Page 1

1

Overview

2

Procedure

Insulation Resistance

Monitoring Device

User's Manual

K7GE-MG

3

Installation and

Wiring

4

Functions Related

to Measurement

5

Using Setting

Parameters

6

Remote Monitoring

Troubleshooting

A

Appendices

I

Index

N224-E1-01

Page 2

NOTE

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in

any form, or by any means, mechanical, electronic, photocopying, recording, or otherwise, without the prior

written permission of OMRON.

No patent liability is assumed with respect to the use of the information contained herein. Moreover, because

OMRON is constantly striving to improve its high-quality products, the information contained in this manual is

subject to change without notice. Every precaution has been taken in the preparation of this manual. Nevertheless, OMRON assumes no responsibility for errors or omissions. Neither is any liability assumed for damages

resulting from the use of the information contained in this publication.

Trademarks

• Microsoft, Windows is either registered trademarks or trademarks of Microsoft Corporation in the United States

and other countries.

• Megger is a registered trademark or trademark of Megger Group Limited.

• Modbus is a registered trademark or trademark of Schneider Electric USA, Inc. in Japan, the United States or

other countries.

Other company names and product names in this document are the trademarks or registered trademarks of their

respective companies.

Copyrights

Microsoft product screen shots reprinted with permission from Microsoft Corporation.

Page 3

Preface

Thank you for purchasing a K7GE-MG Insulation Resistance Monitoring Device. This manual describes

how to use the K7GE-MG.

Read this manual thoroughly and be sure you understand it before attempting to use the K7GE-MG

correctly according to the information provided. Keep this manual in a safe place for easy reference.

A PDF version of this manual can be downloaded from the OMRON website. (http://www.omron.com)

In this manual, "K7GE-MG" refers to the K7GE-MG with its Main Unit connected to the Probe Units.

It is assumed that the load that the K7GE-MG measures is a motor. Before you use it for other

equipment such as a heater or transformer, carefully study the operating specifications of the

K7GE-MG.

Preface

Insulation Resistance Monitoring Device User’s Manual (N224)

1

Page 4

Terms and Conditions Agreement

Terms and Conditions Agreement

Warranty, Limitations of Liability

Warranties

Exclusive Warranty

Omron’s exclusive warranty is that the Products will be free from defects in materials and

workmanship for a period of twelve months from the date of sale by Omron (or such other period

expressed in writing by Omron). Omron disclaims all other warranties, express or implied.

Limitations

OMRON MAKES NO WARRANTY OR REPRESENTATION, EXPRESS OR IMPLIED, ABOUT

NON-INFRINGEMENT, MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OF

THE PRODUCTS. BUYER ACKNOWLEDGES THAT IT ALONE HAS DETERMINED THAT THE

PRODUCTS WILL SUITABLY MEET THE REQUIREMENTS OF THEIR INTENDED USE.

Omron further disclaims all warranties and responsibility of any type for claims or expenses based

on infringement by the Products or otherwise of any intellectual property right.

Buyer Remedy

Omron’s sole obligation hereunder shall be, at Omron’s election, to (i) replace (in the form originally

shipped with Buyer responsible for labor charges for removal or replacement thereof) the

non-complying Product, (ii) repair the non-complying Product, or (iii) repay or credit Buyer an

amount equal to the purchase price of the non-complying Product; provided that in no event shall

Omron be responsible for warranty, repair, indemnity or any other claims or expenses regarding the

Products unless Omron’s analysis confirms that the Products were properly handled, stored,

installed and maintained and not subject to contamination, abuse, misuse or inappropriate

modification. Return of any Products by Buyer must be approved in writing by Omron before

shipment. Omron Companies shall not be liable for the suitability or unsuitability or the results from

the use of Products in combination with any electrical or electronic components, circuits, system

assemblies or any other materials or substances or environments. Any advice, recommendations or

information given orally or in writing, are not to be construed as an amendment or addition to the

above warranty.

See http://www.omron.com/global/ or contact your Omron representative for published information.

Limitation on Liability; Etc

OMRON COMPANIES SHALL NOT BE LIABLE FOR SPECIAL, INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL DAMAGES, LOSS OF PROFITS OR PRODUCTION OR COMMERCIAL LOSS IN

ANY WAY CONNECTED WITH THE PRODUCTS, WHETHER SUCH CLAIM IS BASED IN

CONTRACT, WARRANTY, NEGLIGENCE OR STRICT LIABILITY.

Further, in no event shall liability of Omron Companies exceed the individual price of the Product on

which liability is asserted.

2

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 5

Application Considerations

Suitability of Use

Omron Companies shall not be responsible for conformity with any standards, codes or regulations

which apply to the combination of the Product in the Buyer’s application or use of the Product. At

Buyer’s request, Omron will provide applicable third party certification documents identifying ratings

and limitations of use which apply to the Product. This information by itself is not sufficient for a

complete determination of the suitability of the Product in combination with the end product, machine,

system, or other application or use. Buyer shall be solely responsible for determining appropriateness

of the particular Product with respect to Buyer’s application, product or system. Buyer shall take

application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK TO LIFE OR

PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT THE SYSTEM AS A WHOLE

HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND THAT THE OMRON PRODUCT(S) IS

PROPERLY RATED AND INSTALLED FOR THE INTENDED USE WITHIN THE OVERALL

EQUIPMENT OR SYSTEM.

Terms and Conditions Agreement

Programmable Products

Omron Companies shall not be responsible for the user’s programming of a programmable Product, or

any consequence thereof.

Disclaimers

Performance Data

Data presented in Omron Company websites, catalogs and other materials is provided as a guide for

the user in determining suitability and does not constitute a warranty. It may represent the result of

Omron’s test conditions, and the user must correlate it to actual application requirements. Actual

performance is subject to the Omron’s Warranty and Limitations of Liability.

Change in Specifications

Product specifications and accessories may be changed at any time based on improvements and other

reasons. It is our practice to change part numbers when published ratings or features are changed, or

when significant construction changes are made. However, some specifications of the Product may be

changed without any notice. When in doubt, special part numbers may be assigned to fix or establish

key specifications for your application. Please consult with your Omron’s representative at any time to

confirm actual specifications of purchased Product.

Errors and Omissions

Information presented by Omron Companies has been checked and is believed to be accurate;

however, no responsibility is assumed for clerical, typographical or proofreading errors or omissions.

Insulation Resistance Monitoring Device User’s Manual (N224)

3

Page 6

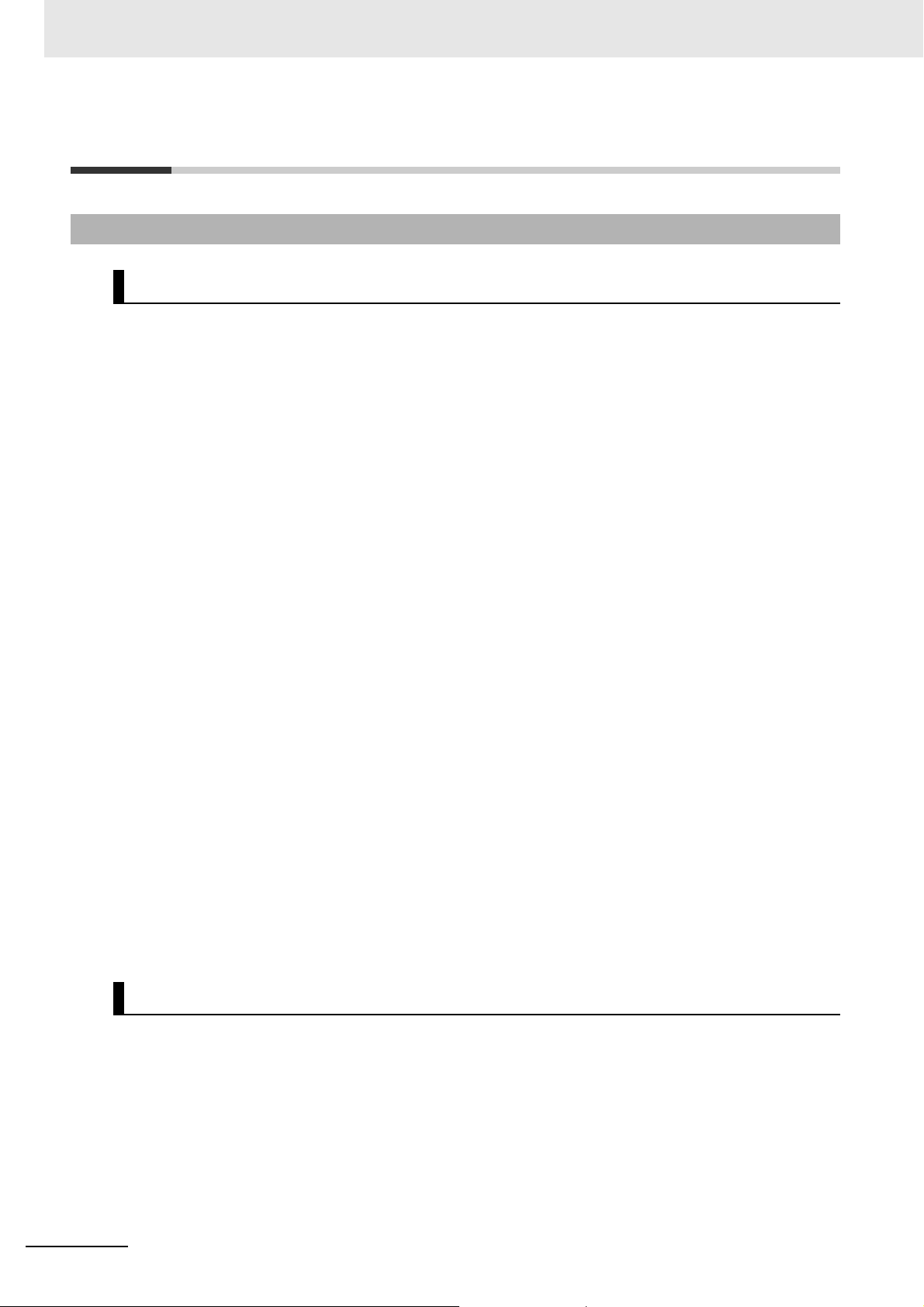

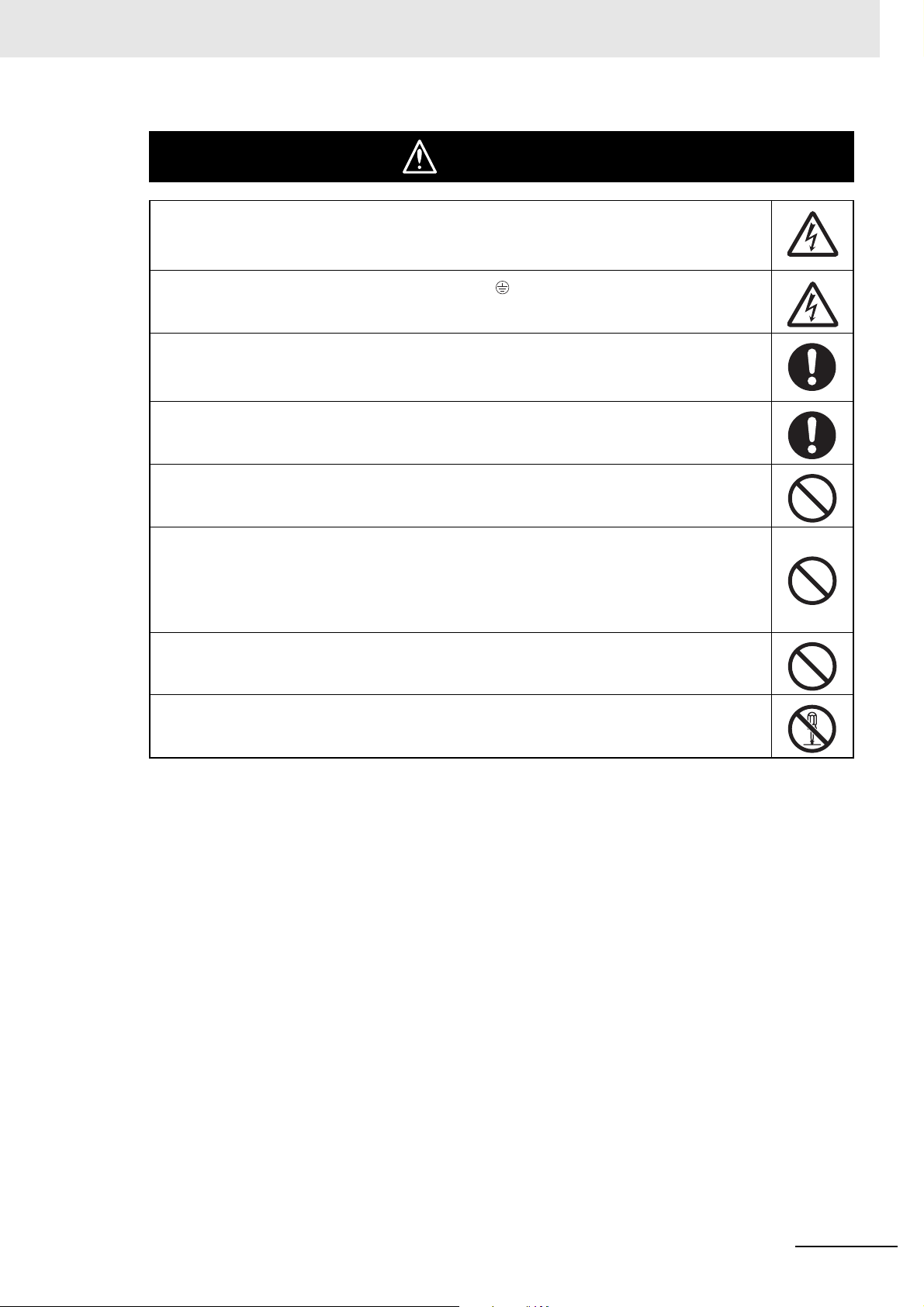

Safety Precautions

Safety Precautions

Definition of Precautionary Information

The following notation is used in this manual to provide precautions required to ensure safe usage of

the K7GE-MG Insulation Resistance Monitoring Device.

The safety precautions that are provided are extremely important to safety. Always read and heed the

information provided in all safety precautions.

The following notation is used.

CAUTION

Indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury, or in property damage.

Symbols

Precautions for

Safe Use

Precautions for

Correct Use

Symbol Meaning

Caution

Prohibition

Mandatory

Caution

Precautions on what to do and what not to do to ensure safe usage

of the product.

Precautions on what to do and what not to do to ensure proper

operation and performance.

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

• Electrical Shock Caution

Indicates possibility of electric shock under specific conditions.

• General Prohibition

Indicates non-specific general prohibitions.

• Disassembly Prohibition

Indicates prohibitions when there is a possibility of injury, such as from electric

shock, as the result of disassembly.

• General Caution

Indicates non-specific general cautions, warnings, and dangers.

4

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 7

Safety Precautions

CAUTION

Minor injury due to electric shock may occasionally occur. Do not touch the Product

except for any buttons (keys) while power is being supplied.

Always connect the protective earthing terminal ( ) to a ground.

Use AWG 16 for the protective conductor.

If the wiring material is inserted in a shallow position, it may cause property damage due

to ignition. When wiring, make sure that the wiring material is properly inserted all the

way into the terminal block.

If used the Product with incorrect wiring, it may cause property damage due to ignition.

Make sure the cable is connected properly when the power supply is turned ON.

Minor electric shock, fire, or malfunction may occasionally occur. Do not allow metal

objects, conductors, or cuttings from installation work to enter the Product.

Perform periodic inspection to the Product. A malfunction in the Product may

occasionally prevent monitoring impossible or alarm outputs, resulting in property

damage to connected equipment or devices. To maintain safety in the event of

malfunction of the Product, take appropriate safety measures, such as installing a

monitoring device on a separate line.

Minor injury due to explosion may occasionally occur.

Do not use the Product where subject to flammable or explosive gas.

Minor electric shock, fire, or malfunction may occasionally occur.

Do not disassemble, modify, or repair the Product or touch the interior of the Product.

Insulation Resistance Monitoring Device User’s Manual (N224)

5

Page 8

Precautions for Safe Use

Precautions for Safe Use

(1) Do not use or store the Product in the following locations:

• Outdoor or locations subject to direct sunlight

• Locations subject to rain and wind damage

• Locations subject to excessive vibration or shock

• Locations subject to rapid temperature changes

• Locations prone to icing and dew condensation

• Locations subject to water or oil

• Locations subject to dust or corrosive gases (particularly sulfurizing gases, ammonia, etc.)

• Locations subject to influence of static electricity and noise

• Locations subject to bugs and small animals

(2) A switch or circuit breaker should be provided close to this Unit. The switch or circuit breaker

should be within easy reach of the operator, and must be marked as a disconnecting means for this

Unit.

(3) Mount the Product in the correct direction for installation.

(4) Be sure to use power terminals carefully, because power supply terminals have hazardous voltage.

(5) Use the wire given in this manual.

(6) Use the power supply voltage within the range of the specifications and rated values. Use the input

voltage within the range of the specifications and rated values.

(7) Make sure the crimp terminals for wiring are of the specified size.

(8) Do not connect anything to terminals that are not being used.

(9) Confirm the wiring the input and output terminals correctly before power is supplied.

(10) The terminal block may be damaged if you insert a flat-blade screwdriver in the release hole with

excessive force. When inserting a flat-blade screwdriver into the release holes, operate with a

force of 15•N or less.

(11) K7GE-MG may be subject to radio disturbances. Do not install the Product near equipment that

generates high frequencies or surges.

(12) The maximum terminal temperature is 80°C. Use wires with a heat resistance of 80°C min to wire

the terminals.

(13) Make sure the LCD and the LEDs for output indicators operate correctly. Depending on the

operating environment, the Product parts may deteriorate faster than expected, causing the

indicators to fail.

(14) Use the cable within the length that is rated in the specification requirements for the wiring between

the sensor and the Product. As for the requirements on the cable distance, refer to 3-6 Wiring the

Communications Cable on page 3-13.

(15) In order to prevent inductive noise, wire the lines connected to the Product separately from power

lines carrying high voltages or currents. Also, do not wire in parallel with or on the same cables as

power lines. Other measures for reducing noise are to separate from ducts including noisy lines.

(16) Do not continue to use the Product if the front surface peels.

(17) The alarm output function is a function for the output of an alarm when the set threshold value is

below. Do not use this function for control, etc.

(18) Use this Product inside the control panel to prevent external noise.

(19) When discarding the Product, properly dispose of it as industrial waste.

(20) Never touch the charging terminal of the load while the K7GE-MG is in measurement operation.

(21) K7GE-MG cannot be used for legal inspection. Be sure to use a periodically calibrated measuring

instrument for legal inspection.

(22) When wiring, wire by enough length.

6

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 9

Precautions for Safe Use

(23) Check terminal polarity when wiring and wire all connections correctly. Do not wire the input and

output terminals incorrectly.

(24) K7GE-MG provides 50 VDC of Megger voltage. Do not use on equipment that may be damaged by

this voltage.

(25) Use and store the Product in a location where the ambient temperature and humidity are within the

specified ranges. If applicable, provide forced cooling.

(26) Please read and understand this manual before using K7GE-MG.

Insulation Resistance Monitoring Device User’s Manual (N224)

7

Page 10

Precaution for Correct Use

Precaution for Correct Use

Observe the following operating methods to prevent failure and malfunction.

(1) During periodic inspection, installation of an additional sensor, or adjustment of sensor position,

use the Product after ensuring that correct operation can be performed.

(2) When mounting K7GE-MG on a DIN Track, follow the installation method described in Mounting to

DIN Track on page 3-4 to install it correctly.

(3) Confirm that wire does not stick up after wiring of stranded cable.

(4) In case of crossover wiring, install these by 10 A per 1 terminal because when Products are

connected more than one in parallel, quite many electric currents to be called off.

(5) The terminal block may be damaged if specialized tool is not used. Use a recommended flat-blade

screwdriver to inserted into a release hole on the terminal block.

(6) This Product is designed for use by qualified personnel with a knowledge of electrical systems.

Read this manual carefully before using the Product.

(7) Use the power supply voltage, input power, and other power supplies and transformers with

suitable capacities and rated outputs.

(8) Use a power supply that will reach the rated voltage within 1 second after the power is turned ON.

(9) Do not install the Product close contact with the heating element.

(10) Do not install the Product near equipment that generates high frequencies or surges.

(11) Install the Product so that the load doesn't span the Product body.

(12) If an error occurs during K7GE-MG operation, stop operation immediately and make suitable

corrections such as replacement.

(13) Do not use K7GE-MG for safety devices or applications that could result in loss of life.

(14) Make sure to connect Main Unit and Probe Units before use.

(15) Make sure that the number of additional Probe Units is within the specified range.

(16) Be sure to install a magnetic contactor, etc. between the power supply and the load, and wire

K7GE-MG on the secondary side of it.

(17) Do not turn ON power to the load while K7GE-MG is measuring.

(18) Set the "Motor stop waiting time" setting value to at least the time from when the contactor is turned

off until the load completely stops.

(19) If you accidentally drop K7GE-MG, the inside of the Product may be damaged, so do not use it.

(20) Do not wire anything to the release holes.

(21) Do not tilt or twist a flat-blade screwdriver while it is inserted into a release hole on the terminal

block. The terminal block may be damaged.

(22) Insert a flat-blade screwdriver into the release holes at an angle. The terminal block may be

damaged if you insert the screwdriver straight in.

(23) Do not allow the flat-blade screwdriver to fall out while it is inserted into a release hole.

(24) Do not bend a wire past its natural bending radius or pull on it with excessive force. Doing so may

cause the wire disconnection.

(25) Do not insert more than one wire into each terminal insertion hole.

(26) Do not use any liquids such as paint thinner, similar solvents or alcohol to clean the Product. Clean

it with a soft, dry cloth.

8

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 11

Regulations and Standards

P1

P2

N

P3

E

E

L1

L2

N

L3

PE

PEN

P1

P2

P3

EE

L1

L2

EE

L1

L2

EE

N

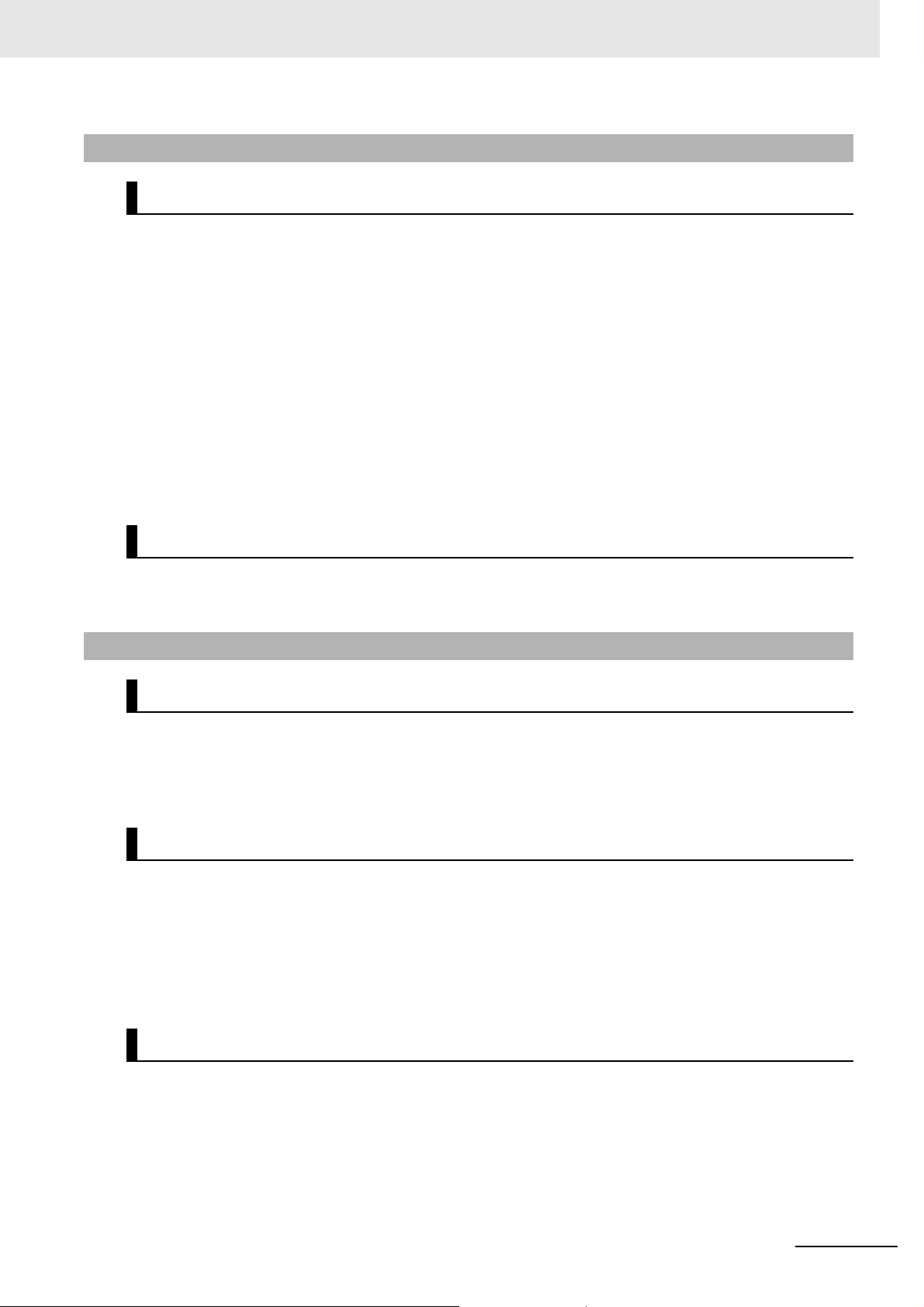

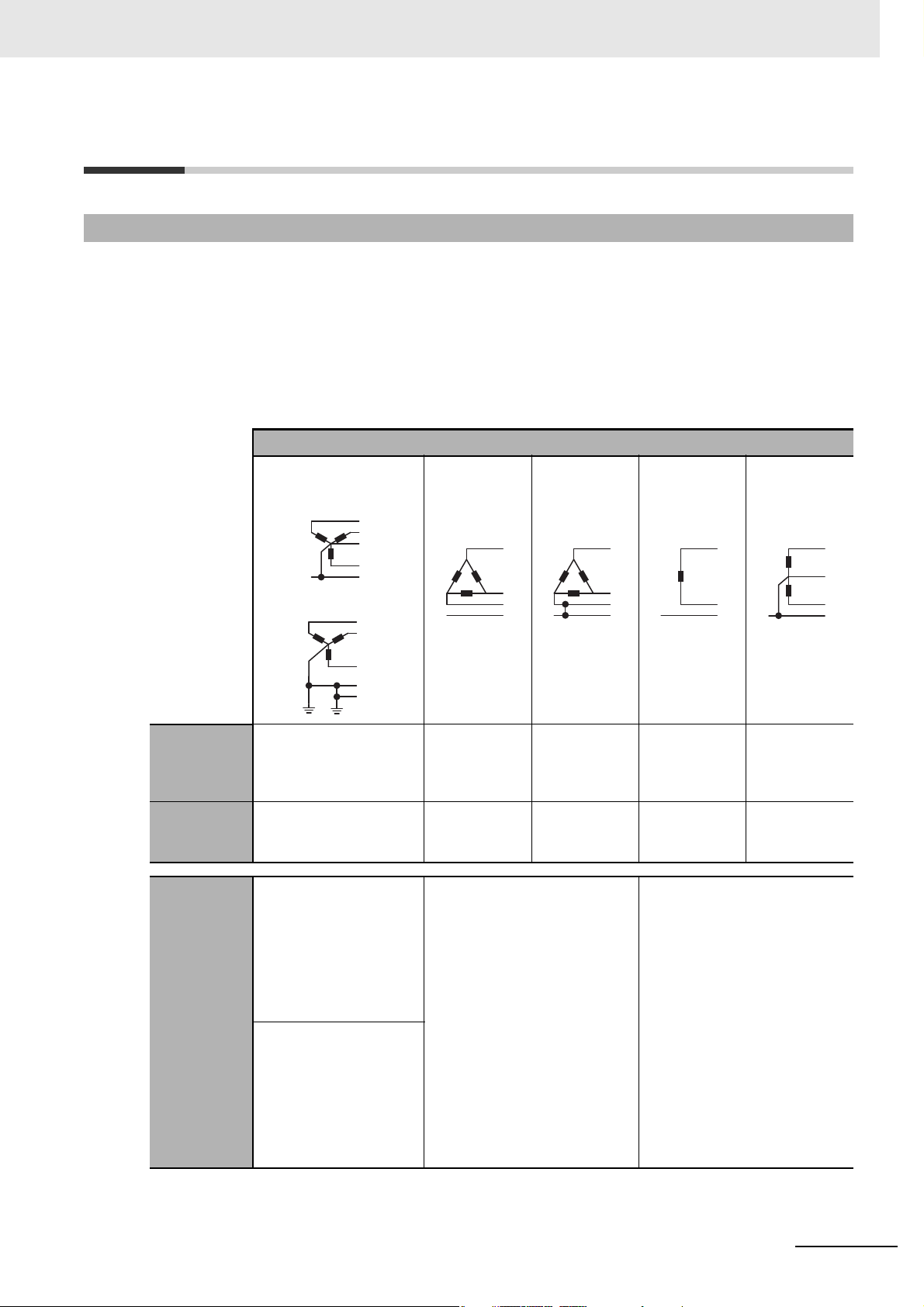

Conformance to Safety Standards

• For wiring from the Probe Unit to the load, use a Class CC, Class J, or Class T fuse with a rated

current of 7A or less.

• The protection provided by the device may be impaired if the device is used in a manner that is

not specified by the manufacturer.

• To use the Product, install it as an embedded device within a control panel.

• The table below shows the nominal voltage and measurement circuit connections available for

each measurement category in the Main Power Supply System Configurations. Do not use the

device under conditions that exceed this category and conditions.

Main Power Supply System Configurations

3-phase, 4-wire type

(neutral point grounding)

TT

3-phase,

3-wire type

(no grounding)

3-phase,

3-wire type

(single-phase

grounding)

P1

Regulations and Standards

Single-phase,

2-wire type

AC or DC

Single-phase

(split phase),

2-wire type

AC or DC

TN-C-S

CAT III Phase voltage/line

voltage

277 V/480 V

Line voltage

300 V

P2

P3

EE

Line voltage

300 V

Line voltage

240 V

Phase

voltage/line

voltage

240 V/480 V

CAT II 347 V/600 V in addition to

the above

Connection

to

measurement

circuit

TT:

Connect E in the diagram

above to the No. 7

terminal (PE) of the

K7GE-MGM.

Connect P1 and P2 to the

480 V in

addition to the

above

480 V in

addition to the

above

Connect E in the diagram above

to the No. 7 terminal (PE) of the

K7GE-MGM.

Connect P1 and P2 to the No. 1

and No. 3 terminals of the

K7GE-MG1.

480 V in

addition to the

Same as

above

above

Connect E in the diagram above

to the No. 7 terminal (PE) of the

K7GE-MGM.

Connect L1 and L2 to the No. 1

and No. 3 terminals of the

K7GE-MG1.

No. 1 and No. 3 terminals

of the K7GE-MG1.

TN-C-S:

Connect PE in the

diagram above to the No.

7 terminal (PE) of the

K7GE-MGM.

Connect L1 and L2 to the

No. 1 and No. 3 terminals

of the K7GE-MG1.

Insulation Resistance Monitoring Device User’s Manual (N224)

9

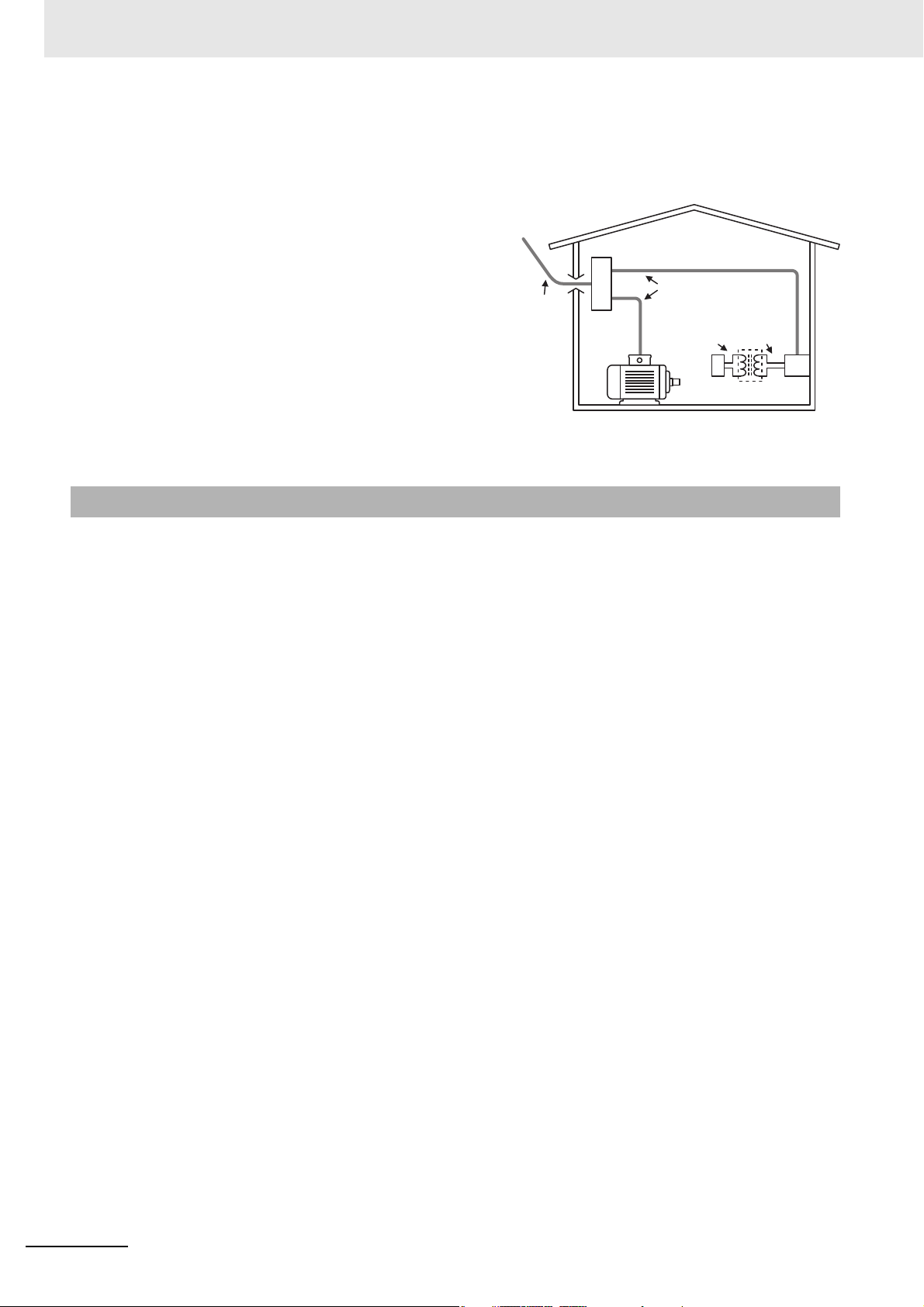

Page 12

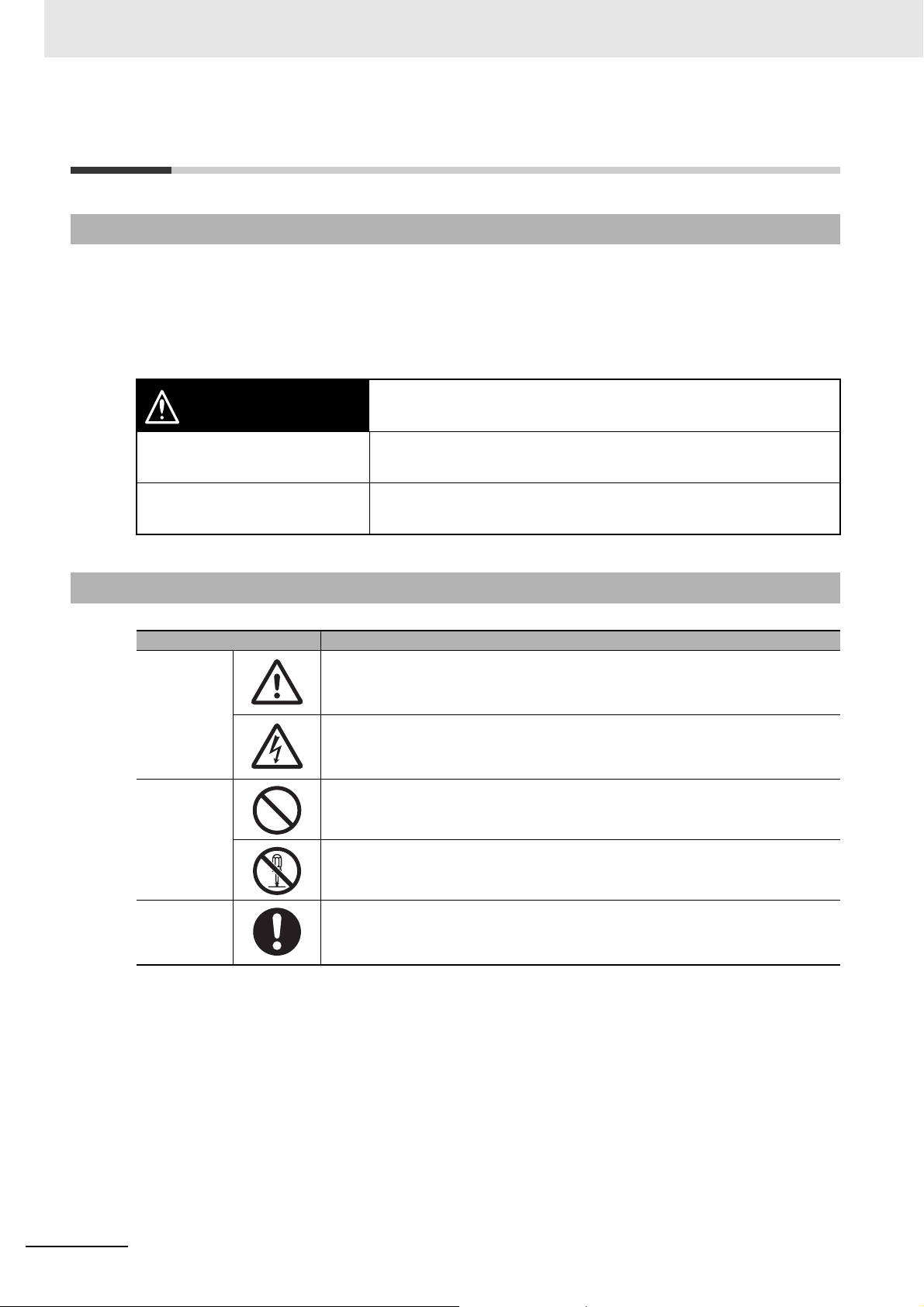

Regulations and Standards

Fixed

equipment

Distribution board

CAT IV

CAT III

CAT IICAT I

Internal wiring

Service

entry wire

Power

outlet

Measurement Category

The measurement category classifies the places and equipment which you can connect to the

measurement terminals, as prescribed in EN/IEC 61010-2-030. Each category is as follows.

CAT I: Equipment to connect to circuits where

measures are taken to limit transient

overvoltages to low levels

CAT II: Energy-consuming equipment with an

energy supply from fixed wiring equipment

(such as a power outlet)

CAT III: Equipment in fixed wiring equipment that

particularly demands equipment reliability

and effectiveness

CAT IV: Equipment to use at the electrical service

entry

Conformance to EN/IEC Standards

This is a class A product. In residential areas it may cause radio interference, in which case the user

may be required to take adequate measures to reduce interference.

10

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 13

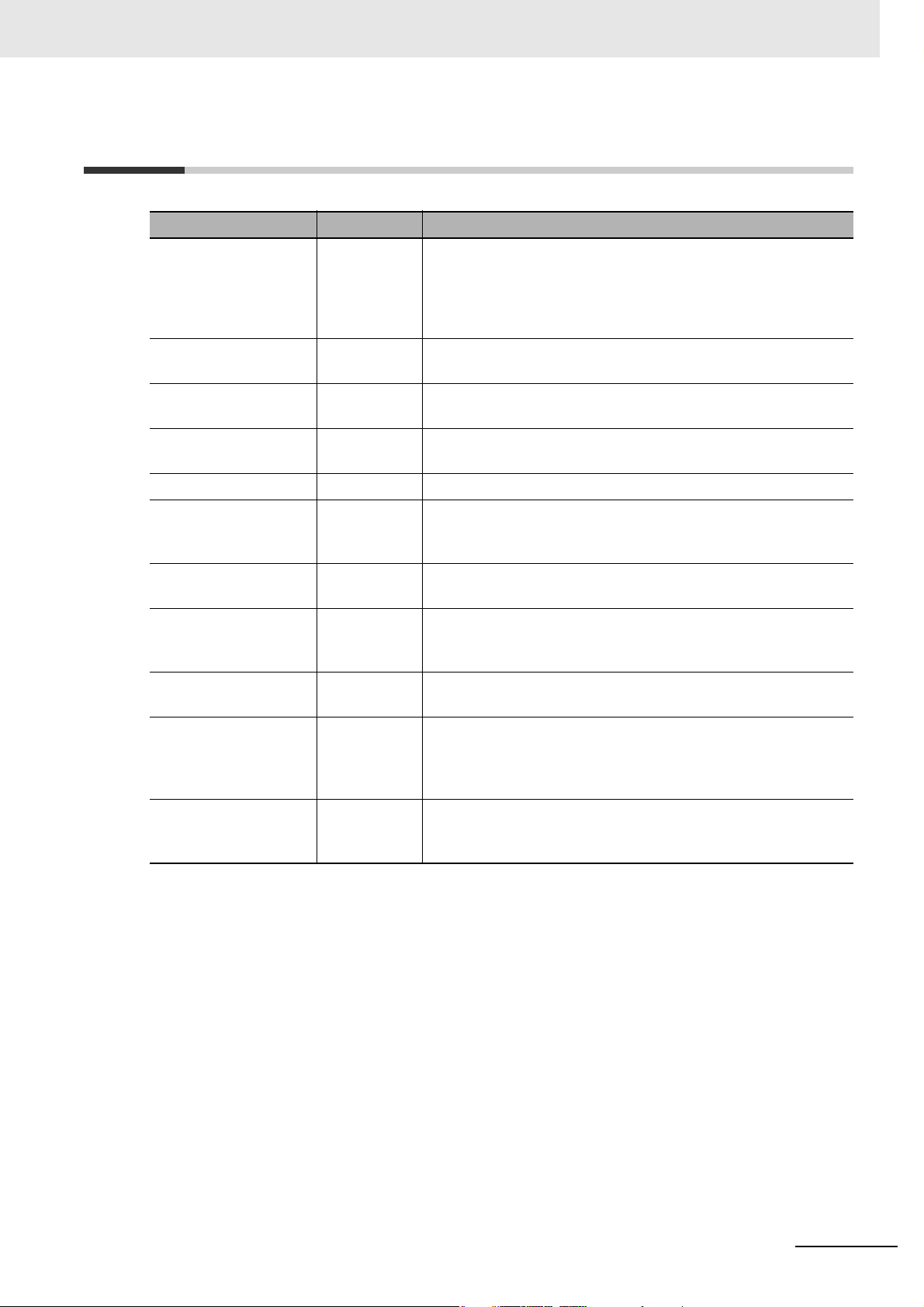

Terminology

Ter m Abbreviation Description

CompoWay/F - CompoWay/F is OMRON's standard communications format for

FINS (Factory Interface

Network Service)

Modbus RTU - This is a standard communications control method that conforms to

Channels CH The units of the insulation measurement loop for the Insulation

Power ON reset - A reset process that runs when the power turns ON.

Terminology

general serial communications. This format uses a standard frame

format as well as the well-established FINS commands used for

OMRON's PLCs. Therefore, it can simplify communications

between components and the host.

FINS The FINS protocol provides message communications between

controllers in OMRON FA networks.

Modicon Inc.'s RTU-mode Modbus Protocol (PI-MBUS-300 Rev. J).

Resistance Monitoring Device.

Protective earthing PE The protective earth to connect to the housing of a device to bring

the housing to the same potential as the ground and allow ground

fault currents to flow to ground.

K7GE-MG - "K7GE-MG" refers to the K7GE-MG with its Main Unit connected to

the Probe Units.

Megohmmeter - An instrument that measures the insulation resistance of electrical

products and indoor wiring, also called an insulation resistance

meter.

Megger voltage - The voltage that the device applies to measure the insulation

resistance. The K7GE-MG applies 50 VDC.

Megger method - A method to measure resistance values by connecting a measuring

circuit between a ground-insulated charged section that is

connected to the power line and a non-charged section such as a

grounded motor frame.

Parasitic capacitance - The capacitance that exists between the charging terminal of the

load and the terminal such as between PE. Also called stray

capacitance.

Insulation Resistance Monitoring Device User’s Manual (N224)

11

Page 14

Manual Structure

A

Manual Structure

Page Structure

Level 2 heading

Special information

Icons indicate precautions,

additional information, or

reference information.

Level 1 heading

Level 2 heading

Gives the current

headings.

Page tab

Gives the number

of the main section.

step in a procedure

Indicates a procedure.

Manual name

Icons

Special information in this manual is classified as follows:

Icon Meaning

No. **

Additional information to read as required.

This information is provided to increase understanding or give hints on operation.

This indicates the position in Section 2 Procedure that provides more detailed information about

trouble and countermeasures.

12

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 15

Revision History

N224-E1-01

Revision code

A manual revision code appears as a suffix to the catalog number on the front cover of the manual.

Revision code Date Revised content

01 January 2021 Original production

Revision History

Insulation Resistance Monitoring Device User’s Manual (N224)

13

Page 16

Revision History

14

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 17

1

3

4

5

6

A

I

4

5

6

7

A

I

Overview

Installation and Wiring

2

Procedure

Functions Related to Measurement

Using Setting Parameters

Remote Monitoring

Troubleshooting

Appendices

Index

3

7

1

2

Sections in this Manual

Insulation Resistance Monitoring Device User’s Manual (N224)

15

Page 18

CONTENTS

Preface ...................................................................................................................... 1

Terms and Conditions Agreement .......................................................................... 2

Warranty, Limitations of Liability .................................................................................................................. 2

Application Considerations .......................................................................................................................... 3

Disclaimers .................................................................................................................................................. 3

Precautions...............................................................................................................4

Definition of Precautionary Information........................................................................................................ 4

Symbols....................................................................................................................................................... 4

Precautions for Safe Use......................................................................................... 6

Precaution for Correct Use......................................................................................8

Regulations and Standards.....................................................................................9

Conformance to Safety Standards............................................................................................................... 9

Conformance to EN/IEC Standards...........................................................................................................10

Terminology ............................................................................................................ 11

Manual Structure .................................................................................................... 12

Page Structure........................................................................................................................................... 12

Icons .......................................................................................................................................................... 12

Revision History .....................................................................................................13

Sections in this Manual .........................................................................................15

CONTENTS..............................................................................................................16

Section 1 Overview

1-1 Overview................................................................................................................................. 1-2

1-2 Features.................................................................................................................................. 1-3

1-3 Model Number Legend..........................................................................................................1-6

1-4 Insulation Resistance Measurement and Monitoring System........................................... 1-7

1-5 Nomenclature and Functions ............................................................................................... 1-8

1-6 Internal Block Diagram .......................................................................................................1-14

1-7 System Configurations ....................................................................................................... 1-16

1-8 Safety Precautions .............................................................................................................. 1-18

Section 2 Procedure

2-1 Procedure............................................................................................................................... 2-2

(1) Advance Preparation........................................................................................................................... 2-2

(2) Installation and Wiring.........................................................................................................................2-3

(3) Initial Setting........................................................................................................................................2-5

(4) Test Operation with Manual Measurement ......................................................................................... 2-7

(5) Starting Operation ............................................................................................................................... 2-8

Troubleshooting......................................................................................................................................2-10

16

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 19

Section 3 Installation and Wiring

3-1 Dimensions ............................................................................................................................ 3-2

3-2 Installation.............................................................................................................................. 3-3

3-3 Setting the Channel Number ................................................................................................ 3-6

3-4 How to Connect to the Push-In Plus Terminal Blocks ....................................................... 3-7

3-5 I/O Wiring.............................................................................................................................. 3-10

3-6 Wiring the Communications Cable .................................................................................... 3-13

3-7 Setting the Unit Number ..................................................................................................... 3-14

3-8 Connecting to a Load or Contactor ................................................................................... 3-15

Section 4 Functions Related to Measurement

4-1 Automatic Measurement....................................................................................................... 4-2

4-1-1 Trigger Input ............................................................................................................................... 4-2

4-1-2 Measurement Steps.................................................................................................................... 4-4

4-1-3 Measurement Step Indicator Operation ...................................................................................... 4-6

4-1-4 Timing Charts ............................................................................................................................. 4-8

4-1-5 Measurement Value Display Automatic Scroll.......................................................................... 4-16

4-2 Manual Measurement .......................................................................................................... 4-17

4-3 Measuring Range and Measuring Accuracy ..................................................................... 4-21

4-4 Voltage Monitoring .............................................................................................................. 4-22

4-5 Current Limiter..................................................................................................................... 4-23

4-6 Reset Key ............................................................................................................................. 4-25

4-7 System Error ........................................................................................................................ 4-26

4-8 Running Time....................................................................................................................... 4-27

4-9 Calculating the Measuring Time Using the Elapsed Time ............................................... 4-28

Section 5 Using Setting Parameters

5-1 Levels ..................................................................................................................................... 5-2

5-2 Setting Parameters and Setting Values............................................................................... 5-4

5-3 Maximum Number of Channels............................................................................................ 5-6

5-4 Alarm Values 1 and 2............................................................................................................. 5-9

5-5 Alarm Polarity ...................................................................................................................... 5-11

5-6 Trigger Signal Reverse........................................................................................................ 5-13

5-7 Motor Stop Waiting Time .................................................................................................... 5-15

5-8 Time to Wait to Stabilize...................................................................................................... 5-17

5-9 Average Processing ............................................................................................................ 5-19

5-10 Use Running Time ............................................................................................................... 5-21

5-11 Software Version ................................................................................................................. 5-23

5-12 Setting Change Protection ................................................................................................. 5-24

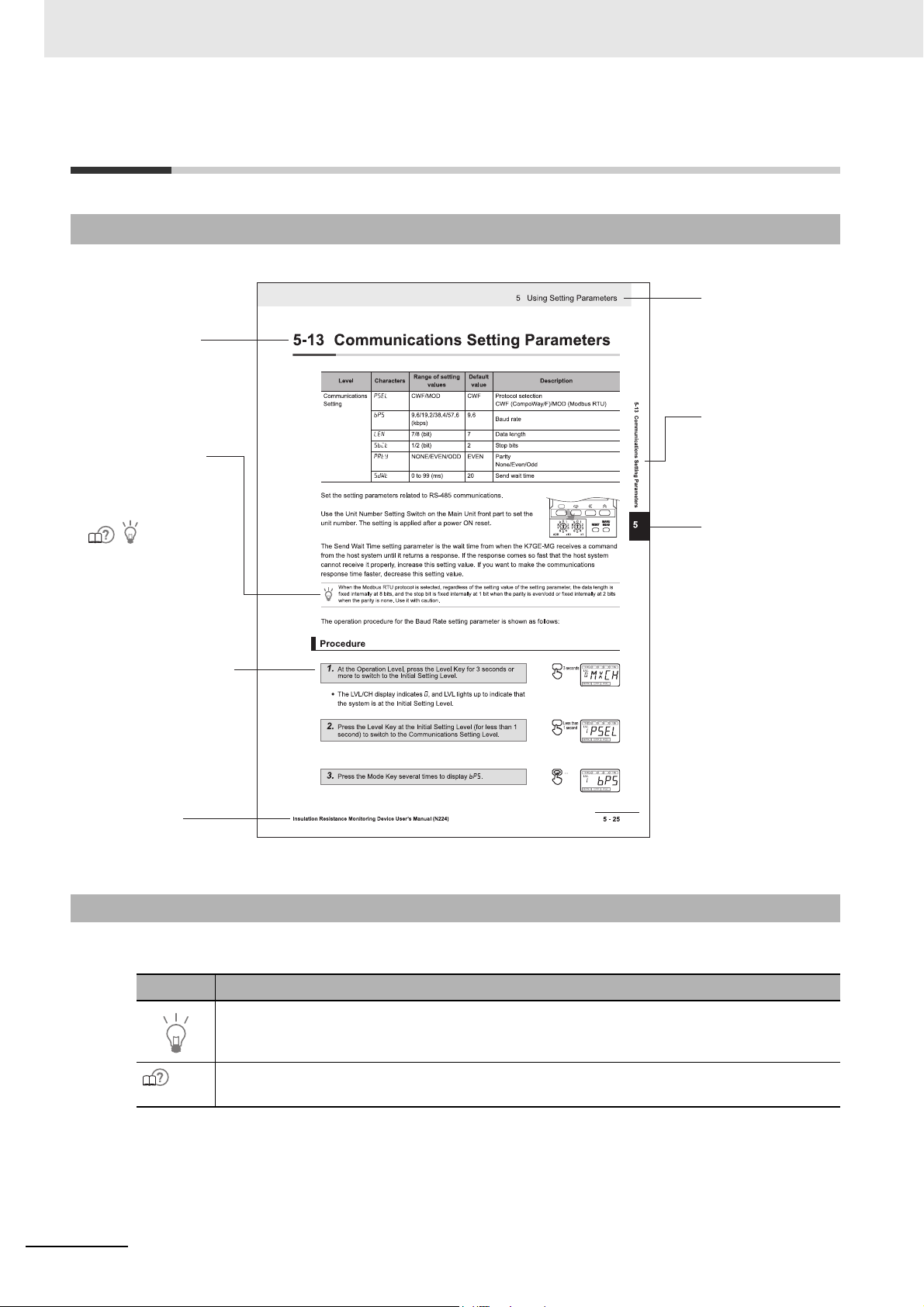

5-13 Communications Setting Parameters................................................................................ 5-26

Insulation Resistance Monitoring Device User’s Manual (N224)

17

Page 20

Section 6 Remote Monitoring

6-1 Remote Monitoring................................................................................................................ 6-2

6-2 Communications Overview .................................................................................................. 6-3

6-3 Variable Area Map.................................................................................................................. 6-5

6-4 Monitoring (Reading) Measurement Values........................................................................ 6-8

6-5 Operation Command ............................................................................................................. 6-9

6-6 Checking (Reading) Setting Parameters ........................................................................... 6-12

6-7 Changing (Writing) Setting Parameters............................................................................. 6-13

6-8 CompoWay/F Communications Format ............................................................................ 6-14

6-8-1 Frame Configurations................................................................................................................6-14

6-8-2 Read Variable Area Command .................................................................................................6-17

6-8-3 Write Variable Area Command..................................................................................................6-18

6-8-4 Operation Command................................................................................................................. 6-20

6-9 Modbus RTU Communications Format ............................................................................. 6-22

6-9-1 Frame Configurations................................................................................................................6-22

6-9-2 Read Variable Area Command .................................................................................................6-25

6-9-3 Write Variable Area Command..................................................................................................6-26

6-9-4 Operation Command................................................................................................................. 6-27

Section 7 Troubleshooting

7-1 Troubleshooting .................................................................................................................... 7-2

Appendices

A-1 Specifications ........................................................................................................................A-2

Ratings and Specifications .......................................................................................................................A-2

Measurement Specifications.....................................................................................................................A-3

Input Specifications of Trigger Input Terminals ........................................................................................A-3

Output Specifications of Transistor Output Terminals ..............................................................................A-4

Input Specifications of Voltage Input Terminals........................................................................................A-4

Communications Specifications................................................................................................................A-5

A-2 Setting Parameters List ........................................................................................................A-6

A-3 Setting Parameter Flow.........................................................................................................A-7

A-4 K7GE-MG Logging Tool ........................................................................................................A-8

Index

18

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 21

Overview

This section describes the features, model number legend, nomenclature and

functions, system configuration, and safety precautions of the K7GE-MG.

1-1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1-3 Model Number Legend . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

1-4 Insulation Resistance Measurement and Monitoring System . . . . . . . . . . 1-7

1-5 Nomenclature and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

1-6 Internal Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

1-7 System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

1-8 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

1

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 1

Page 22

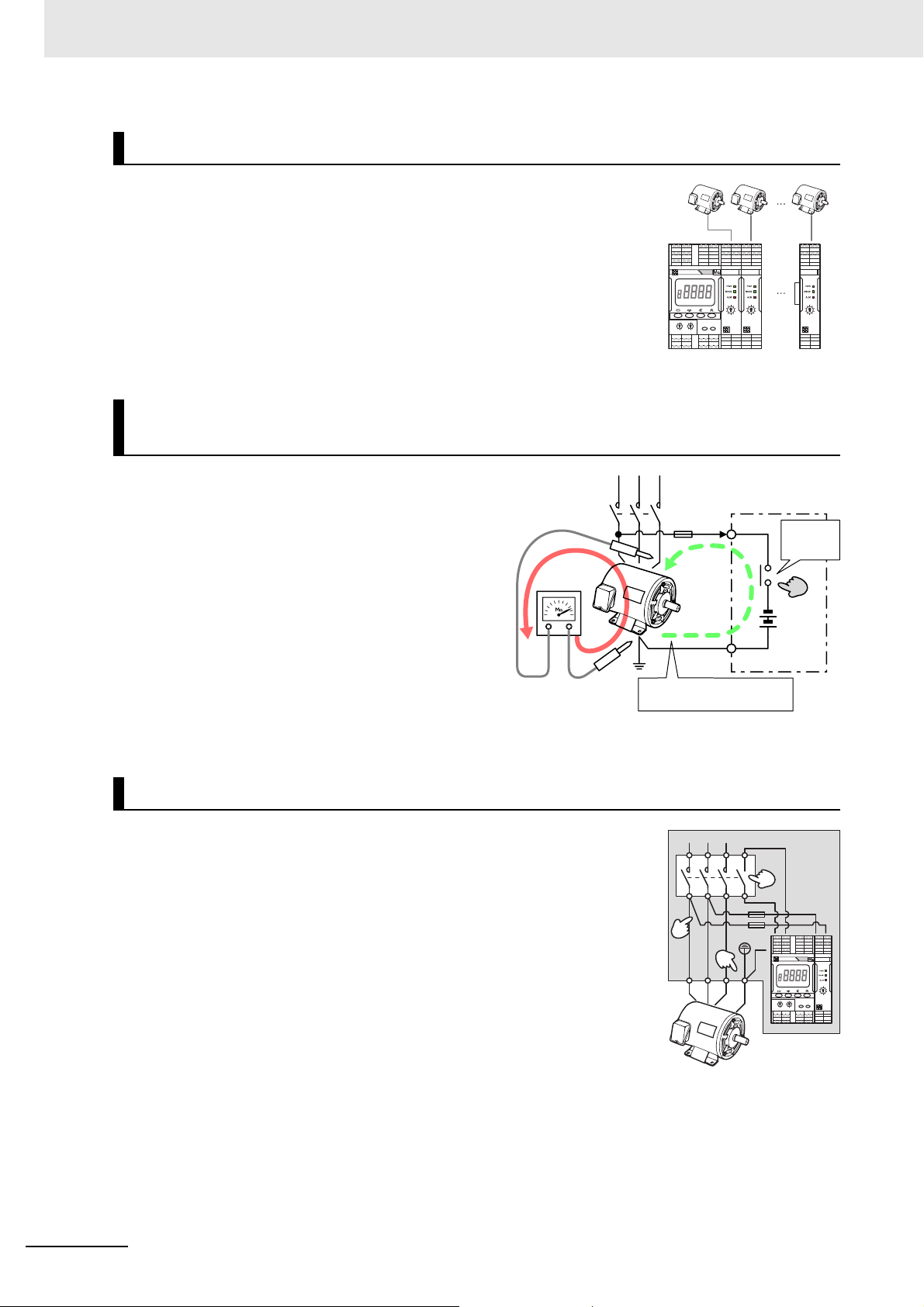

1 Overview

Probe Unit

K7GE-MG1

Main Unit

K7GE-MGM

Probe Unit Probe Unit Probe Unit

Main Unit

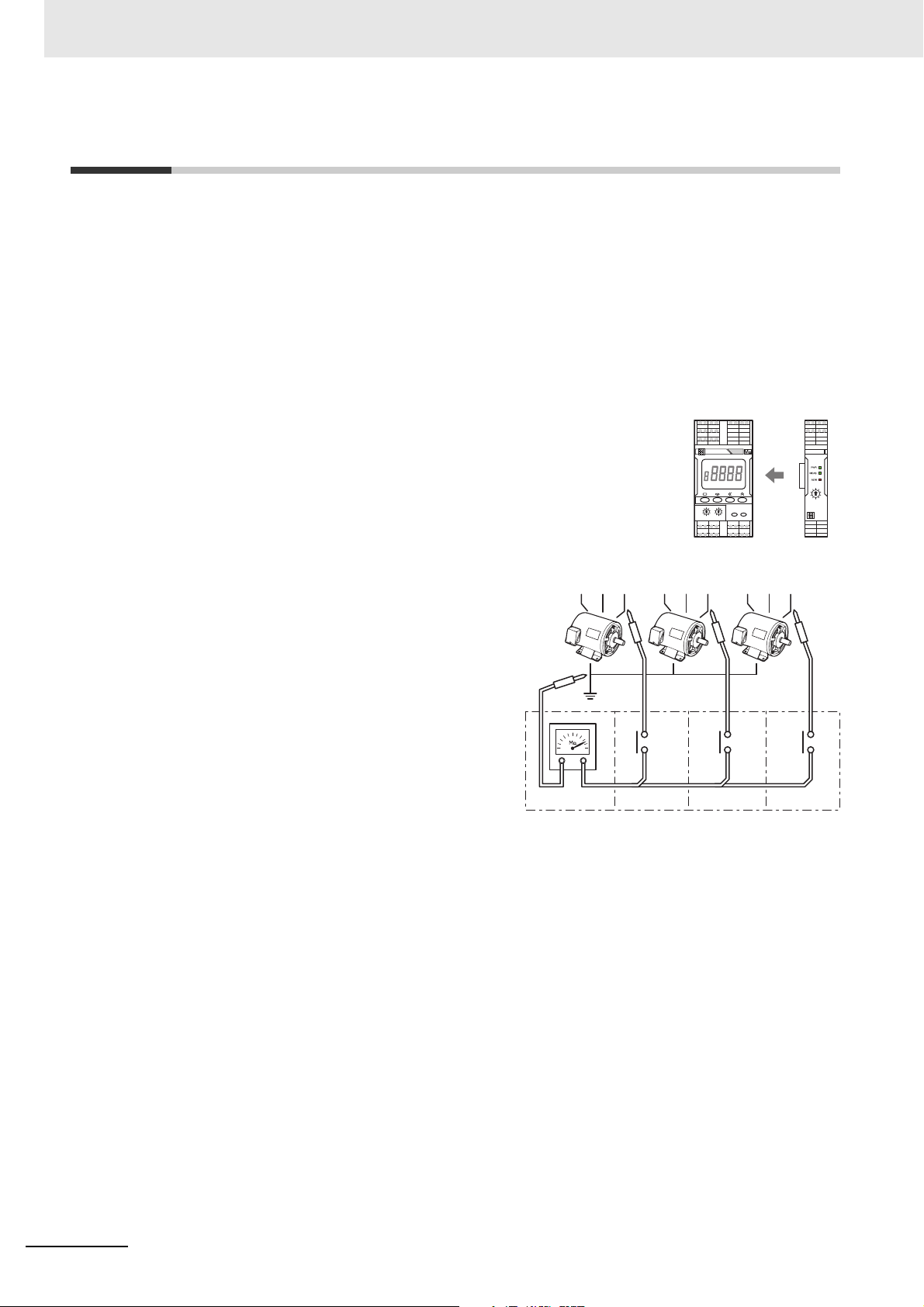

1-1 Overview

The K7GE-MG is a device that automatically measures the insulation resistance of a load and supports

trend monitoring.

Periodic inspections by manpower may cause a unexpected machine stoppage due to a decrease in

insulation resistance of equipment before the next inspection. The K7GE-MG provides automatic

monitoring of the insulation resistance of each load and allows planned maintenance.

The K7GE-MG measures the insulation resistance by the same detection principle (Megger method) as

a Megohmmeter.

To measure the insulation resistance using the K7GE-MG, it is necessary to

combine one Main Unit with at least one Probe Unit.

The functions of the Main Unit and Probe Unit are

shown in the figure on the right.

The Main Unit corresponds to a Megohmmeter,

and the Probe Unit corresponds to a

measurement probe with internal contacts. The

Main Unit turns ON these contacts in sequence

and measure multiple loads individually.

Up to eight Probe Units can be connected to one

Main Unit.

K7GE-MG supports a motor as a measurement load. If you want to measure other loads such as a

heater or transformer, carefully study the operating specifications of the K7GE-MG before use.

1 - 2

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 23

1-2 Features

Note The above diagram shows only the parts of the internal circuit of the K7GE-MG that are

necessary for explanation.

The following features make the K7GE-MG convenient and safe to use.

Uses the Same Detection Principle as a Megohmmeter

1 Overview

1-2 Features

The K7GE-MG measures the insulation

resistance by the same detection principle

Megger method

(Megger method) as a Megohmmeter. Therefore,

the inspection data of the Megohmmeter can be

used, and the smooth introduction of this system

is possible.

Megohmmeter

K7GE-MG

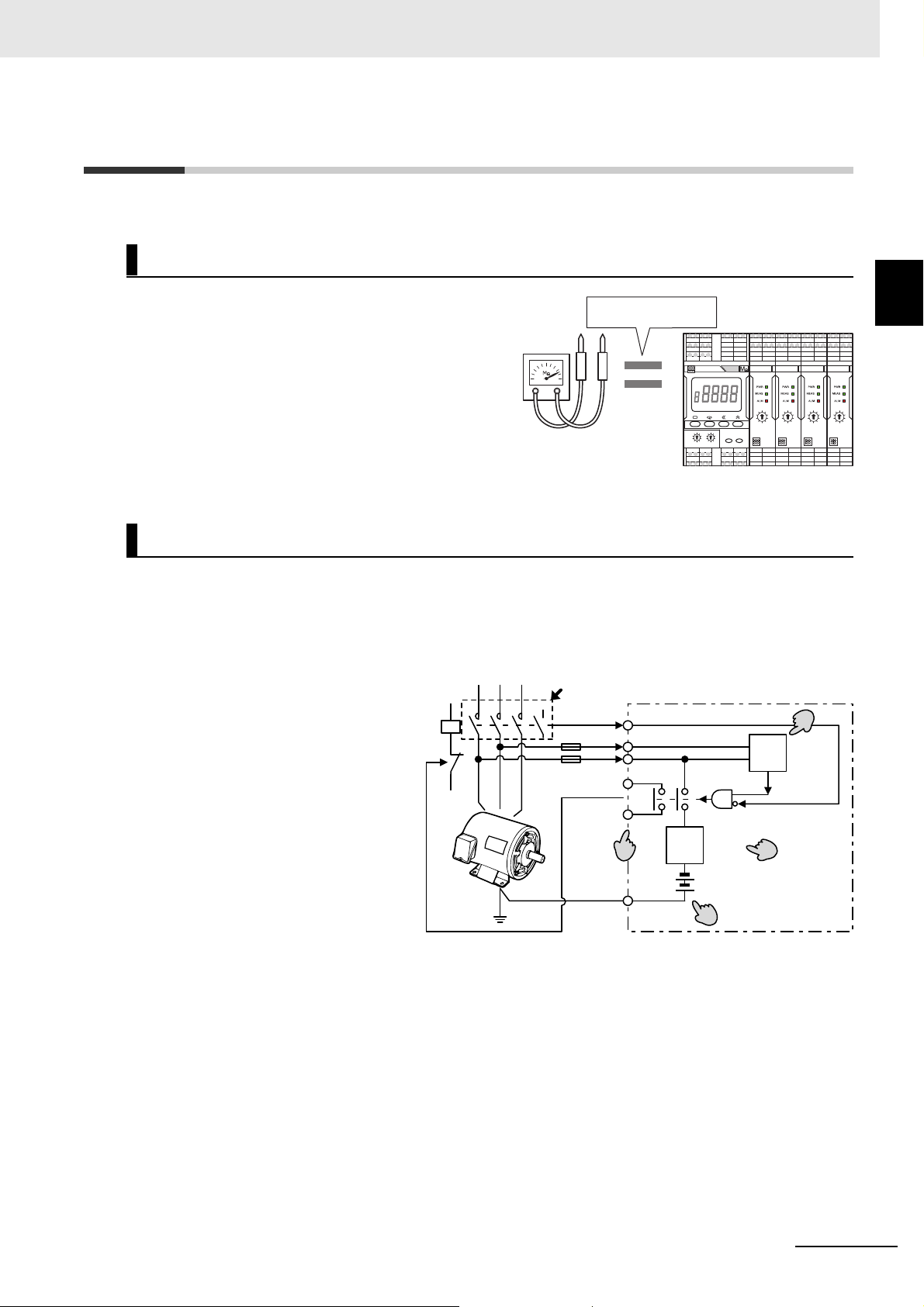

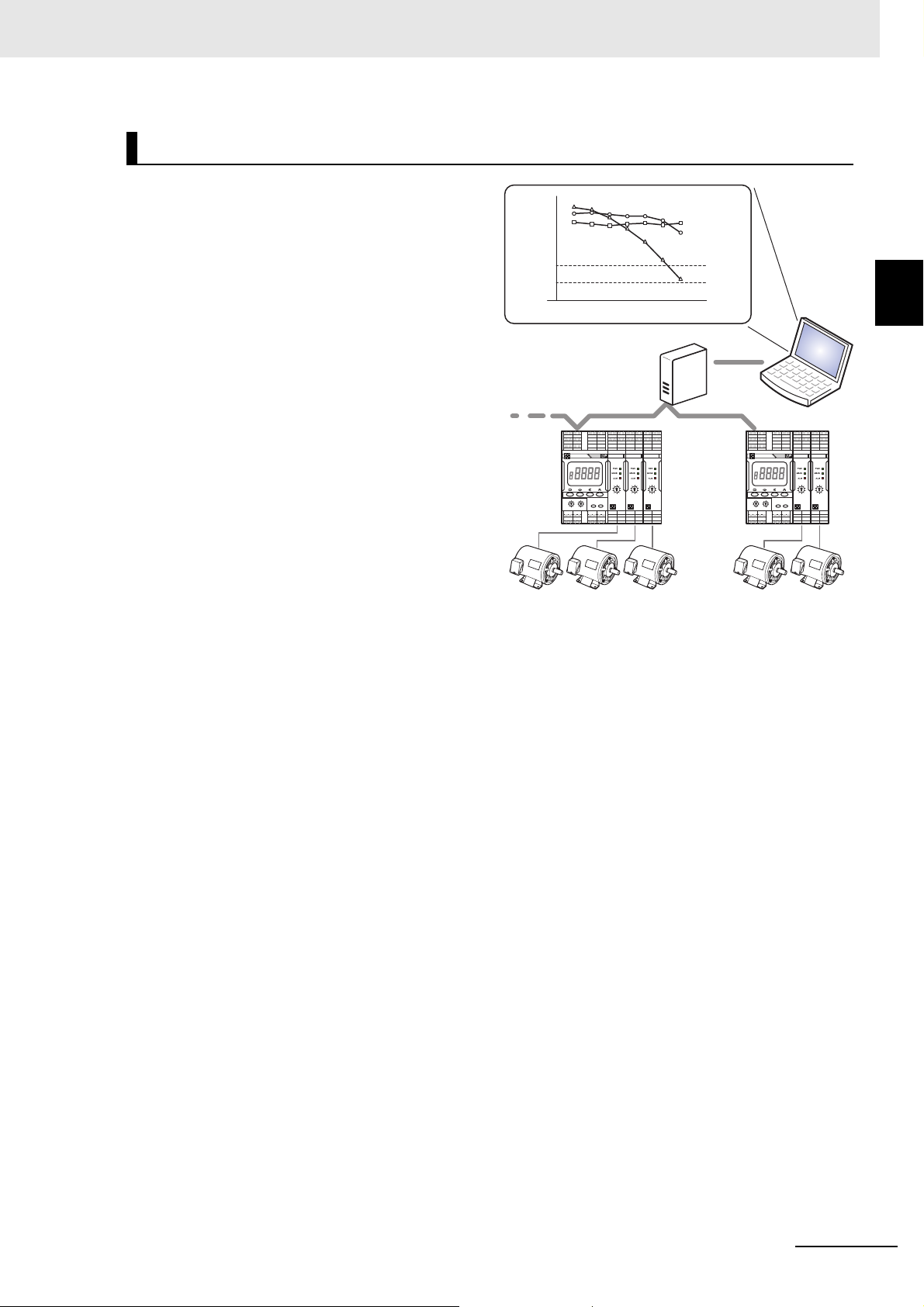

More Support for the Safety Functions

• The K7GE-MG is always monitoring the OFF state of the loads and the power line. K7GE-MG does

not start measurement even if it receives a measurement start signal during load operation. In

addition, K7GE-MG will stop the measurement immediately if the load restarts during the

measurement.

• In addition, the K7GE-MG is

equipped with an overcurrent

limit circuit.

This limits the following

overcurrents to safe levels:

- Instantaneous overcurrent

that flows when the load is

restarted during

measurement.

- Overcurrent that flows when

the insulation resistance

value is extremely low.

MC MC-a

Interlock

Turn OFF

Auxiliary

OFF

contact

L2

L3

Status output

during

measurement

PE

K7GE-MG

Current

limiter

Megger voltage

(50 VDC)

Voltage

monitoring

Overcurrent

prevention

Disconnection

(turn OFF)

monitoring

Disconnection

(turn OFF) OK

Start measurement

1

• To reduce equipment damage

and prevent electric shock, the

K7GE-MG has a low Megger

voltage of 50 VDC*.

* Even if the Megger voltage is 50 VDC, it does not affect the measurement accuracy.

• The K7GE-MG provides a contact output that indicates that measurement is in progress. You can

design an interlock circuit that prevents the load from restarting during the measurement.

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 3

Page 24

1 Overview

K7GE-MG

8 Units max.

Note The above diagram shows only the parts of the internal

circuit of the K7GE-MG that are necessary for explanation.

MC

L3

PE

K7GE-MG

Contact OFF

except during

measurement

Megohmmeter

Measurement current of the

Megohmmeter does not flow

Control

panel

PE

PE

L3

L2

Trigger

input

MC

MC-a

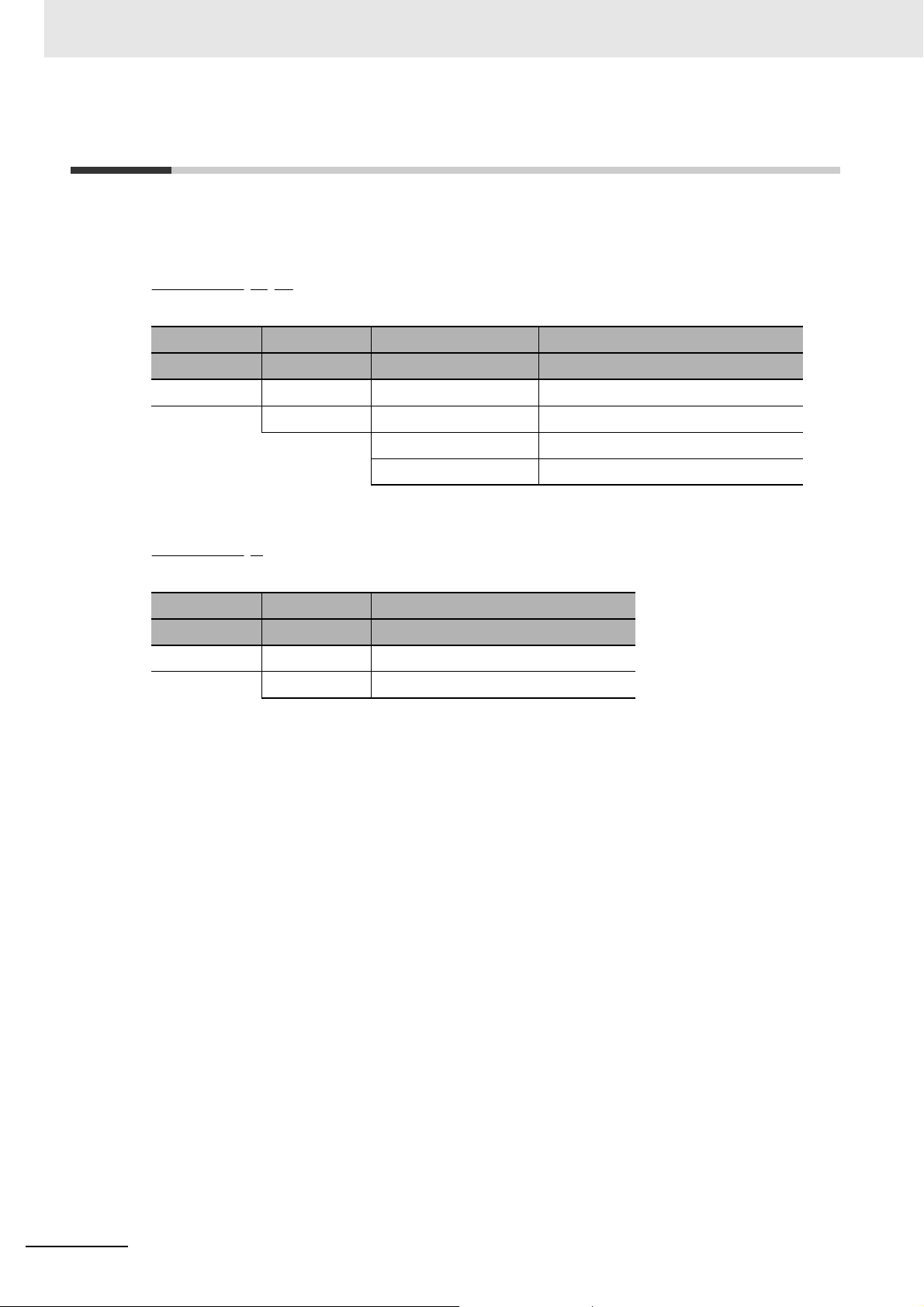

Supports Multiple Channel Measurement

K7GE-MG can be measured up to eight channels per Main Unit by adding

more Probe Units. This reduces cost and installation space per channel.

Periodic Inspection by a Megohmmeter Is Possible with the

K7GE-MG Installed

The K7GE-MG is cut off from the load by the

internal dry contact except during measurement.

This allows inspection using a Megohmmeter

without disconnecting the wiring.

Easy Retrofitting to the Equipment

• The signal wire of the K7GE-MG can be connected in parallel with the

secondary output terminal of the contactor and the PE terminal of the

load. Therefore, it is not necessary to perform large-scale wiring again.

• If you connect the auxiliary contact of the contactor to the trigger input

terminal of the K7GE-MG, you can use it as a measurement start signal. It

contributes to the reduction of parts because no additional sequence is

required.

1 - 4

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 25

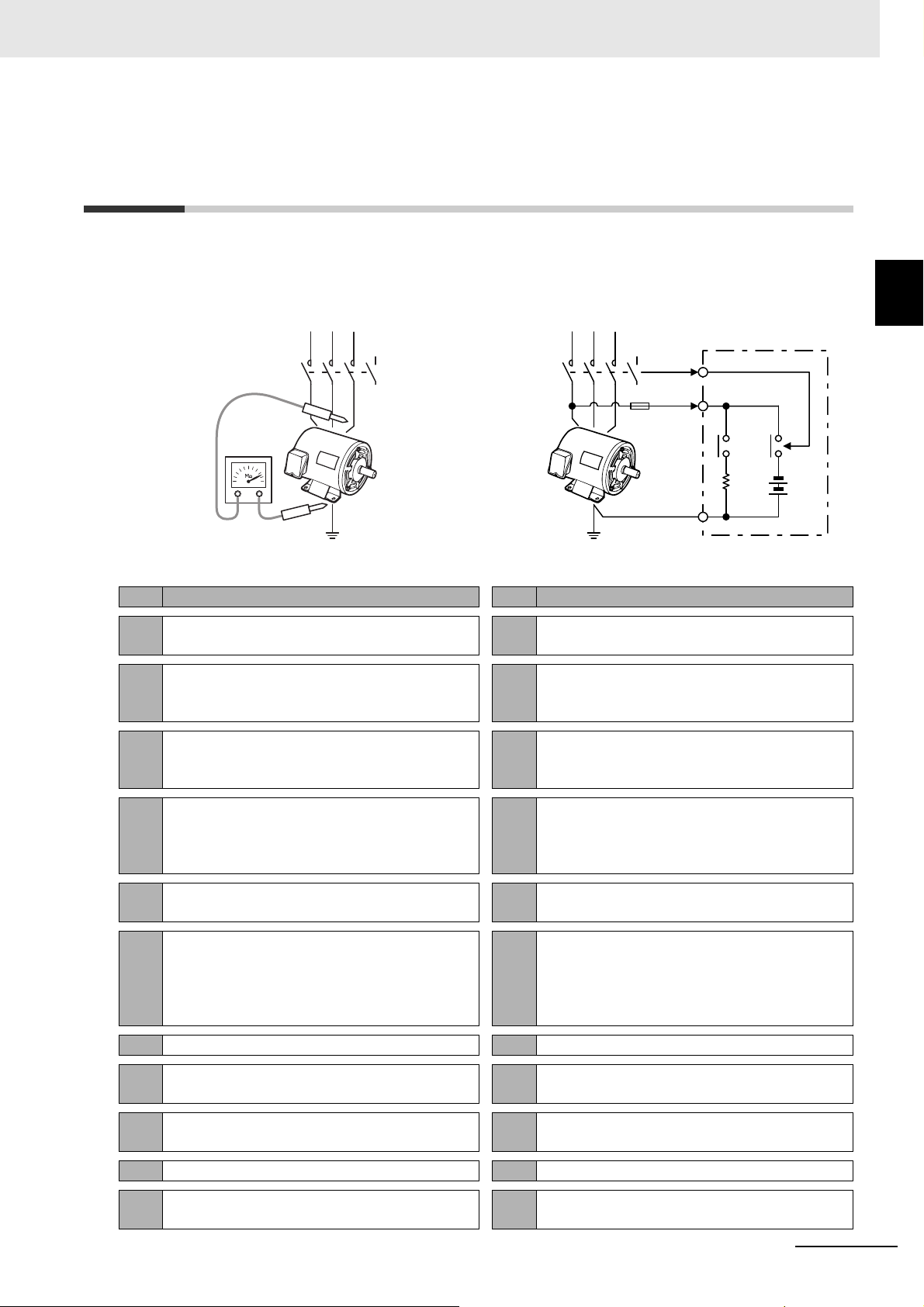

Enables Remote Trend Monitoring

• K7GE-MG automatically collects the measured

values of loads with the communications

function. You can monitor the equipment from a

remote location. Remote monitoring greatly

reduces the man-hours required to measure

and collect data with the Megohmmeter while

patrolling FA systems and facilities.

Measurement

value

Alarm value 1

Alarm value 2

'xx/ 1 2 3 4 5 6 7 Year/Month

Communications converter

Load 1

Load 2

Load 3

1 Overview

PC

1-2 Features

1

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 5

Page 26

1 Overview

K7GE-MG M

□

(1) (2) (3)

K7GE-MG 1

(1) (2)

1-3 Model Number Legend

This section shows the model number legend of the K7GE-MG Main Unit and Probe Units.

• Main Unit

(1) (2) (3) Meaning

Base model Unit type Power supply voltage

K7GE-MG Insulation Resistance Monitoring Device

M Main Unit

A 100 to 240 VAC power supply

D 24 VAC/VDC power supply

• Probe Unit

(1) (2) Meaning

Base model Unit type

K7GE-MG Insulation Resistance Monitoring Device

1 Probe Unit

Refer to A-1 Specifications on page A-2 for the specifications of each model.

1 - 6

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 27

1 Overview

Note The above diagram shows only the parts of the internal

circuit of the K7GE-MG that are necessary for explanation.

1-4 Insulation Resistance Measurement

and Monitoring System

K7GE-MG is automated according to the procedure of manual measurement and monitoring by

Megohmmeter.

The flowchart of measurement and monitoring of K7GE-MG is shown below together with manual

measurement by Megohmmeter.

MC

MC-a

MC

MC-a

Auxiliary

contact

OFF

K7GE-MG

L3

Start measurement

Discharge

of electric

charge

Apply

Megger

voltage

surement and Monitoring System

1-4 Insulation Resistance Mea-

1

PE

Megohmmeter

Step Manual measurement by the Megohmmeter Step Automatic measurement by the K7GE-MG

0

Load operation in progress

Turn OFF the contactor and disconnect the loads from

1

the power line

Waits until the auxiliary contact turns OFF (trigger

0

signal ON)

Trigger signal ON with the contactor OFF

→ Measurement operation starts when the trigger

1

signal is ON

Waits for the loads to stop completely

2

Wait for the loads to stop completely (visual)

(automatic standby based on setting parameters,

2

default value: 10 s)

Wait for the discharge of electric charge accumulated

in the wiring

3

(Decide the time through experience or residual

voltage measurement)

4

Place the probe on the load and apply Megger voltage

Performs forced discharge of electric charge by the

built-in resistor of the K7GE-MG

3

(Waits for 20 s while limiting the peak value of the

discharge current to 1 mA max.)

Internal contact of the Probe Unit turns ON, and

4

application of the Megger voltage starts

Applies Megger voltage until the measurement value

Wait for the measurement value to stabilize (charging

5

time to the wiring capacity)

stabilizes

(Continues the measurement for the time set in the

5

Time to Wait to Stabilize setting parameter, default

value: 60 s)

6

Read the insulation resistance value

7

Remove the probe from the load

Determine if the measurement value is normal or an

8

error

9

If there is more than one load, measure the next load

Record the measurement value and end the series of

10

operations

Insulation Resistance Monitoring Device User’s Manual (N224)

6

Measures the insulation resistance value

The contact of the Probe Unit turns OFF, and

7

application of the Megger voltage stops

Compares the set alarm value and measurement

8

value, and performs alarm output

9

If there is more than one load, measures the next load

Check the measurement value from the display on the

10

front part, or read and record it remotely

1 - 7

Page 28

1 Overview

(A)

(A)

(B)

(C)

(D)

(E)

(A)

(A)

(B)

(C)

Main Unit Probe Unit

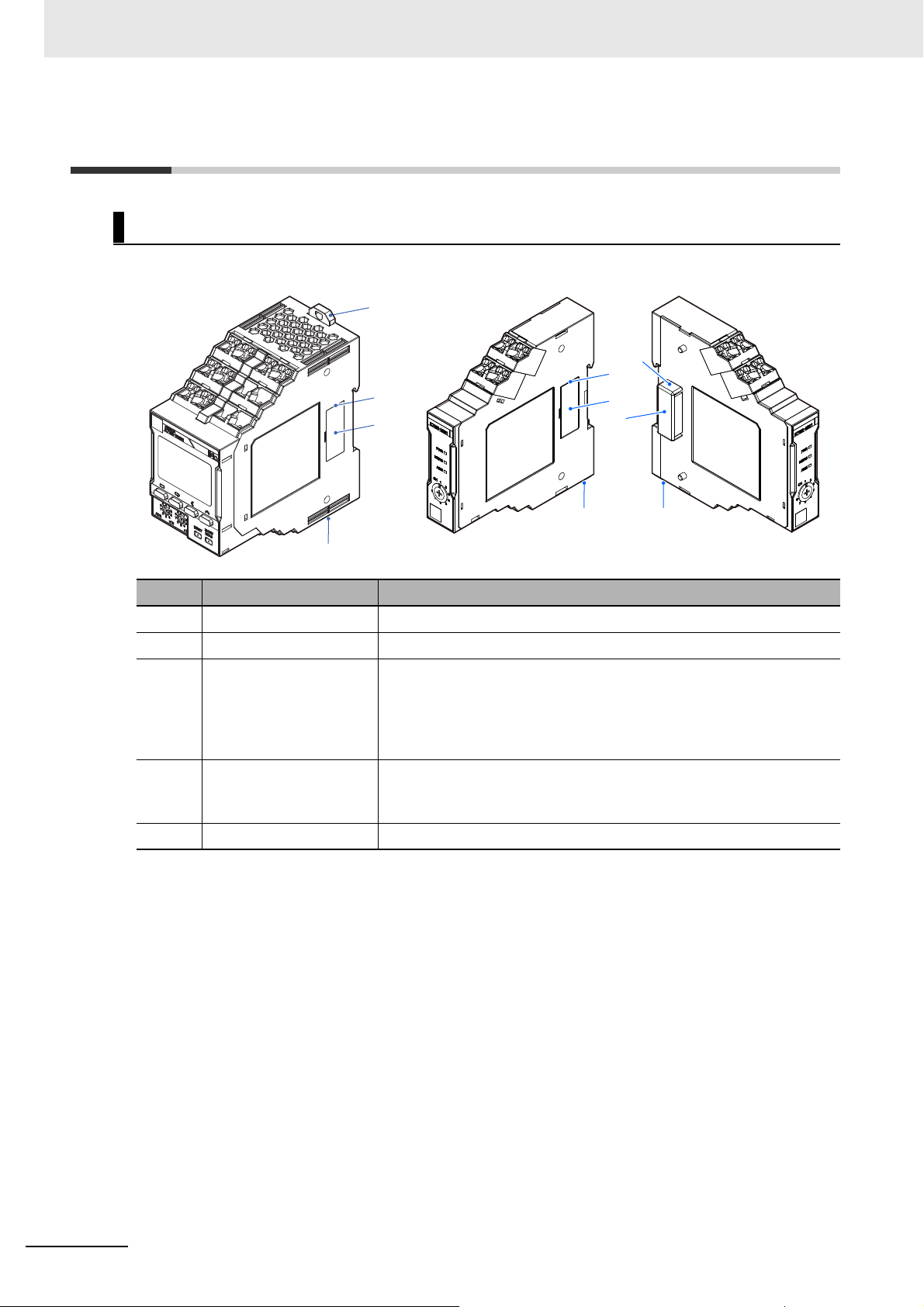

1-5 Nomenclature and Functions

Appearance

Symbol Name Operation

(A) DIN Track mounting hook Used for mounting to the DIN Track.

(B) Right connector Connects the Probe Unit.

(C) Right connector cover A cover for preventing the entry of dust and dirt into the connectors.

Remove this cover when combining the Main Unit and Probe Units, and

during expansion of Probe Units.

However, use the Probe Unit on the extreme right without removing this

connector cover.

(D) Left connector cover A cover for preventing the entry of dust and dirt into the connectors.

Remove this cover when combining the Main Unit and Probe Units, and

during expansion of Probe Units.

(E) Left connector Connects to the Right connector.

1 - 8

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 29

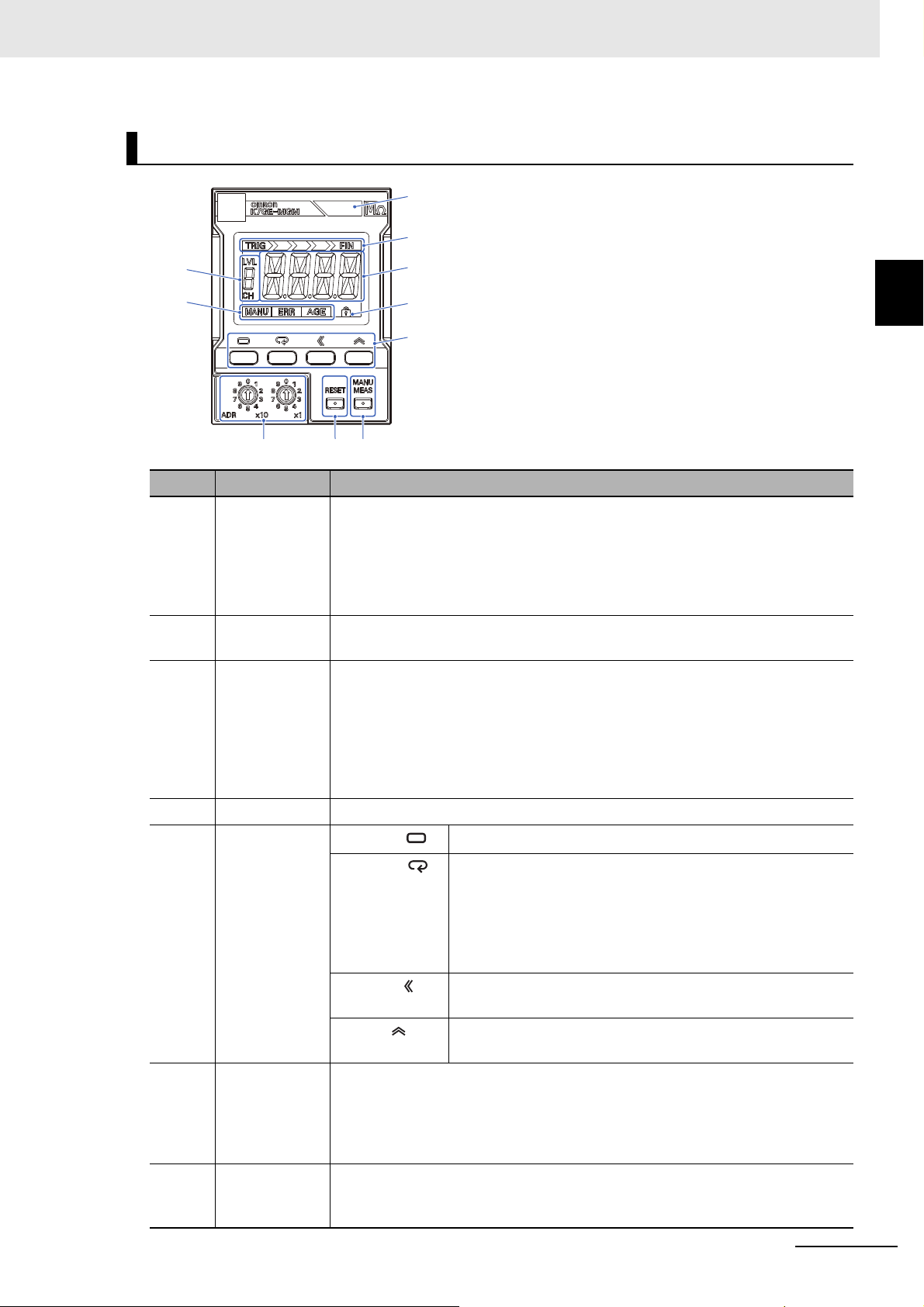

Front Section: Main Unit

(A)

(B)

(C)

(D)

(E)

(F)(G)(H)

(I)

(J)

Symbol Name Operation

(A) Alarm output

indicator

Displays the alarm judgment results of automatic measurement in three colors.

Green: Normal

Yellow: Warning (Alarm 1 occurrence)

Red: Critical (Alarm 2 occurrence)

If the status is different across multiple channels, the display color is decided in the

priority order of red (critical) > yellow (warning) > green (normal).

1 Overview

1-5 Nomenclature and Func-

tions

1

(B) Measurement

step indicator

The automatic measurement operation consists of several steps. This indicator

shows the progress of the step from the start to the end of the measurement.

(C) Main display The following contents are displayed in the operating status of the Main Unit.

Measuring operation: The remaining seconds until the measurement

completes are counted down

After measurement completed: The insulation resistance measurement value, or

characters indicating measurement failure

Setting level: The setting parameter name, or setting value

Error occurs: The characters indicating the error status

(D) Protect indicator Indicates that the protect function of the setting parameter is set.

(E) Operation keys

Level Key ( )

Mode Key ( )

Selects the setting level.

Selects the setting parameter of the Initial Setting Level and

Communications Setting Level.

Displays the measurement value of each channel at the

Operation Level. Also used to select between

enabling/disabling of measurement value display automatic

scroll.

Shift Key ( )

Sets the parameter value to a changeable state. Used for digit

shift in the changeable state.

Up Key ( )

(F) Manual

Measurement

Key

Selects to start or end manual measurement. Manual measurement is used to

check the operation when the system is started up. Automatic measurement

requires a trigger signal to start measurement, but manual measurement does not

require a trigger signal. You can use manual measurement in the same way as a

Megohmmeter.

Increments the value when the parameter is in a changeable

state.

(G) Reset Key Selects to return to the power reset status. Even if the measuring operation is in

progress, priority is given to the Reset Key, and measurement stops to return to the

power reset status. The Reset Key is enabled only in the Operation Level.

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 9

Page 30

1 Overview

Symbol Name Operation

(H) Unit Number

(I) Status display MANU Indicates the manual measurement state.

(J) LVL/CH display Displays the level*, or the value of the channel number.

* Refer to 5-1 Levels on page 5-2 for information on the levels.

Sets to set the unit number during communications.

Setting Switch

ERR Indicates that a system error occurred.

AGE Indicates that it is time to replace the Main Unit (guideline).

LVL Indicates that the value displayed in the LVL/CH display is the

"Level".

CH Indicates that the value displayed in the LVL/CH display is the

"Channel".

1 - 10

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 31

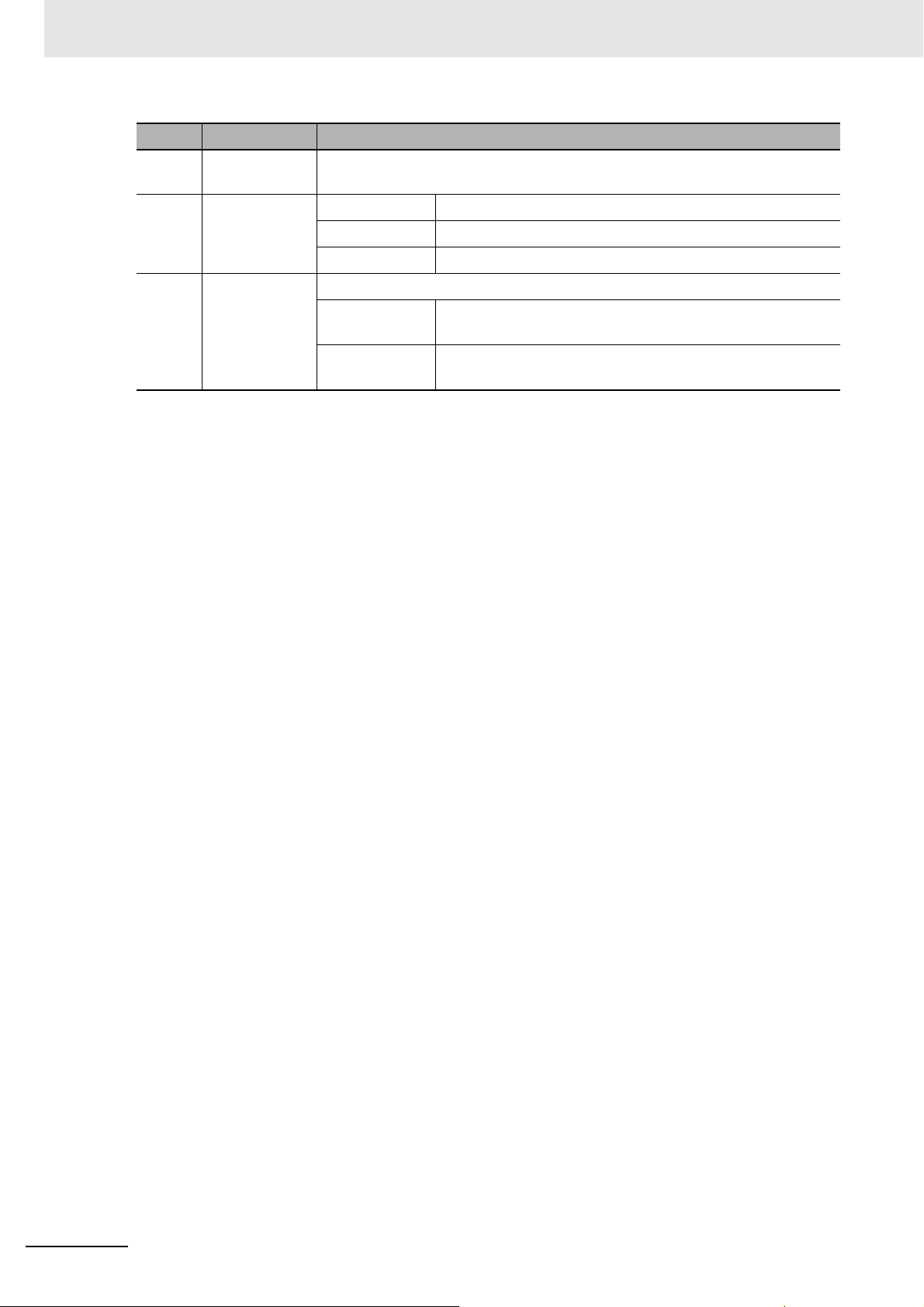

1 Overview

(A)

(B)

(C)

(D)

1-5 Nomenclature and Func-

Front Section: Probe Unit

tions

1

Symbol Name Operation

(A) PWR indicator (green) Indicates that the Probe Unit power is ON.

(B) MEAS indicator (green) Indicates that measurement is in progress for the load connected to

the Probe Unit.

(C) ALM indicator (red) Indicates that an alarm occurred in the load connected to the Probe

Unit.

(D) Channel Number Setting

Switch

Sets a unique channel number for each Unit when multiple Probe

Units are added.

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 11

Page 32

1 Overview

(A)

(E)

(D)

(B)

(C)

(H)

(I)

(F)

(G)

Terminal Section: Main Unit

Symbol

(A) 1 and 2 Operation

Terminal

Number

Name Operation

Connect the operation power supply to the Main Unit.

power supply

(B) 3 and 4 Trigger input Input terminals of the external contact from where a trigger signal is

applied.

No. 3: Collector of the NPN transistor, No. 4: Emitter of the NPN transistor

(C) 5 and 6 RS-485 Connect the RS-485 communications line.

No. 5: +, No. 6: -

(D) 7 PE A protective earthing terminal.

(E) NC NC Do not connect anything to this terminal.

(F) 13 and 14 ALM 1 output Compares the measurement value and alarm value 1, and outputs an

alarm.

No. 13: Collector of the NPN transistor, No. 14: Emitter of the NPN

transistor

(G) 15 and 16 ALM 2 output Compares the measurement value and alarm value 2, and outputs an

alarm.

No. 15: Collector of the NPN transistor, No. 16: Emitter of the NPN

(H) 17 and 18 Status output

during

measurement

transistor

Provides notification that measurement is in progress. The output is

normally open (OFF) You can use this output to design an interlock circuit

to prevent accidental restart of the load during measurement operation.

No. 17: Collector of the NPN transistor, No. 18: Emitter of the NPN

transistor

(I) 19 and 20 Self-diagnosis

error output

Provides notification about system error in the Main Unit. The output is

normally closed (ON).

No. 19: Collector of the NPN transistor, No. 20: Emitter of the NPN

transistor

1 - 12

Perform the wiring according to Section 3 Installation and Wiring.

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 33

Terminal Section: Probe Unit

(A)

(B)

1 Overview

1-5 Nomenclature and Func-

tions

1

Symbol

Terminal

Number

Name Operation

(A) 1 and 3 Voltage input Connect the load terminals.

No. 1: Connect the R-phase in a 3-phase system, and the

L-phase in a single-phase system

No. 3: Connect the S-phase in a 3-phase system, and the

N-phase in a single-phase system

Use the terminal No. 1 to discharge the electric charge

and apply the Megger voltage.

(B) NC NC Do not connect anything to this terminal.

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 13

Page 34

1 Overview

1-6 Internal Block Diagram

This is an internal block diagram of the state when the Main Unit and the Probe Units are connected.

The following describes the main configuration elements.

RS-485

ALM 1 and ALM 2

outputs

Self-diagnosis

error output

Status output during

measurement

Display

switch

RS-485

driver

Trigger

input

Microcomputer

Measurement

Megger

voltage

Current

limiter

Power supply

MC

M

Probe Unit 1Main Unit

Discharge

of electric

charge

PE

MGR

I/O Bus

MC-a

Megger

Apply

voltage

L3PE

L2

Voltage

monitoring

Probe

Unit

control

MC

M

Display

switch

Probe Unit 2

...

Trigger Input

Connect an external contact, and then starts the measurement operation by a signal from this

contact.

When the auxiliary contact of a contactor is connected to a trigger input terminal as an external

contact, the measurement operation can be started at the time the contactor is turned OFF, that is,

when the load is turned OFF from the power line.

Voltage Monitoring

The voltage in the load lines is monitored to determine whether the load is turned ON or turned OFF.

This monitoring is performed at all times, and even when the measurement start signal is input, the

measurement operation does not start if the load is turned ON. Also, even if measurement is

progressing normally, it immediately stops if the load is turned ON during the measurement.

Discharge of Electric Charge

A parasitic capacitance component due to the wiring is present between the charged sections of the

load and the PE. Therefore, even if the contactor is turned OFF, the electric charge accumulated in

the parasitic capacitance component is not discharged immediately. It would take several minutes

for the electric charge to be discharged naturally, so this circuit forcibly discharges the charge. In the

case of a simple short circuit, excessive short-circuit current flows instantaneously, and therefore, by

having a resistance component, the current can be limited to a level where it does not cause any

problem. This processing for the discharge of electric charge is performed before the application of

a Megger voltage.

1 - 14

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 35

1 Overview

Megger Voltage

Generates a voltage of 50 VDC.

Apply Megger Voltage

Turns ON the internal contact and applies Megger voltage to the load.

Measurement

Measures the current flowing through the insulation resistance. Since Megger voltage is a known

value, the insulation resistance value can be calculated from the Megger voltage and the current

value.

Current Limiter

If the load is turned ON when applying a Megger voltage, it is detected by the voltage monitoring

circuit and the measurement operation stops. However, due to a slight time lag, excessive current

flows between the charged sections of the load and the PE at the moment the load is turned ON.

The same thing happens when the insulation resistance value is extremely low even if the load is

properly turned OFF. To protect the load and the peripheral equipment, as well as the internal circuit

of the K7GE-MG from such an overcurrent, the K7GE-MG is equipped with a current limiter circuit

which limits the overcurrent.

1-6 Internal Block Diagram

1

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 15

Page 36

1 Overview

MC

MC-a

Measurement start signal

L3

L2

PE

Status output during measurement

Alarm output

Interlock

Measurement

starts at auxiliary

contact OFF

MC

Alarm output

MC MC

MC-a

Measurement start signal

PE

Status output during

measurement

Interlock

Measurement

starts at auxiliary

contact OFF

1-7 System Configurations

Minimum Configuration

This is the minimum configuration for monitoring the insulation resistance using the K7GE-MG.

The auxiliary contact of the contactor inserted in

front of the load can be used as the measurement

start signal (trigger signal).

You can check the measurement value from the

display on the front part.

The alarm output can be used for external

notification. There are two alarm outputs, and by

setting a threshold value for each alarm output,

judgment can be performed in two stages.

The K7GE-MG has the "Status output during

measurement" terminal that is turned on during

measurement operation. This allows you to

design an interlock circuit that will not restart the

load during measurement operation.

Measurement of Multiple Channels

This configuration is used when monitoring multiple loads collectively.

Design a system configuration that simultaneously

turns ON and OFF the contactors installed on the

loads. The K7GE-MG performs sequential

measurement for one load at a time upon

receiving the measurement start signal (trigger

signal). However, a load that is turned ON at the

time of measurement is treated as "measurement

failed".

In an application such as a duplex alternating pump,

you can use the K7GE-MG by constructing a

sequence in which a trigger signal is input at the time

all loads (pumps) are simultaneously OFF (when

neither water supply nor draining is performed).

In cases where it is not possible to realize the timing

when all loads are simultaneously OFF, use two sets

of the K7GE-MG Main Unit + Probe Units.

1 - 16

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 37

1 Overview

Remote Monitoring by the PLC or PC

This configuration is used when performing remote monitoring of the measurement values with a PLC

or PC as the host.

1-7 System Configurations

When a PC is used as the host, you can

use the K7GE-MG by converting the

Communications

converter

RS-485 to USB or Ethernet using a

commercial communications converter.

The protocol is compatible with

CompoWay/F and Modbus RTU.

The K7GE-MG does not have a function to

retain the past measurement value data.

31 Node max.

500 m max.

RS-485

Also, data is lost when the power is turned

OFF. Therefore, read the measurement

values when the measurement ends and

before the next measurement starts, and

before the power of the Main Unit is turned

OFF.

To know the timing of measurement end, you can use status output during measurement in the K7GE-MG. Status output

during measurement turns ON when the measurement operation starts and turns OFF when measurement ends. This

change from ON to OFF is the timing when measurement ends.

You can also use the communications commands to read the flags synchronous with the status output during

measurement.

PC

1

PLC

Customization of HMI from the Touch Panel

This configuration is used when a touch panel is installed on the front panel to customize the HMI for

checking the measurement values and performing the alarm reset operation.

A connection is established with the touch panel

via the RS-485, and the touch panel is used as

the master.

The protocol is compatible with CompoWay/F and

Modbus RTU.

The K7GE-MG does not support the multi-master

system. Therefore, to further connect a host

system and perform remote monitoring, connect

the host system to the touch panel, and perform

operations such as reading the measurement

values or changing the setting parameters of the

K7GE-MG via the touch panel.

Refer to the manual of the touch panel in use for

details on communications between the host

system and the touch panel.

Touch panel

OMRON NB-series, etc.

USB or

Ethernet

PC

Ethernet

PLC

RS-485

Insulation Resistance Monitoring Device User’s Manual (N224)

1 - 17

Page 38

1 Overview

Incorrect Correct

M

Inverter

K7GE-MG

M

K7GE-MG

Inverter

Contactor

Incorrect Correct

1-8 Safety Precautions

Be sure to install the contactor in front of the load to be measured.

The K7GE-MG uses the same Megger method as a Megohmmeter for detecting insulation resistance.

The Megger method measures resistance values with a measuring circuit connected between the

charged section and the non-charged section. The charged section is usually connected to the power

line and insulated from the ground. Also, the non-charged section is a grounded section such as a

motor frame. The measurement circuit of K7GE-MG is connected between different insulated circuits.

Therefore, if the charged sections turn ON during measurement, it may result in a ground-fault

accident.

M

K7GE-MG

M

Contactor

K7GE-MG

Also, although the voltage is low, applying a Megger voltage to the output circuit of the secondary coil of

the inverter may cause an inverter failure.

1 - 18

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 39

Procedure

This section describes the procedure from preparation to startup of the K7GE-MG.

2-1 Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

(1) Advance Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

(2) Installation and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

(3) Initial Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

(4) Test Operation with Manual Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

(5) Starting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

2

Insulation Resistance Monitoring Device User’s Manual (N224)

2 - 1

Page 40

2 Procedure

MC MC MC

MC-a

PE

Measurement starts at

auxiliary contact OFF

Status output during

measurement

Alarm output

Measurement start signal

Interlock

!

2-1 Procedure

The procedure for starting actual operation is

shown using a system that measures three loads

as an example.

The procedure is described in the following five

steps.

Steps

(1) Advance Preparation

(2) Installation and Wiring

(3) Initial Setting

(4) Test Operation with Manual Measurement

(5) Starting Operation

The " No. **" in the following description is the

reference number in Troubleshooting at the end of

this section. Refer to the corresponding number

when the operation does not run normally even

after following the procedure.

(1) Advance Preparation

Examine the time until the load stops.

• Measure the time until the load stops after the contactor is turned

OFF. Use the setting value of the Motor Stop Waiting Time setting

parameter as a guide.

Use the value of the load that took the longest time from among the three

loads as a guide.

Use a Megohmmeter to measure the insulation resistance during

normal operation of the target load.

2 - 2

• This is the reference value for deciding the Alarm Value 1 and 2

setting parameters.

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 41

(2) Installation and Wiring

*Sold separately

Connect three Probe Units to one Main Unit.

• Remove the right connector cover of the Main Unit and the left

connector cover of the Probe Units.

Use the Probe Unit on the right end with the right connector cover

attached.

2 Procedure

2-1 Procedure

• Join the connectors together. Make sure that the connectors are

connected firmly without any gap between the Units.

Mounting to DIN Track.

• Pull down the DIN Track mounting hook under the Main Unit and

Probe Units to mount the Units on the DIN Track.

• Secure with the DIN Track mounting hook.

• Install an end plate* on the left and right sides.

Be sure to connect the Units together before mounting them on the DIN

Track.

End plate

2

End plate

DIN Track mounting hook

Insulation Resistance Monitoring Device User’s Manual (N224)

2 - 3

Page 42

2 Procedure

MC

MC-a

L3 L2 L3 L2 L3 L2

M

7

17 18

13 14 15 16

1

2

Main Unit

PE

Trigger

input

Operation

power supply

Status output during

measurement

ALM 1 ALM 2

17 18

1 3 1 33 4 1 3

M M

Probe Unit 1 Probe Unit 2 Probe Unit 3

Wire all connections.

• To be safe, always attach a

fuse (2 A max., fast-blow

type) in the wiring from the

Probe Unit to the load.

• The figure shows a

simplified view of the wiring

for status output during

measurement, and ALM 1

and ALM 2 outputs. Use a

suitable relay according to

the switching capacity of the

output transistor.

• The K7GE-MG provides an

output transistor with

specifications of 24 VDC

(+10%) and 50 mA max.

Supply the operation power from a system different from that of the load. If the same system is used, the power

supply to the K7GE-MG will turn OFF when the load contactor turns OFF, and you may not be able to perform

measurement.

2 - 4

Insulation Resistance Monitoring Device User’s Manual (N224)

Page 43

(3) Initial Setting

* This is reference number in Troubleshooting described at

the end. If the K7GE-MG does not operate properly after

performing the procedure, see the reference number.

Set the channel numbers of the Probe Units.

• Set the channel number of the first Probe Unit to 1 with the rotary

DIP switch on the front.

Observe that it is not a DIP switch on the Main Unit side.

2 Procedure

2-1 Procedure

• In the same way, set the channel number of the second Probe

Unit to 2 and that of the third Probe Unit to 3.

Always set the channel number to a serial number starting from 1.

The K7GE-MG will not operate properly if the channel numbers are not

set sequentially from 1 such as 2, 3 and 4 or 1, 2 and 4.

Turn ON the power supply to the Main Unit.

• The Operation Level is displayed immediately after the power is

turned ON.

---- indicates measurement standby.

Move to the Initial Setting Level.

• Press the Level Key for at least 3 seconds to move from the

Operation Level to the Initial Setting Level.

In the Initial Setting Level, LVL and 0 are displayed together on

the LVL/CH display.

No.1*

3 seconds

TRIG FIN

LVL

1

----

CH

MANU ERR AGE

TRIG FIN

LVL

0

mxch

MANU ERR AGE

2

Set the total number of channels.

The total number of channels is used to perform the processing in

the case of a measurement failure when the Main Unit can no

longer recognize the Probe Units due to a malfunction, etc.

• If the main display part does not display mxch, press the Mode

Key several times to display mxch.

• Press the Shift Key to display the setting value.

The setting value is displayed.

Insulation Resistance Monitoring Device User’s Manual (N224)

TRIG FIN

LVL

0

mxch

MANU ERR AGE

TRIG FIN

LVL

0

1

MANU ERR AGE

2 - 5

Page 44

2 Procedure

1

TRIG FIN

LVL

0

MANU ERR AGE

3

TRIG FIN

LVL

0

MANU ERR AGE

alm1

TRIG FIN

LVL

0

MANU ERR AGE

1 second

----

TRIG FIN

LVL

CH

1

MANU ERR AGE

• Press the Shift key again to change the setting value.

• Press the Up Key several times to set the setting value to 3.

• Press the Mode Key to define the changes.

Repeat the process to set the other parameters.

The digits that can be changed start flashing.

In this example, the total number of channels is set to 3

because three Probe Units are used.

The setting value is overwritten, and the next setting parameter

will be displayed.

Parameter name Characters Setting value Description

Alarm Value 1 alm1 xx.x (MΩ) If the measurement value dropped below the alarm

value, the alarm output indicator is lit yellow and ALM

1 (warning) will be output. One alarm value 1 is

provided in common for all channels.

Alarm Value 2 alm2 xx.x (MΩ) If the measurement value dropped below the alarm

value, the alarm output indicator is lit red and ALM 2

(critical) will be output. One alarm value 2 is provided

in common for all channels.

Motor Stop Waiting

Time

If you want to use a user-specified critical threshold, set it to alarm value 2. Alarm value 1 is set between the normal

value measured during advance preparation and alarm value 2.

If you do not have a user-defined critical threshold, the alarm value 2 can be set to 1 MΩ recommended by IEC