Page 1

HOST CONNECTION MANUAL

Programmable Terminals

NS-Series

NS12-TS00(B)-V1, NS12-TS01(B)-V1

NS10-TV00(B)-V1, NS10-TV01(B)-V1

NS8-TV00(B)-V1, NS8-TV01(B)-V1

NS8-TV10(B)-V1, NS8-TV11(B)-V1

NS5-SQ00(B)-V1, NS5-SQ01(B)-V1

Cat.No. V085-E1-02

Page 2

Notice

OMRON products are manufactured for use according to proper procedures by a

qualified operator and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual.

Always heed the information provided with them. Failure to heed precautions can result

in injury to people or damage to property.

! DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

! WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

! Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word "Unit" is also capitalized when it

refers to an OMRON product, regardless of whether or not it appears in the proper name of the

product.

The abbreviation "Ch," which appears in some displays and on some OMRON products, often

means "word" and is abbreviated "Wd" in documentation in this sense.

The abbreviation "PLC" means Programmable Controller.

The abbreviation “host” means a controller, such as an IBM PC/AT or compatible computer,

that controls a PT (Programmable Terminal).

Visual Aids

The following headings appear in the left column of the manual to help you locate different

types of information.

Note

Reference

1, 2, 3...

CS1G-CPU@@-VI Boxes in model numbers indicate variable characters. For example,

© OMRON, 2004

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, or by

any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is

constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for

errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in this

publication.

Indicates information of particular interest for efficient and convenient operation of

the product.

Indicates supplementary information on related topics that may be of interest to

the user.

1. Indicates lists of one sort or another, such as procedures, checklists, etc.

"CS1G-CPU@@-EV1" indicates the following models: CS1G-CPU42-EV1,

CS1G-CPU43-EV1, CS1G-CPU44-EV1, and CS1G-CPU45-EV1.

1

Page 3

Contents

Notice .................................................................................................................................1

About this Manual .................................................................................................................6

Related Manuals...................................................................................................................7

Terminology ..........................................................................................................................8

Introduction ...........................................................................................................................9

Section 1 Possible Combinations

1-1List of combinations

1-2NS-Designer and System Program version

Section 2 Connection of Temperature Controller

2-1Outline

2-2Possible combinations

2-3Configuration

2-4Setting projects

2-5Monitor variables area in temperature controller

2-6Operation of temperature controller

2-7Functional restrictions

Section 3 Connection via Memory Link

3-1How does Memory Link work

3-2Setup

3-3Communications procedures

3-4What has been changed since NT31/631

Page 4

About this Manual

Section 1 Possible Combinations

This section provides information of possible combination of NS-Designer and system program when making connection

with PT and host other than OMRON PLCs.

Section 2 Connection of Temperature Controller

This section provides information on connection methods and communications setting in connecting NS-series PTs with

a Temperature Controller by serial port. It also provides information Temperature Controller which can be connected to

the PT.

Section 3 Connection via Memory Link

This section describes information on connection methods and communication setting in connecting NS-series PTs with

a host by Memory Link.

WARNING

Failure to read and understand the information provided in this manual may result in

personal injury or death, damage to the product, or product failure. Please read each

section in its entirety and be sure you understand the information provided in the section

and related sections before attempting any of the procedures or operations given.

6

Page 5

Related Manuals

The following manuals are used for NS-series PTs. (The boxes at the end of the catalog

numbers indicate the revision code.)

NS Series -V1 Host Connection Manual.....................................V085-E1-@

Provides information on NS Series V1 models (i.e., NS12-V1, NS10-V1, NS8-V1,and

NS5-V1).

Describes how to connect the PT to the host and peripheral devices, methods to setup

communications and operation, and procedures for maintenance.

Refer to the NS Series Programming Manual (V073-E1-@) for information on PT

functions and specific operating procedures.

NS Series -V1 Setup Manual .....................................................V083-E1-@

Provides information on NS Series V1 models (i.e., NS12-V1, NS10-V1, NS8-V1,and

NS5-V1).

Describes how to connect the PT to the host and peripheral devices, methods to setup

communications and operation, and procedures for maintenance.

Refer to the NS Series Programming Manual (V073-E1-@) for information on PT

functions and specific operating procedures.

NS Series Setup Manual……………………………………………..V072-E1-@

NS Series Programming Manual ................................................V073-E1-@

NS-Designer Operation Manual..................................................V074-E1-@

Provides information on existing NS Series models (i.e., NS12, NS10, and NS7).

Describes how to connect the PT to the host and peripheral devices, methods to setup

communications and operation, and procedures for maintenance.

Refer to the NS Series Programming Manual (V073-E1-@) for information on PT

functions and specific operating procedures.

Describes the screen configurations, object functions, and host communications for the

PT.

Describes operating procedures for the NS-Designer, which is used to create the

screens displayed on the PT and transfer them to the PT. It includes screen creation

and transfer procedures.

7

Page 6

Terminology

The following terminology is used in this manual.

PT In this manual, indicates an NS-series Programmable Terminal.

NS Series

PLC Indicates a Programmable Controller in the OMRON SYSMAC CS/CJ, C, or

CS/CJ Series Indicates Programmable Controllers in the OMRON SYSMAC CS/CJ Series of

C Series Indicates products in the OMRON SYSMAC C Series of Programmable

CVM1/CV Series Indicates products in the OMRON SYSMAC CVM1/ CV Series of Programmable

Serial Communications Unit Indicates a Serial Communications Unit for an OMRON CS/CJ-series PLC.

Serial Communications Board Indicates a Serial Communications Board for an OMRON CS-series or CQM1H

Communications Board Indicates a Communications Board for an OMRON C200HX/HG/HE(-Z) PLC.

CPU Unit Indicates a CPU Unit in the OMRON SYSMAC CS/CJ, C, or CVM1/CV Series of

NS-Designer

Host Indicates the PLC, IBM PC/AT or compatible computer, or personal computer

Indicates products in the OMRON NS@@ Series of Programmable Terminals.

CVM1/CV Series of Programmable Controllers.

Programmable Controllers: CS1G, CS1H, CS1G-H, CS1H-H, CJ1G, CJ1M.

Controllers: C200HS, C200HX(-Z), C200HG(-Z), C200HE(-Z), CQM1, CQM1H,

CPM1A, CPM2A, CPM2C.

Controllers: CV500, CV1000, CV2000, CVM1

PLC.

Programmable Controllers.

Indicates the OMRON NS-Designer (NS-NSDC1-V@).

functioning as the control device and interfaced with the NS-series PT.

Programming Manual

Indicates the NS Series Programming Manual (V073-E1-@).

8

Page 7

Introduction

• Intended Audience

This manual is intended for the following personnel, who must also have knowledge of

electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems into production facilities.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and connecting FA systems.

• Personnel in charge of managing FA systems and facilities.

• General Precautions

• The user must operate the product according to the performance specifications

described in the operation manuals.

• Do not use the PT touch switch input functions for applications where danger to human

life or serious property damage is possible, or for emergency switch applications.

• Before using the product under conditions which are not described in the manual or

applying the product to nuclear control systems, railroad systems, aviation systems,

vehicles, combustion systems, medical equipment, amusement machines, safety

equipment, and other systems, machines and equipment that may have a serious

influence on lives and property if used improperly, consult your OMRON representative.

• Make sure that the ratings and performance characteristics of the product are sufficient

for the systems, machines, and equipment, and be sure to provide the systems,

machines, and equipment with double safety mechanisms.

• This manual provides information for connecting and setting up an NS-series PT. Be

sure to read this manual before attempting to use the PT and keep this manual close at

hand for reference during installation and operation.

• Safety Precautions

Do not attempt to take the Unit apart and do not

touch any internal parts while the power is being

supplied. Doing either of these may result in

electrical shock.

• Operating Environment Precautions

1. Do not install the Unit in the following places:

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the

specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to exposure to water, oil, or chemicals

• Locations subject to shock or vibration

9

Page 8

2. Take appropriate and sufficient countermeasures when installing systems in the following

locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

• Application Precautions

1. When unpacking the Units, check carefully for any external scratches or other damage.

Also, shake the Units gently and check for any abnormal sound.

2. The mounting panel must be between 1.6 and 4.8 mm thick. Tighten the Mounting

Brackets evenly to a torque of between 0.5 and 0.6 N⋅m to maintain water and dust

resistance. Make sure the panel is not dirty or warped and that it is strong enough to hold

the Units.

3. Do not let metal particles enter the Units when preparing the panel.

4. If conformance to EC Directives (Low Voltage Directive) is required, use reinforced

insulation for the power supplies.

5. Do not connect an AC power supply to the power terminals.

6. Use a DC power supply with minimal fluctuation voltage.

Rated power supply voltage: 24 VDC

(Allowable range: 20.4 to 27.6 VDC)

Capacity: 25 W min. (NTLP:INFORMATION MISSING IN JAPANESE NS5: ???W min.)

7. Do not perform a dielectric voltage test.

8. Use a twisted-pair cable with a cross-sectional area of at least 2 mm

power terminals and always use M3.5 crimp terminals. Tighten the terminal screws to a

torque of 0.8 N⋅m. Make sure the screws are properly tightened.

9. Ground the Unit correctly to prevent operational errors caused by noise.

10. Do not touch the surface of the circuit board or the components mounted on it with your

bare hands. Discharge any static electricity from your body before handling the board.

11. Confirm that the current capacity of the connected device is 250 mA or less before using

the 5-V power supply from pin 6 of the serial port A, B connectors. The 5-V output of the

PT is 250 mA max. at 5 V ±5%.

12. Turn OFF the power supply before connecting or disconnecting cables.

13. Always tighten the connector screws after connecting communications cables.

14. The maximum tensile load for cables is 30 N. Do not apply loads greater than this.

15. Confirm the safety of the system before turning ON or OFF the power supply or before

pressing the reset button.

16. The whole system may stop depending on how the power supply is turned ON or OFF.

Turn ON or OFF the power supply according to the specified procedure.

17. Start actual system application only after sufficiently checking screen data. macros, and

the operation of the program in the PC (host).

18. Always reset the power supply after changing switch settings.

19. After changing the settings of the DIP switch, always turn the power supply OFF and ON

or reset the PT.

20. Do not perform the following operations while the Memory Card is being accessed:

• Turning OFF the power supply to the PT

• Pressing the PT’s reset switch

• Removing the Memory Card

Always following the specified procedure when removing the Memory Card.

21. Do not press the touch switch with a force greater than 30 N.

22. Confirm the safety of the system before pressing touch switches.

23. Do not accidentally press touch switches when the backlight is not lit or when the display

2

to connect to the

10

Page 9

does not appear.

24. Signals from the touch switches may not be input if the switches are pressed

consecutively at high speed. Confirm each input before proceeding to the next one.

25. Before initializing screen data, confirm that existing data is backed up at the NS-Designer .

26. When changing the password with the system menu, do not reset or turn OFF the power

supply until writing is finished (i.e., until the Write Button returns to its original condition). It

may become impossible to manipulate screens if the password is not set correctly.

27. When using the device monitor, confirm the safety of the system before performing the

following operations.

• Changing monitor data

• Changing operation modes

• Forced setting or resetting

• Changing present values or set values

28. Do not use benzene, paint thinner, or other volatile solvents, and do not use chemically

treated cloths.

29. Dispose of any battery that has been dropped on the floor or otherwise subjected to

excessive shock.

30. Do not attempt to disassemble, repair, or modify the Unit in any way.

31. Dispose of the Units and batteries according to local ordinances as they apply.

32. To ensure system safety, incorporate a program that periodically calls PT operation bits

from the host side to check that the PT is properly operating.

33. Do not connect an USB connector to any device that is not applicable.

34. Before connecting an USB connector to a device, make sure that the device is free of

damage.

35. When mounting the Battery, be sure to use the correct Battery and mount it correctly.

11

Page 10

Section 1 Possible combinations

This section explains in general how to connect hosts other than NS-V1 Series

Omron PLC and whic h models to connect.

1-1List of combinations

1-2NS-Designer and System Program version

1-1

Page 11

1-1 List of combinations

This explains the configuration when host is other than Omron PLCs.

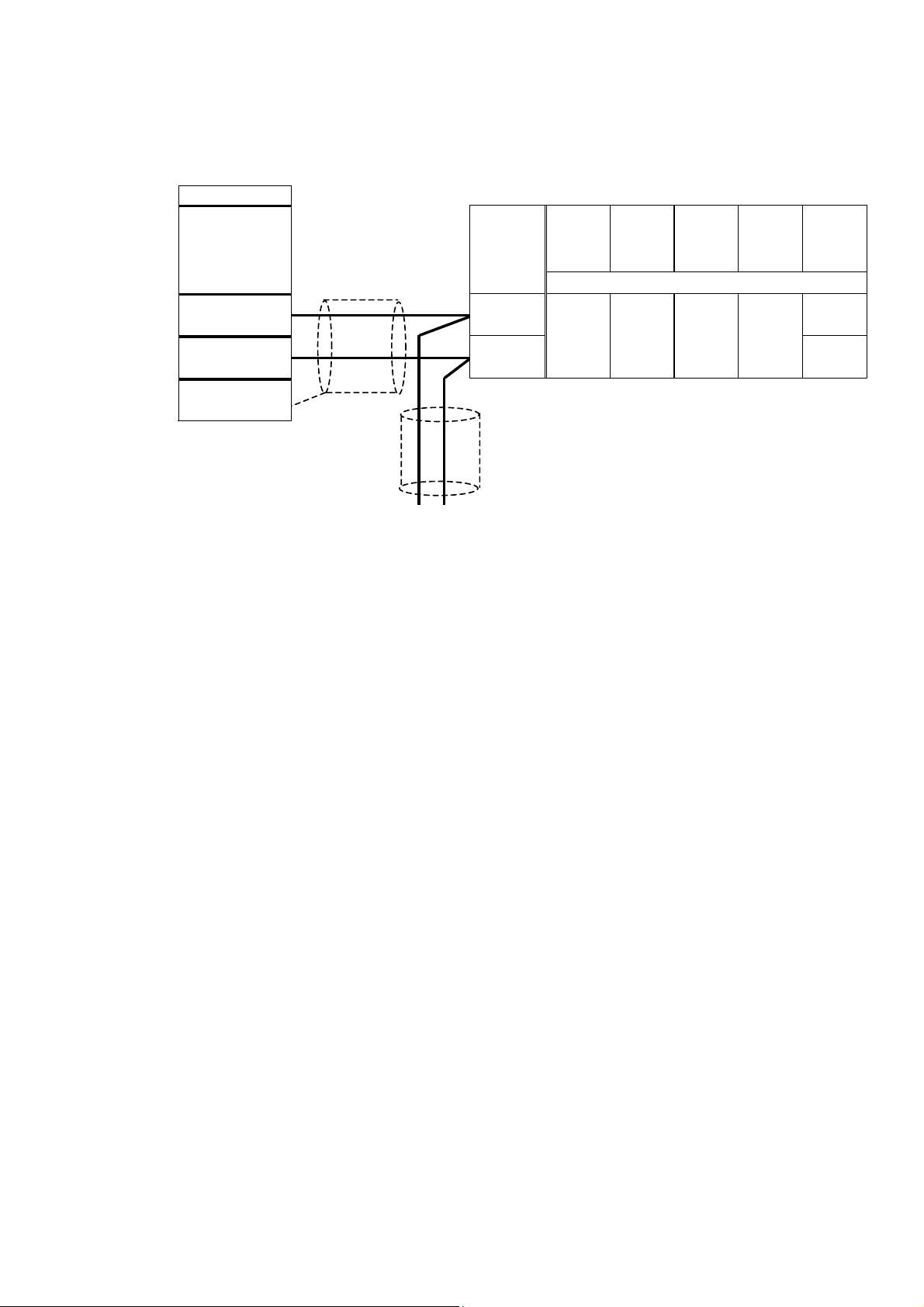

1-1-1 Connection of temperature controller

Communicates with Omron temperature controller via RS-485.

Connect RS-422 converter CJ1W-CIF11 to serial port A or B and set communication

mode to RS-485.

For details, refer to ‘Chapter 2: connection of temperature controller’.

1-1-2 Connection with memory link

When host other than PLC such as board-controller and personal computer is used,

connection via memory link is possible. Use serial port A or B to connect host equipment.

For details, refer to ‘chapter 3: connection via memory

link’.

2

Page 12

1-2 NS-Designer and System Program versions

1-2-1 NS-Designer versions

With NS-Designer Ver.5.0 or later version, you can create and edit projects for

Temperature Controller connections and Memory Link connections.

1-2-2 System Program versions

System program Ver.5.0 or later.

A copy of this version is included NS-Designer Ver.6.0.

NS with -V1 suffix models (NS12/10/8/5 –V1) are supported for those connections.

NS without –V1 suffix models are not supported.

When system program version is earlier than Ver.5.0, you need to upgrade. For details

on how to upgrade, refer to the manual (PDF)(HowToRecoverUpdateVer.6_Eng) in

NS-Designer.

3

Page 13

Section 2 Connection of temperature controller

This section explains how to connect Omron temperature controllers (E5□N)

and digital controllers (E5AR/ER) and which models to connect.

2-1Outline

2-2Possible combinations

2-3Configuration

2-4Setting projects

2-5Monitor variables area in temperature controller

2-6Operation of temperature controller

2-7Functional restrictions

1

Page 14

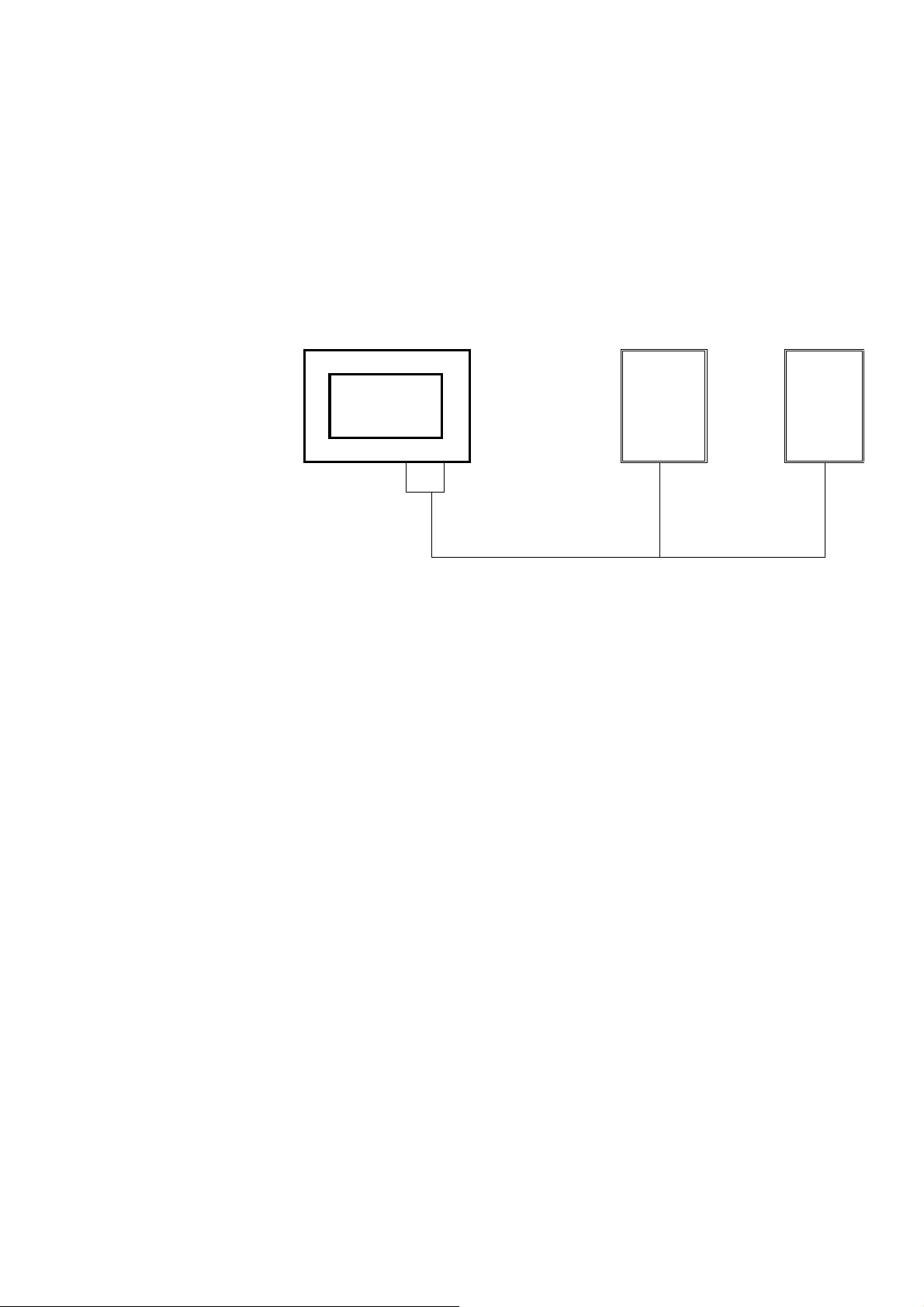

2-1 Outline

This explains how to connect temperature controllers.

Connectable are temperature controllers with a RS-485 port.

Use NS serial port A or B (either one), use converter to transform to RS-485.

1 serial port can accommodate max. 31 temperature controllers.

NS-series PT

Serial port A or B

converter

CJ1W-CIF11

By using another communications port, you can simultaneously connect temperature

controllers and a host. With one more serial port, NS can connect PLC, barcode reader,

Memory Link and can communicate with NS-Designer.

If NS is equipped with Ethernet port, communications with Omron PLC via Ethernet is

possible.

If equipped with Controller Link I/F, communication with Omron PLC via Controller Link is

RS-485

(max.

extension:50m)

Temp.

controller

Temp.

controller

2

possible.

Page 15

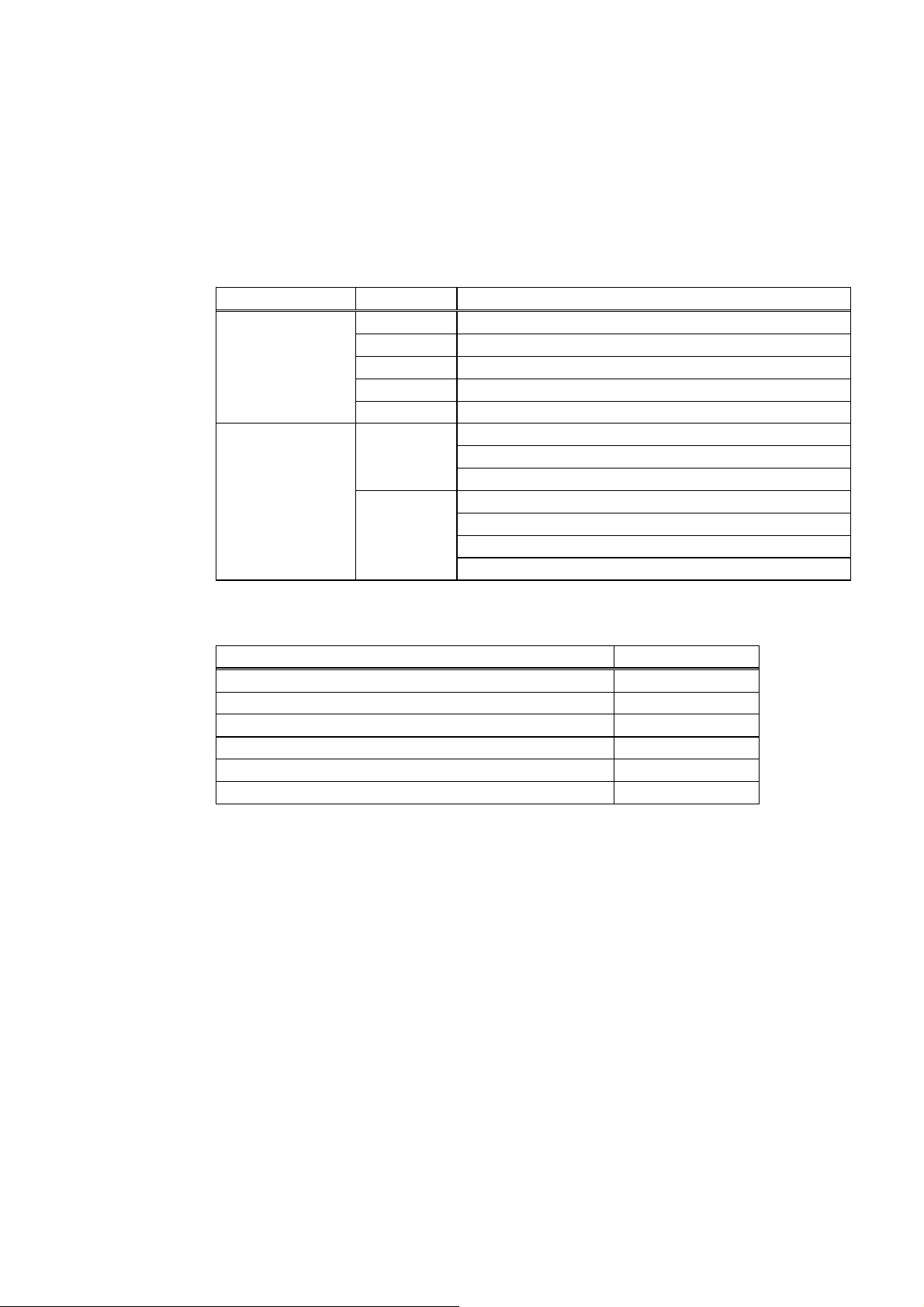

2-2 Possible combinations

2-2-1 Connectable temperature controller

Only models with RS-485 communications port that support CompoWay/F can be used.

The following models are connectable:

Name Series Model

Temperature

controller

Digital

temperature

controller

E5ZN E5ZN-SCT24S (terminal unit)

E5AN

E5EN

E5CN

E5GN

E5AR

E5ER

E5AN-□□□03□-FLK

E5EN-□□□03□-FLK

E5CN-□□□03□-FLK

E5GN-□□□03□-FLK

E5AR-QC43DB-FLK

E5AR-QQ43DW-FLK

E5AR-CC43DWW-FLK

E5ER-QC43B-FLK

E5ER-PRQ43F-FLK

E5ER-QT3DW-FLK

E5ER-CT3DW-FLK

2-2-2 Temperature controller Manuals

Manual name Catalog No.

E5CN/CN-U User’s manual H100-E1

E5GN User’s manual H101-E1

E5□N User’s manual Communications functions

E5EN User’s manual H111-E1

E5AN User’s manual H112-E1

E5AR/ER User’s manual Z182-E1

H102-E1

3

Page 16

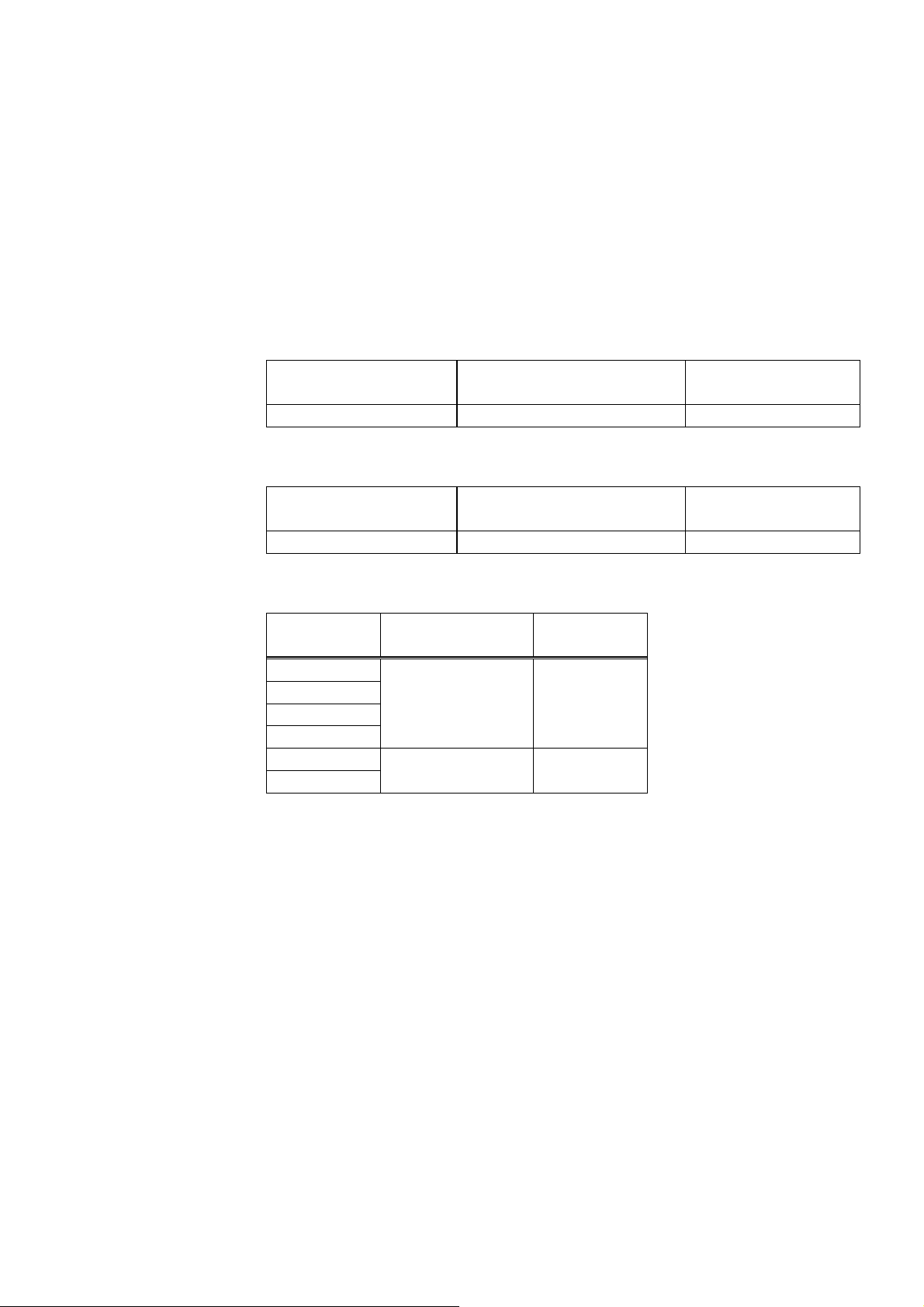

2-3 Configurations

2-3-1 Necessary parts

■RS-422A Converter

CJ1W-CIF11

■Crimp terminal

●CJ1W-CIF11side communications path terminator

Phoenix Contact AI Series

AI-0.5-8WH-B

Crimp tool ZA3 (serial No. 1201882)

●CJ1W-CIF11 side other than communications path terminator

Phoenix Contact AI series

AI-TWIN2×0.5-8WH

Crimp tool UD6 (serial No. 1204436)

●Temperature controller side

Model Terminal block

screw size

E5CN

E5GN

E5EN

E5AN

E5ZN

E5ER/AR

M3.5 7.2mm max.

M3 5.8mm max.

Terminal size

(serial No. 3201369)

(serial No. 3200933)

4

Page 17

2-3-2 Wiring diagram

NS side Temperature controller side

CJ1W-CIF11

SDB(+)

SDA(-)

FG

E5AN

E5ZN

terminal

B(+) 23 11 5 C1 F1

A(+) 24 12 6 C2 F2

E5EN

E5CN

E5GN E5ER E5AR

Terminal number

To next temperature

controller

■ Connection: 1:1 or 1:N. If 1:N, max. 32 units (NS and temperature controllers

combined) can be connected. (in case of E5ZN, the maximum is 16 units).

■ Cable length: In total max. 50 m

■ Use shielded twist pair cables (min. size AWG28)

■ Connect terminating resistance (100 to 125 Ω (1/2W) to both ends of the

communications path. Furthermore, combined resistance must be 54Ω min.

5

Page 18

2-3-3 Temperature controller communications settings

This summarizes temperature controller communications settings.

For more details on settings and operation procedure of setting specifications, refer to the

relevant temperature controller manual.

■ E5ZN

Setup Switch on E5ZN panel

Unit number

0 to 15

Baud rate

Communications setting level

CH Value

Data bits C3 0013 or

C3 0113

Stop bits C3 0014 or

C3 0114

Parity C3 0015 or

C3 0115

Response

Waiting time

C3 0016 or

C3 0116

0 4800 Bps

1 9600 Bps

2 19200 Bps

When using multiple E5ZN units, be

careful not the use the same number

twice.

7 7 bits

2 2 bits

2 Even (EvEn)

0 to 270FH

( 0 t o

9999)

In ms

■ E5GN/E5AN/E5EN/E5CN/E5ER/E5AR

Adjustment level L.Adj

CoWt

writing

Communications setting level L.S

Baud rate bPS

Data bits LEn 7 7 bits

Stop bits Sbit 2 2 bits

Parity Prty EvEn Even

Response

Waiting time

Communications

Unit No.

Protocol select PSEL CyF Compoway/F (E5AR/ER only)

SdWt 0 to 270FH

U-no 0 to 31 E5AR/ER only

on enable Communications

OFF disable

2.4

4.8

9.6

19.2

38.4

( 0 to

9999 )

In kbps

Set all communicating temperature

controllers to match parameters of NS

E5ER/AR: choose between

9.6/19.2/38.4

E5□N: 38.4 cannot be selected.

In ms

E5AR/ER range: 0 to 63H(0 to 99)

6

Page 19

2-3-4 CJ1W-CIF11 setting

Dip switch setting

Pin No. Function setting

1

2

3

4 Not used -

5

6

Terminal resistance

select ON/OFF

Switch between 2/4 line

system

Switch between 2/4 line

system

RD control by RS

select ON/OFF

SD control by RS

Select ON/OFF

ON Terminating resistance (on both

ends of the communications

path)

OFF No terminating resistance (other

than both ends of the

communications path)

ON

ON

OFF

ON RS control function ON

2 line system

2-3-5 NS setting

Before you can connect temperature controllers, you need to store the required project in the

NS. For project setting, refer to ‘2-4 project setting’.

With communications settings under system menu, you can set the speed of

communications.

Baud rate 2400 / 4800 / 9600 / 19200 / 38400 / 57600 /115200 bps

Of these values, 57600 / 115200 are for future use.

Present temperature controllers cannot operate at these rates.

Set PT unit and temperature controller baud rate values to match each other.

7

Page 20

2-4 Setting Project

With this function, you set projects needed to connect temperature controllers.

Select

Select tab

Select Temperature Controller from the pull down menu for Serial Port A ( or Serial B).

Setting - System Setting.

Comm - All

.

System Setting dialogue opens.

Select tab Serial Port A (or Serial Port B) and set baud rate.

Selectable baud rate values are:

2400 / 4800 / 9600 / 19200 / 38400 / 57600 / 115200 (in bps).

Baud rates 57600 / 115200 are for future use. Present temperature controllers cannot

operate at these rates.

8

Page 21

Next, click

controller model to be connected.

Settings

Register Host

-

. Host Registration Dialogue opens. Define temperature

9

Page 22

2-5 Monitor variables area in temperature controller

2-5-1 Variables area in temperature controller

Data stored in variable area of the temperature controller are: Present Value, SP, Heater

burnout alarm status and such.

By reading/writing these data from PT, you can monitor temperature controller status.

Values of variables you can display on PT screen as numbers and you can create save the

changes of those as log data.

Temperature controller status (variable C0, address 0001) is information on bit level. You can

show status by ON/OFF lamp and you can display/save the history log that shows status

changes.

Address of variable are in a Temperature Controller should be assigned to the lamps,

numeral display and input object, or graphs before monitoring the variable area.

Accessible address ranges vary with temperature controller models.

For details on accessible address ranges and definitions of settable address ranges,

numerical values and contact status, refer to the following manuals.

Model Manual

Number

E5AN E5EN E5CN

E5GN

E5ZN H112-E1 5, 5.10 Variables area map

E5AR E5ER Z182-E1 Appendix Settings list

NS-Designer shows accessible address range in accordance with the model specified in the

Register Host dialog so that user can set an appropriate communication address.

H102-E1 3

Chapter

10

Page 23

You can also manually enter a communications address, which is not listed without opening

Address Setting dialog. In this case, enter the desired address directly to the field shown in

the property dialog.

11

Page 24

#

#

2-5-2 Address notation in NS-Designer

Address notation when accessed using word (address for word

communications)

<port>

Address when accessed using bit (address for bit communications)

<port>

Item Value range & definition

<communications

unit No. >

<Variable type> C0 to D7

<Channel> 00 to 03 ch1 to ch4

<Address>

<Pit position> 00 to 31

:

<Communications

unit No..>

:

<communications

unit No.>

SerialA Connected to serial port A <Port>

SerialB Connected to serial port B

00 to 31

<Variable

category>

<Variable

category>

variable

category

C0 to C3 00 to 3F

C4 to CB 00 to 7F

CC to D7 00 to 3F

Address range

<Channel> <Address>

<channel> <address>

<bit

.

position>

Example:

SerialA:24#C4001C PortA:Unit No.24/area category C4/ch1/address 1CH

SerialB:17#D1036E.3 PortB:Unit No.17/area D1/ch4/address6EH/bit3

2-5-3 Use of double word numbers

Variable area in the Temperature Controller is composed of values in double-word

format(32bit length). Negative values are expressed as the two’s complement.

Therefore, select DINT(signed 2 words) as storage type for the variable, which the

decimal value will be stored. Select UDINT(unsigned 2 words) for the variable, which

the hexadecimal value will be stored.

2-5-4 Communications writing enabled/disabled

Before you can write to variable area in temperature controller, you need to go to the

adjustment level and set Communications writing on Enabled: ON. (Default

setting is Disabled: OFF).

For monitoring only, so when no writing is carried out, the setting can be either

Disabled: OFF or Enabled: ON.

12

Page 25

Use either the panel on the Temperature Controller or Setting Tool to set

“Communications Writing” parameter. It can be also set with Smart Active Parts in the

PT.

13

Page 26

2-6 Operation of Temperature Controller

The use of Smart Active Parts, allows you to operate PT screen to change Temperature

Controller running conditions and to disable/enable communications writing.

2-6-1 How to create a Smart Active Part s part

In NS-Designer, you open the arrange Smart Active Parts screen.

When you select

Under list of categories, tree of selectable libraries is shown.

Smart Active Parts for temperature controller you can find under

Parts_E -> Temperature Controller.

Tools - Use Library

, the library dialogue opens.

PartsLib -> Smart Active

14

Temperature controller is grouped by model, channel and broadcast. For each operation

instruction, a Smart Active Parts part is available.

There are 2 categories: Instructions to the unit itself and broadcast .

When same instruction is given to all units, no results response is sent. For that reason error

judgment is omitted.

Page 27

Selectable Smart Active Parts are shown in the preview box on the right. Title of the selected

Smart Active Parts are shown in the bottom center dialogue box.

Select appropriate Smart Active Parts and click

By doing so, the selected Smart Active Parts is pasted onto the screen that is being edited.

The Smart Active Parts part is pasted onto the upper left corner of the screen. Move to the

desired location.

Or, click the Smart Active Parts part and set communications parameters.

Use.

SerialA :when connected to serial port A port to which command

is

SerialB :when connected to serial port B

sent

Destination Unit No.

0 to

31

:Communications unit No. of the

temperature

controller you want to operate.

With broadcast to all parts, this parameter

is not used. Keep default value 0.

15

Page 28

When you want to change the label and color setting of the Smart Active Parts, go to Tools –

Options – Edit/Disp tab and check the Edit Smart Active P arts pro pert ies . Double clic k on

the desired object to open the property dialog and the settings can be changed.

Do not change the communications address when editing the settings. Once it has been

changed, the Smart Active Parts will not function properly anymore.

Furthermore, once you have selected certain options, you cannot set Smart Active Parts

communications settings anymore. So when you want to modify the communications settings,

deselected options.

16

Page 29

2-6-2 Smart Active Parts Operations

Smart Active Parts for Temperature Controllers are grouped by Temperature Controller

model, channel, instruction to single unit/broadcast, control details.

Smart Active Parts title indicates the operating instruction to be executed.

■Communications writing enabled/disabled

You can either enable or disable the writing of set values from communications.

When communications writing is disabled, the writing of set values from

communications and the execution of certain instructions is prohibited.

Default setting is set as

By executing Smart Active Parts

communications writing,

If communications writing is not enabled before writing set values with numeral display

& input object or word button, an error occurs.

Furthermore, by disabling communications writing, you can avoid that set values are

being changed by accident.

A summary of executable/non executable instructions when communications writing is

disabled, is given in table ‘2-6-3 Smart Active Parts list’.

■

Setting area 0/setting area 1

Temperature controller communications has 2 operation modes: setting area 0 and

setting area 1.

Disable

.

Enable communications writing/Disable

you can switch between enabled/disabled.

In setting area 0, control operations are conducted. You cannot modify any set values

that negatively affect the control operations. When power supply is turned on, this mode

is selected.

In Setting area 1, the control operations are stopped. You can modify the set values

protected in Setting area 0.

You can switch to Setting area 1 by executing Smart Active Parts part ‘Move to setting

area 1’.

To change from Setting area 1 to Setting area 0, you can either turn the power off and

then back ON again or you can execute Smart Active Parts part: “ Software Reset”.

Executable operating instructions vary depending on which mode is selected: setting

17

Page 30

area 0 or 1.

Non executable in setting

Area 0

Non executable in setting

Area 1

Initialize set values AT execute/cancel

Move to protect level

Auto/manual

PV hold

18

Page 31

■Confirm command results

Under certain conditions e.g. communications writing disabled, it can happen that a

selected Smart Active Parts instruction cannot be executed.

But, when performing the broadcast, no response is given. In that case there is no

check as to whether the action was completed successfully or not.

Theref,ore adopt a method that checks if the operation was carried out properly, e.g.

lamp indication.

Model

Common

E5ZN

E5□R

Title

(operating instruction)

Communications writing

disabled

Communications writing

enabled

run ch1 CO 0001.24

stop ch 2 CO 0101.24

AT execute ch1 CO 0001.23

AT cancel ch 2 CO 0101.23

Writing mode: back-up ch1 CO 0001.20

Writing mode: RAM ch 2 CO 0101.20

auto ch1 CO 0001.26

manual ch2 CO 0101.26

Cancel alarm 1 latch ch1 C00001.12 to 15

Cancel alarm 2 latch ch2 C00101.12 to 15

Cancel alarm 3 latch

Cancel all alarm latches

Cancel alarm latch

SP mode: local SP ch1 C00001.27

SP mode: remote SP ch 2 C00101.27

Select bank: 0 to 7

AT execute

(confirm executing PID

group No.)

Addresses to be monitored

ch1 CO0001.25

ch 2 CO 0101.25

ch1 CO 0001.22 Move to setup area 1

ch 2 CO 0101.22

*1

ch1 C00001.12 to 15

ch 2 C00101.12 to 15

ch 3 C00201.12 to 15

ch 4 C00301.12 to 15

*1

ch 1 C40408

ch 2 C41408

ch 3 C42408

ch 4 C43408

ch 1 C4040A

ch 2 C4140A

ch 3 C4240A

19

Page 32

ch4 C4340A

*1 Confirm that alarm output has become OFF.

Attention: Under certain conditions such as PV that an alarm

might be output, you cannot confirm because alarm output

remains high even when the latch is cancelled

20

Page 33

2-6-3 List of Smart Active Parts

broadcast

For

for single unit

and

commands respectively.

Model CH Title

(operating instruction)

E5□N

E5ZN

Common

Common

CH1/

CH2 /

Communications writing

disabled

Communications writing

Enabled

Run Start control (run).

stop Stop control (stop).

Multi SP: select target

Value 0

Multi SP: select target

value 1

Multi SP: select target

value 2

Multi SP: select target

value 3

AT execution

AT cancel

Writing mode: back up

Writing mode: RAM

Save RAM data

Reset soft Reset software

Move to setup area 1 Move to settings area 1

Move to protect level Move to protect level

Communications

writing

disabled

Communications writing

enabled

Writing mode: back up

Writing mode: RAM

Save RAM data

Reset soft

Move to setup area 1 Move to settings area 1

Move to protect level Move to protect level

PV hold Save Present value at time of execution.

Initialize parameters Set parameters to default values

Run Start control (run)

stop Stop control (stop)

Outline *1

switch between Communications writing

Enabled/disabled.

Switch between multi SP target values

Execute/cancel AT

Select whether or not to write

operation/adjustment

internal non-volatile memory when writing

from communications

Write operation

settings to internal non-volatile memory.

Switch between communications writing

enabled/disabled.

/ adjustment level

settings to

Select whether or not to write

operation/ adjustment

internal non-volatile memory when writing

from communications

Write operation

settings to internal non-volatile memory.

Reset soft。

/ adjustment

level settings to

level

○

×

○

×

○

21

Page 34

All CH

*1:cannot be executed when communications writing is disabled.

When you execute an operating instruction designated to all channels, models other than the

analog output type E5ZN do not operate properly.

Multi SP:select target

Value 0

Multi SP: select target

Value 1

AT execute Execute AT

AT cancel Cancel AT

auto

manual

Cancel alarm 1 latch

Cancel alarm 2 latch

Cancel alarm 3 latch

Cancel all alarm latches

Switch between multi SP target values

Switch between auto-operation/manual

operation

Cancel alarm latch

×

22

Page 35

Model CH Title

(operating instruction)

E5□R

*1:cannot be executed when communications writing is disabled.

Common

CH1/

CH2/

CH3/

CH4/

All CH

CH1/

CH2

communications writing

disabled

Communications writing

enabled

Writing mode: back up

Writing mode: RAM

Save RAM data

Reset soft Reset soft

Move to setup area 1 Move to setup area 1

Move to protect level Move to protect level

Initialize parameters Set parameters to default values

Run Start control (run)

Stop Stop control (stop)

Switch bank 0

Bank Switch 1

Bank Switch 2

Bank Switch 3

Bank switch 4

Bank switch 5

Bank switch 6

Bank switch 7

AT execution:selected

PID

AT execution: PID 1

AT execution: PID 2

AT execution: PID 3

AT execution: PID 4

AT execution: PID 5

AT execution: PID 6

AT execution: PID 7

At execution: PID 8

AT cancel

Auto

manual

Cancel alarm latch Cancel alarm latch

SP mode: local SP

SP mode: remote SP

Switch between communications writing

enabled/disabled

Select whether or not to write

operation/adjustment level

internal non-volatile memory when writing

from communications

Write operation

settings to internal non-volatile memory.

Switch setting bank of target value, alarm

value, PID group No. setup bank

Execute AT with presently selected PID

or

with designated PID group No. PID.

Cancel A T

Select between Auto-operation/manual

operation

Select SP mode (local SP/remote SP).

outline *1

○

settings to

/adjustment level

×

○

×

When you execute an operating instruction designated to all channels, models other than the

analog output type E5ZN do not operate properly.

23

Page 36

2-7 Restrictions

2-7-1 The behavior of 2 word number in the NS-Designer test function

In the temperature controller, a value equivalent to 2 words (32 bits) is stored for each

communications address, but in the test function, the first 16 bits and the last 16 bits behave

as one and the same value. For that reaso n, test function will not operate successfully wh e n

2 word numbers are designated.

2-7-2 Address display when address error occurs

When faulty device is set to communications address set in functional object, this

communications address is displayed in the device setting error dialogue.

If the communications address is allocated to the temperature controller, not the address for

the temperature controller set with the NS-Designer, but the address in the PLC address

format is displayed. Addresses will be converted as shown below.

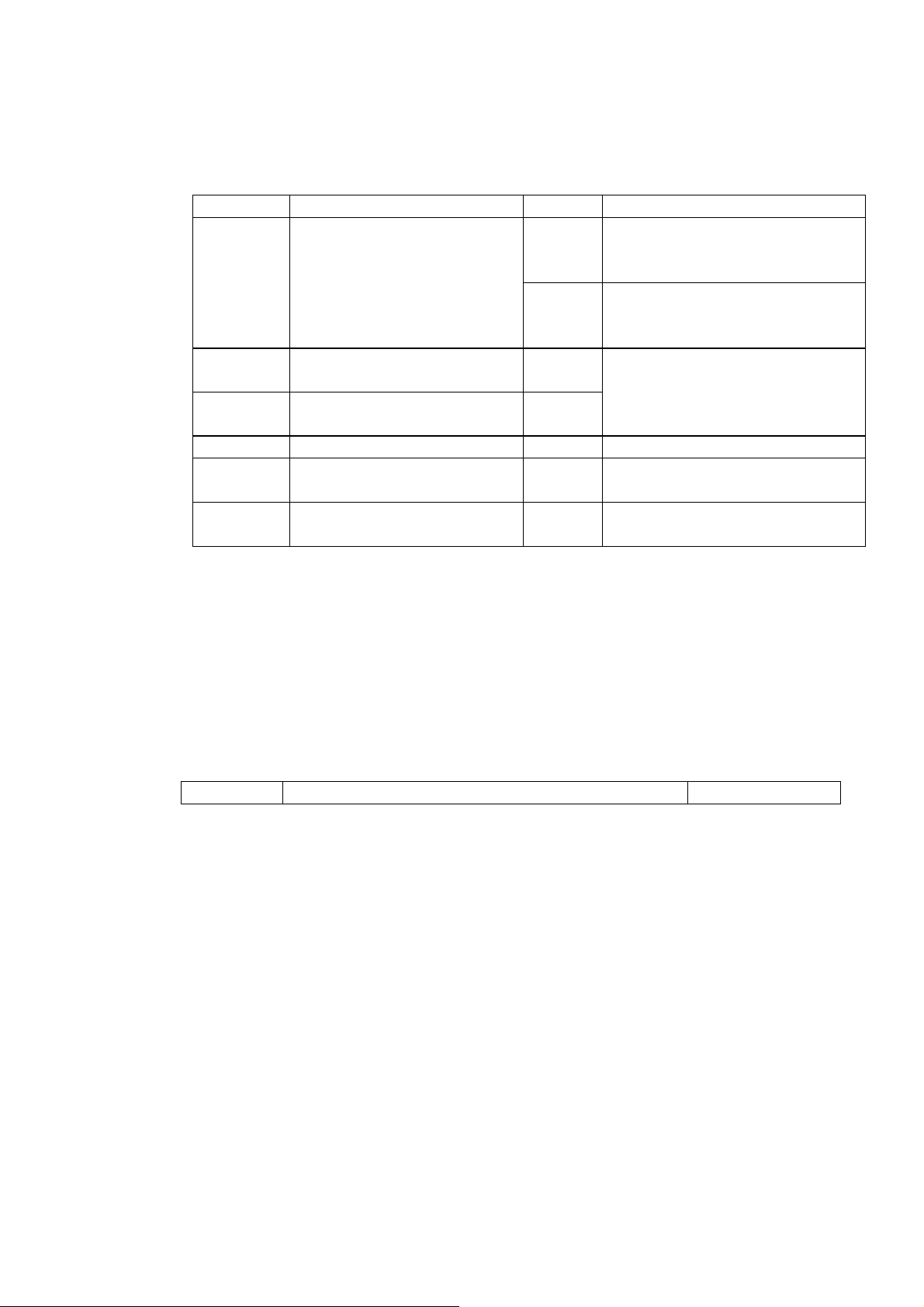

Address displayed when faulty device is set to communications address

<Device>

3 2 1 0 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 7 6 5 4 3 2 1 0

Unit No.

0 to 31

0

Ch

0-3

<variable>

0000 to 7FFF

Word address

0 to F

<address>

0000 to 007F

0 0 0 0

00 to 15

Bit position

Bit position

0 to 31

CH address of temperature controller

<Device>

Unit

No.

Temp

<Variable >

controller

Variable

<Address>

DM 0 1 0 C0 C1 0000 to 003F

EM 2 3 1 C2 C3 0040 to 007F

EM0_ 4 5 2 C4

EM1_ 6 7 3 C5

EM2_ 8 9 4 C6

EM3_ 10 11 5 C7

EM4_ 12 13 6 C8

0000 to 007F

EM5_ 14 15 7 C9

EM6_ 16 17 8 CA

EM7_ 18 19 9 CB

EM8_ 20 21 A CC CD 0040 to 007F

EM9_ 22 23 B CE CF 0000 to 003F

EMA_ 24 25 C D0 D1 0040 to 007F

EMB_ 26 27 D D2 D3 0000 to 003F

EMC_ 28 29 E D4 D5 0040 to 007F

WR 30 31 F D6 D7 0000 to 003F

24

Page 37

Device setting errors are not likely to occur. This because, setting is done using the method

by which a selection is made from a list of accessible addresses for each temperature

controller model.

However, in below cases in which the address is not selected from the list of accessible

addresses an invalid address may have been assigned. In such a case, a device setting

error may occur.

! Communications address set when functional object was copied using

repeat command when index was assigned.

! Communications address set by ‘Allocate Addresses Aut omatically ’ in the

frame property.

! Communications address set by using the macro function.

Furthermore,

! Writing to read-only area

! Writing while communications writing was prohibited

cause device setting errors to occur.

2-7-3 Communications address set when functional part was copied

using repeat command

In NS-Designer, you can select functional object and when you then execute ‘repeat’ , you

can copy while communications addresses are being added.

The temperature controller’s address is a double word address. To increment a double word

address by 1, you need to increment a single word address by 2.

Address in NS-Designer is expressed as a 1 word address. When repeat command is used

to copy functional object, 1 word is added to 1 word address.

For that reason, when communications address offset width is 1 while repeat command is

used, part with the same communications address is copied twice.

Actual address Internal address

Double word Single word

+0 +0 Address originally set for functional

object

+0 (0.5) +1 Omit figures below decimal0.5->0

+1 +2

+1 (1.5) +3 Omit figures below decimal 0.5->0

For that reason, set always offset in multiples of 2 to specify communi cations

address with single word access.

25

Page 38

Section 3 Connection via Memory Link

This chapter explains the Memory Link function and how to use it to

connect host computer.

3-1How does Memory Link work

3-2Setup

3-3Communications procedures

3-4What has been changed since NT31/631

1

Page 39

3-1 How does Memory Link work

3-1-1 PT memory

With Memory Link you assign objects w ord and bit to PT mem ory. PT memory i s an

imaginary PLC area inside the NS. NS performs read/write operations to internal PT

memory. Host reads/writes PT memory as required and so controls and monitors NS.

PT memory consists of 2 territories: Bit ($B) and Word ($W).

PT memory can be also used to store functional object display cha racter strings or as

data area for the macro function.

3-1-2 Command and response

With Memory Link, the following commands enable data transmission between host

and PT.

- Read-out command / response

This is the command for reading out PT memory of PT.

When host gives command, PT responds the contents of the designated data.

There are 2 com mands t hat v ary with t he t ype of PT memor y.

Command Title Action

RM Read out PT ($W) memory Read out $W da ta in PT memory

RB Read out PT ($B) memory Read out $B data i n PT memor y

- Write command/response

This is the command to write designated data to PT memory area in PT.

Host gives command. PT responds whether or not the writing was completed

successfully.

The successful completion response may be omitted by particular setting the

Response parameter in the communications conditions menu.

The following 4 comman ds can be giv en:

Command Title Action

WM Write to PT memory ($W) Write data to PT memory $W

WB Write to PT memory ($B) Write data to PT memory $B

FM FILL PT memory ($W) Write designated data to multiple

FB FILL PT memory ($B) Write designated data (0 or 1) to

PT memory $W

Multiple PT memory $B.

2

- Notify Command

Page 40

This is the command to communicate the results of PT operations to host.

PT gives command. For that reason, there is no response.

The following 2 comman ds can be giv en.

command Title Action

SM PT memory ($W) change

notice

SB PT memory ($B) change

notice

- Error response

Response from PT when the received command is an invalid one.

Command Title Action

ER Error response Notify host of comman d erro r

3-1-3 Action when command is used

There are 5 flows of communications between host and PT, depending on the type of

command and Response Settings in Communications conditions.

Notify host of PT memory $W

changes.

Notify host of PT memory $B

changes.

- Write data command while [response: OFF]

[Host] [PT]

Send command

Process command

- Write Data command while [response: ON]

- Read-out data co mman d

- Invalid command

[Host] [PT]

Send command

Process command

receive response Send response

Write data command

- PT to host communications

[Host] [PT]

PT operation

Change PT

Receive change

notice command.

Communicate command Send change

Receive com mand

command

Receive com mand

memory

notice command

3

Page 41

3-1-4 Notify Command Behavior

When anything has changed in the PT memory, by e.g. touch switch operation on PT,

numerical input or character string input, PT sends change notice command to host.

In addition to Memory Link connection, PT memory ser ves other purposes as well. If

all changes would be communicated to host, the host would be burdened more than is

needed. For that reason, PT communicates only changes from a designated number

and up. Changes in PT memo ry areas w ith a low er numb er are not commun icate d.

Set the number in Communications conditions -> Start Communication $B and Start

Communication &W.

$W

$W0

no notice Number

Notice start $W

notify command

Number

Only changes from specified $W number and up

3-1-4 Flow control

When too many commands are sent, PT cannot process timely. Communications

buffer overflows. Commands and command sequence get lost.

For that reason, set Communications conditions Response to ON when PT to host

command interval frequency becomes high.

PT

operation

input

input

are communicated to host using the

change notice Command.

4

Page 42

3-2 Settings

3-2-1 Making settings for the Project

The Memory Link can be used in combination with

NS system program Ver. 5.0 and later versions

System Ver.5.0 and la ter pr ojects

With NS-Designer V5.0 and later, you can create and edit project developed by System

Ver.5.0 and later pr oject s.

A project created with NS-Designer Ver. 4.0 or earlier can be opened and converted to

the data of Ver.5.0 and later.

In NS-Designer Ver. 5.0 or later open SystemVer.5.0 and later project, click

System Setting

Memory Link

(select from th e pull down m enu).

. Select tab ‘

Comm.– All’

and set Serial Port A (or Serial Port B) to

Settings

–

You cannot simultaneously set Serial Port A and B to

Memory Link

.

5

Page 43

3-2-2 Communications conditions setting

In NS-Designer, select tab ‘Comm.-All’ Serial Port A (or Serial Port B) and set to the

following communications conditions.

Parameter Set value Default value

Baud rate 9600bps / 19200bps / 38400bps 9600bps

Data bits 7 / 8 7

Stop bits 1 / 2 1

Parity None / even / odd none

response OFF / ON OFF

Notice start $B 0 to 32767 16384

Notice start $W

0 to 32767 16384

3-2-3 NS system menu operation

You can also use the NS system menu to set the communications conditions for

the Memory Link connection.

Under system menu, click tab

By pressing the key beside the Serial Port A or Serial Port B, you can switch between

communications met hods.

unused

NT Link 1:1

NT Link 1:N

Bar code reader

Temperature controller

Memory L ink

Host Link

Modem

After you have thus set communications to Memory Link, use the Details key to set

Communications Setting.

↓

↓

↓

↓

↓

↓

↓

6

the communications conditions for the Memory Link connection (for details, refer to

section 2.2). However, with system menu you cannot set the

Notice start $W

.

Notice start $B

and

Set values are no t saved until you press the

Write

key. Also, setting changes will be

effective when you turn the power OFF and then ON again.

Page 44

3-2-4 Connection Diagram

Use either NS Serial Port A or B to connect host computer via Memory Link.

You cannot simultaneously set Serial Port A and B to Memory Link.

The connecting cable varies with the specifications of the host computer

communications port.

Below is a typical example, which shows the wiring diagram when DOS/V PC is

connected.

9pin

Dsub(Female)

3 SD

2 RD

7 RS

8 CS

5 SG

DOS/V PC

Dsub(Male)

9pin

SD 2

RD 3

RS 4

CS 5

SG 9

NS-series PT

Above wiring is identical with the NS to and from NS-Designer wiring.

If the cable lengt h is conf orm, you can us e the f ollowin g cable w ith co nnector.

XW2Z-S002 Omron product

Cable length 2m, 9 pin ⇔9 pin

7

Page 45

y

3-3 Communications procedures

3-3-1 Memory Link Commands

Command/response formats are as mentioned below.

• Read/write/change notify command

ESC command *S *A *L *D SUM CR

• Read/write command (In above-mentioned format, the *L is regarded as

1 (fixed))

ESC command *S *A *D SUM CR

• Write all (FILL) command

ESC command *S *A *B *D SUM CR

• Read type command normal completion response format

ESC command *A *L *D SUM CR

• Other responses

ESC command *D SUM CR

ESC ($1B) Initial Command: ESC($1B) fixed

1 English capital letters which di splay the

type of command

Designates SUM omissi on and *L omission. In

some cases, specifies writ e to mem ory attribut es

as well.

SUM OFF: SUM computing by host can be omitted.

SUM ON: enables judgment if command is invalid

as a result of noise interfe rence.

Initial read/write address

Last Write all (FI LL) addres s

The checksum of the c omman d resp onse is the 2

digit code in hexadecimal which is indicated using

lower one-b

te of the total sum from the ESC to

8

command 2 characters

*S 1 character

*A

*B

*L BCD 2 digits Number of read/write elements

*D Variable length Data section

SUM

Hexadecimal

4 digits

Hexadecimal

4 digits

2 characters

(may be

abbreviated)

Page 46

CR ($0D) Command end: CR($0D) fixed

Memory Link commands are as follows:

Command Command title Action

RM Read PT memory ($W) Re ad cont ents of $W dat a

RB Re ad PT mem ory ($B) Read contents of $B data

WM Write PT memory ($W) Write to $W data

WB Write PT memory ($B) Write to $B data

FM

FB

SM PT memory ($W) change notice Communicate $W changes to host

SB PT memory ($B) change notice Communicate $B changes to host

Fill PT memory ($W) Fill multiple sequential $W with the

Fill PT memory ($B) Fill multiple sequential $B with the

the *D. It can be abbrevi ated by s pec ifying *S. Be

sure that it is added when PT is tran smitting .

same value

same value.

9

Page 47

RM Read PT memory ($W)

Read $W data in PT memory.

Per command, a maximum of 100 words can be read.

Response is up to 50 words per response.

When requesting command is parameter 2: number of words exceeds 51, then the

response is split into two. The first response sends 50 words, the second response

sends the remaining channels.

When entries were made on NS in between the first and second response, change

notice command is not sent until after the second response has been sent.

• Command format

ESC command *S *A *L SUM CR

$1B R M $0D

[Settings]

*S

*A 0000 to

*L 00 to 99 N umber of read-o ut wor ds (BCD 2 digits )

Sum value

0 OFF

1 ON

8 OFF

8 ON

Initial address No. (hexadecimal 4 digits)

7FFF

00 indicates 100.

Omit *L.

Number of read-out words: 1 (fixed)

• Successful completion response format

ESC command *A *L *D SUM CR

$1B R M Variable length $0D

[Settings]

*A 0000 to

7FFF

*L 01 to 50 Number of rea d-out w ords (BCD 2 digit s)

*D 0 to FFFF

“,”

Initial address No. (hexadecimal 4 digits)

Word data (zero suppressed hexadecimal 1 to 4 digits)

From 2

next data.

nd

word onward, enter comma “, “( $2C) before t he

10

Page 48

RB Read PT memory ($B)

Read $B data in PT memory.

Per command, a maximum of 100 bits can be read.

After reading, bit data are displayed and returned per 8 bits as 8 bit value.

• Command format

ESC command *S *A *L SUM CR

$1B R B $0D

[Settings]

*S

*A 0000 to

*L 00 to 99 Re ad-out bit number (BCD 2 digits)

BCD1digit Sum

value

0 OFF

1 ON

8 OFF

9 ON

Initial address No. (hexadecimal 4 digits)

7FFF

00 indicates 100.

Number of tables: 1 (fixed ). Omit Paramet er2.

• Response format

ESC command *A *L *D SUM CR

$1B R B Variable

length

$0D

[Settings]

*A 0000 to

7FFF

*L 00 to 99 Number of bits (BCD 2 digits)

*D 00 to FF Bit data (hexadecimal 2 digit value of 8 bits each)

Initial address No. (hexadecimal 4 digits)

00 indicates 100.

0:OFF, 1: ON

Fills addresses in ascending order starting with first digit.

Turns 8 bits into a binary 8 digit value and displays this as a

hexadecimal 2 digit value. The next hexadecimal 2 digit

value continues with the following 8 bits.

Fills any of the last 8 bits that does not actually have a val id

read-out data with 0.

[example]

from $B10 6 bits have read-out value

11

Page 49

$B10 11 12 13 14 15 * *

1 0 1 0 1 1 0 0 → AC (converted to

hexadecimal form)

12

Page 50

WM Write to PT memory ($W)

Write to $W data in PT memory.

Per command, a maximum of 50 words can be written.

As writing attribute you can select SET, AND, OR, or XOR.

• Command format

ESC command *S *A *L *D SUM CR

$1C W M Variable

[Settings]

$0D

length

*S

*A 0000 to

*L 01to 50 Number of de stinat ion wor ds (BCD 2 digi ts)

*D 0000 to

BCD1digit

0 OFF

1 ON

2 OFF

3 ON

4 OFF

5 ON

6 OFF

7 ON

8 OFF

9 ON

7FFF

FFFF

“,”

SUM Writing

attribute

SET

AND

OR

XOR

SET

Initial address number (hexadecimal 4 digits)

Word data (zero suppressed hexadecimal, 1 to 4 digits)

From 2

data.

Data ending with comma cause error.

nd

word on, enter comma [,] ($2C) before next

Writes designated value just

as it is.

Ands present value of

destination with designated

value and writes outcome .

Ors present value of

destination with designated

value and writes outcome

Xors present value of

destination with designated

value and writes outcome .

Omits *L .

Number of destination

words : 1

(fixed)

• Normal completion response format (only when response under

communications conditions is ON).

ESC command *D SUM CR

$1B W M 0 0 $0D

[Settings]

13

Page 51

*D 00 fixed. Indicates successful

completion.

14

Page 52

WB Write PT memory ($B)

Write to $B data in PT memory.

Per command, a maximum of 100 bits can be written.

• Command format

ESC command *S *A *L *D SUM CR

$1B W B Variable

[Settings]

$0D

length

*S

*A 0000to7FFF Initial address number (hexadecimal 4 digits)

*L 00to99 Entry bit number (BCD 2 digits)

*D 00 to FF Bit data (hexadecimal 1 digit value for 4 bits each)

BCD1 digit SUM value

0 OFF

1 ON

8 OFF

9 ON

When 00, 100 is meant.

0: OFF, 1: ON

Fills data in descending order starting with first digit.

Turns 4 bits into a binary 4 digit value and displays this

as a hexadecimal 1 digit value. The next hexadecimal 1

digit value continues with the following 4 bits.

Fills any of the last 4 bits that does not actually have a

valid read-out dat a with 0.

[example]

from $B10, 6 bit s have re ad-out value

$B10 11 12 13 14 15 * *

1 0 1 0 1 1 0 0 → AC (converted to

hexadecimal form)

Bit number: 1 fixed. Parameter 2 omitted.

• Normal completion response format (only when response under

communications conditions is ON).

ESC command *D SUM CR

$1B W B

0 0

$0D

[Settings]

*D 00 fixed. Indicates normal completion.

15

Page 53

FM Fill PT memory ($W )

Fills PT memory $W with the same word data. Range: first to last address number.

Command format

•

ESC command *S *A *B *D SUM CR

$1B F M $0D

[Settings]

*S

*A 0000 to 7FFF First address number (hexadecimal 4 digits)

*B 0000 to 7FFF Last address number (hexa decimal 4 digits)

*D 0 to FFFF Word data (zero suppressed hexadec imal 1 to 4 digits )

BCD1 digit

0 OFF

1 ON

SUM value

• Normal completion response format (only when response under

communications conditions is ON).

ESC command *D SUM CR

$1B F M 0 0 0 E $0D

[Settings]

*D 00 fixed. Indicates normal completion.

16

Page 54

FB Fill PT memory ($B)

Fills PT memory $B with the same bit data. Range: first to last address number.

• Command format

ESC command *S *A *B *D SUM CR

$1B F B $0D

[Settings]

*S

*A 0000 to 7FFF Initial address number (hexadecimal 4 digits)

*B 0000 to 7FFF Last address number (hexadecimal 4 digits)

*D 0: OFF

BCD1 digit

0 OFF

1 ON

1: ON

SUM value

Bit data (hexadecimal 1 digit)

• Normal completion response format (only when response under

communications conditions is ON).

ESC command *D SUM CR

$1B F B 0 0 $0D

[Settings]

*D 00 fixed. Indicates normal completion.

17

Page 55

SM PT memory ($W) change notice

When PT memory $W changed as a result of PT operation and when this $W address

is higher than the address designated with Notice start $W in the communications

settings menu, this command is sent from PT to host.

Response from host to PT is not needed.

When sent from host to PT, illegal command error occurs.

• Command format

ESC command *A *L *D SUM CR

$1B S M Variable

$0D

length

[Settings]

*A 0000 to 7FFF Changed address num ber (hexadecimal 4 digits)

*L 01 to 50 Number of changed words (BCD 2 digits)

*D 0000 to FFFF

“,”

Word data (zero suppressed hexadecimal 1 to 4 digits)

Divide multiple word data by comma [,] ($2C).

Data ending with comma cause error.

SB PT memory ($B) change notice

When PT memory $B changed as a result of PT operation and when this $B a ddress is

higher than the address designated with Notice start $B in the communications

settings menu, this command is sent from PT to host.

Response from host to PT is not needed.

When sent from host to PT, illegal command error occurs.

• Command format

ESC command *A *B *D SUM CR

$1B S B 0 1 $0D

[Settings]

18

Page 56

*A 0000 to 7FFF Changed address num ber (hexadecimal 4 digits)

*B 01 fixed Number of changed bits (hexadecimal 2 digits)

*D 0: OFF

1: ON

Bit data (hexadecimal 1 digit)

19

Page 57

ER Error response

• Command format

ESC command *D SUM CR

$1B E R $0D

[Settings]

*D Error codes listed bel ow (he xadecima l 2 digit s)

Error

code

01 Illegal command

02 Command length error

03 Boundary value error

04 Illegal operand

05 Comman d form at err or

10 SUM value error

12 Receptio n time out err or

Error contents cause

Command contents lie outside the supported

range

Length of received com mand is il legal for

that command.

•

• Parameter in BCD format includes others

Sum information Set value lies outside

the effective range.

$W/$B command; Data section includes

characters oth er than 0 to F an d “,”.

$W command; data section ends with “,”.

Command with sum value ON. Computed sum

value and the one in the command do not match.

After the initial ESC was received, the interval in

between receiving one byte after the other until

command end [CR] exceeded timeout monitoring

time.

Value set to parameter lies outside the

supported range.

than 0 to 9

These commands are sent from NS to host when the host sent an invalid command

and when a communications error occurred.

20

Page 58

3-4 What has changed

3-4-1 Memory Link Commands

This summarizes the points that need to be given atten tion when switching over from

NT31/631 series to NS series Memory Link.

Memory structure inside PT differs, so the structure of Memory Link commands has

changed as well.

■Memory structure inside PT

NT31/631 series NS series

PT memory

Contact

point

channel

common

0000 to 9999

Contact

point

channel $W0 to 65535

$B0 to 65535

Memory table

Battery backup

Number memory table

Character string m emory

table

bit memory table

Is performed Is not performed

none

■Memory Link command

NT31/631 series NS series

RM Read-out PT m emory Read-out PT memory ($W)

RB Read-out bit memory table Read-out PT memory ($B)

RN Read-o ut num ber memo ry ta ble RS Read-out character string

memory table

WM Write to PT memory Write to PT memory ($W)

WB Write to bit memory table Write to PT memory ($B)

FR Read-out display data comment PT Read-out system conditions WN Write to number memory table WS Write to character string memory

table

FM Fill PT memory Fill PT memory ($W)

FB - Fill PT memory ($B)

CN Clear number memory table CS Clear character string memory

table

CB Clear bit memory tabl e ST Touch switch input notice SN Number input notice -

-

-

-

21

Page 59

SS Character string input notic e PM Direct area change notice SM PT memory change notice PT memory ($W) change notice

SB - PT memory ($B) change notice

MC Switch PT operating mode RR Request resend ER Error response Error response

■Execution of contact notice to $W

While NT31/631 performs contact point change notice and channel change notice in

the same PT memory, the NS splits it into $B an d $W

There, the use of a macro, enables the contact point notice to $W.

th

E.g. Momentary swit ch sen ding n otice to 5

• Create ON/OFF button

•

Designate $B address that is not specified for any other purpose.

bit in $W1000

Destination address may be blank, but in that case the button

does not light when it is being press ed down.

• Edit macro (t ouch ON)

$W1000 = $W1000 | H10;

• Edit macro (touch OFF)

$W1000 = $W1000 & to H10 ;

■

PT memory hold

Battery backup in NT31/631 ensures that PT memory and memory table values are

kept as they were when t he po wer go es off.

Contrary to NT31/6 31, NS h as no batt ery back up and con sequent ly val ues

are cleared when the power is turned off.

NS cannot react t o an unex pecte d power f all out, but th ere is a possibi lity

to store values before the power is turned OFF.

You can save a copy of PT memory $W by saving the contents of this memory as a file

22

on a compact flash card. Then removes this car d.

As it is a file reading/writing operation to a compact flash card, it cannot be done

frequently. In addit ion, yo u cannot s ave a co py of the PT memory $B.

E.g. Manually save the PT memory $W contents.

•

Create a command butt on

Page 60

• Set function selection to No processing

•

Edit macro (touch ON)

WRITECF($W16384,16384,”PTMEM.DAT”,0);

E.g. Recover PT memor y $W cont ents f rom save d file when PT i s start ed up.

•

Edit macro when project is started up

READCF($W16384,16384,”PTMEM.DAT”, 0);

23

Page 61

Revision History

A manual revision code appears as a suf fix to the cat alog number on the cover of the manual.

Man.No. V085-E1-02

Revision code

The following table outlines the changes made to the manual during each revision. Page

numbers refer to the previous version.

Revision code Date Revised content

01 October 2003 Original production

02 July 2004 Addition of information related to NS-Designer Ver.6.0 upgrade

Page 62

OMRON CORPORATION

FA Systems Division H.Q.

66 Matsumoto

Mishima-city, Shizuoka 411-8511

Japan

Tel: (81)55-977-9181/Fax: (81)55-977-9045

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg, IL 60173

U.S.A.

Tel: (1)847-843-7900/Fax: (1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel: (65)6835-3011/Fax: (65)6835-2711

Page 63

Authorized Distributor:

Cat. No. V085-E1-02

Note: Specifications subject to change without notice.

Printed in Japan

Loading...

Loading...