Page 1

Cat. No. Z912-E1-01

NE1A Series

NE1A-EDR01

EtherNet/IP-DeviceNet Router

OPERATION MANUAL

Page 2

NE1A Series EtherNet/IP-DeviceNet Router: NE1A-EDR01

Operation Manual

Produced July 2007

Page 3

iv

Page 4

Notice:

OMRON products are manufactured for use according to proper procedures by a qualified operator

and only for the purposes described in this manual.

The following conventions are used to indicate and classify precautions in this manual. Always heed

the information provided with them. Failure to heed precautions can

result in injury to people or damage to property.

!WARNING Indicates a potentially hazardous situation which, if not avoided, will result in minor or

moderate injury, or may result in serious injury or death. Additionally, there may be significant property damage.

!Caution Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury, or property damage.

Indicates general prohibitions for which there is no specific symbol.

Indicates general mandatory actions for which there is no specific symbol.

OMRON Product References

All OMRON products are capitalized in this manual. The word “Unit” is also capitalized when it refers to

an OMRON product, regardless of whether or not it appears in the proper name of the product.

The abbreviation “PLC” means Programmable Controller. “PC” is used, however, in some Programming Device displays to mean Programmable Controller.

Visual Aids

The following headings appear in the left column of the manual to help you locate different types of

information.

IMPORTANT Indicates important information on what to do or not to do to prevent failure to

operation, malfunction, or undesirable effects on product performance.

Note Indicates information of particular interest for efficient and convenient opera-

tion of the product.

1,2,3... 1. Indicates lists of one sort or another, such as procedures, checklists, etc.

v

Page 5

Trademarks and Copyrights

r

f

CIP, EtherNet/IP, DeviceNet, and DeviceNet Safety are registered trademarks of the Open DeviceNet

Vendors Association.

Windows is a registered trademark of Microsoft Corporation.

Other product names and company names in this manual are trademarks or registered trademarks of

their respective companies.

OMRON, 2007

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form, o

by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior written permission o

OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because OMRON is constantly striving to improve its high-quality products, the information contained in this manual is subject to change without

notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility

for errors or omissions. Neither is any liability assumed for damages resulting from the use of the information contained in

this publication.

vi

Page 6

TABLE OF CONTENTS

PRECAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

1 Intended Audience. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Precautions for Safe Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Regulations and Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

SECTION 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1 EtherNet/IP-DeviceNet Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-2 Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 2

Installation and Network Connections . . . . . . . . . . . . . . . . . 5

2-1 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-3 Connecting to DeviceNet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

2-4 Connecting to Ethernet (EtherNet/IP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-5 ED Router Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 3

Status Indicators and Troubleshooting. . . . . . . . . . . . . . . . . 25

3-1 Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-2 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-3 Error History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

SECTION 4

Accessing Devices by UDP . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-2 Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4-3 Operating Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-4 Mitsubishi Ethernet Interface Module Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-5 Sample Ladder Programs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

4-6 NE1A Series Monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

4-7 DST1 Series Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66

Appendices

A Specifications and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

B Settings from the Network Configurator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

vii

Page 7

TABLE OF CONTENTS

viii

Page 8

About this Manual:

This manual describes the installation and operation of the NE1A-EDR01 EtherNet/IP-DeviceNet

Router. The NE1A-EDR01 EtherNet/IP-DeviceNet Router was developed using OMRON‘s advanced

control technology and vast know-how. It functions to route FA data between EtherNet/IP and

DeviceNet networks.

Please read this manual carefully and be sure you understand the information provided before

attempting to install or operate the NE1A-EDR01 EtherNet/IP-DeviceNet Router. The following manuals are also related to the NE1A-EDR01 EtherNet/IP-DeviceNet Router or NE1A-series Safety Network Controllers. Refer to these manuals as required during installation and operation.

EtherNet/IP-DeviceNet Router Operation Manual (this manual) (Z912)

This manual describes the specifications, functions, and application methods of the EtherNet/IPDeviceNet Router in detail.

DeviceNet Safety System Configuration Manual (Z905)

This manual explains how to configure the DeviceNet Safety system using the Network Configurator.

DeviceNet Safety NE1A Series Safety Network Controller Operation Manual (Z906)

This manual describes the specifications, functions, and usage of the NE1A-SCPU01 and NE1ASCPU02.

DeviceNet Safety Safety I/O Terminal Operation Manual (Z904)

This manual describes the DST1-series Slave models, specifications, functions, and application methods in detail.

DeviceNet Operation Manual (W267)

This manual describes the construction and connection of a DeviceNet network. It provides detailed

information on the installation and specifications of cables, connectors, and other peripheral equipment used in the network, and on the supply of communications power. Obtain this manual and gain a

firm understanding of its contents before using a DeviceNet system.

ix

Page 9

x

Page 10

Read and Understand this Manual

Please read and understand this manual before using the product. Please consult your OMRON

representative if you have any questions or comments.

Warranty and Limitations of Liability

WARRANTY

OMRON's exclusive warranty is that the products are free from defects in materials and workmanship for a

period of one year (or other period if specified) from date of sale by OMRON.

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, REGARDING NONINFRINGEMENT, MERCHANTABILITY, OR FITNESS FOR PARTICULAR PURPOSE OF THE

PRODUCTS. ANY BUYER OR USER ACKNOWLEDGES THAT THE BUYER OR USER ALONE HAS

DETERMINED THAT THE PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR

INTENDED USE. OMRON DISCLAIMS ALL OTHER WARRANTIES, EXPRESS OR IMPLIED.

LIMITATIONS OF LIABILITY

OMRON SHALL NOT BE RESPONSIBLE FOR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES,

LOSS OF PROFITS OR COMMERCIAL LOSS IN ANY WAY CONNECTED WITH THE PRODUCTS,

WHETHER SUCH CLAIM IS BASED ON CONTRACT, WARRANTY, NEGLIGENCE, OR STRICT

LIABILITY.

In no event shall the responsibility of OMRON for any act exceed the individual price of the product on which

liability is asserted.

IN NO EVENT SHALL OMRON BE RESPONSIBLE FOR WARRANTY, REPAIR, OR OTHER CLAIMS

REGARDING THE PRODUCTS UNLESS OMRON'S ANALYSIS CONFIRMS THAT THE PRODUCTS

WERE PROPERLY HANDLED, STORED, INSTALLED, AND MAINTAINED AND NOT SUBJECT TO

CONTAMINATION, ABUSE, MISUSE, OR INAPPROPRIATE MODIFICATION OR REPAIR.

xi

Page 11

Application Considerations

SUITABILITY FOR USE

OMRON shall not be responsible for conformity with any standards, codes, or regulations that apply to the

combination of products in the customer's application or use of the products.

At the customer's request, OMRON will provide applicable third party certification documents identifying

ratings and limitations of use that apply to the products. This information by itself is not sufficient for a

complete determination of the suitability of the products in combination with the end product, machine,

system, or other application or use.

The following are some examples of applications for which particular attention must be given. This is not

intended to be an exhaustive list of all possible uses of the products, nor is it intended to imply that the uses

listed may be suitable for the products:

• Outdoor use, uses involving potential chemical contamination or electrical interference, or conditions or

uses not described in this manual.

• Nuclear energy control systems, combustion systems, railroad systems, aviation systems, medical

equipment, amusement machines, vehicles, safety equipment, and installations subject to separate

industry or government regulations.

• Systems, machines, and equipment that could present a risk to life or property.

Please know and observe all prohibitions of use applicable to the products.

NEVER USE THE PRODUCTS FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO

ADDRESS THE RISKS, AND THAT THE OMRON PRODUCTS ARE PROPERLY RATED AND INSTALLED

FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

PROGRAMMABLE PRODUCTS

OMRON shall not be responsible for the user's programming of a programmable product, or any

consequence thereof.

xii

Page 12

Disclaimers

CHANGE IN SPECIFICATIONS

Product specifications and accessories may be changed at any time based on improvements and other

reasons.

It is our practice to change model numbers when published ratings or features are changed, or when

significant construction changes are made. However, some specifications of the products may be changed

without any notice. When in doubt, special model numbers may be assigned to fix or establish key

specifications for your application on your request. Please consult with your OMRON representative at any

time to confirm actual specifications of purchased products.

DIMENSIONS AND WEIGHTS

Dimensions and weights are nominal and are not to be used for manufacturing purposes, even when

tolerances are shown.

PERFORMANCE DATA

Performance data given in this manual is provided as a guide for the user in determining suitability and does

not constitute a warranty. It may represent the result of OMRON's test conditions, and the users must

correlate it to actual application requirements. Actual performance is subject to the OMRON Warranty and

Limitations of Liability.

ERRORS AND OMISSIONS

The information in this manual has been carefully checked and is believed to be accurate; however, no

responsibility is assumed for clerical, typographical, or proofreading errors, or omissions.

xiii

Page 13

xiv

Page 14

PRECAUTIONS

1 Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

2 General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

3 Precautions for Safe Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvi

4 Regulations and Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

xv

Page 15

Intended Audience 1

1 Intended Audience

This manual is intended for the following personnel, who must have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA and safety systems into production

facilities

• Personnel in charge of designing FA and safety systems

• Personnel in charge of managing FA facilities

• Personnel who have the qualifications, authority, and obligation to provide

safety during each of the following product phases: mechanical design,

installation, operation, maintenance, and disposal

2 General Precautions

The user must operate the product according to the performance specifications described in the operation manuals.

Before using the product under conditions which are not described in the

manual or applying the product to nuclear control systems, railroad systems,

aviation systems, vehicles, combustion systems, medical equipment, amusement machines, safety equipment, and other systems, machines, and equipment that may have a serious influence on lives and property if used

improperly, consult your OMRON representative.

Make sure that the ratings and performance characteristics of the product are

sufficient for the systems, machines, and equipment, and be sure to provide

the systems, machines, and equipment with double safety mechanisms.

This manual provides information for programming and operating the Unit. Be

sure to read this manual before attempting to use the Unit and keep this manual close at hand for reference during operation.

!WARNING It is extremely important that a PLC and all PLC Units be used for the speci-

fied purpose and under the specified conditions, especially in applications that

can directly or indirectly affect human life. You must consult with your OMRON

representative before applying a PLC System to the above-mentioned applications

3 Precautions for Safe Use

■ Handling with Care

Do not drop the EtherNet/IP-DeviceNet Router or subject it to excessive vibration or mechanical shock. The EtherNet/IP-DeviceNet Router may be damaged and may not function properly.

■ Installation and Storage Environment

Do not use or store the EtherNet/IP-DeviceNet Router in any of the following

locations:

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the range specified

in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

xvi

Page 16

Precautions for Safe Use 3

• Locations subject to water, oil, or chemicals

• Locations subject to shock or vibration

Take appropriate and sufficient measures when installing systems in the following locations. Inappropriate and insufficient measures may result in malfunction.

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

■ Installation and Mounting

• Use the EtherNet/IP-DeviceNet Router within an enclosure with IP54 protection or higher according to IEC/EN 60529.

• Use DIN rail (TH35-7.5/TH35-15 according to IEC 60715) to install the

EtherNet/IP-DeviceNet Router into the control panel. Mount the EtherNet/

IP-DeviceNet Router to the DIN rail using PFP-M End Plates (not included

with the EtherNet/IP-DeviceNet Router) to prevent it falling off the DIN rail

because of vibration.

• Space must be provided around the EtherNet/IP-DeviceNet Router, at

least 5 mm from its side and at least 50 mm from its top and bottom surfaces, for ventilation and wiring.

■ Installation and Wiring

• Use the following to wire external I/O devices to the EtherNet/IPDeviceNet Router.

Solid wire

Stranded (flexible) wire

0.2 to 2.5 mm

0.34 to 1.5 mm2 (AWG 22 to AWG 16)

Stranded wires should be prepared by attaching insulated bar

terminals (DIN 46228-4 standard compatible) to the ends before

connecting them.

2

(AWG 24 to AWG 12)

• Disconnect the EtherNet/IP-DeviceNet Router from the power supply

before starting wiring.

• Properly apply the specified voltage to the EtherNet/IP-DeviceNet Router

inputs. Applying an inappropriate DC voltage or any AC voltage may interfere with functionality, may reduce safety, or may cause the EtherNet/IPDeviceNet Router to be damaged or burnt.

• Be sure to separate the communications cables and I/O cables from near

high-voltage/high-current lines.

• Be cautious not to get your fingers caught when attaching connectors to

the plugs on the EtherNet/IP-DeviceNet Router.

• Tighten the DeviceNet connector screws correctly (0.25 to 0.3 N·m).

• Incorrect wiring may lead to loss of safety functions. Wire conductors correctly and verify the operation of the EtherNet/IP-DeviceNet Router before

using the system in which the EtherNet/IP-DeviceNet Router is incorporated.

• After wiring is completed, be sure to remove label for wire clipping prevention on the EtherNet/IP-DeviceNet Router to enable heat to escape or

proper cooling.

■ Power Supply Selection

Use a DC power supply satisfying the following requirements.

xvii

Page 17

Regulations and Standards 4

• The secondary circuits of the DC power supply must be isolated from the

primary circuit by double insulation or reinforced insulation.

• The DC power supply must satisfy the requirements for class 2 circuits or

limited voltage/current circuits given in UL 508.

• The output hold time must be 20 ms or longer.

■ Periodic Inspections and Maintenance

• Disconnect the EtherNet/IP-DeviceNet Router from the power supply

before replacing the EtherNet/IP-DeviceNet Router. Devices connected to

the EtherNet/IP-DeviceNet Router may operate unexpectedly.

• Do not disassemble, repair, or modify the EtherNet/IP-DeviceNet Router.

Doing so may lead to loss of safety functions.

■ Disposal

• Be cautions not to injure yourself when dismantling the EtherNet/IPDeviceNet Router.

4 Regulations and Standards

The EtherNet/IP-DeviceNet Router has been certified as follows:

Certifying organization Standards

UL UL508, UL1604,

CSA22.2 No142, CSA22.2 No213

xviii

Page 18

This section introduced the EtherNet/IP-DeviceNet Router and it’s functionality.

1-1 EtherNet/IP-DeviceNet Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-1-1 Accessing All Devices on a Network from a Network Configurator 2

1-1-2 Monitoring DeviceNet or DeviceNet Safety Systems via Ethernet

from Controllers Made by Other Manufacturers . . . . . . . . . . . . . . . 3

1-2 Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION 1

Overview

1

Page 19

EtherNet/IP-DeviceNet Router Section 1-1

r

1-1 EtherNet/IP-DeviceNet Router

The NE1A-EDR01 EtherNet/IP-DeviceNet Router is an FA router with one

Ethernet port and one DeviceNet port, and is used for routing messages

between Ethernet and DeviceNet Networks. In this manual the NE1A-EDR01

EtherNet/IP-DeviceNet Router is called the “ED Router.”

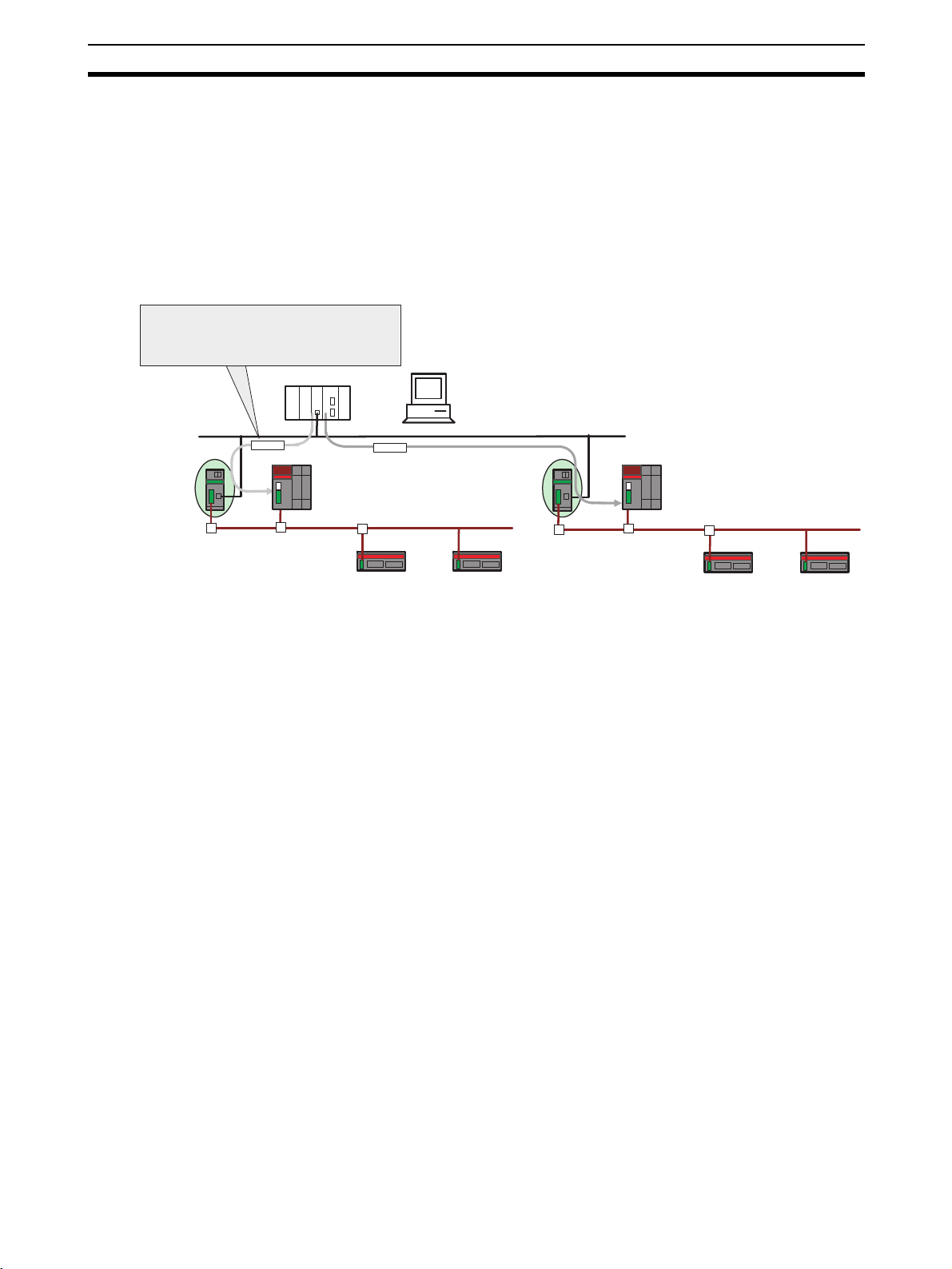

1-1-1 Accessing All Devices on a Network from a Network Configurator

Using an ED Router makes it possible to set devices, such as NE1A-series

Controllers and DST1-series Slaves, from a Network Configurator running on

a PC connected to an Ethernet or EtherNet/IP Network.

In addition, when multiple DeviceNet or DeviceNet Safety Networks are configured for an Ethernet or EtherNet/IP connection using an ED Router, it is

possible to set devices such as NE1A-series Controllers and DST1-series

Slaves connected to another DeviceNet or DeviceNet Safety network from a

Network Configurator running on a PC connected to a DeviceNet or NE1Aseries USB port.

Network

Configurator

Ethernet (EtherNet/IP)

ED Router

(NE1A-EDR01)

Network

USB

DeviceNet Safety

Configurator

DeviceNet Safety

DST1-series Slaves

NE1A Safety Network

Controller

DeviceNet Safety

DeviceNet Safety

DST1-series Slaves

Network

Configurato

Note (1) To access other networks, use the NE1A-SCPU01-V1 (unit version 2.0 or

later) or the NE1A-SCPU02 (unit version 2.0 or later) to connect the Network Configurator.

(2) To access other networks, use Network Configurator version 2.0@ or

higher.

2

Page 20

EtherNet/IP-DeviceNet Router Section 1-1

1-1-2 Monitoring DeviceNet or DeviceNet Safety Systems via Ethernet

from Controllers Made by Other Manufacturers

Devices on a DeviceNet or DeviceNet Safety network can be accessed from

general-purpose controllers (e.g., PLCs or computers) in an Ethernet network

using the UDP service.

This enables monitoring a DeviceNet or DeviceNet Safety control system via

Ethernet from a machine controller or monitor computer that does not support

a DeviceNet interface. This can be used to easily add a DeviceNet Safety control system to an existing system.

Safety controls can be monitored by accessing

devices on the DeviceNet Safety network using the

UDP service from a general-purpose controller on

the Ethernet network (e.g., a PLC or computer).

PLC (OMRON or other maker)

OR

Computer

ED Router

(NE1A-EDR01)

Command via UDP

Ethernet

Command via UDP

DeviceNet Safety

Socket service (UDP)

DeviceNet Safety

DST1-series Slaves

NE1A Safety Network Controller

DeviceNet Safety

DeviceNet Safety

DST1-series Slaves

3

Page 21

Nomenclature Section 1-2

1-2 Nomenclature

The following illustration shows the part names of the ED Router.

Status indicators

DeviceNet node

address switches

DeviceNet

communications connector

Power supply connector

7-segment display

EtherNet/IP

IP address switches

Service switch

DeviceNet communications

baud rate switch

Ethernet connector

Ground connector

4

Page 22

Installation and Network Connections

This section describes how to install and connect the networks.

2-1 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-1 Requirements for Installation and Wiring . . . . . . . . . . . . . . . . . . . . 6

2-1-2 Mounting to the Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1-3 ED Router Dimensions and Weight . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-2-1 General Instructions on Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-2-2 Wiring the Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2-2-3 DeviceNet Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2-2-4 Ethernet (EtherNet/IP) Network Installation . . . . . . . . . . . . . . . . . . 12

2-3 Connecting to DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3-1 Setting the DeviceNet Node Address . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3-2 Setting the DeviceNet Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2-3-3 DeviceNet Node Address and Baud Rate Software Settings . . . . . . 17

2-4 Connecting to Ethernet (EtherNet/IP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4-1 Setting the IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2-4-2 TCP/IP Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2-5 ED Router Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2-5-1 Setting the UDP Port Address and the Address Displayed at the ED

Router . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

SECTION 2

5

Page 23

Installation Section 2-1

2-1 Installation

2-1-1 Requirements for Installation and Wiring

Take the following into account during installation to improve the reliability of

the system and to fully utilize the system's capabilities.

Installation and

Storage Environment

Do not use or store the ED Router in the following locations.

• Locations subject to direct sunlight

• Locations subject to temperatures or humidity outside the ranges specified in the specifications

• Locations subject to condensation as the result of severe changes in temperature

• Locations subject to corrosive or flammable gases

• Locations subject to dust (especially iron dust) or salts

• Locations subject to water, oil, or chemicals

• Locations subject to shock or vibration

Take appropriate and sufficient measures when installing systems in the following locations. Inappropriate and insufficient measures may result in malfunction.

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electromagnetic fields

• Locations subject to possible exposure to radioactivity

• Locations close to power supplies

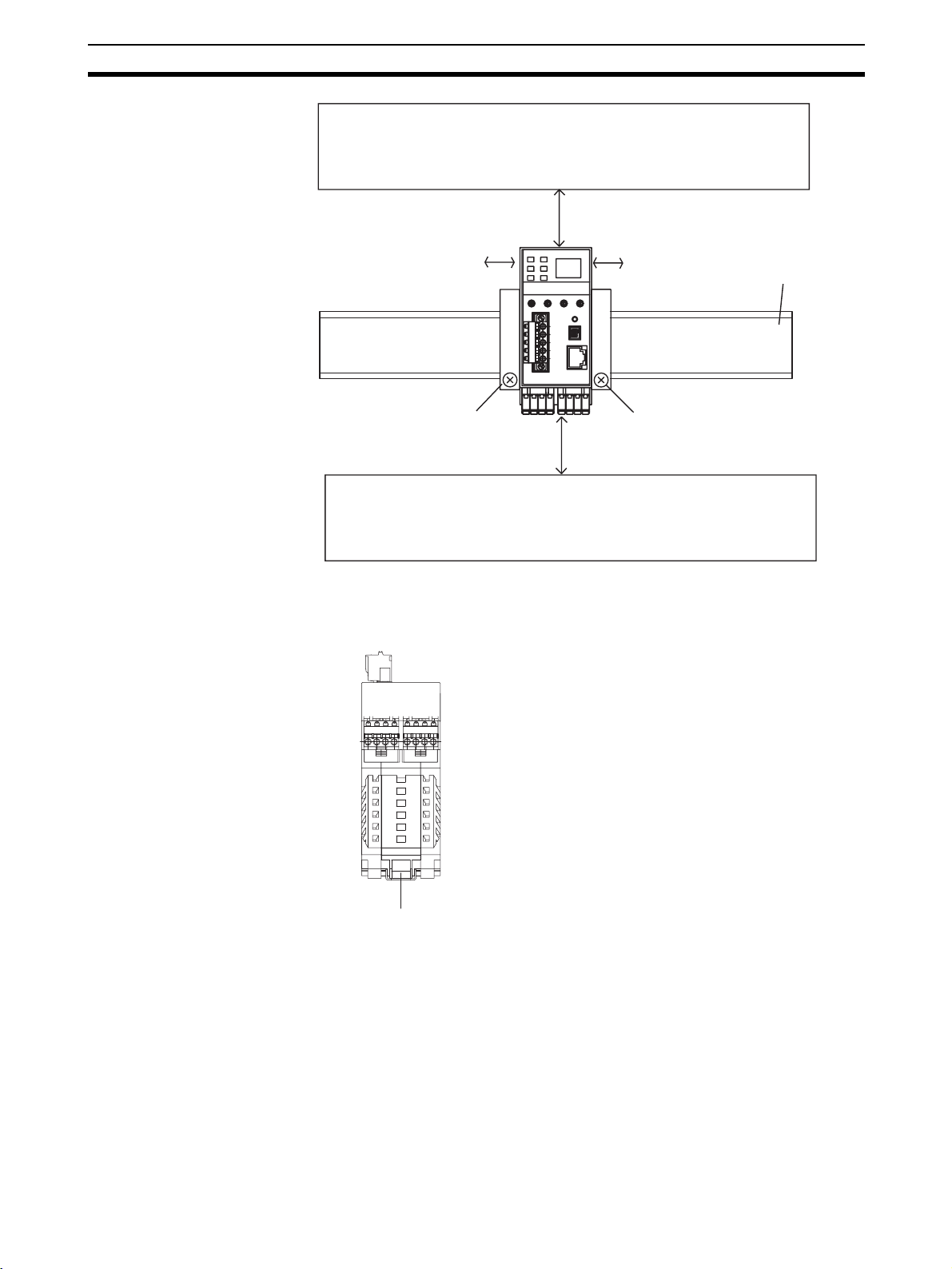

2-1-2 Mounting to the Control Panel

• Use the ED Router in an enclosure with IP54 degree of protection or

higher according to IEC/EN 60529.

• Use DIN Track (TH35-7.5/TH35-15 according to IEC 60715) to mount the

ED Router in the control panel. Mount the Router to the DIN Track using

PFP-M End Plates (not included with the ED Router) to prevent it from

falling off the DIN Track because of vibration.

• Provide sufficient space around the ED Router for ventilation and wiring,

at least 5 mm at the sides and at least 50 mm at the top and bottom.

• The ED Router can be mounted in any direction.

6

Page 24

Installation Section 2-1

k

s

Wiring duct

50 mm max.

Note The ED Router can be mounted only to a DIN Track. Do not screw the Router

DIN Track Mounting

Bracket Positions for the

ED Router

5 mm max. 5 mm max.

End Plate Model: PFP-M End Plate Model: PFP-M

50 mm max.

Wiring duct

to the control panel.

35-mm DIN Trac

DIN Track Mounting Bracket

7

Page 25

Installation Section 2-1

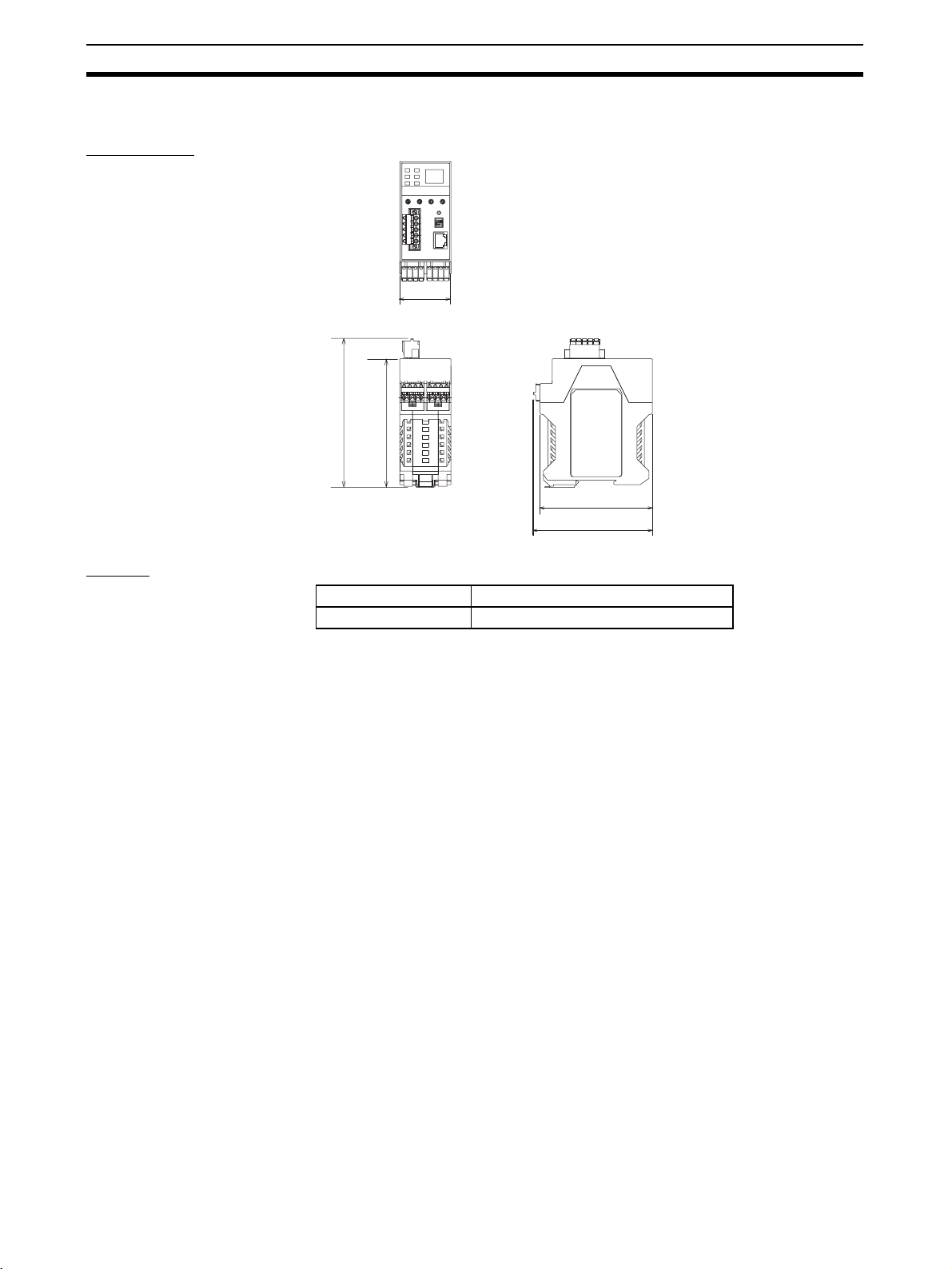

2-1-3 ED Router Dimensions and Weight

Dimensions

45.2

131.4

114.1

101.1

105.1

(Unit: mm)

Weight

Model Weight

NE1A-EDR01 220 g max.

8

Page 26

Wiring Section 2-2

2-2 Wiring

2-2-1 General Instructions on Wiring

Precaution:

• To prevent wire clippings from getting into the ED Router, do not remove

the label on the ED Router before wiring has been completed.

• After wiring has been completed, be sure to remove the label from the

Controller to enable heat dissipation for proper cooling.

• Disconnect the ED Router from the power supply before starting any wiring operations. Devices connected to the ED Router may operate unexpectedly if wiring is performed with the power supply connected.

• Be careful not to get your fingers caught when attaching connectors.

• Faulty wiring can result in a loss of safety functions. Be sure to perform

the wiring correctly, and check it before operation.

2-2-2 Wiring the Power Supply

Wire Sizes Use the following wires.

Solid wire

Stranded (flexible) wire

0.2 to 2.5 mm

0.34 to 1.5 mm

Stranded wires should be prepared by attaching ferrules with plastic

insulation collars (DIN 46228-4 standard compatible) before connecting them.

2

(AWG 24 to AWG 12)

2

(AWG 22 to AWG 16)

Recommended

Materials and Tools

Insulated Pin Terminals Use a pin terminal with an insulated cover compliant with the DIN 46228-4

standard. Pin terminals similar in appearance but not compliant with the standard may not match the terminal block on the ED Router Controller. (The wiring dimensions are rough standards. Confirm the dimensions beforehand.)

Use wires of the same diameter if two-wire pin terminals are used.

Note (1) When wiring with pin terminals, be sure to insert pin terminals all the way

into the terminal block.

(2) When using two-wire pin terminals, use wires of the same diameter.

(3) When using two-wire pin terminals, insert the pin terminal so that metal

portion of the pin terminal is inserted straight into the terminal block, i.e.,

so that the long sides of the insulating cover are vertical.

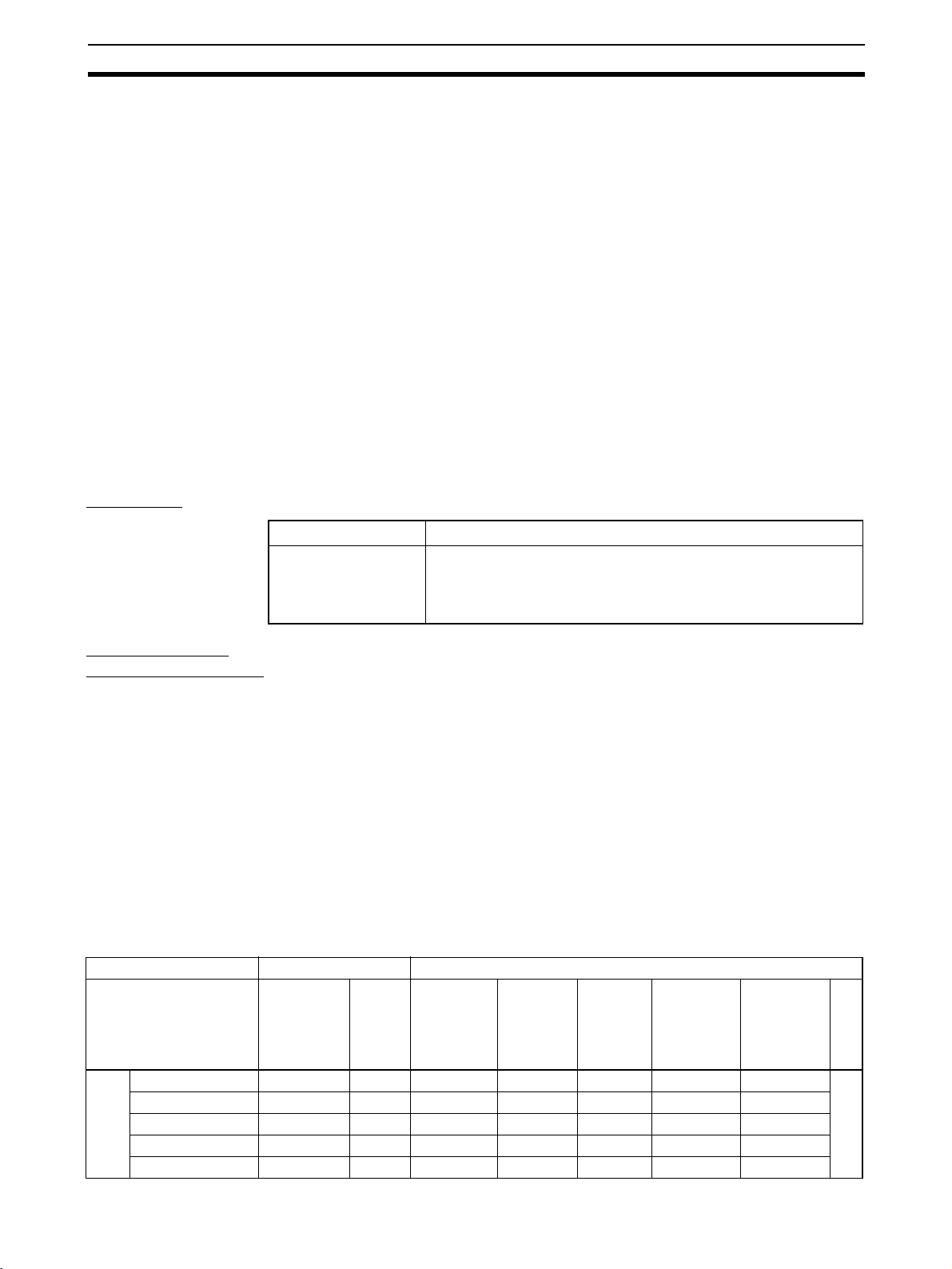

Reference Specifications (Product Specifications for Phoenix Contact)

Model of pin terminal Wire dimensions Pin terminal specifications

Cross-

sectional

area of

conductor

2

(mm

AI 0,34-8TQ 0.34 22 10 12.5 8 0.8 2.0 *1

AI 0,5-10WH 0.5 20 10 16 10 1.1 2.5

AI 0,75-10GY 0.75 18 10 16 10 1.3 2.8

AI 1-10RD 1.0 18 10 16 10 1.5 3.0

terminals

One-wire pin

AI 1,5-10BK 1.5 16 10 18 10 1.8 3.4

AWG Stripped

)

length of

insulation

(mm)

Overall

length L1

(mm)

Length of

metal

part L2

(mm)

Inner

diameter of

conductor

D1 (mm)

Inner

diameter of

insulative

cover D2

(mm)

Dimensions

9

Page 27

Wiring Section 2-2

Model of pin terminal Wire dimensions Pin terminal specifications

AI-TWIN 2 x 0,7510GY

AI-TWIN 2 x 110RD

terminals

Two-wire pin

Cross-

sectional

area of

conductor

2

(mm

2 x 0.75 − 10 17 10 1.8 2.8/5.0 *2

2 x 1 − 10 17 10 2.05 3.4/5.4

*1: One-wire Pin Terminal *2: Two-wire Pin Terminal

Insulative cover

AWG Stripped

)

Dia. D2

length of

insulation

(mm)

Overall

length L1

(mm)

Insulative cover

Length of

metal

part L2

(mm)

Inner

diameter of

conductor

D1 (mm)

Dia. D2

Inner

diameter of

insulative

cover D2

(mm)

Dimensions

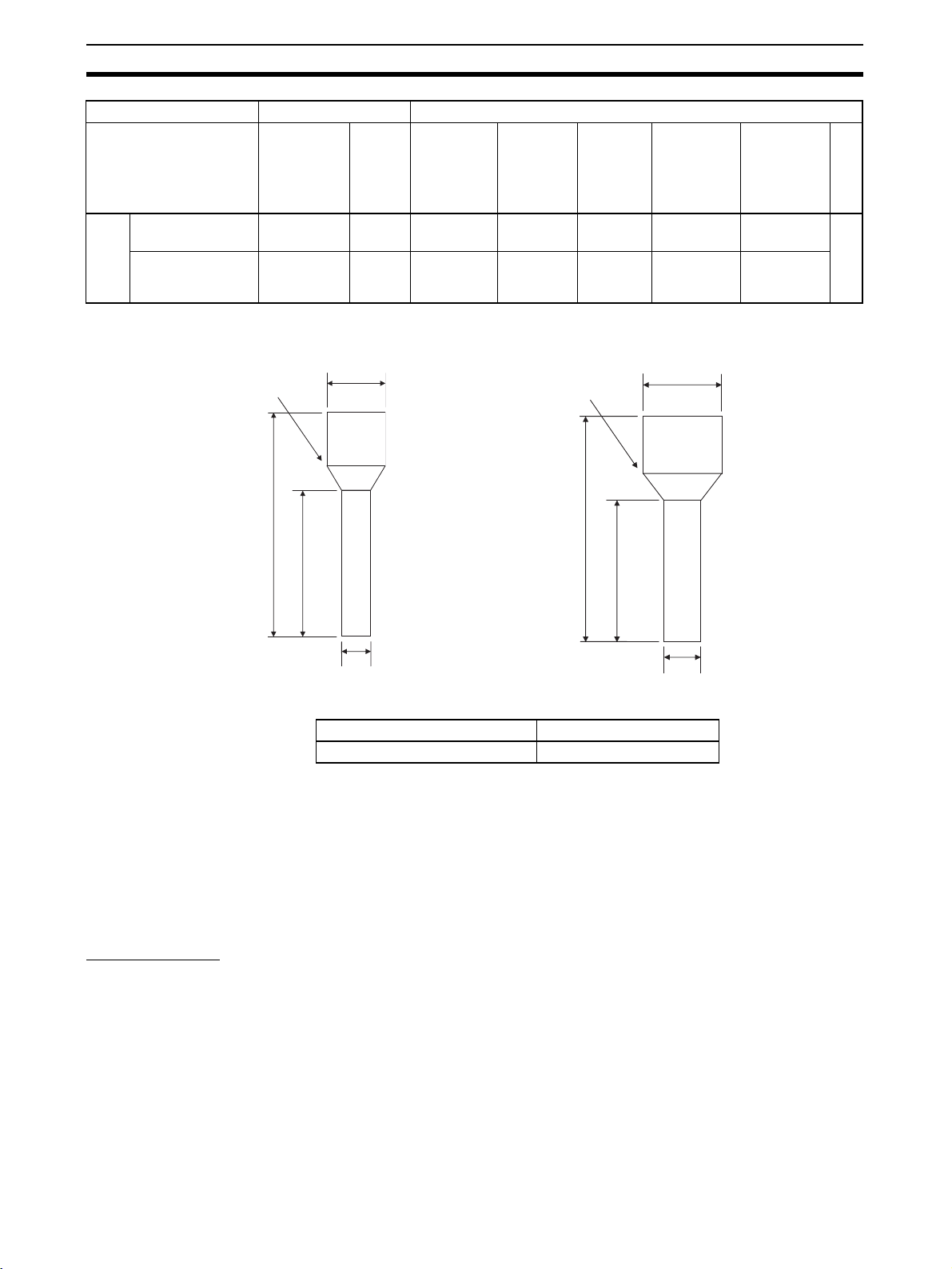

L1

L2

Dia. D1

L1

L2

Dia. D1

Terminal Crimping Tool

Manufacturer Model

Phoenix Contact CRIMPFOX UD6

Power Supply Selection

Use a DC power supply satisfying the following requirements.

• The secondary circuits of the DC power supply must be isolated from the

primary circuit by double insulation or reinforced insulation.

• The DC power supply must satisfy the requirements for class 2 circuits or

limited voltage/current circuits defined in UL 508.

• The output hold time must be 20 ms or longer.

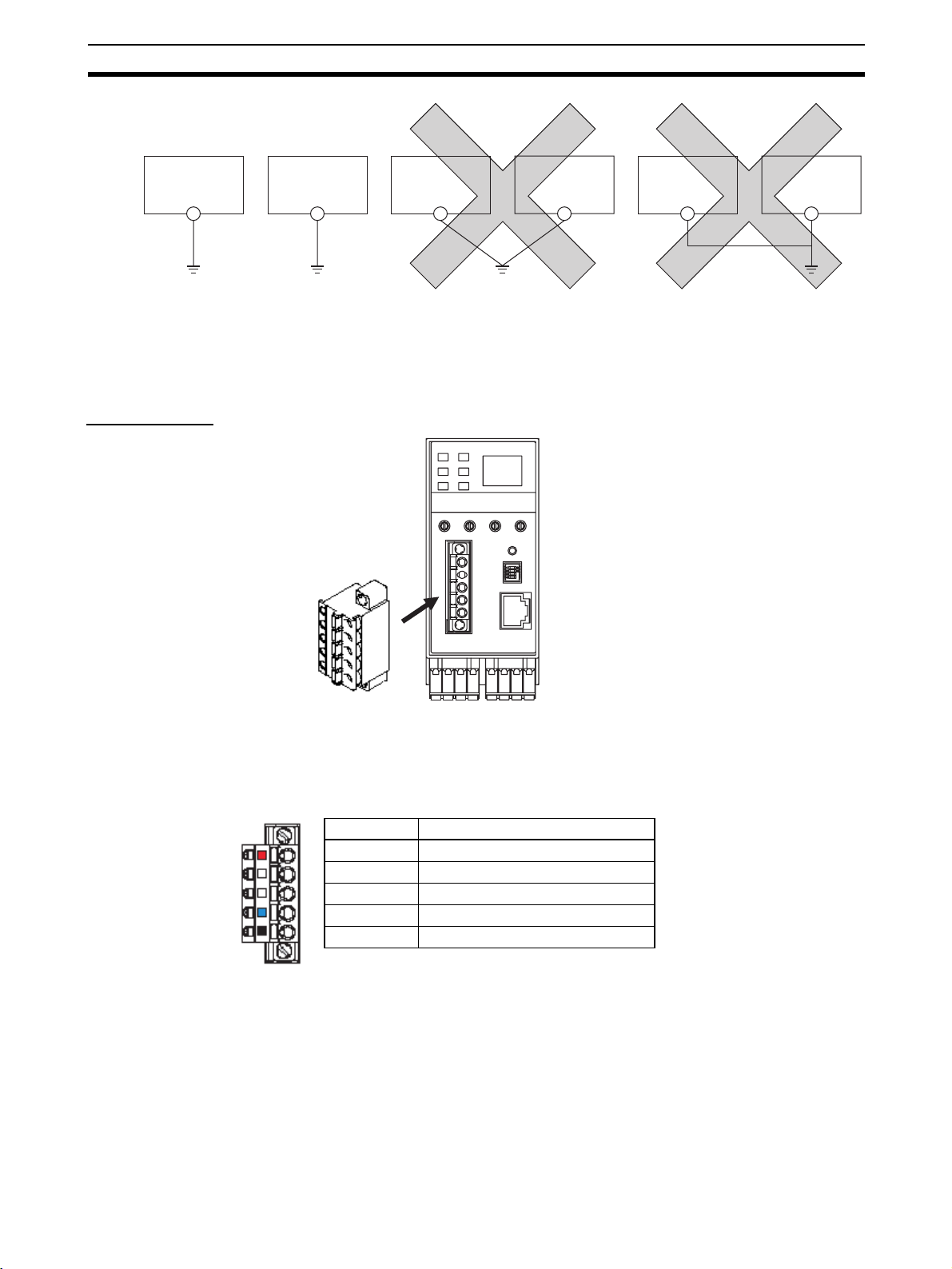

Ground Wiring The ED Router has a functional ground terminal. To prevent electric shock or

malfunctioning due to excessive noise, use an independent ground wire

(2 mm min.) with a maximum ground resistance of 100

ground wire should be no more than 20 m. To avoid grounding problems, do

not share the ground wiring with other devices or connect it to the building

structure. To further reduce noise, connect a noise filter.

Ω. The length of the

10

Page 28

Wiring Section 2-2

ED Router

Ground with max.

resistance of

100-Ω

Independent ground: Correct

Other devices

ED Router

Other devices

Shared ground: Incorrect

ED Router

Other devices

Note Ground correctly to avoid malfunctioning due to noise.

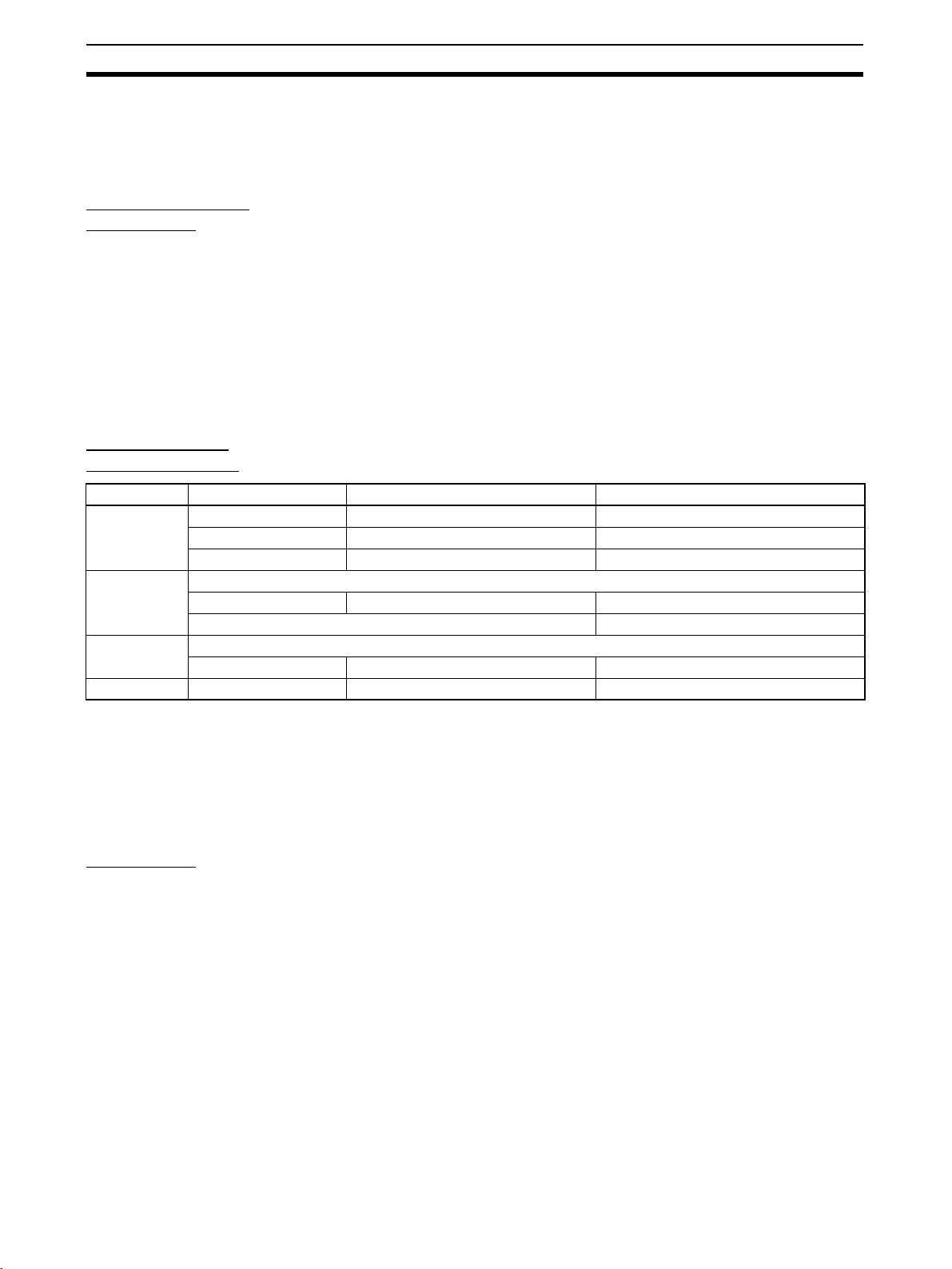

2-2-3 DeviceNet Wiring

Wiring Cables Wire the DeviceNet communications cable as shown in the following diagram.

IMPORTANT

Stickers are placed on the communication connectors based on the color of

each communications wire. By matching the communications wire colors with

the connector sticker colors, you can check to see if wires are in the correct

locations. The colors of the wires are as follows:

Color Description

Red V+

White Signal (CAN H)

-Drain

Blue Signal (CAN L)

Black V−

• Turn OFF the power supply to the NE1A-series Controller, to all nodes on

the network, and to communications lines before starting any wiring operations.

• Tighten the DeviceNet connector to the appropriate torque (0.25 to

0.3 N·m).

• Separate the DeviceNet communications cables from high-voltage/current

lines.

11

Page 29

Wiring Section 2-2

Note Refer to the DeviceNet Operation Manual (W267) for further information on

wiring.

2-2-4 Ethernet (EtherNet/IP) Network Installation

Basic Installation

Precautions

Recommended

Network Devices

Part Maker Model number Inquires

Switching Hub Cisco Systems, Inc. Consult the manufacturer. Cisco Systems, Inc. Main Corporate HQ

Contec USA, Inc. Consult the manufacturer. CONTEC USA Inc.

Phoenix Contact Consult the manufacturer. Phoenix Contact USA Customer Service

Tw is t e d- p ai r

cable

Connectors

(Modular plug)

Boots Tsuko Company MK boot (IV) LV Tsuko Company Japan Headquarters

100BASE-TX

Fujikura F-LINK-E 0.5mm × 4P Fujikura America, Inc.

EtherNet/IP compliant cable ---

STP Plug

Panduit Corporation MPS588 Panduit Corporation US Headquarters

• Take the greatest care when installing the Ethernet System, being sure to

follow ISO 8802-3 specifications. You must obtain a copy of these specifications and be sure you understand them before attempting to install an

Ethernet System.

• Unless you are already experienced in installing communications systems, we strongly recommend that you employ a professional to install

your system.

• Do not install Ethernet equipment near sources of noise. If a noisy environment is unavoidable, take adequate measures against noise interference, such as installing network components in grounded metal cases or

using optical cable in the system.

The following table shows the devices recommended for use with the ED

Router.

Precautions

Precautions on Laying

Twisted-pair Cable

Note • Ask the switching hub manufacturer for setting procedures for the switch-

ing hub.

• Install the switching hub so that its environmental resistance capabilities

are not exceeded.

Ask the switching hub manufacturer for information on the environmental

resistance of the switch hub.

• Noise resistance may be reduced by ground loops, which can occur due

to improper shield connections and grounding. Ground the shield at one

location, as shown in the following diagram.

• Do not connect the shield to the ED Router connector.

• If a cable connects two hubs, connect the shields at only one end.

12

Page 30

Wiring Section 2-2

Hub Hub

Connector Connector Connector Connector Connector

GR GR

STP

(Shield)

Connect shield.

Do not connect shield.

STP

(Shield)

STP

(Shield)

ED Router

Connector

ED Router

Connector

FG

terminal

FG

terminal

• Press the cable connector in firmly until it locks into place at both the

switching hub and the ED Router.

• Do not lay the twisted-pair cable together with high-voltage lines.

• Do not lay the twisted-pair cable near devices that generate noise.

• Do not lay the twisted-pair cable in locations subject to high temperatures

or high humidity.

• Do not lay the twisted-pair cable in locations subject to excessive dirt and

dust or to oil mist or other contaminants.

Switching Hub Installation

Environment Precautions

Switching Hub

Connection Methods

• Do not ground the switching hub in the same location as a drive-system

component such as an inverter.

• Always use a dedicated power supply for the switching hub’s power supply. Do not use the same power supply used for other equipment, such as

an I/O power supply, motor power supply, or control power supply.

• Before installation, check the switching hub’s environment-resistance

specifications, and use a switching hub appropriate for the ambient conditions. Contact the switching hub manufacturer for details on switching

hub’s environment-resistance specifications.

• Connect two hubs to each other as follows: Connect an MDI port to an

MDI-X port with a straight cable; connect two MDI ports with a cross

cable; and connect two MDI-X ports with a cross cable.

Note It is very difficult to distinguish cross cables and straight cables by

appearance. Incorrect cables will cause communications to fail. We

recommend using cascade connections with straight cables whenever possible.

MDI-X port

(cross)

MDI ports

Switching

Hub

Switching

Hub

Switching

Hub

: Straight cable

: Cross cable

Switching

Hub

• Some switching hubs can automatically distinguish between MDI and

MDI-X. When this kind of switching hub is being used, straight cable can

be used between switching hubs.

13

Page 31

Wiring Section 2-2

Note Adjust the ED Router link settings to match the communications settings of

the connected switching hub. If the settings do not match, the link will become

unstable and prevent normal communications. The following table shows the

allowed settings for each switching hub communications mode.

ED Router

Switching hub setting

Auto-negotiation Best --- OK --- OK

10 Mbps

(fixed)

100 Mbps

(fixed)

Full duplex --- OK --- --- ---

Half duplex OK --- OK --- ---

Full duplex --- --- --- Best ---

Half duplex OK --- --- --- OK

Auto-

negotiation

10 Mbps (fixed) 100 Mbps (fixed)

Full

duplex

Half

duplex

Full

duplex

Half

duplex

Best = Recommended; OK = Allowed; --- = Not allowed.

Ethernet Connectors The following standards and specifications apply to the connectors for the

Ethernet twisted-pair cable.

• Electrical specifications: Conforming to IEEE802.3 standards.

• Connector structure: RJ45 8-pin Modular Connector

(conforming to ISO 8877)

Connector pin Signal name Abbr. Signal direction

1 Transmission data + TD+ Output

2 Transmission data – TD– Output

3 Reception data + RD+ Input

4 Not used. --- ---

5 Not used. --- ---

6 Reception data – RD– Input

7 Not used. --- ---

8 Not used. --- ---

Hood Frame ground FG ---

Note The ED Router Ethernet port has auto MDI/MDI-X functionality, so either a

Connecting the Cable

!Caution Turn OFF the ED Router power supply before connecting or disconnecting

!Caution Allow enough space for the bending radius of the twisted-pair cable as shown

straight or cross cable can be used.

twisted-pair cable.

in below.

14

Page 32

Wiring Section 2-2

ED Router

35 mm

1,2,3... 1. Lay the twisted-pair cable.

2. Connect the cable to the switching hub. Be sure to press in the cable until

it locks into place. This procedure should only be performed by qualified

personnel.

3. Connect the twisted-pair cable to the connector on the ED Router.

Be sure to press the connectors (both the switching hub side and Ethernet

side) until they lock into place.

15

Page 33

Connecting to DeviceNet Section 2-3

2-3 Connecting to DeviceNet

2-3-1 Setting the DeviceNet Node Address

Set the DeviceNet node address using the rotary switches (NODE ADR) on

the front of the ED Router.

Method Two-digit decimal number

Range 0 to 63

Note The node address is set to 63 at the factory.

Any node address in the setting range can be used as long as the same

address is not used by another node. If a value between 64 and 99 is set on

the rotary switches, the node address can be set using a software setting on

the Network Configurator.

IMPORTANT

• Turn OFF the power to the ED Router before setting the rotary switches.

• Do not change the rotary switches while the power is ON.

• A node address duplication error will occur if the same address is set for

more than one node. Communications will not start if this error occurs.

Note • Use a small flat-blade screwdriver to set the rotary switches, being careful

not to scratch them.

• Refer to 2-3-3 DeviceNet Node Address and Baud Rate Software Settings

for software setting procedures.

2-3-2 Setting the DeviceNet Baud Rate

The DeviceNet baud rate is set using the DIP switch on the front of the ED

Router. The baud rate settings are shown in the following table:

1 2 3 4

OFF OFF OFF OFF

ON OFF OFF OFF 250 kbit/s

OFF ON OFF OFF 500 kbit/s

ON ON OFF OFF Software setting

ON or

OFF

ON or

OFF

Note The baud rate is set to 125 kbit/s at the factory.

Note Refer to 2-3-3 DeviceNet Node Address and Baud Rate Software Settings for

software setting procedures.

ON or

OFF

ON or

OFF

Pin Baud rate

125 kbit/s

ON OFF

ON or

OFF

ON Automatic baud rate

detection

16

Page 34

Connecting to DeviceNet Section 2-3

2-3-3 DeviceNet Node Address and Baud Rate Software Settings

Use the following procedure to set the ED Router DeviceNet node address

and baud rate from the Network Configurator.

1,2,3... 1. Select Programs - OMRON Network Configurator for DeviceNet Safety

- Network Configurator from the Start Menu. The Network Configurator

will be started.

2. Connect the Network Configurator online. (First set the interface with Op-

tion - Select Interface, and then select Network - Connect.)

3. Select DeviceNet in the Network Configuration Window. (For example,

click the DeviceNet_1 Ta b. )

4. Select Tool - Node Address/Baud Rate Setting.

The following dialog box will be displayed.

5. Specify the present node address of the target ED Router in the Ta r ge t

Node Address Field.

6. To change the node address, specify a new node address in the New Node

Address Field and click the Change Button.

The node address of the ED Router will be changed.

7. To change the baud rate, select the rate in the New Baud Rate Field and

click the Change Button.

The baud rate of the ED Router will be changed.

17

Page 35

Connecting to Ethernet (EtherNet/IP) Section 2-4

2-4 Connecting to Ethernet (EtherNet/IP)

2-4-1 Setting the IP Address

This section describes methods for setting the IP address for the ED Router.

Method 1: The default IP address is 192.168.250.IP_address_switch_set

value.

The IP address is set with the rotary switches on the front of the

ED Router (IP ADR).

→ This method can be used to make a temporary or preliminary

connection to the Ethernet.

In this case, leave the TCP/IP Configuration setting at its

default value.

Method 2: Setting the TCP/IP Configuration from the Network Configura-

tor:

→ To set a particular local IP address, use the Network Configu-

rator.

The methods for setting the ED Router IP address are described below.

Method 1: Using the Default IP Address (192.168.250.IP_address_switch_set value)

The default IP address for the ED Router is

192.168.250.IP_address_switch_set value. The IP address switch is used to

set the IP address host ID.

IP address = 192.168.250.

The host IC can be changed with the IP address switch. If 00 or FF is set, 01

will be used as the host ID.

The TCP/IP settings will be in the following default settings.

Setting Operating status

IP address 192.168.250.IP_address_switch_set value

Subnet mask 255.255.255.0 (class C mask)

Default gateway None (IP routing disabled)

Preferred DNS server None

Alternate DNS server None

Host name None

Domain name None

Baud rate Auto-detect

IP_address_switch_set value

Method 2: Setting the TCP/IP Configuration from the Network Configurator

With this method, set the TCP/IP configuration, including the IP address, from

the Network Configurator.

18

Page 36

Connecting to Ethernet (EtherNet/IP) Section 2-4

2-4-2 TCP/IP Configuration

This section describes the TCP/IP-related settings, such as the ED Router

local IP address and subnet mask. Use the Network Configurator to make

these settings. The settings are stored in the ED Router non-volatile memory.

Note (1) With the default settings, the IP address will be 192.168.250.1 if 00 or FF

is set.

(2) If the IP address switch is set to a value other than 00 or FF, the switch

setting will be used for the rightmost bit of the IP address. To use the value set from the Network Configurator, set the IP address switch to 00 or

FF.

(3) To use the BOOTP server, set the IP address switch to 00 or FF.

Making TCP/IP

Settings with the

Network Configurator

1,2,3... 1. Select Programs - OMRON Network Configurator for DeviceNet Safety

- Network Configurator from the Start Menu. The Network Configurator

will be started.

2. Connect the Network Configurator online. (First set the interface with Op-

tion - Select Interface, and then select Network - Connect.)

3. Select EtherNet/IP in the Network Configuration Window. (For example,

click the EtherNet/IP Tab. )

4. Select Tools - Setup TCP/IP Configuration. The Setup TCP/IP Configuration Dialog Box will be displayed.

The settings are all at their default values.

19

Page 37

Connecting to Ethernet (EtherNet/IP) Section 2-4

5. For the Target IP Address, specify the present IP address of the ED Router

for which the IP address is to be set.

6. To change the IP address, select Use the following IP address and then set

the new IP address.

20

7. Click the Set to the Device Button.

The ED Router will restart automatically.

8. Check the 7-segment display on the ED Router.

If the 7-segment display is tested again after it goes OFF, and finally displays the DeviceNet node address, it indicates that the ED Router has recognized the new TCP/IP Configuration settings.

Note (1) The ED Router will restart automatically when the TCP/IP Configuration's

IP address parameters are downloaded to the ED Router from the Network Configurator. The ED Router must restart to enable the parameter

settings. Download the TCP/IP Configuration's IP address parameters

only after verifying that restarting the Unit will not cause any problems in

the system.

(2) The IP address can be checked on the 7-segment display by pressing the

ED Router service switch for 1 s or longer and then releasing it.

(3) With an ED Router parameter setting, the value normally displayed on the

7-segment display can be changed to the rightmost byte of the IP address.

Page 38

Connecting to Ethernet (EtherNet/IP) Section 2-4

TCP/IP Setting Details The ED Router TCP/IP Configuration settings include the following settings.

• IP address

• Subnet mask

• Default gateway

• Preferred DNS server

• Alternate DNS server

• Domain name

• Link setting

IP Address Sets the ED Router local IP address.

Set the local IP address in this TCP/IP Configuration when not using the

default IP address (default IP address =

192.168.250.IP_address_switch_set_value).

Subnet Mask For the subnet mask, all bits corresponding to the bits in the IP address used

as either the net number or the subnet number are set to 1, and the bits corresponding to the host number are set to 0.

If no subnet mask is set, or if an illegal value is set, the following values will be

used depending on the IP address class.

Class Subnet mask

Class A 255.0.0.0

Class B 255.255.0.0

Class C 255.255.255.0

With the default setting (0.0.0.0), a subnet mask corresponding to the IP

address class is used.

Default Gateway Sets the default gateway’s IP address.

This setting is not required when the default gateway is not being used.

Preferred DNS Server

and Alternate DNS

Server

When accessing another node from the ED Router using the host name, the

DNS server searches for the other node's IP address from the other node's

host name to the DNS server. These settings register the IP addresses of the

preferred and alternate DNS servers that will perform the search. At this time,

the NEIA Series and the ED Router are not equipped with any functions that

require a DNS server, so these settings are not used. Even if the settings are

made, however, they will not cause faulty operation.

Domain Name Sets the domain name of the domain to which the ED Router belongs.

The ED Router does not use a domain name in actual communications.

Link Setting Sets the communications baud rate.

Setting Meaning

Auto (default) The baud rate with the switching hub is detected automati-

10 Mbps, Half Duplex Operates in 10BASE-T, half duplex.

10 Mbps, Full Duplex Operates in 10BASE-T, full duplex.

100 Mbps, Half Duplex Operates in 100BASE-TX, half duplex.

100 Mbps, Full Duplex Operates in 100BASE-TX, full duplex.

cally. If possible, the Unit operates in 100BASE-T (full

duplex).

21

Page 39

Connecting to Ethernet (EtherNet/IP) Section 2-4

Note Adjust the ED Router link settings to match the communications settings of

the connected switching hub. If the settings do not match, the link will become

unstable and prevent normal communications. The following table shows the

allowed settings for each switching hub communications mode.

ED Router

Switching hub setting

Auto-negotiation OK --- OK --- OK

10 Mbps

(fixed)

100 Mbps

(fixed)

Full duplex --- OK --- --- ---

Half duplex OK --- OK --- ---

Full duplex --- --- --- OK ---

Half duplex OK --- --- --- OK

Auto-

negotiation

10 Mbps (fixed) 100 Mbps (fixed)

Full

duplex

Half

duplex

Full

duplex

duplex

OK = Allowed; --- = Not allowed.

Half

22

Page 40

ED Router Settings Section 2-5

2-5 ED Router Settings

2-5-1 Setting the UDP Port Address and the Address Displayed at the

ED Router

Use the Network Configurator to set the address displayed on the ED Router

7-segment display and to set the UDP port address.

■ Setting the Address Displayed at the ED Router

Select either the EtherNet/IP IP address or the DeviceNet node address as

the address to be displayed on the ED Router 7-segment display when the

status is normal.

■ Setting the UDP Port Address

Select a number from 1,024 to 65,535 for the UDP port to be used for device

access by UDP.

1,2,3... 1. Select Programs - OMRON Network Configurator for DeviceNet Safety

- Network Configurator from the Start Menu. The Network Configurator

will be started.

2. Connect the Network Configurator online. (First set the interface with Op-

tion - Select Interface, and then select Network - Connect.)

3. In the Network Configuration Window, double-click the ED Router that is to

be set. The following dialog box will be displayed.

4. Set the address to be displayed at the ED Router, or set the UDP port address.

• To set the address to be displayed at the ED Router, click 0001 Display

Mode and select Low byte of Ethernet IP address (EtherNet/IP IP address) or DeviceNet MAC ID (DeviceNet node address).

• To set the UDP port address, click 0002 UDP Port No. and input a

number from 1,024 to 65,535.

5. After making the setting, click the OK Button.

6. In the Network Configuration Window, select the ED Router. Right-click

and select Parameter - Download. After the parameters have been downloaded, the ED Router will be automatically reset and it will then operate

using the new parameters.

23

Page 41

ED Router Settings Section 2-5

24

Page 42

SECTION 3

Status Indicators and Troubleshooting

This section describes how to interpret the status indicators and how to troubleshoot problems that may occur with the ED

Router.

3-1 Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-1-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3-1-2 Seven-segment Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3-2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3-2-1 ED Router Errors and Error Processing . . . . . . . . . . . . . . . . . . . . . . 29

3-3 Error History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-3-1 Error History Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3-3-2 Error History Code List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

25

Page 43

Status Indicators Section 3-1

3-1 Status Indicators

This section describes the ED Router status indicators (LEDs).

3-1-1 Overview

ED Router and network status are displayed on the following status indicators.

• MS (Module Status): Displays the status of the ED Router.

• NS E (Network Status, EtherNet/IP): Displays the status of the EtherNet/

IP network.

• NS D (Network Status, DeviceNet): Displays the status of the DeviceNet

network.

• 10: Lit when Ethernet is connected by 10Base-T.

• 100: Lit when Ethernet is connected by 100Base-T.

• ACT: Lit when Ethernet communications are detected.

The following table describes the MS, NS E, and NS D indicators in detail.

Indicator name Color Status Meaning

MS

(module status)

NS E, NS D

(Network Status)

Green Operation status

Red Fatal error (Critical fault)

An ED Router failure has occurred, and recovery is not possible. ED Router

operation stops and the NS E and NS D indicators turn OFF.

• ED Router failure.

Fatal error (Abort)

One of the following recoverable errors has occurred. Message communica-

tions routing is enabled.

• Switch changed during operation (failure, unintended operation, etc.)

• Setting error due to power interruption while making settings

- Power is not being supplied.

Green While online, at least one CIP connection is established.

While online, not even one CIP connection is established.

Red Communications are not possible.A non-recoverable communications error

was detected in the network.

• DeviceNet bus OFF error

• DeviceNet node address duplication error

• EtherNet/IP IP address duplication error

A recoverable communications error was detected in the network.

• DeviceNet network power supply error

• DeviceNet communications timeout error

• BOOTP server connection error

• DeviceNet node address switch setting changed after startup.

• EtherNet/IP IP address switch setting changed after startup.

• DeviceNet node baud rate switch setting changed after startup.

- Not connected online.

26

: ON : Flashing : OFF

Page 44

Status Indicators Section 3-1

3-1-2 Seven-segment Display

This section describes the meanings of the 7-segment display.

Normal Status When no error has occurred and communications are enabled, the ED Router

DeviceNet node address is displayed as the initial status on the 7-segment

display.

• Display Example: When the Node Address Is 01

The rightmost byte of the EtherNet/IP IP address can be displayed by a setting from the Network Configurator.

Error Status When an error occurs, the error code is displayed following Er. If multiple

errors occur, the error codes are displayed in order.

• Display Example: When the Error Codes Are d6 and E0

1000 ms Not lit

100 ms.

(Error) (Error)

1000 ms

for

(Error code) (Error code)

Not lit

for

100 ms.

1000 ms

Not lit

for

100 ms.

Not lit

for

300 ms.

Displaying the EtherNet/IP IP Address and the DeviceNet Node Address

The EtherNet/IP IP address and the DeviceNet node address can be displayed on the 7-segment display by pressing the service switch for 1 s or

longer before releasing it.

• Display Example: EtherNet/IP IP Address

• Display Example: EtherNet/IP IP Address when BOOTP Is Set

• Display Example: DeviceNet Node Address

27

Page 45

Status Indicators Section 3-1

• Display Example: When IP Address is 192.200.200.2

The IP address moves across the display from right to left.

300 ms 300 ms 300 ms 300 ms Not lit

for

50 ms.

Not lit

for

50 ms.

Not lit

for

50 ms.

Not lit

for

500 ms.

Not lit

for

50 ms.

Note Errors are indicated by combining the MS indicator, NS indicator, and the 7-

segment display. For further details on specific meanings, refer to 3-2 Trouble-

shooting.

28

Page 46

Troubleshooting Section 3-2

3-2 Troubleshooting

3-2-1 ED Router Errors and Error Processing

Indicators/Display Error Cause ED Router

MS NS D NS E 7-seg-

Hardware-related Errors

Lit red Not lit Not lit Not lit

Flashing

red

Flashing

red

Communications-related Error

--- --- --- --- Illegal mes-

Ethernet Communications-related Errors

--- --- --- E1 Link OFF

--- --- Not lit E3 Server con-

--- --- Lit red F0 IP address

--- --- E9 Memory

--- Not lit F4 Ethernet

ment

or H3

System error ED Router fail-

ure

access error

communications controller error

sage discarded.

error

nection error

duplication

error

An error

occurred in

involatile memory in the Unit.

An Ethernet

communications

controller error

occurred.

The message

was discarded

due to illegal

packet communications.

No link was

detected

between switching hubs.

An error

occurred

between the ED

Router and the

BOOTP server.

• There is no

response from

the BOOTP

server.

• The IP address

received from

the BOOTP

server is illegal.

The ED Router

IP address is the

same as the IP

address set for

another device.

Operation stops. None

Operation stops. 0602

Ethernet communications stop.

Operation stops. 0118 Check the system communi-

Operation continues after error

recovery.

Ethernet communications stop until

a legal IP address

can be received.

Ethernet communications stop.

operation

Error

code

(hex)

or

0601

020F

03D3 Check the Ethernet cable,

03C4 Check the BOOTP server.

0211 Check the IP address set-

Countermeasures

Replace the ED Router if the

problem recurs after restarting.

cations status.

hub, etc.

tings and the network connections.

29

Page 47

Troubleshooting Section 3-2

Indicators/Display Error Cause ED Router

MS NS D NS E 7-seg-

DeviceNet Communications-related Errors

--- Lit red --- F0 Node

--- Lit red --- F1 Bus OFF

--- Not lit --- E0 DeviceNet

--- Flash-

Settings-related Error

Flashing

red

Flashing

red

Flashing

red

Flashing

red

ing

red

--- --- F2 Ethernet

Flashing

red

--- Flash-

Flashing

red

--- E2 DeviceNet

--- C8 DeviceNet

ing

red

--- C8 Baud rate

ment

address

duplication

error

error

network

power supply error

communications timeout

error

basic setting

error

node

address setting changed

during operation

C8 IP address

setting

changed during operation

setting

changed during operation

The ED Router

DeviceNet node

address is the

same as the

node address

set for another

device.

A DeviceNet bus

OFF error was

detected.

The DeviceNet

network power

supply is OFF.

Data could not

be sent in

DeviceNet for

1 s or longer.

An error

occurred in the

data set for the

TCP/IP Configuration.

The node

address switch

setting was

changed during

operation.

The IP address

switch setting

was changed

during operation.

The baud rate

switch setting

was changed

during operation.

DeviceNet operation stops.

DeviceNet communications stop.

DeviceNet communications stop

until the network

power supply is

restored.

DeviceNet communications stop

until normal communications are

restored.

Operation continues, using the

default values for

the TCP/IP Configuration.

Operation continues, using the

value from before

the change.

Operation continues, using the

value from before

the change.

Operation continues, using the

value from before

the change.

operation

Error

code

(hex)

0211 Check the node addresses

0340 Check the DeviceNet net-

0341 Check the DeviceNet net-

0342 Check the following items:

03D0 Check the Ethernet settings.

0214 Check the node address

0214 Check the IP address switch

0214 Check the baud rate switch

Countermeasures

and the network connections

for all devices on the

DeviceNet network.

work for short-circuiting and

check the baud rate.

work power supply and the

communications cable connections.

• Is the baud rate the same

for each node?

• Are the cable lengths (main

and branch lines) correct?

• Are any cables disconnected or loose?

• Is terminating resistance

connected at both ends of

the main line?

switch setting. If the error

persists after the correct setting has been made, replace

the ED Router.

setting. If the error persists

after the correct setting has

been made, replace the ED

Router.

setting. If the error persists

after the correct setting has

been made, replace the ED

Router.

30

Page 48

Troubleshooting Section 3-2

Indicators/Display Error Cause ED Router

MS NS D NS E 7-seg-

Flashing

red

Flashing

red

--- Flashing

red

--- --- E8 Device

ment

F3 Invalid IP

address setting

parameter

error

The IP address

is set to be

received from

the BOOTP

server, but the IP

address switch

is set for a value

other than 00 or

FF.

An error

occurred in the

parameters

downloaded

from the Network Configurator.

Operation continues, using the

value set by the IP

address switch.

Operation continues, using the

default setting.

operation

Error

code

(hex)

0214 Check the IP address switch

021A Make the settings again from

Countermeasures

setting and the configuration, and make the settings

again.

the Network Configurator. If

the error persists after the

correct settings have been

made, replace the ED

Router.

31

Page 49

Error History Section 3-3

3-3 Error History

The error history records errors that the ED Router detects, along with the

total operating time of the ED Router. The results recorded in the error history

can then be read or cleared from the Network Configurator.

Depending on the contents of the error history, some parts are cleared and

some are not cleared when the CPU Unit power is turned OFF or reset.

3-3-1 Error History Table

Error History Table When an error is detected in the ED Router, the error is recorded in the error

history table in the RAM of the ED Router. The error history contains one

record per error and can hold up to 64 records. If the error history table

already contains 64 records, the oldest record is deleted and the new error

data is stored.

The following information is stored in the error history table:

• Time that error occurred (total ED Router operating time)

• Error information

• Detailed information

Error History Saving

Area

Reading and Clearing

the Error History

Table

Note The total operating time of the ED Router is recorded as the accumulated time

The description of an error is recorded in the error history in the RAM of the

ED Router, and if the error is critical, it is also saved in the nonvolatile memory. The error history recorded in nonvolatile memory is retained even when

the power supply of the ED Router is not supplied or restarted. The error history in the nonvolatile memory is copied to the RAM at the start of the ED

Router power cycle.

The error history in RAM is read when reading the error history from the Network Configurator. When clearing the error history, however, the error history

in both the RAM and nonvolatile memory are cleared.

The error history can be displayed in realtime using the Error History Display

function of the Network Configurator. (Select the device, and then select

Device - Monitor.) The error history data can also be saved on the computer.

in 6-minute increments while the power supply for the internal circuit is ON.

32

Page 50

Error History Section 3-3

When the error history is read using the Network Configurator, the time at

which the error occurred (the ED Router total operating time), error information, detailed error information, and the contents of the error are displayed as

shown in the following illustration.

33

Page 51

Error History Section 3-3

3-3-2 Error History Code List

Error

code

(hex)

0118 Illegal message discarded FF hex FF hex Not stored

020F Ethernet communications controller

error

0211 Ethernet IP address duplication error Port No.

0211 DeviceNet node address duplication

error

0214 DeviceNet node address setting

changed during operation

0214 IP address setting changed during

operation

0214 Baud rate setting changed during

operation

0214 Invalid IP address setting FF hex FF hex Stored

021A Device parameter error 00 hex OE hex: Unit name Stored

0340 Bus OFF error 00 hex 00 hex Not stored

0341 DeviceNet network power supply

error

0342 DeviceNet communications timeout

error

03C4 Server connection error 04 hex: BOOTP 01 hex: Specified host does not

03D0 Ethernet basic setting error 01 hex: Ethernet setting

03D3 Link OFF error 00 hex 00 hex Not stored

Error Detailed information Non-

1st byte 2nd byte

00 hex 01 hex Stored

(Ethernet: 02 hex)

Port No.

(DeviceNet: 03 hex)

Port No.

(DeviceNet: 03 hex)

Port No.

(Ethernet: 03 hex)

00 hex Value (hex) detected as changed Stored

00 hex 00 hex Not stored

00 hex 00 hex Not stored

error

02 hex: TCP/IP basic set-

ting error

Rightmost 8 bits of IP address

(hex)

Node address (hex) Stored

Node address (hex) detected as

changed

Rightmost 8 bits of IP address

(hex) detected as changed

exist.

02 hex: No such service at speci-

fied host.

03 hex: Timeout

06 hex: Host name resolution

error

07 hex: Transmission error

08 hex: Reception error

09 hex: Other error

0A hex: Obtaining IP address

error

01 hex: CRC error

11 hex: Invalid IP address

12 hex: Invalid subnet mask

13 hex: Invalid default gateway

address

14 hex: Invalid primary name

server

15 hex: Invalid secondary name

server

16 hex: Invalid domain name

17 hex: Invalid host name

volatile

memory

Stored

Stored

Stored

Not stored

Stored

34

Page 52

Error History Section 3-3

Error

code

(hex)

0601 System error Undetermined Undetermined Stored

0602 Memory access error 01 hex: Read error

Error Detailed information Non-

1st byte 2nd byte

06 hex: Error history

02 hex: Write error

07: Protocol data

09 hex: Identity data

0E hex: Unit name

0F hex: Ethernet basic setting

11 hex: Node address

volatile

memory

Stored

(See note.)

Note If an error occurs in the error log area (non-volatile memory), the

record will not be stored in non-volatile memory.

35

Page 53

Error History Section 3-3

36

Page 54

Accessing Devices by UDP

This section describes how to access network devices using UPD.

4-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-1-1 Accessing Devices by UDP/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4-2 Formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4-2-1 Command Format. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

4-2-2 Response Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4-3 Operating Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-3-1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-3-2 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4-4 Mitsubishi Ethernet Interface Module Settings. . . . . . . . . . . . . . . . . . . . . . . . 43

4-4-1 PC Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-4-2 Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4-5 Sample Ladder Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4-5-1 System Configuration for Sample Ladder Programs . . . . . . . . . . . . 45

4-5-2 PC Parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4-5-3 Sample Ladder Program Processing Flow . . . . . . . . . . . . . . . . . . . . 47

4-5-4 Sample Ladder Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4-6 NE1A Series Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-6-1 Monitoring the NE1A-SCPU01-V1 . . . . . . . . . . . . . . . . . . . . . . . . . 59

4-6-2 Monitoring the NE1A-SCPU02 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

4-7 DST1 Series Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4-7-1 Monitoring the DST1-ID12SL-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

4-7-2 Monitoring the DST1-MD16SL-1 . . . . . . . . . . . . . . . . . . . . . . . . . . 69

4-7-3 Monitoring the DST1-MRD08SL-1 . . . . . . . . . . . . . . . . . . . . . . . . . 73

4-7-4 Monitoring the DST1-XD0808SL-1. . . . . . . . . . . . . . . . . . . . . . . . . 76

SECTION 4

37

Page 55

Overview Section 4-1

4-1 Overview

4-1-1 Accessing Devices by UDP/IP

Devices on a DeviceNet or DeviceNet Safety network can be accessed from

general-purpose controllers (e.g., PLCs or computers) in an Ethernet network

using UDP/IP frame message communications via an ED Router.

This enables monitoring a DeviceNet or DeviceNet Safety control system via

Ethernet from a machine controller or monitor computer that does not support

a DeviceNet interface. This can be used to easily add a DeviceNet Safety control system to an existing system.

Safety controls can be monitored by accessing

devices on the DeviceNet Safety network using the

UDP service from a general-purpose controller on

the Ethernet network (e.g., a PLC or computer).

PLC (OMRON or other maker)

OR

Computer

ED Router

(NE1A-EDR01)

Command via UDP

Ethernet

Command via UDP

DeviceNet Safety

DeviceNet Safety

DST1-series Slaves

Socket service (UDP)

NE1A Safety Network Controller

DeviceNet Safety

DeviceNet Safety

DST1-series Slaves

38

Page 56

Formats Section 4-2

4-2 Formats

4-2-1 Command Format

This section describes the format for UDP/IP messages (i.e., commands) sent

from a device on an Ethernet network. The LSB is placed in the rightmost

address for each parameter.

When this command is sent from a device on the Ethernet network to the ED