Page 1

Cat. No. Z921-E1-01

DeviceNet Safety

NE1A-HDY01

Mobile Console

OPERATION MANUAL

Page 2

DeviceNet Safety NE1A-HDY01 Mobile Console Operation Manual

Produced April 2009

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can result in injury to people or damage to property.

!WARNING Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally, there may be significant property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

Indicates a general CAUTION or WARNING precaution for which there is no specified symbol.

Indicates the risk of explosion under specific conditions.

Indicates general prohibitions for which there is no specific symbol.

Indicates general mandatory actions for which there is no specific symbol.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “PLC” means Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

IMPORTANT Indicates important information on what to do or not to do to prevent failure to

operation, malfunction, or undesirable effects on product performance.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

Trademarks and Copyrights

r

f

DeviceNet, DeviceNet Safety, EtherNet/IP, EtherNet/IP Safety, CIP, and CIP Safety are registered

trademarks of the ODVA.

Windows is a registered trademark of Microsoft Corporation in the United States and other countries.

Other product names and company names in this manual are trademarks or registered trademarks of

their respective companies.

OMRON, 2009

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xx

5 Precautions for Correct Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

6 Regulations and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7 Checking the Contents of the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

8 Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

SECTION 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 Overview of Mobile Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Part Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1-3 Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-4 Stylus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-5 External Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-6 Starting and Stopping the Mobile Console and Standby Mode. . . . . . . . . . . . . . . . . . . . . . . 13

1-7 Using the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-8 Using the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

1-9 Replacing the Clock Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

1-10 Attaching the Hand Strap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 2

Screen Names and Console Settings. . . . . . . . . . . . . . . . . . . 25

2-1 Screen Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-2 Console Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

SECTION 3

Online Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3-1 Basic Online Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-2 Reading Device Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-3 Replacing a Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3-4 Uploading Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3-5 Downloading Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

3-6 Resetting a Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-7 Changing the Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-8 Locking/Unlocking Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

vii

Page 7

TABLE OF CONTENTS

SECTION 4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4-1 Mobile Console Ratings and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

4-2 Battery Pack Ratings and Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

4-3 Charger Ratings and Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4-4 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

viii

Page 8

About this Manual:

This manual describes the NE1A-HDY01 DeviceNet Safety Mobile Console (called simply the Mobile

Console in this manual). Please read this manual carefully and be sure you understand the information

provided before attempting to use the Mobile Console. Be sure to read the precautions provided in the

following section.

The Mobile Console features easy operation by tapping a touch screen with a stylus. It is a portable

maintenance terminal that can be used for maintaining NE0A/NE1A-series Controllers and DST1series Safety I/O Terminals.

The following manuals provide information on the DeviceNet and DeviceNet Safety.

DeviceNet Safety Mobile Console Operation Manual (this manual) (Z921)

This manual describes the specifications, functions, and operating procedures of the Mobile Console.

DeviceNet Safety NE0A Series Safety Network Controller Operation Manual (Z916)

This manual describes the specifications, functions, and operating procedures of the NE0A-series

Safety Network Controllers.

DeviceNet Safety NE1A Series Safety Network Controller Operation Manual (Z906)

This manual describes the specifications, functions, and operating procedures of the NE1A-series

Controllers.

DeviceNet Safety System Configuration Manual (Z905)

This manual explains how to configure the DeviceNet Safety system using the Network Configurator.

DeviceNet Safety I/O Terminal Operation Manual (Z904)

This manual describes the models, specifications, functions, and operating procedures of the DST1

Series.

EtherNet/IP-DeviceNet Router Operation Manual (Z912)

This manual describes the specifications, functions, and operating procedures of the EtherNet/IPDeviceNet Router.

DeviceNet Operation Manual (W267)

This manual describes the construction and connection of a DeviceNet network. It provides detailed

information on the installation and specifications of cables, connectors, and other peripheral equipment used in the network, and on the supply of communications power. Obtain this manual and gain a

firm understanding of its contents before using a DeviceNet network.

CS/CJ Series DeviceNet Units Operation Manual (W380)

This manual describes basic setup and standard communications using CS/CJ-series DeviceNet

Units.

!WARNING Failure to read and understand the information provided in this manual may result in per-

sonal injury or death, damage to the product, or product failure. Please read each section

in its entirety and be sure you understand the information provided in the section and

related sections before attempting any of the procedures or operations given.

ix

Page 9

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

4 Precautions for Safe Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xx

5 Precautions for Correct Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

6 Regulations and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxi

7 Checking the Contents of the Package . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

8 Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xxii

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA and safety systems into production

facilities

• Personnel in charge of designing FA and safety systems

• Personnel in charge of managing FA facilities

• Personnel who have the qualifications, authority, and obligation to provide

safety during each of the following product phases: mechanical design,

installation, operation, maintenance, and disposal

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING Heed the following items during system configuration to ensure that safety-

related components are configured in a manner that allows the system functions to operate sufficiently.

• Risk Assessment

The proper use of safety devices described in this Manual as it relates to

installation conditions and mechanical performance and functions is a prerequisite for their use. When selecting or using a safety device, risk assessment must be conducted with the aim of identifying potential danger factors

in equipment or facilities in which the safety device is to be applied, during

the development stage of the equipment or facilities. Suitable safety devices must be selected under the guidance of a sufficient risk assessment

system. An insufficient risk assessment system may lead to the selection

of unsuitable safety devices.

• Typical related international standards: ISO 14121, Safety of Machinery -- Principles of Risk Assessment

• Safety Measures

When using safety devices to build systems containing safety-related components for equipment or facilities, the system must be designed with the

full understanding of and conformance to international standards, such as

those listed below, and/or standards in related industries.

xvi

Page 16

General Precautions 2

• Typical related international standards: ISO 12100, Safety of Machinery -- Basic Concepts and General Principles for Design

IEC 61508, Safety Standard for Safety Instrumented Systems (Functional Safety of Electrical/Electronic/Programmable Electronic Safetyrelated Systems)

• Role of Safety Device

The safety devices are provided with safety functions and mechanisms as

stipulated in relevant standards, but suitable designs must be used to allow

these functions and mechanisms to operate properly inside system constructions containing safety-related components. Build systems that enable these functions and mechanisms to perform properly, based on a full

understanding of their operation.

• Typical related international standards: ISO 14119, Safety of Machinery -- Interlocking Devices Associated with Guards -- Principles of Design and Selection

• Installation of Safety Device

The construction and installation of systems with safety-related components for equipment or facilities must be performed by technicians who

have received suitable training.

• Typical related international standards: ISO 12100, Safety of Machinery -- Basic Concepts and General Principles for Design

• Complying with Laws and Regulations

The safety devices conform to the relevant regulations and standards, but

make sure that they are used in compliance with local regulations and

standards for the equipment or facilities in which they are applied.

• Typical related international standards: IEC 60204, Safety of Machinery -- Electrical Equipment of Machines

• Observing Precautions for Use

When putting the selected safety devices to actual use, heed the specifications and precautions in this Manual and those in the Operation Manuals

that comes with the products. Using the products in a manner that deviates

from these specifications and precautions will lead to unexpected failures

in equipment or devices, and to damages that result from such failures,

due to insufficient operating functions in safety-related components.

• Moving or Transferring Devices or Equipment

When moving or transferring devices or equipment, be sure to include this

Manual to ensure that the person to whom the device or equipment is being moved or transferred will be able to operate the system properly.

• Typical related international standards: ISO 12100, Safety of Machinery -- Basic Concepts and General Principles for Design

IEC 61508, Safety Standard for Safety Instrumented Systems (Functional Safety of Electrical/Electronic/Programmable Electronic Safetyrelated Systems)

xvii

Page 17

Safety Precautions 3

3 Safety Precautions

!WARNING

Serious personal injury or fire may occasionally occur due to leakage, rupture, combustion, or

heat generation. Use only the peripheral devices specified by OMRON.

• Battery Pack: RB-B2001A

• Charger: RB-C2001

• Power Cable: NE1A-BTCHG-JP

Serious personal injury or fire may possibly occur due to rupture, combustion, or heat generation. Observe the following precautions on the built-in lithium-ion battery and lithium battery.

• Do not use, place, or store the Product at high temperatures or in a location exposed to sunlight.

• Do not heat the Product or expose it to fire.

• Do not allow the Product to be deformed by pressure or subjected to strong shock.

• When replacing the Battery Pack or the clock battery, do not allow the connection terminals to

come into contact with metal parts.

• Do not disassemble or modify the Product.

Serious personal injury or fire may occasionally occur due to rupture, combustion, or heat generation. Do not attempt to charge the clock battery. It is a lithium primary battery.

NE1A-BTCHG-EU (packed together)

Serious personal injury may occasionally occur due to electric shock, rupture, combustion, or

heat generation. Do not place the Product in water or operate it with wet hands.

Serious personal injury may possibly occur due to loss of safety functions. Observe the following

precautions.

• Do not use the NE1A-HDY01 Mobile Console directly or indirectly in applications for detecting

humans to ensure safety.

• Perform a user test before operating the system, and check to make sure that all the device

configuration data and operations are correct.

• After replacing a device, check to make sure that the replacement device is in the appropriate

configuration and is operating correctly

Serious personal injury or fire may possibly occur due to rupture, combustion, or heat generation. Observe the following precautions.

• When carrying or storing the Battery Pack or the clock battery, insulate them with a material

such as tape to prevent metal parts from coming into contact with the Battery Pack connection

terminals.

• If any abnormality, such as smoke or an unusual odor or noise, occurs during operation, immediately turn OFF the power switch and stop using the Product.

Personal injury may occasionally occur. Stop using the Product immediately if the touch screen

is damaged.

• If leaked fluid comes into contact with skin or clothing, immediately flush it thoroughly with

clean water.

• If leaked fluid comes into contact with the eyes or mouth, do not rub it. Flush thoroughly with

clean water and then consult a physician.

Personal injury may occasionally occur. Stop using the Product immediately if leaked fluid or an

unusual odor from the Battery Pack or clock battery is detected.

• If there are flames nearby, move the Product away from the flames. Failure to do so may result

in leaked fluid catching fire, causing rupture or combustion.

• If leaked fluid comes into contact with skin or clothing, immediately rinse it thoroughly with

clean water.

• If leaked fluid comes into contact with the eyes or mouth, do not rub it. Flush thoroughly with

clean water and then consult a physician.

xviii

Page 18

Safety Precautions 3

■ Warnings on RB-B2001A Battery Pack

!WARNING

Serious personal injury or fire may occasionally occur due to rupture, combustion, or heat generation.

• Do not short-circuit the plus (+) and minus (−) terminals of the Battery Pack.

• Do not use, place, or store the Battery Pack in a location exposed to sunlight.

• Do not heat the Battery Pack or expose it to fire.

• Do not drop the Battery Pack or allow it to be subjected to severe shock.

Serious personal injury or fire may occasionally occur due to leakage, rupture, combustion, or

heat generation.

• Do not use a charger other than the one specified by OMRON for charging the Battery Pack.

• Do not disassemble or modify the Battery Pack.

• Do not use the Battery Pack with a device other than the NE1A-HDY01 Mobile Console.

• Do not place the Battery Pack in water or operate it with wet hands.

When carrying or storing the Battery Pack, insulate it with material, such as tape, to prevent

metal parts from coming into contact with the Battery Pack connection terminals. Failure to do

so may result in short-circuiting, occasionally causing serious personal injury or fire due to rupture, combustion, or heat generation.

Personal injury may occasionally occur.

If leakage or an unusual odor from the Battery Pack is detected, stop using the Battery Pack

immediately.

• If there are flames nearby, move the Battery Pack away from the flames. Failure to do so may

result in leaked fluid catching fire, causing rupture or combustion.

• If leaked fluid comes into contact with skin or clothing, immediately rinse it thoroughly with

clean water.

• If leaked fluid comes into contact with the eyes or mouth, do not rub it. Flush thoroughly with

clean water and then consult a physician.

■ Warnings on RB-C2001 Charger

!WARNING

If the charge indicator is flashing red, or if charging does not finish even though the specified

time has been exceeded, stop charging and remove the power plug from the outlet. Failure to do

so may occasionally result in serious personal injury or fire due to leakage, rupture, combustion,

or heat generation.

Using other devices may occasionally result in serious personal injury or fire due to leakage,

rupture, combustion, or heat generation.

Do not use the Charger for charging any Battery Pack other than the one specified by OMRON.

Serious personal injury may occasionally occur due to electric shock, rupture, combustion, or

heat generation. Do not place the Product in water or operate it with wet hands.

Serious personal injury may occasionally occur due to combustion, heat generation, or electric

shock. Observe the following precautions.

• When not charging, remove the power supply plug from the outlet.

• Do not damage the Charger power cable, modify it, place heavy objects on it, or bend it past its

natural bending radius.

xix

Page 19

Precautions for Safe Use 4

4 Precautions for Safe Use

• Before Operation

When opening the package, perform a visual check for any damage. Lightly shake the Product and listen for any unusual sounds.

• Storage and Operating Environments

Do not store or operate the Product in any of the following locations.

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of severe changes in

temperature

• Locations subject to steam.

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to water, oil, or chemicals

• Locations subject to shock or vibration

Take appropriate and sufficient measures when installing systems in the

following locations. Inappropriate and insufficient measures may result in

malfunction.

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

The Mobile Console is a Class A product. It may cause radio interference

in residential areas, in which case the user may be required to take adequate measures to reduce interference.

• Power Supply

Do not connect the Charger to a power supply that exceeds the ratings.

• Periodic Inspections and Maintenance

Always turn OFF the power switch before installing or replacing the Battery

Pack or clock battery.

• Disposal

• When disposing of the Battery Pack or clock battery, insulate the plus

(+) and minus (

• Follow all local government regulations as applicable when disposing

of the Mobile Console and used batteries.

• The Battery Pack is a lithium-ion secondary battery. It can be recycled.

−) terminals of the battery with tape.

xx

Page 20

Precautions for Correct Use 5

5 Precautions for Correct Use

Observe the following precautions in order to prevent Product failure, Product

malfunction, or adverse effects on the performance of the Product.

• Handling the Memory Card

Do not perform any of the following operations while the Memory Card is

being accessed. Doing so may cause data to be lost.

• Turning OFF the Mobile Console power switch

• Removing the Battery Pack

• Removing the Memory Card

• Handling the Touch Screen

• Use the enclosed stylus for touch screen operations. Using a sharp object may scratch the touch screen surface so that the screen cannot be

used for inputs.

• Do not press hard on or rub the touch screen surface. Doing so may

not only cause damage but may break the glass.

• Cleaning

Use a clean, dry cloth for cleaning. If dirt cannot be removed using a dry

cloth, dampen the cloth with a neutral cleaning solution, wring the cloth out

tightly, and then wipe the dirty section.

Never use benzene or thinner, or other volatile solvents or chemical cloths,

to clean the Product. Doing so may discolor the surface or cause damage.

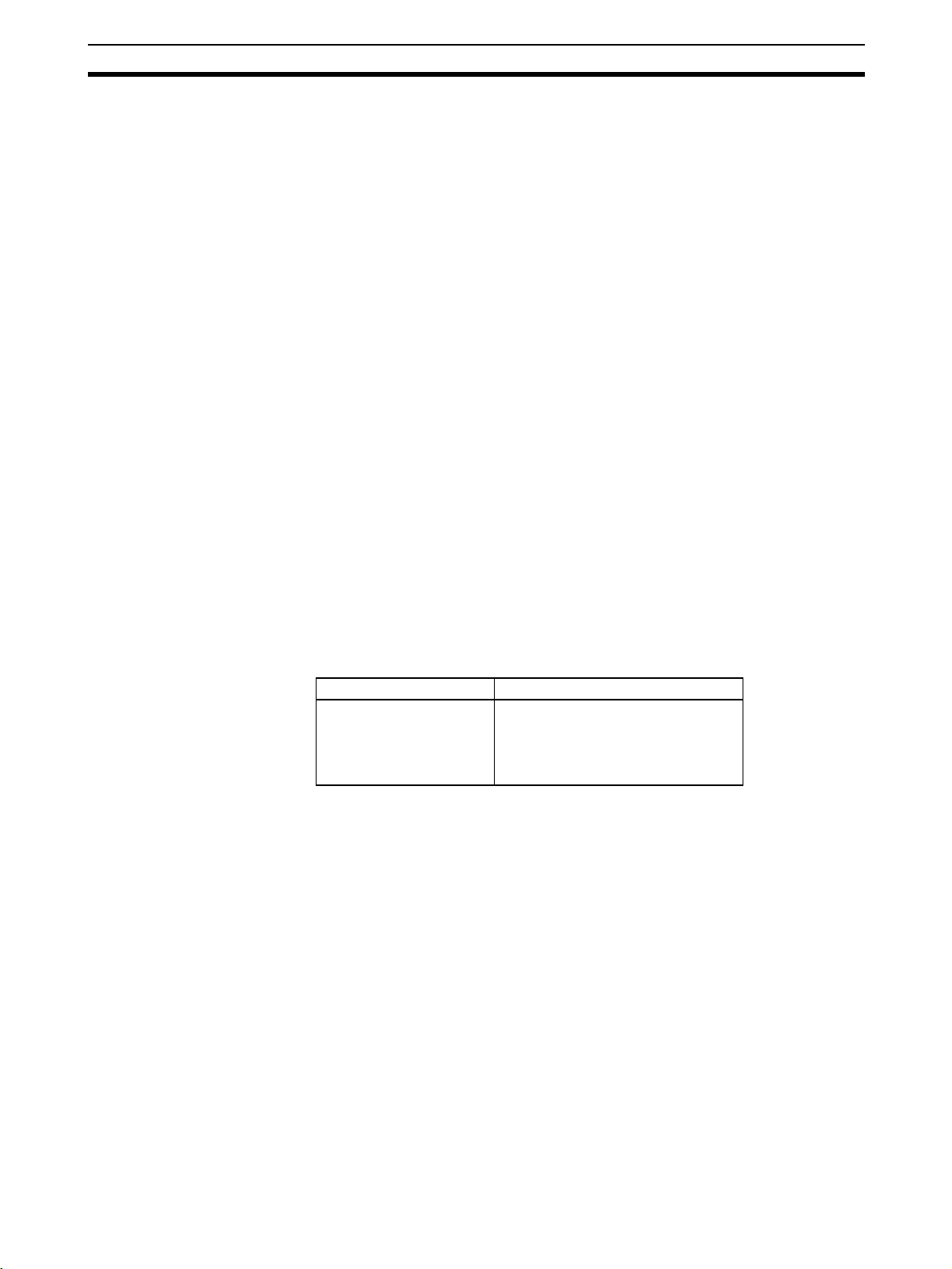

6 Regulations and Standards

The NE1A-HDY01 has been determined to conform to the EC EMC Directive

by conforming to the following standards.

Certifying organization Standards

TÜV Rheinland IEC 61131-2

IEC 61000-6-4

CISPR 16-1-2

CISPR 16-2-1

CISPR 16-2-3

xxi

Page 21

Checking the Contents of the Package 7

7 Checking the Contents of the Package

■ NE1A-HDY01 Mobile Console

The following items should be included in the package. Check to make sure

that all of the items are included, and that there is no leakage or damage.

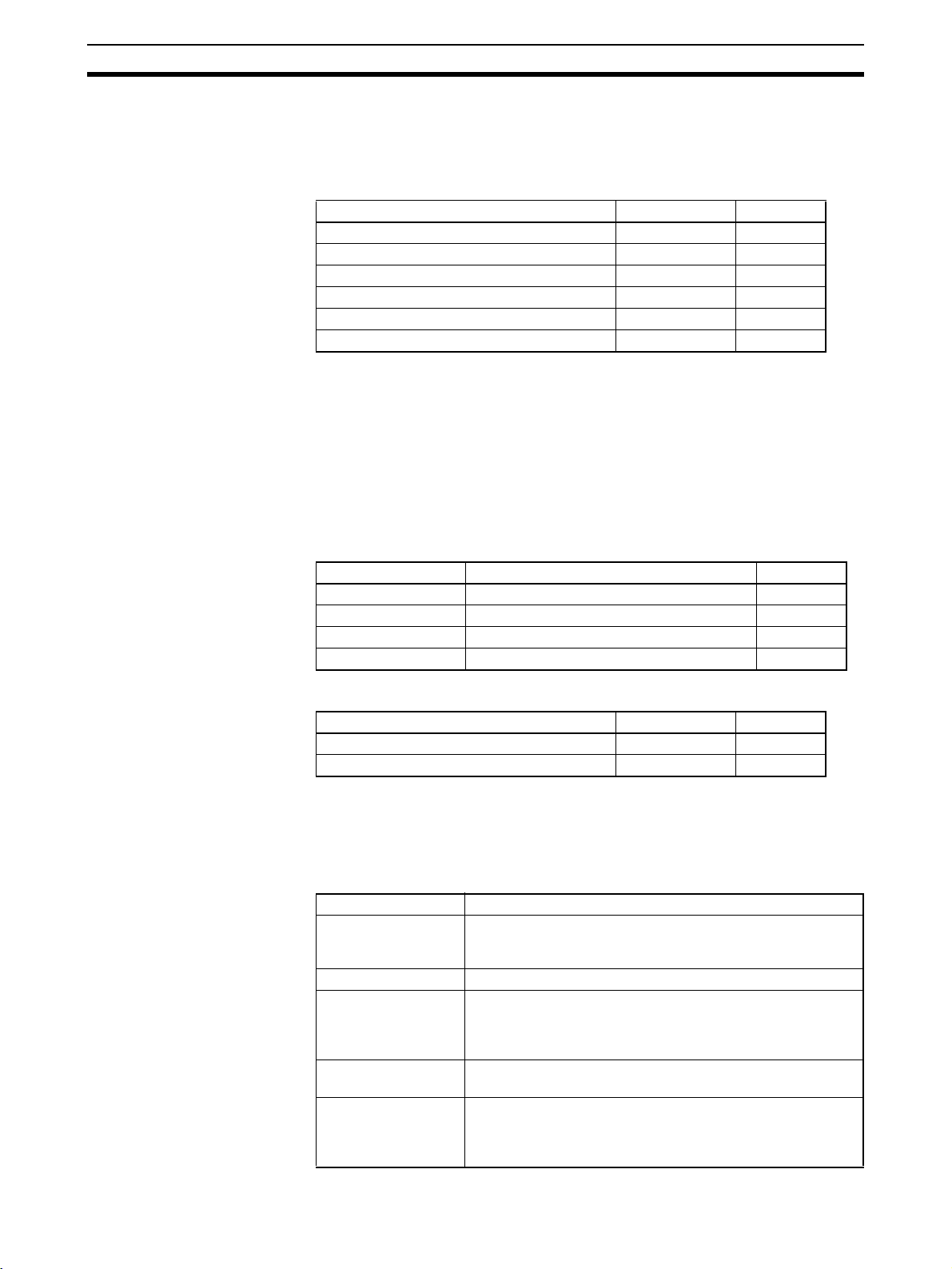

Name Description Quantity

Mobile Console NE1A-HDY01 1

Hand strap 1

Instruction Sheet 1

SYSMAC ID registration card (Japanese) 1

SYSMAC ID registration card (English) 1

Address sheet 1

• Defective Display Pixels

The liquid-crystal panel has been made using very advanced technology,

but there may be defective display pixels that produce gaps or bright points

(points that remain lit) on the display. This is an inherent aspect of liquid

crystals and does not indicate any product failure. We do our utmost to

minimize defective display pixels, but with current manufacturing technology, it is impossible to eliminate them completely.

■ Charger and Battery Set NE1A-BTCHG-JP (for Japan)/NE1A-BTCHG-EU

(for Europe)

Name Description Quantity

Charger RB-C2001 1

Battery Pack RB-B2001A 1

Power Cable Power cable for the specified destination 1

Instruction Sheet 1

■ RB-B2001A Replacement Battery Pack

Battery Pack RB-B2001A 1

Instruction Sheet 1

8 Definition of Terms

The following terms are used in describing the NE1A-HDY01.

Mobile Console A portable terminal that is used to perform maintenance for

Battery Pack The RB-B2001A Lithium-ion Battery Pack.

Network Configurator A software application that is used to build, set, and manage

Safety Refers to devices, functions, or data for which special safety

Standard Refers to devices, functions, or data for Standard applica-

Name Description Quantity

Term Definition

Safety Network Controllers and Safety I/O Terminals. “Mobile

Console” is the name of OMRON’s NE1A-HDY01.

DeviceNet, DeviceNet Safety, and EtherNet/IP networks.

“Network Configurator” is the name of OMRON’s WS02CFSC-J/E.

measures for use in safety controls have been implemented.

tions. “Standard” is used to distinguish Standard Devices,

functions, or data from those for which special safety measures for use in safety controls have been implemented.

xxii

Page 22

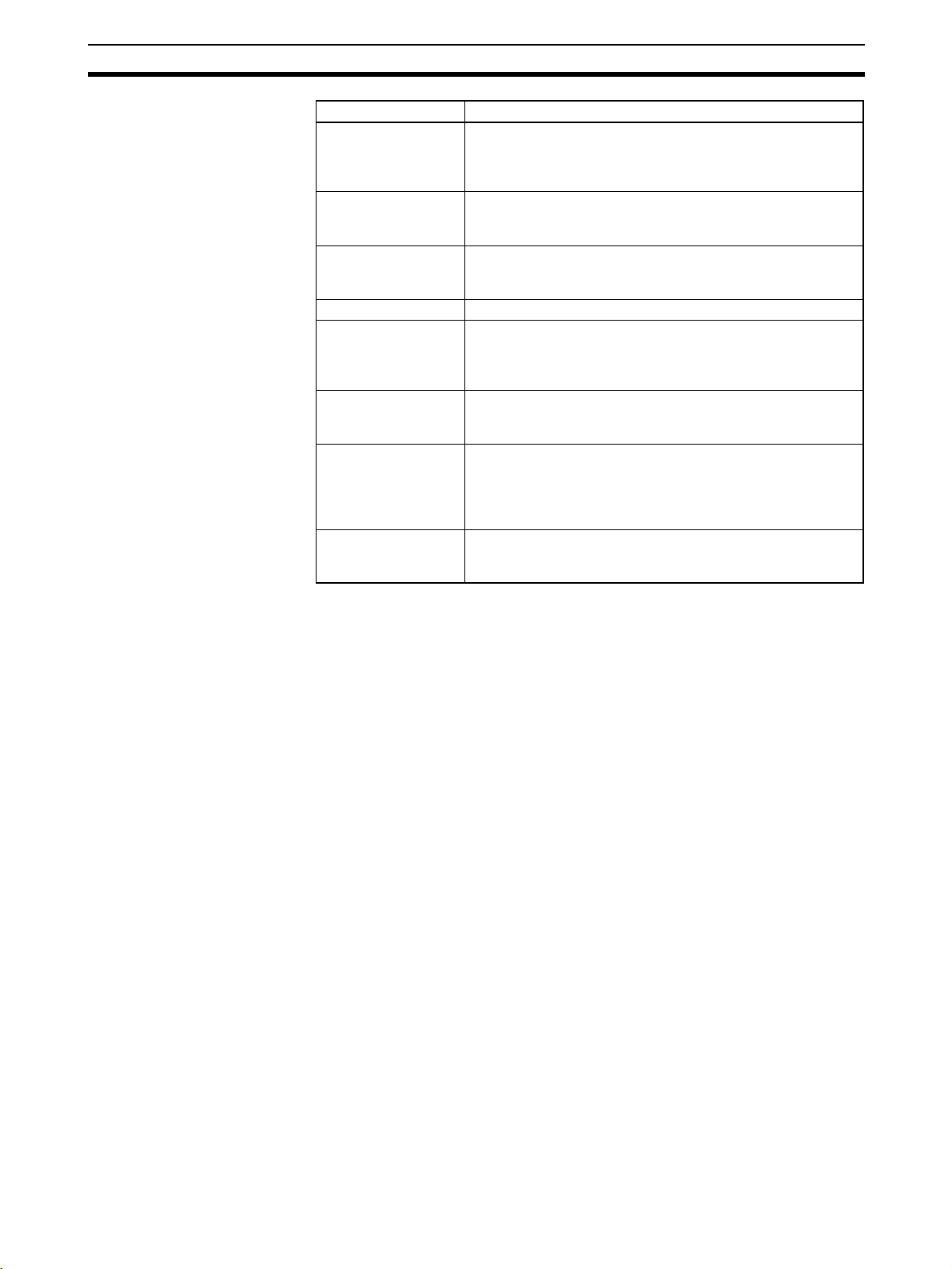

Definition of Terms 8

Term Definition

Safety Network Controller

Standard Programmable Controller

(Standard PLC)

Safety I/O Terminal A Remote I/O Terminal for use in safety controls. “Safety I/O

Remote I/O Terminal A Remote I/O Terminal for use in Standard Controls.

Safety Input device An input device for which special measures for use in safety

Safety Output device An output device for which special measures for use in safety

locking the configuration/device

safety signature A certification for configuration data transferred to a device

A controller that supports Safety Networks and has a high

reliability for use in safety controls. “Safety Network Controller” is the name of the Controllers in OMRON's NE0A Series,

NE1A Series, and other series.

A Programmable Controller (PLC) that is used for Standard

Controls. “Standard PLC” is used to distinguish a PLC for

Standard Controls from a PLC for Safety Controls.

Terminal” is the name of the terminals in OMRON's DST1

Series.

controls have been implemented. Emergency stop switches

and safety door switches are examples of Safety Input

devices.

controls have been implemented. Safety relays are an example of a Safety Output device.

A configuration (device) is locked to indicate that the suitability of downloaded Safety Parameters has been verified by the

user in system testing. Locking the configuration (device) protects the data saved in the device. The configuration data can

be changed by unlocking the configuration (device).

from the Network Configurator. The safety signature is used

by the device to verify that the configuration data is correct.

xxiii

Page 23

Definition of Terms 8

xxiv

Page 24

SECTION 1

Introduction

The section provides an overview of the Mobile Console, describes its parts and functions, describes basic operating

procedures, and provides hardware handling procedures. Read this section before you attempt to use the Mobile Console.

1-1 Overview of Mobile Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Mobile Console. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-2 Mobile Console Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-1-3 Differences with Network Configurator Functions . . . . . . . . . . . . . 6

1-2 Part Names and Functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-1 Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1-2-2 Rear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1-3 Control Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-1 Control Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-2 Power Mode Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-3 Character Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1-3-4 Function Keys. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1-4 Stylus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-4-1 Stylus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1-5 External Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-5-1 External Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1-6 Starting and Stopping the Mobile Console and Standby Mode . . . . . . . . . . . 13

1-6-1 Starting and Stopping the Mobile Console . . . . . . . . . . . . . . . . . . . . 13

1-6-2 Standby Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1-6-3 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

1-7 Using the Battery Pack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-7-1 Replacing the Battery Pack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1-7-2 Charging the Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1-8 Using the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-8-1 Inserting the Memory Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1-8-2 Removing the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1-9 Replacing the Clock Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-9-1 Replacing the Clock Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1-10 Attaching the Hand Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-10-1 Strap Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1-10-2 Attaching the Strap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1

Page 25

Overview of Mobile Console Section 1-1

1-1 Overview of Mobile Console

This section gives an overview of the Mobile Console.

1-1-1 Mobile Console

The Mobile Console is a mobile maintenance terminal for DeviceNet Safety

Networks. It can be connected to Safety Devices on the DeviceNet Safety

Network using a USB cable to monitor individual devices and to support

replacing devices. The user interface features a lightweight, compact body

and an easy touch screen so that work can be carried out standing up, making it useful for identifying the location of device errors using the monitoring

function and reducing the time required for maintenance, such as replacing

devices. The Mobile Console is perfect for maintenance work onsite where a

laptop cannot easily be brought in.

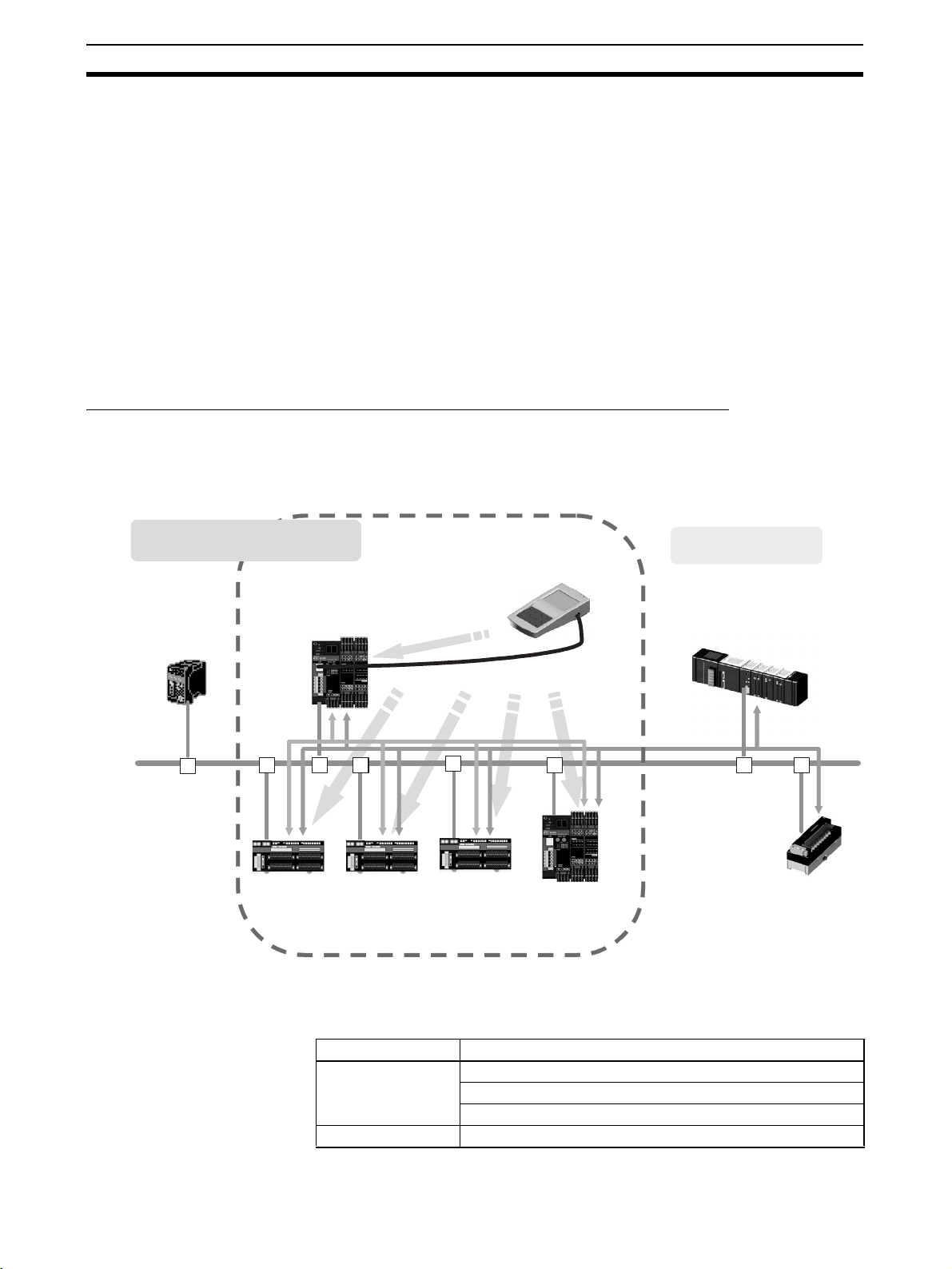

Application Range of Mobile Console on the DeviceNet Safety Network

Application Range of Mobile Console

Devices in the following range can be maintained with the Mobile Console

when it is connected to the Safety Network Controller.

Application Range of Mobile Console

DeviceNet Safety Network to which the

Safety Network Controller is connected

Safety Network Controller

• NE1A Series

EtherNet/IPDeviceNet Router

• NE1A-EDR01

• NE0A Series

Safety I/O

Terminals

• DST1 Series

Connectable DeviceNet Safety Devices

Devices in the following series can be maintained by using the Mobile Console.

Series Model

NE1A Series NE1A-SCPU01

NE0A Series NE0A-SCPU01

Monitoring operation of

individual devices

Replacing devices

Other operations

Safety I/O Communications

NE1A-SCPU01-V1 (unit version 1.0 or 2.0)

NE1A-SCPU02 (unit version 1.0 or 2.0)

Mobile Console

• NE1A-HDY01

USB cable

Safety Network

Controller

• NE1A Series

• NE0A Series

DeviceNet Network connected to a Standard PLC

Standard PLC and Master

Standard I/O Communications

Standard Slave

2

Page 26

Overview of Mobile Console Section 1-1

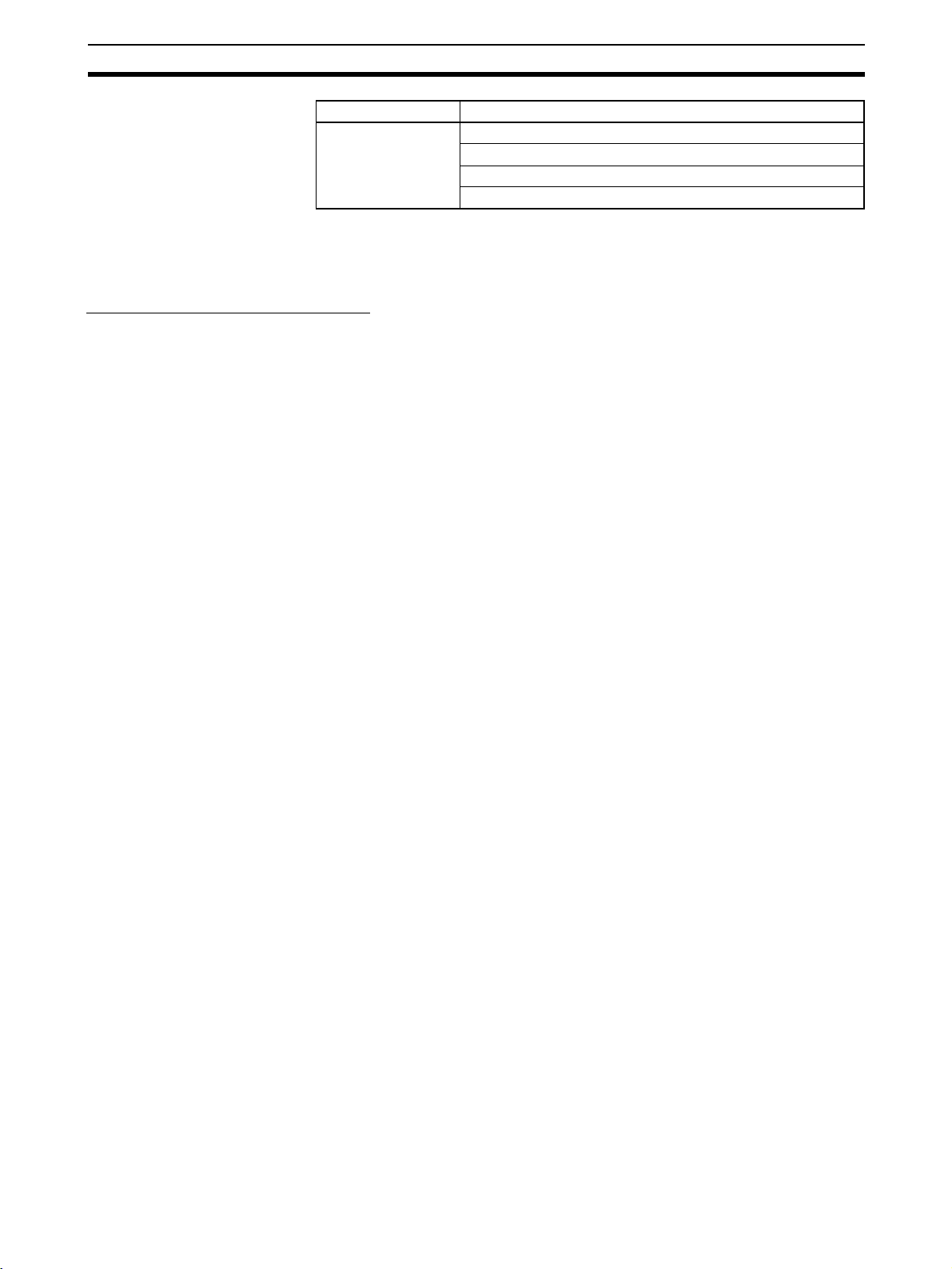

Series Model

DST1 Series DST1-ID12SL-1

DST1-MD16SL-1

DST1-MRD08SL-1

DST1-XD0808SL-1

Note Ethernet/IP-DeviceNet Routers, Standard PLCs, Standard Mas-

ters, and Standard Slaves are not in the application range of the

Mobile Console.

Features of the Mobile Console

Easy Operation with a Touch Screen

Operating the Mobile Console is perform simply by tapping the touch screen

with a stylus.

Compatible with DeviceNet Safety Devices

The Mobile Console is compatible with NE0A/NE1A-SCPU Safety Network

Controllers as well as DST1-series Safety I/O Terminals.

Affinity with the Network Configurator

The Mobile Console uses device parameter files (*.dvf) created by the Network Configurator. Device parameter files can be downloaded to the Safety

Network Controllers and Safety I/O Terminals.

Display of Errors and Countermeasures

The status of and countermeasures for errors are displayed in a dialog box.

3

Page 27

Overview of Mobile Console Section 1-1

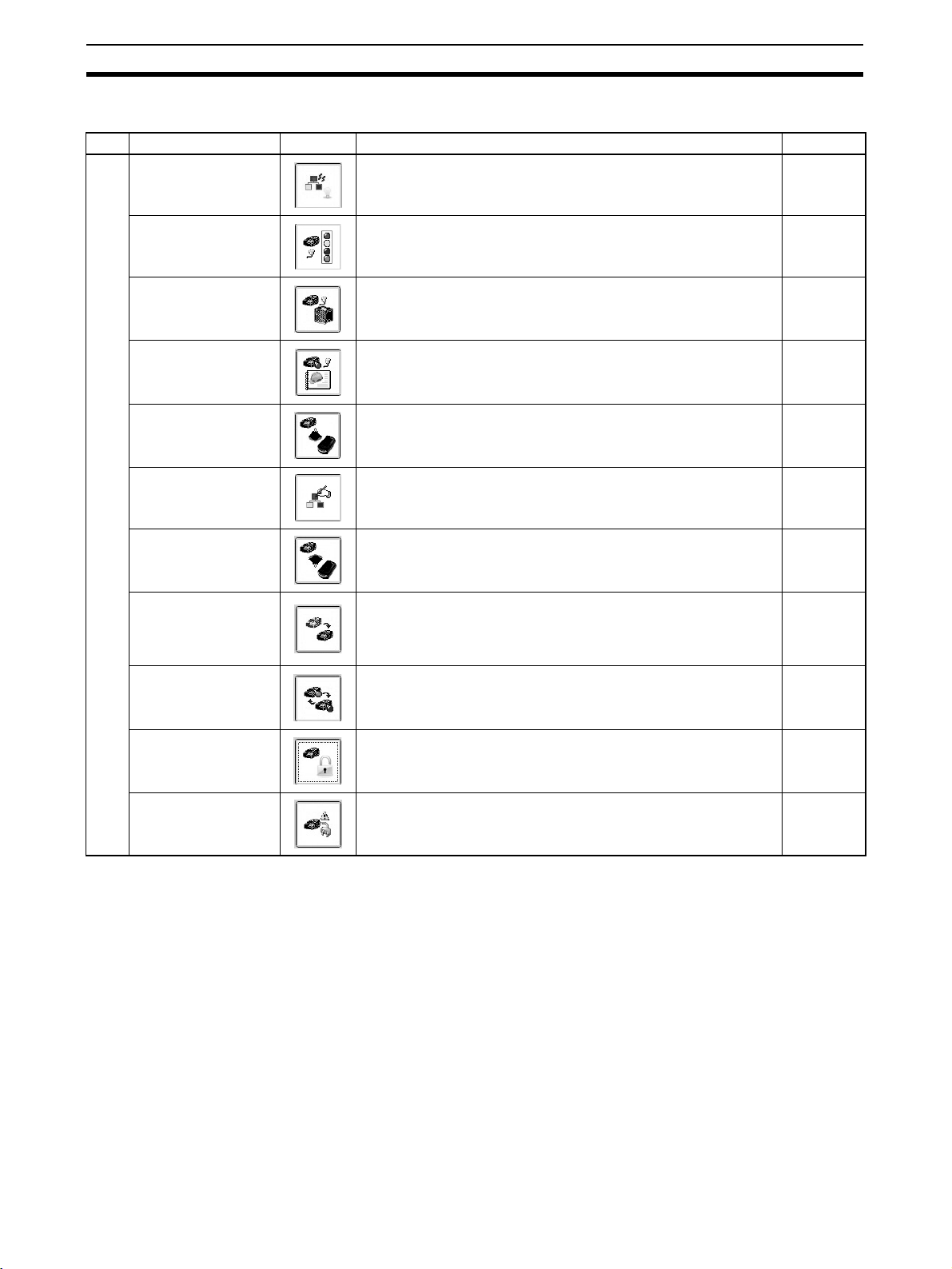

1-1-2 Mobile Console Functions

Function name Icon Description Reference

Monitor Displays the connected device's I/O terminal status. Errors occur-

ring at the connected device will be displayed on the Maintenance

Tab Page.

3-2-2

Device Status Displays the device status as well as information on alarms and

Change Target This function is used to change the connected device. 3-1-3

Error History Displays the error history of the connected device. Errors occur-

Upload Uploads parameters from the connected device and saves them

Device Property Displays the properties of the connected device. 3-2-5

Download Device parameters copied to the Memory Card are downloaded to

Replace Device Device parameters uploaded from the connected device are

Change Mode Changes the operating mode of the connected device. 3-7

DeviceNet Safety System Functions (Online Functions)

warnings. Errors occurring at the connected device will be displayed on the Maintenance Tab Page.

ring at the connected device will be displayed on the Maintenance

Tab Page.

to the Memory Card.

the connected device.

downloaded after replacing the device.

This function cannot be used if a system error occurs due to a

fatal hardware error in the device that is being replaced.

3-2-3

3-2-4

3-4

3-5

3-3

Lock

Unlock

Reset Resets the connected device. 3-6

Locks or unlocks the connected device. 3-8

4

Page 28

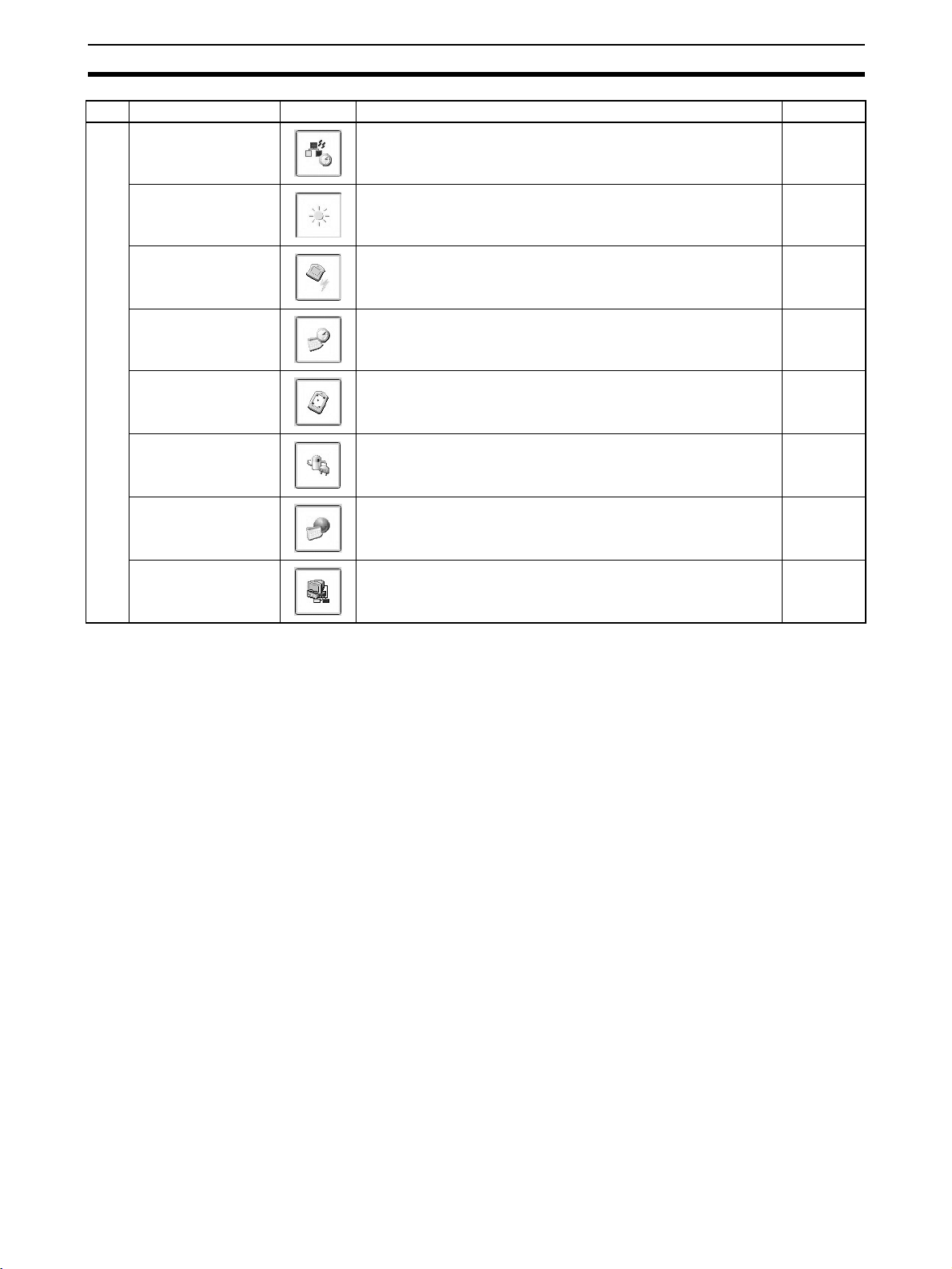

Overview of Mobile Console Section 1-1

Function name Icon Description Reference

Monitor Settings Sets the time interval for refreshing data displayed by the monitor

function.

Brightness The brightness of the screen can be selected from three levels. 2-2-2

Memory Card Format This function is used to format a Memory Card. 2-2-3

Date/Time This function is used to set the date and time. 2-2-4

2-2-1

Stylus This function is used to set the double-tap speed and to calibrate

the touch screen.

Console Settings

Power Management This function is used to set the power saving features. 2-2-6

Language This function is used to set the language used by the Mobile Con-

sole.

Version Displays the Mobile Console version information. 2-2-8

Note Refer to 3-2-6 Saving the Screen Image for information on saving the screen

image showing monitor results (Fn + F2 Keys).

2-2-5

2-2-7

5

Page 29

Overview of Mobile Console Section 1-1

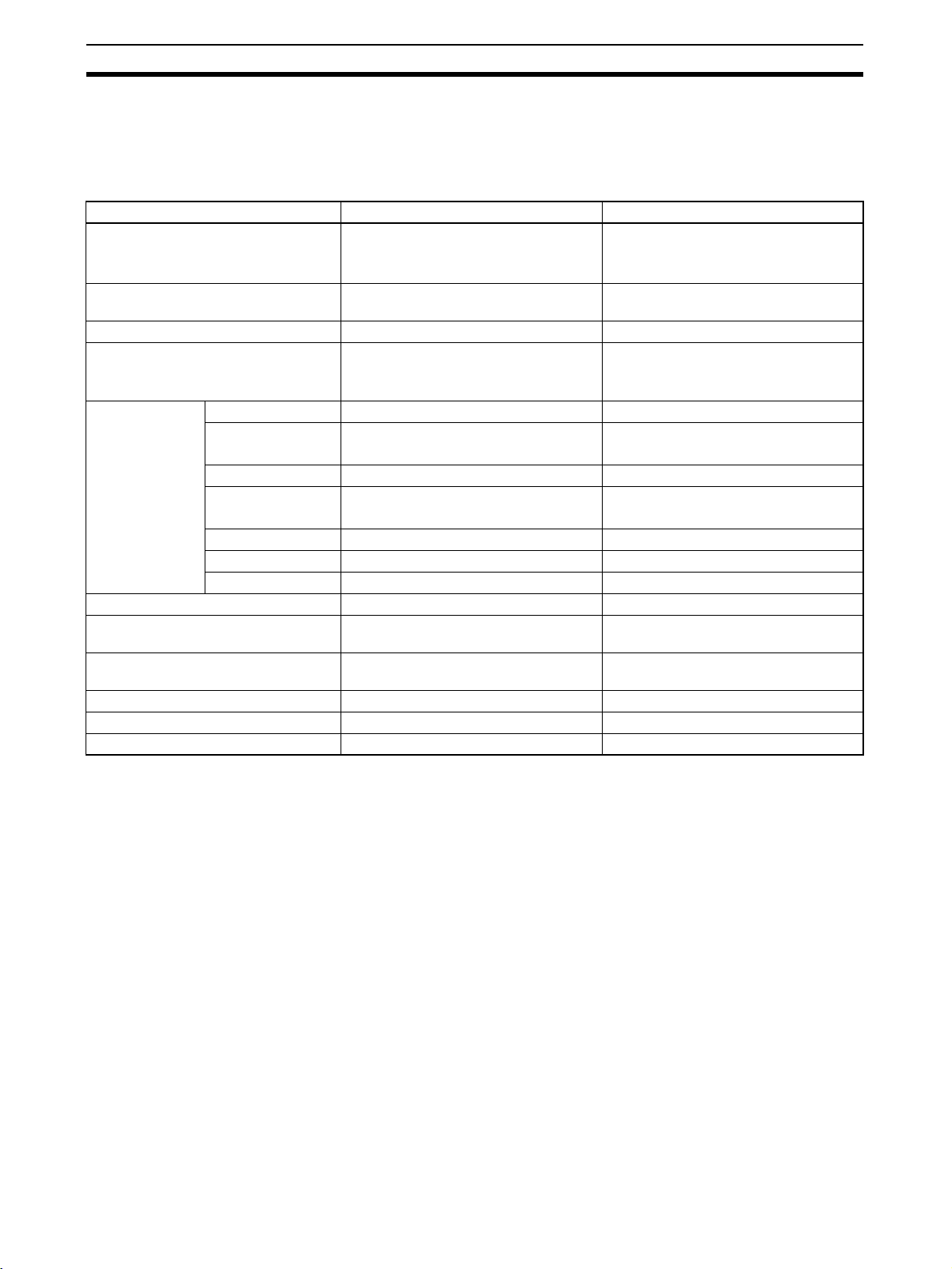

1-1-3 Differences with Network Configurator Functions

The differences between the Mobile Console and Network Configurator functions are outlined in the following table.

OK: Possible, ---: Not possible

Item Mobile Console Network Configurator

Controllable DeviceNet Safety Devices • NE1A-SCPU Series

• NE0A Series

• DST1 Series

Managed files *.dvf (device parameter files) created by

File memory Memory Card only Saved in computer

Changing target connection OK

Parameters Upload OK (by device) OK

Download OK (by device)

Compare --- OK

Lock, Unlock OK

Edit --- OK

Read OK (by device) OK

Save OK (by device) OK

Creating and editing programs --- OK

Monitoring (Monitor, Device Status,

Device Property)

Device replacement (Automatic

upload/download function)

Resetting OK OK

Changing the mode OK OK

Changing passwords --- OK

Network Configurator

(Target connection can be changed

within same network)

Verification executed at the same time.

Verification executed at the same time.

OK OK

OK ---

• NE1A-SCPU Series

• NE0A Series

• DST1 Series

*.ncf (network configuration files)

OK (Change network)

Select Change Connect Network from

the Network Menu.

OK

OK

6

Page 30

Part Names and Functions Section 1-2

1-2 Part Names and Functions

1-2-1 Front

1. LCD panel

2. Control keys

3. Power switch

5. Battery charge indicator

4. Power status indicator

10. LAN port (for future expansion)

7. Stylus holder

8. Memory Card slot

1 LCD panel The LCD panel is a touch screen that can be used with the

2 Control keys Refer to 1-3 Control Keys.

3 Power switch Refer to 1-6-1 Starting and Stopping the Mobile Console.

4 Power status indicator Refer to 1-6-3 Status Indicators.

5 Battery charge indicator Refer to 1-6-3 Status Indicators.

6 Stylus This is a pen for tapping the touch screen to navigate the con-

7 Stylus holder The stylus can be stored in the holder when it is not being

8 Memory Card slot The Memory Card is inserted in this slot. Refer to 1-8 Using

9 USB port The USB port is used to connect the Mobile Console to an

10 LAN port This port is for future expansion. It cannot currently be used.

9. USB port

stylus. Refer to 2-1-1 Main Window for the screen names.

trols. Refer to 1-4 Stylus.

used.

the Memory Card.

NE0A/NE1A-series Safety Network Controller. Refer to 1-5-1

External Connectors.

6. Stylus

7

Page 31

Part Names and Functions Section 1-2

k

1-2-2 Rear

2. Lock lever

3. Clock battery cover

4. Strap hook

1 Battery cover Covers the rechargeable battery pack.

2 Lock lever Locks the battery cover.

3 Clock battery cover Covers the clock battery.

4 Strap hooks Used to attach the hand strap.

4. Strap hook

1. Battery cover

4. Strap hoo

8

Page 32

Control Keys Section 1-3

1-3 Control Keys

1-3-1 Control Keys

Function keys

Character keys

1-3-2 Power Mode Key

The Mobile Console has two standby modes to reduce the rate of consumption of charge of the battery pack. The standby modes are the Suspended

Mode and the Deep Sleep Mode. Refer to 1-6-2 Standby Modes for details.

The Power Mode Key can be used to enter or exit the standby modes.

To enter suspended mode Hold down the Power Mode Key.

To enter deep sleep mode Leave the Mobile Console in Suspended Mode for the

To return from suspended

or deep sleep mode

1-3-3 Character Keys

You can switch between the following character input modes using the NUM/

CHARA Key.

Multiple characters are assigned to one key for the alphabet and symbol input

mode. Press the key a number of times until the desired character is displayed.

1 @!& 1 @ → ! → & → % → | →? → $ → \

2 abc 2 a → b → c → A → B → C

3 def 3 d → e → f → D → E → F

4 ghi 4 g → h → i → G → H → I

Power mode key

Purpose Procedure

set time (15 min max.)

Press the Power Mode Key.

• Number mode

• Alphabet and symbol mode

Key Number mode Alphabet and symbol mode

9

Page 33

Control Keys Section 1-3

Key Number mode Alphabet and symbol mode

5 jkl 5 j → k → l → J → K → L

6 mno 6 m → n → o → M → N → O

7 pqrs 7 p → q → r → s → P → Q → R → S

8 tuv 8 t → u → v → T → U → V

9 wxyz 9 w → x → y → z → W → X → Y → Z

0 .,: 0 . → , → : → ; → " → ' → ` → _

* +/- * + → / → - → = → ^ → ~

# (< # ( → ) → [ → ] → < → > → { → }

1-3-4 Function Keys

Key Function

ESC Escape

F1 Not used.

F2 Not used.

NUM/CHARA Changes the input mode. Refer to 1-3-3 Character Keys.

TA B Ta b

DEL Delete

↑ Move up

↓ Move down

→ Move right

← Move left

OK Enter

SPACE Space

Fn+F1 Not used.

Fn+F2 Print screen

Fn+↑ Page up

Fn+↓ Page down

Fn+Del Backspace

Print Screen: Fn + F2

IMPORTANT The Mobile Console cannot access image files saved to the Memory Card.

The current display on the LCD screen can be converted to an image file and

saved to the Memory Card. The image will be saved with the date and time as

the file name.

Use a computer to access the image files.

10

Page 34

Stylus Section 1-4

1-4 Stylus

1-4-1 Stylus

The Mobile Console has a stylus that can be stored in a special holder on the

back of the Console.

Note (1) Use the enclosed stylus for touch screen operations. Using a sharp object

may scratch the touch screen surface so that the screen cannot be used

for inputs.

(2) Do not press hard on or rub the touch screen surface. Doing so may not

only cause damage but may break the glass.

11

Page 35

External Connectors Section 1-5

1-5 External Connectors

The Mobile Console is equipped with a USB port for connection to external

devices. (It also has a LAN port that is for future expansion.)

1-5-1 External Connectors

To connect a USB cable, remove the protective cap covering the connector

and connect the cable.

LAN port (for future expansion)

USB port

USB Communications Connector

Connect the USB communications connector to the USB port of a NE1Aseries Controller. USB version 1.1 is supported. Use a commercially available

USB cable.

IMPORTANT Make sure that the USB cable is less than 3 m.

LAN Connector

The LAN connector cannot be used. It will be used for future expansion.

Protective caps

12

Page 36

Starting and Stopping the Mobile Console and Standby Mode Section 1-6

1-6 Starting and Stopping the Mobile Console and Standby

Mode

1-6-1 Starting and Stopping the Mobile Console

The Mobile Console will start when the power switch is turned ON. It will stop

when the power switch is turned OFF.

OFF

1-6-2 Standby Modes

ON

Power switch

Standby

mode

Suspended

Mode

Deep Sleep

Mode

The Mobile Console has two standby modes to reduce the rate of consumption of charge in the battery pack. The standby modes are the Suspended

Mode and the Deep Sleep Mode.

Description Setting method Recovery

The Mobile Console is held in the

state it was before it was suspended.

It can be returned to the original state

quickly.

Consumption of battery is even lower

than in Suspended Mode, however

the state of the Mobile Console will

not be held.

1. Hold down the Power Mode Key

or

2. Leave the Mobile Console with the

power turned ON for the set time

without using it (20 min max.).

(See note 2.)

Leave the Mobile Console in Suspended Mode for the set time without

using it (15 min max.). (See note 2.)

method

Press the

Power

Mode Key

Press the

Power

Mode Key

holding time

(See note 1.)

64 hours

1,000 hours

Note (1) The battery holding time is the estimated maximum time that the Mobile

Console can hold the mode if the battery is fully charged. The actual time

will vary with the operating environment and the state of the battery.

(2) Refer to 2-2-6 Power Management Settings for the setting method.

IMPORTANT Turn OFF the power switch if the Mobile Console will not be used for a long

period of time.

Battery

13

Page 37

Starting and Stopping the Mobile Console and Standby Mode Section 1-6

1-6-3 Status Indicators

The power supply mode and amount of charge left in the main battery can be

checked using LED indicators.

Battery charge indicator

Power status indicator

Power Mode

The power mode can be identified according to the combination of the power

status indicator and the battery charge indicator.

Status Power status indicator Battery charge indicator

Power ON Lit Lit

Suspended Mode Not lit Lit

Deep Sleep Mode Not lit Not lit

Power OFF Not lit Not lit

Battery Power

The color of the battery charge indicator changes with the amount of charge

left in the battery pack. A message will be displayed saying that the remaining

charge is low when the remaining charge falls below 10%.

Battery charge

indicator

Green indicator Approx. 70% to 100% --Orange indicator Approx. 30% to 70% To continue using the Mobile Console,

Red indicator Approx. 0% to 30% Immediately replace the battery. After a

Battery power Notes

replace the battery. After an orange indicator, the battery will be exhausted after

about 3.5 hours. (See note.)

red indicator, the battery will be

exhausted after about 1 hour. (See note.)

Note The times are estimates and are provided only as guidelines. The

actual time will depend on the operating environment and operating

conditions.

14

Page 38

Using the Battery Pack Section 1-7

r

1-7 Using the Battery Pack

The RB-B2001A Battery Pack must be used.

IMPORTANT Make sure that the power switch is turned OFF before you install or replace

the battery pack.

1-7-1 Replacing the Battery Pack

1,2,3... 1. Turn OFF the power switch.

2. Slide the lock lever on the back in the direction indicated by the arrow to

unlock the battery cover.

Lock leve

3. Lightly press the grip section of the battery cover and slide it in the direction

indicated by the arrow to remove it.

(1)

(2)

4. Pull out the battery stopper.

Battery stopper

5. Slide the battery pack in the direction indicated by the arrow to remove it.

15

Page 39

Using the Battery Pack Section 1-7

(2)

(1)

6. Insert a charged battery pack and slide it in the direction indicated by the

arrow.

(1)

(2)

7. Place the battery stopper firmly in place.

8. Replace the battery cover.

16

9. Slide the lock lever in the direction indicated by the arrow to lock the battery

cover.

Page 40

Using the Battery Pack Section 1-7

1-7-2 Charging the Battery

The battery must be charged when using the Mobile Console for the first time

or if it has not been used for a long time

1,2,3... 1. Insert the cable into the charger.

2. Insert the AC plug of the cable into an AC socket.

3. Insert the battery pack into the charger. The charger indicator will turn ON

when charging starts.

Charger Indicator

Color Status Meaning

--- Battery is not inserted.

Green Charging complete

Charger indicator

Red Charging

Error

: Lit : Flashing : Not lit

4. Charging the battery has been completed when the green indicator turns

ON.

Note The battery takes approximately 3 hours to recharge depending on the oper-

ating environment, operating conditions, and the state of the battery.

IMPORTANT Make sure that the temperature is between 0 and 40

°C, that the humidity is

between 20% and 85%, and that there is no condensation. The battery may

not charge fully in conditions outside these ranges. It may also damage the

battery pack.

IMPORTANT The capacity of the battery reduces to approximately 60% of its original state

after recharging it 300 times. Replace the Battery Pack if the charge only lasts

for a short time.

17

Page 41

Using the Battery Pack Section 1-7

IMPORTANT When disposing of the Battery Pack, insulate the plus (+) and minus (−) termi-

nals of the battery with tape.

• Follow all local government regulations as applicable when disposing of

the Battery Pack.

• The Battery Pack is a lithium-ion secondary battery. Please recycle it.

!WARNING

If the charge indicator is flashing red, or if charging does not finish even though

the specified time has been exceeded, stop charging and remove the power

plug from the outlet. Failure to do so may occasionally result in serious personal injury or fire due to leakage, rupture, combustion, or heat generation.

Using other devices may occasionally result in serious personal injury or fire

due to leakage, rupture, combustion, or heat generation.

Do not use the Charger for charging any Battery Pack other than the one specified by OMRON.

18

Page 42

Using the Memory Card Section 1-8

d

1-8 Using the Memory Card

The following data is saved in the Memory Card.

• Data to be downloaded to or uploaded from connected devices.

• Images of the screen captured by the print screen function of the Mobile

Console.

Note Use the following OMRON Memory Cards.

• HMC-EF183 128 MB

• HMC-EF283 256 MB

• HMC-EF583 512 MB

1-8-1 Inserting the Memory Card

1,2,3... 1. Pull out the slot cover for the Memory Card on the Mobile Console.

2. Insert the Memory Card into the slot.

3. Return the slot cover to its original position.

Memory Car

19

Page 43

Using the Memory Card Section 1-8

1-8-2 Removing the Memory Card

1,2,3... 1. Pull out the slot cover on the Mobile Console for the Memory Card.

2. The eject lever will be extended if it is pressed in. Press it again to eject the

Memory Card.

Push

3. Pull out the Memory Card by grabbing it with your fingers.

Memory Card

Pull

4. Close the slot cover.

Push

20

Page 44

Replacing the Clock Battery Section 1-9

y

1-9 Replacing the Clock Battery

1-9-1 Replacing the Clock Battery

The Mobile Console uses a battery for the clock to keep the date and time settings when the battery pack is being replaced. If the clock settings are lost,

replace the clock battery with the following procedure.

1,2,3... 1. Remove the stylus.

2. Undo the two screws on the back of the Mobile Console using a Phillips

screwdriver. (Screw size: M2

× 8.)

3. Place your finger where the stylus is inserted and pull off the clock battery

cover.

4. Press the clock battery in the holder as if to insert it and then remove it.

1. Press in

2. Remove

Clock batter

21

Page 45

Replacing the Clock Battery Section 1-9

5. Place a new battery in the holder.

6. Replace the clock battery cover and secure it with the screws.

Clock Battery Model

Use a BR2032 Coin Lithium Battery as the clock battery.

Product specifications BR2032 Coin Type Lithium Battery

Voltage: 3 V

Dimensions: 20.0 (diameter) × 3.2 mm (thickness)

Recommended battery Panasonic Corporation model

IMPORTANT When disposing of the battery, insulate the plus (+) and minus (

the battery with tape. Follow all local government regulations as applicable

when disposing of the battery.

−) terminals of

22

Page 46

Attaching the Hand Strap Section 1-10

p

1-10 Attaching the Hand Strap

A strap can be attached to the Mobile Console for holding the Console. Attach

the strap to the strap hooks for either a left-hand or right-hand grip.

1-10-1 Strap Position

Strap hooks

Holding in the Right Hand Holding in the Left Hand

1-10-2 Attaching the Strap

1,2,3... 1. Thread the strap through the strap hooks for a left-hand or right-hand grip.

2. Fold the ends of the strap over the strap hooks and secure them with the

adjusters.

3. Adjust the length of the strap.

Strap

Strap

Strap hooks

Adjuster

hooks

Stra

23

Page 47

Attaching the Hand Strap Section 1-10

24

Page 48

SECTION 2

Screen Names and Console Settings

This section describes the names of functions of elements on the Mobile Console screen and describes system settings for

the Mobile Console.

2-1 Screen Names and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-1-1 Main Window . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2-1-2 Function Icons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2-2 Console Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-1 Setting the Monitor Refresh Time . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-2 Adjusting the Brightness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2-2-3 Formatting the Memory Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2-2-4 Setting the Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

2-2-5 Setting the Stylus Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2-2-6 Power Management Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2-2-7 Language Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

2-2-8 Displaying the Version Information . . . . . . . . . . . . . . . . . . . . . . . . . 35

25

Page 49

Screen Names and Functions Section 2-1

2-1 Screen Names and Functions

2-1-1 Main Window

When the Mobile Console power supply is turned ON, the Main Window will

be displayed on the screen. Icons for functions supported by the Mobile Console and information about connected DeviceNet Safety Devices will be displayed.

Device Information

The node address and model of the connected

DeviceNet Safety Device is displayed. This information

is not displayed if a device is not connected.

Connect Icon

Tap the Connect Icon

when connecting to the

USB port on another

device.

Function Menu

Tap an icon to execute a function.

If a device is not connected,

online functions will be displayed

in gray, as shown in this example.

They cannot be used.

Page

The current page number

of the Function Menu is

displayed.

Device Status

The status of the connected

device is indicated using

different colors.

Tap the Arrow Key to

scroll to the next page

of the Function Menu.

Main Window When Connected to A DeviceNet Safety Device

26

Main Window When Connected Online to a DeviceNet Safety Device

Page 50

Screen Names and Functions Section 2-1

2-1-2 Function Icons

Icon Function name Description Reference

Monitor Displays the connected device's I/O terminal status. Errors

occurring at the connected device will be displayed on the Maintenance Tab Page.

3-2-2

Device Status Displays the device status as well as details of alarms and warn-

Change Target This function is used to change the connected device. 3-1-3

Error History Displays the error history of the connected device. Errors occur-

Upload Uploads parameters from the connected device and saves them

Device Property Displays the properties of the connected device. 3-2-5

Download Device parameters copied to the Memory Card are downloaded

Replace Device Device parameters uploaded from the connected device are

DeviceNet Safety System Functions (Online Functions)

Change Mode Changes the operating mode of the connected device. 3-7

ings. Errors occurring at the connected device will be displayed

on the Maintenance Tab Page.

ring at the connected device will be displayed on the Maintenance Tab Page.

to the Memory Card.

to the connected device.

downloaded after replacing the device.

This function cannot be used if a system error occurs due to a

fatal hardware error in the device that is being replaced.

3-2-3

3-2-4

3-4

3-5

3-3

Lock

Unlock

Reset Resets the connected device. 3-6

Locks or unlocks the connected device. 3-8

27

Page 51

Screen Names and Functions Section 2-1

Icon Function name Description Reference

Monitor Settings Sets the time interval for refreshing data displayed by the monitor

function.

Brightness The brightness of the screen can be selected from three levels 2-2-2

2-2-1

Console Settings

Memory Card

Format

Date/Time This function is used to set the date and time. 2-2-4

Stylus This function is used to set the double-tap speed and to calibrate

Power Management

Language This function is used to set the language used by the Mobile

Version Displays the Mobile Console version information. 2-2-8

This function is used to format a Memory Card. 2-2-3

2-2-5

the touch screen.

This function is used to set the power saving features. 2-2-6

2-2-7

Console.

Note Refer to 3-2-6 Saving the Screen Image for information on saving the screen

image showing monitor results (Fn + F2 Keys).

28

Page 52

Console Settings Section 2-2

2-2 Console Settings

Set the Mobile Console using the functions on pages 3 and 4 of the Main Window.

2-2-1 Setting the Monitor Refresh Time

Set the monitor refresh timer value for the data acquired by the monitor function.

1,2,3... 1. Tap the Monitor Settings Icon in the Main Window (3/4).

The following dialog box will be displayed.

2. Set the new refresh timer value and tap the OK Button.

The new setting will be applied and the display will return to the Main Win-

dow.

2-2-2 Adjusting the Brightness

The brightness of the screen can be adjusted to one of three levels.

1,2,3... 1. Tap the Brightness Icon in the Main Window (3/4).

The following dialog box will be displayed.

29

Page 53

Console Settings Section 2-2

2. Move the pointer on the brightness scale with the stylus to adjust the

brightness.

3. Tap the OK Button.

The setting will be applied and the display will return to the Main Window.

2-2-3 Formatting the Memory Card

The Memory Card can be formatted.

1,2,3... 1. Insert the Memory Card to be formatted into the Mobile Console.

2. Tap the Memory Card Format Icon in the Main Window (3/4).

The following dialog box will be displayed.

3. After selecting the file system, tap the Start Button.

A confirmation dialog box will be displayed.

4. Tap the Yes Button.

Formatting will start. When formatting the Memory Card has been com-

pleted, the following dialog box will be displayed.

5. Tap the OK Button.

The display will return to the Memory Card Format Dialog Box.

6. If you are finished formatting Memory Cards, tap the Cancel Button.

30

Page 54

Console Settings Section 2-2

The display will return to the Main Window.

Note To format another Memory Card, insert the Memory Card and repeat the

above procedure from step 3.

IMPORTANT All of the data will be deleted from the Memory Card when you format it. Be

sure to copy any required data to a computer before you format the Memory

Card.

2-2-4 Setting the Date and Time

Set the current date, time, and time zone.

Make sure that the date and time settings are correct because the file names

of the screen images captured by the print screen function will consist of date

and time stamps.

1,2,3... 1. Tap the Date/Time Icon in the Main Window (3/4).

The following dialog box will be displayed.

2. Set the current date, time, and time zone.

3. Tap the OK Button.

The settings will be applied and the display will return to the Main Window.

31

Page 55

Console Settings Section 2-2

2-2-5 Setting the Stylus Properties

This function is used to set the double-tap speed and calibrate the touch

screen.

1,2,3... 1. Tap the Stylus Icon in the Main Window (3/4).

The following dialog box will be displayed.

2. Double-tap the checkerboard to set the double-tap speed, then double-tap

the icon at the bottom right of the dialog box to test the settings.

3. To calibrate the touch screen, tap the Calibration Ta b.

4. Tap the Recalibrate Button and follow the instructions that are displayed

on the screen.

32

Page 56

Console Settings Section 2-2

When the instructions have been completed, the following display will appear.

5. Press the OK Key or tap the screen.

The settings will be applied and the display will return to the Stylus Properties Dialog Box.

2-2-6 Power Management Settings

The following parameters can be adjusted to reduce the energy consumed by

the Mobile Console.

• Time until backlight is turned OFF.

• Time from when the backlight turns OFF until entering Suspended Mode.

• Time from entering Suspended Mode until entering Deep Sleep Mode.

1,2,3... 1. Touch the Power Management Icon in the Main Window (3/4).

The following dialog box will be displayed.

2. Set the time until turning OFF the backlight, the time from turning OFF the

backlight until entering Suspended Mode, and the time from entering Suspended Mode until entering Deep Sleep Mode.

3. Tap the OK Button.

The settings will be applied and the display will return to the Main Window.

33

Page 57

Console Settings Section 2-2

2-2-7 Language Settings

Select the language used for the display on the Mobile Console.

Japanese or English can be selected.

1,2,3... 1. Tap the Language Icon in the Main Window (4/4).

The following dialog box will be displayed.

2. Tap the Yes Button.

3. Select the desired language and tap the OK Button.

4. Tap the OK Button.

The setting will be applied when the Mobile Console is restarted. The dis-

play will return to the Main Window.

34

Page 58

Console Settings Section 2-2

2-2-8 Displaying the Version Information

Version information for the Mobile Console can be displayed.

1,2,3... 1. Tap the Version Icon in the Main Window (4/4).

The version information will be displayed.

2. Tap the OK Button.

The display will return to the Main Window.

35

Page 59

Console Settings Section 2-2

36

Page 60

SECTION 3

Online Operations

This section describes how to read device information, replace devices, and otherwise perform device operations online.

3-1 Basic Online Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-1-1 Connecting the Mobile Console . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-1-2 Specifying Network Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3-1-3 Changing the Connected Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3-1-4 Inputting Characters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3-2 Reading Device Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-2-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3-2-2 Reading Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3-2-3 Reading Device Status, Alarms, and Warning Information . . . . . . . 44

3-2-4 Reading the Error History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3-2-5 Displaying Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

3-2-6 Saving the Screen Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3-3 Replacing a Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3-4 Uploading Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

3-5 Downloading Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-5-1 Creating Device Parameter Files . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-5-2 Downloading the File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

3-6 Resetting a Device. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-6-1 Reset Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

3-6-2 Resetting a Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3-7 Changing the Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

3-8 Locking/Unlocking Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

37

Page 61

Basic Online Operations Section 3-1

3-1 Basic Online Operations

This section describes the procedure for online operations. Make sure that

you read through the material before performing online operations.

3-1-1 Connecting the Mobile Console

The Mobile Console can be used by connecting it to the USB port on an

NE0A/NE1A-series Controller.

When the Mobile Console is connected to the USB port of an NE0A/NE1Aseries Controller, the following Main Window will be displayed. The device status will be displayed in the Main Window.

Connect Icon

Tap the Connect Icon when the Mobile Console is

reconnected to the USB port of a different NE0A/NE1Aseries Controller.

Device Status

Note If the USB cable is removed and reconnected to a different NE0A/NE1A-

series Controller after the Mobile Console has been connected online, tap the

Connect Icon.

Device Status

The device status is indicated by the following colors.

Color Status