Page 1

LD-250 Platform

User's Manual

I642-E-04

Page 2

Copyright Notice

The information contained herein is the property of OMRON, and shall not be reproduced in whole or in

part without prior written approval of OMRON The information herein is subject to change without

notice and should not be construed as a commitment by OMRON The documentation is periodically

reviewed and revised.

OMRON, assumes no responsibility for any errors or omissions in the documentation.

Copyright 2020 by OMRON Corporation. All rights reserved.

Any trademarks from other companies used in this publication are the property of those respective companies.

MPEG Layer-3 audio coding technology licensed from Fraunhofer IIS and Thomson.

Acapela© voice technology licensed from ACAPELAGROUP(https://www.acapela-group.com) Copy-

right 2003, all rights reserved.

Created in the United States of America

Page 3

Table of Contents

Chapter 1: Introduction 11

1.1 Definitions

1.2 Product Description

LD-250 Autonomous Navigation 12

LD-250 Localization 13

Acuity Localization Option 13

Custom Payload Structures 13

Chassis and Drive Train 14

What's Included - Basic Components 15

Optional Features and Components (Partial List) 18

Options for Enhancing Your Payload Structures 19

1.3 Software Overview

LD-250 Software 19

SetNetGo 23

1.4 How Can I Get Help?

Related Manuals 24

Support 24

Download a Debuginfo File for Support 24

Configure the Maintenance Network 25

Obtain a DebugInfo File from SetNetGo 26

11

11

19

24

Chapter 2: Safety 29

2.1 General Hazards

2.2 What to Do in an Emergency

Releasing the Brakes to Move the LD-250 Manually 30

Releasing an E-Stop 31

2.3 Dangers, Warnings, and Cautions

Alert Levels 32

Alert Icons 32

Special Information 34

2.4 User's Responsibilities

Understanding Electrical Hazards 34

Magnetic Field Hazards 35

Qualification of Personnel 35

Payload Movement and Transfer 36

Configurable Warning Buzzer 36

Fleet Management 37

2.5 Environment

General Environmental Conditions 37

20472-000 Rev D LD-250 Platform User's Manual 3

29

30

32

34

37

Page 4

Table of Contents

Public Access 38

Clearances when Operating 38

Obstacles 39

Emergency Stops that are Initiated by AMR Safety Lasers 39

Safety System Overspeed Faults 40

2.6 Intended and Non-intended Use

Intended Use 40

Non-Intended Use 41

LD-250 Modifications 42

2.7 Battery Safety

Battery Safety Precautions 43

Battery Maintenance 43

2.8 Additional Safety Information

Mobile Robot LDSafety Guide (Cat. No. I616) 43

2.9 Disposal

40

42

43

43

Chapter 3: Setup 45

3.1 Overview of LD-250 Setup

Tasks 45

3.2 Transport and Storage

LD-250 Shipping and Storage 46

Battery Shipment 47

3.3 Before Unpacking

3.4 Unpacking Considerations

LD-250 Packaging 48

Battery Carton 53

3.5 Installing the Battery

Access the Battery Compartment 53

Battery Installation Procedure 55

3.6 Attaching the Payload Structure and Options

Attach the Payload Structure 57

Attach LD-250 Options 57

E-Stop Jumper on the LD-250 Core 57

3.7 Installing the Docking Station

Docking Station Features and Parts 59

Docking Station Requirements 60

Required Tools and Fasteners 60

Wall Bracket Mount 61

3.8 Installing Software on your Windows PC

45

46

47

48

53

57

58

65

Chapter 4: Configuration 67

4.1 Settings and Configuration

4 LD-250 Platform User's Manual 20472-000 Rev D

67

Page 5

Table of Contents

Maintenance Ethernet Connection 67

Setting Up Wireless Ethernet 70

4.2 Create a Workspace Map

Map Creation Overview 72

Mapping Tasks 73

4.3 Acceleration, Deceleration, and Rotation Limits

4.4 Supplemental Information

Laser Setup 75

72

74

75

Chapter 5: Payload Structures 77

5.1 Safety

Warning Label 77

Warning Lights 77

Warning Buzzer 78

5.2 Considerations

Performance 78

Weight Constraints 78

Power Consumption 79

Power Limits 79

Payload Bay Access 79

Payload Dimensions and Design 80

Mounting Locations in the Payload Bay 81

AMR Coordinate System 86

Center of Gravity (CG) 86

5.3 Payload-Related Tradeoffs

5.4 Connections Between the LD-250 and a Payload Structure

Operator Panel (HMI)on the Payload 90

E-Stop Considerations when Removing the Operator Panel 91

Optional Connections 91

77

78

90

90

Chapter 6: Connectivity 93

6.1 Connections Required for Set Up

6.2 Payload Bay Connections - LD-250 Core

LD-250 Core Front, Upper 94

LD-250 Core Rear Upper Connectors 100

LD-250 Core Right, Upper 107

Internal LD-250 Core Connections 107

Internal Data Pinouts 109

Internal Power Pinouts 110

Chapter 7: Operation 113

7.1 Operating Environment

Intended Use 113

20472-000 Rev D LD-250 Platform User's Manual 5

93

93

113

Page 6

Table of Contents

Side Clearance 114

Obstacles 114

Environment and Floor 115

Avoiding Potential Immobilization Risks 116

7.2 Typical Operation

7.3 Power and Charging

Battery Indicators and Controls 118

Docking Station 119

Manually Charging the Battery 121

Balancing the Battery 122

7.4 Operator Panel

LD-250 Status Screen 124

E-Stop Buttons 125

Positioning an Optional Payload E-Stop 126

ON Button 126

OFF Button 126

Brake Release Button 127

7.5 Other Controls and Indicators

Indications Provided by Light Discs Light Outputs 127

LD-250 Core Status Indicators 132

7.6 Sensors

Lasers 133

Rear Sensor 134

Other Sensors 137

7.7 Start up the LD-250

LD-250 Start Up Procedure 137

Joystick Controls and Description 138

117

118

123

127

133

137

Chapter 8: Maintenance 141

8.1 Considerations During Maintenance

8.2 After Completing Maintenance

8.3 Safety Considerations when Performing Maintenance

Understanding Electrical Hazards 145

Understanding Burn Hazards 145

Understanding Magnetic Field Hazards 145

8.4 Lifting the LD-250 Safely

8.5 Wheel Lift Tool

8.6 Engage and Disengage the Drive Wheel Motors

8.7 Safety Inspection

Warning Devices 149

Warning Labels 150

8.8 Cleaning

6 LD-250 Platform User's Manual 20472-000 Rev D

142

142

144

145

146

148

149

151

Page 7

Table of Contents

Work Area Maintenance 151

Platform Cleaning 151

Lubricating Casters 153

Cleaning ESDCasters 156

Cleaning the Rear Sensor 157

8.9 Maintaining and Replacing Batteries

Maintaining Batteries 157

Replacing the Battery 157

8.10 Replacing Non-Periodic Parts

Distance Traveled by the AMR 161

Docking Station Roller and Bearing 161

Docking Station ACPower and Internal Fuses 163

Light Discs 163

Operator Panel 164

Replace the Motor Brushes 164

Replace the Drive Wheels 165

Replacing Drive Wheels 166

Replace Front or Rear Casters 167

LD-250 Core 170

E-Stop and Safety Laser Commissioning 173

Accessing the Payload Bay 175

Removing and Installing Skins 175

Restoring the Configuration 183

157

160

Chapter 9: Options 185

9.1 Fleet Manager for Multi-AMR Coordination

Mixed LD-60, LD-90, and LD-250 AMR Fleets 185

9.2 Spare Battery

9.3 Payload Structure Bumpers

9.4 Call Buttons and Door Boxes

9.5 Acuity Localization

9.6 Touchscreen

9.7 Rear-Facing Laser

9.8 Side (Supplemental) Lasers

Install Side Lasers 187

Configure Side Lasers 188

9.9 High-Accuracy Positioning System (HAPS)

9.10 ESDOption

185

185

186

186

186

186

186

187

188

189

Chapter 10: Technical Specifications 191

10.1 Dimension Drawings

Width Measurements 192

Component Weight 192

191

20472-000 Rev D LD-250 Platform User's Manual 7

Page 8

Table of Contents

Capabilities 193

10.2 LD-250 Specifications

Physical Dimensions 193

Performance 193

Overhanging Payloads and the AMR Swing Radius 194

Sensors 195

ESD Compliance 195

10.3 Docking Station Specifications

193

196

Chapter 11: Modify the Safety Zones 197

11.1 Default Safety Zones

11.2 Relevant AMR Operating Parameters

11.3 Equipment Required to Modify OS32C Safety Zones

197

198

198

Chapter 12: Glossary 201

8 LD-250 Platform User's Manual 20472-000 Rev D

Page 9

Revision History

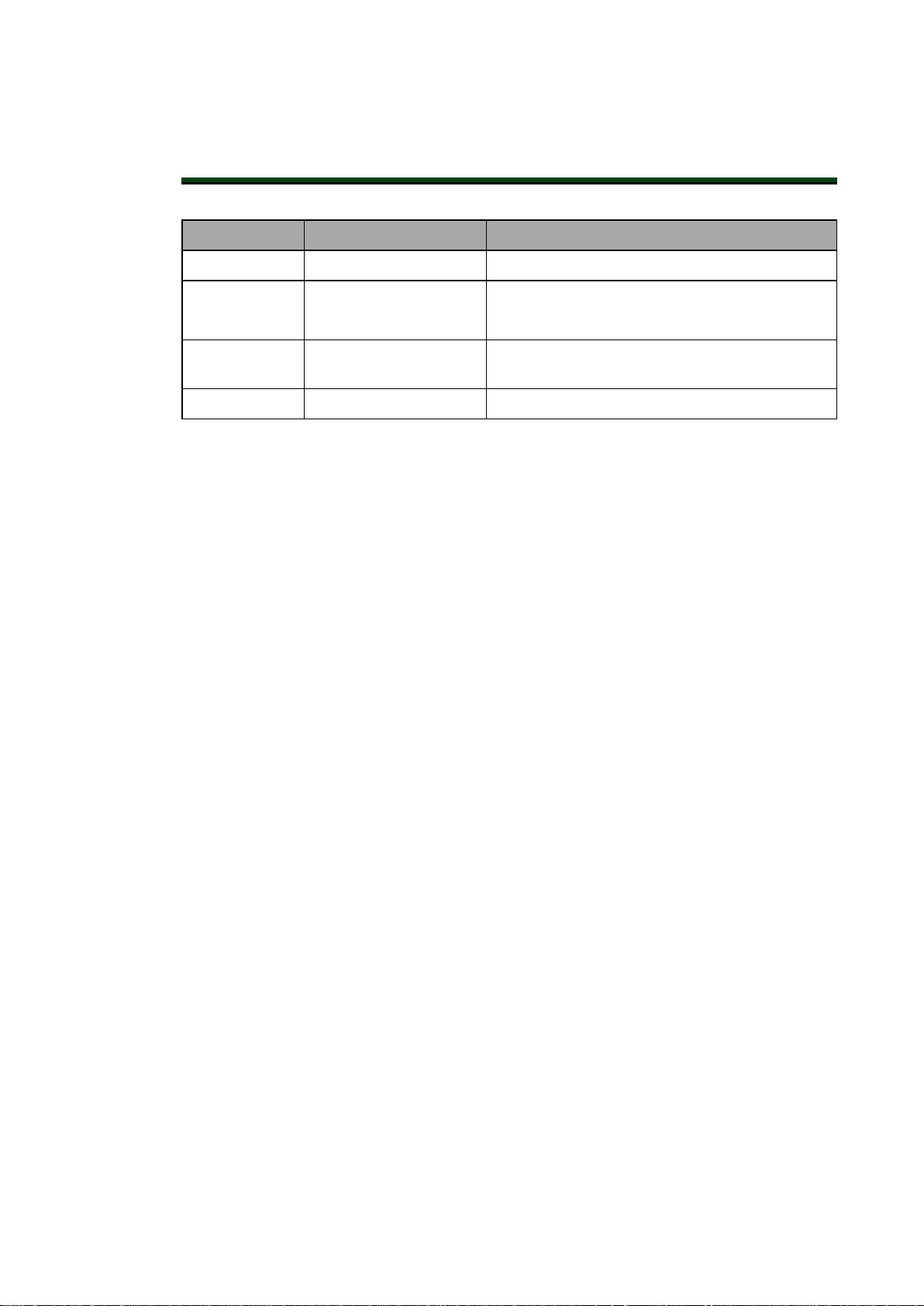

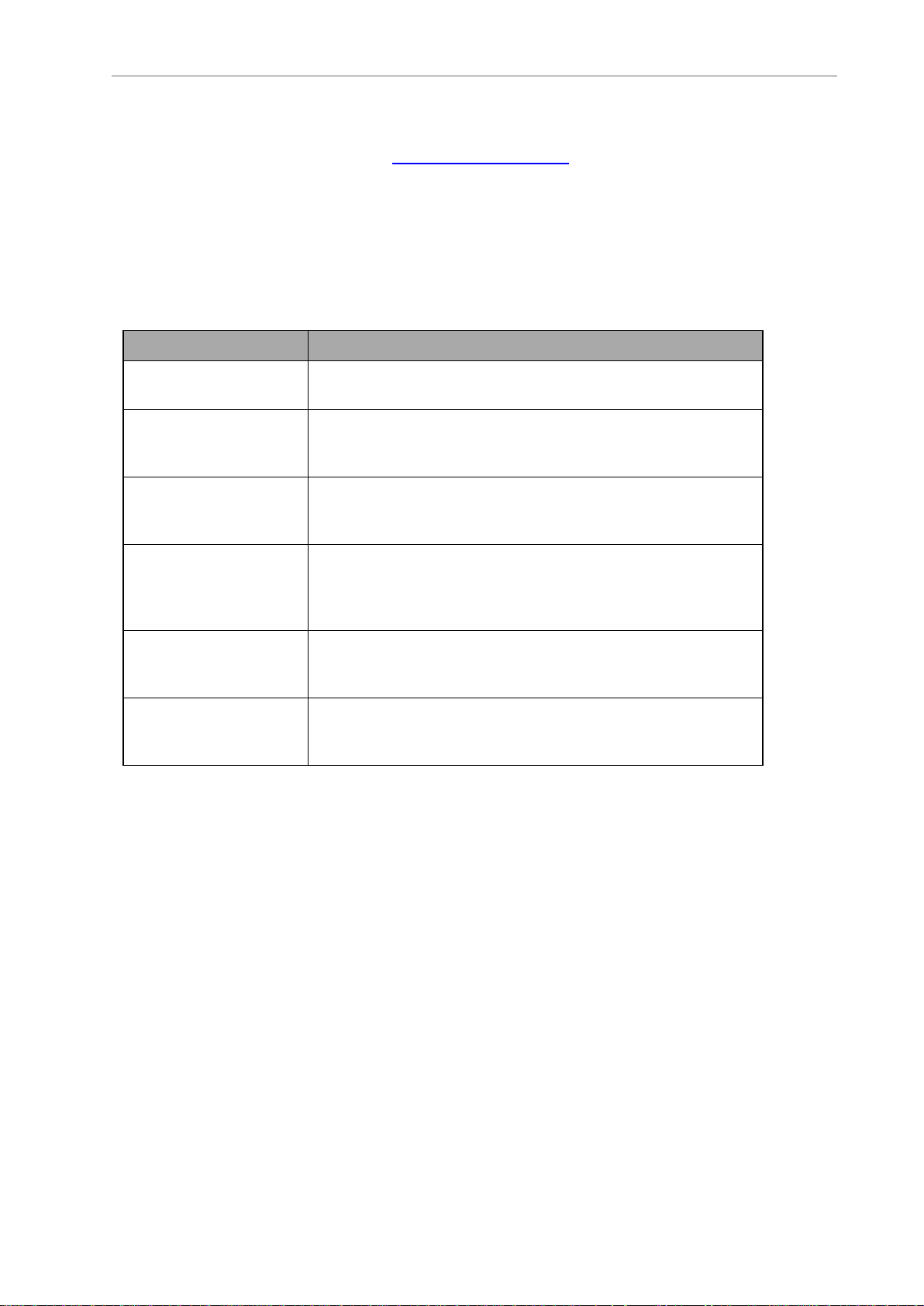

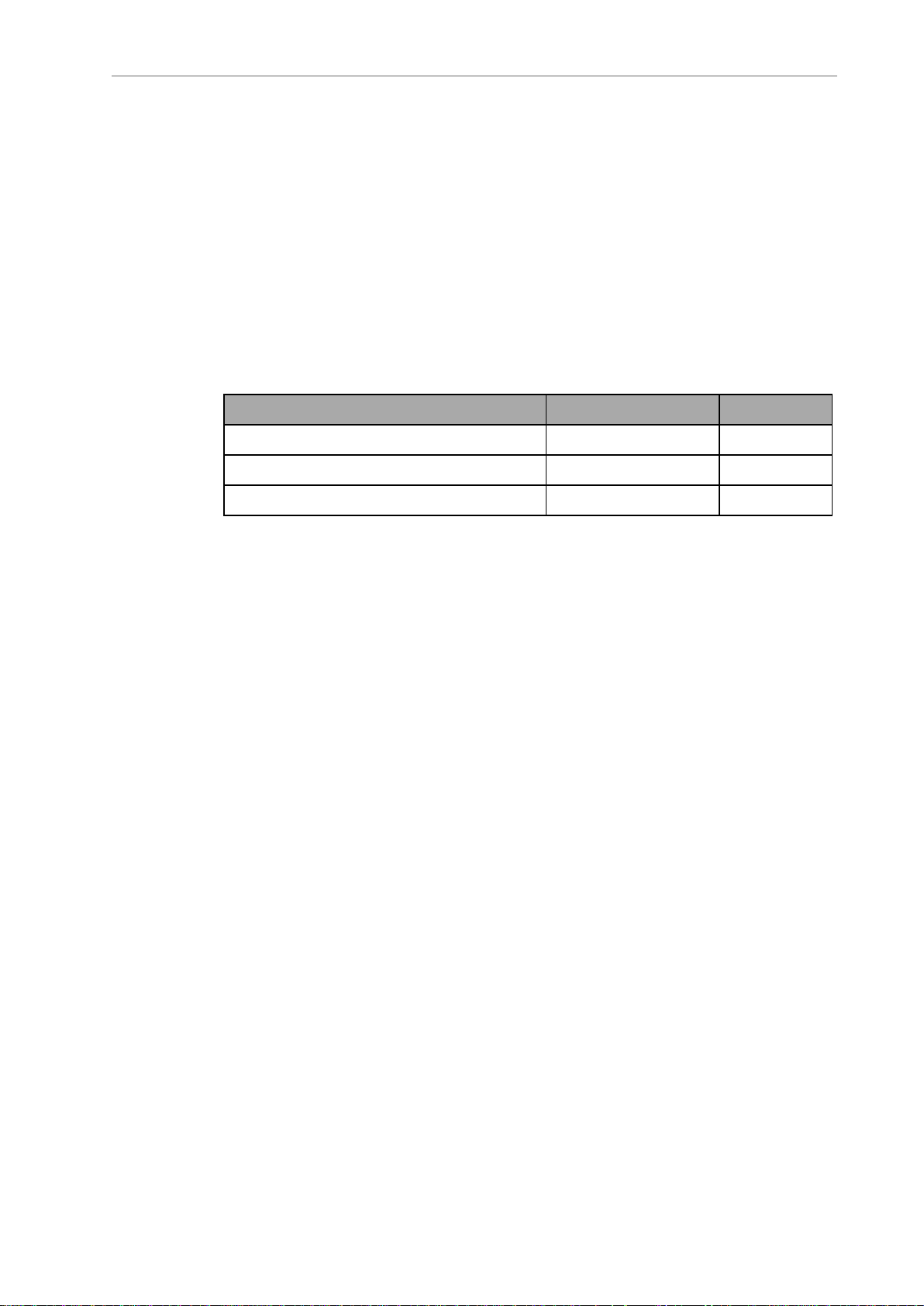

Revision Code Date Revised Content

1.0, Rev (A) November 2019 Original Release.

2.0, Rev (B) December 2019 Added missing information and corrected errors.

3.0, Rev (C) July 2020 Added missing information and corrected clerical

errors.

4.0, Rev (D) October 2020 Added LD-250ESD information.

20472-000 Rev D LD-250 Platform User's Manual 9

Page 10

Page 11

This manual describes the setup, operation, and user maintenance of an LD-250 Autonomous

Mobile Robot (AMR).

This manual does not describe all configuration steps that you perform using the software supplied with an LD-250. The Fleet Operations Workspace Core User's Manual (Cat. No. I635)

describes configuration, operation, and use of the LD-250.

1.1 Definitions

This document uses the following terms to describe the LD-250:

l

AMR (Autonomous Mobile Robot)—This term describes the LD-250 with an attached

payload structure, creating a complete mobile robot.

l

Fleet Manager—A rack-mount computing appliance that you use to manage a fleet of

AMRs. The appliance consists of the EM2100 appliance (EM2100) and the FLOW Core

software.

l

Fleet—Two or more AMRs operating in the same workspace.

l

LD-250—This is the model name of the platform. This document uses the model name

LD-250 when describing the setup, configuration, and connections.

Chapter 1: Introduction

l

Mobile Robot—An alternate industry term for AMR.

l

Payload Structure—Any passive or dynamic device attached to and possibly powered

by the LD-250. This could be as simple as a crate for carrying objects such as factory

parts or as complicated as a robotic arm that picks up and manipulates factory parts.

l

Platform—The base LD-250, including:

o

The chassis, drive motors, suspension, wheels and light discs, casters, battery,

lasers, and rear sensors.

o

An on-board LD-250 Core with a built-in gyroscope, navigation software, and

data and power connectors for a payload structure.

o

An Operator panel otherwise known as the Human-Machine Interface (HMI).

o

The LD-250 skins (external covers) and a payload bay for attaching a payload

structure.

1.2 Product Description

The LD-250 is a general-purpose mobile robot, designed to work in an indoor industrial environment and around trained personnel. It is self-guided and self-charging, with an automated

docking station. It has a maximum capacity of 250kg (551 lbs). Capacity includes the payload

structure and any load carried by that structure.

20472-000 Rev D LD-250 Platform User's Manual 11

Page 12

1.2 Product Description

Figure 1-1 LD-250 Features.

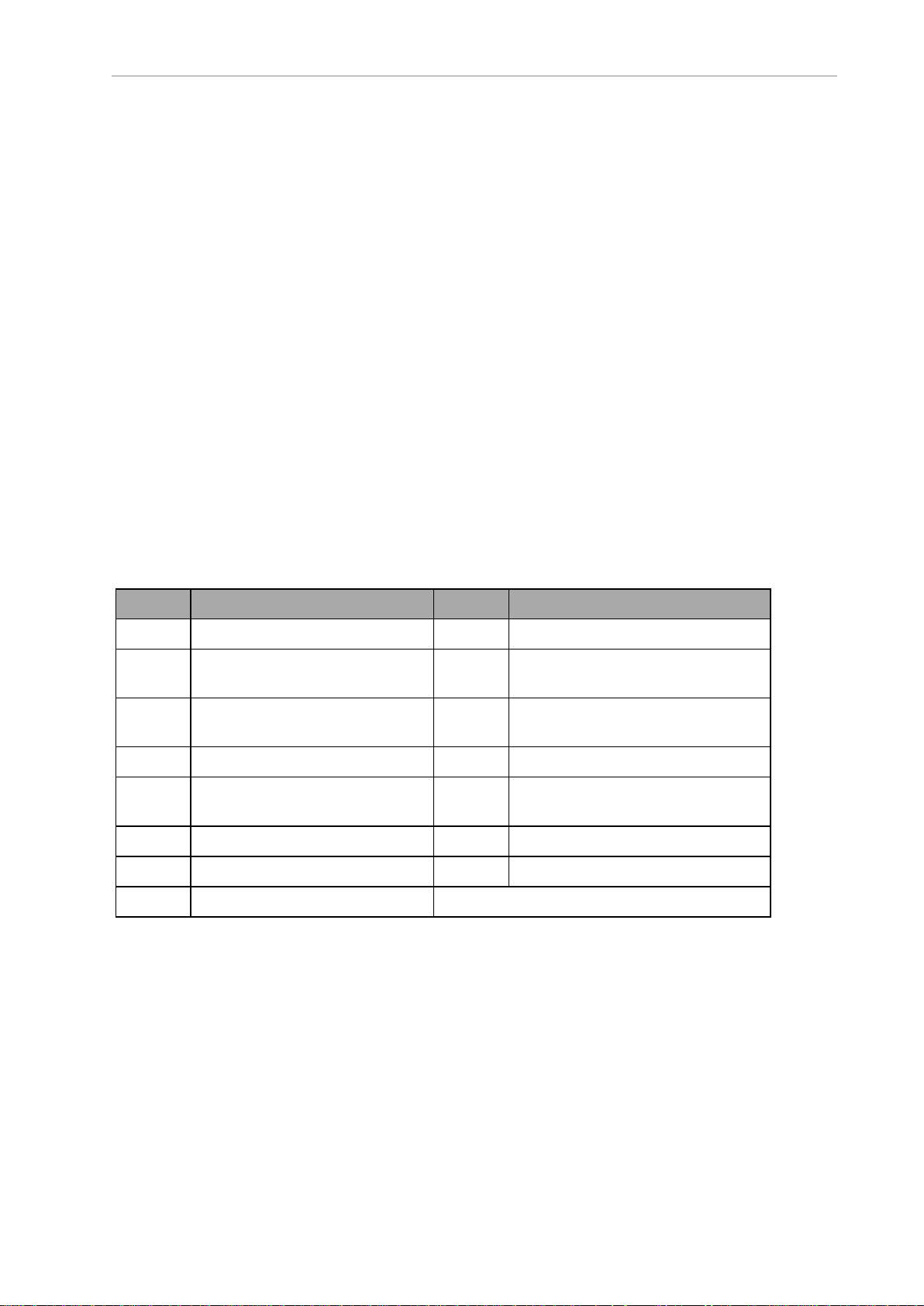

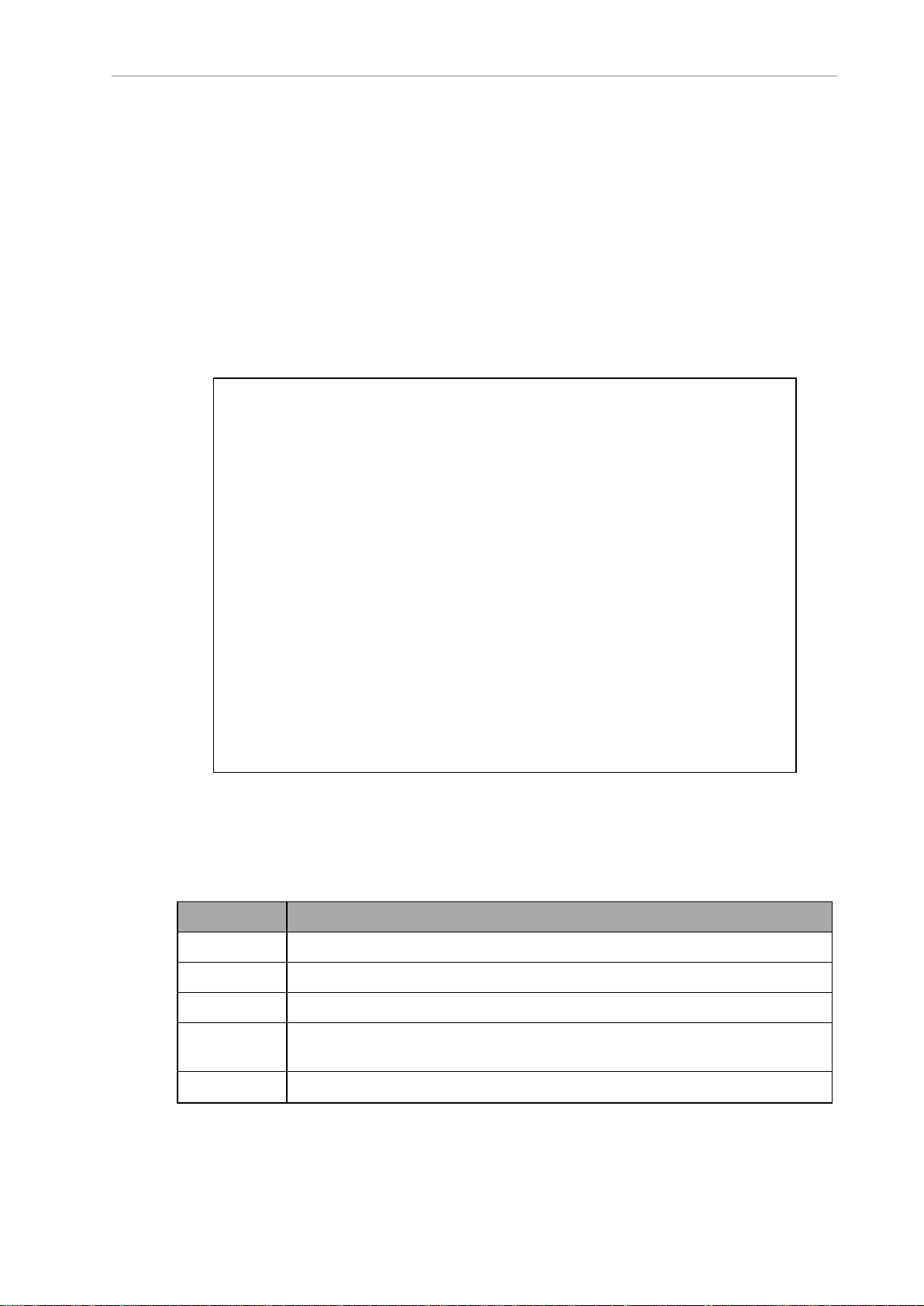

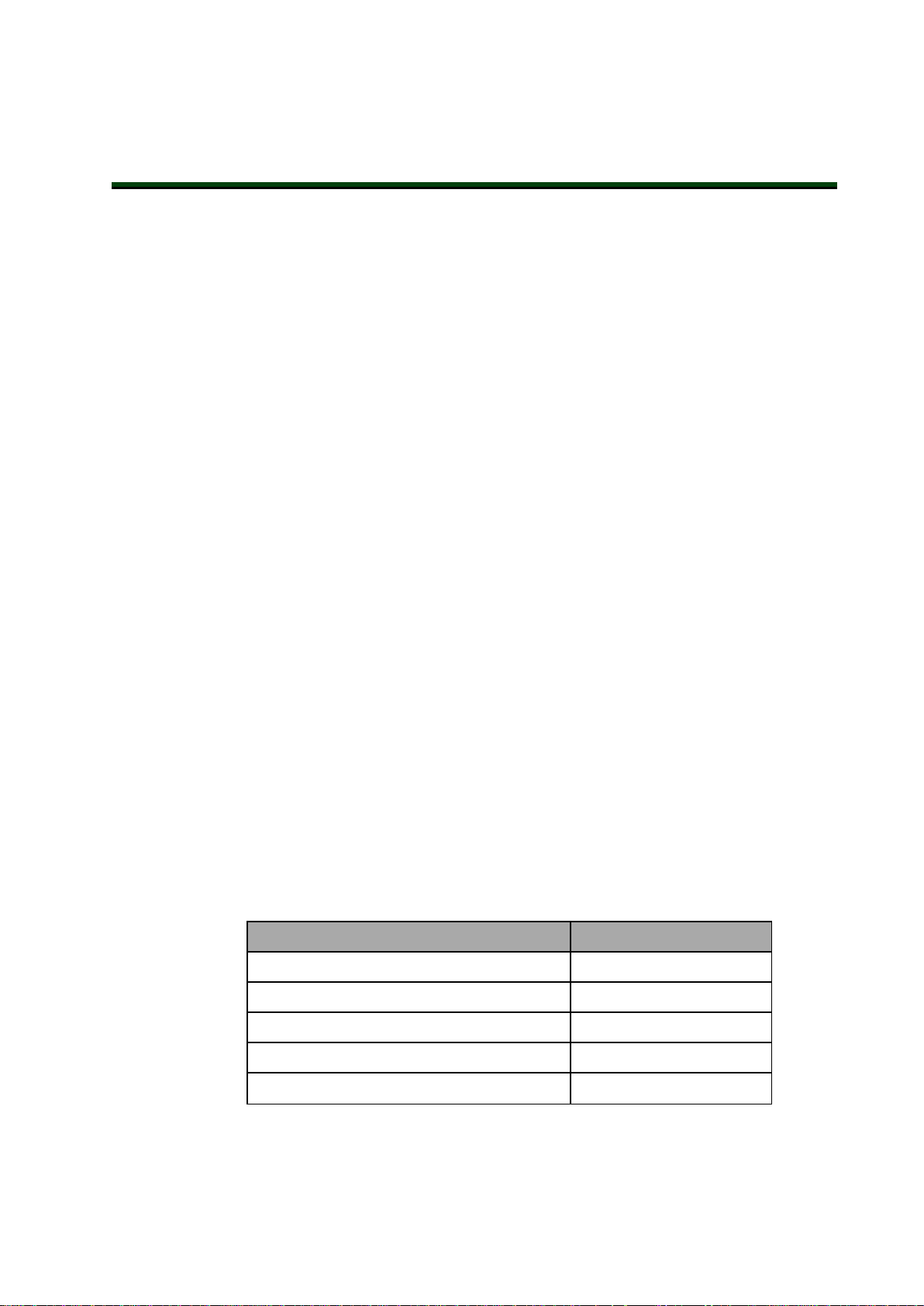

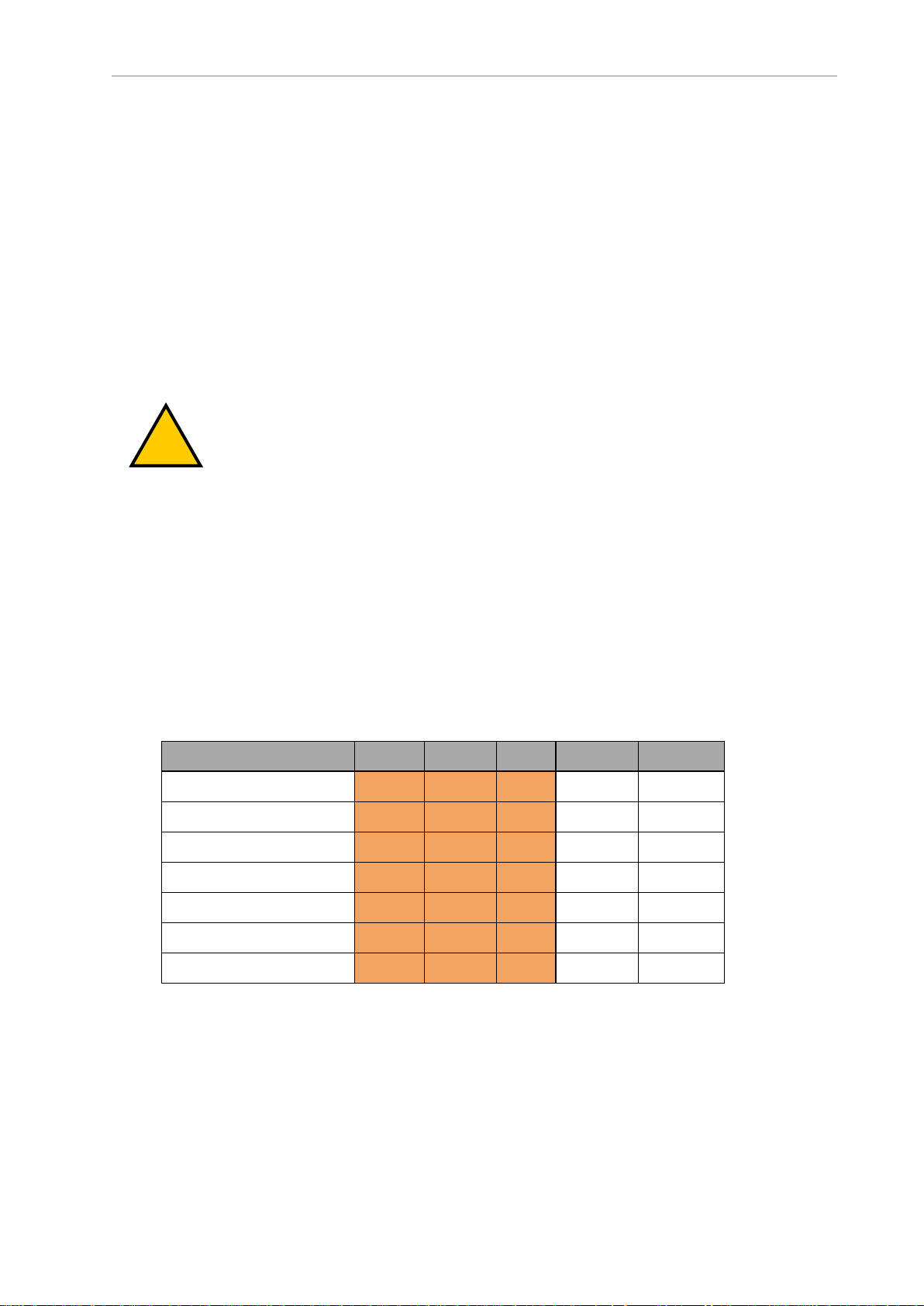

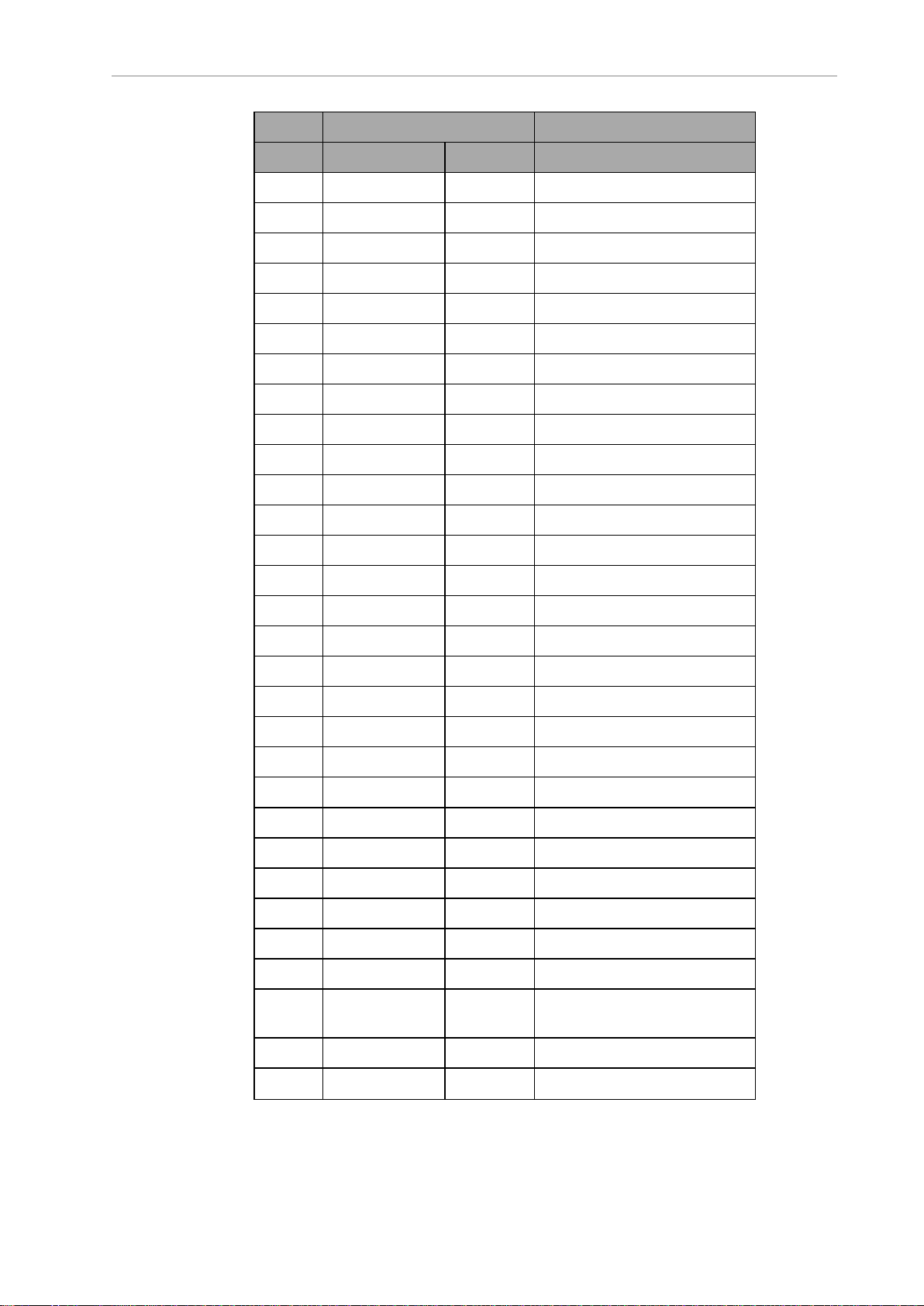

Callout Description Callout Description

A LD-250 Core I Light discs (one each side)

B Operator panel with E-Stop but-

ton

C Payload attachment bars (X-pro-

file)

D Dual wireless antenna L Rear Sensor

E E-Stop button on the Operator

Panel (HMI)

F Low front (toe) laser N Drive wheel (2)

G Navigation and safety laser O Front caster (2)

H E-Stop button (one each side)

J Joystick and communications panel

K Battery access panel and door

M Rear caster (2)

LD-250 Autonomous Navigation

The LD-250 combines hardware and mobile-robotics software to provide an adaptive, mobile

platform to transport your payload. After it scans physical features in its environment, the LD250 navigates safely and autonomously to any accessible destination. It moves continuously

and without human intervention, autonomously recharging itself as necessary.

12 LD-250 Platform User's Manual 20472-000 Rev D

Page 13

Chapter 1: Introduction

The LD-250 uses range data from a Safety Scanning Laser as its primary means of detecting

obstacles and of maintaining an accurate understanding of its location in the environment.

Additionally, it uses data from the following sensors:

l

A low front or toe laser to detect objects below the plane of the main laser.

l

A rear sensor that detects and stops the LD-250 if it senses objects close behind the

AMR.

l

A gyroscope in the LD-250 Core to detect and report LD-250 rotational velocity.

l

An encoder on each drive motor that provides odometry data for the distance traveled

by each drive wheel.

LD-250 Localization

Wheel encoders provide the navigation system with odometry information (how far each

wheel has traveled, and in which direction.) In addition, the LD-250 Core contains an internal

gyroscope to track the LD-250's rotational velocity.

The LD-250 analyzes this odometry data together with LIDARdata from its navigation laser to

calculate its position. This process is called localization.

Acuity Localization Option

For dynamic work environments that are difficult for laserlocalization, OMRON offers Acuity

Localization. Acuity Localization uses a camera to detect overhead lights, enabling the AMR to

localize itself in environments where laser localization alone is not an optimal solution. Laser

localization is tolerant of changing environments. However, it becomes difficult if changing features exceed 80% of the objects detected by the laser. This includes workspaces such as warehouses, where objects such as shipping pallets or rolling carts either change locations often, or

block the laser’s view of mapped features. Acuity is also useful when wide-open spaces do not

provide enough features to map for laser localization.

The LDPlatform Peripherals User's Guide (Cat. No. I613) describes how to install and configure

the Acuity option.

Custom Payload Structures

LD-250 users typically add attachments (a payload structure) to the LD-250 base platform to

customize it for use in specific applications. The LD-250 provides a payload bay that includes

aluminum extruded load bars. T-slots in the load bars provide a strong and adaptable method

of attaching payload structures to the Platform.

A payload structure can be as simple as a crate that contains manufacturing parts or a more

complicated device such as a conveyor or robot arm. The LD-250 Core provides power, logic,

data communication, and safety connections for the payload structure. This includes user connections for warning lights and additional lasers. For more information, see:

l

Payload Structures on page 77 for information about designing a payload.

l

Connectivity on page 93, for information about available user connectors on the LD-250

Core.

20472-000 Rev D LD-250 Platform User's Manual 13

Page 14

1.2 Product Description

!

Chassis and Drive Train

Each LD-250 uses a two-wheel, differential-drive, with passive casters front and rear for balance. The drive-wheels have independent spring suspension, with solid, polyurethane tread.

The wheel axles are located near its center line, making the LD-250 highly maneuverable and

able to rotate in place.

You can disengage the drive wheels by turning a cam lever on the gearbox. This is required for

some set up and maintenance operations. See: Engage and Disengage the Drive Wheel Motors on

page 148.

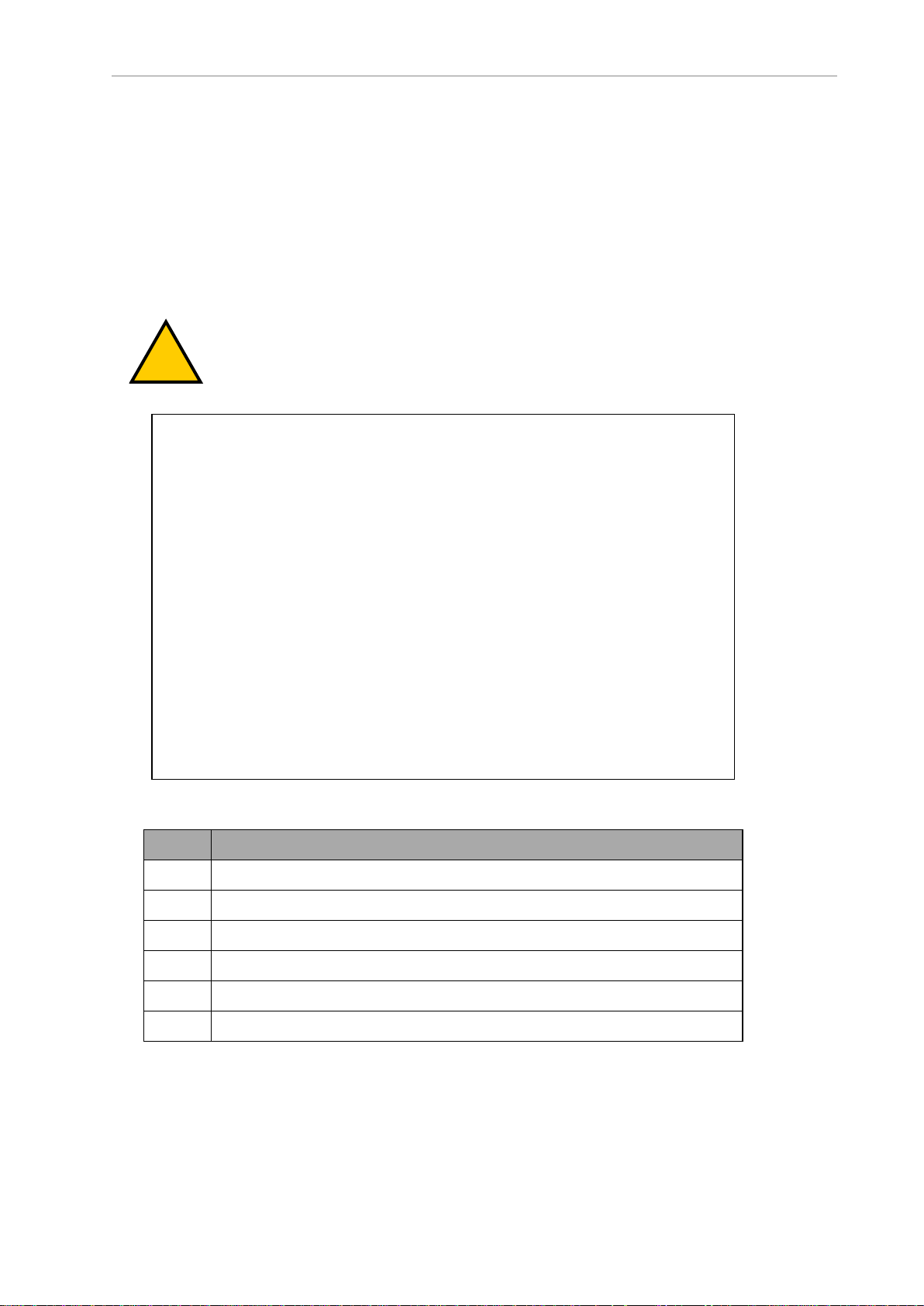

CAUTION: BRAKES DISABLED. When the drive wheels are disengaged, the

AMR brakes are inoperable. Take care when you move the LD-250 on inclined

surfaces.

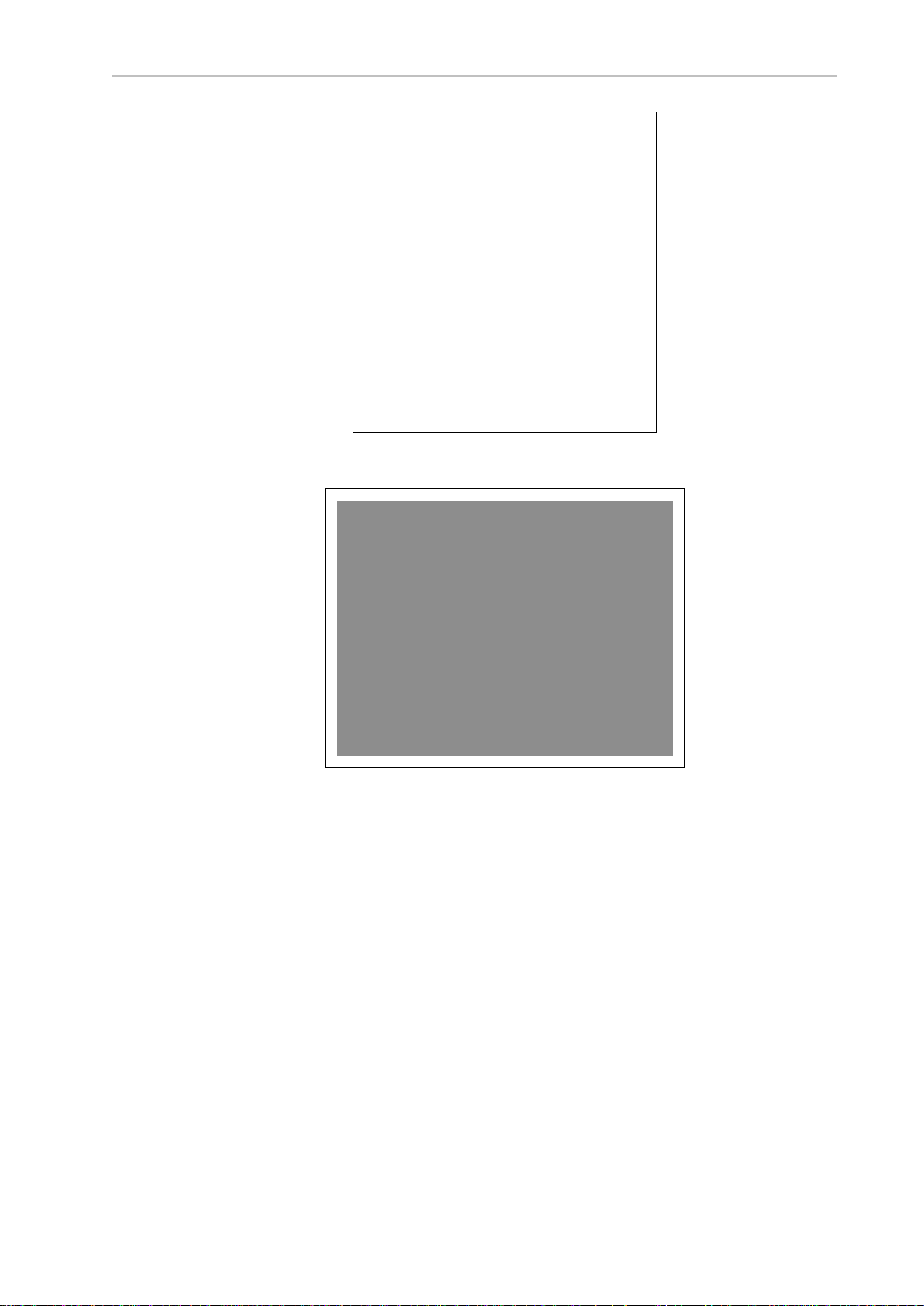

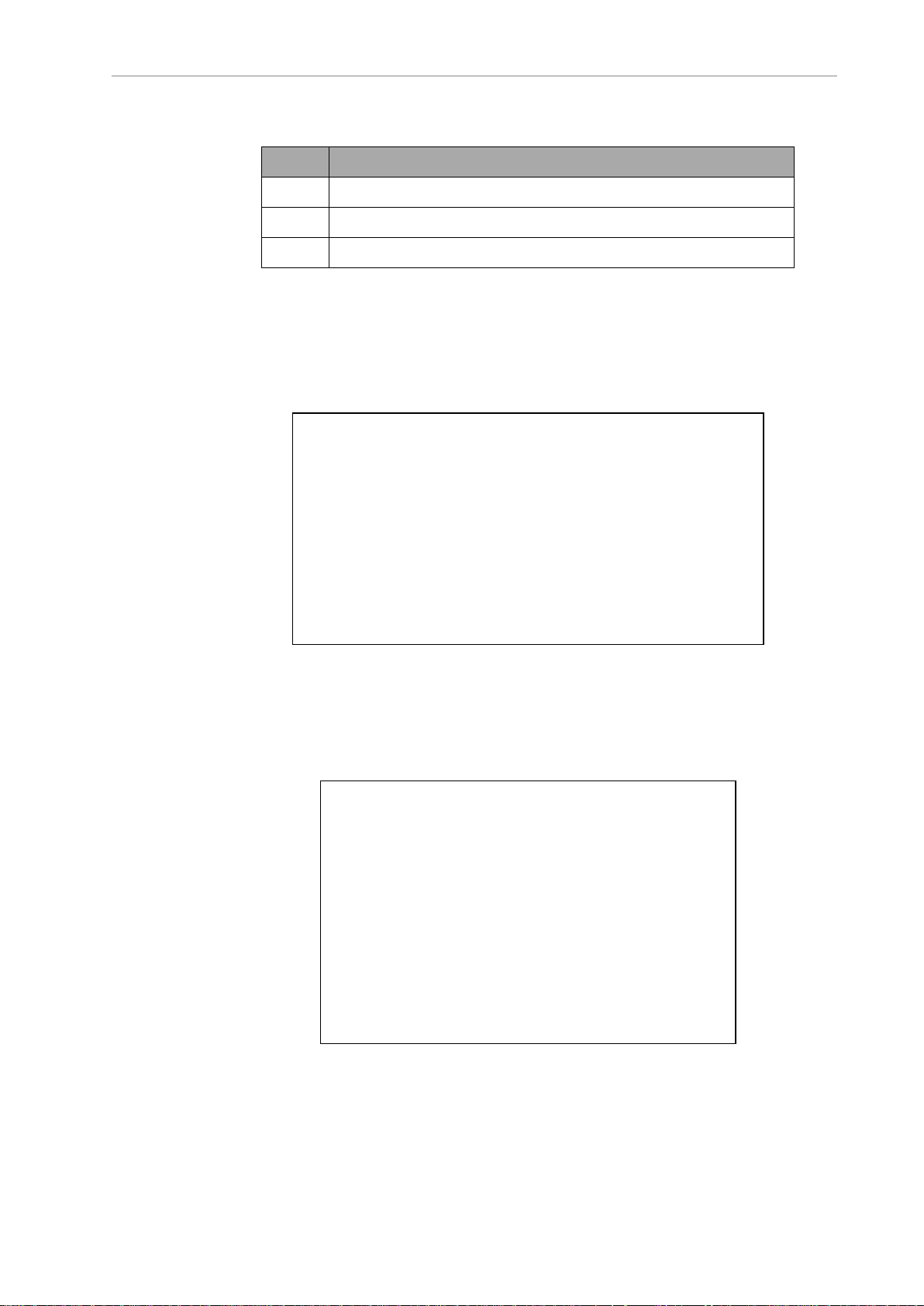

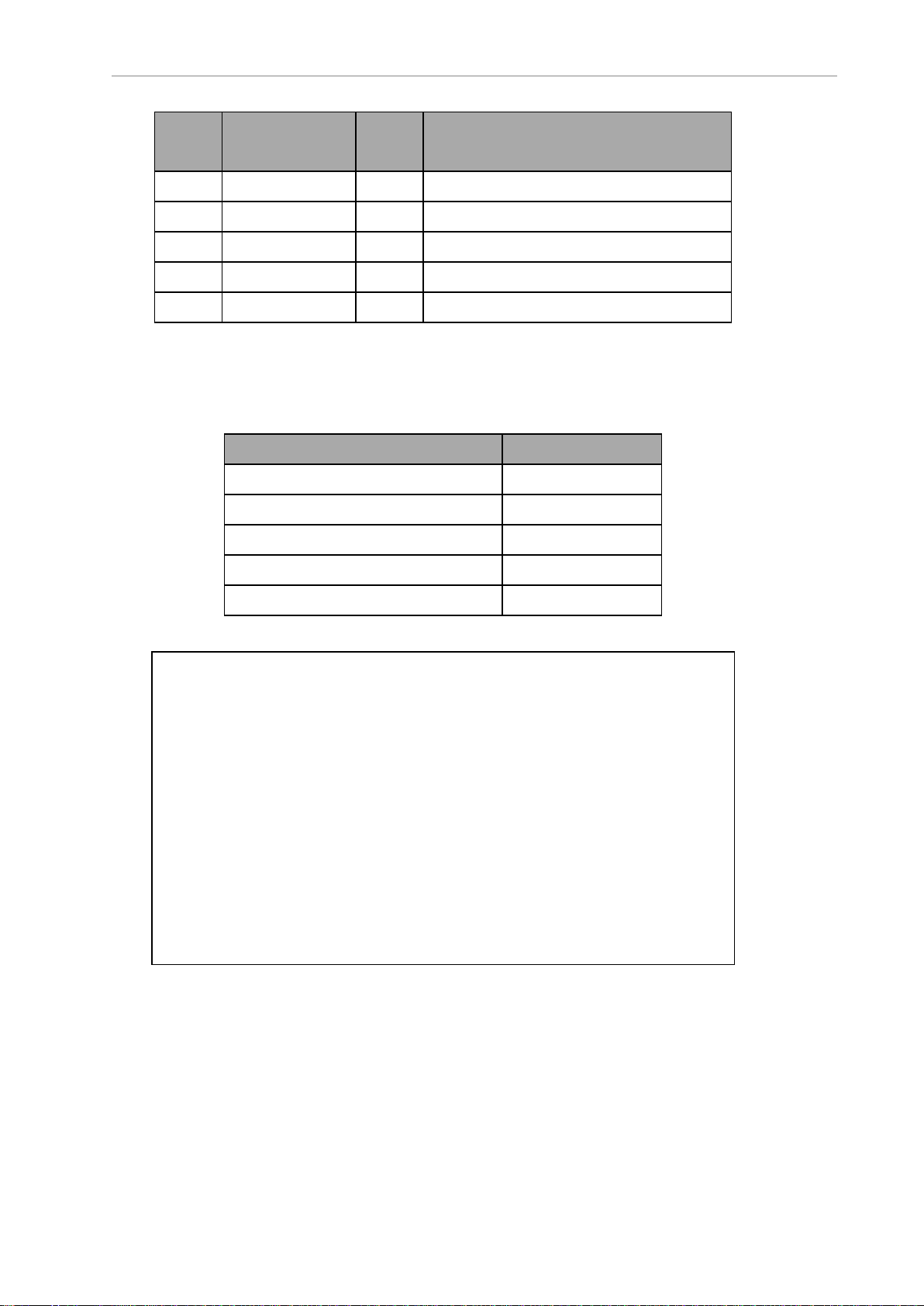

Figure 1-2 Drive Assembly in LD-250 (skins removed).

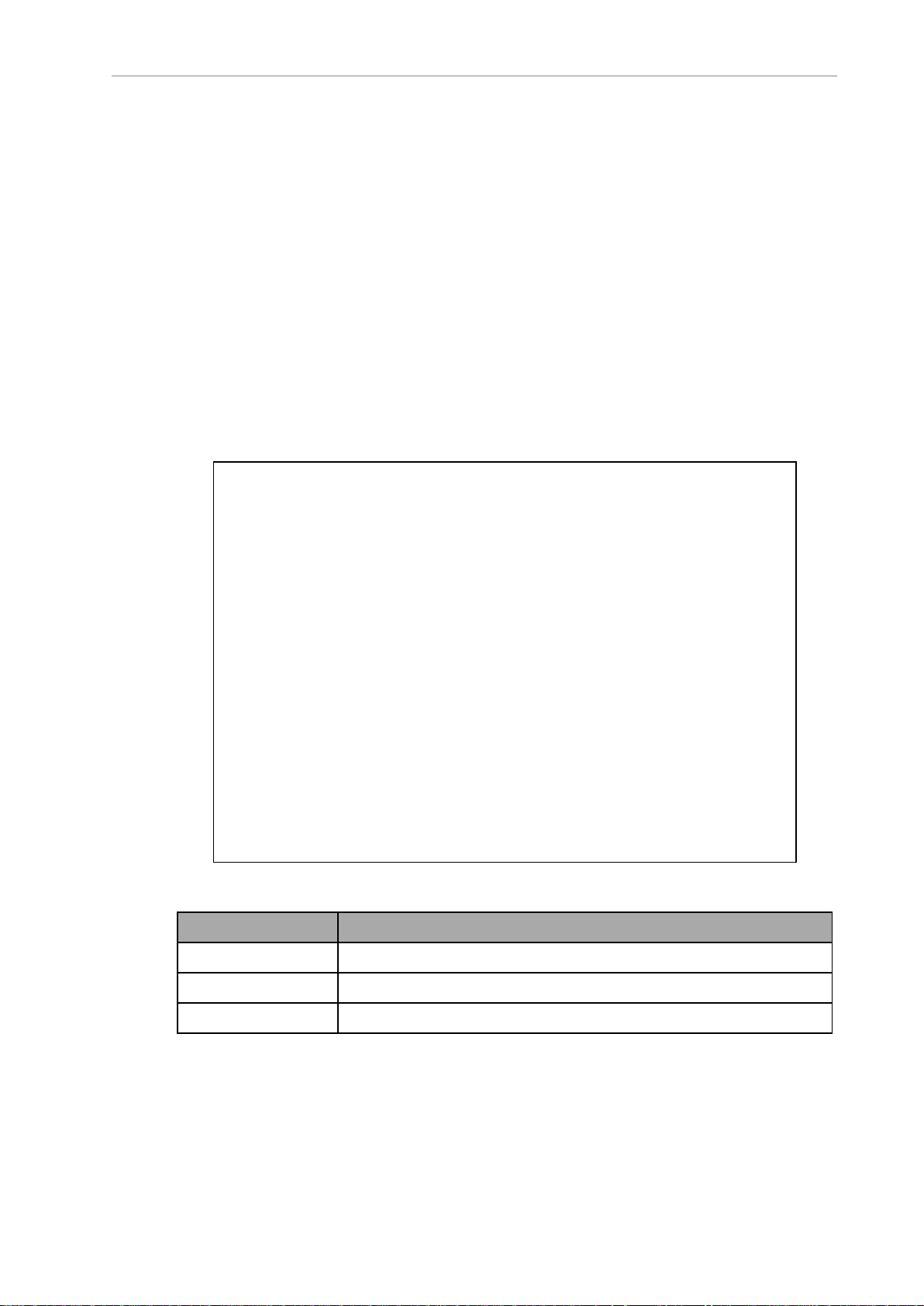

Callout Description

A Drive Train assembly (wheel, suspension and motor).

B Drive motor assembly, containing the gears, encoders, and electric brake.

C Rear caster.

D Drive wheel, aluminum with polyurethane tread.

E Front caster.

F Suspension springs.

14 LD-250 Platform User's Manual 20472-000 Rev D

Page 15

What's Included - Basic Components

l

One fully-assembled LD-250 model platform that includes the following:

o

OMRON OS32CSafety and Navigation Laser (main laser).

o

Low Front Laser.

o

Rear sensor.

o

Differential drive train.

l

LD-250 Core housed inside the LD-250 which consists of:

o

A computing appliancethat runs the SetNetGo operating system and the

Advanced Robotics Automation Management (ARAM) software.

o

A microcontroller that runs the Mobile Autonomous Robot Controller (MARC)

firmware.

o

Other sensor components such as a gyroscope and accelerometer.

o

The amplifiers that supply power to the drive wheels.

Chapter 1: Introduction

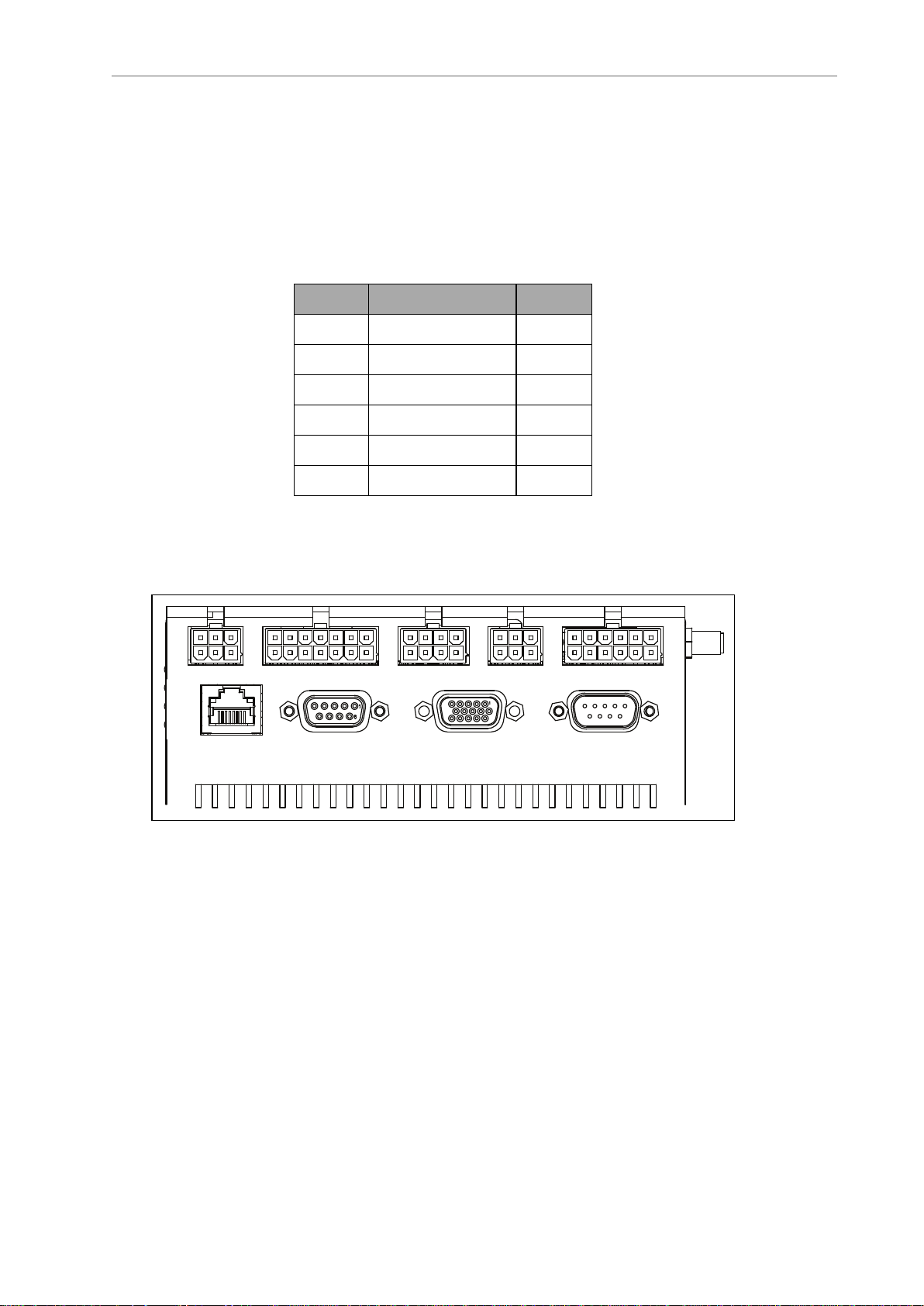

Figure 1-3 LD-250 Core Location (A) in the LD-250,Secured by Two Vented Brackets (B)

l

One battery.

Shipped separately from the LD-250 to comply with dangerous goods shipping regulations.

l Three emergency stop (E-Stop) buttons:

l

One on the Operator panel.

l

One on each side of the chassis.

l

Operator Panel

20472-000 Rev D LD-250 Platform User's Manual 15

Page 16

1.2 Product Description

You can move the operator panel to any preferred position on your payload structure.

However, because the operator panel contains one of the three E-Stop buttons, there are

important safety considerations when relocating or removing this panel. See: Positioning

an Optional Payload E-Stop on page 126 and Operator Panel (HMI)on the Payload on page

90 for more information. The standard Operator Panel includes:

o

6-line status and message display screen.

o

E-Stop button.

o

Vehicle power ON and OFF buttons.

o

Brake release button.

o

2-position key switch for access control. Lock the key switch to disable the off button and prevent accidental or unauthorized shutdowns.

Figure 1-4 Operator Panel

Also available is an optional touch screen that shows more AMR status information

and provides additional functions. See Touchscreen on page 186.

l

Automated docking station

The docking station enables the LD-250 to charge itself, without user intervention. It

includes a wall-mount bracket and a floor plate, for a choice of installation methods. See

Installing the Docking Station on page 58.

When the docking station is not occupied, a manual charging cord enables you to

charge a battery outside the LD-250.

l

A USBflash drive containing software and documentation.

In addition to the items included with every LD-250, you need at least one joystick per robot

fleet. Use this joystick to manually drive the LD-250 and to create a digitized map of the work

environment.

For a fleet of AMRs, the Fleet Operations Workspace Core (FLOW Core) software (running on a

Fleet Manager appliance) shares the map between all AMRs in the fleet. This provides a common frame of reference for navigation and localization, preventing contention between AMRs.

Figure 1-5 shows the joystick and Ethernet port, located on the left rear skin.

16 LD-250 Platform User's Manual 20472-000 Rev D

Page 17

Figure 1-5 Joystick Connection Point

Chapter 1: Introduction

Callout Feature

A Joystick port.

B Direct Ethernet connection that enables you to connect a PC to

the SetNetGo OS. See: Maintenance Ethernet Connection on

page 67.

C Push latch.

Figure 1-6 Joystick Controls

Callout Control Function

A AMR speed control.

B AMR steering and direction of travel.

C Map goal creation button.

D Movement trigger.

20472-000 Rev D LD-250 Platform User's Manual 17

Page 18

1.2 Product Description

Optional Features and Components (Partial List)

Several additional options and features are available for the LD-250. See also: Options on page

185.

l

Fleet Manager—Use an EM2100 appliance and the Fleet Operations Workspace software to operate a fleet of AMRs, for multi-AMR coordination and job management. A

second Fleet Manager provides redundancy and automatic switchover for fleet operations.

l

Acuity Localization—Acuity uses an upward-facing camera to enable AMR localization.

It detects unique patterns in the illumination fixtures (overhead lighting) used in your

workspace.

l

Spare battery—You might require one or more spare batteries to increase AMR productivity by eliminating the time spent recharging. Using the cable provided, you

charge this battery outside the AMR and quickly exchange it with a discharged battery

when necessary.

l

Call Box or Door Box—A call box or door box is a signal device that:

o

Enables you to request an AMR from a remote location.

o

Controls an automated doorway, enabling an AMR to pass through it.

l

High-Accuracy Positioning System (HAPS)— HAPS uses single or double under-body

magnetic sensors on the AMR to detect magnetic tape strips adhered to the workspace

floor. This enables an AMR to achieve highly accurate placement and alignment at a

specific location in the workspace. For example, if an AMR pickup goal is a conveyor

belt where it receives a crate of parts, use HAPS alignment to make sure that the AMR

and the conveyor are aligned precisely.

l

ESD Model -- The skins of a non-ESD AMR can accumulate an electrical charge which,

if discharged into ESD sensitive components, could damage those components.

The optional ESD skins encase the AMR in an electro-conductive surface that provides

a skin-to-chassis-to-caster grounding path that drains off any charge that the AMR

might accumulate during operation.

Figure 1-7 LD-250 ESD AMR

18 LD-250 Platform User's Manual 20472-000 Rev D

Page 19

Options for Enhancing Your Payload Structures

l

Rear Lasers—A rear-facing obstacle-detection laser that scans the horizontal plane to

the rear of the AMR.

l

Side Lasers—Side-mount obstacle-detection lasers that scan the vertical plane on each

side of the AMR. These lasers detect obstacles that are outside the scanning plane of the

main safety laser. You might use side lasers on your payload structure to avoid

obstacles that the main safety and navigation laser cannot detect.

l

Touchscreen—The Touchscreen complements the standard Operator panel, enabling

operators to interact with the AMR and the FLOW Core software directly from the payload structure.

Operators can observe AMR status, select a goal, or do other operations. The Touchscreen does not provide manual operation buttons or an E-Stop. If you remove the Operator panel you must install alternate manual switches and an E-Stop. Otherwise, use a

jumper (part number 13387-000) to bypass the operator panel E-Stop circuit. You must

physically remove any bypassed E-Stop buttons to avoid operator confusion.

Be aware that if you remove the operator panel you might need to add an E-Stop button

elsewhere on the AMR to comply with safety requirements. See: Positioning an Optional

Payload E-Stop on page 126.

Chapter 1: Introduction

See the LDPlatform Peripherals User's Guide (Cat. No. I613) for more information about

the Touchscreen.

1.3 Software Overview

Your LD-250 requires the licensed software described in this section. Software is factoryinstalled on its LD-250 Core.

Access to software features is permitted by use of a USB license dongle that contains secure,

encrypted electronic copies of the operating licenses. Some licenses might have a restricted

term and expire after a specific date. You will receive several warning alerts before the license

expires.

LD-250 Software

The minimal operating configuration for an LD-250 consists of the AMR managed by a

human Operator using a Microsoft Windows PC and optionally from an Android or iOS tablet.

If you have more than one AMR, you must install and configure a Fleet Manager appliance

running the Fleet Operations Workspace software to manage multiple AMRs as a fleet. Fleet

management prevents job contention or collisions between AMRs and provides efficient processing of all tasks that you assign to the AMR fleet.

See the following documents for detailed information:

l

EM2100 Installation Guide (Cat. No. I634)

l

Fleet Operations Workspace Core User's Manual (Cat. No. I635)

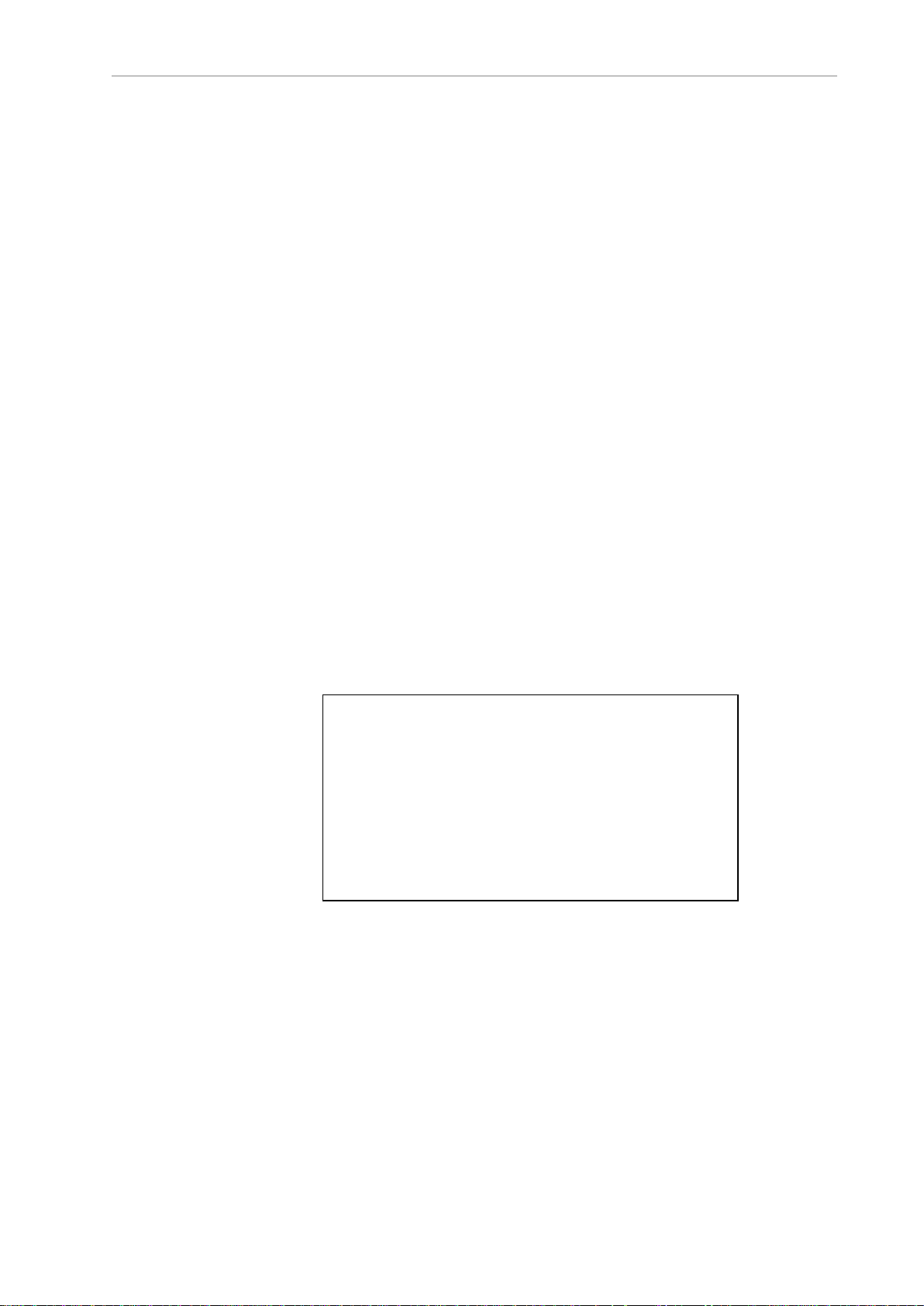

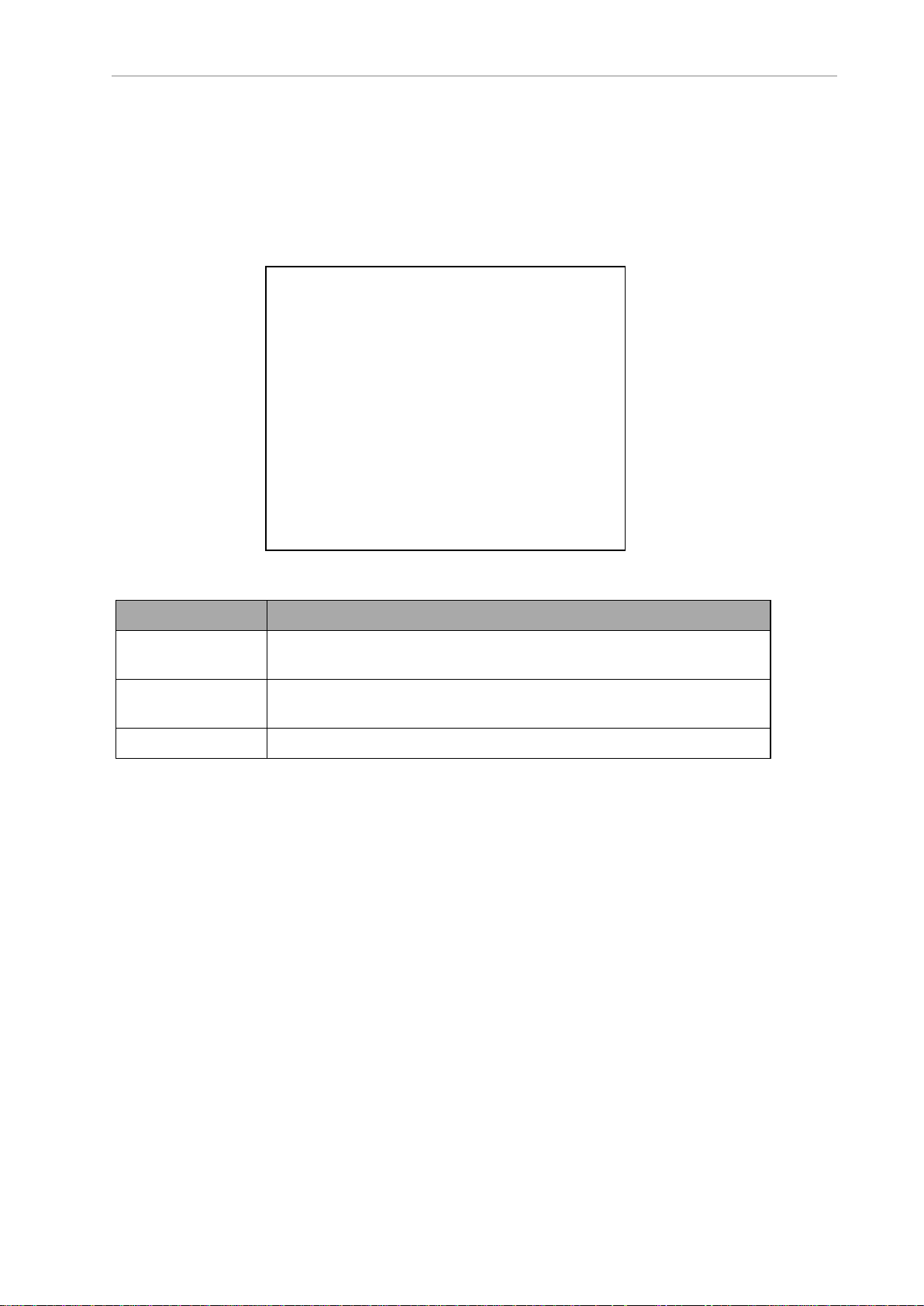

Figure 1-8 shows the devices that you might use to manage one or more AMRs and the software components required for each device, if applicable.

20472-000 Rev D LD-250 Platform User's Manual 19

Page 20

1.3 Software Overview

Figure 1-8 Devices and Software in the AMR's Operating Configuration

AMR administration includes both configuring and operating an AMR and also using the

AMR (or fleet) to perform useful work. The software that enables you to do this management

consists of:

l

The FLOW Core, an integrated set of programs that run on different devices in the environment. You use the MobilePlanner and MobilePlanner Tablet graphical interfaces to

manage individual AMRs or fleets of AMRs. You can also access lower-level functions

through a command-line interface.

l

The SetNetGo OS, a host operating system (OS) which provides a Web interface that

enables Operator access to the AMRs, enabling configuration tasks and tasks such as

upgrading software or obtaining a debugging file.

User-Supplied Components and System Requirements

To configure and manage LD-250 you require a personal computer (PC) running a supported

version of Microsoft Windows

l

Ethernet connection. OMRON recommends that you use a high-speed wireless con-

®. The PC requires:

nection.

Wireless is a requirement for managing multiple AMRs as a fleet. See Fleet Operations

Workspace Core User's Manual (Cat. No. I635).

l

200 megabytes of available hard-disk storage.

Optionally, an Android or iOStablet to run the MobilePlanner Tablet software.

20 LD-250 Platform User's Manual 20472-000 Rev D

Page 21

Chapter 1: Introduction

ARAM

The Advanced Robotics Automation Management software (ARAM) runs on the LD-250 Core.

It is software included with your FLOW Core license. ARAM is responsible for the following

AMR functions and features:

l

Interaction with on-board sensors such as the safety scanning laser, optional side laser

or included rear sensor.

l High-level, autonomous robotics functions such as:

o

Obstacle avoidance

o

Path planning

o

Localization

o

Navigation

l

Motion commands to the MARC firmware.

l

Battery management.

l

Digital I/O ports in the core that enable you to integrate application-specific sensors and

effectors into your payload structure.

ARAM also provides the AMR with an interface to external entities:

l

Manages wired and wireless Ethernet communications with external software for

external monitoring, development, and systems coordination.

l

Provides coordination of a fleet of AMRs through the optional Fleet Manager appliance.

l

Manages integration with other systems, in addition to external monitoring, setup, and

control via the MobilePlanner graphical interface.

ARAMCentral

ARAMCentral runs on the Fleet Manager as part of the Fleet Operations Workspace software.

When managing a fleet, the ARAMCentral software does the following:

l

Stores and distributes:

o

The shared workspace map used by all fleet AMRs.

o

The common AMR configuration.

l

Controls AMR traffic, including:

o

Multi-AMR avoidance

o

AMR Destinations

o

AMR Standby

o

Charging dock access

l

Queuing of jobs

l

Remote I/O (if used)

20472-000 Rev D LD-250 Platform User's Manual 21

Page 22

1.3 Software Overview

MobilePlanner Administrator Mode

MobilePlanner is part of the Fleet Operations Workspace software and runs on the user's PC,

or as a portable tablet version (on Android and iOS tablets). It provides a tabbed graphical

user interface on the PC and a touchscreen interface on tablets. Depending on your level of

access (controlled by your account) the graphical interface provides many options, including:

l

Manage AMR fleet jobs.

l

Create and edit workspace maps.

l

Access the AMR through the SetNetGo Web interface.

l

Commission and configure an AMR and modify its configuration by changing ARAM

parameters.

l

Run custom ARCL commands (See ARCL Protocol on page 23).

l

Manually drive an AMR.

Operator access or View access restricts the tasks that you can do when using MobilePlanner.

Before you assign tasks to an AMR, you use MobilePlanner to create and edit a digitized map

of its work space. During this procedure, you use the joystick to drive the AMR around the

workspace. In mapping mode, the main navigation laser scans features of the workspace, such

as walls, columns, doorways and corners. After you create the map, you open it in MobilePlanner and edit it to add or remove features. For example, if there is an area of the map where you

want the AMR to follow a specific path, you can draw a PreferredLine feature on the map.

You then use MobilePlanner to configure ARAM operating parameters that control the AMR's

operation in the mapped workspace. For example, you might assign a preferred charging dock

to the AMR by specifying the unique map identifier for that docking station. If you have more

than one AMR, you share the map and configuration with identically-equipped AMRs in your

fleet.

Refer to the separate Fleet Operations Workspace Core User's Manual (Cat. No. I635) for instructions about mapping a workspace and preparing the virtual elements, goals, routes, and tasks

for your application. In particular, refer to the descriptions of the following software options:

l

Working With Map Files - Editing a Map File

l

Using the Drawing Tools - Adding Goals and Docks

MobilePlanner Operator Mode

MobilePlanner also operates in a restricted Operator mode that permits only limited access to

user interface features and functions.

MobilePlanner’s Operator Mode allows you to monitor one or more AMR's activities and

assign tasks in the mapped space. For more information, see: Fleet Operations Workspace Core

User's Manual (Cat. No. I635).

Mobile Autonomous Robot Controller (MARC)

The LD-250 Core contains a digital signal processor (DSP)that runs the MARC firmware. This

firmware controls low-level AMR functions, including:

22 LD-250 Platform User's Manual 20472-000 Rev D

Page 23

Chapter 1: Introduction

l

Maintaining the AMR’s driving speed and heading (direction of travel).

l

Acquiring sensor data from the wheel encoders, rear sensors, and internal gyroscope.

l

Reading emergency stop (E-Stop) status to enable and disable the drive motors.

l Joystick input.

l

Computing and reporting the AMR's odometry (the change in X, Y coordinates and the

heading) and other low-level operating conditions to the ARAM software.

ARCL Protocol

The Advanced Robotics Command Language (ARCL) is a programming language integrated

into ARAM and ARAMCentral. Its operating format is a text-based command and response

server. Use ARCL to integrate an AMR (or fleet of AMRs) into an external automation system.

You do not require access to MobilePlanner to use ARCL.

Typical uses of ARCL are:

l

Operating and monitoring the AMR.

l

Operating accessories and peripherals.

l

Sending commands to your payload structure.

For more information, See: Advanced Robotics Command Language Reference Guide (Cat. No. I617).

Touchscreen Support

The FLOW Core suite includes support software for the optional graphical touchscreen.

Support for Call Boxes and Door Boxes

Call boxes and Door boxes require:

l

A software component installed on the box itself.

l

A second software component installed either on the Enterprise Manager, or on a single

AMR.

SetNetGo

The SetNetGo OS runs on the LD-250 Core and EM2100 appliance. It is the host OS in which

the FLOW components ARAM and ARAMCentral run. SetNetGo has a Web graphical user

interface that you access either from a Web browser or from within MobilePlanner as a tab.

Configuring wireless Ethernet access enables wireless access to SetNetGo.

At a minimum, you require:

l

A hardwired connection to the LD-250 Ethernet maintenance port.

l

A LANconnection or direct Ethernet port connection to the EM2100 appliance.

ITdepartment can use SetNetGo to configure network settings without the need to run

MobilePlanner.

Use SetNetGo to configure Ethernet settings, upgrade software, or perform diagnostics such as

retrieving log files.

20472-000 Rev D LD-250 Platform User's Manual 23

Page 24

1.4 How Can I Get Help?

1.4 How Can I Get Help?

Refer to the OMRON corporate website: http://www.ia.omron.com.

Related Manuals

This manual describes the installation, setup, operation, and maintenance of an LD-250. There

are additional manuals that describe configuring the LD-250. See the following table. These

manuals are available on the software media delivered with your LD-250.

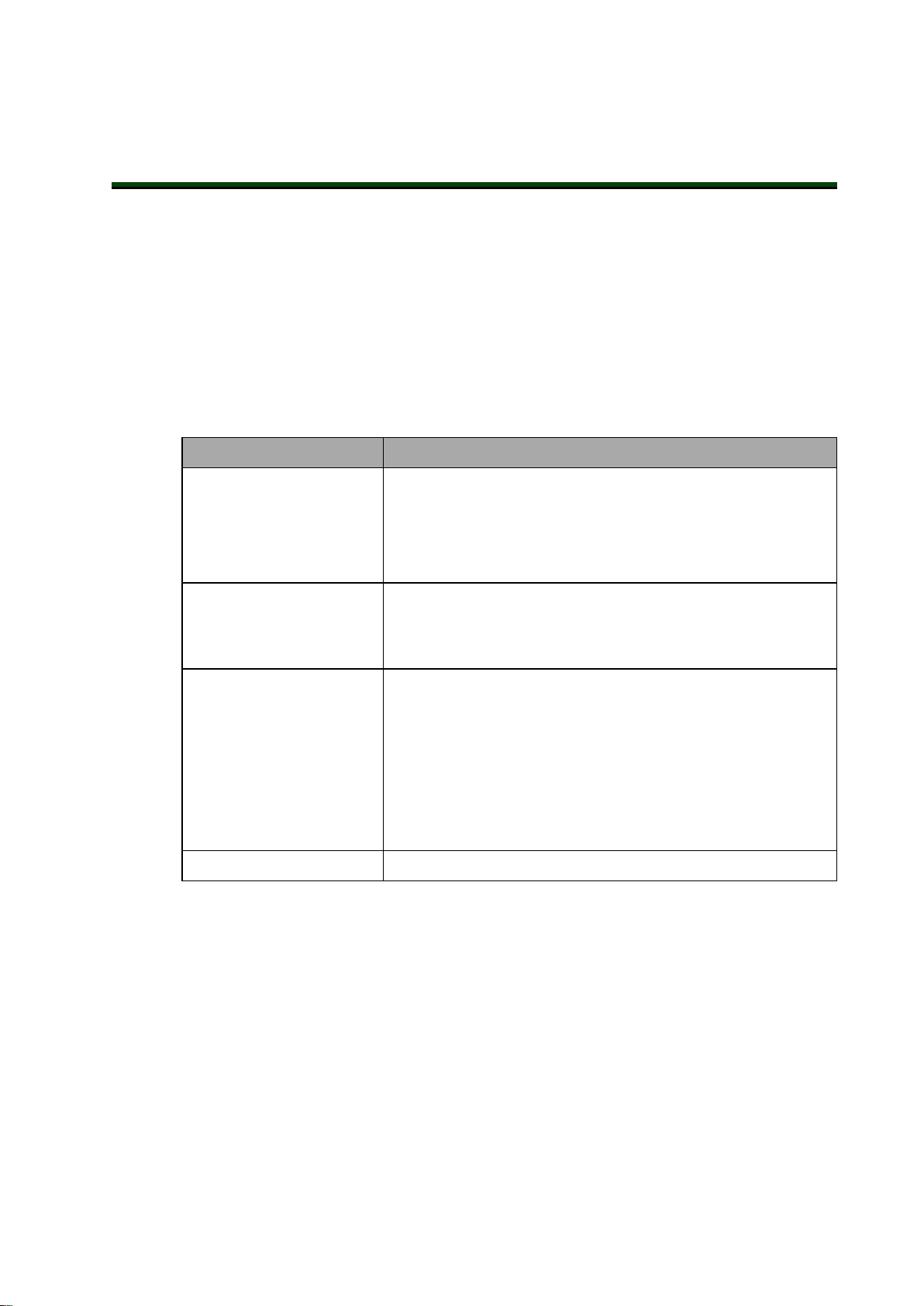

Manual Title Description

Table 1-1 Related Manuals

Mobile Robot LDSafety

Guide (Cat. No. I616)

Fleet Operations Workspace Core User's Manual

(Cat. No. I635)

EM2100 Installation

Guide (Cat. No. I634)

Advanced Robotics Command Language Reference Guide (Cat. No.

I617)

LDPlatform Peripherals

User's Guide (Cat. No.

I613)

Safety Laser Scanner

OS23C Series User's

Manual (Cat. No. Z296)

Contains general safety information for all OMRON AMRs.

Describes Fleet management, MobilePlanner software, the

SetNetGo OS, and most of the configuration procedures for an

LD-250.

Describes the installation of an EM 2100 appliance, as a Fleet

Manager, which runs the Fleet Operations Workspace software

to manage a fleet of AMRs.

Describes how to use the Advanced Robotics Command Language (ARCL) a text-based, command line operating language

Use ARCL to integrate a fleet of AMRs with an external automation system.

Describes optional peripherals (Touchscreen, Call box or Door

box, Acuity Localization, HAPS, and rear-facing laser.)

Describes safety features and operational standards for the

OS32C laser scanner.

Support

Contact your local OMRON Support if you have problems with your LD-250 that are not

described in this manual.

When you contact support, it is useful to provide a DebugInfo file. This is a collection of configuration, log, and system status files that support personnel can use for debugging and

troubleshooting. Refer to: Download a Debuginfo File for Support on page 24.

Visit the OMRON website for your locale to obtain local support telephone numbers and

information.

Download a Debuginfo File for Support

You can download a debuginfo file for troubleshooting problems or if you need to contact your

local OMRON Support.

24 LD-250 Platform User's Manual 20472-000 Rev D

Page 25

Chapter 1: Introduction

NOTE: The AMR's clock must be properly set to ensure accurate timestamps in

the debug file. Contact your local OMRON Supportfor more information.

If your LD-250 is already configured to use a wireless network:

1.

Open MobilePlanner and connect to the AMR's IP address.

2.

Click the SetNetGo tab to open its Web UI.

3.

Click Status and select Debug Info from the left pane.

4.

Click Download Debug Info and then specify a location to save the file.

Otherwise, you must first create a TCP/IP connection to the AMR's maintenance Ethernet port

as described in: Configure the Maintenance Network on page 25.

Configure the Maintenance Network

Use this procedure only if you have not configured your LD-250 for access over a wireless network. Instead, you use a hardwired connection to the LD-250 maintenance port. (See: Main-

tenance Ethernet Connection on page 67.)

1.

Connect a Cat-5 (minimum) Ethernet cable from the maintenance Ethernet port on the

LD-250 to an Ethernet port on your Windows PC.

2.

In the Windows Open or Search box (or at a command prompt) type the following command and press Enter:

ncpa.cpl

This command opens the Network Connections screen, which might look different

depending on your version of Windows.

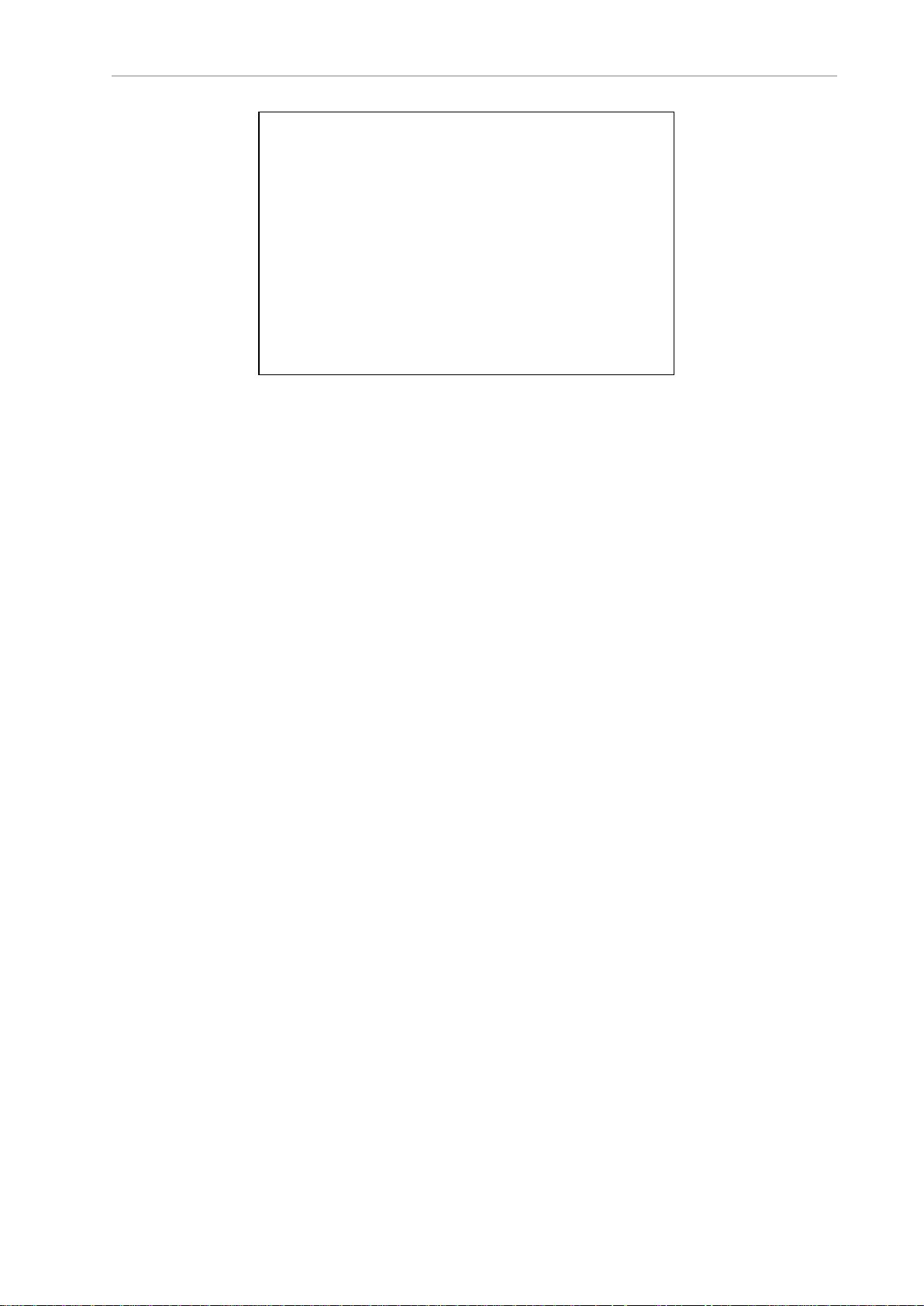

Figure 1-9 Network Connections Screen.

3.

Right-click on the Ethernet N or LAN Connection.

4.

Click Properties, and then double-click the Internet Protocol Version 4 connection item

to open its Properties window.

20472-000 Rev D LD-250 Platform User's Manual 25

Page 26

1.4 How Can I Get Help?

5.

Click the radio button next to Use the following IP address.

6.

Enter 1.2.3.5 as the IP address and 255.255.255.0 as the Subnet mask.

7.

Click OK twice to exit both Properties dialogs, and then close the Network Connections

screen.

Figure 1-10 Dialogs for the Ethernet Properties

You can now use this TCP/IP port connection to access the SetNetGo Web UI:

1.

Open a Web browser on the PC and enter https://1.2.3.4 as the URL.

2.

If prompted to accept security certificates, confirm that you accept them.

To access the DebugInfo file, see: Obtain a DebugInfo File from SetNetGo on page 26.

Obtain a DebugInfo File from SetNetGo

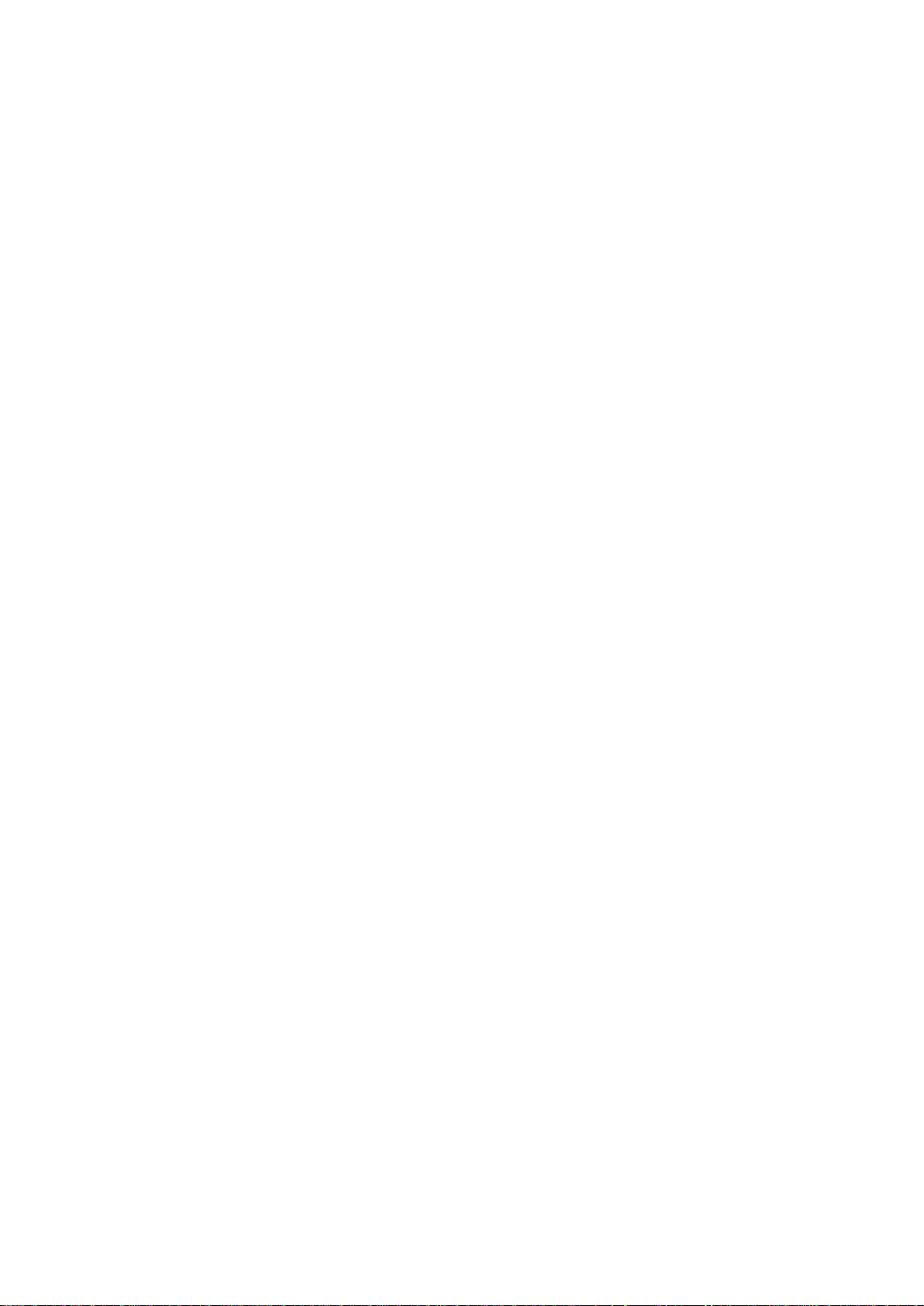

After you access SetNetGo as described in the preceding sections, you will see the following

screen:

Figure 1-11 SetNetGo Status Tab

26 LD-250 Platform User's Manual 20472-000 Rev D

Page 27

1.

In the SetNetGo screen, click the Status tab and then select Debug Info to activate the

Download debug info button.

2.

Click Download debug info.

3.

When prompted, save the downloaded file, and attach it to your support request email.

See: Support on page 24.

Chapter 1: Introduction

20472-000 Rev D LD-250 Platform User's Manual 27

Page 28

Page 29

This chapter describes important personal safety considerations. All persons that operate an

!

LD-250 or work in the vicinity of an LD-250 must read and understand this information.

2.1 General Hazards

This section describes potentially hazardous situations and conditions.

WARNING: The following situations could result in injury or damage to the

equipment.

l

Do not ride on the AMR.

l

Do not exceed the maximum weight limit. Be aware that the maximum payload

decreases as the floor's incline increases.

l

Do not exceed the maximum recommended speed, acceleration, deceleration, or rotation

limits. Refer to Center of Gravity (CG) on page 86 and Acceleration, Deceleration, and Rota-

tion Limits on page 74.

Chapter 2: Safety

Rotational speed becomes more significant when the payload’s center of gravity is

increasingly offset from the AMR's center of gravity.

l

At speeds of less than 225 mm/second, the safety laser is not active. There is a risk of

injury or property damage.

l

Do not disconnect the drive motor encoder cables unless required to do so as part of a

maintenance procedure. Refer to Maintenance on page 141.

l

Do not drop the AMR, run it off a ledge, or otherwise operate it irresponsibly.

l

Do not allow the AMR to drive through an opening that has an automatic gate or door

unless the door and AMR are configured correctly with the Call Box or Door Box option.

Refer to the LDPlatform Peripherals User's Guide (Cat. No. I613) for details on the Call Box

or Door Box.

l

Do not expose the AMR to rain or moisture.

l

Do not continue to run the AMR if hair, yarn, string, or any other items have become

wound around its axles, casters, or wheels.

l

Do not use unauthorized parts to repair the AMR.

l

Do not power on the AMR without its wireless antennas in place.

l

Although the lasers used are Class 1 (eye-safe), OMRON recommends that you not look

into the laser light.

l

Sunlight and reflective surfaces can affect the AMR's laser operation.

l Do not operate the AMR in a flammable gas environment.

20472-000 Rev D LD-250 Platform User's Manual 29

Page 30

2.2 What to Do in an Emergency

!

2.2 What to Do in an Emergency

In case of an emergency such as a fire or collision, you should stop the AMR quickly and

safely.

CAUTION: Combustible LithiumBattery. For AMR fire suppression, use

either a type ABC or BC dry chemical extinguisher.

The LD-250 has two E-Stop buttons, one on either side of the chassis (a red push-lock button

on a yellow background). The Operator Panel (if used) provides an additional E-Stop button.

Use the User Interface port to add E-Stop buttons to your payload structure, if required. See

User Interface (Brake and E-Stop) on page 103

Figure 2-1 E-Stop Button

A user-initiated E-Stop differs from a laser-initiated emergency stop. The latter occurs when the

AMR's safety scanning laser detects an object within its protected zone. In such cases, the

AMR safely stops autonomously and then resumes operation after a two second delay. See:

Emergency Stops that are Initiated by AMR Safety Lasers on page 39.

To use an E-Stop button:

1. Push firmly on the red button until it locks:

l

The AMR uses motor power to come to a controlled stop then engages its motor

brakes and cuts power to its drives.

l

Indicator lights on the AMR show the E-Stop state.

2.

Follow your site-specific emergency and safety procedures.

After correcting the emergency condition, press and hold the brake button to manually move

the AMR. You can also use the joystick to drive the AMR manually, if it is safe to do so.

To enable the AMR's drive motors and put it back into service, follow the procedure described

in: Releasing an E-Stop.

Releasing the Brakes to Move the LD-250 Manually

You can move the LD-250 manually when required. For example, if the battery is too depleted

to power the LD-250 or any other urgent condition. For safety reasons, only qualified persons

should move an LD-250 manually.

NOTE: You should move the LD-250 manually only when absolutely necessary

during an emergency, for safety, or if it is lost or deadlocked. If you find that you

30 LD-250 Platform User's Manual 20472-000 Rev D

Page 31

Chapter 2: Safety

!

!

must frequently move the LD-250, use MobilePlanner to reconfigure its route to

avoid problem areas.

Move the LD-250 only after you have read and understood:

l

This LD-250 user's manual.

l

The Mobile Robot LDSafety Guide (Cat. No. I616).

Application-specific attachments can affect an AMR's stability. All operators should know the

locations on the AMR (or its payload) where they can push safely without tipping the AMR

over or damaging its components. This should be a location low down, close to the center of

gravity. For the safe push points, see: LD-250 Packaging on page 48.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK Manually

pushing an AMR requires significant effort and might cause personal injury or

property damage. Take appropriate care and follow all safety instructions.

To move the LD-250 manually:

1.

Check the battery status before moving an LD-250 manually. Battery power is required

to release the wheel brakes. See the battery level indicator in: LD-250 Status Screen.

2.

Verify that an E-Stop button is engaged (pressed in).

3.

Press the brake release button in the Operator Panel.

4.

Rotate and push the LD-250 in the required direction to a parking or charging station.

5.

If you move an LD-250 while powered off it might be unable to determine its location

when you power it on. Use the localization feature in MobilePlanner or the Localize at

Goal feature in ARAM.

The LD-250 Core provides a brake release circuit that you can use to add a brake release button to your payload in a convenient location. See: User Interface (Brake and E-Stop) on page 103.

To bring the AMR back into service, see: Releasing an E-Stop on page 31.

An alternate method of manually moving an AMR is to disengage the drive motors. You

might want to use this method if the AMR's battery has no charge, or if there is no battery

installed. See: Engage and Disengage the Drive Wheel Motors on page 148.

Releasing an E-Stop

This section describes how to release an E-Stop and bring the AMR back into service.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

If the AMR’s E-Stop is triggered, first correct any condition that caused the

emergency stop. Make sure that all surrounding areas are clear before releasing

the E-Stop.

1.

Make sure that all surrounding areas are clear before you release the E-Stop button so

that the AMR has room to maneuver.

2.

Rotate the E-Stop button in the direction of the arrows and allow it to pop up.

20472-000 Rev D LD-250 Platform User's Manual 31

Page 32

2.3 Dangers, Warnings, and Cautions

!

!

!

!

3.

After you release the E-Stop button, you must enable the motors manually by one of the

following methods:

l

Dialogs in MobilePlanner that describe how to resume operation after an E-Stop.

l

Press the green ON button on the Operator Panel.

l

(Optional, if used) Press the GO button on the Touchscreen.

After you enable the motors the AMR there is a delay of several seconds before it can resume

operation.

2.3 Dangers, Warnings, and Cautions

Alert Levels

There are three levels of alert notation used in our manuals. In descending order of importance, they are:

DANGER: Identifies an imminently hazardous situation which, if not

avoided, is likely to result in serious injury, and might result in fatality or

severe property damage.

WARNING: Identifies a potentially hazardous situation which, if not avoided,

will result in minor or moderate injury, and might result in serious injury, fatality, or significant property damage.

CAUTION: Identifies a potentially hazardous situation which, if not avoided,

might result in minor injury, moderate injury, or property damage.

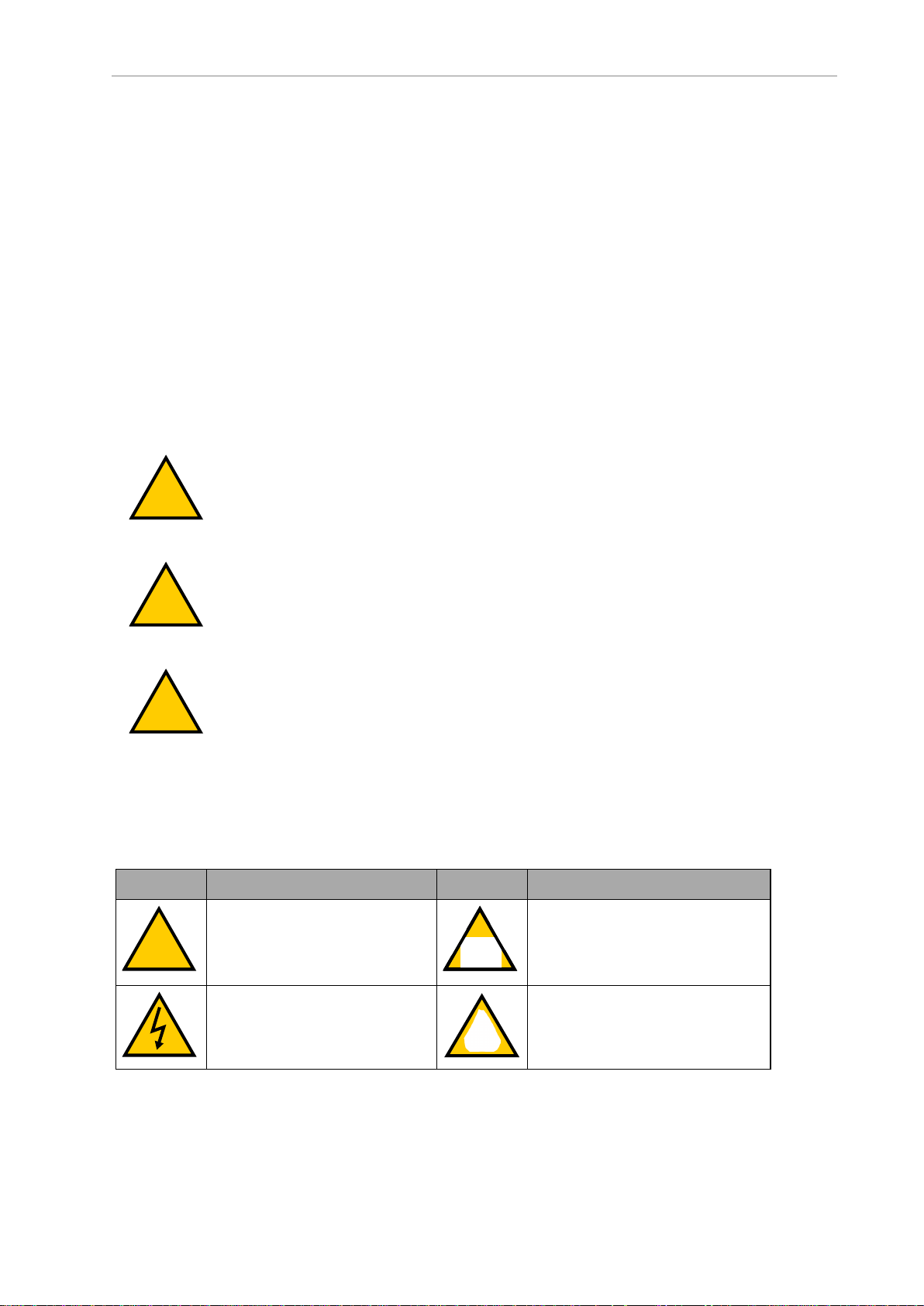

Alert Icons

The icon that starts each alert can be used to indicate the type of hazard. These will be used

with the appropriate signal word - Danger, Warning, or Caution - to indicate the severity of the

hazard. The text following the signal word will specify what the risk is, and how to avoid it.

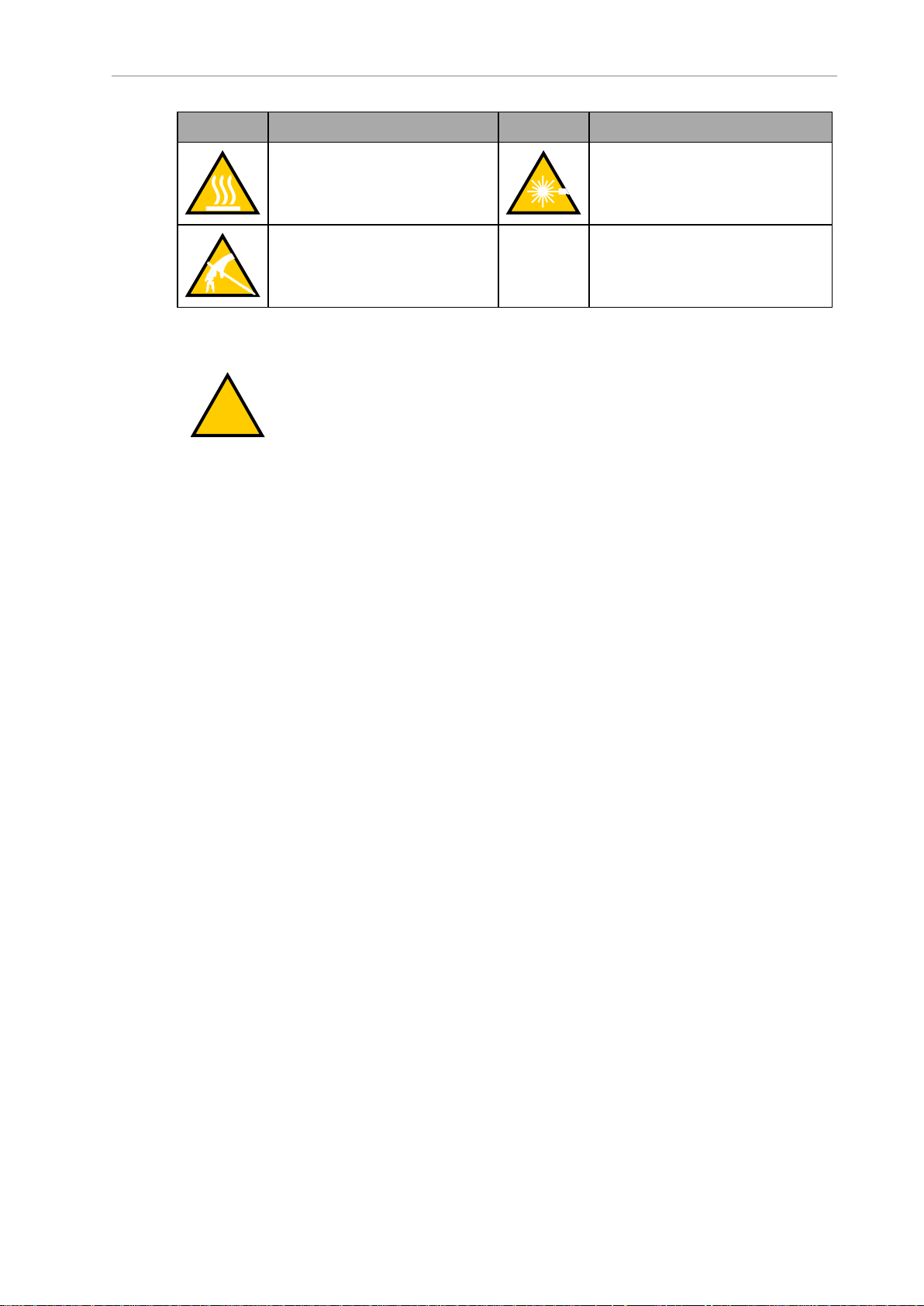

Icon Meaning Icon Meaning

This is a generic alert icon. Any

specifics on the risk will be in

the text following the signal

word.

This identifies a hazardous electrical situation.

This identifies a hazardous entanglement situation.

This identifies a fire risk.

32 LD-250 Platform User's Manual 20472-000 Rev D

Page 33

Chapter 2: Safety

!

Icon Meaning Icon Meaning

This identifies a hazardous

burn-related situation.

This identifies a hazardous ESD

situation.

Falling Hazards

This identifies a laser emitter eye

damage situation.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

The AMR can cause serious injury to personnel or damage to itself or other

equipment if it drives off of a ledge, such as a loading dock, or down stairs.

Physical Barriers

Use physical barriers together with logical barriers (map restrictions) to prevent the AMR from

approaching any fall hazard that is within its operating area. Such hazards include:

l

The edge of a loading dock or ramp.

l

Entrance to downward stairs.

l

Any other vertical drop that exceeds the AMR's maximum step height.

Required characteristics of physical barriers are:

l

Strength—The barrier must be attached to a solid wall or floor and should be strong

enough to stop a fully-laden AMR traveling at maximum speed.

l Continuity—The barrier must extend around the hazard completely.

l

Visibility—Mark all physical barriers to make sure that the AMR's safety and navigation laser can detect them easily. Barriers must extend above and below the laser's

sensing plane, particularly if the floor is not flat.

Logical Barriers

In addition to physical barriers, create forbidden areas or lines on the workspace map to prevent AMRs from closely approaching a fall hazard. These restrictions must be continuous so

that the AMR cannot plan a path around the logical barrier.

You can also use the configuration parameters FrontPaddingAtSlowSpeed and FrontPad-

dingAtFastSpeed to increase the AMR's safety clearances. This causes the AMR to decelerate

as it approaches a hazard. See Fleet Operations Workspace Core User's Manual (Cat. No. I635).

20472-000 Rev D LD-250 Platform User's Manual 33

Page 34

2.4 User's Responsibilities

!

!

Special Information

This manual uses the following typographic styles to identify specific types of information:

IMPORTANT: Information to ensure safe use of the product.

NOTE: Information for more effective use of the product.

Additional Information: Offers helpful tips, recommendations, and best prac-

tices.

Version Information: Information on differences in specifications for different

versions of hardware or software.

2.4 User's Responsibilities

You are responsible for continuous safe use of the AMR.

WARNING: PERSONALINJURYRISK

It is the end-user's responsibility to perform a task-based risk assessment and

to implement appropriate safety measures at the point of use of the AMR in

accordance with local regulations.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

It is the end-user's responsibility to make sure that the AMR design and implementation complies with all local standards and legal requirements.

Safe use of the AMR requires that you:

l

Read the installation and operation instructions, in addition to the Mobile Robot

LDSafety Guide (Cat. No. I616), before using the AMR.

l

Make sure that the environment is suitable for safe operation of the AMR.

Two or more AMR's require a Fleet Management appliance unless you confine and operate each AMR in a separate workspace. See: Fleet Operations Workspace Core User's

Manual (Cat. No. I635).

l

Make sure that any person working with or near an AMR is trained, and has read the

Mobile Robot LDSafety Guide (Cat. No. I616) for safe AMR operation.

l

Mechanically maintain and service AMRs for proper operation of all control and safety

functions.

Understanding Electrical Hazards

WARNING: ELECTROCUTIONRISK

The docking station has ACpower inside. Docking station covers are not interlocked.

34 LD-250 Platform User's Manual 20472-000 Rev D

Page 35

Chapter 2: Safety

!

l

Do not use power extension cords with the docking station unless properly rated.

l

Never access the AMR's interior while it is attached to a charger.

l

Immediately disconnect the battery after you open the battery compartment door.

Avoid shorting the battery terminals.

l

Do not use any charger not supplied by OMRON.

l

If the AMR comes into contact with any liquid:

o

Power off the AMR.

o

Clean off as much liquid as is possible.

o

Allow the AMR to air dry thoroughly before restoring power.

o

Contact your local OMRON Support if you suspect that liquid has penetrated the

skins or contaminated the AMR's interior.

Magnetic Field Hazards

The docking funnel creates a strong magnetic field. This component is located on the underside of the LD-250. Persons using medical implants should not approach the docking funnel.

WARNING: MAGNETIC FIELD - MEDICAL IMPLANT RISK

Magnetic fields can be hazardous if you have a medical implant. Keep a minimum of 30 cm away from the LD-250 when its underside is exposed during

maintenance procedures.

Qualification of Personnel

You must make sure that all personnel who work with or around AMRs have appropriate

training and have a thorough working knowledge. Provide the necessary additional training

for all personnel that work with the system.

As described in this manual, and the Mobile Robot LDSafety Guide (Cat. No. I616), you should

allow only skilled persons or instructed persons to do certain procedures:

l

Skilled persons have technical knowledge or sufficient experience to enable them to

avoid either electrical or mechanical dangers.

l

Instructed persons are adequately advised or supervised by skilled persons to enable

them to avoid either electrical or mechanical dangers.

For example, replacing a battery is a task for a skilled person, while an instructed person can

complete the task of charging a battery.

All personnel must observe industry-prescribed safety practices during the installation, operation, and testing of all electrically-powered equipment.

IMPORTANT: Before working with the AMR, every person must confirm that

they:

20472-000 Rev D LD-250 Platform User's Manual 35

Page 36

2.4 User's Responsibilities

!

l

Have the necessary qualifications and training.

l

Have received the manualss (both this user’s manual, and the Mobile Robot

LDSafety Guide (Cat. No. I616)).

l

Have read the manuals.

l

Understand the manuals.

l

Will work in the manner specified by the manuals.

Payload Movement and Transfer

A typical AMR application uses a payload structure to transport objects within a facility. For

example, the AMR might pick up and carry a crate of engine parts from one conveyor belt

then deliver it to another conveyor belt.

During movement and transfer, you must actively monitor and confirm the transfer operation

to make sure that it completes successfully. If any operation fails, a fail-safe interlock must trigger an AMR E-Stop condition. An E-Stop condition prevents the AMR from moving until you

resolve the problem and confirm that it is safe to restart operations.

Your facility should provide such fail-safe interlocks between the AMR and any facility equipment with which it interfaces. After you attach your payload to the AMR, verify the correct

operation of the fail-safe interlock as part of your risk assessment.

Configurable Warning Buzzer

The LD-250 has a configurable warning buzzer. Configure this buzzer as appropriate for the

facility in which the AMR operates. By default, the buzzer sounds when the AMR is moving

in any direction other than forward motion.

You can also configure the buzzer to activate in other specific situations, or to operate continuously whenever the AMR moves. The buzzer does not have a volume control and you

should make sure it is audible in all workspace locations, particularly where ambient noise

levels are high.

MobilePlanner provides the buzzer configuration parameters described in Table 2-1.

CAUTION: PERSONAL INJURY RISK. Changing buzzer parameter values

might make the AMR unsafe and affect compliance with safety standards.

Refer to the applicable safety standards for your locale before you change any

parameter values.

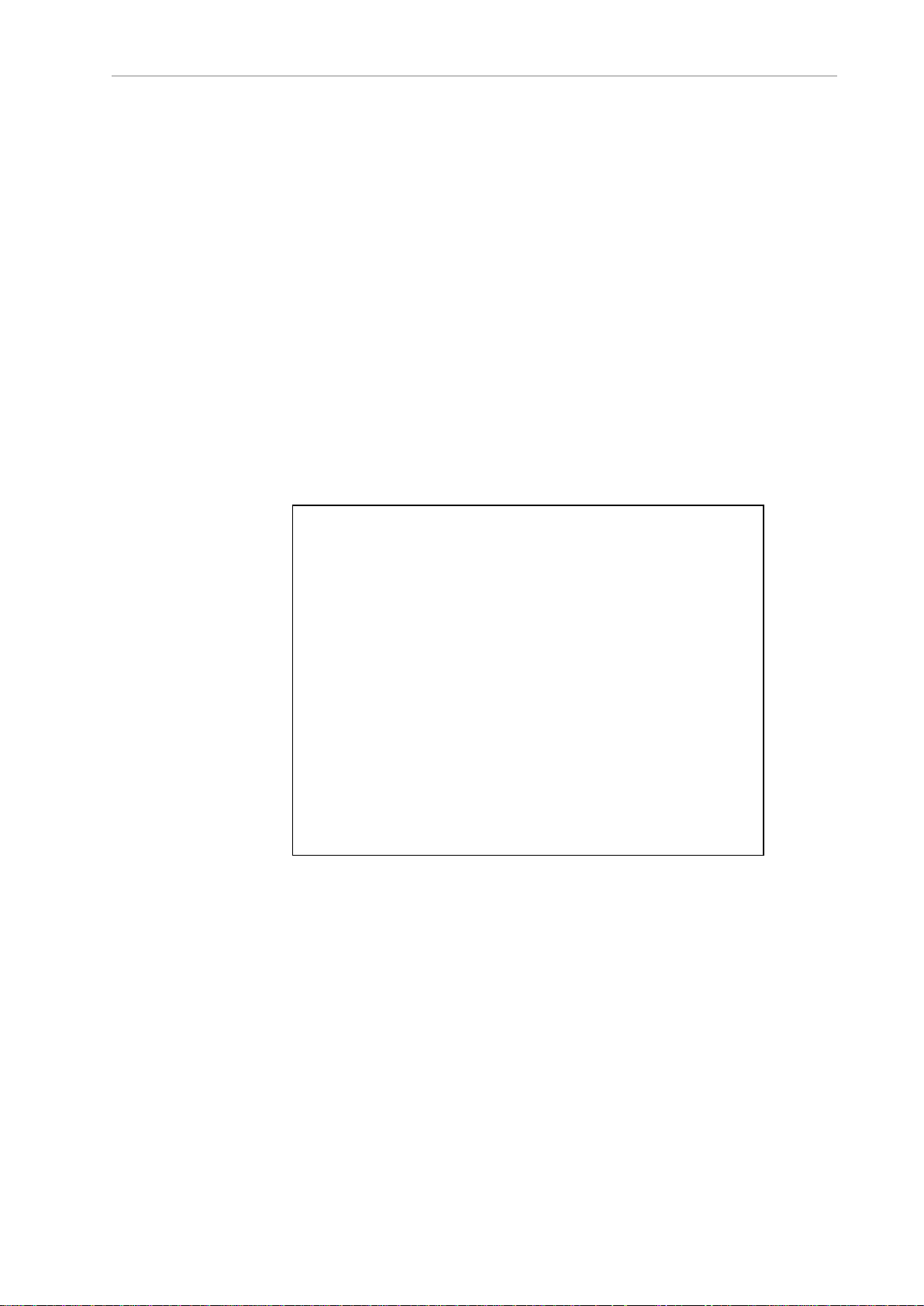

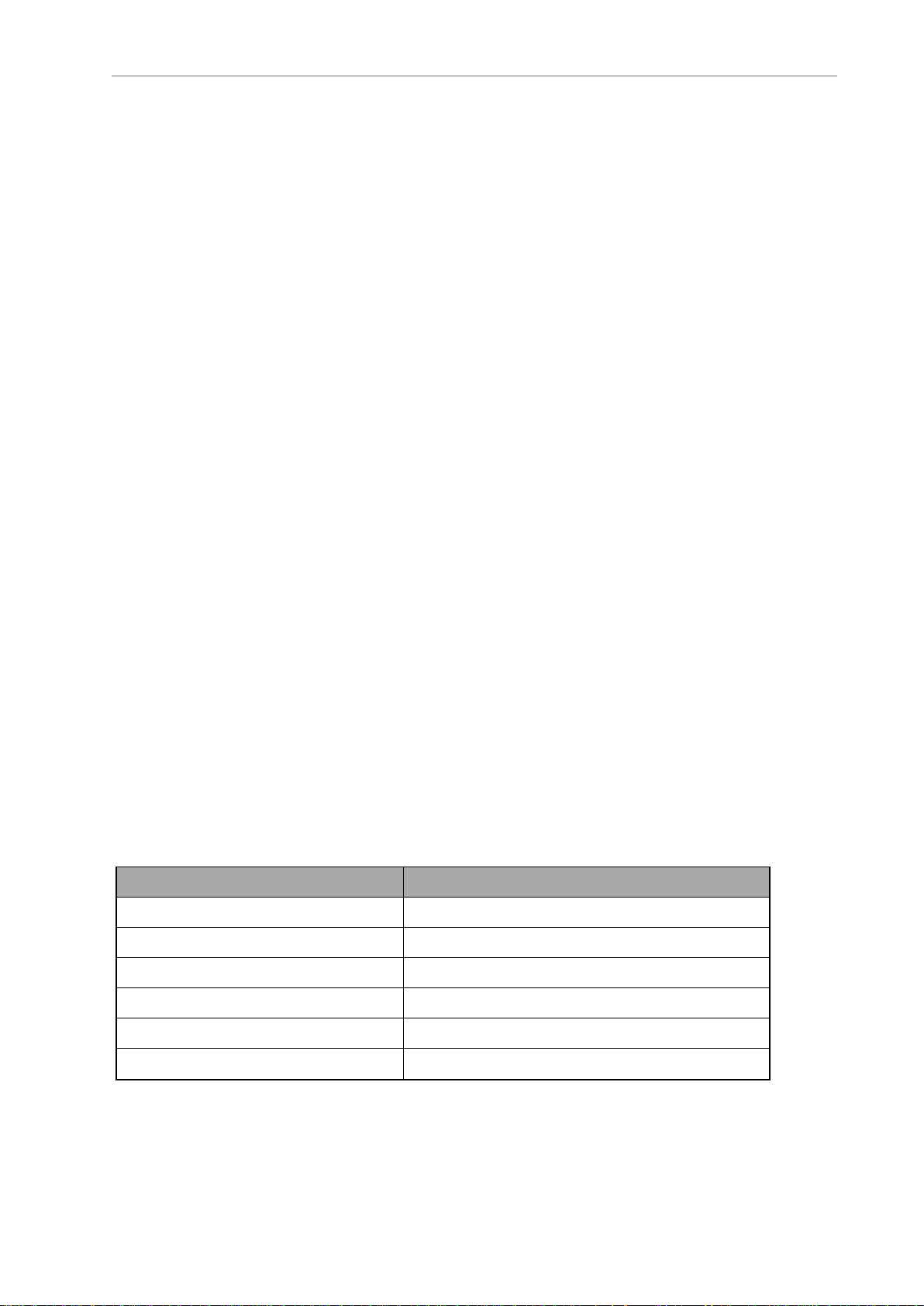

Table 2-1 Buzzer Parameters

Parameter Default Setting

safetyBuzzerDisable_All 0 (Disabled)

safetyBuzzerDisable_Safedrive 0 (Disabled)

safetyBuzzerDisable_FwdMotion 1 (Enabled)

safetyBuzzerDisable_AllMotion 0 (Disabled)

36 LD-250 Platform User's Manual 20472-000 Rev D

Page 37

Chapter 2: Safety

!

!

Fleet Management

When two or more AMRs operate in the same workspace they might not be able to accurately

detect other AMRs, or to precisely determine the dimensions of other AMRs. This might result

in collisions or deadlocks where both AMRs must halt and wait for human intervention.

To manage and administer multiple AMRs in the same workspace, you must use a EM2100

appliance configured as a Fleet Manager, running the Fleet Operations Workspace (FLOW) software.

Regardless of its safety laser type, an individual AMR always operates safely and within specifications. If a fleet includes different LD-series AMRs that also have different types of safety

laser, all AMRs always operate safely. However, a fleet that includes different LD-series AMRs

(such as, LD-60, LD-90, LD-250, etc) that have the same type of safety laser (i.e OS32C) will

have improved fleet performance that meets specifications.

The Fleet Manager controls AMRs over a wireless network (WiFi), reducing the risk of AMR

collisions by sharing the information between all AMRs in the fleet. The shared information

includes:

l

Dynamic X, Y, position and heading (velocity and direction of travel) of the AMR.

l

AMR size (including payload structure).

l

Path planning information (the individual AMR's intended route).

AMRs factor this data into their obstacle avoidance algorithm.

IMPORTANT: Fleet Manager is not an interlocked method of collision prevention. It is your responsibility to implement interlocked methods of collision

prevention where necessary.

For operational redundancy and fail-over you can add a second EM2100 appliance. See the

Fleet Operations Workspace Core User's Manual (Cat. No. I635) for more information.

2.5 Environment

General Environmental Conditions

Make sure that the LD-250‘s operating environment remains safe for the LD-250.

CAUTION: PERSONALINJURYORPROPERTYDAMAGERISK

Improper path planning can result in personal injury or property damage.

WARNING: PERSONALINJURYORPROPERTYDAMAGERISK

An AMR can be unsafe if operated under environmental conditions other than

those specified in this manual.

l

Environmental Hazards—There are areas where it is unsafe for the LD-250 to operate,

for example, steep ramps (greater than 1:12 or 4.7° unloaded), loading docks, or shelves.

20472-000 Rev D LD-250 Platform User's Manual 37

Page 38

2.5 Environment

!

Provide physical barriers that the LD-250 can detect accurately with its scanning laser

so that it does not attempt to drive near the hazard. Be aware that in addition to being

easily detectable, a barrier must be strong enough to resist a fully-loaded AMR traveling

at speed.

l

Restricted Areas—You can also use map features such as preferred lines and forbidden

zones to keep AMRs within their designated area of operation. See the Fleet Operations

Workspace Core User's Manual (Cat. No. I635) for information about editing your workspace map.

While you can use either or both physical barriers and map features to keep AMRs within

their designated workspace, OMRON recommends that you always install physical barriers

where there is a risk of damage or personal safety.

Public Access

The LD-250 is designed to operate in indoor industrial environments. You must deploy it only

in applications where you anticipate and mitigate potential risks to personnel and equipment.

OMRON does not intend the LD-250 for use in uncontrolled areas without risk analysis. For

example, in areas open to general public access. Use of the LD-250 in such areas requires that

you deploy additional safety measures not described in this manual. For assistance, contact

your local OMRON Support.

Clearances when Operating

Side Clearances

The LD-250 is designed to operate in environments that contain doors, passageways, or other

constrained areas that are wide enough for it to traverse.

However, you must maintain adequate side clearance (free space) on both sides of the AMR so

that it cannot trap a person against a wall or other fixed object. Consult the applicable

Autonomous Vehicle and Robotics operating standards for your locale.

An AMR must often maneuver close to machinery, conveyors, or other fixed objects. In such

cases, operating standards usually allow an exception to side clearance requirements.

For more information, see: Side Clearance on page 114, and refer to the Fleet Operations Workspace Core User's Manual (Cat. No. I635) for information about software parameters that you

can use to control the LD-250's front and side clearance zones.

Clearances During Rotation

The LD-250 generally travels in a forward direction and cannot do path planning in the

reverse direction. It reverses only if you create a MobilePlanner macro task that requires it to

move in reverse. Otherwise, the LD-250 only reverses onto its docking station to recharge. To

change direction, the LD-250 rotates on its center of rotation (turns in place). However, when

the LD-250 rotates, obstacles in its path do not trigger a safety system event.

The LD-250's Light Discs display a distinct turn signal pattern when it rotates. For more

information, see:Indications Provided by Light Discs Light Outputs on page 127.

CAUTION: PERSONALINJURYRISK

Personnel who work with or around the AMR should not stand close to the

AMR when it is rotating with no forward motion.

38 LD-250 Platform User's Manual 20472-000 Rev D

Page 39

Chapter 2: Safety

Docking Clearances

You should set a 1.5 m (4.9 ft) distance between docking goals and physical docks to allow sufficient room to maneuver around other AMRs when docking.

Obstacles

Before an AMR enters a high-traffic areas, you must take appropriate precautions to alert

people working in those areas:

l The LD-250 provides active warning features such as a warning buzzer, speech syn-

thesis, and warning indicator lights.

l The LD-250 Core provides user ports that enable you to add warning indicators to your

payload structure. See: Indications Provided by Light Discs Light Outputs on page 127.

If high-traffic areas include other moving vehicles such as fork-lift trucks or autonomous moving machines, consider adjusting the AMR's operating parameters to reduce the risk of a collision. You can do this by:

l

Editing the workspace map to include map features that restrict the AMR's local operation such as restricted entry zones, slow speed zones, or preferred lines.

l

Editing the AMR's operating parameters to restrict its global operation, such as redu-

cing its maximum speed or minimum approach distance.

For more information, see: Fleet Operations Workspace Core User's Manual (Cat. No. I635).

Emergency Stops that are Initiated by AMR Safety Lasers

Under certain conditions, the AMR safety systems might cause an emergency stop.

For example, an AMR reacts to obstacles in its path by slowing and, if necessary, stopping

safely. It then either plans a new path around the obstacle or (if the obstacle has moved)

resumes its original path. The safety laser initiates an emergency stop that occurs any time the

laser detects unavoidable obstacles that are immediately in the AMR's path, but only when the

AMR is moving faster than 300 mm/second.

During the emergency stop, a controlled deceleration slows the AMR up to the maximum

allowable rate and then applies the brakes.

NOTE: An emergency stop initiated by an intrusion into the safety laser's protection field differs from pressing an E-Stop button. After you press an E-Stop button, you must first resolve the problem and then manually resume AMR

operation. See: What to Do in an Emergency on page 30.

Other circumstances might cause an emergency stop, such as:

l

Pushing the AMR in reverse faster than 300 mm/second might cause an over-speed

fault that requires manual intervention to clear.

l

User-supplied sensors connected to the LD-250 Core's User Interface port. User Interface

(Brake and E-Stop) on page 103.

After the AMR comes to a complete emergency stop caused by laser protection zone intrusion,

it waits a minimum of two seconds before it resumes operation. No user intervention is necessary and the AMR does the following:

20472-000 Rev D LD-250 Platform User's Manual 39

Page 40

2.6 Intended and Non-intended Use

!

1.

Verifies that there is adequate space to maneuver.

2.

Plans a local path deviation around the obstacle and resumes its task.

However, if the AMR cannot avoid the obstacle, the following outcomes might occur:

1.

The AMR identifies and plans a revised path to its goal. (This might cause the AMR to

turn around and move in a different direction.)

2.

Fail the current job and wait for Fleet Manager to assign a new job.

3.

If no alternate path is possible, signal an error state to the Fleet Operations Workspace

software and wait for user intervention.

Safety System Overspeed Faults

The LD-250 has an independent safety system that uses a dual complex programmable logic

device (CPLD) to redundantly monitor its velocity. This device makes sure that the AMR

always operates within the speed limits specified by safety standards DIN EN 1525 and ANSI

B56.5.

Both safety standards specify that an AMR's velocity is limited to less than 300 mm/second

when traveling in any direction that is not scanned by its safety laser.

If the AMR operates outside this specified velocity limit, its CPLDs report a Channel 1 or Channel 2 system fault to its operating firmware and begins an emergency stop (ESTOP) sequence.

In autonomous operation, the fault triggers the AMR's motion controllers to execute a controlled stop.

If motion is already disabled (for example, an E-Stop button is engaged) and you override the

brake release, the safety system cannot stop the AMR. This is because power to the drive

motors is already cut off. After you resolve the error condition the safety system stops reporting

safety fault to the motion controllers and the normal start-up process begins.

Motion control configuration parameters in the ARAM software (such as AbsoluteMaxTransVel) limit the maximum allowable velocities. Use MobilePlanner to modify the

value of these parameters. Refer to the Fleet Operations Workspace Core User's Manual (Cat. No.

I635).

2.6 Intended and Non-intended Use

Intended Use

The LD-250 is designed to operate in indoor industrial environments. In general, if a wheelchair user can safely and easily navigate the environment (open, and mostly flat with only

gentle inclines and wide doorways), then it is navigable by an LD-250.

DANGER: PERSONALINJURYRISK

There is risk of serious injury by crushing if the AMR tips over as a result of

improper operation on inclines that do not comply with the operating specifications.

The following guidelines apply:

40 LD-250 Platform User's Manual 20472-000 Rev D

Page 41

Chapter 2: Safety

l

Floor—Clean and dry floors that you sweep regularly and routinely keep free of debris,

dust, and liquids.

l

Typical Inclines—The LD-250 is intended to operate in a workspace that has a mostly

flat floor. If the workspace includes inclined areas, OMRON recommends a gentle

incline typical of wheelchair ramps. Be aware that the payload structure and any loads

transported can:

l

Reduce the AMR's ability to traverse an incline.

l

Change its operating center of gravity (CG).

l

Inclines (Ramps)—With a properly designed and stable payload, the LD-250 can operate on ramps at full payload capacity. However, extended periods of operation on

ramps will affect battery duration and speed is limited to 600 mm/second on inclines

such as ramps. Operational recommendations are:

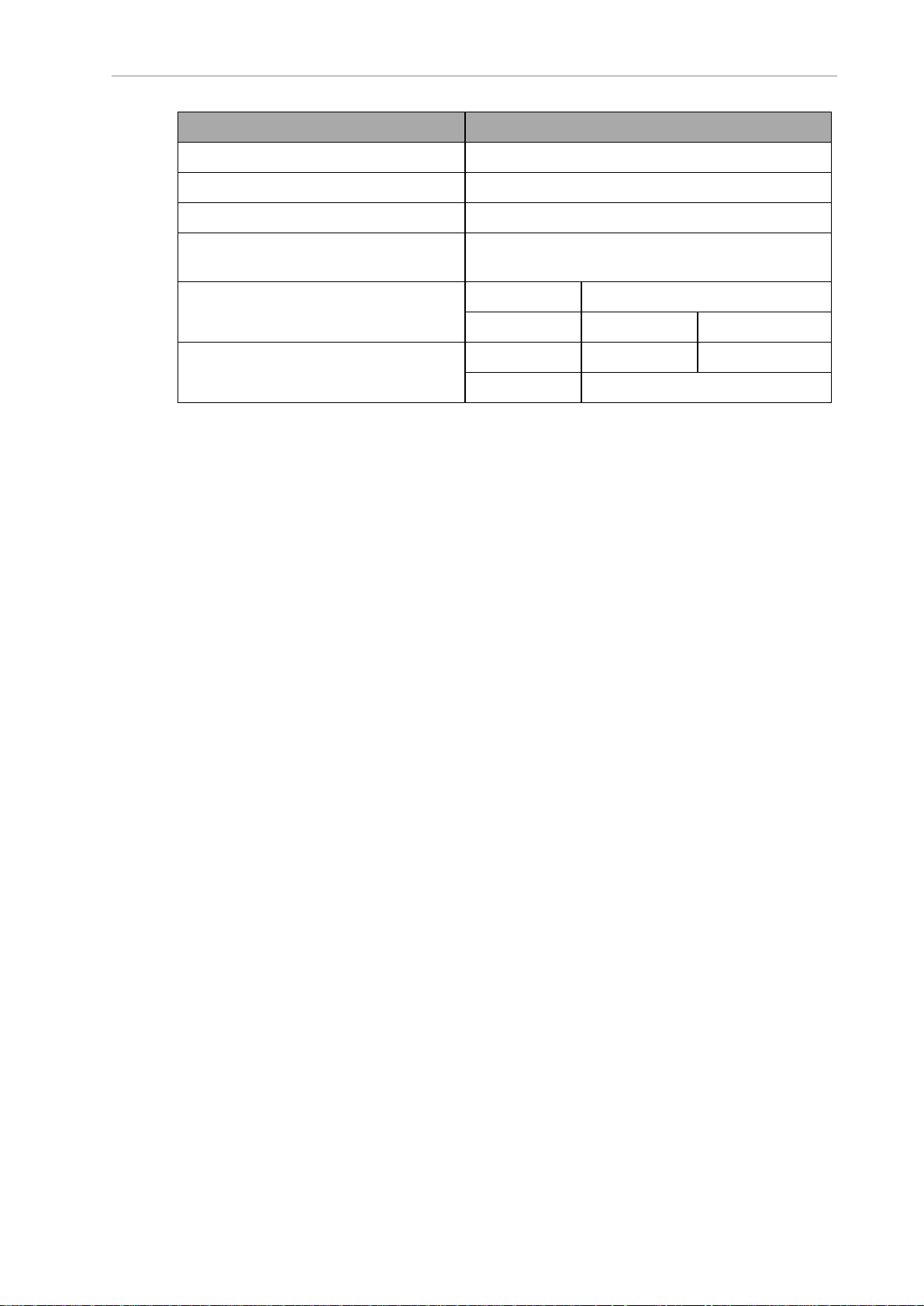

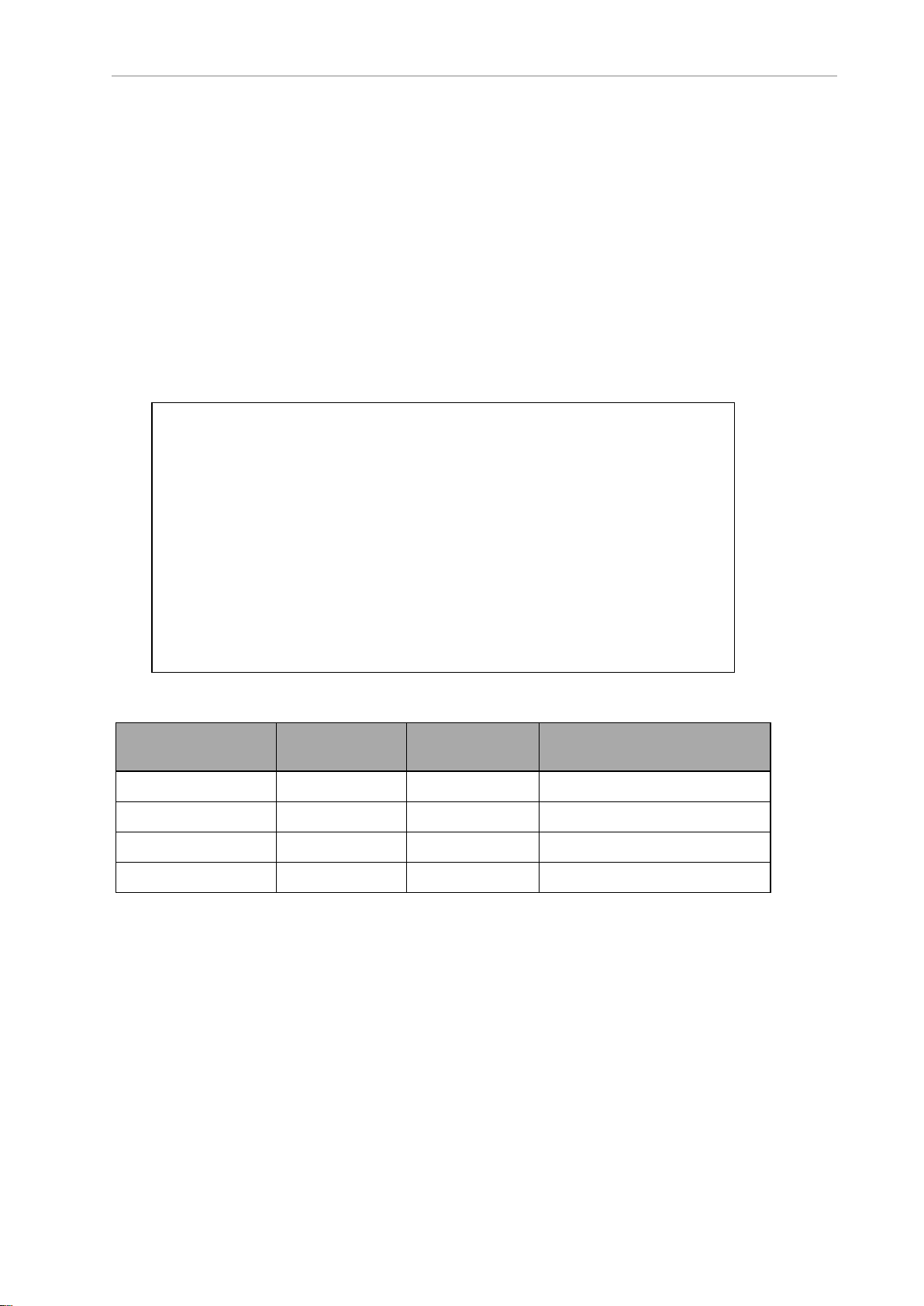

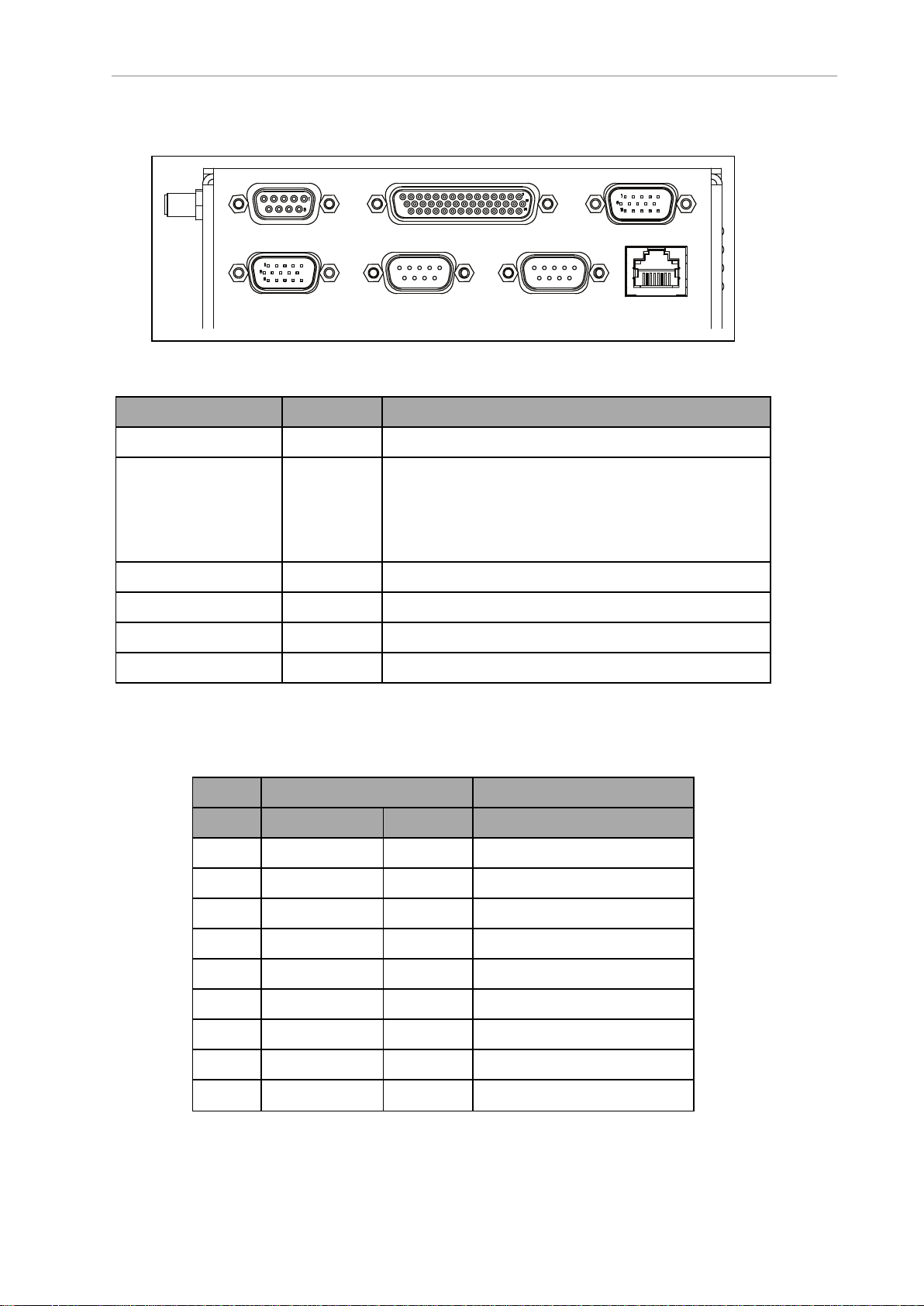

Slope Payload Restriction Speed Limit

1.7° (3% grade) No restriction No restriction

3° slope 200 kg 600 mm/s

4.75° (1:12 slope, typical wheelchair ramp) 165 kg 600 mm/s

l

Temperature—5 to 40°C, with a recommended humidity range of 5% to 95%, non-condensing. Operating the LD-250 at high or low ambient temperatures (particularly with a

full payload and high speeds) can cause the battery to exceed its operating temperature

limits. If this happens, you are notified by escalating software messages as follows:

o

The battery is approaching a high or low temperature limit. Change the LD-250's

operating conditions so that the battery can return to within its ambient temperature limits.

o

The battery has exceeded an initial limit, the LD-250 continues to operate but

charging is deferred until the battery has returned to within its ambient temperature limits

o

The battery has exceeded its temperature limits and the LD-250 will shut down

immediately.

The LD-250 has an ingress protection rating of IP20 and is not liquid-proof. Keep floors dry

because liquids might get into the AMR. Damp, dusty, or greasy floors might also cause its

drive wheels to slip or skid. Such traction problems can affect both braking and accuracy.

Non-Intended Use

When deploying an AMR, anticipate potential risks to personnel and equipment. OMRON

intends the LD-250 for use in a carefully controlled and managed environment with restricted

access granted only to trained personnel.

You should conduct a risk analysis before you deploy the LD-250 in other environments. For

example, deployments in areas that are open to general public access such as retail stores.

Application of the LD-250 in such areas generally requires additional safety measures.

OMRON does not intend the LD-250 for deployment in environments that contain:

20472-000 Rev D LD-250 Platform User's Manual 41

Page 42

2.7 Battery Safety

l

Hazardous (explosive or corrosive) atmospheres.

l

Ionizing or non-ionizing radiation.

l

Extreme heat or humidity.

l Floors that are damp or have any standing water.

IMPORTANT: The LD-250 is not waterproof. Keep all floors dry. Dampness can

cause drive wheels to slip, affecting both braking and navigation.

In addition, OMRON does not intend the LD-250 for deployment in the following environments:

l

Life-support systems.

l

Residential installations.

l

Mobile installations, including moving floors or any type of land vehicle, watercraft, or

aircraft. (LD-250 navigation is assisted by a gyroscope embedded in the LD-250 Core.

For accuracy, the gyroscope requires a stationary environment).

IMPORTANT: Observe all instructions for operation, installation, and maintenance provided in this manual and in the Mobile Robot LDSafety Guide (Cat.

No. I616).

Non-intended use of an LD-250 can:

l

Cause injury to personnel.

l

Damage the LD-250 or other equipment.

l

Reduce reliability and performance.

If there is any doubt concerning the application, ask your local OMRON Support to determine

whether it is an intended use.

LD-250 Modifications

OMRON recognizes that customers or integrators make modifications to the LD-250 to adapt it

to a specific application. When doing so, make sure that:

l

You use the LD-250 Core's User Interface connection to include appropriate safety

devices into the LD-250's integrated safety systems.

l

The modification causes no hazardous sharp edges, corners, or protrusions and does

not extend further than the LD-250 footprint. (This might affect the safety zones.)

l

There is no reduction in functionality.

l

All safety features (such as lasers and brakes) are functional and operate within the specifications determined by local standards for AMRs.

2.7 Battery Safety

The LD-250 requires one lithium ion battery. Use only the battery of the correct model number

supplied by OMRON. The FLOW software determines whether the battery is the correct type

42 LD-250 Platform User's Manual 20472-000 Rev D

Page 43

Chapter 2: Safety

!

for the LD-250.

Effective April 1, 2016, IATA regulations (UN 3480, PI 965) require that air-shipped lithium ion

batteries must be transported at a state of charge not exceeding 30%. Fully charge the battery

immediately upon receipt to avoid total discharge. (The battery might arrive fully charged if it

is not shipped by air.)

CAUTION: BATTERYDAMAGERISK

Fully charge the battery immediately after delivery. Failing to do so might

cause the battery to discharge below a usable state, requiring its replacement.

See also: Battery Shipment on page 47.

Battery Safety Precautions

l

Store batteries upright and within the following temperature range:

l

One month: +5 to 45°C (41 to 113°F)

l

One year: 20 to 25°C (68 to 77°F)

l

Batteries stored at temperatures greater than 54°C or less than -6°C must stabilize for an

hour or longer until within the nominal operating temperature before use.

l Never expose the battery to water. If the battery is leaking, submerge it in mineral oil

and contact your local OMRON Support.

l

In case of fire, use a type ABC or BC dry chemical extinguisher.

Battery Maintenance

Every six months:

l Inspect the battery for damage or leaks.

l Connect the battery to a charger and allow it to fully balance all cells.

2.8 Additional Safety Information

Contact your local OMRON Support for other sources of safety information.

Mobile Robot LDSafety Guide (Cat. No. I616)

The Mobile Robot LDSafety Guide (Cat. No. I616) is included with your LD-250 and provides

detailed information about safe operation of your LD-250. It also provides resources for information about relevant standards.

2.9 Disposal

Dispose of in accordance with applicable regulations.

20472-000 Rev D LD-250 Platform User's Manual 43

Page 44

2.9 Disposal

Customers can contribute to resource conservation and protecting the environment by the

proper disposal of WEEE (Waste Electronics and Electrical Equipment). All electrical and electronic products should be disposed of separately from the municipal waste system via designated collection facilities. For information about disposal of your old equipment, contact your

local OMRON Support.

44 LD-250 Platform User's Manual 20472-000 Rev D

Page 45

This chapter describes how to set up your LD-250 and configure it for operation. It includes

information for optional features.

3.1 Overview of LD-250 Setup

Setup tasks consist of preparing the LD-250 for use by unpacking it and completing some

mechanical configuration such as installing the battery and the docking station. This includes