Page 1

i

Software Manual

I626-E-09

TMflow

Original Instruction

Page 2

This Manual contains information of the Techman Robot product series (hereinafter referred to as the TM

Robot). The information contained herein is the property of Techman Robot Inc. (hereinafter referred to as

the Corporation). No part of this publication may be reproduced or copied in any way, shape or form without

prior authorization from the Corporation. No information contained herein shall be considered an offer or

commitment. It may be subject to change without notice. This Manual will be reviewed periodically. The

Corporation will not be liable for any error or omission.

logo is registered trademark of TECHMAN ROBOT INC. in Taiwan and other countries and the

company reserves the ownership of this manual and its copy and its copyrights.

Software Manual TMflow Software version: 1.82

Page 3

3

Contents

Revision History Table ................................................................................................................................ 20

1. General................................................................................................................................................... 21

Overview ....................................................................................................................................... 21

Warning and Caution Symbols ....................................................................................................... 21

Safety Precautions ........................................................................................................................ 22

Validation and Responsibility ......................................................................................................... 23

Limitation of Liability ...................................................................................................................... 23

Functional Note Symbol ................................................................................................................. 23

2. Start up and Activation ............................................................................................................................ 24

Overview ....................................................................................................................................... 24

Start Up ......................................................................................................................................... 24

Plug in the Power .................................................................................................................... 24

Start up from Packing Pose ..................................................................................................... 24

Standard Start Up ................................................................................................................... 28

TM Robot HMI TMflow Operation ............................................................................................ 29

Local Operation Method ................................................................................................... 30

Wireless Access Point Connection Method ....................................................................... 30

Wired Network Connection Method .................................................................................. 31

3. Safety Settings ....................................................................................................................................... 33

Overview ....................................................................................................................................... 33

Safety Permission Settings ............................................................................................................ 33

Safety Setting ................................................................................................................................ 33

Performance Safety Settings ................................................................................................... 34

Human – Machine Safety Settings .......................................................................................... 35

Safety IO Settings ................................................................................................................... 38

Resume Setting of User Connected External Safeguard Input Port .................................. 39

Resume Setting of User Connected External Safeguard Input Port for Human - Machine

Safety Settings ............................................................................................................................. 39

Safeguard Port Setting for the Hardware Version prior to 2.00 (inclusive) ......................... 40

Enabling Device Setting (HW 3.2 or newer exclusive) ...................................................... 40

4. Start Your First Project ............................................................................................................................ 44

Software Manual TMflow Software version: 1.82

Cartesian Limit A & B .............................................................................................................. 41

Project Speed Adjustment Setting ........................................................................................... 41

Switch between Modes ........................................................................................................... 42

Overview ....................................................................................................................................... 44

Page 4

4

Initial Setting .................................................................................................................................. 44

M/A Mode and FreeBot .................................................................................................................. 44

Build and Run Your First Project .................................................................................................... 46

Shutdown ...................................................................................................................................... 49

5. Operation Interface ................................................................................................................................. 51

Overview ....................................................................................................................................... 51

Login/Logout .................................................................................................................................. 51

Connection .................................................................................................................................... 52

Local Connection .................................................................................................................... 52

Remote Connection ................................................................................................................ 52

View .............................................................................................................................................. 53

Display Board .......................................................................................................................... 53

Flow ........................................................................................................................................ 55

IO ............................................................................................................................................ 56

Simulator ................................................................................................................................. 56

Status ...................................................................................................................................... 57

Vision Viewer .......................................................................................................................... 57

Run Setting .................................................................................................................................... 58

Project ........................................................................................................................................... 59

Project Editing Toolbar ............................................................................................................ 60

Create New Project ........................................................................................................... 60

Save Project ..................................................................................................................... 61

Open Project..................................................................................................................... 61

Step Run .......................................................................................................................... 62

Point Manager .................................................................................................................. 63

Base Manager .................................................................................................................. 65

Controller .......................................................................................................................... 66

Variables ........................................................................................................................... 70

EditBlock .......................................................................................................................... 70

Current Base and Base List ............................................................................................ 71

Current TCP and TCP List .............................................................................................. 71

Display Manager ............................................................................................................. 72

Node Menu and Flow Editing Area .......................................................................................... 73

Project Function Menu ............................................................................................................ 74

Search Function ............................................................................................................... 75

Operation Space ............................................................................................................... 76

Software Manual TMflow Software version: 1.82

Page 5

5

Modbus Device ................................................................................................................. 76

Set IO while Project Error ................................................................................................. 76

Set IO while Project Stop .................................................................................................. 76

Stop Watch ....................................................................................................................... 76

View.................................................................................................................................. 77

F/T Sensor ........................................................................................................................ 77

Serial Port ......................................................................................................................... 78

Path Generate ................................................................................................................ 79

Joint Loading .................................................................................................................. 80

Network Device .............................................................................................................. 80

Robot Setting ................................................................................................................................. 81

Wizard ..................................................................................................................................... 81

Vision Setting .......................................................................................................................... 81

TCP ......................................................................................................................................... 81

IO Setup .................................................................................................................................. 81

Safety ...................................................................................................................................... 82

Controller ................................................................................................................................ 82

Speech .................................................................................................................................... 82

End Button .............................................................................................................................. 83

Component ............................................................................................................................. 84

Operation Space ................................................................................................................... 84

Command .............................................................................................................................. 84

Connection ............................................................................................................................ 84

Posture Setting...................................................................................................................... 85

Global Variables .................................................................................................................... 86

Text File Manager .................................................................................................................. 86

TMmanager ........................................................................................................................... 86

Motion Setting ....................................................................................................................... 86

System Setting .............................................................................................................................. 87

Language ................................................................................................................................ 88

System Update ....................................................................................................................... 88

Group ...................................................................................................................................... 89

User Account ........................................................................................................................... 90

Network Setting ....................................................................................................................... 90

Import/Export .......................................................................................................................... 91

Date Time................................................................................................................................ 93

Software Manual TMflow Software version: 1.82

Page 6

6

Administrator Setting ............................................................................................................... 93

Network Service ...................................................................................................................... 94

Backup\Restore..................................................................................................................... 95

Input/Display Devices ............................................................................................................ 96

Pop-out Keyboard ........................................................................................................... 96

Input Devices (HW 3.2 or newer exclusive) ..................................................................... 97

Auto Remote Mode ............................................................................................................... 97

Hard Disk Space Analysis ..................................................................................................... 98

6. Point and Base ..................................................................................................................................... 100

Overview ..................................................................................................................................... 100

Base and Right-hand Rule ........................................................................................................... 101

Right-hand Rule .................................................................................................................... 101

Types of Base ....................................................................................................................... 101

Robot Base ..................................................................................................................... 101

Vision Base ..................................................................................................................... 102

Custom Base .................................................................................................................. 102

Tool Coordinate .............................................................................................................. 103

Point Parameter ........................................................................................................................... 103

Base Shift.............................................................................................................................. 104

Tool Shift ............................................................................................................................... 106

7. Create Base ......................................................................................................................................... 108

Create Vision Base ...................................................................................................................... 108

Create a Custom Base ................................................................................................................ 108

Create New Base Node ............................................................................................................... 109

Create a New Base by Multiple Bases .................................................................................. 11 0

Create a New Base with Two Vision Bases ..................................................................... 11 0

Create a New Base with Three Vision Bases .................................................................. 110

Create a New Base with Three Points ................................................................................... 111

Create a New Base with Three Points on the Vision Base .............................................. 11 2

Create a New Base with Three Dynamic Points .............................................................. 113

8. Create the TCP ..................................................................................................................................... 114

Overview ..................................................................................................................................... 114

TCP Setting ................................................................................................................................. 114

Create Parameters of TCP with Hand Guidance Teaching .................................................... 115

Create Tool Center Point by Input Parameters ...................................................................... 11 8

9. Motion Programming ............................................................................................................................ 120

Software Manual TMflow Software version: 1.82

Page 7

7

Overview ..................................................................................................................................... 120

Point to Point (PTP) ..................................................................................................................... 121

PTP is the Fastest Way to Move ........................................................................................... 121

Speed of PTP Motion ............................................................................................................ 121

Plan for PTP Movement ........................................................................................................ 122

PTP Smart Pose Choosing.................................................................................................... 122

Line ............................................................................................................................................. 123

Line Moves the Shortest Distance ......................................................................................... 123

Speed of Line Motion ............................................................................................................ 123

Plan for Line Movement ........................................................................................................ 124

Two-Steps Motion (WayPoint) ...................................................................................................... 125

WayPoint ............................................................................................................................... 125

Plan for WayPoint Movement ................................................................................................ 126

Blending ...................................................................................................................................... 127

Blending in Movement ........................................................................................................... 127

Blending Speed Change Chart .............................................................................................. 127

Set the Blending Percentage ................................................................................................. 127

Set the Blending by Radius ................................................................................................... 128

Motion Nodes .............................................................................................................................. 128

Point Node ............................................................................................................................ 130

Generation Method of Point node ................................................................................... 130

Point Node Setting .......................................................................................................... 131

F-Point Node ......................................................................................................................... 131

Move Node ............................................................................................................................ 133

Plan for the Move Node .................................................................................................. 134

Circle Node ........................................................................................................................... 134

Circle Node Setting ......................................................................................................... 134

Reach End Point ............................................................................................................. 135

Target Central Angle ....................................................................................................... 135

Path Node ............................................................................................................................. 136

Path and PLine ............................................................................................................... 136

Path Node Setting .......................................................................................................... 136

Path File Import and Export ............................................................................................ 138

Pallet Node ........................................................................................................................... 138

Listen Node ........................................................................................................................... 140

10. Logic Programming............................................................................................................................. 142

Software Manual TMflow Software version: 1.82

Page 8

8

Overview ................................................................................................................................... 142

Variable System ......................................................................................................................... 142

Local Variables .................................................................................................................... 142

Global Variables............................................................................................................ 143

Logic Nodes .............................................................................................................................. 145

Start Node ........................................................................................................................... 145

SET Node ........................................................................................................................... 145

IF Node ............................................................................................................................... 149

WaitFor Node ...................................................................................................................... 150

Gateway Node .................................................................................................................... 150

M-Decision Node ................................................................................................................. 151

Process ..................................................................................................................................... 152

Process Nodes .................................................................................................................... 152

Subflow Node ...................................................................................................................... 154

Thread................................................................................................................................. 156

11. Vision Node ........................................................................................................................................ 157

12. Communication and Display ............................................................................................................... 159

Modbus ...................................................................................................................................... 159

Modbus System Hardware Structure ................................................................................... 159

Modbus System Software Structure .................................................................................... 159

Set Modbus TCP .......................................................................................................... 159

Set Modbus RTU .......................................................................................................... 160

Application of Modbus in Project ......................................................................................... 160

Network ..................................................................................................................................... 164

Network Node ..................................................................................................................... 165

IO .............................................................................................................................................. 166

User Defined IO .................................................................................................................. 166

External IO .......................................................................................................................... 166

Status IO ............................................................................................................................. 167

Command Node ........................................................................................................................ 167

TmComm Instruction Set ..................................................................................................... 168

File Command ..................................................................................................................... 174

Log Node ................................................................................................................................... 177

Display Node ............................................................................................................................. 178

Voice Node ................................................................................................................................ 179

13. Component ......................................................................................................................................... 181

Software Manual TMflow Software version: 1.82

Page 9

9

14. Force Related Node ............................................................................................................................ 184

Compliance node ....................................................................................................................... 184

F/T Sensor ................................................................................................................................. 188

Communication Setting ....................................................................................................... 188

Position Setting ................................................................................................................... 189

Import/Export Settings of F/T Sensor .................................................................................. 191

Force Value and Charts ....................................................................................................... 191

Touch Stop Node ....................................................................................................................... 192

Function Type: Compliance ................................................................................................. 192

Function Type: Line ............................................................................................................. 193

Touch Stop Function Type: Force Sensor ............................................................................ 195

Smart Insert Node ..................................................................................................................... 197

Approaching ........................................................................................................................ 197

Approaching principle description ................................................................................. 197

Approaching parameters setting ................................................................................... 198

Searching ............................................................................................................................ 199

Method for searching: Spiral ......................................................................................... 200

Method for searching: Linear ........................................................................................ 201

Pushing ............................................................................................................................... 202

Parameter Setting ......................................................................................................... 202

Force Control Node ................................................................................................................... 203

15. Operation Space ................................................................................................................................. 210

Overview ................................................................................................................................... 210

Operation Space Setting Page .................................................................................................. 211

Add / Modify Page ..................................................................................................................... 212

Plane Page ......................................................................................................................... 212

Cube Page .......................................................................................................................... 213

Operation Space Setting Page in the Project Editing Page ........................................................ 214

Export/Import Operation Space.................................................................................................. 216

Export Operation Space ...................................................................................................... 216

Import Operation Space ...................................................................................................... 216

16. TM Component Editor ......................................................................................................................... 219

Starting to create your first component ...................................................................................... 219

Overview ............................................................................................................................. 219

TM Component Editor settings ............................................................................................ 219

Start node ..................................................................................................................... 219

Software Manual TMflow Software version: 1.82

Page 10

10

Node settings ................................................................................................................ 222

TM Component Editor Naming Rule .................................................................................... 224

Component Naming ...................................................................................................... 224

Global Variables Naming .............................................................................................. 225

Devices ...................................................................................................................................... 226

Modbus Devices .................................................................................................................. 226

Network Devices ................................................................................................................. 226

Force Sensing Devices ....................................................................................................... 227

Features & Applicable Examples ............................................................................................... 227

Global Variables .................................................................................................................. 227

Use component in TM Component Editor ............................................................................ 228

Component Inheritance ....................................................................................................... 228

The example of point parameterization application .............................................................. 229

The example of making parameterized devices ................................................................... 231

Use thread in TM Component Editor ................................................................................... 232

Use subflow in TM Component Editor ................................................................................. 232

Hide parameters .................................................................................................................. 232

Using your component ............................................................................................................... 233

Open the component ........................................................................................................... 233

Import/Export Components ................................................................................................. 234

17. Collision Check Node ......................................................................................................................... 235

Appendix A: Modbus List .......................................................................................................................... 236

Appendix B: Display of Indication Light Ring ............................................................................................. 251

Appendix C: Tables of Safety Parameter Upper and Lower Bounds ......................................................... 255

Appendix D: Ethernet Slave Data Table .................................................................................................... 263

Appendix E: PROFINET Data Table ......................................................................................................... 269

Appendix F: Error Descriptions and Suggestions ...................................................................................... 274

Figures

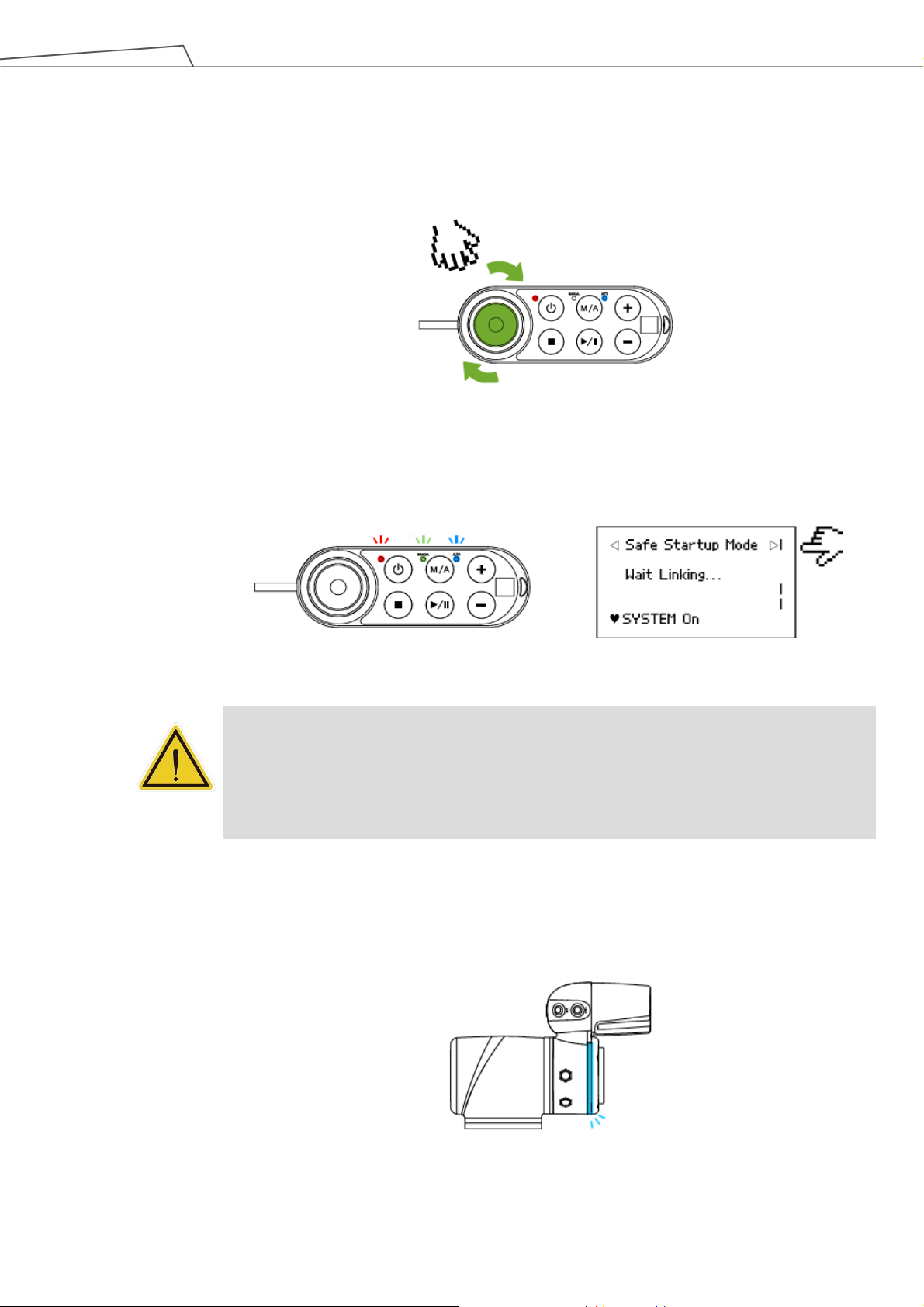

Figure 1: Release the Emergency Switch ..................................................................................... 25

Figure 2: The Three Lights on The Robot Stick Flashing .............................................................. 25

Figure 3: The Indication Light Ring of The End Module Flashing in Light Blue ............................. 25

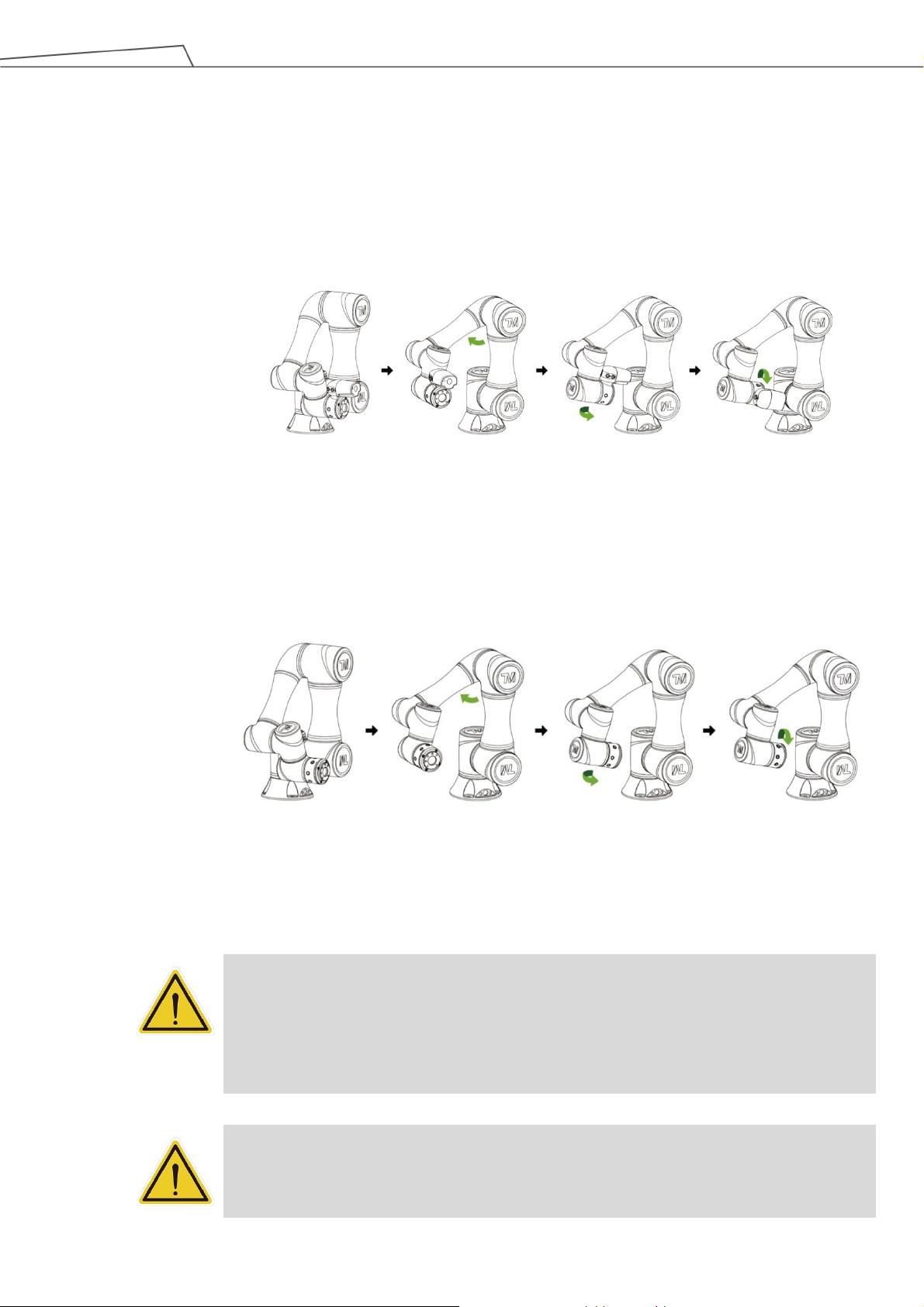

Figure 4: The Recommended Operating Sequence of Moving the Joints of TM Robot from Packing

Pose to Safe Posture............................................................................................................. 26

Figure 5: The Recommended Operating Sequence of Moving the Joints of X series TM Robot from

Packing Pose to Safe Posture ............................................................................................... 26

Software Manual TMflow Software version: 1.82

Page 11

11

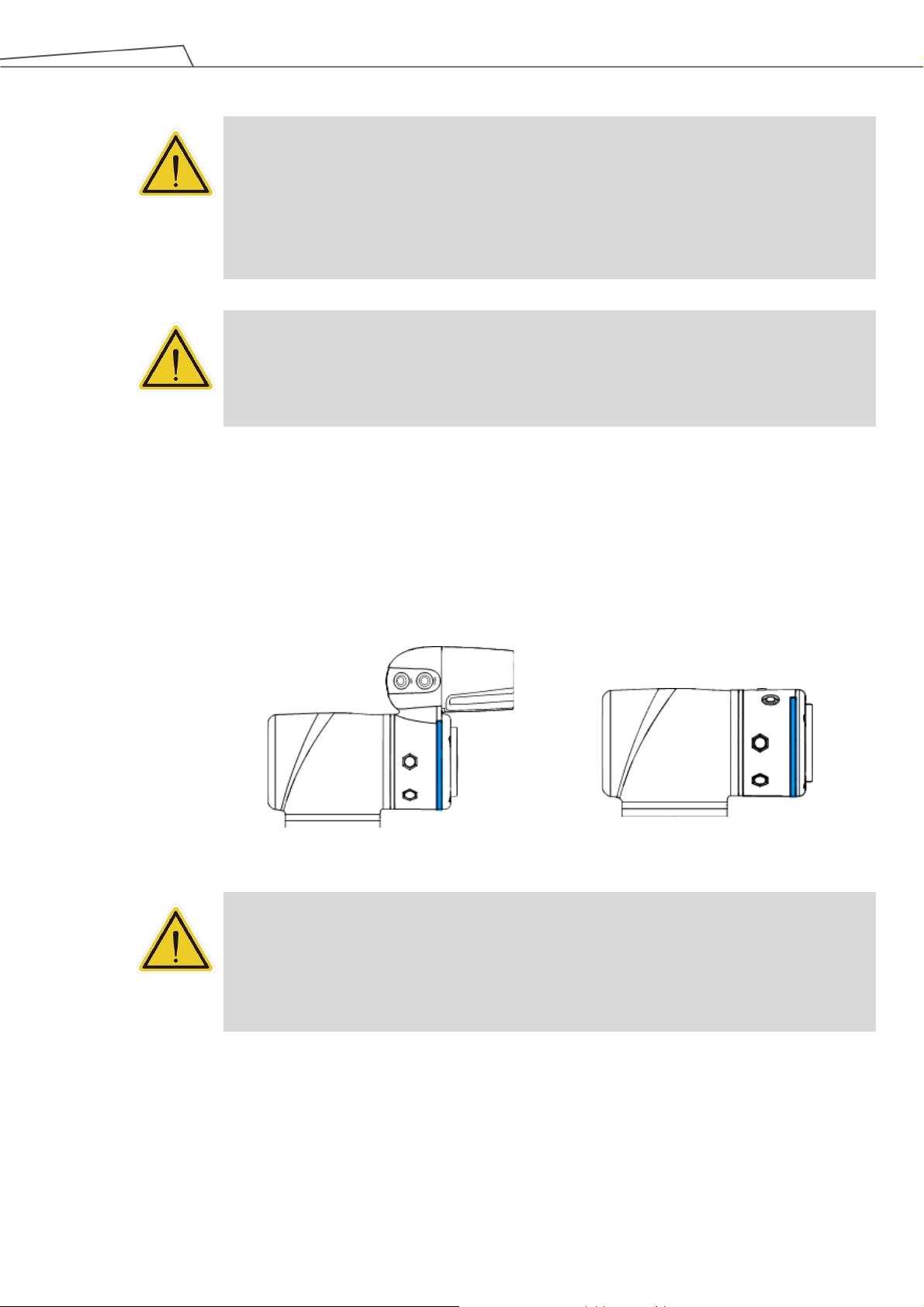

Figure 6: The Indication Light Ring of The End Module Returns to Blue Light .............................. 27

Figure 7: The Normal Poses ......................................................................................................... 28

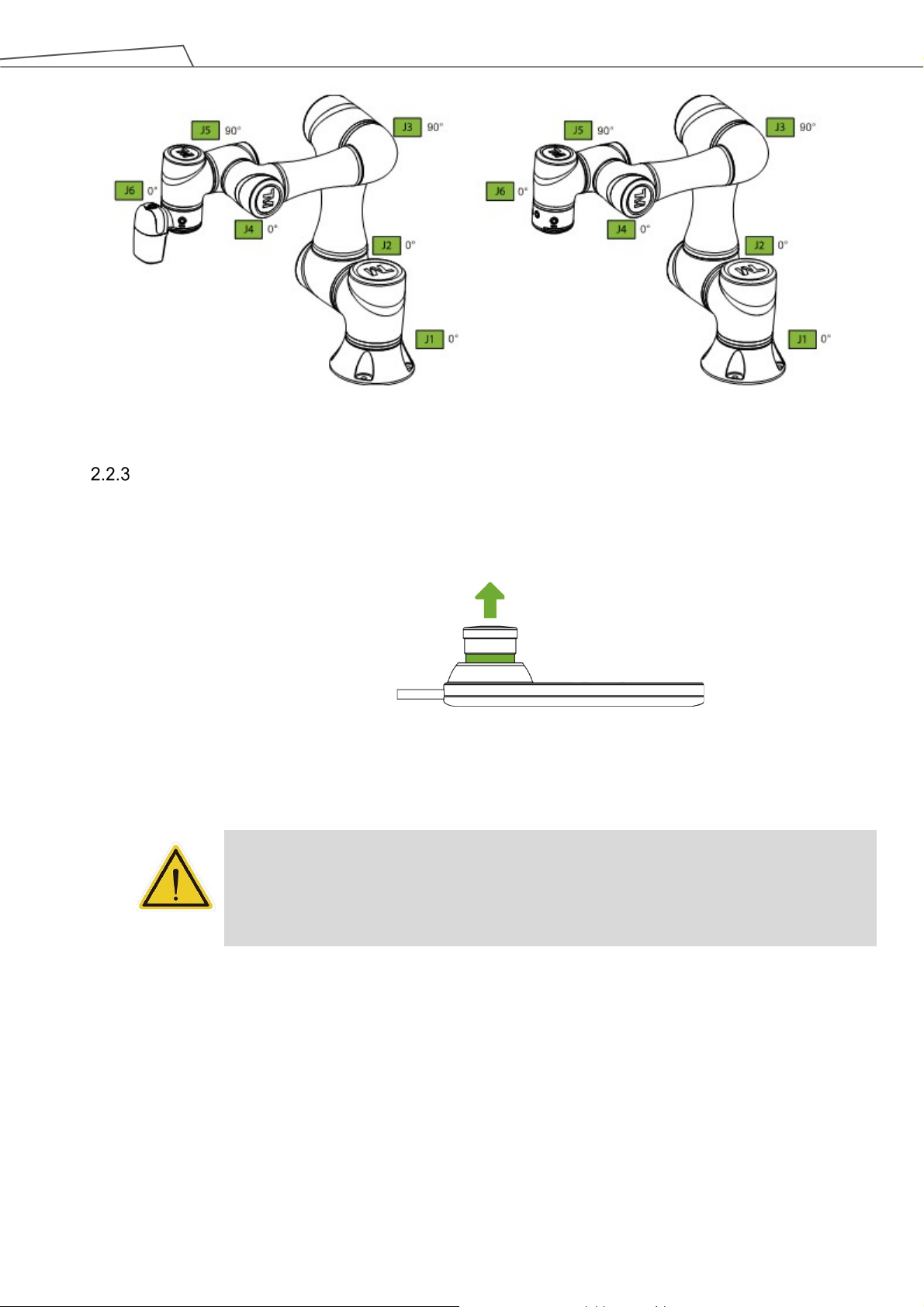

Figure 8: Release the Emergency Switch of Robot Stick .............................................................. 28

Figure 9: The Power Light on The Robot Stick Flashing ............................................................... 29

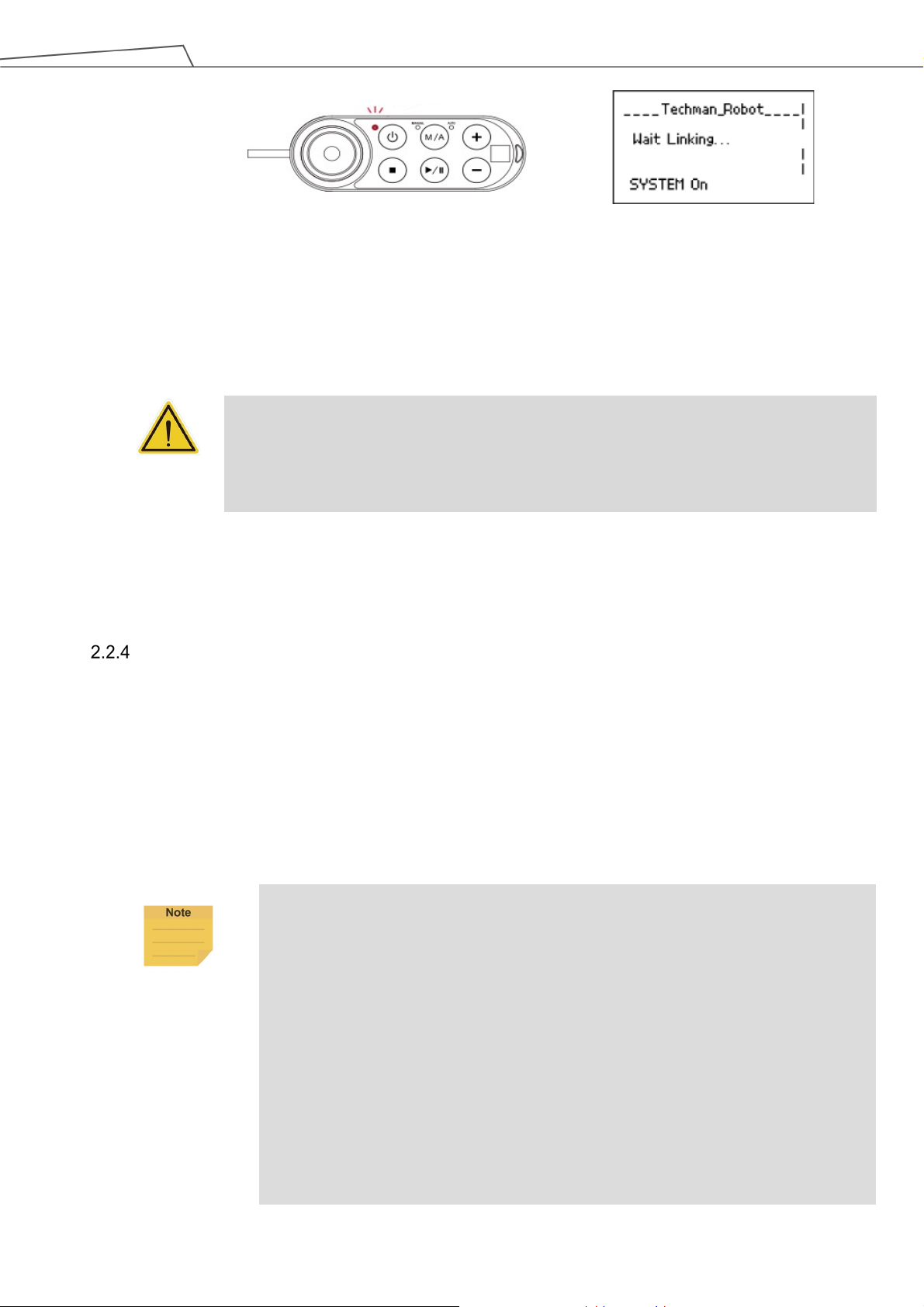

Figure 10: Wireless Access Point Connection Method (1/2) ......................................................... 30

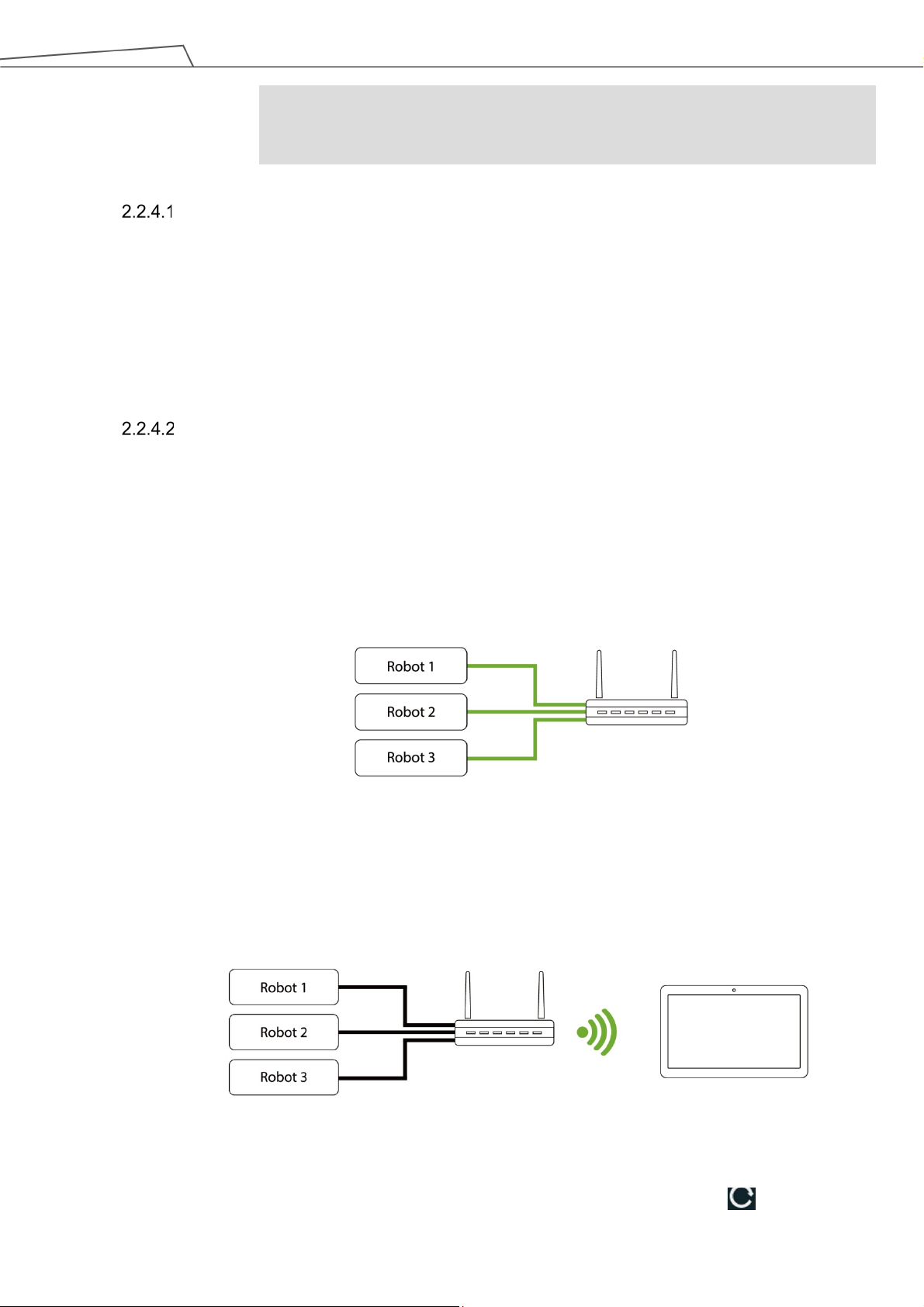

Figure 11: Wireless Access Point Connection Method (2/2) ......................................................... 30

Figure 12: Wired Network Connection Method (1/2) ..................................................................... 32

Figure 13: Wired Network Connection Method (2/2) ..................................................................... 32

Figure 14: Safety Setting .............................................................................................................. 34

Figure 15: Angle Setting ............................................................................................................... 35

Figure 16: Human – Machine Safety Settings (1/2) ...................................................................... 36

Figure 17: Human – Machine Safety Settings (2/2) ...................................................................... 38

Figure 18: Safety IO Settings ........................................................................................................ 39

Figure 19: Auto Mode / Manual Mode (1/3) .................................................................................. 45

Figure 20: Auto Mode / Manual Mode (2/3) .................................................................................. 45

Figure 21: Auto Mode / Manual Mode (3/3) .................................................................................. 45

Figure 22: The Robot Stick for HW 3.2 or newer .......................................................................... 46

Figure 23: Build and Run Your First Project (1/5) ......................................................................... 47

Figure 24: Build and Run Your First Project (2/5) ......................................................................... 47

Figure 25: Build and Run Your First Project (3/5) ......................................................................... 48

Figure 26: Build and Run Your First Project (4/5) ......................................................................... 49

Figure 27: Build and Run Your First Project (5/5) ......................................................................... 49

Figure 28: Shutdown .................................................................................................................... 50

Figure 29: Function Menu ............................................................................................................. 51

Figure 30: Get/Release Control (Local) ........................................................................................ 52

Figure 31: View ............................................................................................................................ 53

Figure 32: Display(1/3) ................................................................................................................. 54

Figure 33: Display(2/3) ................................................................................................................. 54

Figure 34: Display(3/3) ................................................................................................................. 55

Figure 35: IO ................................................................................................................................ 56

Figure 36: Simulator ..................................................................................................................... 57

Figure 37: Status .......................................................................................................................... 57

Figure 38: Vision Viewer ............................................................................................................... 58

Figure 39: Single Project Icon ....................................................................................................... 59

Figure 40: Project Editing Page .................................................................................................... 60

Figure 41: Open and Delete Project View ..................................................................................... 62

Software Manual TMflow Software version: 1.82

Page 12

12

Figure 42: Step Run ..................................................................................................................... 63

Figure 43: Point Manager (1/2) ..................................................................................................... 64

Figure 44: Point Manager (2/2) ..................................................................................................... 64

Figure 45: Base Manager ............................................................................................................. 66

Figure 46: Controller ..................................................................................................................... 66

Figure 47: Controller (IO Control) ................................................................................................. 68

Figure 48: Controller (FreeBot Control)......................................................................................... 69

Figure 49: EditBlock ..................................................................................................................... 71

Figure 50: Base List...................................................................................................................... 71

Figure 51: Tool List ....................................................................................................................... 72

Figure 52: Display Manager .......................................................................................................... 72

Figure 53: Project Edit (1/3) .......................................................................................................... 73

Figure 54: Project Edit (2/3) .......................................................................................................... 74

Figure 55: Project Edit (3/3) .......................................................................................................... 74

Figure 56: Project Function Menu ................................................................................................. 75

Figure 57: Searching Pane ........................................................................................................... 76

Figure 58: Stop Watch Setting Page ............................................................................................. 77

Figure 59: View Tool Floating Window ......................................................................................... 77

Figure 60: Serial Port (1/2) ........................................................................................................... 78

Figure 61: Serial Port (2/2) ........................................................................................................... 78

Figure 62: Robot Setting ............................................................................................................... 81

Figure 63: Output Default Value Setting ....................................................................................... 82

Figure 64: Speech Setting ............................................................................................................ 83

Figure 65: Gripper Button ............................................................................................................. 84

Figure 66: Posture Setting ............................................................................................................ 85

Figure 67: System Setting ............................................................................................................ 88

Figure 68: Language Setting ........................................................................................................ 88

Figure 69: System Update (1/2) .................................................................................................... 89

Figure 70: System Update (2/2) .................................................................................................... 89

Figure 71: Group .......................................................................................................................... 90

Figure 72: User Account ............................................................................................................... 90

Figure 73: Network Setting (1/2) ................................................................................................... 91

Figure 74: Network Setting (2/2) ................................................................................................... 91

Figure 75: Date Time .................................................................................................................... 93

Figure 76: Administrator Setting ................................................................................................... 94

Figure 77: Network Services ......................................................................................................... 94

Software Manual TMflow Software version: 1.82

Page 13

13

Figure 78: Backup\Restore ........................................................................................................... 96

Figure 79: Pop-out Keyboard ........................................................................................................ 97

Figure 80: Input Devices ............................................................................................................... 97

Figure 81: Auto Remote Mode (1/2) ............................................................................................. 98

Figure 82: Auto Remote Mode (2/2) ............................................................................................. 98

Figure 83: Base Value of the Point ............................................................................................. 100

Figure 84: Coordinate Axis Rotation ........................................................................................... 100

Figure 85: Right-Hand Base ....................................................................................................... 101

Figure 86: Robot Base ................................................................................................................ 102

Figure 87: Servoing Vision Base is on the Camera ..................................................................... 102

Figure 88: Fix-point Vision Base is on the Object ....................................................................... 102

Figure 89: Tool Coordinates ....................................................................................................... 103

Figure 90: Point Parameter Information ...................................................................................... 104

Figure 91: Shift Function of Point Node ...................................................................................... 104

Figure 92: Base Shift Schematic Diagram .................................................................................. 105

Figure 93: Node with Base Shift ................................................................................................. 105

Figure 94: Node with Tool Shift .................................................................................................. 106

Figure 95: Tool Shift Using Keep Pose ....................................................................................... 106

Figure 96: Tool Shift Using Keep Path ........................................................................................ 107

Figure 97: Base Manager ........................................................................................................... 108

Figure 98: Build a Base by 3 Points ............................................................................................ 109

Figure 99: New Base Node......................................................................................................... 110

Figure 100: Create a New Base with Two Vision Bases ............................................................. 110

Figure 101: Create a New Base with Three Vision Bases ........................................................... 111

Figure 102: Create a New Base with Three Points ..................................................................... 112

Figure 103: Create a New Base with Three Points on the Vision Base ....................................... 112

Figure 104: Create a New Base with Three Dynamic Points ....................................................... 113

Figure 105: TCP Definition ......................................................................................................... 114

Figure 106: TCP Setting ............................................................................................................. 115

Figure 107: Set the times of calibration....................................................................................... 116

Figure 108: Teaching Screen ..................................................................................................... 116

Figure 109: The Robot Posture Needs to Change during Teaching (1/2) .................................... 117

Figure 110: The Robot Posture Needs to Change during Teaching (1/2) .................................... 117

Figure 111: Save Teaching Result .............................................................................................. 118

Figure 112: Manual Input TCP Values ........................................................................................ 119

Figure 113: TM Robot Motion Types .......................................................................................... 120

Software Manual TMflow Software version: 1.82

Page 14

14

Figure 114: PTP Motion .............................................................................................................. 121

Figure 115: Speed of PTP Motion............................................................................................... 122

Figure 116: PTP Application Examples....................................................................................... 122

Figure 117: PTP Smart Pose Choosing ...................................................................................... 123

Figure 118: Line Motion Simulation ............................................................................................ 123

Figure 119: Speed of Line Motion ............................................................................................... 123

Figure 120: Link to Project Speed............................................................................................... 124

Figure 121: Line Application Example ........................................................................................ 125

Figure 122: WayPoint Motion Status .......................................................................................... 125

Figure 123: WayPoint Setting ..................................................................................................... 126

Figure 124: WayPoint Application Examples .............................................................................. 126

Figure 125: Blending in Space .................................................................................................... 127

Figure 126: Blending Speed Change Chart ................................................................................ 127

Figure 127: Set the Blending Percentage or Set the Blending by Radius.................................... 128

Figure 128: Motion Nodes Support Variable as the Inputs .......................................................... 129

Figure 129: Speed Adjust and Speed Indication on the Node. .................................................... 130

Figure 130: Point Node ............................................................................................................... 130

Figure 131: Point Node Setting ................................................................................................... 131

Figure 132: F-Point Node ........................................................................................................... 132

Figure 133: F-Point Node Setting ............................................................................................... 132

Figure 134: Adjust F-Point Parameter during Project Running .................................................... 133

Figure 135: Move Node Setting .................................................................................................. 133

Figure 136: Plan for the Move Node ........................................................................................... 134

Figure 137: The Circle Node Plans Arc Path with 3-Point Setting Circle ..................................... 134

Figure 138: Circle Node Setting .................................................................................................. 135

Figure 139: The Circle Motion Status of Reach End Point Settting ............................................. 135

Figure 140: The Circle Motion Status of Set Angle =270° ........................................................... 136

Figure 141: PLine Blending Relationship Chart .......................................................................... 136

Figure 142: Path Node Setting ................................................................................................... 137

Figure 143: Pallet Node (1/2) ...................................................................................................... 138

Figure 144: Pallet Node (2/2) ...................................................................................................... 139

Figure 145: Pallet Patterns ......................................................................................................... 139

Figure 146: Listen Node ............................................................................................................. 140

Figure 147: Variable System ...................................................................................................... 142

Figure 148: Global Variable Setting ............................................................................................ 144

Figure 149: Global Variables after Project Is Run ....................................................................... 144

Software Manual TMflow Software version: 1.82

Page 15

15

Figure 150: SET Node ................................................................................................................ 146

Figure 151: Variable Count ......................................................................................................... 146

Figure 152: Expression Editor Parameters (1/2) ......................................................................... 147

Figure 153: Expression Editor Parameters (2/2) ......................................................................... 148

Figure 154: Add Expression ....................................................................................................... 148

Figure 155: Analog I/O Setting ................................................................................................... 149

Figure 156: IF Node.................................................................................................................... 149

Figure 157: IF Node Stop Criteria Setting ................................................................................... 150

Figure 158: Gateway Node Judges Five Conditions ................................................................... 151

Figure 159: IF Node Judges Four Conditions ............................................................................. 151

Figure 160: Stop Node Ends Project .......................................................................................... 152

Figure 161: Goto Node Flow Transfer ........................................................................................ 153

Figure 162: Goto Node Connection ............................................................................................ 153

Figure 163: Warp Node Transfers to another Project .................................................................. 153

Figure 164: Subflow Node Modularization Concept .................................................................... 154

Figure 165: Menu to Create Subpages ....................................................................................... 155

Figure 166: Select a subflow in the subflow node (1/2) ............................................................... 155

Figure 167: Select a subflow in the subflow node (2/2) ............................................................... 156

Figure 168: Thread ..................................................................................................................... 156

Figure 169: Vision Node ............................................................................................................. 157

Figure 170: Vision Node Flow ..................................................................................................... 157

Figure 171: Vision Node Setting ................................................................................................. 158

Figure 172: Robot Modbus Protocol ........................................................................................... 159

Figure 173: Modbus Device Access ........................................................................................... 160

Figure 174: Modbus TCP Local IP .............................................................................................. 161

Figure 175: Modbus Device Setting ............................................................................................ 162

Figure 176: Modbus X Axis Position Parameter Setting .............................................................. 162

Figure 177: Save the Variable of Modbus Value ......................................................................... 163

Figure 178: Use the obtained variable of SET node to obtain the value of Modbus .................... 163

Figure 179: Display displays the value obtained by Modbus ....................................................... 164

Figure 180: Network Setting ....................................................................................................... 165

Figure 181: Status IO Setting (1/2) ............................................................................................. 167

Figure 182: Status IO Setting (2/2) ............................................................................................. 167

Figure 183: Instruction Set Communicates with HMI .................................................................. 168

Figure 184: Enable TmComm Instruction Set ............................................................................. 168

Figure 185: Directive Summary Flow .......................................................................................... 170

Software Manual TMflow Software version: 1.82

Page 16

16

Figure 186: Command Node Gets RS-232 Information .............................................................. 171

Figure 187: Set and Open Serial Port (1/2) ................................................................................. 171

Figure 188: Set and Open Serial Port (2/2) ................................................................................. 172

Figure 189: Read Data and Receive as a Variable ..................................................................... 172

Figure 190: SET Node Setting .................................................................................................... 173

Figure 191: Display Node Displays the Obtained Value .............................................................. 174

Figure 192: Remotely Add Notepad and Write information ......................................................... 176

Figure 193: Display Node Displays Received Variables ............................................................. 176

Figure 194: Remotely Delete Notepad File ................................................................................. 177

Figure 195: Log Node Gets the Current Angle ............................................................................ 177

Figure 196: Log Node Setting ..................................................................................................... 178

Figure 197: Node Text Example ................................................................................................. 178

Figure 198: Display Node Displays the Robot's Position ............................................................. 179

Figure 199: Voice Node in TMflow Application............................................................................ 179

Figure 200: Select Components ................................................................................................. 181

Figure 201: Robot Setting Page Component .............................................................................. 182

Figure 202: Gripper Button Setting Page .................................................................................... 183

Figure 203: Compliance Node .................................................................................................... 184

Figure 204: Compliance Node Teach Setting ............................................................................. 186

Figure 205: Line Direction .......................................................................................................... 187

Figure 206: Rotation Direction .................................................................................................... 187

Figure 207: Compliance Variable Selection ................................................................................ 187

Figure 208: F/T Sensor ............................................................................................................... 188

Figure 209: Read Values after Setting F/T Sensor ..................................................................... 189

Figure 210: Position Setting ........................................................................................................ 190

Figure 211: Select Position Setting ............................................................................................. 190

Figure 212: Input Values ............................................................................................................ 191

Figure 213: Charts ...................................................................................................................... 191

Figure 214: Touch Stop-Compliance Settings ............................................................................ 192

Figure 215: Touch Stop-Line Settings ........................................................................................ 194

Figure 216: Force Sensor ........................................................................................................... 195

Figure 217: Force Sensor ........................................................................................................... 196

Figure 218: Approaching Principle .............................................................................................. 198

Figure 219: Approaching Parameter Setting ............................................................................... 199

Figure 220: Spiral Searching Method ......................................................................................... 199

Figure 221: Line Searching Method (1/2) .................................................................................... 200

Software Manual TMflow Software version: 1.82

Page 17

17

Figure 222: Line Searching Method (2/2) .................................................................................... 200

Figure 223: Spiral Searching Parameter Setting Interface .......................................................... 201

Figure 224: Linear Searching Parameter Setting Interface ......................................................... 202

Figure 225: Pushing Parameter Interface ................................................................................... 203

Figure 226: Force Control Node Settings .................................................................................... 203

Figure 227: Tool Coordinate System .......................................................................................... 204

Figure 228: Base Coordinate System ......................................................................................... 204

Figure 229: Trajectory Coordinate System ................................................................................. 205

Figure 230: Possible Conversion Error ....................................................................................... 205

Figure 231: F/T Operation Modes – Setpoint .............................................................................. 206

Figure 232: F/T Operation Modes – Trajectory (1/3) ................................................................... 207

Figure 233: F/T Operation Modes – Trajectory (2/3) ................................................................... 207

Figure 234: F/T Operation Modes – Trajectory (3/3) ................................................................... 208

Figure 235: Stop Criteria – F/T Reached .................................................................................... 209

Figure 236: Operation Space Setting .......................................................................................... 211

Figure 237: Plane ....................................................................................................................... 212

Figure 238: Cube (1/2) ............................................................................................................... 213

Figure 239: Cube (2/2) ............................................................................................................... 214

Figure 240: Project Editing Page and Operation Space Setting .................................................. 215

Figure 241: Click the Save Button to Save the File ..................................................................... 216

Figure 242: Start Node ............................................................................................................... 220

Figure 243: Component Icon Resolution ..................................................................................... 221

Figure 244: Node Setting (1/2) ................................................................................................... 223

Figure 245: Node Setting (2/2) ................................................................................................... 224

Figure 246: Global Variables Naming ......................................................................................... 226

Figure 247: Global Variables ...................................................................................................... 227

Figure 248: The Example of Point Parameterization Application (1/4) ........................................ 229

Figure 249: The Example of Point Parameterization Application (2/4) ........................................ 229

Figure 250: The Example of Point Parameterization Application (3/4) ........................................ 230

Figure 251: The Example of Point Parameterization Application (4/4) ........................................ 231

Figure 252: The Example of Making Parameterized Devices ...................................................... 231

Figure 253: Hide Parameters ...................................................................................................... 233

Figure 254: Open the Component .............................................................................................. 234

Figure 255: Collision Check Node .............................................................................................. 235

Tables

Software Manual TMflow Software version: 1.82

Page 18

18

Table 1: Hardware Versions and Applicability ............................................................................... 21

Table 2: Warning and Caution Symbols........................................................................................ 22

Table 3: Functional Note Symbols ................................................................................................ 23

Table 4: Keyboard Hot Keys in TMflow ......................................................................................... 60

Table 5: FreeBot Degree of Freedom Limitation ........................................................................... 69

Table 6: User Defined IO Setting Table ........................................................................................ 82

Table 7: Valid Blending Setting (Moving from P1 to P2) ............................................................. 128

Table 8: Variable Data Types ..................................................................................................... 143

Table 9: SET Syntax List ............................................................................................................ 147

Table 10: If Judgment Operators ................................................................................................ 150

Table 11: TM Robot Coordinates in the Modbus List .................................................................. 160

Table 12: User Defined IO Setting Table .................................................................................... 166

Table 13: TmComm Instruction set ............................................................................................. 170

Table 14: File Commands .......................................................................................................... 175

Table 15: Spiral Searching Function Setting Parameters Definition ............................................ 201

Table 16: Linear Searching Function Setting Parameter Definition ............................................. 202

Table 17: Pushing Parameter Definitions .................................................................................... 202

Table 18: Component Naming .................................................................................................... 224

Table 19: Naming Rule for Items after Components ................................................................... 225

Table 20: Modbus – Classify ...................................................................................................... 236

Table 21: Modbus – Robot Status 1 ........................................................................................... 236

Table 22: Modbus – Robot Status 2 ........................................................................................... 236

Table 23: Modbus – Control Box DI/O ........................................................................................ 237

Table 24: Modbus – End Module ................................................................................................ 237

Table 25: Modbus – Control Box AI/O ........................................................................................ 238

Table 26: Modbus – External Module ......................................................................................... 238