Page 1

Cat. No. W465-E1-05

SYSMAC CS and CJ Series

CS1W-EIP21 (100Base-TX)

CJ1W-EIP21 (100Base-TX)

CJ2H-CPU6@-EIP (100Base-TX)

CJ2M-CPU3@ (100Base-TX/10Base-T)

EtherNet/IP Units

OPER ATION M ANUAL

Page 2

Page 3

CS1W-EIP21 (100Base-TX)

CJ1W-EIP21 (100Base-TX)

CJ2H-CPU6@-EIP (100Base-TX)

CJ2M-CPU3@ (100Base-TX/10Base-T)

EtherNet/IP Units

Operation Manual

Revised February 2010

Page 4

iv

Page 5

Notice:

r

f

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury . Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury . Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this man ual. The w ord “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON produc ts, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displa ys to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another , such as procedures, checklists, etc.

Trademarks and Copyrights

EtherNet/IP is a registered trademark of the ODVA (Open DeviceNet Vendor Association).

Ethernet is a trademark of the Xerox Corporation.

Microsoft, Windows, Windows NT, Windows 2000, Windows XP, and Windows Vista are registered

trademarks of the Microsoft Corporation.

Other names of systems or products that appear in this document are trademarks or registered trade-

marks of the respective company.

OMRON, 2007

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of th e information contained herein. Moreo v er, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevert heless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

v

Page 6

vi

Page 7

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

5 Application Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xxiv

6 Conformance to EC Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

SECTION 1

Overview of EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 EtherNet/IP Unit Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Devices Required for Constructing a Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Support Software Required to Construct a Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-4 Communications Services Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Network Configurator Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

SECTION 2

Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-1 EtherNet/IP Unit and Built-in EtherNet/IP Port Specifications . . . . . . . . . . . . . . . . . . . . . . 14

2-2 Nomenclature and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-3 Selecting the Network Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

SECTION 3

Installation and Initial Setup . . . . . . . . . . . . . . . . . . . . . . . . . 33

3-1 Overview of Initial Setup Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3-3 Mounting to a PLC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-4 Network Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-5 Connecting to the Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

3-6 Creating I/O Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-7 Setting the Local IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

3-8 TCP/IP and Link Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

3-9 Tag Data Link Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

3-10 Other Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3-11 Communications Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

vii

Page 8

TABLE OF CONTENTS

SECTION 4

Memory Allocations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4-1 Overview of Memory Allocated to the EtherNet/IP Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

4-2 CIO Area Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

4-3 DM Area Allocations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4-4 User Settings Area. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

4-5 Auxiliary Area Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

SECTION 5

Determining IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

5-1 IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

5-2 IP Addresses in FINS Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

5-3 Private and Global Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

SECTION 6

Tag Data Link Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

6-1 Overview of Tag Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

6-2 Setting Tag Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

6-3 Ladder Programming with Tag Data Links. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

SECTION 7

Message Communications Functions . . . . . . . . . . . . . . . . . . 187

7-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

7-2 FINS Message Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

7-3 Explicit Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

7-4 Message Communications Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

7-5 Message Communications Error Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

7-6 Message Communications Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

SECTION 8

FINS Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

8-1 Overview of FINS Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

8-2 FINS/UDP Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

8-3 FINS/TCP Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

8-4 Routing Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

8-5 Using FINS Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .211

8-6 Communicating between OMRON PLCs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

8-7 Precautions on High Traffic in FINS Communications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

SECTION 9

Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

9-1 Sending Explicit Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .234

9-2 Receiving Explicit Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

viii

Page 9

TABLE OF CONTENTS

SECTION 10

Communications Performance and Communications Load 261

10-1 Communications System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .262

10-2 Adjusting the Communications Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

10-3 I/O Response Time in Tag Data Links. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 283

10-4 Tag Data Link Performance for CJ2M Built-in EtherNet/IP Ports . . . . . . . . . . . . . . . . . . . . 291

10-5 Message Service Transmission Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 294

SECTION 11

FTP Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 301

11-1 Overview and Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .302

11-2 FTP Server Function Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .303

11-3 Using the FTP Server Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

11-4 FTP Server Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

11-5 Using FTP Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .308

11-6 Checking FTP Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

11-7 Using File Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315

11-8 FTP File Transfer Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

11-9 Host Computer Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

SECTION 12

Automatic Clock Adjustment Function . . . . . . . . . . . . . . . . 323

12-1 Automatic Clock Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324

12-2 Using the Automatic Clock Adjustment Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

12-3 Automatic Clock Adjustment Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

12-4 Automatic Clock Adjustment Error Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

SECTION 13

Maintenance and Unit Replacement. . . . . . . . . . . . . . . . . . . 331

13-1 Maintenance and Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332

13-2 Simple Backup Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .333

13-3 Using the Backup Tool . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336

SECTION 14

Troubleshooting and Error Processing. . . . . . . . . . . . . . . . . 339

14-1 Checking Status with the Network Configurator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

14-2 Using the LED Indicators and Display for Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . 347

14-3 Connection Status Codes and Error Processing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358

14-4 Error Log Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364

14-5 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368

14-6 Troubleshooting with FINS Response Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 371

ix

Page 10

TABLE OF CONTENTS

Appendices

A CS/CJ-series Ethernet Unit Function Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375

B Ethernet Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377

C TCP Status Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .379

D CIP Message Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 381

E FINS Commands Addressed to EtherNet/IP Units or Built-in EtherNet/IP Ports . . . . . . . . 391

F EDS File Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 419

G Precautions for Using Windows XP, Vista, or Windows 7 . . . . . . . . . . . . . . . . . . . . . . . . . . 423

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 427

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 435

x

Page 11

About this Manual:

This manual describes the operation of the CS/CJ-series EtherNet/IP Units and the b uilt-in EtherNet /IP

ports on a CJ2 CPU Unit for constructing applications and includes the sections described below.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the EtherNet/IP Unit or built-in EtherNet/IP port. Be sure to read the

precautions provided in the following section.

Precautions provides general precautions for using the CS/CJ-series E therNet/IP Units and built-in

EtherNet/IP ports.

Section 1 introduces the functions and protocols used in EtherNet/IP Unit or built-in EtherNet/IP port

communications services.

Section 2 provides the specifications of EtherNet/IP Units and introduces recommend ed network configuration devices.

Section 3 explains how to install and make t he initial settings required for operation of the EtherNet/IP

Unit or built-in EtherNet/IP port.

Section 4 describes the words allocated in the CIO Area and the DM Area for EtherNet/IP Units or

built-in EtherNet/IP ports.

Section 5 explains how to manage and use IP addresses.

Section 6 describes tag data link functions and related Network Configurator operations.

Section 7 describes message communications using FINS messages and explicit messages.

Section 8 provides information on communicating on EtherNet/IP Systems and interconnected net-

works using FINS commands. The infor mation provided in the section deals only with FINS communications in reference to EtherNet/IP Units or built-in EtherNet/IP ports.

Section 9 describes message communications using FINS commands sent from the ladder program

in the CPU Unit of the PLC.

Section 10 describes the communications performance in an EtherNet/IP network, and shows how to

estimate the I/O response times and transmission delays.

Section 11 describes the functions provided by the FTP server.

Section 12 provides an overview of the automatic cloc k adjustment fu nction, including d etails on spec-

ifications, required settings, operations from CX-Programmer, and troubleshooting.

Section 13 describes cleaning, inspection, and Unit replacement procedures, as well as the Simple

Backup Function.

Section 14 describes error processing, periodic maintenance operations, and troubleshooting proce-

dures needed to keep the EtherNet/IP netw ork operating properly. We recommend re ading through the

error processing procedures before operation so that operating errors can be identified and correc ted

more quickly.

Appendices provide information on EtherNet/IP network parameters, the buffer configuration, TCP

status transitions, ASCII characters, maintenance, and inspections.

xi

Page 12

Relevant Manuals

The following table lists CS- and CJ-series manuals that contain information relevant to EtherNet/IP

Units or built-in EtherNet/IP ports.

Manual

number

W465 CS1W-EIP21

CJ1W-EIP21

CJ2H-CPU6@-EIP

CJ2M-CPU3@

W420 CS1W-ETN21

CJ1W-ETN21

W421 CS1W-ETN21

CJ1W-ETN21

W343 CS1W-ETN01

CS1W-ETN11

CJ1W-ETN11

W342 CS1G/H-CPU@@H

CS1G/H-CPU@@-V1

CS1W-SCU@@-V1

CS1W-SCB@@-V1

CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ2M-CPU@@

CJ1G/H-CPU@@H

CJ1G-CPU@@

CJ1M-CPU@@

CJ1W-SCU@@-V1

CP1E-E@@D@-@

CP1E-N@@D@-@

CP1H-X@@@@-@

CP1H-Y@@@@-@@

W472 CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ2M-CPU@@

W473 CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ2M-CPU@@

Model Name Contents

EtherNet/IP Units

Operation Manual

(this manual)

Ethernet Units Operation Manual

Construction of Networks

Ethernet Units Operation Manual

Construction of

Applications

Ethernet Units Operation Manual

Communications

Commands Reference Manual

CJ-series CJ2 CPU

Unit Hardware

User’s Manual

CJ-series CJ2 CPU

Unit Software User’s

Manual

Provides information on operating and installing EtherNet/IP Units, including details on basic settings, tag data

links, and FINS communications.

Refer to the Communications Commands Reference

Manual (W342) for details on FINS commands that can

be sent to CS-series and CJ-series CPU Units when

using the FINS communications service.

Refer to the Ethernet Units Operation Manual

Construction of Applications (W421) for details on constructing host applications that use FINS communications.

Provides information on operating and installing

100Base-TX Ethernet Units, including details on basic

settings and FINS communications. Refer to the Commu-

nications Commands Reference Manual (W342) for

details on FINS commands that can be sent to CS-series

and CJ-series CPU Units when using the FINS communications service.

Provides information on constructing host applications for

100Base-TX Ethernet Units, including functions for sending/receiving mail, socket service, automatic clock adjustment, FTP server functions, and FINS communications.

Describes the installation and operation of the 10Base-5

and 10Base-T Ethernet Units.

Describes the C-series (Host Link) and FINS communications commands used when sending communications

commands to CS-series, CJ-series, CP-series, and SYSMAC One NSJ-series CPU Units.

Provides hardware information for the CJ2 CPU Units.

Information is included on features, system configuration,

component names, component functions, installation,

setting procedures, and troubleshooting.

Use together with the CJ-series CJ2 CPU Unit Software

User’s Manual (W473).

Provides software information for the CJ2 CPU Units.

Information is included on CPU Unit operation, internal

memory, programming, setting procedures, and CPU

Unit functions.

Use together with the CJ-series CJ2 CPU Unit Hardware

User’s Manual (W472).

xii

Page 13

Manual

number

W474 CJ2H-CPU6@-EIP

CJ2H-CPU6@

CJ2M-CPU@@

CS1G/H-CPU-@@H

CS1G/H-CPU-@@-V1

CJ1G/H-CPU@@H

CJ1M-CPU@@

CJ1G-CPU@@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

W339 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

W393 CJ1G/H-CPU@@H

CJ1G-CPU@@

W394 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

CJ1G/H-CPU@@H

CJ1G-CPU@@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

W340 CS1G/H-CPU@@H

CS1G/H-CPU-@@V1

CJ1G/H-CPU@@H

CJ1G-CPU@@

NSJ@-@@@@(B)-G5D

NSJ@-@@@@(B)-M3D

W463 CXONE-AL@@C-V4

CXONE-AL@@D-V4

W446 WS02-CXPC@-V9 CX-Programmer

W464 CXONE-AL@@C-V4/

CXONE-AL@@D-V4

Model Name Contents

Programmable Controllers Instructions

Reference Manual

Programmable Controllers Operation

Manual

Programmable Controllers Operation

Manual

Programmable Controllers Programming Manual

Programmable Controllers Instructions

Reference Manual

CS-One Setup Manual

Operation Manual

CS/CJ/CP/NSJseries CX-Integrator

Ver. 2.@ Operation

Manual

Describes the ladder diagram programming instructions

supported by CS-series and CJ-series PCs. Use this

manual for CJ2 CPU Units.

Provides an outline of, and describes the design, installation, maintenance, and other basic operations for the CSseries PLCs. Information is also included on features,

system configuration, wiring, I/O memory allocations, and

troubleshooting.

Use together with the Programmable Controllers Pro-

gramming Manual (W394).

Provides an outline of, and describes the design, installation, maintenance, and other basic operations for the CJseries PLCs. Information is also included on features,

system configuration, wiring, I/O memory allocations, and

troubleshooting.

Use together with the Programmable Controllers Pro-

gramming Manual (W394).

Describes programming, tasks, file memory, and other

functions for the CS-series, CJ-series, and NS-J-series

PLCs.

Use together with the Programmable Controllers Opera-

tion Manual (W339 for CS-series PLCs and W393 for CJseries PLCs).

Describes the ladder diagram programming instructions

supported by CS-series and CJ-series PCs. Use together

with the Programmable Controllers Operation Manual

(W339 for CS-series PLCs and W393 for CJ-series

PLCs), and the Programmable Controllers Programming

Manual (W394).

Describes the setup procedures for the CX-One. Information is also provided on the operating environment for the

CX-One.

Provides inf ormation on h ow to use the CX-Programmer,

a Windows-based programming device. Use together

with the Programmable Controllers Operation Manual

(W339 for CS-series PLCs and W393 for CJ-series

PLCs), Programmable Controllers Programming Manual

(W394) and the Programmable Controllers Instructions

Reference Manual (W340) to perform programming.

Describes the operating procedures of the CX-Integrator

that can be used to set up and monitor networks.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

xiii

Page 14

xiv

Page 15

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in mat erials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no eve nt shall the responsibil ity of OMR ON fo r any act e xcee d the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xv

Page 16

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an e xhaustive list of all possible uses of the products, nor is it inte nded to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable pr oduct, or any

consequence thereof.

xvi

Page 17

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, sp ecial model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON represe ntative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Perf ormance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been ca refully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xvii

Page 18

xviii

Page 19

Unit Versions of CS/CJ-series

Unit Versions A “unit version” has been introduced to manage Units in the CS/CJ Series

according to differences in functionality accompanying Unit upgrades.

Notation of Unit Versions

on Products

The unit version is given to the right of the lot number on the nameplate of the

products for which unit versions are being managed, as shown below.

■ CS1W-EIP21/CJ1W-EIP21

Product nameplate

CS1W-

UNIT

Lot No.

Lot No. 040401 0000 Ver.1.0

OMRON Corporation MADE IN JAPAN

Unit version

Example for unit version 1.0

■ CJ2H-CPU@@-EIP/CJ2M-CPU3@

Product nameplate

CJ2H-

UNIT

Indicates that the unit

version of the CPU Unit

is 1.0.

Indicates that the unit

Lot No. 080701 CPU Ver. 1.0 EIP Ver.2.0

OMRON Corporation MADE IN JAPAN

version of the built-in

EtherNet I/P port is 2.0.

Confirming Unit Versions

with Support Software

In this manual, the version of the EtherNet/IP port built into the CJ2HCPU@@-EIP/CJ2M-CPU3@ CPU Unit is given as the unit version.

CX-Programmer version 4.0 can be used to confirm the unit version using the

Unit Manufacturing Information.

Note The unit versions of Pre-Ver.1.0 Units cannot be confirmed in U nit Manufac-

turing Information. The following dialog box is displayed.

In the IO Table Window, right-click and select Unit Ma nufacturing informa-

tion - CPU Unit.

The following Unit Manufacturing information Dialog Box will be displayed.

xix

Page 20

Unit version

Note The unit version will be displayed in the Unit Manufacturing Information Dialog

Box.

Using Unit Version Label The following unit version label is provided with the EtherNet/IP Unit.

This label can be attached to the front of the EtherNet/IP Unit to differentiate

between EtherNet/IP Units with different unit versions.

Unit Versions and CX-Programmer Versions

Use the following versions of the CX-Programme r to mak e the Unit sett ings f or

the EtherNet/IP Unit.

Unit version CX-Programmer

Ver. 7.1 or lower Ver. 8.0 Ver. 8.02 or higher

Unit version 1.0 --- OK* OK

Unit version 2.0 --- OK OK

* The following auto update must be applied to use CX-Programmer version 8.0:

CX-Common Components/CPS Upgrade Software 2008.08 0302

Unit Version Notation In this manual, the unit version of a EtherNet/IP Unit is given as shown in the

following table.

Product nameplate Notation used in this manual Special remarks

Ver. 1.0 or later number

shown to right of the lot

number

Ethernet Unit Ver. 1.0 or later (See note.) Information without reference to specific Unit

Versions applies to all versions of the Unit.

Note Some Support Software products call the EtherNet/IP Unit version the “revi-

sion.” “Revision” is also sometimes used in this manual.

CIP Revisions and

Unit Versions

The CIP revisions corresponding to the unit versions of the EtherNet/IP Unit

are given in the following table.

Unit version CIP revision

Version 1.0 Revision 1.01

Version 2.0 Revision 2.01 or 2.02

xx

Page 21

PRECAUTIONS

This section provides general precautions for using the CS/CJ-series EtherNet/IP Units and built-in EtherNet/IP ports.

The information contained in this section is important for the safe and reliable application of EtherNet/IP Units or

built-in EtherNet/IP ports. You must read this section and understand the informati on contained bef or e attempting

to set up or operate an EtherNet/IP Unit or built-in EtherNet/IP port.

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

4 Operating Environment Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

5 Application Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxiv

6 Conformance to EC Directives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6-1 Applicable Directives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

6-2 Concepts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxvi

xxi

Page 22

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must also have

knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of installing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of managing FA systems and facilities.

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in a pplications that

can directly or indirectly aff ect huma n life. You must consult with your OMR ON

representative before applying a PLC System to the above-mentioned applications.

3 Safety Precautions

!WARNING Do not attempt to take any Unit apart while the power is being supplied. Doing

so may result in electric shock.

!WARNING Do not touch any of the terminals or terminal blocks while the power is being

supplied. Doing so may result in electric shock.

!WARNING Do not attempt to disassemble, repair, or modify any Units. Any attempt to do

so may result in malfunction, fire, or electric shock.

xxii

Page 23

Safety Precautions 3

!WARNING Provide safety measures in external circuits (i.e., not in the Programmable

Controller), including the following items, to ensure safety in the system if an

abnormality occurs due to malfunction of the Programmable Controller or

another external factor affecting the operation of the Programmable Controller. “Progr ammable Controller” indicates the CPU Unit and all other Units and

is abbreviated “PLC” in this manual.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instr uction is executed.

As a countermeasure for such errors, external safety measures must be

provided to ensure safety in the system.

• The PLC will turn OFF all outputs when its self-diagnosis function detects

any error or when a severe failure alarm (FALS) instr uction is executed.

Unexpected operation, however, may still occur for errors in the I/O control section, errors in I/O memory, and other errors that cannot be

detected by the self-diagnosis function. As a countermeasure for all such

errors, external safety measures must be provided to ensure safety in the

system.

• Provide measures in the computer system and programming to ensure

safety in the overall system even if errors or malfunctions occur in data

link communications or remote I/O communications.

!Caution Execute online editing only after confirming that no adverse effects will be

caused by extending the cycle time. Otherwise, the input signals may not be

readable.

• Emergency stop circuits, interlock circuits, limit circuits, and similar safety

measures must be provided in external control circuits.

!Caution Fail-safe measures must be taken by the customer to ensure safety in the

event of incorrect, missing, or abnormal signals caused b y brok en sig nal lines,

momentary power interruptions, or other causes. Serious accidents may

result from abnormal operation if proper measures are not provided.

!Caution Confirm safety at the destination node before changing or transferring to

another node the contents of a program, the PLC Setup, I/O tables, I/O memory, or parameters. Changing or transferring any of these without confirming

safety may result in injury.

!Caution Tighten the screws on the term inal block of the AC Power Su pply Unit to the

torque specified in the operation manual. The loose screws may result in

burning or malfunction.

xxiii

Page 24

Operating Environment Precautions 4

4 Operating Environment Precautions

!Caution Do not operate the control system in the following locations:

• Locations subject to direct sunlight.

• Locations subject to temperatures or humidity outside the range specified

in the specifications.

• Locations subject to condensation as the result o f severe changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust (especially iron dust) or salts.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

!Caution Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields.

• Locations subject to possible e xposure to radioactivity.

• Locations close to power supplies.

5 Application Precautions

Observe the following precautions when using the EtherNet/IP Unit or built-in

EtherNet/IP port.

!WARNING Always heed these precautions. Failure to abide by the following precautions

could lead to serious or possibly fatal injury.

• Always connect to a g round of 100 Ω or less when installing the Units. Not

connecting to a ground of 100 Ω or less may result in electric shock.

• Always turn OFF the power supply to the CPU Unit and Slaves before

attempting any of the following. Not turning OFF the power supply may

result in malfunction or electric shock.

• Mounting or dismounting Power Supply Units, I/O Units, CPU Units,

Memory Packs, or Master Units.

• Assembling the Units.

• Setting DIP switches or rotary switches.

• Connecting cables or wiring the system.

• Connecting or disconnecting the connectors.

!Caution Failure to abide by the following precautions could lead to faulty operation of

the EtherNet/IP Unit, built-in EtherNet/IP port, or the system, or could damage

the Ethernet Unit. Always heed these precautions.

xxiv

• Interlock circuits, limit circuits, and similar safety measures in external circuits (i.e., not in the Programmable Controller) must be provided by the

customer.

Page 25

Application Precautions 5

• Always use the pow er supply voltages specified in the operation manuals.

An incorrect voltage may result in malfunction or burning.

• Take appropriate measures to ensure that the specified power with the

rated voltage and frequency is supplied. Be particularly careful in places

where the power supply is unstable. An incorrect power supply may result

in malfunction.

• Install external breakers and tak e other safety measures against short-circuiting in external wiring. Insufficient safety measures

• Make sure that all the Backpla ne mountin g screws, terminal block screws,

and cable connector screws are tightened to the torque specified in the

relevant manuals. Incorrect tightening torque may result in malfunction.

• Leave the label att ached to the Un it when wiring. Removing the label may

result in malfunction if foreign matter enters the Unit.

• Remove the label after th e comple tion of wiring to ensure proper heat di ssipation. Leaving the label attached may result in malfunction.

• Use crimp terminals for wiring. Do not connect bare stranded wires

directly to terminals. Connection of bare stranded wires may result in

burning.

• Observe the following precautions when wiring the communications

cable.

• Separate the communications cabl es from the powe r lines or high-tension lines.

• Do not bend the communications cables past their nat ural be nding r adius.

• Do not pull on the communications cables.

• Do not place heavy objects on top of the communications cables.

• Always lay communications cable inside ducts.

• Use appropriate communications cables.

• Make sure that the terminal blocks, expansion cable connectors, and

other items with locking devices are locked in place.

• Wire all connections correctly according to instructions in this manual.

• Double-check all wiring and switch settings before turning ON the power

supply. Incorrect wiring may result in burning.

• Mount terminal blocks and connectors only after checking the mounting

location carefully.

• Check the user program (ladder program and other programs) and

parameters for p roper execution before actually running it on the Unit. Not

checking the program may result in unexpected operation.

• Confirm that no adverse effect will occur in the system before attempting

any of the following. Not doing so may result in an unexpected operation.

• Changing the operating mode of the PLC.

• Force-setting/force-resetting any bit in memory.

• Changing the present value of any word or any set value in memory.

• After replacing a Unit, resume operation only after transferring to the new

CPU Unit, Special I/O Unit, or CPU Bus Unit the contents of the DM Area,

HR Area, programs, parameters, and other data required for resuming

operation. Not doing so may result in an unexpected operation.

• Before touching a Unit, be sure to first touch a grounded metallic object in

order to discharge any static b uild -u p. Not doing so may result in malfunction or damage.

xxv

Page 26

Conformance to EC Directives 6

• When transporting the Unit, use special packing boxes and protect it from

being exposed to excessive vibration or impacts during transportation.

• CPU Bus Units will be restar ted when routing tables are transferred from

a Programming Device to the CPU Unit. Restarting these Units is required

to read and enable the new routing tables. Confirm that the system will

not be adversely affected before allowing the CPU Bus Units to be reset.

• When the settings (IP address or tag data link se ttin gs) of t he Et her Net/I P

Unit or built-in EtherNet/IP port are transferred from a Programming

Device, all of the destination EtherNet/IP Units or built-in EtherNet/IP

ports (nodes) will be reset in order to enable the transferred settings.

Transfer settings to the Ether Net/IP Un its or b u ilt-in Et herNet/IP ports only

after verifying that restarting the Units will not cause any problems in the

system.

• If a repeater hub is used for EtherNet/ IP tag d ata links (cyclic comm unications), the network's communications load will increase, data collisions

will occur frequently, and stable communications will be impossible.

Always use a switching hub when using tag data links in the network.

• Before resetting a CPU Bus Unit or Special I/O Unit, always verify that

restart the Unit will not cause any problems in the system.

6 Conformance to EC Directives

6-1 Applicable Directives

•EMC Directives

• Low Voltage Directive

6-2 Concepts

EMC Directives

OMRON devices that comply with EC Directives also confor m to the related

EMC standards so that they can be more easily built into other devices or the

overall machine. The actual products have been checked for conformity to

EMC standards (see the following note). Whether the products conform to the

standards in the system used by the customer, however, must be checked by

the customer.

EMC-related performance of the OMRON devices that comply with EC Directives will vary depending on the configuration, wiring, and other conditions of

the equipment or control panel on which the OMRON devices are installed.

The customer must, therefore, perform the final check to confirm that devices

and the overall machine conform to EMC standards.

Note Applicable EMS (Electromagnetic Susceptibility) and EMI (Electromagnetic

Interference) Standards in the EMC (Electromagnetic Compatibility) standards are as follows:

EtherNet/IP Unit EMS EMI

CS1W-EIP21

CJ1W-EIP21

EN61000-6-2

EN61000-6-4

(Radiated emission: 10-m

regulations)

xxvi

Low Voltage Directive

Always ensure that devices operating at voltages of 50 to 1,000 V AC and 75

to 1,500 V DC meet the required safety standards for the PLC (EN61131-2).

Page 27

SECTION 1

Overview of EtherNet/IP

This section introduces the functions and protocols used in EtherNet/IP Unit or built-in EtherNet/IP port communications

services.

1-1 EtherNet/IP Unit Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Devices Required for Constructing a Network . . . . . . . . . . . . . . . . . . . . . . . . 4

1-3 Support Software Required to Construct a Network. . . . . . . . . . . . . . . . . . . . 4

1-4 Communications Services Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1-5 Network Configurator Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-5-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-5-2 Network Configurator Requirements . . . . . . . . . . . . . . . . . . . . . . . . 10

1-5-3 Precautions When Using the Network Configurator . . . . . . . . . . . . 11

1

Page 28

EtherNet/IP Unit Features Section 1-1

1-1 EtherNet/IP Unit Features

CX-One Support

Software

Ethernet (LAN) port

High-speed, High-capacity

Data Exchange through

Data Links

(3) Switching hub

(2) T wisted-pair cable

(1) Built-in EtherNet/IP port on

100 m

max.

(1) CS1W-EIP21 EtherNet/IP

Unit for CS-series

CS-series

PLC

EtherNet/IP System Configuration Example

(1) CJ1W-EIP21

EtherNet/IP Unit

CJ-series

PLC

CJ2 CPU Unit

(CJ2H-CPU@@-EIP/

CJ2M-CPU3@)

CJ-series

PLC

EtherNet/IP is an industrial multi-vendor network that uses Ether net components. The EtherNet/IP specifications are open standards managed by the

OD VA (Open DeviceNet Vendor Association), just like DeviceNet.

EtherNet/IP is not just a network between controllers; it is also used as a field

network. Since EtherNet/IP uses standard Ethernet technology, various general-purpose Ethernet devices can be used in the network. The EtherNet/IP

Unit and built-in EtherNet/IP port have the following features .

The EtherNet/IP protocol supports implicit communications, which allows

cyclic communications (called tag data links in this manual) with EtherNet/IP

devices. Data can be exchanged at high speed between Controllers and

devices, using high-volume tag sets (up to 640 words for the CJ2M and up to

184,832 words for other CPU Units) between PLCs.

Tag Data Link (Cyclic

Communications) Cycle

Time

Note The communications load to the nodes m ust be within the Units’ allo w ed com-

Communicating with FINS

Messages (FINS/TCP and

FINS/UDP)

Note There are no particular restrictions when sending FINS messages to OMRON

Network Connections with

Controller Link

Tag data links (cyclic communications) can operate at the cyclic period specified for each application, regardless of the number of nodes. Data is

exchanged over the network at the refresh cycle set for each connection, so

the communications refresh cycle will not increase even if the number of

nodes is increased, i.e., the synchronicity of the connection’s data is preserved.

Since the refresh cycle can be set for each connection, each application can

communicate at its ideal refresh cycle. For example, a processes interlocks

can be transferred at high speed while the production commands and the status monitor information are transferred at low speed.

munications bandwidth.

Data can be exchanged with other OMRON FA devices using SEND, RECV,

and CMND instruc tions from the ladder program, because Ether Net/IP supports OMRON’s standard FINS message communications services.

There are two kinds of message services, using UDP/IP and TCP/IP (called

FINS/UDP and FINS/TCP), allowing flexible data exchange for different applications.

Ethernet Units (CS1W-ETN21 or CJ1W-ETN21) in an Ethernet network.

Mutual connections of Controller Link and EtherNet/IP are also supported

(using the FINS communications service). The Controller Link connection

allows a PLC on the Controller Link networ k to be monitored from a PLC on

the EtherNet/IP network. Conversely, data can be exchanged with a PLC on

the EtherNet/IP network from a PLC on the Controller Link network.

2

Page 29

EtherNet/IP Unit Features Section 1-1

FTP Server A built-in FTP server is provided to enable transferring files in the PLC to and

from a host computer. This enables transferring large amounts of data from a

client without any additional ladder programming.

Automatic PLC Clock

Adjustment

Note A separate SNTP server is necessary to automatically adjust the PLC clocks.

Manage the Network with

an SNMP Manager

Note A separate SNMP mana ger is necessary for network managemen t.

Specify Servers with Host

Names

Note (1) A separate DNS server is necessary to use host names with the DNS cli-

Set Classless IP Address

with CIDR

Plentiful Troubleshooting

Functions

The clocks built into PLCs connected to Ethernet can be automatically

adjusted to the time of the clock in the SNTP ser ver. If all of the clocks in the

system are automatically adjusted to the same time , ti me stam ps can be use d

to analyze various production histories.

Internal status information from the EtherNet/IP Unit or built-in EtherNet/IP

port can be passed to network management software that uses an SNMP

manager.

DNS client functionality allows you to use host nam es instead of IP addresses

to specify SNTP ser vers a nd SNMP managers. This is useful, for ex ample,

when server IP addresses change for system revisions because the IP

addresses are automatically found when host names are used.

ent.

(2) The DNS server is specified directly using its IP address.

A subnet mask can be set to use clas sless IP addres ses, allowing more flexibility in address settings.

A variety of functions are provided to quickly identify and handle errors.

• Self-diagnosis at power ON

• PING command to check the connection with another node

• Error Log functions record the time of occurrence and other error details

Note The CIP (Common Industrial Protocol) is a shared industrial protocol for the

OSI application layer. The CIP is used in networks such as EtherNet/IP, ControlNet, and DeviceNet. Data can be routed easily between networks that are

based on the CIP, so a transparent network can be easily configured from the

field device level to the host level.

The CIP has the following advantages.

• Destination nodes are specified by a relative path, without fixed routing

tables.

• The CIP uses the producer/consumer model. Nodes in the network are

arranged on the same level and it is possible to communicate with

required devices whenever it is necessary.

The consumer node will receive data sent from a producer node when the

connection ID in the packet indicates that the node requires the data.

Since the producer can send the same data with the same characteristics

in a multicast (either multicast or unicast can be selected), the time

required for the transfer is fixed and not dependent on the number of consumer nodes.

3

Page 30

Devices Required for Constructing a Network Section 1-2

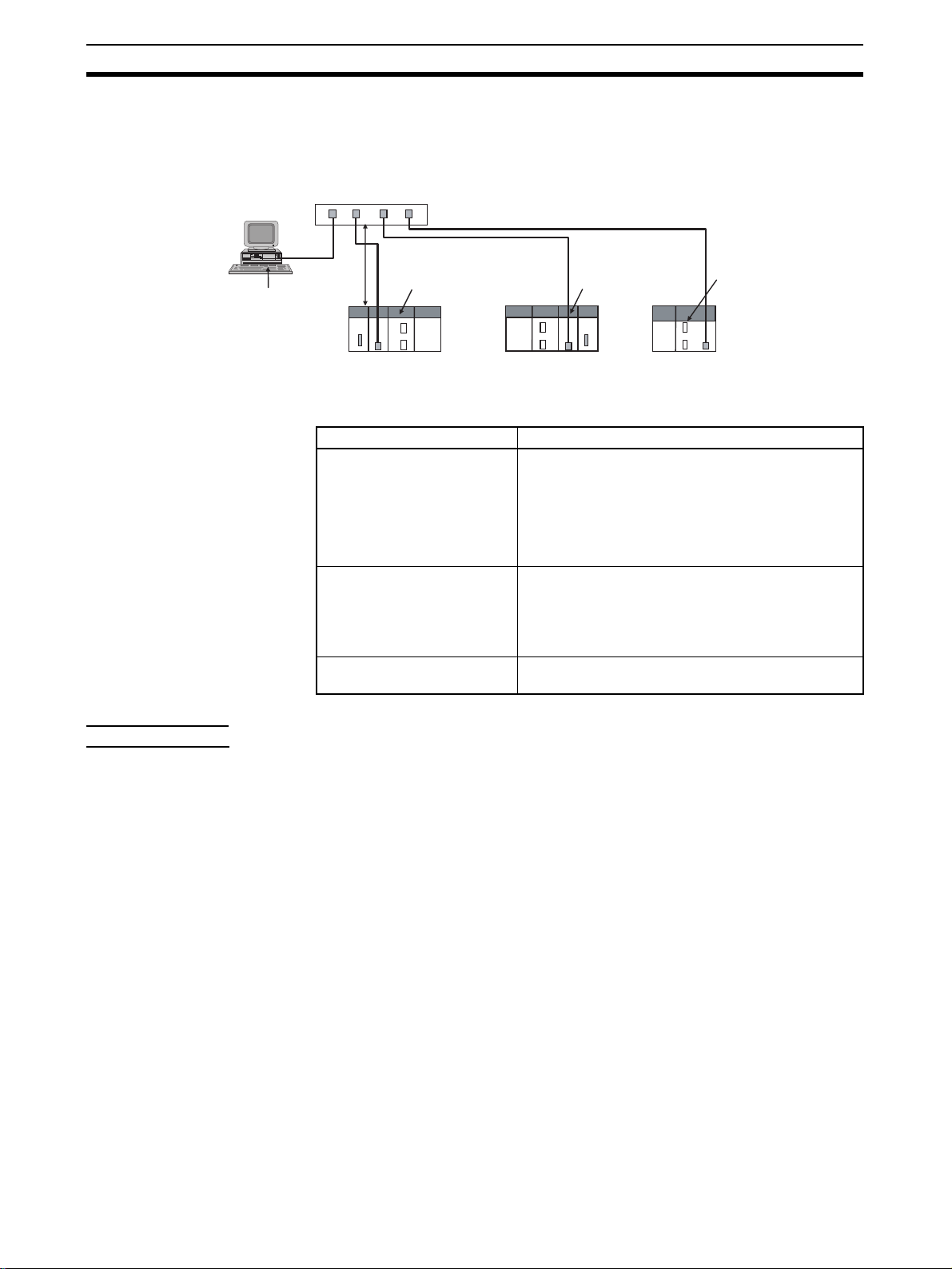

1-2 Devices Required for Constructing a Network

The basic configuration for an EtherNet/IP System consists of one switching

hub to which nodes are attached in star configuration using twisted-pair ca bl e.

CX-One Support

Software

Ethernet (LAN) port

(3) Switching hub

(2) T wisted-pair cable

(1) Built-in EtherNet/IP port on

100 m

max.

(1) CS1W-EIP21 EtherNet/IP

Unit for CS-series

CS-series

PLC

(1) CJ1W-EIP21

EtherNet/IP Unit

CJ-series

PLC

CJ2 CPU Unit

(CJ2H-CPU@@-EIP/

CJ2M-CPU3@)

CJ-series

PLC

The devices shown in the following table are required to configure a network

with CS1W-EIP21 and CJ1W -EIP21 Ethe rNet/IP Units or the b uilt-in EtherNet/

IP port in CJ2H-CPU@@-EIP/CJ2M-CPU3@ CPU Units.

Network device Contents

(1) CS1W-EIP21 EtherNet/IP

Units for CS-series PLCs,

CJ1W-EIP21 EtherNet/IP

Units for CJ-series PLCs,

or built-in EtherNet/IP port

in CJ2H-CPU@@-EIP/

CJ2M-CPU3@ CPU Units

(2) Twisted-pair cable The twisted-pair cable connects EtherNet/IP Units or

(3) Switching Hub This is a relay device that connects multiple nodes in

These are Communications Units or built-in ports

that connect a CS-series or CJ-series PLC to an EtherNet/IP network.

built-in EtherNet/IP ports to the switching hub, with

an RJ45 Modular Connector at each end.

Use an STP (shielded twisted-pair) cable of category

5, 5c, or higher.

a star-shaped LAN.

Recommended

Switching Hubs

For details on recommended devices for constructing a network, refer to 2-3-1

Recommended Network Devices.

Note If a repeater hub is used for EtherNet/IP tag data links (cyclic communica-

tions), the network’s communications load will increase, data collisions will

occur frequently, and stable communications will be impossible. Always use a

switching hub when using tag data links in the network.

1-3 Support Software Required to Construct a Network

This section describes the Support Software that is required to construct an

EtherNet/IP network. Make the tag data link settings and Unit setup settings

for the EtherNet/IP Unit or built-in EtherNet/IP port . Both of thes e settings are

stored in the EtherNet/IP Unit’s non-volatile memory (See note.). Support

Software is provided for each, as described below.

Note Unlike the Ethernet Units, the EtherNet/IP Unit’s TCP/IP settings are not

stored in the CPU Unit’s CPU Bus Unit System Setup Area. The settings are

stored in the EtherNet/IP Unit itself.

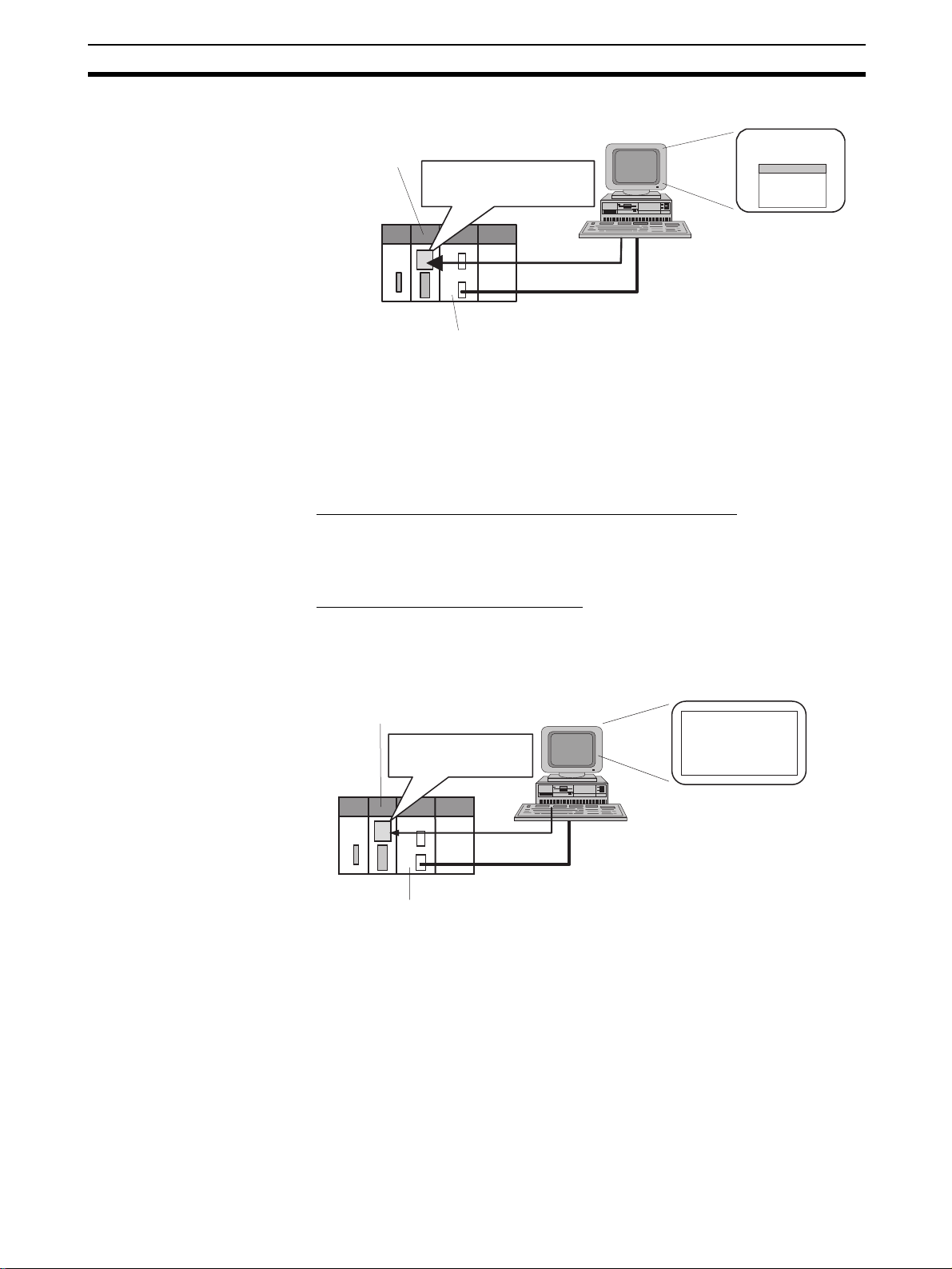

Unit Setup: CXProgrammer

The CX-Programmer is used to set basic parameters, such as the local IP

address of the EtherNet/IP Unit or built-in EtherNet/IP port and the subnet

mask. (The CX-Programmer is included in the CX-One.)

The CX-Programmer can also be used to check if data I/O is being performed

correctly for ta g data links.

4

Page 31

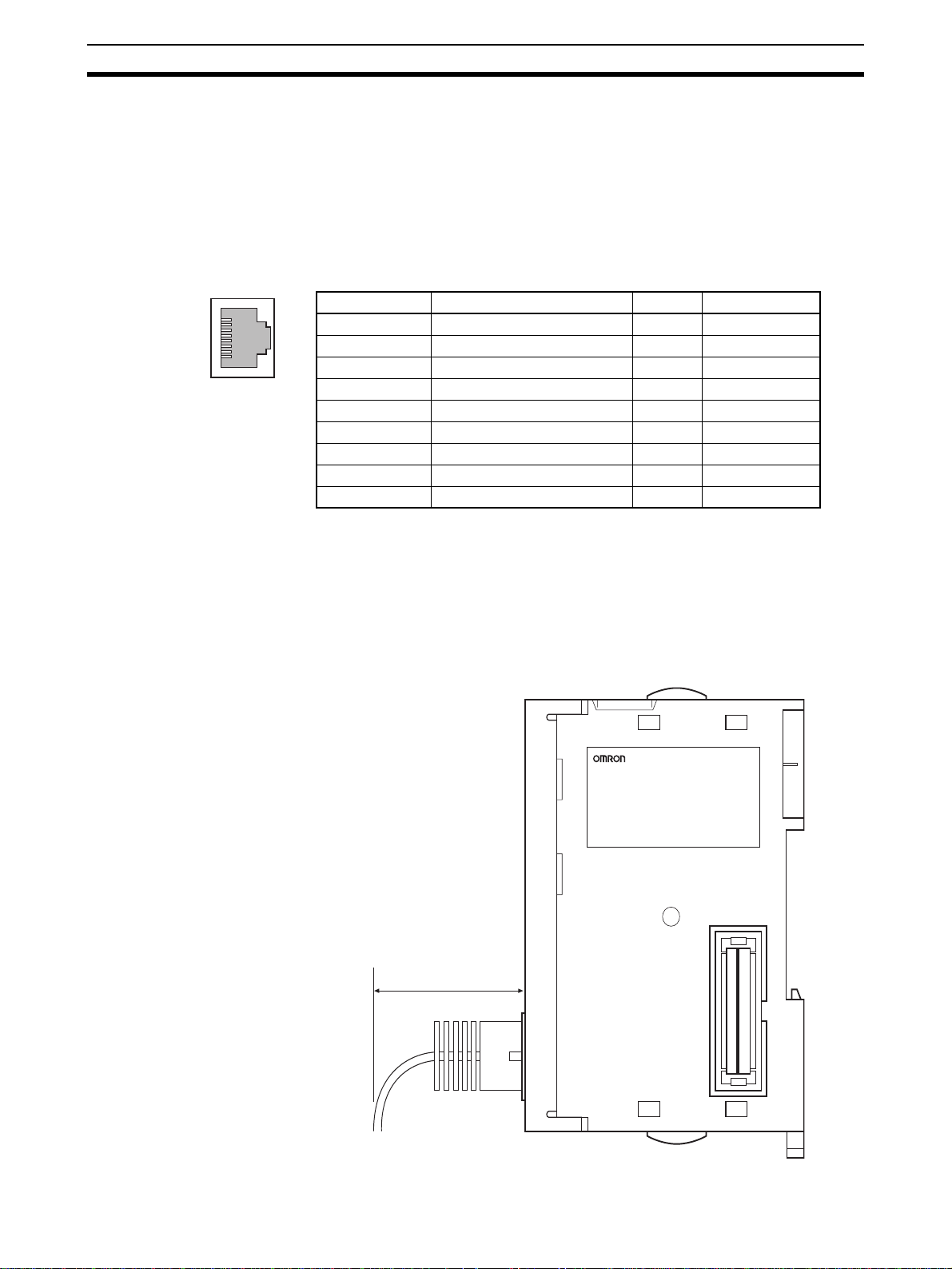

Support Software Required to Construct a Network Section 1-3

Computer

EtherNet/IP Unit

or built-in

EtherNet/IP port

Unit settings

(Built-in non-volatile memory)

CX-Programmer

Edit Parameters

Dialog Box

Tag Data Link Settings:

Network Configurator

CS/CJ-series CPU Unit

Refer to the CX-Programmer Operation Manual (Cat. No. W446) for info rma-

tion on the CX-Programmer.

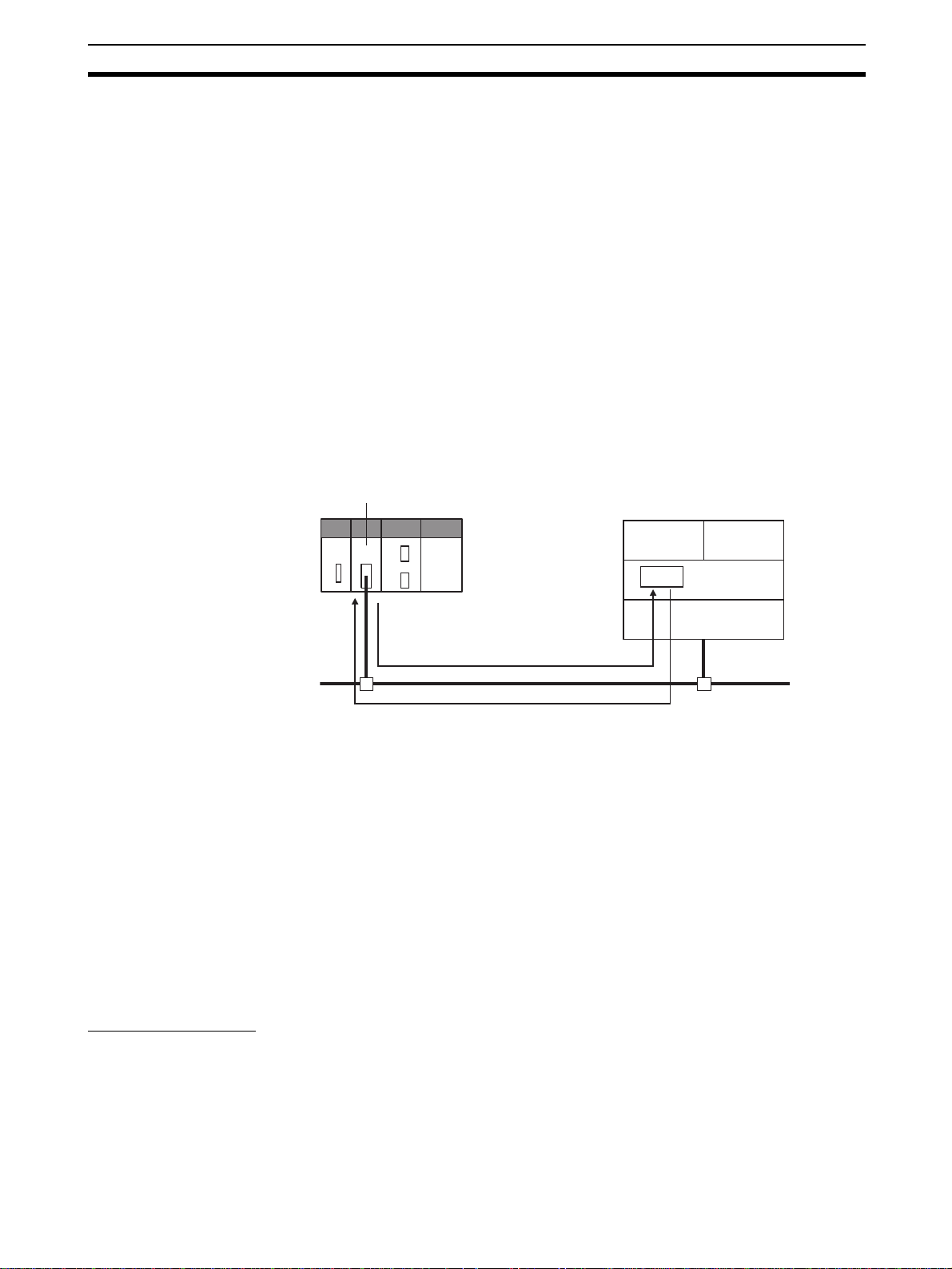

The Network Configurator is used to set the tag data links for the EtherNet/IP

Unit or built-in EtherNet/IP port. (The Network Configurator is included in CXOne version 3.0 or higher.) The main functions of the Network Configurator

are given below.

1) Setting and Monitoring Tag Data Links (Connections)

The network device configuratio n a nd tag data links (co nne ction s) can be created and edited. After connecting to the netw o rk, the device configuration and

tag data link settings can be uploaded and monitored.

2) Multivendor Device Connections

EDS files can be installed and deleted to enable constructing, setting, and

managing networks that contain EtherNet/IP devices from other companies.

The IP addresses of EtherNet/IP devices can also be changed.

EtherNet/IP Unit

or built-in EtherNet/IP port

Tag Data Link Settings

(Built-in non-volatile memory)

Computer

Network Configurator

Edit Device

Parameters

Dialog Box

Routing Table Settings:

CX-Integrator

Transferred

CS/CJ-series CPU Unit

For details on the Network Configurator, refer to SECTION 6 Tag Data Link

Functions.

Propriety OMRON FINS network system can be constructed from OMRON

Communications Units. When FINS services are used, the CX-Integrator

allows you to set routing tables to define transmission paths. (The CX-Integrator is included in the CX-One.) If FINS services are not used, then routing

tables are not required.

5

Page 32

Communications Services Overview Section 1-4

Personal computer

running Windows

CX-Integrator

Routing table

EtherNet/IP Unit or

built-in EtherNet/IP port

Routing T ab le Area

CS/CJ-series CPU Unit

settings

Refer to the CX-Integrator Operation Manual (Cat. No. W464) for information

on the CX-Integrator.

1-4 Communications Services Overview

The following communications services are supported.

CIP (Common Industrial Protocol) Communications Services

CS1W-EIP21

CJ1W-EIP21

CJ2H-CPU@@-EIP

Total size of all tags ≤

184,832 words

Maximum size of 1 tag ≤ 722

words

(The maximum size is 721

words when the tag set

includes the PLC status.)

Number of registrable tags ≤

256

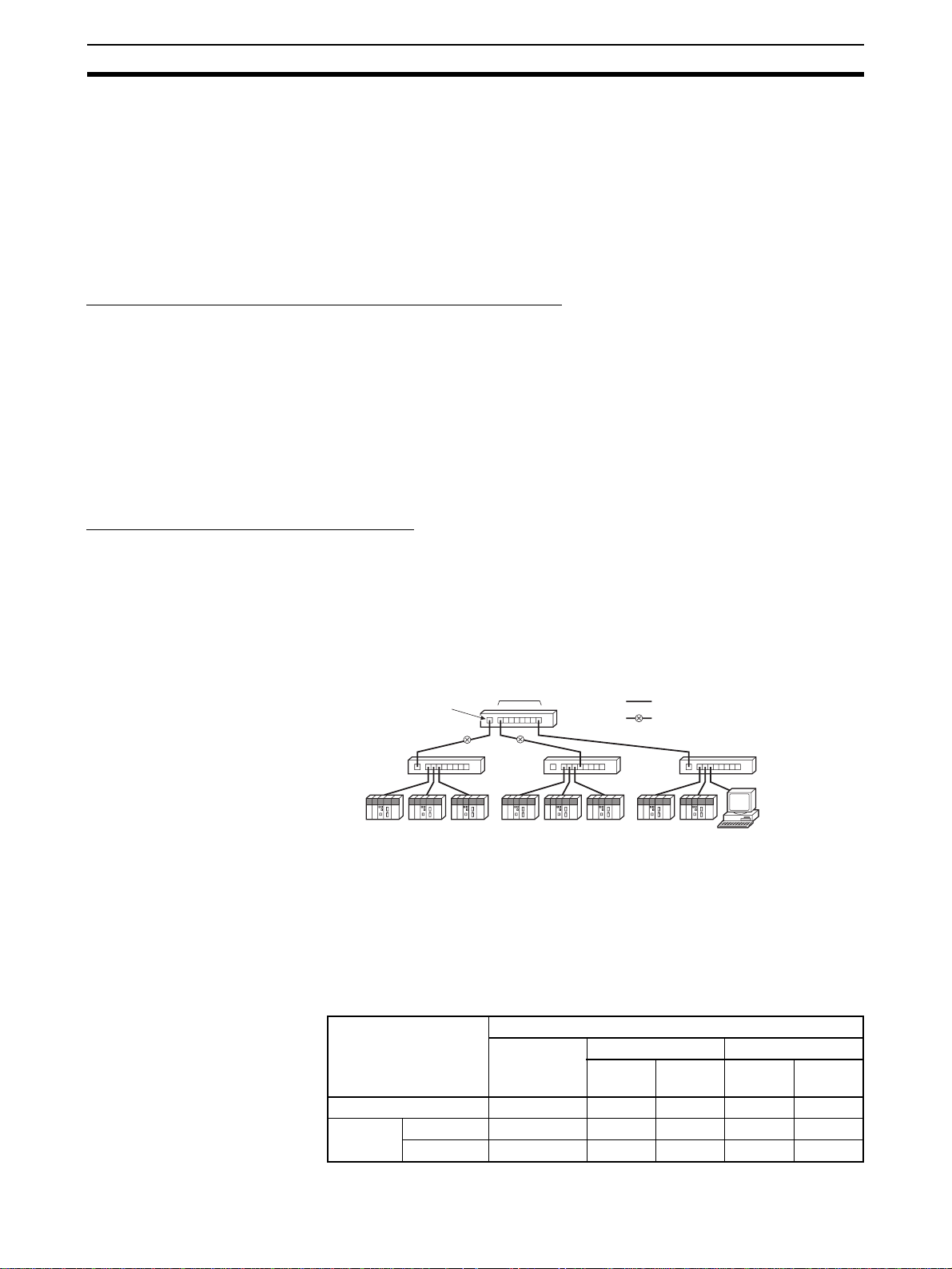

1) Tag Data Links (Cyclic Communications)

A program is not required to perform cyclic data exchang es with other devices

in the EtherNet/IP network.

Normally, the tag data links in an EtherNet/IP Unit or built-in EtherNet/IP port

are started by grouping the tags created with the Network Configurator into a

tag set, and establishing a connection with the target device using that group

of tags. One connection is used per group (tag set). Up to 32 connections fo r

the CJ2M and up to 256 connections for other CPU Units) can be registered.

The following table gives the tag and tag set specifications.

Tags Tag sets

CJ2M-CPU3@ CS1W-EIP21

CJ1W-EIP21

CJ2H-CPU@@-EIP

Total size of all tags ≤ 640

words

Maximum size of 1 tag ≤ 20

words

(The maximum size is 19

words when the tag set

includes the PLC status.)

Number of registrable tags ≤ 32Number of registrable ta g

Maximum size of 1 tag set ≤

722 words

(The maximum size is 721

words when the tag set

includes the PLC status.)

Number of tags per tag set ≤ 8

(7 tags/tag set when the tag set includes the PLC status)

Note Input and output variables cannot be combined.

sets ≤ 256

CJ2M-CPU3@

Maximum size of 1 tag set ≤

20 words

(The maximum size is 19

words when the tag set

includes the PLC status.)

Number of registrabl e ta g

sets ≤ 32

6

Page 33

Communications Services Overview Section 1-4

Connection information

• Target IP address

• Target tag set

• Originator tag set

• Packet interval (RPI)

Connection

Tag Set (Inputs)

Tag set name: S

P1_IN

PLC Status

Tag a

Tag b

Tag c

Data flow

Tag Set (Outputs)

Tag set name: S

P1_IN

PLC Status

Tag i

Tag ii

:

Tag g

Originator

device

EtherNet/IP

Target

device

Note In this example, a connection is established with the originator’s tag list con-

taining tags a to g (inputs), which are grouped in a tag set called SP1_IN, and

the target’s tag list containing tags i and ii (outpu ts), which are grouped in a

tag set called SP1_OUT.

2) Message Communications (Unconnected Message Service)

User-specified CIP commands can be sent to devices on the EtherNe t/IP net work. CIP commands, such as those for reading and writing data, can be sent

and their responses received by executing the CMND instruction from the CS/

CJ-series CPU Unit’s user program (without using a connection).

EtherNet/IP Unit

CS/CJ-series CPU Unit

CMND

CIP command

Response

Ethernet

(EtherNet/IP)

CIP messages (CIP commands and responses) can also be transferred to

another CIP-based network via the EtherNet/IP Unit or built-in EtherNet/IP

port using the CIP routing function for message commun ications.

In the CS/CJ Series, CIP routing is possible only through two EtherNet/IP

Units or built-in EtherNet/IP port.

7

Page 34

Communications Services Overview Section 1-4

t

EtherNet/IP

FINS

Communications

Service

CS/CJ-series CPU Unit

EtherNet/IP Unit

EtherNet/IP Unit

Ethernet

(EtherNet/IP), etc.

FINS commands can be sent to or received from other PLCs or computers on

the same Ethernet network by executing SEND(090), RECV(098), or

CMND(490) instructions in the ladder diagram program. This enables various

control operations such as the reading and writing of I/O memory between

PLCs, mode changes, an d file memory operations.

Note There are no particular restrictions when sending FINS messages to OMRON

Ethernet Units (CS1W-ETN21 or CJ1W-ETN21) in an Ethernet network.

Ethernet (EtherNet/IP)

UDP or TCP

IP

CS/CJ-series CPU

Unit

FINS IP FINS

UDP or TCP

EtherNet/IP Unit

User program

SEND(090),

RECV(098), or

CMND(490)

instruction

Ethernet Unit

EtherNet/IP Uni

Various control operations (such as the reading and writing of I/O memory

between PLCs, mode changes, and file memor y operations) can be executed

from the host computer by sending the corresponding FINS command with a

UDP/IP or TCP/IP header attached.

For ex ample , it is possib le to co nnect online via Ethernet from FINS comm unications applications such as the CX-Programmer, and to perform remote programming and monitoring. (See note.)

Note Use CX-Programmer v ersion 4. 0 to use TCP/IP. For lo w er v ersio ns of CX-Pro-

grammer, FinsGateway Version 2003 or higher is required to use TCP/IP.

8

Page 35

Communications Services Overview Section 1-4

Ethernet (EtherNet/IP)

UDP or TCP

IP FINS

CS/CJ-series CPU

Unit

EtherNet/IP Unit

The FINS gateway function enables access to PLCs on not only the same

Ethernet network but on various other networks, including SYSMA C LINK and

Controller Link.

9

Page 36

Network Configurator Overview Section 1-5

1-5 Network Configurator Overview

1-5-1 Overview

The Network Configurator Ver. 3.0 or higher is a software package designed

for building, setting, and controlling a multi-vendor EtherNet/IP Networ k using

OMRON's EtherNet/IP. It is included in CX-One version 4.0 or higher. The

Network Configurator provides th e f ollo wing fu nctions for building, setting, and

controlling EtherNet/IP.

Network Control The Network configuration can be created and edited regardless of whether

the Network Configurator is online or offline. The Network configuration can

be read from a file or the network.

Hardware (EDS File)

EDS files used by the Network Configurator can be installed and deleted.

Control

1-5-2 Network Configurator Requirements

Item Specification

Operating environment Refer to the CX-One Setup Manual (W463).

CXONE-AL@@C-V4/CXONE-AL@@D-V4

Network

connection

method

Location on Network A single node address is used (only when directly connected to EtherNet/IP).

Number of Units that can be

connected to Network

Main func-

tions

Supported file formats Configurator network configuration files (*.nvf)

Serial interface CPU Unit’s Peripheral or RS-232C port CPU Unit’s USB or RS-232C port

Ethernet interface EtherNet/IP Unit’s Ethernet port CPU Unit’s Ethernet port

A single Network Configurator per network (More than one Configurator cannot be

used in the same system.)

Network control

functions

Hardware control

functions

• The network configuration can be created and edited regardless of whether the Network Configurator is online or offline.

•The network configuration can be read from a file or the network.

The EDS files used by the Network Configurator can be installed and deleted.

Configuration files (*.ncf) created using the Network Configurator for EtherNet/IP

(version 2) can be imported by selecting External Data - Import from the File

Menu.

CS1/CJ1 CJ2

EtherNet/IP Unit’s Ethernet port

10

Page 37

Network Configurator Overview Section 1-5

1-5-3 Precautions When Using the Network Configurator

Only an OMRON EtherNet/IP Unit can be set as the originator for a connection using the Network Configurator.

• The Network Configurator can be connected to the EtherNet/IP network

through the follo wing ports:

• CS1/CJ1-series CPU Unit’s serial port (peripheral or RS-232C) or

Ethernet port on EtherNet/IP Unit

• CJ2-series CPU Unit’s serial port (USB or RS-232C), Ethernet port on

EtherNet/IP Unit or built-in EtherNet/IP port

• The Network Configurator can be connected directly to the EtherNet/ IP

network from the computer’s Ethernet por t. When connecting directly to

the EtherNet/IP network, an Ethernet port must be set up in the computer

in advance. In this case, the Network Configurator will be connected to

the EtherNet/IP network as a single node. If there isn’t an unused node

address availab le , the Netw ork Configurator can ’t be connected d irectly to

the EtherNet/IP network.

11

Page 38

Network Configurator Overview Section 1-5

12

Page 39

SECTION 2

Unit Specifications

This section provides the specifications of EtherNet/IP Units and introduces recommended network configuration devices.

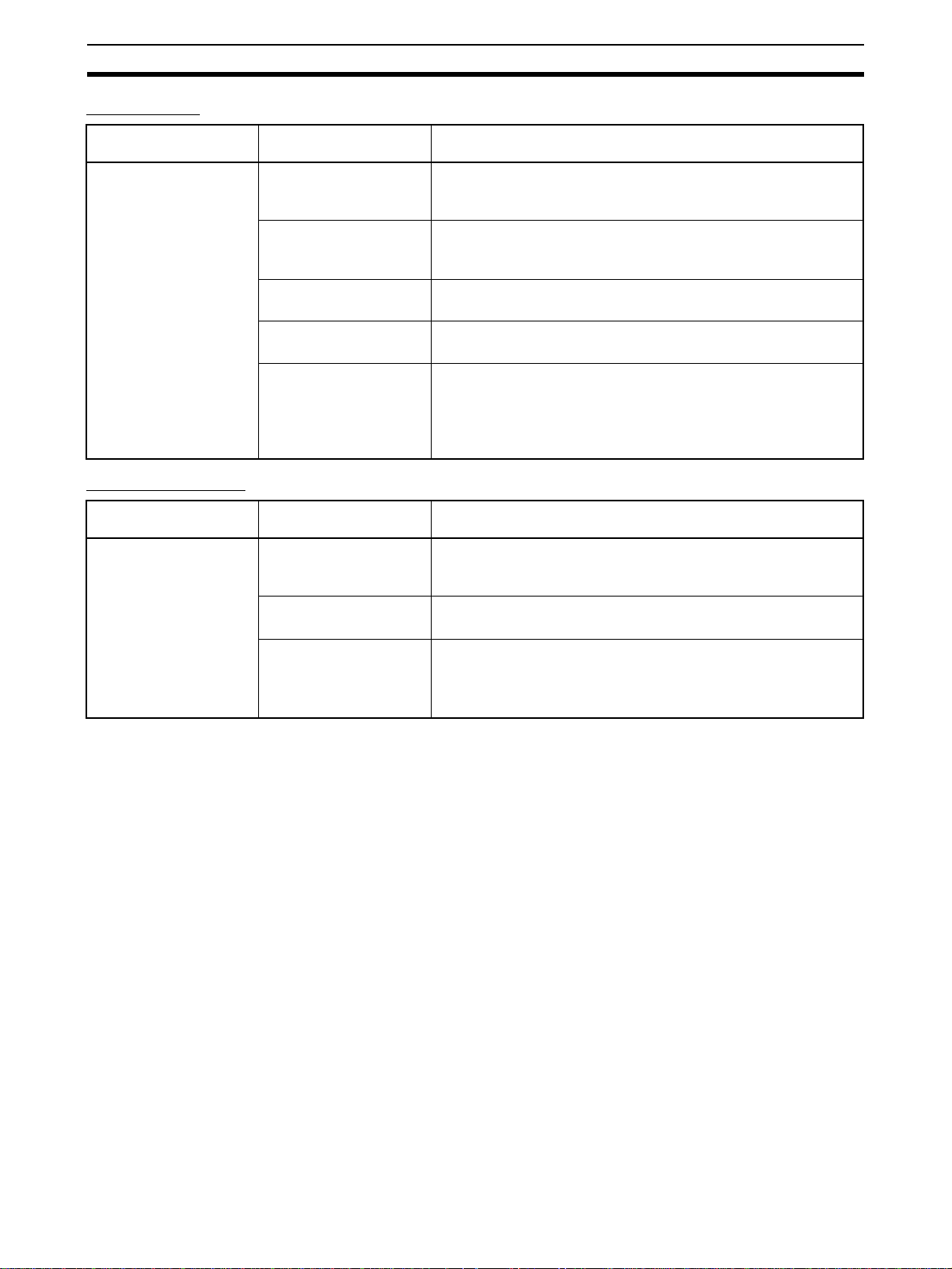

2-1 EtherNet/IP Unit and Built-in EtherNet/IP Port Specifications . . . . . . . . . . . 14

2-1-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-1-2 Unit Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2-1-3 Communications Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2-1-4 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-1-5 Software Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2-2 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-2-1 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2-2-2 Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-3 Selecting the Network Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3-1 Recommended Network Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3-2 Network Devices Manufactured by OMRON . . . . . . . . . . . . . . . . . 28

2-3-3 Switching Hub Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2-3-4 Switching Hub Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-3-5 Precautions When Selecting a Switching Hub . . . . . . . . . . . . . . . . . 29

13

Page 40

EtherNet/IP Unit and Built-in EtherNet/IP Port Specifications Section 2-1

2-1 EtherNet/IP Unit and Built-in EtherNet/IP Port

Specifications

2-1-1 General Specifications

The general specifications conform to those of th e CS-series and CJ-series

PLCs.

2-1-2 Unit Specifications

CS-series EtherNet/IP Units

Item Specifications

Model number CS1W-EIP21

Type 100Base-TX (See note.)

Applicable PLCs CS-series PLCs

Unit classification CS-series CPU Bus Unit

Mounting location CPU Rack or Expansion Rack

Number of Units that can be

mounted

CPU Unit

words used

Non-volatile memory within EtherNet/IP Unit (See note.)

Transfer

specifications

Current consumption (Unit) 410 mA max. at 5 V DC

Weight 171 g max.

Dimensions 35 × 130 × 101 mm (W × H × D)

Other general specifications Other specifications conform to the general specifications of the CS-series

Allocated CIO Area

words (CPU Bus Unit

words)

Allocated DM Area

words (CPU Bus Unit

words)

User-set area Any usable data area words

CPU Bus Unit System

Setup

Media access method CSMA/CD

Modulation method Baseband

Transmission paths Star form

Baud rate 100 Mbit/s (100Base-TX)

Transmission media Shielded twisted-pair (STP) cable

Transmission distance 100 m (distance between hub and node)

Number of cascade

connections

8 max. (including Expansion Racks)

25 words/Unit (one unit number’s words)

These words contain control bits and flags, the target node PLC’s operating and

error information, Unit status, communications status, registered/normal target

node information, and FINS/TCP connection status.

100 words/Unit (one unit number’s words)

These words contain the IP address display/setting area

Target node PLC’s operating and error information, and registered/normal target

node information

Not used.

The following settings are stored in the EtherNet/IP Unit’s non-volatile memory.

Note Unlike the regular Ethernet Units, the CPU Bus Unit Setup Area in the CPU

Unit is not used for these settings.

1. Unit setup (communications settings for the EtherNet/IP Unit, such as the IP address, DNS server settings, host name, baud rate, FINS/UDP settings, and FINS/

TCP settings)

2. Tag data link settings (device parameters)

Categories: 100 Ω at 5, 5e

There is no limitation when a switching hub is used.

14

Note If tag data links are being used, use 100Base-TX. Otherwise, 10Base-T can

be used, but this is not recommended.

Page 41

EtherNet/IP Unit and Built-in EtherNet/IP Port Specifications Section 2-1

CJ-series EtherNet/IP Unit

Item Specifications

Model number CJ1W-EIP21

Type 100Base-TX (See note.)

Applicable PLCs CJ-series PLCs

Unit classification CJ-series CPU Bus Unit

Mounting location CPU Rack or Expansion Rack

Number of Units that can be

mounted

CPU Unit

words used

Non-volatile memory within EtherNet/IP Unit (See note.)

Transfer

specifications

Current consumption (Unit) 410 mA max. at 5 V DC

Weight 94 g max.

Dimensions 31 × 90 × 65 mm (W × H × D)

Other general specifications Other specifications conform to the general specifications of the CJ-series.

Allocated CIO Area

words (CPU Bus

Unit words)

Allocated DM Area

words (CPU Bus

Unit words)

User-set area An y usable data area words

CPU Bus Unit System Setup

Media access

method

Modulation method Baseband

Transmission paths Star form

Baud rate 100 Mbit/s (100Base-TX)

Transmission media Shielded twisted-pair (STP) cable

Transmission distance

Number of cascade

connections

8 max. (including Expansion Racks)

Note Up to seven EtherNet/IP Units can be connected to a CJ2H-CPU@@-EIP CPU

Unit. Up to two EtherNet/IP Units can be connected to a CJ2M CPU Unit.

25 words/Unit (one unit number’s words)

These words contain control bits and flags, the target node PLC’s opera ting and error

information, Unit status, communications status, registered/normal target node information, and FINS/TCP connection status.

100 words/Unit (one unit number’s words)

These words contain the IP address display/setting area.

Target node PLC’s operating and error information, and registered/normal ta rget

node information

Not used.