Page 1

Manual No.

TOEP-C71080601-01-OY

JUNMA SERIES SERVO DRIVE

Model: SJDE-##APA-OY

USER’S MANUAL

Page 2

Copyright © 2006 YASKAWA ELECTRIC CORPORATION

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or

transmitted, in any form, or by any means, mechanical, electronic, photocopying, recording, or

otherwise, without the prior written permission of Yaskawa. No patent liability is assumed with

respect to the use of the information contained herein. Moreover, because Yaskawa is constantly

striving to improve its high-quality products, the information contained in this manual is subject to

change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, Yaskawa assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained in this publication.

Page 3

Introduction

This instruction manual describes the JUNMA series AC SERVOPACKs. To properly use the JUNMA

series AC SERVOPACK, read these instructions thoroughly and retain for easy reference for inspections,

maintenance, and so on. Make sure that the end user receives this manual.

Related Manuals

Refer to the following manuals as required.

Manual Name Manual Number

JUNMA series AC SERVOMOTOR INSTRUCTIONS TOEPC23026101

Safety Information

The following conventions are used to indicate precautions in this manual. Failure to heed these precautions can result in serious or possibly even fatal injury or damage to the products or to related equipment

and systems.

WARNING

CAUTION

PROHIBITED

MANDATORY

Indicates precautions that, if not heeded, could possibly result in loss of life or

serious injury.

Indicates precautions that, if not heeded, could result in relatively serious or minor

injury, damage to the product, or faulty operation.

In some situations, the precautions indicated could have serious consequences if

not heeded.

Indicates prohibited actions that must not be performed. For example, this sym-

bol would be used as follows to indicate that fire is prohibited: .

Indicates compulsory actions that must be performed. For example, this symbol

would be used as follows to indicate that grounding is compulsory: .

2

Page 4

Notes for Safe Operation

Read these instructions thoroughly before checking products on delivery, storage and transportation,

installation, wiring, operation and inspection, and disposal of the AC SERVOPACK.

WARNING

• Be sure to correctly connect the SERVOPACK connectors, CNA and CNB.

Incorrect wiring may result in electric shock, injury, or damage to the equipment. For the

wiring method, refer to 3.8 Wiring the Power Supply/Regenerative Unit Connector (CNA)

and 3.9 Wiring the Servomotor Main Circuit Cable Connector (CNB).

• Make sure that the emergency-stop circuit turns OFF the Servo ON signal and the power

supply of the main circuit when the EMG (emergency stop) signal turns ON.

Because of residual voltage, the servomotor rotates for a few seconds after the power

supply has turned OFF. This may result in injury or damage to the equipment. Make sure

that the EMG means the stop of the motor rotation.

• Never touch any rotating motor parts while the motor is running.

Failure to observe this warning may result in injury.

• Before starting operation with a machine connected, make sure that an emergency stop

can be applied at any time. Also, design the circuit's power supply to be automatically cut

off if

/S-ON signal is OFF, and an emergency stop occurs at the same time.

Failure to observe this warning may result in injury.

• Never touch the inside of the SERVOPACKs.

Failure to observe this warning may result in electric shock.

• Do not touch terminals for five minutes after the power is turned OFF.

Residual voltage may cause electric shock.

• Follow the procedures and instructions for trial operation precisely as described in this

manual.

Malfunctions that occur after the servomotor is connected to the equipment not only damage the equipment, but may also cause an accident resulting in death or injury.

• Do not remove the front cover, cables, connectors, or optional items while the power is

ON.

Failure to observe this warning may result in electric shock.

• Installation, wiring, advice on inspection and malfunction must be performed only by

authorized personnel.

Failure to observe this warning may result in fire, electric shock, or injury.

• Do not damage, press, exert excessive force or place heavy objects on the cables or the

cables between other objects where they might be pinched.

Failure to observe this warning may result in electric shock, stopping operation of the

product, or burning.

• Provide an appropriate stopping device on the machine side to ensure safety.

A holding brake for a servomotor with brake is not a stopping device for ensuring safety.

Failure to observe this warning may result in injury.

3

Page 5

WARNING

• Do not come close to the machine immediately after resetting momentary power loss to

avoid an unexpected restart.

Take appropriate measures to ensure safety against an unexpected restart. Failure to

observe this warning may result in injury.

• Do not modify the product.

Failure to observe this warning may result in injury or damage to the product.

• Be sure to correctly ground the SERVOPACK and the servomotor.

• Connect the SERVOPACK’s ground terminal to electrical codes (ground resistance: 100 Ω

or less).

Improper grounding may result in electric shock or fire.

Checking on Delivery

WARNING

• Always use the servomotor and SERVOPACK in one of the specified combinations.

Failure to observe this caution may result in fire or malfunction.

Storage and Transportation

WARNING

• Do not store or install the product in the following places.

Failure to observe this caution may result in damage to the product.

• Locations subject to direct sunlight.

• Locations subject to temperatures outside the range specified in the storage or installation temperature conditions.

• Locations subject to humidity outside the range specified in the storage or installation

humidity conditions.

• Locations subject to condensation as the result of extreme changes in temperature.

• Locations subject to corrosive or flammable gases.

• Locations subject to dust, salts, or iron dust.

• Locations subject to exposure to water, oil, or chemicals.

• Locations subject to shock or vibration.

• Do not hold the product by the cables or motor shaft while transporting it.

Failure to observe this caution may result in injury or malfunction.

• Do not place any load exceeding the limit specified on the packing box.

Failure to observe this caution may result in injury or malfunction.

4

Page 6

Installation

• Make sure to follow the conditions on 2.1 Installation Conditions.

Failure to observe this caution may result in electric shock, fire, or SERVOPACK’s malfunction.

• Do not step on or place a heavy object on the product.

Failure to observe this caution may result in injury.

• Do not cover the inlet or outlet parts and prevent any foreign objects, such as metalic frag-

ment, or combustibles from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or fire.

• Be sure to install the product in the correct direction.

Failure to observe this caution may result in malfunction.

• Provide the specified clearances between the SERVOPACK and the control panel or with

other devices.

Failure to observe this caution may result in fire or malfunction.

• SERVOPACK is precision equipment. Do not apply any strong impact.

Failure to observe this caution may result in malfunction.

Wiring

• Do not connect a three-phase power supply to the U, V, or W output terminals.

Failure to observe this caution may result in injury or fire.

• Securely connect the power supply terminals, regenerative unit connection terminal, and

motor main circuit cable terminals.

Failure to observe this caution may result in fire.

• Do not bundle or run power and signal lines together in the same duct. Keep power and

signal lines separated by at least 30 cm (11.81 in).

Failure to observe this caution may result in malfunction.

• Use twisted-pair shielded wires or multi-core twisted pair shielded wires for I/O signal

cable and encoder cable.

The maximum length is 3 m (118.11 in) for reference input lines and is 20 m (787.40 in) for

PG feedback lines.

• Do not touch the power terminals for five minutes after turning the power supply LED

(PWR) are OFF because high voltage may still remain in the SERVOPACK.

Make sure the charge indicator is turned OFF first before starting an inspection.

• Avoid frequently turning power ON and OFF. Do not turn power ON or OFF more than once

per minute.

Since the SERVOPACK has a capacitor in the power supply, a high charging current flows

for 0.2 seconds when power is turned ON. Frequently turning power ON and OFF causes

main power devices such as capacitors and fuses to deteriorate, resulting in unexpected

problems.

WARNING

WARNING

5

Page 7

WARNING

• Observe the following precautions when wiring connector for power supply/regenerative

unit.

• Remove the connector for power supply/regenerative unit from the SERVOPACK prior to

wiring.

• Insert only one wire per terminal on the connector for power supply/regenerative unit.

• Make sure that the core wire is not electrically shorted to adjacent core wires.

• Be sure to wire correctly and securely.

Failure to observe this caution may result in motor overrun, injury, or malfunction.

• Always use the specified power supply voltage of single-phase 200 V to 230 V without

connecting directly to a voltage of 400 V.

The SERVOPACK will be destroyed.

• Take appropriate measures to ensure that the input power supply is supplied within the

specified voltage fluctuation range. Be particularly careful in places where the power supply is unstable.

An incorrect power supply may result in damage to the product.

• Install external breakers or other safety devices against short-circuiting in external wiring.

Failure to observe this caution may result in fire.

• Take appropriate and sufficient countermeasures for each when installing systems in the

following locations.

Failure to observe this caution may result in damage to the product.

• Locations subject to static electricity or other forms of noise.

• Locations subject to strong electromagnetic fields and magnetic fields.

• Locations subject to possible exposure to radioactivity.

• Locations close to power supplies including power supply lines.

• Do not reverse the polarity of the battery when wiring with regenerative unit.

Failure to observe this caution may result in damage to the product.

6

Page 8

Operation

WARNING

• Conduct trial operation on the servomotor alone with the motor shaft disconnected from

machine to avoid any unexpected accidents.

Failure to observe this caution may result in injury.

• Before starting any operation with a machine connected, change the settings of the SERVOPACK’s reference pulse with the PULSE rotary switch to match those of the machine.

Starting operation without matching the proper settings may cause the machine to run out

of control or malfunction.

• When using the servomotor for a vertical axis, install safety devices to prevent workpieces

from falling off because of alarms.

Workpiece’s falling off may result in injury or malfunction.

• Do not touch the SERVOPACK heatsinks, regenerative unit, or servomotor while power is

ON or soon after the power is turned OFF.

Failure to observe this caution may result in burns due to high temperatures.

• When an alarm occurs, remove the cause, turn OFF the power and ON again after confirming safety, and then resume operation.

Failure to observe this caution may result in injury.

• Do not use the holding brake of the servomotor for ordinary braking.

Failure to observe this caution may result in malfunction.

Maintenance and Inspection

WARNING

• Do not open the SERVOPACK case for 5 minutes after the power supply lamp (PWR LED)

goes out. High voltage may remain in the SERVOPACK after the power supply has been

turned OFF.

• After turning OFF the power supply, wait 15 minutes before replacing the cooling fan.

Failure to observe this caution may result in burns because the cooling fan is hot.

• Mount the cooling fan in the correct way explained in 6.3 Replacement of Cooling Fan.

Mounting the cooling fan in the incorrect direction may result in the breakdown of the SERVOPACK.

• Do not attempt to change wiring while the power is ON.

Failure to observe this caution may result in electric shock or injury.

Disposal

WARNING

• When disposing of the products, treat them as general industrial waste.

7

Page 9

General Precautions

Note the following to ensure safe application.

• The drawings presented in this manual are sometimes shown without covers or protective guards.

Always replace the cover or protective guard as specified first, and then operate the products in

accordance with the manual.

• The drawings presented in this manual are typical examples and may not match the product you

received.

• This manual is subject to change due to product improvement, specification modification, and

manual improvement. When this manual is revised, the manual code is updated and the new

manual is published as a next edition.

• If the manual must be ordered due to loss or damage, inform your nearest representative of

OMRON YASKAWA Motion Control B.V. (OYMC) or one of the offices listed on the back of this

manual.

• OYMC will not take responsibility for the results of unauthorized modifications of this product.

OYMC shall not be liable for any damages or troubles resulting from unauthorized modification.

8

Page 10

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Related Manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Notes for Safe Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 BEFORE USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.1 Warning Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.2 Checking Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Model Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 SERVOPACKs and Applicable Servomotors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reference Pulse Setting (PULSE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reference Filter Setting Rotary Switch (FIL) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Reference Display (REF) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Alarm Display (AL1, AL2, and AL3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2 INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Installation Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Installation Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Installation Method and Direction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Space between SERVOPACK Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3 WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.1 Precautions on Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Protection for Power Supply Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Caution for Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Caution for Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Other Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Power Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Molded-Case Circuit Breaker (MCCB) or Fuse Capacity Relation to Power-Supply

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Noise Prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.2 System Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Standard Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Installation and Wiring Conditions on CE Marking . . . . . . . . . . . . . . . . . . . . . . . . . 25

Attaching the Ferrite Core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Fixing the Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Shield Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.5 SERVOPACKs and Applicable Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.6 Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

9

Page 11

3.7 SERVOPACK Main Circuit Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Cable Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Wire Size and Allowable Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Supply Input Terminals (L1, L2), Motor Connection Terminals (U, V, W),

and Regenerative Unit Connection Terminals (+, -) 28

Ground Terminal () . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Encoder signal connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

I/O signal connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.8 Wiring the Power Supply/Regenerative Unit Connector (CNA) . . . . . . . . . . . . . . . . 30

Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connector for Power Supply/Regenerative Unit (CNA) . . . . . . . . . . . . . . . . . . . . 31

3.9 Wiring the Servomotor Main Circuit Cable Connector (CNB) . . . . . . . . . . . . . . . . . 32

Servomotors without Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Servomotors with Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.10 Wiring the Encoder Connector (CN2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Connection Diagram for Standard Encoder Cable . . . . . . . . . . . . . . . . . . . . . . . 35

3.11 Wiring I/O Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connection Diagram for Standard I/O Cable

(supplied by Yaskawa Electric Company . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Connection Diagram and Description for the General-purpose control cables

(R7A-CPZ@@@S) supplied by OMRON Company. . . . . . . . . . . . . . . . . . . . . . . . 37

3.12 Connection Examples of Input Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Line Driver Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Open-collector Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.13 Connection Example of Output Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.14 EMG Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.15 Explanation of I/O Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4 TRIAL OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5 TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.1 Alarm Indicator Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

5.2 Troubleshooting for Malfunctions when Alarm Indicators Are Not Lit . . . . . . . . . . . 51

6 INSPECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.1 Regular Inspections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2 Part's Life Expectancy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

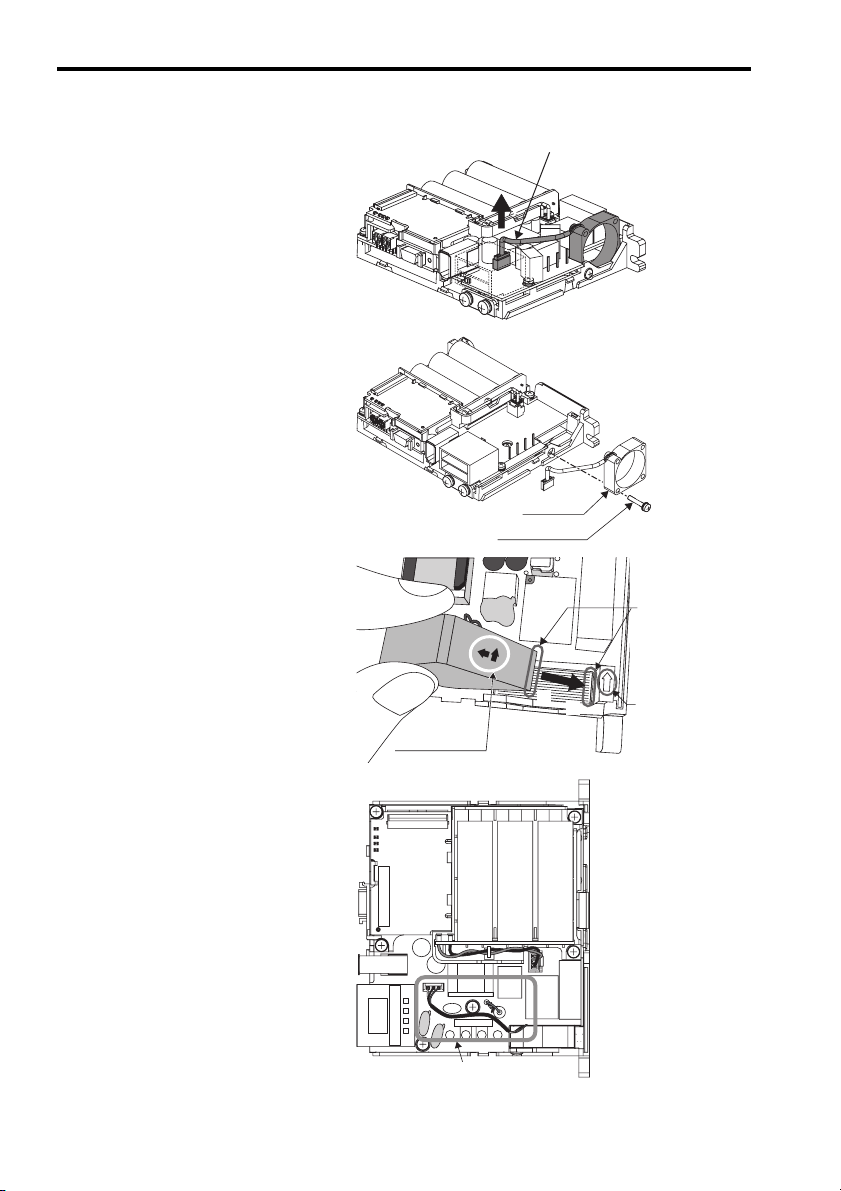

6.3 Replacement of Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.1 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

7.2 Overload Protection Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10

Page 12

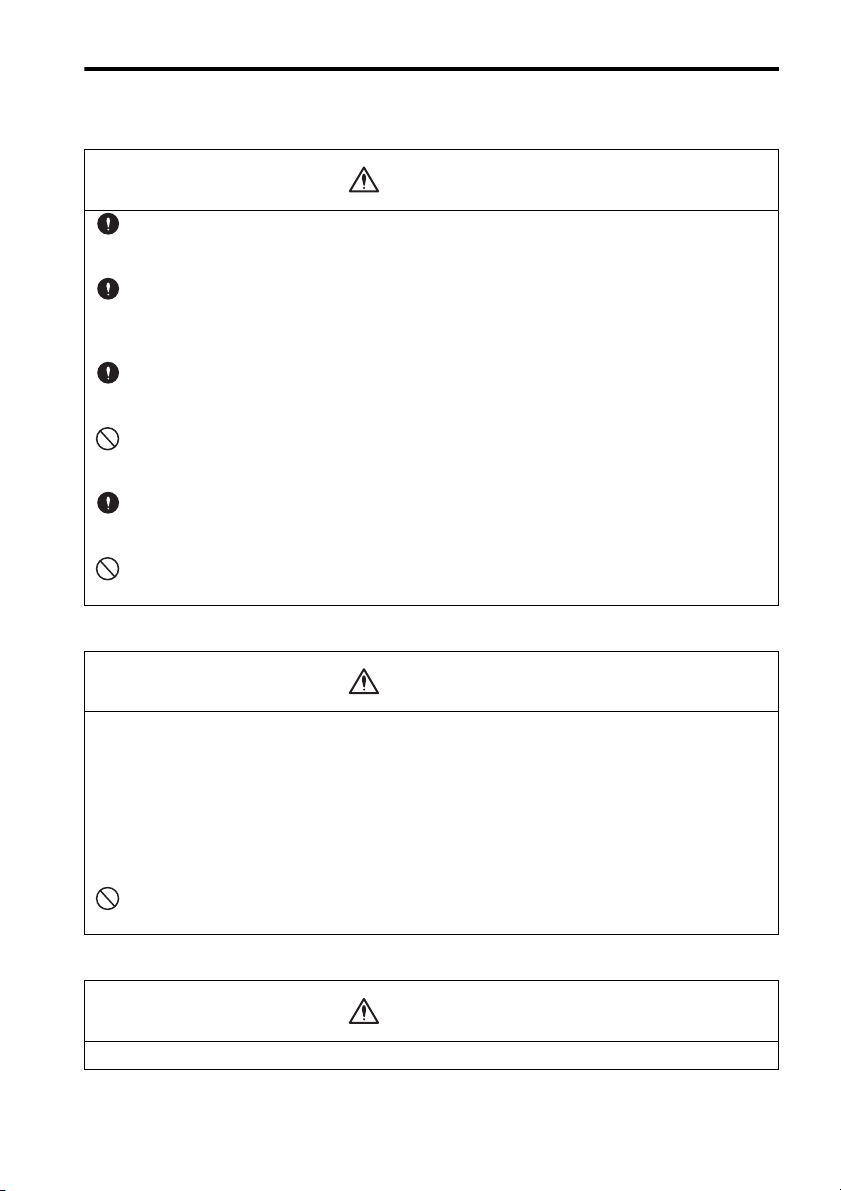

1.1 Warning Label

1 Before Use

1.1 Warning Label

A warning label is located on the side of the SERVOPACK.

SERVOPACK's Warning Label

1.2 Checking Products

Confirm that the following items have been delivered together with the SERVOPACK. Verify that the

ordered product as received by the model number marked on the nameplate on the SERVOPACK.

If you find any irregularities such as incorrect SERVOPACK model, damages, and missing parts or items,

contact your OYMC representative or the dealer from whom you purchased the products.

SJDE

SERVOPACK

OMRON

A

9

8

7

A

9

8

7

D

C

B

6

5

4

D

C

B

6

5

4

APA-OY

R

E

F

0

1

2

3

E

F

0

1

2

3

E

F

Applicable

power supply

Order number

Serial number

Nameplate

SERVOPACK

model

Applicable motor

capacity

One screwdriver for selecting

the pulse and setting the filter

Connector Part Number JZSP-CHG9-1

One copy of this

Instruction Manual

11

Page 13

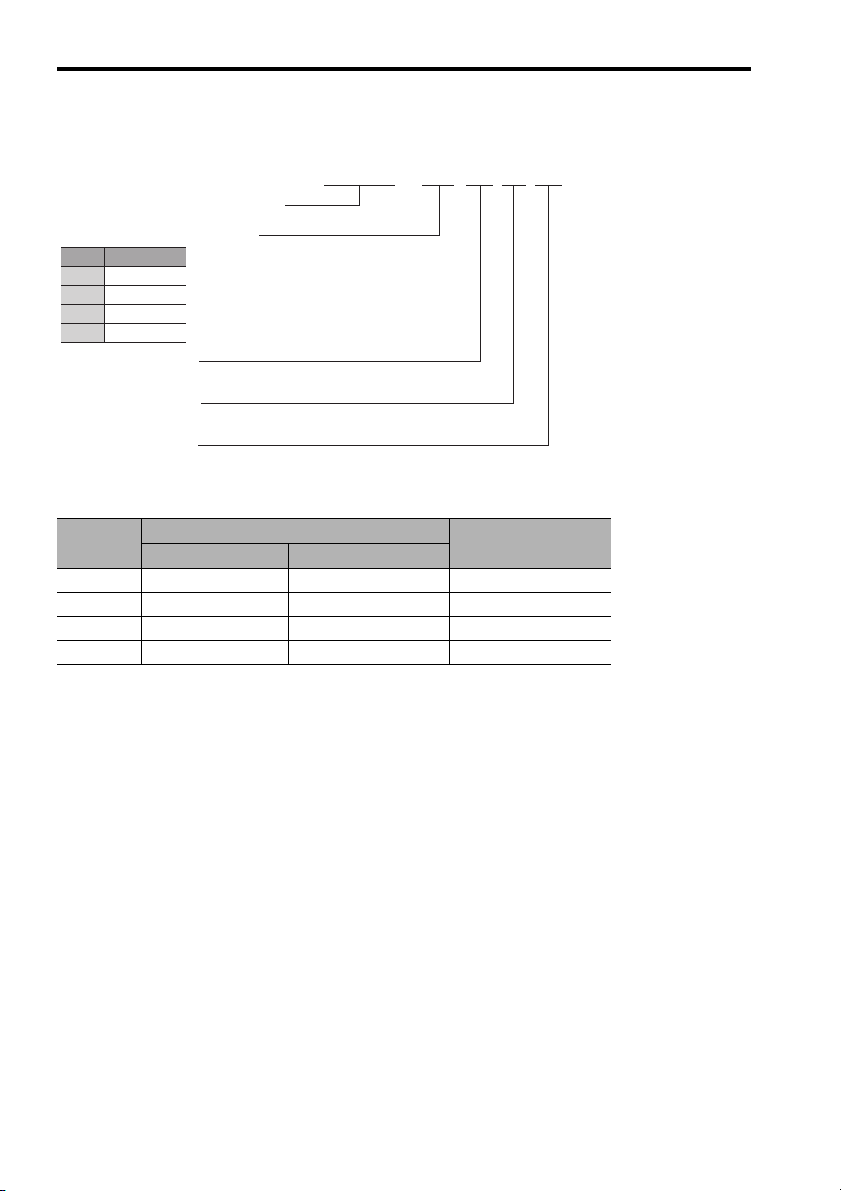

1.3 Model Designation

A

A

A

1.3 Model Designation

SJDE—02 A P A —OY

JUNMA series SERVOPACK SJDE

pplicable servomotor capacity

Code

Output (W)

100

01

200

02

400

04

750

08

Power supply voltage

: 200 VAC

Interface specification

P: Pulse train reference

Design revision order

1.4 SERVOPACKs and Applicable Servomotors

Rated

Output

100W SJME-01AMB41-OY SJME-01AMB4C-OY SJDE-01APA-OY

200W SJME-02AMB41-OY SJME-02AMB4C-OY SJDE-02APA-OY

400W SJME-04AMB41-OY SJME-04AMB4C-OY SJDE-04APA-OY

750W SJME-08AMB41-OY SJME-08AMB4C-OY SJDE-08APA-OY

Without Brakes With Brakes

Servomotor SERVOPACK

12

Page 14

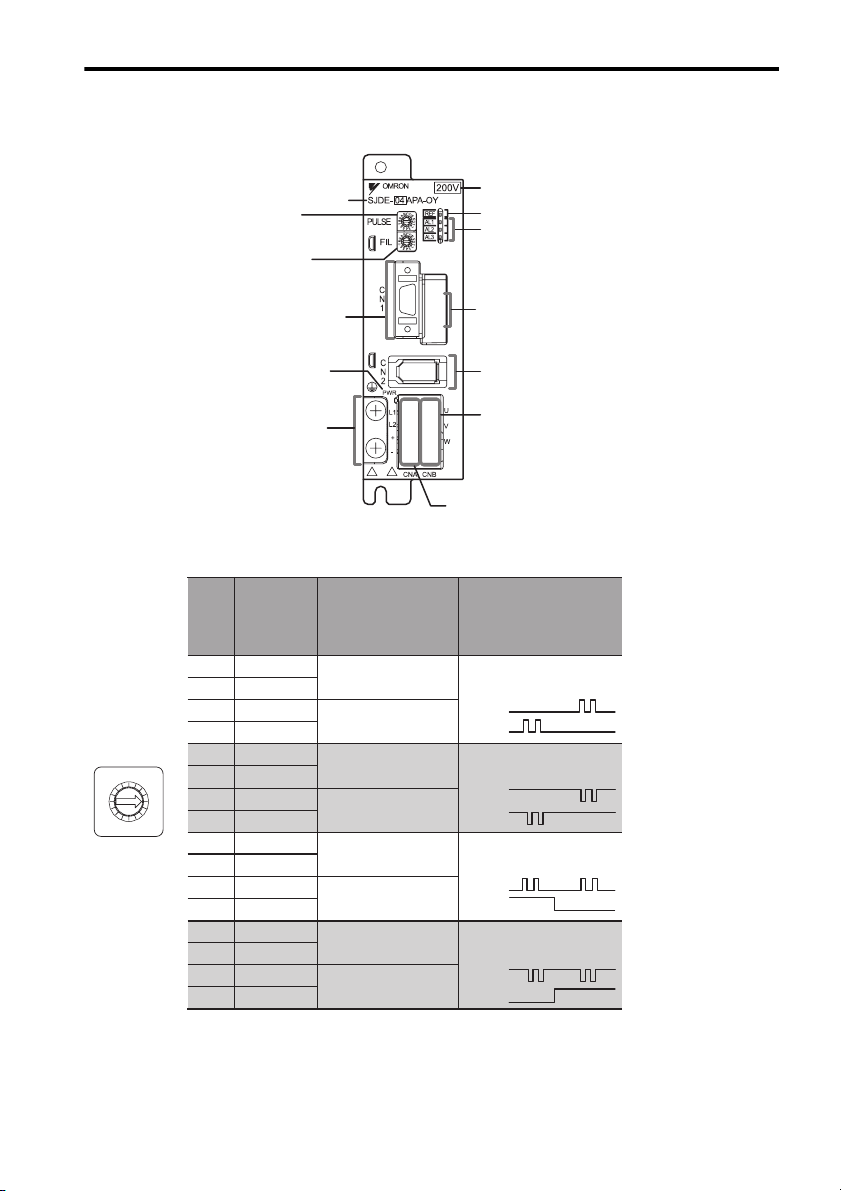

1.5 Part Names and Functions

1.5 Part Names and Functions

Rotary switch for reference

pulse setting (PULSE)

Rotary switch for reference

filter setting (FIL)

I/O signal connector (CN1)

Power supply indicator

(PWR)

Ground terminal

Ty pe

Reference Pulse Setting (PULSE)

Reference

Set

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Pulse

Resolution

(P/REV)

1000

2500

5000

10000

1000

2500

5000

10000

1000

2500

5000

10000

1000

2500

5000

10000

Value

PULSE

D

C

B

E

A

F

9

0

8

1

7

2

6

3

5

4

Note: 1. Make settings after turning OFF the power.

2. The factory setting is 0.

Reference Pulse

Connection Method

Open collector

or line driver

Line driver

Open collector

or line driver

Line driver

Open collector

or line driver

Line driver

Open collector

or line driver

Line driver

Input voltage

Reference indicator (REF)

Alarm indicators (AL1 to AL3)

This connector is for factory use only.

(Do not use!)

Encoder connector (CN2)

Connector for motor main

circuit cable (CNB)

Connector for power supply /

regenerative unit (CNA)

Reference

Pulse Type

CW + CCW

Positive logic

CW

CCW

CW + CCW

Negative logic

CW

CCW

Mark + pulse sequence,

Positive logic

PULS

SIGN

Mark + pulse sequence,

Negative logic

PULS

SIGN

13

Page 15

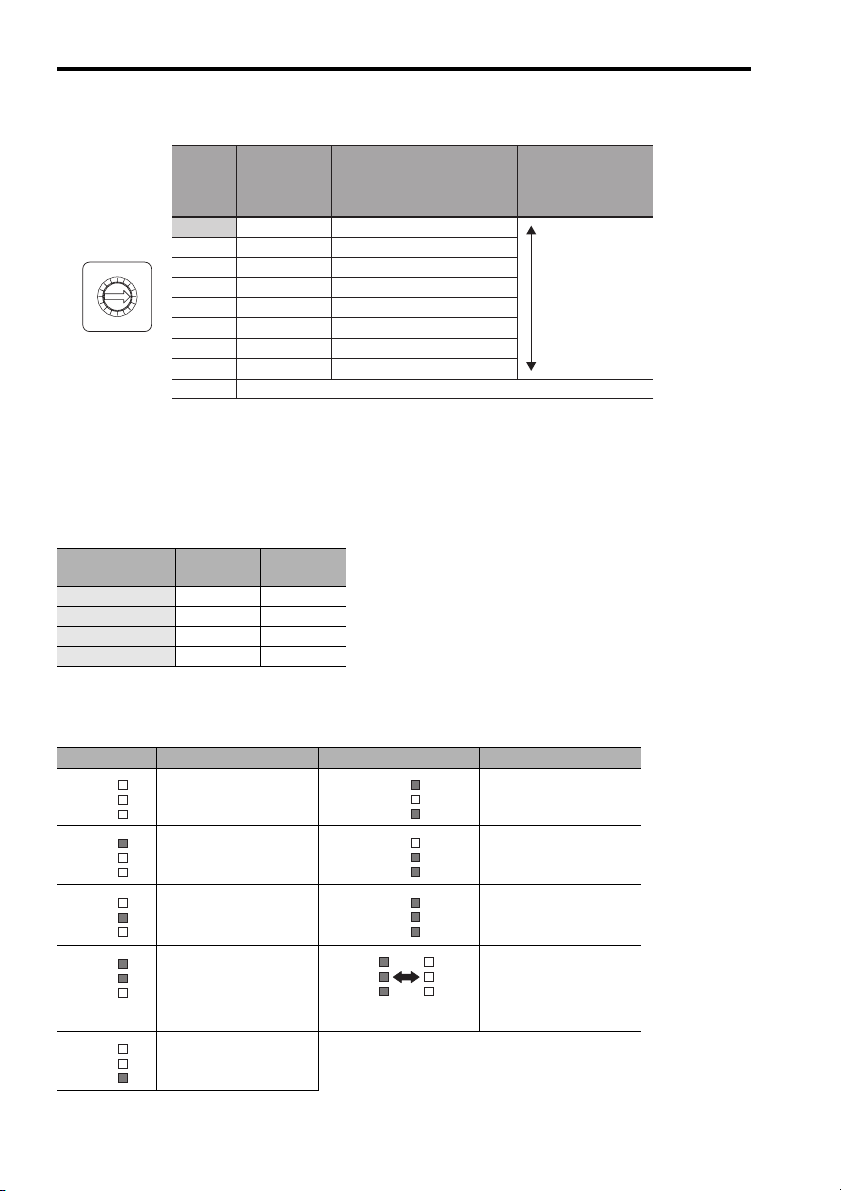

1.5 Part Names and Functions

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

A

Reference Filter Setting Rotary Switch (FIL)

Acceleration/

Filter

Deceleration

Time for Step

2

Reference

1

0*

1

2

3

4

5

6

7

Do not set 8 through F.

8 to F

45 ms

50 ms

60 ms

65 ms

70 ms

80 ms

85 ms

170 ms

FIL

A

9

8

7

Setting

Value*

D

C

B

E

F

0

1

2

6

3

5

4

* 1. The factory setting is 0. If the machine vibrates, this value must be changed.

* 2. If the machine vibrates when starting or stopping the machine, set a larger value.

* 3. The value depends on conditions such as the level of command acceleration and

deceleration, the machine rigidity and the motor resolution (PULSE switch).

* 4. Select the correct servomotor capacity with these values if using a step reference

that has no acceleration or deceleration time.

Approx. Time between

Completing Reference and

Completing Positioning

*4

(Settling Time)*

100 to 200 ms

110 to 220 ms

130 to 260 ms

150 to 300 ms

170 to 340 ms

200 to 400 ms

250 to 500 ms

500 to 1000 ms

Description

3

Small filter time

constant (short

positioning time)

Large filter time

constant

(little vibration

with a long

positioning time)

Reference Display (REF)

Indicators* Motor

Power

Lit orange. OFF −

Blinks orange. OFF Input

Lit green. ON −

Blinks green. ON Input

* Lit yellow for 1s when the clear signal is input.

Reference

Pulses

Alarm Display (AL1, AL2, and AL3)

Indicators Meaning of Alarm Indicators Meaning of Alarm

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

L1

L2

L3

Normal Overcurrent

Speed error

Overload System error

Encoder error

L1

L2

L3

L1

L2

L3

L1

L2

L3

AL1

AL2

AL3

Blinks at regular

intervals.

SERVOPACK’s built-in

fan stop

Rotary switch for

reference pulse setting

(PULSE) changed.

Voltage error

14

Page 16

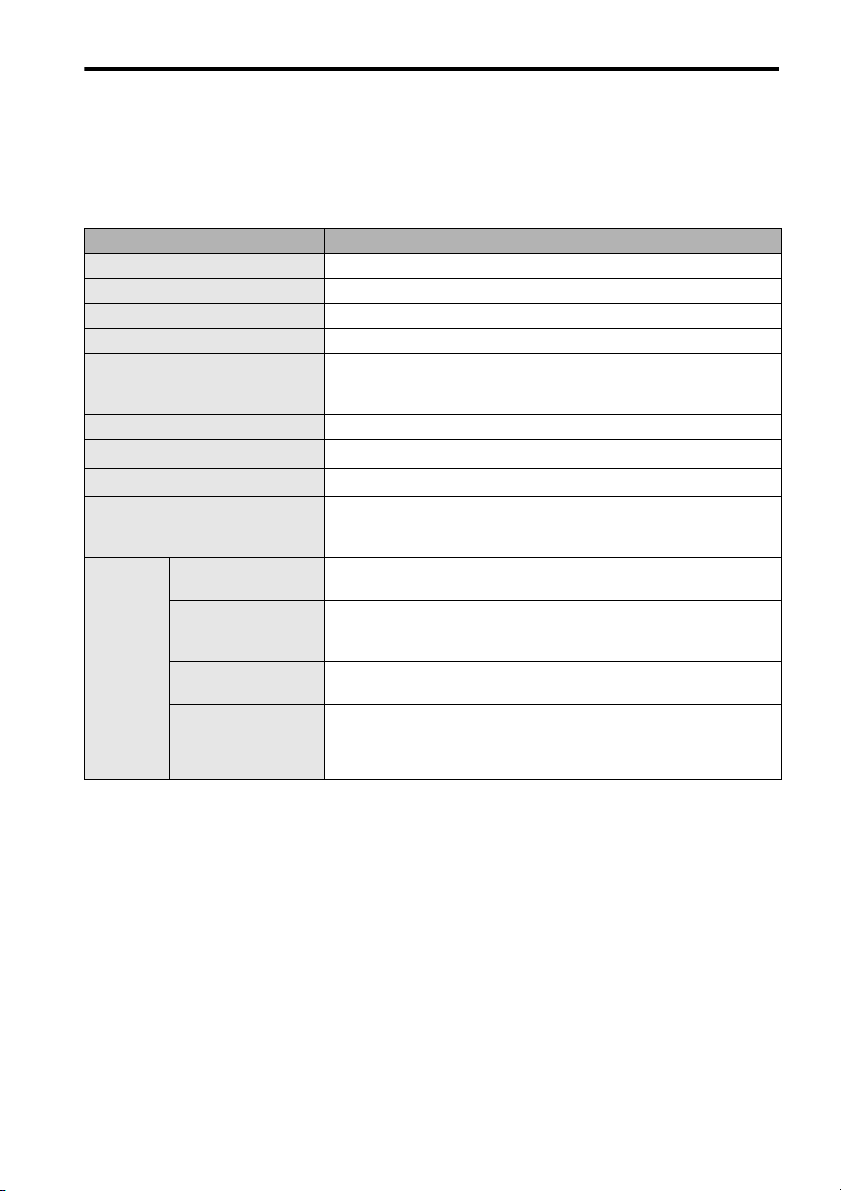

2.1 Installation Conditions

2 Installation

The following shows the installation location and method of the SERVOPACK.

2.1 Installation Conditions

Item Specifications

Operating temperature 0 ° C to +55 °C

Operating humidity 90% RH or less (with no condensation)

Storage temperature -20 ° C to +70 ° C

Storage humidity 90% RH or less (with no condensation)

Installation site Free of corrosive gases

Altitude 1000 m or below

Vibration resistance

Shock resistance

Operating conditions Installation category (overvoltage category): II

Installation in a control

panel

Installation near a

heating unit

Installation

Site

Installation near a

source of vibration

Installation at a site

exposed to corrosive

gas

Free of dust and iron powder

Clean and dry

2

4.9m/s

2

19.6m/s

Pollution degree: 2

Protection class: IP10 (EN50178)

Design the control panel size, unit layout, and cooling method so

the temperature around the SERVOPACK does not exceed 55 ° C.

Minimize the heat radiating from the heating unit as well as any

temperature rise caused by natural convection so the temperature

around the SERVOPACK does not exceed 55 ° C.

Install a vibration isolator beneath the SERVOPACK to avoid subjecting

it to vibration.

Corrosive gas does not have an immediate effect on the SERVOPACK

but will eventually cause the electronic components and contactor-

related devices to malfunction. Take appropriate action to avoid corrosive gas.

15

Page 17

2.2 Installation Method

2.2 Installation Method

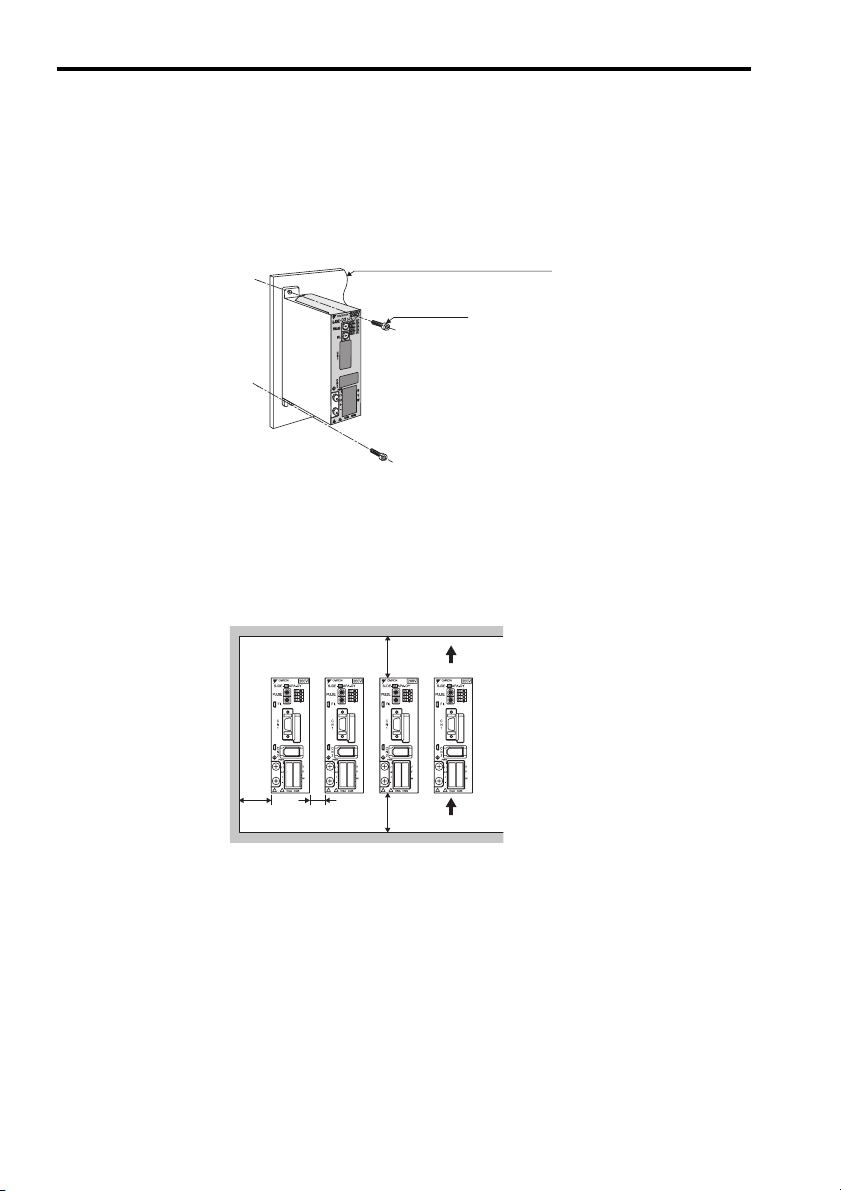

Installation Method and Direction

• Install the SERVOPACK perpendicular to the wall. The SERVOPACK contains a built-in fan for cooling

and must be mounted in the specified direction.

• Connect the mounting holes securely to the mounting surface with M4 screws (two mounting holes).

SERVOPACK installation plate

M4 screw

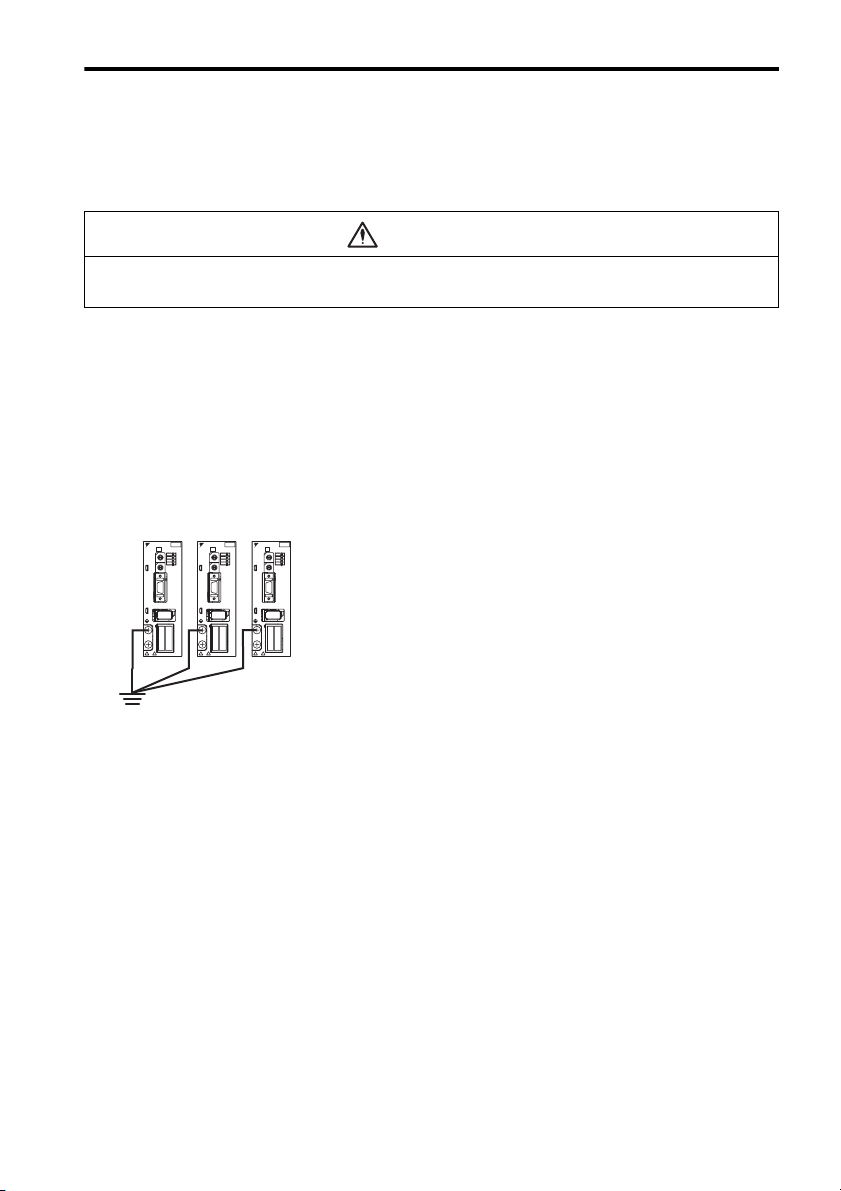

Space between SERVOPACK Units

• Be sure to keep a space between adjacent SERVOPACK units if they are mounted inside the control

panel so that the units can be cooled.

• Do not cover the inlet or outlet parts and prevent any foreign objects, such as metalic fragment, or

combustibles from entering the product.

Failure to observe this caution may cause internal elements to deteriorate resulting in malfunction or

fire.

30 mm

min.

10 mm

min.

50 mm

min.

50 mm

min.

16

Air outlet direction

Air inlet direction

Page 18

3.1 Precautions on Wiring

3 Wiring

3.1 Precautions on Wiring

WARNING

• Be sure to correctly ground the SERVOPACK and the servomotor.

• Wiring must be performed by an authorized person qualified in electrical work.

Protection for Power Supply Line

• Use a molded-case circuit breaker and fuse to protect the power supply line from high voltage. The

SJDE SERVOPACK connects directly to a commercial power supply without a transformer, so always

use a circuit breaker and fuse to protect the SERVOPACK from accidental high voltage.

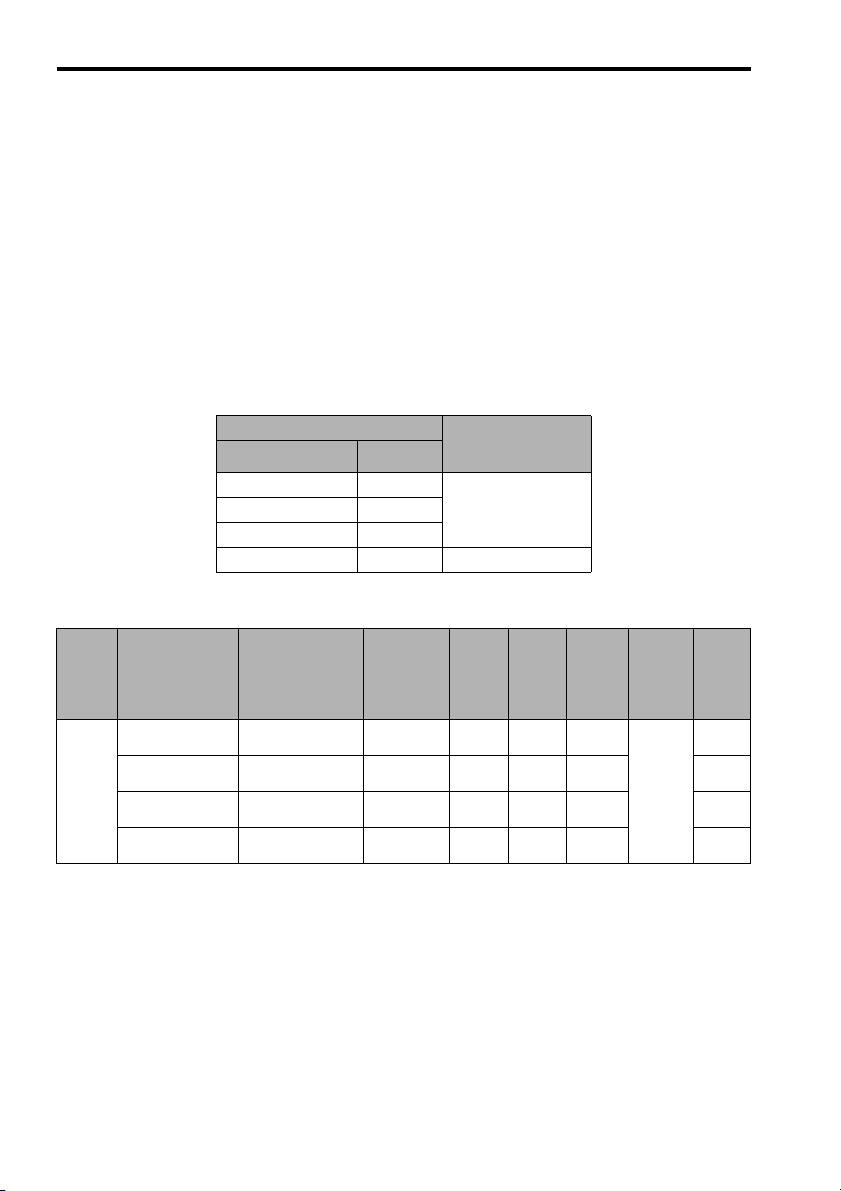

Caution for Grounding

Consider the following conditions when grounding the SERVOPACK.

• For a ground wire, use as thick a cable as possible (2.0 mm2 or thicker).

• A ground resistance of 100 (Ω) or less is recommended.

• Ground to one point only.

OMRON

SJDE- 04 APA-OY

9

PULSE

9

FIL

C

N

1

C

N

2

PWR

L1

L2

+

-

OMRON

OMRON

200V

200V

SJDE- 04 APA-OY

C

C

D

D

B

B

E

E

CTL

A

A

F

F

9

0

0

8

8

1

1

AL1

PULSE

7

7

2

2

6

6

3

3

4

4

5

5

AL2

C

C

AL3

D

D

B

B

E

E

A

A

F

F

9

0

0

8

8

1

1

FIL

7

7

2

2

6

6

3

3

4

4

5

5

C

N

1

C

N

2

PWR

U

L1

V

L2

+

W

-

CNA CNB

CNA CNB

200V

SJDE- 04 APA-OY

C

D

B

E

CTL

CTL

A

F

9

0

8

1

AL1

AL1

PULSE

7

2

6

3

4

5

AL2

AL2

C

AL3

AL3

D

B

E

A

F

9

0

8

1

FIL

7

2

6

3

4

5

C

N

1

C

N

2

PWR

U

U

L1

V

V

L2

+

W

W

-

CNA CNB

Caution for Cable

• For wiring, use the specified cables. Use cables that are as short as possible.

• Do not bend or apply tension to cables. The conductor of a signal cable is very thin (0.08 to

0.12 mm2), so handle the cables carefully.

17

Page 19

3.1 Precautions on Wiring

Other Precautions

• Make sure that the emergency-stop circuit turns OFF the /S-ON signal as well as the power supply of

the main circuit. Refer to 3.14 EMG Sequence.

• An overtravel function is not provided for the SERVOPACK.

For system safety, include a sequence so that the /S-ON signal will turn OFF when the limit switch is

activated.

• If the servomotor is used to drive a vertical axis, install a safety device with an alarm function to prevent the workpiece from falling down. Failure to observe this precaution may result in injury or damage to the equipment from fallen workpieces.

• Install an interlock system in the circuit to avoid any accident when opening or closing the machine’s

protective cover.

• Whether the electricity is served or not to the motor, do not use the motor being rotated from the outside.

• When restarting the power supply soon after turning OFF, alarm may occur to the SERVOPACK. Refer

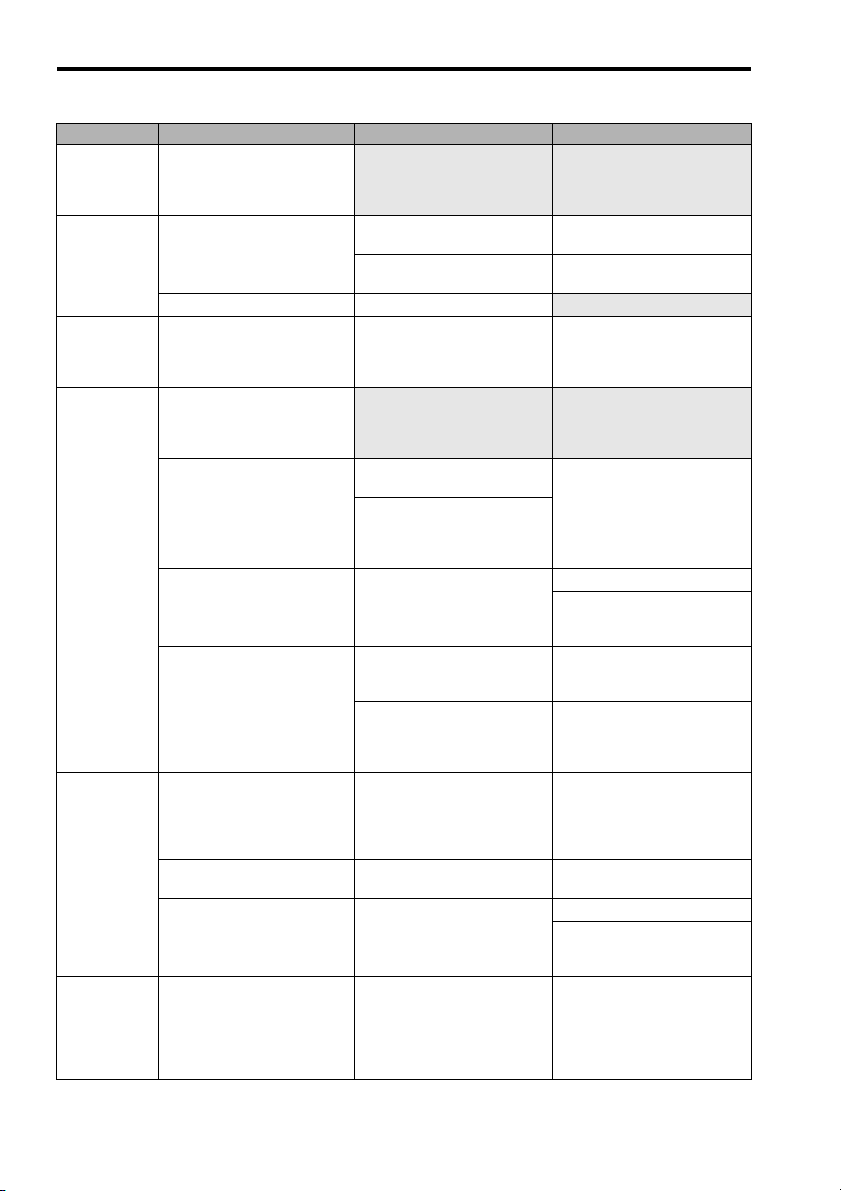

to the power supply holding time in the following table to restart the power supply correctly.

SERVOPACK Min. Waiting Time

Model Capacity

SJDE-01APA-OY

SJDE-02APA-OY

SJDE-04APA-OY

SJDE-08APA-OY

100W

200W

400W

750W

before Restarting

(s)

20

30

Power Loss

Power Loss with SERVOPACK Rated Output

Main

Circuit

Power

Supply

Single-

phase

200 V

Max. Applicable

Servomotor

Capacity

kW

0.1 SJDE-01APA-OY 0.84 6 0.9 4.2 9 15

0.2 SJDE-02APA-OY 1.1 8 1.8 5.8 17

SERVOPACK

Model No.

Output

Current

(Effective

Value)

A

Main

Circuit

Power

Loss

W

Diode

Power

Loss

W

IPM

Power

Loss

W

Control

Circuit

Power

Loss

W

To ta l

Power

Loss

W

0.4 SJDE-04APA-OY 2.0 16 3.6 11.9 25

0.75 SJDE-08APA-OY 3.7 27 6.4 20.3 36

Note: Valued obtained with the servomotor with the rated output.

18

Page 20

3.1 Precautions on Wiring

Molded-Case Circuit Breaker (MCCB) or Fuse Capacity Relation to Power-Supply Capac-

ity

MCCB or Fuse Capacity Relation to Power-Supply Capacity

Main

Circuit

Power

Supply

Single-

phase

200 V

* 1. Valued obtained with the servomotor with the rated output.

* 2. Fuse manufactured by Littelfuse Inc.

NOTE

SERVOPACK Applicable Ser-

Capac-

ity

kW

0.1 SJDE-01APA-OY SJME-01APA-OY 0.4 4 0KLK 015.T

0.2 SJDE-02APA-OY SJME-02APA-OY 0.75

0.4 SJDE-04APA-OY SJME-04APA-OY 1.2 8

0.75 SJDE-08APA-OY SJME-08APA-OY 2.2 16 0KLK 030.T

Ground Fault

The ground protection circuit is designed for ground fault inside the motor windings while the

motor is running. Therefore, it may not protect the system under the following conditions.

To configure a safer system, install an earth leakage breaker for protection against overloads and

short-circuiting, or install an earth leakage breaker combined with a wiring circuit breaker for

ground protection.

Model No.

• A low-resistance ground fault occurs between the main circuit cable and connector for the

servomotor.

• The power supply is turned ON during a ground fault.

vomotor Model

PowerSupply

Capacity

kVA

MCCB

Current

Capacity

Arms

External Fuse

[Power-Supply

∗1

Model No.

Capacity

∗2

Arms]

[15]

[30]

Inrush

Current

A

30

60

19

Page 21

3.1 Precautions on Wiring

r

Noise Prevention

Example of Wiring for Noise Prevention

SERVOPACK

SJDE

L1

L2

Grounding plate

Groudning: Ground to one point only.

Min. grounding resistance: 100 Ω

CN1

2

*1.

U

V

W

CN2

Min. wire size

: 3.5 mm

Min. wire size

: 3.5 mm

200 VAC

Min. wire size

: 3.5 mm

Noise filter

2LF

2

Casing

*1.

• Operation relay sequence

• User signal generating circuit

P

P

Casing

Casing

Min. wire size: 3.5 mm

1LF

*2.

P

2

AVR

(Grounding)

Casing

*1.

2 mm2 or larger

Min. wire size: 3.5 mm

Casing

* 1. For the wires connected to the casings for installation purposes, use wires with a diameter of 3.5 mm2

or larger. Flat braided copper wires are recommended.

2

2

Servomoto

(FG)

PG

M

* 2. Use twisted pair wires for section P.

Correct Grounding

• Servomotor frame grounding:

Be sure to connect the FG grounding terminal on the frame of the servomotor to the grounding terminal on the SERVOPACK.

• Be sure to ground the grounding terminal of the SERVOPACK.

• If the wires of the servomotor’s main circuit are laid in a metal conduit, ground the conduit and the

grounding box.

One-point grounding must be used.

20

Page 22

Noise Filters

Use noise filters to prevent any noise interference from the power-supply line.

The following table lists the recommended noise filters.

Recommended Noise Filters

PowerSupply

Voltage

SERVOPACK Model Recommended Noise Filters

Model Specifications Manufacturer

3.1 Precautions on Wiring

Single-

phase

200 V

SJDE-01APA to -

04APA-OY

SJDE-08APA-OY

R7A-FIZP105-BE Single-phase 250 VAC, 5A Block

R7A-FIZP109-BE Single-phase 250 VAC, 9A

Transformatoren

Elektronik

GmbH & Co. KG.

21

Page 23

3.1 Precautions on Wiring

Filter dimensions for model R7A-FIZP105-BE

Filter dimensions for model R7A-FIZP109-BE

22

Page 24

3.2 System Configuration

Power supply

Single-phase 200 VAC

L1 L2

Molded-case circuit breaker

To protect the equipment and wiring,

always connect a molded-case circuit

breaker.

Noise filter

Used to eliminate suppress noise

from power lines for CE marking

requirements.

Surge protector

To protect the

system from

lightening surge.

AC reactor

Used for a power

supply harmonic

suppression.

Fuse

To protect the

equipment, always

install fuses.

Magnetic contactor

Used to turn OFF the servo

power supply when using a

regenerative unit or in case

of emergency.

Vari stor

WARNING

Correctly connect the

connectors CNA and

CNB.

Incorrect wiring may

result in electric shock,

injury, or damage to

the equipment.

After wiring, install the

connectors as explained

in 3.8 Wiring the Power

Supply/Regenerative

Unit Connector (CNA)

and 3.9 Wiring the

Servomotor Main Circuit

Cable Connector (CNB).

Used for a

regenerative unit.

Regenerative unit

Used if regenerative

energy is high.

Used for a

servomotor

with a brake.

24-VDC

power

supply

*

Brake relay

Connectors for motor

main circuit cable (CNB

Connectors for power

supply/regenerative unit

(

)

CNA

SJDE

SERVOPACKs

I/O signal cable

Motor main circuit cable

(

for relay)

)

SJME

Servomotors

3.2 System Configuration

CAUTION

Never open the protective cover for

the connector.

Do not use the connector since the

connector is reserved for adjustment

by the manufacturer.

If the connector is used, a

SERVOPACK failure may result.

CJ-series PLC

Encoder cable (for relay

)

To the control

circuits of

magnetic

contactor

* Prepare a 24-VDC power supply for the brake separately from the sequence power supply.

23

Page 25

3.3 Standard Connection

A

3.3 Standard Connection

Power supply

Single-phase 200 V to 230 VAC

50/60Hz

L1

L2

Molded-case circuit breaker

Surge protector

Noise

VR2

24 V power

supply

filter

200 V to

230 VAC

+

24V

SW1

0V

SW2

MC1

Regenerative unit

C1 C2

JUSP-

RG08D

MC1

MC1

Spark

killer

Y4

Y5

AVR1 *

24 V power supply

200 V to

230 VAC

SERVOPACK

Fuse

Fuse

L2

+

−

CNA CNB

1L1

2

3

4

Reactor

+

−

Ry1

+

24V

0V

Shell

Vari stor

U

1

V

2

W

3

Shield

5

6

1

2

V

3

4

Brake

U

Servomotor

W

FG

Note: 1. AVR1:24 VDC power

supply for brake

AVR2: 24 VDC power sup-

SW1: Power OFF switch

SW2: Power ON switch

MC1: Magnetic contactor

Ry1: Brake relay

Controller

2.2kΩ

Flywheel diode

ply for sequence

MC1

Ry1

CN1 CN2

Shield

/CW,/PULS

CCW,SIGN

/CCW,/SIGN

CLR

/CLR

PCO

SG-PCO

+24VIN

/S-ON

ALM

/BK

/COIN

SG-COM

1

2

3

4

8

9

10

11

5

6

12

13

14

7

Shell

75Ω

75Ω

75Ω

75Ω

75Ω

75Ω

3.4kΩ

1

PG5VCW,PULS

2

PG0V

+

A

3

4

A−

+

5

B

6

B−

7

/Z

8

U

9

V

10

W

Shell

Shield

* Prepare a 24-VDC power supply

for the brake separate from the

sequence power supply.

• Parts example

Spark killer Okaya Electric Industries Co., Ltd. CRE-50500

Flywheel diode Toshiba Corporation 1NH42

Brake relay OMRON Corporation MY series

Varistor Nippon Chemi-Con Corporation TNR7V121K

24

1

2

3

4

5

6

7

8

9

10

12

Encoder

Page 26

3.4 Installation and Wiring Conditions on CE Marking

2. The ground protection circuit is designed for ground fault inside the motor windings while the

motor is running. Therefore, it may not protect the system under the following conditions.

• A low-resistance ground fault occurs between the main circuit cable and connector for

the servomotor.

• The power supply is turned ON during a ground fault.

To configure a safer system, install an earth leakage breaker for protection against overloads and

short-circuiting, or install an earth leakage breaker combined with a wiring circuit breaker for

ground protection.

* Prepare a 24 VDC power supply for sequence separately from the 24 VDC power supply for brake.

3.4 Installation and Wiring Conditions on CE Marking

To adapt a combination of a SJME servomotor and a SJDE SERVOPACK to EMC Directives (EN55011,

group 1, class A and EN61000-6-2), the following conditions must be satisfied. After installing the SERVOPACK, do a test run to make sure that the machine operates correctly.

The actual EMC level may differ depending on the actual system's configuration, wiring, and

NOTE

other conditions.

Ground Plate

Brake power

supply

Cable joint

Power Supply

Single-phase

200 VAC

PE

SERVOPACK

Clamp

Surge

protector

Noise

filter

Regenerative

unit

L1, L2

+, −

CN1

U, V, W

CN2

core

Ferrite

core

Ferrite

Host controller

Symbol Cable Name Specifications

I/O Signals cable Shield cable

c

Servomotor Main Circuit cable Shield cable

d

Encoder cable Shield cable

e

AC Line cable Shield cable

f

25

Clamp

core

Ferrite

core

Ferrite

core

Ferrite

Cable joint

Brake

Servo-

motor

Encoder

Page 27

3.4 Installation and Wiring Conditions on CE Marking

Attaching the Ferrite Core

Coil the motor main circuit cable (as a connection) around the ferrite core with two turns, then attach

them by the SERVOPACK. Refer to the diagram in the previous page.

Cable (two turns)

Ferrite core

Note: Recommended Ferrite-core

Model: ESD-SR-25 (Tokin. Corp.)

Fixing the Cable

Fix and ground the cable shield using a piece of conductive metal.

• Example of Cable Clamp

Host

controller

side

Ground plate

Cable

Cable

clamp

Shield (cable sheath stripped)

Fix and ground the cable shield

using a piece of conductive metal.

Remove paint on mounting surface.

Shield Box

A shield box, which is a closed metallic enclosure, should be used for shielding magnetic interference.

The structure of the box should allow the main body, door, and cooling unit to be attached to the ground.

The box opening should be as small as possible.

26

Page 28

3.5 SERVOPACKs and Applicable Peripheral Devices

3.5 SERVOPACKs and Applicable Peripheral Devices

SERVOPACK Power

Ty pe Capa-

SJDE01APA-OY

SJDE02APA-OY

SJDE-

100 W 0.40 4 0KLK

200 W 0.75 X5053

400 W 1.2 8 X5054

city

Supply

Capacity

per

SERVO-

PAC K

kVA

04APA-OY

SJDE08APA-OY

750 W 2.2 16 0KLK

Manufacturer - - Littelfuse

* 1. Nominal value at the rated load. The specified derating is required to select the appropriate molded-

case circuit breaker.

* 2. Cut-off characteristics (25 °C): 200 % two seconds min. and 700 % 0.01 seconds min.

Note: 1. The ground protection circuit is designed for ground fault inside the motor windings while the

motor is running. Therefore, it may not protect the system under the following conditions.

• A low-resistance ground fault occurs between the main circuit cable and connector for the servomotor.

• The power supply is turned ON during a ground fault.

To configure a safer system, install an earth leakage breaker for protection against overloads and

short-circuiting, or install an earth leakage breaker combined with a wiring circuit breaker for

ground protection.

2. It is recommended to use a general-purpose circuit breaker of the rated current 200 mA or more,

or a circuit breaker for inverters (for high-frequency).

Current

Capacity of

Molded-case

Circuit

Breaker

*1 *2

Arms

Current

Capacity

and Model

of Exter-

nal Fuse

015.T

(15 Arms)

030.T

(30 Arms)

Inc.

Inrush

Magnetic

Cur-

Contac-

rent

A0-p

30 HI-11J R7A-

Noise Fil-

*3

tor

FIZP105BE

60 HI-15J R7A-

FIZP109BE

-Yaskawa

Controls

Co., Ltd.

Block

Elec-

tronik

GmbH

ter

Surge

Protector

xCxM-

R

601BQZ4

Okaya

Electric

Industries

Co., Ltd.

AC

Reactor

X5052

X5056

Yas ka wa

Controls

Co., Ltd.

3.6 Main Circuit Wiring

• SJDE SERVOPACKs are suitable where the power supply is less than 5000 Arms (230 V max.).

• SERVOPACKs must be used with UL-listed fuses or circuit breakers, in accordance with the National

Electrical Code (NEC).

• Use 75 ° C heat-resistant copper wires or an equivalent.

27

Page 29

3.7 SERVOPACK Main Circuit Wire Size

3.7 SERVOPACK Main Circuit Wire Size

Cable Types

Symbol Name Allowable Conductor Temperature

PVC

IV

HIV

Normal vinyl cable

600 V vinyl cable

Temperature-resistant vinyl cable

• Wire sizes are selected for three cables per bundle at 40 ° C ambient temperature with the rated current.

• Use cables with a minimum withstand voltage of 600 V for main circuits.

• If cables are bundled in PVC or metal ducts, consider the reduction ratio of the allowable current.

• Use heat-resistant cables under high ambient or panel temperatures where normal vinyl cables will

rapidly deteriorate.

• Do not use cables under continuous regenerative state.

Wire Size and Allowable Current

The following table shows the wire size and allowable current for three cables. Use a cable whose specifications meet or are less than allowable current in the table.

• 600 V Heat-resistant Vinyl Cables (HIV)

AWG

Nominal Cross

Size

Section Diameter

20 0.5 19/0.18 39.5 6.6 5.6 4.5

- 0.75 30/0.18 26.0 8.8 7.0 5.5

18 0.9 37/0.18 24.4 9.0 7.7 6.0

16 1.25 50/0.18 15.6 12.0 11.0 8.5

14 2.0 7/0.6 9.53 23 20 16

Note: The values in the table are only for reference.

mm

2

Configuration

Number of

wires/mm

2

Conductive

Resistance

2

Ω/mm

Allowable Current at Ambient Temperature

30 ° C 40 ° C 50 ° C

−

60 ° C

75 ° C

A

Power Supply Input Terminals (L1, L2), Motor Connection Terminals (U, V, W),

and Regenerative Unit Connection Terminals (+, -)

CapacityWSERVOPACK Type Ter mi n a l S y m b ol

L1, L2 U, V, W +, -

100

200

400

750

Note: Connectors are used for all wiring.

SJDE-01APA-OY

SJDE-02APA-OY

SJDE-04APA-OY

SJDE-08APA-OY

HIV1.25 mm

HIV2.0 mm

2

2

HIV1.25mm

Wiring length:

20 m max.

2

HIV1.25mm

Wiring length:

0.5 m max.

Ground Terminal ( )

Wire Size Ter mi n a l S c r e w S i z e Tightening Torque

HIV 2.0 mm

2

min.

M4 1.2 to 1.4Nxm

28

2

Page 30

3.7 SERVOPACK Main Circuit Wire Size

Encoder signal connector

Item Specifications

Cable Use OYMC specified wires, or shielded twisted-pair wires.

Maximum cable length 20 m

Applicable wires

Finished cable outer

diameter

AWG22 (0.33 mm

Used AWG22 for the encoder power supply and AWG26 for signal lines.

φ9 mm max.

2

) and AWG26 (0.12 mm2)

I/O signal connector

Item Specifications

Cable Use twisted-pair wires or shielded twisted-pair wires.

Maximum cable length 3 m

Applicable wires

Finished cable outer

diameter

AWG24 (0.2 mm

φ8 mm max.

2

), AWG26 (0.12 mm2), AWG28 (0.08 mm2)

29

Page 31

3.8 Wiring the Power Supply/Regenerative Unit Connector (CNA)

G

3.8 Wiring the Power Supply/Regenerative Unit Connector (CNA)

WARNIN

• Observe the following precautions when wiring main circuit connector.

• Remove the connector from the SERVOPACK prior to wiring.

• Insert only one wire per terminal opening on the connector.

• Make sure that the core wire is not electrically shorted to adjacent core wires.

Use the following procedure when connecting the SERVOPACK to the power supply/regenerative unit

connector.

1. Remove the connector from the SERVOPACK.

Make sure to remove the connector from the SERVOPACK when wiring.

2. Strip the outer coating.

Straighten the wire core with your fingers to prevent the wires from unwinding.

9 to 10 mm

3. Open the wire terminal on the power supply connector housing (plug) with the tool (lever for wiring)

using the procedure shown in Fig. A or B.

• Insert the connection hook end of the provided tool into the slot as shown in Fig. A.

Tool must be purchased by the customer.

• Use a standard flat-blade screwdriver (blade width of 2.5 to 3.0 mm (0.09 to 0.12 in)). Put the blade

into the slot, as shown in Fig. B, and press down firmly to open the wire terminal.

Either the procedure shown in Fig. A or B can be used to open the wire insert opening.

fig A fig B

Tool Type: J-FAT-OT

(JST. Mfg Co., Ltd)

4. Insert the wire core into the opening and then close the opening by releasing the tool hook or removing the screwdriver.

Wire Size

Item Wire Size

Conductor

Size

Sheath Dimension

Braided wire

Single wire

AWG14 to AWG22

φ1.6mm to φ0.65mm

φ3.8mm to φ1.7mm

30

Page 32

3.8 Wiring the Power Supply/Regenerative Unit Connector (CNA)

c

5. Connect the connector to the SERVOPACK.

After wiring the connector, reconnect the connector to the SERVOPACK.

Power supply

Single-phase, 200 VAC

L2 L1

Molded-case circuit breaker

Noise filter

Magnetic contactor

AC reactor

CNA connector

Power supply/Regenerative Unit connector

JZSP-CHG9-1

(This connector is supplied with the servopa

Regenerative Unit

+(Y3)

—

Y4

Y5

C1

C2

FuseFuse

1

2

3

4

Note: 1. Pull lightly on the wires to confirm that they are securely connected.

2. Be sure that none of the insulating sheaths of the wires are caught in the springs.

Connector for Power Supply/Regenerative Unit (CNA)

Pin No. Symbol Signal Name

1L1

Power supply input terminals

2L2

3+

4 −

Regenerative unit connection terminals

31

Page 33

3.9 Wiring the Servomotor Main Circuit Cable Connector (CNB)

3.9 Wiring the Servomotor Main Circuit Cable Connector (CNB)

Wire the connector for the servomotor main circuit cable (CNB) in the same way as the connector for the

power supply/regenerative unit (CNA). Refer to the previous section for details and the procedure.

Controller

Separate by 300 mm or more

Power Supply

IMPORTANT

• The distance between the cable for the servomotor’s main circuit and the encoder as

well as the I/O cable is 300 mm or more.

• Do not bundle or run the servomotor main circuit cable in the same duct with other

cables.

• Be sure that the maximum wiring length of the servomotor main circuit cable is 20 m.

Servomotors without Brakes

Connector for servomotor

main circuit cable

04JFAT-SAYGF-N

(JST. Mfg. Co., Ltd)

Connector provided with

Servomotor main circuit cable

Green/Yellow

Motor

Note: Pin numbers are given on the connector as well. Confirm all pin numbers.

Red

White

Blue

Phase U

Phase V

Phase W

FG

Green/Yellow

Servomotor main circuit cable

(for relaying)

CNB connector

32

Page 34

3.9 Wiring the Servomotor Main Circuit Cable Connector (CNB)

Connection Diagram for Standard Servomotor Main Circuit Cable

If a user-prepared servomotor main circuit cable is used, refer to the following connection diagram for

the standard cable (JZSP-CHM000- Cable with Connectors on Both Ends) and wire the servomotor

main circuit cable.

Motor end

L

SERVOPACK end

50mm

Connector (crimp type)

Receptacle: 5557-06R-210

Terminal: 5556T (Chain) or

5556TL (Loose wires)

(Molex)

Servomotor Connector

(Viewed from cable insertion side)

456

123

Pin No.

1

2

3

4

5

6

Connect the FG pin to the grounding terminal of the SERVOPACK.

∗:

Phase U

Phase V

Phase W

FG

—

—

Lead ColorSignal Name

Green/Yellow

Servomotors with Brakes

Connector provided with

Servomotor main circuit cable

Red

White

Blue

Green/Yellow

Black

Black

Phase U

Phase V

Phase W

FG

Break

Break

Red

White

Blue

—

—

M4 crimped terminal

Connector (crimp type)

Receptacle: F32FSS-04V-KY

Rececontact: SF3F-01GF-P2.0 or SF3F-41GF-P2.0

(JST. Mfg. Co., Ltd.)

SERVOPACK Connector

(Viewed from soldered side)

14

1

2

3

4

Shielded cable

Crimped terminal

Connector for servomotor

main circuit cable

04JFAT-SAYGF-N

(JST. Mfg. Co., Ltd)

Phase U

Phase V

Phase W

—

∗

FG

Lead ColorSignal NamePin No.

Red

White

Blue

—

Green/Yellow

CNB connector

Varistor

Motor

Green/Yellow

Black

Black

Servomotor main circuit cable

(for relaying)

Note: 1. Prepare a double-insulated 24-VDC power supply.

2. Connect the varistor in parallel with the 24-V power supply terminal and GND terminal to suppress

the surge voltage resulting from the holding brake turned ON and OFF.

3. Pin numbers are given on the connector as well.

33

24 VDC

DC power

supply

Brake relay

Page 35

3.9 Wiring the Servomotor Main Circuit Cable Connector (CNB)

4. If using the servomotor to drive a vertical axis, provide a circuit to turn the holding brake ON so

that the movable section will not be pulled down by gravity when the power supply of the SERVOPACK is turned OFF.

Connection Diagram for Standard Servomotor Main Circuit Cable

If a user-prepared servomotor main circuit cable is used, refer to the following connection diagram for

the standard cable (JZSP-CHM030- Cable with Connectors on Both Ends) and wire the servomotor

main circuit cable.

Motor end

Connector (crimp type)

Receptacle: 5557-06R-210

Terminal: 5556T (Chain) or

5556TL (Loose wires)

(Molex)

Servomotor Connector

(Viewed from cable insertion side)

456

123

Phase U

Phase V

Phase W

FG

Brake

Brake

Lead ColorSignal Name

Red

White

Blue

Green/Yellow

Black

Black

Pin No.

1

2

3

4

5

6

Connect the FG pin to the grounding terminal of the SERVOPACK.

∗1:

2: No polarity for connection to the brake.

∗

L

M4 crimped terminal

Connector (crimp type)

Receptacle: F32FSS-04V-KY

Rececontact: SF3F-01GF-P2.0 or SF3F-41GF-P2.0

(JST. Mfg. Co., Ltd.)

Shielded cable

SERVOPACK end

50mm

SERVOPACK Connector

(Viewed from soldered side)

14

1

Phase U

2

Phase V

3

Phase W

FG

Brake

Brake

—

4

Crimped terminal

Crimped terminal

Crimped terminal

∗1

∗2

∗2

Lead ColorSignal NamePin No.

Red

White

Blue

—

Green/Yellow

Black

Black

34

Page 36

3.10 Wiring the Encoder Connector (CN2)

3.10 Wiring the Encoder Connector (CN2)

D

C

B

E

A

F

9

0

8

1

7

2

6

3

5

4

D

C

B

E

A

F

9

0

8

1

7

2

6

3

5

4

C

N

1

C

N

2

• Separate the encoder cable at least 300 mm from power lines (i.e., high-voltage lines such as the

NOTE

power supply line and servomotor main circuit cable).

• Do not bundle with or run the encode cable in the same duct as power lines.

• Be sure that the maximum wiring length of the encoder cable is 20 m.

Connection Diagram for Standard Encoder Cable

If a user-prepared encoder cable is used for relaying, refer to the following connection diagram for the

standard cable (JZSP-CHP800- Cable with Connectors on Both Ends) and wire the encoder cable.

SERVOPACK end

Separate by

300 mm or more

Power Supply

Motor end

Crimp type (Gray)

Plug and Cable Cover Set: 54599-1005

Plug Housing: 51209-1001

Crimp Terminals: 59351-8087(Chain) or

59351-8187 (Loose wires)

(Molex)

SERVOPACK Connector

(Viewed from soldered side)

97531

Pin No. Signal Name

PG5V

1

PG0V(GND)

2

Phase A (+)

3

Phase A (-)

4

Phase B (+)

5

Phase B (-)

6

Phase /Z

7

Phase U

8

Phase V

9

Phase W

10

Shell

—

Lead Color

Blue/White

Yellow/White

Orange

Solder type (Black)

Shell Kit: 36310-3200-008

Receptacle: 36210-0100FD (3M)

246810

Red

Black

Blue

Yellow

Purple

Gray

Green

Shield

Shield wire

Note: Pin numbers are given on the connector as well.

Servomotor Connector

(Viewed from cable insertion side)

12 11 10 8 79

654321

1

2

3

4

5

6

7

8

9

10

11

12

35

Receptacle: 5557-12R-210

Terminals: 5556T2 (Chain) or

5556T2L(Loose wires)

(Molex)

Lead ColorPin No. Signal Name

PG5V

PG0V(GND)

Phase A (+)

Phase A (-)

Blue/White

Phase B (+)

Phase B (-)

Yellow/White

Phase /Z

Phase U

Phase V

Phase W

—

Shield

Red

Black

Blue

Yellow

Purple

Gray

Green

Orange

—

Shield

Page 37

3.11 Wiring I/O Connectors

3.11 Wiring I/O Connectors

Controller

Separate by

300 mm or more

Power supply

Note: Do not apply excessive force when connecting or disconnecting the cable or the

connector. Damage to the cable or connectors may cause the product to stop

operating or malfunction.

• Separate the I/O cable at least 300 mm from power lines (i.e., high-voltage lines, such as the

NOTE

Connection Diagram for Standard I/O Cable (supplied by Yaskawa Electric Company

If a user-prepared I/O cable is used for relaying, refer to the following connection diagram for the

standard cable (JZSP-CHI003- Cable with Connector) and wire the encoder cable.

power supply line and servomotor main circuit cable).

• Be sure that the maximum wiring length of the I/O cable is 3 m.

• The longer the I/O cable is, the lower the maximum transmission frequency will be.

Host controller endSERVOPACK end

Plug (14P): 10114-6000EL

Shell Kit: 10314-52A0-008

3M

Pin

I/O Code Signal Name Lead

No.

1 Input CW, PULS Reverse pulse,

SERVOPACK Connector (Plug)

SERVOPACK Connector (Plug)

SERVOPACK Connector (Plug)

SERVOPACK Connector (Plug)

(Viewed from soldered side)

(Viewed from soldered side)

(Viewed from soldered side)

(Viewed from soldered side)

8 9 1011 131412

1

543276

2Input/CW, /PULS Red

3 Input CCW, SIGN Forward pulse,

4 Input /CCW, /SIGN Red

5 Input +24VIN External input power supply White Black

6 Input /S-ON Servo ON Red

7 Output SG-COM Output signal ground Yellow Black

8 Input CLR Position deviation Pulse

9 Input /CLR Pink Black

10 Output PCO Phase-C signal Red

11 Output SG-PCO Phase-C signal ground Orange 2 Black

12 Output ALM Servo alarm Red

13 Output /BK Brake Li ght

14 Output /COIN Positioning completion Red

Shell −− FG −−

Note: Pin numbers are given on the connector as well.

36

(φ5.6)

Reference pulse

Reference sign

clear

Color

Orange 1 Black

Light

gray

gray

Dot Mark

Number Color

Black

Red

Black

Page 38

3.11 Wiring I/O Connectors

Connection Diagram and Description for the General-purpose control cables (R7A-

CPZ@@@S) supplied by OMRON Company.

A General-purpose Control Cable connects to the Servo Driver's Control I/O Connector (CN1). There is

no connector on the controller end. Wire a connector to match the controller if you are connecting to a

Position Control Unit and a compatible cable is not available, or if the drive is connected to a controller

manufactured by another company.

Cable Models

Model Length (L) Outer Diameter of the

R7A-CPZ001S 1 m

R7A-CPZ002S 2m

cable

5,6 mm Approx. 0.1 kg

5,6 mm Approx. 0.2 kg

Weig ht

Connection Configuration and Dimensions

Controller end Servo Driver end

R7D-ZP@

Wiring

No. Wire Color/Mark Color Signal Name

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Connector plug: 10114-3000VE (Sumitomo 3M)

Connector case: 10314-52A0-008 (Sumitomo 3M)

Wires with the same wire color and the same number of marks are twisted pairs

Orange/Red (-) +CW/PULS

Orange/Black (-) -CW/PULS

Gray/Red (-) +CCW/SIGN

Gray/Black (-) -CCW/SIGN

White/Red (-) +24VIN

Yellow/Black (-) RUN

White/Black (-) OGND

Pink/Red (-) +ECRST

Pink/Black (-) -ECRST

Orange/Red (--) Z

Orange/Black (--) ZCOM

Gray/Red (--) /ALM

Gray/Black (--) BKIR

Yellow/Red (-) INP

37

Page 39

3.11 Wiring I/O Connectors

Connector Pin Arrangement

2

4

6

1

3

5

7

9

11

13

8

10

12

14

38

Page 40

3.12 Connection Examples of Input Signal

3.12 Connection Examples of Input Signal

Line Driver Output

Applicable line driver: SN75174 or MC3487 (Manufactured by Texas Instruments or equivalent)

24VDC Power Supply

+24V

Host Controller

0V

Twisted-pair wires∗

∗

+24VIN

/S-ON

PULS

/PULS

SIGN

/SIGN

/CLR

CLR

SERVOPACK

CN1

3.4kΩ

6

5

7mA

75Ω

1

75Ω

2

75Ω

3

75Ω

4

75Ω

8

75Ω

9

Photocoupler

Open-collector Output

Set the current limit resistors R1 through R3 so that the input current (i) will be within the following

range.

Input Current (i) = 7 mA to 15 mA

24VDC Power Supply

+24V

Host Controller

0V

Vcc

R1

Tr1

R2

Tr2

R3

Tr3

+24VIN

/S-ON

∗

i

PULS

/PULS

i

SIGN

/SIGN

i

CLR

/CLR

SERVOPACK

CN1

3.4kΩ

6

5

7mA

75Ω

1

75Ω

2

75Ω

3

75Ω

4

75Ω

8

75Ω

9

Photocoupler

Photocoupler

Examples:

When Vcc is +24V: R1 through R3=2.2 kΩ

When Vcc is +12V: R1 through R3=1 kΩ

When Vcc is +5V: R1 through R3=180 Ω

Note: The following signal logic applies for an

open-collector output.

Tr1 to Tr3 ON Equivalent to high level input.

Equivalent to low level input.Tr1 to Tr3 OFF

Twisted-pair wires∗

39

Page 41

3.13 Connection Example of Output Signal

3.13 Connection Example of Output Signal

Set the load so that the output current (i) will fall within 50 mA or less.

Photocoupler output (Per output signal)

Max. voltage: 30VDC

Max. current: 50m ADC

SERVOPACK

Photocoupler

50mA max.

CN1

10

11

12

14

13

7

PCO

SG-PCO

ALM

/COIN

BK

SG-COM

24VDC Power Supply

+24V 0V

Load

Load

Load

Load

40

Page 42

3.14 EMG Sequence

3.14 EMG Sequence

WARNING

• Make the emergency stop circuit to turn OFF the Servo ON signal as well as the main circuit

power supply when the EMG (emergency stop) signal turns ON.

The residual voltage rotates the servomotor for a few seconds after the power supply has turned

OFF, which may result in injury or damage to the equipment.

IMPORTANT

• Use the power ON/OFF signals or the servo ON/OFF signals only when necessary to

turn the servomotor’s power supply ON or OFF.

Failure to observe this caution may result in unpredictable performance of the servomotor.

Power supply

Single-phase 200VAC to 230VAC

50/60Hz

L2

L1

Noise filter

DC24V

MC1

Power ONPower

OFF

MC1

MC1

Servo ON

EMG

CNA

MC1

SUP

SERVOPACK

1

2

CN1

+24VIN

/S-ON

41

Page 43

3.15 Explanation of I/O Signals

A

3.15 Explanation of I/O Signals

Pulse train references are given to control the position of the servomotor. The following pulse train forms

from the host controller are supported.

• Line driver output

• +24-V open-collector output

• +12-V open-collector output

• +5-V open-collector output

I/O Signal Timing Examples

Servo ON (/S-ON)

Motor ON

Brake (/BK)

Sign + pulse train

Positioning completed (/COIN)

(SIGN)

(PULS)

Clear (CLR)

t3

t1

ON

Motor ON

Brake released

H

H

ON

t1: Approx. 40 ms

ON

t2: Approx. 130 ms

t3 ≥ 40 ms

(Motor with brake: 100 ms)

*

t4

≥ 20 μs

t2

L

t4

3

*

1

*

2

* 1. The interval from when the servo ON signal is turned ON until the reference pulse is input must be at

least 40 ms, or the reference pulse may not be received by the SERVOPACK. If a motor with a brake is

in used, more time will be required to release the brake. Therefore, provide an interval of at least 100

ms.

* 2. The error counter clear signal must be ON for at least 20 μs. If the reference pulse is stopped when the

clear signal is turned ON, the motor will stop at that position.

* 3. The lag time for the brake is 100 ms. Use a relay for brakes with an operating time of 30 ms or less.

Note: 1. The maximum lag time from the time that the error or fault is detected until the time that the alarm

signal is turned ON is 2 ms.

larm detection

ALM

2ms max.

2. If using the phase-C output signal, use an edge when the signal changes from OFF to ON at the

start, so that the wave form will rise after a set time lag.

PCO

42

Page 44

3.15 Explanation of I/O Signals

Reference Pulse Signal Form Electrical Specifications Remarks

Sign + pulse train input

(SIGN + PULS signal)

Maximum reference frequency:

750 kpps (187.5 kpps for an

open-collector output)

CW pulse + CCW pulse

Maximum reference frequency:

750 kpps (187.5 kpps for an

open-collector output)

SIGN

PULS

CCW

CW

t1

T

Forward reference

T

Forward reference

t2 t3

Reverse reference

t1

Reverse reference

t1, t2, t3 >

0.65μs

τ ≥

(

)

×

100 ≤ 50%

τ/T

μs

t1 > 3

τ ≥

0.65μs

(

)

×

100 ≤ 50%

τ/T

3μs

Sign (SIGN):

High = Forward

reference

Low = Reverse

reference

43

Page 45

4 Trial Operation

Use the following procedure to perform trial operation.

Step Details

1. Installation • Install the SERVOPACK and servomotor under the installation conditions.

Do not connect the servomotor shaft to the machine.

2. Wiring and PULSE Settings • Wire the power supply connector, servomotor main circuit cable,

Select the

PULSE setting

with the rotary

switch.

Screwdriver

3. LED Check • Turn ON the power and confirm that the REF indicator is lit orange

Check that the

color of the REF

indicator changes

to orange or green.

4. PULSE Reference Input 1 • Input the reference pulse from the controller, and then check on

Controller

Reference pulse

encoder cable, and the I/O signal cable correctly following the procedures in Section 3.

• If a servomotor with a brake is used, connect all signal cables

including those for the brake power supply and the relay.

• Use the PULSE rotary switch to select the type of controller’s output pulse and set the resolution of the servomotor.

Note: Use the screwdriver to change the set-

ting on the rotary switch. Never use

the screwdriver for any purpose other

than setting the rotary switch.

or green. If the indicator is orange, turn ON the servo ON (S-ON)

input signal and check that the color of the REF indicator changes

from orange to green.

• If the REF indicator is not orange or green, or the indicator of the

AL1, AL2 or AL3 alarm is red, refer to Section 5 Troubleshooting

and clear the alarm.

the number of the pulses and servomotor’s rotational direction.

Make sure the servomotor rotates in the correct direction while the

REF indicator is blinking green.

• If the servomotor does not rotate according to the reference, refer

to Section 5 Troubleshooting and clear the alarm.

5. Servomotor Shaft Coupling • Set the servomotor to servo OFF (servomotor OFF) status to turn

OFF the power. Couple the servomotor shaft to the machine under

the conditions outlined in the servomotor instructions.

44

Page 46