Page 1

Screen Designer for NS Series

NS-CXDC1-V1

CX-Designer – Brand new screen Designer for NS-series PTs.

Greatly reduces the effort of creating screens.

Page 2

The NS-series Screen Designer Now

The integrated development environment

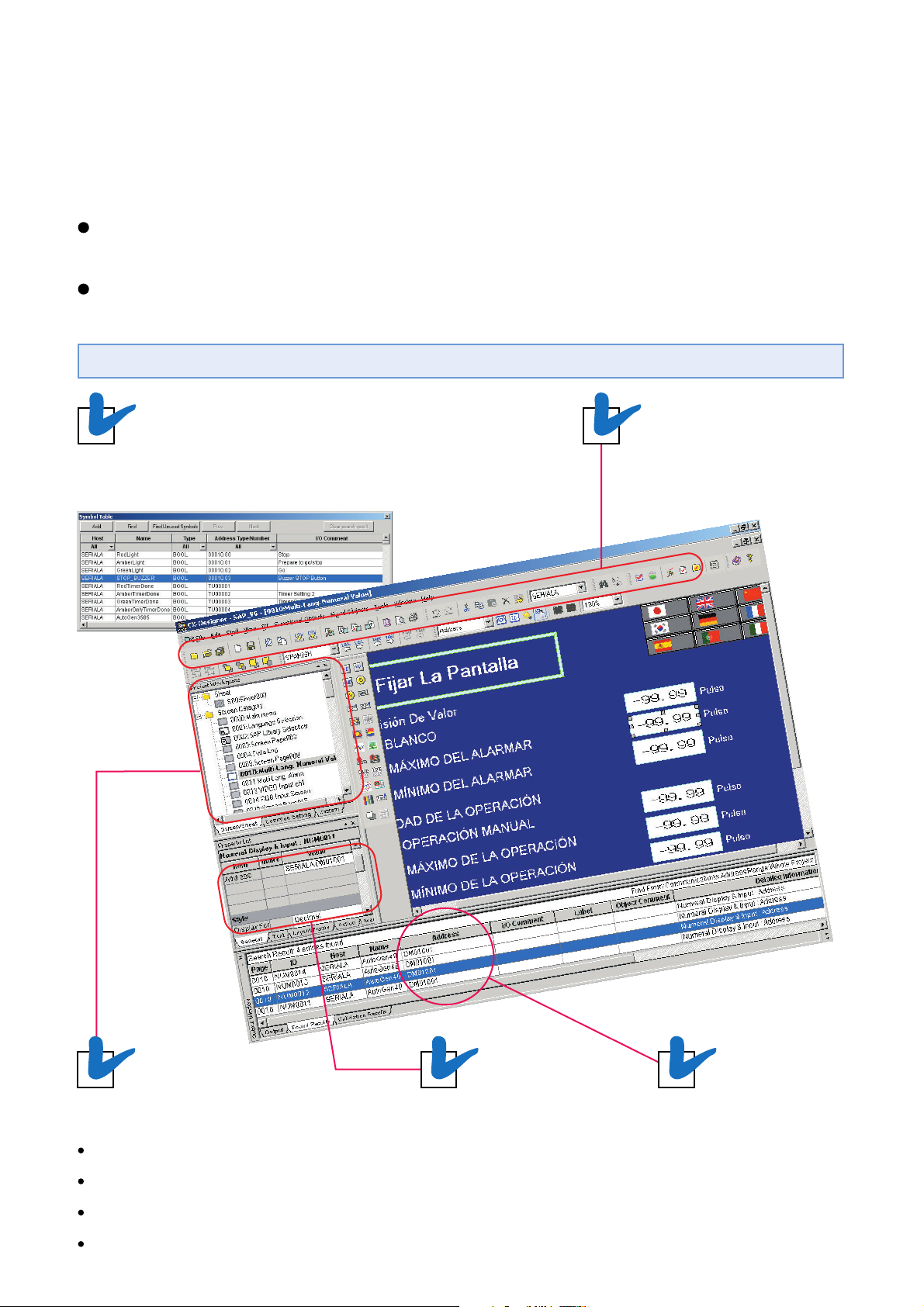

Addresses for screen objects can be set referring to newly added Symbol Tables.

Work hours spent setting addresses can be greatly reduced by importing CX-Programmer

Symbol Tables.

The project Workspace and Output Window are used for the user interface just as with the

other Support Software packaged in the CX-One.

User Interface with the Utmost in Efficiency

All addresses and comments can be managed

using a single Symbol Table.

Shows a list of addresses, names, and comments used in project

screen data. Addresses, names, and I/O comments for the

CX-Programmer can also be imported.

Improved Icons and Help

The project Workspace enables the user

to look through the entire project.

Screens you want to edit can be opened right

away.

Perform screen management, such as copying or

deleting screens, by simply right-clicking.

Reusing screens from other projects is easy with

the CX-Designer.

Settings for alarms, data logs, communications,

and other functions can be easily accessed.

Drastically reduce

the number of clicks in

the project.

Just click on the object once to

display or change properties.

Multiple objects can be selected

to display and change shared

properties all at once.

The Output Window

shows search results.

In addition to addresses and

I/O comments used in screen

data, labels can also be used

as search strings and the

results can be displayed.

Page 3

Renewed as the CX-Designer

Drag & Drop!

Drag & Drop!

greatly reduces the effort of building screens.

Do You Type Addresses Twice When Creating Ladder

Do You Type Addresses Twice When Creating Ladder

Programs and Screens?

Programs and Screens?

Previously, creating screens required typing in

addresses for lamps and switches while looking at

symbol tables (i.e., addresses, names, and comments).

This resulted in typing mistakes in addition to having

to input addresses for buttons and lamps twice.

Importing the symbol tables solves the problem of

wasted effort and typing mistakes to greatly reduce

labor spent designing screens.

Import Symbol Tables from CX-Programmer

Symbol tables used in the CX-Programmer can be

imported into the CX-Designer, eliminating the need

to type addresses twice. Also, allocation errors are

prevented by allocating

addresses from the symbol

table list without re-typing

them.

Drag & Drop!

Example of Easy Address Allocation

1

Create a switch on

the screen.

2

Check the comment then drag-and-drop the symbol from the symbol table to the property list.

3

Allocations for buttons

and lamps can also be

checked on the screen

using comments

imported from the

CX-Programmer.

Drag & Drop!

Page 4

A variety of newly added functions greatly improves editing, reusing, and search

Drag & Drop!

functions for screens and objects.

Reusing Screens and Objects Is

Troublesome.

Easily Reuse Screens and Objects

Screens can be easily reused between projects by dragging

and dropping them. Changes to allocation information,

such as changing the screen number for the screen switch

button after reuse, is minimized.

Project B

Project A

Drag & Drop!

Finding the Screen to Edit from among

Many Screens Is Troublesome.

Guidance from the

Search Results to the

Correct Location

Associated objects can also be

searched for using I/O

comments and labels in addition

to addresses, with the results

displayed in the search window.

Click.

Setting Each Object on the Screen One

by One Is Troublesome.

Edit Properties

• Show a list of the objects on

the screen and easily edit

the display.

• Properties shared even by

objects of different types can

be extracted and changed

collectively.

Editing Overlapping Objects Is

Troublesome.

Select Object List

• Overlapping objects can be

selected.

• Use the display filter to

display only the desired

objects.

Transferring All Screens Was Required Even

Though a Few Screens Were Changed…

Quick Transfer

Previously, all screens had to be transferred even if only a

few communications settings or alarms were changed. The

quick transfer function automatically identifies the change

and transfers only the changed screens.

Search results

displayed.

Click the search

results.

Jump.

What?

The tool changed?

But I was used to

the old tool!

The previous easy operation

has been retained, so object

dialog boxes, alarms, and

other objects can be set as

easily as before.

The Same Easy Operation

Page 5

Using the CX-Designer reduces the time spent on creating

Drag & Drop!

Drag & Drop!

screens from 23 minutes to 4 minutes 35 seconds.

Customer Requests

Reusing existing screens

takes time.

Existing screens are reused to

improve design efficiency, but

each screen must be imported

individually and alarm settings

must be imported.

Incorporating ten

pages and setting the

alarms required

6

minutes.

Multiple objects can't be

changed all in one

batch.

Shared settings, such as the frame

color and interlock addresses for

numeric inputs, must be changed

after importing screens. Changing

36 addresses and colors one by

one is a hassle.

6 minutes required to

change 36 items.

6 minutes

reduced

to 1

6 minutes

reduced to

20 seconds

The CX-Designer greatly reduces design time.

Multiple projects can be started at the same time.

Start the multiple

projects, select the

screens to be reused, and

simply drop them where

they will be reused.

Multiple screens and

alarm settings can be

imported in one

operation.

Drag & Drop!

6 times

6 times

as fast

as fast

Completed in 1 minute with the CX-Designer.

Changes can be made all in one batch in the property list.

When 36 objects are

selected as a group, the

shared properties of those

objects will be displayed in

the property list. When the

address or frame color is

changed in the property

list, they are instantly

changed for all the objects.

18 times

18 times

as fast

as fast

Completed in 20 seconds with the CX-Designer.

Inputting addresses is a

hassle.

Addresses for the touch panel

were typed into the PLC but the

same addresses has to be

typed again into the screen

creation tool.

6 minutes required to

input 36 addresses.

Creating screens is a

hassle.

There's not enough time to

create screens. And, debugging

is a hassle . . .

Just creating a

Temperature

Controller faceplate

takes

5 minutes.

6 minutes

reduced

to 3

5 minutes

reduced to

15 seconds

Addresses can be directly selected from symbol tables.

The CX-Designer can

import PLC symbol

tables. Simply select the

address input from the

symbol table list and click

the OK Button. I/O

comments are included,

so address selection is

easy.

Twice

Twice

as fast

as fast

Completed in 3 minutes with the CX-Designer.

Creating screens is easy with the Smart Active

Part library.

Select the Smart Active

Part in the library and

simply drag and drop it.

The Smart Active Parts

are produced by OMRON,

so debugging is not

required.

Drag & Drop!

20 times

20 times

as fast

as fast

Completed in 15 seconds with the CX-Designer.

The figures above are reference values based on comparisons made by OMRON.

CX-Designer version 1.0 was used for the measurements. Actual figures may vary with the computer's

operating environment.

Page 6

Standard Models

Name

Specifications

Model

CXONE-AL01C-E1 license

CXONE-AL03C-E3 licenses

CXONE-AL10C-E10 licenses

CXONE-AL30C-E30 licenses

CX-One

FA Integrated

Tool Package

Ver. 1.1

The CX-One is an integrated tool pack that

provides programming and monitoring

software for OMRON PLCs and components. The

CX-One runs on any of the following

operating systems: Windows 98 SE, Me, NT 4.0

(Service Pack 6a), 2000 (Service Pack 3 or higher),

or XP.

CX-Designer version 1. is included in the CX-One.

Refer to the CX-One catalog (R134) for details.

CXONE-AL50C-E50 licenses

The CX-Designer can also be ordered individually using the following model number.

CXDesigner

Ver.1.

Site licenses are also available for users that need to use the CX-One on many computers.

Ask your OMRON representative for details.

OS: Window 98 SE, Me, NT 4.0 (Service Pack 6a or

higher), 2000 (Service Pack 3 or higher), or XP.

The Ladder Monitor Software is included.

One license

NS-CXDC1-V1

CX-Designer Operating Environment

Recommended CPU Pentium 3, 1 GHz MHz min. required

Recommended memory 256 Mbytes min.

Hard disk free space

CD-ROM drive Required for installation.

Display A minimum resolution of 800 x 800 pixels is recommended.

Compatible OS

Note: Approx. 1.8 GB of available hard disk space is required to install the CX-One.

Precaution on CX-Designer Operating System

The CX-Designer will not run on Microsoft Windows 95 or on operating systems with service packs older than those given in the

system requirements. If you are using Window 95 or an older service pack than given in the specifications, you must upgrade

your operating system before installing the CX-Designer. The required system and hard disk free space depend on your system

environment.

700 Mbytes are required at setup. (See note.)

Windows 98 SE, Me, NT 4.0 (Service Pack 6a),

2000 (Service Pack 3 or higher), or XP

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and

workmanship for a period of one year (or other period if specified) from date of sale by

OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED,

REGARDING NON-INFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR

PURPOSE OF THE PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER

OR USER ALONE HAS DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE

REQUIREMENTS OF THEIR INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES,

EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, LOSS OF PROFITS, OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH

THE PRODUCTS, WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY,

NEGLIGENCE, OR STRICT LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the

product on which liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER

CLAIMS REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE

PRODUCTS WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND

NOT SUBJECT TO CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE

MODIFICATION OR REPAIR.

Note: Do not use this document to operate the Unit.

OMRON Corporation

Control Devices Division H.Q.

Shiokoji Horikawa, Shimogyo-ku,

Kyoto, 600-8530 Japan

Tel: (81)75-344-7109

Fax: (81)75-344-7149

Regional Headquarters

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD Hoofddorp

The Netherlands

Tel:(31)2356-81-300/

Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

1 East Commerce Drive, Schaumburg,

IL 60173 U.S.A.

Tel: (1)847-843-7900/Fax :(1)847-843-8568

OMRON ASIA PACIFIC PTE. LTD.

83 Clemenceau Avenue,

#11-01, UE Square,

Singapore 239920

Tel:(65)6835-3011/Fax : (65)6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120 China

Tel: (86)21-5037-2222/Fax: (86)21-5037-2200

This catalog mainly provides information that is necessary for selecting suitable models, and

does not contain precautions for correct use. Always read the precautions and other

required information provided in product operation manuals before using the product.

The application examples provided in this catalog are for reference only. Check functions

and safety of the equipment before use.

Never use the products for any application requiring special safety requirements, such as

nuclear energy control systems, railroad systems, aviation systems, medical equipment,

amusement machines, vehicles, safety equipment, or other application involving serious risk

to life or property, without ensuring that the system as a whole has been designed to

address the risks, and that the OMRON products are properly rated and installed for the

intended use within the overall equipment or system.

Printed on 100%

Recycled Paper

Authorized Distributor:

Note: Specifications subject to change without notice. Cat. No. V404-E1-01

Printed in Japan

0306-1M

Loading...

Loading...