Page 1

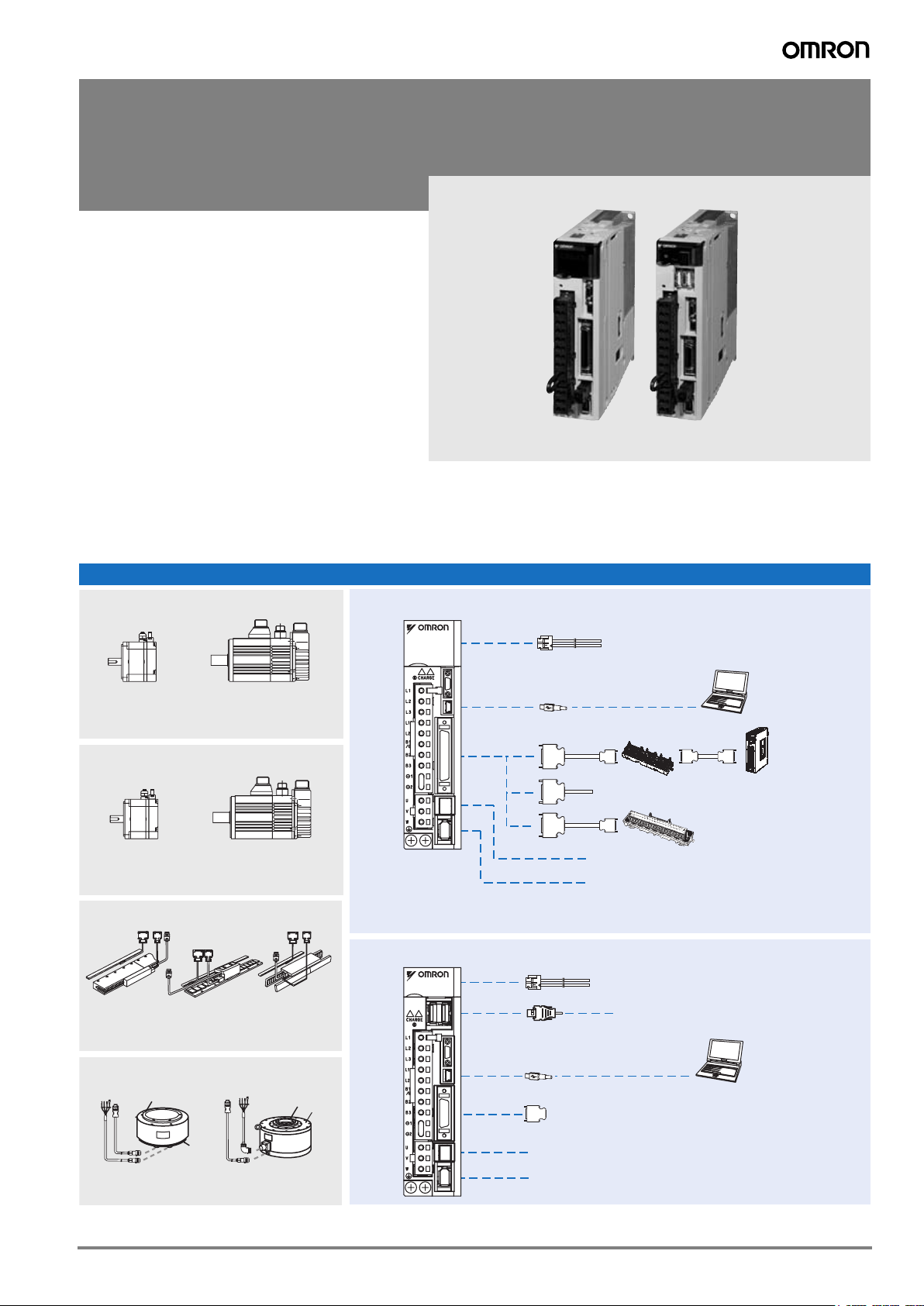

SGDV-@

Sigma-5 servo drive

The High perfomance servo family for motion

control. Compact size, reduced space and

integrated MECHATROLINK-II.

• Advance autotuning function

• Enhanced vibration supression function

• Standard support for analog voltage/pulse train reference series or MECHATROLINK-II communications reference series.

• Support for direct drive servomotors, linear servomotors and linear sliders

• Integrated safety stop function

• Oscilloscope available via software tool

• Windows based configuration and commissioning

software

Ratings

• 230 VAC Single-phase 50 W to 1.5 kW (4.77 Nm)

• 400 VAC Three-phase 500 W to 15 kW (95.4 Nm)

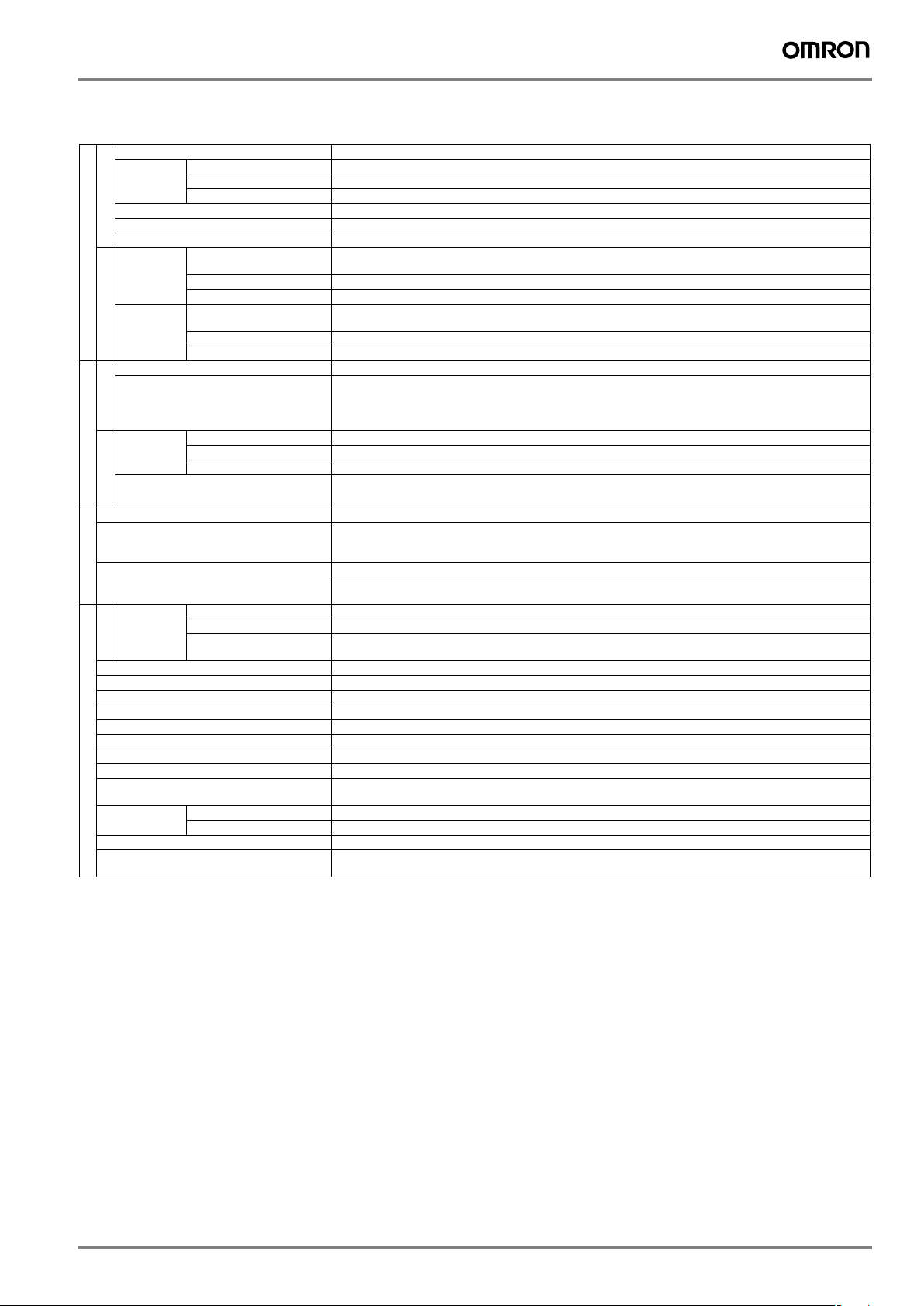

System configuration

(Refer to chapter Sigma-II rotary motors)

SGMAH, SGMPH

Servo Motor

(Refer to chapter Sigma-5 rotary motors)

SGMJV, SGMAV, SGMEV

Servo Motor

(Refer to chapter Sigma linear motors)

SGLG_ linear

Servo Motor

(Refer to chapter Sigma direct drive motors)

SGMGH, SGMUH, SGMSH,

SGMBH Servo Motor

SGMGV, SGMSV

Servo Motor

SGLF_ linear

Servo Motor

SGLT_ linear

Servo Motor

Sigma-5 Analog/Pulse Reference Servo Drive

CN5

CN7

CN1

CN8

CN2

Sigma-5 MECHATROLINK-II Servo Drive

CN5

CN6

CN7

Analog monitor cable

USB cable

General purpose cable

Terminal block

position control

Safety cable

Battery case for absolute encoder

Analog monitor cable

MECHATROLINK-II network

USB cable

Unit

Personal

computer

Position control unit

Personal

computer

Direct drive servo motor

SGMCS-@-@B, C, D, E

Direct drive servo motor

SGMCS-@-@M, N

CN1

CN8

CN2

General purpose connector

Safety cable

Battery case for absolute encoder

1Sigma-5 servo drive

Page 2

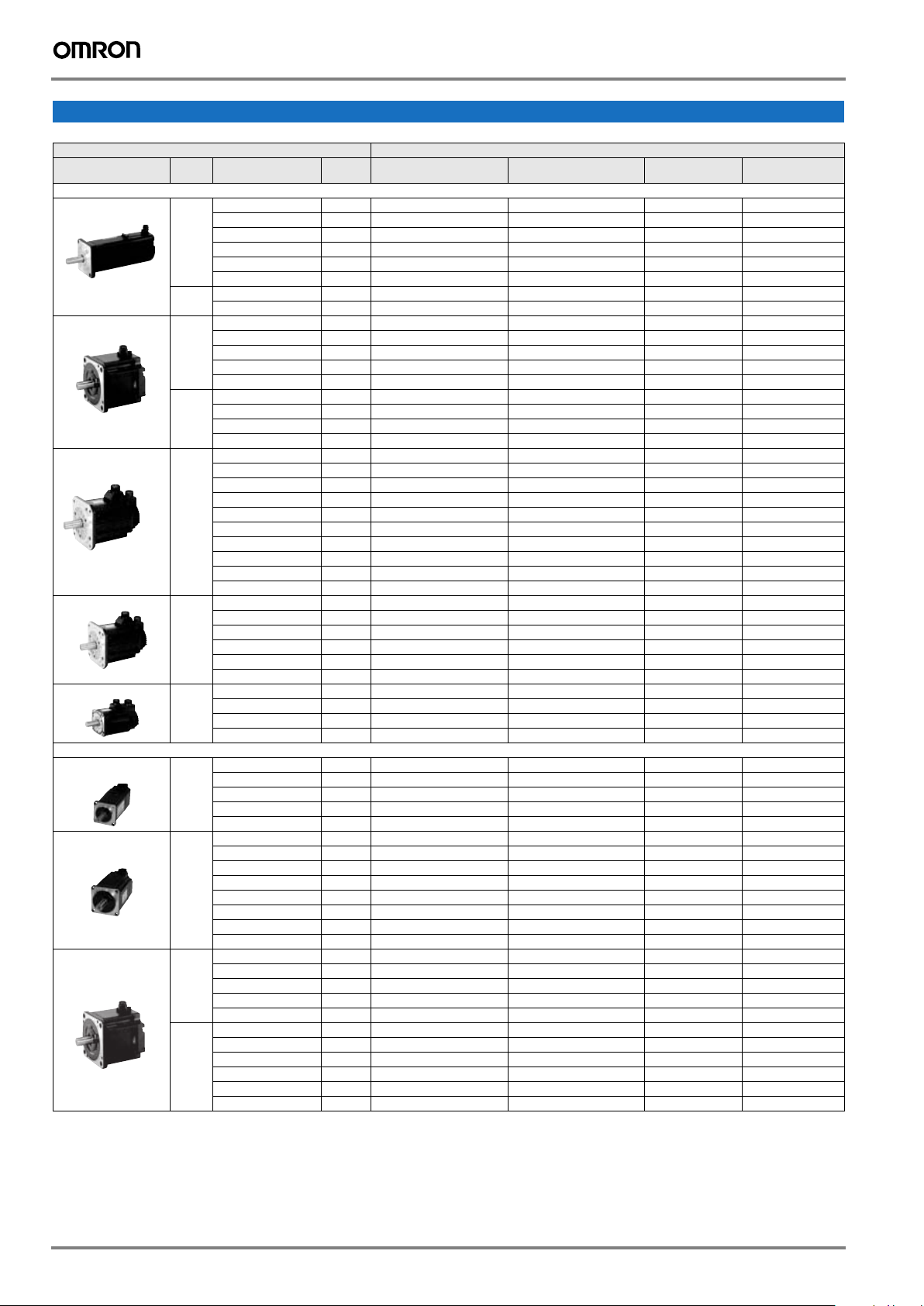

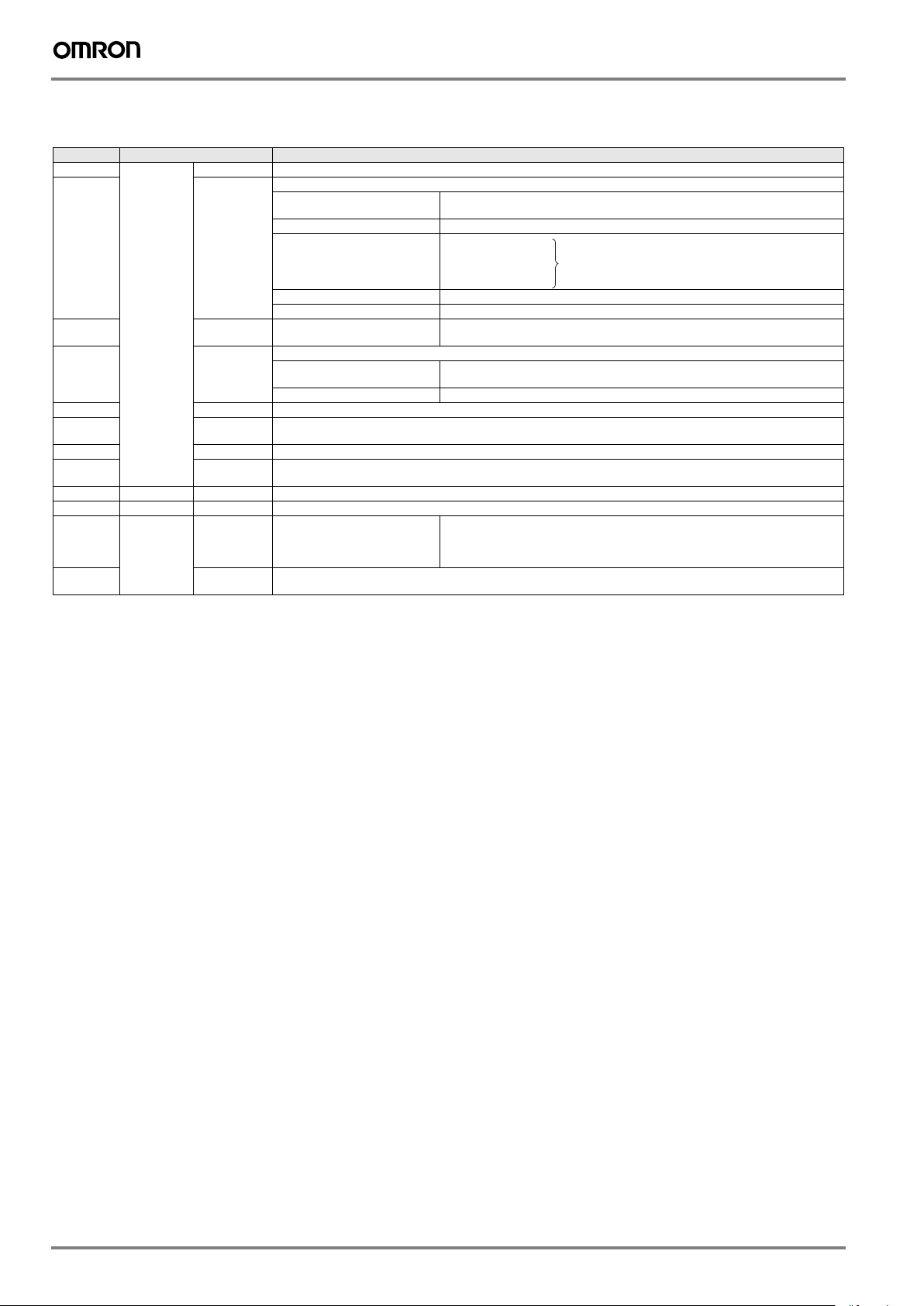

Servo motor / servo drive combination

Family Voltage Rated torque Capacity 230 V (1 phase)

Sigma-II series motors (refer to the Sigma-II rotary motors chapter for details)

SGMAH (3000 min

-1

) 230 V 0.0955 Nm 30 W SGDV-A5A01A-OY SGDV-A5A11A-OY - -

Analog/Pulse

0.159 Nm 50 W SGDV-A5A01A-OY SGDV-A5A11A-OY - -

0.318 Nm 100 W SGDV-01A01A-OY SGDV-01A11A-OY - -

0.637 Nm 200 W SGDV-02A01A-OY SGDV-02A11A-OY - -

1.27 Nm 400 W SGDV-04A01A-OY SGDV-04A11A-OY - -

2.39 Nm 750 W SGDV-08A01A-OY SGDV-08A11A-OY - -

400 V 0.955 Nm 300 W - - SGDV-05D01A-OY SGDV-05D11A-OY

Servo motor Sigma-5 Servo drive

SGMPH (3000 min

-1

)230 V 0.318 Nm 100 W SGDV-01A01A-OY SGDV-01A11A-OY - -

2.07 Nm 650 W - - SGDV-10D01A-OY SGDV-10D11A-OY

0.637 Nm 200 W SGDV-02A01A-OY SGDV-02A11A-OY - -

1.27 Nm 400 W SGDV-04A01A-OY SGDV-04A11A-OY - -

2.39 Nm 750 W SGDV-08A01A-OY SGDV-08A11A-OY - -

4.77 Nm 1500 W SGDV-15A01A-OY-008000 SGDV-15A11A-OY-008000 - -

400 V 0.637 Nm 200 W - - SGDV-05D01A-OY SGDV-05D11A-OY

1.27 Nm 400 W - - SGDV-05D01A-OY SGDV-05D11A-OY

2.39 Nm 750 W - - SGDV-10D01A-OY SGDV-10D11A-OY

SGMGH (1500 min

-1

)400 V 2.84 Nm 0.45 kW - - SGDV-05D01A-OY SGDV-05D11A-OY

4.77 Nm 1500 W - - SGDV-15D01A-OY SGDV-15D11A-OY

5.39 Nm 0.85 kW - - SGDV-10D01A-OY SGDV-10D11A-OY

8.34 Nm 1.3 kW - - SGDV-15D01A-OY SGDV-15D11A-OY

11.5 Nm 1.8 kW - - SGDV-20D01A-OY SGDV-20D11A-OY

18.6 Nm 2.9 kW - - SGDV-30D01A-OY SGDV-30D11A-OY

28.4 Nm 4.4 kW - - SGDV-50D01A-OY SGDV-50D11A-OY

35.0 Nm 5.5 kW - - SGDV-210D01A SGDV-210D11A

48.0 Nm 7.5 kW - - SGDV-260D01A SGDV-260D11A

70.0 Nm 11 kW - - SGDV-280D01A SGDV-280D11A

SGMSH (3000 min

-1

) 400 V 3.18 Nm 1.0 kW - - SGDV-10D01A-OY SGDV-10D11A-OY

95.4 Nm 15 kW - - SGDV-370D01A SGDV-370D11A

4.90 Nm 1.5 kW - - SGDV-15D01A-OY SGDV-15D11A-OY

6.36 Nm 2.0 kW - - SGDV-20D01A-OY SGDV-20D11A-OY

9.80 Nm 3.0 kW - - SGDV-30D01A-OY SGDV-30D11A-OY

12.6 Nm 4.0 kW - - SGDV-50D01A-OY SGDV-50D11A-OY

SGMUH (6000 min

-1

) 400 V 1.59 Nm 1.0 kW - - SGDV-10D01A-OY SGDV-10D11A-OY

15.8 Nm 5.0 kW - - SGDV-50D01A-OY SGDV-50D11A-OY

2.45 Nm 1.5 kW - - SGDV-15D01A-OY SGDV-15D11A-OY

4.9 Nm 3.0 kW - - SGDV-30D01A-OY SGDV-30D11A-OY

6.3 Nm 4.0 kW - - SGDV-50D01A-OY SGDV-50D11A-OY

Sigma-5 series motors (refer to the Sigma-5 rotary motors chapter for details)

SGMJV (3000 min

-1

) 230 V 0.159 Nm 50 W SGDV-A5A01A-OY SGDV-A5A11A-OY - -

0.318 Nm 100 W SGDV-01A01A-OY SGDV-01A11A-OY - -

0.637 Nm 200 W SGDV-02A01A-OY SGDV-02A11A-OY - -

1.27 Nm 400 W SGDV-04A01A-OY SGDV-04A11A-OY - -

SGMAV (3000 min

-1

) 230 V 0.159 Nm 50 W SGDV-A5A01A-OY SGDV-A5A11A-OY - -

2.39 Nm 750 W SGDV-08A01A-OY SGDV-08A11A-OY - -

0.318 Nm 100 W SGDV-01A01A-OY SGDV-01A11A-OY - -

0.477 Nm 150 W SGDV-02A01A-OY SGDV-02A11A-OY - -

0.637 Nm 200 W SGDV-02A01A-OY SGDV-02A11A-OY - -

1.27 Nm 400 W SGDV-04A01A-OY SGDV-04A11A-OY - -

1.75 Nm 550 W SGDV-08A01A-OY SGDV-08A11A-OY - -

2.39 Nm 750 W SGDV-08A01A-OY SGDV-08A11A-OY - -

SGMEV (3000 min

-1

)230 V 0.318 Nm 100 W SGDV-01A01A-OY SGDV-01A11A-OY - -

3.18 Nm 1.0 kW SGDV-15A01A-OY-008000 SGDV-15A11A-OY-008000 - -

0.637 Nm 200 W SGDV-02A01A-OY SGDV-02A11A-OY - -

1.27 Nm 400 W SGDV-04A01A-OY SGDV-04A11A-OY - -

2.39 Nm 750 W SGDV-08A01A-OY SGDV-08A11A-OY - -

4.77 Nm 1.5 kW SGDV-15A01A-OY-008000 SGDV-15A11A-OY-008000 - -

400 V 0.637 Nm 200 W - - SGDV-05D01A-OY SGDV-05D11A-OY

0.955 Nm 300 W - - SGDV-05D01A-OY SGDV-05D11A-OY

1.27 Nm 400 W - - SGDV-05D01A-OY SGDV-05D11A-OY

2.07 Nm 650 W - - SGDV-10D01A-OY SGDV-10D11A-OY

2.39 Nm 750 W - - SGDV-10D01A-OY SGDV-10D11A-OY

4.77 Nm 1.5 kW - - SGDV-15D01A-OY SGDV-15D11A-OY

230 V (1 phase)

MECHATROLINK-II

400 V (3 phase)

Analog/Pulse

400 V (3 phases)

MECHATROLINK-II

2 AC servo systems

Page 3

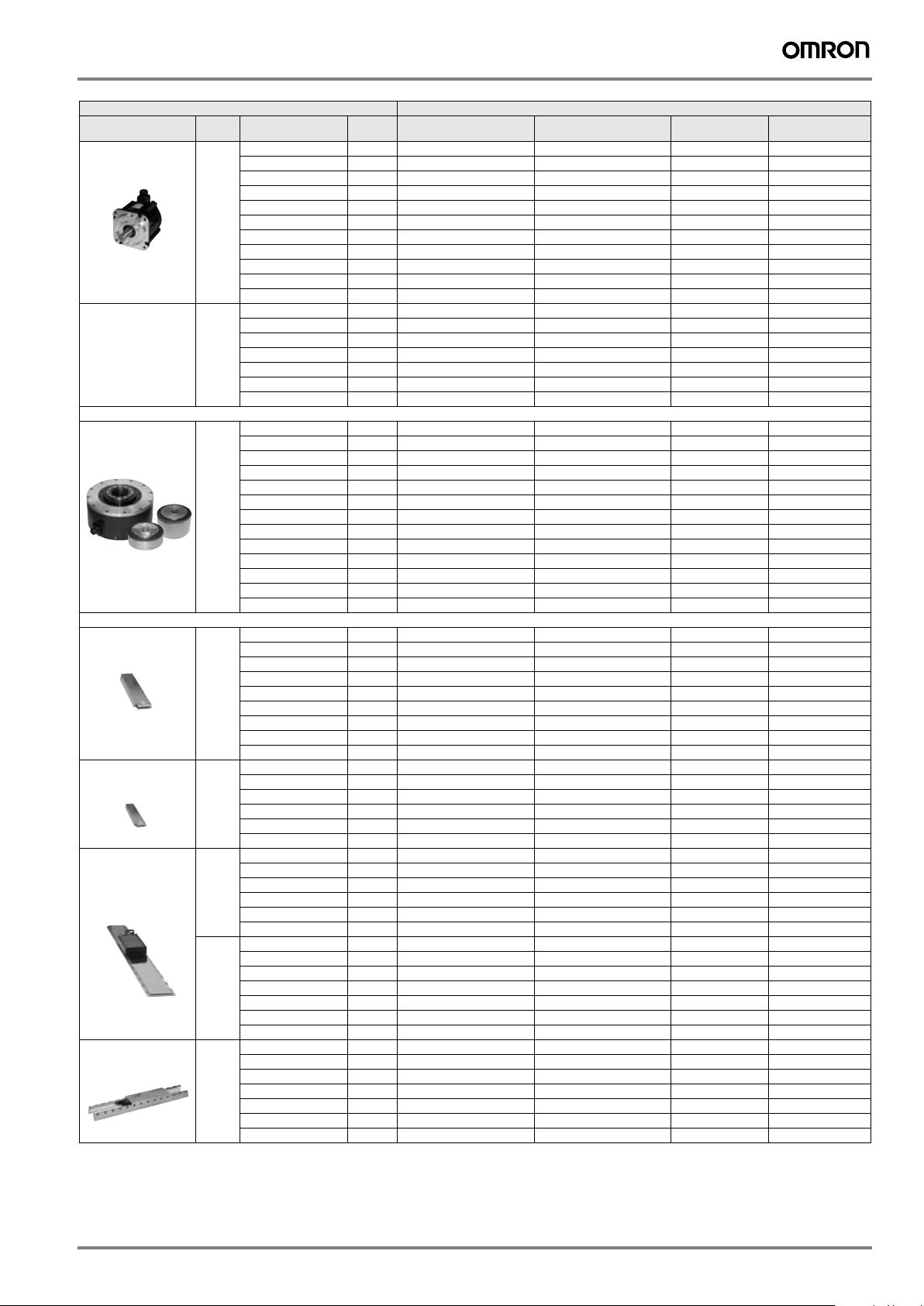

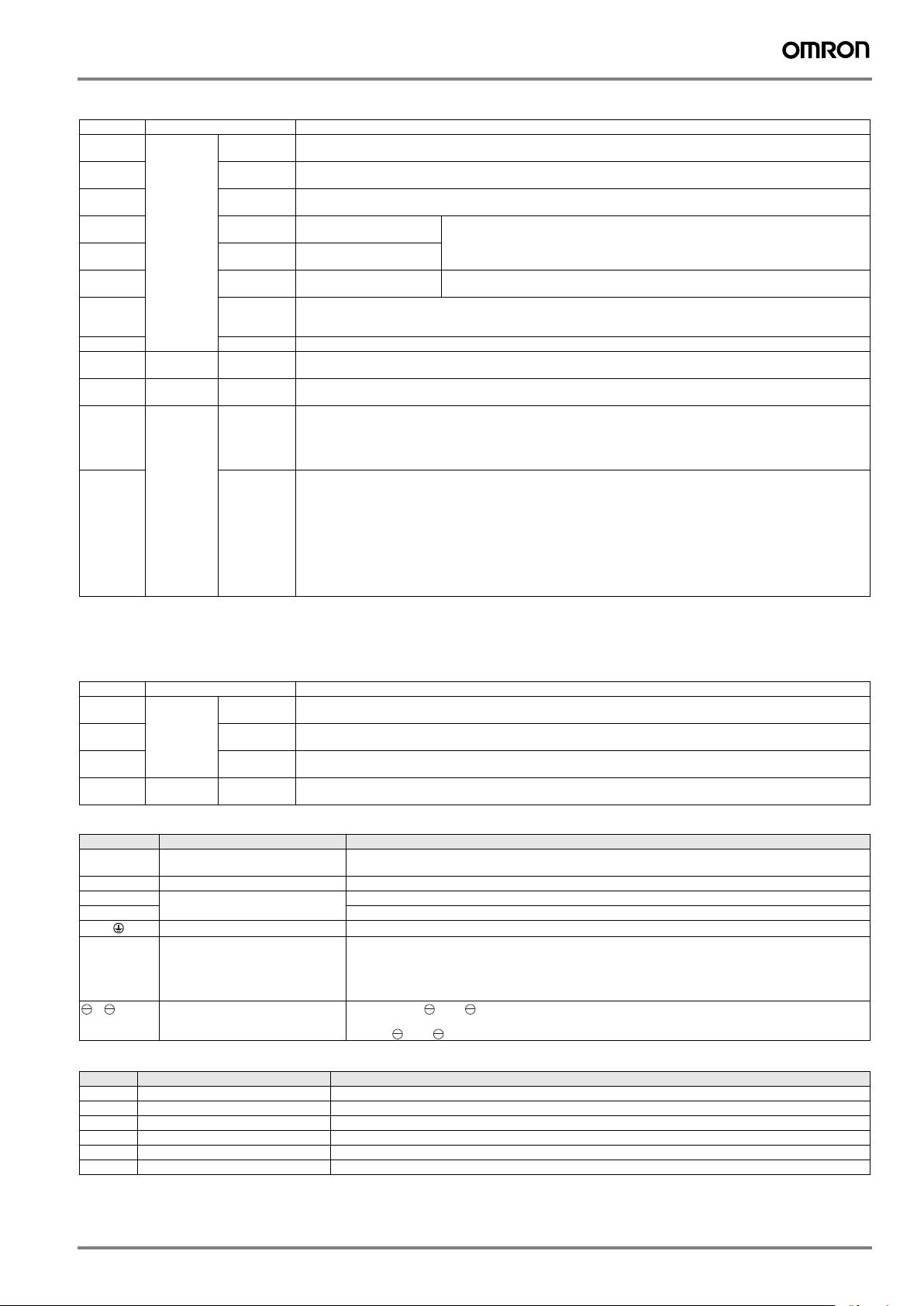

Family Voltage Rated torque Capacity 230 V (1 phase)

Analog/Pulse

230 V (1 phase)

MECHATROLINK-II

400 V (3 phase)

Analog/Pulse

400 V (3 phases)

MECHATROLINK-II

SGMGV (1500 min-1) 400 V 1.96 Nm 300 W - - SGDV-05D01A-OY SGDV-05D11A-OY

2.86 Nm 450 W - - SGDV-05D01A-OY SGDV-05D11A-OY

5.39 Nm 850 W - - SGDV-10D01A-OY SGDV-10D11A-OY

8.34 Nm 1.3 kW - - SGDV-15D01A-OY SGDV-15D11A-OY

11.5 Nm 1.8 kW - - SGDV-20D01A-OY SGDV-20D11A-OY

18.6 Nm 2.9 kW - - SGDV-30D01A-OY SGDV-30D11A-OY

28.4 Nm 4.4 kW - - SGDV-50D01A-OY SGDV-50D11A-OY

35.0 Nm 5.5 Kw - - SGDV-210D01A SGDV-210D11A

48.0 Nm 7.5 Kw - - SGDV-260D01A SGDV-260D11A

70.0 Nm 11 Kw - - SGDV-280D01A SGDV-280D11A

Servo motor Sigma-5 Servo drive

SGMSV (3000 min

-1

) 400 V 3.18 Nm 1 kW - - SGDV-10D01A-OY SGDV-10D11A-OY

95.4 Nm 15 Kw - - SGDV-370D01A SGDV-370D11A

4.9 Nm 1.5 kW - - SGDV-15D01A-OY SGDV-15D11A-OY

6.36 Nm 2 kW - - SGDV-20D01A-OY SGDV-20D11A-OY

7.96 Nm 2.5 kW - - SGDV-30D01A-OY SGDV-30D11A-OY

9.8 Nm 3 kW - - SGDV-30D01A-OY SGDV-30D11A-OY

12.6 Nm 4 kW - - SGDV-50D01A-OY SGDV-50D11A-OY

15.8 Nm 5 kW - - SGDV-50D01A-OY SGDV-50D11A-OY

Sigma direct drive motors (refer to the Sigma direct drive motors chapter for details)

SGMCS (200 min

-1

) 230 V 2.0 Nm 42 W SGDV-04A01A-OY SGDV-04A11A-OY - -

5.0 Nm 105 W SGDV-04A01A-OY SGDV-04A11A-OY - -

7.0 Nm 147 W SGDV-02A01A-OY SGDV-02A11A-OY - -

4.0 Nm 84 W SGDV-04A01A-OY SGDV-04A11A-OY - -

10.0 Nm 209 W SGDV-04A01A-OY SGDV-04A11A-OY - -

14.0 Nm 293 W SGDV-04A01A-OY SGDV-04A11A-OY - -

8.0 Nm 168 W SGDV-04A01A-OY SGDV-04A11A-OY - -

17.0 Nm 356 W SGDV-04A01A-OY SGDV-04A11A-OY - -

25.0 Nm 393 W SGDV-04A01A-OY SGDV-04A11A-OY - -

16.0 Nm 335 W SGDV-08A01A-OY SGDV-08A11A-OY - -

35.0 Nm 550 W SGDV-08A01A-OY SGDV-08A11A-OY - -

45.0 Nm 707 W SGDV-15A01A-OY-008000 SGDV-15A11A-OY-008000 - -

80.0 Nm 1260 W SGDV-15A01A-OY-008000 SGDV-15A11A-OY-008000 - -

Sigma linear motors (refer to the Sigma linear motors chapter for details)

SGLGW coreless

standard-force

magnetic ways

230 V 12.5 N (40 N peak) - SGDV-A5A05A-OY SGDV-A5A15A-OY - -

25 N (80 N peak) - SGDV-01A05A-OY SGDV-01A15A-OY - 47 N (140 N peak) - SGDV-01A05A-OY SGDV-01A15A-OY - 70 N (220 N peak) - SGDV-02A05A-OY SGDV-02A15A-OY - 93 N (280 N peak) - SGDV-02A05A-OY SGDV-02A15A-OY - -

140 N (420 N peak) - SGDV-04A05A-OY SGDV-04A15A-OY - 140 N (440 N peak) - SGDV-04A05A-OY SGDV-04A15A-OY - 210 N (660 N peak) - SGDV-08A05A-OY SGDV-08A15A-OY - -

325 N (1300 N peak) - SGDV-15A05A-OY-008000 SGDV-15A15A-OY-008000 - -

SGLGW coreless

high-force

magnetic ways

230 V 57 N (230 N peak) - SGDV-02A05A-OY SGDV-02A15A-OY - -

114 N (460 N peak) - SGDV-02A05A-OY SGDV-02A15A-OY - 171 N (690 N peak) - SGDV-08A05A-OY SGDV-08A15A-OY - -

85 N (360 N peak) - SGDV-02A05A-OY SGDV-02A15A-OY - -

170 N (720 N peak) - SGDV-08A05A-OY SGDV-08A15A-OY - -

255 N (1080 N peak) - SGDV-08A05A-OY SGDV-08A15A-OY - -

SGLFW

Linear motors

230 V 25 N (86 N peak) - SGDV-02A05A-OY SGDV-02A15A-OY - -

40 N (125 N peak) - SGDV-01A05A-OY SGDV-01A15A-OY - 80 N (220 N peak) - SGDV-02A05A-OY SGDV-02A15A-OY - -

160 N (440 N peak) - SGDV-04A05A-OY SGDV-04A15A-OY - 280 N (600 N peak) - SGDV-08A05A-OY SGDV-08A15A-OY - -

560 N (1200 N peak) - SGDV-15A05A-OY-008000 SGDV-15A15A-OY-008000 - -

400 V 80 N (220 N peak) - - - SGDV-05D05A-OY SGDV-05D15A-OY

160 N (440 N peak) - - - SGDV-05D05A-OY SGDV-05D15A-OY

280 N (600 N peak) - - - SGDV-10D05A-OY SGDV-10D15A-OY

560 N (1200 N peak) - - - SGDV-15D05A-OY SGDV-15D15A-OY

1120 N (2400 N peak) - - - SGDV-30D05A-OY SGDV-30D15A-OY

1500 N (3600 N peak) - - - SGDV-20D05A-OY SGDV-20D15A-OY

2250 N (5400 N peak) - - - SGDV-30D05A-OY SGDV-30D15A-OY

SGLTW

Linear motors

400 V 300 N (600 N peak) - - - SGDV-10D05A-OY SGDV-10D15A-OY

600 N (1200 N peak) - - - SGDV-20D05A-OY SGDV-20D15A-OY

450 N (900 N peak) - - - SGDV-10D05A-OY SGDV-10D15A-OY

900 N (1800 N peak) - - - SGDV-20D05A-OY SGDV-20D15A-OY

670 N (2600 N peak) - - - SGDV-30D05A-OY SGDV-30D15A-OY

1000 N (4000 N peak) - - - SGDV-50D05A-OY SGDV-50D15A-OY

1300 N (5000 N peak) - - - SGDV-50D05A-OY SGDV-50D15A-OY

Sigma-5 servo drive 3

Page 4

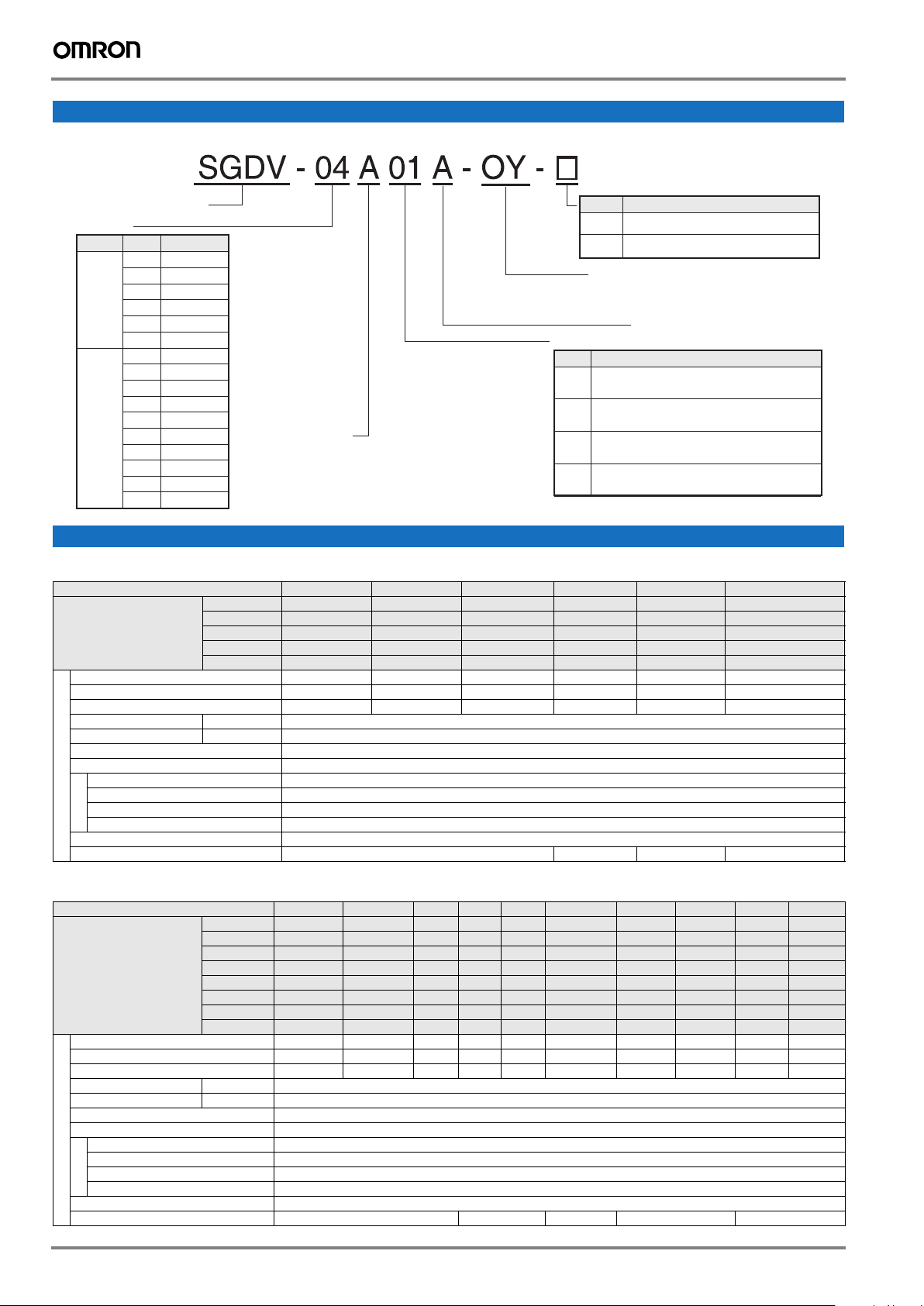

Type designation

Servo drive

Sigma-5 servo drive

Capacity

A5

01

02

04

08

15

05

10

15

20

30

50

210

260

280

370

Output

50 W

100 W

200 W

400 W

750 W

1.5 kW

500 W

1.0 kW

1.5 kW

2.0 kW

3.0 kW

5.0 kW

6.0 kW

7.5 kW

11 kW

15 kW

Voltage Code

230 V

400 V

Source voltage

A: 230 V

D: 400 V

Code

Blank

008000

Servo drive 1.5 kW single-phase 230 V

Omron-Yaskawa Motion Control B.V.

(Note: all models except 6 to 15 kW)

Interface

Code

Analog voltage/pulse train reference type

01

Analog voltage/pulse train reference type

05

MECHATROLINK-II comms reference type

11

MECHATROLINK-II comms reference type

15

Specifications

Standard

Design Revision Order: A, B...

Specifications

(for rotary servomotors)

(for linear servomotors)

(for rotary servomotors)

(for linear servomotors)

Servo drive specifications

Single-phase, 230 V

Servo drive type SGDV- @ A5A@@A-OY 01A@@A-OY 02A@@A-OY 04A@@A-OY 08A@@A-OY 15A@@A-OY-008000

Applicable

servo motor

Max. applicable motor capacity W 50 100 200 400 750 1500

Continuous output current Arms 0.66 0.91 1.6 2.8 5.5 11.6

Max. output current Arms 2.1 2.9 6.5 9.3 16.9 28

Input power Main circuit Single-phase, 200 to 230 VAC + 10 to -15% (50/60 Hz)

Supply Control circuit Single-phase, 200 to 230 VAC + 10 to -15% (50/60 Hz)

Control method Single phase full-wave rectification / IGBT / PWM / sine-wave current drive method

Feedback Serial encoder (incremental/absolute)

Usage/storage temperature 0 to +55 °C / -20 to 85 °C

Usage/storage humidity 90%RH or less (non-condensing)

Basic specifications

Altitude 1000m or less above sea level

Vibration/shock resistance 4.9 m/s

Conditions

Configuration Base mounted

Approx. weight Kg 0.9 1.0 1.5 2.8

SGMAH-@ A3A@/A5A@ 01A@ 02A@ 04A@ 08A@ -

SGMPH-@ - 01A@ 02A@ 04A@ 08A@ 15A@

SGMJV-@ A5A@ 01A@ 02A@ 04A@ 08A@ -

SGMAV-@ A5A@ 01A@ C2A@/02A@ 04A@ 06A@/08A@ 10A@

SGMEV-@ - 01A@ 02A@ 04A@ 08A@ 15A@

2

/ 19.6 m/s

2

Three-phase, 400 V

Servo drive type SGDV-@ 05D@ 10D@ 15D@ 20D@ 30D@ 50D@ 210D@ 260D@ 280D@ 370D@

Applicable

servo motor

Max. applicable motor capacity kW 0.5 1.0 1.5 2.0 3.0 5.0 6.0 7.5 11 15

Continuous output current Arms 1.9 3.5 5.4 8.4 11.9 16.5 20.8 25.4 28.1 37.2

Max. output current Arms 5.5 8.5 14 20 28 42 55 65 70 85

Input power Main circuit Three-phase, 380 to 480 VAC + 10 to -15% (50/60Hz)

Supply Control circuit 24 VDC +/-15%

Control method Three phase full-wave rectification / IGBT / PWM / sine-wave current drive method

Feedback Serial encoder (incremental/absolute)

Usage/storage temperature 0 to +55 °C / -20 to +85 °C

Usage/storage humidity 90%RH or less (non-condensing)

Basic specifications

Altitude 1000 m or less above sea level

Vibration/shock resistance 4.9 m/s

Conditions

Configuration Base mounted

Ap prox. weigh t Kg 2.7 3. 7 5. 6 11. 3 16 .2

SGMAH-@ 03D@ 07D@ - - - - - - - -

SGMPH-@ 02D@/04D@ 08D@ 15D@ - - - - - - -

SGMGH-@ 05D@ 09D@ 13D@ 20D@ 30D@ 44D@ 55D@ 75D@ 1AD@ 1ED@

SGMSH-@ - 10D@ 15D@ 20D@ 30D@ 40D@/50D@ - - - -

SGMUH-@ - 10D@ 15D@ - 30D@ 40D@ - - - -

SGMEV-@ 02/03/04D@ 07D@/08D@ 15D@ - - - - - - -

SGMGV-@ 03D@/05D@ 09D@ 13D@ 20D@ 30D@ 44D@ 55D@ 75D@ 1AD@ 1ED@

SGMSV-@ - 10D@ 15D@ 20D@ 25D@ 40D@/50D@ - - - -

2

/ 19.6 m/s

2

4 AC servo systems

Page 5

Sigma-5 Analog/Pulse Reference Servo Drive

General specifications

Speed control range 1:5000

Speed

variance

Frequency characteristics 1.6 kHz

Torque control accuracy (Repeatability) ±1%

Performance

Soft start time setting 0 to 10 s (acceleration, deceleration can each be set.)

Speed

reference

input

Torque

Speed/torque control mode

reference

Input signal

input

Feedforward compensation 0 to 100% (setting resolution: 1%)

Position completed width setting 0 to 1073741824 command units (setting resolution: 1 command unit)

Load variance During 0 to 100% load ±0.01% max. (at rated speed)

Voltage variance Rated voltage ±10%:0% (at rated speed)

Temperature variance 25 ±25 °C: ±0.1 % max. (at rated speed)

Reference voltage ±6 VDC (forward motor rotation if positive reference) at rated speed: Set at delivery

Input impedance Approx. 14 kΩ

Circuit time constant Approx. 30 µs

Reference voltage ±3 VDC (forward rotation if positive reference) at rated torque: Set at delivery

Input impedance Approx. 14 KΩ

Circuit time constant Approx. 30 µs

Variable setting range: ±2 to ±10 VDC at rated speed/ max. input voltage: ±12 V

Variable setting range ±1 to ±10 VDC at rated torque reference, max. input voltage: ±12 V

performance

Command

pulse

Control signal Clears error pulse by external signal

Position control mode

Input signal

Position signal output A-phase, B.phase, C-phase: line driver output.

Sequence input signal Servo ON, P control (or control mode switching, forward/reverse motor rotation by internal speed setting, zero

Sequence output signal Servo alarm, alarm codes (3-bit output): CN1 output terminal is fixed

I/O signal

USB

Communications

Automatic load inertia detection Automatic motor parameter setting. One parameter rigidity setting.

Dynamic brake (DB) Operates during main power OFF, servo alarm, servo OFF or overtravel

Regenerative processing Internal resistor included in models from 500 W to 5 kW. Regenerative resistor externally mounted (option).

Overtravel (OT) prevention function DB stop, deceleration stop or coast to stop during P-OT, N-OT operation

Encoder divider function Optional division pulses possible

Electronic gearing 0,01< Numerator/Denominator<100

Internal speed setting function 3 speeds may be set internally

Protective functions Overcurrent, overvoltage, low voltage, overload, regenerative error

Analog monitor functions for supervision Integrates analog monitor connector for supervision of the speed and torque reference signals, etc.

Integrated functions

Panel operator Display functions CHARGE, 7-segments LEDx5

Safety functions Hard wire base block signal and status monitor (fixed output) of safety circuit

Others Reverse connection, zero search, automatic motor discrimination function, and DC reactor connection terminal

Input pulse type Sign + pulse train, 90° phase displacement 2-phase pulse (A-phase+ B-phase) or CCW/CW pulse train

Input pulse form Non-insultated line driver (+5 V level) , open collector.

Input pulse frequency 0 to 4 Mpps (200 Kpps max. at open collector)

clamp, command pulse inhibit), forward/reverse run prohibit, forward/reverse current limit (or internal speed

switching), alarm reset.

It is possible to output three types of signal form incl.: positioning complete, speed coincidence detection, servo-

Interface Personal computer

Communications standard Compliant with USB1.1 standard (12 Mbps)

Function Status display, parameter settings, adjustment functions, utility functions, alarm traceback display, JOG run/au-

Panel operator keys Used to set parameters (4 keys)

motor rotation detection, servo ready, current limit detection, speed limit detection, brake release, warning, NEAR.

totuning operations and graphing functions for speed/torque command signal, etc

Number of channels: 2 (Output voltage: +/-10V DC)

for high frequency power suppression function.

Sigma-5 servo drive 5

Page 6

I/O specifications

I/O signals (CN1) - input signals

Pin No. Signal name Function

40 Common /S-ON Servo ON: Turns ON the servo motor.

41 /P-CON Function selected by parameter.

42

43

45

46

44 /ALM-RST Alarm reset: releases the servo alarm state.

47 +24VIN Control power supply input for sequence signals: users must provide the +24 V power supply.

4 (2) SEN Initial data request signal when using an absolute encoder.

21

22

5 (6) Speed V-REF Speed reference input: ±2 to ±10 V/rated motor speed (Input gain can be modified using a parameter).

9 (10) Torque T-REF Torque reference input: ±1 to ±10 V/rated motor torque (Input gain can be modified using a parameter).

7

8

11

12

15

14

Position PULS

P-OT

N-OT

/P-CL

/N-CL

BAT (+)

BAT (-)

/PULS

SIGN

/SIGN

CLR

/CLR

Proportional control reference Switches the speed control loop from PI (proportional/integral) to P (proportional)

Direction reference With the internal set speed selected: switch the rotation direction.

Control mode

switching

Zero-clamp reference Speed control with zero-clamp function: reference speed is zero when ON.

Reference pulse block Position control with reference pulse stop: stops reference pulse input when ON.

Forward run prohibited

Reverse run prohibited

Function selected by parameter.

Forward external torque limit ON

Reverse external torque limit ON

Internal speed switching With the internal set speed selected: switches the internal speed settings.

Allowable voltage fluctuation range: 11 to 25 V

Connecting pin for the absolute encoder backup battery.

Do not connect when the encoder cable for the battery case is used.

Reference pulse input

for line driver only

Positional error pulse clear input: clears the positional error pulse during position control.

control when ON.

Position

↔

speed

Position

↔

torque

Enables control mode switching

To rque ↔ speed

Overtravel prohibited: Stops servo motor when movable part travels beyond the

allowable range of motion.

Current limit function enabled when ON.

Input mode is set from the following pulses:

Sign + pulse string

CCW/CW pulse

Two-phase pulse (90° phase differential)

Note: 1. Pin numbers in parentheses () indicate signal grounds.

2. The functions allocated to /S-ON, /P-CON. P-OT, N-OT, /ALM-RST, /P-CL, and /N-CL input signals can be changed by using the

parameters.

3. The voltage input range for speed and torque references is a maximum of ±12 V.

6 AC servo systems

Page 7

I/O signals (CN1) - output signals

Pin No. Signal Name Function

31

32

27

28

29

30

33

34

35

36

19

20

37 (1)

38 (1)

39 (1)

Shell FG Connected to frame ground if the shield wire of the I/O signal cable is connected to the connector shell.

25

26

25

26

- Reserved /CLT

3

13

16

17

18

23

24

48

49

50

Common ALM+

Speed /V-CMP+

Position /COIN+

ALM/TGON+

/TGON/S-RDY+

/S-RDY PAO

/PAO

PBO

/PBO

PCO

/PCO

ALO1

ALO2

ALO3

/V-CMP-

/COIN-

/VLT

/BK

/WARN

/NEAR

- Terminals not used.

Servo alarm: Turns OFF when an error is detected.

Detection during servo motor rotation: detects when the servo motor is rotating at a speed higher than the motor speed

setting.

Servo ready: ON if there is no servo alarm when the control/main circuit power supply is turned ON.

Phase-A signal Two-phase pulse encoder output pulse signal

Phase-B signal

Phase-C signal

Alarm code output: Outputs 3-bit alarm codes.

Turns ON when whether the motor speed is within the setting range is detected and if it matches the reference speed

value.

Turns ON when the number of position error pulse reaches the value set.

Reserved terminals

The functions allocated to /TGON, /S-RDY, and /V-CMP (/COIN) can be changed by using the parameters.

/CLT, /VLT, /BK, /WARN and /NEAR signals can also be changed.

Do not connect.

Zero-point pulse signal

Note: 1. Pin numbers in parentheses () indicate signal grounds.

2. The functions allocated to /TGON, /S-RDY, and /V-CMP (/COIN) output signals can be changed by using the parameters. /CLT, /VLT, /

BK, /WARN and /NEAR signals can also be changed.

I/O signals (CN8) - safety signals

Pin No. Signal Name Function

4

3

6

5

8

7

1

2

Common /HWBB1+

Reserved - Terminals not used.

/HWBB1/HWBB2+

/HWBB2EDMI+

EDMI-

Hard wire baseblock input 1

Hard wire baseblock input 2

Monitored circuit status output 1:

ON when the hard wire baseblock function is normally activated.

Do not connect.

Terminal specifications

Symbol Name Function

L1, L2 or

L1, L2, L3

U, V, W Servo motor connection terminal Terminals for outputs to the servo motor.

L1C, L2C Control power input terminal AC power input terminals for the control circuit.

24V, 0V 24V DC power input terminals for the control circuit.

B1/ ⊕, B2, B3 Main circuit DC output terminal Up to 400 W: If the regenerative capacity is insufficient, connect an external regenerative resistor

1, 2 DC reactor connection terminal for

Main circuit AC input terminal AC power input terminals for the main circuit

Frame ground Ground terminal. Ground to a maximum of 100 Ω. (class 3).

(option) between B1/ ⊕ and B2.

From 500 W to 5 kW: Normally short B2 and B3. If the internal regenerative resistor is insufficient, remove

the wire between B2 and B3 and connect an external regenerative resistor between

B1/ ⊕ and B2.

suppressing power supply harmonic

waves

Normally, short 1 and 2.

If a countermeasure against power supply harmonic waves is needed, connect a DC reactor

between 1 and 2.

Encoder connector (CN2)

Pin No. Signal Name Function

1 E5V Encoder power supply + 5 V

2 E0V Encoder power supply ground

3 BAT+ Battery + (used only with absolute encoder)

4 BAT– Battery – (used only with absolute encoder)

5 S+ Encoder serial signal input

6 S– Encoder serial signal input

Sigma-5 servo drive 7

Page 8

Sigma-5 MECHATROLINK-II Servo Drives

General specifications

Speed control range 1:5000

Speed

variance

Frequency characteristics 1.6 kHz

Torque control accuracy (Repeatability) ±1%

Performance

Soft start time setting 0 to 10 s (acceleration, deceleration can each be set.)

MECHATROLINK

Communication

Command input

Position/speed/torque control mode

Position signal output A-phase, B.phase, C-phase: line driver output.

Sequence input signal Homing deceleration limit switch, forward/reverse run prohibited, external latch signals, forward/reverse current

Sequence output signal It is possible to output three types of signal form incl.: positioning complete, speed coincidence detection, servo-

I/O signal

USB

Communications

Mechatrolink

Communications

Communications

Automatic load inertia detection Automatic motor parameter setting. One parameter rigidity setting.

Dynamic brake (DB) Operates during main power OFF, servo alarm, servo OFF or overtravel

Regenerative processing Internal resistor included in models from 500 W to 5 kW. Regenerative resistor externally mounted (option).

Overtravel (OT) prevention function DB stop, deceleration stop or coast to stop during P-OT, N-OT operation

Encoder divider function Optional division pulses possible

Electronic gearing 0,01< Numerator/Denominator<100

Internal speed setting function 3 speeds may be set internally

Protective functions Overcurrent, overvoltage, low voltage, overload, regeneration error

Analog monitor functions for supervision Integrates analog monitor connectors for supervision of the speed and torque reference signals, etc.

Panel operator Display functions CHARGE, 7-segments LEDX1

Safety functions Hard wire base block signal and status monitor (fixed output) of safety circuit

Others Reverse connection, zero search, automatic motor discrimination function, and DC reactor connection terminal

Integrated functions

Load variance During 0 to 100% load ±0.01% max. (at rated speed)

Voltage variance Rated voltage ±10%:0% (at rated speed)

Temperature variance 25 ±25 °C: ±0.1 % max. (at rated speed)

MECHATROLINK-II commands

(for sequence, motion, data setting/reference, monitor, adjustment and other commands)

limit.

Interface Personal computer

Communications standard Compliant with USB1.1 standard (12 Mbps)

Function Status display, parameter setting, adjusting functions, utility functions, alarm traceback display, JOG run/autotun-

Communications protocol MECHATROLINK-II

Station Address 41H to 5FH (max. number of slaves: 30)

Transmission Speed 10 Mbps

Transmission Cycle 250 µs, 0.5 to 4.0 ms (multiple of 0.5 ms)

Data length 17-bytes and 32-bytes

Switches Rotary switch: MECHATROLINK-II station address setting (16 channels)

motor rotation detection, servo ready, current limit detection, speed limit detection, brake release, warning, NEAR.

ing operations and graphing functions for speed/torque command signal, etc

Number of channels: 2 (Output volatge: +/-10V DC).

DIP switch: MECHATROLINK-II communications setting (4 channels)

for high frequency power suppression function.

I/O specifications

I/O signals (CN1) - input signals

Pin No. Signal name Function

9 Common /DEC Homing deceleration limit switch Connects the deceleration limit switch for homing.

7

8

10

11

12

6 +24VIN Control power supply input for sequence signals: users must provide the +24 V power supply.

14

15

13 /SIO General-purpose input signal:

Note: 1. The functions allocated to /DEC, P-OT, N-OT, /EXT1,-/EXT2 and /EXT3 input signals can be changed by using the

parameters.

2. If the Forward/ Reverse run prohibited function is used, the software can be used to stop the Servo drive. If the application does not satisfy

the requirements, add an external circuit for safety reasons as required.

P-OT

N-OT

/EXT 1

/EXT 2

/EXT 3

BAT (+)

BAT (-)

Forward run prohibited

Reverse run prohibited

External latch signal 1

External latch signal 2

External latch signal 3

Allowable voltage fluctuation range: 11 to 25 V.

Connecting pin for the absolute encoder backup battery.

Do not connect when a battery is connected to the host controller.

Monitored in the I/O monitor field of MECHATROLINK-II.

Overtravel prohibited: Stops servo motor when movable part travels beyond the

allowable range of motion.

Connects the external signals that latch the current feedback pulse counter.

8 AC servo systems

Page 9

I/O signals (CN1) - output signals

Pin No. Signal Name Function

3

4

1

2

23

24

25

26

16 FG Signal ground:

17

18

19

20

21

22

5 Reserved - Terminal not used. Do no connect.

Common ALM+

ALM/BK+

(/SO1+)

/BK(/SO1-)

O2+

/S

O2-

/S

O3+

/S

O3-

/S

PAO

/PAO

PBO

/PBO

PCO

/PCO

Servo alarm: Turns OFF when an error is detected.

Brake interlock signal Controls the brake. The brake is released when the signal turns ON.

General-purpose output signal.

Note: Set the parameter to allocate a function.

Connected to frame ground if the shield wire of the I/O signal cable is connected to the connector shell.

Phase-A signal Dividing ratio can be set by parameter

Phase-B signal

Phase-C signal

Allocation can be changed to general-purpose output signals (/SO1+, /SO1-).

(proper line receiver is SN75175 manufactured by Texas instruments or the equivalent

corresponding to MC3486)

I/O signals (CN8) - safety signals

Pin No. Signal Name Function

4

3

6

5

8

7

1

2

Common /HWBB1+

Reserved - Terminals not used.

/HWBB1/HWBB2+

/HWBB2EDMI+

EDMI-

Hard wire baseblock input 1

Hard wire baseblock input 2

Monitored circuit status output 1:

ON when the hard wire baseblock function is normally activated.

Do not connect.

Terminal specifications

Symbol Name Function

L1, L2 or

L1, L2, L3

U, V, W Servo motor connection terminal Terminals for outputs to the servo motor.

L1C, L2C Control power input terminal AC power input terminals for the control circuit.

24V, 0 24V DC power input terminals for the control circuit.

B1/ ⊕, B2, B3

or

B1, B2, B3

1, 2 DC reactor connection terminal for

Main circuit AC input terminal AC power input terminals for the main circuit

Frame ground Ground terminal. Ground to a maximum of 100 Ω. (class 3).

Main circuit DC output terminal Up to 400 W: If the regenerative capacity is insufficient, connect an external regenerative resistor

suppressing power supply harmonic

waves

(option) between B1/ ⊕ and B2.

From 500 W to 5 kW: Normally short B2 and B3. If the internal regenerative resistor is insufficient, remove

the wire between B2 and B3 and connect an external regenerative resistor between

B1/ ⊕ and B2.

Normally, short 1 and 2.

If a countermeasure against power supply harmonic waves is needed, connect a DC reactor

between 1 and 2.

Encoder connector (CN2)

Pin No. Signal Name Function

1 E5V Encoder power supply + 5 V

2 E0V Encoder power supply ground

3 BAT+ Battery + (used only with absolute encoder)

4 BAT– Battery – (used only with absolute encoder)

5 S+ Encoder serial signal input

6 S– Encoder serial signal input

Sigma-5 servo drive 9

Page 10

Operation

/

/

/

/

/

Sigma-5 Analog/Pulse Reference Servo Drive

Panel operator

With front cover open

Display panel

Keys

Changing modes

To change modes, press the MODE/SET key.

Power ON

(Display example)

Status Display Mode

MODE/SET

Utility Function Mode

MODE/SET

Param. setting mode

MODE/SET

Monitor mode

MODE/SET

Baseblock

Alarm history display mode

Function selection switch

Speed feedback

Status display mode

Control-circuit power supply ON

Baseblock

Speed coincidence

(during speed/torque control)

Positioning complete

(during position control)

Bit display Symbol display

Symbol Status

bb Baseblock (servo OFF)

rUn Operating (servo on)

p%t Forward rotation prohibited (forward overtravel)

n%t Reverse rotation prohibited (reverse overtravel)

h.bb Hard Wire Base Block. Servo drive is baseblocked by the safe-

ty function

tst Mode test without motor

020 Alarm. Blinks the alarm number

Motor rotation detection

Speed command being input

(during speed control)

Command pulses being input

(during position control)

To rque command being input

(during torque control)

Error counter reset signal being

input (during position control)

Main-circuit power supply ON

Keys

Key name SGDV-@@@0@A-OY Function

MODE/SET

Key

MODE/SET

UP Key

MODE/SET

DOWN Key

MODE/SET

DATA/SHIFT

Key

UP Key

DOWN Key

MODE/SET

+

MODE/SET

Selects the display mode (status display mode, utility function mode, parameter setting mode and monitor

mode). Used as a data setting key

while in setting mode.

DATA

Turns the servo ON or OFF while jog

operations are being perfomed.

Increments parameter settings. Used

as a forward rotation start key during

jog operation.

DATA

Decrements parameter settings.

Used as a reverse rotation start key

during jog operation.

DATA

To set and display the set value.

Selects the digit whose setting is to be

changed. When selected, the digit

flashes.

DATA

Pressing the UP Key and the Down

Key simultaneoulsy, resets an alarm.

DATA

Sigma-5 MECHATROLINK-II Servo Drives

Display panel Status display mode

With front cover open

Display panel

Bit display

Symbol Status

a.e60 A.E60.Alarm number 60

h. b b Hard Wire Base Block. Servo drive is baseblocked by the safe-

ty function

tst Mode test without motor

Baseblock

Motor rotation detection

Command reference being input

Control-circuit power supply ON

10 AC servo systems

Page 11

Dimensions

Sigma-5 Analog/Pulse Reference Servo Drive

SGDV-A5A0@A-OY to -02A0@A-OY (230 V, 50 to 200 W)

(17)

(20)

Nameplate

Two Terminals

CN3

CN7

CN1

160

CN8

CN2

(120˚)

Cooling Fan

2-M4 Screw Holes

5

Servo drive

Rear View

160

150±0.5(Mounting Pitch)

Ground Terminal

2-M4 Screws

40

SGDV-04A0@A-OY (230 V, 400 W)

Nameplate

160

Two Terminals

Ground Terminal

2-M4 Screws

CN3

CN7

CN1

CN8

CN2

40

SGDV-08A0@A-OY (230 V, 750 W)

(25)

(75)

(25)

(75)

(17)

(20)

(120˚)

23

23

140

Cooling Fan

170

(4)

(4)

35

40

Mounting Hole Diagram

5

160

150±0.5(Mounting Pitch)

Mounting Hole Diagram

2-M4 Screw Holes

Servo drive

Rear View

5

40

30±0.5

(Mounting

Pitch)

Nameplate

160

Two Terminals

Ground Terminal

2-M4 Screws

70

CN3

CN7

CN1

CN8

CN2

(25)

(75)

(17)

(20)

(120˚)

23

Cooling Fan

180

(4)

5

160

0.5(Mounting Pitch)

±

150

58±0.5

6

70

Mounting Hole Diagram

3-M4

Screw Holes

Servo drive

Rear View

(Mounting Pitch)

Sigma-5 servo drive 11

Page 12

SGDV-15A0@A-OY (230 V, 1.5 kW)

Air Flow

Nameplate

180

Input Voltage

Model

CN3

CN7

CN1

CN8

CN2

(20)

(120˚)

(17)

180

5

±0.5(Mounting Pitch)

170

4-M4 Screw Holes

SERVOPACK

Rear View

Ground Terminal

2-M4 Screws

Terminal

14-M4 Screws

Air Flow

100

(75)

(100˚)

(40)

22

Cooling Fan

SGDV-05D0@A-OY to -15D0@A-OY (400 V, 0.5 to 1.5 kW)

Nameplate

Two Terminals

Ground Terminal

2-M4 Screws

195

7237

17.5

CN3

CN7

CN1

160

CN8

CN2

110

(20)

(120˚)

(25)

(75)

23

(17)

24.5

180

(2)

180

90±0.5

(4)

5

(Mounting Pitch)

100

Mounting Hole Diagram

7.5

7

4-M4 Screw Holes

Servo drive

Rear View

195

166 Min.

180±0.5(Mounting Pitch)

50±0.5

48

(Mounting Pitch)

110

Mounting Hole Diagram

Cooling Fan

12 AC servo systems

Page 13

SGDV-20/30D0@A-OY (400 V, 2/3 kW)

4-M5 Screw Holes

)

20 80

)

5

Nameplate

285

Ground Terminal

2-M4 Screws

15

17.5

250

80

CN3

CN7

CN1

CN8

CN2

110

(20)

(120˚

(100˚)

(75)

(40)

(17)

22

Cooling Fan

(2)

24.5

180

7.5

285

270±0.5(Mounting Pitch)

6

258 Min.

30

110

Mounting Hole Diagram

Servo drive

Rear View

50±0.5

(Mounting Pitch)

Te r mi n al

14-M4 Screws

Te r mi n al Details

SGDV-50D0@A-OY (400 V, 5 kW)

Cooling Fan

Nameplate

7.5

285

270±0.5(Mounting Pitch)

4-M5 Screw Holes

6

258 Min.

Servo drive

Rear View

17.

285

250

Terminal

6-M5 Screws

135

CN3

CN7

CN1

CN8

CN2

Te r mi n al

5-M4 Screws

Terminal

3-M5 Screws

(20

(120˚)

22

(75)

(100˚)

(83)

(17)

(2)

24.5

230

Ground Terminal

35

135

2-M5 Screws

50±0.5

(Mounting Pitch)

Terminal Details

Sigma-5 servo drive 13

Page 14

SGDV-210D0@A to 260D0@A (400 V, 6 to 7.5 kW)

Input Voltage

Model

3

CN

7

CN

1

CN

8

CN

2

CN

350

Terminal

46-M Screws

Terminal

66-M Screws

)

)

˚

120

20

(

(

(

)

17

5

.

7

350

±0.5 (Mounting Pitch)

46-M Screw Holes

Servo drive

Rear View

335

Ter m in al

24-M Screws

230

Ground Terminal

26-M Screws

SGDV-280D0@A to 370D0@A (400 V, 11 to 15 kW)

Input Voltage

Model

3

CN

7

CN

1

CN

8

CN

2

CN

Terminal

46-M Screws

Terminal

66-M Screws

Ground Terminal

26-M Screws

Ter m in al

24-M Screws

400

230

13

(75)

)

20

(

(

120

210

)

˚

(

)

17

25

(

Mounting Pitch

Mounting Hole Diagram

5

.

7

400

±0.5 (Mounting Pitch)

385

13 180

(

)

75

250

25

(

Mounting Hole Diagram

180±0.5

230

)

46-M Screw Holes

±0.5

Mounting Pitch

230

)

Servo drive

Rear View

14 AC servo systems

Page 15

Sigma-5 MECHATROLINK-II Servo Drives

SGDV-A5A1@A-OY to -02A1@A-OY (230 V, 50 to 200 W)

(7)

(15)

(25)

(75)

(120˚)

23

Nameplate

Two Terminals

Ground Terminal

2-M4 Screws

160

CN6

CN3

CN7

CN1

CN8

CN2

40

SGDV-04A1@A-OY (230 V, 400 W)

(7)

(15)

Nameplate

Two Terminals

160

Model

CN6

CN3

CN7

CN1

CN8

CN2

(120˚)

Cooling Fan

140

Cooling Fan

(4)

5

2-M4 Screw Holes

Servo drive Rear View

160

±0.5(Mounting Pitch)

150

35

40

Mounting Hole Diagram

2-M4 Screw Holes

5

Servo drive Rear View

160

±0.5(Mounting Pitch)

150

Ground Terminal

2-M4 Screws

40

SGDV-08A1@A-OY (230 V, 750 W)

Model

CN6

ameplate

160

o Terminals

Ground Terminal

2-M4 Screws

70

CN3

CN7

CN1

CN8

CN2

(25)

(75)

(15)

(25)

(75)

23

(120˚)

23

(7)

170

Cooling Fan

180

(4)

(4)

5

Mounting Hole Diagram

5

160

0.5(Mounting Pitch)

±

150

6

(Mounting Pitch)

Mounting Hole Diagram

40

58±0.5

70

30±0.5

(Mounting Pitch)

3-M4 Screw Holes

Servo drive Rear View

Sigma-5 servo drive 15

Page 16

SGDV-15A1@A-OY (230 V, 1.5 kW)

Air Flow

Nameplate

180

Input Voltage

Model

CN6

CN3

CN7

CN1

CN8

CN2

(15)

(120˚)

(17)

4-M4 Screw Holes

6

SERVOPACK Rear View

180

±0.5(Mounting Pitch)

170

Ground Terminal

2-M4 Screws

Terminal

14-M4 Screws

Air Flow

100

(100˚)

(75)

(40)

22

Cooling Fan

SGDV-05D1@A-OY to -15D1@A-OY (400 V, 0.5 to 1.5 kW)

(7)

(120˚)

Nameplate

Two Te rm in als

160

Model

(15)

CN6

CN3

CN7

CN1

CN8

CN2

180

90±0.5

(4)

5

(Mounting Pitch)

100

Mounting Hole Diagram

4-M4 Screw Holes

(Mounting Pitch)

160

5.5

0.5

±

149.5

Servo drive Rear View

Ground Terminal

2-M4 Screws

110

(25)

(75)

23

Cooling Fan

(4)

180

100±0.5

5

(Mounting Pitch)

110

Mounting Hole Diagram

16 AC servo systems

Page 17

SGDV-20/30D1@A-OY (400 V, 2/3 kW)

Nameplate

Ground Terminal

2-M4 Screws

250

110

Model

CN6

CN3

CN7

CN1

CN8

CN2

(15)

(100˚)

(120˚)

(75)

(40)

22

Cooling Fan

(7)

6

250

4-M5 Screw Holes

Servo drive

Rear View

±0.5(Mounting Pitch)

238.5

100±0.5

(4)

180

5

(Mounting Pitch)

110

Mounting Hole Diagram

Terminal

14-M4 Screws

Terminal Details

SGDV-50D1@A-OY (400 V, 5 kW)

Cooling Fan

Nameplate

4-M5 Screw Holes

6

Terminal

6-M5 Screws

Servo drive Rear View

250

135

Input Voltage

Model

CN6

CN3

CN7

CN1

CN8

CN2

(120˚)

(75)

(100˚)

(15)

(7)

22

230

(1.6)

250

238.5±0.5 (Mounting Pitch)

5

125±0.5

(Mounting Pitch)

135

Ground Terminal

2-M5 Screws

Terminal Details

Terminal

5-M4 Screws

Terminal

3-M5 Screws

(83)

(3.2)

Sigma-5 servo drive 17

Page 18

SGDV-210D1@A to 260D1@A (400 V, 6 to 7.5 kW)

Input Voltage

Model

6

CN

3

CN

7

CN

1

CN

8

CN

2

CN

350

Terminal

46-M Screws

Terminal

66-M Screws

)

˚

)

120

(

(

15

(

)

7

350

5

.

7

±0.5 (Mounting Pitch)

46-M Screw Holes

Servo drive

Rear View

335

Ter m in al

24-M Screws

230

Ground Terminal

26-M Screws

SGDV-280D1@A to 370D1@A (400 V, 11 to 15 kW)

Input Voltage

Model

6

CN

3

CN

7

CN

1

CN

8

CN

2

CN

Ter m in al

46-M Screws

Ter m in al

66-M Screws

Ground Terminal

26-M Screws

Ter m in al

24-M Screws

400

230

13

(75)

)

15

(

13

(75)

(

120

25

210

)

˚

(

)

7

180±0.5

(

Mounting Pitch

230

Mounting Hole Diagram

5

.

7

46-M Screw Holes

)

Servo drive

Rear View

400

±0.5 (Mounting Pitch)

385

25

250

Mounting Hole Diagram

±0.5

180

(

Mounting Pitch

230

)

18 AC servo systems

Page 19

Filters

R88A-FI5-1005-RE

Units: mm

5

7

200±1

190

R88A-FI5-3004-RE

164±120±1

150

Units: mm

mounts

Ø5.0

5

7

200±1

190

164±120±1

150

44±1

3 x M4

drive mounts

30

mounts Ø5.0

M5 Earth Stud

each end

30

CABLE SIZE

2

0 to 6 mm

.

strip 7 mm

(1) Connect to the servodrive ground in case not footprint installation

R88A-FI5-1009-RE

Units: mm

CABLE SIZE

0 to 6 mm

strip 7 mm

mounts

2

.

Ø5.0

72±1

5

7

58

drive mounts

3 x M4

M5 Earth Stud

30

each end

(1) Connect to the servodrive ground in case not footprint installation

200±1

190

164±120±1

150

R88A-FI5-1016-RE

Units: mm

mounts

Ø5.0

90

104±1

5

7

drive mounts

M4

220±1

210

184±120±1

170

output flexes 18AWG

2 x 320mm with ferrules

15

(1)

output flexes 18AWG

2 x 320mm with ferrules

15

(1)

20 12

CABLE SIZE

2

0 to 6 mm

strip 7 mm

R88A-FI5-3008-RE

Units: mm

50 11

CABLE SIZE

2

0 to 6 mm

.

strip 7 mm

R88A-FI5-3012-RE

Units: mm

80 12

100

114±1

drive mounts

4 x M4

.

M5 Earth Stud

40

each end

(1) Connect to the servodrive ground in case not footprint installation

290±1

290±1

279

255±120±1

239

279

255±120±1

239

mounts

mounts

6

8

Ø5.5

100

116±1

drive mounts

4 x M5

M5 Earth Stud

40

each end

(1) Connect to the servodrive ground in case not footprint installation

6

8

Ø5.5

(1)

output flexes 16AWG

3 x 350mm with ferrules

20

(1)

output flexes 16AWG

3 x 350mm with ferrules

20

90 12

90 13

CABLE SIZE

2

.

0 to 6 mm

strip 7 mm

40

M5 Earth Stud

each end

(1) Connect to the servodrive ground in case not footprint installation

(1)

output flexes 16AWG

2 x 350mm with M4 spades

20

CABLE SIZE

0 to 6 mm

strip 7 mm

125

141±1

(1)

drive mounts

4 x M5

output flexes 16AWG

3 x 420mm with ferrules

2

.

M5 Earth Stud

40

each end

(1) Connect to the servodrive ground in case not footprint installation

20

115 13

Sigma-5 servo drive 19

Page 20

Single-phase, 230 VAC

Single-Phase 200 to 230 VAC

Noise filter

Powe r

Off

Powe r

ON

Alarm processing

Be sure to attach a surge suppressor to the excitation

∗

3

coil of the magnetic contactor and relay

SGDV

Analog/Pulse Reference

Servo Drive

Servo motor

Optical encoder

Speed reference

(±2 to ±10 V/rated motor speed)

Tor que reference

(

±1 to ±10 V/rated torque)

PULS

CW

Phase A

Position

reference

Forward run prohibited

(Prohibited when OFF)

Reverse run prohibited

(Prohibited when OFF)

Safety device *4

SIGN

CCW

Phase B

CLR

Backup battery ∗2

2.8 to 4.5 V

SEN signal input

Servo ON

(Servo ON when ON)

P control

(P control when ON)

Alarm reset

(Reset when ON)

Forward current limit

(Limit when ON)

Reverse current limit

(Limit when ON)

24 V

fuse

0 V

+5 V

0 V

+24 V

Be sure to

ground

Switch

V-REF

SG

T-REF

SG

PULS

/PULS

SIGN

/SIGN

CLR

/CLR

BAT(+)

BAT(-)

SEN

SG

+24 VIN

/S-ON

/P-CON

P-OT

N-OT

/ALM-RST

/P-CL

/N-CL

/HWBB1+

/HWBB1-

/HWBB2+

/HWBB2-

5

LPF

∗

1

6

9

10

7

8

11

12

15

14

21

22

4

2

47

40

41

42

43

44

45

46

4

3

6

5

3.3 k

(SI0)

(SI1)

(SI2)

(SI3)

(SI4)

(SI5)

(SI6)

LPF

150Ω

150Ω

150

A / D

∗

1

Ω

Ω

CN8

CN1

Connector

shell

FG

Connect shield to

connector shell.

(SO1)

(SO2)

(SO3)

Be sure to prepare the end of

the shielded wire properly

37

ALO1

ALO2

38

39

ALO3

33

PAO

34

/PAO

35

PBO

/PBO

36

19

PCO

20

/PCO

SG

1

/V-CMP+ (/COIN+)

25

26

/V-CMP- (/COIN-)

/TG

ON

27

/TG

ON

28

/S-RDY+

29

30

/S-RDY-

31

ALM+

32

ALM-

8

EDM1+

7

EDM1-

Alarm code output

Max. operating voltage:

30 VDC

Max. operating current:

20 mA DC

Encoder output pulses

Applicable line receiver

SN75175 or MC3486

manufactured by Texas

Instruments or the equivalent

Speed coincidence detection

(ON when speed coincides)

(COIN: Positioning completed

(ON when positioning

+

-

Photocoupler output

completes.))

Running output

(ON when the motor speed

exceeds the settings.)

Servo ready output

(ON when ready)

Servo alarm output

(OFF for an alarm)

Max. operating voltage:

30 VDC

Max. operating current:

50 mA DC

Monitored circuit status output

(ON when the hard wire baseblock

function is normally activated)

*1 The time constant for the primary filter is 30 µs.

*2 Connect when using an absolute encoder. When the encoder cable for the battery case is connected, do not connect a backup battery.

*3 Regenerative resistor can be connected between B1 and B2. For 750 W servo drives types normally short B2 and B3.

*4 For servo ON, connect to safety device and set wiring to enable safety function. When not using the safety function, use the servo drive with

the plug (JZSP-CVH05-E, provided as an accessory) inserted into the CN8.

20 AC servo systems

Page 21

Three-phase, 400 VAC

Three-Phase 380 to 480 VAC

Noise filter

∗

5

Power supply

24 VDC +10%,-15%

+24 V

0 V

Powe r

Off

Powe r

ON

SGDV

3

Analog/Pulse Reference

24 V

Servo Drive

0 V

Alarm processing

∗

3

Be sure to attach a surge suppressor to the excitation

coil of the magnetic contactor and relay

3

Servo motor

Optical encoder

Speed reference

(±

2 to ±10 V/rated motor speed)

Tor que reference

(

±

1 to ±10 V/rated torque)

PULS

CW

Phase A

Position

SIGN

reference

CCW

Phase B

CLR

Backup battery ∗2

2.8 to 4.5 V

SEN signal input

Servo ON

(Servo ON when ON)

P control

(P control when ON)

Forward run prohibited

(Prohibited when OFF)

Reverse run prohibited

(Prohibited when OFF)

Alarm reset

(Reset when ON)

Forward current limit

(Limit when ON)

Reverse current limit

(Limit when ON)

24 V

fuse

Safety device *4

0 V

+5 V

0 V

+24 V

Be sure to

ground

Switch

V-RE F

SG

T-RE F

SG

PULS

/PULS

SIGN

/SIGN

CLR

/CLR

BAT(+)

BAT(-)

SEN

SG

+24 VIN

/S-ON

/P-CON

P-OT

N-OT

/ALM-RST

/P-CL

/N-CL

/HWBB1+

/HWBB1-

/HWBB2+

/HWBB2-

CN8

A / D

CN1

Connector

shell

FG

Connect shield to

connector shell.

(SO1)

(SO2)

(SO3)

5

LPF

∗

1

6

9

LPF

∗

10

1

150Ω

7

8

150Ω

11

12

150

Ω

15

14

21

22

4

2

3.3 k

Ω

47

40

(SI0)

41

(SI1)

42

(SI2)

43

(SI3)

44

(SI4)

45

(SI5)

46

(SI6)

4

3

6

5

Be sure to prepare the end of

the shielded wire properly

37

ALO1

Alarm code output

ALO2

38

Max. operating voltage:

30 VDC

39

ALO3

Max. operating current:

20 mA DC

33

PAO

34

/PAO

35

36

19

20

1

25

26

27

28

29

30

31

32

Encoder output pulses

PBO

Applicable line receiver

/PBO

SN75175 or MC3486

manufactured by Texas

Instruments or the equivalent

PCO

/PCO

SG

/V-CMP+ (/COIN+)

/V-CMP- (/COIN-)

/TG

ON

+

Running output

(ON when the motor speed

/TG

ON

exceeds the settings.)

/S-RDY+

Servo ready output

(ON when ready)

/S-RDY-

ALM+

Servo alarm output

(OFF for an alarm)

ALM-

Photocoupler output

Max. operating voltage:

30 VDC

Max. operating current:

50 mA DC

8

EDM1+

Monitored circuit status output

(ON when the hard wire baseblock

function is normally activated)

7

EDM1-

Speed coincidence detection

(ON when speed coincides)

(COIN: Positioning completed

(ON when positioning

completes.))

*1 The time constant for the primary filter is 30 µs.

*2 Connect when using an absolute encoder. When the encoder cable for the battery case is connected, do not connect a backup battery.

*3 Normally short B2 and B3. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an external re-

generative resistor between B1 and B2.

*4 For servo ON, connect to safety device and set wiring to enable safety function. When not using the safety function, use the servo drive with

the plug (JZSP-CVH05-E, provided as an accessory) inserted into the CN8.

*5 It is the user’s responsibility to obtain 24 VDC power supply.

Sigma-5 servo drive 21

Page 22

Single-phase, 230 VAC

Single-Phase 200 to 230 VAC

Noise filter

Powe r

Off

Powe r

ON

Alarm processing

Be sure to attach a surge suppressor to the excitation

∗

2

coil of the magnetic contactor and relay

SGDV

MECHATROLINK-II

Servo Drive

Servo motor

Optical encoder

Control power supply

for sequence signal

Forward run prohibited

(Prohibited when OFF)

Reverse run prohibited

(Prohibited when OFF)

Homing deceleration

switch

(Decelerated when ON)

External latch signal 1

(Latched when ON)

External latch signal 2

(Latched when ON)

External latch signal 3

(Latched when ON)

General purpose

Backup battery ∗1

2.8 to 4.5 V

Be sure to

ground

+24 VIN

P-OT

N-OT

/DEC

/EXT1

/EXT2

/EXT3

+24V

/SI1

/SI2

/SI3

/SI4

/SI5

/SI6

/SIO

BAT(+)

BAT(-)

Be sure to prepare the end of

3

4

1

2

23

24

25

26

17

18

19

20

21

22

16

ALM+

ALM-

SO1+ / BK+

SO1- / BK-

/SO2+

/SO2-

/SO3+

/SO3-

PAO

/PAO

PBO

/PBO

PCO

/PCO

SG

the shielded wire properly

Photocoupler output

Max. operating voltage:

30 VDC

Max. operating current:

50 mA DC

Servo alarm output

(OFF for an alarm)

Brake interlock

(Brake released when ON)

Encoder output pulses

Applicable line receiver

SN75175 or MC3486

manufactured by Texas

Instruments or the equivalent

Signal ground

CN1

3.3 k

Ω

6

7

8

9

10

11

12

13

14

15

24 V

Safety device *3

0 V

fuse

Switch

/HWBB1+

/HWBB1-

/HWBB2+

/HWBB2-

4

3

6

5

CN8

Connector

shell

FG

Connect shield to

connector shell.

8

EDM1+

Monitored circuit status output

(ON when the hard wire baseblock

7

function is normally activated)

EDM1-

*1 Connect when using an absolute encoder. When the encoder cable for the battery case is connected, do not connect a backup battery.

*2 Regenerative resistor can be connected between B1 and B2. For 750 W servo drives types normally short B2 and B3.

*3 For servo ON, connect to safety device and set wiring to enable safety function. When not using the safety function, use the servo drive with

the plug (JZSP-CVH05-E, provided as an accessory) inserted into the CN8.

22 AC servo systems

Page 23

Three-phase, 400 VAC

Single-Phase 200 to 230 VAC

Noise filter

Powe r

Off

Powe r

ON

Alarm processing

∗

2

Be sure to attach a surge suppressor to the excitation

coil of the magnetic contactor and relay

3

Servo motor

∗

Power supply

24 VDC +10%,-15%

Control power supply

for sequence signal

Forward run prohibited

(Prohibited when OFF)

Reverse run prohibited

(Prohibited when OFF)

Homing deceleration

switch

(Decelerated when ON)

External latch signal 1

(Latched when ON)

External latch signal 2

(Latched when ON)

External latch signal 3

(Latched when ON)

4

General purpose

+24 V

0 V

Be sure to

ground

+24 VIN

P-OT

N-OT

/DEC

/EXT1

/EXT2

/EXT3

+24V

/SI1

/SI2

/SI3

/SI4

/SI5

/SI6

/SIO

24 V

0 V

6

7

8

9

10

11

12

13

3

SGDV

MECHATROLINK-II

3.3 k

Servo Drive

Ω

CN1

3

4

1

2

23

24

25

26

ALM+

ALM-

SO1+ / BK+

SO1- / BK-

/SO2+

/SO2-

/SO3+

/SO3-

Optical encoder

Be sure to prepare the end of

the shielded wire properly

Photocoupler output

Max. operating voltage:

30 VDC

Max. operating current:

50 mA DC

Servo alarm output

(OFF for an alarm)

Brake interlock

(Brake released when ON)

17

PAO

18

/PAO

19

20

21

22

16

8

7

Encoder output pulses

PBO

Applicable line receiver

/PBO

SN75175 or MC3486

manufactured by Texas

Instruments or the equivalent

PCO

/PCO

SG

Signal ground

EDM1+

Monitored circuit status output

(ON when the hard wire baseblock

function is normally activated)

EDM1-

Backup battery ∗1

2.8 to 4.5 V

24 V

Safety device *3

0 V

fuse

Switch

BAT(+)

BAT(-)

/HWBB1+

/HWBB1-

/HWBB2+

/HWBB2-

14

15

4

3

6

5

CN8

Connector

shell

FG

Connect shield to

connector shell.

*1 Connect when using an absolute encoder. When the encoder cable for the battery case is connected, do not connect a backup battery.

*2 Normally short B2 and B3. If the internal regenerative resistor is insufficient, remove the wire between B2 and B3 and connect an external

regenerative resistor between B1 and B2.

*3 For servo ON, connect to safety device and set wiring to enable safety function. When not using the safety function, use the servo drive with

the plug (JZSP-CVH05-E, provided as an accessory) inserted into the CN8.

*4 It is the user’s responsibility to obtain 24 VDC power supply.

Sigma-5 servo drive 23

Page 24

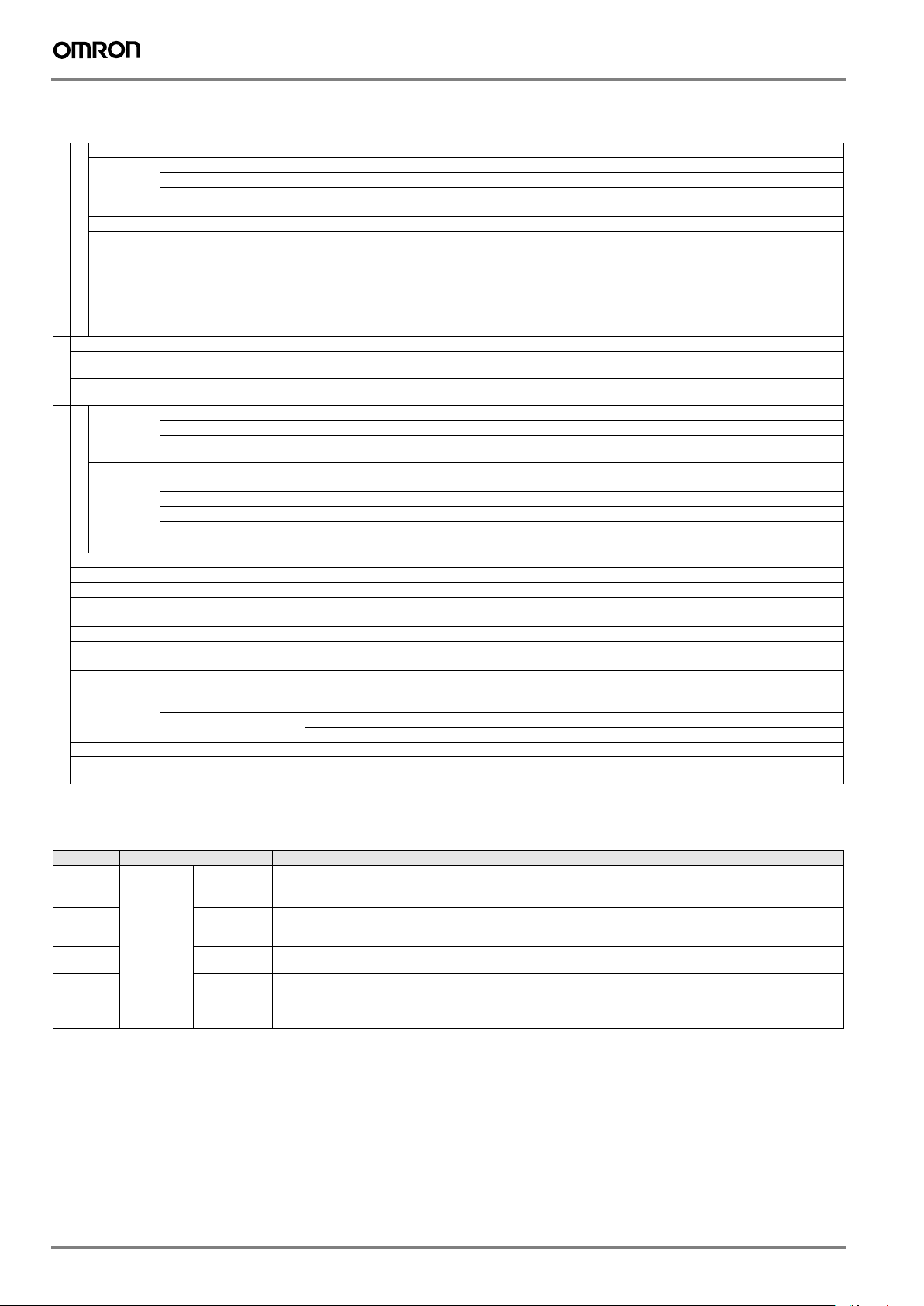

Ordering information

Sigma-5 Analog/Pulse Reference Configuration

C

Sigma-5

Servo Drives

M

Filter

Analog/Pulse

Models

(Refer to chapter Sigma-II rotary motors)

SGMAH, SGMPH

A

Servo Motor

CN5

CN7

CN1

CN8

CN2

Cables

B

SGMGH, SGMUH, SGMSH, SGMBH

A

Servo Motor

Analog monitor cable

J

USB cable

E

D

F

G

General purpose cable

H

Safety cable

L

Battery case for absolute encoder

I

(Refer to chapter Sigma linear motors)

SGLG_ linear

A

Servo Motor

Terminal block

position control

Unit

K

SGLF_ linear

A

Servo Motor

Personal

computer

Position control unit

Cables

B

SGLT_ linear

A

Servo Motor

(Refer to chapter Sigma-5 rotary motors)

SGMJV, SGMAV

A

Servo Motor

A

SGMGV, SGMSV

Servo Motor

B

Cables

(Refer to chapter Sigma direct drive motors)

Direct drive servo motor

A A

SGMCS-@-@B, C, D, E

Cables

B

Direct drive servo motor

SGMCS-@-@M, N

Note: The symbols ABCDE... show the recommended sequence to select the components in a Sigma-5 servo system

Servo motors, power & encoder cables

Note: AB Refer to the servo motors chapter for detailed motor specifications and selection

24 AC servo systems

Page 25

Servo drives

Symbol Specifications Model Compatible rotary servo motors A Compatible direct drive motors A Compatible linear motors A

C

1 phase

230 VAC

3 phase

400 VAC

50 W SGDV-A5A01A-OY SGMAH-A5D@, SGMJV-A5A@,

SGDV-A5A05A-OY - - SGLGW-30A050@

100 W SGDV-01A01A-OY SGMAH-01A@, SGMPH-01A@,

SGDV-01A05A-OY - - SGLGW-30A080@,

200 W SGDV-02A01A-OY SGMAH-02A@, SGMPH-02A@,

SGDV-02A05A-OY - - SGLGW-60A140@,

400 W SGDV-04A01A-OY SGMAH-04A@, SGMPH-04A@,

SGDV-04A05A-OY - - SGLGW-40A365@,

750 W SGDV-08A01A-OY SGMAH-08A@, SGMPH-08A@,

SGDV-08A05A-OY - - SGLGW-60A365A@,

1.5 kW SGDV-15A01A-OY SGMPH-15A@, SGMAV-10A@,

SGDV-15A05A-OY - - SGLGW-90A200A@,

0.5 kW SGDV-05D01A-OY SGMAH-03D@, SGMPH-04D@,

SGDV-05D05A-OY - - SGLFW-35D@

1.0 kW SGDV-10D01A-OY SGMAH-07D@, SGMPH-08D@,

SGDV-10D05A-OY - - SGLFW-50D200@,

1.5 kW SGDV-15D01A-OY SGMPH-15D@, SGMGH-13D@,

SGDV-15D05A-OY - - SGLFW-50D380@,

2 kW SGDV-20D01A-OY SGMGH-20D@, SGMSH-20D@,

SGDV-20D05A-OY - - SGLFW-1ED380@,

3 kW SGDV-30D01A-OY SGMGH-30D@, SGMSH-30D@,

SGDV-30D05A-OY - - SGLFW-1ZD380@,

5 kW SGDV-50D01A-OY SGMGH-44D@, SGMSH-50D@,

SGDV-50D05A-OY - - SGLTW-40D60@,

6 kW SGDV-210D01A SGMGH-55D@, SGMGV-55D@ --

7.5 kW SGDV-260D01A SGMGH-75D@, SGMGV-75D@ --

11 kW SGDV-280D01A SGMGH-1AD@, SGMGV-1AD@ --

15 kW SGDV-370D01A SGMGH-1ED@,

SGMAV-A5A@

SGMJV-01A@, SGMAV-01A@,

SGMEV-01A@

SGMJV-02A@, SGMAV-02A@,

SGMEV-02A@

SGMJV-04A@, SGMAV-04A@,

SGMEV-04A@

SGMJV-08A@, SGMAV-08A@,

SGMEV-08A@

SGMEV-15A@

SGMGH-05D@, SGMEV-04D@,

SGMGV-05D@

SGMGH-09D@, SGMSH-10D@,

SGMUH-10D@, SGMEV-08D@,

SGMGV-09D@, SGMSV-10D@,

SGMSH-15D@, SGMUH-15D@,

SGMEV-15D@, SGMGV-13D@,

SGMSV-15D@

SGMGV-20D@, SGMSV-20D@

SGMUH-30D@, SGMGV-30D@,

SGMGV-30D@

SGMUH-40D@, SGMGV-44D@,

SGMSV-50D@

SGMGV-1ED@ --

--

- -

SGMCS-07B@ -

SGMCS-02B@, SGMCS-05B@,

SGMCS-04C@, SGMCS-10C@,

SGMCS-14C@, SGMCS-08D@,

SGMCS-17D@, SGMCS-25D@

SGMCS-16E@, SGMCS-35E@ -

SGMCS-45M@, SGMCS-80M@,

SGMCS-80N@

--

--

--

--

-

--

SGLGW-40A140@

SGLGW-40A253@,

SGLFW-20A@,

SGLFW-35A120@

-

SGLGW-60A253A@

SGLFW-35A230@,

SGLFW-50A200@

-

SGLFW-50A380@,

SGLFW-1ZA200@

SGLTW-35D170@,

SGLTW-50D170@

SGLFW-1ZD200@

SGLTW-35D320@,

SGLTW-50D320@

-

SGLFW-1ED560@,

SGLTW-40D400@

SGLTW-80D400@

Sigma-5 servo drive 25

Page 26

Control cables (for CN1)

Symbol Description Connect to Model

Servo relay unit CJ1W-NC1@3 XW2B-20J6-1B (1 axis)

D

CJ1W-NC2@3/4@3 XW2B-40J6-2B (2 axis)

CJ1M-CPU22/23 XW2B-20J6-8A (1 axis)

XW2B-40J6-9A (2 axis)

E Cable to servo drive Servo relay units XW2B-@0J6-@B 1 m XW2Z-100J-B4

F Position control unit

connecting cable

CJ1W-NC113 0.5 m XW2Z-050J-A14

CJ1W-NC213/413 0.5 m XW2Z-050J-A15

CJ1W-NC133 0.5 m XW2Z-050J-A18

CJ1W-NC233/433 0.5 m XW2Z-050J-A19

CJ1M-CPU22/23 0.5 m XW2Z-050J-A27

2 m XW2Z-200J-B4

1 m XW2Z-100J-A14

1 m XW2Z-100J-A15

1 m XW2Z-100J-A18

1 m XW2Z-100J-A19

1 m XW2Z-100J-A27

G Control cable For general purpose controllers 1 m R88A-CPW001S

H Relay terminal block cable General purpose controller 1 m R88A-CTW001N

2 m R88A-CPW002S

Relay terminal block - XW2B-50G5

2 m R88A-CTW002N

Battery backup for absolute encoder (for CN2 encoder cable)

Symbol Name Model

I

Note: when the encoder cables with a battery case are used, no battery is required for CN1 (between pin 21 and 22). Battery for CN1 is ER6VCN3.

Battery JZSP-BA01

Cable (for CN5)

Symbol Name Model

J

Analog monitor cable R88A-CMW001S

DE9404559

USB personal computer cable (for CN7)

Symbol Name Note

K

Note: doble shield USB cable recommended

USB Mini Connector cable JZSP-CVS06-02-E

Cable for Safety Functions (for CN8)

Symbol Name Model

L

Note: when using the safety function, connect this cable to the safety devices.

Even when not using the safety function, use servo drive with the Safe Jumper

Connector (JZSP-CVH05-E) connected.

Safety connector with 3 m cable (with

Loose Wires at one End)

JZSP-CVH03-03-E

Filters

Symbol Applicable servo drive Filter model Rated current Rated voltage

M SGDV-A5A@@A-OY,SGDV-01A@@A-OY, SGDV-02A@@A-OY, SGDV-04A@@A-OY R88A-FI5-1005-RE 5 A 250 VAC single-phase

SGDV-08A@@A-OY R88A-FI5-1009-RE 9 A

SGDV-15A@@A-OY R88A-FI5-1016-RE 16 A

SGDV-05D@@A-OY, SGDV-10D@@A-OY, SGDV-15D@@A-OY R88A-FI5-3004-RE 4.3 A 400 VAC three-phase

SGDV-20D@@A-OY, SGDV-30D@@A-OY R88A-FI5-3008-RE 8.6 A

SGDV-50D@@A-OY R88A-FI5-3012-RE 14.5 A

Connectors

Specifications Model

I/O connector kit (for CN1) R88A-CNU11C

Sigma-5 drive encoder connector (for CN2) JZSP-CMP9-1

Safe Jumper Connector JZSP-CVH05-E

Computer software

Specifications Model

Configuration and monitoring software tool for servo drives and inverters. (CX-drive version 1.50 or higher) CX-drive

Complete OMRON software package including CX-drive. (CX-One version 3.0.2 or higher) CX-One

26 AC servo systems

Page 27

Ordering information

Sigma-5 MECHATROLINK Servo Drive Configuration

Sigma-5

C

Servo Drives

J

Filter

MECHATROLINK-II

Models

(Refer to chapter Sigma-II rotary motors)

SGMAH, SGMPH

A

Servo Motor

(Refer to chapter Sigma-5 rotary motors)

CN5

CN6

CN7

CN1

CN8

CN2

Cables

B

A

SGMGH, SGMUH, SGMSH, SGMBH

Servo Motor

B

Cables

Analog monitor cable

F

G

MECHATROLINK-II network

USB cable

General purpose connector

D

I

Safety cable

Battery case for absolute encoder

E

(Refer to chapter Sigma linear motors)

SGLG_ linear

A

Servo Motor

(Refer to chapter Sigma direct drive motors)

H

SGLF_ linear

A

Servo Motor

Personal

computer

B

Cables

B

A

Cables

SGLT_ linear

Servo Motor

SGMJV, SGMAV

A

Servo Motor

SGMGV, SGMSV

A

Servo Motor

Direct drive servo motor

A

SGMCS-@-@B, C, D, E

Direct drive servo motor

A

SGMCS-@-@M, N

Note: The symbols ABCDE... show the recommended sequence to select the components in a Sigma-5 servo system

Servo motors, power & encoder cables

Note: AB Refer to the servo motors chapter for detailed motor specifications and selection

Sigma-5 servo drive 27

Page 28

Servo drives

Symbol Specifications Model Compatible rotary servo motors A Compatible direct drive motors A Compatible linear motors A

C

1 phase

230 VAC

3 phase

400 VAC

50 W SGDV-A5A11A-OY SGMAH-A5D@, SGMJV-A5A@,

SGDV-A5A15A-OY - - SGLGW-30A050@

100 W SGDV-01A11A-OY SGMAH-01A@, SGMPH-01A@,

SGDV-01A15A-OY - - SGLGW-30A080@,

200 W SGDV-02A11A-OY SGMAH-02A@, SGMPH-02A@,

SGDV-02A15A-OY - - SGLGW-60A140@,

400 W SGDV-04A11A-OY SGMAH-04A@, SGMPH-04A@,

SGDV-04A15A-OY - - SGLGW-40A365@,

750 W SGDV-08A11A-OY SGMAH-08A@, SGMPH-08A@,

SGDV-08A15A-OY - - SGLGW-60A365A@,

1.5 kW SGDV-15A11A-OY SGMPH-15A@, SGMAV-10A@,

SGDV-15A15A-OY - - SGLGW-90A200A@,

0.5 kW SGDV-05D11A-OY SGMAH-03D@, SGMPH-04D@,

SGDV-05D15A-OY - - SGLFW-35D@

1.0 kW SGDV-10D11A-OY SGMAH-07D@, SGMPH-08D@,

SGDV-10D15A-OY - - SGLFW-50D200@,

1.5 kW SGDV-15D11A-OY SGMPH-15D@, SGMGH-13D@,

SGDV-15D15A-OY - - SGLFW-50D380@,

2 kW SGDV-20D11A-OY SGMGH-20D@, SGMSH-20D@,

SGDV-20D15A-OY - - SGLFW-1ED380@,

3 kW SGDV-30D11A-OY SGMGH-30D@, SGMSH-30D@,

SGDV-30D15A-OY - - SGLFW-1ZD380@,

5 kW SGDV-50D11A-OY SGMGH-44D@, SGMSH-50D@,

SGDV-50D15A-OY - - SGLTW-40D60@,

6 kW SGDV-210D11A SGMGH-55D@, SGMGV-55D@ --

7.5 kW SGDV-260D11A SGMGH-75D@, SGMGV-75D@ --

11 kW SGDV-28 0D11A SGMGH-1AD@, SGMGV-1AD@- -

15 kW SGDV-370D11A SGMGH-1ED@,

SGMAV-A5A@

SGMJV-01A@, SGMAV-01A@,

SGMEV-01A@

SGMJV-02A@, SGMAV-02A@,

SGMEV-02A@

SGMJV-04A@, SGMAV-04A@,

SGMEV-04A@

SGMJV-08A@, SGMAV-08A@,

SGMEV-08A@

SGMEV-15A@

SGMGH-05D@, SGMEV-04D@,

SGMGV-05D@

SGMGH-09D@, SGMSH-10D@,

SGMUH-10D@, SGMEV-08D@,

SGMGV-09D@, SGMSV-10D@,

SGMSH-15D@, SGMUH-15D@,

SGMEV-15D@, SGMGV-13D@,

SGMSV-15D@

SGMGV-20D@, SGMSV-20D@

SGMUH-30D@, SGMGV-30D@,

SGMGV-30D@

SGMUH-40D@, SGMGV-44D@,

SGMSV-50D@

SGMGV-1ED@- -

--

- -

SGMCS-07B@ -

SGMCS-02B@, SGMCS-05B@,

SGMCS-04C@, SGMCS-10C@,

SGMCS-14C@, SGMCS-08D@,

SGMCS-17D@, SGMCS-25D@

SGMCS-16E@, SGMCS-35E@ -

SGMCS-45M@, SGMCS-80M@,

SGMCS-80N@

--

--

--

--

-

--

SGLGW-40A140@

SGLGW-40A253@,

SGLFW-20A@,

SGLFW-35A120@

-

SGLGW-60A253A@

SGLFW-35A230@,

SGLFW-50A200@

-

SGLFW-50A380@,

SGLFW-1ZA200@

SGLTW-35D170@,

SGLTW-50D170@

SGLFW-1ZD200@

SGLTW-35D320@,

SGLTW-50D320@

-

SGLFW-1ED560@,

SGLTW-40D400@

SGLTW-80D400@

28 AC servo systems

Page 29

Battery backup for absolute encoder (for CN2 encoder cable)

Symbol Name Model

E

Battery JZSP-BA01

USB personal computer cable (for CN7)

Symbol Name Note

H

USB Mini Connector cable JZSP-CVS06-02-E

Note: when the encoder cables with a battery case JUSP-BA01 are used, no battery is required for CN1 (between pin 21 and 22). Battery for CN1 is ER6VCN3.

Cable (for CN5)

Symbol Name Model

F

Analog monitor cable R88A-CMW001S

DE9404559

Note: doble shield USB cable recommended

Cable for Safety Functions (for CN8)

Symbol Name Model

I

Note: when using the safety function, connect this cable to the safety devices.

Even when not using the safety function, use servo drive with the Safe Jumper

Connector (JZSP-CVH05-E) connected.

Safety connector with 3 m cable (with

Loose Wires at one End)

JZSP-CVH03-03-E

Mechatrolink-II cables (for CN6)

Symbol Specifications Length Model

G Mechatrolink-II Terminator resistor JEPMC-W6022

Mechatrolink-II Cables 0.5 m JEPMC-W6003-A5

Filters

Symbol Applicable servo drive Filter model Rated current Rated voltage

1 m JEPMC-W6003-01

3 m JEPMC-W6003-03

5 m JEPMC-W6003-05

10 m JEPMC-W6003-10

20 m JEPMC-W6003-20

30 m JEPMC-W6003-30

J SGDV-A5A@@A-OY,SGDV-01A@@A-OY, SGDV-02A@@A-OY, SGDV-04A@@A-OY R88A-FI5-1005-RE 5 A 250 VAC single-phase

SGDV-08A@@A-OY R88A-FI5-1009-RE 9 A

SGDV-15A@@A-OY R88A-FI5-1016-RE 16 A

SGDV-05D@@A-OY, SGDV-10D@@A-OY, SGDV-15D@@A-OY R88A-FI5-3004-RE 4.3 A 400 VAC three-phase

SGDV-20D@@A-OY, SGDV-30D@@A-OY R88A-FI5-3008-RE 8.6 A

SGDV-50D@@A-OY R88A-FI5-3012-RE 14.5 A

Connectors

Specification Model

I/O connector kit (for CN1) R88A-CNW01C

Sigma-5 drive encoder connector (for CN2) JZSP-CMP9-1

Safe Jumper Connector JZSP-CVH05-E

Computer software