NS SERIES

O n e - t o u c h m a c h i n e ma n a g e m e n t

»

H i gh - q ua l i ty sc re en wi th 3- ye ar wa rra nt y

»

Connect to any device

»

‘ D ra g & D ro p ’ s i m p l i c i t y of Sma r t Ac t i v e Pa r t s

Total control at your fingertips

Omron’s NS series looks like a normal HMI, but

it is not. Designed on Smart Platform, the NS series

provides enhanced communication even across

multiple networks, to manage all devices in

a machine for true industrial machine management.

We provide functions to let you perform diagnoses

and maintenance to make your machine competitive

in an easy way. This is why we call it: one touch

Machine Management. And that’s why it’s more than

just an HMI terminal!

3

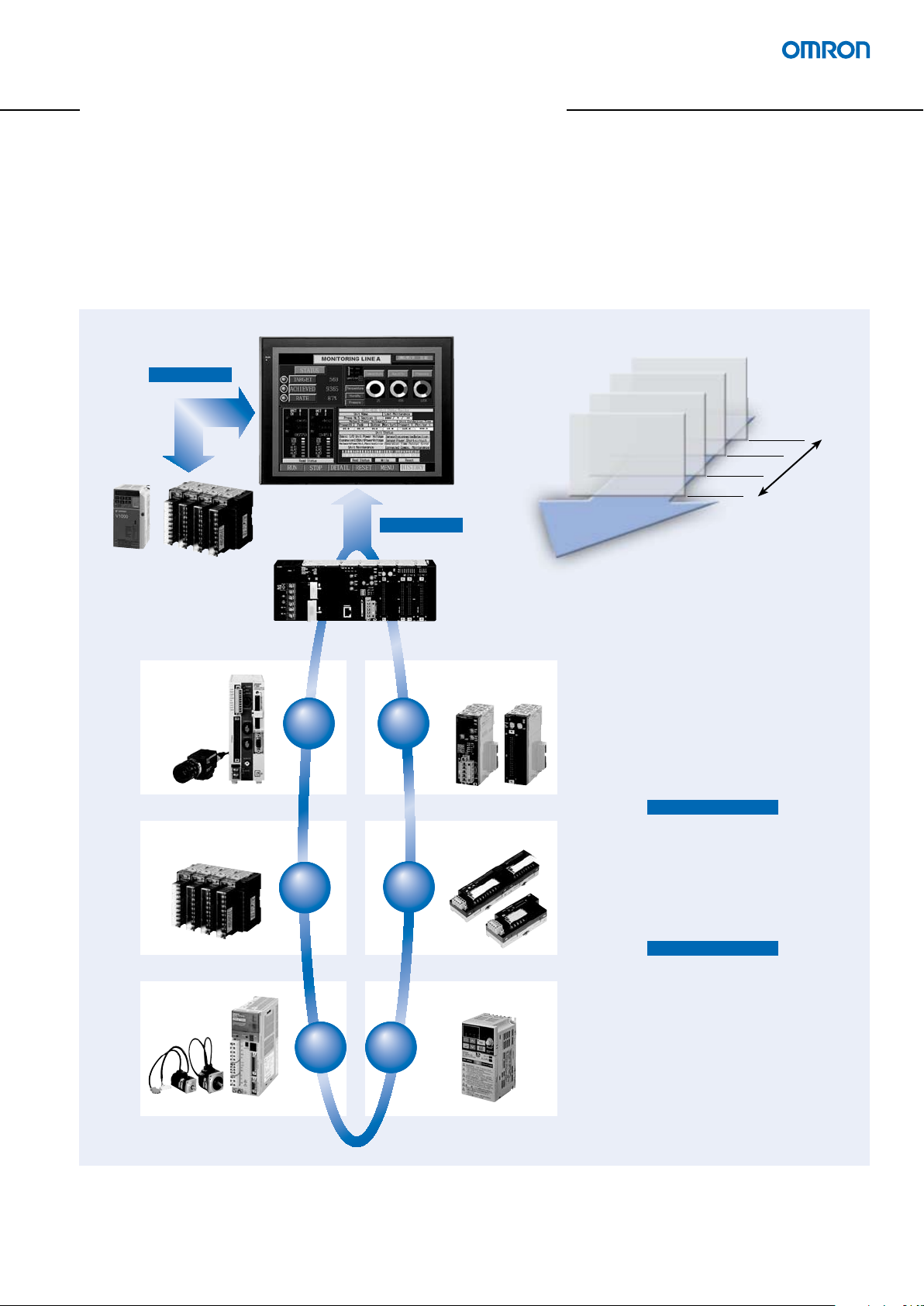

Outstanding connectivity

Used together with Omron PLCs and other field-

programmable devices, such as temperature controllers and

inverters, the NS series gives enhanced communication and

programming capabilities, even across multiple networks,

allowing you to manage all devices in your machine from

a single terminal.

A built-in USB connection enables simple and fast connection

of peripherals, while a built-in Ethernet interface allows fast

connection to multiple PLCs and computers.

The NS series is also capable of connecting to many non-

Omron devices to give you total flexibility in managing

your machine.

YEAR

WARRANTY

Machine management tool vs. HMI terminal

The NS HMI has, beside the generic HMI functions, many

other functions to be able to use the NS as a real machine

management tool. With the NS HMI you can configure,

commission, maintain and operate many Omron devices and

even third party devices. This means you can simple configure

some settings, display errors or statuses, up- and download

parameters all with the NS HMI terminal.

The NS HMI allows you to create and use the diagnostics

functions for many devices you need to manage your machine.

By providing diagnoses and maintenance functions on the

NS, Omron allows a full insight into the machine’s state and

the flexibility to quickly troubleshoot on-site with minimum of

work for the machine builder, system integrator or end-user.

Proven reliability

For over a decade Omron has been a global supplier

of HMI solutions and high-reliability industrial touch-screen

technology. Omron has supplied more than 500,000 pieces

of HMI through more than 200 Omron Sales & Support offices

world-wide, each offering after-sales support, service and

training in local languages.

Sysmac One

Integrated Machine Management: Sysmac One series

The Sysmac One series combine an NS touch screen with

a powerful CJ1 PLC and the choice of different network

interfaces in a compact housing occupying less panel space.

Complete transparency enables the PLC, network (including

field devices) and HMI to be accessed via a single port – a big

advantage when servicing your machine remotely.

With the Sysmac One you get the best of both worlds:

One touch Machine Management HMI and the flexible, fast

and easiest logic controller in the market.

Smart Platform

Omron’s Smart Platform concept enables complete machine

and plant automation from one single platform without

having to worry about field buses, integration of various

software and above all without being locked into one

dominant supplier. Smart Platform will minimize the time

and effort you spend on automation.

http://smartplatform.info/

4

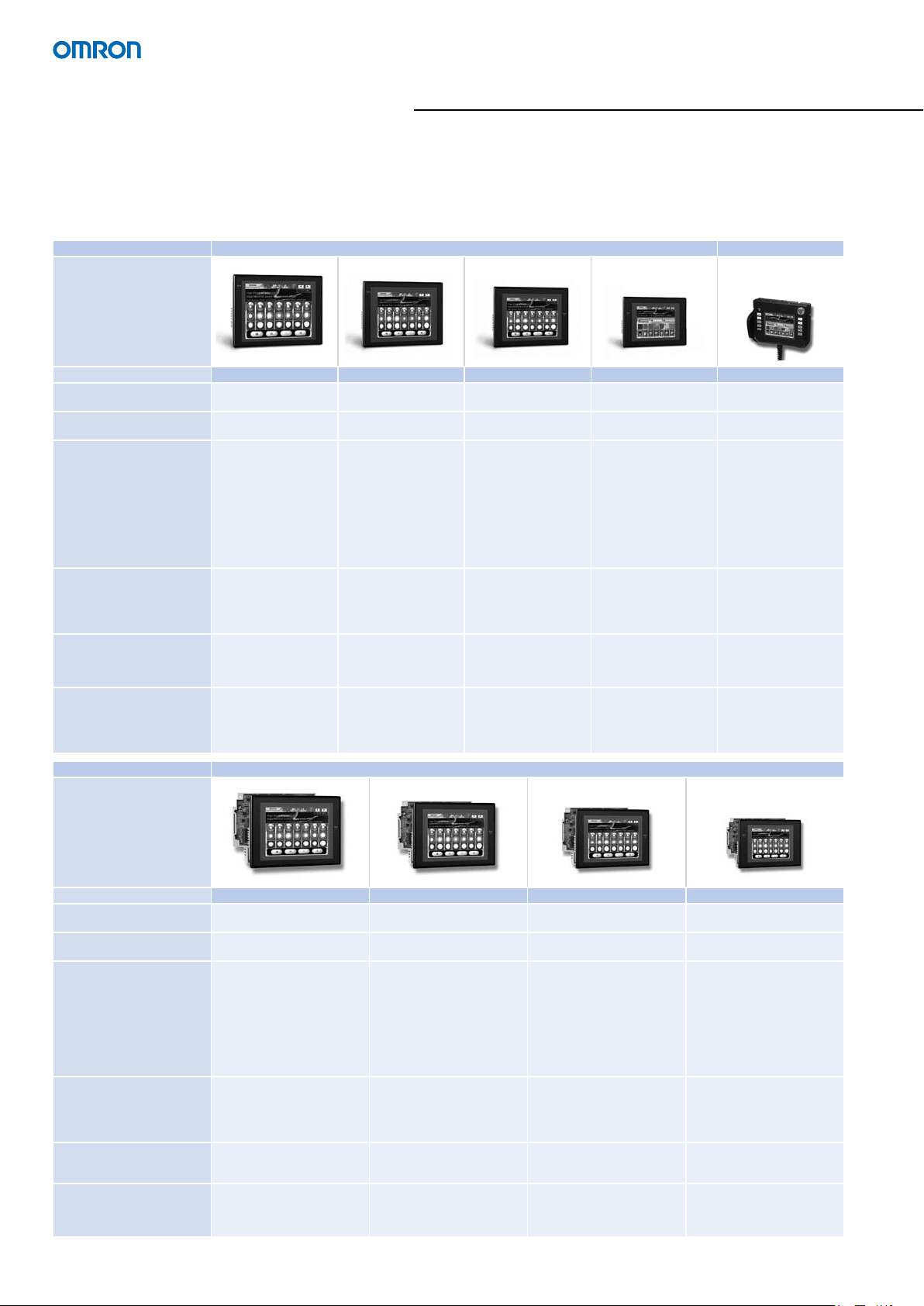

NS Series Portfolio

Advanced HMI – NS

Model NS12 NS10 NS8 NS5 NS5 Handheld

Display 12.1 inch TFT colour 10.4 inch TFT colour 8.4 inch TFT colour 5.7 inch Monochrome or

STN/TFT colour

5.7 inch STN colour

Resolution 800×600 pixels 640×480 pixels 640×480 pixels 320×240 pixels 320×240 pixels

Number of colours 256

(32,768 for image data)

256

(32,768 for image data)

256

(32,768 for image data)

Monochrome 16 greyscales, STN/TFT 256

colours

(STN 4096, TFT 32,768

for image data)

256 colours

(4096 colours for

image data)

Memory Size 60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

Options Ethernet,

Controller Link,

Video input board

(RGB/Composite)

Ethernet,

Controller Link,

Video input board

(RGB/Composite)

Ethernet,

Video input board

(RGB/Composite)

Ethernet RS-232 or RS-422

communication

depending on cable

Size in mm (HxWxD) 241×315×48.5 241×315×48.5 177×195×48.5 142×195×54 176×223×70.5

(excl. emergency

button)

HMI & Control – SYSMAC One

Model NSJ12 NSJ10 NSJ8 NSJ5

Display 12.1 inch colour TFT 10.4 inch colour TFT 8.4 inch colour TFT 5.7 inch colour TFT or STN

Display Size / Resolution 246×184.5 mm

(800×600 pixels)

215.5×162.4 mm

(640×480 pixels)

170.9×128.2 mm

(640×480 pixels)

117.2×88.4 mm

(320×240 pixels)

Control CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1M-CPU13;

20k-steps program memory,

32k-words data memory,

logic instruction time 0.04 µs

CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1M-CPU13;

20k-steps program memory,

32k-words data memory,

logic instruction time 0.04 µs

Communication DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

Expansion (1 board max.) Ethernet, Controller Link,

I/O extension

Ethernet, Controller Link,

I/O extension

Ethernet, Controller Link,

I/O extension

Ethernet, Controller Link,

I/O extension

Size in mm (HxWxD) Without expansion unit

241×315×73.3

With expansion unit

241×315×89.3

Without expansion unit

241×315×73.3

With expansion unit

241×315×89.3

Without expansion unit

177×232×73.3

With expansion unit

177×232×89.3

Without expansion unit

195×142×79

With expansion unit

195×142×95

4 NS SERIES

Advanced Industrial Automation

5

Outstanding Connectivity

Save time on programming and designing with Smart Active Parts

Unlike conventional visualization objects, Smart Active Parts communicate, across multiple networks, with their corresponding devices. They can

be used to configure, commission, operate and maintain these devices, without a single line of code needed to be written in the PLC or the HMI.

This allows you to add powerful functionality to your application within minutes.

Inverter

PLC

Temperature

Controllers

Inverter

NS

Vision

Sensor

Temperature

Controllers

CPU Bus

Units

and

Special I/O

Units

Vision

Sensor

260,000-colour

video input

Temperature

Controllers

CPU, I/O and Communication Units

Remote I/O

Inverter

Servomotor

Servo Driver

Remote I/O

Terminal

Easy Access

Easy Access

Servomotor

Servo Driver

Easy Access

Easy-to-use Software

The NS-series HMI

makes it easy to connect

to the PLC and many

other devices and show

data data from them

without any PLC programming.

With Smart Active Parts

you can support functions

to be performed on-site

without using Software

programs, like CX-Programmer or CX-Thermo.

1. Create a new project

3. Choose a Smart Active Part

4. Configure the communication

settings

2. Open the Smart Active

Parts Library

Click and Configure in four steps.

few minutes

5NS SERIES

6

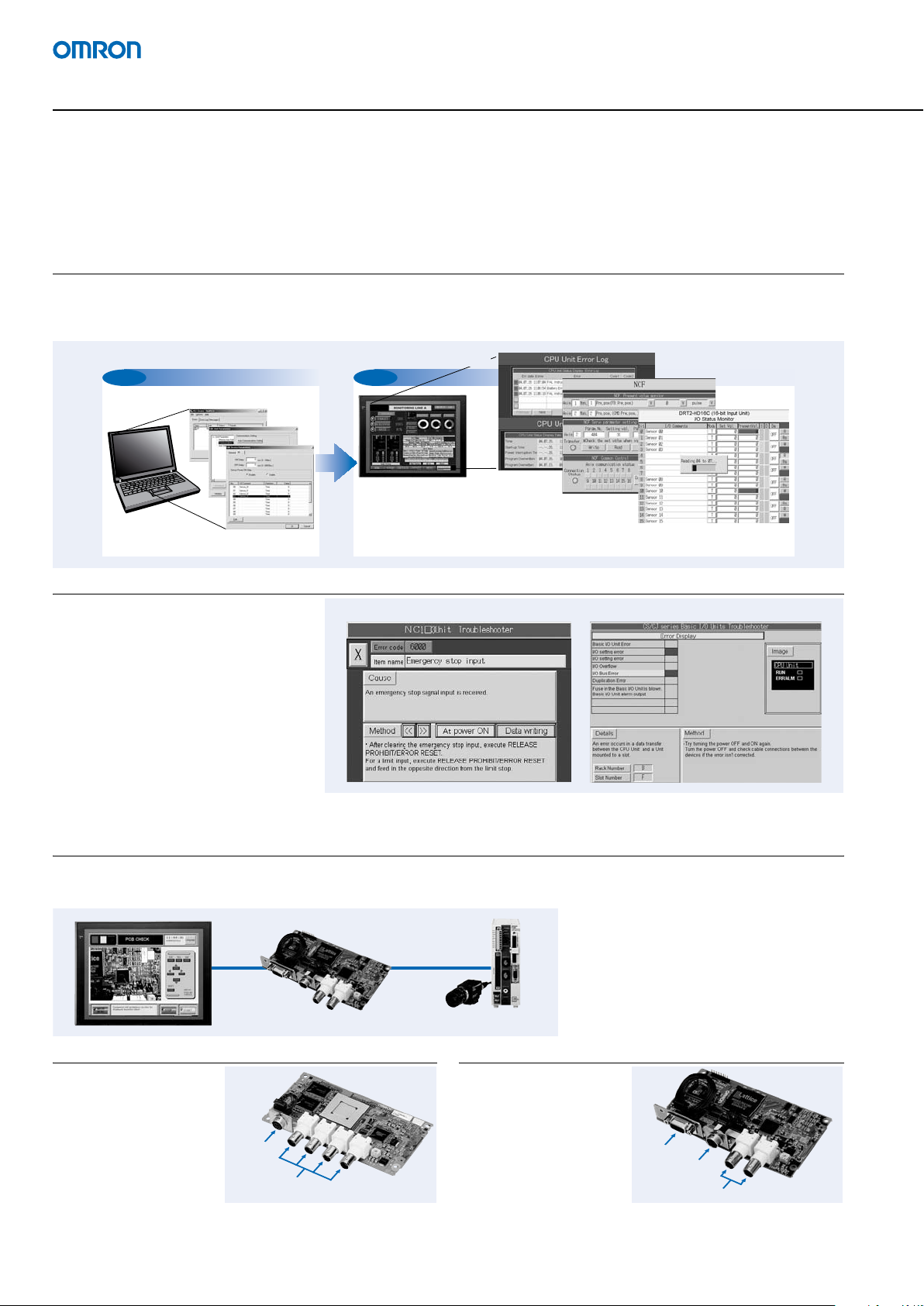

Using Smart Active Parts: just a few simple steps

Dramatically reduces the effort required to create ladder programming and screens.

A library with more than 2,000 Smart Active Parts is available, which can directly access OMRON PLCs and other devices. You can drag & drop

Smart Active Parts in an application in just 4 simple steps.

With Smart Active Parts you can for instance monitor device errors in understandable text, donwload parameters to devices and check Network

statuses without the need for a computer with software tools.

The SAP library also provides PLC I/O Unit Troubleshooter SAPs

Troubleshooter Smart Active Parts are available

to troubleshoot specific PLC units. When an error occurs in an unit, the Troubleshooter SAP

provides an easy-to-understand explanation of

the cause of the error as well as which counter

measures to take to resolve the error.

In this way you can quickly resolve errors onsite even without using documentation.

260,000-colour Video Display

Display the production steps on the HMI via optional video inputs!

Two kinds of video interfaces are available to connect to various applications. Provides compatibility with OMRON Vision Sensors (F150, F160,

and F250) in addition to video and CCD camera connections. The NS-series HMI contain some useful functions like capturing and browsing images

and operating the Console functions in the vision sensor.

NS-CA001 Video Input Unit

Four video inputs or CCD

cameras can be connected

and up to four images can be

displayed simultaneously if

the image size is

320x240 pixels.

NS-CA002 RGB/Video Input Unit

There is an analog RGB input

terminal in addition to the two

video input terminals. Either

the video signals or the

analog RGB signal can be

displayed on the NS-series

HMI.

Computer support tools

PLC CPU Unit

monitoring

screen

From To

DeviceNet

monitoring screen

NCF Unit

setting screen

Example screens using support tool objects (Tool Function SAP Library)

Troubleshooter SAP for a Position Control Unit Troubleshooter SAP for Basic I/O Unit

NS

RGB/Video Input Unit Vision Sensor

Console

Camera

NS-CA001

Console

RGB

Camera

NS-CA002

6 NS SERIES

Loading...

Loading...