Page 1

Power Monitor

model KM-N2-FLK

Users Manual

1.Overview of the unit

2.Installation and wiring

3.Basic use

Thank you for purchasing this power monitor, model KM-N2-FLK

(referred to as model KM-N2 in this manual).

This Users Manual describes the functions, performance, and

application methods needed for optimum use of the unit.

Please observe the following when using this unit.

• This product is designed for use by qualified personnel with a

knowledge of electrical systems.

• Before using the product, thoroughly read and understand this Users

Manual to ensure correct use.

• Keep this Users Manual in a safe location so that it is available for

reference whenever required.

4.Settings needed to measure

electricity

5.Other Functions

6.

Detailed settings for communications

7.Troubleshooting

8.Appendices

Catalog no. N200-E1-03

Page 2

Index

Agreement regarding use..................................................................................................4

Safety precautions .............................................................................................................7

Important safety points......................................................................................................9

Precautions for correct use.............................................................................................10

Manual revision history ...................................................................................................11

1. Overview of the unit

1.1 Main features ..............................................................................................................12

1.2 Device configuration ..................................................................................................13

1.3 Names of the parts and their functions....................................................................14

1.4 Dimensions .................................................................................................................19

1.5 Multi-circuit metering .................................................................................................21

1.6 Multi-address system.................................................................................................23

1.7 Mode configuration ....................................................................................................24

2. Installation and wiring

2.1 Attaching the body of the unit...................................................................................25

2.2 Wiring the CTs ............................................................................................................27

2.3 Wiring for power and monitored voltage input........................................................29

2.4 Fitting the CTs to the measuring wires ....................................................................31

2.5 Pulse output wiring ....................................................................................................32

2.6 RS-485 wiring..............................................................................................................36

2.7 Wiring diagrams .........................................................................................................38

3. Basic use

3.1 Turning the power on.................................................................................................41

3.2 Switching between modes.........................................................................................42

3.3 How to read the measurements ................................................................................44

3.4 How to read the setting values..................................................................................49

2

Page 3

Index

(continued)

4. Settings needed to measure electricity

4.1 Setting items for measuring electricity ....................................................................53

4.2 Circuit settings ...........................................................................................................54

4.3 RS-485 communication settings ...............................................................................59

4.4 Pulse output settings .................................................................................................62

5. Other Functions

5.1 Voltage assignment....................................................................................................63

5.2 Measuring high voltage .............................................................................................64

5.3 Display unit conversion .............................................................................................65

5.4 Power saving mode....................................................................................................67

5.5 Warning for voltage miss-wiring...............................................................................68

5.6 Tariff feature................................................................................................................69

5.7 Change password.......................................................................................................70

5.8 Checking software version........................................................................................71

5.9 Initialize .......................................................................................................................72

6. Detailed settings for communications

6.1 Overview of communications....................................................................................74

6.2 Modbus........................................................................................................................75

6.3 CompoWay/F...............................................................................................................84

6.4 Address map...............................................................................................................98

7. Troubleshooting

7.1 Warnings ...................................................................................................................102

7.2 Troubleshooting .......................................................................................................103

8 Appendices

8.1 Specifications ...........................................................................................................106

8.2 ASCII code table .......................................................................................................109

8.3 14 segment displays and 7 segment displays.......................................................111

3

Page 4

2

Agreement regarding use

Unless otherwise specifically agreed, you agree that the conditions in this agreement apply to your use of this Omron

product, irrespective of the place of purchase.

1. Definitions

This defines some terms used in this agreement.

(1) Omron products: FA system equipment, general-purpose control devices, sensors, and electronic/mechanical

components under Omron brand.

(2) Catalogs: Omron catalogues, including, without limitation, Omron "Best" Control Equipment Catalog, and

General Catalog for Electronic/Mechanical Components, specifications, instructions and user manuals for

Omron Products, whether or not provided electronically.

(3) Usage Conditions: Usage conditions, rating, performance, operating environment, handling instructions,

warnings, restrictions on use, etc. of Omron Products described in the Catalogs.

(4) Customer Application: Any application of Omron Products by a customer to include, but are not limited to,

embedding and/or using Omron Products in their parts/components, electronic substrates, devices, equipment

or systems manufactured by customers.

(5) Fitness: (a) fitness for a particular purpose, (b) performance, (c) non-infringement of third-party intellectual

property, (d) compliance with laws and regulations and (e) conformity to standards of an Omron Product in the

Customer Application.

2. Cautions regarding content

Be aware of the following points with regard to the content of Catalogs.

(1) Rated values and performance values are based on stand-alone tests using each separate condition, and

Omron does NOT warrant any rated values and performance values for multiple composite conditions.

(2) Reference data is provided for your reference only. Omron does NOT warrant that Omron Products work

properly at all times as provided in the reference data.

(3) Application examples are provided for your reference only. Omron does NOT warrant the Fitness of Omron

Products under such application.

(4) Omron may discontinue the production of Omron Products or change their specifications for the purpose of

improving such products or for other reasons entirely at its own discretion.

3. Precautions

You are deemed to accept the following terms when you adopt or use Omron Products:

(1) Use Omron Products in compliance with Usage Conditions including rating and performance.

(2) Confirm Fitness of Omron Products in Customer Application and use your own judgment to determine the

appropriateness of using them in such application. Omron does NOT warrant the Fitness of Omron Products in

Customer Application.

(3) Confirm beforehand that Omron Products are properly wired and installed for their intended use in your overall

system.

(4) When using Omron Products, make sure to (i) maintain a margin of safety in relation to the published rated and

performance values, such as introducing redundancy, (ii) design to minimize risks to any Customer Application

in case of failure of any Omron Products, (iii) adopt system-wide safety measures to notify risks to users, and

(iv) conduct regular maintenance on Omron Products and Customer Application.

4

Page 5

Agreement regarding use (continued)

(5) Omron Products are designed and manufactured as general-purpose products for use in general industrial

products. They are not intended to be used in the applications described below, therefore if you use Omron

products in these applications, Omron provides no warranty for Omron products. However, this excepts cases

where the use is a special use intended by Omron or where Omron has specifically agreed, even when used in

the following applications.

(a) Applications with stringent safety requirements (For example, nuclear power control equipment, combustion

equipment, aerospace equipment, railway equipment, elevator and lift equipment, amusement equipment,

medical equipment, safety equipment, and other applications that could cause physical injury or result in the loss

of life.)

(b) Applications that require high reliability (For example, supply systems for gas, water and electricity, etc., 24 hour

continuous operating systems, financial settlement systems and other applications that handle rights and

property.)

(c) Applications under severe conditions or in severe environments (For example, outdoor equipment, equipment

exposed to chemical contamination, equipment exposed to electromagnetic interference and equipment

exposed to vibration and shocks.)

(d) Applications under conditions or environments not described in catalogs or other publications.

(6) In addition to the applications listed in 3.(5) (a) to (d), the products in this publication are not intended for use in

automobiles (including for two-wheeled vehicles, and this description applies hereafter). Do not use for

applications involving fitting to automobiles. Consult Omron staff for information about products suitable for use

in automobiles.

5

Page 6

Agreement regarding use (continued)

4. Warranty

The warranty for Omron Products are as follows:

(1) Warranty period: The Warranty shall apply for one year from the date of purchase.

(Unless otherwise described in Catalogs.)

(2) Warranty content: Omron will provide, at its own discretion, either of the following two services as the sole

remedy for a malfunctioning Omron Product:

(a) Repair of the malfunctioning Omron Product(s) at an Omron maintenance service location at no charge to the

customer (This repair service is not available for electronic/mechanical parts.)

(b) Replacement of the malfunctioning Omron Product(s) with the same number of replacement/alternative products

at no charge to the customer.

(3) Exceptions: This warranty of Omron Products does not apply if the cause of the malfunction falls under any of

the following:

(a) Usage in a manner other than the original intended use for the Omron Products.

(b) Usage other than as described in the Usage Conditions.

(c) Usage that is not in accordance with Section 3 (Precautions) above.

(d) Modification or repair made to the Omron Products by other than Omron personnel.

(e) Software program by other than Omron staff

(f)

Causes which could not have been foreseen with the level of science and technology at the time of shipping

from Omron.

(g) Causes other than those above originating from other than Omron or Omron Products (including force majeure

such as natural disasters).

5. Limitation of liability

The warranty express in this agreement is the entire warranty for this Omron product.

Omron and dealers selling Omron products accept no responsibility for damages arising from the use of Omron

products.

6. Export control

Comply with the applicable laws and regulations of Japan and related nations relating to security export controls

when exporting or providing this Omron product or technical documents to non-residents. If you do not comply with

these laws and regulations, we may be unable to supply you with Omron products or technical documents.

Notice

• It is not permitted to reproduce, copy, or reprint this manual in part or in full without permission.

• Changes to this manual may be made without notice.

• Every effort has been made to ensure the accuracy of this manual, however please contact us or your dealer

at one of the addresses shown at the back of this manual if you find any unclear points or errors.

At this time, please also advise us of the catalog number found at the back of this manual.

6

Page 7

Safety precautions

Regarding the displays used to ensure safe operation and their meanings

The following indications and symbols are used in this manual for precautions so that you can use the product

safely. The precautions here include important information regarding safety. Please follow these instructions.

The indications and symbols are as follows.

Warning displays

Indicates a potentially hazardous situation which, if not avoided, will

Caution

Meanings of the symbols

• Mandatory actions

Indicates a general action that must be performed by the user.

• Explosion caution

Indicates possibility of explosion under special conditions.

result in minor or moderate injury, or there may be property damage.

• Electrical shock caution

Indicates possibility of electric shock under special conditions.

• Disassembly prohibition

This indicates that there is the danger of electric shock or other injury if the unit

is disassembled.

• General prohibitions

Indicates a general prohibition without particular categorization.

7

Page 8

Safety precautions (continued)

Caution

Property damage may occur due to fire.

Tighten the terminal screws to the specified torques.

After tightening the screw, check that the screw is not loose.

M3.5 screw : 0.8N·m

M3 screw : 0.5 to 0.6N·m

M3 screw (KM-NCT-E's output terminal) : 0.3N·m

Minor or moderate injury or property damage may occur due to explosion.

Do not use in locations exposed to flammable or explosive gases.

Breakdown or explosion may occasionally occur.

Use the power voltage and load within the specified and rate ranges.

Electric shock may occasionally occur.

Do not touch any of the terminals while the power is being supplied.

Electric shock may occasionally occur.

Always make sure that the power to the circuit the CT is being attached to is turned

OFF before connecting the CT*.

Electric shock may occasionally occur.

Be sure to mount to coated wire with at least the basic insulation when mounting KMNCT-E.

Burns may occasionally occur.

Do not touch the product while power is being supplied or immediately after power is

turned OFF.

Use the electric wire that heat resistant temperature is 85 degrees or more when wiring

to the product.

Minor electric shock, fire, or malfunction may occasionally occur.

Do not supply a current to the CT input terminal that exceeds the maximum CT

secondary current.

Minor electric shock, fire, or malfunction may occasionally occur.

Never disassemble, modify, or repair the product.

*

CT: Current Transformer

8

Page 9

Important safety points

Observe the following to ensure safe use of model KM-N2.

• Do not use or store the product in any of the following locations.

– Locations subject to shock or vibration

– Unstable locations

– Locations subject to temperatures or humidity outside rated ranges

– Locations subject to condensation as the result of severe changes in temperature

– Outside or otherwise exposed to direct sunlight and weather

– Locations subject to static electricity or other forms of noise

– Locations exposed to electromagnetic fields

– Locations subject to exposure to water or oil.

– Locations subject to exposure to salt water spray.

– Locations subject to corrosive gases (in particular, sulfide gas and ammonia gas).

– Locations subject to dust (including iron dust).

– Locations subject to exposure to solvents

• Use AWG24 to 14 to wire the power and input voltage terminals. The heat resistant temperature of the wire is 85

degrees or more.

• Use AWG18 to 14 to wire the CT terminals. The heat resistant temperature of the wire is 85 degrees or more.

• Use AWG24 to 14 to wire the communication terminals. The heat resistant temperature of the wire is 85 degrees or

more.

• For wiring to KM-NCT-E's output terminal, use a Y-shape terminal compatible with AWG18 to 14 electric wire (with

a cross-section of 0.75 to 2.0mm

• The recommended tightening torque of the M3 screw of KM-NCT-E's output terminal is 0.3N·m.

• When mounting the KM-NCT-E to the measurement wire, push the fitting claw until it clicks.

• Be sure to wire properly with the correct terminal number. Do not wire unused terminals.

• Be sure to check that the wiring is correct before turning on the power.

• Before using or maintaining the product, thoroughly read and understand the instraction manual.

• Understand the user manual before setting the device.

• Do not pull cables.

• Use only as described in the INSTRUCTION MANUAL. Using the unit in a manner not described mayresult in the

safety functionality of the device being compromised.

• In order that workers may turn off the power immediately, install a branch circuit breaker conforming to

requirements in the country where the device is being used (USA: UL Listed, CANADA: cUL Listed, other country:

e.g. IEC60947-1 and IEC60947-3 ) and display instructions properly.

<Recommended ratings of a branch circuit breaker>

Rated current : 1A.

• Always check the wiring and confirm that it is correct before turning ON the power supply. Incorrect or improper

wiring may result in electrical shock, injury, accidents, failure, or malfunction.

• KM-NCT-E is a dedicated CT for KM-N2-FLK and KM-N3-FLK. Do not use it for other power monitors.

• The surface temperature of the CT may become high due to the heat generated by the primary power cable. Be

sure to check that the surface temperature of the CT went down before touching the CT immediately after turning

ON the power supply.

• Do not install the product close to heat-producing devices (those using coil elements, for instance).

• Ensure the screws fixing the DIN rails are tight. Also ensure that the DIN rails and the body are attached properly.

Looseness may cause the DIN rails, body, and wires to separate if vibrations or impacts occur.

• Use 35mm width DIN rails (OMRON, model PFP-50N/-100N).

• When mounting the product on the DIN rail, slide the DIN hook unit until a clicking sound is heard.

• Separate the product wiring from high-voltage or high-current power lines to prevent inductive noise. Do not place

the product wiring parallel to or in the same ducts or conduits as power lines. Use separate ducts, separate

conduits, or shielded cables to prevent noise.

• This is a “class A” product. In residential areas it may cause radio interference. The user may be required to take

adequate measures to reduce interference if this occurs.

2

) and M3 screw.

9

Page 10

Precautions for correct use

• This product is not categorized as "a specified measuring instrument" officially approved by an organization

specified in relevant measurement acts. It cannot be used to certify power usage.

• Set the parameters of the product so that they are suitable for the system being measured.

• Mount this product on DIN rails for use.

• Use varistors between the outer power and voltage measuring input wires when this product is installed in an

overvoltage category

• This product cannot be used to measure the inverter’s secondary side.

• Ensure that the rated voltage is reached within 2 seconds of turning the power on.

• Do not use thinners for cleaning. Use commercial alcohol.

• When cleaning the unit, make sure the power is off and wipe the surface of the unit with a soft dry cloth. Do not use

chemicals including solvents such as thinners, benzine, or alcohol.

• You cannot use the CT dedicated for use with the Omron KM series (model series KM20-CTF, model series KM-

NCT) . Use a CT whose secondary output is 1A or 5A.

• Use ferrule terminals to connect CTs to the CT terminals on the main unit to ensure the assembly complies with

standards.

• The data for active energy is saved at 5 minute intervals. The data for the 5 minutes preceding the unit powering off

may not be saved under some circumstances.

• Dispose of this product appropriately as industrial refuse in accordance with local and national regulations.

• This product is intended for use in industrial environments. Do not use it in residential environment.

III environment.

Trademark Information

• Modbus is a registered trademark of Schneider Electric.

• Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

10

Page 11

Manual revision history

Revision number

Catalog no. N200-E1-03

A manual revision code appears as a suffix to the catalog number on the front cover and back cover of the manual.

Revision

number

01 A April 2016 First edition

02 July 2017 Description of operability-confirmed converter: Modified

03 May 2018 Description of dedicated CT: Added

Date of revision Reason for revision, pages revised

11

Page 12

1.Overview of the unit

1. Overview of the unit

1.1 Main features

• Supports international standards

It complies with the international IEC accuracy standards and can be connected using generic CTs.

• Multi-circuit metering

Multi-circuit metering is possible with one unit, with up to four circuits metered by 1-phase 2-wire, and up to 2

circuits metered by 1-phase 3-wire and 3-phase 3-wire. It is also possible to measure multiple 1-phase 2-wire with

different phases branching off a 1-phase 3-wire, and to simultaneously measure both 1-phase 3-wire and 1-phase

2-wire.

• Multi-address system

There can be a maximum of 4 circuits in one unit. The circuits act as independent power monitors, each able to

measure, each having different settings, and each able to be allocated different communications addresses. You

can manage individual circuits as electricity monitors from a host system, so it is easy to build a communications

system and add places for measuring.

• Pulse output

The unit has 4 ports for outputting pulses each time the active energy exceeds set values. You can allocate each

circuit a pulse output port in a multi-circuit metering setup.

• RS-485 communications

You can use the Modbus (*1) and CompoWay/F (*2) protocols for RS-485 communications.

*1. Modbus is a communications control system that conforms with the RTU Mode of the Modbus Protocol.

*2. CompoWay/F is Omron's unified communication procedure for general serial communications. It has a unified

framework format and has commands compliant with FINS which works well with Omron programmable controllers, for

instance, simplifying communications between host devices (computers for example) and components.

12

Page 13

1.2 Device configuration

Breaker

Operating power and

metered voltage

Power Monitor

Model KM-N2-FLK

For example:

PLC

Pulse output 1

Host device

RS-485

Modbus

CompoWay/F

Generic CT

Pulse output 2

Pulse output 3

Pulse output 4

Generic CT

Generic CT

Generic CT

For example:

PLC

For example:

PLC

For example:

PLC

1.Overview of the unit

• The CT of OMRON's dedicated KM series output type cannot be used with this product.

• Although a generic CT with the secondary side output of 1A or 5A can be connected, CTs dedicated for use with

KM-N2-LFK and KM-N3-FLK of 1A output type are available as listed on the table below. By using a CT listed

below in combination with a KM-N2-FLK, the CE standard is supported including the use of CT and power

monitors.

• A cable to connect the CT and power monitor is separately required.

Name Model Description

KM-NCT-E100A Rated 100A, output 1A

CT dedicated for 1A output type

KM-NCT-E250A Rated 250A, output 1A

KM-NCT-E500A Rated 500A, output 1A

13

Page 14

1.Overview of the unit

88888

888888888

88

yw

ywyw

ywyw

ywywywywyw

LCD for display (enlarged)

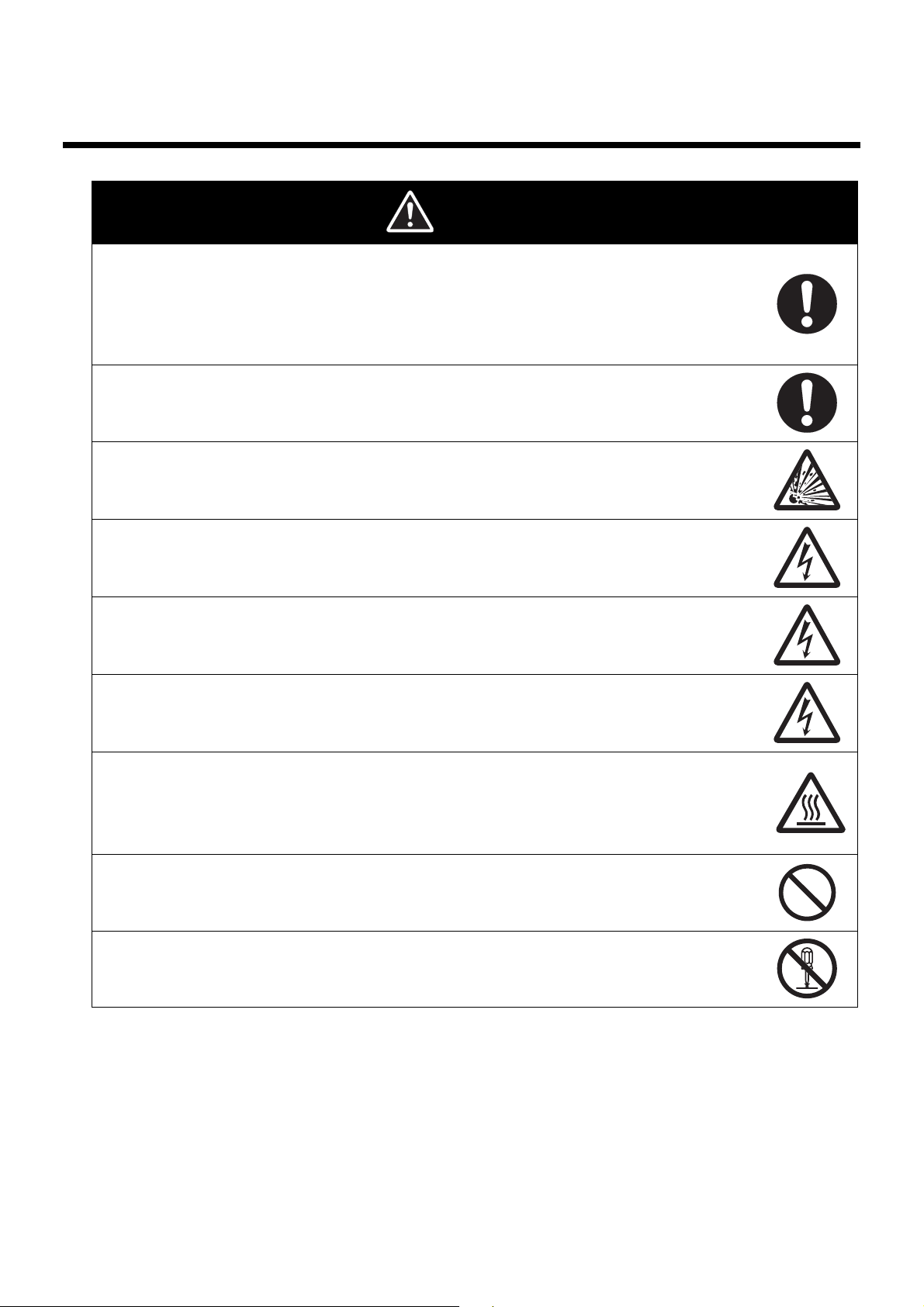

1.3 Names of the parts and their functions

[Main unit]

Front

Terminal panel cover removed

1Power LED (green) Lights when power is supplied

2Error LED (red) Flashes when there is an error such as a malfunction

3Alarm LED (orange) Flashes to indicate a warning

4Communication LED (yellow) Lights when communicating

5Pulse LED (yellow) Lights during pulse output

6Communication address/Menu display

7Status display

8Measured value/setting

value display

88

ywyw

yw

ywywywywyw

Name Description

OUTPUT Lights when setting pulse output

1 Lights when outputting pulse from OUT1

2 Lights when outputting pulse from OUT2

3 Lights when outputting pulse from OUT3

4 Lights when outputting pulse from OUT4

SET Lights in setting mode

Main display

Sub display

9Tariff display

14

888888888

ywyw

88888

When ADDRESS is illuminated (in measuring mode):

Displays the communication address

When MENU is illuminated (in setting mode):

Displays the menu number

Displays measured values and setting values (9 places on the upper

line)

Displays the units for the measured values and the names of the

setting items (5 places on the lower line)

Displays the tariff number (T1 to T4) when saving active energy

(import)

Page 15

1.Overview of the unit

1.3 Names of the parts and their functions (continued)

Name Description

:CT usage display Displays the CT number (CT1 to CT4) when measuring or setting

;<</MODE key

< Key Change setting or value (up)

= Key Change setting or value (down)

>ENTER key Confirm setting or value

?ESC key Cancels items or values

@Rotary SW

RS-485i(1) RS-485iterminal

RS-485j(1) RS-485jterminal

ARS-485 communication

terminals

BPulse output terminal

CVoltage input terminals

DCT input terminals Terminal for connecting the CT cables for CT1 to CT4

EDIN Hook Hook for attaching to the DIN rail

* Refer to "1.6 Multi-address system" ( 23) for circuit A.

RS485i(2) RS-485iterminal (for crossover wiring)

RS485j(2) RS-485jterminal (for crossover wiring)

RS485 E RS-485 terminating resistor terminals

OUT1 Pulse output 1 terminal

OUT2 Pulse output 2 terminal

OUT3 Pulse output 3 terminal

OUT4 Pulse output 4 terminal

COM Common terminal for pulse output

Short press: switch circuit/move place

Press and hold: switch mode

Sets the communication address* (left (x10): increase in units of ten,

right (x1): increase in units of 1)

Terminals for inputting the power and voltage (combined with the

input for measured voltage)

15

Page 16

1.Overview of the unit

Enlarged terminal layout label

1.3 Names of the parts and their functions (continued)

Right side surface

Name Description

FTerminal layout label

GTerminal panel cover Terminal panel cover with seal

Label with information such as the model, power voltage, connector layout, and

serial number

16

Page 17

1.Overview of the unit

(Front) (Back)

(Bottom) (Bottom (terminal cover removed))

1.3 Names of the parts and their functions (continued)

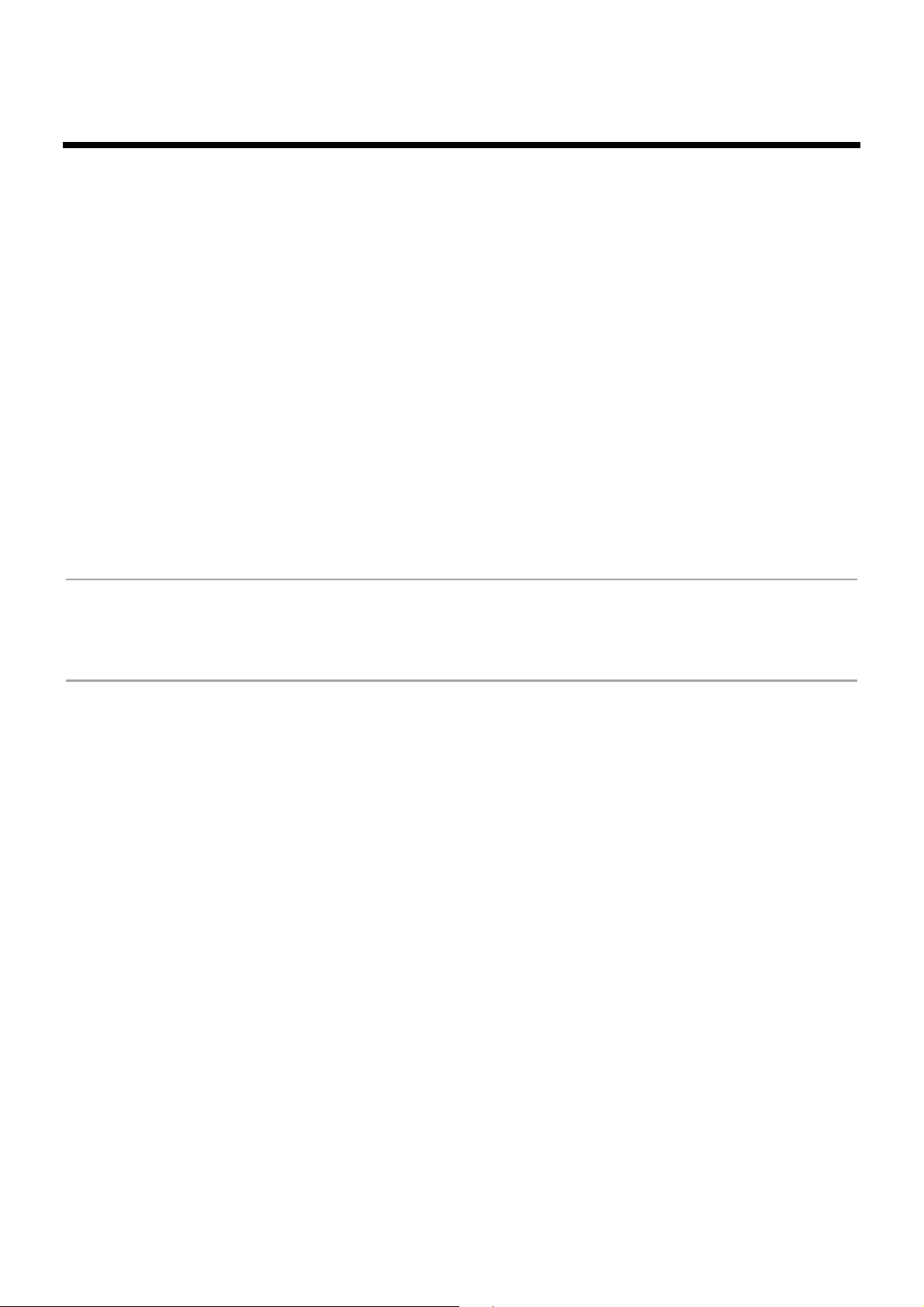

[Dedicated CT]

KM-NCT-E100A, -250A

Name Function

1Label

2Output terminal block

3Terminal cover Protective cover of the output terminal block

4Fitting claw

5Fixing claw

Polarity of the primary side wiring, and models are written on this label

Secondary side current is output to this terminal block

Claw that clamps the wire and fits the top and bottom of the transformer

Used to reinforce the retention of the unit and insulation lock

17

Page 18

1.Overview of the unit

(Front) (Back)

(Bottom) (Bottom (terminal cover removed))

1.3 Names of the parts and their functions (continued)

KM-NCT-E500A

Name Function

1Label

2Output terminal block

3Terminal cover Protective cover of the output terminal block

4Fitting claw

5Fixing claw

Polarity of the primary side wiring, and models are written on this label

Secondary side current is output to this terminal block

Claw that clamps the wire and fits the top and bottom of the transformer

Used to reinforce the retention of the unit and insulation lock

18

Page 19

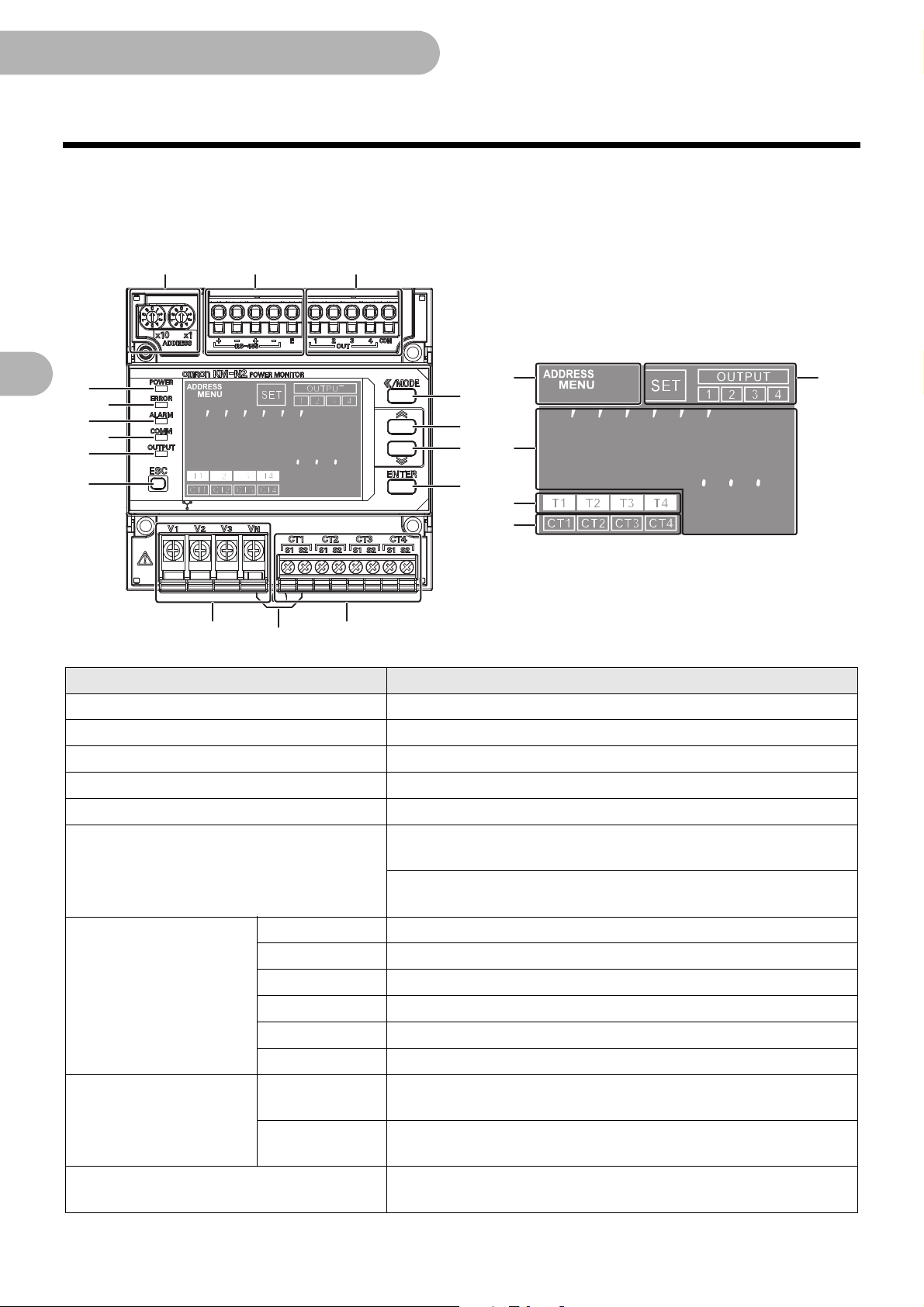

1.4 Dimensions

11

90

1.4

61

66.44

43

90

45

(49)

(41.2)

R20 . 3

R20 . 3

5

43

Units (mm)

(Front)

(Right side surface)

(Left side surface)

DIN rail

Part A

Part B

Part A Dimensions

of moving part

Part A Dimensions

of moving part

Part B Dimensions

of moving part

[Main unit]

1.Overview of the unit

19

Page 20

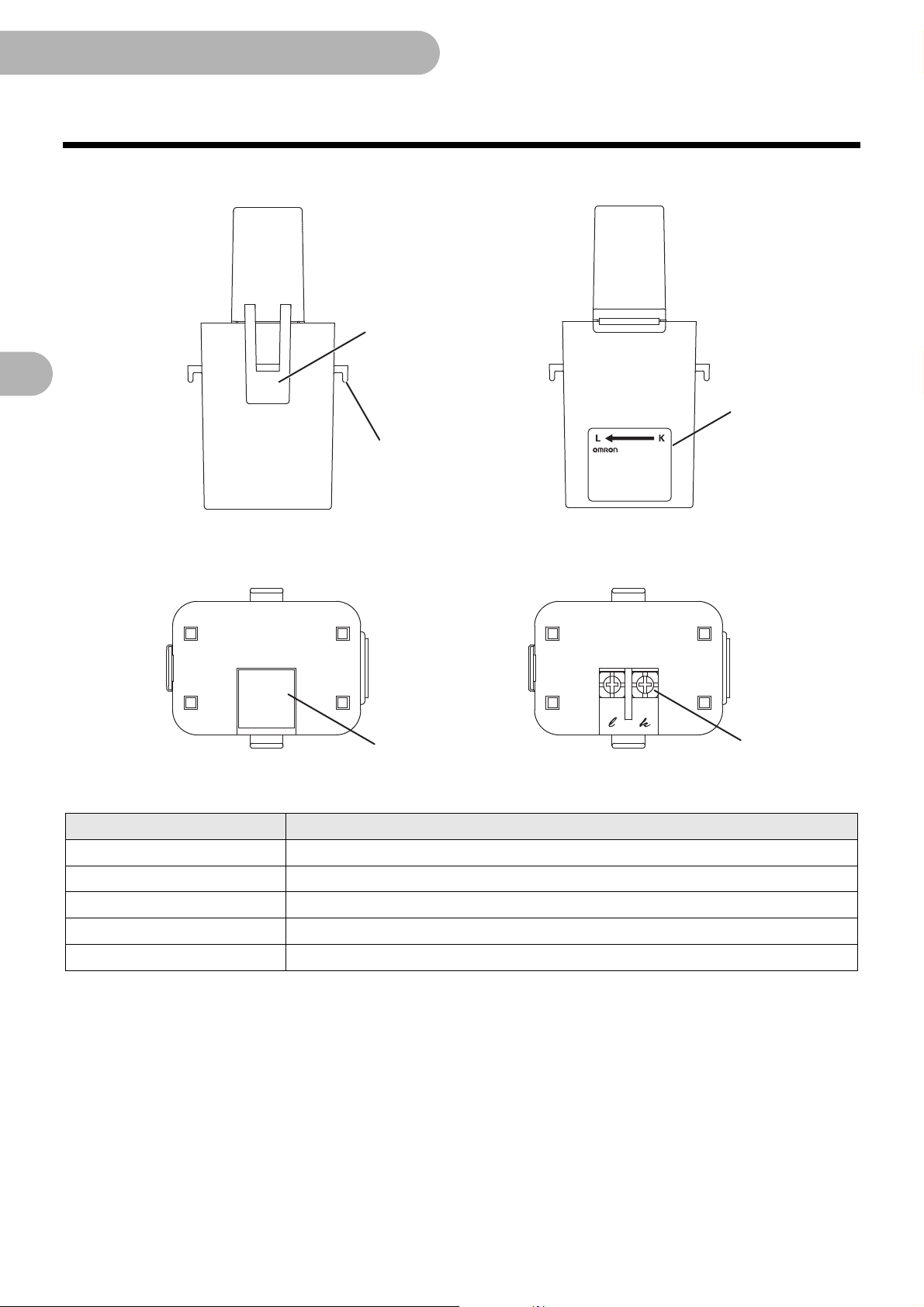

1.Overview of the unit

CT INNER DIAMETER

Units (mm)

57 (2.5)(1.5) 40.5

22

(4)(4)

ɸ36

4-R13.5

91

61

56.5

36

36

CT INNER DIAMETER

Units (mm)

1.4 Dimensions (continued)

[Dedicated CT]

KM-NCT-E100A, -250A

KM-NCT-E500A

ɸ24

45

(2.5)(1.5)

46.5

(4) (4)34

22

4-R8.5

24

24

74.5

49.5

20

Page 21

1.Overview of the unit

1.5 Multi-circuit metering

Multi-circuit metering is possible with this product. Measuring circuit refers to the measurement point where electricity

measuring is conducted. Furthermore, this product measures voltage commonly across all circuits and measures

current with each separate circuit by using generic CTs.

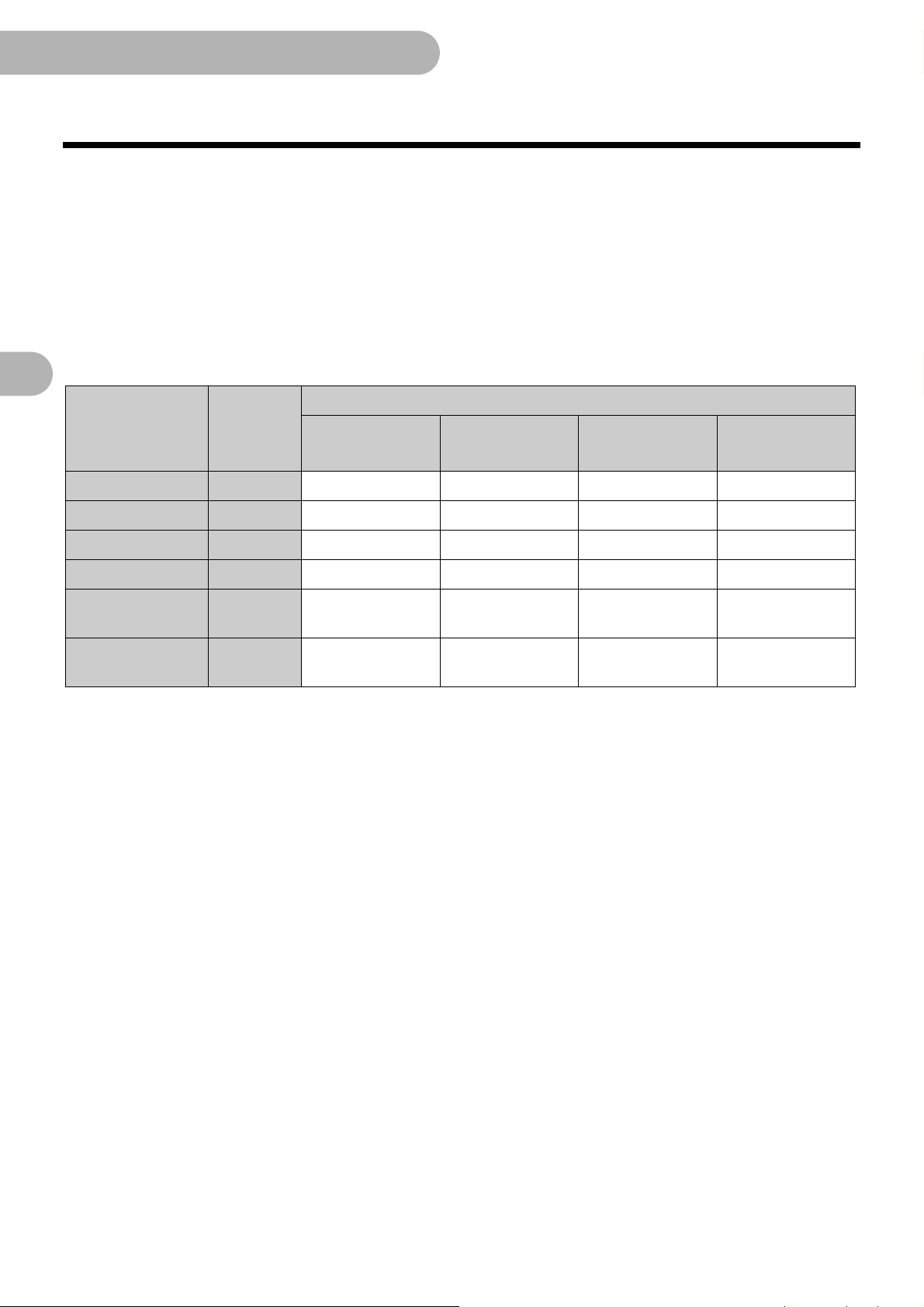

● Maximum number of measuring circuits for each phase

and wire type

You can connect up to 4 generic CTs to this unit. The phase and wire types and the usable number of measuring

circuits are shown in the following table.

Refer to "2.7Wiring diagrams ( 38)" for more on wiring each of the phase and wire types.

Abbreviatio

Phase and wire type

3-phase 4-wire 3P4W 1 circuit Circuit A

ns for

phase and

wire types

Maximum number of

measuring circuits

Circuits used

1-phase 2-wire 1P2W 4 circuit Circuit A, Circuit B, Circuit C, Circuit D

1-phase 3-wire 1P3W 2 circuit Circuit A, Circuit C

3-phase 3-wire 3P3W 2 circuit Circuit A, Circuit C

1-phase 2-wire

voltage selected

1-phase 3-wire

composite

• Set 1-phase 2-wire voltage selected when measuring multiple 1-phase 2-wire with different phases branching off a

1-phase 3-wire switchboard.You can measure 1-phase 2-wire by selecting the corresponding voltage.

• Set 1-phase 3-wire composite to measure both the main 1-phase 3-wire switchboard and a 1-phase 2-wire

branching off.

You can measure 1-phase 2-wire by selecting the corresponding voltage.

• Refer to "5.1Voltage assignment ( 63)" for more on 1-phase 2-wire voltage selected and 1-phase 3-wire

composite.

1P2W2 4 circuit Circuit A, Circuit B, Circuit C, Circuit D

1-phase 3-wire: 1 circuit Circuit A

1P3W2

1-phase 2-wire: 2 circuit Circuit C, Circuit D

21

Page 22

1.Overview of the unit

1.5 Multi-circuit metering (continued)

● Allocating the circuits used and the CTs for each phase

and wire type

The following table shows the phase and wire types and the CT allocations for each measuring circuits. As circuit

A is used irrespective of the phase and wire type, you must make settings for measurement ("Circuit A

settings( 54)").

By enabling circuits B to D to increase the number of measurement points ("Settings for circuits B to D (when

measuring 2 circuits or more) ( 56)"), you can meter electricity using the required number of circuits. This are

disabled by default.

Abbreviatio

Phase and wire

type

3-phase 4-wire 3P4W

1-phase 2-wire 1P2W CT1 CT2 CT3 CT4

1-phase 3-wire 1P3W CT1, CT2

3-phase 3-wire 3P3W CT1, CT2

1-phase 2-wire

voltage selected

1-phase 3-wire

composite

ns for

phase and

wire types

1P2W2 CT1 CT2 CT3 CT4

1P3W2 CT1, CT2

Circuit A Circuit B Circuit C Circuit D

CT1, CT2, CT3

Measuring circuits

CT3, CT4

CT3, CT4

CT3 CT4

22

Page 23

1.Overview of the unit

Circuit D

Measured

value

Setting

value

Communi

cation

address

For 1-phase 2-wire (maximum of 4 circuits) For 1-phase 3-wire, 3-phase 3-wire

(maximum of 2 circuits)

Model KM-N2 Model KM-N2

Circuit C

Measured

value

Setting

value

Circuit B

Measured

value

Setting

value

Circuit A

Measured

value

Setting

value

Communi

cation

address

Communi

cation

address

Communi

cation

address

Circuit A

Measured

value

Setting

value

Communi

cation

address

Circuit C

Measured

value

Setting

value

Communi

cation

address

1.6 Multi-address system

This product is a multi-address system where different communications addresses (numbered in order) are allocated

to each circuit.The communications addresses correspond to each measuring point, so data transmission

management from the host device is simplified.

The following diagram is an overview of the multi-address system.

The measurement values and setting values for individual circuits are accessed via communications addresses for

each of the circuits. The common settings are common to all of the circuits, so they can be accessed using any of the

communications addresses, which allows changes to settings for all of the circuits at once.

Refer to "6.Detailed settings for communications ( 74)" for details about commands, responses, and address maps.

Caution

• Each circuit on this product needs to be allocated different communications addresses (numbered in order).

Even if you connect several of these products on the same RS-485 line, all of the circuits need to be allocated

different communications addresses.

23

Page 24

1.Overview of the unit

Start

Circuit A

Measured

value

Circuit B

Measured

value

Circuit C

Measured

value

Circuit D

Measured

value

Measuring

mode

Setting mode

Communication

setting mode

Press

and

hold

Circuit A

Setting

item

Circuit B

Setting

item

Circuit C

Setting

item

Circuit D

Setting

item

Common

Setting

item

Others

Setting

item

Command

Change settings from

host device using RS485 communication.

Password input

Command

1.7 Mode configuration

This model has three modes: measuring mode, setting mode, and communication setting mode.

– Measuring mode: The measured values for each circuit are displayed.

– Setting mode: By operating keys on the body of the unit you can change settings for each of the circuits, and

make common settings for communications, output, the display, etc.

– Communication setting mode: Make settings on the units using RS-485 communication.

MODE

MODE

MODE

• In the measuring mode and setting mode, the circuit B to D items are displayed by switching the enable/disable

settings for each of the circuits to "ON" (enabled). (The circuits indicated inside the dotted lines in the above

diagram are "OFF" (disabled) in the default state.)

24

Page 25

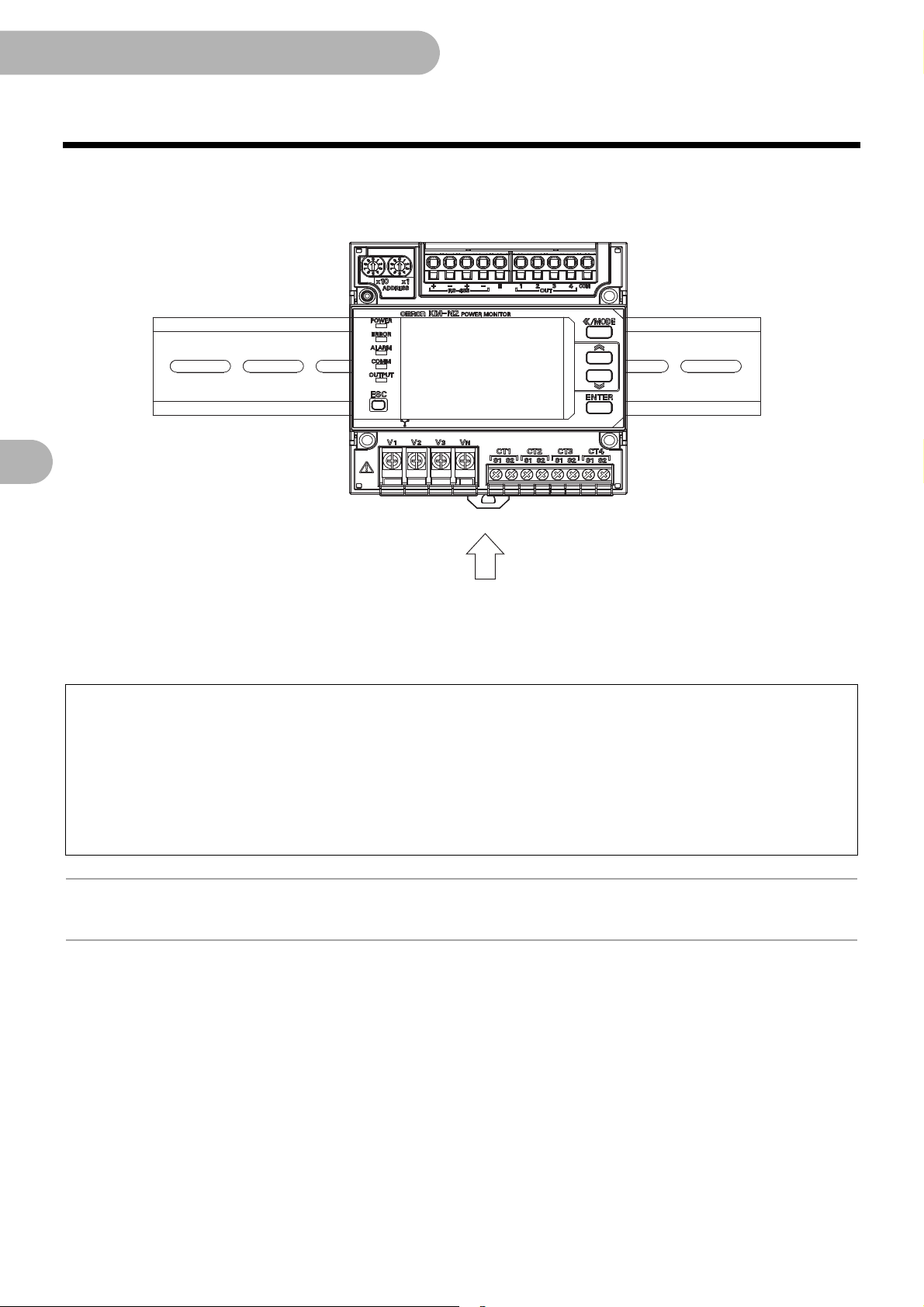

2.Installation and wiring

DIN hook

Pull down

DIN rai

2. Installation and wiring

2.1 Attaching the body of the unit

For safety purposes, install the unit in a location where you won't touch the terminals when operating the main unit.

For example, install so that the terminals are hidden within the control board so that a person working on the unit will

not be able to touch live wires.

1 Fix the DIN rail to the installation location

– DIN rail (recommended product): Model PFP-50N/-100N (from Omron)

2 Pull down the DIN hook on the bottom of the body of the unit

3 Fit the flanges of the body onto the DIN rail as shown in the below

diagram, and click into place

25

Page 26

2.Installation and wiring

Raise

2.1 Attaching the body of the unit (continued)

4 Raise the DIN hook and fix the body to the DIN rail

Detaching the body of the unit

When removing the body from the DIN rail, use a flathead screwdriver to flick open the DIN hook and open

downwards.

Important

• Ensure that the DIN rails and the body are attached properly. Looseness may cause the DIN rails, body,

and wires to separate if vibrations or impacts occur.

• Fix end plates to the body units at each end of the DIN rail.

These stop the units from jumping off the DIN rail due to vibration or impacts.

– End plate (recommended part): model PFP-M (from Omron)

• Make sure you install so there is space for wiring above and below the body of the unit.

(about 50mm above the unit and 30mm below the unit)

Information

• You can attach multiple model KM-N2 to the DIN rail and fit the bodies next to each other.

26

Page 27

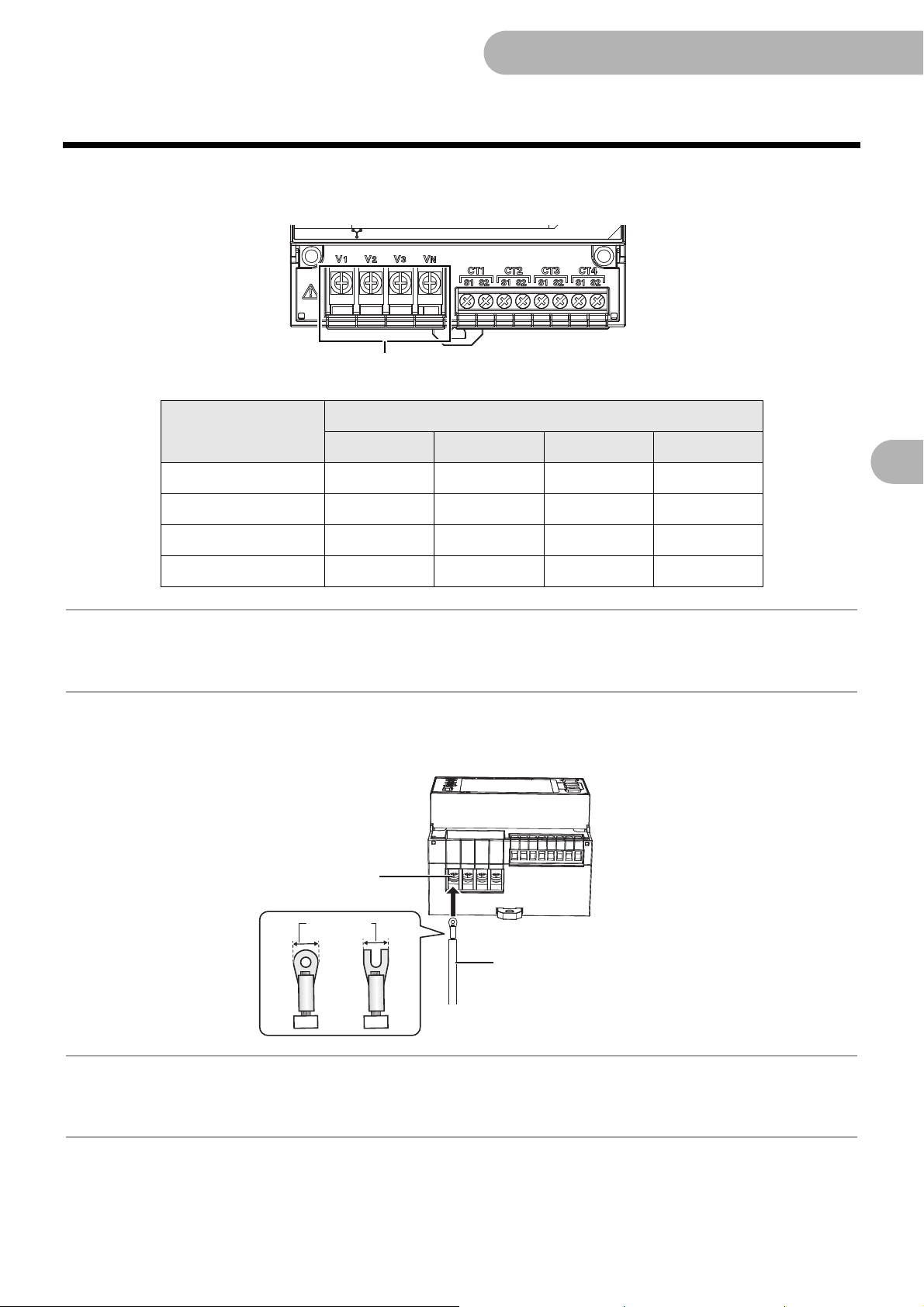

2.Installation and wiring

CT input terminals

Wiring

8mm

Under 2.7mm

Under

2.0mm

M3 screw

CT input terminals

2.2 Wiring the CTs

You can connect up to a maximum of 4 generic CTs to this unit (21). The number of CTs used depends on the phase and wire type

of the power source being monitored. The following table shows the phase and wire types and the CTs to use for each. For example,

use CT1 when measuring only one 1-phase 2-wire circuit. Further, when measuring two 1-phase 3-wire circuits, use CT1 and CT2 for

circuit A and use CT3 and CT4 for circuit C.

The layout of CT input terminals is as follows.

The following table shows the phase and wire types and the CT allocations for each measuring circuits.

Abbreviations

Phase and wire

type

3-phase 4-wire 3P4W

1-phase 2-wire 1P2W CT1 CT2 CT3 CT4

1-phase 3-wire 1P3W CT1, CT2

3-phase 3-wire 3P3W CT1, CT2

1-phase 2-wire

voltage selected

1-phase 3-wire

composite

• Connect the CT cables for CT1/CT2/CT3/CT4 to the terminals on the main unit that are labeled CT1/CT2/CT3/CT4.

• For details about how to wire the CTs, refer to the manual of the CTs you are using.

for phase

and

wire types

1P2W2 CT1 CT2 CT3 CT4

1P3W2 CT1, CT2

Circuit A Circuit B Circuit C Circuit D

CT1, CT2, CT3

Measuring circuits

CT3, CT4

CT3, CT4

CT3 CT4

Important

• Do not try to connect or disconnect CTs or CT cables during measurement or while the power of this

product is on. There is a danger of electric shock. Furthermore, this may cause this unit and the CT to

malfunction.

• For wiring to the CT input terminals, use 18 to 14 AWG (cross section surface area of 0.75 to 2.0mm

electrical wire.

• Use ferrule terminals suitable for the wire diameter to connect to the CT input terminals.

• The recommended torque for the 3mm screws is between 0.5 and 0.6Nm. Make sure the ferrule terminal

is pushed all the way in and tightened firmly. After fixing the wiring in place, pull gently to confirm that

the wiring is fixed firmly.

2

)

27

Page 28

2.Installation and wiring

2.2 Wiring the CTs (continued)

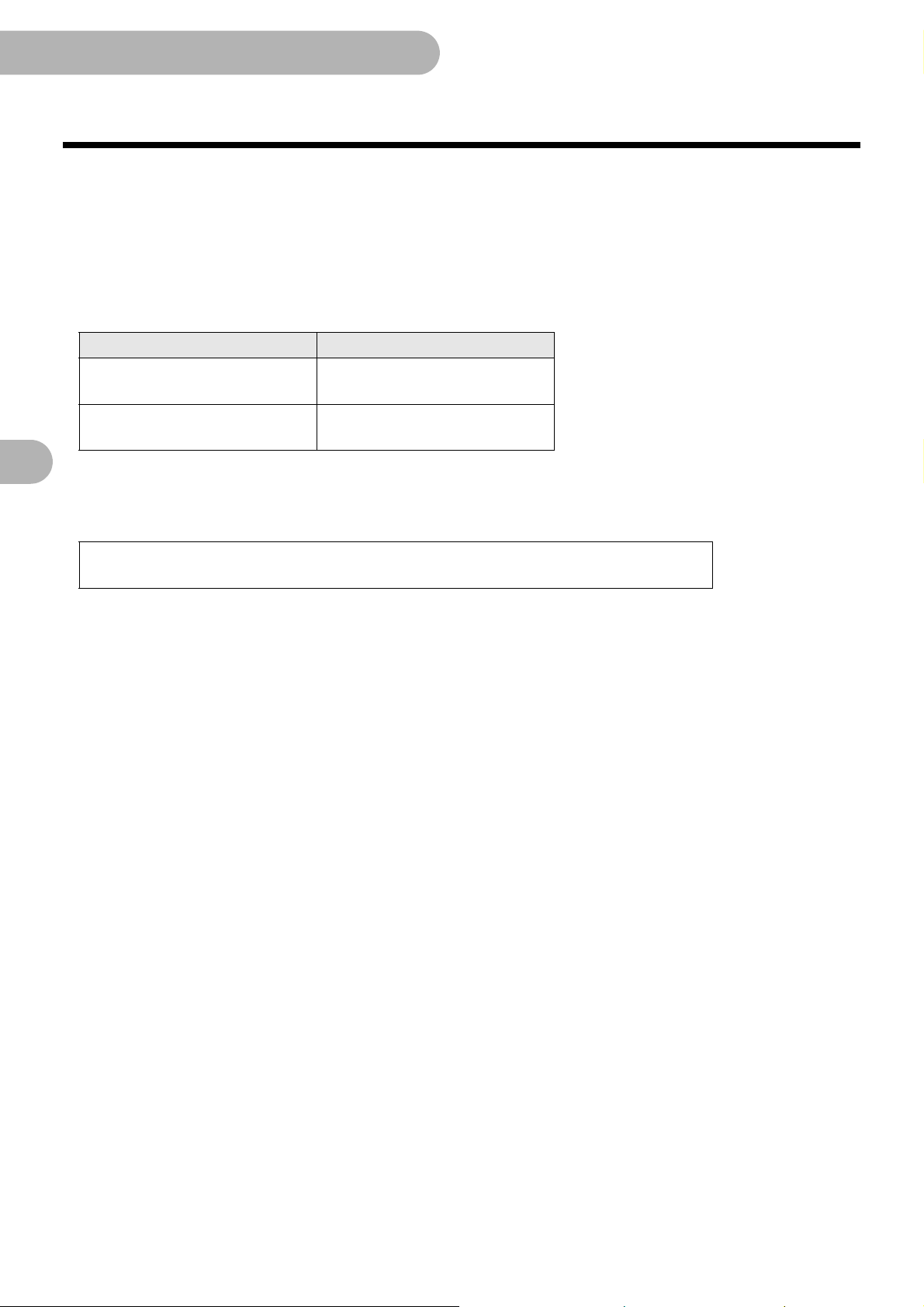

Using KM-NCT-E@@@A

The wiring method when using the KM-NCT-E@@@A, a dedicated CT for 1A output, is as follows.

• For wiring of the output terminal of CT, use AWG18-14 electric wire (with a cross-section of 0.75-2.0mm

shape terminal compatible with the M3 screw.

• The recommended torque for screwing the M3 screws onto the output terminal is 0.3 N·m. Make sure the Y

terminal is pushed all the way in and tightened firmly. After fixing the wiring, confirm that the wire is fixed securely.

• The guideline of the maximum wiring length between the main unit and CT is as follows.

Wiring diameter Guideline for wiring length limit

0.75 mm

(AWG18 equivalent)

2.0 mm

(AWG14 equivalent)

• The limit of the wiring length can also be calculated by the following formula. Calculate the wiring length limit

according to the conductor resistivity of the wiring and keep the wiring length below the limit.

• The limits of the wiring length as shown on the table and expression below are for reference only. They do not

guarantee proper use. They do not guarantee proper use.

2

15m

2

43m

2

) and Y-

Wiring extension limit value (one-way) (m) = 0.475/conductor resistivity (/m)

28

Page 29

2.Installation and wiring

Voltage input terminals

3.5mm screw

Under 6.7mm

Wiring

2.3 Wiring for power and monitored voltage input

Voltage input terminals V1/V2/V3/VN on this product act as both operating power terminals and as voltage measuring

terminals.

The layout of voltage input terminals is as follows.

Phase and wire type

V1 V2 V3 VN

4-phase 3-wire R S T N

1-phase 2-wire L

1-phase 3-wire R

3-phase 3-wire R S T

Information

• R/S/T/N may be labeled U/V/W/O or L1/L2/L3/N in some cases.

• R/N/T may be labeled U/O/W or L1/N/L2 in some cases.

To wire the voltage input terminal, loosen the 3.5mm screw on the terminal panel, push the wire completely into the

terminal, and fix in place with the crimping terminal.

Voltage input terminals

TN

N

Information

• The terminal panel cover fixes in place when you open it fully so it won't get in your way when you are tightening the

screws, etc.

29

Page 30

2.Installation and wiring

R

S

T

N

N

L

R

N

T

R

S

T

Branch circuit breaker

1-phase 3-wire

(1-phase 2-wire voltage selected, 1-phase 3-wire composite)

3-phase 3-wire

1-phase 2-wire3-phase 4-wire

Branch circuit breaker

Branch circuit breaker

Branch circuit breaker

2.3 Wiring for power and monitored voltage input (continued)

Wire the device according to the phase and wire type as shown in the following diagram.

Install a branch circuit breaker between the wiring for each of R/S/T/N, L/N and R/N/T so that the power can be

turned off immediately.

Important

• For safety purposes, turn off the mains power and set the branch circuit breaker to off to ensure there is

no power supply while you are working.

• Wire correctly so the phase sequence is correct. You will be unable to measure the power and energy

correctly if you fail to do so.

• For the wiring for the power and measured voltage, use 24 to 14 AWG (cross section surface area of 0.2

to 2.0mm

• The recommended torque for screwing the 3.5mm screws is 0.8Nm. Make sure the crimping terminal is

2

) electrical wire and ring or U-shaped crimp connectors suitable for 3.5mm screws.

pushed all the way in and tightened firmly. After fixing the wiring in place, pull gently to confirm that the

wiring is fixed firmly.

• During use, make sure the terminal panel cover is closed.

30

Page 31

2.Installation and wiring

CT

Power side

Load side

LoadBreaker

L

N

KL

2.4 Fitting the CTs to the measuring wires

When monitoring one circuit with 1-phase 2-wire, you need one CT. When monitoring one circuit with 1-phase 3-wire,

you need 2 CTs. When monitoring one circuit with 3-phase 4-wire, you need 3 CTs. The following diagram is an

example of fitting CTs when monitoring one circuit with 1-phase 2-wire.

• For details about how to connect the CTs to the measuring wires, refer to the manual of the CTs you are using.

• Fit the CTs to the measuring wires after connecting the CT cables to the unit.

• Attach to the L-phase if measuring 1-phase 2-wire.

Attach to the R-phase and T-phase if measuring 1-phase 3-wire or 3-phase 3-wire.

Attach to the R-phase, S-phase, and T-phase if measuring 3-phase 4-wire.

• Refer to "2.7 Wiring diagrams ( 38)" for more on attaching CTs according to the phase and wire types.

• CTs have polarity. Check the directionality of the power side (K) and the load side (L) before connecting. You will

be unable to measure correctly if you make a mistake with the directions.

Important

• Electric shock may occasionally occur.

Always make sure that the power is turned OFF before connecting the CT.

• Make sure that the primary electrical wire clamped at the CT is insulated coated wire.

• Do not expose the CTs to excessive vibrations or impacts.

31

Page 32

2.Installation and wiring

Pulse output terminal

Under

2.7mm

Under 2.7mm

8 to 10mm

Pulse output terminal

Release hole

Wiring

2.5 Pulse output wiring

Wire the pulse output terminals if using the pulse output feature. The layout of pulse output terminals is as follows.

Terminal

number

1 OUT1 Pulse output 1

2 OUT2 Pulse output 2

3 OUT3 Pulse output 3

4 OUT4 Pulse output 4

5 COM Common (common to the four outputs)

Push the wire to the very back of the pulse output terminals while pressing on the release hole.

Refer to "Cautions when connecting the Push-In Plus terminal (RS-485 communication terminal and pulse output

terminal)( 34)" for details about wiring and connections.

Terminal

name

Description

32

Page 33

2.Installation and wiring

Load Load Lo adLoad

−+

Load Load LoadLoad

PNP output connection diagramNPN output connection diagram

DC40V(max)

50mA(max)

DC40V(max)

50mA(max)

OUT2 OUT3 OUT4OUT1 COM

OUT2 OUT3 OUT 4OUT1 COM

2.5 Pulse output wiring (continued)

The following diagram shows wiring for pulse output.

This unit is equipped with 4 pulse outputs. The common terminal (number 5) is a common terminal.

−+

The table below shows the output specifications.

Output capacity DC40V, 50mA or less

Residual voltage when

ON

Current leakage when

OFF

Less than 1.5V (when output current is 50mA)

0.1mA or less

Pulse output units 1,10,100,1k,5k,10k,50k,100kWh

Pulse ON time 500ms fixed

Important

• The terminal panel is the push-in type. Also read "Cautions when connecting the Push-In Plus terminal

(RS-485 communication terminal and pulse output terminal) ( 34)" when wiring.

• Do not directly connect an external power source to OUT or COM. Make sure the load is connected.

• For wiring to the pulse output terminals, use 24 to 14 AWG (cross section surface area of 0.2 to 2.0mm

electrical wire.

• Single wires, stranded wires, and ferrule terminals can be used. The recommended stripped wire length

when using single wires or stranded wire is 8 to 10mm (however, 10mm must be used when using

AWG14).

• To avoid the influence of noise, use separate wiring for the signals and for the power.

• Output for circuit A is allocated to OUT1, circuit B to OUT2, circuit C to OUT3, and circuit D to OUT4.

These allocations are fixed.

2

)

33

Page 34

2.Installation and wiring

Terminal

(Insertion) hole

Release hole

Release hole

Terminal (Insertion) hole

Ferrules and Solid Wires

10〜12°

Flat-blade screwdriver

3

2

1

2.5 Pulse output wiring (continued)

Cautions when connecting the Push-In Plus terminal (RS-485 communication

terminal and pulse output terminal)

Follow the below steps when connecting the Push-In Plus terminal

1 Connecting Wires to Push-In Plus Terminal Block

• Part Names of the Terminal Block

• Connecting Wires with Ferrules and Solid Wires

Insert the solid wire or ferrule straight into the terminal

block until the end strikes the terminal block.

If a wire is difficult to connect because it is too thin,

use a flat-blade screwdriver in the same way as when

connecting stranded wire.

• Connecting Stranded Wires

Use the following procedure to connect the wires to

the terminal block.

1 Hold a flat-blade screwdriver at an angle and

insert it into the release hole. The angle should be

between 10e and 12e. If the flat-blade screwdriver

is inserted correctly, you will feel the spring in the

release hole.

2 With the screwdriver still inserted into the release

hole, insert the wire into the terminal hole until it

strikes the terminal block.

3 Remove the flat-blade screwdriver from the

release hole.

34

Page 35

2.5 Pulse output wiring (continued)

10〜12°

Flat-blade screwdriver

1

3

2

Side Front

2.5 dia.

2.5 mm

0.4 mm

• Checking Connections

• After the insertion, pull gently on the wire to make

sure that it will not come off and the wire is securely

fastened to the terminal block.

• To prevent short circuits, insert the stripped part of a

stranded or solid wire or the conductive part of a

ferrule until it is hidden inside the terminal insertion

hole. (See right diagram.)

2 Removing Wires from Push-In Plus

Terminal Block

Use the following procedure to remove wires from the

terminal block. The same method is used to remove

stranded wires, solid wires, and ferrules.

1 Hold a flat-blade screwdriver at an angle and

insert it into the release hole.

2 With the screwdriver still inserted into the release

hole, remove the wire from the terminal insertion

hole.

3 Remove the flat-blade screwdriver from the

release hole.

2.Installation and wiring

2 Removing Wires from Push-In Plus Terminal Block

• ecommended Flat-blade Screwdriver

Use a flat-blade screwdriver to connect and remove wires.

Use the following flat-blade screwdriver.

Model Manufacturer

XW4Z-00B Omron

35

Page 36

2.Installation and wiring

RS-485 terminal

Under 2.7mm

8 to 10mm

RS-485 terminal

Release hole

Wiring

Under

2.7mm

2.6 RS-485 wiring

Wire the RS-485 terminals if using the RS-485 communication feature. The layout of RS-485 terminals is as follows.

Terminal

number

1 RS-485

2 RS-485jjterminal for RS-485

3 RS-485

4 RS-485j RS-485jterminal (for crossover wiring)

5 RS-485 E Terminating resistor for RS-485 (ON when shorted with terminal number 4)

TTerminal number 1 and 3 and terminal number 2 and 4 are electrically connected inside this product.

Push the wire to the very back of the RS-485 terminal while pressing on the release hole.

Refer to "Cautions when connecting the Push-In Plus terminal (RS-485 communication terminal and pulse output

terminal)( 34)" for details about wiring and connections.

Terminal

name

ii

i

Description

terminal for RS-485

RS-485iterminal (for crossover wiring)

36

Page 37

2.Installation and wiring

+

−

Communications

master

(host device)

Maximum transmission distance 1200m

Terminating resistor

terminal and short

Rotary switch (units of 10)

Rotary switch (units of 1)

2.6 RS-485 wiring (continued)

The following diagram shows wiring for RS-485 communication.

The configuration of the connection should be either 1:1 or 1:N. If the 1:N connection is Modbus, up to 99 of this

product can be connected. If CompoWay/F, up to 31 can be connected. Enable the terminating resistor that shorts

terminal numbers 4 and 5 in the end unit.

Setting the communication address

When wiring is finished, turn the rotary switch to set the communication address.

The value on the left is circuit A communication address tens place and the value on the right is the ones.

Important

• The terminal panel is the push-in type. Also read "Cautions when connecting the Push-In Plus terminal

(RS-485 communication terminal and pulse output terminal) ( 34)" when wiring.

• Only the communication address for circuit A can be set with the rotary switch. Refer to "Settings for circuits B to D

(when measuring 2 circuits or more)" (

• The addresses for circuits B to D are automatically set, where 1 is added for each circuit in order to the address set

for circuit A. Refer to "Settings for circuits B to D (when measuring 2 circuits or more) (

• If the communications address exceeds 99 when multi-circuit metering, the value is invalid.

• If the host device you are using does not have its own built in terminating resistor, connect a terminating

resistor to the host device. The terminating resistance is 120Ω (1/2W).

• Do not wire in a terminating resistor terminal on any of these products that are along the transmission

path. This can cause communication failures.

• There is no FG terminal on this product. Connect only the

• Use twisted pair cables.

• For wiring to the RS-485 terminals, use 24 to 14 AWG (cross section surface area of 0.2 to 2.0mm2) electrical wire.

• Single wires, stranded wires, and ferrule terminals can be used. The recommended stripped wire length when using

single wires or stranded wire is 8 to 10mm (however, 10mm must be used when using AWG14).

• To avoid the influence of noise, use separate wiring for the RS-485 communications and for the power.

• Irrespective of the transmission distance and number of units connected, perform communications

checks with the actual units.

• During use, make sure the terminal panel cover is closed.

[Reference]

• If the upstream device does not support RS-485 communications, refer to the table below to select a converter for your purpose.

56) to set the communications addresses for circuits B to D.

56)" for details.

i

wire and j wire of RS-485.

Protocol KM-N Setting Tool USB/RS-485 converter operability confirmed

Modbus

CompoWay/F

Yes

Yes

No K3SC-10 (Omron), SI-35USB (LINEEYE Co.,Ltd.)

SI-35USB (LINEEYE Co., Ltd.)No

37

Page 38

2.Installation and wiring

RSTN

Power side

Load

Circuit A (CT1 to 3)

Branch

circuit

breaker

LN

Power side

Load

Circuit A (CT1)

Breaker

Load

Load

Load

Circuit B (CT2)

Circuit C (CT 3)

Circuit D (CT4)

Breaker

Breaker

Breaker

Branch

circuit

breaker

2.7 Wiring diagrams

The below table shows the wiring for voltage, current, and CT by each phase and wire type.

■ For 3-phase 4-wire

3-phase 4-wire measures one circuit, as shown in the following diagram.

■ For 1-phase 2-wire

As shown below, 1-phase 2-wire can measure a maximum of 4 circuits. The CT must be attached to the L-phase.

38

Page 39

2.Installation and wiring

RNT

Power side

Load

Circuit A (CT1 to 2)

Breaker

Load

Circuit C (CT 3 to 4)

Breaker

Branch

circuit

breaker

RS T

Load

Circuit A (CT1 to 2)

Load

Circuit C (CT 3 to 4)

Power side

Breaker

Breaker

Branch

circuit

breaker

2.7 Wiring diagrams (continued)

■ For 1-phase 3-wire

As shown below, 1-phase 3-wire can measure a maximum of 2 circuits. Use CT1,CT2 when measuring only 1 circuit.

The CT must be attached to the R-phase and the T-phase.

■ For 3-phase 3-wire

As shown below, 3-phase 3-wire can measure a maximum of 2 circuits. Use CT1,CT2 when measuring only 1 circuit.

The CT must be attached to the R-phase and the T-phase.

39

Page 40

2.Installation and wiring

RN

Power side

Load

Circuit A (CT1)

Breaker

Breaker

Breaker

Breaker

Load

Load

Load

Circuit B (CT2)

Circuit C (CT 3)

Circuit D (CT4)

T

Branch

circuit

breaker

RN

Power side

Load

Circuit A (CT1 to 2)

Load

Load

Circuit C (CT 3)

Circuit D (CT4)

T

Breaker

Breaker

Breaker

Branch

circuit

breaker

2.7 Wiring diagrams (continued)

The following wiring is also possible as a further method of measuring.

■ For 1-phase 2-wire voltage selected

The 1-phase 2-wire branching off from the 1-phase 3-wire is measured. With this connection, a setting is required

according to which of R-N phase, T-N phase, or R-T phase is connected to the 1-phase 2-wire circuit. ( 63) The CT

must be attached to the R-phase or the T-phase.

■ For 1-phase 3-wire composite

The 1-phase 3-wire circuit and the 1-phase 2-wire branching off from it are measured at the same time. With this

connection, a setting is required according to which of R-N phase, T-N phase, or R-T phase is connected to the 1phase 2-wire circuit. ( 63) The 1-phase 2-wire circuit CT must be attached to the R-phase or the T-phase.

40

Page 41

3.Basic use

(Example of Ver.1.0.X)

3. Basic use

3.1 Turning the power on

Important

• Before turning on the power, ensure that there are no problems with the wiring.

Turn the branch circuit breaker on and then turn this product on.

• The software version is shown on the main display, the model number "KM-N2" is shown on the sub-display, and

all of the LEDs light.

• After this, the measuring mode is moved to automatically and the active energy (import) (kWh) for circuit A is

displayed.

KM-N2

POWER

ERROR

ALARM

COMM

OUTPUT

ESC

OMRON

SMART POWER MONITOR

/MODE

10

o1 v

ENTER

2n-mk

o1v

2n-mk

oooo

hWk

41

Page 42

3.Basic use

w4p3

1a

EDOM

TES

wssap

oooo

Settingmode

Screens

<</MODE

Press and hold

Password

Authenticated

Automatic transition

Measuring mode

Settingmode

Screens

<</MODE

Press and hold

Automatic transition

Setting mode

Settingmode

Screens

<</MODE

Press and hold

Automatic transition

Setting mode

EDOM

MMOC

Measuringmode

Screens

Command

Setting mode

Command Automatic transition

EDOM

EVASMMOC

hwk

oooo

10

Command Automatic transition

3.2 Switching between modes

Switching between the measuring mode and the setting mode

Switch between the measuring mode and setting mode by pressing and holding the [<</MODE] key.

• "Press and hold" means pressing the key for 1 or more seconds.

■ Measuring mode → Setting

mode

Screen to enter the password

Enter password

(password authentication OK)

"SET MODE" displayed Setting mode

■ Setting mode → Measuring mode

1If settings are not changed in the setting mode

"MEASR MODE" displayed Measuring mode

2If settings are changed in the setting mode

"SAVE" display restart Measuring mode

– Restarting is done automatically.

rsaem

EDOM

EVAS

10

oooo

hwk

10

oooo

hwk

Switching between the measuring mode and the communication setting mode

You can switch between the communication setting mode and the measuring mode by sending particular commands.

Refer to "6.Detailed settings for communications ( 74)" for details about the commands to move to each mode.

■ Switching from measuring mode to

communication setting mode

Command sent "COMM MODE" displayed

("COMM MODE" is displayed while in communication

setting mode)

■ Switching from communication setting

42

mode to measuring mode

Command sent "MEASR MODE" displayed

Measuring mode

1If settings are not changed in the communication setting

mode

"MEASR MODE" displayed Measuring mode

2If settings are changed in the communication setting mode

"SAVE" displayed restart Measuring mode

– Restarting is done automatically.

10

rsaemMMOC

EDOM

EDOM

oooo

hwk

Page 43

3.Basic use

Command

Setting mode

12

3.2 Switching between modes (continued)

Switching between the setting mode and the communication setting mode

You can switch between the setting mode and the communication setting mode by sending particular commands.

Refer to "6.Detailed settings for communications ( 74)" for details about the commands.

It is not possible to move from the communication setting mode to the setting mode.

■ Switching from the setting mode to the

communication setting mode

Command sent "COMM MODE" displayed

("COMM MODE" is displayed while in communication setting mode)

How to enter the password

• When moving from the measuring mode to the setting mode, you need to enter the password that has been set.

• The default password is "0001".

• You can set a password of 4 numerals between 0000 and 9999. Change the password as necessary. (5.7Change

password ( 70))

MMOC

EDOM

■ Enter the password (Ex.: enter password "3060")

1 Enter "3060" with the [ ][ ] keys in the password entry screen.

– Press the [<</MODE] key to move one place to the left.

– If you press the [<</MODE] key on the end at the left, the cursor moves to the right end.

2 The password is verified when you press the [ENTER] key and "OK" is displayed.

After this, the transition to setting mode is automatic.

oooo

wssap

NG" is displayed if the password you entered was wrong.

"

Reenter the password.

o6o3

wssap

ko

wssap

gn

wssap

43

Page 44

3.Basic use

<</MODE <</MODE <</MODE

<</MODE

<</MODE <</MODE

<</MODE

<</MODE <</MODE

<</MODE

<</MODE <</MODE <</MODE

<</MODE

<</MODE <</MODE

<</MODE

3-phase 4-wire

(3P4W)

1-phase 2-wire

(1P2W)

1-phase 3-wire

(1P3W)

3-phase 3-wire

(3P3W)

selected

(1P2W2)

1-phase 3-wire

composite

(1P3W2)

Circuit A

Circuit A

Circuit A

Circuit A

Circuit BCircuit C

Circuit D

Circuit C

Circuit C

Circuit C

Circuit C

Circuit B

Circuit D

Circuit D

Circuit A

Circuit A

3.3 How to read the measurements

The measurements are shown for circuits A to D in the measuring mode. Depending on the phase and wire type

selected, the display changes as follows.

The parts in broken lines (circuits B to D) are displayed if you have enabled the circuit settings ( 56).

44

Page 45

3.Basic use

WK

2oc

hwk

oooo

20

oooo

20

-b-

20

ooOo

20

WK

2oc

hWk

oooo

30

o ooo

30

-C-

30

ooOo

30

WK

2 oc

HWk

oooo

40

oooo

40

-D-

40

ooOo

40

hwk

WK

2oc

ooOo

10

oooo

10

oooo

10

-A-

10

/MODE

/MODE/MODE/MODE

Automatic

transition

Automatic

transition

Automatic

transition

Automatic

transition

Circuit D Circuit C Circuit B Circuit A

Start

(Display example for 1-phase 2-wire (1P2W))

-a-

10

3.3 How to read the measurements (continued)

● Switching circuits

Press the [<</MODE] key to switch the circuit displayed.The measuring items are displayed after the screen for

showing the destination circuit.

• The measuring items for circuits B to D are displayed when the circuit settings are enabled (ON).

• With 3P4W, only circuit A is displayed. With 1P3W and 3P3W, only circuits A and C are displayed.

• Press the [][] keys to switch the items measured.

● Switching the measured values display

Press the [][] keys to switch the items measured. Depending on the phase and wire type, some items are not

displayed.

• Refer to "Measurement display list ( 46)" for details about measuring items.

■ Display of CTs used

The measurements are shown for each of the circuits in the measuring

mode. The CTs being used by each circuit are displayed in the display of CTs

used at this time.

For example, for 1-phase 3-wire or 3-phase 3-wire, the measurement display

for circuit A also displays CT1 and CT2 as shown at right.

45

Page 46

3.Basic use

3.3 How to read the measurements (continued)

■ Measurement display list

Order of

display

1

2

3

4

5

6

7

8

Item Main display/numerals Sub display/units Remarks

Active energy

(import)

Active power -99999.999 to 999999.999 kW

Current 1 0.000 to 999999.999

Current 2 0.000 to 999999.999

Current 3 0.000 to 999999.999

Phase voltage 1 0.0 to 99999999.9

Phase voltage 2 0.0 to 99999999.9

Phase voltage 3 0.0 to 99999999.9

0.000 to 999999.999 kWh

1000.000 to 999999.999 MWh

A_R : 3-phase 4-wire

A : 1-phase 2-wire

A_R : 1-phase 3-wire

A_R : 3-phase 3-wire

A

A (Circuit A only A_R) : 1-phase 3-wire composite

A_S : 3-phase 4-wire

None : 1-phase 2-wire

A_N : 1-phase 3-wire

A_S : 3-phase 3-wire

None

None (Circuit A only A_3) : 1-phase 3-wire composite

A_T : 3-phase 4-wire

None

A_T : 1-phase 3-wire

A_T : 3-phase 3-wire

None

None (Circuit A only A_T) : 1-phase 3-wire composite

V_R : 3-phase 4-wire

V : 1-phase 2-wire

V_R : 1-phase 3-wire

None : 3-phase 3-wire

V_R,V_T,V_R-T

V_R,V_T,V_R-T

(Circuit A onlyV_R)

None (Circuit A only V_T) : 1-phase 3-wire composite

*1

*2

V_S : 3-phase 4-wire

None : 1-phase 2-wire

None : 1-phase 3-wire

None : 3-phase 3-wire

None : 1-phase 2-wire voltage

None : 1-phase 3-wire composite

V_T : 3-phase 4-wire

None : 1-phase 2-wire

V_T : 1-phase 3-wire

None : 3-phase 3-wire

None

: 1-phase 2-wire voltage

selected

: 1-phase 2-wire voltage

selected

: 1-phase 2-wire voltage

selected

: 1-phase 2-wire voltage

selected

: 1-phase 2-wire voltage

selected

: 1-phase 3-wire composite

selected

: 1-phase 2-wire voltage

selected

Units automatically switch*

*1 Varies according to the voltage

*2 Varies according to the voltage

assignment settings

assignment settings

* The units change automatically the maximum value is reached, with the display value on the unit returning to 0, but recording

continues. Accurate values can be obtained by using the communication function.

46

Page 47

3.3 How to read the measurements (continued)

3.Basic use

Order of

display

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Item Main display/numerals Sub display/units Remarks

V_R-s : 3-phase 4-wire

None : 1-phase 2-wire

None : 1-phase 3-wire

Inter-wire voltage 1 0.0 to 99999999.9

Inter-wire voltage 2 0.0 to 99999999.9

None (Circuit A only V_R-t) : 1-phase 3-wire composite

Inter-wire voltage 3 0.0 to 99999999.9

Frequency 45.0 to 65.0 Hz

Power factor -1.00 to 1.00 PF

Reactive power -99999.999 to 999999.999 kVAR

Active energy

(export)

Cumulative total

reactive power

Reactive energy

(import)

Reactive energy

(export)

T1 Active energy

(import)

T2 Active energy

(import)

T3 Active energy

(import)

T4 Active energy

(import)

0.000 to 999999.999 -kwh

1000.000 to 999999.999 -mwh

0.000 to 999999.999 kVARh

1000.000 to 999999.999 mVARh

0.000 to 999999.999 -kVRh

1000.000 to 999999.999 -mVRh

0.000 to 999999.999 +kVRh

1000.000 to 999999.999 +mVRh

0.000 to 999999.999 kwh

1000.000 to 999999.999 mwh

0.000 to 999999.999 kwh

1000.000 to 999999.999 mwh

0.000 to 999999.999 kwh

1000.000 to 999999.999 mwh

0.000 to 999999.999 kwh

1000.000 to 999999.999 mwh

V_R-s : 3-phase 3-wire

: 1-phase 2-wire voltage

None

selected

None : 1-phase 3-wire composite

V_R-t : 3-phase 4-wire

None : 1-phase 2-wire

V_R-t : 1-phase 3-wire

V_R-t : 3-phase 3-wire

: 1-phase 2-wire voltage

None

selected

V_s-t : 3-phase 4-wire

None : 1-phase 2-wire

None : 1-phase 3-wire

V_s-t : 3-phase 3-wire

: 1-phase 2-wire voltage

None

selected

None : 1-phase 3-wire composite

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

* The units change automatically the maximum value is reached, with the display value on the unit returning to 0, but recording

continues. Accurate values can be obtained by using the communication function.

47

Page 48

3.Basic use

3.3 How to read the measurements (continued)

Order of

display

23

24

25

26

27

28

29

30

31

32

Item Main display/numerals Sub display/units Remarks

Active energy

(import)

(resettable)

Active energy

(export)

(resettable)

Cumulative total

reactive power

(resettable)

Reactive energy

(import)

(resettable)

Reactive energy

(export)

(resettable)

T1 Active energy

(import)

(resettable)

T2 Active energy

(import)

(resettable)

T3 Active energy

(import)

(resettable)

T4 Active energy

(import)

(resettable)

Conversion value

0.000 to 999999.999 kwh (flashes)

1000.000 to 999999.999 mwh (flashes)

0.000 to 999999.999 -kwh (flashes)

1000.000 to 999999.999 -mwh (flashes)

0.000 to 999999.999 kVARh (flashes)

1000.000 to 999999.999 mVARh (flashes)

0.000 to 999999.999 -kVRh (flashes)

1000.000 to 999999.999 -mVRh (flashes)

0.000 to 999999.999 +kVRh (flashes)

1000.000 to 999999.999 +mVRh (flashes)

0.000 to 999999.999 kwh(flashes)

1000.000 to 999999.999 mwh (flashes)

0.000 to 999999.999 kwh (flashes)

1000.000 to 999999.999 mwh (flashes)

0.000 to 999999.999 kwh (flashes)

1000.000 to 999999.999 mwh (flashes)

0.000 to 999999.999 kwh (flashes)

1000.000 to 999999.999 mwh (flashes)

0.000 to 999999.999 xxx (Setting can be changed)

1000.000 to 999999.999 MXXx (Setting can be changed)

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*

Units automatically switch*1000.000 to 999999.999 kXXx (Setting can be changed)

* The units change automatically the maximum value is reached, with the display value on the unit returning to 0, but recording

continues. Accurate values can be obtained by using the communication function.

48

Page 49

3.Basic use

<</MODE

<</MODE

<</MODE

<</MODE

<</MODE

<</MODE

3-phase 4-wire

(3P4W)

1-phase 2-wire

(1P2W)

1-phase 3-wire

(1P3W)

3-phase 3-wire

(3P3W)

Circuit A

Circuit A

Circuit A

Circuit A

Circuit A

Circuit B

Circuit C

Circuit D

Circuit C

Circuit C

Circuit C

Circuit B

Circuit D

Circuit A

Circuit D

Circuit C

1-phase 2-wire voltage

selected

(1P2W2)

1-phase 3-wire

composite

(1P3W2)

Common

Others

Common

Others

Common

Others

Common

Others

Common

Others

Common

Others

3.4 How to read the setting values

The setting mode is organized into the categories "Individual setting items for circuits A to D", "Common settings",

and "Other settings".

Category Description

Circuits (A, B, C, D) Individual setting items for the circuits

Common (CMMN) Setting items common to all of the circuits (communication, pulse output, etc.)

Others (ETC) Settings for initializing, resetting cumulative values, etc.