Cat. No. V099-E1-05

NS-Series

CX-Designer

Ver. 3.@

NS-CXDC1-V3

USER’S MANUAL

CX-Designer

Ver. 3.@

NS-CXDC1-V3

User’s Manual

Revised December 2009

iv

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!DANGER Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury. Additionally, there may be severe property damage.

!WARNING Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury. Additionally, there may be severe property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “Ch,” which appears in some displays and on some OMRON products, often means

“word” and is abbreviated “Wd” in documentation in this sense.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

Terminology

NS-series PT A Programmable Terminal in the NS Series manufactured by OMRON.

PLC A Programmable Logic Controller manufactured by OMRON.

Host A PLC, factory computer, personal computer or other controller controlling an NS-

NS-Designer The NS-NSDC1-V@ NS-Designer produced by OMRON. The NS-Designer is an

CX-One The CXONE-AL@@C-V3/AL@@D-V3 CX-One FA Integrated Tool Package produced

CX-Designer The NS-CXDC1-V3 CX-Designer produced by OMRON.

NS-Runtime The NS-Runtime software runs on Windows XP and provides the same functionality

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

series PT.

applications software package that enables creating screen data for NS-series PTs.

by OMRON. This applications software package provides all of the software packages

for OMRON PLCs and components.

as an NS-series PT.

v

OMRON, 2008

r

f

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

vi

TABLE OF CONTENTS

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Features of the CX-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Basic Operation Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SECTION 2

Setting Up the CX-Designer. . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-1 Preparations for Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Installing the CX-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

2-3 Uninstalling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4 Installing USB Drivers for NS-Series PTs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SECTION 3

Basic Operations of the CX-Designer . . . . . . . . . . . . . . . . . . 21

3-1 Starting and Exiting CX-Designer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2 Menu Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-3 User Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

SECTION 4

Useful Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-1 Creating Screens Using Symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

4-2 Using Screens from Other Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4-3 Classifying Screens by Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4-4 Checking and Changing Functional Object Properties

without Opening Property Setting Dialog Boxes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4-5 Listing and Editing Functional Object Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4-6 Editing Overlapping Objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4-7 Creating Multi-language Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4-8 Checking Address Usage Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4-9 Searching for Embedded Macros. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4-10 Transferring Only Edited Data to PT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4-11 Creating Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4-12 How to Use Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4-13 Integrated Simulation for the Entire System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-14 Setting Security for Data Transfers with the PT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4-15 Setting Symbol Names and I/O Comments for Use as Labels . . . . . . . . . . . . . . . . . . . . . . . 63

4-16 Executing Multiple Functions with a Single Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-17 Replacing a Lamp with a Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

4-18 Creating Polygonal Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

4-19 Registering Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4-20 Using Machine Navigator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

4-21 Enlarging Objects Proportional to Screen Size during Data Conversion . . . . . . . . . . . . . . . 77

4-22 Batch-setting Label Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

vii

TABLE OF CONTENTS

Appendices

A Comparison of Functions with NS-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

B Shortcut Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

C Exchanging Data between NS-series Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

viii

About this Manual:

The CX-Designer is a software package that enables creating screens for OMRON Programmable Terminals. Please be sure you understand the functions and performance of the CX-Designer to ensure

correct application of the Programmable Terminals.

Please read this manual and related manuals carefully and be sure you understand the information

provided before attempting to use the CX-Designer.

Section 1 provides an overview of the CX-Designer and its features and explains basic operating

methods.

Section 2 describes how to install and uninstall the CX-Designer.

Section 3 describes the CX-Designer menus and basic procedures.

Section 4 describes convenient functions of the CX-Designer.

The Appendices provide a comparison between the CX-Designer and NS-Designer, tables of shortcut keys, and data transfer procedures between different versions of NS-series PT.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Guide to Version Upgrade

From CX-Designer Version 1.0 to Version 2.0

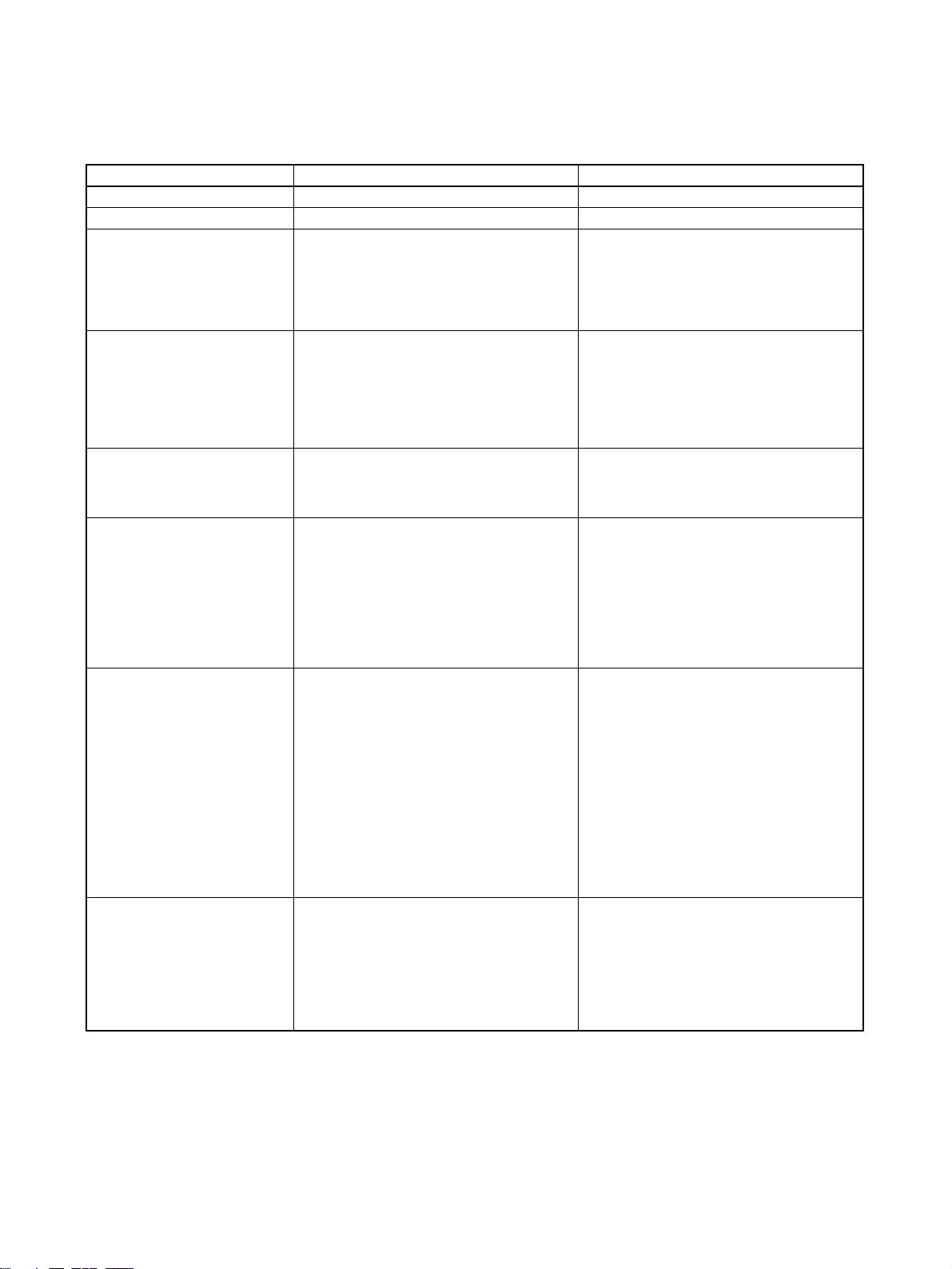

Item Previous versions New version

CX-Designer Version 1.0 (NS-CXDC1-V1) Version 2.0 (NS-CXDC1-V2)

NS system software Version 6.2 or 6.5 Version 6.6

Integrated simulation The only function available was simulated

testing of PT screen operations on a personal computer.

Symbol programming without

addresses

Multi-vendor connectivity Not supported. It is now possible to connect OMRON NS-

Data security The following two types of data transfers

User security Any of five levels of passwords could be set

Consecutive line drawing Not available. Data in memory is treated as X and Y coor-

Symbol names, addresses, and comments

were entered in symbol tables. Then the

required symbols were selected from the

symbol tables when creating screens.

are possible between CX-Designer (running on a personal computer) and a PT:

•Data transfers with the PT.

•With data transfers using a Memory Card,

data can be uploaded and downloaded by

any user.

for each functional object. A dialog box asking for the password was displayed each

time an attempt was made to use a functional object for which a password had

been set, and the object could not be used

unless the password was input.

Using a personal computer, a virtual PT

can be connected to a virtual PLC (CXSimulator) or to an actual PLC, and the

operation of the entire PT-PLC system can

be simulated. This makes it possible to

reduce the total time involved in debugging.

Symbol names and comments can be input

for symbol tables with no addresses. This

allows screens to be created using symbol

names without inputting addresses. Entering symbols in screen designs without

addresses makes it possible to reduce the

total time involved in design.

series PTs to Mitsubishi FX-series PLCs,

A-series PLCs, and Siemens S7-series

PLCs.

A password can now be set for creating

data. When data with a set password is

transferred to a PT, the password is then

required in order to upload the data. This

prevents users who do not know the password from obtaining that data from the PT.

In addition, a password can be required to

transfer data to the PT. This prevents data

from being accidentally overwritten.

Once a user inputs the password to use a

functional object for which a password has

been set, the password does not have to be

input again as long as the user continues

using only functional objects for which

lower level passwords have been set. Functional objects with a higher-level password

cannot be manipulated. (A warning message will be displayed if an attempt is

made.) This makes it possible to create

applications that permit only the necessary

operations by users who have entered

passwords, and thus helps prevent faulty

operations.

dinates, and straight lines are drawn

between the applicable coordinates to create consecutive line drawing. This makes it

possible to handle applications involving

the drawing of various graphics in twodimensional space that could not be drawn

using the existing graph components.

x

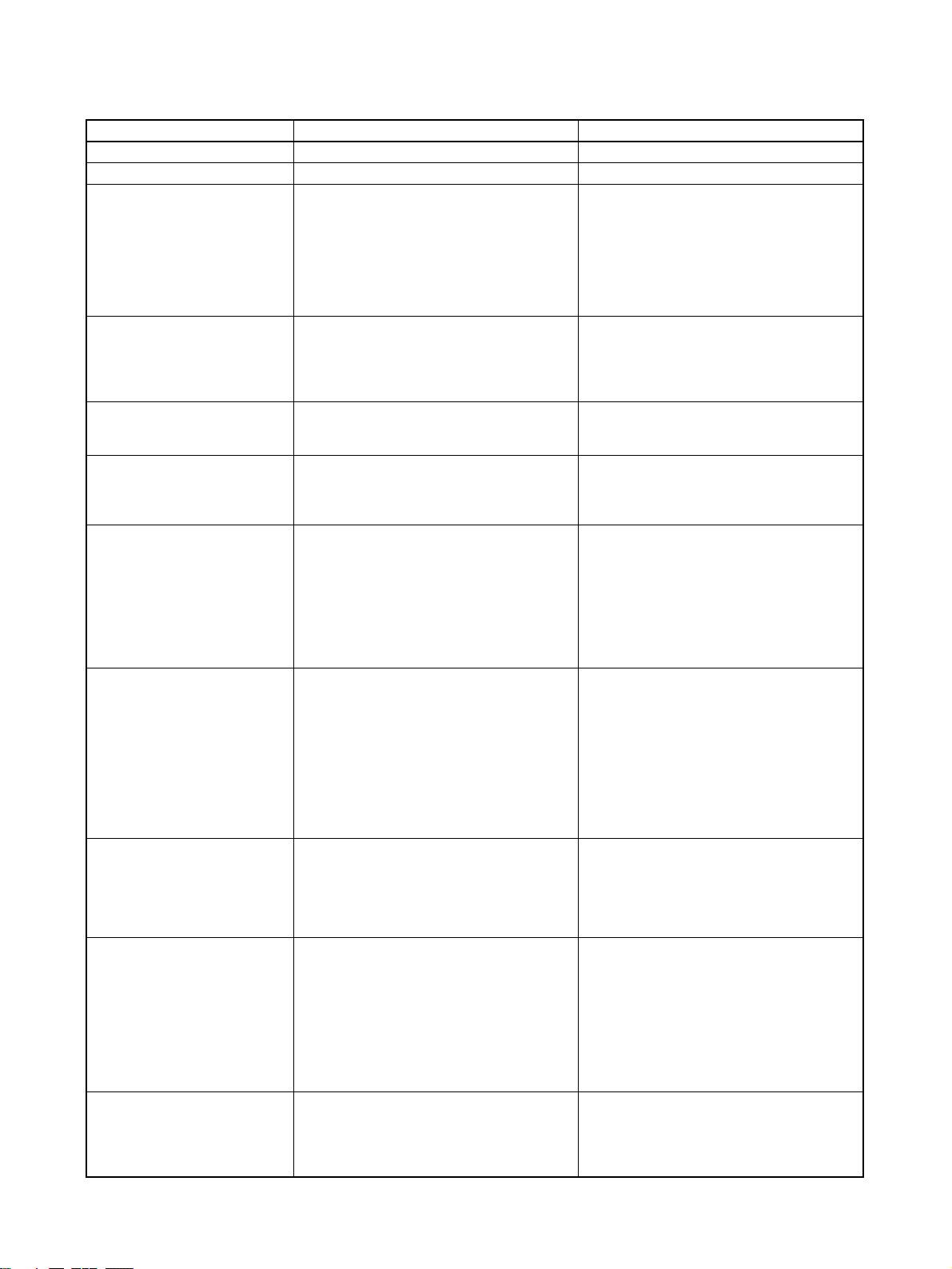

Item Previous versions New version

Improvements in broken-line

graph

Ladder Monitor To use the Ladder Monitor it was necessary

Symbol table transfers when

transferring screen data

Holding log and alarm information when transferring screen

data

PLC data trace reading Not supported. (This was a function of the

Addition of European fonts With the built-in raster fonts in NS-series

Japanese file names Two-byte characters could not be used for

Video display mode setting Image quality could not be adjusted when

SAP (Smart Active Parts) --- SAP has been added for the EJ1 Modular

Automatic using symbol names

and I/O comments as labels

and alarm messages

NS-Runtime --- Projects can be created for NS-Runtime.

Temperature Controllers

Number of monitor points: 256 max. •Number of monitor points: 1,000 max.

•Batch reading

•Graph overwriting

•Indirect specification of starting display

position

•Indirect specification of displaying/hiding

graph lines

•Indirect specification of displaying/hiding

scale lines

With version-2 NS-series PTs (except for

to copy the Ladder Monitor software from a

CD-ROM to a Memory Card and to install

the Memory Card in an NS-series PT. In

addition, the PT was reset when starting or

exiting the Ladder Monitor.

Symbol tables set using the CX-Designer

could be managed only by the CXDesigner, and symbol data was lost when

data was uploaded from an NS-series PT.

All of the log and alarm information in the

PT was initialized when screen data was

downloaded.

CX-Programmer.)

PTs, Russian and Greek characters were

full-width and not all characters were available.

project file names.

an NS-CA002 RGB/Video Input Unit was

used.

--- Symbol names and I/O comments of the

Only the E5

Controllers can be set as hosts.

@N and E5@R Temperature

the NS5-V2 and NSJ5), ladder monitoring

is built into the PT as a standard feature, so

no separate Memory Card is required. (A

Memory Card is required for version-1 PTs,

however, just as before.) In addition, neither

version-1 nor version-2 PTs are reset when

starting or ending the Ladder Monitor when

Ladder Monitor version 2.8 is used. These

improvements make the Ladder Monitor

easier to use and reduce operating time.

When screen data is downloaded from the

CX-Designer, the symbol tables are down-

loaded together with it. Likewise, when

screen data is uploaded, the symbol tables

are uploaded too.

It is now possible to select whether log and

alarm information is to be initialized when

screen data is downloaded.

Trace results from data traces (which is a

CPU Unit function) can now be read by the

PT and displayed in time chart format.

(CSV files cannot be saved.) This makes it

possible, using just the PT without CX-Pro-

grammer, to isolate the causes of errors

that occur on-site.

All Russian and Greek characters are now

available, and all characters are half-width.

Two-byte characters can now be used for

project file names.

It is now possible to select from three pat-

terns for image quality adjustment. When a

visual sensor is connected, even small dis-

play characters can be read. It is now also

possible to adjust the display position for

RGB display.

Temperature Controller, G3ZA Multi-chan-

nel Power Controller, and Troubleshooters.

communications addresses can be auto-

matically used as functional object labels

and alarm messages.

The EJ1 Modular Temperature Controller

can now also be set as a host.

xi

From CX-Designer Version 2.0 to Version 2.1

Item Previous versions New version

CX-Designer Version 2.0 Version 2.1

NS system software Version 6.6 Version 7.0

Multi-vendor connectivity --- It is now possible to connect NS-series PTs

NT compatibility --- System memory can now be allocated to

Holding previous system memory values

Multilingual system capability The system supported two languages:

Multifunction Objects Macros were required in order to executed

Machine Navigator function Multiple objects, such as frames, labels,

Flicker function The only flicker method for objects was dis-

Improved alarm/event summary and history display

Fonts Raster fonts could be set for objects with

When an NS-series PT was started, the initial screen set in the System Setup was

always opened.

English and Japanese.

multiple processes for a single functional

object.

and bitmaps, were used to change displays

such as on-screen characters and BMP

files. Contents of displays were set individually, which was time-consuming and made

maintenance troublesome.

play color inversion.

When the history was displayed using the

Alarm/event Summary & History command,

the same alarm/event was displayed in

multiple places for each date of occurrence.

This made it difficult to check the frequency

of occurrence.

In addition, in some cases there were many

items to be displayed and not all of them

could fit on the screen.

changing display character strings, such as

numeric displays and inputs. Rounded

areas became rough, however, when the

font size was increased.

to the following devices.

• OMRON Trajexia Motion Controllers

• Yaskawa MP-series Machine Controllers

• Yaskawa F7-series Varispeed and VS

Mini V7-series Machine Controllers

• Mitsubishi Q-series PLCs

PLC memory areas in the same way as for

the NT Series, enabling PLC ladder programs to be easily transferred when migrating from the NT Series to the NS Series.

It is now possible to display at the next startup the screen that was being displayed

when the program was closed.

In addition to English and Japanese, the

system now also supports German,

French, Italian, Spanish, and Chinese (both

traditional and simplified).

Multifunction Objects have been added to

functional objects.

With Multifunction Object, multiple processes can be registered and can then be

executed with the press of a button.

Processes that previously required the creation of macros can now be executed by

simply setting properties.

A Machine Navigator function and a functional object contents display function have

been added. Machine Navigator provides

unified control of text and image files (i.e.,

“contents”) to be displayed, and the new

display function displays those contents.

Contents requiring association can be

managed in ID units, and the display can

be easily changed by simply changing the

ID specification.

The following flicker methods have been

added.

• Display/hide (entire object or label)

• Flicker color specification (fill color, character, and line colors)

A function has been added to provide a

summary of a particular alarm/event on a

single line, making it possible to quickly

check conditions without unnecessary displays.

A horizontal scrolling function has also

been added to allow all items to be

checked.

Scalable fonts have been added to enable

smooth displays. Gothic numeral and 7segment displays have also been added to

allow more attractive and up-to-date

screens to be created.

xii

Item Previous versions New version

Improved screen switching

function

Improved connection operations

SAP Library allocated unit

number and communications

setting information display

Bar codes The maximum length of data that could be

Test screens --- The following functions have been added to

DXF files DXF files could not be accessed. It is now possible to convert DXF files to

Initialization options for alarm/

event history data

Changing host settings with

the System Menu

--- Speed and bitmap performance have been

When serial ports A and B were both set for

use for NT Links, “Connecting” was displayed if either of the hosts was not connected.

SAP Library settings could not be checked

even by displaying addresses using screen

data checking from the System Menu.

processed by an NS-series PT was 40

bytes.

When the alarm/event history data was

cleared by using $SB32, all history data

was cleared including current alarms or

events.

The settings of a host connected by Ethernet or Controller Link could not be checked

with the System Menu.

improved for switching screens.

Even if one host is not connected, the mon-

itoring results of the connected host can be

displayed on the screen without “Connecting” being displayed.

The following information can now be displayed.

• Command destination port names

• Destination network addresses

• Destination node addresses

• Destination unit numbers

• DeviceNet Slave Unit address and

Inverter node addresses

The maximum data length has been

increased to 254 bytes, allowing the data to

be processed by two-dimensional bar code

readers.

test screens.

• Zoom

• Always displaying on top

• Starting test screens in the previous display position and zoom status

graphics and position them with the CXDesigner.

System Memory $SW40 has been added

so that it is now possible to specify initializing cleared or confirmed history data.

A list of hosts can now be displayed by

selecting Communications Settings from

the System Menu. It is now also possible to

change the host network address, node

address, and host type.

xiii

From CX-Designer Version 2.1 to Version 3.0

Item Previous versions New version

CX-Designer Version 2.1 Version 3.0

NS system software Version 7.0 Version 8.0

CJ2 compatible --- Connections to CJ2-series PLCs are now

EtherNet/IP compatible --- Tag message communications are now

Ladder Monitor --- Ladder Monitor functionality and operability

Operation log Previously, operations other than those on

the PT, such as the switches on the front of

the control board, could not be logged.

PLC data trace Previous versions supported only bit data

tracing.

supported.

supported.

have been greatly improved. The main

functionality improvements are as follows.

• The Ladder Monitor can be started from

the alarm/event summary and history.

Communications addresses set as alarms

or events can be searched for automatically.

• The display color and size was updated.

• I/O comments can be read from the PLC.

• The number of rows of I/O comments displayed can be changed.

• Search functionality, such as address

searches and return searches, have been

added, making searching much more

powerful.

• The number of points that can be registered for I/O monitoring was increased.

• It is possible to search for or change the

present value of the address the cursor is

on.

• The input format of the display of present

values for words can be changed between

hexadecimal, decimal, and signed decimal format.

• The display can be captured and saved as

a bitmap file.

The following functions have been added to

the operation log.

• It is possible to log ON/OFF changes for a

specified communications address. For

example, by assigning a communications

address to the switch on the front of the

control panel, operations other than those

on the PT display can also be logged.

• Messages can be set in the operation log.

• It is possible to save history files (csv files)

and display the operation log screen from

the System Menu using a Multifunction

Object.

• Multiple history files can be saved.

The following functions have been added to

the PLC data trace.

• Data traces for words are now supported.

• Data trace results can now be saved as

CSV files.

• The PLC data trace display can be captured and saved as a bitmap file.

• The PLC symbol table can be read, and

the I/O comments for the communications

addresses being traced can be displayed.

xiv

Item Previous versions New version

Screen transfers Previously, when uploading project data

from the PT, the user display on the PT

would change to the transfer screen. Also,

after transfer finished, it was necessary to

reset the PT.

When uploading project data, it is no longer

necessary to change to the transfer screen

while uploading, nor is it necessary to reset

the PT when the transfer has finished. Now,

the user can continue operating the PT

screens even while uploading.

Multivendor support --- The PT can now be connected to the fol-

lowing devices.

• Rockwell Automation (Allen-Bradley)

SLC500 Controller, MicroLogix, PLC-5,

CompactLogix, and ControlLogix

• Modbus RTU-compatible devices

Screen saver --- The time until the screen saver starts can

be indirectly specified.

String table support for alarms

and events

Disable function for screen

inputs

--- Alarm and event message text strings can

now be viewed from string tables.

--- It is now possible to enabled or disable

inputs and outputs to the entire screen

when a specified communications address

is turned ON or OFF.

From CX-Designer Version 3.0 to Version 3.007

Item Previous versions New version

CX-Designer Version 3.0 Version 3.007

NS system software Version 8.0 Version 8.1

Printer --- PictBridge-compatible printers are now

supported (except they are not supported

by the NS5-@@0@, NSJ5-@@0@, and

NSH5).

Multivendor support --- The following PLCs can now be connected

Ladder Monitor --- • CJ2-series PLCs are now supported.

Data log graphs A line appeared on the data log graph while

data was being logged and then blank

spaces occurred at times when no data

was logged.

B

to an NS-series PT.

• Yokogawa Electric FA-M3-series and FA-

M3R-series PLCs.

• The host connected to an NS-series PT

over an EtherNet/IP network can now be

monitored.

It is now possible to display a dialog box

asking for a password if data will be modified, such as when changing present values.

A setting has been added to provide an

option to compress the times when data

was not logged so those times will not be

displayed. This way only logged data will be

displayed as one continuous line.

B

A

Logging was stopped.

A

Periods when logging

was stopped are displayed on a reduced

time scale.

No data logged. Display showing compressed time when no

data was logged.

xv

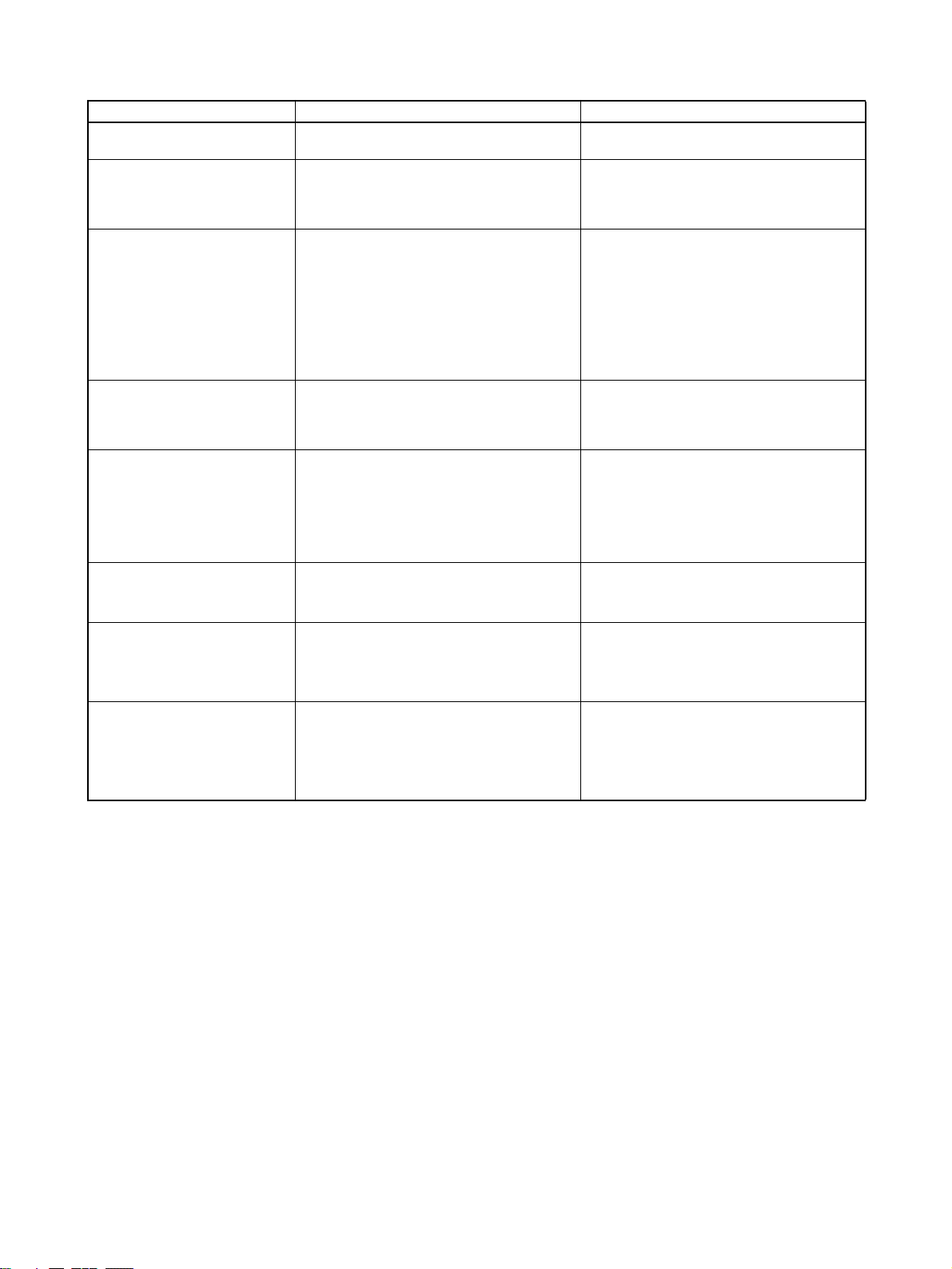

Item Previous versions New version

Initialization of alarm/event history data

Number of objects per screen The maximum number of objects, including

Improved screen switching performance

Project data conversion When project data was converted, the posi-

Importing labels from CSV files When label text strings were imported from

Changing initial values of functional objects

When the alarm/event history data was

cleared by using $SB32 or $SW40, the

number of times alarm/events occurred

was held in memory even though the other

data was cleared.

graphs and functional objects (i.e., frames

and tables), was 1,024 per screen.

--- The speed for switching screens when the

tion and size of the screen objects were left

unchanged by the conversion. Also NSRuntime projects could not be converted to

NS projects.

a CSV file, the original font that was set for

an object was subsequently applied to the

object after importing the file.

--- The initial values of the following functional

A setting has been added to provide an

option to clear the number of times alarm/

events occurred along with the other alarm/

event history data that was cleared.

The number of objects per screen has been

increased to a maximum of 1,024 functional objects (i.e., frames and tables) and

up to 2,048 graphs.

drawing method is set to Display frames

and fixed objects first has now been

improved. (This capability requires project

version 8.1 or higher.)

It is now possible to change the position

and size of all objects proportional to the

size of the screen, such as when converting data for a low-resolution PT to data for a

high-resolution PT.

In addition, NS-Runtime projects can now

be converted to NS projects.

Now the font for groups of labels can be

changed all at once when label text strings

are imported from a CSV file.

objects can be changed to make them easier to use.

• Numeral Display & Input

• String Display & Input

• Alarm/Event Summary & History

•Frame

From CX-Designer Version 3.007 to Version 3.008

Item Previous versions New version

CX-Designer Version 3.007 Version 3.008

NS system software Version 8.1 Version 8.1

NS15 compatibility --- Connection to an NS15 PT is now sup-

ported.

From CX-Designer Version 3.008 to Version 3.1

Item Previous versions New version

CX-Designer Version 3.008 Version 3.1

NS-series PT software version Version 8.1 Version 8.2

Device data transfer --- Conditions can be set to transfer data from

SPMA transfers --- Screen data transfers can be performed

Batch format settings --- The format for all labels can be set at the

Batch label settings --- A specified character string can be set for

a source to a destination.

through USB to access other devices. For

details, refer to CX-Designer Online Help.

same time.

all of the labels for objects at the same

time.

xvi

Item Previous versions New version

String Display and Input

objects

Analogue Meter improvements --- The shape of the needle can be set to a

Password input keyboards --- The user can specify the keyboards to use

Macros added --- Trigonometric and floating-point functions

Screen switch settings --- The default setting for the display sequence

Improvements in creation

methods for fixed objects

Data log graphs for 128 points The previous maximum was 50 points. The total number of addresses for constant

Data blocks with 512 KB The previous size was 100 KB. The size of one data block was increased

--- An input method setting was added to

move the input focus to in front of the character string when the focus is set.

straight line, arrow, or triangle arrow. The

line width can be changed to up to 3 dots.

to input passwords.

were added.

for screens now gives priority to displaying

fixed objects and frames first.

--- The method to create sectors and arcs has

been improved.

logging was increased to 128 points max.

to 512 KB.

xvii

Related Manuals:

The manuals related to using the CX-Designer are listed below. Manual suffixes have been omitted.

Please be sure you have the most recent version for your area.

Installing the CX-Designer

CX-Designer User’s Manual - - - - - - - - - - - - - - - -V099

This manual describes how to install the CX-Designer and the user interface. It also describes

characteristic functions and application methods.

Confirming Functional/Fixed Object Setting Procedures when Using

the CX-Designer

CX-Designer Help

The online help feature explains CX-Designer operating methods and settings (including

detailed settings for functional and fixed objects).

It also explains how to transfer screen data to the NS-series PT.

Using NS-series PT Functions and Troubleshooting Errors

NS-Series PT Programming Manual - - - - - - - - - -V073

This manual describes using NS-series PT functions and application methods. It also provides

troubleshooting methods in the event that problems occur with the PT.

Checking NS-series PT Functions, Operations, and Restrictions

NS-V1/V2-series PT Setup Manual - - - - - - - - - -V083

This manual describes installation and connection procedures, general specifications, and

other hardware information for NS-V1/V2-series PTs (NS15-V2, NS12-V1/V2, NS10-V1/V2,

NS8-V1/V2, and NS5-V1/V2).

NS-series PT Setup Manual- - - - - - - - - - - - - - - -V072

This manual describes installation and connection procedures, general specifications, and

other hardware information for NS-series PTs (NS12, NS10, and NS7).

Installing the CX-Designer from the CX-One

CXONE-AL@@C-V4/AL@@D-V4 CX-One Ver. 4.0 Setup Manual

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -W463

This manual provides an overview of the CX-One FA Integrated Tool Package and describes

installation methods.

Using an NS-series PT for the First Time

CX-Designer Introduction Guide - - - - - - - - - - - - -V089

This tutorial describes using a NS-series PT for first-time users, from simple screen creation to

system operation.

xviii

Using NS-series PT Macros

Macro Reference (Installed from CX-Designer CD-ROM.)

The online help for the CX-Designer provides detailed descriptions of the NS-series PT macro

function. The same level of detail is also provided in this reference manual, which is installed

on the hard disk as a PDF file when the CX-Designer is installed. Use either the online help or

this reference as required.

Checking PLC Functions and Operation

Operation Manuals for the PLC Being Used

For information on PLC operation and functions, refer to the operation manuals for the CPU

Unit, Special I/O Units, CPU Bus Units, Communications Units, or other Units that you are

using.

Checking NS-Runtime Functions, Operations, and Restrictions

NS-Runtime User's Manual - - - - - - - - - - - - - - - -V093

This manual describes the special functions of NS-Runtime.

xix

xx

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

(1) The warranty period for the Software is one year from either the date of purchase or the date on which

the Software is delivered to the specified location.

(2) If the User discovers a defect in the Software (i.e., substantial non-conformity with the manual), and

returns it to OMRON within the above warranty period, OMRON will replace the Software without charge

by offering media or downloading services from the Internet. And if the User discovers a defect in the

media which is attributable to OMRON and returns the Software to OMRON within the above warranty

period, OMRON will replace the defective media without charge. If OMRON is unable to replace the

defective media or correct the Software, the liability of OMRON and the User's remedy shall be limited to

a refund of the license fee paid to OMRON for the Software.

LIMITATIONS OF LIABILITY

(1) THE ABOVE WARRANTY SHALL CONSTITUTE THE USER'S SOLE AND EXCLUSIVE REMEDIES

AGAINST OMRON AND THERE ARE NO OTHER WARRANTIES, EXPRESSED OR IMPLIED,

INCLUDING BUT NOT LIMITED TO, WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT WILL OMRON BE LIABLE FOR ANY LOST PROFITS OR

OTHER INDIRECT, INCIDENTAL, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF

USE OF THE SOFTWARE.

(2) OMRON SHALL ASSUME NO LIABILITY FOR DEFECTS IN THE SOFTWARE BASED ON

MODIFICATION OR ALTERATION OF THE SOFTWARE BY THE USER OR ANY THIRD PARTY.

(3) OMRON SHALL ASSUME NO LIABILITY FOR SOFTWARE DEVELOPED BY THE USER OR ANY

THIRD PARTY BASED ON THE SOFTWARE OR ANY CONSEQUENCE THEREOF.

Application Considerations

SUITABILITY FOR USE

THE USER SHALL NOT USE THE SOFTWARE FOR A PURPOSE THAT IS NOT DESCRIBED IN THE

ATTACHED USER MANUAL.

xxi

Disclaimers

CHANGE IN SPECIFICATIONS

The software specifications and accessories may be changed at any time based on improvements or for

other reasons.

EXTENT OF SERVICE

The license fee of the Software does not include service costs, such as dispatching technical staff.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xxii

SECTION 1

Overview

This section describes the features of the CX-Designer and the startup procedures for NS-series PTs for first-time users.

1-1 Features of the CX-Designer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Basic Operation Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1

Features of the CX-Designer Section 1-1

1-1 Features of the CX-Designer

The CX-Designer is software that can be run on Windows 2000, XP, Vista, or

7 to create screen data for NS-series Programmable Terminals (PTs).

The CX-Designer has a variety of functions to enable efficient screen creation

and debugging.

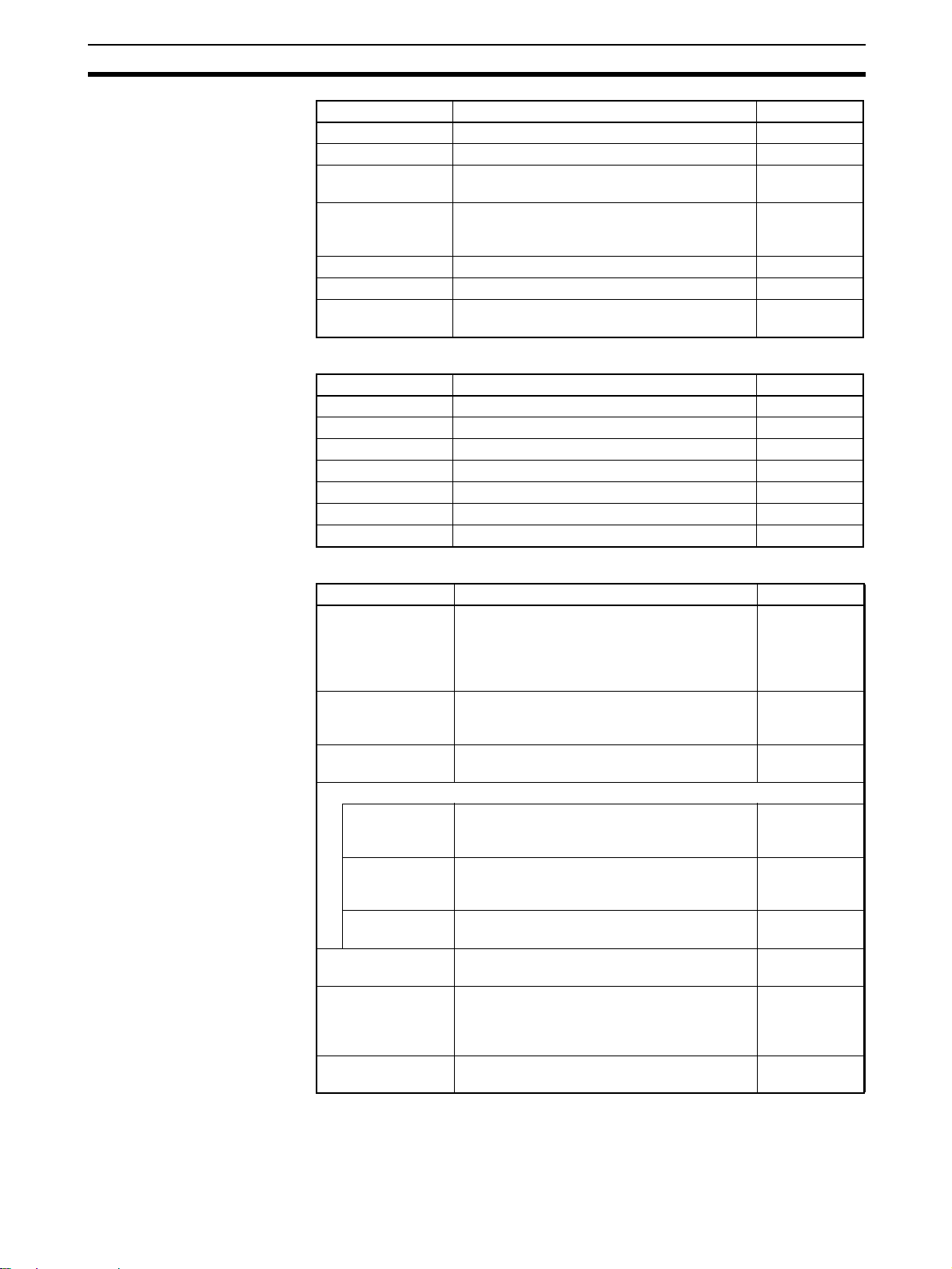

Project Workspace

The entire project structure can

be displayed in a directory tree.

Property List

Functional object property

settings can be changed and

checked without having to open

a properties dialog box.

Output Window

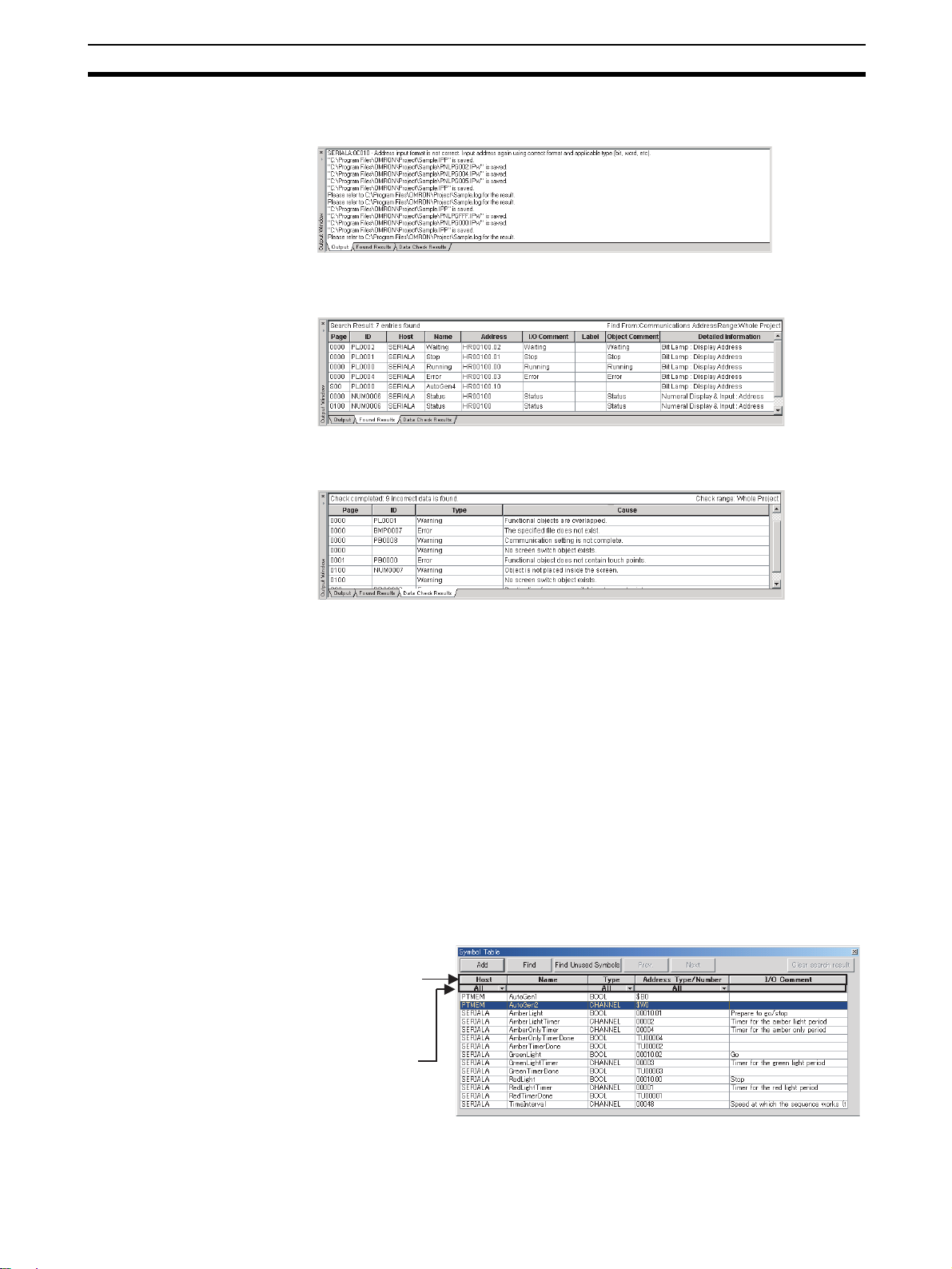

Displays data such as search

results and error details.

Edit Screens

Screen data displayed on the PTs

can be created for a group of objects.

1-1-1 Features

Screens Can Be Created

Using Symbols

Project Management

Using Project Workspace

Easy Reuse of Screens Screens and settings can be copied between multiple CX-Designer project

Screen Classification by

Application for Easy

Management

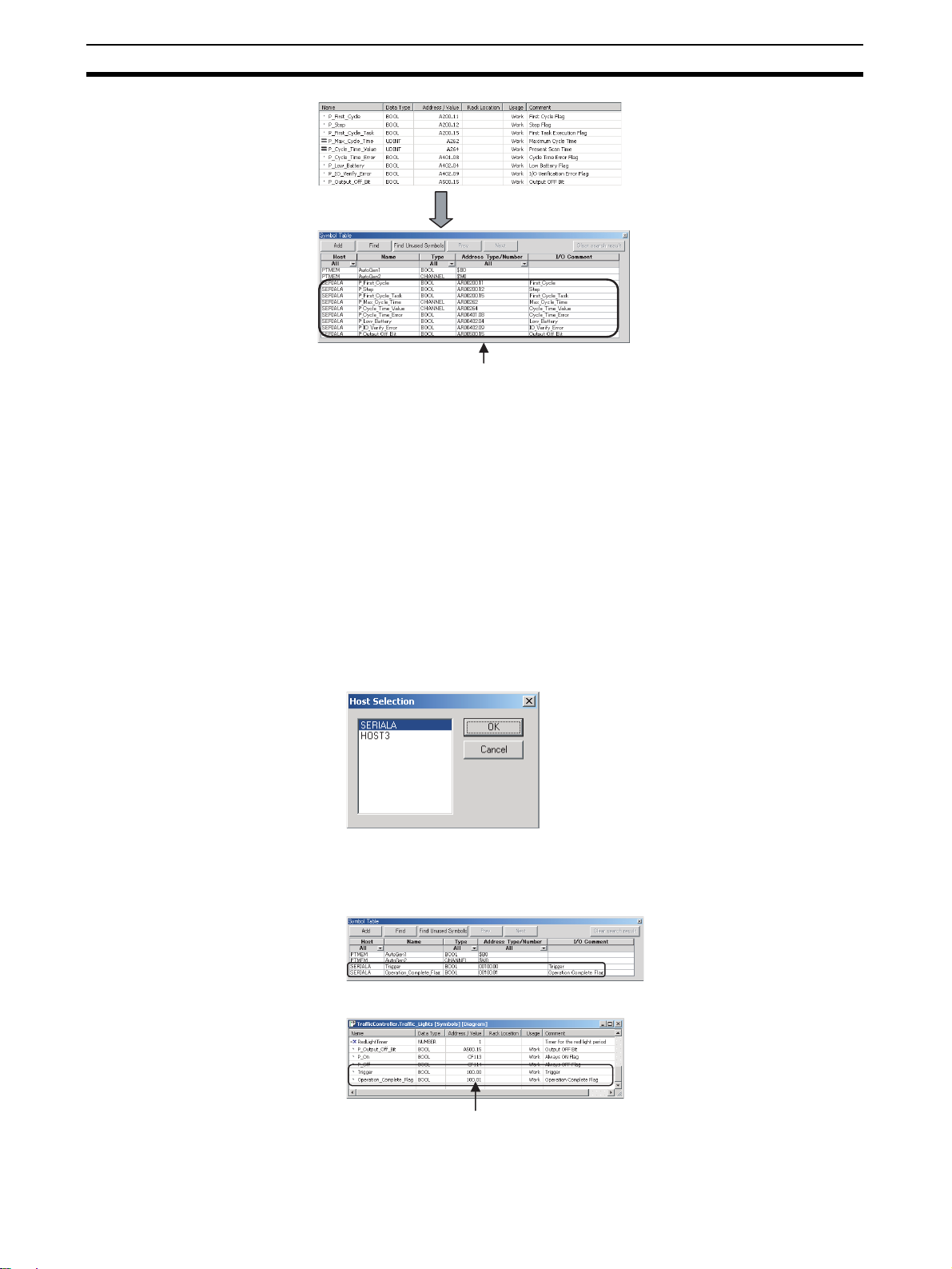

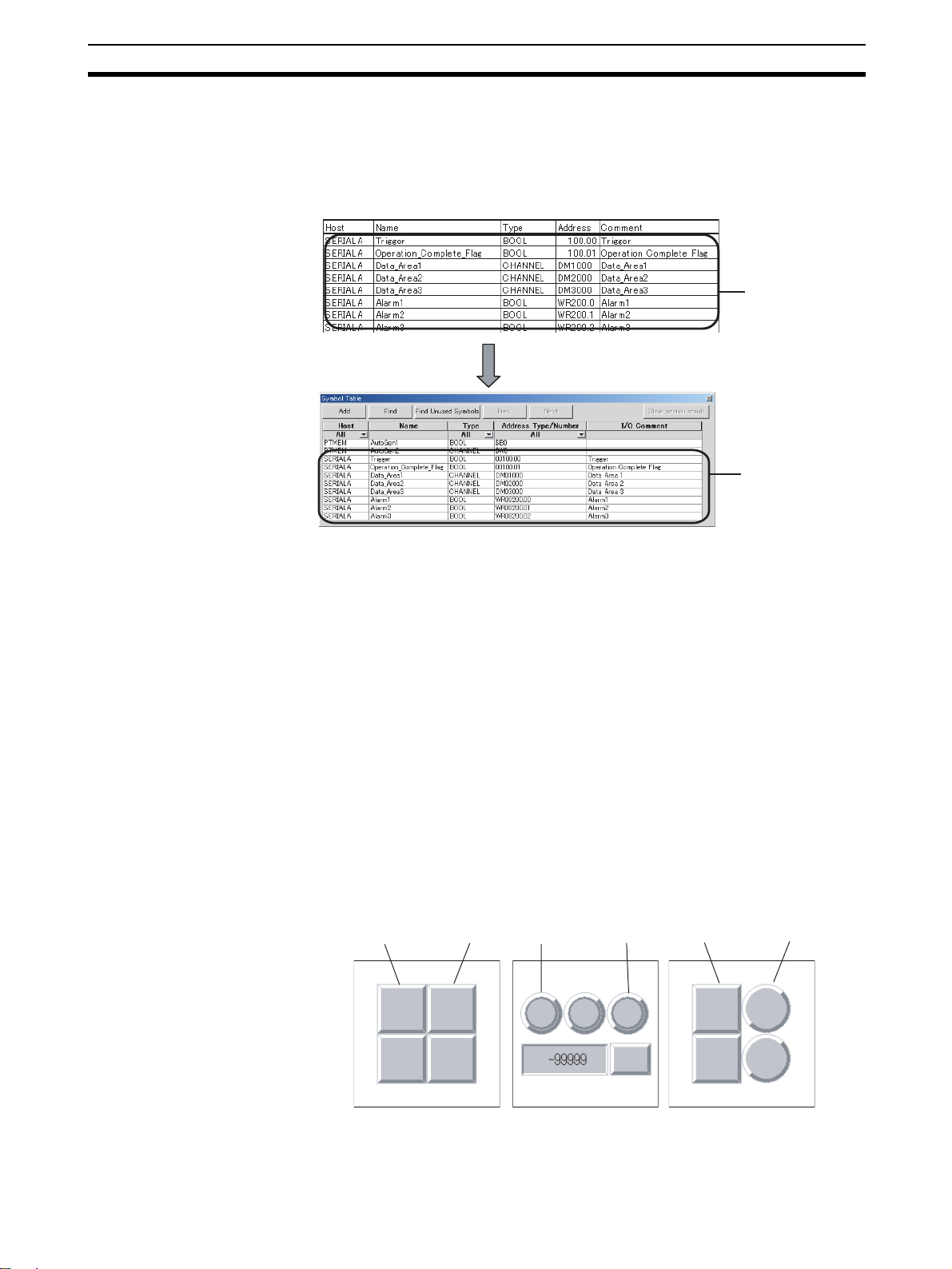

Symbols can be used with the CX-Designer. Symbols are addresses to which

names have been assigned. In addition to the existing method of directly

inputting addresses to be browsed by functional objects, the addresses can

also be set by using symbols (names). When the address allocated for a symbol is changed, the address is changed for all objects that access that symbol.

This makes it easy to change address allocations and reuse screens. Symbols can also be shared by the CX-Designer and CX-Programmer by copying

the symbols from CX-Programmer symbol tables to the CX-Designer.

Refer to 4-1 Creating Screens Using Symbols for details.

Screens, alarms, and other common settings can be displayed in a directory

tree in the CX-Designer project workspace. Projects are easy to manage

because the entire project structure can be checked at a glance.

Screens and settings can be copied between multiple CX-Designer project

workspaces. Screens can also be copied within the same project workspace.

Refer to 4-2 Using Screens from Other Projects for details.

workspaces. Screens can also be copied within the same project workspace.

The common settings accessed by screens are also copied automatically.

If symbols are used, it also becomes easy to change addresses after screens

have been copied. Refer to 4-2 Using Screens from Other Projects for details.

Screens can be classified into any category, e.g., by application, and displayed in a directory tree. When screens are created, consecutive screen

numbers are automatically applied to screens in the same category. These

numbers can also be changed. This makes screen management even easier.

Refer to 4-3 Classifying Screens by Application for details.

2

Features of the CX-Designer Section 1-1

Functional Object

Property Settings Using

Property Lists

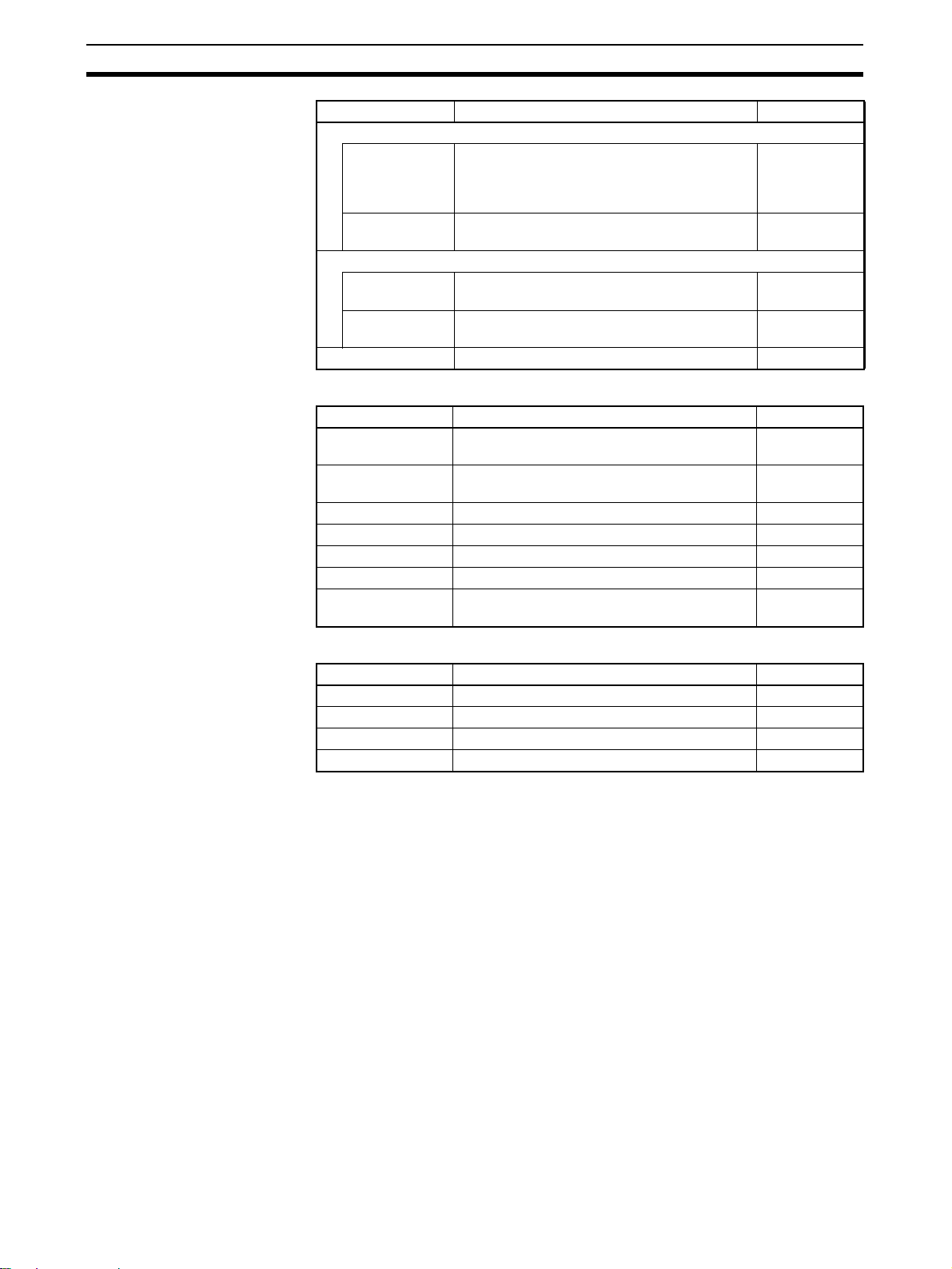

Edit Properties from Lists Properties of objects on the screen can be displayed in table format and the

Select and Display

Specified Objects

Find Macros Embedded macros can be listed.

Functional object settings can be changed and checked without having to

open a dialog box.

When more than one object is selected, common settings for those objects

can be changed in one operation from the property list.

Refer to 4-4 Checking and Changing Functional Object Properties without

Opening Property Setting Dialog Boxes.

settings changed.

Settings for more than one object can be changed at the same time and con-

secutive addresses can be automatically set.

Refer to 4-5 Listing and Editing Functional Object Properties for details.

Objects on the screen can be listed and specified objects selected. The

screen display can also be limited to specified objects.

This makes it easy to check and change the property settings for overlapping

objects.

Refer to 4-6 Editing Overlapping Objects for details.

This improves debugging efficiency by no longer requiring individual object

property settings to be opened to find objects that use macros.

Refer to 4-9 Searching for Embedded Macros for details.

Automatic Transfer of

Edited Data Only

Easy Document Creation Common settings and property settings for objects in screens can be output in

Integrated Simulation for

Entire PT-PLC System

(CX-Designer Version 2.0

and Higher)

Once screens have been transferred to the PT, quick transfers of only the

changed data can be made automatically. Screens are edited and data transferred many times during debugging, so the quick transfer function greatly

reduces transfer time and increases efficiency.

Refer to 4-10 Transferring Only Edited Data to PT for details.

rich text format (.rtf). The output settings are displayed in a list for easier viewing.

Screen images can also be output to bmp and jpg files.

Refer to 4-11 Creating Documents for details.

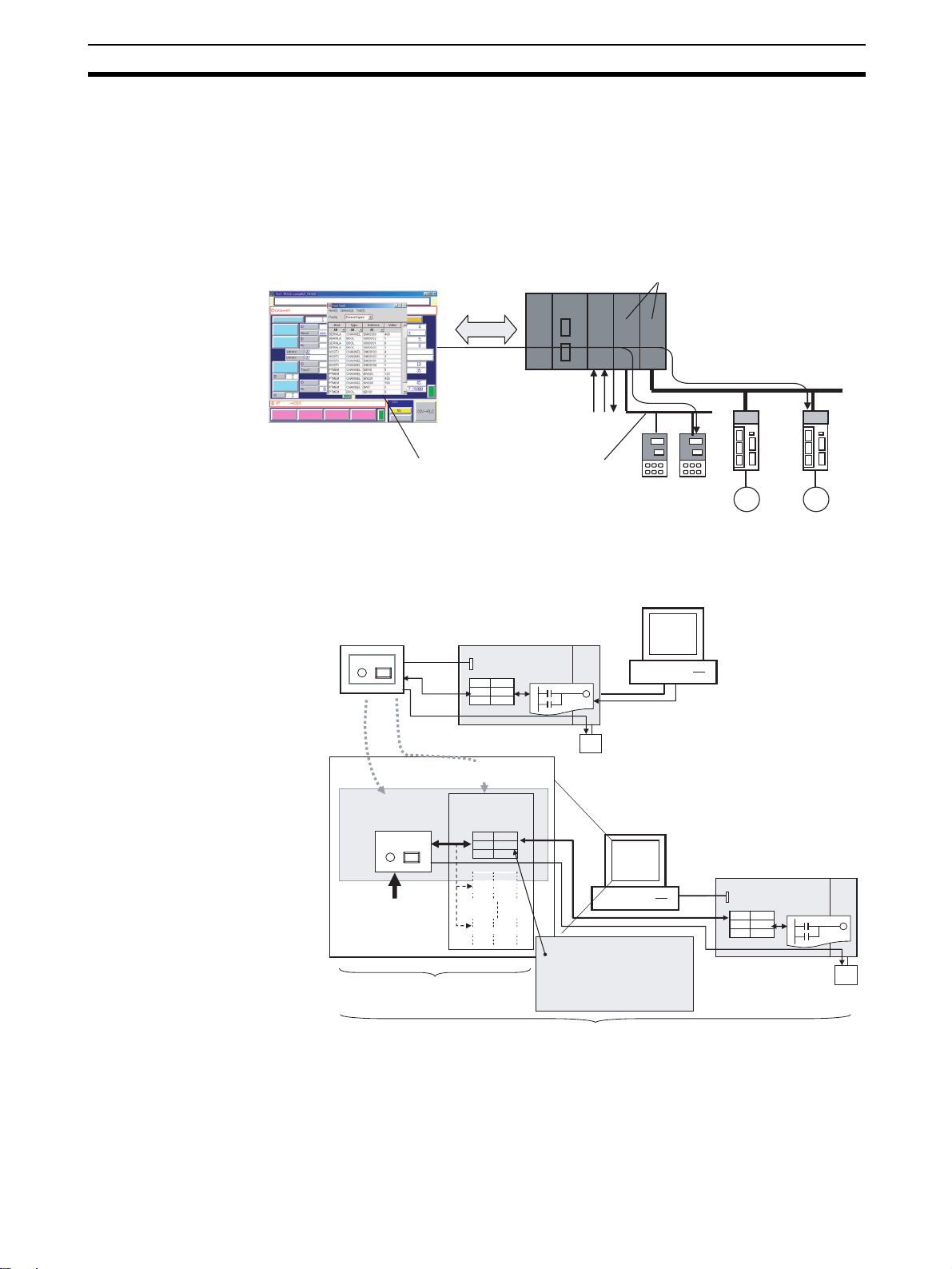

The CX-Designer test function can be connected to the CX-Simulator (a virtual PLC). When the CX-Simulator is started, the PLC user program created

using the CX-Programmer can be debugged on a personal computer together

with screen data.

3

Features of the CX-Designer Section 1-1

In addition, the test function can be connected directly to an actual PLC. This

enables debugging (including monitoring and settings) using actual I/O, Special I/O Units, and CPU Bus Units connected to the PLCs, as well as data

from external devices and PLC data on the network.

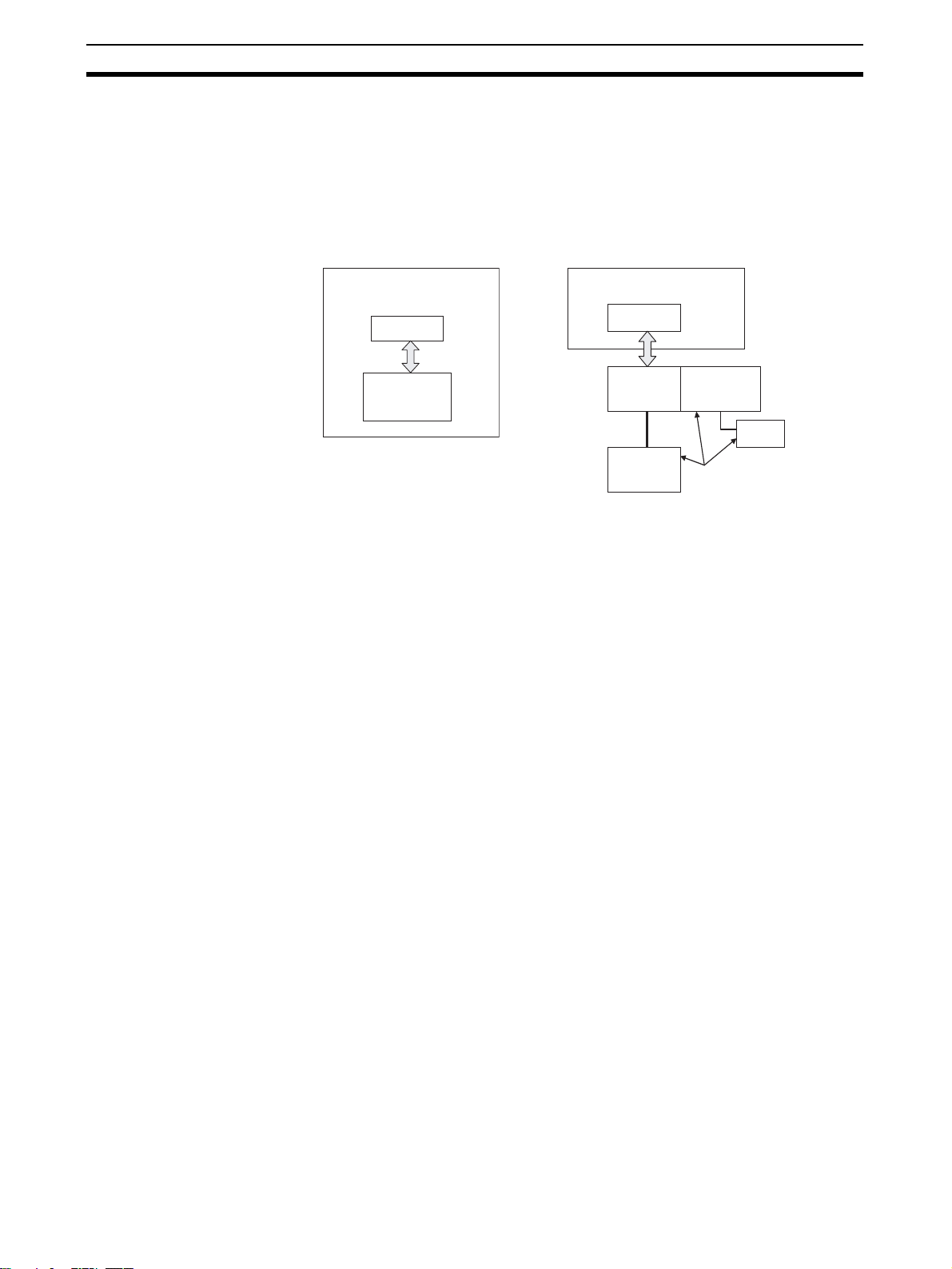

1. Integrated operations with

screens and user programs

can be tested on a personal

computer

2. Screen operations can be tested

while connected to the actual PLC

System (including external devices).

Prevent Unauthorized

Uploading of Data from

the PT (CX-Designer

Version 2.0 and Higher)

Note Project data created using the NS-Designer can be used with the CX-

Personal computer

Virtual PT

Virtual PLC

CX-Simulator

Personal computer

Virtual PT

Actual PLC

Actual PLC

Basic I/O Units,

Special I/O Unit,

CPU Bus Units

External

devices

Settings and monitoring are enabled

for CPU Bus Units, Special I/O Units,

external devices, and PLCs on the network.

To prevent data theft from the PT, a password can be required to upload

project data. Data cannot be uploaded from the PT unless the correct password is input. A password can also be required for downloading data to prevent data from being accidentally overwritten.

Designer. Project data created using the CX-Designer can also be used with

the NS-Designer. (Only project data versions supported by NS-Designer,

however, can be used.)

4

Basic Operation Procedures Section 1-2

1-2 Basic Operation Procedures

This section describes the basic procedures for creating screens using CXDesigner, transferring data to the PT, and displaying screens. Refer to the CXDesigner online help and the NS Series Setup Manual and NS Series Pro-

gramming Manual for details.

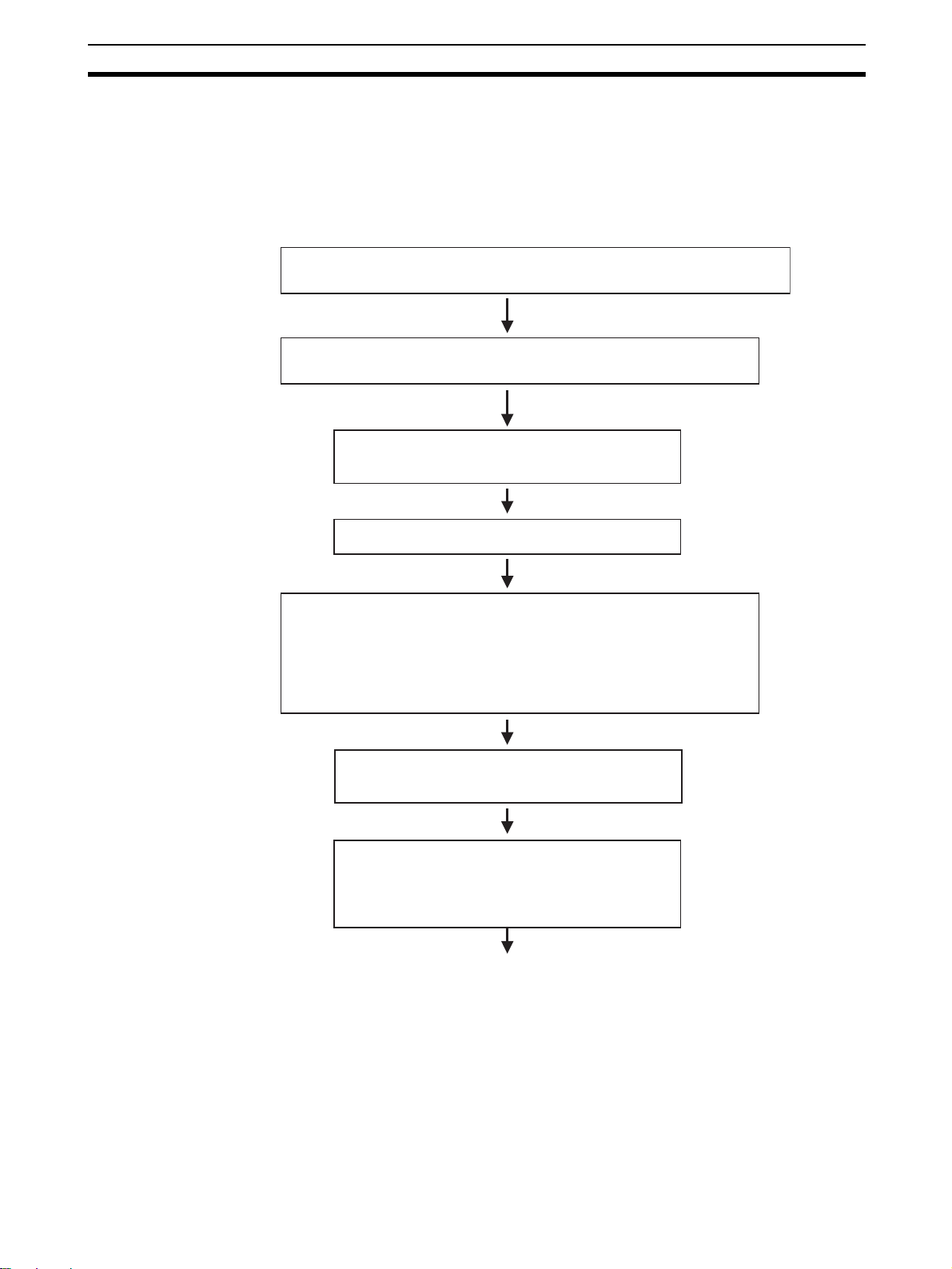

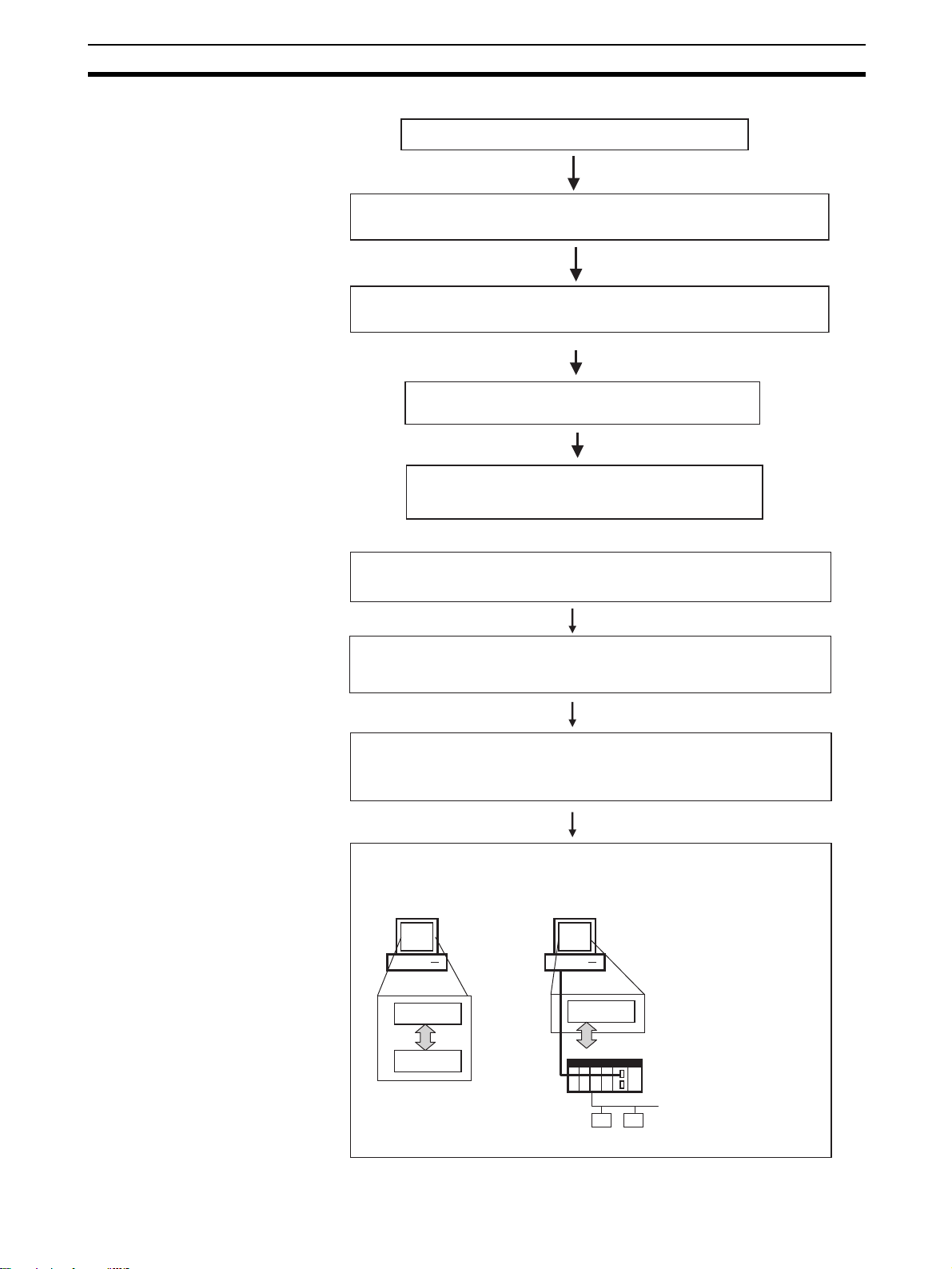

Creating Projects and Screens on the CX-Designer

Start CX-Designer.

Select Programs - OMRON - CX-One - CX-Designer - CX-Designer Ver. @.

Refer to 3-1 Starting and Exiting CX-Designer

in this manual.

Create New Project.

Select File - New Project.

Set the PT model, PT system version, and file

name in the New Project Dialog Box.

Specify the screen number for the new screen in the

New Screen Dialog Box.

Make Project Communications Settings and Register Host.

Decide the settings for the PT and PLC and register the PLC host for

communications.

Select Communication Setting on the project workspace System Tab

Page.

Alternatively, select PT - Communication Setting.

Set whether or not to use Serial Port A, Serial Port B,

Ethernet, and Controller Link networks and set the

communications conditions.

Click the Add Host Button in the Communication

Setting Dialog Box to set the host name, host type,

network address, and node address.

Note: Up to 98 hosts can be registered in addition to

SERIAL A and SERIAL B.

5

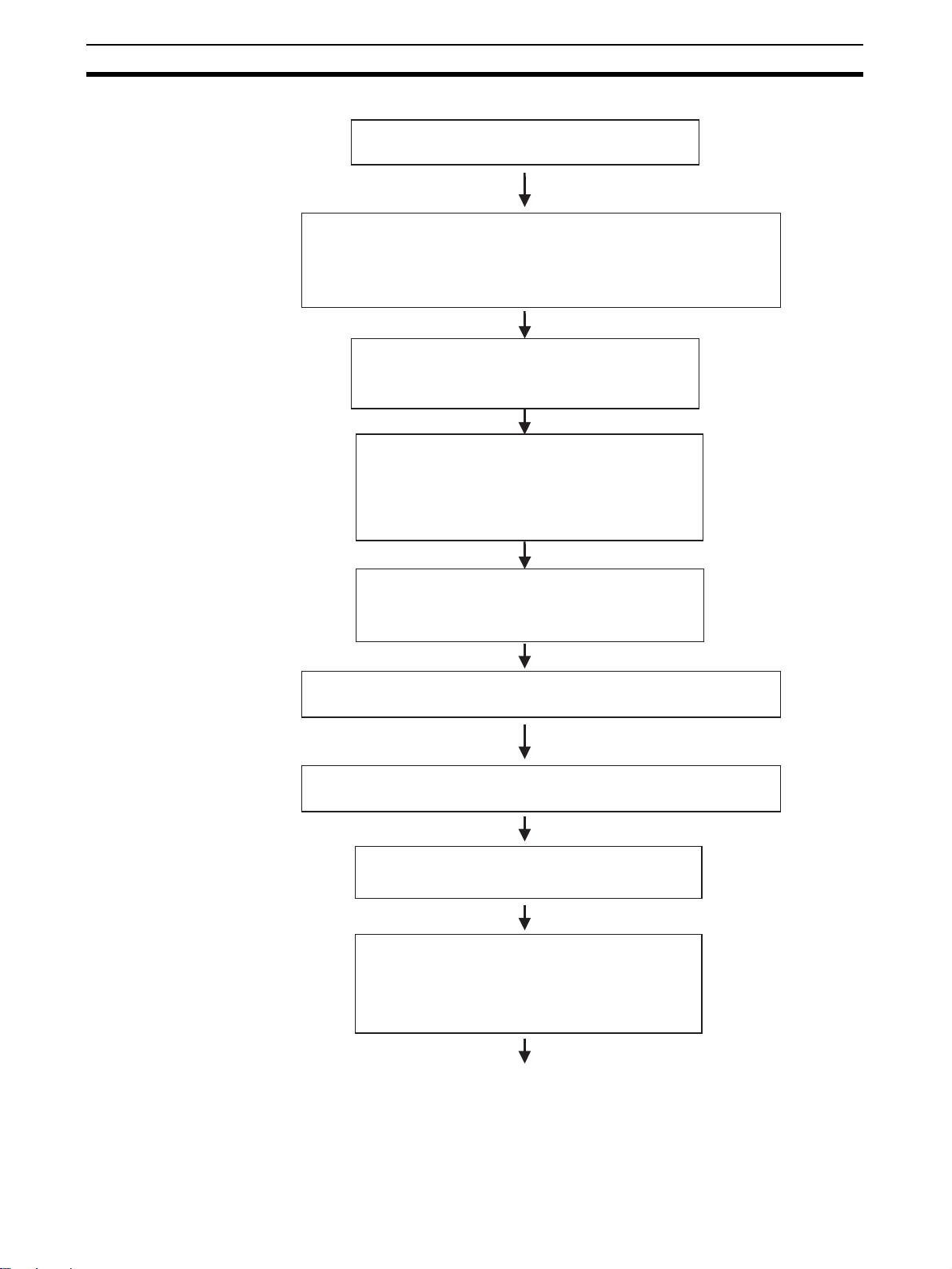

Basic Operation Procedures Section 1-2

Copy symbols from the CX-Programmer Symbol

Table as required.

Refer to 4-1 Creating Screens Using Symbols

for details.

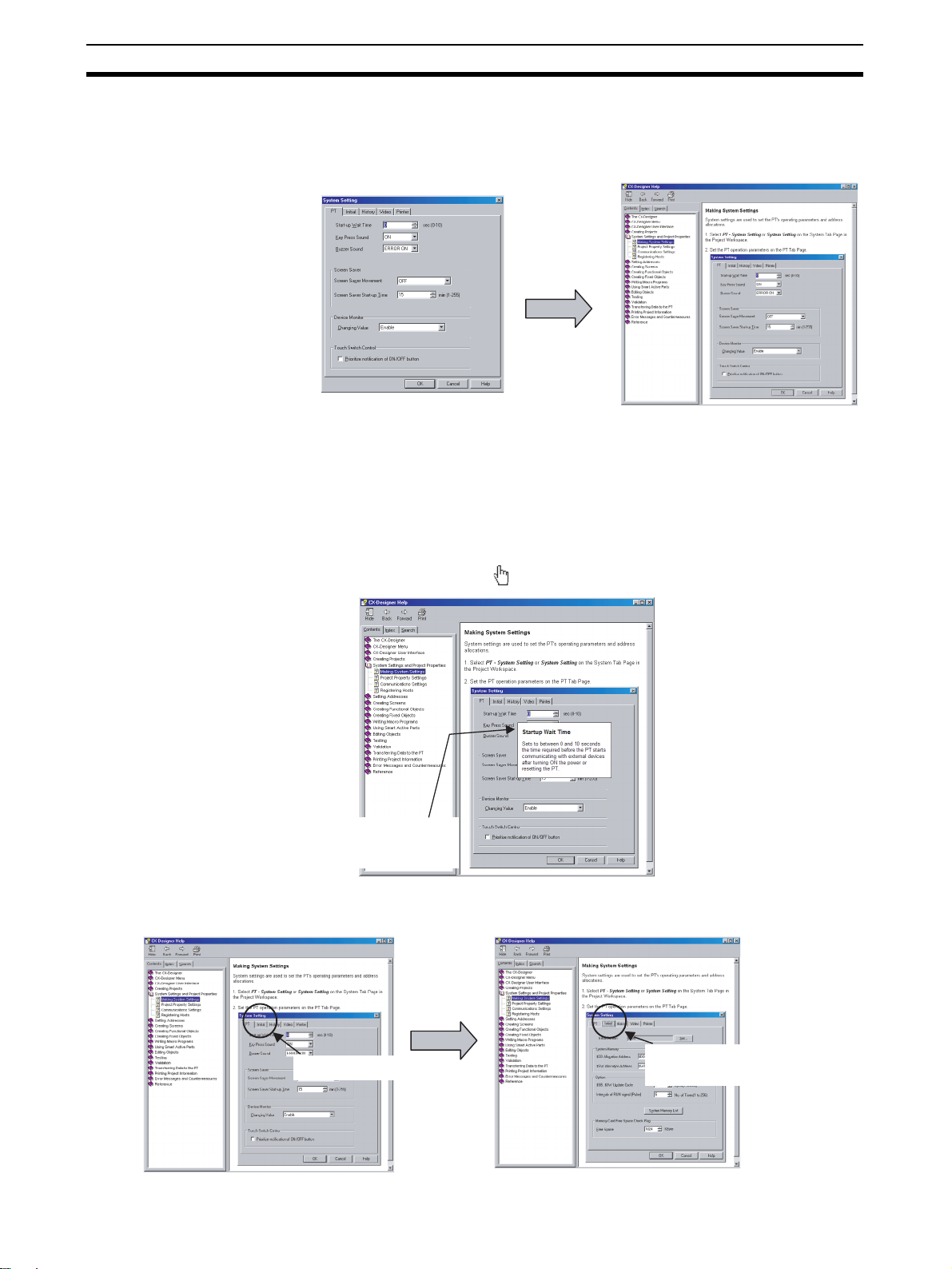

Make Project System Settings.

Select System Setting on the project workspace System Tab Page.

Alternatively, select PT - System Setting.

The address allocation settings for system memory

and the screen number to be displayed at startup are

set on the Initial Tab Page in the System Setting

Dialog Box.

Set the project properties as required. Make settings

such as language selection and label settings for

when using the switch label function.

Select Project Properties on the project workspace

System Tab Page.

Alternatively, select PT - Project properties.

Set the screen properties as required. Set the screen

title, size, pop-up screen setting, background and

other settings.

Select PT - Screen/sheet properties.

Create New Screen.

Select File - New Screen.

Create Functional Objects.

Select the functional object from the toolbar. Move

the cursor to the screen and drag the cursor from

the start point to the end point of the functional object.

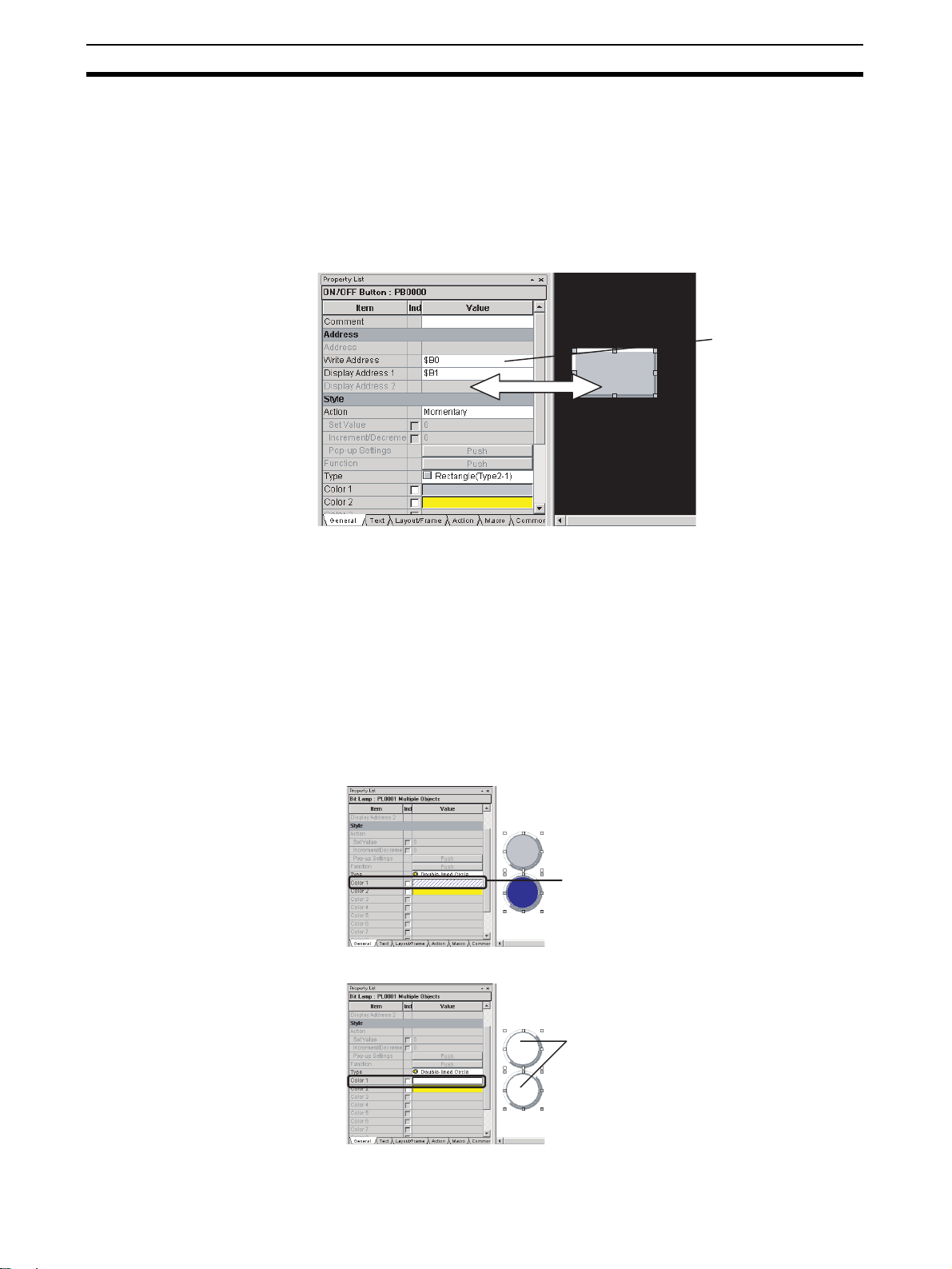

Select the functional object just placed on the screen

and make address and other settings from the

property list. (Select the host name and set the

address. The address can also be set by selecting a

symbol from the symbol table.)

6

Basic Operation Procedures Section 1-2

Debugging Newly Created

Screen Data while

Integrated with a Virtual or

Actual PLC (CX-Designer

Version 2.0 or Later)

Also set the properties for that functional object.

Save Screen.

Select File - Save Screen/Sheet.

Save Project.

Select File - Save All.

Print data as required. Select File - Print.

Check operation using the screen data on the

CX-Designer if required.

Select Tools - Test.

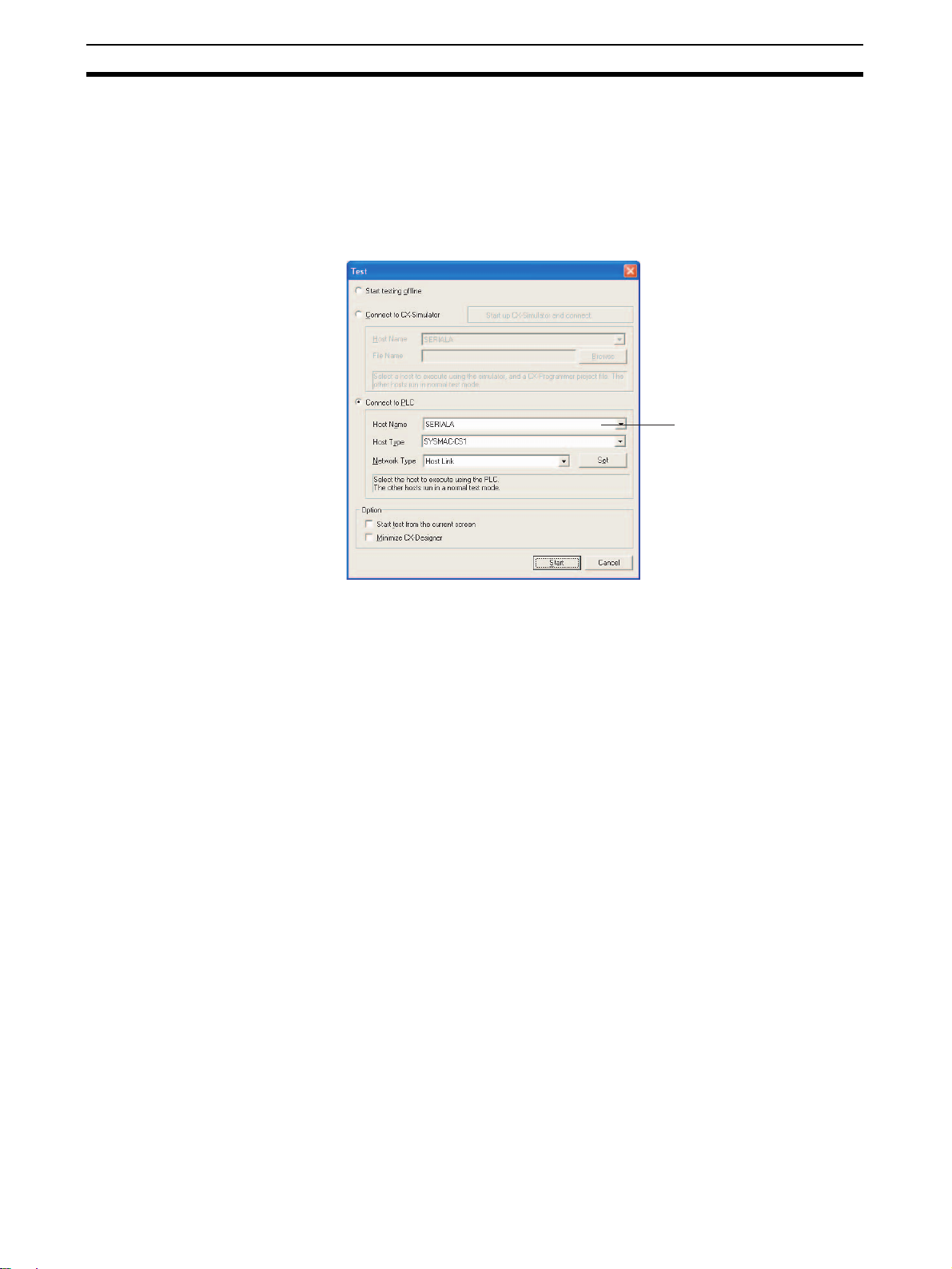

When using integration simulation with an actual PLC:

Connect the personal computer to the actual PLC.

Start the Test Tool.

Select Tool - Test.

Connect to the virtual PLC (CX-Simulator) or to the actual PLC.

Select Connect to CX-Simulator or Connect to PLC, and then click the

Start Button.

Run the user program and execute the integrated simulation with the

PLC. Run the virtual PLC (CX-Simulator) or the actual PLC user program

to debug the PT and the entire PLC System.

In personal

computer

Virtual PT

Virtual PLC

or

In personal

computer

Virtual PT

Actual PLC

External devices

7

Basic Operation Procedures Section 1-2

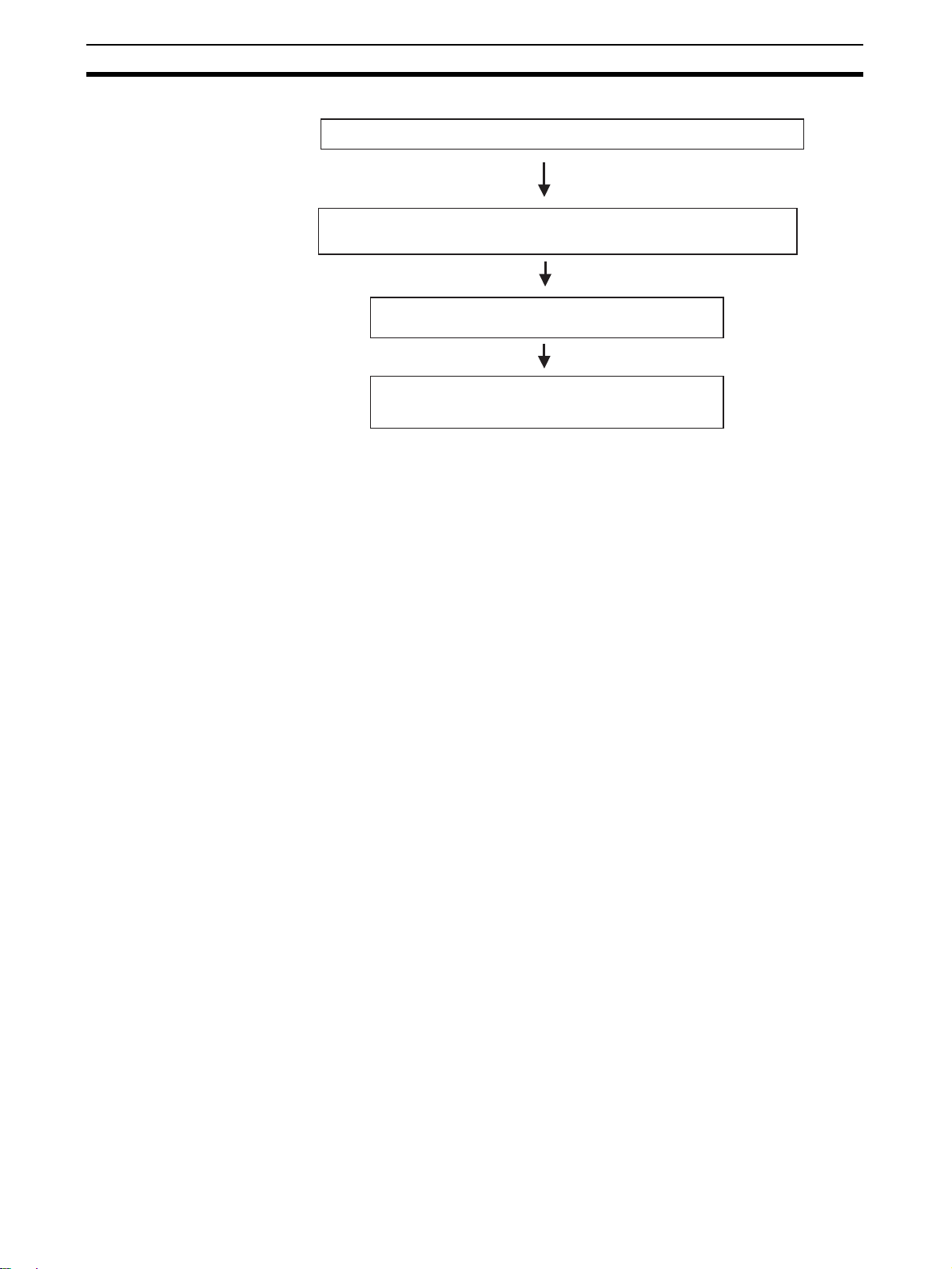

Transferring Projects and

Screens to the PT

Connect the CX-Designer (Computer) and the PT.

Refer to 3-3 Connecting the CX-Designer

in the NS Series Setup Manual.

Transfer Screen Data to PT.

Refer to Transferring Data to the PT in the

online help for the CX-Designer.

Select the communications method.

Select PT - Transfer - Transfer Setting.

Transfer the screen data.

Select PT - Transfer - Transfer [Computer → PT].

8

Basic Operation Procedures Section 1-2

Communications between

the PT and PLC

Connect the PT and PLC.

Use a Serial, Ethernet, or Controller Link network to connect the PT and PLC.

Confirm Communications Settings.

Match the PT communications settings to the PLC system settings on the PLC.

Use either of the methods outlined below.

1. Check the PT communications settings under the PT System Menu. If

required, change the settings on the PT or change the PLC system settings

on the PLC.

• Select System Menu - Comm. Tab Page and check the settings. (The default

baud rate under the CX-Designer communications settings is High-Speed and

the default NT link unit number is 0.

• Match these settings to the serial communications mode settings under the

PLC system settings on the CX-Programmer. Check that the RS-232C port

serial communications mode is set to NT Link and that the maximum unit

number for NT Link mode is higher than the number of units used. (The default

baud rate in the PLC system settings is Standard and the default maximum

unit number for NT Link mode is 0.)

If the unit number for NT Link mode is set to 0, set the maximum NT Link unit

number to 1 or higher in the PLC Setup.

2. Use the automatic NT Link connection setting function in CX-Integrator.

• Start CX-Integrator and click the right mouse button on the CPU Unit

in the Online Connection Information Window. Select NT Link Tool -

NT Link Automatic Connection.

The NT Link automatic connection function automatically detects the

communications settings on the PT connected to the PLC by a serial

network and automatically changes the serial port settings under the PLC

system settings on the PLC.

CX-Integrator

• Serial connection

(Toolbus or Host Link)

• Network connection

Start Operation.

(If the System Menu is displayed on the PT, press the Exit Button.)

Automatically changes the serial port settings

on the PLC to match the serial port settings

on the NS-series PT.

Automatic serial connection using

NT Link (using RS-232C port)

Refer to 6-10 Starting Operation in the

NS Series Setup Manual.

9

Basic Operation Procedures Section 1-2

10

SECTION 2

Setting Up the CX-Designer

The CX-Designer must be installed on the computer before it can be used for the first time. The CX-Designer is application

software that runs on a Windows 2000, XP, Vista, or 7 operating system. This section describes how to install the CXDesigner assuming that the Windows 2000, XP, Vista, or 7 operating system has already been installed on the computer.

2-1 Preparations for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2-2 Installing the CX-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2-3 Uninstalling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4 Installing USB Drivers for NS-Series PTs.. . . . . . . . . . . . . . . . . . . . . . . . . . . 18

11

Preparations for Installation Section 2-1

2-1 Preparations for Installation

Check to be sure that the following system requirements have been met

before installing the CX-Designer.

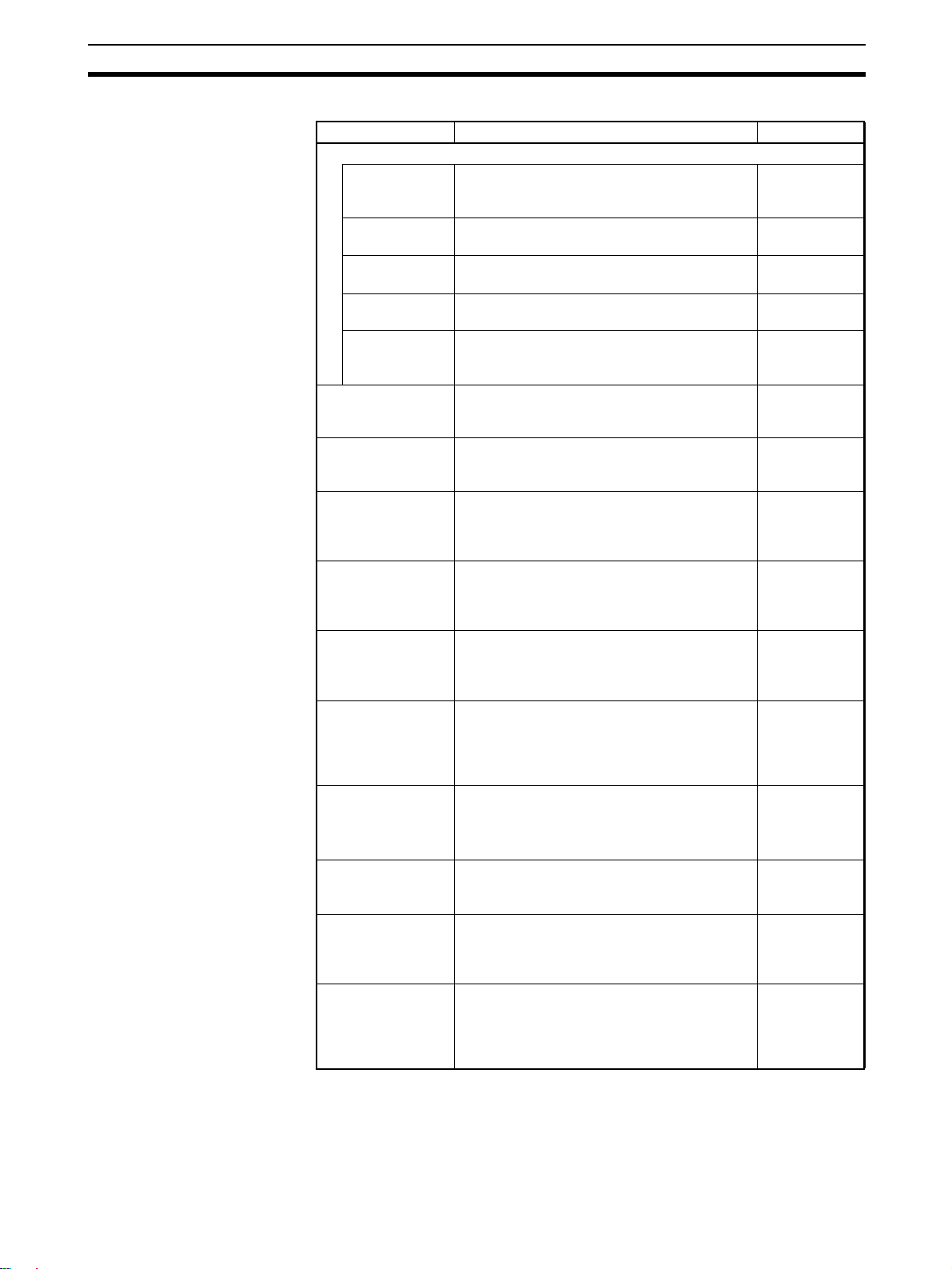

System Requirements The system requirements for the CX-Designer are given in the following table.

Item Requirement

Operating system (OS)

(See note 1.)

Japanese or English system

Computer IBM PC/AT or compatible with a Pentium II

Memory A minimum of 256 MB of memory is

Hard disk Approx. 700 MB or more available space is required to install.

Display SVGA (800 × 600) or better high-resolution display with 256 colors min.

Disk drive CD-ROM drive

Communications ports 1 port minimum, either RS-232C or USB (See note 2.)

Other Internet access is required for online user registration, including a modem or other hard-

Microsoft Windows

2000 (Service Pack 4

or higher)

333 MHz or faster processor

(Pentium III 1 GHz or faster recommended.)

required, and a minimum of 1 GB is recommended.

ware connection method.

Microsoft Windows XPMicrosoft Windows Vista or 7 (except for 64-

bit edition) (See note 3.)

IBM AT-compatible personal computer with

the processor recommended by Microsoft.

A minimum of 1 GHz is recommended.

A minimum of 1 GB of memory is required,

and a minimum of 1.5 GB is recommended.

Using CX-Designer with

Windows Vista or 7

(1) CX-Designer Operating System Precaution

The CX-Designer will not run on Microsoft Windows 95, 98, NT, Me, or

any other OS not listed above. If such an OS is being used on the client

computer, the OS must be upgraded before installing the CX-Designer.

System requirements and hard disk space may vary with the system en-

vironment.

(2) An RS-232C or USB port is required to connect to the NS-series PT.

(3) The following restrictions apply when using CX-Designer version 2.1 or

higher with Microsoft Windows Vista or 7.

Some help files cannot be referenced.

Help files can be referenced if the help program (WinHlp32.exe) for Win-

dows Vista or 7 (distributed by Microsoft Corporation) is imported. For de-

tails, either refer to the Microsoft home page below or contact Microsoft

Corporation. (When connected online, the download page is displayed

automatically by opening the help file.)

http://support.microsoft.com/kb/917607/en

The following restrictions apply when using CX-Designer with Windows Vista

or 7.

Item Contents

Fonts When project data created outside of Windows Vista or 7

is saved in Windows Vista or 7, characters using fonts

that are different in Windows Vista or 7 will be changed.

Similarly, characters in project data using fonts added or

changed in Windows Vista or 7 will be changed when

saved outside of Windows Vista or 7.

Memory Card Transfer

Support Software

Two-bytes characters used in file names and folder

names on the Memory Card will not be displayed normally.

12

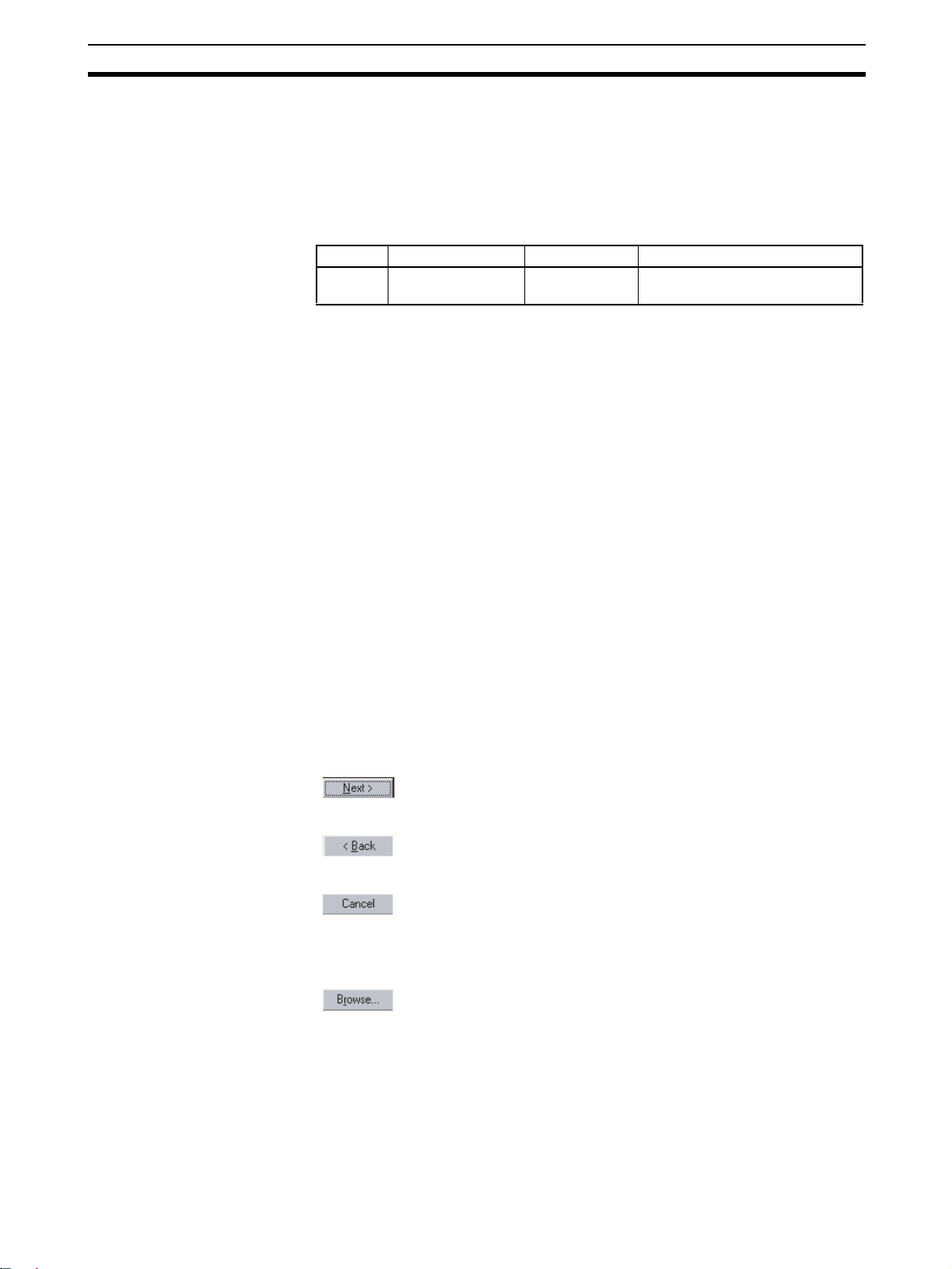

Installing the CX-Designer Section 2-2

2-2 Installing the CX-Designer

Install the CX-Designer in the hard disk.

To install the CX-Designer, execute the installation program provided.

For details on procedures for installing the CX-Designer from CX-One FA Inte-

grated Tool Package, refer to the CX-One Ver. 2.1 Setup Manual provided with

CX-One.

Cat. No. Model Manual name Contents

W463 CXONE-AL@@C-

V4/AL@@D-V4

Note If the CX-Designer was previously installed from the CX-One and it's neces-

sary to install it from the individual CX-Designer CD-ROM, always uninstall

the CX-Designer using the following procedure before installing it from its individual CD-ROM. The CX-Designer will not operate properly if it is installed

without first uninstalling it.

1,2,3... 1. Insert the CX-One installation disk 1 into the CD-ROM drive.

2. Select the Modify Option to enable modifying the Support Software that is

installed.

3. In the Select Features Dialog Box, clear the selection of only the CX-Designer. Do not change any other selections.

4. Continue by following the instructions in the dialog boxes to modify the installation and uninstall CX-Designer.

5. Once the CX-Designer uninstallation process has been completed, place

the individual CD-ROM disk for the CX-Designer into the CD-ROM drive

and install the CX-Designer. (See note.)

Note If the version of the CX-Server bundled on the individual CX-De-

signer CD-ROM is lower than the version of the CX-Server bundled

with the CX-One, install only the CX-Designer and NOT the CXServer. If a version of CX-Server that is lower than the version with

the CX-One is installed, the CX-One will not operate properly.

The main buttons that are displayed during installation are as follows:

Confirms the settings in the window displayed and moves to the next

window.

CX-One Setup

Manual

Installation and overview of CXOne FA Integrated Tool Package.

Cancels the settings in the window displayed and returns to the previous window.

Closes the window currently being displayed. The settings in the window are cancelled.

Installation can be cancelled by pressing this button in the installation

window. A confirmation message will be displayed.

The actual folder configuration is displayed in a tree format, from

which the folders where installation files are to be installed can be

selected.

13

Installing the CX-Designer Section 2-2

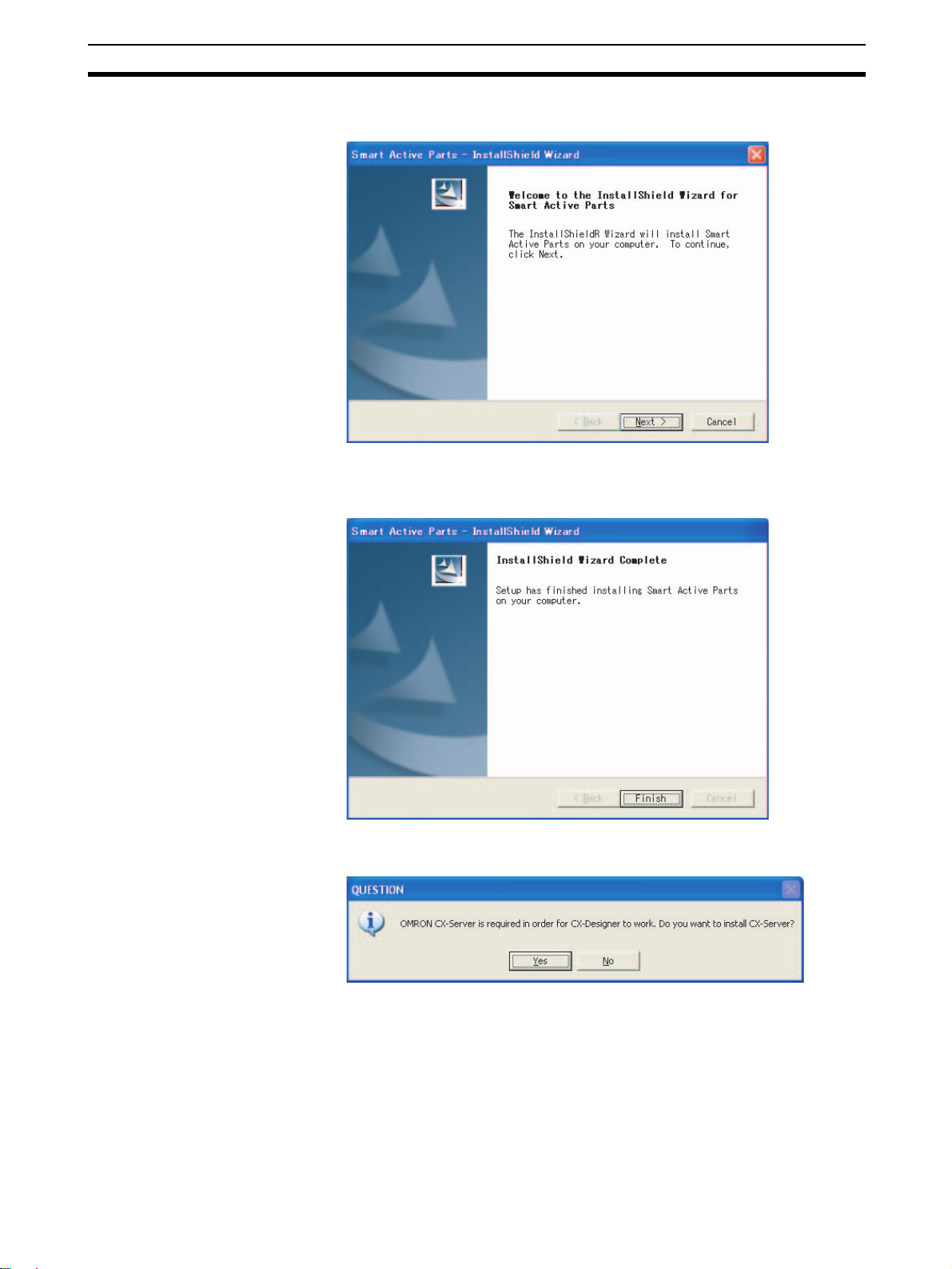

Installation Procedure

1,2,3... 1. Start up Windows.

2. Close all applications before executing installation. Place the CX-Designer

CD-ROM in the CD-ROM drive. The setup program is started automatically. If the setup program does not start automatically, such as after executing uninstall, locate Setup.exe in the CD-ROM using Windows Explorer,

and then double-click the file to execute the setup program.

Note If CX-Designer is already installed, a dialog box to confirm deletion of this ver-

sion will be displayed. Click the OK Button to start deleting this version. To exit

the setup program, click the Cancel Button and then click the Exit Button. FinsGateway and CX-Server will not be uninstalled by this operation.

3. The CX-Designer Setup Wizard will be displayed.

Install the CX-Designer by following the instructions in the Setup Wizard.

4. During installation, the installation progress is displayed as a percentage.

5. When CX-Designer installation has been completed, a message to confirm

installation of Smart Active Parts will be displayed. Click the Yes Button to

start the installation. If Smart Active Parts installation is not required, click

the No Button and proceed to step 10.

Smart Active Parts are libraries containing setting/monitoring screens

(e.g., Position Control Unit setting screens and Temperature Controller

monitoring screens).

14

Installing the CX-Designer Section 2-2

6. The following dialog box will be displayed. Install the software according

the instructions given in window messages.

7. During installation, the installation progress is displayed as a percentage.

When installation has been completed, the following dialog box will be displayed. Click the Finish Button.

8. A message will be displayed to confirm installation of the CX-Server. Click

the Yes Button.

15

Installing the CX-Designer Section 2-2

9. When installation has been completed, the following dialog box will be displayed. Select whether or not to restart the computer immediately, and

click the Finish Button to complete the installation.

Always restart the computer before using CX-Designer.

Note (1) When installing CX-Designer in Windows 2000, XP, Vista, or 7, log onto

the computer as the administrator to ensure that system DLL files can be

overwritten. If overwriting system DLL files fails, CX-Designer may not operate properly.

(2) When adding Smart Active Parts after installation of CX-Designer, dou-

ble-click the CD-ROM directory \SmartActiveParts\Setup.exe from Windows Explorer to execute the setup program. Select all the Smart Active

Parts to be used in the dialog box for selecting components.

(3) Refer to the How to manage after conversion file in the Programs Folder

under the Windows Start Menu for details after NT31C/NT631C Conversion Support Tool conversion.

(4) Internet Explorer Ver 5.5 or higher is required to transfer data.

16

Installing the CX-Designer Section 2-2

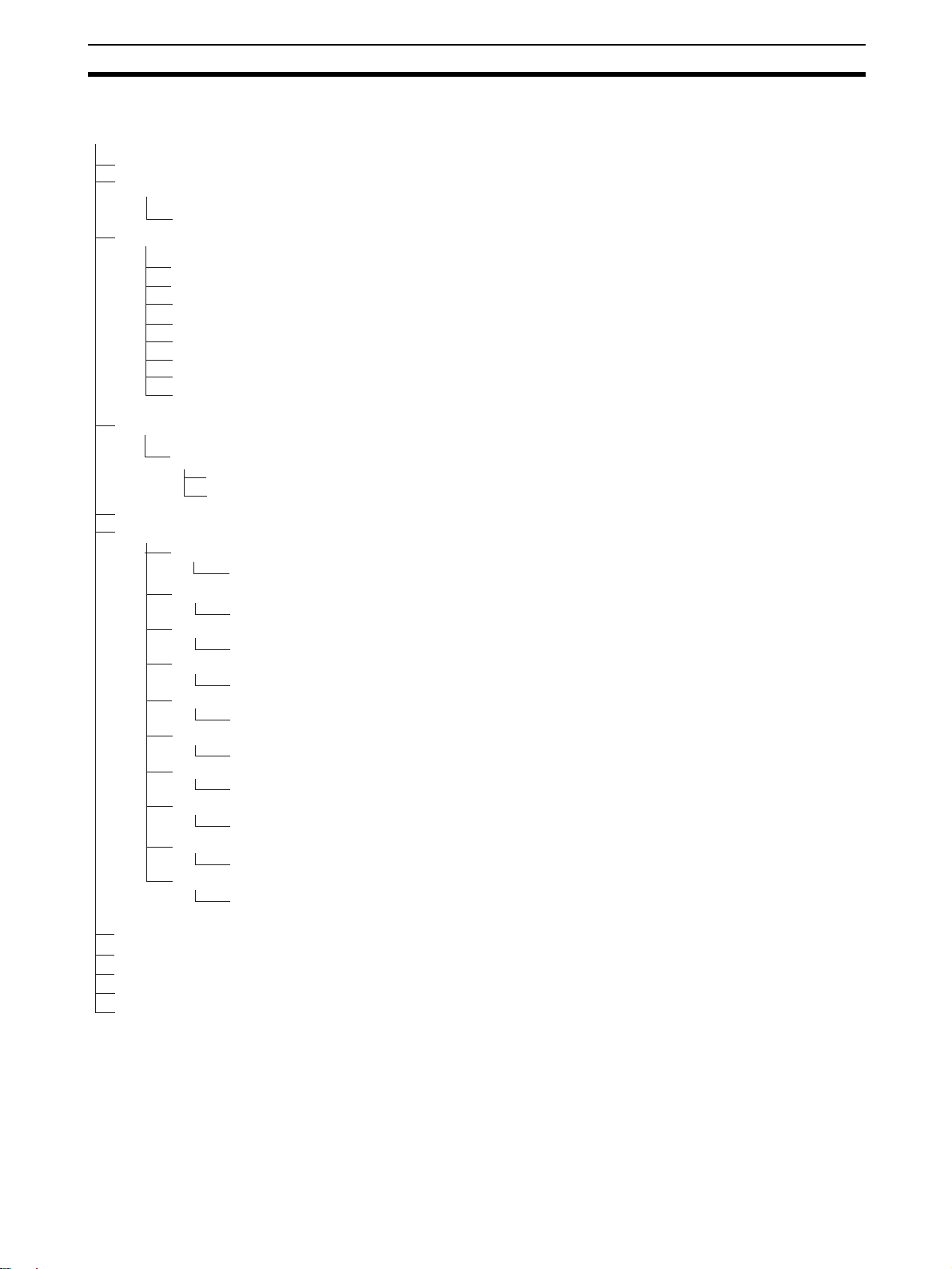

The folder structure after installation is as follows:

CX-Designer

bldparts

intaparts

BMPfiles

Manual

Guide

Users

Macro

Setup

Programming

SmartActiveParts

HostConnection

RGB_Video (NS-CA002)

library

SAP

SmartActiveParts_E

SAPmini_E

runparts

System Backup (See note.)

NS15_V2

V@_@

NS12_V1_V2

NSJ12

NS10_V1_V2

NSJ10

NS8_V1_V2

NSJ8

NS5_V1_V2

NSJ5

NSH5

V@_@

V@_@

V@_@

V@_@

V@_@

V@_@

V@_@

V@_@

V@_@

Parts Collection (bitmaps)

Directory containing manuals

Introductory Guide

User's Manual/NSH Operation Manual

Macro reference

Setup manual

Programming manual

How to use Smart Active Parts

Host Connection Manuals (Temp. Controller and Memory Links/Host Links/Multivendor)

NS-CA002 RGB/Video Input Unit Manual

Smart Active Parts for NS8/NS10/NS12/NS15

Smart Active Parts for NS5

NS15-V2 system folder (Version

NS12-V1/-V2 system folder (Version

NSJ12 system folder (Version

NS10-V1/-V2 system folder (Version

NSJ10 system folder (Version

NS8-V1/-V2 system folder (Version

NSJ8 system folder (Version

NS5-V1/-V2 system folder (Version

NSJ5 system folder (Version

NSH5 system folder (Version

@.@

@.@

@.@

@.@

@.@

@.@

)

)

)

)

)

)

@.@

@.@

@.@

@.@

)

)

)

)

RecoverUpdate

NT631C_Cnv

Thermo

Readme_E.txt

Screen Data

Most recent version of the recovery/update program

Directory containing NT31C/NT613C Conversion Support Tool

Please read. (Contains precautionary information.)

Collection of sample screen data

Note The System Backup folder is created only when the CX-Designer is installed

from its individual CD-ROM.

17

Uninstalling Section 2-3

2-3 Uninstalling

Operation Procedure

1,2,3... 1. To uninstall the CX-Designer, click the Windows Start Button and select

Settings - Control Panel.

2. Double-click Add/Remove Applications.

@.@

3. Select CX-Designer_V

(“@.@” represent the version number.) Follow the instructions displayed in

the window messages to uninstall the CX-Designer.

4. When uninstalling the CX-Designer has been finished, a message will be

displayed indicating that the uninstall operation has been completed.

Check the message and then click the Finish Button.

from the list and click the Edit/Delete Button

2-4 Installing USB Drivers for NS-Series PTs.

Install the NS-series USB driver in the personal computer. After installation,

data can be transferred between the personal computer and NS-series PT via

USB.

Note (1) With NS-V1 Series models, make sure that the PT has a lot number that

supports USB transmission. The system program version of the NS-series PT must also support USB transmission. For details, refer to 3-3-2

Connecting via USB in the NS series Setup Manual (Cat. No. V083).

(2) If an NS-series USB driver has already been installed for use with the NS-

Designer, the NS-series USB driver must be installed again to use the

CX-Designer.

(3) Do not install the NS-series USB driver for the NS-Designer while the CX-

Designer is being used.

Applicable Operating

Systems

Operation Procedure

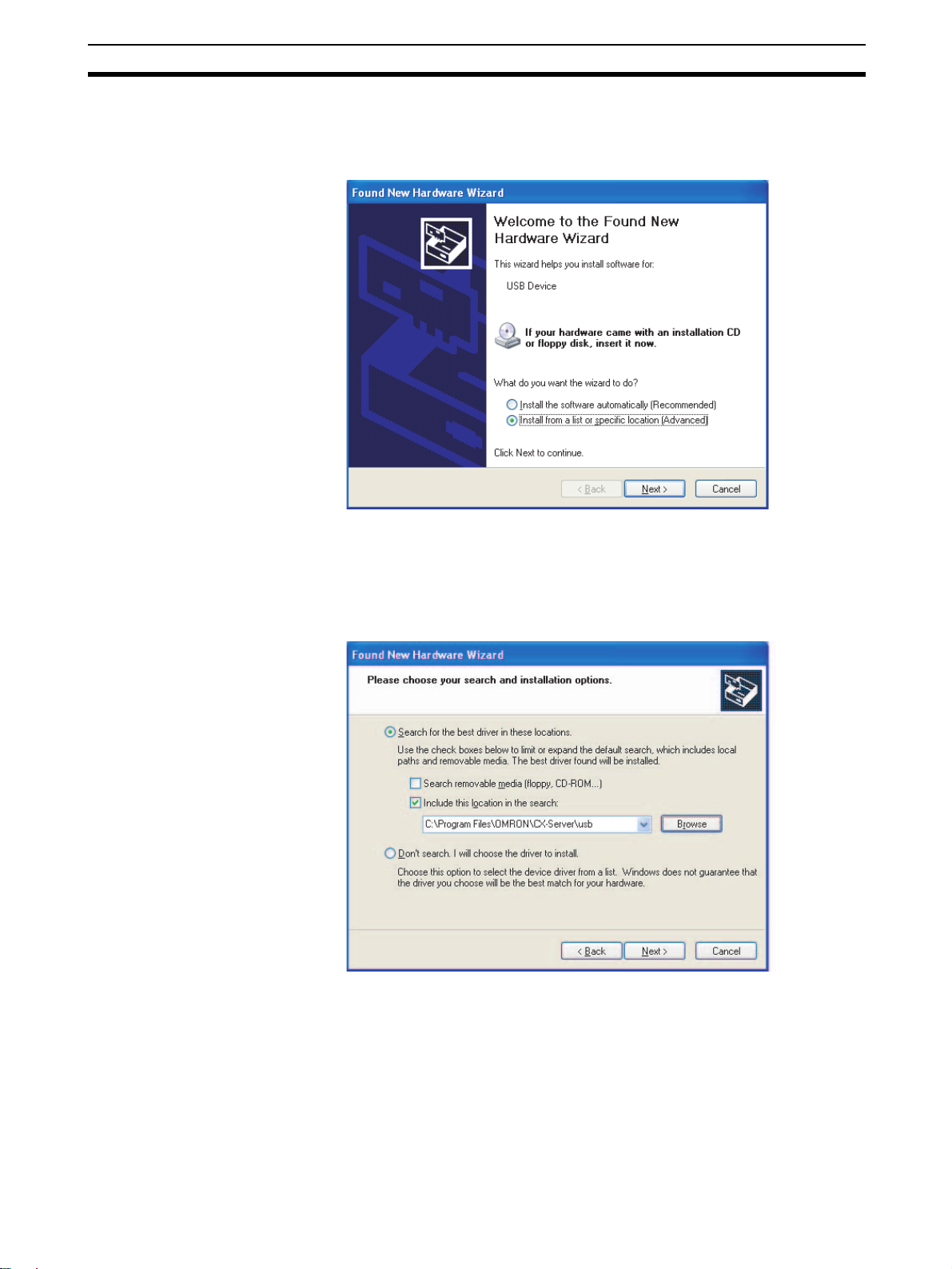

1,2,3... 1. Start Windows.

Windows 2000, Windows XP, Windows Vista, and Windows 7

2. Connect the personal computer to the NS-series PT USB slave connector

using the USB cable. The following Found New Hardware Wizard will be

displayed.

18

Installing USB Drivers for NS-Series PTs. Section 2-4

3. For Windows 2000, select Display a list of the known drivers for this device

so that I can choose a specific driver and click the Next Button. For Win-

dows XP, select Install from a list or specific location (Advanced) and click

the Next Button.

4. The dialog box shown below will be displayed. Confirm that Search for the

best driver for my device (Recommended) is selected. Select the Include this location in the search option, click the Browse Button and

specify the following CX-Server installation directory folder:

\USB

Then click the Next Button.

19

Installing USB Drivers for NS-Series PTs. Section 2-4

5. The dialog box shown below will be displayed. Click the Continue Anyway

Button.

6. When installation is completed, the following dialog box will be displayed.

Click the Finish Button.

20

SECTION 3

Basic Operations of the CX-Designer

This section describes basic functions and operation methods, such as starting and exiting CX-Designer and the user

interface.

3-1 Starting and Exiting CX-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-1-1 Startup Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-1-2 Exiting CX-Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3-2 Menu Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3-3 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3-3-1 Names of Basic Screen Components . . . . . . . . . . . . . . . . . . . . . . . . 30

3-3-2 CX-Designer Functions and Screens . . . . . . . . . . . . . . . . . . . . . . . . 37

21

Starting and Exiting CX-Designer Section 3-1

3-1 Starting and Exiting CX-Designer

This section describes how to start and exit the CX-Designer.

3-1-1 Startup Method

To start the CX-Designer, click the Windows Start Button, and then select

Programs - OMRON - CX-One - CX-Designer - CX-Designer Ver. @ (The

items displayed may vary according to the program folder specified during

installation). Alternatively, right-click the NS-series PT in the Network Configuration Window of CX-Integrator, and select Start Special Application - Start

Only.

When the CX-Designer startup is completed, the Main Window will be displayed, as follows:

Note (1) More than one copy of the CX-Designer application can be run at the

same time.

(2) To start CX-Designer, log in as the administrator when using a personal

computer running Windows 2000, XP, Vista, or 7.

3-1-2 Exiting CX-Designer

Use one of the following operations to exit the CX-Designer.

•Select Exit from the File Menu.

• Click the Close Button at the top right of the Main Window.

• Double-click the CX-Designer icon at the top left of the Main Window.

• Click the CX-Designer icon at the top left of the Main Window and select

Close from the Control Menu Box.

• Press the Alt + F4 Keys.

If the project data that is open has not been saved, a confirmation message

will be displayed.

When the CX-Designer is exited, the system will return to the Windows display.

22

Menu Commands Section 3-2

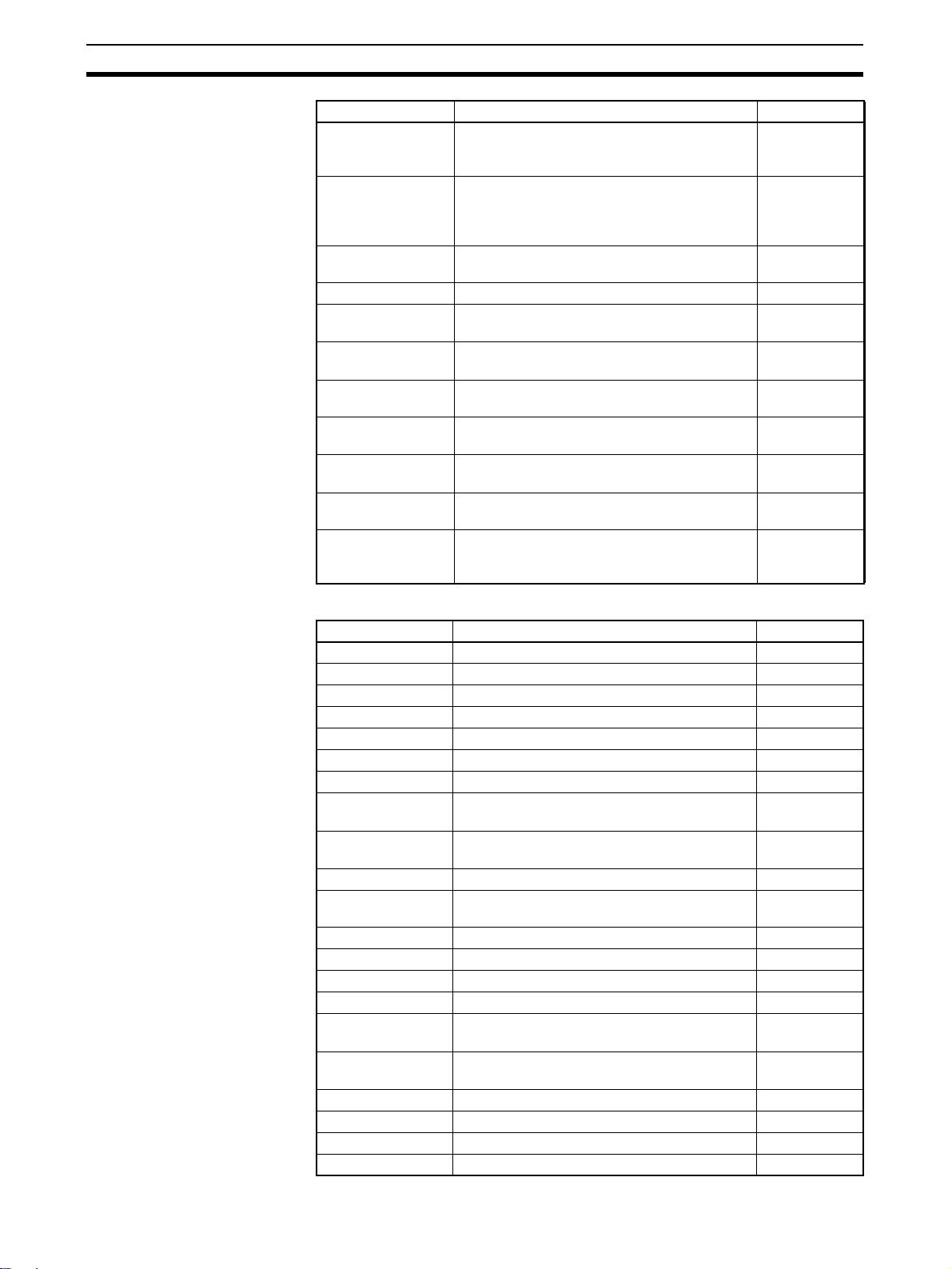

3-2 Menu Commands

The commands that appear on the pull-down menus of the CX-Designer and

their functions are described in the following tables.

File Menu

Command Function Shortcut keys

New Project Creates a new project. --Open Project Opens an existing project. --Close Project Closes the project currently open without

exiting the CX-Designer.

Save Project As Saves the current project under a specified

Save All Saves (overwrites) all of the data for the cur-

New Screen Creates a new screen under the current

Open Screen Opens the project workspace. Ctrl+O

Save Screen/Sheet Saves the current screen or sheet. Ctrl+Shift+S

New Sheet Creates a new sheet under the current

Apply Sheet Sets a screen with overlapping sheets. Ctrl+J

Import CSV File Imports project or screen data saved in CSV

Export CSV File Exports the current project or screen data to

Page Setup Makes the printer settings. --Preview Shows a preview of the printed image. --Print Outputs current project or screen information

Data Transfer Security

New Data Transfer Security Setting

Change Data

Transfer Security Setting

Cancel Data

Transfer Security Setting

Recent Projects Displays a list of currently edited projects.

Exit Ends the CX-Designer. ---

name.

rent project.

project.

project.

format to the current project or screen.

a file in CSV format.

to a printer or to a file. Select Print to display

a preview.

Sets a password to be input when transferring data.

Changes data transfer security setting. ---

Deletes data transfer security setting. ---

(Up to ten projects are displayed.)

---

---

Ctrl+S

Ctrl+N

Ctrl+Shift+N

---

---

Ctrl+P

---

---

23

Menu Commands Section 3-2

Edit Menu

Command Function Shortcut keys

Undo Discards changes and restores the previous

status.

Redo Restores the changes discarded with Undo.Ctrl+Y

Cut Deletes the selected objects and places them

in the internal buffer.

Copy Copies the selected objects and places them

Paste Pastes objects that have been cut or copied. Ctrl+V,

Paste (Style Only) Pastes objects that have been cut or copied

Delete Deletes the selected objects. DEL

Group

Group Groups more than one functional or fixed

Ungroup Ungroups grouped objects. Ctrl+U

Order

Front Brings the currently selected object to the

Back Sends the currently selected object to the

Bring Forward Brings the currently selected object forward. --Send Backward Sends the currently selected object back. ---

Align/Distribute

Align Left Aligns the currently selected objects to the

Center in a

Column

Align Right Aligns the currently selected objects to the

Align Top Aligns the currently selected objects to the

Center in a Row Aligns the horizontal centers of the currently

Align Bottom Aligns the currently selected objects to the

Distribute

Horizontally

Distribute

Vert ically

Make Same Size

Smallest Width Aligns the currently selected objects to the

Largest Width Aligns the currently selected objects to the

Smallest Height Aligns the currently selected objects to the

Largest Height Aligns the currently selected objects to the

Table Column

Width

Ta ble R ow

Height

in the internal buffer.

using the default address settings.

object to create a single object.

front.

back.

left.

Aligns the vertical centers of the currently

selected objects.

right.

top.

selected objects.

bottom.

Distributes the currently selected objects equi-

distant (between mid-points) horizontally.

Distributes the currently selected objects equi-

distant (between mid-points) vertically.

smallest width.

largest width.

smallest height.

largest height.

Aligns table columns to equal widths. ---

Aligns table rows to equal heights. ---

Ctrl+Z

Ctrl+X,

Shift+DEL

Ctrl+C

Shift+Ins

---

Ctrl+G

---

---

---

---

---

---

---

---

---

---

---

---

---

---

24

Menu Commands Section 3-2

Command Function Shortcut keys

Nudge

Up Moves the selected object one dot or one grid

Down Moves the selected object one dot or one grid

Left Moves the selected object one dot or one grid

Right Moves the selected object one dot or one grid

Rotate/Flip

Rotate Right 90

Degrees

Rotate Left 90

Degrees

Rotate Right 90

Degrees

Around Center

of Screen/

Frame

Rotate Left 90

Degrees

Around Center

of Screen/

Frame

Flip Horizontal Flips the currently selected object horizontally. --Flip Vertical Flips the currently selected object vertically. --Flip Horizontal

Around Center

of Screen/

Frame

Flip Vertical

Around Center

of Screen/

Frame

Edit Node Changes the positions of the vertices to

Select All

All Objects Selects all objects on the screen. Ctrl+A

Same Type

Objects

Repeat Makes multiple copies of the selected objects. Ctrl+W

Edit Properties Displays a list of functional objects on screen

unit up.

unit down.

unit to the left.

unit to the right.

Rotates the currently selected object 90

degrees to the right.

Rotates the currently selected object 90

degrees to the left.

Rotates the currently selected object 90

degrees to the right around the center of the

screen or frame.

Rotates the currently selected object 90

degrees to the left around the center of the

screen or frame.

Flips the currently selected object horizontally

around the center of the screen or frame.

Flips the currently selected object vertically

around the center of the screen or frame.

change the shape of a fixed object node.

Selects all objects of the same type as the

currently selected object.

to enable changing property settings.

↑

↓

←

→

---

---

---

---

---

---

---

Ctrl+D

Ctrl+L

Find Menu

Command Function Shortcut keys

Find Searches for address or character string key-

Replace Replaces the specified addresses. Ctrl+H

Address Cross Ref-

erence

Macro Cross Refer-

ence

Replace Host Replaces the host for all addresses in the

words.

Finds locations where an address is used and

lists the results.

Lists macro locations. ---

project.

Ctrl+F

Ctrl+R

---

25

Menu Commands Section 3-2

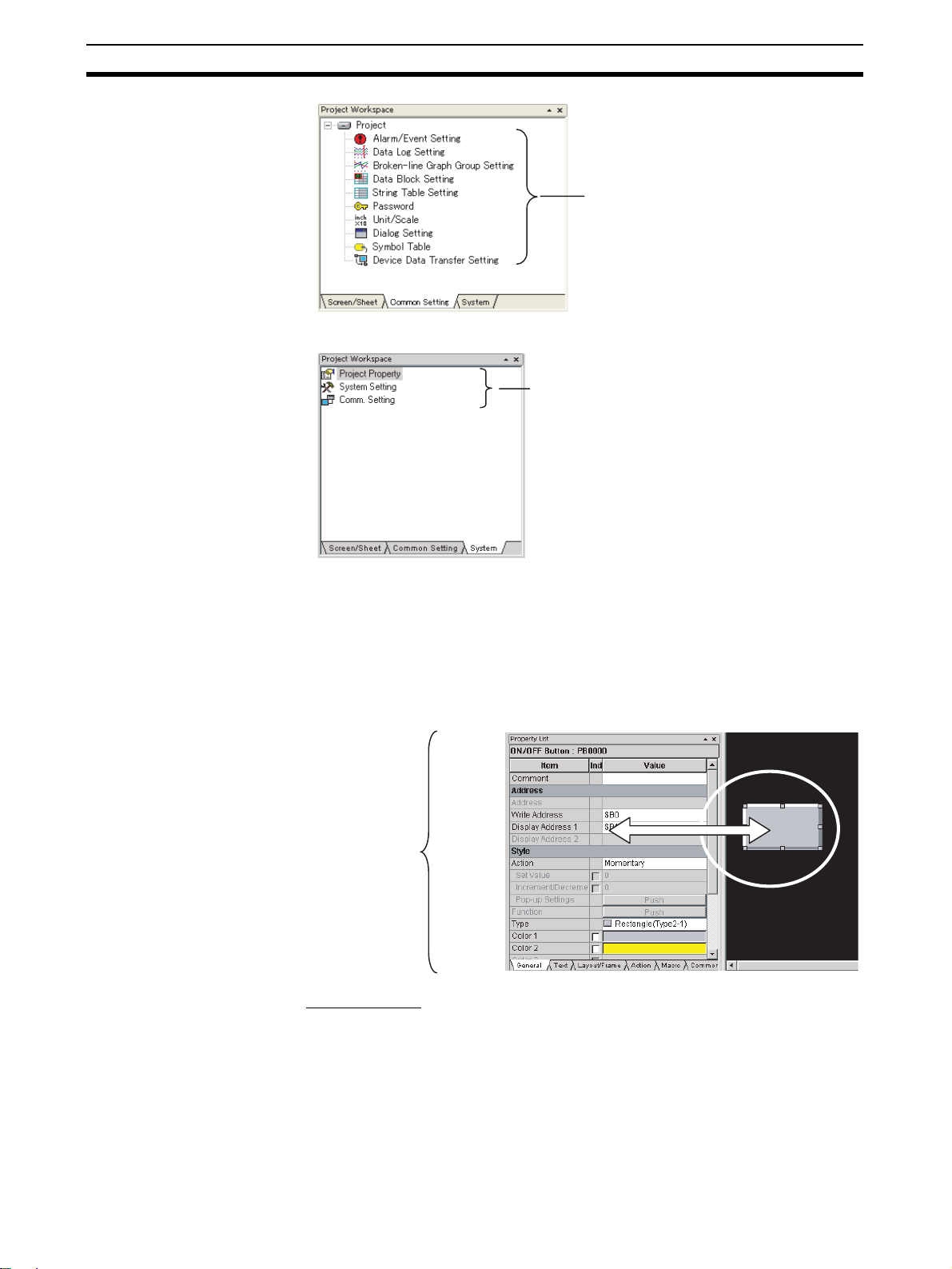

View Menu

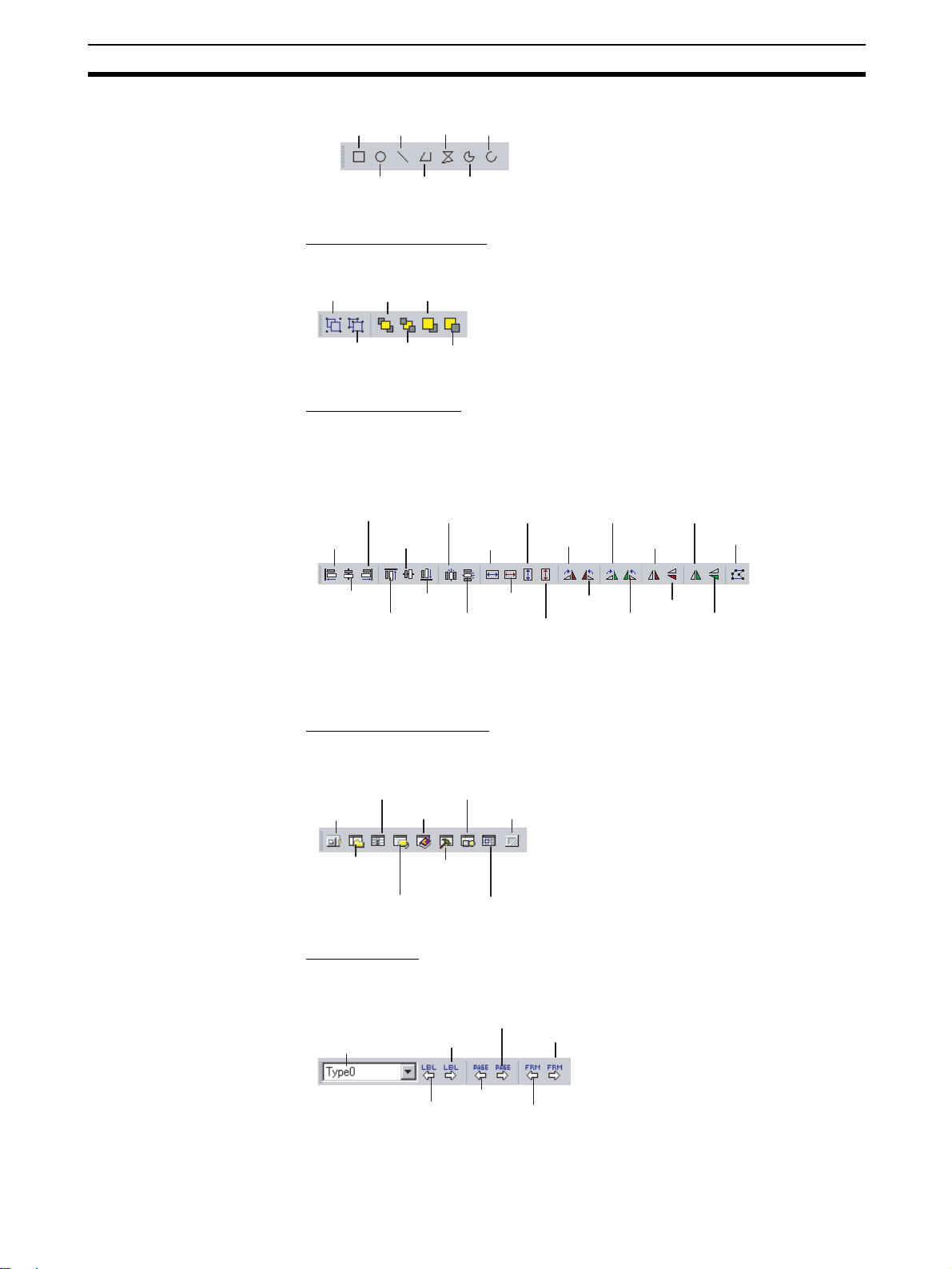

Command Function Shortcut keys

Toolbar Displays and hides the toolbar. --Window

Project

Workspace

Symbol Table Displays and hides the symbol table. Alt+2

Property List Displays and hides the property list. Alt+3

Library Displays and hides the Library Window. Alt+4

Select Object Displays and hides the object selection. Alt+5

Address in Use

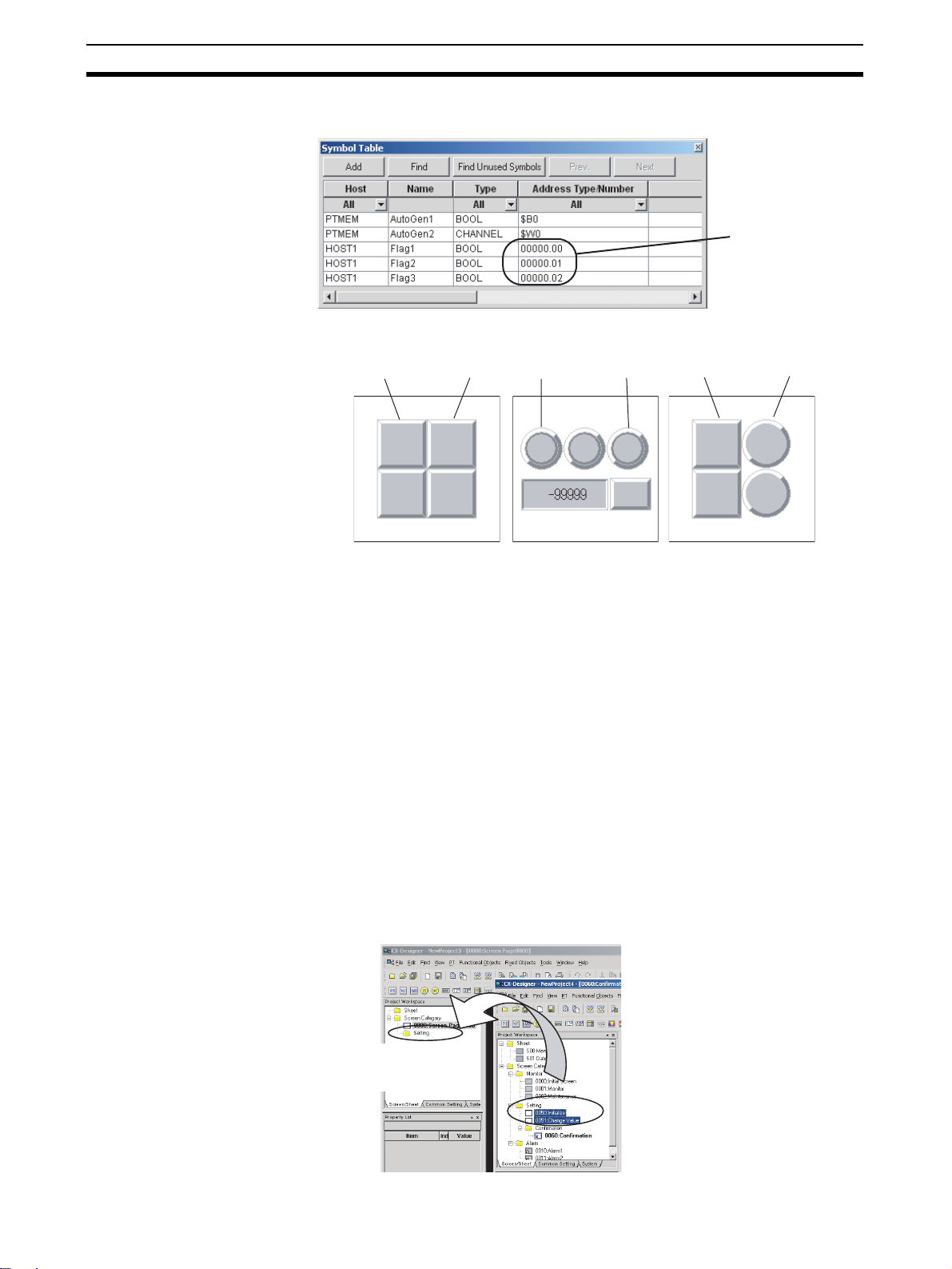

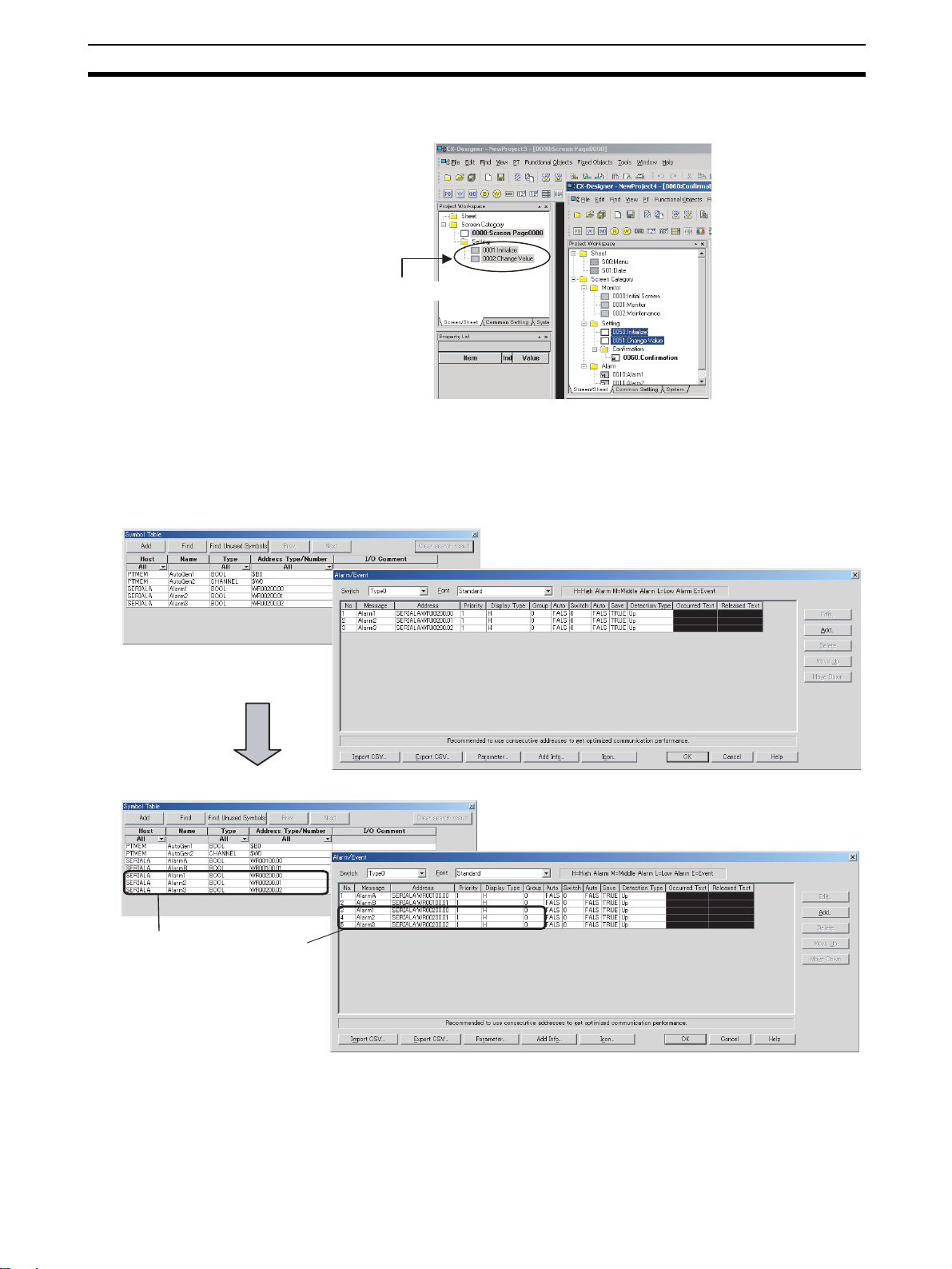

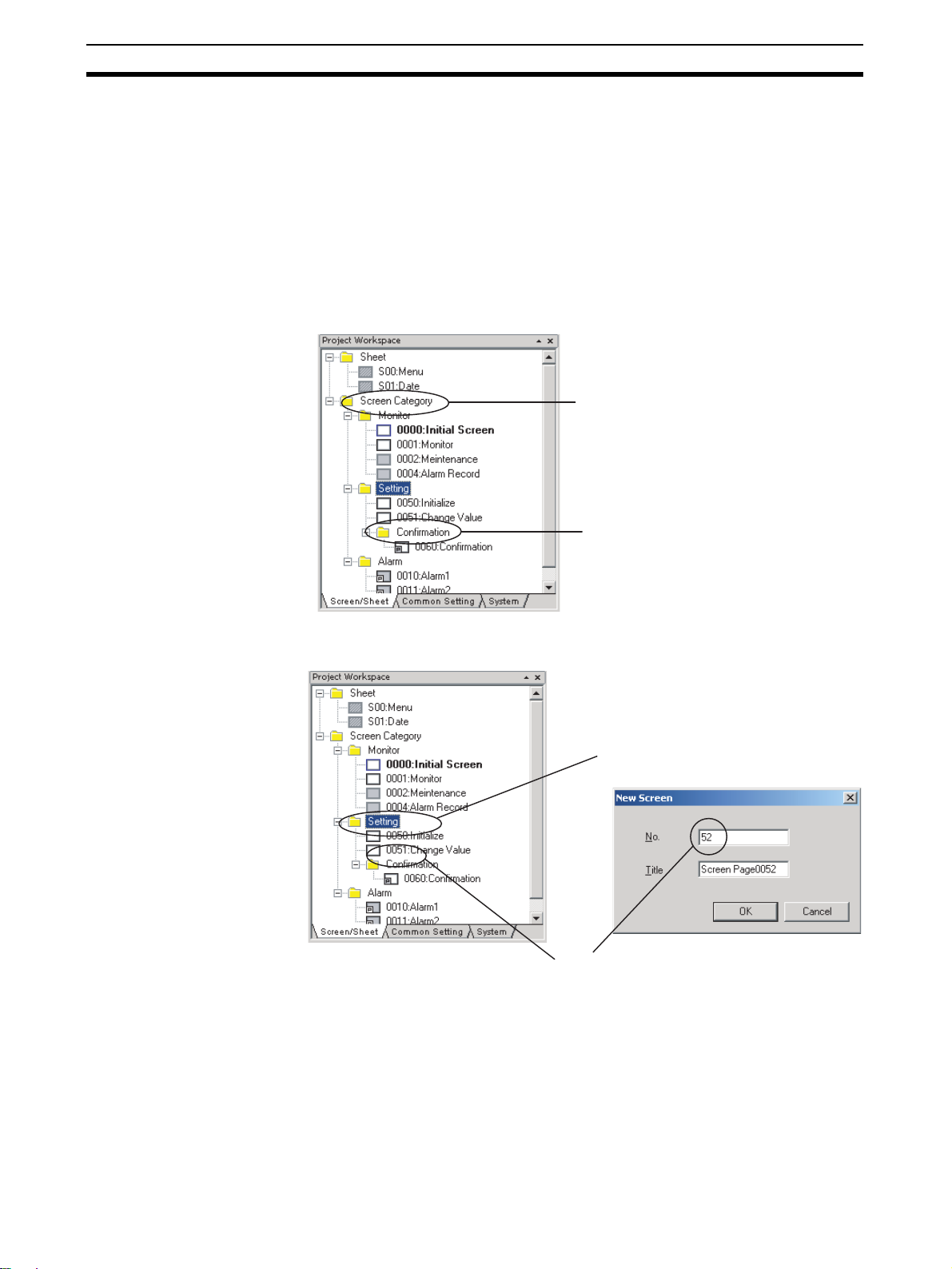

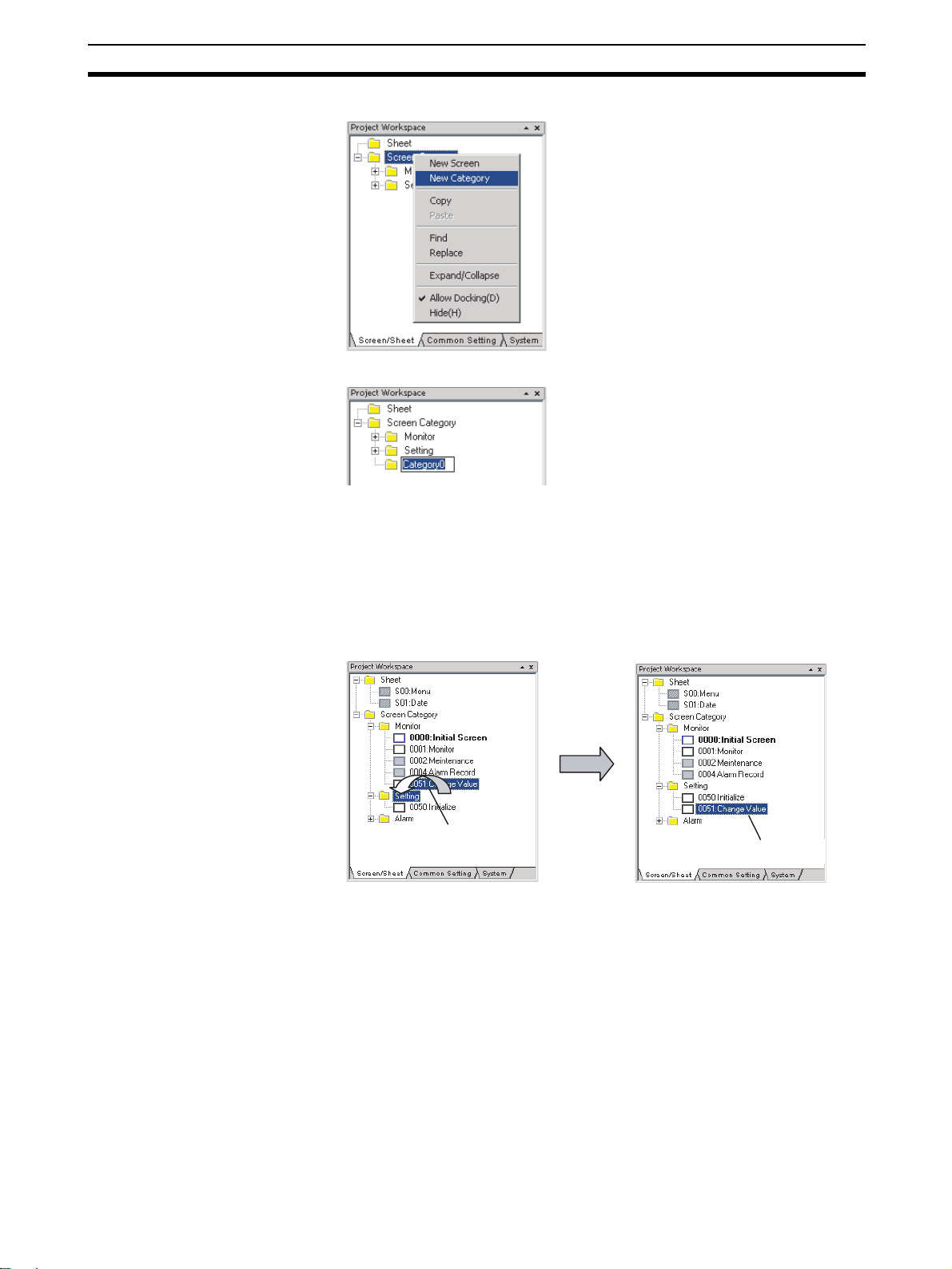

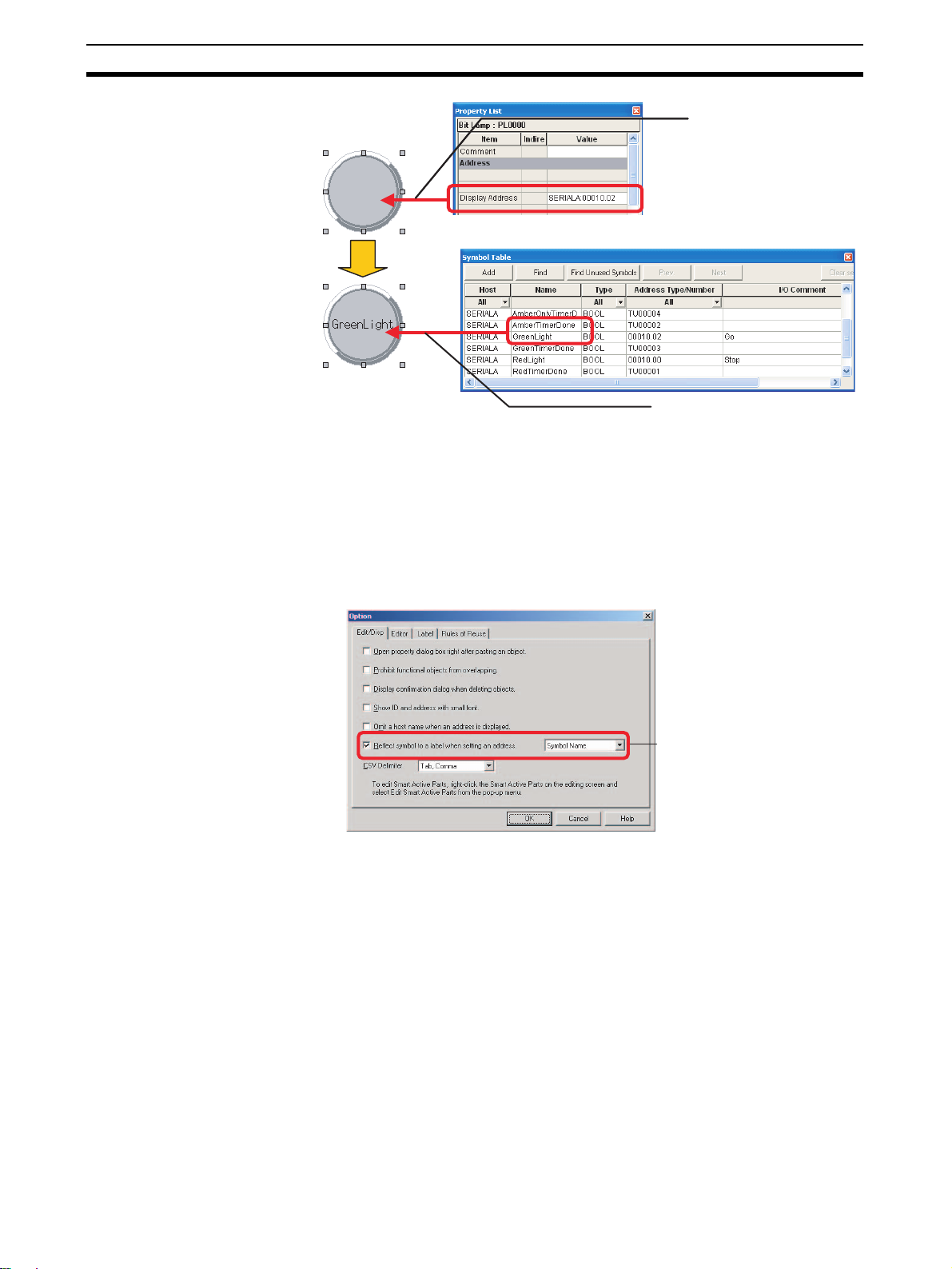

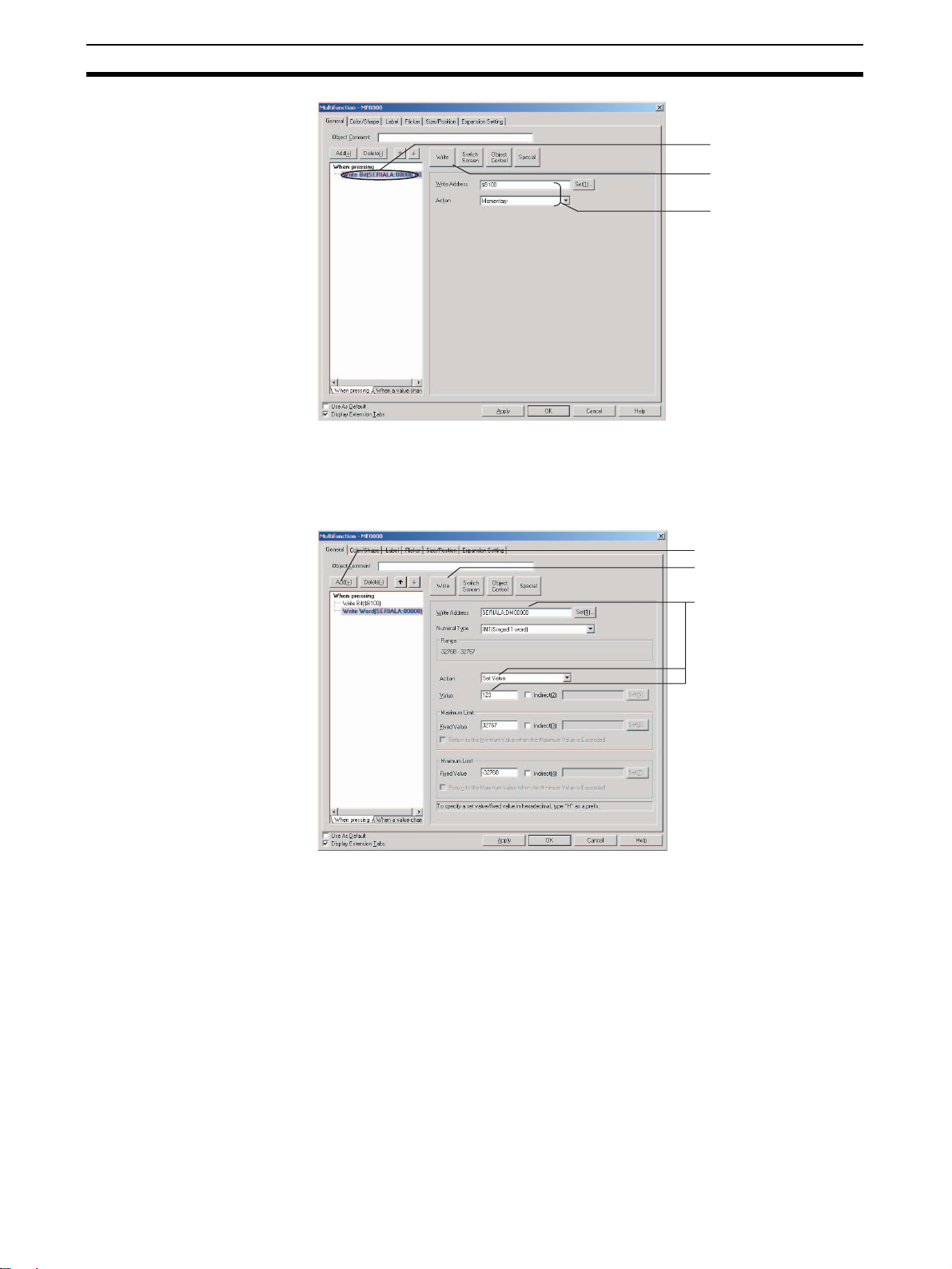

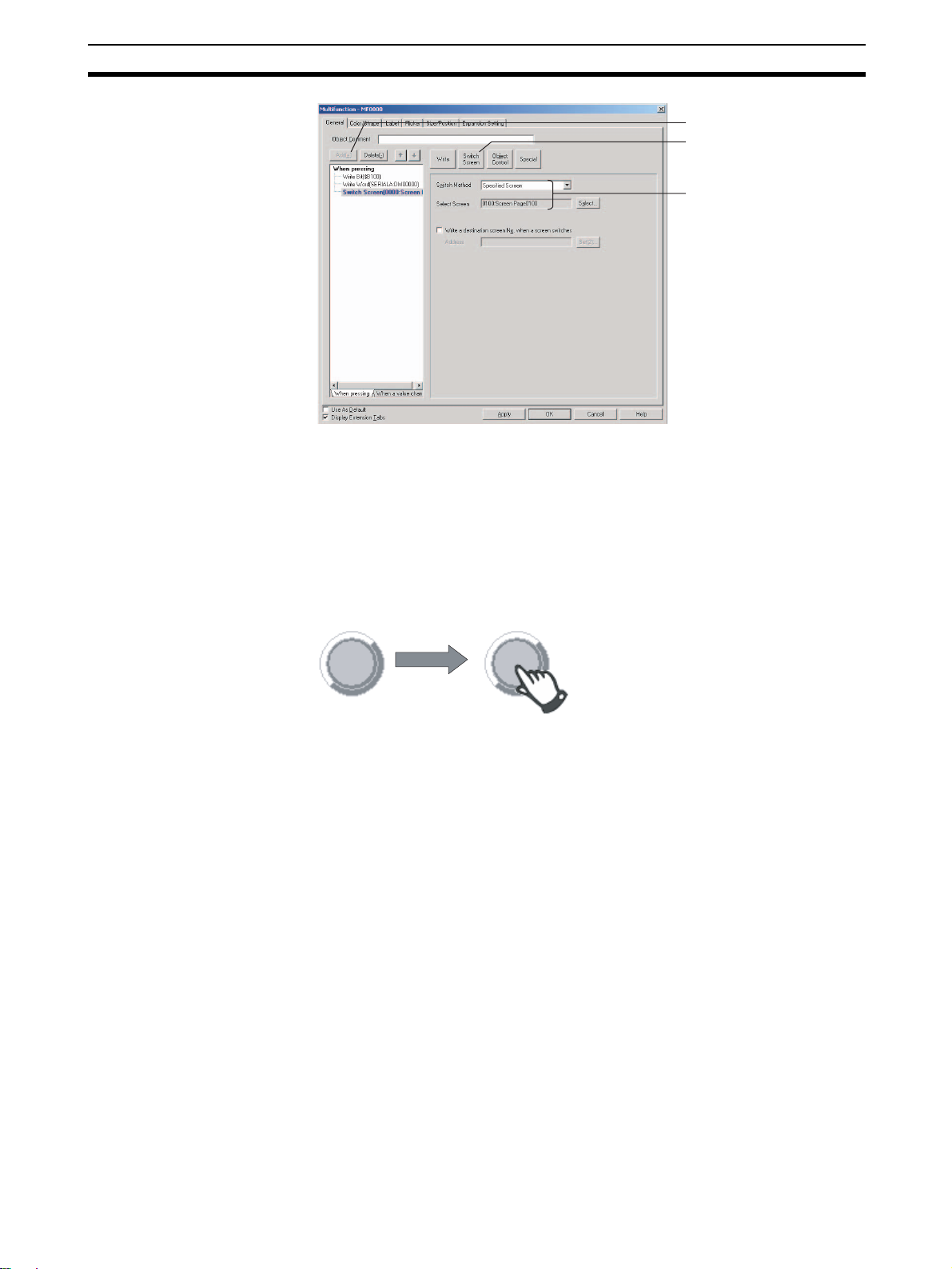

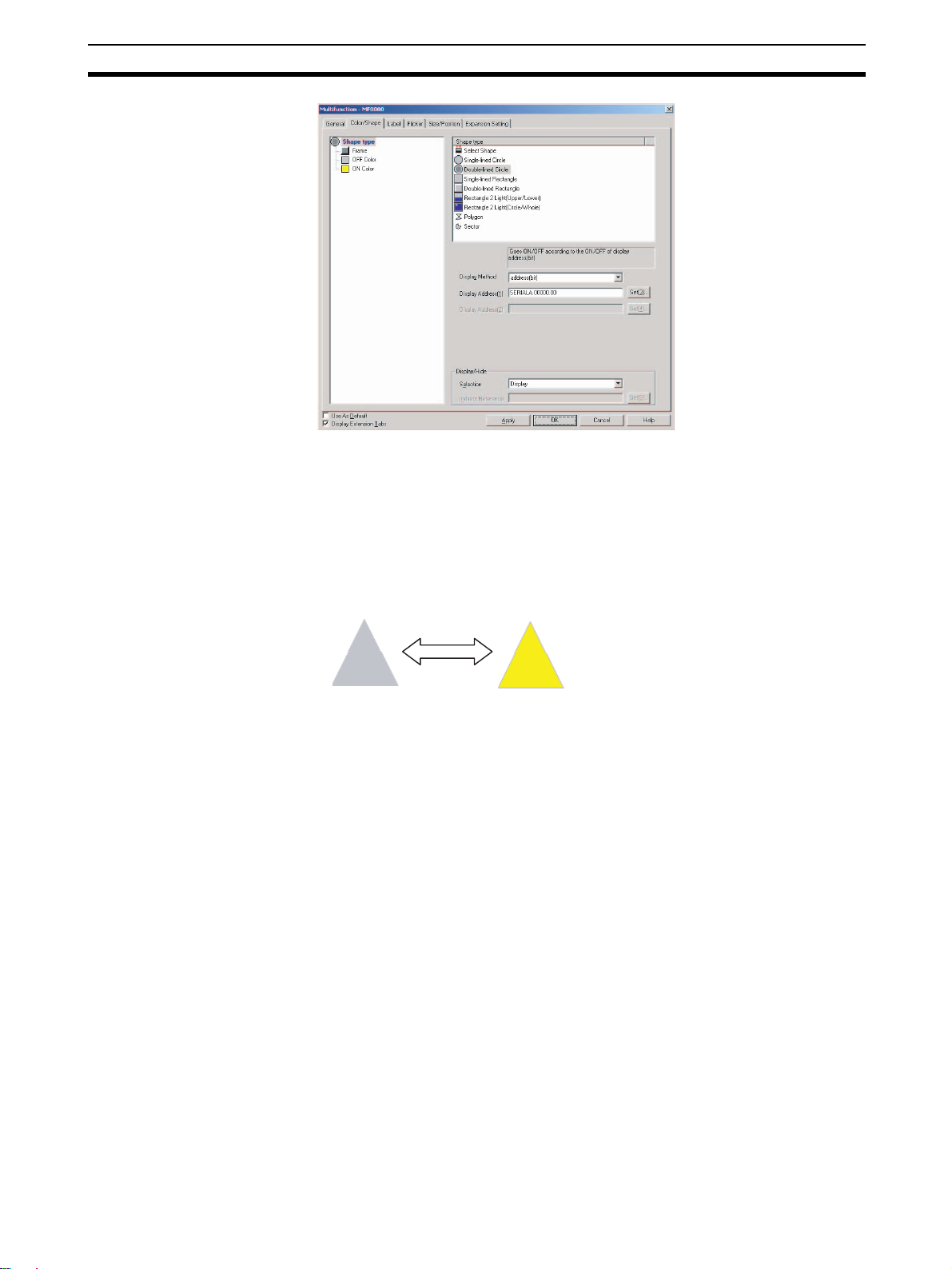

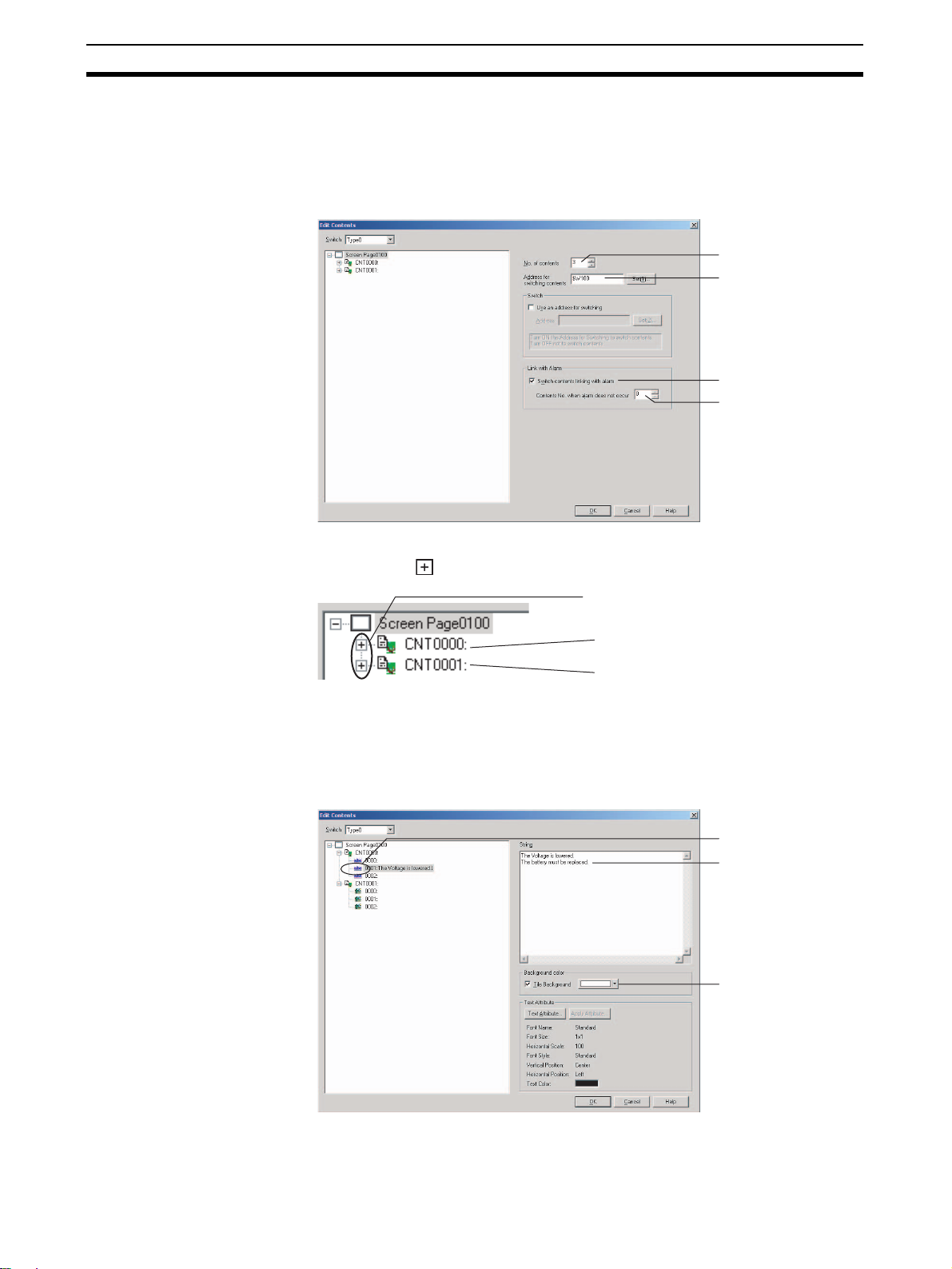

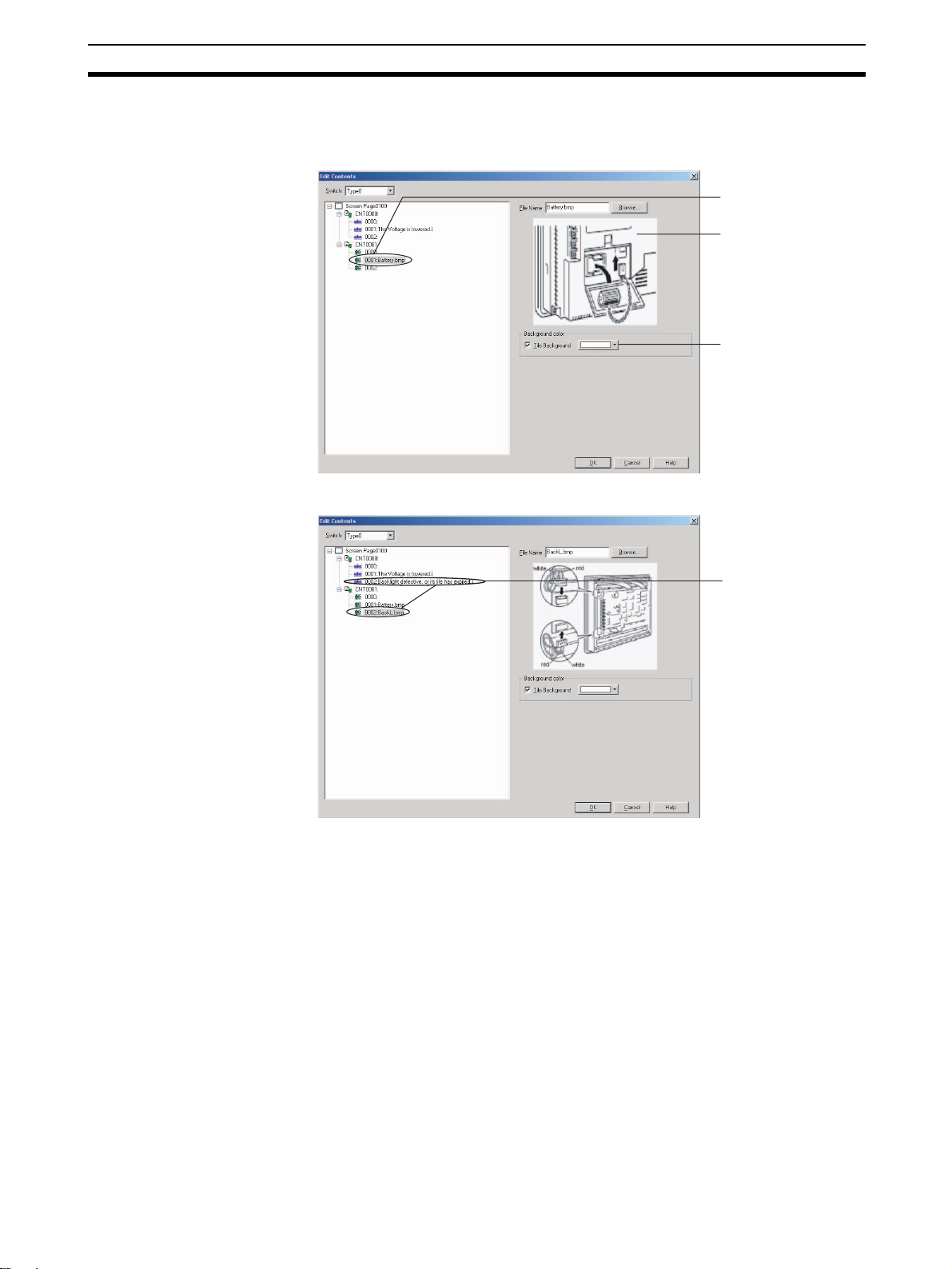

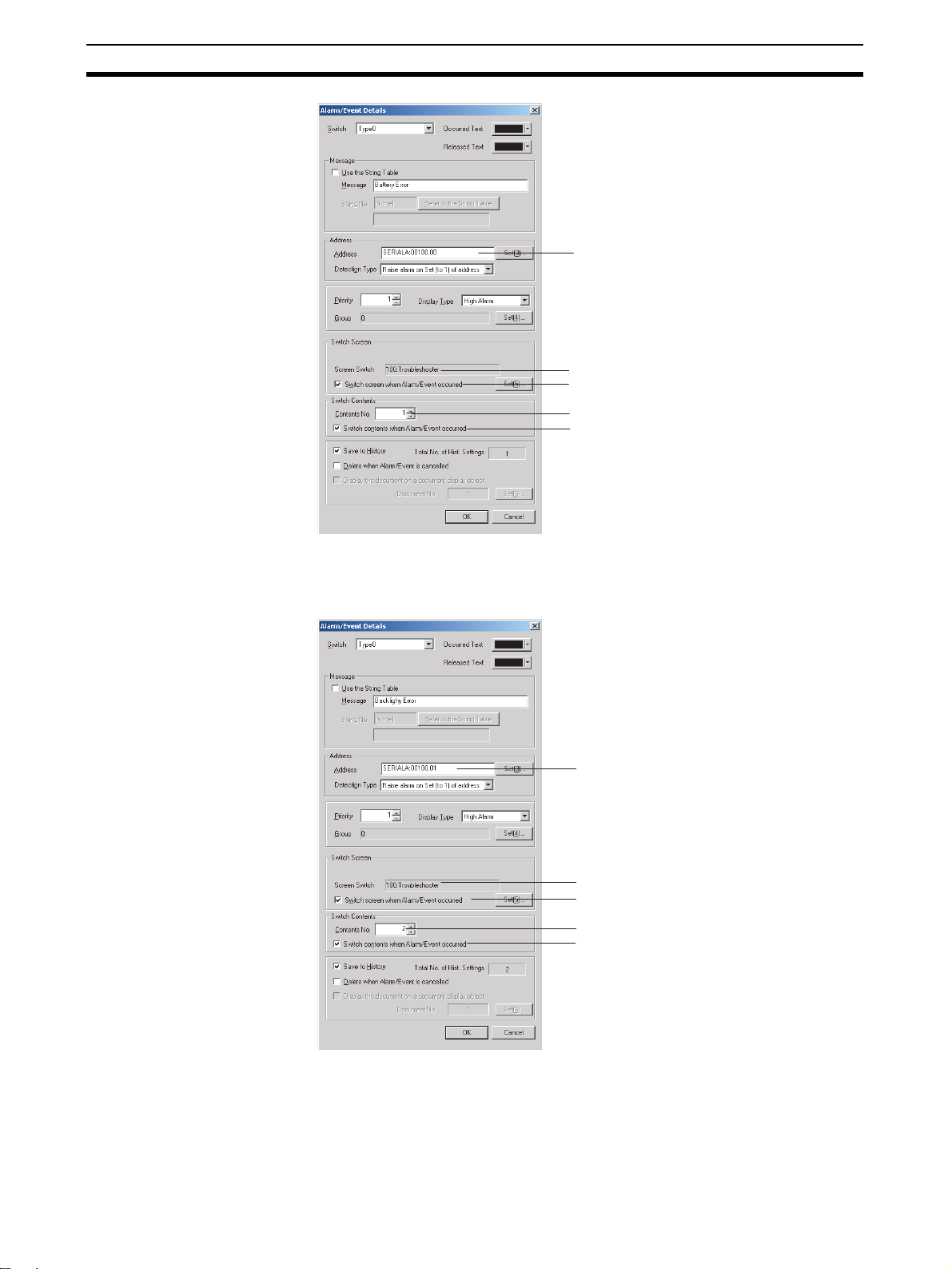

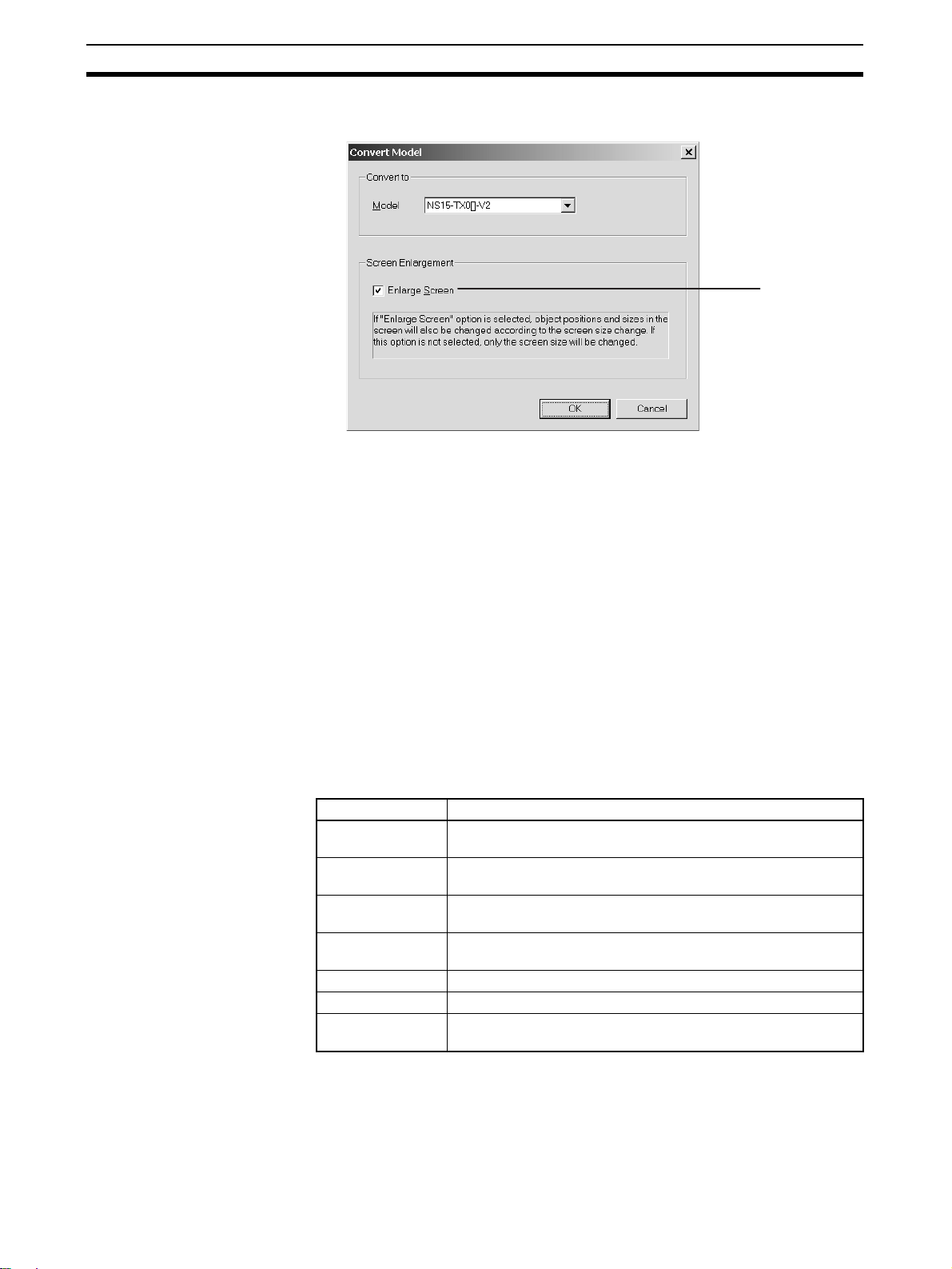

List