the power cable to a minimum (less than 3 m).

3. Labels

• For labels with a highly gloss surface, reading errors may occur because of regular

reflection of the LED light. If this occurs, provide a skew angle of 15

label.

° against the

V400-R1CF/R1CS

User’s Manual

9

Page 11

Introduction

Introduction

4. Cleaning of the reading window

• Install the product so that the front area of the reading window is free of dust and oil

droplets.

If dust or oil droplets are found, clean the surface using the following method.

• Blow large particles off using a blower brush (for camera lenses).

Do not blow using your own breath.

• Gently wipe off small particles using a soft cloth (lens wiper) moistened with a small

amount of alcohol. Avoid vigorous wiping. Scratches on the reading window may

result in reading errors.

10

V400-R1CF/R1CS

User’s Manual

Page 12

How to Use This Manual

Introduction

Introduction

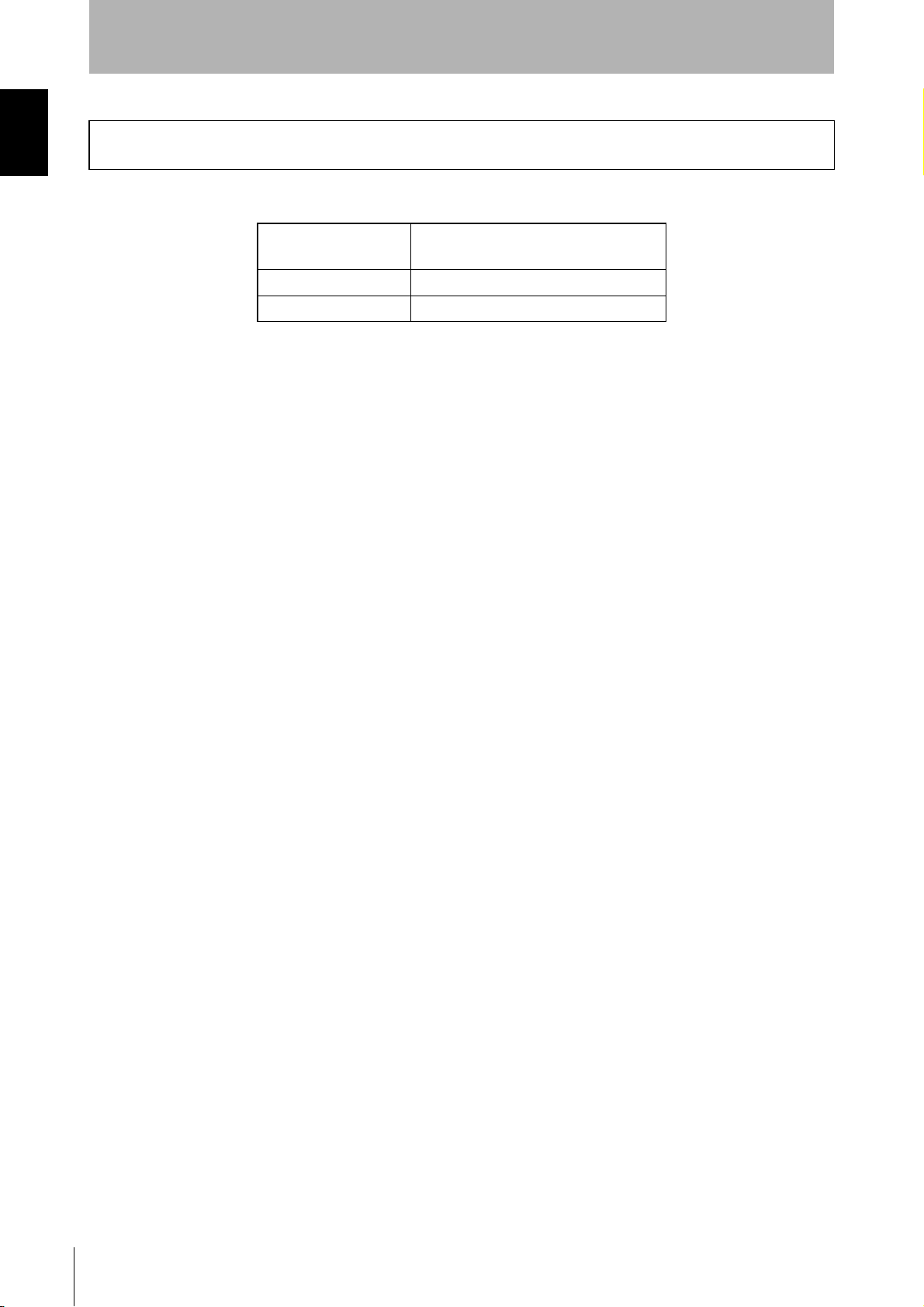

Part names of a code

In this manual, each part of a code is described as follows.

Bar code

Bar code

Margin

2D code

Label

(Paper which a bar code is printed on)

Width

Margin

How to Use This Manual

Narrow bar

(Slim lines)

Height

2D code

Label

(Paper on which a 2D code is printed on)

Cell size

Matrix size

Margin

V400-R1CF/R1CS

User’s Manual

11

Page 13

Introduction

How to Use This Manual

Introduction

Page format

Title of each section

Overviews and points

Index label

Indicates the current section and the

title of the section.

You can quickly reach the page

containing the information you need.

Illustration

Operation procedure and additional explanation

Shows the operation procedure.

Tips and reference pages that may be useful during operation are indicated with a mark.

* This page does not actually exist.

12

V400-R1CF/R1CS

User’s Manual

Page 14

Visual Aids

Introduction

Introduction

Indicates points that are important for using product functions or in application procedures.

Indicates page numbers providing related information.

Indicates information helpful for problem solving or explanation of technical terms.

Visual Aids

V400-R1CF/R1CS

User’s Manual

13

Page 15

Introduction

Introduction

Visual Aids

14

V400-R1CF/R1CS

User’s Manual

Page 16

Section 1

Product Overview

This section explains the features, ratings, and performance of this product.

Features 16

Basic Configuration 18

Part Names and Functions 19

Section 1 Product Overview

V400-R1CF/R1CS

User’s Manual

15

Page 17

Section 1

Product Overview

Features

Section 1 Features

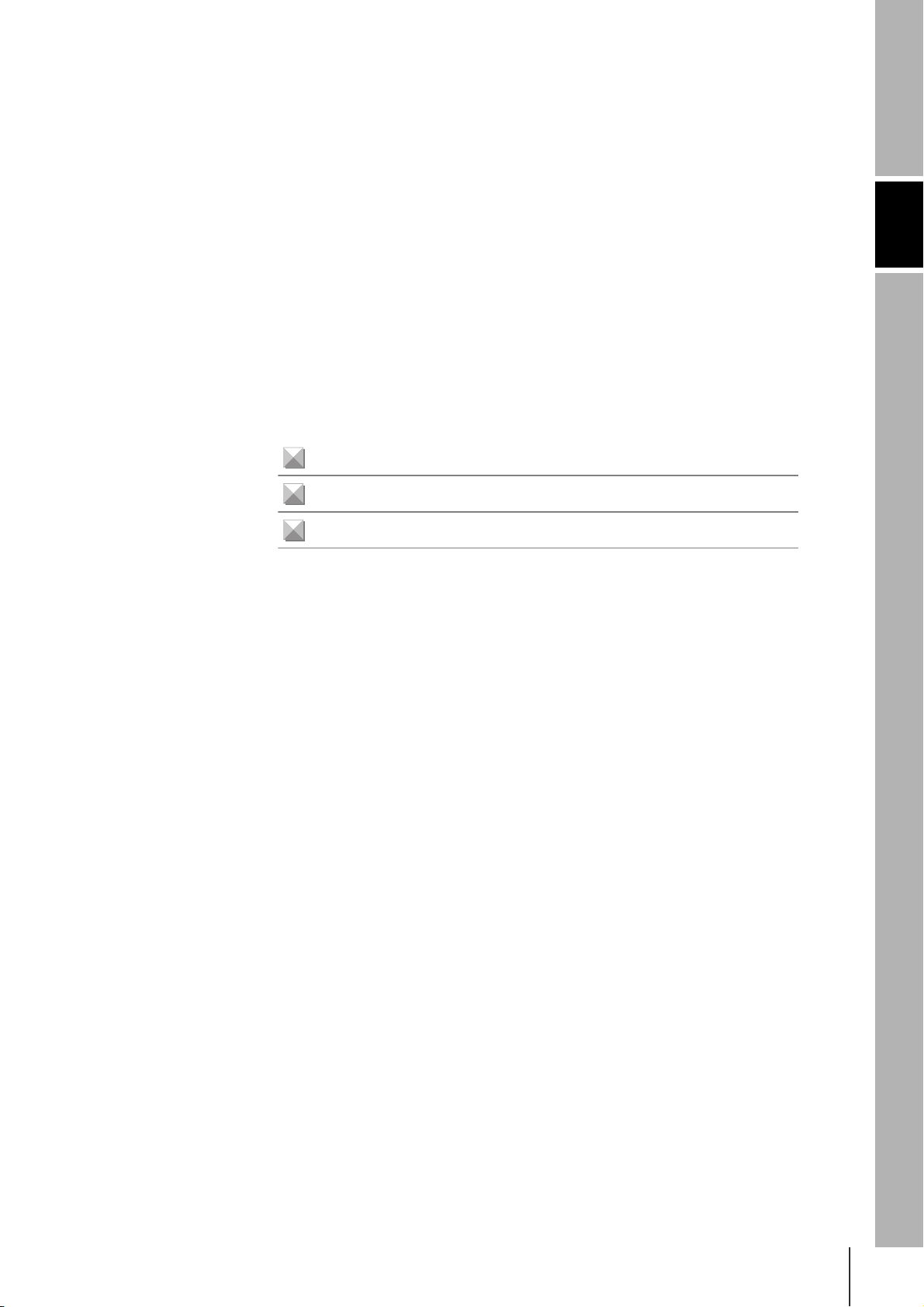

This product is an ultra-compact, setup-free multi-code reader that reads most 2D and 1D

symbols on paper or labels. Various types of information can be managed efficiently by using it

with a PC and programmable controllers.

A setup-free multi-code reader that recognizes most 1D and 2D codes

printed on paper or labels

It can read various 1D and 2D codes without requiring special settings.

QR code

(Automobile part) (HDD)

DataMatrix

Code 39

(PCB)

A 1.3-mega pixel (SXGA) CMOS image sensor

With a vertical resolution of 1024 pixels, difference in code position is compensated.

Bar codes containing narrow bars (slim bars) with a width down to 0.1 mm and 2D

codes as small as 0.169 mm can be read.

Green LED aiming function

The green LED aiming function quickly recognizes the area to be read.

16

V400-R1CF/R1CS

User’s Manual

Page 18

Product Overview

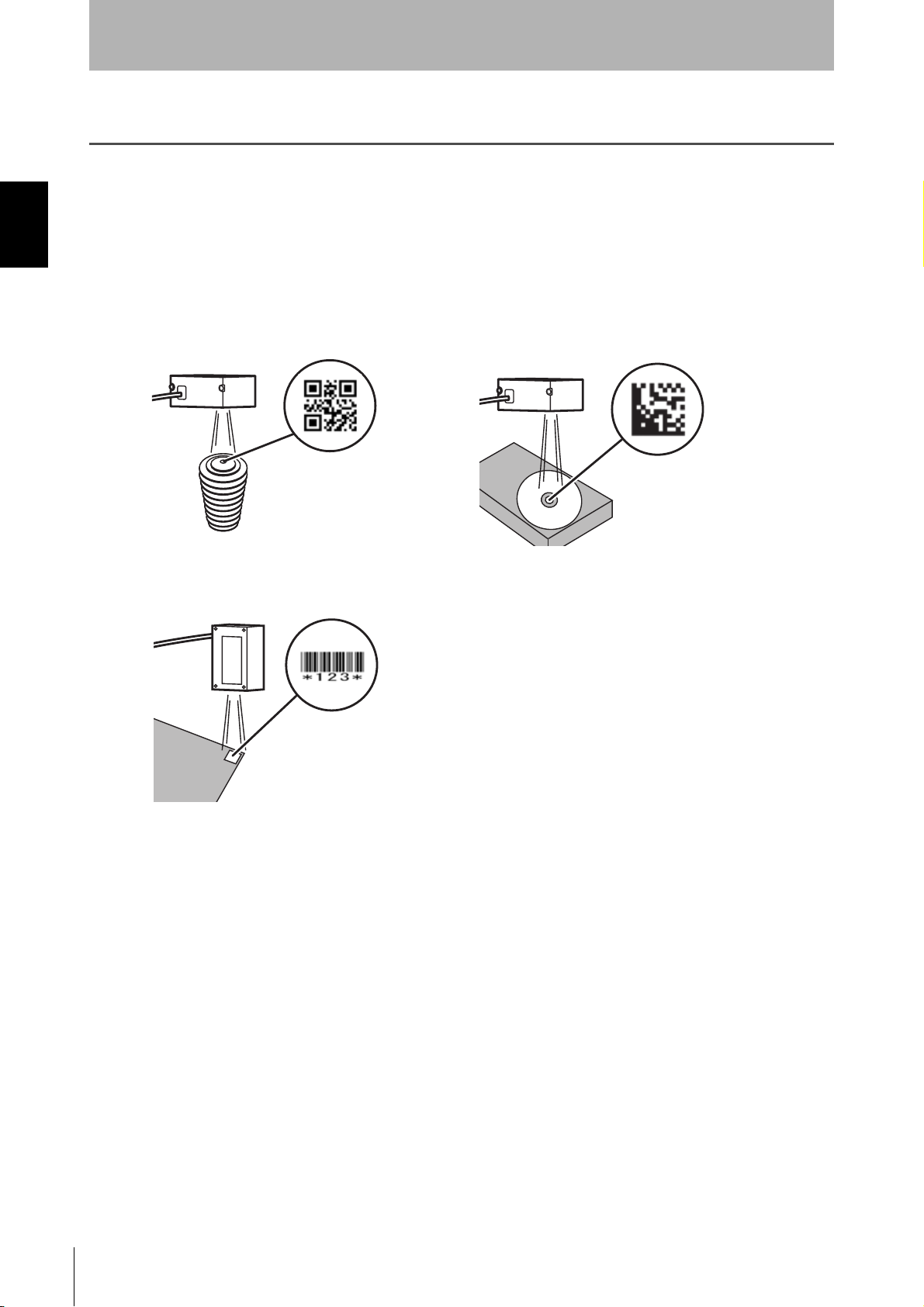

Two types of ultra-compact body for highly flexible installation

The main body is very small, only 58.0 × 46.0 × 24.2 mm.

Section 1

The front and side view types are available to suit your installation environment.

58.0 mm

24.2 mm

46.0 mm

SCAN

SCAN

OKING

OKING

Section 1 Features

Side view type

V400-R1CS

Front view type

V400-R1CF

V400-R1CF/R1CS

User’s Manual

17

Page 19

Section 1

Product Overview

Basic Configuration

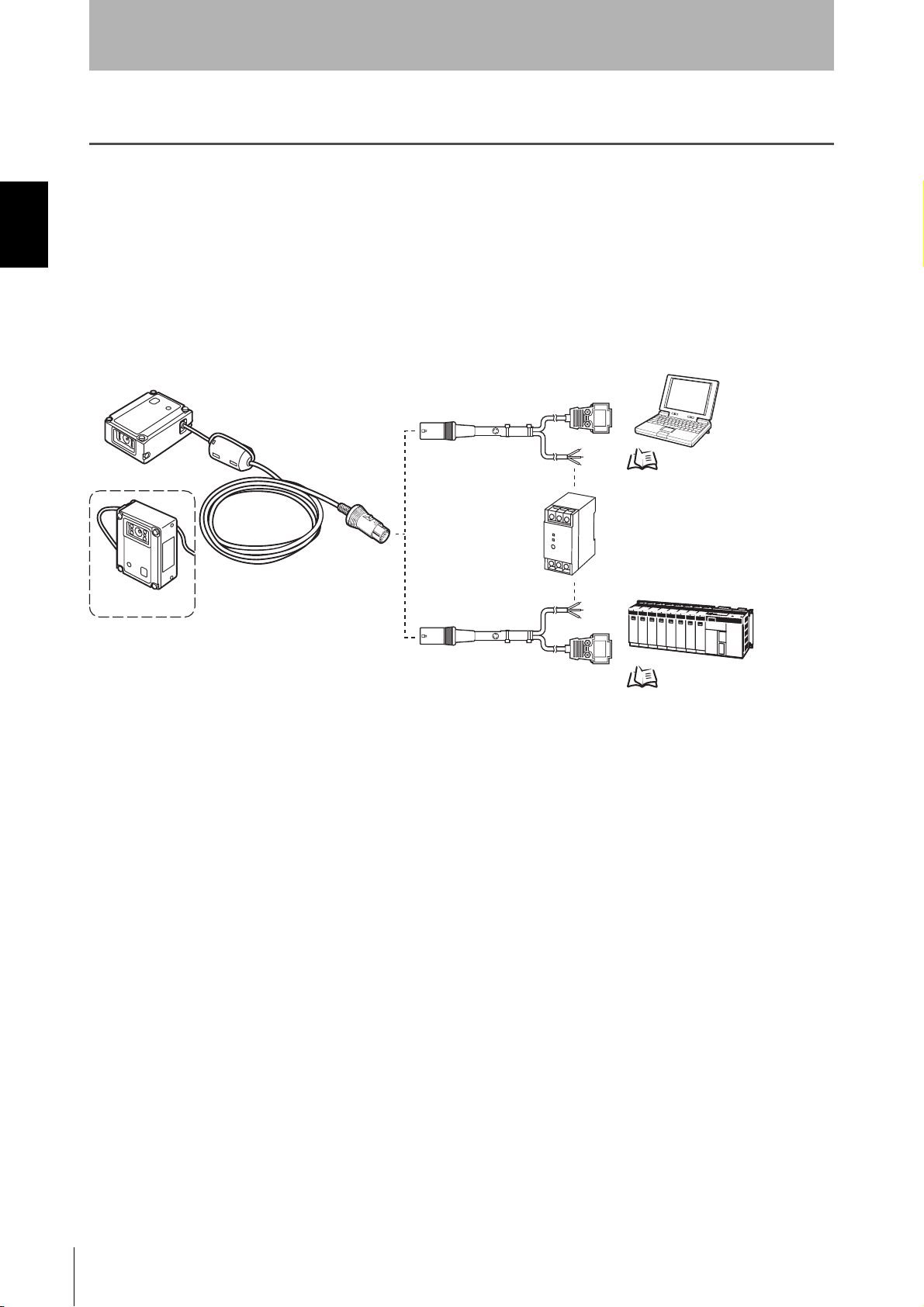

Section 1 Basic Configuration

This product is used by connecting with upper equipment such as a PC and programmable

controllers.

The upper equipment receives the information this product reads, and records and verifies it

with the registered information.

The cable has a connector at the end. Use the appropriate connecting cable for the upper

equipment.

Multi-code reader

V400-R1CF/R1CS

PC/AT compatible

Cable for connecting PC/AT compatible

V509-W011D

p.31

V400-R1CF

Power supply (5 VDC)

Dedicated product: S8VS-01505

(made by OMRON)

Programmable controller

V400-R1CS

Programmable controller made by OMRON

Connecting cable

V509-W011

p.32

18

V400-R1CF/R1CS

User’s Manual

Page 20

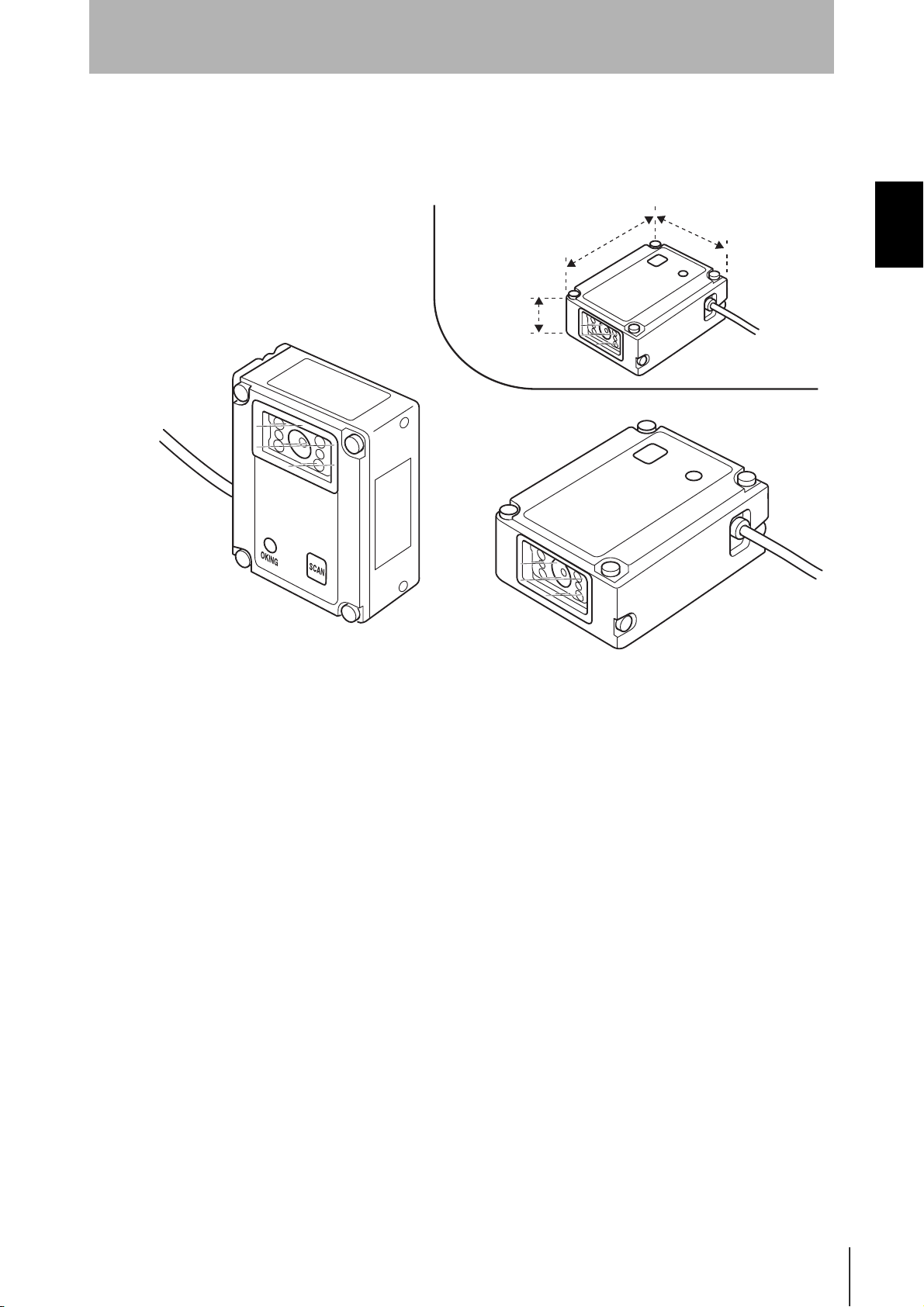

Part Names and Functions

Section 1

Product Overview

This section explains the names and functions of each part.

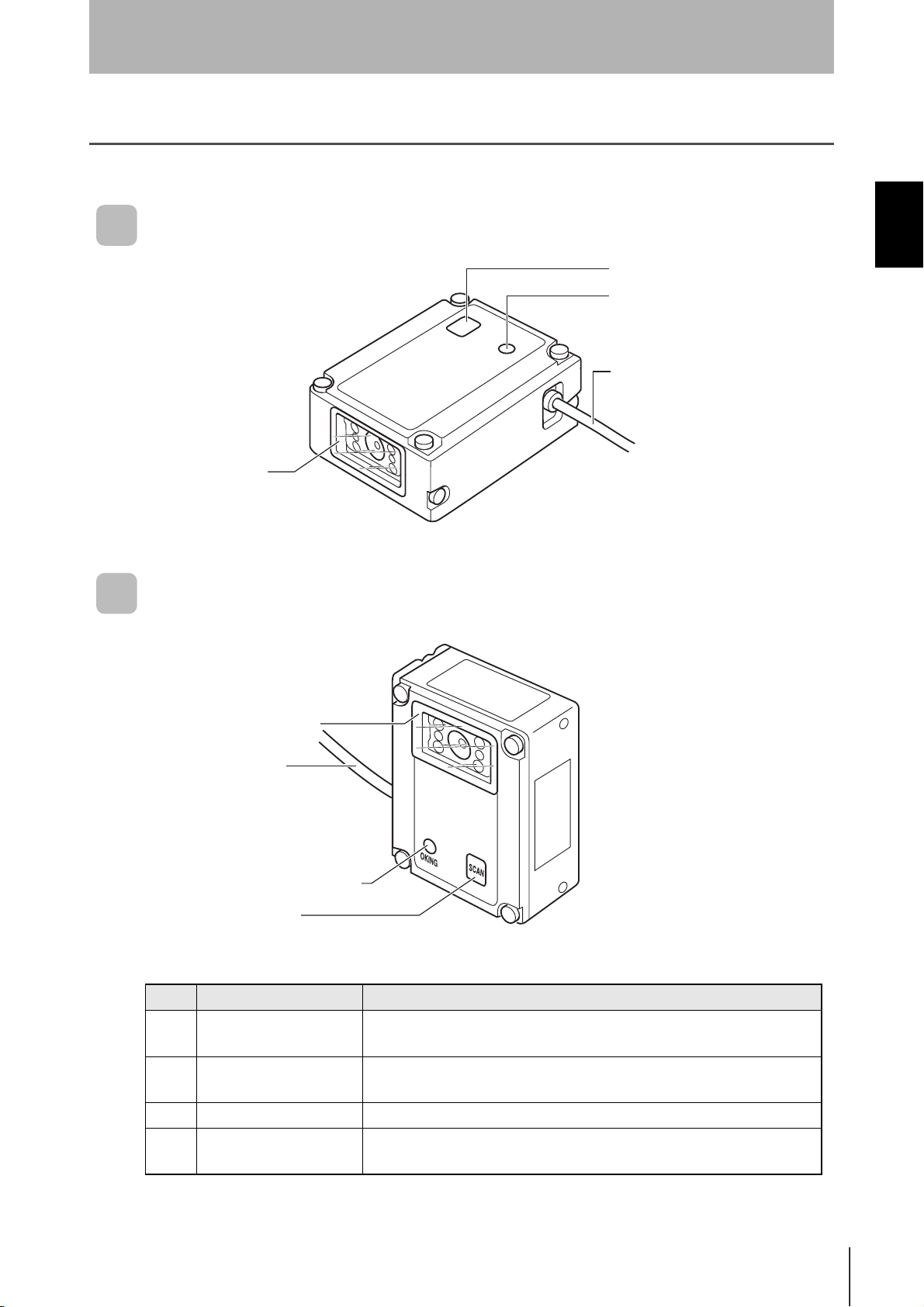

V400-R1CF (Front view type)

SCAN

OKING

(1) Reading window

V400-R1CS (Side view type)

Section 1 Part Names and Functions

(2) SCAN button

(3) Read confirmation LED

(4) Main cable

(1) Reading window

(4) Main cable

(3) Read confirmation LED

(2) SCAN button

No. Part name Function

(1) Reading window

(2) SCAN button

(3) Read confirmation LED Illuminates to indicate a successful read.

(4) Main cable

Aiming light and illumination LED light is emitted from here for

capturing images.

The button for performing a reading test. Pressing it once performs

reading once.

Connected to a cable for connecting PC/AT compatible or a

programmable controller made by OMRON. The length is 1.5 m.

V400-R1CF/R1CS

User’s Manual

19

Page 21

Section 1

Product Overview

MEMO

Section 1 Part Names and Functions

20

V400-R1CF/R1CS

User’s Manual

Page 22

Section 2

Introduction Procedure

A flow chart of preliminary examination, installation, and introduction of the

product is as shown below.

Introduction Flow Chart 22

Preliminary Examination 24

Wiring and Connection 29

Preparation 35

Installation and Reading 40

Section 2 Introduction Procedure

V400-R1CF/R1CS

User’s Manual

21

Page 23

Section 2

Introduction Procedure

Introduction Flow Chart

A flow chart of preliminary examination, installation, and introduction of the product is as

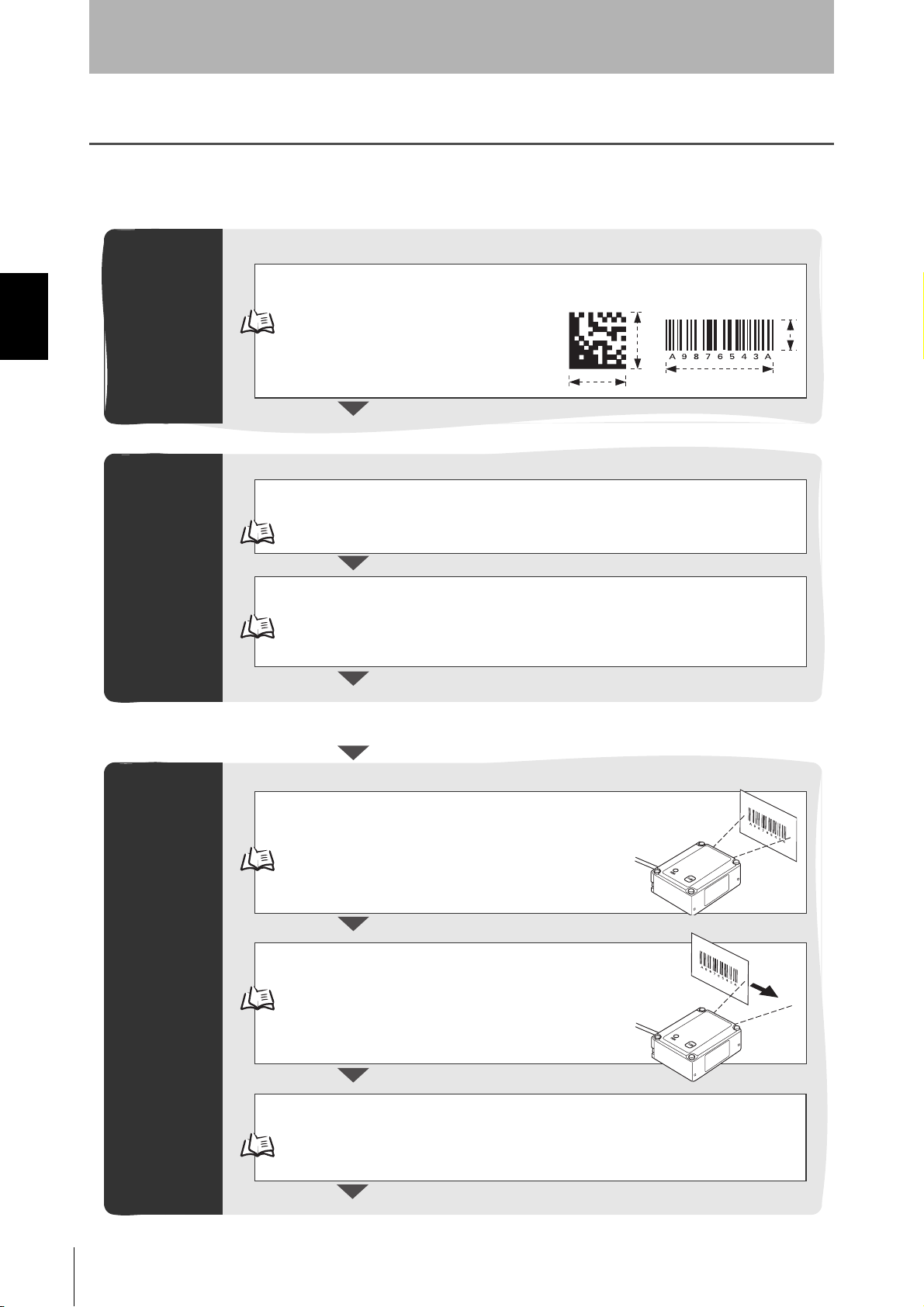

shown below.

Section 2 Introduction Flow Chart

Preliminary

examination

Wiring and

connection

Check the type, width, height, and the number of digits of 2D codes

and bar codes.

p.24 Supported code list

p.26 Reading range performance

p.27 Reading angle performance

Complete wiring.

p.29 Pin arrangement and input/output circuit

Connect peripheral equipment.

p.31 Example of connection with a PC

p.32 Example of connection with programmable controller (CS1)

Preparation

Turn on the power switch.

Press the SCAN button to check whether

the code is read.

p.35 Testing

Investigate the reading timing.

p.36 Investigation into the reading timing

p.44 Basic operation flow chart

Set the reading condition corresponding to the purpose.

p.37 Setting the reading conditions

p.56 Menu Sheet/Command List

22

V400-R1CF/R1CS

User’s Manual

Page 24

Install the reader.

p.40 Installation

Section 2

Introduction Procedure

Section 2 Introduction Flow Chart

Installation

and reading

In case of trouble:

Test in the actual usage environment.

p.35 Testing

Execute reading.

I do not know the

communication specification.

p.50 Communication Data Format

I cannot understand the

operation flow.

p.44 Operation Flow Chart

V400-R1CF/R1CS

User’s Manual

23

Page 25

Section 2

Introduction Procedure

Preliminary Examination

The following are typical specifications you should consider.

Check the type, width, height, and the number of digits of 2D codes and bar codes while

considering the supported codes, reading range performance, and reading angle performance.

Section 2 Preliminary Examination

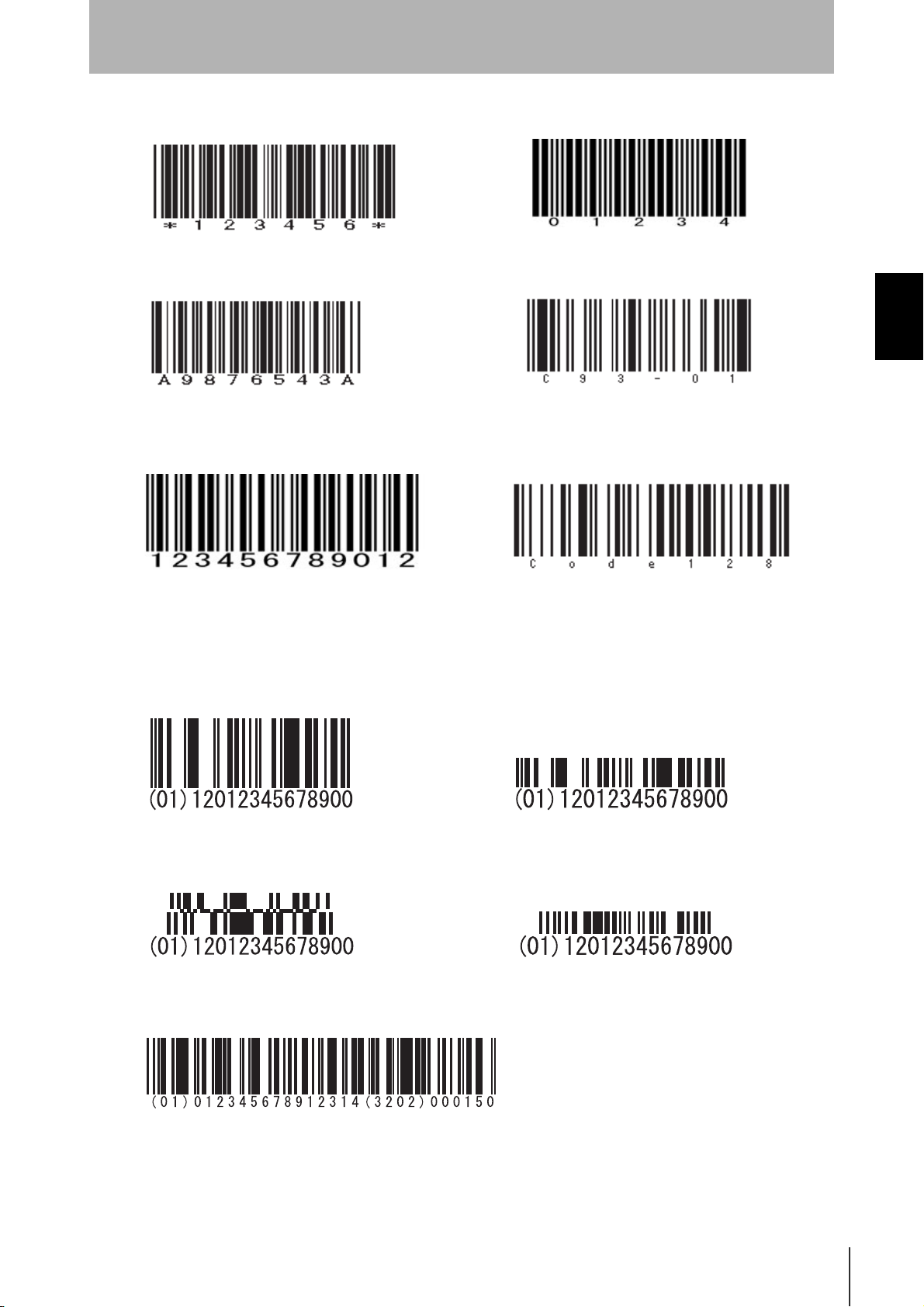

Supported code list

2D code

DataMatrix QR code

ECC200

10 × 10 to 64 × 64

8 × 18 to 16 × 48

PDF417 code

QR code

Models 1 and 2

21 × 21 to 57 × 57

(Versions 1 to 10)

Micro QR code

11 × 11 to 17 × 17

24

Bar codes

JAN/EAN and UPC

V400-R1CF/R1CS

User’s Manual

Page 26

CODE39 STF

Section 2

Introduction Procedure

NW-7 CODE93

ITF CODE128

RSS codes

RSS-14 standard RSS-14 truncated

Section 2 Preliminary Examination

RSS-14 stacked RSS-Limited

RSS-Expanded

V400-R1CF/R1CS

User’s Manual

25

Page 27

Section 2

Introduction Procedure

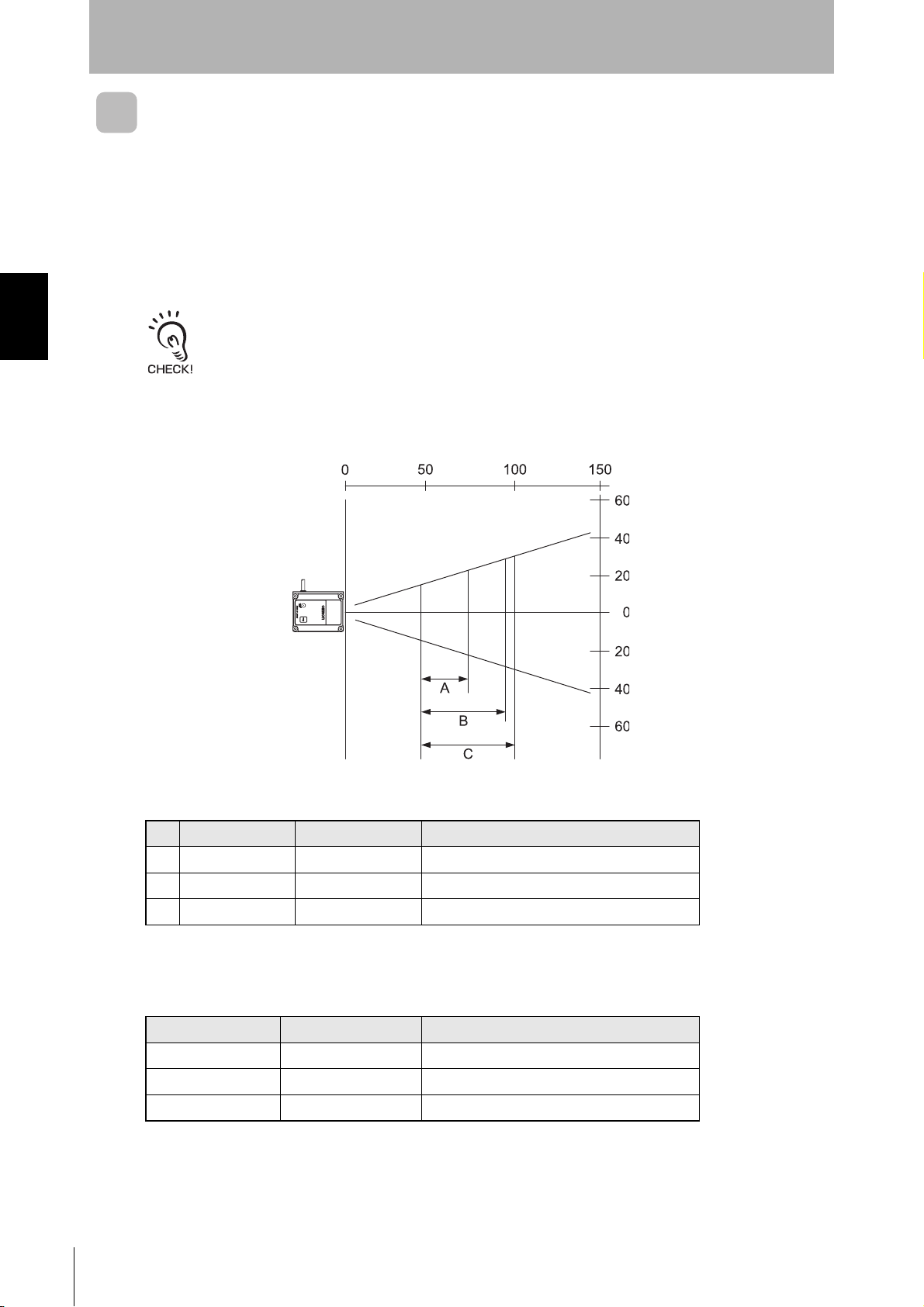

Reading range performance

Explained with examples of following conditions:

•Contrast: MRD 63% (PCS = 0.9)

•Installation condition: Pitch angle α = 0°, skew angle β = 15°

Tilt angle γ = 0°, curvature R = ∞

Section 2 Preliminary Examination

•Reading rate: 70% or more in 10 tries

2D code

The reading range is a reference value, not a guaranteed value.

(Unit: mm)

26

(Unit: mm)

Cell size Reading distance Field-of-view size at reading distance

A 0.169 45.0 to 70.0 31.5 × 21.5 to 47.0 × 32.0

B 0.339 45.0 to 90.0 31.5 × 21.5 to 59.3 × 40.4

C 0.508 45.0 to 100.0 31.5 × 21.5 to 65.4 × 44.6

Bar code (typical example)

(Unit: mm)

Code Narrow bar width Reading distance

Code39 0.1 45.0 to 70.0

Code128 0.2 45.0 to 80.0

JAN13 0.39 50.0 to 100.0

V400-R1CF/R1CS

User’s Manual

Page 28

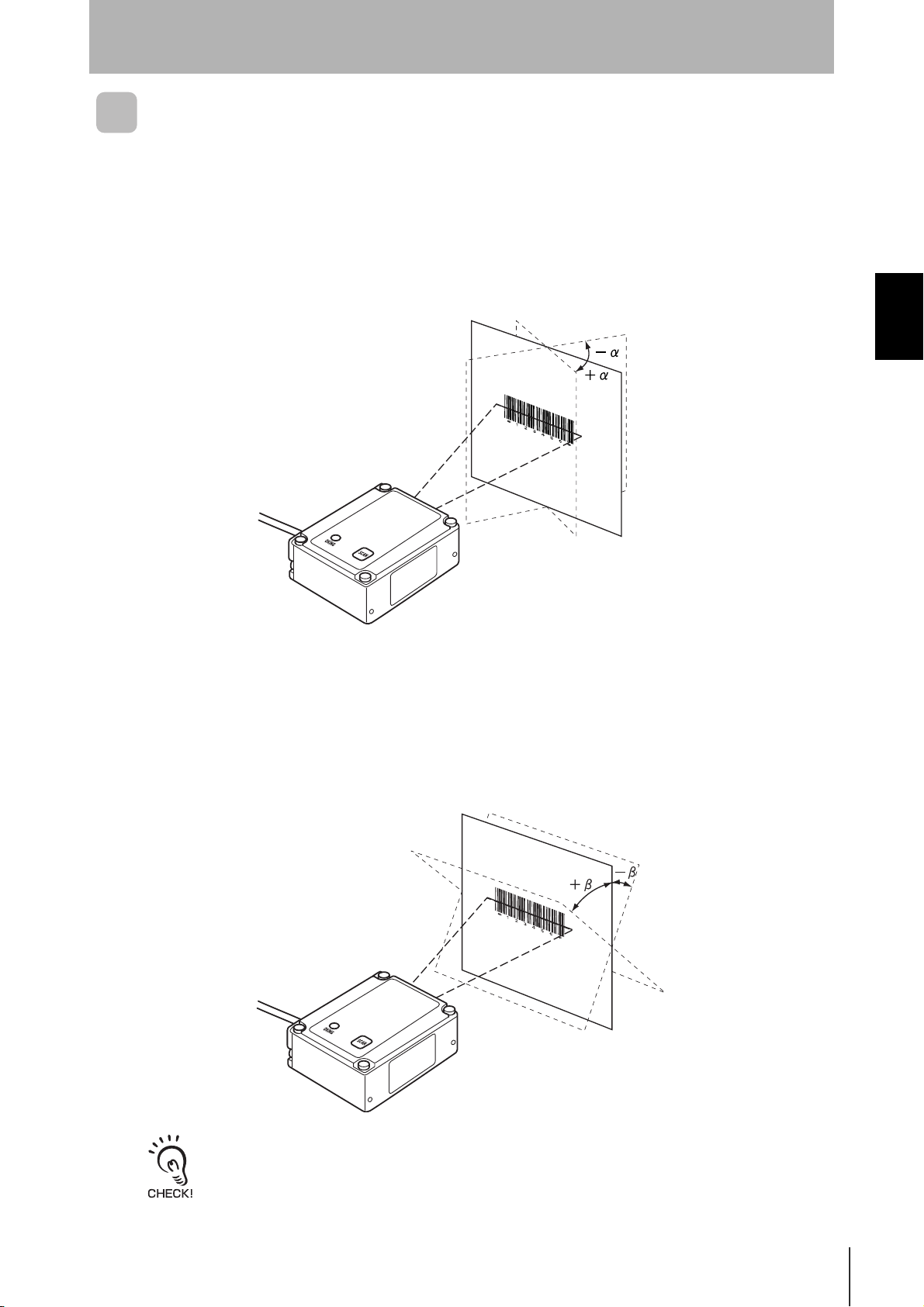

Introduction Procedure

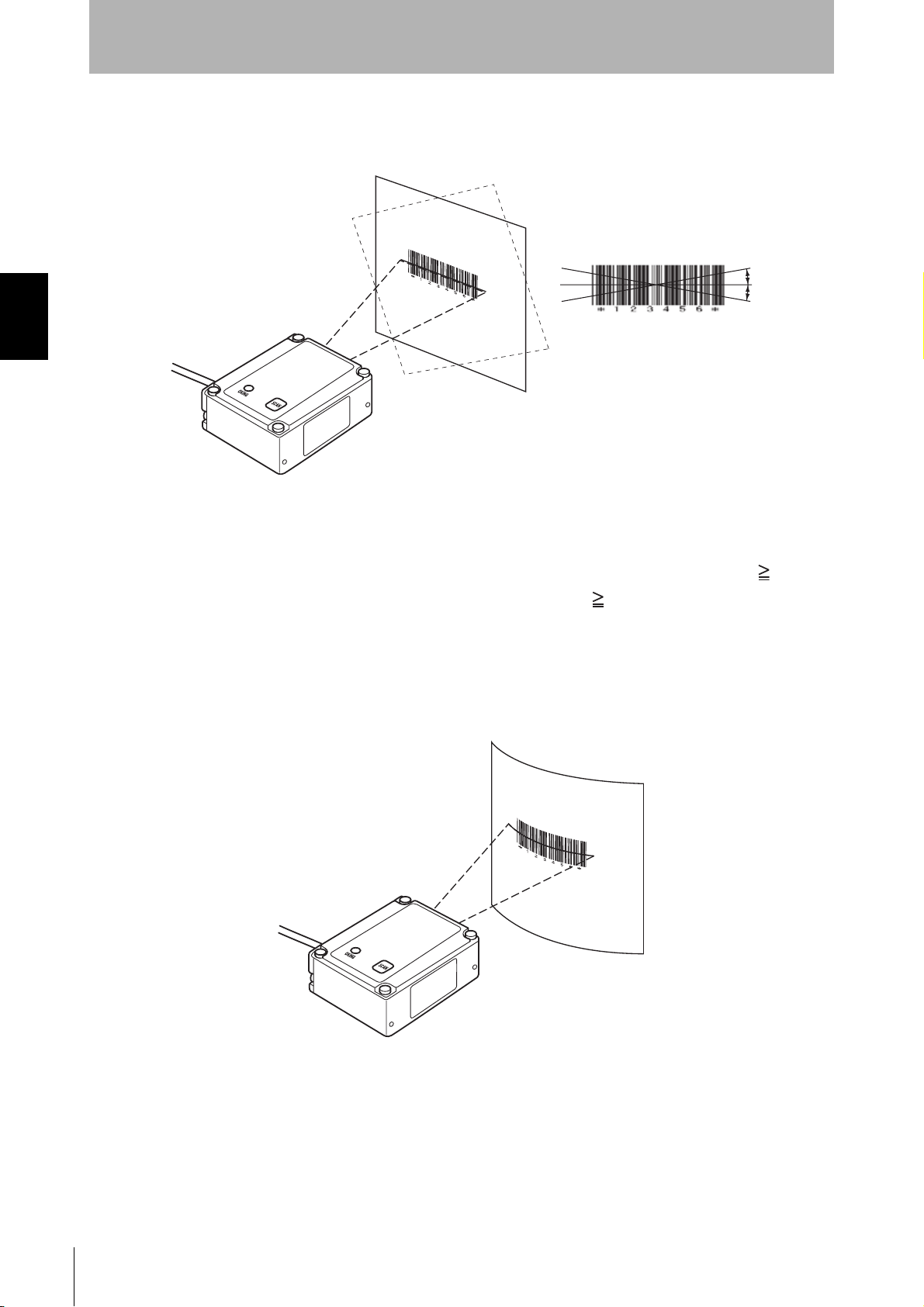

Reading angle performance

Pitch angle (α)

In the following conditions, readable up to α = 50° on either side.

• Code: Resolution = 0.254 mm, CODE39 (2 digits),

MRD 63% (PCS = 0.9)

Section 2

• Reading distance: 57 mm from the case end

• Installation condition: Skew angle β = 15°, tilt angle γ = 36°, curvature R = ∞

Skew angle (β)

In the following conditions, readable up to β = +/-50°.

• Code: Resolution = 0.254 mm, CODE39 (2 digits),

Section 2 Preliminary Examination

MRD 63% (PCS = 0.9)

• Reading distance: 57 mm from the case end

• Installation condition: Pitch angle α = 0°, tilt angle γ = 360°, curvature R = ∞

Reading performance for bar codes on a highly gloss surface such as glossy paper or a card case

may be impaired because reflected illumination LED light or room illumination light enters the

reading window.

If reflected illumination LED light is the culprit, reading performance can be improved by providing

an angle of about 15° in the skew direction or turning off the illumination LED light.

V400-R1CF/R1CS

User’s Manual

27

Page 29

Section 2

Introduction Procedure

Tilt angle

Readable at all angles.

Section 2 Preliminary Examination

Curvature

In the following conditions, 8-digit JAN codes can be read within a range of R 15 mm

and 13-digit JAN codes can be read within a range of R 20 mm.

• Code: 8-digit JAN, resolution = 0.26 mm, PCS = 0.9

13-digit JAN, resolution = 0.39 mm, PCS = 0.9

• Reading distance: 57 mm from the case end

• Installation condition: Pitch angle α = 0°, skew angle β = 15°, tilt angle γ = 360°

28

V400-R1CF/R1CS

User’s Manual

Page 30

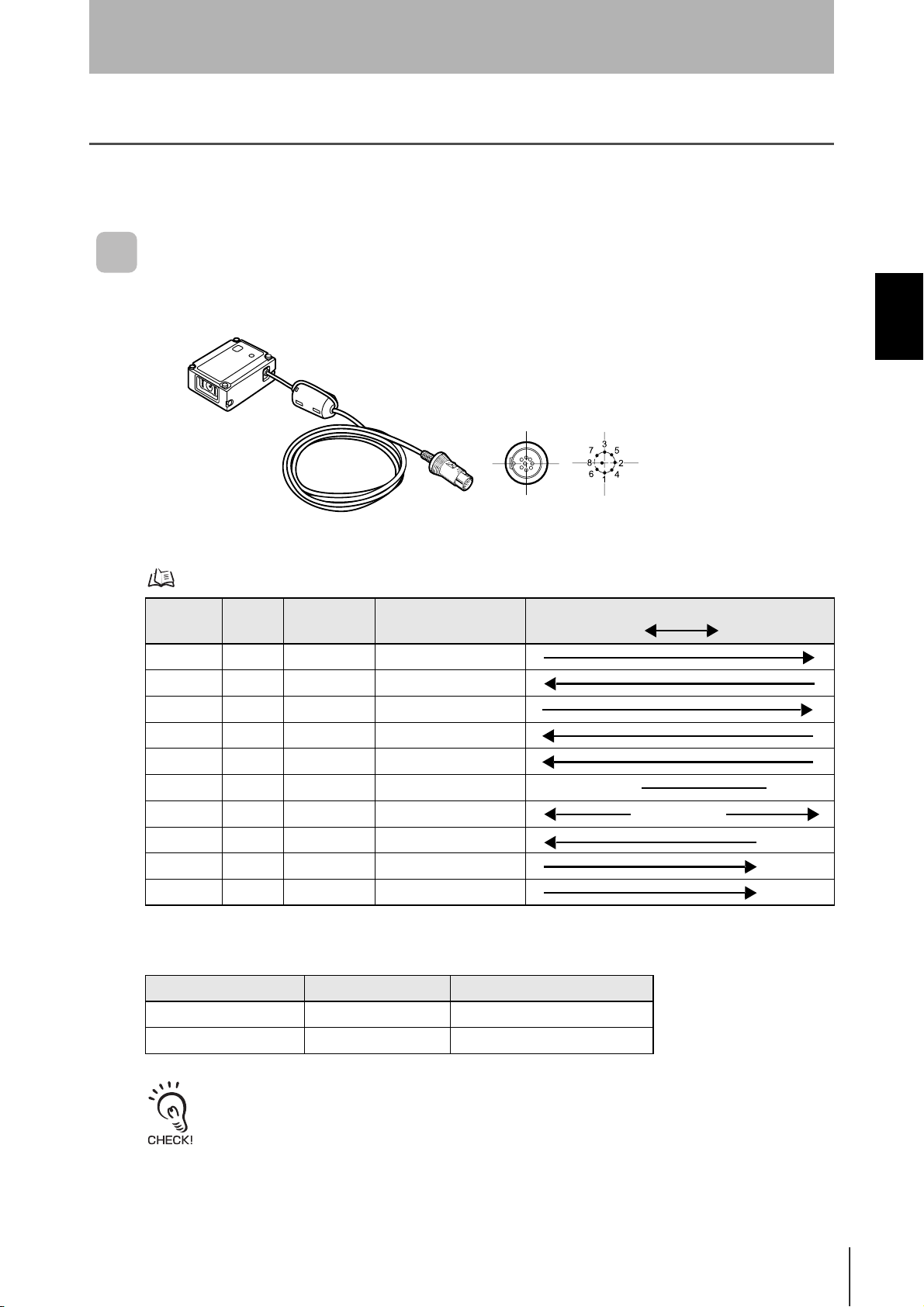

Section 2

Introduction Procedure

Wiring and Connection

This section explains the pin arrangement, the input/output circuit, and the method of

connection to upper equipment.

Pin arrangement and input/output circuit

Pin arrangement

(Pin alignment)

Connector part (DIN: 8P plug)

Made by Hosiden Corporation

TCP1394-715267 (Type A)

Connection with upper equipment p.31, p.32

Wire color Pin No. Signal name Function

Green 1 SD Transmission data

White 2 RD Received data

Blue 3 RS Transmission request

Gray 4 CS Transmission allowed

Brown 5 TRIG External trigger signal

- 6 NC Not connected

Black 7 S.GND 0 V

Red 8 VCC Power supply

Yellow - (Note) OK READ OK output External

Orange - (Note) NG READ NG output External

Reader

Signal direction

Upper equipment

External

Section 2 Wiring and Connection

External

When you make a connection cable, use the following connectors.

Recommended parts for the connector

Usage Manufacturer Model

For cable relay Hosiden Corporation TCS8587-0170477

For panel installation Hosiden Corporation TCS1080-0120177

The OK and NG output lines are not connected to the DIN 8-pin connector. To use the OK and NG

outputs, cut the cables.

V400-R1CF/R1CS

User’s Manual

29

Page 31

Section 2

Introduction Procedure

Input/output circuit

External trigger signal input circuit

Section 2 Wiring and Connection

Vcc

External trigger signal

Terminal voltage Von when a

transistor is turned on

Terminal voltage Voff when a

transistor is turned off

TRIG

Von/off

SG

Item Minimum value Maximum value

0 V 1.3 V

2.5 V Vcc

READ OK/NG signal output circuit

OK/NG

SG

Vcc

Internal

circuit

Internal

circuit

Item Specification

Output system NPN open collector

Rated load 24 VDC 30 mA

Leak current at OFF 0.5 mA or less

Residual voltage at ON 1.0 V or less

30

V400-R1CF/R1CS

User’s Manual

Page 32

Example of connection with a PC

Example of connection with PC/AT compatible is explained.

Multi-code reader

V400-R1CF/R1CS

PC/AT compatible

Special cable

V509-W011D

Dedicated power supply for multi-code reader

S8VS-01505 (made by OMRON)

Section 2

Introduction Procedure

Section 2 Wiring and Connection

100 VAC

Wiring

Reader side

Pin No. Wire color

5BrownTRIG

-YellowOK

- Orange NG

4GrayCS

3BlueRS

2WhiteRD

1 Green SD

8RedVCC

7 Black S.GND

Shield F.GND

Communication with upper equipment

Check that the product has started up, and then start communication with upper equipment.

Indefinite signals may be generated from the upper interface while the product starts up. Clear the

receive buffer of the devices before starting initial operation.

Signal name

Shield

5 VDC (Supplied from the

dedicated power supply)

0 V

Upper equipment side

(Example with PC/AT compatible)

Pin No.

12RD

3SD

4ER

5SG

6DR

7CS

8RS

9-

Cover Shield

Signal name

V400-R1CF/R1CS

User’s Manual

31

Page 33

Section 2

Introduction Procedure

Example of connection with programmable controller

(CS1)

Connection with programmable controller CS1 (made by OMRON) is explained.

Reader

Section 2 Wiring and Connection

V400-R1CF/R1CS

Power supply unit

C200HW-PA204S

Special cable

V509-W011

CPU unit

CS1H-CPU67H

100 VAC

Dedicated power supply for multi-code reader

S8VS-01505 (made by OMRON)

Input unit

CS1W-ID21

Trigger

switch

Special cable

CS1W-CN224

Programming console

C200H-PRO27

Connect the connection cable of this reader to RS-232C port of the CPU unit.

Wiring

Reader side

CS1

RS-232C port

Pin No. Wire color

5BrownTRIG

-YellowOK

- Orange NG

4GrayCS

3BlueRS

2WhiteRD

1 Green SD

8RedVCC

7 Black S.GND

Shield F.GND

Signal name

Shield

5 VDC (Supplied from the dedicated power supply)

0 V

Pin No.

1FG

2SD

3RD

4RS

5CS

6789SG

Signal name

32

V400-R1CF/R1CS

User’s Manual

Page 34

Section 2

Introduction Procedure

Settings on the reader

Specify the settings as follows to establish communication with the programmable

controller.

Setting item Setting content Command

Communication speed 9600 bps (Factory default setting)

Data length 8 bits (Factory default setting)

Parity None (Factory default setting)

Stop bit 1 bit (Factory default setting)

Header None (Factory default setting)

Footer CR (Factory default setting)

Reading valid time Trigger + 2 sec. (Factory default setting)

Process failed reading Transmits “NL” when no label is found

Transmits “ND” when reading has failed

TH0N0L

TI0N0D

Settings on OMRON programmable controller CS1

Section 2 Wiring and Connection

For information about the detailed setting method, refer to the operation manual of your

programmable controller.

Setting item Setting content

Dip switch of CPU unit OFF

Program controller system settings 160[830E]

161[0006]

162[0000]

164[000D]

165[0100]

DM setting Set [1B5A] to DM00100

(Memorize “[ESC]Z” of the ASCII code)

Program controller system settings - Details

160 b15 Presence of the arbitrary

communication setting

b11-8 Serial communication mode “11” Nonprocedural

b3 Data length “1” 8 bits

b2 Stop bit “1” 1 bit

b1-0 Parity “01” None

161 b7-0 Communication speed 0×06 9600 bps

162 b15-0 Transmission delay time 0×0000 No delay

164 b15-8 Start code 0×00 None

b7-0 End code 0×0D CR

165 b12 Presence of the start code “0” None

b9-8 Presence of the end code “01” The end code is present

“1” Arbitrary setting

* 0×00 means a hexadecimal number, and “0” means a binary number.

V400-R1CF/R1CS

User’s Manual

33

Page 35

Section 2

Introduction Procedure

Section 2 Wiring and Connection

Example of program

When the trigger switch is turned on, the reader executes the reading operation and stores the

read data to DM (data memory) of CS1.

The content is displayed on the programming console.

When the code cannot be read within the duration which is set beforehand (2 sec. in this

example), “NL” or “ND” is transmitted.

To check the read data with the programming console, press “Clear > FUN > Monitor” in this

order.

00000

00000

DIFU(13)00101

00002

00006

00101

A39206

A39205

TXD(236)

DM00100

#0000

#0002

BSET(71)

#0000

DM00200

DM00220

RXD(235)

DM00200

#0000

A393

MSG(46)

&0

DM0200

Transmits the read command “Z” stored at

address DM00100.

Clears the address for storage DM00200.

Receives data from the reader and stores it in a

memory area starting at the address DM00200.

Displays the data on the programmable console.

34

Communication with upper equipment

Check that the product has started up, and then start communication with upper equipment.

Indefinite signals may be generated from the upper interface while the product starts up. Clear the

receive buffer of the devices before starting initial operation.

V400-R1CF/R1CS

User’s Manual

Page 36

Section 2

Introduction Procedure

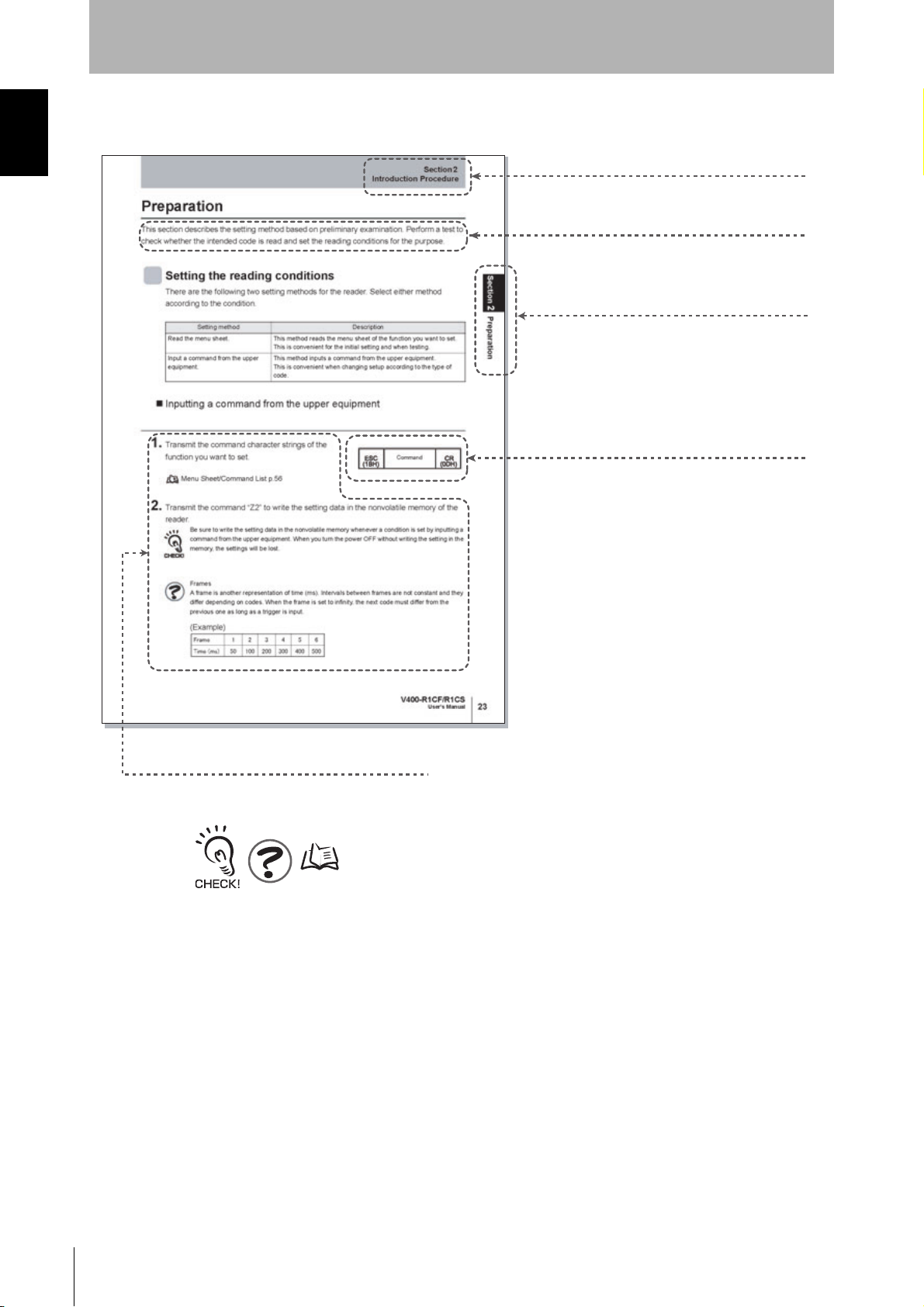

Preparation

This section describes the setting method based on preliminary examination. Perform a test to

check whether the intended code is read and set the reading conditions for the purpose.

Testing

You can check how stably the intended code can be read.

Read the code at rest ten times and calculate the reading rate.

Entering the reading rate measurement mode

1. Place the code in the reading position.

2. Input the command “[XU8”.

The reader enters the reading rate measurement mode.

The reading rate in every 10 reading operations is measured.

3. To exit the reading rate measurement mode, restart the reader.

The reader returns to the normal measurement mode.

Do not execute write command “Z2” to nonvolatile memory.

A sample setting condition is overwritten and stored, which erases the already set reading condition.

Section 2 Preparation

Output format

In reading rate measurement mode, the reading rate in every 10 reading operations is

output continuously to the upper equipment.

The number of times of successful decoding (no verification)

10 reading tries

10/10

ABCDEFG

Communication data format

Header

Header

Footer

Correct

reading data

Correct reading data

Footer

Footer

V400-R1CF/R1CS

User’s Manual

35

Page 37

Section 2 Preparation

Section 2

Introduction Procedure

Investigation into the reading timing

This reader uses the “trigger reading” system. Trigger reading uses the following trigger

input systems and reading operations.

Setting method p.68

Reading system Trigger reading

Reading is executed by applying a reading trigger from outside.

Trigger input method External trigger

signal

RS-232C command Reading starts when the communication command is sent from the

Reading operation Single reading When the reading succeeds, the reader outputs the data and finishes

Plural reading The reader reads codes continuously while the trigger is ON or for the

Continuous reading The reader reads codes continuously while the trigger is ON or for the

Reading starts when the external trigger signal is turned on. The

“Trigger controlled system” performs reading while the trigger is ON,

and the “Effective duration designation system” performs reading only

for the predetermined effective duration (*) that starts when the trigger

is ON.

upper equipment. After receiving the command, the reader performs

reading only for the effective duration (*) you have set beforehand.

the reading operation.

effective duration (*). When the first reading is completed, the data is

output once. While the reader is reading the same code continuously,

it outputs no data. The reader outputs data only when the new data

differs from that of the previous code.

effective duration (*). The reader outputs data even if it reads the same

code.

* Effective duration of reading

When the trigger input method is external trigger signal effective duration designation system or RS-232C

command, effective duration setting is required beforehand. The effective duration is set between 0 and 10

seconds.

Effective duration setting method p.69

36

V400-R1CF/R1CS

User’s Manual

Page 38

Section 2

Introduction Procedure

Setting the reading conditions

There are the following two setting methods for the reader. Select either method

according to the condition.

Setting method Description

Read the menu sheet. This method reads the menu sheet of the function you want to set.

This is convenient for the initial setting and when testing.

Input a command from the upper

equipment.

Read the menu sheet.

The menu sheet is a special code used to set the reader function.

Setting can be changed by reading this menu sheet.

This method inputs a command from the upper equipment.

This is convenient when changing setup according to the type of

code.

Section 2 Preparation

1. Read the menu sheet “ZZ” that starts/ends the setting procedure.

The buzzer sounds continuously, indicating that the reader has entered the setting mode.

_ZZ_

2. Read the menu sheet “U2” that restores the factory default settings.

_U2_

3. Read the menu sheet for the setting item you want to change.

Menu Sheet/Command List p.56

4. To finish, read the menu sheet “ZZ” that starts/ends the setting procedure.

The buzzer stops and the reader returns to the normal mode.

_ZZ_

V400-R1CF/R1CS

User’s Manual

37

Page 39

Section 2

Introduction Procedure

How to create a menu sheet

Menu sheets use the CODE39 code system. However, the code used for this reader is

special as a space mark is used as the start and stop codes. (Normally “*”)

You can create a menu sheet using readily available code creation software, as shown

below.

Section 2 Preparation

E.g.: When creating a menu sheet “A3”

Create “* A3 *” and cut the parts of “*” with scissors to create the menu sheet “A3”.

*_A3_*

Cutting off section

Cutting off section

38

V400-R1CF/R1CS

User’s Manual

Page 40

Introduction Procedure

Inputting a command from the upper equipment

Section 2

Upper equipment

Transmits command character strings

Multi-code reader

V400-R1CF/R1CS

SCAN

OKING

1. Transmit the command character strings of the function you want to set.

Command

Menu Sheet/Command List p.56

2. Transmit the command “Z2” to write the setting data in the nonvolatile memory of the

reader.

Be sure to write the setting data in the nonvolatile memory whenever a condition is set by inputting a

command from the upper equipment. When you turn the power OFF without writing the setting in the

memory, the settings will be lost.

Section 2 Preparation

Transmission method of the command by designating values and characters is

explained as follows.

E.g.: Setting “AB” on header (Designating codes directly)

Header setting

command

Character

“A”

Character

“B”

V400-R1CF/R1CS

User’s Manual

39

Page 41

Section 2

Introduction Procedure

Installation and Reading

This section explains how to install the reader and conduct a final check to confirm that the

reader works successfully in the actual environment.

Section 2 Installation and Reading

Installation

Installing the reader

Install the reader at a distance where it captures the code correctly.

Field of view and distance in relation to the code

For information about the installation distance and code resolution, refer to “Reading range

performance” on p.26.

Installing the mounting bracket

To avoid regular reflection of illumination light, install the bracket at an angle of about

15 to 30 against the bar code.

The mounting bracket supplied with the reader can be tilted between -30

Use this mounting bracket.

(Tightening torque: 0.54 N

·m)

° and +30°.

1. Attach the mounting bracket to the reader (4-M3 screws × 4).

Mounting bracket

4-M3 screw

40

V400-R1CF/R1CS

User’s Manual

Page 42

Introduction Procedure

2. Install the mounting bracket to the installation location (2-M5 screw × 4)

Section 2

30°

Insulation board

2-M5 screw

2-M5 screw

• Do not apply stress to the cable when installing or using.

• The reading distance and angle ranges may differ depending on labels.

Before installing the reader, check that the label is read successfully.

• Be sure to install the supplied insulation board to reduce the influence of inductive noise on the

reader.

Use the attached screws to install the insulation board.

30°

Section 2 Installation and Reading

V400-R1CF/R1CS

User’s Manual

41

Page 43

Section 2 Installation and Reading

Section 2

Introduction Procedure

MEMO

42

V400-R1CF/R1CS

User’s Manual

Page 44

Section 3

Basic Knowledge of Operation

This section explains main functions of the reader.

Operation Flow Chart 44

Communication Data Format 50

Section 3 Basic Knowledge of Operation

V400-R1CF/R1CS

User’s Manual

43

Page 45

Section 3

Basic Knowledge of Operation

Operation Flow Chart

Basic operation flow charts by reading operation, data transmission charts by communication

protocol, and timing charts of buzzer and LED indication are shown below.

Basic operation flow chart

In case of single reading

Section 3 Operation Flow Chart

Power on

Wait for the reading

trigger

Illumination light on

Reading process execution

Has reading

succeeded?

Repeat

Is the external

trigger finished?

(*1)

Has reading effective

duration passed?

(*2)

44

Illumination light off

READ OK LED illuminates

Reading data output

Repeat

Process when reading succeeded

*1: When the trigger by a command is used, ignore this clause.

*2: When the trigger controlled system is used (codes are read while the trigger is ON), the reading effective duration

is set to 0.

*3: This LED illuminates when the error message output is set to ON. It does not illuminate with the factory default

setting.

Illumination light off

READ NG LED illuminates (*3)

Process when reading failed

Process when reading failed

V400-R1CF/R1CS

User’s Manual

Page 46

In case of plural reading

Power on

Wait for the reading

trigger

Illumination light on

Illumination light on

Reading process execution

Has reading

succeeded?

Section 3

Basic Knowledge of Operation

Repeat

Section 3 Operation Flow Chart

Is the data different from

the previous reading?

READ OK LED illuminates

Reading data output

Process when reading

is OK

No label in the front?

Has the reset time

passed?

Is the external

trigger finished?

(*1)

Has reading effective

duration passed?

Illumination light off

Is the external

trigger finished?

(*1)

Has reading effective

duration passed?

(*2)

Illumination light off

READ NG LED illuminates (*3)

Process when reading failed

Process when reading is NG

Previous reading data is reset

*1: When the trigger by a command is used, ignore this clause.

*2: When the trigger controlled system is used (codes are read while the trigger is ON), the reading effective duration

is set to 0.

*3: This LED illuminates when the error message output is set to ON. It does not illuminate with the factory default

setting.

V400-R1CF/R1CS

User’s Manual

45

Page 47

Section 3

Basic Knowledge of Operation

In case of continuous reading

Section 3 Operation Flow Chart

Repeat

Power on

Wait for the reading

trigger

Illumination light on

Repeat

Reading process execution

Has reading

succeeded?

READ OK LED illuminates

Reading data output

Process when reading is OK

Is the external

trigger finished?

(*1)

Has reading effective

duration passed?

(*2)

Illumination light off

READ NG LED illuminates (*3)

Process when reading failed

Process when reading is NG

46

*1: When the trigger by a command is used, ignore this clause.

*2: When the trigger controlled system is used (codes are read while the trigger is ON), the reading effective duration

is set to 0.

*3: This LED illuminates when the error message output is set to ON. It does not illuminate with the factory default

setting.

V400-R1CF/R1CS

User’s Manual

Page 48

Section 3

Basic Knowledge of Operation

Communication protocol

The following two systems exist for transmitting the data read by the reader to the

equipment.

Nonprocedural system (no protocol system)

The reader transmits the data to the upper equipment and ends the communication.

Multi-code reader

V400-R1CF/R1CS

SCAN

OKING

Upper equipment

Data

End

Section 3 Operation Flow Chart

ACK/NAK system

The reader waits for a response from the upper equipment after transmitting the data.

When ACK (06H) 1 byte is received from the upper equipment, a buzzer sounds

indicating normal finishing and ends data transmission.

Multi-code reader

V400-R1CF/R1CS

SCAN

OKING

Upper equipment

When NAK (15H) 1 byte is received from the upper equipment, the data is transmitted

again. When the time-up time set beforehand comes, the time-up buzzer sounds and

the data transmission ends.

Multi-code reader

V400-R1CF/R1CS

Data

End

SCAN

OKING

Upper equipment

Data

Data

Data

V400-R1CF/R1CS

User’s Manual

47

Page 49

Section 3

Basic Knowledge of Operation

In case of reading OK (single reading)

Section 3 Operation Flow Chart

Communication timing chart

This section explains the timing of the buzzer and LED indication.

Trigger input

Illumination

light on

Reading

operation

LED

Communication

Time Description

T0

T2

T3

T4 Communication time. This differs depending on communication conditions.

T5 Trigger signal minimum OFF time. Be sure to set 1 s or more.

Trigger ON time. Keep the external trigger ON for at least 50 ms.

The reading time depends on the “trigger effective duration” setting.

Reading valid time. (The factory default setting is 2 sec. It can be changed.) In case of reading

OK, the illumination LED turns off and the reading operation finishes as soon as the operation

succeeds.

Buzzer and indication LED illumination time. (The factory default settings are 50 ms for the

buzzer and 200 ms for the indication LED. They can be changed.)

• In case of continuous reading and plural reading, illumination light is emitted throughout the reading

effective duration that starts when a trigger is input. The concept of T0 to T4 is the same as that in

the case of single reading.

• Concept of communication time

Communication =

time (ms)

(Data length) + (In case when parity exists) + (Number of stop bits)

(Communication speed)

x (Number of digits of

communication data + Number of

header characters + Number of

footer characters) x 10

3

48

V400-R1CF/R1CS

User’s Manual

Page 50

In case of reading NG (single reading)

Trigger input

Illumination

light on

Reading

operation

Section 3

Basic Knowledge of Operation

Section 3 Operation Flow Chart

LED

Communication

Time Description

T0

T2

T3 When the error message output is set to ON, this is the indication LED illumination time.

T4

T5 Trigger signal minimum OFF time. Be sure to set 1 s or more.

Trigger ON time. Keep the external trigger ON for at least 50 ms.

Here, it is assumed that the reading time is “trigger controlled”.

Reading valid time. (The factory default setting is 2 sec. It can be changed.)

In case of “trigger controlled” and reading NG, the illumination LED turns off and the reading

operation finishes as soon as the external trigger turns off.

This is the error message transmission time when the error message output is set to ON. This

differs depending on communication conditions.

• In case of continuous reading and plural reading, illumination light is emitted throughout the reading

effective duration that starts when a trigger is input. The concept of T0 to T4 is the same as that in

the case of single reading.

• Concept of communication time

Communication=

time (ms)

(Data length) + (In case when parity exists) + (Number of stop bits)

(Communication speed)

T3

x (Number of digits of

communication data + Number of

header characters + Number of

footer characters) x 10

3

V400-R1CF/R1CS

User’s Manual

49

Page 51

Section 3

Basic Knowledge of Operation

Communication Data Format

This section explains the format of communication between the reader and upper equipment.

Section 3 Communication Data Format

Upper equipment

Input command

Reading data output

Multi-code reader

V400-R1CF/R1CS

SCAN

OKING

Inputting a reading trigger using an RS-232C command

The reading trigger command format is as shown below.

or

Inputting a setting command

The reading condition setting command can be transmitted from the upper equipment.

The format is as follows.

Command

For details about the commands, refer to Section 4.

p.56

Data output format to indicate a successful read

When code reading succeeds, the following data is transmitted to the upper equipment.

Header

Output item Description

Header

Number of

digits

Footer

Number

of digits

A character string to be added to the head of transmission characters.

Up to four characters can be set.

The number of digits of the read data is output in ASCII code.

Whether or not to output the number of digits can be selected from the

following choices.

• “Bar code: 2 digits, 2D code: 6 digits”

• “Bar code and 2D code: 6 digits”

•None

A character string to be added to the end of the transmission data.

Up to four characters can be set.

Data of the read code Footer

Factory default

setting

None

None

CR (0DH)

50

Setting method p.82, p.83

V400-R1CF/R1CS

User’s Manual

Page 52

Basic Knowledge of Operation

Process for failed reading

The error message transmitted when reading fails depends on the setting.

Section 3

Output item Description

Error message - No label This message is returned when no code exists

in the field of view.

Error message - Decoding failure This message is returned when the code

cannot be read.

Factory default

setting

Not transmitted

Not transmitted

Setting method p.72

Data transfer contents of each reading code type

Reading code Description

UPC-A You can select whether or not to transfer the head character “0” for

transfer digit number adjustment and check digit C/D. (“0” is an

additional character to be combined with C/D to adjust the number of

digits to be identical to JAN/EAN-13.)

0 S X1 X2 X3 X4 X5 X6 X7 X8 X9 X10 C/D

S: Number system character (Automatically decided according to the

combination of each character of X1 to X10.)

UPC-E You can select whether or not to transfer the head character “0” for

transfer digit number adjustment and check digit C/D. (“0” is an

additional character to be combined with C/D to adjust the number of

digits to be identical to JAN/EAN-13.)

0 S X1 X2 X3 X4 X5 X6 C/D

S: Number system character (Automatically decided according to the

combination of each character of X1 to X10.)

JAN/EAN Reading data (8-digit or 13-digit) is transferred as it is.

ITF, STF (2 of 5 bars) Transfers in the order from the next character of the start code to the

character before the stop code. (The start code and stop code are not

transferred.)

NW-7, CODE39 You can select whether or not to transfer the start code and stop code.

When the transfer of the start code and stop code is permitted, you can

select whether the transferred start/stop code of NW-7 is in lower-case

“a/b/c/d” or in upper-case “A/B/C/D”.

The transfer start/stop code of CODE39 is “*”.

EAN128 When the EAN128 conversion is enabled, the control character “]C1”

(ASCII code: 5D, 43, 31) which indicates EAN128 is added to the head

of the transfer data. Also, the FNC1 character, which is used as a

separating character, is replaced with the GS (ASCII code: 1DH)

character before it is transferred.

2D code Only the reading data is transferred.

Section 3 Communication Data Format

Setting method p.63

Communication with upper equipment

Check that the product has started up, and then start communication with upper equipment.

Indefinite signals may be generated from the upper interface while the product starts up. Clear the

receive buffer of the devices before starting initial operation.

V400-R1CF/R1CS

User’s Manual

51

Page 53

Section 3 Communication Data Format

Section 3

Basic Knowledge of Operation

MEMO

52

V400-R1CF/R1CS

User’s Manual

Page 54

Section 4

Setting Method

This section explains setting methods using a menu sheet and by entering a

command from the upper equipment.

How to Use a Menu Sheet/Command 54

Menu Sheet/Command List 56

Section 4 Setting Method

V400-R1CF/R1CS

User’s Manual

53

Page 55

Section 4

Setting Method

How to Use a Menu Sheet/Command

The following two setting methods are available for the reader. Select either method

depending on the condition.

Setting method Description

Reading a menu sheet This method reads the menu sheet of the function you want to set.

This is convenient for the initial setting and when testing.

Inputting a command from the upper

equipment

Reading a menu sheet

This method inputs a command from the upper equipment.

This is convenient when changing setup according to the type of code.

Section 4 How to Use a Menu Sheet/Command

The menu sheet is a special code used to set the reader function.

Setting can be changed by reading this menu sheet.

1. Read the menu sheet “ZZ” that starts/ends the setting procedure.

The buzzer sounds continuously, indicating that the reader has entered the setting mode.

_ZZ_

2. Read the menu sheet “U2” that restores the factory default settings.

_U2_

3. Read the menu sheet for the setting item you want to change.

Menu Sheet/Command List p.56

4. To finish, read the menu sheet “ZZ” that starts/ends the setting procedure.

The buzzer stops and the reader returns to the normal mode.

54

_ZZ_

V400-R1CF/R1CS

User’s Manual

Page 56

Section 4

Setting Method

How to create a menu sheet

Menu sheets use the CODE39 code system. However, the code used for this reader is

special as a space mark is used as the start and stop codes. (Normally “*”)

You can create a menu sheet using readily available code creation software, as shown

below.

E.g.: When creating a menu sheet “A3”

Create “* A3 *” and cut the parts of “*” with scissors to create the menu sheet “A3”.

*_A3_*

Cutting off sectionCutting off section

Section 4 How to Use a Menu Sheet/Command

Inputting a command from the upper equipment

Refer to “Inputting a command from the upper equipment” (p.39).

V400-R1CF/R1CS

User’s Manual

55

Page 57

Section 4 Menu Sheet/Command List

Section 4

Setting Method

Menu Sheet/Command List

Groups are classified as follows. Please refer to the corresponding pages.

Setting item Reference

Start/end setting using menu sheets p.57

Write setting contents on the nonvolatile memory p.57

Setting for external trigger signal p.57

Return to the factory default setting p.58

Setting of reading permission and prohibition p.60

Detail setting for reading code p.63

Setting of inverted code p.67

Setting for the number of times of reading coincidence p.68

Setting for reading operation p.68

Setting for reading effective duration p.69

Setting for plural reading reset time p.71

Setting for failed reading p.72

Setting for the number of reading digits p.73

Setting for the READ OK LED p.74

Setting for the buzzer p.74

Setting for READ OK signal output p.76

Setting for label registration p.78

Setting for communication conditions p.79

Setting for the communication protocol p.81

Setting for the header and footer p.82

Number of digit output p.83

Direct code designation p.84

56

V400-R1CF/R1CS

User’s Manual

Page 58

Section 4

Setting Method

Start/end setting using menu sheets

When setting the reader using menu sheets, read this menu sheet at the start and end

of the procedure.

Menu sheet Command

Start/end setting using menu sheets

None

_ZZ_

Write setting contents on the nonvolatile memory

Be sure to write the settings in the nonvolatile memory whenever a condition is set by

inputting a command from the upper equipment. When you turn the power OFF without

writing the setting in the memory, the settings will be lost.

Menu sheet Command

Write the contents set with a command in the nonvolatile

memory.

(No menu sheet)

Z2

Setting for external trigger signal

Select positive logic or negative logic of the external trigger signal.

Menu sheet Command

External trigger signal, positive logic (H active)

YA

_YA_

External trigger signal, negative logic (L active) (factory

default setting)

YB

Section 4 Menu Sheet/Command List

_YB_

V400-R1CF/R1CS

User’s Manual

57

Page 59

Section 4 Menu Sheet/Command List

Section 4

Setting Method

Return to the factory default setting

Menu sheet Command

Return to the factory default setting

U2

_U2_

Factory default setting

Item Setting content

Readable code types JAN/UPC (A and E)/EAN(13 and 8), CODE39, NW-7,

Industrial2of5, ITF, CODE128/EAN128, CODE93, DataMatrix

(ECC200), QR code, Micro QR code, PDF417, and RSS

Detail

conditions

Reading

conditions

LED READ OK LED illumination time: 200 ms

Buzzer Enable the buzzer

External trigger signal Negative logic (L active)

READ OK/NG

signal output

Label registration None

UPC/EAN detail

settings

CODE39 detail

settings

NW-7 detail settings Not calculate C/D

Industrial2of5 detail

settings

CODE128/EAN128

detail settings

Inverted code Normal (regular) code

Number of times of

reading coincidence

Reading operation Single reading

Failed reading Transmit nothing

Number of reading

digits

Reading valid time 2 seconds

Plural reading reset

time

Signal output Output signals

Signal output system External trigger synchronous system (positive logic, H active)

UPC-A: Transfer C/D without an 0 in the beginning

UPC-E: Transfer C/D without an 0 in the beginning

EAN-13: Transfer C/D

EAN-8: Transfer C/D

Not calculate C/D

Transfer C/D

Not transfer ST/SP

Transfer C/D

Not transfer ST/SP

Data character of at least 5 digits

Not calculate C/D

Transfer C/D

Data character of at least 5 digits

Disable EAN128 conversion

Reading twice and verification once

Unlock number of digits for all codes (For 2of5 and NW-7, a

minimum of 5 digits)

6 frames

Single-tone buzzer

Buzzer sound duration: 50 ms

Buzzer sound volume: Max

58

V400-R1CF/R1CS

User’s Manual

Page 60

Communication

conditions

Section 4

Setting Method

Item Setting content

Communication speed 9600 bps

Data length 8 bits

Parity None

Stop bit 1 bit

Header None

Footer CR

Number of digit output None

RS/CS control None (no protocol system)

CS waiting time Not limited

Section 4 Menu Sheet/Command List

V400-R1CF/R1CS

User’s Manual

59

Page 61

Section 4

Setting Method

Setting of reading permission and prohibition

Select the types of code to be read.

For higher reading reliability, prohibit reading of codes that will not be read.

Menu sheet Command

All codes except add-ons (Factory default setting)

_A0_

A0

Section 4 Menu Sheet/Command List

Reading permission for all bar codes

_BCM_

Reading permission for all 2D codes

_BCN_

Reading prohibition for all codes

_B0_

Reading permission for UPC codes

_R1_

Permission for UPC add-on 2-digit codes

[BCM

[BCN

B0

R1

R2

_R2_

Permission for UPC add-on 5-digit codes

_R3_

Reading permission for EAN codes

_R4_

Permission for EAN add-on 2-digit codes

_R5_

R3

R4

R5

60

V400-R1CF/R1CS

User’s Manual

Page 62

Menu sheet Command

Permission for EAN add-on 5-digit codes

_R6_

Section 4

Setting Method

R6

Reading permission for CODE39 codes

_B2_

Reading permission for NW-7 codes

_B3_

Reading permission for Industrial2of5 codes

_R7_

Reading permission for ITF codes

_R8_

Reading permission for CODE128 codes

B2

B3

R7

R8

B6

Section 4 Menu Sheet/Command List

_B6_

Reading permission for CODE93 codes

_B5_

Reading permission for RSS-14 codes

_JX_

Reading permission for RSS-limited codes

_JY_

Reading permission for RSS-expanded codes

_DR_

B5

JX

JY

DR

V400-R1CF/R1CS

User’s Manual

61

Page 63

Section 4

Setting Method

Reading permission only for DataMatrix (ECC200) codes

Menu sheet Command

[BCC

_BCC_

Section 4 Menu Sheet/Command List

Reading permission for QR codes

_BCD_

Reading permission for Micro QR codes

_D2U_

Reading permission for PDF417 codes

_BCF_

[BCD

[D2U

[BCF

62

V400-R1CF/R1CS

User’s Manual

Page 64

Section 4

Setting Method

Detail setting for reading code

Conditions for details about reading codes, such as whether to use the check digit (C/

D) or to transmit the start code/stop code (ST/SP), are set.

UPC-A

Menu sheet Command

Transfer C/D without an 0 in the beginning (Factory default setting)

E3

_E3_

Not transfer C/D without an 0 in the beginning

_E5_

Transfer C/D with 0 in the beginning

_E2_

Not transfer C/D with 0 in the beginning

_E4_

UPC-E

Menu sheet Command

Transfer C/D without an 0 in the beginning (Factory default setting)

_E7_

E5

Section 4 Menu Sheet/Command List

E2

E4

E7

Not transfer C/D without an 0 in the beginning

_E9_

Transfer C/D with 0 in the beginning

_E6_

Not transfer C/D with 0 in the beginning

_E8_

E9

E6

E8

V400-R1CF/R1CS

User’s Manual

63

Page 65

Section 4

Setting Method

EAN-13

Transfer C/D (Factory default setting)

Menu sheet Command

6K

_6K_

Section 4 Menu Sheet/Command List

Not transfer C/D

_6J_

EAN-8

Menu sheet Command

Transfer C/D (Factory default setting)

_6I_

Not transfer C/D

_6H_

CODE39

Menu sheet Command

Not calculate C/D (Factory default setting)

6J

6I

6H

C1

_C1_

Calculate C/D

_C0_

Transfer C/D (Factory default setting)

_D9_

Not transfer C/D

_D8_

Transfer ST/SP

_D0_

C0

D9

D8

D0

64

V400-R1CF/R1CS

User’s Manual

Page 66

Menu sheet Command

Not transfer ST/SP (Factory default setting)

_D1_

NW-7

Menu sheet Command

Not calculate C/D (Factory default setting)

_H7_

Section 4

Setting Method

D1

H7

Calculate C/D

_H6_

Transfer C/D (Factory default setting)

_H8_

Not transfer C/D

_H9_

Not transfer ST/SP (Factory default setting)

_F0_

ST/SP: ABCD/ABCD

H6

Section 4 Menu Sheet/Command List

H8

H9

F0

F3

ST/SP: abcd/abcd

ST/SP: ABCD/TN*E

ST/SP: abcd/tn*e

_F3_

_F4_

_F1_

_F2_

F4

F1

F2

V400-R1CF/R1CS

User’s Manual

65

Page 67

Section 4

Setting Method

ST/SP: <DC1><DC2><DC3><DC4>/<DC1><DC2><DC3><DC4>

Menu sheet Command

HJ

_HJ_

Section 4 Menu Sheet/Command List

Data character of at least 1 digit

_HC_

Data character of at least 3 digits

_HB_

Data character of at least 5 digits (Factory default setting)

_HF_

Industrial2of5

Menu sheet Command

Not calculate C/D (Factory default setting)

_G0_

HC

HB

HF

G0

Calculate C/D

_G1_

Transfer C/D (Factory default setting)

_E0_

Not transfer C/D

_E1_

Data character of at least 1 digit

_GE_

Data character of at least 3 digits

G1

E0

E1

GE

GF

66

_GF_

V400-R1CF/R1CS

User’s Manual

Page 68

Menu sheet Command

Data character of at least 5 digits (Factory default setting)

_GI_

CODE128/EAN128

Menu sheet Command

Disable EAN128 conversion (Factory default setting)

_X/0_

Section 4

Setting Method

GI

[X/0

Enable EAN128 conversion

[X/4

_X/4_

Setting of inverted code

Normally, codes are printed in black on a white background. However, some codes are

white on a black background.

Black codes on a white background are called normal (regular) codes, and white codes

in a black background are inverted codes.

Inverted codes can be read when the “Inverted code” option is selected.

Menu sheet Command

Normal (regular) code (Factory default setting)

V2

_V2_

Section 4 Menu Sheet/Command List

_V2_

Normal (regular) and inverted codes

_V4_

_V4_

V4

V400-R1CF/R1CS

User’s Manual

67

Page 69

Section 4

Setting Method

Setting for the number of times of reading

coincidence

When reading result coincides the number of times you have set, the reading result is

output to the RS-232C interface.

The verification system is AND verification (Continuous coincidence system). (This

cannot be changed.)

Menu sheet Command

Reading once and verification zero times

X0

_X0_

Section 4 Menu Sheet/Command List

Reading twice and verification once (Factory default setting)

_X1_

Reading three times and verification twice

_X2_

Reading four times and verification three times

_X3_

Setting for reading operation

The reading operation is set.

Menu sheet Command

Single reading (Factory default setting)

X1

X2

X3

S0

68

Plural reading

Continuous reading

V400-R1CF/R1CS

User’s Manual

_S0_

S1

_S1_

S2

_S2_

Page 70

Section 4

Setting Method

Setting for reading effective duration

The time during which the reading continues after a trigger is input is set. When it is set

to 0 sec., reading is controlled by the external trigger and the trigger is effective while

the external trigger is ON.

Menu sheet Command

0 seconds (controlled by the external trigger)

Y0

_Y0_

1 second

_Y1_

2 seconds (Factory default setting)

_Y2_

3 seconds

_Y3_

4 seconds

_Y4_

5 seconds

Y1

Section 4 Menu Sheet/Command List

Y2

Y3

Y4

Y5

6 seconds

7 seconds

8 seconds

_Y5_

_Y6_

_Y7_

_Y8_

Y6

Y7

Y8

V400-R1CF/R1CS

User’s Manual

69

Page 71

Section 4

Setting Method

9 seconds

Menu sheet Command

Y9

_Y9_

Section 4 Menu Sheet/Command List

Infinity

YM

_YM_

70

V400-R1CF/R1CS

User’s Manual

Page 72

Section 4

Setting Method

Setting for plural reading reset time

This setting has effect when plural reading is enabled.

This setting specifies the number of frames (length of time) during which the reader

should be kept away from the code before reading the same code again.

Frames

A frame is another representation of time (ms). Intervals between frames are not constant and they

differ depending on codes. When the frame is set to infinity, the next code must differ from the

previous one as long as a trigger is input.

(Example)

Frame 123456

Time (ms) 50 100 200 300 400 500

Section 4 Menu Sheet/Command List

1 frame

2 frames

3 frames

4 frames

5 frames

Menu sheet Command

AH

_AH_

AI

_AI_

AJ

_AJ_

AK

_AK_

AL

6 frames (Factory default setting)

_AM_

Infinity

_AG_

_AL_

AM

AG

V400-R1CF/R1CS

User’s Manual

71

Page 73

Section 4

Setting Method

Setting for failed reading

Process for failed reading is set.

With the factory default setting, nothing is transmitted in the event of failed reading.

Error message - No label

Direct input characters of up to 4 digits can be set. These characters are transmitted

when no code (label) is detected during the reading time.

• The error message is disabled when no direct input characters are read after the command.

• This may be output simultaneously with “Error message - Decoding failure”.

Section 4 Menu Sheet/Command List

Error message - Decoding failure

Direct input characters of up to 4 digits can be read. These characters are transmitted

when a code (label) is detected during the reading time but nothing is read.

• The error message is disabled when no direct input characters are read after the command.

• This may be output simultaneously with “Error message - No label”.

E.g.: In the following two examples, the “NL<CR>” message is set for “No label” and the “ND<CR>” message

for “Decoding failure”. Those two examples may occur at the same time.

When no code is detected

during the reading time

Setting start (ZZ)

Error - No label (TH)

N (0N)

When a code is detected during

the reading time but nothing is

read

Setting start (ZZ)

Error - Decoding failure (TI)

N (0N)

72

Error message - No label

V400-R1CF/R1CS

User’s Manual

L (0L)

<CR> (1M)

Setting end (ZZ/Z2)

Menu sheet Command

_TH_

D (0D)

<CR> (1M)

Setting end (ZZ/Z2)

TH

Page 74

Error message - Decoding failure

Section 4

Setting Method

Menu sheet Command

TI

_TI_

Not transmit an error message (Factory default setting)

TG

_TG_

Setting for the number of reading digits

When the number of reading digits is fixed, all codes having other lengths than that

specified can be rejected. Up to two reading digits can be set.

This setting is effective for codes such as Interleaved 2 of 5 for which security against

partial reading is insufficient.

While the number of reading digits to be fixed can be set by reading the code, the

number of reading digits cannot be set with a command since a code of the necessary

length must be read.

• To read codes of a known length, it is recommended that the number of digits be fixed.

• While the number of reading digits to be fixed can be set by reading the code, it is not affected by a

detail setting (p.63) for reading codes, including “Transfer ST/SP”, “Not transfer ST/SP”, “Transfer C/

D” and “Not transfer C/D”.

• Fixing the number of reading digits does not affect WPC (JAN/EAN/UPC) or other fixed-length codes

and DataMatrix or other 2D codes.

Section 4 Menu Sheet/Command List

E.g.: The following describes the steps for fixing the number of reading digits.

Setting start (ZZ)

Fixed number of digits ON (H1)

Read the first code of the necessary length

Read the second code of the necessary length

Setting end (ZZ)

Menu sheet Command

Fixed number of digits OFF for all codes (Factory default setting)

_H0_

Fixed number of digits ON for all codes

_H1_

H0

None

V400-R1CF/R1CS

User’s Manual

73

Page 75

Section 4

Setting Method

Setting for the READ OK LED

The READ OK LED is disabled or its illumination time is set. The READ OK LED

illuminates when reading succeeds.

Menu sheet Command

Disable the READ OK LED

T4

_T4_

Section 4 Menu Sheet/Command List

READ OK LED illumination time: 200 ms (Factory default setting)

T5

_T5_

READ OK LED illumination time: 400 ms

T6

_T6_

READ OK LED illumination time: 800 ms

T7

_T7_

Setting for the buzzer

The buzzer is enabled or disabled or its type and sound duration and volume are set.

The buzzer sounds when reading succeeds.

74

Disable the buzzer

Enable the buzzer (Factory default setting)

Single-tone buzzer (Factory default setting)

V400-R1CF/R1CS

User’s Manual

Menu sheet Command

W0

_W0_

W8

_W8_

W1

_W1_

Page 76

High-low buzzer

Section 4

Setting Method

Menu sheet Command

W2

_W2_

High-high buzzer

_W3_

Buzzer sound duration: 50 ms (Factory default setting)

_W7_

Buzzer sound duration: 100 ms

_W4_

Buzzer sound duration: 200 ms

_W5_

Buzzer sound duration: 400 ms

W3

W7

W4

W5

W6

Section 4 Menu Sheet/Command List

_W6_

Buzzer sound volume: Max (Factory default setting)

_T0_

Buzzer sound volume: High

_T1_

Buzzer sound volume: Medium

_T2_

Buzzer sound volume: Low

_T3_

T0

T1

T2

T3

V400-R1CF/R1CS

User’s Manual

75

Page 77

Section 4

Setting Method

Setting for READ OK signal output

When you want to output reading succeeded to the READ OK signal, set the conditions

of output system and duration, then set them for “signal output (X*Q)”.

The READ NG signal is output when any code other than the labels registered in

“Setting for label registration” (p.78) is read.

Menu sheet Command

Output the signal (Factory default setting)