Page 1

TJ

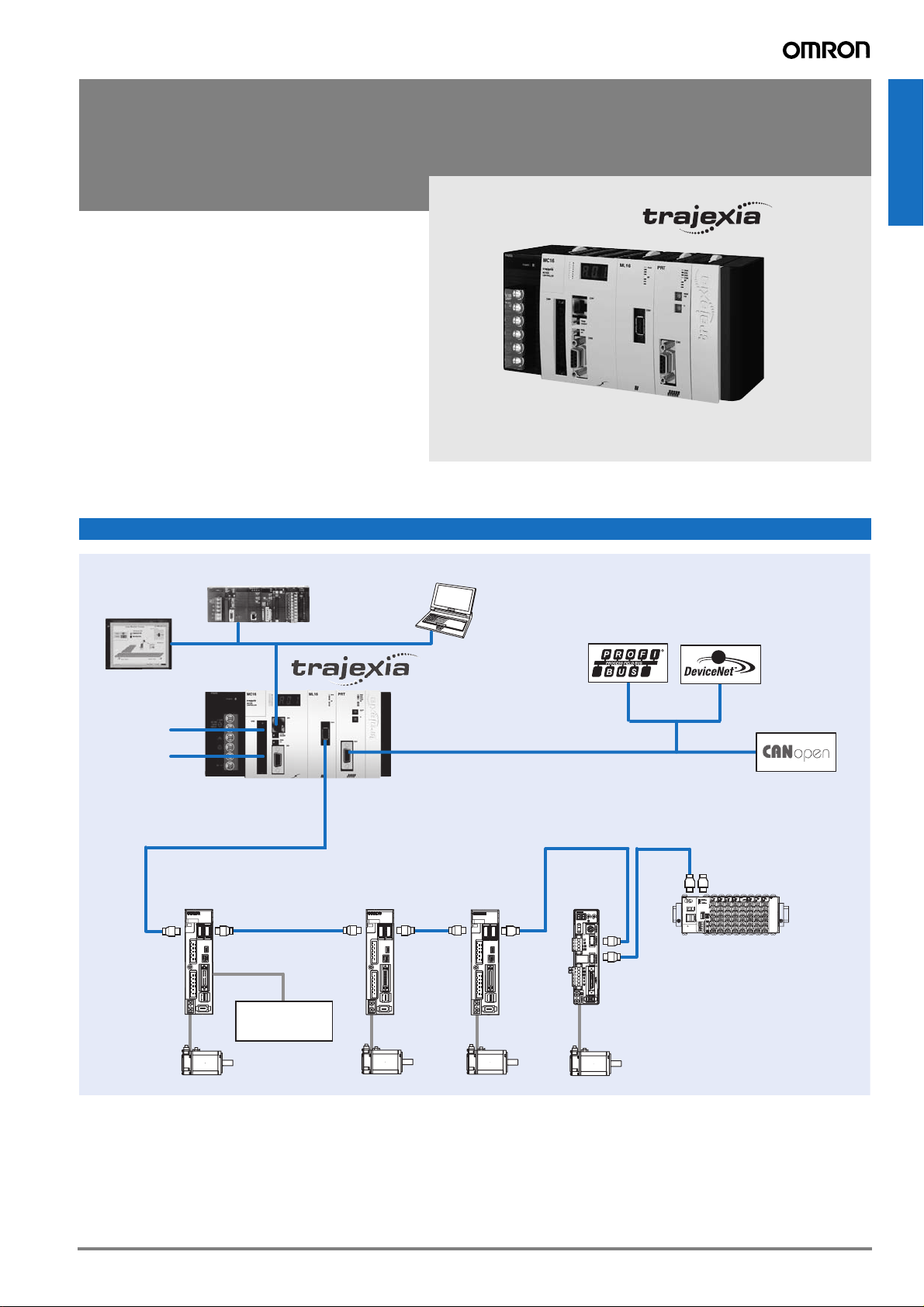

Trajexia motion controller

Stand-alone advanced motion controller over

MECHATROLINK-II motion bus

• Control of up to 64 axes over a robust and fast

motion bus

• Supports position, speed and torque control

• Advanced motion control such as CAM control,

registration control, interpolation and axes synchronization via simple motion commands

• Advanced debugging tools including data trace and

oscilloscope functions

• Control of servos, inverters and I/Os over a single

motion network

• Multi-tasking controller capable of running up to

22 tasks simultaneously

• Open communication: Serial Ethernet built-in,

PROFIBUS-DP, DeviceNet and CANopen

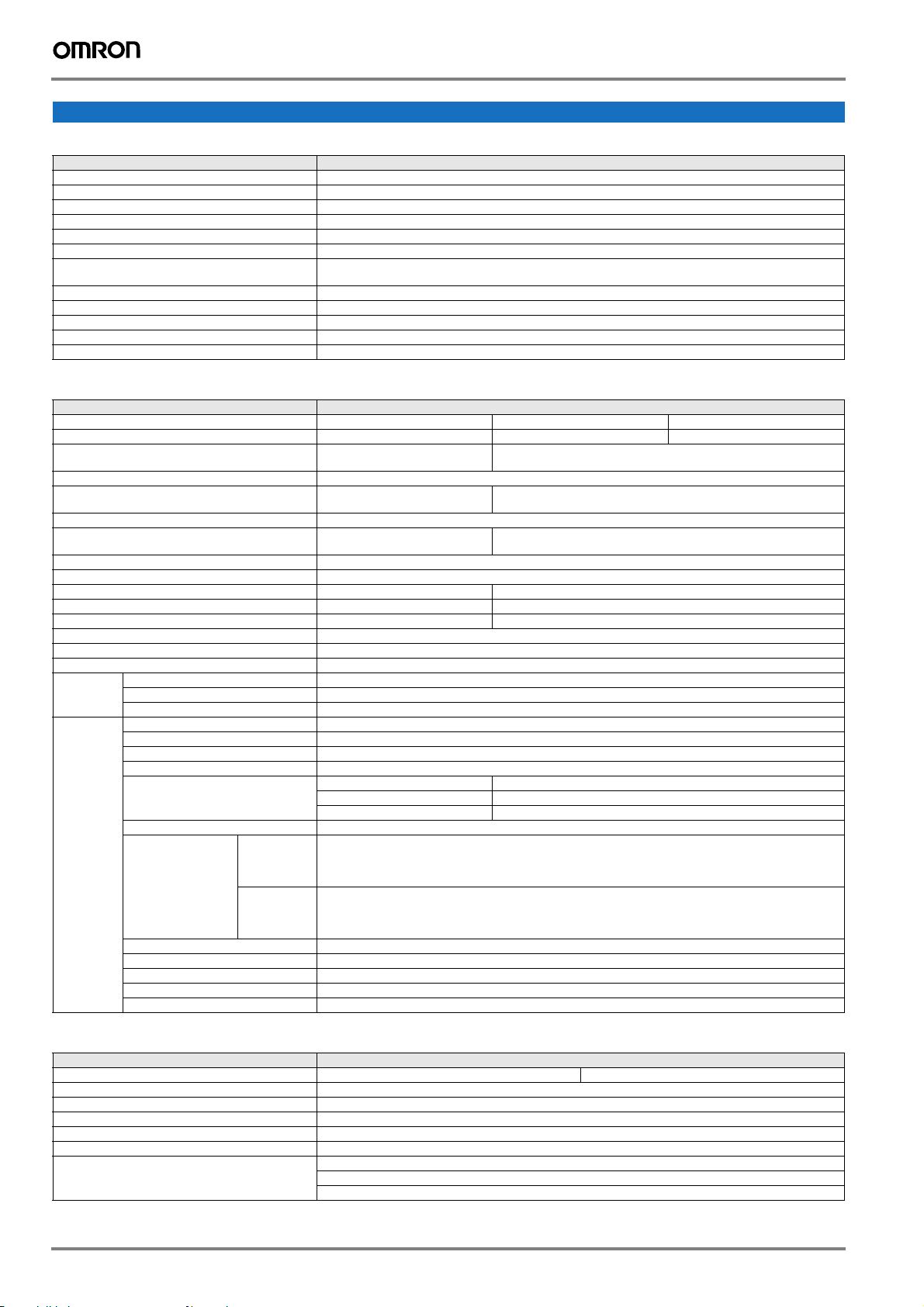

System configuration

Motion controllers

NS-series

HMI

Digital I/Os

Host-link

Accurax G5 series

Servo motors

CJ-series PLC

Motion controller

Accurax G5 series

Servo drive

Input

Fast registration

inputs, home and

limits switches...

Ethernet

Personal computer software:

CX-One (CX-Motion Pro)

Trajexia Studio

PROFIBUS-DP

Fieldbus

MECHATROLINK-II

G- Series

Servo drive

AC SERVO DRIVER

ADR

1

1

0

0

9

2

2

8

3

3

7

4

6

5

X10

X1

COM

SP

IM

G

G-Series

Servo motors

Master

DeviceNet

Master

Terminator

GRT1-ML2

SW1 SW2

CN2

CN1

A/B

SmartSlice IOs

CANopen

Devices

23Trajexia motion controller

Page 2

Specifications

Trajexia general specifications

Item Details

Model TJ@

Ambient operating temperature 0 to 55°C

Ambient operating humidity 10 to 90%RH

Ambient storage temperature -20 to 70°C

Ambient storage humidity 90% max. (with no condensation)

Atmosphere No corrosive gases

Vibration resistance 10 to 57 Hz: (0.075 mm amplitude)

Shock resistance 143 m/s

Insulation resistance 20 MOhm

Dielectric strength 500 Volt

Protective structure IP20

International standards CE, EN 61131-2, cULus, Lloyds, RoHS compliant

57 to 100 Hz Acceleration: 9,8 m/s

2

, 3 times each X, Y and Z directions.

Trajexia motion control units

Item Details

Model TJ2-MC64 TJ1-MC16 TJ1-MC04

Number of axes 64 16 4 (+1 using TJ1-FL02 unit)

Number of inverters and I/O modules Up to 64 (Inverters in position,

Number of MECHATROLINK-II master units Up to 4 MECHATROLINK-II master units (see below TJ1-ML16/ML04) can be connected

Cycle time Selectable 0.25 ms, 0.5 ms, 1 ms or

Programming language BASIC-like motion language

Multi-tasking Up to 22 tasks running simulta-

Built-in digital I/O 16 inputs and 8 outputs, for general purpose

Measurement units User definable

Available memory for user programs 8 MB 500 KB

Data storage capacity Up to 32 MB Flash data storage Up to 2 MB Flash data storage

Saving program data, motion controller Flash-ROM SRAM with battery backup and Flash-ROM

Saving program data, personal computer Via CX-Motion Pro/Trajexia Studio software

Communication ports 1 Ethernet port and 2 serial ports

Firmware update Via CX-Motion Pro/Trajexia Studio software

Ethernet port Electr i cal characteristics Conform to IEEE 802.3 (100BaseT)

Connector RJ45 Ethernet connector

Transmission protocol Modbus TCP slave

Serial port Electrical characteristics Conform 1 port to RS232C and 1 port to RS485/RS422A (selectable by switch)

Connector SUB-D9 connector (Counterpart included in the package)

Synchronization Start-stop synchronization (asynchronous)

Baud rate 1200 / 2400 / 4800 / 9600 / 19200 / 38400 bps

Transmission format Databit length 7 or 8 bit

Transmission mode Point-to-multipoint (1:N)

Transmission protocol RS-232C (1:1) Host Link master protocol,

RS-485 (1:N)

RS-422A (1:N)

Galvanic isolation RS422A port

Communication buffers 254 bytes

Flow control None

Terminator Yes, selectable by switch

Cable length 15 m for RS232 and 500 meter for RS422/485

speed or torque mode)

2 ms

neously

Stop bit 1 or 2 bit

Parity bit Even/Odd/None

Host Link slave protocol,

ASCII general-purpose,

Modbus TCP slave

Host Link master protocol,

Host Link slave protocol,

ASCII general-purpose,

Modbus TCP slave

2

, in X, Y and Z directions for 80 minutes.

8 maximum (Inverters in position, speed or torque mode)

Selectable 0.5 ms, 1 ms or 2 ms

Up to 14 tasks running simultaneously

Trajexia MECHATROLINK-II master units

Item Specifications

Model TJ1-ML16 TJ1-ML04

Controlled devices with MECHATROLINK-II interface Accurax G5 and G-Series servo drives ML-II built-in and SmartSlice IOs

Electrical characteristics Conforms to MECHATROLINK standard

Communication ports 1 MECHATROLINK-II master

Transmission speed 10 Mbps

Communication cycle 0.5 ms, 1 ms or 2 ms

Stations slave types Axes or servo drives

Frequency inverters

I/O modules

24 Motion Control

Page 3

Item Specifications

Number of stations per master / Cycle time Max.16 Stations/2 ms Max. 4 Stations/2 ms

Transmission distance Max. 50 meters without using repeater

Max. 8 Stations/1 ms Max. 4 Stations/1ms

Trajexia PROFIBUS slave unit

Items Specifications

Model TJ1-PRT

PROFIBUS standard Conforms to PROFIBUS-DP standard EN50170 (DP-V0)

Communication ports 1 PROFIBUS-DP slave

Transmission speed 9.6, 19.2, 45.45, 93.75, 187.5, 500, 1500, 3000, 6000 and 1200 0kbps

Node numbers 0 to 99

I/O size 0 to 122 words (16 bit), configurable, for both directions

Galvanic isolation Yes

Trajexia DeviceNet slave unit

Items Specifications

Model TJ1-DRT

PROFIBUS standard Conforms to DeviceNet standard of CIP edition 1

Communication ports 1 DeviceNet slave

Transmission speed 125, 250 and 500 Kbps, auto-detect

Node numbers 0 to 63

I/O size 0 to 32 words (16 bit), configurable, for both directions

Galvanic isolation Yes

Trajexia CANopen unit

Items Specifications

Model TJ1-CORT

Electrical Characteristics Conforms to CAN 2.0 B

Communication ports 1 CANopen

Transmission speed 20, 50, 125 and 500 Kbps

Implemented CiA Standards DS301, DS302

PDO Support 8 TPDO and 8 RPDO

PDO Mapping Each PDO can be mapped into TJ1-MC16/04 VR, table, analogue and digital IO.

CANopen slave configuration Any SDO message can be sent using BASIC during start-up and operation

CANopen network states CANopen network can be set to pre-operational and operational using BASIC

CANopen slave emergencies Available using BASIC command

Galvanic isolation Yes

*1. TJ2-MC64 and TJ1-MC16/04 CPUs support a total of 256 digital IO points and 36 analogue IO points.

BASIC commands assign mapping and start address

*1

Motion controllers

Trajexia flexible axis unit

Items Specifications

Model TJ1-FL02

Number of axes 2. Every axis has 1 analog output, 1 encoder in/out -software configura ble - and several digital I/O

Control methods

(independent per axis)

Encoder Encoder protocols Abs SSI 200 kHz, Abs EnDat 1 MHz, Abs Tamagawa and Incremental Line driver AB

Encoder Input maximum frequency 6 MHz

Encoder/pulse output max. frequency 2 MHz

Auxiliary I/Os 2 fast registration inputs, 2 definable inputs, 2 enable output, 4 position switch outputs or axes reset

Galvanic isolation Yes

±10 V analogue output + encoder input (closed loop)

Line driver AB output

Stepper pulse output in closed loop or pulse train output in open loop

SmartSlice MECHATROLINK-II interface unit

Item Specifications

Model GRT1-ML2

Electrical characteristics Conform to MECHATROLINK standard

Communication cycle 0.5, 1 or 2 ms

Power supply 24 VDC

Number of connectable Slices Up to 64 slices with a maximum amount of 128 bytes

IO mapping Automatic ana logue and digital IO mapping into TJ1-MC16/04 CPU

Slice unit configuration Not supported

Supported slice units See ordering information section

*1. TJ2-MC64 and TJ1-MC16/04 CPUs support a total of 256 digital IO points and 36 analogue IO points.

*1

Trajexia motion controller 25

Page 4

Nomenclature

Trajexia motion controller unit - TJ2-MC64, TJ1MC-16/04

LEDs

Battery

compartment

Digital I/O

connector

Display

Ethernet port

RS422A/RS485

switches

RS-232C and

RS422A/485

serial ports

Trajexia DeviceNet slave unit - TJ1-DRT

Unit LEDs

3

2

4

1

5

0

6

9

7

8

3

2

4

1

5

0

6

9

7

8

Node selection

Trajexia MECHATROLINK-II master unit - TJ1-ML16/04

ML16

RUN

8F

CN1

Unit LEDs

MECHATROLINK-II master port

Trajexia CANopen unit - TJ1-CORT

CORT

Unit LEDs

3

2

4

1

5

0

6

9

7

8

3

2

4

1

5

0

6

9

7

8

Node selection

V-

CAN L

DRAIN

CAN H

V+

Trajexia PROFIBUS-DP unit - TJ1-PRT

H

B

3

2

4

1

5

0

6

9

7

8

3

2

4

1

5

0

6

9

7

8

DeviceNet slave port

Unit LEDs

PROFIBUS node

selection

PROFIBUS-DP slave port

V-

CAN L

DRAIN

CAN H

V+

Trajexia Flex axis unit - TJ1-FL02

FL02

CANopen port

Unit LEDs

15 pin connector

(Encoders IN/Out)

18 pin connector

(Digital and Analogue IOs)

26 Motion Control

Page 5

SmartSlice MECHATROLINK-II interface unit - GRT1-ML2

GRT1-ML2

SW1

SW2

CN2

CN1

A/B

RUN

ALARM

ML COM

TS

UNIT PWR

I/O PWR

ON

MECHATROLINK-II node selection

Unit LEDs

FG connector

REGS

1

NC2

ADR

3

BACK4

UNIT

+V

-V

I/O

+V

-V

DC24V

INPUT

Slice-master switches

ML vonnectors

Unit power

IO power

Dimensions

Trajexia motion controller - TJ2-MC64, TJ1-MC16/04 Trajexia modules - TJ1-ML16/04, -PRT, -DRT, -CORT, -FL02

94

90

94

90

Motion controllers

65

70.3

62

71

Trajexia system - CJ1W-PA202 + TJ1-MC16 + one module + TJ1-TER

65

PA202

70.30

31

39.9

94

90

62

29.73145

Trajexia motion controller 27

Page 6

SmartSlice communication unit - GRT1-ML2

SmartSlice end unit - GRT1-END

SmartSlice I/O units - GRT1-_

28 Motion Control

Page 7

Ordering information

Motion controllers

Power

Supply

Motion

controller

Axes

control

Communication

slave

End cover

(Included into the Motion controller)

Trajexia motion controller

Name Model

Trajexia motion controller unit, up to 4 axes. (Trajexia end cover unit TJ1-TER is included) TJ1-MC04

Trajexia motion controller unit, up to 16 axes. (Trajexia end cover unit TJ1-TER is included) TJ1-MC16

Trajexia motion controller Unit, up to 64 axes. (Trajexia end cover unit TJ1-TER is included) TJ2-MC64

Power supply for Trajexia system, 100-240 VAC CJ1W-PA202

Power supply for Trajexia system, 24 VDC CJ1W-PD022

Trajexia - axes control modules

Name Model

Trajexia MECHATROLINK-II master unit (up to 4 stations) TJ1-ML04

Trajexia MECHATROLINK-II master unit (up to 16 stations) TJ1-ML16

Trajexia flexible axis unit (for 2 axes) TJ1-FL02

Note: The TJ1-ML04 and TJ1-ML16 supported by the TJ2-MC64 motion controller are V2 (Version 2) and lot number equal

or above Lot No.091019 (YYMMDD).

Trajexia - communication modules

Name Model

Trajexia DevicNet slave unit TJ1-DRT

Trajexia PROFIBUS-DP slave unit TJ1-PRT

Trajexia CANopen unit TJ1-CORT

MECHATROLINK-II - related devices

Servo system & frequency inverters

Name Model

Accurax G5 servo drive ML-II built-in R88D-KN@@@-ML2

G-Series servo drive ML-II built-in R88D-GN@@H-ML2

Note: Refer to servo systems section for detailed specs and ordering information

SmartSlice IOs system

Function Specification Model

SmartSlice Interface unit SmartSlice MECHATROLINK-II inteface unit GRT1-ML2

End plate, one unit required per bus interface GRT1-END

4 NPN inputs 24 VDC, 6 mA, 3-wire connection GRT1-ID4

4 PNP inputs 24 VDC, 6 mA, 3-wire connection GRT1-ID4-1

8 NPN inputs 24 VDC, 4 mA, 1-wire connection + 4xG GRT1-ID8

8 PNP inputs 24 VDC, 4 mA, 1-wire connection + 4xV GRT1-ID8-1

4 NPN outputs 24 VDC, 500 mA, 2-wire connection GRT1-OD4

4 PNP outputs 24 VDC, 500 mA, 2-wire connection GRT1-OD4-1

4 PNP outputs with short-circuit protection 24 VDC, 500 mA, 3-wire connection GRT1-OD4G-1

8 NPN outputs 24 VDC, 500 mA, 1-wire connection + 4xV GRT1-OD8

8 PNP outputs 24 VDC, 500 mA, 1-wire connection + 4xG GRT1-OD8-1

8 PNP outputs with short-circuit protection 24 VDC, 500 mA, 1-wire connection + 4xG GRT1-OD8G-1

2 relay outputs 240 VAC, 2 A, normally-open contacts GRT1-ROS2

2 analogue inputs, current/voltage ±10 V, 0-10 V, 0-5 V, 1-5 V, 0-20 mA, 4-20 mA GRT1-AD2

2 analogue outputs, voltage ± 10 V, 0-10 V, 0-5 V, 1-5 V GRT1-DA2V

2 analogue outputs, current 0-20 mA, 4-20 mA GRT1-DA2C

Note: Refer to Automation systems catalogue for detailed specs and accesories information

Trajexia motion controller 29

Page 8

MECHATROLINK-II cables

Name Remarks Model

MECHATROLINK-II cables 0.5 meter JEPMC-W6003-A5

MECHATROLINK-II terminator Terminating resistor JEPMC-W6022

MECHATROLINK-II repeater Network repeater JEPMC-REP2000

1 meter JEPMC-W6003-01

3 meters JEPMC-W6003-03

5 meters JEPMC-W6003-05

10 meters JEPMC-W6003-10

20 meters JEPMC-W6003-20

30 meters JEPMC-W6003-30

Computer software

Specifications Model

CX-Motion Pro V1.22 or higher CX-One

Trajexia Studio

*1. When the Trajexia Studio software is included in CX-One, then it is called CX-Motion Pro.

*1

V1.22 or higher

TJ1-Studio

ALL DIMENSIONS SHOWN ARE IN MILLIMETERS.

To convert millimeters into inches, multiply by 0.03937. To convert grams into ounces, multiply by 0.03527.

Cat. No. I53E-EN-03A

In the interest of product improvement, specifications are subject to change without notice.

30 Motion Control

Loading...

Loading...