Page 1

Programmable Terminal

NA-series

Hardware (-V1)

User’s Manual

NA5-15101-V1

NA5-12101-V1

NA5-9001-V1

NA5-7001-V1

V125-E1-01

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Sysmac and SYSMAC are trademarks or registered trademarks of OMRON Corporation in Japan and other

countries for OMRON factory automation products.

• Microsoft, Windows, Windows Vista, Excel, and Visual Basic are either registered trademarks or trademarks of

Microsoft Corporation in the United States and other countries.

• EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• ODVA, CIP, CompoNet, DeviceNet, and EtherNet/IP are trademarks of ODVA.

• The SD and SDHC logos are trademarks of SD-3C, LLC.

• Portions of this software are copyright 2014 The FreeType Project (www.freetype.org). All rights reserved.

• Celeron, Intel, Intel Core and Intel Atom are trademarks of Intel Corporation in the U.S. and / or other countries.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Introduction

Thank you for purchasing an NA-series Programmable Terminal.

This manual contains information that is necessary to use the NA-series Programmable Terminal.

Please read this manual and make sure you understand the functionality and performance of the

NA-series Programmable Terminal before you attempt to use it in a control system.

Keep this manual in a safe place where it will be available for reference during operation.

Intended Audience

This manual is intended for the following personnel, who must also have knowledge of electrical systems (an electrical engineer or the equivalent).

• Personnel in charge of introducing FA systems.

• Personnel in charge of designing FA systems.

• Personnel in charge of installing and maintaining FA systems.

• Personnel in charge of managing FA systems and facilities.

Introduction

Applicable Products

This manual covers the following products.

• NA-series Programmable Terminals NA5-

W-V1

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

1

Page 4

Relevant Manuals

Relevant Manuals

The basic information required to use an NA-series PT is provided in the following four manuals.

• NA-series Programmable Terminal Hardware User’s Manual (Cat. No. V117)

• NA-series Programmable Terminal Hardware(-V1) User's Manual (Cat. No. V125)

• NA-series Programmable Terminal Software User’s Manual (Cat. No. V118)

• NA-series Programmable Terminal Device Connection User’s Manual (Cat. No. V119)

• NA-series Programmable Terminal Soft-NA User's Manual (Cat. No. V126)

Operations are performed from the Sysmac Studio Automation Software.

Refer to the Sysmac Studio Version 1 Operation Manual (Cat. No. W504) for information on the Sys-

mac Studio.

Other manuals are necessary for specific system configurations and applications.

The following manual is also available to walk you through installations and operations up to starting

actual operation using simple examples.

Refer to it as required.

• NA-series Programmable Terminal Startup Guide Manual (Cat. No. V120)

2

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 5

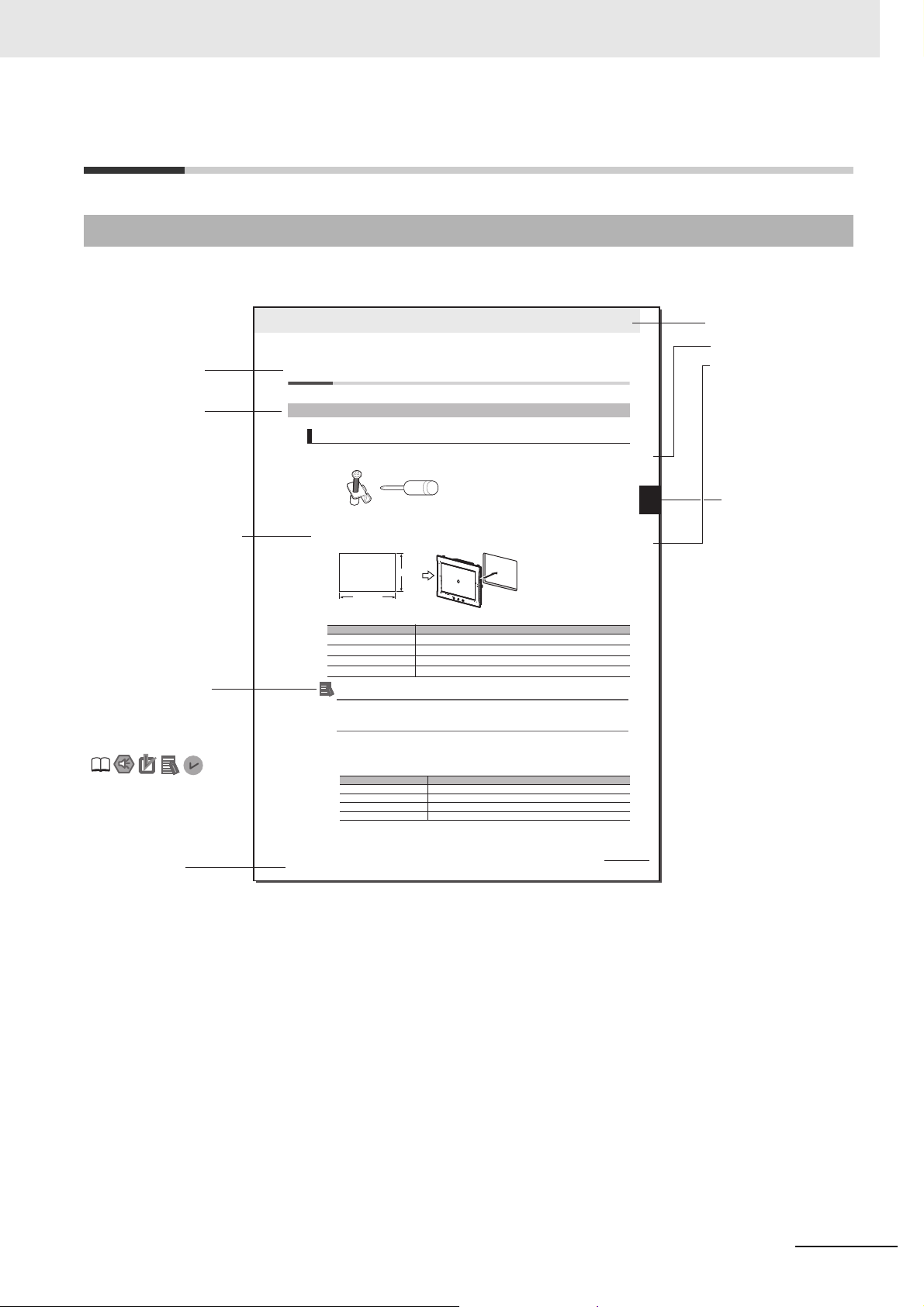

Manual Structure

Level 1 heading

Level 2 heading

Level 3 heading

Level 2 heading

A step in a procedure

Manual name

Special information

Level 3 heading

Page tab

Give the current

headings.

Indicates a procedure.

Icons indicate precautions,

additional information, or

reference information.

Gives the number

of the main section.

3 - 5

3 Installation and Wiring

NA Series Programmable Terminal Hardware User’s Manual (V117)

3-3 Installing NA-series PTs

3

3-3-1 Installation in a Control Panel

3-3 Installing NA-series PTs

The NA-series PT is installed by embedding it in a control panel. Panel Mounting Brackets and a Phillips screwdriver are

required to mount the NA-series PT. The required number of Panel Mounting Brackets are included with the NA-series PT.

Use the following installation procedure.

1 Open a hole in which to embed the NA-series PT with the following dimensions and insert the

NA-series PT from the front side of the panel.

Additional Information

You can use an NS-USBEXT-1M USB Relay Cable to extend the USB slave connector on the

back panel of the NA-series PT to the front surface of a control panel. If you use the USB Relay

Cable, open a hole with the following dimensions and install the Cable.

2 Attach the panel mounting brackets from the back of the panel as shown in the following figure.

The number of mounting brackets depends on the size of the NA-series PT, as shown in the following

table. Refer to Bracket Mounting Locations for Different NA-series PT Sizes on page 3-8, below.

Catch the brackets in the mounting holes in the NA-series PT, pull forward lightly, and then use

a Phillips screwdriver to tighten the screws and secure the NA-series PT to the panel, which will

be held between the mounting brackets and the NA-series PT.

3-3-1 Installation in a Control Panel

Installation in a Control Panel

Model Dimensions

NA5-15W

392

+1/-0

× 268

+1/-0

mm (horizontal × vertical)

NA5-12W

310

+1/-0

× 221

+1/-0

mm (horizontal × vertical)

NA5-9W

261

+1/-0

× 166

+1/-0

mm (horizontal × vertical)

NA5-7W

197

+ 0.5/-0

× 141

+0.5/-0

mm (horizontal × vertical)

Model Number of Panel Mounting Brackets

NA5-15W 8 locations

NA5-12W 6 locations

NA5-9W 4 locations

NA5-7W 4 locations

Panel Mounting Bracket Phillips screwdriver

Vertical

Horizontal

Recommended panel thickness: 1.6 to 6.0 mm

Page Structure and Markings

The following page structure is used in this manual.

Manual Structure

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Note This illustration is provided only as a sample. It may not literally appear in this manual.

3

Page 6

Manual Structure

Precautions for Safe Use

Precautions for Correct Use

Additional Information

Version Information

Special Information

Special information in this manual is classified as follows:

Precautions on what to do and what not to do to ensure safe usage of the product.

Indicates precautions on what to do and what not to do to ensure proper operation and performance.

Additional information to read as required.

This information is provided to increase understanding or make operation easier.

Information on differences in specifications and functionality with different versions is given.

4

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 7

Appendices

Troubleshooting

Maintenance

System Program

Installation and Wiring

Configuration Units

Introduction to the NA-series Programmable Terminals

1

2

3

4

5

6

1

2

3

4

6

5

A

A

I

I

Index

Sections in this Manual

Sections in this Manual

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

5

Page 8

Sections in this Manual

6

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 9

CONTENTS

Introduction .............................................................................................................. 1

Relevant Manuals..................................................................................................... 2

Manual Structure...................................................................................................... 3

Sections in this Manual........................................................................................... 5

Terms and Conditions Agreement ........................................................................11

Safety Precautions................................................................................................. 13

Precautions for Safe Use ...................................................................................... 16

Precautions for Correct Use ................................................................................. 19

CONTENTS

Regulations and Standards .................................................................................. 20

Conformance to Shipbuilding Standards ............................................................ 22

Related Manuals..................................................................................................... 24

Terminology............................................................................................................ 31

Revision History..................................................................................................... 32

Section 1 Introduction to the NA-series Programmable Terminals

1-1 NA-series Programmable Terminals.................................................................................... 1-2

1-1-1 Features...................................................................................................................................... 1-2

1-2 System Configurations ......................................................................................................... 1-4

1-2-1 Connecting to the Support Software........................................................................................... 1-4

1-2-2 Network Configuration with Other Devices................................................................................. 1-4

1-3 Available Products ................................................................................................................ 1-5

1-3-1 NA Units...................................................................................................................................... 1-5

1-3-2 Support Software........................................................................................................................ 1-5

1-3-3 Other Optional Products ............................................................................................................. 1-6

1-4 Specifications ........................................................................................................................ 1-7

1-4-1 General Specifications................................................................................................................ 1-7

1-4-2 Performance Specifications...................................................................................................... 1-10

Section 2 Configuration Units

2-1 NA Units ................................................................................................................................. 2-2

2-1-1 Components and Functions........................................................................................................ 2-2

2-2 SD Memory Cards.................................................................................................................. 2-9

2-2-1 Models and Specifications.......................................................................................................... 2-9

2-2-2 Applications ................................................................................................................................ 2-9

2-2-3 Installing and Removing ............................................................................................................. 2-9

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

7

Page 10

CONTENTS

2-3 USB Memory Devices..........................................................................................................2-11

2-3-1 Models and Specifications ........................................................................................................ 2-11

2-3-2 Applications ............................................................................................................................... 2-11

2-3-3 Installing and Removing ............................................................................................................ 2-11

2-4 Support Software................................................................................................................. 2-13

2-4-1 Connection Methods .................................................................................................................2-13

Section 3 Installation and Wiring

3-1 Processing at Power ON and Power OFF ........................................................................... 3-2

3-1-1 Power ON Operation...................................................................................................................3-2

3-1-2 Power OFF Operation .................................................................................................................3-2

3-2 Fail-safe Measures ................................................................................................................ 3-3

3-2-1 Power ON Sequence ..................................................................................................................3-3

3-3 Installing NA Units................................................................................................................. 3-4

3-3-1 Installation in a Control Panel .....................................................................................................3-5

3-4 Wiring Methods...................................................................................................................... 3-9

3-4-1 Power Supply Wiring...................................................................................................................3-9

3-4-2 Wiring the Ethernet Port............................................................................................................3-12

3-4-3 Wiring the Serial Port ................................................................................................................3-12

3-5 Control Panel Installation ................................................................................................... 3-13

3-5-1 Temperature..............................................................................................................................3-13

3-5-2 Humidity ....................................................................................................................................3-14

3-5-3 Vibration and Shock ..................................................................................................................3-15

3-5-4 Atmosphere ...............................................................................................................................3-15

3-5-5 Electrical Environment ..............................................................................................................3-16

3-5-6 Grounding ................................................................................................................................. 3-19

Section 4 System Program

4-1 System Program and NA Unit Startup Status ..................................................................... 4-2

4-2 System Recovery................................................................................................................... 4-3

4-3 System Menu Overview ........................................................................................................4-6

4-3-1 System Menu Configuration ........................................................................................................4-6

4-3-2 Using the System Menu ..............................................................................................................4-9

4-4 System Menu Details........................................................................................................... 4-11

4-4-1 Display Settings (Project System Menu)................................................................................... 4-11

4-4-2 Language Settings (Project System Menu)...............................................................................4-12

4-4-3 External Device Settings (Project System Menu) .....................................................................4-12

4-4-4 User Accounts (Project System Menu) .....................................................................................4-13

4-4-5 NJ/NX/NY Troubleshooter (Project System Menu) ...................................................................4-14

4-4-6 Alarm Viewer (Project System Menu) .......................................................................................4-26

4-4-7 Project System Menu Settings (Project System Menu) ............................................................4-28

4-4-8 Print Settings (Project System Menu) .......................................................................................4-28

4-4-9 Buzzer Settings (Project System Menu) ...................................................................................4-29

4-4-10 Operation Log Viewer ...............................................................................................................4-30

4-4-11 Safety Monitor...........................................................................................................................4-35

4-4-12 Date & Time Settings (Device System Menu)........................................................................... 4-47

4-4-13 Language Settings (Device System Menu)...............................................................................4-47

4-4-14 Interface Settings (Device System Menu).................................................................................4-48

4-4-15 Brightness Settings (Device System Menu)..............................................................................4-53

4-4-16 Transfer Operations (Device System Menu)............................................................................. 4-54

4-4-17 Hardware Diagnostics (Device System Menu).......................................................................... 4-59

4-4-18 Production Information (Device System Menu)......................................................................... 4-63

8

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 11

Section 5 Troubleshooting

5-1 Operation after an Error........................................................................................................ 5-2

5-1-1 Checking NA Unit Status ............................................................................................................ 5-2

5-1-2 Fatal Errors in the NA Unit.......................................................................................................... 5-3

5-1-3 Nonfatal Errors in the NA Unit .................................................................................................... 5-4

5-2 Troubleshooting .................................................................................................................... 5-5

5-2-1 Confirming NA Unit Operation .................................................................................................... 5-5

5-2-2 Correcting Fatal Errors in the NA Unit ........................................................................................ 5-6

5-2-3 Troubleshooting Non-fatal Errors................................................................................................ 5-6

5-2-4 Causes and Correction When You Cannot Go Online from the Sysmac Studio......................... 5-7

5-2-5 Troubleshooting NA Unit Errors................................................................................................ 5-12

Section 6 Maintenance

6-1 Periodic Maintenance and Inspection ................................................................................. 6-2

6-1-1 Preparations for Problems.......................................................................................................... 6-2

6-1-2 Periodic Inspection ..................................................................................................................... 6-2

6-1-3 Precautions When Replacing the NA Unit .................................................................................. 6-4

6-1-4 Cleaning...................................................................................................................................... 6-4

6-2 Replacing the Battery............................................................................................................ 6-5

6-2-1 Battery Replacement .................................................................................................................. 6-5

6-2-2 Operation without a Battery ........................................................................................................ 6-6

CONTENTS

Appendices

A-1 Dimensions ............................................................................................................................A-2

A-2 Available Products ................................................................................................................A-6

Index

A-1-1 NA Units......................................................................................................................................A-2

A-2-1 Optional Products ....................................................................................................................... A-6

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

9

Page 12

CONTENTS

10

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 13

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and workmanship for a period of twelve months from the date of sale by Omron (or such other period expressed in

writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an amount equal

to the purchase price of the non-complying Product; provided that in no event shall Omron be

responsible for warranty, repair, indemnity or any other claims or expenses regarding the Products

unless Omron’s analysis confirms that the Products were properly handled, stored, installed and

maintained and not subject to contamination, abuse, misuse or inappropriate modification. Return of

any Products by Buyer must be approved in writing by Omron before shipment. Omron Companies

shall not be liable for the suitability or unsuitability or the results from the use of Products in combination with any electrical or electronic components, circuits, system assemblies or any other materials or substances or environments. Any advice, recommendations or information given orally or in

writing, are not to be construed as an amendment or addition to the above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN ANY

WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN CONTRACT,

WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

11

Page 14

Terms and Conditions Agreement

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a complete determination of the suitability of the Product in combination with the end product, machine, system, or other application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system. Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

12

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate; however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 15

Safety Precautions

Indicates a potentially hazardous situation which, if

not avoided, could result in mild or moderate injury or

at the worst, serious injury or death. Additionally,

there may be severe property damage.

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury, or

property damage.

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the NA-series Programmable Terminal. The safety precautions that are provided are extremely important to safety. Always read and heed the information provided in all safety precautions.

The following notation is used.

WARNING

Safety Precautions

Indicates precautions on what to do and what not to do to ensure safe usage of the product.

Indicates precautions on what to do and what not to do to ensure proper operation and performance.

Symbols

Caution

Precautions for Safe Use

Precautions for Correct Use

The circle and slash symbol indicates operations that you must not do.

The specific operation is shown in the circle and explained in text.

This example indicates prohibiting disassembly.

The triangle symbol indicates precautions (including warnings).

The specific operation is shown in the triangle and explained in text.

This example indicates a general precaution.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

13

Page 16

Safety Precautions

WARNING

Warnings

Do not attempt to take the NA Unit apart and do not touch the product inside while the

power is being supplied. Otherwise it may result in electric shock.

Always ensure that the personnel in charge confirm that installation, inspection, and

maintenance were properly performed for the NA Unit. “Personnel in charge” refers to

individuals qualified and responsible for ensuring safety during machine design,

installation, operation, maintenance, and disposal.

Ensure that installation and post-installation checks are performed by personnel in charge

who possess a thorough understanding of the machinery to be installed.

Do not use the input functions such as the touch panel or function keys of the NA Unit, in

applications that involve human life, in applications that may result in serious injury, or for

emergency stop switches.

Do not attempt to disassemble, repair, or modify the NA Unit. It may cause NA Unit to lose

its safety function.

Never press two points or more on the touch panel of the NA Unit at a time. Touching two

points or more interrupts normal touch panel operations.

To conform to UL Type 4X standards, always use the NA5-W-V1 with a

High-pressure Waterproof Attachment (PWA). If you do not use a PWA, there is a risk of

water entry, which may cause severe equipment damage.

Always pay attention to the inside dimensions when you mount a PWA on the

NA5-W-V1. If you do not mount the PWA correctly, there is a risk of water entry,

which may cause severe equipment damage.

14

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 17

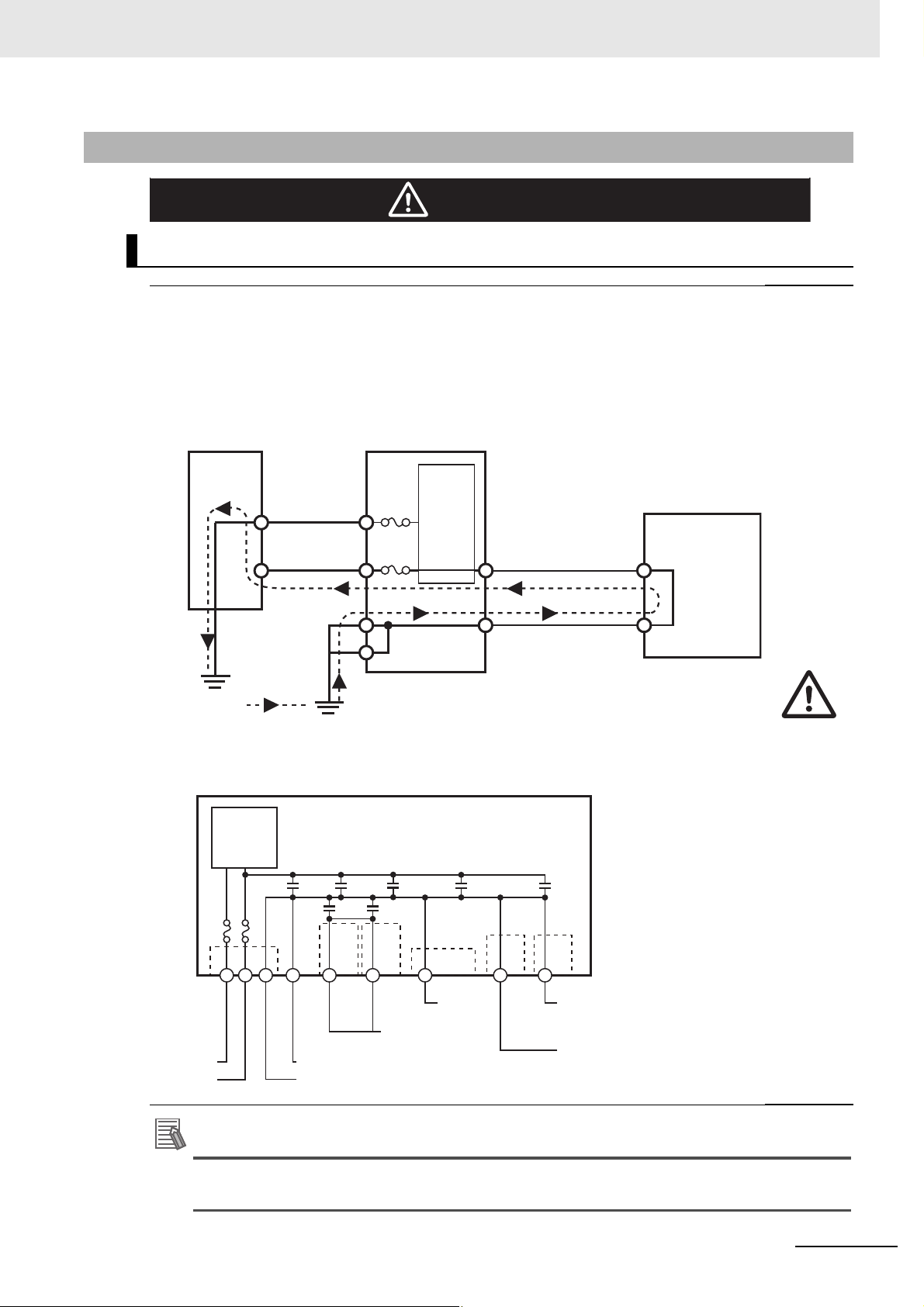

Additional Information

Precaution

WARNING

Internal

non-isolated

power

supply

NA5-W-V1

SG

External

non-isolated

device

SG

24 V

0 V

+

GND

Power

Supply

Grounding

Grounding

Protective ground

Functional ground

Shielded

cable

Hood

PC

USB memory device

Hood

Fuse

Fuse

Non-isolated

power

supply

24 VDC

GND

PE (Protective ground)

Ethernet

connector

hood

Serial

connector

hood

USB slave

connector

hood

USB host

connector

hood

FG (Functional ground)

Wiring

Observe the following precautions when wiring the NA5-W-V1.

The internal power supply in the NA5-W-V1 is a non-isolated DC power supply. Never

ground the 24 V side. If the 24 V power supply to the NA is grounded positively, a short circuit will

occur as shown below and may result in damage to the device.

24 V Grounding Power Supply

Safety Precautions

NA5-W-V1 grounding diagram

The internal power supply of the NA5-W Product uses an isolated DC power sup-

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

ply, and therefore is not susceptible to the effects of grounding of the 24 V side.

15

Page 18

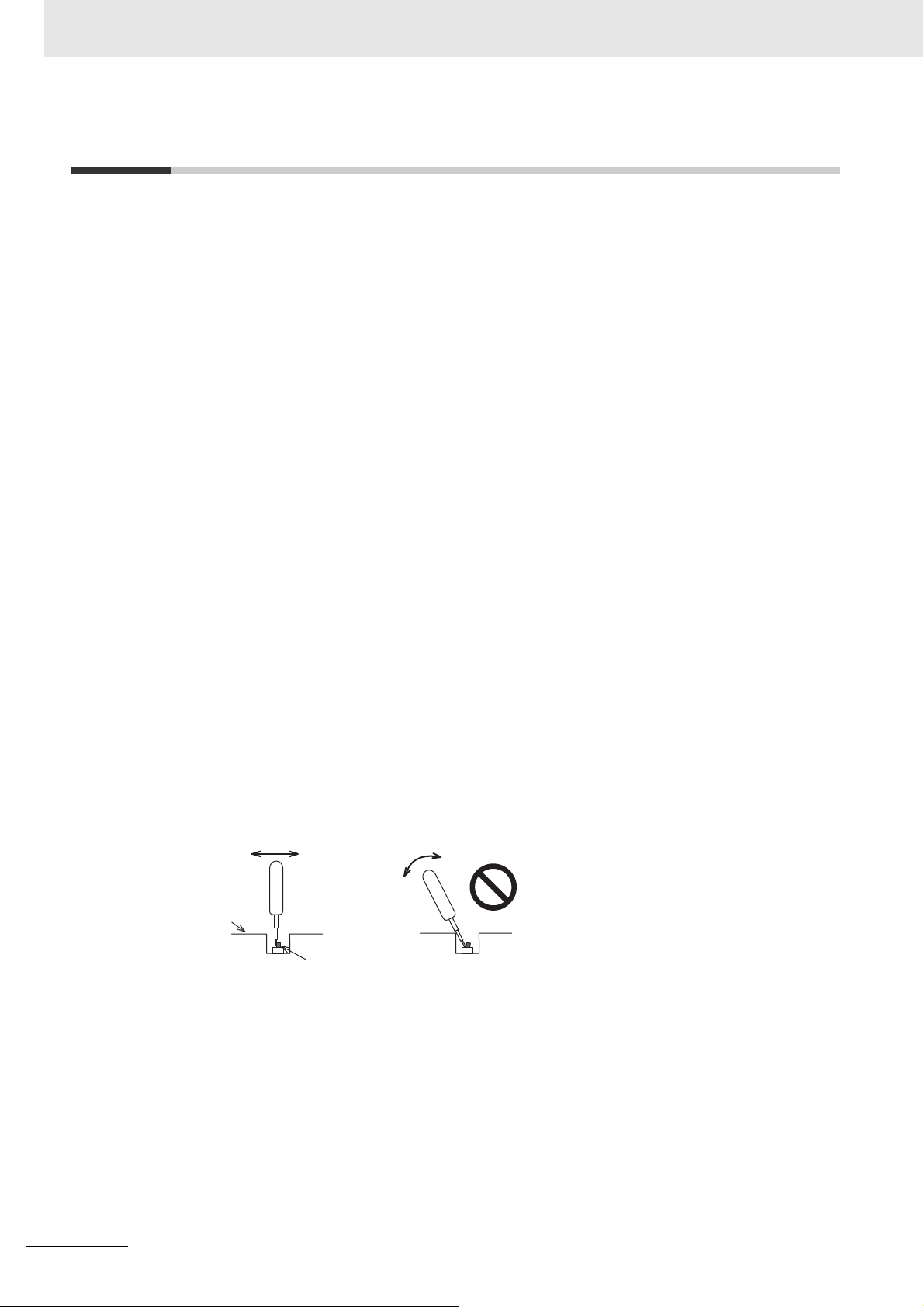

Precautions for Safe Use

Back of the case

DIP switch

Correct technique

Incorrect technique

Precautions for Safe Use

• When unpacking the NA Unit, check carefully for any external scratches or other damages. Also,

shake the NA Unit gently and check for any abnormal sound.

• The NA Unit must be installed in a control panel.

• To conform to UL Type 1 standards, the mounting panel thickness must be 1.6 to 6.0 mm.

To conform to UL Type 4X standards, the thickness must be 1.6 to 4.5 mm.

To conform to UL Type 4X standards, always use the NA5-W-V1 with a High-pressure

Waterproof Attachment (PWA). If you do not use a PWA, there is a risk of water entry, which may

cause severe equipment damage. Do not use the NA Unit outdoors. Tighten the Mounting Brackets

evenly to a torque of between 0.5 and 0.6 N·m to maintain water and dust resistance. If the tightening

torque exceeds the specified value, or the tightening is not even, deformation of the front panel may

occur. What is more, make sure the panel is not dirty or warped, that the front surface is smooth, and

that the panel is strong enough to hold the NA Unit.

• Do not let metal particles enter the NA Unit when preparing the panel.

• Turn OFF the power supply before connecting or disconnecting cables.

• Periodically check the installation conditions in applications where the NA Unit is subject to contact

with oil or water.

• Be certain to use the cables with lock mechanism such as serial cable or the Ethernet cable after

confirming if it is securely locked.

• Do not touch the packaging part of the circuit board with your bare hands. Discharge any static electricity from your body before handling the board.

• Do not use volatile solvents such as benzene and thinners or chemical cloths.

• Water and oil resistance will be lost if the front sheet is torn or is peeling off. Do not use the NA Unit,

if the front sheet is torn or is peeling off.

• As the rubber packing will deteriorate, shrink, or harden depending on the operating environment,

periodical inspection is necessary.

• Confirm the safety of the system before turning ON or OFF the power supply, or pressing the reset

switch.

• The whole system may stop depending on how the power supply is turned ON or OFF. Turn ON/OFF

the power supply according to the specified procedure.

• Operate DIP switch according to the following way.

16

The DIP switch may break if it is levered with a tool against the case as shown in the figure.

• Once the DIP switch settings are changed, reset by pressing the reset switch, or restart the power

supply.

• Initialize the project, after confirming that existing project is backed up at the Sysmac Studio.

• When changing the password, do not reset or turn OFF the power supply until the writing is completed. A failure to store the password may cause the project to fail to function.

• While uploading or downloading a project or a system program, do not perform the operations as follows. Such operations may corrupt the project or the system program:

• Turning OFF the power supply of the NA Unit.

• Resetting the NA Unit.

• Removing the USB devices or SD card.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 19

Precautions for Safe Use

• Disconnecting the cable between a support tool and the NA Unit.

• Do not connect an AC power supply to the DC power terminals.

• Do not perform a dielectric strength test.

• Use a DC power with a slight voltage fluctuation and that will provide a stable output even if the input

is momentarily interrupted for 10 ms. Also use the one with reinforced insulation or double insulation.

Rated Power Supply Voltage: 24 VDC (Allowable range 19.2 to 28.8 VDC)

• Use a power cable with AWG#12 to #22 thick (0.35 mm

and tighten the terminal screw with the torque in the range of 0.5 to 0.6 N·m. Also confirm if the terminal screw is tighten appropriately.

• Ground the NA Unit correctly.

• When using the NA5-W-V1, to help prevent electrical shock, ground to 100 Ω or less by

using dedicated ground wires (with cross-section area of 2 mm

screw on the protective ground terminal to a torque of 1.0 to 1.2 N·m.

• Do not use any battery if strong impact is applied to it (e.g. by dropping on the floor) because such a

battery may cause a leakage.

• Confirm the type of the battery to install the battery properly.

• Apply power for at least five minutes before changing the battery. Mount a new battery within five

minutes after turning OFF the power supply. If power is not supplied for at least five minutes, the

clock data may be lost. Check the clock data after changing the battery.

• Do not dismantle a battery nor let it short-circuit.

• Do not apply an impact with the lithium battery, charge it, dispose it into a fire, or heat it. Doing either

of them may cause an ignition or a bursting.

• Dispose of the NA Units and batteries according to local ordinances as they apply.

2

to 3.31 mm2). Peel the coating 7 mm length

2

or larger) and tighten the terminal

• The following precaution must be displayed on all products containing lithium primary batteries with a

perchlorate content of 6 ppb or higher when exporting them to or shipping them through California,

USA.

Perchlorate Material - special handling may apply.

See www.dtsc.ca.gov/hazardouswaste/perchlorate

The NA-Series contains a lithium primary battery with a perchlorate content of 6 ppb or higher. When

exporting a product containing the NA-Series to or shipping such a product through California, USA,

label all packing and shipping containers appropriately.

• Do not connect the USB devices in the environment subject to the strong vibration.

• Use a USB memory device for temporary purposes such as data transfer.

• Do not connect USB devices which are not allowed to connect to NA Unit.

• Start actual system application only after checking normal operation of the system including storage

devices such as USB memory and SD card.

• When connecting peripheral devices which do not meet the performance level of the NA Unit for

noise and static electricity, ensure sufficient countermeasures against noise and static electricity during installation of the peripheral devices to the NA Unit.

• Do not carry out the following operations when accessing USB devices or SD card:

• Turning OFF the power supply of the NA Unit

• Press the Reset switch of the NA Unit

• Pull out the USB devices or SD card

• When using the No. 6 pin of the serial port connector for a voltage of DC+5 V, make sure the supply

equipment's current capacity is below 250 mA before using it. The DC+5 V voltage output of the NA

Unit is +5 V±5%, and the maximum current is 250 mA.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

17

Page 20

Precautions for Safe Use

• To ensure the system's safety, make sure to incorporate a program that call periodically signals during the operation at connected device side and can confirm the normal functionality of the NA Unit

before running the system.

• Start actual system application only after sufficiently checking project, subroutine and the operation of

the program at the connected device side.

• To execute a subroutine with multiple threads, fully check the operation of the program that takes

multithreads into consideration, before starting actual system application.

• To use numeric input functions safely, always make maximum and minimum limit settings.

• Do not press the touch panel with a force greater than 30 N.

• Do not use hard or pointed objects to operate or scrub the screen, otherwise the surface of the

screen may be damaged.

• The deterioration over time may cause the touch points to move on the touch panel. Calibrate the

touch panel periodically.

• A touch position detection error of approximately 20 pixels may occur due to the precision of the

touch panel. Always take this into account when positioning objects on the panel so adjoining objects

will not be activated by mistake.

• Confirm the safety of the system before pressing the touch panel.

• Do not accidentally press the touch panel when the backlight is not lit or when the display does not

appear or is too dark to identify visually.

• You can change the brightness by changing the setting such as in the system menu or by downloading project.

If the brightness is set to very dark, it causes flickering or unreadable screen. Additionally, the brightness can be restored by transferring the project again after setting the property of the brightness

appropriately.

In a case of the applications where end users can control the brightness, create the applications so

as keeping on operations by such as assigning the function which restores the brightness to one of

function keys, if necessary.

• Signals from the touch panel may not be entered if the touch panel is pressed consecutively at high

speed. Make sure to go on the next operation after confirming that the NA Unit has detected the input

of the touch panel.

• The function keys have the restrictions as follows:

• When you use gloves or others, the function keys may not work correctly depending on the material and thickness of the gloves. Take actual conditions of the gloves usage into considerations

prior to the system startup to perform the confirmation.

• The function keys do not work when covered with water. Remove the water completely before

use.

18

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 21

Precautions for Correct Use

Do not install or store the NA Unit in any of the following locations:

• Locations subject to severe changes in temperature

• Locations subject to temperatures or humidity outside the range specified in the specifications

• Locations subject to condensation as the result of high humidity

• Locations subject to corrosive or flammable gases

• Locations subject to strong shock or vibration

• Locations outdoors subject to direct wind and rain

• Locations subject to strong ultraviolet light

• Locations subject to dust

• Locations subject to direct sunlight

• Locations subject to splashing oil or chemicals

Precautions for Correct Use

Take appropriate and sufficient countermeasures when installing systems in

the following locations:

• Locations subject to static electricity or other forms of noise

• Locations subject to strong electric field or magnetic field

• Locations close to power supply lines

• Locations subject to possible exposure to radioactivity

Mounting Panel

• To conform to UL Type 1 standards, the mounting panel thickness must be 1.6 to 6.0 mm.

• To conform to UL Type 4X standards, the thickness must be 1.6 to 4.5 mm.

To conform to UL Type 4X standards, always use the NA5-W-V1 with a High-pressure

Waterproof Attachment (PWA). If you do not use a PWA, there is a risk of water entry, which may

cause severe equipment damage.

• Tighten the Mounting Brackets evenly to a torque of between 0.5 and 0.6 N·m to maintain water

and dust resistance. If the tightening torque exceeds the specified range or the tightening is not

even, deformation of the front panel may occur. Make sure the panel is not dirty or warped, that

the front surface is smooth, and that the panel is strong enough to hold the NA Unit.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

19

Page 22

Regulations and Standards

Regulations and Standards

Conformance to EC Directives

Applicable Directives

• EMC Directive

Concepts

EMC Directive

OMRON devices that comply with EC Directives also conform to the related EMC standards so that

they can be more easily built into other devices or the overall machine. The actual products have

been checked for conformity to EMC standards.*

Whether the products conform to the standards in the system used by the customer, however, must

be checked by the customer. EMC-related performance of the OMRON devices that comply with EC

Directives will vary depending on the configuration, wiring, and other conditions of the equipment or

control panel on which the OMRON devices are installed. The customer must, therefore, perform

the final check to confirm that devices and the overall machine conform to EMC standards.

* Applicable EMC (Electromagnetic Compatibility) standards are as follows:

EMS (Electromagnetic Susceptibility): EN 61131-2:2007

EMI (Electromagnetic Interference): EN 61131-2:2007

Conformance to EC Directives

The NA-series PTs comply with EC Directives. To ensure that the machine or device in which the

NA-series PT is used complies with EC Directives, the NA-series PT must be installed as follows:

• The NA Unit must be installed in a control panel.

• You must use reinforced insulation or double insulation for the DC power supplies connected to

the NA Unit.

• NA-series PTs that comply with EC Directives also conform to the Common Emission Standard

(EN 61000-6-4). Radiated emission characteristics (10-m regulations) may vary depending on the

configuration of the control panel used, other devices connected to the control panel, wiring, and

other conditions.

You must therefore confirm that the overall machine or equipment complies with EC Directives.

• This is a Class A product (for industrial environments). In a residential environment, it may cause

radio interference, in which case the user may be required to take appropriate measures.

20

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 23

Conformance to KC Standards

When you use this product in South Korea, observe the following precautions.

This product meets the electromagnetic compatibility requirements for business use. There is a risk of

radio interference when this product is used in home.

Regulations and Standards

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

21

Page 24

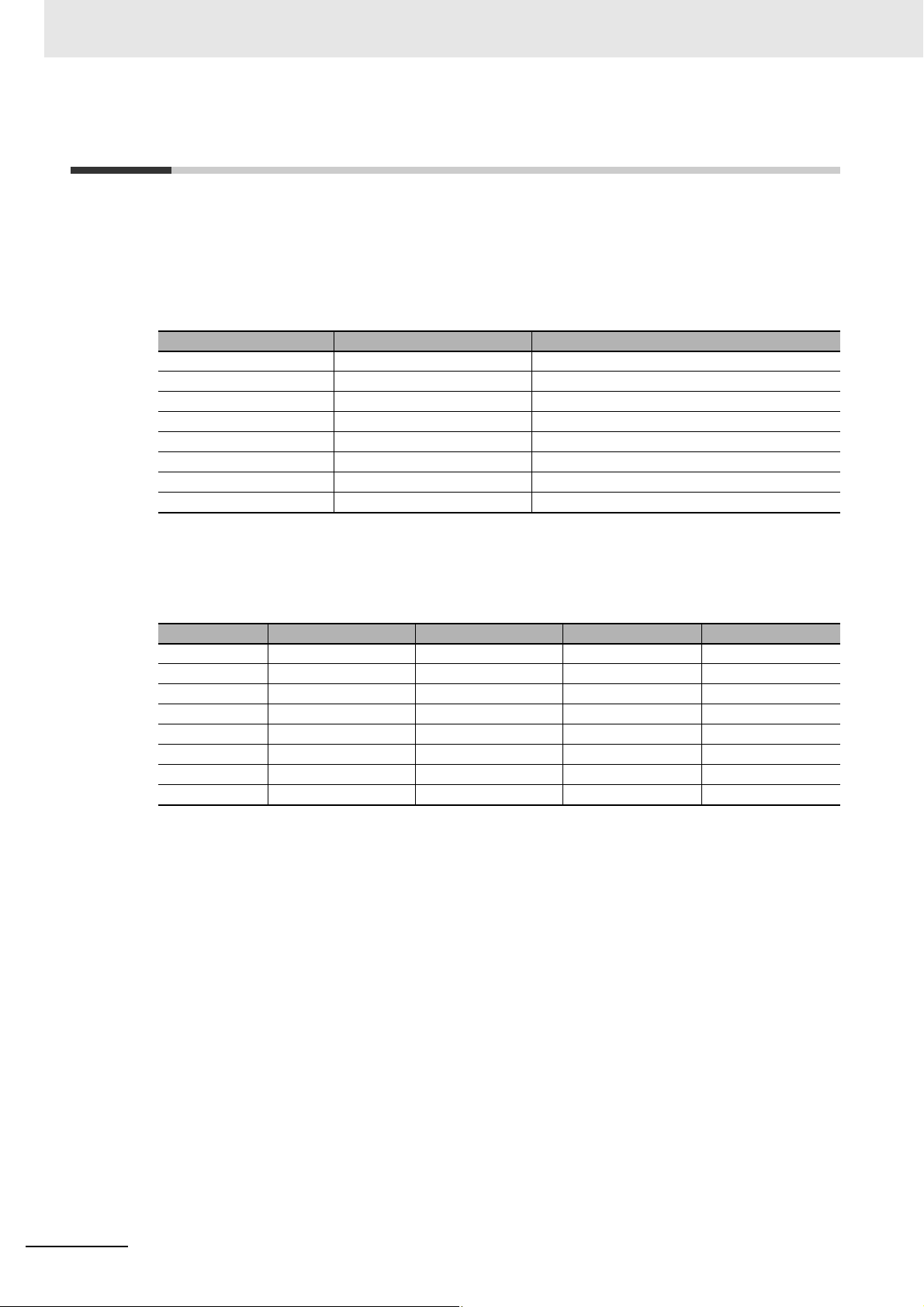

Conformance to Shipbuilding Standards

Conformance to Shipbuilding Standards

The NA-series Programmable Terminals comply with shipping standards. Application conditions are set

for compliance for individual shipping standards, and it may not be possible to use the product in some

installation locations. Contact an OMRON sales representative before using the product.

International Shipping Standards

Shipping Standards of Various Countries

Abbreviation Country Name

NK Japan ClassNK

LR Great Britain Lloyd’s Register of Shipping

DNV·GL Norway and Germany Det Norske Veritas Germanischer Lloyd

RINA Italy Registro Italiano Navale

BV France Bureau Veritas

ABS USA American Bureau of Shipping

KR South Korea Korean Register of Shipping

CR Taiwan China Corporation Register of Shipping

Certification Status for NA Units

The following table shows the certification status with shipping standards for NA Units as of December 2019. For the latest applicable standards for each model, refer to our website

(www.fa.omron.co.jp or www.ia.omron.com) or check with your OMRON representative.

Abbreviation NA5W-15-V1 NA5W-12-V1 NA5W-9-V1 NA5W-7-V1

NK Certified Certified Certified Certified

LR Certified Certified Certified Certified

DNV·GL Certified Certified Certified Certified

RINA Uncertified Uncertified Uncertified Uncertified

BV Certified Certified Certified Certified

ABS Uncertified Uncertified Uncertified Uncertified

KR Uncertified Uncertified Uncertified Uncertified

CR Uncertified Uncertified Uncertified Uncertified

22

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 25

Conformance to Shipbuilding Standards

Certification Zones for Shipping Standards

b. Bridge

a. Deck

Ocean

e. Boiler room

Air conditioning

No air conditioning

d. Engine room

a. Deck zone

b. Zones with and without air conditioning on the bridge (e.g., helm room)

c. Depends on the ship type. Emergency power supply devices on bulk carrier ships carrying lique-

fied gas or hazardous chemicals.

d. Engine room zone (devices mounted on machinery that has strict vibration conditions, such as

diesel engines or air compressors)

Air conditioning

No air conditioning

Devices on deck or bridge

Devices not on deck or bridge

c. Depends on ship type

Emergency power supply devices on

bulk carrier ships carrying liquefied

gas or hazardous chemicals

e. Zones with and without air conditioning not on the bridge or deck (e.g., boiler room)

NA Unit Certification Zones for Shipping Standards

Stan-

dards

NK

LR

DNV·GL

RINA

BV

ABS

KR

CR

b. Bridge c. Ship

a. Deck

No air con-

ditioning

Uncertified Certified

Uncertified Certified Certified Uncertified Uncertified Certified Certified

Uncertified

Uncertified

Uncertified

Uncertified

Uncertified

Uncertified

Certified Certified

Uncertified Uncertified

Certified Certified Uncertified Uncertified Certified Certified

Uncertified Uncertified Uncertified Uncertified Uncertified Uncertified

Uncertified Uncertified Uncertified Uncertified Uncertified Uncertified

Uncertified Uncertified Uncertified Uncertified Uncertified Uncertified

With air

condition-

ing

Certified

type (e.g.,

bulk ship

with lique-

fied gas)

Uncertified Uncertified Certified Certified

Uncertified Uncertified

Uncertified Uncertified

d. Engine

(e.g.)

e. Not on deck or bridge

No air con-

ditioning

Certified Certified

Uncertified Uncertified

Precautions for Compliance with Shipping Standards

Always install the NA Unit in a control panel.

With air

condition-

ing

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

23

Page 26

Related Manuals

Related Manuals

The following manuals are related to the NA-series PTs. Use these manuals for reference.

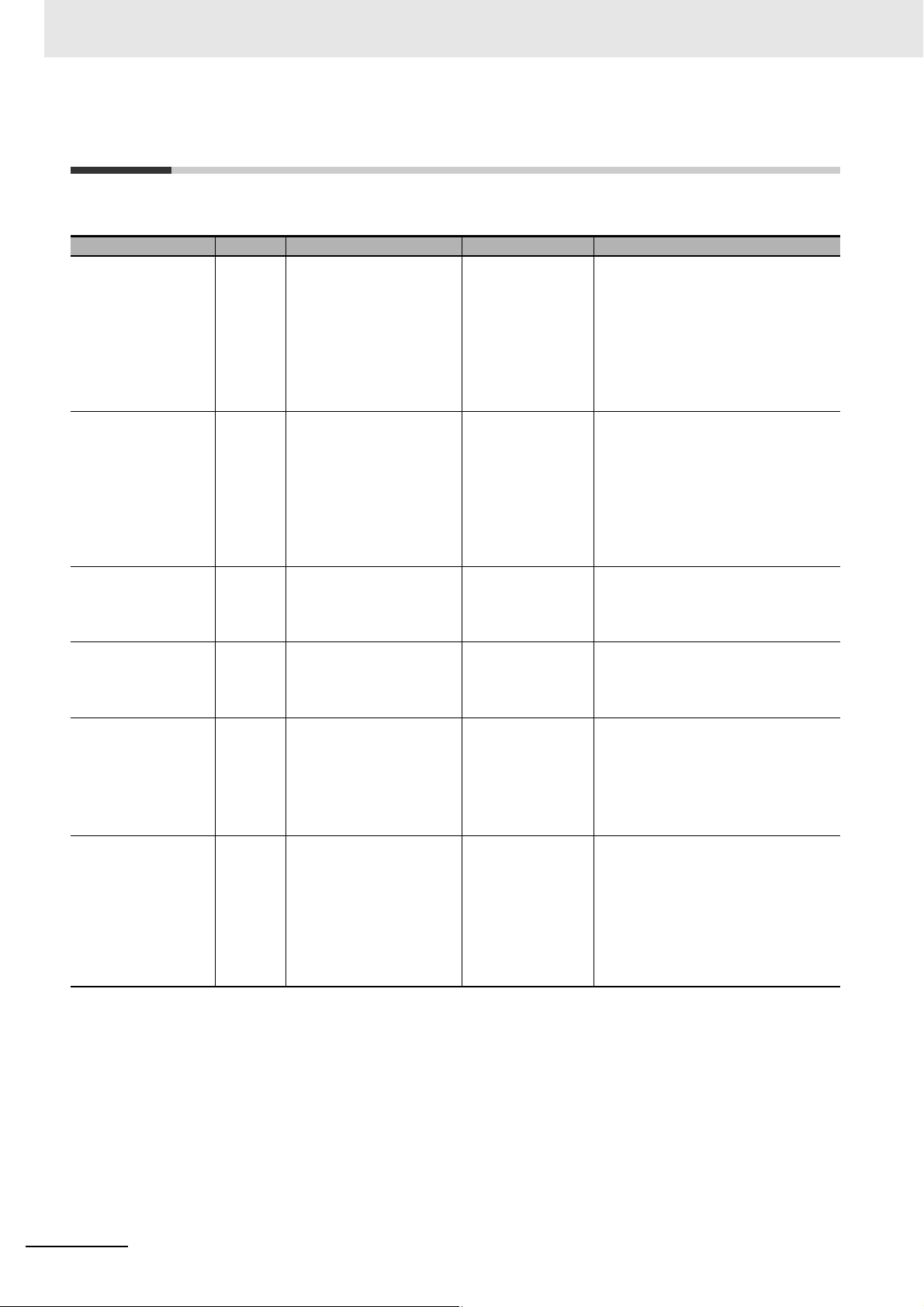

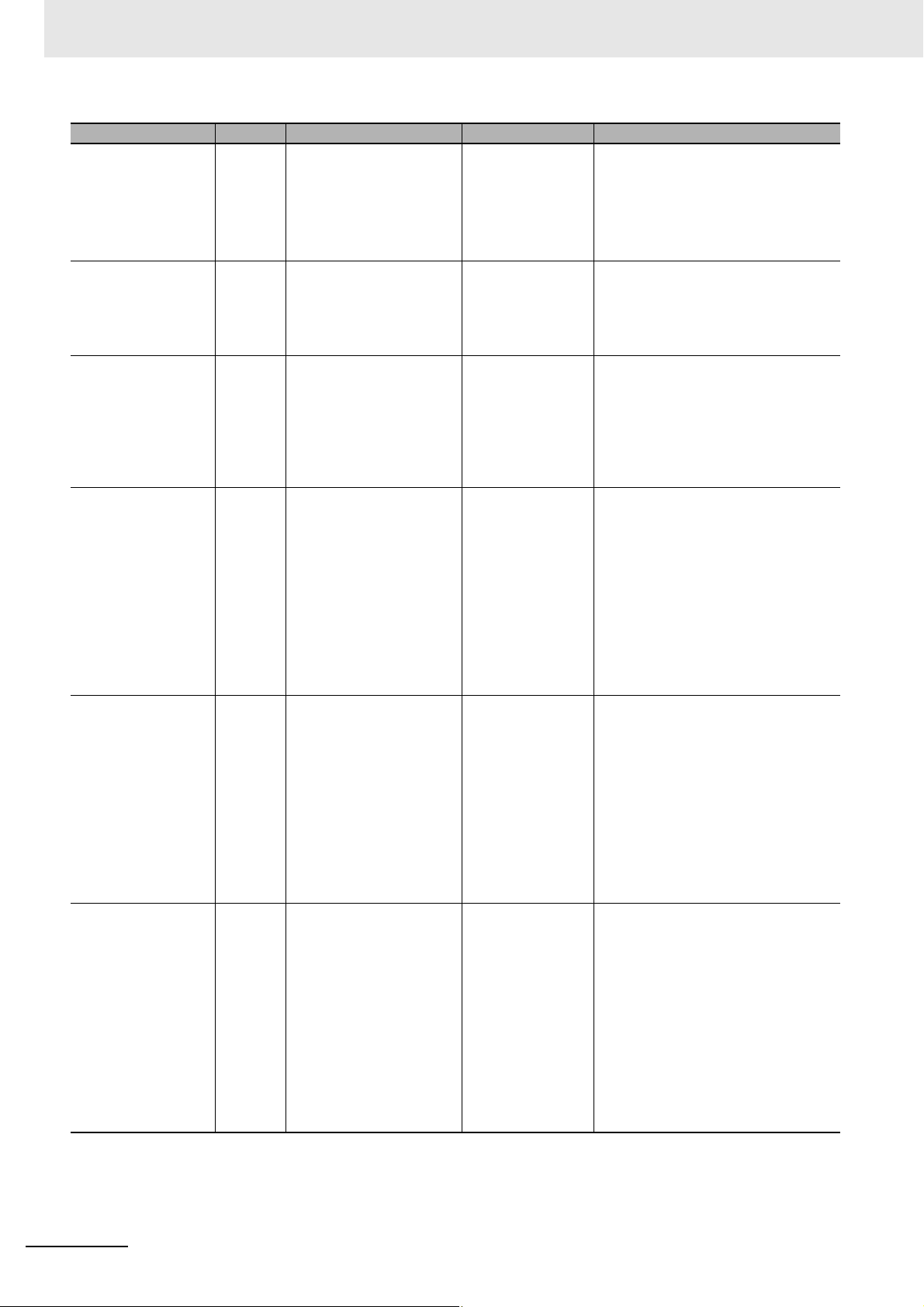

Manual name Cat. No. Models Applications Description

NA-series Programmable Terminal Hardware User’s Manual

NA-series Programmable Terminal Hardware(-V1) User’s

Manual

NA-series Programmable Terminal Software User’s Manual

NA-series Programmable Terminal

Device Connection

User’s Manual

NA-series Programmable Terminal

Soft-NA User’s Manual

NA-series Programmable Terminal

Startup Guide

V117 NA5-W

V125 NA5-W-V1

V118 NA5-W(-V1)

V119 NA5-W(-V1) Learning the speci-

V126 NA-RTLD Learning about the

V120 NA5-W Learning in con-

Learning the specifications and settings required to

install an NA-series

PT and connect

peripheral devices.

Learning the specifications and settings required to

install an NA-series

PT and connect

peripheral devices.

Learning about

NA-series PT pages

and object functions.

fications required

to connect devices

to an NA-series PT.

procedure to install

the Soft-NA and

differences from

the NA5 series.

crete terms information required to

install and start the

operation of an

NA-series PT.

Information is provided on NA-series

PT specifications, part names, installation procedures, and procedures to

connect an NA Unit to peripheral

devices.

Information is also provided on maintenance after operation and troubleshooting.

Information is provided on NA-series

PT specifications, part names, installation procedures, and procedures to

connect an NA Unit to peripheral

devices.

Information is also provided on maintenance after operation and troubleshooting.

NA-series PT pages and object functions are described.

Information is provided on connection

procedures and setting procedures to

connect an NA-series PT to a Controller or other device.

Information is provided on the specifications of the Soft-NA and differences

from the NA5 series.

Information is also provided on maintenance after operation and troubleshooting.

The part names and installation procedures are described followed by page

creation and transfer procedures with

the Sysmac Studio. Also operation,

maintenance, and inspection procedures after the project is transferred

are described. Sample screen captures are provided as examples.

24

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 27

Related Manuals

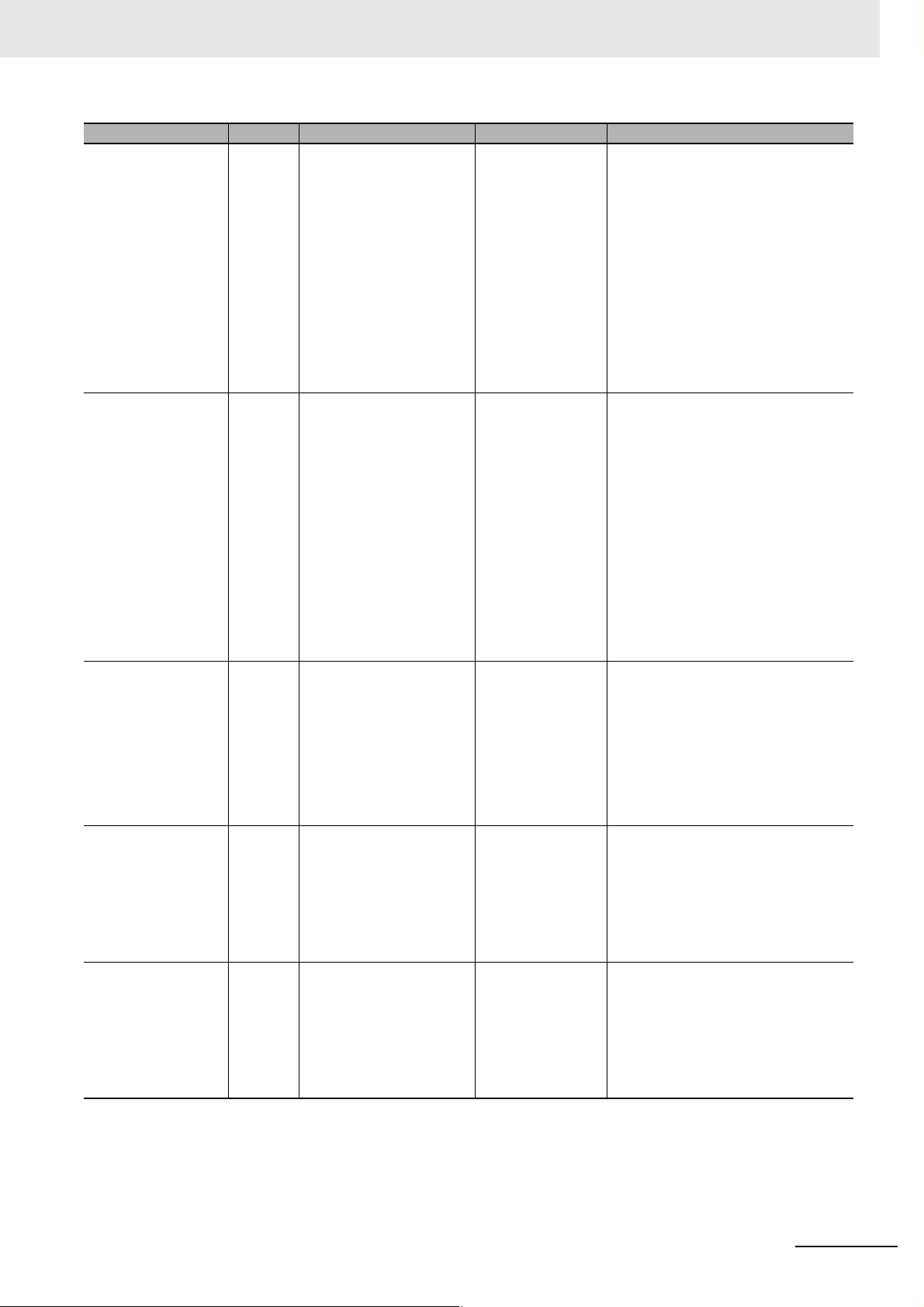

Manual name Cat. No. Models Applications Description

NX-series CPU Unit

Hardware User's

Manual

NJ-series CPU Unit

Hardware User’s

Manual

NJ/NX-series CPU

Unit Software User´s

Manual

NJ/NX-series Instructions Reference Manual

NJ/NX-series Troubleshooting Manual

W535 NX701- Learning the basic

specifications of

the NX-series CPU

Units, including

introductory information, designing,

installation, and

maintenance.

Mainly hardware

information is provided.

W500 NJ501-

NJ301-

NJ101-

W501 NX701-

NX1P2-

NX102-

NJ501-

NJ301-

NJ101-

W502 NX701-

NX102-

NX1P2-

NJ501-

NJ301-

NJ101-

W503 NX701-

NX102-

NX1P2-

NJ501-

NJ301-

NJ101-

Learning the basic

specifications of

the NJ-series CPU

Units, including

introductory information, designing,

installation, and

maintenance.

Mainly hardware

information is provided.

Learning how to

program and set

up an

NJ/NX-series CPU

Unit.

Mainly software

information is provided.

Learning detailed

specifications on

the basic instructions of an

NJ/NX-series CPU

Unit.

Learning about the

errors that may be

detected in an

NJ/NX-series Controller.

An introduction to the entire NX-series

system is provided along with the following information on the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Use this manual together with the

NJ/NX-series CPU Unit Software

User's Manual (Cat. No.W501).

An introduction to the entire NJ-series

system is provided along with the following information on a Controller

built with a CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Inspection and maintenance

Use this manual together with the

NJ-series CPU Unit Software User’s

Manual (Cat. No. W501).

Provides the following information on

a Controller built with an NJ/NX-series

CPU Unit.

• CPU Unit operation

• CPU Unit features

• Initial settings

• Programming based on IEC

61131-3 language specifications

The instructions in the instruction set

(IEC 61131-3 specifications) are

described.

Concepts on managing errors that

may be detected in an NJ/NX-series

Controller and information on individual errors are described.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

25

Page 28

Related Manuals

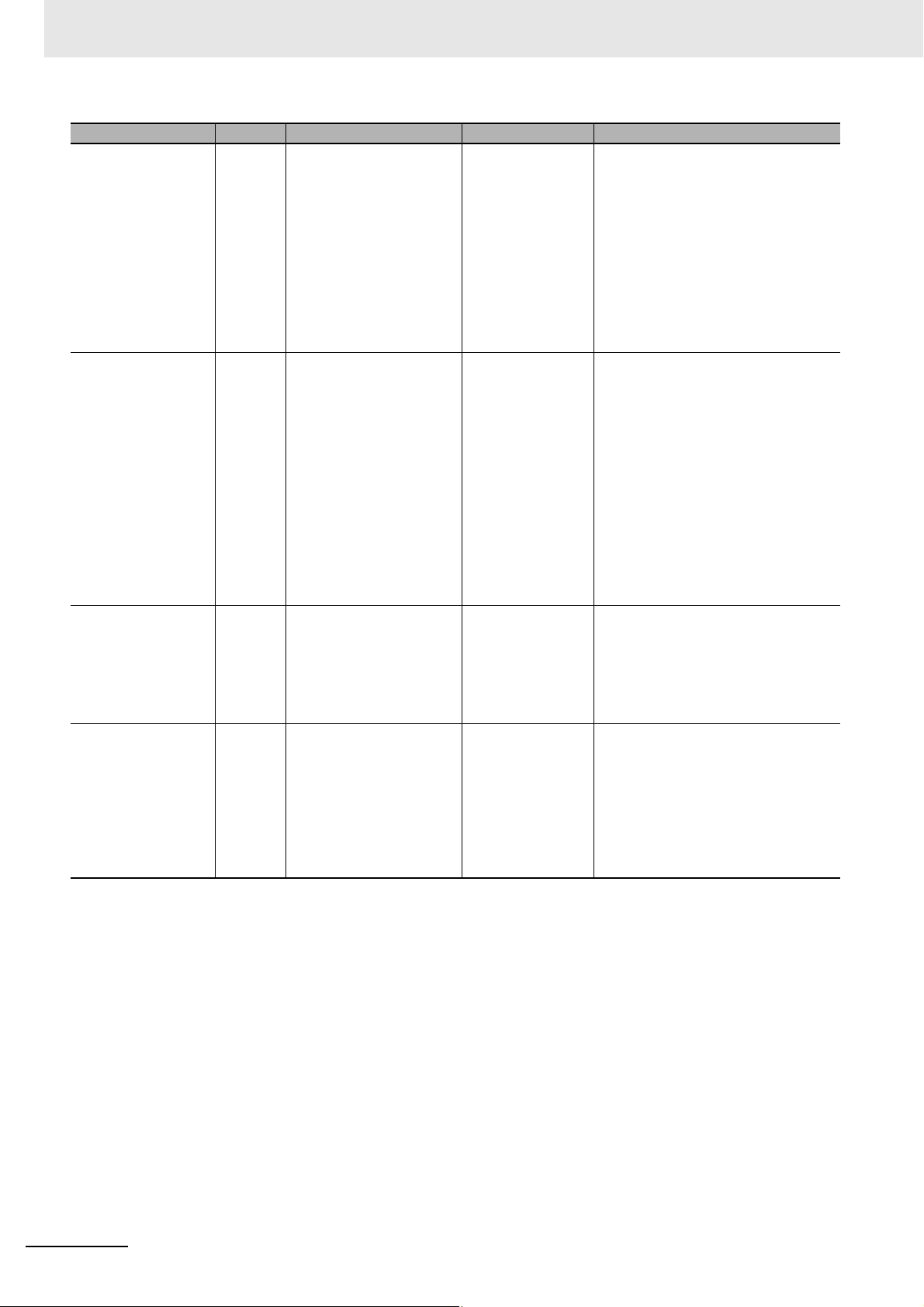

Manual name Cat. No. Models Applications Description

CJ Series Programmable Controllers

Operation Manual

CS/CJ/NSJ Series

Programmable Controllers Operation

Manual

CS/CJ/NSJ Series

Instructions Reference Manual

CS/CJ Series Programming Consoles

Operation Manual

W393 CJ1H-CPUH-R

CJ1G/H-CPUH

CJ1G-CPUP

CJ1M-CPU

CJ1G-CPU

W394 CS1G/H-CPUH

CS1G/H-CPU-V1

CS1D-CPUH

CS1D-CPUS

CJ1H-CPUH-R

CJ1G/H-CPUH

CJ1G-CPUP

CJ1M-CPU

CJ1G-CPU

NSJ-(B)-G5D

NSJ-(B)-M3D

W340 CS1□-CPU--

CJ1□-CPU--

CJ2H-CPU--

NSJ--

W341 CQM1H-PRO01

CQM1-PRO01

C200H-PRO27

+CS1W-KS001

Learning the basic

specifications of

the CJ-series

PLCs, including

introductory information, designing,

installation, and

maintenance.

Learning about the

functions of the

CS/CJ-series and

NSJ-series PLCs.

Learning detailed

information on programming instructions.

Learning the operating procedures of

the Programming

Consoles.

The following information is provided

on a CJ-series PLC.

• Introduction and features

• System configuration design

• Installation and wiring

• I/O memory allocation

• Troubleshooting

Use this manual together with the

Programming Manual (Cat. No.

W394).

The following information is provided

on a CS/CJ-series or NSJ-series

PLC.

• Programming

• Master function

• File memory

• Other functions

Use this manual together with the

Operation Manual (CS-series PLCs:

W339, CJ-series PLCs: W393).

Instructions are described in detail.

When programming, use this manual

together with the Operation Manual

(CS-se

ries PLCs: W339, CJ-series

PLCs: W393) an

Manual (W394).

The operating procedures of the Programming Consoles are described.

When programming, use this manual

together with the Operation Manual

(CS-series PLCs: W339, CJ-series

PLCs: W393), the Programming Man-

ual (W394), and the Instructions Reference Manual (W340).

d the Programming

26

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 29

Related Manuals

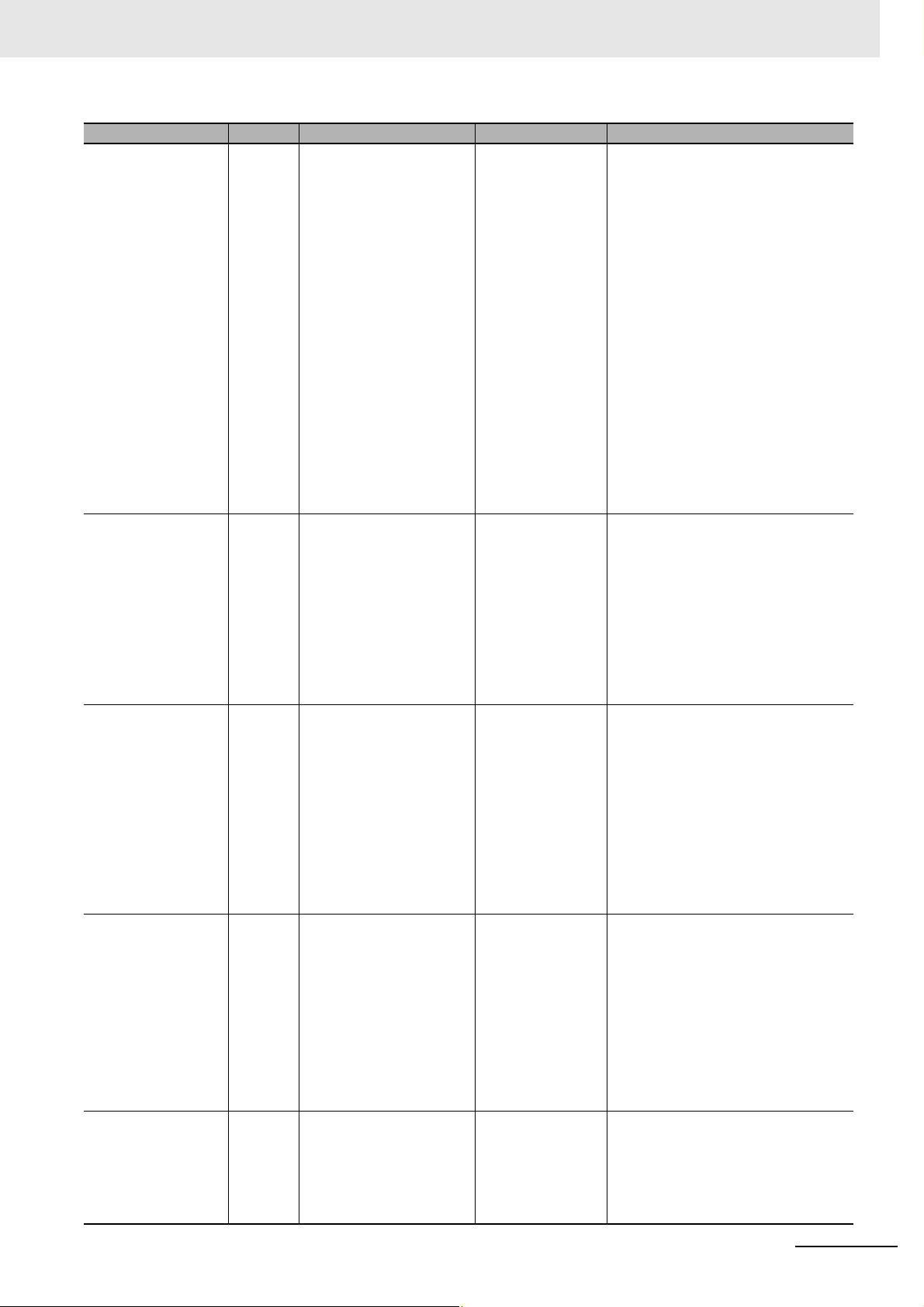

Manual name Cat. No. Models Applications Description

CS/CJ/NSJ Series

Communications

Commands Reference Manual

CJ-series CJ2 CPU

Unit Hardware User’s

Manual

CJ-series CJ2 CPU

Unit Software User’s

Manual

Ethernet Units Operation Manual Construction of Networks

Ethernet Units Operation Manual Construction of

Applications

W342 CS1G/H-CPUH

CS1G/H-CPU-V1

CS1D-CPUH

CS1D-CPUS

CS1W-SCU-V1

CS1W-SCB-V1

CJ1G/H-CPUH

CJ1G-CPUP

CJ1M-CPU

CJ1G-CPU

CJ1W-SCU-V1

W472 CJ2H-CPU6-EIP

CJ2H-CPU6

CJ2M-CPU

W473 CJ2H-CPU6-EIP

CJ2H-CPU6

CJ2M-CPU

W420 CS1W-ETN21

CJ1W-ETN21

W421 CS1W-ETN21

CJ1W-ETN21

Learning detailed

specifications on

the communications instructions

addressed to

CS/CJ-series CPU

Units and

NSJ-series PLCs.

Learning the hardware specifications of CJ2 CPU

Units.

Learning the software specifications of CJ2 CPU

Units.

Learning how to

use an Ethernet

Unit.

Learning how to

use an Ethernet

Unit.

1) C-mode commands and 2) FINS

commands are described in detail.

Refer to this manual for information

on communications commands

(C-mode commands and FINS commands) addressed to CPU Units.

Note This manual describes com-

munications commands that

are addressed to a CPU Unit.

The communications path is

not relevant. (The communications commands can be

sent through the serial communications port of the CPU

Unit, the communications port

of a Serial Communications

Board/Unit, or a communications port on another Commu-

nications Unit.)

The following information is provided

on a CJ2 CPU Unit.

• Introduction and features

• Basic system configuration

• Part names and functions

• Installation and setting procedures

• Troubleshooting

Use this manual together with the Software User’s Manual (Cat. No. W473).

The following information is provided

on a CJ2 CPU Unit.

• CPU Unit operation

• Internal memory

• Programming

• Settings

• Functions built into the CPU Unit

Use this manual together with the

Hardware User’s Manual (Cat. No.

W472).

Information is provided on the Ethernet Units.

Information is provided on the basic

setup and FINS communications.

Refer to the Communications Com-

mands Reference Manual (Cat. No.

W342) for details on FINS commands

that can be sent to CS/CJ-series CPU

Units when using the FINS communications service.

Information is provided on constructing host applications, including functions for sending/receiving mail,

socket service, automatic clock

adjustment, FTP server functions,

and FINS communications.

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

27

Page 30

Related Manuals

Manual name Cat. No. Models Applications Description

CS/CJ-series EtherNet/IP™ Units Operation Manual

Sysmac Studio Version 1 Operation

Manual

CX-Programmer

Operation Manual

NY-Series Industrial

Box PC User's Manual

NY-Series Industrial

Panel PC User's

Manual

NY-Series IPC

Machine Controller

Industrial Box PC

Hardware User's

Manual

W465 CJ2H-CPU6-EIP

CJ2M-CPU3

CS1W-EIP21

CJ1W-EIP21

W504 SYSMAC-SE2 Learning about the

W446 CXONE-ALC-V4

CXONE-ALD-V4

W553 NYB-1 Learning the basic

W555 NYP-1-W

C100

W556 NY512-1 Learning the basic

Learning how to

use the built-in EtherNet/IP port of the

CJ2 CPU Units.

operating procedures and functions of the

Sysmac Studio.

Learning about the

CX-Programmer

except for information on function

blocks, ST programming, and

SFC programming.

specifications of

the NY-series

Industrial Box PCs,

including introductory information,

designing, installation, and maintenance.

Learning the basic

specifications of

the NY-series

Industrial Panel

PCs, including

introductory information, designing,

installation, and

maintenance.

specifications of

the NY-series

Industrial Box PCs,

including introductory information,

designing, installation, and maintenance.

Mainly hardware

information is provided.

Information is provided on the built-in

EtherNet/IP port and EtherNet/IP

Units.

Basic settings, tag data links, FINS

communications, and other functions

are described.

The operating procedures of the Sysmac Studio are described.

The operating procedures of the

CX-Programmer are described.

An introduction to the entire NY-series

system is provided along with the following information on the Industrial

Box PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NY-series

system is provided along with the following information on the Industrial

Panel PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

An introduction to the entire NY-series

system is provided along with the following information on the Industrial

Box PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

28

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 31

Related Manuals

Manual name Cat. No. Models Applications Description

NY-Series IPC

Machine Controller

Industrial Panel PC

Hardware User's

Manual

NY-Series IPC

Machine Controller

Industrial Panel PC /

Industrial Box PC

Software User's Manual

NY-Series Instructions Reference Manual

NY-Series Troubleshooting Manual

NX-series NX1P2

CPU Unit Hardware

User's Manual

W557 NY532-1 Learning the basic

specifications of

the NY-series

Industrial Panel

PCs, including

introductory information, designing,

installation, and

maintenance.

Mainly hardware

information is provided.

W558 NY532-1

NY512-1

W560 NY532-1

NY512-1

W564 NY532-1

NY512-1

W578 NX1P2- Learning the basic

Learning how to

program and set

up the Controller

functions of an

NY-series Industrial PC.

Learning detailed

specifications on

the basic instructions of an

NY-series Industrial PC.

Learning about the

errors that may be

detected in an

NY-series Industrial PC.

specifications of

the NX-series

NX1P2 CPU Units,

including introductory information,

designing, installation, and maintenance.

Mainly hardware

information is provided.

An introduction to the entire NY-series

system is provided along with the following information on the Industrial

Panel PC.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

The following information is provided

on the NY-series Controller functions.

• Controller operation

• Controller features

• Controller settings

• Programming based on IEC

61131-3 language specifications

The instructions in the instruction set

(IEC 61131-3 specifications) are

described.

Concepts on managing errors that

may be detected in an NY-series Controller and information on individual

errors are described.

An introduction to the entire NX1P

system is provided along with the following information on the NX1P2

CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

29

Page 32

Related Manuals

Manual name Cat. No. Models Applications Description

NX-series NX1P2

CPU Unit Built-in I/O

and Option Board

User's Manual

NX-series NX102

CPU Unit Hardware

User's Manual

NX-series Safety

Control Unit / Communication Control

Unit User’s Manual

NX-series Communication Control Unit

Built-in Function

User’s Manual

W579 NX1P2- Learning about the

details of functions

only for an

NX-series NX1P2

CPU Unit and an

introduction of

functions for an

NJ/NX-series CPU

Unit.

W593 NX102- Learning the basic

specifications of

NX102 CPU Units,

including introductory information,

design, installation, and maintenance. Mainly

hardware information is provided.

Z395 NX-SL5

NX-SI

NX-SO

NX-CSG

Z396 NX-CSG Learning about the

Learning how to

use the NX-series

Safety Control

Units and Communications Control

Units.

built-in functions of

an NX-series Communications Control Unit.

Of the functions for an NX1P2 CPU

Unit, the following information is provided.

• Built-in I/O

• Serial Option Boards

• Analog Option Boards

An introduction of following functions

for an NJ/NX-series CPU Unit is also

provided.

• Motion control functions

• EtherNet/IP communications functions

• EtherCAT communications functions

An introduction to the entire NX102

system is provided along with the following information on the CPU Unit.

• Features and system configuration

• Introduction

• Part names and functions

• General specifications

• Installation and wiring

• Maintenance and inspection

Describes the hardware, setup methods, and functions of the NX-series

Safety Control Units and Communications Control Units.

Describes the software setup methods and communicantions functions

of an NX-series Communications

Control Unit.

30

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 33

Terminology

Term Description

HMI A general term for interface devices that indicates both hardware and software elements. In

this manual, “HMI” refers to an OMRON Sysmac-brand product unless otherwise specified.

PT The hardware elements of the HMI.

NA Series The NA Series of Programmable Terminals and peripheral devices.

NA5 Series NA5-W-V1 and NA5-.

HMI Project A Sysmac Studio project for an HMI.

NA Unit An NA-series Programmable Terminal.

Download Transferring data from the Sysmac Studio to an HMI.

Upload Transferring the project from an HMI to the Sysmac Studio.

IAG collection When you provide IAGs, you provide them as IAG collections. IAGs are also imported as

IAG collections. An IAG collection contains one or more IAGs.

Terminology

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

31

Page 34

Revision History

Cat. No.

V125-E1-01

Revision code

Revision History

A manual revision code appears as a suffix to the catalog number on the front and back covers of the

manual.

Revision code Date Revised content

01 April 2020 Original production

32

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 35

Introduction to the NA-series Programmable Terminals

This section describes the features, basic system configuration, specifications, and

overall operating procedure of the NA-series Programmable Terminals.

1-1 NA-series Programmable Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-1-1 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-1 Connecting to the Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-2-2 Network Configuration with Other Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

1-3 Available Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3-1 NA Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3-2 Support Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

1-3-3 Other Optional Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-4-1 General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

1-4-2 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

1

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

1 - 1

Page 36

1 Introduction to the NA-series Programmable Terminals

NJ/NX/NY-series Controller

Ethernet

NA-series PT

Automation Software

Sysmac Studio

Specifications with Only

Variables from Objects on

Screens

Programming with

Variables to Eliminate

Worrying about the

Memory Map

1-1 NA-series Programmable Terminals

The NA-series Programmable Terminals represent the next generation of HMIs for industrial applications. They display information on FA manufacturing sites and function as control interfaces while providing safety, reliability, and maintainability. They provide all of the functions of traditional programmable

terminals with a clearer, easy-to-use interface.

OMRON offers the new Sysmac Series of control devices designed with unified communications specifications and user interface specifications.

The NA-series Programmable Terminals are Sysmac devices that you can use together with the

NJ/NX/NY-series Machine Automation Controllers and the Sysmac Studio Automation Software to

achieve optimum functionality and ease of operation.

If you connect an NA-series Programmable Terminal to an NJ/NX/NY-series Controller, all you have to

do to specify memory in the Controller is to specify the Controller variables for the objects on the Programmable Terminal screens. This allows you to create screens without being concerned with the

memory map of the Controller.

1-1-1 Features

1 - 2

Hardware Features

High-resolution Display Panels

High-resolution display panels are used to more clearly display large amounts of information than

was possible with previous OMRON products.

Two Ethernet Ports (Standard Feature)

You can use both Ethernet ports to separate the segment attached to control devices from the segment attached to maintenance devices. Access is possible from both segments at the same time.

You can connect the following devices.

• NJ/NX/NY-series Controllers

•PLCs

•Computers

• Sysmac Studio

NA-series Programmable Terminal Hardware(-V1) User’s Manual (V125)

Page 37

1 Introduction to the NA-series Programmable Terminals

Standard-feature SD Memory Card Slot

You can use an SD Memory Card inserted in the NA Unit to automatically transfer the project you

created on the Sysmac Studio to the NA Unit, to update the system program in the NA Unit, or to

save the log data from the NA Unit.

Software Features

1-1 NA-series Programmable

Ter min als

Specifications with Variables for Superior Reusability

If you connect to an NJ/NX/NY-series Controller, all you have to do to specify memory in the Controller is to specify the Controller variables. This allows you to create objects that are not dependent on

specific devices or memory maps. This in turn makes the objects much more reusable than they

were with previous PTs.

Program with Visual Basic

You can use Microsoft’s Visual Basic to program advanced functions that you cannot achieve with

standard objects.

A Wealth of Security Features

The many security features of the NA-series PTs include operation authority settings and execution

restrictions with IDs.

Use the Integrated Development Environment of Sysmac Studio Automation

Software

You use the Sysmac Studio to create applications for the NA-series Programmable Terminals.