Page 1

»

Connect to any device

»

H i g h - q u a l i ty s c reen w i t h 3- year warra nty

»

‘ D ra g & Dro p’ s i m p l i c i t y o f Sm ar t Act iv e Pa rt s

NS SERIES

O n e - t ou c h m a c h i ne ma n a g e m en t

Page 2

Outstanding connectivity

Used together with Omron PLCs and other field-

programmable devices, such as temperature controllers and

inverters, the NS series gives enhanced communication and

programming capabilities, even across multiple networks,

allowing you to manage all devices in your machine from

a single terminal.

A built-in USB connection enables simple and fast connection

of peripherals, while a built-in Ethernet interface allows fast

connection to multiple PLCs and computers.

The NS series is also capable of connecting to many non-

Omron devices to give you total flexibility in managing

your machine.

Total control at your fingertips

Omron’s NS series looks like a normal HMI, but

it is not. Designed on Smart Platform, the NS series

provides enhanced communication even across

multiple networks, to manage all devices in

a machine for true industrial machine management.

We provide functions to let you perform diagnoses

and maintenance to make your machine competitive

in an easy way. This is why we call it: one touch

Machine Management. And that’s why it’s more than

just an HMI terminal!

3

YEAR

WARRANTY

Page 3

Machine management tool vs. HMI terminal

The NS HMI has, beside the generic HMI functions, many

other functions to be able to use the NS as a real machine

management tool. With the NS HMI you can configure,

commission, maintain and operate many Omron devices and

even third party devices. This means you can simple configure

some settings, display errors or statuses, up- and download

parameters all with the NS HMI terminal.

The NS HMI allows you to create and use the diagnostics

functions for many devices you need to manage your machine.

By providing diagnoses and maintenance functions on the

NS, Omron allows a full insight into the machine’s state and

the flexibility to quickly troubleshoot on-site with minimum of

work for the machine builder, system integrator or end-user.

Proven reliability

For over a decade Omron has been a global supplier

of HMI solutions and high-reliability industrial touch-screen

technology. Omron has supplied more than 500,000 pieces

of HMI through more than 200 Omron Sales & Support offices

world-wide, each offering after-sales support, service and

training in local languages.

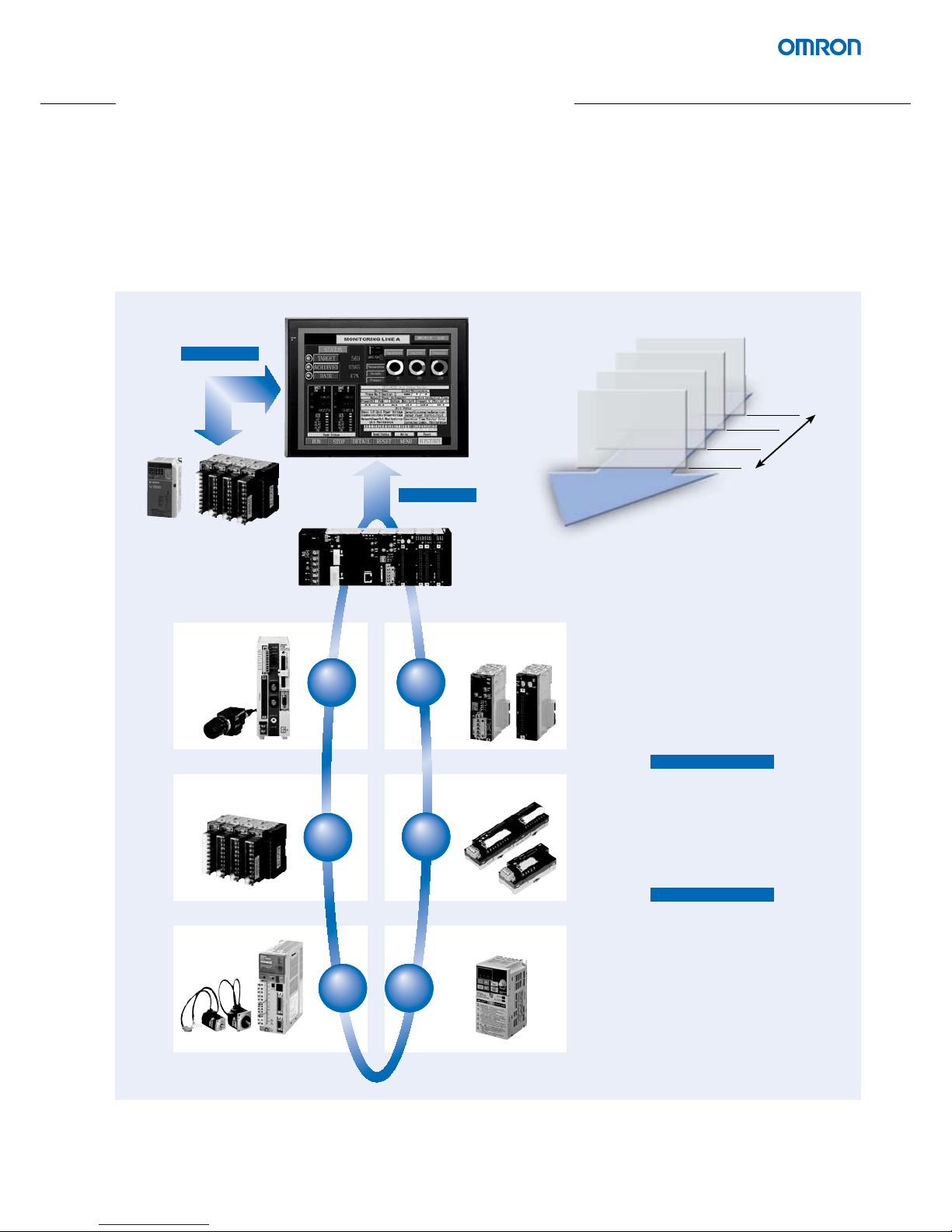

Sysmac One

Integrated Machine Management: Sysmac One series

The Sysmac One series combine an NS touch screen with

a powerful CJ1 PLC and the choice of different network

interfaces in a compact housing occupying less panel space.

Complete transparency enables the PLC, network (including

field devices) and HMI to be accessed via a single port – a big

advantage when servicing your machine remotely.

With the Sysmac One you get the best of both worlds:

One touch Machine Management HMI and the flexible, fast

and easiest logic controller in the market.

Smart Platform

Omron’s Smart Platform concept enables complete machine

and plant automation from one single platform without

having to worry about field buses, integration of various

software and above all without being locked into one

dominant supplier. Smart Platform will minimize the time

and effort you spend on automation.

http://smartplatform.info/

Page 4

4

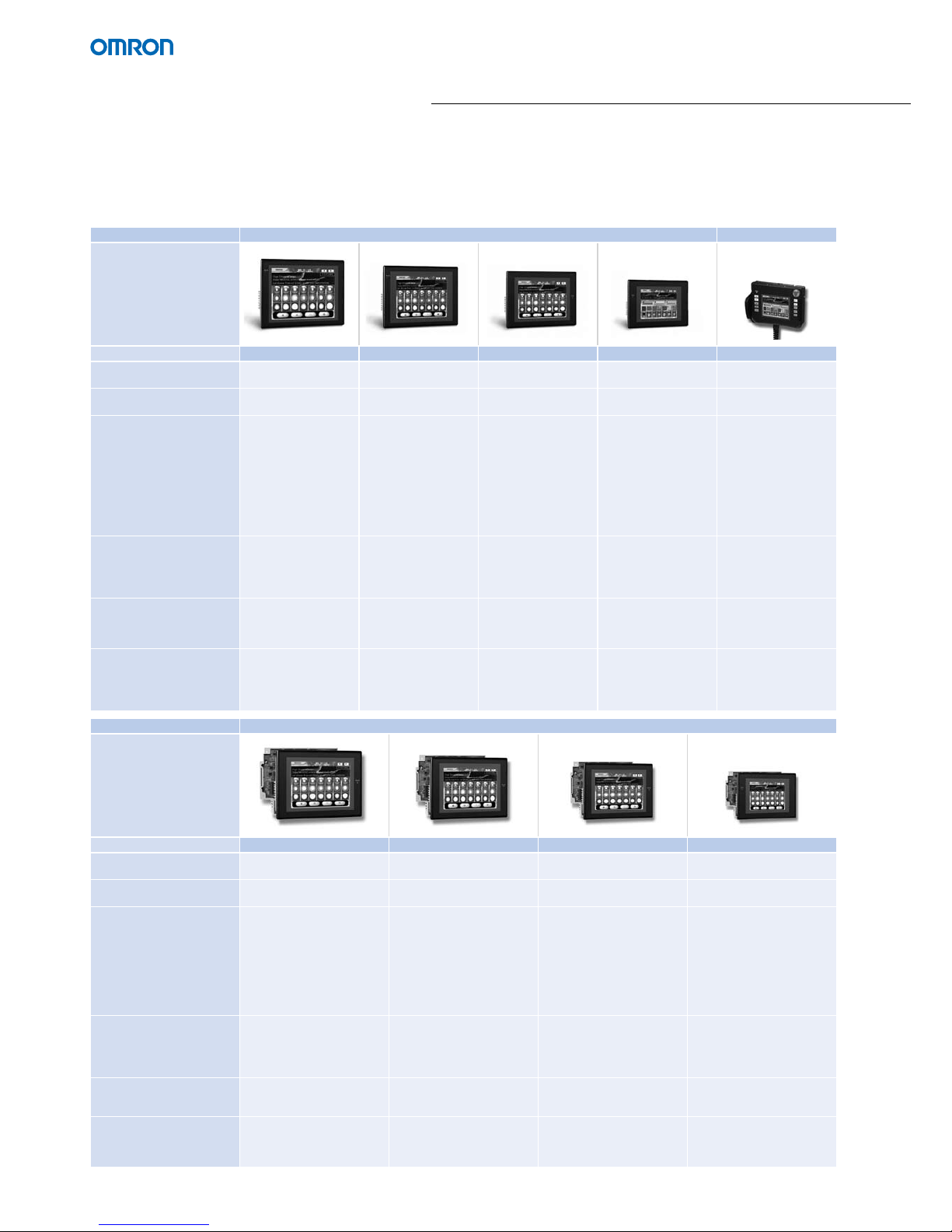

NS Series Portfolio

Advanced HMI – NS

Model NS12 NS10 NS8 NS5 NS5 Handheld

Display 12.1 inch TFT colour 10.4 inch TFT colour 8.4 inch TFT colour 5.7 inch Monochrome or

STN/TFT colour

5.7 inch STN colour

Resolution 800×600 pixels 640×480 pixels 640×480 pixels 320×240 pixels 320×240 pixels

Number of colours 256

(32,768 for image data)

256

(32,768 for image data)

256

(32,768 for image data)

Monochrome 16 greyscales, STN/TFT 256

colours

(STN 4096, TFT 32,768

for image data)

256 colours

(4096 colours for

image data)

Memory Size 60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

60MB screen memory,

32,768 words + 32,768

bits internal memory and

8192 words + 8192 bits

retentative memory

Options Ethernet,

Controller Link,

Video input board

(RGB/Composite)

Ethernet,

Controller Link,

Video input board

(RGB/Composite)

Ethernet,

Video input board

(RGB/Composite)

Ethernet RS-232 or RS-422

communication

depending on cable

Size in mm (HxWxD) 241×315×48.5 241×315×48.5 177×195×48.5 142×195×54 176×223×70.5

(excl. emergency

button)

HMI & Control – SYSMAC One

Model NSJ12 NSJ10 NSJ8 NSJ5

Display 12.1 inch colour TFT 10.4 inch colour TFT 8.4 inch colour TFT 5.7 inch colour TFT or STN

Display Size / Resolution 246×184.5 mm

(800×600 pixels)

215.5×162.4 mm

(640×480 pixels)

170.9×128.2 mm

(640×480 pixels)

117.2×88.4 mm

(320×240 pixels)

Control CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1M-CPU13;

20k-steps program memory,

32k-words data memory,

logic instruction time 0.04 µs

CJ1G-CPU45H;

60k-steps program memory,

128k-words data memory,

logic instruction time 0.04 µs

CJ1M-CPU13;

20k-steps program memory,

32k-words data memory,

logic instruction time 0.04 µs

Communication DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

DeviceNet Master/Slave or

PROFIBUS Master and

optional Ethernet interface

Expansion (1 board max.) Ethernet, Controller Link,

I/O extension

Ethernet, Controller Link,

I/O extension

Ethernet, Controller Link,

I/O extension

Ethernet, Controller Link,

I/O extension

Size in mm (HxWxD) Without expansion unit

241×315×73.3

With expansion unit

241×315×89.3

Without expansion unit

241×315×73.3

With expansion unit

241×315×89.3

Without expansion unit

177×232×73.3

With expansion unit

177×232×89.3

Without expansion unit

195×142×79

With expansion unit

195×142×95

4 NS SERIES

Page 5

Advanced Industrial Automation

5

Outstanding Connectivity

Save time on programming and designing with Smart Active Parts

Unlike conventional visualization objects, Smart Active Parts communicate, across multiple networks, with their corresponding devices. They can

be used to configure, commission, operate and maintain these devices, without a single line of code needed to be written in the PLC or the HMI.

This allows you to add powerful functionality to your application within minutes.

Inverter

PLC

Temperature

Controllers

Inverter

NS

Vision

Sensor

Temperature

Controllers

CPU Bus

Units

and

Special I/O

Units

Vision

Sensor

260,000-colour

video input

Temperature

Controllers

CPU, I/O and Communication Units

Remote I/O

Inverter

Servomotor

Servo Driver

Remote I/O

Terminal

Easy Access

Easy Access

Servomotor

Servo Driver

Easy Access

Easy-to-use Software

The NS-series HMI

makes it easy to connect

to the PLC and many

other devices and show

data data from them

without any PLC programming.

With Smart Active Parts

you can support functions

to be performed on-site

without using Software

programs, like CX-Programmer or CX-Thermo.

1. Create a new project

3. Choose a Smart Active Part

4. Configure the communication

settings

2. Open the Smart Active

Parts Library

Click and Configure in four steps.

few minutes

5NS SERIES

Page 6

6

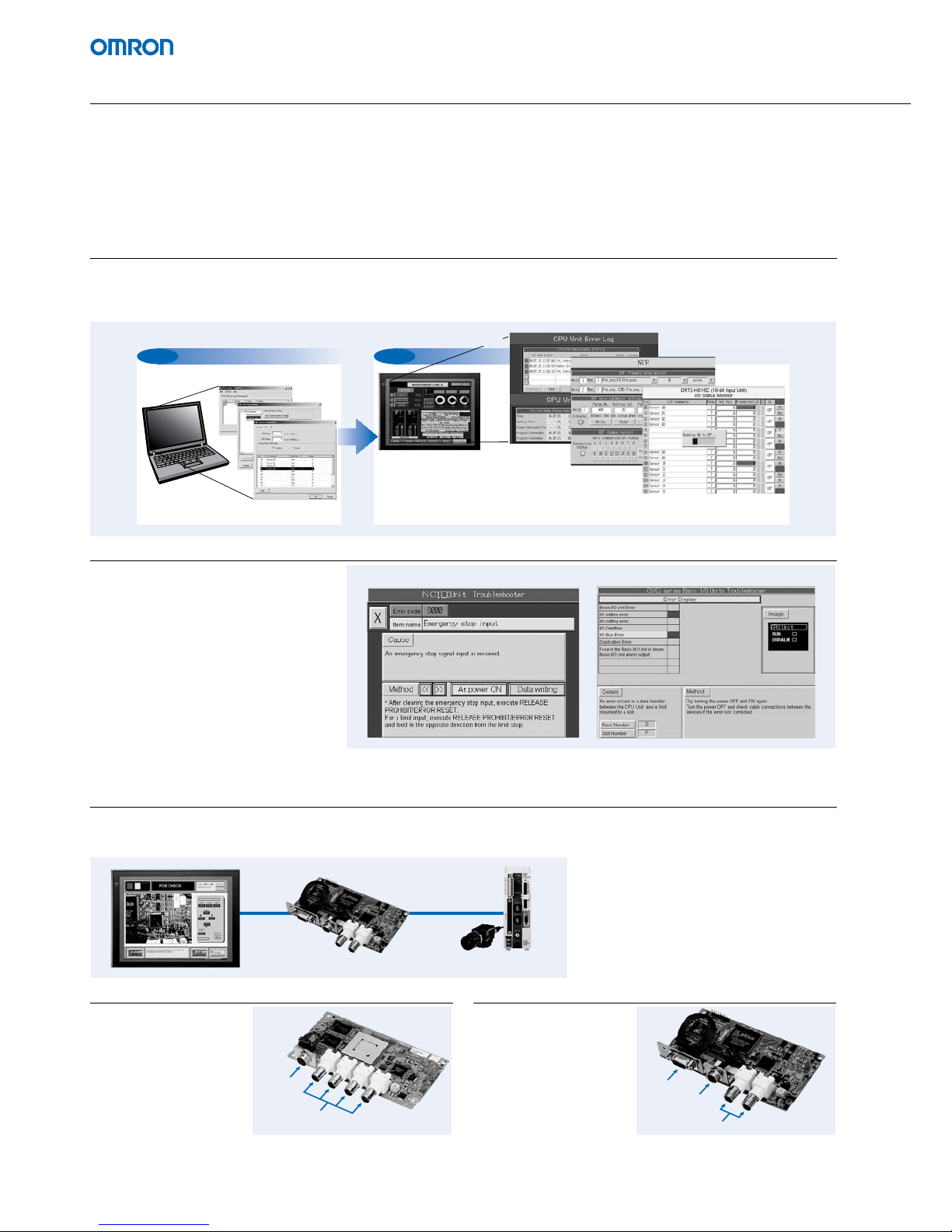

Using Smart Active Parts: just a few simple steps

Dramatically reduces the effort required to create ladder programming and screens.

A library with more than 2,000 Smart Active Parts is available, which can directly access OMRON PLCs and other devices. You can drag & drop

Smart Active Parts in an application in just 4 simple steps.

With Smart Active Parts you can for instance monitor device errors in understandable text, donwload parameters to devices and check Network

statuses without the need for a computer with software tools.

The SAP library also provides PLC I/O Unit Troubleshooter SAPs

Troubleshooter Smart Active Parts are available

to troubleshoot specific PLC units. When an error occurs in an unit, the Troubleshooter SAP

provides an easy-to-understand explanation of

the cause of the error as well as which counter

measures to take to resolve the error.

In this way you can quickly resolve errors onsite even without using documentation.

260,000-colour Video Display

Display the production steps on the HMI via optional video inputs!

Two kinds of video interfaces are available to connect to various applications. Provides compatibility with OMRON Vision Sensors (F150, F160,

and F250) in addition to video and CCD camera connections. The NS-series HMI contain some useful functions like capturing and browsing images

and operating the Console functions in the vision sensor.

NS-CA001 Video Input Unit

Four video inputs or CCD

cameras can be connected

and up to four images can be

displayed simultaneously if

the image size is

320x240 pixels.

NS-CA002 RGB/Video Input Unit

There is an analog RGB input

terminal in addition to the two

video input terminals. Either

the video signals or the

analog RGB signal can be

displayed on the NS-series

HMI.

Computer support tools

PLC CPU Unit

monitoring

screen

From To

DeviceNet

monitoring screen

NCF Unit

setting screen

Example screens using support tool objects (Tool Function SAP Library)

Troubleshooter SAP for a Position Control Unit Troubleshooter SAP for Basic I/O Unit

NS

RGB/Video Input Unit Vision Sensor

Console

Camera

NS-CA001

Console

RGB

Camera

NS-CA002

6 NS SERIES

Page 7

Advanced Industrial Automation

7

Single Port Multi Access (SPMA)

The PLC program and screen data can be transferred from a single port!

With SPMA you can transfer the PLC program and HMI project data with one cable connection. It does not even matter if you connect first to HMI

or PLC, you can always transfer the data and keep on operating the HMI or PLC.

The HMI can transfer data across different network levels.

Computer (Serial/USB/Ethernet) Æ NS-series HMI (Ethernet) Æ PLC (Ethernet or Controller Link) Æ PLC

SPMA significantly improves maintenance efficiency when the NS-series HMI and PLC are connected over longer distances.

Computer (Serial/USB/Ethernet) Æ PLC (Serial, Ethernet or Controller Link) Æ NS-series HMI

Note: SPMA can be used in CS/CJ-series PLCs with lot number 030201 or later.

Direct Connection to Temperature Controllers and Inverters

Connect OMRON Temperature Controllers and Inverters to the NS-series HMI.

OMRON Temperature Controllers can be connected directly to the NS-series HMI RS-232C port. Data does not pass through the PLC, so ladder

programming is not required. There are many SAPs in the Library for Temperature Controllers. Temperature Controller screens can be created

easily just by pasting objects from the SAP Library onto the screens.

The Omron inverters can also be connected to the NS-series HMI. This makes it easy to read and change parameters for the inverters without any

PLC programming.

NS

PLC

Ladder program

Ladder program

PLC

Serial/USB

or Ethernet

Ethernet

Ethernet or Controller Link

NS

CX-Programmer

The ladder program can be transferred.

Stay connected.

PLC

Serial

Ethernet or Controller Link

Serial

Serial

CX-Designer

PLC

NSNS

Stay connected. The ladder program can be transferred.

Screen data

Screen data

Screen data

NS

CJ1W-CIF11

RS-422A Serial Adapter

RS-485 Serial Adapter

OMRON Temperature Controllers

OMRON V1000 Inverters

7NS SERIES

Page 8

8

Exceptional Functionality

Easy maintenance with the Ladder Monitor

The NS HMI (except for the NS5 series) has a Ladder Monitor built in

as a standard feature. A Ladder Monitor is an application that allows

you to monitor the ladder program in the CS/CJ series PLC. With the

Ladder Monitor you can monitor the execution status of the ladder program in the connected PLC without the need to use software (CX-Programmer). Many useful functions are provided with the Ladder Monitor

like viewing I/O comments, monitor and change values, search

addresses, easy navigation and capture ladder image.

Easily utilizing advanced functions

Data block (Recipe) function

Data blocks (recipe function) allow several numeric values and/or

character strings to be transferred to/from memory areas, such as PLC

data areas. Data blocks can be used to change the system’s production

setup even faster.

Communication drivers

The NS-series HMI can connect to several non-Omron devices. This

means the NS HMI can have communication on one port to an Omron

devices and on the second port to a non-Omron device. Contact Omron

for up-to-date information on the available communication drivers for

the NS HMI series.

Macro functions

The NS provide an extensive set of macro functions that can be used

to perform many different operations.

These functions allows the HMI to process screen display actions or

calculate some data, which was performed by PLC before. Also the

HMI project can be made more interactive using some macro functions

in combination with PLC memory.

Macro functions can be used with screen pages, functional objects, like

buttons and lamps or on specific timing operation.

In general we provide macro functions to perform the following actions

using Conditional and Logical operations:

• Convert and manipulate data

• Read/Write data to a device

• Perform string manipulation

• Perform screen/popup operations

• Store/retrieve data from CF

• Set date/time

• Influence Screen navigation

• Perform loop operation

NS-series

Data Block

Product A

Width Height Colour

100 52 Red

150 54 Blue

200 56 Yellow

300 62 Red

400 64 Blue

Product B

Product C

Product D

Product E

Product B

CS/CJ-series

PLC

Select product

B’s information and

set it in the PLC.

To other

equipment

8 NS SERIES

Page 9

Advanced Industrial Automation

9

Trend Graphs & Data Logging

Easily log and display any data over time

A variety of graphing functions are built into the NS-series HMI, such

as the trend graph, which can log data over a longer period of time, and

the line graph, which can display overlapping graphs.

Logging data is stored as a CSV file in the Memory Card mounted in

the NS-series HMI. The data stored in the Memory Card can be read

or deleted from the screen.

Log files can be saved automatically, just by selecting the Save the data periodically Option in the Data Log Setting Window.

Trend Graph Function

Data stored/logged by the PLC can be displayed in overlapping graphs, so a device's operation can be compared for evaluation and analysis. In

addition, up to 1,000 words of consecutive data can be displayed as a line graph, data can be displayed together, and any region can be magnified.

Continuous Line Graph

A graph can be plotted in any position by specifying the X and Y coordinates of the vertices.

Also, the graph can be moved on the screen by

specifying the movements from the PLC.

Read file button

A list of log files is retrieved

from the memory card and

shown in a popup menu.

LOG001.CSV 04/06/04 10:00

LOG002.CSV 04/06/05 10:00

LOG003.CSV 04/06/06 10:00

LOG004.CSV 04/06/07 10:00

LOG005.CSV 04/06/08 10:00

LOG006.CSV 04/06/09 10:00

LOG007.CSV 04/06/10 10:00

Suffixes are automatically added to

file names set in the CX-Designer.

It is possible to make a one-week log

by automatically saving the data

seven times.

Logging data for each day (43,200 points)

is saved in the Memory Card in CSV format.

Memory

Card

Automatically saved

(1) Graphs can be superimposed. (2) The display can be magnified.

D0000

D0001

D0002

X1

Y1

X2

Y2

X3

Y3

(X1, Y1)

(X2, Y2)

(X3, Y3)

Y

X

PLC

Information in the PLC's format can be plotted

moment-by-moment.

9NS SERIES

Page 10

10

Diverse Network possibilities to fit any application

The NS-series provide very strong networking skills. With serial NT-Link communications supporting both 1:1 and 1:N connections you can connect

multiple HMI's to the PLC. The NS-series HMI can also support communications with multiple PLCs and multiple HMI's through Controller Link and

Ethernet connections, so the network can be configured freely to match the requirements and scale of the application. In addition, using the NSRuntime makes it possible to monitor machine status and log data from the host.

NS-seriesNS-series

CS/CJ-series PLC

NS-series

CS/CJ-series

PLC

CS/CJ-series

PLC

NS-series

CS/CJ-series

PLC

Personal computer

3

Ethernet

2

Controller Link

1

Serial connection

1

Serial

connection

4

Connections

across network

levels

Software for Machine Monitoring and

Data Logging

(sold separately)

1

NS:PLC = 1:1

Connecting with the PLC through port A or port B

1:1 NT Link or Host Link

PLC

NS-series

NS-series

PLCPLC

Serial connection

NS:PLC = 1:2

Up to 8 NS-series can be connected to each of the PLC's RS-232C/RS-422A ports.

NS-series NS-series NS-series

NS-AL002 Converter

(Converts between

RS-232C and RS-422A.)

NS-series NS-series NS-series

PLC

1:N NT Link

NS:PLC ratio = 8:1 max.

10 NS SERIES

Page 11

Advanced Industrial Automation

11

The NS-series HMI can connect to a variety of devices in the network, through as many as 3 network levels. For example, if SAP (Smart Active

Parts) are being used, an NS-series HMI connected by Ethernet can be used to monitor the information in a PLC connected through Controller

Link as well as the information in the DeviceNet Slaves connected to that PLC.

2

NS-CLK21

The HMI can be connected to an OMRON Controller Link network by mounting a Controller Link Interface Unit.

NS Series

PLC PLC PLC

Controller Link Connection

If a Controller Link connection is

used, data links can be configured

between PLCs and multiple

PLCs can be monitored from the

NS-series HMI screen.

· Baud rate

2 Mbps (500 m max.)

1 Mbps (800 m max.)

500 kbps (1 km max.)

· Max. number of nodes: 32 nodes

3

NS Series

NS Series

PLC PLC Trajexia motion controller

Personal computer

Ethernet Connection

W

hen using the NS-series HMI with Ethernet you can connect to any Omron controller with an Ethernet port. Beside this you can also use a FTP

c

lient to gather data from the NS and even transfer project data to different NS HMI terminals.

4

Connections across Different Network Levels

DeviceNet

NS Series NS Series

Seamless and

Program-less

Seamless and

Program-less

Ethernet

Controller Link

PLC

PLC PLC

11NS SERIES

Page 12

12

User-Friendly Software

Integrated Simulation

Simulate the HMI program with the PLC program on your PC.

The integrated simulation function allows you to test the ladder program with the HMI progam in an interactive way. You can quickly make changes

and test the function to see if it works as desired. Therefore the integrated simulation function significantly increases debugging efficiency.

Programming with Symbols

Screens can be created even when addresses are unknown.

Screens can be created even if the addresses have not been determined. Addresses can be input as either names or actual addresses and the

addresses can be input from the symbol table after the addresses are determined.

The symbol table created in our PLC programming package, CX-Programmer can be shared with CX-Designer by simply dragging and dropping

them in the software.

Interactive

Interactive

Touch Panel

Ladder Program

PLC program

HMI project

[Input from the Symbol Table]

Addresses are

input in the

symbol table after

the addresses

are determined.

Symbols input for addresses, which

have not yet been determined.

Addresses input as addresses

because addresses have been

determined

12 NS SERIES

Page 13

Advanced Industrial Automation

13

Multi-language Support

Easily export/import text to translate in many different international languages.

As the NS-series HMI support Unicode you can use many different languages from Asia and Europe. In runtime you can switch between 16 languages.

With CX-Designer it is very easy to export and import texts for translation as it is using CSV format. When you import a new language you can

even choose to apply the same label properties (e.g. font, colour, etc.) as an existing language.

Advanced functions

Remote machine servicing over the WWW

The NS HMI series have a web-interface built into the HMI terminal. The web-interface function allows you to see the local NS HMI screen, which

is also seen by the operator, remotely in any standard web browser without the need to install software on your PC. This makes it very easy to see

what is happening at the site where the machine is located. You can see the alarms and actual values and even operate the HMI from your remote

location.

The web-interface

1)

can run in a monitor mode, which allows you to only monitor certain screens, or it can run in the operation mode so that you

can operate the HMI terminal as if you where located at the machine.

You can also show all the files stored on the local CF card, e.g. log files created by the NS data logger, and open or download these files from your

remote location.

1)

Web-interface function will be delivered with CX-One v3.1

Import

Multi-language CSV dataNS Series

Convenient!

Support for

42 International

Languages

13NS SERIES

Page 14

14

NS-Runtime

Machine monitoring and reporting at the production site

Machine Viewer

The NS-Runtime software provides functions equivalent to the NS Series, and enables you to display information and perform operations for a

complete production line. NS-Runtime will run the NS project, created with CX-Designer, on Windows XP including the DyaloX Series. Beside the

existing NS functionality, the NS-Runtime also provides some additional functions explained in more detail below.

Data Logger

Data can be logged through background processing, with up to 160,000 points stored in one

file. The logged data is stored in CSV format,

and data can be displayed on data log graphs.

Example: 160,000 Points

Data can be logged for approximately 7.4 days,

assuming data is logged every two seconds for

12 hours a day. By using automatic file saving,

data logging can be continued even longer than

7.4 days.

Display documents

The display document function in NS-Runtime

makes it possible to show documents (e.g. PDF

file) in the screen itself. This is useful for maintenance instructions or reporting. You can even

show a different document every time an alarm

occurs.

Application Startup Function

You can start any user application from NSRuntime by simply clicking a button. This allows

you to open documents like Excel or any other

software tool you need to use.

Wide Screen

Computer output can be displayed on another

wide-screen monitor.

XGA (1,024 x 768 dots) and up to a maximum

screen size of 3,840 x 2,400 is supported.

Alarms occurring in devices or the line can be

monitored.

Other applications can be

overlapped on the screen

data, and they can be

used at the same time

Displays a PDF file

on a screen

NS S

erie

s

NS S

erie

s

PL

C

PLCPLC

P

ersonal computer

14 NS SERIES

Page 15

Advanced Industrial Automation

15

NSH5 Series

The NSH5 is the mobile version of the NS5 HMI. So it comes with the same strong HMI functions, but allows you to move around the machine with

the HMI in your hand. For this we provide the NSH5 with an extremely tough casing that can withstand severe shock and is also completely water

resistant.

Options

Docking Station

The Docking Station is designed in a way that the emergency stop switch

line will not turn OFF to trigger the emergency stop circuit even if the

NSH5 is disconnected from the station. This eliminates the need for adding an external circuit. Power is disconnected via a key. You can connect a maximum of 15 Docking Stations to a PLC.

Visor

Installing a visor helps to protect the Emergency Stop Switch and

prevents improper operation from occurring inadvertently when the HMI

is laid down.

OMRON

Memory Card

UL-listed Cables

USB

RS-232C

cable

RS-232C

cable

RS-422A

cable

Docking Station

RS-232C Connecting Cable for the NSH5

NSH5-232CN-3M (Length: 3 m)

RS-232C Connecting Cable for the NSH5

NSH5-232CN-10M (Length: 10 m)

USB Slave

Memory

Card interface

Docking Station

connection

RS-232C

RS-422A

RS422A

PLCPLC

PLC

PLC

RS-232C Connecting Cable for the NSH5

NSH5-232UL-3M (Length: 3 m)

RS-232C Connecting Cable for the NSH5

NSH5-232UL-10M (Length: 10 m)

RS-422A Connecting Cable for the NSH5

NSH5-422UL-10M (Length: 10 m)

Function Keys

The NSH5 has 10 Function-keys.

F1, F2, F6, F7: Wired outputs

F3 to F5, F8 to F10: Communications outputs

3-Position Enable Switch

Increased safety with DPST-NO structure

(wired outputs).

Superior Shock Resistance

Consistent with JIS B 3502, IEC 61131-2

(drop shock).

Memory Card Interface and USB Slave

Connector.

Easily transfer screens or save logs at high speed

using a USB connection.

Emergency Stop Switch

3PST-NC Structure

DPST-NC: Increase safety (wired outputs).

SPST-NC: Input to internal NSH5 memory, output

to a lamp for emergency stop switch operation, or

output via communications, e.g., to a PLC.

Water Resistance to IP65

The water-resistant structure is equivalent to IP65

on all surfaces.

HMI and Cable Sold Separately

Select the Cable according to the application

(RS-232C/RS-422A).

Loose wires or connector, UL connector,

3 m or 10 m.

15NS SERIES

Page 16

16

Sysmac One Series

Integrated Machine Management: Sysmac One series

The Sysmac One series combine an NS touch screen with a powerful CJ1 PLC and the choice of different network interfaces in a compact housing

occupying less panel space. With the standard USB port you can program both the controller part and the graphical display. The Sysmac One

series are available in different screen sizes and two different controller types. The controller is running on a separate CPU so that you have the

best performance on both screen and controller. Another benefit of this is that the controller can continue operating even if the screen is accidentally

broken.

Sysmac One Appearance

Easy Maintenance using Troubleshooter function

Quickly see Errors and Statusses of Controller and Network device

The standard-equipped Troubleshooter contributes to solving problems during device startup and operation. When an error occurs, simply follow

the on-screen instructions to confirm the error details and quickly implement counter measures, without referring to the manual.

Display Section

5.7 Inches

8.4 Inches 10.4 Inches 12.1 Inches Main Differences in Specifications

Colour STN Colour TFT

Controller Section

(Designated by model

number suffix)

M3x

��� --

• I/O capacity: 640

• User memory: 20 Ksteps

• Expanded data memory: None

G5x

�����

• I/O capacity: 1,280

• User memory: 60 Ksteps

• Expanded data memory: 32 Kwords x 3

banks

Expansion Unit

Controller Link Unit

(The photo shows

the NSJ8 Controller.)

Expansion Unit interface

USB port

Controller

Section

Display Section

Ethernet Unit

I/O Control Unit

One Expansion

Unit

Your HMI application Troubleshooter Menu

This button takes you directly back to

your HMI application.

16 NS SERIES

Page 17

Advanced Industrial Automation

17

Expansion Units

For the Sysmac One series we have three different expansion units available. It is only possible to use one expansion unit on a single Sysmac

One model. Two expansion units are providing extra network possibilities on Controller Link and Ethernet. The third expansion unit allows you to

connect the standard CJ1 units to the Sysmac One model.

Controller Link Unit (NSJW-CLK21-V1)

High-speed, large-capacity data link

The PLC data link function can be used to provide a high-speed, large-capacity data link between Controllers over the Controller Link network.

I/O Control Unit (NSJW-IC101)

Easily connect Special I/O Units and CPU Bus Units

Used to mount Motion Control Units and other Special I/O Units or CPU Bus Units to the NSJ-series Controller, for excellent expandability.

Note: Used to mount Motion Control Units and other Special I/O Units or CPU Bus Units to the NSJ-series Controller, for excellent expandability.

Ethernet Unit (NSJW-ETN21)

Full use of versatile Ethernet functions

The Ethernet expansion unit provides extra Ethernet functions like sending/receiving messages, using CMND instruction and sending/receiving

E-mails.

I/O Interface Unit

CJ1W-II101

10 Units max.

CJ-series Basic I/O Unit

CJ-series Special I/O Unit

CJ-series CPU Bus Unit

I/O Control Unit

NSJW-IC101

3 Racks max. (3 x 10 Units max.)I/O Connection Cable (CS1W-CN1 )

Power Supply

Unit

Ethernet Unit

NSJW-ETN21

Ethernet 100BASE-TX

CS/CJ-series PLC

•FINS communications

•FTP server

•E-mail

•SMTP clients, etc.

Controller

Troubleshooter

Network

Troubleshooter

The error details are displayed.

The necessary counter measure is displayed.

17NS SERIES

Page 18

18

Control Panel Standardization

By standardizing control panels based on SYSMAC One, design steps can be reduced and software assets can be reused to eliminate redundancy

and inconsistency all the way from the design stage to system startup.

Ethernet

Basic Module

Standardization

Standardization

S

elect module

for each machine.

U

se smart

distributed I

/O

Display Section

S

mart Active Parts

(SAP Library)

C

ontroller Section

Smart FB Librar

y

I

D ta

g

Application Modules

Software Modules

Example of

Standardized System

Screen and

ladder program

modules can also

b

e use

d.

18 NS SERIES

Page 19

Advanced Industrial Automation

19

NS-series HMI:

Outstanding connectivity

USB host

USB slave

Ethernet

RS-232C port A

RS-232C port B

PROFIBUS

DeviceNet

RS-422A/485 conversion unit

CJ1W-CIF11 (~50m)

NS-AL002 (~500m)

DeviceNet or

PROFIBUS

RS-232C

Port C

Memory card interface

(Controller part)

Memory card interface

(Display part)

(Picture represents backside of a SYSMAC One unit)

For screen captures, recipes and

saving data log, etc.

For application back up and

saving PLC data, etc.

USB Host cable (for printer)

NS-US22 (2m)

NS-US52 (5m)

General purpose USB cable

RS-232C, NS-PLC connection cable

XW2Z-200T (2m)

XW2Z-500T (5m)

Barcode reader

RS-232C, DOS/V transfer cable

XW2Z-S002 (2m)

USB, serial conversion cable

CS1W-CIF31

Memory link, single board Computer, etc.

CompoWay/F(direct serial connection to HMI)

Inverter

RS-422A/485

Printer

PC

PLC

PLC

PC

PLC

PC

Temperature controller, E5_N, EJ1, etc.

Wireless

WE70

RS-232C, DOS/V transfer cable

XW2Z-S002 (2m)

USB serial conversion cable

CS1W-CIF31

PC

Barcode reader

Printer

Temperature controller

E5_N, EJ1, etc.

I/O terminals

Inverters

CIMR-V7/F7, etc.

GRT1 series

SmartSlice I/O

Other company´s equipments

RS-422A/485 conversion unit

CJ1W-CIF11

NS-AL002

Serial

Serial

Single connection port on NS and SYSMAC One series

Only available on SYSMAC One series

Available for NS HMI functions on NS and

SYSMAC One series

CF

CF

non-Omron

equipment

M

any of equipment can be

connected to the NS HMI and

Sysmac One Series in addition

to the variety of highly

compatible OMRON control

components.

19NS SERIES

Page 20

Control Systems

• Programmable logic controllers • Human-machine interfaces • Remote I/O

Motion & Drives

• Motion controllers • Servo systems • Inverters

Control Components

• Temperature controllers • Power supplies • Timers • Counters • Programmable relays

• Digital panel indicators • Electromechanical relays • Monitoring products • Solid-state relays

• Limit switches • Pushbutton switches • Low voltage switch gear

Sensing & Safety

• Photoelectric sensors • Inductive sensors • Capacitive & pressure sensors • Cable connectors

• Displacement & width-measuring sensors • Vision systems • Safety networks • Safety sensors

• Safety units/relay units • Safety door/guard lock switches

Authorised Distributor:

Although we strive for perfection, Omron Europe BV and/or its subsidiary and affiliated companies do not warrant

or make any representations regarding the correctness or completeness of the information described in this document.

We reserve the right to make any changes at any time without prior notice.

OMRON EUROPE B.V.

Wegalaan 67-69, NL-2132 JD, Hoofddorp, The Netherlands. Tel: +31 (0) 23 568 13 00 Fax: +31 (0) 23 568 13 88 www.industrial.omron.eu

KPP_NS_EN_INT01

Austria

Tel: +43 (0) 2236 377 800

www.industrial.omron.at

Belgium

Tel: +32 (0) 2 466 24 80

www.industrial.omron.be

Czech Republic

Tel: +420 234 602 602

www.industrial.omron.cz

Denmark

Tel: +45 43 44 00 11

www.industrial.omron.dk

Finland

Tel: +358 (0) 207 464 200

www.industrial.omron.fi

France

Tel: +33 (0) 1 56 63 70 00

www.industrial.omron.fr

Germany

Tel: +49 (0) 2173 680 00

www.industrial.omron.de

Hungary

Tel: +36 1 399 30 50

www.industrial.omron.hu

Italy

Tel: +39 02 326 81

www.industrial.omron.it

Netherlands

Tel: +31 (0) 23 568 11 00

www.industrial.omron.nl

Norway

Tel: +47 (0) 22 65 75 00

www.industrial.omron.no

Poland

Tel: +48 (0) 22 645 78 60

www.industrial.omron.pl

Portugal

Tel: +351 21 942 94 00

www.industrial.omron.pt

Russia

Tel: +7 495 648 94 50

www.industrial.omron.ru

South-Africa

Tel: +27 (0)11 579 2600

www.industrial.omron.co.za

Spain

Tel: +34 913 777 900

www.industrial.omron.es

Sweden

Tel: +46 (0) 8 632 35 00

www.industrial.omron.se

Switzerland

Tel: +41 (0) 41 748 13 13

www.industrial.omron.ch

Turkey

Tel: +90 216 474 00 40

www.industrial.omron.com.tr

United Kingdom

Tel: +44 (0) 870 752 08 61

www.industrial.omron.co.uk

More Omron representatives

www.industrial.omron.eu

Loading...

Loading...